Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduced operational reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

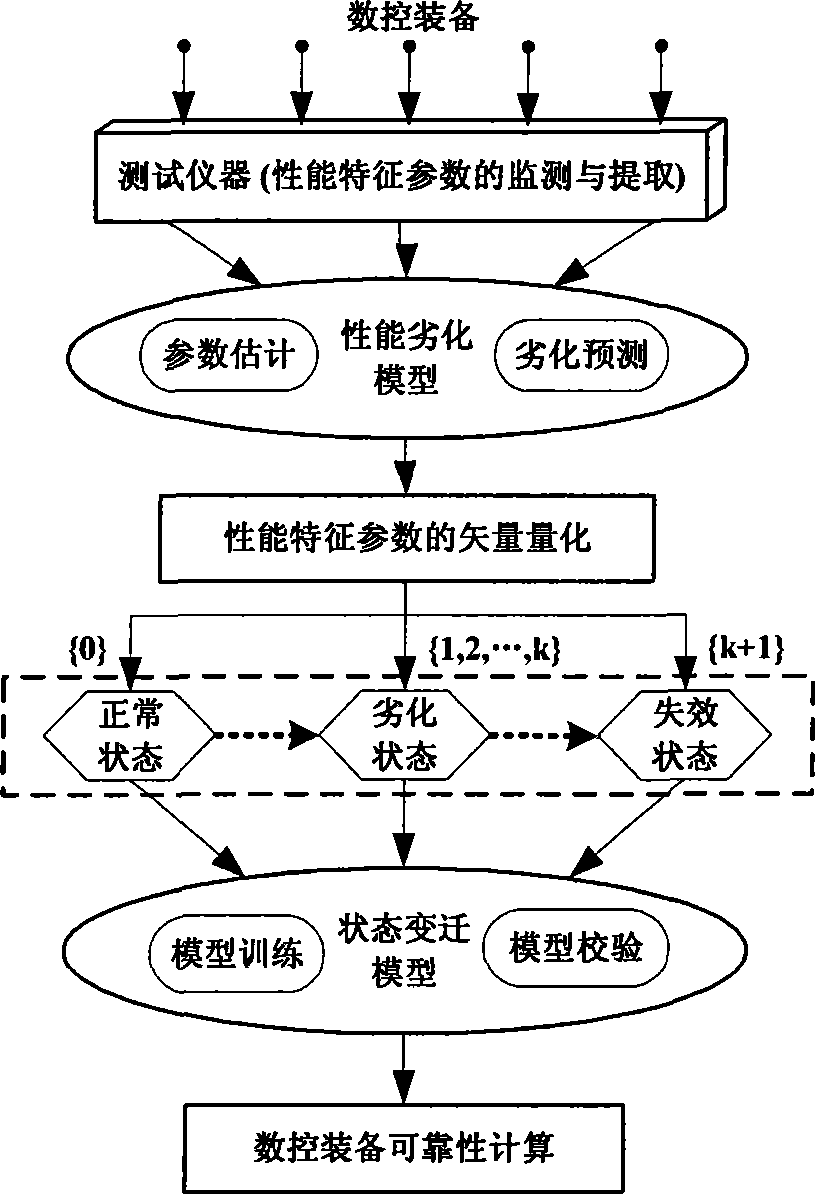

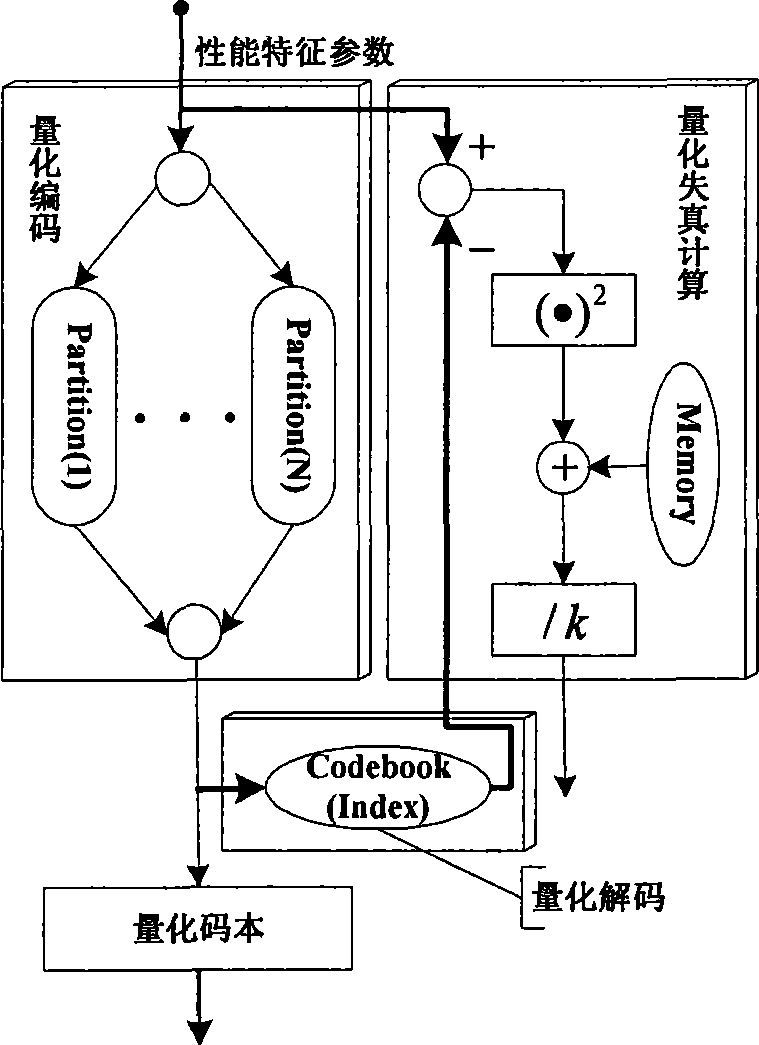

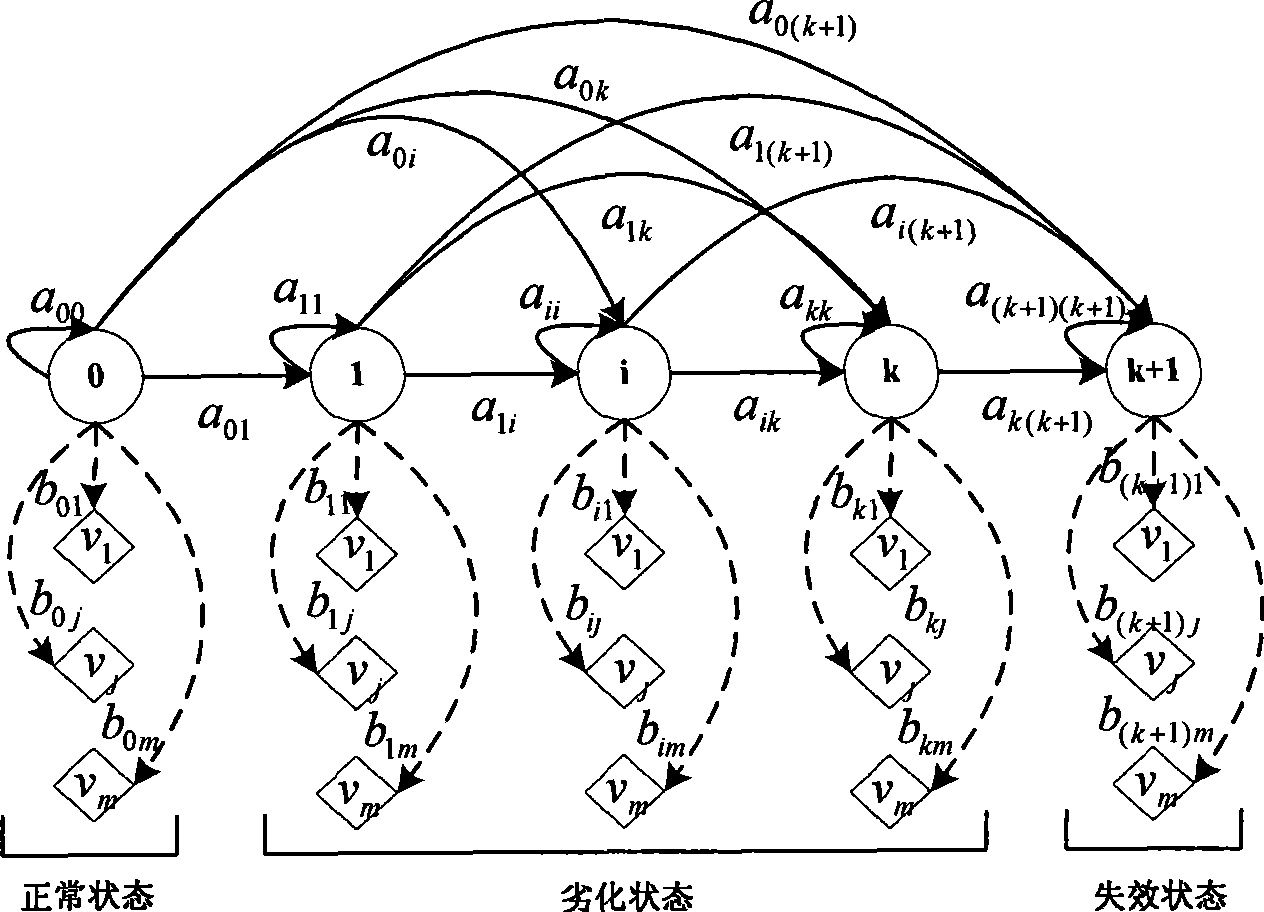

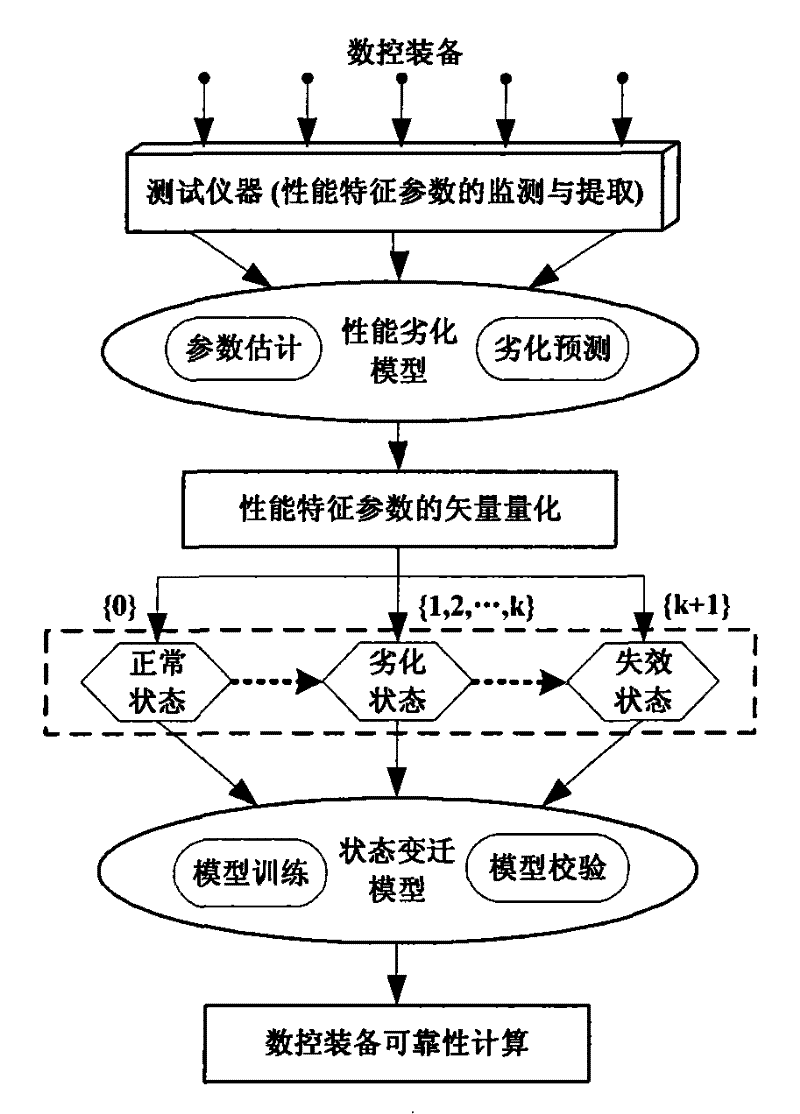

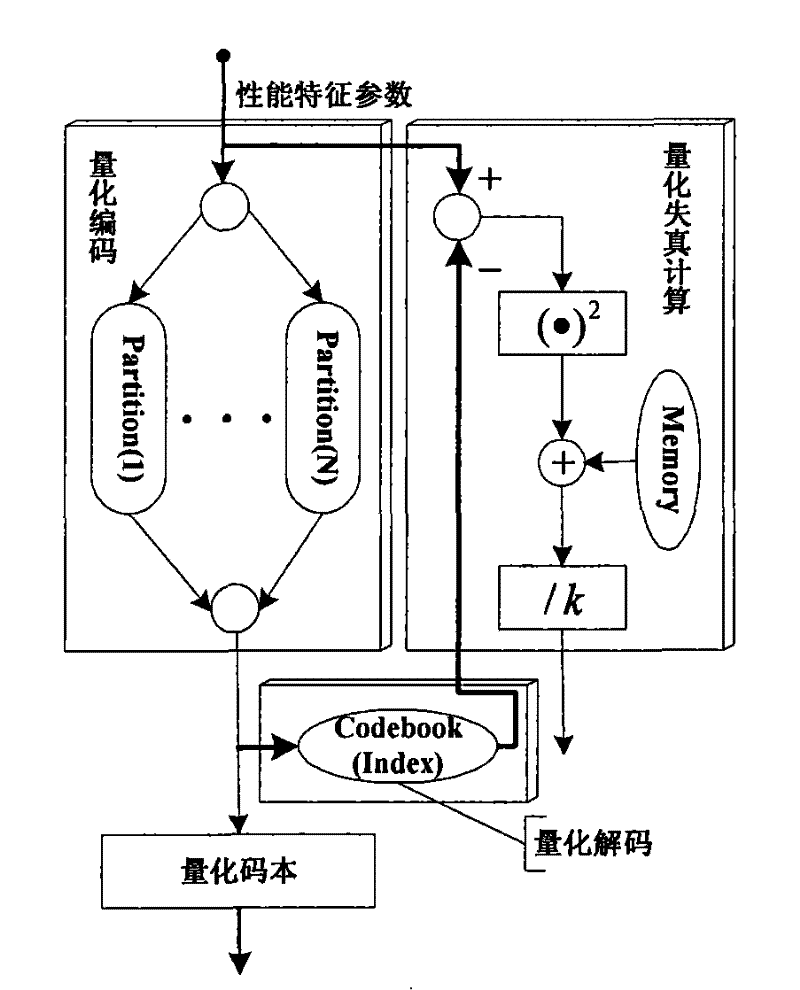

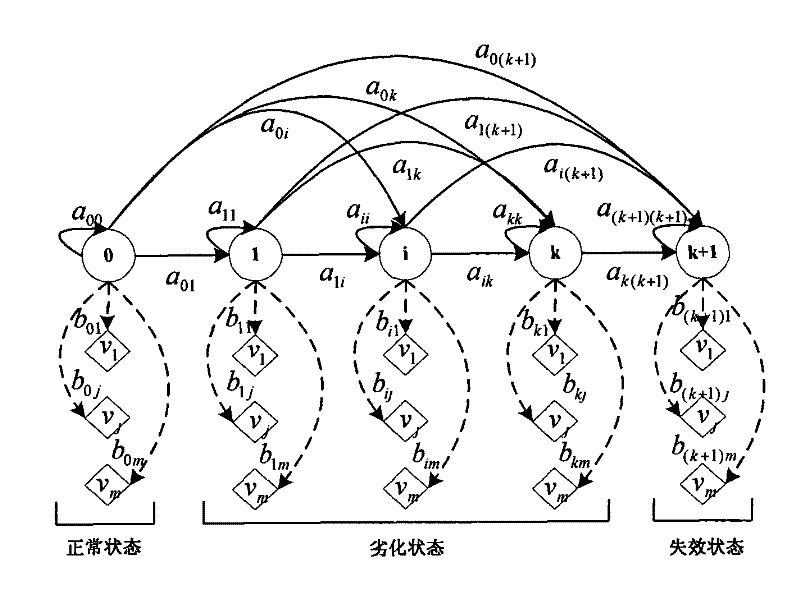

Analysis method for reliability of numerical control equipment based on hidden Markov chain

InactiveCN101520651AReduced operational reliabilityFailure to achieveProgramme controlComputer controlNumerical controlHidden markov chain model

The invention provides an analysis method for reliability of numerical control equipment based on a hidden Markov chain. The method particularly comprises the following steps: 1, monitoring dynamic performance signals of the numerical control equipment, and abstracting the performance characteristic parameter values showing the change of the reliability of the numerical control equipment; 2, constructing a predictive model of the performance characteristic parameter values; 3, using the predictive model to predict the performance characteristic parameter values within the time needed for vectorization, and adopting the source coding method to vectorize the predictive values of the performance characteristic parameter values; 4, adopting the discrete hidden Markov chain model to identify the state transition probability of the numerical control equipment; and 5, utilizing the Chapman-Kolmogorov differential equation to establish a relational expression of the operational state and the state transition probability so as to deduce the probability of the numerical control equipment in different operating states, namely obtaining the reliability of the numerical control equipment. The method can accurately analyze, evaluate and predict the change of the reliability of the numerical control equipment before the numerical control equipment goes wrong, thereby avoiding the fault of the numerical control equipment and improving the operational reliability of the numerical control equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

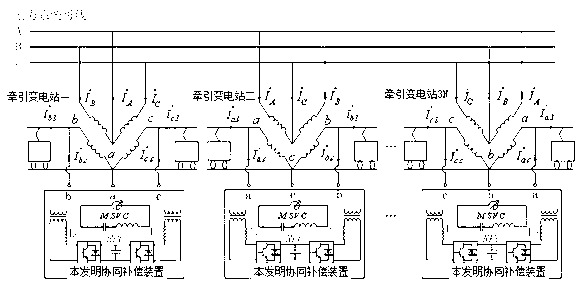

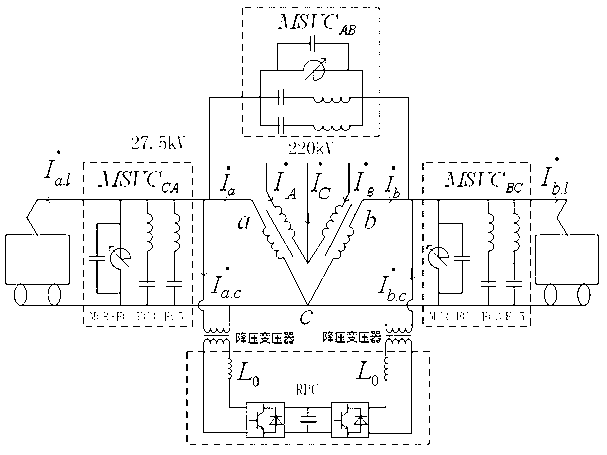

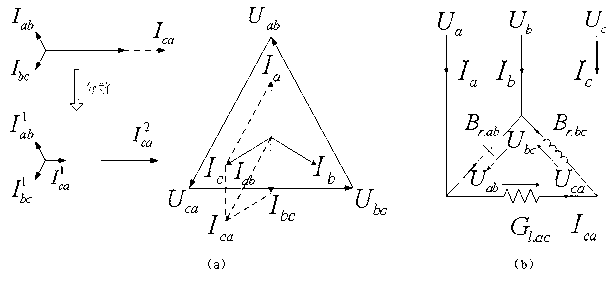

Electromagnetic hybrid device and method for synergetic compensation of high-speed railway multi-station electric energy quality

ActiveCN102810870AReduce workloadFast dynamic responseReactive power adjustment/elimination/compensationReactive power compensationPower qualityPower conditioner

The invention discloses an electromagnetic hybrid device and a method for synergetic compensation of the high-speed railway multi-station electric energy quality. Active power three-phase transfer of a multi-station traction power supply system is achieved by the aid of an RPC (railway power conditioner), reactive power of designated capacity is outputted for compensation, bus negative sequence components are further reduced with power factor guaranteed, and an MSVC (magnetic-control static var compensator) outputs reactive power to compensate residual bus negative sequence current. By the aid of multi-station synergetic optimum compensation and RPC power transfer characteristics, installed capacity of the MSVC is effectively saved, local dynamic response speed is increased, manufacture cost of the whole device are reduced, and running reliability of the whole device is improved. The device and the method can be used for compensating the electric energy quality of the electrified railway traction power supply system and particularly used for negative sequence compensation, reactive compensation and harmonic wave filtering, and have good application prospect on the occasions that high-speed railways are extremely unbalanced in load.

Owner:WUHAN UNIV

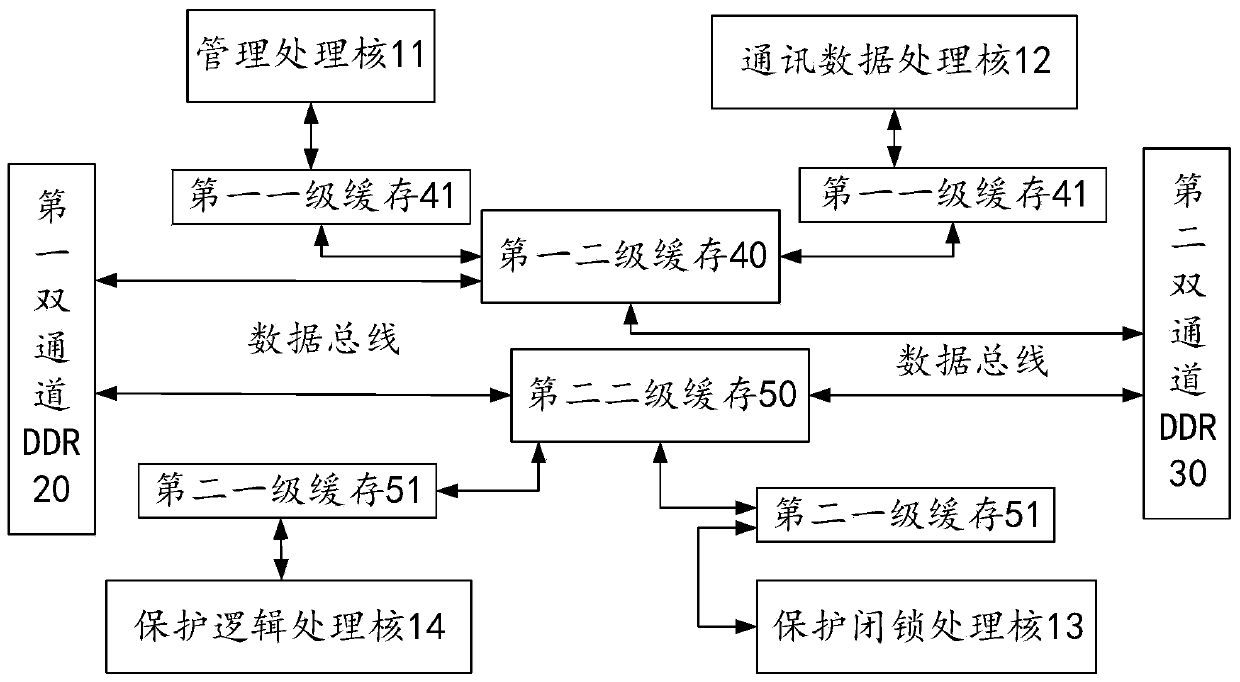

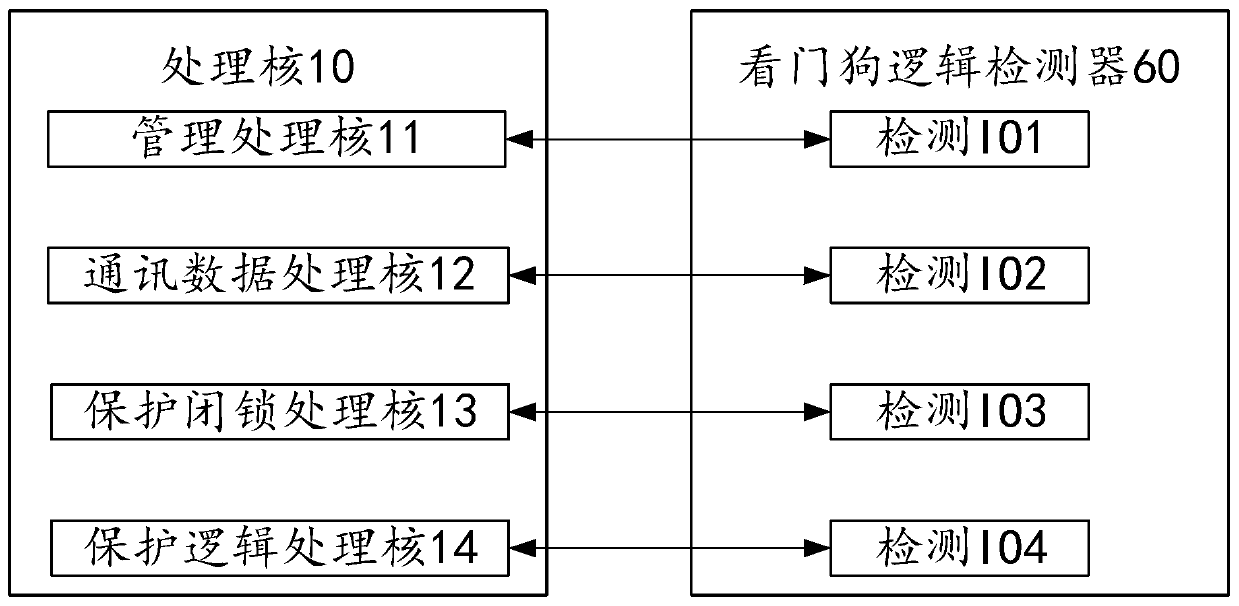

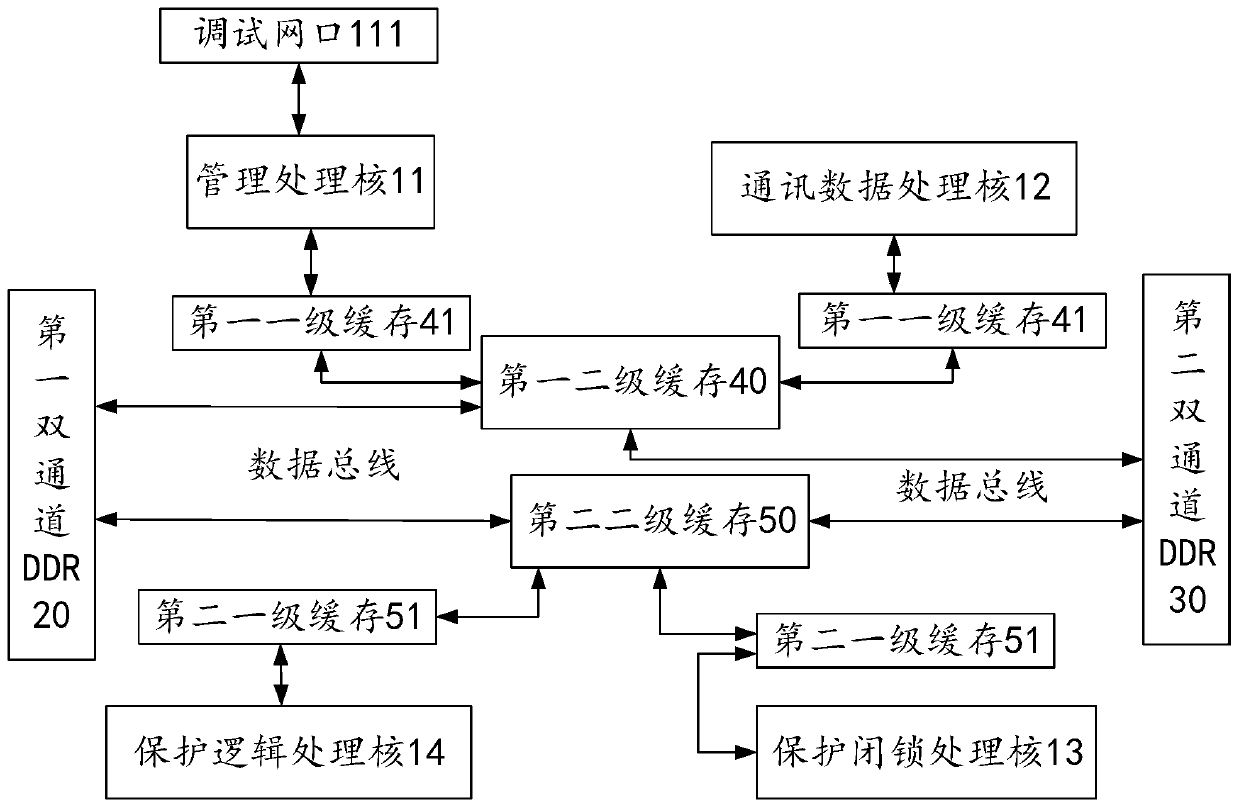

Relay protection system and special multi-core Soc chip architecture thereof

InactiveCN111427840AReduced operational reliabilityReduced operational stabilityFault responseArchitecture with single central processing unitComputer architectureProcessing core

The embodiment of the invention relates to a relay protection system and a special multi-core Soc chip architecture thereof. The special multi-core Soc chip architecture comprises a first dual-channelDDR, a second dual-channel DDR, a management processing core, a communication data processing core, a protection locking processing core, a protection logic processing core, a first secondary cache and a second secondary cache which are integrated on a chip. According to the special multi-core Soc chip architecture for the relay protection system, the four processing cores, the first dual-channelDDR, the second dual-channel DDR, the first secondary cache and the second secondary cache are integrally arranged on the chip, so that the original complex multi-chip hardware architecture is simplified; and low operation reliability and stability of the relay protection system caused by unstable connection of a multi-chip hardware structure are also avoided, and the operation reliability and stability of the relay protection system are improved. The technical problem that the operation stability and reliability of a relay protection product are influenced due to the fact that an existing relay protection multi-chip framework adopts a framework that a plurality of chips adopt a plurality of clamping plates and the multi-chip framework is complex is solved.

