Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Sweet aroma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

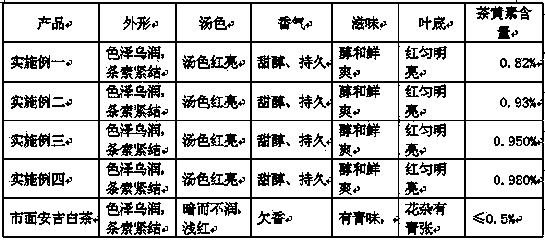

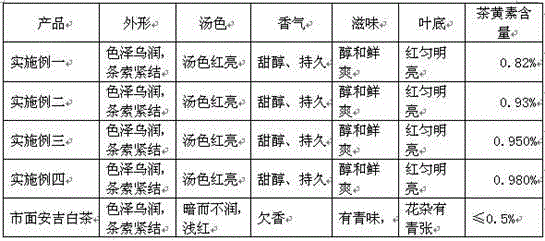

Method for preparing congou black tea from anji white tea

ActiveCN103749755AControl temperature and humidityTransformed properlyPre-extraction tea treatmentFermentationBlack teas

The invention relates to a black tea preparing method and particularly relates to a method for preparing congou black tea from anji white tea. The method sequentially comprises the following steps: picking based on a one-bud and one-leaf standard; withering; rolling; fermenting: arranging the rolled leaves to be fermented into a bamboo basket, controlling the leaf stacking thickness to be 8-10cm, uniformly spreading, and layering the leaves on a fermentation rack; fermenting by using a tea fermenting machine, controlling the air temperature at 35-40 DEG C, keeping the leaf temperature 30-32 DEG C, the relative humidity over 95% and sufficient oxygen supply, recording the fermentation time beginning from the rolling time, and controlling the fermentation time to be 5.5-6.0h. At the later period of fermentation, the temperature of a fermentation chamber is lowered and is controlled at 30-35 DEG C, so that the excessive fermentation is avoided; the moderate fermentation is carried out, and the fermented leaves are removed from the fermentation chamber, subjected to heat radiation, cooled and dried. By using the method, the anji white tea can be prepared into the congou black tea which is dark in luster, compact in strip, sweet and durable in fragrance, red bright in liquor color as well as pure, mild and fresh in taste.

Owner:浙江安吉宋茗白茶有限公司

Method for extracting natural rose essential oil from rose

The invention relates to a method for extracting natural rose essential oil from fresh rose, which comprises: pretreating the rose, placing the pretreated rose into flavor-extracting petroleum ether, performing repeated leaching and filtration, removing residue, and obtaining leachate; distilling the flavor-extracting petroleum ether in the leachate, and obtaining an extract; adding the extract into ethanol for dissolution, freezing and filtration, removing undissolved substances, and obtaining an alcohol extract; and concentrating the alcohol extract under vacuum, removing the ethanol, and obtaining the rose essential oil. The essential oil extracted by the method maintains the special flavor of the rose; the method has rich resources of raw materials, fully utilizes the prior resources, and has simple technique and low cost; and the obtained product has unique flavor and long flavor lasting time, and is an ideal additive of food, cosmetics and the like.

Owner:庆阳市康惠玫瑰发展有限责任公司

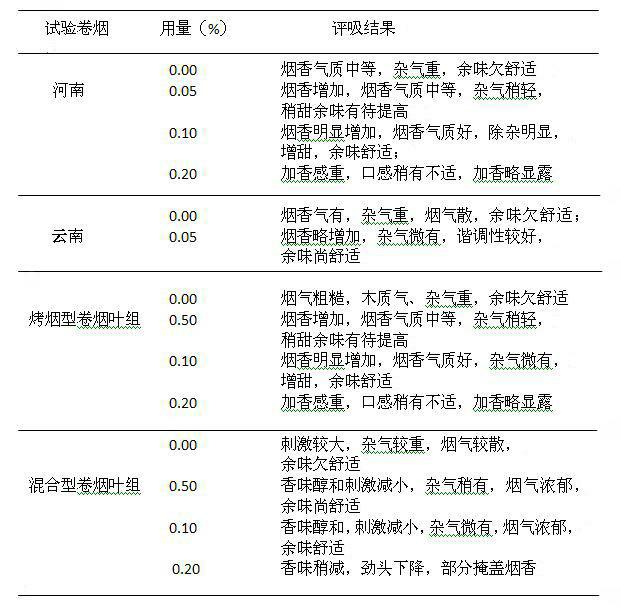

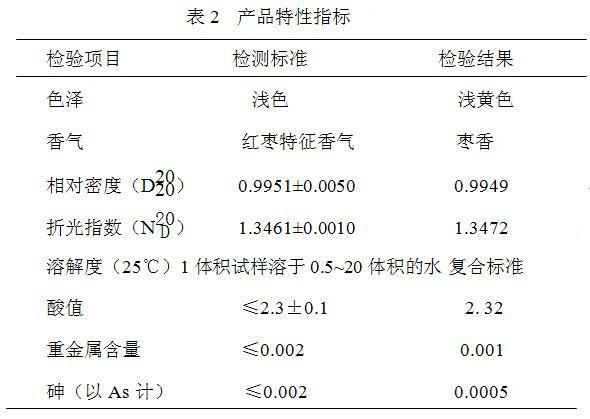

Jujube flavor base, and preparation method and application thereof

ActiveCN101942361ARich aroma componentsSweet scentTobacco preparationEssential-oils/perfumesBiotechnologyAroma aroma

The invention discloses a jujube flavor base, and a preparation method and application thereof. The preparation method for the flavor base comprises the following steps of: 1) performing pre-treatment on jujubes to obtain jujube particles; 2) adding ethanol and performing ultrasonic treatment to obtain jujube extract liquid; 3) performing rotary evaporation and concentration to obtain jujube extract; and 4) performing molecular distillation, separation and purification to obtain a light-component substance, an intermediate-component substance and a heavy-component substance, and performing extraction, overnight standing, filtration and filtrate concentration on the intermediate-component substance to obtain the jujube flavor base. The jujube flavor base of the invention can be used for preparing natural perfume materials for cigarettes and foods, also can be directly used as the natural perfume material, is prepared from the jujubes serving as the raw material, not only has the advantages of transparency, colorlessness, high liquidity and sweet perfume, also has the nutritional and healthcare effects of the jujubes, can be added into the cigarettes to effectively reduce miscellaneous odors in tobacco leaves, improve suction flavor and remaining taste, improve the natural fragrance of the tobacco leaves, comfort throats and treat pharyngitis, and also can be added into the foods to achieve the effects of increasing the flavor and making pure the flavor.

