Numerical-control petroleum workover line

An operation line and workover technology, which is applied to drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problems of unstable lifting tubing, low installation efficiency, easy shaking, etc., and achieve fast and stable installation or disassembly process, damage small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

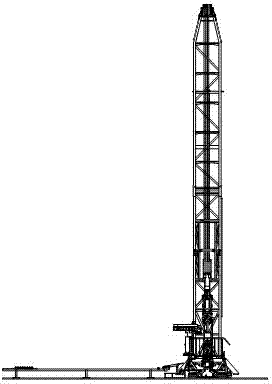

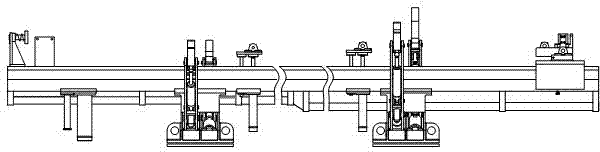

[0027]Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a derrick 1, the derrick 1 is installed on the platform 2, a tubing material rack 9 is provided on the side of the derrick 1, and the feature is that: a tubing pick-up slide 5 is provided at the end of the tubing material rack 9, A trolley for pushing the oil pipe to move is provided on the oil pipe transfer slideway 5, and a hydraulic pipe wrench manipulator 3 capable of lifting one end of the oil pipe is provided at the end of the oil pipe transfer slideway 5, and a hydraulic pipe wrench manipulator 3 is provided to change the oil pipe from the lifting state to the grasping state. And transfer the tubing lifting to the tubing manipulator 5 in the next process. The main and auxiliary elevators 6 are arranged on the derrick to adjust the tubing to the middle and upper part of the platform and can move up and down. In the center of the lower platform 2 of the main and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com