Owner:CHINA SOUTHERN POWER GRID DIGITAL GRID RES INST CO LTD

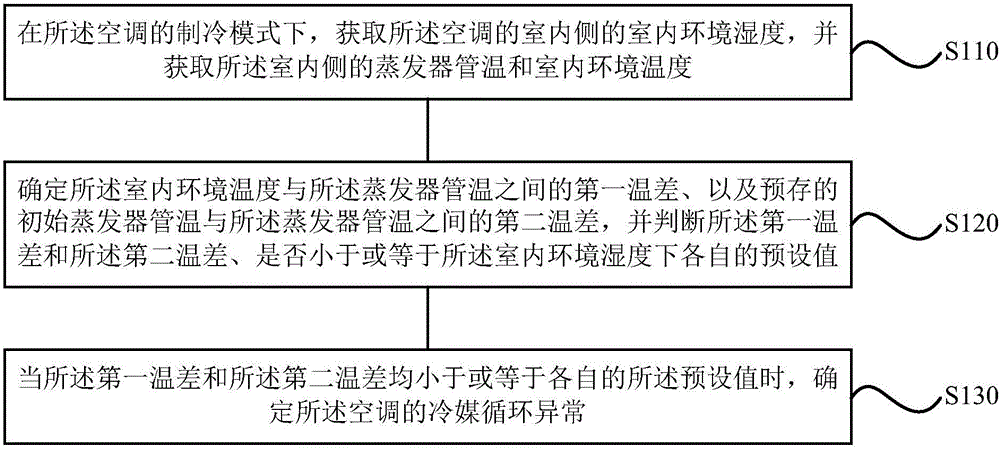

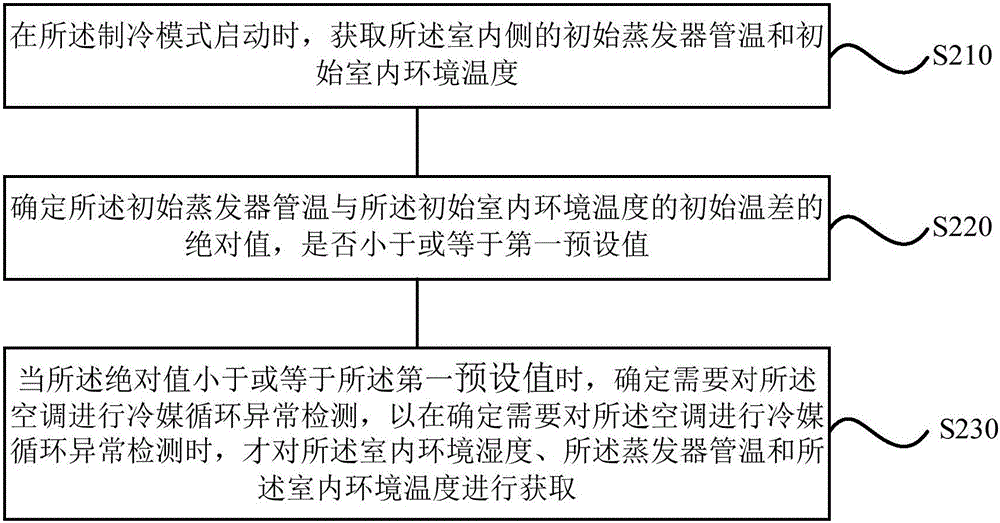

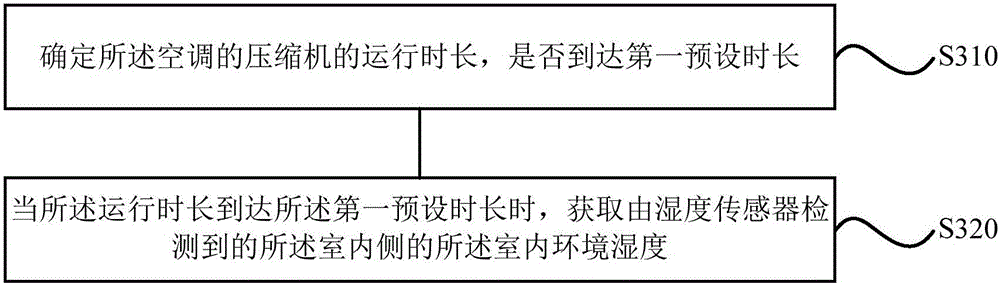

Method and device for determining abnormal circulation of air conditioner refrigerants and air conditioner

ActiveCN106595152ASolve protection problemsProblem solvingCompression machinesRefrigeration safety arrangementEngineeringTemperature difference

The invention discloses a method and device for determining abnormal circulation of air conditioner refrigerants and an air conditioner. The method includes the steps that in a refrigeration mode of the air conditioner, the indoor environment humidity of the indoor side of the air conditioner is acquired, and the evaporator pipe temperature and the indoor environment temperature of the indoor side are acquired; a first temperature difference between the indoor environment temperature and the evaporator pipe temperature and a second temperature difference between the pre-stored initial evaporator pipe temperature and the evaporator pipe temperature are determined, and whether the first temperature difference and the second temperature difference are smaller than or equal to corresponding preset values under the indoor environment humidity or not is judged; and when the first temperature difference and the second temperature difference are both smaller than or equal to the corresponding preset values, the abnormal circulation of the refrigerants of the air conditioner is determined. By means of the scheme, the defects that in the prior art, the mistaken judgment rate is high, the running reliability is low, and the maintaining difficulty is large can be overcome, and the beneficial effects that the mistaken judgment rate is low, the running reliability is high, and the maintaining difficulty is small can be achieved.

