Primary support method for new caverns

A technology for initial support and cavern, which is used in earthwork drilling, underground chambers, shaft equipment, etc., can solve problems such as voids, and achieve the effects of reducing loose circles, protecting surrounding rocks, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing.

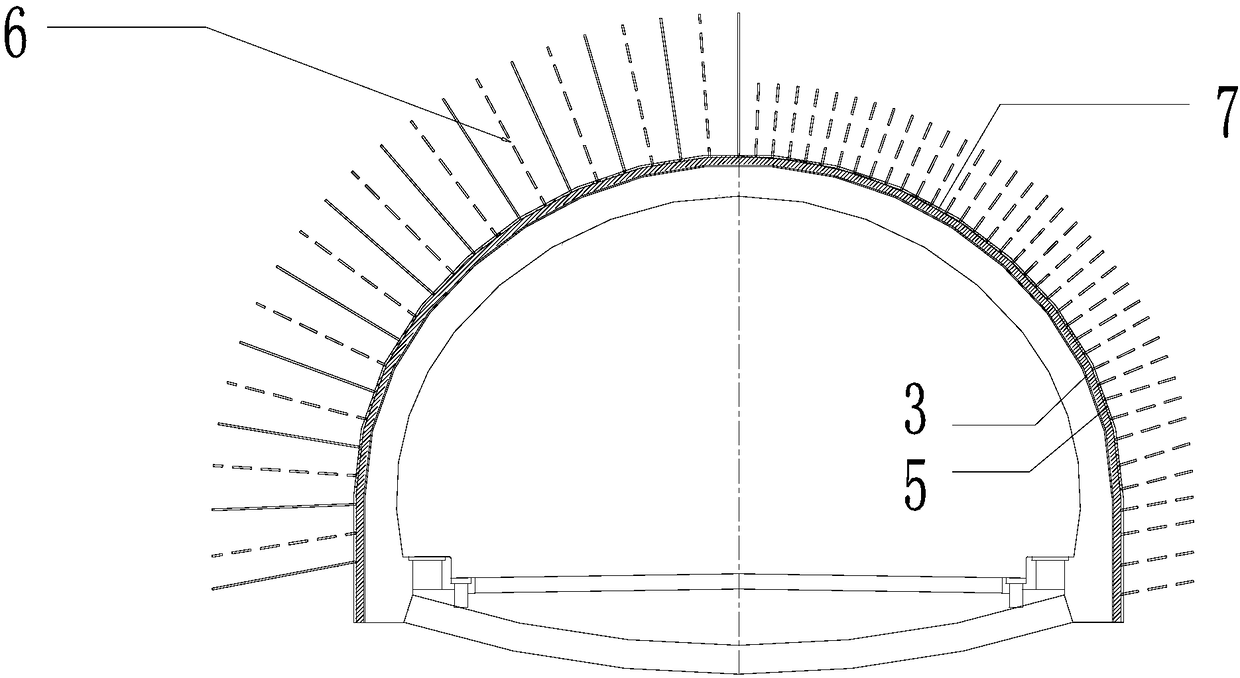

[0054] Such as figure 1 As shown, in order to solve the problems of the technologies described above, the initial support method of the newly-built cavern that the present invention adopts comprises the following steps:

[0055] 1. The initial support method for a new cavern is characterized in that it includes the following steps:

