Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Sufficient alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

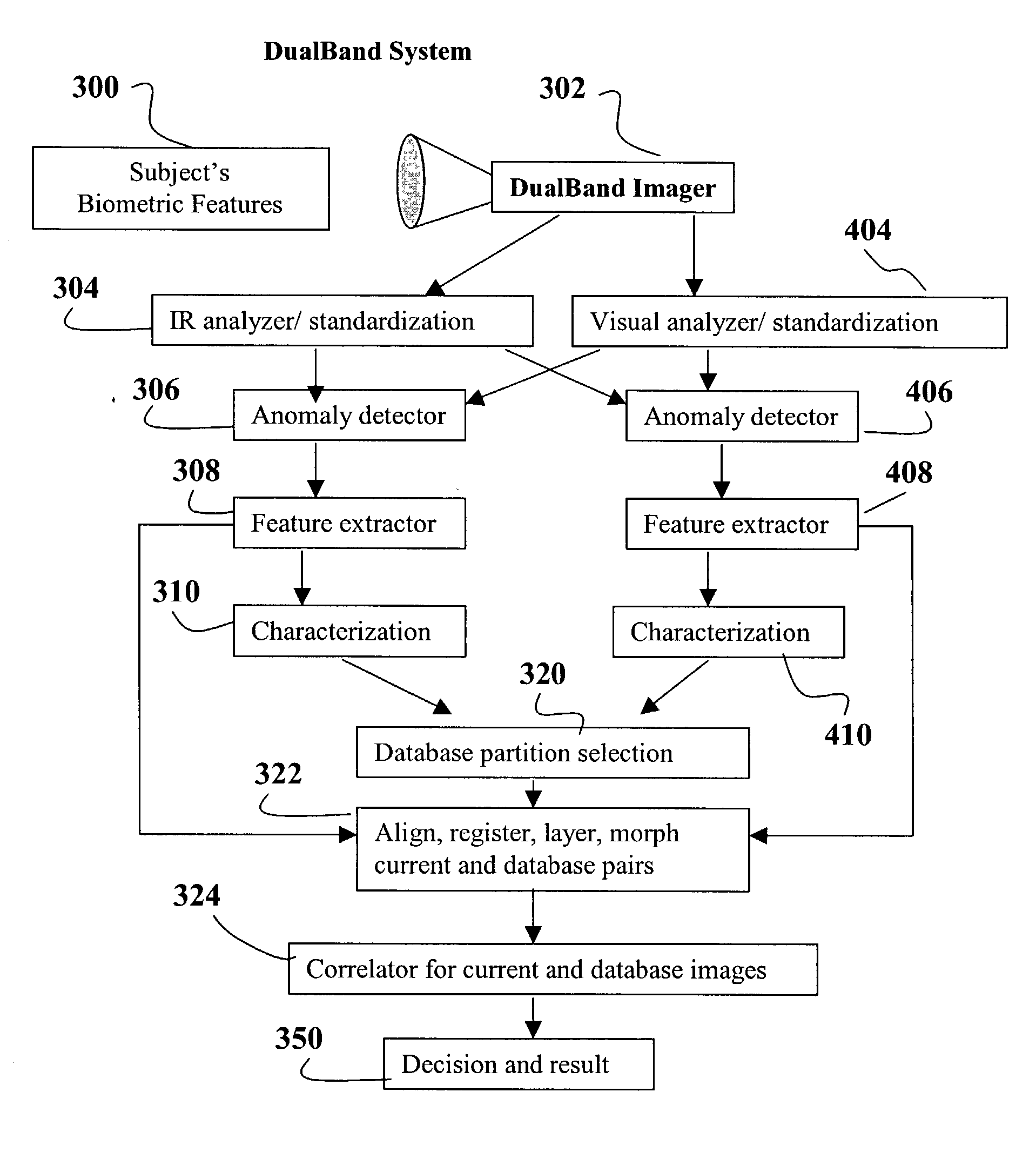

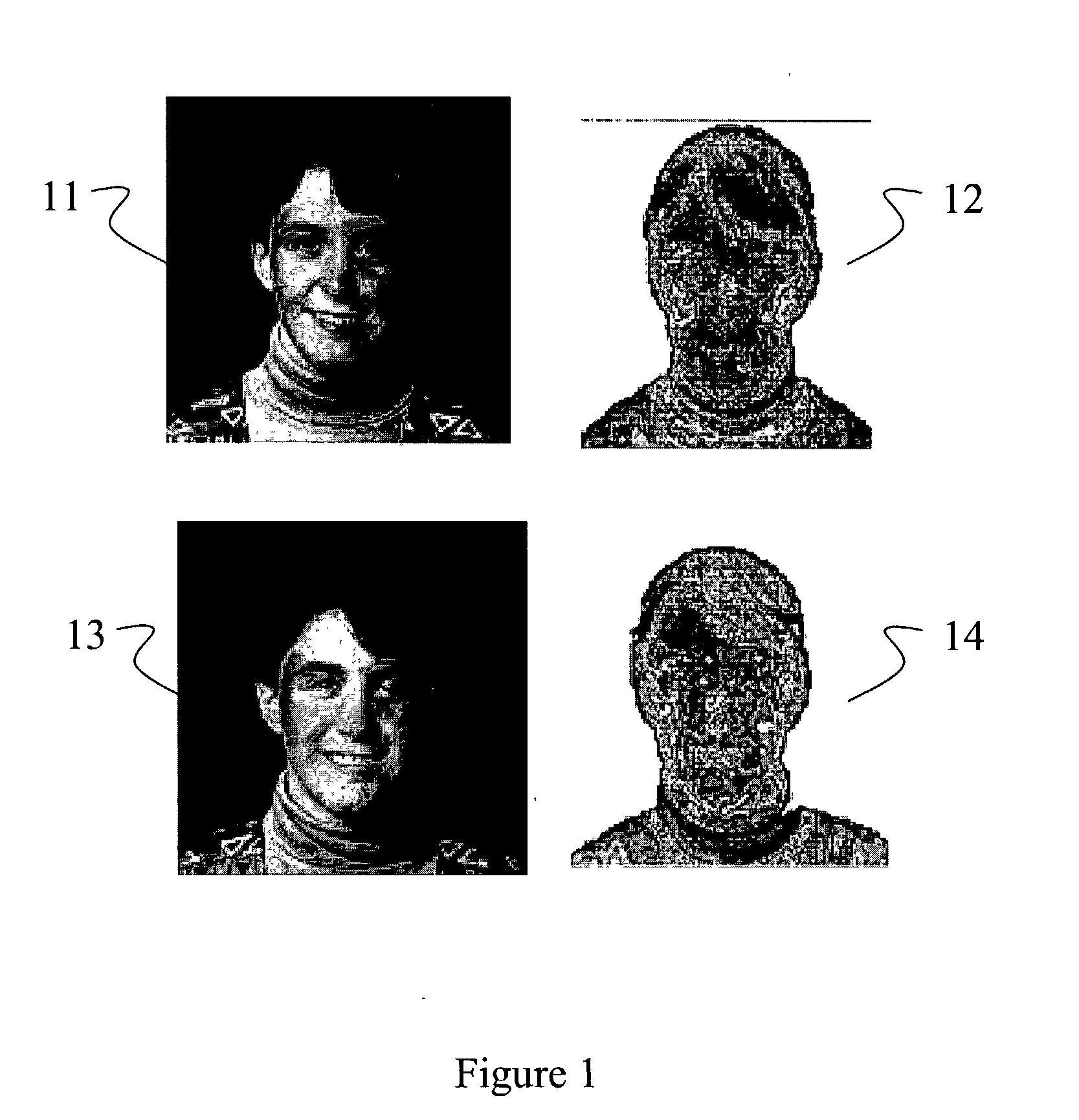

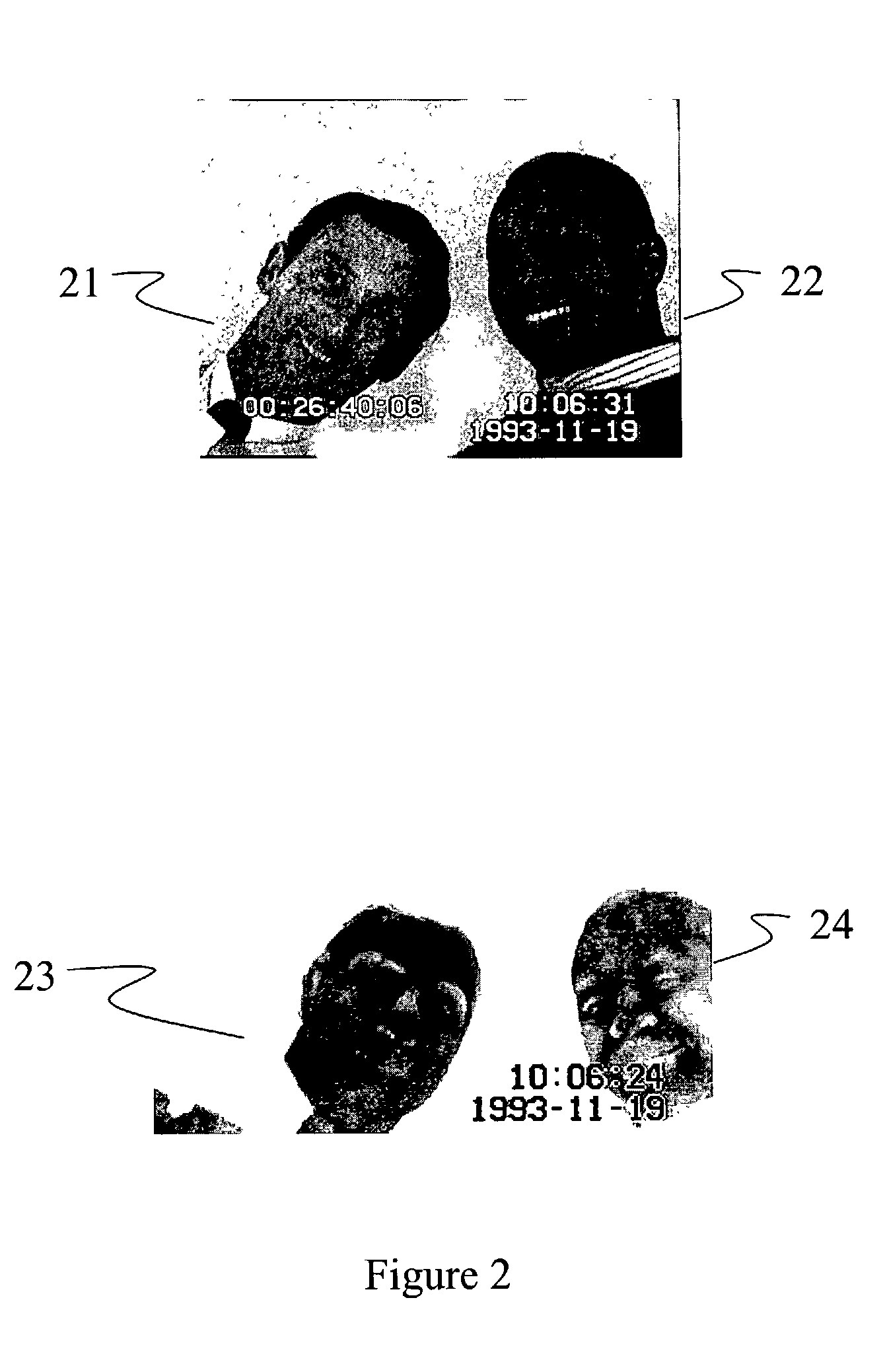

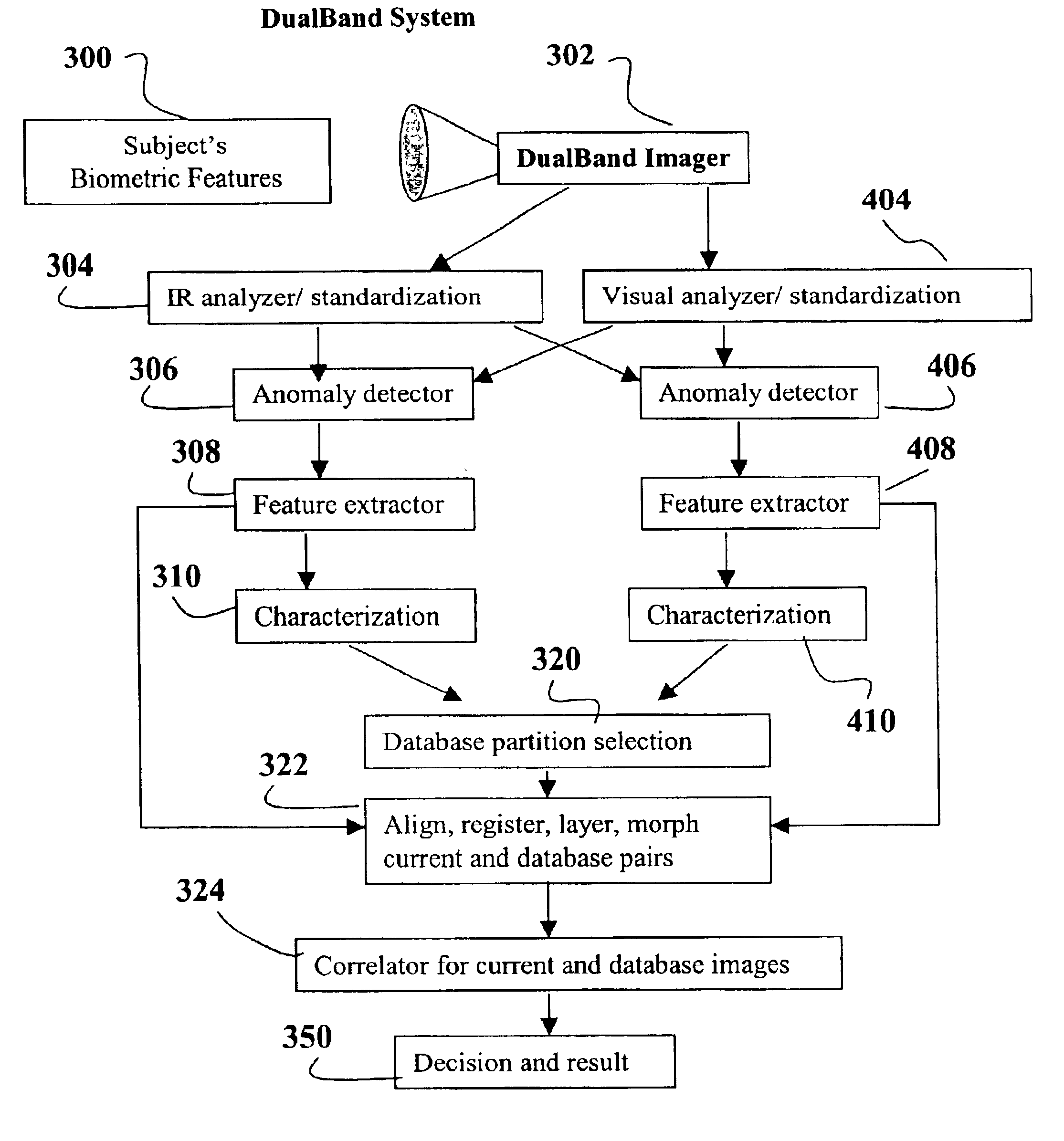

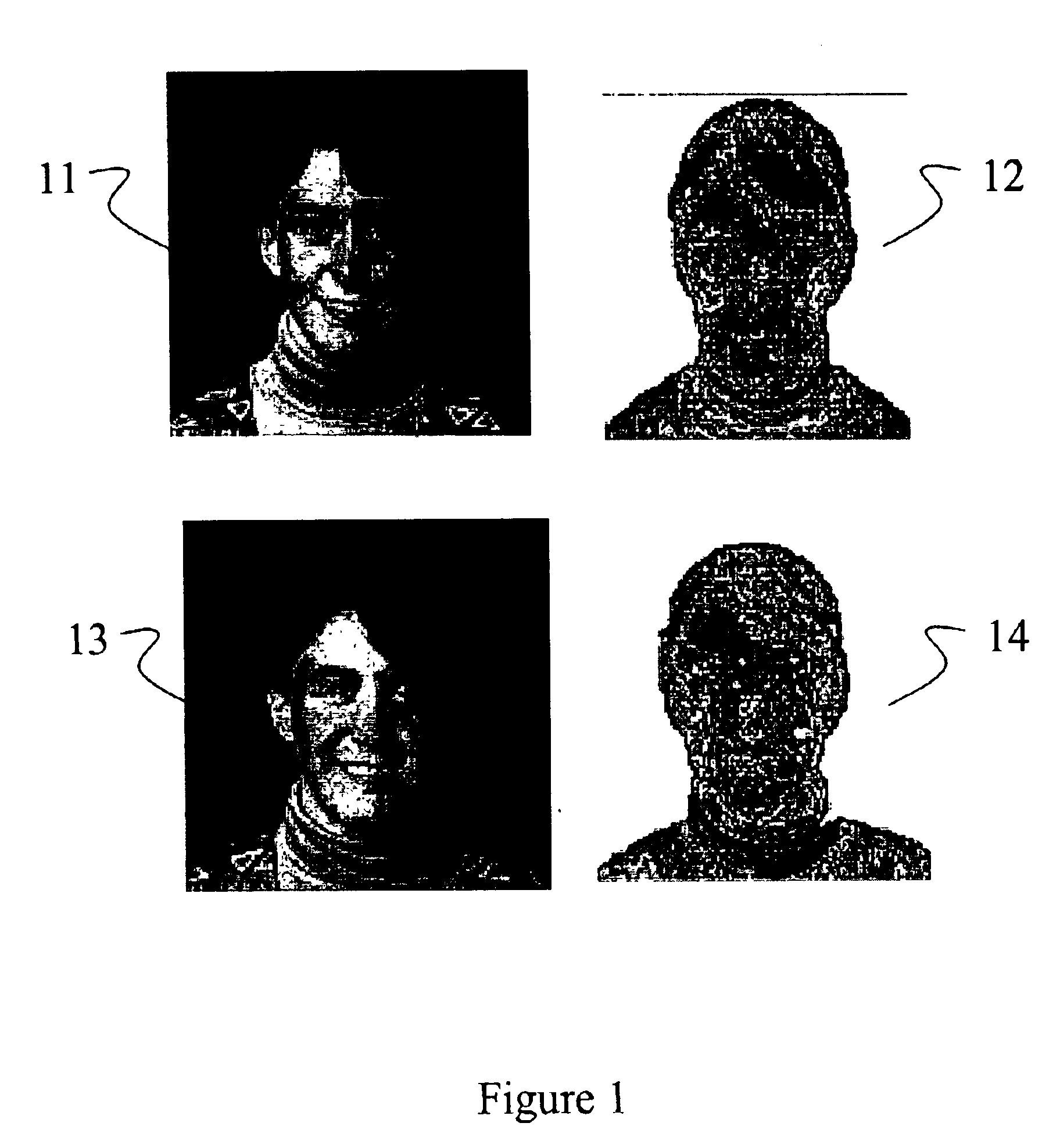

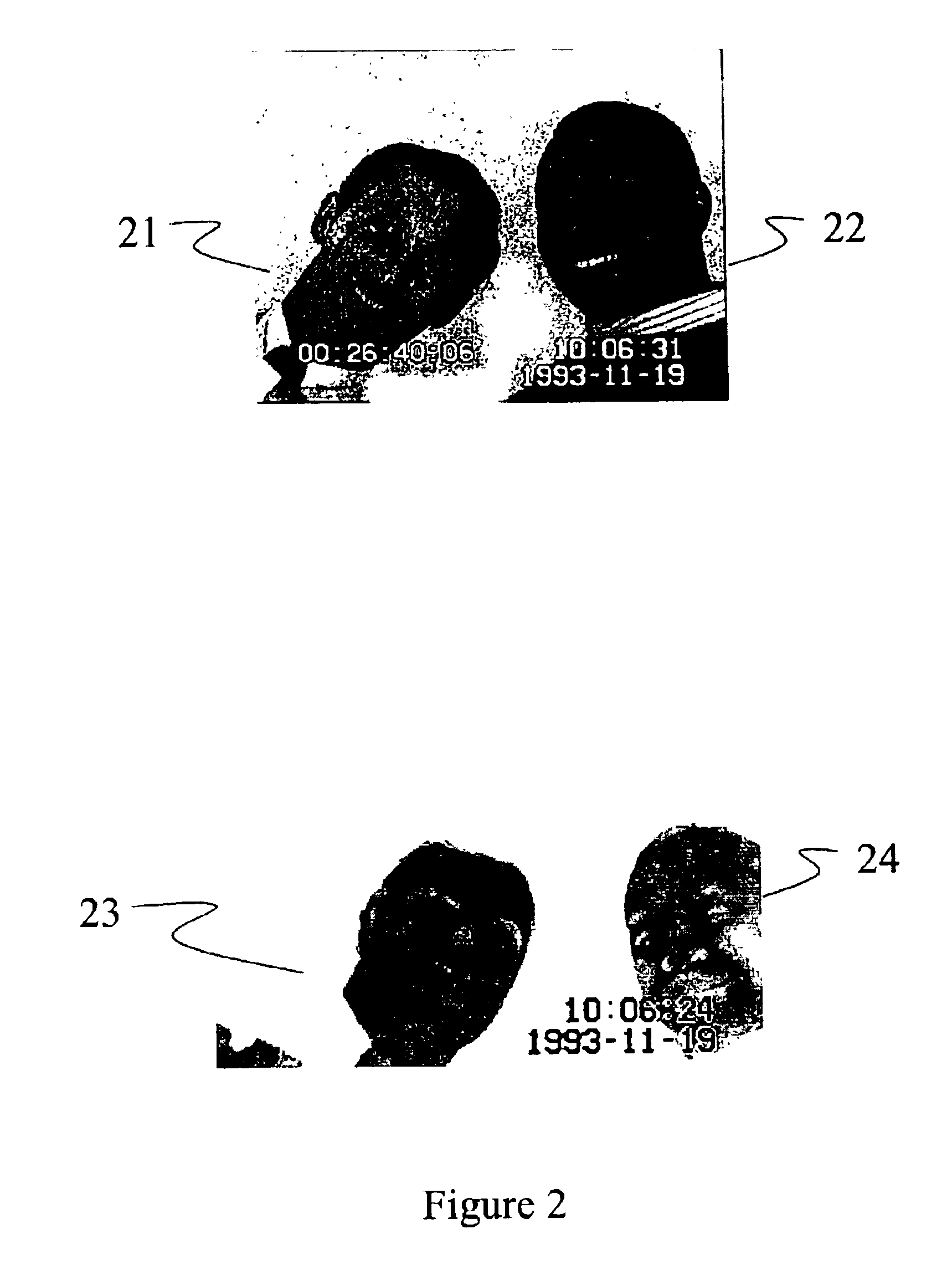

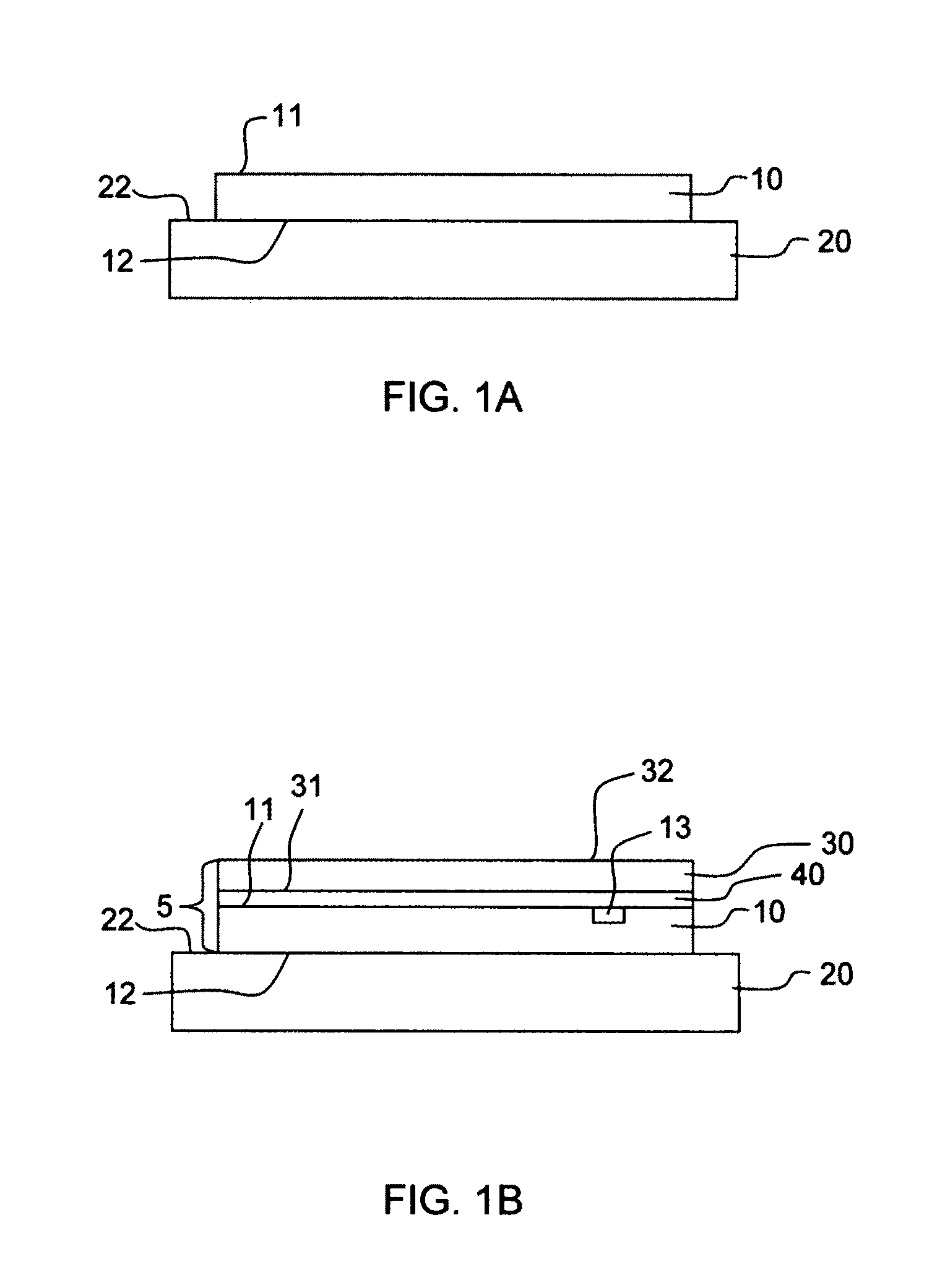

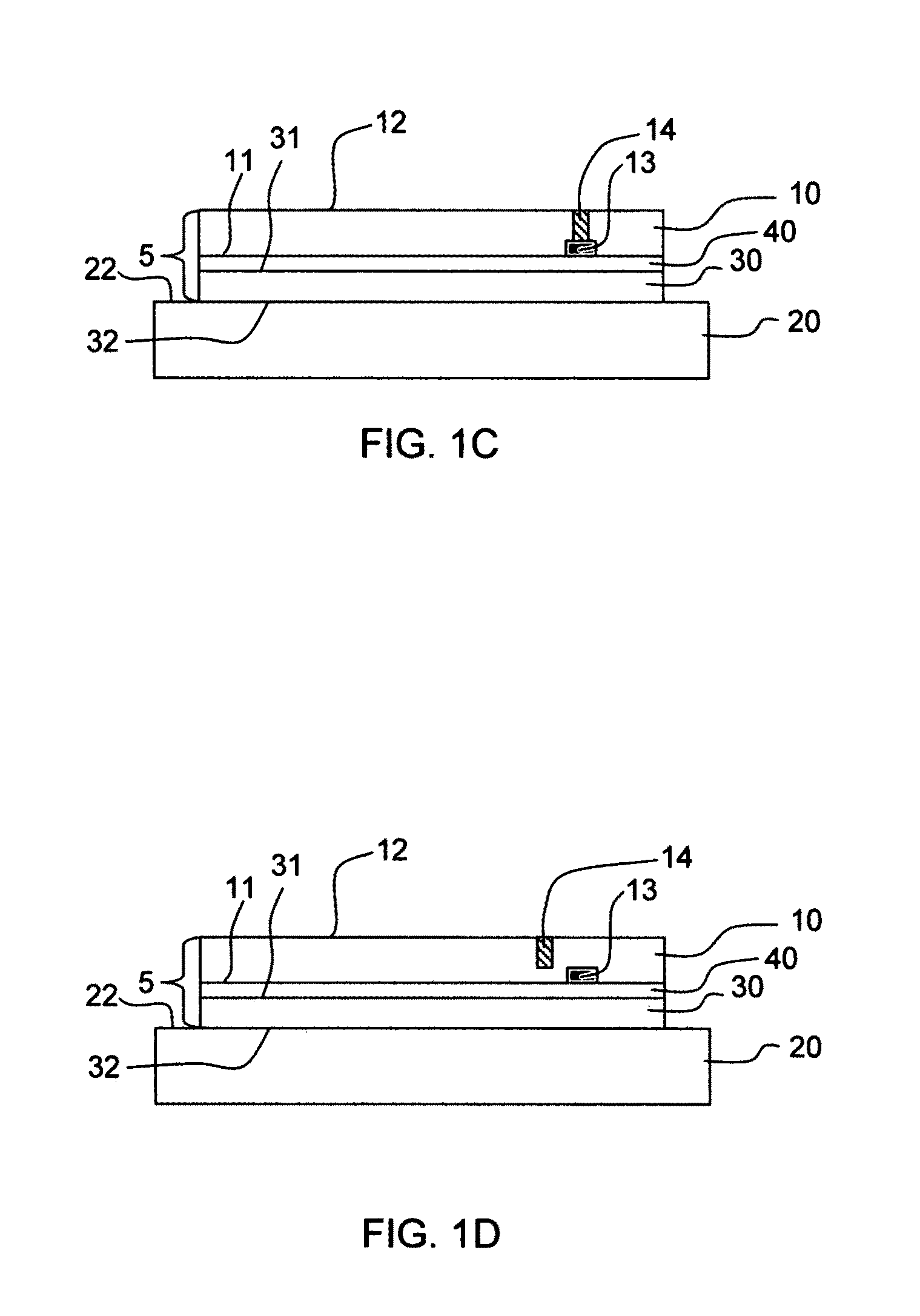

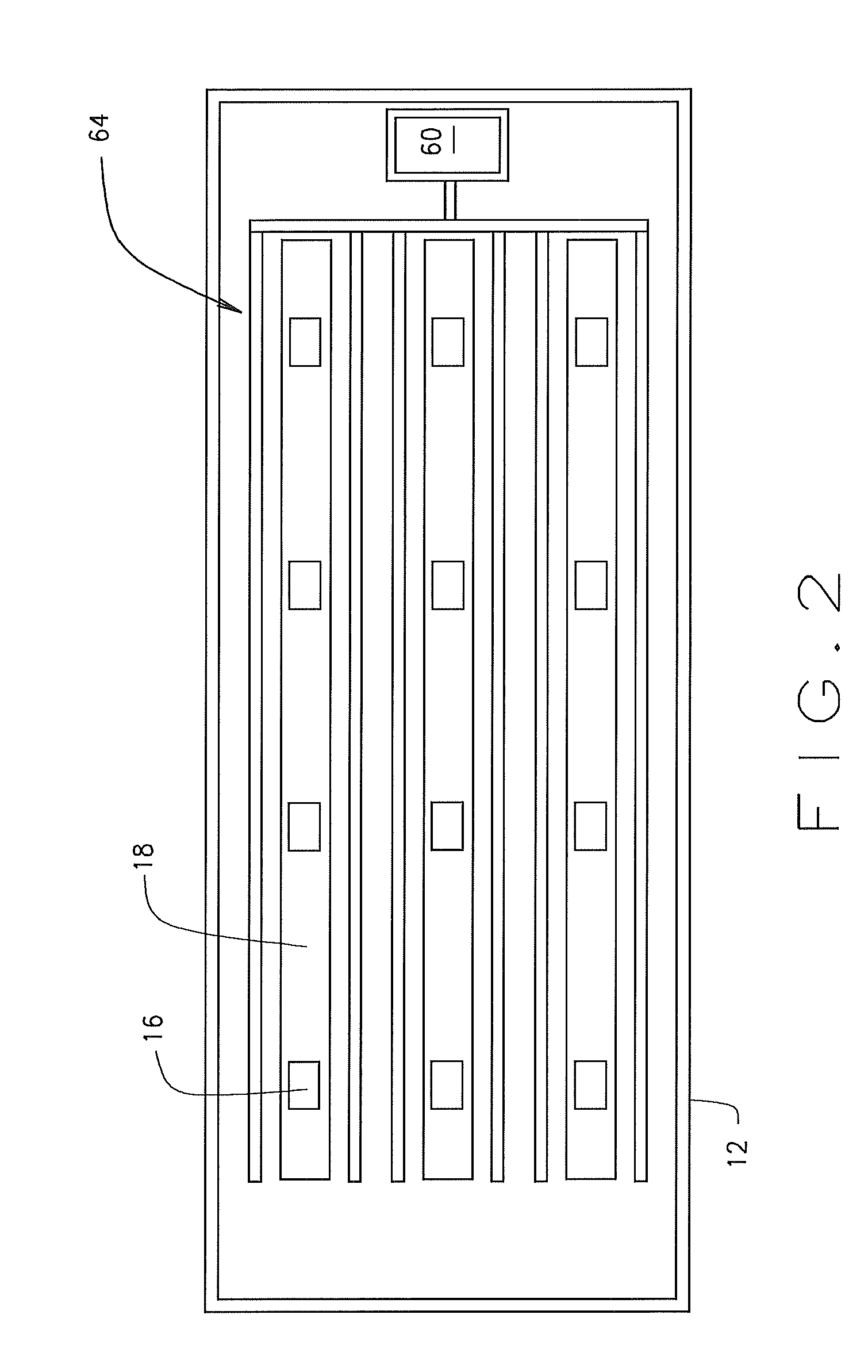

Dual band biometric identification system

InactiveUS20020136435A1Raise the possibilityEfficient and optimized useSpoof detectionSubcutaneous biometric featuresIr imageFingerprint

A biometric identification system directed toward use of dual-band visual-infrared imaging with appropriate techniques for integrating the analysis of both images to distinguish less reliable from more reliable image components, so as to generate a composite image comprised of layers. Correlation and analysis of the composite layers enables improved reliability in identification. The method and apparatus of the invention provide for efficient and optimized use of dual-band imaging for biometric identification of faces, fingerprints, palm and hand prints, sweat pore patterns, wrist veins, and other anatomical features of humans and animals. One embodiment includes the addition of a thermal infrared