Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Suspension implementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

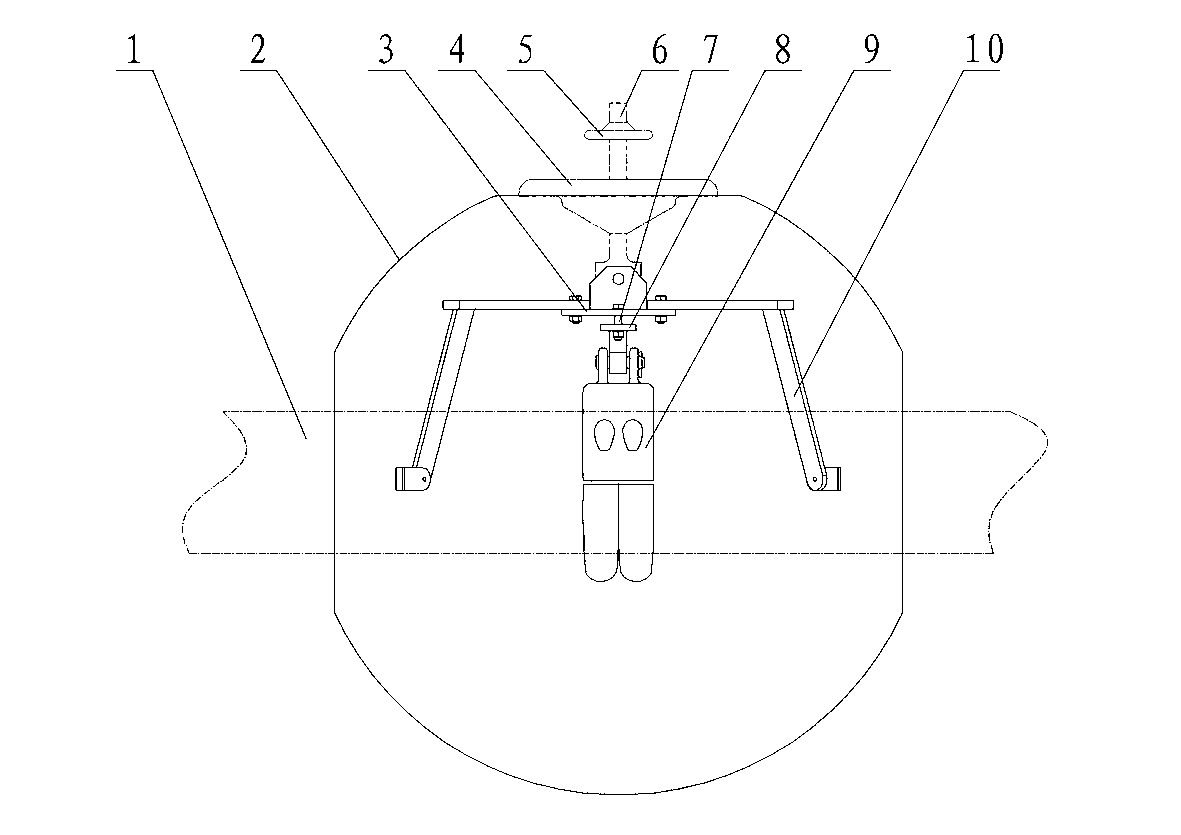

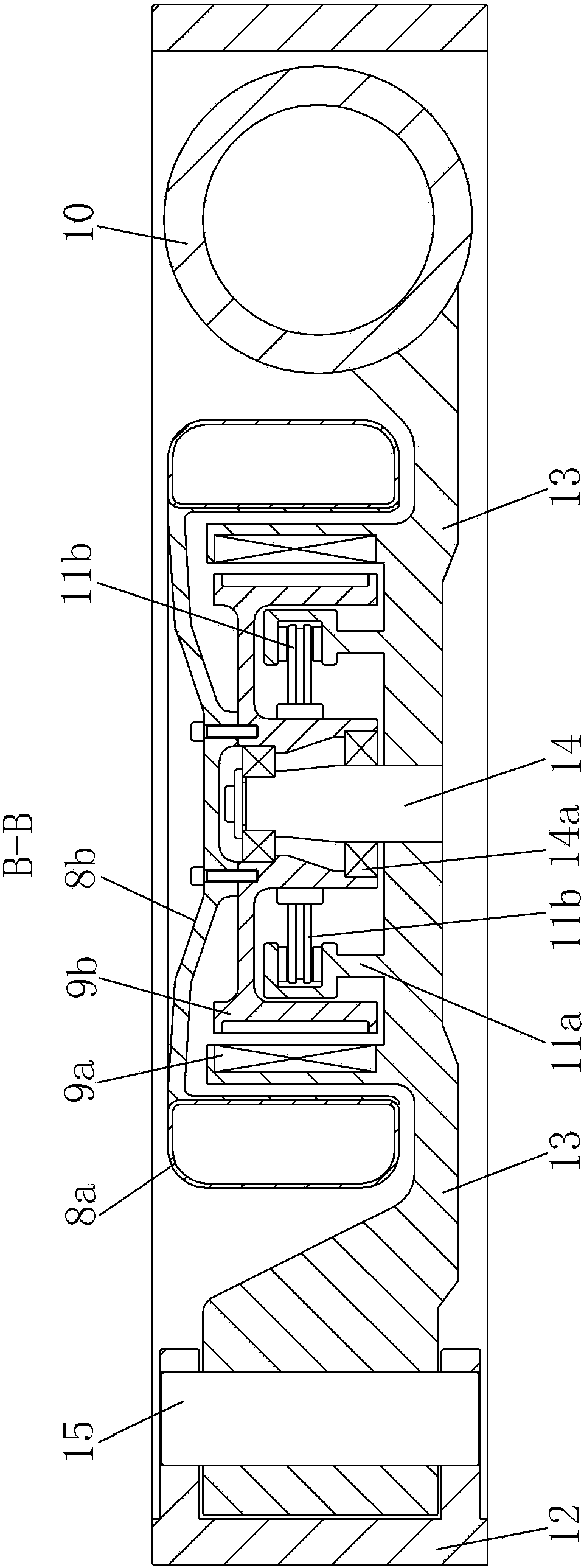

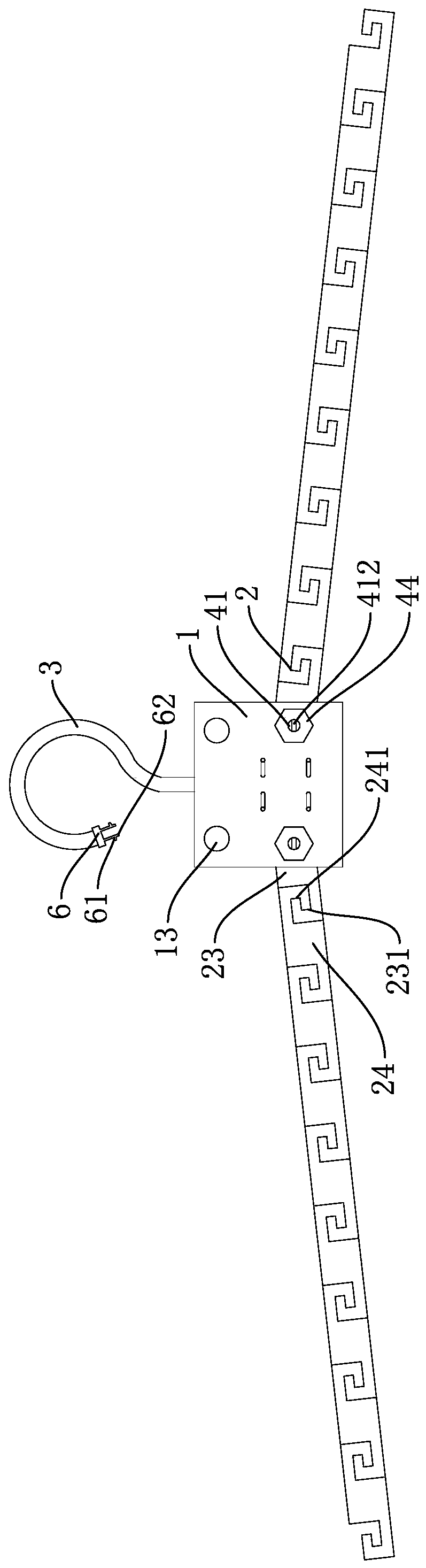

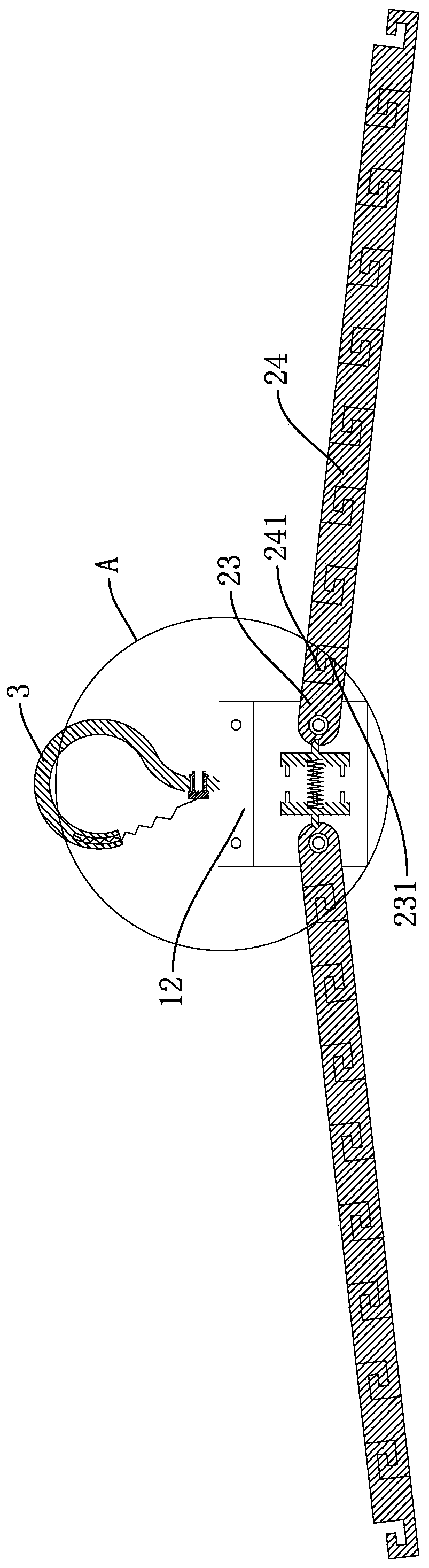

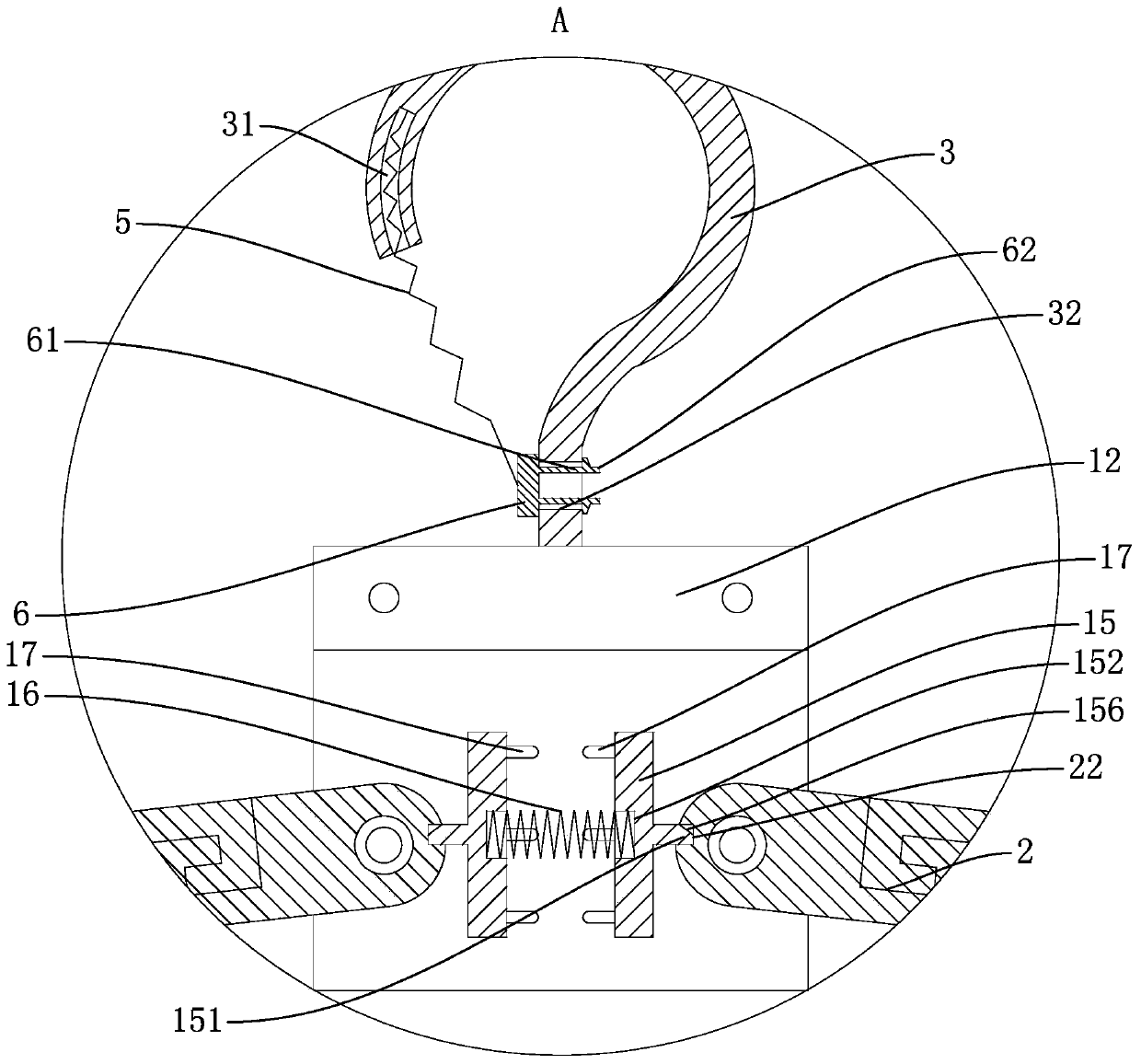

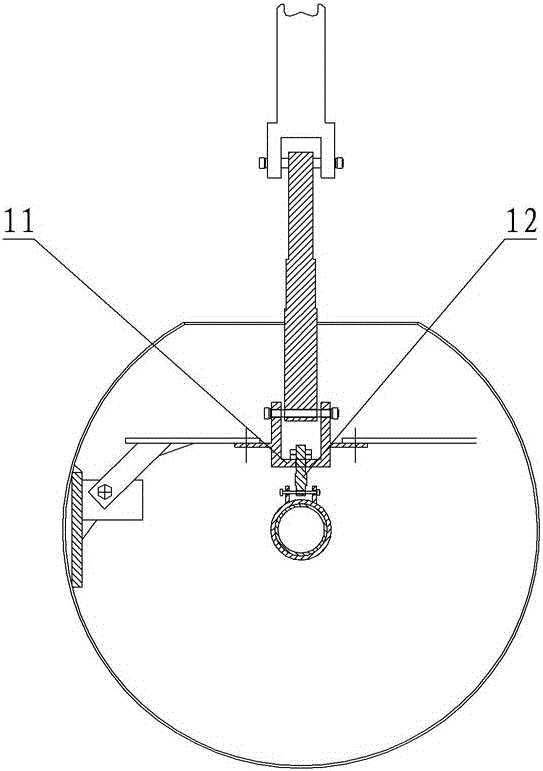

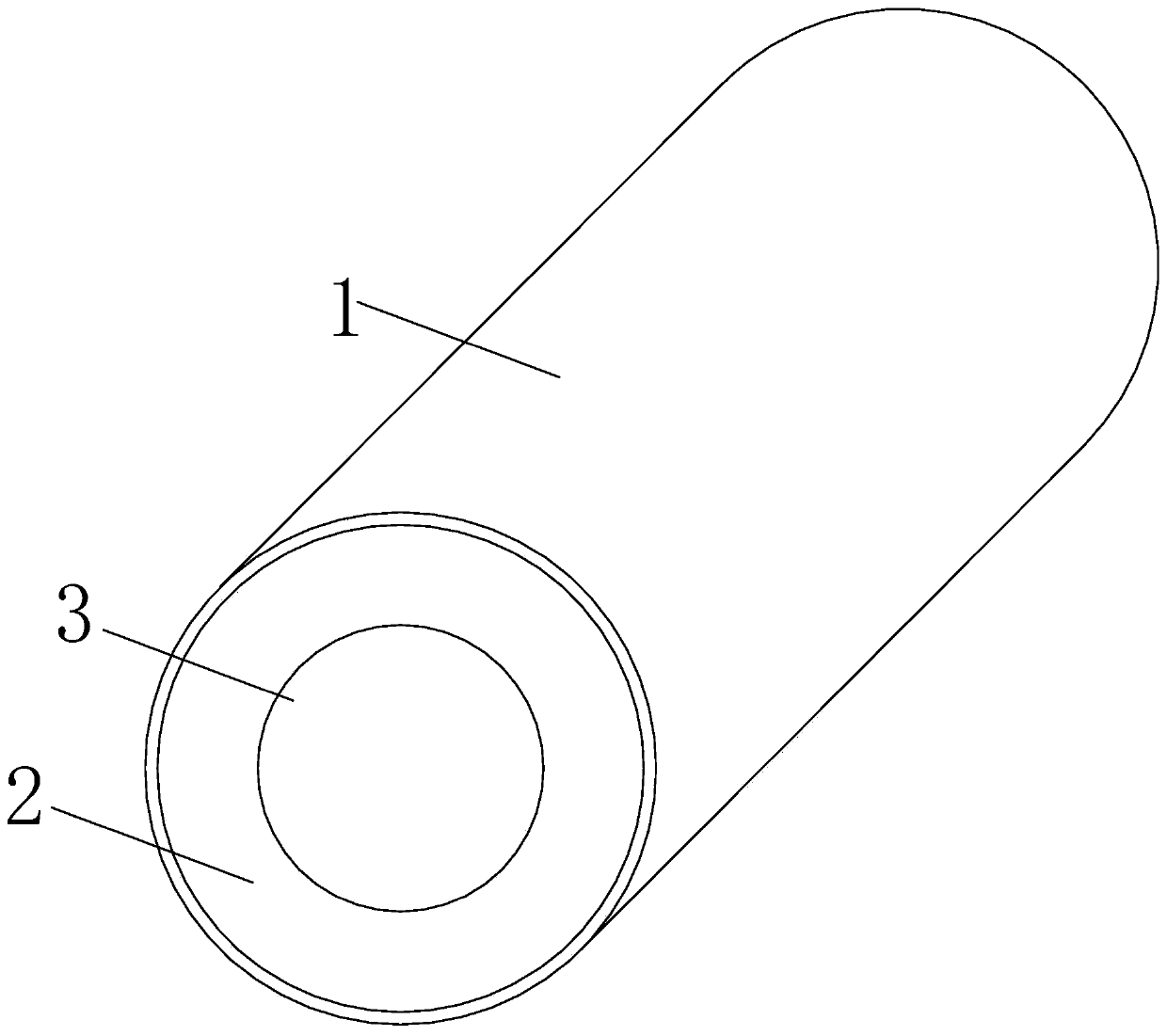

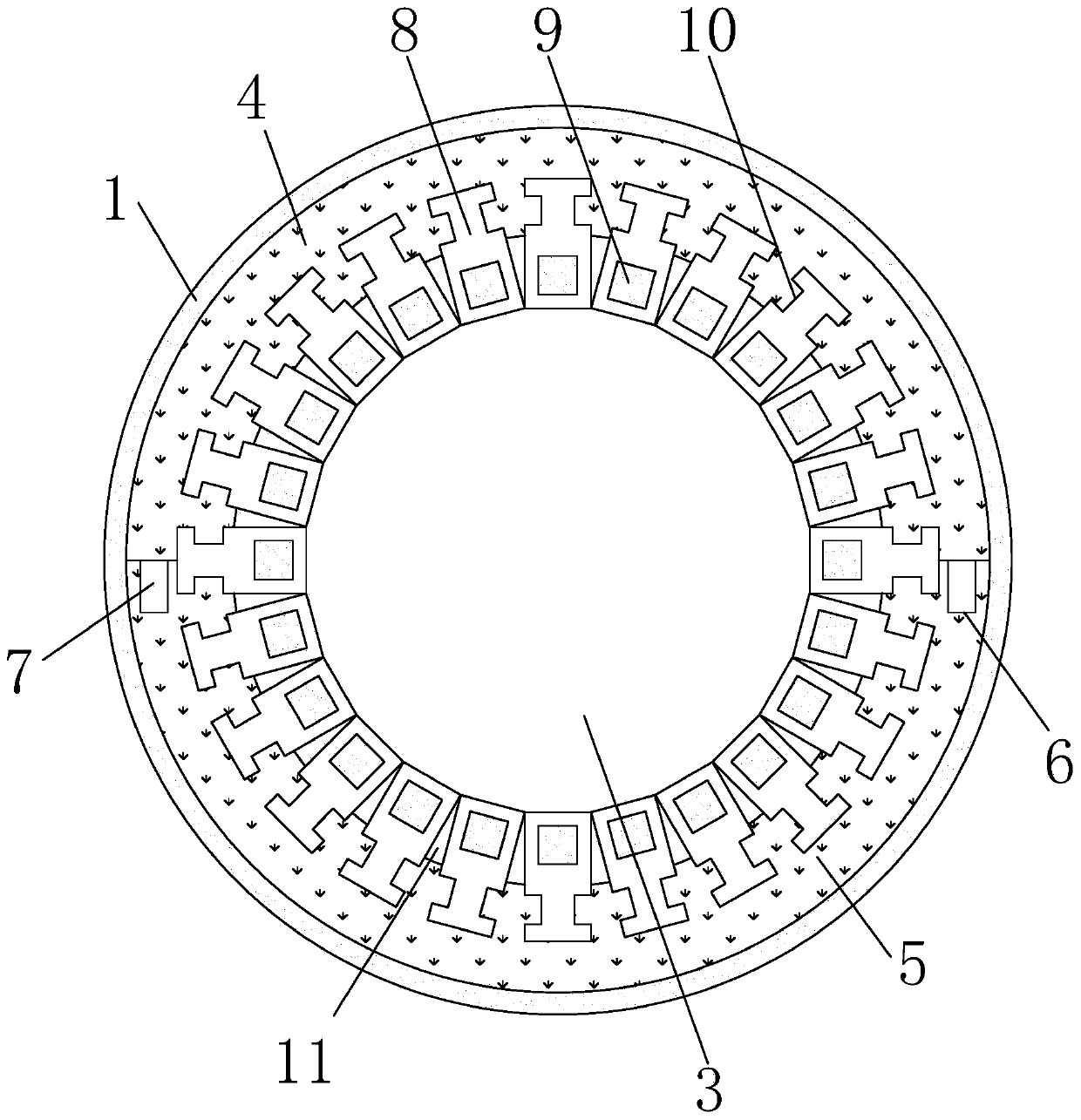

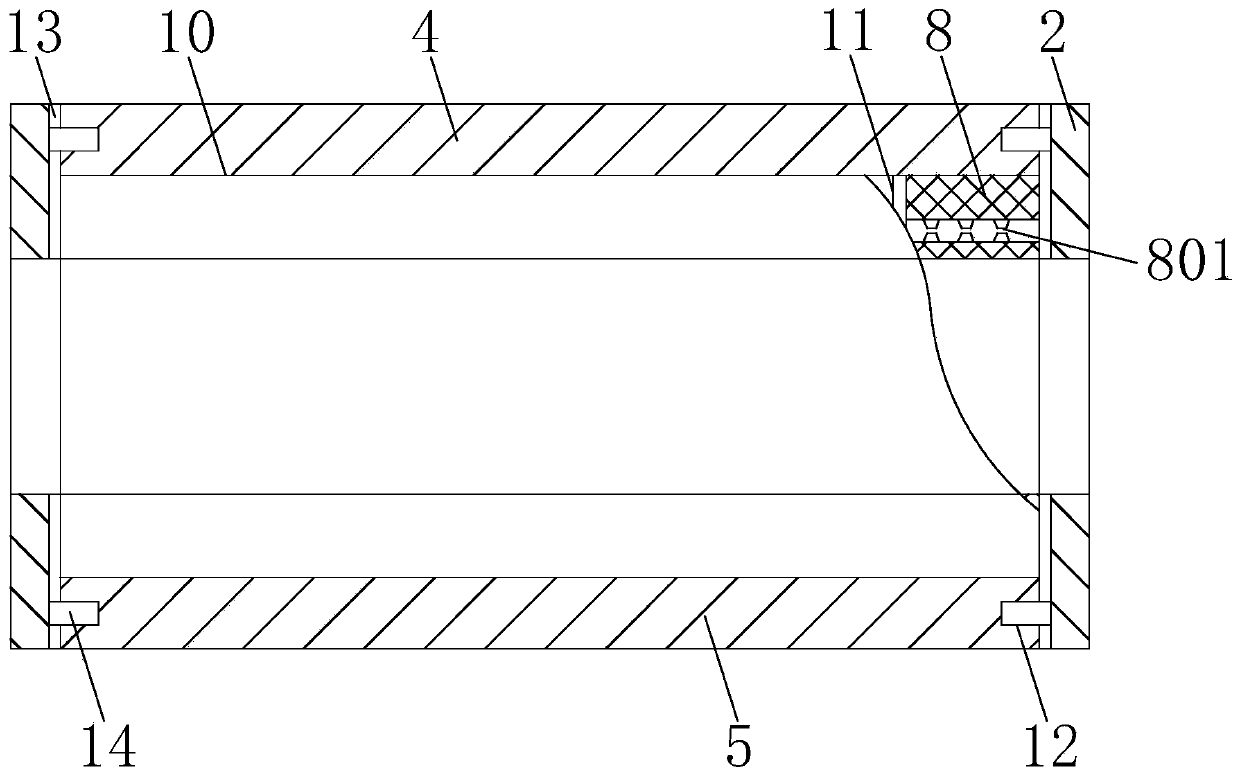

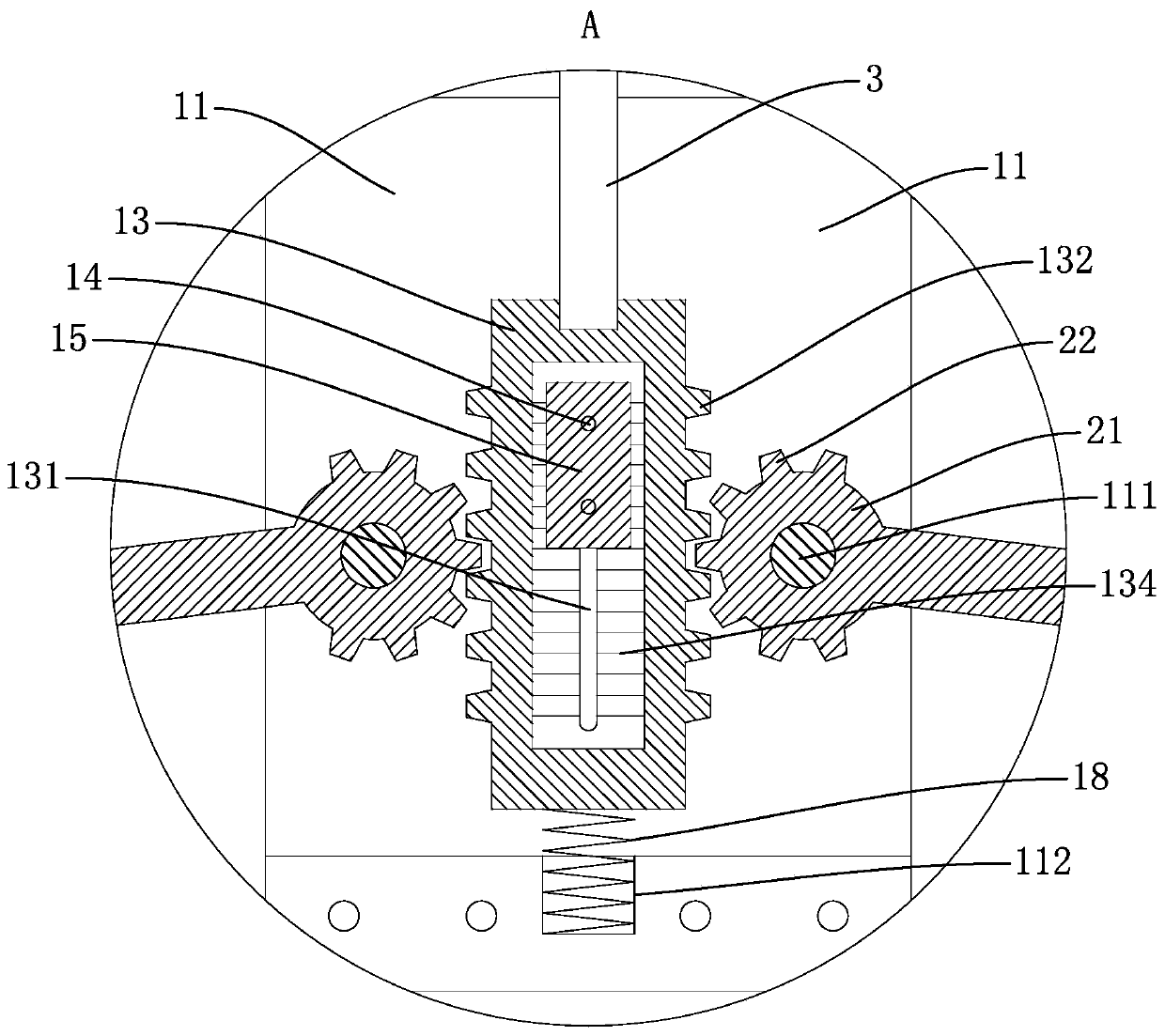

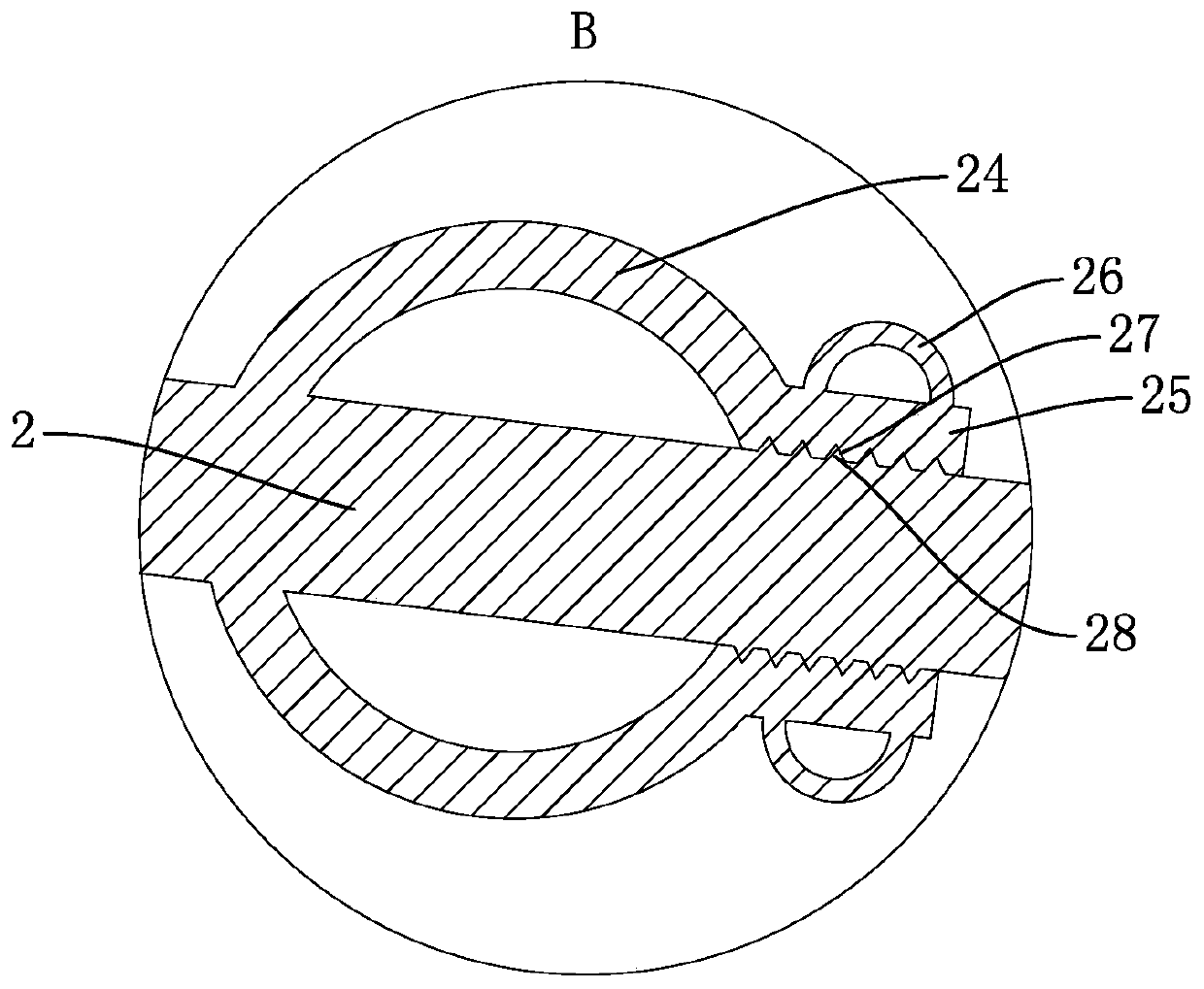

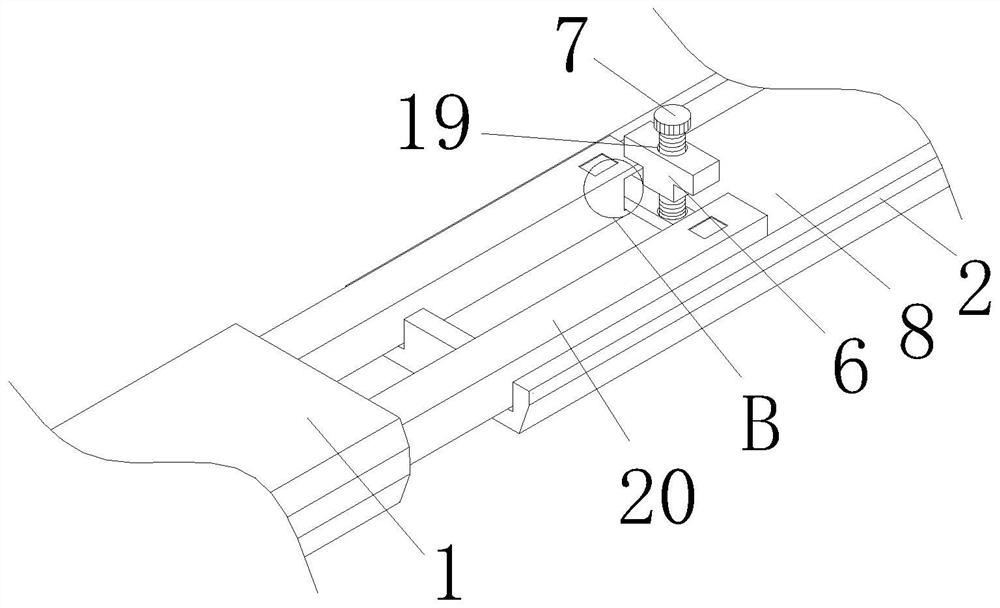

Tube busbar suspension fitting for converter station valve hall

ActiveCN103296623ASuspension implementationMeet suspension needsBus-bar installationBusbarEngineering

The invention discloses a tube busbar suspension fitting for a converter station valve hall. The tube busbar suspension fitting comprises an anti-corona ball and a hanging rack which is fixedly arranged on the inner sphere of the anti-corona ball and which is used for suspending a tube busbar. The hanging rack comprises a hanging rod which penetrates the top of the anti-corona ball and which is used for connecting to insulator strings on the top of the valve hall. An adjustable connecting rack with longitudinally adjustable length is hinged to the lower end portion of the hanging rod, and supporting claws distributed along circumstance of the anti-corona ball evenly are connected between the adjustable connecting rack and the anti-corona ball. A tube busbar clamp for matching with the tube busbar in a hoop manner is hinged to the bottom of the adjustable connecting rack. A single tube busbar is clamped through the tube busbar clamp to realize suspension of the single tube busbar in the valve hall, the need of suspending the single tube busbar can be met, and the tube busbar suspension fitting has the advantages of convenience and rapidness in mounting; furthermore, the length of the adjustable connecting rack can be adjusted longitudinally, accordingly the length of the tube busbar clamp in the valve hall can be adjusted directly, and the need of clamping tube busbars of different lengths through the tube busbar clamp can be met.

