Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Solve the problem of low assembly efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

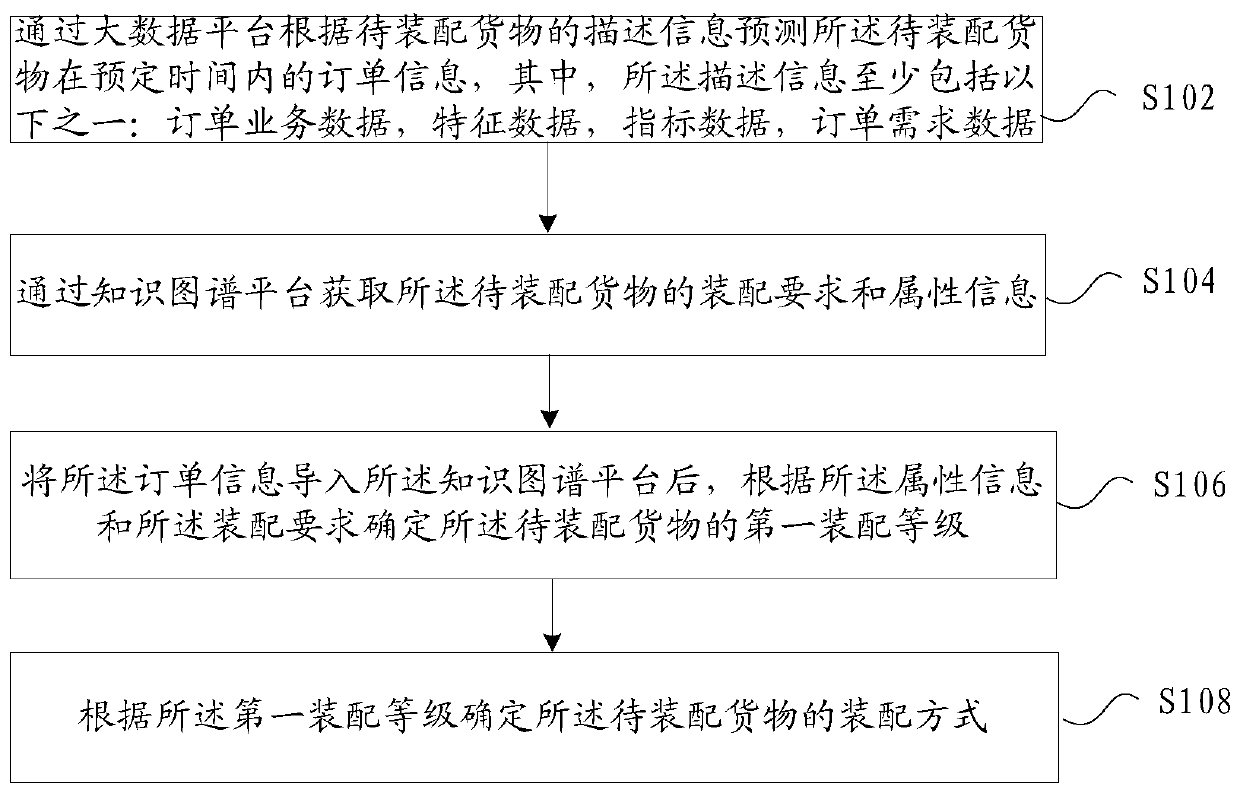

Goods assembling method and device, storage medium and electronic device

InactiveCN110705805ASolve the problem of low assembly efficiencyImprove assembly efficiencyForecastingBuying/selling/leasing transactionsBusiness dataFeature data

The invention provides a cargo assembling method and device, a storage medium and an electronic device. The method comprises the steps of predicting order information of to-be-assembled goods within preset time through a big data platform according to description information of the to-be-assembled goods, and the description information at least comprises one of order business data, feature data, index data and order demand data; obtaining assembly requirements and attribute information of the to-be-assembled goods through a knowledge graph platform; importing the order information into the knowledge graph platform, and determining a first assembly level of the to-be-assembled goods according to the attribute information and the assembly requirements; and determining an assembly mode of theto-be-assembled goods according to the first assembly level. According to the method, the problem of low assembly efficiency caused by manual assembly of goods is solved.

Owner:MIAOZHEN INFORMATION TECH CO LTD

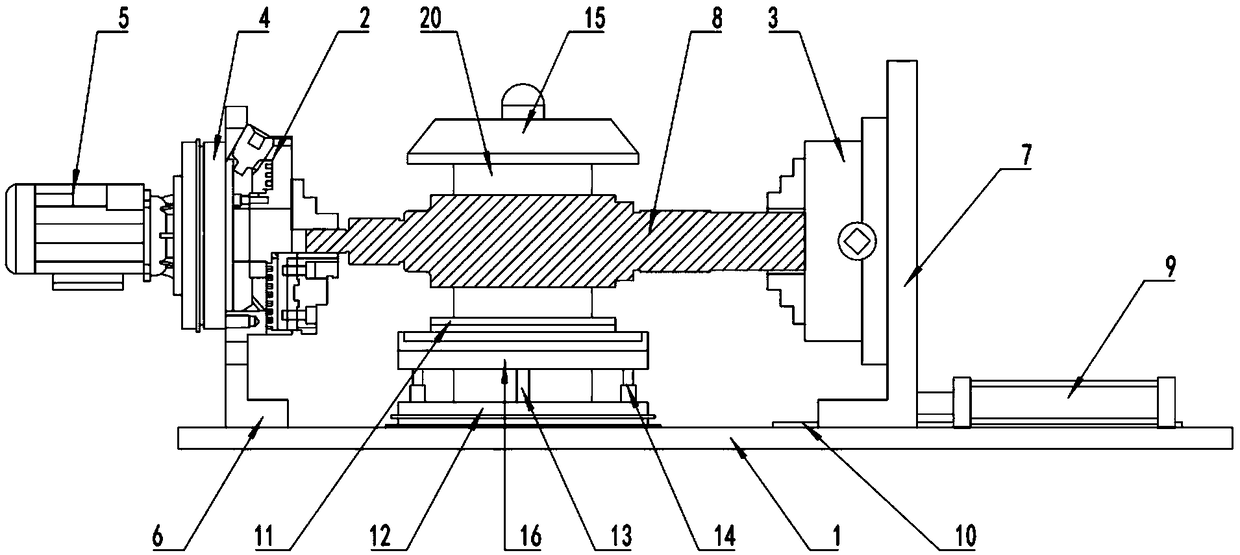

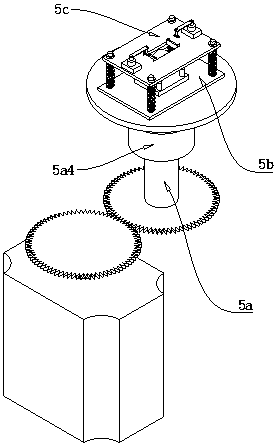

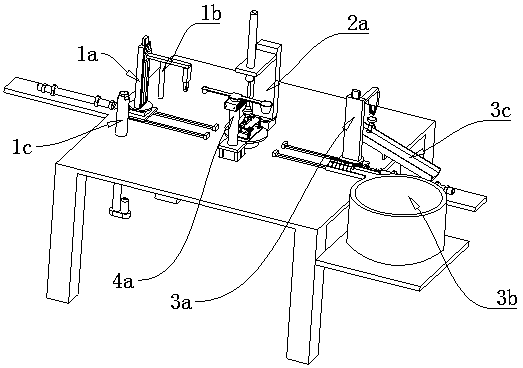

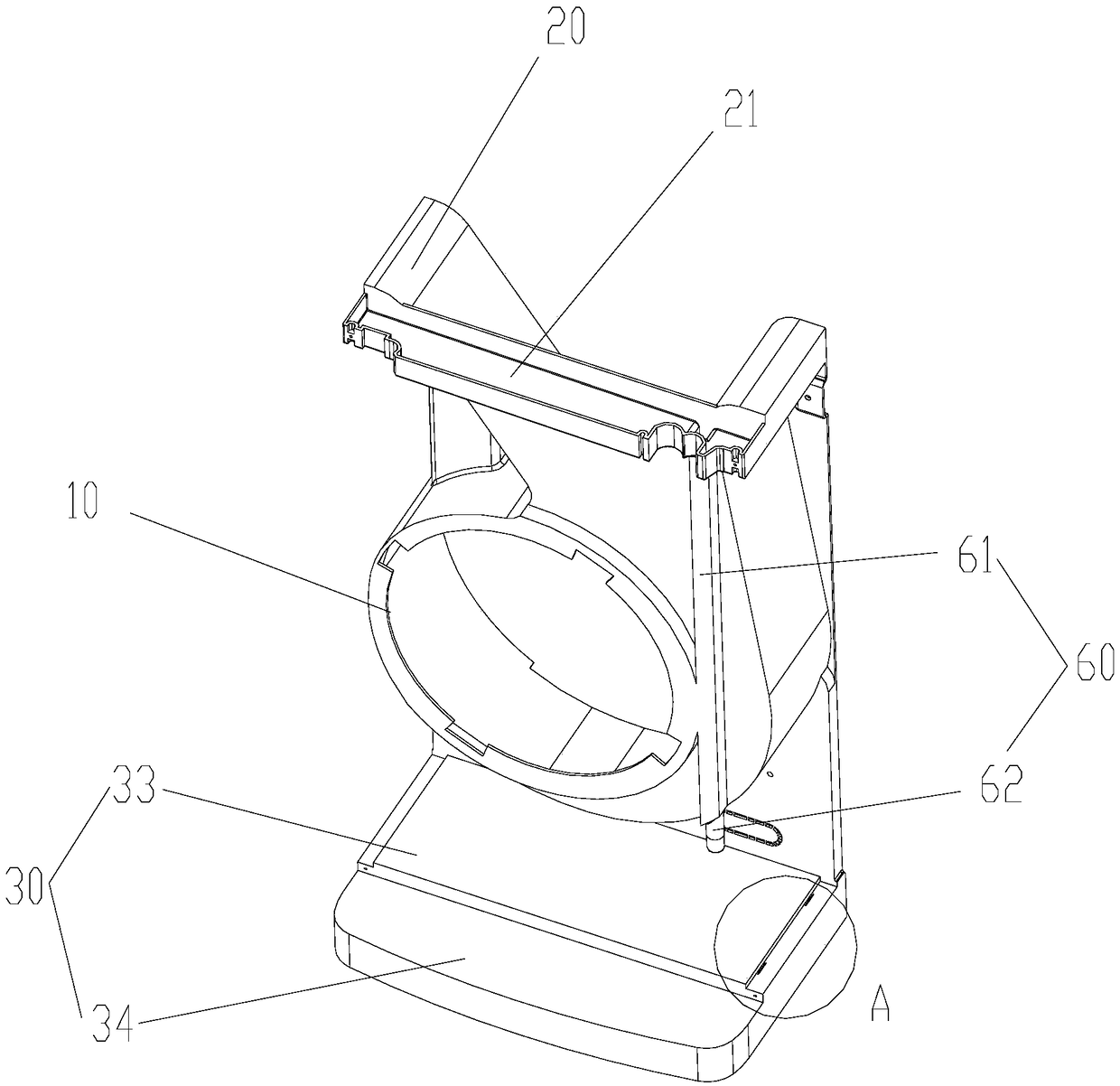

Mechanism for automatically pasting magnetic shoe of servo motor

ActiveCN109450192AEasy rotor loading and unloadingSolve the low assembly efficiencyManufacturing stator/rotor bodiesDrive motorSpeed reduction

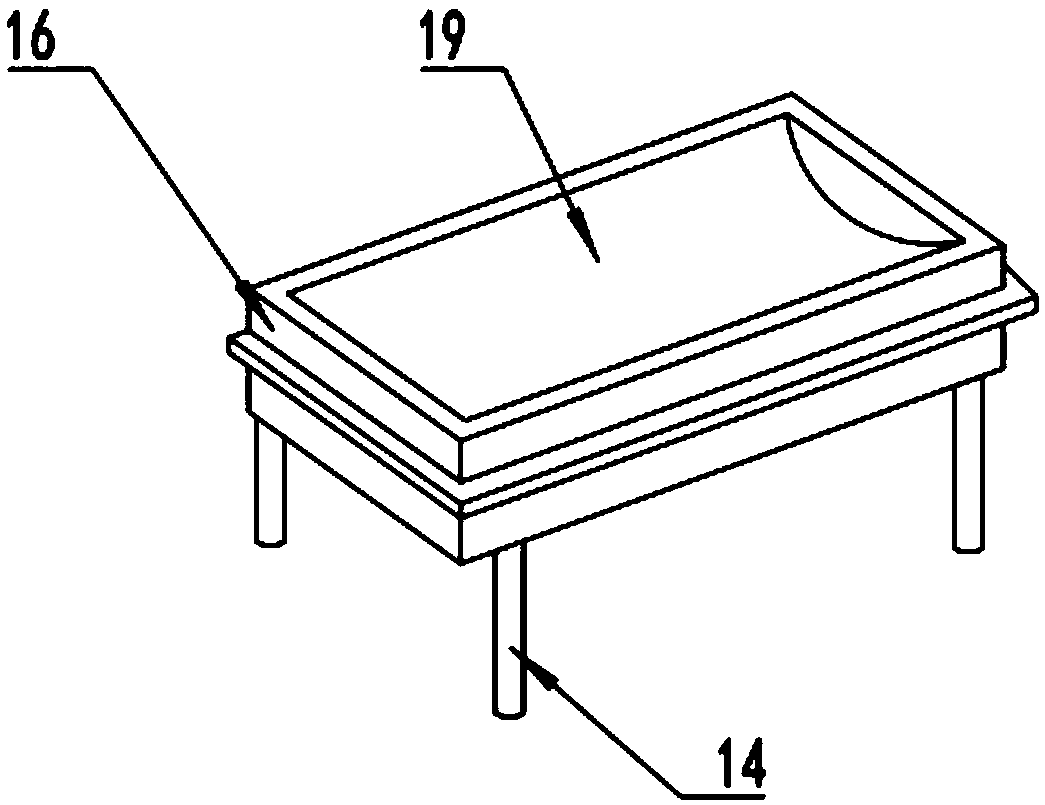

The invention discloses a mechanism for automatically pasting the magnetic shoe of a servo motor, and belongs to the technical field of automatic assembly. The mechanism comprises a machining table, amain three-jaw chuck, an auxiliary three-jaw chuck, a lifting cylinder and a magnetic shoe mold, wherein the main three-jaw chuck and the auxiliary three-jaw chuck are mounted on the machining tablethrough a main three-jaw chuck mounting rack and an auxiliary three-jaw chuck mounting rack respectively; the main three-jaw chuck is driven by a drive motor to rotate through a speed reduction box; the drive motor is a stepper motor; a rotor is arranged between the main three-jaw chuck and the auxiliary three-jaw chuck; a base is further mounted on the machining table; the magnetic shoe mold in sliding fit with the base is arranged on the base; and a cavity matched with the shape of the magnetic shoe is formed in the magnetic shoe mold. The mechanism has the mechanism that clamping fixation is carried out on the rotor by using the main three-jaw chuck and the auxiliary three-jaw chuck, and the magnetic shoe is driven to be pasted automatically by using the magnetic shoe mold; and moreover, the solidification of glue further can be facilitated, and just one clamping is needed in the pasting process of the magnetic shoe mold, so that the mechanism is extremely convenient.

Owner:宁波斯凯勒智能科技有限公司

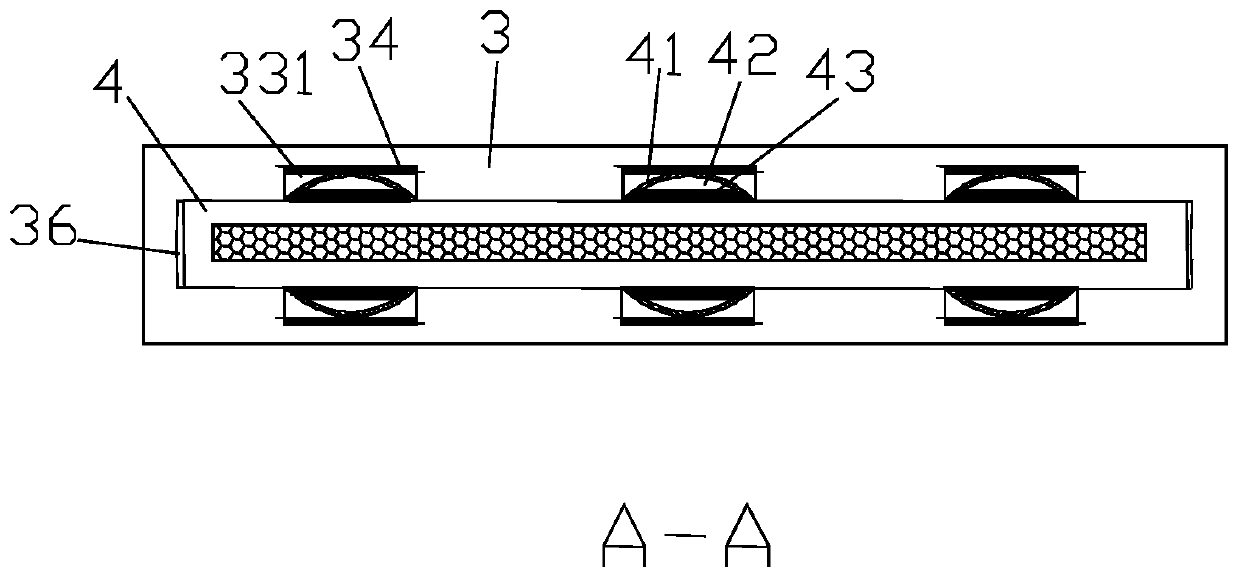

Rolling ball assembly tooling and bearing assembly equipment with rolling ball assembly tooling

The invention provides a rolling ball assembly tooling and bearing assembly equipment with the rolling ball assembly tooling. The rolling ball assembly tooling comprises an assembly rack, a rolling ball arranging plate and a material storage storehouse, wherein the rolling ball arranging plate is installed on the assembly rack and is provided with a plurality of rolling ball containing grooves forcontaining rolling balls, and the plurality of rolling ball containing grooves are arranged at intervals in the peripheral direction to make the multiple rolling balls distributed inside the plurality of rolling ball containing grooves be matched with a holding rack of a bearing component; the material storage storehouse is arranged above the rolling ball arranging plate, and the position betweena material outlet of the material storage storehouse and the rolling ball arranging plate is provided with a material feeding gap used for making the rolling balls inside the material storage storehouse drop into and be positioned inside the rolling ball containing grooves; and the rolling ball arranging plate is movably arranged relative to the material storage storehouse to make the rolling balls dropping out of the material storage storehouse be arranged and distributed inside the plurality of rolling ball containing grooves. By means of the rolling ball assembly tooling, the problem in the prior art that the assembly efficiency of plastic bearings is low is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

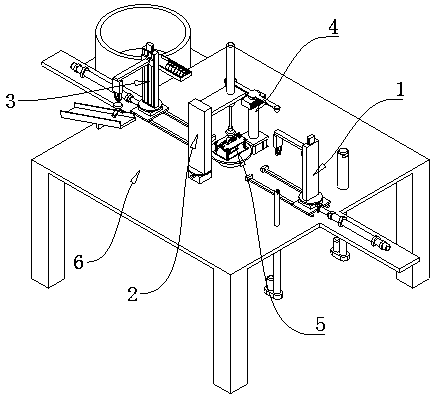

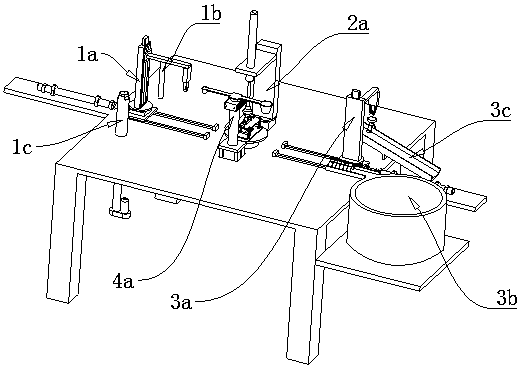

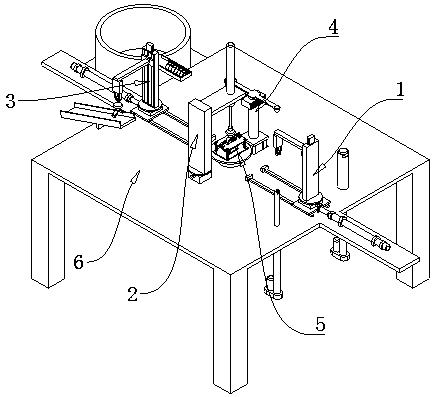

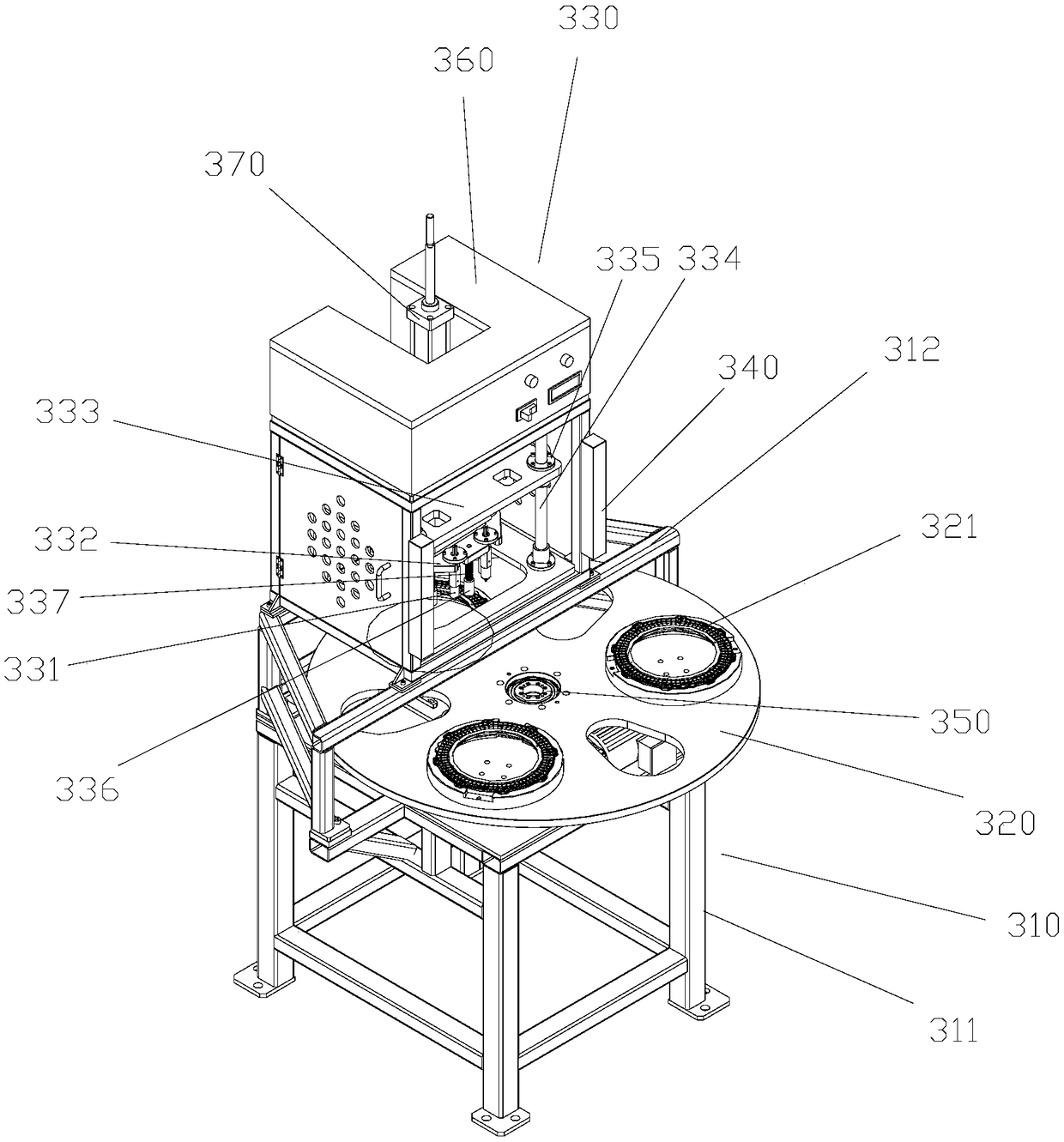

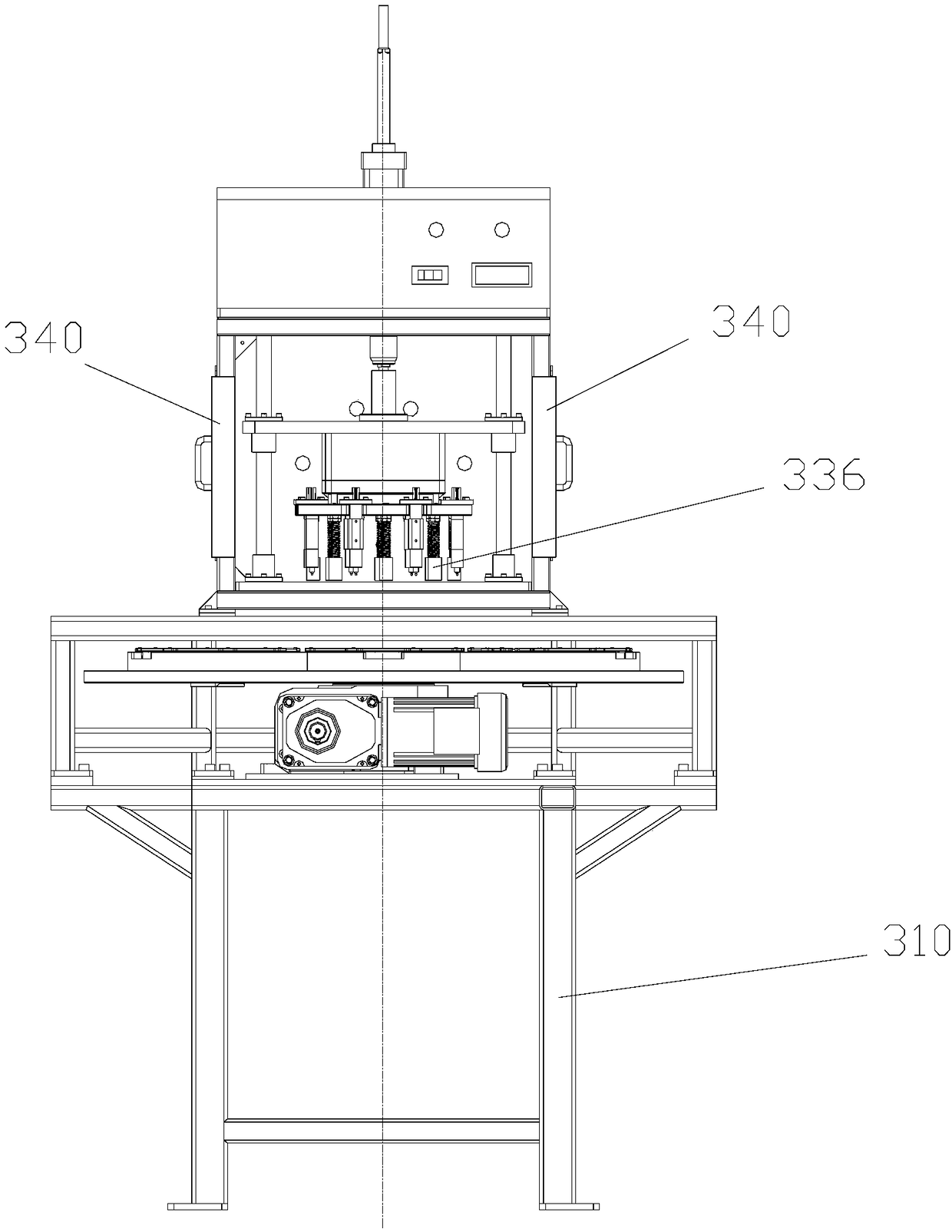

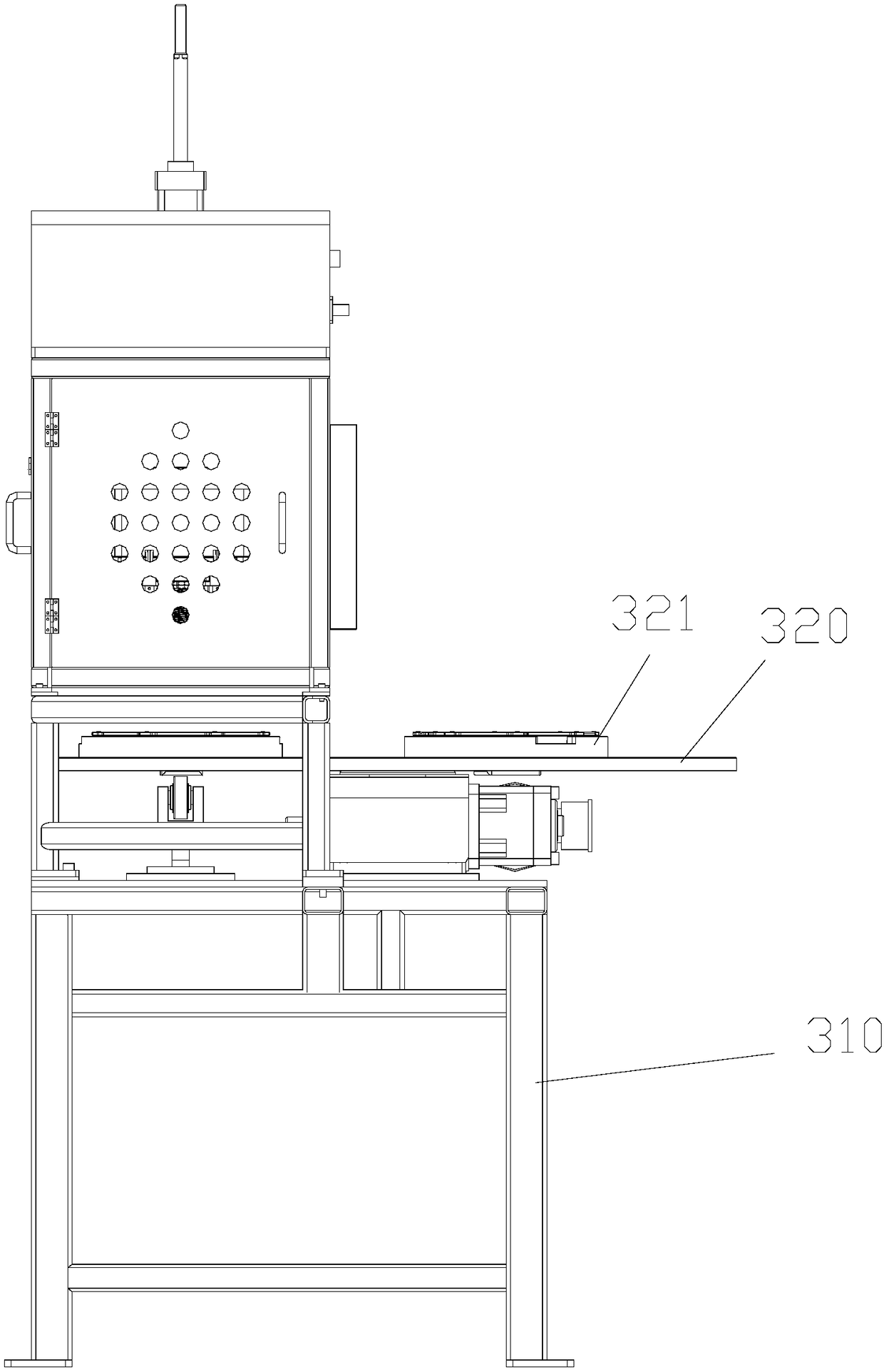

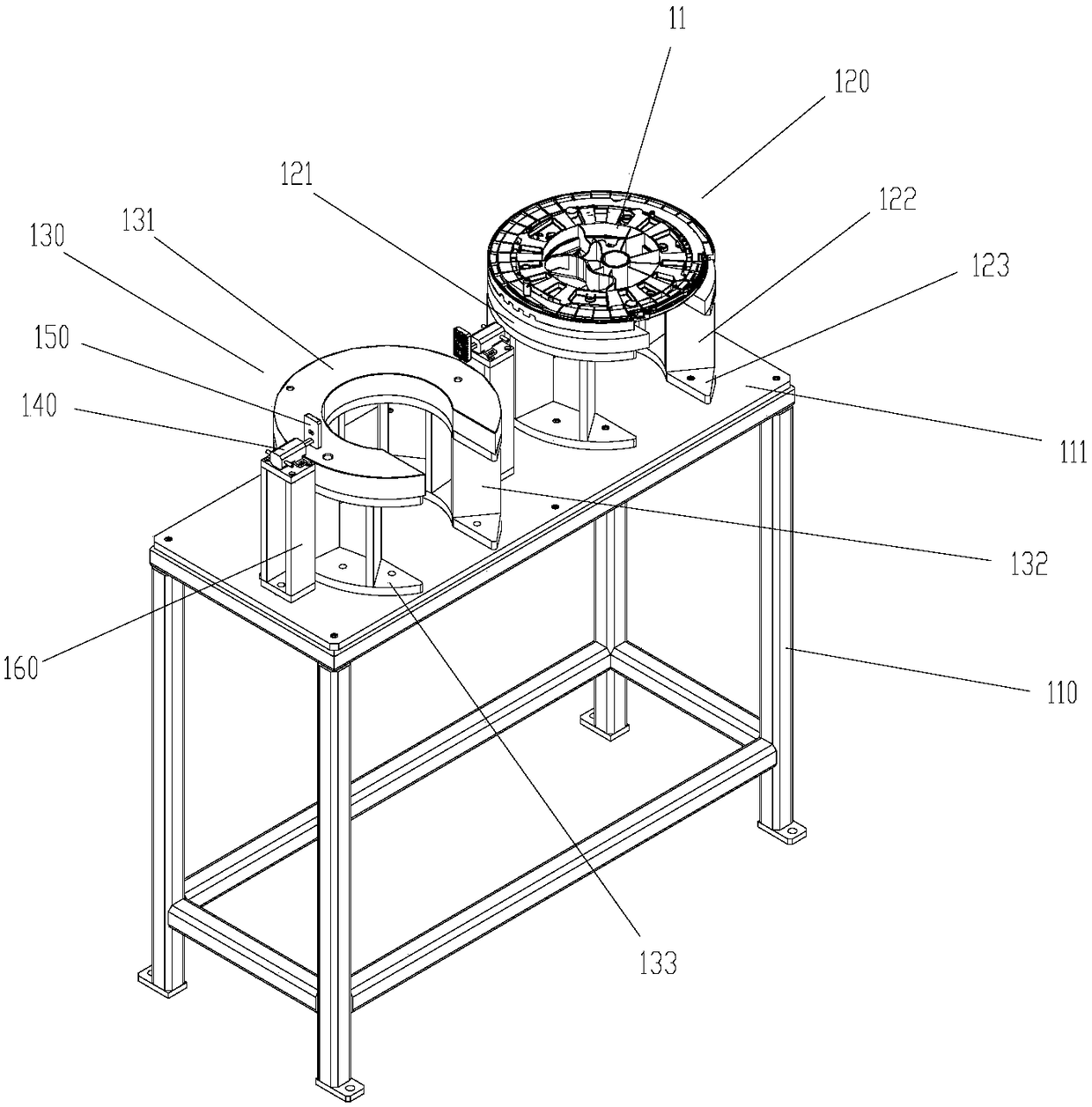

Automatic assembling equipment for fast ship steering wheel

ActiveCN108544213AReduce in quantitySolve the problem of low assembly efficiencyMetal working apparatusSteering wheelReciprocating motion

