Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Shorten support time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

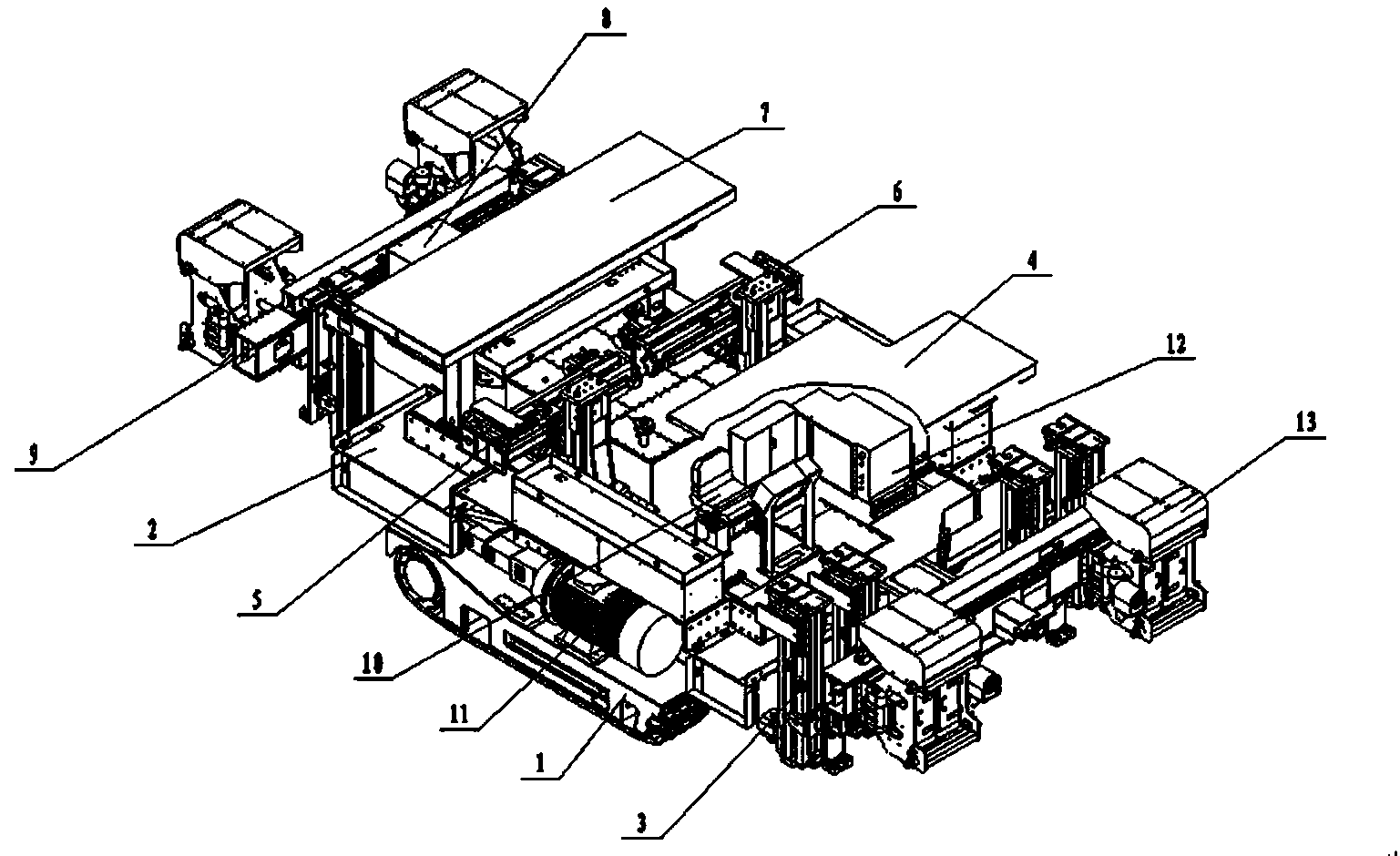

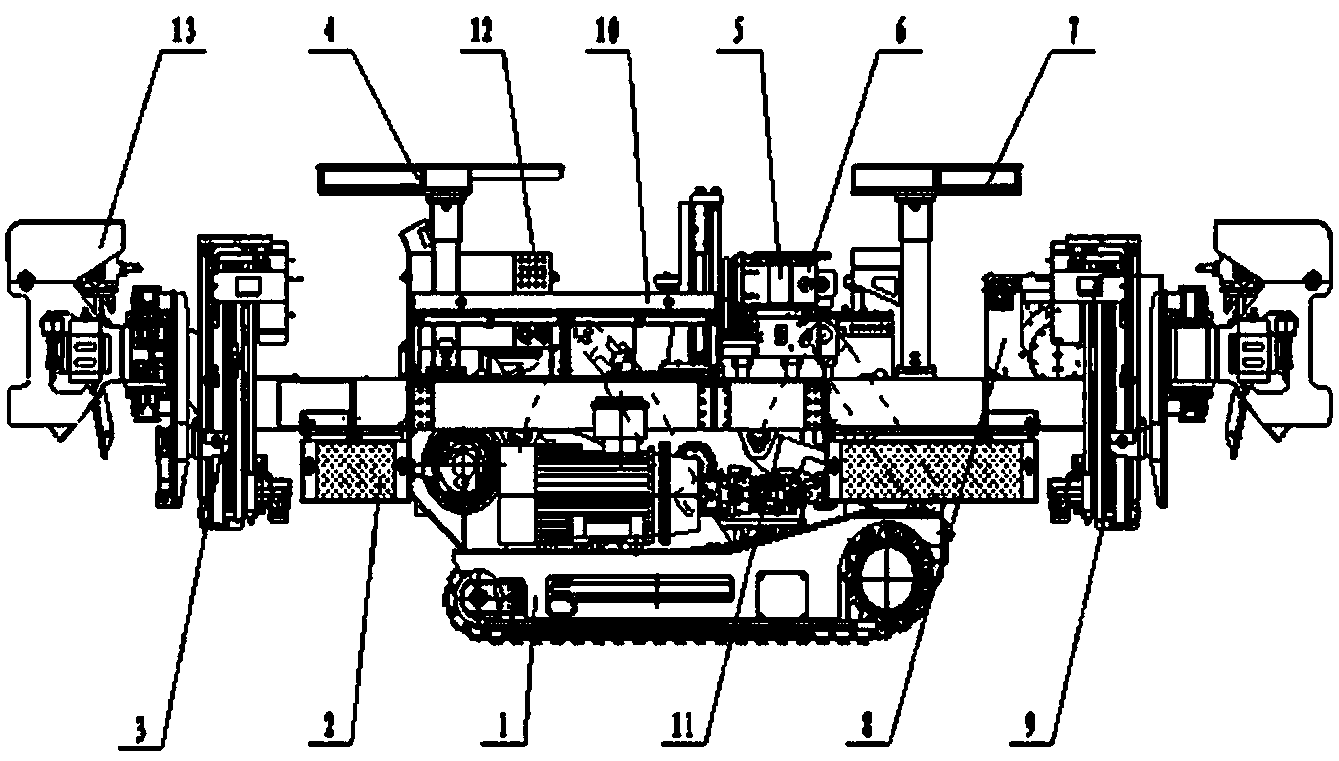

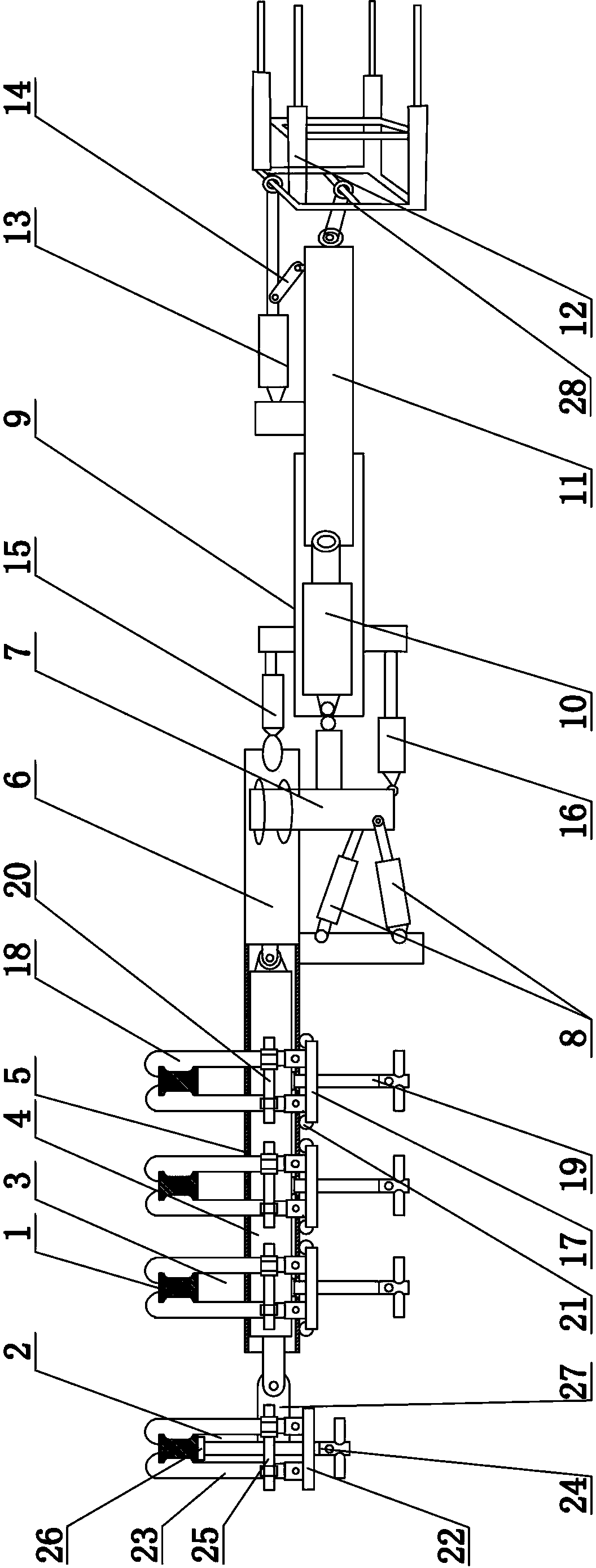

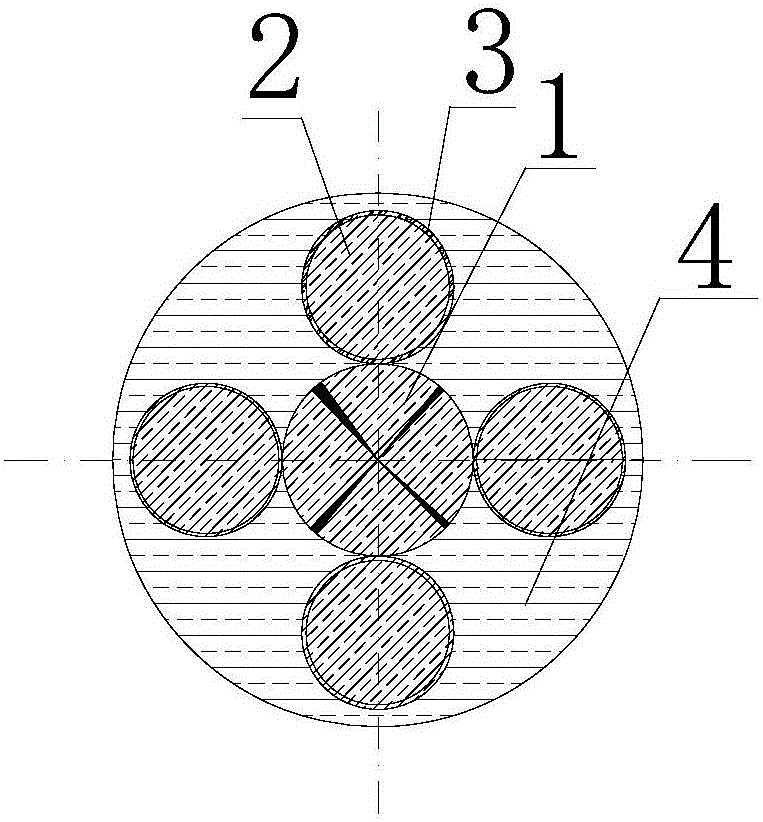

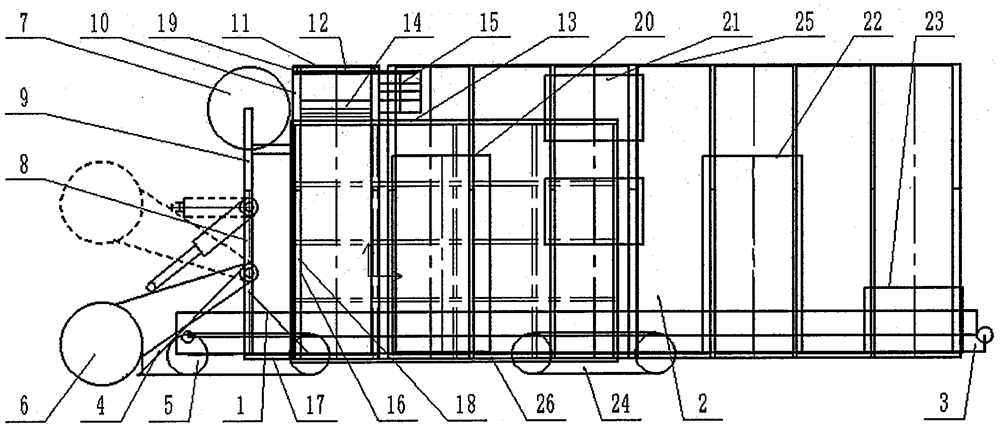

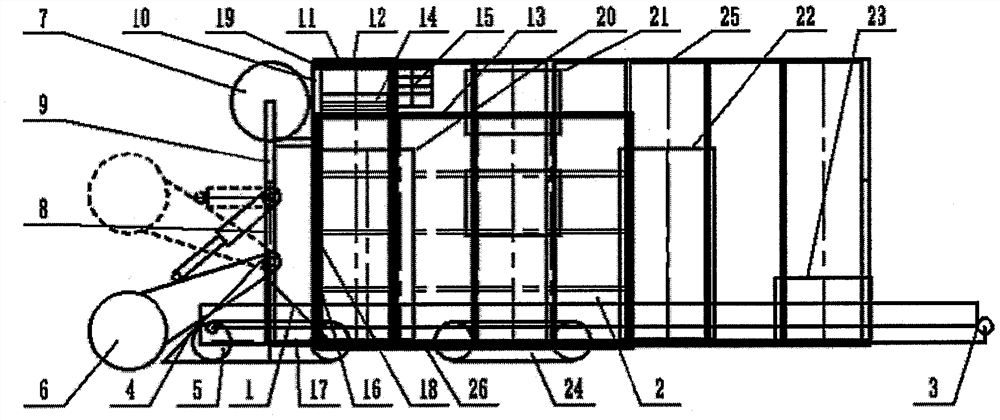

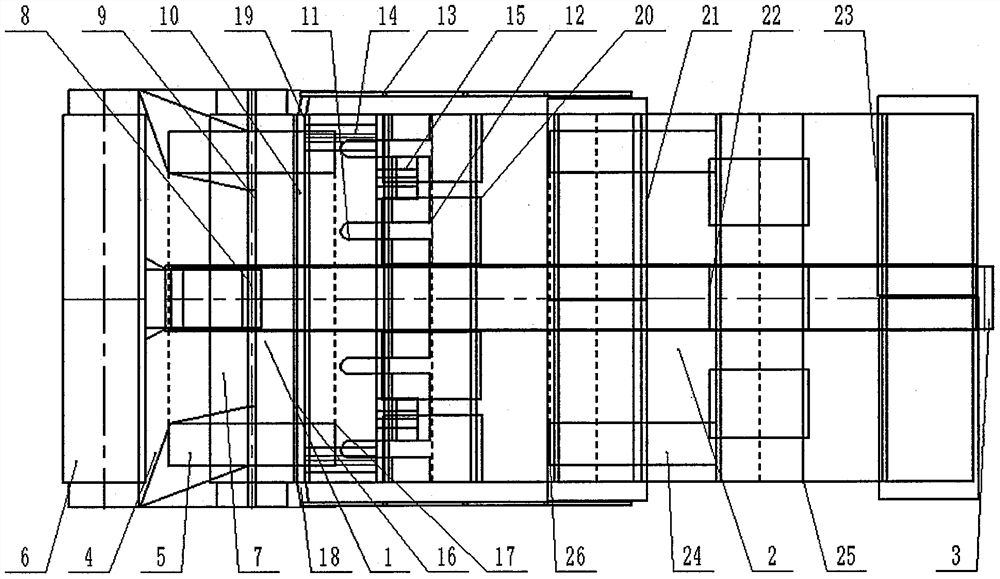

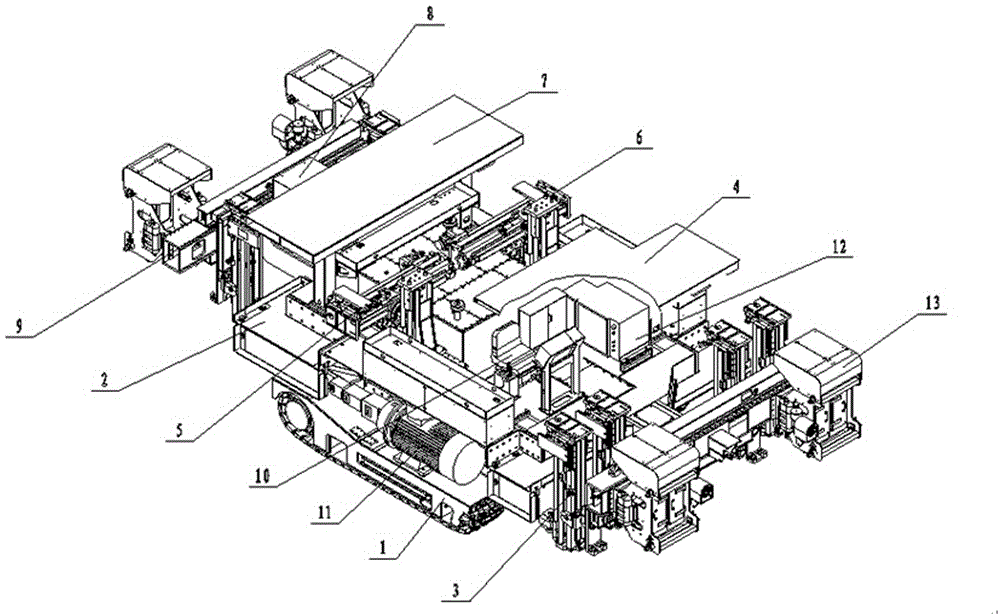

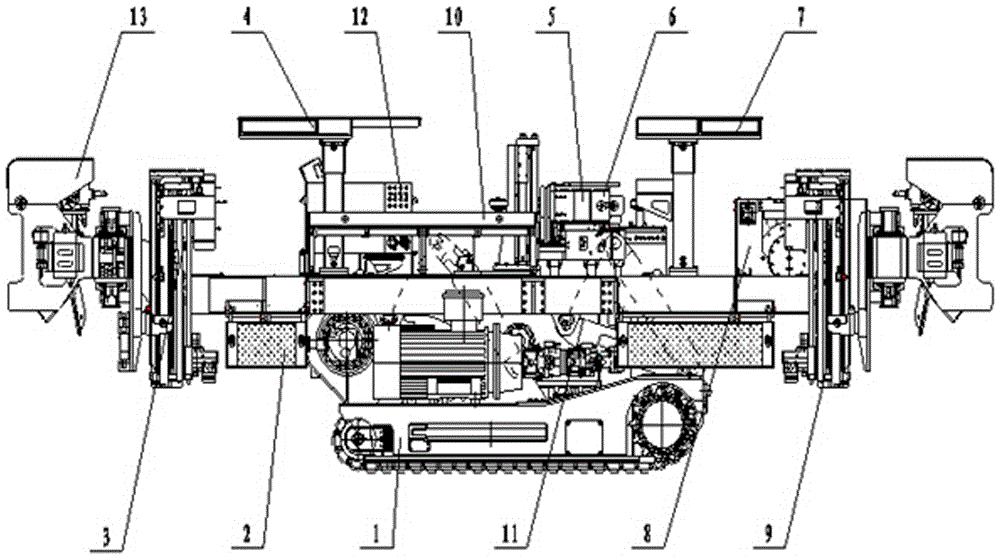

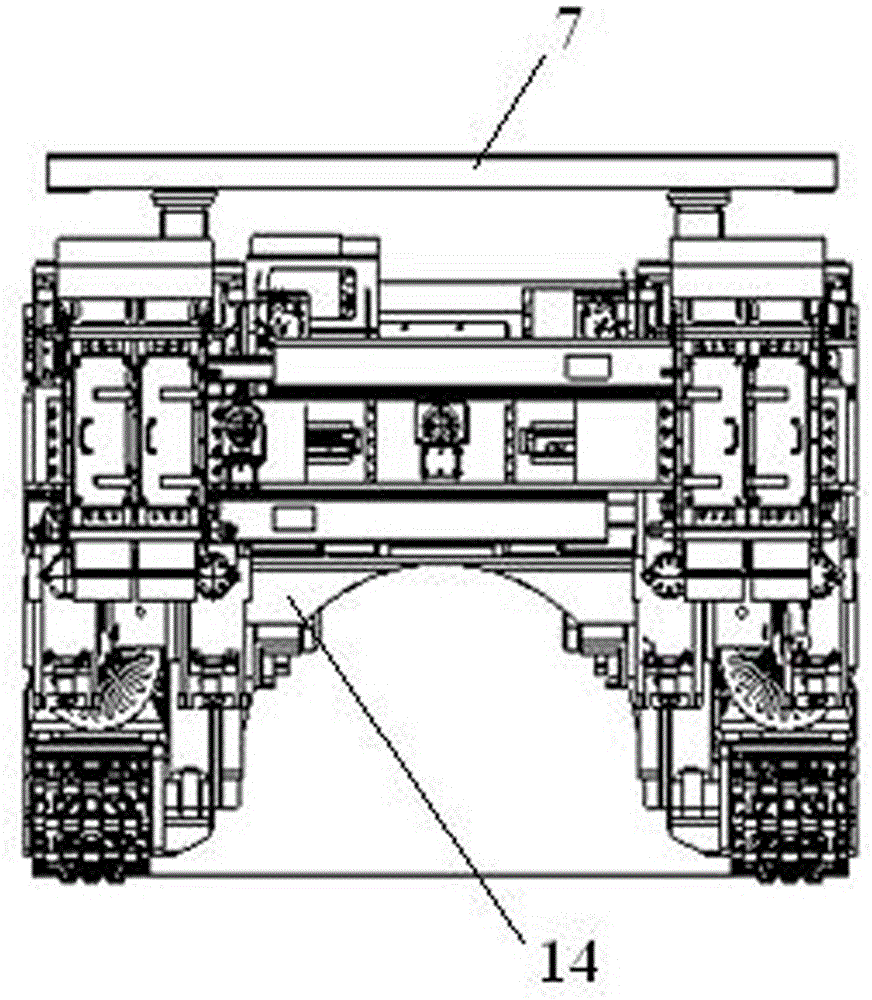

Anchor rod drill carriage integrating coal mine digging, supporting and transportation parallel fast operation

ActiveCN104213831AImprove tunneling efficiencyImplement parallel jobsDerricks/mastsSlitting machinesSelf adaptiveDrill