Owner:STATE GRID CORP OF CHINA +1

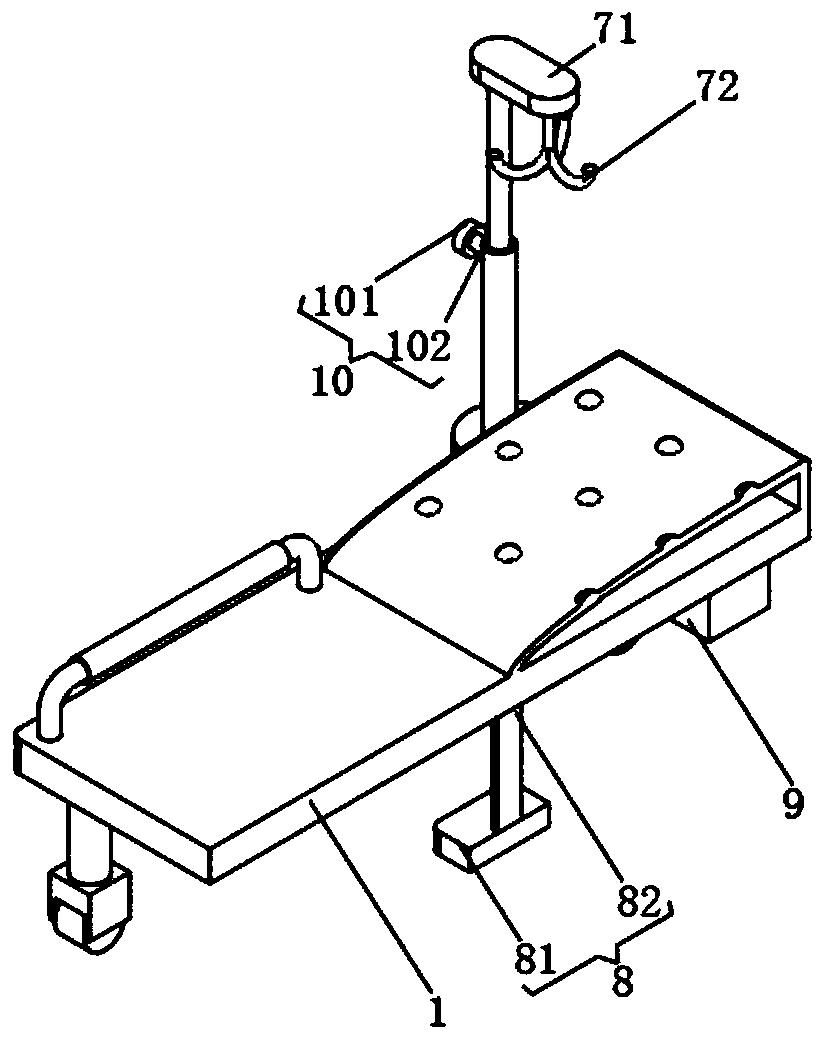

Effusion drainage device for cardiovascular medicine department

InactiveCN110236849ASuspension implementationVersatileOperating tablesInfusion devicesEffusionEngineering

The invention discloses an effusion drainage device for a cardiovascular medicine department. The device includes a bed, a control switch set, a first servo motor and a second servo motor; a uniformly distributed moving structure is arranged on the edge of the lower end face of the bed, an auxiliary fixing structure is arranged on the middle part of the lower end face of the bed, two outer plates which are opposite in front and back are connected to the left and right end of the bed separately, a guide rod is connected between the two outer plates at the left end, a first lead screw is connected between the two outer plate at the right end, the first lead screw is in threaded connection with the lower side of the right end of a portal frame, the guide rod is in slidable connection with the lower side of the left end of the portal frame, and a guide sliding grove is formed in the middle part of the transverse plate of the portal frame. According to the effusion drainage device for the cardiovascular medicine department, by arranging the corresponding fixing structure, a patient undergoing drainage can be fixed, and additional pain caused by the patient's own movements during drainage is avoided; by arranging a corresponding infusion bottle hanging structure, infusion bottle hanging can be achieved.

Owner:徐卫娟

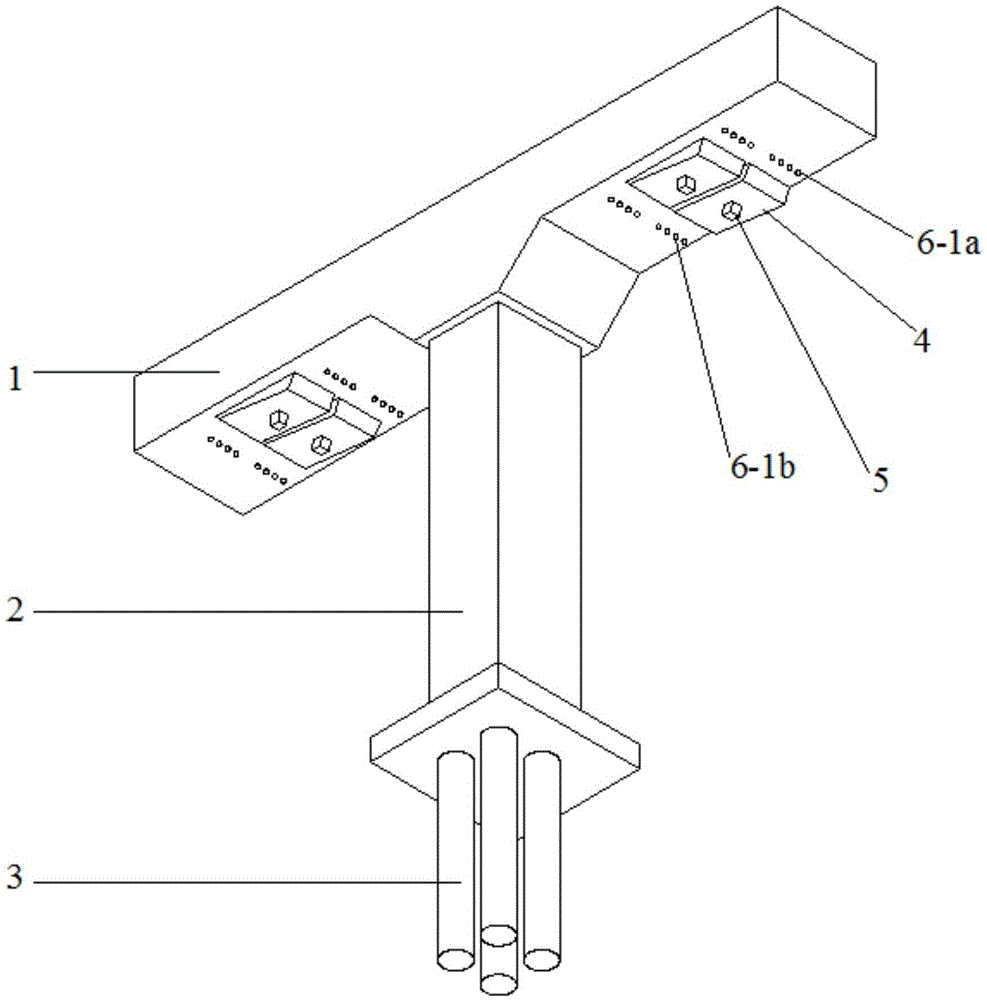

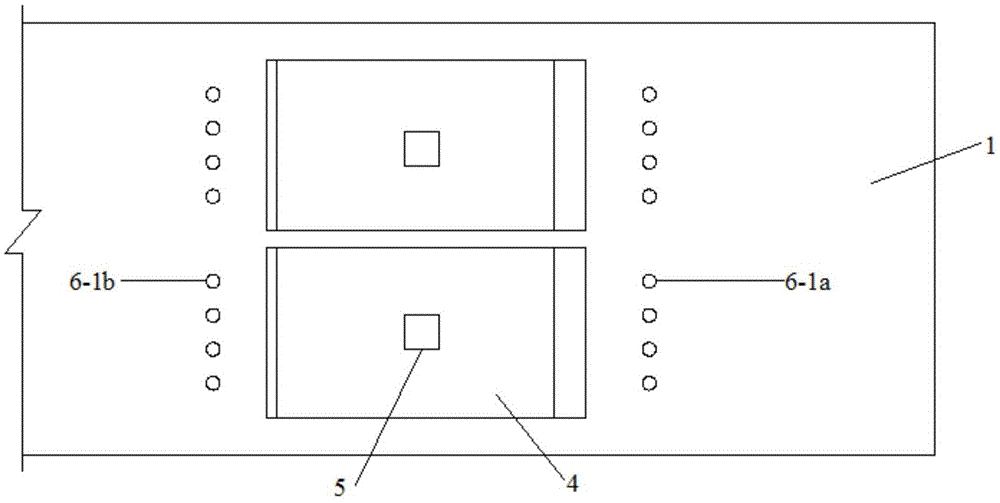

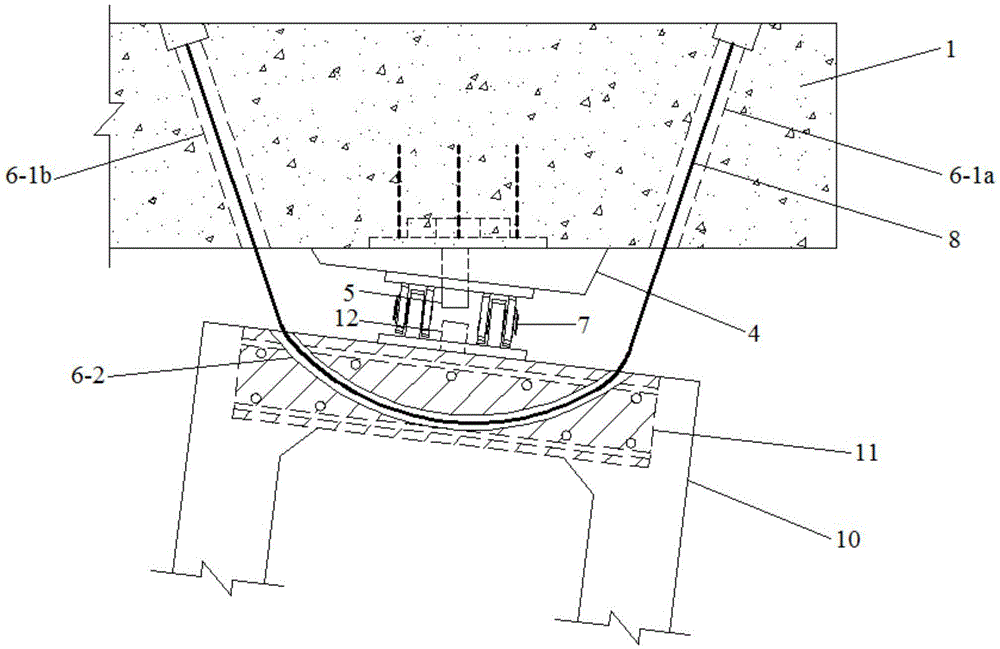

Concrete pier system for suspension type monorail traffic and construction process

PendingCN105568844ASuspension implementationRailway tracksBridge structural detailsLinear controlEngineering

The invention relates to a concrete pier system for suspension type monorail traffic and a construction process applied to the suspension type monorail traffic. A suspension cable (8) penetrates into a concrete cover beam reserved duct (6-1a), a base reserved duct (6-2) and a concrete cover beam reserved duct (6-1b), so that a track beam (10) is suspended below a concrete cover beam (1), and the suspension cable (8), a bearing pad stone (4), support upper pendulum anti-shearing tenons (5) and a base (11) jointly form the concrete pier system for suspension type monorail traffic. According to the concrete pier system for suspension type monorail traffic and the construction process, the track beam is suspended below the concrete cover beam through a stay cable, so that suspension of the track beam is achieved, and the problems that a borne vehicle is small in load, vibration resistance is not facilitated, a track beam is prone to great deformation, linear control of the track beam is not facilitated, a metallic structure is prone to corrosion, and durance is difficult to guarantee are solved.

Owner:BEIJING JIAOTONG UNIV

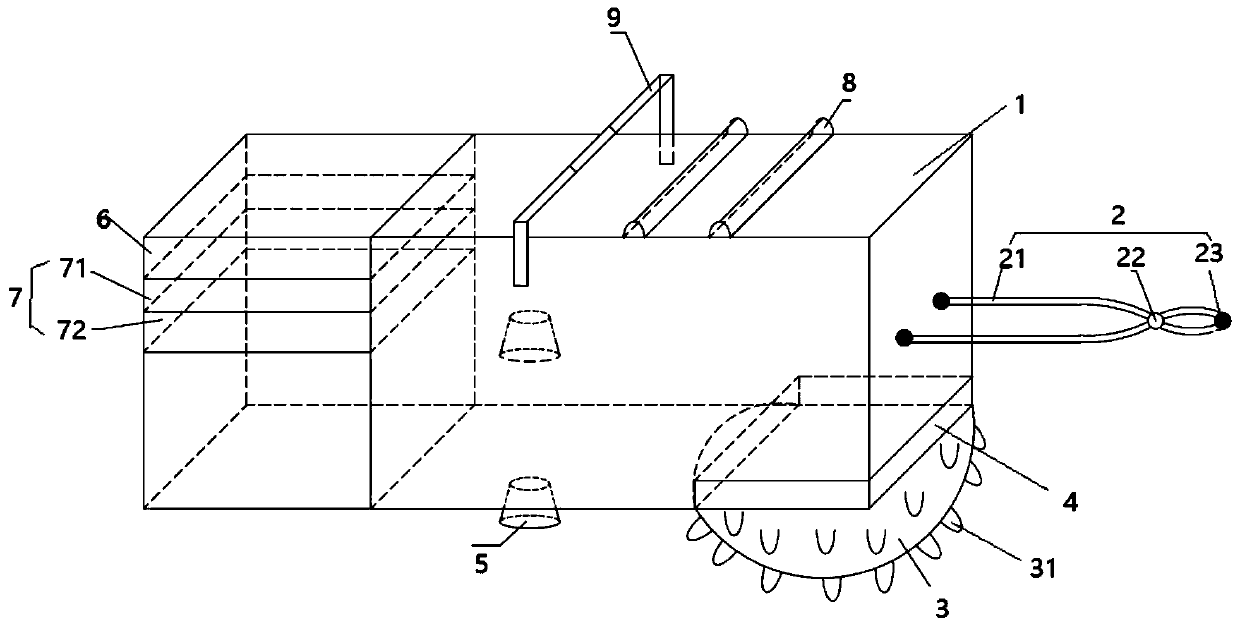

Tramcar based on rubber wheel and virtual track technology

ActiveCN103863334ARealize track-guided operationAchieve normal operationSpeed controllerRailway componentsControl systemEngineering

The invention discloses a tramcar based on rubber wheel and virtual track technology. The tramcar based on the rubber wheel and virtual track technology comprises a car body (1), a control system (6) and a wheel assembly, and is characterized in that the wheel assembly is a rubber wheel with a drive motor and a brake device, and both the drive motor and the brake device are respectively connected with the control system (6); the bottom of the car body (1) is also provided with a sensor (4) for detecting a ground virtual track mark (3), and the output end of the sensor (4) is connected with the control system (6); or the car body (1) is provided with a satellite locator which is connected with the control system (6). The tramcar does not need a steel rail and is low in running noise and small in influence on the urban environment; the smoothness of a pavement and completeness and attractiveness of a street, in which the tramcar runs, can be guaranteed, and the running of other traffic tools and the passing of the pedestrians also can be conveniently realized.

Owner:SOUTHWEST JIAOTONG UNIV

Special nursing bed for spine nursing

InactiveCN110974567AStorage and placement to avoidHumanized designDiagnosticsInfusion devicesBed boardsBiomedical engineering

The invention discloses a special nursing bed for spine nursing. The special nursing bed comprises a bed board, a hanging unit, a supporting unit and a storage unit, wherein uniformly-distributed moving units are arranged at the edge of the lower end surface of the bed board; two armrest units which are opposite front and back are arranged at the left end of the upper end surface of the bed board;a backrest unit is arranged on the part, close to the left end, of the upper end surface of the bed board; the hanging unit is located on the part, close to the right end, of the rear side of the bedboard; the supporting unit is located at the central part of the lower end of the bed board; the storage unit is located at the lower end of the bed board; the special nursing bed also comprises a control switch group which is fixedly arranged on the bed board; and the input end of the control switch group is electrically connected with the output end of an external power supply. The special nursing bed provided by the invention has the advantages: through corresponding arrangement of an article storage structure, articles of a patient can be stored and can be prevented from being lost; and through corresponding arrangement of an infusion suspension structure, great convenience can be brought to a medical worker during medicine application for the patient.

Owner:白翠霞

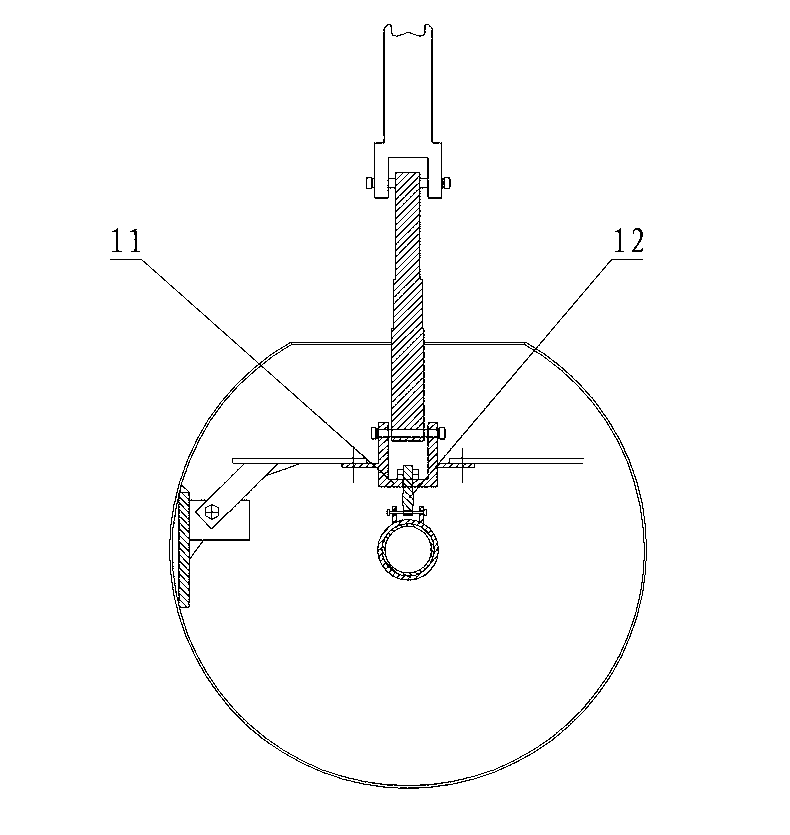

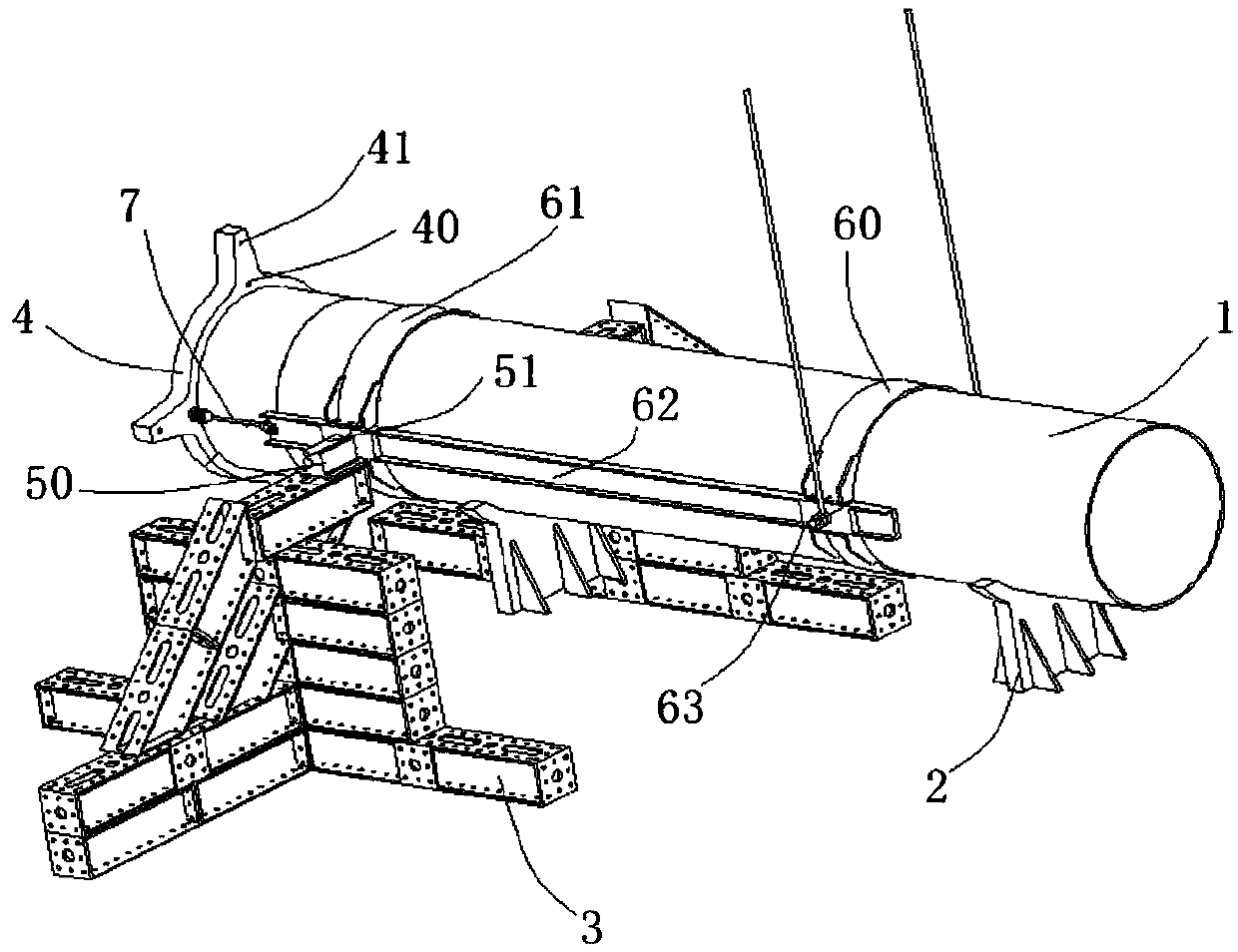

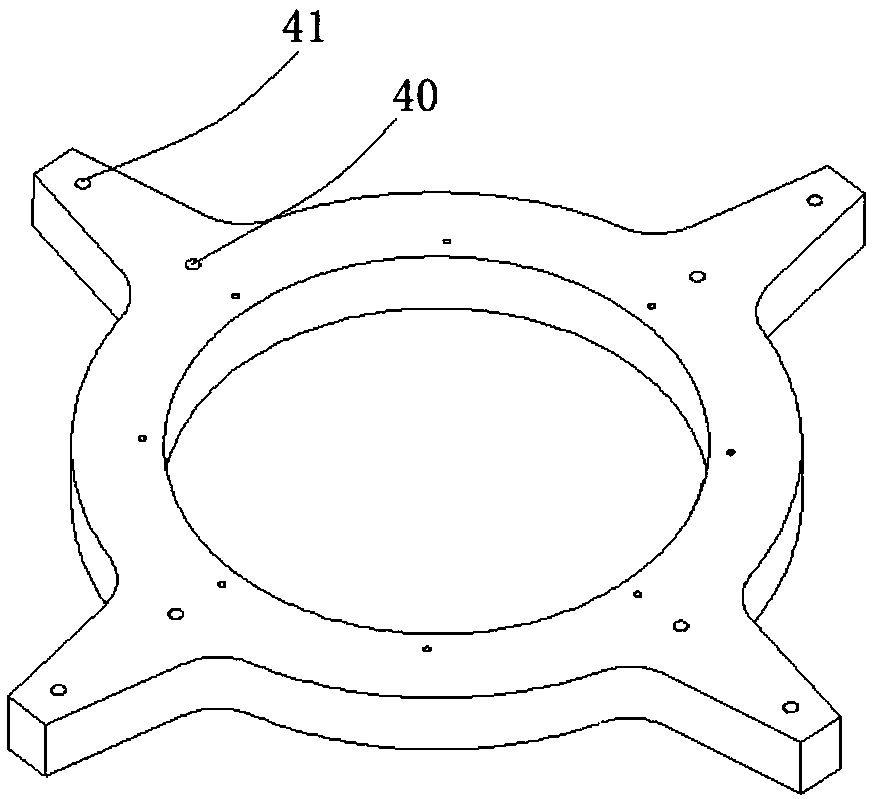

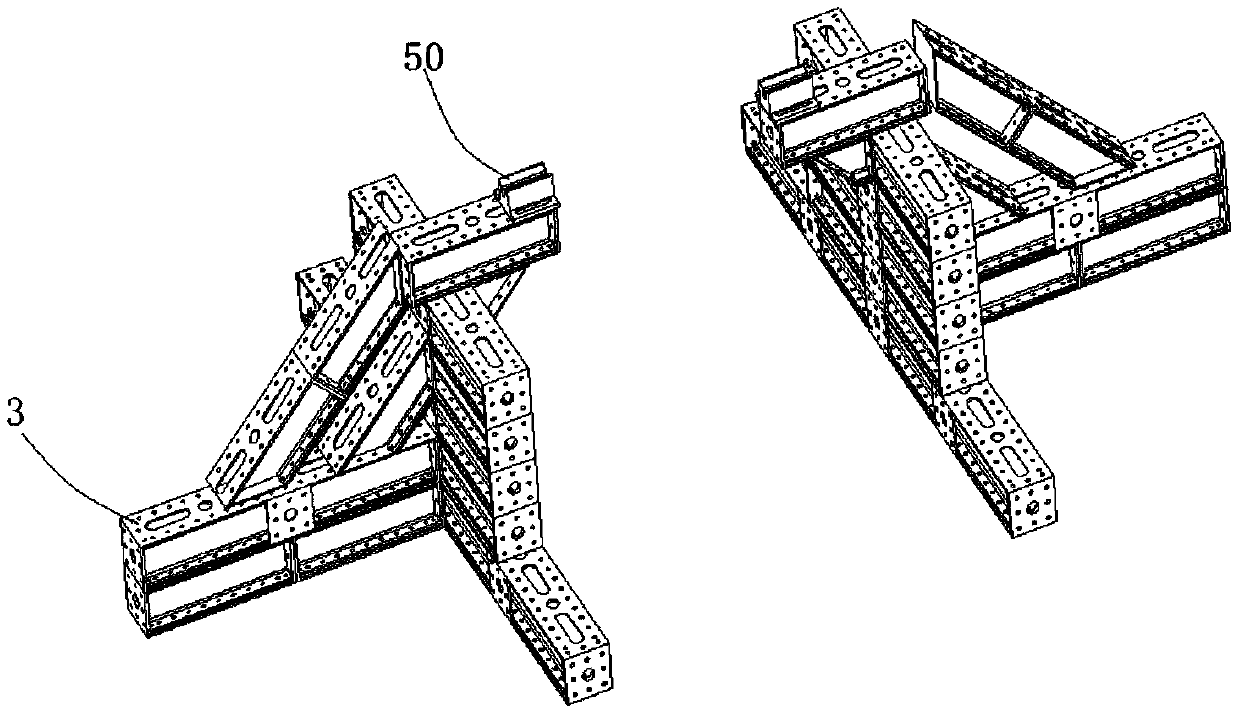

Overturning and suspension device for projectile body vertical mode test and use method thereof

ActiveCN109607382AThe turning process is smooth and controllableSimple structureLoad-engaging elementsEngineeringProjectile

