based on tm 01 Method for generating vortex laser by mode light conversion and vortex laser

A laser and optical conversion technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of fixed output mode, complex manufacturing process, low production efficiency, etc., achieve low operational reliability, simple structural design, Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

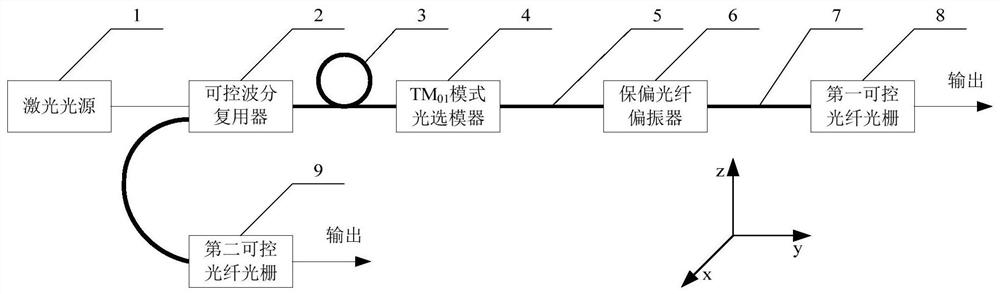

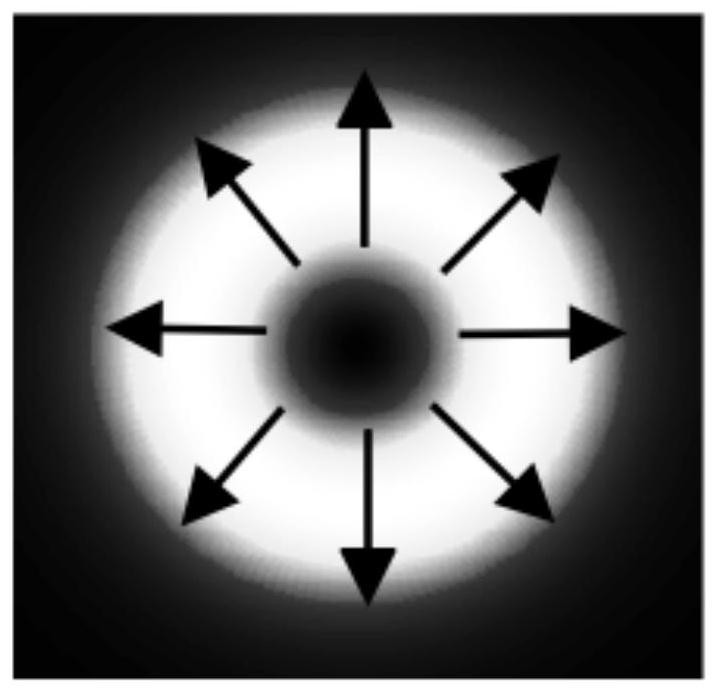

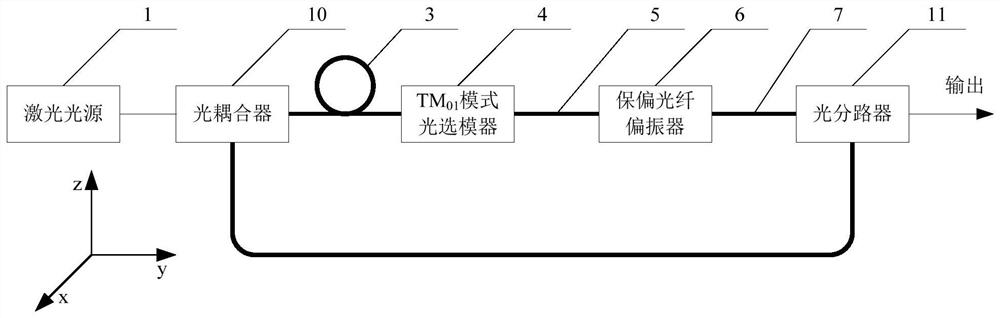

[0029] The present invention provides a method based on TM 01 Swirl pattern converted laser light generating method using a laser emitted by the laser light source low-doped gain fiber molding produced TM 01 Mode light, then using TM 01 After the optical axis perpendicular to the mode TM 01 λ mode light incident direction / 4-wave plate converts the optical fiber forming the optical vortex, the vortex is formed by the laser output and then vortex optical resonator. Thus, the present invention provides a new solution to produce a swirl of laser light.

[0030] Based on the above vortex generating laser, the present invention also provides a laser scroll design following.

[0031] As based TM 01 The scroll mode laser light design conversion, as figure 1 Shown, which comprises a laser light source 1, a controllable wavelength division multiplexer 2, less die-doped gain fiber 3, TM 01 Mode optical mode selection device 4, λ / 4 optical wave plate 5, 6 of optical fiber polarization, po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com