Supporting method for narrow coal pillar in gob-side entry driving

A narrow coal pillar and coal wall technology, which is applied in the direction of earthwork drilling, mining equipment, bolt installation, etc., can solve the problem that narrow coal pillars cannot guarantee the stability of narrow coal pillars, and achieve the improvement of overall support strength and wide practicability , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

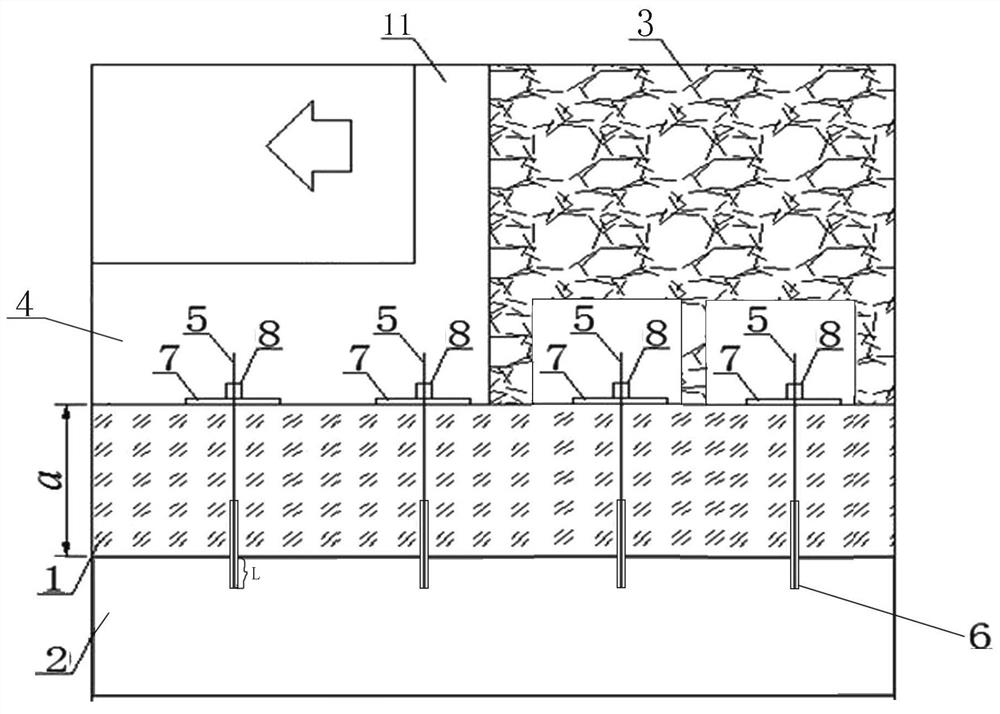

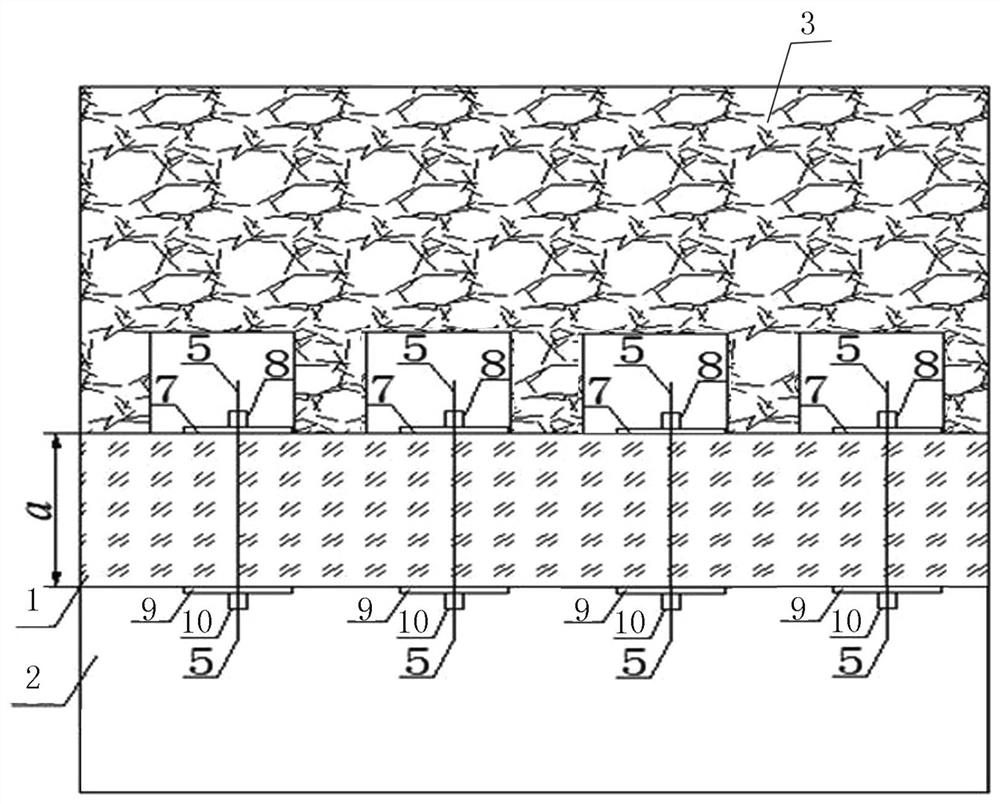

[0012] A support method for narrow coal pillars in gob-side entry is realized by the following steps:

[0013] 1) Determine the width a of the reserved narrow coal pillar 1 according to the law of surface movement;

[0014] 2) Excavate in the section entry 4 of the adjacent section of the goaf 3. After the excavation is completed, the coal wall on the side of the reserved narrow coal pillar 1 close to the goaf 3 needs to be supported: firstly, in the reserved Anchor cable holes are drilled one by one on the coal wall of the narrow coal pillar 1 near the goaf 3, and the anchor cable holes pass through the reserved narrow coal pillar 1 along the width direction of the reserved narrow coal pillar 1 and extend to the reserved The length of the extension part is L, and then the anchoring agent 6 is sent into the bottom of the anchor cable hole one by one, and then one end of the anchor cable 5 is inserted into the bottom of the anchor cable hole, and the other end of the anchor cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com