Owner:GREE ELECTRIC APPLIANCES INC

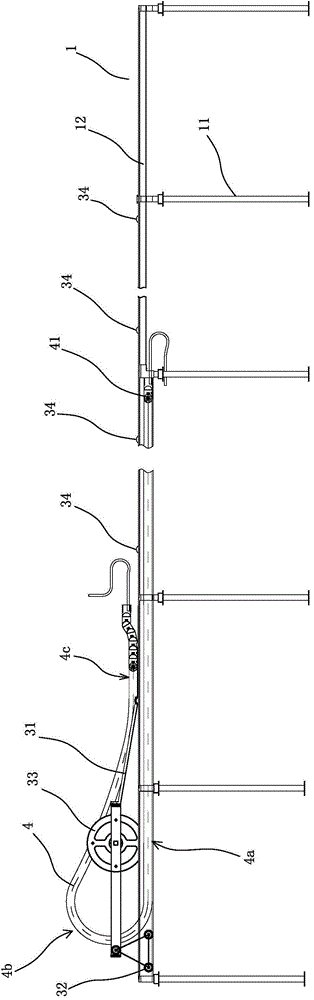

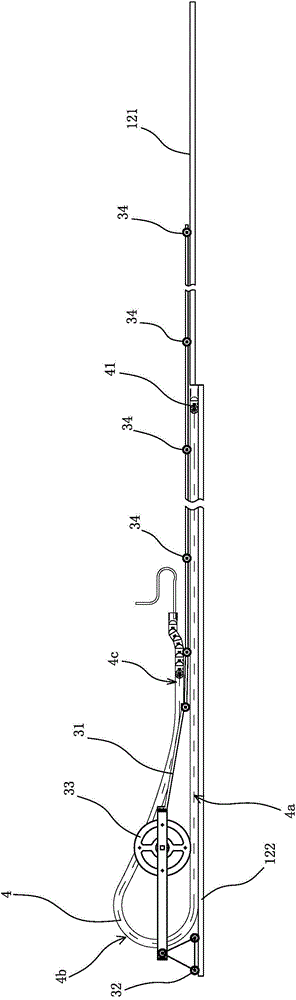

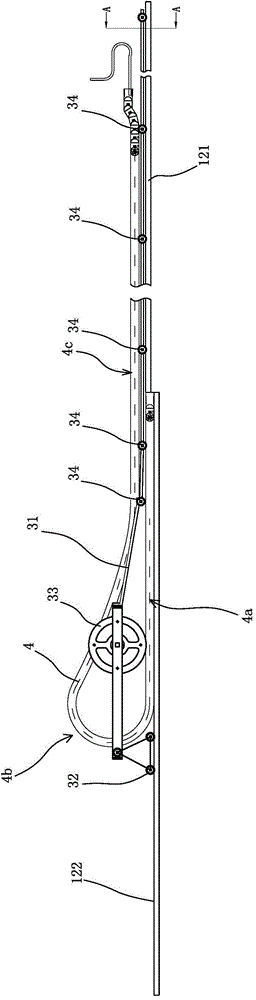

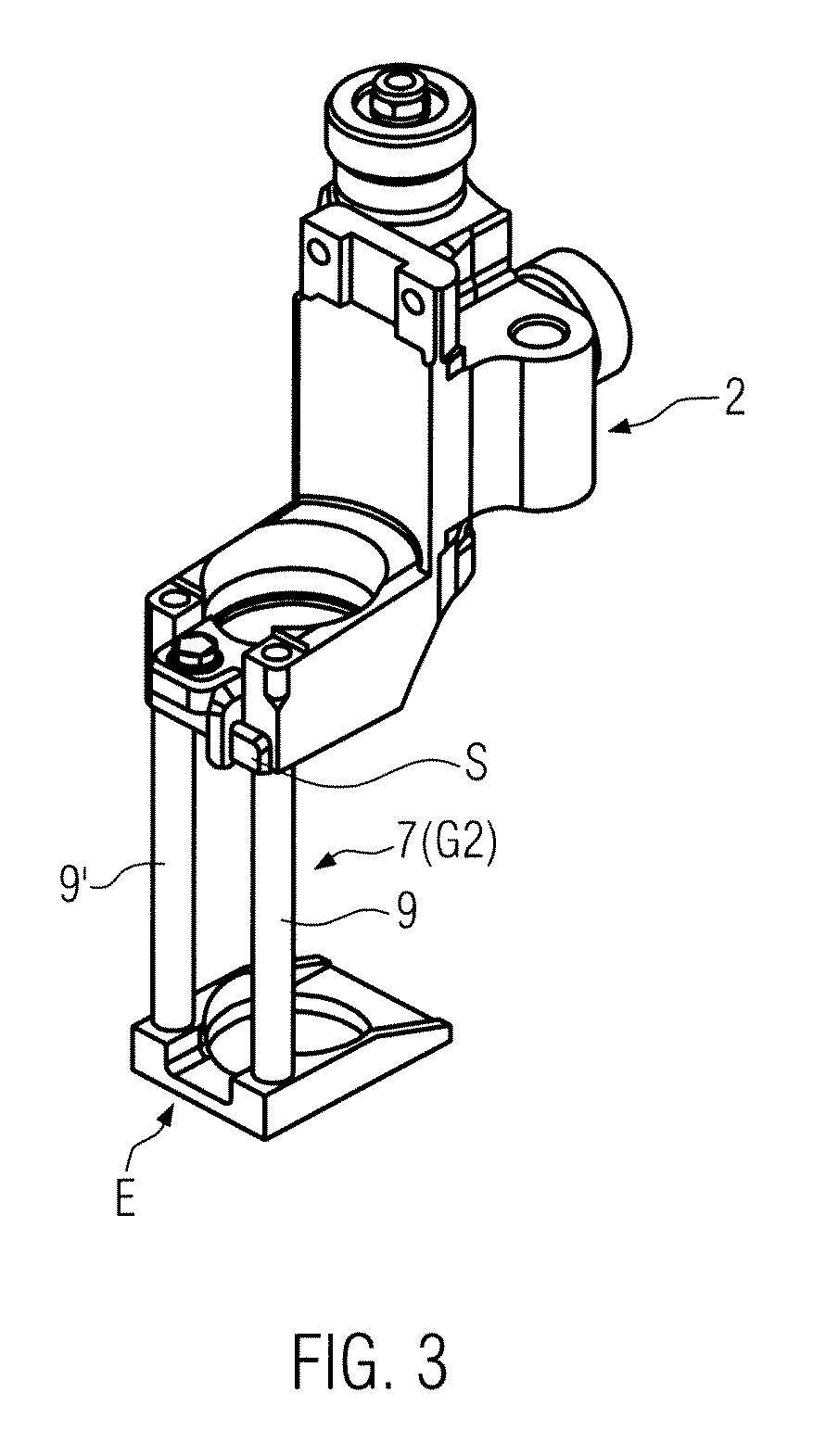

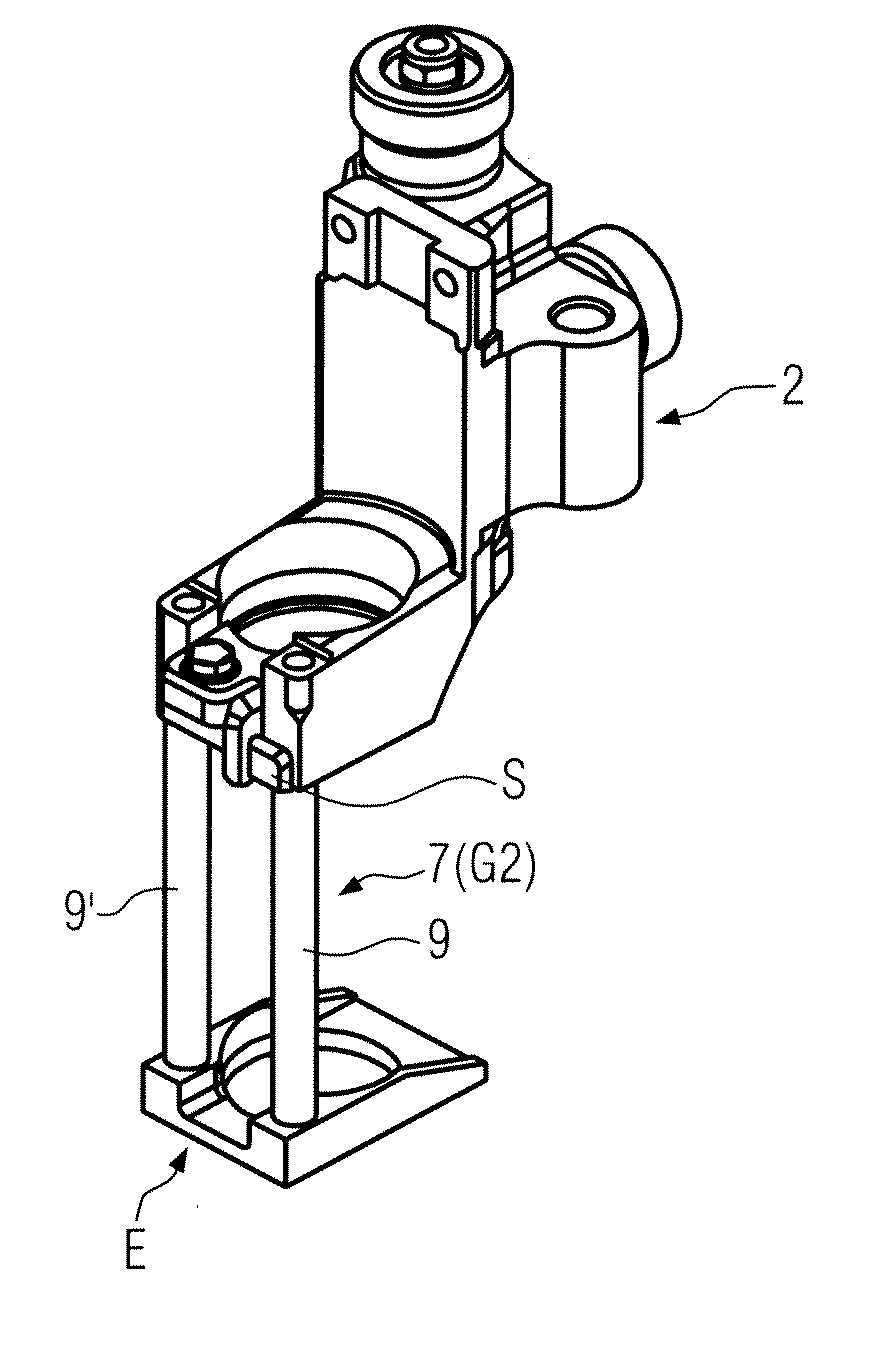

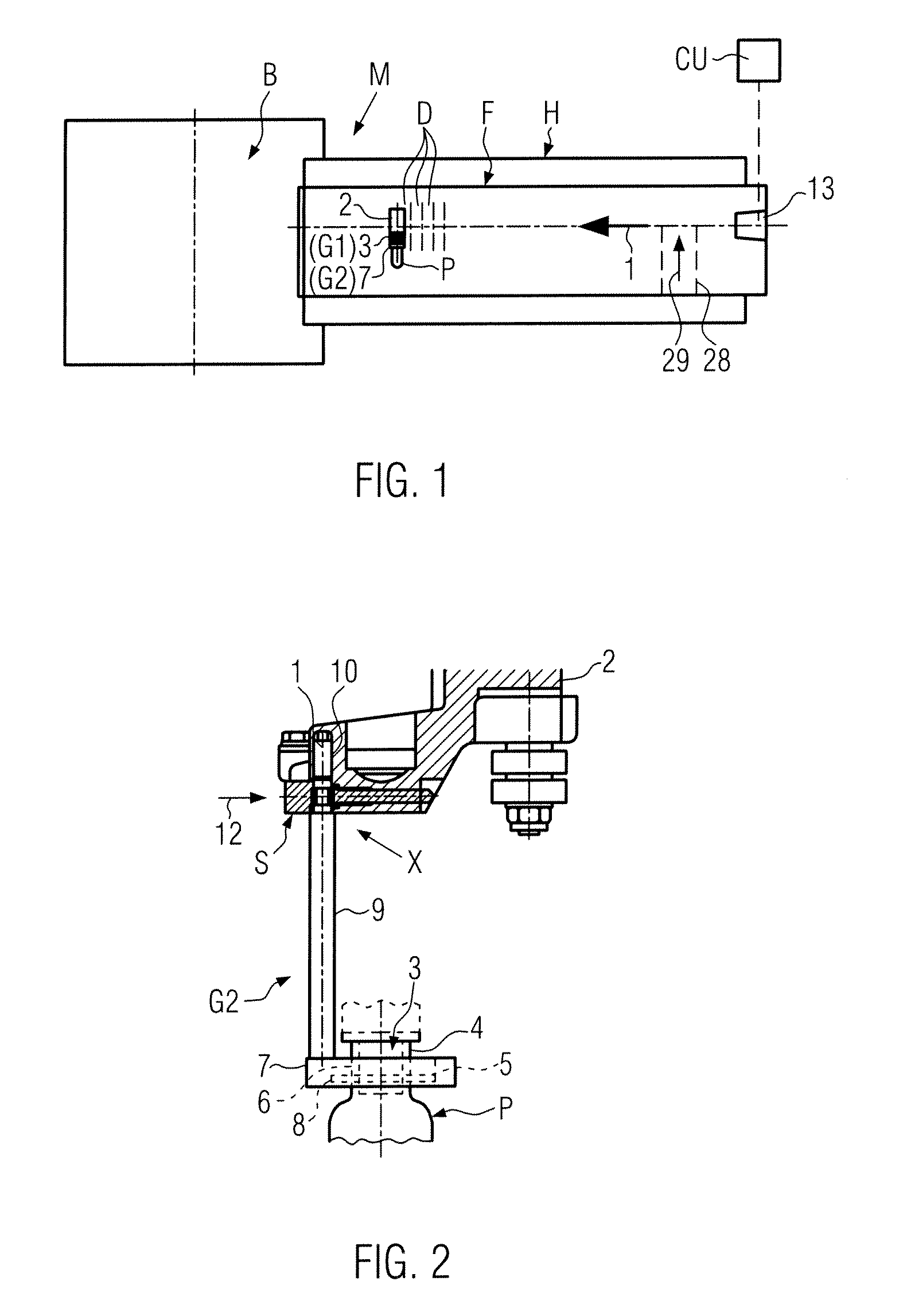

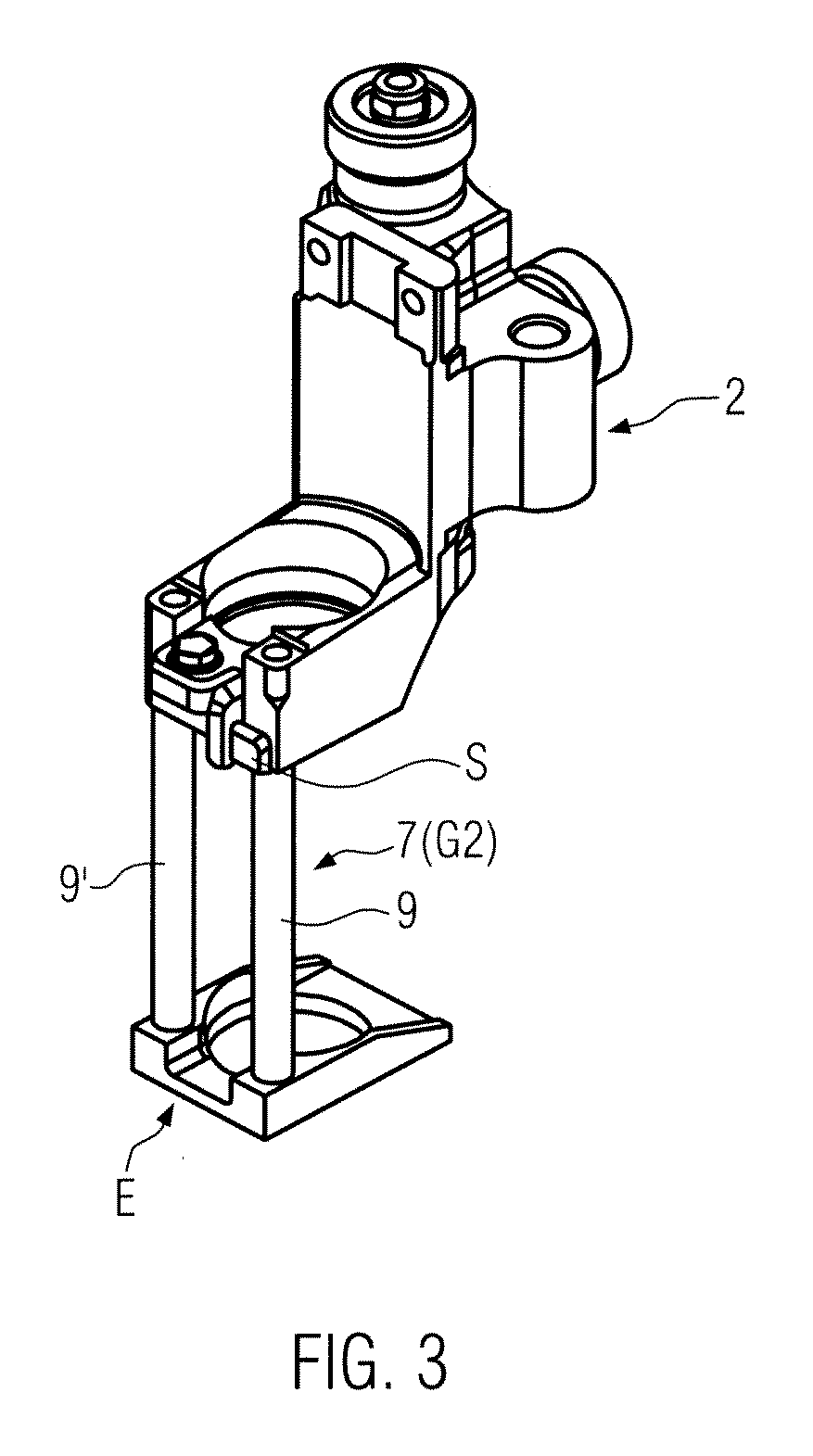

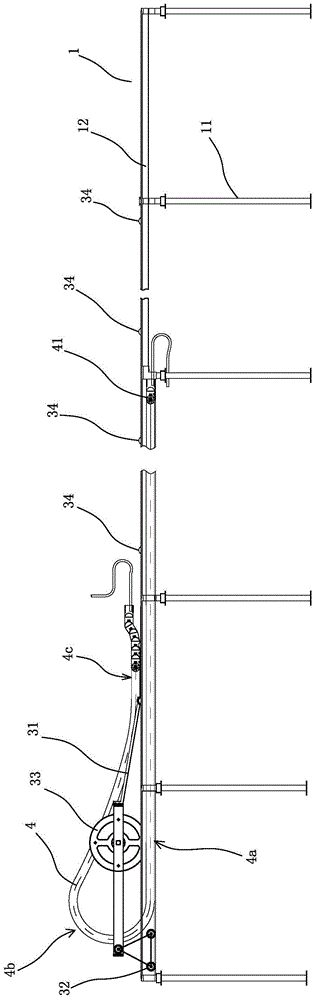

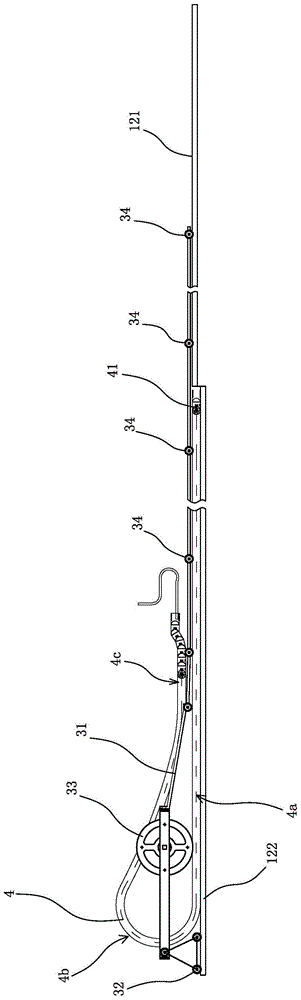

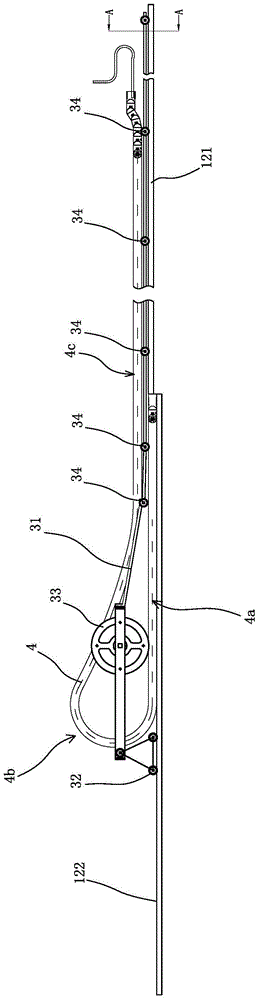

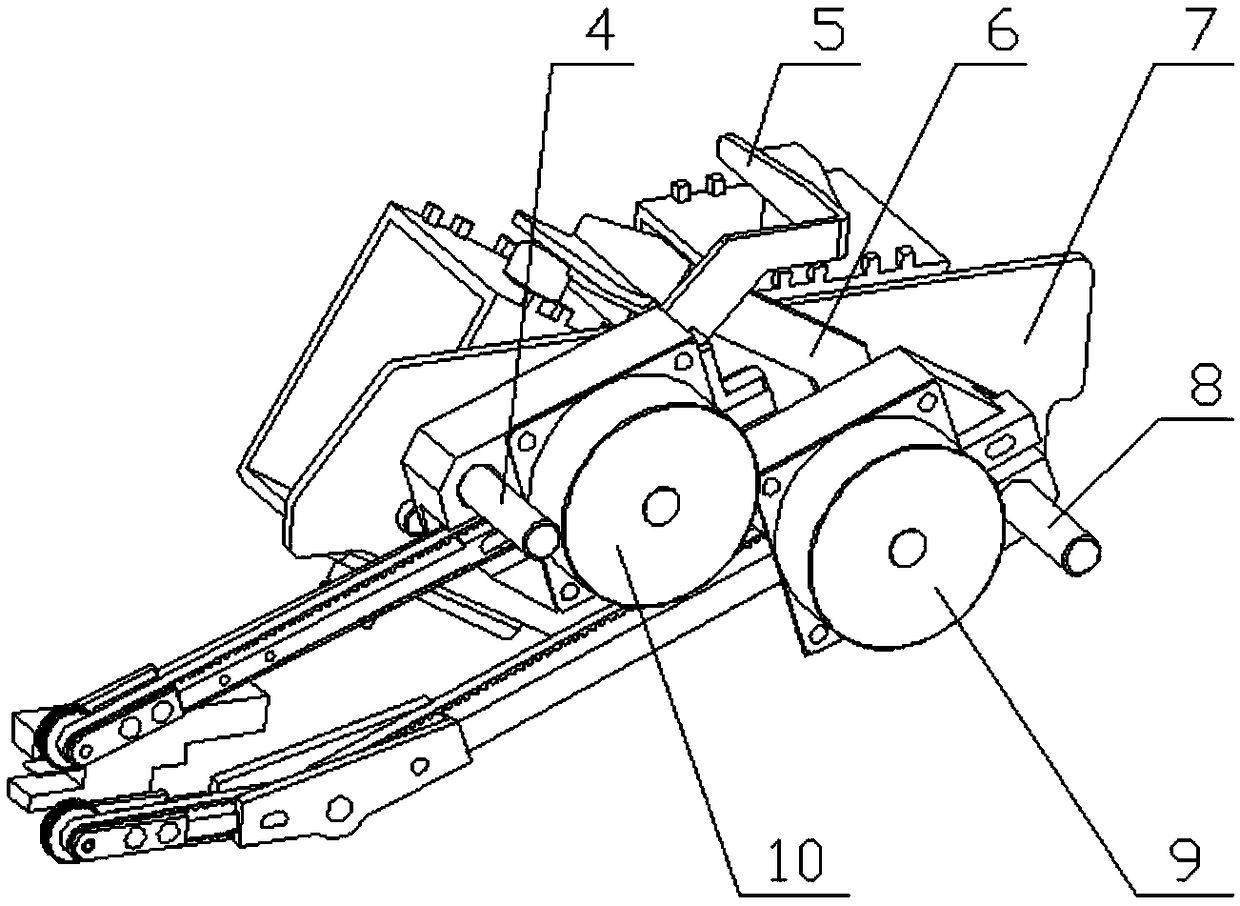

Long-distance heavy-load drag chain supporting device

ActiveCN104085657AExtended service lifePrevent disengagementConveyorsRollersEngineeringCable carrier

A long-distance heavy-load drag chain supporting device comprises a bearing frame used for bearing a drag chain and a supporting mechanism used for supporting the upper segment of the drag chain, wherein the bearing frame and the supporting mechanism horizontally extend in the transverse direction. The supporting mechanism comprises a supporting frame capable of being arranged on the bearing frame in a transversely moving mode, a plurality of supporting wheels arranged on the supporting frame at intervals and used for supporting the bottom of the upper segment of the drag chain, and a roller arranged on the supporting frame and located in a steering annular segment of the drag chain. When the steering annular segment of the drag chain moves transversely, the roller can be driven to transversely move, and thus the supporting frame is driven to transversely move and the upper segment of the drag chain is kept being supported by the supporting wheels. The long-distance heavy-load drag chain supporting device has the advantages of being simple in structure, high in adaptability, and capable of effectively preventing friction between the upper segment of the drag chain and the lower segment of the drag chain so that the service life of the drag chain can be prolonged.

Owner:ZHEJIANG JINFULONG MACHINE TOOL ACCESSORIES

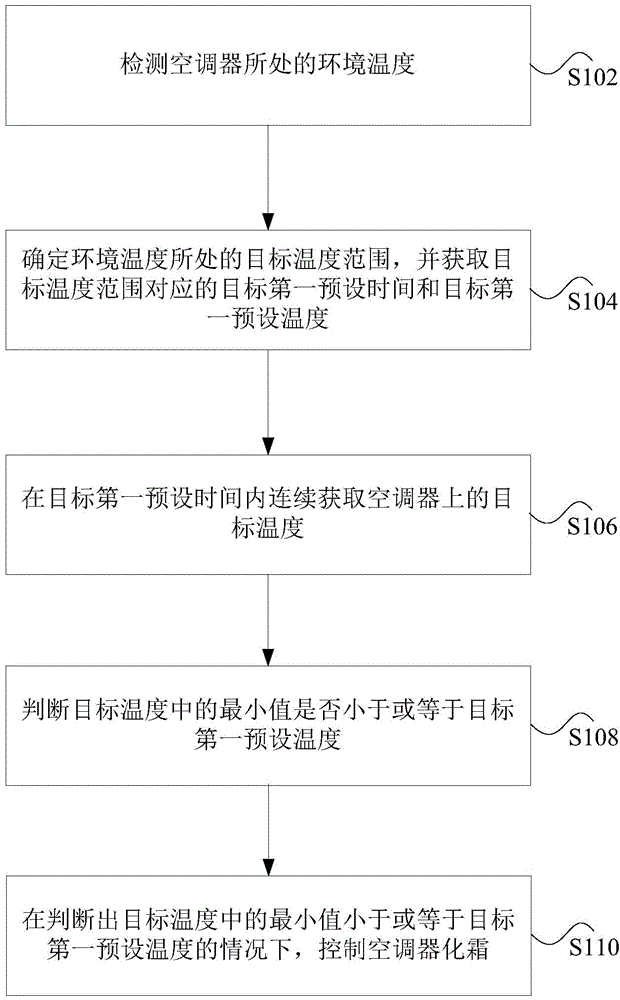

Air conditioner, air conditioner control method and air conditioner control device

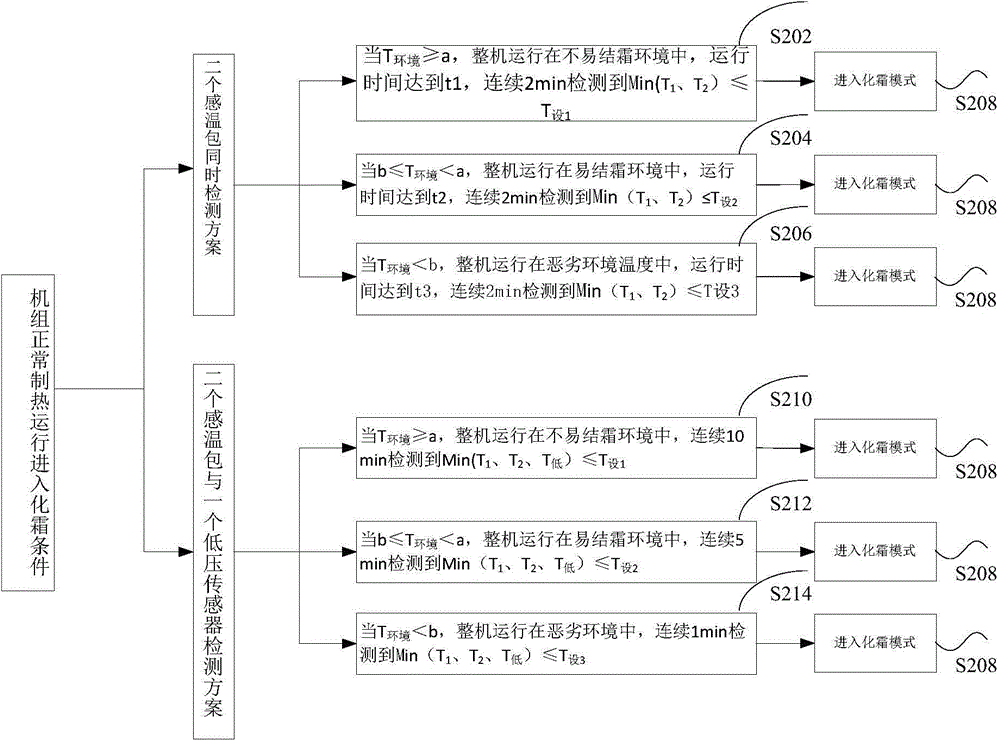

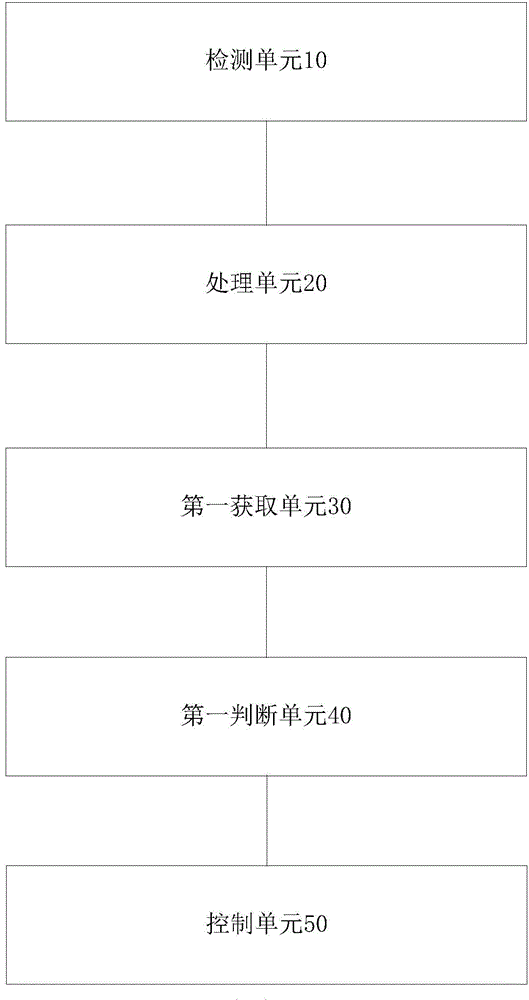

ActiveCN104566820ASolve the problem of inaccurate defrosting control modeHigh precisionMechanical apparatusSpace heating and ventilation safety systemsControl mannerEngineering

An embodiment of the invention discloses an air conditioner, an air conditioner control method and an air conditioner control device. The air conditioner control method includes: detecting the environment temperature of the air conditioner; determining a target temperature range of the environment temperature, and acquiring a first target preset time and a first target preset temperature corresponding to the target temperature range; continuously acquiring target temperatures on the air conditioner within the first target preset time, wherein the target temperatures at least include a plurality of temperatures detected from fins of an outdoor unit of the air conditioner; judging whether a minimum value in the target temperatures is smaller than or equal to the first target preset time or not; under the condition that the minimum value in the target temperatures is smaller than or equal to the first target preset time, controlling the air conditioner to defrost. By the aid of the air conditioner, the air conditioner control method and the air conditioner control device, the problem of inaccuracy of a frosting control manner of the air conditioner in the prior art is solved, the problem of reduction of operational reliability and capability of a unit due to uncleanness in defrosting or frostless frosting can be further avoided, and frosting accuracy of the air conditioner is improved.

Owner:GREE ELECTRIC APPLIANCES INC

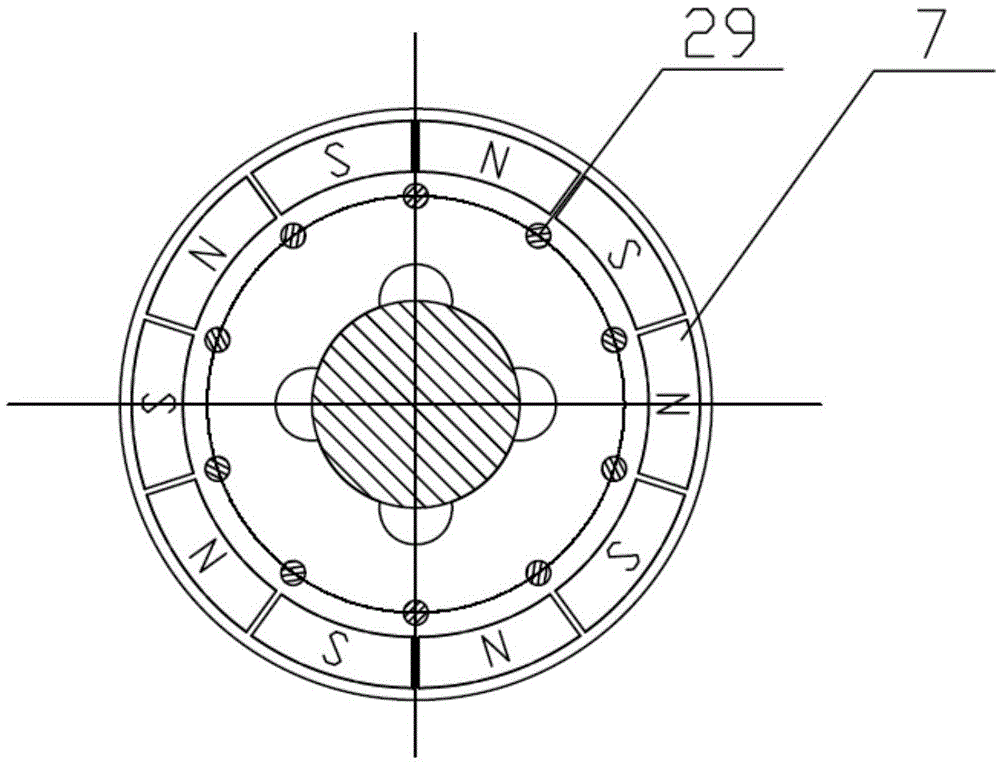

Transmission mechanism for permanent magnetic gear

InactiveCN104901510AElectromagnetic structure is simpleReduce manufacturing costsDynamo-electric gearsElectrical conductorPower flow

The invention discloses a transmission mechanism for a permanent magnetic gear. The transmission mechanism comprises a stator assembly, an adjustable magnetic ring assembly, a rotor assembly and an enclosure assembly. The transmission mechanism is only provided with a layer of permanent magnet, so that the processing and assembling difficulty is smaller while a permanent magnet is saved. The permanent magnet is fixed by a built-in hole in a rotor core, and the condition that the permanent magnet is thrown away due to a centrifugal force generated by the rotor core during high-speed rotation is avoided, so that the permanent magnet is safe and reliable. The transmission ratio of the transmission mechanism can be changed according to the requirement; the output rotating speed of the transmission mechanism can be set to be constant according to the requirement. A damping bar made of a conductor material is arranged on the rotor core and can be used for cutting a magnetic field generated by a stator winding and forming induced current; a lorentz force generated by the induced current can form damping, so that the rotating speed and the torque of the rotor after starting are rapidly converged and the rotor stably operates; heat generated by the stator assembly, the adjustable magnetic ring assembly and the rotor assembly can be taken away by air current of the transmission mechanism.

