Mechanism for automatically pasting magnetic shoe of servo motor

A servo motor and magnetic tile technology, applied in the field of servo motor magnetic tile automatic pasting mechanism, can solve problems such as low efficiency, achieve the effect of easy rotor loading and unloading, and solve the effect of low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

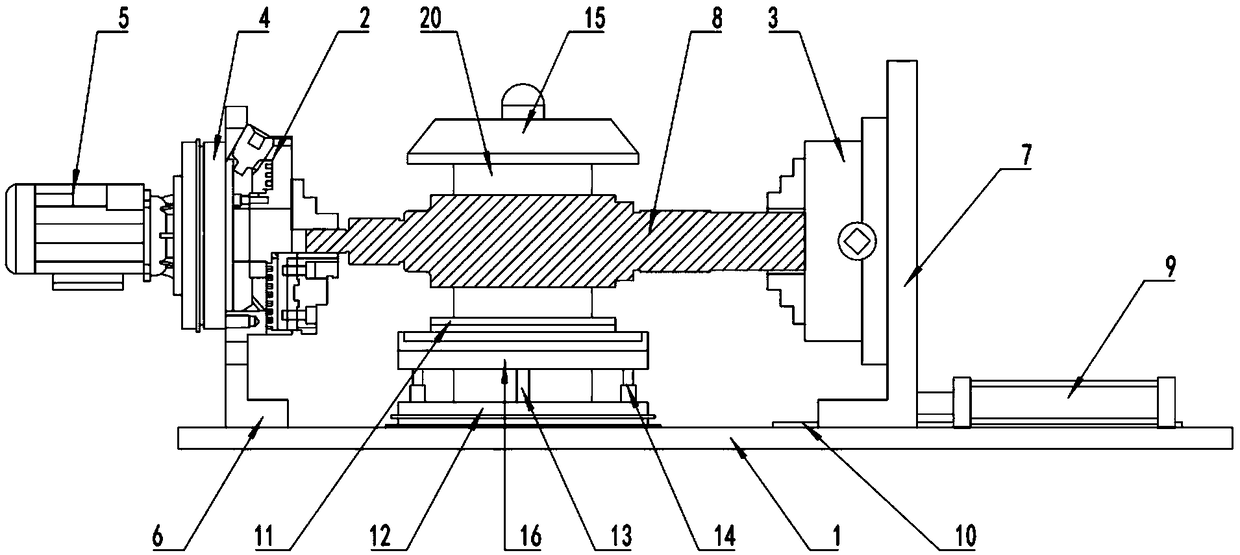

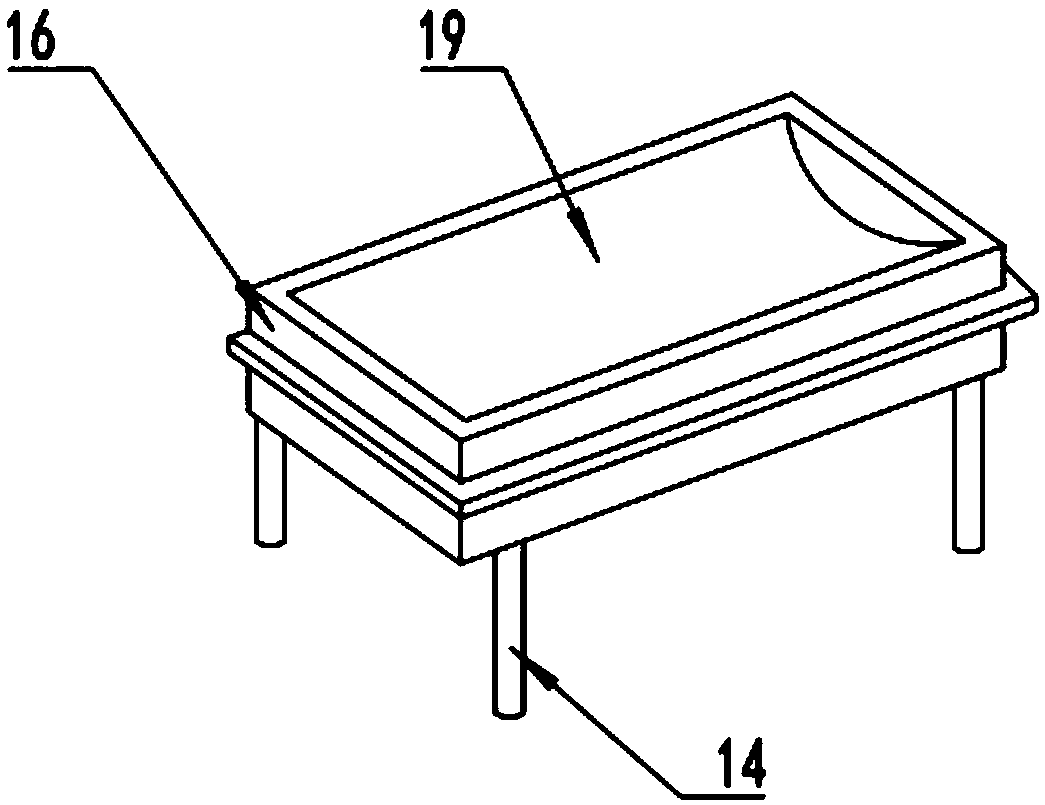

[0020] see Figure 1~2 , in an embodiment of the present invention, a servo motor magnetic tile automatic pasting mechanism includes a processing table 1, a main three-jaw chuck 2, an auxiliary three-jaw chuck 3, a lifting cylinder 13 and a magnetic tile mold 16, and the main three-jaw chuck The chuck 2 and the auxiliary three-jaw chuck 3 are installed on the processing table 1 through the main three-jaw chuck mounting frame 6 and the auxiliary three-jaw chuck mounting frame 7 respectively, and in this embodiment, the main three-jaw chuck 2 can be Rotate independently relative to the main three-jaw chuck mounting frame 6, the main three-jaw chuck 2 is driven to rotate by the drive motor 5 through the reduction box 4, in this embodiment, the drive motor 5 is a stepping motor, and the main three-jaw chuck 2 There is a rotor 8 between the auxiliary three-jaw chuck 3, the main three-jaw chuck 2 and the auxiliary three-jaw chuck 3 are used to position the shaft end of the rotor 8, ...

