Flexible flywheel

A flexible flywheel and signal disc technology, applied in the direction of flywheel, spring/shock absorber, vibration suppression adjustment, etc., to offset axial shock and torsional vibration, ensure stiffness, reduce part cost and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

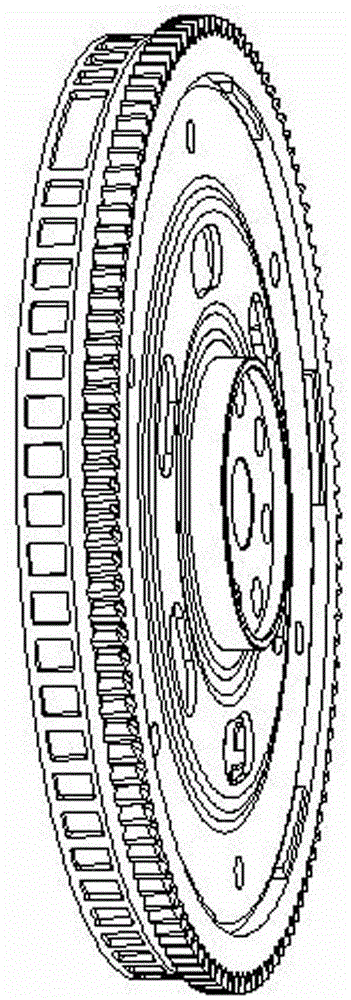

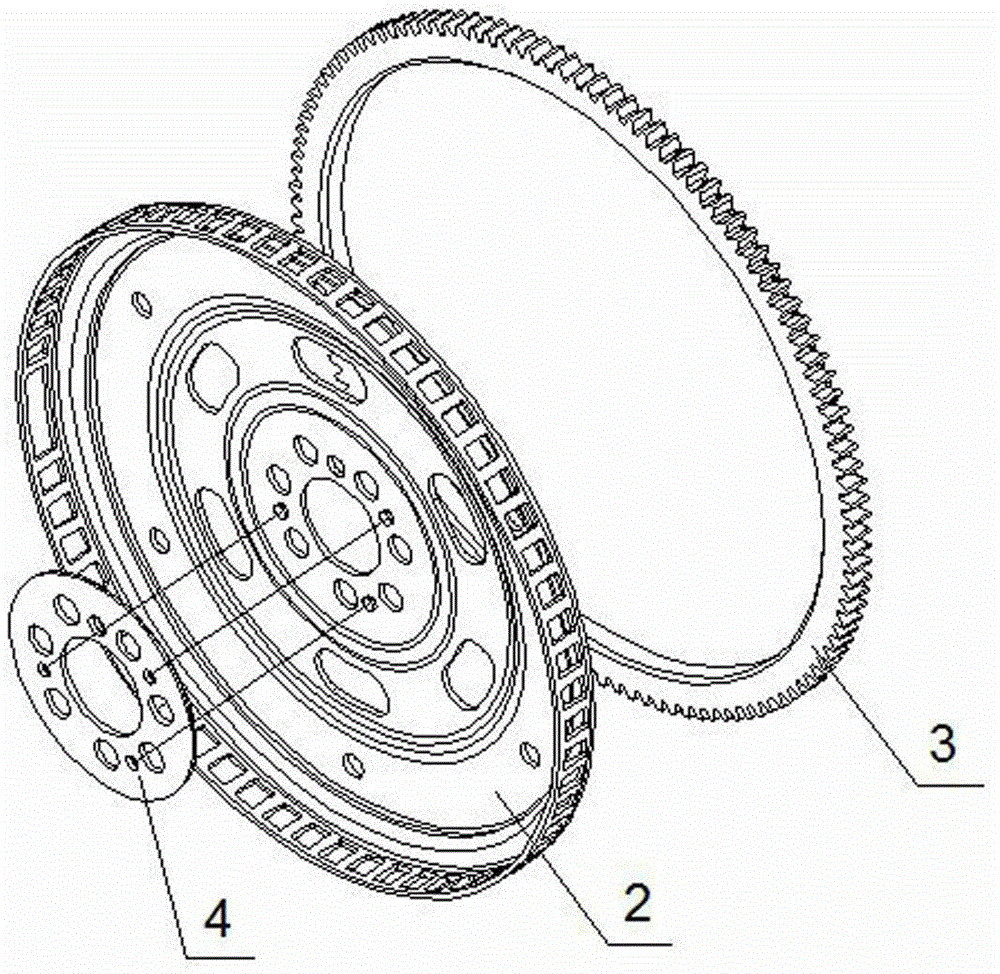

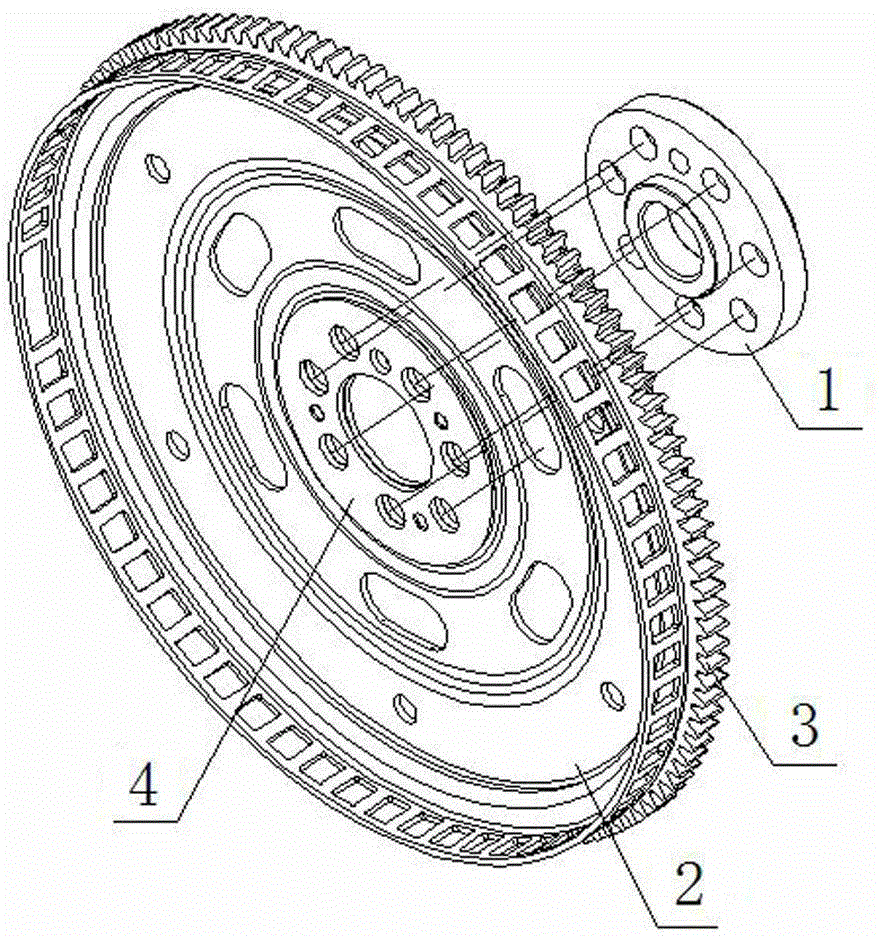

[0018] figure 1 , figure 2 and image 3 The flexible flywheel includes a connecting flange 1, a signal plate 2, a start tooth 3 and a pressure plate 4; the pressure plate 4 is fixed on the middle of one side of the signal plate 2 by riveting, and the start tooth 3 is fixed on the signal plate 2 by welding On the other side; then the signal plate 2 and the connecting flange 1 are fixed on the output end of the engine crankshaft by bolts; the signal plate 2 is arranged with a reinforcing rib in the forward and reverse directions, and the forward reinforcing rib 7 faces the pressure plate 4. Slightly protruding in the direction, and 6 long oval-shaped material removal holes 5 are evenly distributed on the upper circumference of the reverse rib 6 to optimize its rigidity; 58 signal teeth are distributed on the signal plate 2, and the width of each tooth is 5.1 mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com