Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Sufficient engagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

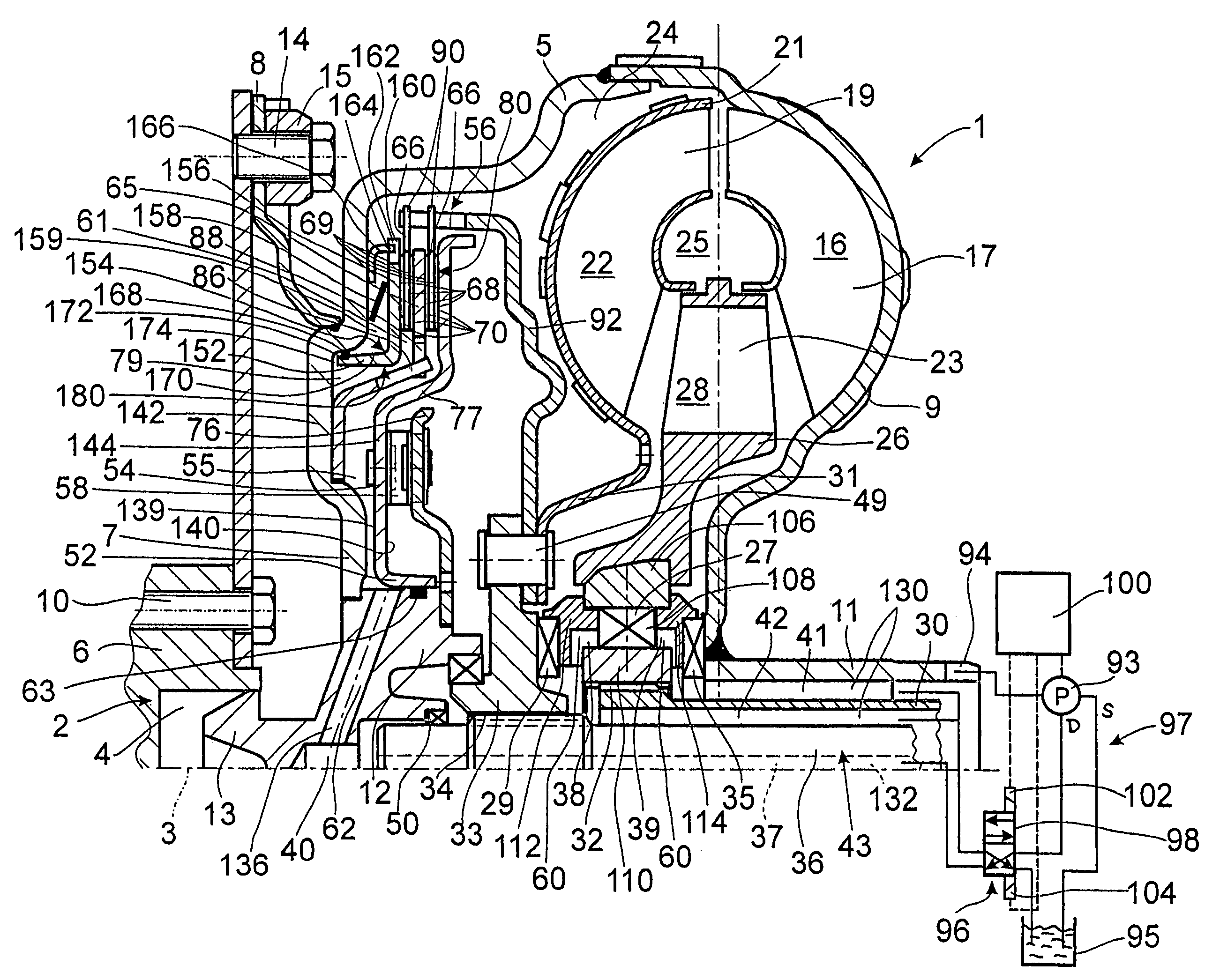

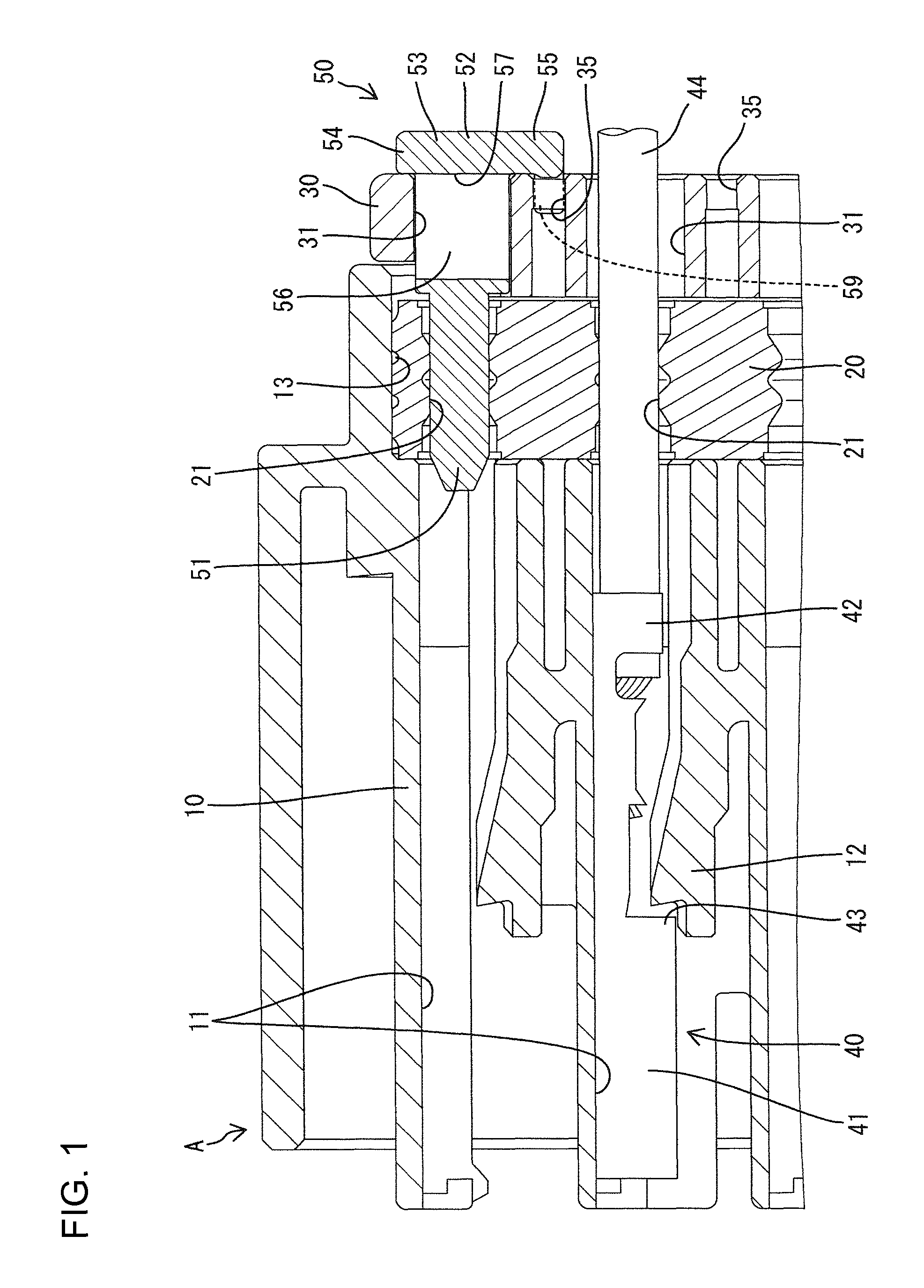

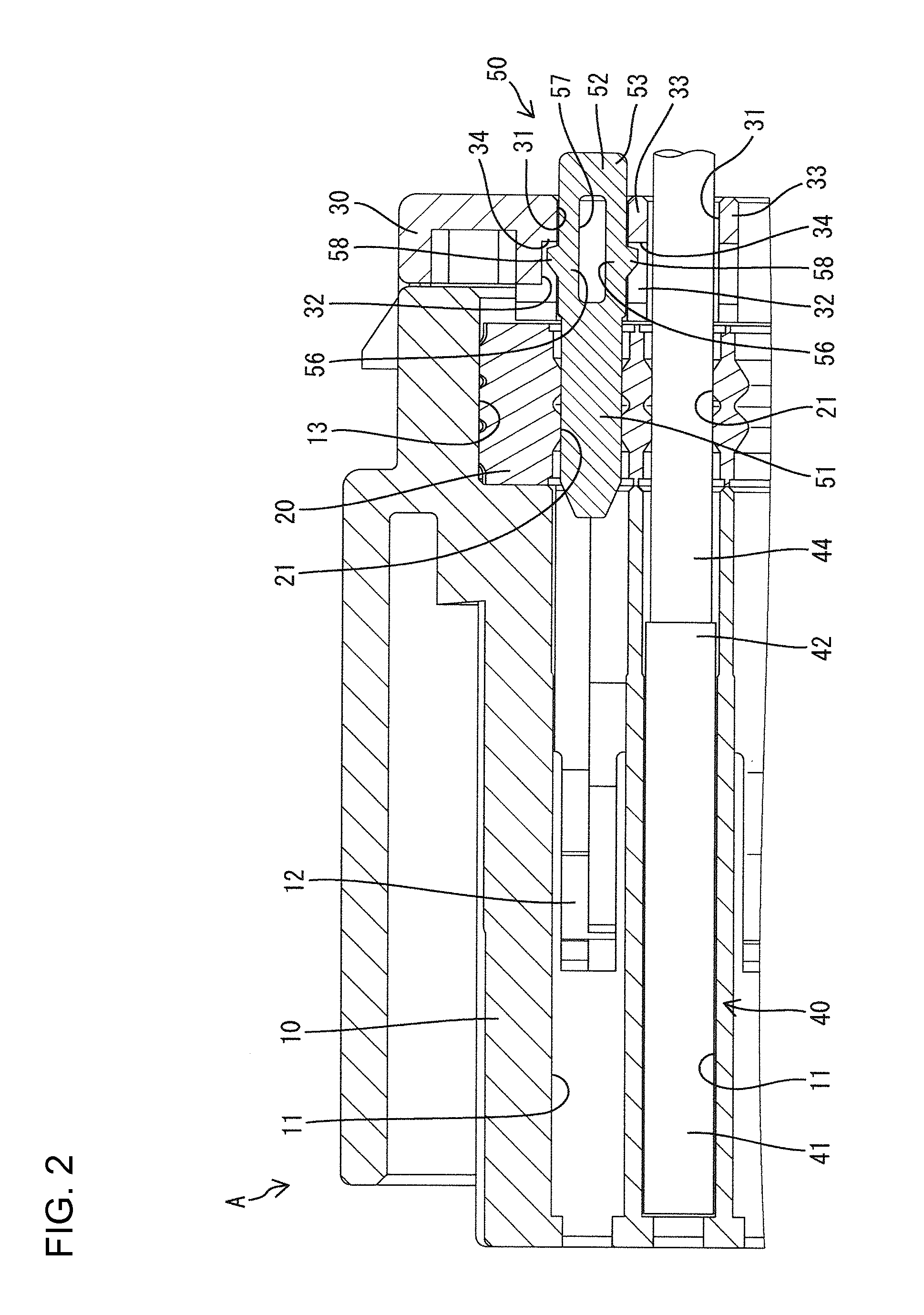

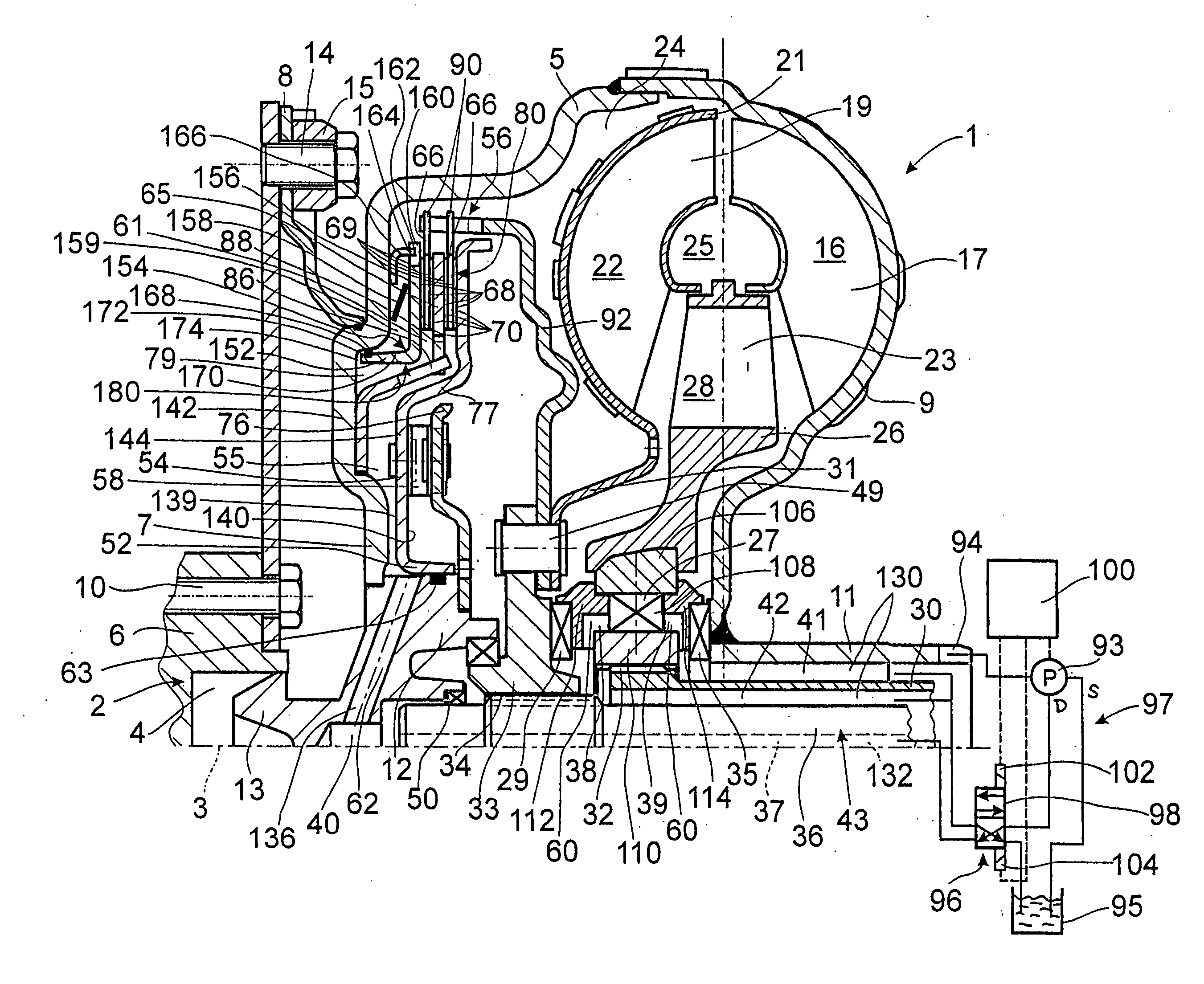

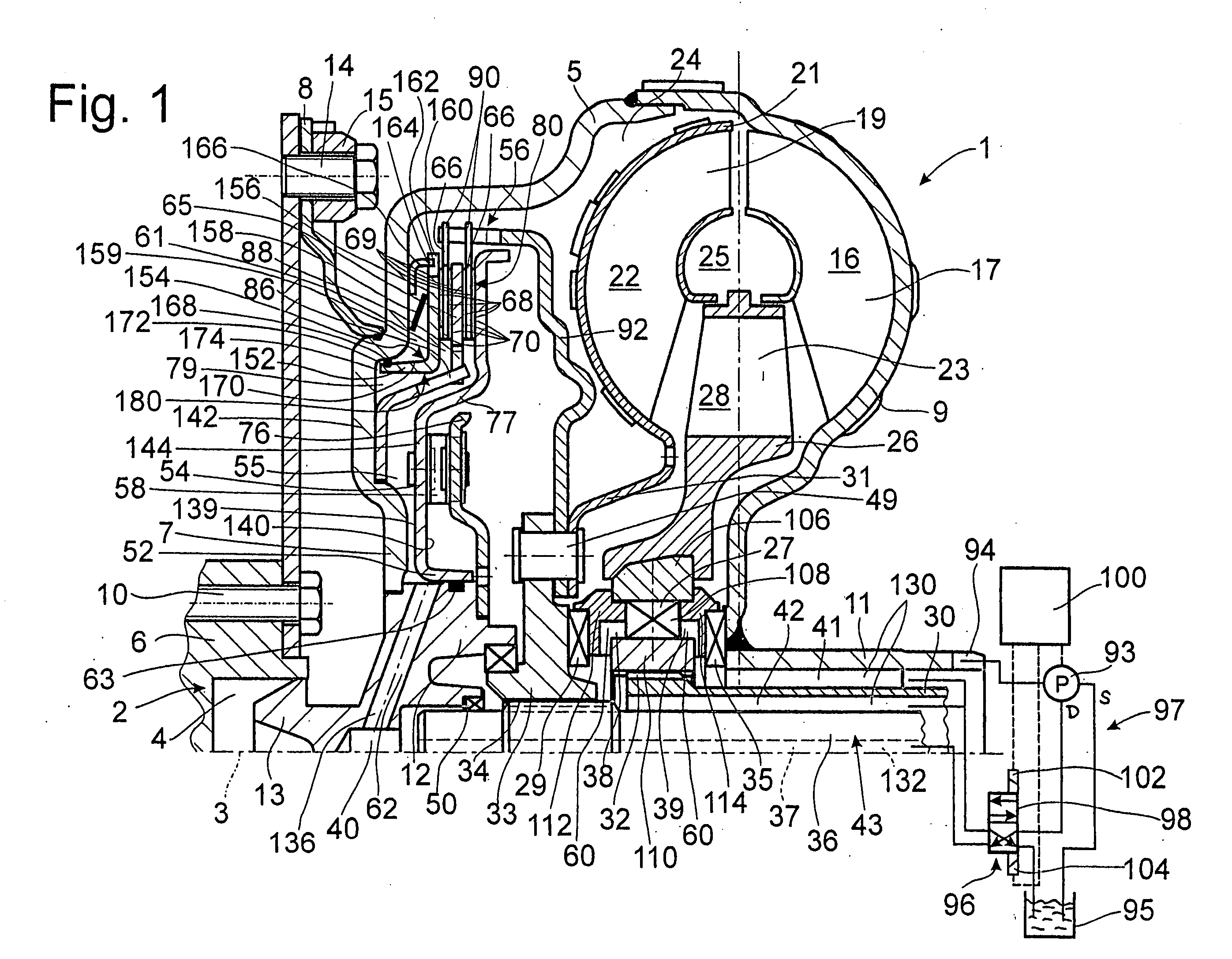

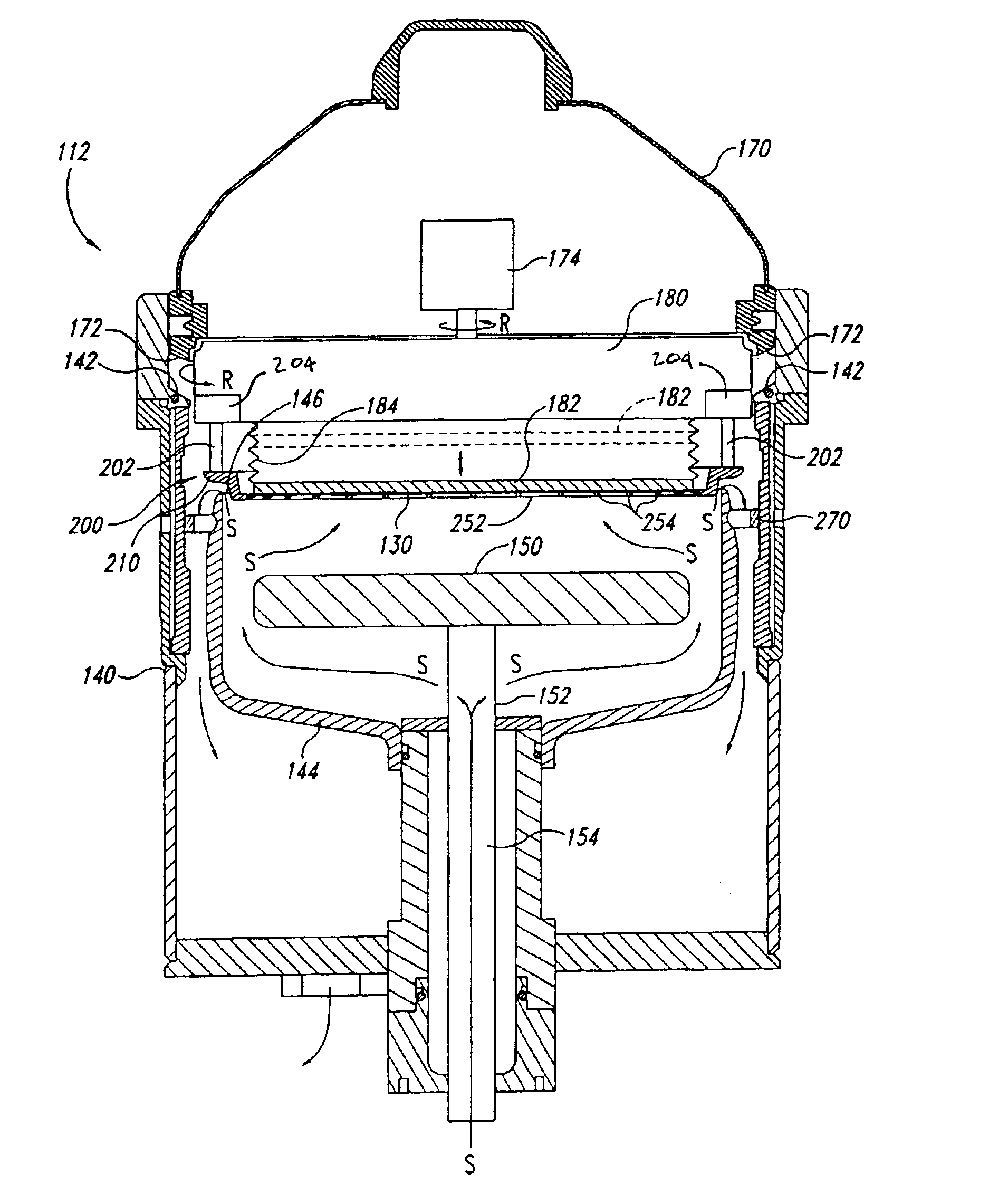

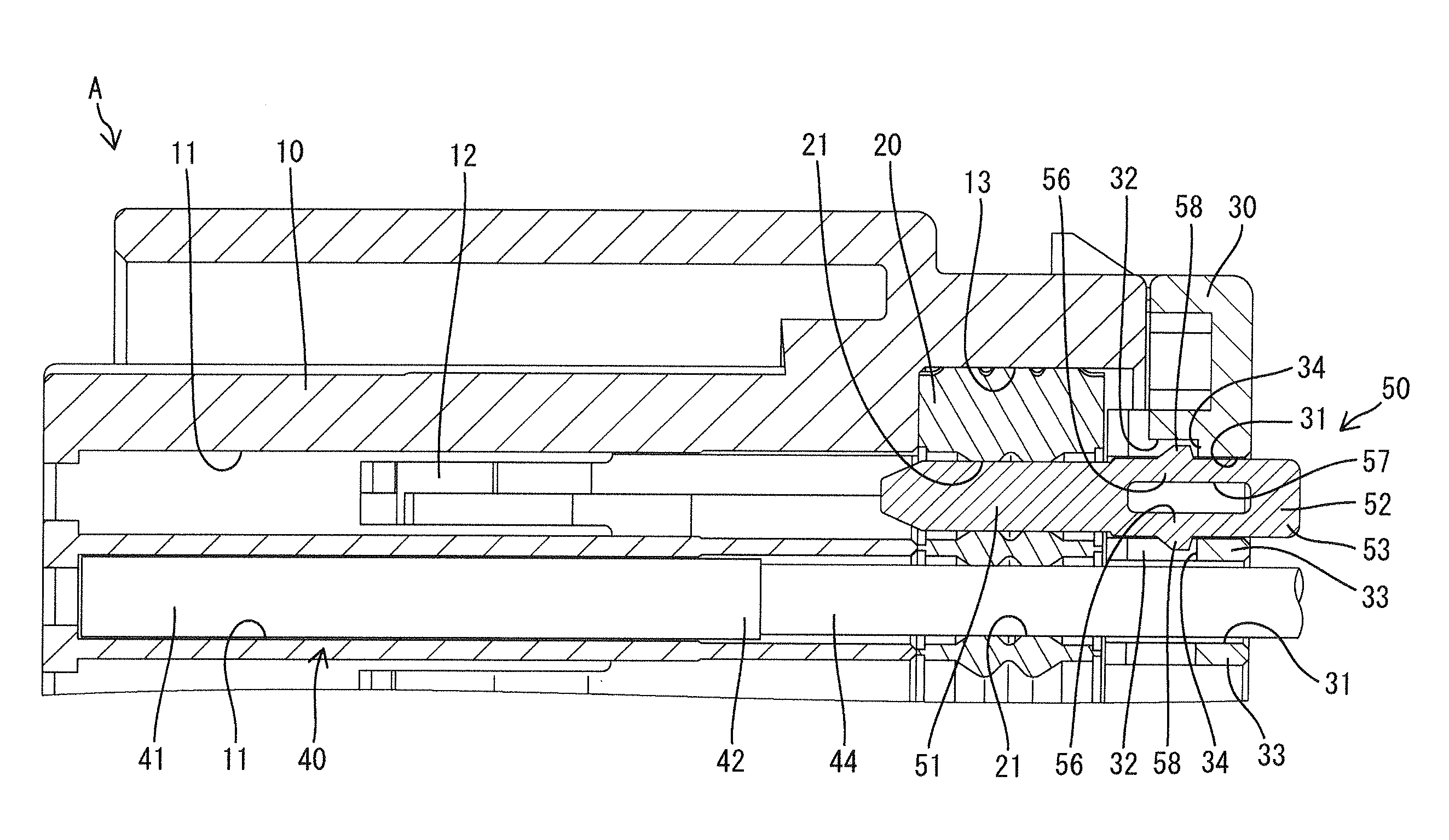

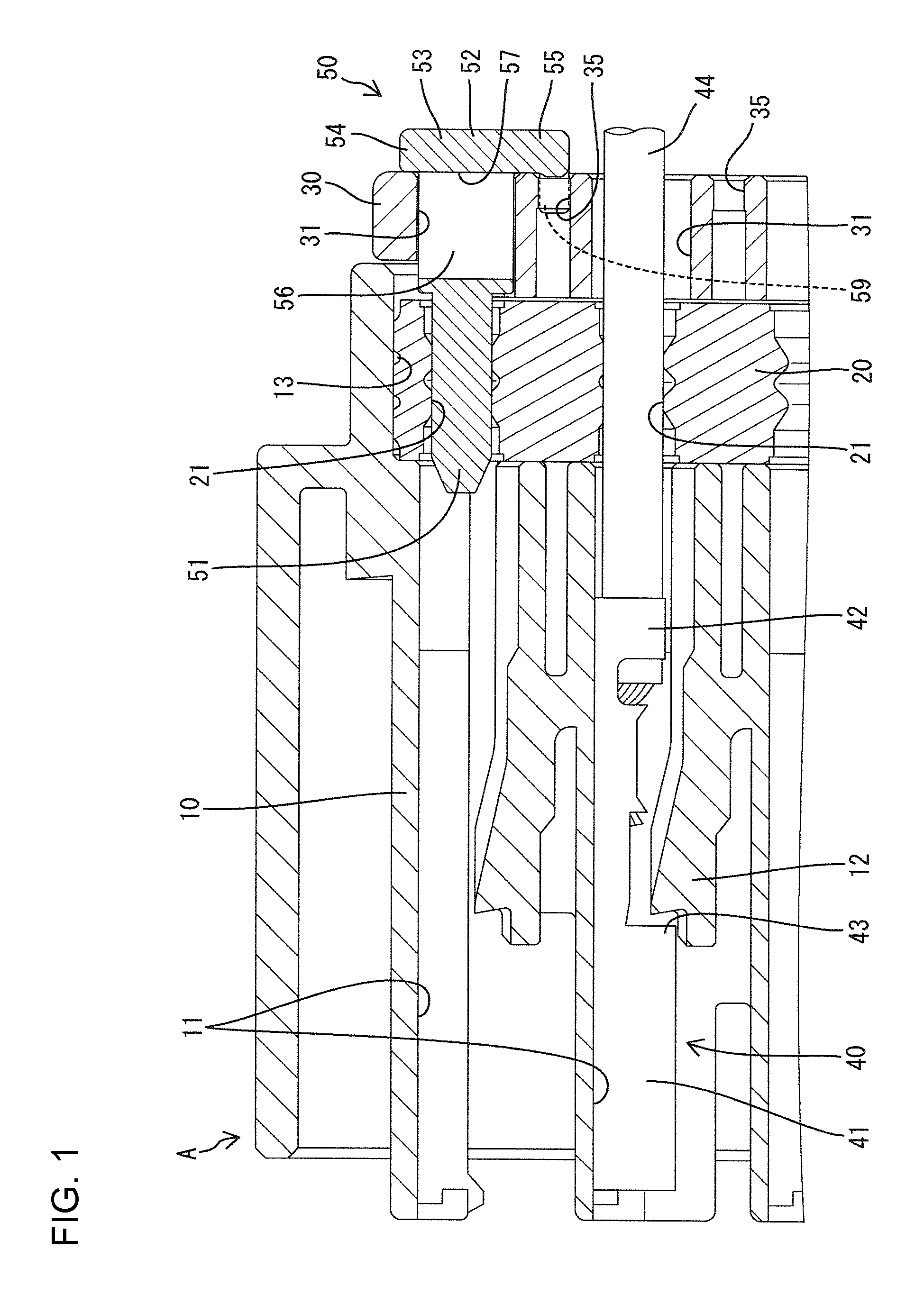

Hydrodynamic clutch device

InactiveUS7478713B2Disadvantageous effectReduce pressureRotary clutchesFluid gearingsImpellerEngineering