Owner:DALIAN JIAOTONG UNIVERSITY

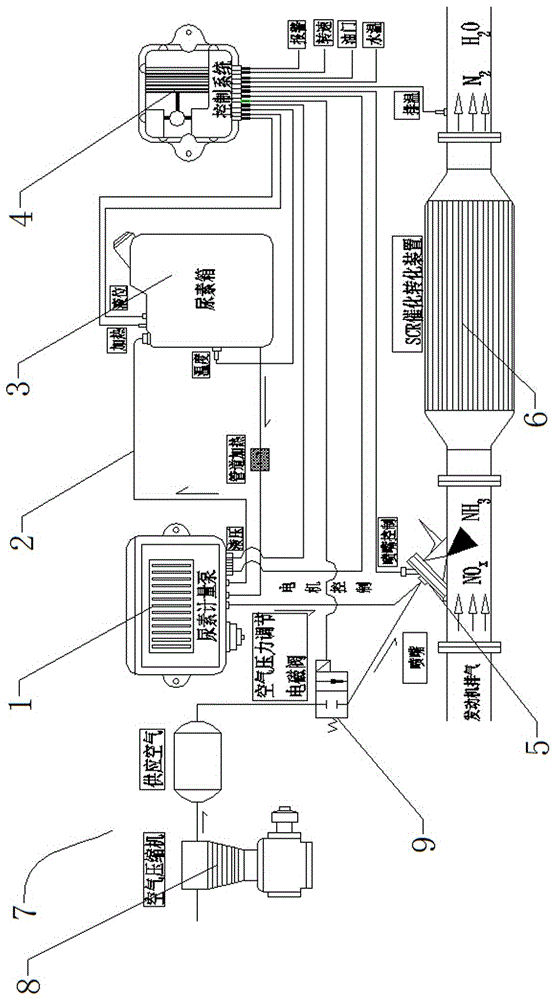

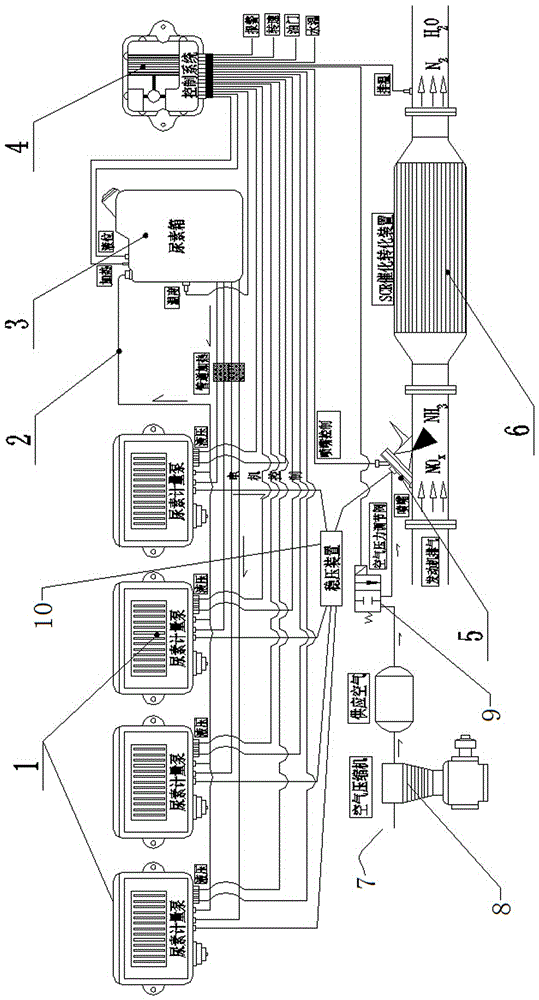

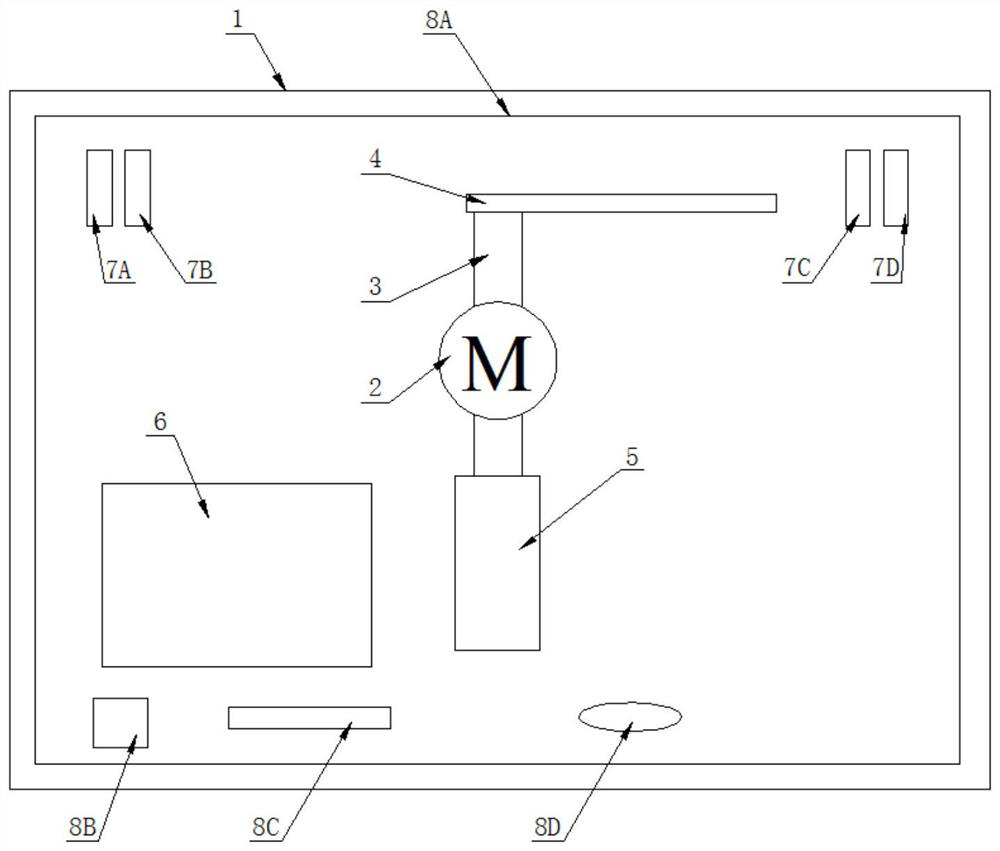

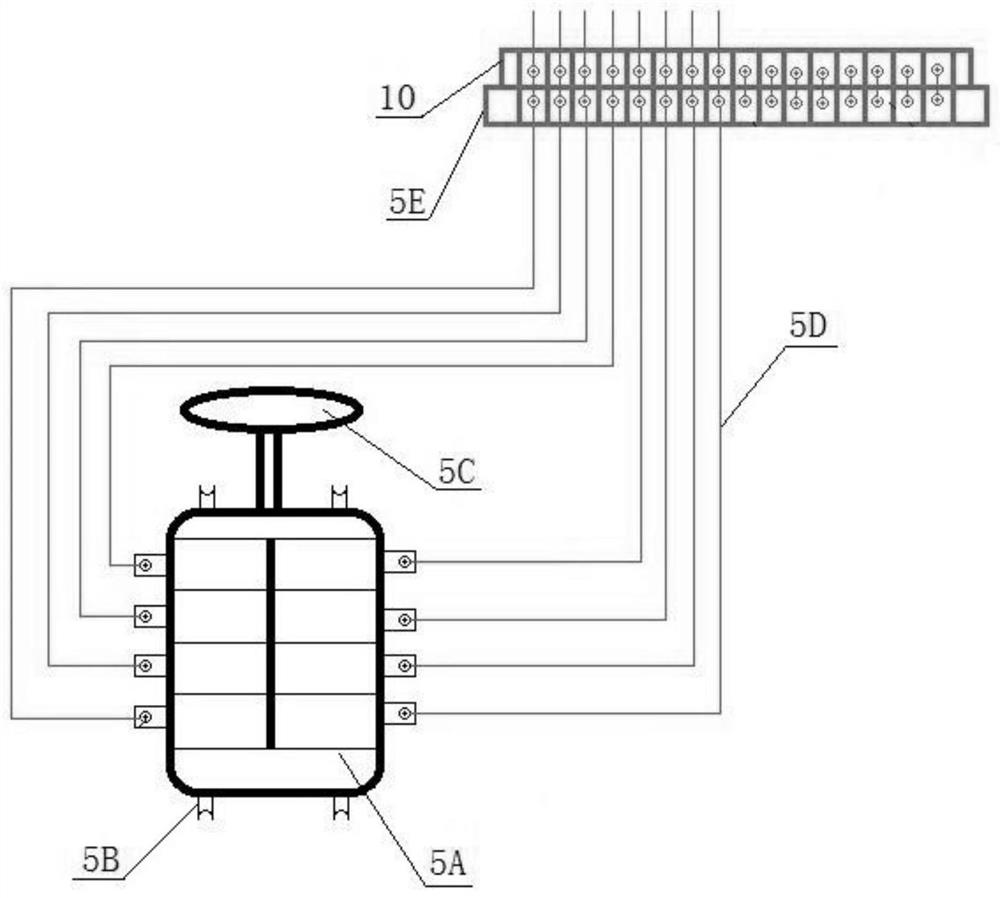

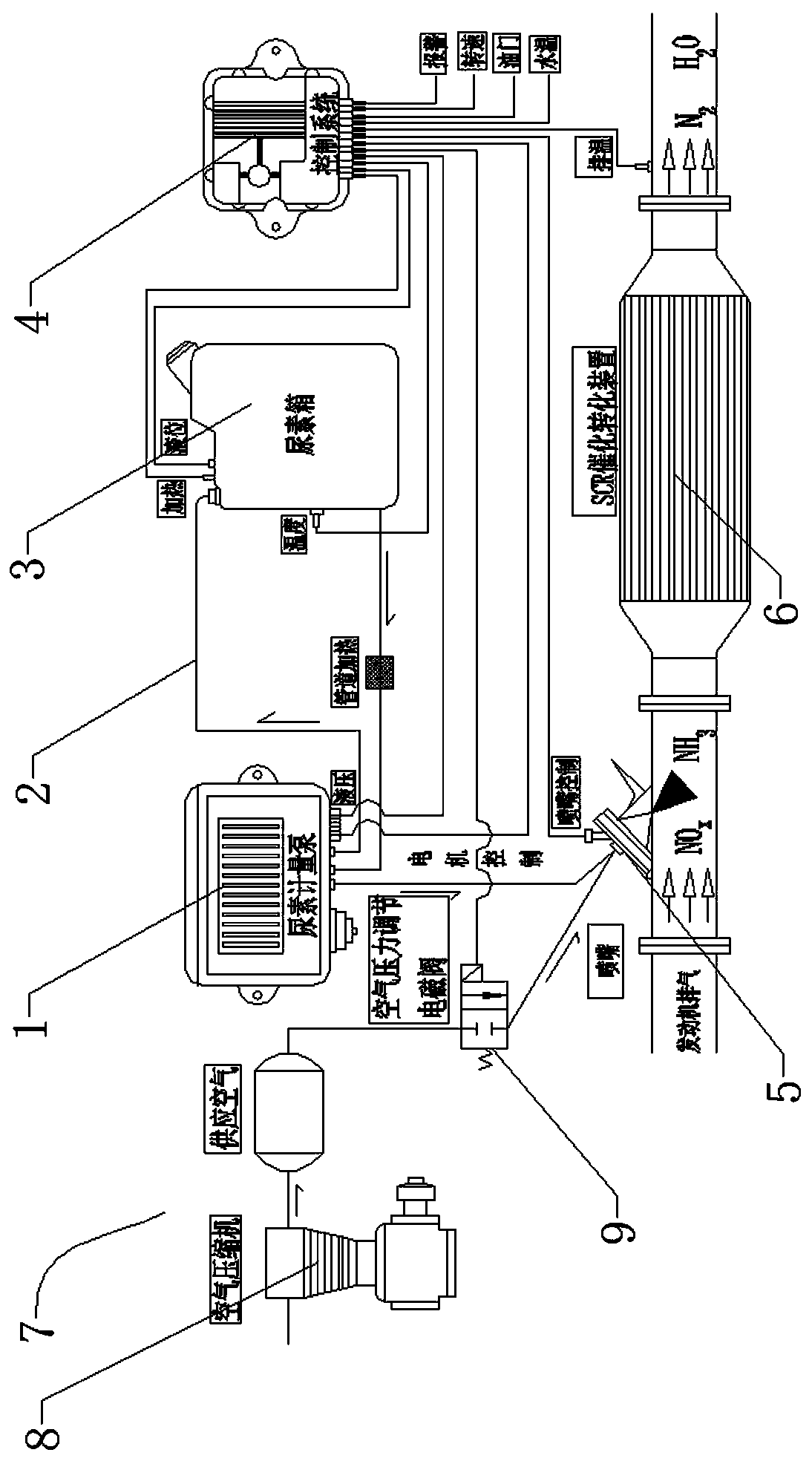

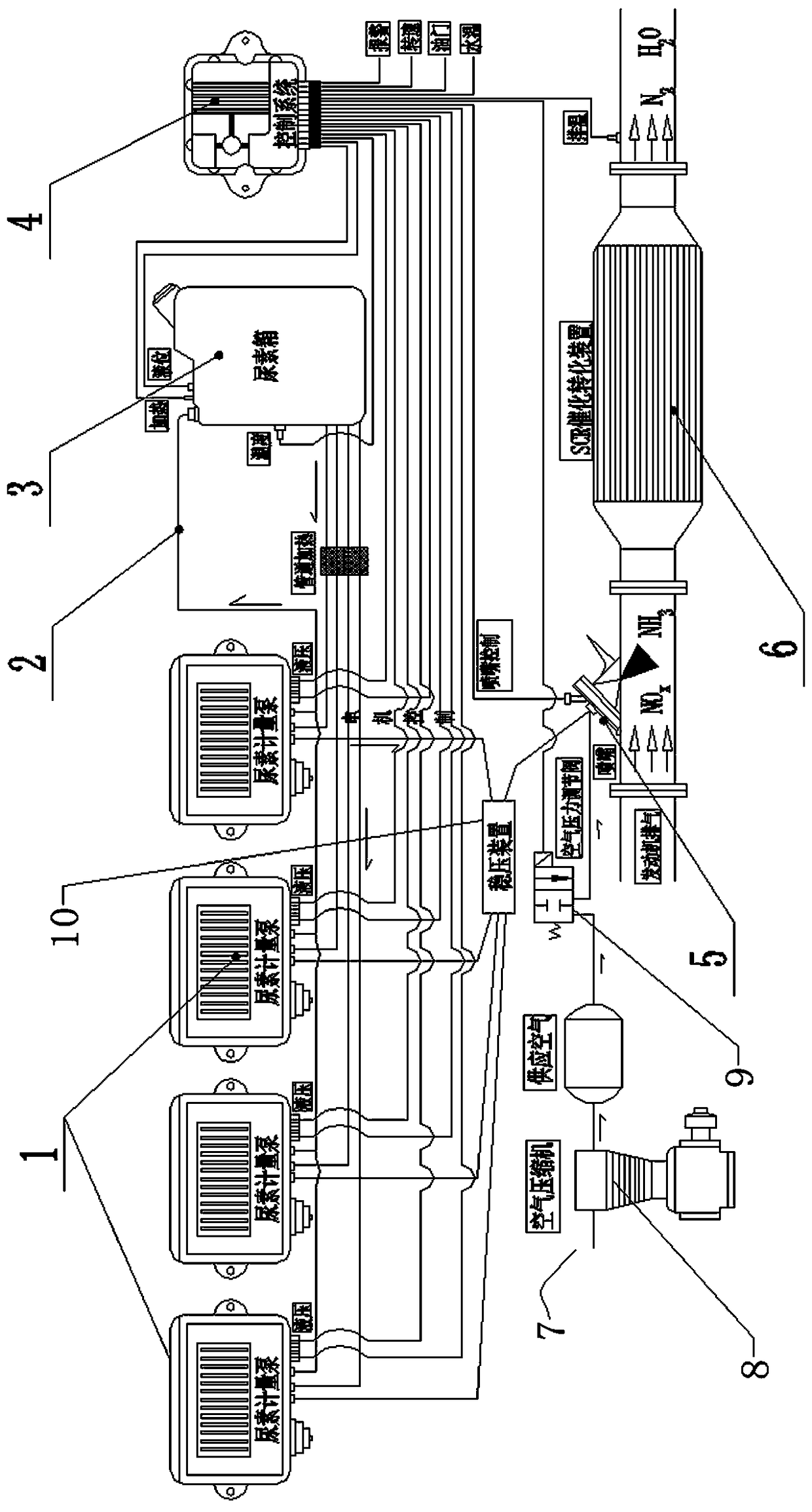

Selective catalytic reduction (SCR) after-treatment system urea supply device and treatment method

ActiveCN106050369AEase of mass productionReduce manufacturing costInternal combustion piston enginesExhaust apparatusAfter treatmentPulp and paper industry

The invention discloses a selective catalytic reduction (SCR) after-treatment system urea supply device and a treatment method. The device comprises a urea tank which is connected with at least two urea metering pumps in parallel through wiring harnesses and pipelines. By the adoption of the technical scheme, the SCR after-treatment system urea supply device and the treatment method have the following technical effects that a single urea metering pump is changed into the two or more urea metering pumps connected in parallel, the multiple small-power urea metering pumps for vehicles are combined into a whole to replace a large-power urea metering pump, and therefore mass production of the urea metering pumps is facilitated, and production cost is remarkably reduced; in addition, after the urea metering pumps are connected in parallel, the number of the urea metering pumps can be increased or decreased according to the power requirement, so that flexibility, convenience and interchangeability of designing and matching are greatly improved; and the matching attribute of the urea demand quantity of an engine and the supply quantity of the urea metering pumps is better, the requirement for the power of different engines can be met, energy saving performance is good, consumption can be reduced effectively, and operation is reliable.

Owner:山东康钧环保科技有限公司

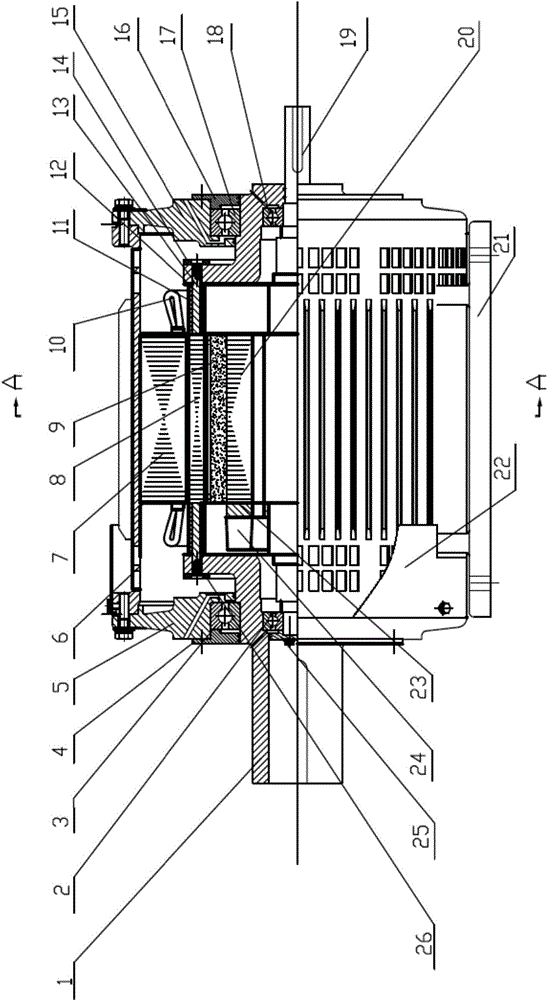

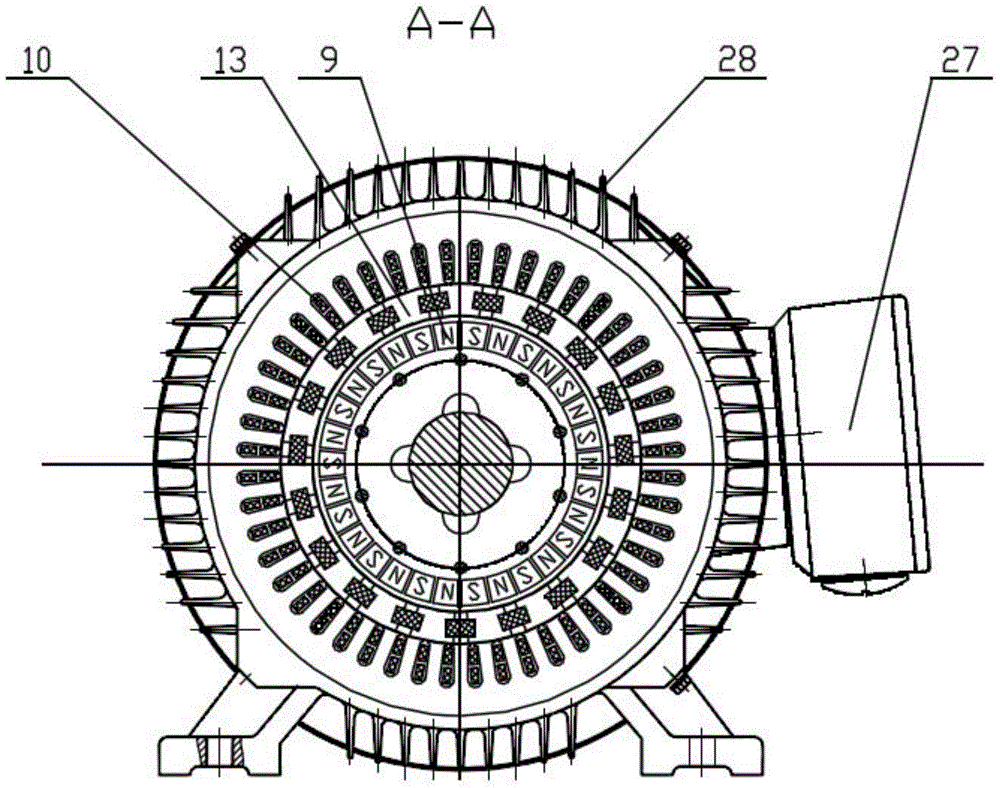

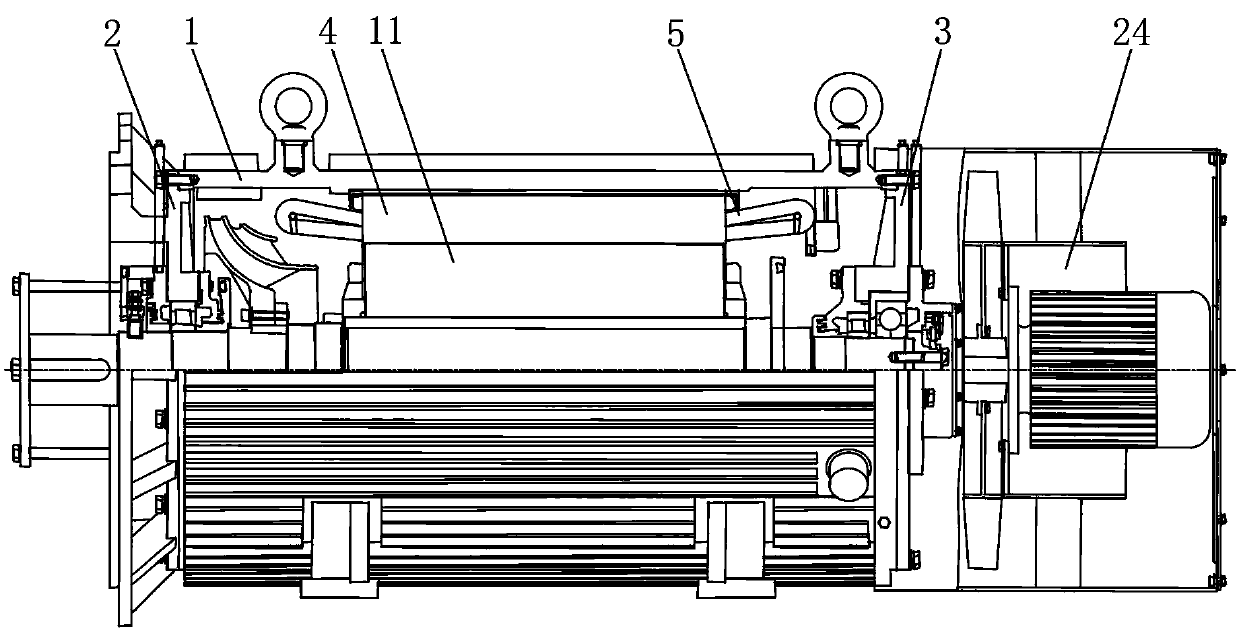

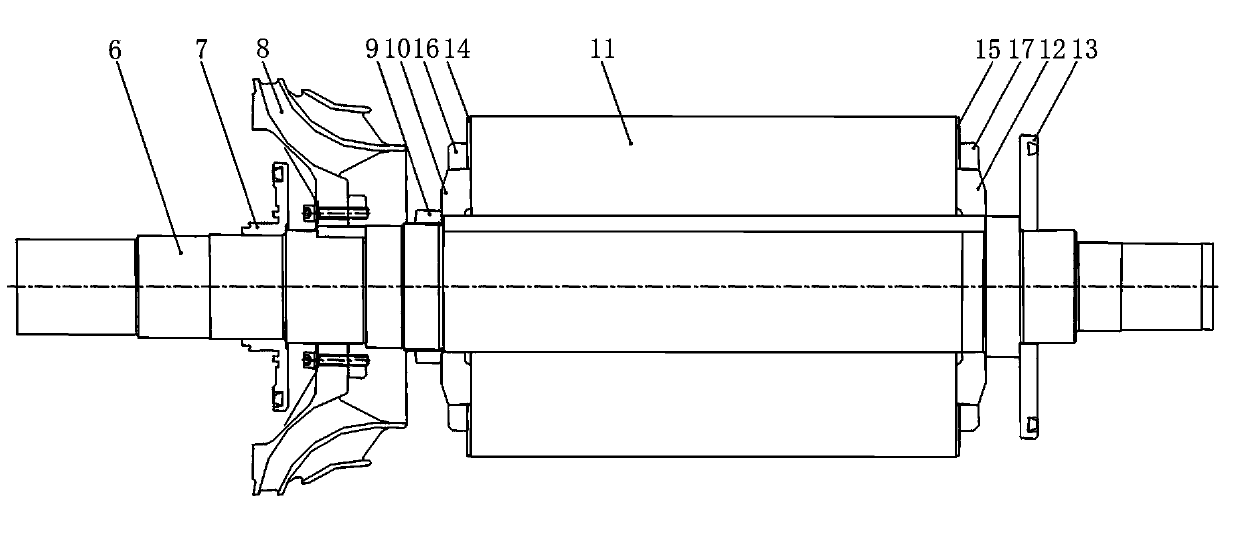

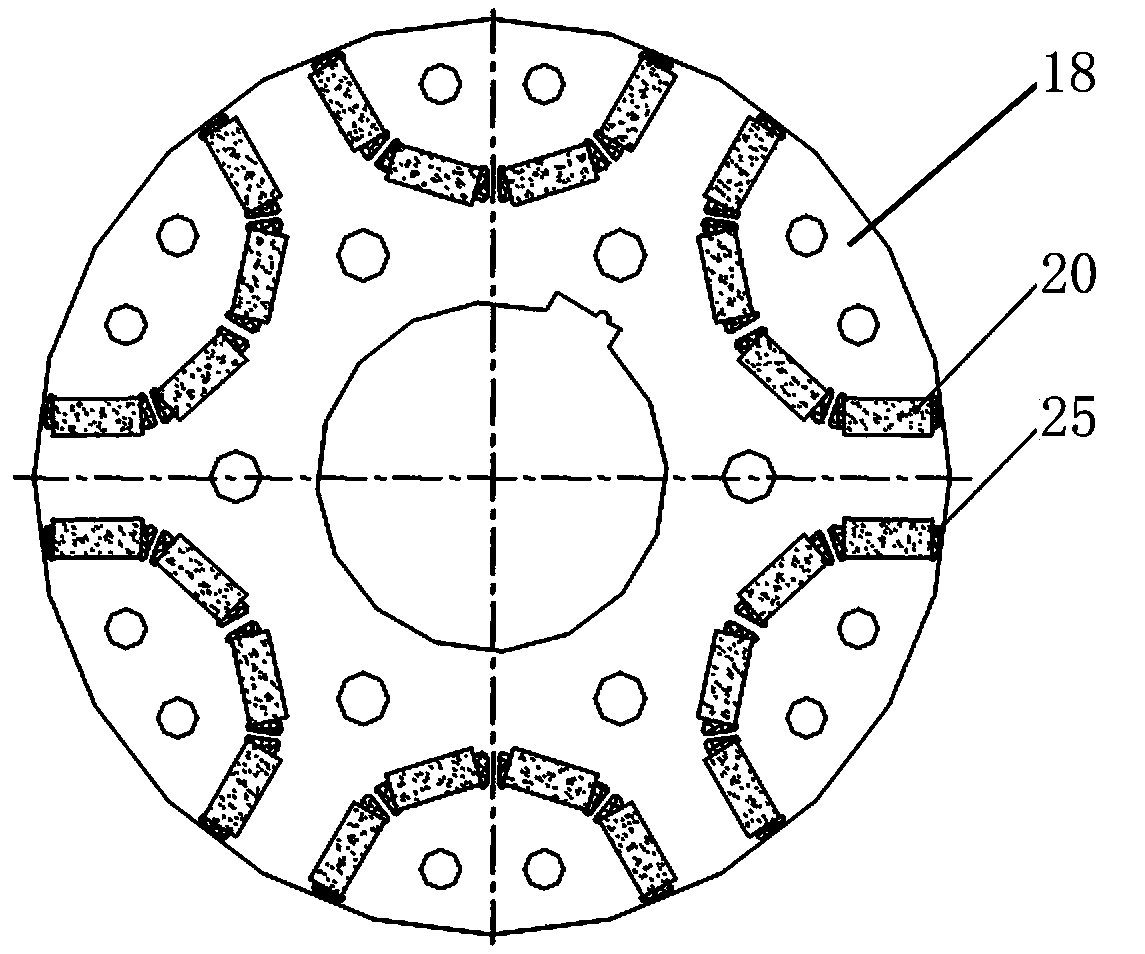

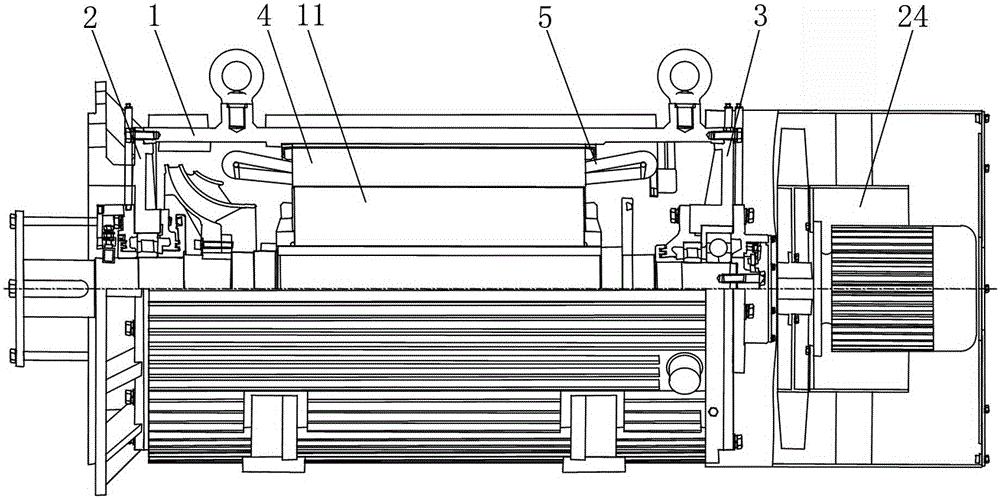

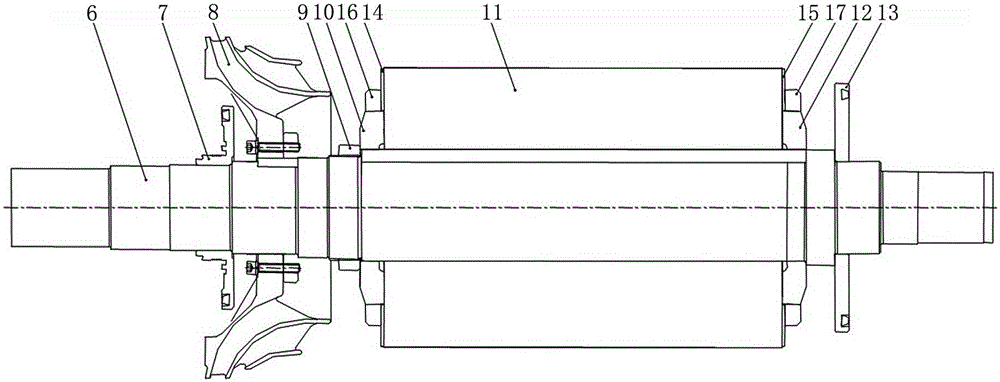

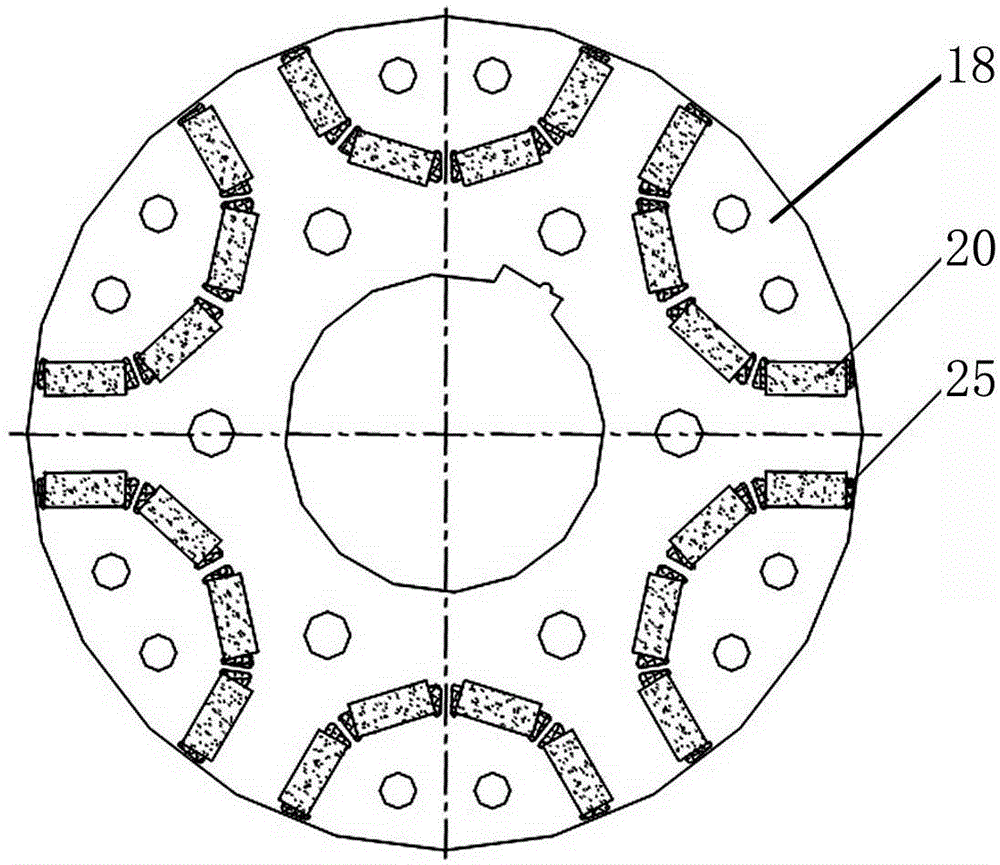

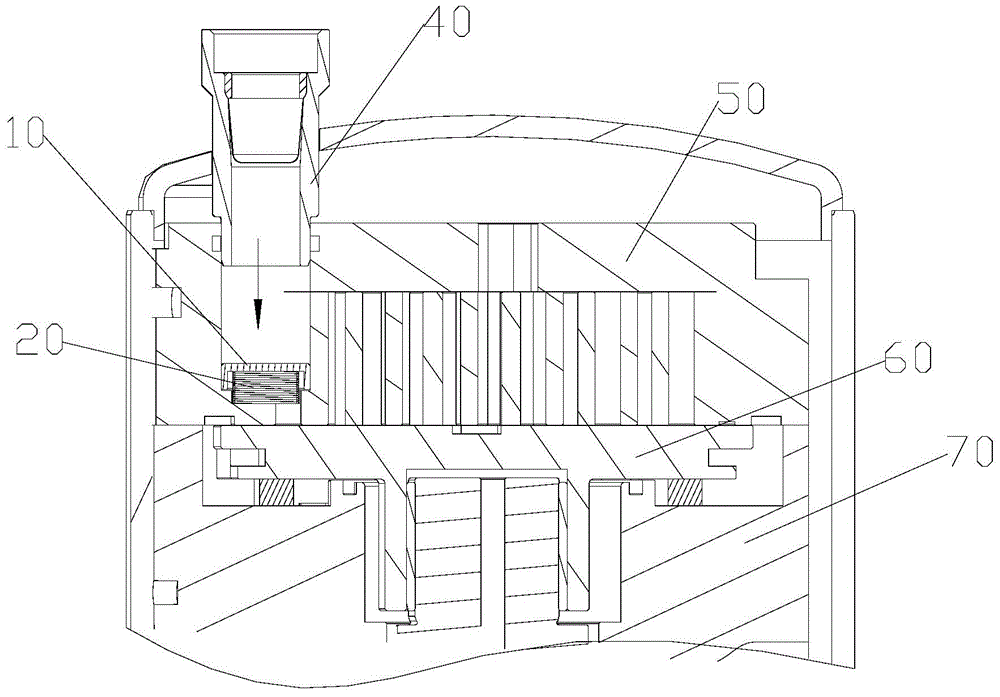

Ship propelling-type permanent-magnetic motor

ActiveCN103746530ALarge crimping areaReduce tooth expansionMagnetic circuit rotating partsMechanical energy handlingStatorMarine engineering

The invention relates to a permanent-magnetic motor, in particular to a ship propelling-type permanent-magnetic motor, which aims at solving the problems of the existing permanent-magnetic motor that the reliability in running is low, the capacity expansion is limited, the air-pore magnetic density is low, the power density is low, the structural strength is low, the temperature increasing is difficult for meeting the running requirement, and the oblique running working condition of a ship propelling system is difficult to satisfy. The ship propelling-type permanent-magnetic motor comprises a stand, a front end cover, a rear end cover, a stator structure, a rotor structure, a three-bearing structure and an air cooling structure; the rotor structure comprises a rotating shaft, an inner seal ring, a fan, a circular nut, a first rotor pressure ring, a rotor iron core, a second rotor pressure ring and a balance disc; the outer side surface of the first rotor pressure ring and the outer side surface of the second rotor pressure ring are respectively and uniformly provided with N outer teeth which are equally spaced along the circumferential direction; the outer ring of the end surface of the rotor iron core is circumferentially provided with N groups of magnetic steel grooves at intervals; each group of magnetic steel grooves consists of four magnetic steel grooves which are symmetrically distributed in a U shape. The ship propelling-type permanent-magnetic motor is applicable to a ship propelling system.