The invention discloses an overturning and suspension device for a projectile body vertical mode test and a use method of the overturning and suspension device for the projectile body vertical mode test. The overturning and suspension device for the projectile body vertical mode test comprises a bearing frame, two supporting platforms, a rotating assembly and a suspension piece. The bearing frameis used for supporting the projectile body. The two supporting platforms are used for providing rotation supporting platforms for the projectile body. The rotating assembly comprises a fixing piece and rotating pieces which are symmetrically arranged on the two sides of the fixing piece. One end of each rotating piece is connected with the corresponding fixing piece, and the other end of each rotating piece is fixed to the corresponding supporting platform. Each fixing piece is used for arranging on the projectile body in a sleeving manner. When the fixing pieces are lifted, the fixing piecesdrive the projectile body to rotate around the rotating pieces within a preset angle range. The suspension device is arranged at one end of the projectile body and used for assisting the projectile body in suspension. The invention also provides a use method of the overturning and suspension device for the projectile body vertical mode test. The overturning and suspension device for the projectilebody vertical mode test is suitable for overturning and vertical suspension of the projectile body which has large mass, cannot bear pull and bend and can only bear pressure, and the overturning andsuspension device for the projectile body vertical mode test has the features of being simple in structure, low in cost and safe.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

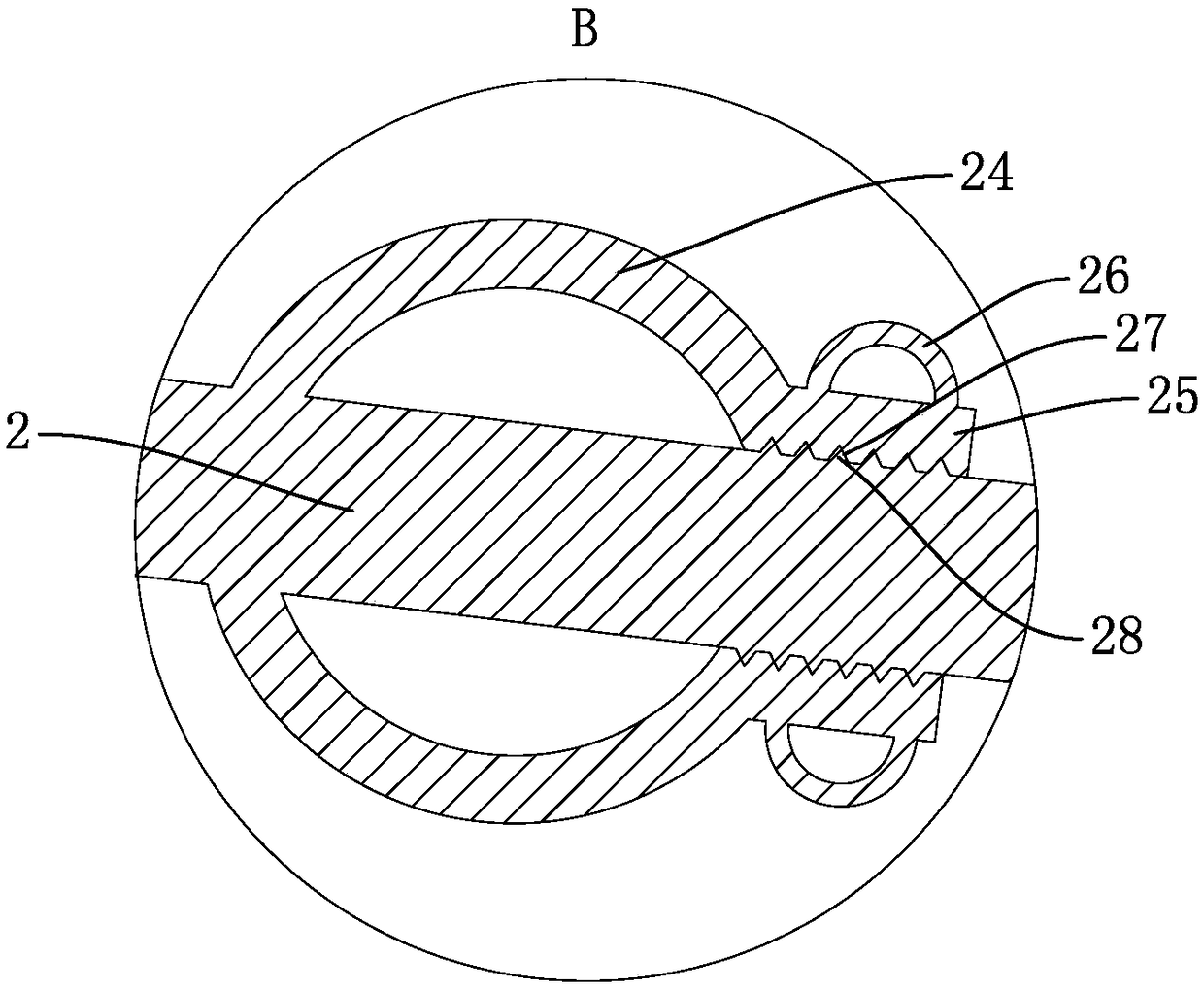

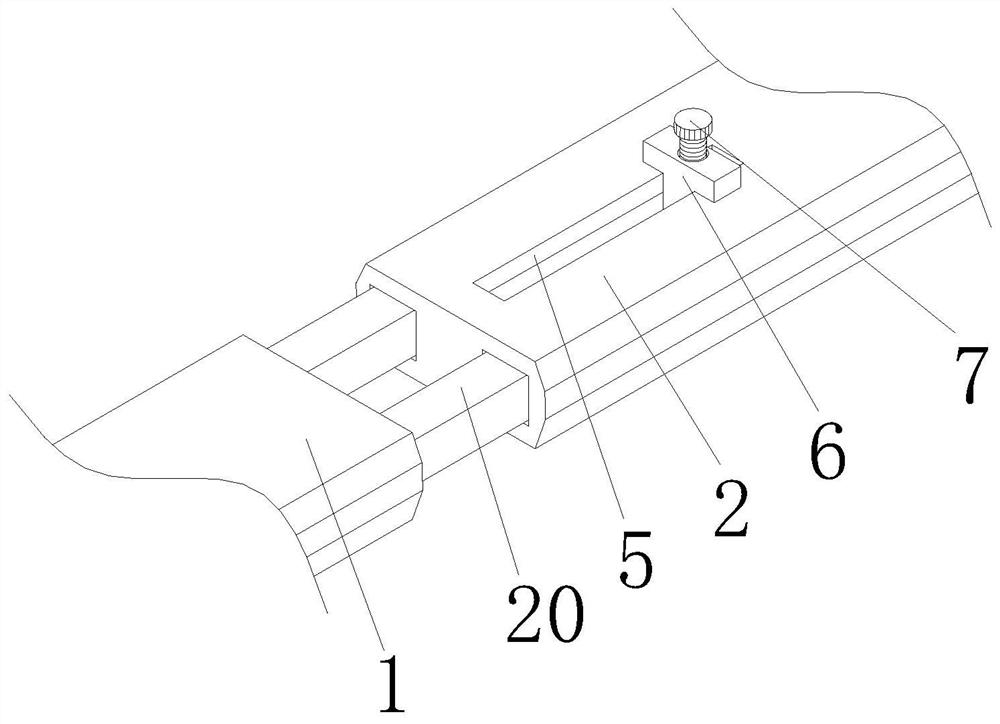

Foldable hanger

The invention discloses a foldable hanger. The hanger comprises a bracket, suspension arms mounted on two sides of the bracket and a hook mounted on the upper end of the bracket, the bracket comprisesa base and a cover, the base is provided with a sliding block, a guide rail penetrates through the base and the cover plate from front to back, the lower end of the hook is threadedly connected to the upper end of the sliding block and movably penetrates through the base, the end portion of the end, facing the sliding block, of suspension arm is provided with a circular portion, the circular portion is rotatably connected with a rotating shaft, the outer side wall of the circular portion is provided with a plurality of tooth heads, the outer walls of the two sides of the sliding block are provided with rack portions, the front side of the sliding block is provided with a limiting block, the bottoms of grooves in both sides of a long groove are provided with first sawtooth strips, two sides of the rear end face of the limiting block are provided with second sawtooth strips, the outer portion of the guide rail between the limiting block and the cover plate is sleeved with a first spring, and one end, located at the limiting block, of a push rod is in threaded connection with the limiting block; the two suspension arms inside the hanger can be gathered to facilitate the drying of clothes.

Owner:诸暨绿康生物科技有限公司

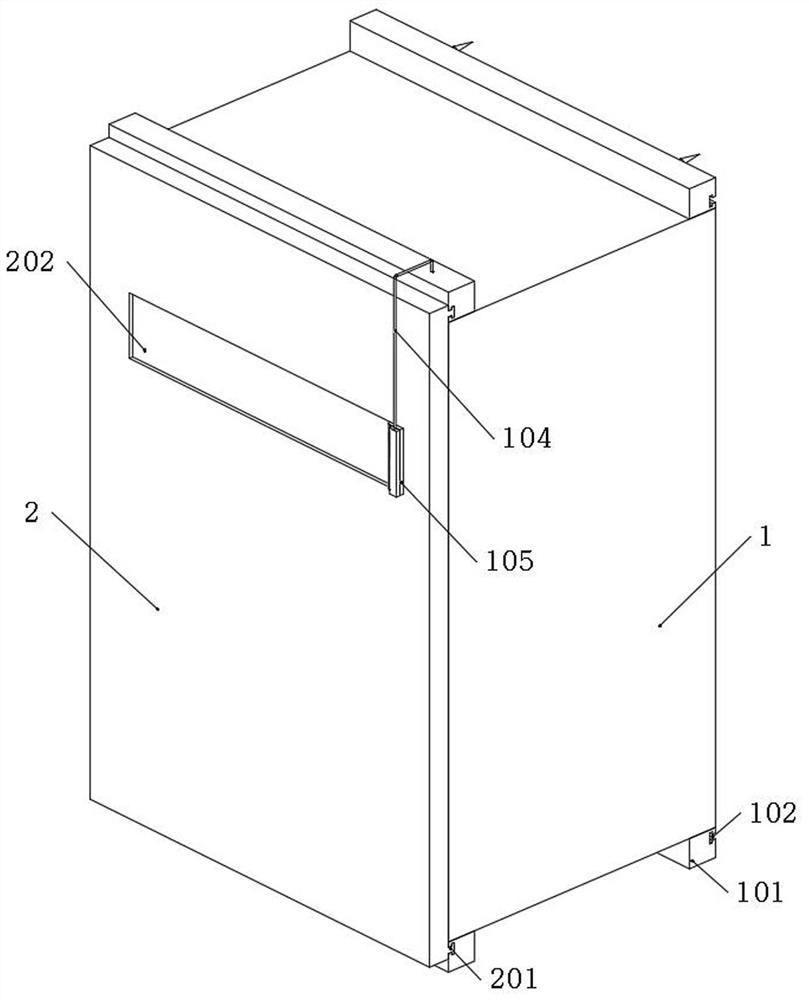

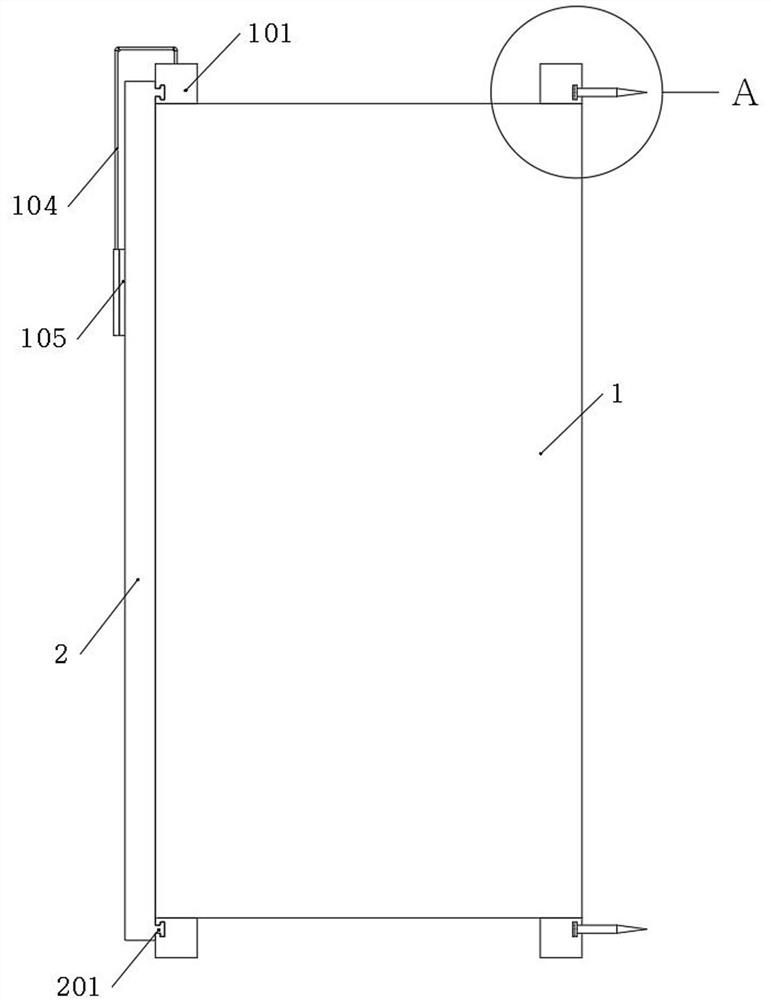

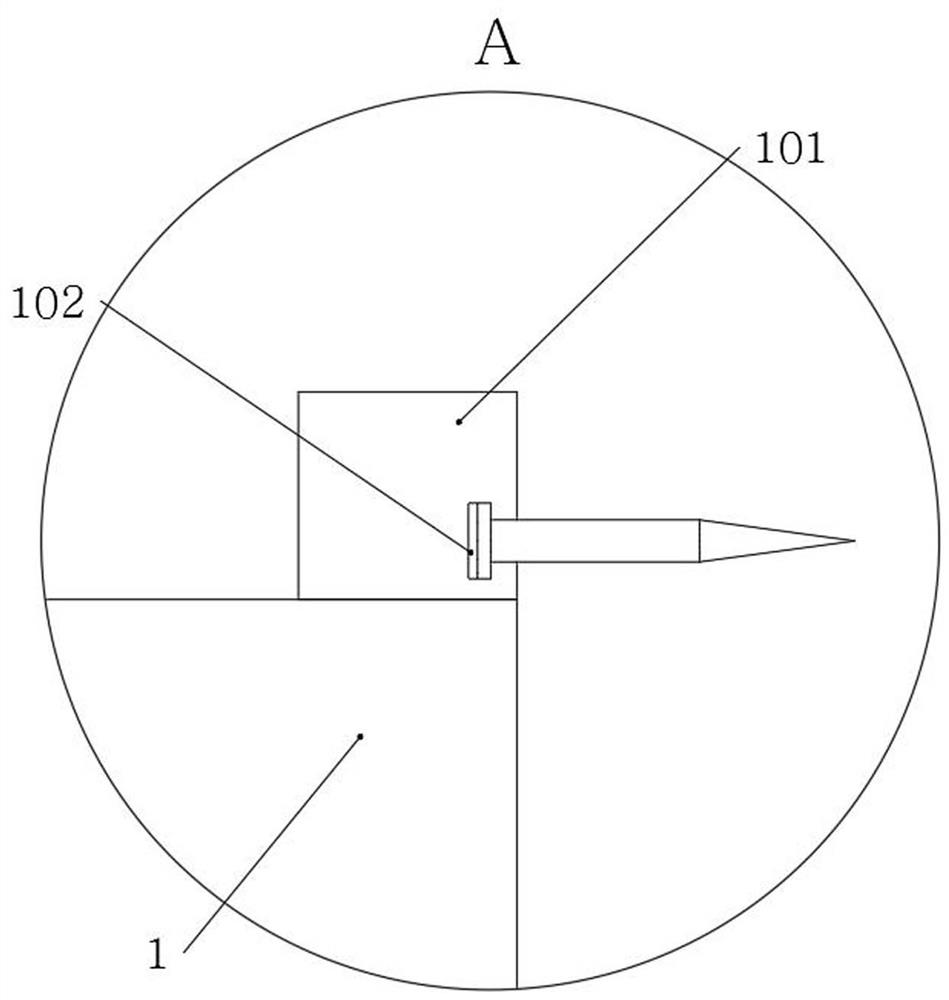

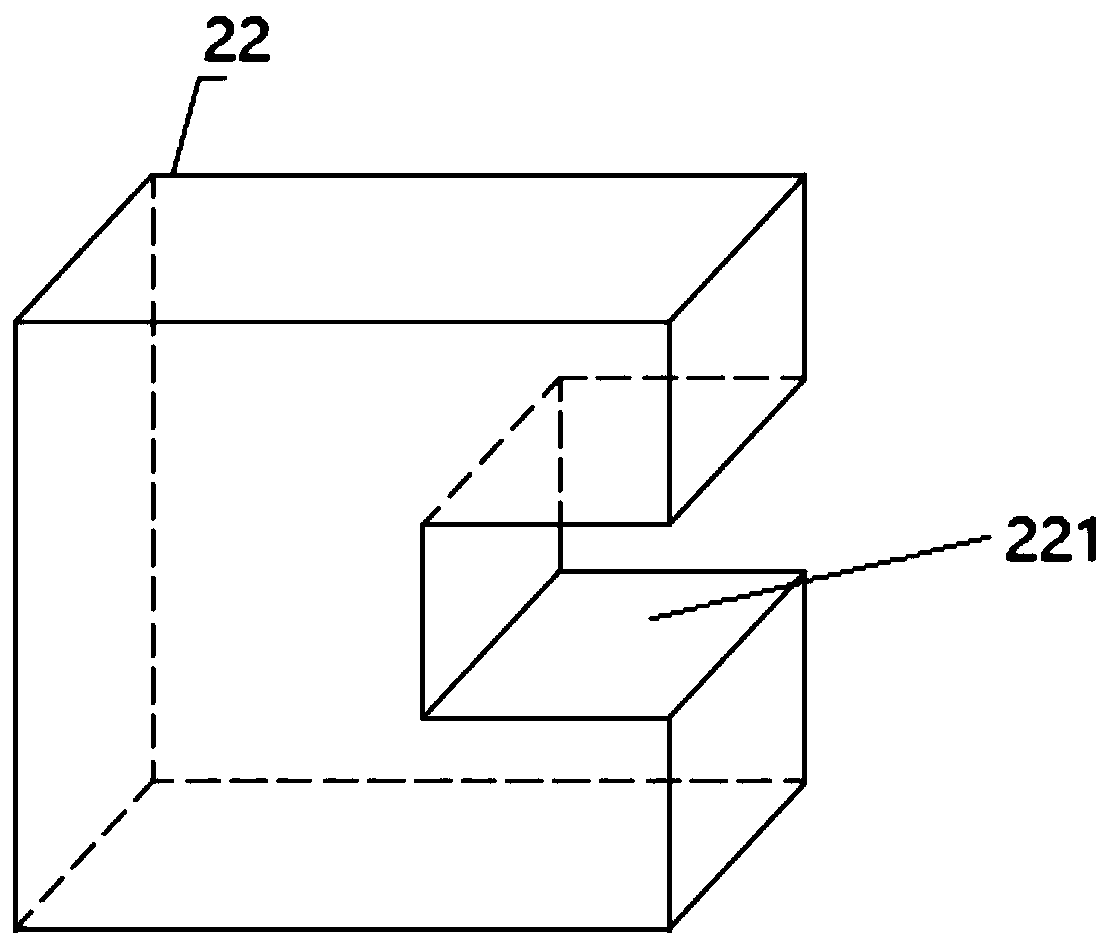

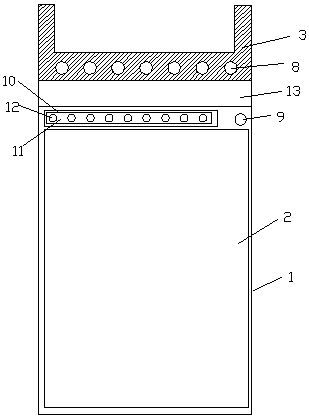

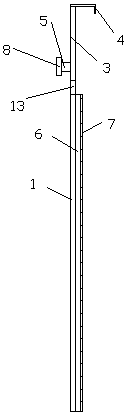

Storage device for internal accessories of filter

ActiveCN113561144AAchieve supportPrevent rustDrying gas arrangementsCleaning using toolsBlock structureControl theory

The invention provides a storage device for internal accessories of a filter, and relates to the technical field of part storage devices. The storage device solves the problems that a sliding seat for sliding a door plate is arranged, but the sliding seat does not have a supporting function, and the sliding seat does not have a hanging and fixing function. The storage device for the internal accessories of the filter comprises a storage box; and the storage box is of a rectangular box-shaped structure, a door plate is installed on the storage box, and four containing parts are installed in the storage box in a linear array shape. The top end face and the bottom end face of the storage box are fixedly connected with two sliding seats through bolts, the four sliding seats are all of rectangular block structures, and the two sliding seats on the lower portion jointly form a supporting structure of the storage box so that supporting during storage of the storage box can be achieved, and corrosion of the bottom of the storage box caused by direct contact between the storage box and the ground is avoided.