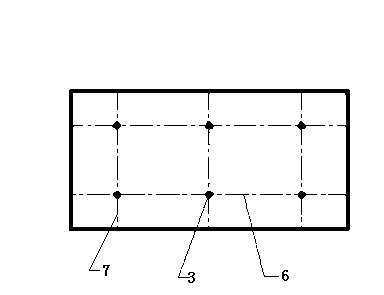

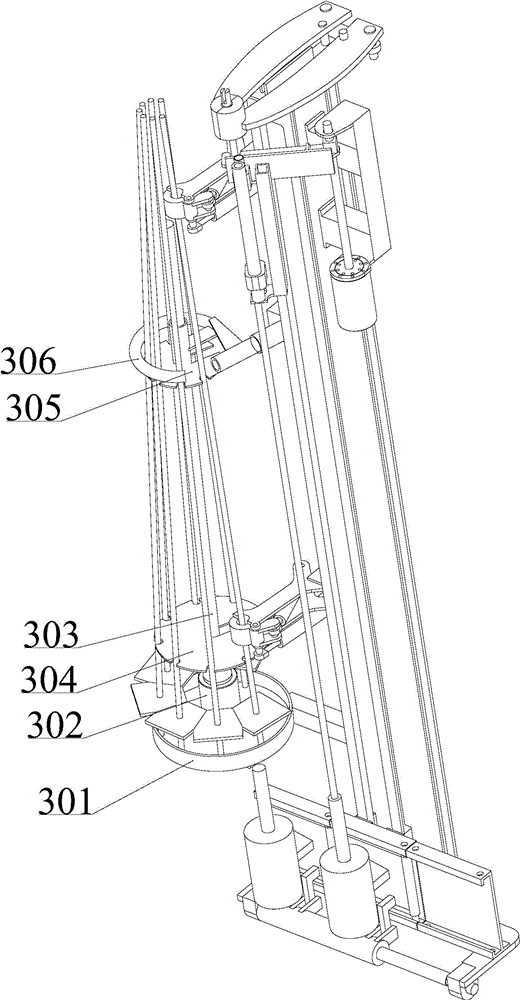

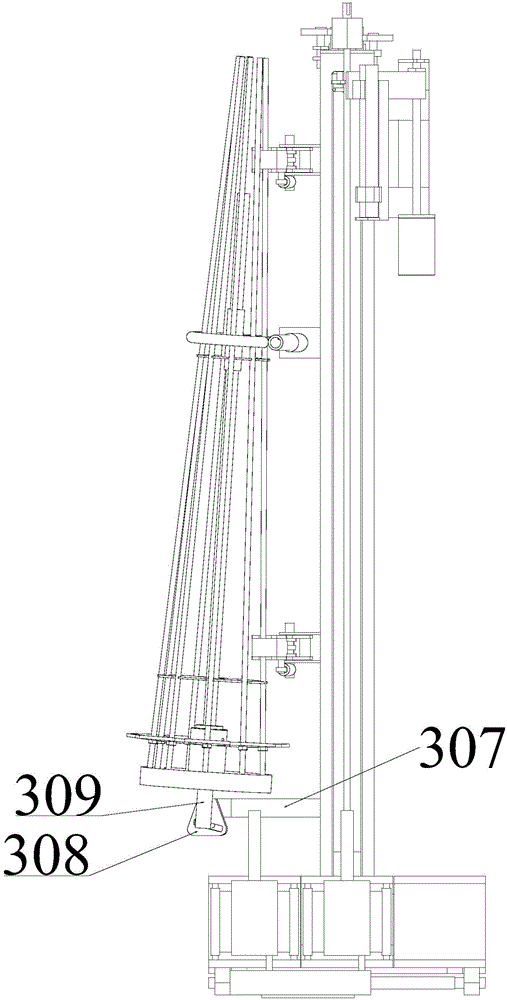

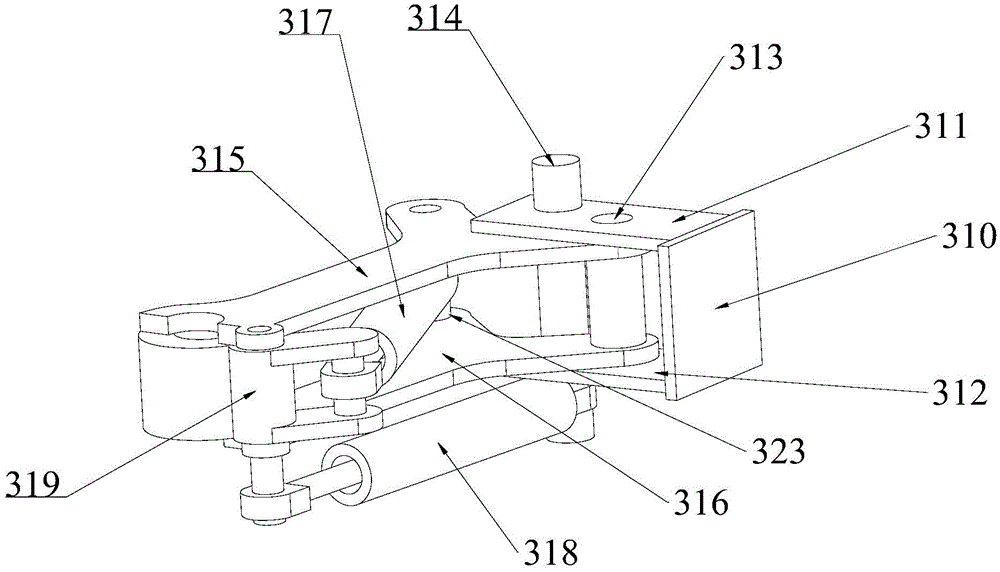

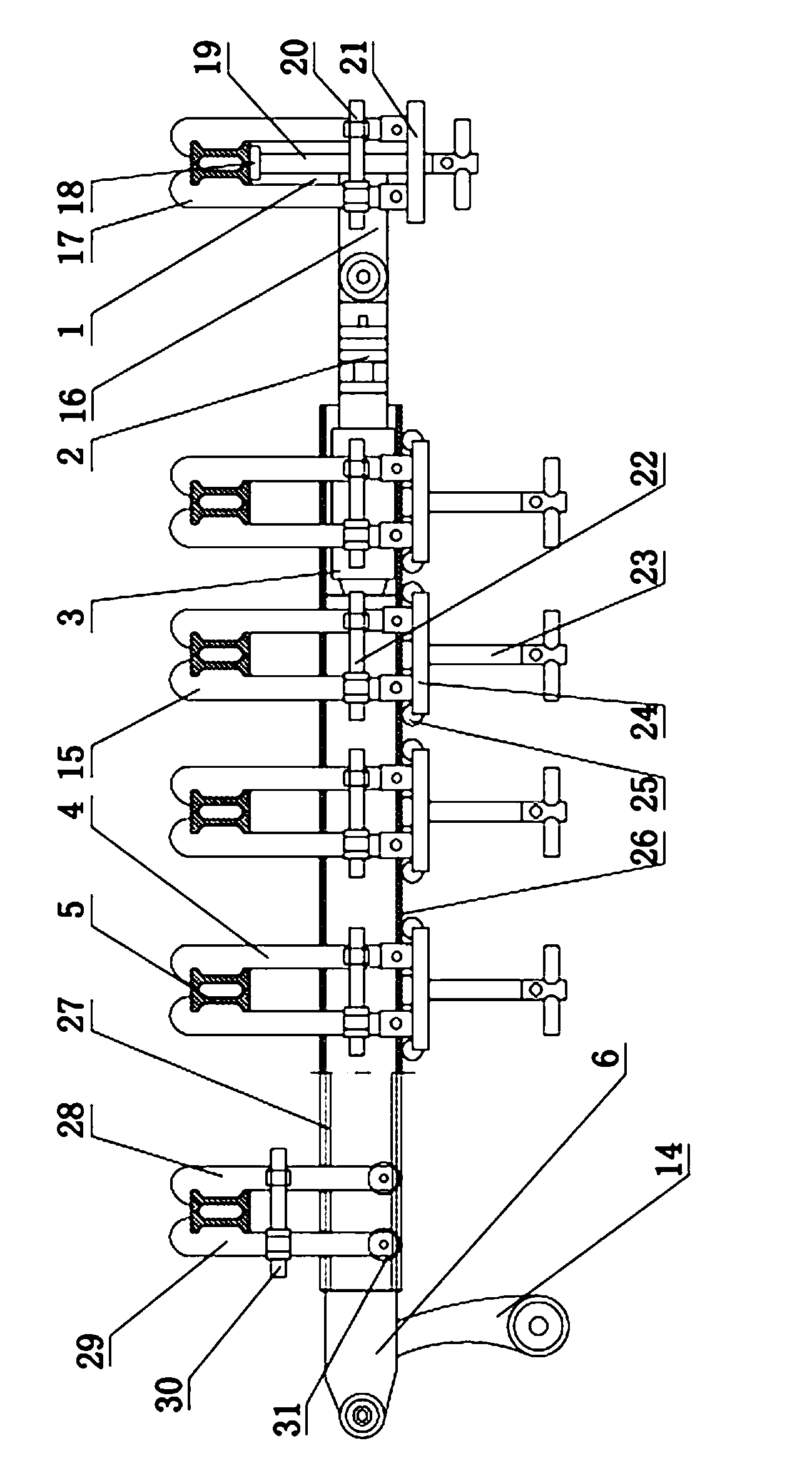

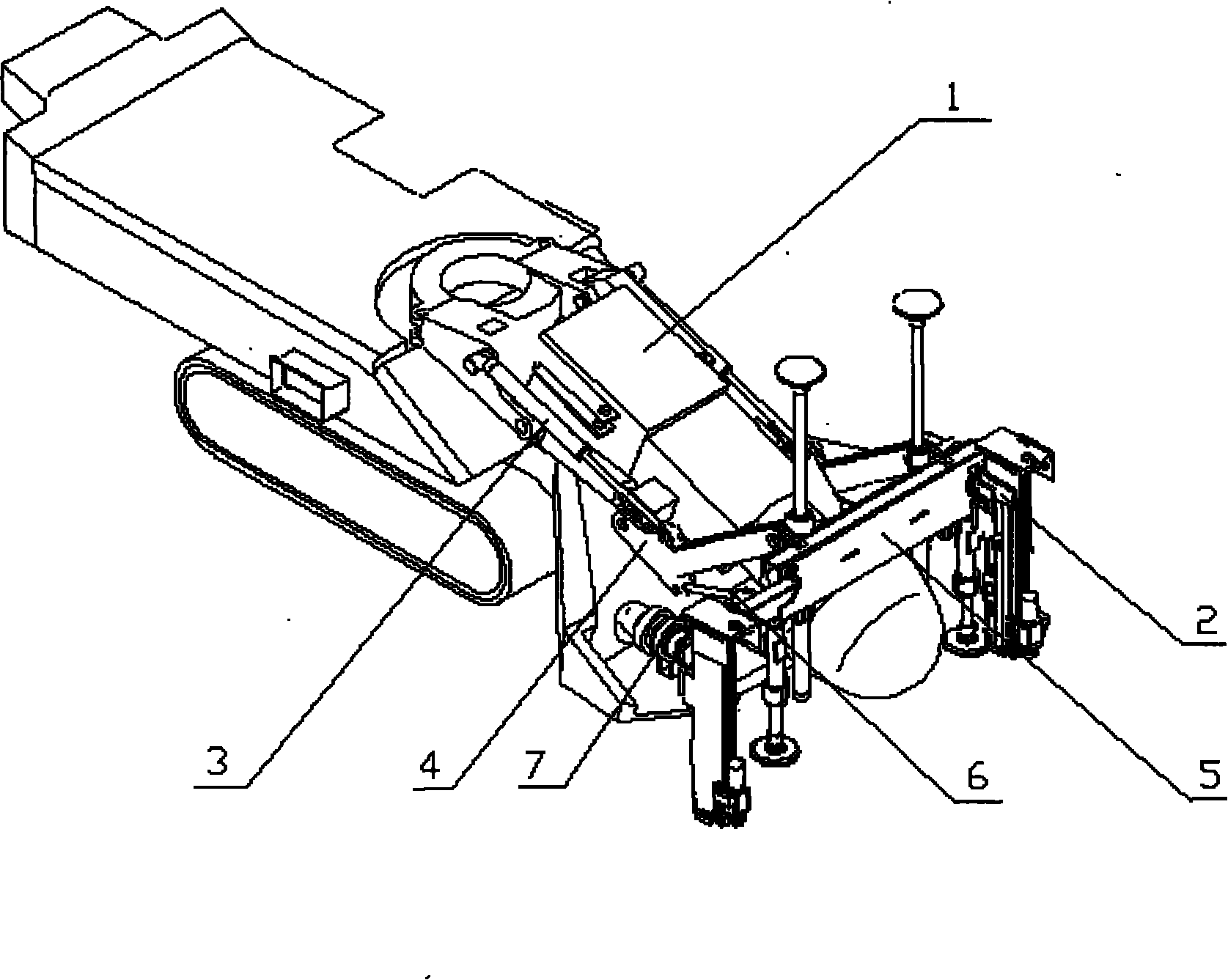

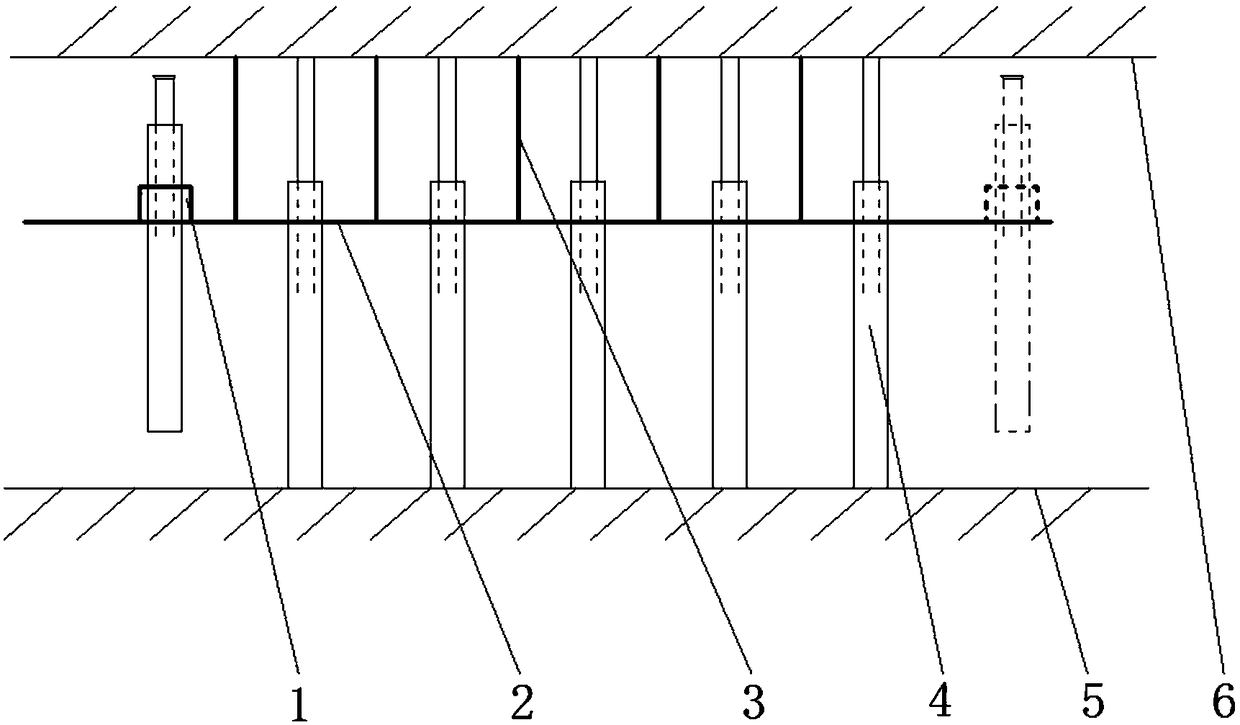

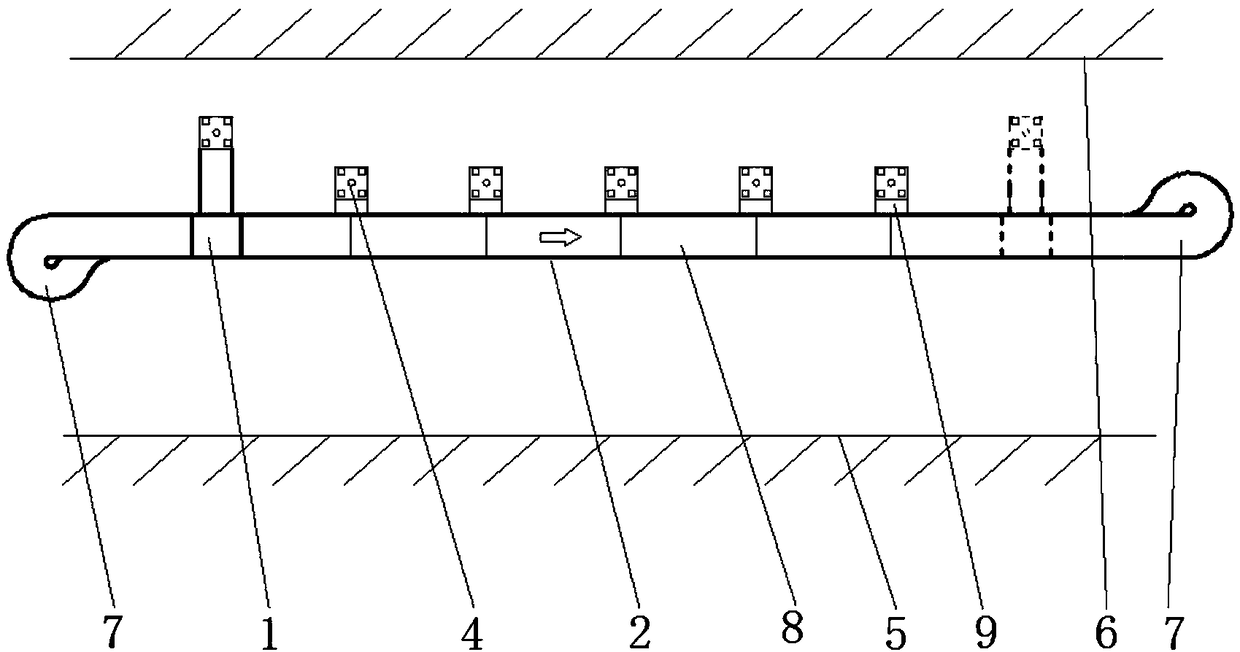

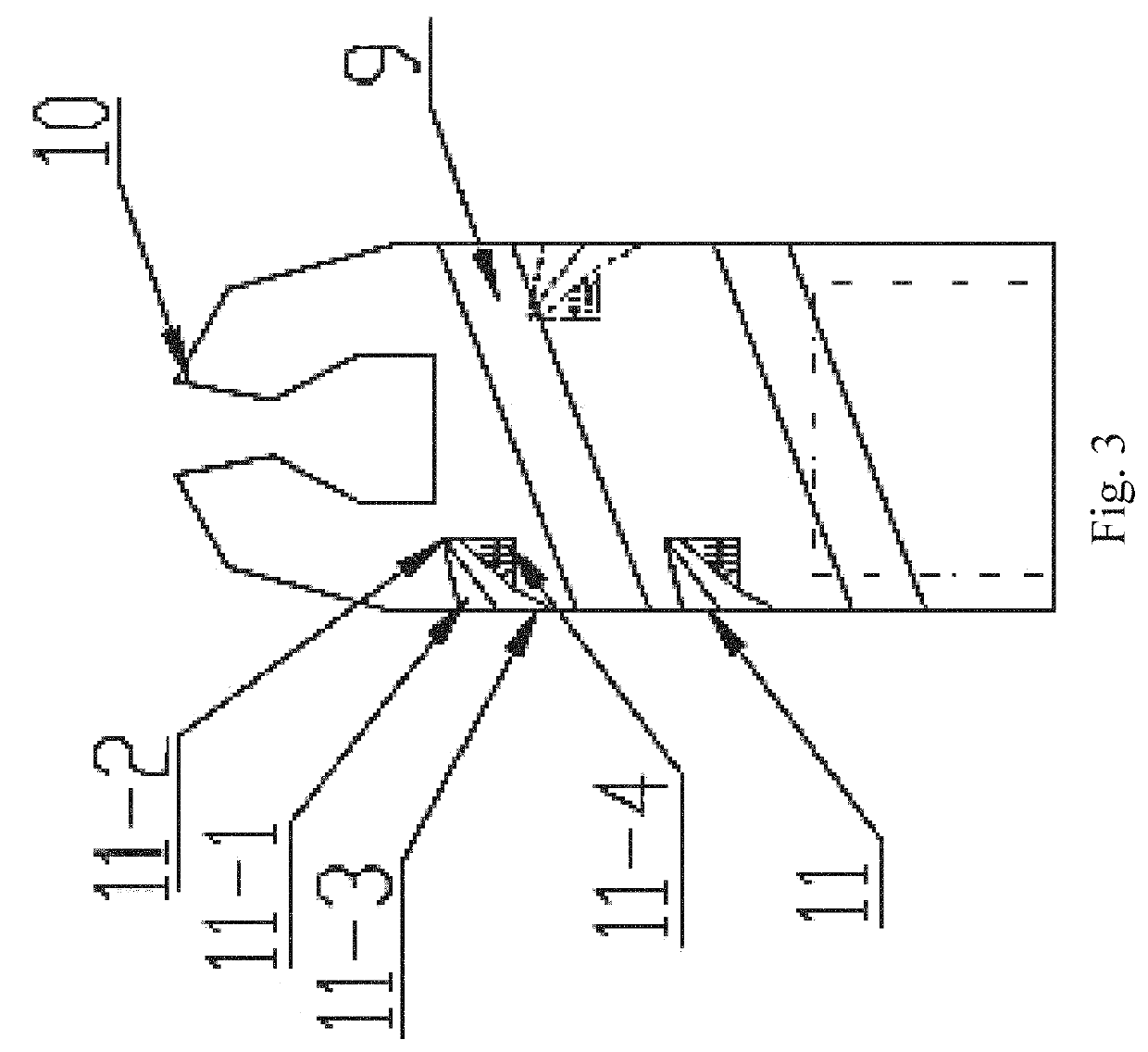

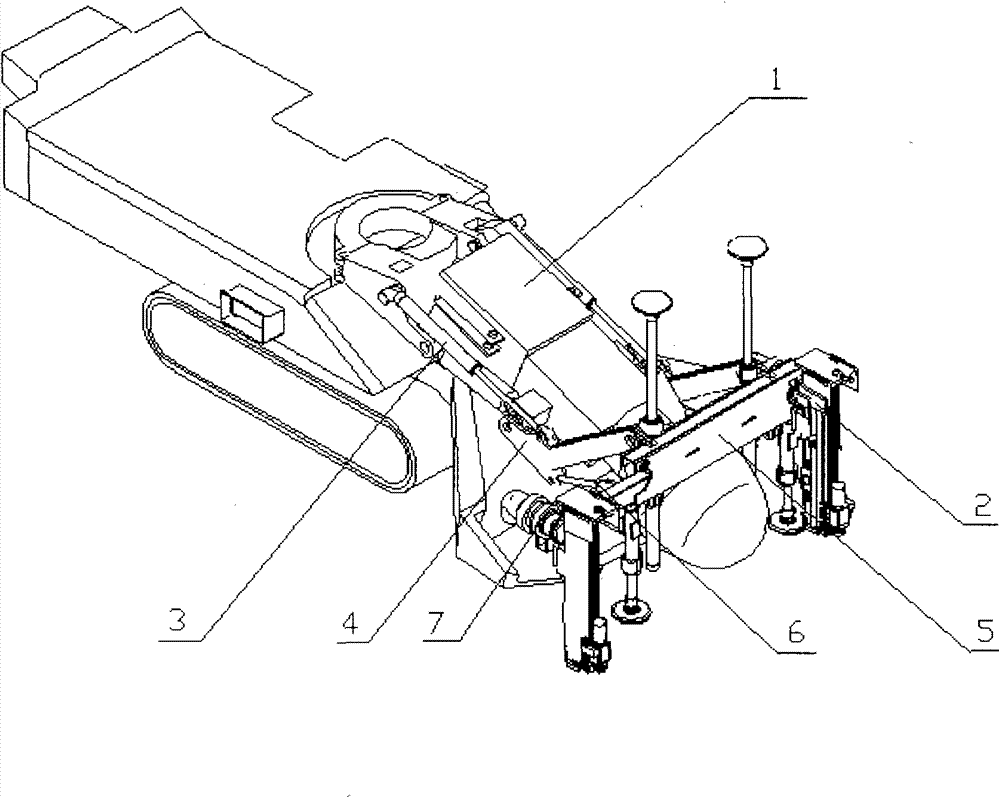

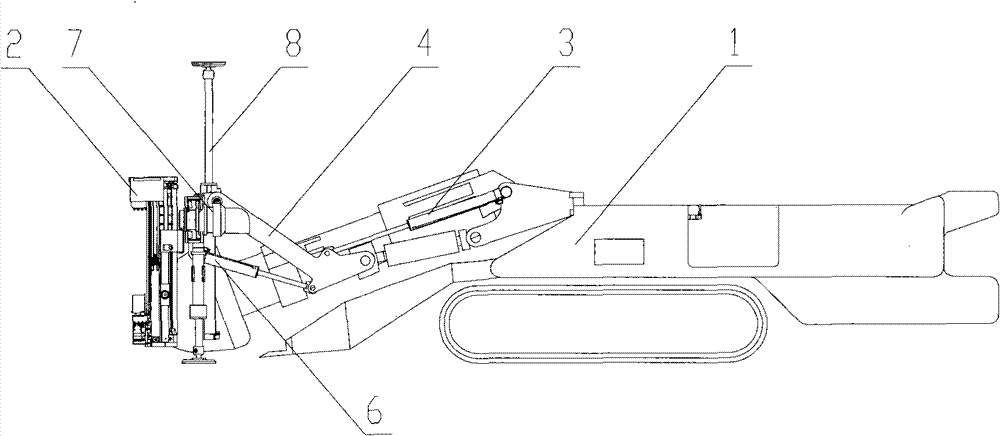

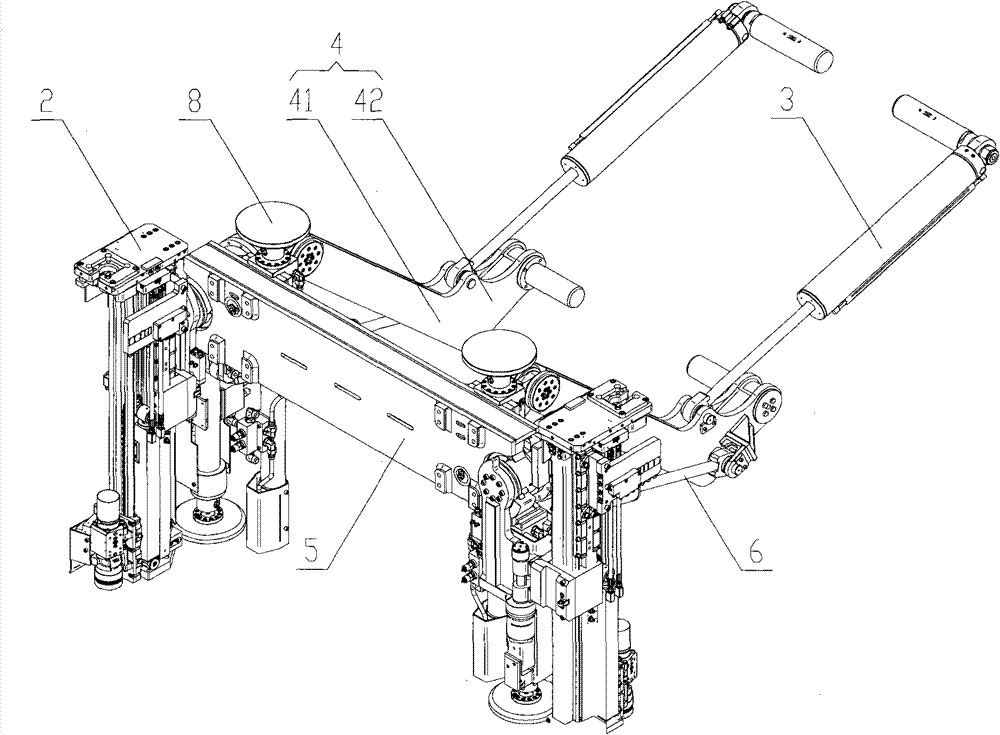

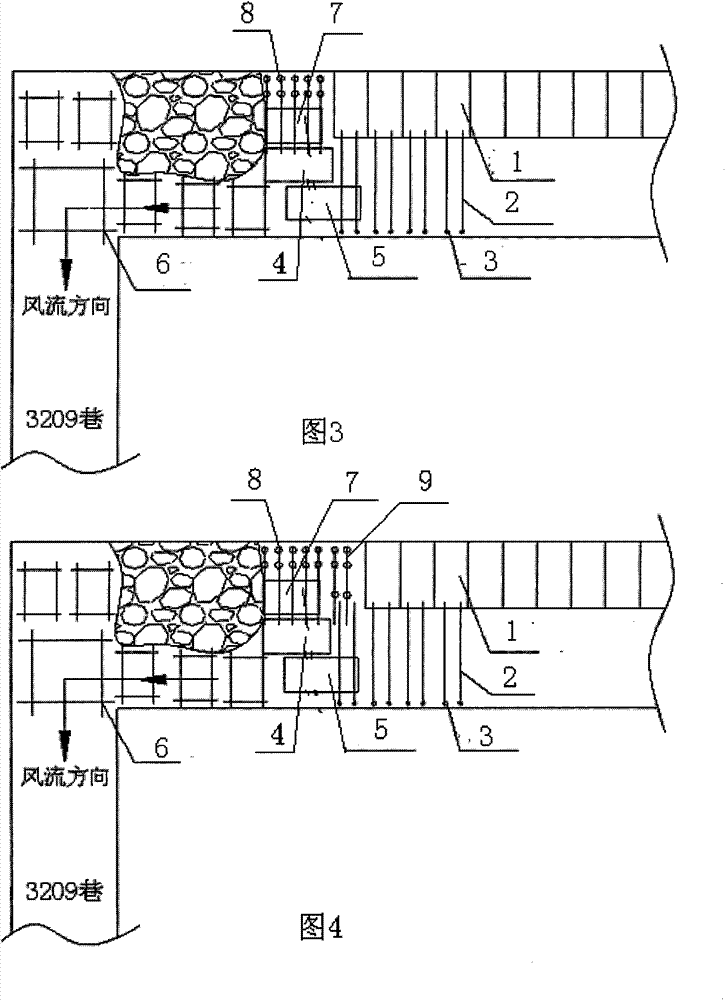

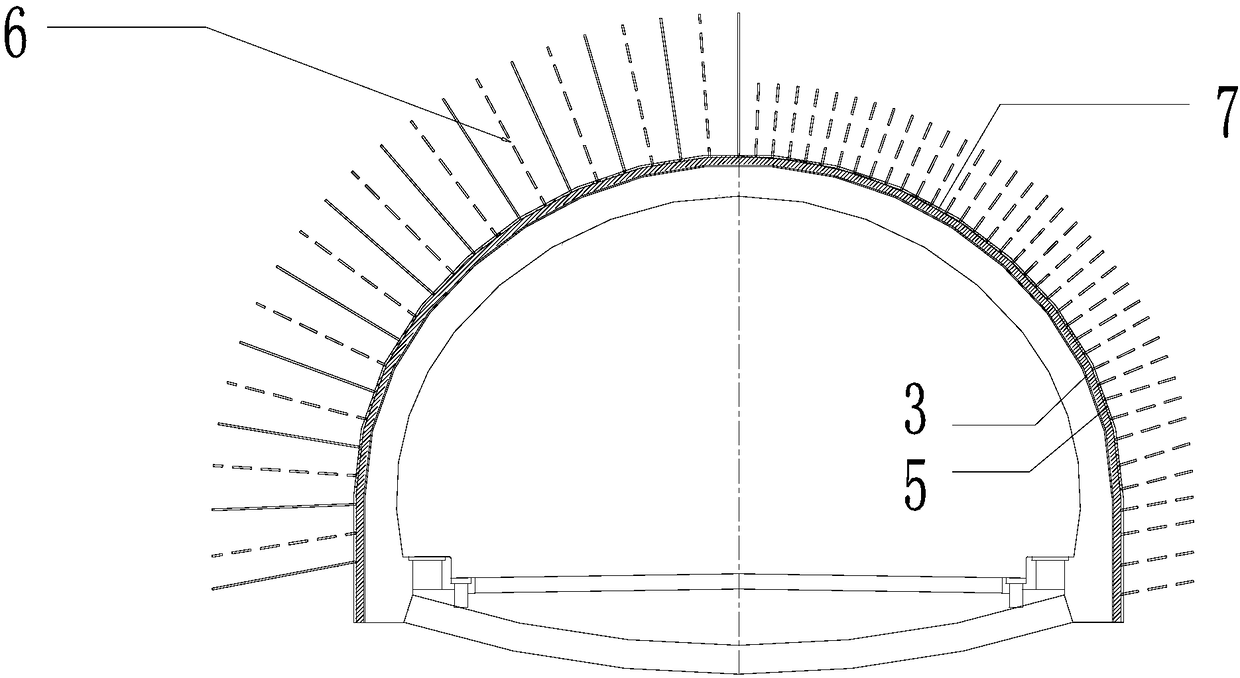

The invention relates to the field of coal mine underground roadway digging, in particular to an anchor rod drill carriage integrating coal mine digging, supporting and transportation parallel fast operation. The anchor rod drill carriage solves the problems of complexity and time waste of the existing machine debugging process, low roadway digging efficiency, digging and supporting unbalance and the like. A middle frame is of an arc-shaped structure, belt conveyor pin tooth transmission traction mechanisms connected with a mine traction type self-adaptive belt conveyor are symmetrically arranged at the two sides of the middle frame, and the mine traction type self-adaptive belt conveyor passes through an arc-shaped space below the middle frame and extends to a position under a digging machine discharging part; eight sets of drill arms are matched, respectively include four sets of front anchoring and protecting drill arms, two sets of back anchoring and protecting drill arms and two sets of side upper anchoring and protecting drill arms, and are arranged in three rows at the front side and the back side, in addition, each set of drill arms can slide for a certain displacement stroke, the adjustable supporting ranging distance height can be realized, 6-top 2-upper anchor rod supporting can be completed in one step through parallel operation, the supporting time is shortened, the supporting efficiency is improved, a belt conveying passage can be provided, and the one-supporting and one-conveying operation parallel operation can be realized.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

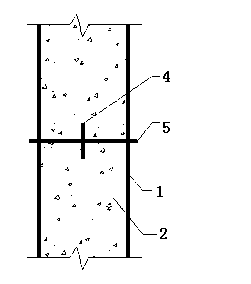

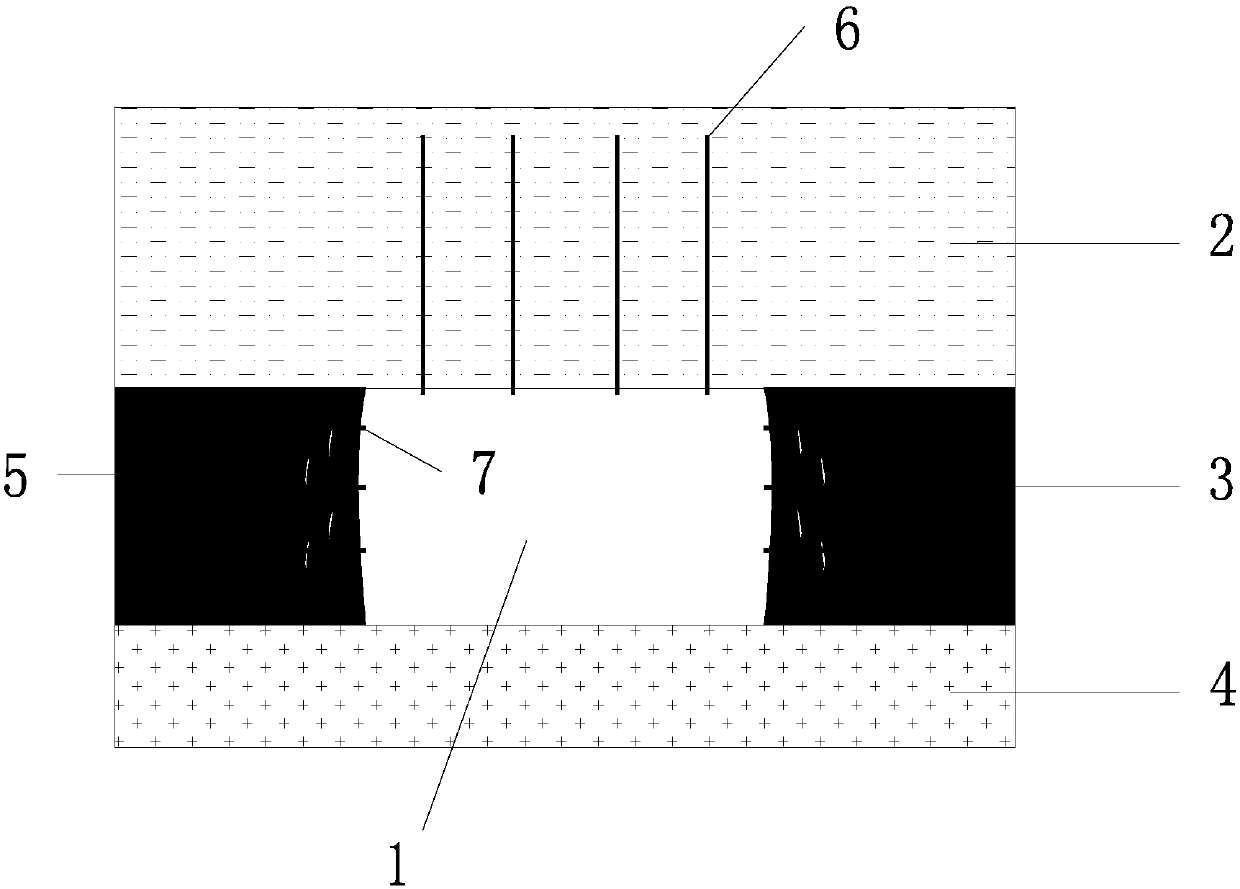

