Method and control unit for determining a mass flow in a high-pressure exhaust gas recirculation system of an internal combustion engine

A technology of exhaust gas recirculation and recirculation system, which is used in exhaust gas recirculation, electrical control, engine control, etc., and can solve problems such as inaccurate throttling model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

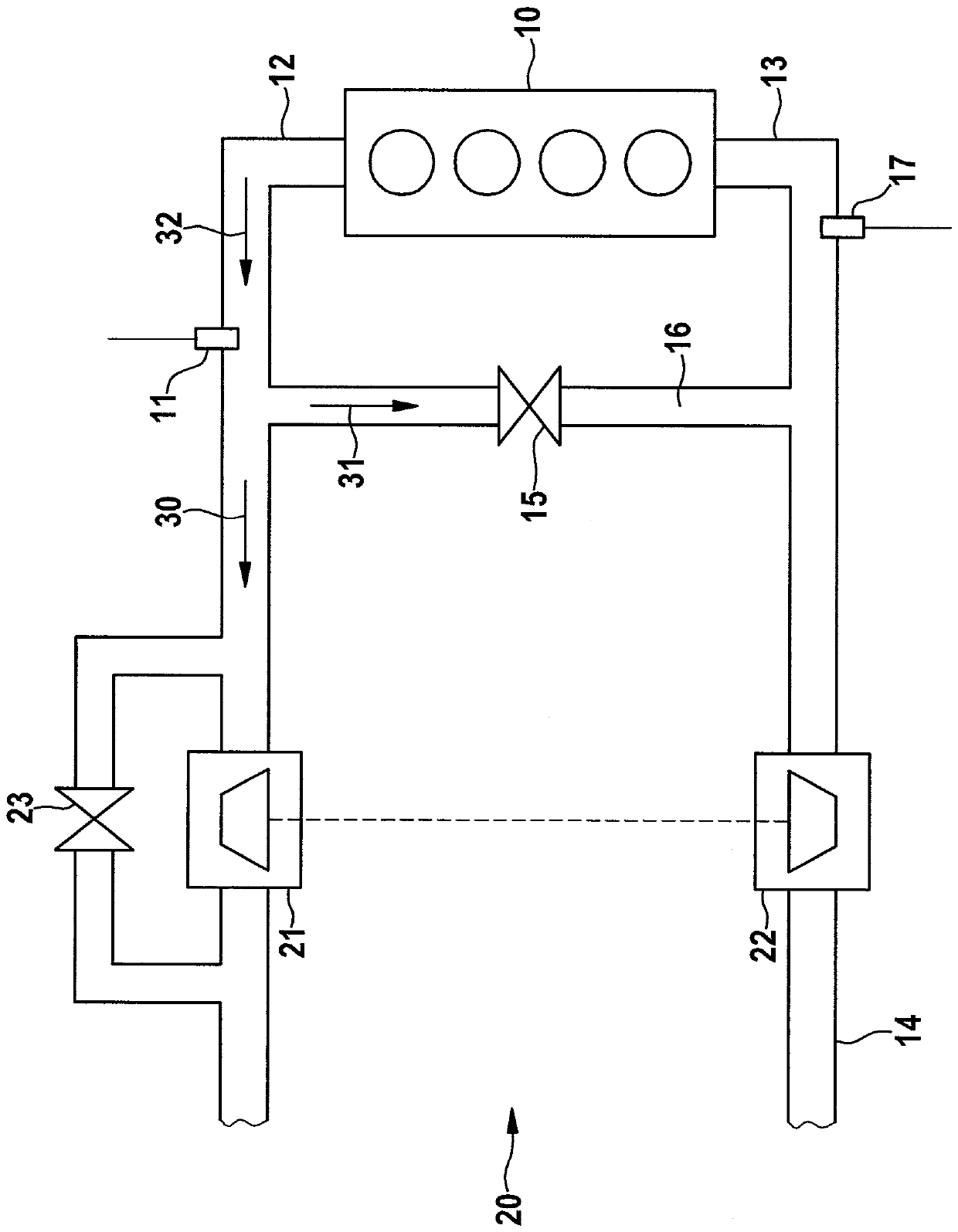

[0028] figure 1 An internal combustion engine 10 with a turbocharger 20 and a high-pressure exhaust gas recirculation system 15 is shown schematically. The illustration is here limited to those components which are essential for the description of the invention. Along the intake duct 14 , fresh air is supplied to the internal combustion engine 10 via the compressor 22 of the turbocharger 20 and the intake line 13 . The intake structure is divided into a low-pressure region upstream of the compressor 22 and a high-pressure region downstream of said compressor 22 in the flow direction. A first pressure sensor 17 is arranged in the intake pipe 13 .

[0029] Exhaust gas from internal combustion engine 10 is discharged from internal combustion engine 10 via exhaust train 12 via exhaust gas turbine 21 of turbocharger 20 and exhaust valve 23 bypassing exhaust gas turbine 21 to an exhaust gas aftertreatment system (not shown). The exhaust gas structure is also divided into a high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com