Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Reduce refrigerant consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

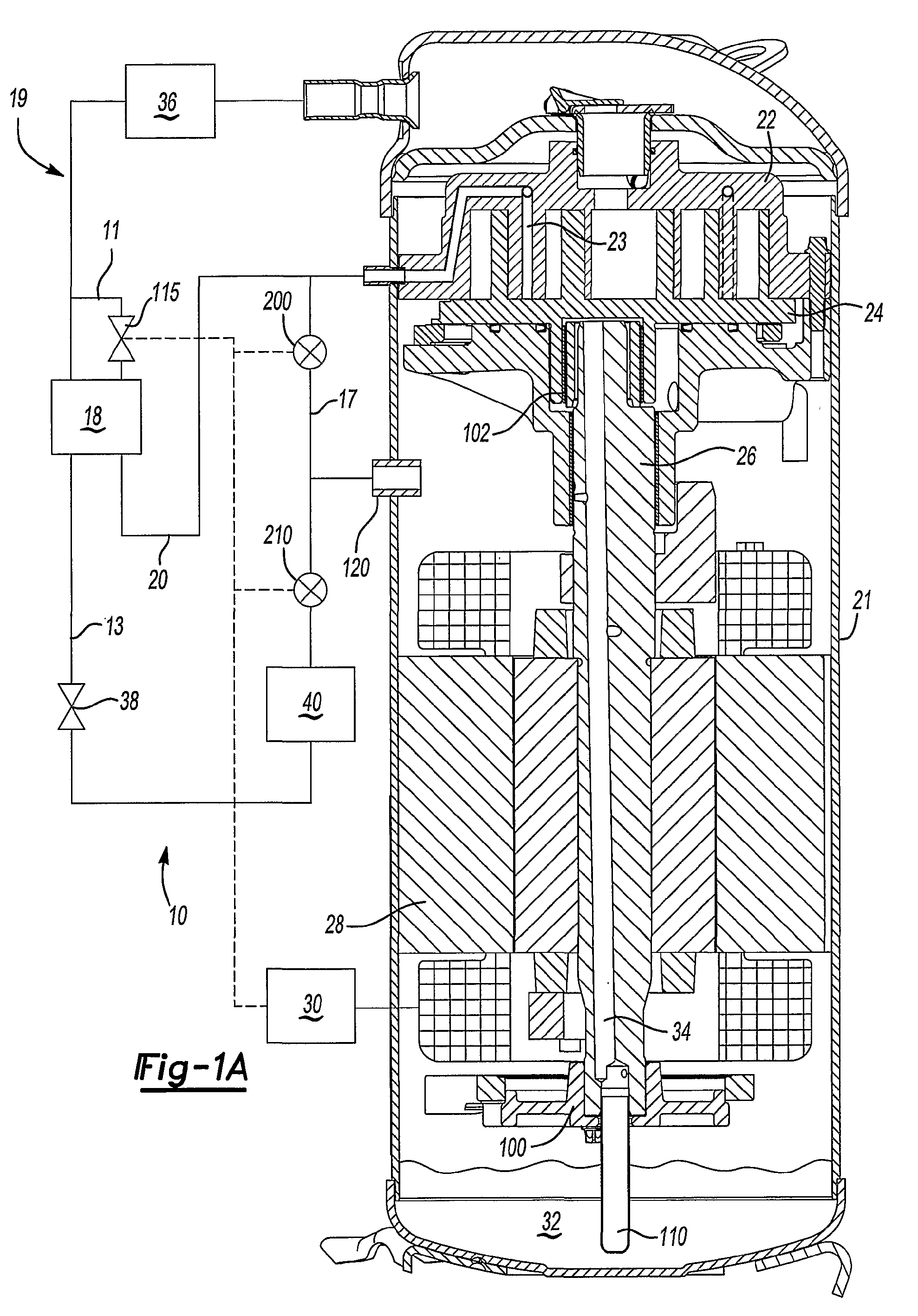

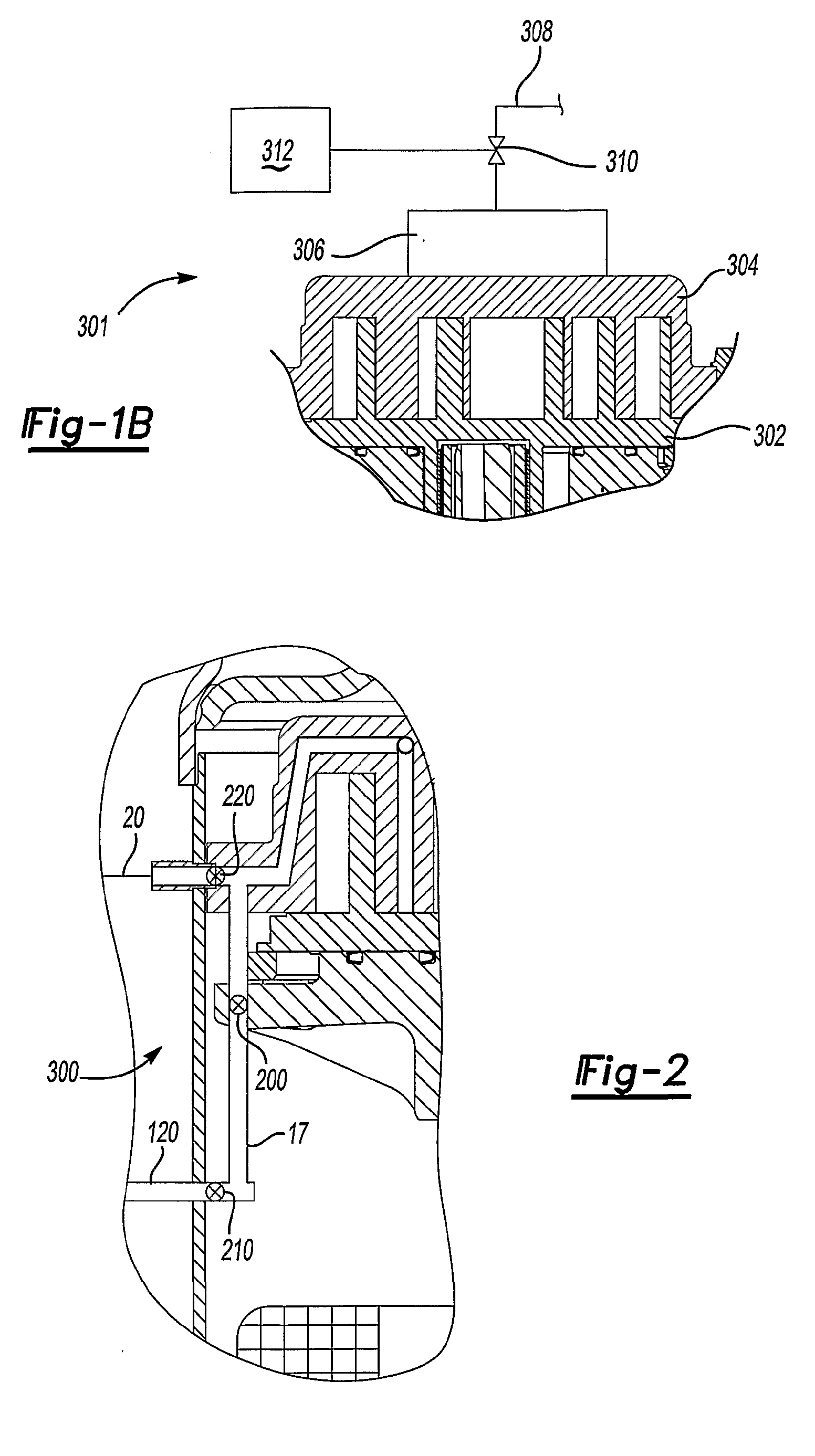

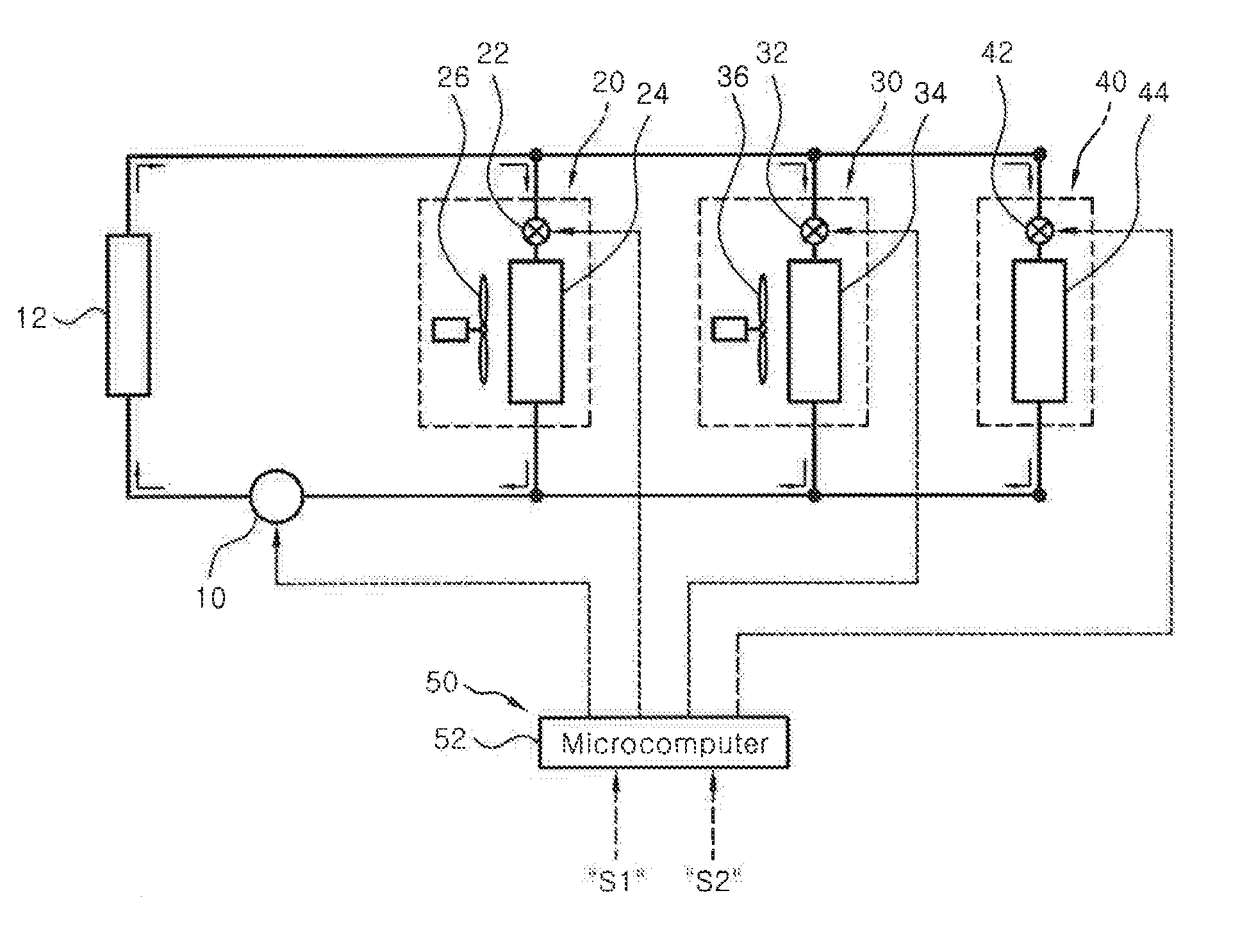

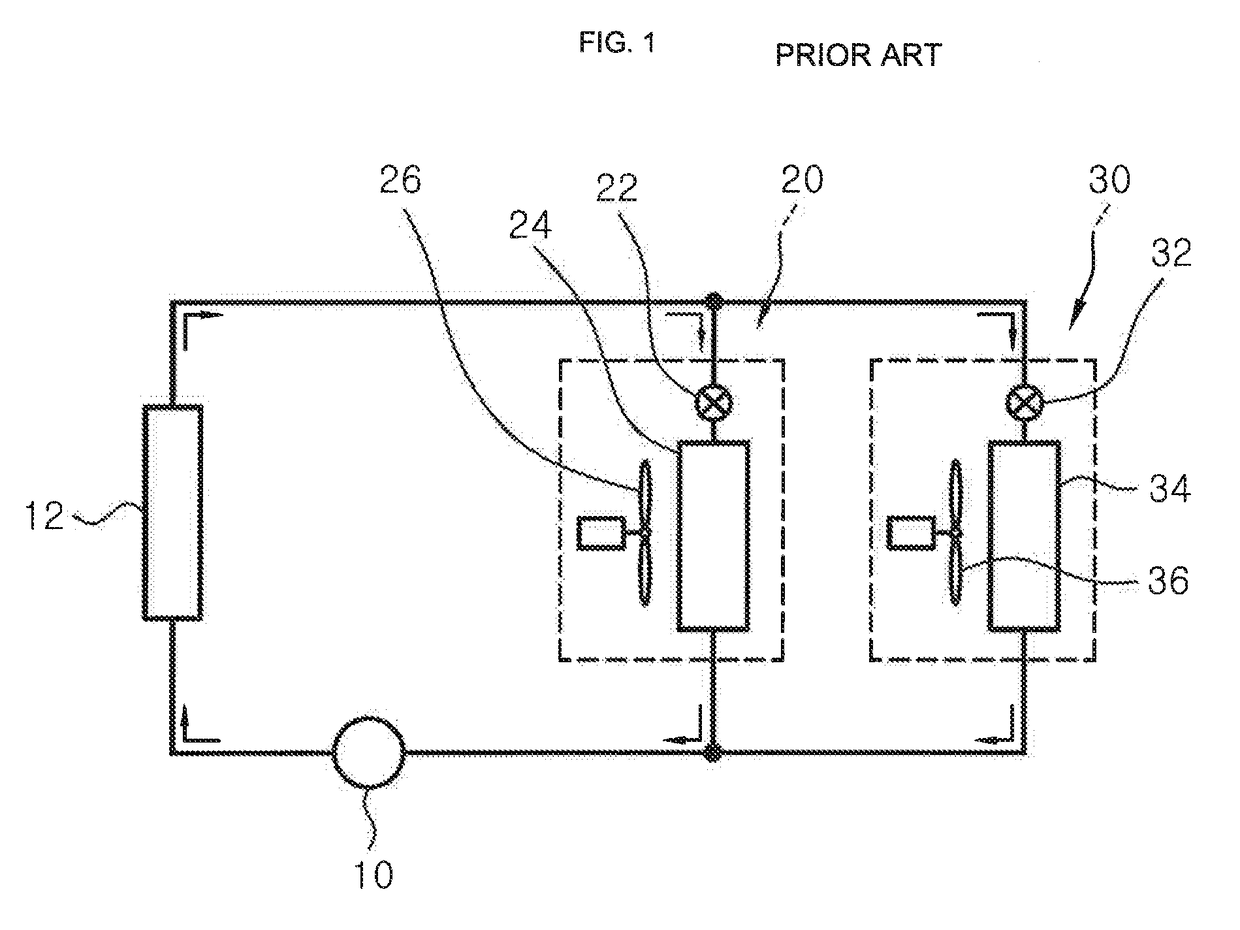

Refrigerant System with Pulse Width Modulated Components and Variable Speed Compressor

InactiveUS20080223057A1Reduce refrigerant consumptionReduce capacityCompression machines with non-reversible cycleEfficient regulation technologiesLow speedLow load

A variable speed drive is provided for operating a compressor motor in a refrigerant system. When a low load situation has been determined by the refrigerant system controls, the variable speed drive operates the compressor motor at lower speed mode of operation. Further, the operation of the variable speed drive is combined with a pulse width modulation control of different system components. In particular, at least one valve or compressor can be can be rapidly cycled by the control to regulate amount of refrigerant passing through the valve or compressor. Example valves would include a shut-off valve for an economizer cycle, an unloader valve, or a suction modulation valve.