camera to a visual facial recognition system, with the IR image used to determine that the subject is alive and locate any features which are disguised. Another embodiment adds a visual camera to a thermal infrared facial recognition system, with areas of the visual image used to add colors and to fill-in behind eyeglasses which block the thermal infrared signature.

Owner:MIKOS

Dual band biometric identification system

InactiveUS6920236B2Improve accuracyRaise the possibilitySpoof detectionSubcutaneous biometric featuresVirtual cameraVisual perception

Owner:MIKOS

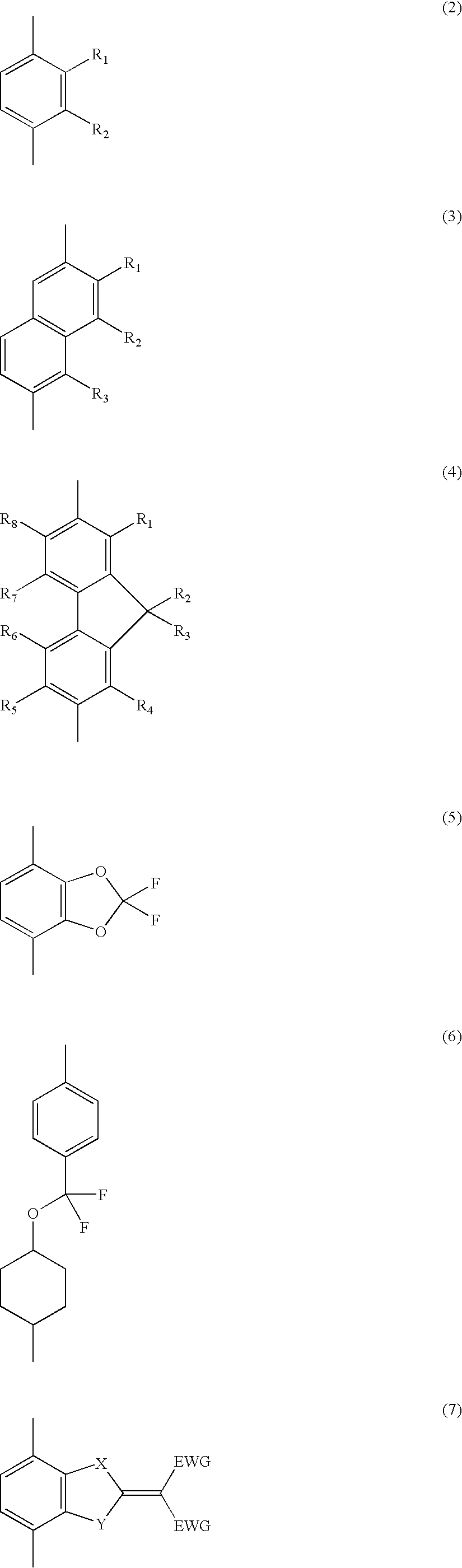

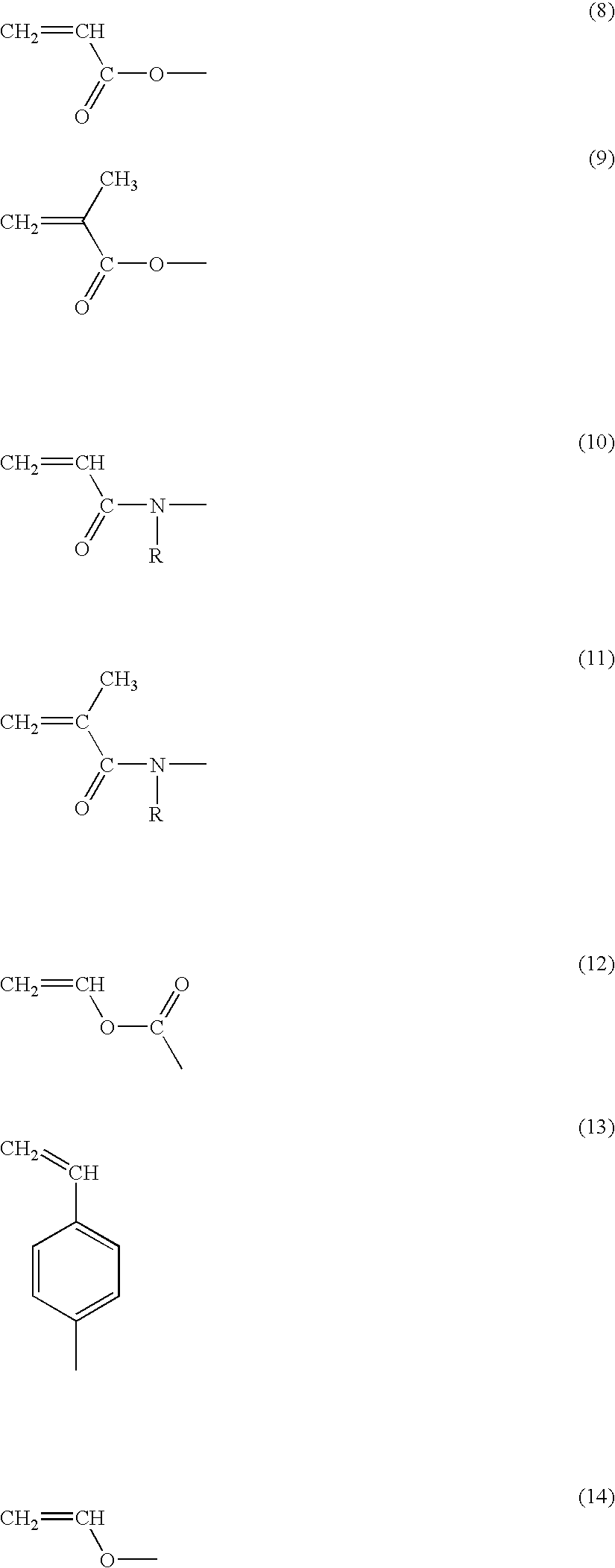

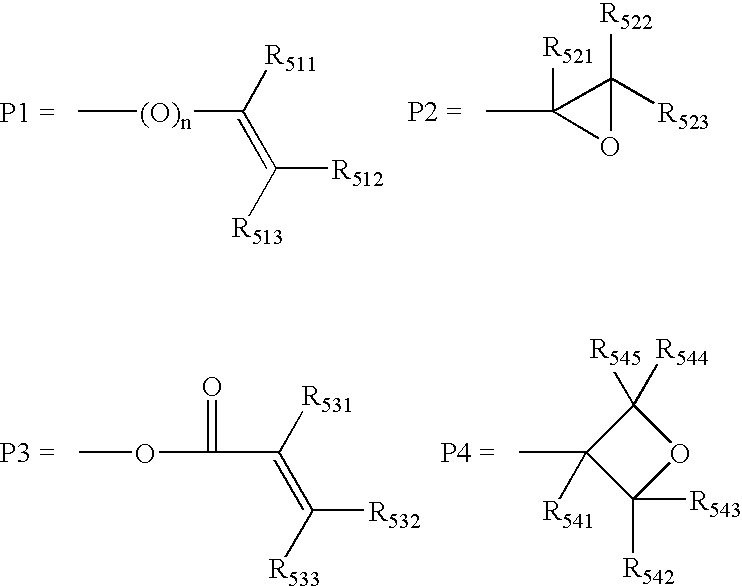

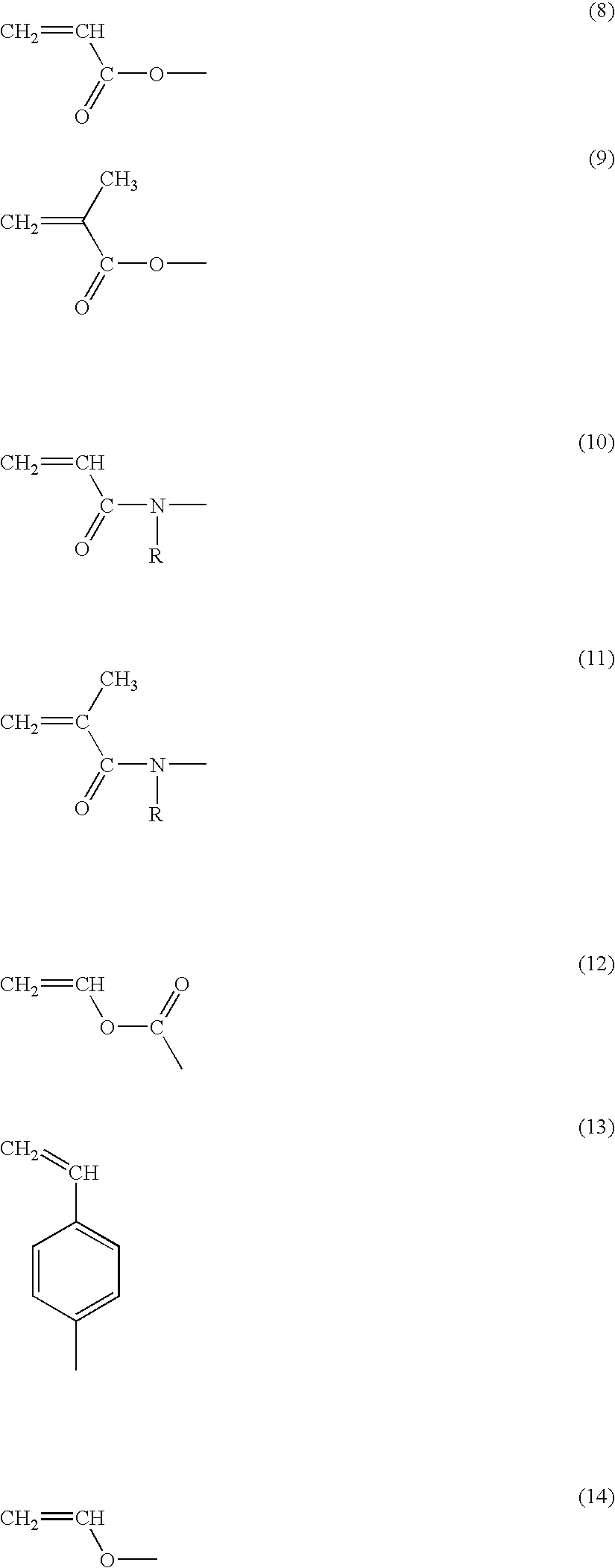

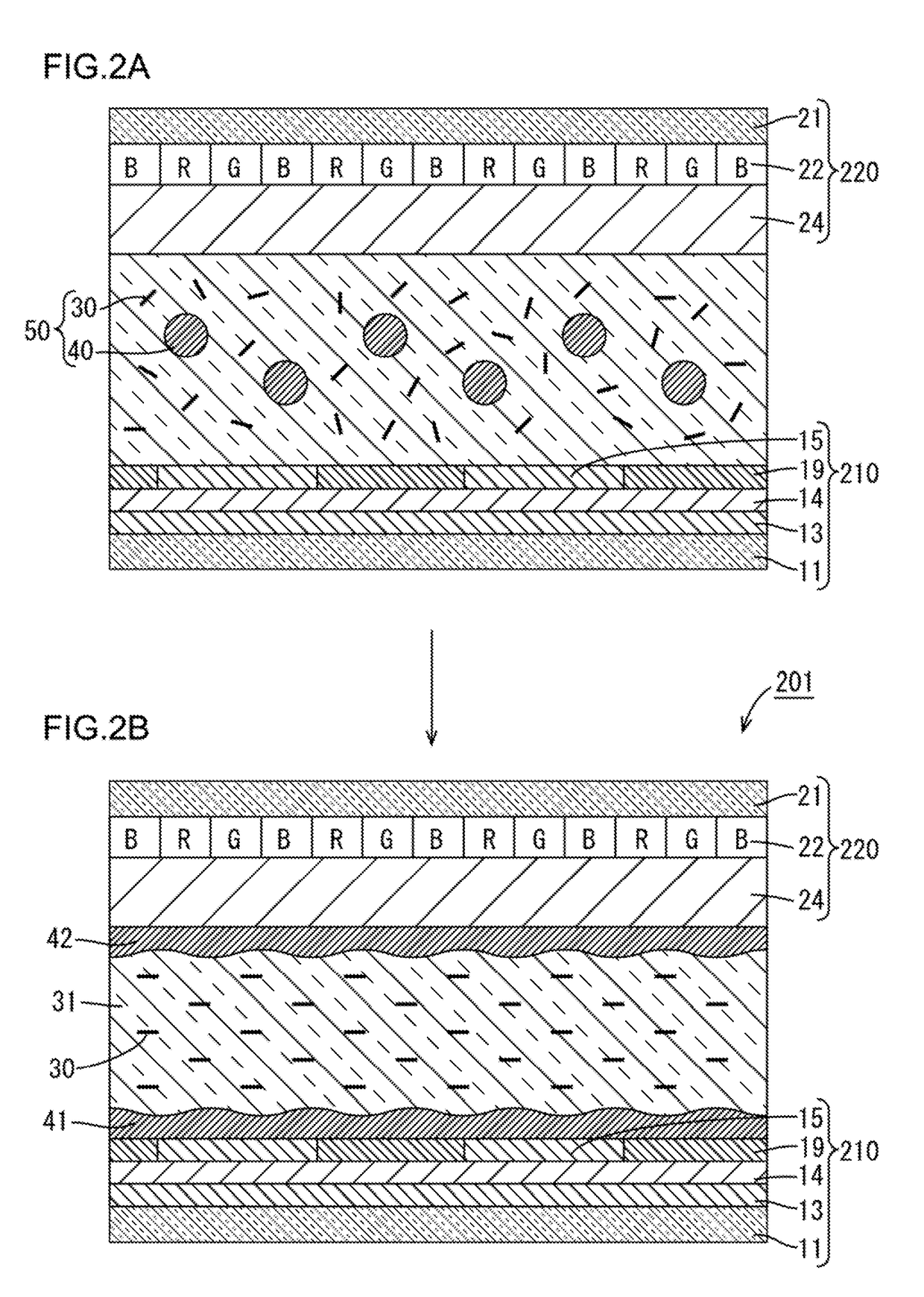

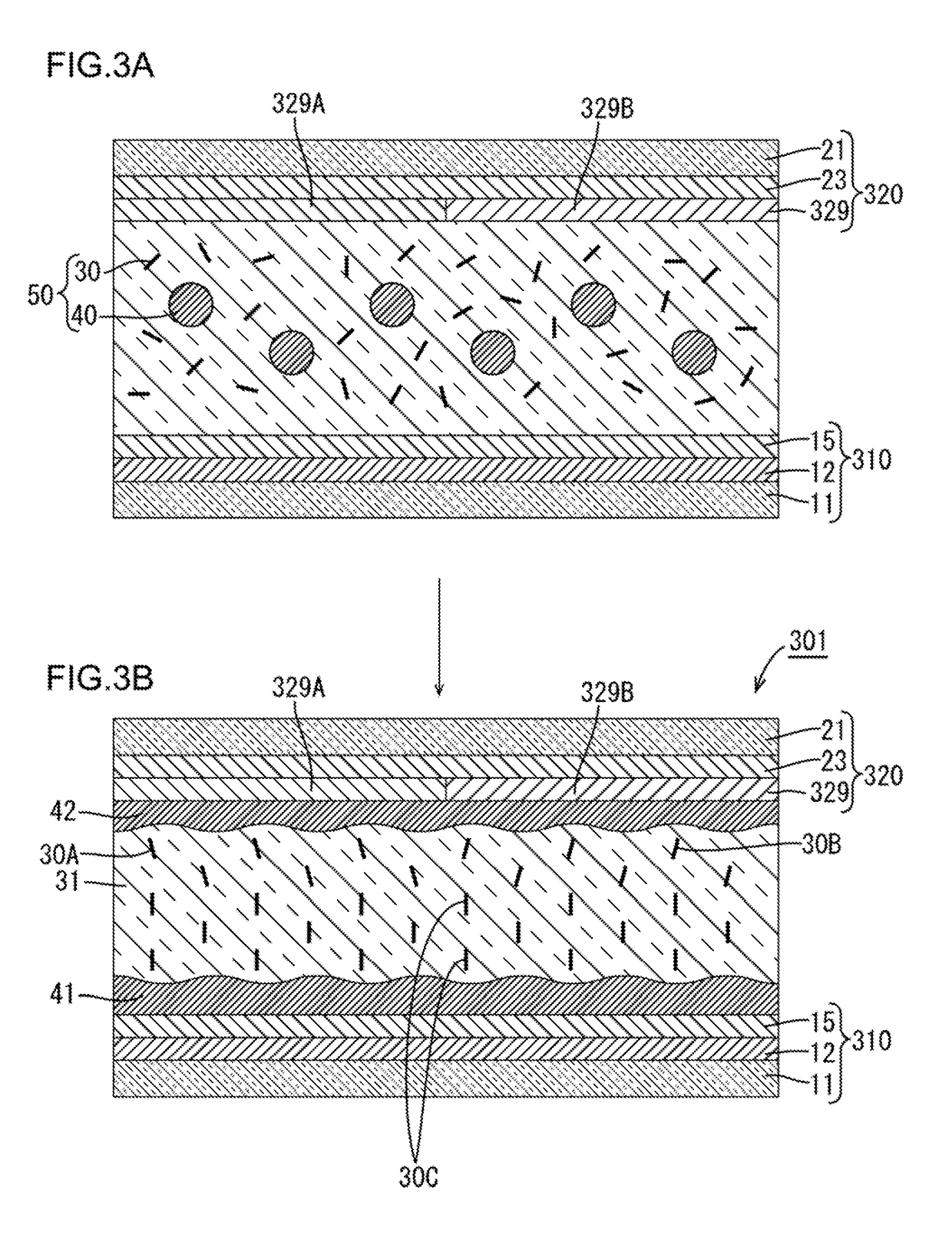

Vertical alignment film and va mode liquid crystal cell

InactiveUS20090268143A1Short timeSufficient alignmentLiquid crystal compositionsThin material handlingVertical alignmentLiquid crystal cell

The present invention provides a vertical alignment film having a polymerizable liquid crystal compound having negative dielectric constant anisotropy, where the polymerizable liquid crystal compound is vertically aligned against the surface of the substrate, and then the polymerizable liquid crystal compound is fixed to form the vertical alignment film.

