Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Small retardation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic Resin Films and Process for Producing the Same

InactiveUS20070243364A1Increase resistanceHigh transparencySynthetic resin layered productsOptical elementsGlutaric anhydrideFolding endurance

An acrylic resin film, in which acrylic elastic particles are mixed with an acrylic resin containing glutaric anhydride units, has a total light transmittance of 91% or more, a haze value of 1.5% or less, a folding endurance value (times) of 20 or more, and a heat shrinkage rate of less than 5% at least in either the machine direction or the transverse direction in a heat shrinkage test.

Owner:TORAY IND INC

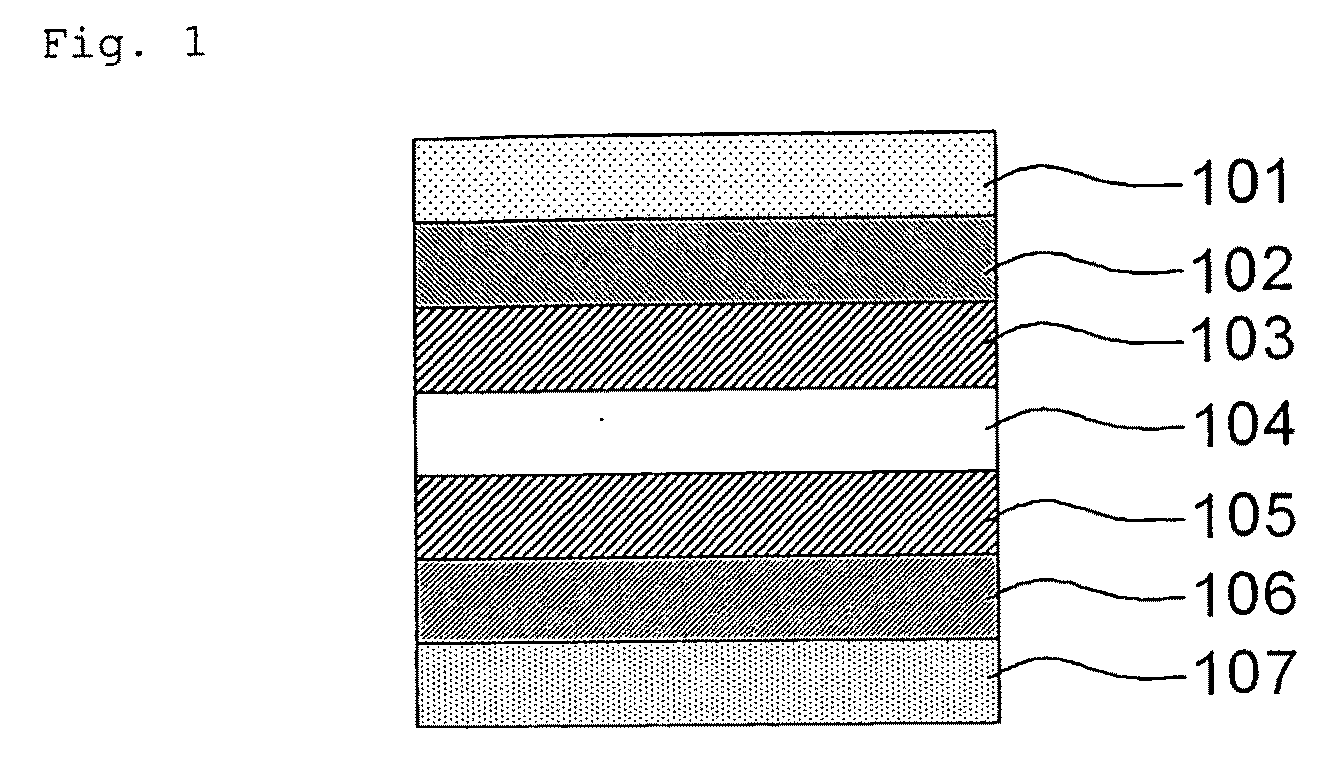

Transparent film

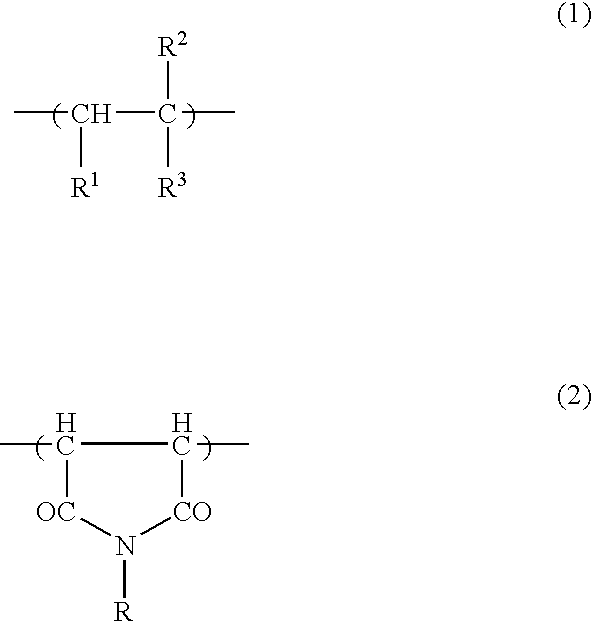

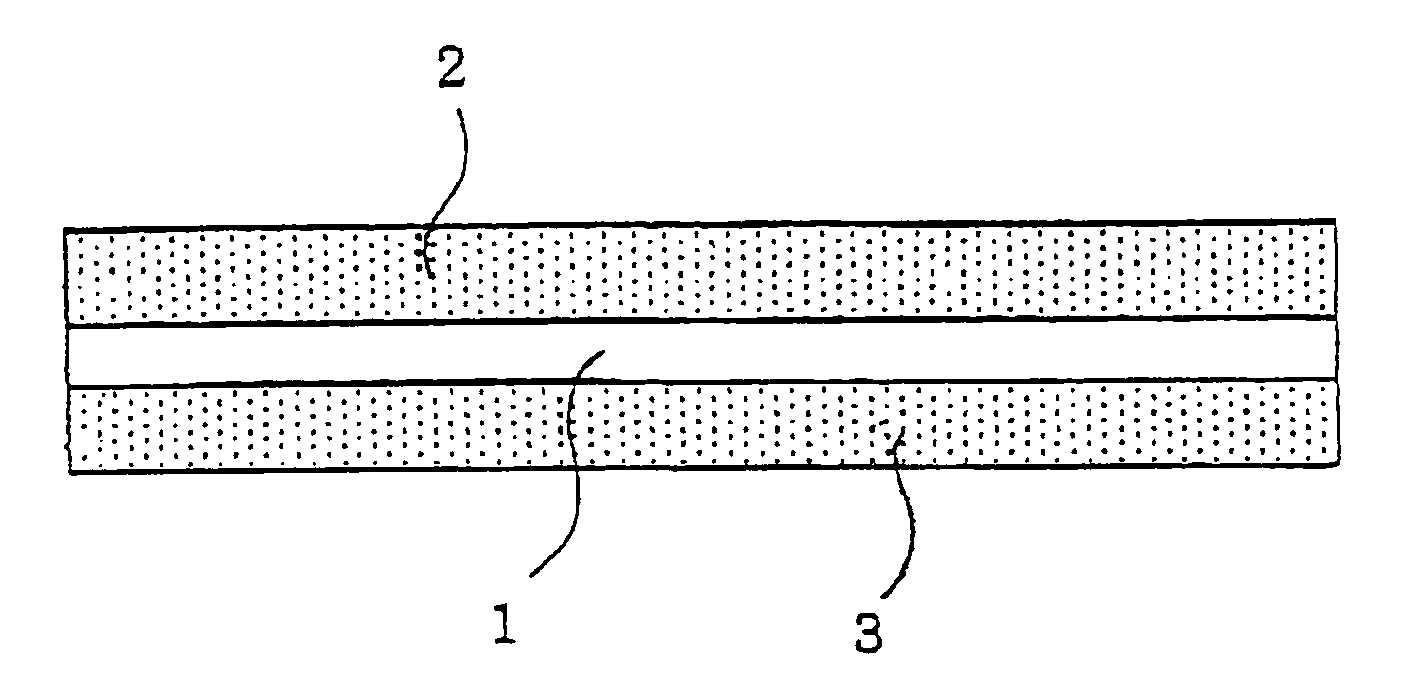

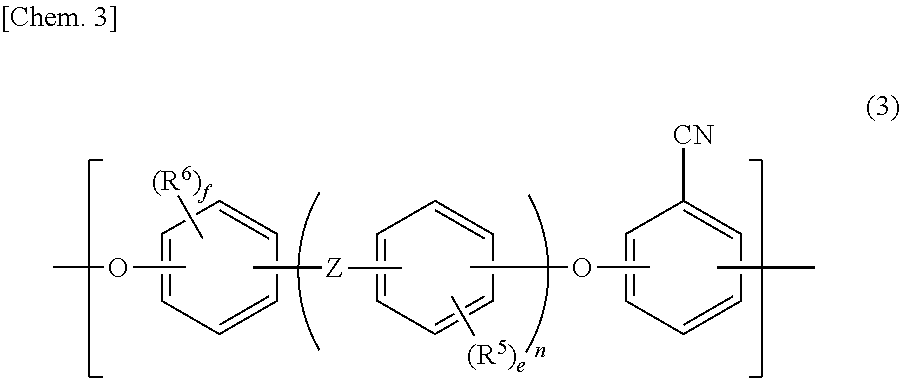

InactiveUS20050096431A1Small retardationMeasurement wavelength dependence can be easily controlledSynthetic resin layered productsPolarising elementsImideSide chain

A film is provided which comprises a thermoplastic resin A having a substituted or non-substituted imide group at a side chain of the resin A, and a thermoplastic resin B having a substituted or non-substituted phenyl group and a nitrile group at a side chain of the resin B. The film has a retardation value of 0 to 1000 nm, a light transmission of 85% or more, and a haze of 2% or less.

Owner:KANEKA CORP

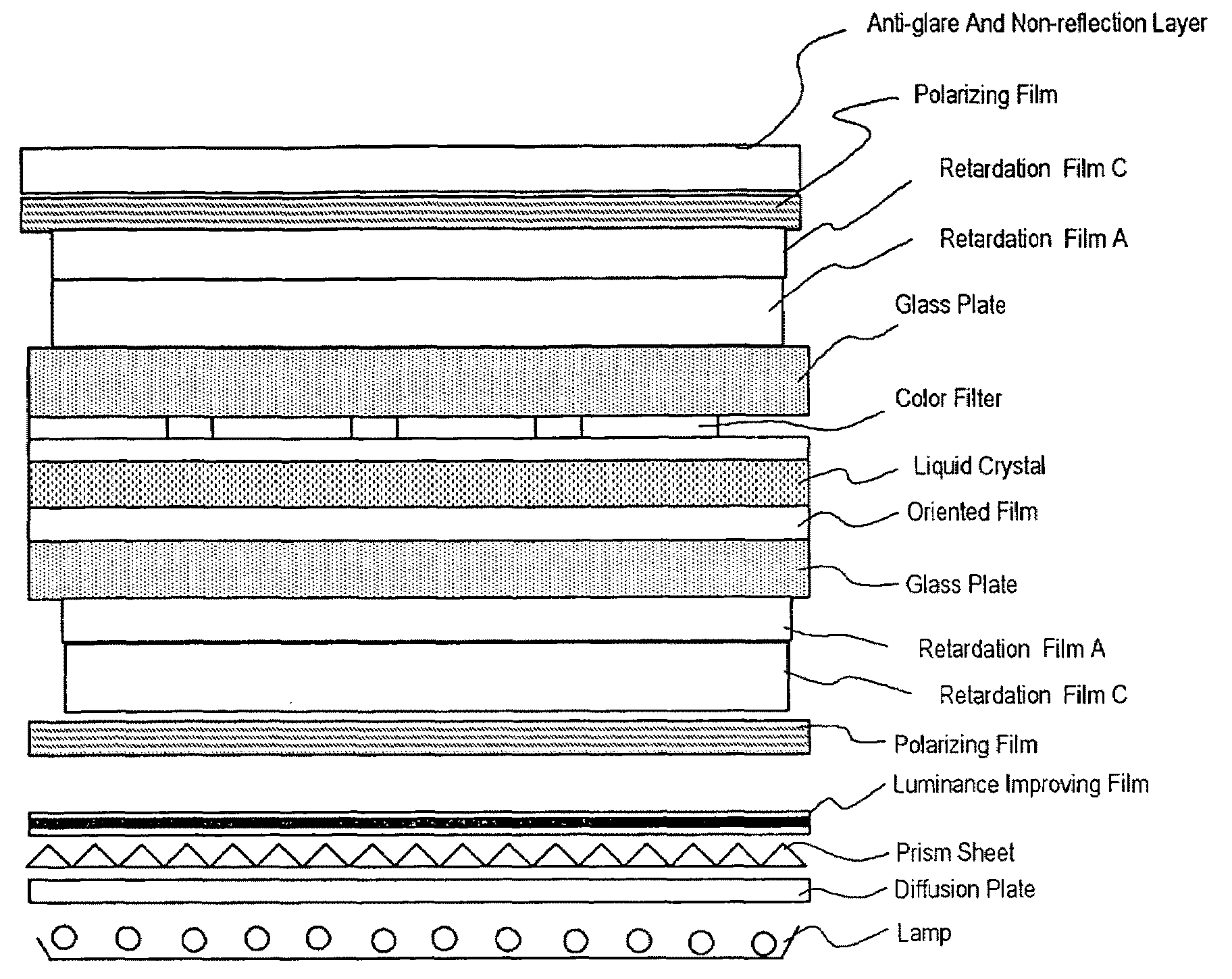

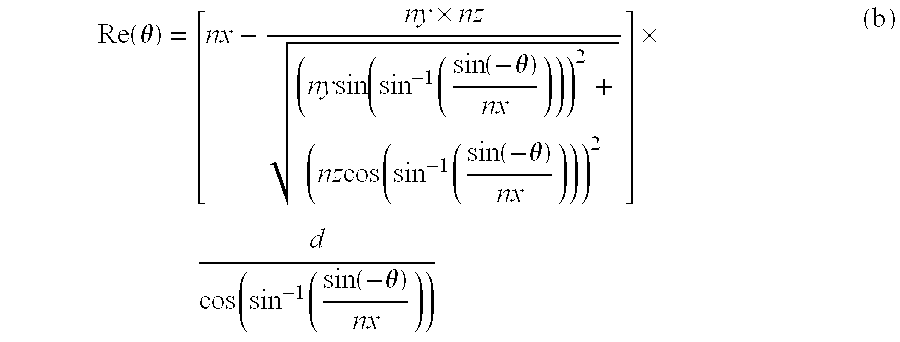

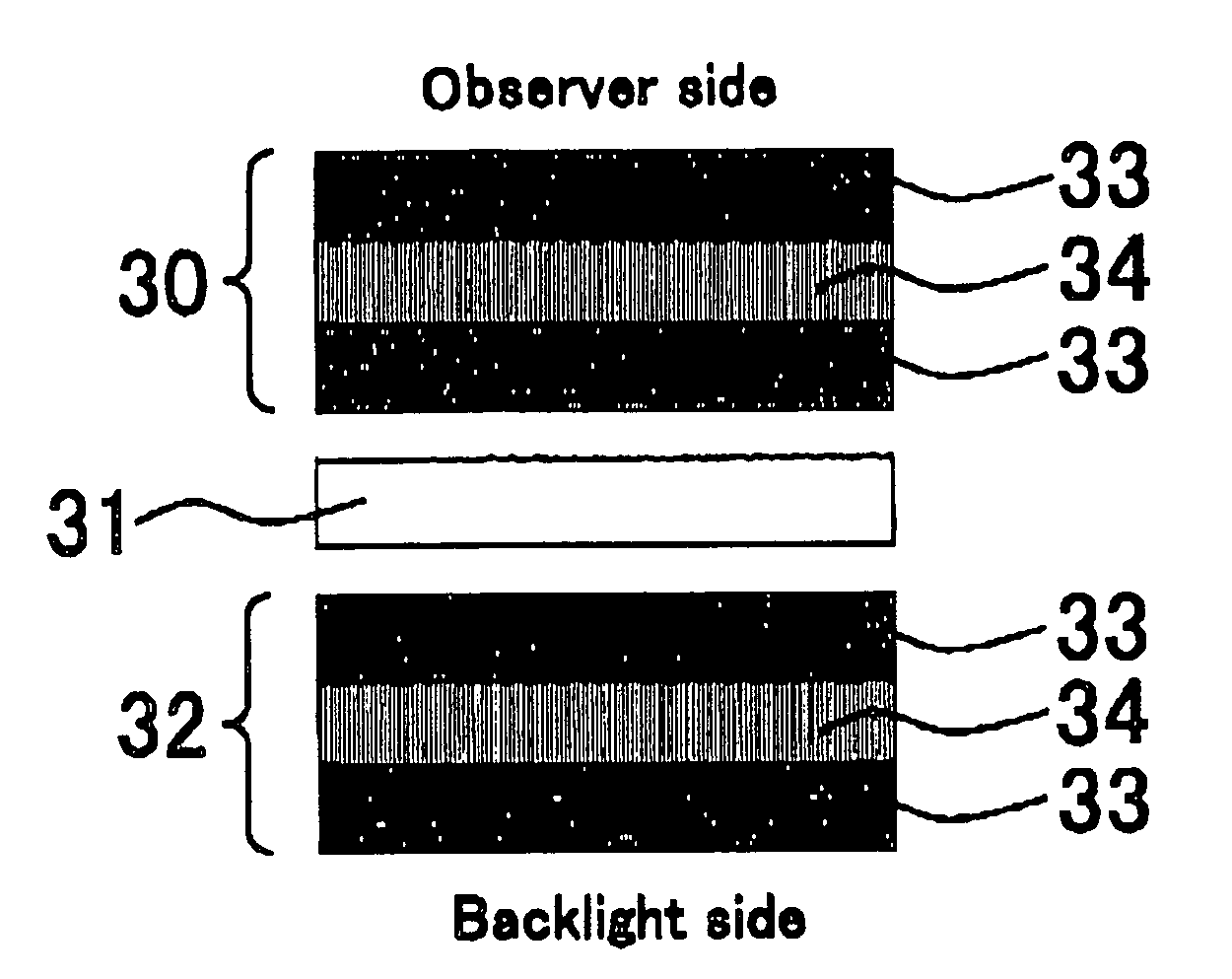

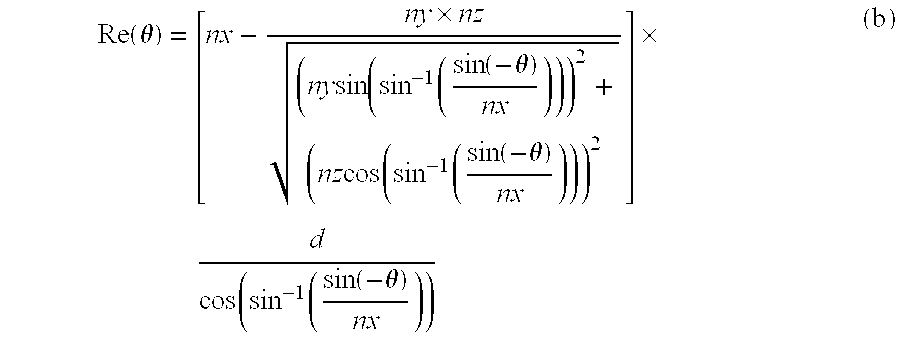

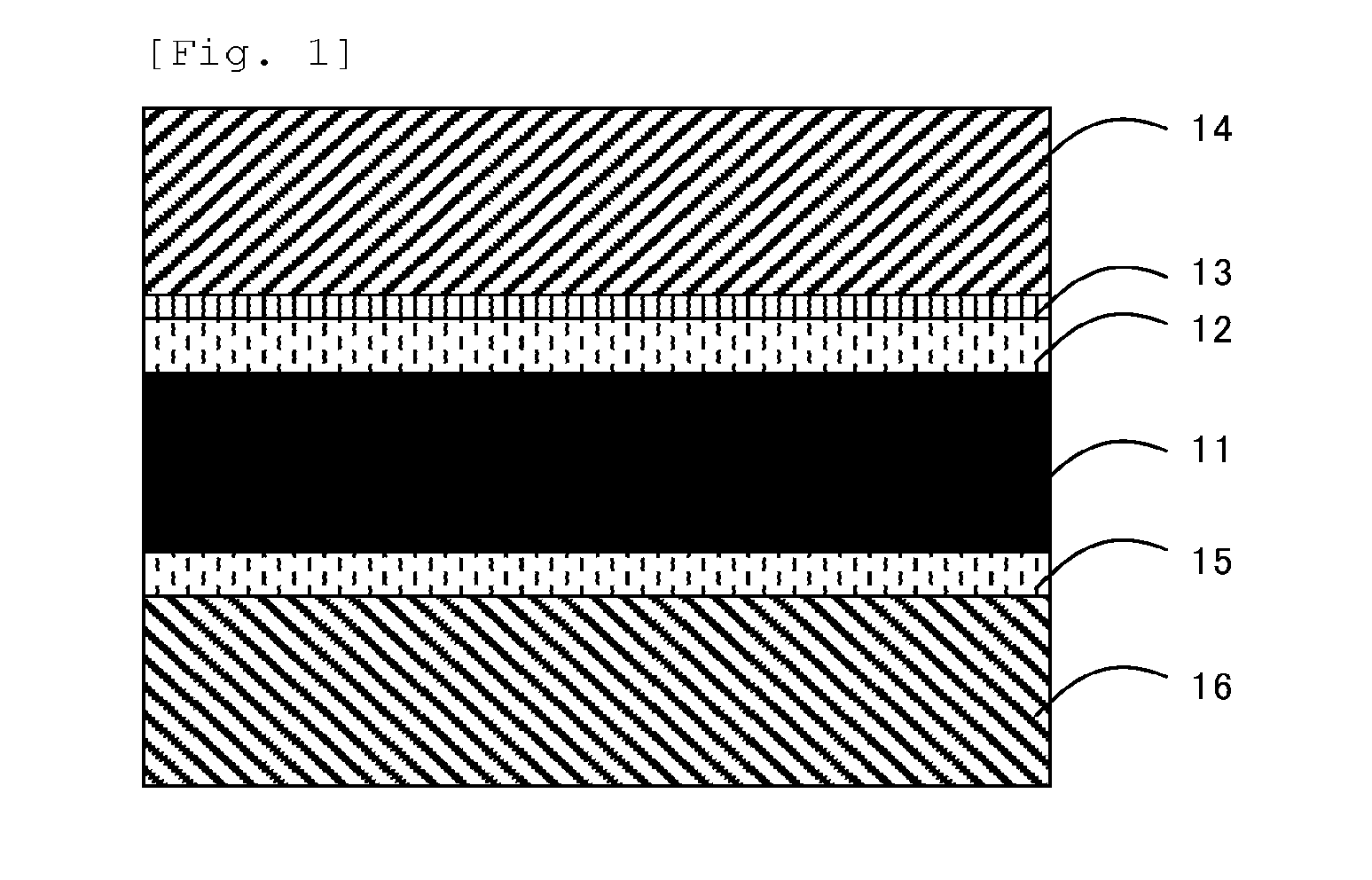

Liquid crystal display element, and use of phase difference film used the same for

InactiveUS20040239852A1Reduce light leakageSmall retardationNon-linear opticsLiquid-crystal displayPhase difference

The present invention provides a liquid crystal display device of VA mode having decreased leakage of light over a wide range and giving a clear and almost achromatic black display by using a retardation film A having smaller retardation with shorter wavelength in combination with a retardation film C having larger retardation with shorter wavelength. Accordingly, a high-quality liquid crystal display device having excellent picture quality can be produced by the present invention.

