Wiring connector

A technology of connectors and cables, which is applied in the direction of connection, clamping/spring connection, parts of connection devices, etc., can solve the problem of low assembly efficiency of wiring connectors, achieve the effect of convenient installation and improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

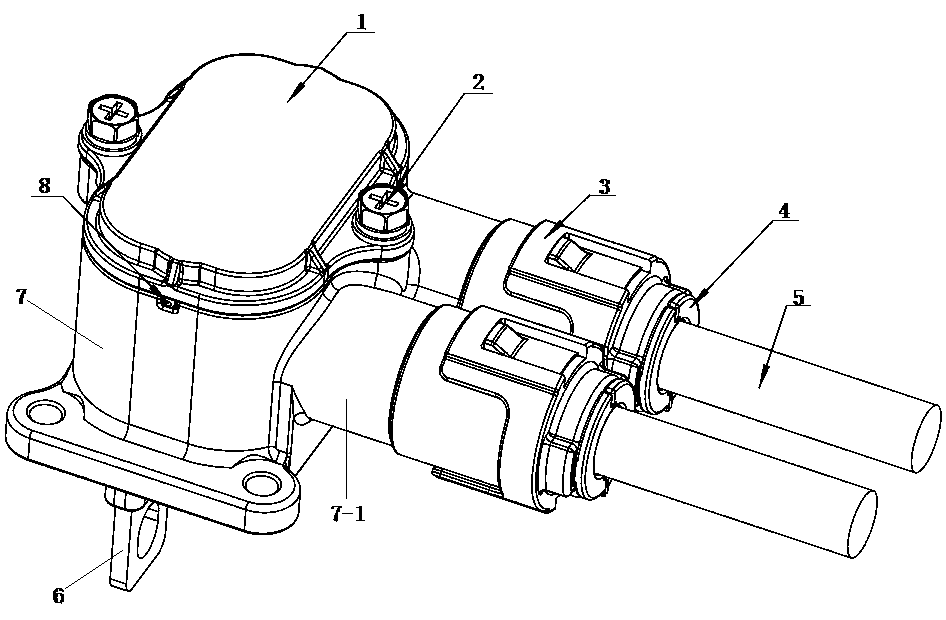

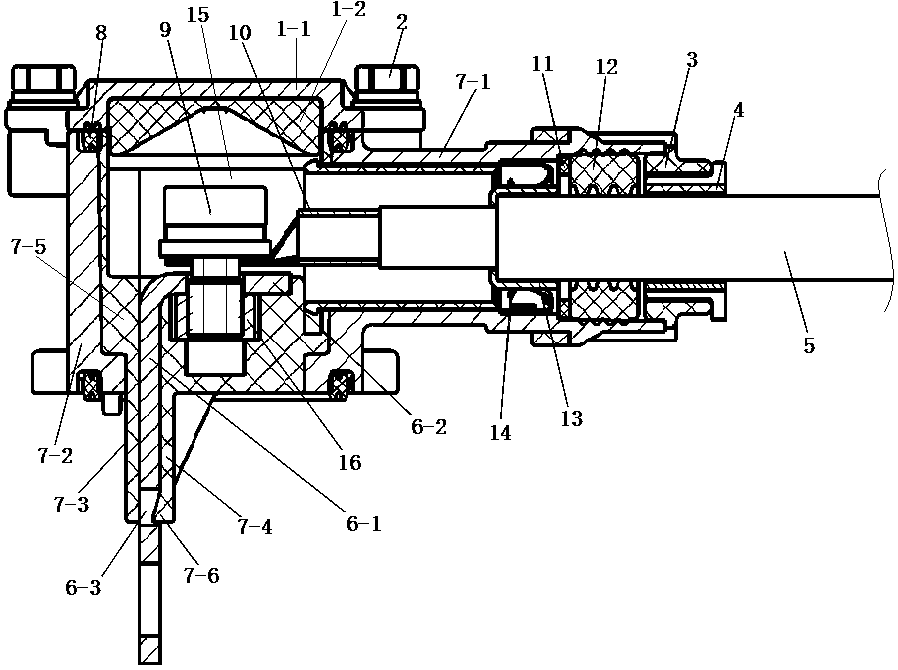

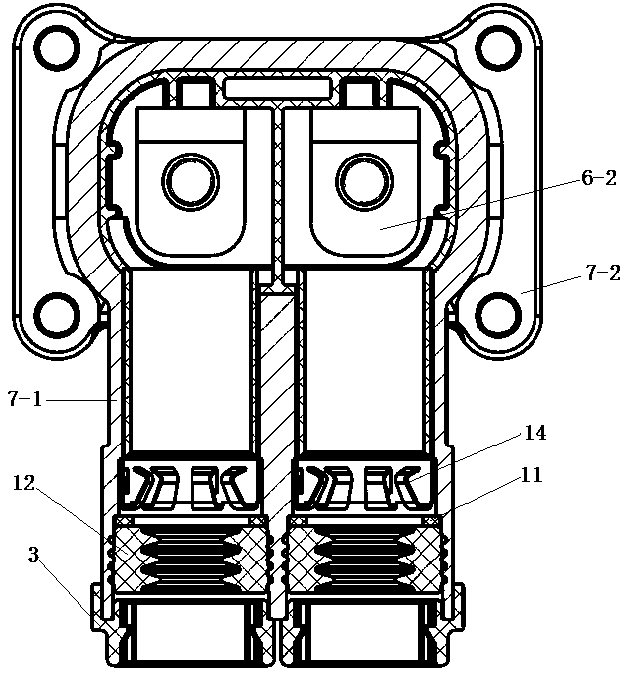

[0022] An example of the wiring connector in the present invention is Figure 1~Figure 8 As shown, it includes a base 7 and an upper cover 1 that is buckled and connected with the base 7. The base 7 and the upper cover 1 together form a wiring cavity 15. The upper cover 1 includes an upper cover housing 1-1 and an upper cover housing 1. The upper cover insulator 1-2 in -1, the base 7 includes a base shell 7-2 and a base insulator 7-5 arranged in the base shell 7-2, wherein the base shell 7-2 includes an integrally formed front and rear The cylinder section 7-1 extending in the direction, the cylinder section 7-1 communicates with the wiring cavity 15, the inner hole of the cylinder section 7-1 constitutes a threading hole for the cable 5 to pass through, so that the cable 5 end The connection terminal 10 protrudes into the connection cavity 15 from the back to the front.

[0023] In order to facilitate the wiring and improve the assembly efficiency of the wiring connector, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com