Owner:FUJIFILM CORP

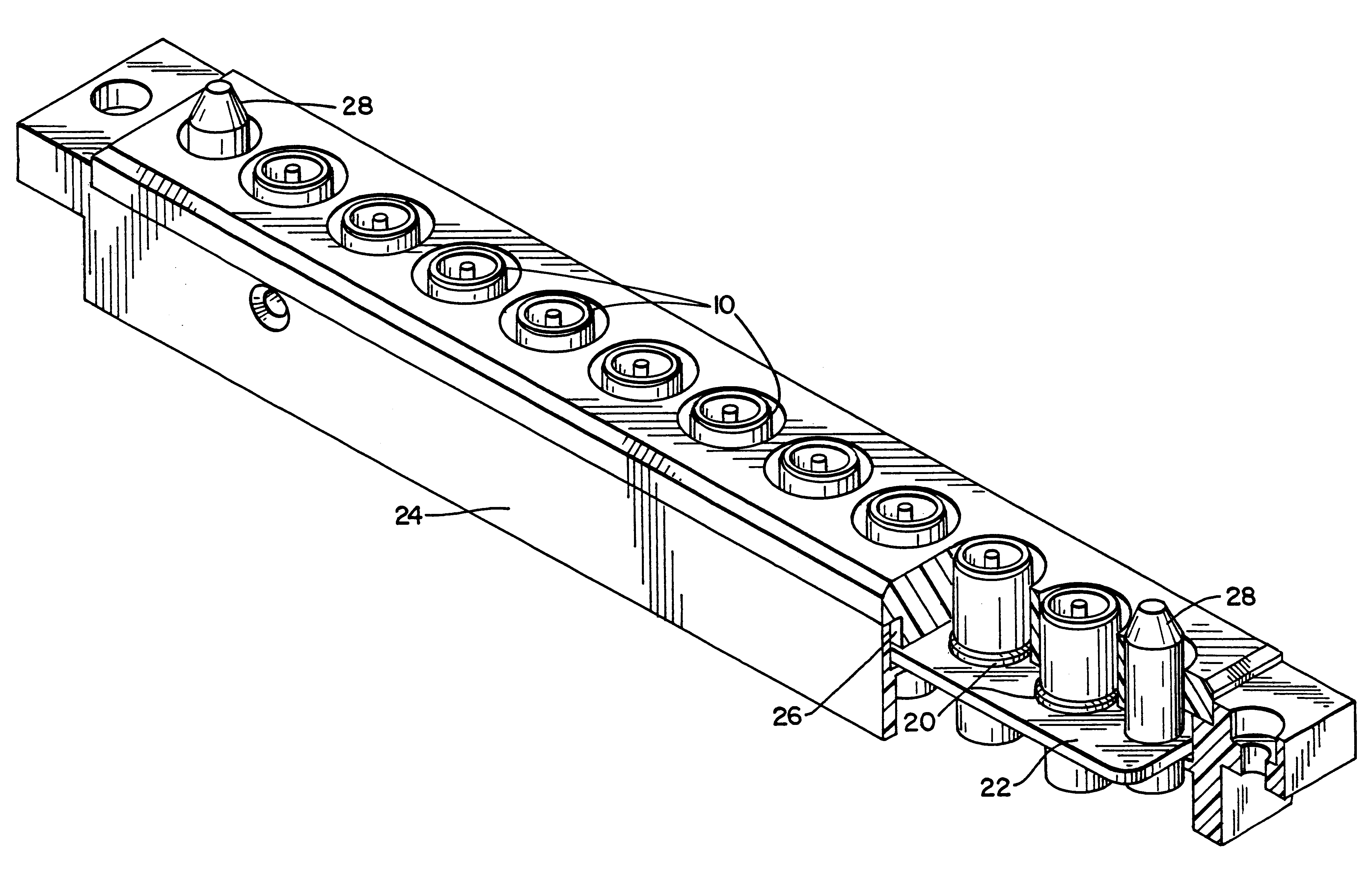

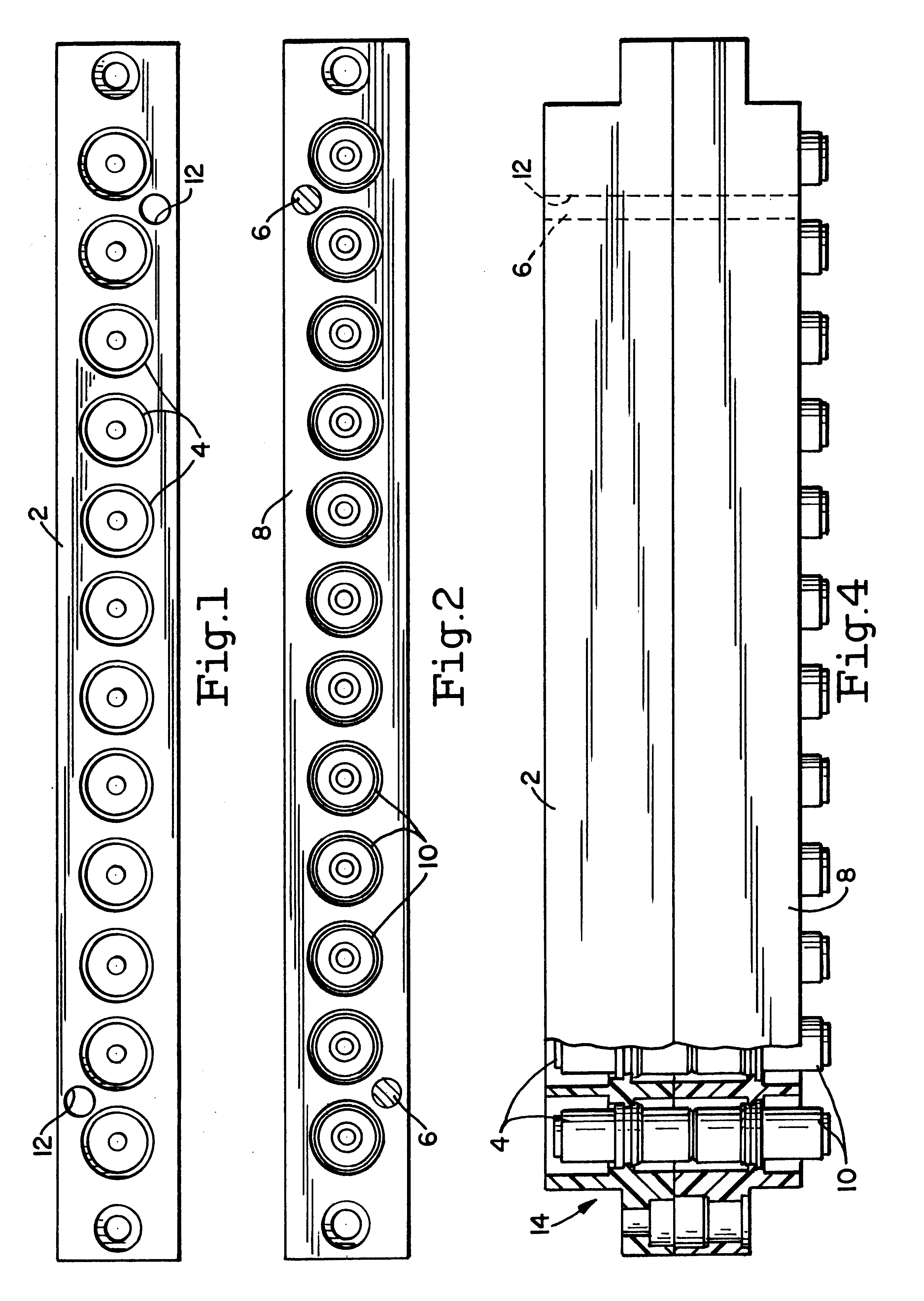

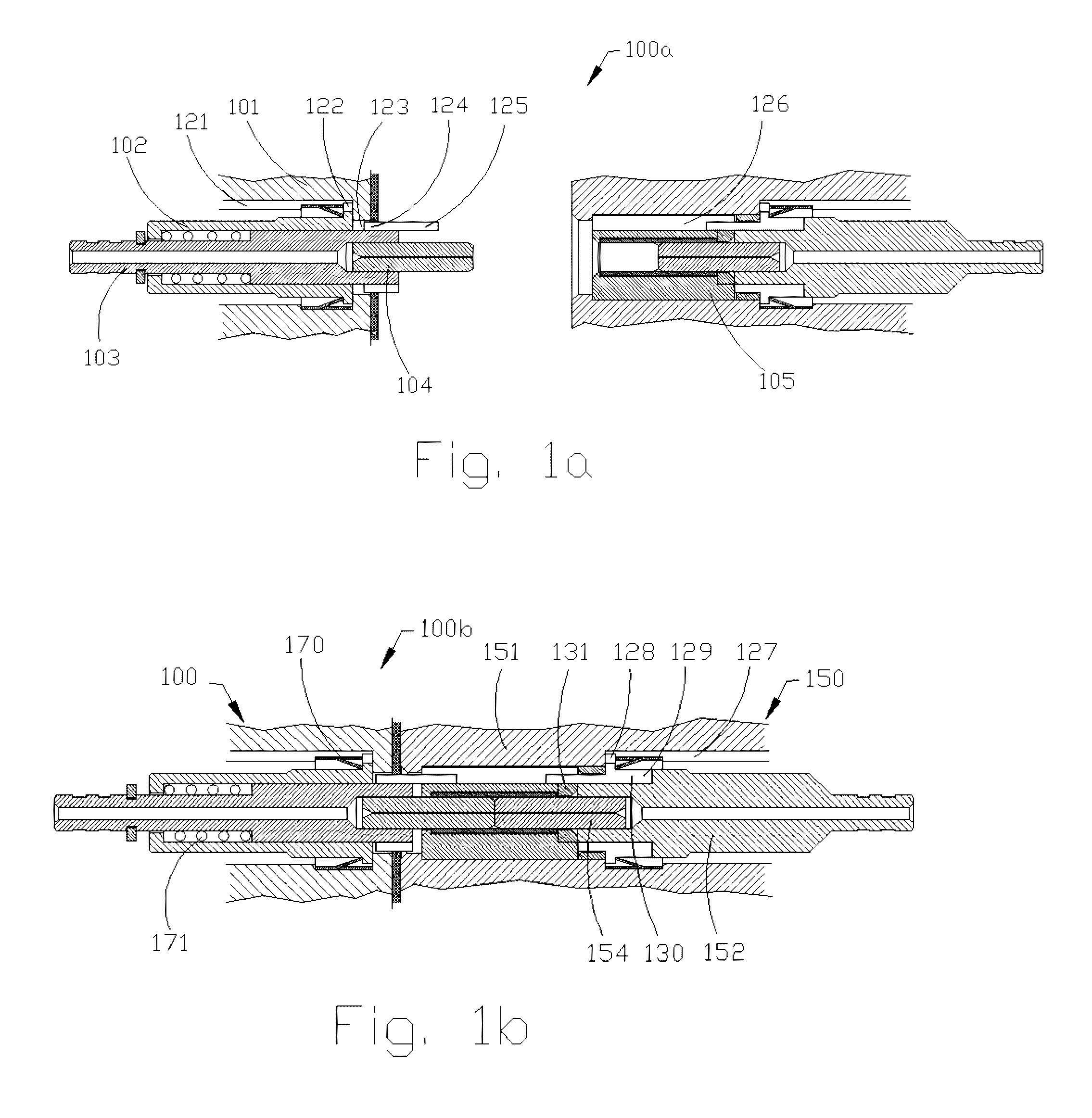

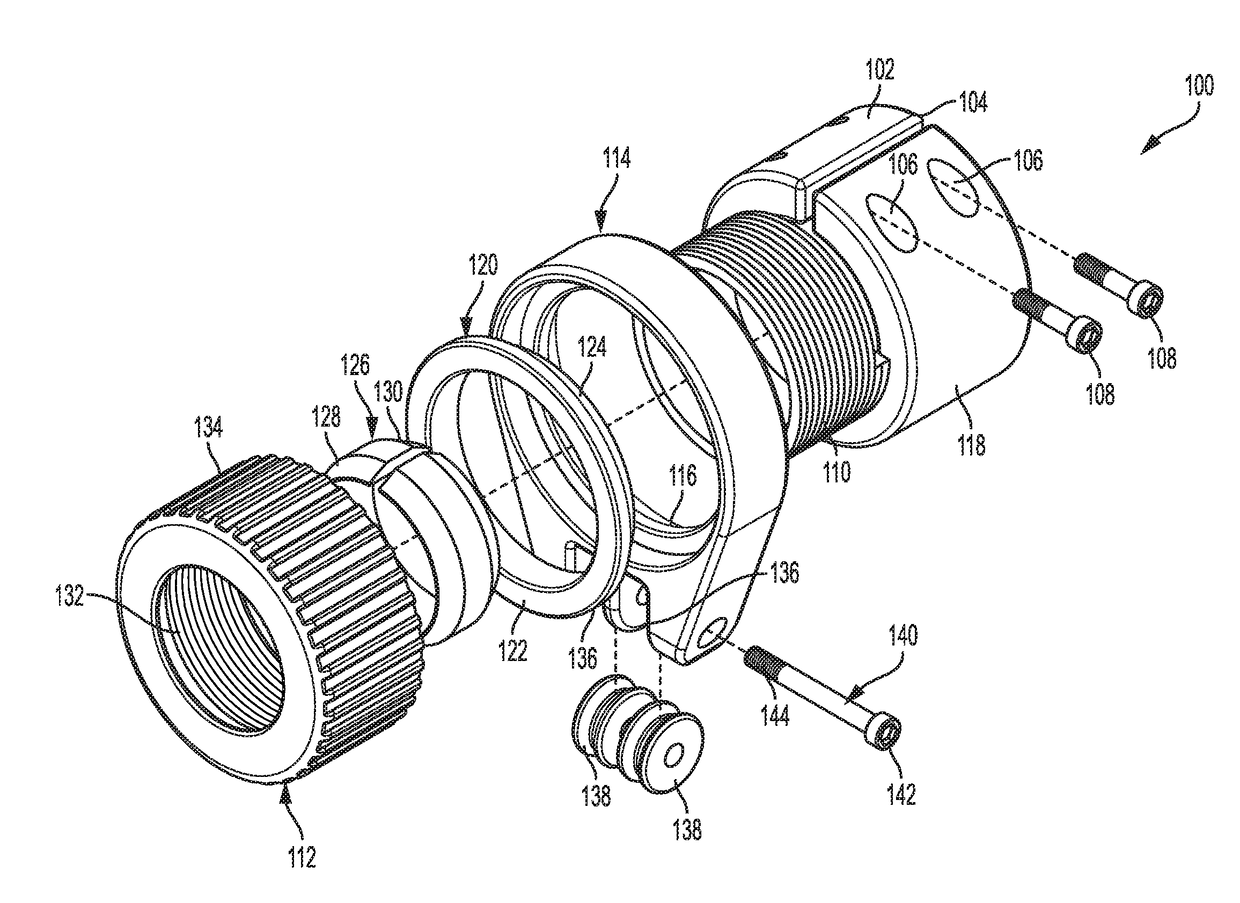

Planar blind-mate connectors

InactiveUS6409550B1Reduce contact wearEliminate crosstalkTwo pole connectionsAntenna connectorsInterconnectionEngineering

A planar connector is constructed to permit large numbers of two part connectors to be ganged for concurrent interconnection with virtually no cross talk between adjacent connectors and minimal damage due to misalignment of the large number in the array that are concurrently connected. Cross talk is minimized by having contact of the connector elements occur in shielded regions or below the plane of contact of the opposing contact members while the engaging members are planar mating interfaces at the point of engagement, thus materially reducing wear relative to a pin and socket type contact. This feature allows these planar blind-mate connectors to operate over one hundred thousand mating cycles. Contact with antennas and printed circuits is provided, and floating inner and outer contacts provide a superior long life rotary joint providing excellent r.f. performance. The connector body is held in a support and remains stationary in said support in the presence of movement of the planar contacts.

Owner:AEROFLEX WEINSCHEL

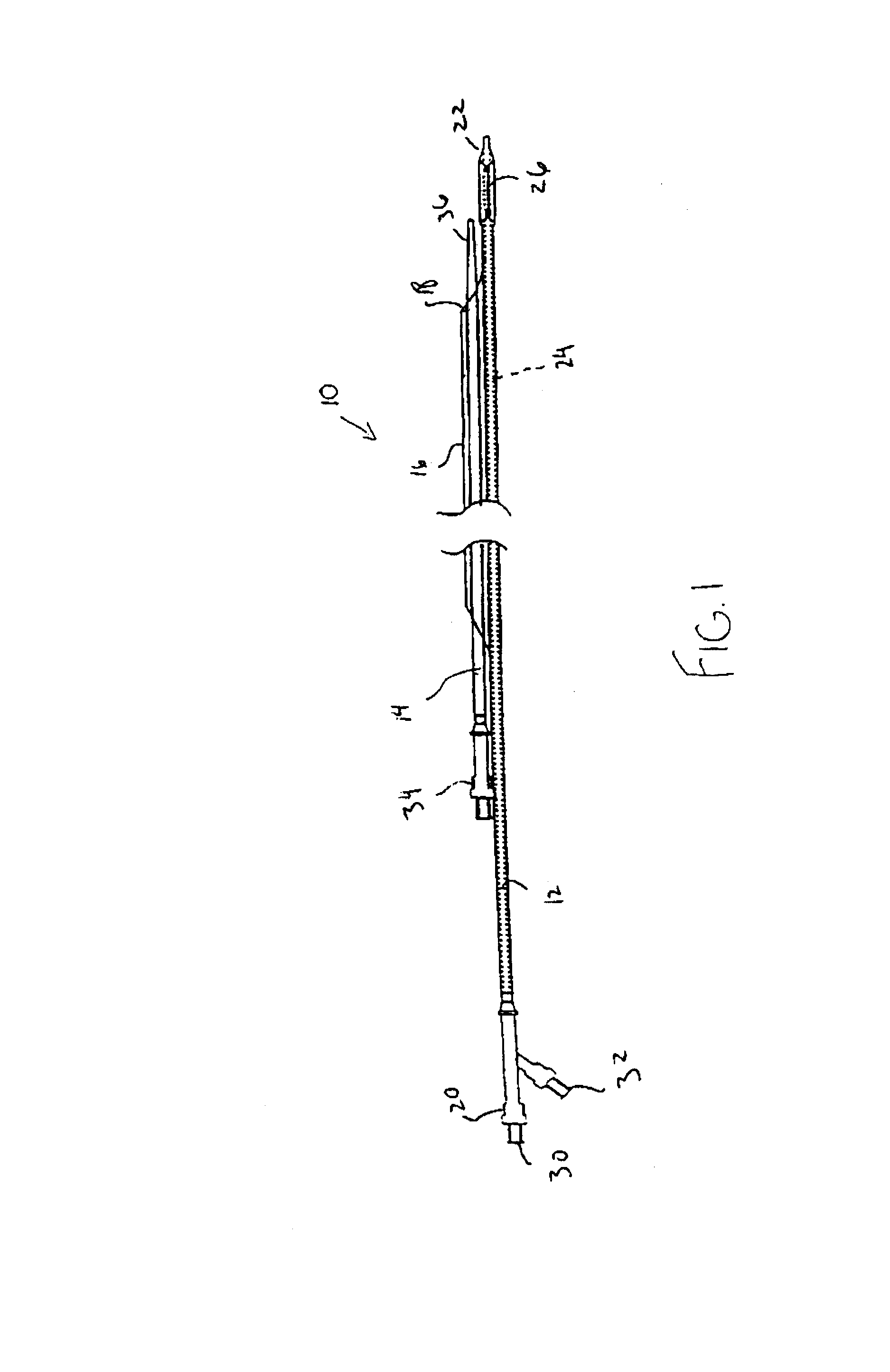

Catheter with side sheath and methods

A catheter system comprises a catheter having a catheter body with a distal end, a proximal end, a main vessel guidewire lumen for receiving a main vessel guidewire and a balloon disposing at the distal end of the catheter body. The catheter further includes a side member that is disposed adjacent to the catheter body. The side member has a distal end, a proximal end, and a branch vessel guidewire lumen for receiving a branch vessel guidewire. A stent having a side hole is disposed over the balloon, and a distal portion of the side member is disposed beneath at least a portion of the stent while being adjacent to and movable with respect to the balloon.

Owner:BOSTON SCI SCIMED INC

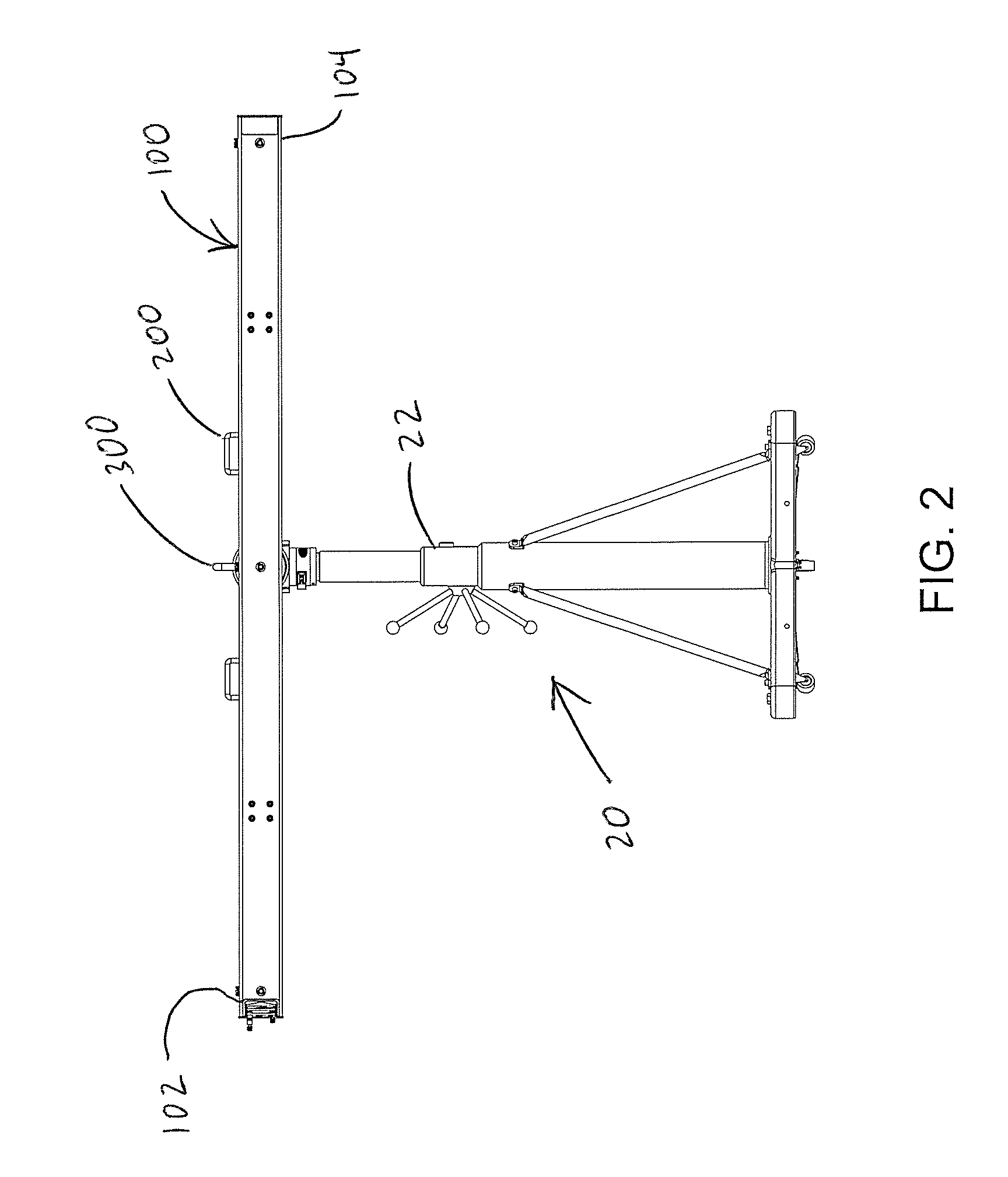

Projector mount

InactiveUS20080179475A1Sufficient alignmentEasy to adjustCandle holdersLighting support devicesSupporting systemProjection screen

A low profile projector mount for media projectors, enabling images of a media projector to be sufficiently aligned with a projection screen upon which the images are to be displayed. The alignment of the low profile projector mount is achieved through pitch, roll, and / or yaw adjustment mechanisms incorporated into the low profile projector mount. The low profile projector mount can be flush mounted to a ceiling or attached to an extension column or other intermediary support system. A quick-release system allows a projector attached to the low profile, projector mount to be removed without disturbing the low profile, projector mount. In addition, retractable members for effectuating the pitch, roll, and / or yaw adjustments are utilized.

Owner:PEERLESS INDS

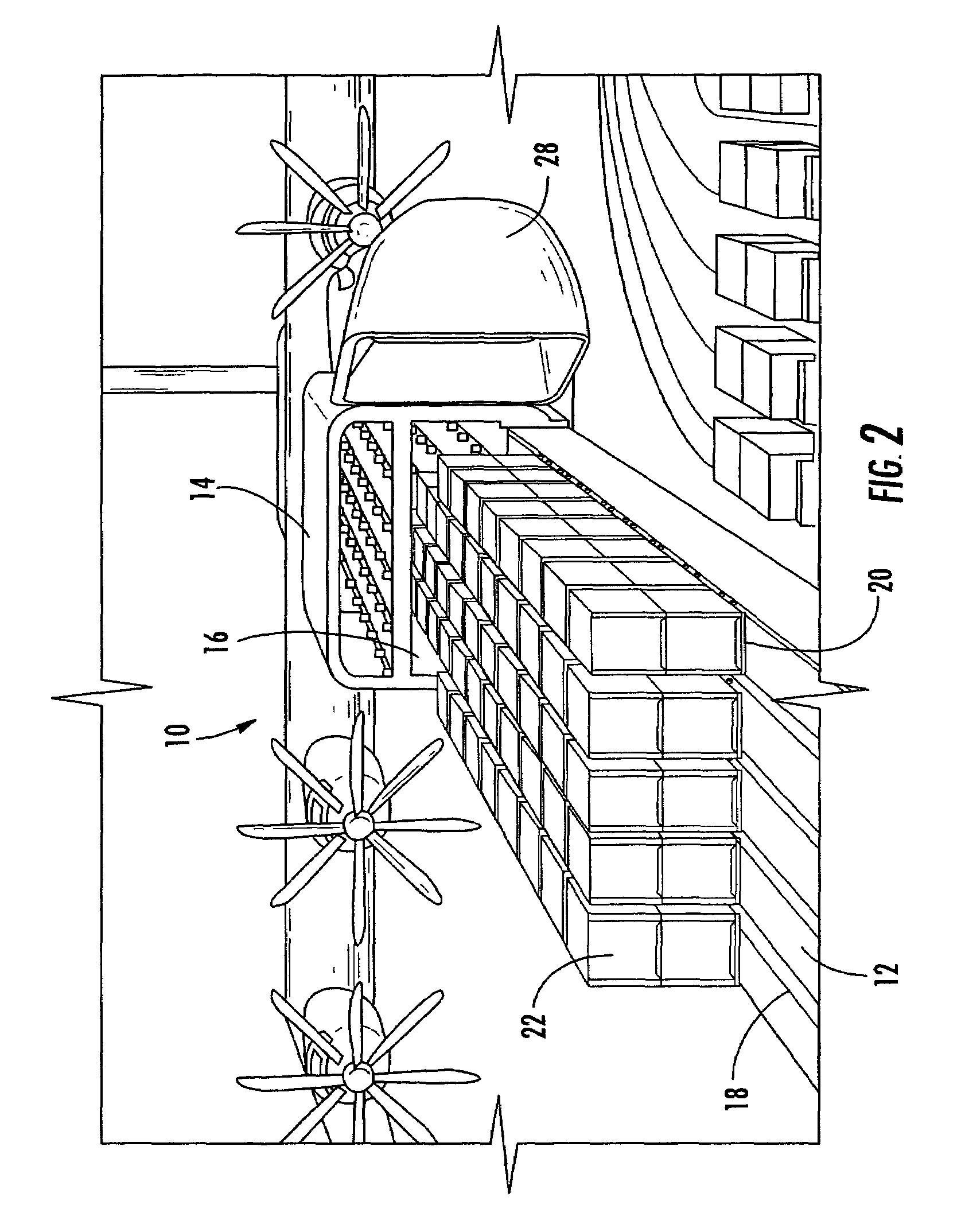

Cargo container handling system and associated method

InactiveUS7534082B2Efficiently and effectively transportingPrecise alignmentVehicle with removable loadingLoad accommodationEngineeringHandling system

A system and method for cargo handling is provided. The system includes a transport vehicle including a cargo bay capable of housing a plurality of cargo containers, and a loading dock for coupling to the cargo bay. The system also includes at least one railcar and pylons positioned along a floor of the cargo bay. A predetermined number of pylons are operable to elevate and lower a cargo container within the cargo bay. The present invention also provides a railcar for transporting cargo containers, as well as an apparatus for positioning at least one cargo container within a transport vehicle. The present invention also provides a system for aligning a loading dock and a transport vehicle that includes a mechanism for adjusting the height of the transport vehicle or loading dock, or a plurality of engagement members that are capable of aligning the loading dock and transport vehicle.

Owner:THE BOEING CO

Substrate-alignment using detector of substrate material

ActiveUS7751067B1Sufficient accuracySufficient alignmentPhotomechanical treatmentUsing optical meansOptical detectorsOptical detector

Methods and apparatuses are provided for positioning a substrate having a target that may be located on either the front-side or the backside of the substrate. The optical detector that views the target contains a signal-generating material that is substantially identical to the substrate material.