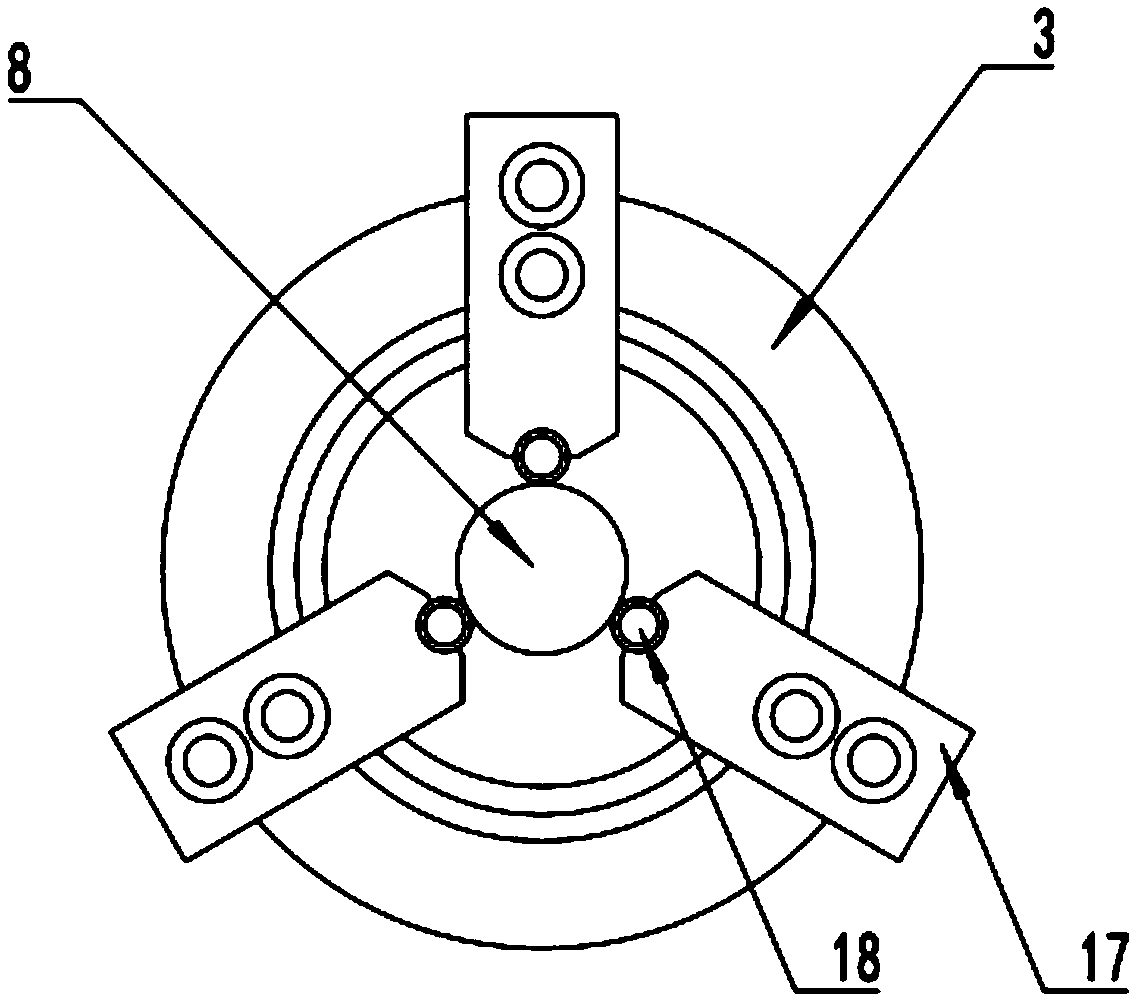

The invention relates to the relevant field of ships, in particular to automatic assembling equipment for a fast ship steering wheel. The automatic assembling equipment comprises a base, and further comprises a bearing and power-assisting ball feeding station, an assembling station, a clamping hoop feeding and workpiece discharging station, a positioning station and a positioning jig, wherein thepositioning jig is arranged in the middle of the base; the bearing and power-assisting ball feeding station, the assembling station, the clamping hoop feeding and workpiece discharging station and thepositioning station are sequentially arranged on the base along the circumferential direction of the positioning jig; and the bearing and power-assisting ball feeding station comprise a first mechanical arm used for feeding bearings and power-assisting balls, the assembling station comprises an assembling mechanical arm used for assembling workpieces, the clamping hoop feeding and workpiece discharging station comprises a second mechanical arm used for feeding clamping hoops and discharging the workpieces, and the positioning station comprises a positioning mechanical arm. According to the automatic assembling equipment, the problem of time consumption of assembling is solved, the yield is increased, and the number of defective products is reduced through the reciprocating motions of theequipment.

Owner:平庆义

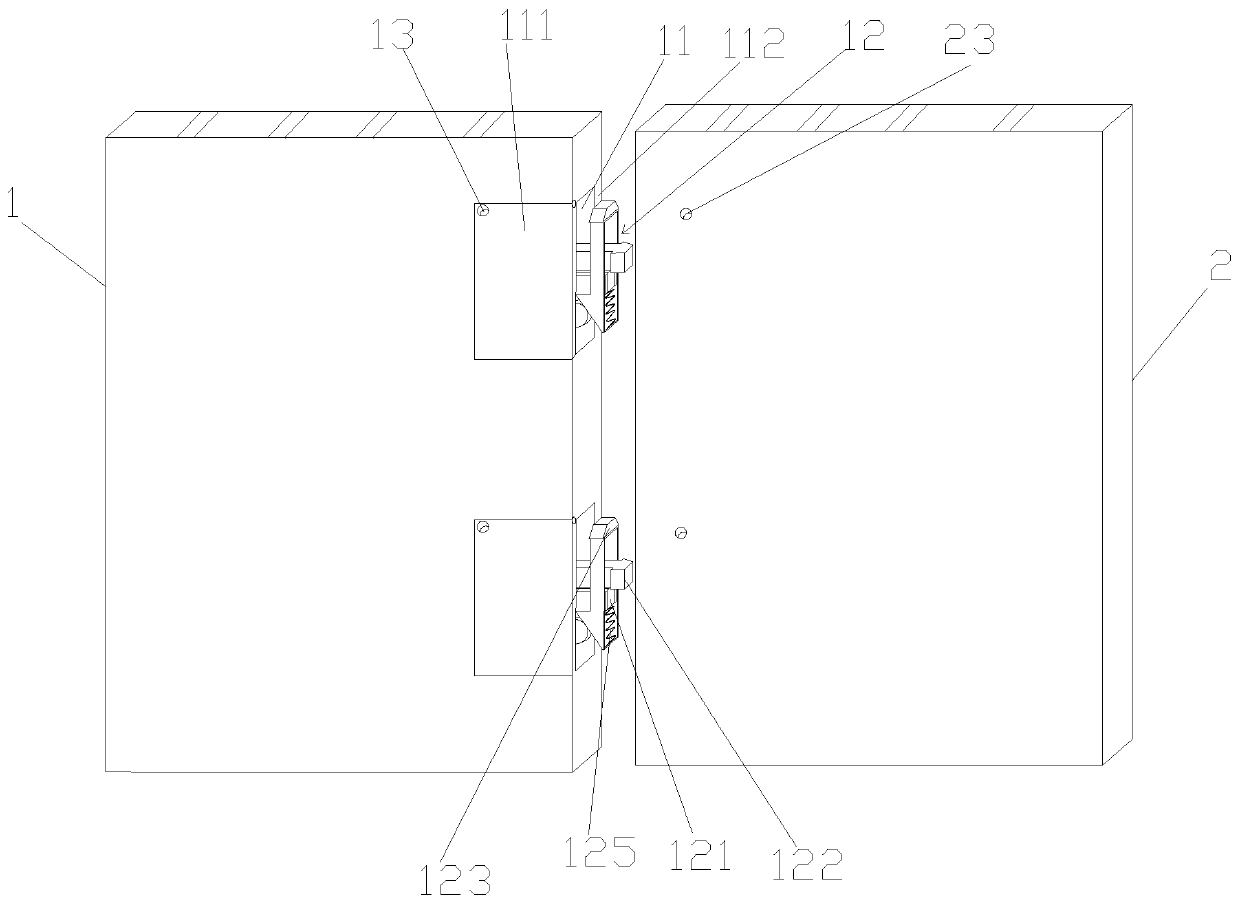

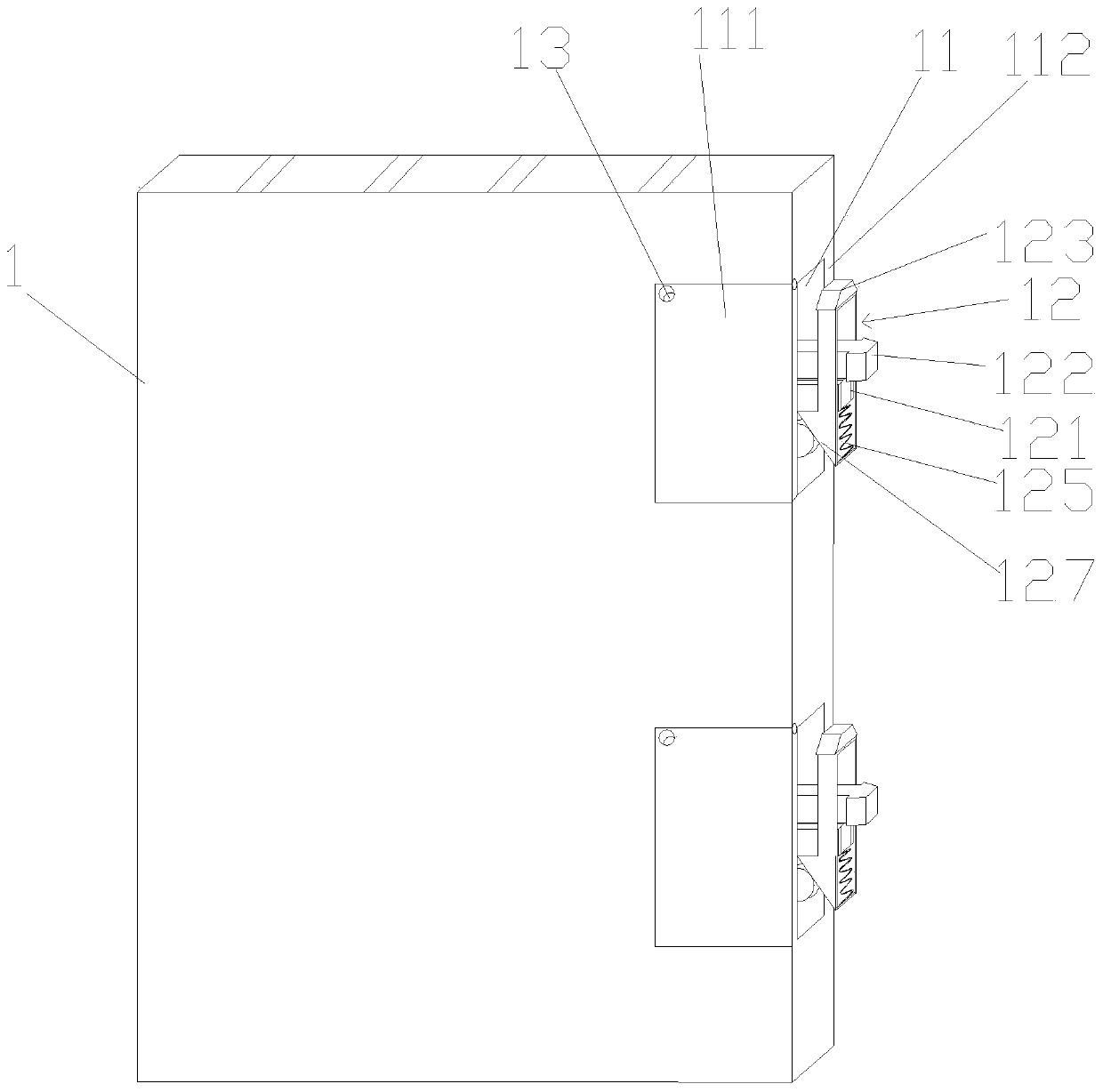

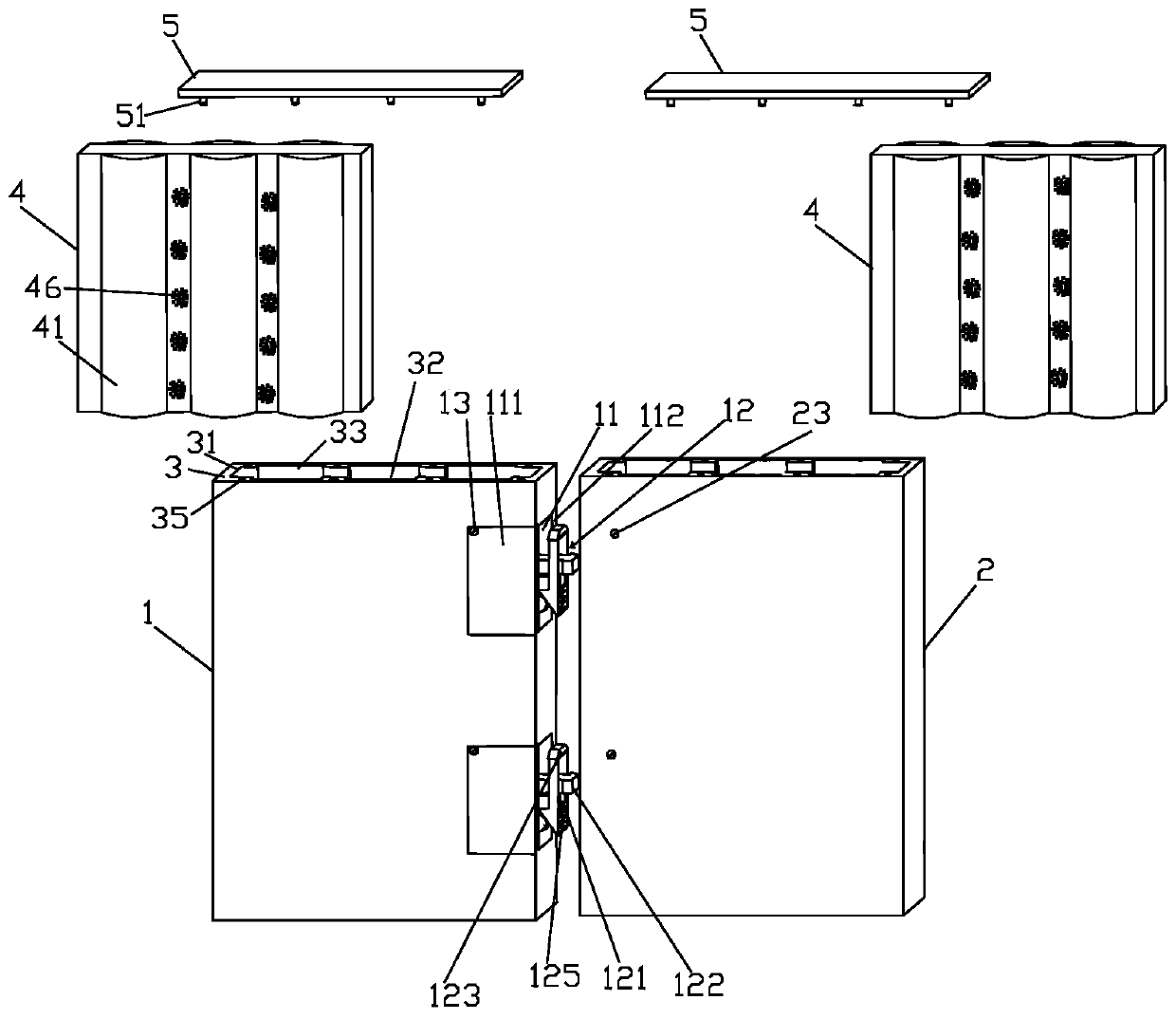

Prefabricated wallboard, combined wall and fabricated building

ActiveCN111321822AImprove assembly efficiencyReduced assembly effortWallsButt jointArchitectural engineering

The invention discloses a prefabricated wallboard, a combined wall and a fabricated building. The prefabricated wallboard comprises a first wallboard body and a second wallboard body. A first mountinggroove is formed in one side of the first wallboard body, and a second mounting groove is formed in one side of the second wallboard body. A first connecting structure is mounted in the first mounting groove, and a second connecting structure capable of being clamped with the first connecting structure is mounted in the second mounting groove. The first wallboard body is provided with a first grouting hole communicating with the first mounting groove, and the second wallboard is provided with a second grouting hole communicating with the second mounting groove. According to the prefabricatedwallboard, the combined wall and the fabricated building, the first mounting groove and the second mounting groove are in direct butt joint, then the first connecting structure and the second connecting structure are clamped and matched, and assembling of the two wallboard bodies is completed; then mortar and other fluid are injected into the grooves, wall body connection is reinforced, only positioning and simple assembling are needed in the whole process, the assembling efficiency is greatly improved, and the assembling workload is reduced.

Owner:河北水利电力学院

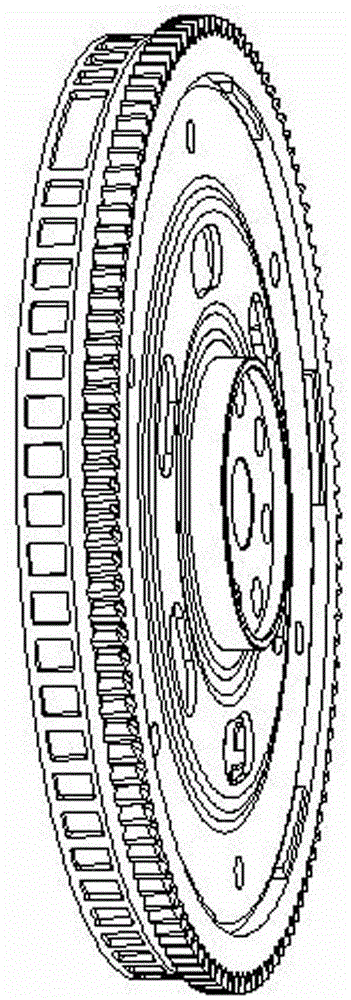

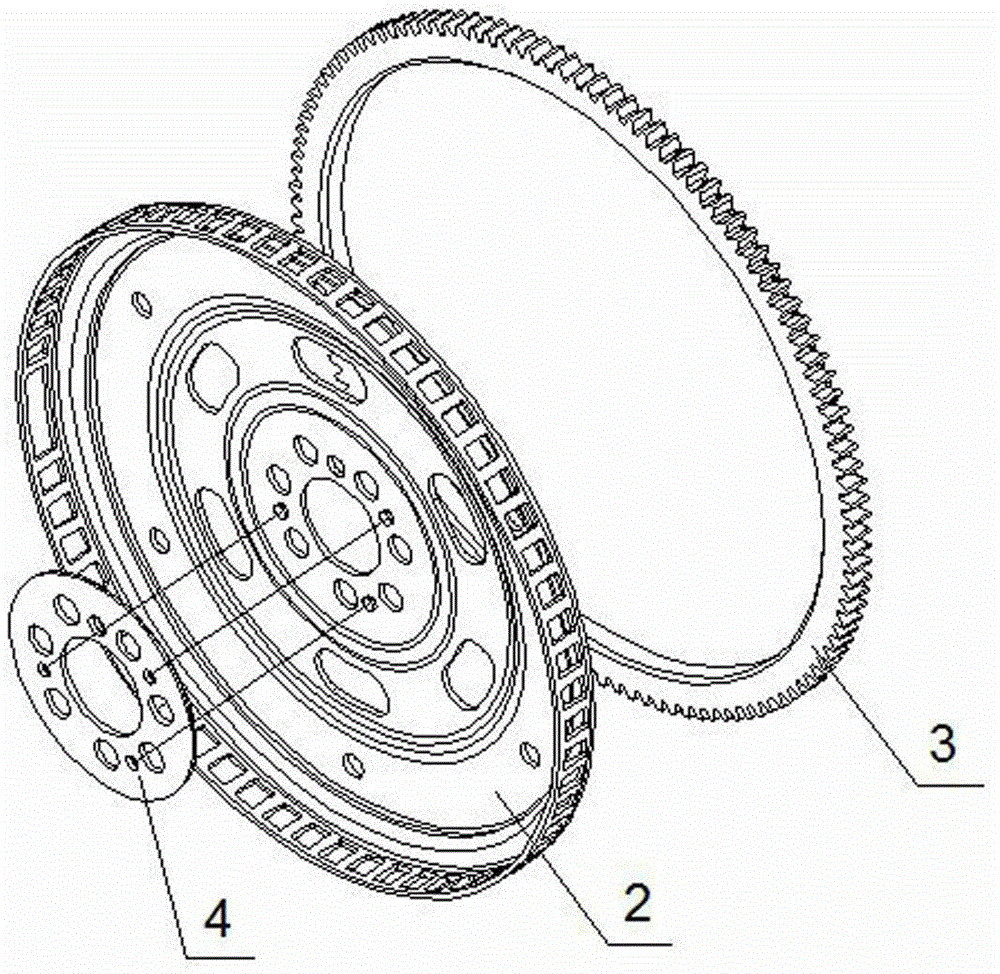

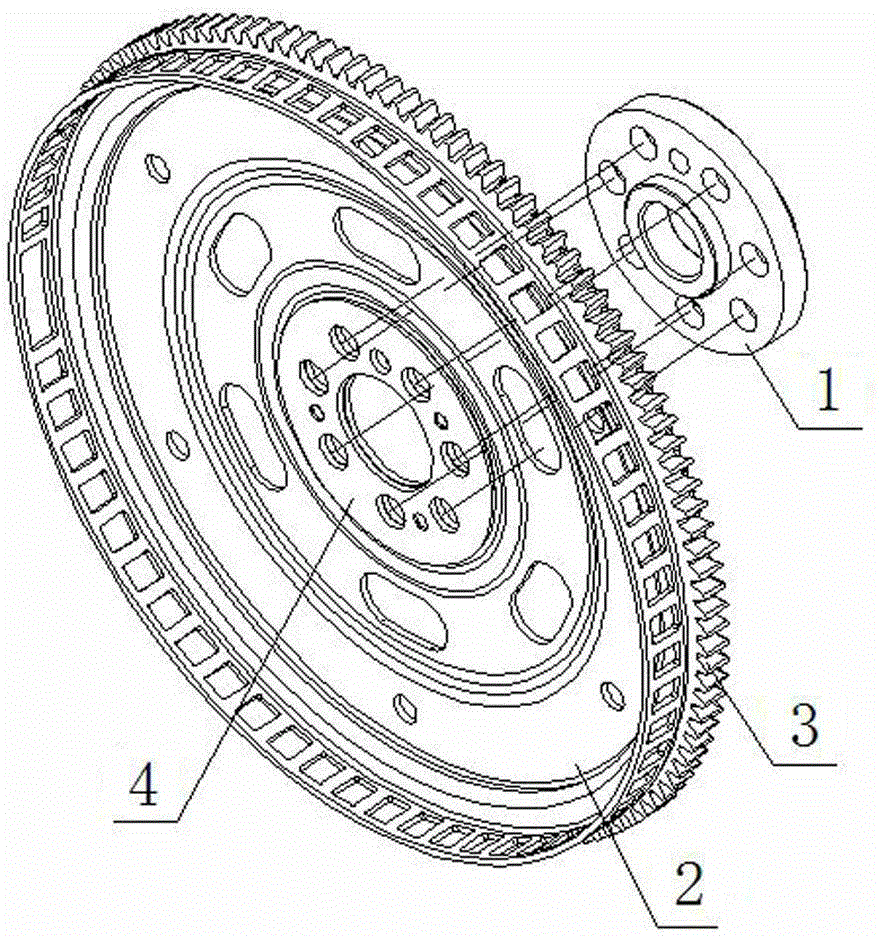

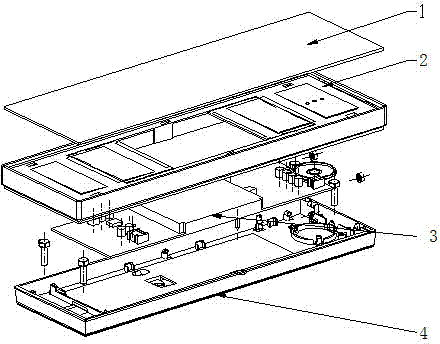

Flexible flywheel

InactiveCN104930118ASolve the problem of low assembly efficiencyLow costFlywheelsFlywheelEngineering

The invention discloses a flexible flywheel, and relates to the technical field of automobile components. The flexible flywheel comprises a connecting flange, a signal panel, starting teeth and a compressing disk; the compressing disk is connected with the middle of the one side of the signal panel in a pressing manner; the starting teeth are fixed on the other side of the signal panel; the other side of the signal panel opposite to the compressing disk is fixedly connected with the connecting flange; a forward reinforcing rib and a reverse reinforcing rib are arranged on the signal panel; the forward reinforcing rib is bulged towards the compressing disk; material removal holes are distributed at the periphery of the reverse reinforcing rib; 58 signal teeth are distributed on the signal panel; the width of each signal tooth is 5.1mm; and the signal panel and the connecting flange are provided with location holes. With the adoption of the flexible flywheel, switchover between a crankshaft and a hydraulic torque converter in a vehicle can be realized, and the starting performance and the NVH (Noise Vibration and Harshness) comfort of the vehicle are improved.

