Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Uniform spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

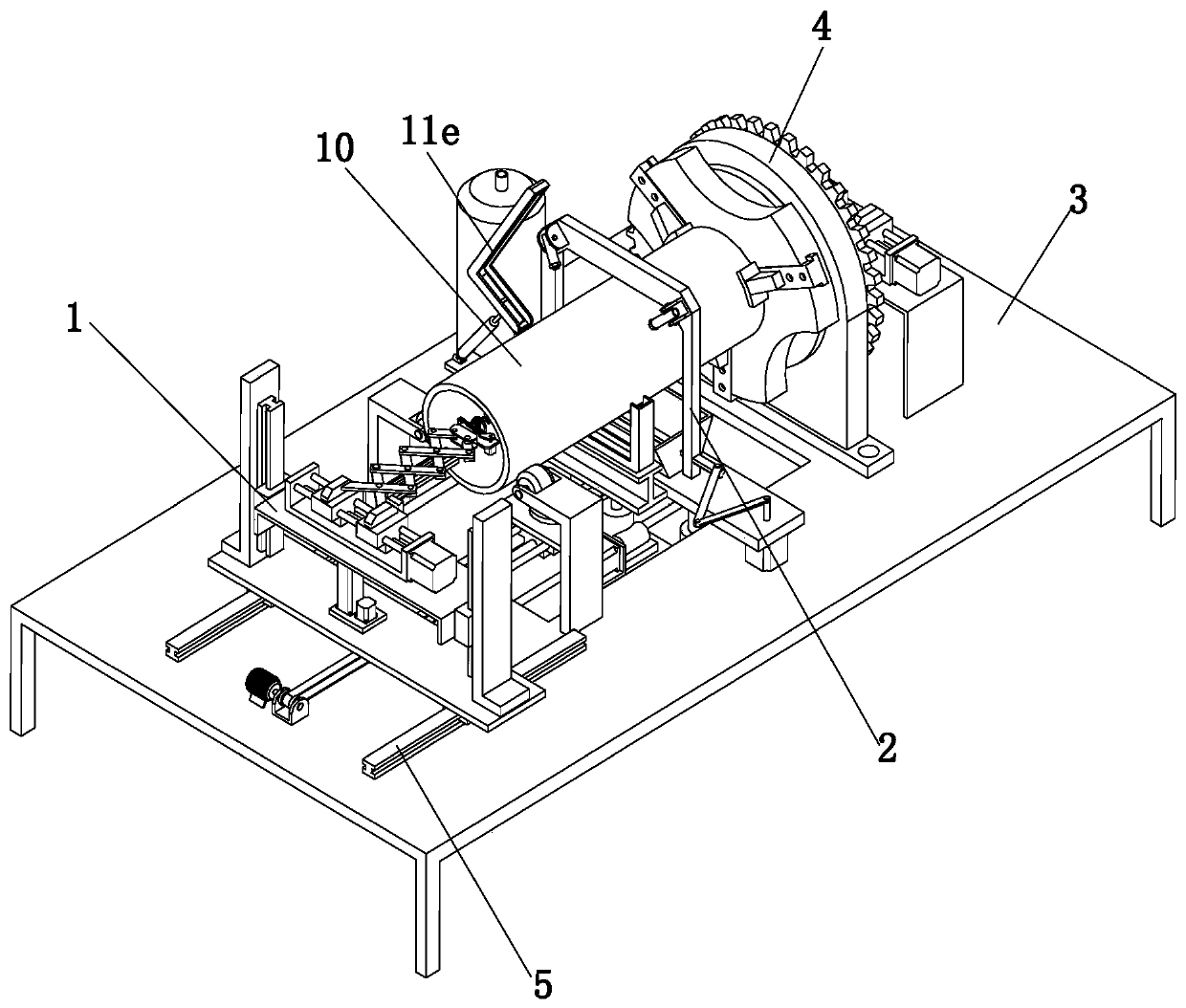

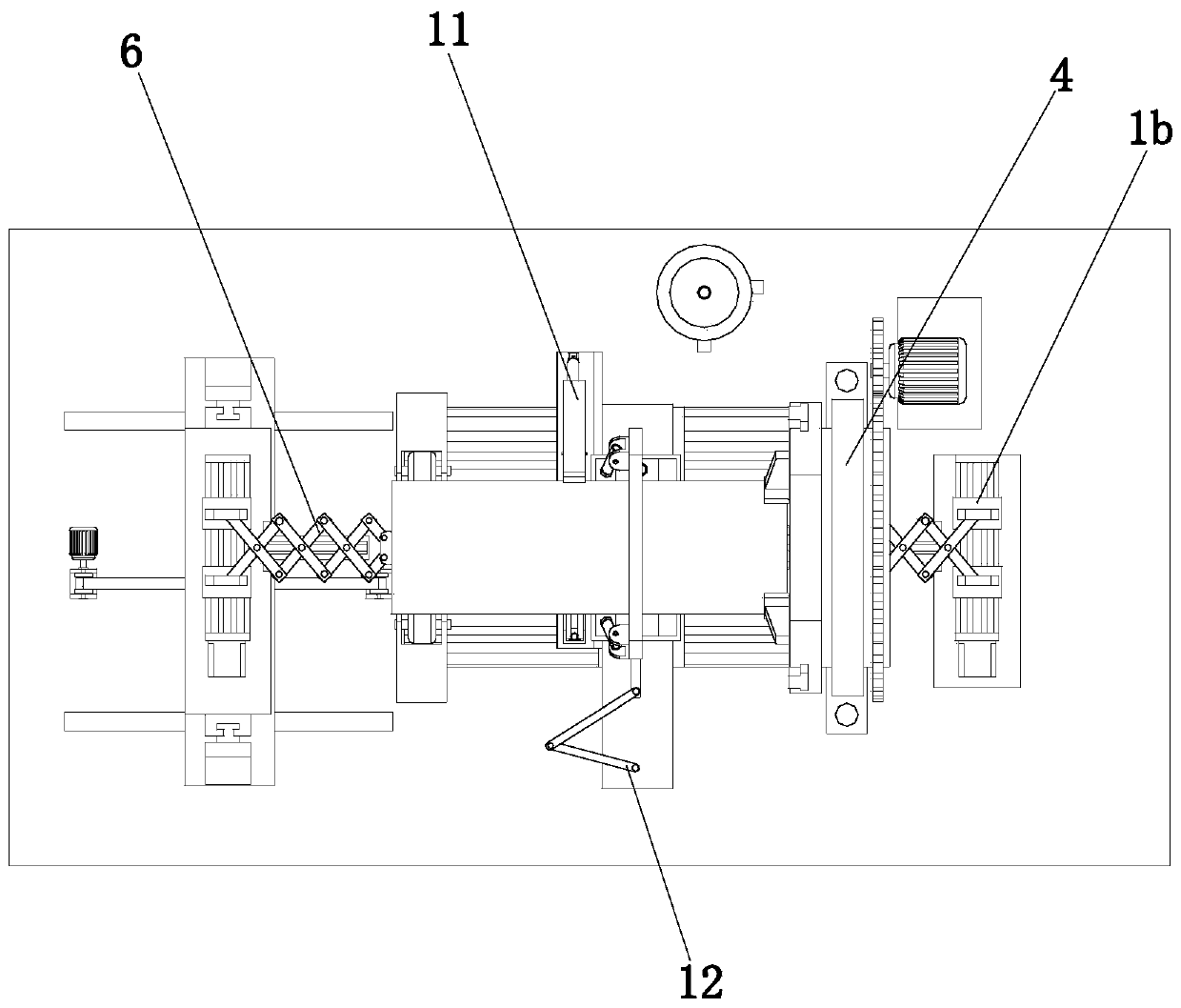

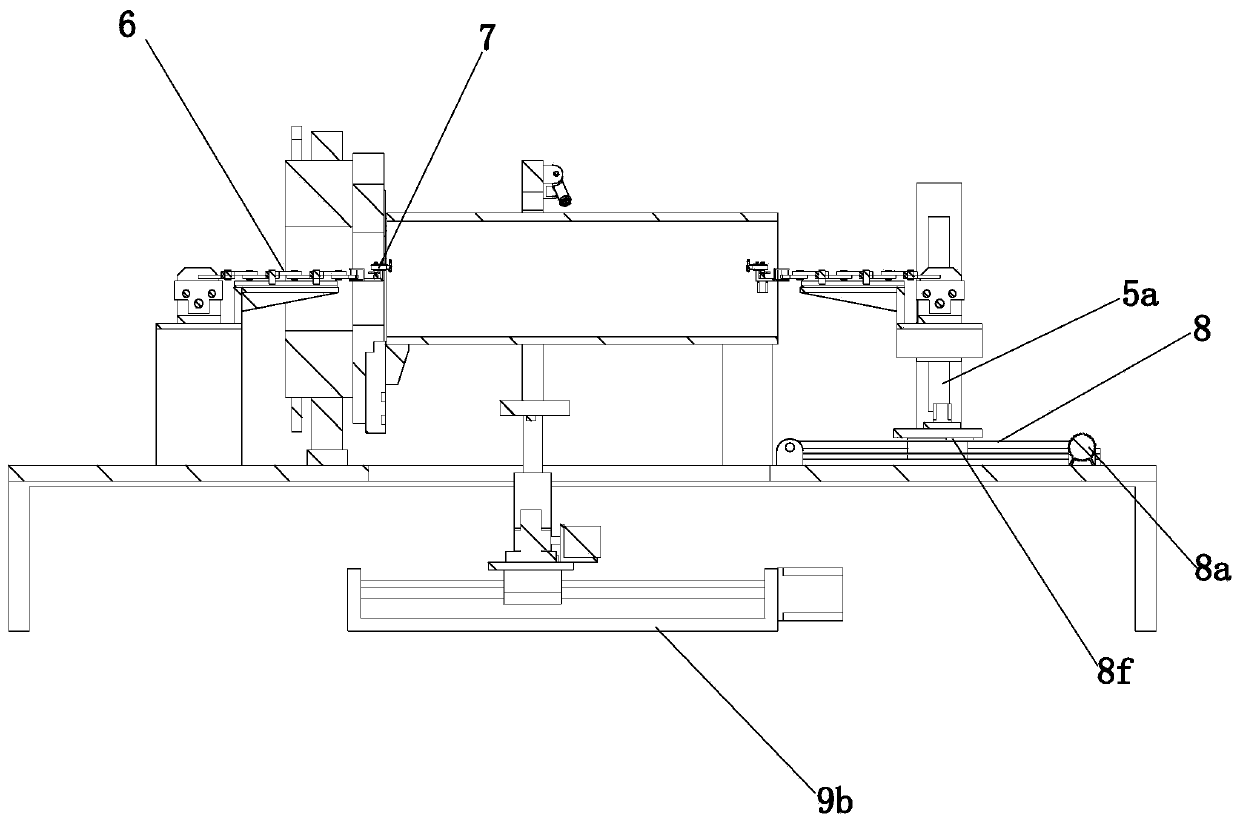

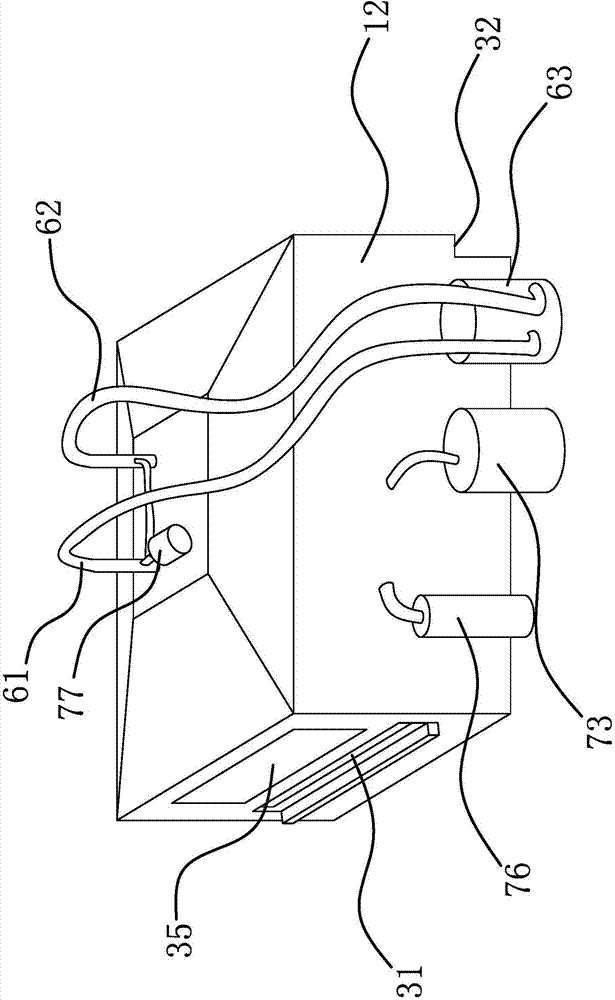

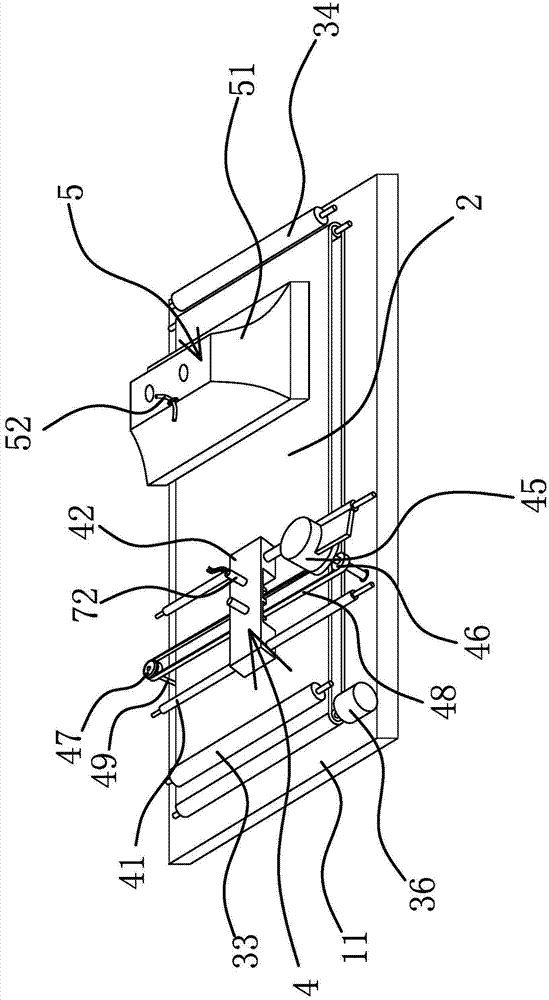

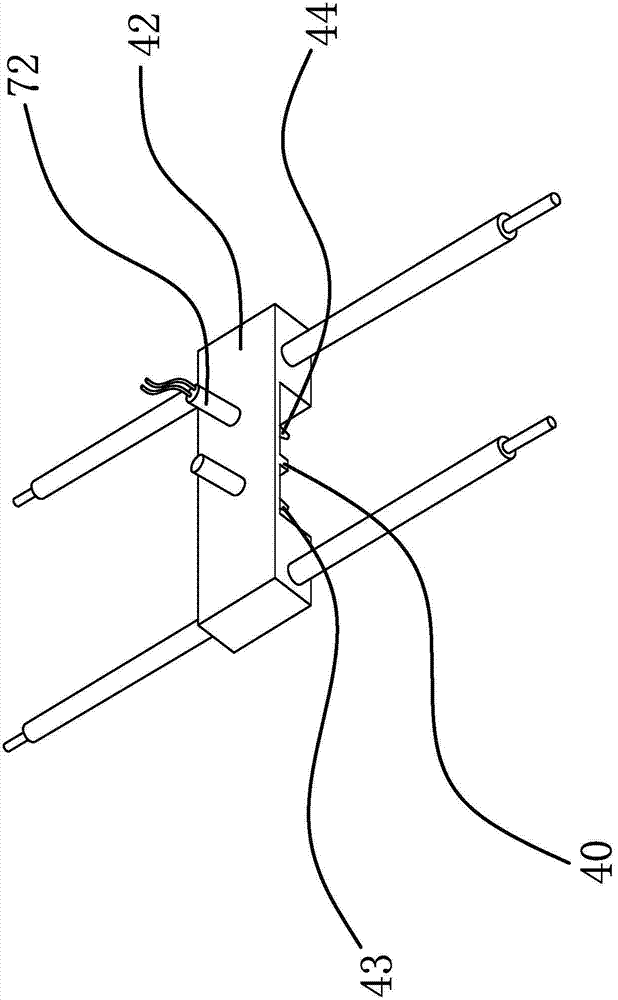

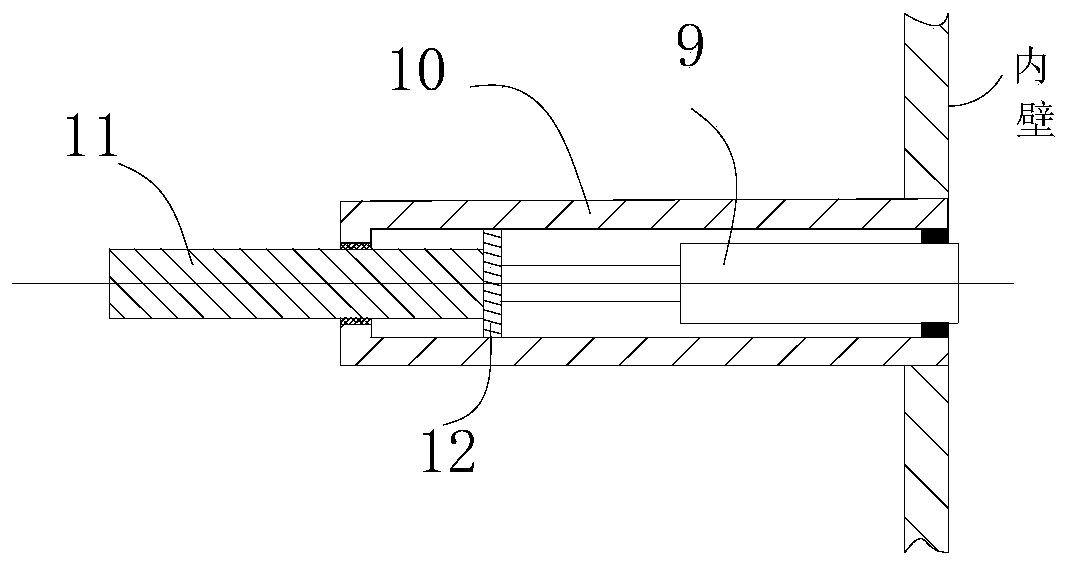

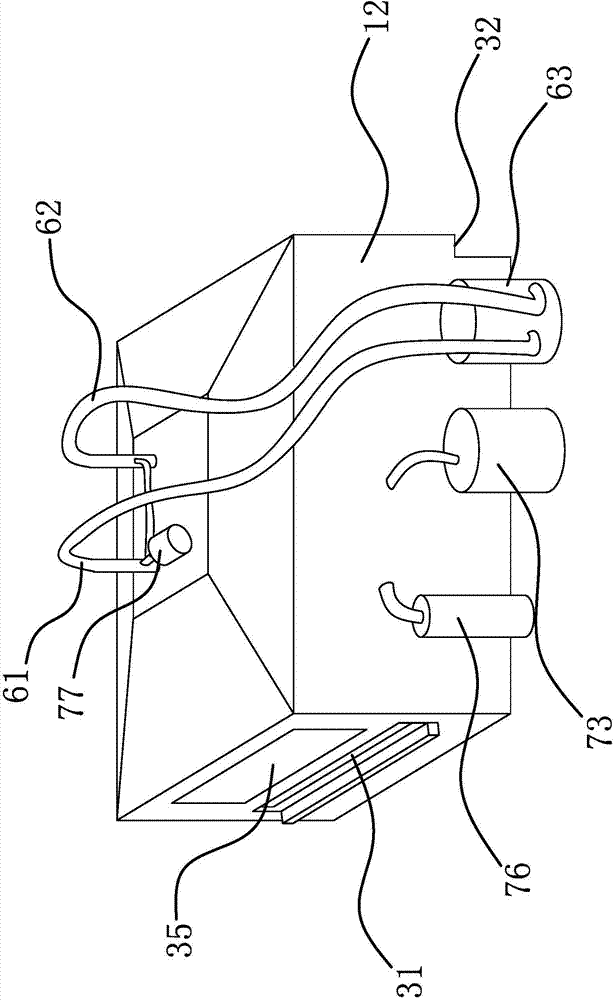

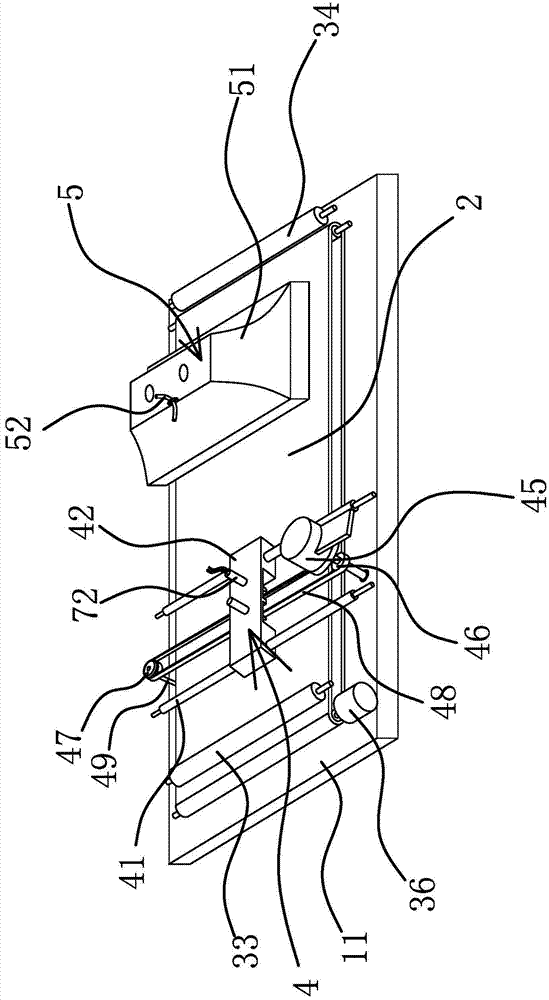

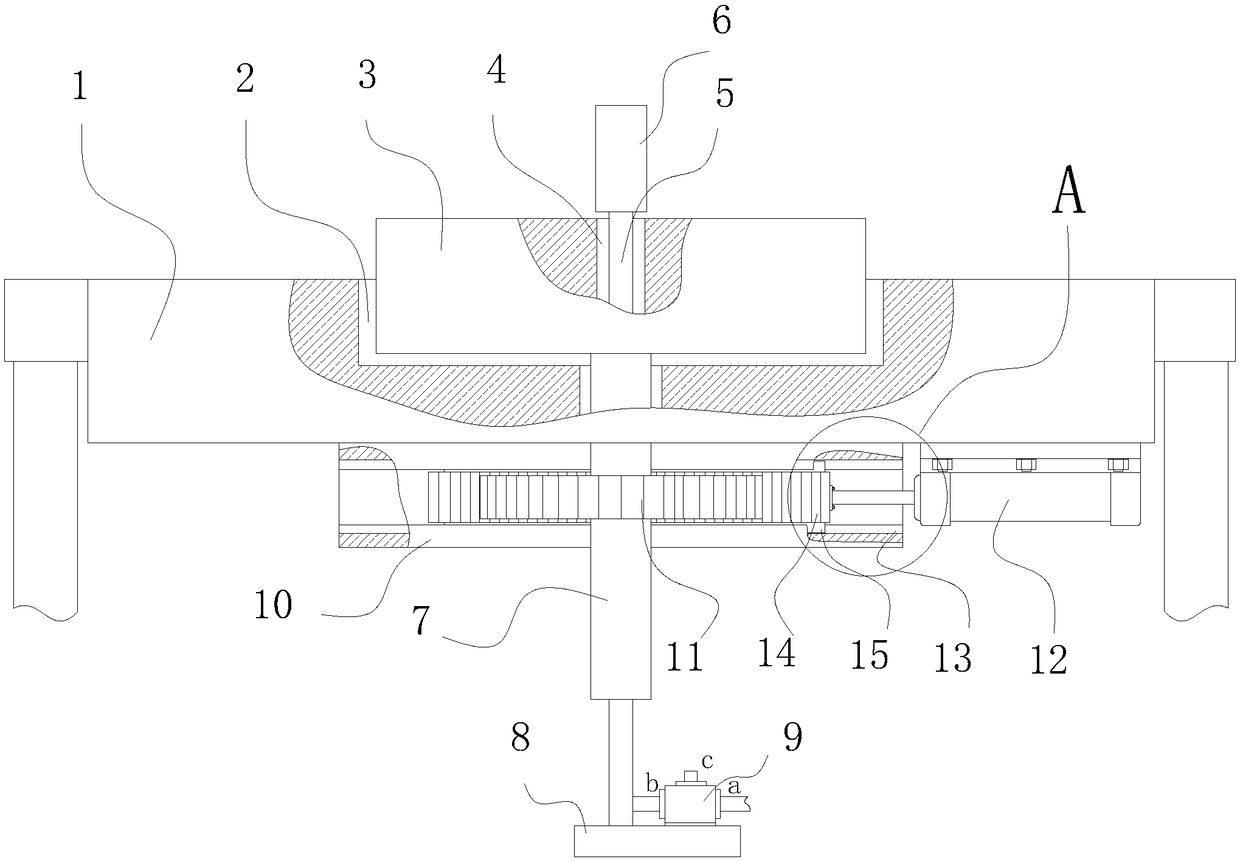