Owner:河南省新郑金叶香料有限公司

Chinese yam full flour and preparation method thereof

InactiveCN105166768ARetain nutrientsIncrease profitFood dryingFood ingredient functionsWater bathsFreeze-drying

The present invention discloses a Chinese yam full flour and a preparation method thereof, belonging to the technical field of food processing. The Chinese yam full flour is prepared by the following steps: (1) cleaned Chinese yams are placed into a boiling water bath for 10-40 min, the boiled Chinese yams are taken out and cooled, the cooled Chinese yams are drained and the drained Chinese yams are sliced for standby application; (2) the cut Chinese yam slices are placed in a color protection solution for 0.5-2 h and the soaked Chinese yams are taken out to be beat for standby application; (3) alpha-amylase is added into the beat Chinese yam pulp, the Chinese yam pulp is subjected to enzymolysis at a temperature of 45-85 DEG C under a pH of 5.0-7.5 for 30-120 min, and the enzymolyzed Chinese yam pulp is subjected to enzyme inactivation and filtration to obtain an enzymatic hydrolysate and residue for standby application; (4) the enzymatic hydrolysate is concentrated to a soluble solid content of 10-30%, an excipient is added, and the mixture is spray-dried to obtain a Chinese yam powder A; and (5) the residue is subjected to microwave vacuum freeze-drying to obtain a Chinese yam powder B, the Chinese yam powder B is mixed evenly with the Chinese yam powder A, and thereby the Chinese yam full flour is obtained. The Chinese yam full flour is nutrient-rich, has a bright color with a slight brown color, is mellow in sweet and fragrant taste, is uniform in texture, is fine in powder, and is good in reconstituability.

Owner:HENAN UNIV OF SCI & TECH

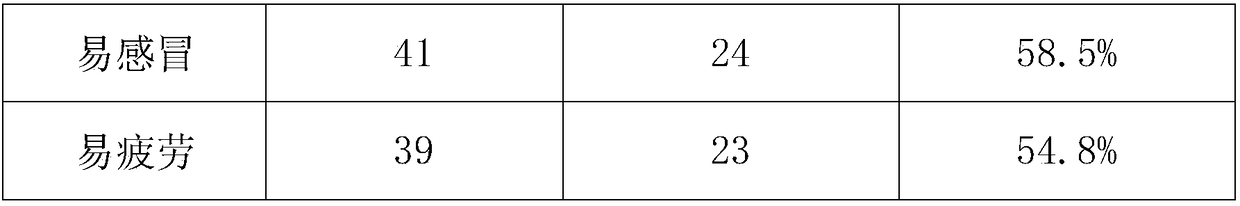

Ginseng and rhizoma polygonati solid beverage and preparation method thereof

InactiveCN108185258AStrong aromaSweet aromaAntinoxious agentsUnknown materialsMedicinal herbsPhysical strength

The invention discloses a ginseng and rhizoma polygonati solid beverage. The ginseng and rhizoma polygonati solid beverage is prepared from the following raw materials in percentage by mass: 10-12% ofginseng, 15-17% of rhizoma polygonati, 10-12% of Chinese yams, 4.5-6.5% of poria cocos, 2.5-4.5% of fructus alpiniae oxyphyllae, 2.0-4.0% of Chinese wolfberry fruits, 2.0-4.0% of licorice roots, 2.0-4.0% of honey and 43-45% of crystal sugar. The invention further discloses a preparation method of the ginseng and rhizoma polygonati solid beverage. The solid beverage is soft, fragrant and sweet inmouth feel, besides, can achieve the effects of strengthening the constitutions, nourishing the kidney, and boosting essence, is particularly suitable for crowds making physical strength labor and being high in intelligence labor intensity. According to a preparation method, a dry granulation technology is adopted, compared with a wet granulation technology, the dry granulation technology has theadvantages that the process flows are shortened, the industrial continuous production is convenient, the technical problem that wet granulation cannot be performed due to high amount of medicinal material thick paste is solved, and the instant ginseng and rhizoma polygonati solid beverage can dissolve quickly when being in contact with hot water, and is high in clarity.

Owner:吉林新开河食品有限公司

Preparation method of noni fruit tea

The invention discloses a preparation method of noni fruit tea. The preparation method comprises three steps as follows: 1. preparing noni fruit powder and burdock fruit powder; 2. preparing noni leaf powder, partridge tea powder and noni fermented pomace powder; and 3. mixing, sieving, performing microwave drying and packaging. The noni fruit tea comprises dry noni fruits, noni fruit leaves, the pomace of noni fermented juice and the like. Compared with the traditional process, the preparation method has the advantages that wet crushing and low-temperature continuous drying processes can be adopted, so that multiple nutrient substances are dissolved out and few nutrient substances are lost. The prepared product is solid beverage, thus being easy to store and convenient to carry. After the noni fruit tea is taken with hot water, the nutrient substances are dissolved out quickly, the fragrance is strong, the taste is soft, the tea is clear, the original flavor and nutrition of the noni fruits are maintained, extremely convenient noni solid beverage is provided for people, a new way is opened up for comprehensive utilization of precious noni resources, and the noni fruit tea with extremely high market competitiveness is provided for health of people.