Owner:启东市昶鑫环保设备有限公司

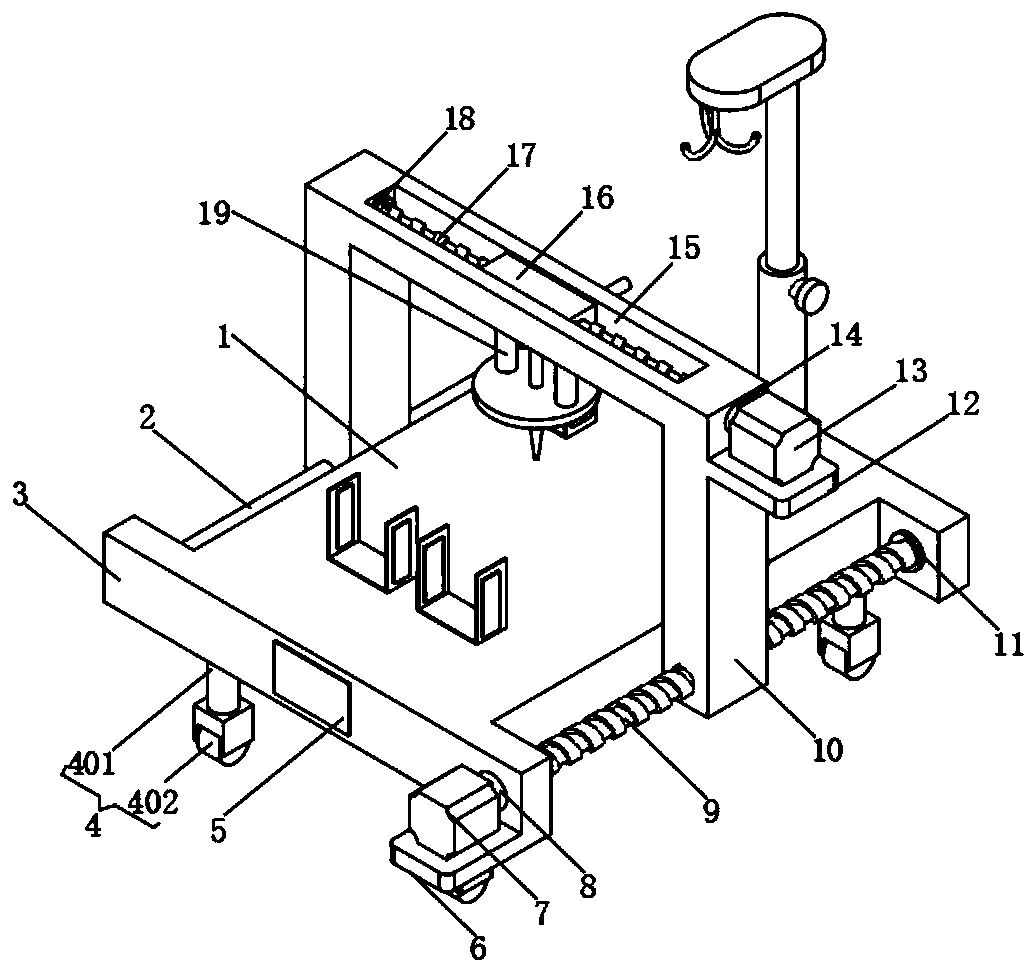

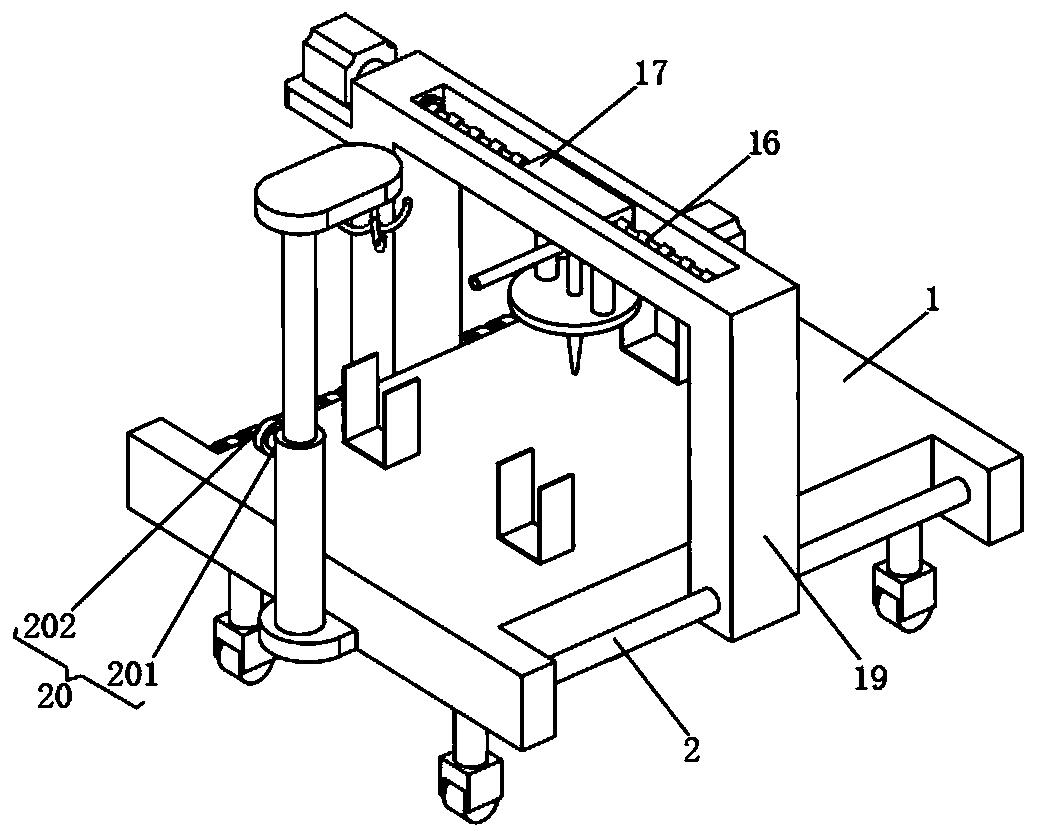

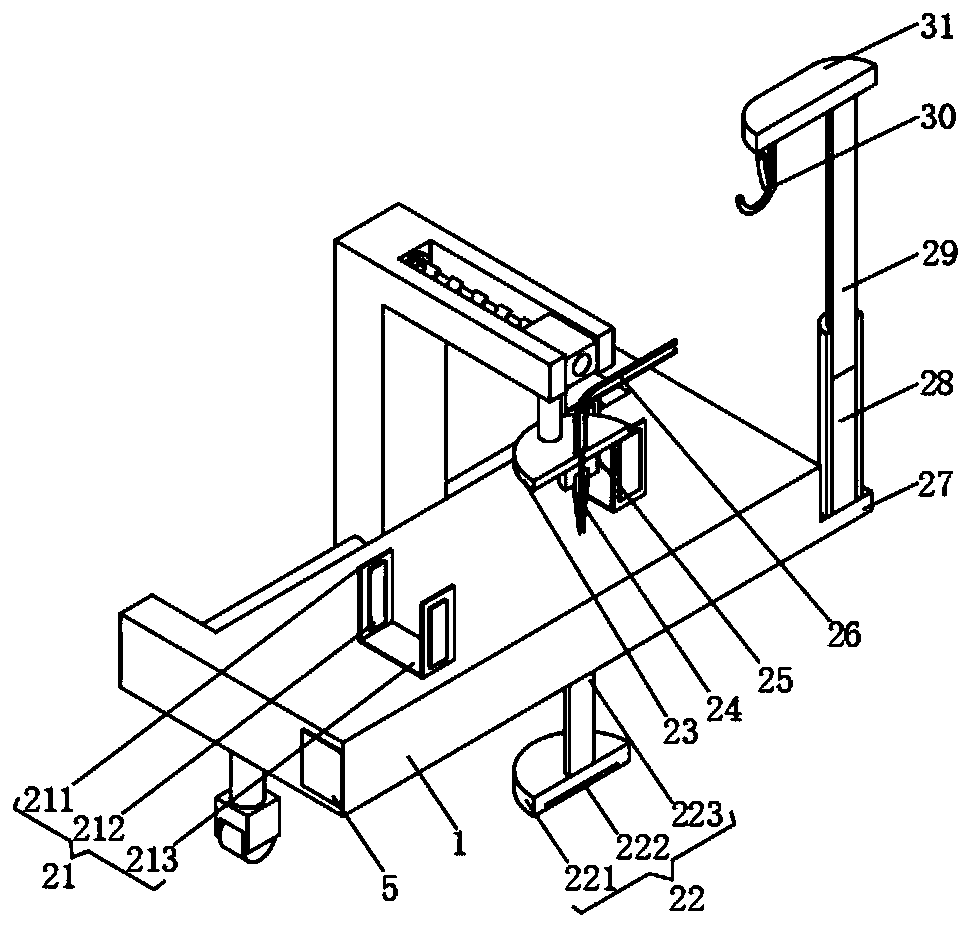

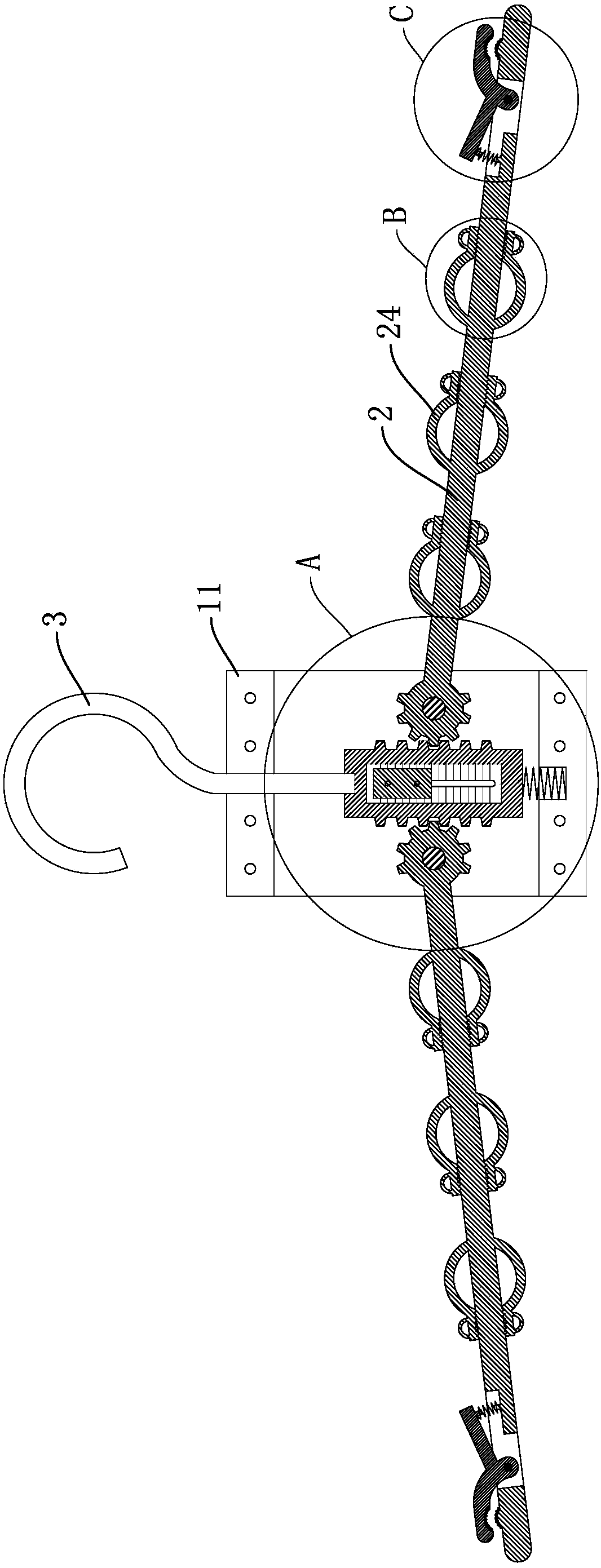

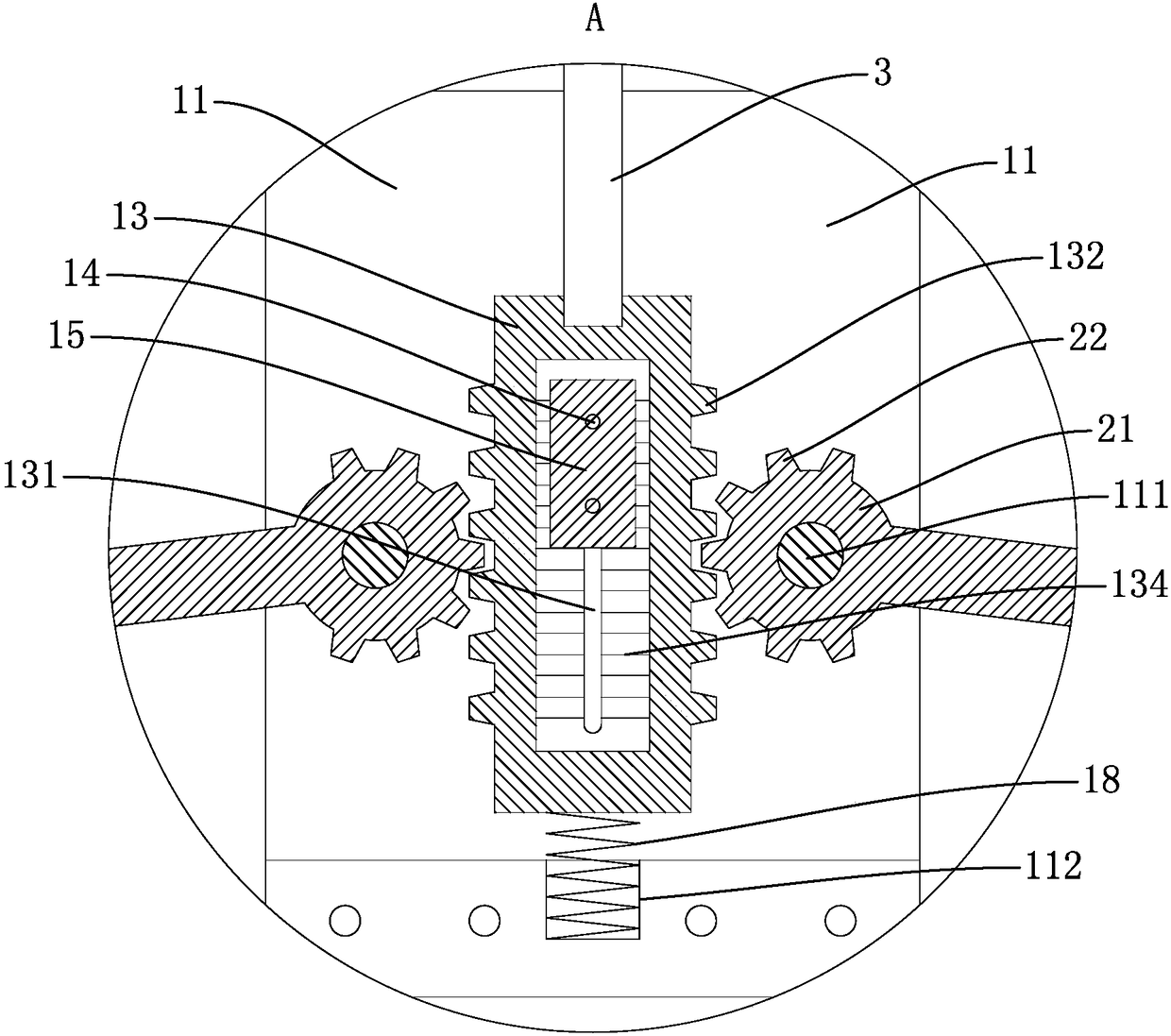

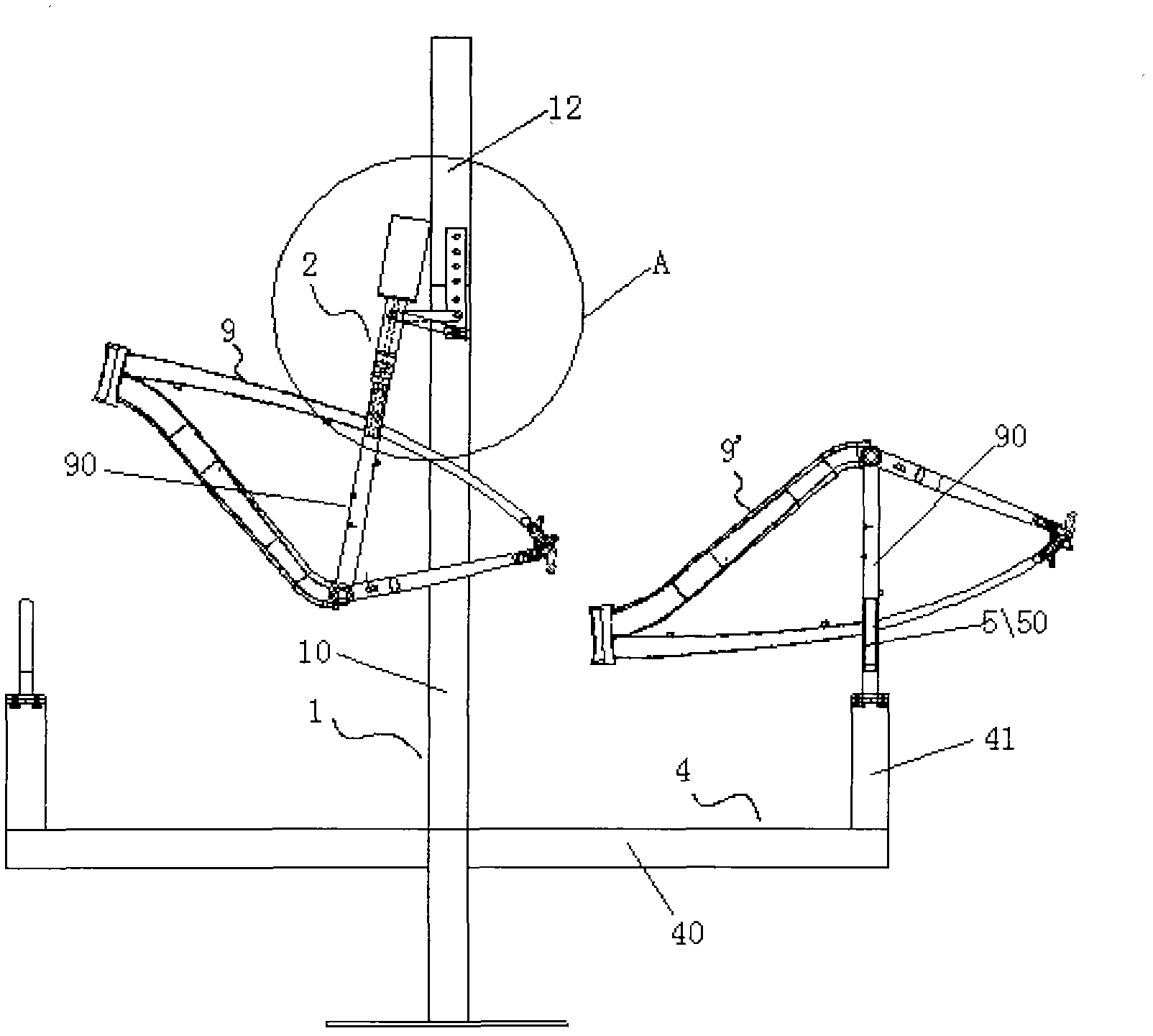

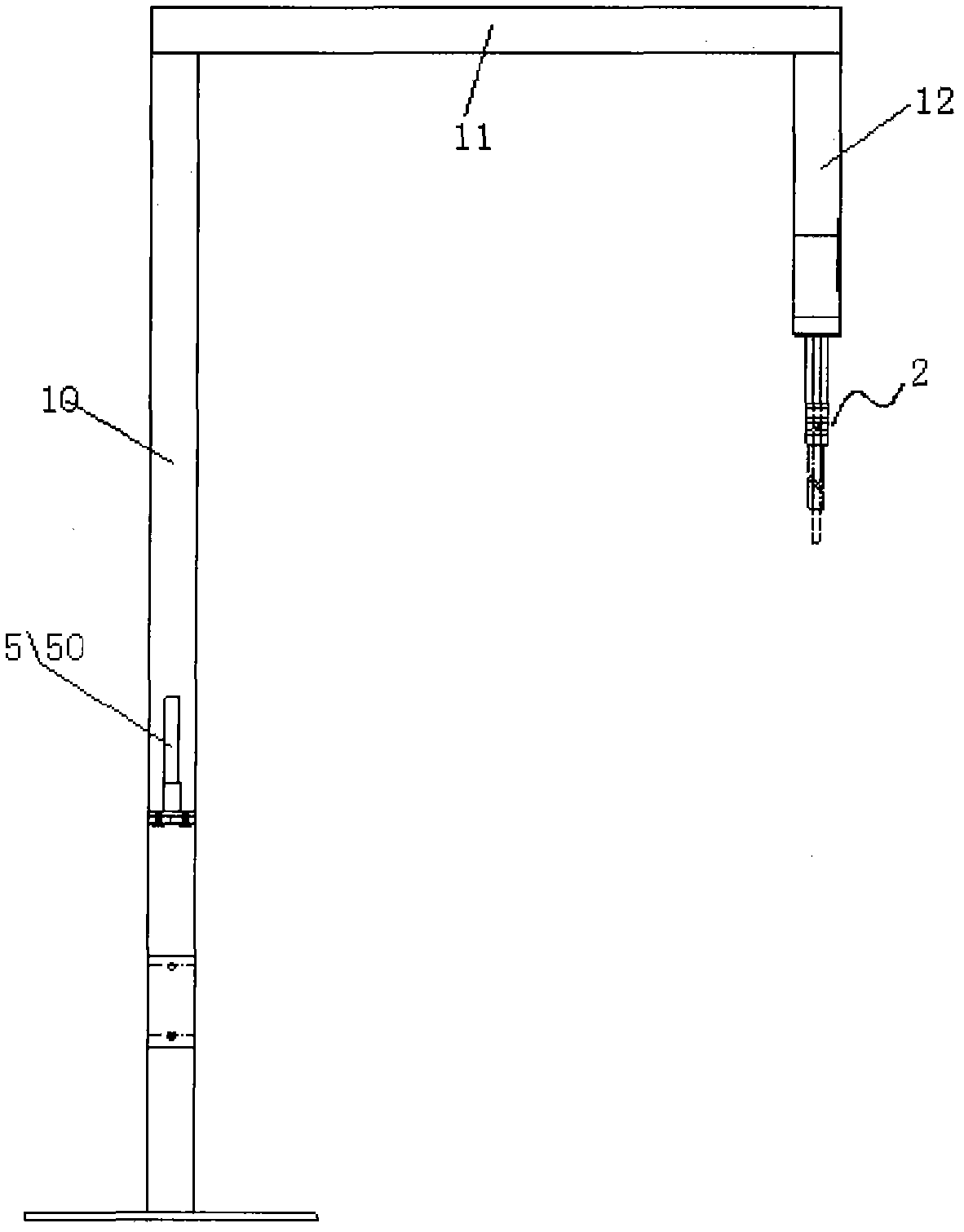

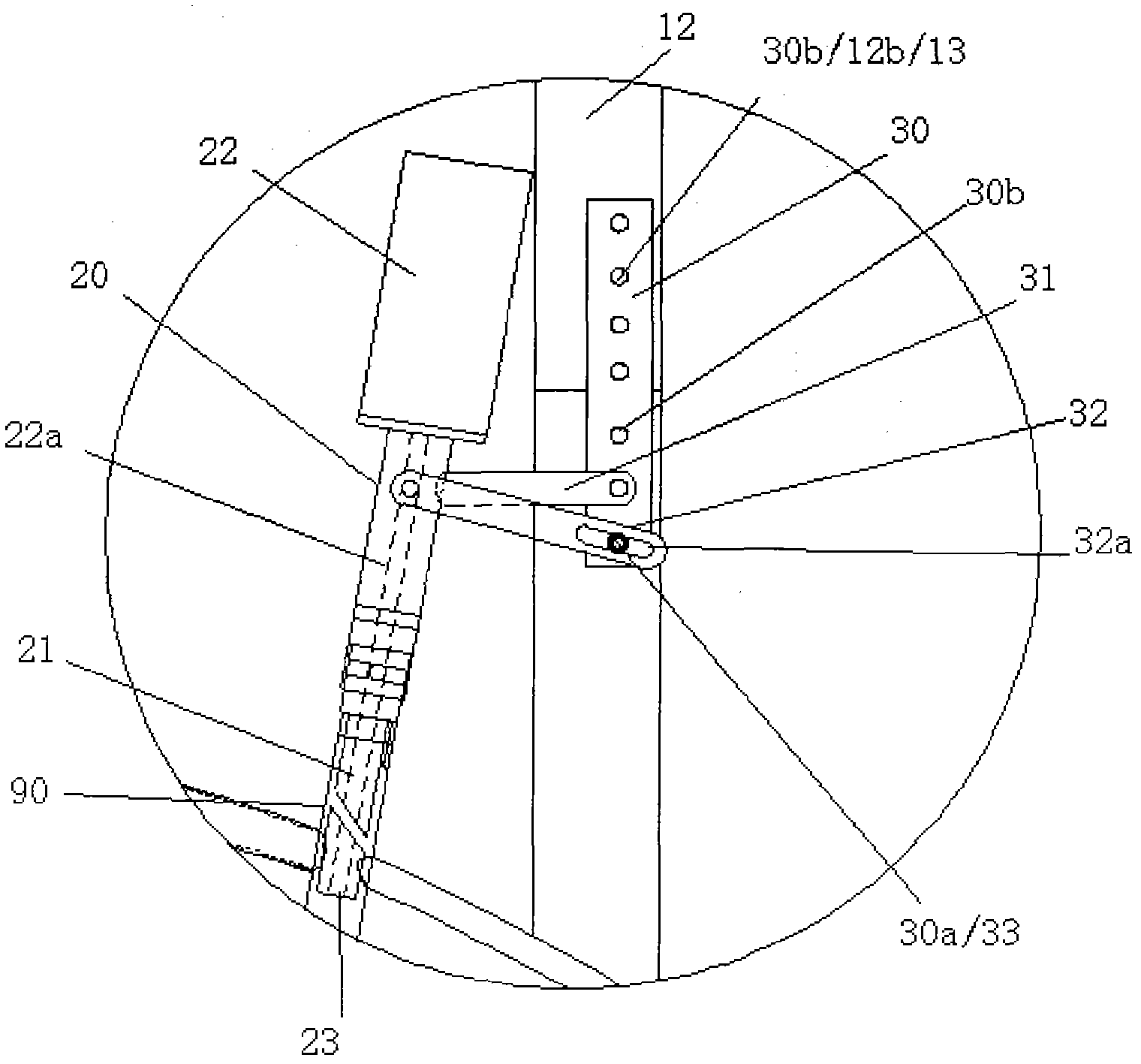

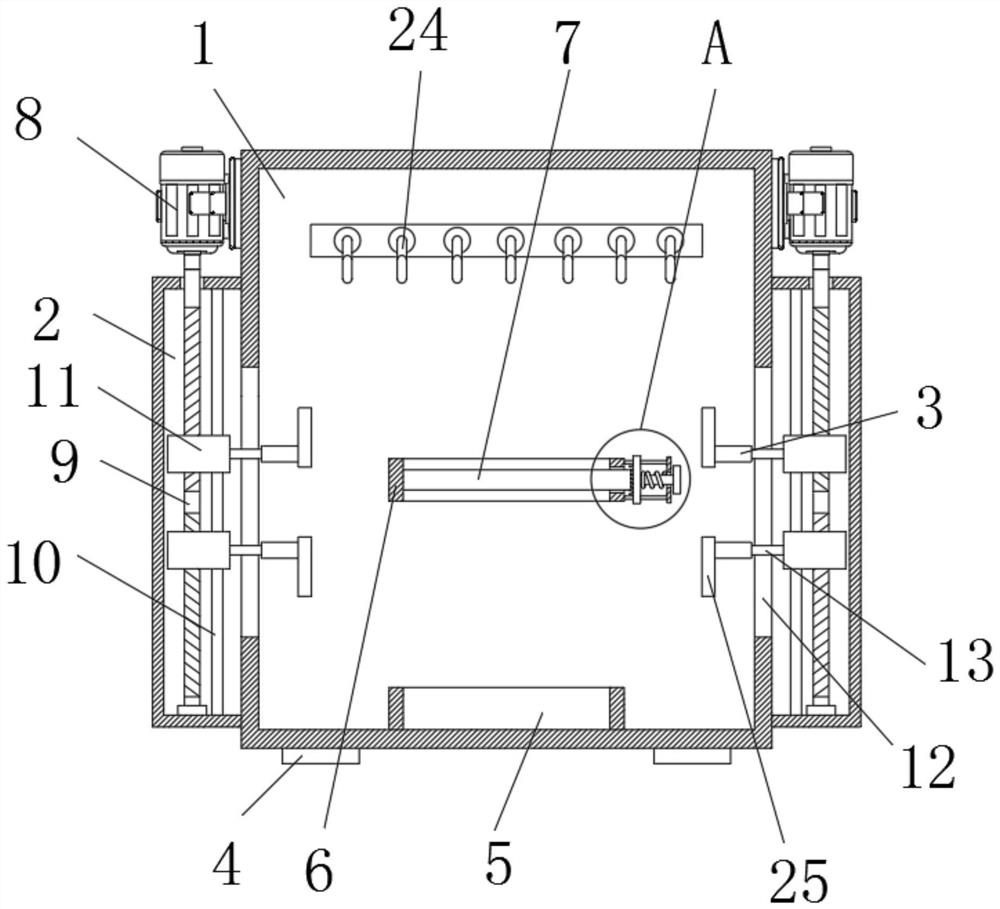

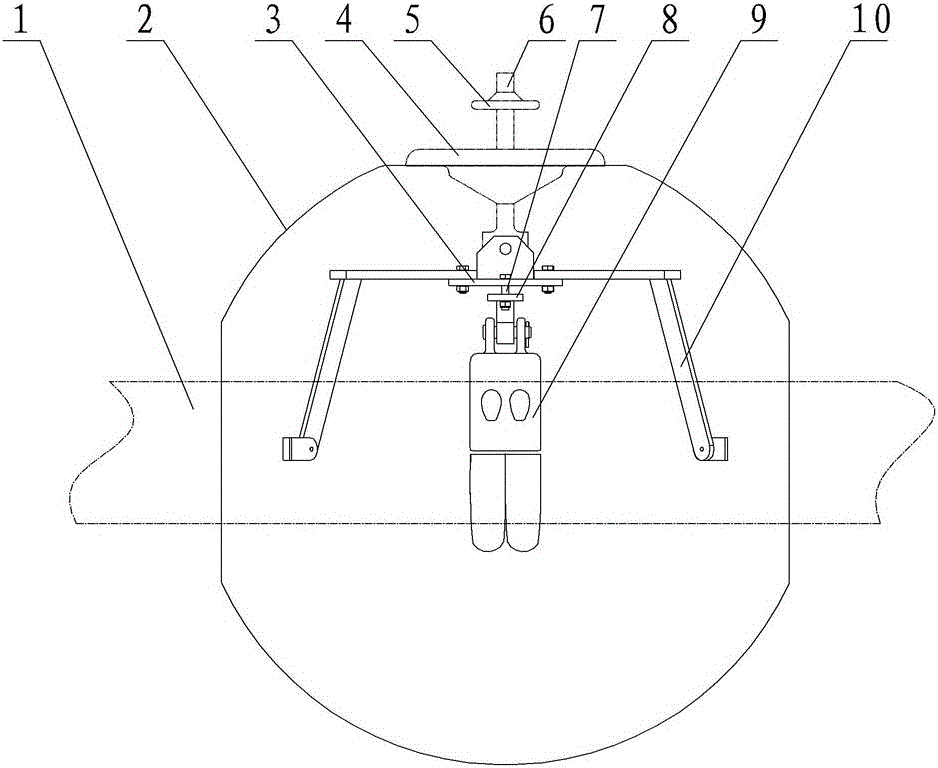

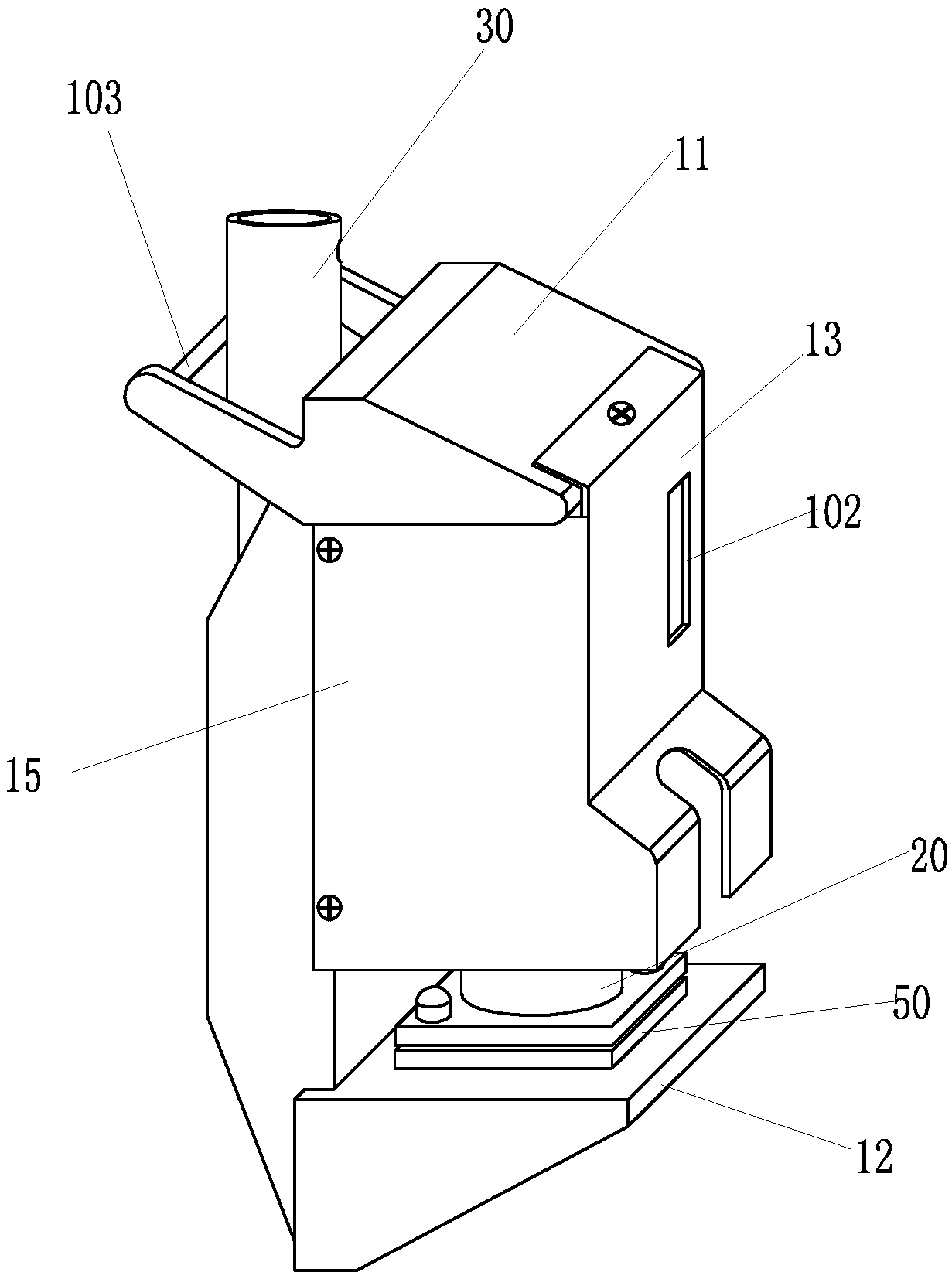

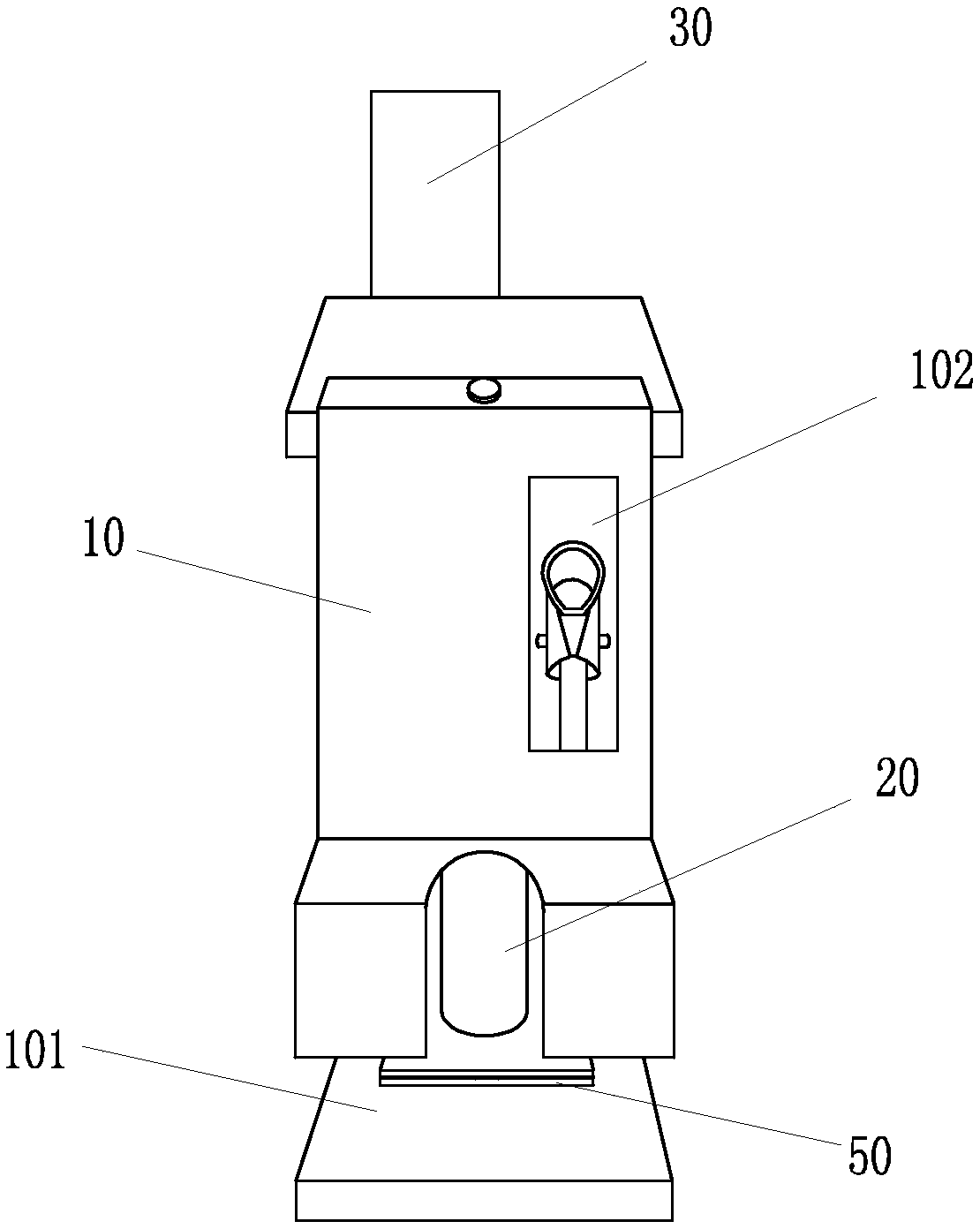

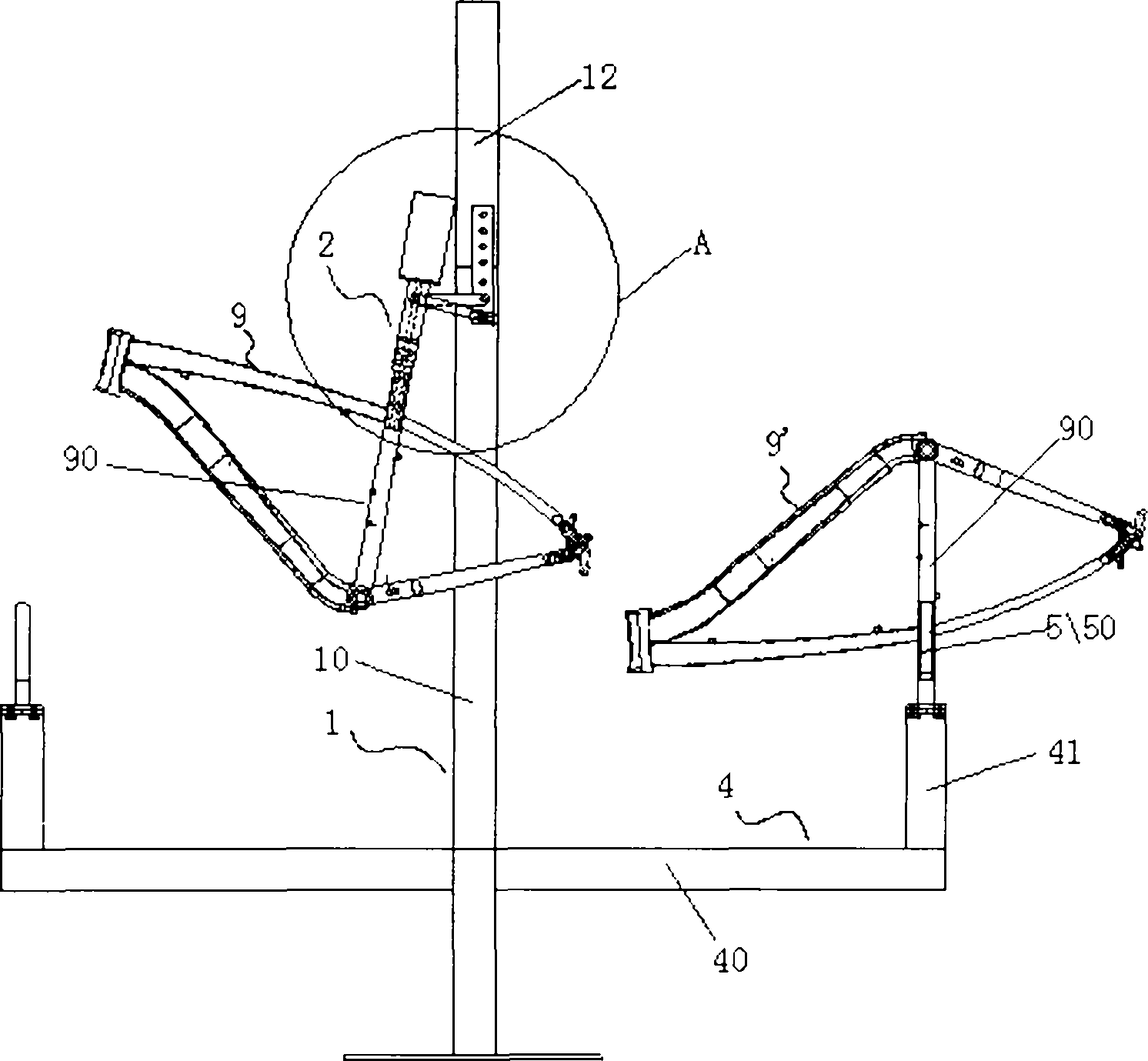

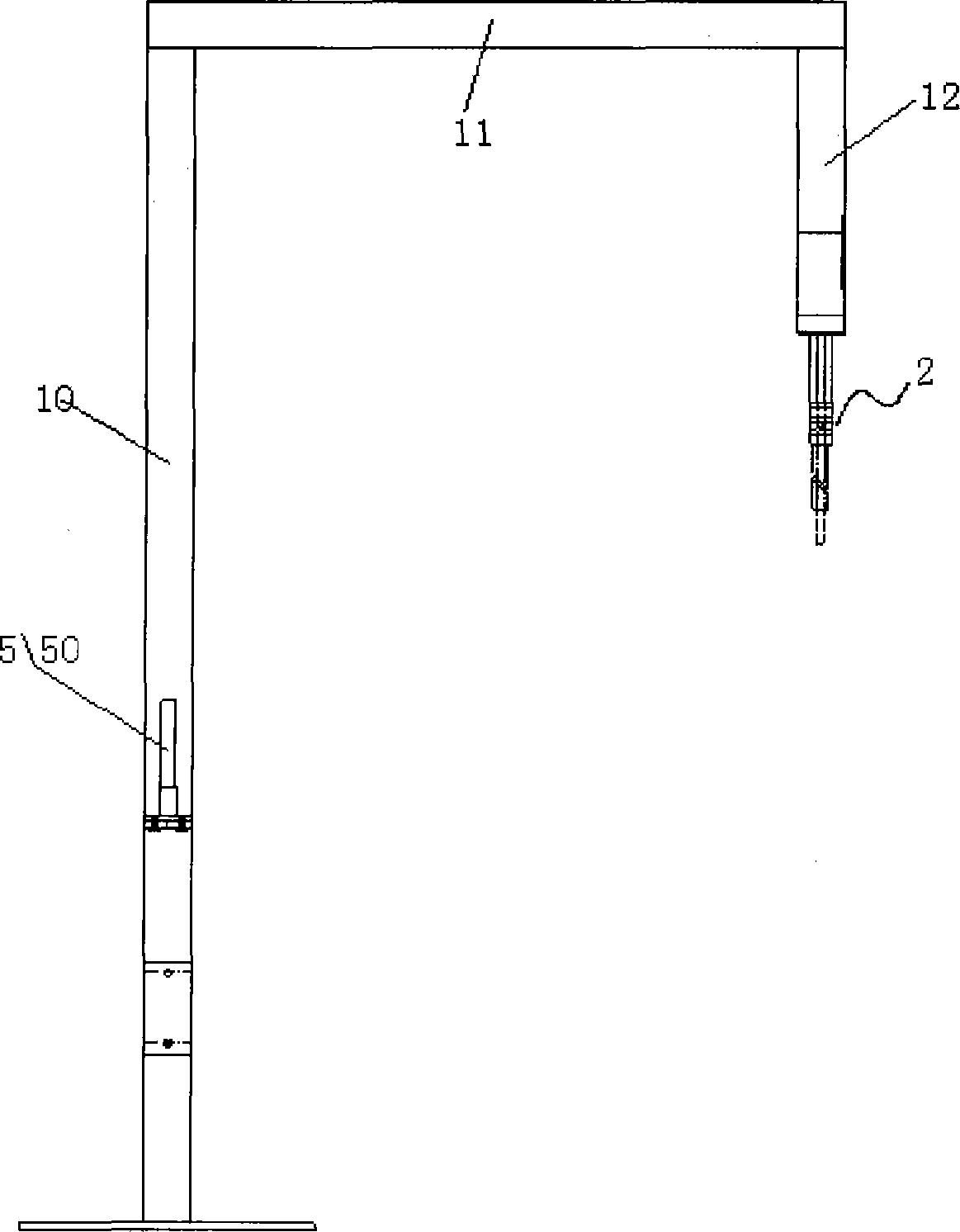

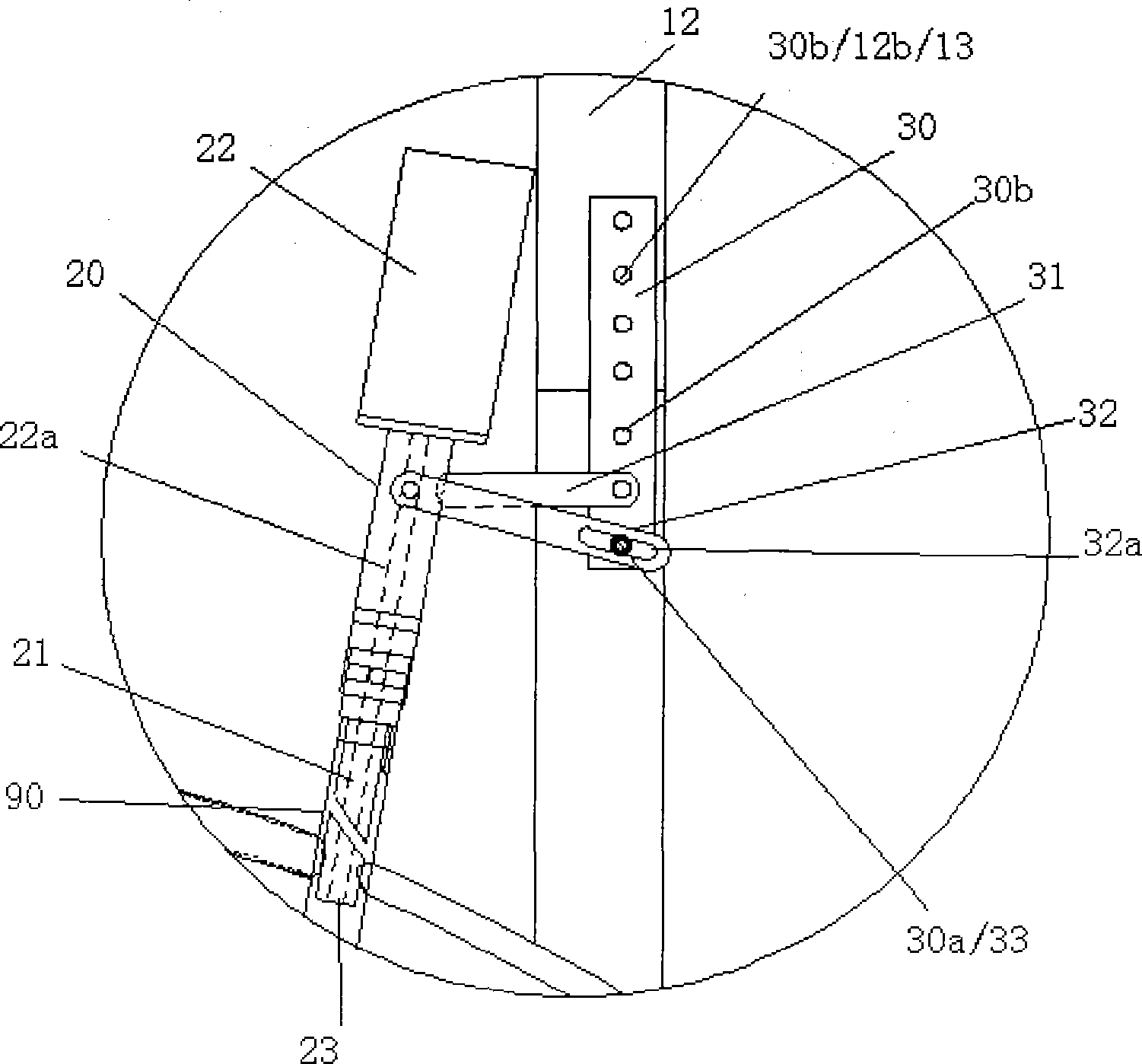

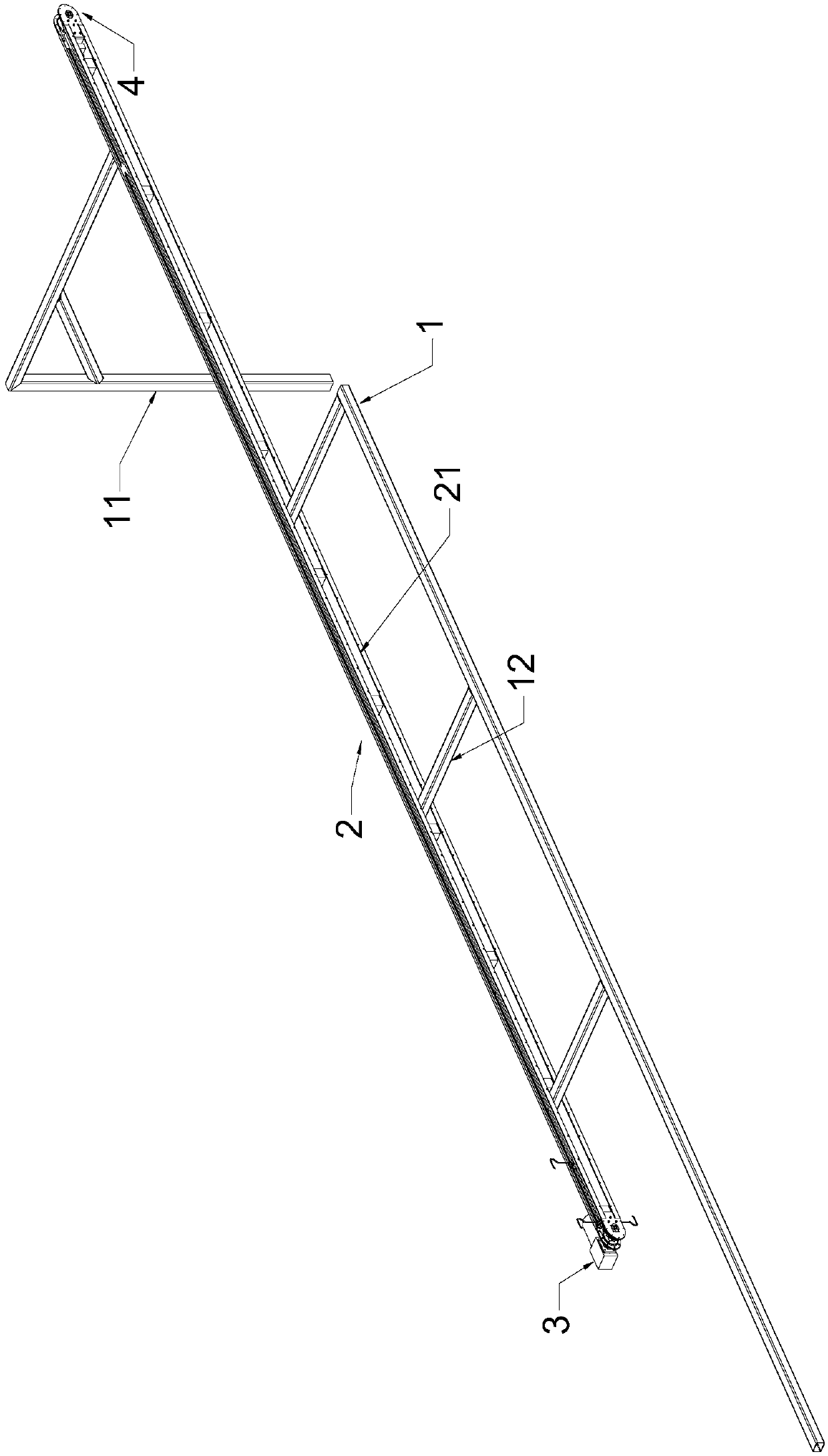

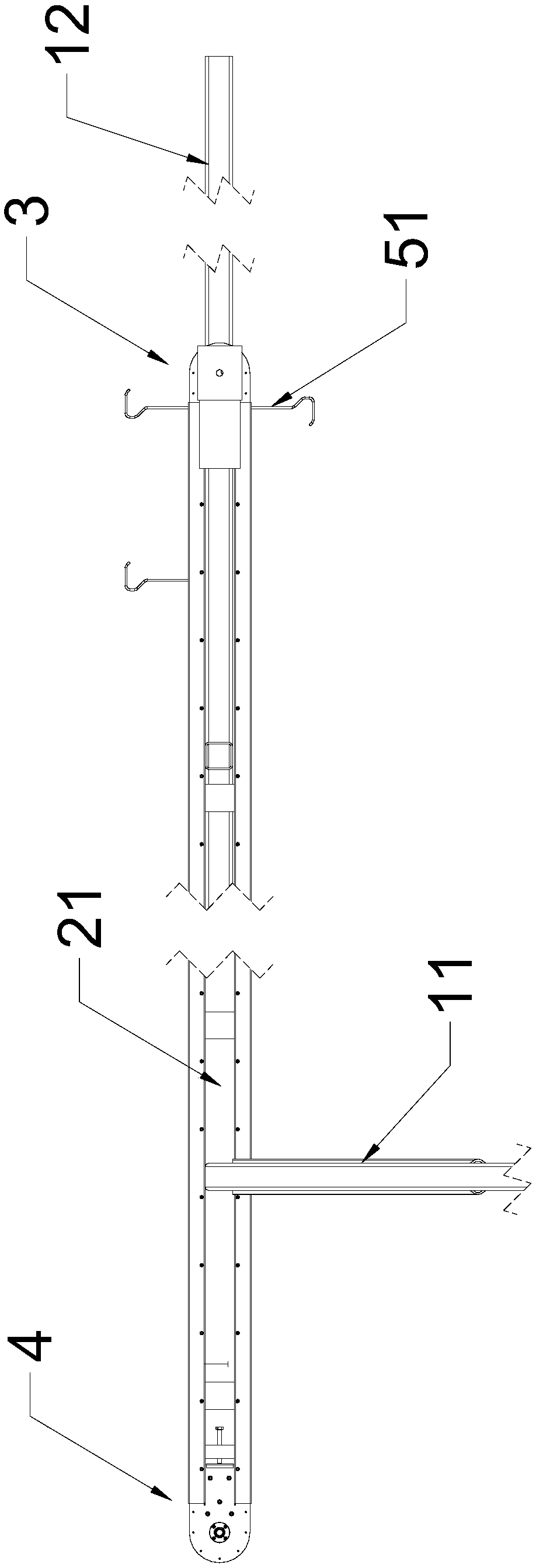

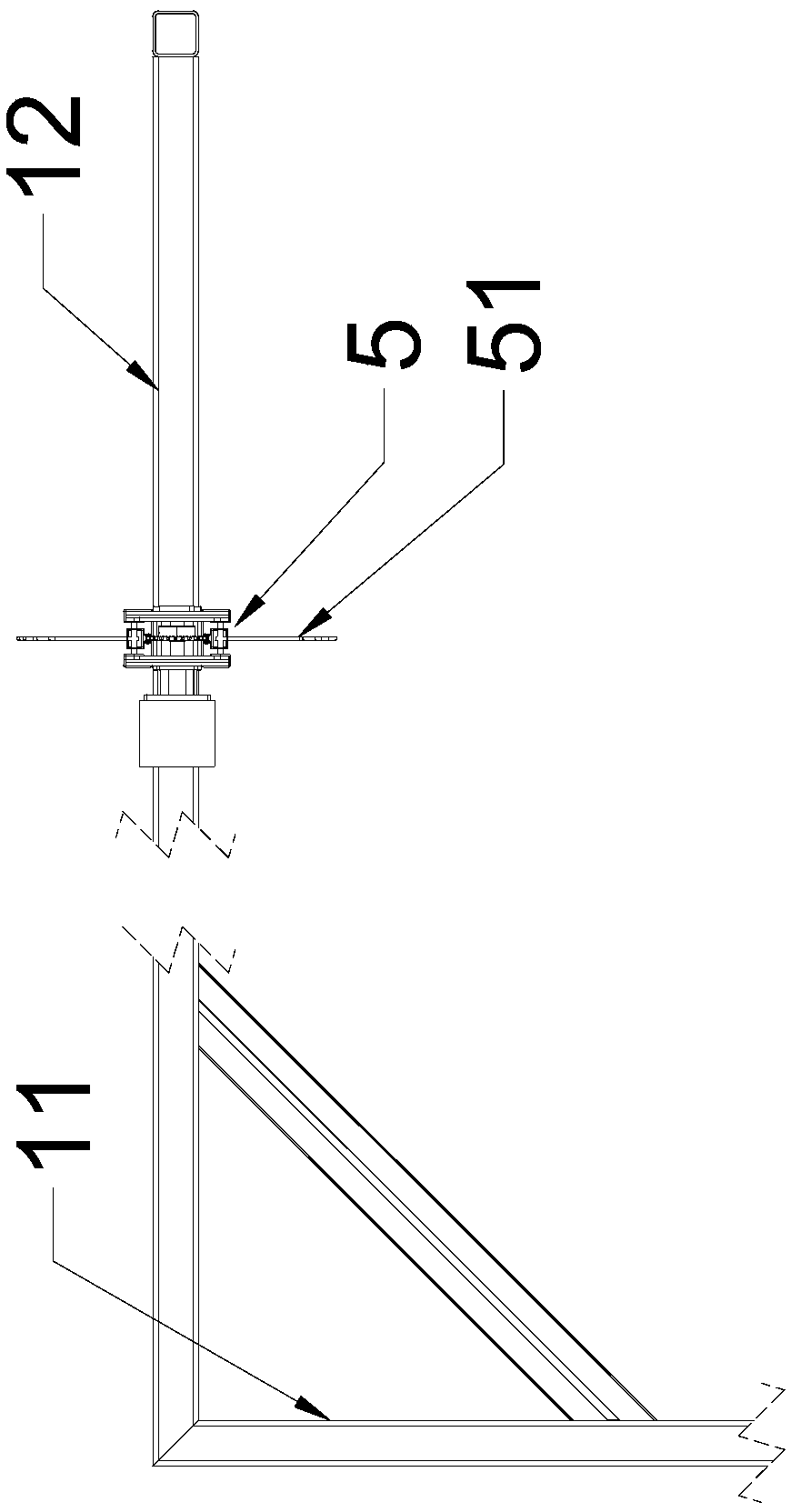

Multifunctional bicycle assembly workbench

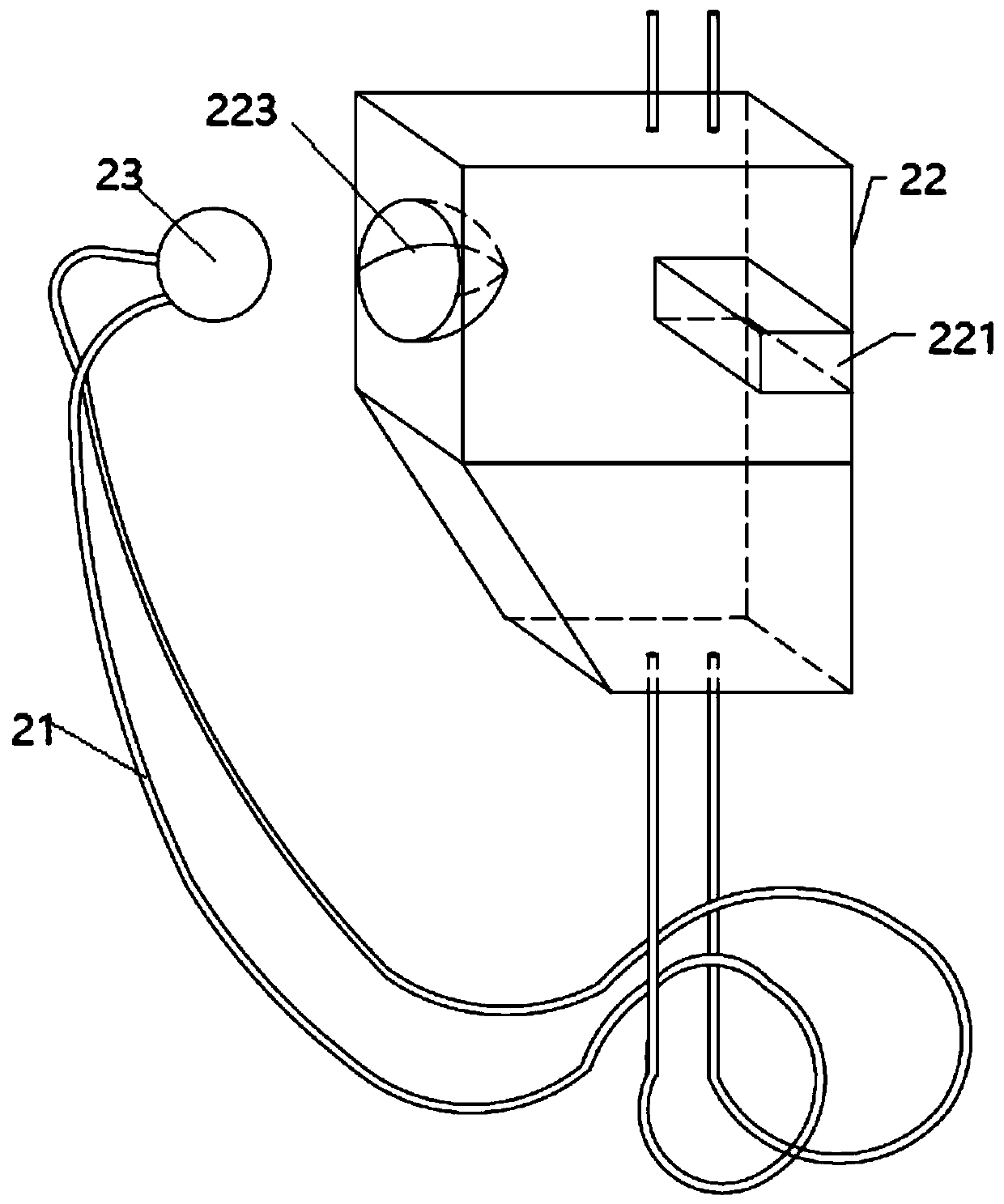

The invention discloses a multifunctional bicycle assembly workbench which is characterized by including a main support frame (1) and a hanging device (2), wherein the hanging device (2) is arranged on the main support frame (1) and used for hanging and fixing a bicycle frame so as to carry out forward assembly on a whole bicycle. The forward assembly and the backward assembly of the bicycle can be carried out according to the needs, so that the actual using status of bicycles can be simulated for debugging the bicycle; moreover, assembling and debugging for the multiple bicycles can be carried out simultaneously, working efficiency is high, and the occupied space is reduced.

Owner:TIANJIN GOLDEN WHEEL BICYCLE GRP +1

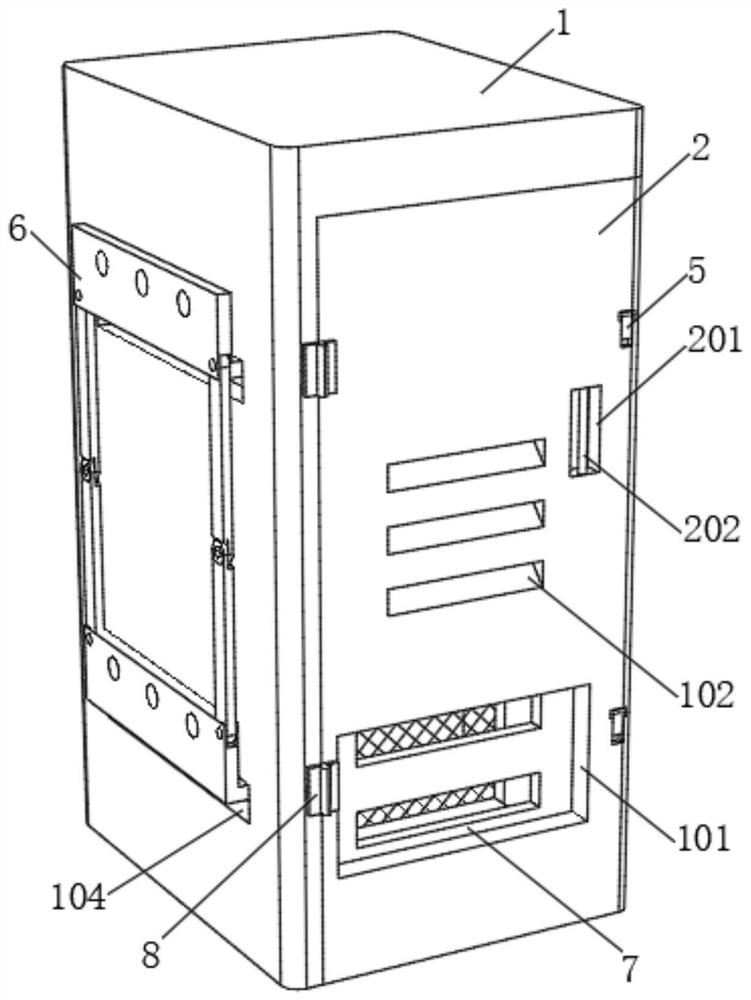