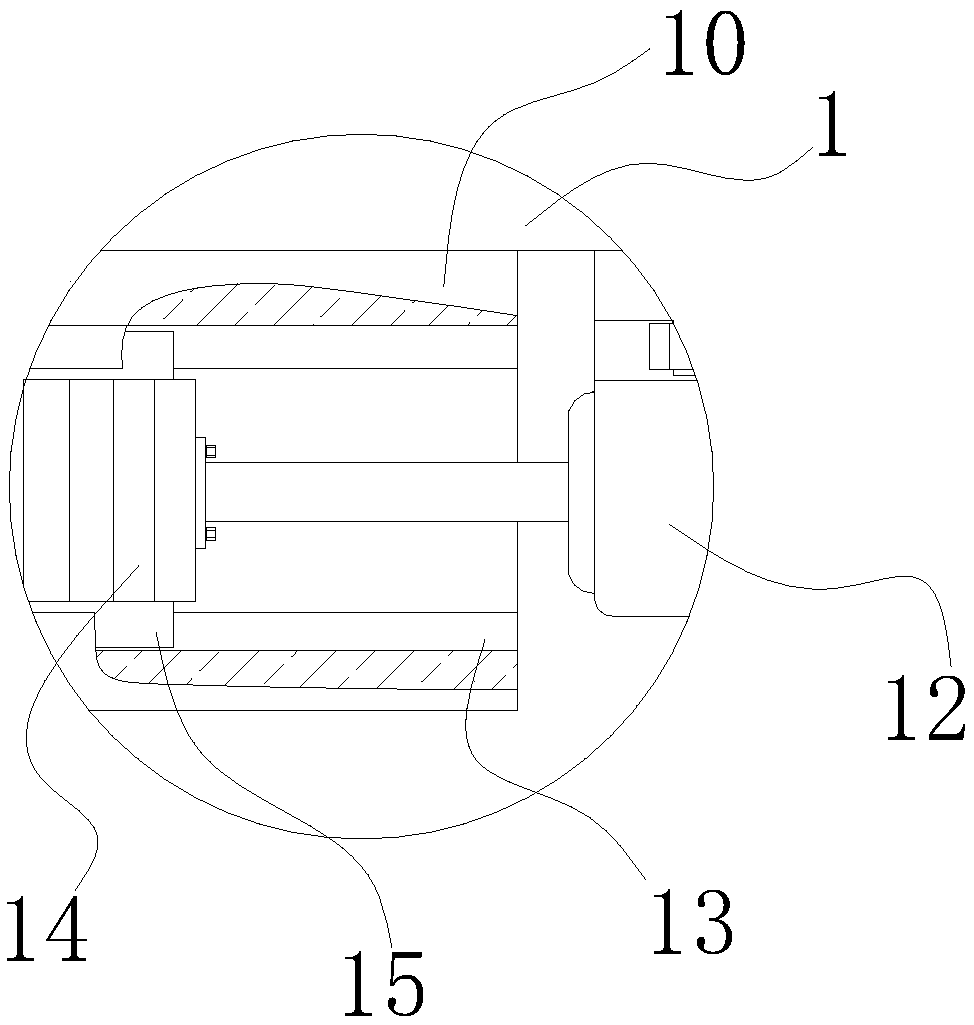

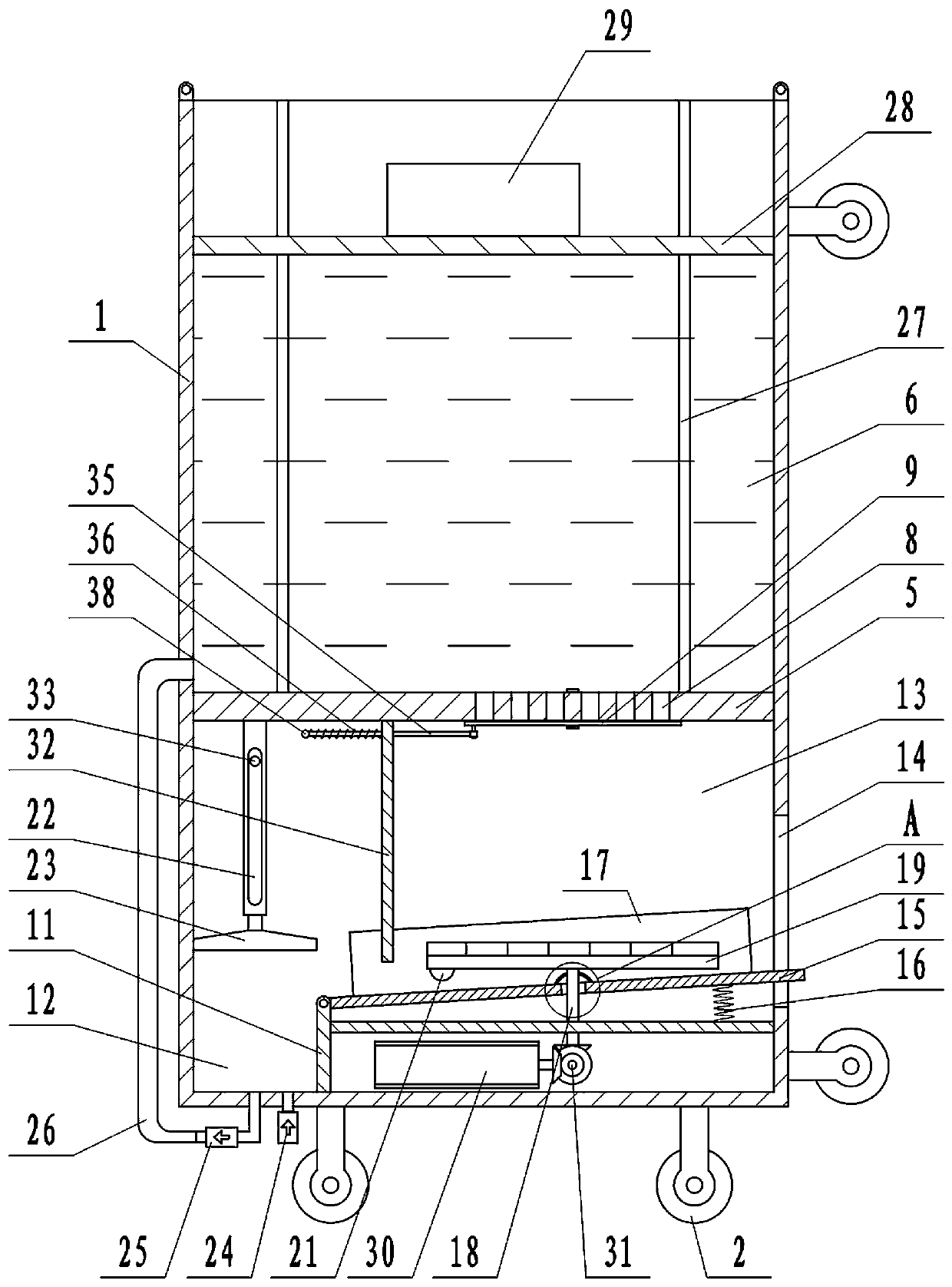

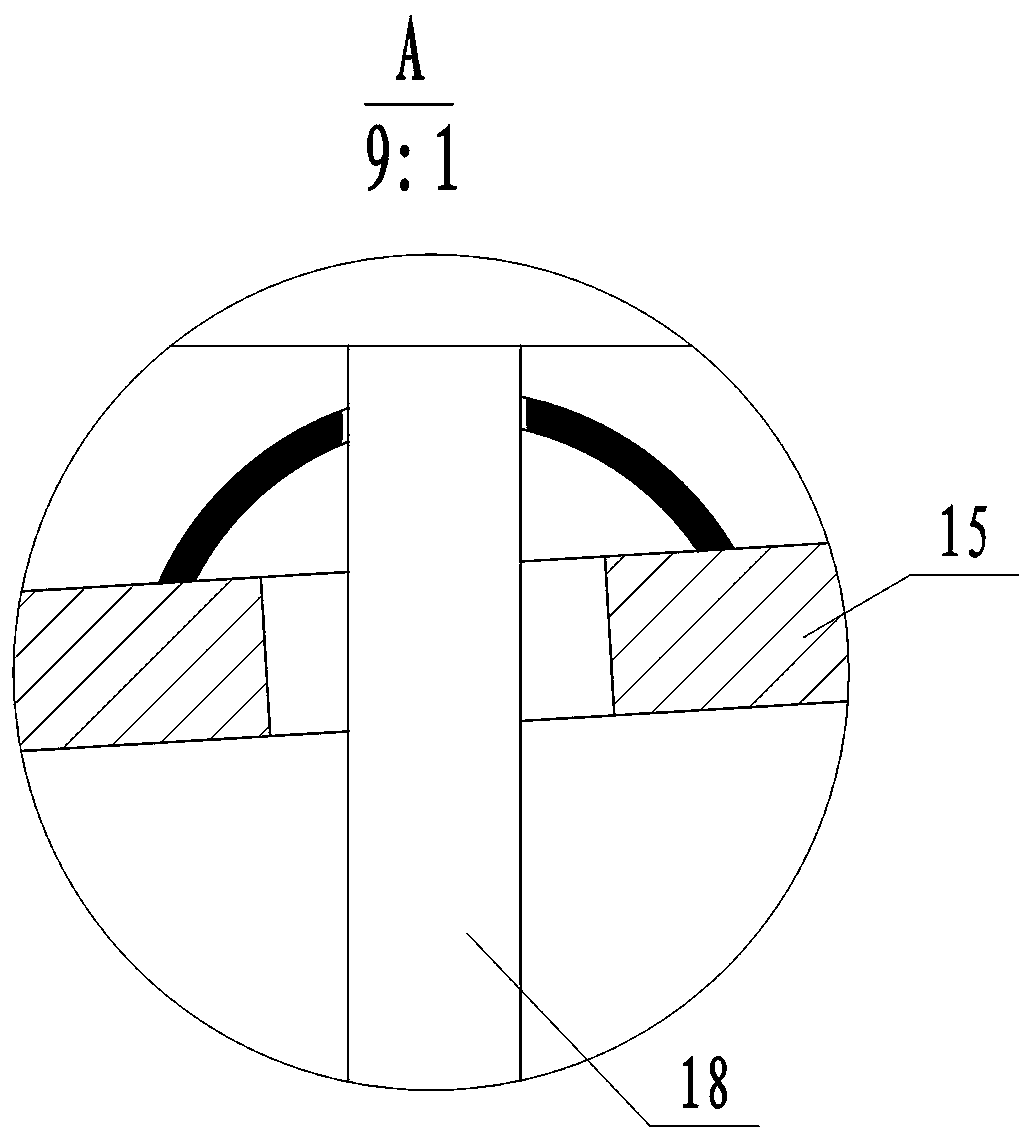

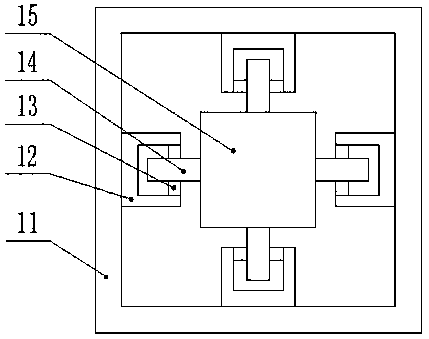

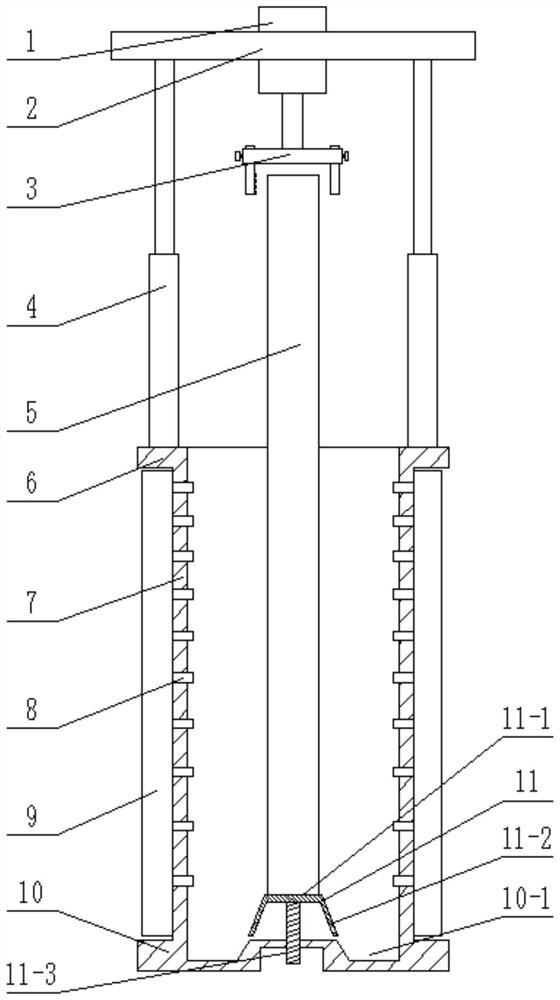

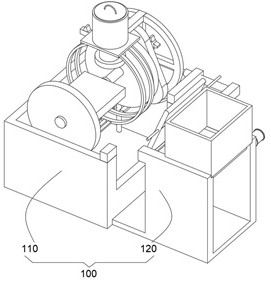

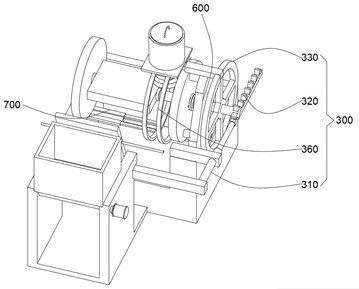

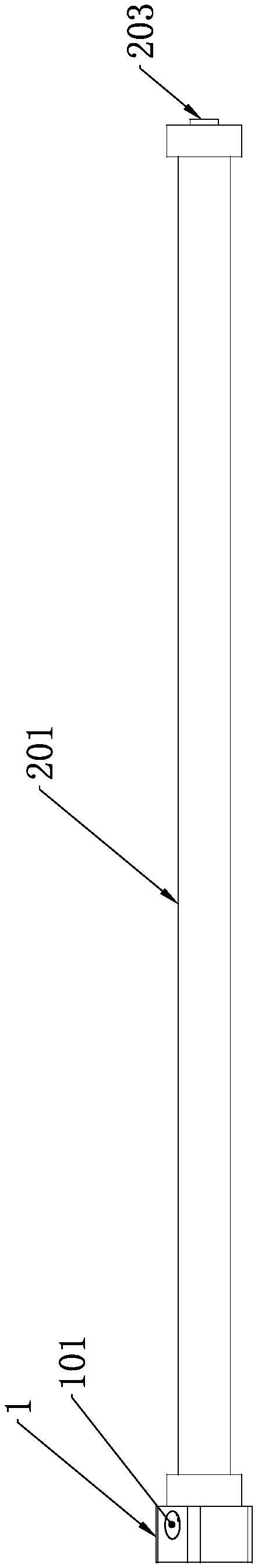

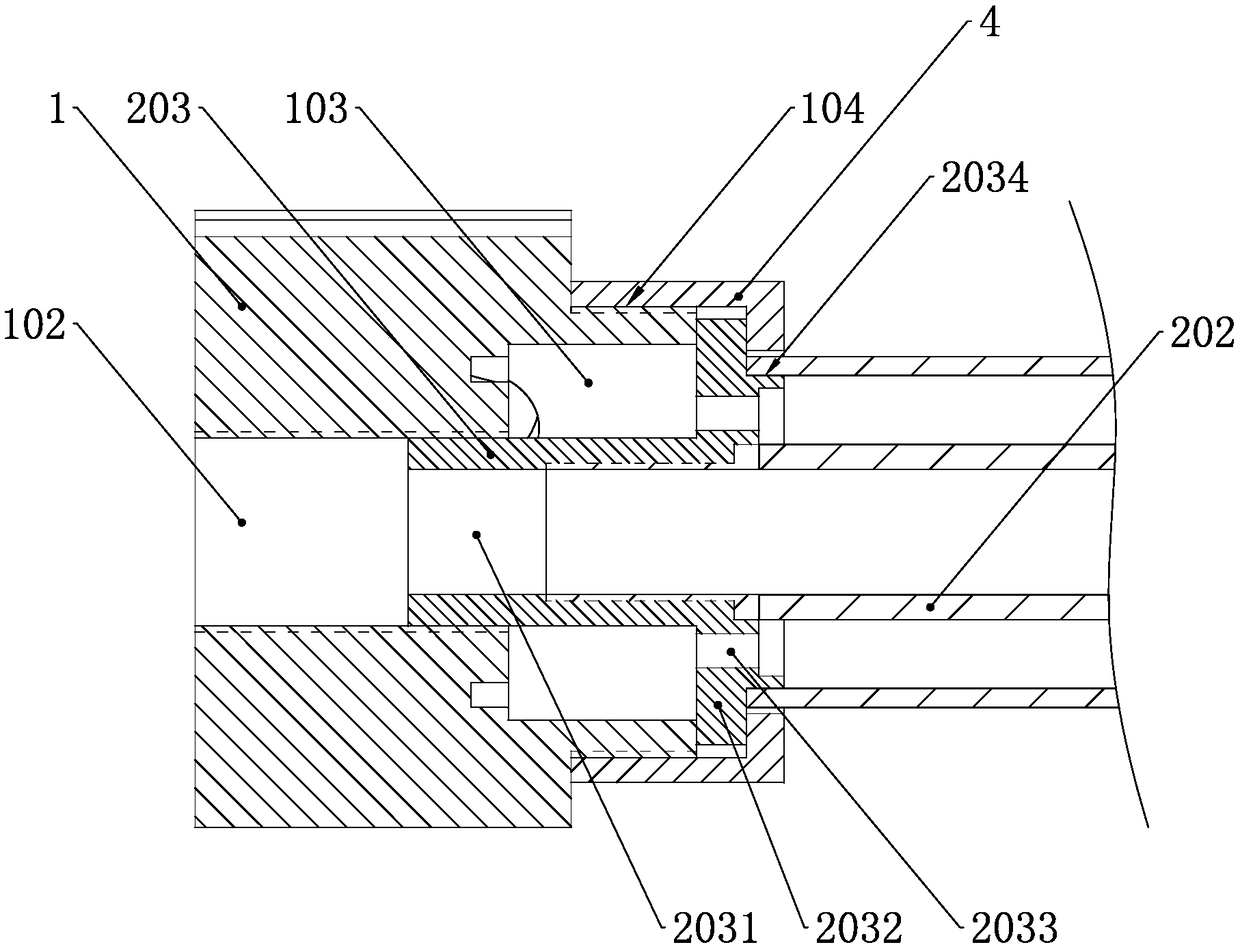

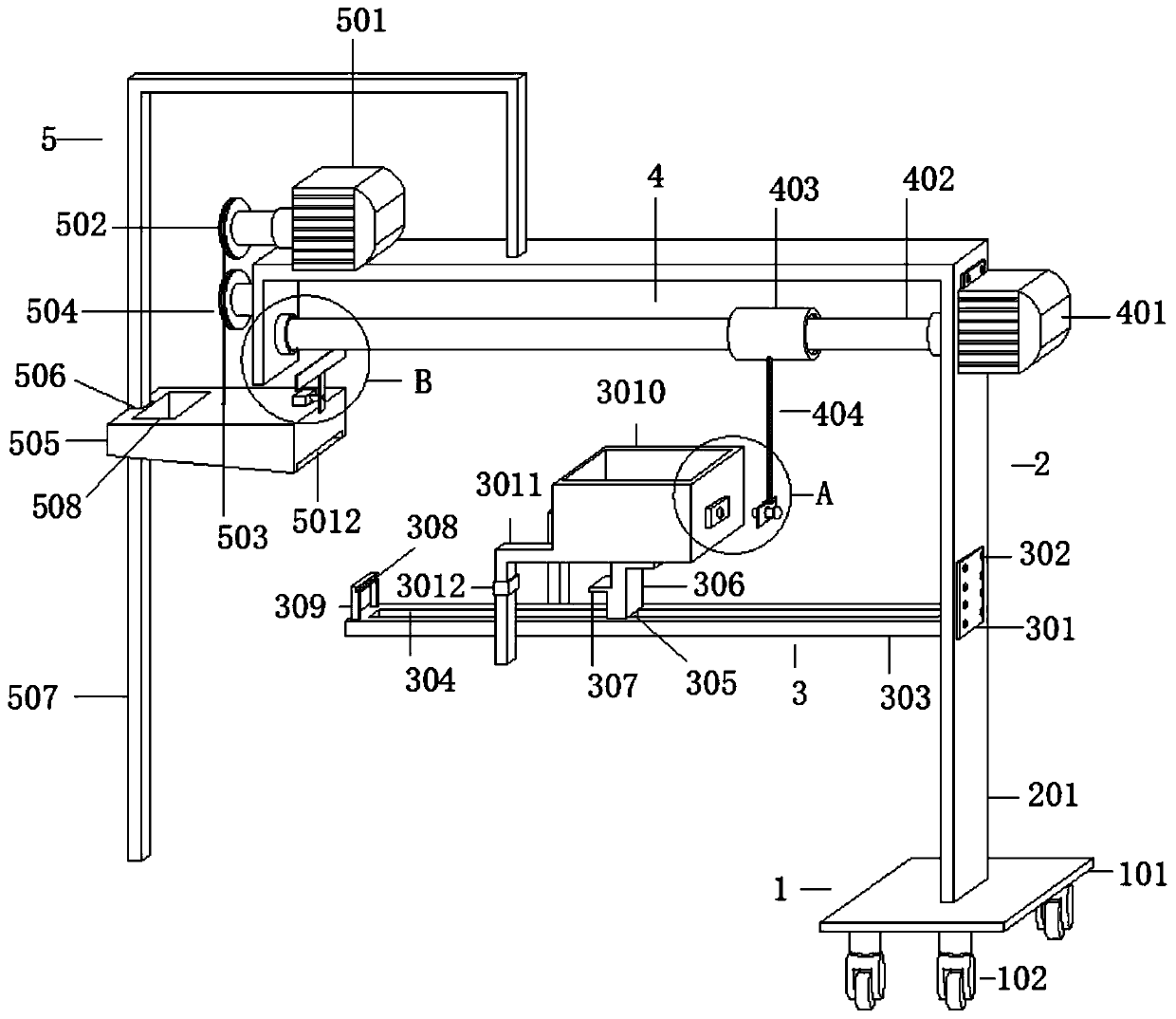

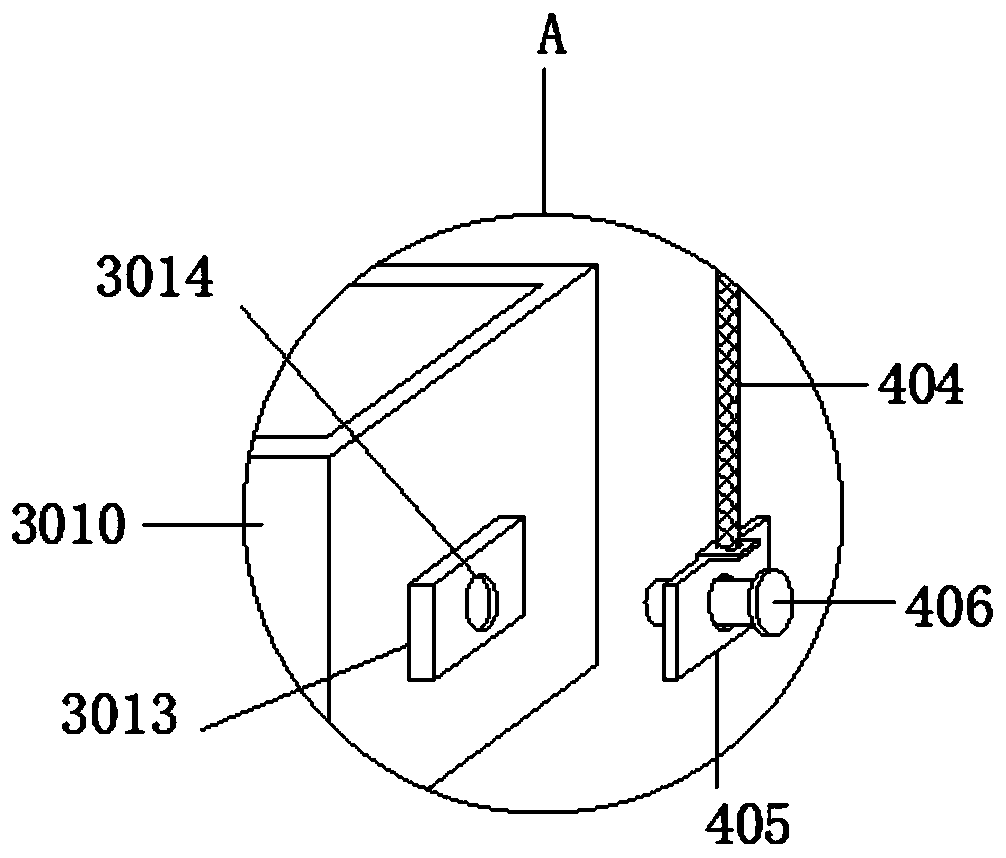

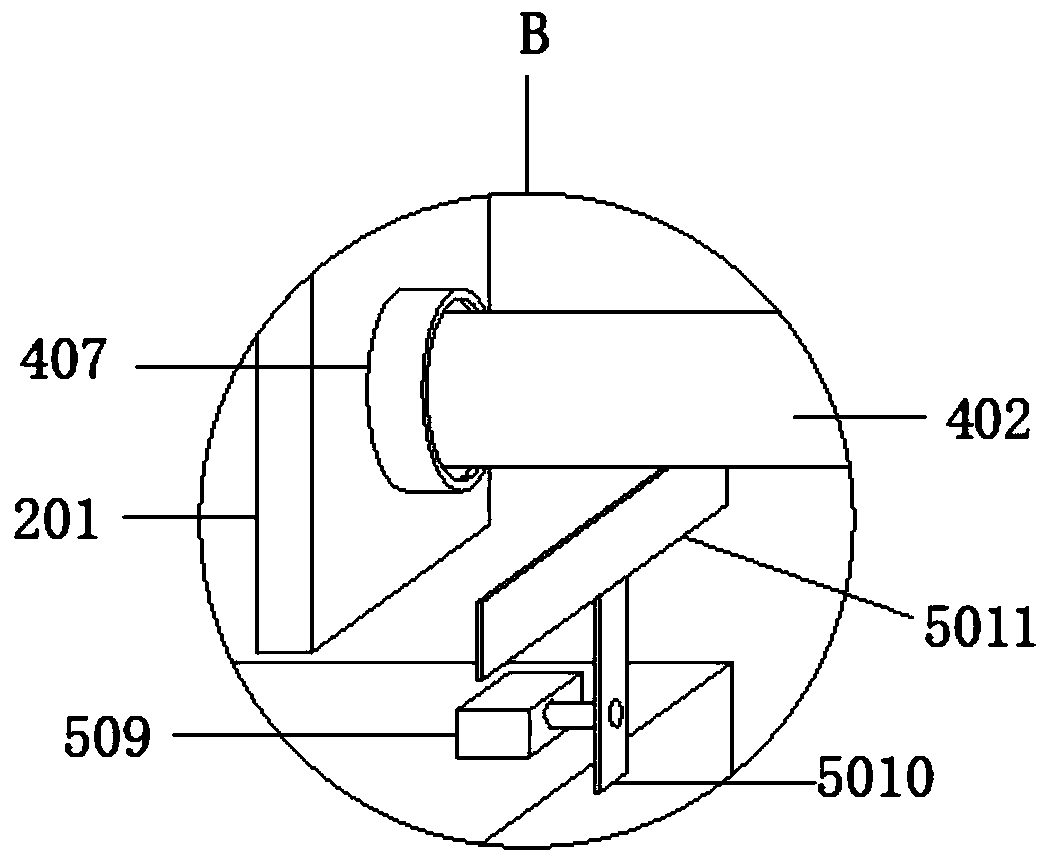