Owner:海南西沙诺丽生物科技有限公司

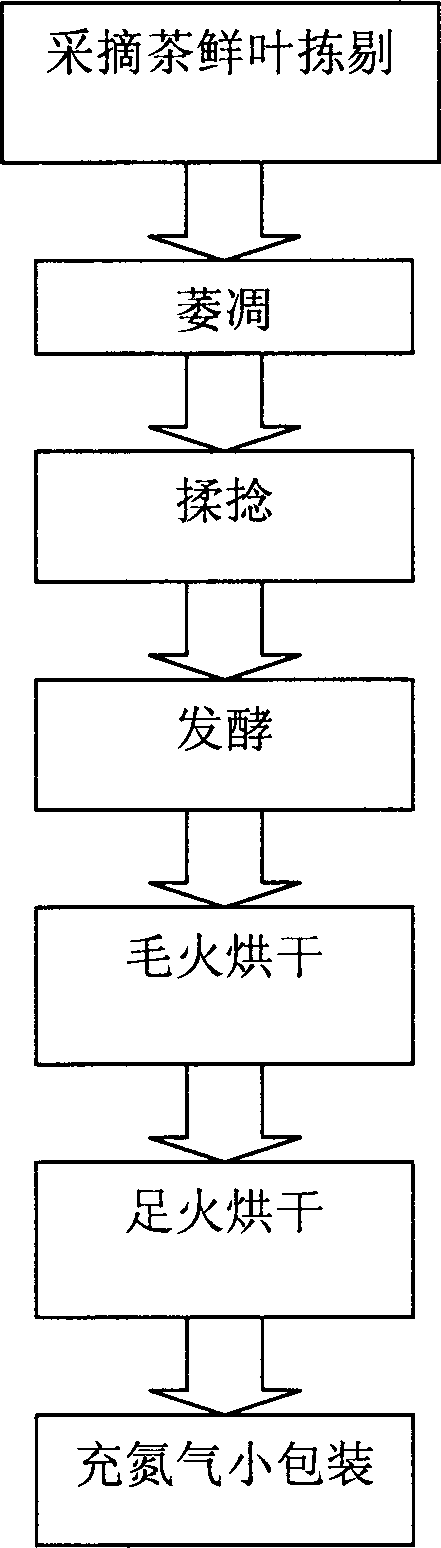

Production method of cup black tea

The invention relates to a production method of cup black tea. The method comprises the following steps: S1, picking fresh tea leaves, and selecting according to a standard of one bud and two leaves; S2, wilting the selected fresh tea leaves naturally indoors on a wilting machine, and turning on a fan to blow natural wind according to the water content of the fresh tea leaves; S3, rolling the wilted tea leaves; S4, fermenting the rolled tea leaves; S5, drying the fermented tea leaves with gross fire; S6, drying the tea leaves with enough fire; and S7, charging nitrogen and packaging the tea leaves, which are dried with enough fire, into small packages. Through changing the production method of the black tea, the quality on the aspects of color, fragrance and taste is greatly improved, the made black tea is fragrant and sweet, the taste is rich and fresh, the liquor color is orange red and bright, the tea grounds are red-yellow and bright, and the astringency is high.

Owner:SUZHOU DENGWEI TEA

Making method of Danfeng peony tea

The invention discloses a making method of a Danfeng peony tea. The making method comprises the following steps: picking up fresh petals, cleaning the picked petals within 24 hours, draining the cleaned petals in the shade, drying and disinfecting the drained petals with microwaves, wherein the microwave drying temperature is 80-120 DEG C, and the drying time is 20-30min, sufficiently rolling the dried petals, screening for removing large flower buds, stir-frying the screened petals for flavor enhancement, and after stir-frying the screen petals, spreading for cooling the petals so as to obtain finished products of the Danfeng peony tea. According to the making method disclosed by the invention, the effective nutrients of peonies are reserved to the maximum extent, the made peony tea is in the shape of lumps and is white with yellow in color, the tea type of the brewed tea is good, the tea soup is clear, and the tea soup is fragrant.

Owner:菏泽花品天香牡丹科技有限公司

Black tea and preparation method thereof

The invention discloses black tea and a preparation method thereof. The preparation method includes the following steps of firstly, conducting withering, and obtaining withered leaves, wherein fresh leaves are spread on a withering tank and withered till the water content is 50-55%; secondly, conducting rolling, and obtaining rolled leaves, wherein a two-section rolling method is adopted, and the rolling time of each section is controlled at 44-46 minutes; thirdly, conducting fermentation, wherein rolled leaves stand and ferment for 8-10 hours; fourthly, conducting drying. Dulcitol of black tea prepared through the preparation method is naturally formed, and the product is sweet and strong in fragrance, sweet in taste, free of high-fired fragrance and capable of meeting requirements of consumers in China.

Owner:广东鸿雁茶业有限公司 +1

Black silver needle tea and processing technology thereof

ActiveCN104938666AFull play of qualityChange the defect of lack of strong tastePre-extraction tea treatmentBlack teaBud

The invention discloses a black silver needle tea which is characterized by being prepared by the following steps: adopting early sprouted fresh leaves, each of which has the tenderness of one bud or one bud and one leaf, as raw materials, and conducting thin spreading, withering, carding, fermenting, primary drying and fully drying. The obtained black silver needle tea is round, straight and needle-like in appearance, golden, tippy, and fresh in color and luster; when the black silver needle tea is brewed with 90 DEG C boiled water, bud heads suspend in water one by one and then slowly sink to the bottom of a cup, and the tea water is yellow at first and then is slowly changed to be fresh red, and smells fragrant and tastes mellow. Through addition of carding and organic combination of fermentation and heaping for yellowing, the defects that the conventional silver needle type tea leaves are loose in appearance and light in taste are radically overcome, the black silver needle tea with the advantages of both the yellow tea and the black tea is produced, and the domestic gap is filled.

Owner:HUNAN MIJIANGYUAN KUDZU TEA

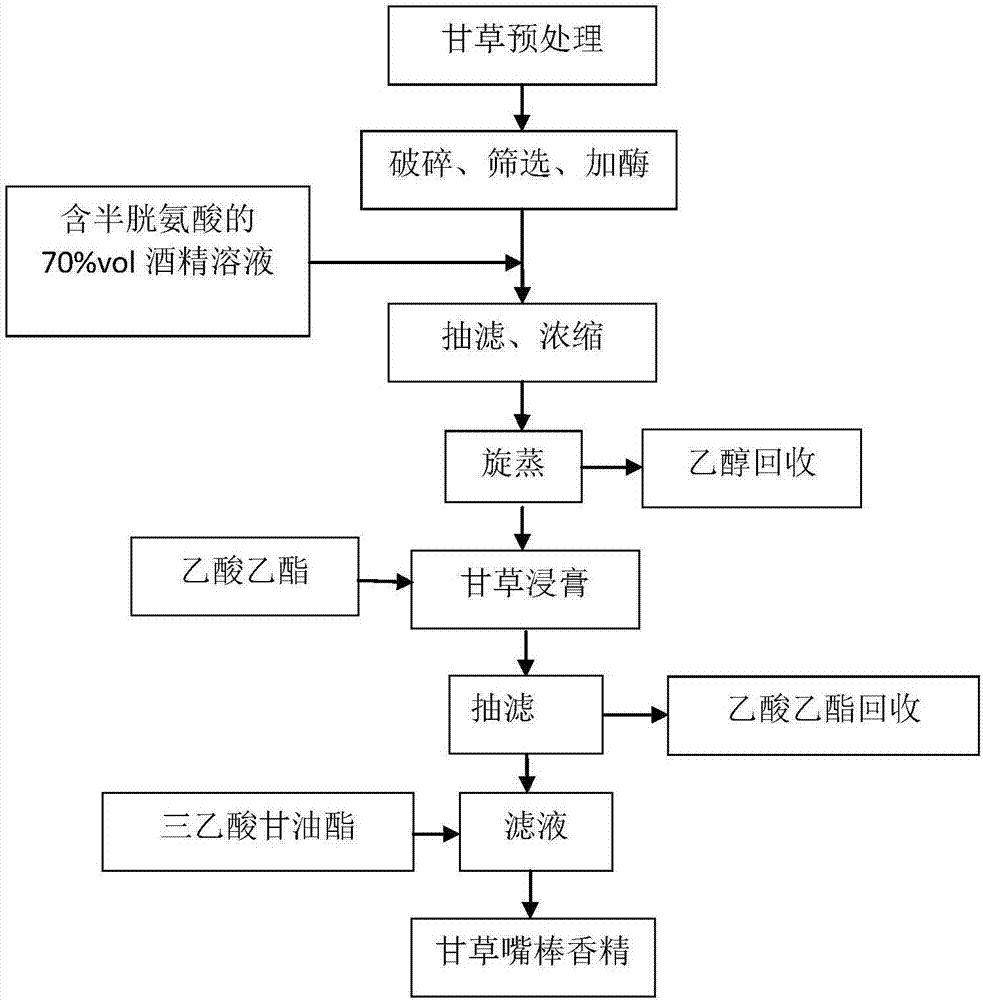

Preparation method of glycyrrhiza sweetening and moistening essence for mouth stick

