A coal mine digging and anchoring integrated machine and a method for parallel operation

An all-in-one machine and operation technology, which can be used in slitting machinery, cutting machinery, mining equipment, etc., and can solve problems such as inability to support real-time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

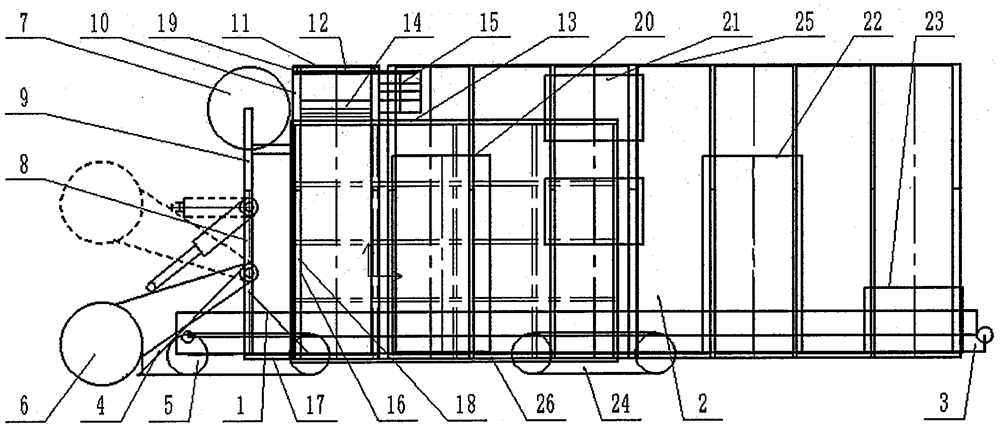

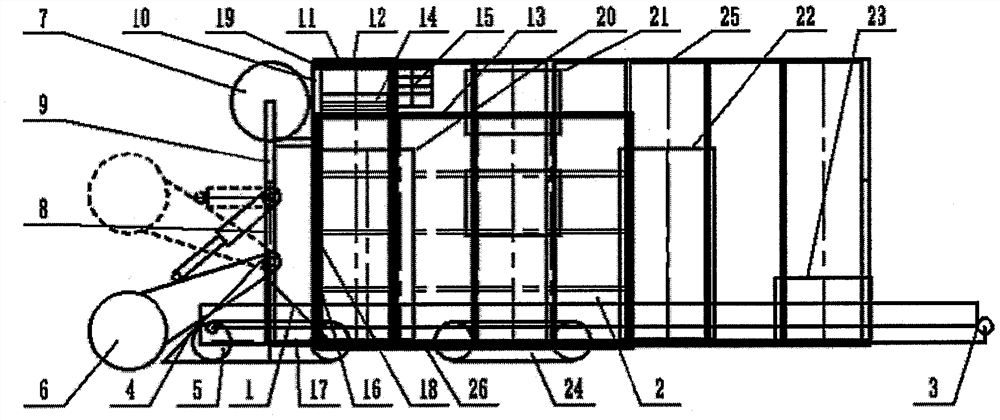

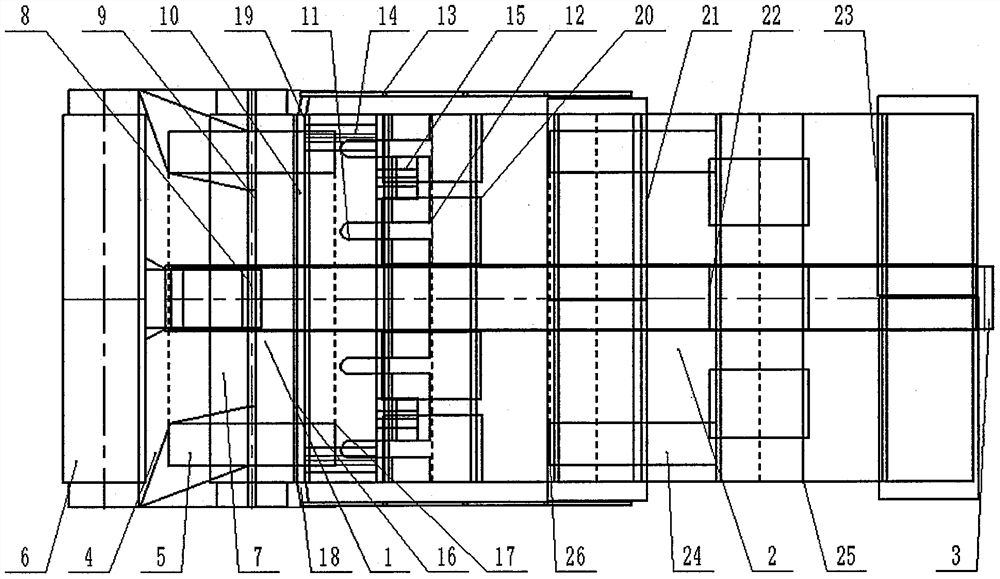

[0037] When the excavating and anchoring integrated machine is working, it performs parallel operations of excavation, temporary support, network laying, steel belt laying, and bolt support. It is suitable for excavation, temporary support and anchor net support of rectangular coal roadway. The overall dimensions of the model are about 11m in length, 3.8m in height and 5m in width, and are suitable for large-section coal roadway excavation. The specific height and width of the roadway can be met through equipment design and manufacture.

[0038] The excavation work described. The cutting mechanism adopts two horizontal drum structures with telescopic sections, the diameter of the drum is 1000mm, and the length is the same as the width of the roadway. The lower cutting drum (6) is the main cutting mechanism, which is fixed by the fixed structure frame (8), and can move up and down around the fixed rotating shaft to expand the cutting range and connect with the upper cutting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com