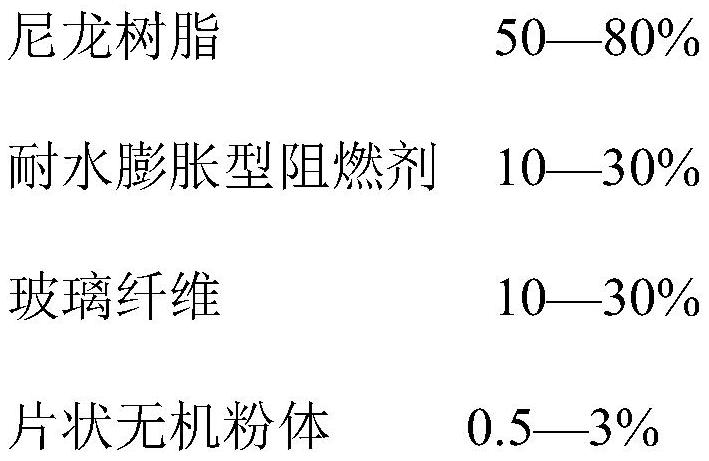

A water-swellable flame retardant and its preparation method and application

An intumescent flame retardant and reaction technology, applied in the field of flame retardants, can solve the problems of loss of flame retardant active ingredients, poor water resistance, etc., achieve excellent flame retardant performance, improve compatibility and dispersibility, and easily obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

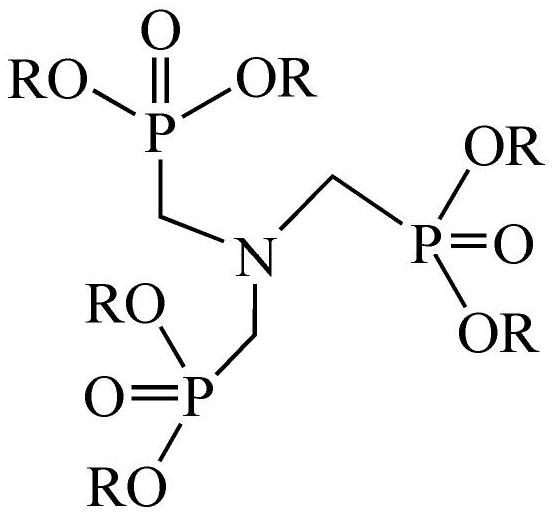

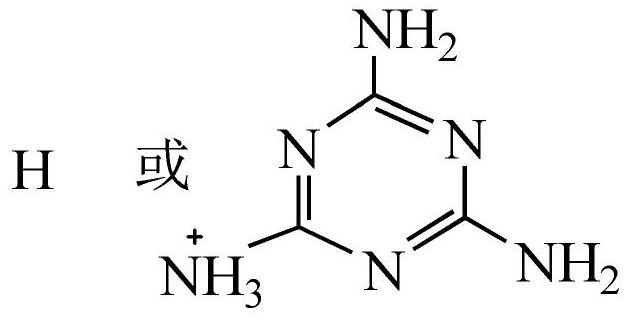

[0042] Amino trimethylene phosphonic acid melamine (relative molecular weight 551 Da) 15 grams (0.018 mole), add in the internal mixer of temperature 180 ℃, after melting, add the copolymer 41.4 grams of styrene-GMA again (epoxy value: 0.14 unit), under the condition of rotating speed 60 rpm, reacted for 20 minutes to obtain the block copolymer of aminotrimethylene phosphonic acid melamine-styrene-GMA, marked as A.

Embodiment 2

[0044] Amino trimethylene phosphonic acid melamine (relative molecular weight 551Da) 20 grams (0.036 mole), add in the Haake rheometer of temperature 150 ℃, after melting, add bisphenol A type epoxy resin 40.36 grams (epoxy value 0.52 ), reacted for 40 minutes under the condition of rotating speed 60 revs / min, obtained the block copolymer of aminotrimethylene phosphonic acid melamine-epoxy resin, marked as B.

Embodiment 3

[0046]20 grams (0.036 mole) of amino trimethylene phosphonic acid melamine (relative molecular weight 551 Da) was added in the Haake rheometer at a temperature of 200 ° C. After melting, 50.8 grams of polypropylene glycol diisocyanate (number average molecular weight 700 Da, 0.072 mol), under the condition of 60 rev / min of rotating speed, reacted for 30 minutes to obtain the block copolymer of aminotrimethylene phosphonic acid melamine-polypropylene glycol diisocyanate, marked as C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com