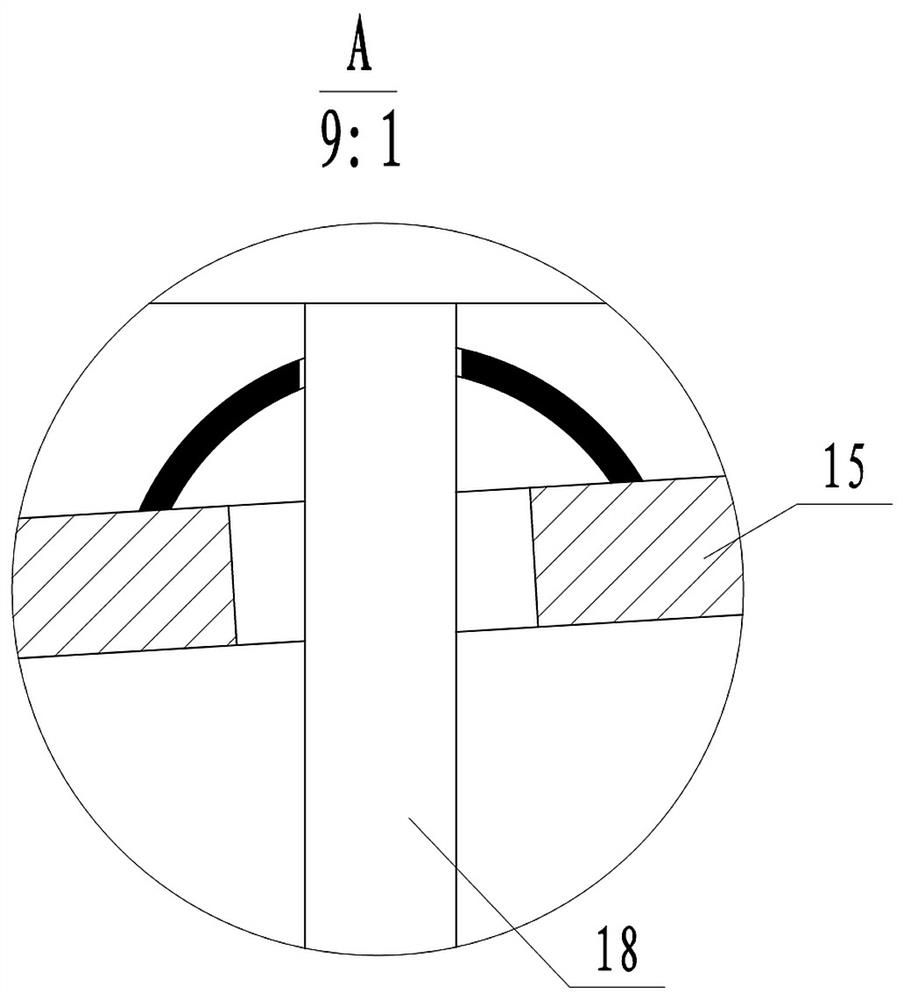

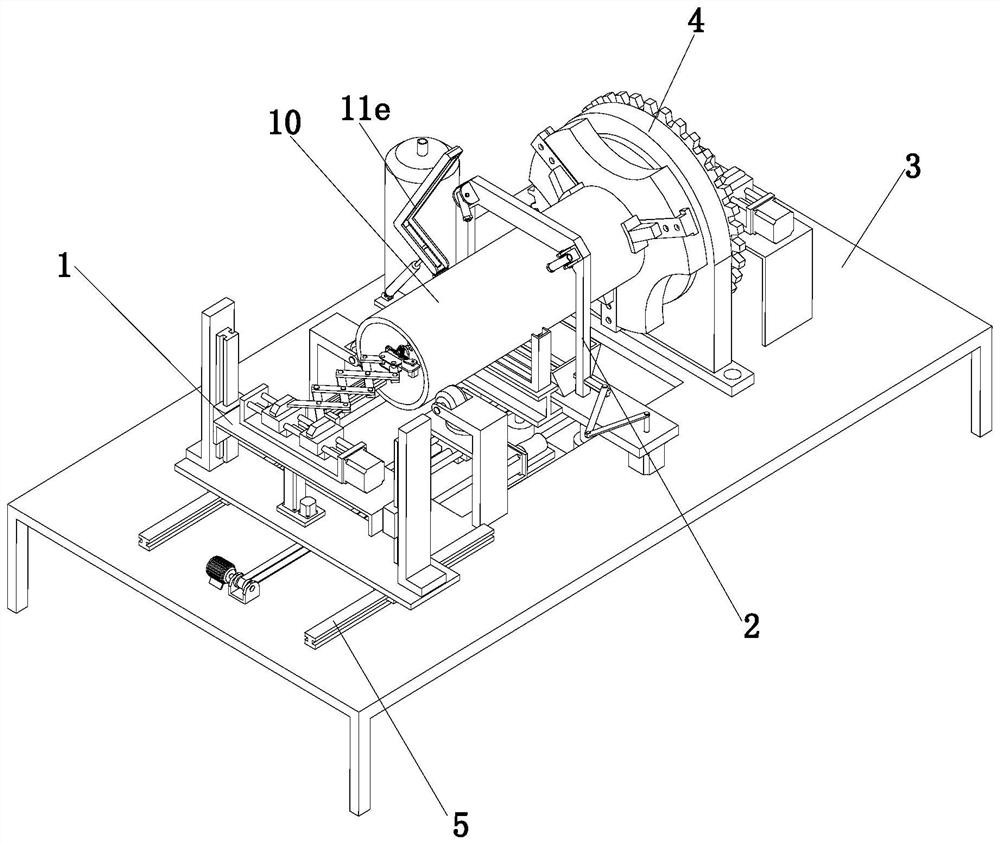

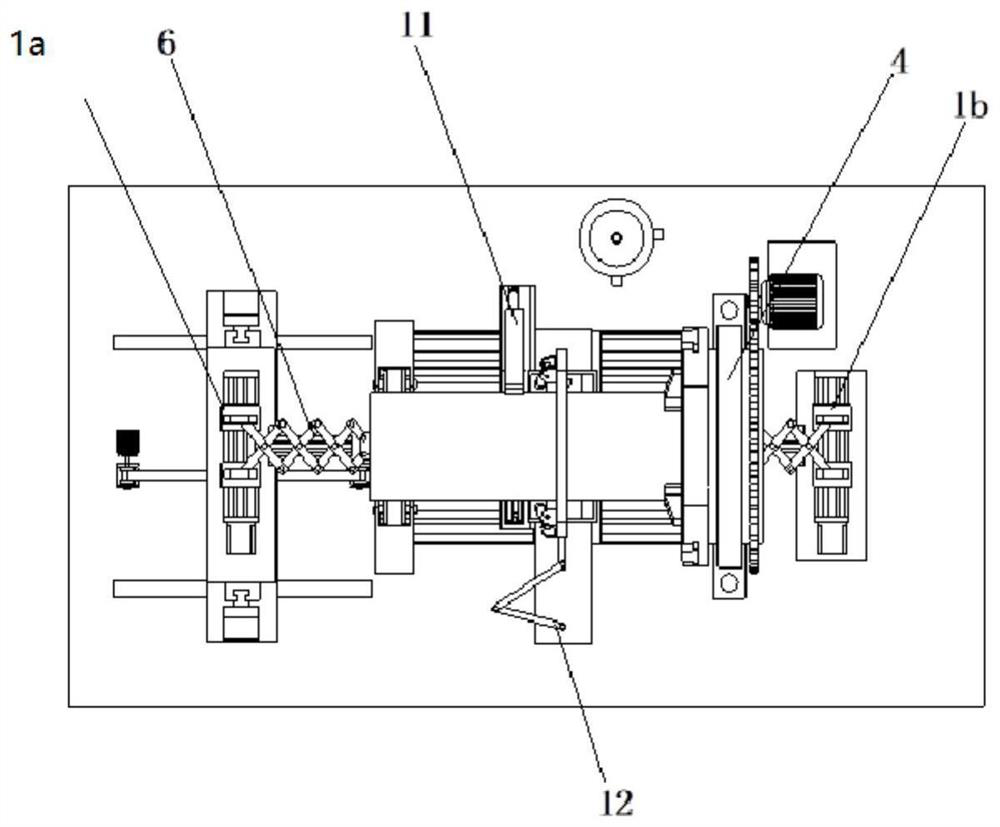

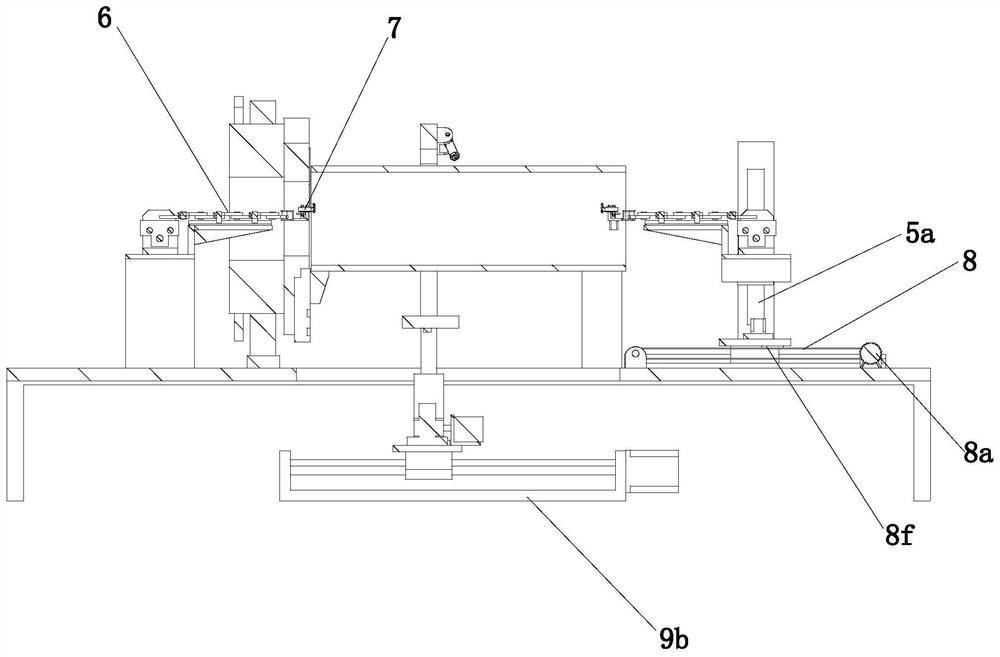

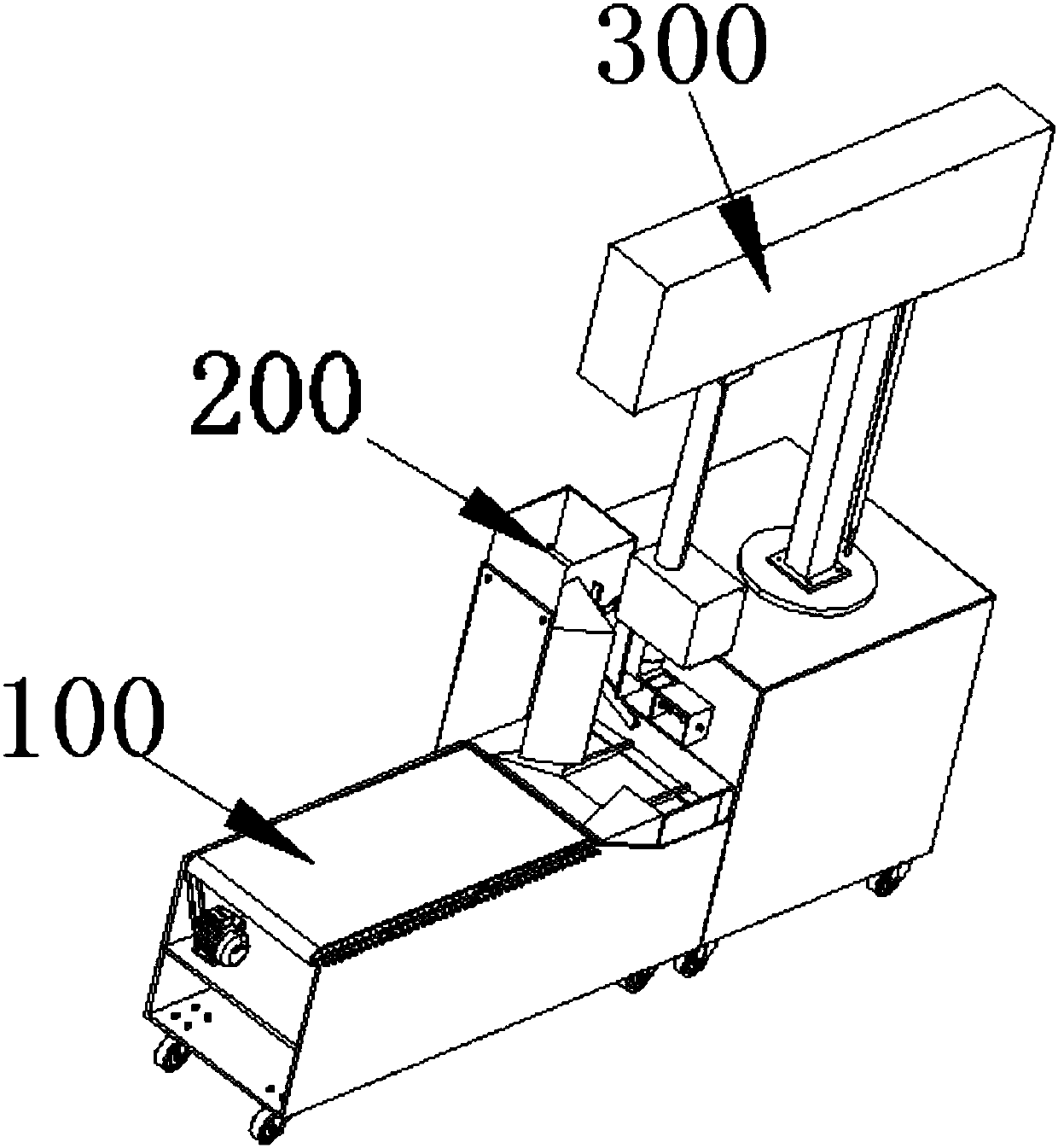

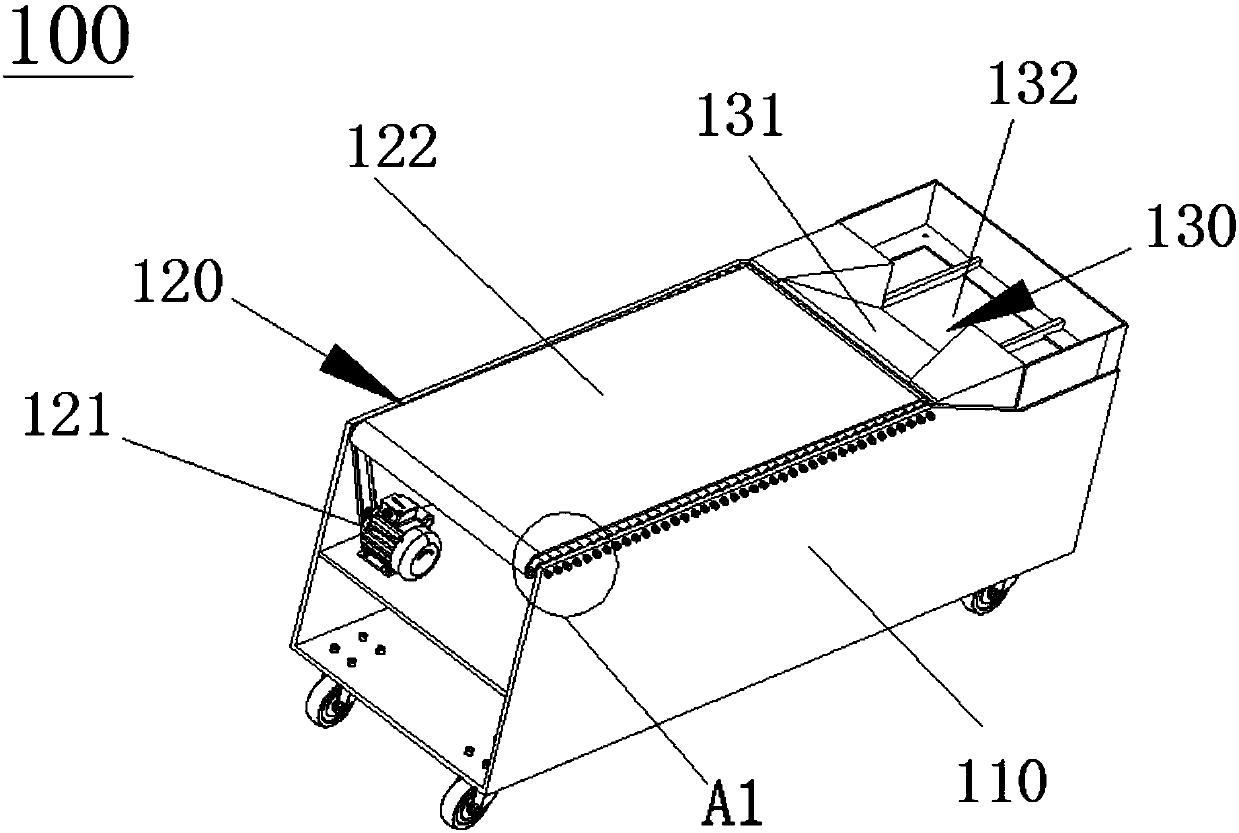

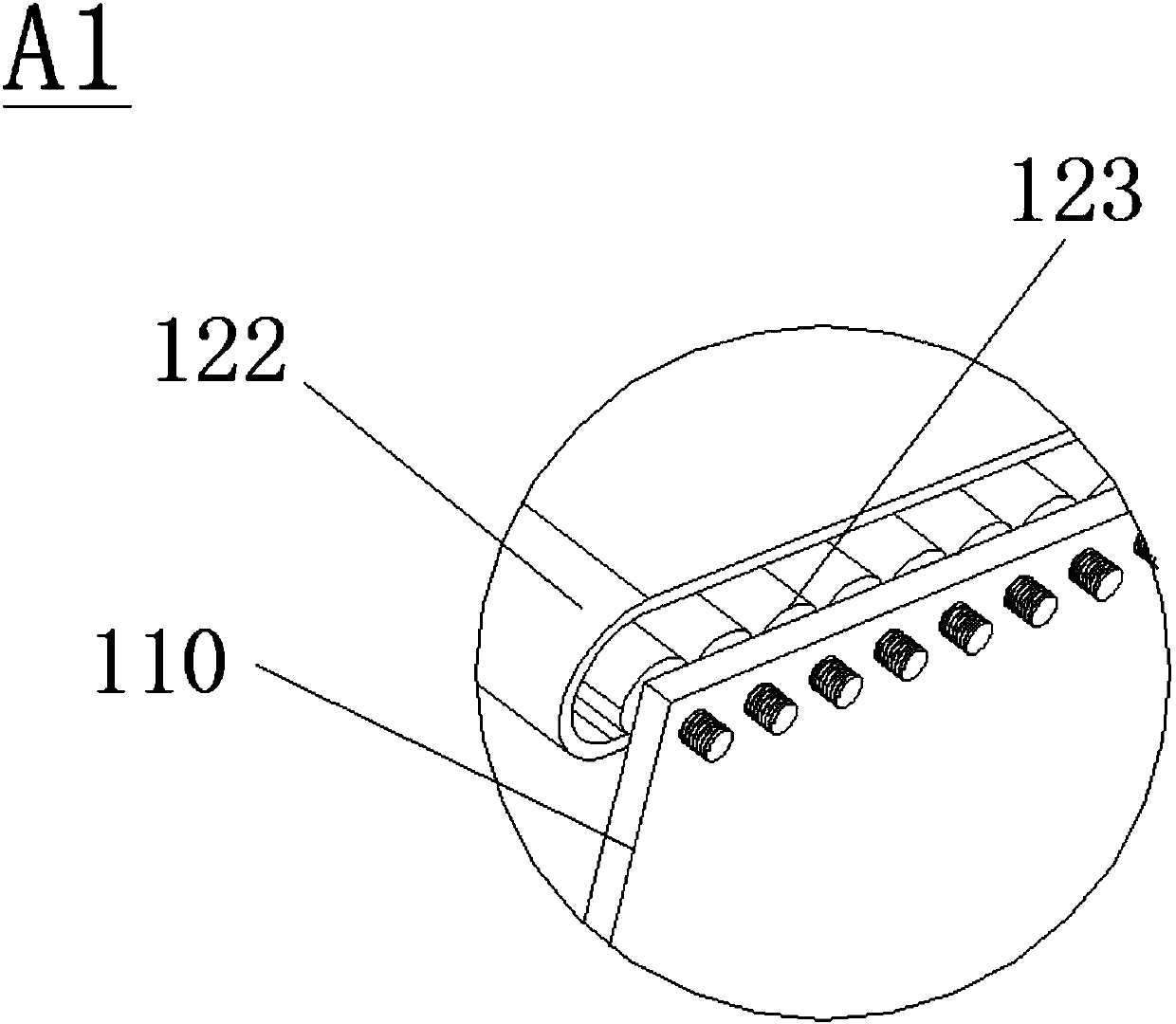

Automatic spraying machine for inner wall and outer wall of steel pipe

ActiveCN109746144AAvoid Unsprayed SituationsSolve the difficulty of spraying the entire inner wall of the steel pipePretreated surfacesCoatingsEngineeringAutomation