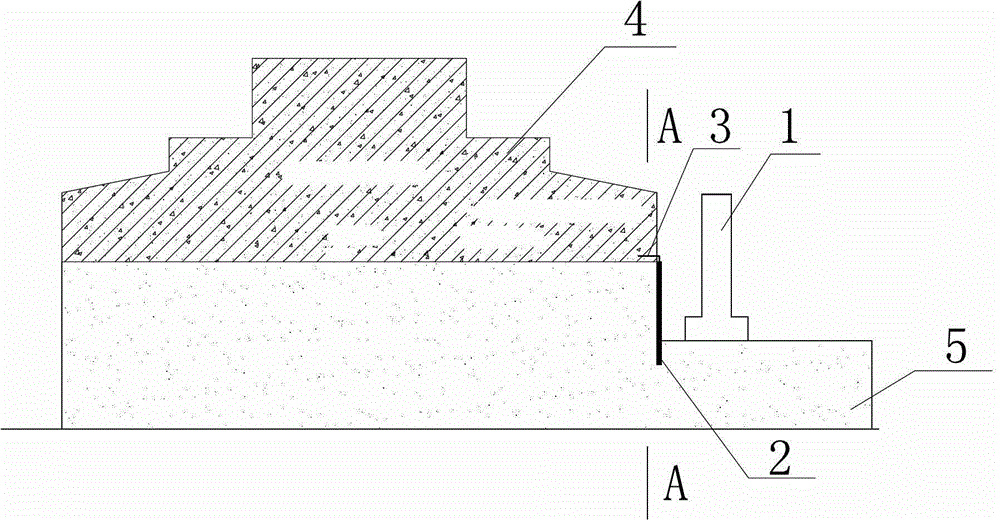

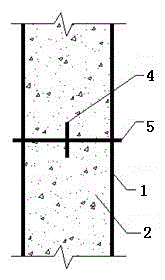

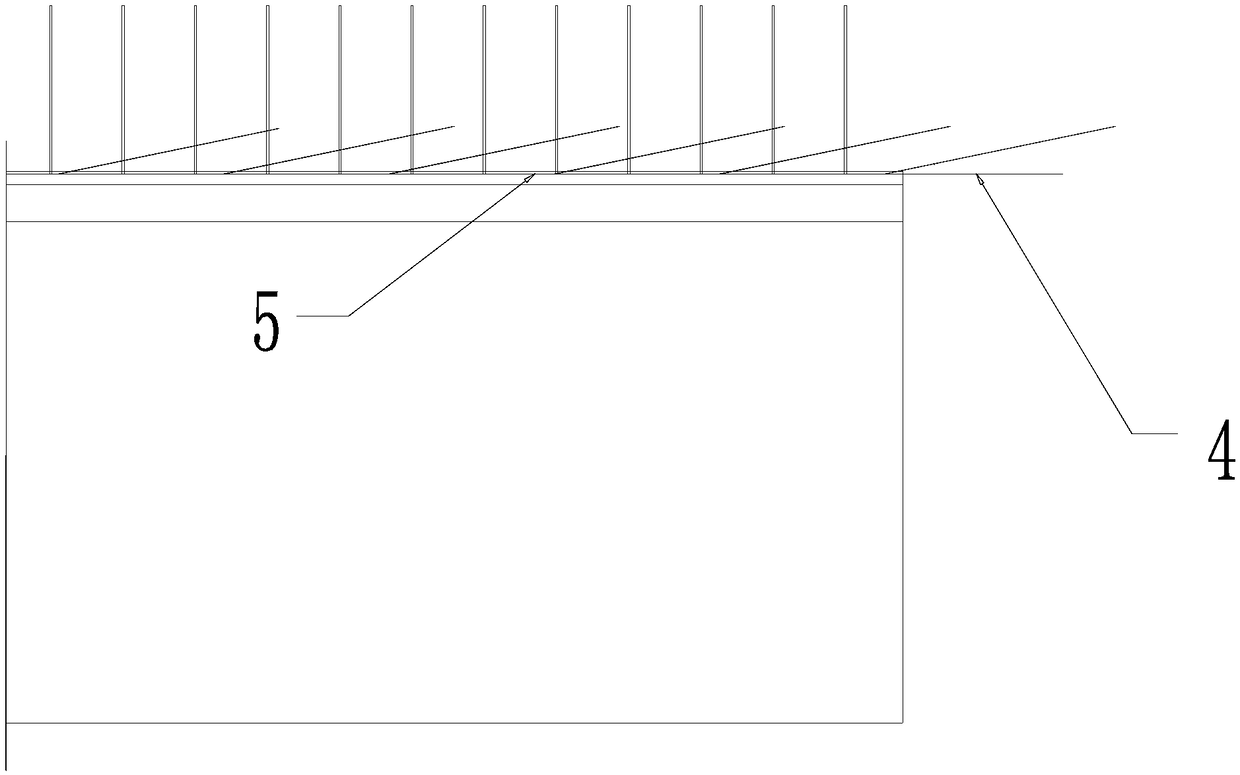

Integral casting process for reinforced concrete wastewater tank in predrilling engineering

ActiveCN103015719AShorten construction timeShorten the construction periodBuilding material handlingReinforced concreteWastewater

The invention discloses an integral casting process for a reinforced concrete wastewater tank in predrilling engineering. The integral casting process comprises the following steps of a, construction of a foundation and a bedding layer, digging a foundation pit, and casting the concrete bedding layer after determining that the foundation bearing force meets the design requirements; b, manufacturing and installation of reinforced bars, manufacturing and installing on site, wherein the overlapping length of the reinforced bars should not be less than 40 times of the diameter (mm) of each reinforced bar, and the overlapping area of the reinforced bars same in cross section should not be more than 50% of the total area; c, supporting of die plates, binding the die plates into the shapes of the bottom and the wall of a concrete tank; d, casting of concrete, after completing the construction of the reinforced bars and the die plates, carrying out the casting construction of concrete, firstly casting the bottom of the concrete tank and the wall with the height less than 1m, leveling the top of the wall of the concrete tank, and reserving no step to complete the first time of casing; casting the residual wall of the concrete tank in at least one hour after completing the first time of casting; and e, removal of the die plates, removing the die plates when the strength of the cast concrete being more than 1.2MPa. The integral casting process has the advantages that the construction time of the wastewater tank in the predrilling engineering is reduced, the construction period of the whole predrilling engineering is shortened, the condition of drilling machines not waiting for well fields is ensured, the construction seams are not reserved in the construction, and the leakage problem caused by the construction seams is avoided.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

