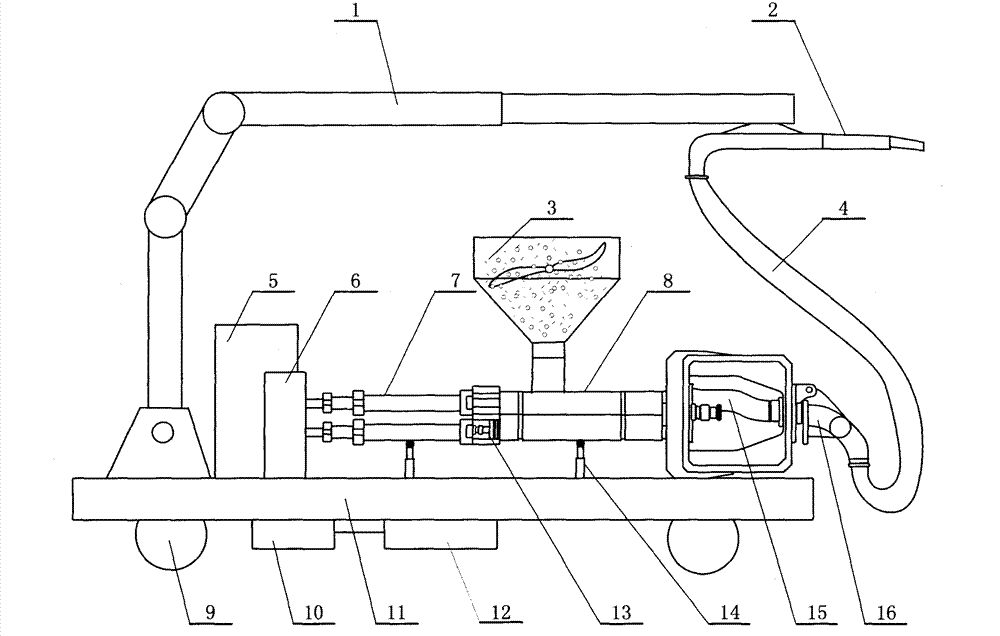

Wet concrete slurry-spray robot

A shotcrete and machine technology, applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of low reliability and inconvenient control, and achieve the effect of compact structure, uniform shotcrete and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] exist figure 1 Among them, the wet concrete spraying robot is provided with a square chassis 11, and the lower part of the chassis 11 is provided with an engine 10, a chassis electrical system cabinet 12 and two pairs of symmetrical wheels 9, and the chassis electrical system cabinet 12 includes a walking drive system, steering system and braking system, the output end of the chassis electrical system cabinet 12 is connected with the transmission shaft of the wheel 9, and controls the start, stop and steering of the wheel 9; Fixedly connected with the support base, the manipulator 1 bends upwards and stretches forward; the upper part of the chassis 11 is provided with an electrical control cabinet 5 and a hydraulic pump 6. The electrical control cabinet 5 is used to control the swing and expansion of the manipulator 1. The oil cylinder 7, the piston 13, the delivery cylinder 8, the S pipe 15 and the outlet elbow 16 are connected, the side of the delivery cylinder 8 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com