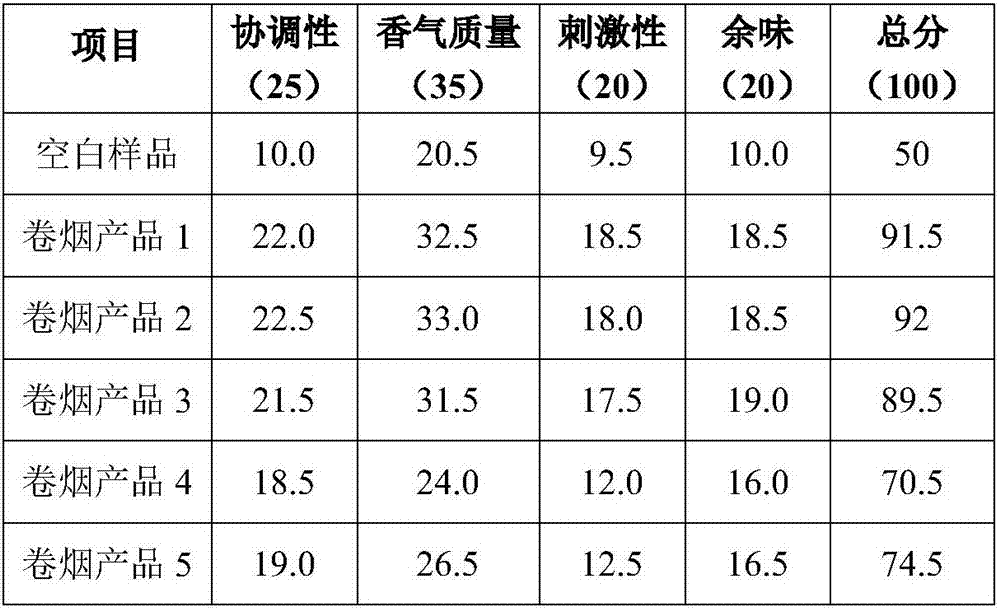

ActiveCN107057856AAvoid lossAvoid pyrolysisTobacco smoke filtersEssential-oils/perfumesAlcoholIrritation

The invention belongs to the technical field of tobacco flavors and in particular relates to a method of preparing essence of a mouth stick for a cigarette by taking glycyrrhiza as extract. The essence is used for improving sucking sweet feel of tobacco and enhancing the sensing comfort, so that the sucking quality of tobacco is effectively enhanced. The preparation method of glycyrrhiza sweetening and moistening essence for the mouth stick comprises the following steps: enzymolysis, alcohol extraction, extraction and the like. The prepared essence is directly added in a mouth stick processing step, so that escape and pyrolysis of essence in the storage and ignition and suction processes of tobacco are avoided, the loss of flavors in static igniting period of the tobacco can be also avoided, throttling of cut tobacco and filter tip on the flavors can be reduced, and the transfer efficiency is increased. The glycyrrhiza sweetening and moistening essence for the mouth stick prepared by the invention can remarkably improve the quality of fragrance of the cigarette, reduce the irritation and improve the quality of the cigarette.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Black tea processing method capable of increasing cell breakage rate

InactiveCN106472721AIncreased damage rateSame starting point of fermentationPre-extraction tea treatmentChemistryCamellia sinensis

The invention discloses a black tea processing method capable of increasing a cell breakage rate. The black tea processing method comprises the following working procedures of picking fresh camellia sinensis leaves, performing withering, performing rolling, performing fermentation and performing drying, wherein before withering, a potassium silicate solution of which the concentration is 0.1-0.6mmol / L is sprayed on picked fresh leaves, and a liquor ratio is 100g to (1-5)ml. According to the black tea processing method disclosed by the invention, the cell injury rate during rolling can be increased, the rolling time can be shortened, consistent tea leaf fermentation starting points is guaranteed, and the condition that theaflavin and thearubigins are converted into theabrownin due to excessive fermentation is avoided. After the black tea prepared by the black tea processing method disclosed by the invention is brewed, tea soup is pleasant in fragrance, rich in taste and bright in color.

Owner:广西神海云峰农业综合开发有限公司

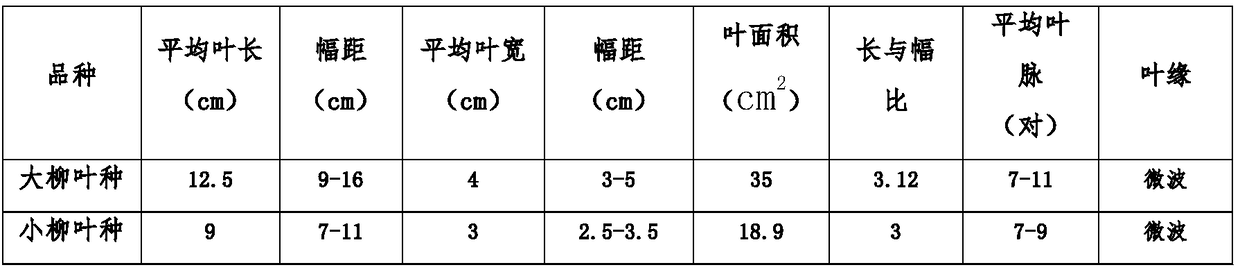

Manual making method of willow leaf species Yongxi houqing tea

InactiveCN108812971ADark green colorBright colorPre-extraction tea treatmentCell buddingAgroforestry

The invention belongs to the field of tea making technologies and specifically relates to a manual making method of willow leaf species Yongxi houqing tea. The method comprises the following steps: tea picking, fresh leaf pretreatment, de-enzyme, shaking-rolling-spreading, stir-frying of tea base, pan frying, screening and storage. The picking standard of two true leaves and one terminal bud is adopted, and tea leaves are picked eight centimeters from the tip of tea; the stir-frying of tea base comprises stir-frying of first tea base and stir-frying of second tea base; the preparatory work before pan frying is pan washing, tea juice and tea ash on the inner wall of the pan are removed to keep the pan wall smooth and bright and the tea soup pure and clear; and pan frying is a process of shaping and drying, the frying method is changed in the process, and smokeless charcoal fire is adopted for long-time low-temperature drying. By manual manufacture of Yongxi houqing tea, the original natural features of Yongxi houqing tea are maintained, and color of the obtained tea is blackish green and apparent and gloss is obvious; fragrance is rich and long-lasting. As the formed tea is dried atlow temperature, fragrance of the tea is more refreshing, fresh and lasting, and the taste is mellow and thick.