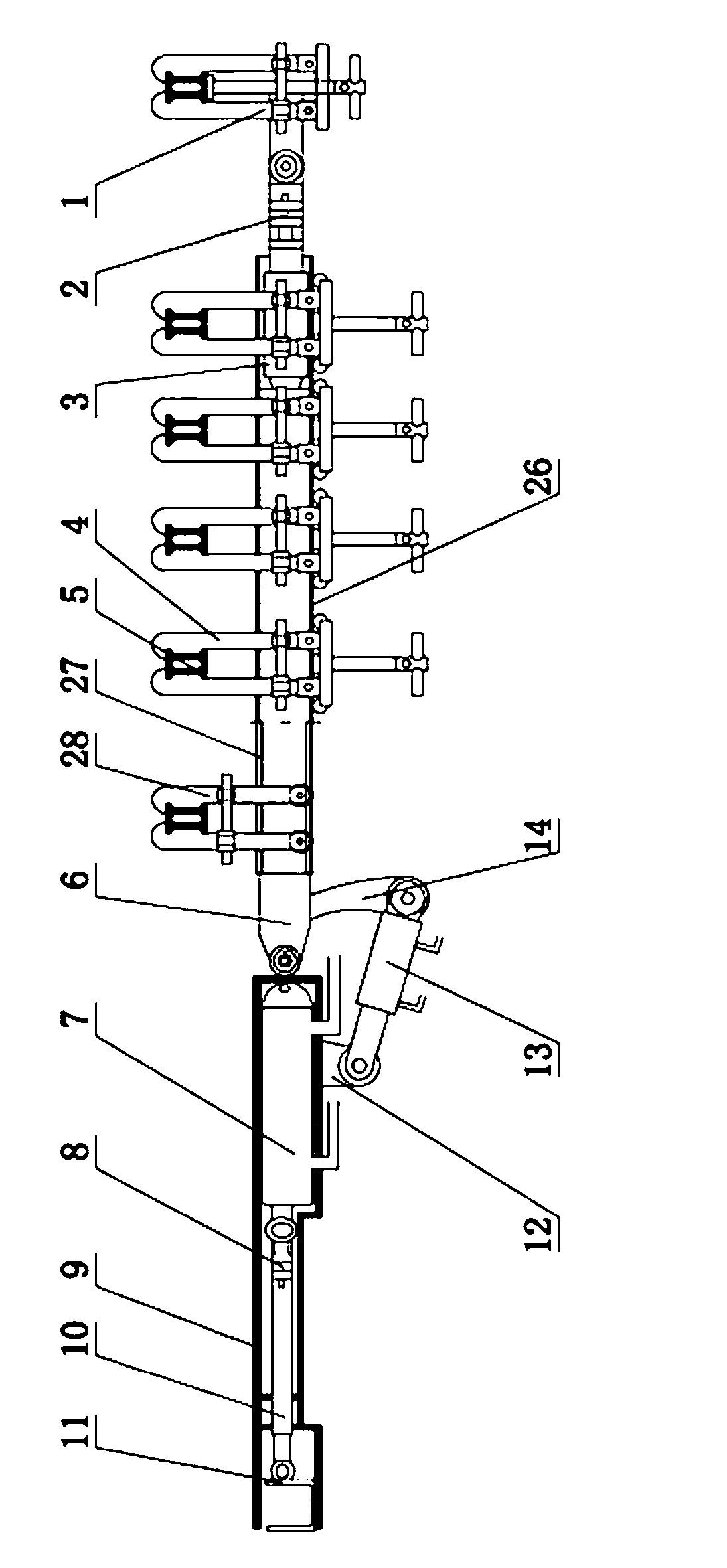

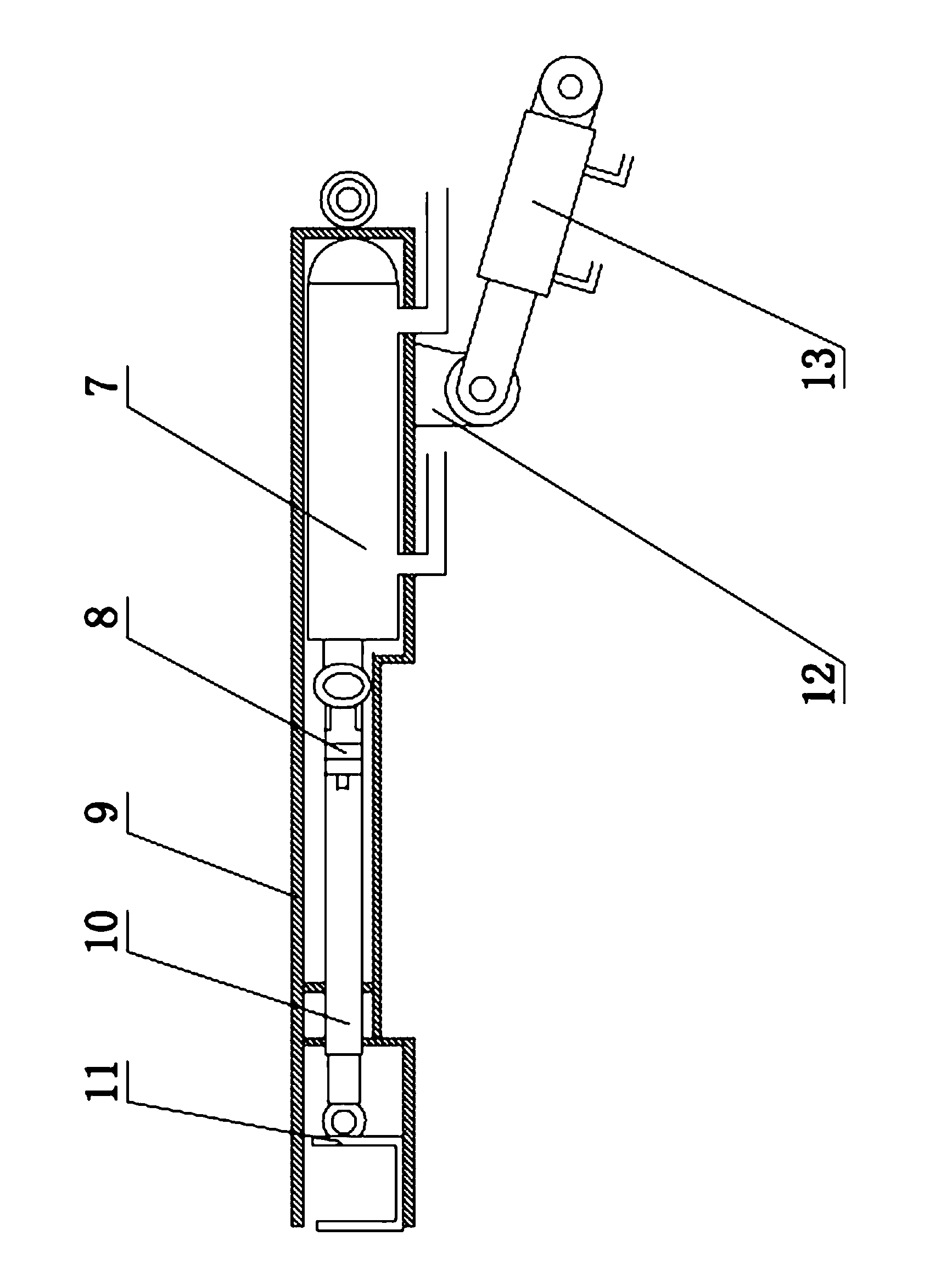

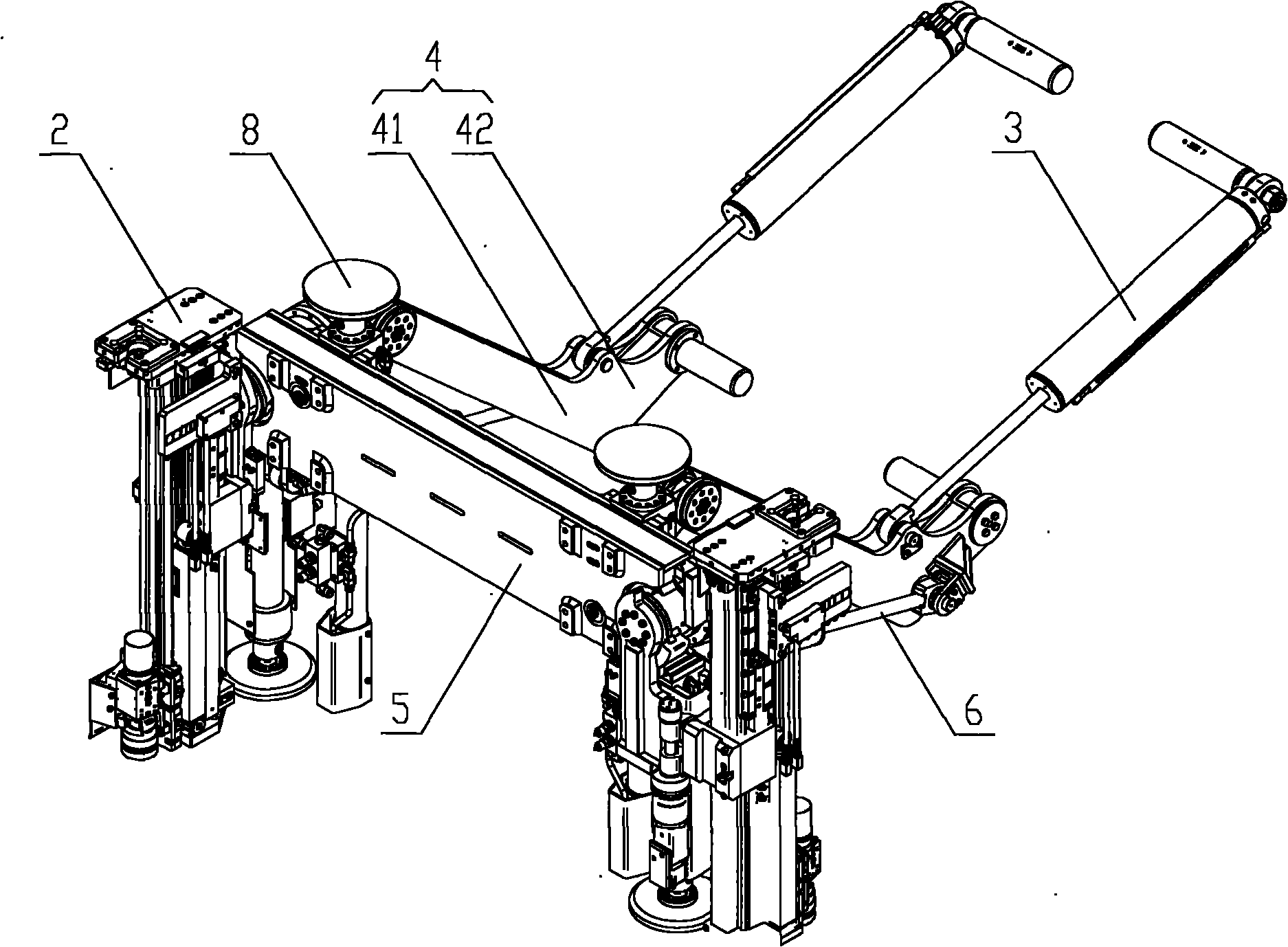

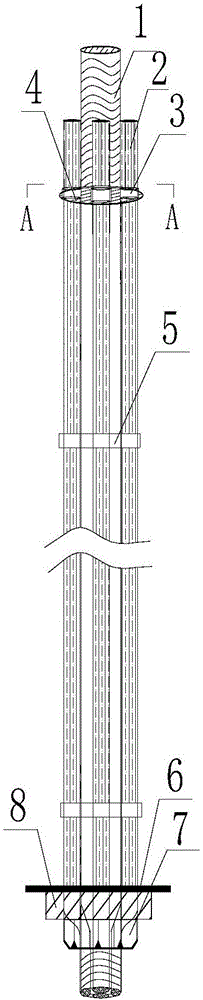

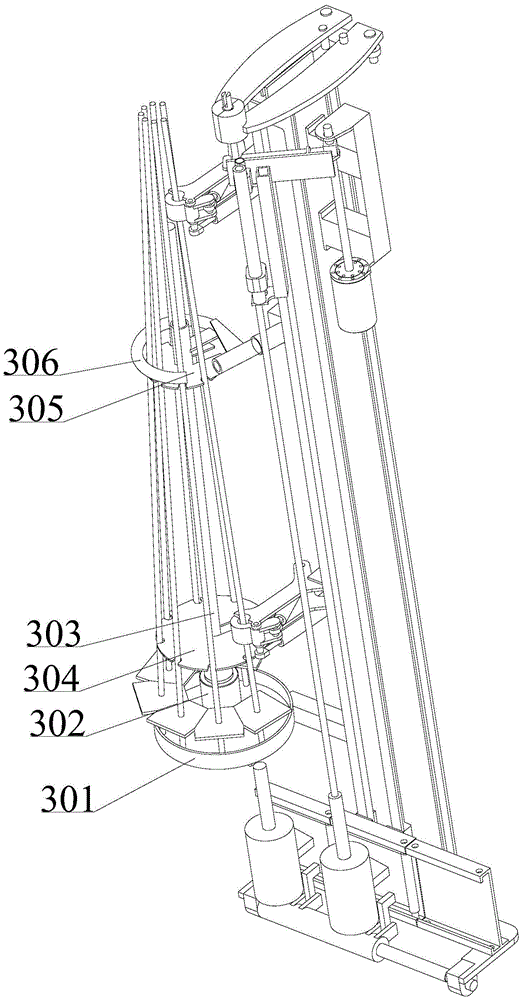

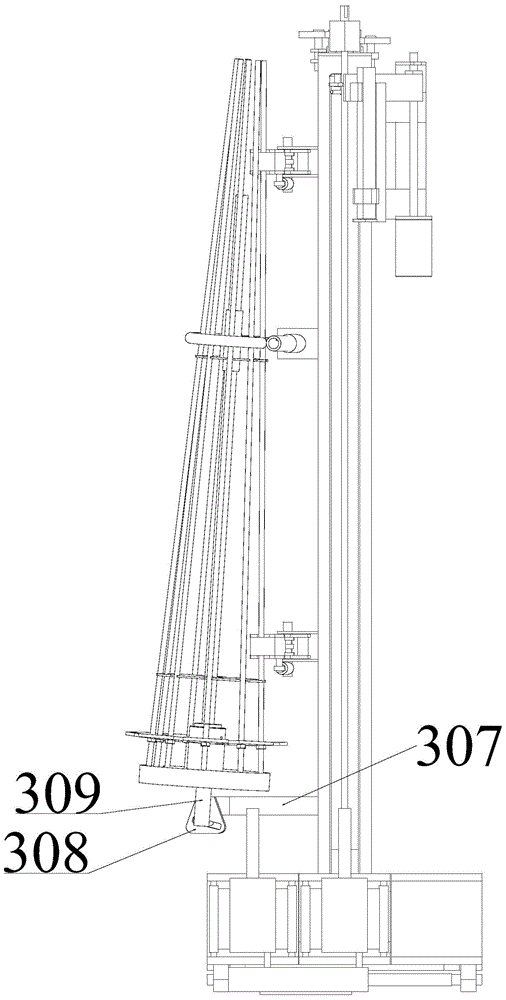

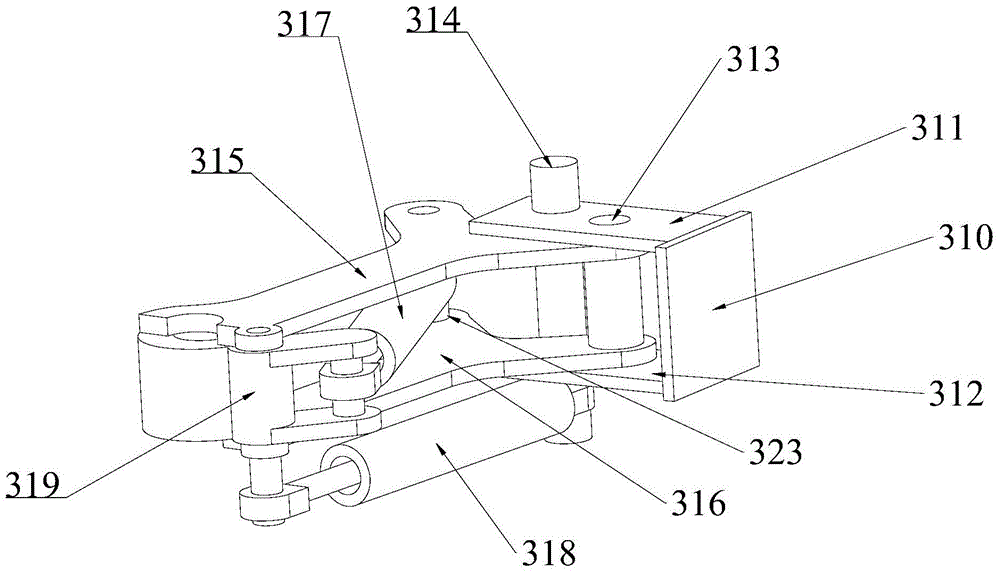

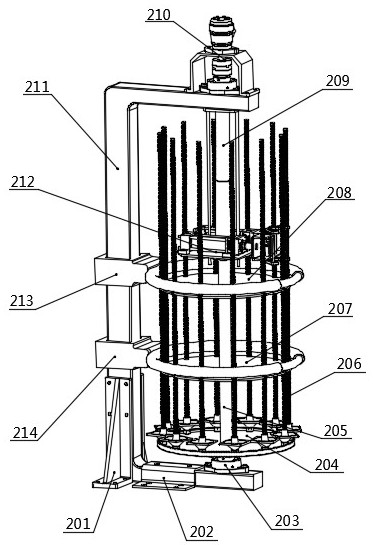

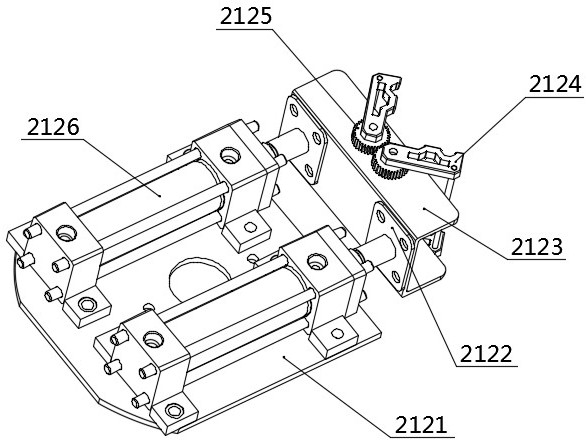

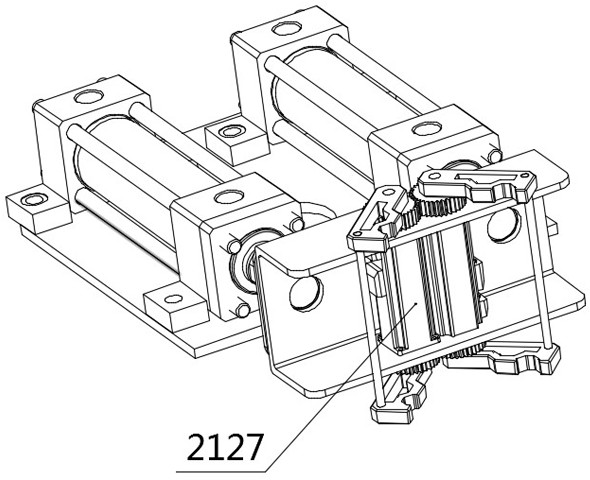

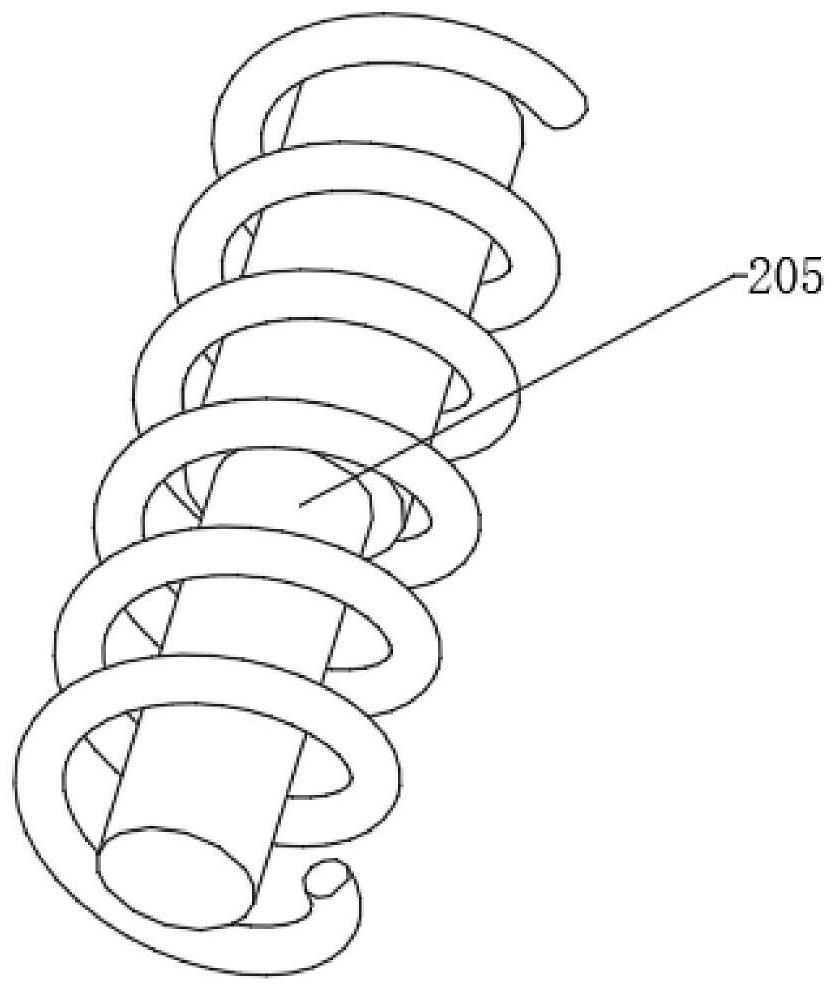

Automatic rod feeding device for mine anchor rod drilling machine

InactiveCN104806277AAutomate operationsImprove dressing efficiencyAnchoring boltsEngineeringRock bolt

The invention discloses an automatic rod feeding device for a mine anchor rod drilling machine. The device comprises an anchor rod storing mechanism, a first manipulator, a second manipulator and a fixing seat. According to the device, an anchor rod is stored into semicircular grooves in an upper index plate and a lower index plate through the anchor rod storing mechanism; the anchor rod is grasped, conveyed and positioned through the first manipulator and the second manipulator; therefore, automatic conveying of the anchor rod is achieved; the replacing efficiency of the anchor rod and a drilling rod can be increased; the time of supporting the tunnel is reduced; the risk of collapse of the tunnel is reduced.

Owner:王发秀

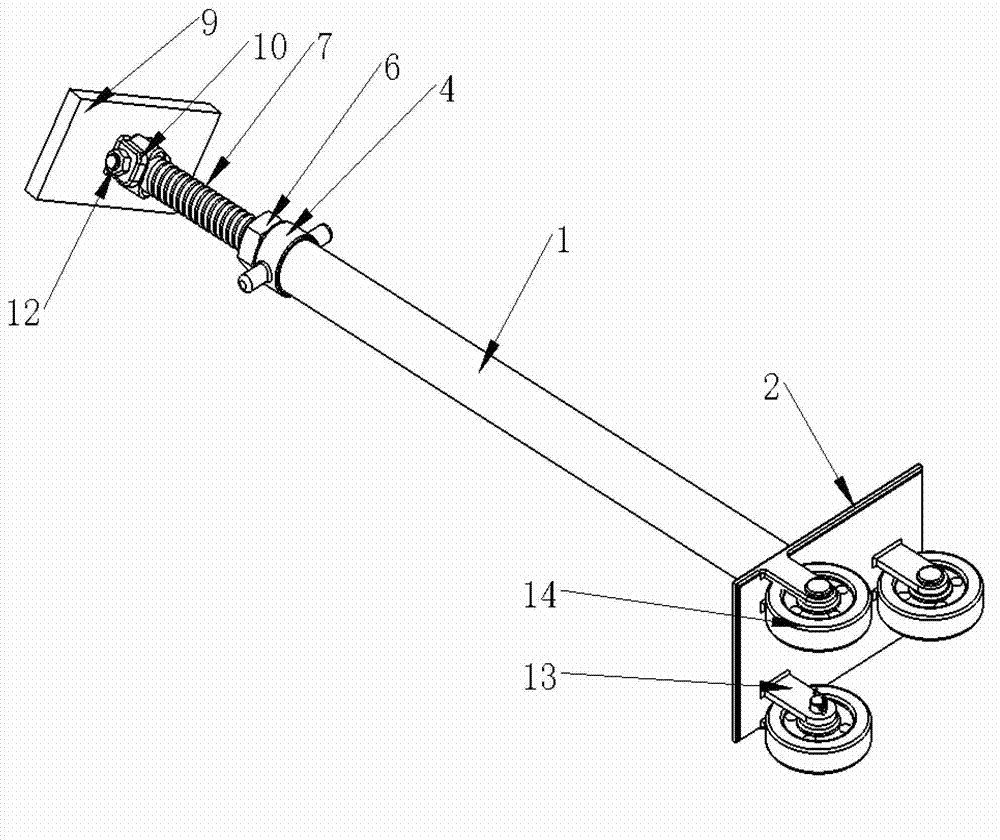

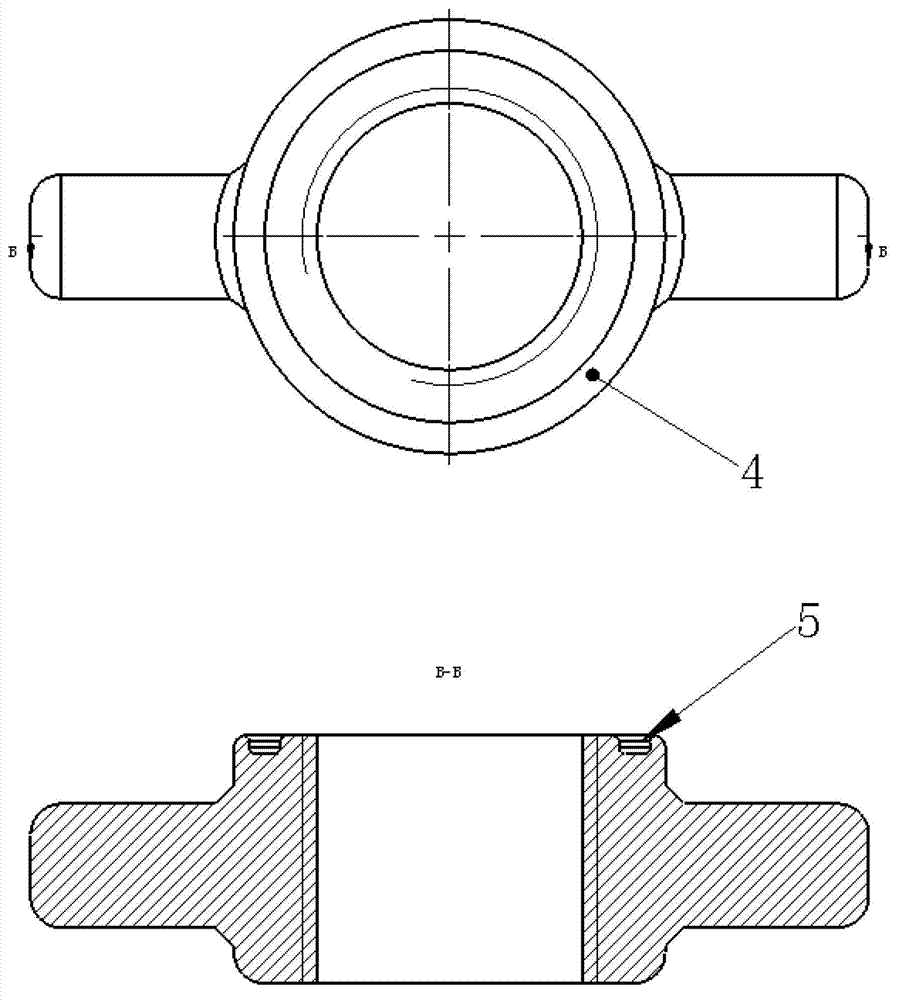

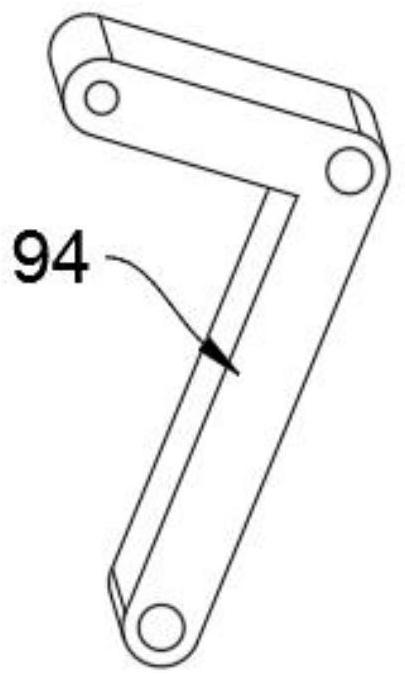

Adjustable strut

ActiveCN103395409ALow costEasy to assemble and disassembleVehicle fittings for liftingEngineeringSelf locking

The invention relates to an adjustable strut which is used in mining engineering, various machinery and other fields of engineering vehicles and comprises a fixing circular tube. One end of the fixing circular tube is connected with a fixing plate, the other end of the fixing circular tube is connected with an adjusting handle, a trapezoidal screw is arranged on the adjusting handle, a connecting hole is formed in the trapezoidal screw, a connecting support is arranged on a supporting plate, a bolt hole is formed in the connecting support, and a bolt penetrates the bolt hole in the connecting support and the connecting hole in the trapezoidal screw, so that the trapezoidal screw can be connected with the connecting support. The adjustable strut has the advantages that the expansion stability of the strut is strengthened owing to a double-nut reverse self-locking mechanism, so that the safety of personnel is protected, and loss of the adjusting handle further can be prevented; the rotatable handle can be turned, so that supporting force of the strut can be further increased by the aid of the lever principle, the strut is high in bearing capacity, the operation, repair and maintenance safety under operation conditions with supporting requirements is improved, and cost decreasing and benefit increasing effects can be realized for enterprises.

