Pressure-stabilizing aerial fog distributor

A distributor and gas distribution technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of complex branch pipelines, unstable pressure, insufficient pressure, etc., achieve uniform spray, reduce damage, prevent effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

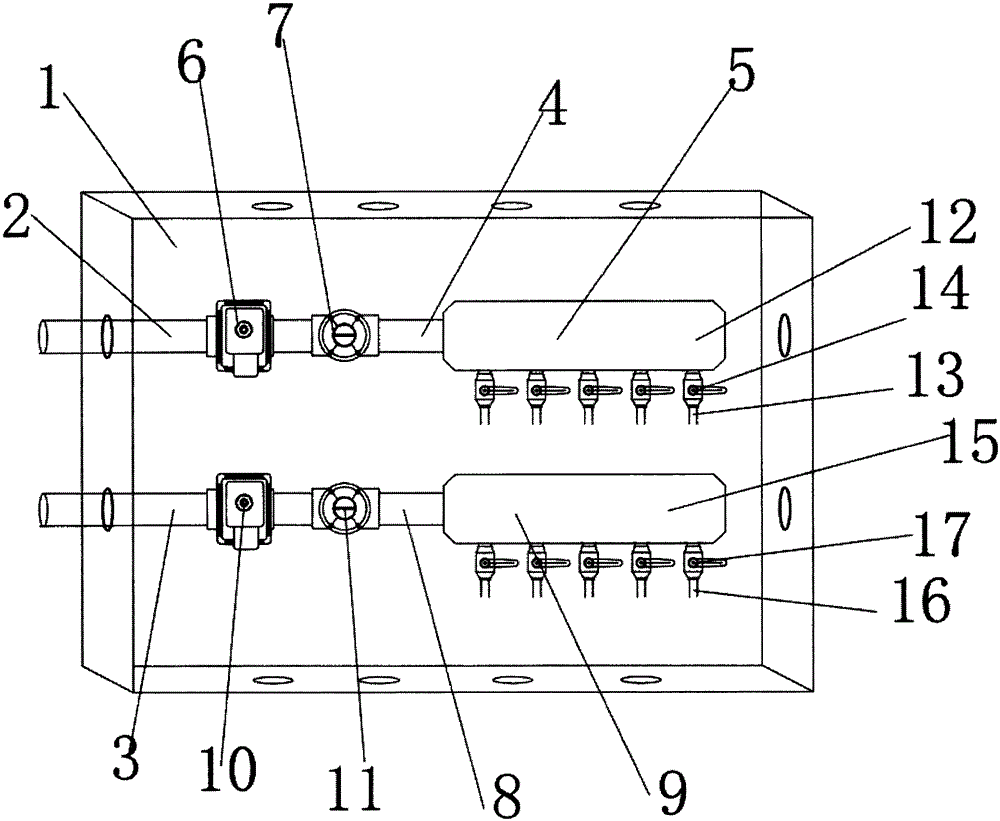

[0011] Such as figure 1 As shown, the aerosol stabilized pressure distributor provided in this embodiment 1 includes a box body 1, a waterway device 2 and an airway device 3 are installed in the box body 1, and the gasway device 3 is located below the waterway device 2 , the waterway device 2 is composed of a waterway output pipeline 4 and a waterway distribution valve assembly 5, and a first electromagnetic valve 6 and a first pressure balance valve 7 are sequentially installed on the waterway output pipeline 4, and the airway device 3 is composed of a gas The air output pipeline 8 and the air distribution valve assembly 9 are composed of a second electromagnetic valve 10 and a second pressure balance valve 11 installed on the air output pipeline 8 in sequence, and the water distribution valve assembly 5 includes a water distributor 12, Several waterway nozzles 13 are installed on the waterway distributor 12, a waterway valve 14 is installed on each of the waterway nozzles 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com