Automatic assembling equipment for fast ship steering wheel

A technology of automatic assembly and steering wheel, which is applied in the field of ships to achieve the effect of improving efficiency and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

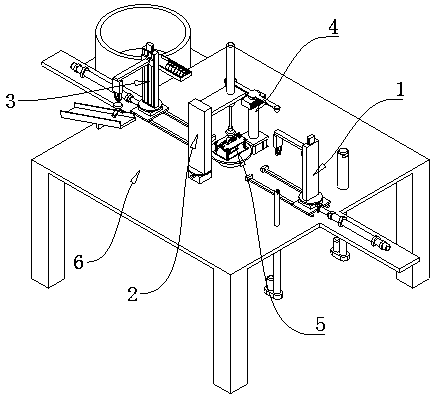

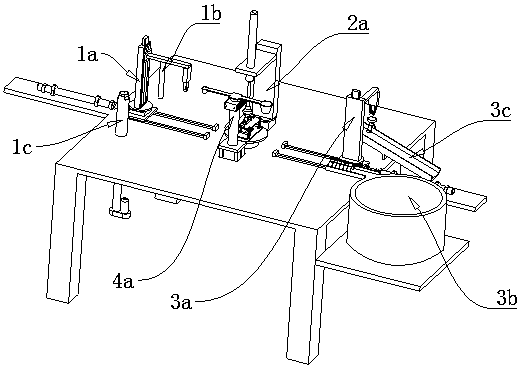

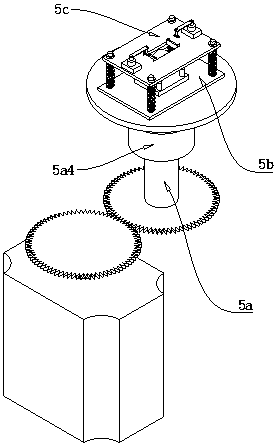

[0031] refer to Figure 1 to Figure 11 The shown automatic assembly equipment for the fast wheel of the ship steering wheel includes a base 6, and also includes a bearing and power ball loading station 1, an installation station 2, a clamp loading and workpiece unloading station 3, and a positioning station Position 4 and positioning jig 5, the positioning jig 5 is installed in the middle of the base 6, bearing and booster ball feeding station 1, installation station 2, hoop loading and workpiece unloading station 3, positioning station Position 4 is successively installed on the base 6 along the circumferential direction of the positioning jig 5, and the bearing and booster ball loading station 1 includes a first mechanical arm 1a for bearing and booster ball loading, a bearing feeder 1b and The booster ball loade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com