Owner:ULTRATECH INT INC

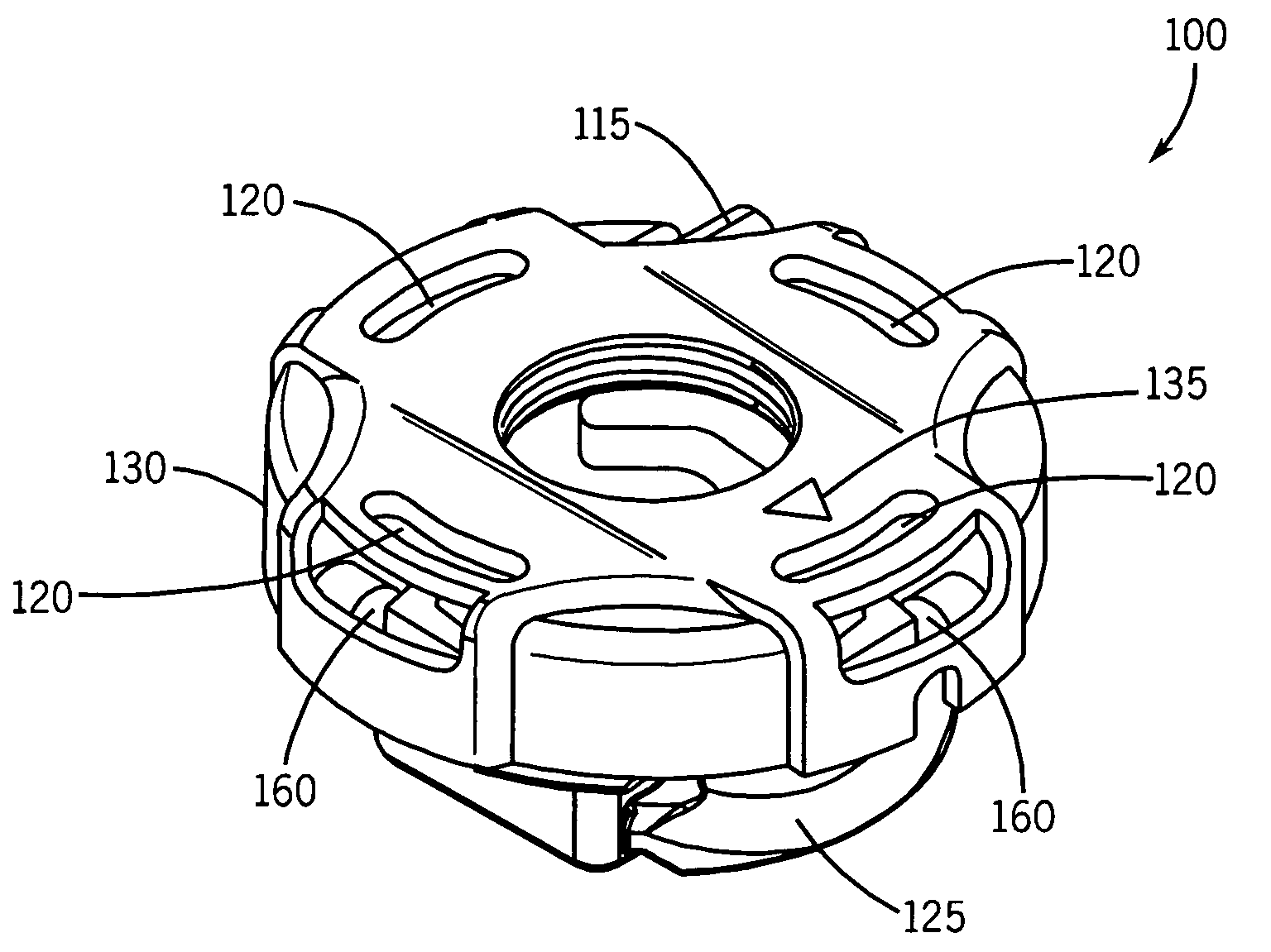

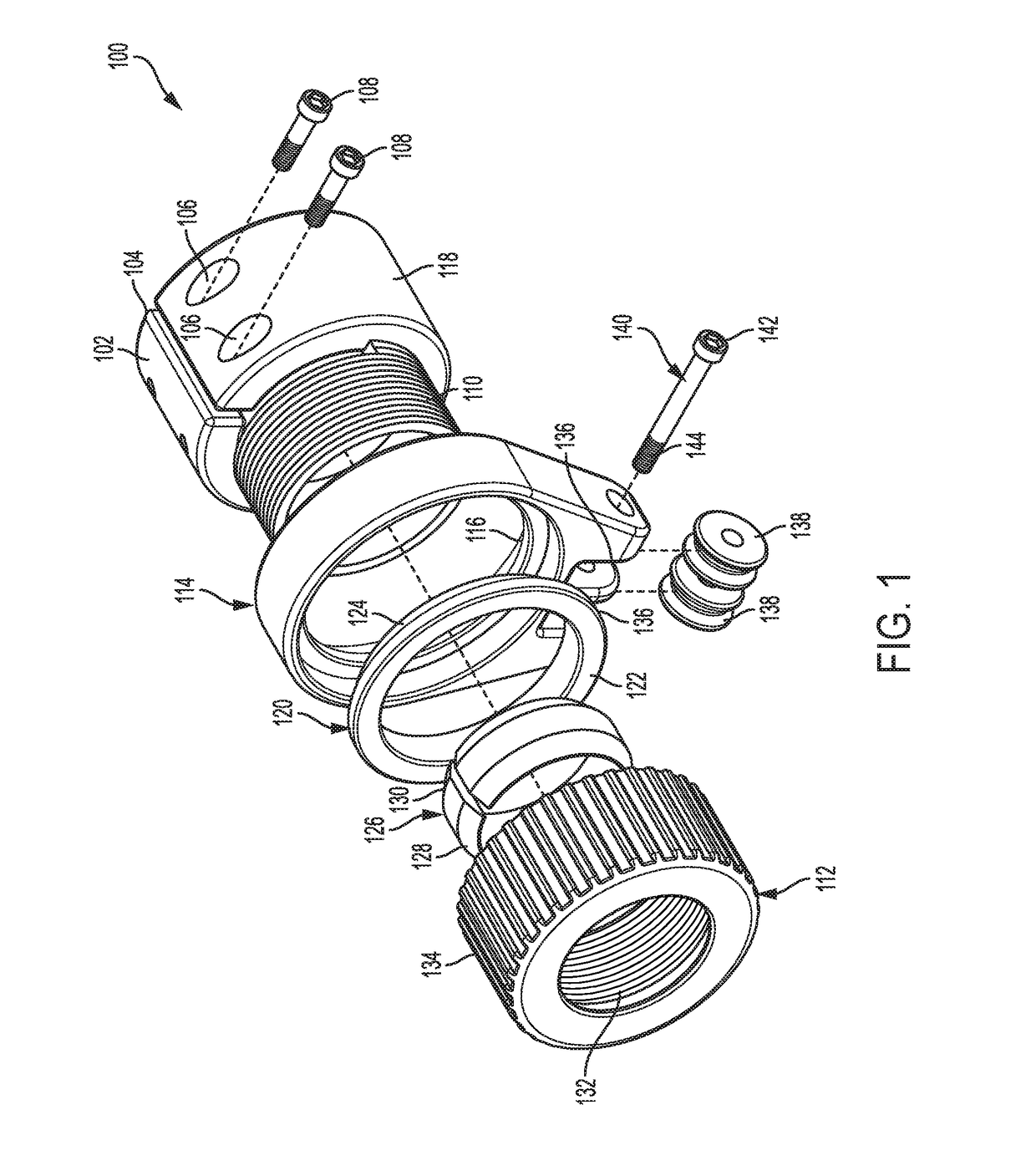

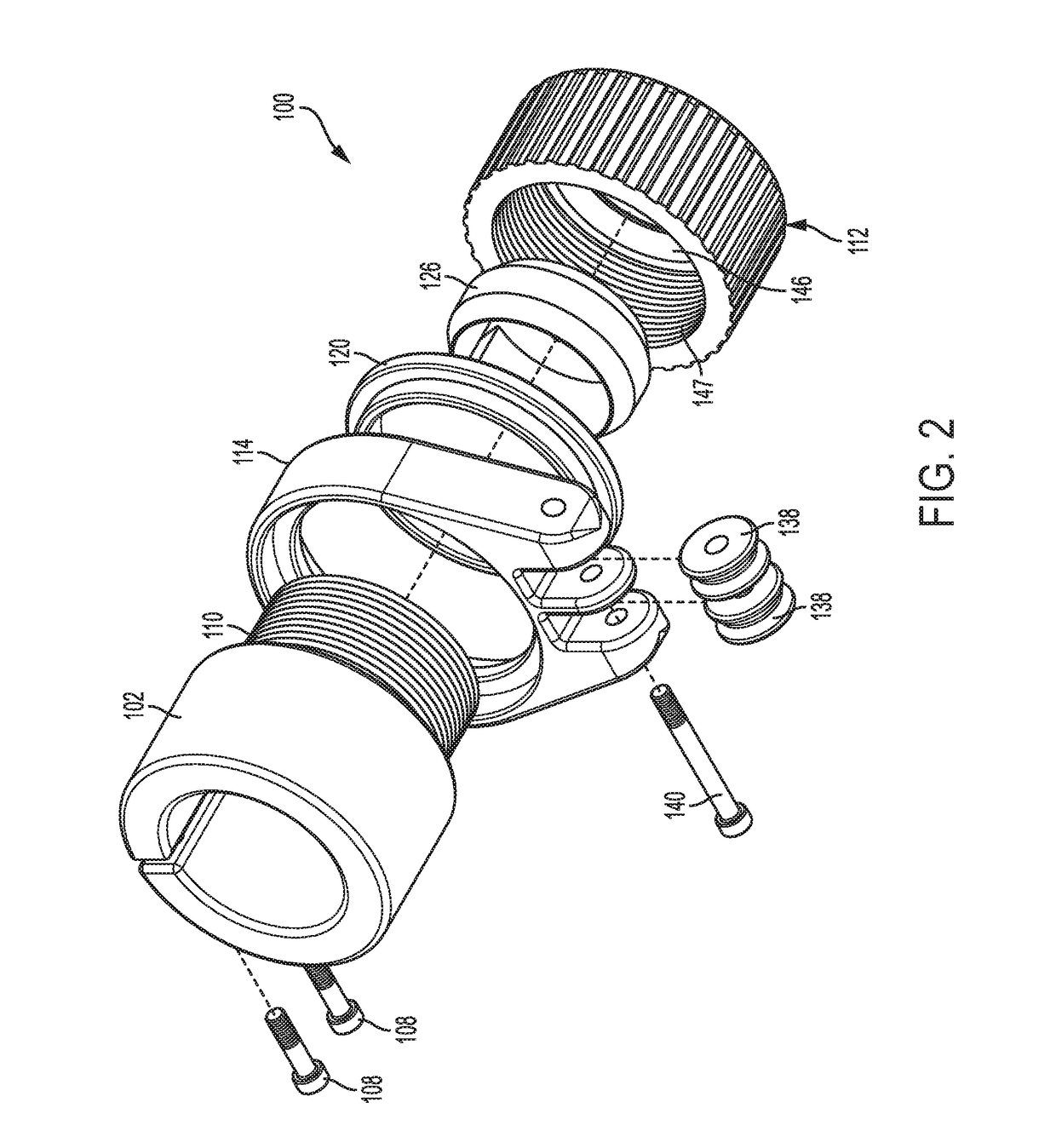

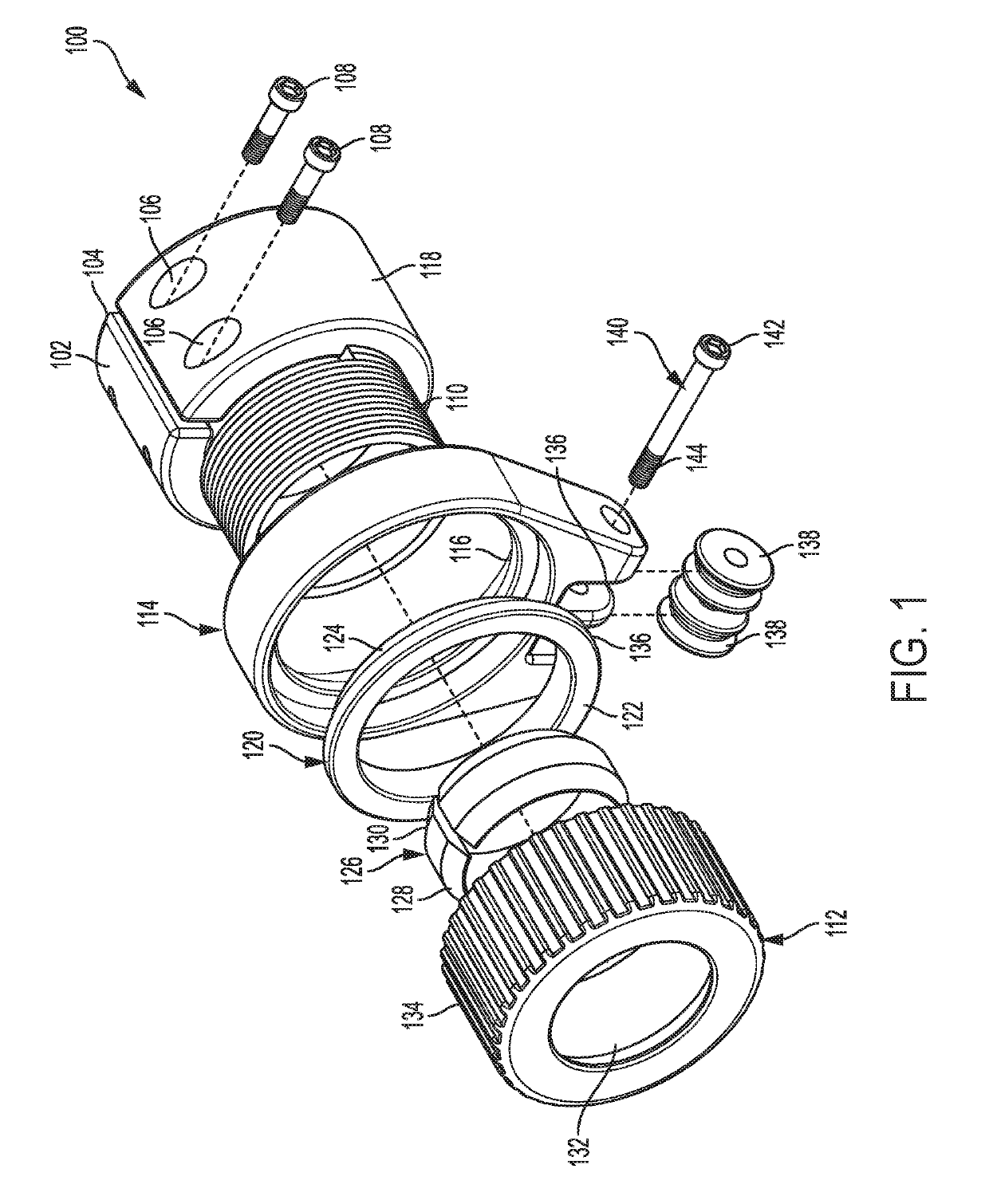

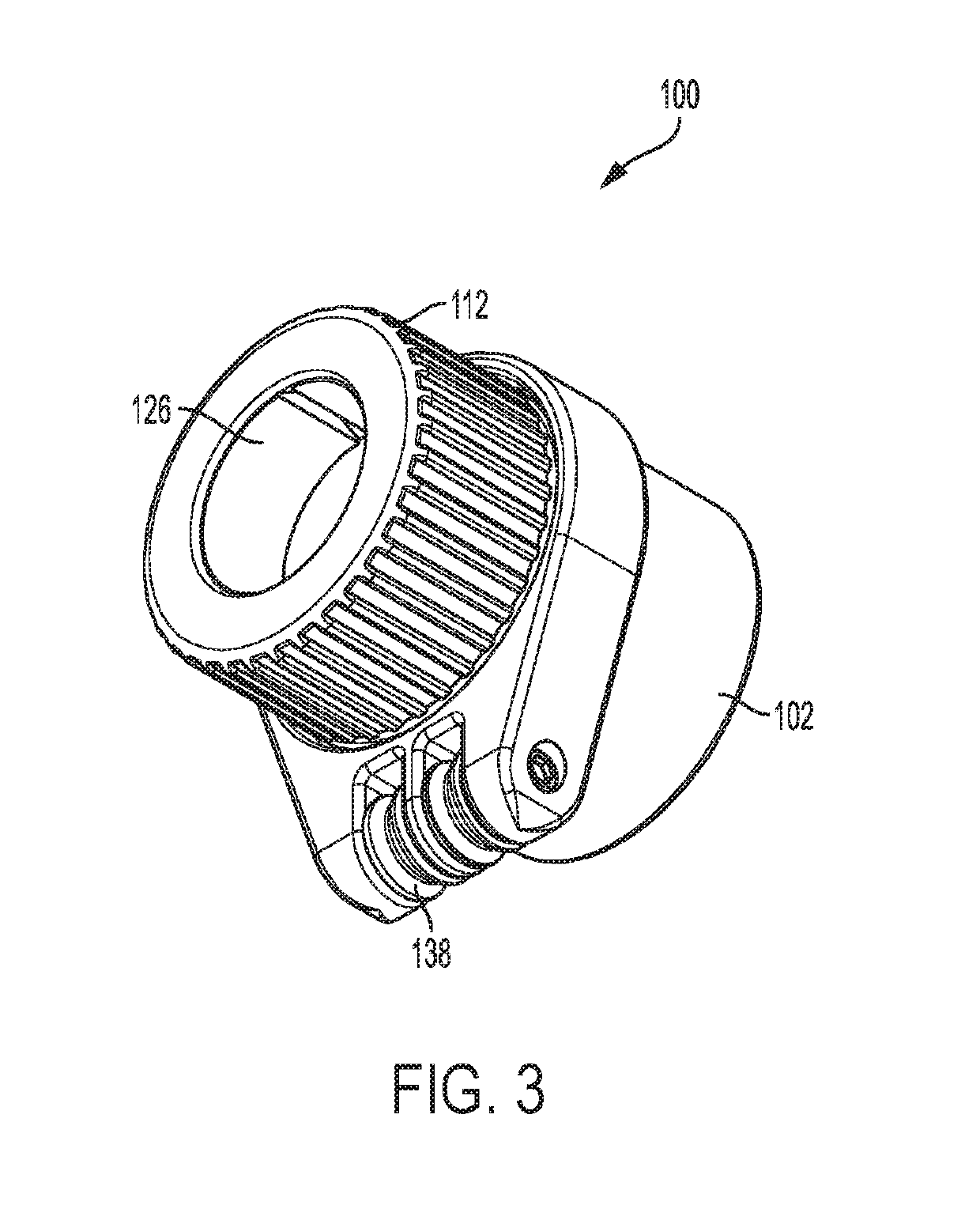

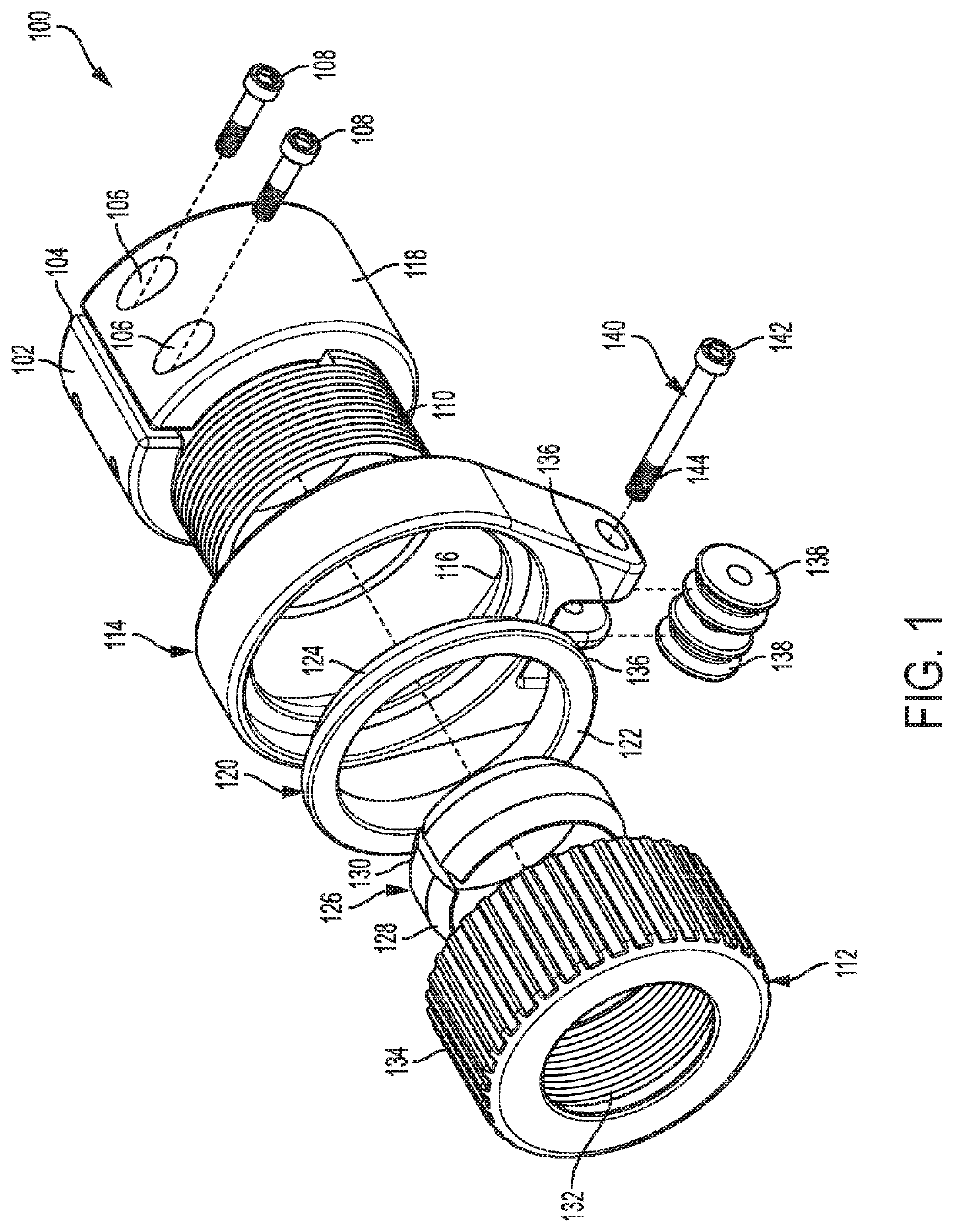

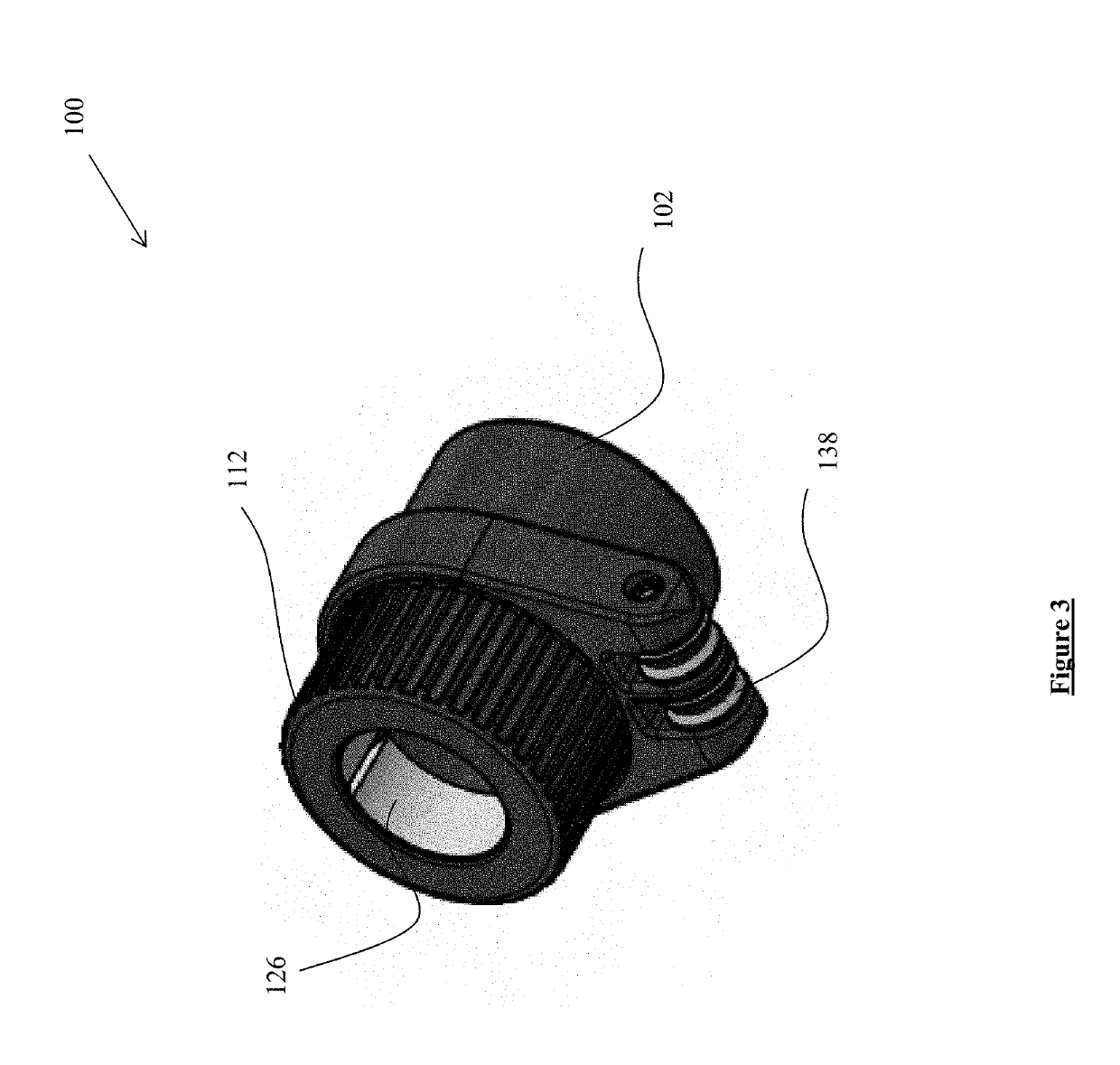

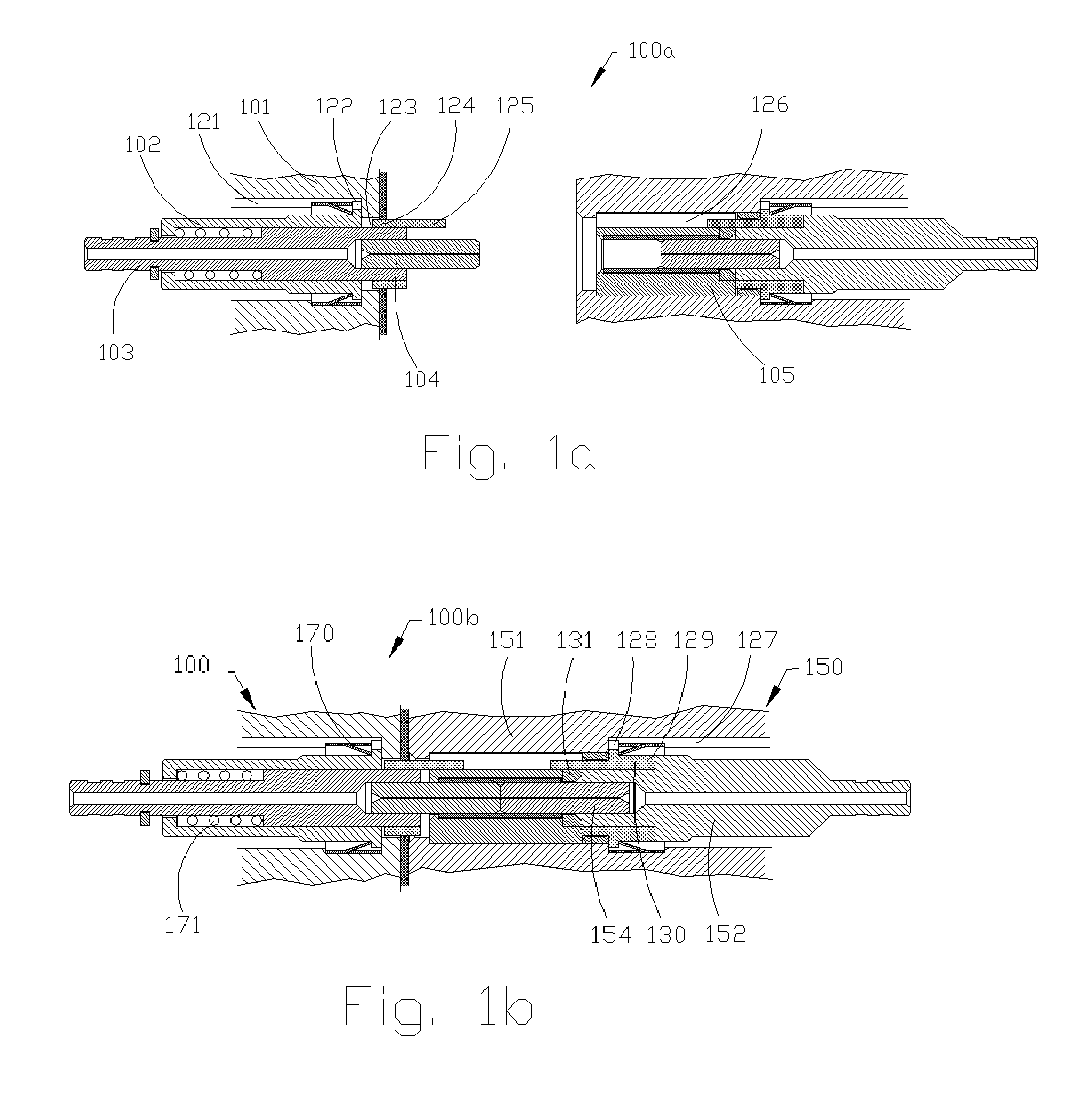

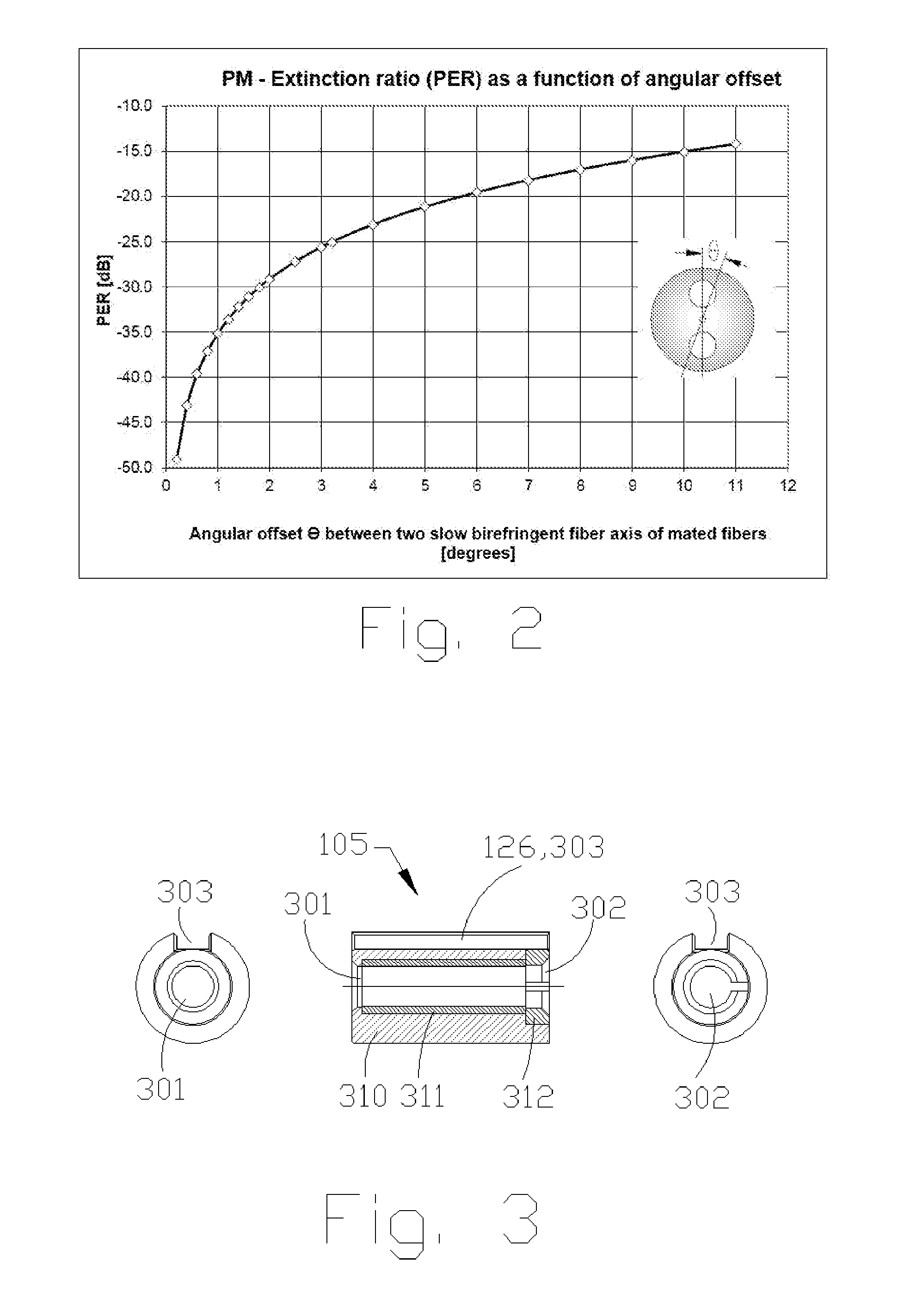

Polarization maintaining connectors

ActiveUS9470847B2Minimal angular offsetMinimize angular offsetCoupling light guidesEngineeringMechanical engineering