Owner:ZF FRIEDRICHSHAFEN AG

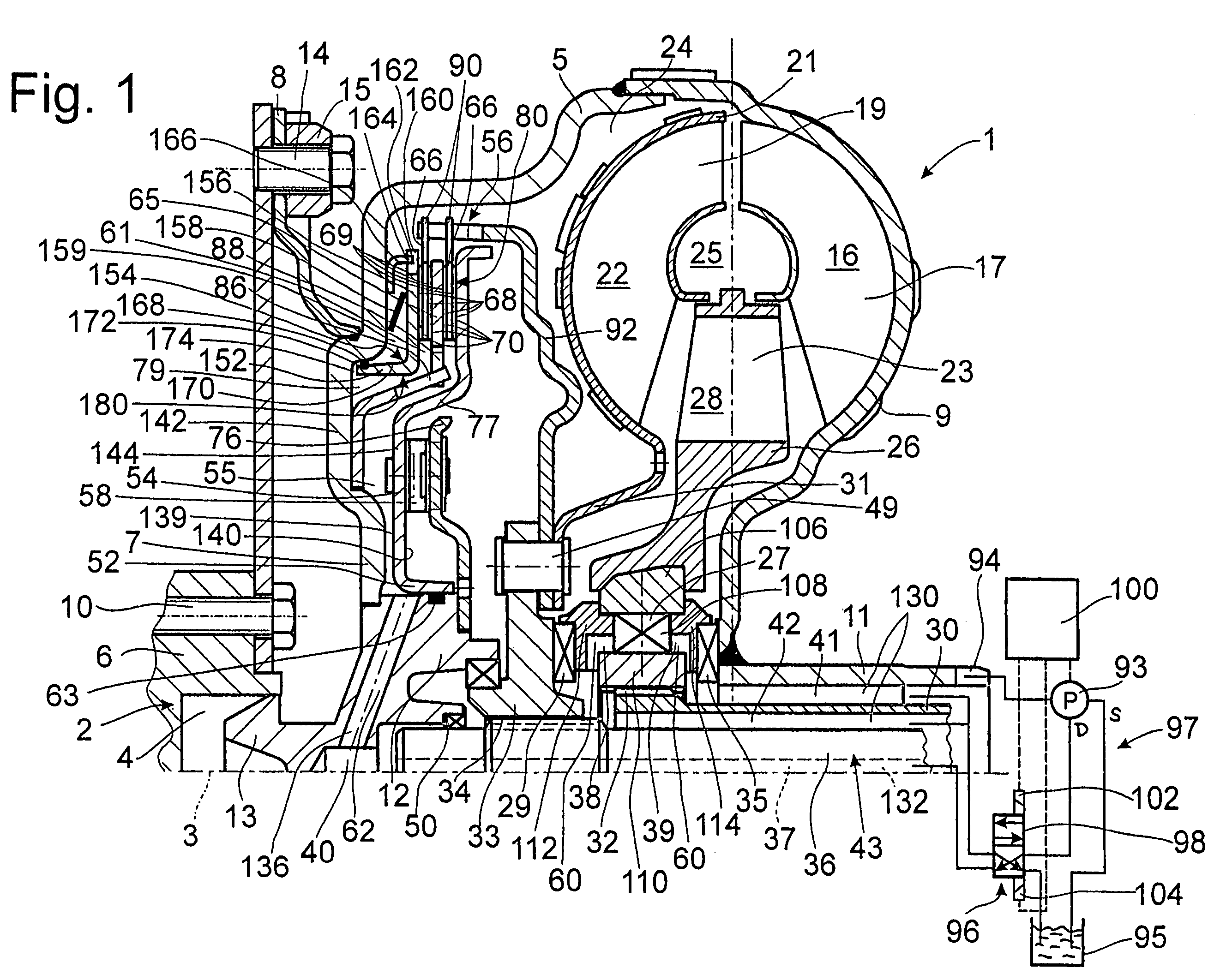

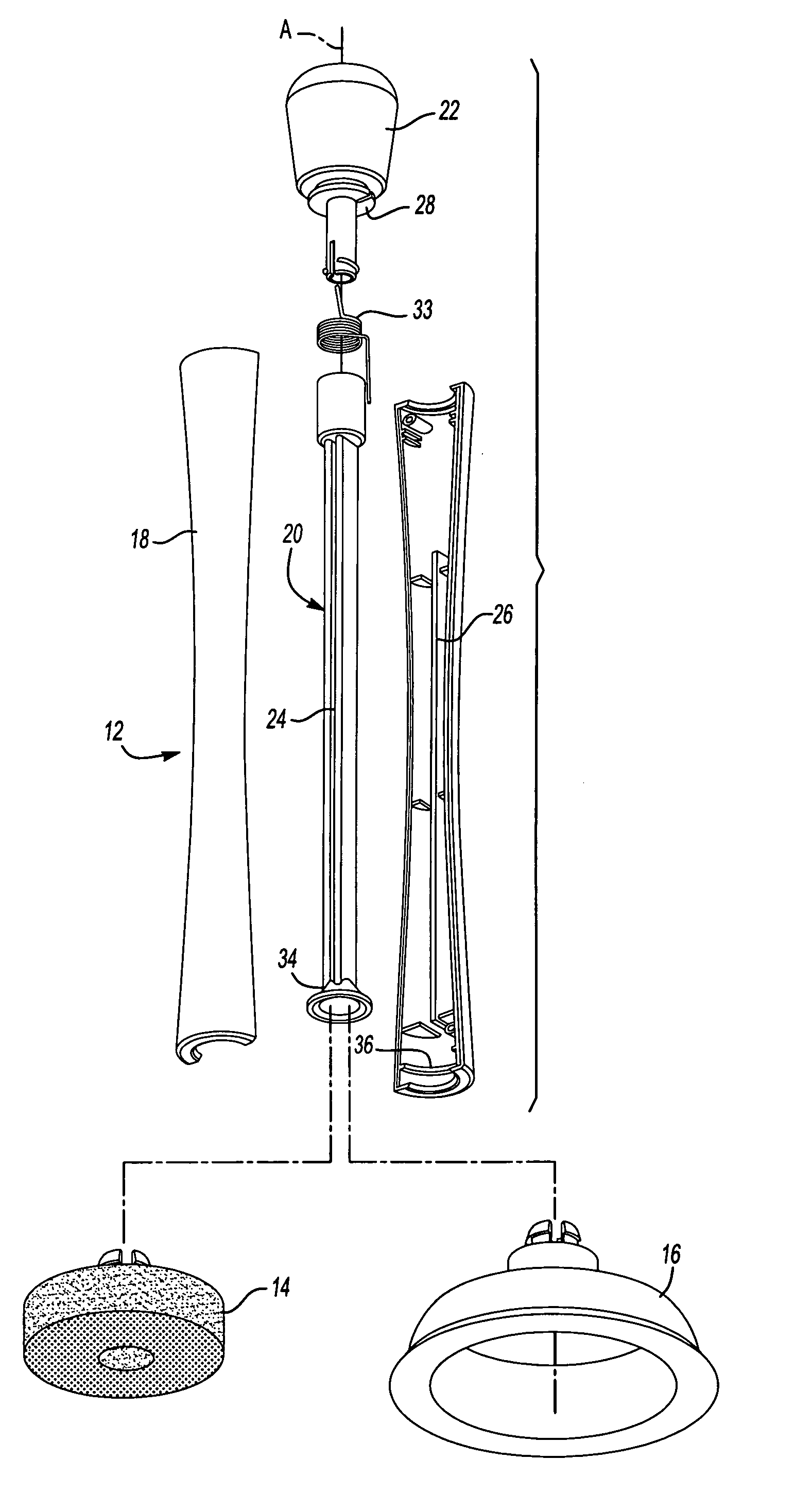

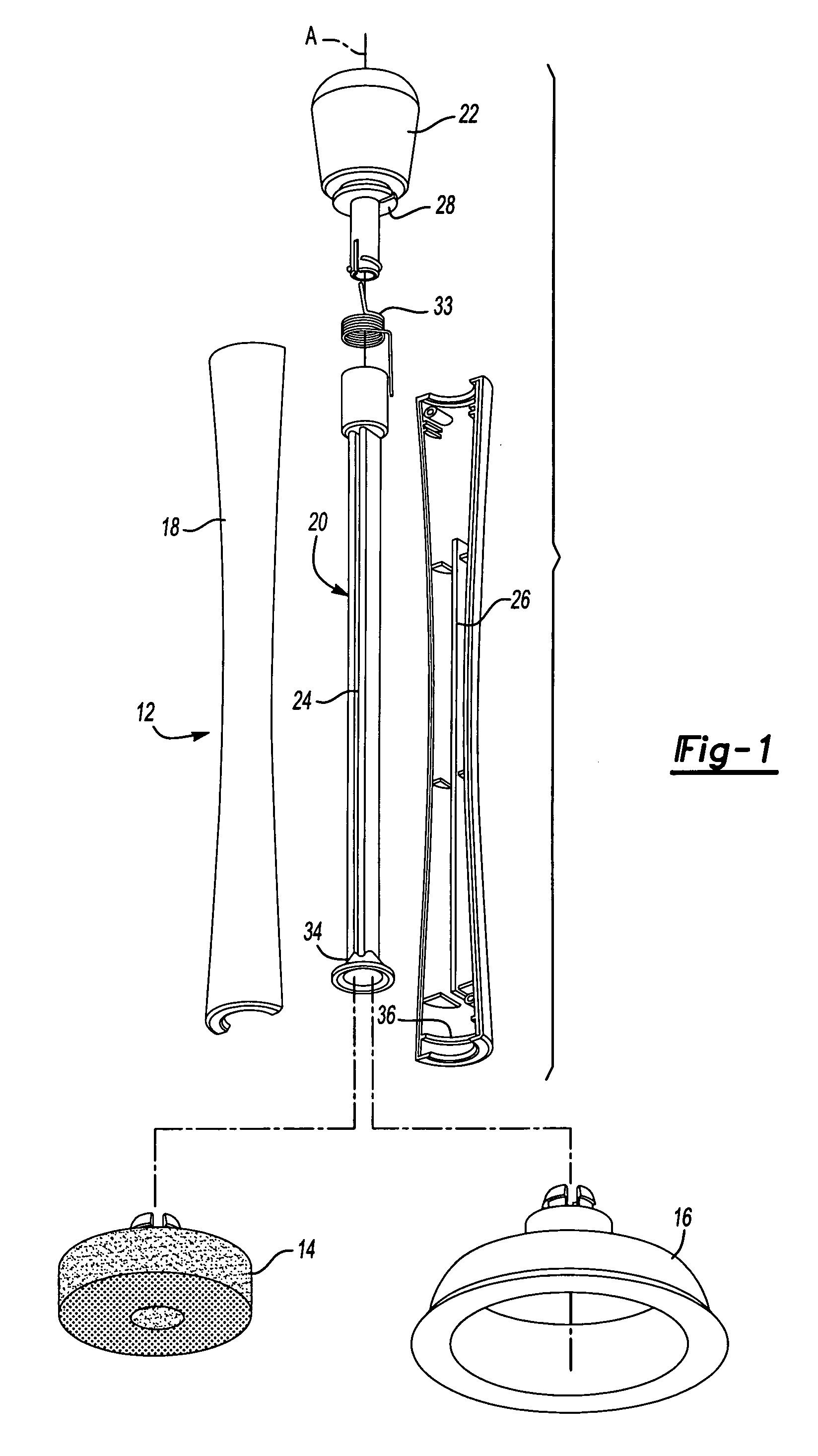

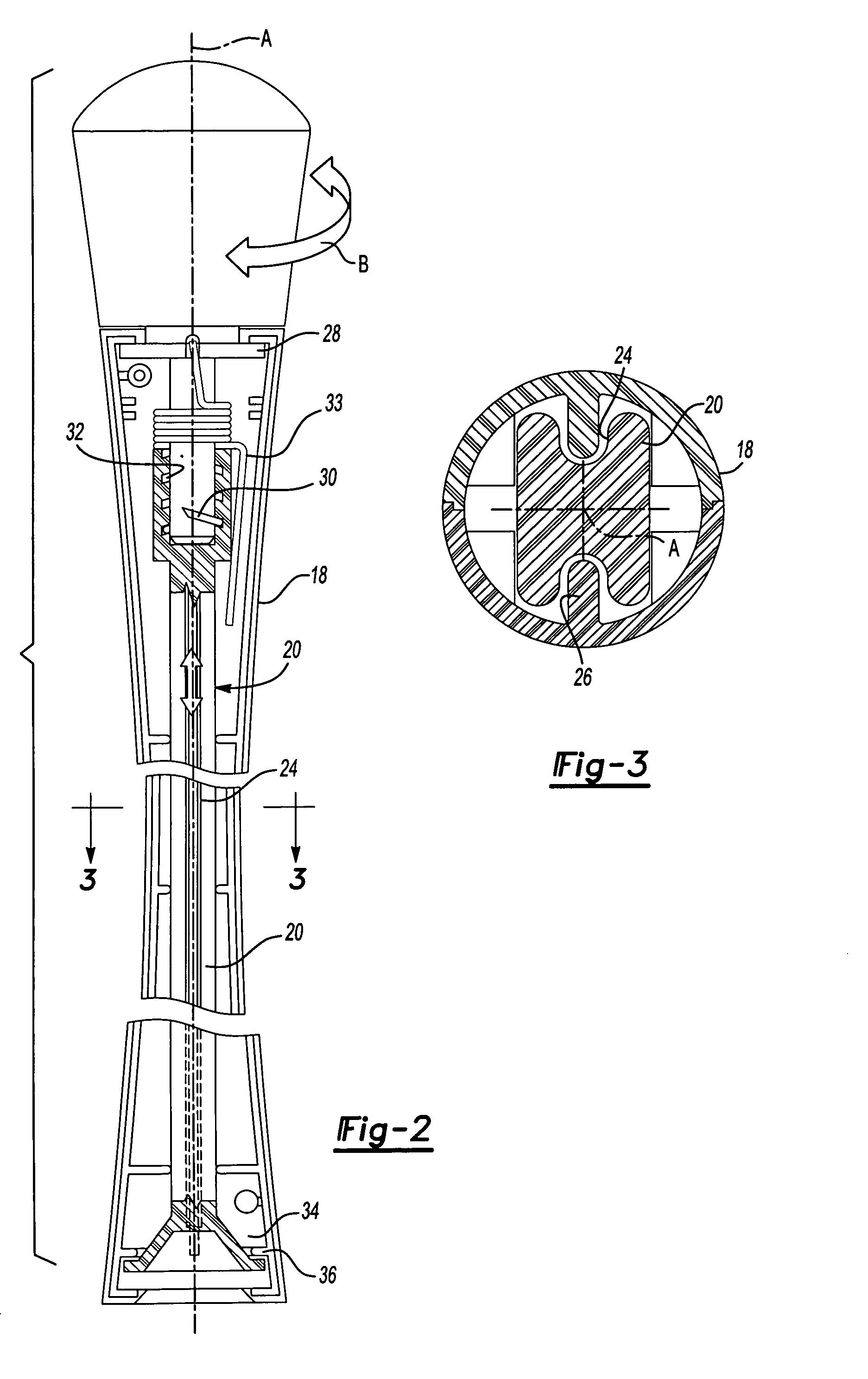

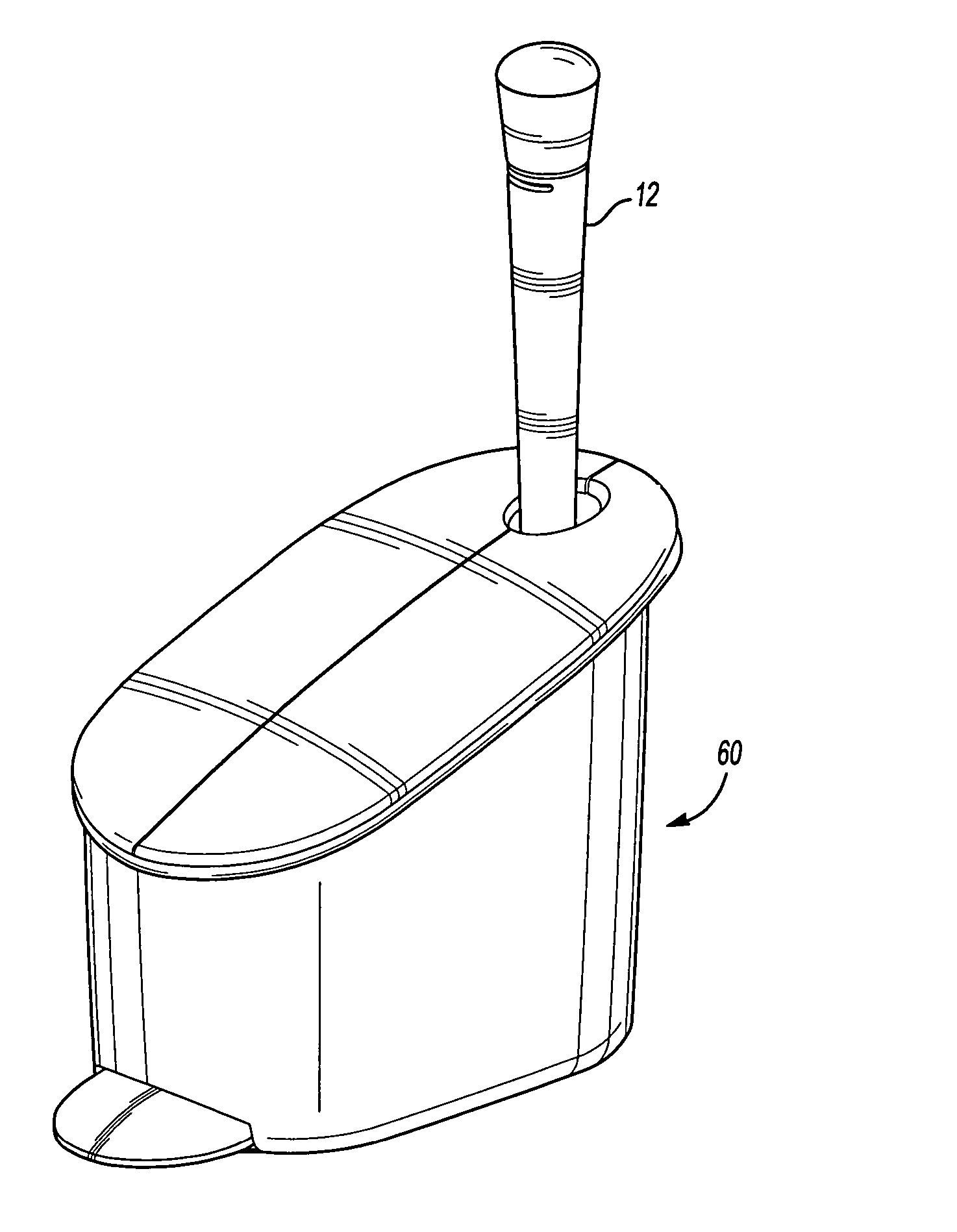

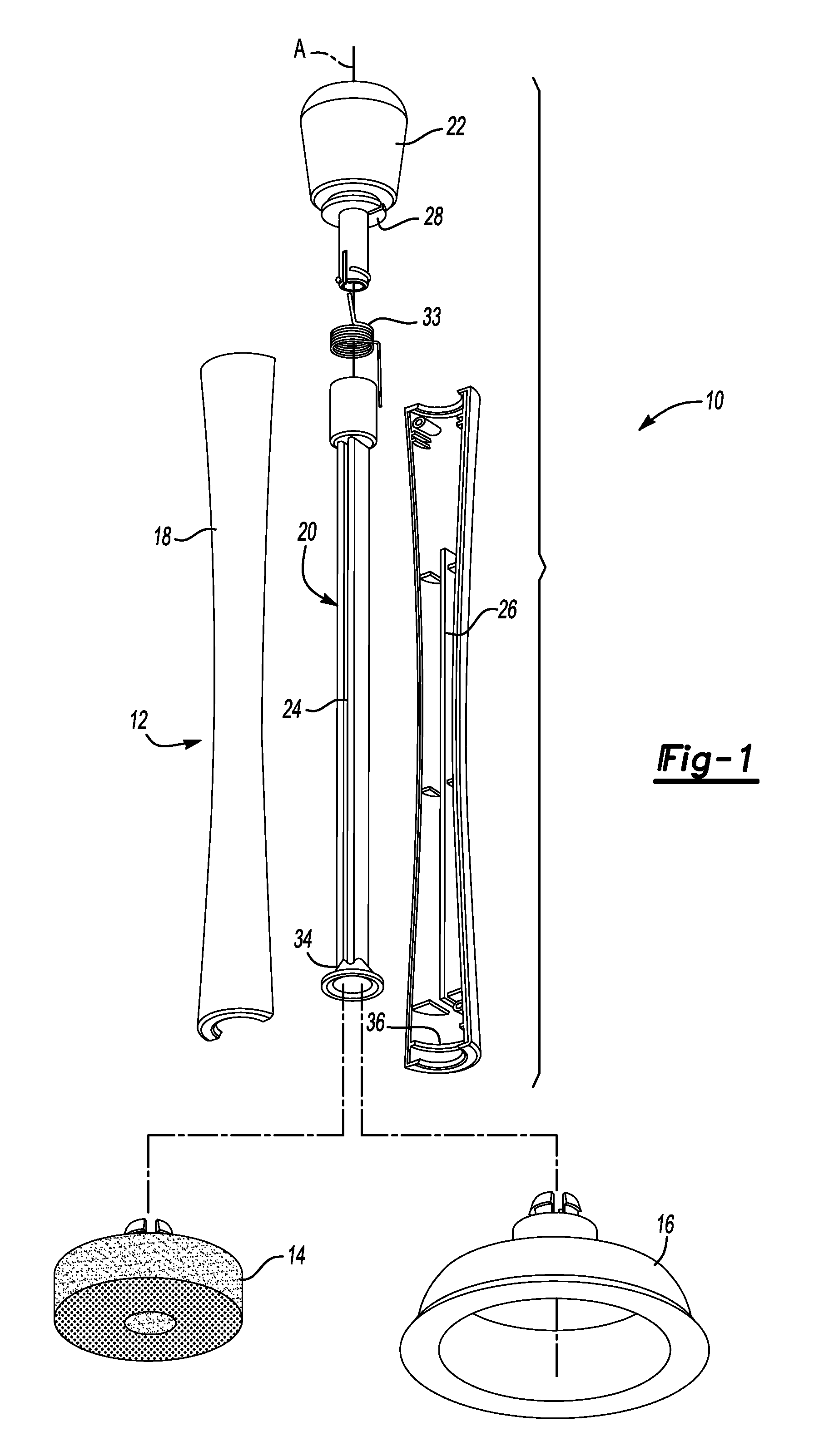

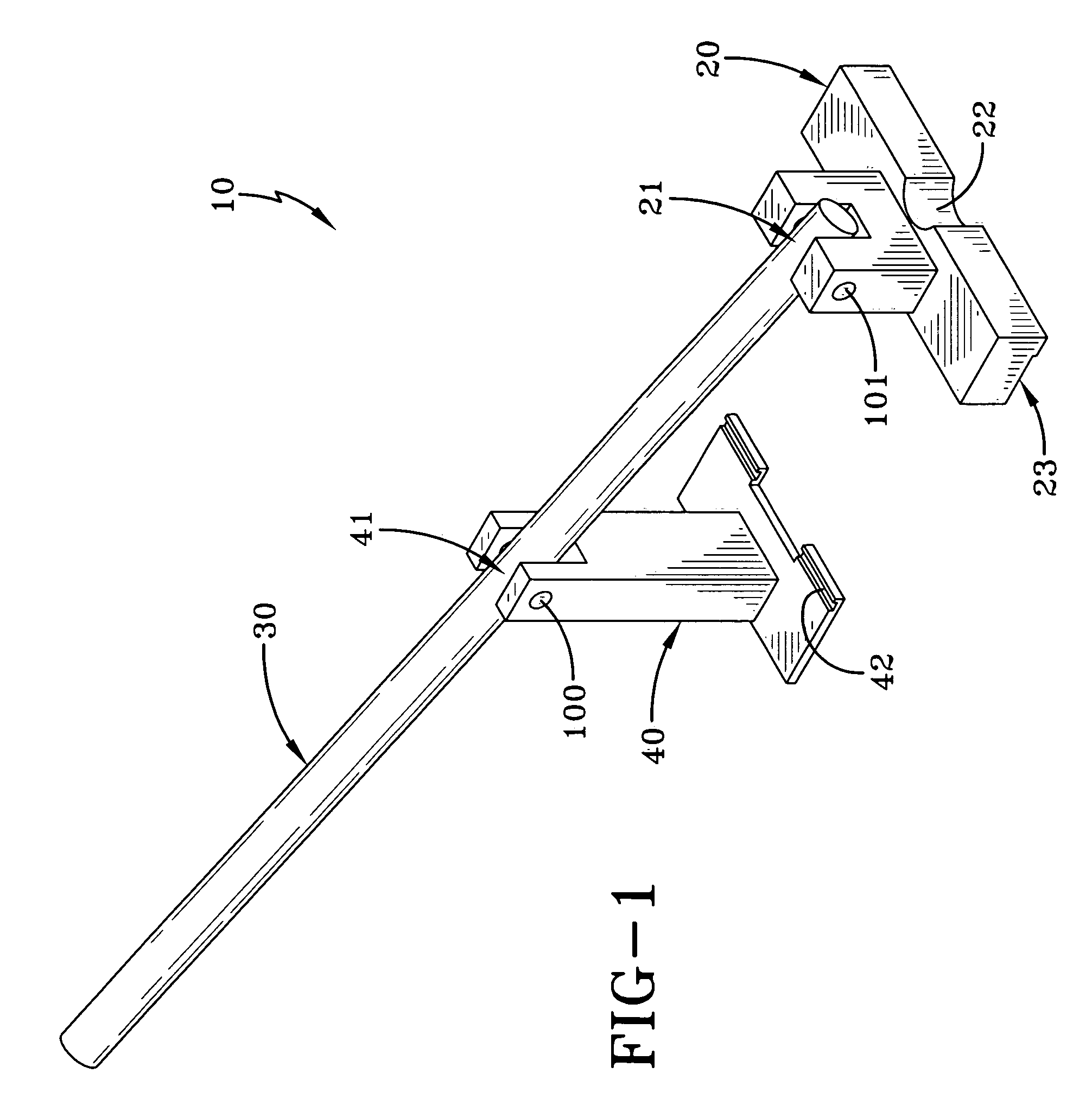

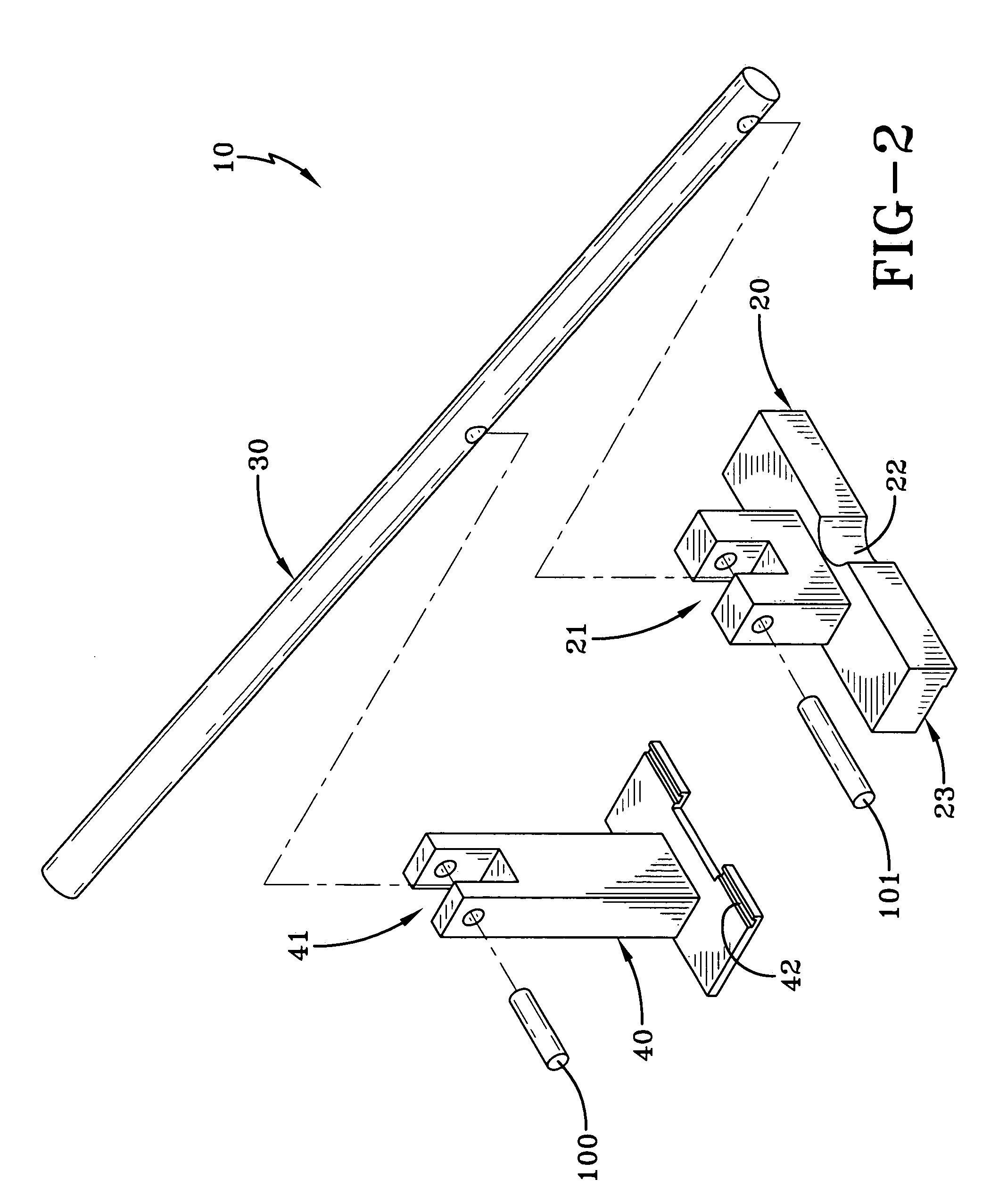

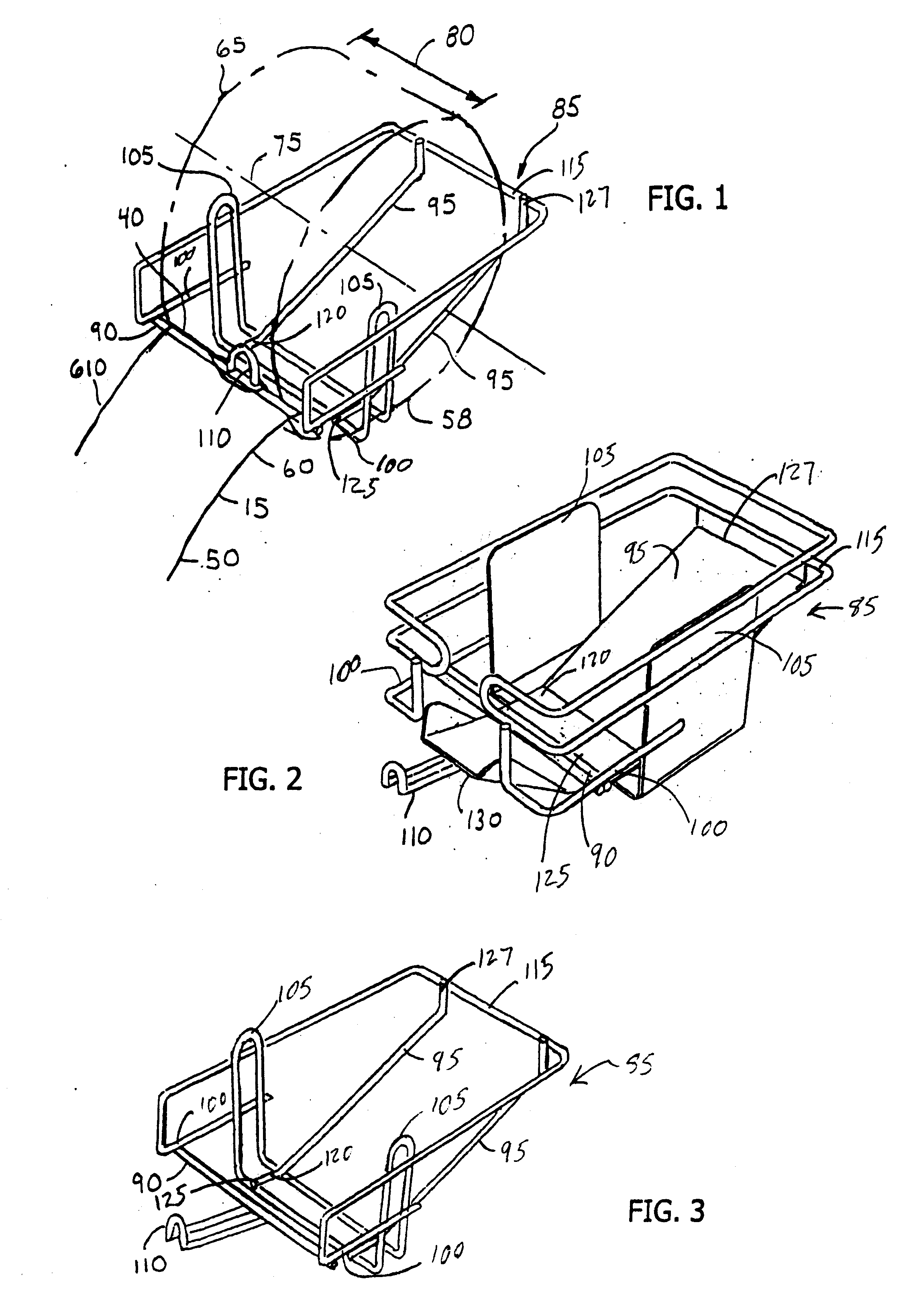

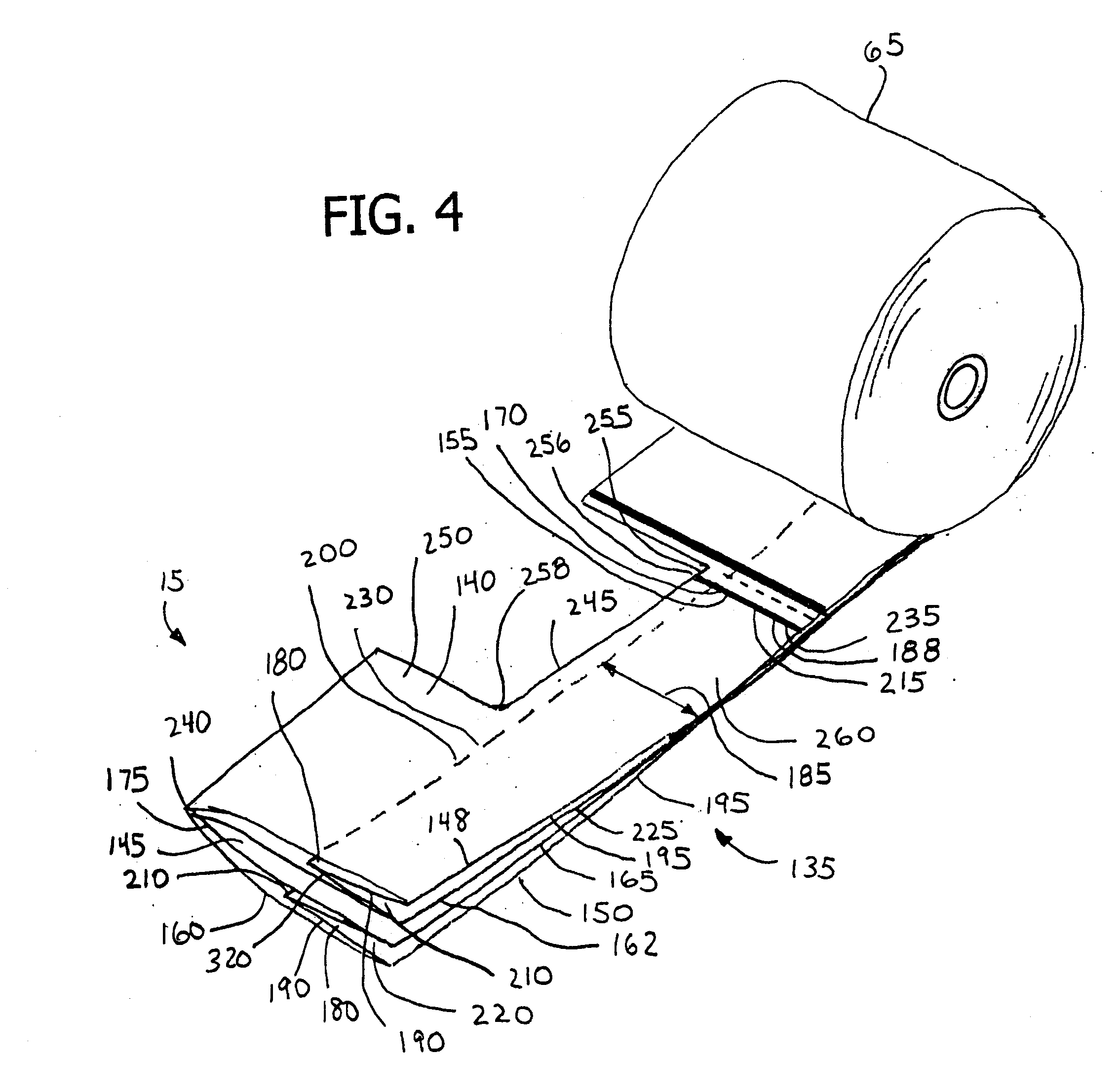

Roll mounted bags and dispensers for same

A series of roll mounted bags and dispensers are described. The bags may be folded along at least one axis and rolled. The compact roll of bags is placed in various dispensers. As the upper portion of the first bag is pulled from the roll, the roll will rotate, presenting the succeeding bag for dispensing after the first bag is removed. Variations of the dispenser include one with a bag opening means with a mounting member and bag opening element causing the bags to open as they are pulled from the dispenser. The dispenser includes mechanisms for supporting the bag roll and constraining its movement along its horizontal axis. Another variation of the dispenser has a perforation parting means that facilitates separation of one bag from a subsequent bag. The dispenser may be removably attached to a dispenser support that attaches to a surface.

Owner:DANIELS MARK E

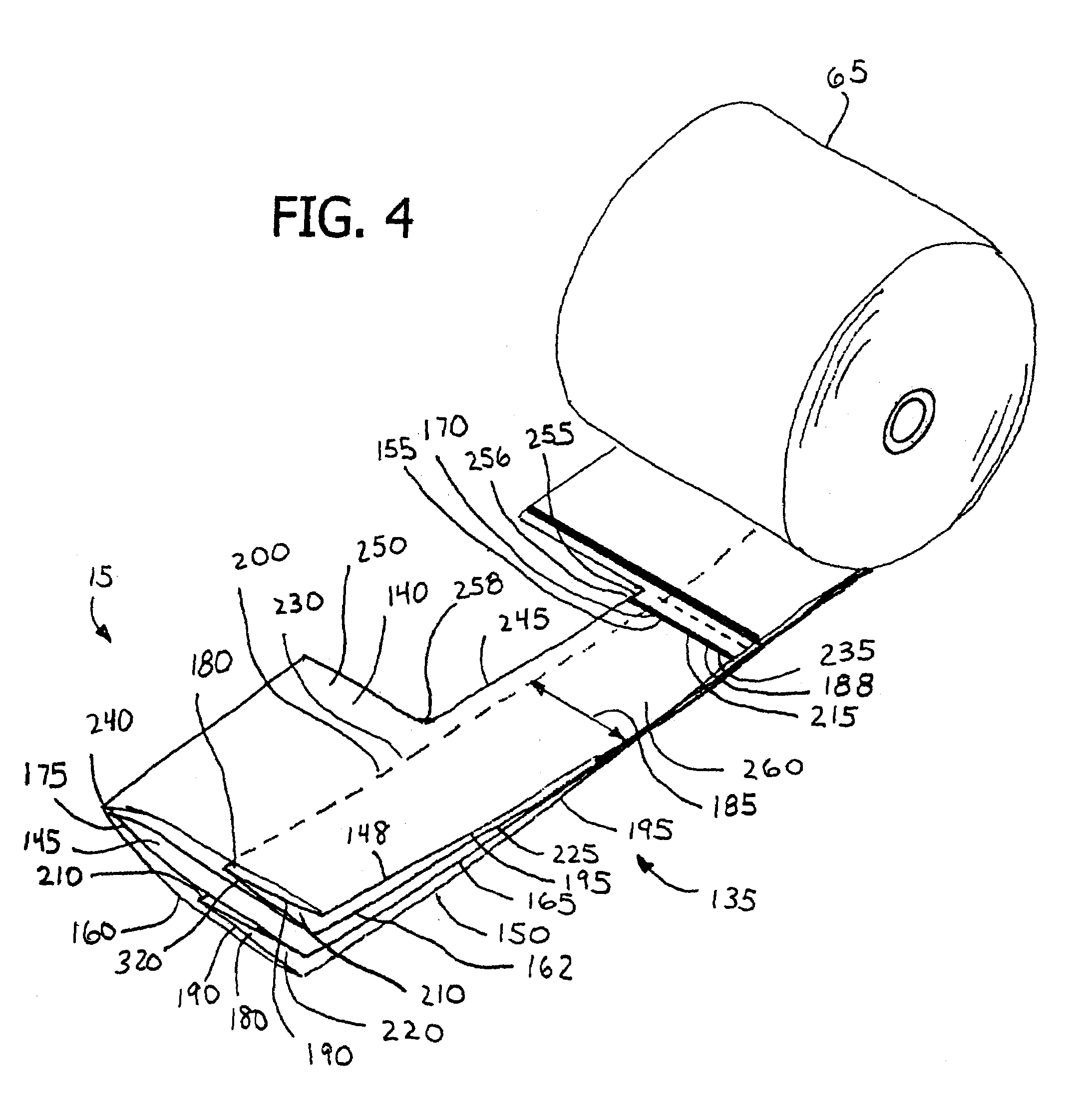

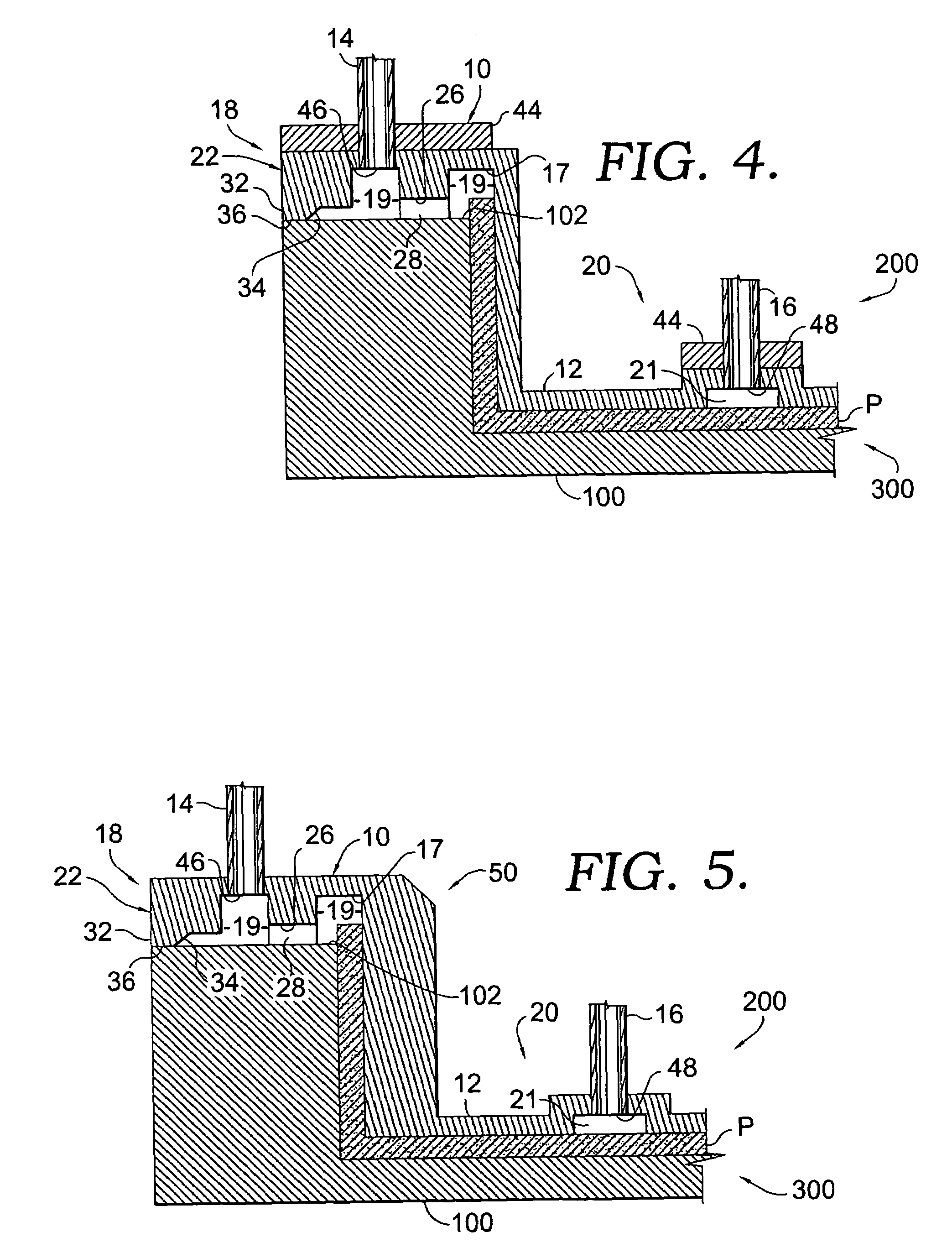

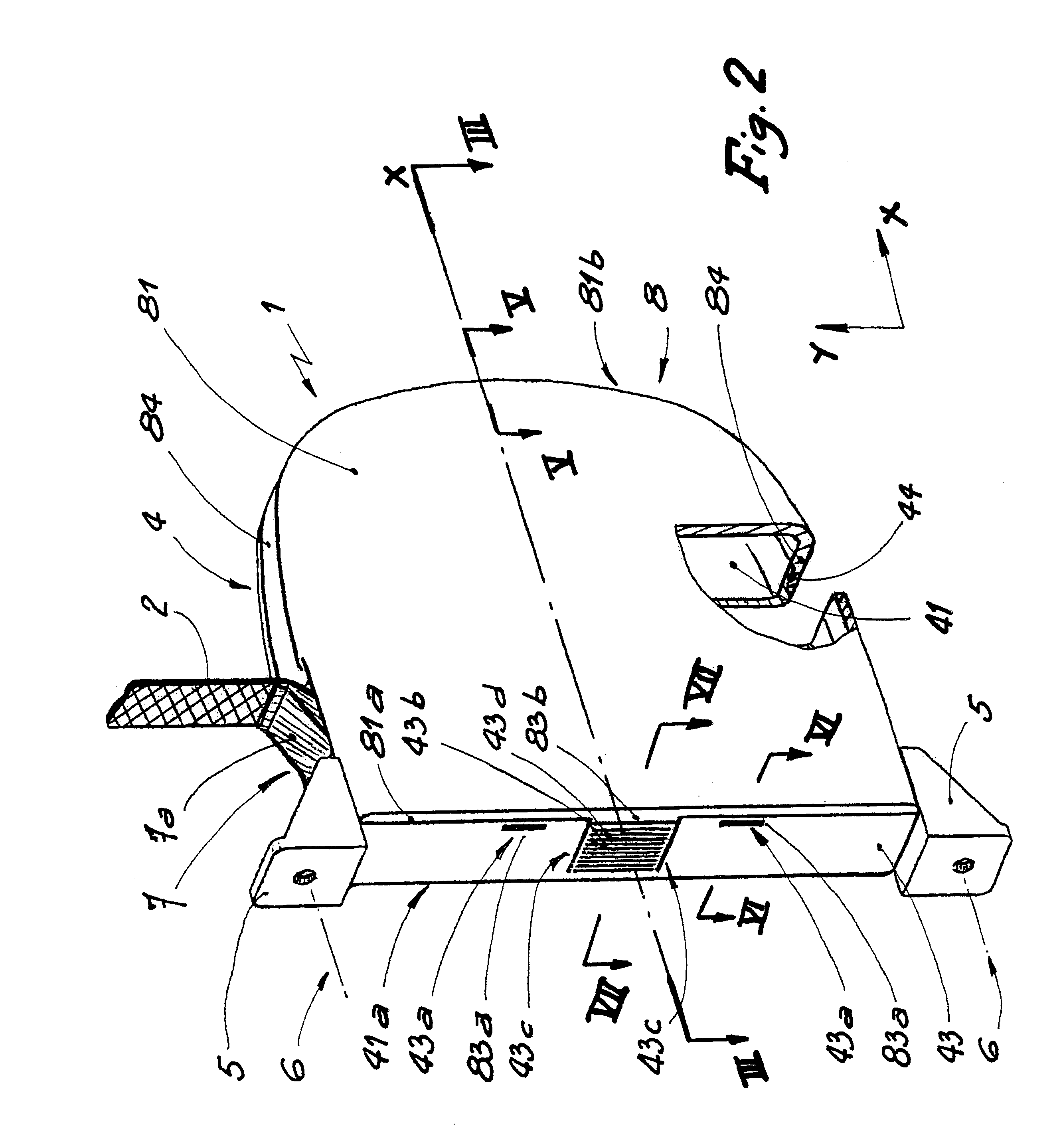

Closed molding tool

ActiveUS7160498B2Promote sportsSufficient flexibilityConfectioneryWood working apparatusFiber-reinforced composite

