Concrete pier system for suspension type monorail traffic and construction process

A technology of monorail transportation and construction technology, which is applied in the direction of bridges, tracks, bridge construction, etc., and can solve the problems of easy corrosion of metal structures, unfavorable control of track beam alignment, and difficulty in ensuring durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

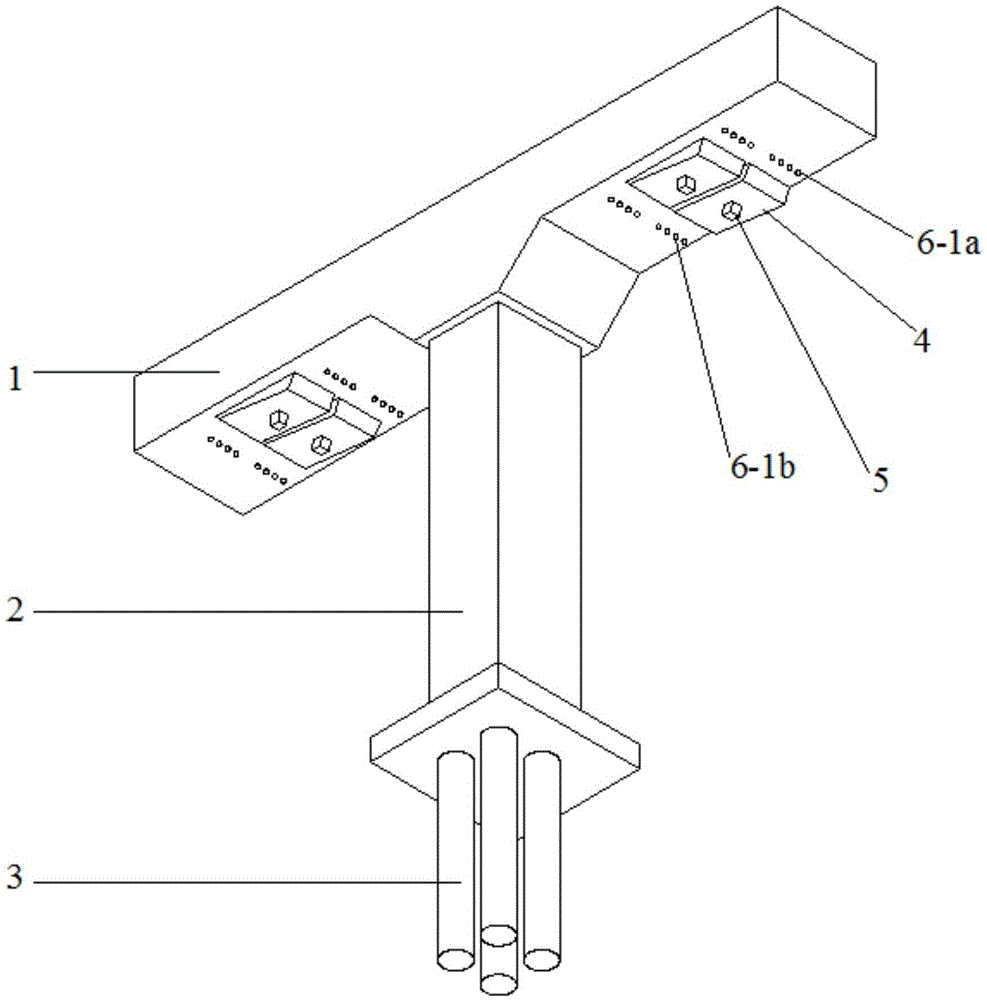

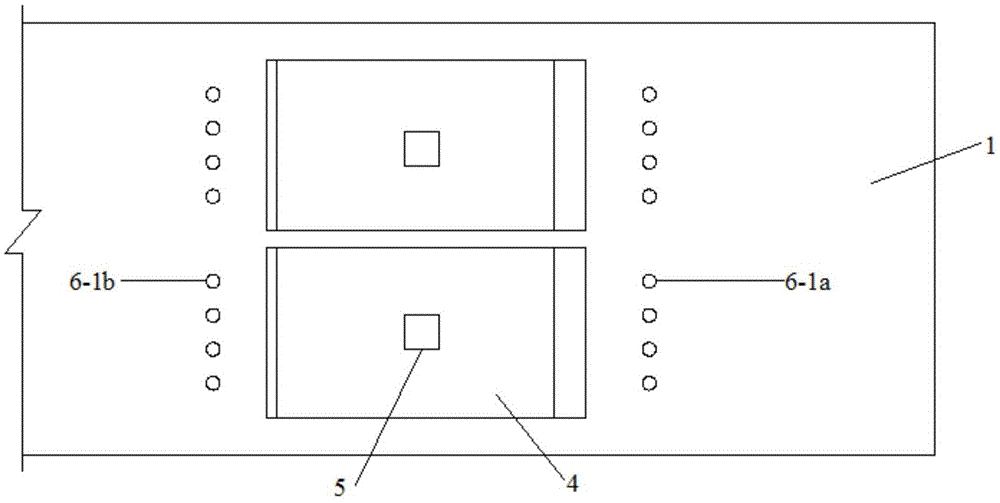

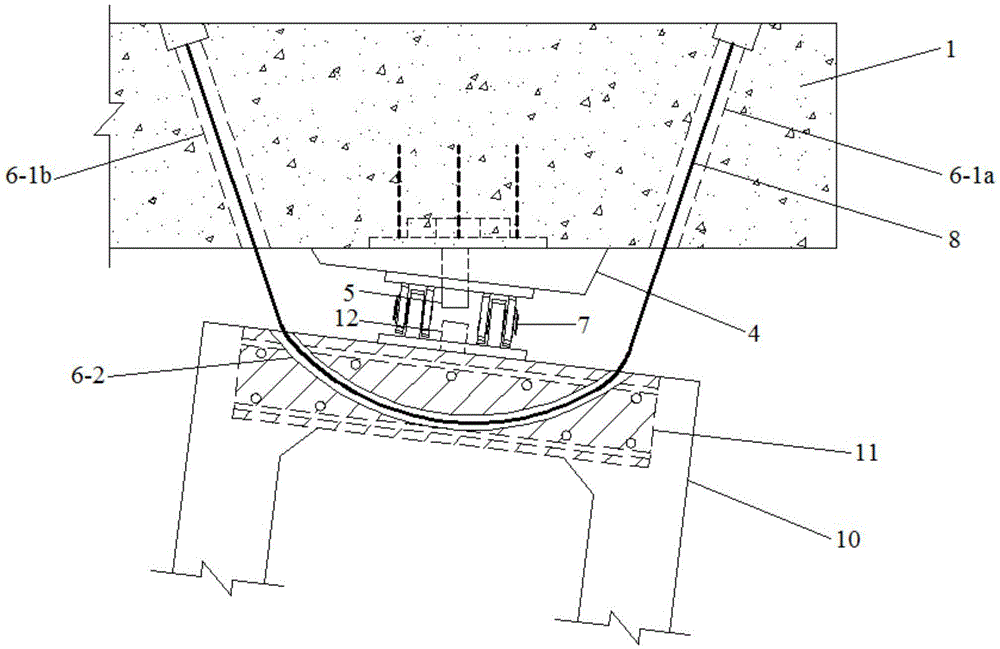

[0019] The present invention will be further explained in conjunction with the drawings:

[0020] Example A suspended monorail transportation concrete structure simply supported system adopts concrete piers, using concrete cap beam 1, pier column 2, pier foundation 3, supporting cushion 4, upper pendulum shear tenon on the support, and reserved concrete cap beam Channel 6-1a, concrete cover beam reserved channel 6-1b, base reserved channel 6-2, fixed support 7, cable 8, movable support 9, track beam 10, base 11 and support hem shear tenon 12.

[0021] Step 1 Prefabricated the track beam 10 with the pre-embedded base 11 in the workshop, and transported to the site to prepare the beam.

[0022] Step 2 In the on-site construction stage, pouring the main part of the concrete bridge pier system for suspended monorail transportation, including concrete cap beam 1, pier column 2, pier foundation 3, concrete cap beam reserved channel 6-1a, concrete cap beam reserved Channel 6-1b, and bury ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com