Owner:TEIJIN LTD

Transparent film

InactiveUS6964814B2Small retardationMeasurement wavelength dependence can be easily controlledSynthetic resin layered productsPolarising elementsImidePolymer science

A film is provided which comprises a thermoplastic resin A having a substituted or non-substituted imide group at a side chain of the resin A, and a thermoplastic resin B having a substituted or non-substituted phenyl group and a nitrile group at a side chain of the resin B. The film has a retardation value of 0 to 1000 nm, a light transmission of 85% or more, and a haze of 2% or less.

Owner:KANEKA CORP

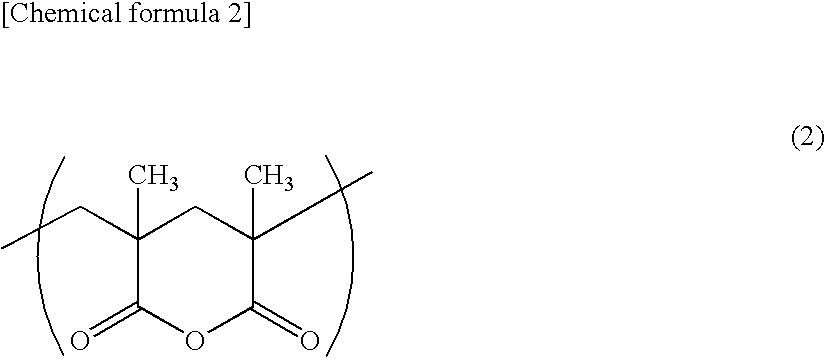

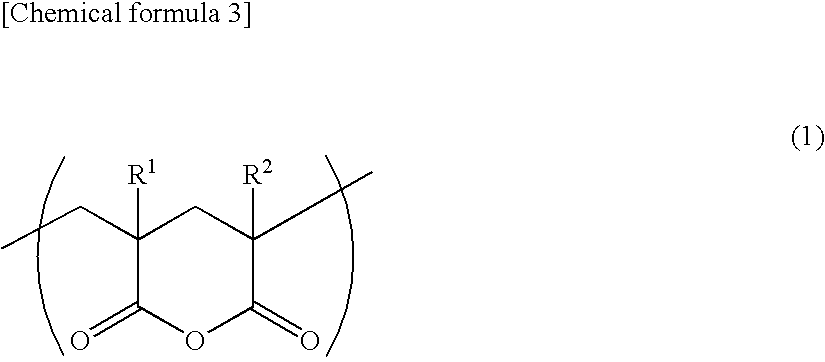

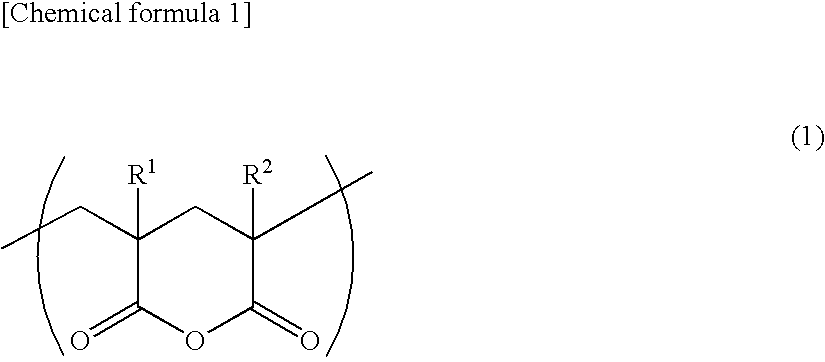

Optical Planar Thermoplastic Resin Composition

ActiveUS20090137743A1High transparencyExhibit characteristicSynthetic resin layered productsGlass/slag layered productsThermoplasticPolymer science

Disclosed is an optical planar thermoplastic resin composition including a lactone ring-containing polymer as a main component thereof, or including a lactone ring-containing polymer and at least one other thermoplastic resin. The optical planar thermoplastic resin composition of the present invention has high transparency, high heat resistance, and high optical isotropy, and therefore, can sufficiently exhibit characteristics according to various optical applications.

Owner:NIPPON SHOKUBAI CO LTD

Method of Compensating Wavelength Dependence of Birefringence of Optical Part, Optical Part, and Display Obtained with these

InactiveUS20090161045A1Small retardationImprove balanceLiquid crystal compositionsPolarising elementsPenteneDisplay device

The present invention is to provide a method of compensating the wavelength dependence of birefringence of an optical part (B) which comprises using a film (a) made of a (co)polymer (α) obtained from at least one olefin selected among 4-methyl-1-pentene, 3-methyl-1-pentene, and 3-methyl-1-butene as a (co)monomer ingredient.

Owner:MITSUI CHEM INC +1

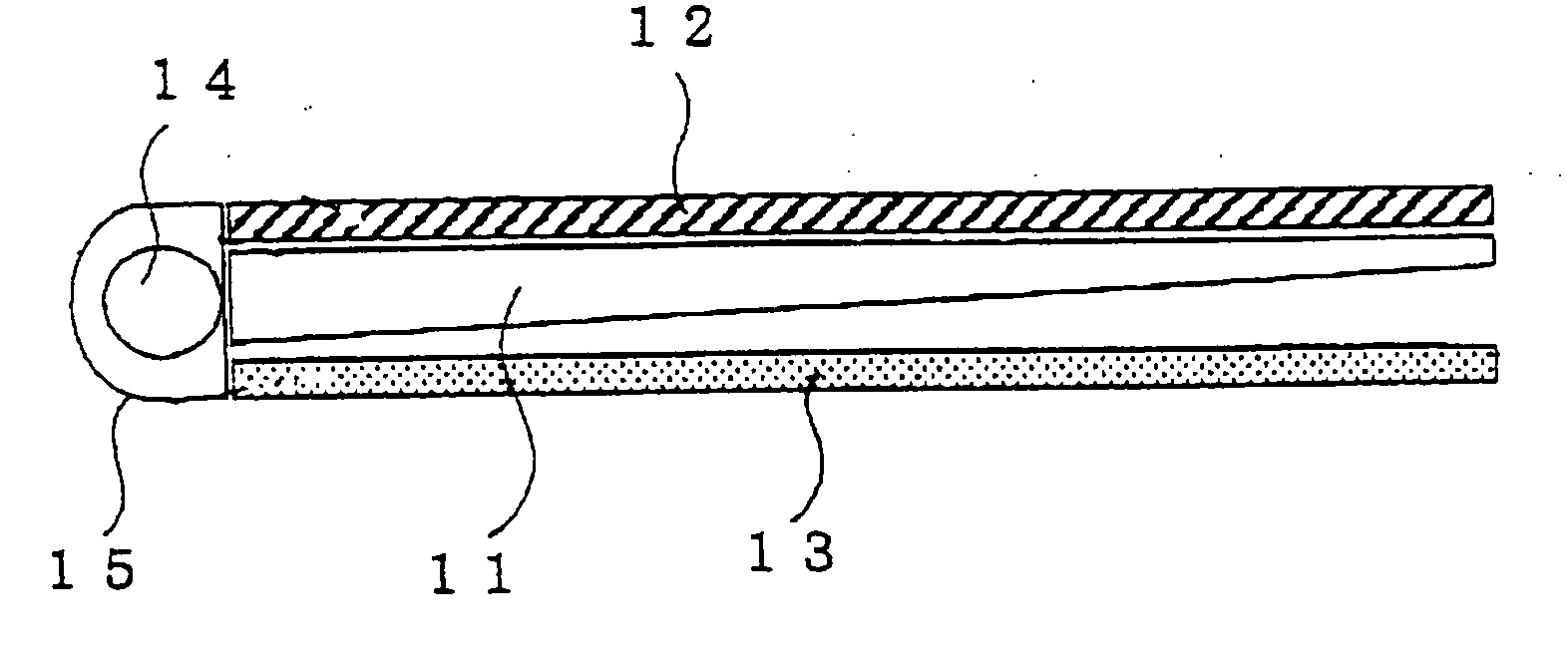

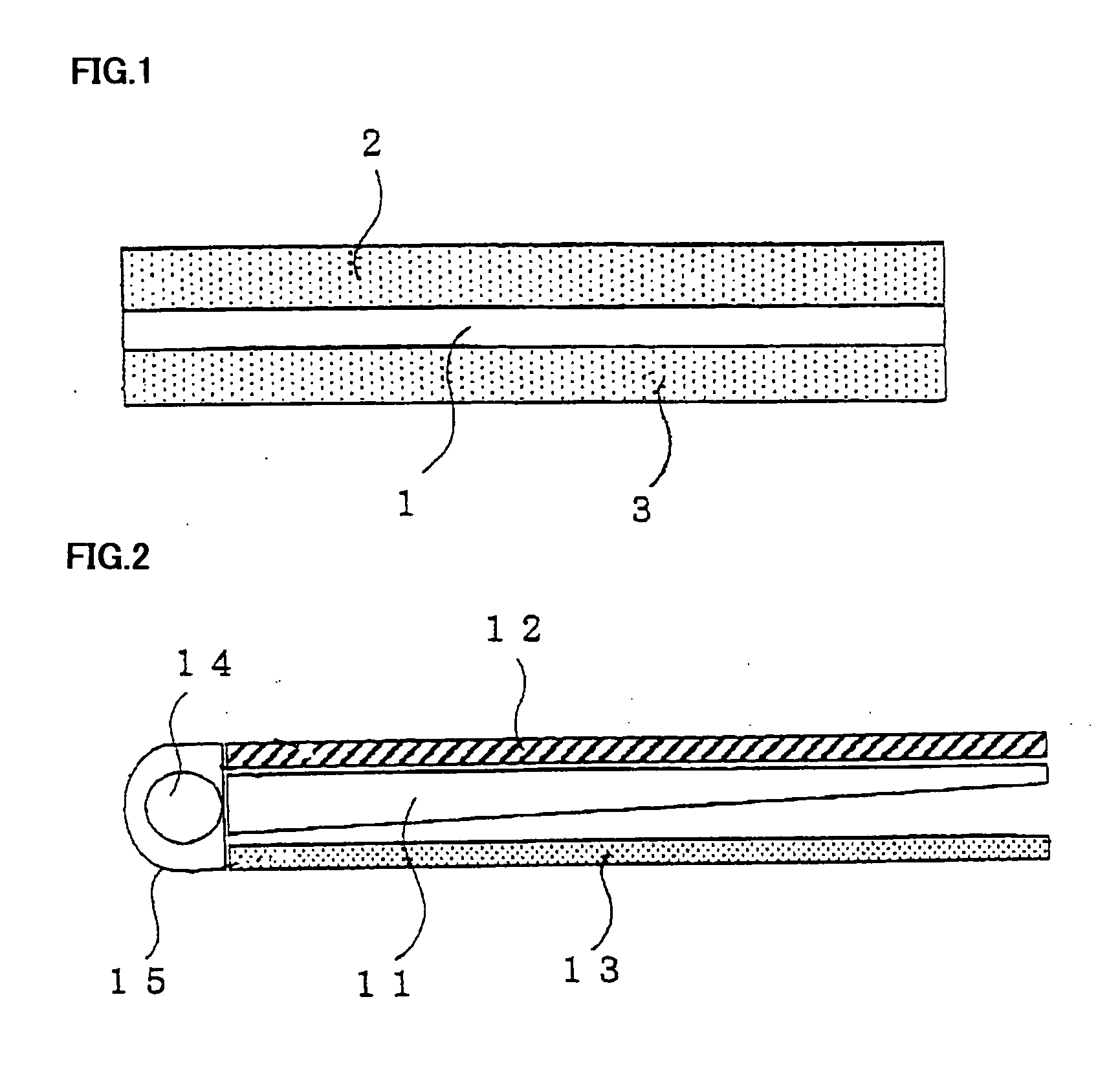

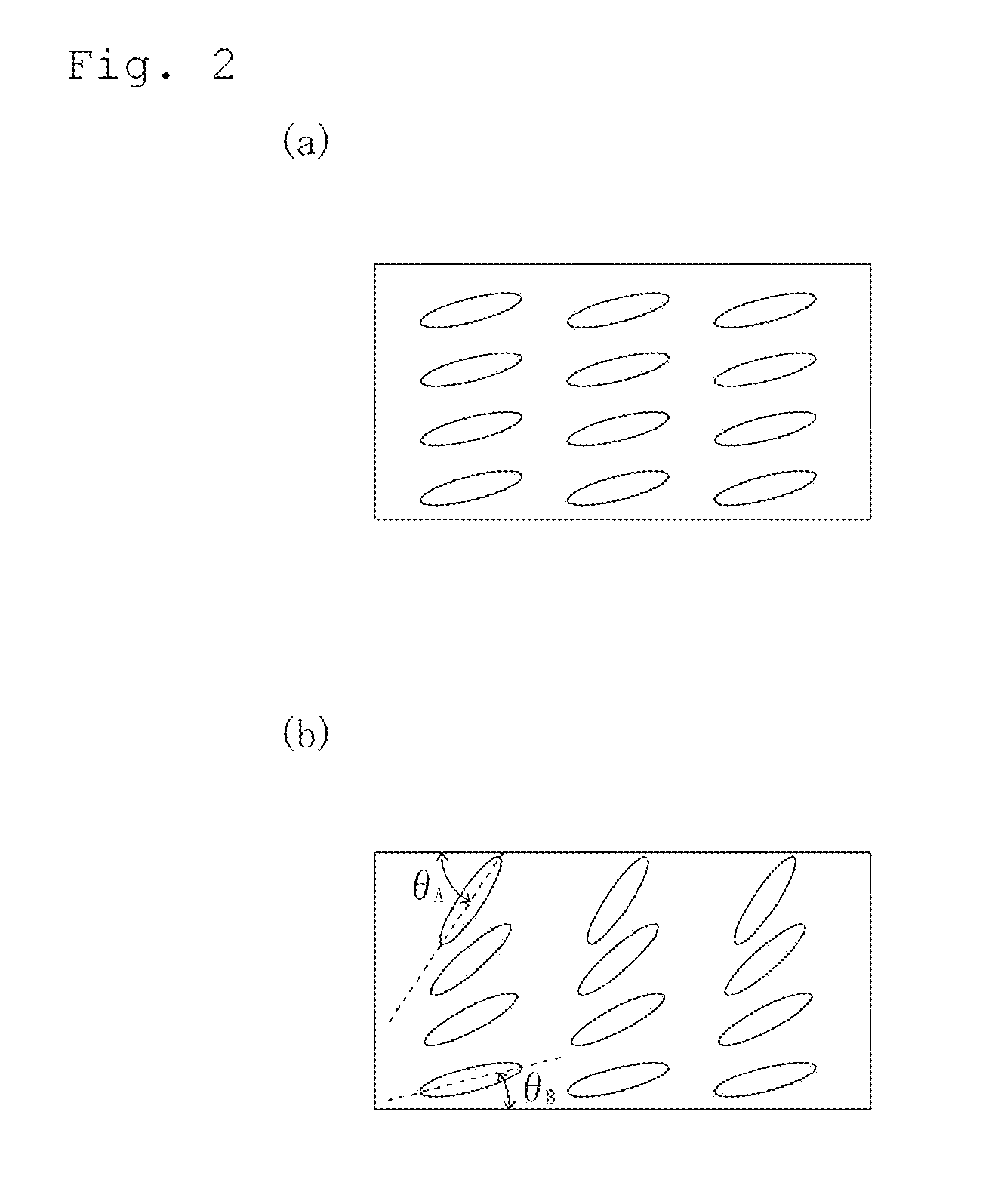

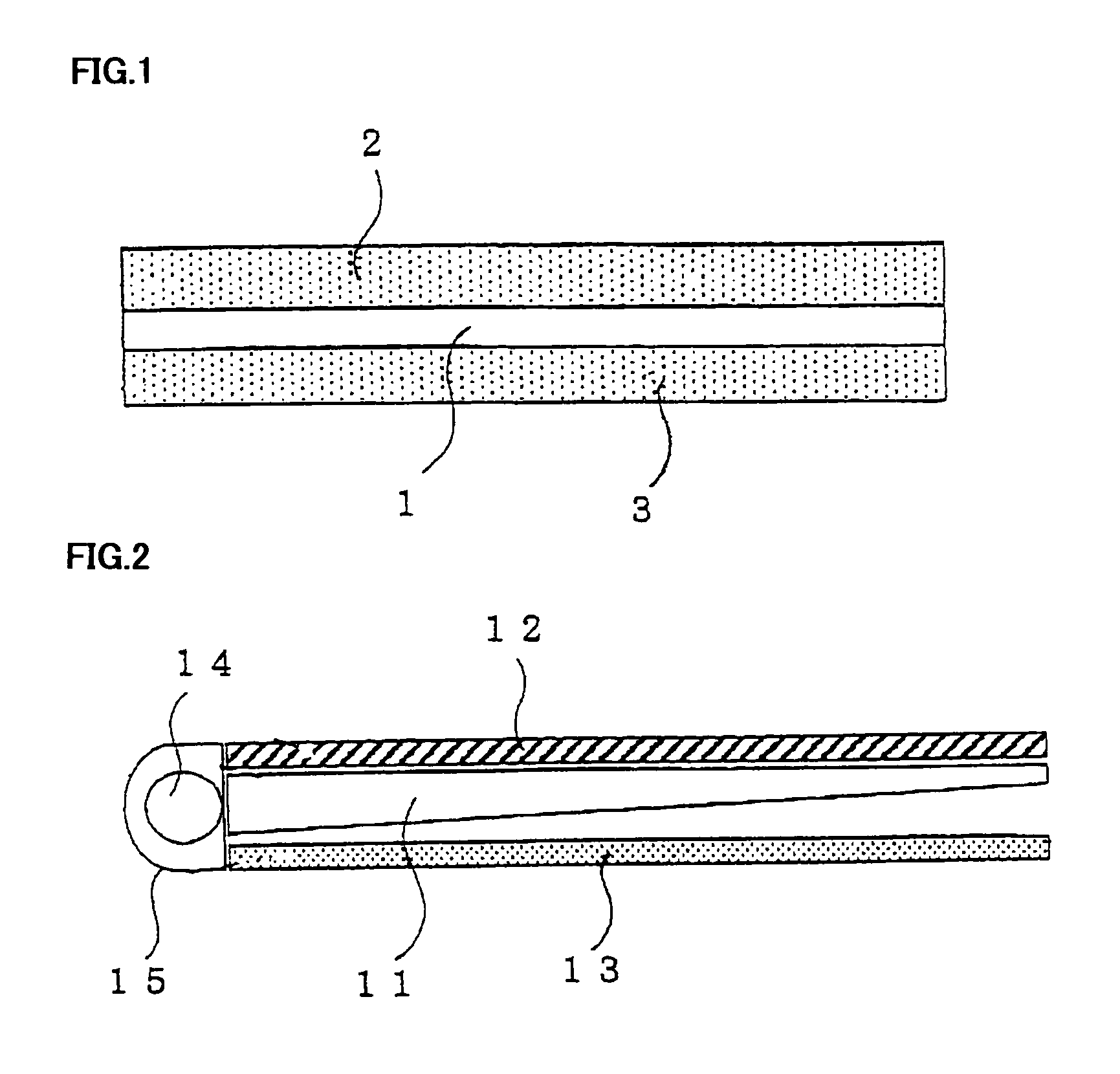

Laminate optical body, optical film, liquid crystal display apparatus using said optical film, and method for producing laminate optical body

InactiveUS20120003400A1Improve production efficiencySmall retardationLiquid crystal compositionsAdhesive processesHydrophilic polymersLiquid-crystal display

The present invention provides a laminate optical body, which is excellent in production efficiency, shows an extremely small axis shift and can realize a liquid crystal display apparatus showing small display unevenness. The laminate optical body of the present invention includes an elongated polarizing film having an absorption axis in a short direction thereof, and including a base material layer and a hydrophilic polymer layer to which a dichromatic substance adsorbs; and an elongated retardation film having a slow axis in a lengthwise direction thereof. The polarizing film is a laminate including the base material layer and the hydrophilic polymer layer to which a dichromatic substance adsorbs. The laminate optical body is elongated. Preferably, the hydrophilic polymer layer has a thickness of 1 μm to 10 μm.