Owner:乌海包钢矿业有限责任公司

Combined type pneumatic pick hung on I-steel support of coal mine

The invention relates to a combined type pneumatic pick suspended on an I-steel support of a coal mine. Four pneumatic picks are combined into the combined type pneumatic pick which is hung on the I-steel support of a coal mine roadway, and a hydraulic system is used for driving the combined type pneumatic pick to move so as to carry out coal seam tunneling, so that a conventional manual coal breaking manner is replaced, the labor intensity of workers is alleviated, the speed is increased, the efficiency is improved, the input of manpower and material resources is reduced, and the safety factors are improved. The combined type pneumatic pick swings from side to side by adjusting a direction adjustment air cylinder, so that the width range of tunneling of the combined type pneumatic pick is extended; the combined type pneumatic pick swings up and down by adjusting an upper height adjustment oil cylinder and a lower height adjustment air cylinder, so that the height range of tunneling of the combined type pneumatic pick is extended; the height range of tunneling of the combined type pneumatic pick can also be extended by an upper oil cylinder; the combined type pneumatic pick is pushed to tunnel continuously and forwards by pushing an oil cylinder and a telescopic cylinder.

Owner:HENAN YONGHUA ENERGY

Shed upper beam device of I-beam shed for coal mine laneway

The invention relates to a shed upper beam device of an I-beam shed for a coal mine laneway, which includes a cantilever, wherein the cantilever is arranged in a sleeve; the sleeve is hung on an erected I-beam shed upper beam through a fixator; a propulsion support is hung on the erected I-beam shed upper beam; the rear end of the cantilever is connected with the propulsion support through a propulsion device; the front end of the cantilever is hinged with the rear end of a height adjusting arm; the height adjusting arm adopts a hollow structure, and is internally provided with a width adjusting device, a connecting rod and an outrigger device; the rear end of the width adjusting device is fixed with the inner bottom surface of the height adjusting arm; the front end of the width adjusting device is connected with one end of the connecting rod through a width universal joint; the other end of the connecting rod is fixed with the outrigger device; and the bottom of the height adjusting arm is connected with the front lower part of the cantilever through a height adjusting device. The I-beam shed upper beam can be installed through firstly adjusting the mounting position of the I-beam shed upper beam through the width adjusting device and the height adjusting device, and finally through manually fixing the I-beam shed upper beam.

Owner:HENAN YONGHUA ENERGY

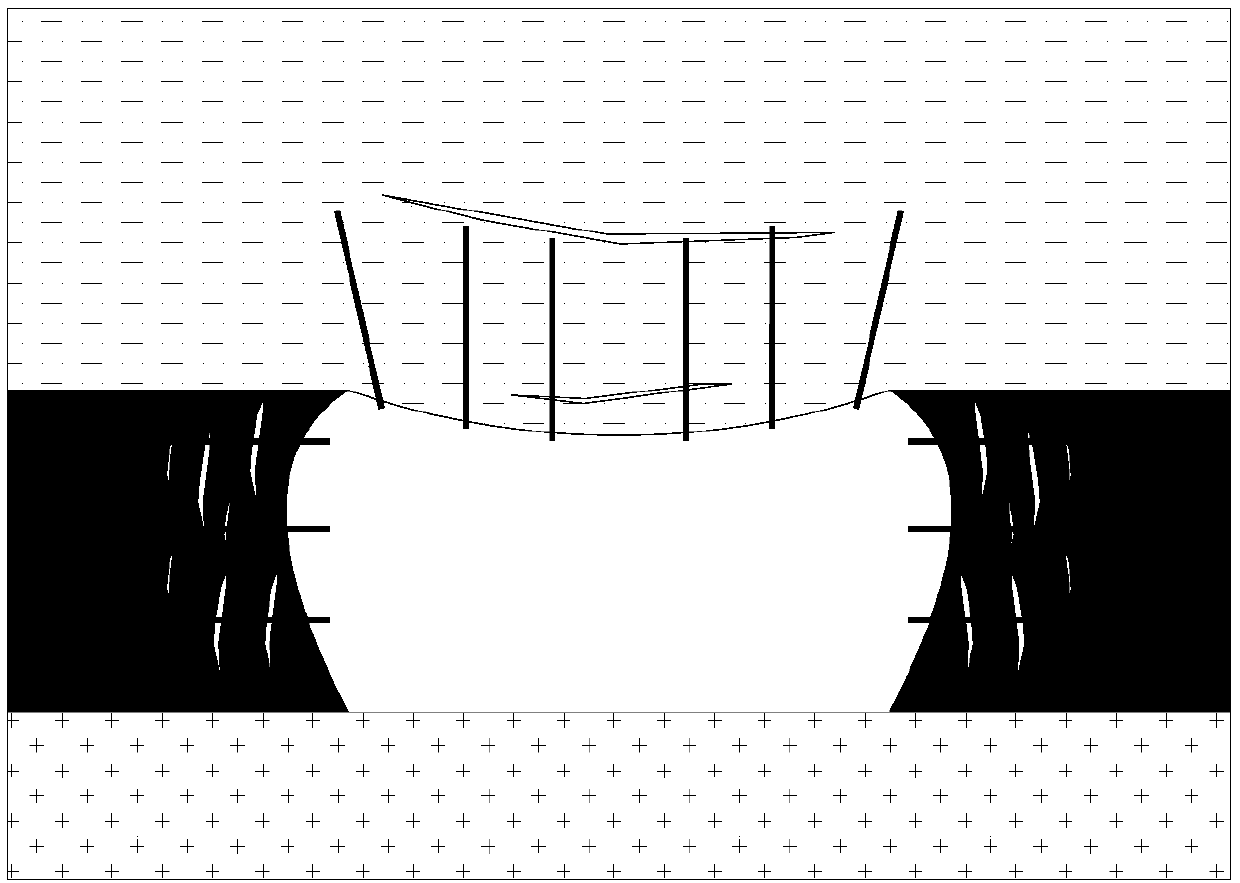

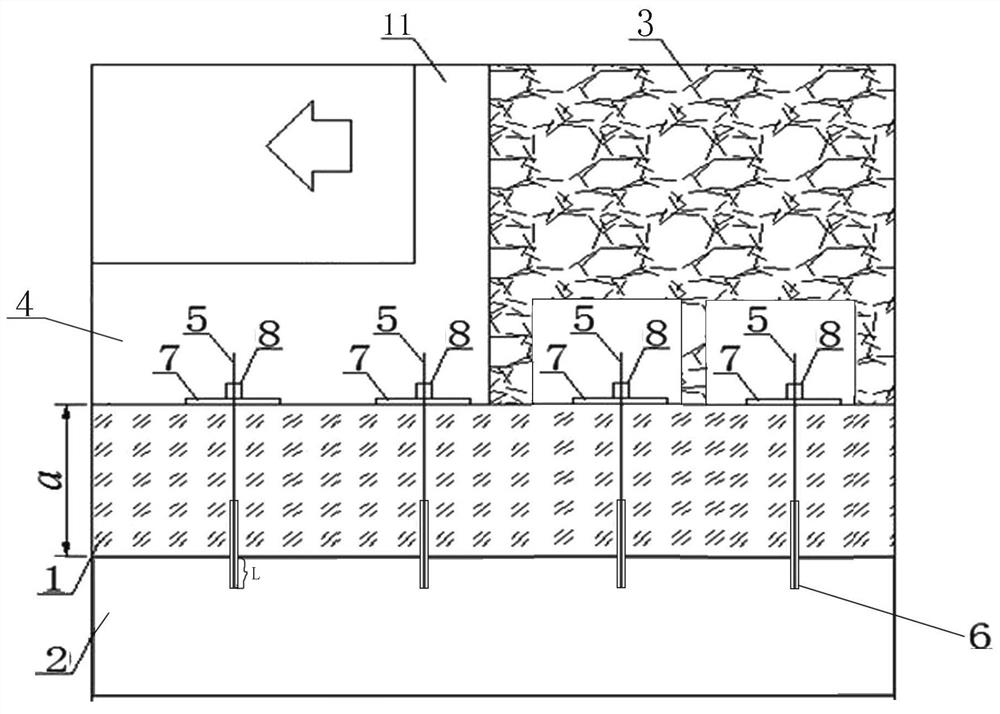

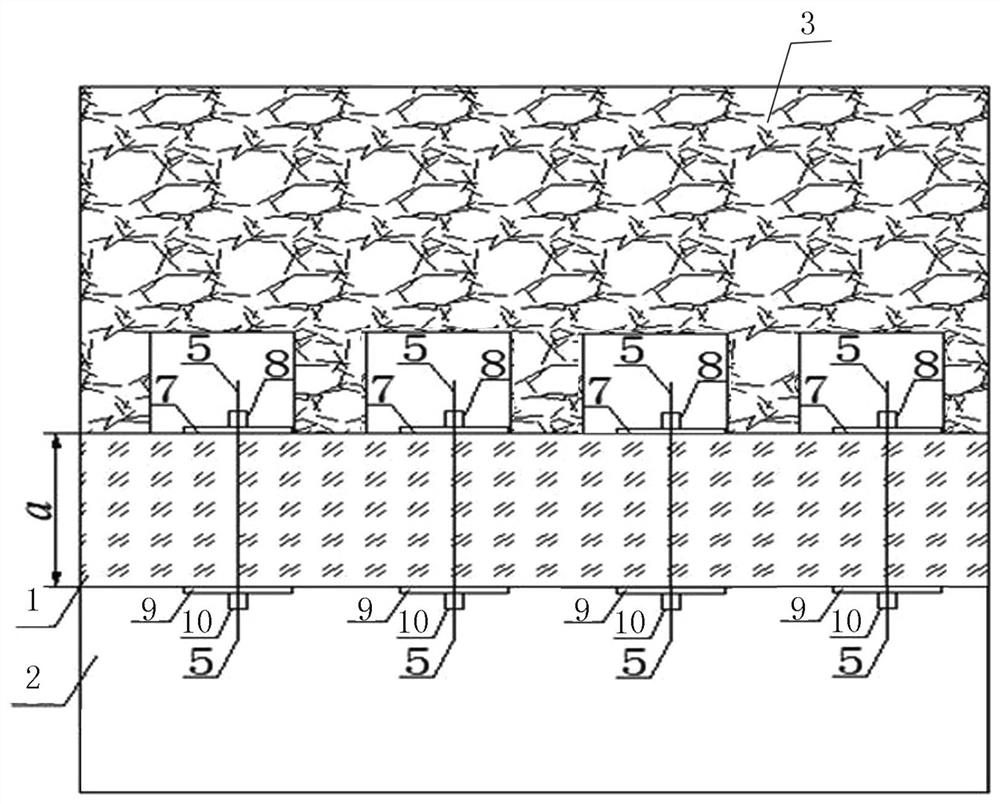

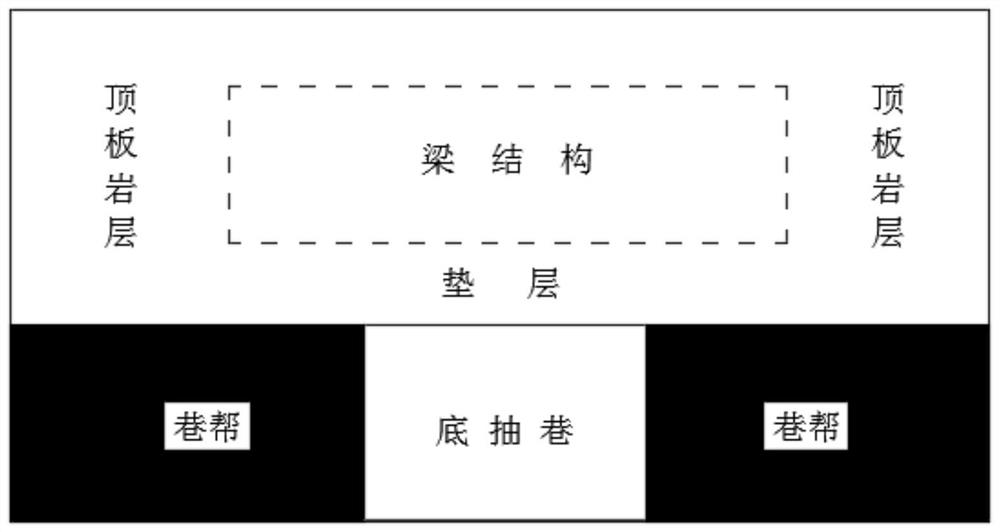

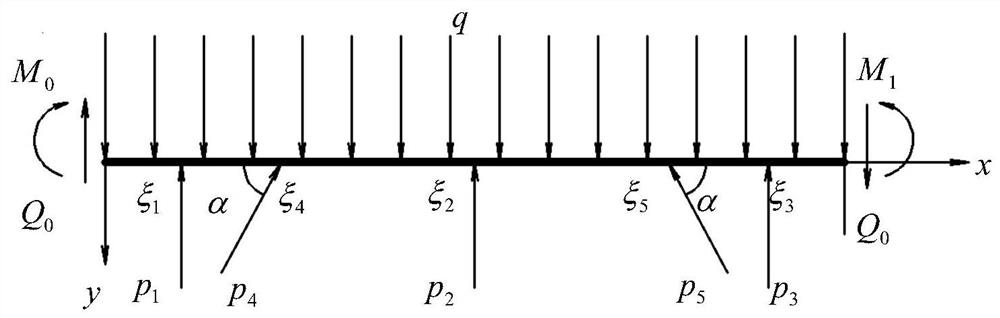

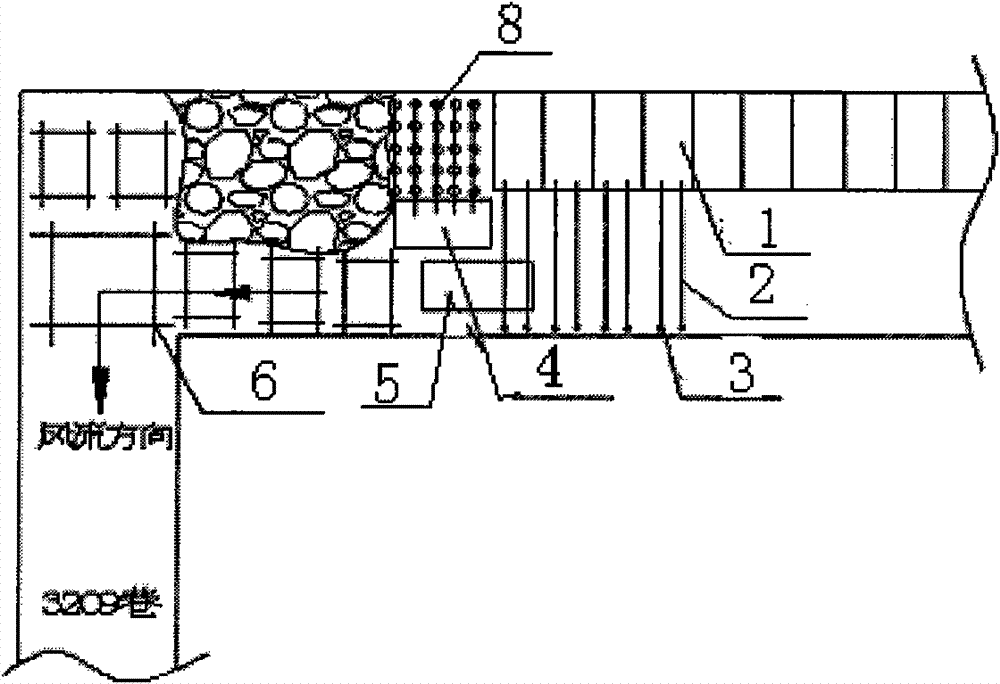

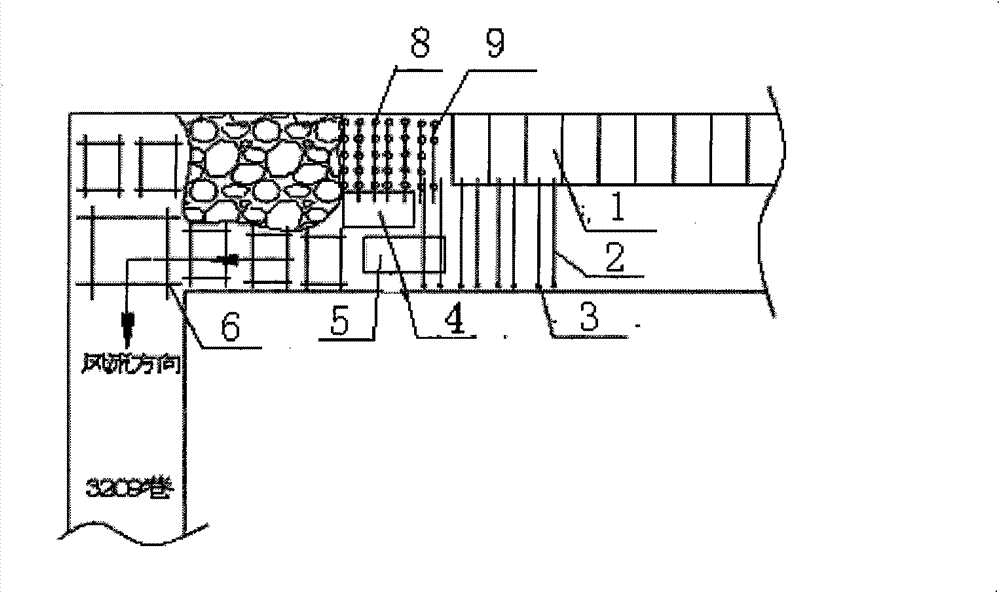

Coal roadway roof reinforcing and upper protecting anchor rod supporting method based on top plate stability

InactiveCN108035752ARow spacing increasedIncrease the speed of excavationMaterial strength using tensile/compressive forcesEarth material testingRock coreEngineering

A coal roadway roof reinforcing and upper protecting anchor rod supporting method based on top plate stability is suitable for the field of roadway supporting. A roadway top plate is divided into different areas, rock core information of each area is analyzed, and therefore the rock integrity of each area of the top plate is obtained; the testing result of each area is analyzed, the mass index ofrock in each area of the top plate is judged, when the rock mass index is larger than a preset value, a plurality of anchor rods or anchor ropes are evenly and perpendicularly distributed in the areaof the top plate to conduct simplex reinforcing supporting, and a plurality of anchor rods are evenly and perpendicularly distributed within corresponding ranges of coal uppers on the two sides. The anchor rod supporting array pitch is greatly increased, supporting time is saved, and the advance rate is remarkably increased; due to the increase of strength and length of the anchor rods of the topplate and the increase of the pretightening force of the anchor rods, an anchoring rock beam of a sufficient thickness is formed by the top plate, and therefore the overall roadway stability is improved; meanwhile, the peak pressure positions of the uppers are transferred to be close to the coal wall side, and the deformation of the coal uppers can be controlled through the low-strength short anchor rods.

Owner:CHINA UNIV OF MINING & TECH

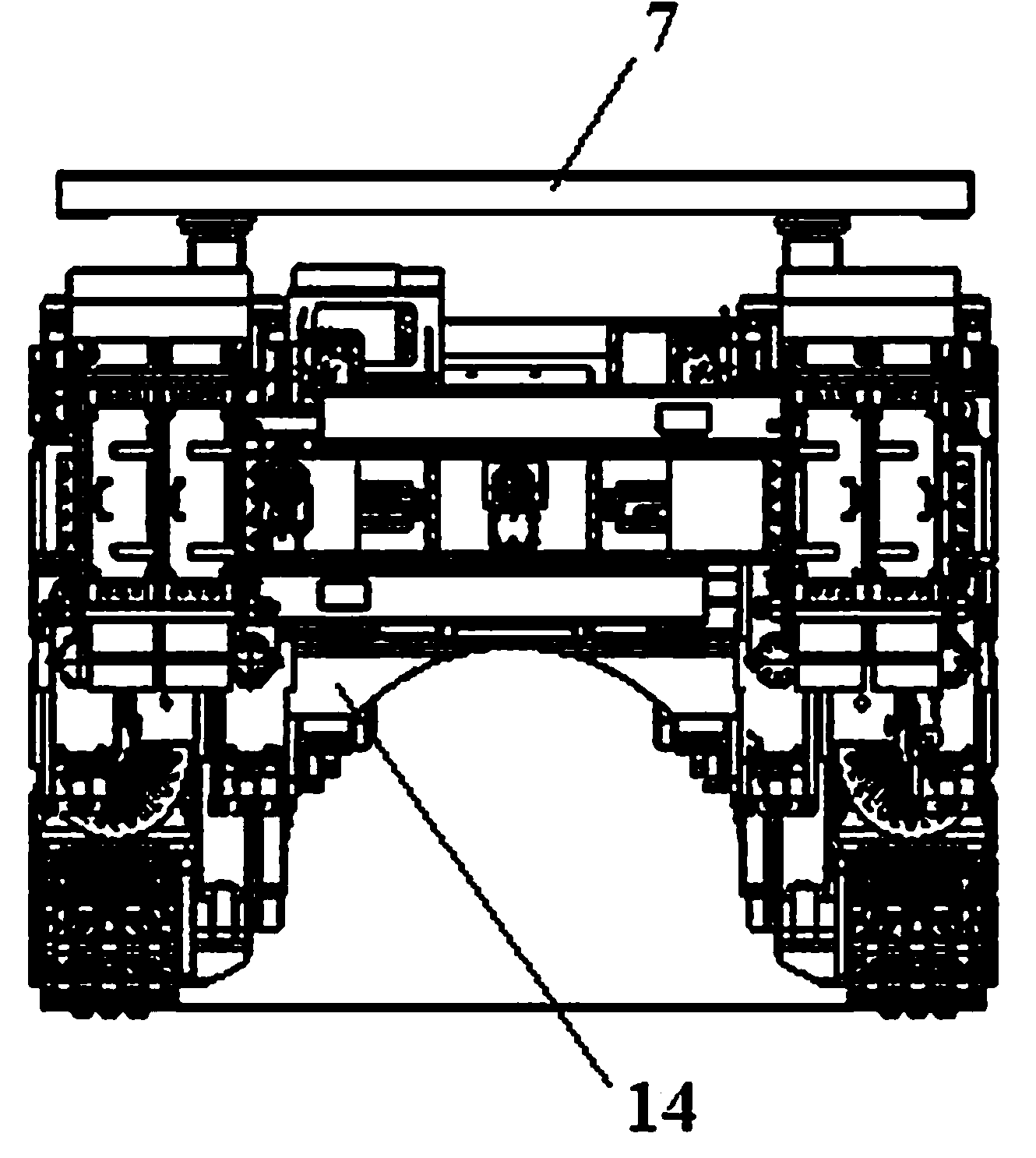

Development machine

The invention discloses a development machine, comprising a development machine body (1) as well as a supporting device (2) and a driving device (3) for driving the supporting device (2) to move; wherein the supporting device (2) is arranged at the front part of the development machine body (1), and the supporting device (2) can be in supported position under the action of the driving device (3). The development machine provided by the invention can widen application range thereof while ensuring use cost to be low, and meanwhile the time required by supporting is reduced, the labor intensity of workers is reduced, and the work efficiency is improved.