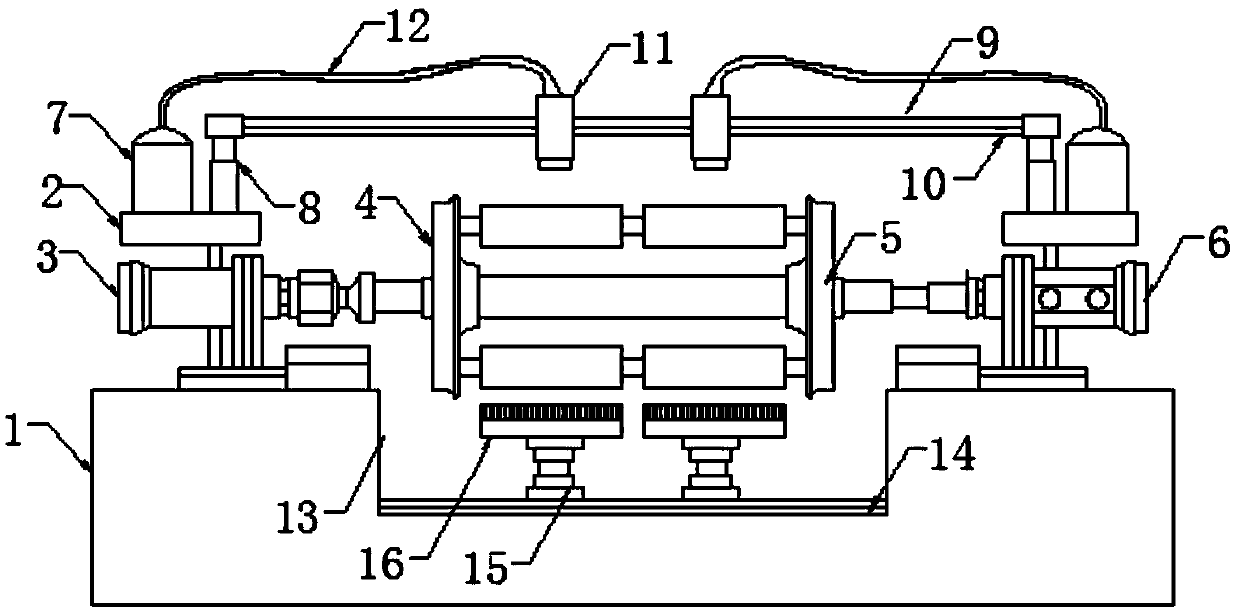

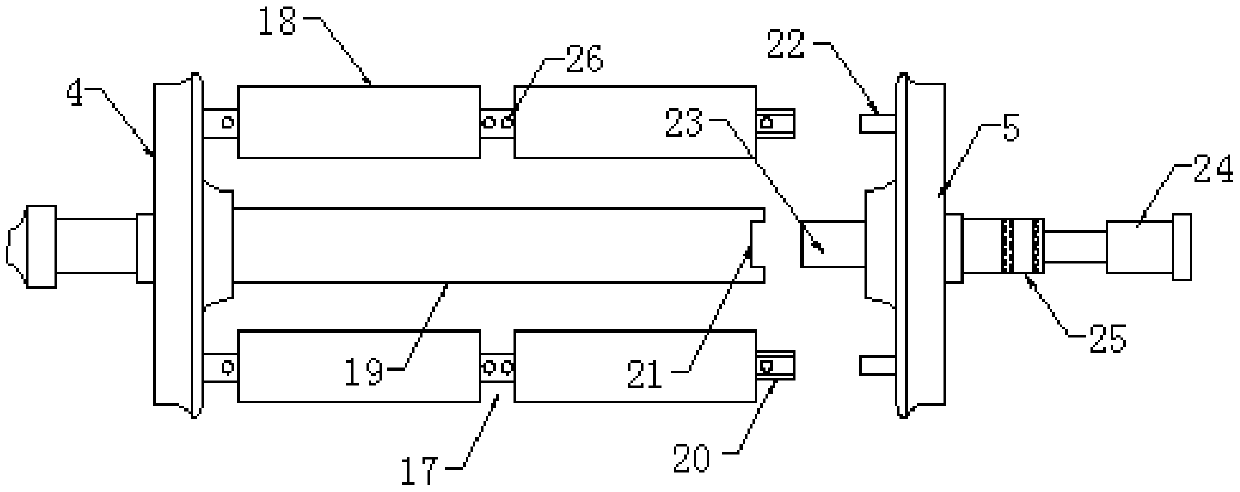

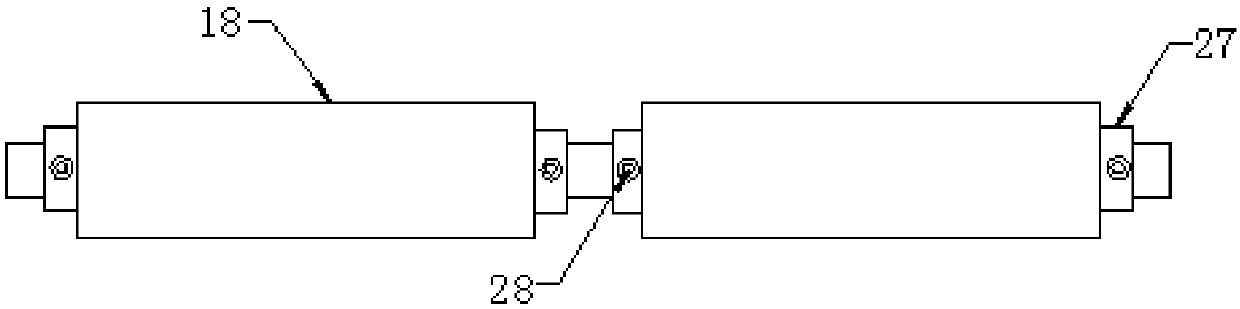

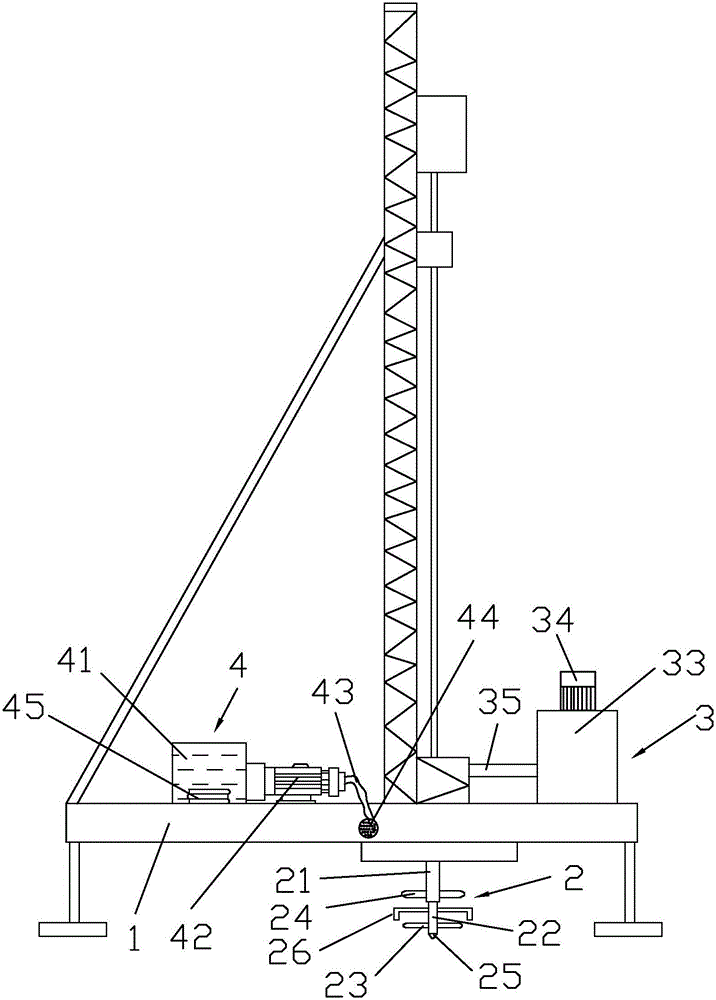

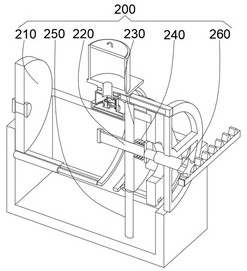

The invention discloses an automatic spraying machine for the inner wall and the outer wall of a steel pipe, and belongs to the field of steel pipe spraying equipment. The automatic spraying machine comprises an inner wall spraying mechanism, an outer wall spraying mechanism, an operation table and a rotating mechanism, wherein the inner wall spraying mechanism comprises a first spraying assembly,a second spraying assembly and a material moving assembly; the first spraying assembly and the second spraying assembly comprise an extending and feeding component and a rotating and spraying component; the material moving assembly comprises a lifting component, a material moving plate and a material moving component; and the lifting component is arranged at the top of the material moving plate.According to the automatic spraying machine disclosed by the invention, the inner wall spraying mechanism can extend to the inner part of the steel pipe and automatically perform the operation of uniform spraying on the inner wall of the steel pipe, the situation that the local inner wall of the steel pipe is not sprayed is avoided; and the operation of spraying can be automatically performed on the outer wall of the steel pipe through the outer wall spraying mechanism, so that the automation degree is high, and the situation that a worker manually performs the operation of spraying on the outer wall of the steel pipe is not needed.

Owner:浙江金汇休闲制品有限公司

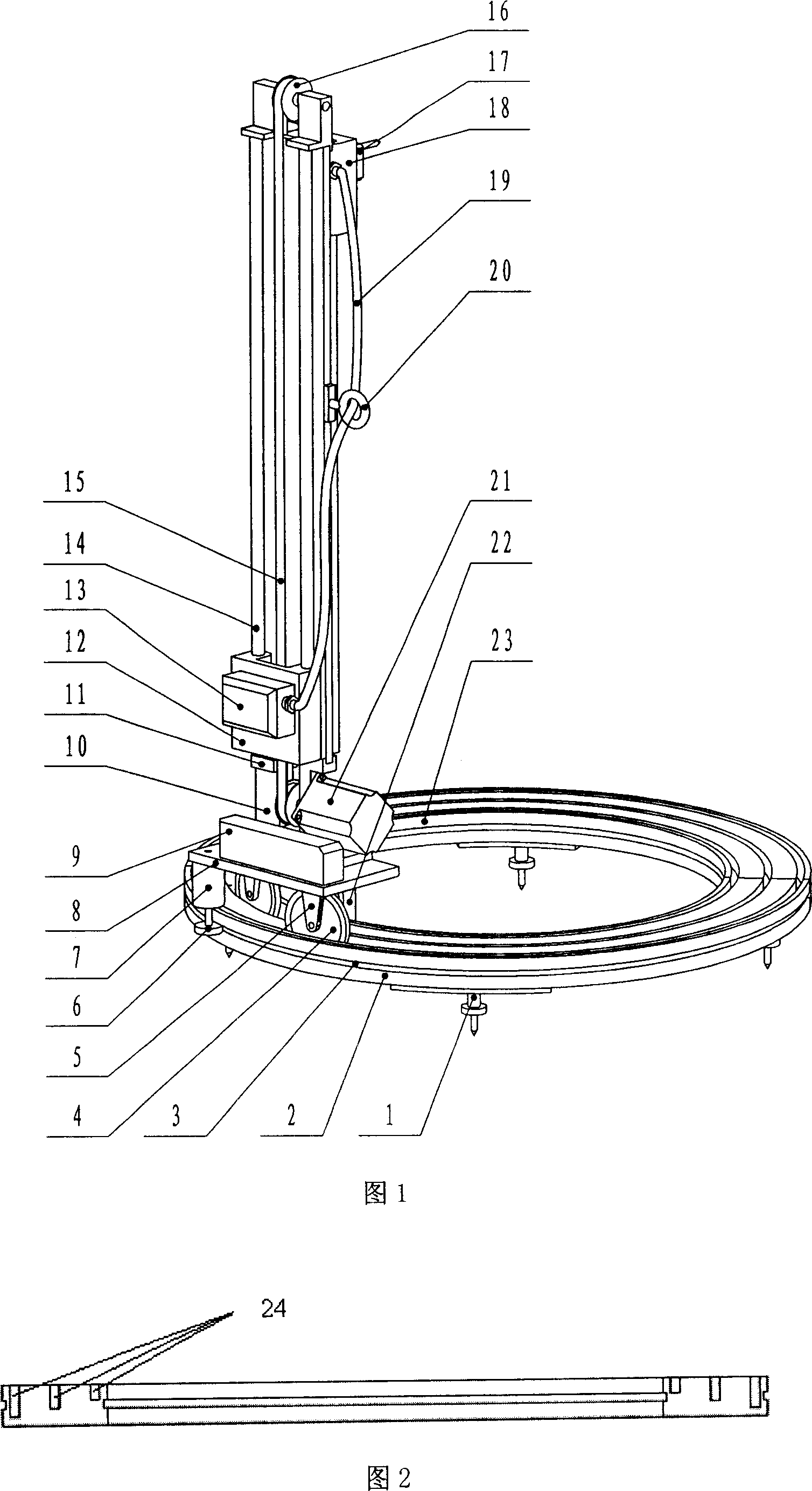

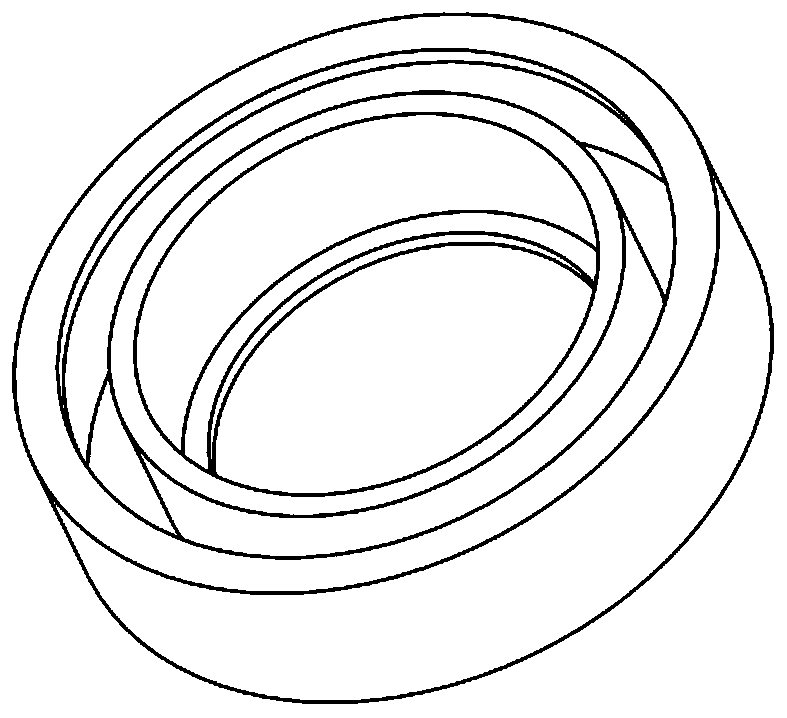

Robot for spray coating medicated liquor on trunk

InactiveCN1969621AEasy to operateSpray uniformProgramme-controlled manipulatorInsect catchers and killersAgricultural engineeringEngineering

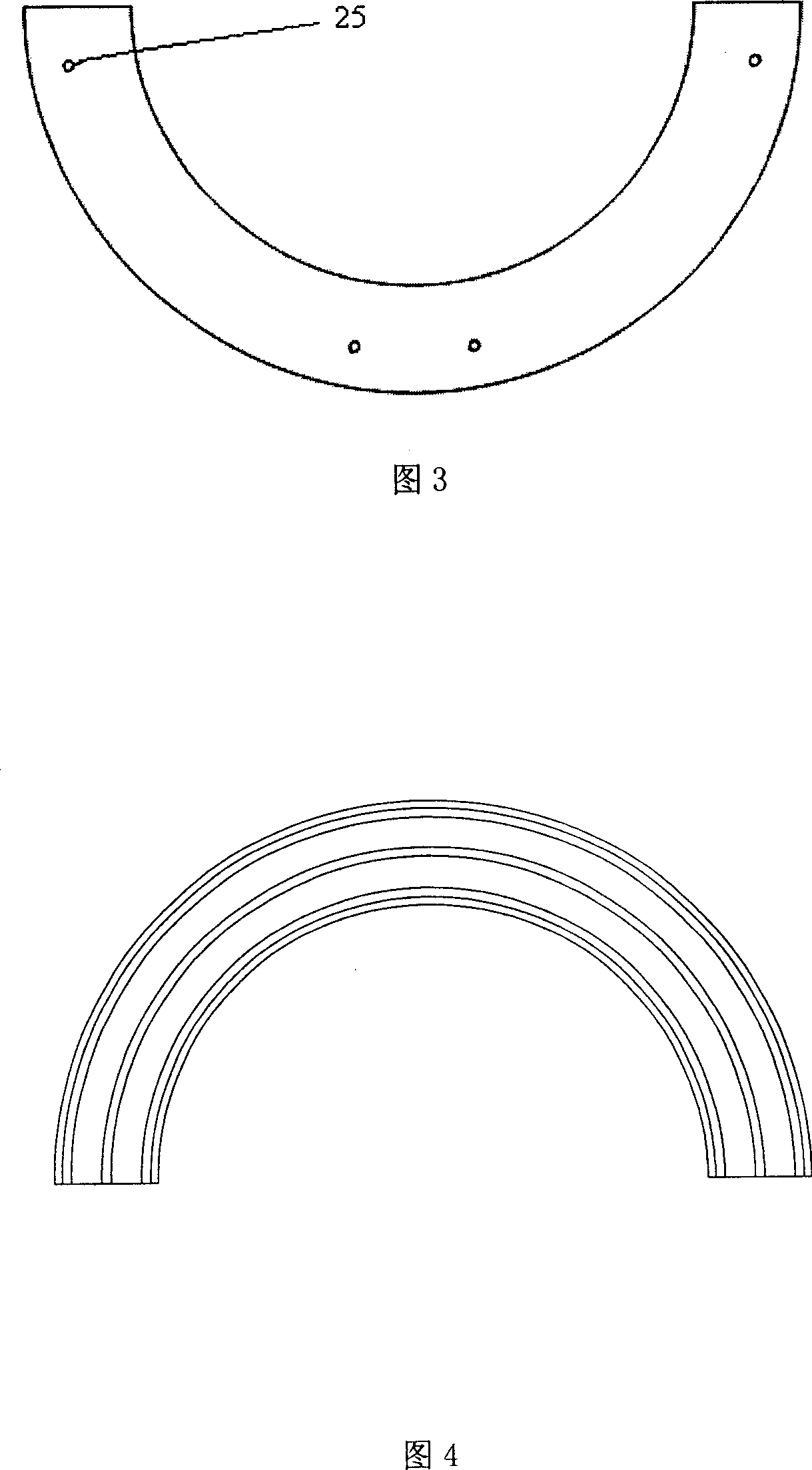

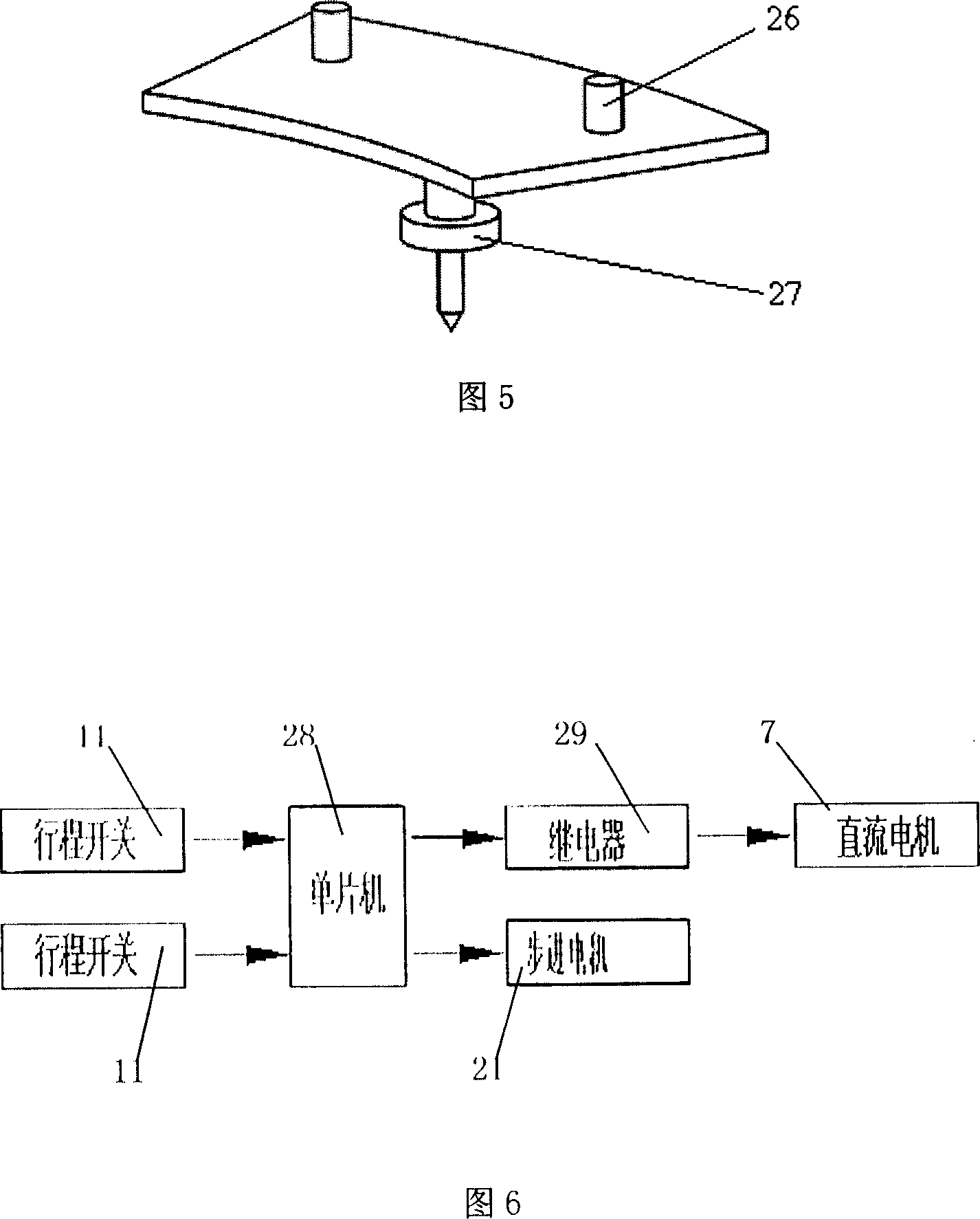

The invention discloses a trunk soup spraying robot, which comprises the following parts: ring-shaped rail, rack device, mobile device, spraying device and controller, wherein the support board is set on the bottom of ring-shaped rail and guide groove is set on the ring-shaped rail; the rack device is assembled on the guide groove of ring-shaped rail, which moves along guide groove; the mobile device is assembled on the rack device, which anchors rack device to move; the spraying device is set on the rack device, which moves along rack device; the mobile device and spraying device connect controller electrically.

Owner:SHANDONG JIANZHU UNIV

Workpiece surface spraying device

ActiveCN107744898AExtended service lifeAvoid affecting the work effectSpraying apparatusCleaning using toolsHydraulic cylinderFixed frame

The invention discloses a workpiece surface spraying device. The workpiece surface spraying device comprises a worktable, racks, a driving motor, a rotating seat, a supporting seat, a hydraulic cylinder, storage cylinders, lifting frames, a cross beam, a sliding rail, high-pressure spray heads, liquid transferring pipes, a groove, a sliding groove, lifting bases, brush heads, mounting frames, workpieces, a fixing frame, mounting frame bayonets, a fixing frame bayonet, mounting frame pressure heads, a fixing frame pressure head, a hydraulic rod, a movable connector, positioning holes, clampingrings and limiting pins. The workpiece surface spraying device is compact in structure, convenient to use and capable of conducting surface spraying operation on the multiple sleeve workpieces simultaneously, and the service life of the workpieces is prolonged; meanwhile, the surfaces of the workpieces can be subjected to impurity removing before being sprayed, so that the situation that the operation effect is affected by excessive impurities and dust is avoided, using is convenient, and the various using requirements in the spraying process of the workpieces are met; and the workpiece surface spraying device is used flexibly overall, uniform spraying is achieved, the working efficiency is high, high practicability is achieved, the operation effect is guaranteed, and using of manpower iseffectively reduced.

Owner:雷震

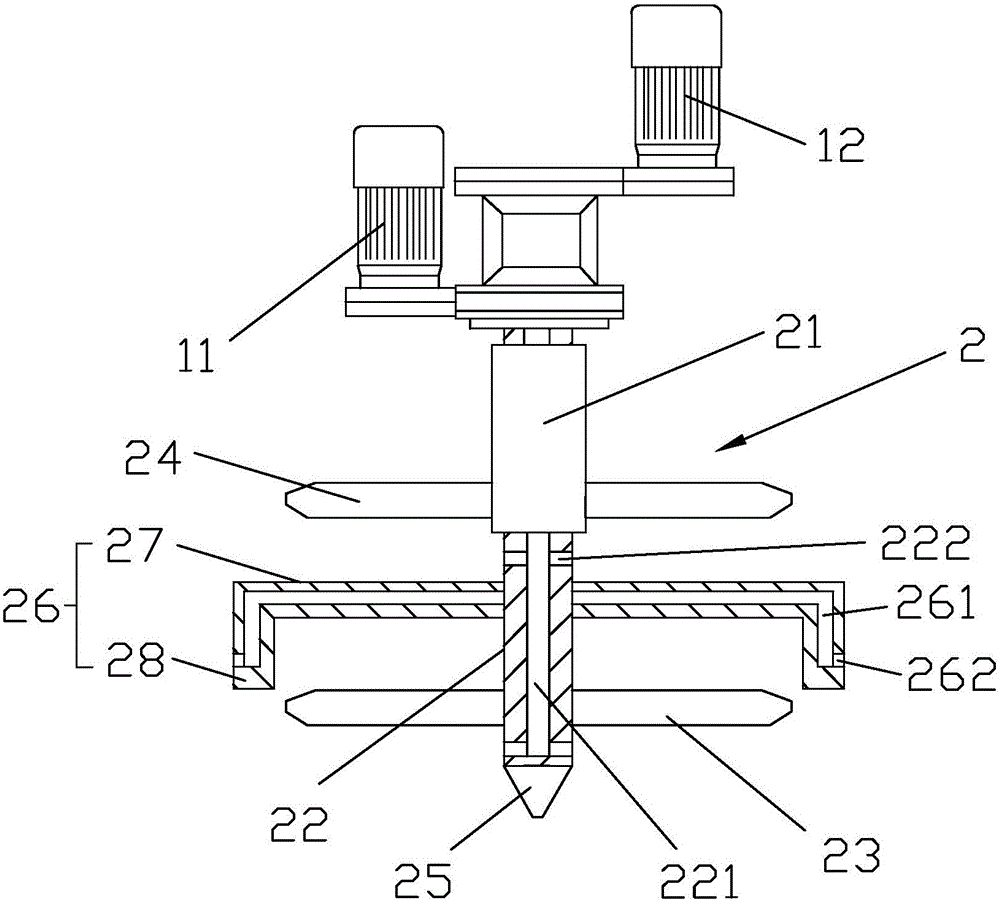

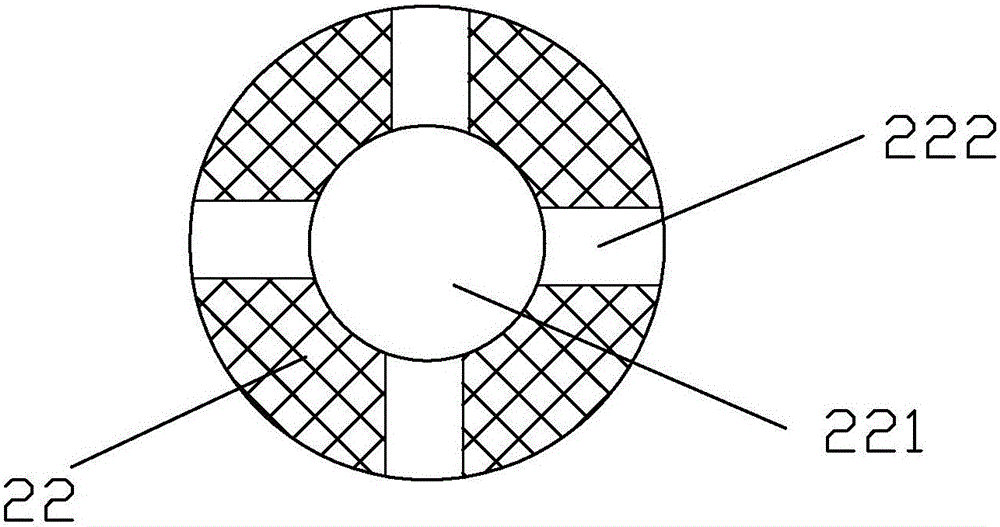

Stirring device and method for stirring sea mud

The invention mainly discloses a stirring device and method for stirring sea mud. According to the technical scheme, the stirring device comprises a chassis, a first motor, a second motor, a stirring machine head and a conveying device; the stirring machine head comprises an outer drill pipe, an inner drill pipe, first stirring blades and second stirring blades; the inner drill pipe is provided with a drill bit and third stirring blades; the drill bit is located at the bottom end of the inner drill pipe, and the third stirring blades are located between the first stirring blades and the second stirring blades; the inner drill pipe is provided with a first conveying channel and two first discharging sections; and the third stirring blades are provided with a second conveying channel and a second discharging section. The method comprises the steps of primary stone crushing, grout spraying, stirring and sinking, in-situ stirring, detecting, grout spraying, stirring and ascending, secondary detecting and stirring machine head cleaning. According to the stirring device and method, the multiple stirring blades are adopted, stirring is uniform, and the stirring efficiency and the stirring mixing effect are improved; and the multiple discharging sections are arranged, the one-time grout spraying amount is large, the pile forming speed is high, the pile forming quality is good, and the construction cost is saved.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