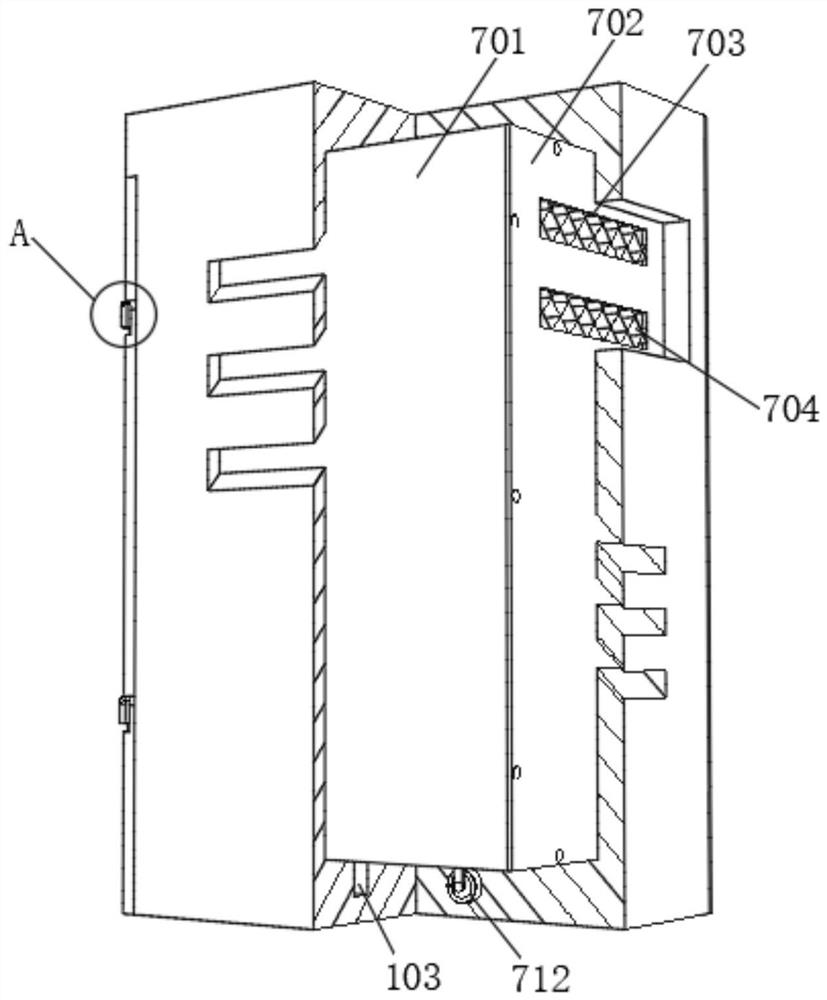

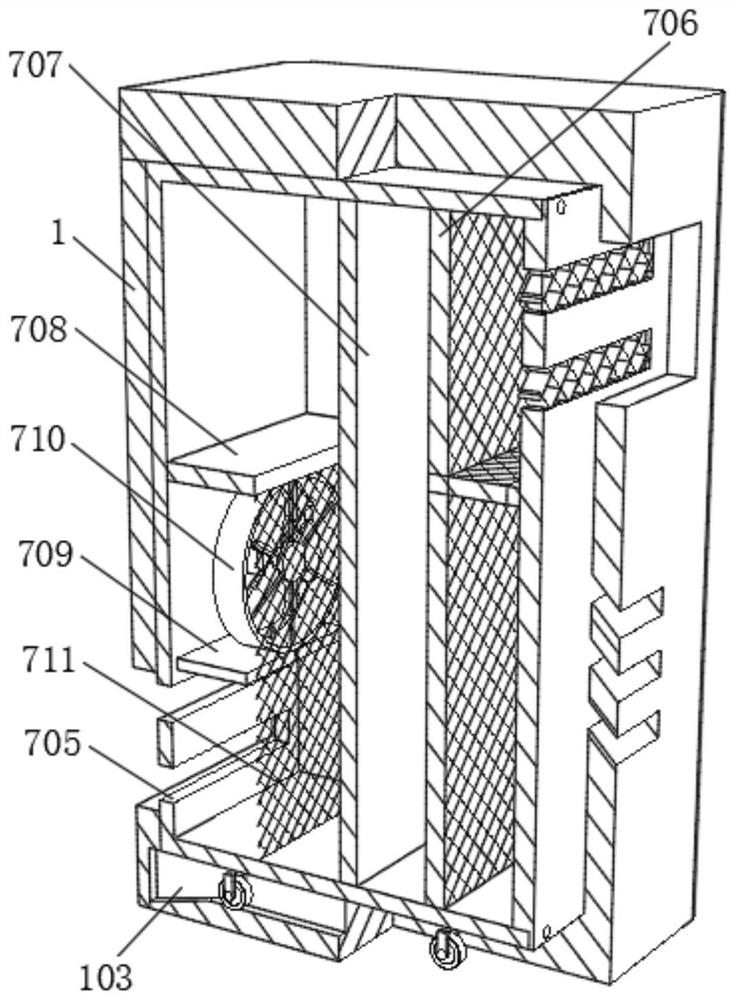

Power plant safety tool intelligent management device

InactiveCN113696152AAvoid intertwiningSuspension implementationWork tools storagePlant safetyAgricultural engineering

The invention discloses a power plant safety tool intelligent management device, and relates to the technical field of appliance storing and taking devices. The power plant safety tool intelligent management device comprises a machine shell, sliding boxes, telescopic cylinders, supporting legs, a fixing seat, supporting plates and a fixing belt, the two sliding boxes are fixedly installed on the left side and the right side of the outer wall of the machine shell correspondingly, and sliding assemblies are correspondingly arranged in inner cavities of the two sliding boxes; the four telescopic cylinders are movably connected to the inner sides of the two sliding assemblies through telescopic assemblies correspondingly, the four supporting legs are fixedly installed at the four corners of the bottom end of the machine shell correspondingly, the fixing base is fixedly installed at the bottom end of an inner cavity of the machine shell, and the two supporting plates are fixedly installed on the rear side of the inner cavity of the machine shell correspondingly. The problems that when a safety appliance storing and taking device is used, safety ropes are not convenient to store, the safety ropes are mutually wound, the use is influenced, and when rod-shaped appliances are stored, no fixing device is provided, the rod-shaped appliances are scattered are solved.