Owner:CRRC YONGJI ELECTRIC CO LTD

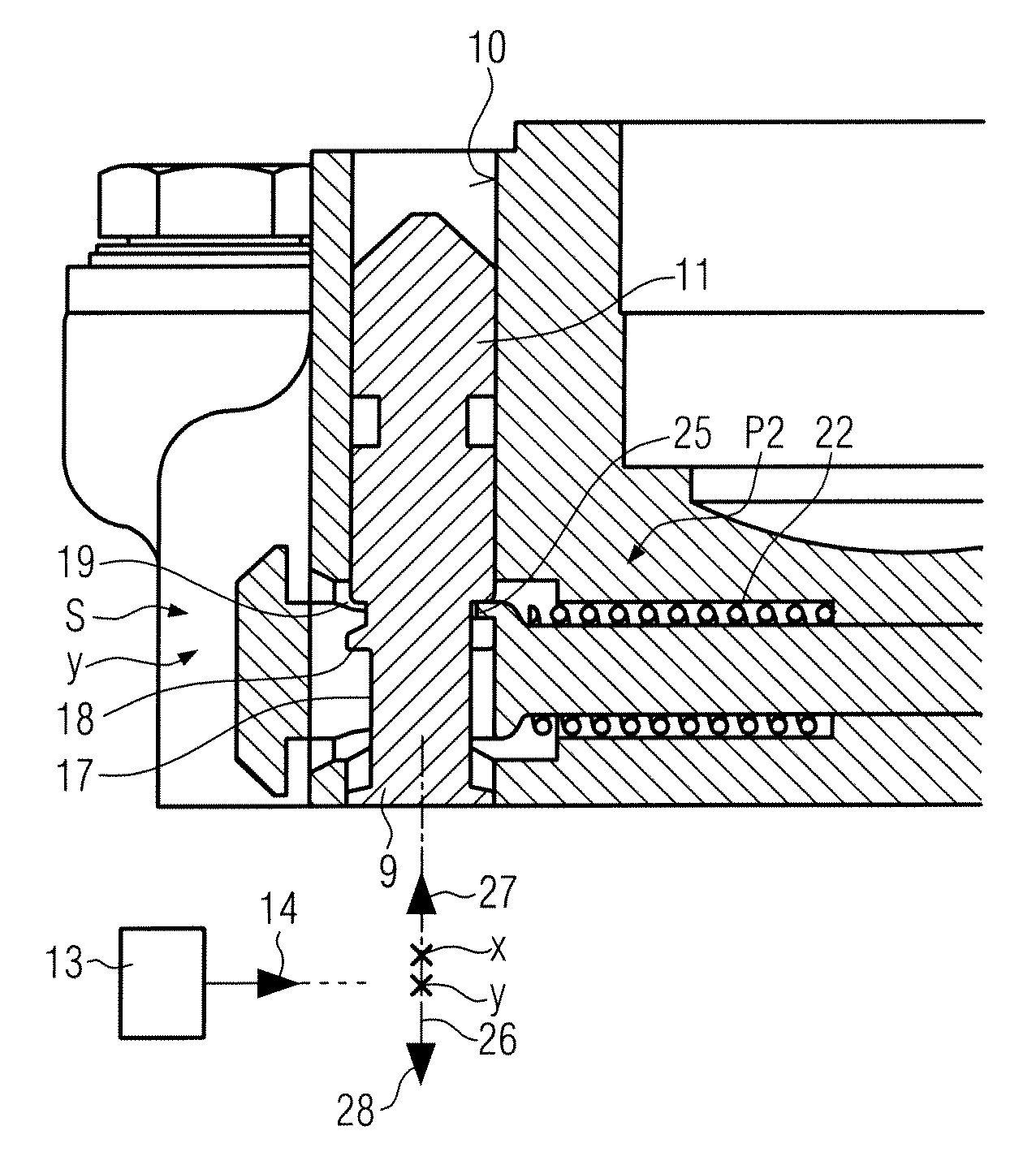

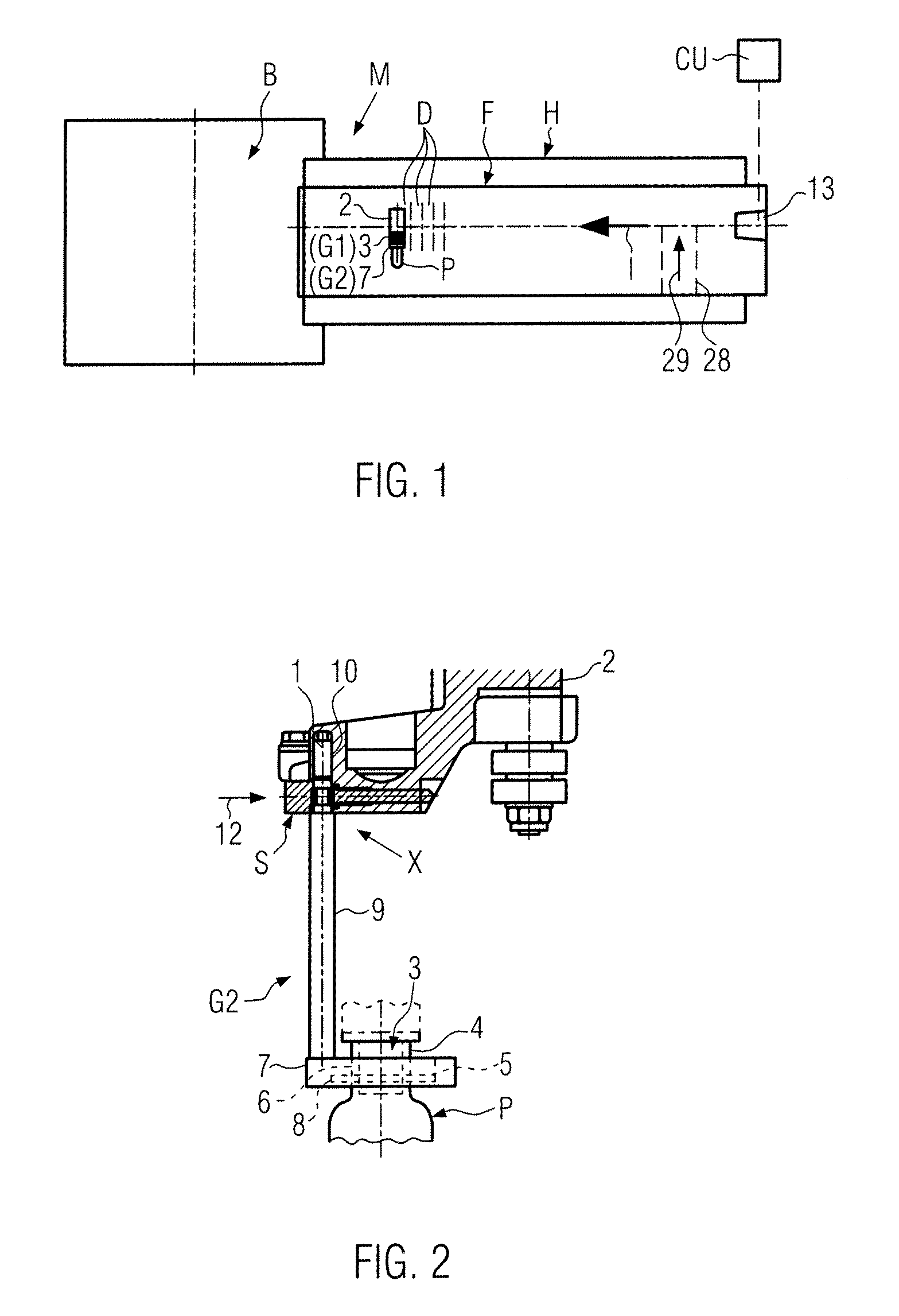

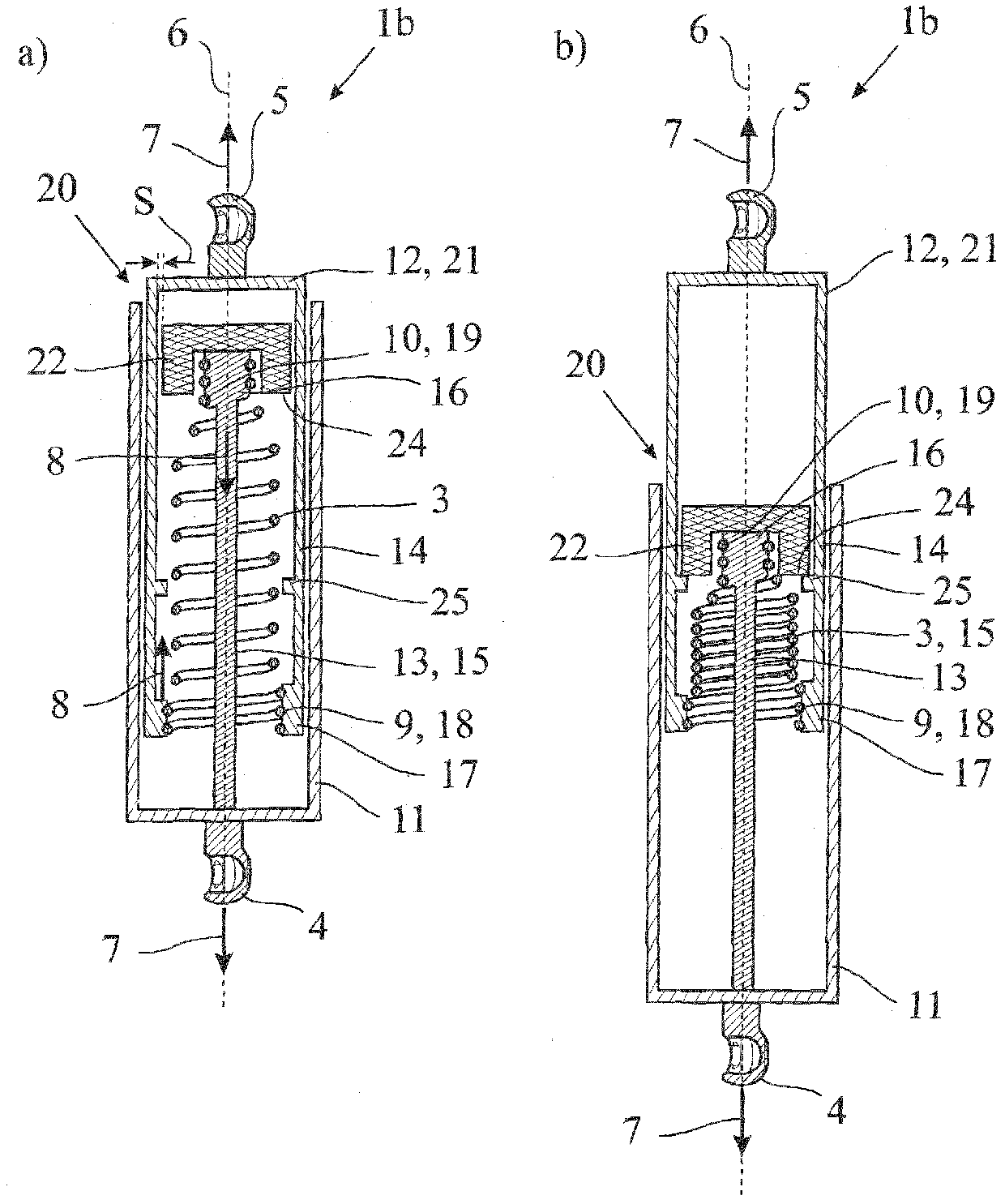

Quick-change system and operating method for a container processing machine

ActiveUS8939746B2Reduced operational reliabilityEasy to detectConfectioneryAssembly machinesEngineeringFixed position

In a quick-change system for exchangeable machine elements, particularly in a container processing machine in which the machine element (E) can be brought into a target position and can be localized in a target position by a securing unit comprising at least one securing element, at least a second securing unit (P2) is provided with which a machine element that either has not been brought into the target position or that has moved out of the target position (X) can be localized in a securing position. The securing position is detected and evaluated as grounds for a corrective action before commencing an operation or during the operating sequence before a corrective action is initiated and executed.

Owner:KRONES AG

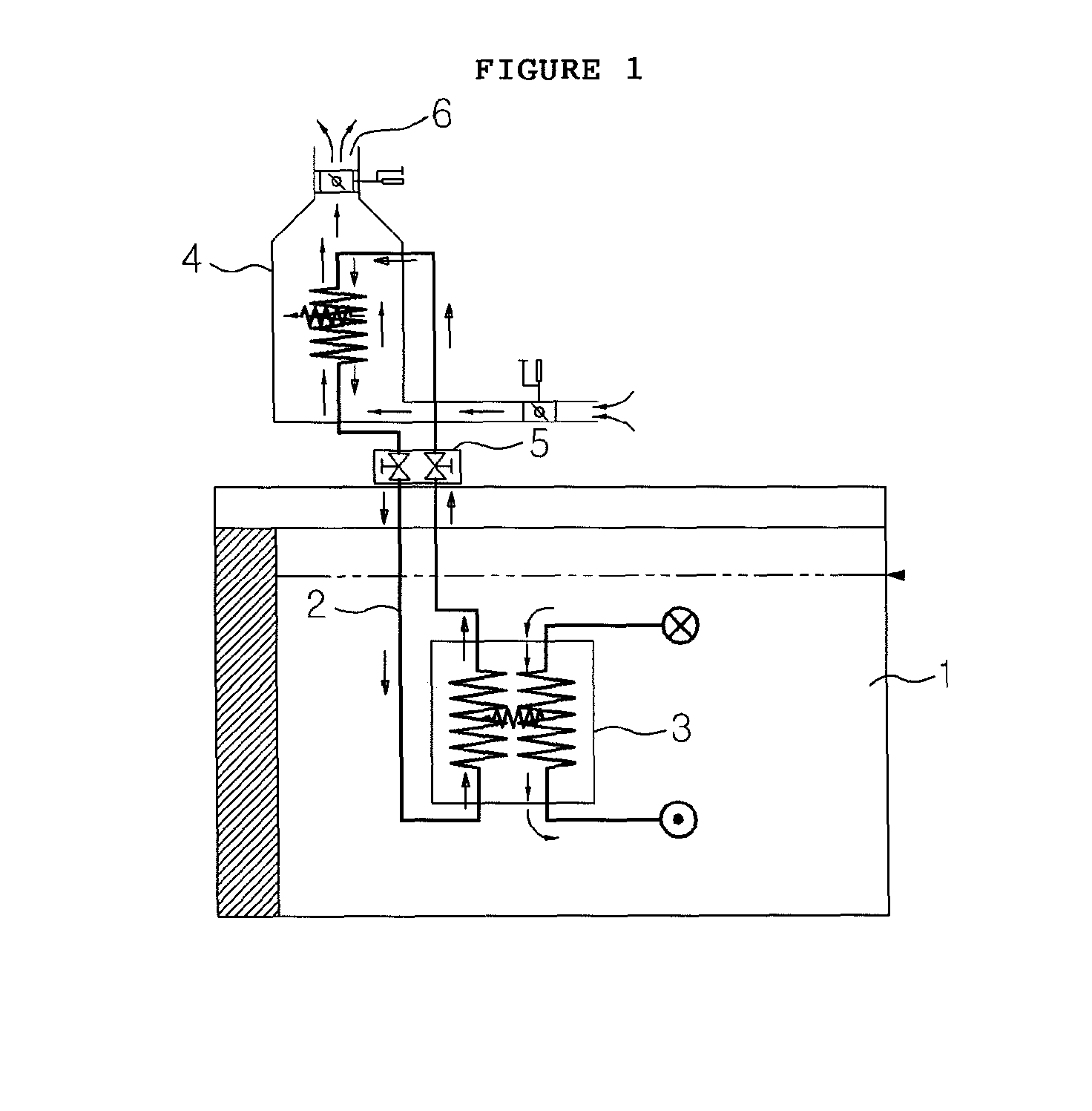

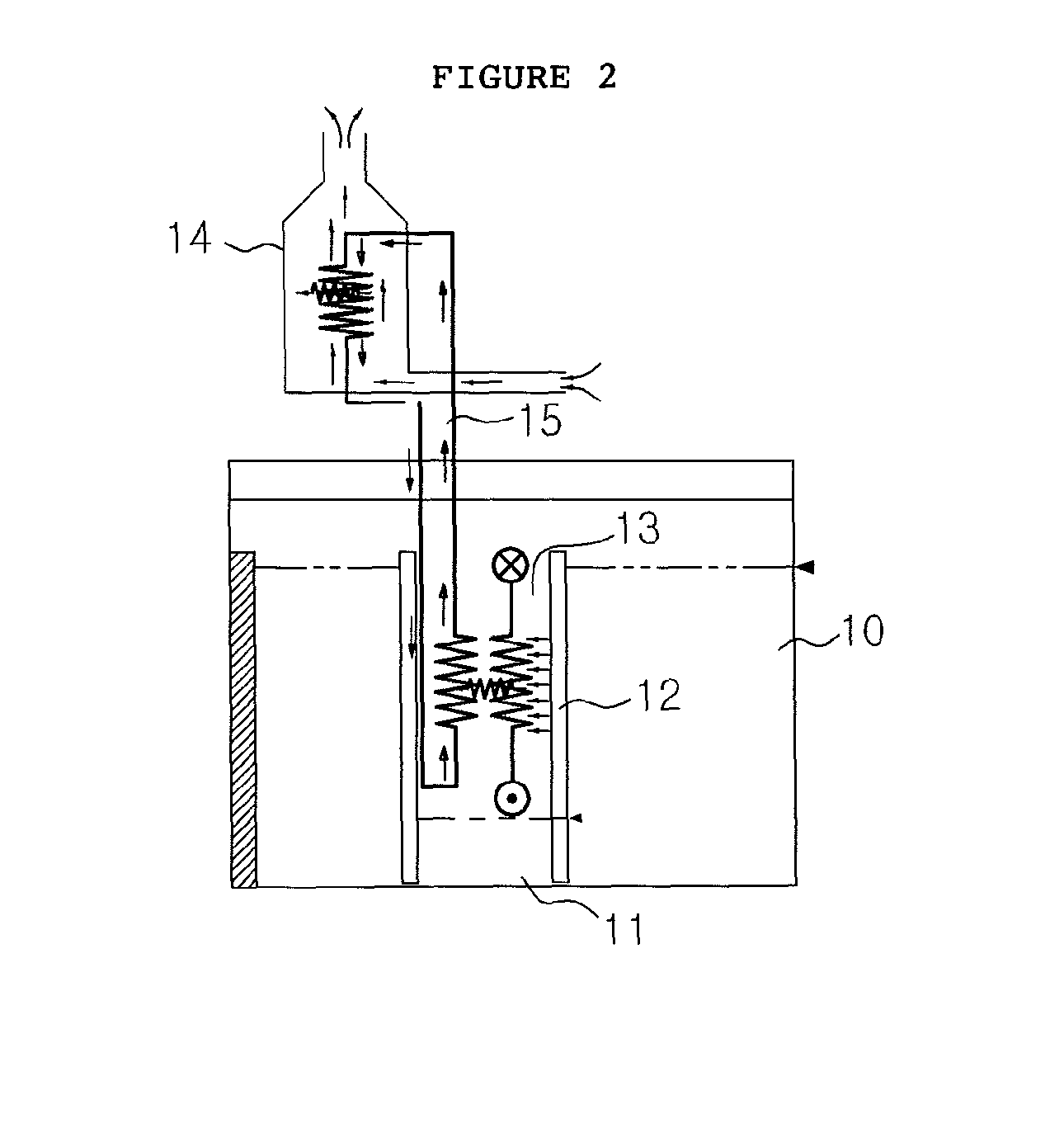

Fully passive decay heat removal system for sodium-cooled fast reactors that utilizes partially immersed decay heat exchanger

ActiveUS8670518B2Eliminate possibility of interventionReduced operational reliabilityNuclear energy generationFast fission reactorsIntermediate heat exchangerSodium-cooled fast reactor

