Mortar spraying device of crystal multi-wire cutting machine

A multi-wire cutting machine and shotcrete technology, which is applied to fine working devices, work accessories, stone processing equipment, etc., can solve the problems of reducing the quality of crystal processing, affecting the uniformity of shotcrete, etc., so as to improve the processing quality and save costs. , the effect of reducing air content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

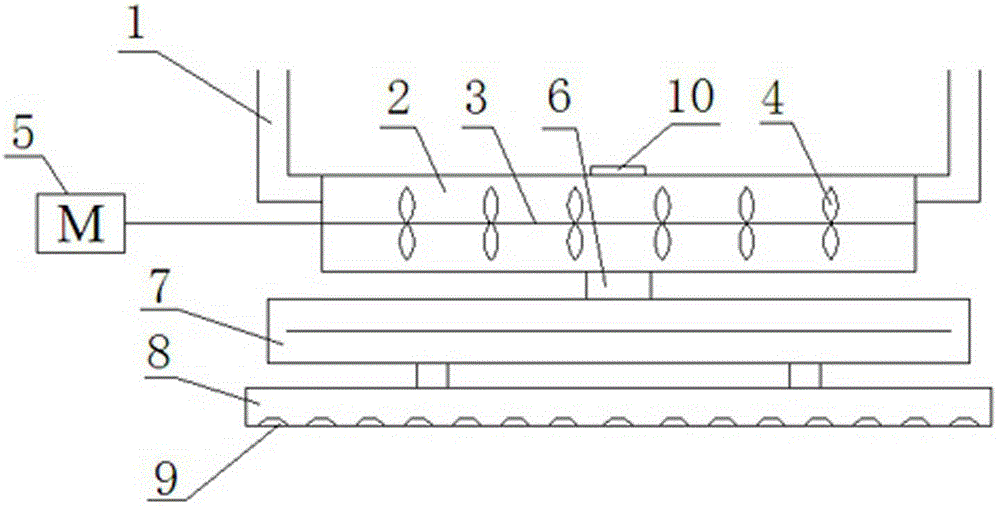

[0011] Referring to the accompanying drawings, a spraying device for a crystal multi-wire cutting machine includes a slurry inlet pipe 1, a stirring pipe 2, a rotating shaft 3, blades 4, a motor 5, a slurry outlet pipe 6, a cooling pipe 7, a spray pipe 8, a spray Slurry port 9 and exhaust port 10; slurry inlet pipe 1 is provided on both sides above the stirring tube 2, and a rotating shaft 3 is arranged on the axis of the stirring pipe 2, and the blade 4 is welded on the rotating shaft 3, and the motor 5 is connected to one side of the rotating shaft 3; 2 There is an exhaust port 10 in the middle of the top, the bottom is connected to the cooling pipe 7 through the outlet pipe 6, the cooling pipe 7 is connected to the spray pipe 8, and the bottom of the spray pipe 8 is provided with a number of spray ports 9, and the spray port 9 is Conical shape.

[0012] The blade 4 is arc-shaped with a deflection angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com