Owner:PANJI BRANCH OF FINLAY COAL DRESSING ENG & TECH BEIJING CO LTD

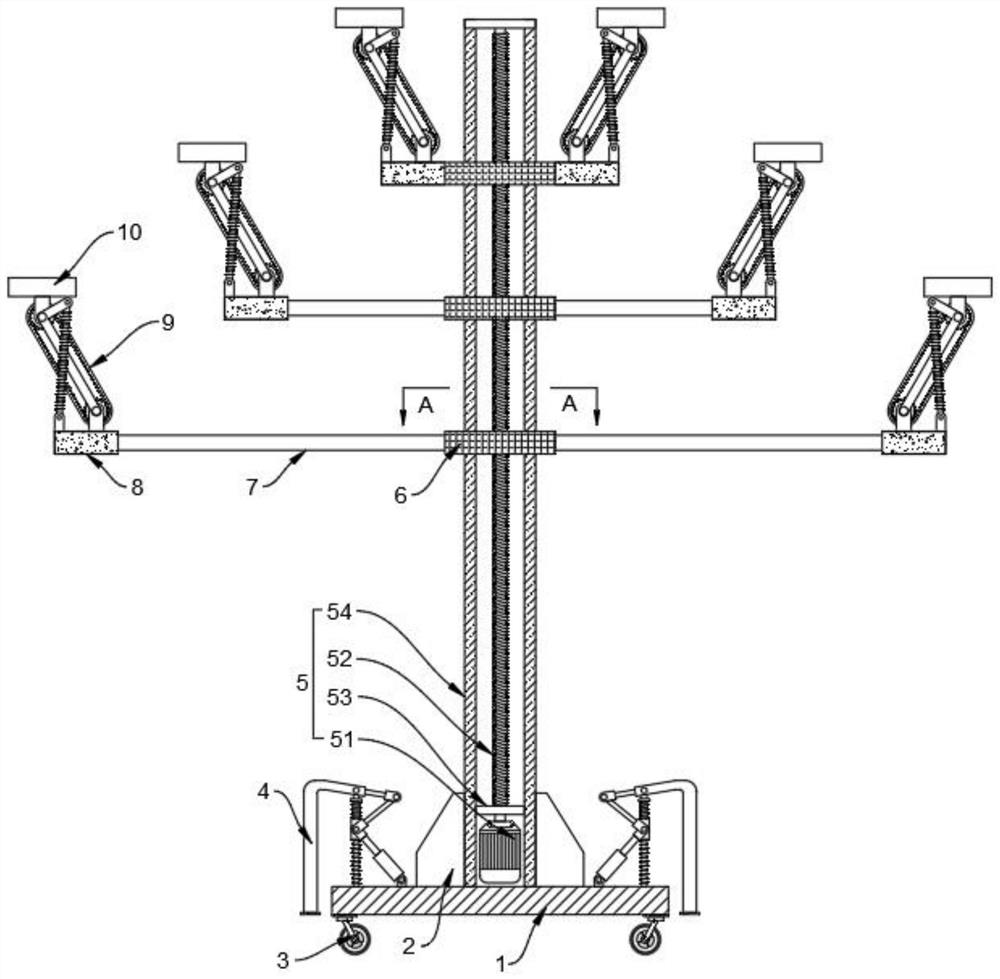

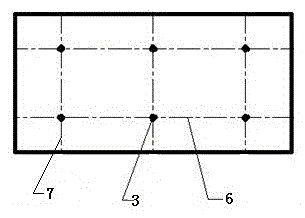

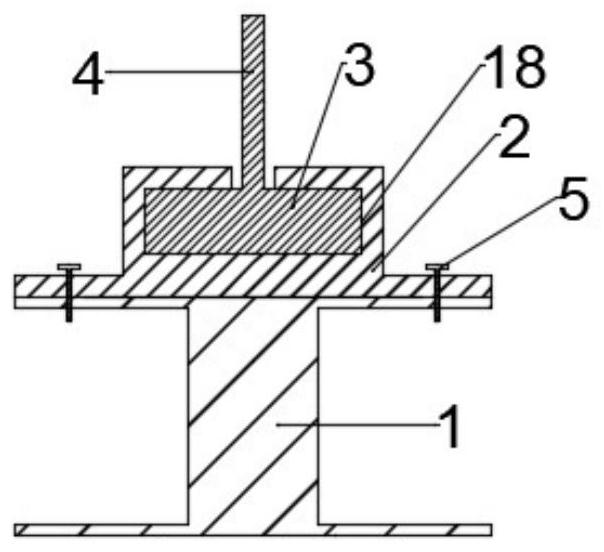

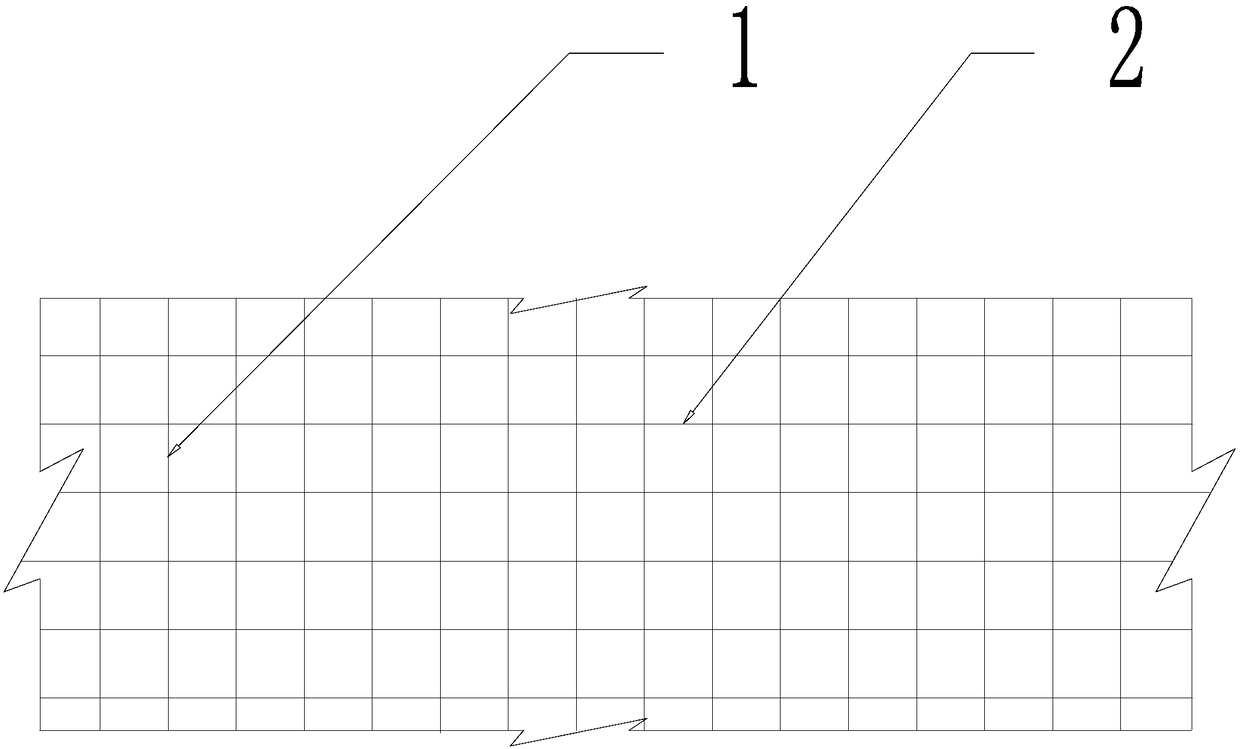

Fixing support for constructional engineering formwork

ActiveCN114293816AShorten support timeImprove fixation efficiencyShoresIndustrial engineeringSupport surface

The invention is applicable to the technical field of constructional engineering, and provides a constructional engineering template fixing support which comprises a fixing base and further comprises a lifting mechanism, a plurality of lifting seats are movably arranged on the lifting mechanism, telescopic modules are arranged on the two sides of each lifting seat, a mounting seat is fixedly arranged at one end of each telescopic module, and the mounting seats are movably arranged on the fixing base. An adjusting mechanism is fixedly arranged on the mounting seat and comprises a first adjusting seat, a second adjusting seat, an electric element, a rotating part, a rotating module, a second elastic part and a first telescopic part. According to the fixing support for the constructional engineering formwork, the lifting bases with the same number as the supporting faces of the stepped formwork are installed on the lifting mechanism, the lifting mechanism drives the lifting bases and the supporting bases to ascend and descend, the adjusting mechanism adjusts the horizontal positions of the supporting bases, and the lifting mechanism and the adjusting mechanism are matched; the ladder-shaped formwork is supported and fixed, the supporting stability of the formwork is improved, and then the formwork supporting efficiency and quality are improved.

Owner:杨文超

Supporting method for narrow coal pillar in gob-side entry driving

InactiveCN112127926AEasy to operateGuaranteed stabilityAnchoring boltsCoal briquetteMining engineering

The invention relates to the technical field of gob-side entry driving, in particular to a supporting method for narrow coal pillar in gob-side entry driving. In order to solve the problem that a narrow coal pillar supporting method in the prior art cannot guarantee the stability of a narrow coal pillar, the invention provides the novel supporting method for the narrow coal pillar in gob-side entry driving. The supporting method comprises the steps that an anchor cable is constructed on a gateway of coal face zones of adjacent zones, the anchor cable penetrates through the other side of the reserved narrow coal pillar, and meanwhile the end, close to a goaf side, of the anchor cable is anchored; gob-side entry driving is carried out after stoping of coal faces of the adjacent zones is completed and an overlying rock layer is stabilized, one end of the anchor cable on the other side of the narrow coal pillar is exposed and anchoring agents and coal briquettes are cleaned in the drivingprocess, and a tray and a lock are sequentially installed to conduct tensioning. The supporting method is simple, convenient and fast to operate, anchor cables do not need to be rearranged on one sideof the narrow coal pillar in gob-side entry driving, and supporting materials and construction time are saved.

Owner:XISHAN COAL ELECTRICITY GRP

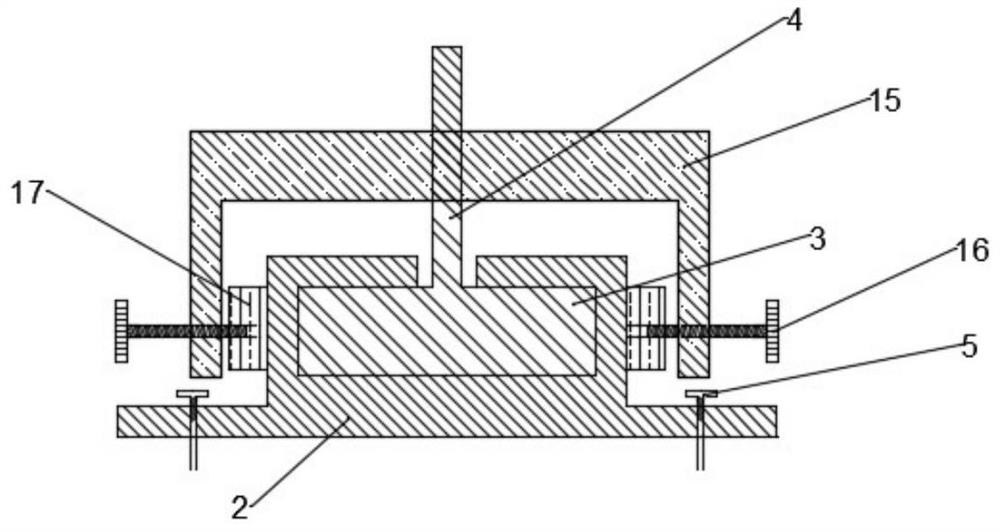

Breaking-resistant anchoring apparatus suitable for large-deformation roadway surrounding rock

The invention discloses a breaking-resistant anchoring apparatus suitable for large-deformation roadway surrounding rock and a construction method of the breaking-resistant anchoring apparatus. The breaking-resistant anchoring apparatus comprises an anchor rod and a plurality of anchor ropes; a plurality of grooves are formed in the side wall of the rear end of the anchor rod, and the rear ends of the anchor ropes are embedded inside the corresponding grooves; a nut, a base plate and a supporting plate are arranged at the position, adjacent to the rear end, of the anchor rod, the nut is arranged adjacent to the rear end of the anchor rod, and the base plate is disposed between the supporting plate and the nut; a plurality of anchor rope through holes are respectively formed in the base plate and the supporting plate, and the anchor ropes are fixed in the anchor rope through holes of the base plate by virtue of anchorage devices; and a retainer ring is arranged at the front end of the anchor rod, a plurality of anchor rope through holes are formed in the retainer ring, the front end of each anchor rope penetrates through the anchor rope through hole, a clamp is arranged in each anchor rope through hole, and the front end of each anchor rope is fixed by virtue of the clamp; and a part, disposed between the supporting plate and the retainer ring, of the anchor rope is wound at the outer side of the anchor rod. The breaking-resistant anchoring apparatus is simple in structure, convenient to install, and low in supporting cost; and the elongation percentage is large, the deformation of the roadway surrounding rock can be effectively controlled, and the long-term stability and normal use of the roadway surrounding rock can be ensured.

Owner:HUNAN UNIV OF SCI & TECH

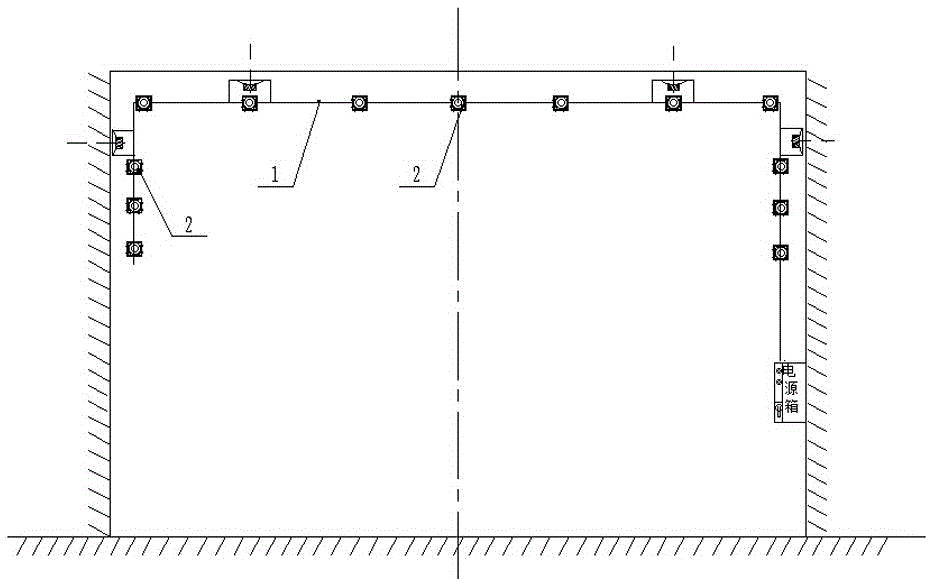

Infrared laser alignment full-section forming device for tunneling working face and use method

The invention discloses an infrared laser alignment full-section forming device for a tunneling working face and a use method and belongs to the field of auxiliary devices for tunneling working faces. The problems that in an existing tunneling working face, a roadway forming effect is poor, and an anchor rod is inaccurately positioned are solved. According to the technical scheme, the forming device comprises a U-shaped adjustable frame fixedly arranged on an anchor rod and a plurality of infrared laser alignment instruments arranged on the top and the two side edges of the U-shaped adjustable frame, and the infrared laser alignment instruments are connected with an electric control system.

Owner:SHANXI LINGZHIDA COAL IND

A mobile device for underground heavy support

ActiveCN106869982BMeet the needs of rapid movementImprove stabilityMine roof supportsEngineeringHeavy duty

Owner:CHINA UNIV OF MINING & TECH

Construction method for adopting concrete breast board piles to support side slope with height difference of foundation pit

ActiveCN103205971BPrevent leakageImprove support strengthExcavationsBulkheads/pilesWhole bodyEconomic benefits

The invention relates to a construction method for adopting concrete breast board piles to support a side slope with height difference of a foundation pit. The construction method includes: step 1, the concrete breast board piles are manufactured, anchor bars are embedded at the tops of the breast board piles, female grooves is arranged on one sides of the breast board piles, and seam allowances matched with the female grooves are arranged on the other sides of the breast board piles; step 2, a shallow foundation pit is excavated; step 3, a plurality of breast board piles are hung in supporting positions, the seam allowances on the breast board piles are inserted in the female grooves of the adjacent breast board piles, and the plurality of breast board piles forms a whole body and are fixed; step 4, cement mortar or fine stone concrete is poured in the female grooves; step 5, the anchor bars are welded onto a main reinforcement of a bottom plate in a foundation of the shallow foundation pit, the lower portions of the breast board piles are embedded in a soil layer, and the upper portions of the breast board piles, the lower portion of the foundation of the shallow foundation pit and the soil layer form into a whole body; and step 6, a deep foundation pit is excavated. The construction method is simple to construct and high in safety and has good comprehensive technical and economic benefits.

Owner:CHINA FIRST METALLURGICAL GROUP

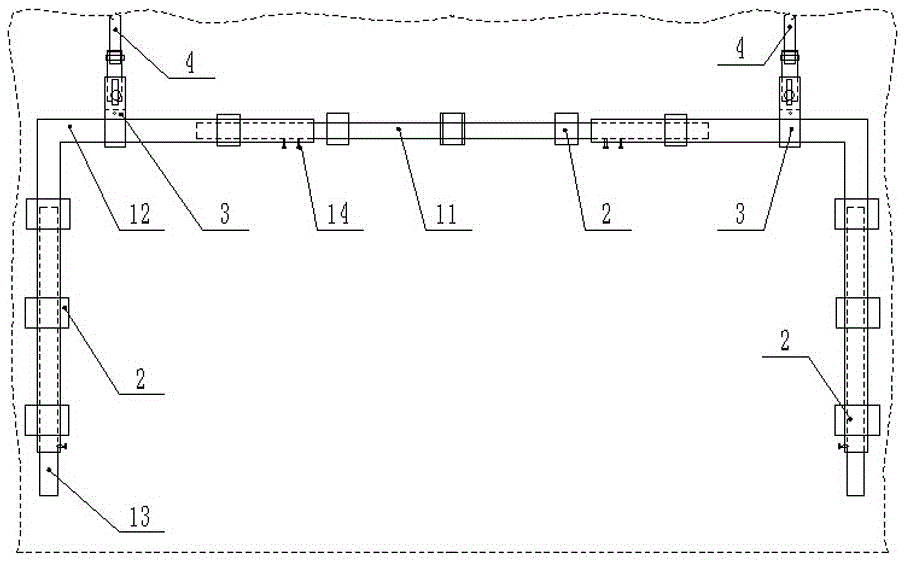

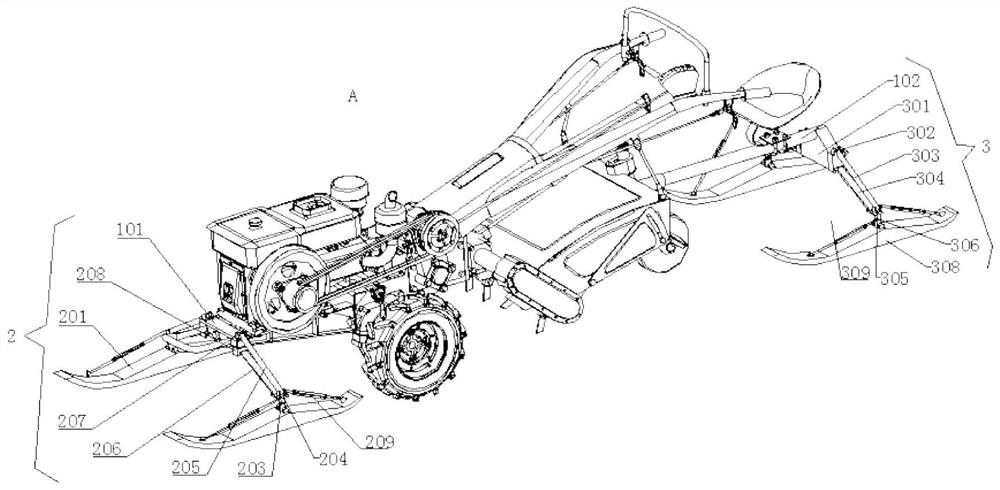

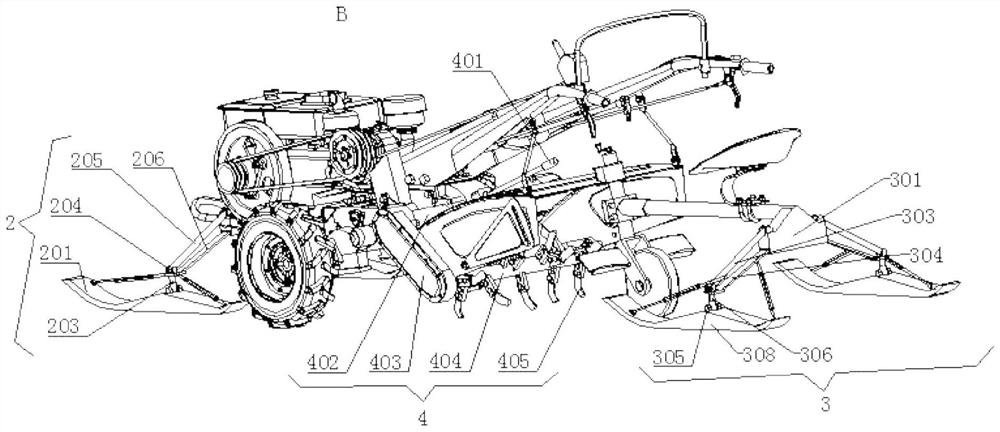

A coal mine digging and anchoring integrated machine and a method for parallel operation

ActiveCN110593870BImprove effectivenessWon't collapseUnderground chambersSlitting machinesAgricultural engineeringTruck

The invention relates to a parallel operation method for tunneling, temporary support, connection net laying, steel strip laying and anchor bolt support in the tunneling process of a coal roadway of acoal mine and a tunneling, supporting and anchoring integrated machine, and belonging to the field of coal mine coal roadway tunneling complete equipment and technical methods. The tunneling, supporting and anchoring integrated machine is characterized by being composed of a tunneling and supporting truck, an anchor bolt locomotive and a scraper conveyor; and devices required by coal roadway tunneling cutting, temporary support, connection net laying and steel strip laying are all arranged on the tunneling and supporting truck. According to the roof-cut temporary support parallel operation method, full-length cutting horizontal rollers are adopted, the lower cutting roller protrudes forwards to cut a roof coal roof, the upper cutting roller does not move up and down in the post cutting process, and temporary support is carried out on a newly exposed roof in real time; and all anchor bolt (cable) drilling machines required for roadway anchoring are arranged on the frame type anchor bolt locomotive in sections. The method comprises the steps that in the operation cycle initial state, connection net laying and steel strip laying operation should be completed; firstly, the tunneling and supporting truck advances to execute cutting and temporary support operation, and simultaneously, the anchor bolt locomotive executes anchor bolt support operation in situ; secondly, after the tunneling and supporting truck advances by a preset distance, connection net laying and steel strip laying operation is executed; and finally, the anchor bolt locomotive follows to advance to merge with the tunneling and supporting truck.