Owner:DONGFENG LIUZHOU MOTOR

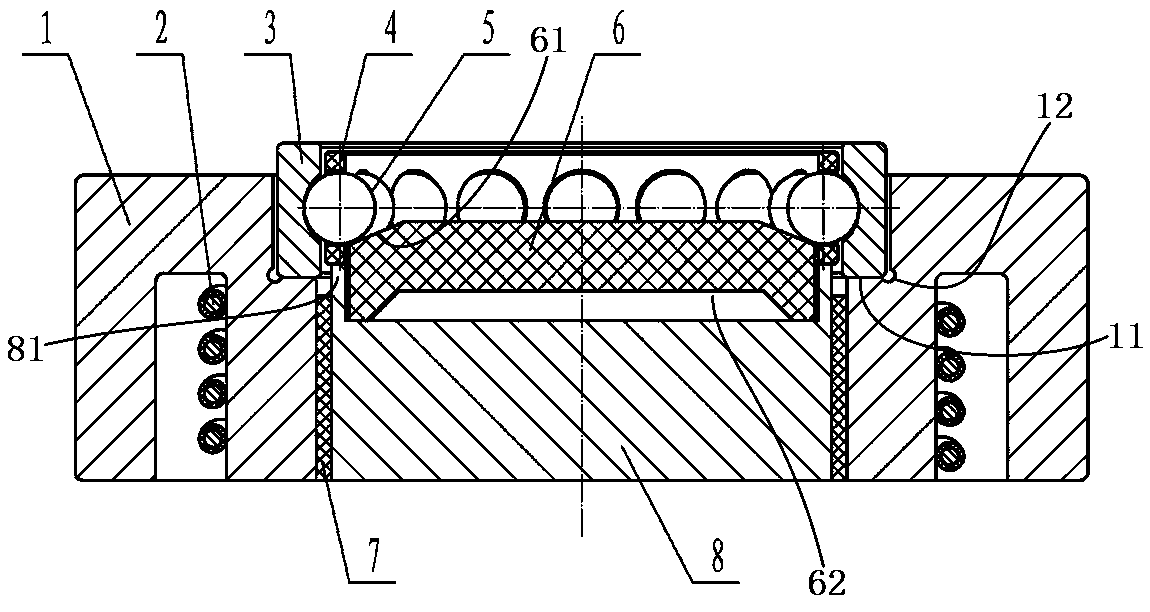

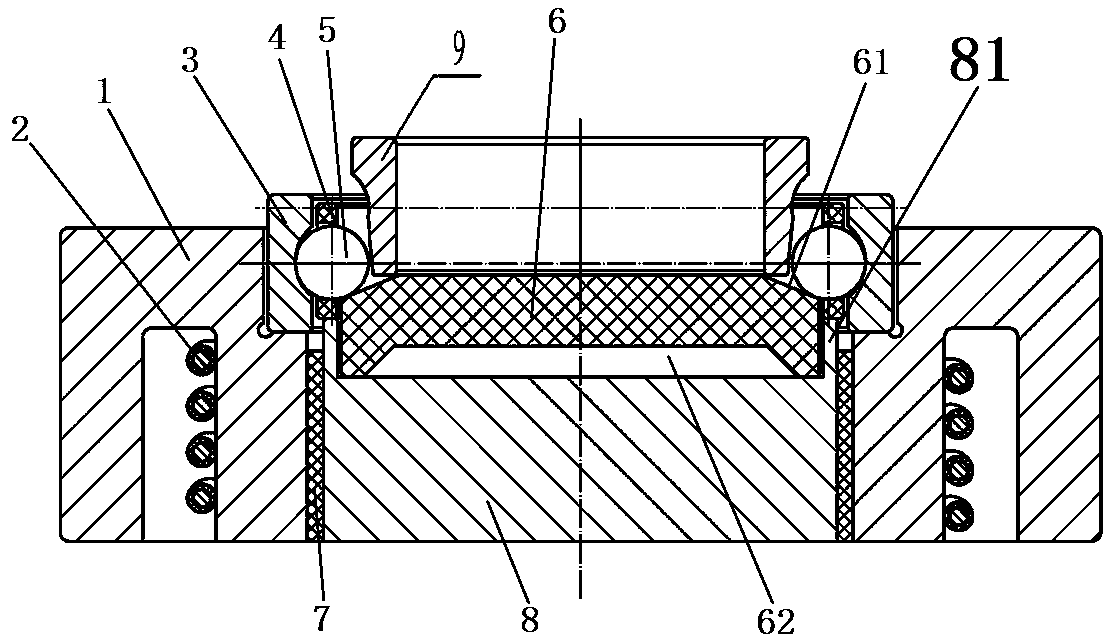

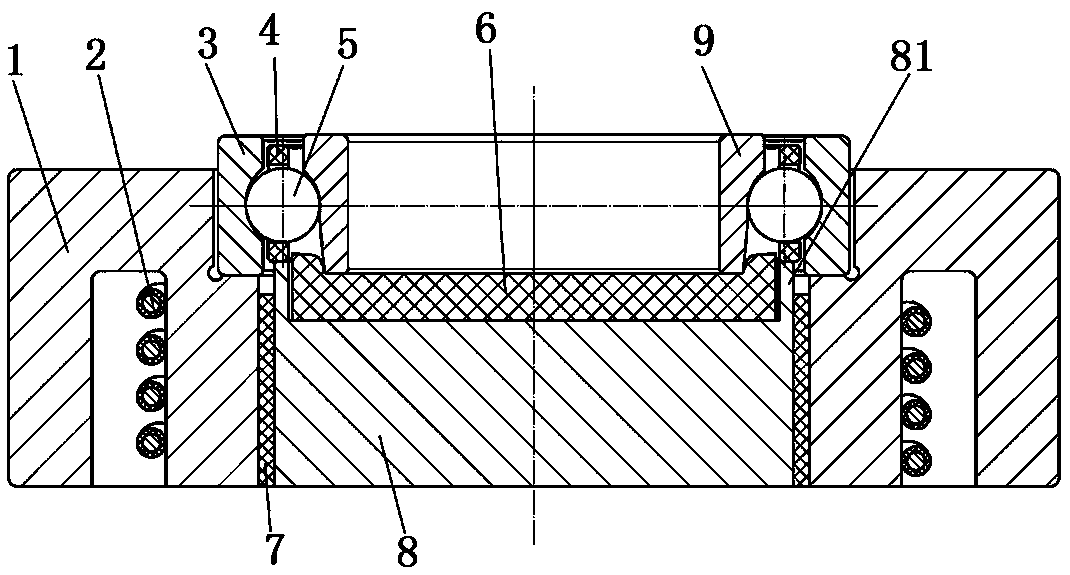

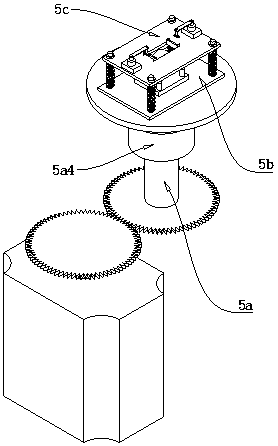

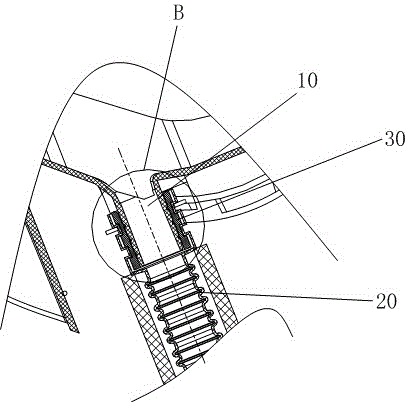

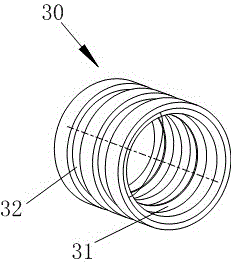

Angular contact ball bearing assembly fixture

ActiveCN107725616ASolve the problem of low assembly efficiencyEasy to operateBearing assemblyShaft assemblyBall bearingSteel ball

The invention relates to an angular contact ball bearing assembly fixture. When angular contact ball bearing assembling is carried out, a heated bearing outer ring is placed on an outer ring supporting step of a base assembly, a holder is placed on a holder supporting part of the base assembly, then a steel ball is placed on a supporting part of an elastic supporting piece, the steel ball is keptin a pocket, a bearing inner ring is finally installed in an inner hole defined by a holder ball in a pressing manner, the elastic supporting piece is compressed and deformed in the inner ring pressing fit process, and interference in the inner ring pressing fit process is avoided. In the using process of the assembly fixture, the supporting part of the elastic supporting piece is kept in the pocket of the holder, a lubrication agent is not needed for pasting the steel ball and the holder together, and lubrication agent washing after assembly in place is not needed; and when the fixture is used for assembling, operation is simple and convenient, and the problem that when an existing fixture is used for assembling, a lubrication agent is needed, and consequently the assembly efficiency is low is solved.

Owner:LUOYANG BEARING RES INST CO LTD

Combined sound insulation wallboard and fabricated building with same

ActiveCN111321823AImprove sound insulationImprove assembly efficiencyWallsSound proofingEngineeringAcoustic board

The invention discloses a combined sound insulation wallboard and a fabricated building with the same. The combined sound insulation wallboard comprises a first wallboard and a second wallboard, wherein each of the first wallboard and the second wallboard comprises a wall body, a sound insulation board and a plugging structure; a mounting space is formed in the top of each wall body, and a plurality of silencing grooves are formed in the inner wall of each mounting space; the sound insulation boards are located in the mounting spaces, a plurality of arc-shaped sound attenuation boards are arranged on the board surfaces of the sound insulation boards, and the arc-shaped sound attenuation boards are matched with the multiple silencing grooves in a one-to-one correspondence mode; and the first wallboard and the second wallboard are clamped and matched. The sound insulation effect is improved through the arc-shaped sound attenuation boards, the silencing grooves and honeycomb sound absorption holes; and during assembling, a first mounting groove and a second mounting groove are directly in butt joint, then a first connecting structure and a second connecting structure are matched in aclamped mode, assembling of the two wallboards is completed, only positioning and simple assembling are needed in the whole process, the assembly efficiency is greatly improved, and the assembly workload is reduced.

Owner:河北水利电力学院

Automatic assembling device for rapid wheel of ship steering wheel

ActiveCN108555596AReduce in quantitySolve the problem of low assembly efficiencySteering initiationsAssembly machinesSteering wheelReciprocating motion

The invention relates to the relevant field of ships and particularly relates to an automatic assembling device for a rapid wheel of a ship steering wheel. The automatic assembling device comprises abase, a bearing-assistance ball loading station, a mounting station, a hoop loading and workpiece unloading station, a positioning station and a positioning jig, wherein the positioning jig is mountedin the middle of the base, the bearing-assistance ball loading station, the mounting station, the hoop loading and workpiece unloading station and the positioning station are sequentially mounted onthe base along the peripheral direction of the positioning jig; the bearing-assistance ball loading station comprises a first mechanical arm which is used for loading bearings and assistance balls; the mounting station comprises an assembling mechanical arm which is used for assembling workpieces; the hoop loading and workpiece unloading station comprises a second mechanical arm which is used forloading hoops and unloading the workpieces; and the positioning station comprises a positioning mechanical arm which is used for assembling the workpieces. According to the automatic assembling device, the time consuming problem caused by the assembling is solved, the yield is increased, and the number of defective goods is reduced by virtue of a reciprocating motion of equipment.

Owner:安徽维嵩生产力促进有限公司

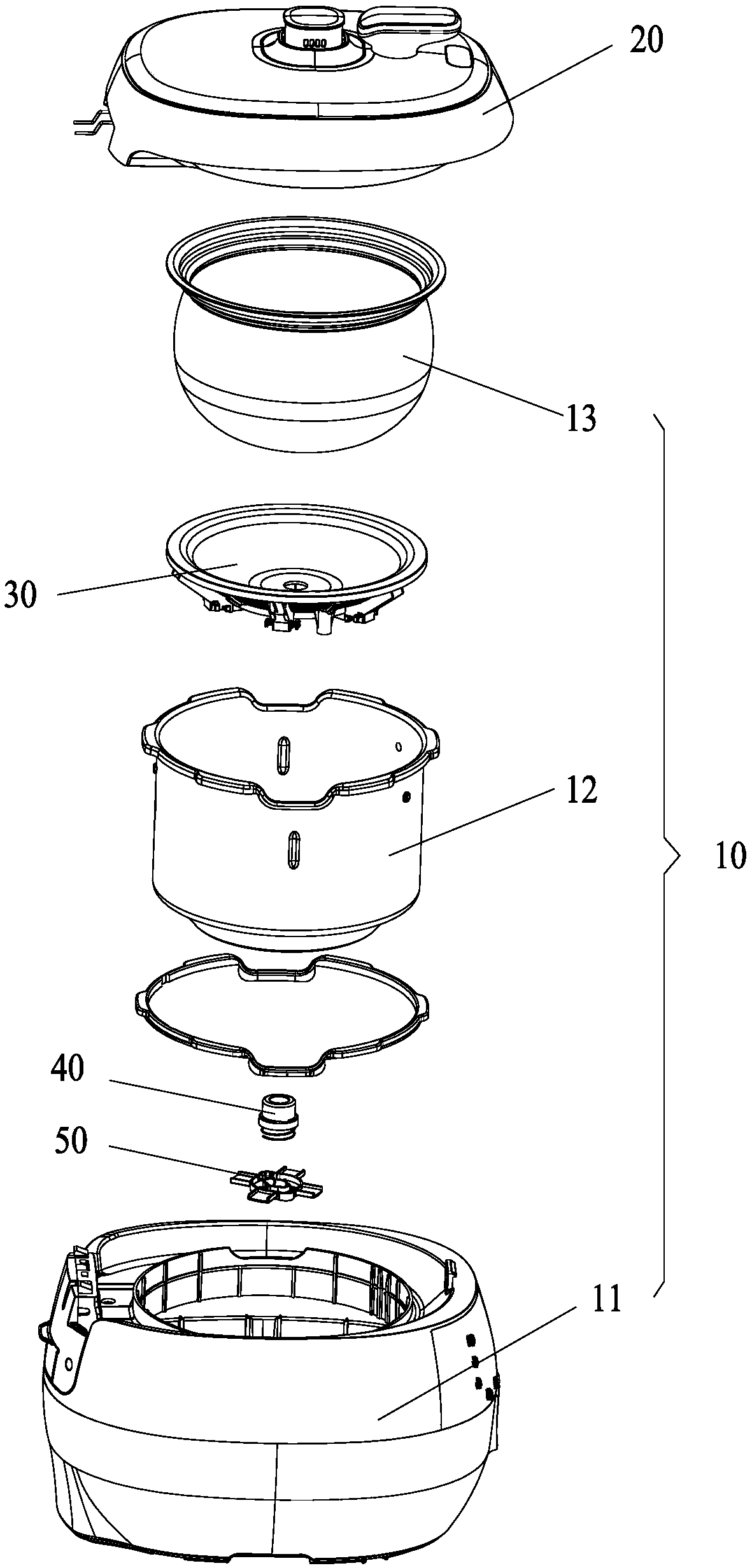

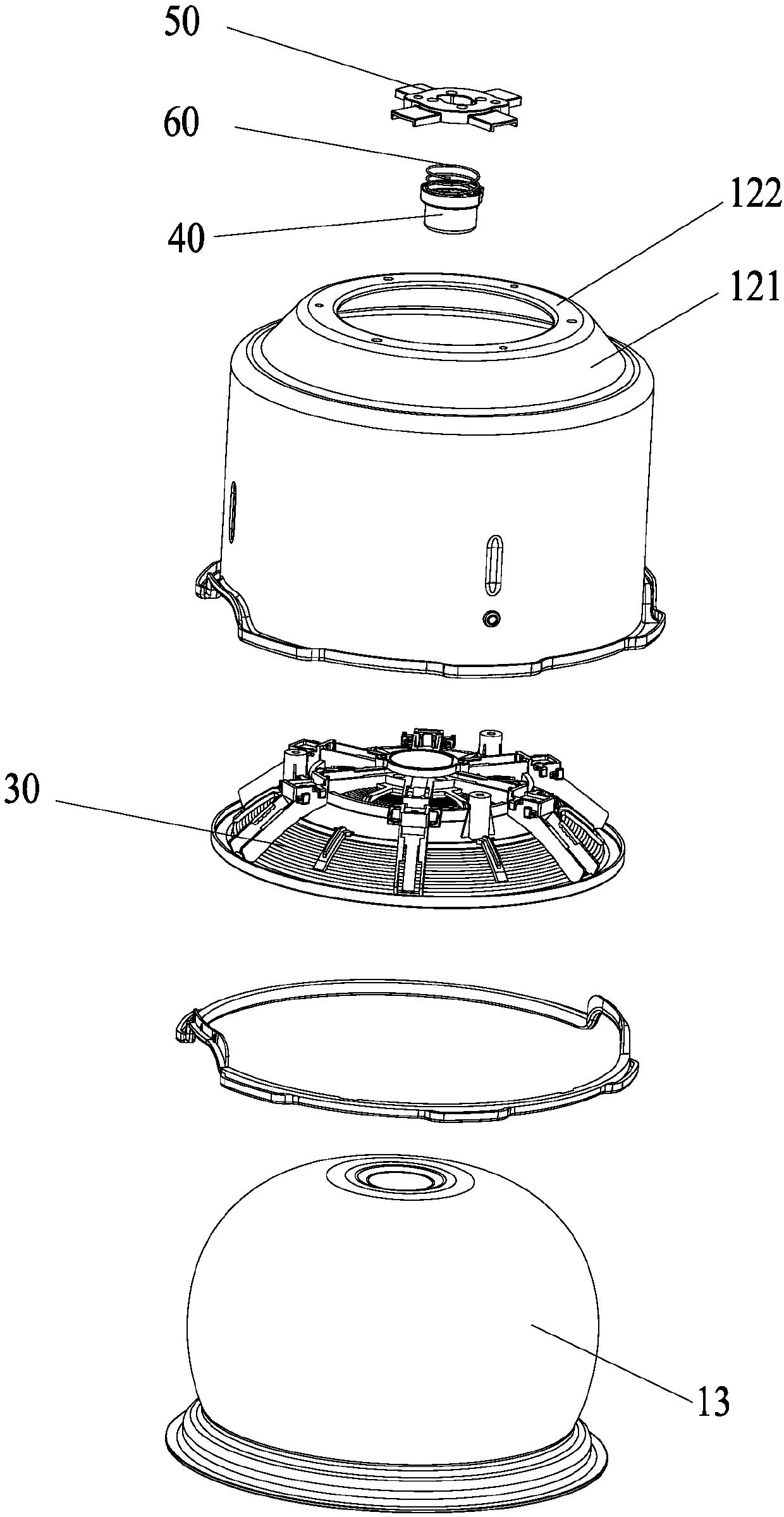

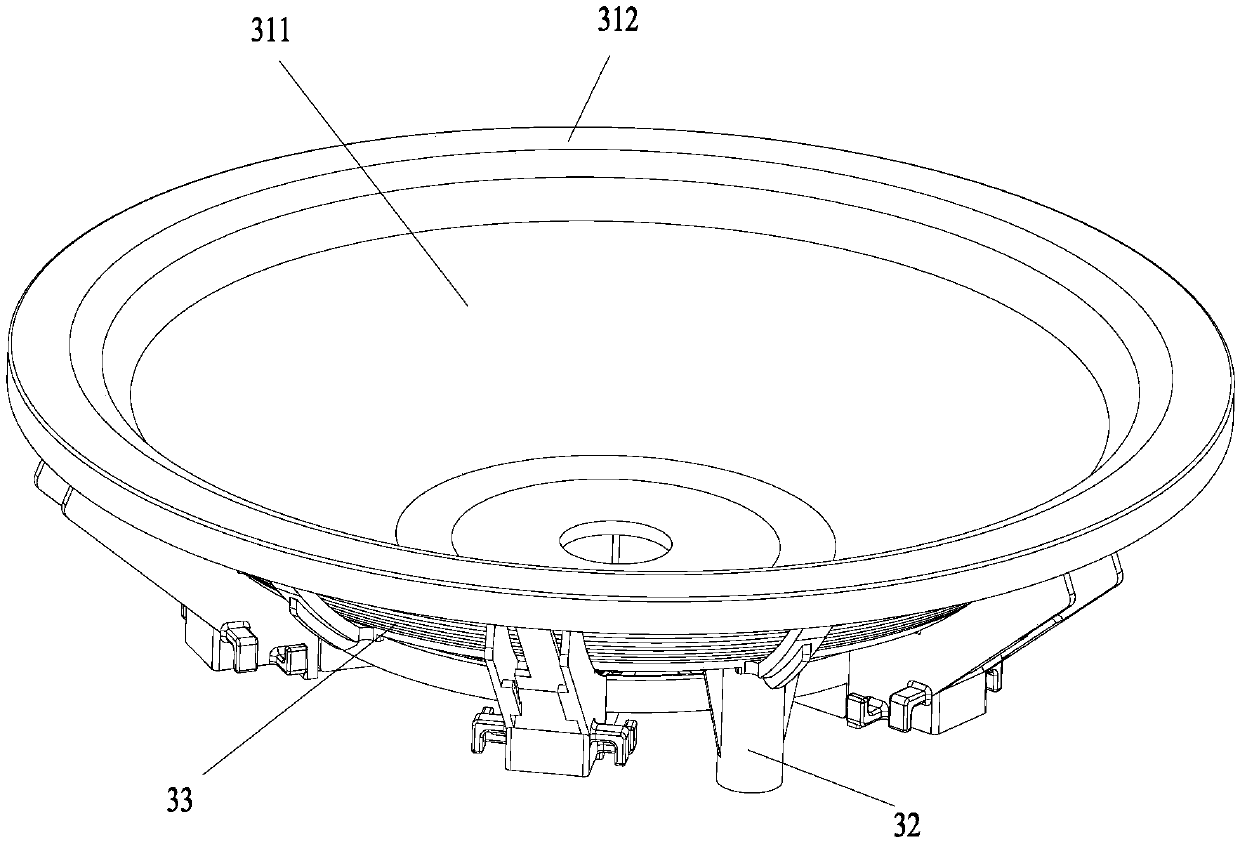

Electric pressure cooker

PendingCN110313812ASimple structureReduce manufacturing costPressure-cookersWarming devicesCookerEngineering

The invention discloses an electric pressure cooker. The electric pressure cooker comprises a cooker body, a cooker lid and an electromagnetic heating device; the cooker body comprises an outer cooker, a heat-preservation cover and an inner cooker which are sequentially arranged from outside to inside; a sealed cooking cavity is formed between the cooker lid and the inner cooker, the cooker lid isprovided with cover teeth, and the heat-preservation cover is provided with cooker teeth matched with the cover teeth so as to enable the cooker lid to be locked on the heat-preservation cover; and the electromagnetic heating device comprises a coil disc body, a supporting part and a coil, wherein the supporting part is arranged at the bottom of the coil disc body and integrally formed with the coil disc body, the inner cooker is supported at the bottom of the heat-preservation cover through the supporting part of the electromagnetic heating device, the coil is fixed to the bottom of the coildisc body, and a distance is formed between the coil and the inner cooker. By applying the technical scheme, the problem of low assembly efficiency of an electric pressure cooker in the prior art canbe effectively solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

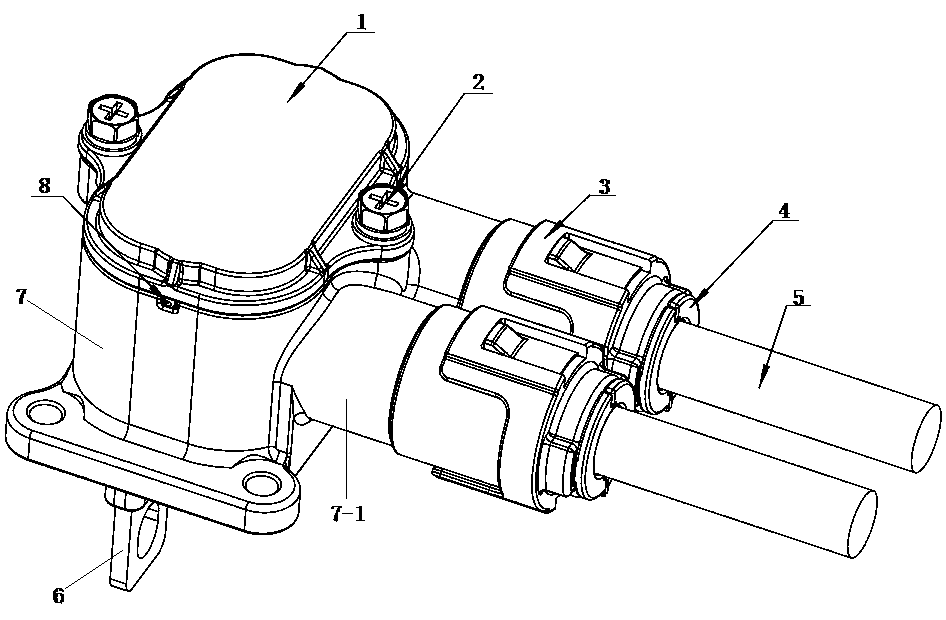

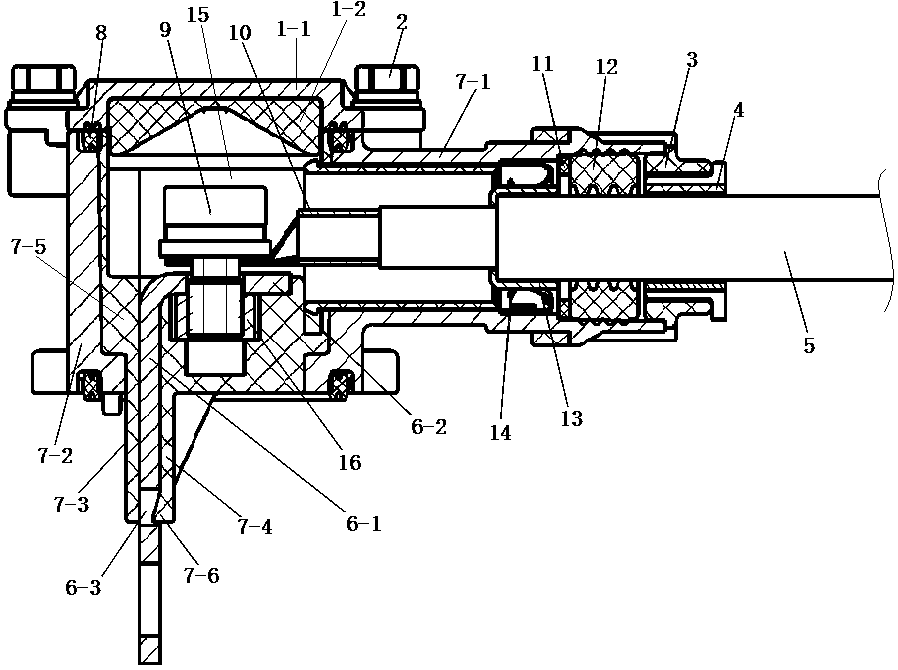

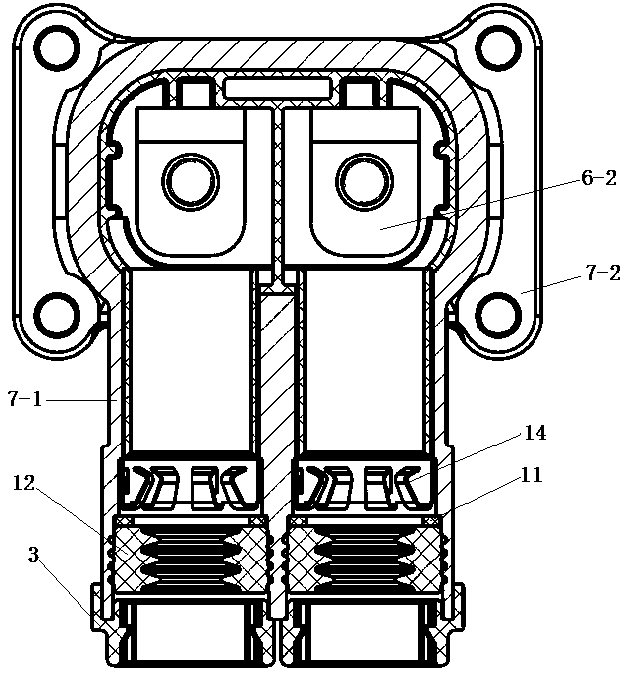

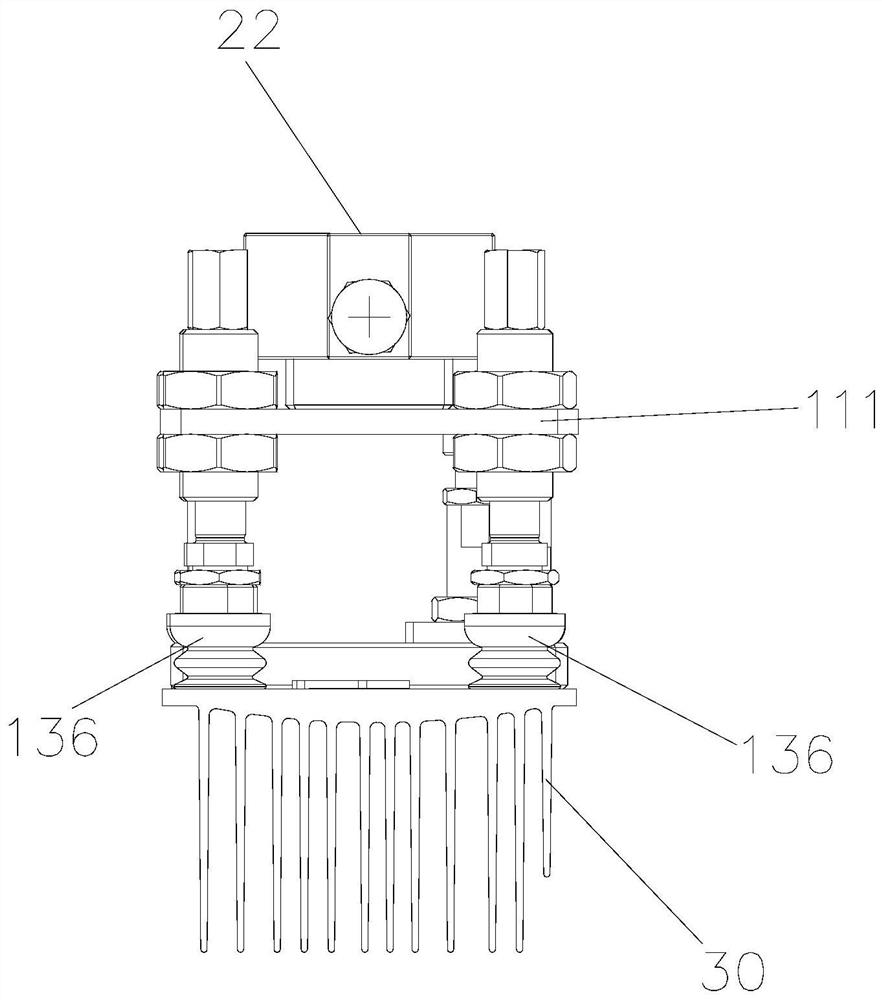

Wiring connector

InactiveCN110611199ASolve the problem of low assembly efficiencyCoupling contact membersCouplings bases/casesEngineeringMechanical engineering

The invention provides a wiring connector which comprises a base and an upper cover relatively fastened to the base. One of the base and the upper cover is provided with a cylinder body section through which a cable passes. Inside the cylinder body section, a wire sealing body which sleeves the cable is installed. The tail end of the cylinder body section is provided with a tail cover for the cable to pass through, and the tail cover blocks the wire sealing body in the cylinder body. An anti-swinging washer which sleeves the cable to prevent the cable from being bent excessively is arranged inthe tail cover. The anti-swaying washer comprises at least two petal rings surrounding a complete ring. The anti-swaying washer is snap-connected with the tail cover through a snap structure on the anti-swaying washer to prevent falling off in the axial direction. The wiring connector has the advantages that the tail cover does not need to sleeve the cable when wiring is carried out; the gap between the inner wall of the tail cover and the cable can allow the cable to pass through the cylinder section smoothly; after the cable is installed, multiple petal rings directly wrap and surround thecable to form a complete circle, and then are arranged in the tail cover and snap-connected with the tail cover; the installation is very convenient; and the assembly efficiency of the wiring connector is greatly improved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

