Automatic rod feeding device for mine anchor rod drilling machine

A bolt drilling rig and automatic technology, which is applied in the field of parts and components, can solve the problems of low operation efficiency, long support process time, and increase the risk of roadway collapse, so as to improve the replacement efficiency, reduce the collapse risk, and shorten the support process time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

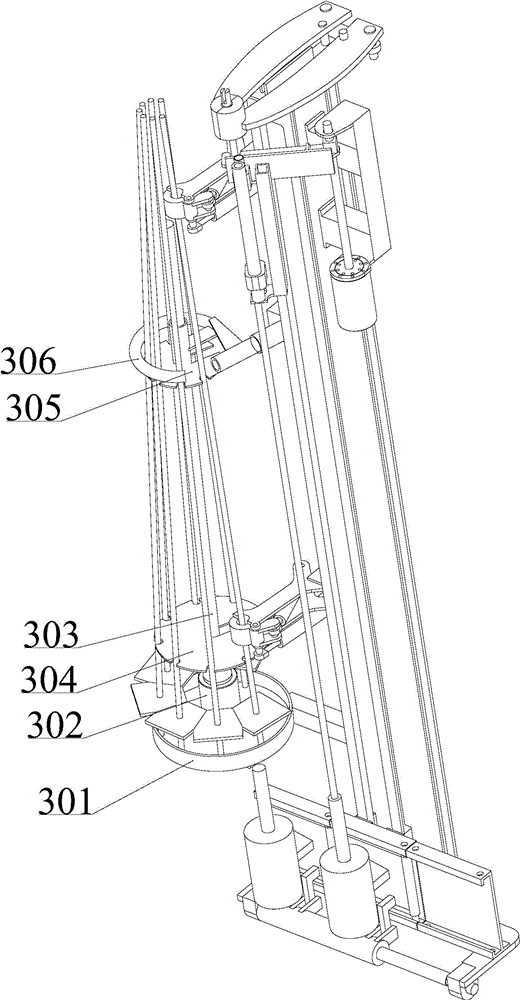

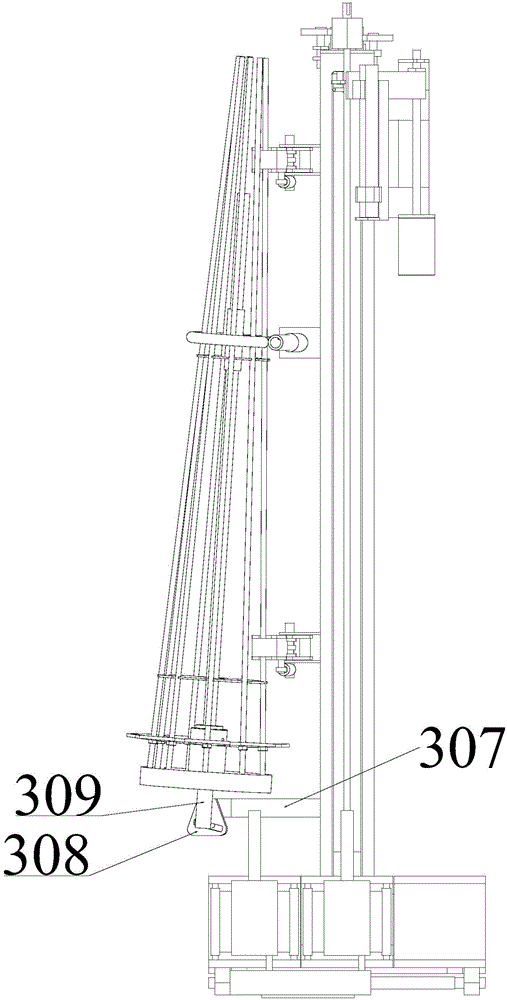

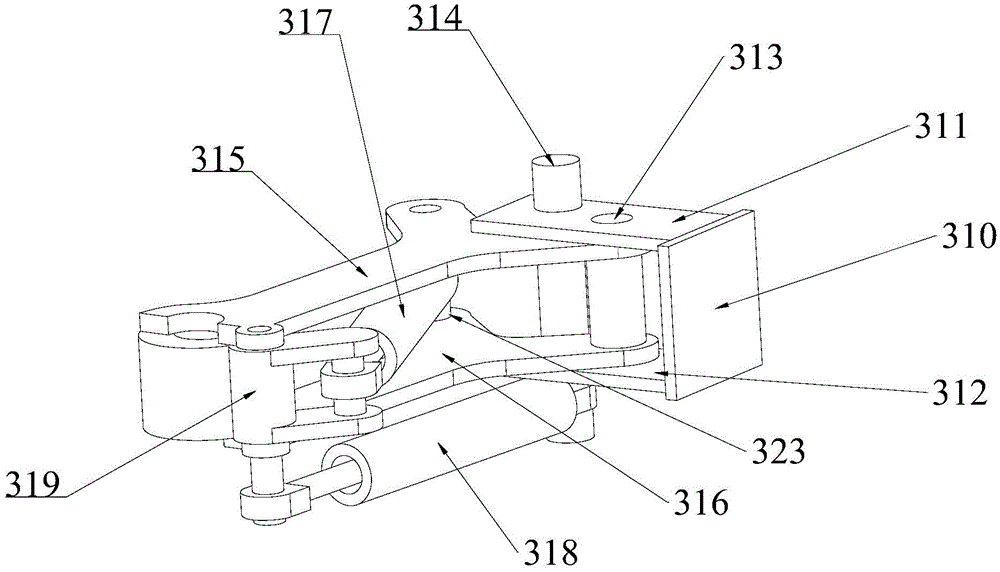

[0031] This embodiment provides an automatic rod-feeding device for a coal mine bolter, which includes a bolt storage mechanism, a first manipulator, a second manipulator and a fixing seat;

[0032] The anchor rod storage mechanism includes a lower supporting plate 301, a rotating power part 302, a central shaft 303, a lower sub-dial 304, an upper sub-dial 305 and an upper fixed retaining ring 306;

[0033] The lower supporting plate 301 is circular, and its edge protrudes upwards.

[0034] The rotary power part 302 can be a motor, or a power device such as a hydraulic motor. On rotating parts, such as rotors of electric motors and hydraulic motors; the axis of the central shaft 303 is perpendicular to the lower support plate 301 .

[0035] The center of the lower dial 304 is provided with a first through hole, and the side wall of the lower dial 304 is provided with a plurality of semicircular grooves along the axial direction of the lower dial 304. The lower part can be pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com