A connector comprising an outer housing having a first keying element, an inner housing at least partially disposed in the outer housing and having second and third keying elements, the second keying element cooperating with the first keying element to align angularly the inner housing with the outer housing, a ferrule assembly at least partially disposed in the inner housing and having a ferrule and fourth and fifth keying elements, the fourth keying element cooperating with the third keying element to align angularly the ferrule assembly with the inner housing, an alignment member receiving at least a portion of the ferrule assembly, the alignment member having a sixth keying element to cooperate with the fifth keying element to align angularly the ferrule assembly with the alignment member, and wherein the clearance between the fifth and sixth keying elements is less than that between the first and second keying elements, and between the third and fourth keying elements.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

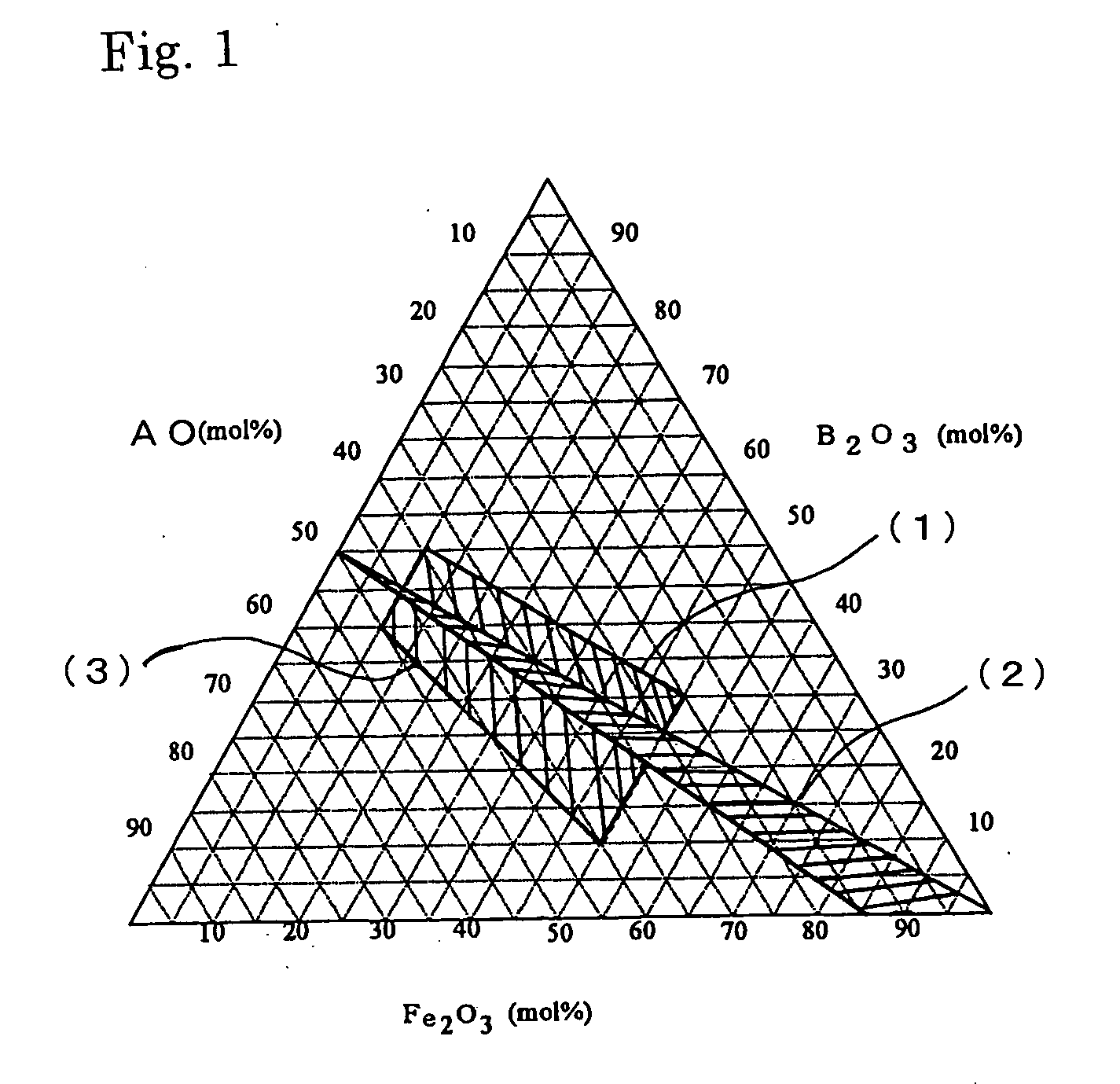

Hexagonal ferrite magnetic powder, process for producing the same, and magnetic recording medium

InactiveUS20050282043A1Increase the proportionSufficient alignmentMaterial nanotechnologyMagnetic materials for record carriersMaterials scienceHexagonal ferrite

A hexagonal ferrite magnetic powder having an average tabular diameter of from 15 to 30 nm, an average tabular ratio of from 3.0 to 4.9, an Hc of from 2,020 to 5,000 Oe (from 161.6 to 400 kA / m) and an SFD of from 0.3 to 0.7, and comprising at least one tetravalent element in a proportion of from 0.004 to 0.045 atoms based on one atom of Fe.

Owner:FUJIFILM CORP +2

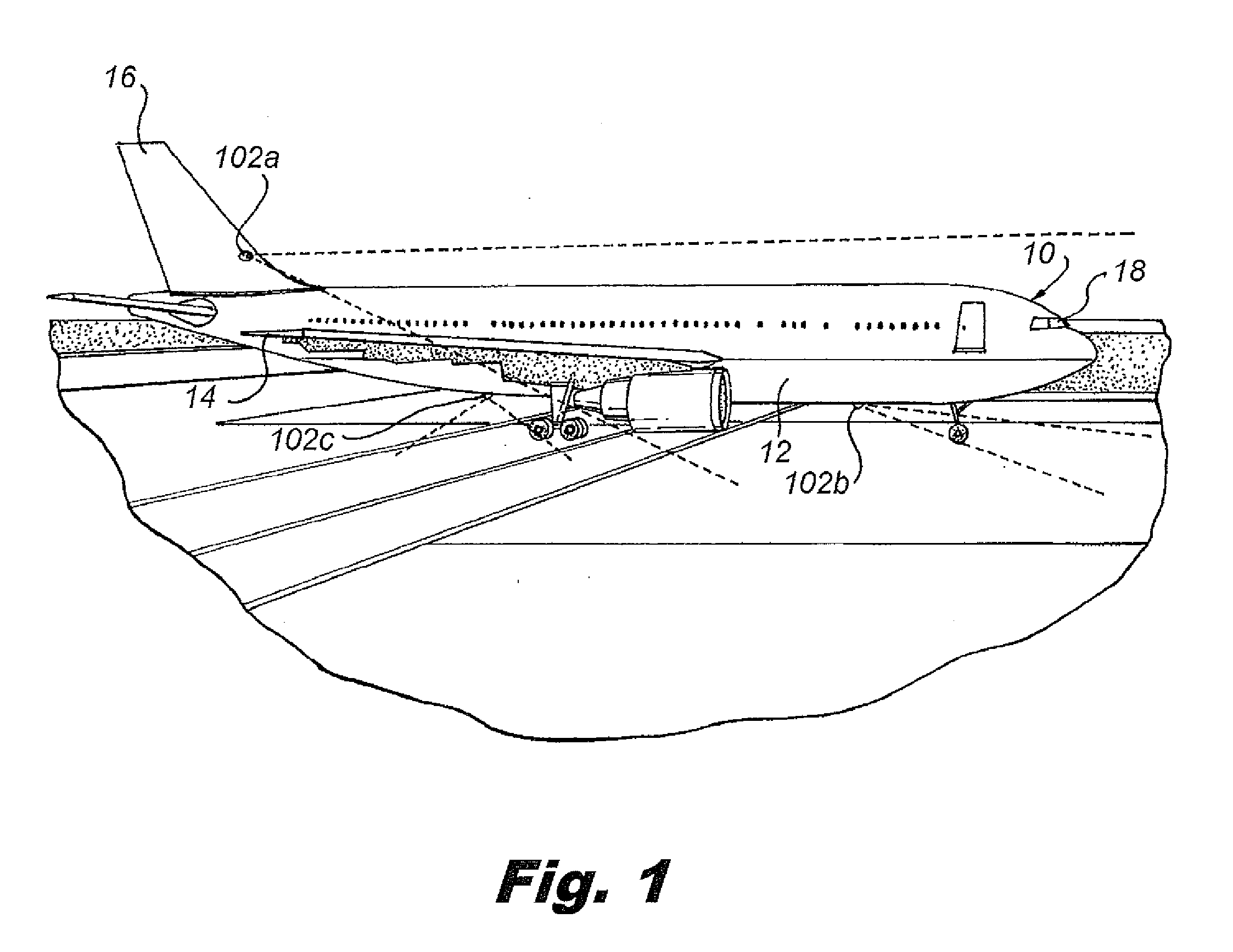

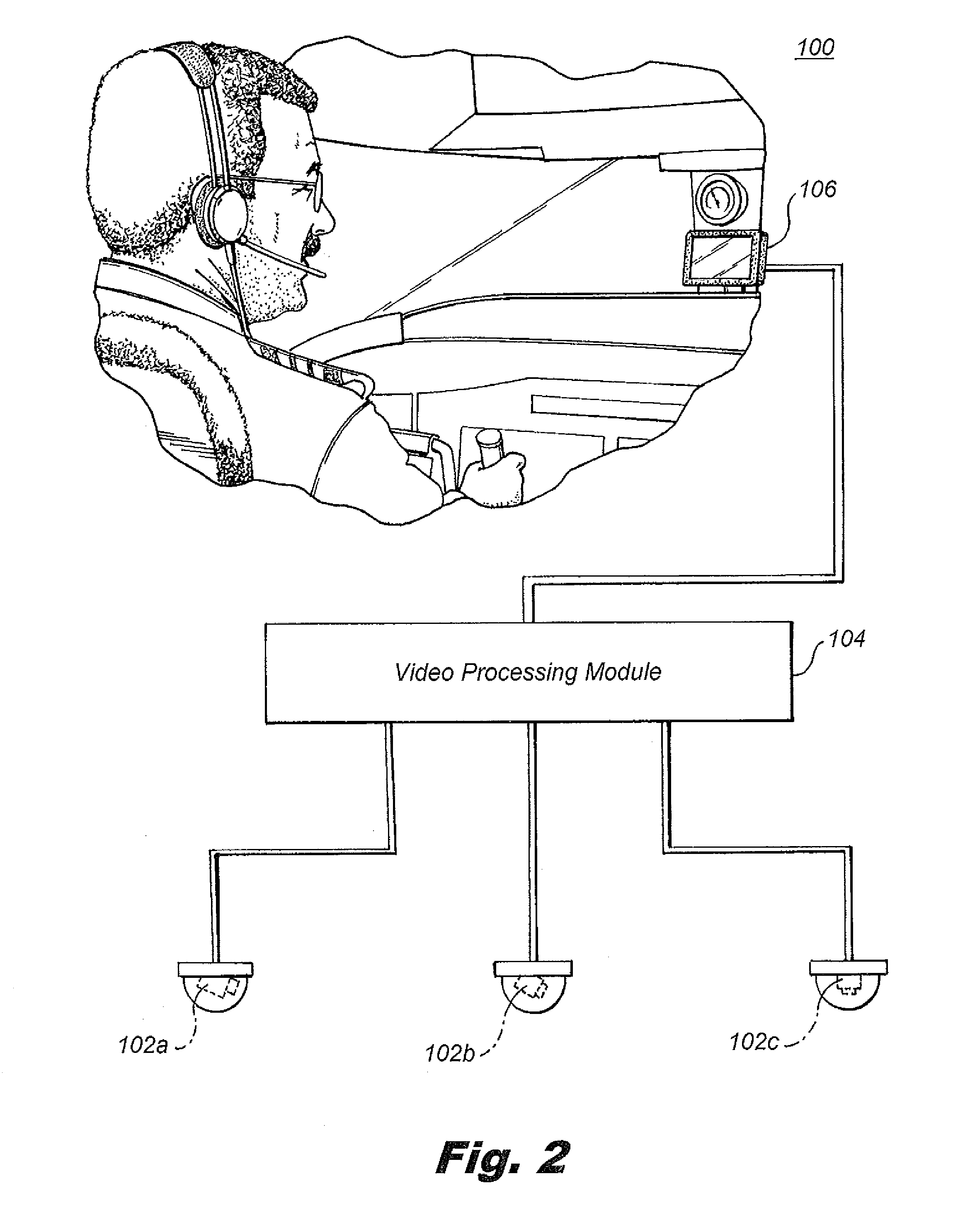

Airplane cockpit video system

InactiveUS20120224058A1Sufficient alignmentEasy to installImage enhancementRegistering/indicating working of vehiclesJet aeroplaneVideo processing

A cockpit video system for an airplane includes a camera assembly positioned on the airplane, a video monitor for receiving a signal from the camera assembly, and a video processing module for electronically aligning the signal so that a pilot of the airplane is presented with an aligned image on the video monitor. Preferably, the signal is an over-sized field of view and the alignment module performs the electronic aligning by cropping and re-aligning the over-sized field of view to fit the video monitor. The camera assembly is adapted and configured to attach to the exterior of the airplane.

Owner:ROSEMOUNT AEROSPACE

Electrical connector

InactiveUS7510402B2Fully contactedSufficient alignmentEngagement/disengagement of coupling partsCoupling contact membersElectrical connectorMechanical engineering

Owner:HON HAI PRECISION IND CO LTD

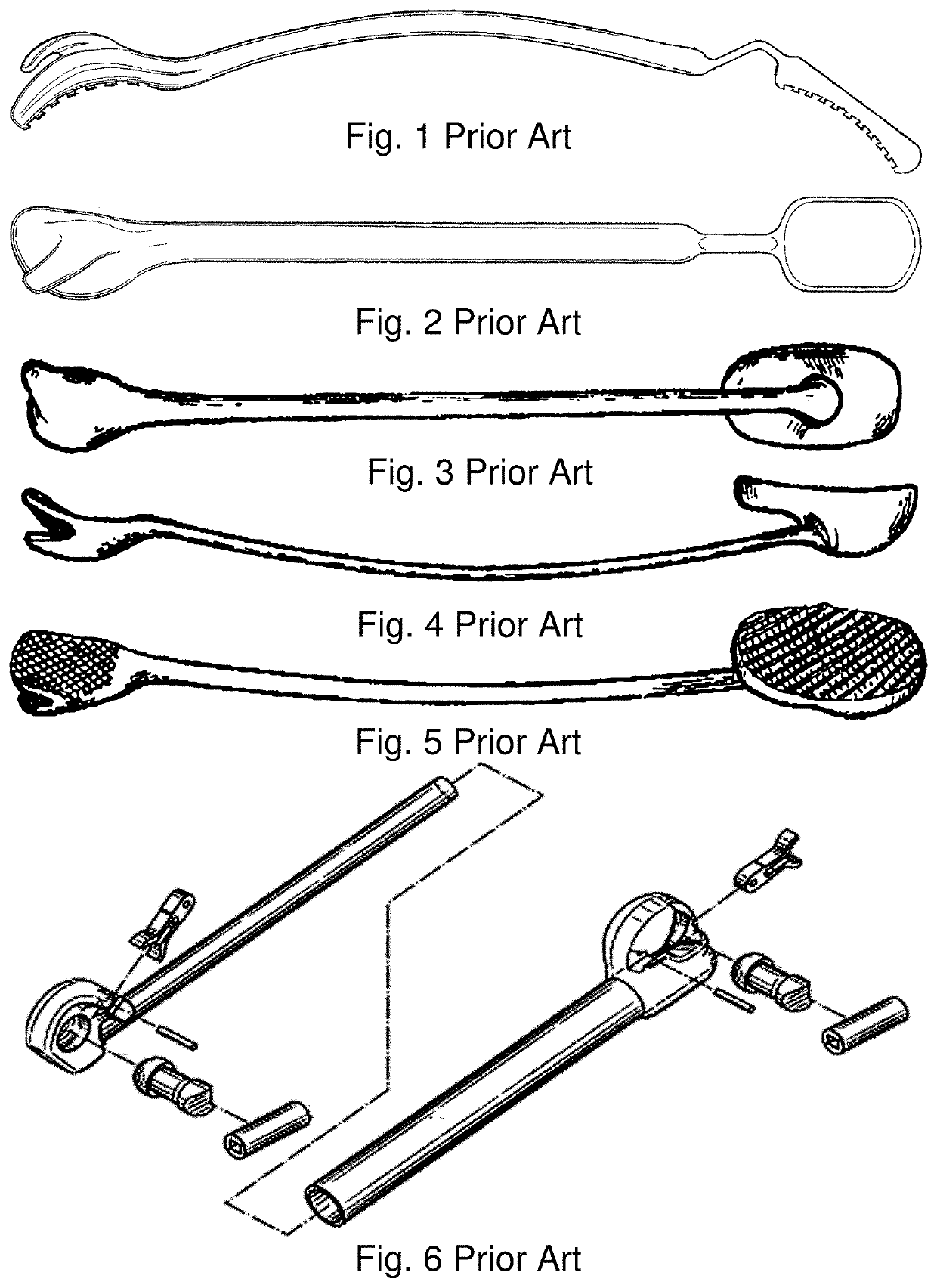

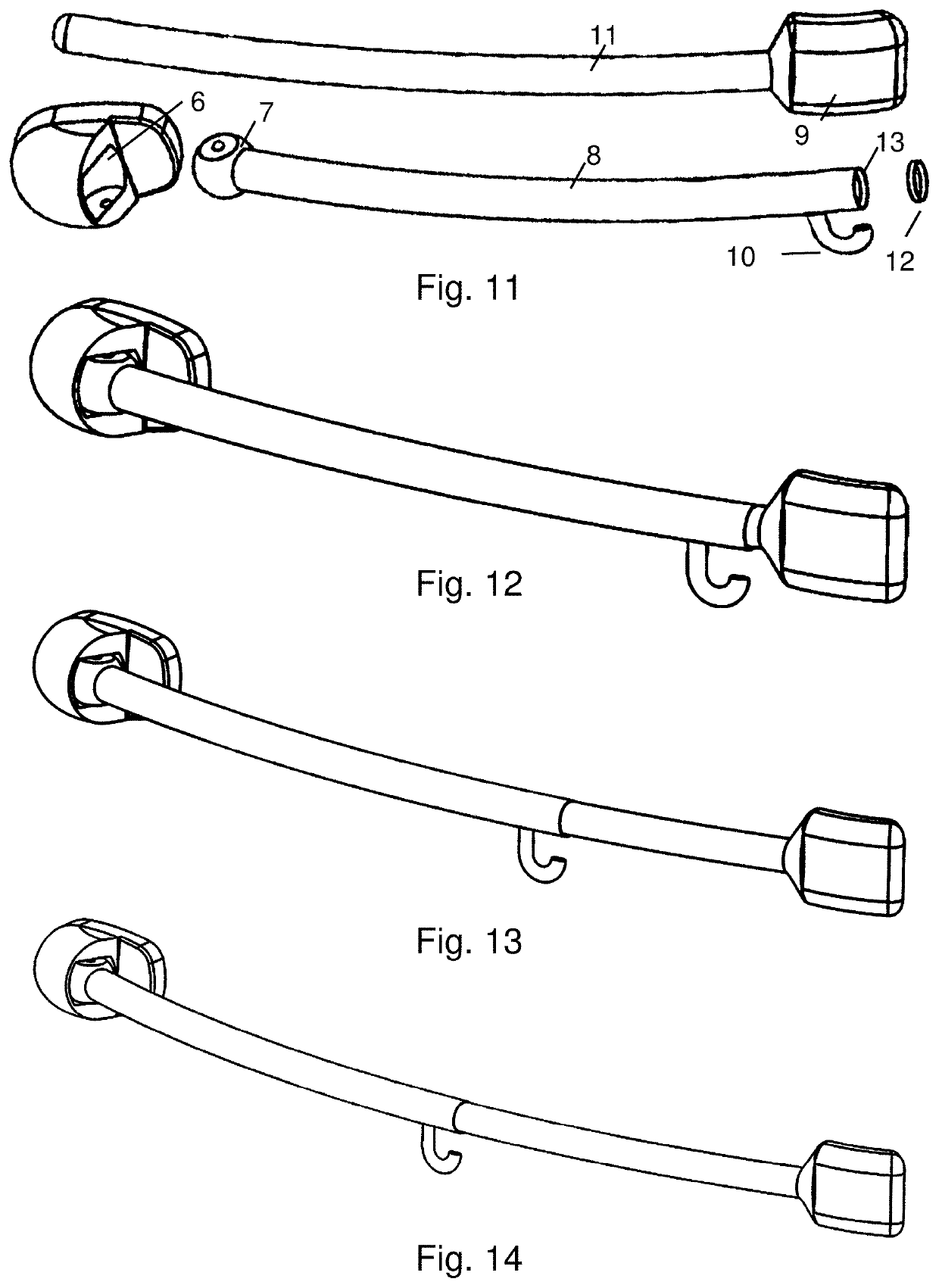

Outrigger Clamp with Attachment Point

ActiveUS20180014522A1Prevent crease and kinkPrevent the filament from becoming creased or kinkedRodsRod connectionsEngineeringMechanical engineering

An outrigger clamp to couple together two or more nestable tubes. The clamp includes a guide for retaining filament, and an attachment point for receiving accessories without interfering with the filament and guides. The guide and attachment point can rotate about an axis based on the forces applied to the outrigger to better align the filament and guides, and therefore align the forces applied to the outrigger and filament. The retainer can be, for example, one or more rollers that help prevent the filament from becoming creased or kinked during use.

