Ultra-white glass

A technology of ultra-white glass and thick glass, applied in the field of glass preparation, can solve problems such as affecting the quality of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

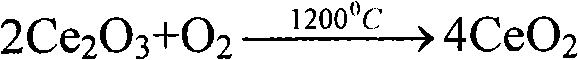

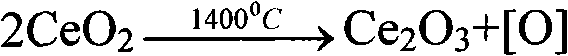

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be described in more detail by the following examples, but the present invention is not limited to the following examples.

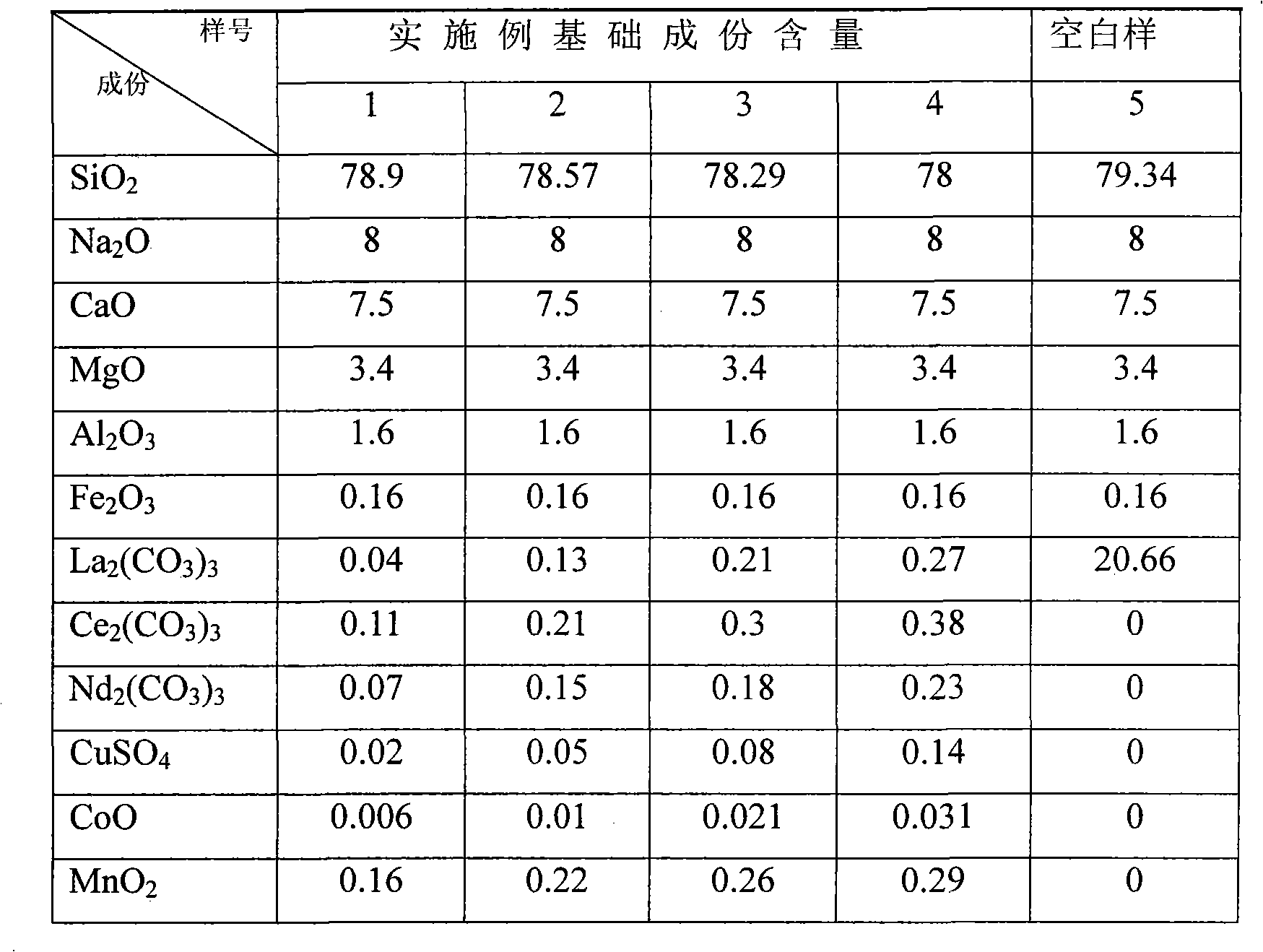

[0086] All use the basic batching of common float glass in the following examples, and each composition content is as table 1:

[0087] Table 1 Example Basic Batching Component Table / % (by weight percentage)

[0088]

[0089] Introduce the above basic components through sandstone, dolomite, limestone, and soda ash, and add the required La 2 (CO 3 ) 3 、Ce 2 (CO 3 ) 3 、Nd 2 (CO 3 ) 3 , MnO 2 , CoO, CuSO 4 , fully mix the batch materials, the total mass is 100g, put it into a corundum crucible, and then put it on the platform in the glass melting furnace, after 5 hours, cast the molten glass liquid on the steel plate coated with zirconium powder, put Anneal in a holding furnace at 550°C. The thickness of the prepared sample is about 6mm, and the thickness is 4mm after rough grinding and polishing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com