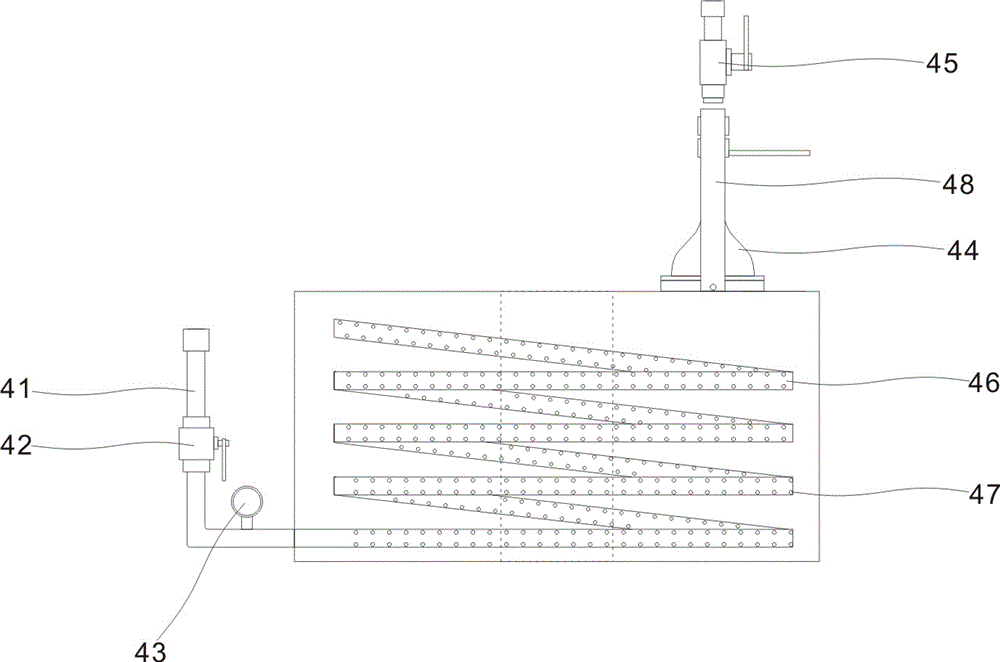

Leather spray device in improved structure

InactiveCN104278115AIncrease productivityWon't flow outLeather/skins/hides/pelt chemical treatment apparatusEngineeringConveyor belt

The invention provides a leather spray device in an improved structure, belonging to the technical field of leather processing equipment and solving the technical problems that existing leather spray devices in an improved structure have low production efficiency and pollute the atmosphere. The leather spray device in an improved structure comprises a bottom plate and a sealing base arranged on the bottom plate in a sleeving manner, wherein a conveyor belt is arranged on the bottom plate; a feeding hole is formed at one end of the sealing base, and a discharge hole is formed at the other end of the sealing base; a spraying mechanism and a drying mechanism are arranged in the sealing base; a dust residue discharge pipe and a waste gas discharge pipe, which are communicated with the interior of the sealing base, are arranged at the top of the sealing base; a cleaning barrel is arranged on the outer wall of the sealing base; the dust residue discharge pipe and the waste gas discharge pipe are connected with the cleaning barrel. The leather spray device has the advantages of high production efficiency, no pollution, and the like.

Owner:江苏东方金狐狸服饰有限公司

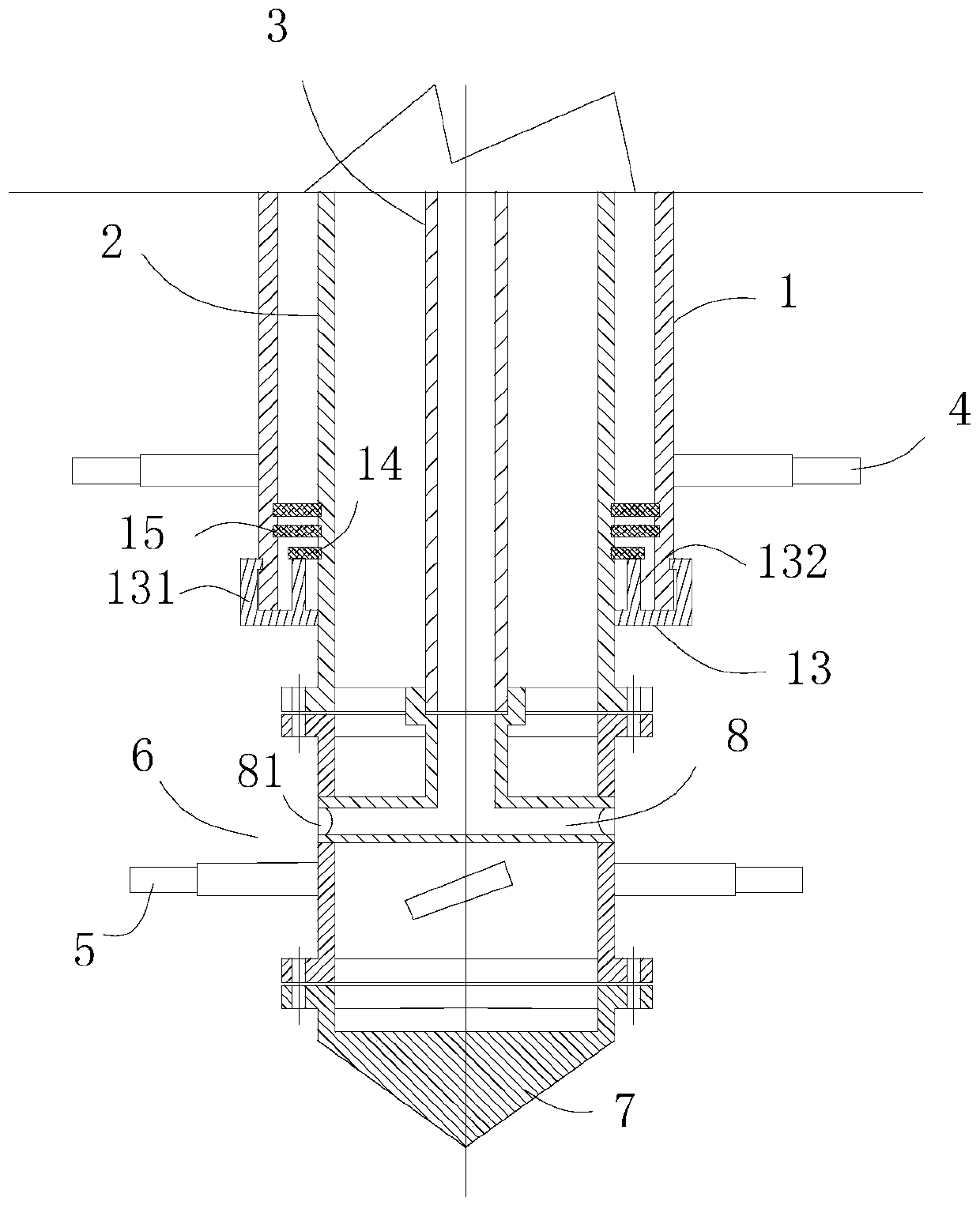

Cross-section-variable drilling tool for cement mixing pile

InactiveCN110080685AEasy to assemble and disassembleEasy to cleanDrill bitsBulkheads/pilesHydraulic cylinderStructural engineering

The invention relates to a cross-section-variable drilling tool for a cement mixing pile. The cross-section-variable drilling tool comprises an outer drill rod and an inner drill rod which are concentrically and coaxially arranged, a conveying pipe is arranged in the inner drill rod, outer drill rod blades are arranged on the lower portion of the outer drill rod, a spraying rod is connected to theend of the inner drill rod through a flange board, an inner drill bit is connected to the lower portion of the spraying rod through a flange board, a jet pipe is installed on the upper portion of thespraying rod, inner drill rod blades are installed on the lower portion of the spraying rod, one end of the jet pipe is hermetically connected with a conveying pipe for conveying a jet medium, jet orifices are formed in the other two ends of the jet pipe respectively, each of the outer drill rod blades and the inner drill rod blades comprises a fixed blade and a movable blade, the movable bladesare slidably connected with the outer drill rod blades, the other ends of the movable blades are connected with a hydraulic cylinder, the hydraulic cylinder is fixedly installed at one end, close to the inner wall of the outer drill rod or the spraying rod, of the fixed blade or directly installed on the spraying rod. The cross-section-variable drilling tool has the advantages of being simple in reducing structure, good in sealing performance, easy to control, high in adaptability and convenient to replace and clean.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

Leather spray machine with nozzle

InactiveCN104278114AIncrease productivityWon't flow outLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingEngineeringConveyor belt

The invention provides a leather spray machine with a nozzle, belonging to the technical field of leather processing equipment and solving the technical problems that existing leather spray machines with nozzles have low production efficiency and pollute the atmosphere. The leather spray machine with the nozzle comprises a bottom plate and a sealing base arranged on the bottom plate in a sleeving manner, wherein a conveyor belt is arranged on the bottom plate; a feeding hole is formed at one end of the sealing base, and a discharge hole is formed at the other end of the sealing base; a spraying mechanism and a drying mechanism are arranged in the sealing base; a dust residue discharge pipe and a waste gas discharge pipe, which are communicated with the interior of the sealing base, are arranged at the top of the sealing base; a cleaning barrel is arranged on the outer wall of the sealing base; the dust residue discharge pipe and the waste gas discharge pipe are connected with the cleaning barrel. The leather spray machine has the advantages of high production efficiency, no pollution, and the like.

Owner:江苏东方金狐狸服饰有限公司

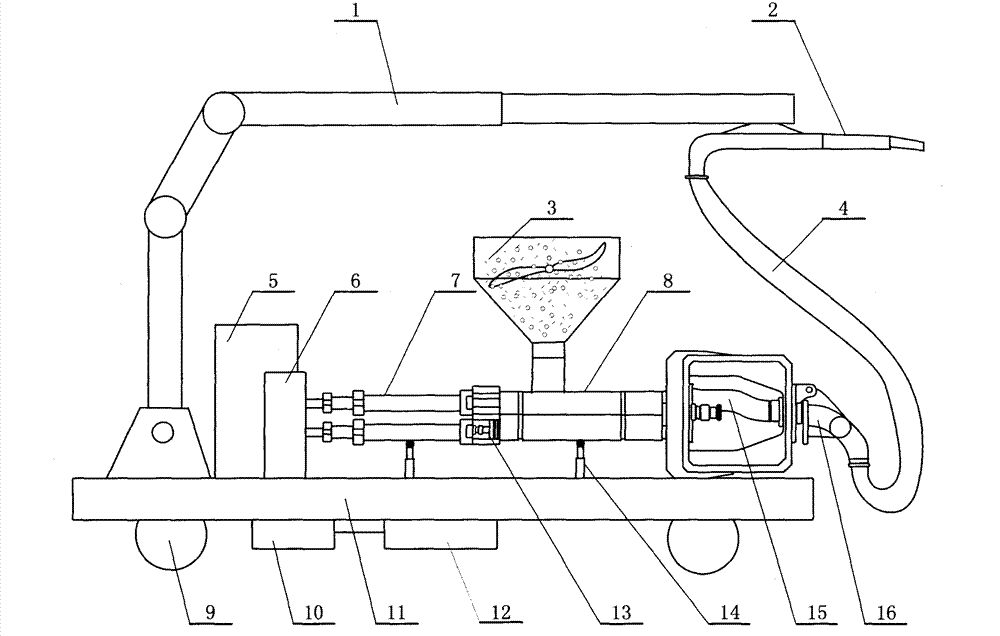

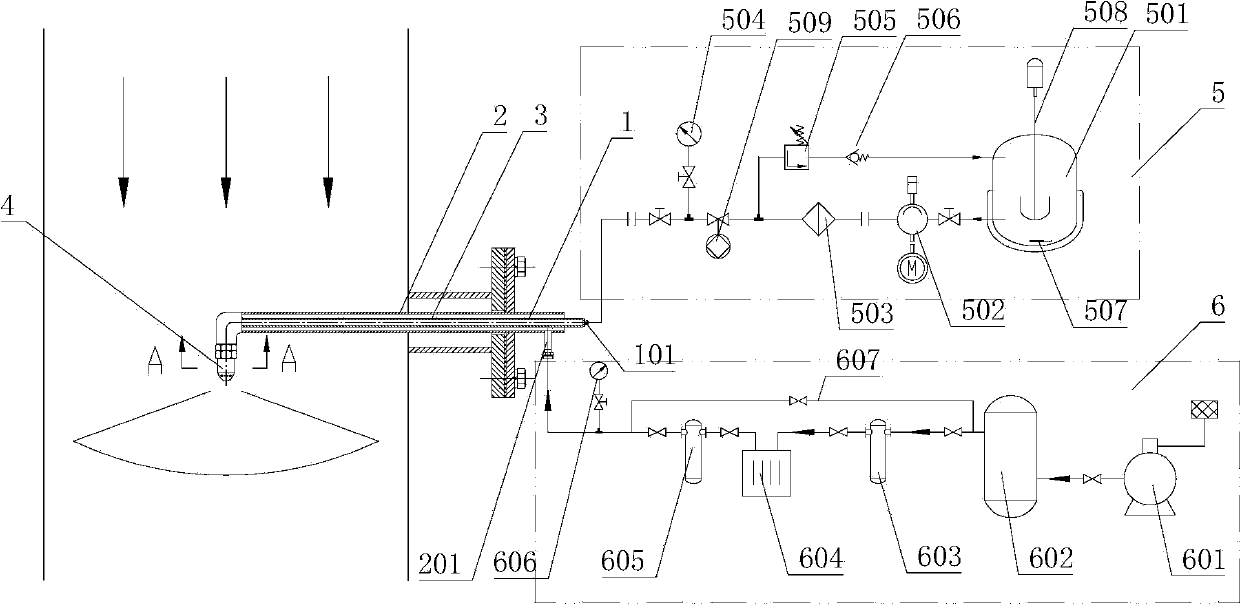

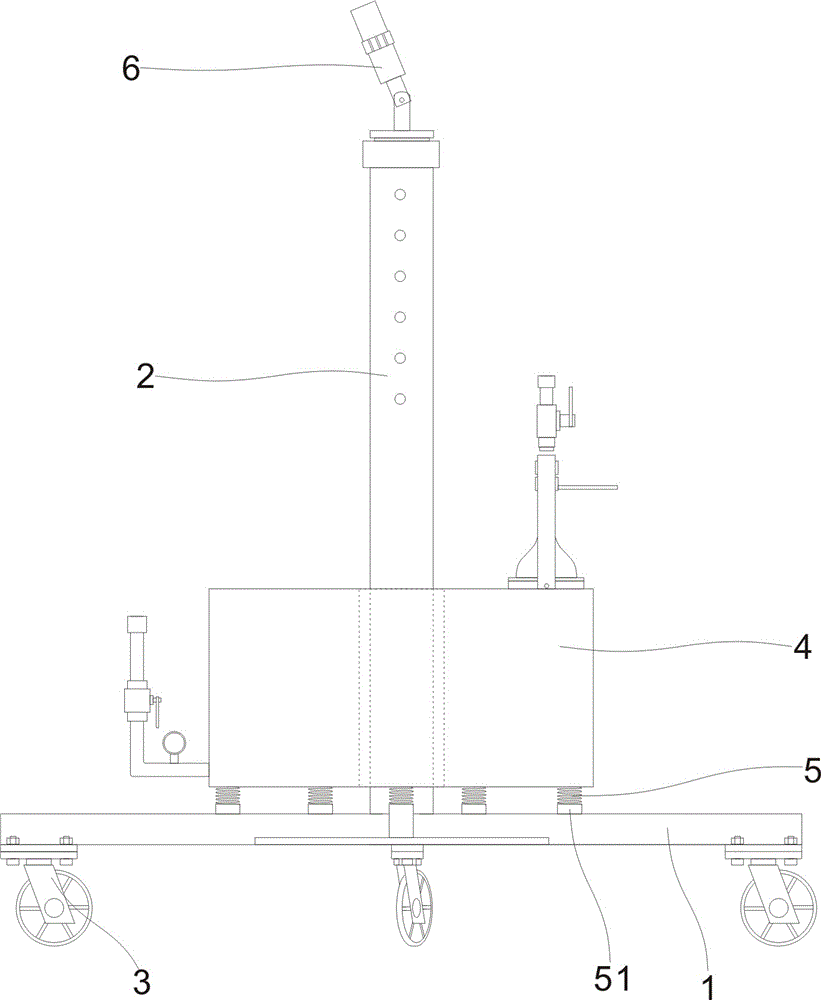

Wet concrete slurry-spray robot

InactiveCN102733822AUniform sprayingCompact structureUnderground chambersFoundation engineeringElectricityHydraulic pump

Owner:毛杰

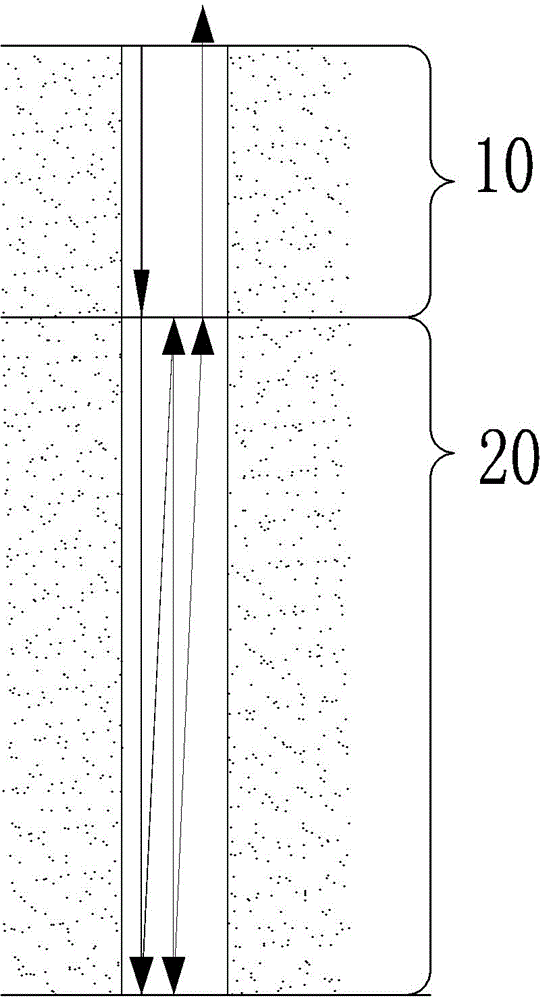

Construction technology and equipment for cement mixing pile

The invention discloses a construction technology and equipment for a cement mixing pile. The construction technology comprises the steps that when the hollow pile section is constructed, clear water is ejected from a grout ejecting opening, the clear water is also ejected by the grout ejecting opening in the first sinking process of the solid pile section, a mixing head is lifted and sunk for many times in the lifting process of the solid pile section, and cement grout is ejected from the grout ejecting opening. According to the construction technology for the cement mixing pile, the cement is distributed in the solid pile section uniformly, and the cement grout is combined with soil body in the solid pile section, so that the pile forming quality of the solid pile section is guaranteed, waste of the cement grout is avoided, and follow-up digging work of the hollow pile section is convenient.

Owner:中国能源建设集团广东电力工程局有限公司

Mining spiral feeder

ActiveCN104819001AGood transportabilityExcellent fill factorUnderground chambersTunnel liningEngineeringCam

The invention discloses a mining spiral feeder. The mining spiral feeder is composed of a body, a frame and wheels; the body is hinged to the frame; the wheels for moving back and forth are symmetrically mounted at the bottom of the frame. The body comprises an explosion-proof motor, a burdening mechanism and a water spraying device, all of which are located on the same inclined surface; the explosion-proof motor is mounted at the bottom end of the body and used for driving a cam vibrating screen mechanism and a stirring conveying trough. The cam vibrating screen mechanism is arranged under the burdening mechanism; the stirring conveying trough is arranged under the cam vibrating screen mechanism; the burdening mechanism is communicated with the stirring conveying trough by use of the cam vibrating screen mechanism. The mining spiral feeder has the advantages of reducing the underground operating personnel, saving the material cost, reducing the labor intensity of workers and improving the field operating environment; meanwhile, the guniting feeding is also even and the guniting quality is improved certainly.

Owner:SHANDONG UNIV OF SCI & TECH

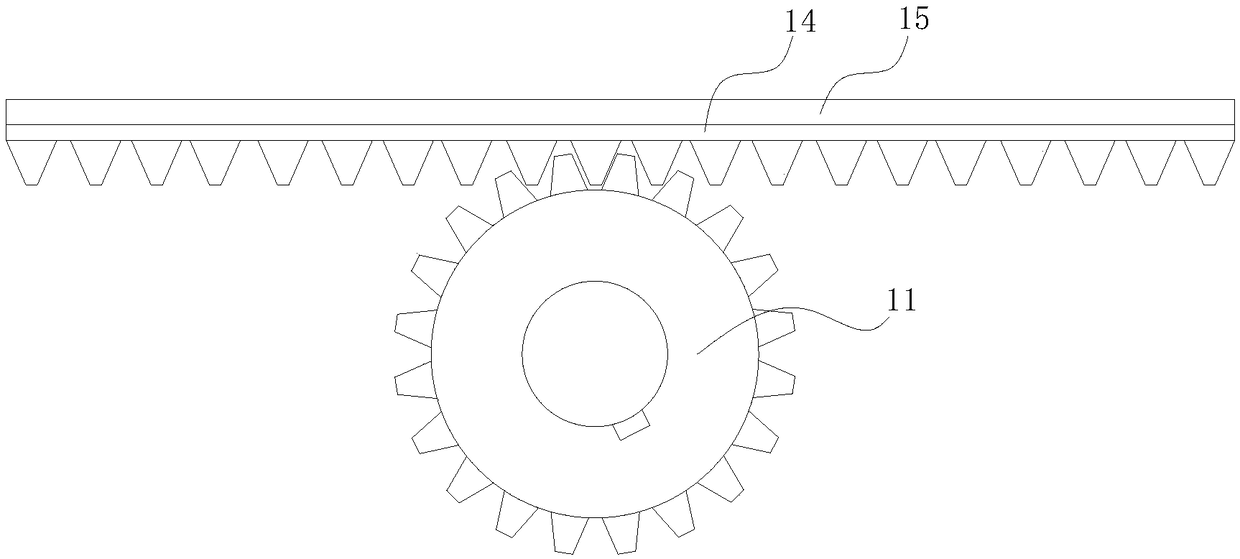

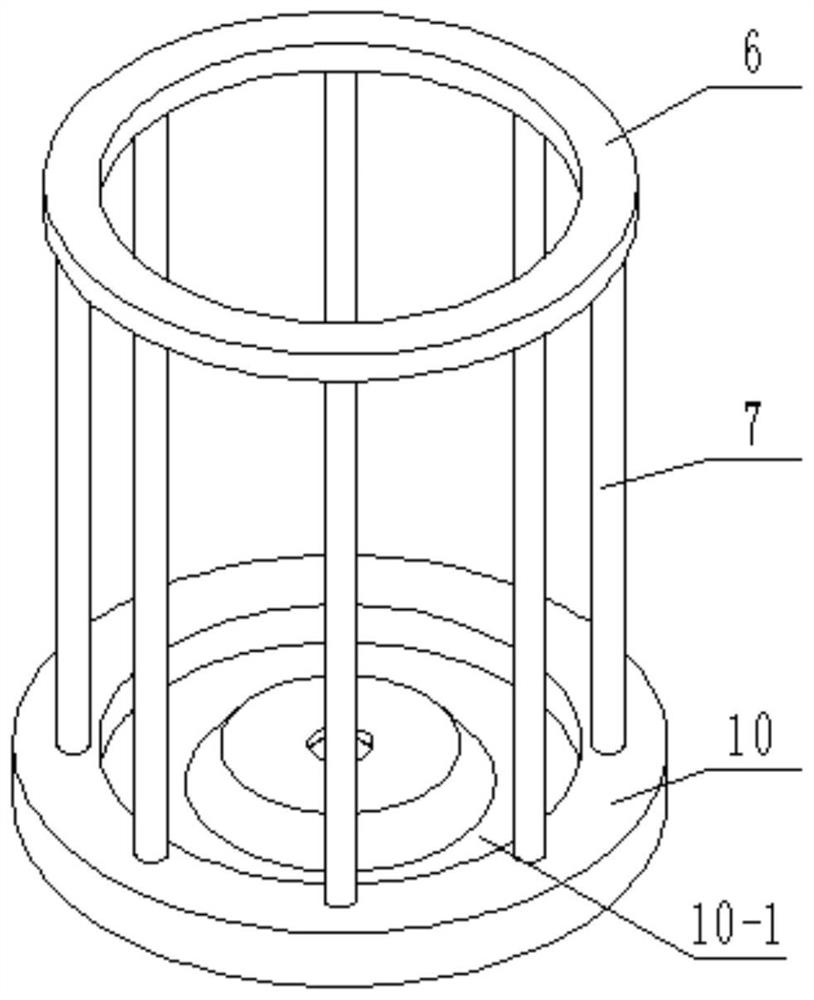

Rotating locating mechanism for spray coating of glass bottle outer wall

The invention relates to technical field of glass bottle production devices, in particular to a rotating locating mechanism for spray coating of a glass bottle outer wall. The rotating locating mechanism for spray coating of the glass bottle outer wall comprises a supporting platform and a rotating locating mechanism body arranged on the supporting platform. The rotating locating mechanism is composed of a rotating mechanism and a locating assembly. The rotating mechanism is composed of a rotating seat, a drive shaft and a transmission assembly of the rotating mechanism. The transmission assembly is composed of a gear and a rack. The lower end face of the supporting platform is provided with a linear drive assembly. The drive end of the linear drive assembly is connected with one end of the rack in a fastened manner. The gear is installed on the drive shaft in a fastened manner and meshed with the rack. The locating assembly is composed of a base, a round pipe, an air pipe, a tee-jointair valve and a high-pressure air bag. The rotating locating mechanism for spray coating of the glass bottle outer wall is simple in structure, when spray coating is conducted on the outer wall of aglass bottle, the glass bottle can be stably located, the spray coating uniformity is improved, and therefore the production quality of the glass bottle is improved.