A flexible molding component used with a base mold improves on existing methods of forming fiber reinforced composite parts. The molding component is formed of a flexible body structure having an interfacing surface and a perimeter region including a perimeter seal configured for sealing engagement with the base mold. Resin and vacuum distribution channels are formed in the interfacing surface to deliver resin to a fiber lay up disposed on the base mold and draw the resin across and through the lay up, respectively, to properly mix the resin / fiber combination which forms the desired part. Application of the vacuum causes the perimeter seal of the flexible body structure to sealingly engage with the base mold to enclose materials between the body structure and the mold, as well as causing the interfacing surface to draw against the resin / fiber combination and the mold to shape the combination into the desired part.

Owner:TRACKER MARINE LP

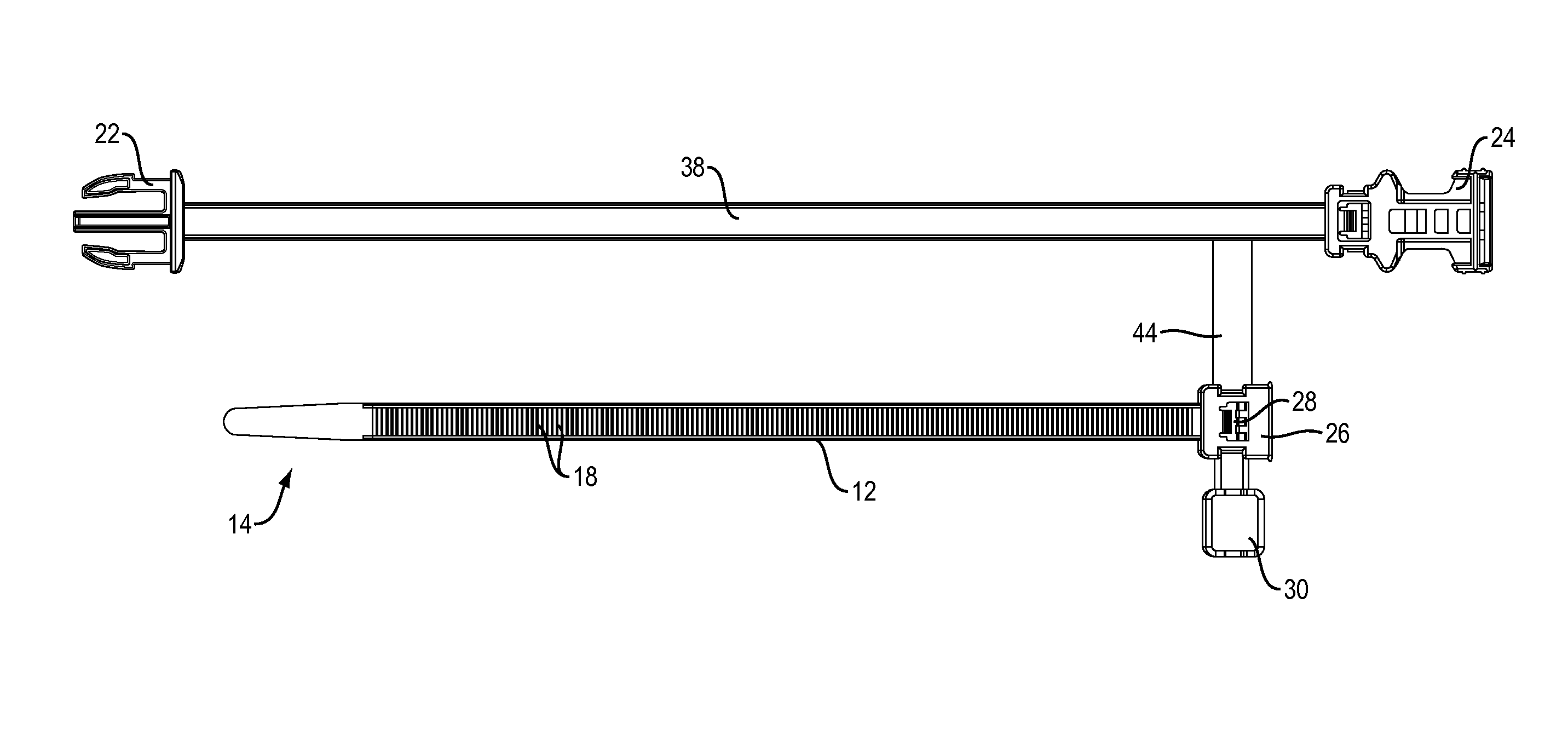

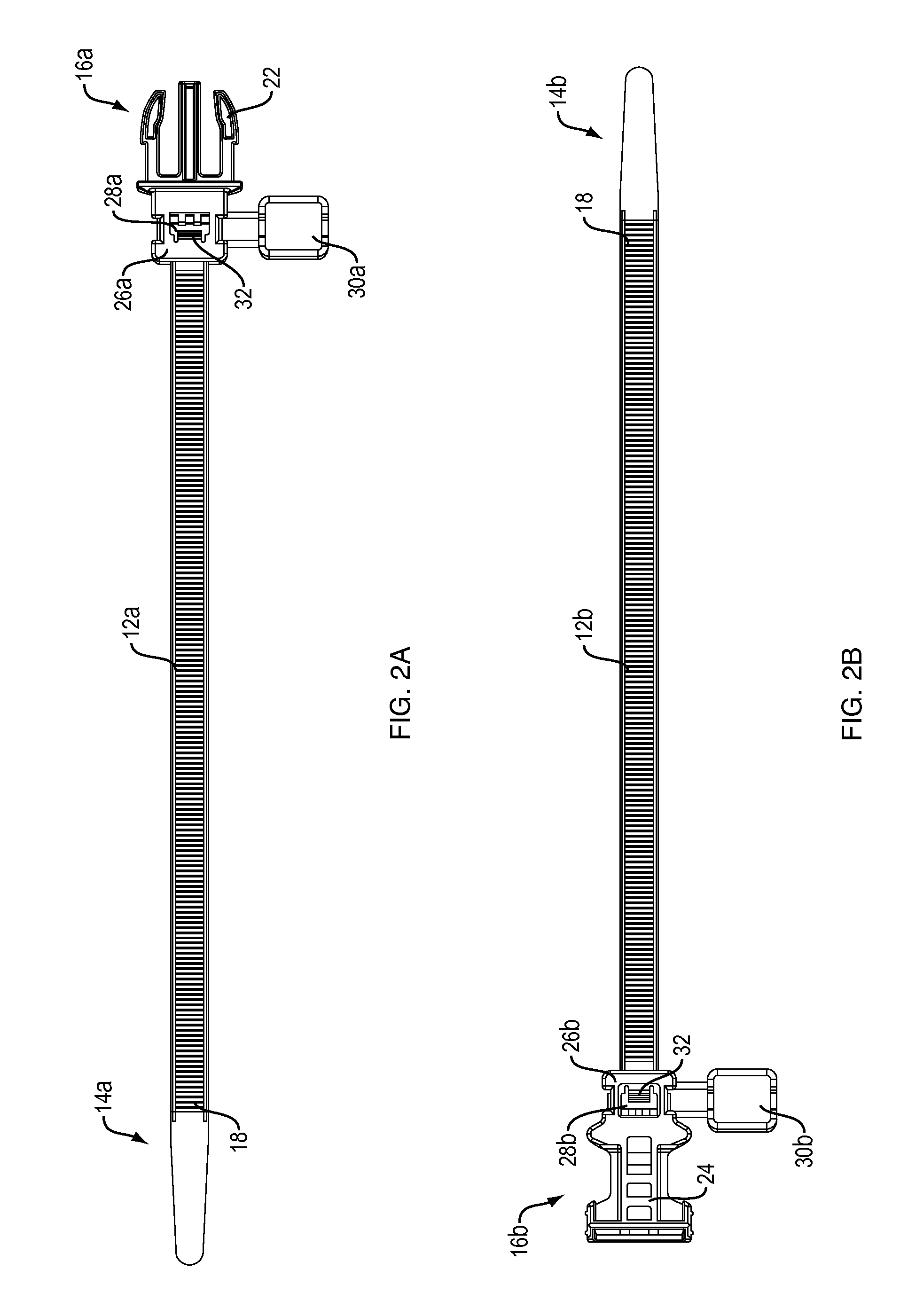

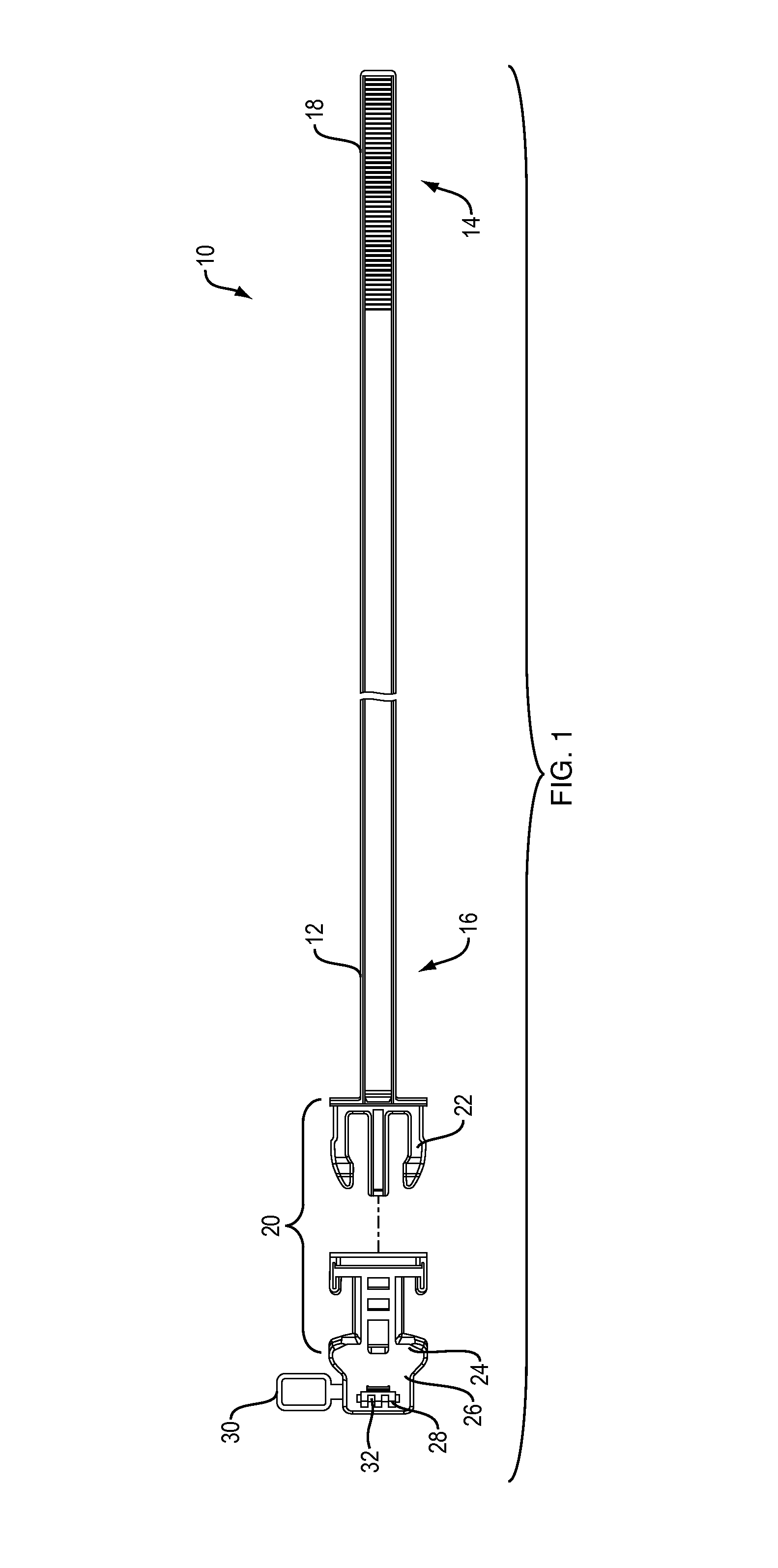

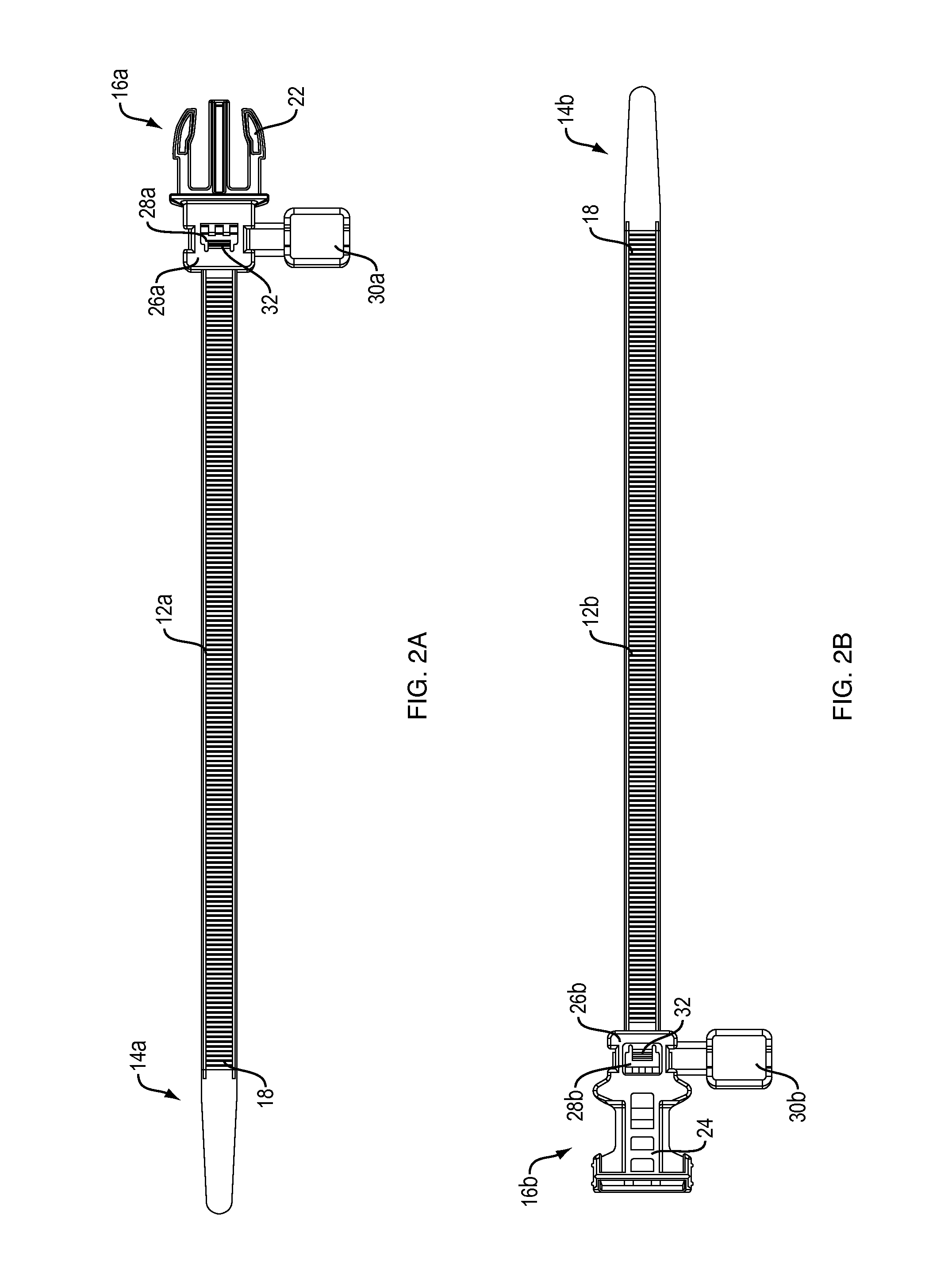

Releasable handle mechanism for a disposable toilet implement

InactiveUS20070089224A1Easy to receiveSufficient engagementWater closetsDomestic plumbingEngineeringHands free

A toilet tool generally includes a handle assembly and one or more disposable toilet tool implements such as a cleaning pad and a plunger cup. The handle assembly receives either the cleaning pad or the plunger cup with sufficient engagement to prevent inadvertent release during use yet is easily released in a hands-free manner for disposal.