Owner:吴建华

Black tea soup taste improving processing method for black tea

InactiveCN106509215AThe shape is tight and well-proportionedBright red tea soupPre-extraction tea treatmentLiquid ratioBlack tea

The present invention discloses a black tea soup taste improving processing method for black tea. The processing method comprises the processes of fresh tea tree leaf picking, withering, kneading, fermenting and drying. Before the withering, an orthosilicic acid solution at a concentration of 0.1-0. 6 mmol / L is sprayed on the picked fresh leaves. A material to liquid ratio is 100 g:(1-5) ml. The processing method can improve the cell damage rate during the kneading, shortens the kneading time, ensures the starting points of the fermentation of the tea leaves to be same, and avoids the conversions of theaflavins and thearubigins into theabrownin caused by excessive fermentation. The prepared black tea is mellow in tea soup taste and bright in color and luster after brewing.

Owner:广西神海云峰农业综合开发有限公司

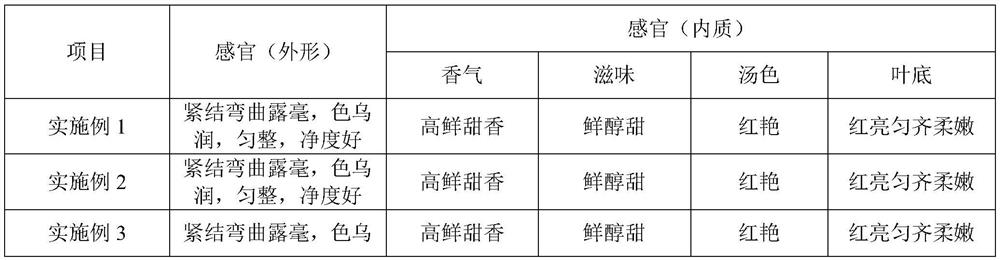

Preparation method of strip-shaped black tea

The invention discloses a preparation method of strip-shaped black tea, and relates to the technical field of black tea preparation. The preparation method comprises the following preparation steps: 1) picking fresh leaves: picking and selecting fresh leaves with one bud and one leaf and fresh leaves with one bud and two leaves as tea leaf raw materials; 2) performing withering: putting the pickedtea leaves into a withering tank for graded heating withering; 3) performing rolling: rolling the withered tea leaves in a rolling machine until the tea leaves are rolled into strips; 4) performing fermentation: putting the rolled tea leaves into a fermentation machine for fermentation; 5) performing drying: drying the fermented tea leaves; 6) performing aroma enhancement: standing the dried tealeaves, enhancing aroma, and performing spreading for cooling so as to obtain the strip-shaped black tea. According to the preparation method disclosed by the invention, a graded heating withering manner is performed, and physical and chemical reactions are strictly controlled through different gradient blast heating manner, so that the prepared black tea is compact and bent in appearance, hair-exposed, black and smooth in color and uniform, and besides, the black tea is high in freshness and sweetness in internal texture sense, fresh, mellow and sweet in taste, red and bright in soup color and uniform, soft and tender in leaf bottoms.

Owner:上海牛奶集团黄山茶林场有限公司

Method for processing high-aroma black tea

InactiveCN106417707AIncreased damage rateSame starting point of fermentationPre-extraction tea treatmentBlack teaThearubigin

The invention discloses a method for processing high-aroma black tea. The method comprises the procedures of tea tree fresh leaf picking, withering, rolling, fermenting and drying. Before withering, a disilicate solution with the concentration being 0.1 mmol / L to 0.3 mmol / L is sprayed to picked fresh leaves, and the solid-liquid ratio is l00 g:(1-5) ml. According to the method, the cellular damage rate during rolling can be increased, the rolling time can be shortened, it is guaranteed that the tea fermentation starting point is consistent, it is avoided that theaflavin and thearubigins are converted into theabrownin due to excessive fermentation, and the black tea made through the method is fragrant in tea soup after being brewed, strong in taste and bright in color.

Owner:广西神海云峰农业综合开发有限公司

Processing method of twisted old-leaf black tea

ActiveCN102715293BSweet aromaSweet and mellow soup colorPre-extraction tea treatmentBlack teaRaw material

A processing method of twisted old-leaf black tea includes the steps of picking fresh leaves, withering the fresh leaves, rolling the fresh leaves, treating the rolled leaves, fermenting the rolled leaves, primarily baking the leaves, enhancing health function and drying to obtain finished products. Single ripe fresh leaves are used as raw material, procedures of continuously processing and rolling for multiple times, treating the rolled leaves and enhancing the health function are adopted in the processing process of the old-leaf black tea, complete strip of the leaves is kept without breakage, contents of the old-leaf black tea are converted, soluble substances are increased, and the old-leaf black tea which can be made into soup with sweet fragrance, orange and bright color and fresh taste is finally formed.

Owner:萧氏茶业集团有限公司

Quick ageing processing method for Liubao tea

InactiveCN109221454AColor dark brown smoothThe taste is mellow and refreshingPre-extraction tea treatmentClimate change adaptationBetelEngineering

The invention discloses a quick ageing processing method for Liubao tea. The quick ageing processing method comprises the following steps: performing wet-hot alternative conversion on sun-cured Liubaotea in an ageing room for three times; spraying mountain spring water for one time while getting damp; spraying light hawthorn wine twice; adopting a low temperature steaming and pressing technologyfor pressing and molding; sealing and storing aged Liubao tea in a Nixing pottery. According to the method, the ageing time is short, the operation is simple and the acquired aged Liubao tea is in black brown and glossy color, has a strong red bright color of tea soup, has a mellow and cool taste, tastes slightly sweet and smooth, has a mellow and pure fragrance and has the fragrance of betel nut.

Owner:横县南方茶厂

Liquid tea and application thereof

The invention relates to liquid tea and application thereof. The liquid tea product is characterized in that a processing method of the liquid tea product comprises the following steps: (1) slightly drying tea; (2) rinsing; (3) grinding the tea into paste; (4) immersing the tea paste to obtain tea liquid; (5) filtering and extracting; (6) boiling the liquid tea; and (7) cooling and then filling. The liquid tea aims to solve the problem that existing tea is complex to brew and cannot be standardized; the liquid tea is convenient to brew, is completely standardized and is fully uniform in taste.