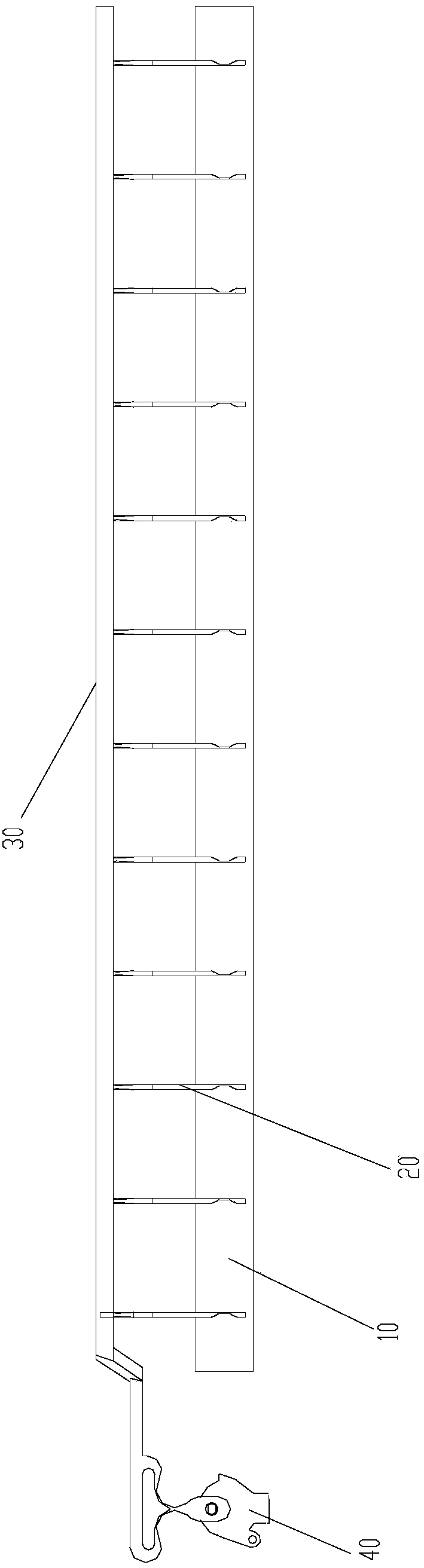

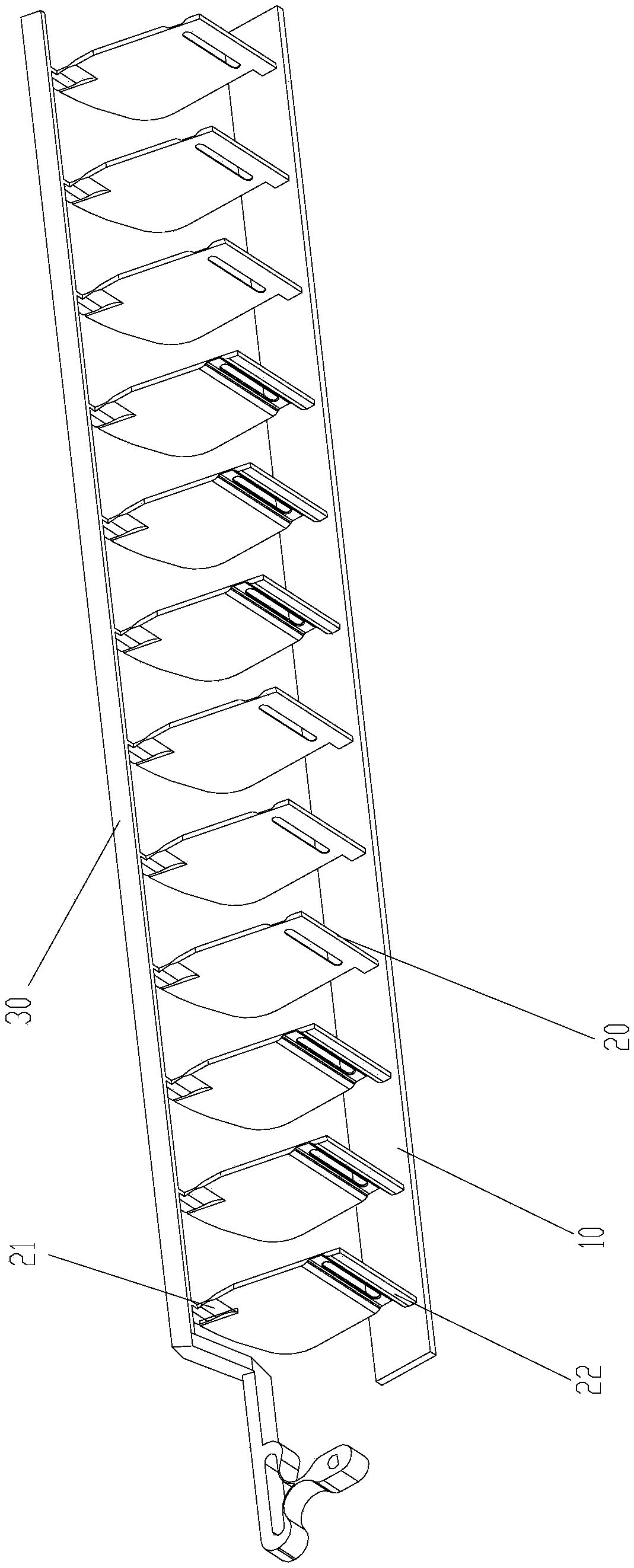

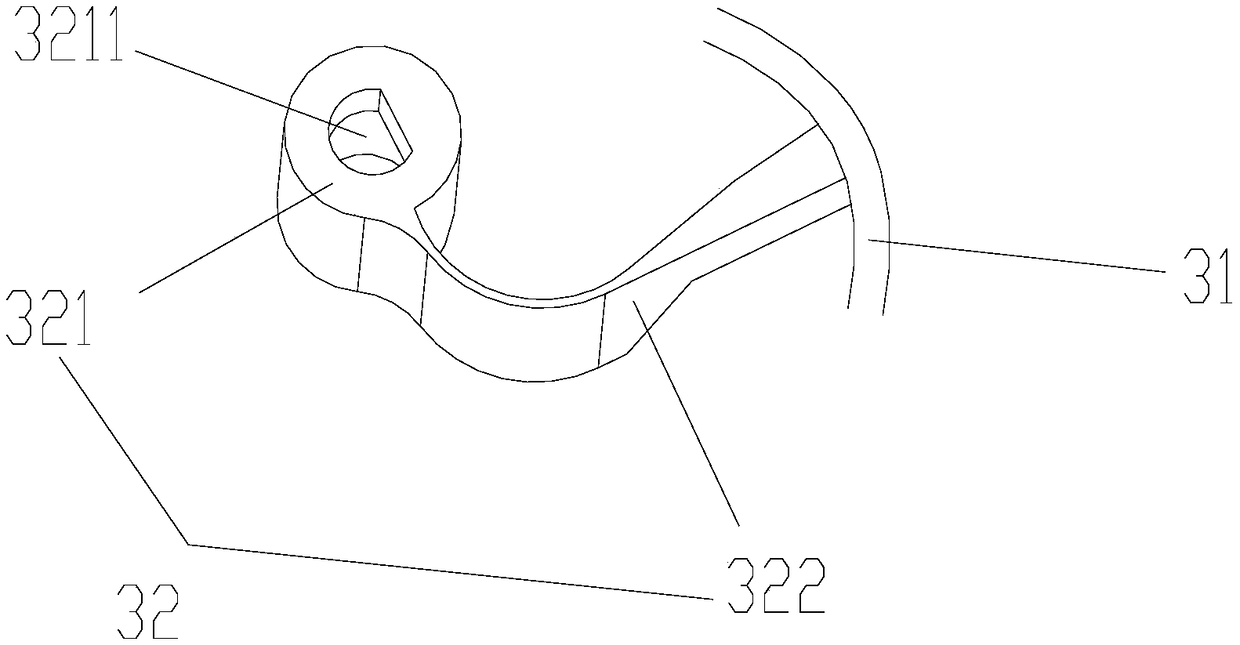

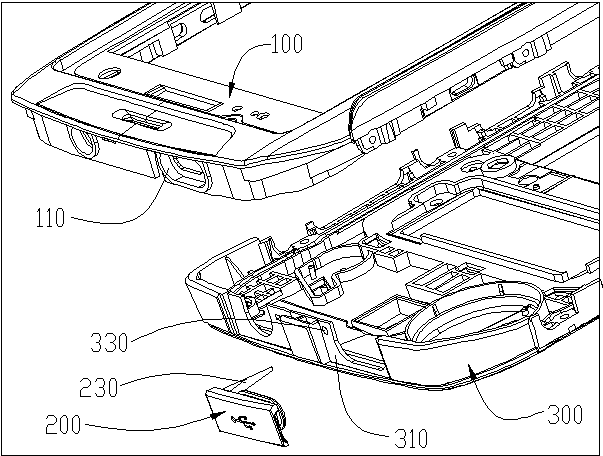

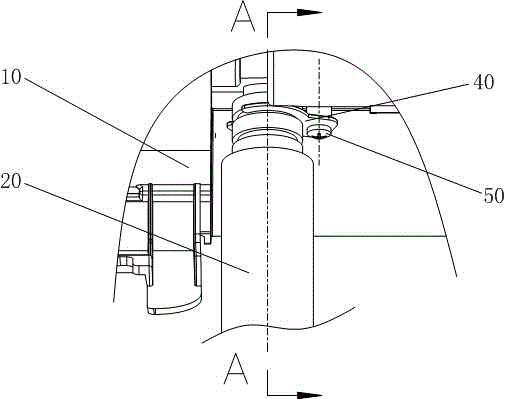

Wind sweeping mechanism and air conditioner with same

PendingCN108131813AImprove assembly efficiencySolve the problem of low assembly efficiencyLighting and heating apparatusAir conditioning systemsEngineering

The invention provides a wind sweeping mechanism and an air conditioner with the same. The wind sweeping mechanism comprises a mounting part, wind sweeping blades and a driving rod, wherein the mounting part is used for being mounted on a housing of the air conditioner; the wind sweeping blades are connected with the mounting part; the driving rod is connected with the wind sweeping blades, and the position of the driving rod is adjustably arranged; and the wind sweeping blades and the driving rod are integrally formed, at least a part of each wind sweeping blade is a flexible part, and the driving rod drives at least part of each wind sweeping blade to move. According to the wind sweeping mechanism, the problem that assembly efficiency of a wind sweeping mechanism in the prior art is lowis solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

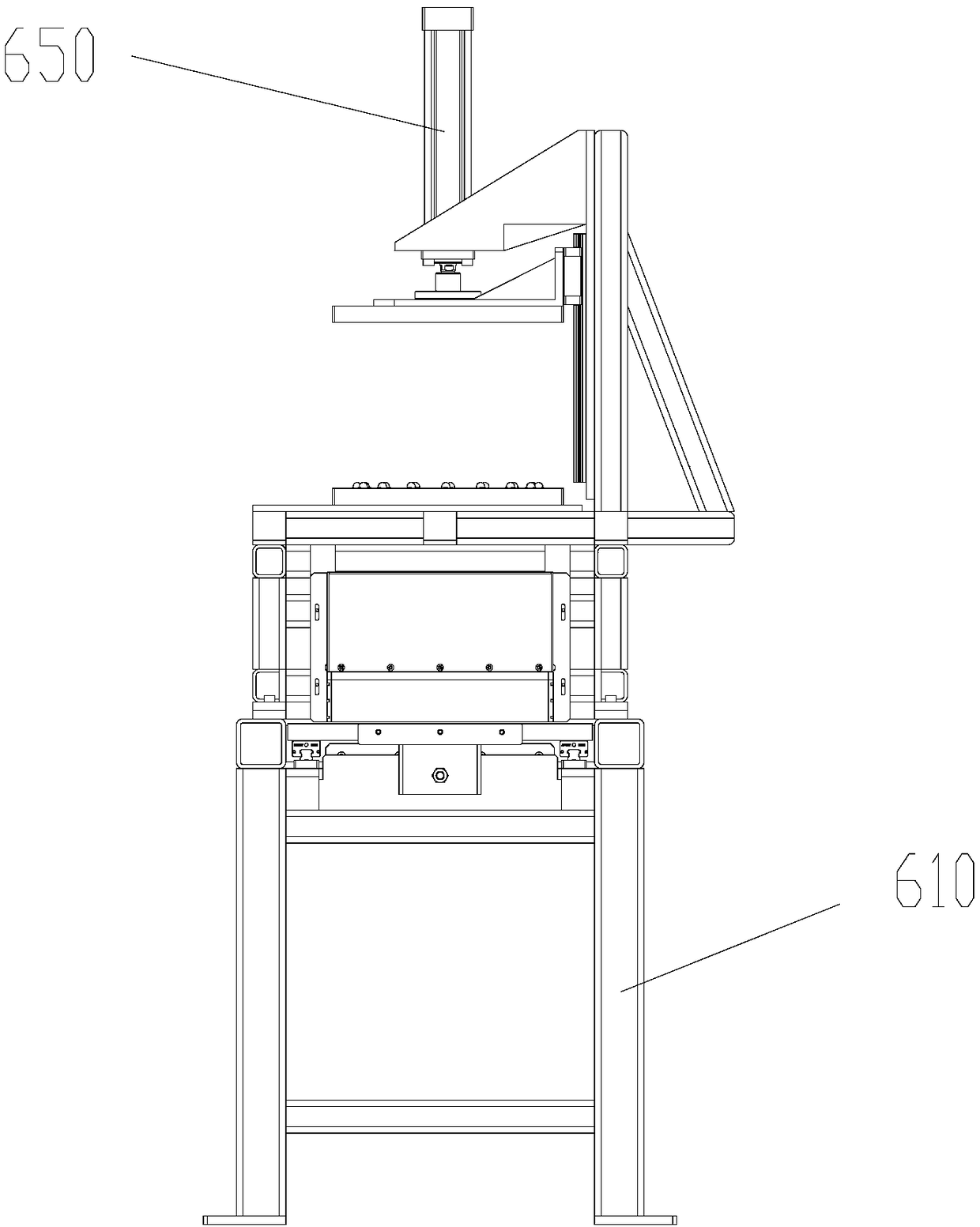

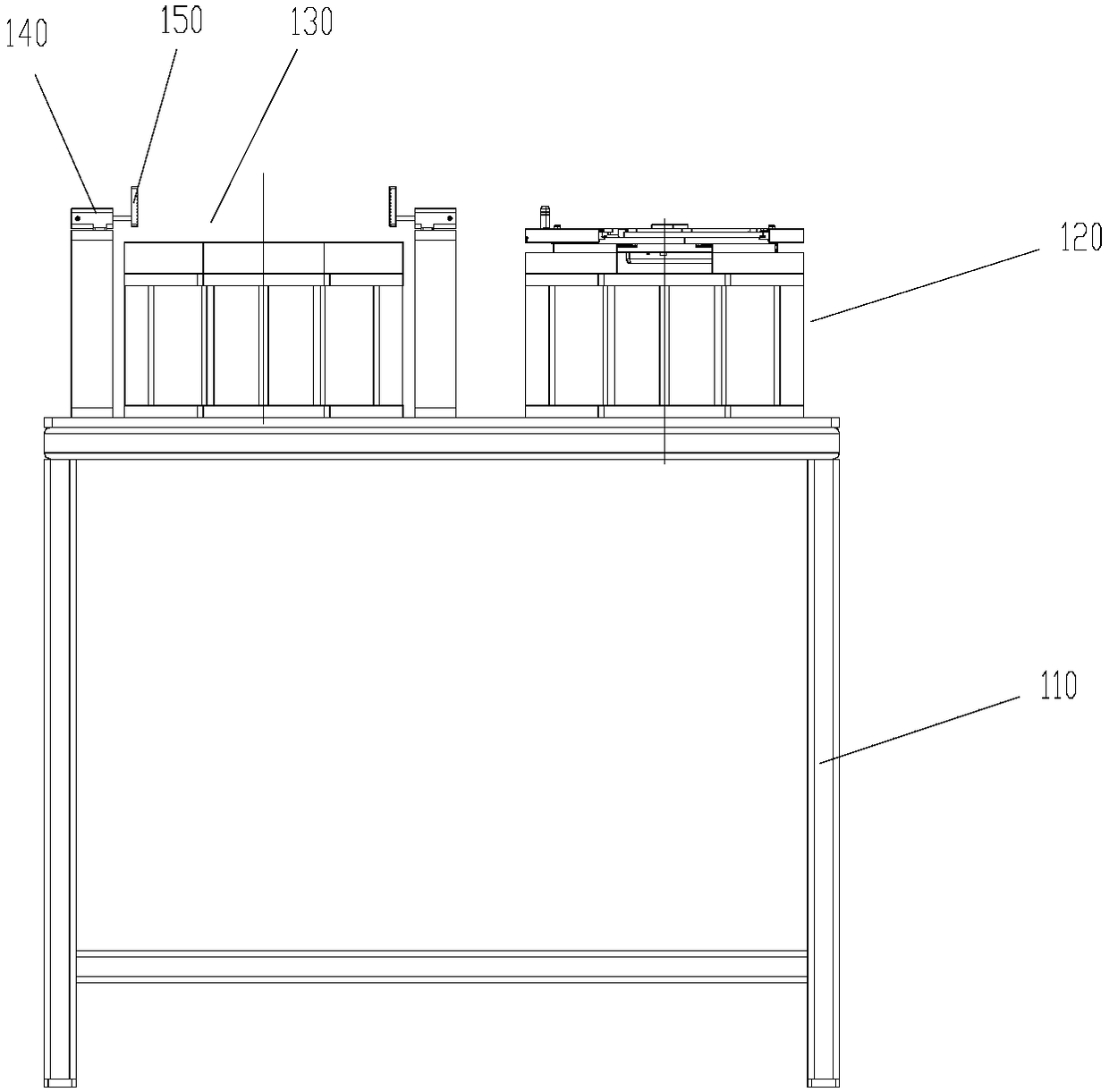

Bearing hot welding machine and bearing assembling equipment with same

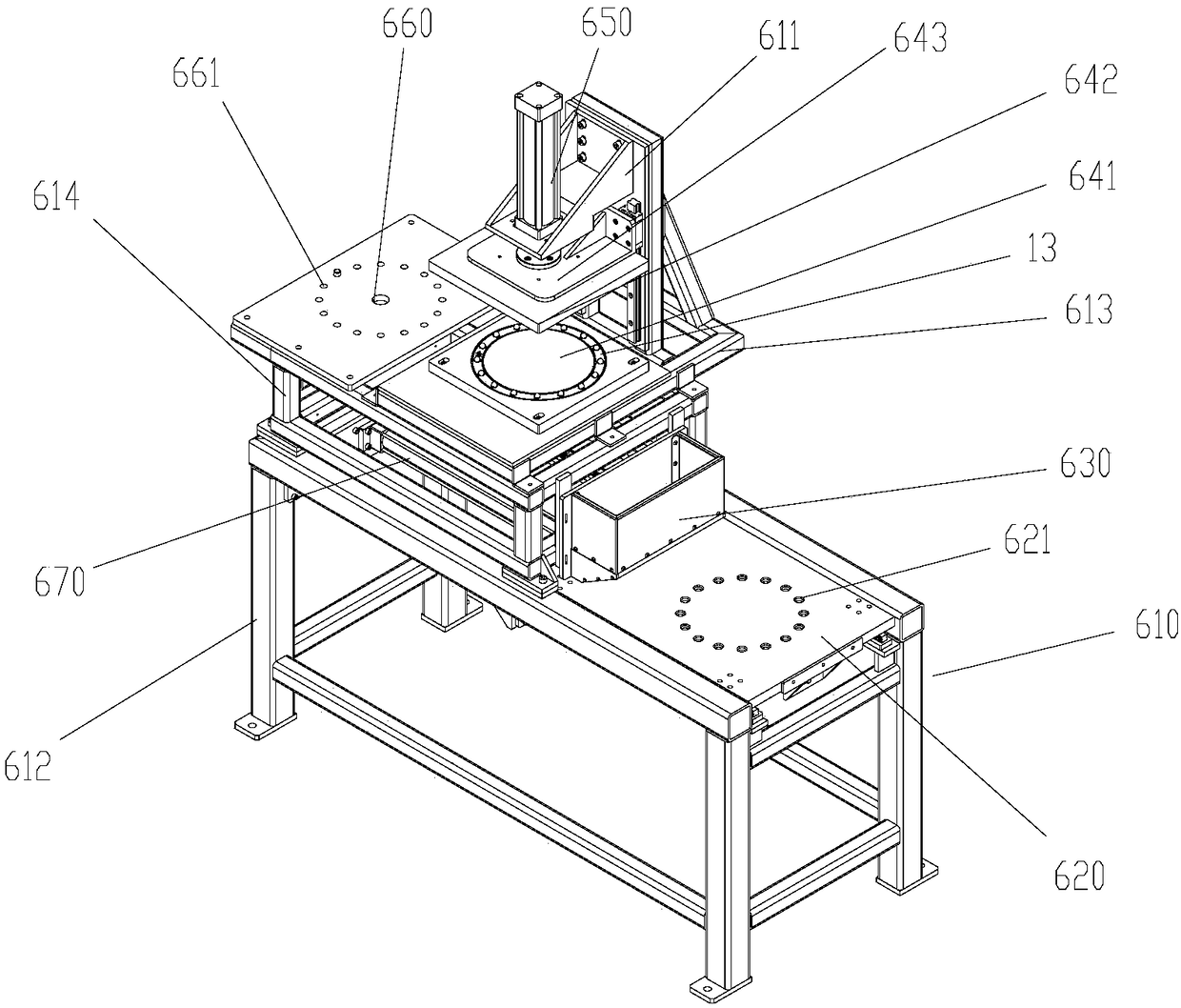

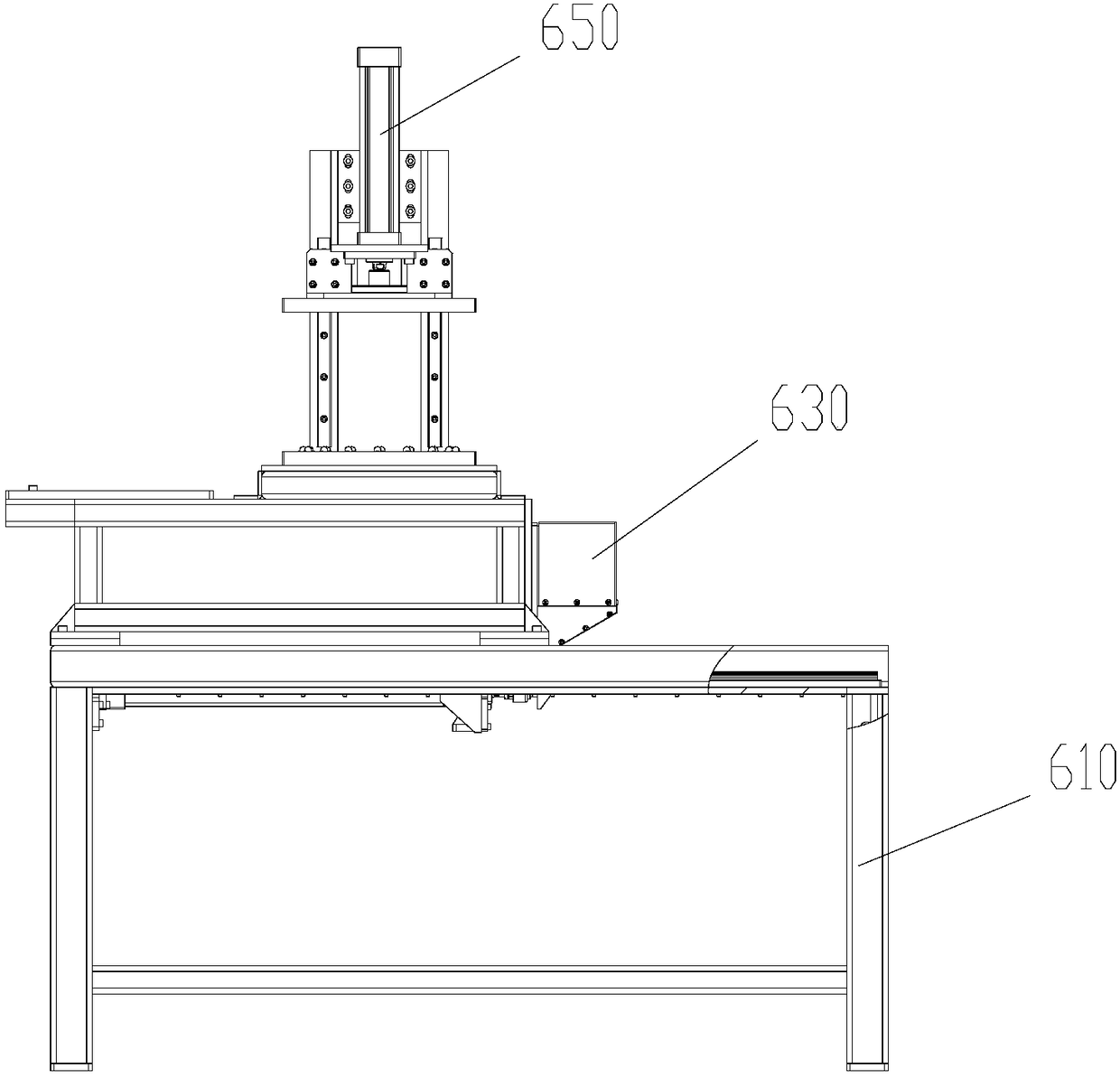

PendingCN108099213AImprove processing efficiencySolve the problem of low assembly efficiencyDomestic articlesHot meltEngineering

The invention provides a bearing hot welding machine and bearing assembling equipment with the same. The bearing hot welding machine comprises a hot welding machine frame, a hot welding disk and a hotmelting assembly, wherein the hot welding disk is provided with a hot welding feeding base used for positioning a bearing assembly and is further installed on the hot welding machine frame in a position-adjustable mode, so that the hot welding feeding base moves to a preset hot welding position; and the hot melting assembly is arranged above the hot welding disk and is further provided with a hotwelding head used for welding the bearing assembly located on the hot welding feeding base. By adoption of the bearing hot welding machine, the problem that the assembling efficiency of a plastic bearing is low in the prior art is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

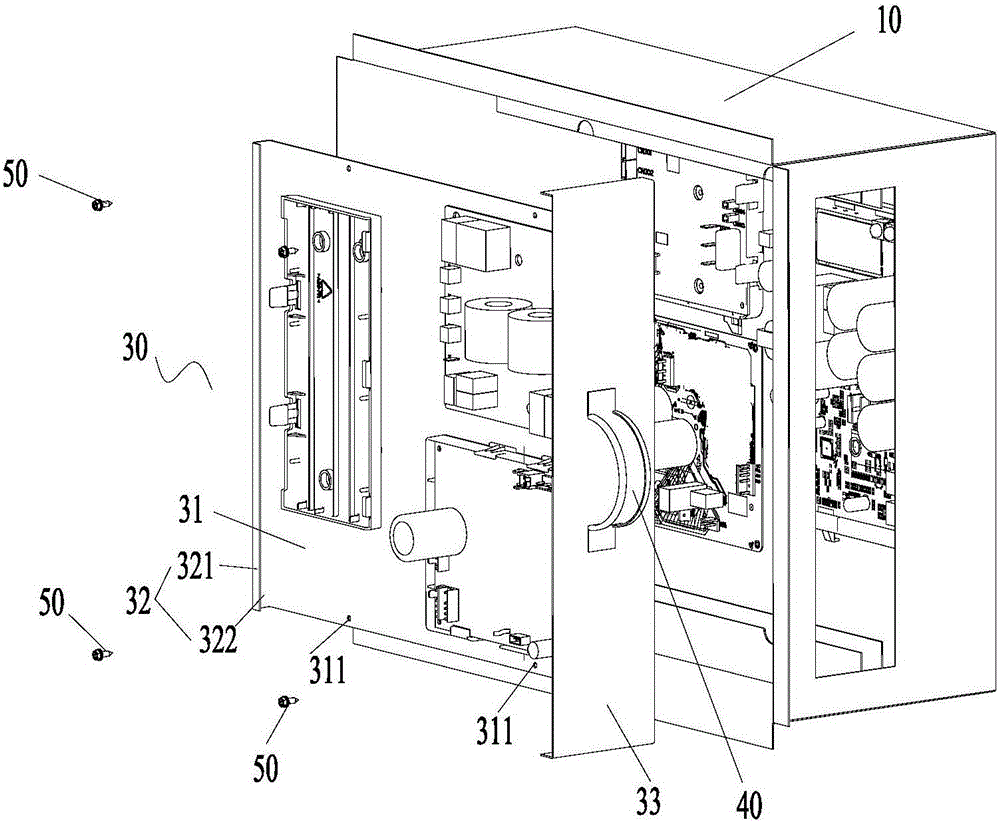

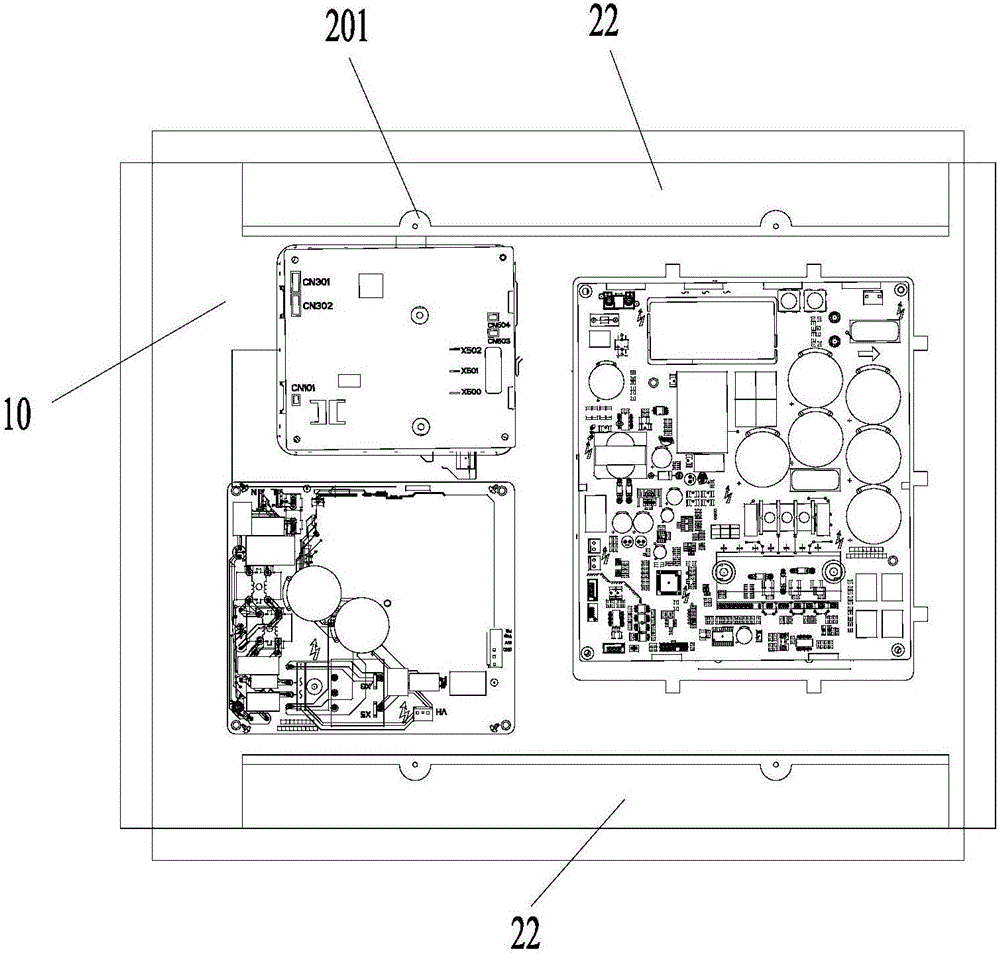

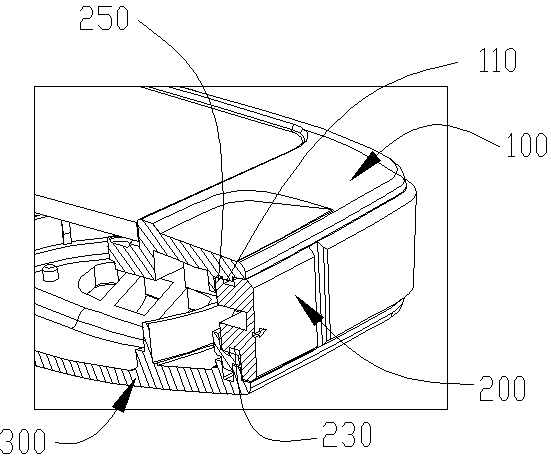

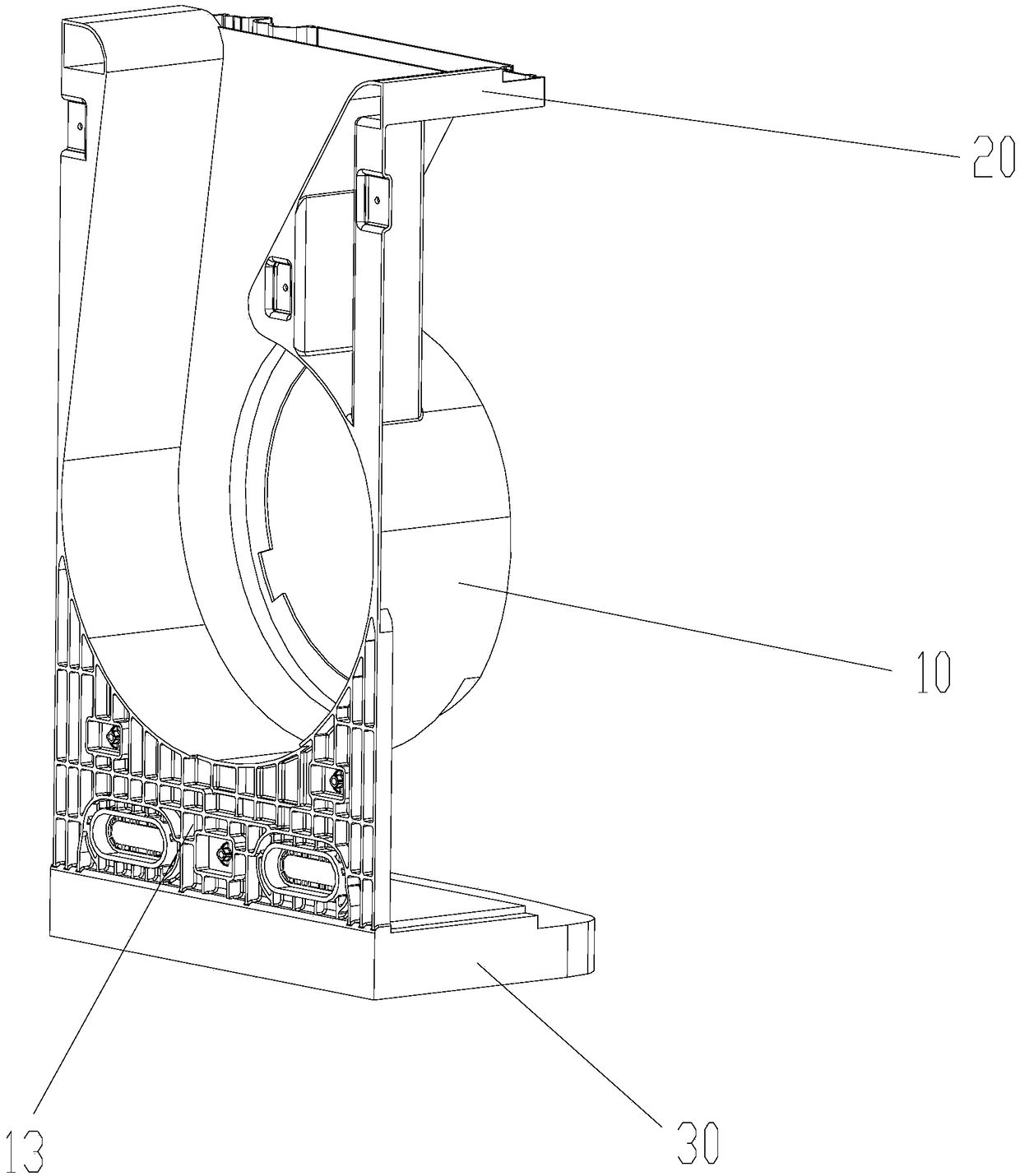

Electrical box and air conditioner with same

InactiveCN106211689AImprove assembly efficiencySolve low assembly efficiencyCasings/cabinets/drawers detailsStackable modulesEngineeringFunctional module