Owner:CLEAN ENERGY BRANCH OF HUANENG (ZHEJIANG) ENERGY DEV CO LTD

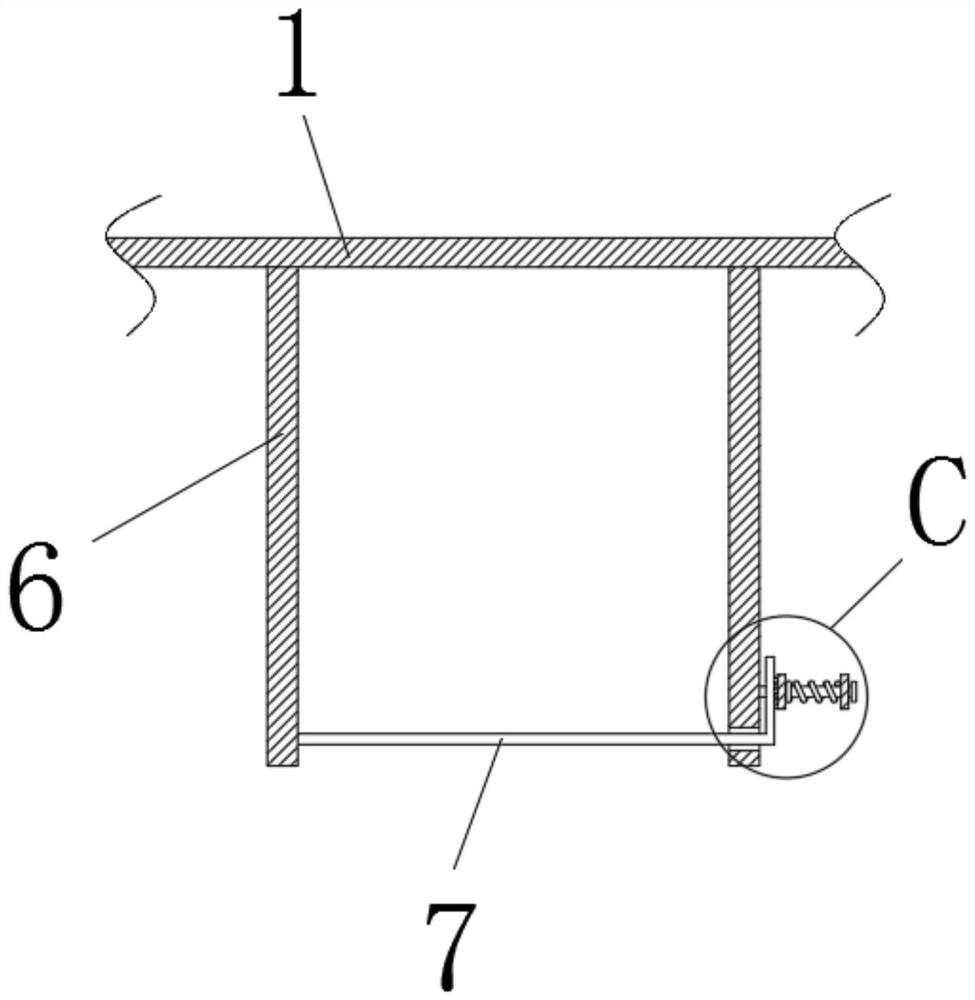

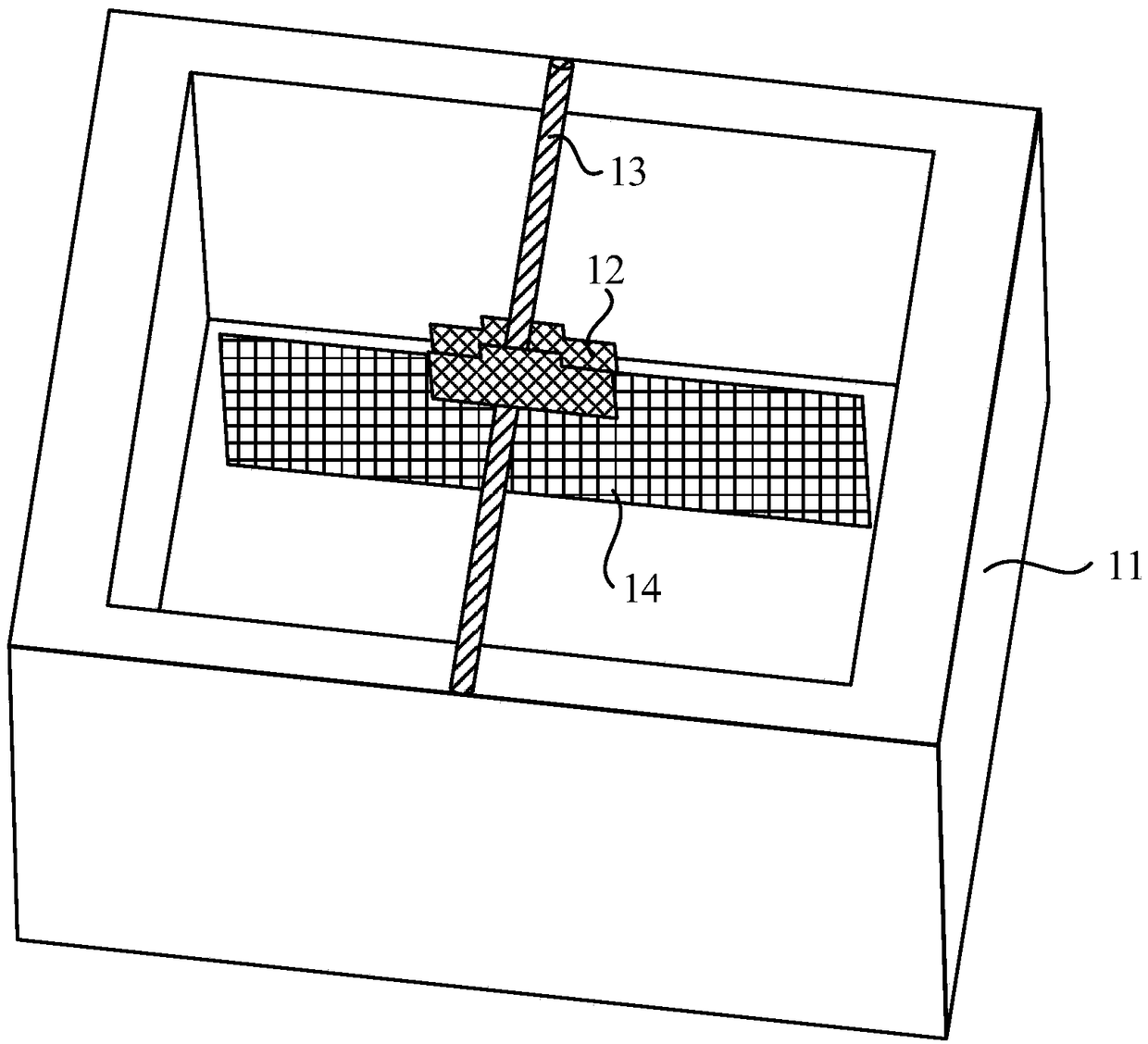

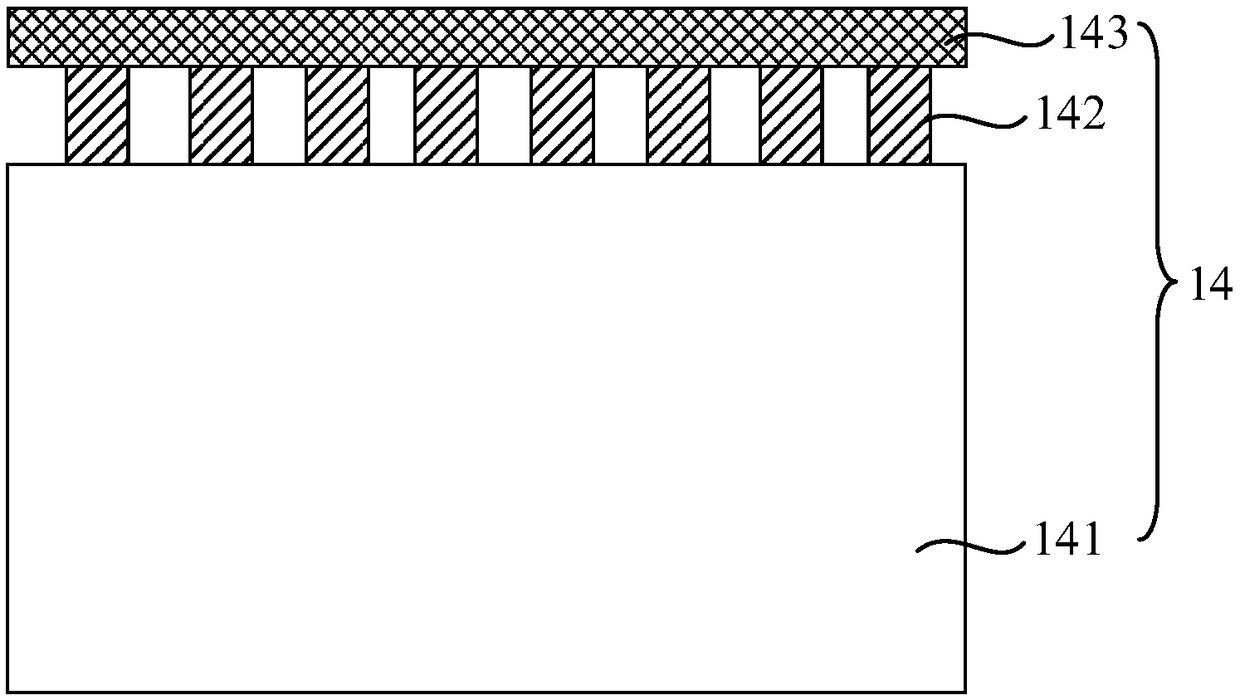

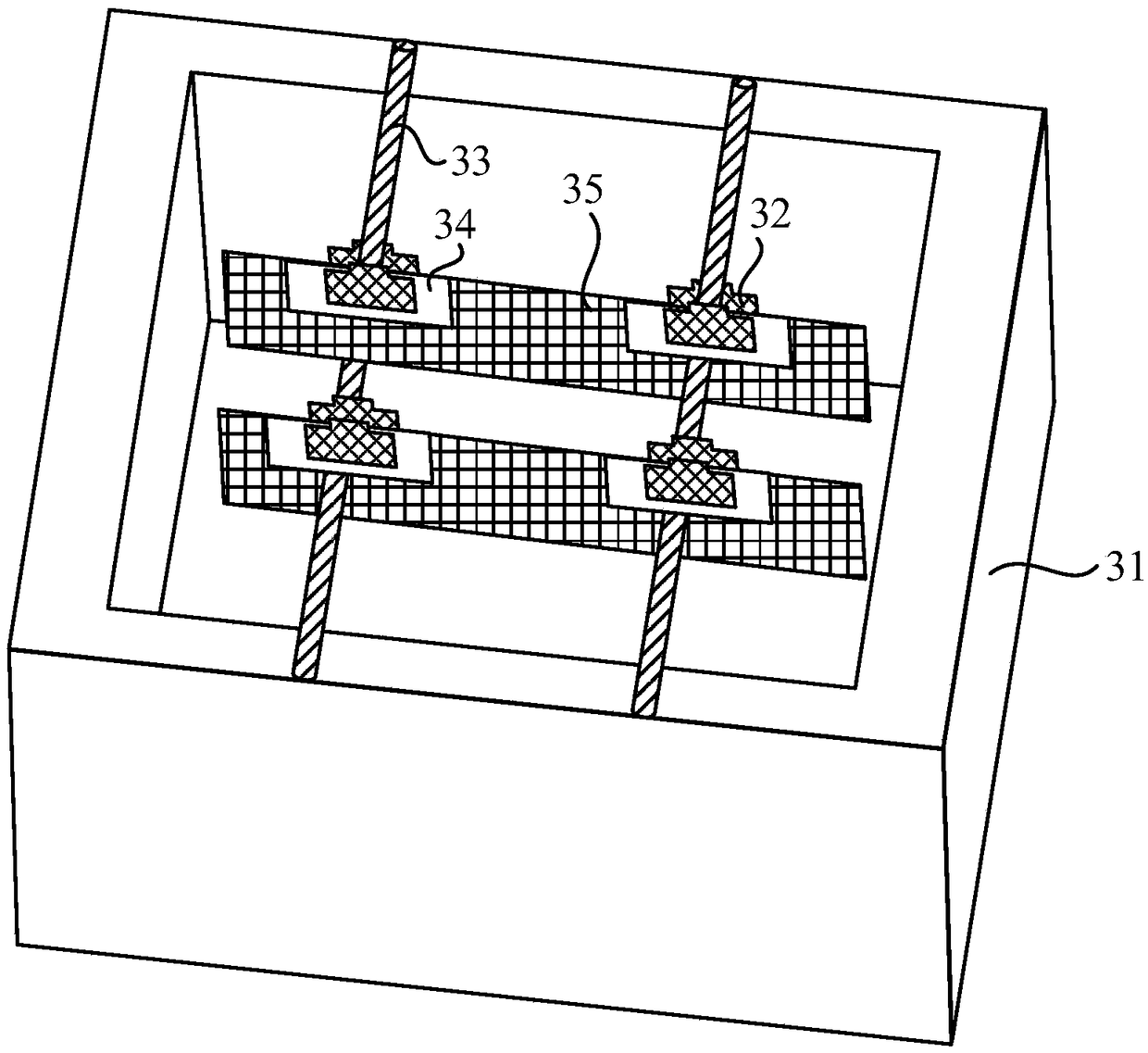

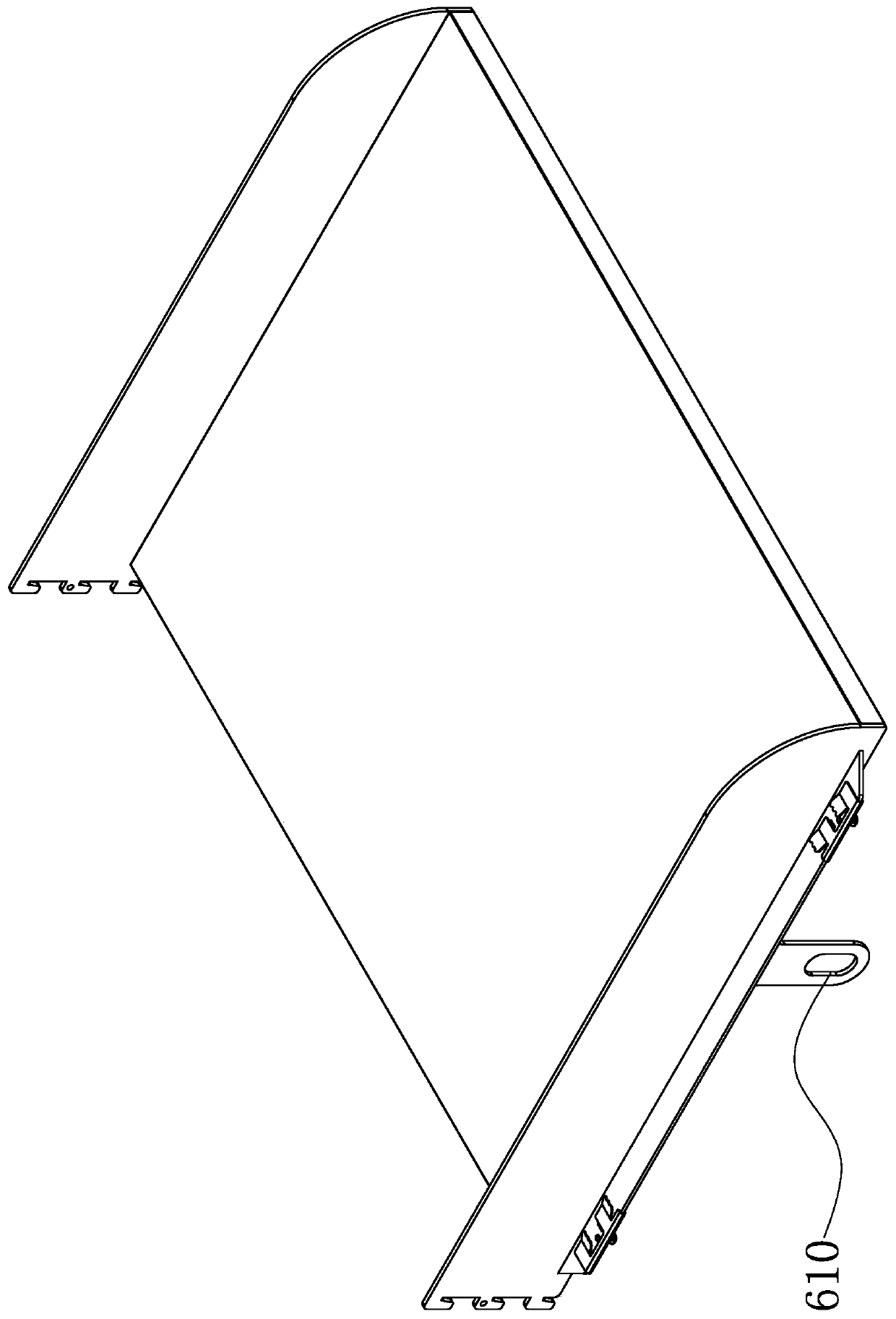

Packaging device for display panel

ActiveCN108820491ASuspension implementationPrevent crushingContainers to prevent mechanical damageDamagable goods packagingEngineeringElectrical and Electronics engineering

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

Coat hanger

The invention discloses a clothes hanger. The clothes hanger comprises a support, suspension arms connected to the two sides of the support and a hook fixed to the upper end of the support, the support comprises a cover plate and an L-shaped base, and the cover plate is fixed on the base through bolts; hinge pins are arranged on the base, through holes are formed in the ends, facing the support, of the suspension arms, and torsional springs sleeve the hinge pins between the suspension arms and the base; two sliding blocks are connected to the portion, between the two hinge pins, on the base, clamping blocks are arranged on the outer side walls of the two sliding blocks, and clamping grooves are formed in the suspension arms; a first spring is arranged between the two sliding blocks, insertion grooves are formed in the two sliding blocks, and push rods are in threaded connection with the backs of all the sliding blocks; a ball head part is arranged at the end, away from the corresponding sliding block, of each push rod, and a first long-shaped hole is formed in the base. According to the clothes hanger, the suspension arms can be folded and unfolded, in this way, the suspension armscan penetrate through collars of clothes and be inserted into the clothes conveniently, and the situation can be effectively avoided that the collars of the clothes are pulled to be enlarged.

Owner:蔡丹

Tube busbar suspension fittings for valve hall of converter station

ActiveCN103296623BSuspension implementationMeet suspension needsBus-bar installationBusbarPipe fitting

Owner:STATE GRID CORP OF CHINA +1

Refractory bricks for rotary kiln

InactiveCN111365984AImprove heat insulation effectReduce heat lossLining supportsRotary drum furnacesRotary kilnInsulation layer

The invention belongs to the field of refractory bricks, and in particular relates to refractory bricks for a rotary kiln. Each refractory brick comprises a glass fiber heat insulation layer, fixing limiting rings, a kiln cavity, a rock wool upper cover, a rock wool lower cover, embedding grooves, embedding limiting blocks, refractory clamping bricks, a filling groove cavity, glass fiber filling blocks, embedding clamping grooves, a first refractory slurry layer, mounting holes, a second refractory slurry layer and mounting strips. According to the refractory bricks, the structure is reasonable; after being used, the refractory bricks perform fire resisting through the self-refractory property, and meanwhile, through the cooperation of the glass fiber filling blocks, the rock wool round covers and the glass fiber heat insulation layer, heat insulating can be effectively carried out, so that the integral heat insulation effect of the rotary kiln is improved, and the heat loss is reduced; when the refractory clamping bricks are laid to form the kiln cavity, the refractory clamping bricks and the embedding clamping grooves are clamped, so that suspending is carried out, and limiting is realized; and mounting and stacking are simple, and when laying is carried out, the refractory clamping bricks are not needed to be manually supported, so that the convenience is provided for construction.

Owner:明光市龙盛瑞新材料科技有限公司

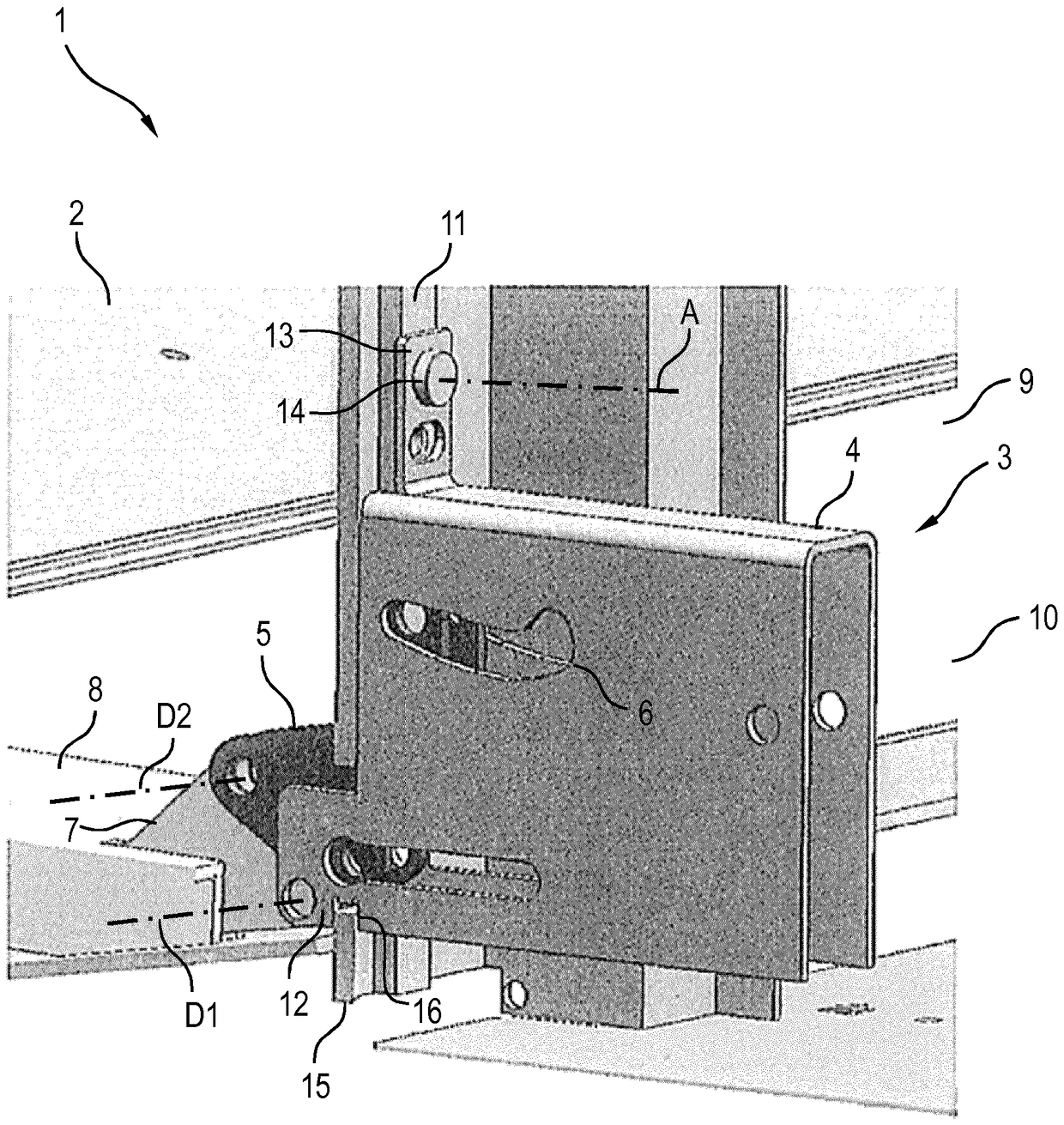

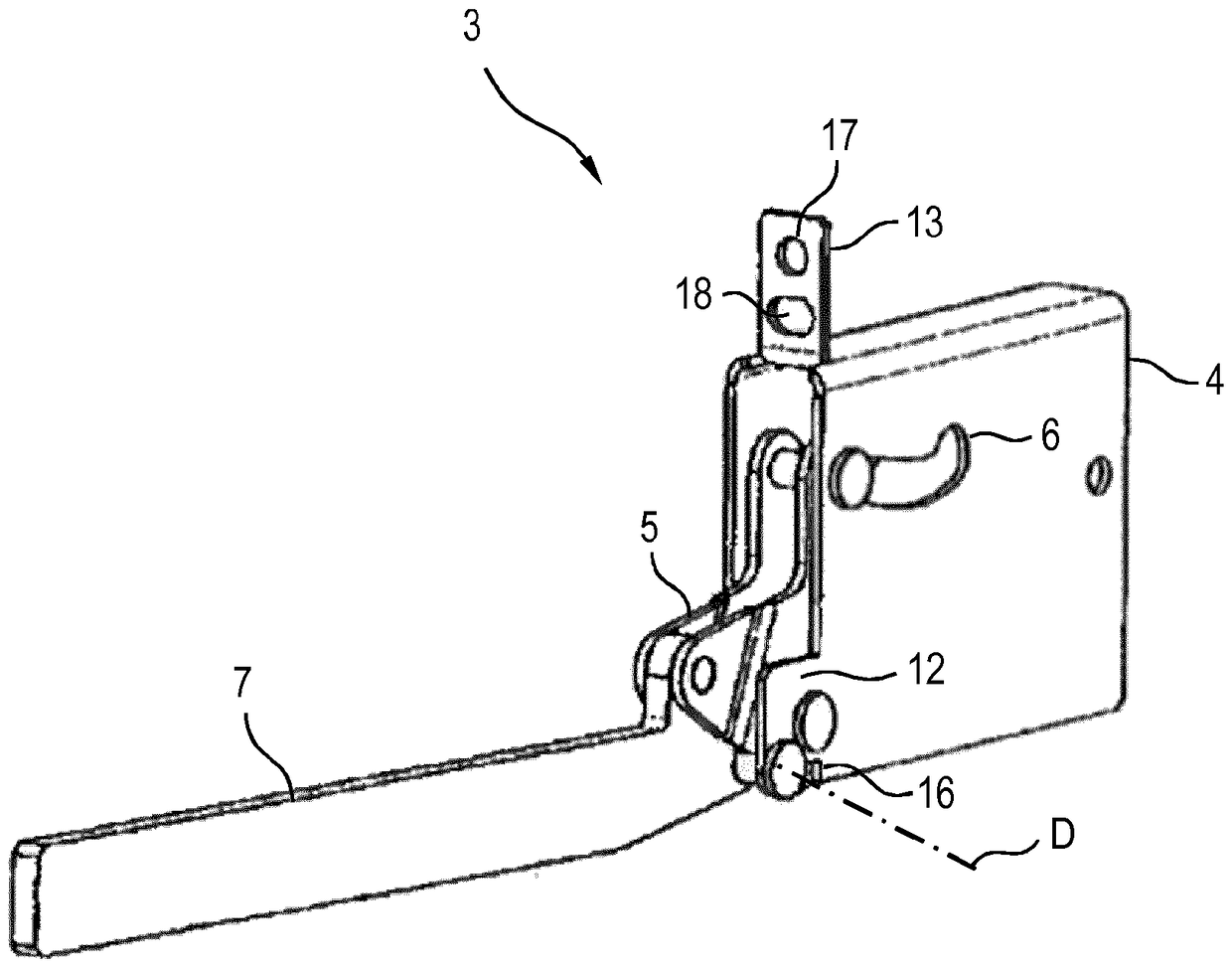

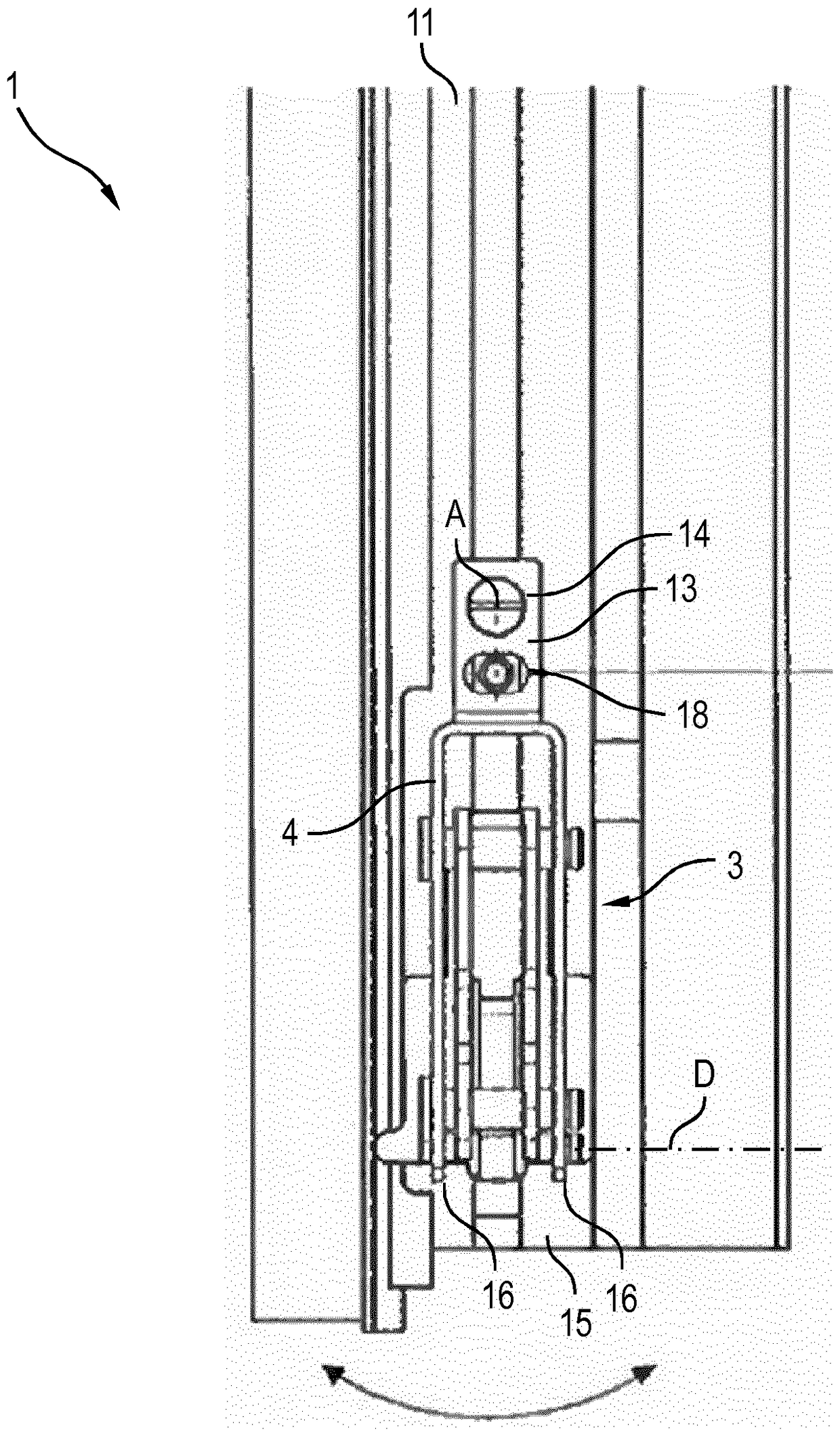

Household appliance

ActiveCN108369012ANo noiseEasy to assembleDoors for stoves/rangesDomestic stoves or rangesCooking & bakingFront loading

A household appliance (1) comprises a processing chamber (10) with a front loading opening (9) and a horizontally pivoting door (2) for closing the loading opening (9). The door (2) is joined to the remaining household appliance (1) by hinges (3), wherein a hinge (3) is floatingly joined to the remaining household appliance (1). The invention can be used particularly advantageously in cooking appliances, in particular baking ovens having a horizontally pivoting oven door.

Owner:BOSCH SIEMENS HAUSGERATE GMBH

Hanging device

InactiveCN110916467ASuspension implementationConvenient and flexible useKitchen equipmentDomestic articlesStructural engineeringMechanical engineering

The invention discloses a hanging device which comprises a hanging body and a hanging rope structure fixedly arranged on one side of the hanging body. The hanging rope structure comprises at least twohanging ropes, a limiting body and a fixing body, one ends of the two hanging ropes are fixed to one side of the hanging body in a spaced mode, the other ends of the two hanging ropes penetrate through the limiting body, and the ends of the two hanging ropes are fixed through the fixing body. The limiting body is provided with a limiting part used for limiting sliding of the hanging ropes and a fixing part used for fixing the fixing body. According to the invention, the hanging rope structure is arranged on the hanging body; during use, the position of the limiting body is adjusted to adjustthe length of the acting end of the hanging rope structure, the fixing body penetrates through the space between the two hanging ropes and then is fixed to the fixing part of the limiting body, at themoment, a fixing ring used for tying an article can be formed on the hanging rope structure, the article is placed in the fixing ring, and the article can be hung by tensioning the hanging ropes. Articles in various shapes can be hung in the hanging device, hanging ropes do not need to be arranged on the articles, and the hanging device is convenient and flexible to use.

