Steel wire rope oiling gun

A steel wire rope and oiling technology, applied in spraying devices, liquid spraying devices, etc., can solve the problems of oil dripping, oil dripping, reduce friction coefficient, etc., achieve uniform spraying degree, improve oiling efficiency, and ensure oiling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended invention purpose, the following will be described in detail in conjunction with the accompanying drawings and preferred embodiments.

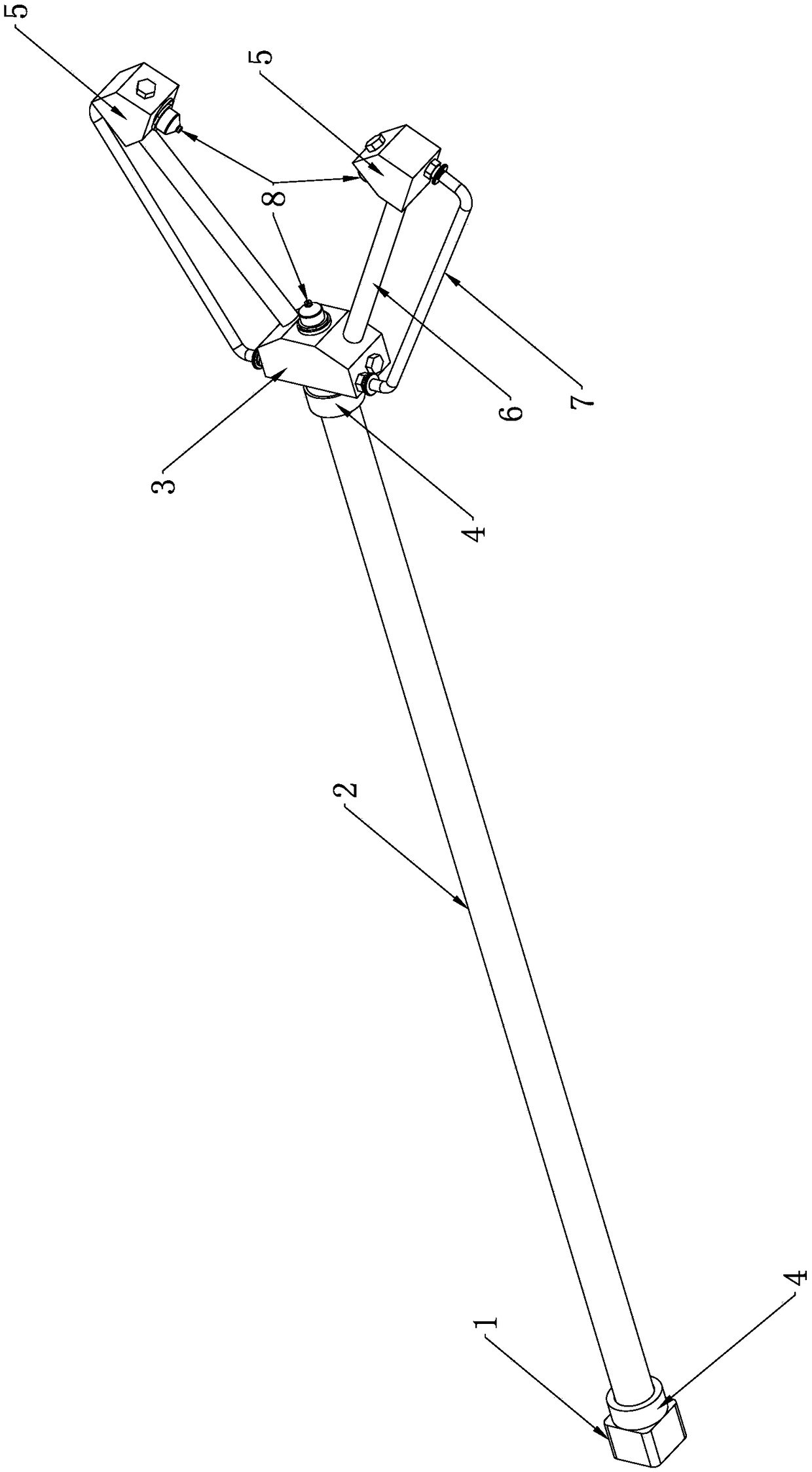

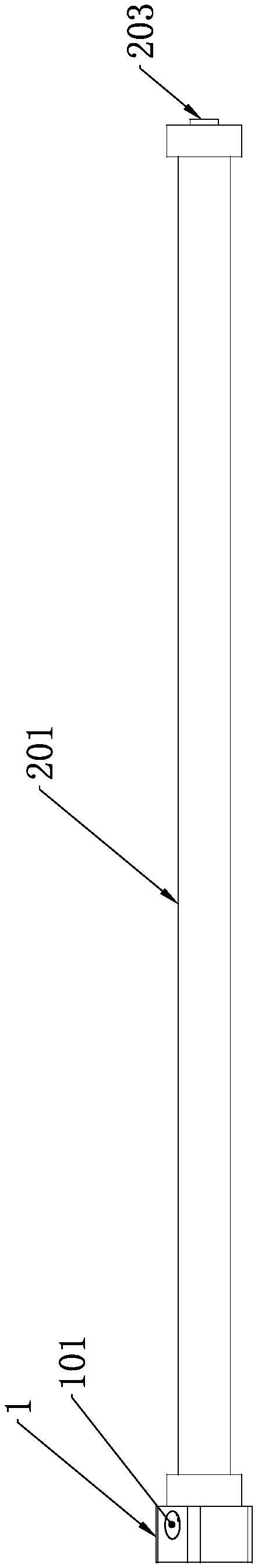

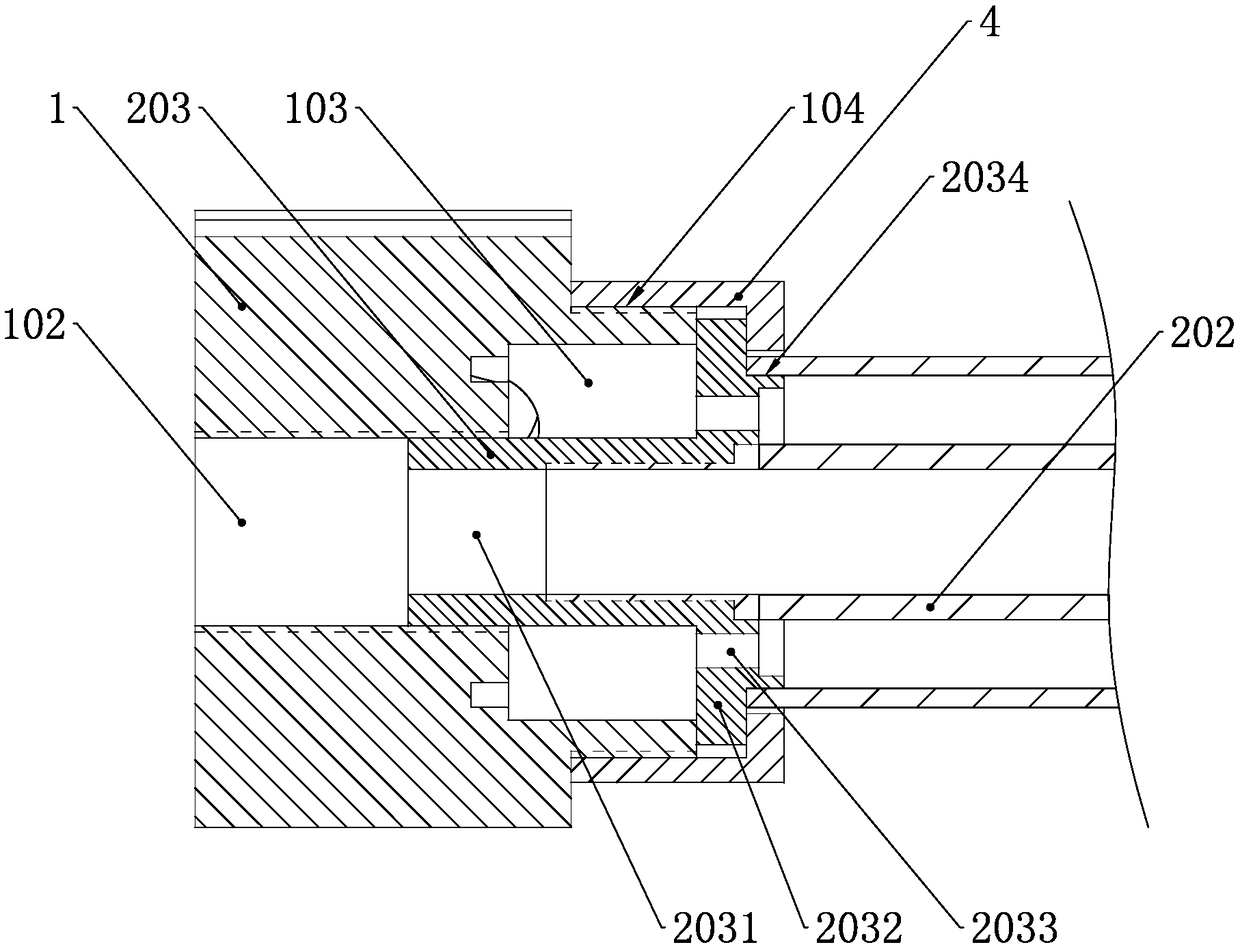

[0051] see figure 1, a wire rope oiling gun, comprising an oil inlet head 1, a gun shaft 2, a distribution head 3, a mixing nozzle 5, the oil inlet head 1 is respectively connected with an oil inlet pipe and an air inlet pipe to realize the supply of oil and gas. One end of the gun shaft 2 is connected with the oil inlet head 1 and compressed by a sealing pressure ring 4 , and the other end is connected with the distribution head 3 and is compressed by another sealing pressure ring 4 . The distribution head 3 is connected to the mixing nozzle 5 through a group of oil pipes 6 and air pipes 7 respectively, and a nozzle 8 is respectively installed on the distribution head 3 and the two mixing nozzles 5 . Through the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com