Owner:GEM PROD LLC

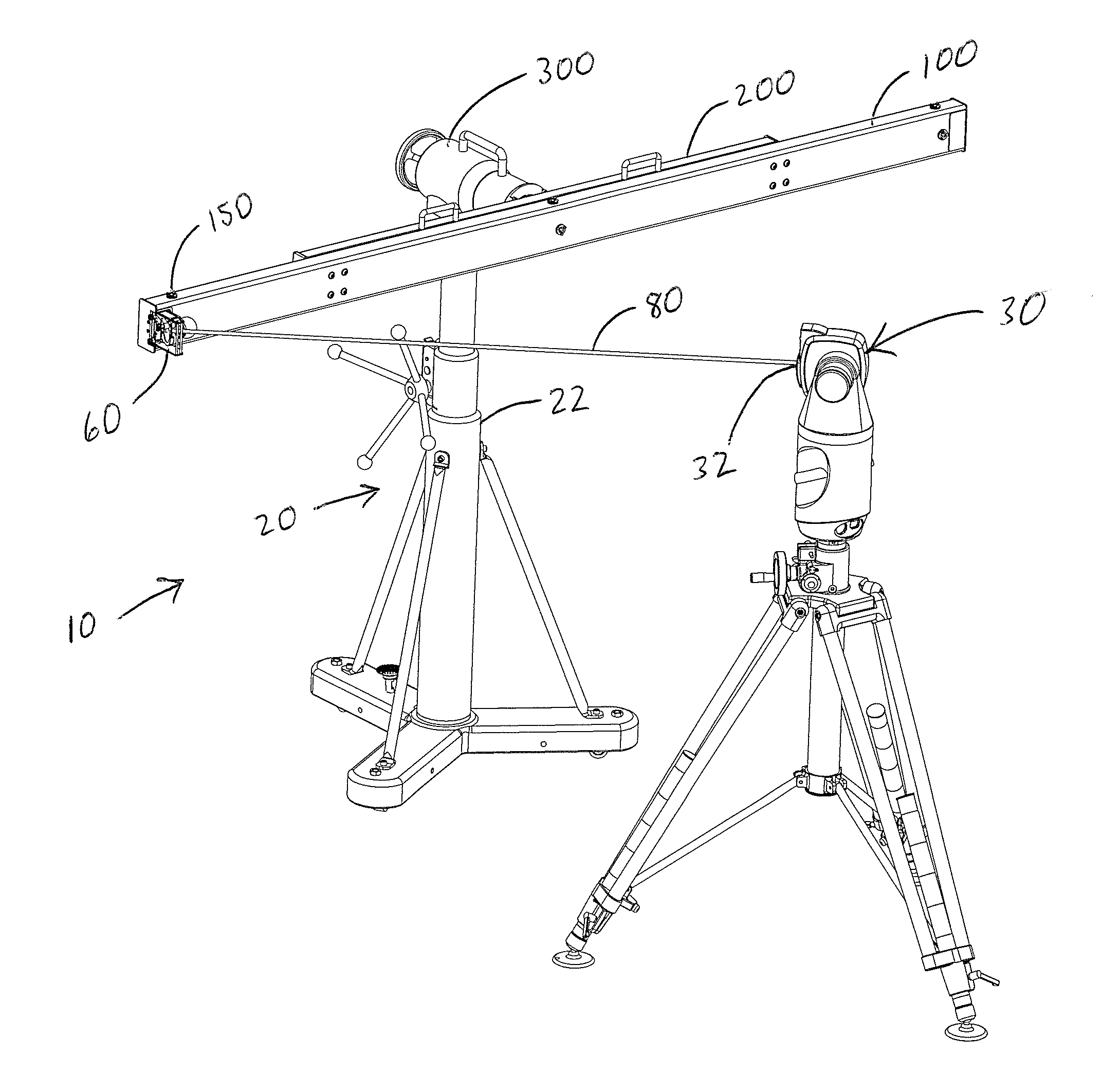

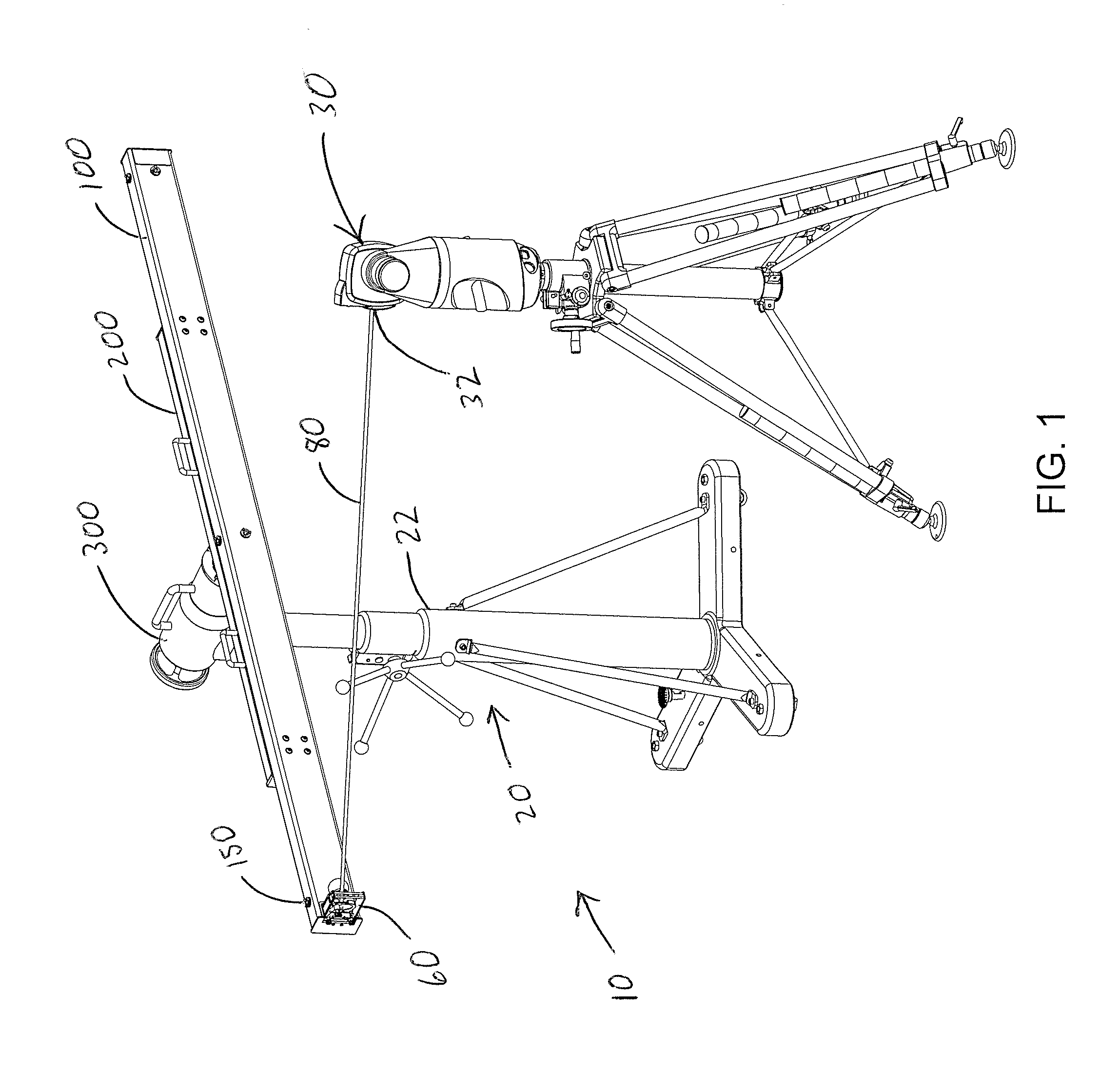

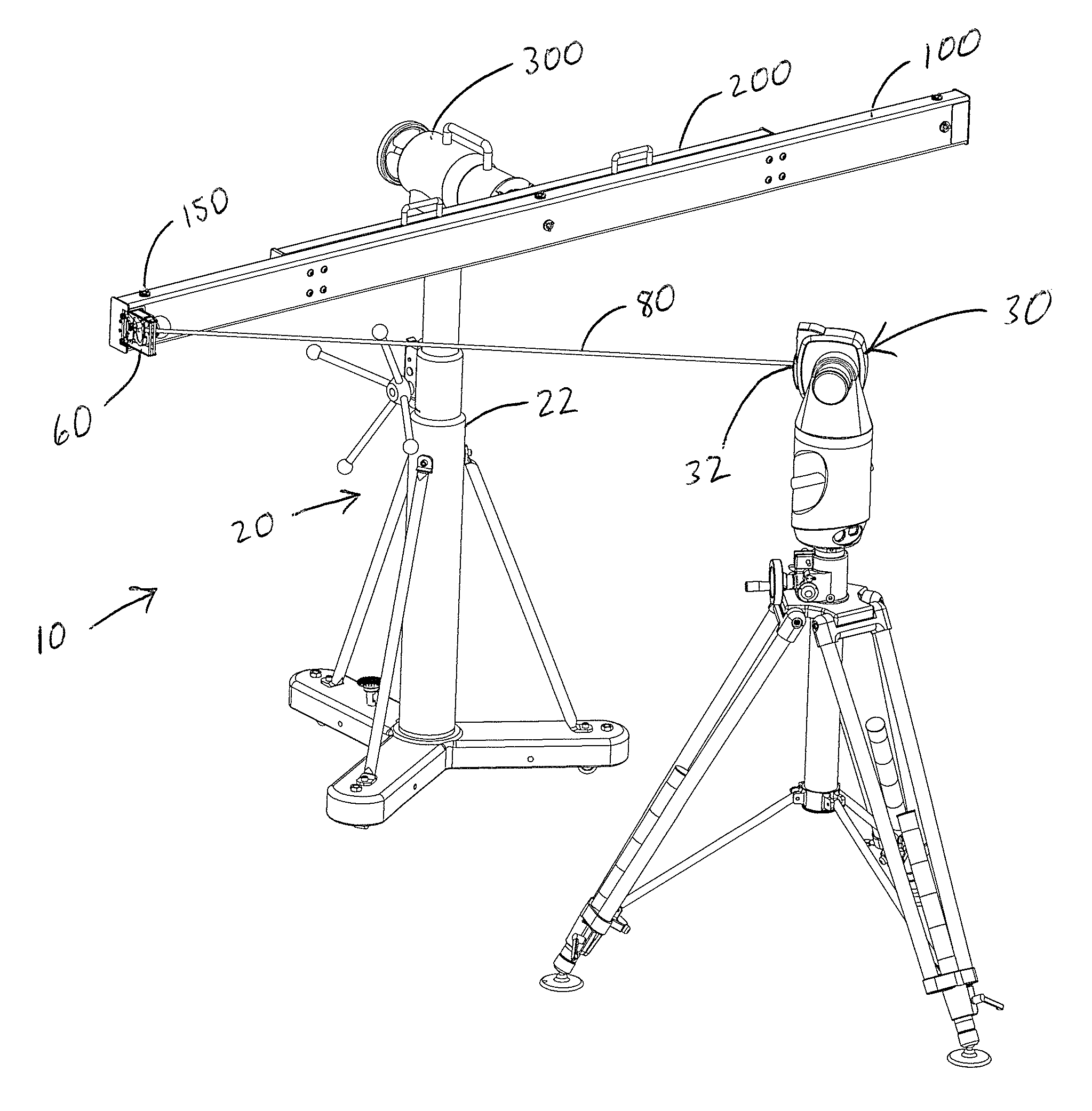

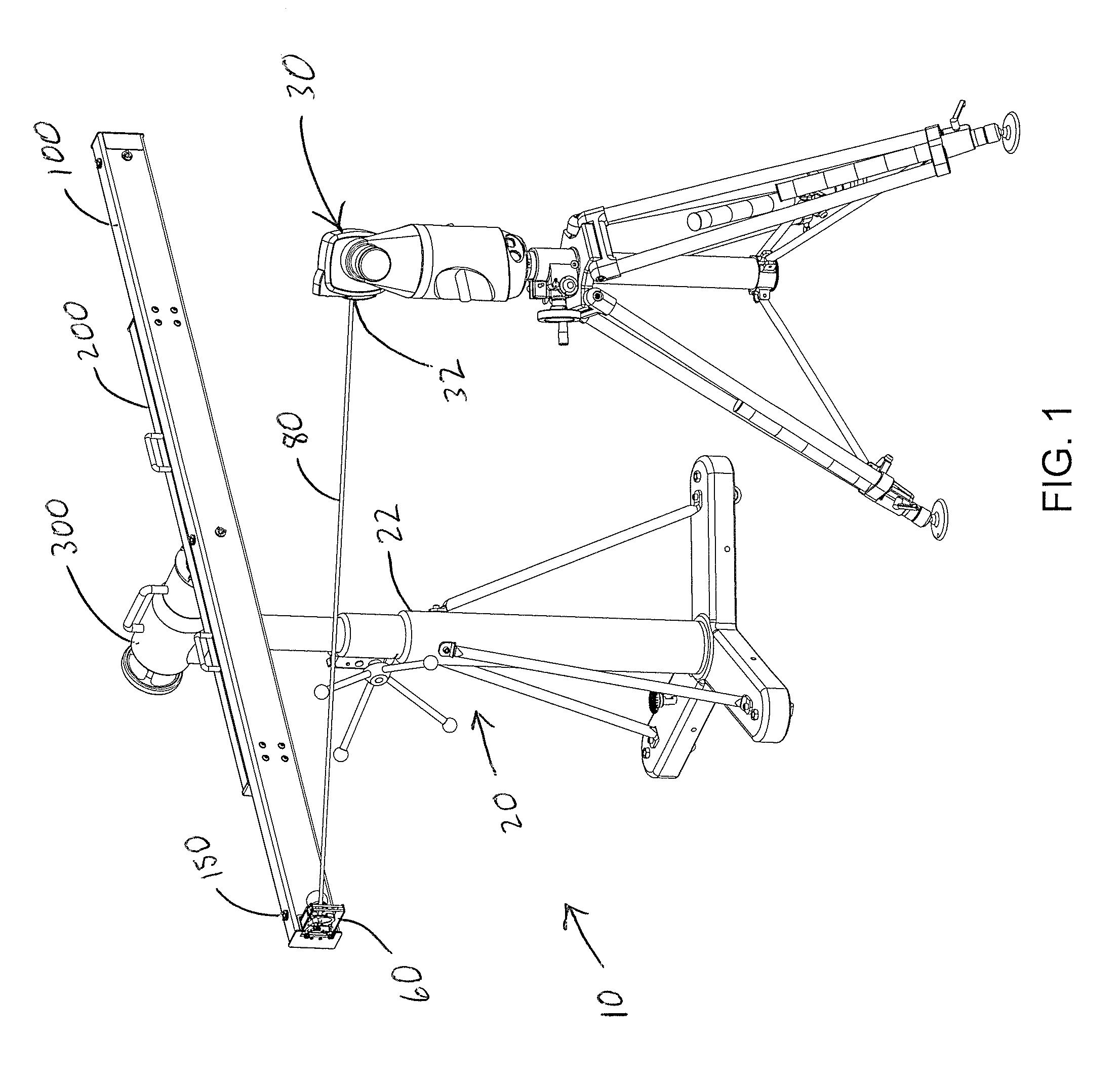

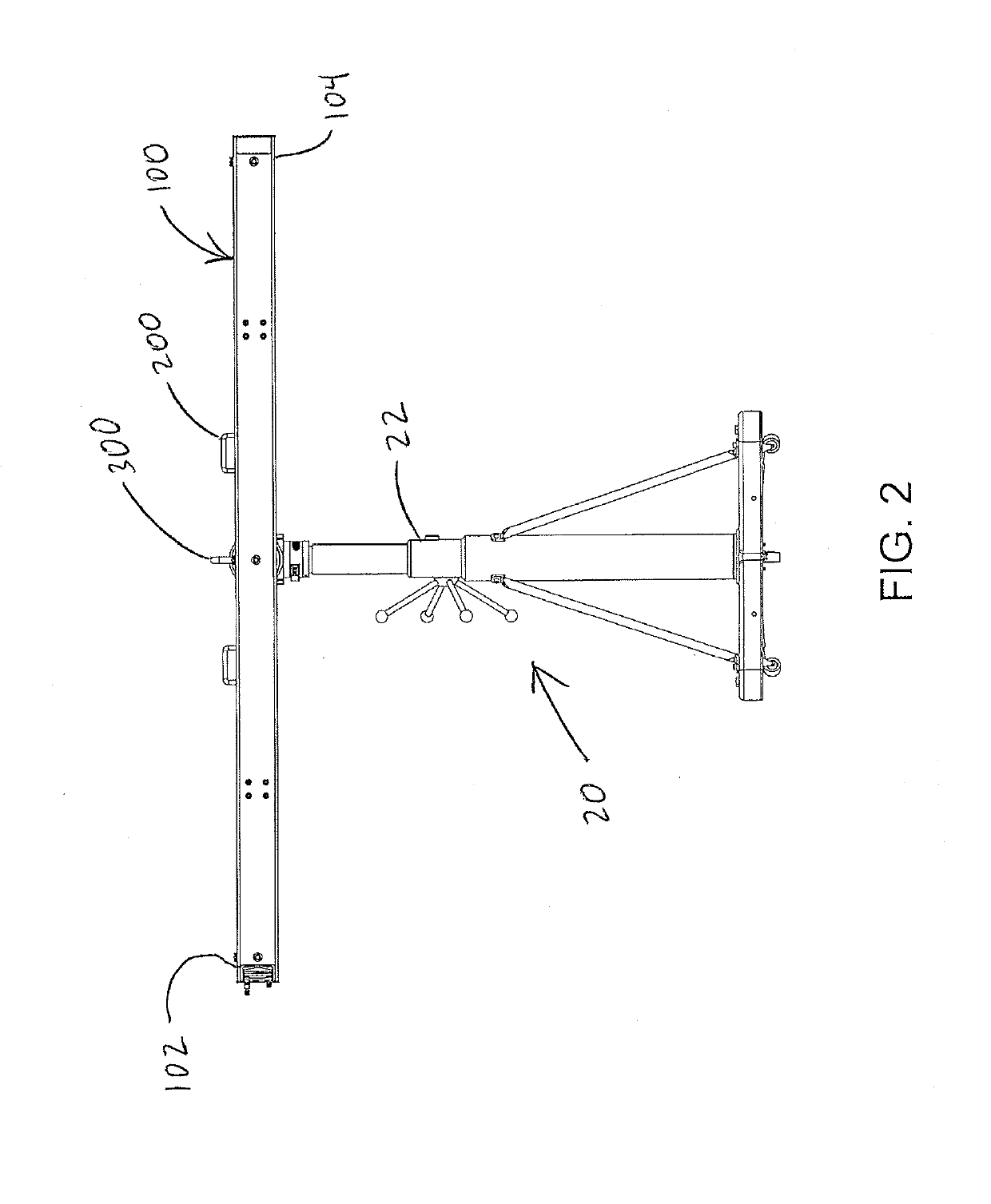

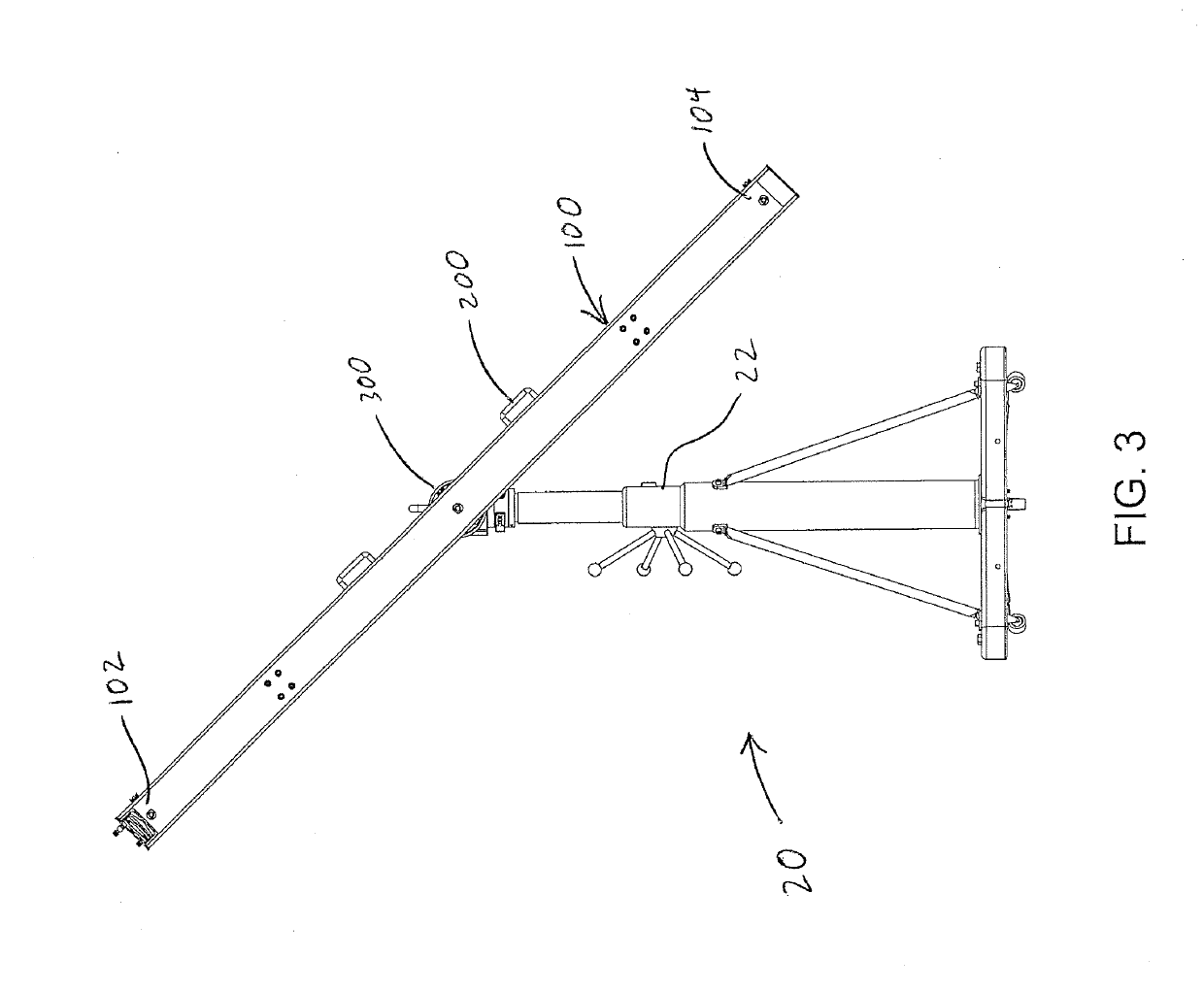

Laser tracker calibration system and methods

ActiveUS20160011303A1Quickly and easily accuracySufficient alignmentPhotometry using reference valueInstruments for comonautical navigationSupporting systemEngineering

A system and method of calibrating a laser tracker is provided. The system includes a support system for quickly and easily moving an artifact to a desired position and orientation and for holding the artifact in the position and orientation. An adjustable alignment mirror is coupled to a first end of the artifact so that the more accurate ranging system of the laser tracker can be isolated to determine a reference length of the artifact. Additional measurements are then taken to exercise one or more error source within the tracker. The support system includes a positioner and a support beam for positioning and supporting the artifact. The artifact is coupled to the support beam using kinematic clamps that are designed to reduce or eliminate errors associated with over-constraining the artifact.

Owner:BRUNSON INSTR

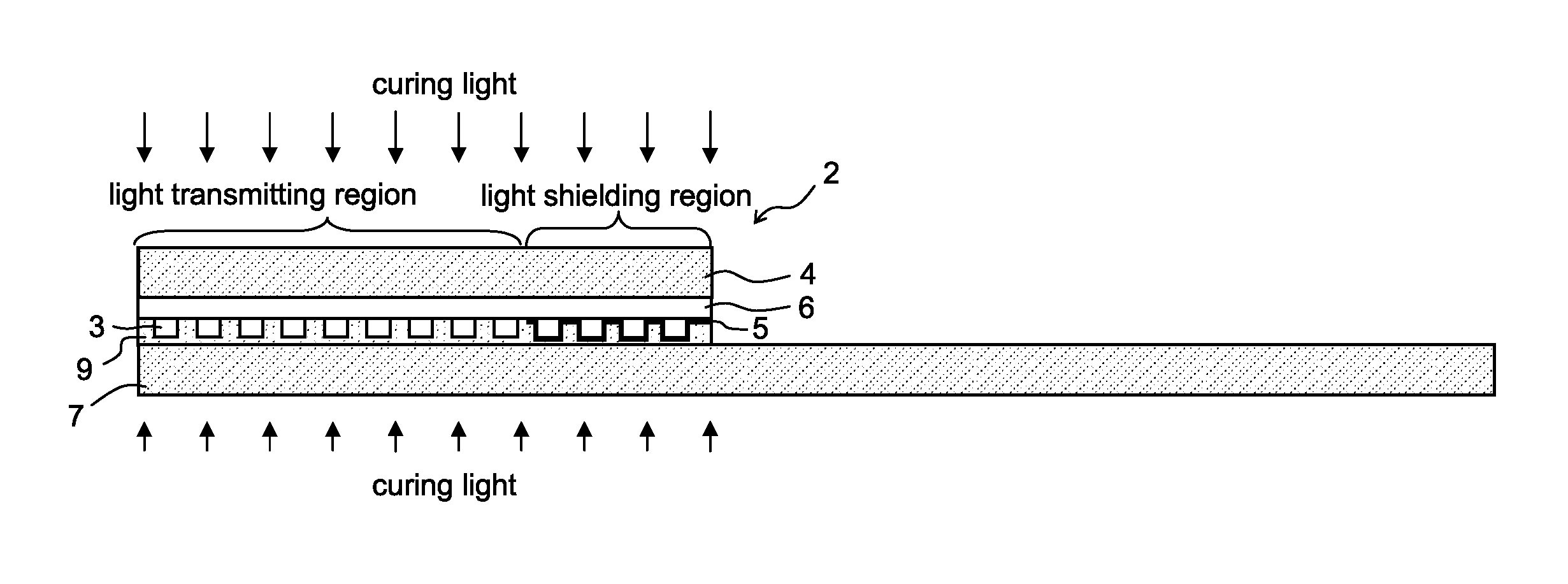

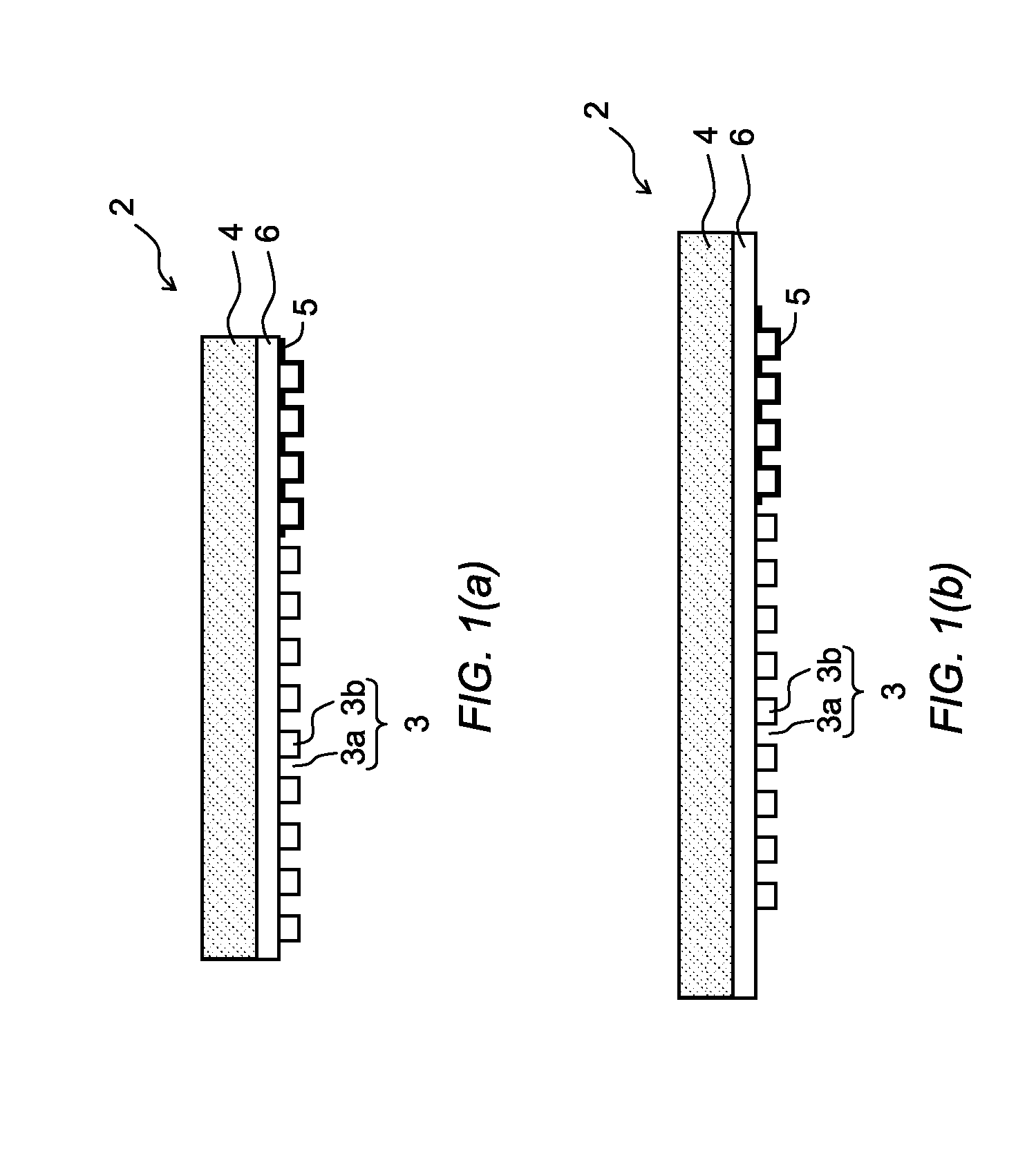

Light-transmitting imprinting mold and method for manufacturing large-area mold

InactiveUS20150306792A1Easy to transformModest accuracyPhotomechanical apparatusAuxillary shaping apparatusOptoelectronicsPhoto curing

An imprint method including the steps of: an exposing step to irradiate a photo curing resin, coated on a large-area substrate, with a curing light while the light-transmitting imprint mold is pressed against the photo curing resin, an amount of the curing light applied onto the photo curing resin in a light shielding region provided with the light shielding member made less than an amount of the curing light applied onto the photo curing resin in a light transmitting region of the mold so that a portion of the photo curing resin in the light shielding region is semi-cured by the use of the light shielding member provided so as to reproduce the concave-convex pattern of the transparent substrate.