Owner:李镇阔

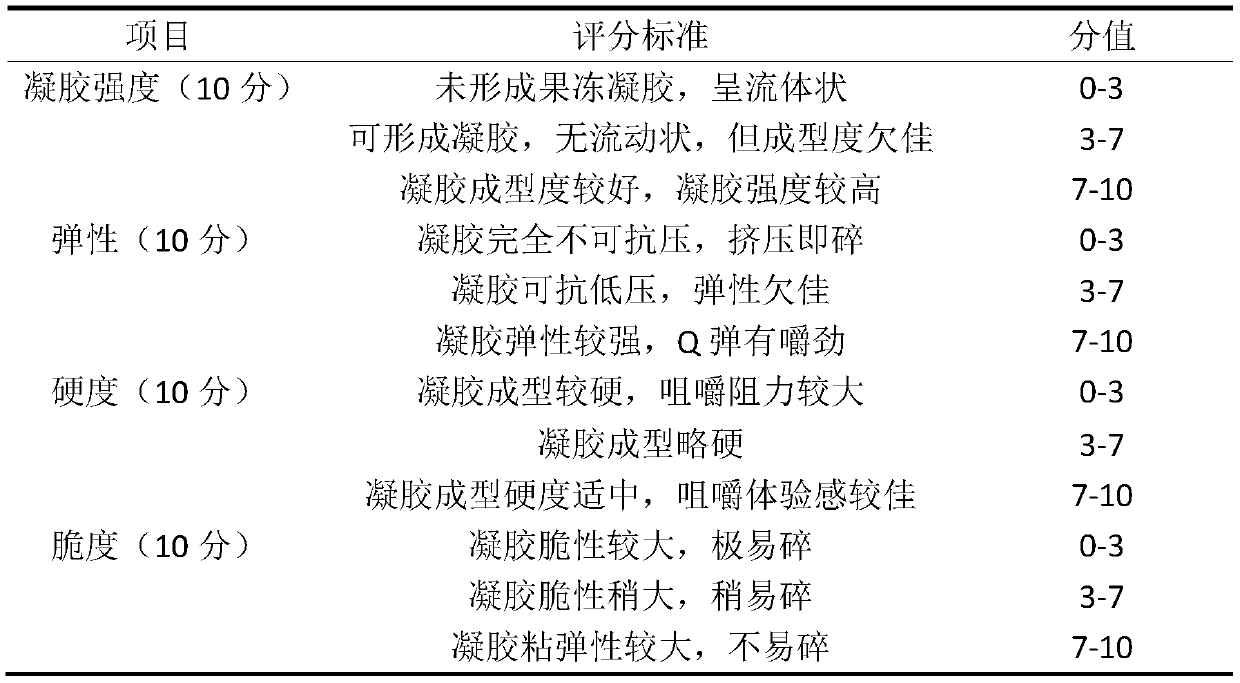

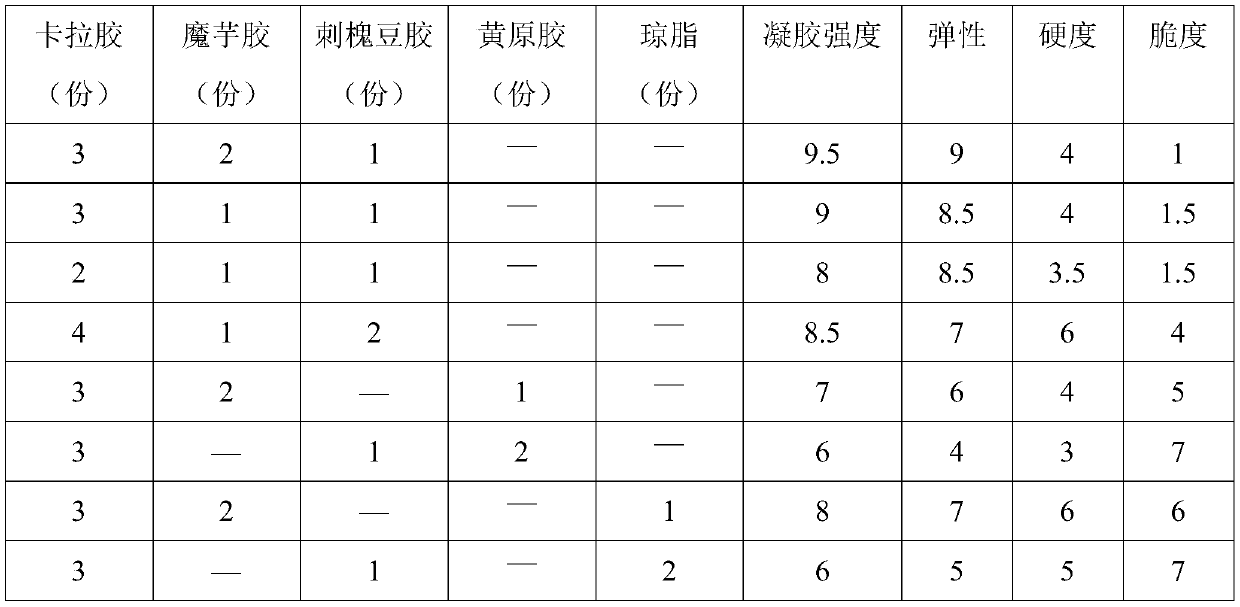

Lucid ganoderma-Momordica grosvenori jelly and preparation method thereof

PendingCN111011784AElegant floralSweet aromaFood thermal treatmentFood ingredient as taste affecting agentChemistrySucrose

The invention discloses a lucid ganoderma-Momordica grosvenori jelly and a preparation method thereof. The lucid ganoderma-Momordica grosvenori jelly is prepared from the following raw materials in parts by weight: 20-40 parts of fresh sweet-scented osmanthus flowers, 40-100 parts of fresh Momordica grosvenori, 10-30 parts of lucid ganoderma, 5-15 parts of liquorice, 30-70 parts of xylitol, 30-80parts of a water-retaining agent, 10-30 parts of a gel, 0.1-0.3 part of sucralose and 0.2-0.5 part of stevioside. The jelly product disclosed by the invention integrates the flower fragrance of the fresh sweet-scented osmanthus flowers and the characteristic fragrance of Momordica grosvenori, the flower fragrance is faint and elegant, the characteristic fragrance of Momordica grosvenori is sweet,and fused fragrance is rich and long-lasting; the prepared jelly is pleasant in flower fragrance, fresh and sweet in taste, rich in elasticity, good in water-retaining property and unique in flavor, has relatively good effects of moistening lung and relieving sore throat, and clearing away heat and toxic materials, and is a healthy instant food capable of clearing away heat and moistening throat.