Owner:KOREA ATOMIC ENERGY RES INST +1

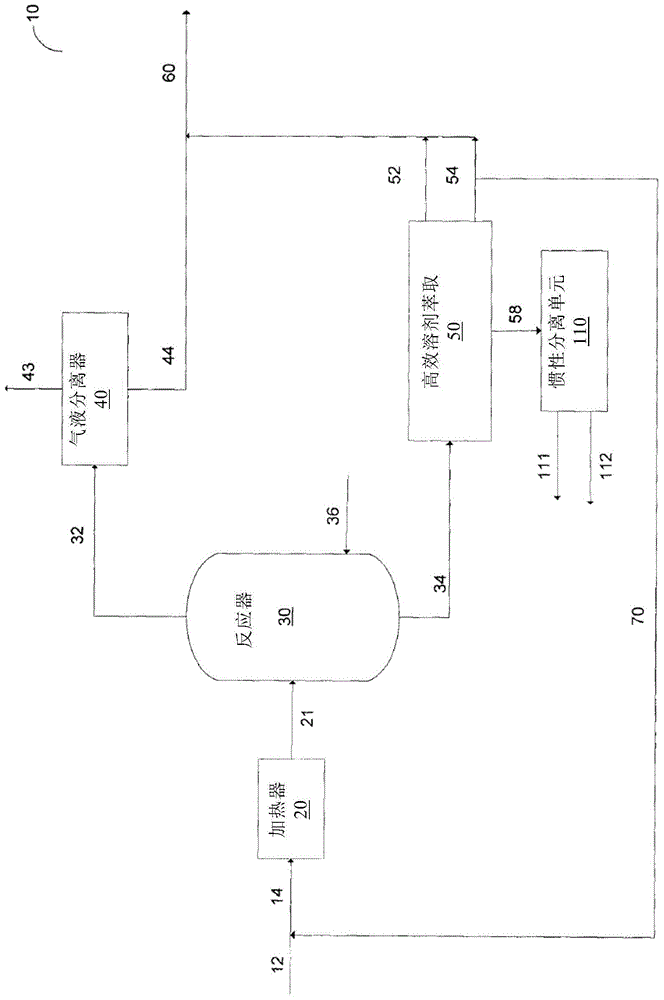

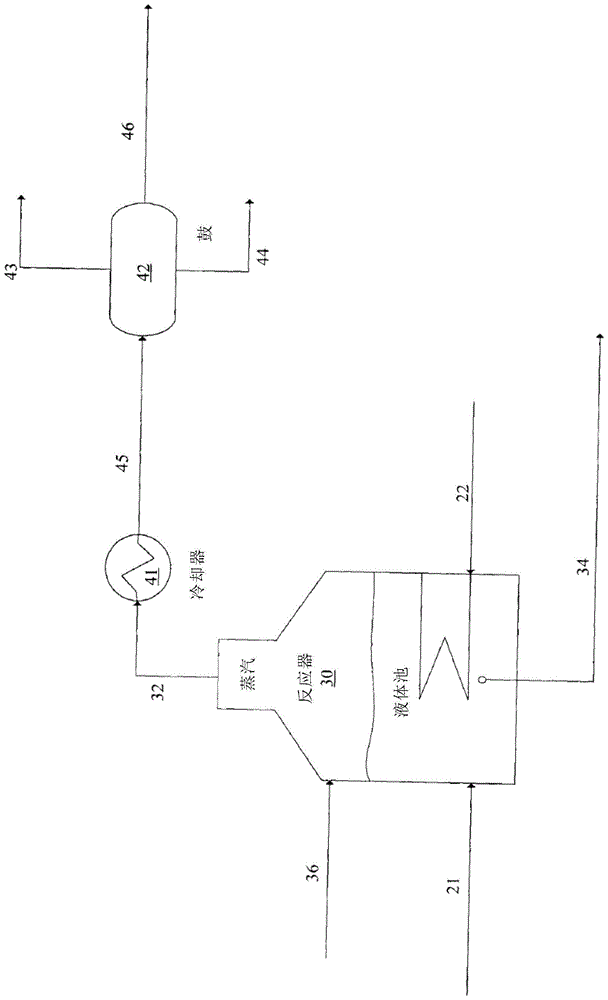

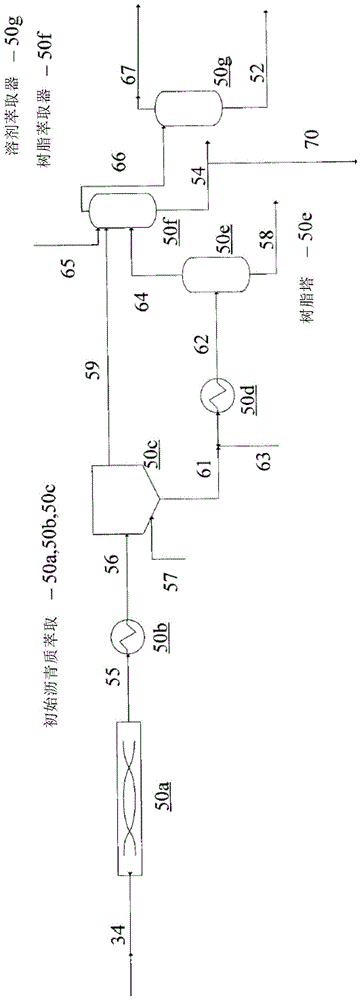

Low complexity, high yield conversion of heavy hydrocarbons

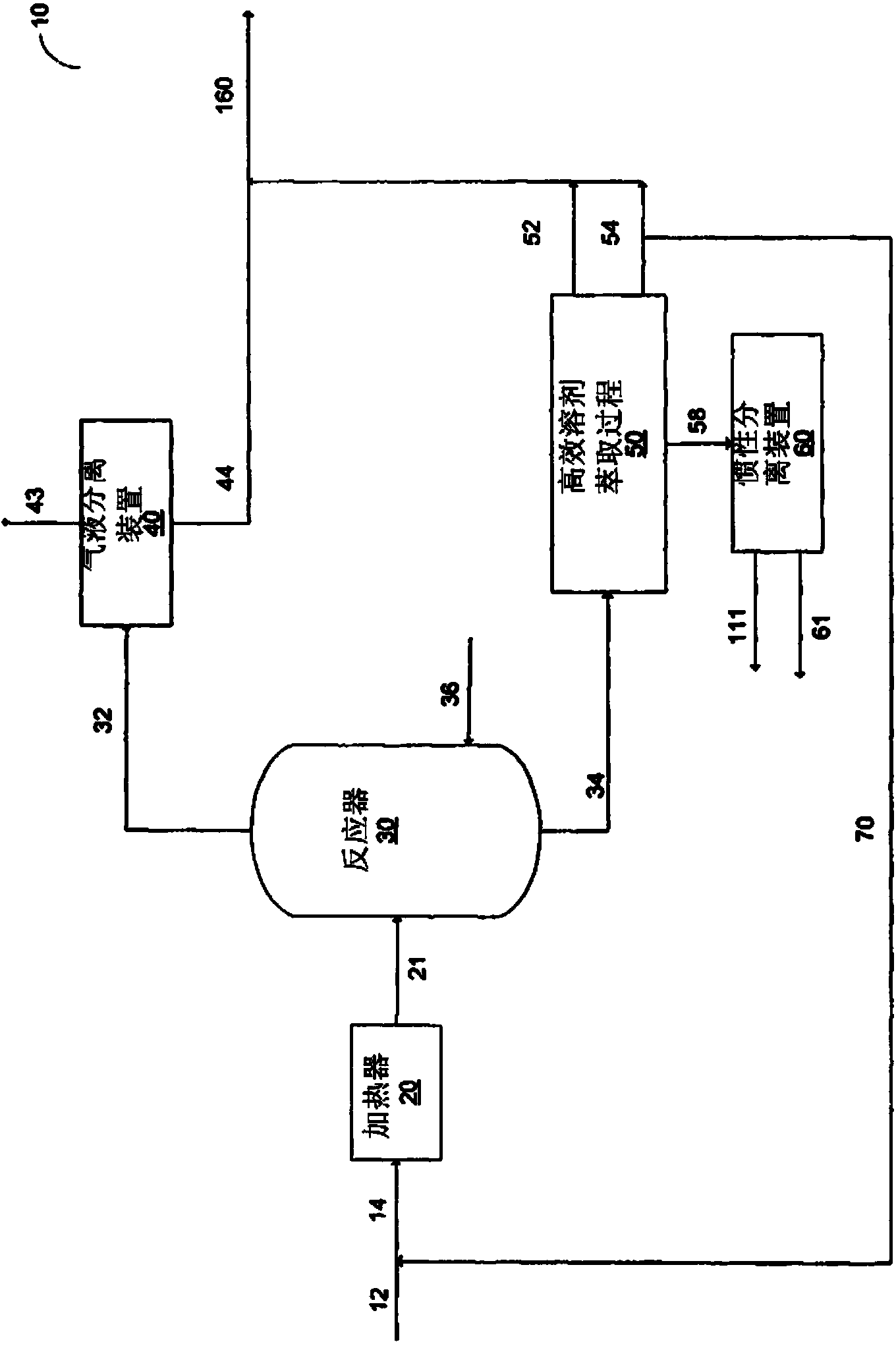

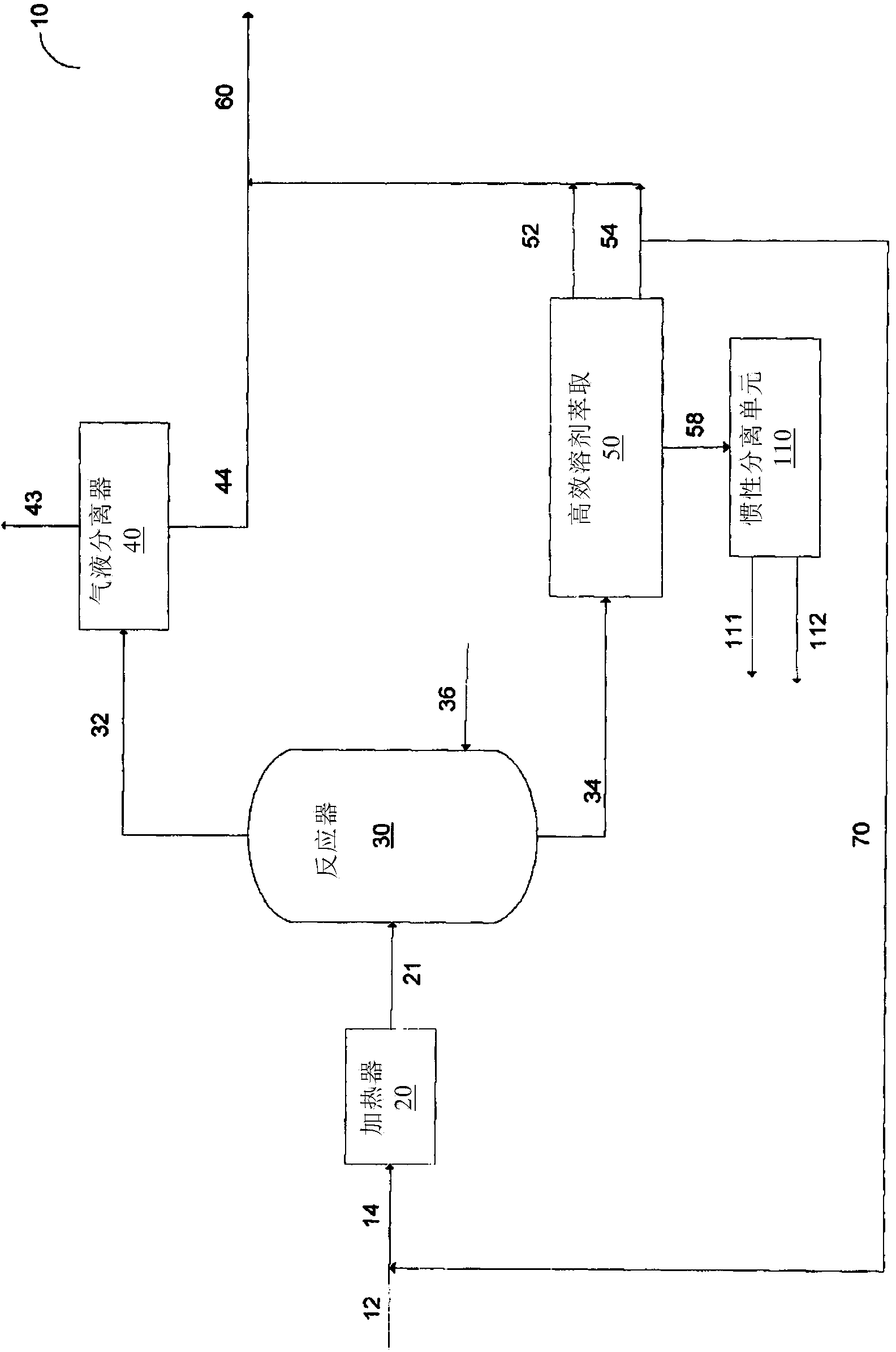

InactiveCN104114677AIncrease productionReduce crude oil productionWorking-up pitch/asphalt/bitumen by selective extractionTreatment with plural serial stages onlySolventAsphaltene

A process for producing pipeline-ready or refinery-ready feedstock from heavy hydrocarbons using a high-performance solvent extraction process with high local solvent-to-process fluid ratios yet maintaining low overall solvent- to-process fluid ratios, by first performing mild thermal cracking on the heavy hydrocarbons and then separating asphaltene-rich fractions from a resulting thermally affected fluid so that the high solvent-to-oil ratio portion of the process acts only on those asphaltene-rich fractions, and producing a dry, solid asphaltene as an end-product.

Owner:MEG ENERGY CORP

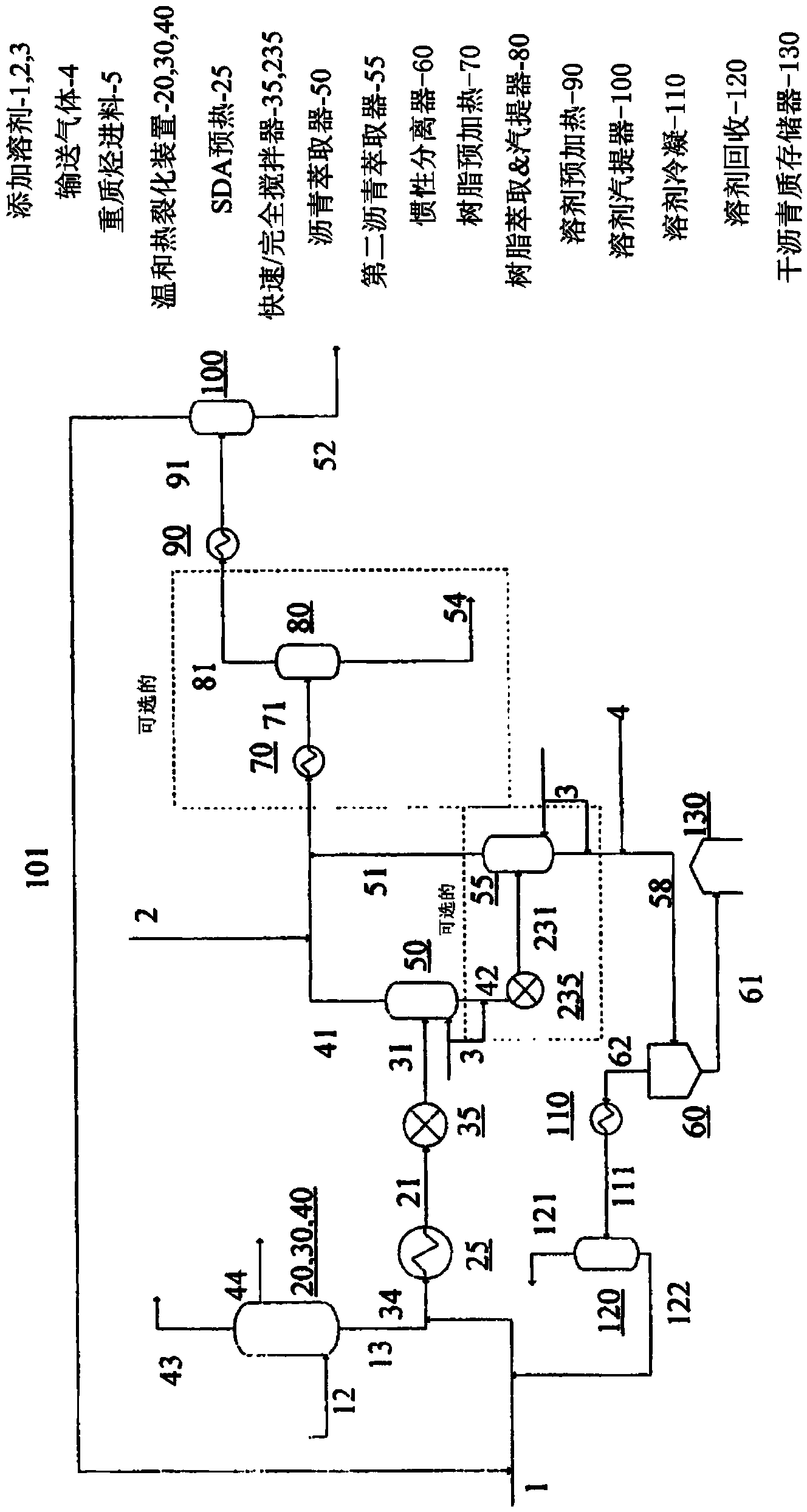

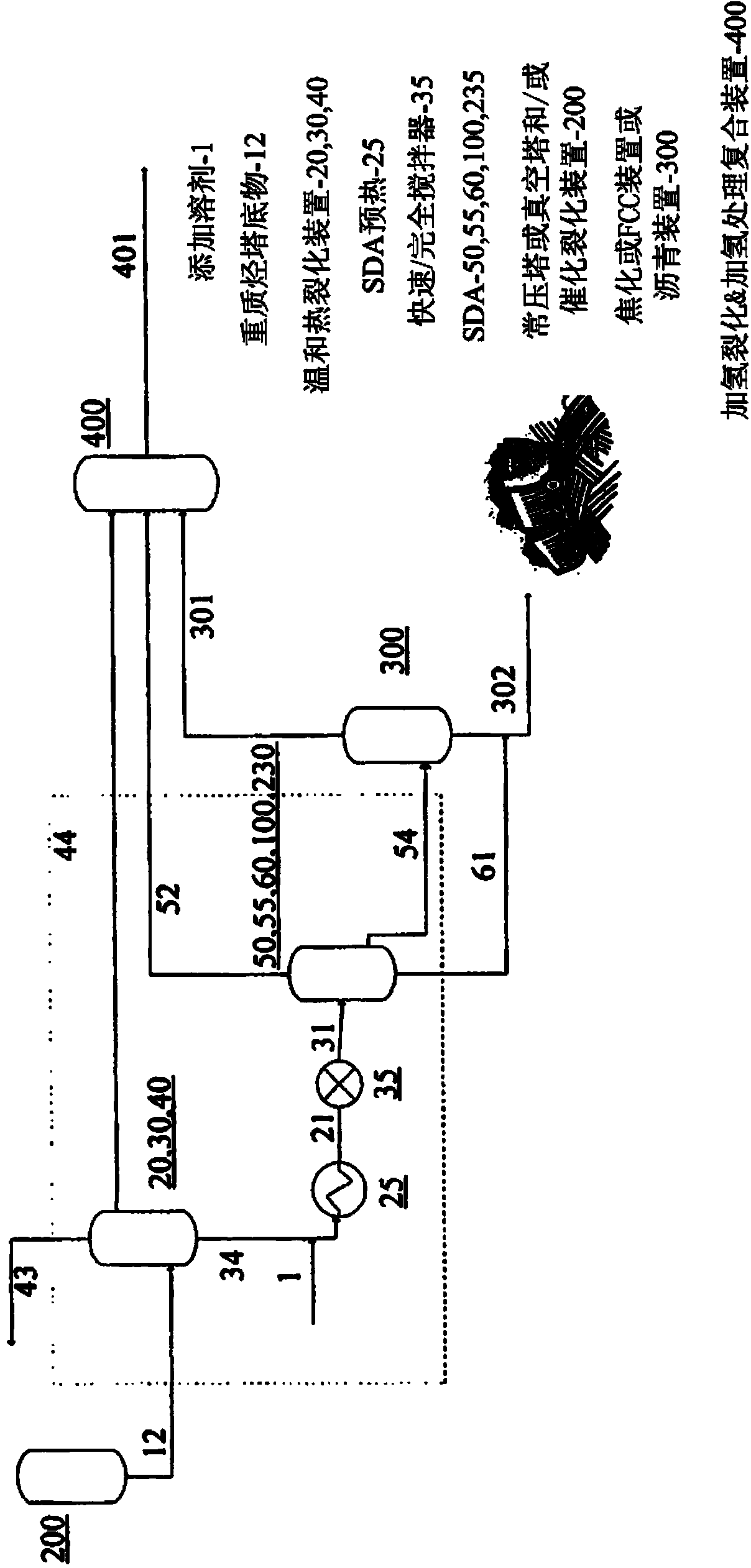

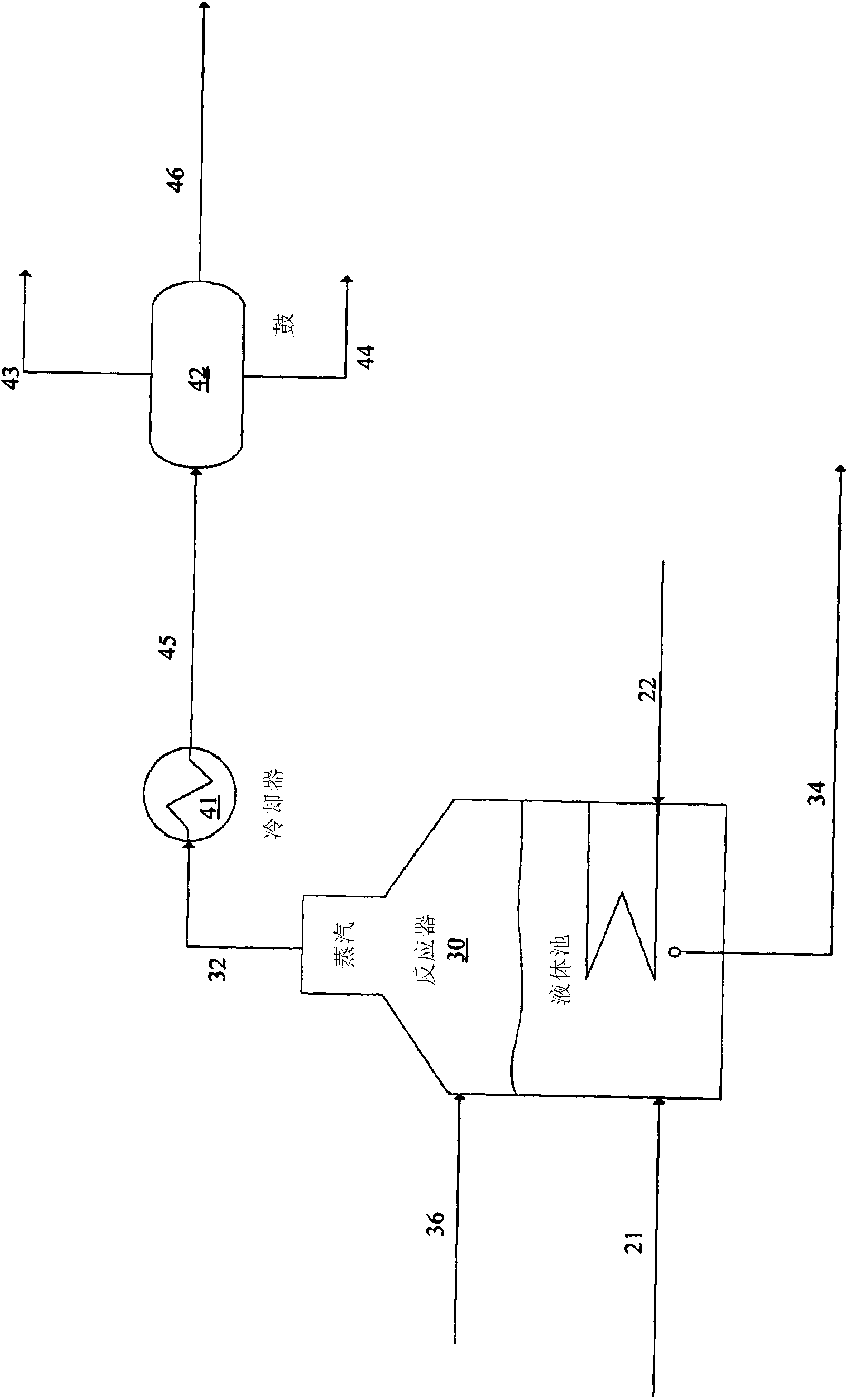

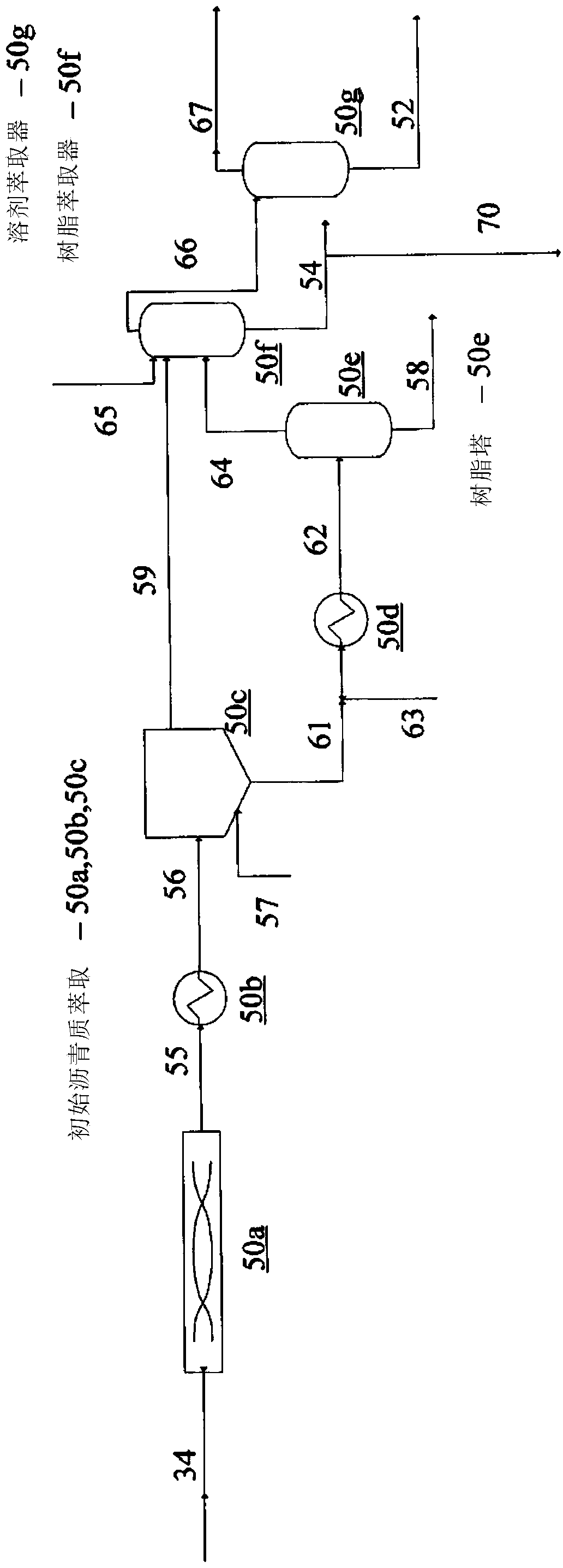

Solvent de-asphalting with cyclonic separation

InactiveCN104105780AIncrease productionHigh operating costsThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionPipeline transportCyclonic separation

The present invention relates to a method of improving a heavy hydrocarbon, such as bitumen, to a lighter more fluid product and, more specifically, to a final hydrocarbon product that is refinery-ready and meets pipeline transport criteria without the addition of diluent. A solid asphaltene by-product is created for easy handling and further processing. The invention is targeted to enhance Canadian bitumen, but has general application in improving any heavy hydrocarbon. The process comprises: (a) pre-heating a process fluid in a heater to a designed temperature; (b) moving the pre-heated process fluid to a reactor, and optimally converting asphaltenes in the process fluid within the reactor to produce a stream of thermally affected asphaltene-nch fraction( s), and a stream of non-condensible vapour and lighter liquid hydrocarbon(s); (c) deasphalting the thermally affected asphaltene-nch stream with a solvent extraction process into a stream of heavy deasphalted oil (DAO) and a second stream containing concentrated asphaltene; (d) separating dry thermally affected asphaltene solids from the second stream in a separation unit, recovering the process solvent; (e) a produced refinery feedstock comprising at least one of the produced streams.

Owner:MEG ENERGY CORP

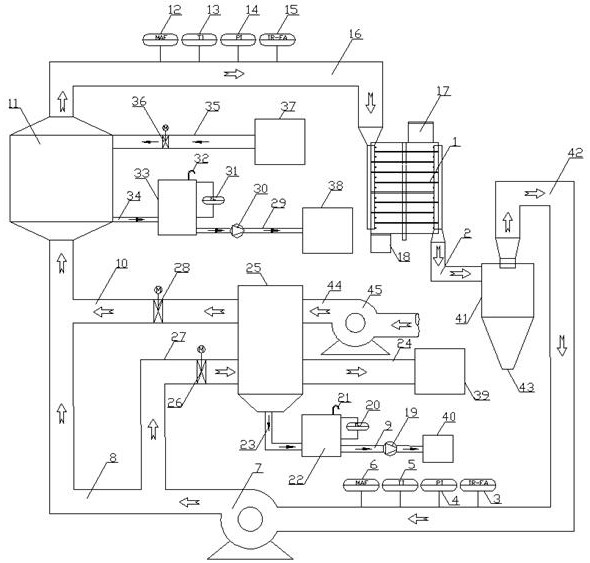

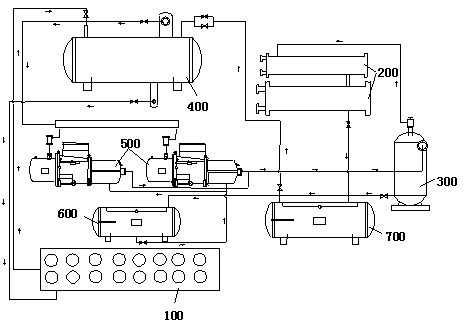

Novel air medium type sludge drying system

PendingCN112661383AScientific and reasonable structureEasy to useSludge treatment by de-watering/drying/thickeningDispersed particle separationSludgeHot blast

The invention discloses a novel air medium type sludge drying system which comprises a sludge drying machine, the bottom end of the sludge drying machine is connected with an air outlet duct, the air outlet duct is connected with an inlet of a cyclone dust collector, the top end of the cyclone dust collector is connected with a circulating air return duct, and the bottom end of the cyclone dust collector is connected with an ash discharge port. The circulating air return duct is connected with the inlet of a circulating fan. The sludge drying system is scientific and reasonable in structure and safe and convenient to use, a closed hot air circulation sludge drying system is adopted, a hot air heating system with electricity or steam as a heat source is high in operation energy consumption, a system with a heat pump as a hot air heating device is complex in structure, a waste gas condensation system generates a large amount of condensed waste water, and the treatment cost is high; in addition, components and flow of the hot air can be changed after the hot air is recycled for a long time, and finally safety of system equipment and stability of a system are affected.