Owner:SOKEN CHEM & ENG CO LTD

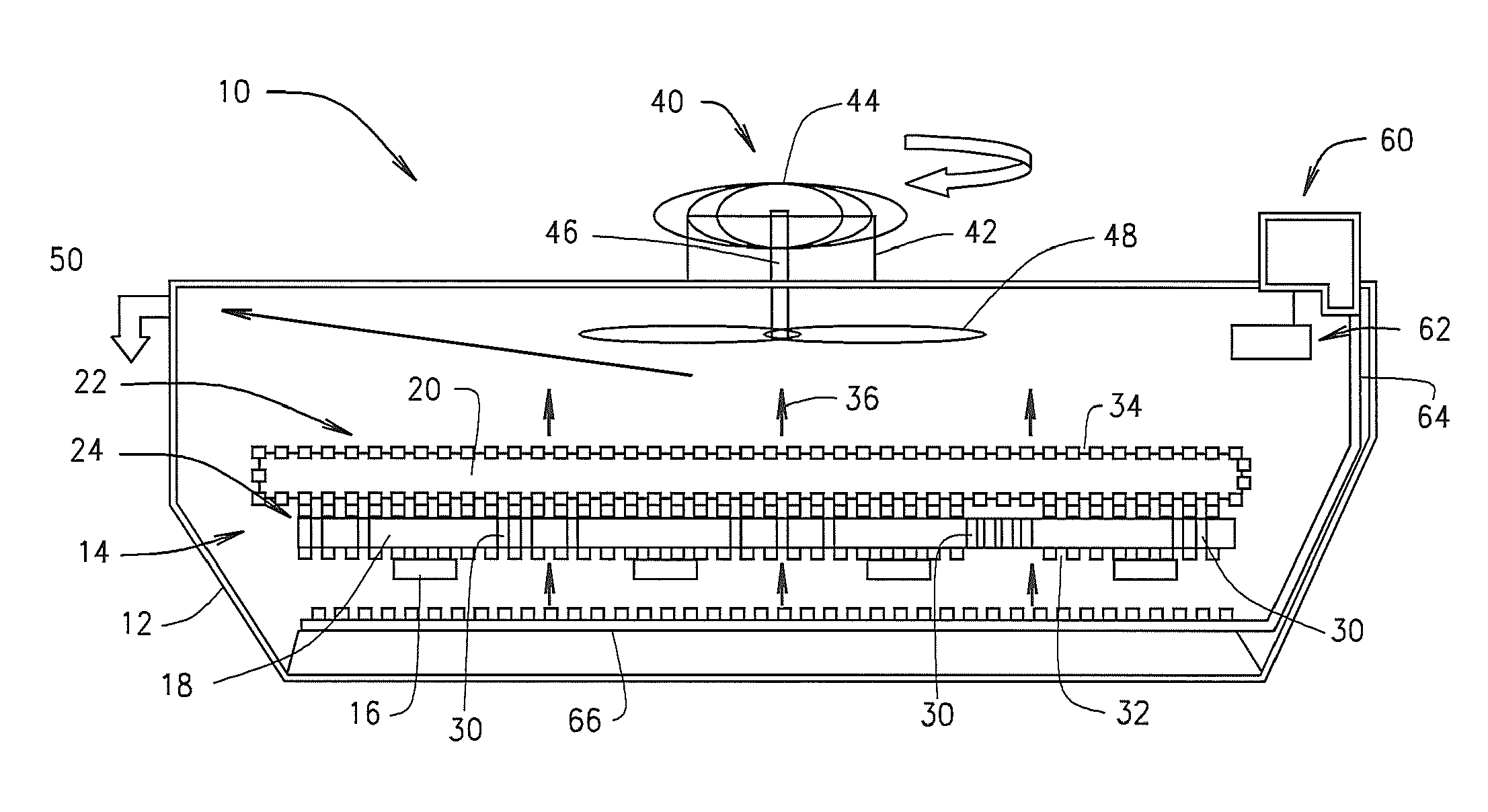

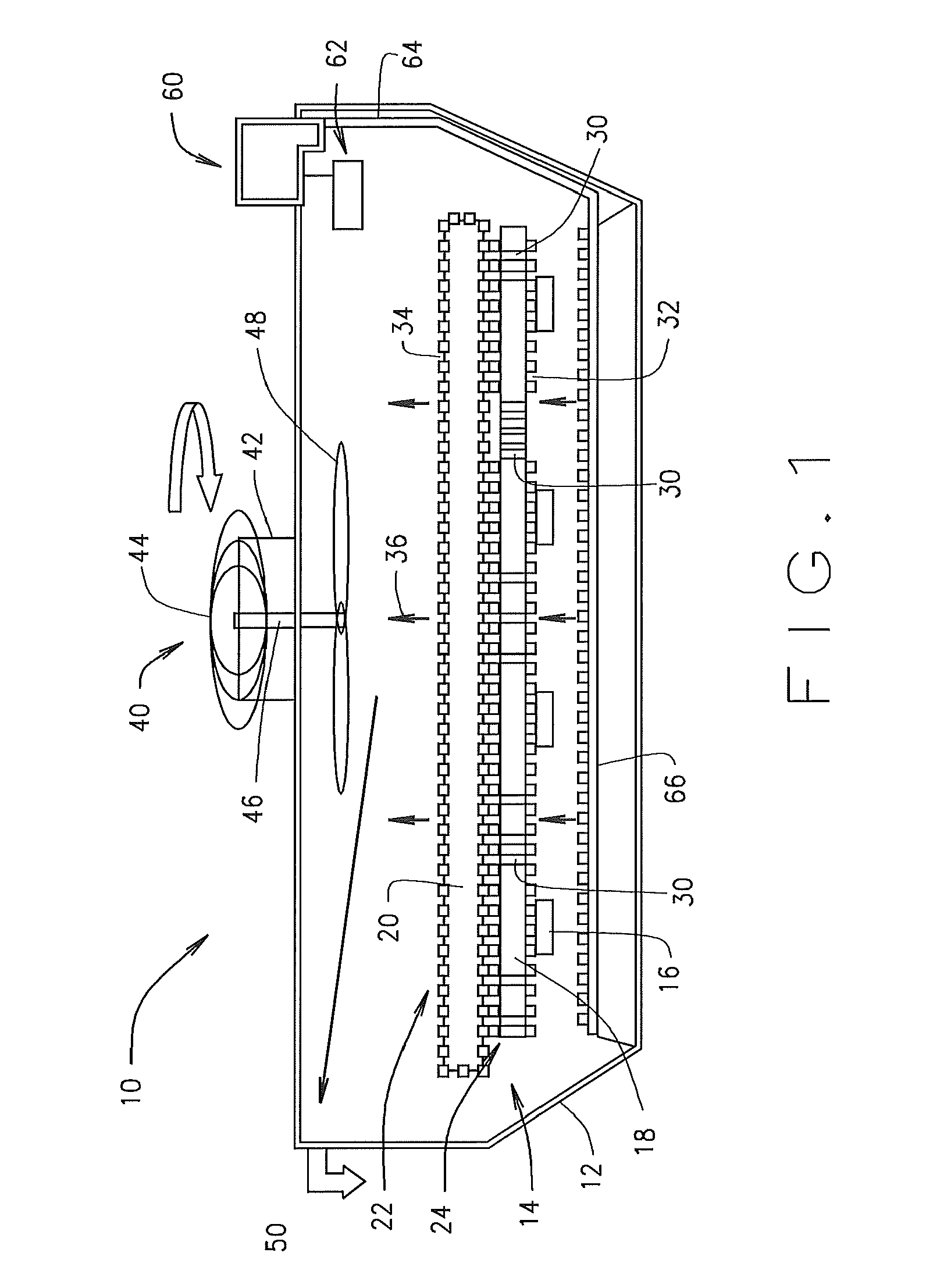

Luminaire cooling apparatus

InactiveUS20110292656A1Sufficient alignmentPlanar light sourcesMechanical apparatusImpellerOutdoor area

An outdoor area light has a housing, a light source comprised of a printed circuit board, a plurality of LEDs, and a heat sink. The heat sink is disposed in thermally conductive proximity to said light source to conduct heat away from it for temperature control. The light source and heat sink are mounted in the housing. A passive impeller is mounted on the housing. A separate active impeller is also mounted on the housing. A conduit for air is in fluid communication with the active impeller and disposed to direct cooling air over the light source and / or the heat sink. The printed circuit board and / or the heat sink and / or their mounts have holes through them. The holes define fluid throughways disposed to convect heat away from the light source via air moving through the throughways. The fluid throughways may be sufficiently aligned to establish laminar flow through them. In high heat, the active impeller is engaged to cool the light; otherwise the passive impeller keeps the light cool.

Owner:HELLA KG HUECK & CO

Laser tracker calibration system and methods

ActiveUS9575163B2Quickly and easily accuracySufficient alignmentUsing optical meansElectromagnetic wave reradiationSupporting systemEngineering

A system and method of calibrating a laser tracker is provided. The system includes a support system for quickly and easily moving an artifact to a desired position and orientation and for holding the artifact in the position and orientation. An adjustable alignment mirror is coupled to a first end of the artifact so that the more accurate ranging system of the laser tracker can be isolated to determine a reference length of the artifact. Additional measurements are then taken to exercise one or more error source within the tracker. The support system includes a positioner and a support beam for positioning and supporting the artifact. The artifact is coupled to the support beam using kinematic clamps that are designed to reduce or eliminate errors associated with over-constraining the artifact.

Owner:BRUNSON INSTR

Outrigger clamp

ActiveUS10337547B2Prevent crease and kinkPrevent the filament from becoming creased or kinkedRodsVessel partsEngineering

An outrigger clamp to couple together two or more nestable tubes. The clamp can include a guide for retaining filament. The guide can rotate about an axis based on the forces applied to the outrigger to better align the filament and guides, and therefore align the forces applied to the outrigger and filament. The retainer can be, for example, one or more rollers that help prevent the filament from becoming creased or kinked during use.

Owner:GEM PROD LLC

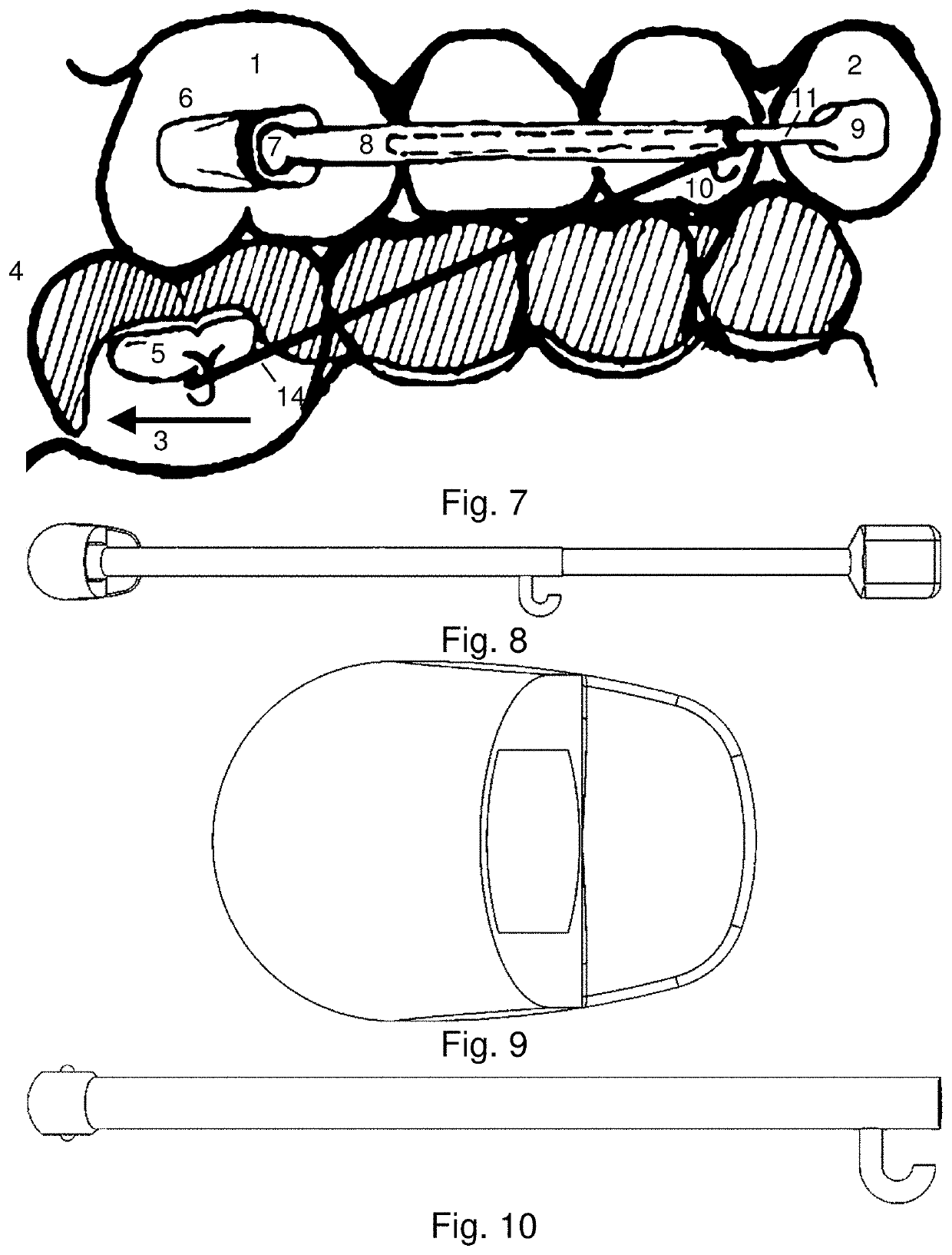

Unimpeded distalizing jig

ActiveUS20200163742A1Improving interdigitationIncrease spacingBracketsPosterior ToothBiomedical engineering

An unimpeded distalizing jig, comprising a pair of tooth bond pads, an intra dental arch telescoping assembly, comprising a rod-like insertion and a tubular shell, which constrains the rod-like insertion to move with respect to the tubular shell along an elongated axis, which may be a radial path; and a force generating structure configured to supply an off-axis distalizing force to the intra dental arch telescoping assembly, such that the distalizing force is provided to the posterior tooth substantially without applying an anteriorizing force on the anterior tooth. The force generating structure may be an elastic band fixed by a hook to the tubular shell on one side, and to a molar on an opposing dental arch on the other side.

Owner:SURIANO ANTHONY T +1

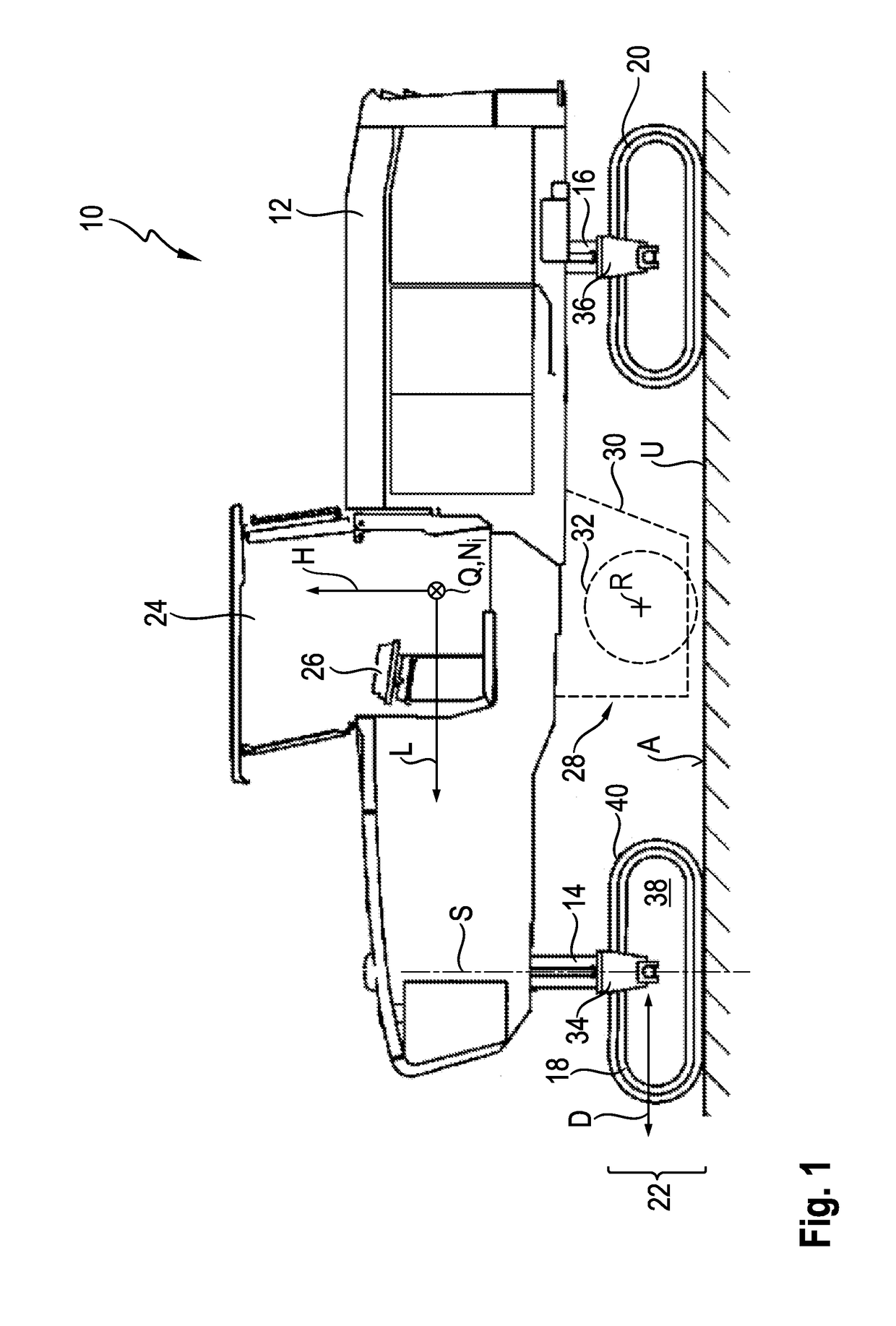

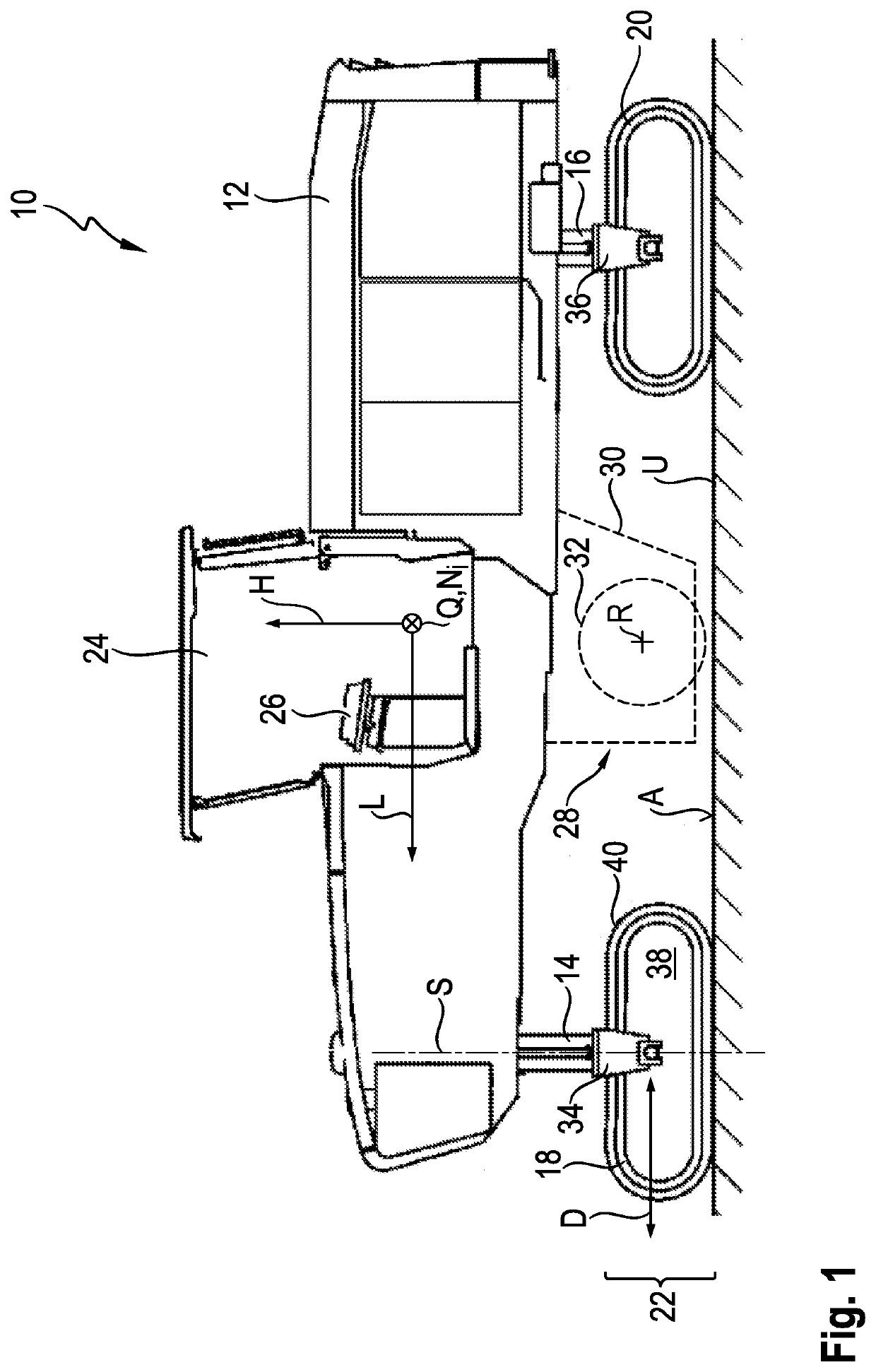

Method for Coupling a Machine Frame of an Earth Working Machine to a Working Device, Earth Working Machine, and Connecting Apparatus for the Method

A method for coupling a machine frame (12) of an earth working machine (10) to a working device (28) between the machine frame (12) and a substrate (U) encompasses the following steps:arranging the machine frame (12) and the working device (28) between the machine frame (12) and the substrate (U);aligning the receiving portion (42) and working device (28) relative to one another in such a way that fastening formations (56, 60) of the working device (28) are lined up, along a spacing direction, with fastening counter-formations (58, 62) of the machine frame (12);bringing the fastening formations (56, 60) and fastening counter-formations (58, 62) closer to one another; andoperably fastening the working device (28) onto the receiving portion (42).According to the present invention the aligning step encompasses the following sub-steps:connecting the machine frame (12) and the working device (28) to one another by means of a connecting apparatus (76), in such a way that the working device (28) is movable in response to its weight, parallel to the effective direction of gravity (g) and orthogonally thereto, relative to the machine frame (12); thenallowing the working device (28) to hang on the machine frame (12); and thensupporting the working device (28).

Owner:WIRTGEN GMBH

Outrigger clamp with attachment point

ActiveUS10575512B2Prevent crease and kinkPrevent the filament from becoming creased or kinkedRodsRod connectionsClassical mechanicsEngineering

An outrigger clamp to couple together two or more nestable tubes. The clamp includes a guide for retaining filament, and an attachment point for receiving accessories without interfering with the filament and guides. The guide and attachment point can rotate about an axis based on the forces applied to the outrigger to better align the filament and guides, and therefore align the forces applied to the outrigger and filament. The retainer can be, for example, one or more rollers that help prevent the filament from becoming creased or kinked during use.

Owner:GEM PROD LLC

Outrigger clamp

ActiveUS10470451B2Prevent crease and kinkPrevent the filament from becoming creased or kinkedRodsVessel partsEngineering

An outrigger clamp to couple together two or more nestable tubes. The clamp can include a guide for retaining filament. The guide can rotate about an axis based on the forces applied to the outrigger to better align the filament and guides, and therefore align the forces applied to the outrigger and filament. The retainer can be, for example, one or more rollers that help prevent the filament from becoming creased or kinked during use.

Owner:GEM PROD LLC

Polarization maintaining connectors

ActiveUS20160202428A1Facilitate interengagementMinimal angular offsetCoupling light guidesEngineeringMechanical engineering

A connector comprising an outer housing having a first keying element, an inner housing at least partially disposed in the outer housing and having second and third keying elements, the second keying element cooperating with the first keying element to align angularly the inner housing with the outer housing, a ferrule assembly at least partially disposed in the inner housing and having a ferrule and fourth and fifth keying elements, the fourth keying element cooperating with the third keying element to align angularly the ferrule assembly with the inner housing, an alignment member receiving at least a portion of the ferrule assembly, the alignment member having a sixth keying element to cooperate with the fifth keying element to align angularly the ferrule assembly with the alignment member, and wherein the clearance between the fifth and sixth keying elements is less than that between the first and second keying elements, and between the third and fourth keying elements.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