The invention provides an electrical box and an air conditioner with the same. The electrical box comprises a housing, a first function module and a second function module, wherein the housing is provided with an accommodating space; the first function module is accommodated into the accommodating space; and the second function module is accommodated into the accommodating space and the second function module and the first function module are superposed. By the technical scheme provided by the invention, the problem of low assembly efficiency of the electrical box in the prior art can be effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

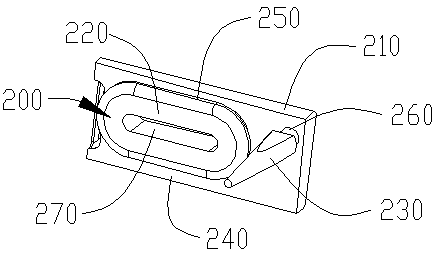

Waterproof plug structure and waterproof mobile phone comprising same

ActiveCN104270484AUniform and reliable deformationSolve the difficulty of waterproofingTelephone set constructionsAgricultural engineeringMobile phone

The invention relates to a waterproof plug structure. The waterproof plug structure comprises a front shell, a waterproof plug and a rear shell. The waterproof plug comprises a hard rubber body which is provided with a supporting part. The waterproof plug further comprises a soft rubber layer, wherein the soft rubber layer is wrapped on the outer surface of the supporting part, and the soft rubber layer and the supporting part are integrally formed. The waterproof plug further comprises an elastic connector. The rear shell is provided with a blind groove. The elastic connector is movably clamped in the blind groove of the rear shell in a matched mode and is further connected with the front shell and the rear shell through assembly of the front shell and the rear shell, and meanwhile the soft rubber layer and the front shell are assembled in an interference fit mode. The waterproof plug is formed by the hard rubber body, the soft rubber layer and the elastic connector in a three-shot molding mode; since the soft rubber layer is arranged on the outer surface of the supporting part, when the soft rubber layer and a shell body are in assembly interference, the soft rubber layer bears uniform pressure from the two sides of the shell body and the supporting part and form uniform deformation, and the waterproofness is reliable.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

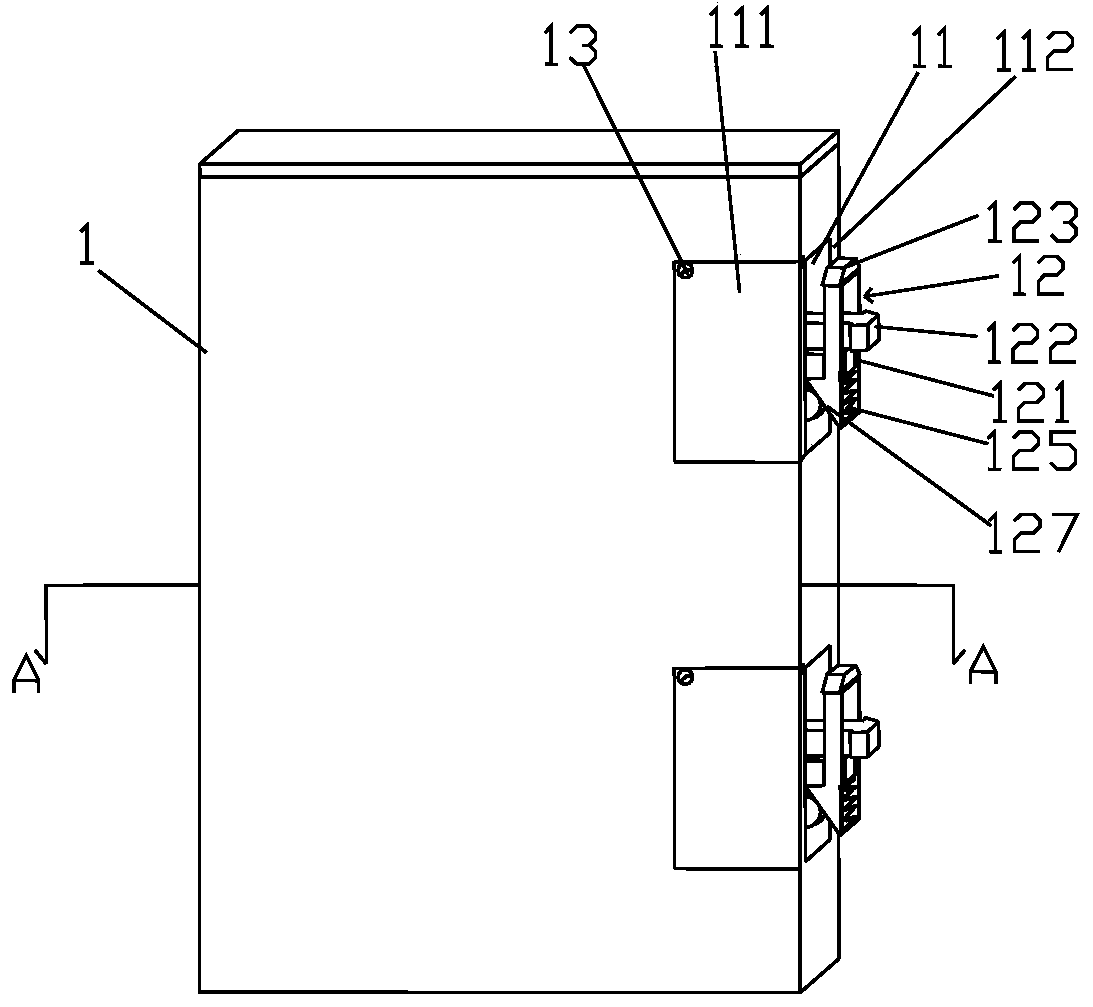

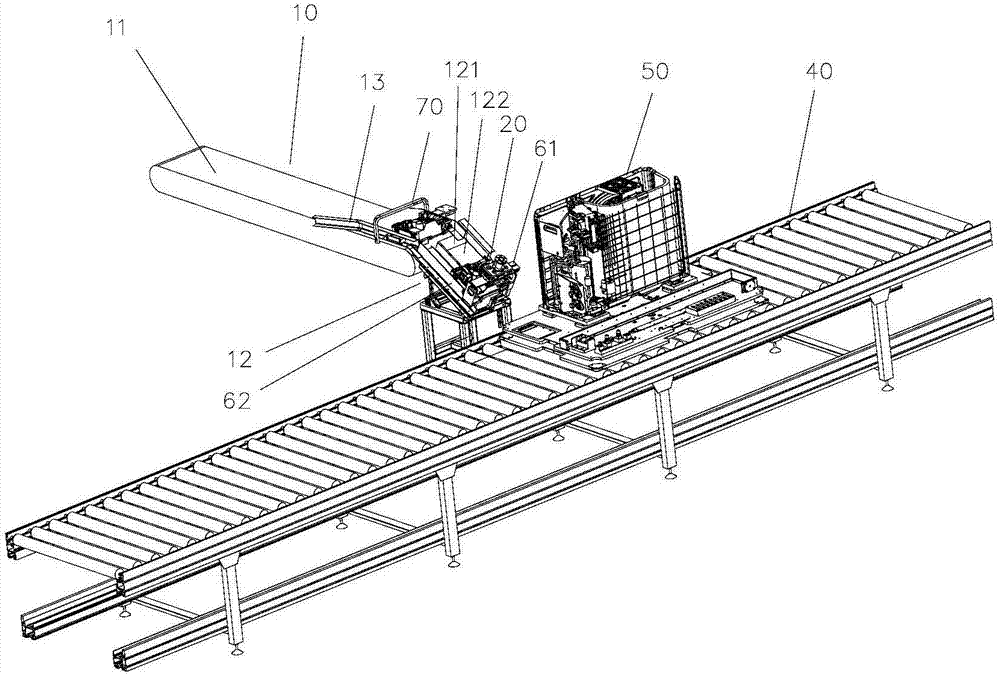

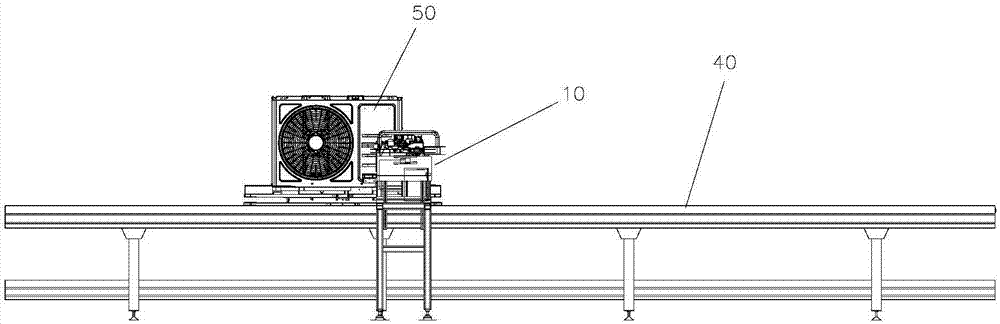

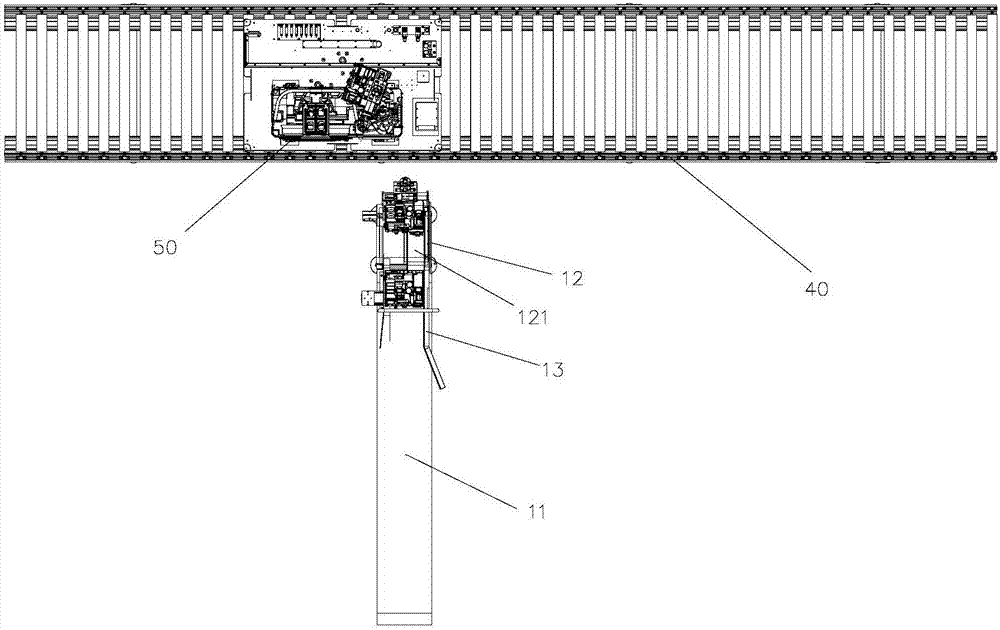

Installation mechanism of electric box and assembly device for external unit of air-conditioner

InactiveCN107300225AAchieve installationSolve the problem of low assembly efficiencyLighting and heating apparatusMetal working apparatusEngineeringElectrical and Electronics engineering

The invention provides an installation mechanism of an electric box and an assembly device for an external unit of an air-conditioner. The installation mechanism of the electric box includes an electric box conveying line for conveying the electrical box to be installed, and an electric box gripping device, wherein the electric box gripping device is arranged at one side of the electric box conveying line, and is used for gripping the electric box on the electric box conveying line and placing the gripped electric box at an external unit assembling line so as to convey the gripped electric box onto a partition board of the external unit of the air conditioner. According to the installation mechanism of the electric box and the assembly device for the external unit of the air-conditioner, the problem that the assembly efficiency of the external unit of the air conditioner is low in the prior art is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

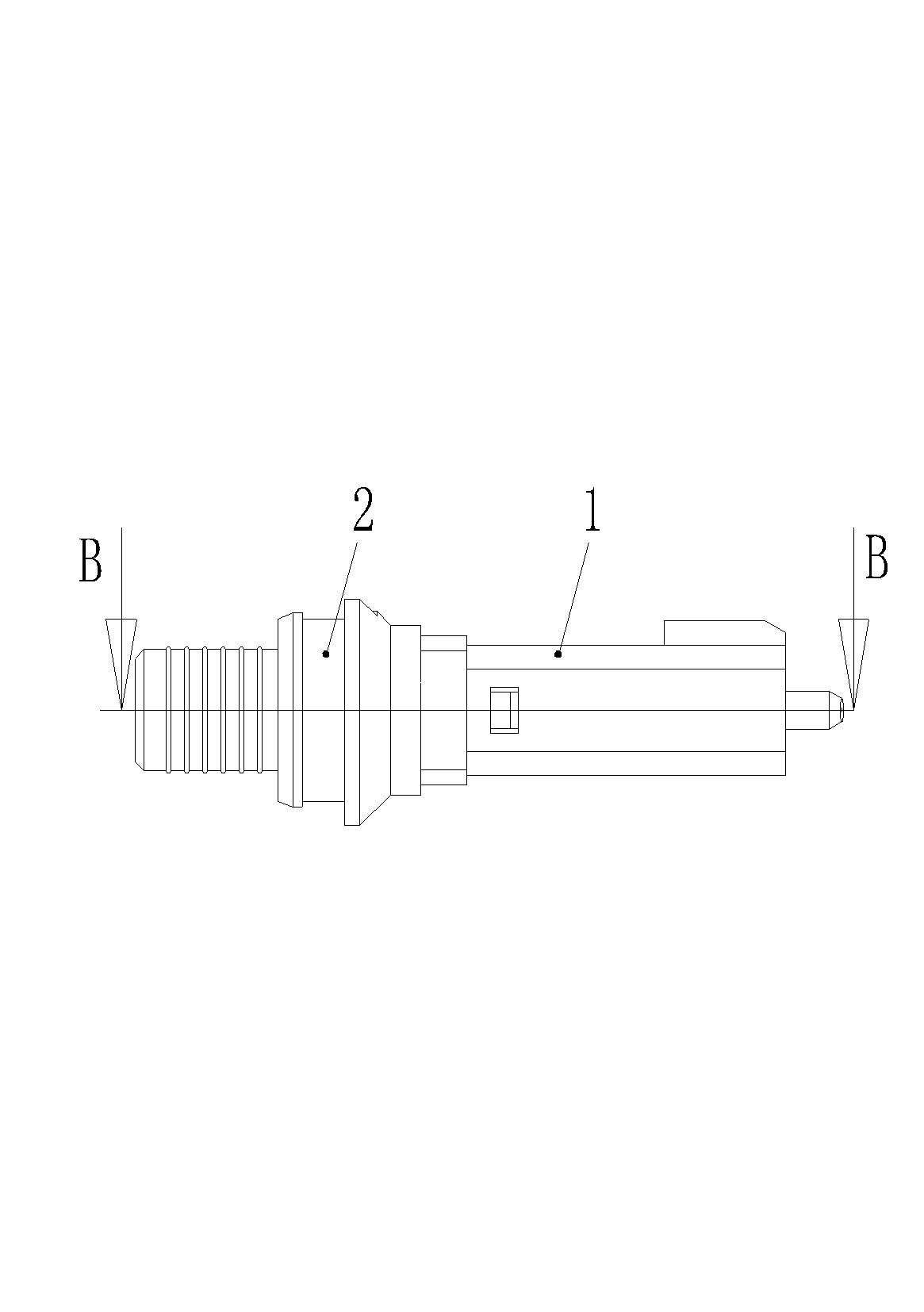

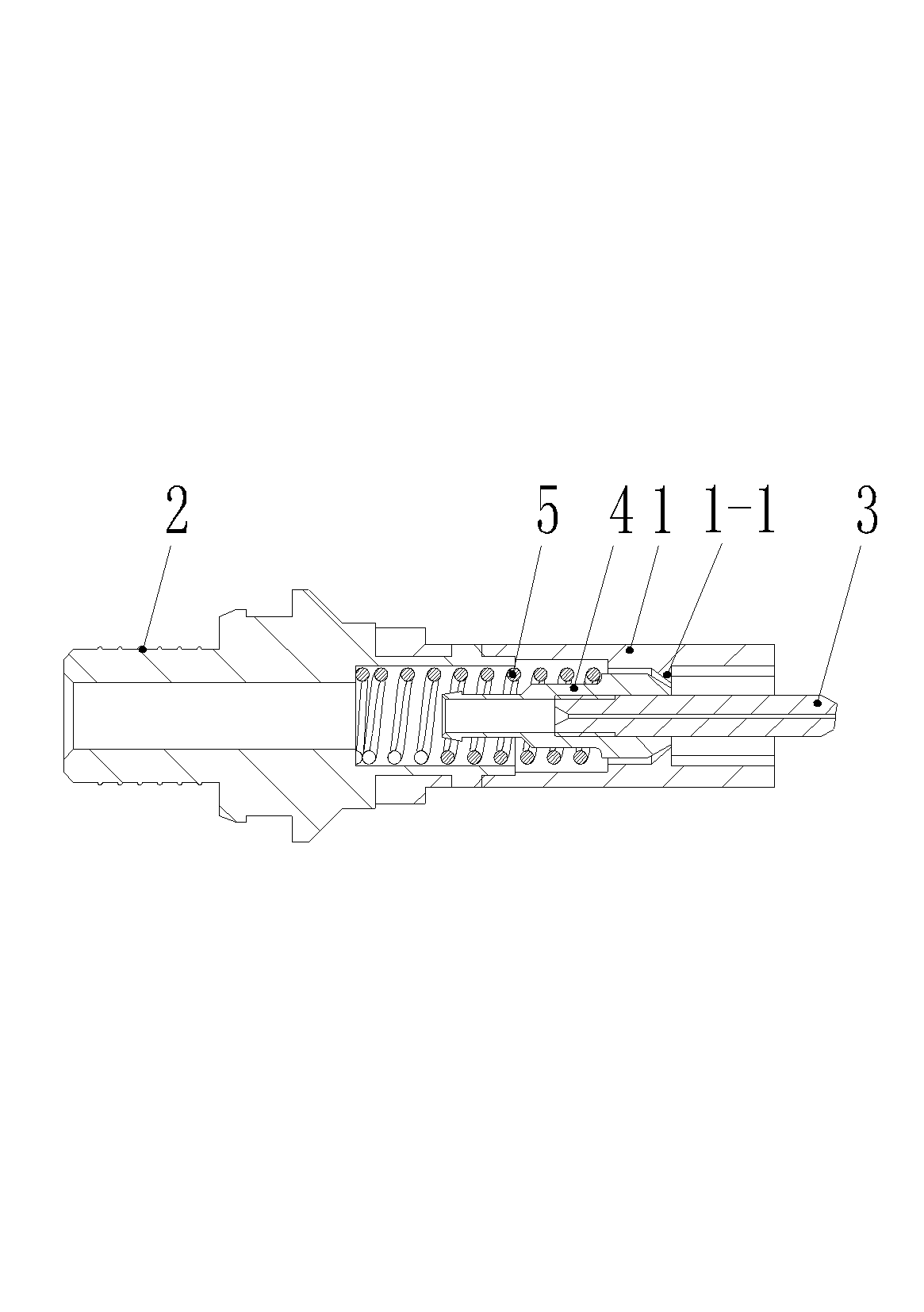

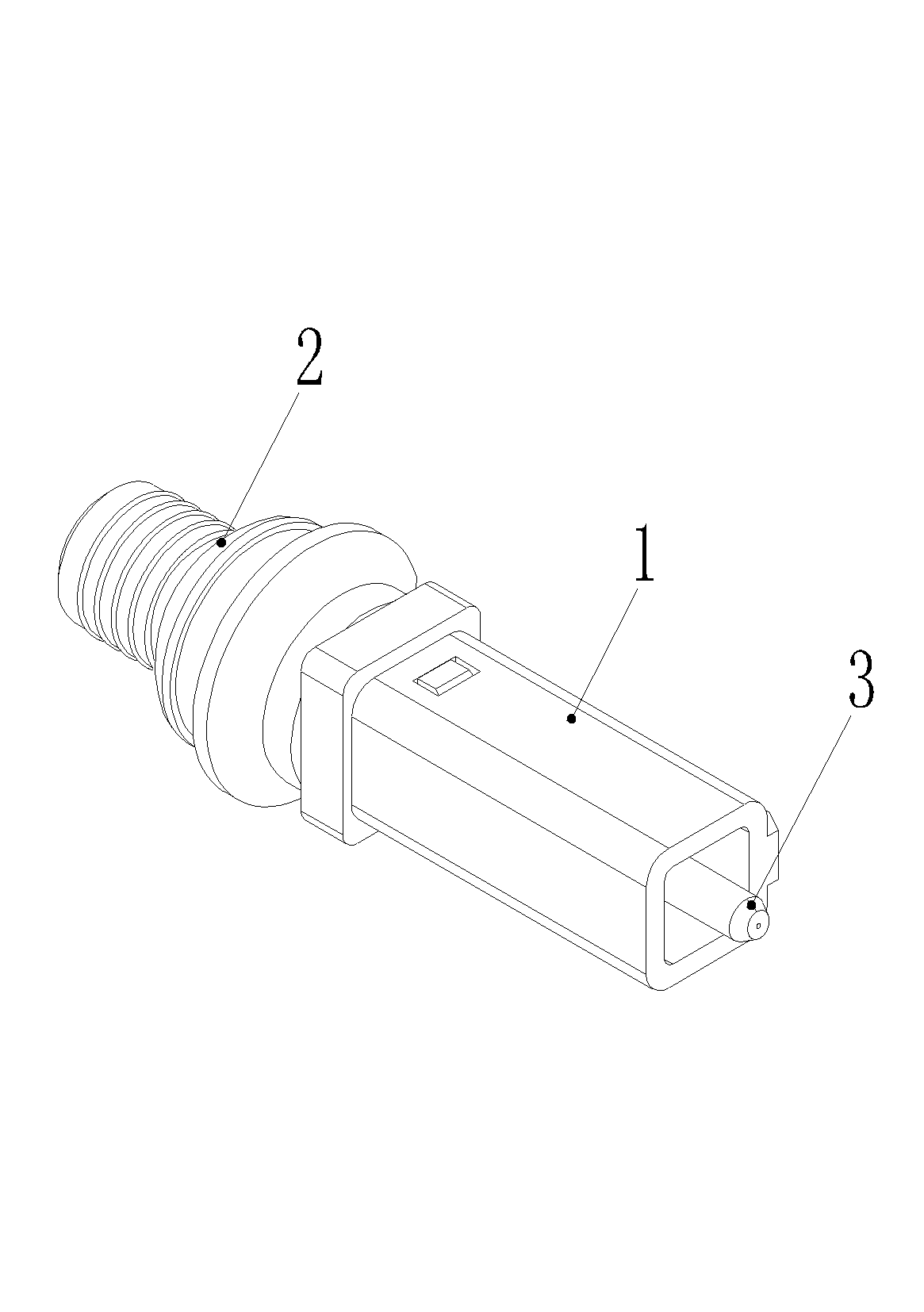

Contact pin assembly of optical fiber connector

The invention relates to a contact pin assembly of an optical fiber connector, comprising a contact pin shell formed by a front shell and a rear shell. An annular groove is coaxially arranged on the outer wall surface of the rear shell, and a convex ring on the inner wall surface of a corresponding protective shell can be embedded in the annular groove; and fitting surfaces which are in interference fit with the convex ring on the inner wall surface of the corresponding protective shell are arranged on the front and rear groove walls and / or the bottom of the annular groove. As the annular groove is arranged on the rear shell of the contact pin assembly of the optical fiber connector, and the fitting surfaces which are in interference fit with the convex ring on the inner wall surface of the corresponding protective shell are arranged on the front and rear groove walls and / or the bottom of the annular groove, in assembly, only the contact pin component needs to be assembled in the corresponding protective shell forcibly so as to fix the contact pin assembly with an inner shell, and to avoid the processing steps of rubber filling, pressing mounting and the like of a traditional optical fiber connector, thereby solving the problem of low assembly efficiency during the manufacturing of the optical fiber connector.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

