Industrial production method of high-F-value corn oligopeptide with alcohol dispelling and liver protection activities

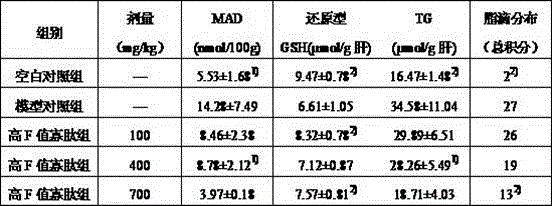

A technology of corn oligopeptides, sobering up and protecting the liver, which is applied in the field of deep processing of plant protein, can solve the problems of high F value corn oligopeptide industrial production, complex process, high bitterness value, etc., to achieve improved purity and activity, simple production process, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

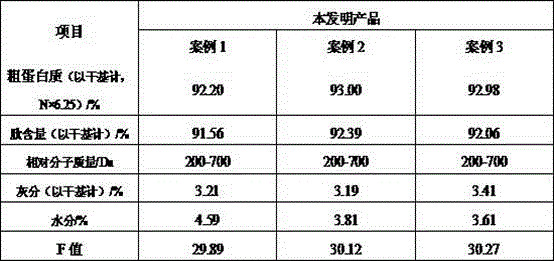

Embodiment example 1

[0023] (1) Emulsification of CGM: Add water to 100kg of CGM according to the ratio of material to liquid ratio of 1:9, and emulsify in an emulsification tank at 8000r / min high-speed shear for 30min.

[0024] (2) Enzymolysis, enzyme inactivation, filtration: transfer the emulsion into an enzymolysis tank, adjust the temperature to 50°C, pH9, add alkaline protease and compound flavor protease according to the enzyme activity ratio of 3:1, and perform enzymolysis for 1-3 hours. After the enzymatic hydrolysis is completed, the temperature of the enzymatic hydrolysis tank is raised to 90°C to inactivate the enzyme for 10 minutes. After inactivating the enzyme, perform frame filtration.

[0025] (3) Activated carbon adsorption: adjust the pH of the above filtrate to 2.5, add activated carbon at a solid-to-liquid ratio of 1:10, and statically adsorb for 2 hours. And perform plate and frame filtration.

[0026] (4) Separation and purification: the above filtrate is subjected to grad...

Embodiment example 2

[0029] (1) Emulsification of CGM: Add water to 100kg of CGM according to the ratio of material to liquid ratio of 1:9, and emulsify in an emulsification tank at 9000r / min high-speed shear for 45min.

[0030] (2) Enzymolysis, enzyme inactivation, filtration: transfer the emulsion into an enzymolysis tank, adjust the temperature to 55°C, pH 10, add alkaline protease and compound flavor protease according to the enzyme activity ratio of 4:1, and enzymatically hydrolyze for 2 hours. After the enzymatic hydrolysis is completed, the temperature of the enzymatic hydrolysis tank was raised to 95°C to inactivate the enzyme for 13 minutes. After inactivating the enzyme, use a frame filter to filter the enzymatic hydrolyzate.

[0031] (3) Activated carbon adsorption: adjust the pH of the above filtrate to 3, add activated carbon at a solid-to-liquid ratio of 1:10, and statically adsorb for 2.5 hours. And perform plate and frame filtration.

[0032] (4) Separation and purification: the ...

Embodiment example 3

[0035] (1) Emulsification of CGM: Add water to 100kg of CGM according to the ratio of material to liquid ratio of 1:9, and emulsify in an emulsification tank at 10000r / min high-speed shear for 60min.

[0036] (2) Enzymolysis, enzyme inactivation, filtration: transfer the emulsion into an enzymolysis tank, adjust the temperature to 60°C, pH 11, add alkaline protease and compound flavor protease according to the enzyme activity ratio of 5:1, and enzymatically hydrolyze for 3 hours. After the enzymatic hydrolysis is completed, the temperature of the enzymatic hydrolysis tank is raised to 100°C to inactivate the enzyme for 15 minutes. After inactivating the enzyme, use a frame filter to filter the enzymatic hydrolyzate.

[0037] (3) Activated carbon adsorption: Adjust the pH of the above filtrate to 3.5, add activated carbon at a solid-to-liquid ratio of 1:10, and statically adsorb for 3 hours. And perform plate and frame filtration.

[0038] (4) Separation and purification: the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com