Owner:张蔚秧

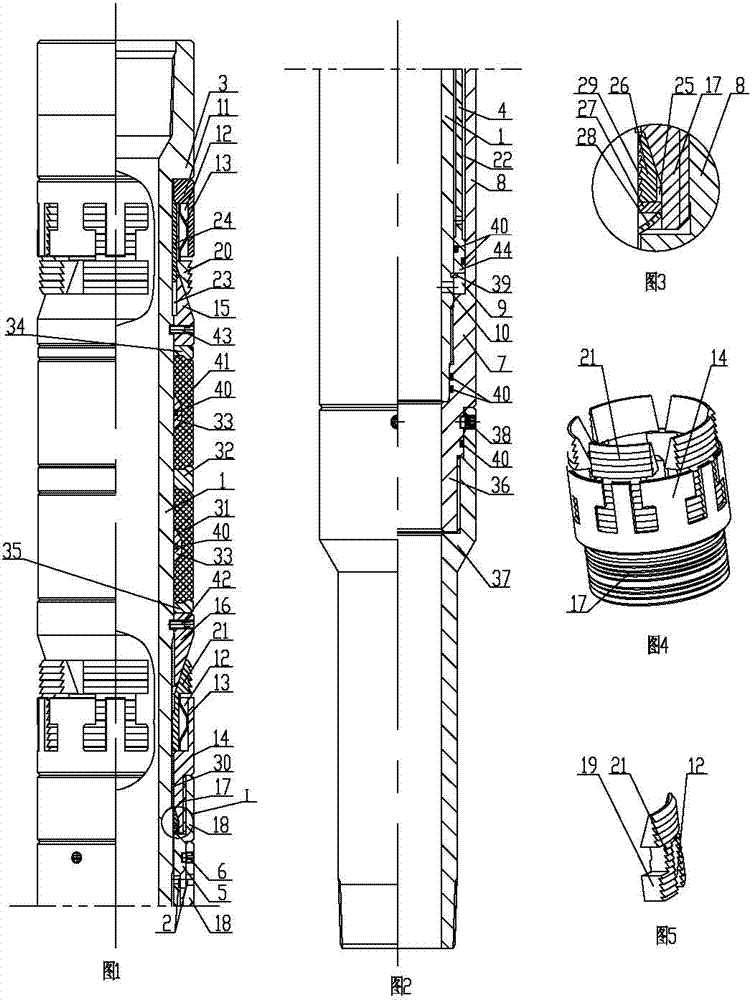

Hydraulic Suspension Packer with Anti-separation Slips

The invention relates to the technical field of a hanging packer, and discloses an anti-fall split slip hydraulic hanging packer, which comprises a central shaft, a piston, a cavity sleeve, a first sleeve, a second sleeve and a slide bushing, wherein the cavity sleeve is fixedly arranged outside the lower end of the central shaft; the upper end of the cavity sleeve is fixedly provided with the first sleeve with internal diameter of greater than the internal diameter of the cavity sleeve; and a piston axial movement sliding chute is formed between the first sleeve and the central shaft. The anti-fall split slip hydraulic hanging packer has the advantages of rational and compact structure, convenience in use, capabilities of compressing a clamp spring in an upper slip cap and a lower slip cap by an upper slip hanging seat and a lower slip hanging seat respectively through the action of an upper conical sleeve and a lower conical sleeve when a piston is pushed to ascend through hydraulic force, realizing hanging through radial expansion of the lower part of an upper slip and the upper part of a lower slip to a lower layer of bushing and meanwhile realizing siting through bulging of rubber sleeves under the action of thrust, easiness in operation, convenience in mounting and capabilities of realizing self-locking and improving the reliability of hanging through engagement of inner teeth and outer teeth of an inverted tooth ring and improving a sitting effect by arranging bearing rings in an upper rubber sleeve and a lower rubber sleeve respectively.

Owner:CNPC XIBU DRILLING ENG

Safety belt hanging device for maintenance of main transformer

Owner:ZHANGZHOU POWER SUPPLY COMPANY STATE GRID FUJIANELECTRIC POWER +1

Shelf with hanging function and coatroom

PendingCN110859439ASimple structureEasy to assemble and disassembleWardrobesFurniture partsLiving roomEngineering

The invention provides a shelf with a hanging function and a coatroom, and belongs to the technical field of home decoration. The shelf comprises at least one partition plate, two side fasteners, a plurality of locking members and a clothes hanging rod, wherein the at least one partition plate serves as a bearing structure; the two side fasteners are located on the two sides of the partition platerespectively and are in concave-convex nested fit with the partition plate; a first connecting part is arranged at one end of each side fastener; a second connecting part is arranged at the other endof each side fastener; the plurality of locking members are located on the two sides of the partition plate and used for locking connection between the side fasteners and the partition plate; and thetwo ends of the clothes hanging rod are connected with the second connecting parts on the two side fasteners respectively. The shelf with the hanging function and the coatroom are simple in structure, clothes can be hung, the phenomenon that the clothes are wrinkled when being are worn for the first time is avoided, and the shelf is applied to the coatroom, a living room and a study room and alsocan be used as a writing desk top, a dressing room table, a wall bar counter, a wall table of a dining store, a store clothes display rack, a storage room shelf and the like.

Owner:NINGBO OULIN WHOLE KITCHEN CO LTD

Multifunctional bicycle assembly workbench

Owner:TIANJIN GOLDEN WHEEL BICYCLE GRP +1

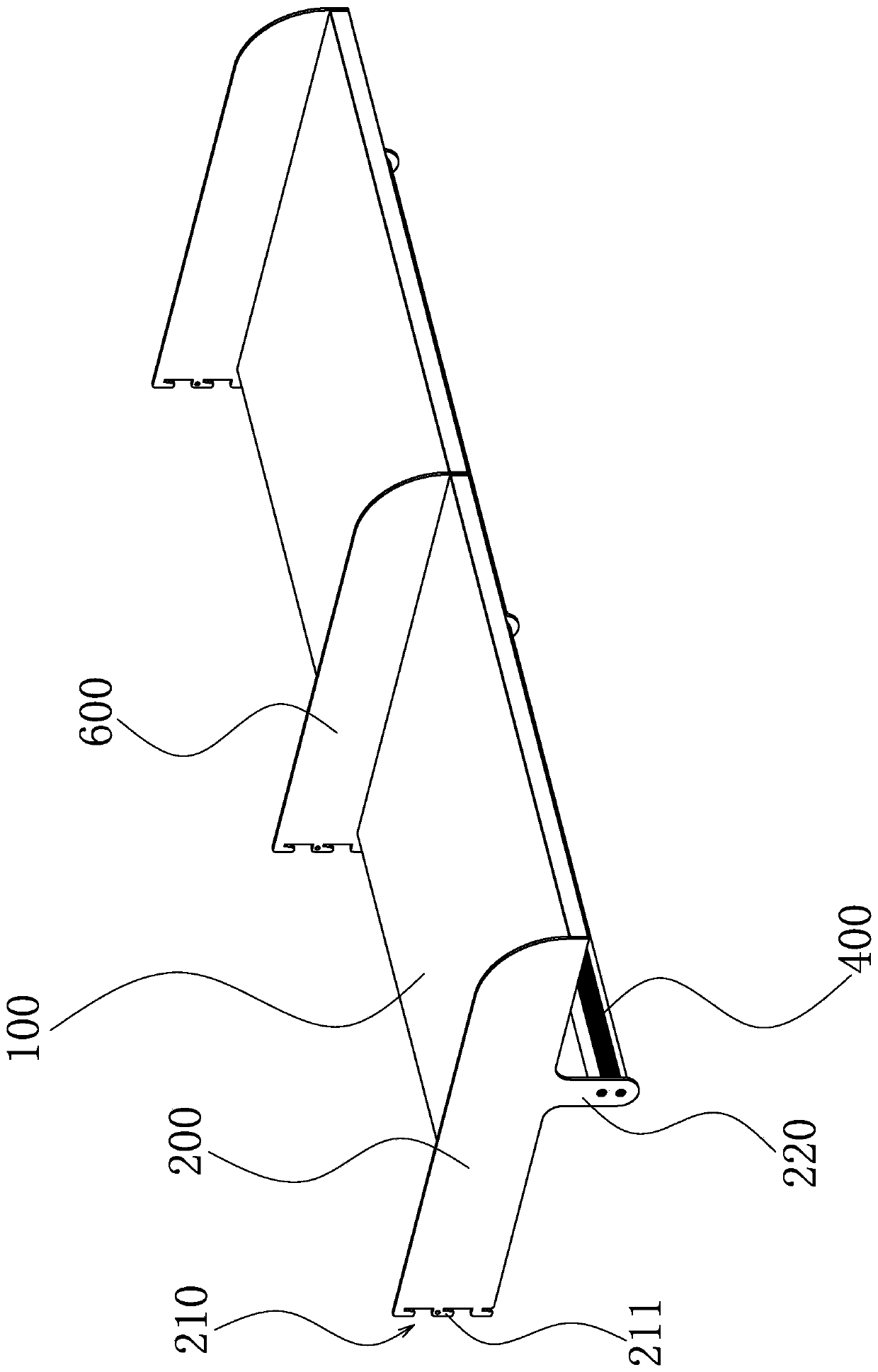

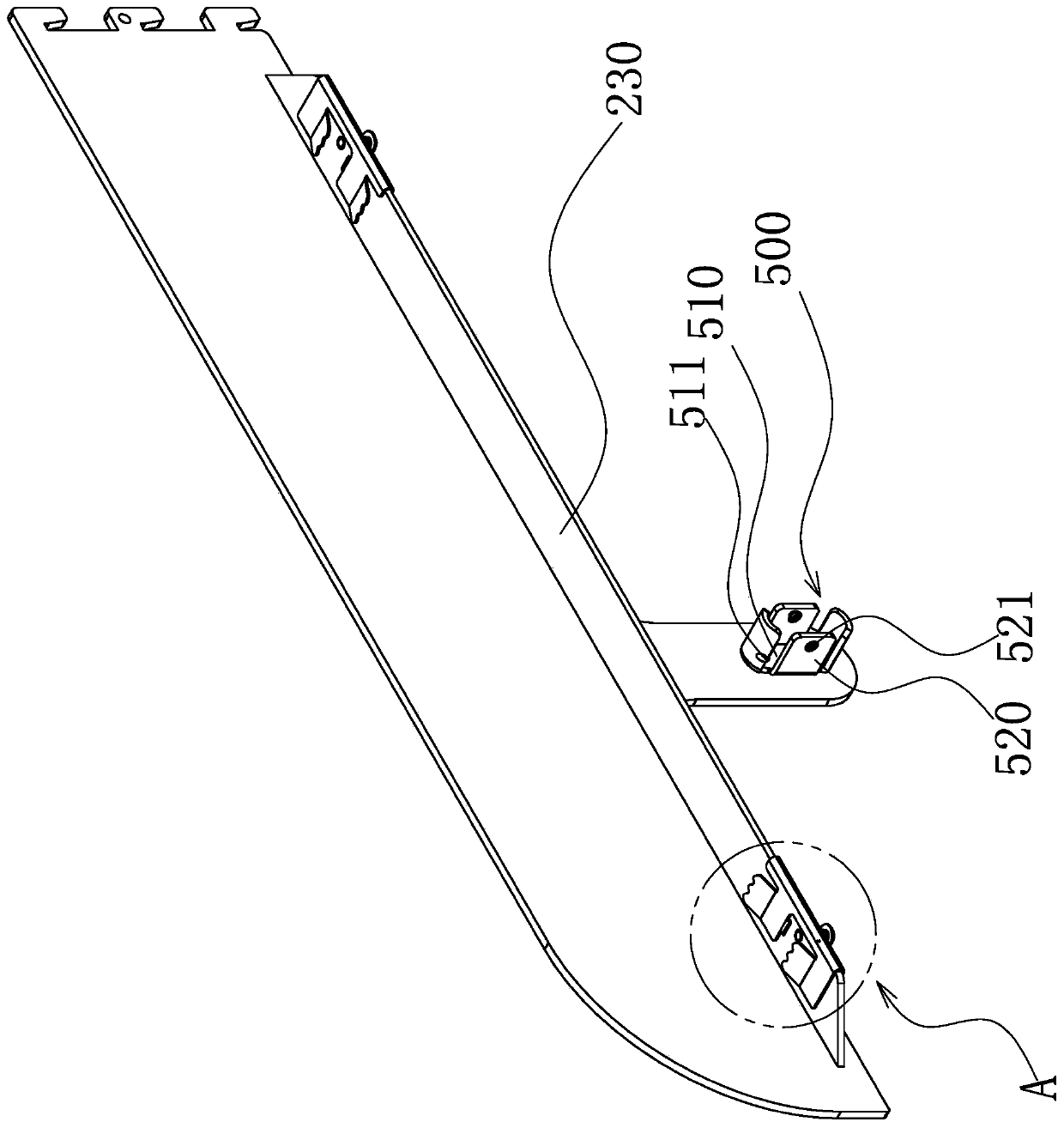

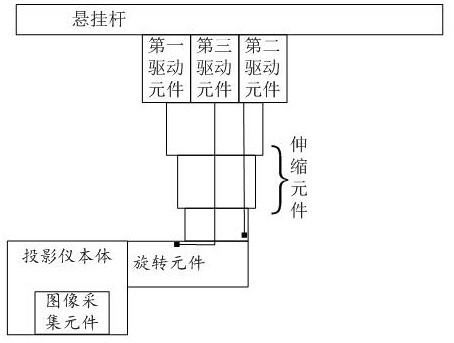

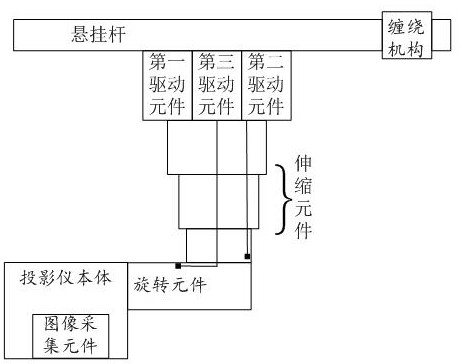

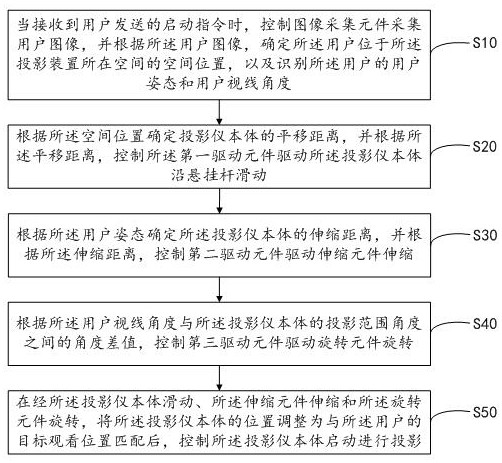

Suspended projection device, control method thereof, and readable storage medium

ActiveCN113075851BEasy to useSuspension implementationProjectorsStands/trestlesComputer hardwareEngineering

The invention discloses a suspended projection device, a control method thereof, and a readable storage medium, comprising: a projector body, a conducting assembly, a driving mechanism and a suspension rod; an image acquisition element is arranged on the projector body, and the conducting assembly includes a rotating element and the telescopic element, the two ends of the rotating element are respectively connected with the projector body and the telescopic element; the driving mechanism is connected with the telescopic element, including a first driving element, a second driving element and a third driving element; the first driving element is based on the image acquisition element The collected user image drives the projector body to slide; the second drive element drives the telescopic element to drive the projector body to expand and contract according to the user image; the third drive element drives the rotation element to drive the projector body to rotate according to the user image; at the same time, the suspension rod is connected with the drive mechanism , to hang the projector body. The position of the user is reflected by the user image, and the translation, extension and rotation of the projector body are realized, which is convenient for the user to use and has a high degree of automation.

Owner:SHENZHEN LUCKYSTAR TECH CO LTD

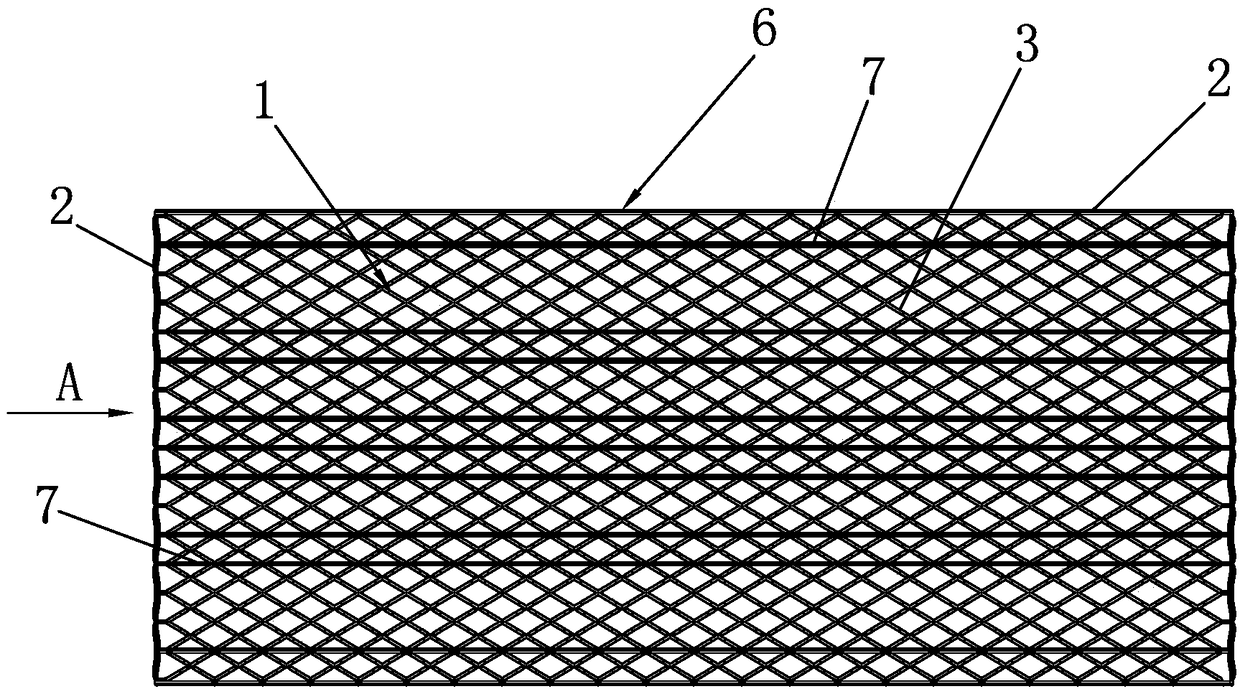

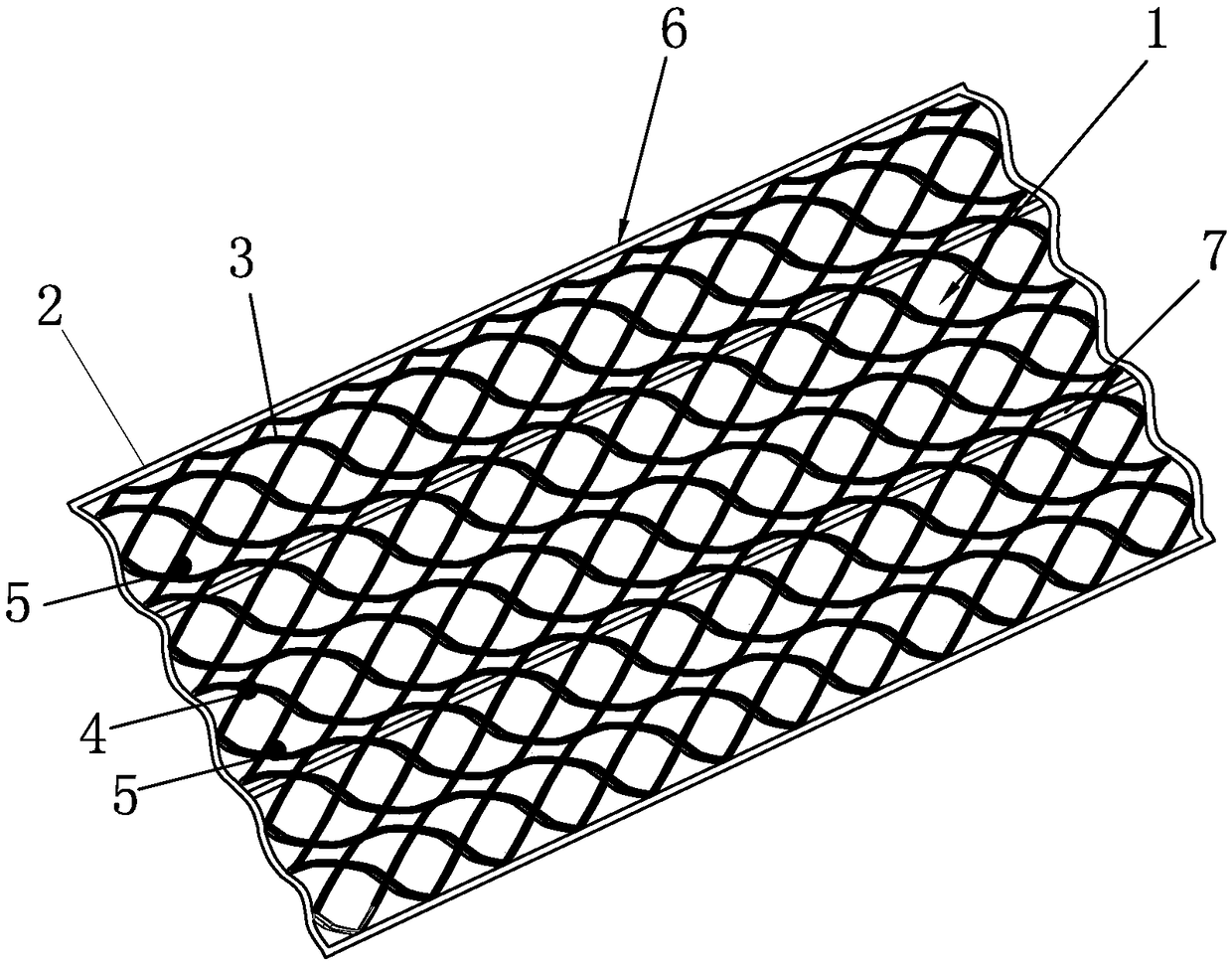

Convenient cocooning tool and placement method thereof

The invention discloses a convenient cocooning tool. The cocooning tool includes cocooning nets, supporting side strips are arranged on the four sides of each cocooning net respectively, and each cocooning net includes cocooning strips, wherein the cocooning strips are intersected with one another to form latticed cocooning net bodies, and each cocooning net body is folded. The placement method ofthe cocooning tool includes the following steps of (1) installation of storage racks; (2) installation of the cocooning tool; (3) installation of the storage racks and a fixing bracket. According tothe convenient cocooning tool, the cocooning tool adopts a frameless design, raw materials can be effectively saved, the cost can be effectively reduced, actual processing and manufacturing are facilitated better, and through the design of the supporting side strips, the structural strength of the whole cocooning tool can be improved at the same time. Therefore, the structures of the cocooning nets are not easily deformed, and in a process of conveying and placing the cocooning tool, impact of an external force can be better resisted; the service life of the cocooning tool is effectively prolonged, and compared with the design of a cocooning tool with a frame, the frameless cocooning tool has the advantages that the work difficulty of a manipulator can be reduced, and more practical mechanical conveying operation is achieved.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

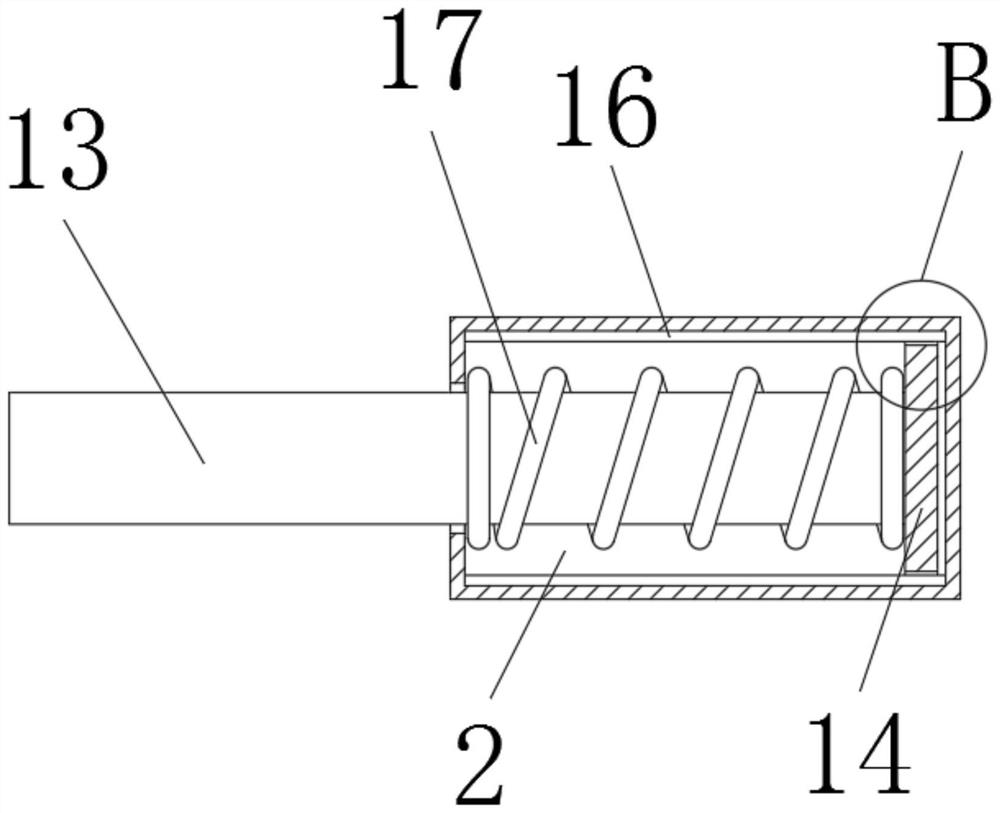

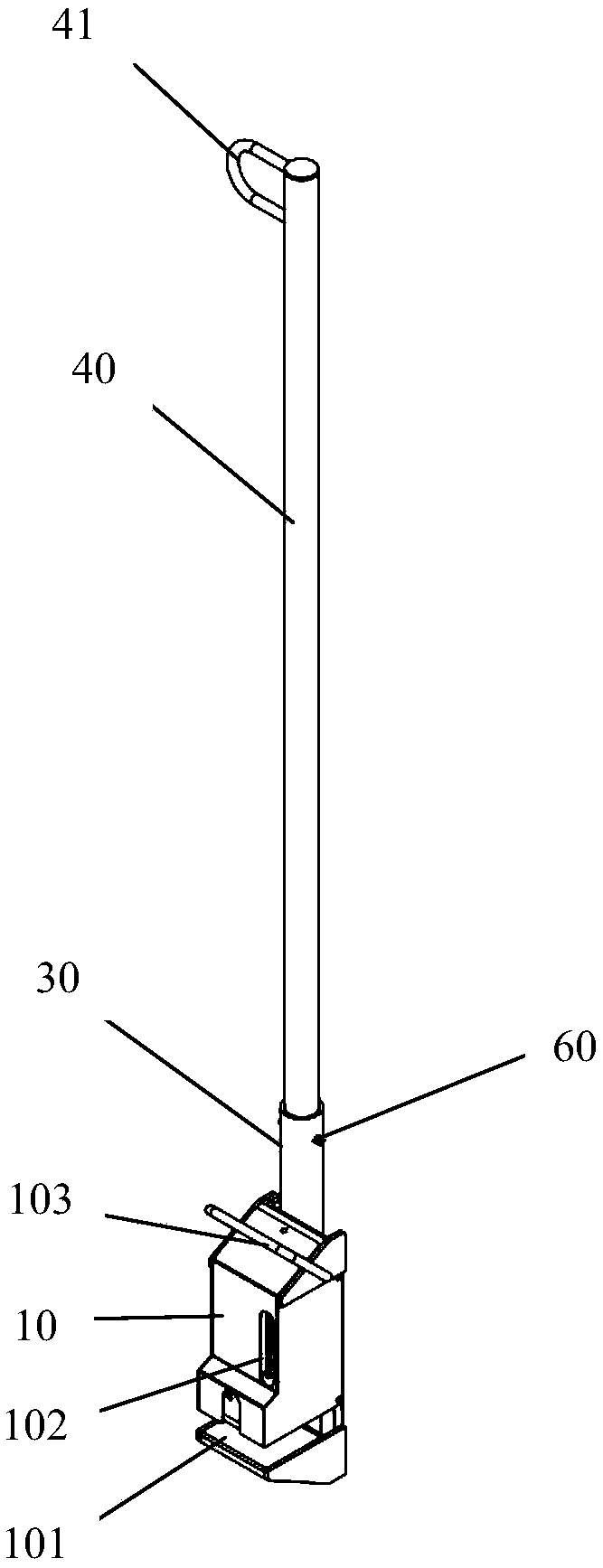

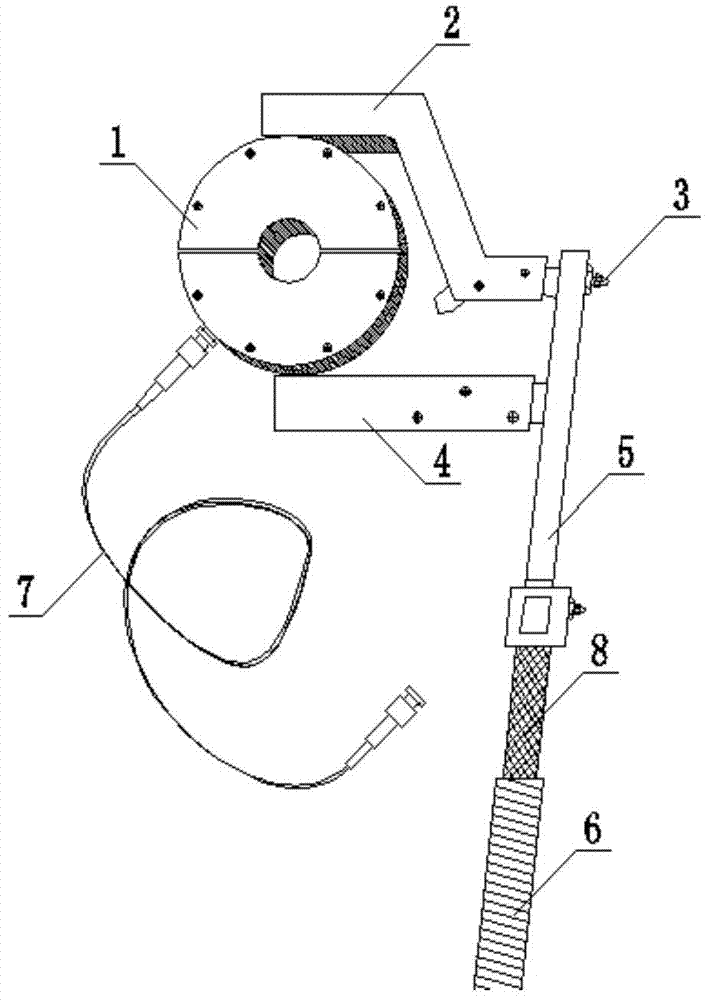

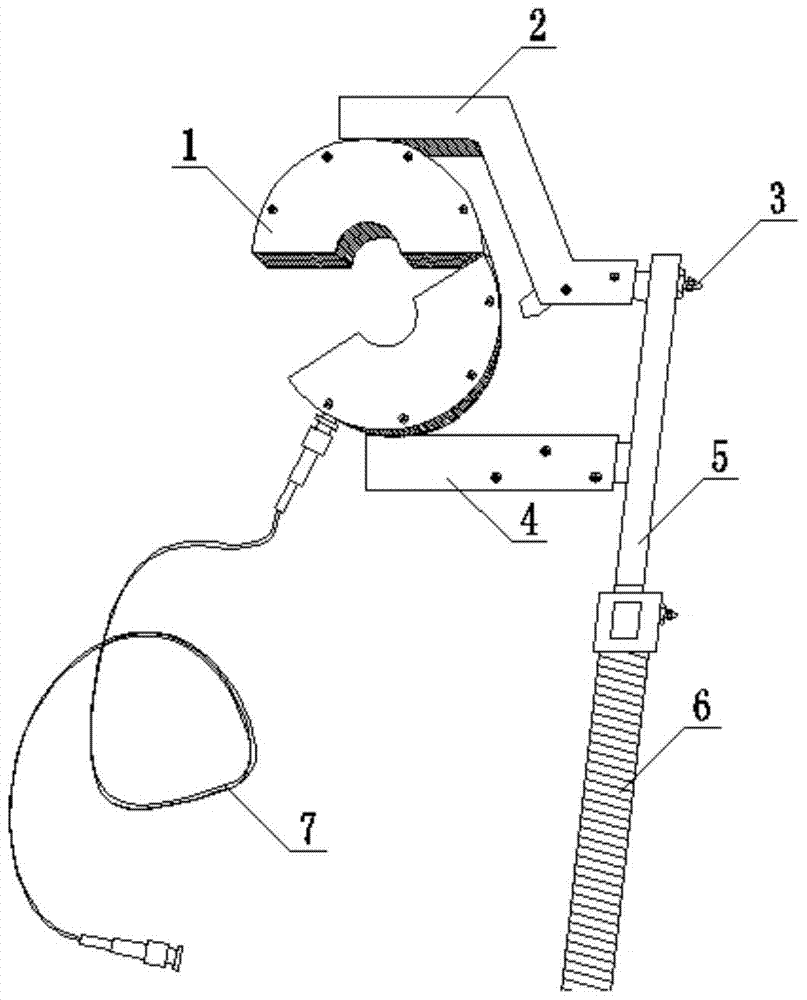

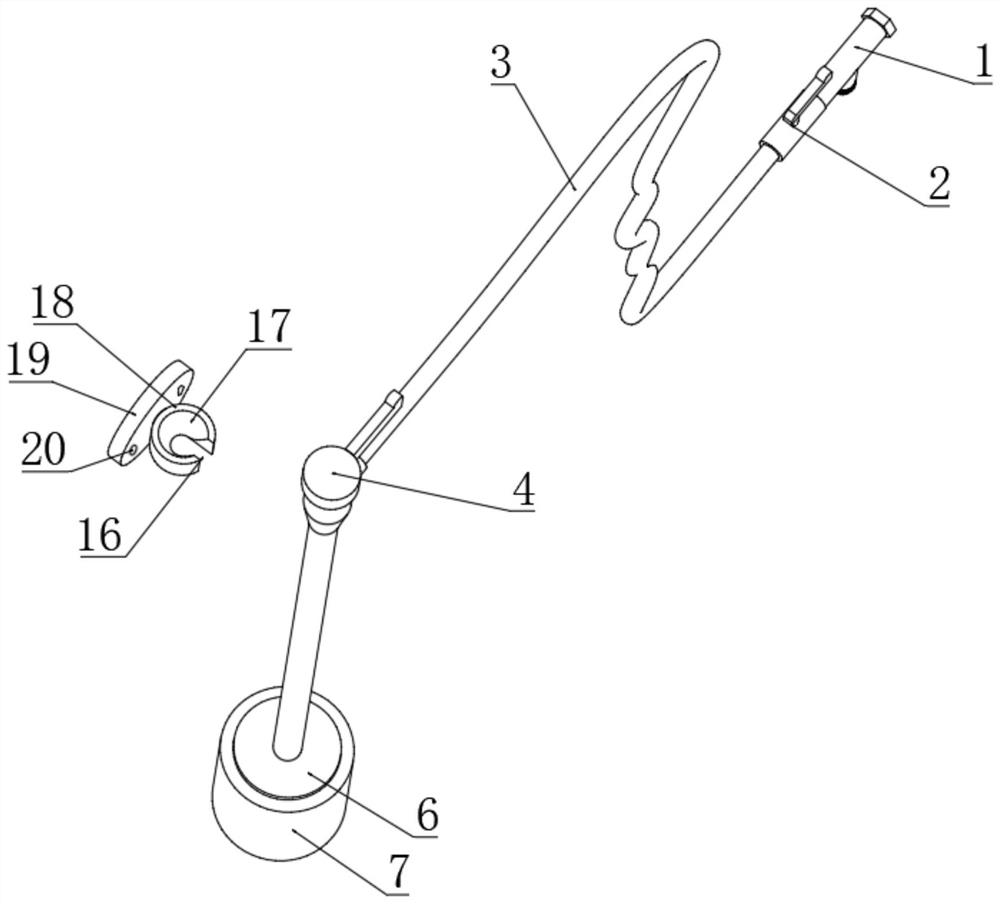

An Open Type Rogowski Coil Current Sensor Convenient for Mounting at High Places

ActiveCN104407196BEasy to hangEasy to disassembleCurrent/voltage measurementCurrent sensorEngineering

The invention discloses an open-type Rogowski coil current sensor which is convenient to be mounted at a high place. ; The hanging support rod is a hollow structure, one end of the telescopic inner support rod is sleeved in one end of the hanging support rod, the other end of the telescopic inner support rod is connected with one end of the connecting rod, and the side surface of the other end of the connecting rod is It is connected with one end of the main support frame and the fixed pulley, and the connecting rod is provided with a clamping slot along the axial direction, and one end of the push plate is clamped in the clamping slot; one end of the rope is fixed on the push plate, and the other end of the rope After the fixed pulley is fixed on the other end of the hanging strut, the signal transmission line is connected with the output end of the current sensor. The user can stand at a low place and suspend the current sensor of the present invention to a high place, and the operation is simple and the safety is high.

