Contact pin assembly of optical fiber connector

An optical fiber connector and pin technology, applied in the field of optical fiber connector pin assemblies, can solve the problems of low assembly efficiency of optical fiber connectors, and achieve the effect of solving low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

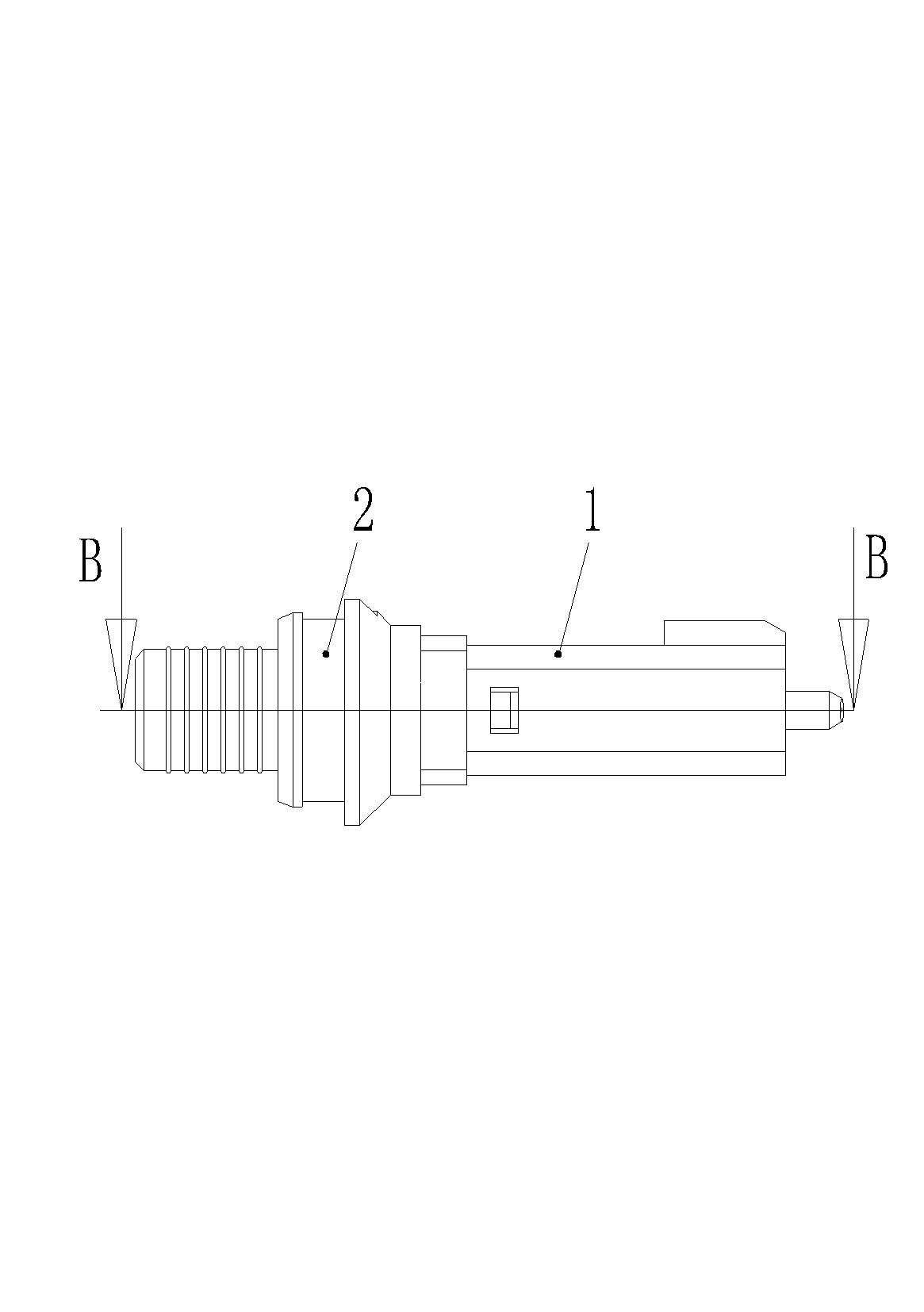

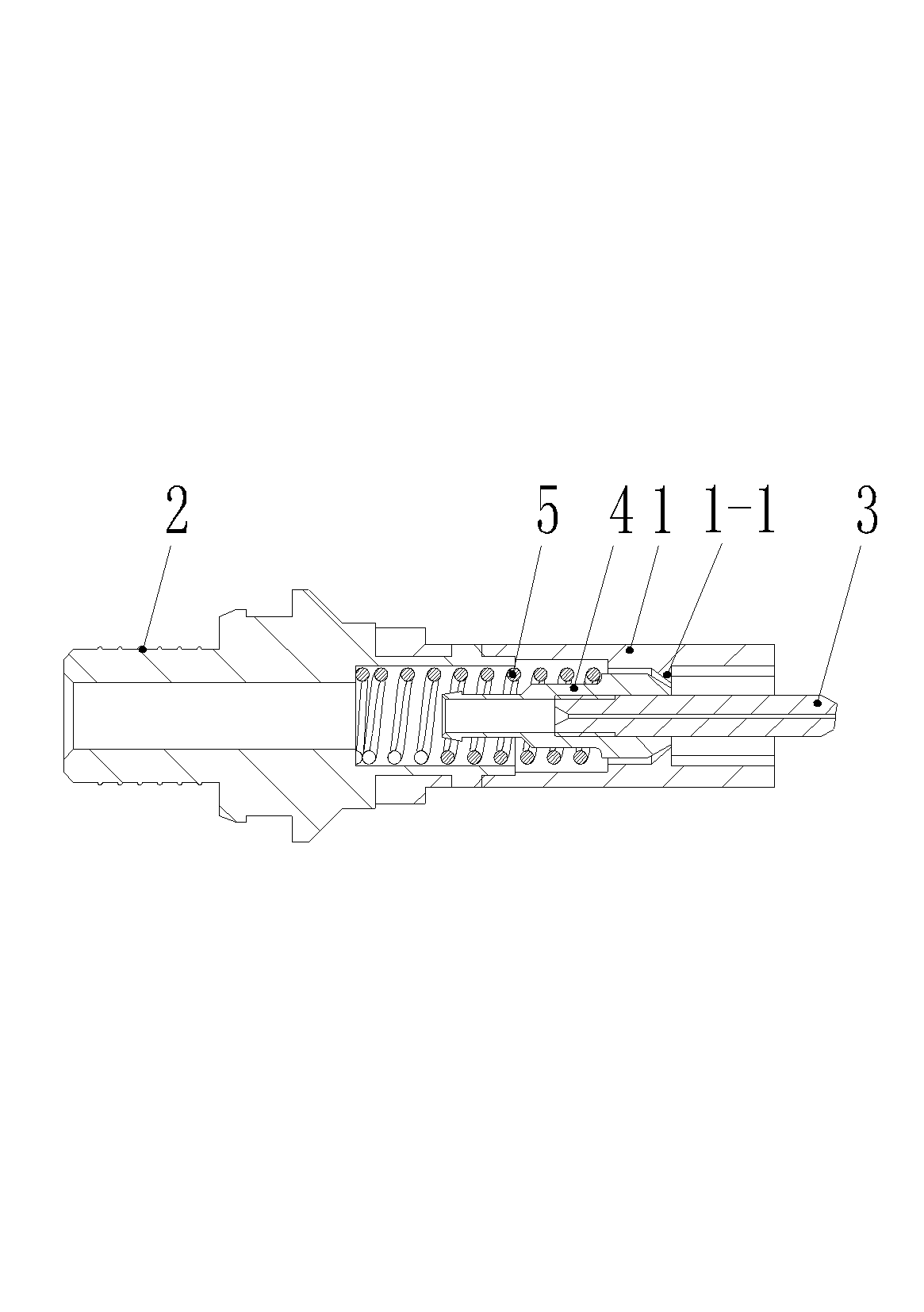

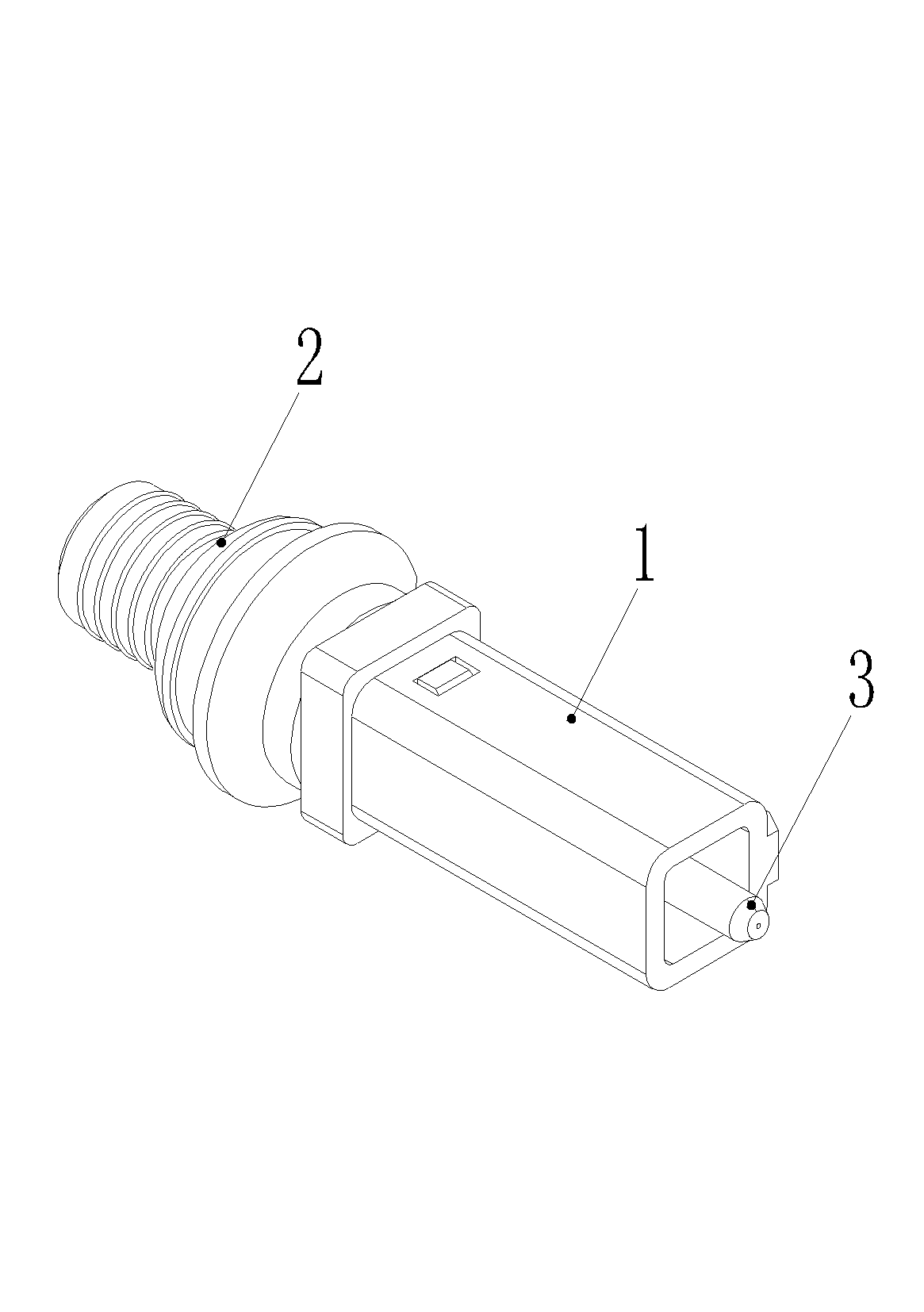

[0015] Embodiment 1 of an optical fiber connector ferrule assembly, such as Figure 1-5 As shown, there is a front housing 1 and a rear housing 2. The outer contour of the front housing 1 is rectangular and has an inner hole extending axially. A baffle plate 1-1 is arranged in the inner hole of the front housing 1. The plate 1-1 has a through hole through the front and back, and the pin 3 is installed in the through hole along the axial movable guide. The rear side of -1 is limited in position, and its rear end is provided with a buffer spring 5; the front housing 1 is provided with a front housing hanging hole 1-2 on its circumference, that is, a through hole located on the circumference of the front housing The front end of the rear housing 2 is provided with elastic wedges 2-1 which can be elastically deformed in the radial direction. After the front end of the rear housing 2 is inserted into the rear end of the front housing 1, each elastic wedge is embedded In the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com