Owner:NITTO DENKO CORP

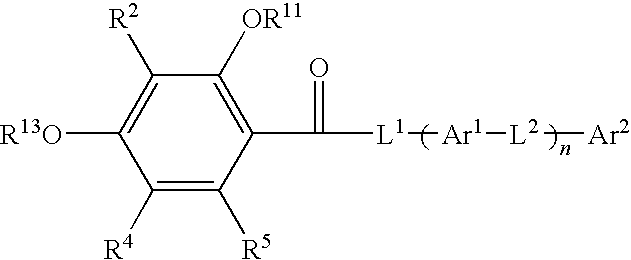

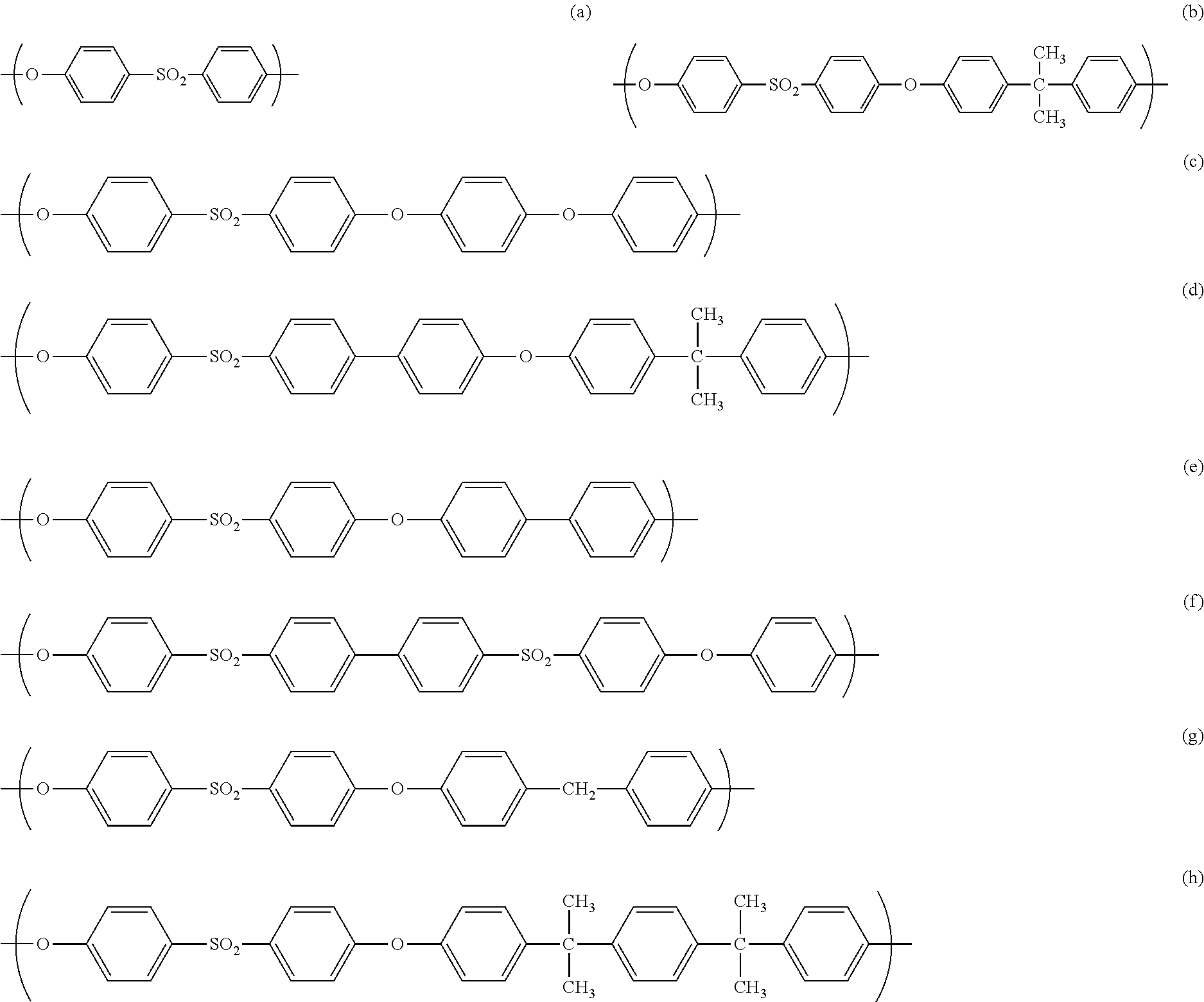

Optical film and information technology apparatus comprising the same

ActiveUS20090197020A1Improve heat resistanceHigh mechanical strengthLiquid crystal compositionsDiffusing elementsIn planeAromatic moiety

The present invention relates to an optical film that comprises an aromatic based resin comprising a chain having the hydroxy group containing portion and aromatic moiety and a polarizing plate and an information electronic device that include the same. The in-plane retardation Rin is in the range of 0 to 600 nm and the thickness retardation Rth is in the range of 0 to 400 nm.