Owner:BRASSCRAFT MFG CO

Releasable handle mechanism for a disposable toilet implement

InactiveUS7900287B2Easy to receiveSufficient engagementWater closetsDomestic plumbingEngineeringHands free

Owner:BRASSCRAFT MFG CO

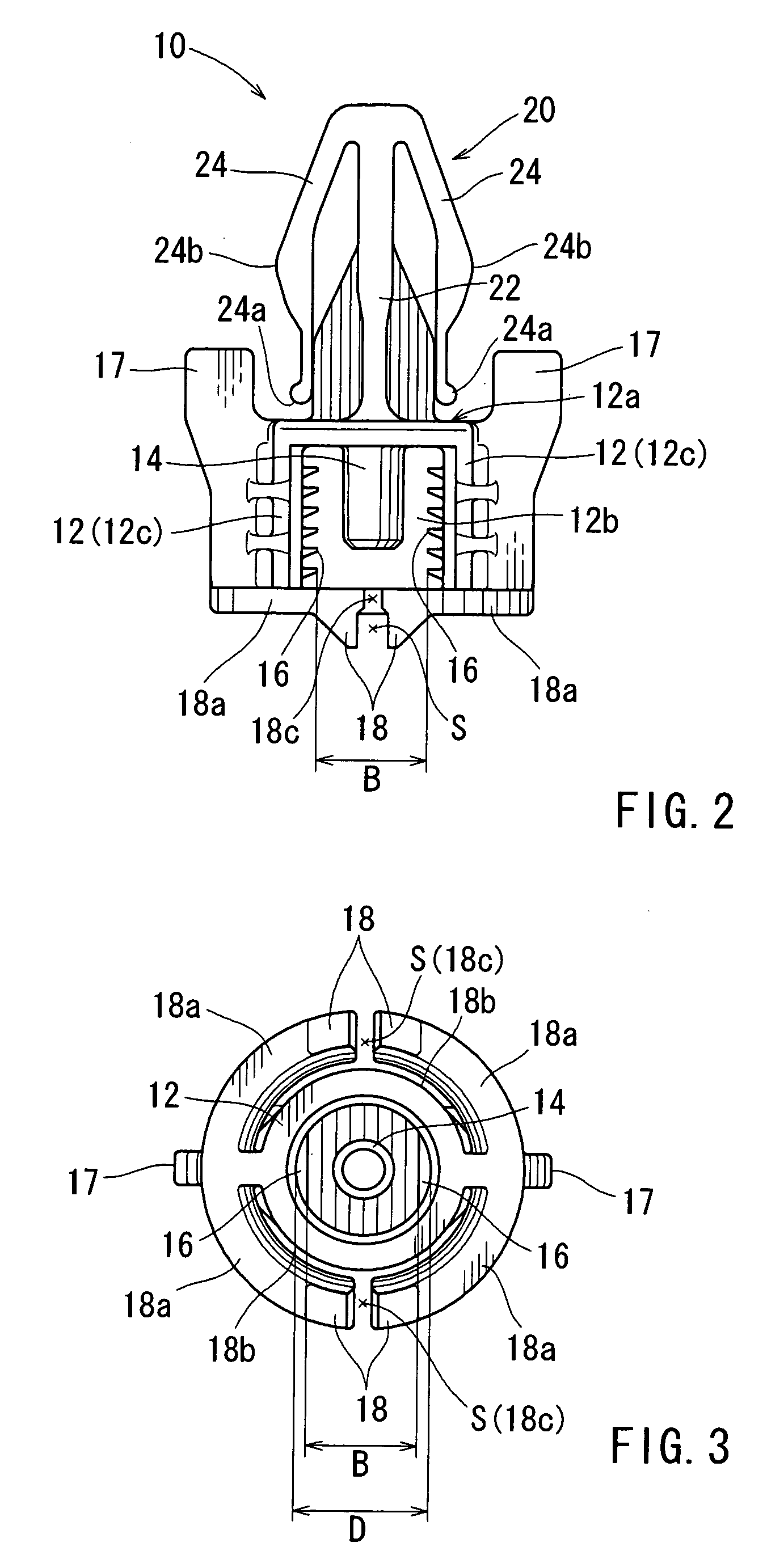

Dummy plug

InactiveUS8662921B2Large warping marginImprove rigiditySecuring/insulating coupling contact membersCouplings bases/casesEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

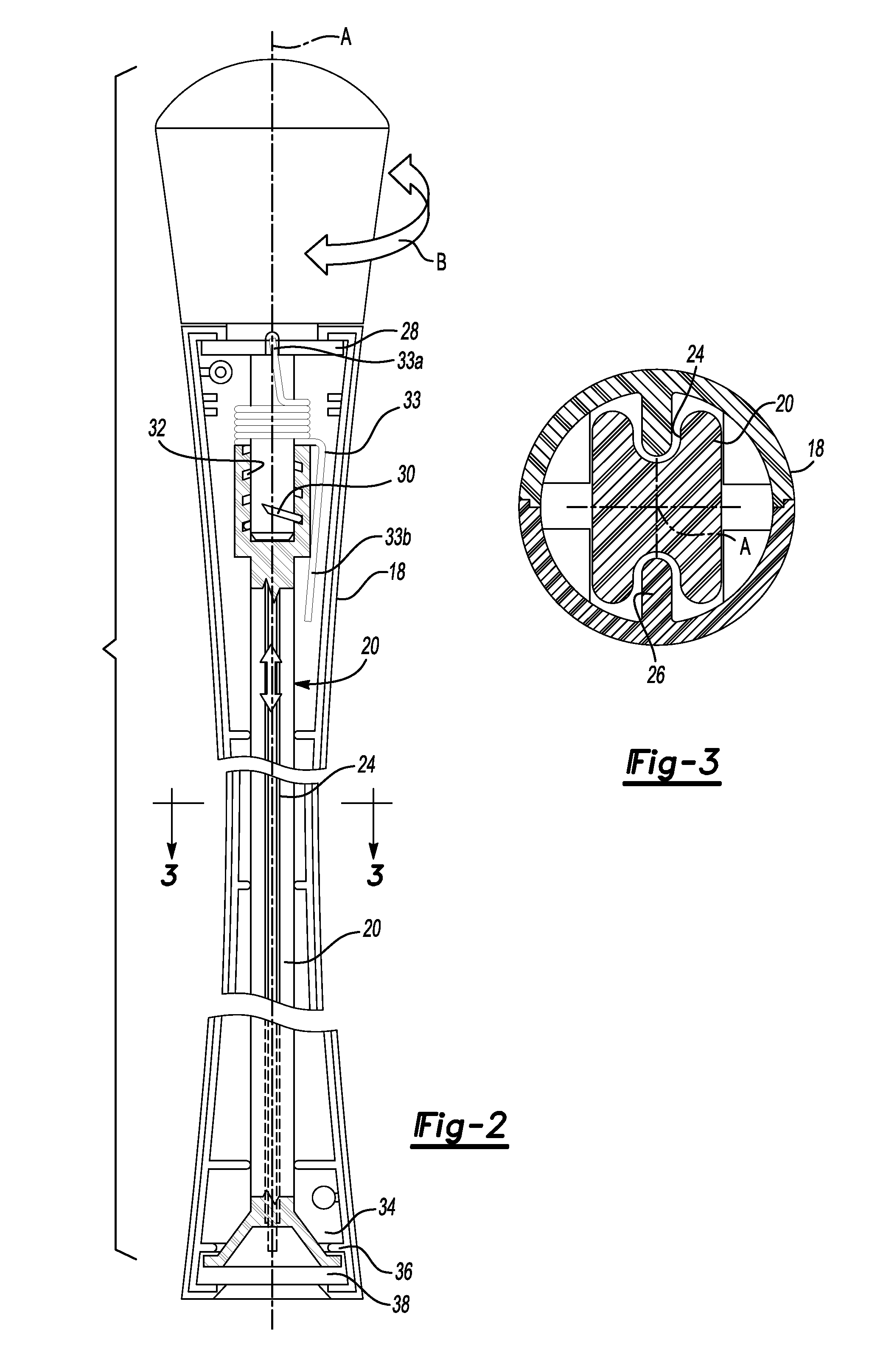

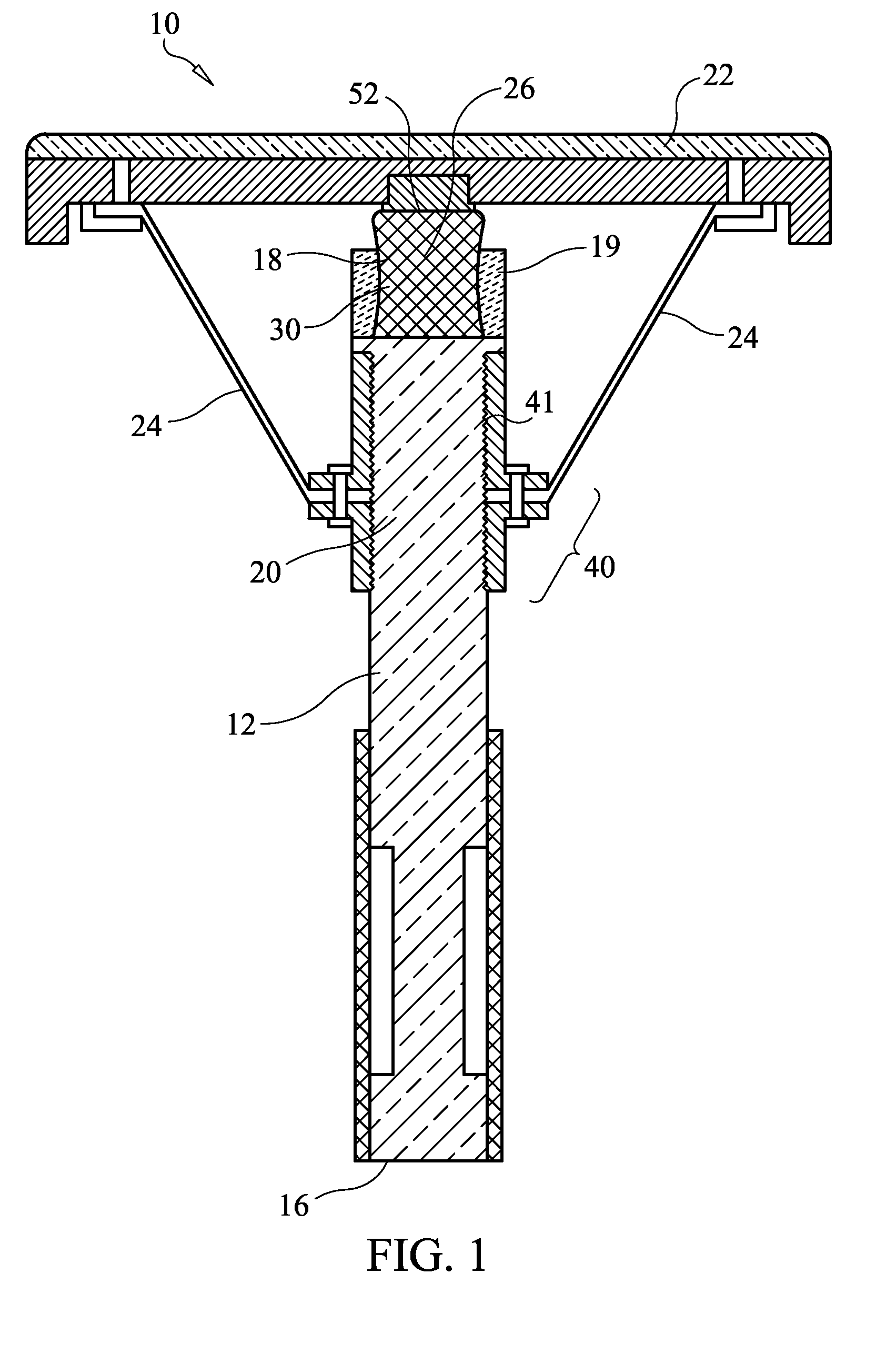

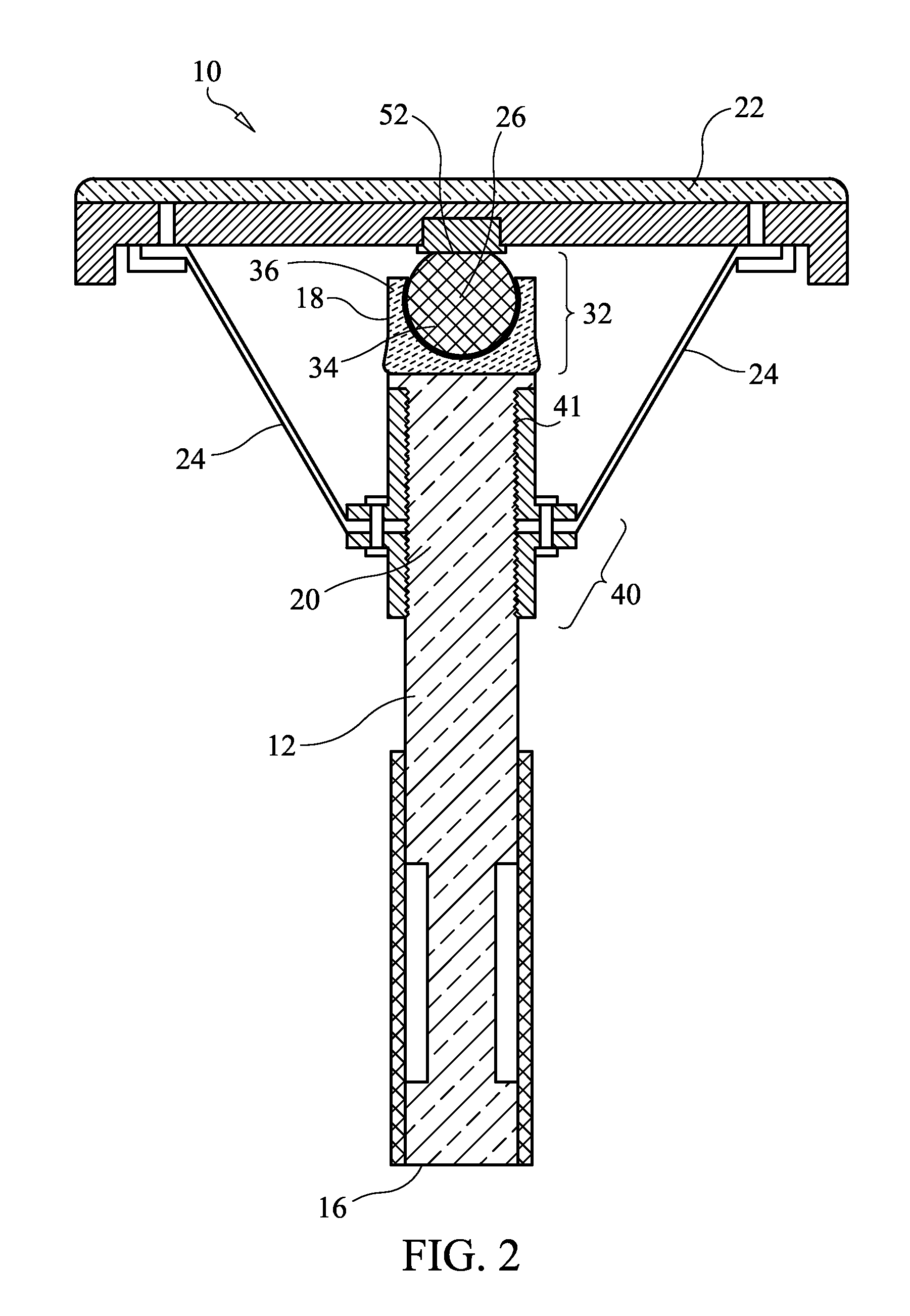

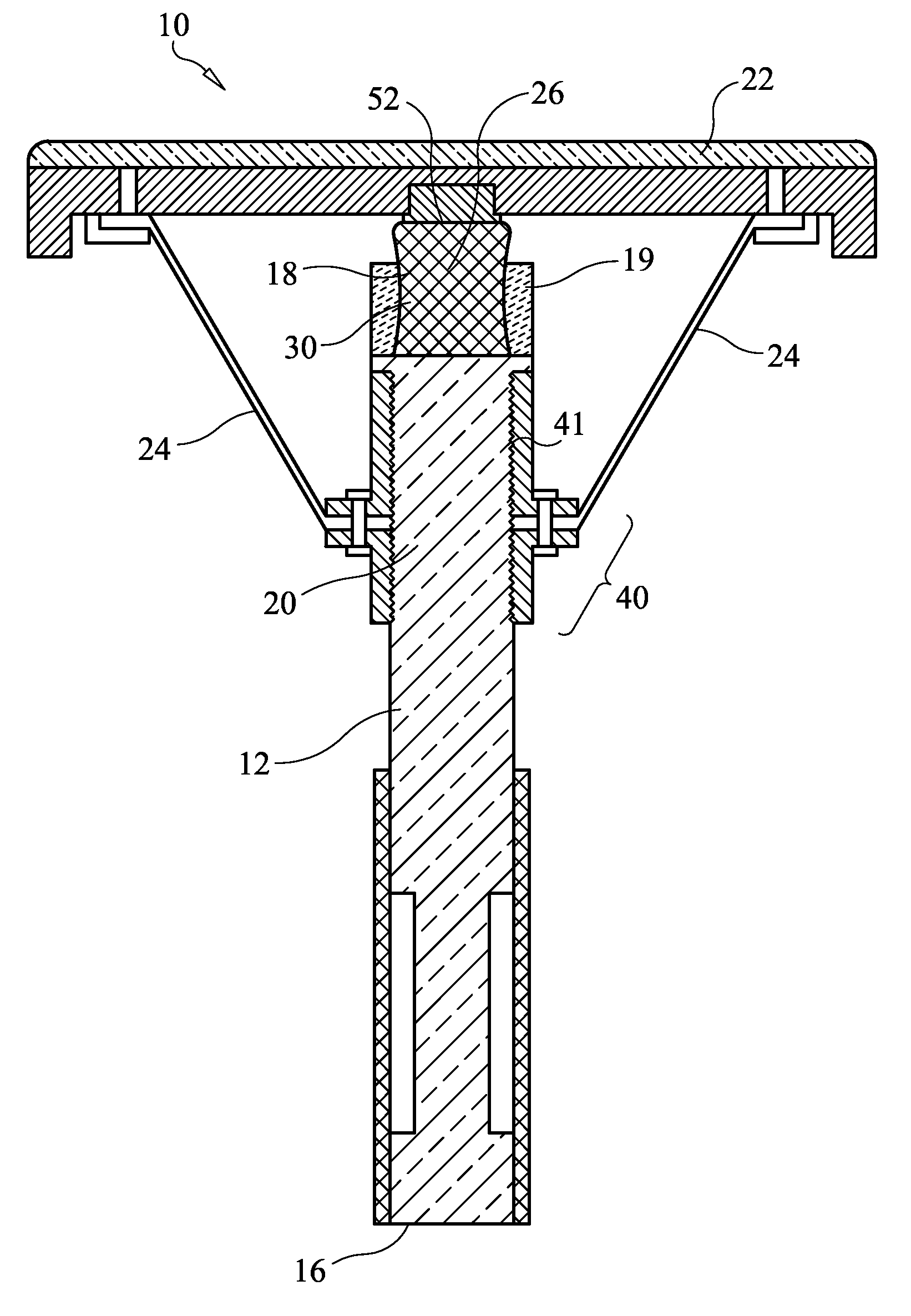

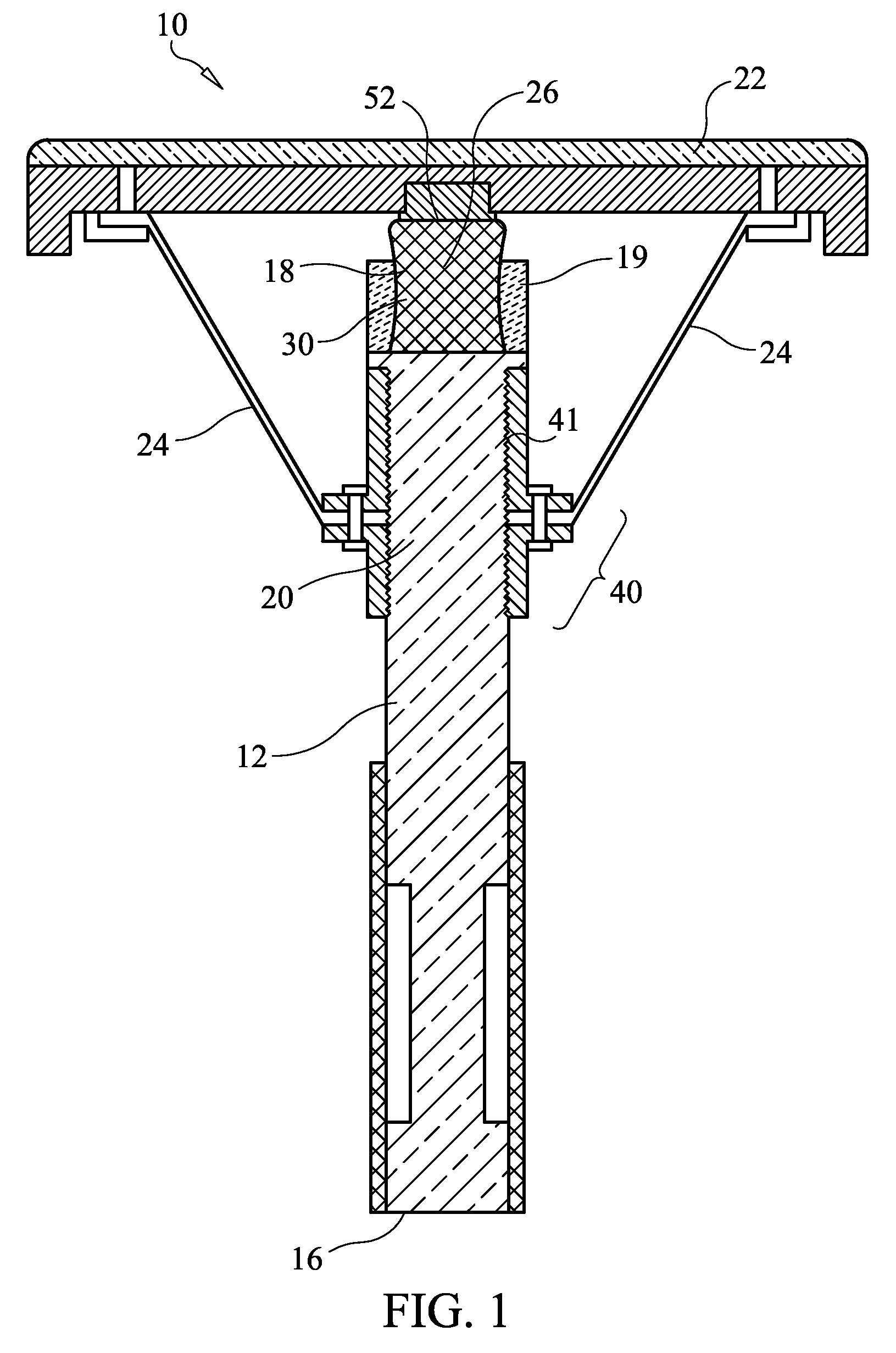

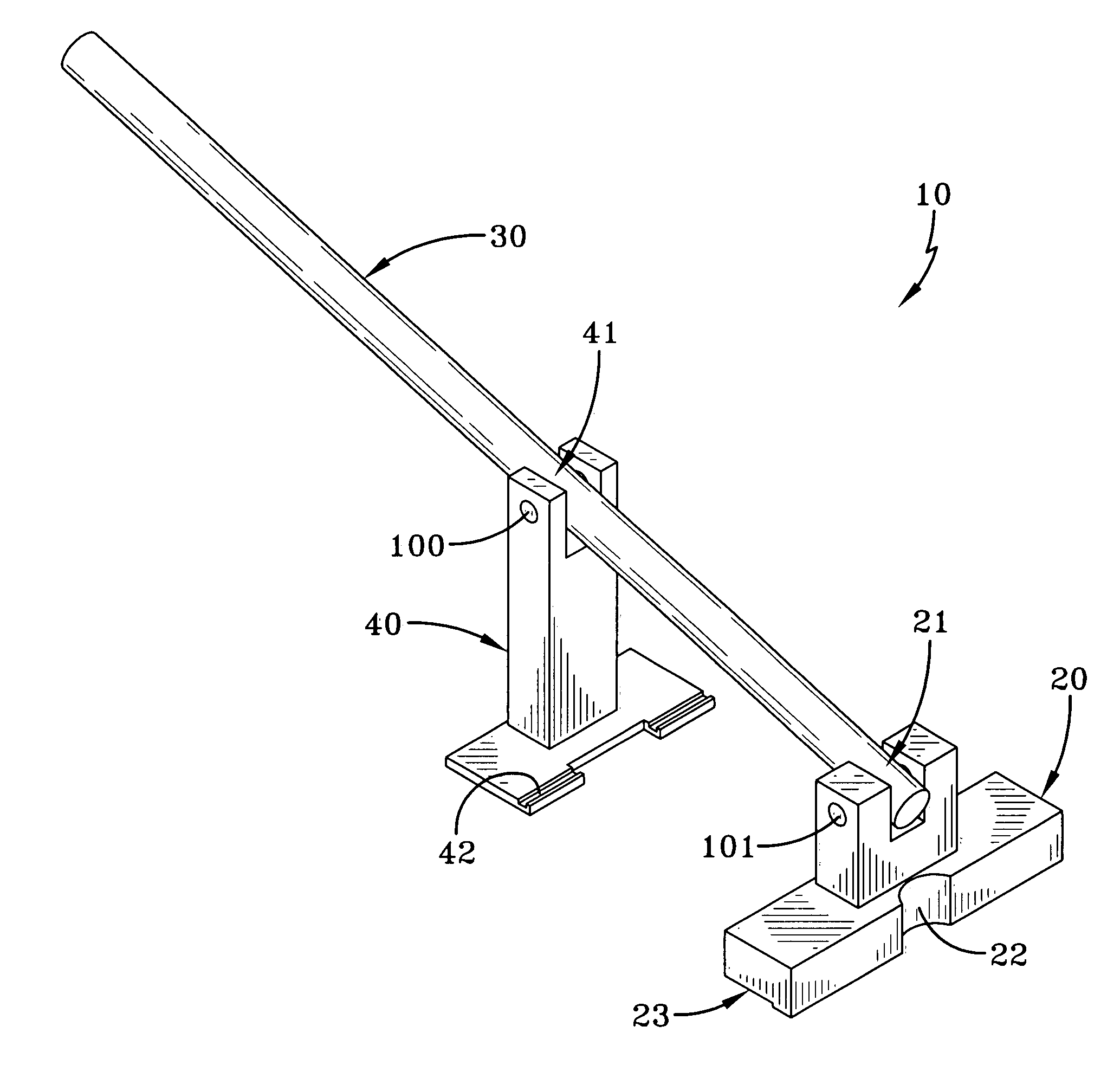

Balance Chair

InactiveUS20120292968A1Sufficient engagementPrevent the user from leaning excessively or falling sidewaysOperating chairsDental chairsEngineering

A balance chair includes a central vertical post with a base attached at a lower end of the central post; a flexible joint attached at an upper end of the central post, a seat attached atop the flexible joint; and a plurality of resistance members attached to the central post and the seat, wherein the plurality of resistance members are arranged around the post in a spaced-apart manner, wherein the flexible joint supports the seat and enables the seat to pivot about an effective pivot point as defined by the shape and composition of the flexible joint, and wherein the resistance members resist but do not prevent pivoting of the seat about the effective pivot point. The flexible joint and the resistance members support pivoting of the seat both side-to-side and fore-and aft and any combination thereof. The resistance members limit a degree of pivoting of the seat.

