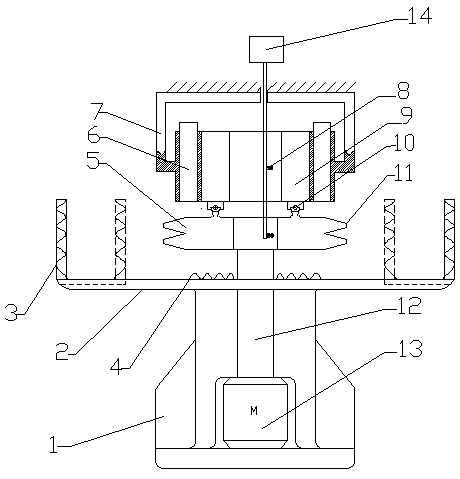

Novel centrifugal melt electrostatic spinning device

A new type of melt electrospinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of increasing spinning temperature and unsatisfactory results, and achieve industrial production , the effect of improving spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

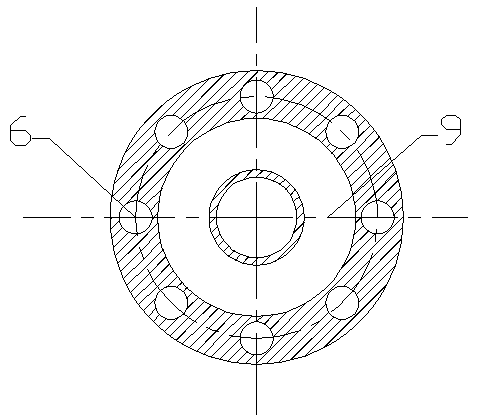

[0012] figure 1 and figure 2 , adjust the distance between the nozzle (11) and the collection cylinder (3) to be 17 cm, and put 30 grams of polypropylene into the feeding chamber (9). Turn on the power supply of the heating rod (6) and the electric heating plate (4), when the temperature of the feeding chamber (9) and the spray chamber (5) both reach 230°C, keep the heat for 10 minutes, then open the valve (10), and the polypropylene The melt flows into the spray chamber (5), and a voltage of 20KV is applied between the nozzle (11) and the collecting cylinder (3), and the speed of the motor (13) is gradually adjusted from 0 to 13000 rpm, and the high-speed rotating The spinning nozzle (5) spins the melt and falls on the collecting cylinder (3). After the spinning is finished, the power is turned off, and the spun filaments are collected. After measurement, the fiber diameter is 200-600 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com