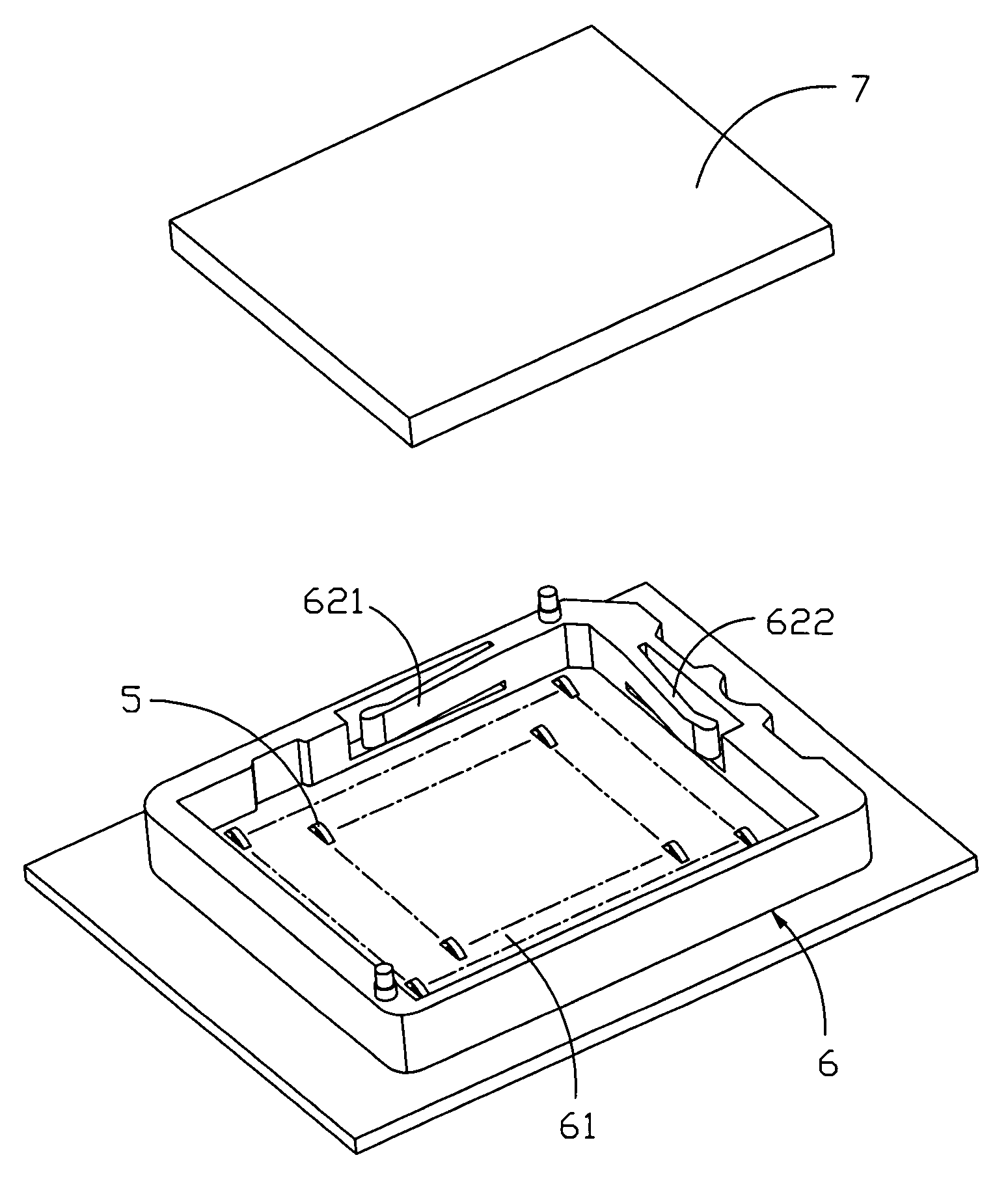

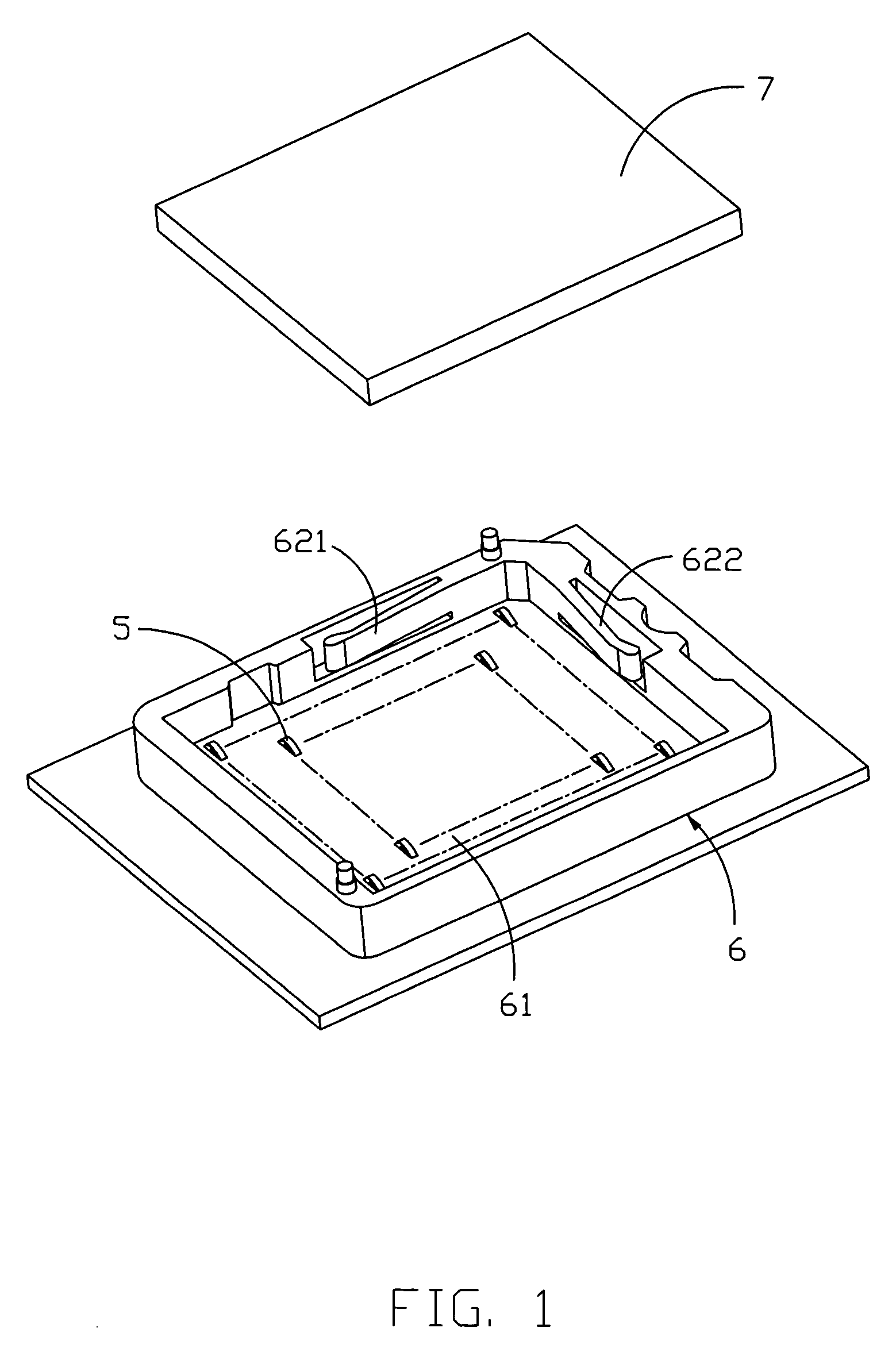

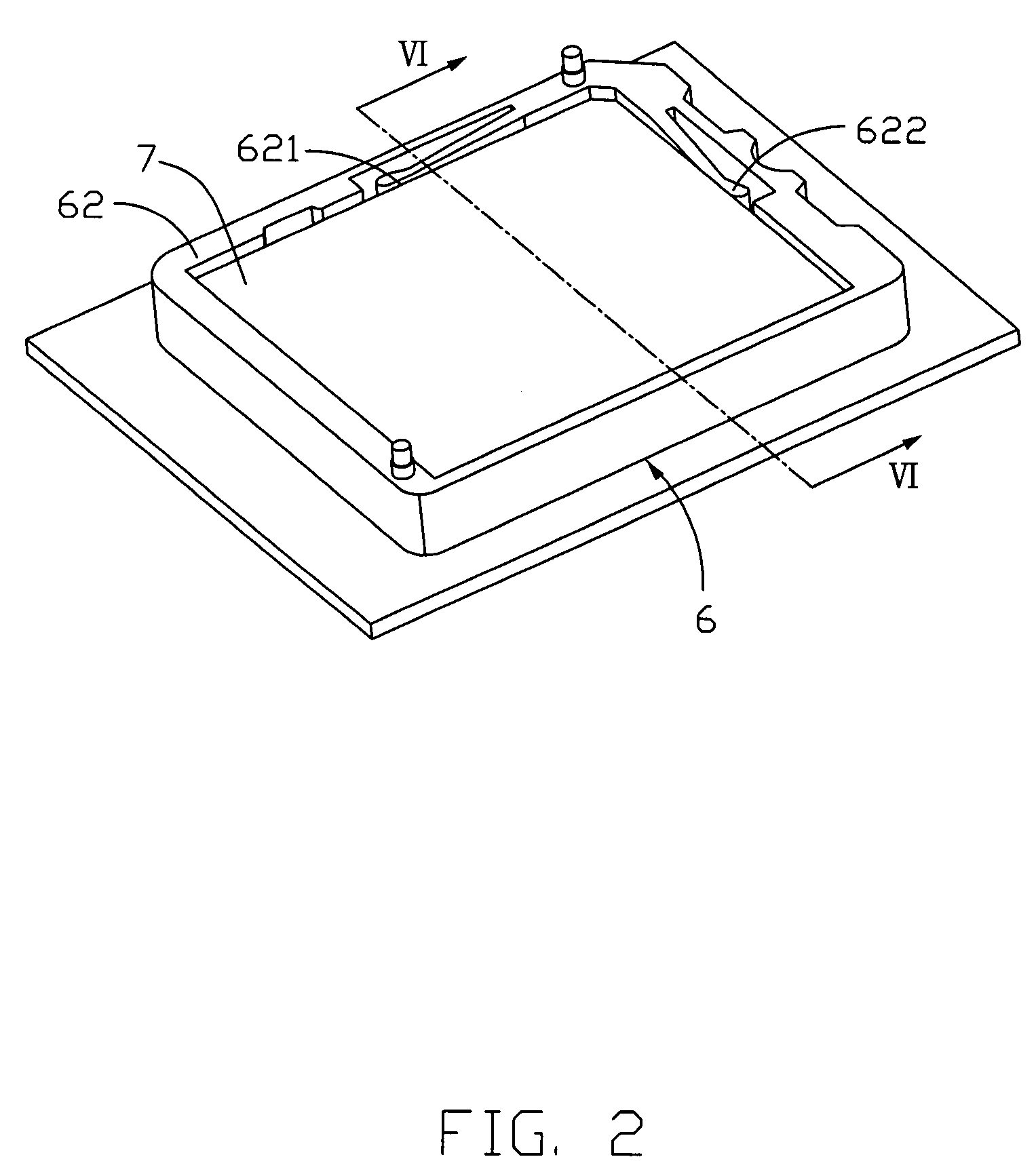

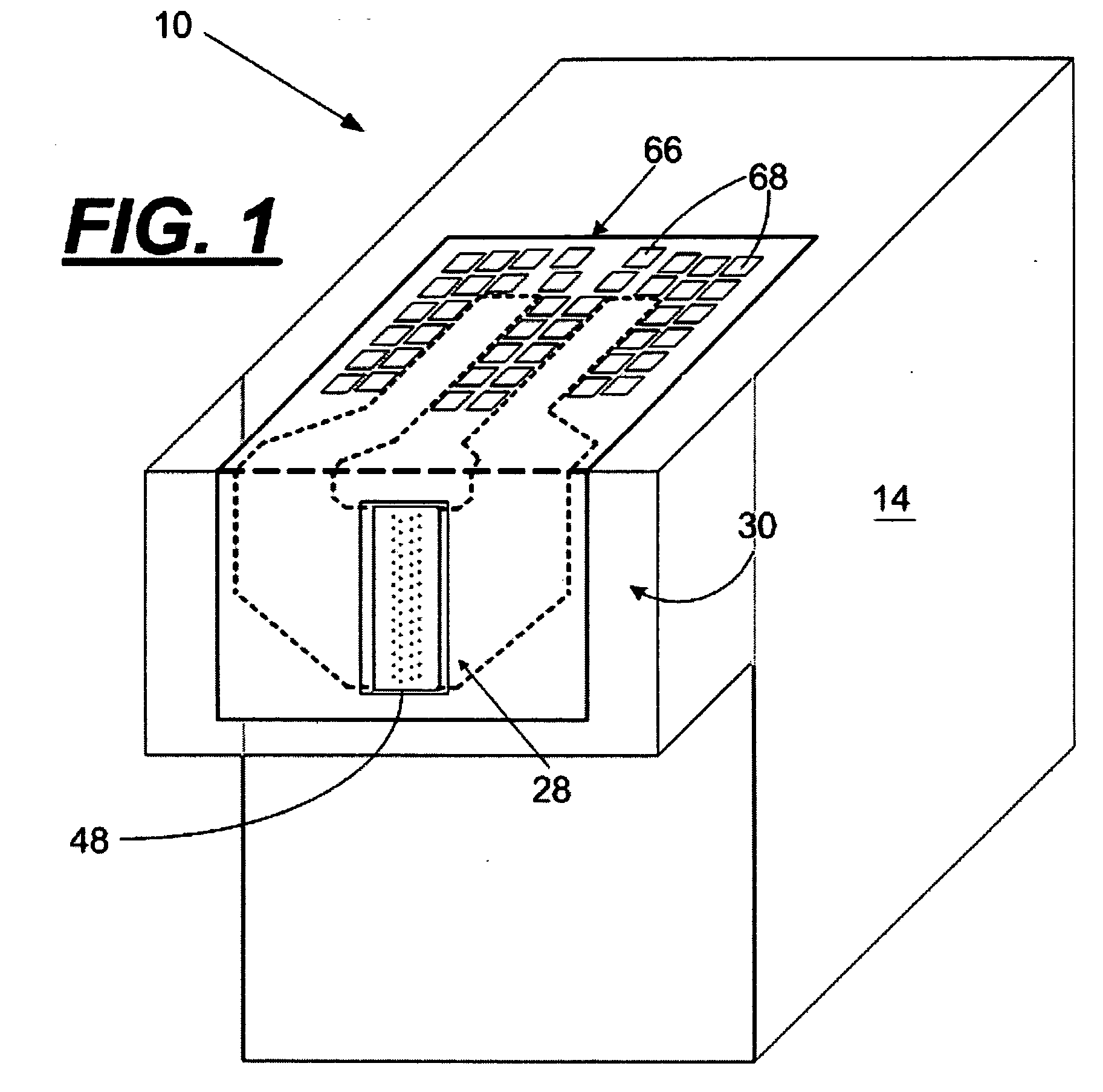

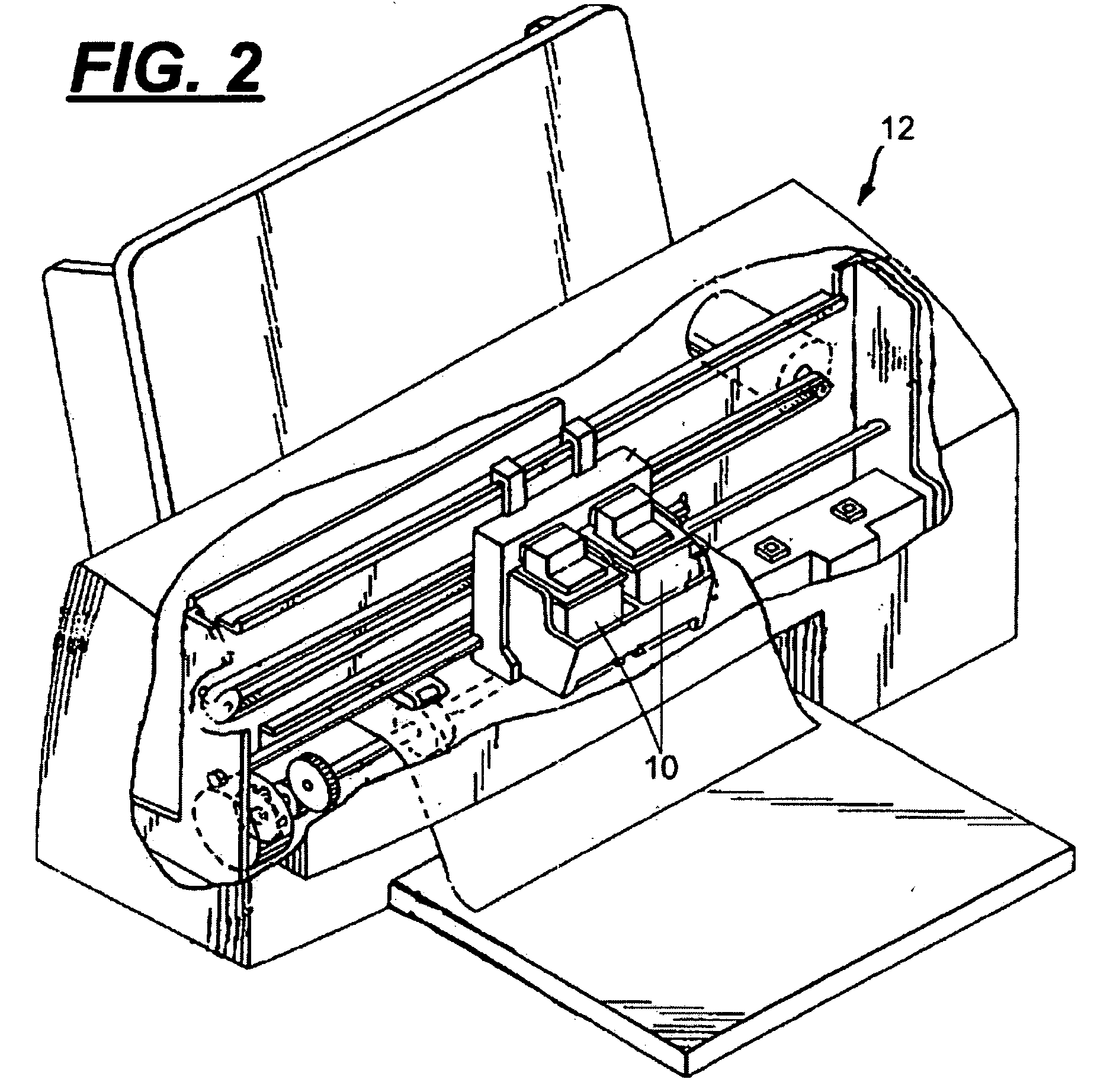

Die attach methods and apparatus for micro-fluid ejection device

ActiveUS20060114297A1Less-costly to manufactureMiniaturizationPrintingBond lineBiomedical engineering

A micro-fluid ejection device structure, a multi-fluid cartridge containing the ejection device structure, and methods for making the ejection device structure and cartridge. The micro-fluid ejection device structure includes a fluid supply body containing at least three fluid supply slots therein. An ejection head substrate having fluid feed slots therein is attached to the fluid supply body. Each of the fluid supply slots in the body is in flow communication with at least one of the fluid feed slots in the substrate. A plurality of adhesive bond lines adhesively attach the ejection head substrate and the fluid supply body to one another. Each of the adhesive bond lines have a width of less than about 600 microns and are located between adjacent ones of the fluid supply slots in the body.

Owner:FUNAI ELECTRIC CO LTD

Vertical alignment film and VA mode liquid crystal cell

InactiveUS7811469B2Short timeSufficient alignmentLiquid crystal compositionsThin material handlingVertical alignmentLiquid crystal cell

The present invention provides a vertical alignment film having a polymerizable liquid crystal compound having negative dielectric constant anisotropy, where the polymerizable liquid crystal compound is vertically aligned against the surface of the substrate, and then the polymerizable liquid crystal compound is fixed to form the vertical alignment film.

Owner:FUJIFILM CORP

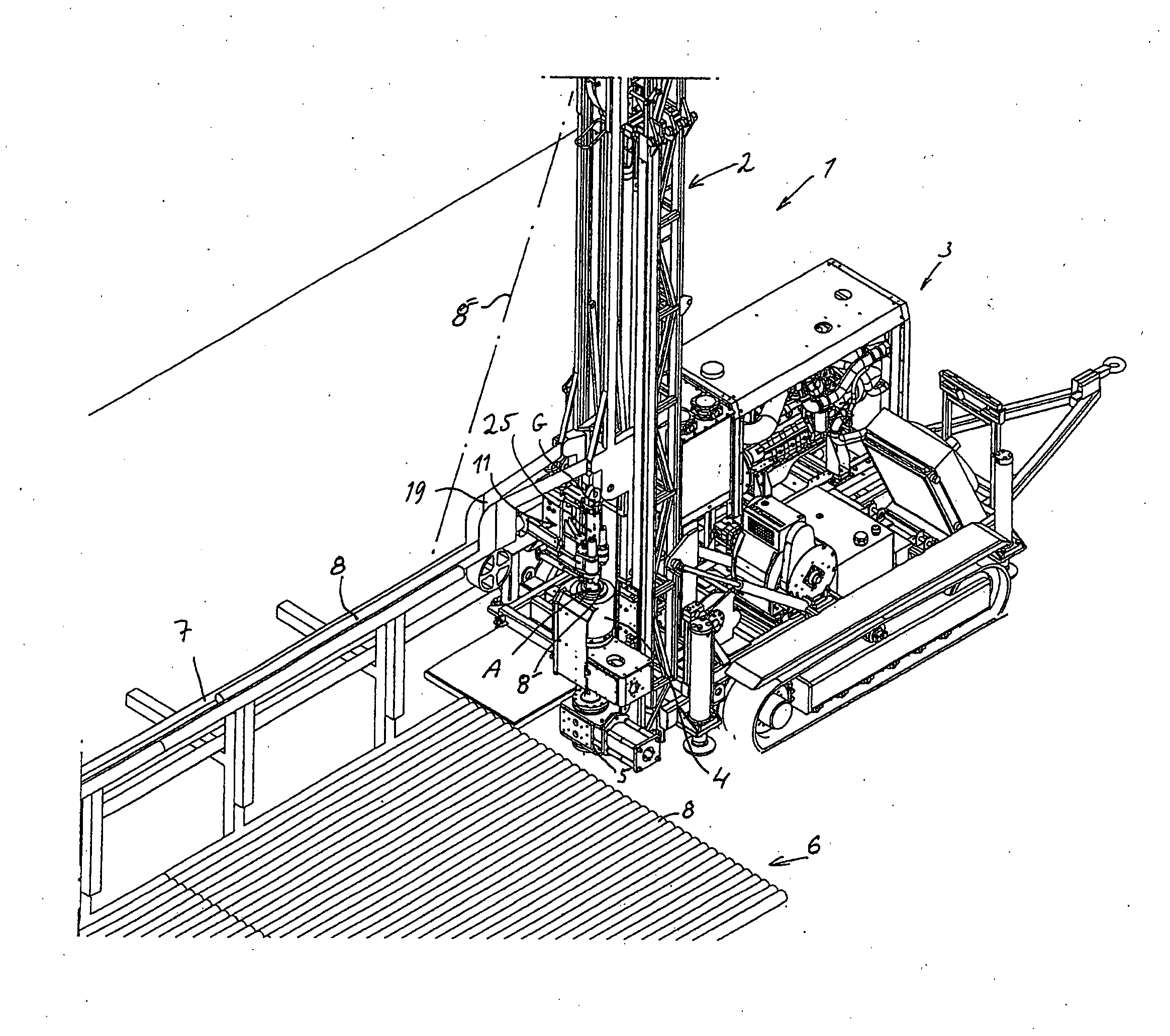

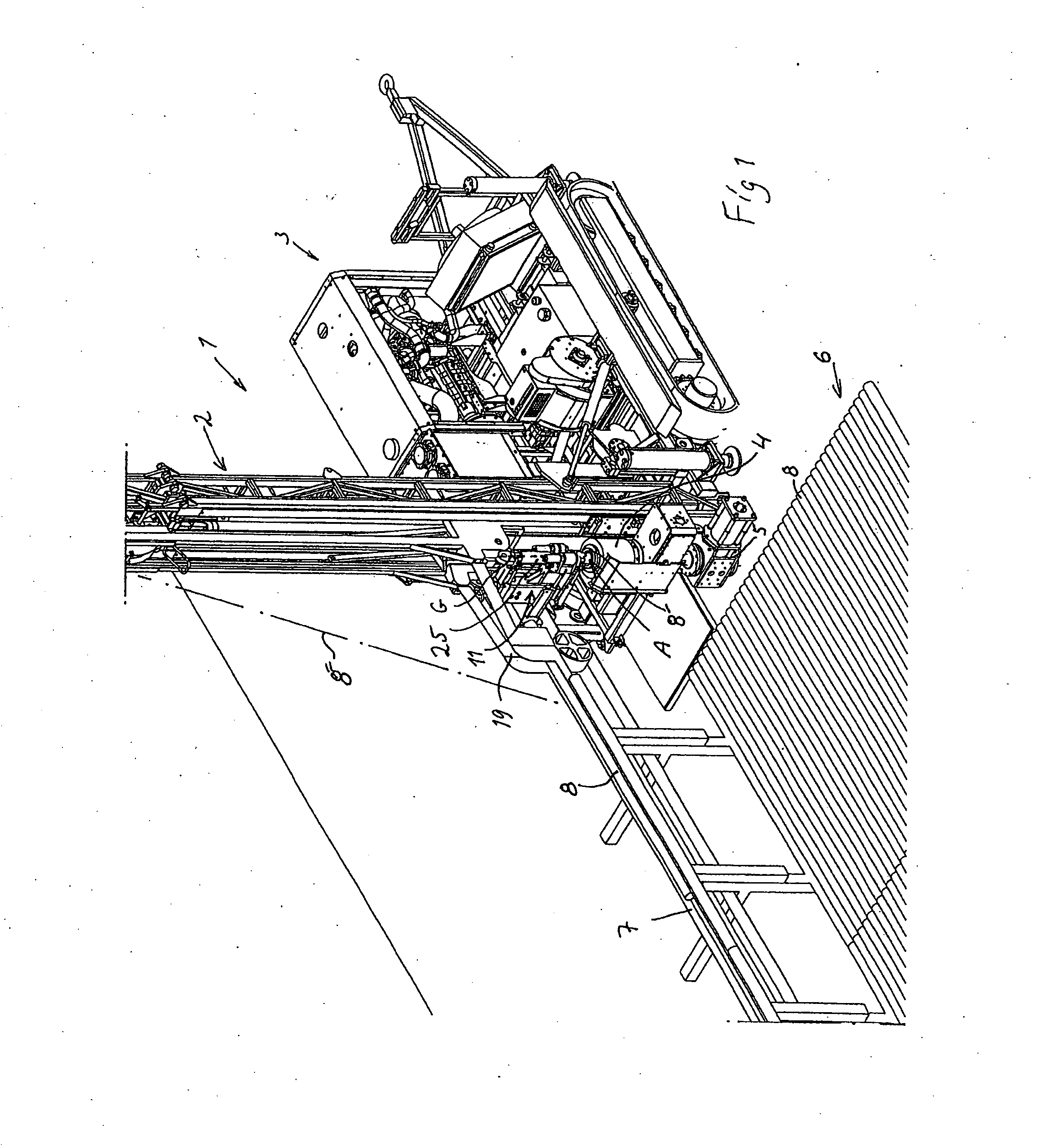

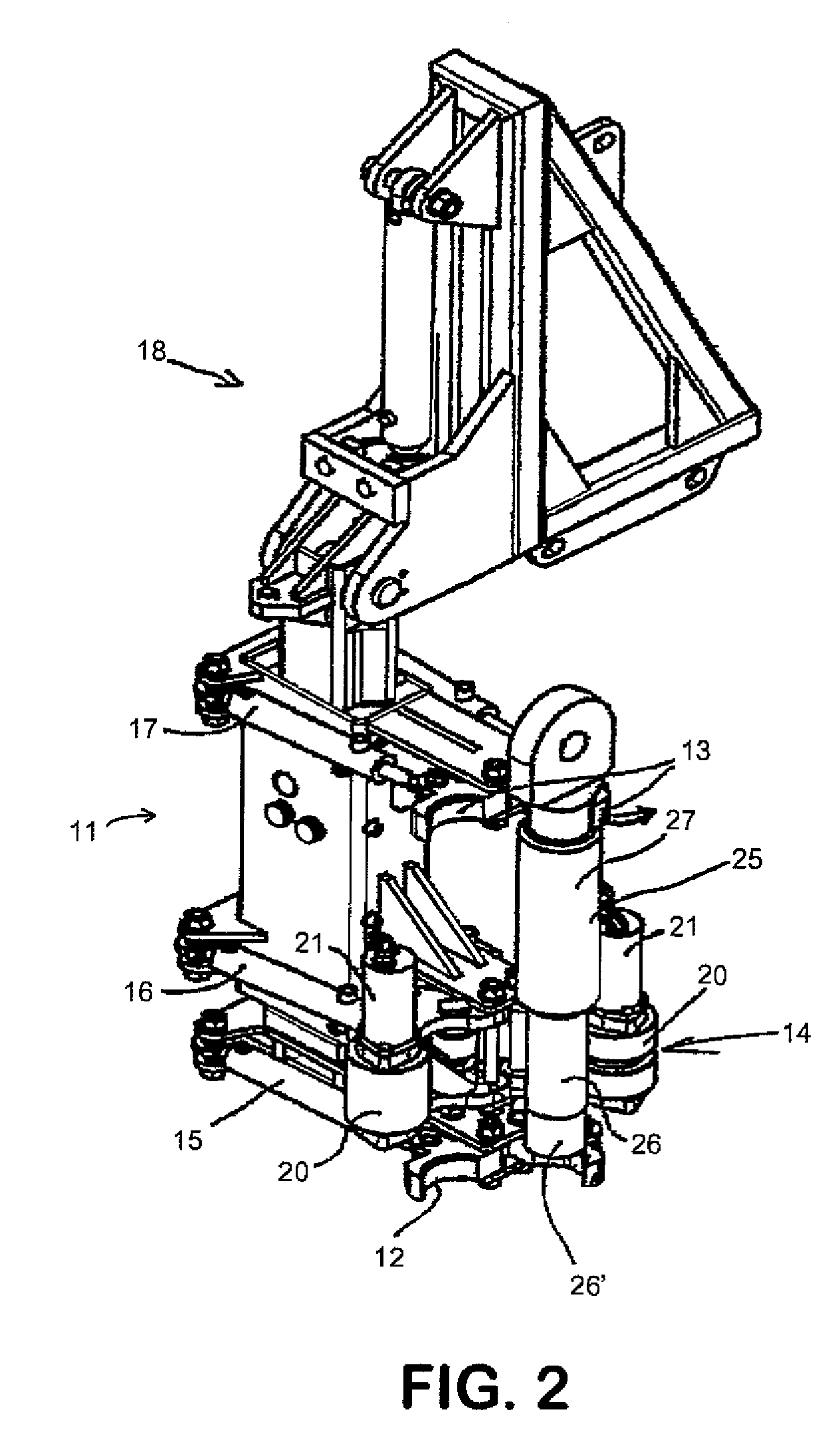

Device and method for handling drill string components, as well as rock drilling rig

ActiveUS20130327541A1Sufficient alignmentFully processedDrilling rodsFluid removalDrill stringEngineering

A handling device for handling drill string components (8, 8′,8″) in a rock drilling rig (1), wherein the handling device includes a gripper unit (11) for gripping drill string components (8, 8′,8″) to be put into and be brought out from the rock drilling rig, and wherein the gripper unit (11) includes grippers (12,13,14) operational for gripping components positioned in a gripping position, which defines a grip position axis (G). The gripper unit (11) is supported swingable between: a) a first position, wherein the gripper unit is positioned for engagement with an end portion of a first drill string component (8′) and an end portion of a second drill string component (8″) in and aligned with said active drill string position (A), and b) a second position, wherein a gripper unit (11) is positioned for engagement with an end portion of a drill string component in a delivering position for drill string components that are to be brought into respectively taken away from said active drill string position (A). The invention also concerns a rock drilling rig and a method.

Owner:EPIROC AB

Method for Coupling a Machine Frame of an Earth Working Machine to a Working Device, Earth Working Machine, and Connecting Apparatus for the Method

A method for coupling a machine frame (12) of an earth working machine (10) to a working device (28) between the machine frame (12) and a substrate (U) encompasses the following steps:arranging the machine frame (12) and the working device (28) between the machine frame (12) and the substrate (U);aligning the receiving portion (42) and working device (28) relative to one another in such a way that fastening formations (56, 60) of the working device (28) are lined up, along a spacing direction, with fastening counter-formations (58, 62) of the machine frame (12);bringing the fastening formations (56, 60) and fastening counter-formations (58, 62) closer to one another; andoperably fastening the working device (28) onto the receiving portion (42).According to the present invention the aligning step encompasses the following sub-steps:connecting the machine frame (12) and the working device (28) to one another by means of a connecting apparatus (76), in such a way that the working device (28) is movable in response to its weight, parallel to the effective direction of gravity (g) and orthogonally thereto, relative to the machine frame (12); thenallowing the working device (28) to hang on the machine frame (12); and thensupporting the working device (28).

Owner:WIRTGEN GMBH

Laser tracker calibration system and methods

ActiveUS20190178999A1Quickly and easily accuracySufficient alignmentRod connectionsUsing optical meansSupporting systemEngineering

A system and method of calibrating a laser tracker is provided. The system includes a support system for quickly and easily moving an artifact to a desired position and orientation and for holding the artifact in the position and orientation. An adjustable alignment mirror is coupled to a first end of the artifact so that the more accurate ranging system of the laser tracker can be isolated to determine a reference length of the artifact. Additional measurements are then taken to exercise one or more error source within the tracker. The support system includes a positioner and a support beam for positioning and supporting the artifact. The artifact is coupled to the support beam using kinematic clamps that are designed to reduce or eliminate errors associated with over-constraining the artifact. The artifact is movable between a deployed configuration for use and a stowable configuration for ease of storage and transportation.

Owner:BRUNSON INSTR

Liquid crystal display and production method therefor

ActiveUS20190079356A1Increase contrastExcellent reliabilityLiquid crystal compositionsNon-linear opticsChemistryLiquid-crystal display

A liquid crystal display includes a pair of substrates, a liquid crystal layer, and an alignment-controlling layer. The liquid crystal layer is disposed between the pair of substrates and includes a liquid crystal material. The alignment-controlling layer, which is formed by polymerization of a polymerizable monomer added to a liquid crystal composition forming the liquid crystal layer so as to be brought into contact with the liquid crystal layer, and controls an alignment of the liquid crystal material to the substrate at a predetermined angle. One substrate of the pair of substrates has an alignment film coated and formed so as to be brought into contact with the alignment-controlling layer, and the other substrate has no alignment film.

Owner:SHARP KK

Device and method for handling drill string components, as well as rock drilling rig

ActiveUS9428970B2Sufficient alignmentFully processedDrilling rodsFluid removalPinch gripClassical mechanics

A handling device for handling drill string components (8, 8′,8″) in a rock drilling rig (1), wherein the handling device includes a gripper unit (11) for gripping drill string components (8, 8′,8″) to be put into and be brought out from the rock drilling rig, and wherein the gripper unit (11) includes grippers (12,13,14) operational for gripping components positioned in a gripping position, which defines a grip position axis (G). The gripper unit (11) is supported swingable between: a) a first position, wherein the gripper unit is positioned for engagement with an end portion of a first drill string component (8′) and an end portion of a second drill string component (8″) in and aligned with said active drill string position (A), and b) a second position, wherein a gripper unit (11) is positioned for engagement with an end portion of a drill string component in a delivering position for drill string components that are to be brought into respectively taken away from said active drill string position (A). The invention also concerns a rock drilling rig and a method.

Owner:EPIROC AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com