Owner:芜湖中义玻璃有限公司

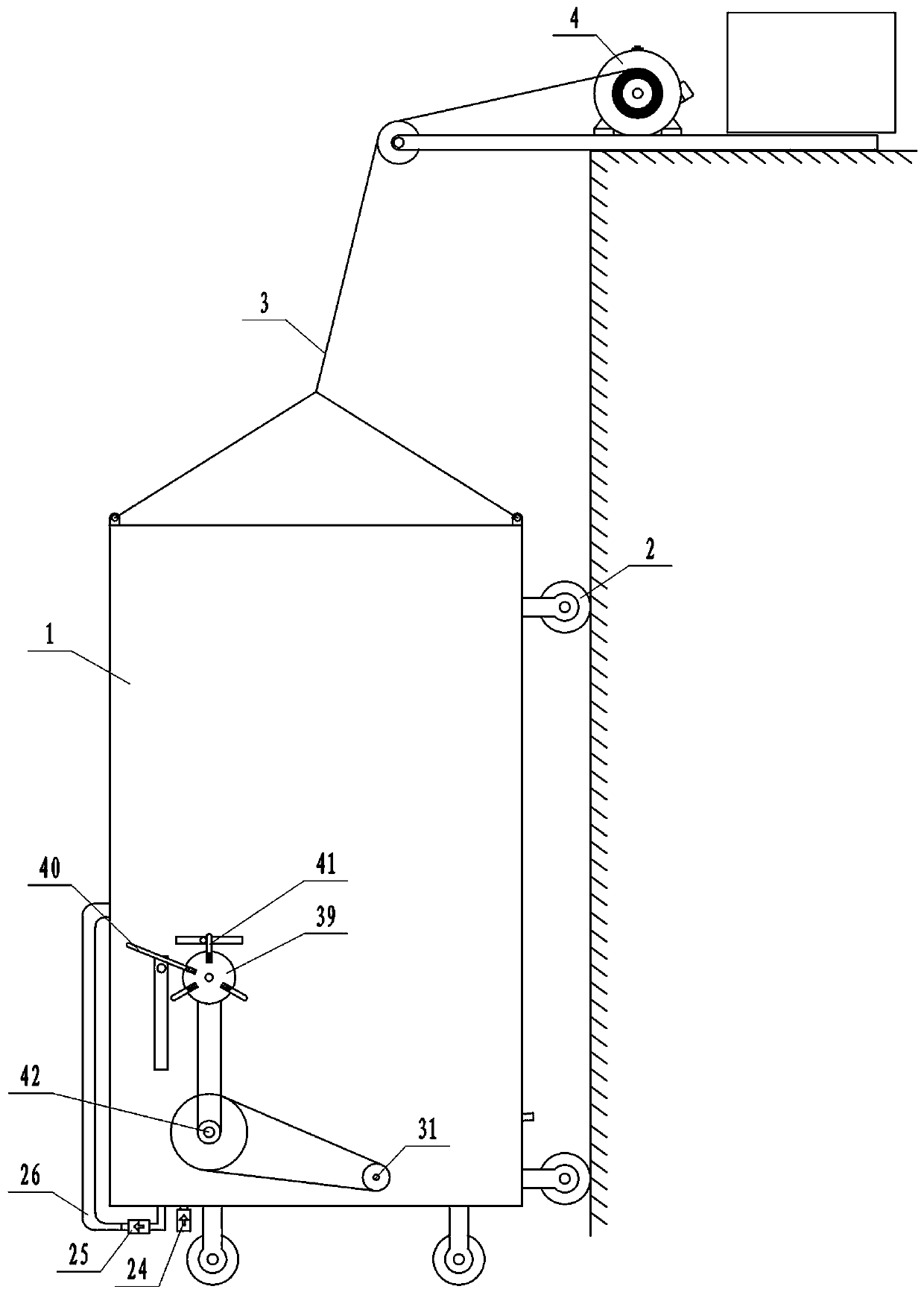

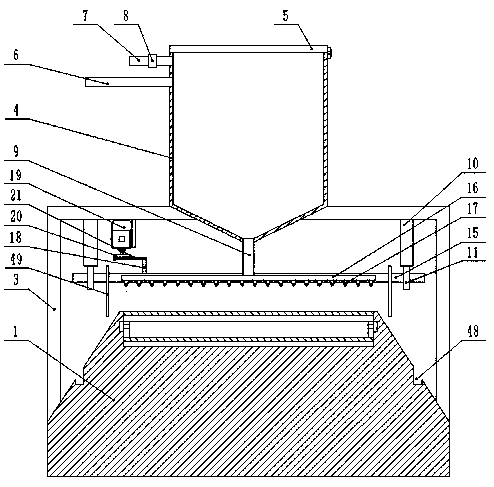

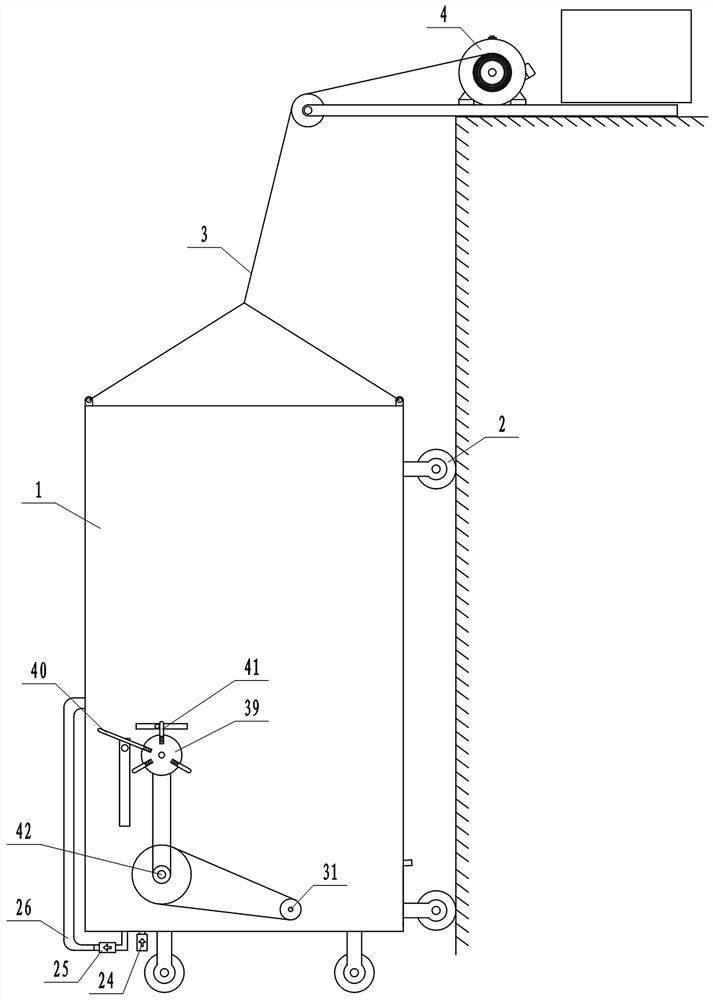

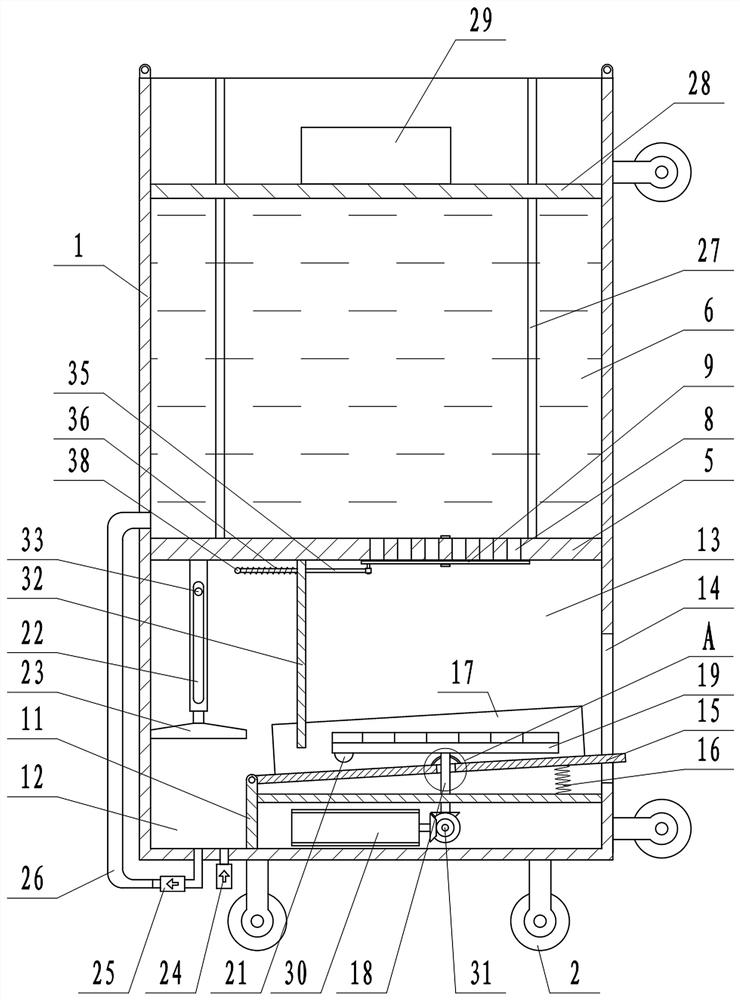

External wall suspension type automatic slurry throwing machine

ActiveCN111287419ARealize self-recyclingUniform sprayingBuilding constructionsCircular discInlet valve

The invention relates to an external wall suspension type automatic slurry throwing machine. The problems of low slurry throwing efficiency and large labor amount of an external wall are effectively solved. According to the technical scheme, the machine comprises a suspended box body, a partition plate is arranged in the middle of the box body, a material storage area is arranged above the partition plate, a plurality of through holes are formed in the partition plate, a baffle plate capable of rotating is arranged below the through holes, and the baffle plate rotates reciprocally to open or close the through holes; a bottom plate of the box body is provided with a vertical plate, the left side of the vertical plate is a material returning area, the right side of the vertical plate is a material throwing area, and the right side face of the material throwing area is provided with an opening; a vibration plate is hinged to the vertical plate, a disc is installed at the bottom of the boxbody, and after the disc rotates, the vibration plate can be extruded to vibrate through a convex block; a telescopic rod is fixed on the lower end face of the partition plate, an extrusion plate isinstalled at the lower end of the telescopic rod, a one-way liquid inlet valve and a one-way liquid outlet valve are installed at the bottom of the material returning area, a pipeline with the upper end arranged in the material storage area is connected to the liquid outlet valve, and materials in the material returning area can be extruded through reciprocating up-down movement of the extrusion plate so as to flow back.

Owner:中基建工防水装饰集团有限公司

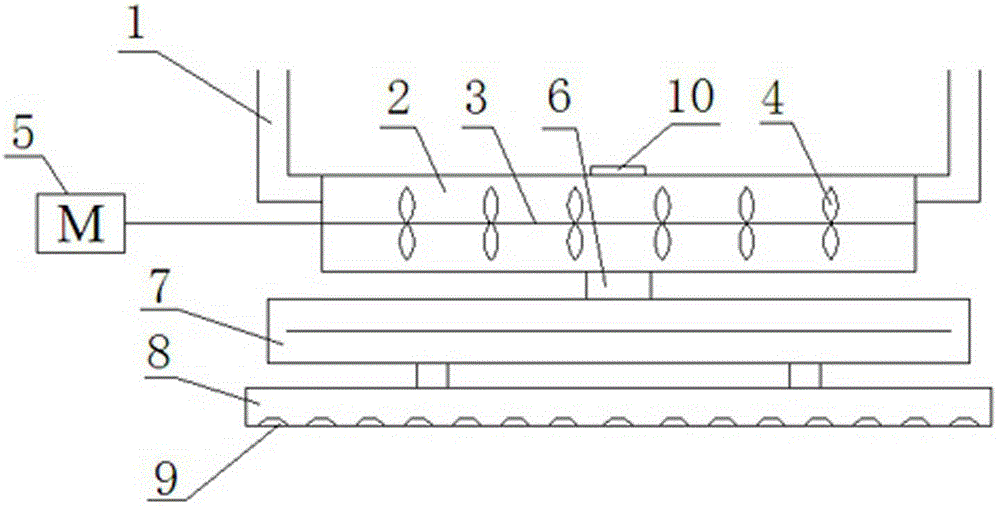

Efficient fabric homogenizing equipment

ActiveCN110258046AGuaranteed uniformityEvenly dispersedLiquid spraying apparatusTextile treatment by spraying/projectingSpray nozzleEngineering

The invention discloses efficient fabric homogenizing equipment which comprises a trapezoidal base. A fabric conveying transmission device is arranged at one end above the trapezoidal base, a controller is arranged on one side of the trapezoidal base, a reciprocating-shaking size spraying device is arranged at the center above the trapezoidal base, and an adjusting-type angular scraper device is arranged on the other side at the center above the trapezoidal base. Through action of air pressure, size can be quickly delivered; through action of an eccentric wheel, a size spraying transverse rod is driven to transversely shake in a reciprocating manner to enable a size spraying nozzle to spray the size in a reciprocating shaking manner, so that the size can be sprayed to fabric uniformly; through action of a backflow groove and a size spraying retaining plate, waste of the size can be avoided effectively, and the size can be recycled effectively; through two-time contact between an angular frame as well as an oblique scraper and the fabric, the size on the fabric is homogenized twice through the oblique scraper to be uniformly dispersed, so that homogenizing uniformity is ensured effectively.

Owner:博兴兴博投资有限公司

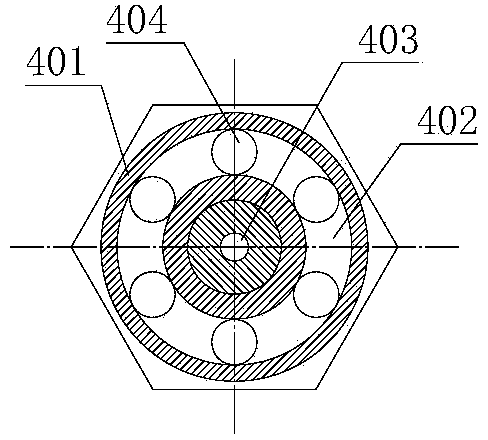

Active exciting agent atomization device for metal tailing grinding system

ActiveCN104190567AEffective mist sprayingUniform sprayingLiquid spraying apparatusEngineeringDust collector

An active exciting agent atomization device for a metal tailing grinding system comprises a spray gun, an air-liquid mixing nozzle, a liquid supply system and an air supply system, wherein the spray gun is composed of an inner tube and an outer sleeve in an assembly welding mode, an air intake ring cavity is formed between the outer sleeve and the inner tube, one end of the air intake ring cavity is a closed end, the other end of the air intake ring cavity is an open end, the spray gun is installed on a connection pipeline between a vertical mill and a bag type dust collector, the side wall of the position, located outside the connection pipeline, of the outer sleeve is provided with an air inlet, and the end, located outside the connection pipeline, of the inner tube stretches out of the outer sleeve to form a liquid intake end; the air-liquid mixing nozzle is installed at the open end of the spray gun; the liquid supply system is connected with the liquid intake end, and the air supply system is connected with the air inlet. The device can be used for effectively and uniformly atomizing and spraying active exciting agents in the pipeline, thereby well guaranteeing uniform mixing of the active exciting agents and micro powder finished products of raw materials, and guaranteeing that the active exciting agents can be effectively attached to interfaces of particles of the micro powder finished products. The device prevents a hot air environment in the mill from affecting performance of the active exciting agents, thereby reducing volatilization and losses of the active exciting agents. The device can be used for regulating and controlling the additive amount, and therefore different production requirements can bet met.

Owner:中材(天津)粉体技术装备有限公司 +1

Adjuvant composition, agrochemical spray aqueous solution containing the same and control method using the same

The present invention relates to an adjuvant composition characterized by containing the following (A) and (B):(A) Sodium dialkylsulfosuccinate and polyoxyethylene alkyl ether, the total content being 45% to 85% by mass;(B) 5 to 40% by mass of component for pour-point depressant,and the adjuvant composition can uniformly adhere agrochemical active ingredients to crops, has an effect to stabilize the agrochemical efficacy and particularly exerts a pronounced effect when used in drift-reducing spraying.

Owner:NAT AGRI & FOOD RES ORG +1

Mortar spraying device of crystal multi-wire cutting machine

InactiveCN105196432AImprove processing qualityReduce air contentWorking accessoriesFine working devicesWire cuttingAir content

The invention relates to the technical field of a cutting device, in particular to a mortar spraying device of a crystal multi-wire cutting machine. The mortar spraying device comprises a mortar inlet pipe, a stirring pipe, a rotating shaft, blades, a motor, a mortar outlet pipe, a cooling pipe, a mortar spraying pipe, mortar spraying openings and an exhausting opening; the mortar inlet pipe is arranged at two sides above the stirring pipe, the rotating shaft is arranged in the axis of the stirring pipe, the blades are welded on the rotating shaft, and one side of the rotating shaft is connected with the motor; the exhausting opening is formed in the middle position above the stirring pipe, the bottom of the stirring pipe is connected with the cooling pipe by virtue of the mortar outlet pipe, the cooling pipe is communicated with the mortar spraying pipe, a plurality of mortar spraying openings are formed in the bottom of the mortar spraying pipe, and each mortar spraying opening is in a truncated cone shape. By adopting the mortar spraying device, the air content in the mortar can be reduced, the uniformity in mortar spraying is facilitated, the machining quality of crystals is improved, and the cost is saved.

Owner:YANTAI RONGSHENG PRESSURE VESSEL MFG

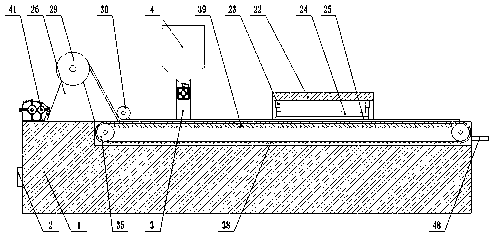

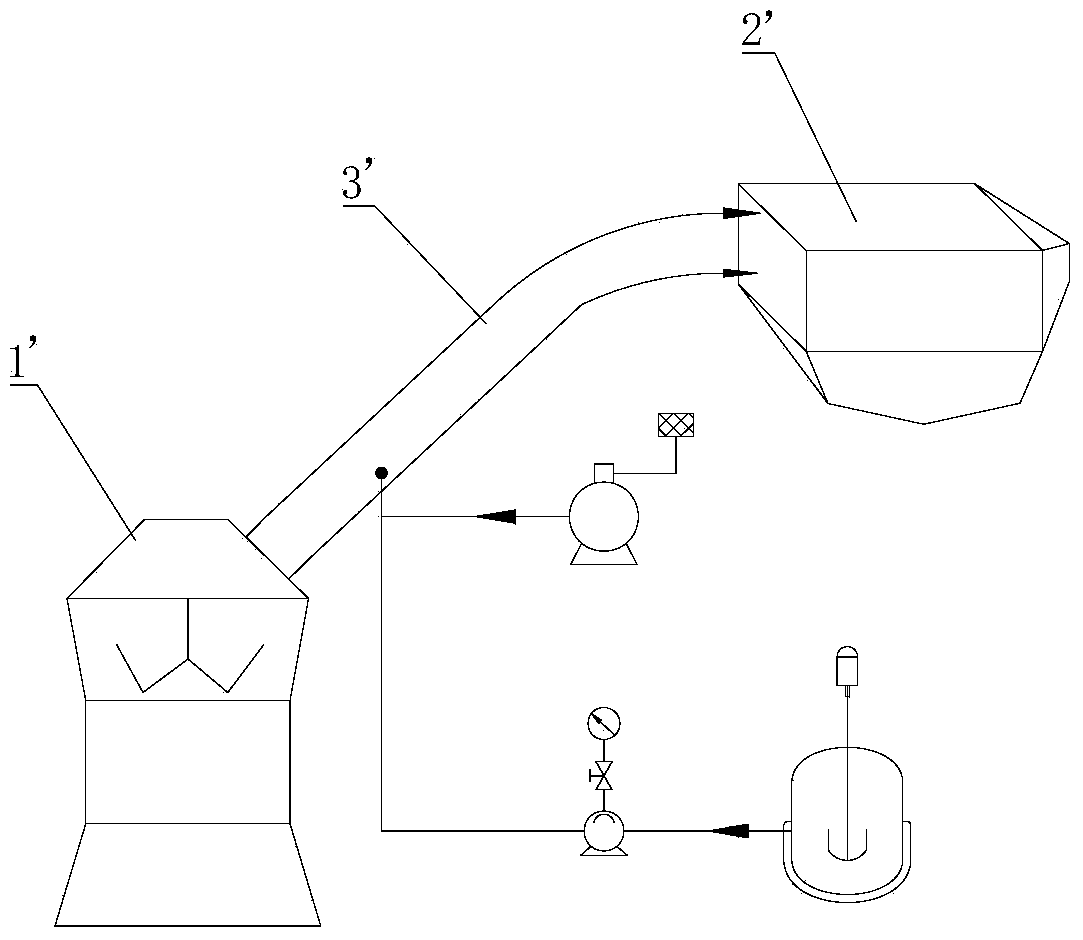

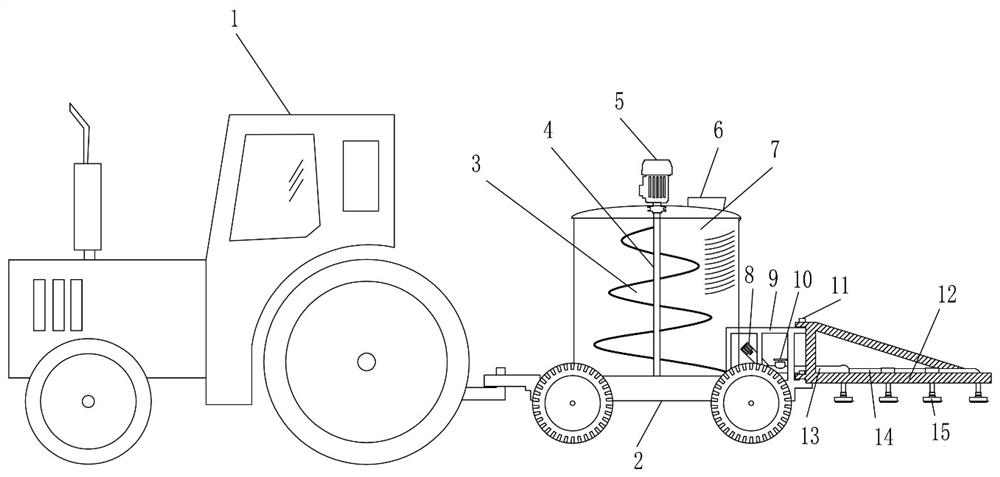

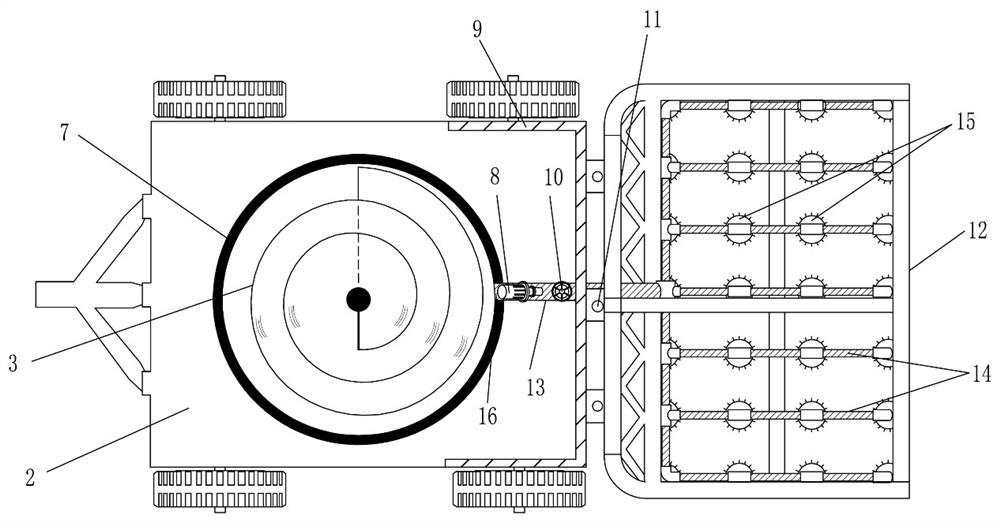

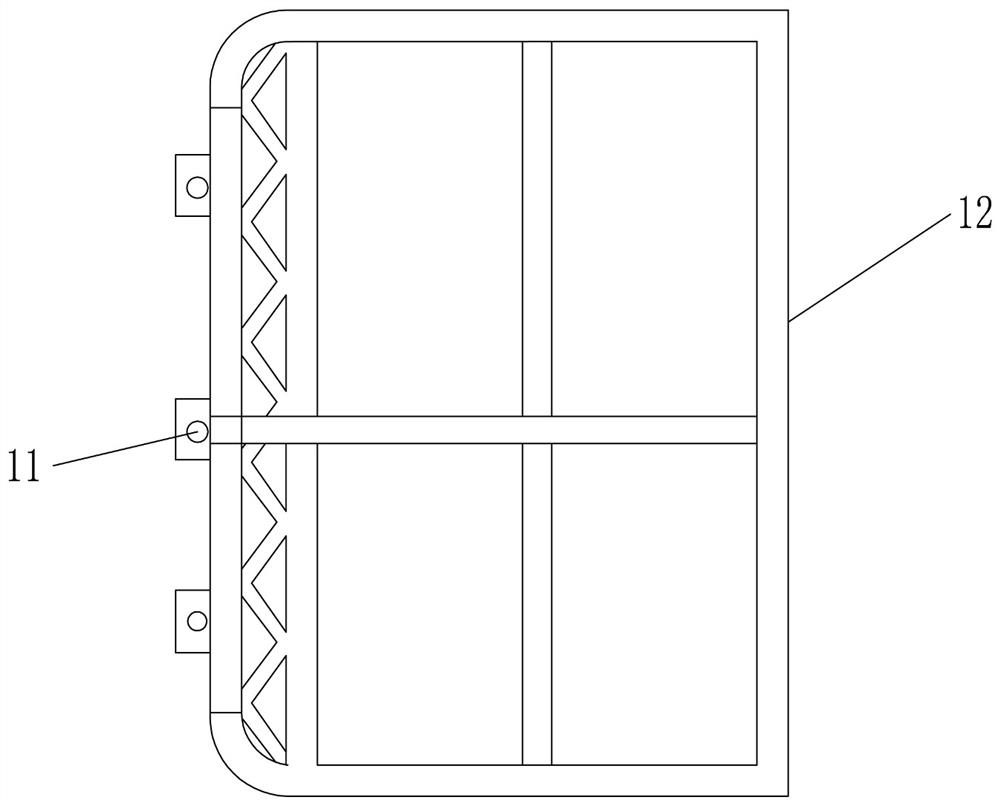

Slurry stirring and spraying machine for cemented sand and gravel dam

InactiveCN111906940AGuaranteed uniformityConditions affecting normal useFoundation engineeringCement mixing apparatusEngineeringSlurry