Owner:LG CHEM LTD

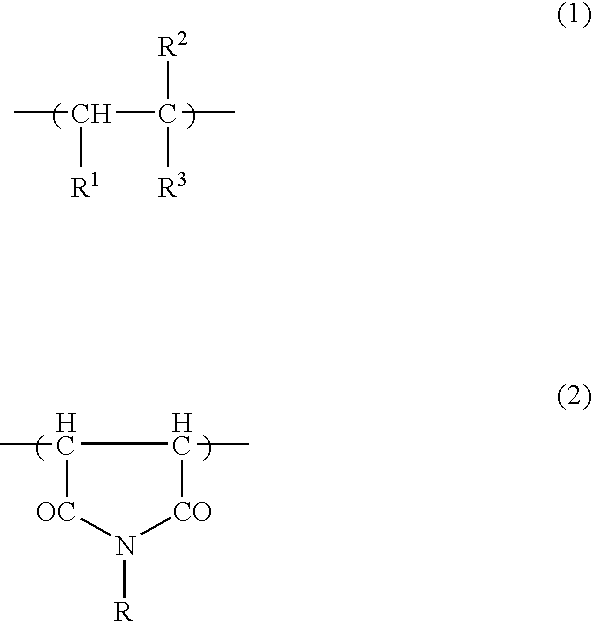

Optical film

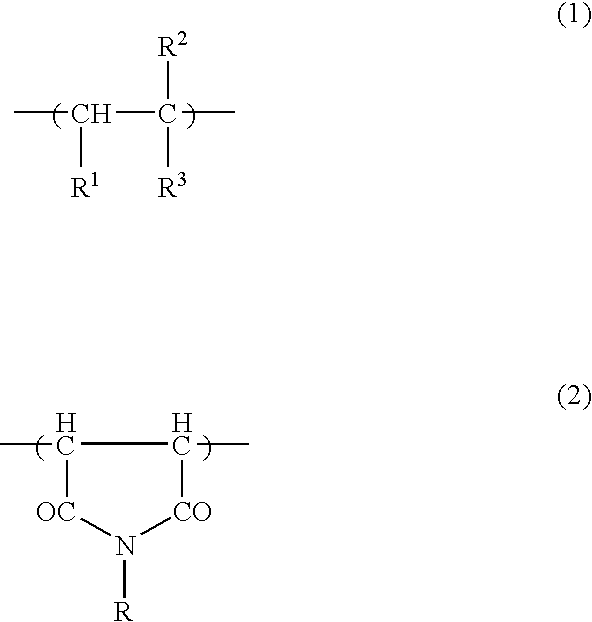

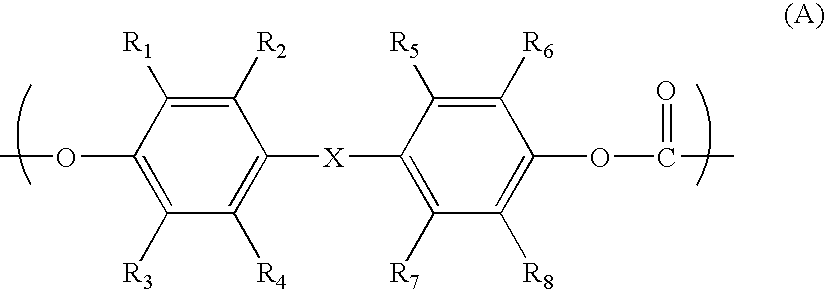

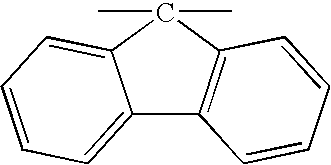

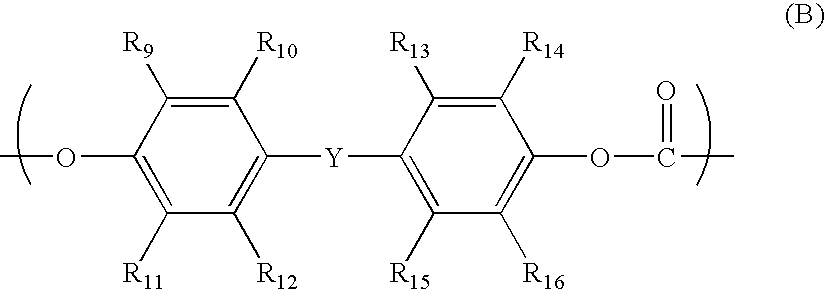

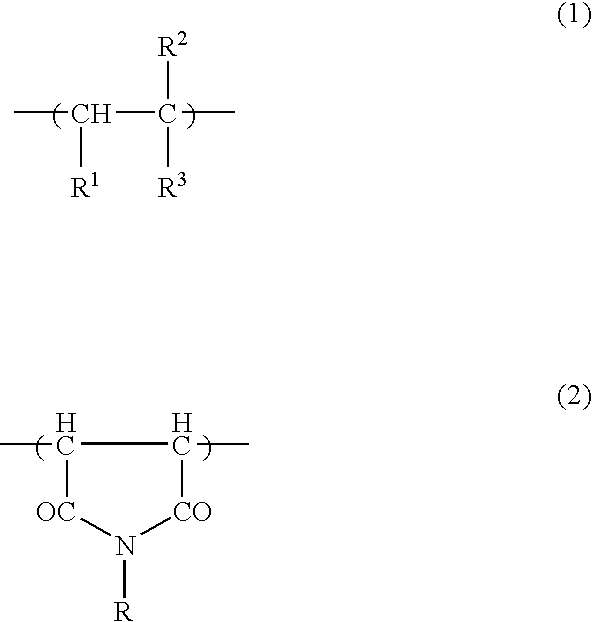

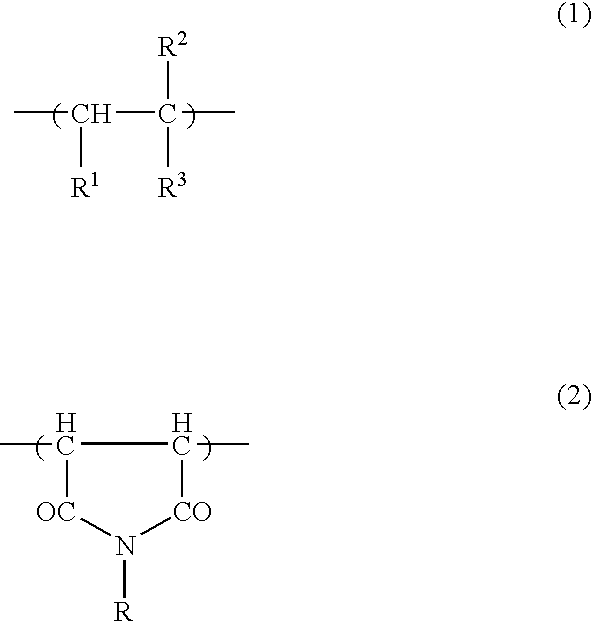

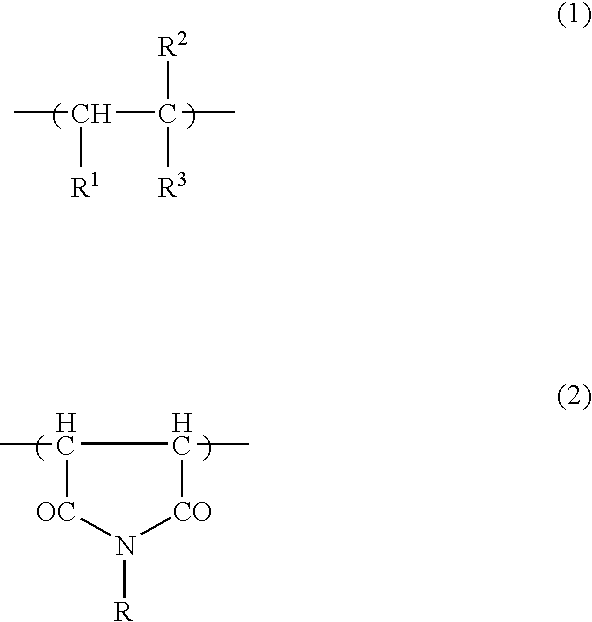

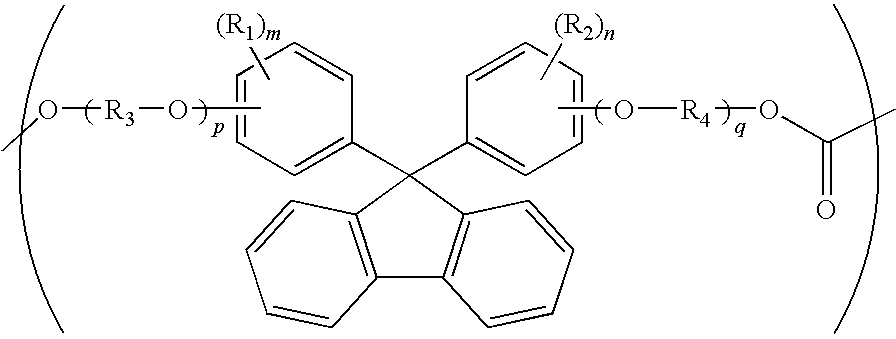

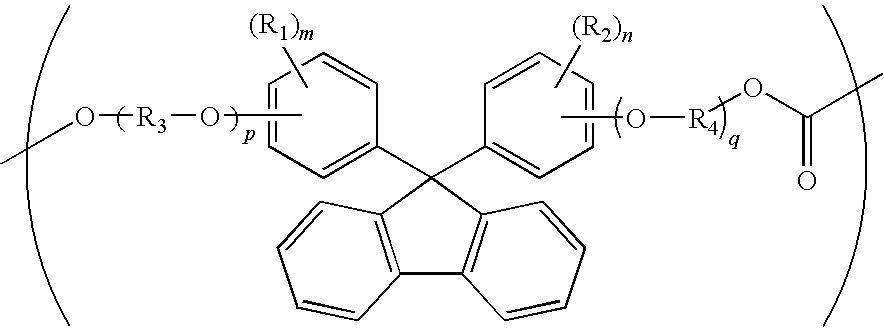

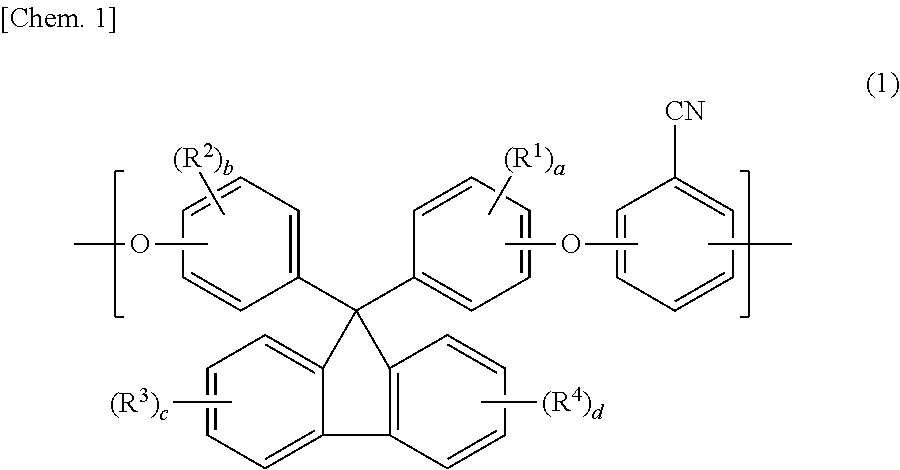

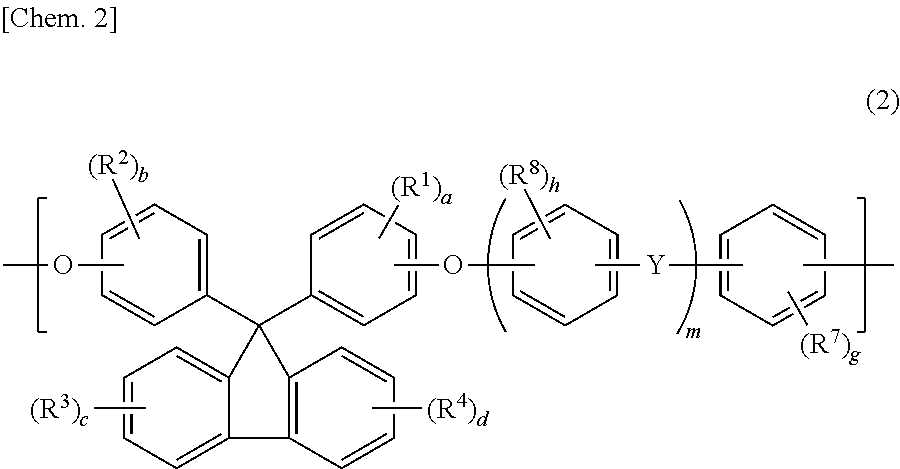

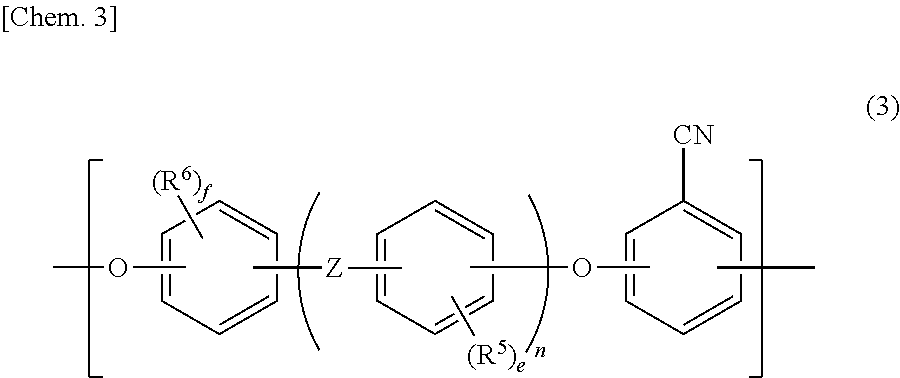

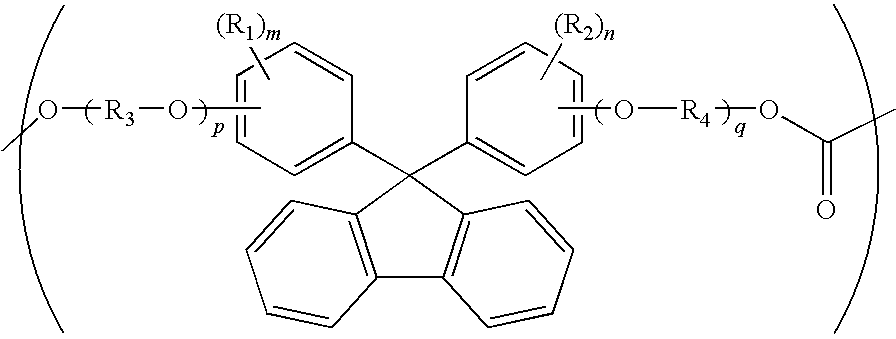

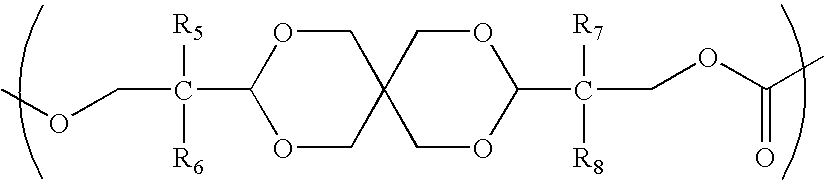

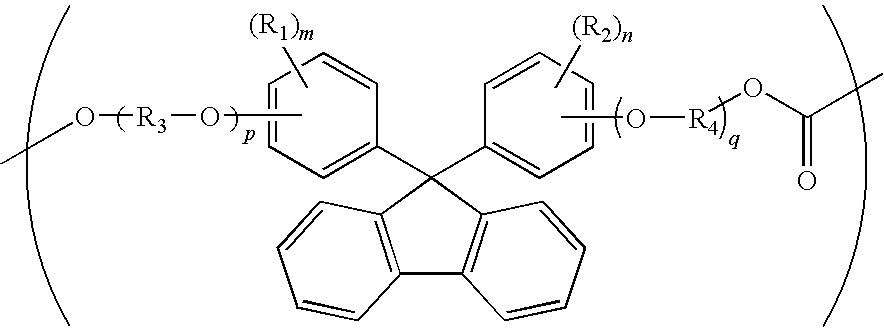

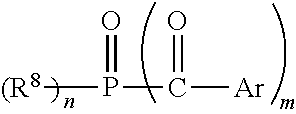

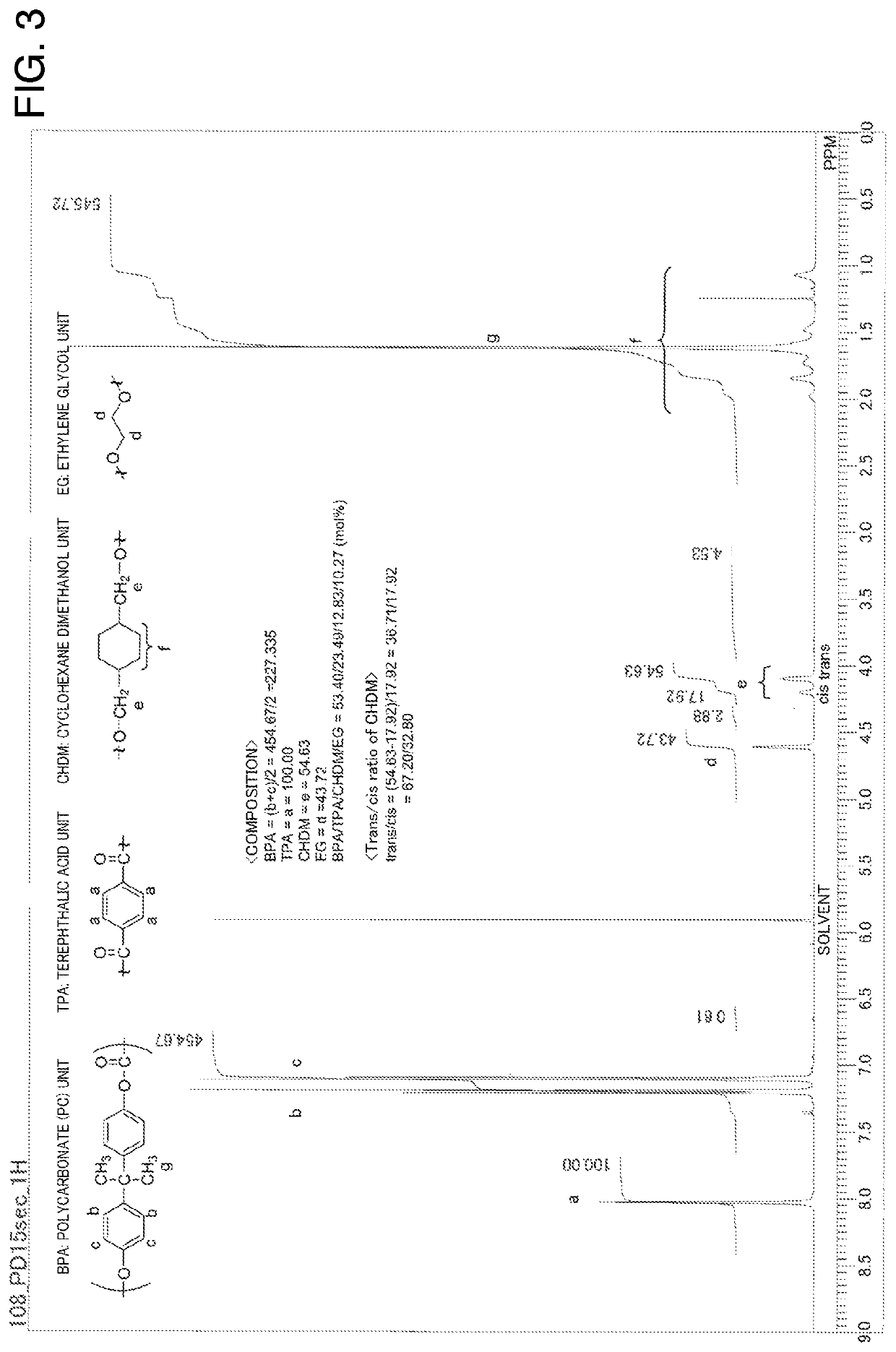

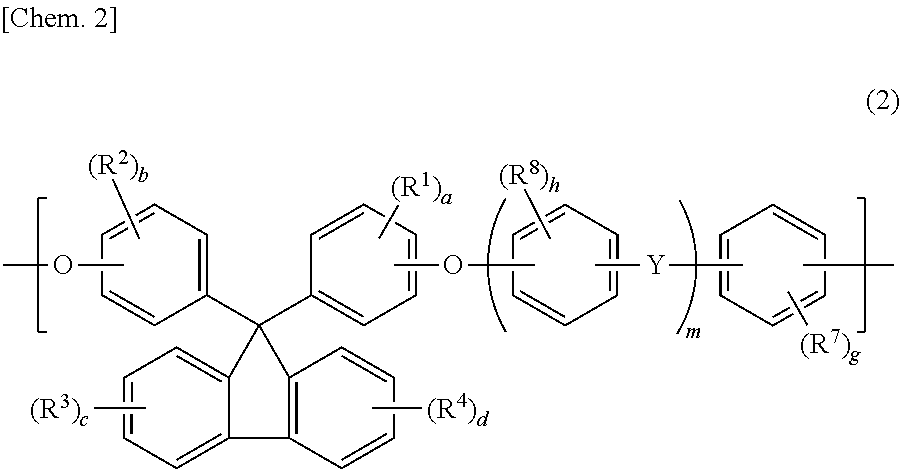

ActiveUS20100104777A1Low photoelastic constantSmall retardationLiquid crystal compositionsPolarising elementsPolycarbonateBisphenol-A-polycarbonate

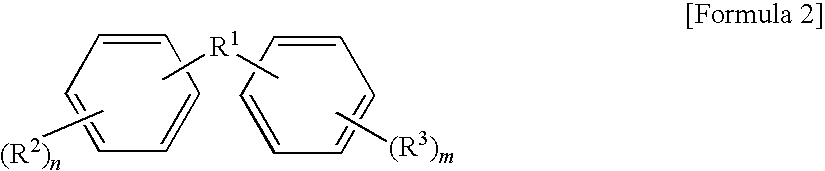

It is an object of the present invention to provide an optical film which has reverse chromatic dispersibility that its retardation becomes smaller as the wavelength becomes shorter and a low photoelastic constant.The optical film is made of a polycarbonate copolymer containing a unit (A) represented by the following formula:wherein R1 and R2 are each independently a hydrogen atom, hydrocarbon group having 1 to 10 carbon atoms or the like, R3 and R4 are each independently a hydrocarbon group having 1 to 10 carbon atoms or the like, “m” and “n” are each independently an integer of 0 to 4, and “p” and “q” are each independently an integer of 0 or more,and a unit (B) represented by the following formula:wherein R5 to R8 are each independently a hydrogen atom or alkyl group having 1 to 10 carbon atoms,the (A / B) molar ratio of the unit (A) to the unit (B) is 10 / 90 to 90 / 10 and which satisfies the following expression (1):R(450)<R(550)<R(650) (1)wherein R(450), R(550) and R(650) are retardation values within the plane of the film at wavelengths of 450 nm, 550 nm and 650 nm, respectively.

