Halogen-free flame-resistant glass fiber reinforced polyformaldehyde composite material and preparation method thereof

A technology of composite materials and polyoxymethylene, which is applied in the field of flame-retardant polyoxymethylene composite materials and its preparation, can solve the problem of accelerating the melting of polyoxymethylene system with flame dripping, the complicated preparation process of coated red phosphorus micropowder, and the scope of application of polyoxymethylene system Limitations and other issues, to improve thermal stability, ensure stable processing, and avoid severe degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

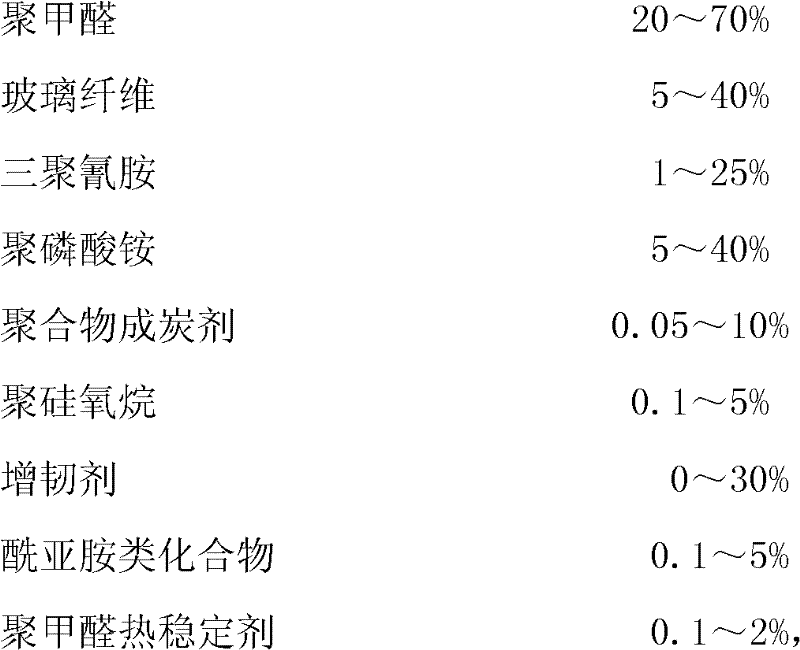

Method used

Image

Examples

Embodiment 1

[0034] First put 60 g of melamine, 240 g of type II ammonium polyphosphate with a degree of polymerization of 1000, 5 g of melamine formaldehyde resin, 10 g of silicone oil (number average molecular weight 10000), 10 g of phthalimide and 264 5 g of antioxidant in a high-speed mixer Mix for 2 minutes, then add 470 g of polyoxymethylene and continue mixing for 5 minutes. Then the obtained mixture is added to a twin-screw extruder and melted and extruded at a temperature of 180 ° C. At the same time, 200 g of chopped glass fibers are evenly added to the side feeding port in front of the main feeding port of the extruder, and the extruder rotates at a speed of 30 rpm. , The extrudate was cooled by water, cut into pellets, and dried at 60°C for 4 hours to obtain the flame-retardant composite material pellets. The pellets were injection molded into standard test specimens through an injection molding machine, and the injection molding temperature was 190°C. After testing, the verti...

Embodiment 2

[0036] First, 10 g of melamine, 190 g of type I ammonium polyphosphate with a degree of polymerization of 10, 8 g of thermoplastic phenolic resin, 2 g of melamine formaldehyde resin, 1 g of silicone powder (number average molecular weight 1,500,000), 20 g of succinimide, and phthalamide Imine 10g, antioxidant 245 6g and antioxidant 1010 4g were mixed in a high-speed mixer for 3 minutes, then polyoxymethylene copolymer 649g, POE 45g and ET-TPU 5g were added and mixed for 4 minutes. Then, the obtained mixture is added to a twin-screw extruder and melted and extruded at a temperature of 190°C. At the same time, 50 g of continuous long glass fibers are evenly added to the side feeding port in front of the main feeding port of the extruder, and the extruder rotates at 100 rpm. , The extrudate was cooled by water, cut into pellets, and dried at 80°C for 8 hours to obtain the flame-retardant composite material pellets. The pellets were injection molded into standard test specimens th...

Embodiment 3

[0038] First, 50 g of melamine, 300 g of type II ammonium polyphosphate with a polymer degree of 1500, 50 g of urea-formaldehyde resin, 20 g of silicone rubber (number-average molecular weight 1,000,000), 1 g of bismaleimide, and 1 g of N-phenylmaleimide , Antioxidant 264 4g and antioxidant 719 4g were mixed in a high-speed mixer for 4 minutes, then added homopolyoxymethylene 200g, copolymerized polyoxymethylene 150g, PEO 60g and POE 40g and continued to mix for 6 minutes. Then, the obtained mixture was added to a twin-screw extruder and melted and extruded at a temperature of 195°C. At the same time, 120 g of chopped glass fibers were evenly added to the side feeding port in front of the main feeding port of the extruder, and the extruder rotated at 500 rpm. , The extrudate was cooled by water, cut into pellets, and dried at 90°C for 6 hours to obtain the flame-retardant composite material pellets. Take the pellets and inject them into standard test specimens through an injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com