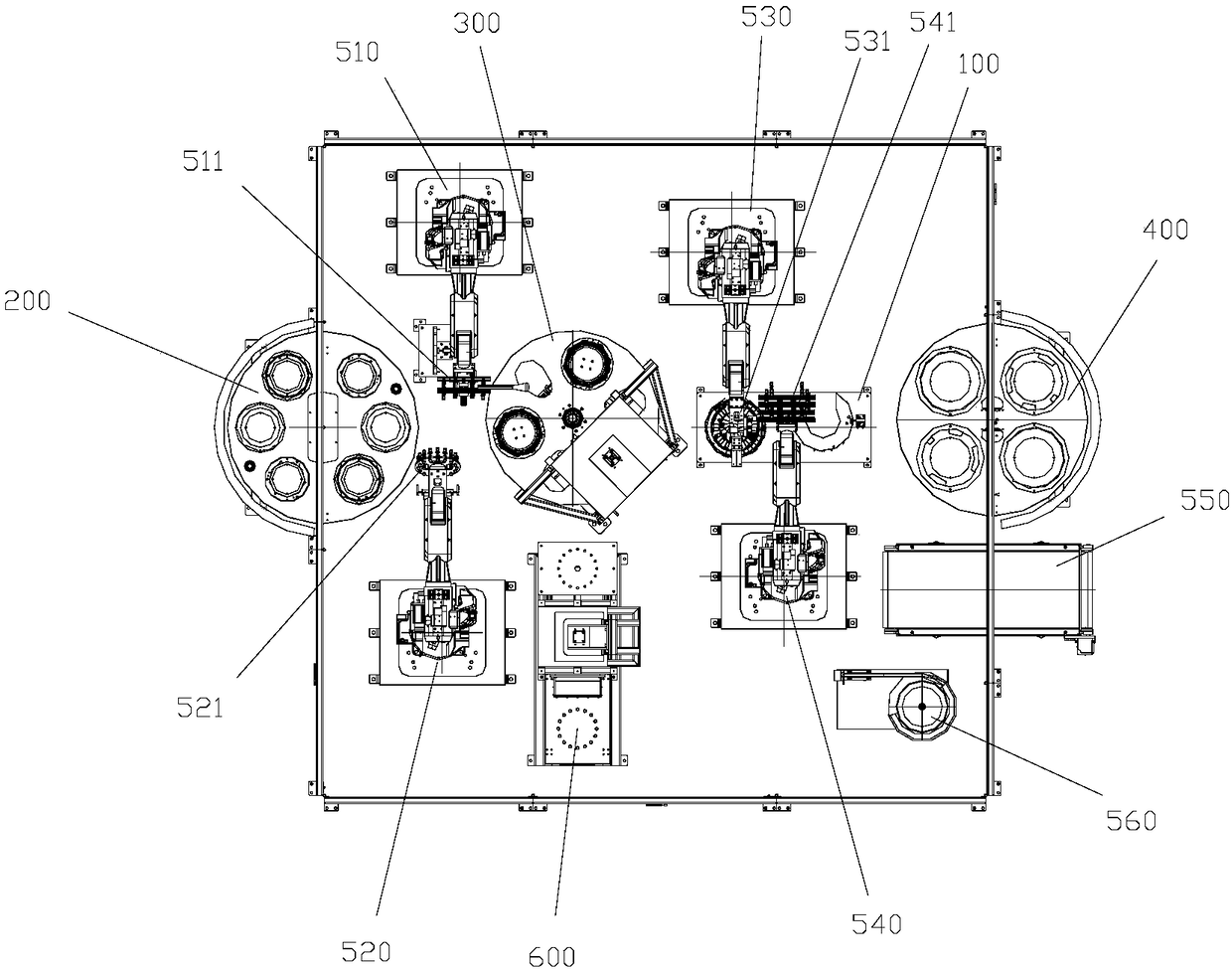

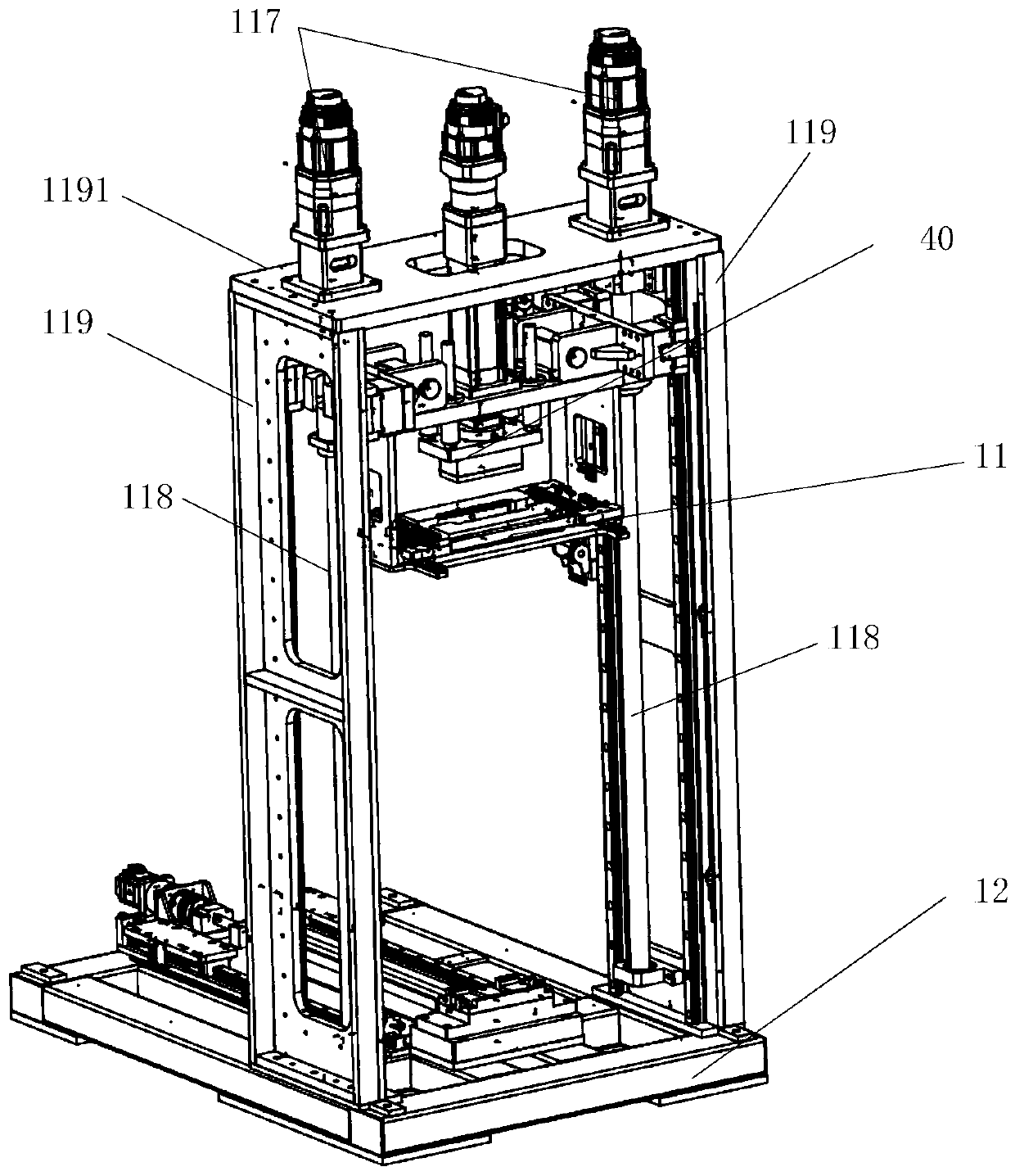

Bearing assembly equipment

PendingCN108248049AImprove assembly efficiencySolve the problem of low assembly efficiencyBearing componentsDomestic articlesFixed frameHot melt

The invention provides bearing assembly equipment. The bearing assembly equipment is used for assembling a plastic bearing and comprises a bearing part feeder and a bearing hot welding machine. The bearing part feeder comprises a frame locating seat, a shaft washer locating seat and a bottom washer locating seat. The frame locating seat is used for bearing a fixed frame and a holder of a bearing assembly. The shaft washer locating seat is used for bearing a shaft washer of the bearing assembly. The bottom washer locating seat is used for bearing a bottom washer of the bearing assembly. The bearing hot welding machine comprises a hot welding feeding seat for locating the bearing assembly, and a hot melting assembly. The hot melting assembly is arranged on the hot welding feeding seat and isprovided with a hot melting head for welding the bearing assembly located on the hot welding feeding seat. The bearing hot welding machine is arranged on one side of the bearing part feeder, so thata first robot located between the bearing part feeder and the bearing hot welding machine grabs the fixed frame, the holder, the shaft washer and the bottom washer located on the bearing part feeder onto the bearing hot welding machine, and assembly hot welding is conducted. The problem of low assembly efficiency of plastic bearings in the prior art is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Lift direction lamp display device

InactiveCN104724564APrevent shrinkage deformationGuaranteed smooth assemblyElevatorsDisplay boardDisplay device

The invention relates to a lift direction lamp display device. The lift direction lamp display device comprises a printed panel, a substrate, a circuit board and a base plate. An installation groove where the circuit board can be installed is formed in the upper surface of the base plate. The circuit board is installed in the installation groove. The circuit board is provided with a plurality of electrical elements and two display boards, wherein each display board is composed of a light-emitting diode and a sound making loudspeaker. The substrate is installed on the base plate and covers the circuit board. The base plate is provided with through holes enabling the display boards to be exposed. The substrate is further provided with a plurality of installation grooves arranged in an array. The upper surface of the substrate is covered with the printed panel. The lift direction lamp display device has the advantages that a groove is formed in the periphery of the bottom of the substrate installation groove, the display device is prevented from being shrunk and deformed in forming, the display device can be smoothly assembled, the assembly speed of the display device is not influenced, the display device can normally work, and the problem that the assembly efficiency is too low is solved.

Owner:JIANGSU SHENXIANG ELECTROMECHANICAL

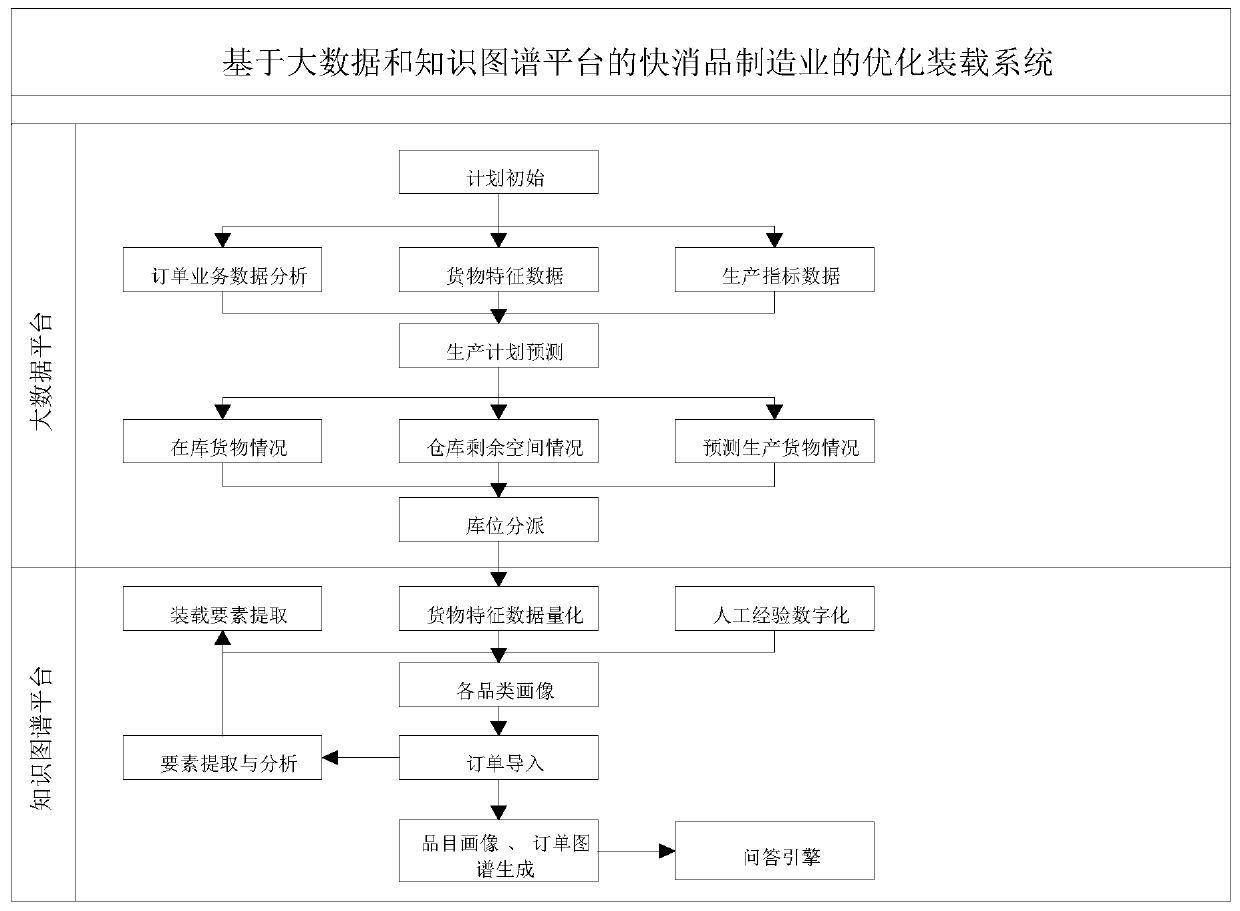

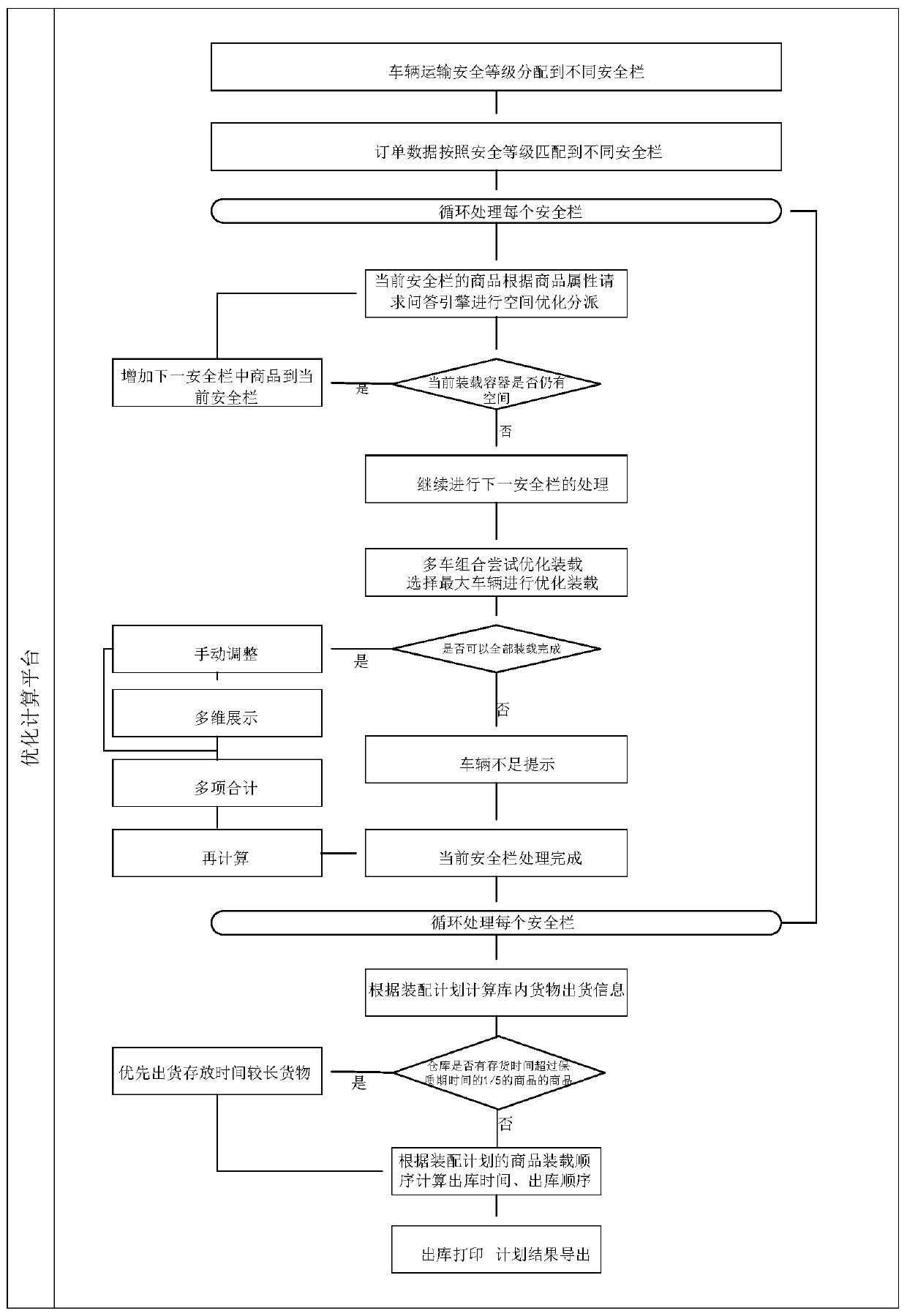

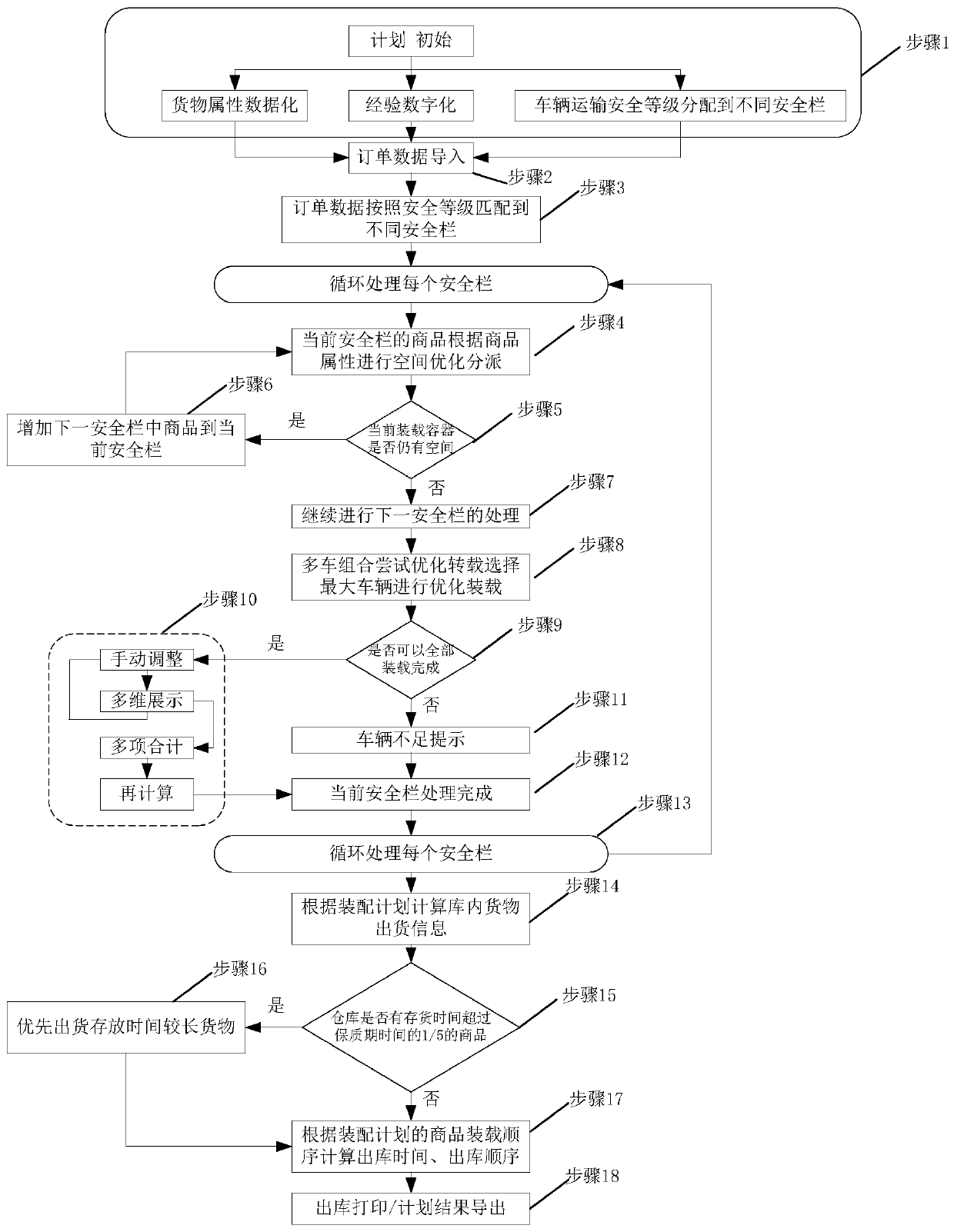

Cargo assembling method and device

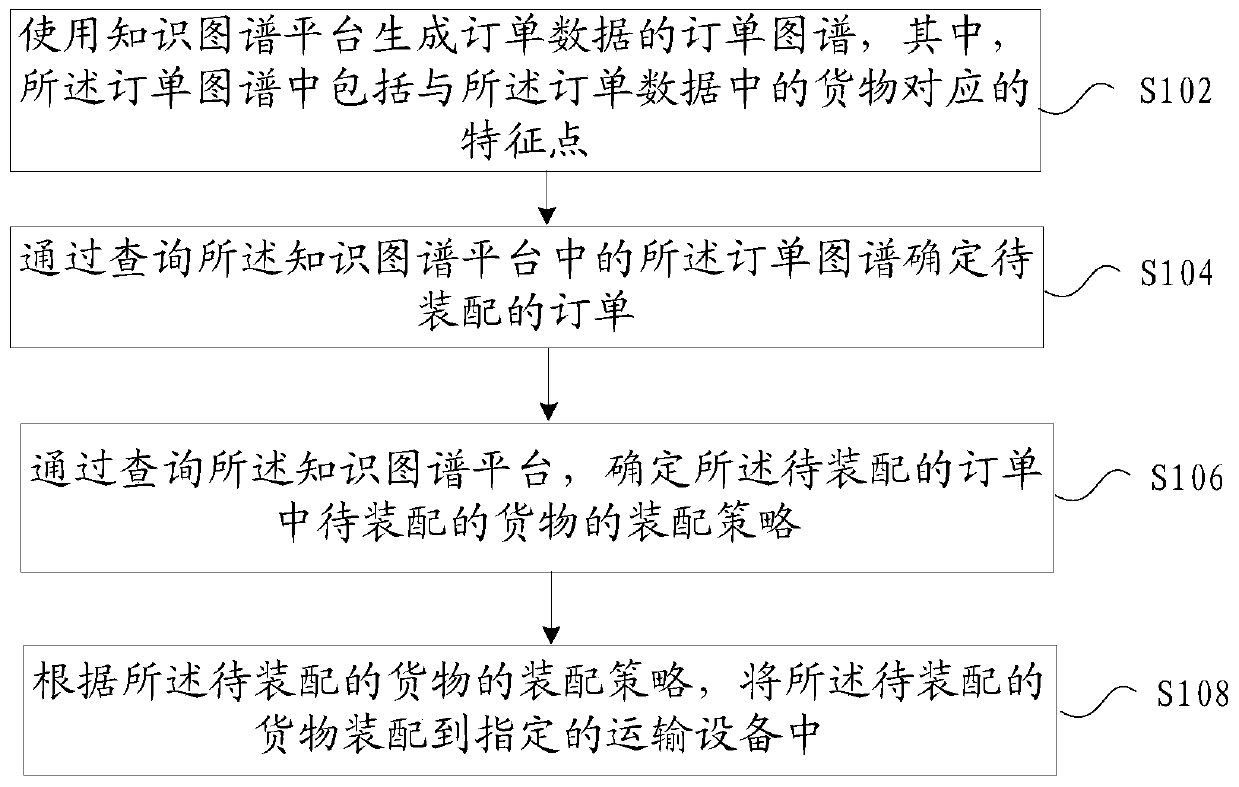

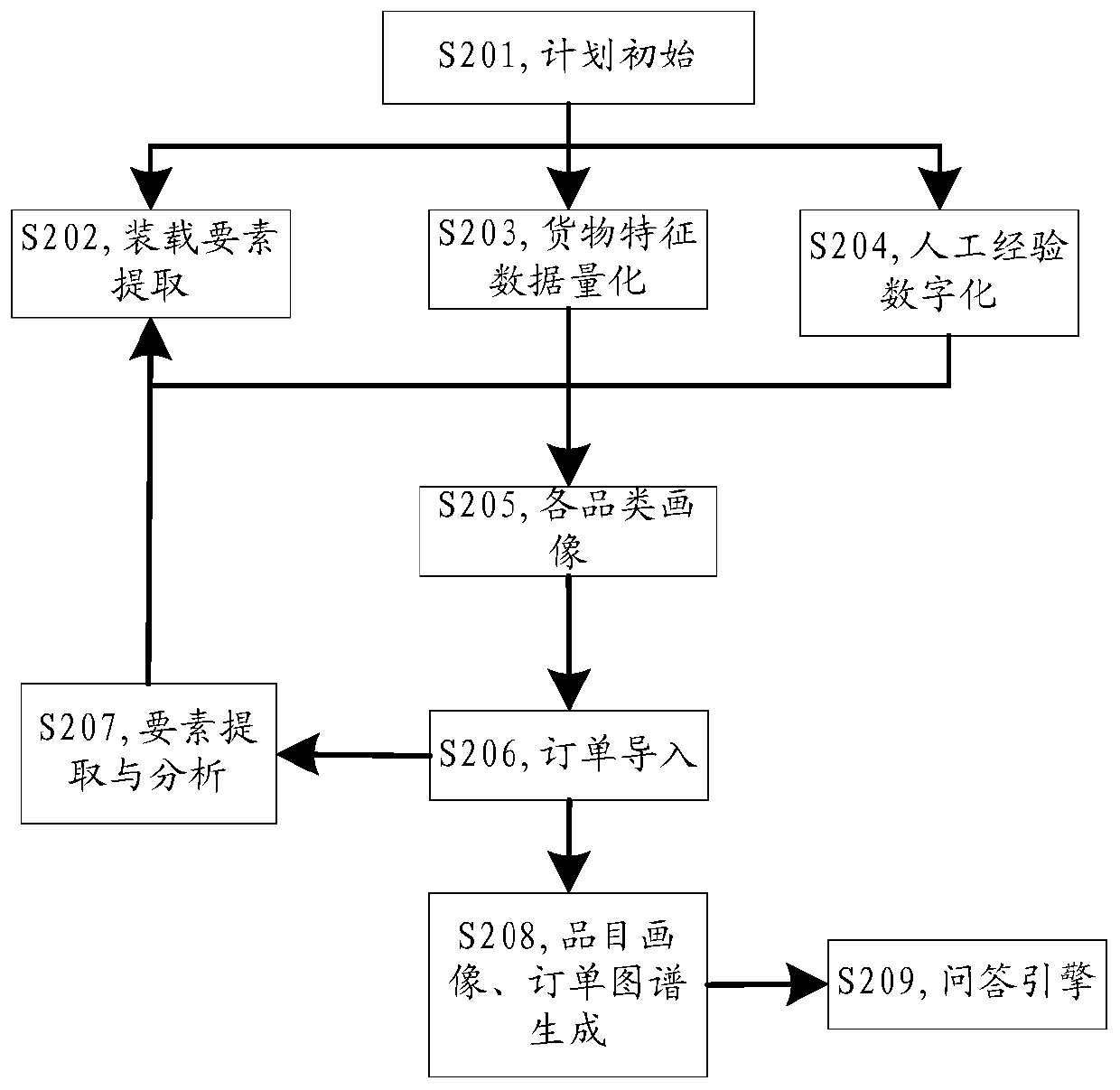

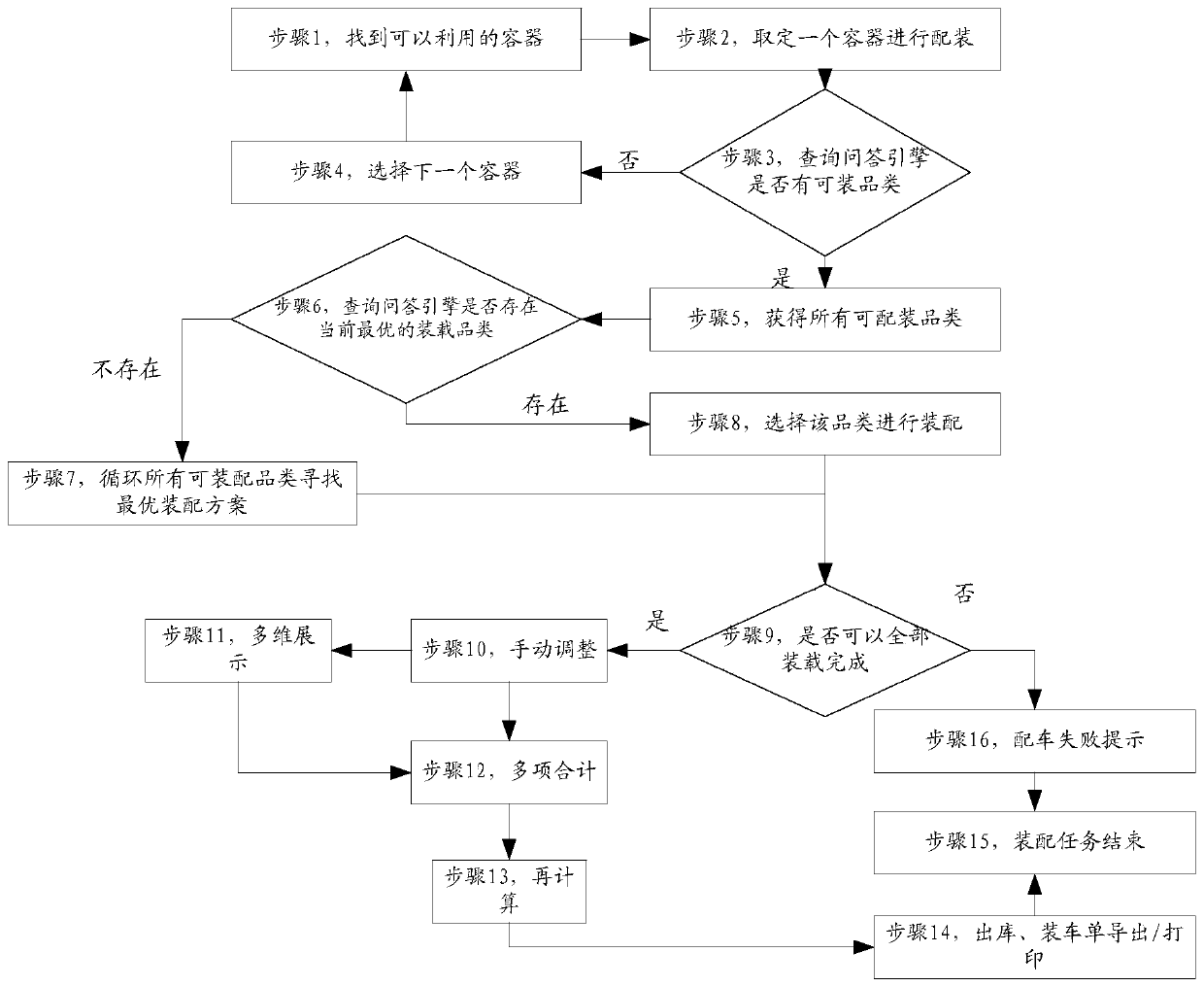

PendingCN110738372AImprove assembly efficiencySolve the problem of low assembly efficiencyForecastingLogisticsProcess engineeringKnowledge graph

The invention provides a cargo assembling method and a device, and the method comprises the steps: generating an order atlas of order data through employing a knowledge atlas platform, and the order atlas comprises feature points corresponding to cargos in the order data; determining a to-be-assembled order by querying the order graph in the knowledge graph platform; determining an assembly strategy of the to-be-assembled goods in the to-be-assembled order by querying the knowledge graph platform; and according to the assembling strategy of the to-be-assembled goods, assembling the to-be-assembled goods into specified transportation equipment. By means of the cargo assembling method and the device, the problem that the assembling efficiency is low due to the fact that cargoes are assembledmanually is solved, and the cargo assembling efficiency is improved.