Owner:上海国惠环境科技股份有限公司

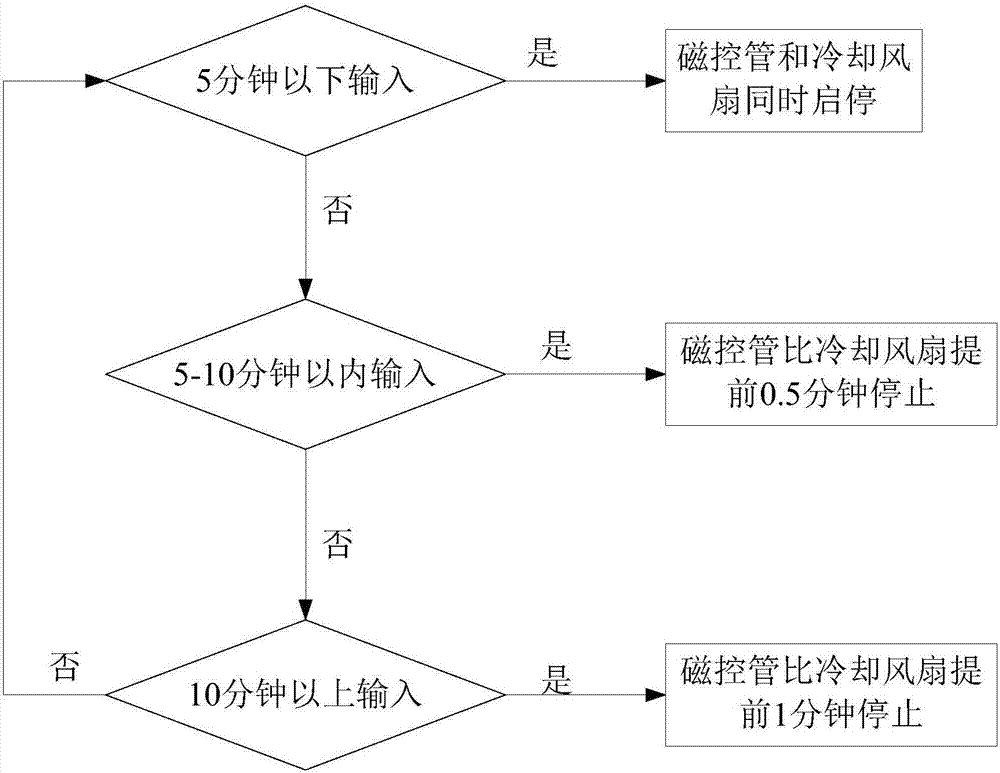

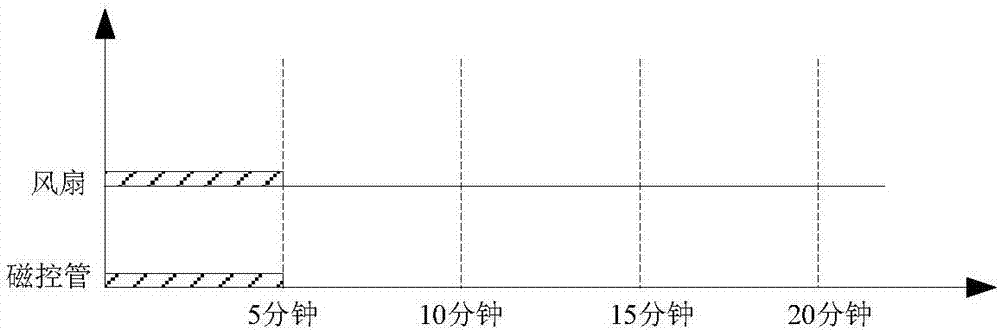

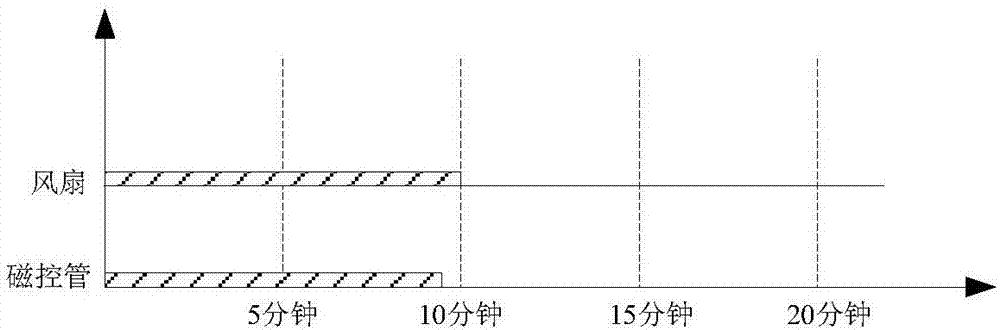

Magnetron cooling control method for microwave oven, and microwave oven

InactiveCN107396480AReduce fabrication and installation costsImprove working reliability and service lifeDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

The embodiment of the invention provides a magnetron cooling control method for a microwave oven, and the microwave oven, and belongs to the field of microwave ovens. The interior of the microwave oven is provided with a magnetron for generating microwave, and a cooling fan for cooling the magnetron. The method comprises the steps: detecting set work time T of the microwave oven; controlling the magnetron and the cooling fan to start at the same time when the set work time T is greater than a threshold value Ts, wherein the operation time of the magnetron is T-t, and the operation time of the cooling fan is T, so as to enable the magnetron to stop earlier than the cooling fan by the time t (t is within the range shown in the description). According to the technical scheme of the invention, the method can reduce the manufacturing and installation cost of the microwave oven while improving the working reliability of the microwave oven and prolonging the service life of the microwave oven.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Ship propulsion vertical permanent magnet motor

ActiveCN103746530BReduce tooth expansionIncrease the magnetic flux per poleMagnetic circuit rotating partsMechanical energy handlingMarine engineeringPermanent magnet motor

The invention relates to a permanent-magnetic motor, in particular to a ship propelling-type permanent-magnetic motor, which aims at solving the problems of the existing permanent-magnetic motor that the reliability in running is low, the capacity expansion is limited, the air-pore magnetic density is low, the power density is low, the structural strength is low, the temperature increasing is difficult for meeting the running requirement, and the oblique running working condition of a ship propelling system is difficult to satisfy. The ship propelling-type permanent-magnetic motor comprises a stand, a front end cover, a rear end cover, a stator structure, a rotor structure, a three-bearing structure and an air cooling structure; the rotor structure comprises a rotating shaft, an inner seal ring, a fan, a circular nut, a first rotor pressure ring, a rotor iron core, a second rotor pressure ring and a balance disc; the outer side surface of the first rotor pressure ring and the outer side surface of the second rotor pressure ring are respectively and uniformly provided with N outer teeth which are equally spaced along the circumferential direction; the outer ring of the end surface of the rotor iron core is circumferentially provided with N groups of magnetic steel grooves at intervals; each group of magnetic steel grooves consists of four magnetic steel grooves which are symmetrically distributed in a U shape. The ship propelling-type permanent-magnetic motor is applicable to a ship propelling system.

Owner:CRRC YONGJI ELECTRIC CO LTD

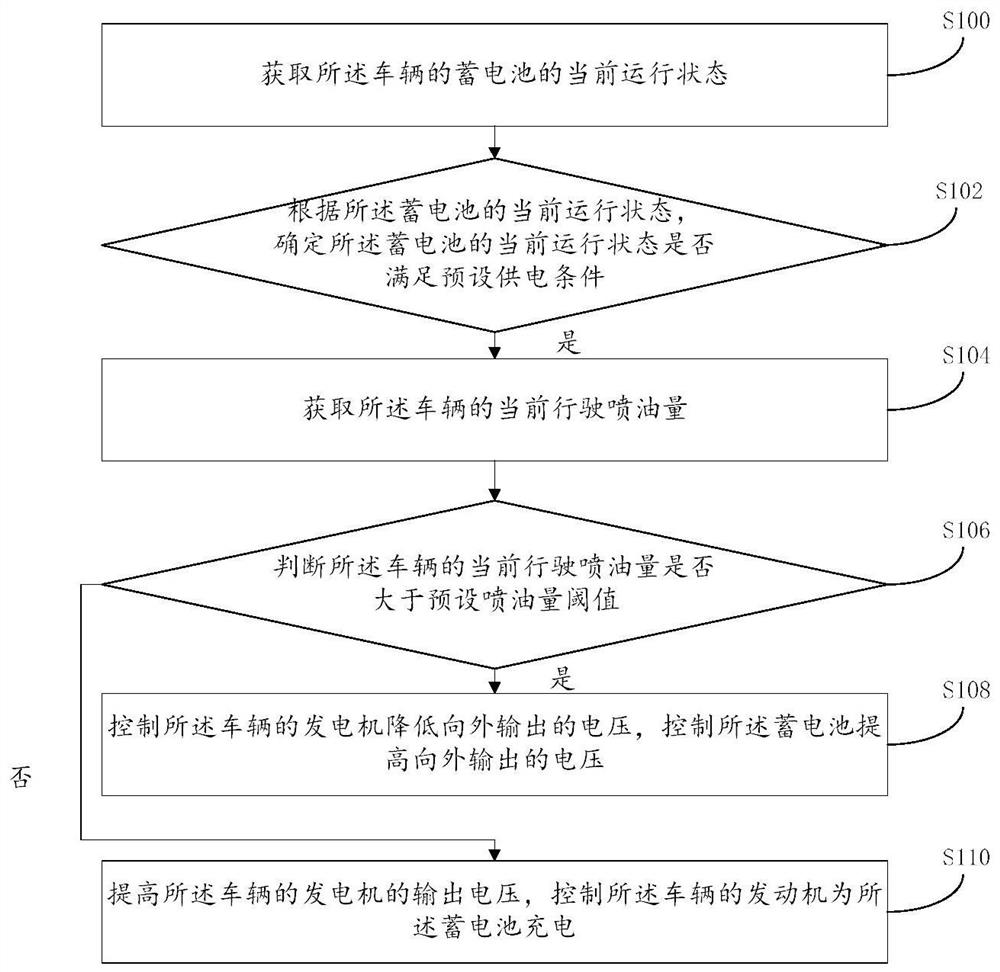

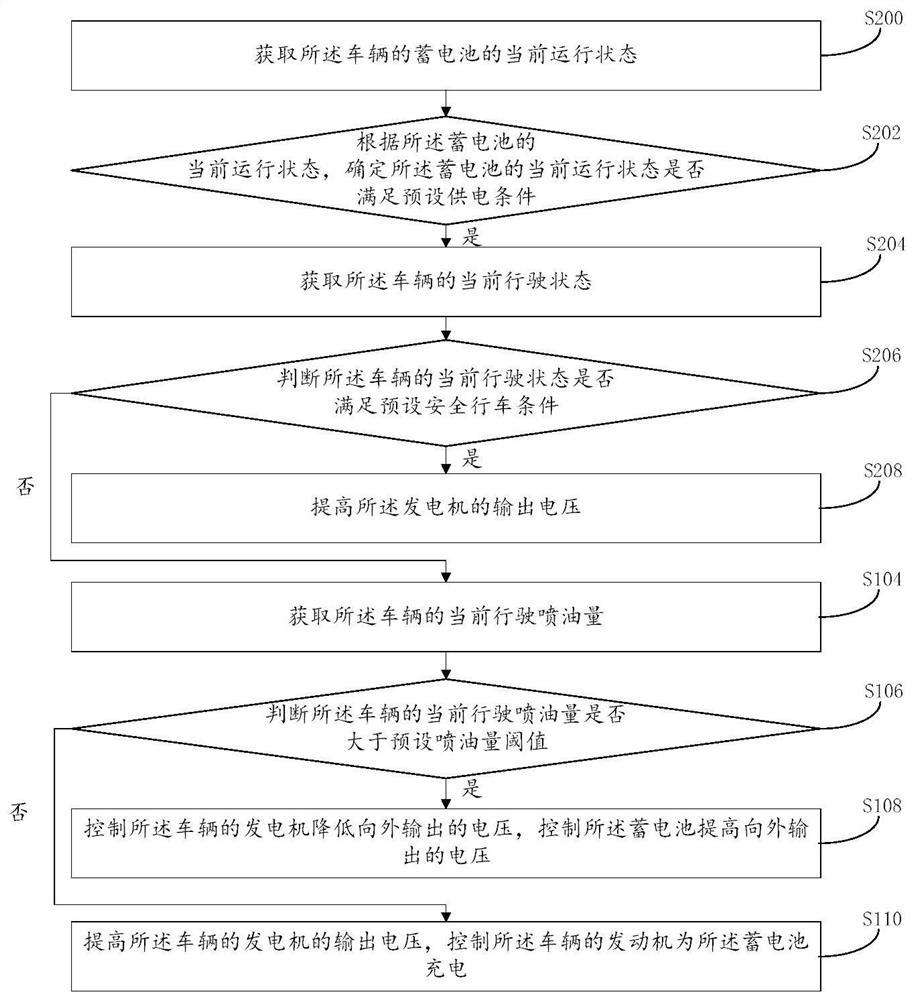

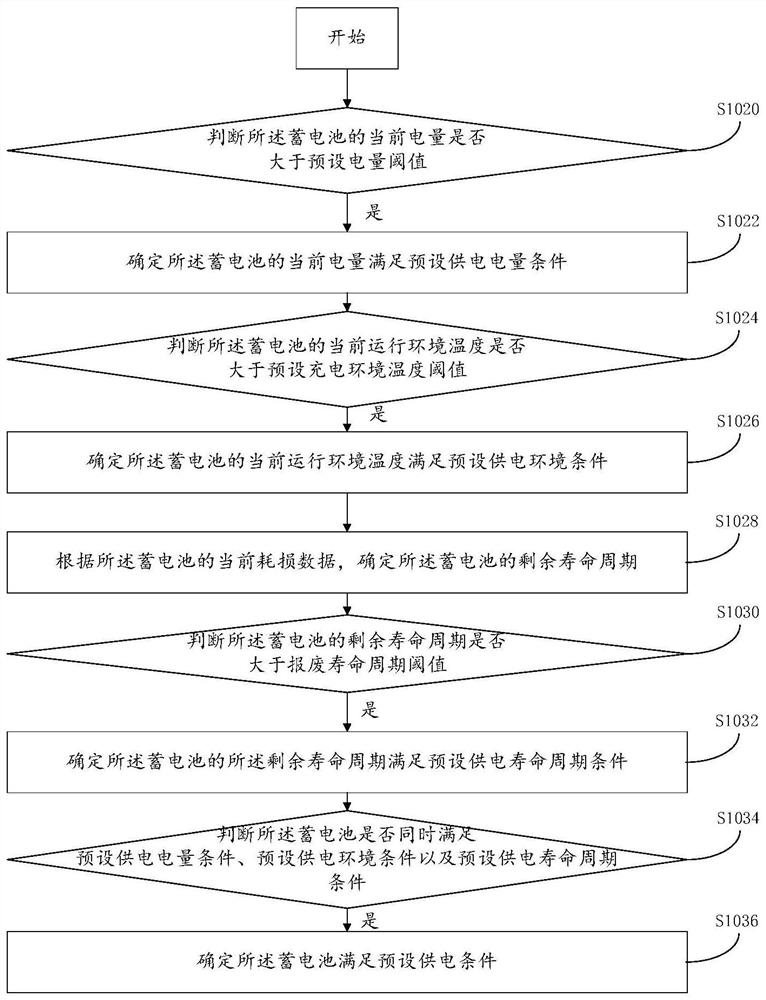

Vehicle control method and device and computer storage medium

PendingCN112793524AAvoid feedingReduce output powerCircuit monitoring/indicationElectric powerControl theoryVoltage control

The invention relates to the technical field of vehicle control, and particularly discloses a vehicle control method and device and a computer storage medium. The method comprises the steps of obtaining a current operation state of a storage battery of a vehicle; judging whether the current operation state of the storage battery meets a preset power supply condition or not; if the current operation state of the storage battery meets the preset power supply condition, obtaining the current driving fuel injection quantity of the vehicle; judging whether the current driving fuel injection quantity of the vehicle is larger than a preset fuel injection quantity threshold value or not; and if the current driving fuel injection quantity of the vehicle is larger than the preset fuel injection quantity threshold value, controlling a generator of the vehicle to reduce the voltage output outwards, and controlling the storage battery to increase the voltage output outwards. On the premise that the storage battery can provide the output voltage, the fuel injection quantity of the vehicle is determined, and when the fuel injection quantity is large, the storage battery is controlled to supply power, and the generator is controlled not to supply power, so that the output power of the engine to the generator is reduced, the load of the engine is reduced, and the fuel consumption of the engine is reduced on the premise of avoiding feed of the storage battery.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

Quick-change system and operating method for a container processing machine

ActiveUS20120153524A1High level of operational reliabilityDangerous damageConfectionerySweetmeatsFixed positionSecure unit

In a quick-change system for exchangeable machine elements, particularly in a container processing machine in which the machine element (E) can be brought into a target position and can be localized in a target position by a securing unit comprising at least one securing element, at least a second securing unit (P2) is provided with which a machine element that either has not been brought into the target position or that has moved out of the target position (X) can be localized in a securing position. The securing position is detected and evaluated as grounds for a corrective action before commencing an operation or during the operating sequence before a corrective action is initiated and executed.

Owner:KRONES AG

Solvent deasphalting with cyclone separation

InactiveCN104105780BIncrease productionHigh operating costsThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionThermodynamicsCyclonic separation

The present invention relates to a method of improving a heavy hydrocarbon, such as bitumen, to a lighter more fluid product and, more specifically, to a final hydrocarbon product that is refinery-ready and meets pipeline transport criteria without the addition of diluent. A solid asphaltene by-product is created for easy handling and further processing. The invention is targeted to enhance Canadian bitumen, but has general application in improving any heavy hydrocarbon. The process comprises: (a) pre-heating a process fluid in a heater to a designed temperature; (b) moving the pre-heated process fluid to a reactor, and optimally converting asphaltenes in the process fluid within the reactor to produce a stream of thermally affected asphaltene-nch fraction( s), and a stream of non-condensible vapour and lighter liquid hydrocarbon(s); (c) deasphalting the thermally affected asphaltene-nch stream with a solvent extraction process into a stream of heavy deasphalted oil (DAO) and a second stream containing concentrated asphaltene; (d) separating dry thermally affected asphaltene solids from the second stream in a separation unit, recovering the process solvent; (e) a produced refinery feedstock comprising at least one of the produced streams.

Owner:MEG ENERGY CORP

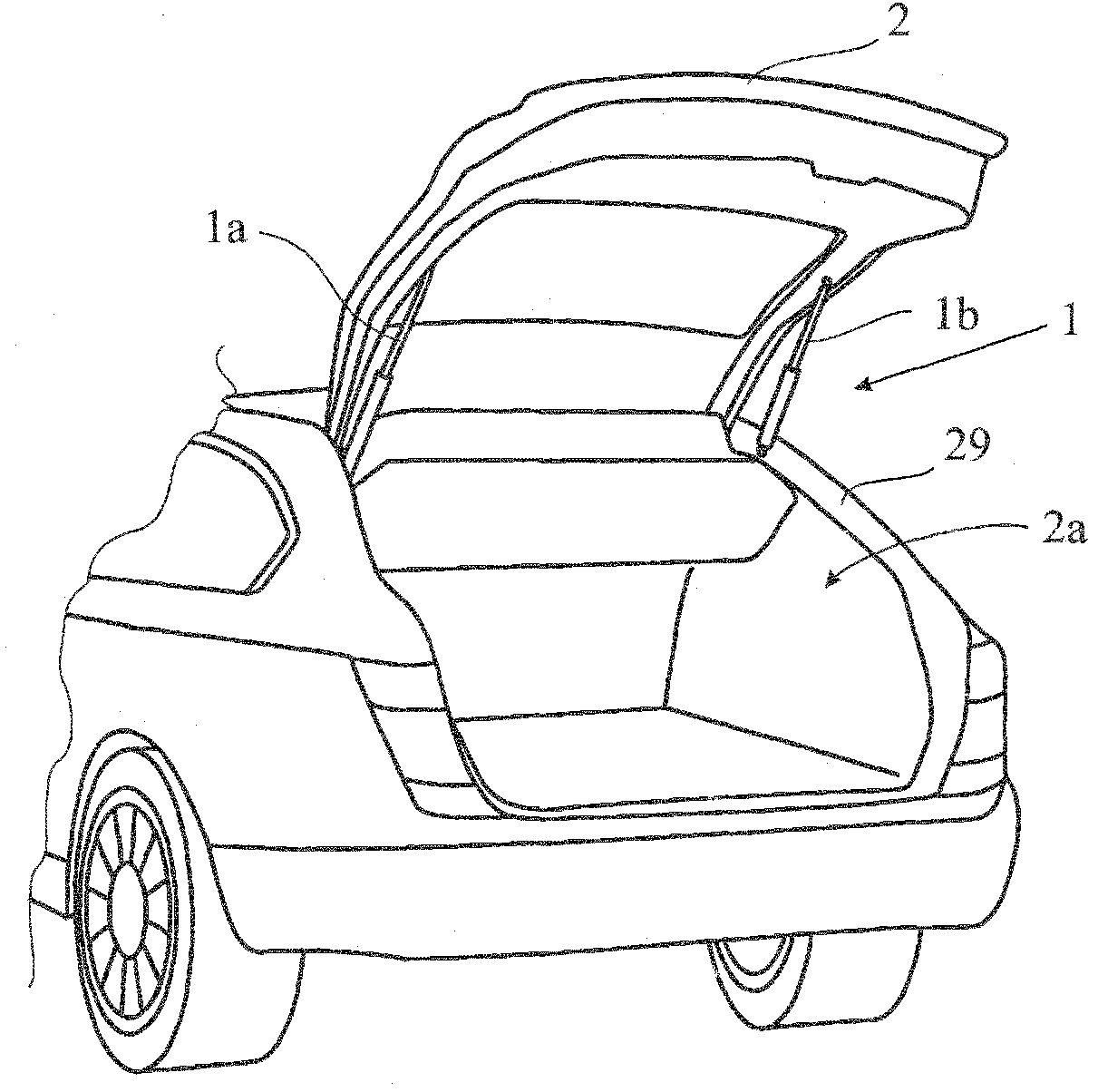

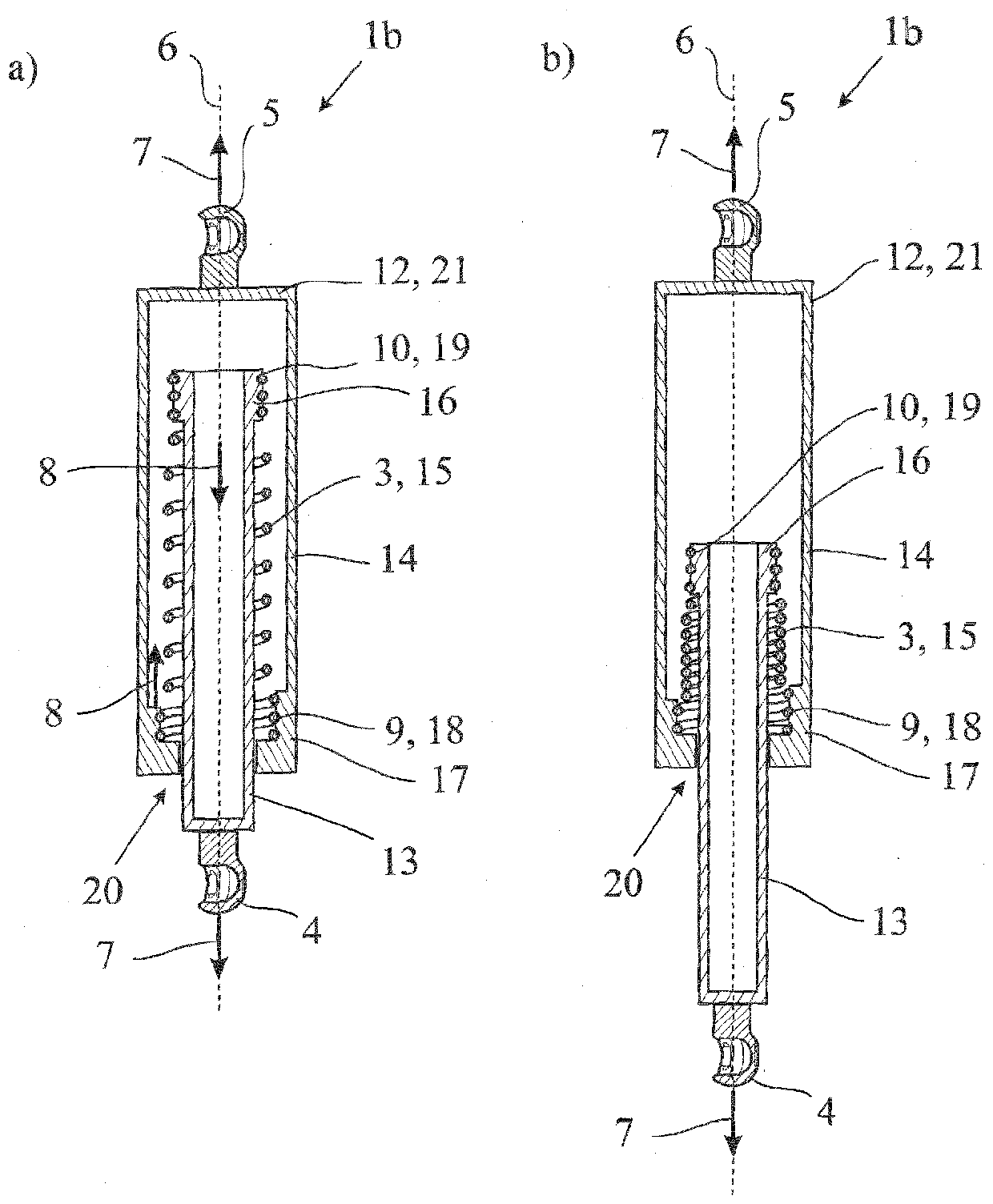

Spring actuators for closing elements of motor vehicles

ActiveCN106489041BImprove assembly reliabilityImprove operational reliabilityPower-operated mechanismGas based dampersMechanical engineeringControl theory

Owner:博泽(哈尔施塔特)汽车零部件有限公司

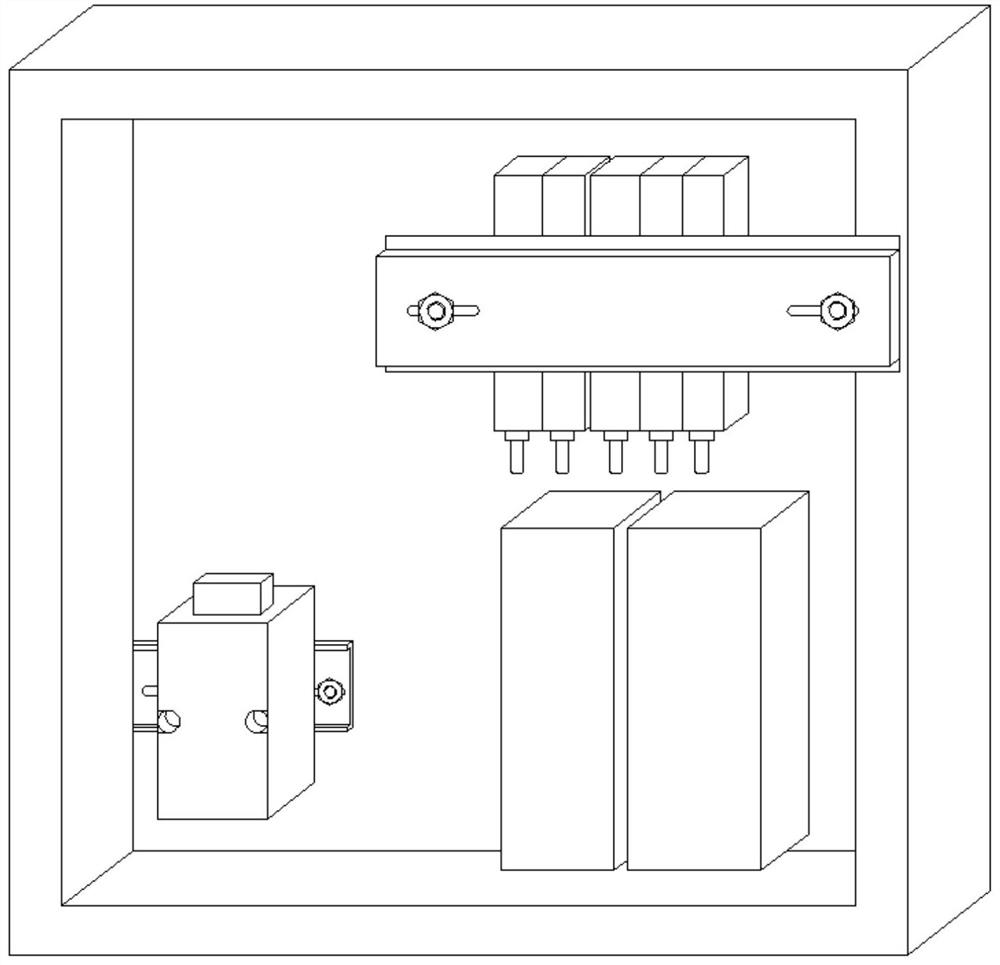

Isolating switch operating mechanism with modularly designed control loop and using method

ActiveCN112002593AOptimize work processEasy to troubleshootAir-break switch detailsTemperature controlElectric machine

The invention discloses an isolating switch operating mechanism with a modularly designed control loop, which comprises a box body with a cover plate, a motor is arranged in the box body, and the output end of the motor is connected with the input ends of the action unit and the auxiliary switch assembly through a transmission device; the motor is connected with the control unit through a wire andcontrolled by the control unit. The control unit is electrically connected with the auxiliary switch assembly, the opening and closing assembly and the temperature control assembly. According to themechanism disclosed in the invention, the problem of the isolation switch operation box at present is effectively solved.