Embodiment 2

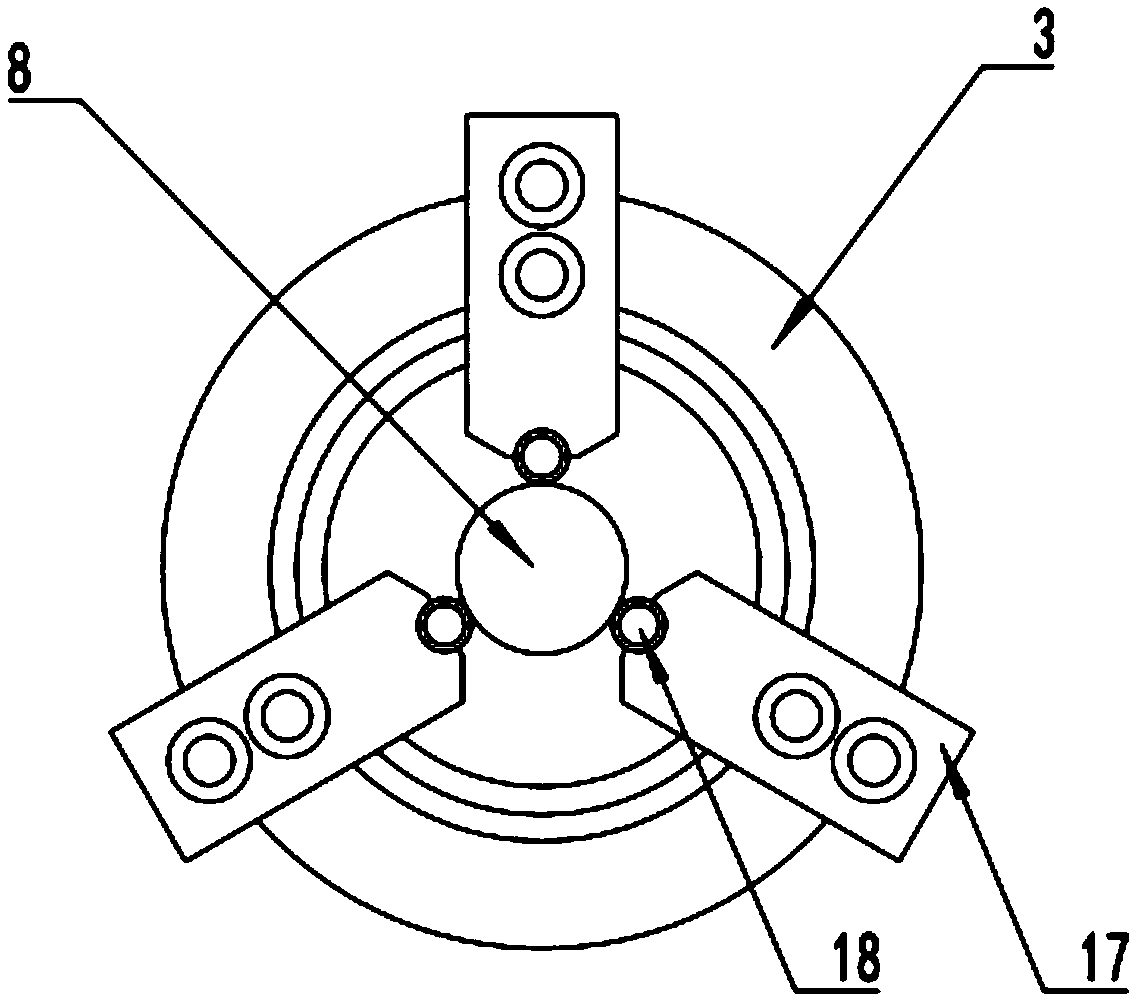

[0022] see image 3 , in the embodiment of the present invention, a servo motor magnetic tile automatic pasting mechanism also includes a rolling body 18, the rolling body 18 is installed on the claw 17 of the auxiliary three-jaw chuck 3, and the surface of the rolling body 18 is in contact with the rotor The surface of the shaft end of 8 is in contact. After the rolling body 18 is added, firstly, the rolling body 18 has no effect on the normal clamping of the rotor 8. In addition, when the next magnetic tile 11 is pasted after the pasting of one magnetic tile 11 is completed, At this time, the rotor 8 needs to be flipped at a certain angle, so at this time, the rolling elements 18 will not affect the rotation of the rotor 8, and re-clamping is not required. Preferably, the rolling elements 18 are cylindrical rollers or spherical rollers.

Embodiment 3

[0024] In order to facilitate the rapid curing of the glue and realize the rapid fixation of the rotor 8 and the magnetic tile 11, please refer to figure 1 , in the embodiment of the present invention, a servo motor magnetic tile automatic pasting mechanism also includes an oven 15, the oven 15 is located directly above the rotor 8, the oven 15 is installed on the processing table 1 through the fixing frame 20, the opening of the oven 15 It is opposite to the rotor 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com