Owner:张忠国

Integral Pouring Technology of Reinforced Concrete Wastewater Pool in Pre-drilling Project

ActiveCN103015719BShorten construction timeShorten the construction periodBuilding material handlingReinforced concreteWastewater

The invention discloses an integral casting process for a reinforced concrete wastewater tank in predrilling engineering. The integral casting process comprises the following steps of a, construction of a foundation and a bedding layer, digging a foundation pit, and casting the concrete bedding layer after determining that the foundation bearing force meets the design requirements; b, manufacturing and installation of reinforced bars, manufacturing and installing on site, wherein the overlapping length of the reinforced bars should not be less than 40 times of the diameter (mm) of each reinforced bar, and the overlapping area of the reinforced bars same in cross section should not be more than 50% of the total area; c, supporting of die plates, binding the die plates into the shapes of the bottom and the wall of a concrete tank; d, casting of concrete, after completing the construction of the reinforced bars and the die plates, carrying out the casting construction of concrete, firstly casting the bottom of the concrete tank and the wall with the height less than 1m, leveling the top of the wall of the concrete tank, and reserving no step to complete the first time of casing; casting the residual wall of the concrete tank in at least one hour after completing the first time of casting; and e, removal of the die plates, removing the die plates when the strength of the cast concrete being more than 1.2MPa. The integral casting process has the advantages that the construction time of the wastewater tank in the predrilling engineering is reduced, the construction period of the whole predrilling engineering is shortened, the condition of drilling machines not waiting for well fields is ensured, the construction seams are not reserved in the construction, and the leakage problem caused by the construction seams is avoided.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

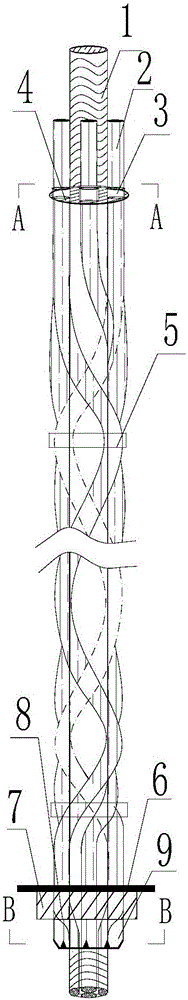

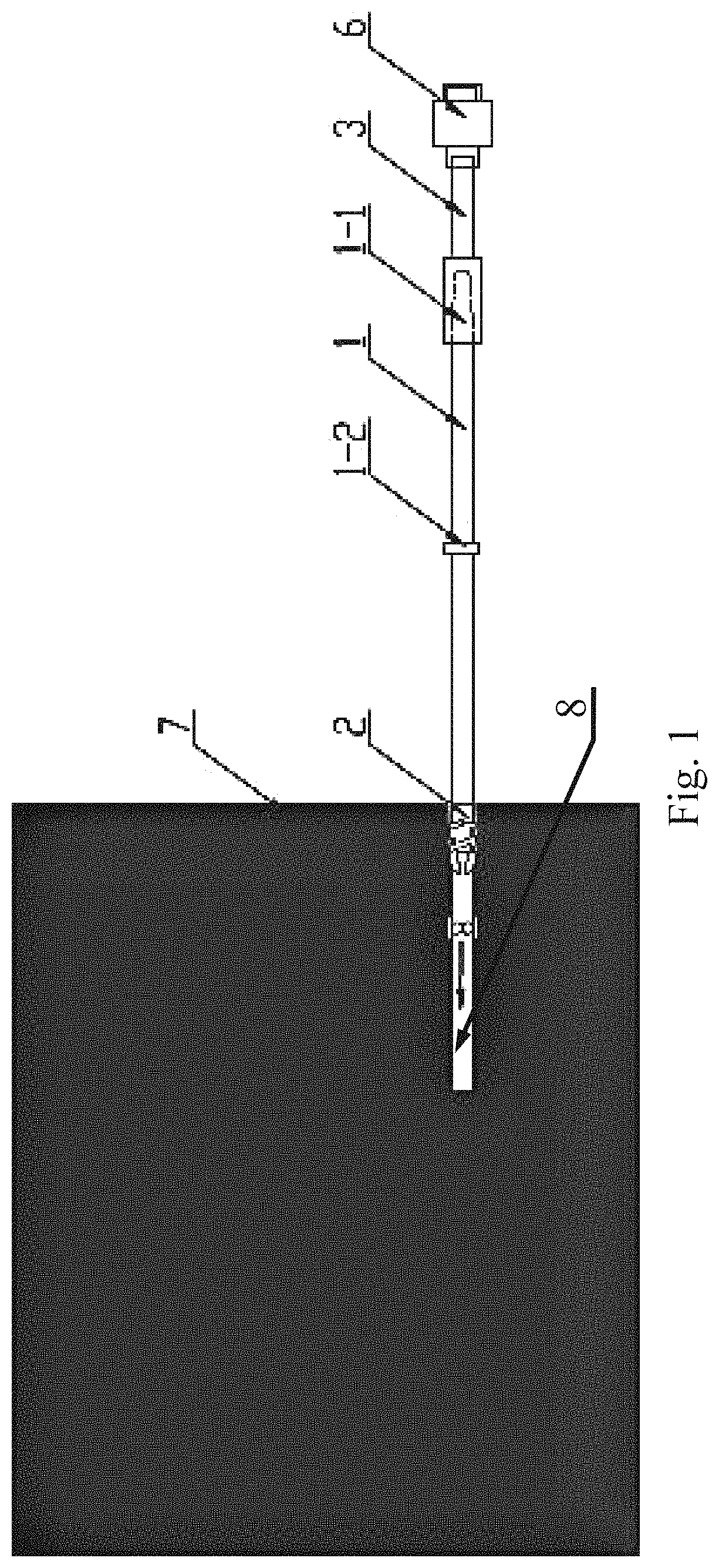

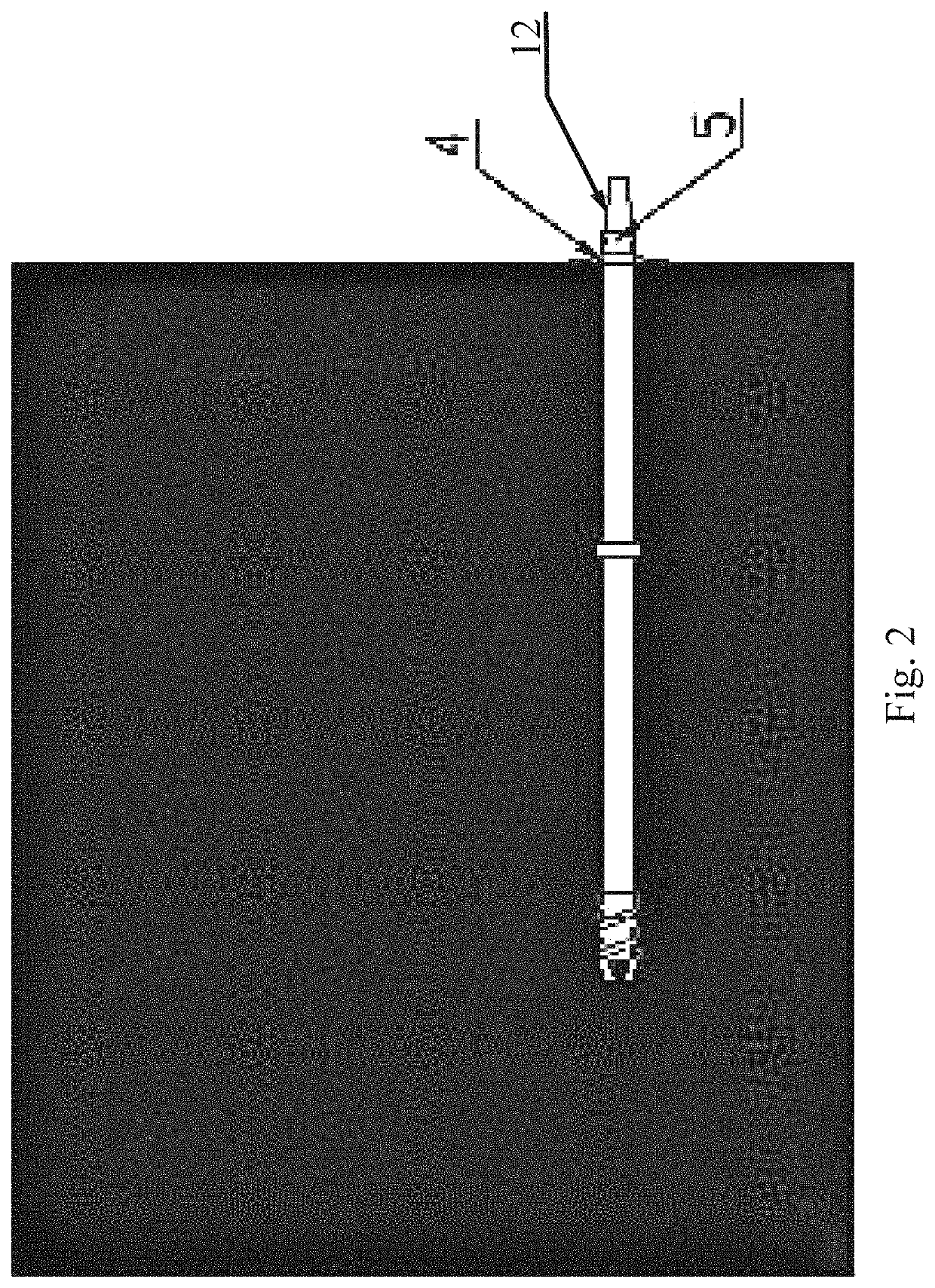

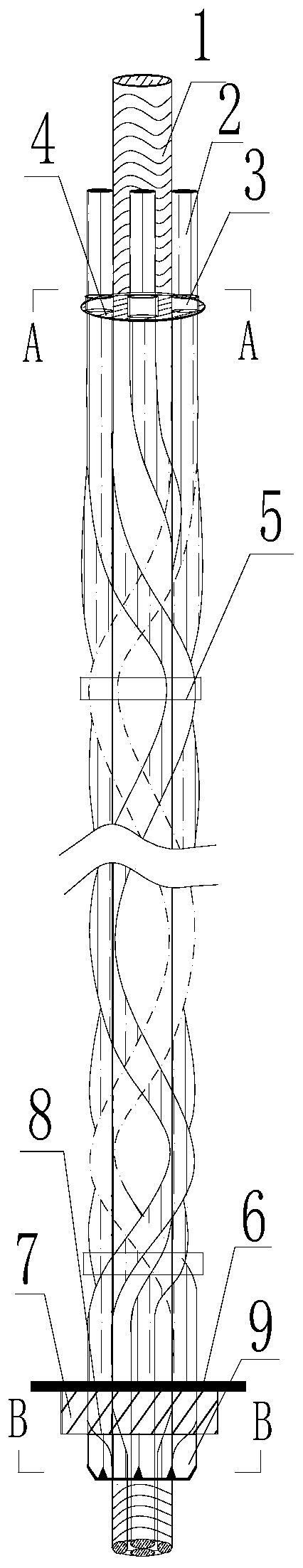

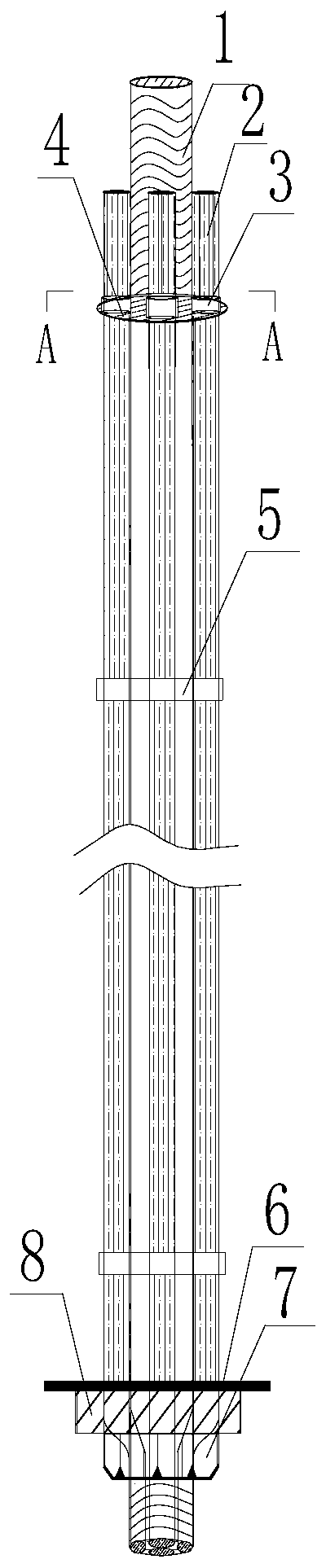

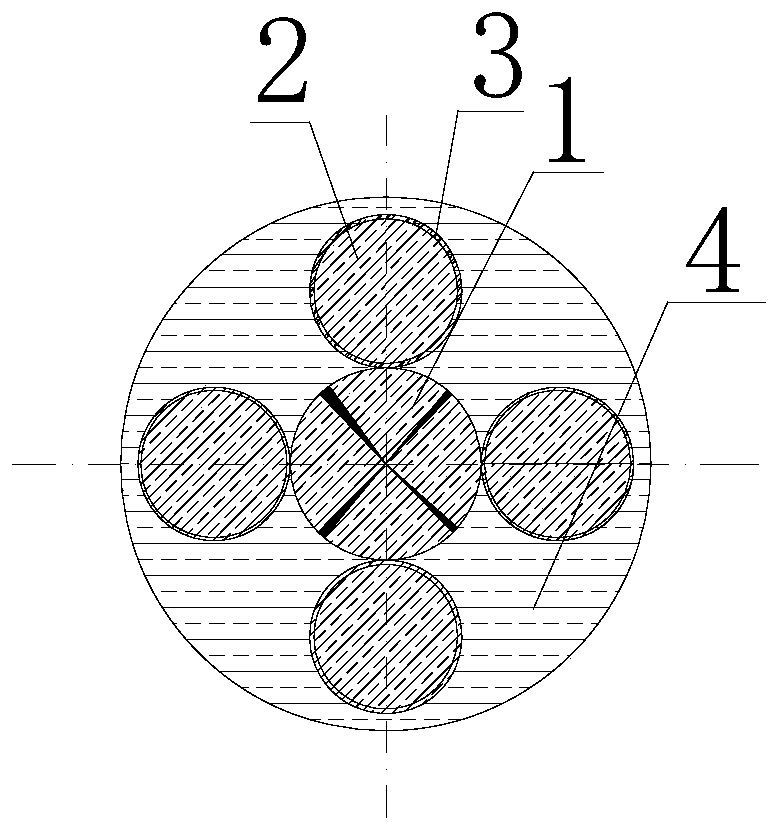

Reaming and self-rotating anchor rod and using method thereof

ActiveUS10907474B2Easy to manufactureLow costMining devicesUsing optical meansRock boltMechanical engineering

A reaming and self-rotating anchor rod includes a rod body, a drill bit, a connecting member, a tray, and a nut. One end the connecting member is snap-fixed to the tail part of the rod body, the other end of the connecting member is connected to an anchor rod bolter. The rod body has an annular protrusion at its middle part to block powder so that the powder fills up the clearance between the rod body and the coal mass. The drill bit has female threads and can be screwed into the front part of the rod body, and the drill bit has baffle pawls and spiral grooves on its side surface.

Owner:CHINA UNIV OF MINING & TECH

Development machine

The invention discloses a development machine, comprising a development machine body (1) as well as a supporting device (2) and a driving device (3) for driving the supporting device (2) to move; wherein the supporting device (2) is arranged at the front part of the development machine body (1), and the supporting device (2) can be in supported position under the action of the driving device (3).The development machine provided by the invention can widen application range thereof while ensuring use cost to be low, and meanwhile the time required by supporting is reduced, the labor intensity of workers is reduced, and the work efficiency is improved.

Owner:PANJI BRANCH OF FINLAY COAL DRESSING ENG & TECH BEIJING CO LTD

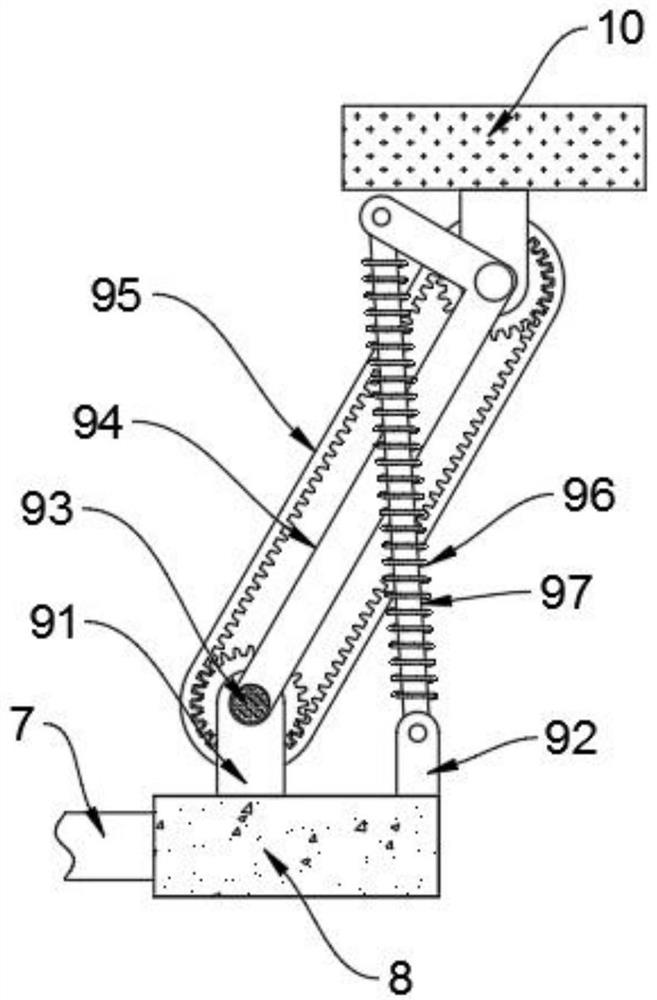

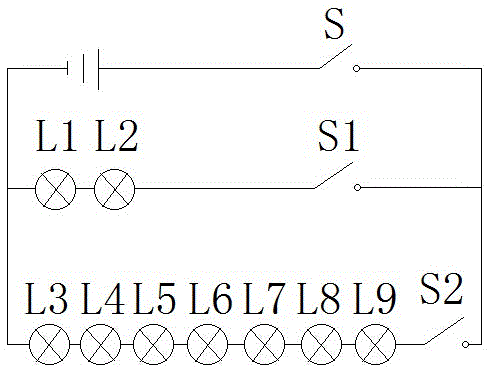

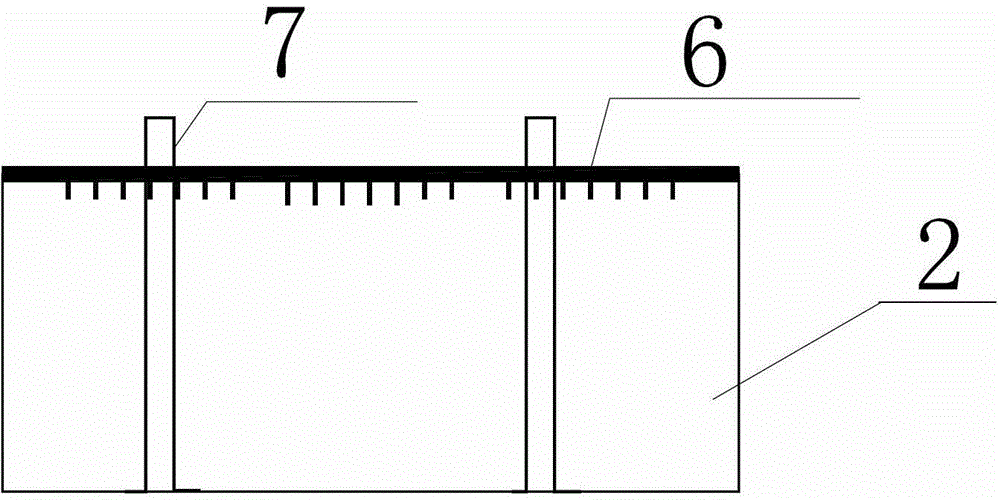

Coalface floor stepping type hydraulic supporting frame

InactiveCN102966364AShorten support timeEliminate the risk of injury or deathMine roof supportsControl valvesPiston rod

A coalface floor stepping type hydraulic supporting frame comprises a left support and a right support, top beams of the supports are connected with bases through hydraulic lift cylinders, the left support base is provided with a left support-fixing arm, the right support base is provided with a right support-fixing arm, the body of a hydraulic telescopic cylinder is articulated with the left support-fixing arm, the piston rod of the hydraulic telescopic cylinder is articulated with the right support-fixing arm, the hydraulic telescopic cylinder is connected with a third control valve through an oil line, the left hydraulic lift cylinders are connected with a second control valve through oil lines, the right hydraulic lift cylinders are connected with a first control valve through oil lines, and the first control valve, the second control valve and the third control valve are respectively connected with an oil inlet tube and an oil outlet tube. The left support top beam and the right support top beam can advance in turn by means of the hydraulic telescopic cylinders, consequently, the head-supporting time and the tail-supporting time are shortened, and personal injury accidents caused by the manual moving of the top beams and single beams are prevented; because the left support top beam and the right support top beam are extend ed forward from the bases, the unsupported area of the a roof is reduced, and the supporting range is broadened.