The invention relates to the technical field of slurry spraying, in particular to a slurry stirring and spraying machine for a cemented sand gravel dam. The slurry stirring and spraying machine is characterized in that a traction mechanism is connected and fixed to a supporting traveling mechanism, a slurry stirring system is arranged above the supporting traveling mechanism, a supporting frame isconnected to the tail end of the supporting traveling mechanism, a spray head system is arranged on the supporting frame, and the spray head system is connected with the slurry stirring system. According to the slurry stirring and spraying machine for the cemented sand gravel dam, a cementing material can be uniformly sprayed on an aggregate, so that uniform slurry spraying on the sand and gravelworking face is realized, the penetration degree of sprayed slurry adapts to the laying thickness of the aggregate, the slurry spraying amount per unit area can be accurately controlled, a water-cement mixture of the cementing material can be continuously stirred, and the phenomenon of water-cement separation is avoided.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

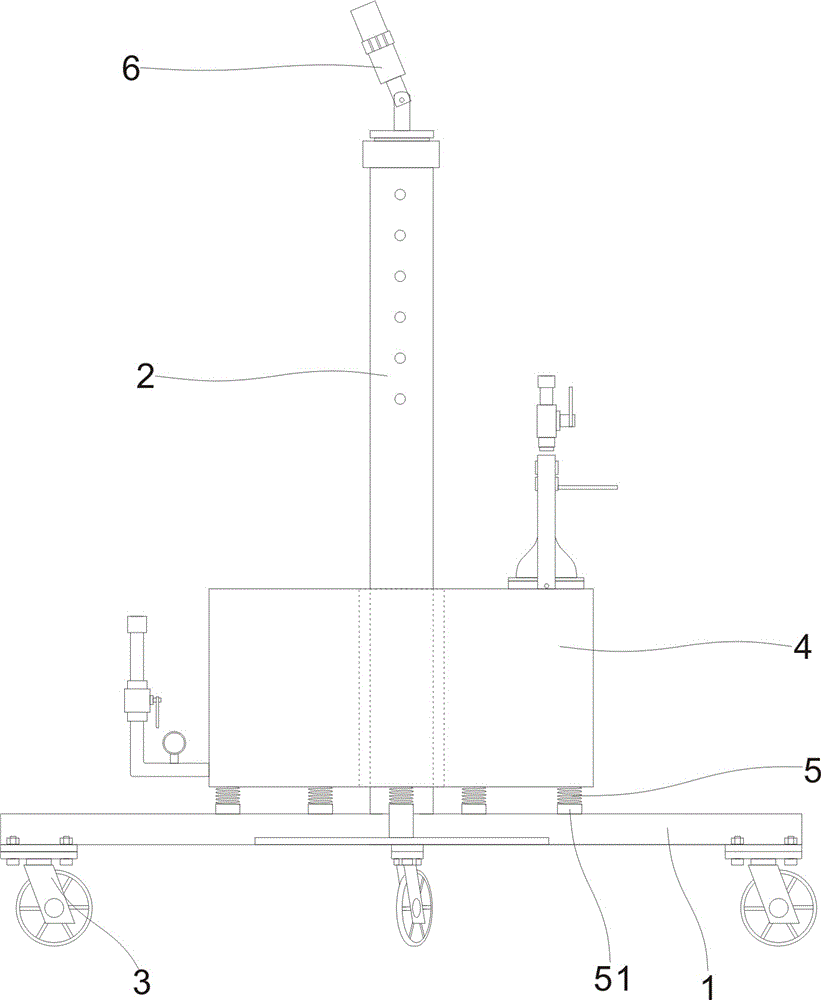

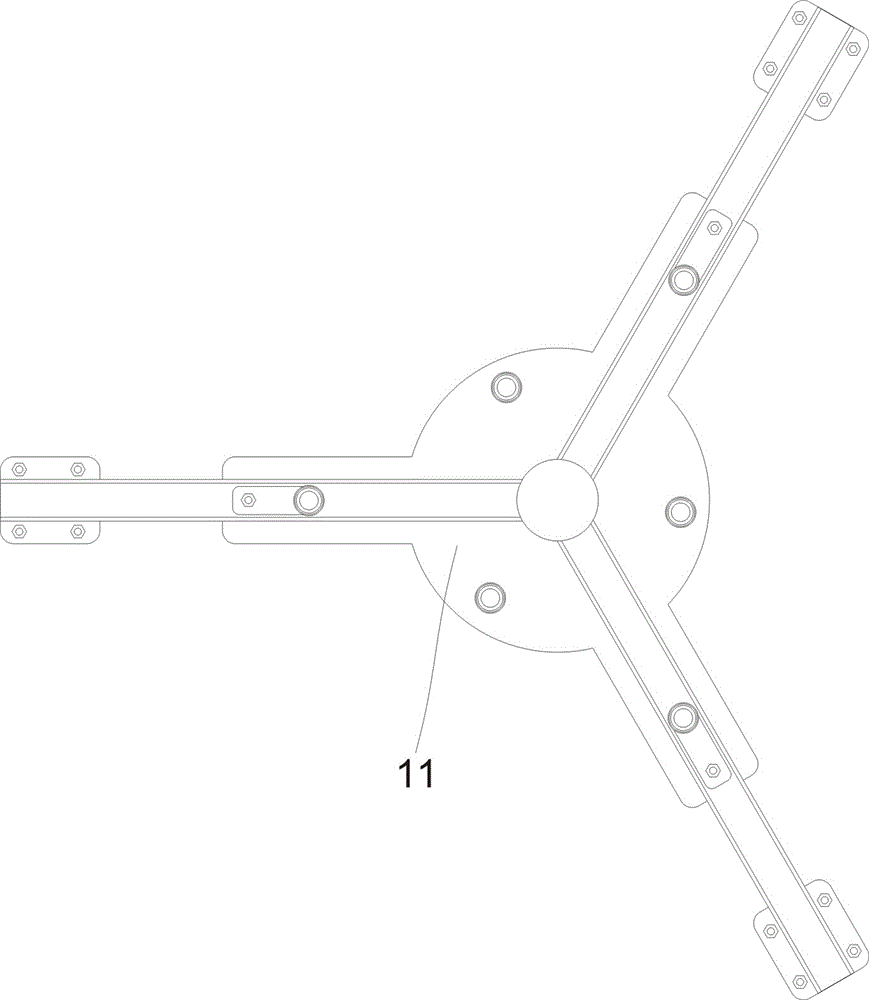

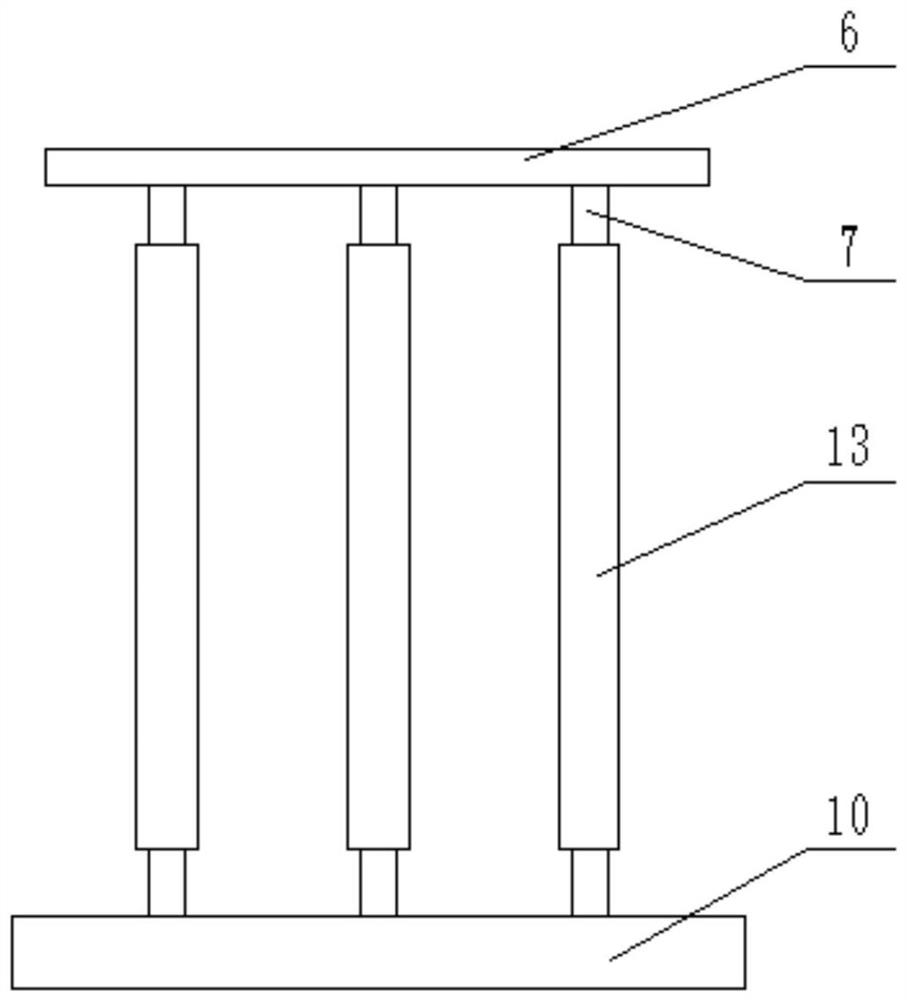

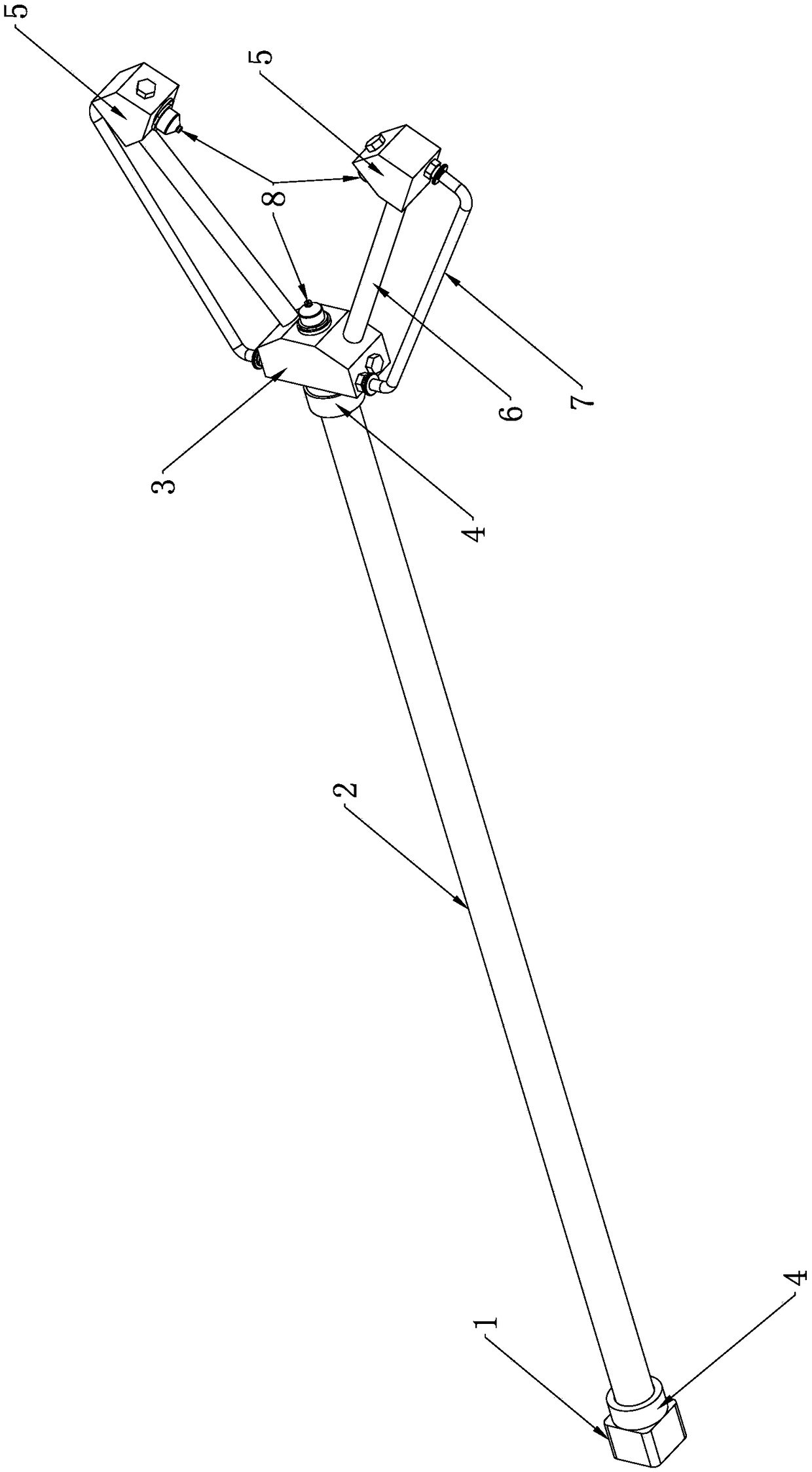

Filling and guniting support frame for dry powder accelerating agent

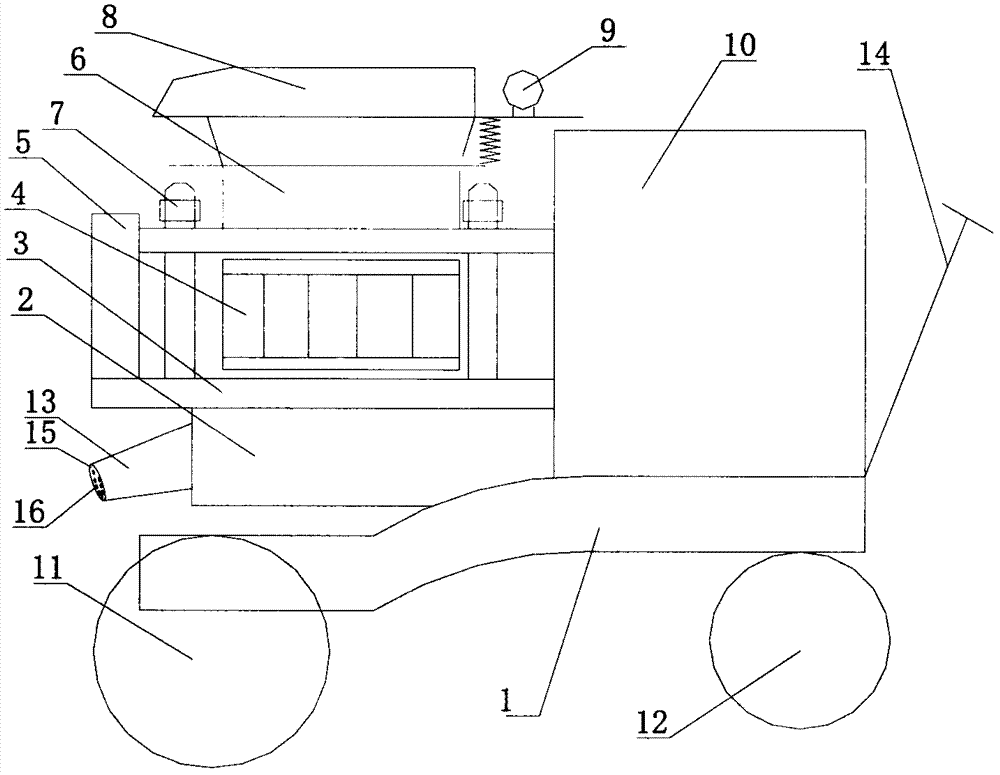

InactiveCN104481120AAchieve sprayingFlexible and convenient to moveUnderground chambersBuilding constructionsEngineeringFoot type

The invention provides a filling and guniting support frame for dry powder accelerating agent. The filling and guniting support frame comprises a base, a lifting strut, travelling wheels, a dust raising box, springs and a pipe clamp. The filling and guniting support frame combines the supporting and the filling of the accelerating agent into a whole and has a simple integral structure, but the mixing evenness of the accelerating agent is much higher than the mixing evenness of the existing equipment. A spiral dust raising pipeline is arranged in the dust raising box, the pipe wall of the dust raising pipeline is provided with small through holes which are evenly distributed, one end of the dust raising pipeline is connected to an air inlet pipeline, and the other end of the dust raising pipeline is sealed. According to the filling and guniting support frame for the dry powder accelerating agent, the spray gun of a guniting machine can be fixed, the spraying of concrete is realized, the height and the angle of a sprayer can be regulated in a spraying process, the equipment can flexibly and conveniently move in a working process by a three-foot type base, and the flexibility of the equipment is increased.

Owner:平顶山鸿顺源工贸有限公司

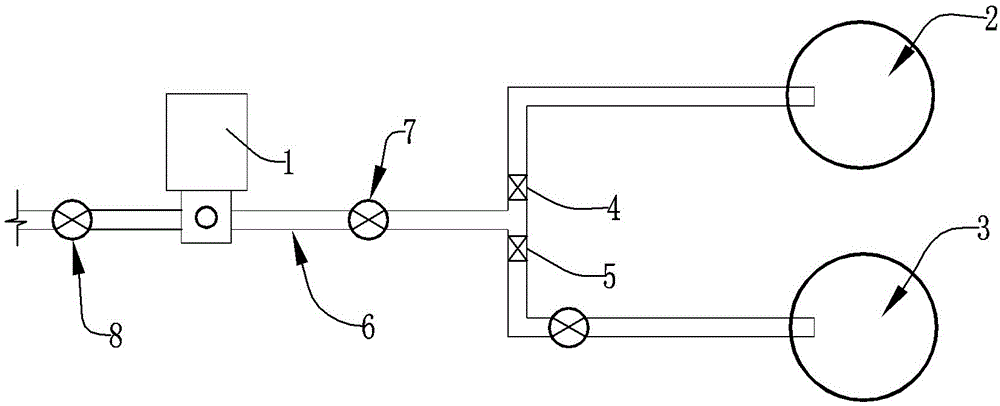

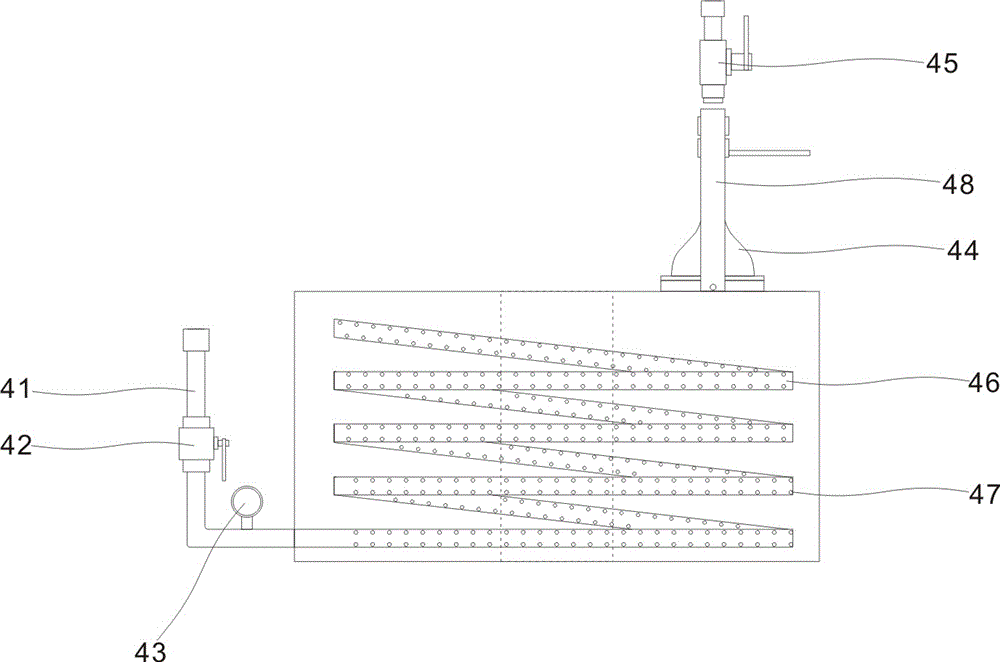

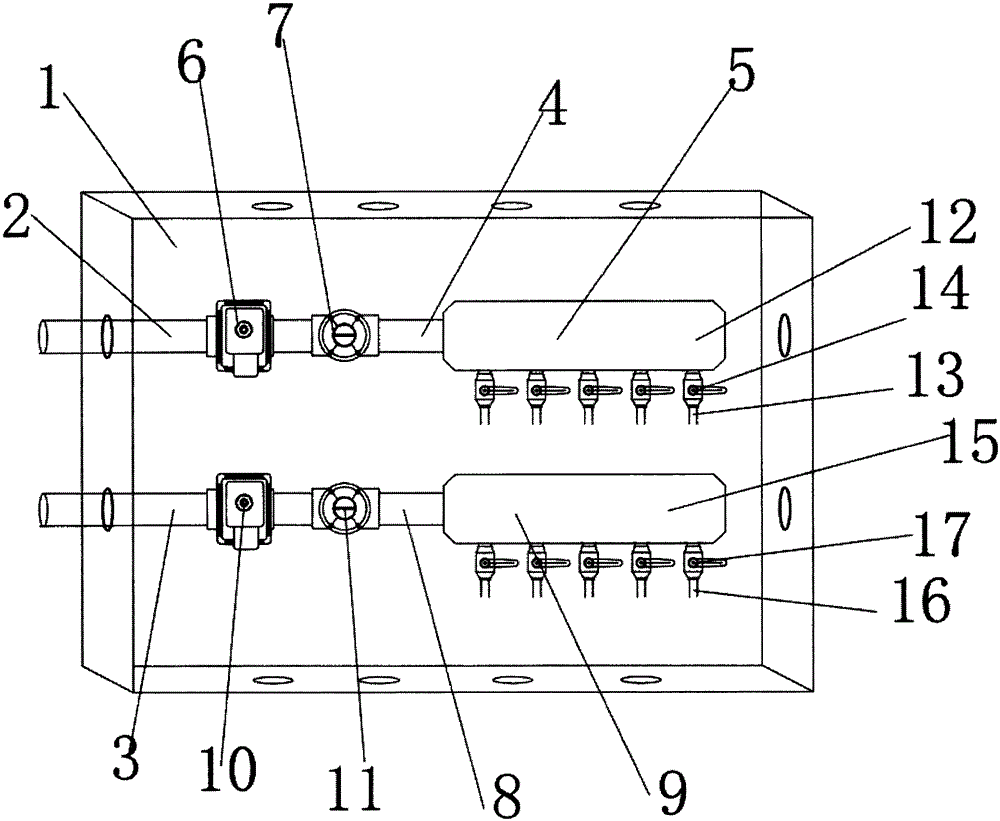

Pressure-stabilizing aerial fog distributor

InactiveCN105056667AAir pressure balanceUniform sprayingUsing liquid separation agentWater channelSpray nozzle

The invention relates to a pressure-stabilizing aerial fog distributor. The pressure-stabilizing aerial fog distributor comprises a box body, wherein a water channel device and a gas channel device are mounted in the box body; the gas channel device is located below the water channel device; the water channel device consists of a water channel output pipeline and water channel device distributing valve components; a first electromagnetic valve and a first pressure stabilizing valve; the gas channel device consists of a gas channel output pipeline and gas channel device distributing valve components; a second electromagnetic valve and a second pressure balancing valve are sequentially mounted on the gas channel output pipeline. The water channel device and the gas channel device are mounted in the box body in an integrated manner, so that dust can be effectively prevented, and unnecessary damage can be reduced; the electromagnetic valves and the pressure stabilizing valves are mounted on both the water channel device and the gas channel device to adjust the water pressure and the gas pressure of the output pipelines, so that the water pressure and the gas pressure of a plurality of nozzles configured on each output pipeline are balanced and consistent, and accordingly, the effect of unified and balanced integral spraying of water-mist dust suppression equipment can be achieved.