Owner:XI AN JIAOTONG UNIV

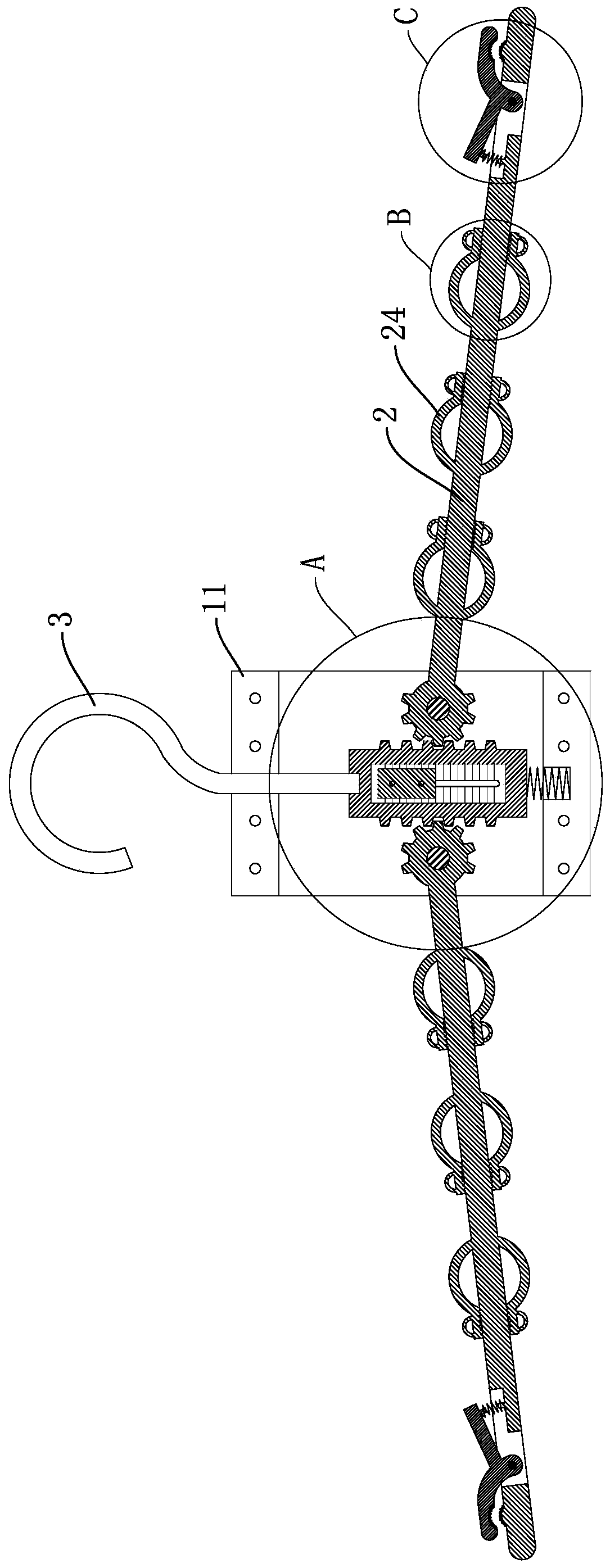

One-way type hanging conveying device

PendingCN109625786AFlexible structure installationSimple structure installationConveyorsControl devices for conveyorsEngineeringSprocket

The invention discloses a one-way type hanging conveying device. The one-way type hanging conveying device comprises a support, a drive side assembly, a driven side assembly, a conveying assembly anda hanging assembly. The conveying assembly comprises a conveying frame, C-shaped steel, a chain and installing pieces. The conveying frame is arranged between the drive side assembly and the driven side assembly, and the installing pieces are arranged on the chain according to the preset interval. The drive side assembly comprises a drive motor and a drive chain wheel. The driven side assembly comprises a driven chain wheel, the drive motor drives the drive chain wheel to rotate, and the drive chain wheel drives the driven chain wheel to rotate through the chain. The hanging assembly comprisesa vehicle body, wheels, an axle and a hook, wherein the vehicle body is in rigidity connection with the installing pieces, and the hook is in rigidity fixation to the vehicle body. Through the technical scheme, when the empty hook returns, space occupation in the horizontal direction is avoided, hanging of multiple products is achieved, the distance can be adjusted according to needs, and the whole conveying device is flexible and simple in structure installation.

Owner:BEIJING YANFENG BEIQI AUTOMOTIVE UPHOLSTERY CO LTD

foldable hanger

ActiveCN108542235BEasy to pass throughEasy to insertApparel holdersEngineeringMechanical engineering

The invention discloses a foldable hanger. The hanger comprises a bracket, suspension arms mounted on two sides of the bracket and a hook mounted on the upper end of the bracket, the bracket comprisesa base and a cover, the base is provided with a sliding block, a guide rail penetrates through the base and the cover plate from front to back, the lower end of the hook is threadedly connected to the upper end of the sliding block and movably penetrates through the base, the end portion of the end, facing the sliding block, of suspension arm is provided with a circular portion, the circular portion is rotatably connected with a rotating shaft, the outer side wall of the circular portion is provided with a plurality of tooth heads, the outer walls of the two sides of the sliding block are provided with rack portions, the front side of the sliding block is provided with a limiting block, the bottoms of grooves in both sides of a long groove are provided with first sawtooth strips, two sides of the rear end face of the limiting block are provided with second sawtooth strips, the outer portion of the guide rail between the limiting block and the cover plate is sleeved with a first spring, and one end, located at the limiting block, of a push rod is in threaded connection with the limiting block; the two suspension arms inside the hanger can be gathered to facilitate the drying of clothes.

Owner:诸暨绿康生物科技有限公司

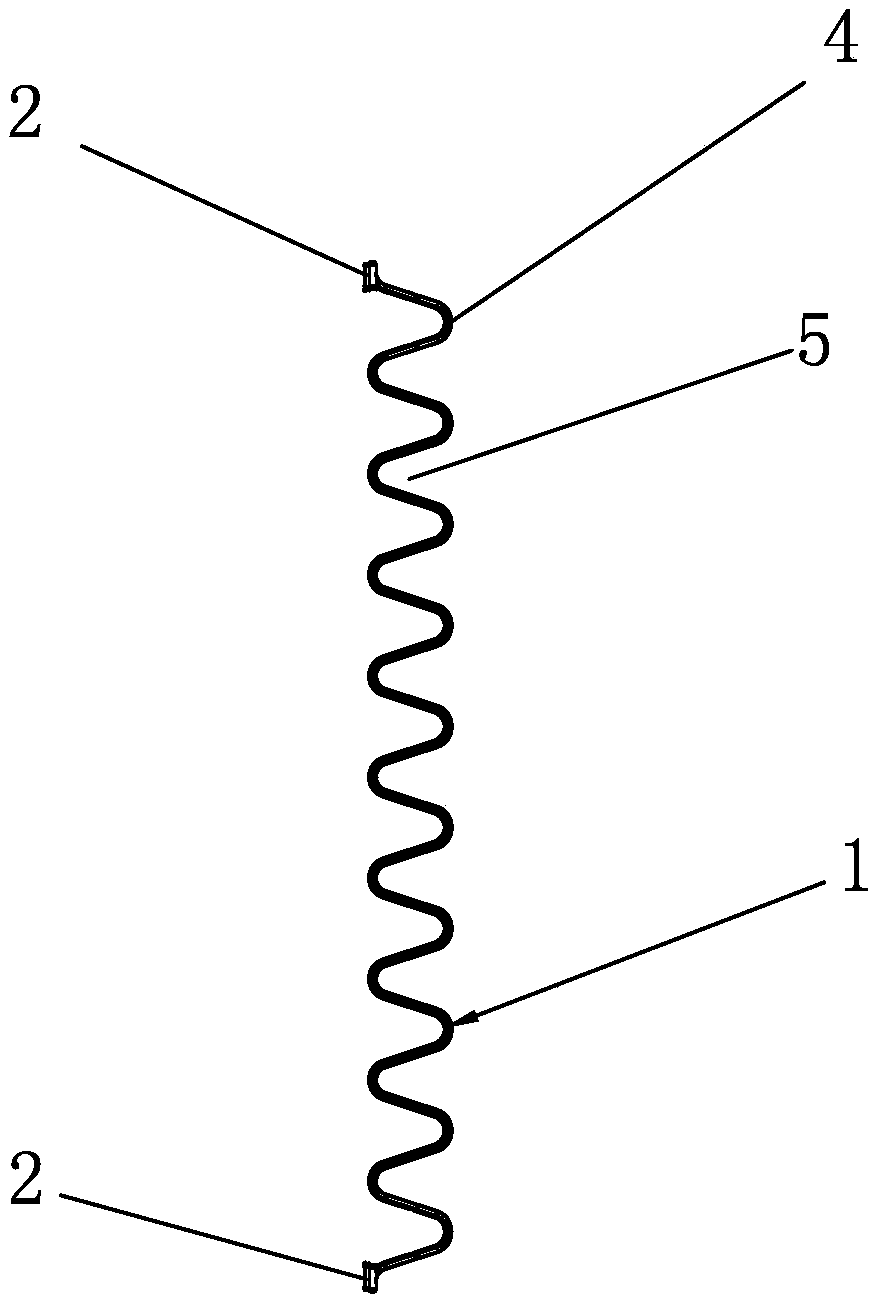

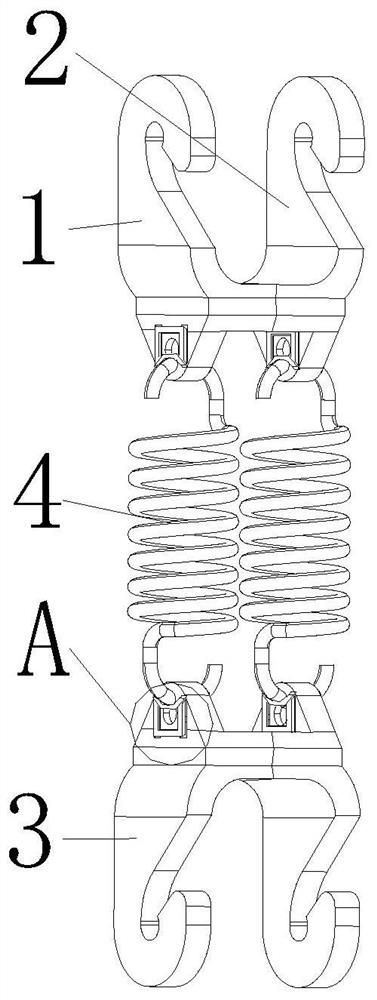

A Multi-Hanging Coil Spring for Parallel Manipulator

ActiveCN112405596BSuspension implementationImprove installation speedJointsCoil springParallel manipulator

The invention relates to the technical field of manipulators, and discloses a multi-hanging coil spring for parallel manipulators, which includes a first fixing frame, a second fixing frame is arranged on the right side of the first fixing frame, and the first Both the fixed frame and the second fixed frame are hook-shaped, and the right side of the first fixed frame is fixedly connected with a positioning rod, and the inside of the second fixed frame is provided with a first sliding groove, and the first sliding groove is a horizontal "U" shape. The multi-hanging coil spring used for parallel manipulators realizes the suspension of the coil spring by suspending the first fixed frame and the third fixed frame, thereby reducing the labor intensity of workers to a certain extent, so that workers can be more convenient At the same time, the speed of installation and disassembly of the driven arm by workers is improved, and at the same time, the fixing of the driven arm is more stable and firm through the relative force at both ends of the coil spring.

Owner:CHONGQING VOCATIONAL INST OF ENG

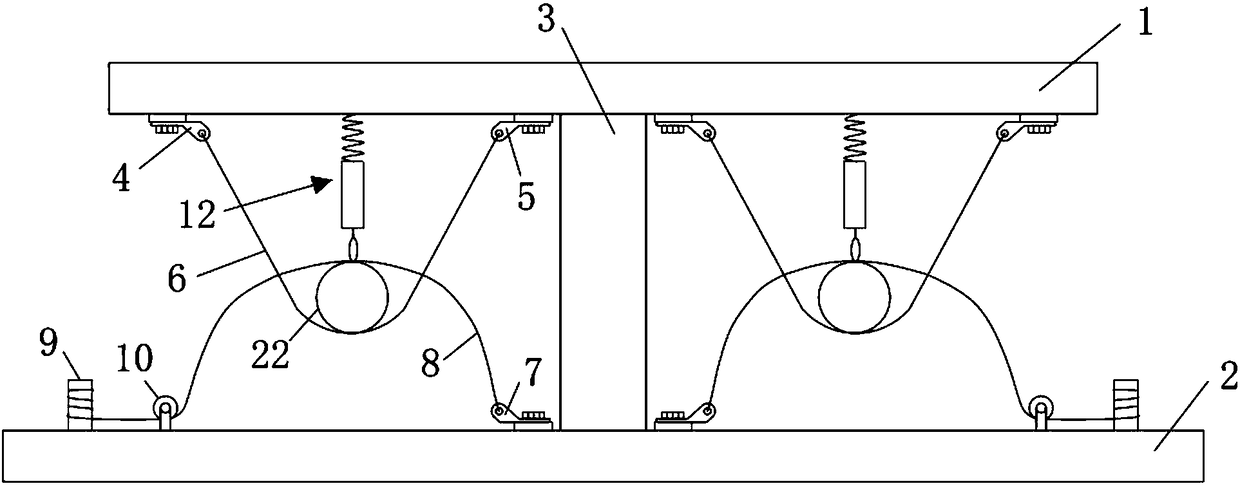

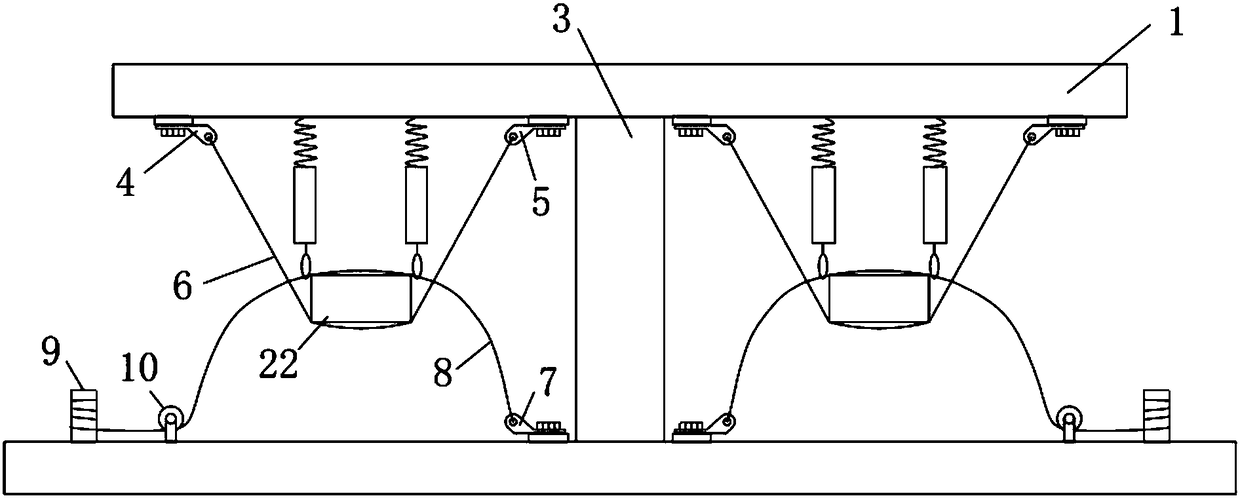

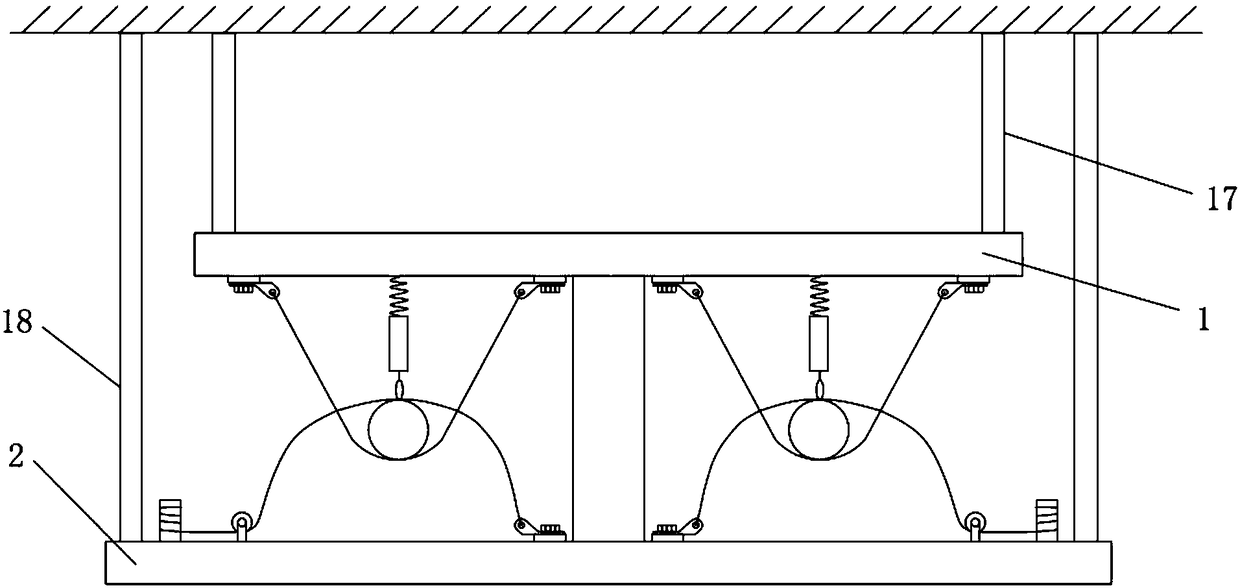

A flexible anti-seismic support system for air duct equipment

ActiveCN107101048BProduce flexible anti-seismic effectRealize flexible anti-seismic supportPipe supportsSupporting systemArchitectural engineering

The invention discloses a flexible anti-seismic support system for air pipe equipment. The flexible anti-seismic support system comprises an upper support rod, a lower support rod, a fixing column and flexible anti-seismic systems, wherein the upper support rod and the lower support rod are arranged in a spaced mode, the two ends of the fixing column are connected to the upper support rod and the lower support rod correspondingly, and the flexible anti-seismic systems are arranged on the two sides of the fixing column. Each flexible anti-seismic system comprises a first steel wire rope connecting piece, a second steel wire rope connecting piece, a supporting rope, a third steel wire rope connecting piece, a pressing rope, a locking column and a pressing rope suspending mechanism. The pressing rope suspending mechanisms are connected to the middles of the pressing ropes and comprise sliding blocks, springs, mounting rods and sleeving rings, and the middles of the pressing ropes are sleeved with the sleeving rings. The flexible anti-seismic support system for the air pipe equipment can simultaneously support air pipes of diversified sizes, and the air pipe equipment does not move at random; and when shock is generated under external force, through the effects of the supporting ropes and the pressing ropes, flexible supporting and clamping of the air pipe equipment can be well achieved, and damage and influence to / on a support and the air pipe equipment are greatly reduced.

Owner:HEFEI YUANKANG ENVIRONMENT SCI & TECH

Suspended type dressing mirror with object suspending function

InactiveCN108542201ASuspension implementationGuaranteed stabilityPicture framesLighting elementsPhysics

The invention provides a suspended type dressing mirror with an object suspending function. The dressing mirror comprises a mirror frame and a mirror surface, the mirror surface is arranged on the mirror frame, and the dressing mirror further comprises a suspending assembly; the suspending assembly comprises a hanger, hooks and multiple object suspending columns, a U-shaped hanger is adopted as the hanger, the hooks are arranged at the two ends of the hanger respectively, the object suspending columns are arranged in the middle of the hanger, the hanger is connected with a connecting plate, the connecting plate is connected to the mirror frame, the mirror frame is provided with a gasket and a rubber strip, and the gasket is arranged on the mirror frame and the rubber strip. According to the suspended type dressing mirror with the object suspending function, the function of suspending objects can be achieved while the mirror surface is used normally; through integral arrangement of themirror frame and the hanger, the mirror frame can be suspended, and the positioning stability of the mirror frame is achieved.

Owner:苏州众曼精密机械有限公司

Air purification device for smart home life

InactiveCN112361522AEasy to installSuspension implementationMechanical apparatusLighting and heating apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of air purification, and discloses an air purification device for smart home life. The air purification device comprises a mounting box, wherein the left side of the front face of the mounting box is hinged to the left side of the front face of a box door through hinges; a handle groove is formed in the right side of the front face of the box door; a handle rod is fixedly connected to the front side of the inner wall of the handle groove; ventilation grooves are formed in the bottom of the front face of the box door and the top of the back face of the mounting box; and heat dissipation grooves are formed in the middle of the front face of the box door and the top of the right side face and the bottom of the back face of the mounting box. According to the air purification device for smart home life, the mounting box and a hanging device are used in cooperation, hanging of the purification device is achieved, the mounting box is more convenient to dismount, operation of people is facilitated, the purification device is located in the mounting box, mounting of the purification device is more stable, the ventilation grooves are formed, the purification device can normally run, and safety of the device is improved.

Owner:广州初色科技有限公司

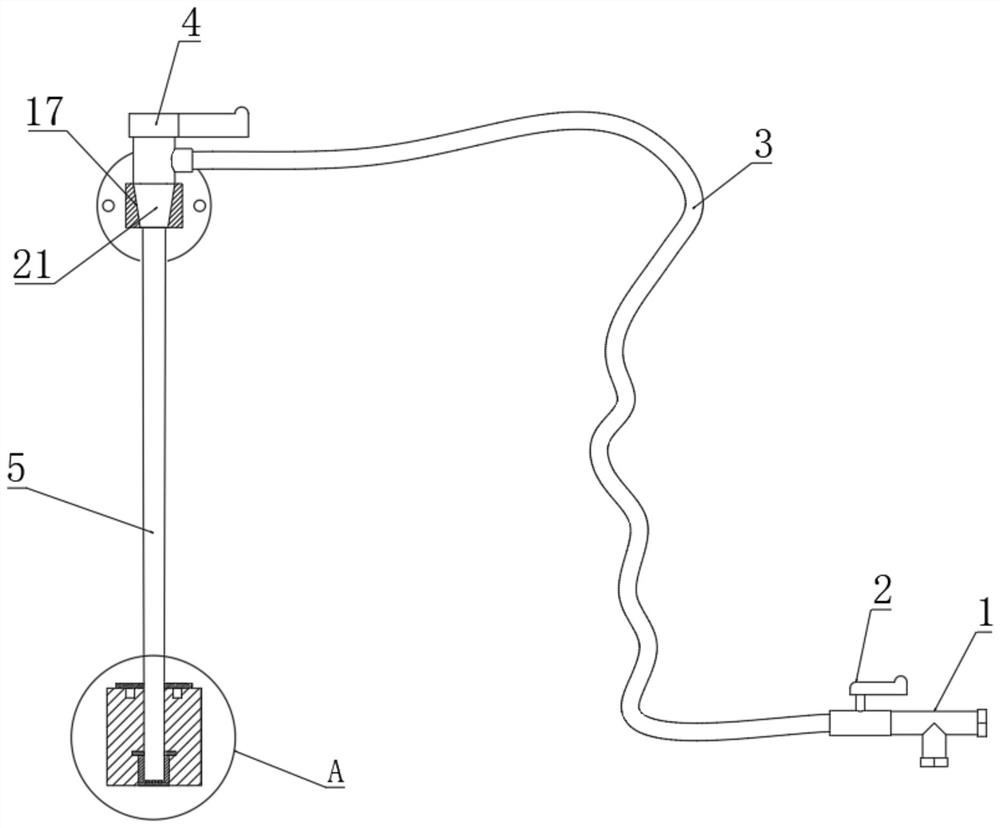

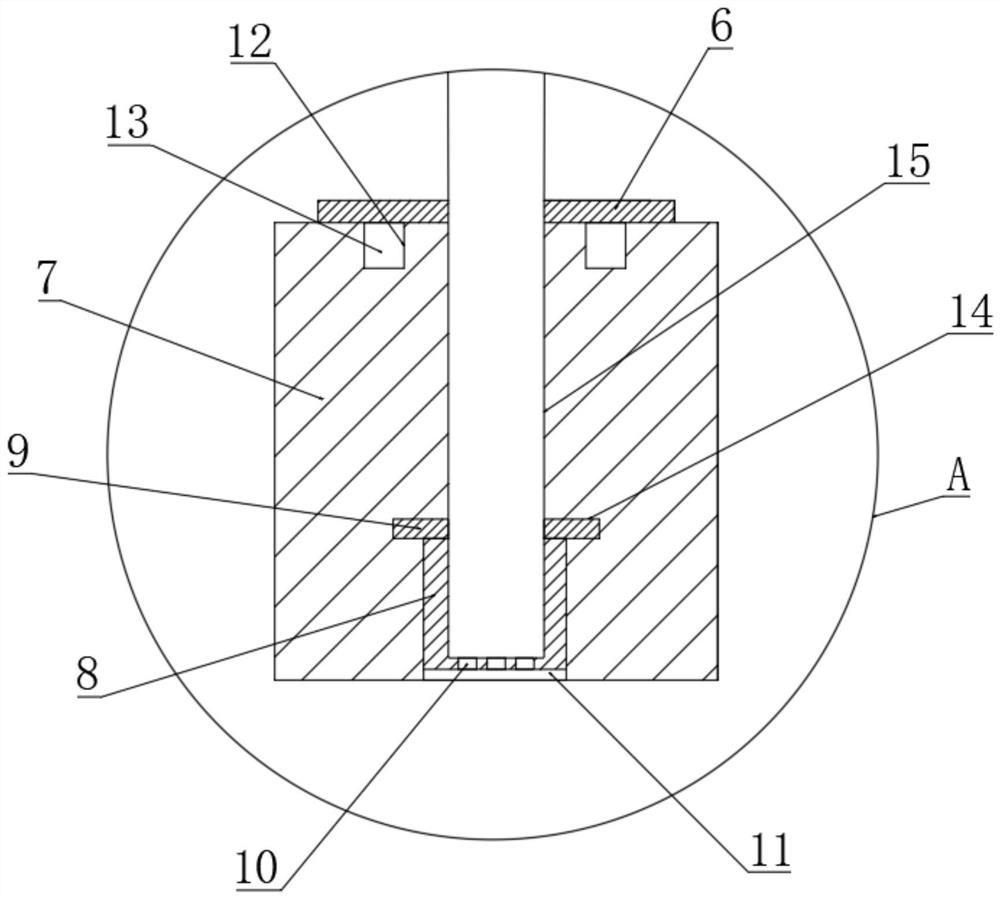

Multifunctional excrement crushing anti-blocking device connected with water pipe of closestool

PendingCN114054439ASolve the blockageSuspension implementationHollow article cleaningHigh pressure waterMechanical engineering

The invention discloses a multifunctional excrement crushing anti-blocking device connected with a water pipe of a closestool, which comprises an elastic excrement crushing head, a water jetting head and a pull limiting ring, wherein if the excrement crushing function needs to be used, a connecting pipe is held, the water jetting head abuts against excrement, a second valve is opened, the excrement is crushed through high-pressure water sprayed out of a water jetting hole, the elastic excrement crushing head can also be used for directly crushing the excrement, if the dredging function needs to be used, the connecting pipe is held and inclined by a certain angle, the elastic excrement crushing head and the water jetting head are inserted into a sewage discharging channel opening of the closestool to conduct push-pull dredging, the diameter of the elastic excrement crushing head is slightly larger than the aperture of the sewage discharging channel opening of the closestool, the elastic excrement crushing head can also be used for blocking the sewage discharging channel opening of the closestool, then high-pressure water flushed out of the water jetting hole is used for impact dredging, and when the cleaning function is needed, the water jetting head is aligned with the excrement attached to the wall of the closestool, the excrement on the wall of the closestool is washed away through the impact of the high-pressure water, and excrement which is not easy to wash away can be scrubbed through the elastic excrement crushing head.

Owner:吴留勤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com