Owner:CHONGQING SONGZAO COAL & ELECTRICITY CO LTD

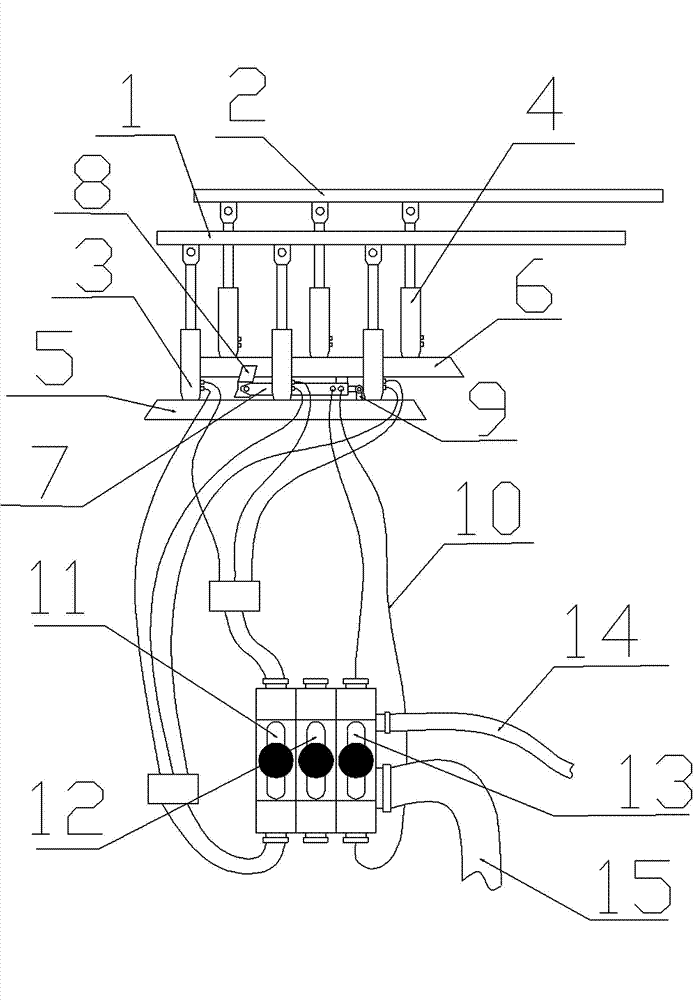

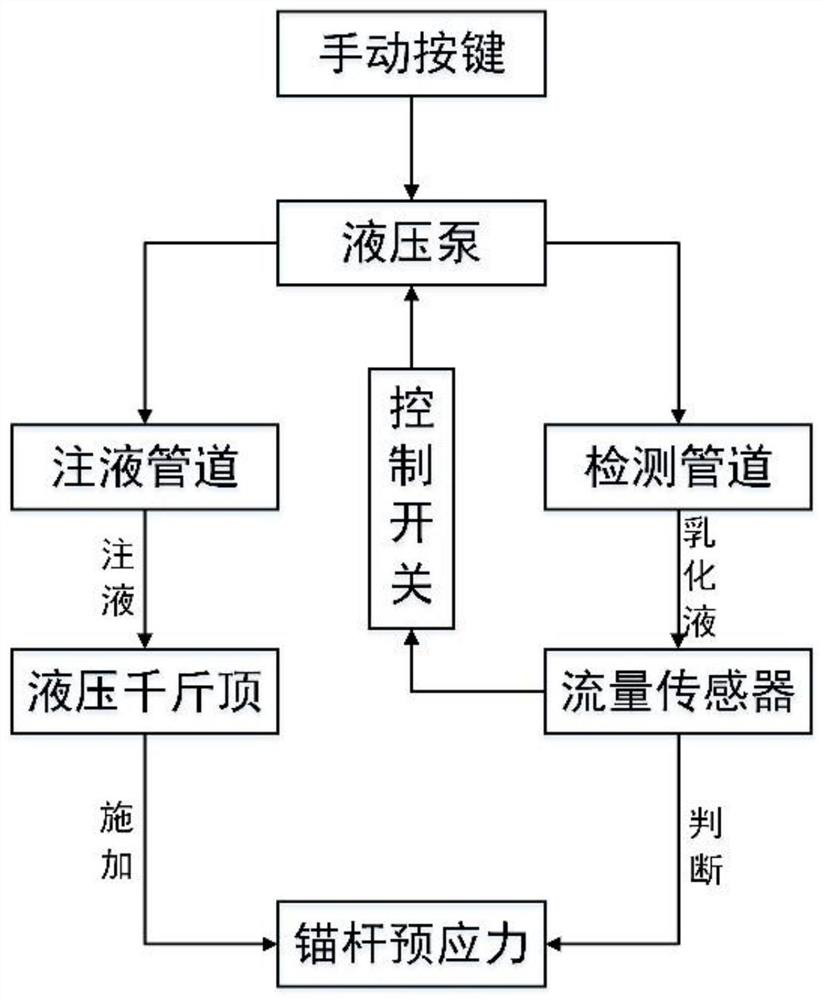

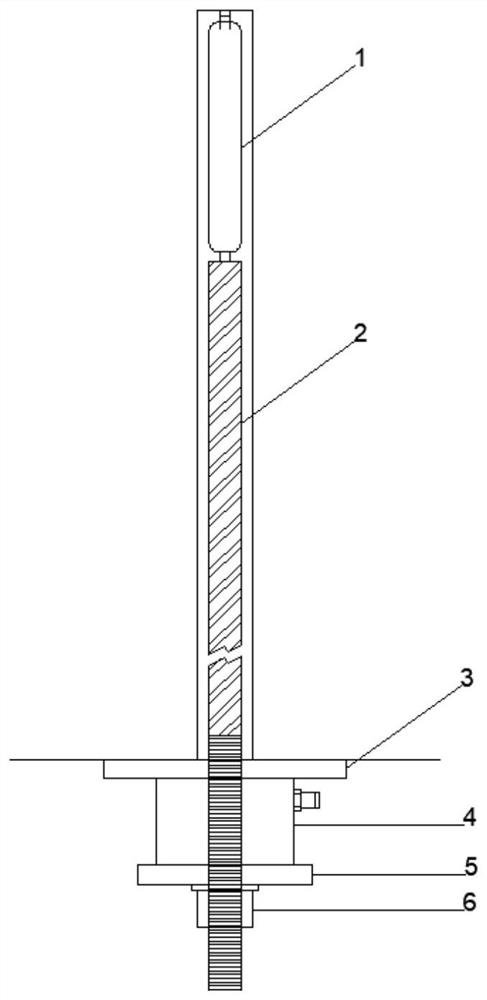

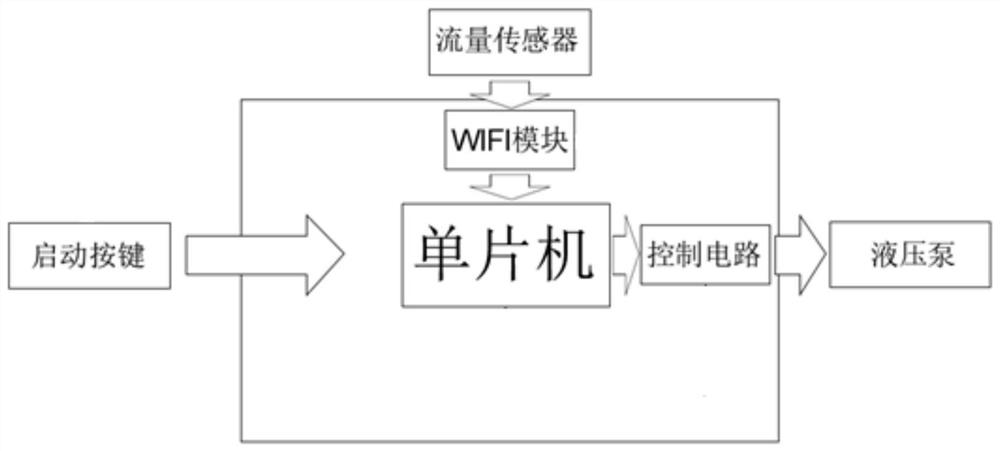

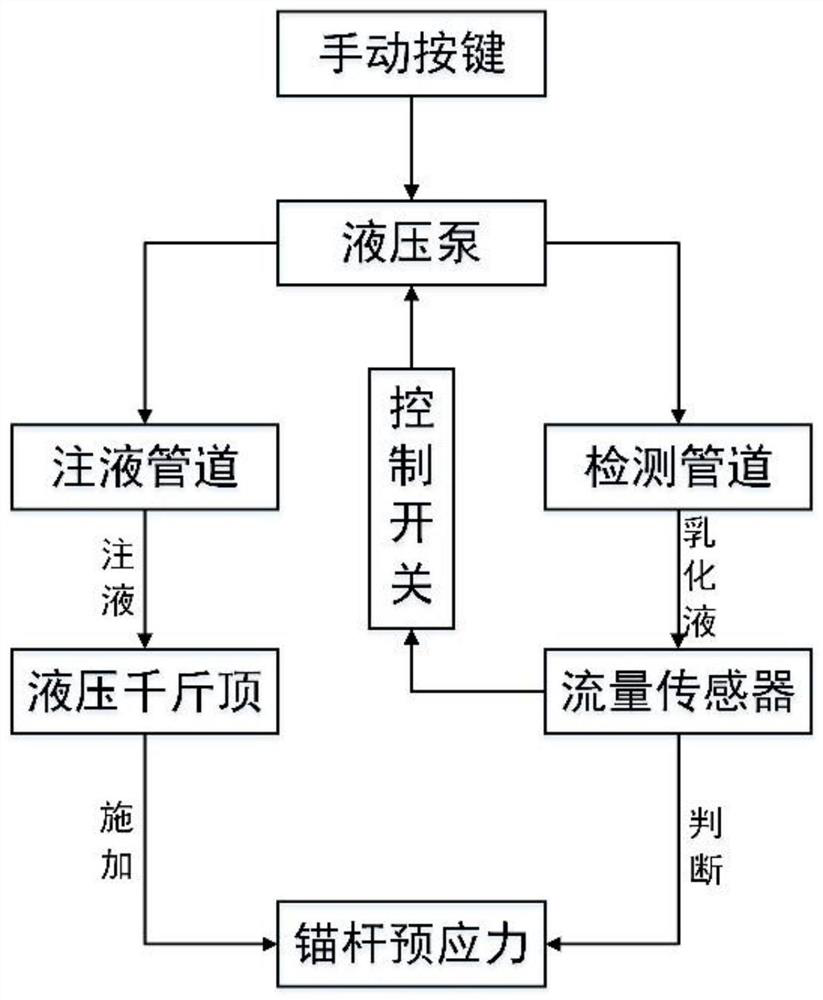

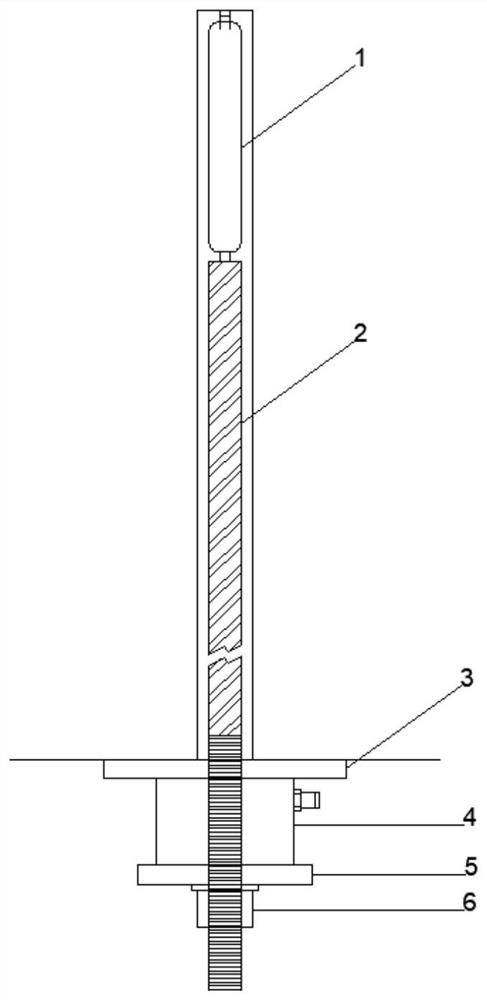

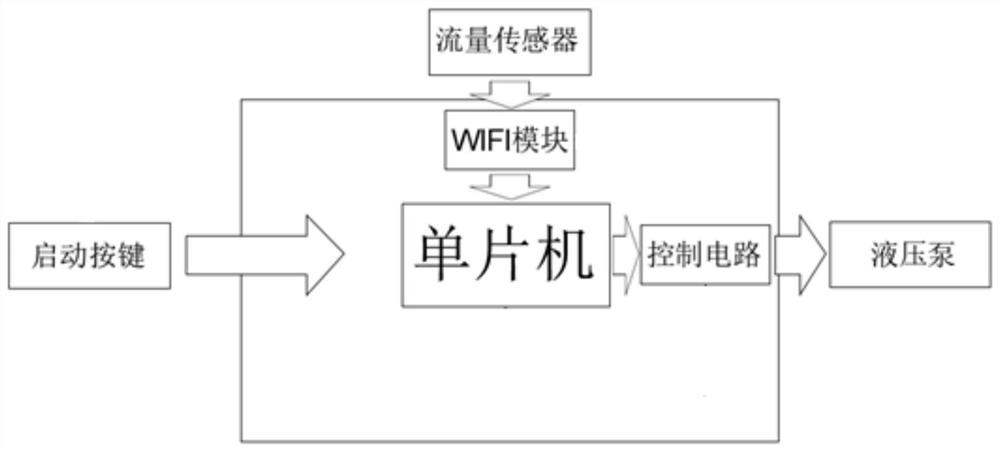

An intelligent fast application method of bolt prestress

The invention discloses an intelligent fast application method of bolt prestress. The steps are as follows: S1: through on-site actual observation of the supported roadway, determine the magnitude of the warning force of the warning force bolt; S2: install the constant resistance hydraulic pressure At the same time, the hydraulic pump injects liquid into the constant resistance hydraulic jack through the liquid injection pipeline; S3: Set the threshold value of the pressure valve of the detection pipeline, and the constant resistance hydraulic jack injects the emulsion into the detection pipeline according to the threshold value of the pressure valve, and passes the detection The flow sensor in the pipeline monitors the emulsion in the detection pipeline; S4: According to the monitoring results of the flow sensor, determine the prestress applied on the anchor rod, and compare the determined prestress applied on the anchor rod with the early warning force comparison, and at the same time determine whether the hydraulic pump continues to inject liquid into the constant resistance hydraulic jack according to the comparison result. The intelligent application method of the present invention not only has high reliability and high efficiency, but also complies with the current development trend of intelligent equipment.

Owner:CHINA UNIV OF MINING & TECH

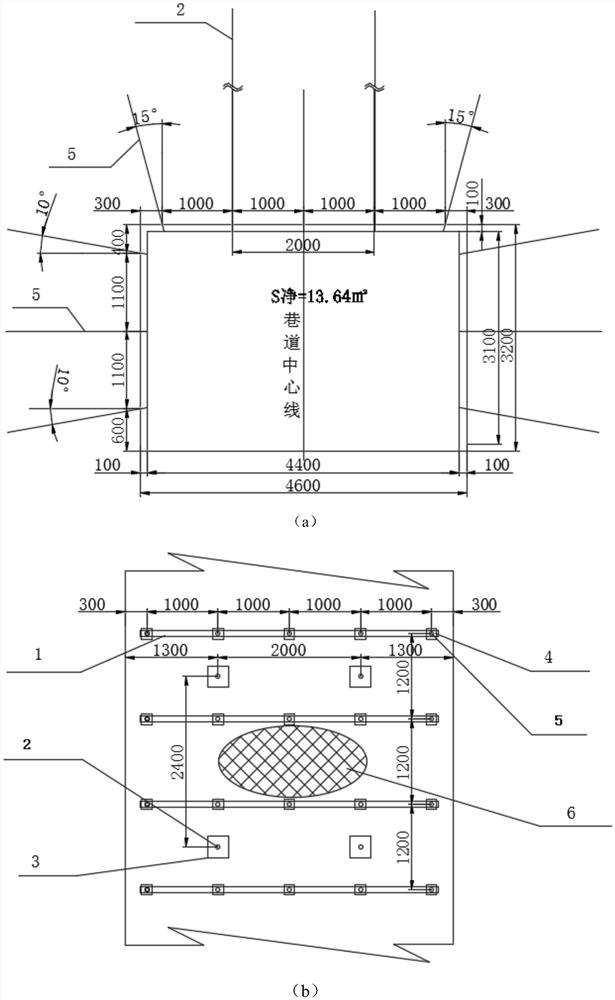

Rapid tunneling method for coal mine bottom drainage roadway

PendingCN113494293AImprove tunneling efficiencyShorten cycle timeUnderground chambersDust removalMining engineeringRock bolt

The invention provides a rapid tunneling method for a coal mine bottom drainage roadway, and relates to the technical field of coal roadway tunneling. According to the method, a roadway support design scheme is determined, wherein bottom drainage roadway support parameter design and bottom drainage roadway support design checking are involved; in the bottom drainage roadway support parameter design, an anchor net and anchor cable combined support mode is adopted, and roadway roof support parameter design and roadway two-side support parameter design are involved; the rapid bottom drainage roadway tunneling process comprising gangue cutting, shed erecting, anchor cable permanent support and lagging anchor rod reinforcing support is adopted, wherein the construction process of the rapid tunneling process comprises the following steps of performing gangue cutting, performing shed erecting, performing anchor cable permanent support and constructing a top angle anchor rod and a side angle anchor rod on the side of an air duct; and parallel operation is performed, wherein anchor rod reinforcing support after secondary transportation is performed, and then returning to the shed is performed. The method utilizes the geological conditions of a bottom drainage roadway roof well, fully utilizes equipment, time and space of the tunneling working face, achieves parallel operation of all tunneling procedures to the maximum extent, shortens the circulation time, increases the daily circulation times, and greatly improves the tunneling efficiency of the bottom drainage roadway.

Owner:LIAONING TECHNICAL UNIVERSITY

A rock bolter that collects coal mine mining, support and transportation in parallel and fast operation

ActiveCN104213831BImprove tunneling efficiencyImplement parallel jobsDerricks/mastsSlitting machinesEngineeringBalance problems

The invention relates to the mining field of underground roadways in coal mines, in particular to a bolter drilling rig for mining, supporting and transporting parallel and rapid operations in coal mines. Balance and other issues, the middle frame is an arched structure, and the belt conveyor pin tooth drive traction mechanism connected with the mining traction adaptive belt conveyor is arranged symmetrically on both sides of the middle frame. The shaped space passes through and extends below the unloading part of the roadheader; it is equipped with 8 sets of drill booms, which are four sets of front anchor protection drill booms, two sets of rear anchor protection drill booms, and two sets of side support anchor protection drill booms. Arranged in rows, and each set of drill booms can slide for a certain displacement stroke to realize the height adjustment of the support row distance. Parallel operation can complete the bolt support of 6 tops and 2 gangs at one time, which shortens the support time and improves the support efficiency. It can also provide a channel for belt transportation to realize the parallel operation of excavation-support-transportation operations.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Method for supporting triangular area in coal mine support-dismantling process

ActiveCN102003188BReduce physical exertionGood effectUnderground chambersMine roof capsRecovery methodEngineering

The invention relates to a moving and recycling method of comprehensive collecting equipment, in particular to a method for supporting a triangular area in a coal mine support-dismantling process and solves the problem of low efficiency of a maintenance method of a support-dismantling space top plate in a support-dismantling process of the traditional comprehensive collecting working face. Three shielding frames are arranged at the original triangular area; after a support is dismantled, two frame canopies are arranged at the place of the original support in a direction vertical to the shielding frames; three columns are used for supporting; plate beams are used for supporting above a single column, and then the shielding frames are drawn, wherein the drawing sequence of the shielding frames is that: the shielding frame close to a coal upper side is drawn firstly to bear the plate beams on the front ends of the supports to be dismantled, after chocks are piled behind the shielding frame and the shielding frame is returned to the back of a coal upper column, the middle shielding frame is drawn secondly to make the ends of the beams bear the plate beams in the triangular area, and the shielding frame close to an old pond side is drawn finally to bear the plate beams; and after an old pond and the single column affecting the dismantling of the support are returned back, the supporting and circulating process of shielding the support is finished. By the method, the working efficiency is improved and materials are saved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD +1

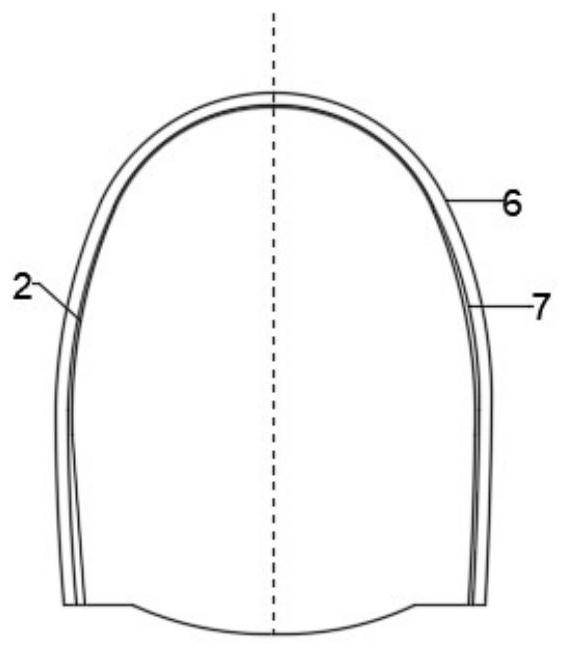

Adjustable tunnel support positioning and primary support inner contour line monitoring device

PendingCN113074021AShorten support timeShorten working timeMining devicesUnderground chambersInfraredShotcrete

The invention discloses an adjustable tunnel support positioning and primary support inner contour line monitoring device. The adjustable tunnel support positioning and primary support inner contour line monitoring device comprises a fixing device and an infrared emitting device, wherein the fixing device comprises a fixing support, a sliding piece and a first fixing piece, the fixing support is arranged along the inner wall of a primary support arch frame, a sliding groove is formed in the fixing support, the sliding piece is arranged in the sliding groove, and the first fixing piece is arranged on the sliding piece; the infrared emitting device is arranged on the first fixing piece. According to the adjustable tunnel support positioning and primary support inner contour line monitoring device, the problems that measurement points need to be marked during tunnel excavation and are lost after excavation is solved, tunnel excavation and primary support stand operation are guided, operation time is saved, measurement and construction efficiency is improved, manpower resources are saved, whether serious over-excavation or under-excavation exists in completed primary support sprayed concrete or not can be monitored, and potential quality hazards are reduced.

Owner:CCCC TUNNEL ENG

Primary support method for new caverns

ActiveCN106499409BEasy to installReduce Loose CirclesUnderground chambersTunnel liningSteel frameRebar

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

An automatic rod feeding device for a rock bolter used in coal mines

InactiveCN110454205BAutomate operationsShorten support timeDrilling rodsDrilling casingsMining engineeringRock bolt

The invention belongs to the technical field of jumbolter equipment for coal mines, and particularly relates to an automatic rod feeding device of a jumbolter for a coal mine. The problem that the operation efficiency of an existing roof bolter for the coal mine is low, thus the time of the support process of a roadway is long, and consequently the landslide risk of the roadway is increased is solved. The automatic rod feeding device comprises an anchor storeroom support, a rotatable anchor rod support plate is located at the bottom of the anchor rod storeroom support and arranged horizontally, the anchor rod support plate is provided with anchor rods arranged in a circle shape, a rotating center shaft arranged vertically is fixed to the position, on the circle center of the anchor rod support plate, of the anchor rod storeroom support, an anchor grasping mechanical arm fixing sleeve tube is arranged on the upper part of the rotating center shaft in a concentric mode, the anchor grasping mechanical arm fixing sleeve tube is provided with an anchor grasping mechanical arm, and a hydraulic driving device fixedly connected with the upper surface of a second cross arm is arranged at the top of the anchor rod storeroom support. According to the automatic rod feeding device, the changing and mounting efficiency of the anchor rods is effectively improved, the time of the support process of the roadway is shortened, and the landslide risk of the roadway is reduced.

Owner:潍坊格盛建筑安装工程有限公司

Tilling device for coastal beaches

ActiveCN110278722BPrevent the problem of sinking too deepIncrease contact areaPloughsHydraulic cylinderTidal flat

The invention discloses a plowing device for coastal tidal flats. An auxiliary support drag mechanism I is provided at the front bottom of the tiller, and an auxiliary support drag mechanism II is arranged at the rear bottom of the tiller. In this way, it can Effectively increase the front and rear auxiliary supporting carriages, increase the contact area, and prevent the device from sinking into the soil; the hydraulic cylinder first roughly adjusts the overall height, and then the adjustment rod is precisely adjusted to ensure the accuracy of the tillage. At the same time, the tiller When moving forward to plow the coastal beach, the auxiliary support carriage I of the auxiliary support carriage mechanism I and the auxiliary support carriage II of the auxiliary support carriage mechanism II all swing up and down along the forward direction of the tiller The auxiliary support setting, through the swing setting, can reduce the support time at a certain position, and can effectively prevent the tiller from sinking too deep as it advances.

Owner:YANCHENG TEACHERS UNIV

An anti-breakage anchorage device and its construction method adapted to the surrounding rock of large-deformation roadway

ActiveCN106837394BEasy to useImprove carrying capacityAnchoring boltsStructure of the EarthEngineering

The invention discloses a breaking-resistant anchoring apparatus suitable for large-deformation roadway surrounding rock and a construction method of the breaking-resistant anchoring apparatus. The breaking-resistant anchoring apparatus comprises an anchor rod and a plurality of anchor ropes; a plurality of grooves are formed in the side wall of the rear end of the anchor rod, and the rear ends of the anchor ropes are embedded inside the corresponding grooves; a nut, a base plate and a supporting plate are arranged at the position, adjacent to the rear end, of the anchor rod, the nut is arranged adjacent to the rear end of the anchor rod, and the base plate is disposed between the supporting plate and the nut; a plurality of anchor rope through holes are respectively formed in the base plate and the supporting plate, and the anchor ropes are fixed in the anchor rope through holes of the base plate by virtue of anchorage devices; and a retainer ring is arranged at the front end of the anchor rod, a plurality of anchor rope through holes are formed in the retainer ring, the front end of each anchor rope penetrates through the anchor rope through hole, a clamp is arranged in each anchor rope through hole, and the front end of each anchor rope is fixed by virtue of the clamp; and a part, disposed between the supporting plate and the retainer ring, of the anchor rope is wound at the outer side of the anchor rod. The breaking-resistant anchoring apparatus is simple in structure, convenient to install, and low in supporting cost; and the elongation percentage is large, the deformation of the roadway surrounding rock can be effectively controlled, and the long-term stability and normal use of the roadway surrounding rock can be ensured.

Owner:HUNAN UNIV OF SCI & TECH

Anchor rod prestress intelligent fast construction method

InactiveCN111622790AImprove reliabilityImprove efficiencyAnchoring boltsFlow transducerArchitectural engineering

The invention discloses an anchor rod prestress intelligent fast construction method. The anchor rod prestress intelligent fast construction method comprises the following steps that S1, a supported roadway is subjected to on-site actual observation, and the early warning force of an early warning anchor rod is determined; S2, a constant-resistance hydraulic jack is mounted, and meanwhile a hydraulic pump injects liquid inlet the constant-resistance hydraulic jack through a liquid injecting pipeline; S3, the threshold value of a pressure valve of a detecting pipeline is set, emulsified liquidis injected into the detecting pipeline through the constant-resistance hydraulic jack according to the threshold value of the pressure valve, and the emulsified liquid in the detecting pipeline is monitored through a flow sensor in the detecting pipeline; and S4, according to the monitoring result of the flow senor, prestress applied to an anchor rod is determined, the determined prestress applied to the anchor rod is compared with the early warning force, and meanwhile according to the comparison result, whether the hydraulic pump needs to continue to inject the liquid into the constant-resistance hydraulic jack or not is determined. The intelligent construction method is high in reliability and efficiency, and accords with the intelligent development trend of current equipment.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com