Owner:GUANGDONG YIFANG PHARMA

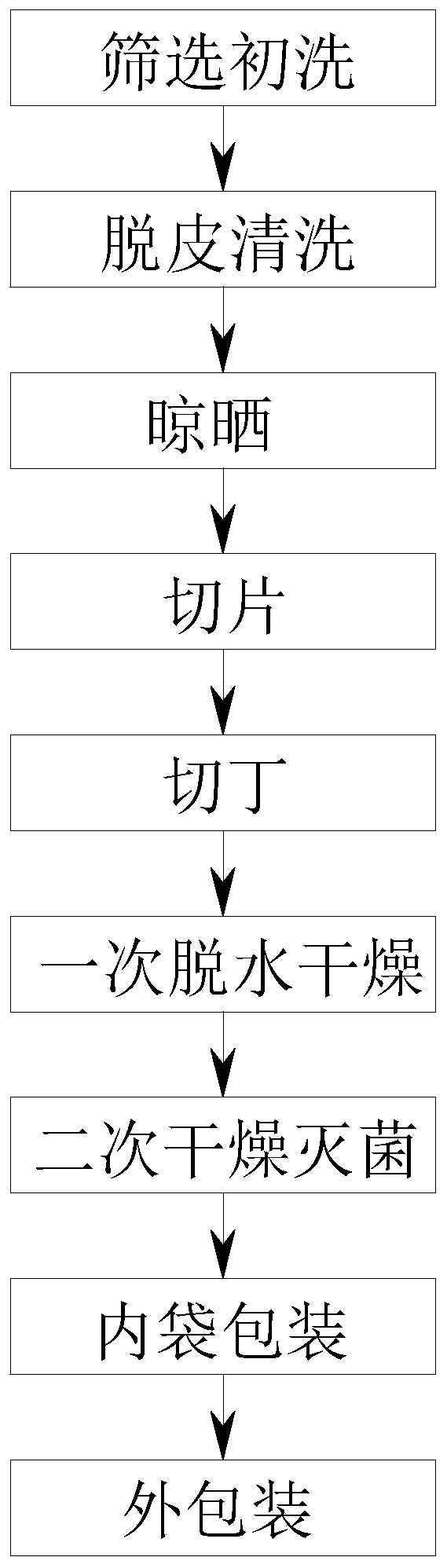

Production technology of radix puerariae tea

The invention discloses a production technology of radix puerariae tea. The production technology comprises 9 making technological processes of performing screening and first washing, performing peeling and cleaning, performing airing, performing cutting into slices, performing cutting into dices, performing primary dehydrating and drying, performing secondary drying and sterilization, performingpackaging with inner bags and performing external packaging. The production technology specifically comprises the following steps of performing primary cleaning: selecting radix puerariae which is free from mildew and rot and free from insect holes in appearance, and is not deteriorated, rejecting the radix puerariae of which the crusts are in drying shrinkage, placing the treated radix puerariaein a soaking pond, adding circulating water until the radix puerariae is immersed, performing soaking for 3-4 hours, then fishing out the soaked radix puerariae, and flushing silt on the surfaces of the fished-out radix puerariae with a high-pressure water torch until the crusts are clean and free from dirt; and performing peeling and cleaning: putting the flushed radix puerariae in a peeler special for radix puerariae, performing cleaning and crust grinding, removing the crusts of the radix puerariae, then performing thorough flushing with the high-pressure water torch, and placing the flushed radix puerariae on a rack. According to the production technology disclosed by the invention, through setting 9 making technological processes of performing screening and first washing, performing peeling and cleaning, performing airing, performing cutting into slices, performing cutting into dices, performing primary dehydrating and drying, performing secondary drying and sterilization, performing internal packaging and performing external packaging, the produced radix puerariae tea is red bright in soup color, sweet in aftertaste and rich in fragrance.

Owner:青川县青野葛业有限公司

Rose vinegar

The invention discloses rose vinegar. A process method of the rose vinegar includes: subjecting roses serving as raw materials to dry crushing, extraction by edible alcohol, alcoholic strength adjustment, acetic fermentation, clarifying, ageing, filtering, mixing, filling and sterilization so that a rose vinegar finished product is obtained. The rose vinegar fully retains nutrition and efficacy of the roses, is rich in multiple amino acids, vitamins, mineral substances and antioxidant components of polyphenol, flavone and the like, and has the efficacy of detoxification, keeping young, promoting qi to activate blood, inducing resuscitation, removing stasis, soothing the liver, refreshing the mind, promoting biliation, easing digestion and regulating mechanism. The rose vinegar is free from addition of any spice and chemical component, rich in nutrition, sweet in aroma and suitable for ladies to drink and has the efficacy of maintaining beauty and keeping young.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

Black tea processing method capable of avoiding excessive fermentation

InactiveCN106490219AIncreased damage rateSame starting point of fermentationPre-extraction tea treatmentBlack teaSODIUM SILICATE SOLN

The invention discloses a black tea processing method capable of avoiding excessive fermentation. The method comprises the procedures of picking fresh leaves of tea trees, withering, rolling, fermenting and drying, wherein before the procedure of withering, a sodium silicate solution with the concentration of 0.1 to 0.6 mmol / L is sprayed on the picked fresh leaves and the ratio of the material to the liquid is 100 g: (1-5) ml. By the method, the cell damage rate during rolling can be increased, the rolling time is shortened, the consistency of fermentation starting points of tea is guaranteed, and the fact that theaflavin and thearubigin are transformed into theabrownin due to excessive fermentation is avoided. The black tea prepared by the method has pleasant tea soup fragrance, strong taste and bright color after being brewed.

Owner:广西神海云峰农业综合开发有限公司

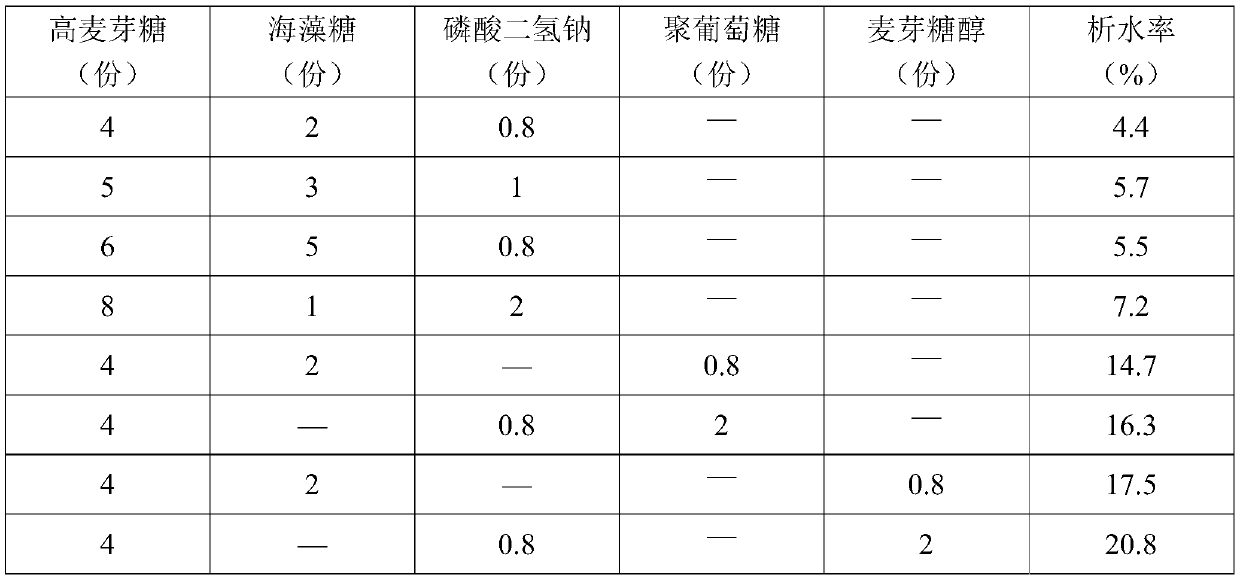

Fresh and sweet type humectant for cigarettes

The invention discloses a fresh and sweet type humectant for cigarettes. The fresh and sweet type humectant is prepared from a solvent, natural plant extract and a humidity-keeping accelerant, whereinthe solvent is one or a mixture of propylene glycol and ethanol; the natural plant extract is mixed extract of apples, green plums and shaddock peels; the humidity-keeping accelerant is a moss extracting solution. According to the fresh and sweet type humectant disclosed by the invention, the humectant is prepared by reasonably compounding the apples, the green plums and the shaddock peels for the first time; the prepared humectant has a fresh and sweet spice aroma and abundant layers; the aroma of the cigarettes can be increased, the dry sensation of smoke is reduced and the comfort of the cigarettes is improved; meanwhile, the fresh and sweet type humectant has good humidity-keeping performance and has a good market prospect and application value.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Black tea and its preparation method