Owner:LEE REBECCA M

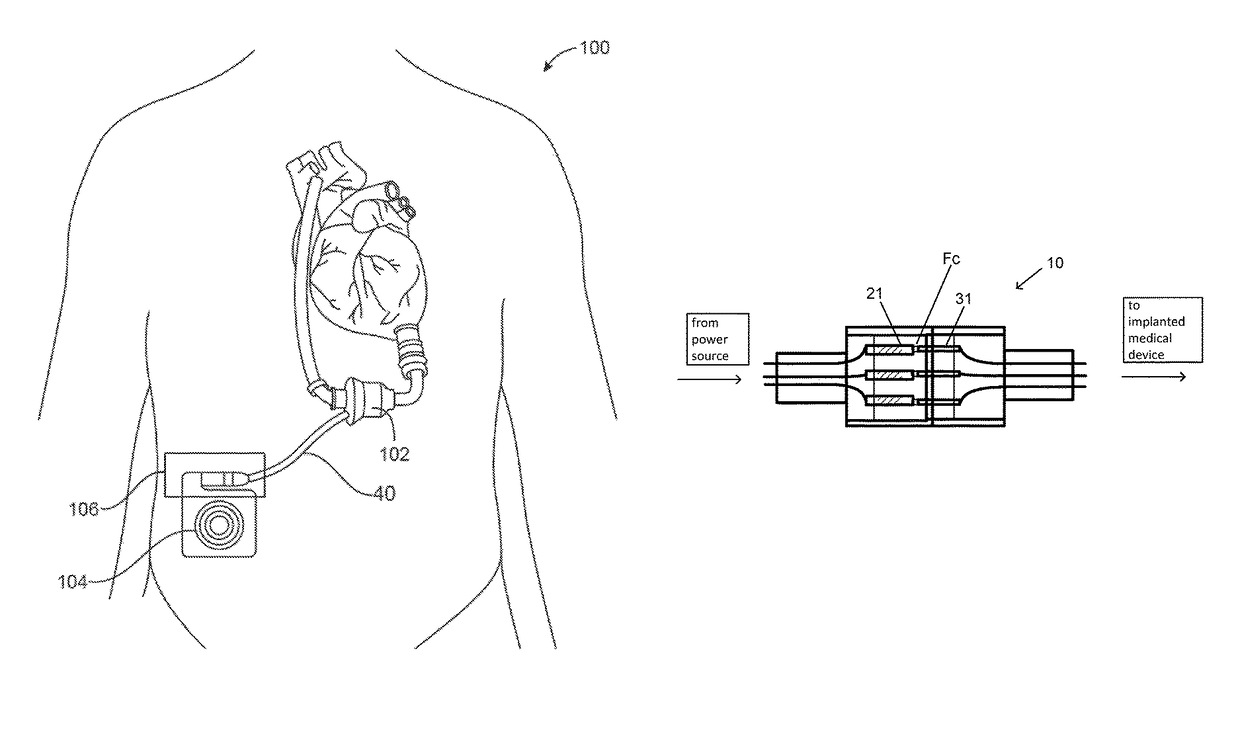

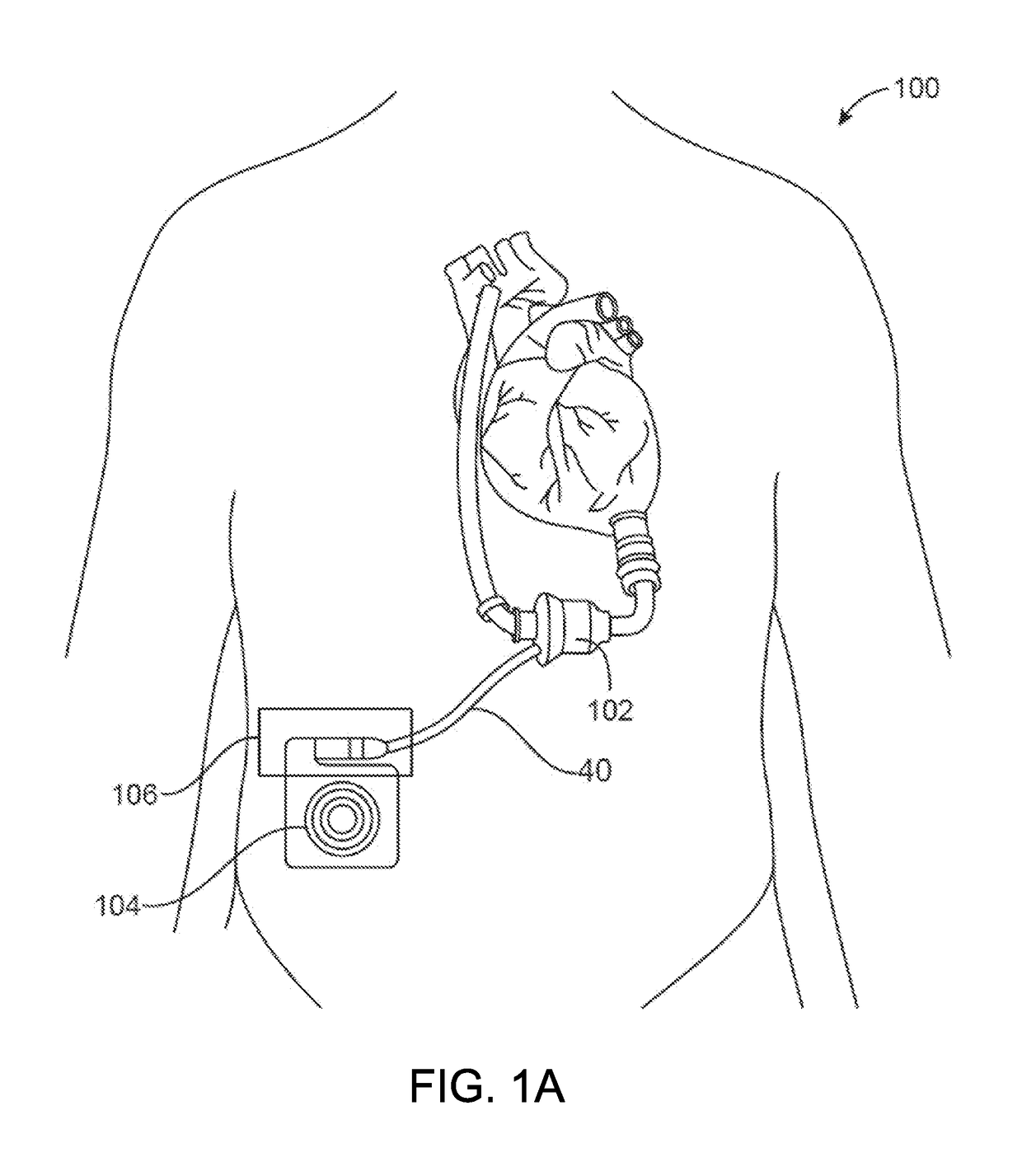

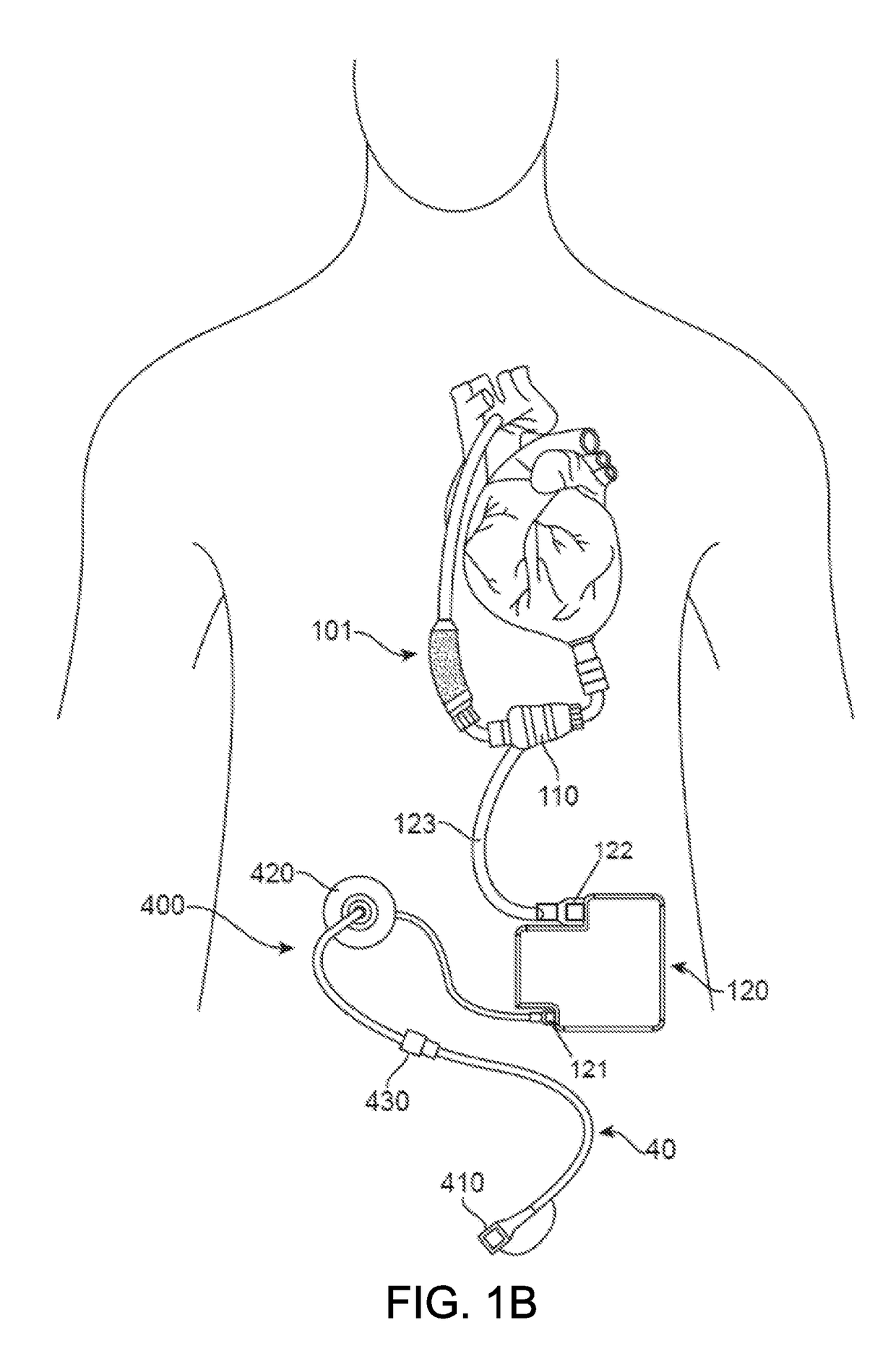

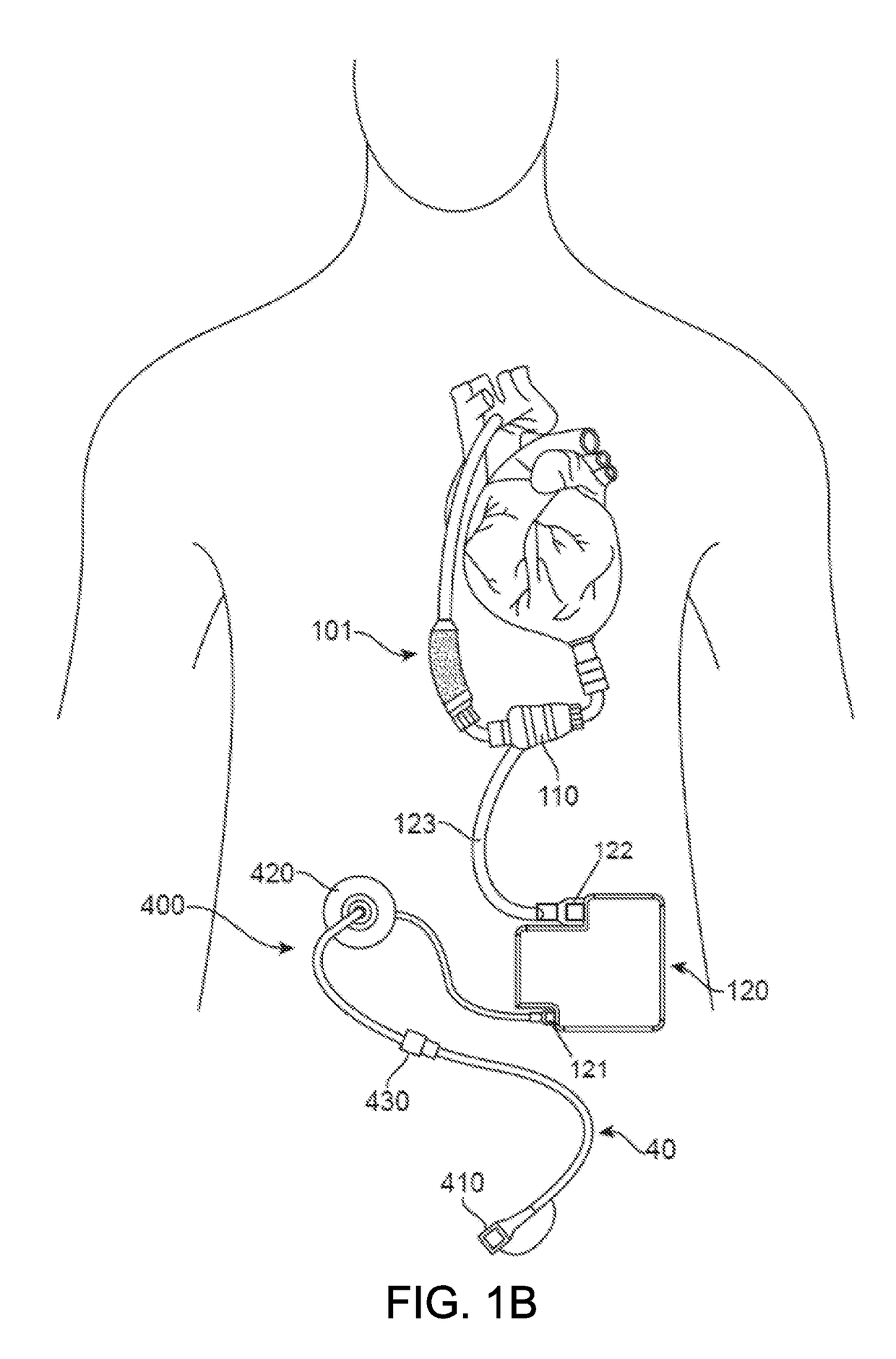

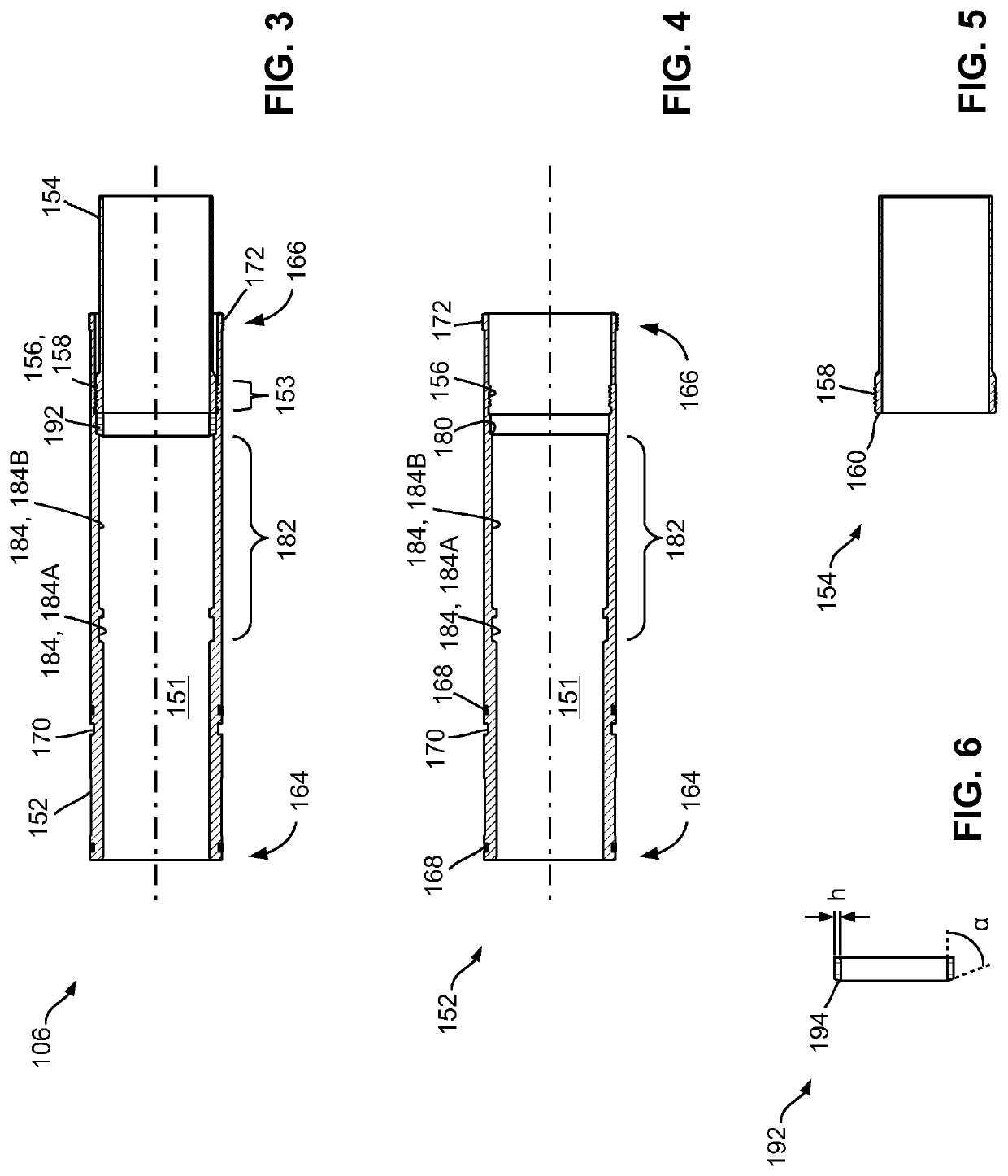

Compliant implantable connector and methods of use and manufacture

ActiveUS9985374B2Reduce strainReduce stressCoupling device engaging/disengagingMedical devicesIridiumElectrical resistance and conductance

Owner:TC1 LLC

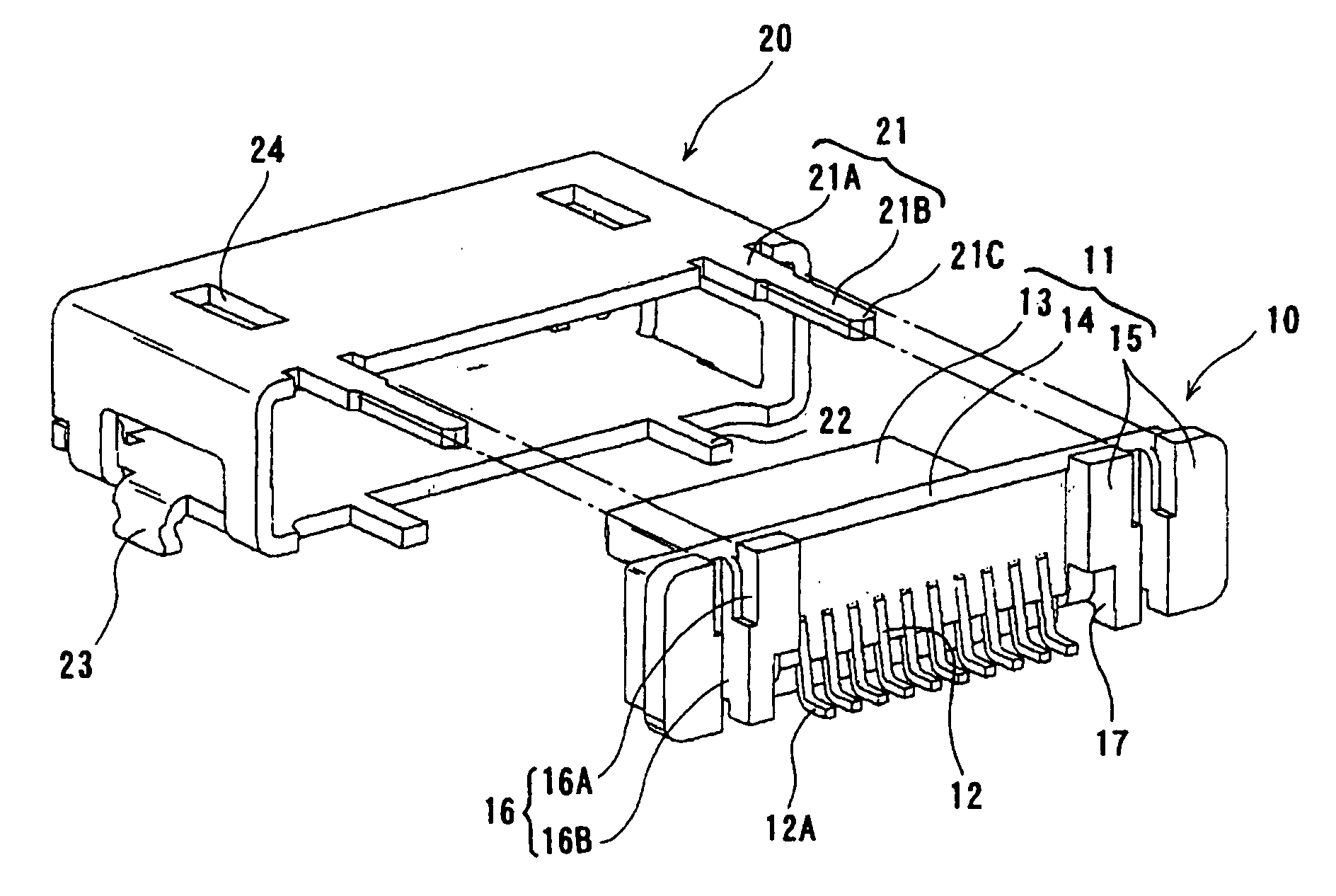

Electrical connector with shield case

InactiveUS7182641B2Small rangeWider widthCoupling protective earth/shielding arrangementsMating connectionEngineering

In an electrical connector with a shield case, the shield case made of a metal plate is attached to a housing having a front portion to be a fitting side relative to a mating connector. The shield case includes an engaging piece extending from a rear portion of the shield case. The engaging piece of the shield case fitted in is bent toward an outer surface of the housing to engage the housing. In the connector with the shield case, the engaging piece includes an attaching end portion at a portion thereof extending downwardly beyond a bottom surface of the connector after being bent toward the outer surface of the housing. The attaching end portion is inserted into a corresponding hole formed in an attaching object member of the connector for attaching to the attaching object member.

Owner:HIROSE ELECTRIC GROUP

Balance chair

InactiveUS9060612B2Sufficient engagementPrevent the user from leaning excessively or falling sidewaysOperating chairsDental chairsEngineering

A balance chair includes a central vertical post with a base attached at a lower end of the central post; a flexible joint attached at an upper end of the central post, a seat attached atop the flexible joint; and a plurality of resistance members attached to the central post and the seat, wherein the plurality of resistance members are arranged around the post in a spaced-apart manner, wherein the flexible joint supports the seat and enables the seat to pivot about an effective pivot point as defined by the shape and composition of the flexible joint, and wherein the resistance members resist but do not prevent pivoting of the seat about the effective pivot point. The flexible joint and the resistance members support pivoting of the seat both side-to-side and fore-and aft and any combination thereof. The resistance members limit a degree of pivoting of the seat.

Owner:LEE REBECCA M

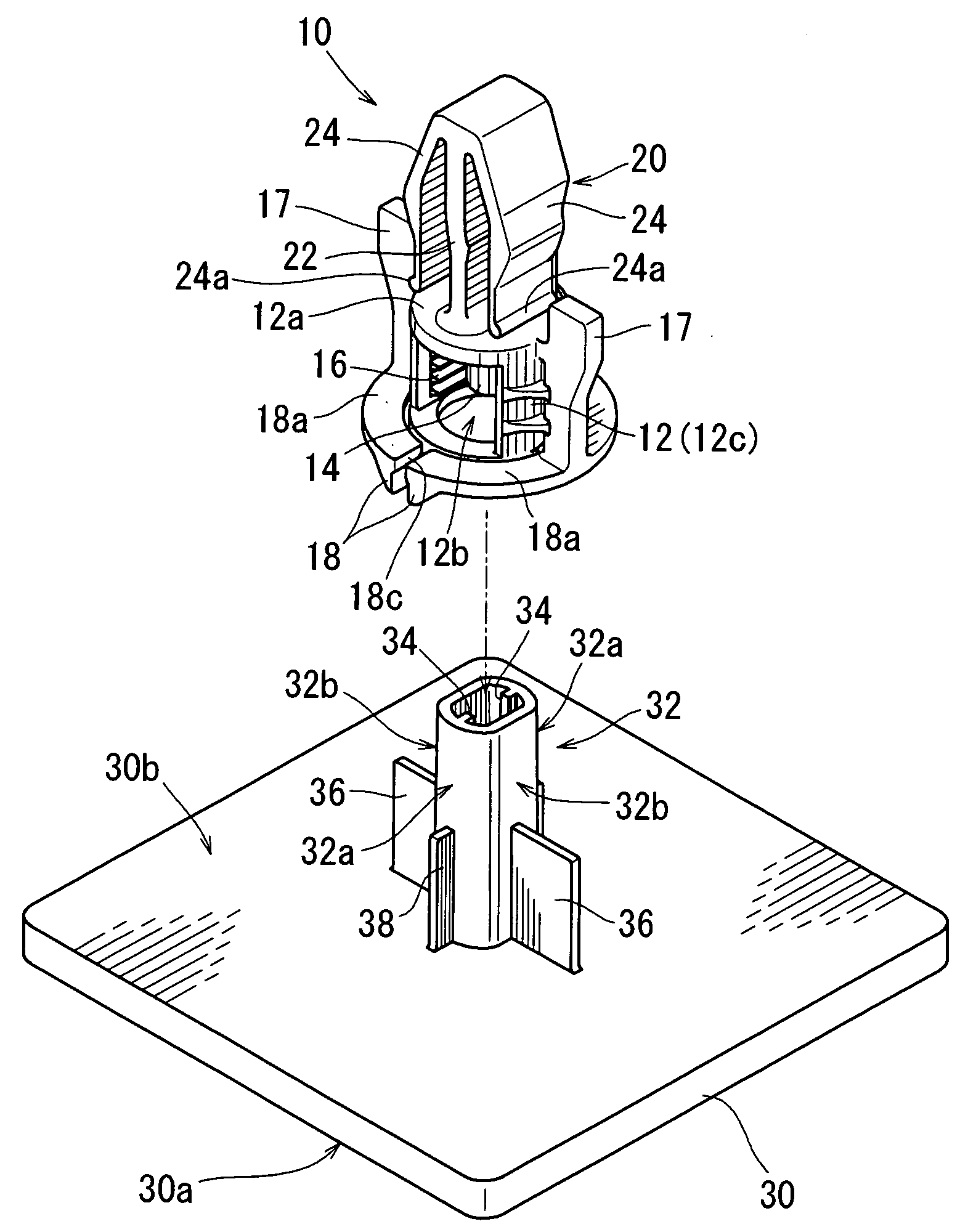

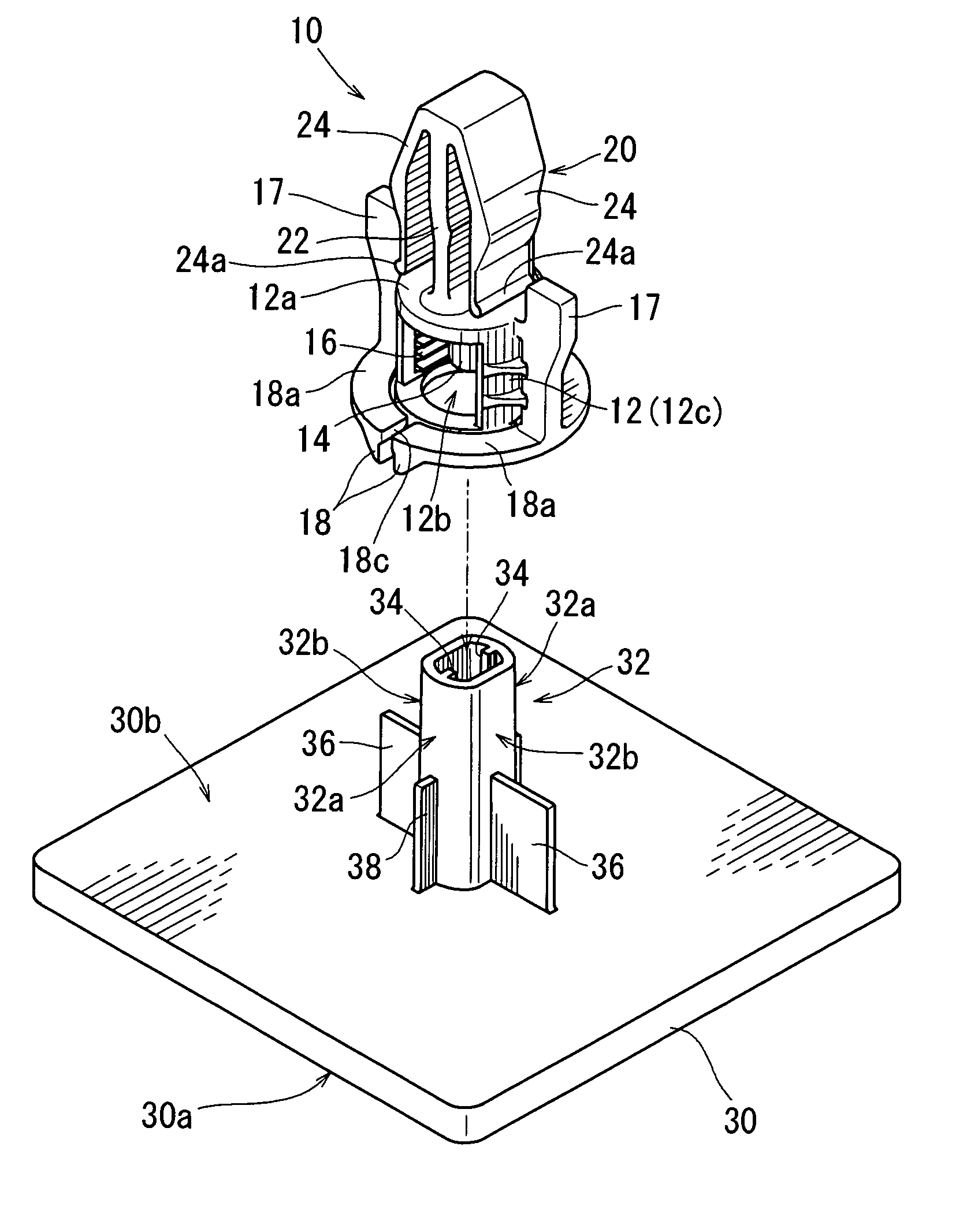

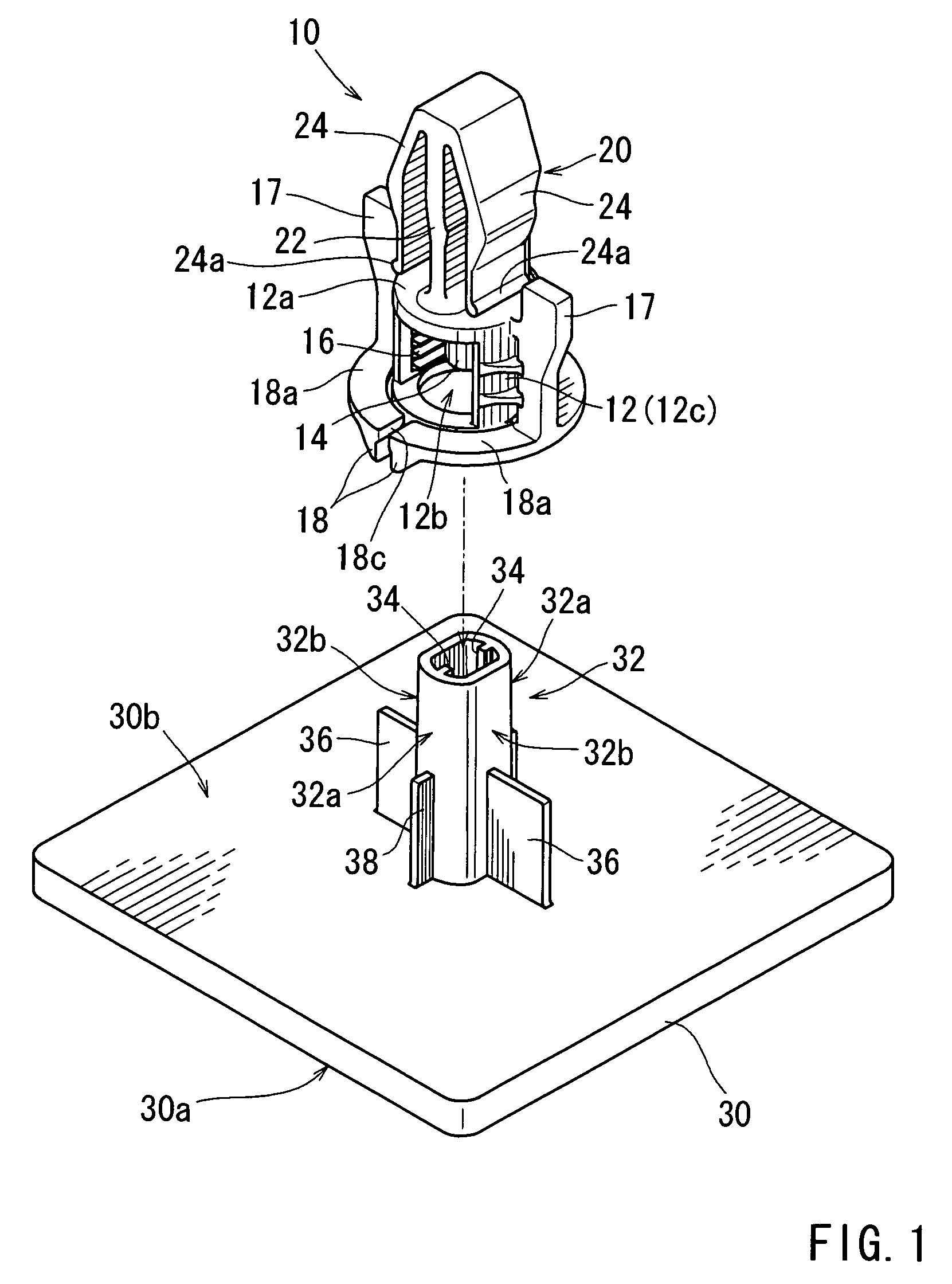

Connecting structures

InactiveUS20100050401A1Reliably securedSufficient engagementSnap fastenersSnap-action fastenersEngineeringMechanical engineering

