Solvent de-asphalting with cyclonic separation

A solvent and asphaltene technology, which is applied in the field of solvent deasphalting with cyclone separation, can solve the problems of reducing the value of solid asphaltenes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0160] The following detailed description, given in conjunction with the accompanying drawings, is intended to illustrate various embodiments of the invention and is not intended to represent all embodiments contemplated by the inventors. The detailed description includes specific details for the purpose of providing a thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without these specific details.

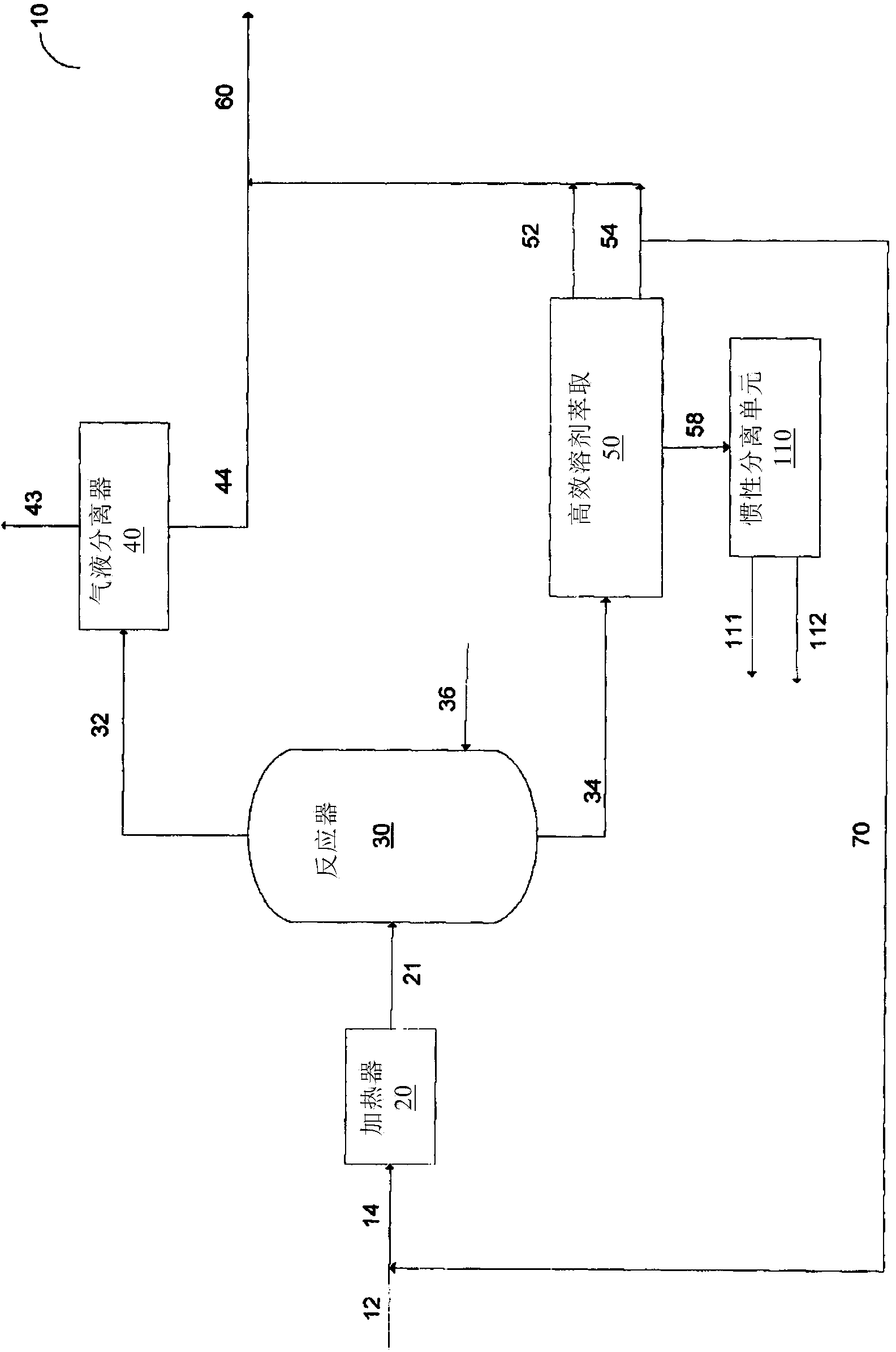

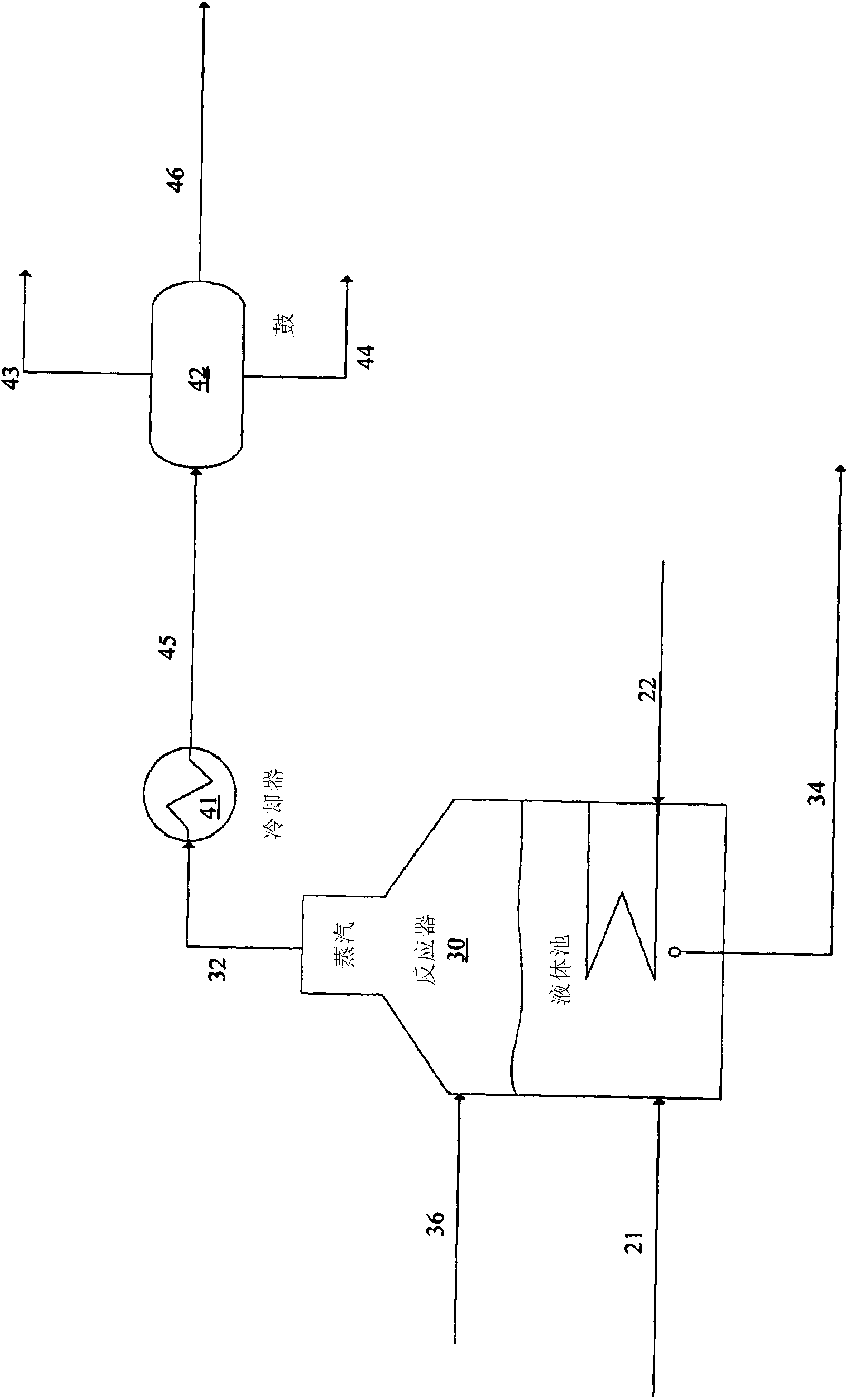

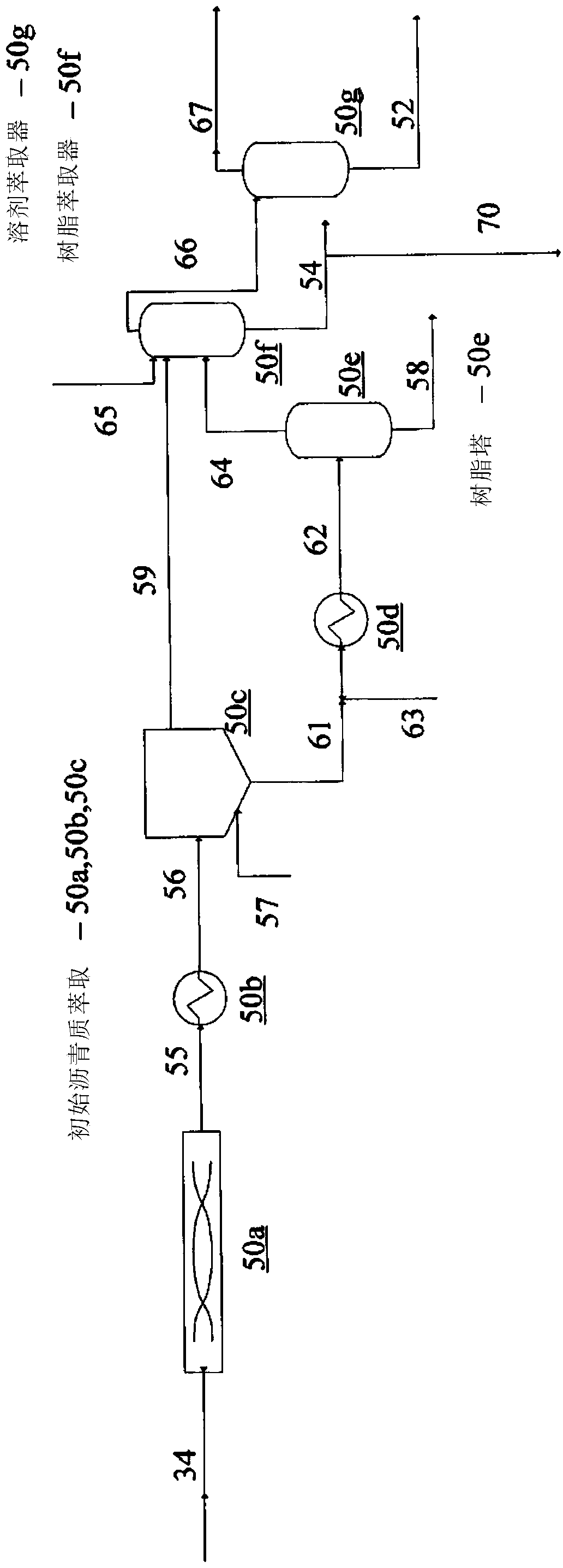

[0161] figure 1 is a process flow diagram illustrating a process 10 for forming a hydrocarbon product 60 from a hydrocarbon feedstock 12 in which the final hydrocarbon product 60 has properties sufficient to meet minimum pipeline transportation requirements (minimum API gravity of 19), which is compelling Satisfied Refinery Feedstock. Process fluid 14 formed from heavy hydrocarbon feedstock 12 may be heated to a desired temperature level via heater 20 prior to entering reactor 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com