Owner:MIAOZHEN INFORMATION TECH CO LTD

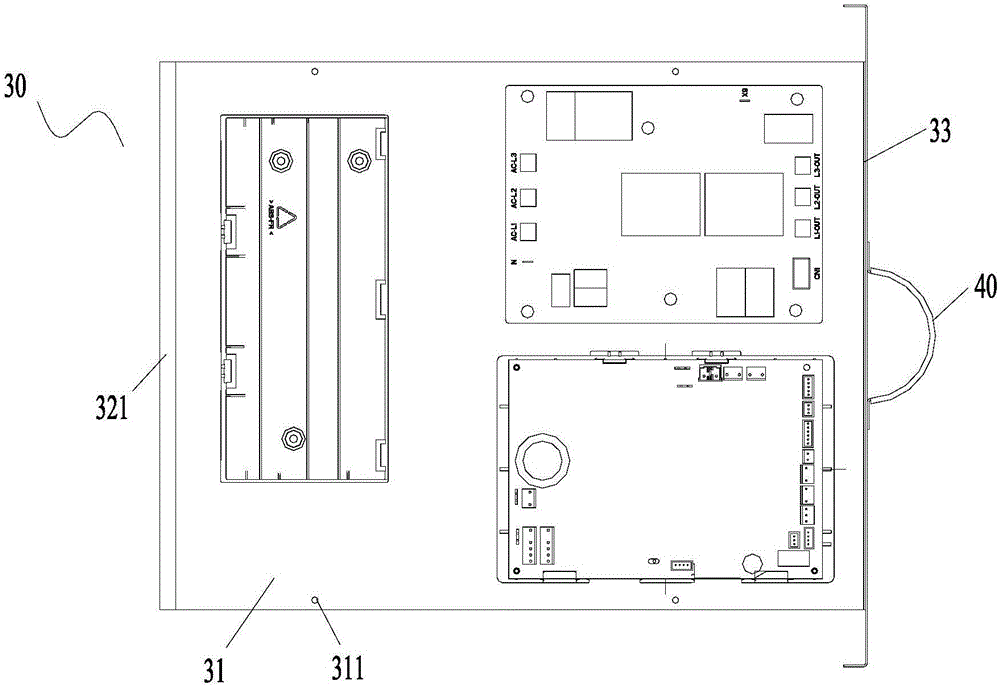

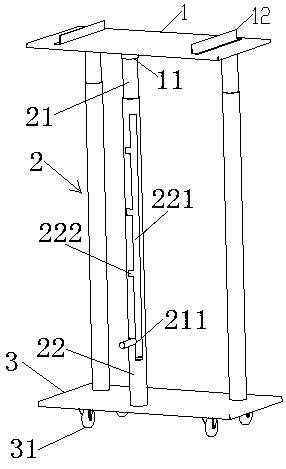

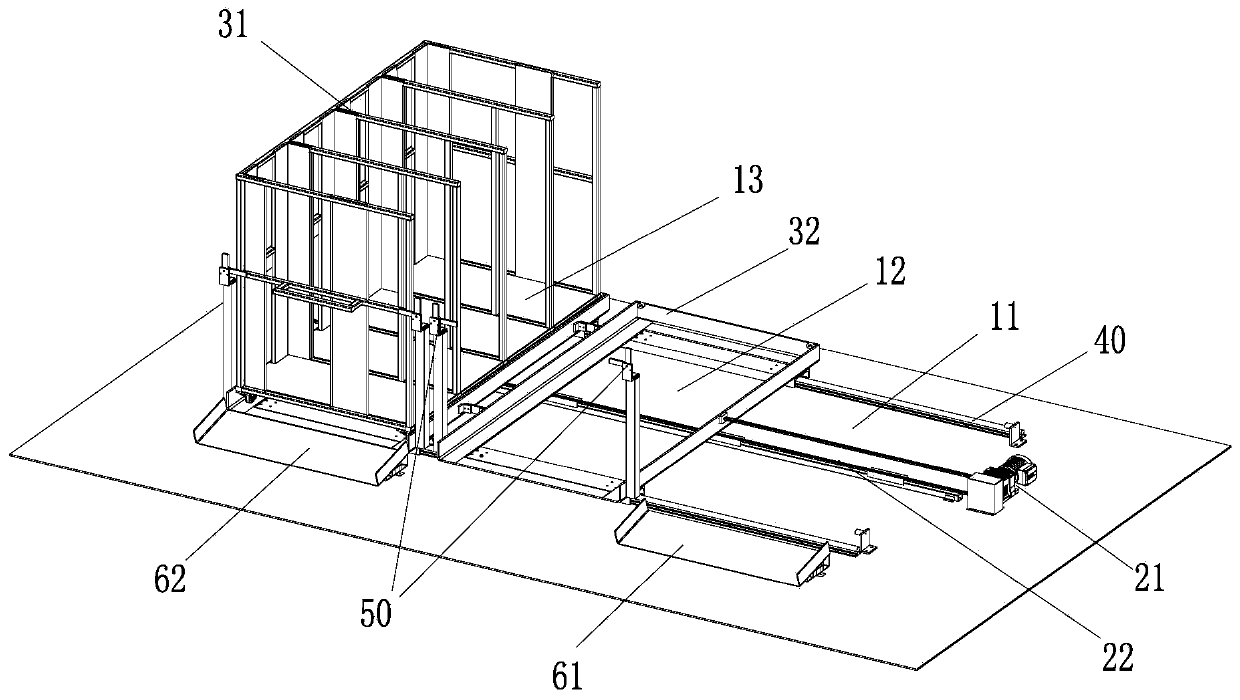

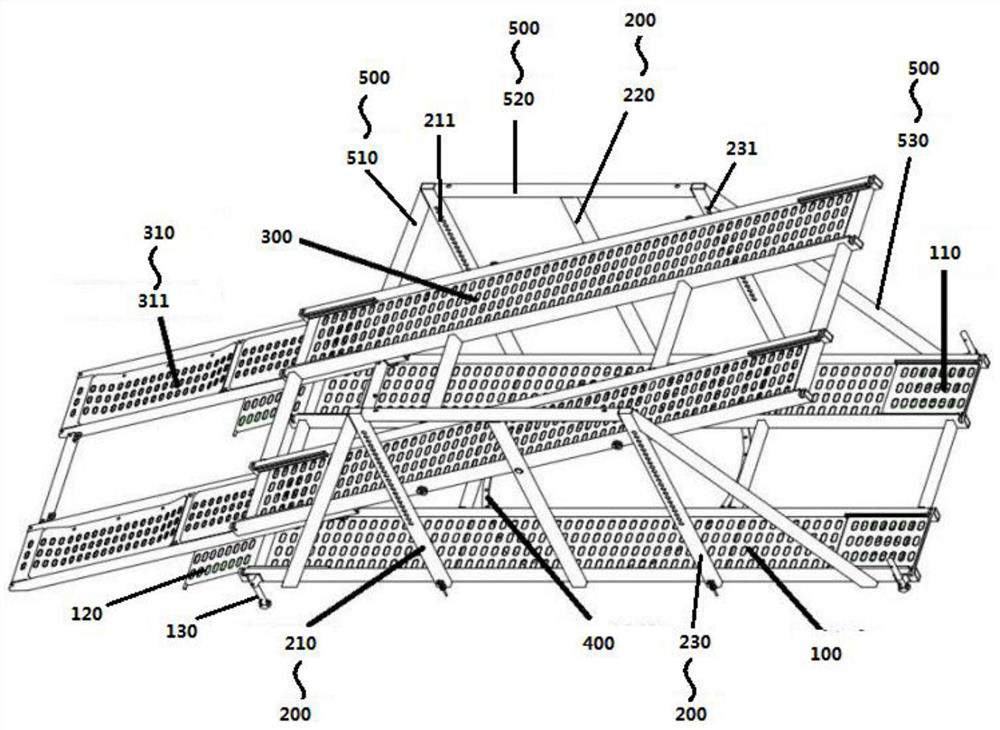

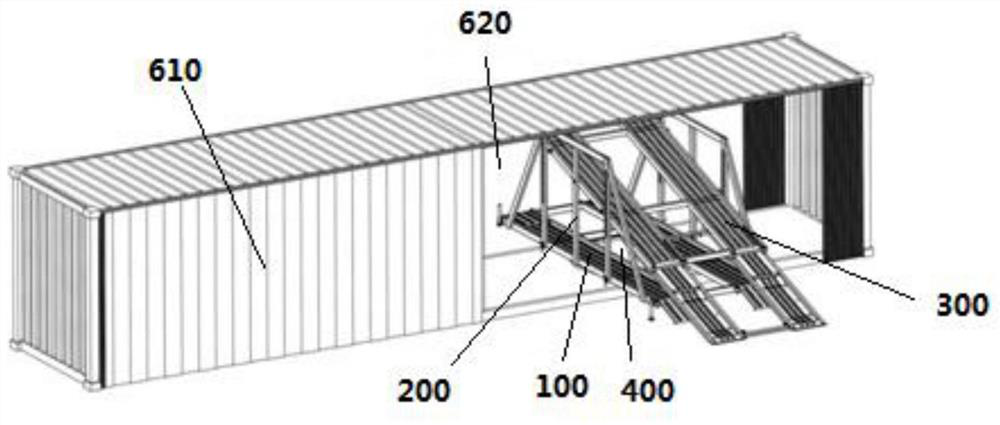

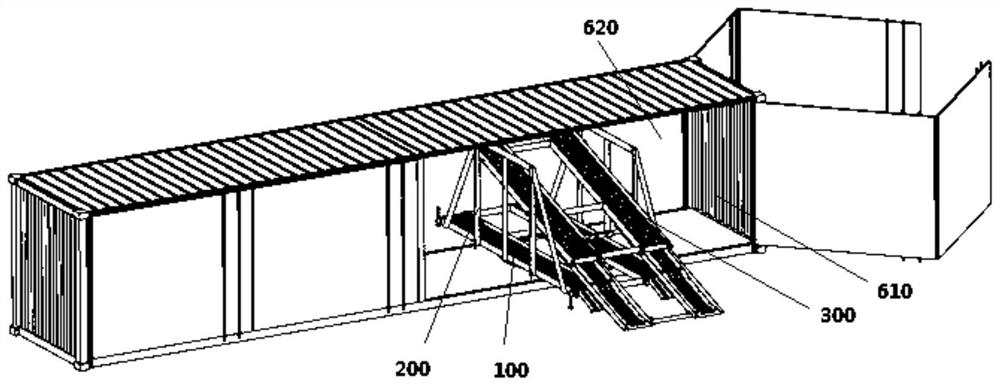

Assembling tool for secondary equipment modules of prefabricated cabin

InactiveCN108500891ASolve the problem of low assembly efficiencySimple structureWork benchesOther workshop equipmentComputer moduleElectrical and Electronics engineering

Owner:STATE GRID HUNAN ELECTRIC POWER +3

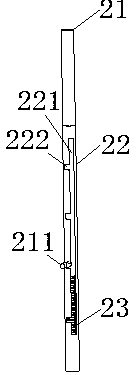

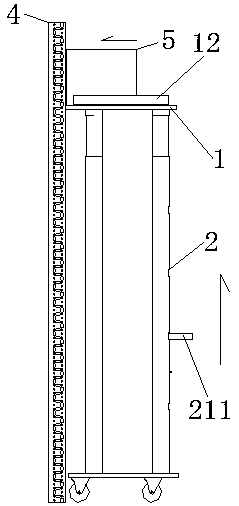

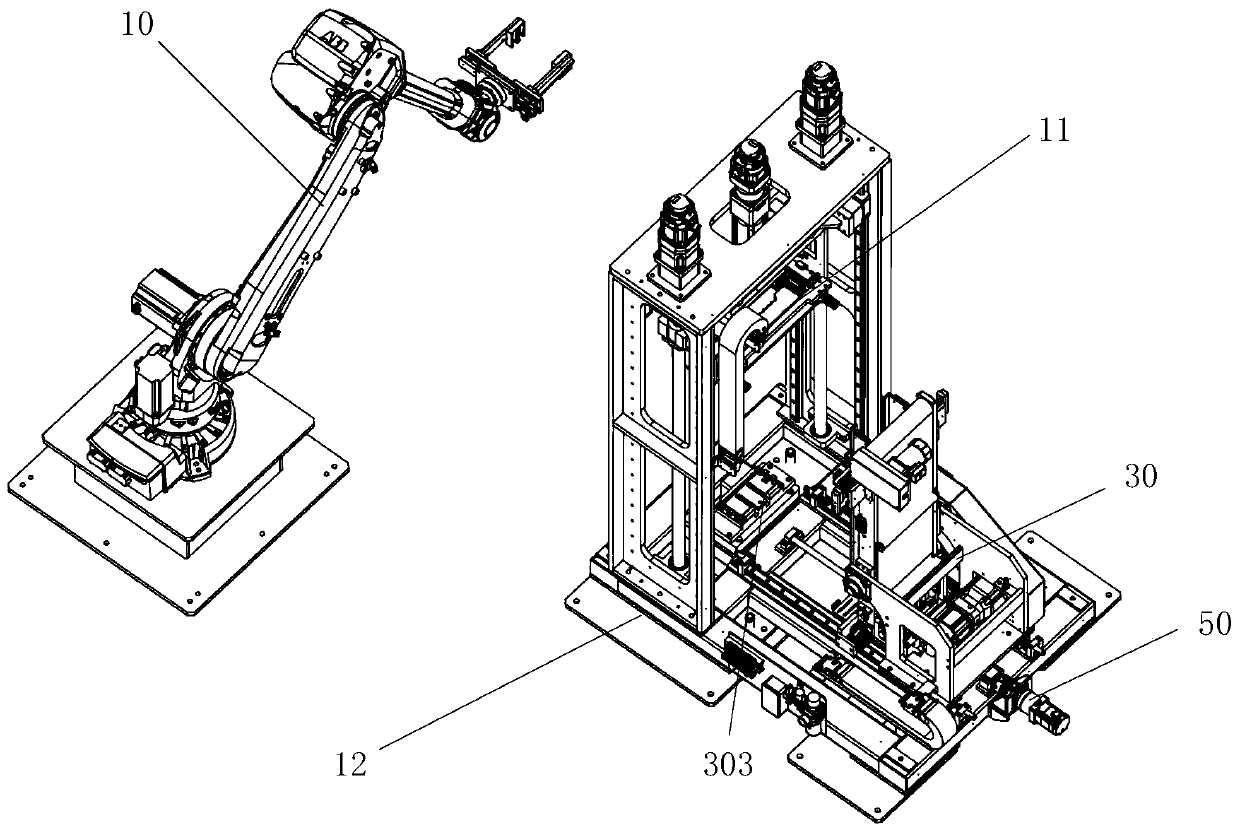

Feeding device and assembling equipment with same

ActiveCN110524215ASolve the problem of low assembly efficiencyMetal working apparatusManipulatorTemporary storage

The invention provides a feeding device and assembly equipment with the same, the feeding device is provided with a buffer station and a feeding station, the feeding device comprises a manipulator which is movably arranged relative to the feeding station so as to grab a workpiece located on the feeding station; and a carrying mechanism which is movably arranged relative to the temporary storage station and the feeding station, so that after the workpieces located on the feeding station are grabbed, the carrying mechanism transfers the workpieces located on the temporary storage station to thefeeding station, and the mechanical arm continues to grab the workpieces located on the feeding station. The feeding device solves the problem that in the prior art, the assembling efficiency of an air conditioner outdoor unit is low.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

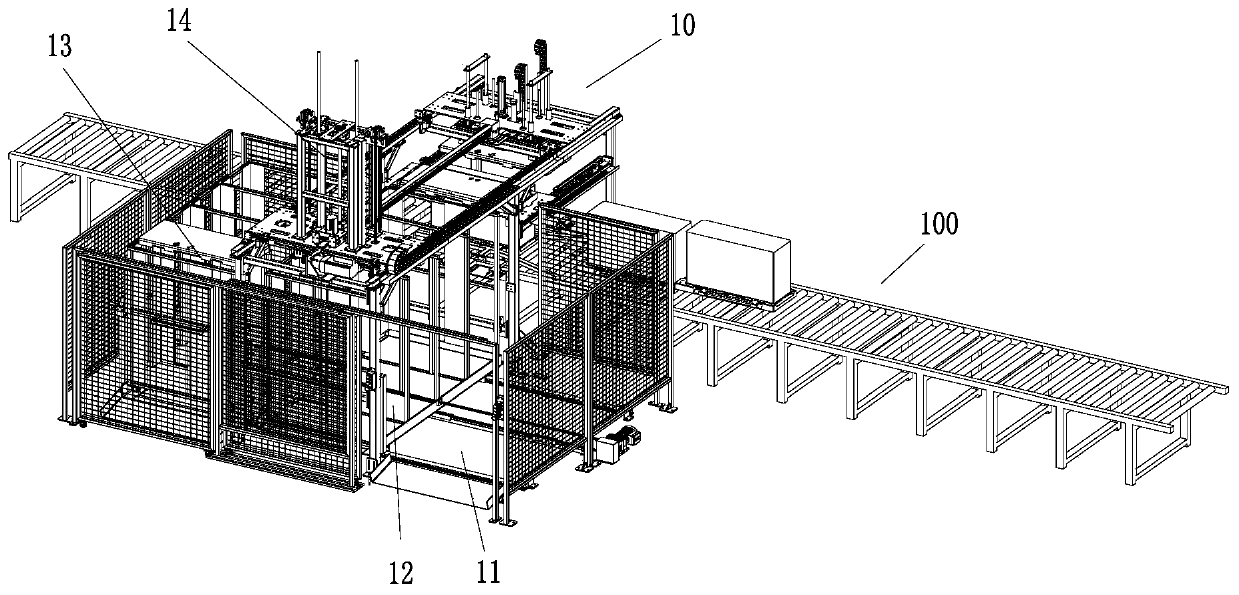

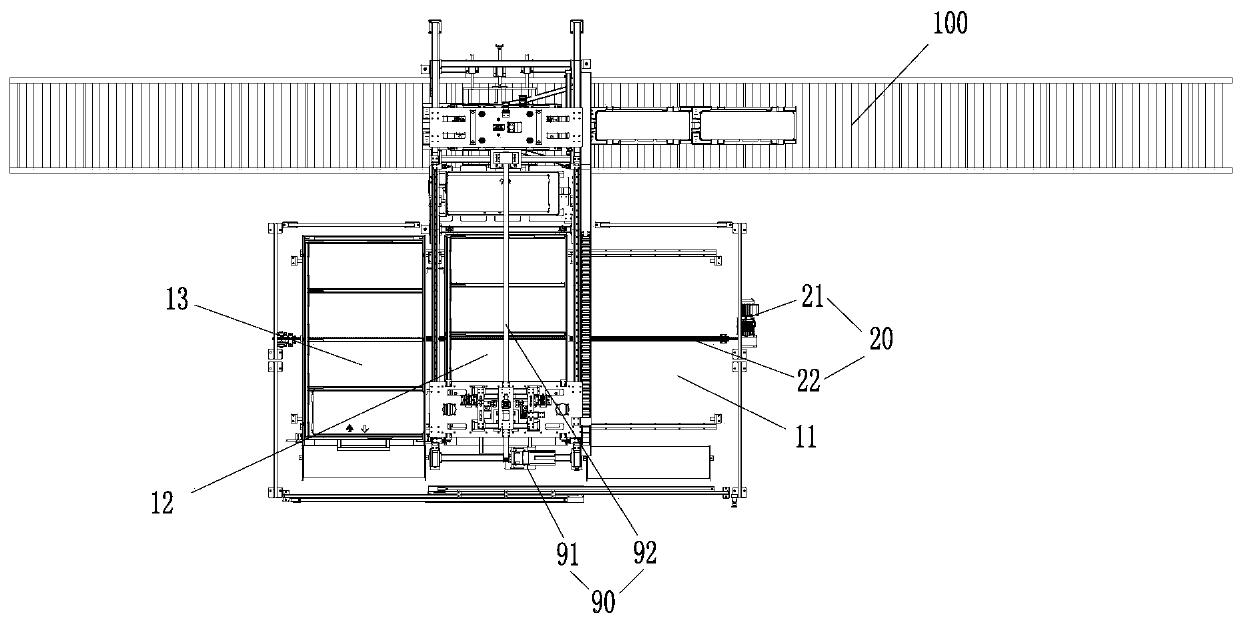

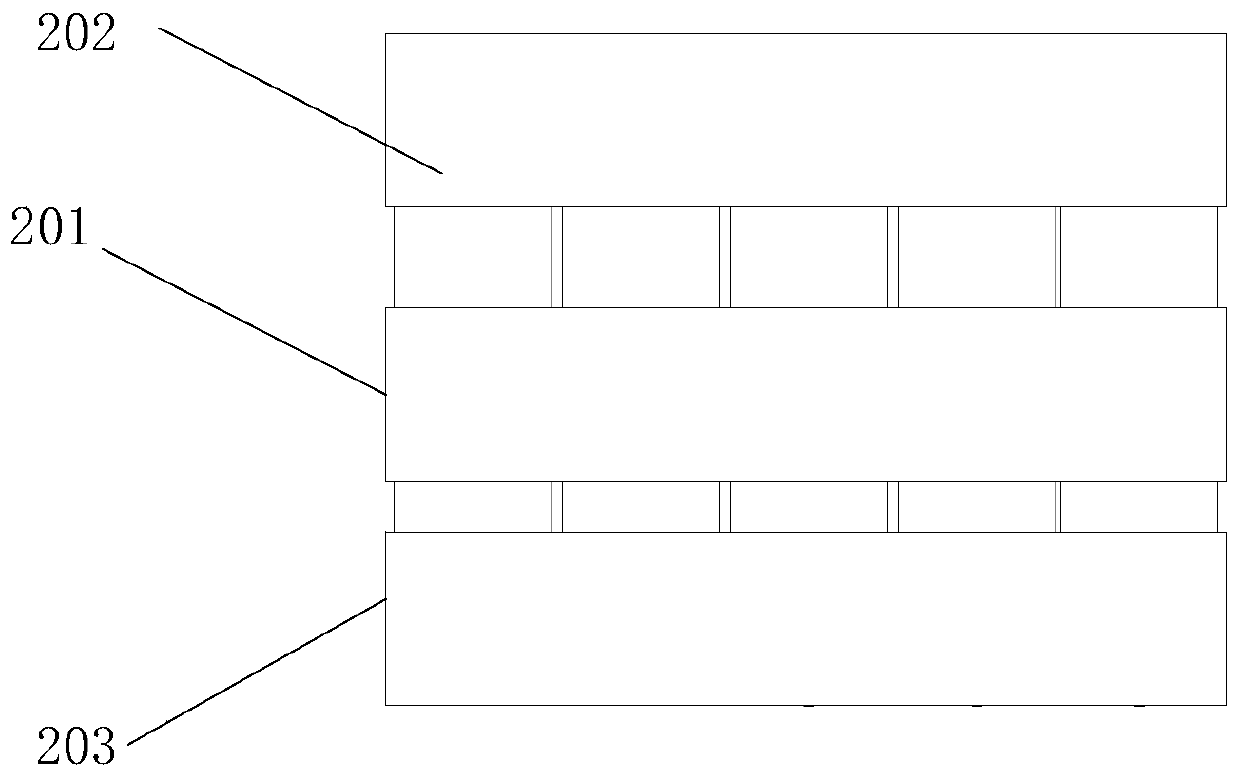

Stacking equipment

PendingCN109823853ASolve the problem of low assembly efficiencyImprove assembly efficiencyStacking articlesDe-stacking articlesBiochemical engineeringElectrical battery

The invention discloses stacking equipment and belongs to the technical field of battery module assembly. The stacking equipment comprises a feeding mechanism, an arranging mechanism and a first base,wherein the feeding mechanism stacks at least one battery module on the first base, and the arranging mechanism arranges the battery modules at the top end of the first base every time when each battery module is stacked at the top end of the first base. The problem that the assembling efficiency in the assembling process of the battery module is low is solved, and the effect of improving the assembling efficiency of the battery module is achieved.

Owner:WUXI AOTEWEI INTELLIGENT EQUIP CO LTD

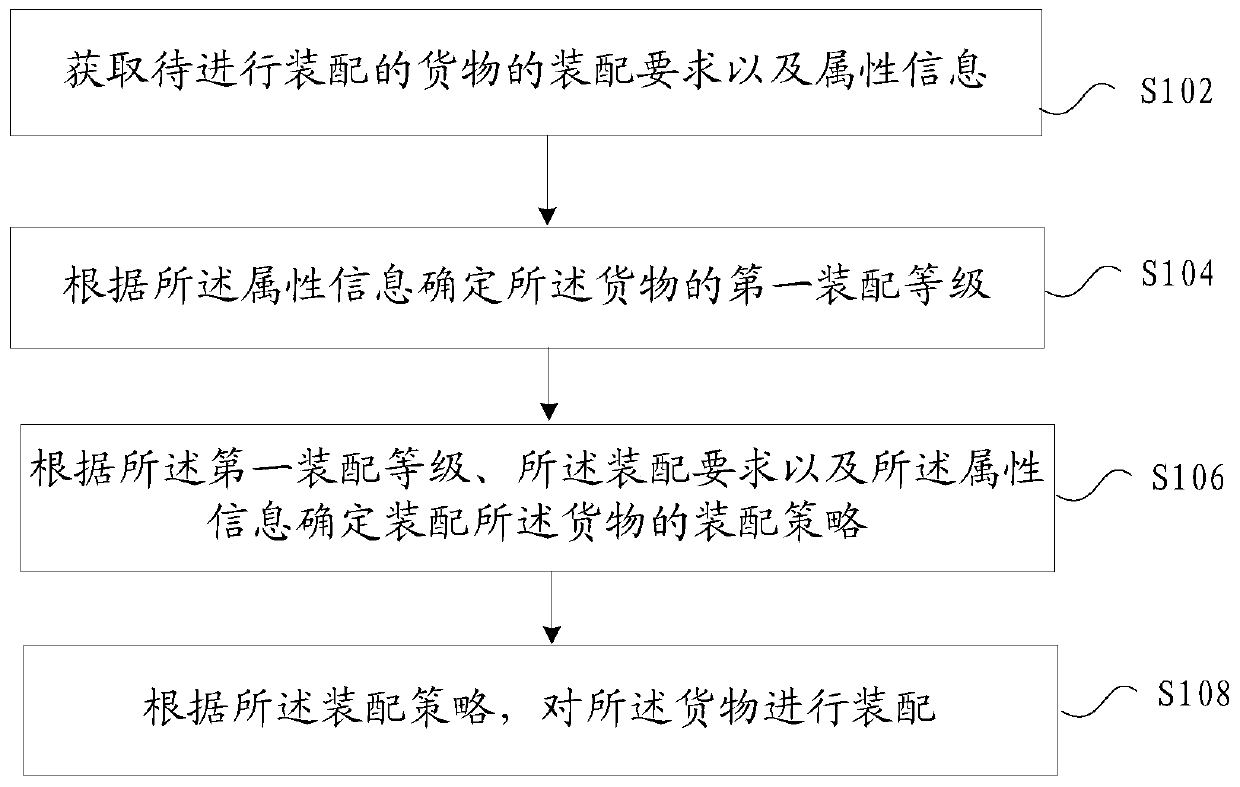

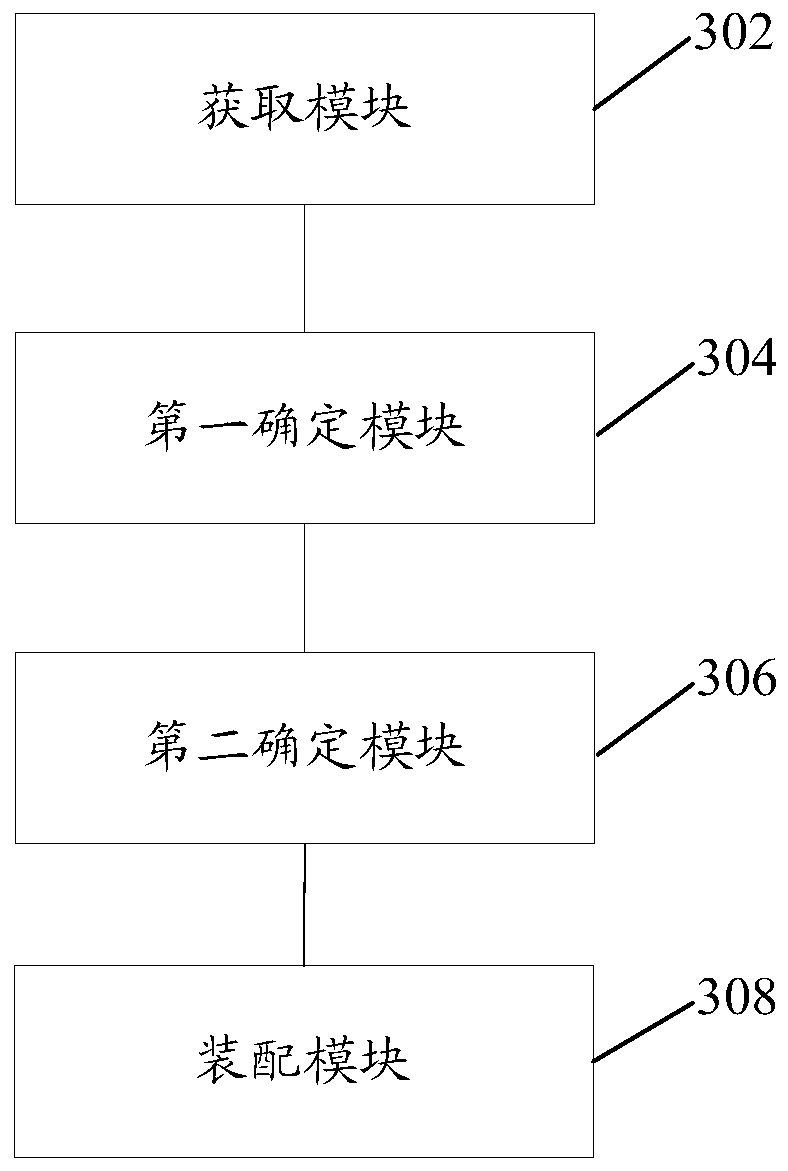

Cargo assembling method and device

PendingCN110738374ASolve the problem of low assembly efficiencyImprove assembly efficiencyForecastingLogisticsIndustrial engineeringManufacturing engineering

The invention provides a goods assembling method and a device. The method comprises the steps of acquiring the assembling requirement and attribute information of goods to be assembled; determining afirst assembly level of the goods according to the attribute information; determining an assembly strategy for assembling the goods according to the first assembly level, the assembly requirement andthe attribute information; and assembling the goods according to the assembling strategy. According to the method, the problem of low assembly efficiency caused by manual assembly of goods is solved.

Owner:MIAOZHEN INFORMATION TECH CO LTD

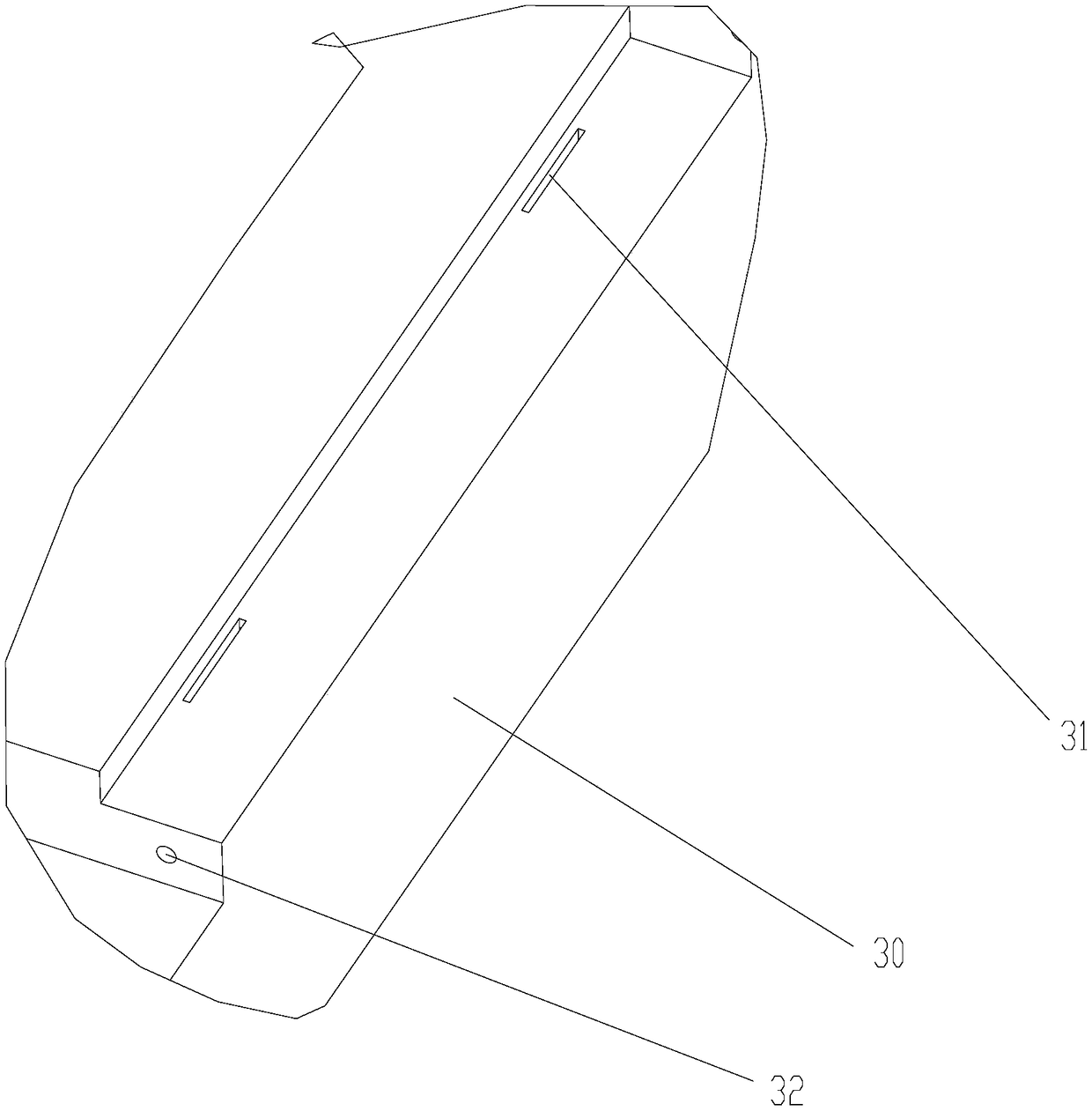

Volute structure and air-conditioner with same

PendingCN108759058ASolve the problem of low assembly efficiencyImprove assembly efficiencyCondensate preventionLighting and heating apparatusEngineeringChassis

The invention provides a volute structure and an air-conditioner with same. The volute structure comprises a volute part, a water receiving disc part and a chassis part which are integrally molded. Bymeans of the volute structure, the problem the assembly efficiency of a volute, a water receiving disc and a chassis in the prior art is low is solved.