Owner:DAIWA KASEI IND CO LTD

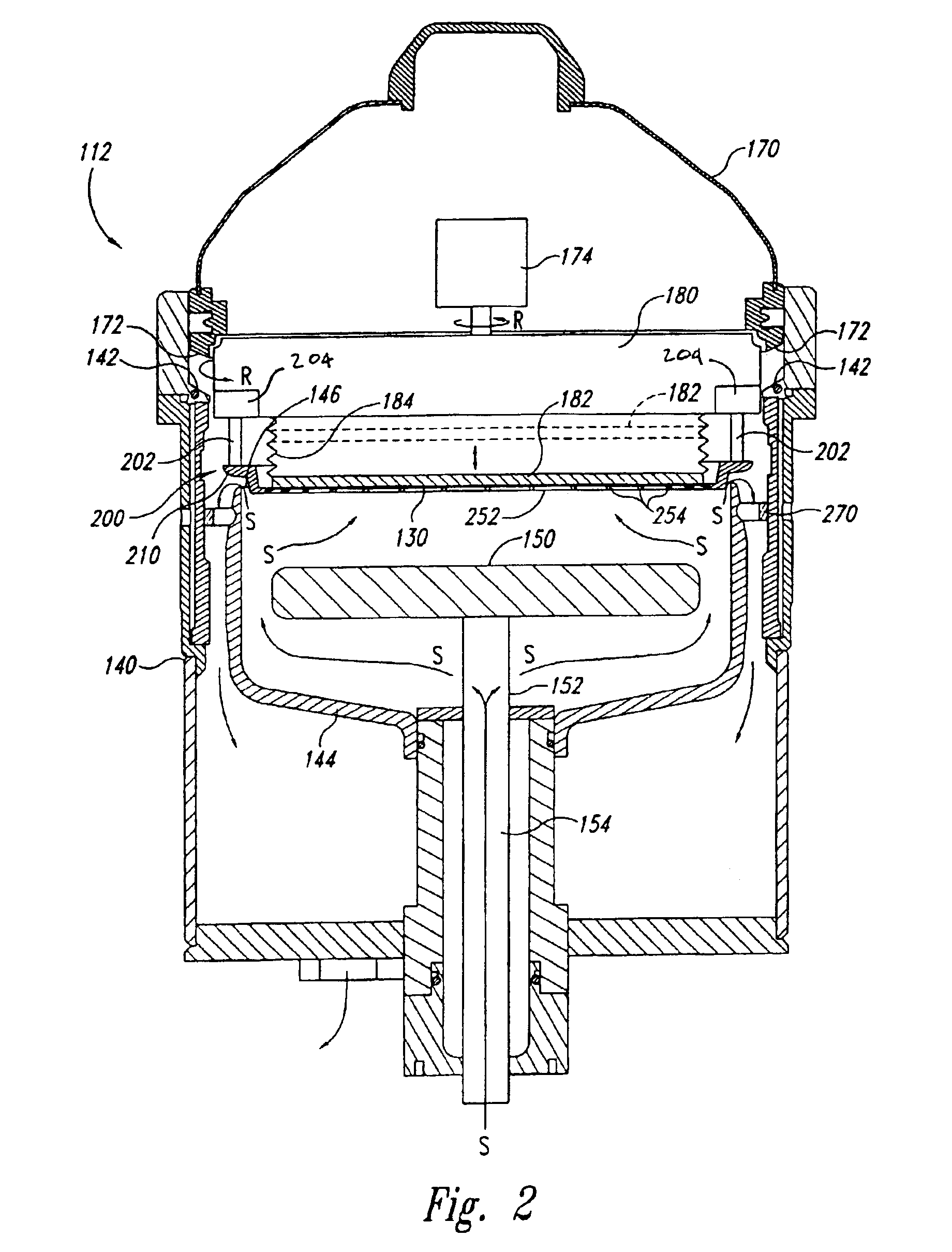

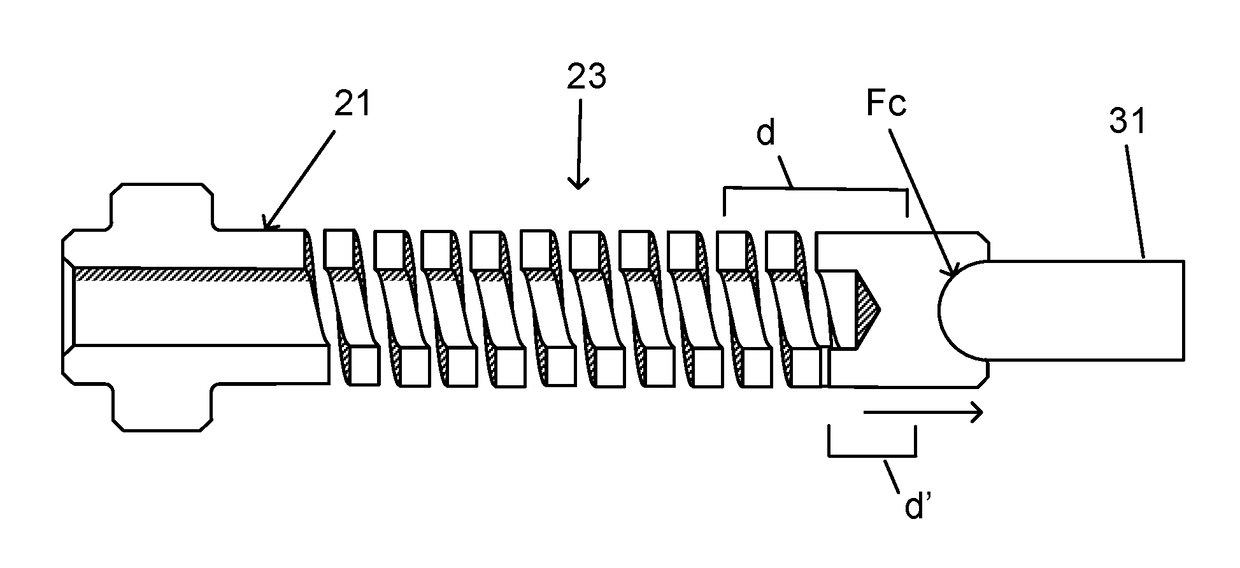

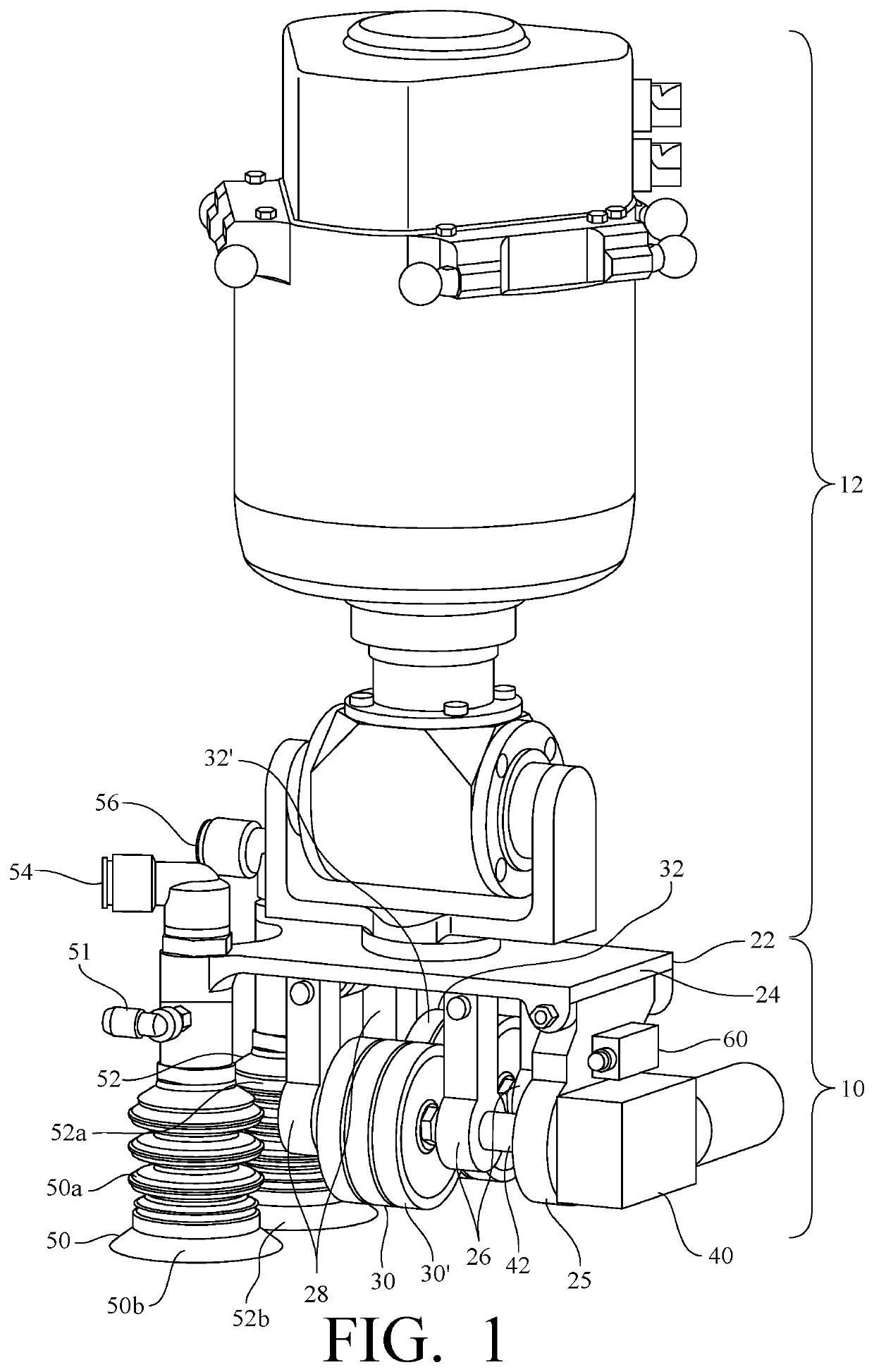

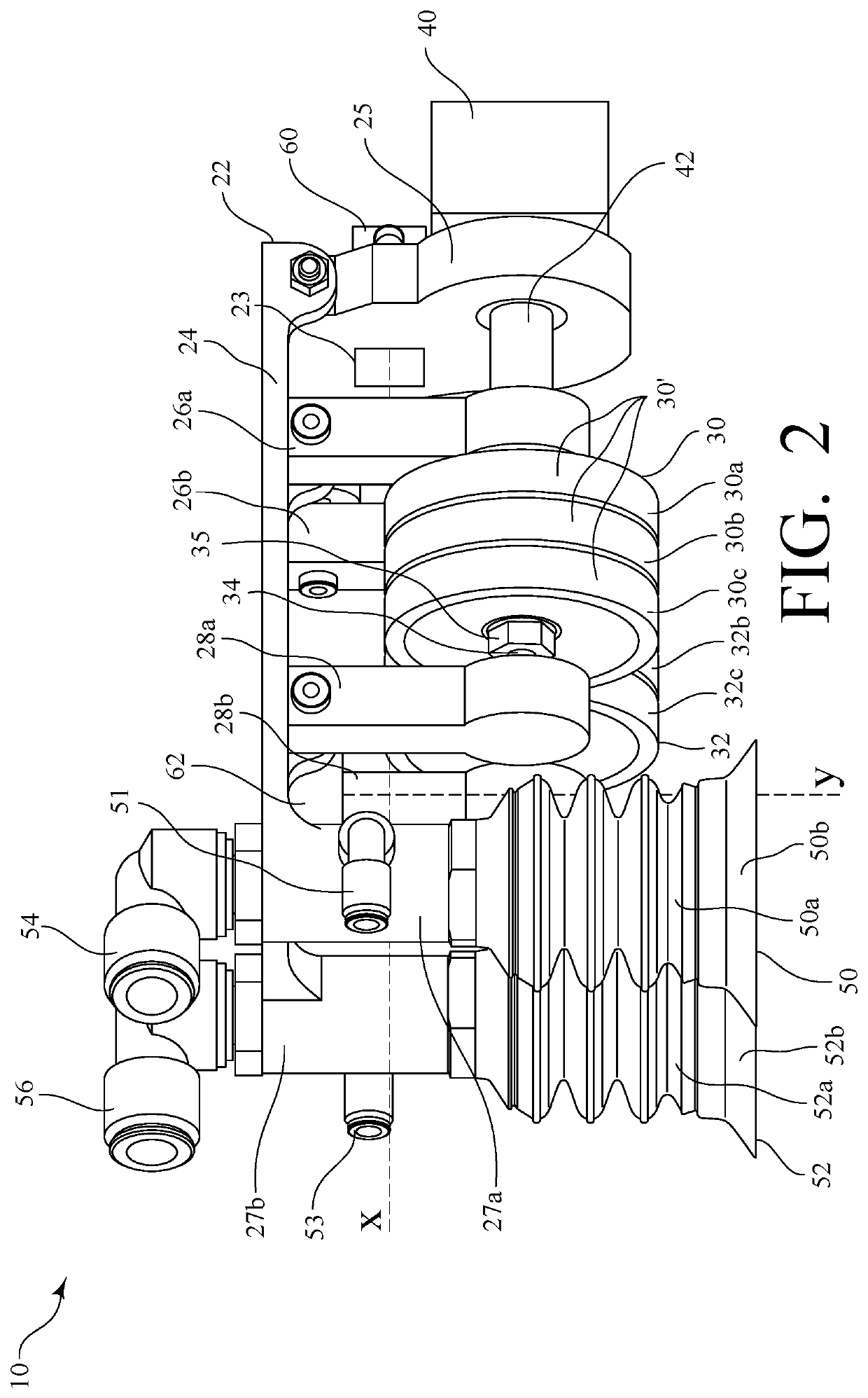

Hydrodynamic clutch device

InactiveUS20060207853A1Disadvantageous effectReduce pressureRotary clutchesFluid gearingsTurbine wheelEngineering

A hydrodynamic clutch device has at least one pump wheel, connected to a drive by way of a clutch housing, and a turbine wheel, connected to a takeoff, to form a hydrodynamic circuit. The device also has a bridging clutch with at least one piston, which can shift between a released position and an engaged position, and at least one friction surface acting between this piston and an adjacent support to connect the drive to the takeoff. When the piston is in the released position, the bridging clutch allows the hydrodynamic circuit to be used to transmit at least most of the torque between the drive and takeoff, whereas, when the piston is in the engaged position, the bridging clutch produces a bypass around the hydrodynamic circuit for the transmission of torque. The barrier clutch cooperates with at least one pressure barrier installed between the hydrodynamic circuit and the pressure space. This separation more-or-less completely prevents the exchange of clutch fluid between the hydrodynamic circuit and the pressure space, regardless of the instantaneous position of the piston between its released position and its engaged position and thus regardless of the shift status of the bridging clutch.

Owner:ZF FRIEDRICHSHAFEN AG

Fastener and fastener system

ActiveUS20130312227A1Improve securitySufficient engagementSnap fastenersPackage recyclingEngineeringFastener

A reusable connecting device that includes a strap with a first end a second end, wherein the strap features teeth located on one of the ends. The reusable tie wrap includes a housing with an opening, which is configured to engage with the teeth of the strap. An attachment mechanism is located on the tie wrap, which is configured to allow for connection, disconnection and reconnection with an attachment mechanism of another device. The attachment mechanism may be a two part buckle enclosure or side-release buckle. In another embodiment, the reusable connecting device may also be coupled to an adjustable connecting device. The adjustable connecting device is configured to be secured to an object with which the reusable connecting device is to be utilized.

Owner:WHEELWRIGHT TROY

Engine cover puller

InactiveUS7114233B1Easy to separateEasy to removeBottle/container closureCrowbarsEngineeringAutomotive engineering