Owner:NINGBO HAICHEN TIANLI MACHINERY

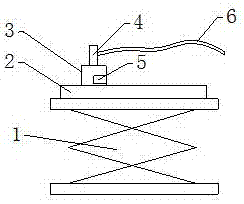

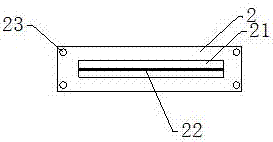

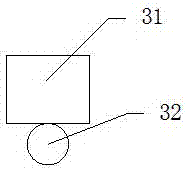

Sliding spray coater

The present invention is a sliding spraying machine, which includes a lifting platform, a sliding platform, a matching block, a spray gun, a controller and a feeding pipe. There is a groove on the sliding platform, and a protruding strip is arranged in the middle of the groove. There are round holes around the sliding platform. The matching block is composed of a fixed block and a pulley. The sliding platform is fixedly installed on the lifting platform. The matching block is installed on the sliding platform through the cooperation of the pulley and the raised strip. The matching block The spray gun is fixedly installed on the upper surface, and the controller is fixedly installed on the side of the matching block. The spray gun has a matching hole matched with the feeding pipe; the invention can realize the spraying operation on the balance weight of the forklift, and the spraying surface is more comprehensive and uniform. Guaranteed multi-directional movement, wide spraying area.

Owner:刘学洋

Building construction material spraying device

ActiveCN112974091APrevent splashFlexible useSpray boothsArchitectural engineeringMechanical engineering

The invention discloses a building construction material spraying device. The device comprises a supporting assembly, a clamping assembly and a spraying assembly, wherein the clamping assembly is arranged at the upper part of the supporting assembly; the supporting assembly is of a frame structure; a to-be-sprayed material is placed in the supporting assembly, and the upper end of the to-be-sprayed material is fixed through the clamping assembly; the spraying assembly comprises a coating shell; the coating shell is made of a bendable material; the spraying assembly comprises a plurality of spraying heads arranged at the inner side of the coating shell; all the spraying heads are connected with spraying equipment through material conveying pipes; and the coating shell coats the outer side of the supporting assembly in the circumferential direction of the supporting assembly. By replacing a manual spraying mode, the building construction material spraying device is higher in efficiency, uniform in spraying and more reliable.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Soldering flux spraying equipment for new energy automobile liquid cooling plate production

The invention discloses soldering flux spraying equipment for new energy automobile liquid cooling plate production, which comprises a frame module, a clamping module, a spraying module, an anti-blocking module and a feeding module, and is characterized in that the frame module comprises a frame and a rack connected with the frame; the clamping module comprises a pressure bearing assembly connected with the frame, a T-shaped rod installed on the rear side of the pressure bearing assembly, a disc body, a spring, a supporting rod connected between the frame and the disc body and a first electric push rod installed at the rear end of the T-shaped rod, wherein the disc body and the spring are movably connected to the outer side of the T-shaped rod in a sleeving mode. The spraying module comprises a second electric push rod located on the rear side of the frame. According to the spraying device, the first electric push rod is started, the first electric push rod pushes the T-shaped rod forwards, the spring shrinks, then the liquid cooling plate is fixed, the steps are simple, use is convenient, the liquid cooling plate is firmly clamped under the condition that the contact area with the liquid cooling plate is small, and the spraying efficiency is improved.

Owner:常州市飞荣达电子材料有限公司

Concrete guniting mechanism

InactiveCN104500104AReasonable design organizationUniform sprayingUnderground chambersFoundation engineeringCycloneEngineering

The invention relates to a concrete guniting mechanism. The concrete guniting mechanism comprises a base, a cyclone, a panel, a rotor body, a limiting base, a hopper base, a pressing mechanism, a hopper, an electric vibrator and an electric meter box, wherein a large rubber wheel is arranged in the front of the lower end of the base, a small rubber wheel is arranged in the rear of the lower end of the base, the cyclone is installed on the base, the panel is arranged on the cyclone, a spraying opening is formed in the side face of the front end of the cyclone and connected with a spraying pipe, the rotor body is connected to the panel, the hopper base is installed above the rotor body, both the limiting base and the pressing mechanism are connected between the hopper base and the panel, the hopper is connected to the hopper base, the electric vibrator is connected with the hopper, and the electric meter box has control over the electric vibrator, the rotor body and the cyclone. By the adoption of the design of the concrete guniting mechanism, the designed mechanism is reasonable and can achieve uniform guniting, and a good guniting effect is achieved.

Owner:GUANGXI PROVINCE NANNING CITY ZHIJIANZHIFAN TECH CONSULTING

Dry powder accelerator filling and shotcrete support

InactiveCN104481120BAchieve sprayingFlexible and convenient to moveUnderground chambersBuilding constructionsShotcreteEngineering

The invention provides a filling and guniting support frame for dry powder accelerating agent. The filling and guniting support frame comprises a base, a lifting strut, travelling wheels, a dust raising box, springs and a pipe clamp. The filling and guniting support frame combines the supporting and the filling of the accelerating agent into a whole and has a simple integral structure, but the mixing evenness of the accelerating agent is much higher than the mixing evenness of the existing equipment. A spiral dust raising pipeline is arranged in the dust raising box, the pipe wall of the dust raising pipeline is provided with small through holes which are evenly distributed, one end of the dust raising pipeline is connected to an air inlet pipeline, and the other end of the dust raising pipeline is sealed. According to the filling and guniting support frame for the dry powder accelerating agent, the spray gun of a guniting machine can be fixed, the spraying of concrete is realized, the height and the angle of a sprayer can be regulated in a spraying process, the equipment can flexibly and conveniently move in a working process by a three-foot type base, and the flexibility of the equipment is increased.

Owner:平顶山鸿顺源工贸有限公司

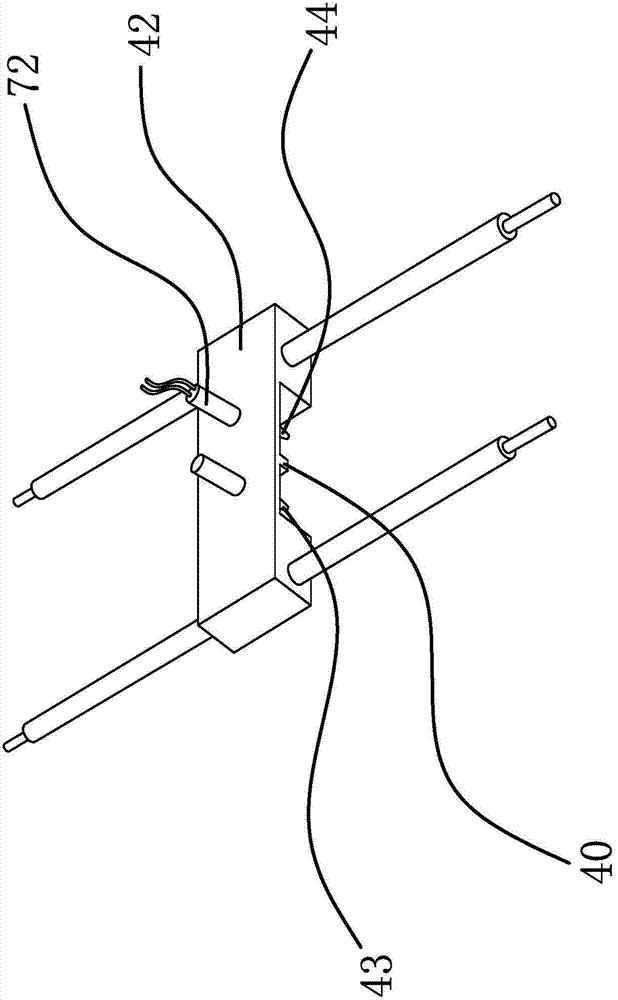

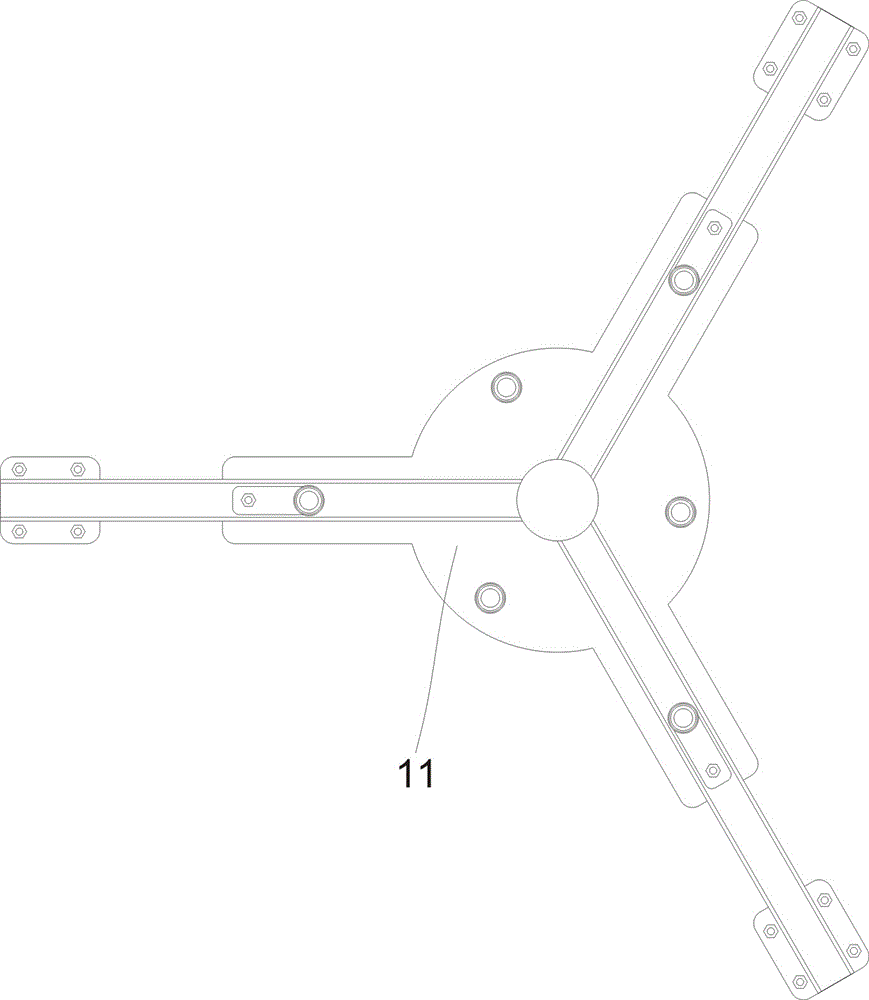

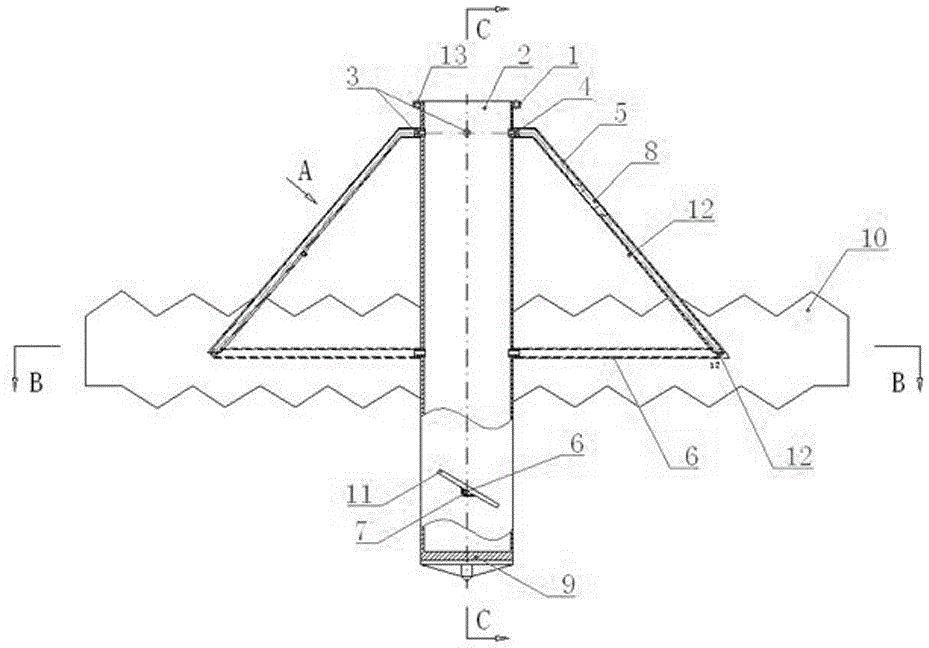

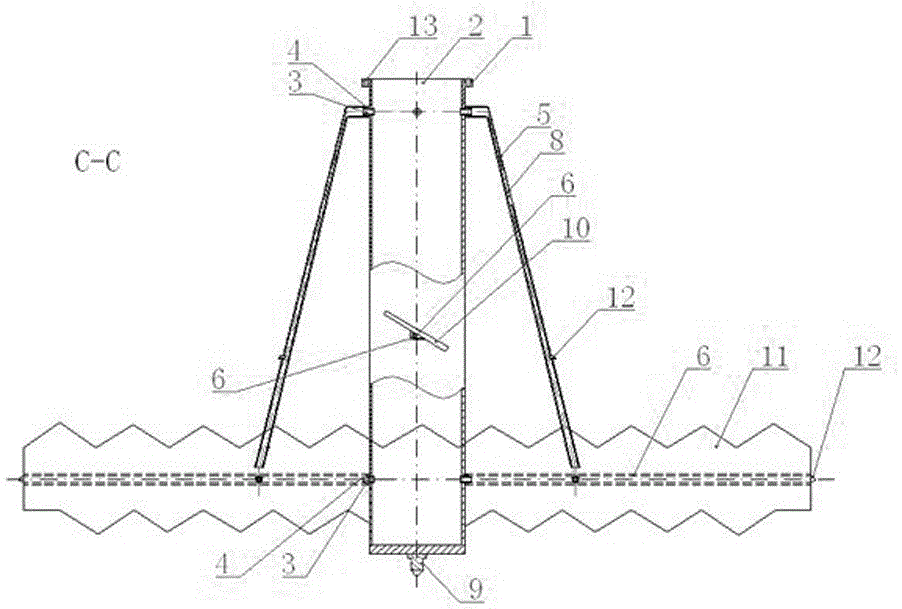

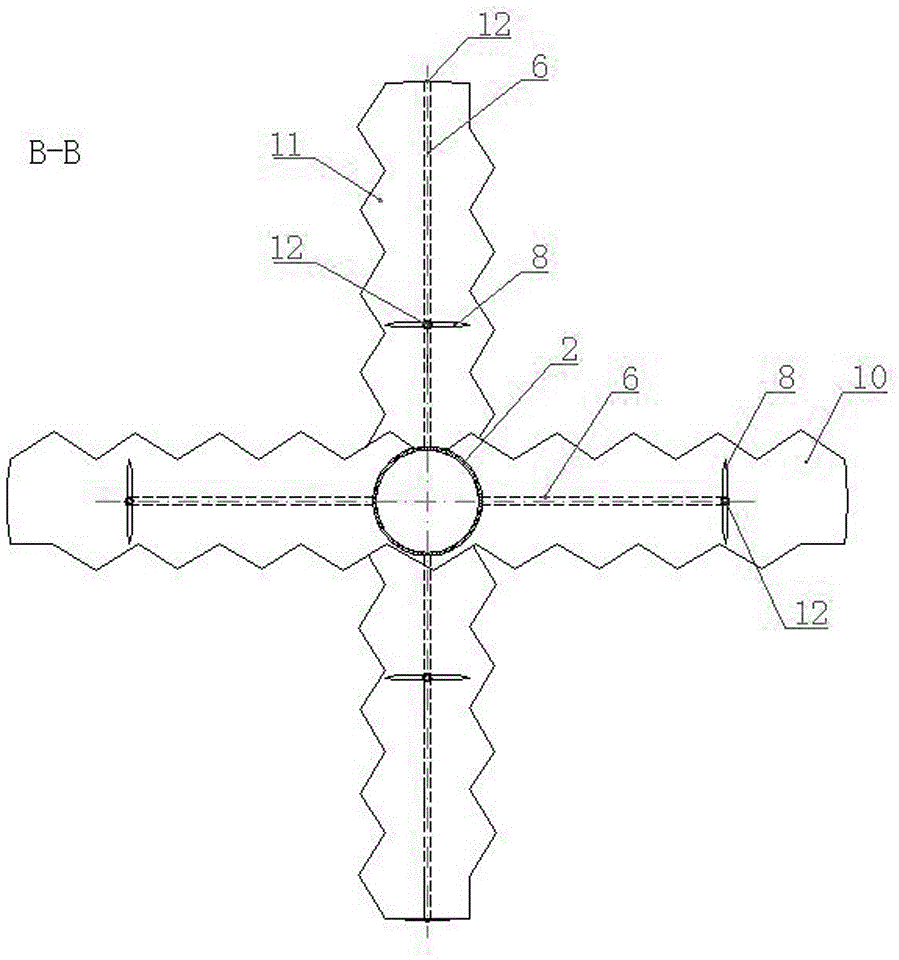

Large-diameter quickly-accomplished homogeneous cement-soil pile high pressure jet grouting micropore spouting nozzle group stirrer

ActiveCN106120775AReduce the difficulty of quality supervision and managementSpeed up the construction progressBulkheads/pilesHorizontal projectionSite management

The invention discloses a large-diameter quickly-accomplished homogeneous cement-soil pile high pressure jet grouting micropore spouting nozzle group stirrer which comprises a grouting main pipe. The middle and the lower portion of the grouting main pipe are provided with an upper-layer transverse flat bayonet and a lower-layer transverse flat bayonet respectively, and the horizontal projections of the upper-layer transverse flat bayonet and the lower-layer transverse flat bayonet are in a cross shape. Inclined branch pipes are arranged between the upper portion of the grouting main pipe and the upper-layer transverse flat bayonet and between the upper portion of the grouting main pipe and the lower-layer transverse flat bayonet respectively. The inclined branch pipes and transverse branch pipes arranged on the back face of the upper-layer transverse flat bayonet and the back face of the lower-layer transverse flat bayonet are connected. The grouting main pipe, the inclined branch pipes and the transverse branch pipes are interconnected. The large-diameter quickly-accomplished homogeneous cement-soil pile high pressure jet grouting micropore spouting nozzle group stirrer has the technical effects that by the adoption of the stirrer for construction, a drill rod moves back and forth one time instead of moving back and forth three times in design requirements to manufacture a cement-soil pile, quality supervision and management work difficulty of on-site management staff is lowered, the construction progress is greatly accelerated, the working efficiency is improved, the pile forming quality is ensured, the operation is rapid and convenient, and the ideal target for large-diameter quickly-accomplished homogeneous cement-soil heavy curtain piles is achieved.

Owner:北京顺鑫天宇建设工程有限公司 +1

Steel wire rope oiling gun

The invention discloses a steel wire rope oiling gun. The steel wire rope oiling gun comprises an oil inlet head, a gun rod, a distribution head and two mixing spray heads, the oil inlet head correspondingly communicates with an oil inlet pipe and a gas inlet pipe, one end of the gun rod is connected with the oil inlet head and is tightly pressed through a sealing pressing ring, the other end of the gun rod is connected with the distribution head and is tightly pressed through the other sealing pressing ring, the distribution head is connected with the two mixing spray heads through a group ofoil pipes and a groups of gas pipes correspondingly, and the distribution head and the two mixing spray heads each are provided with a nozzle. Oil and gas supplied from the oil inlet head are separately conveyed into the distribution head through the gun rod, the oil and the gas are distributed into three groups through the distribution head, one group of oil and gas is directly sprayed out through the nozzle arranged on the distribution head, and the other two groups of ol and gas enter the two mixing spray heads through the group of oil pipes and the group of gas pipes correspondingly, andthen are sprayed out through the nozzles arranged on the mixing spray heads correspondingly. According to the steel wire rope oiling gun, the three nozzles are arranged in a triangular shape so that the atomizing area of the three nozzles can completely cover the outer circle surface of a steel wire rope, then the efficiency of the nozzles is improved, and the spraying effect is guaranteed at thesame time.

Owner:LUOYANG INST OF SCI & TECH

Concrete spraying equipment for bridge construction

InactiveCN110820581AImprove mobilityEasy to moveBridge erection/assemblyBridge materialsArchitectural engineeringStructural engineering

The invention discloses concrete spraying equipment for bridge construction. The concrete spraying equipment comprises a moving mechanism, wherein a supporting mechanism is arranged on the moving mechanism, a concrete spraying mechanism is arranged on the supporting mechanism, an adjusting mechanism is arranged on the supporting mechanism above the concrete spraying mechanism, and a feeding mechanism is arranged on the other end, relative to the moving mechanism, of the supporting mechanism. The concrete spraying equipment has the beneficial effects that according to the concrete spraying equipment, the adjusting mechanism is arranged, and a first servo motor of the adjusting mechanism is used for driving a threaded rod to rotate, so that a threaded sleeve is free to move on the threaded rod, a material box in the concrete spraying mechanism below is driven to move left and right, uniform concrete spraying is achieved; and the feeding mechanism is arranged, and a second servo motor inthe feeding mechanism can be used for driving a rotating wheel to rotate, so that a feeding box moves upwards through the traction of a connecting rope, when the feeding box moves upwards to one sideabove the material box, and a third servo motor is started, so that a material baffle is moved away from one side of a discharging opening for material box feeding; and through the above design, feeding of the equipment is more convenient.

Owner:瑞安市浙工大创新创业研究院

A kind of external wall suspension type automatic pulp throwing machine

ActiveCN111287419BRealize self-recyclingUniform sprayingBuilding constructionsCircular discInlet valve

The invention relates to an external wall suspension type automatic slurry throwing machine. The problems of low slurry throwing efficiency and large labor amount of an external wall are effectively solved. According to the technical scheme, the machine comprises a suspended box body, a partition plate is arranged in the middle of the box body, a material storage area is arranged above the partition plate, a plurality of through holes are formed in the partition plate, a baffle plate capable of rotating is arranged below the through holes, and the baffle plate rotates reciprocally to open or close the through holes; a bottom plate of the box body is provided with a vertical plate, the left side of the vertical plate is a material returning area, the right side of the vertical plate is a material throwing area, and the right side face of the material throwing area is provided with an opening; a vibration plate is hinged to the vertical plate, a disc is installed at the bottom of the boxbody, and after the disc rotates, the vibration plate can be extruded to vibrate through a convex block; a telescopic rod is fixed on the lower end face of the partition plate, an extrusion plate isinstalled at the lower end of the telescopic rod, a one-way liquid inlet valve and a one-way liquid outlet valve are installed at the bottom of the material returning area, a pipeline with the upper end arranged in the material storage area is connected to the liquid outlet valve, and materials in the material returning area can be extruded through reciprocating up-down movement of the extrusion plate so as to flow back.

Owner:中基建工防水装饰集团有限公司

Working method of automatic spraying machine for inner and outer walls of steel pipe

The invention discloses a working method of an automatic spraying machine for inner and outer walls of steel pipes, belonging to the field of steel pipe spraying equipment. The automatic spraying machine for inner and outer walls of steel pipes includes an inner wall spraying mechanism, an outer wall spraying mechanism, a workbench and a rotating mechanism. The inner wall spraying mechanism includes There are a first spraying assembly, a second spraying assembly and a material transfer assembly, the first spraying assembly and the second spraying assembly both include stretching feeding parts and rotating spraying parts, and the material moving assembly includes a lifting part, a material moving plate and a material moving part , the lifting parts are set on the top of the moving plate. The invention can extend into the inside of the steel pipe through the inner wall spraying mechanism and automatically spray the inner wall of the steel pipe uniformly, avoiding the situation that the inner wall of the steel pipe is not sprayed locally, and can automatically spray the outer wall of the steel pipe through the outer wall spraying mechanism. High, no need for workers to manually spray the outer wall of the steel pipe.

Owner:德高金属制品宿迁有限公司

Walling robot equipment

ActiveCN107806248AReduce participationQuick clampingSolid waste managementBuilding material handlingControl cellProcess engineering

The invention discloses walling robot equipment. The walling robot equipment includes a material delivery mechanism, a whitewashing mechanism and a bricking mechanism. The material delivery mechanismincludes a conveying machine table, a conveying belt unit and a brick positioning die. The whitewashing mechanism includes a slurry container, a slurry spraying pipe and a slurry spraying control unit. The bricking mechanism includes a handle unit, a first rotating unit, a horizontal displacement unit, a lifting unit, a second rotating unit and a walling machine table. The walling robot equipmentintegrates the material delivery mechanism, the whitewashing mechanism and the bricking mechanism, and completes the whole process of material delivery, slurry spraying and bricking in an automation mode, thereby greatly reducing participation of manpower, especially participation of heavy-physical processes.

Owner:XIAMEN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com