Owner:GREE ELECTRIC APPLIANCES INC

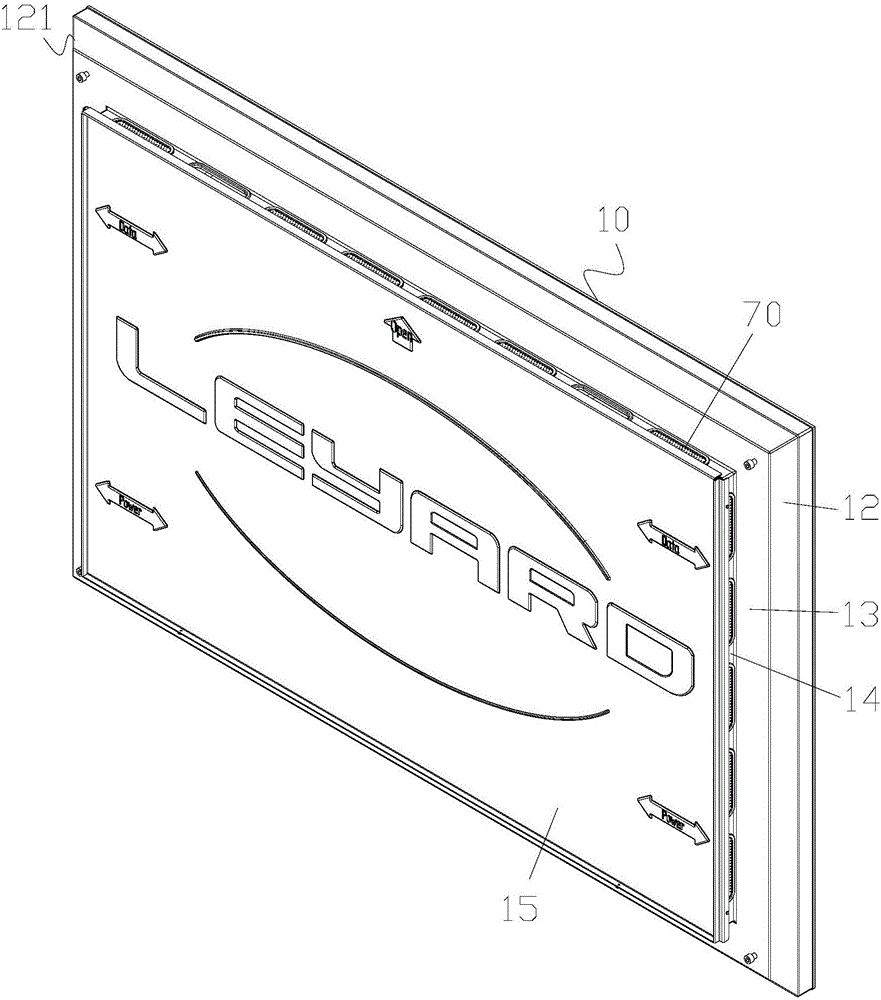

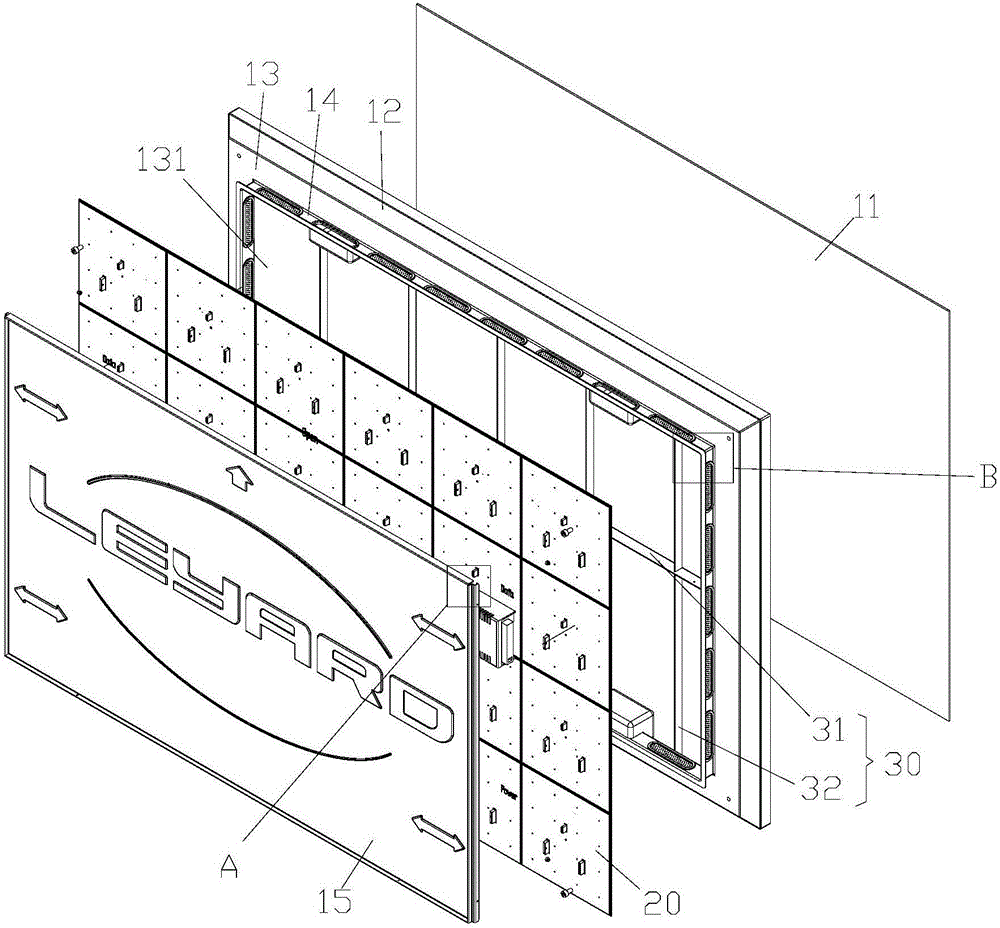

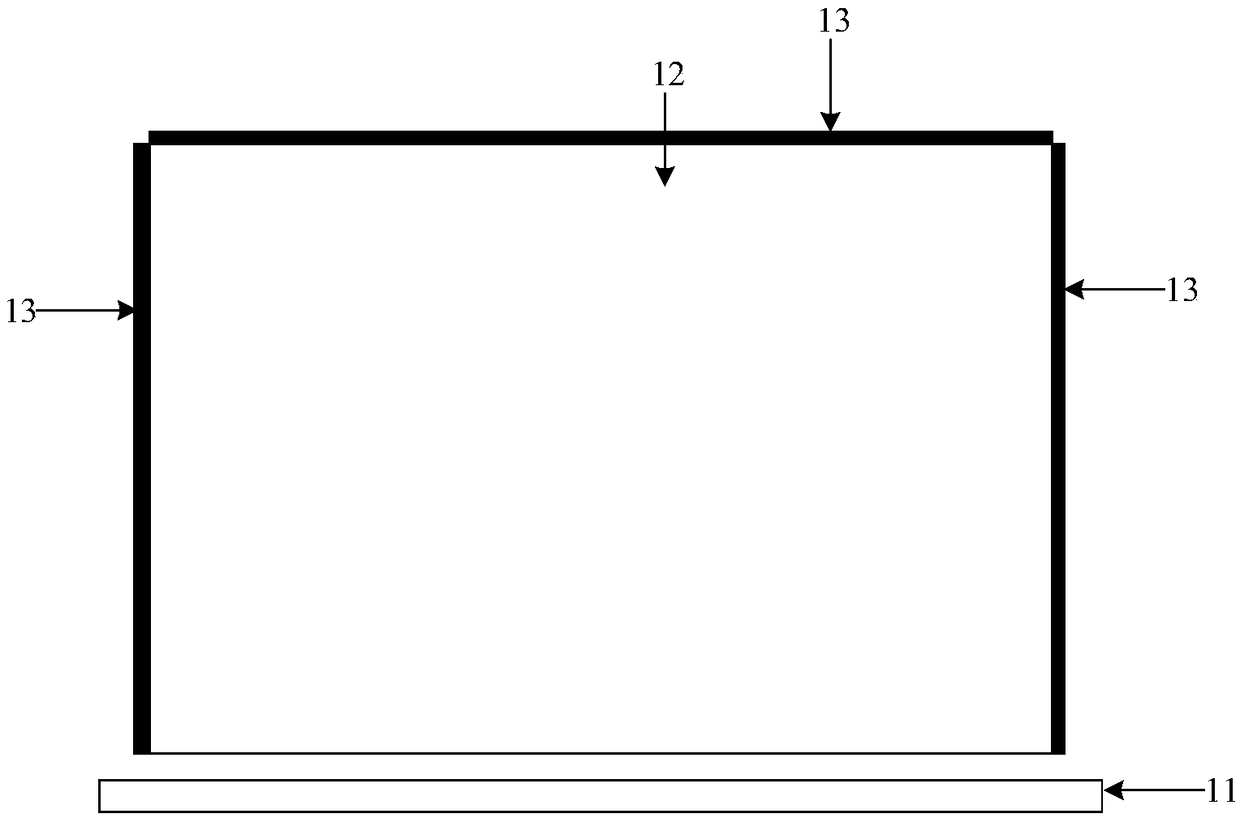

Display device

ActiveCN106448457ASolve the problem of low assembly efficiencySimple and fast operationIdentification meansDisplay deviceEngineering

The invention provides a display device which comprises a box, a lamp panel arranged in the box and a first positioning structure arranged in the box. The first positioning structure is matched with the side wall of the lamp panel and locates the lamp panel in the box. According to the technical scheme, the problem of low assembly efficiency of the display device in the prior art is solved.

Owner:LEYARD

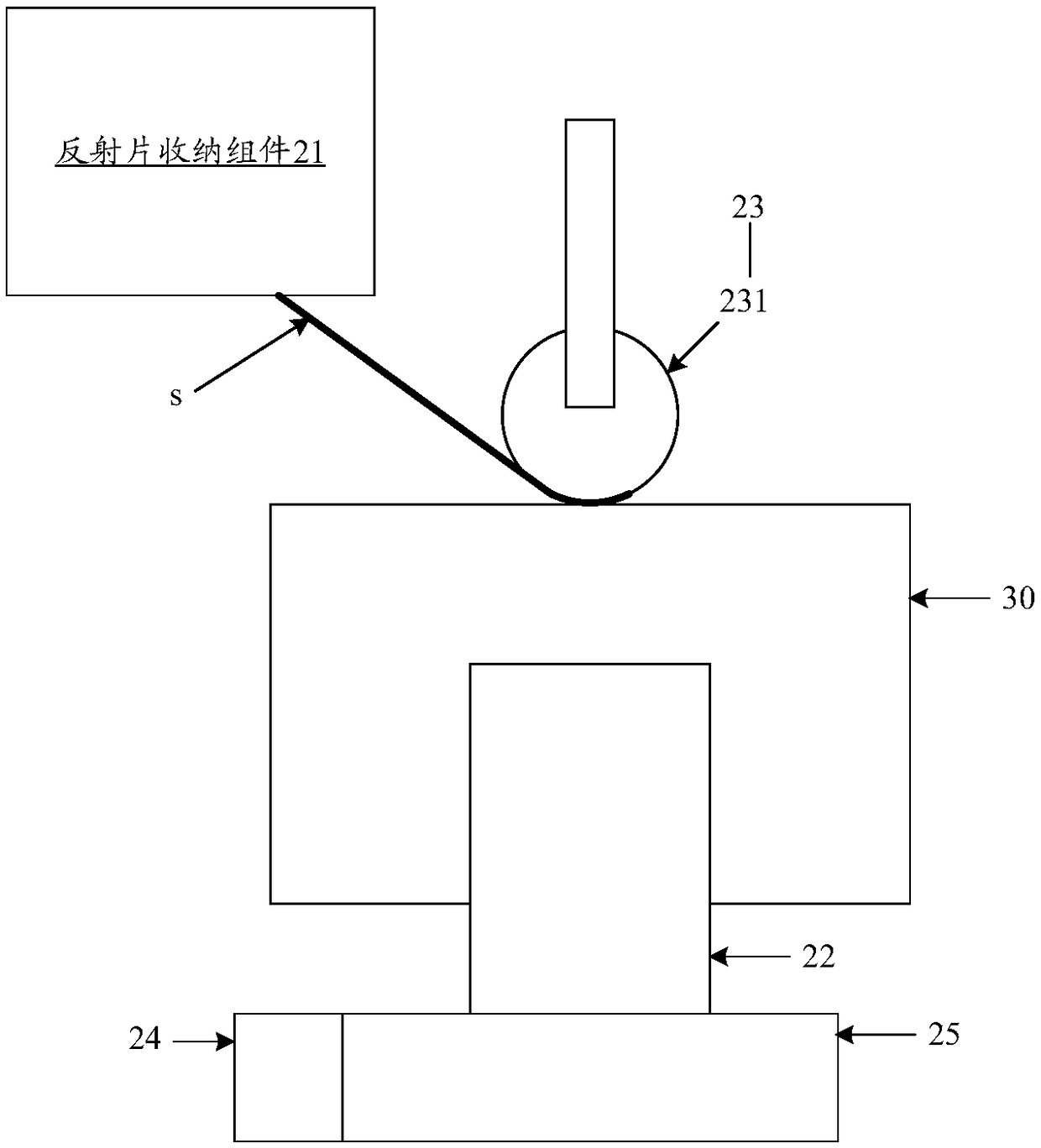

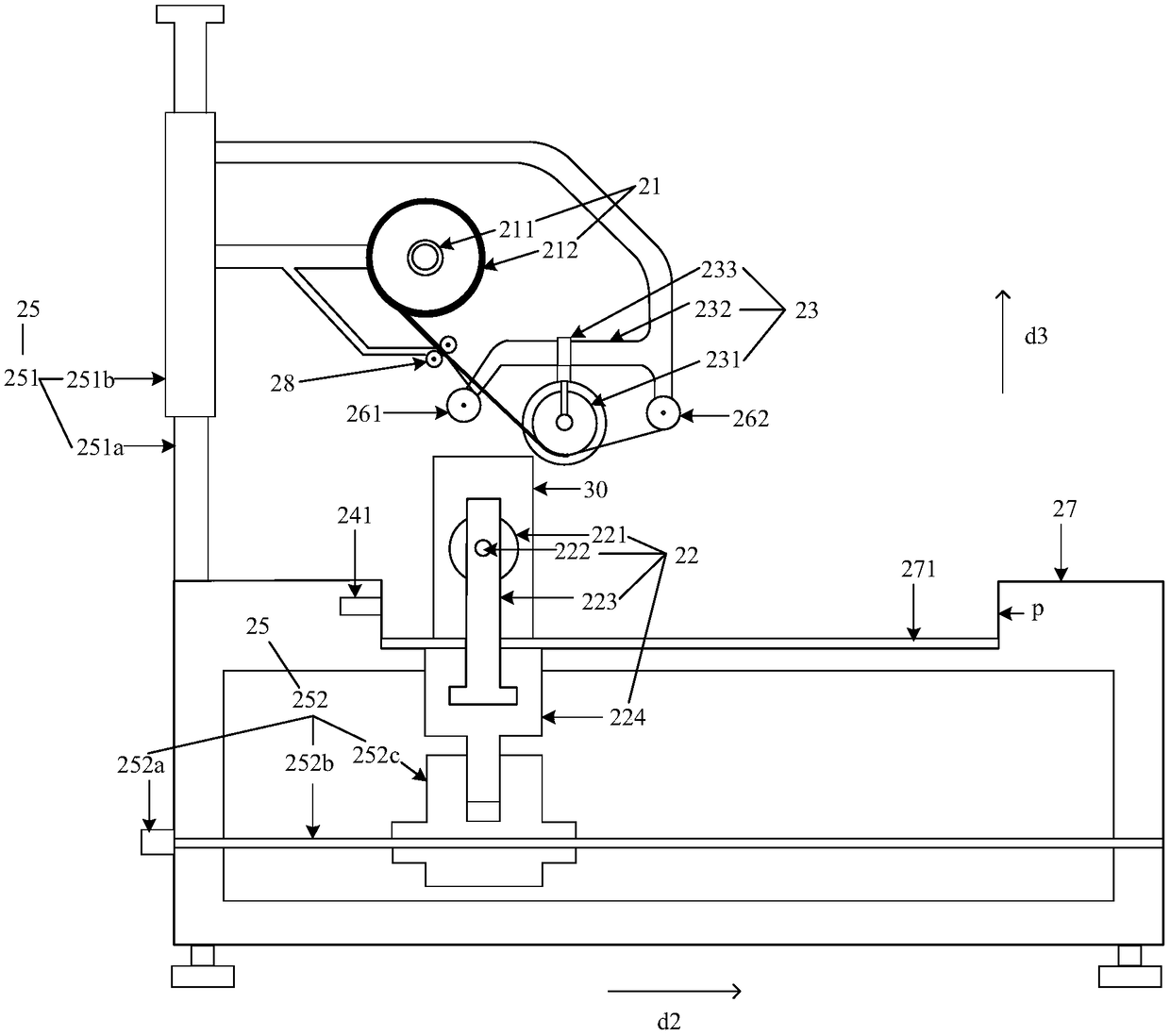

Reflective plate assembling device and reflective plate assembling method

ActiveCN109239836ASolve the problem of low assembly efficiencyImprove assembly efficiencyOptical light guidesLight guideEngineering

The invention discloses a reflective plate assembling device and a reflective plate assembling method and belongs to the technical field of displaying. The reflective plate assembling device comprisesa reflective plate accommodating subassembly, a light guide plate fixing subassembly, an adhesion subassembly, a positioning subassembly and a movement subassembly, wherein the adhesion subassembly includes an adhesion rolling wheel; one end of a strip-shaped reflective plate is located at the adhesion rolling wheel; the positioning subassembly is used for determining a light guide sheet adhesionposition of at least one light guide plate according to the size of at least one light guide plate; the movement subassembly is used for enabling the adhesion rolling wheel to locate at the light guide sheet adhesion position of at least one light guide plate and to move relatively. According to the reflective plate assembling device and the reflective plate assembling method, the light guide sheet adhesion position is determined through the positioning subassembly, the adhesion rolling wheel is enabled to locate at the light guide sheet adhesion position through the movement subassembly, theadhesion rolling wheel is enabled to move relatively with the light guide plate, the reflective sheet can be adhered on the light guide plate; the light guide sheet adhesion position is accurately determined through the size of the light guide plate; the problem of low assembling efficiency of the reflective plate in a related technology is solved, and the effect of improving the assembling efficiency of the reflective plate is achieved.

Owner:HEFEI BOE DISPLAY LIGHT +1

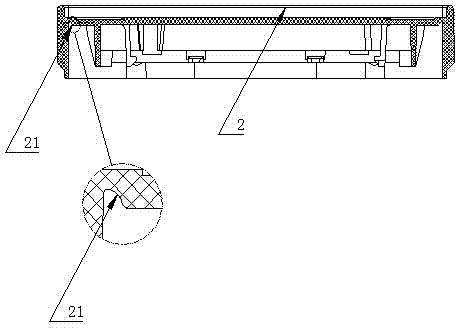

Air conditioner indoor unit drainage nozzle sealing structure and air conditioner indoor unit

InactiveCN106052077AEasy to assemble and disassembleEasy to fixCondensate preventionLighting and heating apparatusWater leakageEngineering

The invention provides an air conditioner indoor unit drainage nozzle sealing structure. The air conditioner indoor unit drainage nozzle sealing structure comprises a drainage nozzle, a drainage pipe and a seal ring. The seal ring is inlaid into the assembling end of the drainage pipe. The seal ring is cylindrical in whole, at least one annular protrusion is disposed on the inner wall of the seal ring, and the drainage nozzle is assembled in the seal ring. The invention further provides an air conditioner indoor unit adopting the drainage nozzle sealing structure. By improving the structure of the seal ring, the assembling contact surface is reduced, so that the friction force is reduced, the assembling is easier, the same sealing effect is maintained, water seepage and water leakage are avoided, and accordingly, the problem of difficult air conditioner indoor unit drainage nozzle sealing assembling is solved. The sealing structure does not need any lubrication assistance, the problem of low assembling efficiency is solved, and the sealing structure can be applied to all split wall-hanging indoor units.

Owner:HISENSE (GUANGDONG) AIR CONDITIONER

Vehicle transporting frame and container with same

Owner:CRRC QIQIHAR ROLLING CO LTD +1

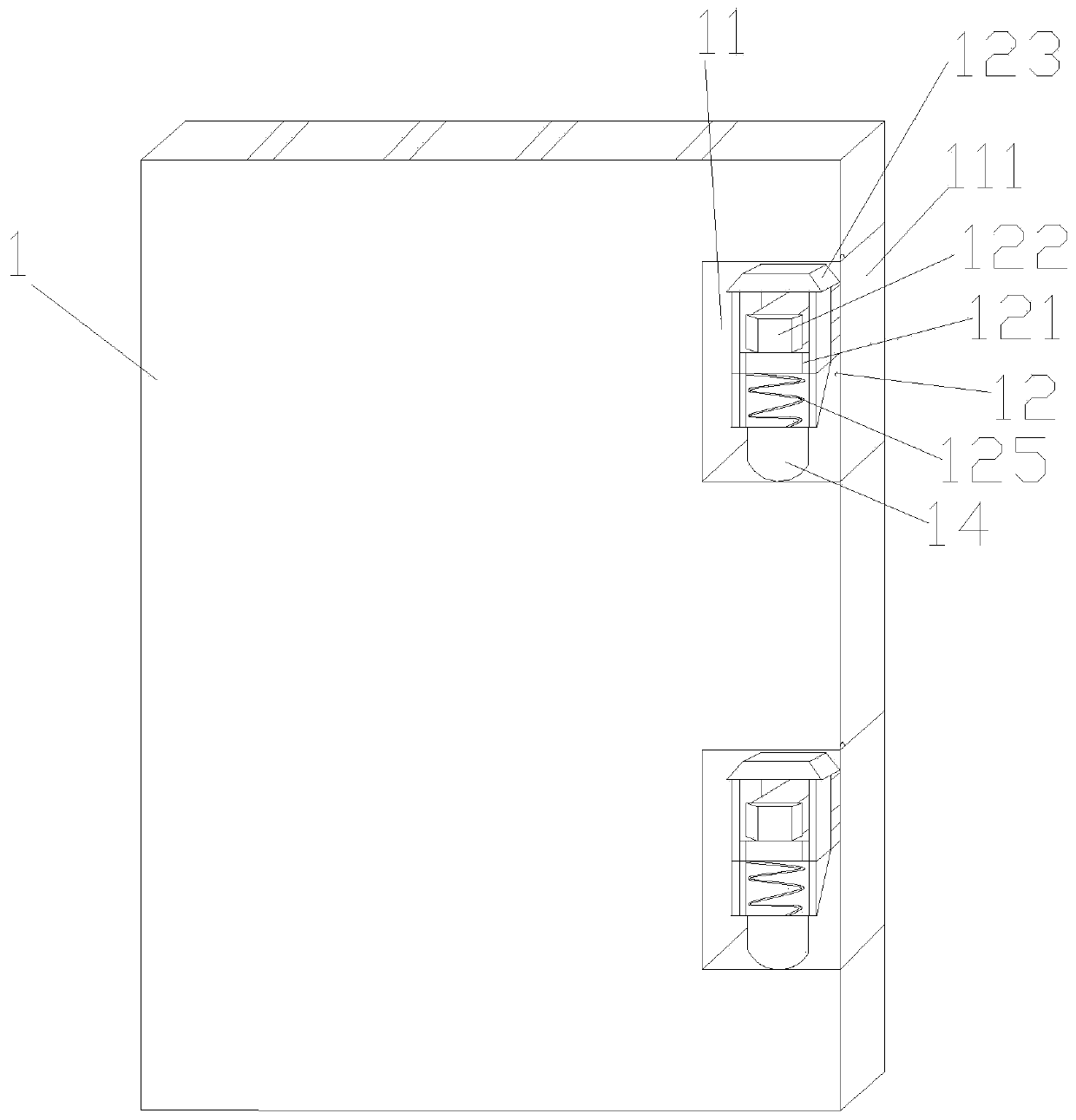

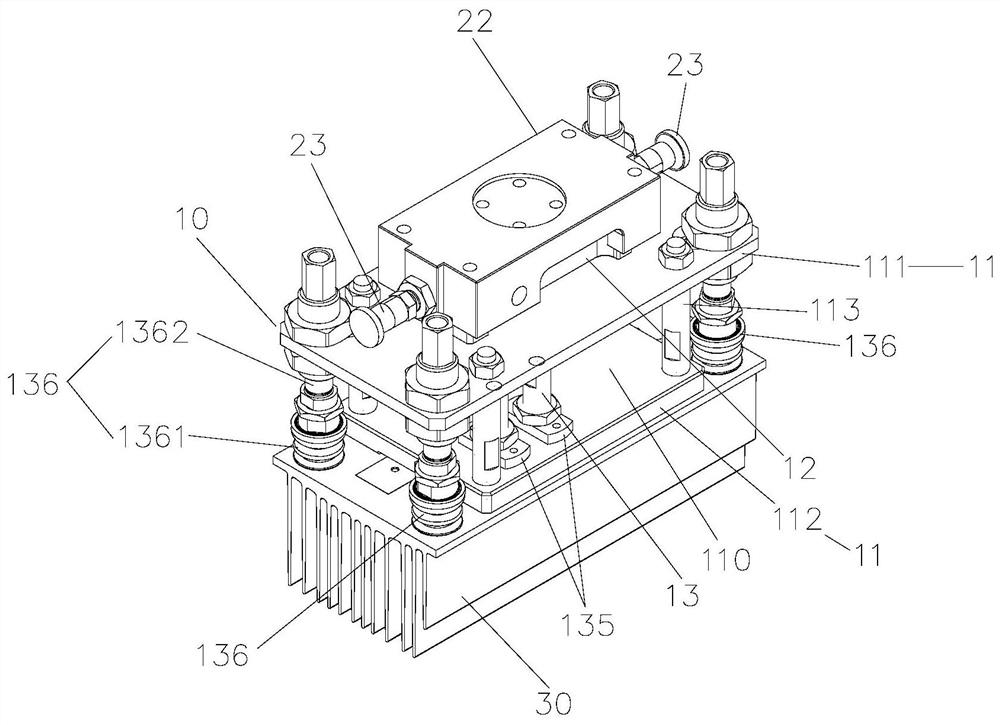

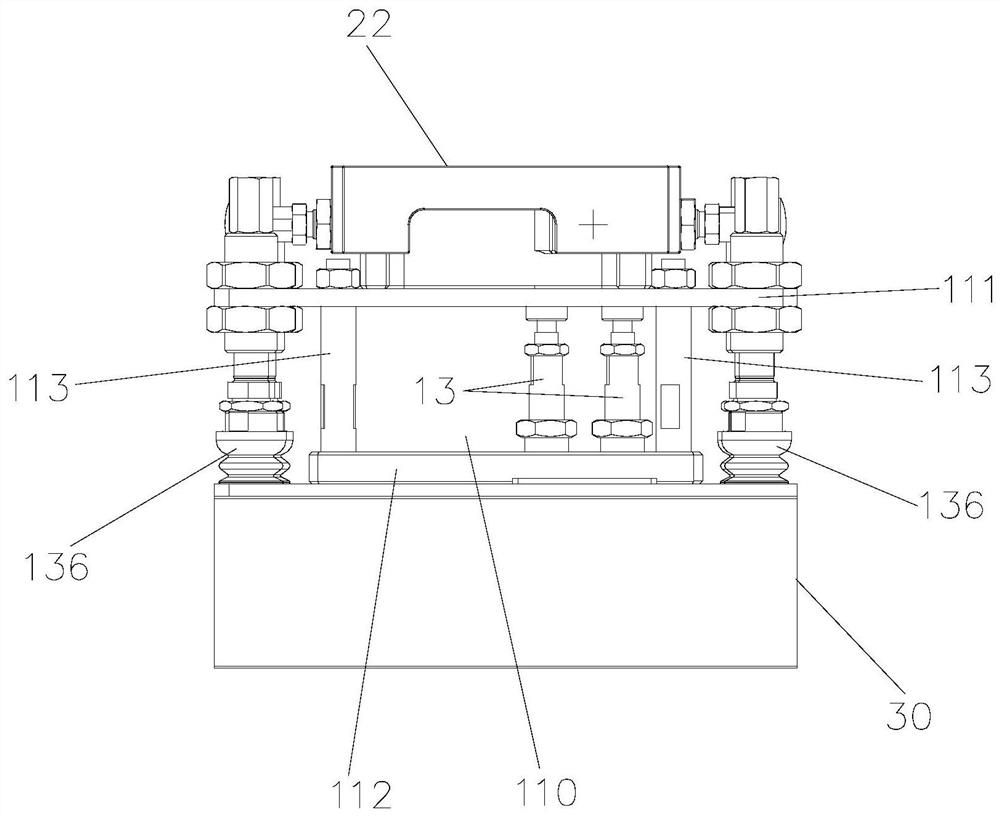

Positioning mechanism, moving device and assembling system

ActiveCN112276514AAchieve positioningImprove assembly efficiencyGripping headsMetal working apparatusEngineeringPhysics

The invention provides a positioning mechanism, a moving device and an assembling system. The positioning mechanism comprises a mounting assembly with a mounting space, a first connecting part and a positioning assembly, and the first connecting part and the positioning assembly are arranged on the mounting assembly. The positioning assembly comprises a fixing part and a positioning part. The fixing part is arranged in the mounting space, and the fixing part is provided with a buffer channel. The positioning part is movably arranged in the buffer channel in a penetrating manner. The first connecting part is connected with a mechanical arm of a robot, and the positioning part penetrates out of the buffer channel and the mounting space to be connected with a workpiece, so that the workpieceis positioned by the robot, and the robot drives the workpiece to move. The workpiece refers to a radiator. The robot can be used for driving the radiator to be moved into an electric appliance box, so that the assembling work of the radiator and the electric appliance box is automated, the assembling efficiency of the radiator and the electric appliance box is further improved, and the problem that the assembling efficiency of the radiator and the electric appliance box in the prior art is low is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com