Owner:TEIJIN CHEM LTD

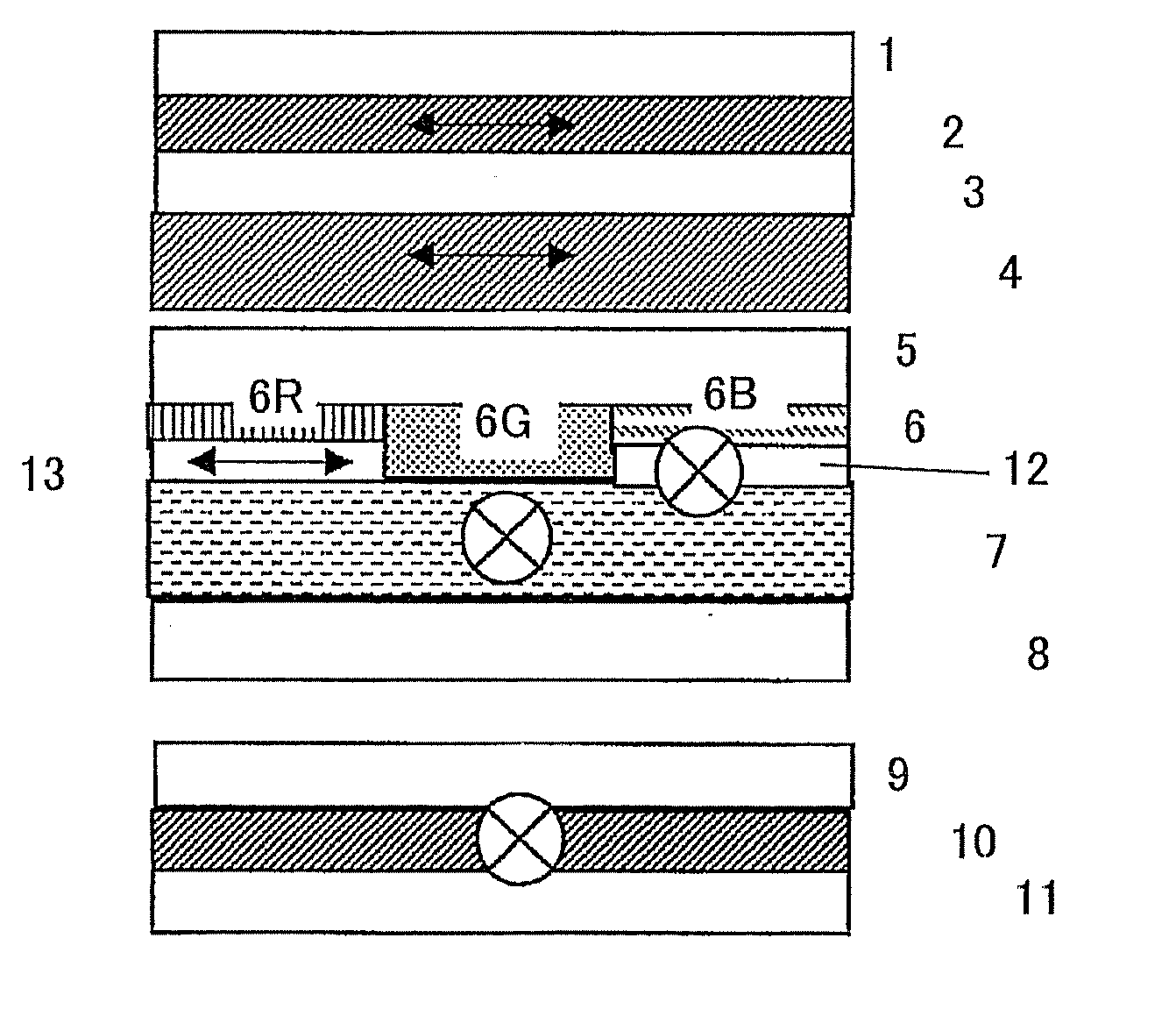

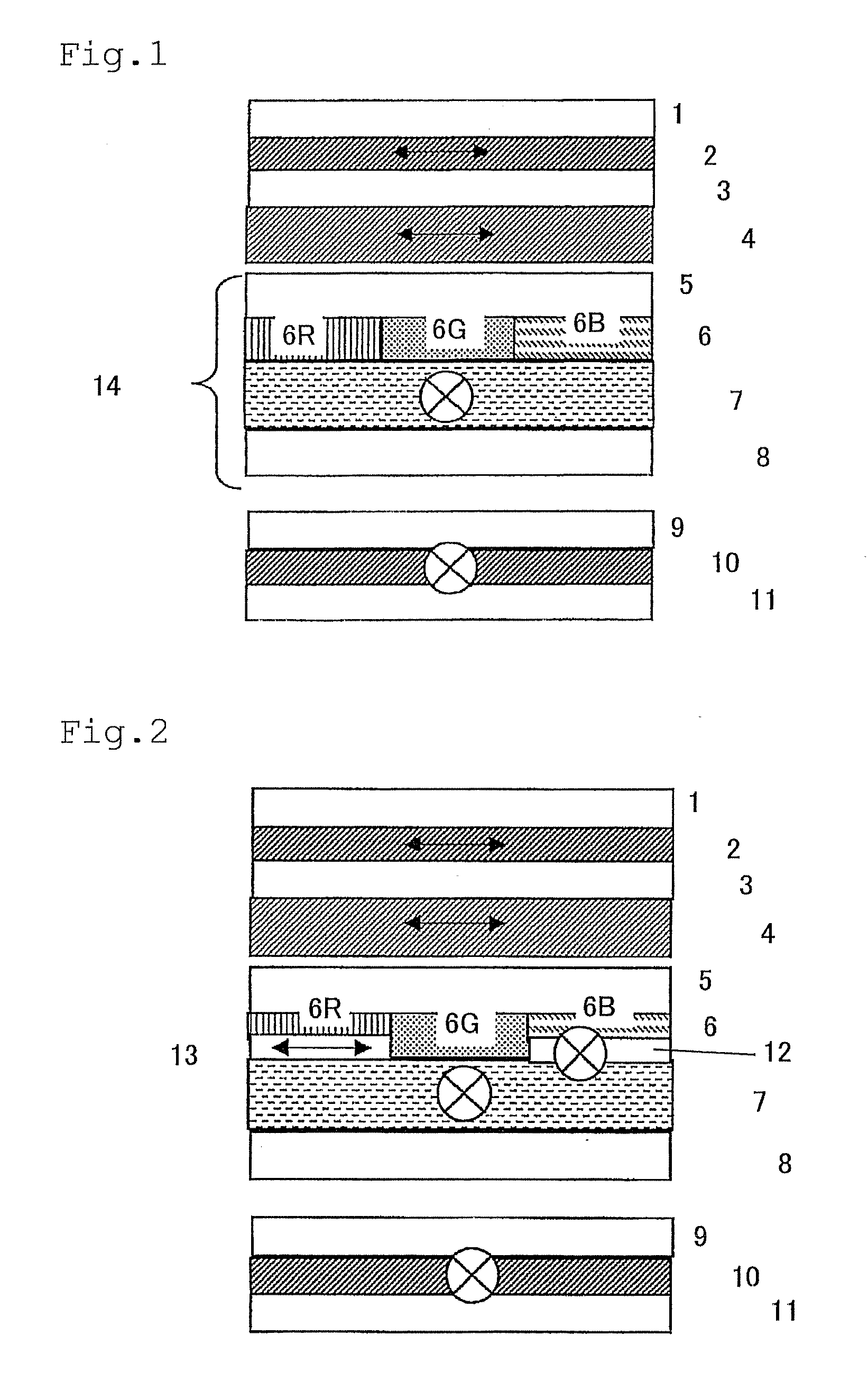

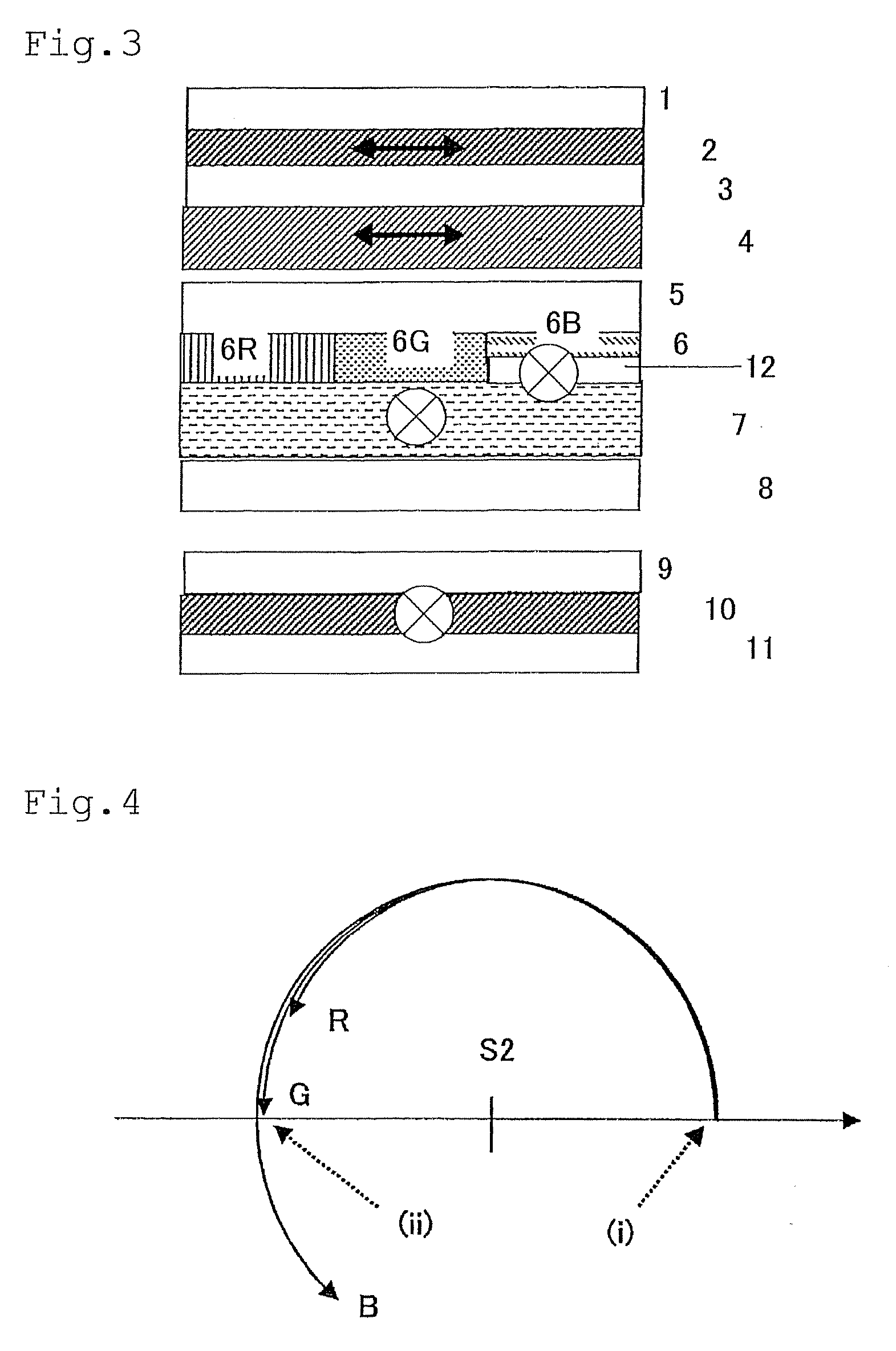

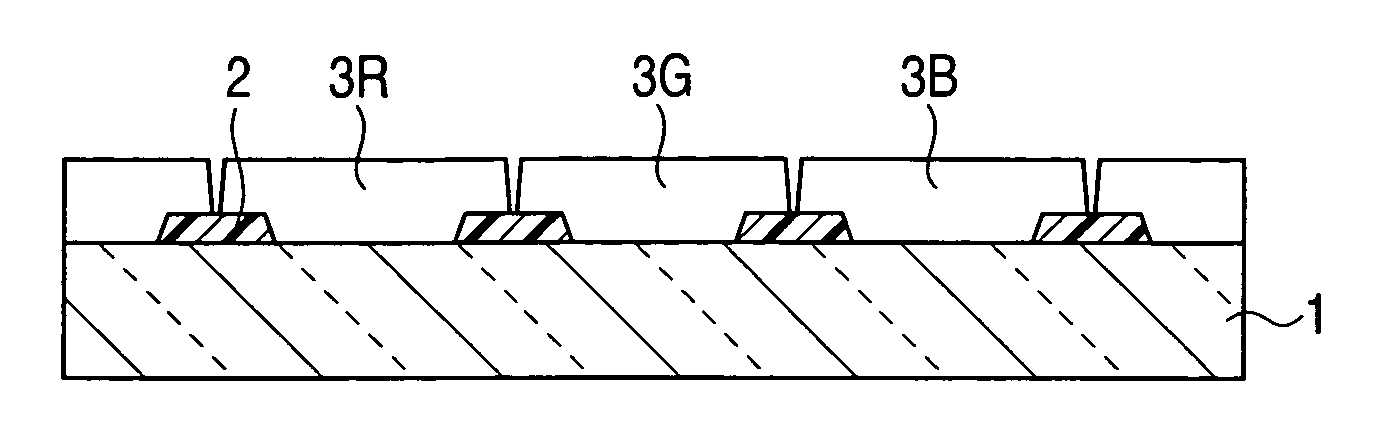

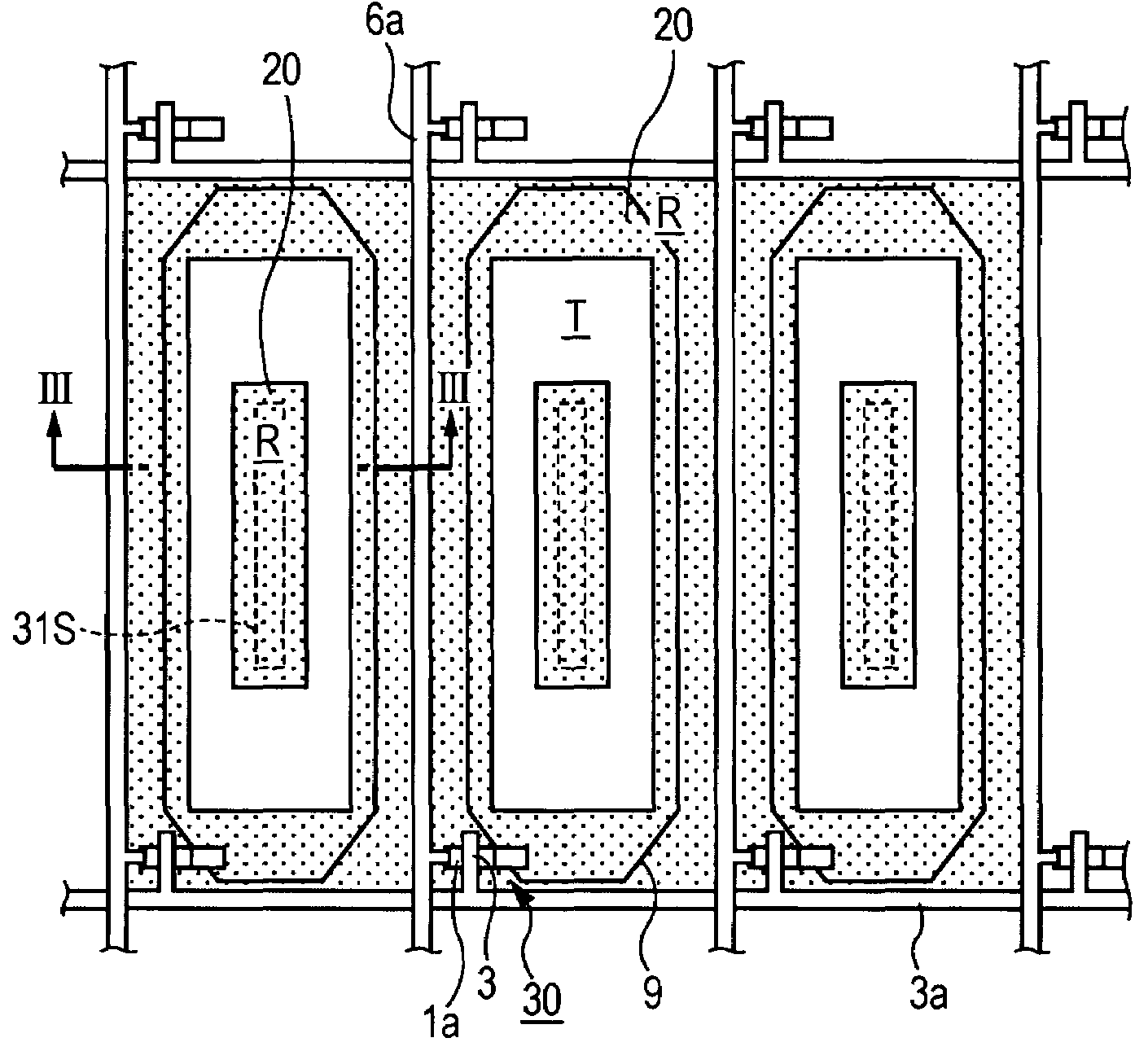

Liquid crystal display device

ActiveUS20090168001A1Reduce light pass-throughImprove black levelNon-linear opticsLength waveLiquid crystal cell

A liquid crystal display device comprising a pair of substrates, at least one polarizing film provided outside the pair of substrates, a liquid crystal cell having a red color filter, a green color filter and a blue color filter provided inside the pair of substrates, a first retardation film compensating for light of a wavelength or wavelengths corresponding to a color or colors of any one or two of the three color filters, and a second retardation film compensating for light of a wavelength that is not compensated for by the first retardation film.

Owner:FUJIFILM CORP

Cellulose acylate film and method for producing same, and retardation film, polarizing plate and liquid crystal display device comprising the film

ActiveUS7569261B2Good optical performanceImprove reliabilityLiquid crystal compositionsOptical articlesCelluloseCrystallography

Owner:FUJIFILM CORP

Cellulose acylate film, polarizing plate, and liquid crystal display device

InactiveUS7615264B2Increase valueLittle changeLiquid crystal compositionsDiffusing elementsCelluloseLiquid-crystal display

Owner:FUJIFILM CORP

Cellulose acylate film and method for producing same, and retardation film, polarizing plate and liquid crystal display device comprising the film

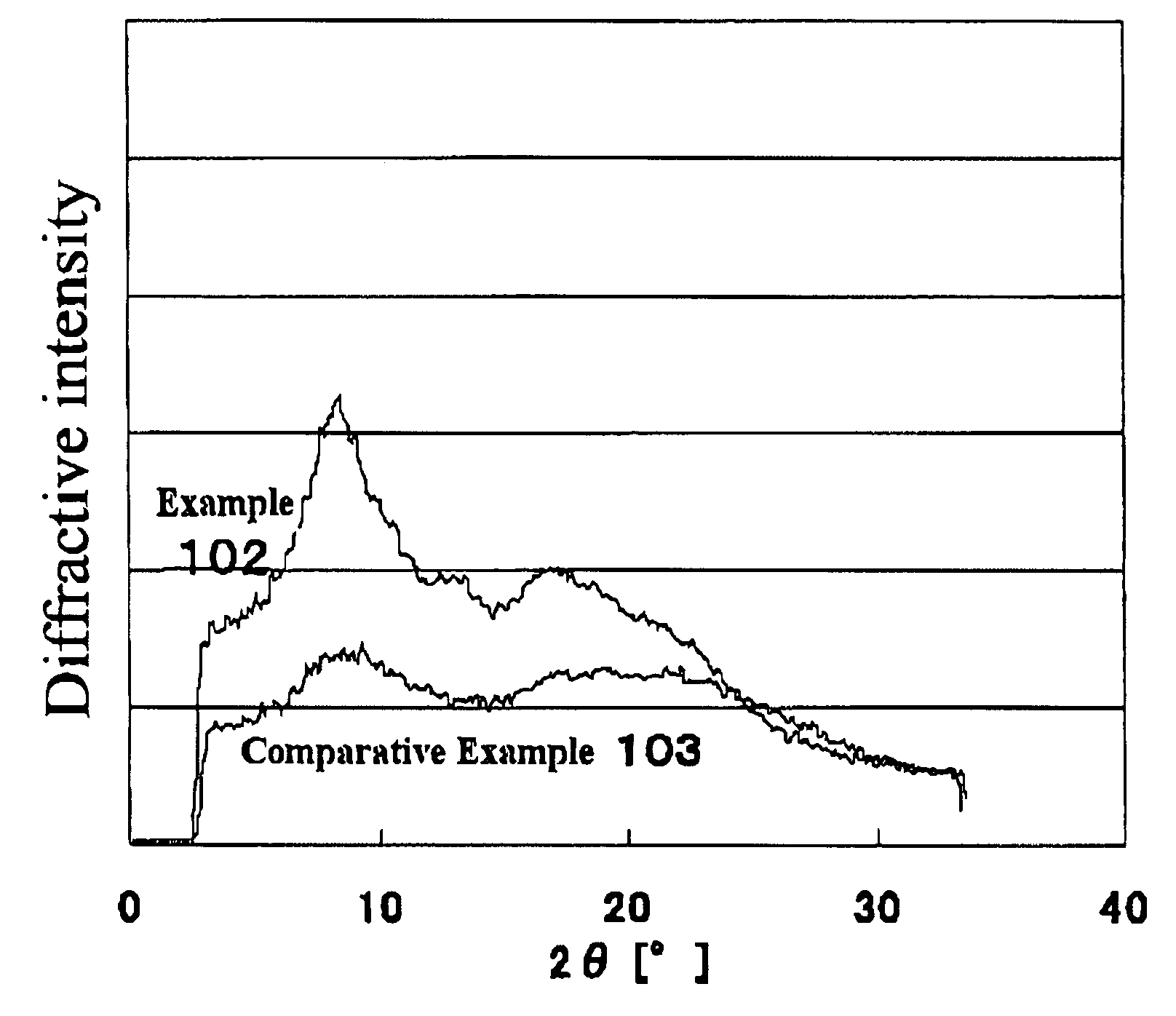

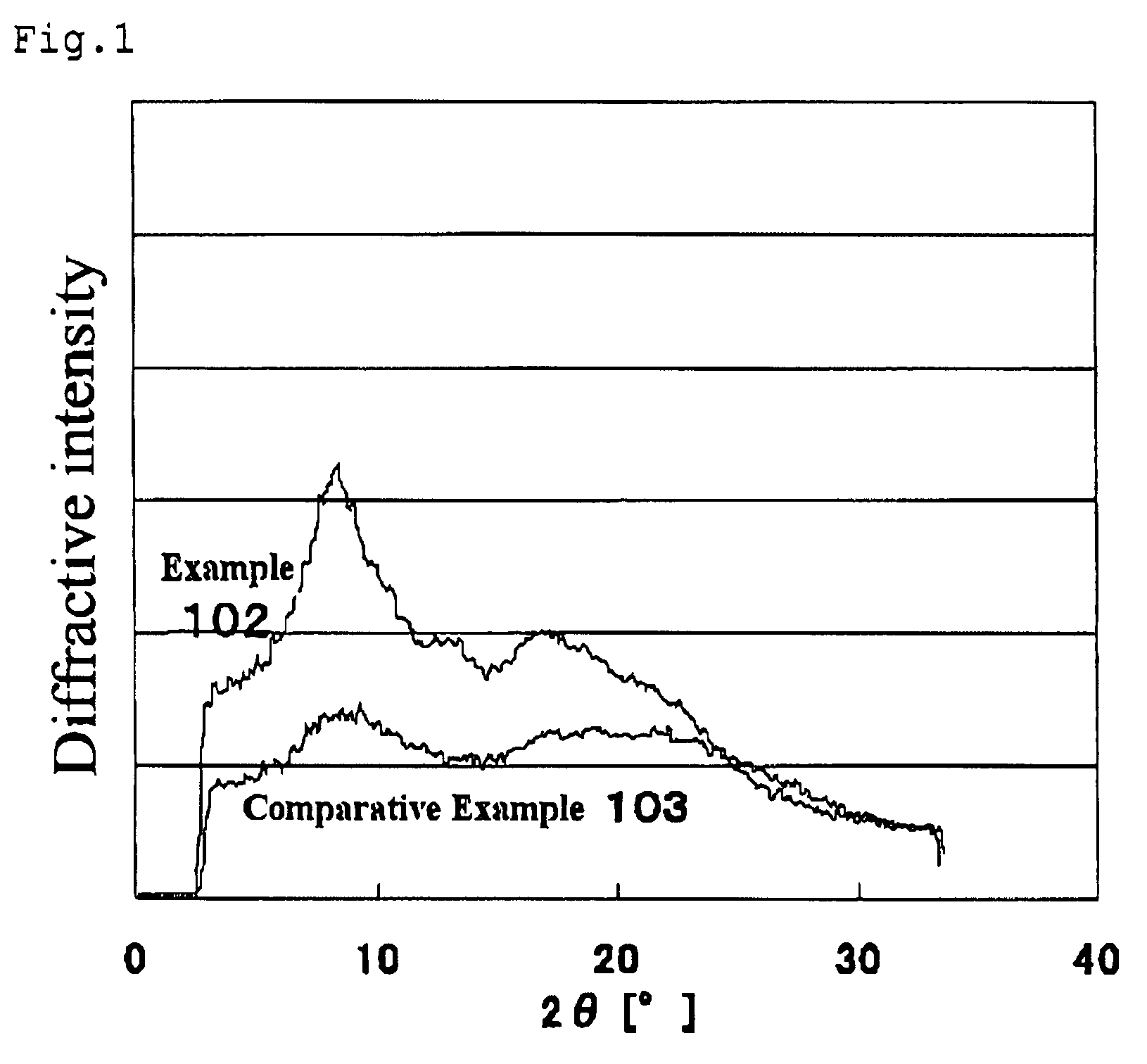

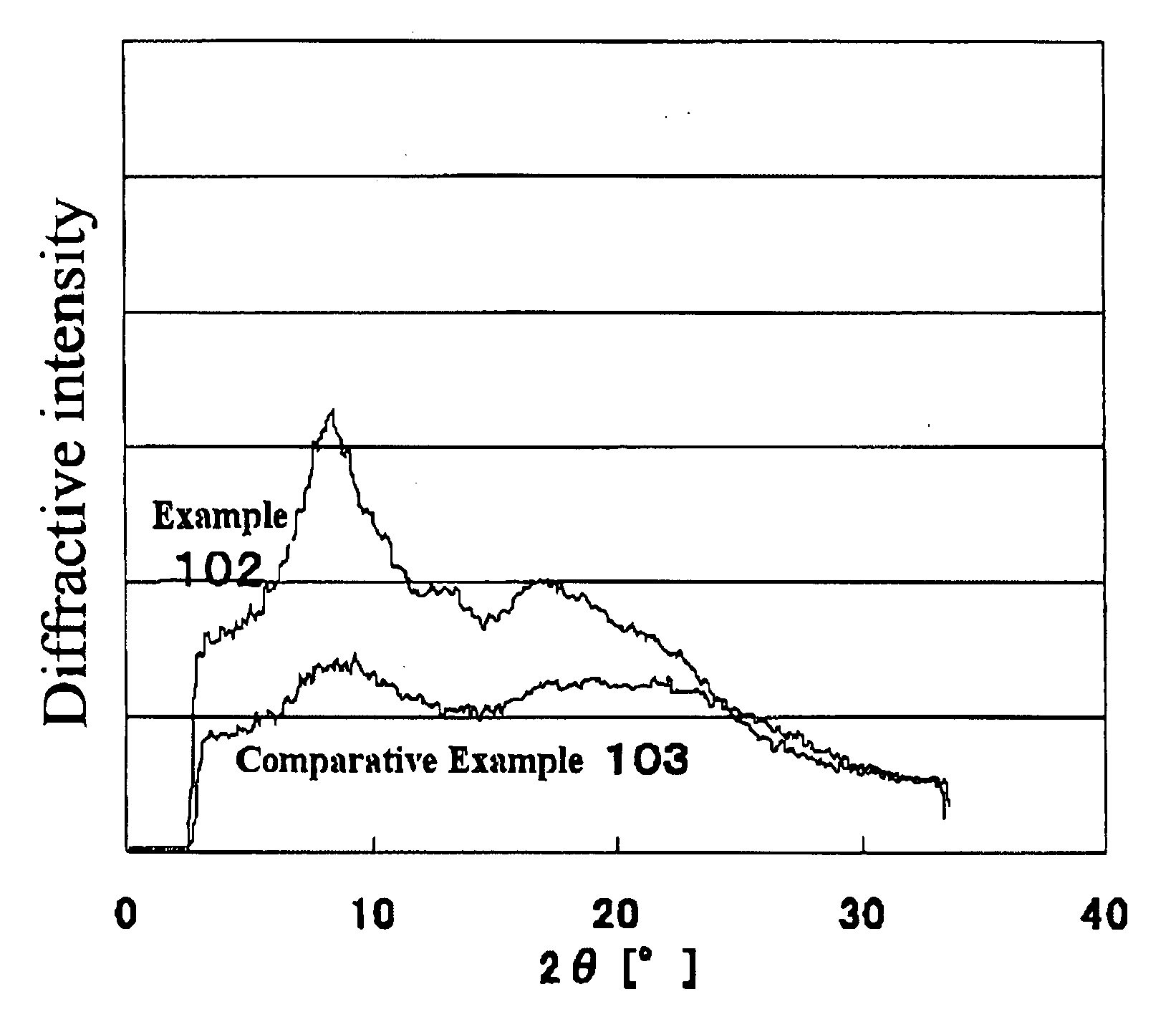

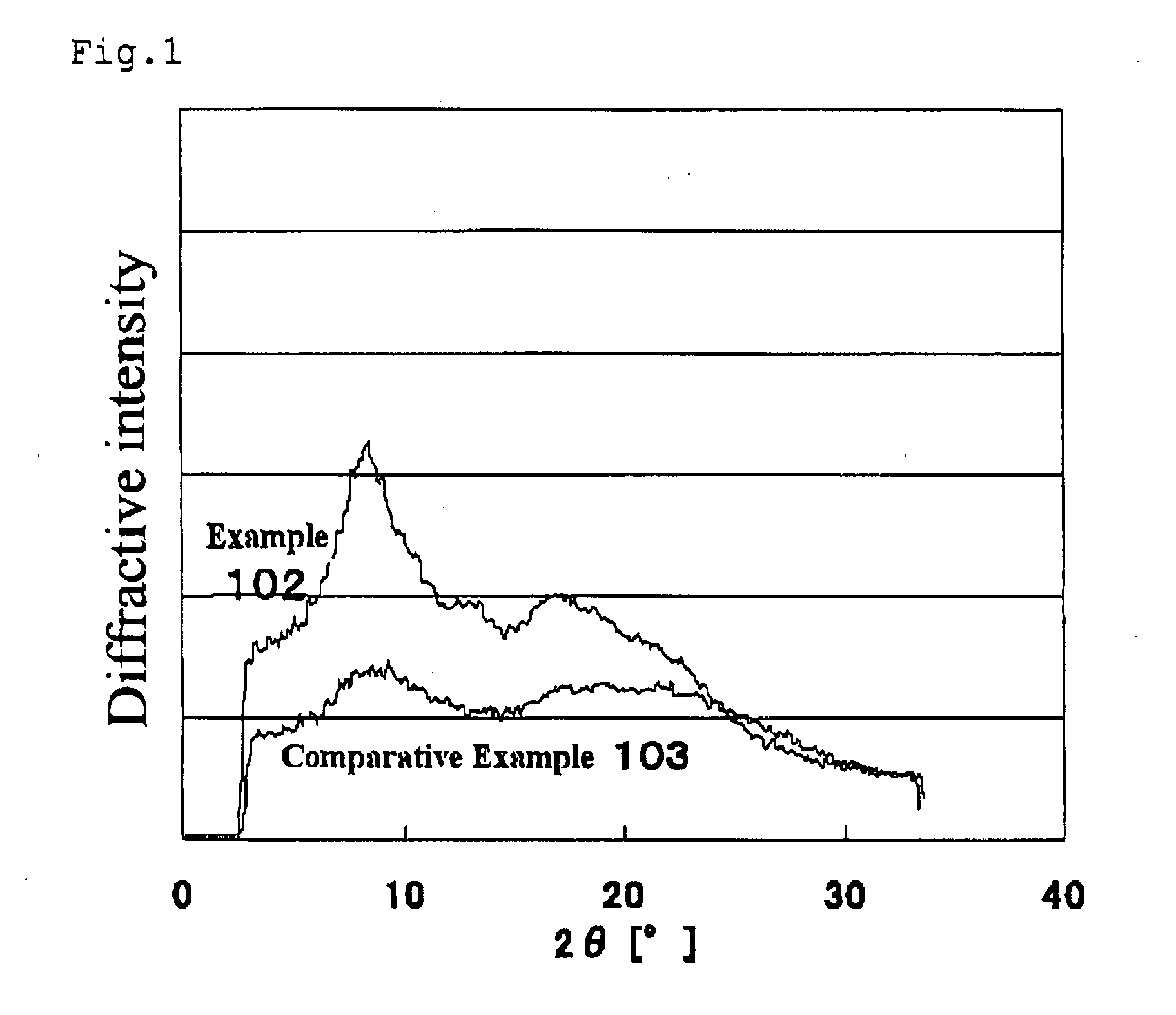

ActiveUS20070269617A1Small retardationExcellent visibilityLiquid crystal compositionsOptical articlesLiquid-crystal displayCellulose

A Cellulose acylate film, in which X-ray diffraction intensity satisfies following formulae and a half-value width of the peak at 2θ2 is greater than 3° and not greater than 7°: 0.40≦Ic2 / (Iam2+Ic2) ≦0.75;Iam2I1+{(I3−I1) / (2θ3−2θ1)×(2θ2−2θ1)}; andIc2=2−Iam2,wherein when it is assumed that θis the Bragg angle, 2θ1 and 2θ3 indicate 2θ at which the intensity becomes the minimum in the 2θ range of 4° to 5° and 14° to 16°, respectively, 2θ2 indicates 2θ at which the intensity becomes the maximum in the 2θ range of 5° to 10°, and I1, I2 and I3 indicate a diffractive intensity at 2θ1, 2θ2 and 2θ3, respectively.

Owner:FUJIFILM CORP

Color filter substrate and liquid crystal display device

InactiveUS20110149215A1Increase brightnessExcellent oblique visibilityNon-linear opticsOptical elementsColor gelZinc phthalocyanine

Disclosed is a color filter substrate provided with a transparent substrate, and a plurality of color pixels including a green pixel and formed on the transparent substrate. The green pixel contains halogenated zinc phthalocyanine-based green pigment and at least one kind of yellow pigment and satisfies prescribed three conditions, and absolute value of retardation in thickness direction (Rth) of the green pixel is confined to no more than 2 nm.