ActiveCN105394221BSweet and smooth tasteSweet aromaPre-extraction tea treatmentBlack teaFermentation

Owner:广东鸿雁茶业有限公司 +1

Plant hair dye and preparation method thereof

InactiveCN107184454ASmell fresh and naturalNot easy to splitCosmetic preparationsHair cosmeticsNutrientChemistry

The invention discloses a plant hair dye and preparation method thereof. The plant hair dye is composed of, by weight percentage, 42-58% of indigo, 13-16 parts of emblica officinals, 13-16% of roseleaves, 8-10% of eclipta alba, 4-8% of red tea solution and 4-8% of mulberry. Due to the fact of being composed of natural plant components, the plant hair dye is fresh and natural in flagrance and free from damage to body health during long-term application; meanwhile, by mixing multiple plant nutrients, the plant hair dye achieves deep scalp nourishing effects to maintain smooth hair quality and to avoid splitting, and greatly improves the dyeing fixation effects as well as the dyeing durability.

Owner:陈婷婷

Calcium tablet prepared from prunus humilis bunge and preparation method of calcium tablet

The invention discloses a calcium tablet prepared from prunus humilis bunge. The calcium tablet is prepared from the following raw materials in parts by weight of 30-50 parts of prunus humilis bunge powder, 10-15 parts of milk powder, 5-8 parts of rose petals, 3-5 parts of durian sugar powder, 2-4 parts of pomegranate juice, 3-5 parts of maltodextrin, 3-5 parts of carboxymethyl-beta-cyclodextrin,3-5 parts of rhamnose and a proper amount of water. The preparation method comprises the following steps of S1, crushing rose petals, mixing the crushed rose petals with the prunus humilis bunge powder, the milk powder and the durian sugar powder, performing uniform stirring, and adding a proper amount of water so as to obtain a thick substance A; S2, adding pomegranate juice and rhamnose into thethick substance A, uniformly stirring, drying to prepare a soft material, and cutting into particles B; and S3, mixing maltodextrin, carboxymethyl-beta-cyclodextrin and a proper amount of water to prepare a solution C, soaking in the solution C, taking out, drying and tabletting. The calcium tablet has rich nutritional value, calcium naturally exists in fruits and has no side effect when being eaten, and the addition of the auxiliary materials not only increases the taste, but also enriches the nutrition.

Owner:上海欧李优食品科技有限公司

Rose strip containing natural aromatic plant

InactiveCN101181578BSweet aromaSafety and health regulationOrganic active ingredientsDermatological disorderMalariaPhenylethyl Alcohol

The invention relates to a rose strip which contains natural fragrant plants, comprising 80 to 85 parts of roses, 10 to 15 parts of citrus aurantium flower, 4 to 6 parts of nervilia fordiis, 2 parts of fructus amomis, 2 parts of banksian rose and 2 parts of sodium carboxymethyl cellulose. The invention is a composite, wherein, the rose has the effects of promoting the flow of qi, relieving stagnancy, regulating blood and dissipating blood stasis, and because the rose is rich in a plurality of volatile fragrances such as citronellol, nerol, geraniol, phenylethyl alcohol and benzoic alcohol, etc. the rose has sweet fragrance; the citrus aurantium flower has the effects of dispersing stagnated liver qi for regulating stomach, promoting the flow of qi and relieving stagnancy; the nervilia fordiis has effects of clearing fever, dissipating blood stasis, moistening the lung and detoxifying; the fructus amomi has the effects of eliminating dampness, dispelling cold, expelling phlegm and preventing recurrence of malaria; and the banksian rose has effects of promoting circulation of qi and relieving pain. In addition, when matched with the well-known adjustable needle warming moxibustion apparatus, the invention can realize safe health regulation for people, and can be used in skin-beautifying upkeep and health care physical therapy such as promoting the flow of qi, relieving stagnancy,regulating blood and dissipating blood stasis; moreover, the invention has the advantages of obvious physical therapy effect, delightful fragrance and low cost.

Owner:刘晓芸

A kind of humectant for clear and sweet tobacco

ActiveCN107603738BWon't breakAvoid churnTobacco preparationTobacco treatmentBiotechnologyPropylene glycol

The invention discloses a moisturizing agent for clear and sweet tobacco, which comprises a solvent, a natural plant extract and a moisturizing promoter, the solvent is one or more of propylene glycol or ethanol, and the natural plant extract It is a mixed extract of apple, green plum and pomelo peel, and the moisturizer is moss extract. For the first time in the present invention, apples, green plums and pomelo peels are rationally compounded to prepare humectant. The fragrance of the prepared humectant is fresh, sweet, and rich in layers, which can increase the aroma of cigarettes, reduce the dryness of smoke, and improve the comfort of cigarettes. , At the same time, it has excellent moisture retention performance, and has good market prospects and application value.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Method for preparing congou black tea from anji white tea

ActiveCN103749755BControl temperature and humidityTransformed properlyPre-extraction tea treatmentBlack teaBud

The invention relates to a black tea preparing method and particularly relates to a method for preparing congou black tea from anji white tea. The method sequentially comprises the following steps: picking based on a one-bud and one-leaf standard; withering; rolling; fermenting: arranging the rolled leaves to be fermented into a bamboo basket, controlling the leaf stacking thickness to be 8-10cm, uniformly spreading, and layering the leaves on a fermentation rack; fermenting by using a tea fermenting machine, controlling the air temperature at 35-40 DEG C, keeping the leaf temperature 30-32 DEG C, the relative humidity over 95% and sufficient oxygen supply, recording the fermentation time beginning from the rolling time, and controlling the fermentation time to be 5.5-6.0h. At the later period of fermentation, the temperature of a fermentation chamber is lowered and is controlled at 30-35 DEG C, so that the excessive fermentation is avoided; the moderate fermentation is carried out, and the fermented leaves are removed from the fermentation chamber, subjected to heat radiation, cooled and dried. By using the method, the anji white tea can be prepared into the congou black tea which is dark in luster, compact in strip, sweet and durable in fragrance, red bright in liquor color as well as pure, mild and fresh in taste.

Owner:浙江安吉宋茗白茶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com