Coalface floor stepping type hydraulic supporting frame

A technology for coal mining face and hydraulic support, applied in mine roof support, mining equipment, earth-moving drilling and other directions, can solve problems such as personal injury, long time required, and difficulty in ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

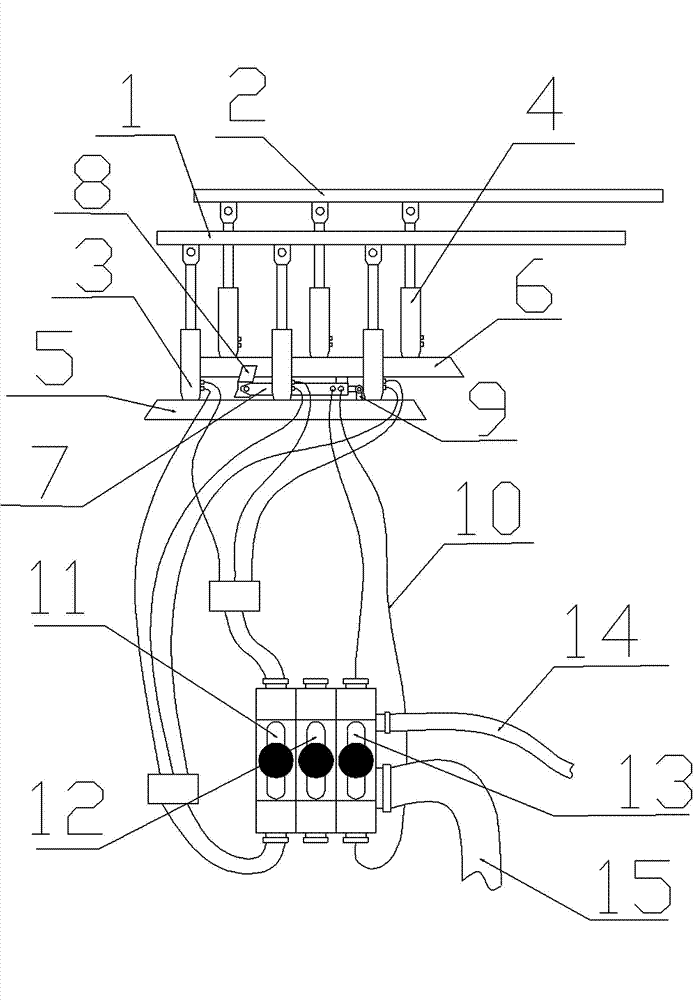

[0013] see figure 1 , a bottom step hydraulic support frame in a coal mining face, including a left support and a right support composed of a base, a top beam and a lifting hydraulic cylinder respectively. It is connected with the base through a plurality of side-by-side lifting hydraulic cylinders. In this embodiment, the top beam is hinged and fixed on the top of the lifting hydraulic cylinders. There are three left lifting hydraulic cylinders and three right lifting hydraulic cylinders. The left support base 6 is provided with two left support fixed arms 8 extending to the right support, the left support top beam 2 extends forward from the left support base 6, and the right support base 5 is provided with a right support extending to the left support The fixed arm 9, the right bracket top beam 1 extends out of the right bracket base 5 forward, the cylinder body of the telescopic hydraulic cylinder 7 is fixedly connected to the left bracket fixed arm 8 through hinges, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com