Owner:TOPPAN PRINTING CO LTD

Optical planar thermoplastic resin composition

ActiveUS8394504B2High transparencyImprove heat resistanceSynthetic resin layered productsPolarising elementsThermoplasticPolymer science

Owner:NIPPON SHOKUBAI CO LTD

Polyamic acid, varnish comprising same and polyimide film

ActiveUS20160032055A1Small retardationHigh light transmittanceFinal product manufactureSynthetic resin layered productsPhase differenceTransmittance

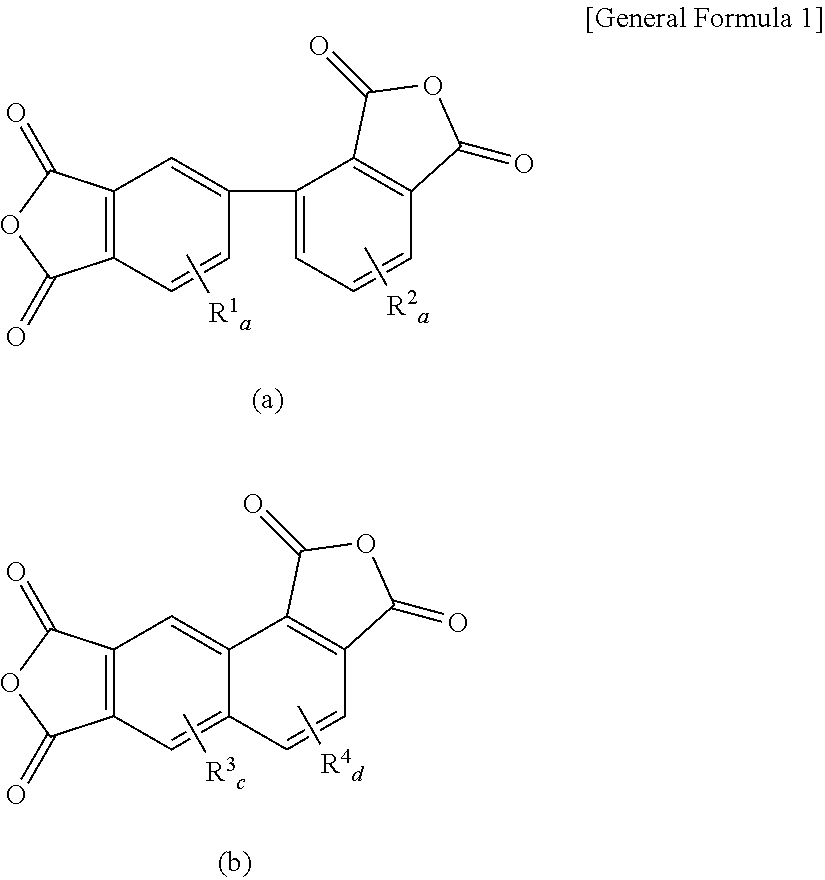

The present invention addresses the problem of providing: a polyimide film that has a small phase difference in the thickness direction and has a low coefficient of linear thermal expansion; and a polyamic acid and varnish to obtain the same. In order to solve this problem, the present invention provides a polyimide film which comprises polyimide that is produced by reacting a diamine component and a tetracarboxylic dianhydride component, the polyimide film having a coefficient of linear thermal expansion of 35 ppm / K or less over a temperature range of 100 to 200 DEG C, an absolute value of phase difference in the thickness direction of 200 nm or less per 10 μm thickness, a glass transition temperature of 260 DEG C or more, and a total light transmittance of 85% or more.

Owner:MITSUI CHEM INC

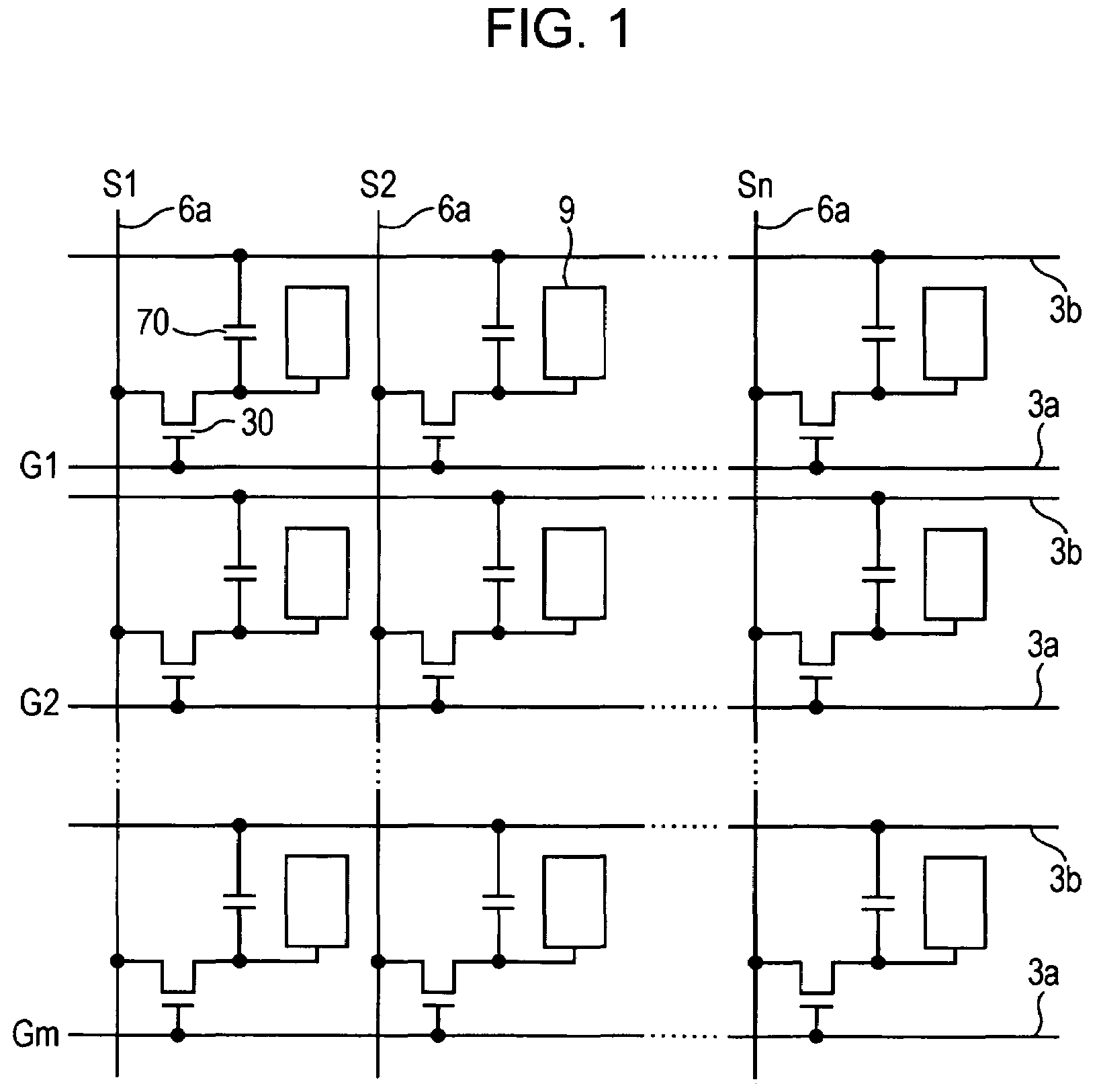

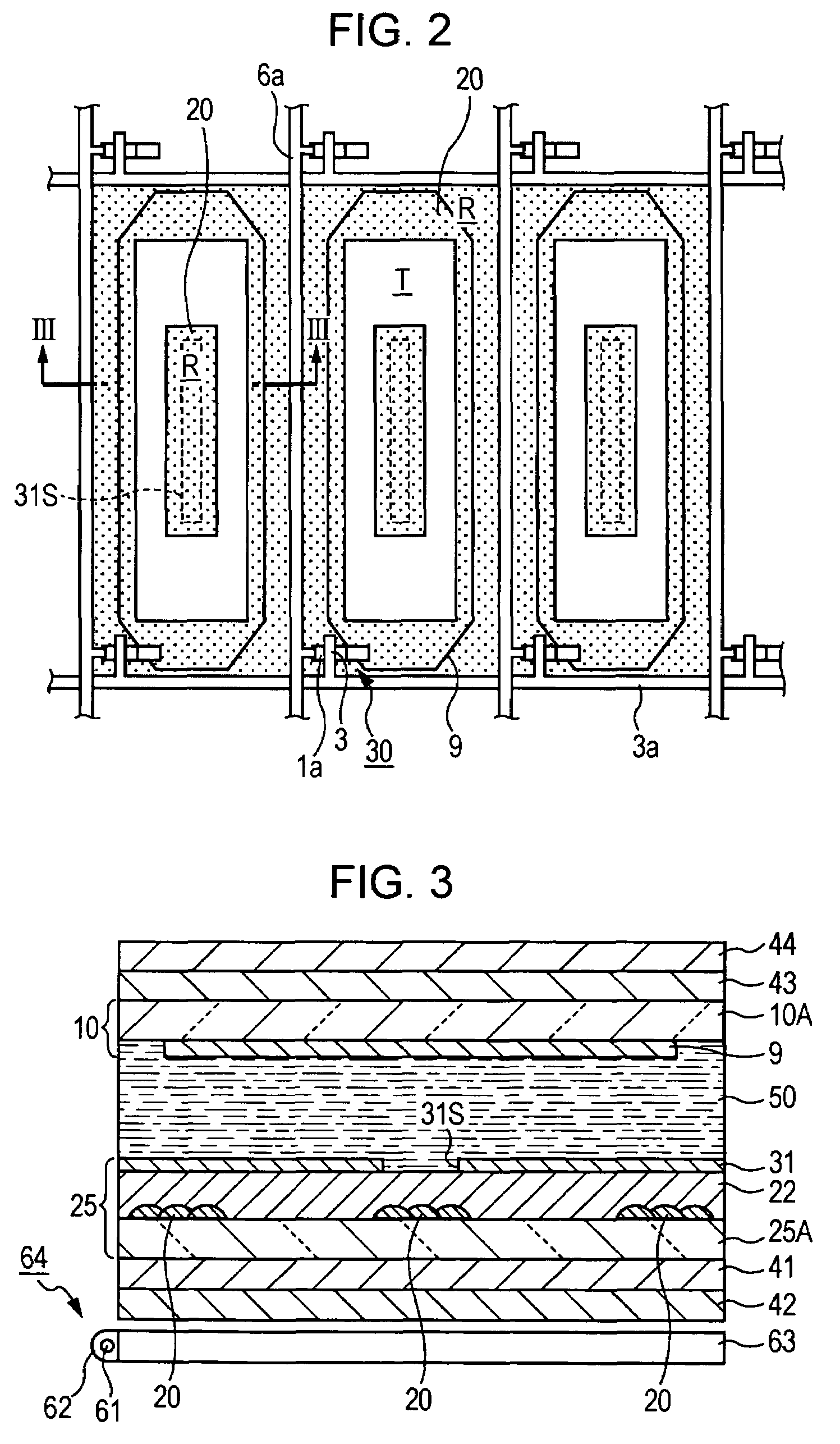

Liquid crystal display device and electronic apparatus

A liquid crystal display device includes: a pair of substrates including an element substrate and a counter substrate; a liquid crystal layer interposed between the pair of substrates, the liquid crystal layer being composed of liquid crystal having negative dielectric anisotropy, an initial alignment state thereof being vertical; pixel electrodes provided on the element substrate to drive the liquid crystal layer; and a transmissive display region for transmissive display and a reflective display region for reflective display provided within one dot region. At least an outer region of the pixel electrodes and a region overlapping edges of the pixel electrodes in plan view become the reflective display region, and the thickness of the liquid crystal layer in the reflective display region is approximately equal to that of the liquid crystal layer in the transmissive display region.

Owner:BOE TECH GRP CO LTD

Optical filter and imaging device comprising the same

ActiveUS20130128361A1Increase resistanceHigh strengthOptical filtersCamera body detailsPhysical chemistryLight filter

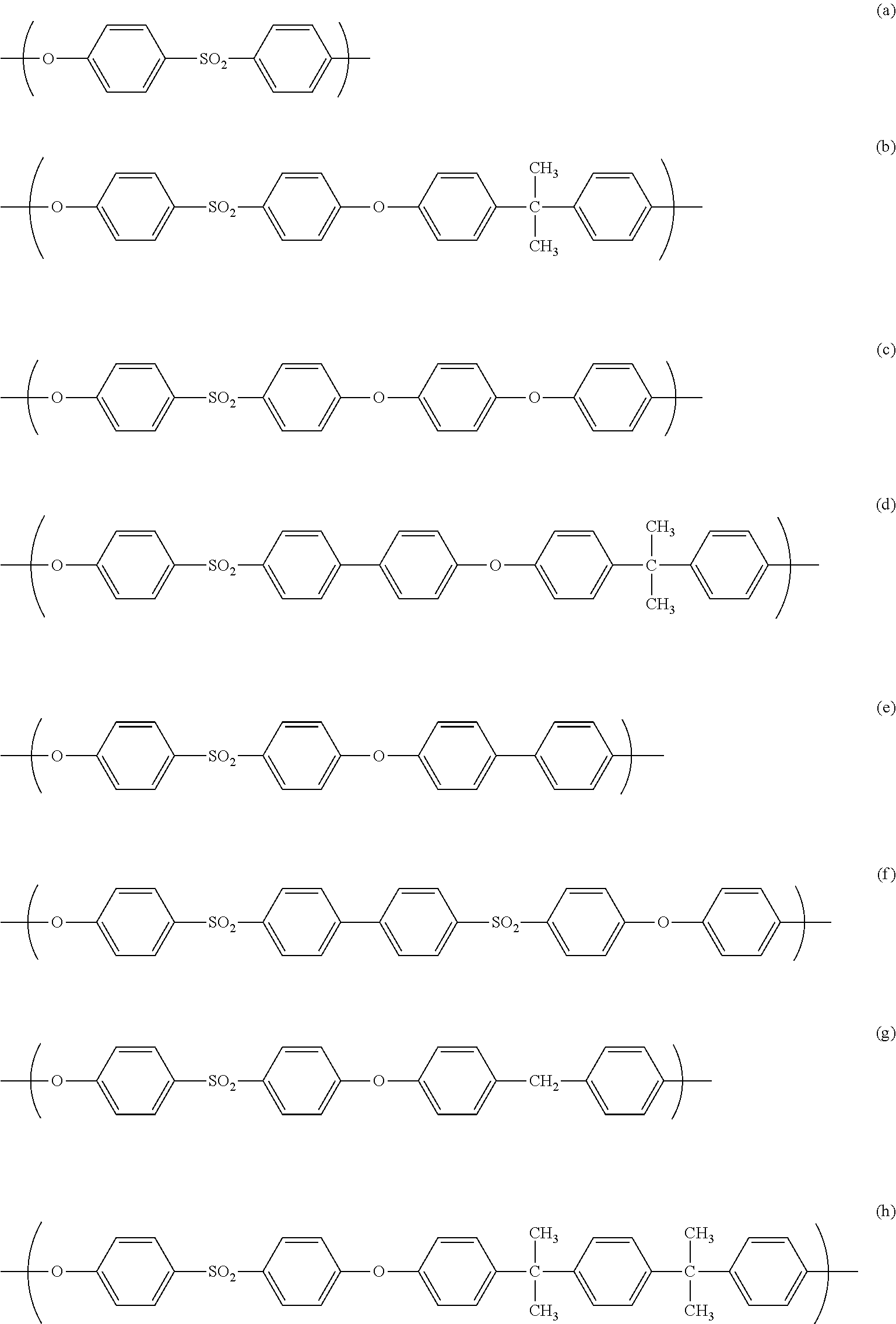

An optical filter comprising a substrate and a dielectric multilayer film formed on at least one surface of the substrate, wherein the substrate comprises an aromatic polyether-based polymer having a glass transition temperature (Tg), measured via differential scanning calorimetry (DSC, heating rate: 20° C. / min), of from 230 to 350° C.

Owner:JSR CORPORATIOON

Enzymatically modified lignins

InactiveUS20170267816A1Simple processEasy to handleOxidoreductasesFermentationPhenyl groupWater soluble

The present invention relates to water-soluble modified lignins preparable by enzymatic reaction of at least one water-insoluble lignin with at least one organic compound which possesses at least one group selected from primary or secondary amino group, hydroxyl group and phenyl group and has an average molecular weight in the range from 75 to 2500 g / mol. The water-soluble modified lignins are preparable under mild conditions in a simple process. They can be used as dispersants for mineral binder compositions, where they act as plasticizers and in so doing prolong the setting time to much less of an extent than the water-insoluble lignins used in their preparation.

Owner:SIKA TECH AG +1

Optical film

ActiveUS8877304B2Low photoelastic constantSmall retardationLiquid crystal compositionsSynthetic resin layered productsHydrogen atomLength wave

It is an object of the present invention to provide an optical film which has reverse chromatic dispersibility that its retardation becomes smaller as the wavelength becomes shorter and a low photoelastic constant.The optical film is made of a polycarbonate copolymer containing a unit (A) represented by the following formula:wherein R1 and R2 are each independently a hydrogen atom, hydrocarbon group having 1 to 10 carbon atoms or the like, R3 and R4 are each independently a hydrocarbon group having 1 to 10 carbon atoms or the like, “m” and “n” are each independently an integer of 0 to 4, and “p” and “q” are each independently an integer of 0 or more,and a unit (B) represented by the following formula:wherein R5 to R8 are each independently a hydrogen atom or alkyl group having 1 to 10 carbon atoms,the (A / B) molar ratio of the unit (A) to the unit (B) is 10 / 90 to 90 / 10 and which satisfies the following expression (1):R(450)<R(550)<R(650) (1)wherein R(450), R(550) and R(650) are retardation values within the plane of the film at wavelengths of 450 nm, 550 nm and 650 nm, respectively.

Owner:TEIJIN KASEK KK

Film

ActiveUS20170010390A1High transparencyImprove compatibilityPolarising elementsPolarizerStructural unit

A film obtained by molding a methacrylic resin composition, the methacrylic resin composition comprises: a methacrylic resin having a triad syndiotacticity (rr) of not less than 50% and a weight average molecular weight of 80000 to 200000 and comprising not less than 92% by mass of a structural unit derived from methyl methacrylate, and a polycarbonate resin having an MVR of 130 to 250 cm3 / 20 min at 300° C. and 1.2 Kg, in which a mass ratio of the methacrylic resin to the polycarbonate resin is 91 / 9 to 99 / 1, and the total content of the methacrylic resin and the polycarbonate resin is 80 to 100% by mass. The film is layered to at least one surface of a polarizer to give a polarizing plate.

Owner:KURARAY CO LTD

Enzymatically modified lignins

InactiveUS10202495B2Easy to handleReduce mineral contentOxidoreductasesFermentationPlasticizerWater insoluble

The present invention relates to water-soluble modified lignins preparable by enzymatic reaction of at least one water-insoluble lignin with at least one organic compound which possesses at least one group selected from primary or secondary amino group, hydroxyl group and phenyl group and has an average molecular weight in the range from 75 to 2500 g / mol. The water-soluble modified lignins are preparable under mild conditions in a simple process. They can be used as dispersants for mineral binder compositions, where they act as plasticizers and in so doing prolong the setting time to much less of an extent than the water-insoluble lignins used in their preparation.