Owner:GUIZHOU POWER GRID CO LTD

A kind of urea supply device and treatment method of SCR post-treatment system

ActiveCN106050369BEase of mass productionReduce manufacturing costInternal combustion piston enginesExhaust apparatusAfter treatmentPulp and paper industry

Owner:山东修时环保科技有限公司

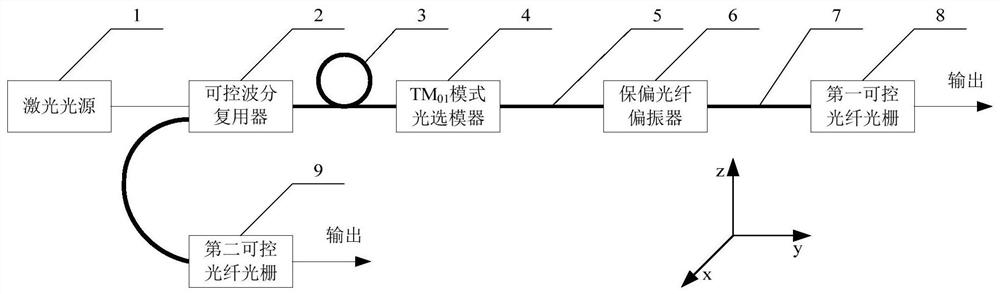

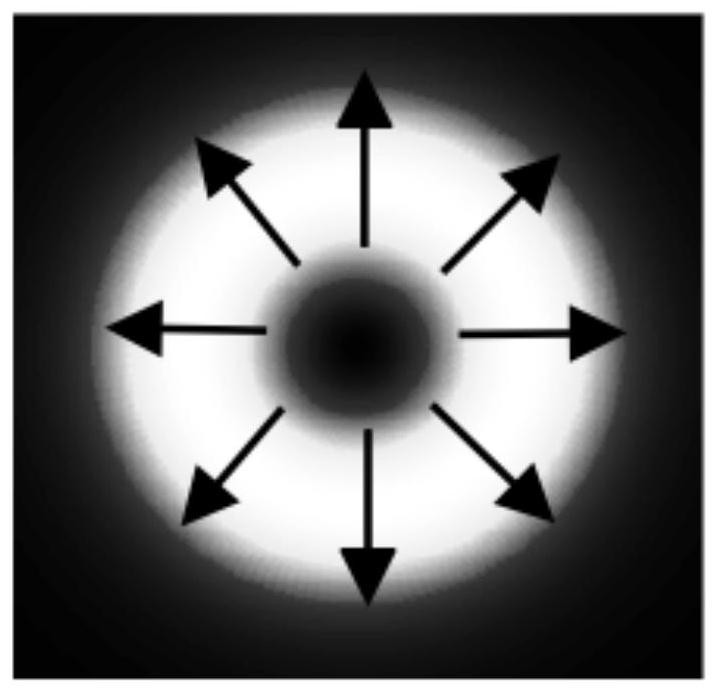

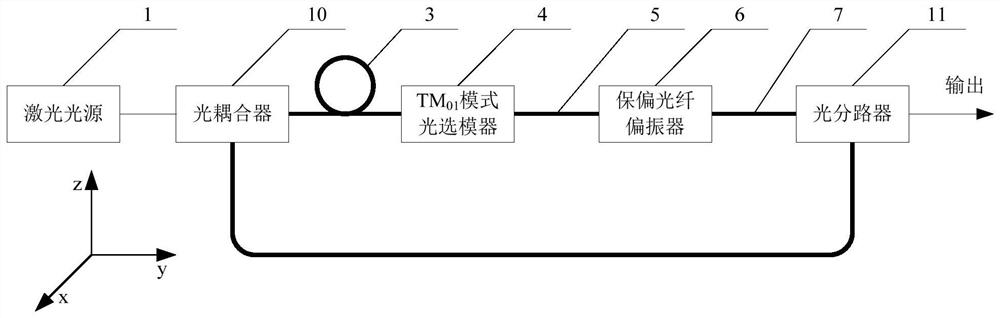

based on tm 01 Method for generating vortex laser by mode light conversion and vortex laser

ActiveCN111525376BLow costReduced operational reliabilityActive medium shape and constructionOptical axisLaser light

The invention discloses a TM-based 01 The vortex laser generation method of mode light conversion, using the laser light emitted by the laser source to generate TM through the few-mode doped gain fiber 01 pattern light, and then utilize TM 01 Mode light passes through the optical axis perpendicular to the TM 01 The λ / 4 fiber wave plate in the incident direction of the mode light is converted into vortex light, and then the vortex laser output is formed through the resonance of the vortex light, which provides a new solution for the generation of vortex laser; in addition, the present invention is also based on the vortex laser generation method that provides a TM-based 01 Mode light conversion vortex laser design scheme, simple structure design, stable and reliable operation, can better take into account the low cost and operational reliability of vortex lasers, and can further control the optical path to achieve controllable selection of output lines Polarized vortex light or left-handed circularly polarized vortex light provides a new solution for outputting vortex lasers with different polarization states.

Owner:YANGTZE NORMAL UNIVERSITY

A long-distance heavy-duty drag chain supporting device

ActiveCN104085657BExtended service lifePrevent disengagementConveyorsRollersEngineeringCable carrier

A long-distance heavy-duty drag chain supporting device, including a support frame extending horizontally and horizontally for carrying the drag chain and a supporting mechanism for supporting the upper section of the drag chain. The supporting bracket on the frame, the supporting wheels set on the supporting bracket at intervals to support the bottom of the upper section of the drag chain, the rollers arranged on the supporting bracket and located in the steering ring section of the drag chain, when the drag chain turns to the ring section The lateral movement can drive the roller to move laterally, thereby driving the support bracket to move laterally so that the upper section of the towline is always supported on the supporting roller. The invention has the advantages of simple structure and strong adaptability, and can effectively prevent the upper section of the towline from rubbing against the lower section of the towline. , prolong the service life of the drag chain.

Owner:ZHEJIANG JINFULONG MACHINE TOOL ACCESSORIES

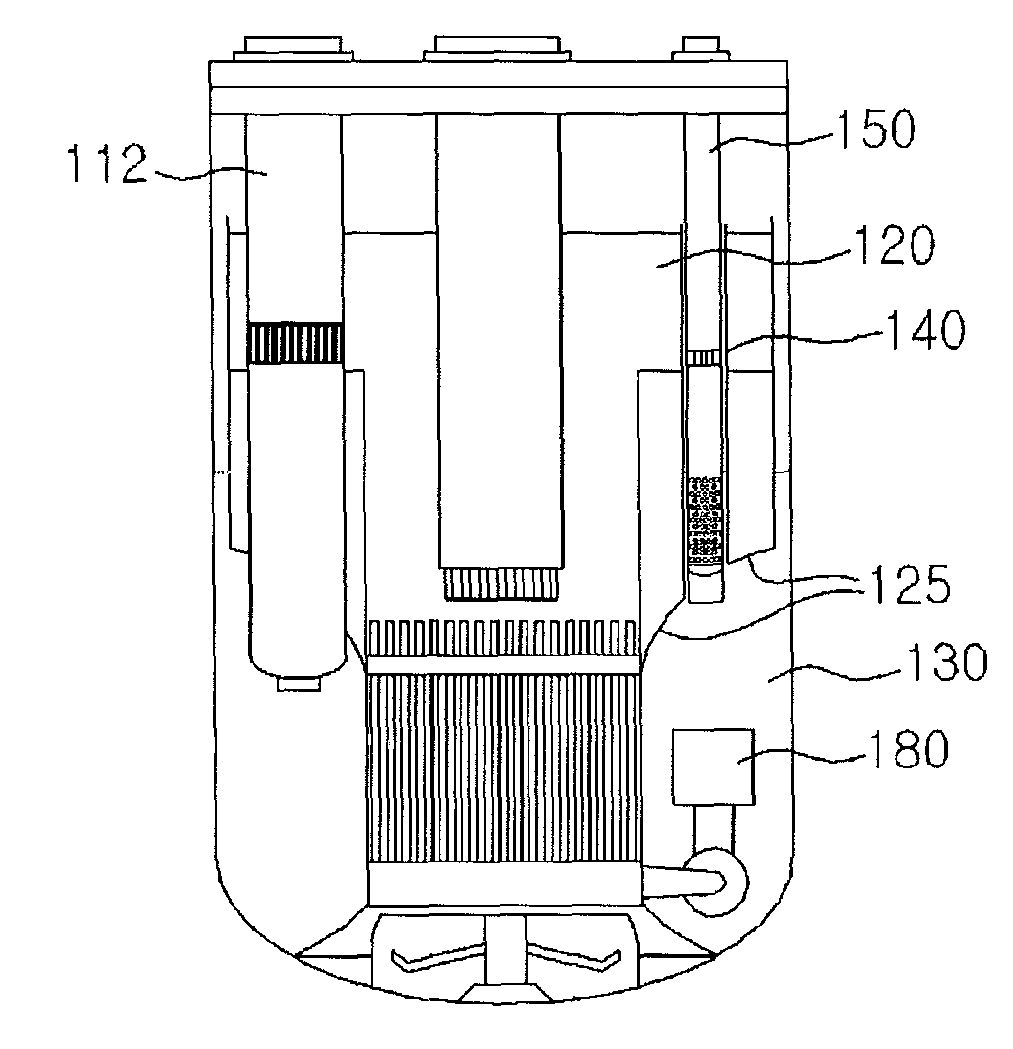

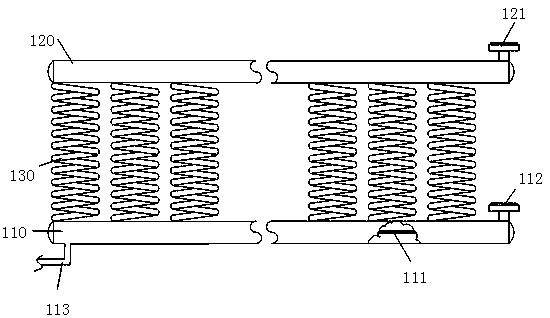

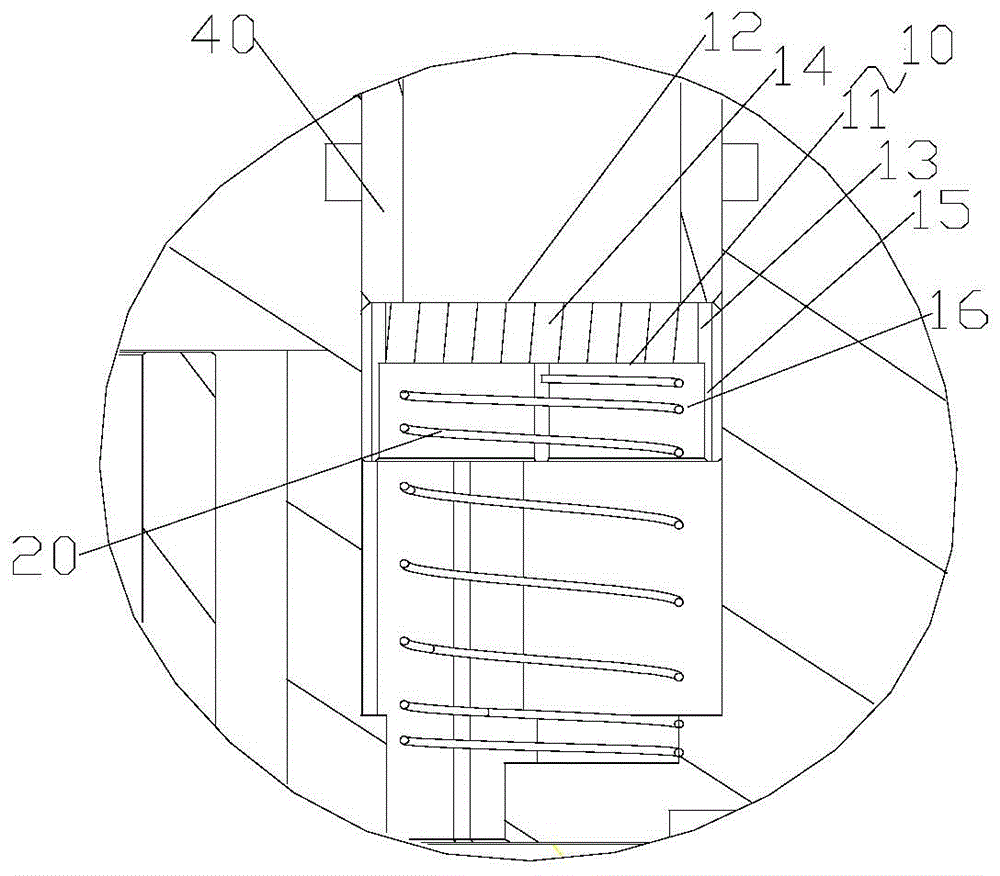

Spiral evaporator for flooded central air conditioning system

ActiveCN105333650BReduced operational reliabilityImprove operational reliabilityEvaporators/condensersProcess engineeringEngineering

The invention provides a spiral evaporator for a hydraulic filling type central air conditioning system. The spiral evaporator comprises an input pipe provided with a refrigerating agent inlet and an output pipe provided with a refrigerating agent outlet. Spiral pipe banks are arranged between the input pipe and the output pipe side by side. The two ends of each spiral pipe bank are communicated with the input pipe and the output pipe respectively. A separation board used for separating a refrigerating agent and engine oil is arranged in the input pipe. The separation board is distributed in the pipe diameter direction of the input pipe, so that the interior of the input pipe is divided into an upper space and a lower space which are communicated. By the adoption of the spiral evaporator for the hydraulic filling type central air conditioning system, engine oil backflow efficiency can be improved through the evaporator, the problems that refrigerating efficiency and operation reliability are lowered due to engine oil sedimentation of a refrigerating system can be effectively solved, the refrigerating efficiency of the air conditioning system adopting the spiral evaporator can be improved, operation reliability is improved to a great extent, and operation cost is reduced.

Owner:谭洪德

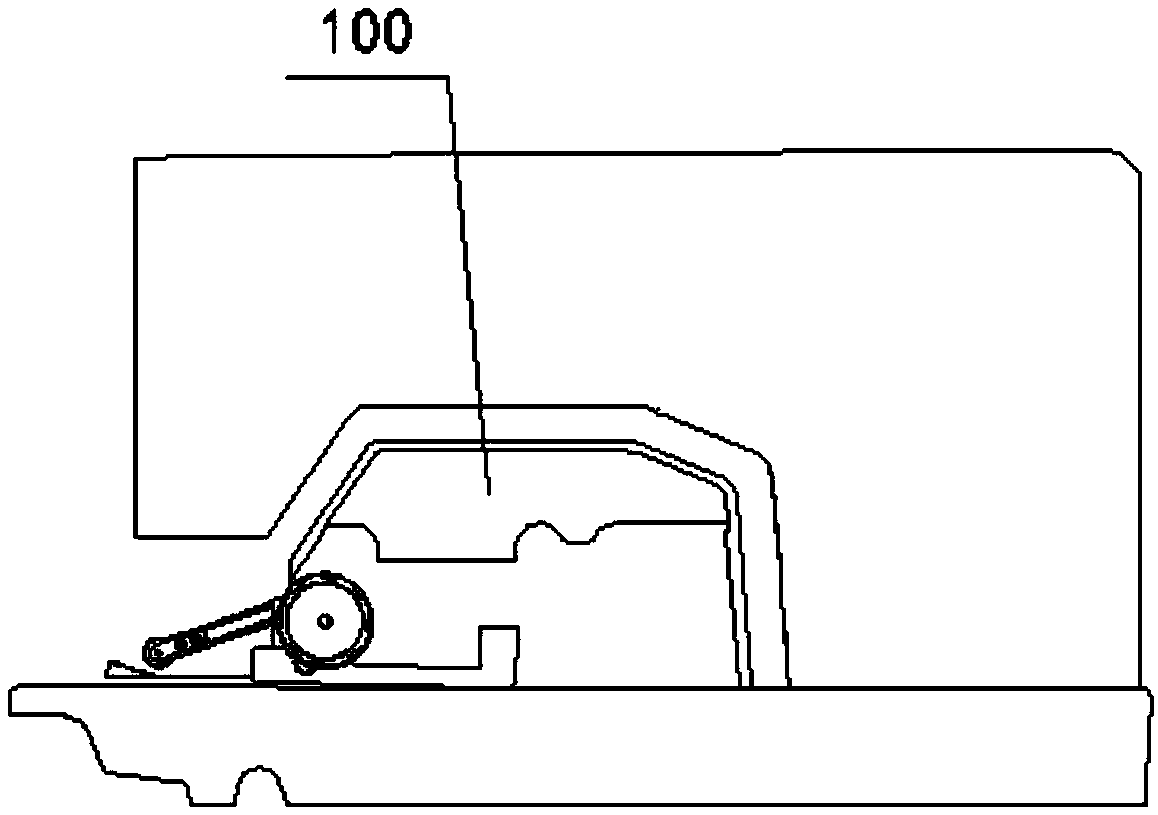

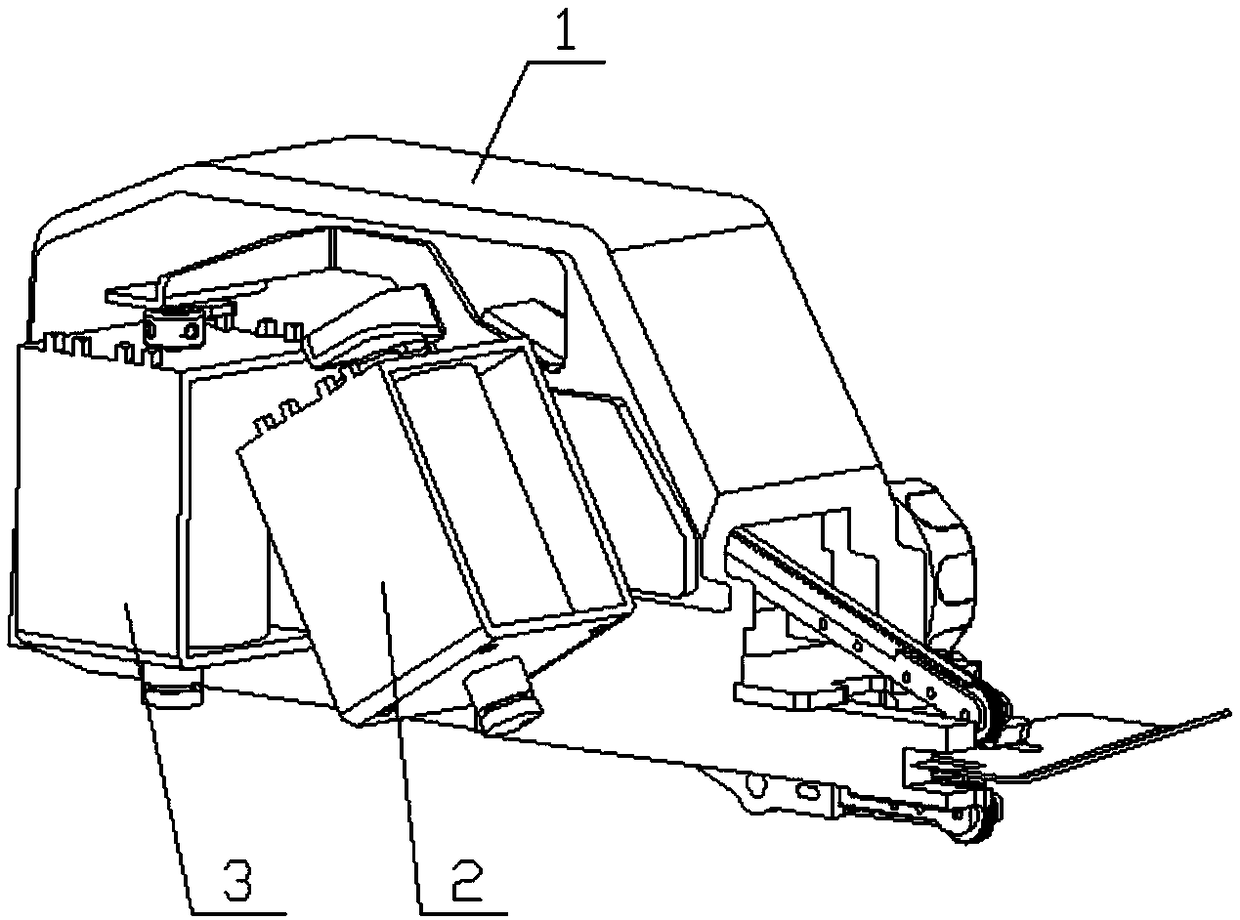

Sewing machine and edge aligning device thereof

The invention discloses an edge aligning device for aligning edges of upper and lower fabrics. The edge aligning device includes a manipulator; the manipulator includes a manipulator casing; a lower mechanical arm for controlling a lower fabric to move to a predetermined position and an upper mechanical arm for controlling an upper fabric to move to a predetermined position located at one side areconnected to the interior of the manipulator casing; a lower manipulator electromagnetic component for controlling the lower mechanical arm to rotate and an upper manipulator electromagnetic component for controlling the upper mechanical arm to rotate located on the other side are arranged in the manipulator casing. The invention also discloses a sewing machine including the edge aligning device.The edge aligning device can effectively utilize the space, simplify the overall structure, and achieve an efficient fabric edge aligning effect.

Owner:JACK SEWING MASCH CO LTD

Machine examination method for electric power post capability model skill assessment

PendingCN110298015ASimple algorithmEasy to implementResourcesComplex mathematical operationsAlgorithmSkill sets

The invention discloses a machine examination method for an electric power post capability model skill assessment. The system comprises an answering time calculation system, a mouse sliding distance calculation system, a mouse acceleration calculation system, an error option modification statistics system and a hesitance scoring system, and the hesitance scoring system carries out score evaluationaccording to data of other systems, so that the proficiency of a position where an examinee is located is evaluated. The method has the advantages that the method is simple in algorithm, easy to implement and low in cost, extra hardware is not needed, psychological means such as guessing and eliminating during answering can be detected to a certain extent, the hesitance degree serves as an examination reference basis, the truth degree in the choice question examination process is effectively improved, and the choice question examination quality is expected to be improved to a certain extent.

Owner:浙江科达电力工程有限公司温州培训中心 +4

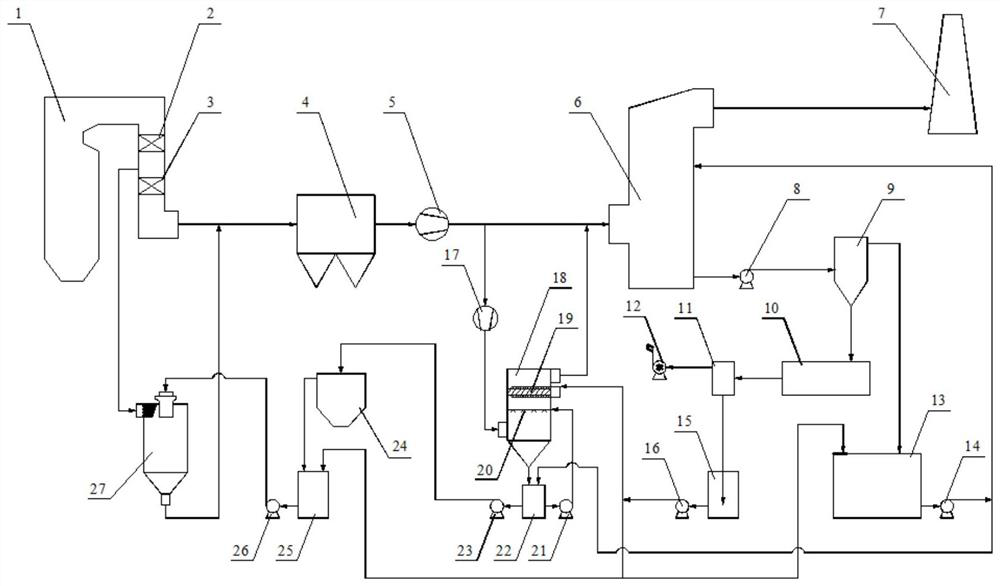

A zero-discharge treatment method and system for desulfurization wastewater adapted to multiple working conditions

ActiveCN111928286BLow solid contentMeet flushing requirementsWater/sewage treatment by centrifugal separationGas treatmentFlue gasWastewater

The invention discloses a zero-discharge treatment method and system for desulfurization wastewater suitable for multiple working conditions, including a boiler, a dust collector, a desulfurization absorption tower, a chimney, a gypsum cyclone, a filtrate water tank, a gypsum dehydrator, a gas-liquid separation tank, and a waste water. Collection box, waste water concentration tower, thick pulp box, clarifier, spray water tank and waste water drying tower, the system and method can adapt to the treatment of various flue gas components, and have the characteristics of high reliability, energy saving and economy.

Owner:XIAN THERMAL POWER RES INST CO LTD +3

Anti-reverse structure for compressor and compressor

InactiveCN105987003AReduce vibrationReduce noiseRotary piston pumpsRotary piston liquid enginesAtmospheric pressureMechanical engineering

The invention provides an anti-reverse structure for a compressor and the compressor. The anti-reverse structure comprises an anti-reverse valve plate and an elastic element, wherein the anti-reverse valve plate is provided with a first surface and a second surface which are arranged oppositely in the thickness direction of the anti-reverse valve plate; the anti-reverse valve plate is further provided with a communication structure penetrating in the thickness direction of the anti-reverse valve plate; the elastic element is propped against the first surface of the anti-reverse valve plate; in the compression process of the elastic element, the first surface and the second surface of the anti-reverse valve plate can be communicated through the communication structure; when the elastic element returns and springs back, the first surface and the second surface of the anti-reverse valve plate are not communicated. Due to the fact that the anti-reverse valve plate is provided with the penetrating communication structure, gas on two sides of the anti-reverse valve plate can be communicated through the communication structure, so that the pressure values of the gas on the two sides of the anti-reverse valve plate are balanced, the vibration and the noise of the anti-reverse valve plate can be effectively reduced, and the operation noise of the compressor is further reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Analysis method for reliability of numerical control equipment based on hidden Markov chain

InactiveCN101520651BReduced operational reliabilityFailure to achieveProgramme controlComputer controlNumerical controlHidden markov chain model

The invention provides an analysis method for reliability of numerical control equipment based on a hidden Markov chain. The method particularly comprises the following steps: 1, monitoring dynamic peThe invention provides an analysis method for reliability of numerical control equipment based on a hidden Markov chain. The method particularly comprises the following steps: 1, monitoring dynamic performance signals of the numerical control equipment, and abstracting the performance characteristic parameter values showing the change of the reliability of the numerical control equipment; 2, constrformance signals of the numerical control equipment, and abstracting the performance characteristic parameter values showing the change of the reliability of the numerical control equipment; 2, constructing a predictive model of the performance characteristic parameter values; 3, using the predictive model to predict the performance characteristic parameter values within the time needed for vectoructing a predictive model of the performance characteristic parameter values; 3, using the predictive model to predict the performance characteristic parameter values within the time needed for vectorization, and adopting the source coding method to vectorize the predictive values of the performance characteristic parameter values; 4, adopting the discrete hidden Markov chain model to identify thrization, and adopting the source coding method to vectorize the predictive values of the performance characteristic parameter values; 4, adopting the discrete hidden Markov chain model to identify the state transition probability of the numerical control equipment; and 5, utilizing the Chapman-Kolmogorov differential equation to establish a relational expression of the operational state and the se state transition probability of the numerical control equipment; and 5, utilizing the Chapman-Kolmogorov differential equation to establish a relational expression of the operational state and the state transition probability so as to deduce the probability of the numerical control equipment in different operating states, namely obtaining the reliability of the numerical control equipment. The mtate transition probability so as to deduce the probability of the numerical control equipment in different operating states, namely obtaining the reliability of the numerical control equipment. The method can accurately analyze, evaluate and predict the change of the reliability of the numerical control equipment before the numerical control equipment goes wrong, thereby avoiding the fault of theethod can accurately analyze, evaluate and predict the change of the reliability of the numerical control equipment before the numerical control equipment goes wrong, thereby avoiding the fault of the numerical control equipment and improving the operational reliability of the numerical control equipment.numerical control equipment and improving the operational reliability of the numerical control equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com