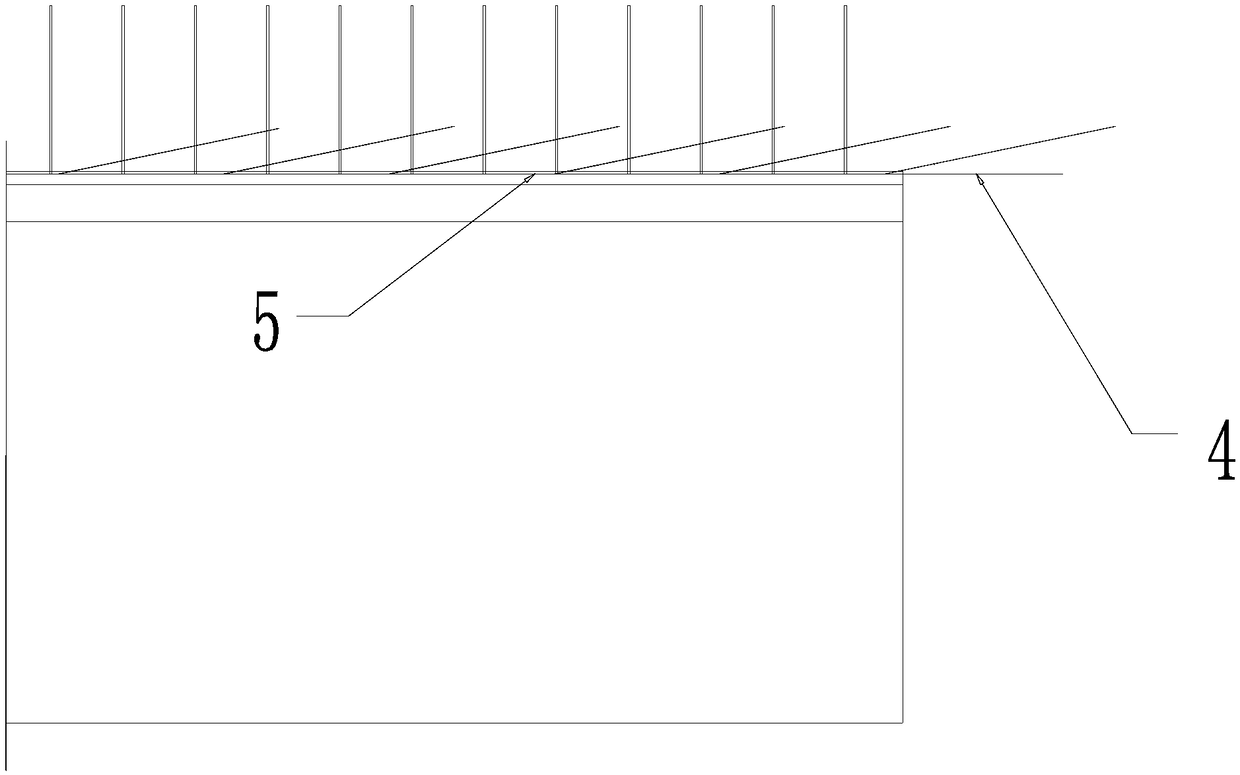

[0056] a. Before the excavation of the cavern, drill a hole for longitudinal reinforcement along the excavation contour surface of the cavern and ahead of the tunnel face;

[0057] b. Cut the material at the installation site of the steel bar and make it into the steel bar of the actual required length;

[0058] c. Insert 3 to 5 sections of wetted anchoring agent into the reinforcement hole;

[0059] d. Insert the advanced longitudinal reinforcement along the drilled reinforcement hole;

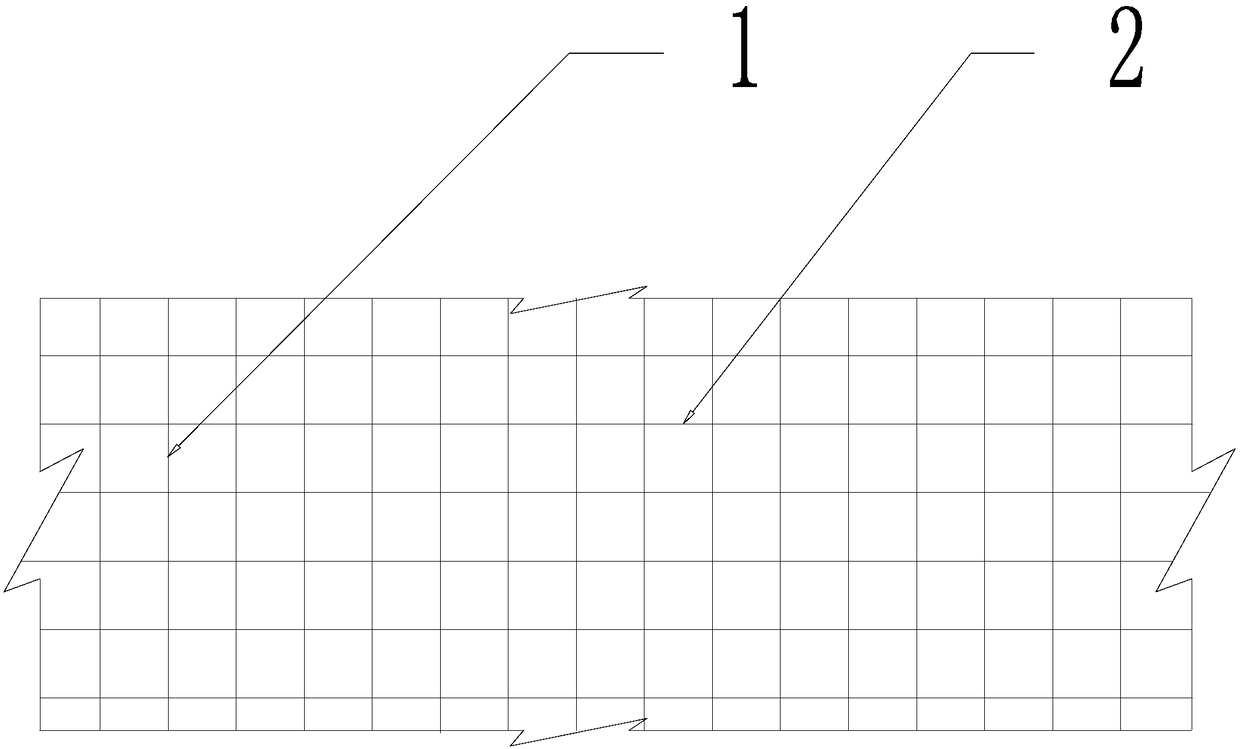

[0060] e. The exposed part of the steel bar is bound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com