Owner:SIKA TECH AG +1

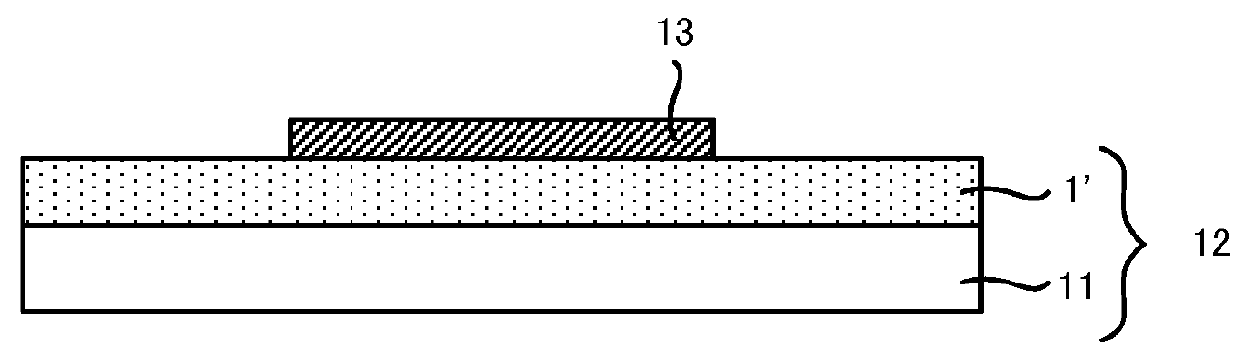

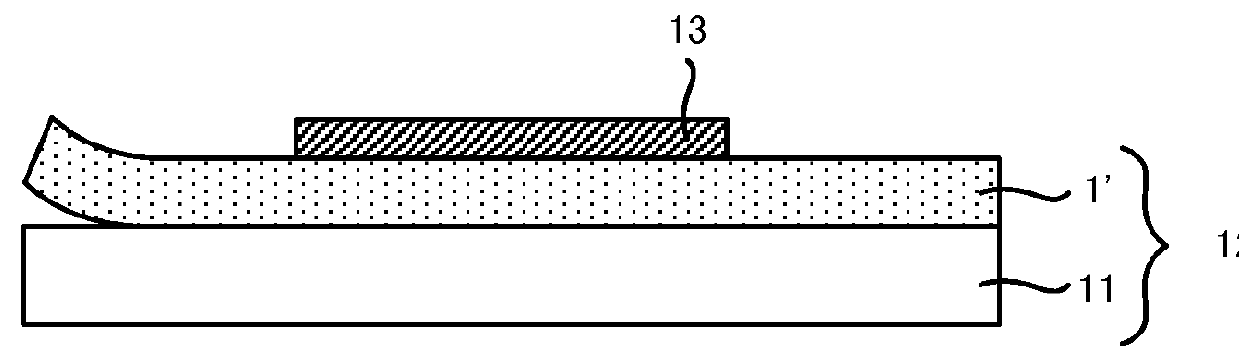

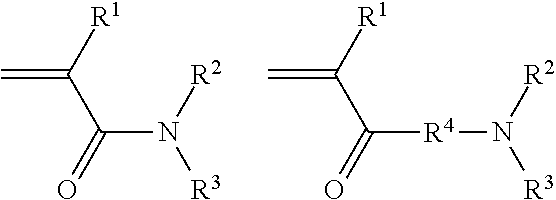

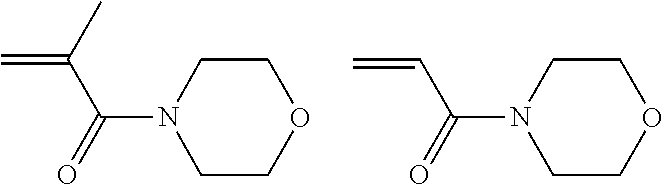

Curable resin composition, curable resin molded body, cured resin molded body, method for producing each of same, and laminate body

ActiveUS9023913B2Improve heat resistanceSmall retardationSurgical adhesivesLavatory sanitoryPolymer scienceGlass transition

The present invention is: a curable resin composition comprising a thermoplastic resin (A), a curable monomer (B), and a photoinitiator (C), the thermoplastic resin (A) including an aromatic ring in its molecule, and having a glass transition temperature (Tg) of 140° C. or more, and the photoinitiator (C) having an absorbance at 380 nm of 0.4 or more when measured in a 0.1 mass % acetonitrile solution; a curable resin formed article obtained by forming the curable resin composition; a cured resin formed article obtained by curing the curable resin formed article; a laminate comprising at least one layer that is formed of a cured resin obtained by curing the curable resin composition. The present invention provides: a cured resin formed article that exhibits excellent heat resistance, includes only a small amount of residual low-boiling-point substance (e.g., solvent and curable monomer), and has small in-plane retardation, a method for producing the same, a curable resin composition and a curable resin formed article that are useful as a raw material for producing the cured resin formed article, and a laminate that includes a layer formed of a cured resin.

Owner:LINTEC CORP

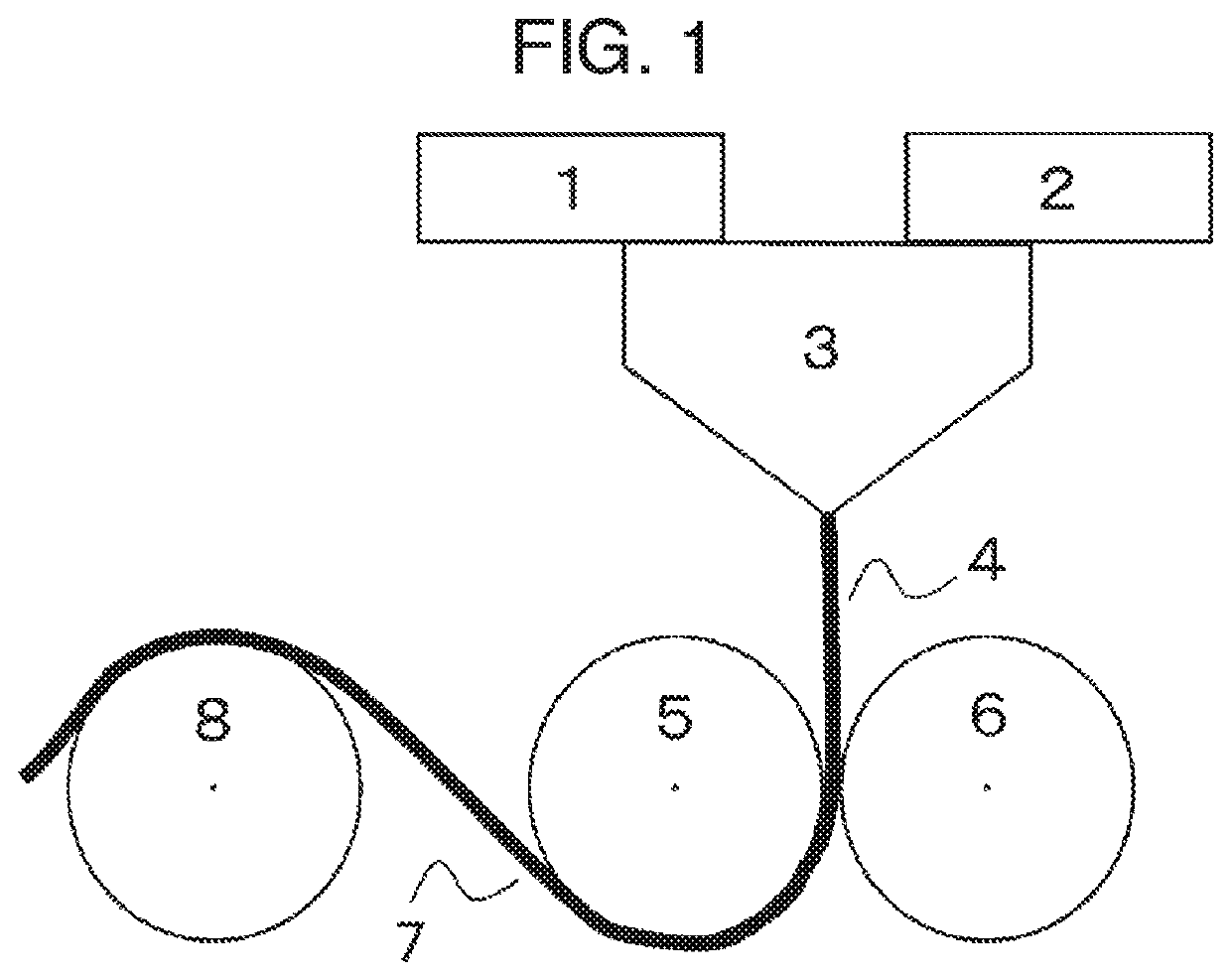

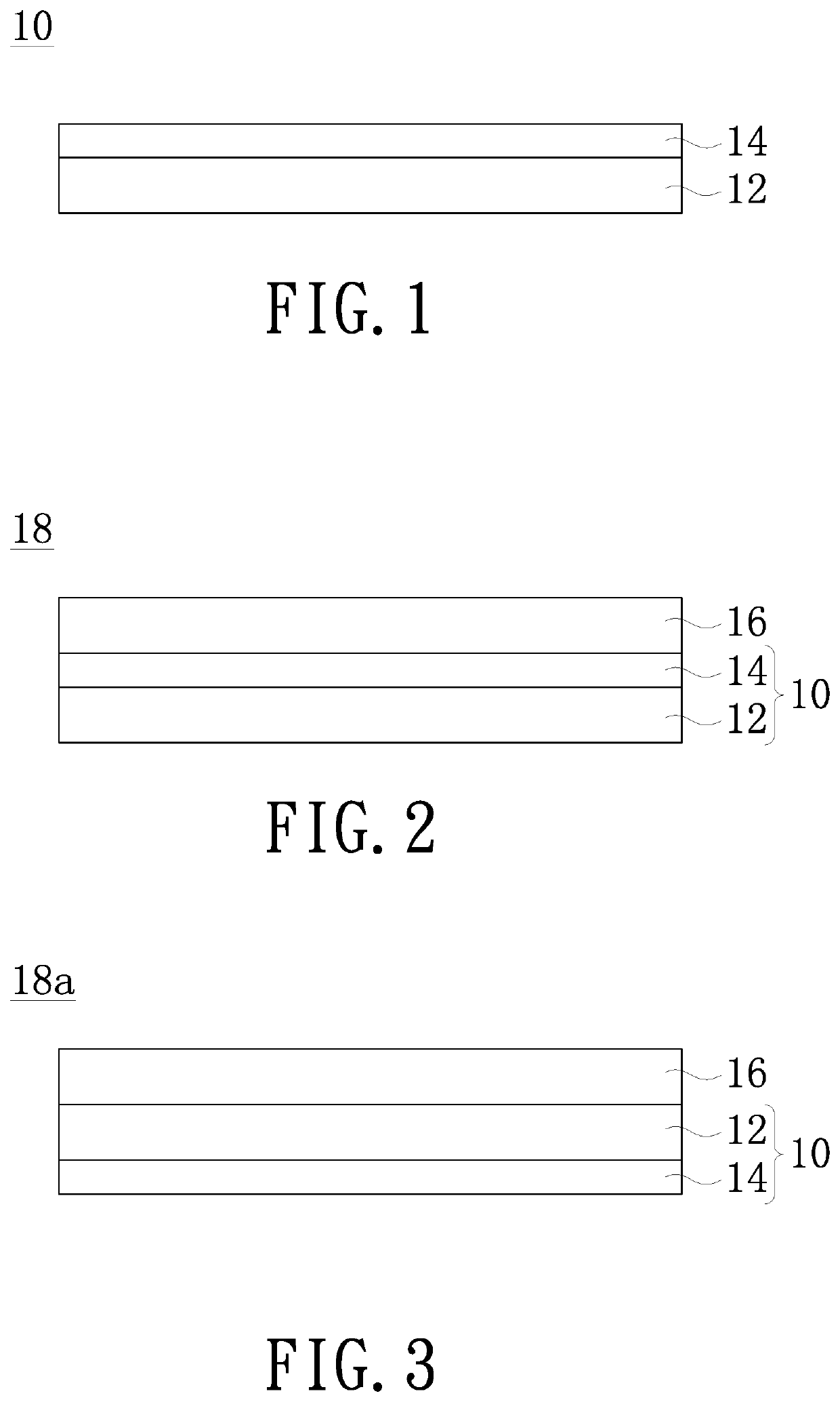

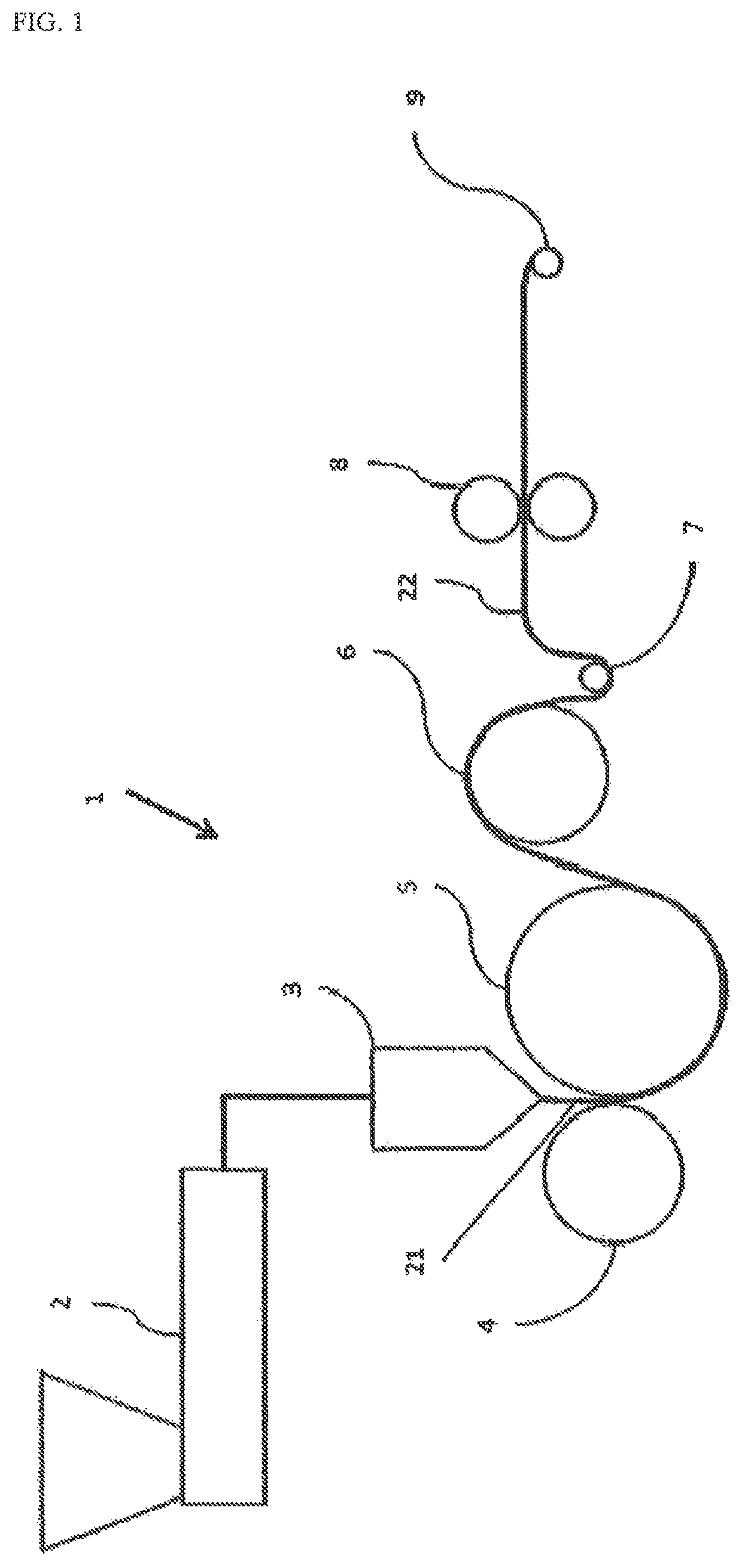

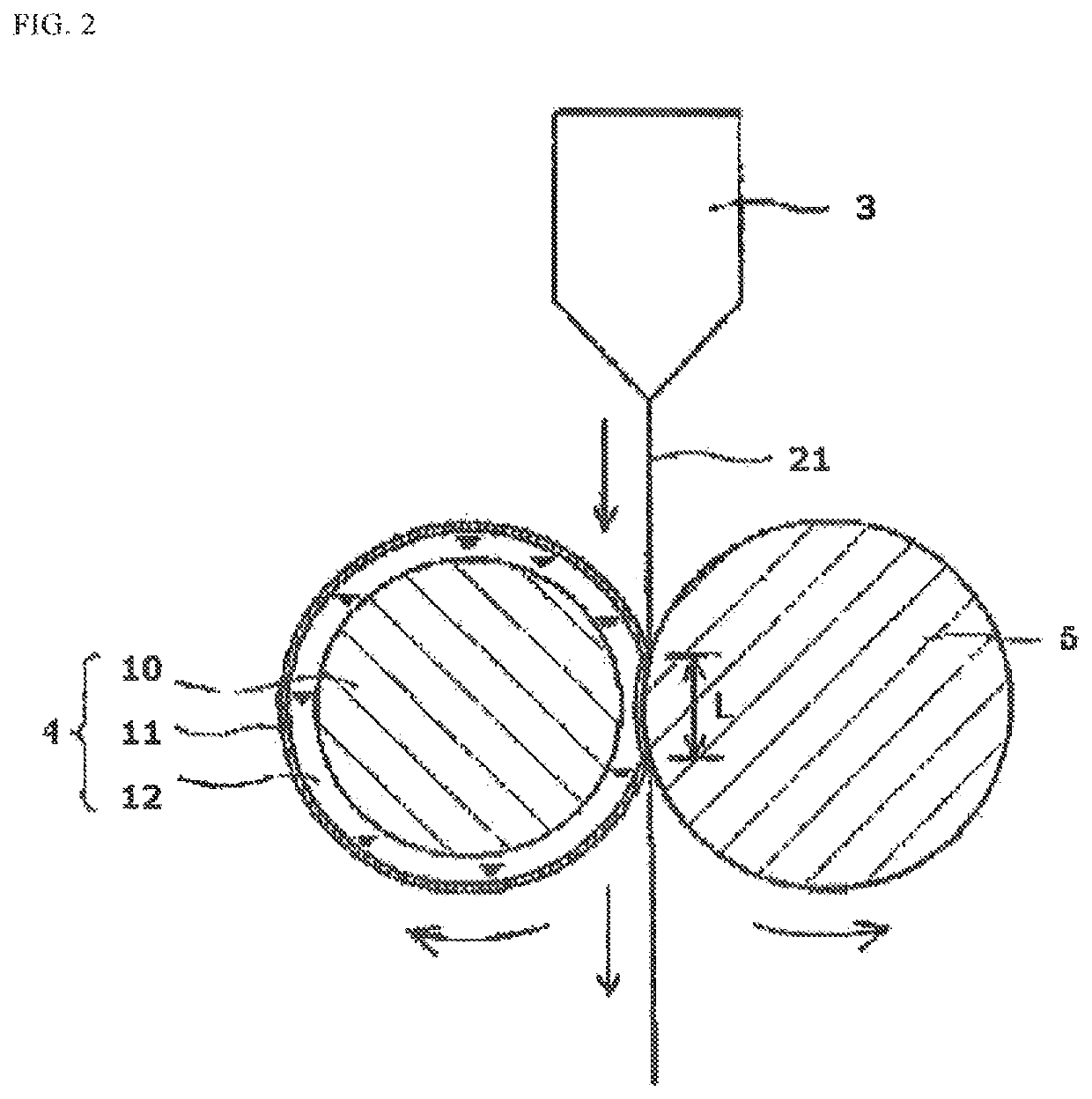

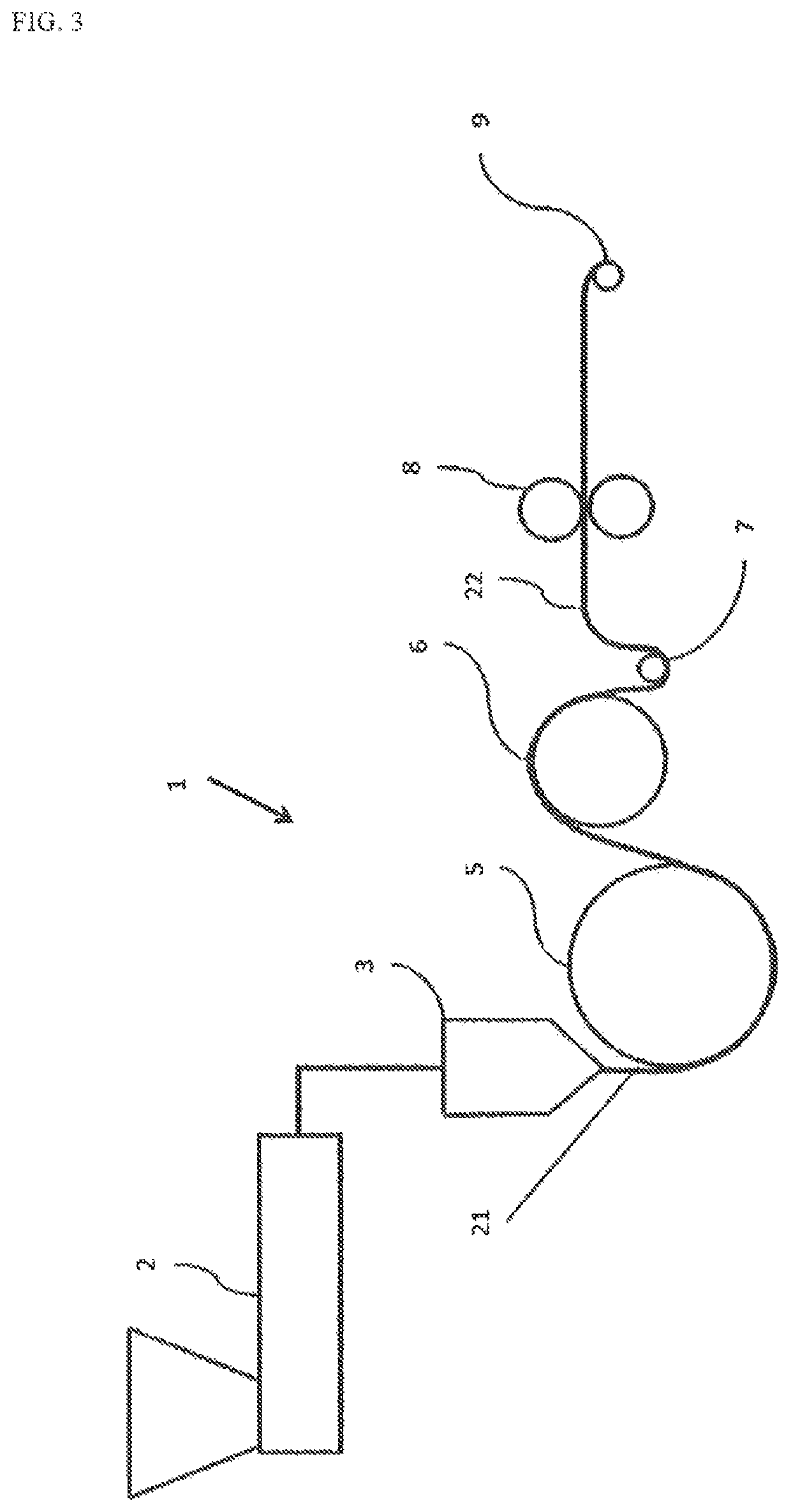

Method for producing multilayer film

ActiveUS11465323B2Nice appearanceGood colorSynthetic resin layered productsCellulosic plastic layered productsMultilayer membranePolymer science