Owner:HONDA MOTOR CO LTD

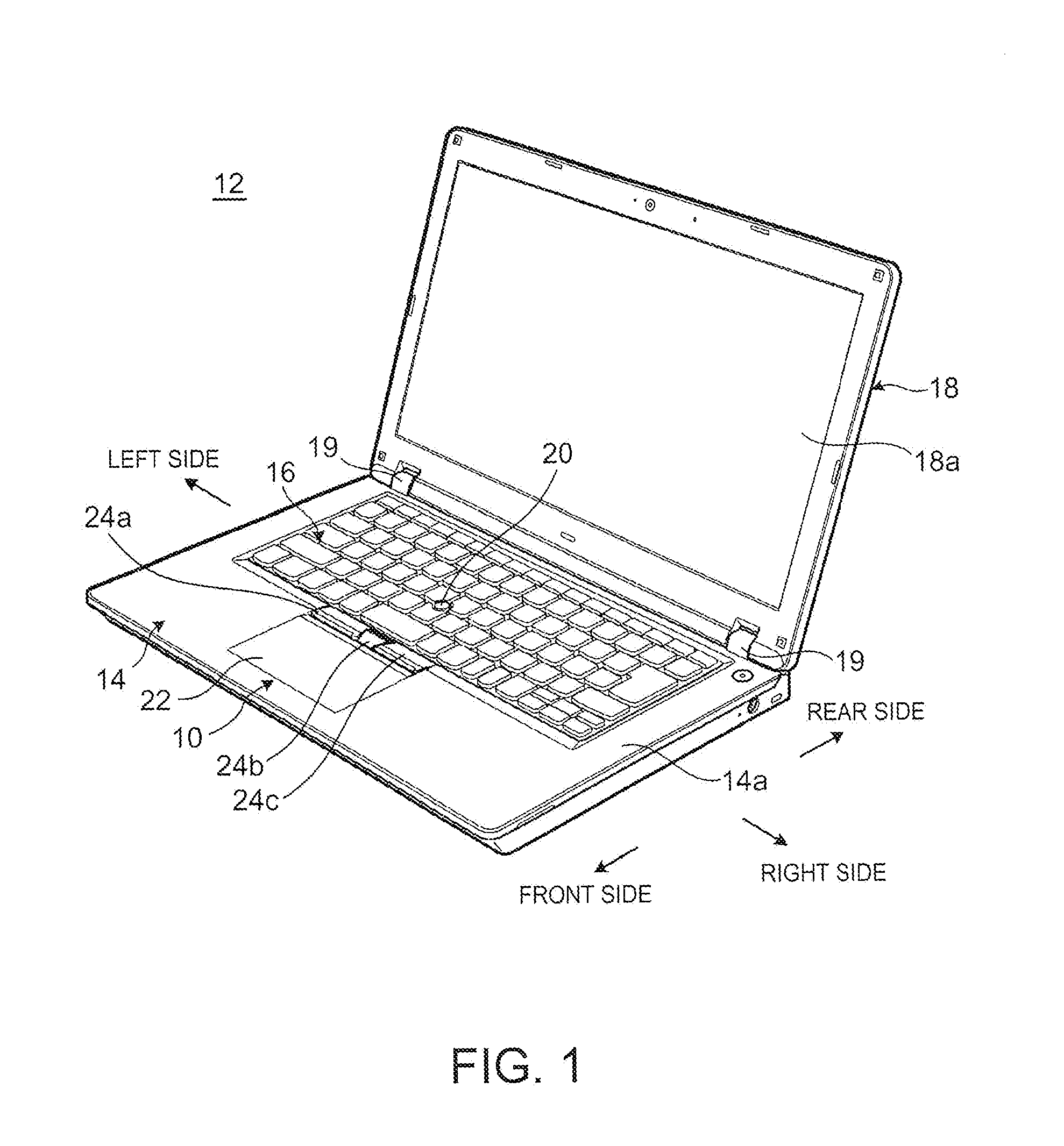

Coupling structure for input devices

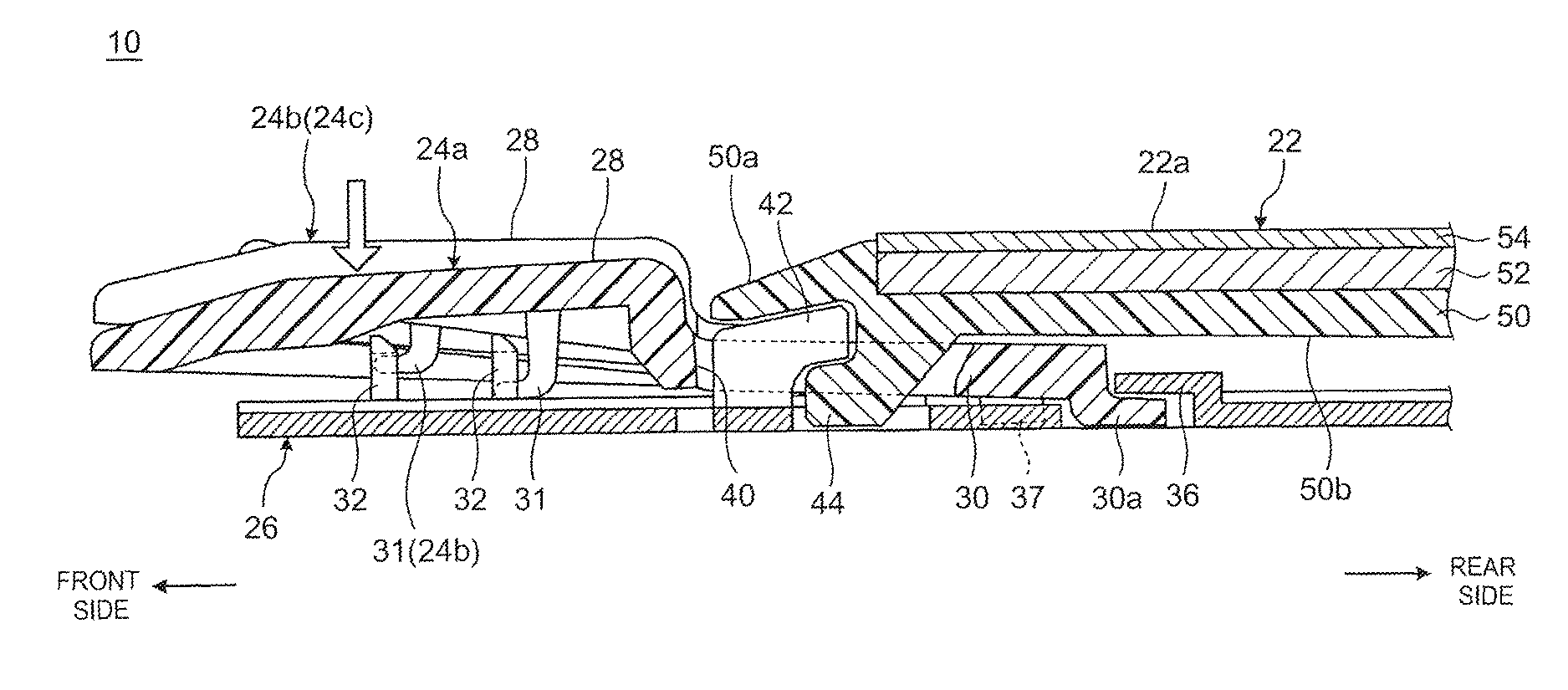

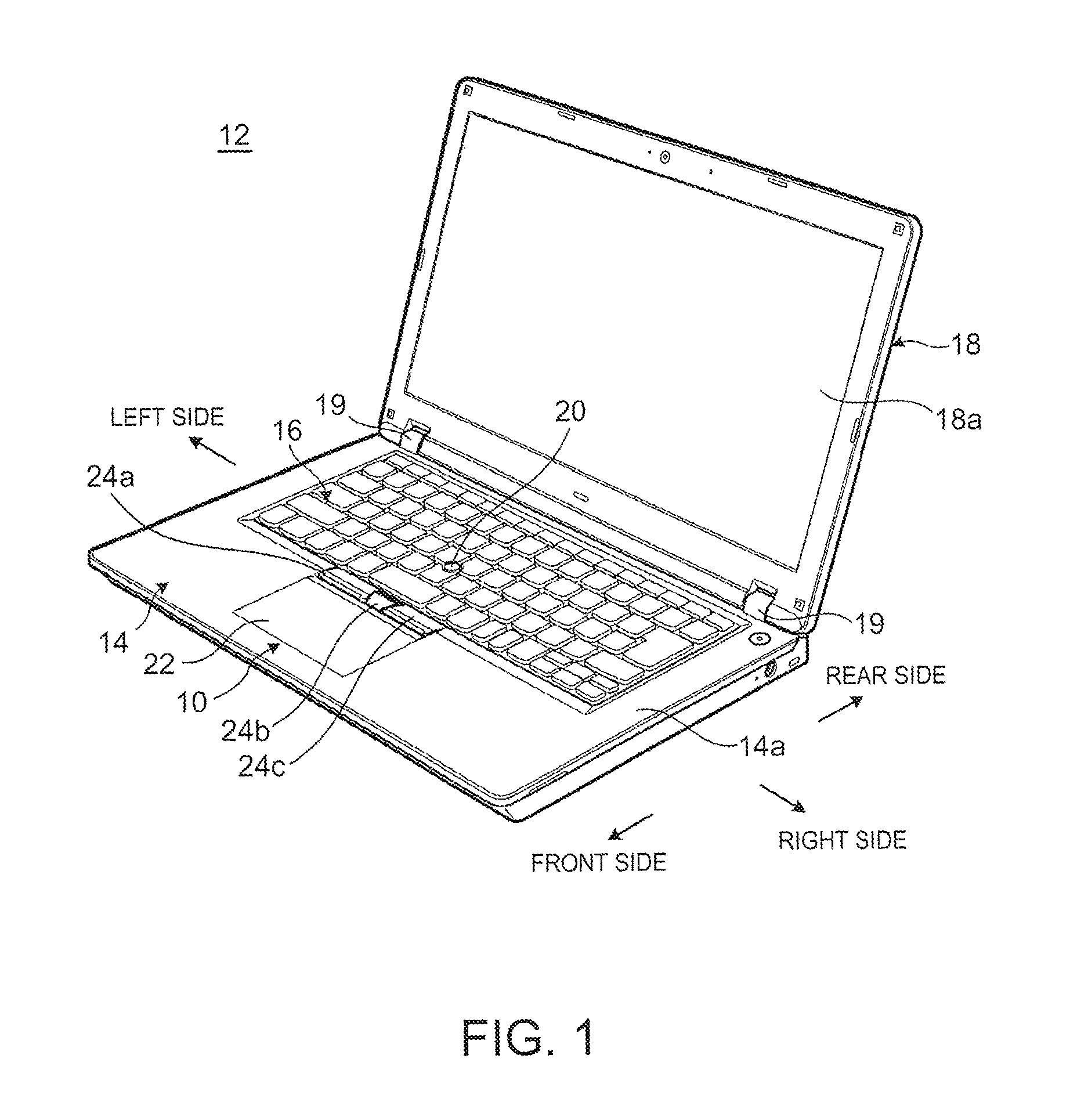

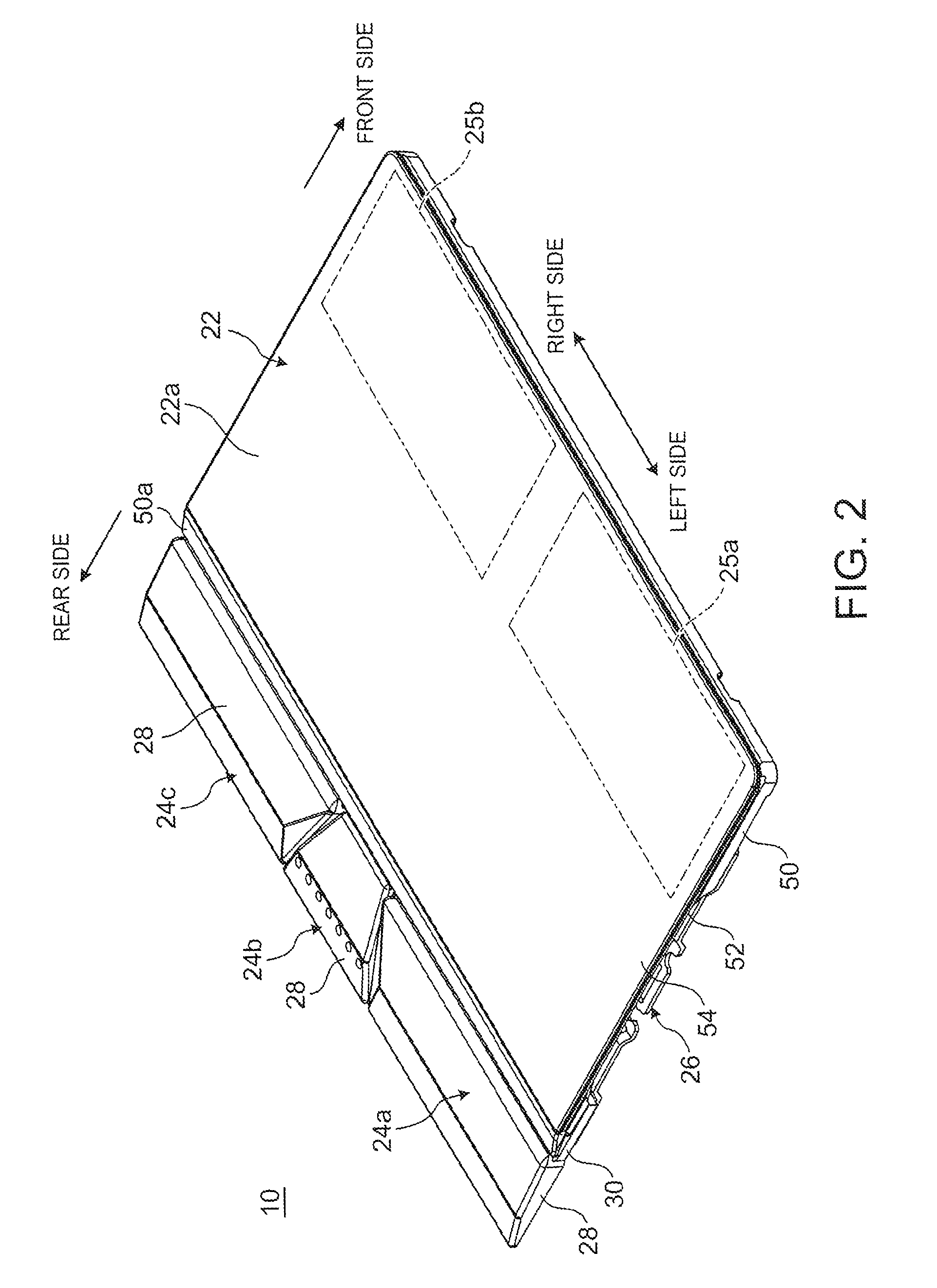

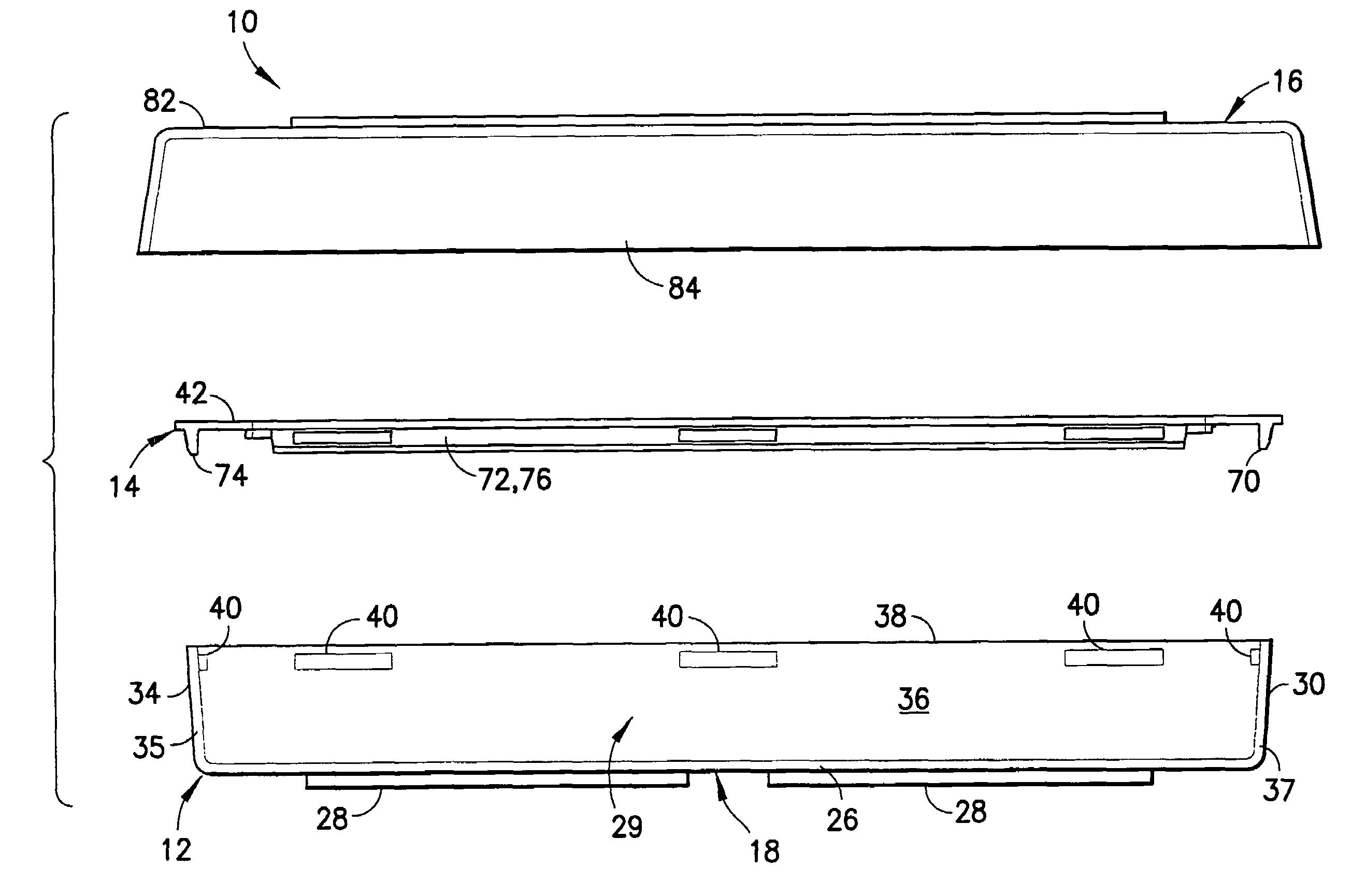

ActiveUS20160139637A1Increase volumeSufficient flexural amountDetails for portable computersElectrical apparatus contructional detailsInput deviceCoupling strength

A coupling structure capable of coupling a metal plate-like member and a resin chassis member with high assembling efficiency and sufficient coupling strength while preventing damage to parts is disclosed. The coupling structure is a structure for coupling a housing plate as a resin chassis member to a base plate as a metal plate-like member in a direction to overlap the housing plate with the base plate. The housing plate includes a latch having a pair of arm members extending along a direction parallel with a coupling face to the base plate and whose distal ends are spaced out from each other, and the base plate includes a coupling hook formed upright toward the side of the housing plate and engaged between the pair of arm members.

Owner:LENOVO PC INT

Closed molding tool

ActiveUS20050194716A1Promote sportsSufficient flexibilityConfectioneryWood working apparatusFiber-reinforced composite

A flexible molding component used with a base mold improves on existing methods of forming fiber reinforced composite parts. The molding component is formed of a flexible body structure having an interfacing surface and a perimeter region including a perimeter seal configured for sealing engagement with the base mold. Resin and vacuum distribution channels are formed in the interfacing surface to deliver resin to a fiber lay up disposed on the base mold and draw the resin across and through the lay up, respectively, to properly mix the resin / fiber combination which forms the desired part. Application of the vacuum causes the perimeter seal of the flexible body structure to sealingly engage with the base mold to enclose materials between the body structure and the mold, as well as causing the interfacing surface to draw against the resin / fiber combination and the mold to shape the combination into the desired part.

Owner:TRACKER MARINE LP

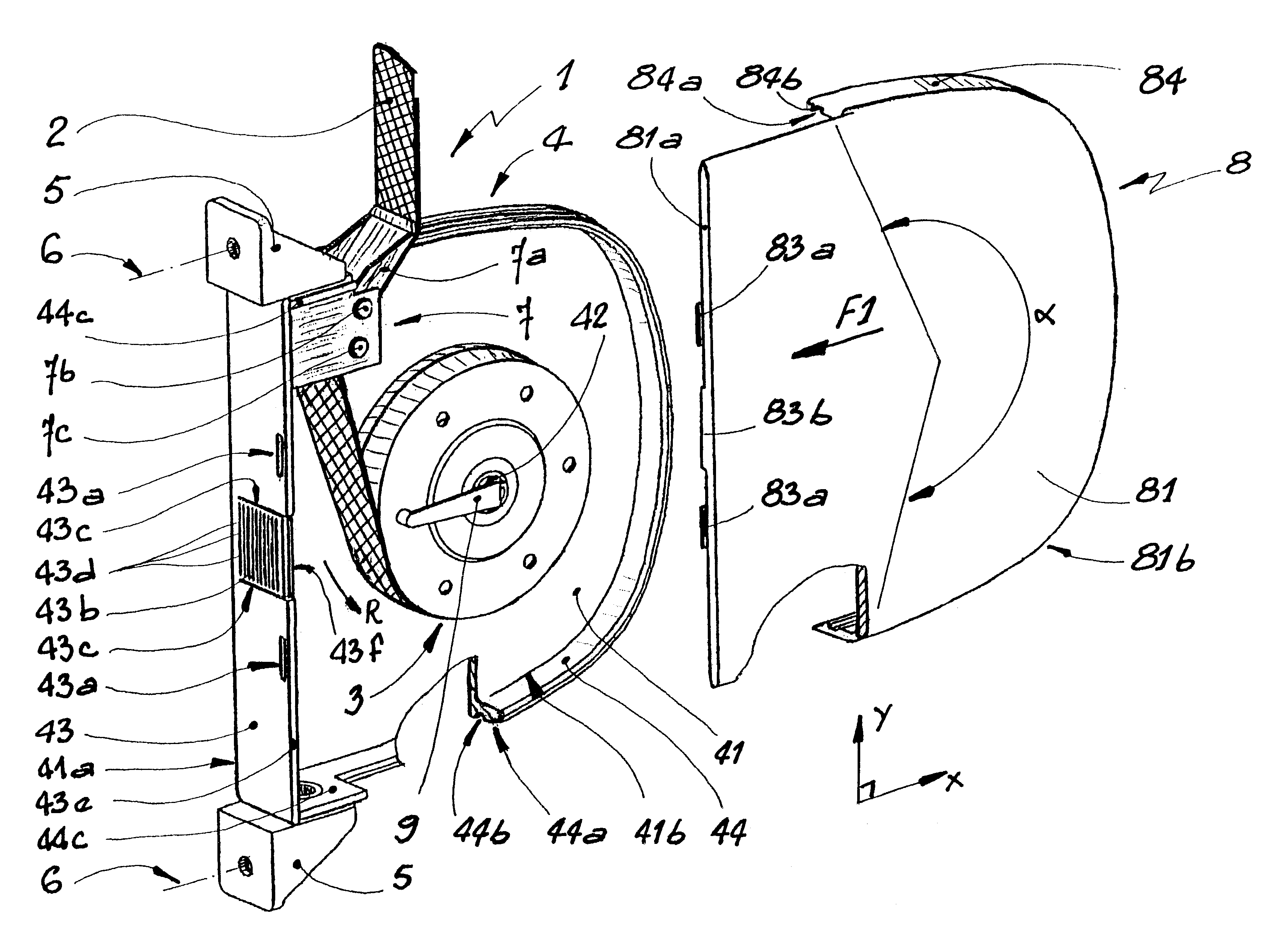

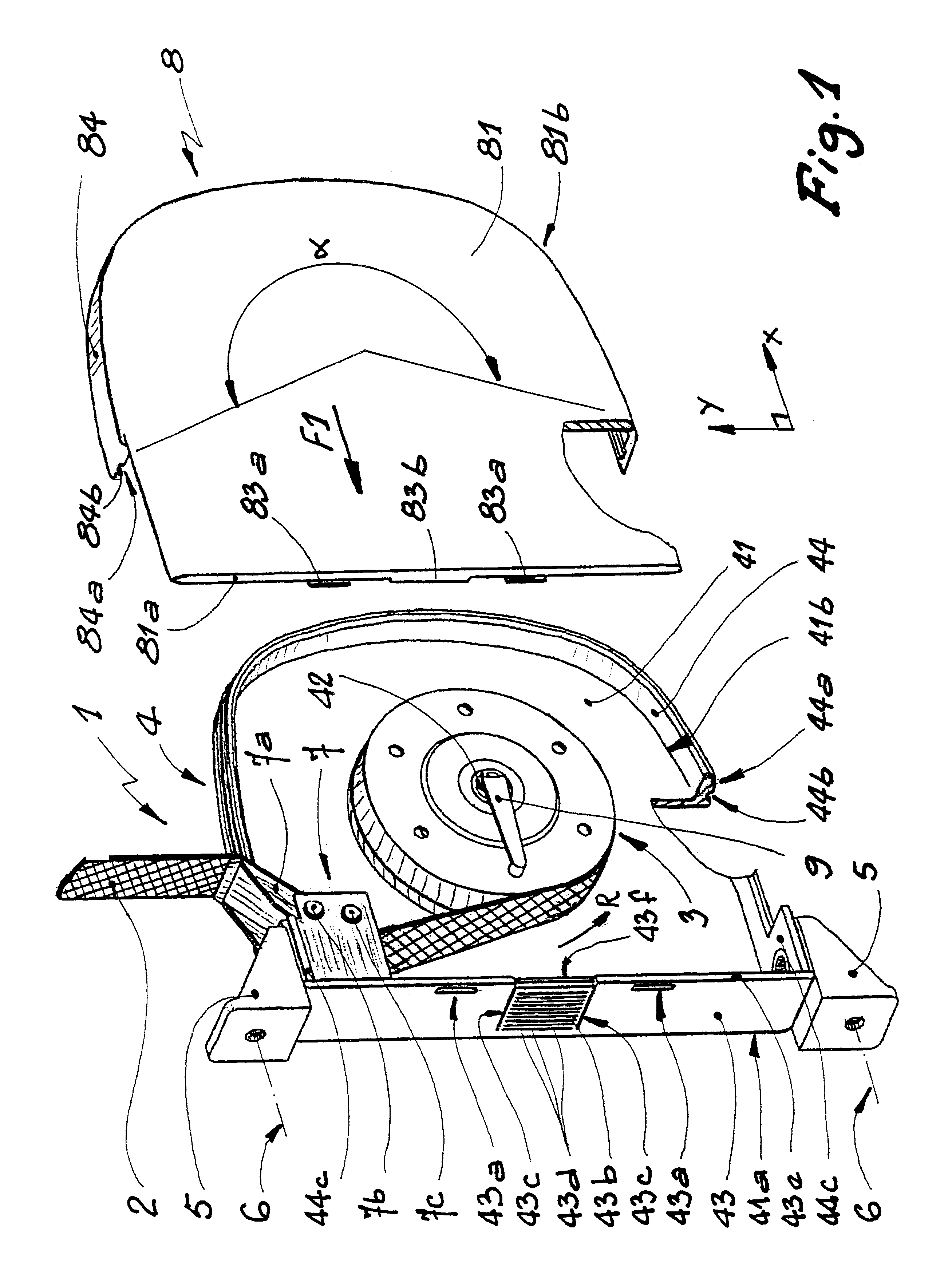

Device for maneuvering a shutter or roller-type closure member and process for manufacturing such a closure member

InactiveUS6398146B1Sufficient engagementEasy to brakeDoor/window protective devicesFilament handlingMutual engagementEngineering

A device for winding a strap or strip of material for maneuvering a shutter, roller blind or equivalent device comprising a member for winding and tensioning the strap disposed inside a box formed by two shells each including at least one edging extending in a direction substantially perpendicular to a principal web of each shell. The edgings are adapted to be brought into mutual engagement by a relative translation in a direction substantially parallel to the respective principal webs of the shells, in a configuration where an edging of a first shell is covered by an edging of a second shell.

Owner:I M B A C

Fastener and fastener system

ActiveUS9210969B2Sufficient engagementImprove securitySnap fastenersPackage recyclingEngineeringElectrical and Electronics engineering

A reusable connecting device that includes a strap with a first end a second end, wherein the strap features teeth located on one of the ends. The reusable tie wrap includes a housing with an opening, which is configured to engage with the teeth of the strap. An attachment mechanism is located on the tie wrap, which is configured to allow for connection, disconnection and reconnection with an attachment mechanism of another device. The attachment mechanism may be a two part buckle enclosure or side-release buckle. In another embodiment, the reusable connecting device may also be coupled to an adjustable connecting device. The adjustable connecting device is configured to be secured to an object with which the reusable connecting device is to be utilized.

Owner:WHEELWRIGHT TROY

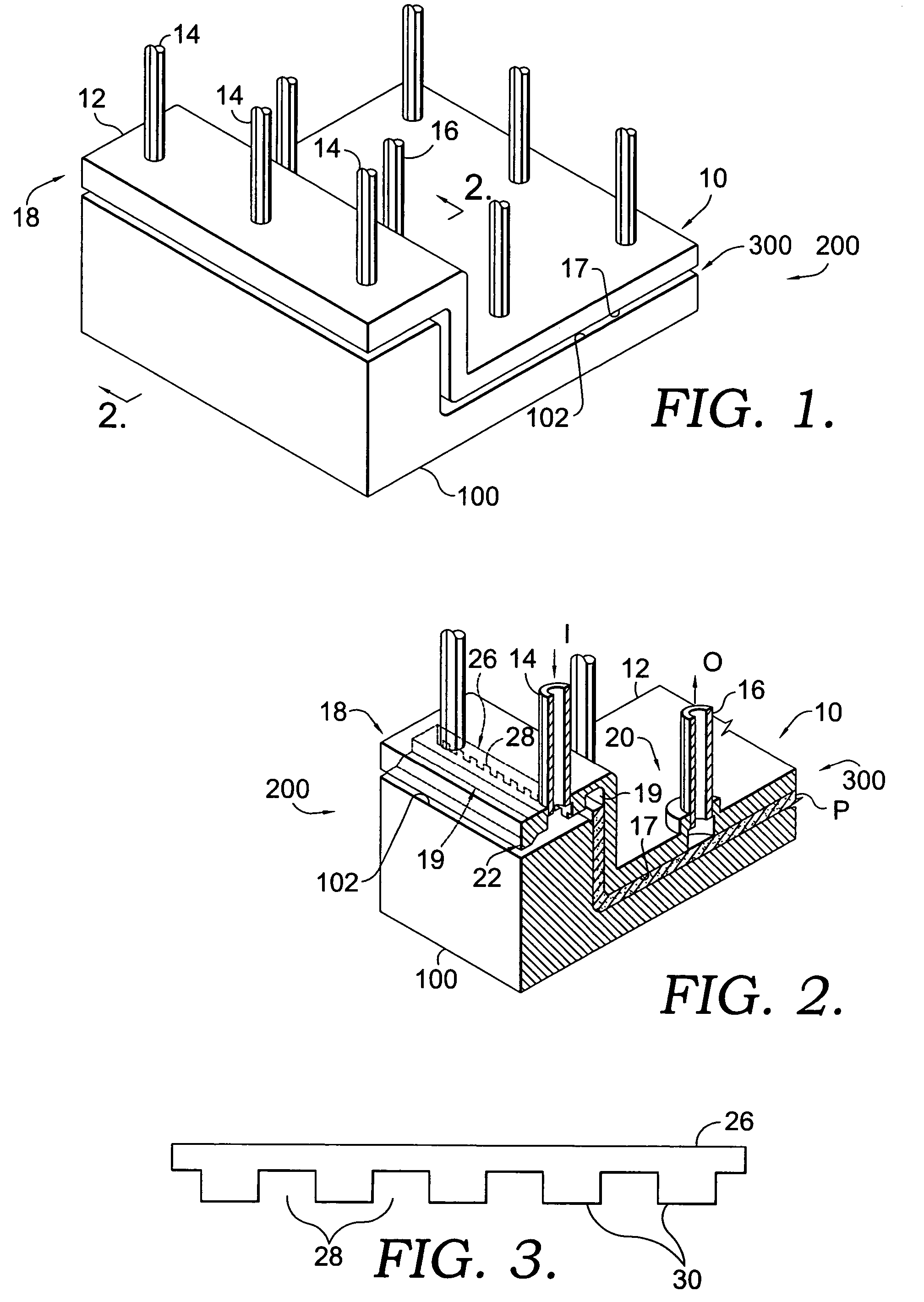

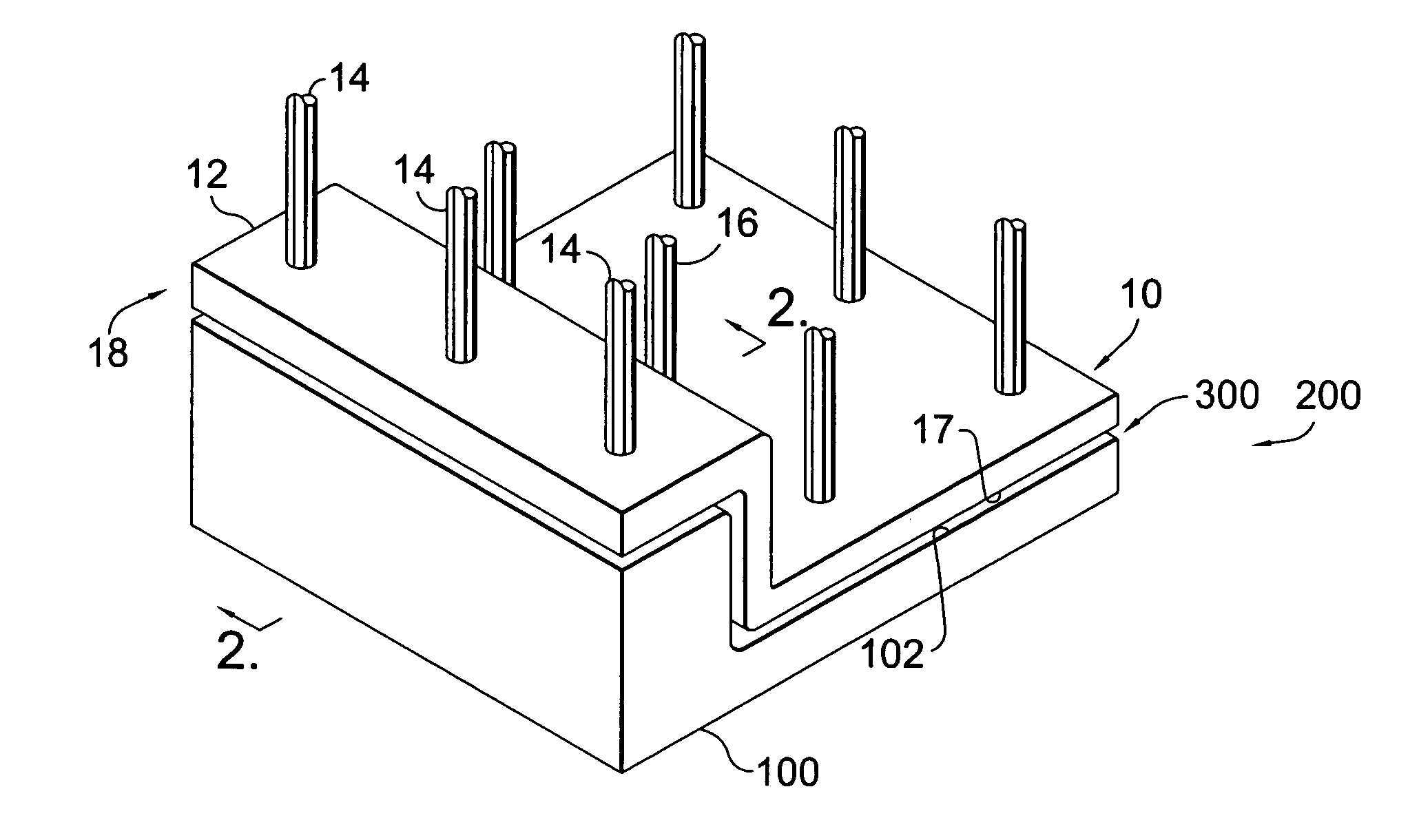

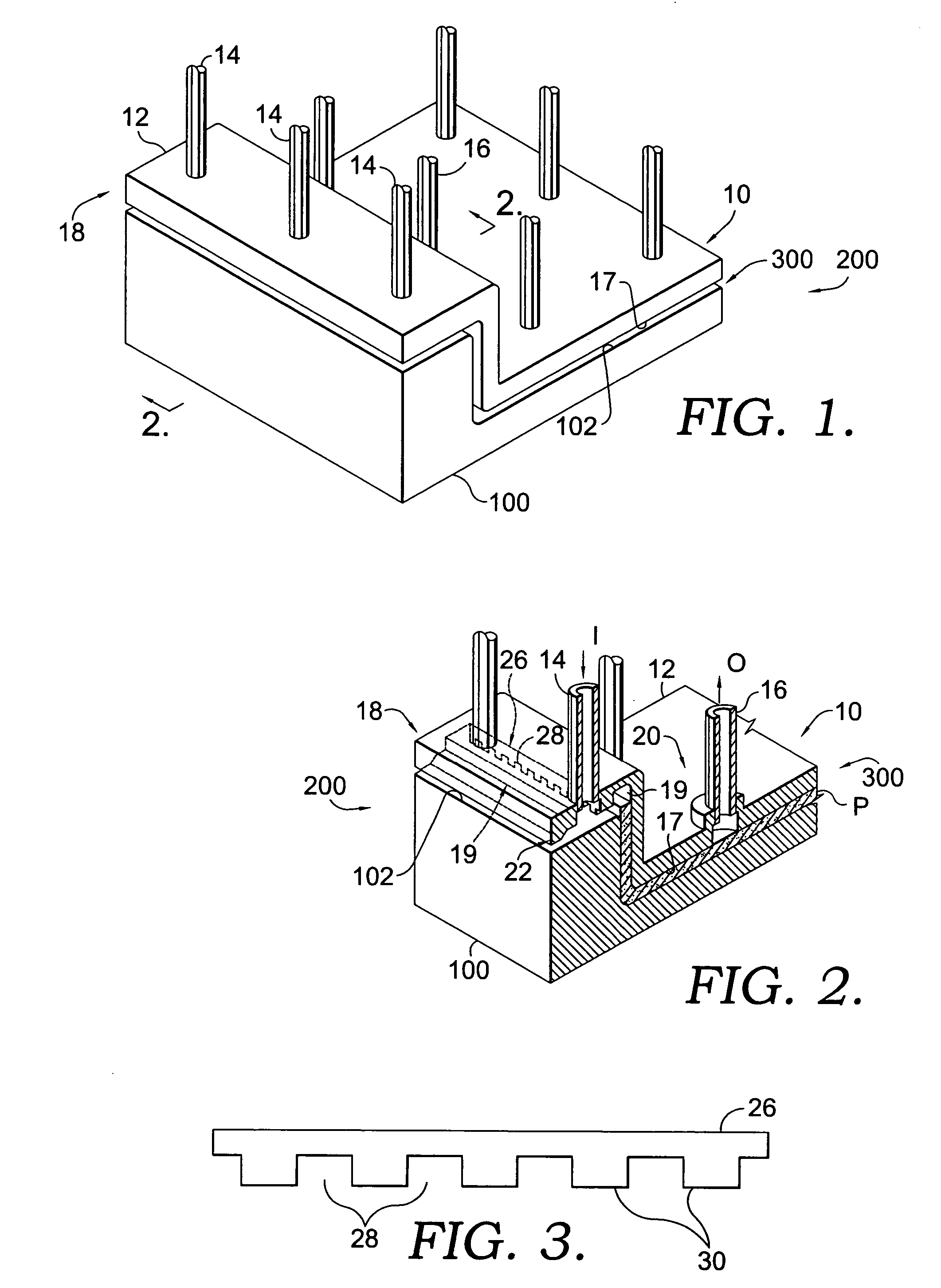

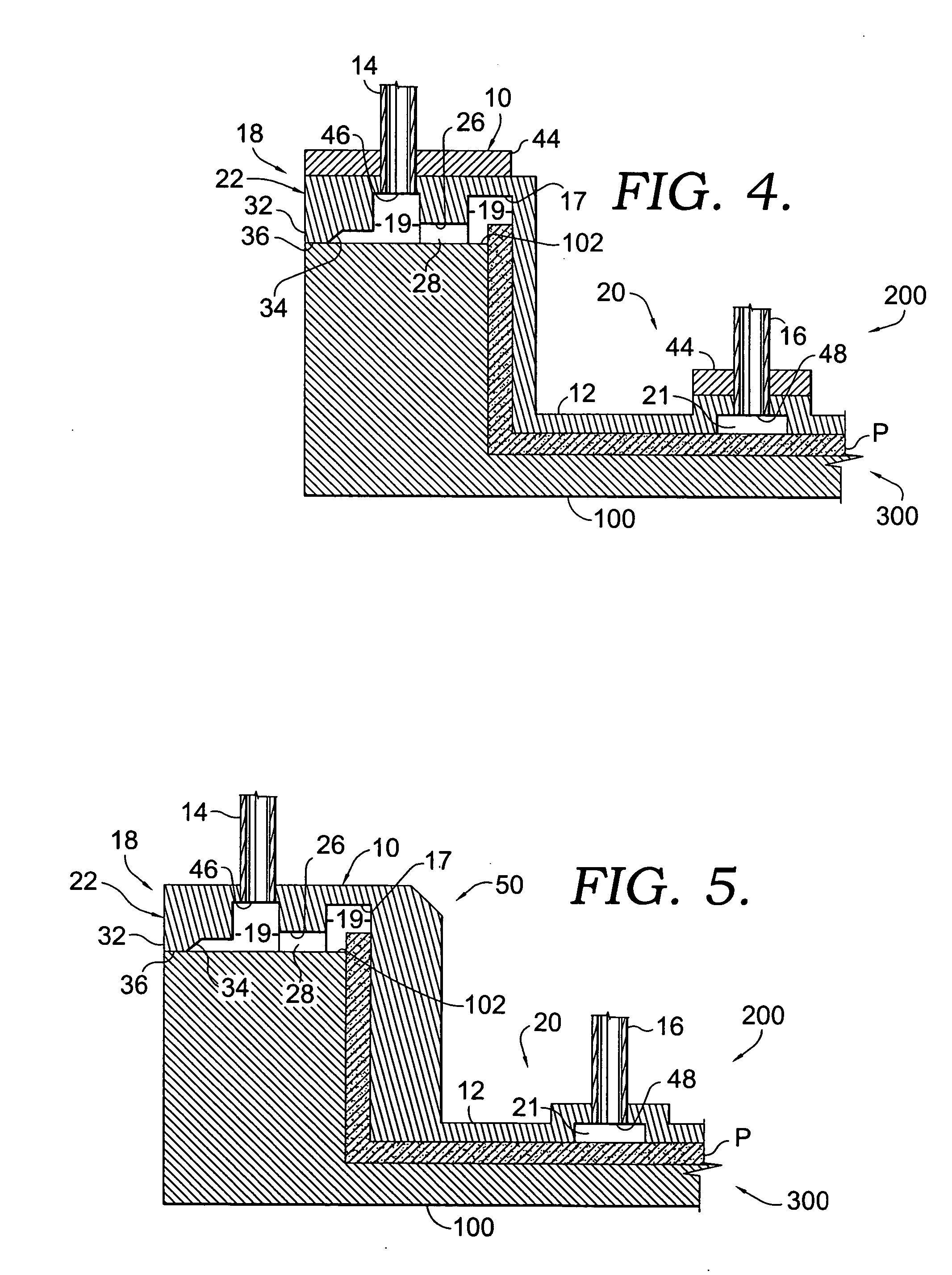

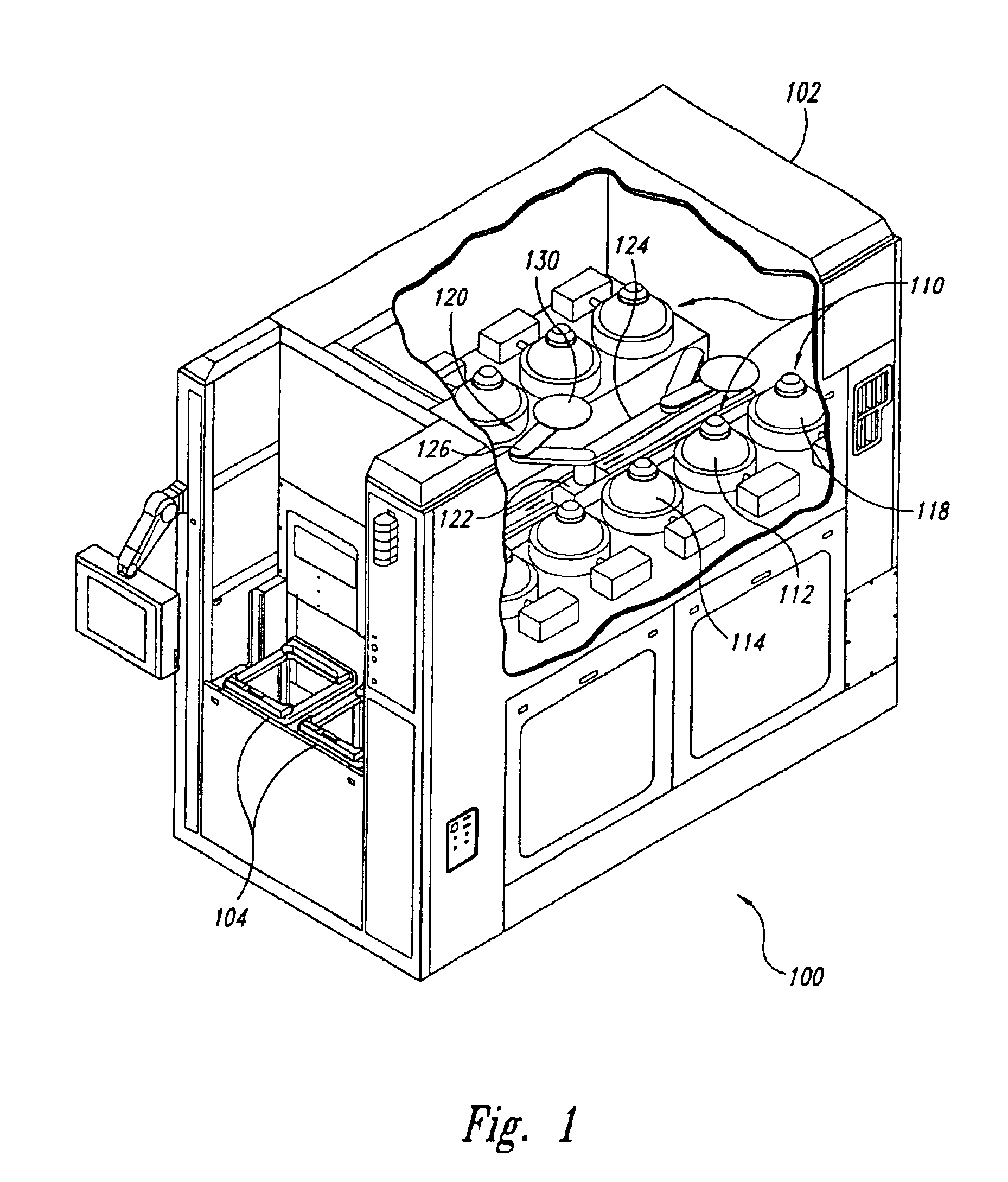

Contact assemblies, methods for making contact assemblies, and plating machines with contact assemblies for plating microelectronic workpieces

InactiveUS6939448B2Mitigates galvanic etchingReduce exposureMachining electrodesCellsEngineeringContact system

Contact assemblies, electroplating machines with contact assemblies, and methods for making contact assemblies that are used in the fabrication of microelectronic workpieces. The contact assemblies can be wet-contact assemblies or dry-contact assemblies. A contact assembly for use in an electroplating system can comprise a support member and a contact system coupled to the support member. The support member, for example, can be a ring or another structure that has an inner wall defining an opening configured to allow the workpiece to move through the support member along an access path. In one embodiment, the support member is a conductive ring having a plurality of posts depending from the ring that are spaced apart from one another by gaps. The contact system can be coupled to the posts of the support member. The contact system can have a plurality of contact members projecting inwardly into the opening relative to the support member and transversely with respect to the access path. The contact members can comprise electrically conductive biasing elements, such as fingers, that have a contact site and a dielectric coating covering at least a portion of the biasing elements. The contact members can also have a raised feature configured to engage the seed-layer on the workpiece for conducting the current to the seed-layer.

Owner:SEMITOOL INC

Roll Mounted Bags and Dispensers for Same

A series of roll mounted bags and dispensers are described. The bags may be folded along at least one axis and rolled. The compact roll of bags is placed in various dispensers. As the upper portion of the first bag is pulled from the roll, the roll will rotate, presenting the succeeding bag for dispensing after the first bag is removed. Variations of the dispenser include one with a bag opening means with a mounting member and bag opening element causing the bags to open as they are pulled from the dispenser. The dispenser includes mechanisms for supporting the bag roll and constraining its movement along its horizontal axis. Another variation of the dispenser has a perforation parting means that facilitates separation of one bag from a subsequent bag. The dispenser may be removably attached to a dispenser support that attaches to a surface.

Owner:DANIELS MARK E

Compliant implantable connector and methods of use and manufacture

ActiveUS20170324185A1Maintain integrityMaintaining longevityCoupling device engaging/disengagingMedical devicesElectrical resistance and conductanceElectricity

An implantable connector utilizing having improved electrical and mechanical properties is described herein. In one aspect, the implantable connector utilizes electrical contact pins fabricated from a corrosion resistant metal alloy, such as platinum-iridium, that engage longitudinally and include one or more urging members on a proximal portion of the pin so as to provide at least a desired contact force between conductively coupled pins. Such a configuration allows contact between contact pins to be maintained in applications where the connector may be subject to movement and further allows for reduced resistance so as to allow transmission of voltages and current associated with higher powered implanted devices. In some embodiments, the urging member is defined as a helical cut potion in one or both electrical contacts. Methods of use and manufacture of such connectors are also provided herein.

Owner:TC1 LLC

Collet with ball-actuated expandable seal and/or pressure augmented radially expandable splines

ActiveUS10584559B2Reduce overall outer diameterEasily downholeConstructionsFluid removalSpool valveAcute angle

A sliding valve has a valve body, a sliding sleeve received in a longitudinal bore of the valve body, and a collet receivable in a longitudinal bore of the sliding sleeve. The valve body has one or more fluid ports on an uphole portion of the sidewall thereof. The sliding sleeve is movable between an uphole closed position closing the one or more fluid ports and a downhole open position opening the one or more fluid ports. The collet comprises a metal portion about an uphole end of the collet, and a ball seat having a ball-seat surface radially inwardly sloped from uphole to downhole at an acute slope angle with respect to a longitudinal axis of the collet. The metal portion is radially outwardly expandable under a radially outward pressure to form a metal-to-metal seal at the interface between the collet and the sliding sleeve when the collet is received in the sliding sleeve.

Owner:SC ASSET CORP

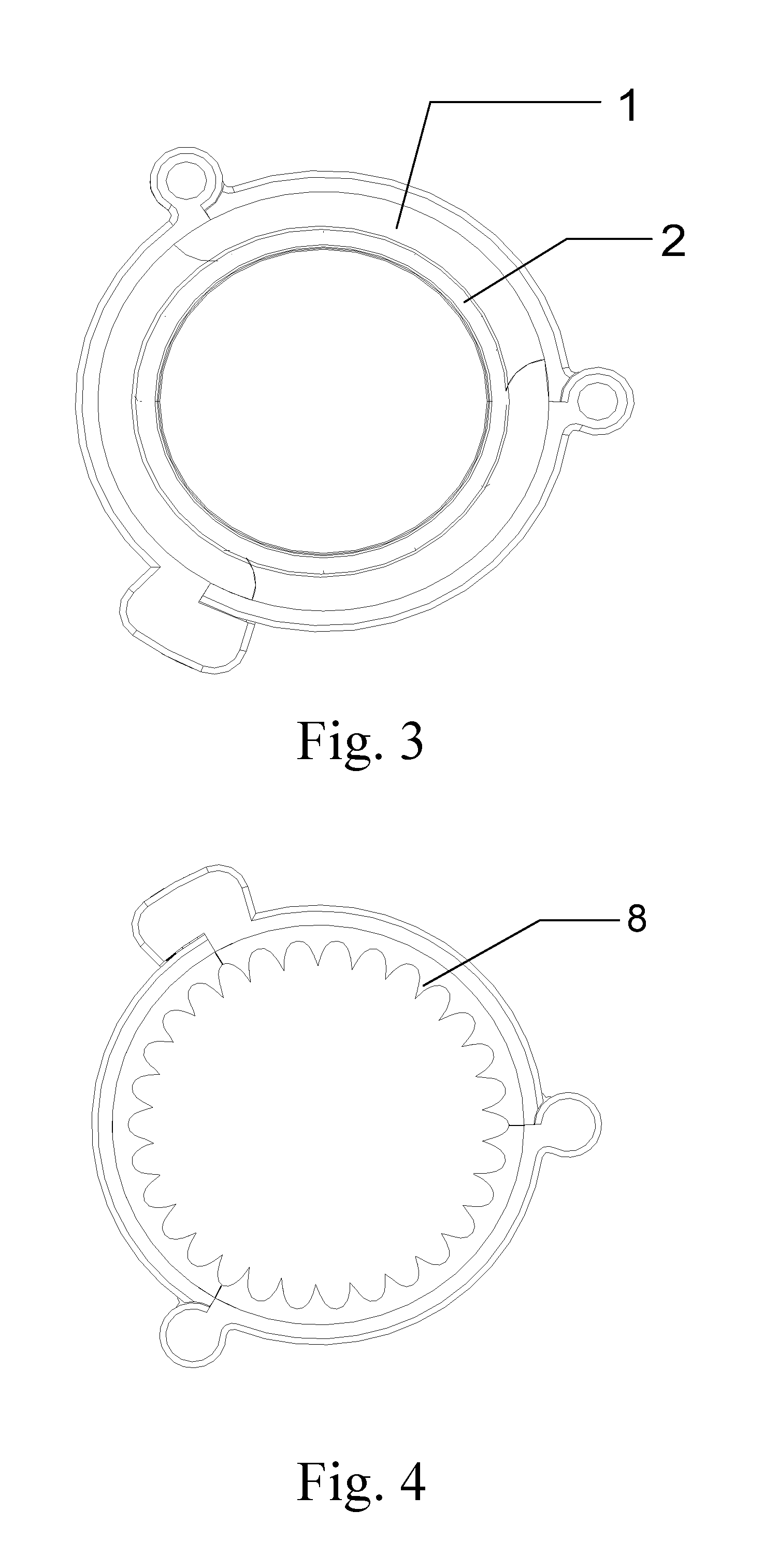

Disposable circumcision anastomat

A disposable circumcision anastomat includes: an inner ring (2) and an outer ring (1) corresponding to the inner ring (2); wherein the outer ring (1) includes arc sidewalls, and the arc sidewalls are connected to arc blades (7); a loop blade faces inwards; convex structures (8) are repeatedly arranged at internal portion of the outer ring (1) for fixing, and the arc blades (7) form containing spaces (6) with the convex structures (8). With the disposable circumcision anastomat for removing redundant prepuce or phimosis, incision is neat, postoperative bleeding hardly happens, operation is easy, operation time is short, healing is fast, side effects is slight, patients suffer less, and postoperative recovery is fast.

Owner:ZHAO YONGJIU

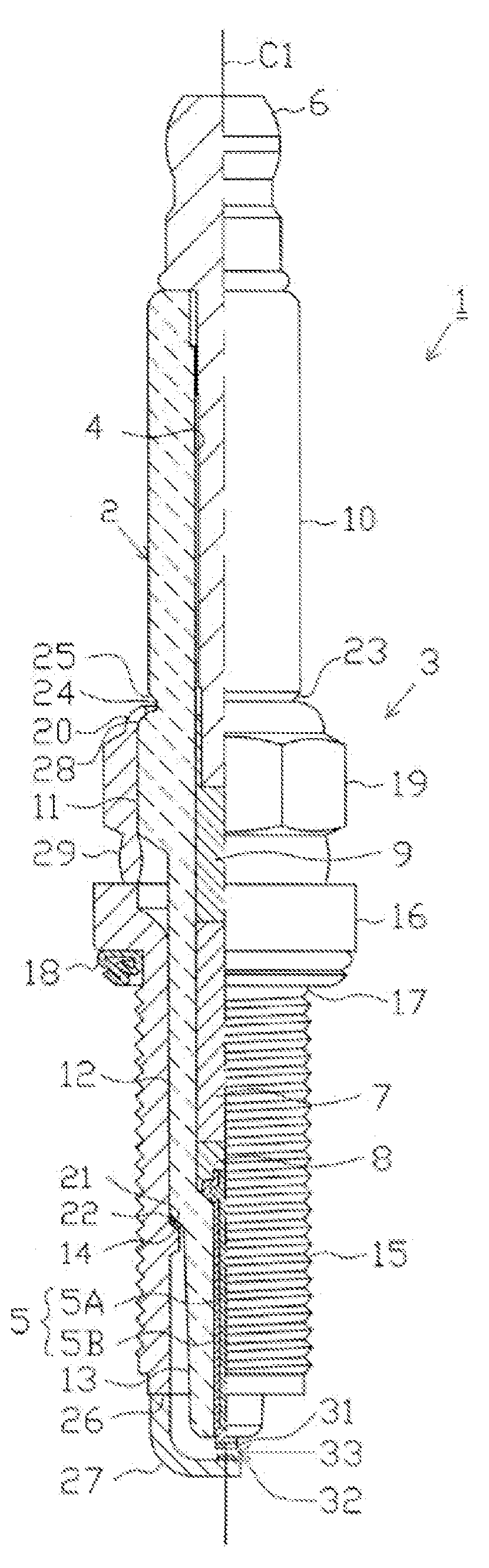

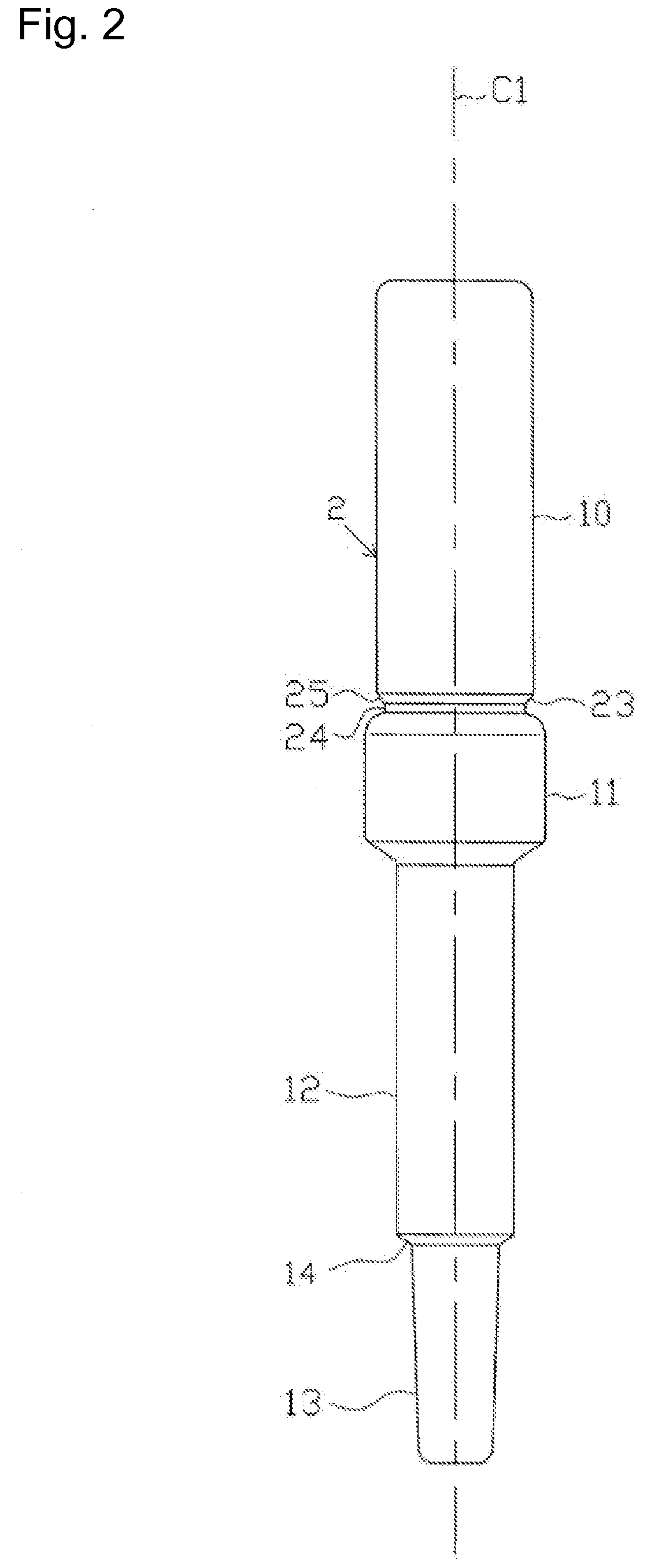

Spark plug for internal combustion engine

InactiveUS20080238284A1Avoid stress concentrationPrevent a decline in gas-tightnessSparking plugsEngineeringInternal combustion engine

A spark plug (1) for an internal combustion engine includes: a cylindrical insulator (2) having an axial hole (4) penetrating in a direction of an axis (C1); a center electrode (5) partially inserted in the axial hole (4); a metal shell (3) surrounding an outer periphery of the insulator (2) and which is fixed to the insulator (2) by means of a crimped portion (20) provided at a rear end portion of the metal shell (3); and a ground electrode (27) joined to the metal shell (3) such that a portion of the ground electrode (27) opposes a leading end portion of the center electrode (5) via a spark discharge gap (33), wherein the insulator (2) has an annular groove portion (23) which opposes an inner edge of the crimped portion (20).

Owner:NGK SPARK PLUG CO LTD

Connecting structures

InactiveUS8156615B2Reliably securedSufficient engagementSnap fastenersSnap-action fastenersMechanical engineering

Owner:DAIWA KASEI IND CO LTD

End effector for engaging the flexible packaging materials of parcels

ActiveUS20200262070A1Increase engagementEfficiently definedProgramme-controlled manipulatorConveyorsControl engineeringPack material

An end effector for engaging flexible packaging materials includes a frame, along with a first and second wheel mounted for rotation with respect to the frame. The first wheel and the second wheel are mounted to the frame relative to each other so that the outer surfaces of the two wheels are positioned opposite of each other. The first wheel and the second wheel can be driven in opposing directions to effectively define a roller intake which can be used to draw the flexible packaging materials of a target parcel between the first wheel and the second wheel. The end effector of the present invention can be combined with a robot to provide an improved system for engaging the flexible packaging materials of a parcel.

Owner:MATERIAL HANDLING SYST INC

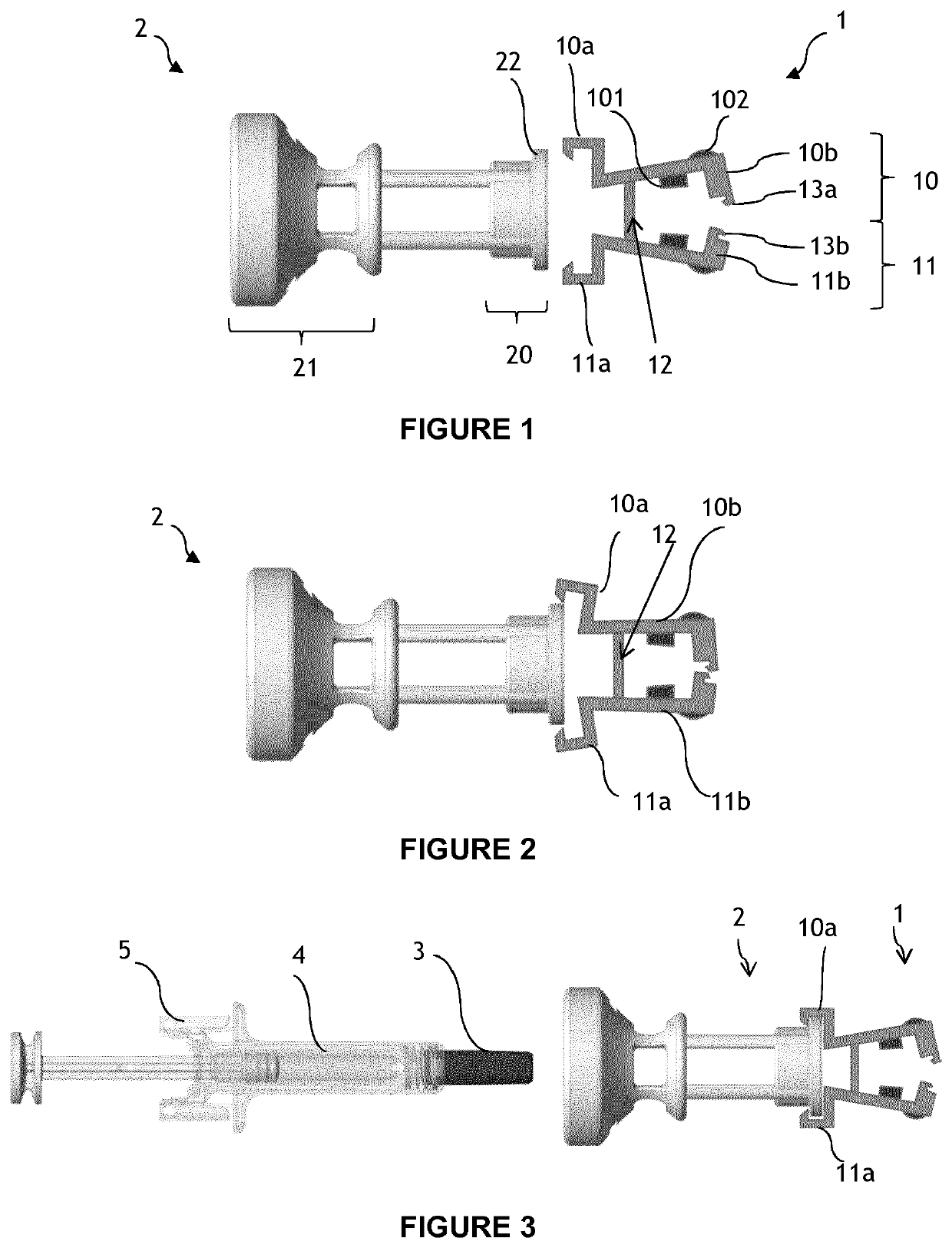

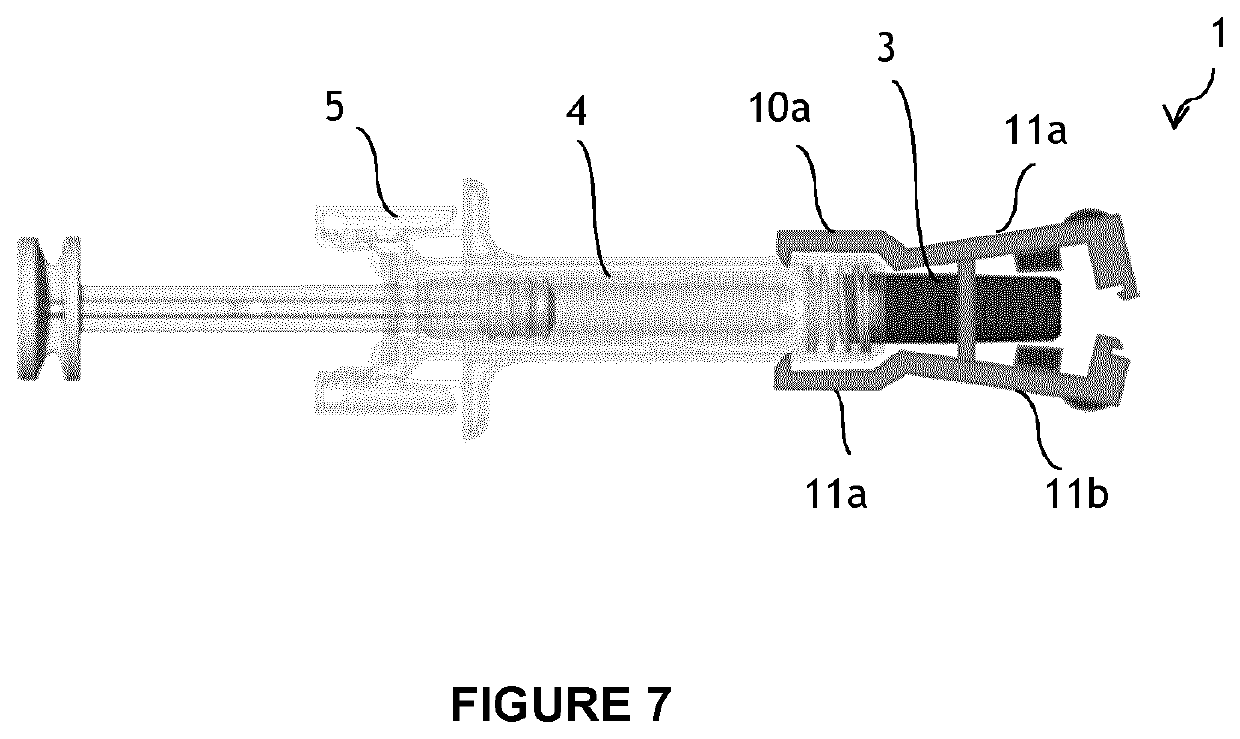

Tool for Removing a Cap From a Medical Injection Device

PendingUS20210030972A1Easy to usePrevents any coringInfusion syringesMedical devicesDistal portionSurgery

A tool for removing a cap from a medical injection device comprising a body and a needle extending distally from the body, the cap covering the needle, the tool being characterized in that it comprises a pair of opposite jaws connected by an elastic interface, each jaw comprising: a distal portion forming a distal clamp configured to surround at least a part of the cap; and a proximal portion forming a proximal clamp configured to be removably axially fixed to a body of the medical injection device, the elastic interface forming a fulcrum located between the distal and proximal portions such that a pinching force exerted radially inwardly onto the distal portion of the jaws causes the proximal portion of the jaws to expand radially outwardly.

Owner:BECTON DICKINSON FRANCE

Coupling structure for input devices

ActiveUS9582045B2Increase volumeSufficient flexural amountDetails for portable computersEngineeringUltimate tensile strength

A coupling structure capable of coupling a metal plate-like member and a resin chassis member with high assembling efficiency and sufficient coupling strength while preventing damage to parts is disclosed. The coupling structure is a structure for coupling a housing plate as a resin chassis member to a base plate as a metal plate-like member in a direction to overlap the housing plate with the base plate. The housing plate includes a latch having a pair of arm members extending along a direction parallel with a coupling face to the base plate and whose distal ends are spaced out from each other, and the base plate includes a coupling hook formed upright toward the side of the housing plate and engaged between the pair of arm members.

Owner:LENOVO PC INT

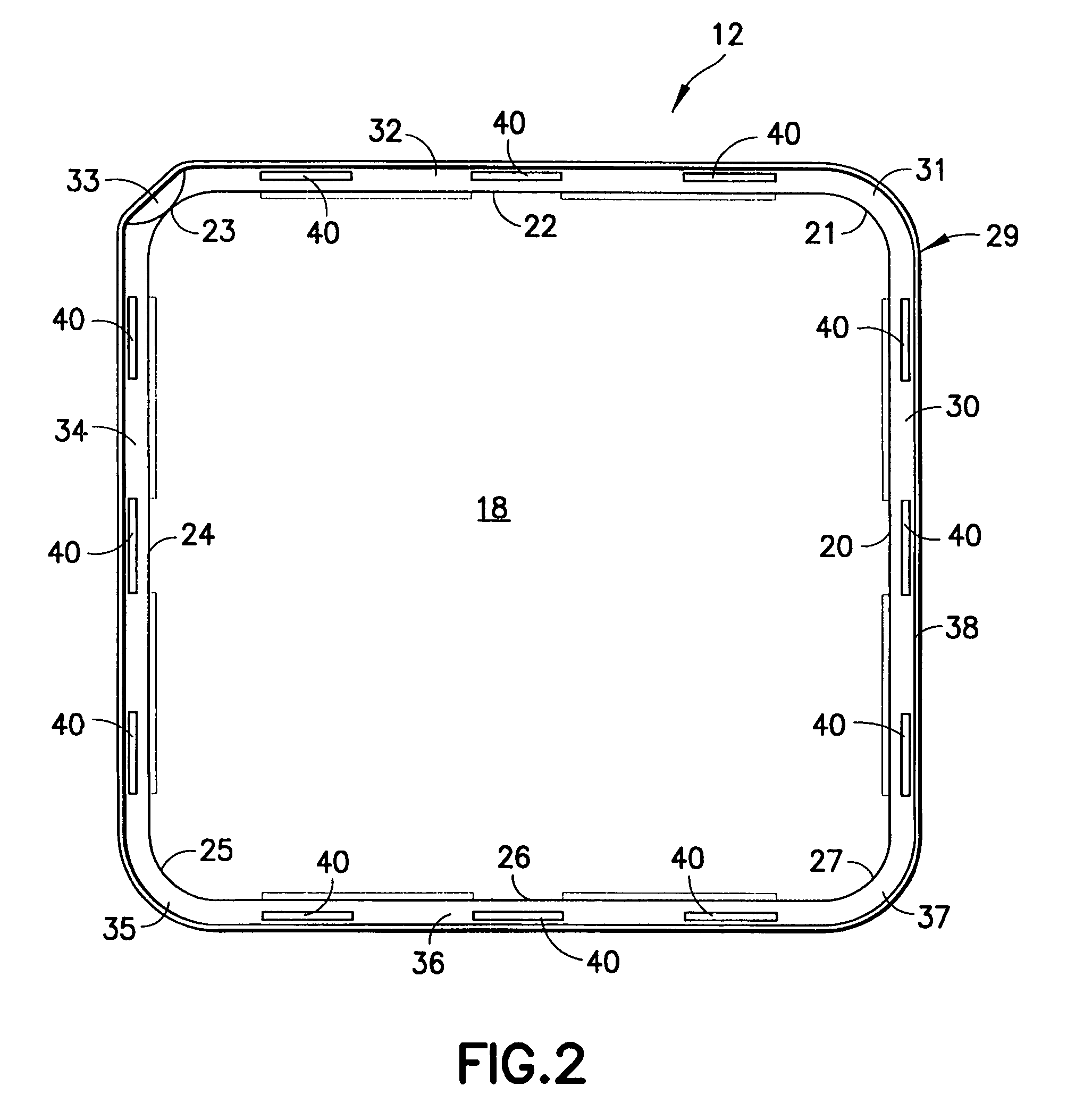

Fluid containment for laboratory containers

ActiveUS7449332B2Efficient stackingEfficiently stackedBioreactor/fermenter combinationsBiological substance pretreatmentsStress concentrationEngineering

A culture dish assembly includes a polygonal culture dish with a bottom wall and a side wall enclosure formed by a plurality of generally planar panels joined consecutively to one another by non-planar corners. The side wall enclosure includes a generally planar top edge. Inner surface regions of a plurality of the planar panels are formed with a plurality of projections or recesses that are spaced from one another and spaced from the corners. A splash guard includes engagement flanges disposed for nesting with inner peripheral surface regions of the panels of the side wall enclosure. The engagement flanges include projections or recesses disposed for releasably engaging the projections or recesses on the side wall enclosure to hold the splash guard on the culture dish without creating stress concentrations in the corners.

Owner:CORNING INC

Dummy plug

InactiveUS20120238135A1Large warping marginImprove rigiditySecuring/insulating coupling contact membersCouplings bases/casesMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com