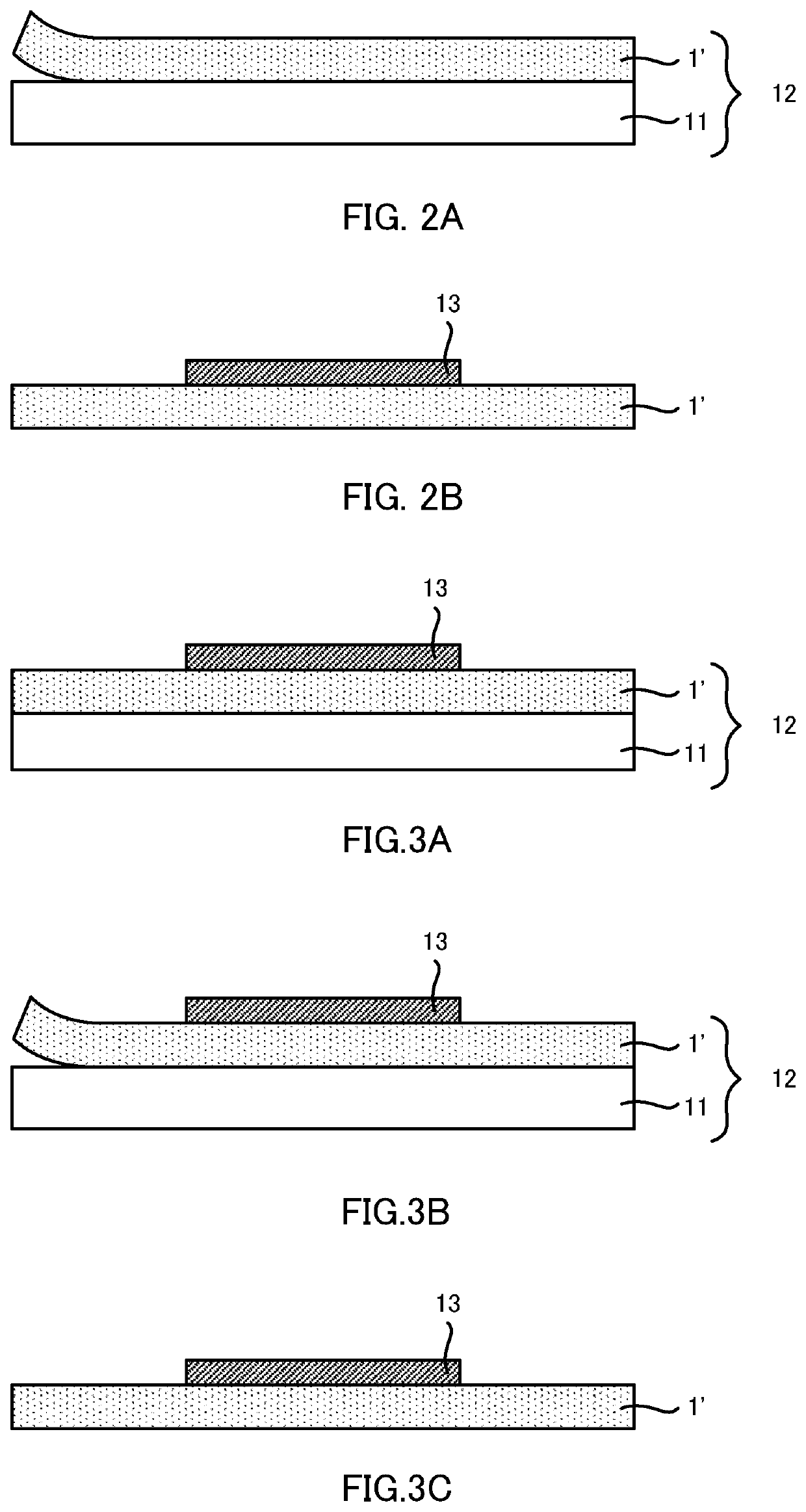

Embodiments provide a method for producing a multilayer film, the method including: (A) a step for continuously coextruding from a T die (3) a molten film (4) of a multilayer film in which a first acrylic resin layer (α1), an aromatic polycarbonate resin layer (β), and a second acrylic resin layer (α2) are directly laminated in the stated order using a coextrusion apparatus; (B) a step for feeding and pressing the molten film of the multilayer film between a first mirror surface body (5) that rotates or revolves and a second mirror surface body (6) that rotates or revolves so that the first acrylic resin layer (α1) is disposed on the first-mirror-surface-body side; and (C) a step for holding the pressed multilayer film against the first mirror surface body and sends the pressed multilayer film to the subsequent third mirror surface body (8) that rotates or revolves, where TR1 (surface temperature of first mirror surface body), TR2 (surface temperature of second mirror surface body), Tα1 (glass transition temperature of first acrylic resin), Tα2 (glass transition temperature of second acrylic resin), and Tβ (glass transition temperature of aromatic polycarbonate resin) satisfy a prescribed relationship.

Owner:RIKEN TECHNOS CORP

Multilayer film

ActiveUS11396165B2Nice appearanceGood colorProtective equipmentSynthetic resin layered productsPolyesterPolymer science

Embodiments provide a multilayer film in which: a first acrylic resin layer (α1), an aromatic polycarbonate resin layer (β), and a second acrylic resin layer (α2) are directly laminated in the stated order; the aromatic polycarbonate resin constituting the aromatic polycarbonate resin layer (β) is a product of ester exchange between a polycarbonic acid ester of an aromatic dihydroxy compound and a low-crystalline or amorphous aromatic polyester; and the relationships (Tβ−Tα1)≤30 and (Tβ−Tα2)≤30 (where Tα1 is the glass transition temperature of the acrylic resin constituting the first acrylic resin layer (α1), Tα2 is the glass transition temperature of the acrylic resin constituting the second acrylic resin layer (α2), Tβ is the glass transition temperature of the aromatic polycarbonate resin constituting the aromatic polycarbonate resin layer (β), and all of the temperatures are measured in degrees Celsius) are satisfied. The glass transition temperature of the aromatic polycarbonate resin should be 100-140° C.

Owner:RIKEN TECHNOS CORP

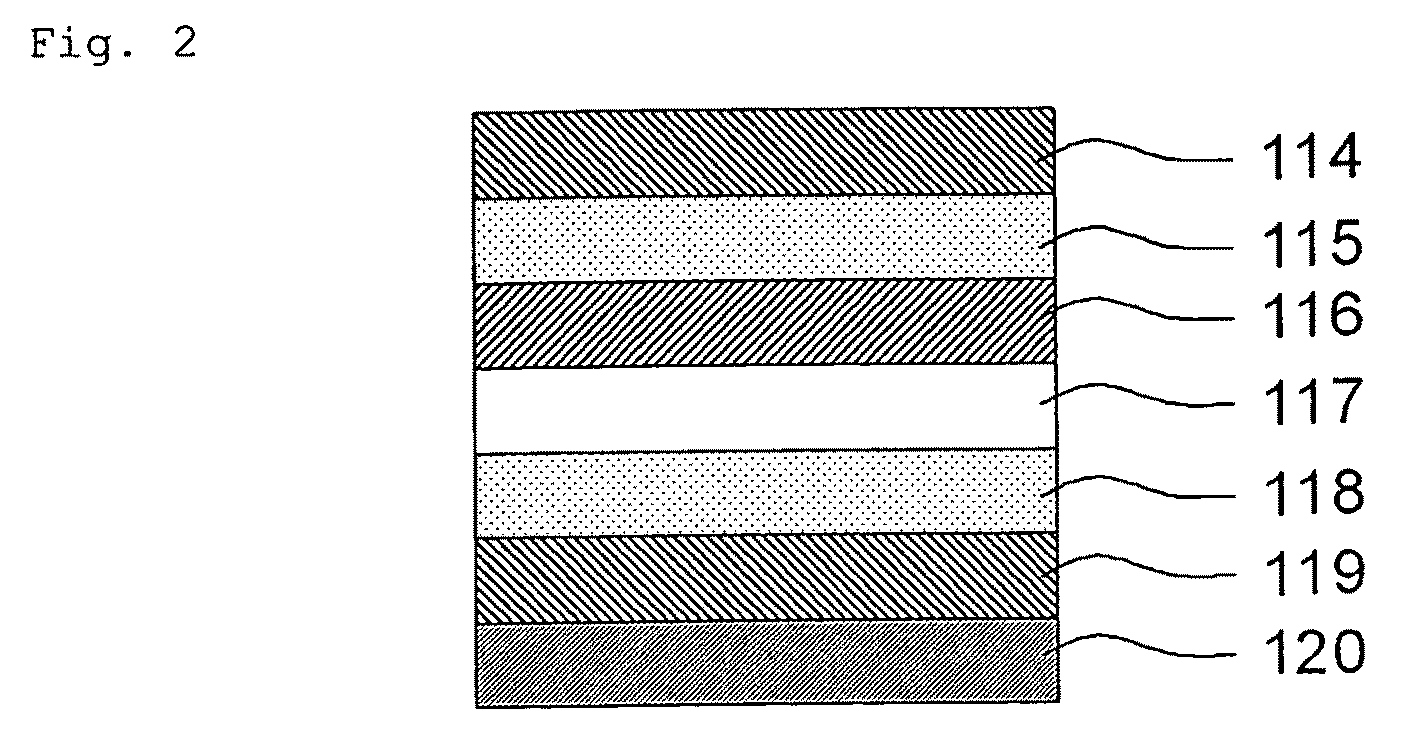

Phase retardation film and compensation film

PendingUS20220291435A1Simple manufacturing processLow production costSolid-state devicesSemiconductor/solid-state device manufacturingChemistryComposite material

A phase retardation film is applied to an organic light-emitting diode display device and includes a biaxially stretched polymer substrate and a liquid crystal layer. The polymer substrate has a positive wavelength dispersion characteristic. A thickness of the polymer substrate is between 5 μm and 100 μm. The liquid crystal layer is directly coated on the polymer substrate by a full coating process, and there is no adhesion layer between the liquid crystal layer and the polymer substrate. A thickness of the liquid crystal layer is between 0.4 μm and 5 μm. One of the polymer substrate and the liquid crystal layer has a phase retardation of λ / 2, and the other has a phase retardation of λ / 4. A compensation film using the phase retardation film is also provided.

Owner:SICHUAN LONGHUA FILM CO LTD

Optical filter and imaging device comprising the same

ActiveUS9057840B2Increase resistanceHigh strengthOptical filtersCamera body detailsPhysical chemistryLight filter

Owner:JSR CORPORATIOON

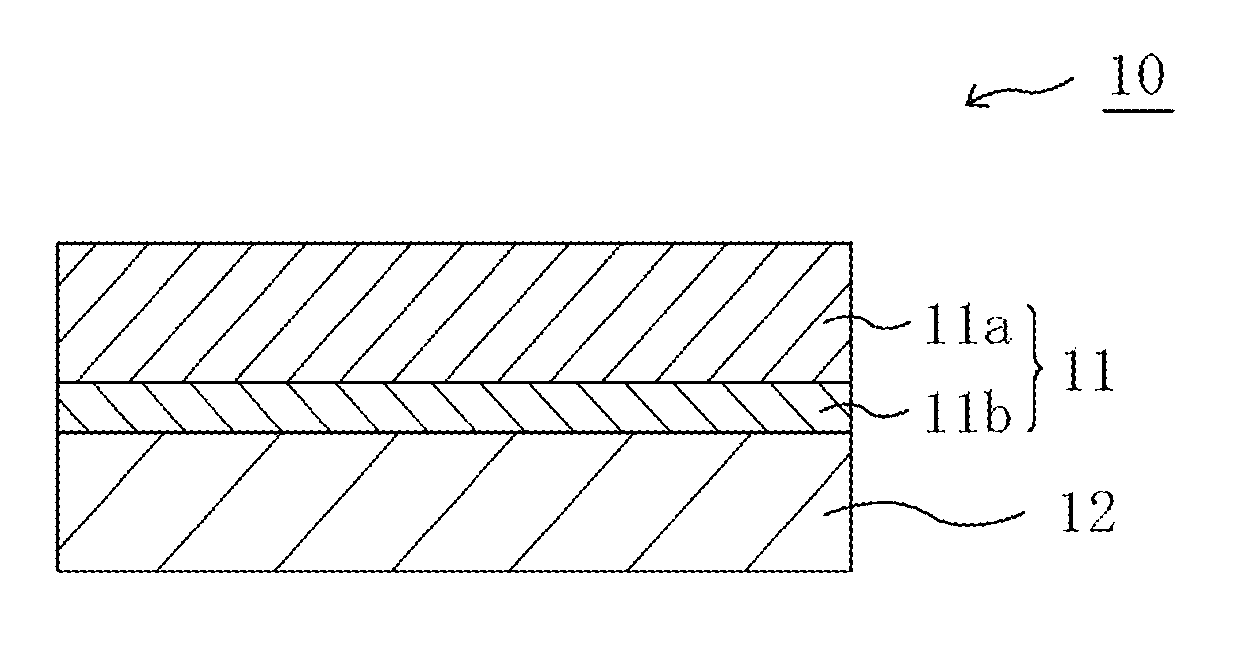

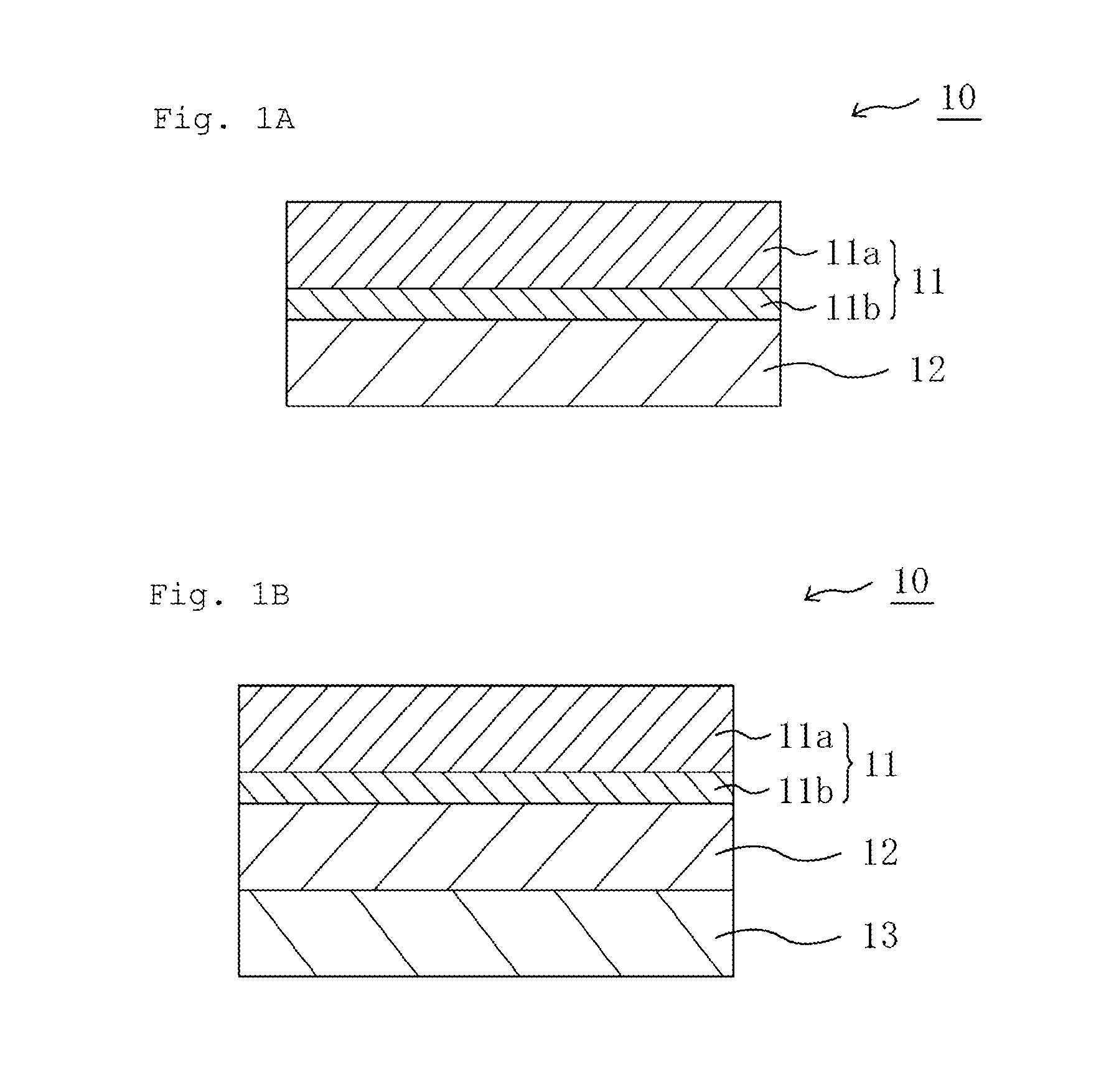

Optical film, multilayer optical film including same, and method for producing optical film

ActiveUS10649123B2Small retardationLarge retardationSynthetic resin layered productsOptical articlesOptical thin filmMaterials science

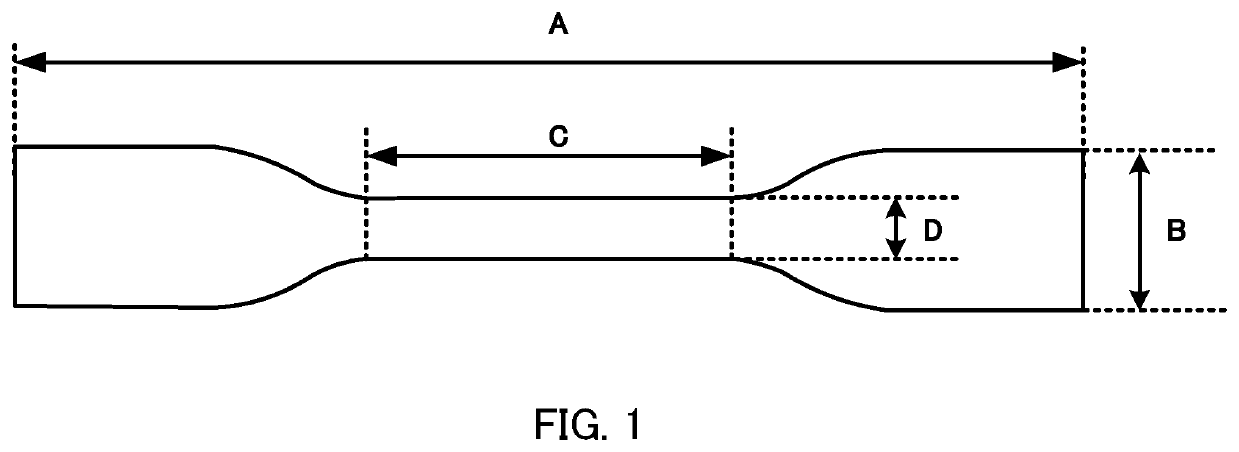

Provided are: an optical Elm that has a good appearance, small in-plane retardation Re, and large thickness-direction retardation Rth; and a method for producing such an optical film. Also provided is a multilayer optical film that uses the optical film, that exhibits little change in retardation as a result of wavelength, and that has small retardation at low wavelengths. The optical film is obtained by sandwiching a melted resin between a first cooling roll comprising an elastic metal roll and a second cooling roll comprising a non-elastic metal roll and molding said melted resin. The optical film has a good appearance, the absolute value of the in-plane retardation Re thereof is 10 nm or less, and the thickness-direction retardation Rth thereof is 40 nm or more.

Owner:MITSUBISHI GAS CHEM CO INC +1

Polyamic acid, varnish containing same, film, touch panel display, liquid crystal display, and organic el display

PendingUS20210261732A1High tensile elongationSmall thickness-direction retardationCoatingsThermal dilatationPolymer science

The purpose of the present invention is to provide: a film having high thermal stability, high bending strength (tensile elongation), small retardation in the thickness direction, a low coefficient of thermal expansion, and high transparency; and a polyamic acid or varnish for obtaining the film. The film satisfies all of requirements (i)-(vi) below. (i) The average value of the coefficient of thermal expansion in the range of 100-200° C. is 35 ppm / K or less. (ii) The absolute value of the retardation in the thickness direction is 200 nm or less per 10 μm of thickness. (iii) The glass transition temperature is 340° C. or higher. (iv) The total light transmittance is at least 85%. (v) The b* value in the L*a*b* color system is 5 or less. (vi) The tensile elongation is at least 10%.

Owner:MITSUI CHEM INC

Curable resin composition, curable resin molded body, cured resin molded body, method for producing each of same, and laminate body

ActiveUS9102833B2Low birefringenceEfficiently obtainedPretreated surfacesCoatingsHeat resistanceRefractive index

Provided is a curable resin composition comprising a thermoplastic resin (A) that includes a cyclic structure in its main chain, and has a glass transition temperature (Tg) of 140° C. or more, and a monofunctional curable monomer (B). The present invention provides: a cured resin formed article that has heat resistance and low birefringence, a method for producing the same, a curable resin composition and a curable resin formed article that are useful as a raw material for producing the cured resin formed article, and a laminate that includes a layer formed of a cured resin.

Owner:LINTEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com