Owner:CARRIER CORP

Refrigerator

InactiveUS20130186129A1Improve energy efficiencySave energyMechanical apparatusCompression machines with non-reversible cycleEngineeringDistributor

A refrigerator is provided. The refrigerator includes a compressor configured to compresses a refrigerant, a condenser configured to condense the refrigerant compressed by the compressor, a first evaporator and a second evaporator configured to evaporate the refrigerant condensed by the condenser, a distributor configured to distribute the refrigerant condensed by the condenser to at least one of the first evaporator and the second evaporator, a plurality of first refrigerant channels configured to supply the refrigerant distributed from the distributor to the first evaporator, at least one second refrigerant channel configured to supply the refrigerant distributed from the distributor to the second evaporator and a capillary tube disposed in each of the first refrigerant channels and the at least one second refrigerant channel.

Owner:LG ELECTRONICS INC

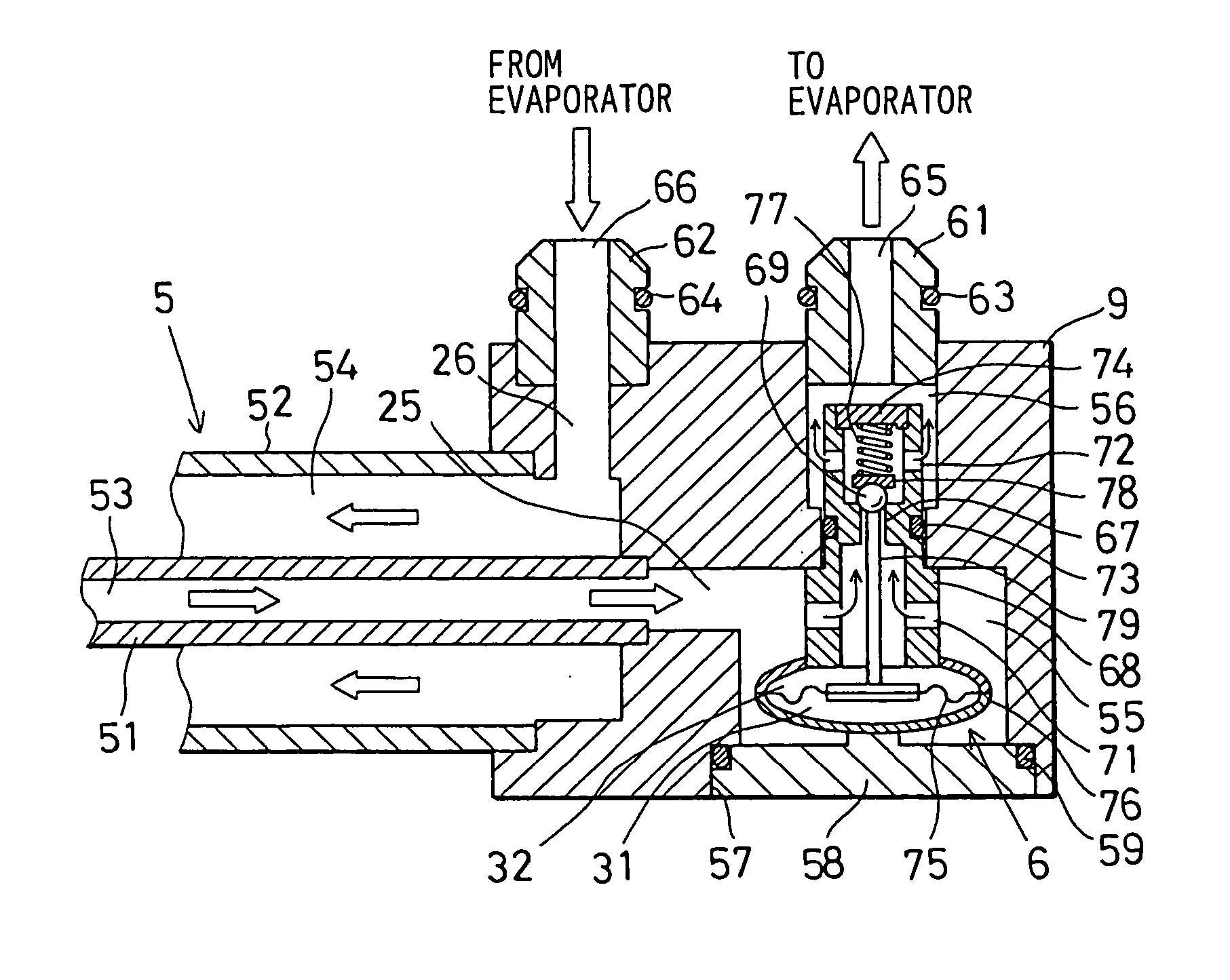

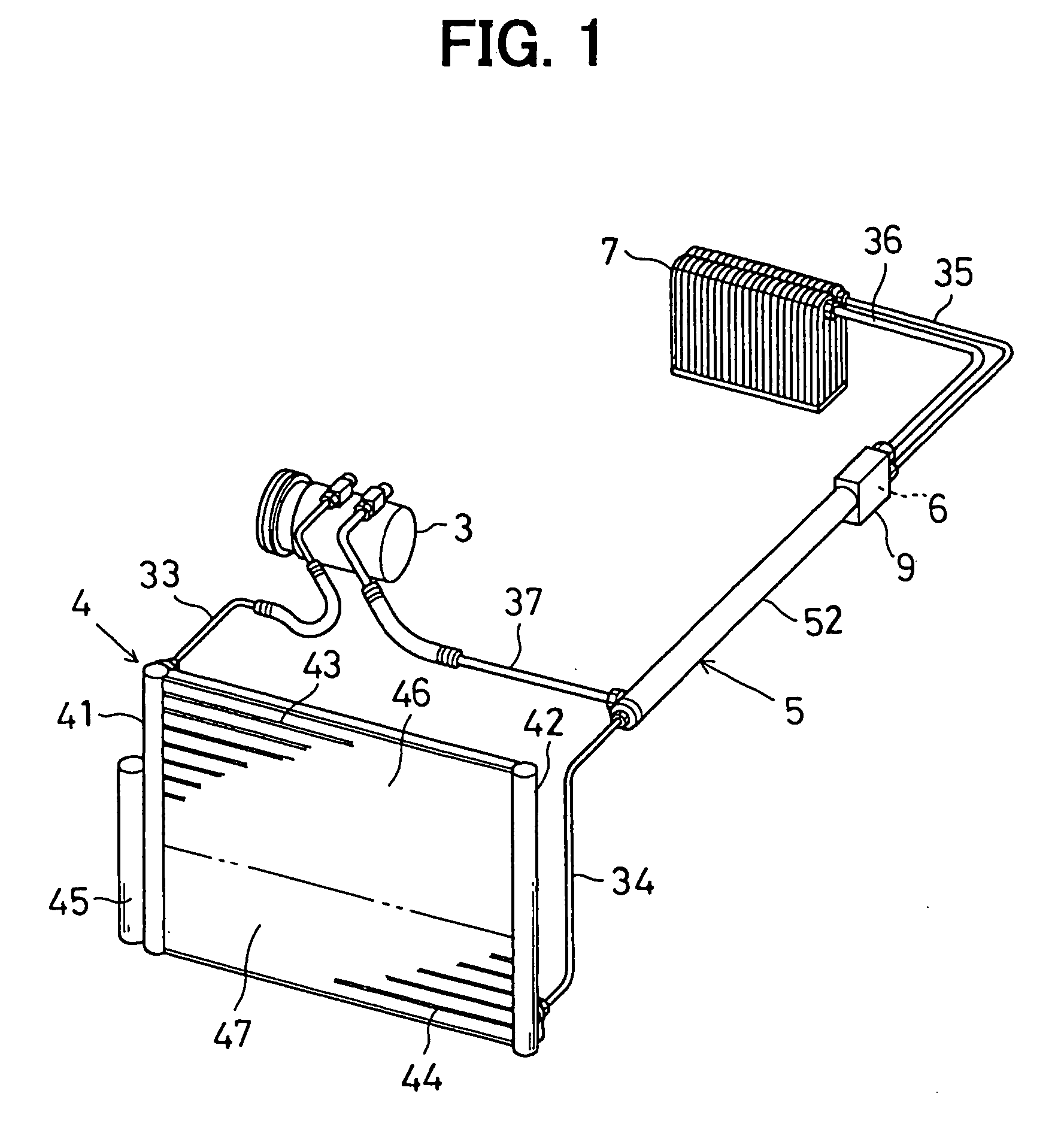

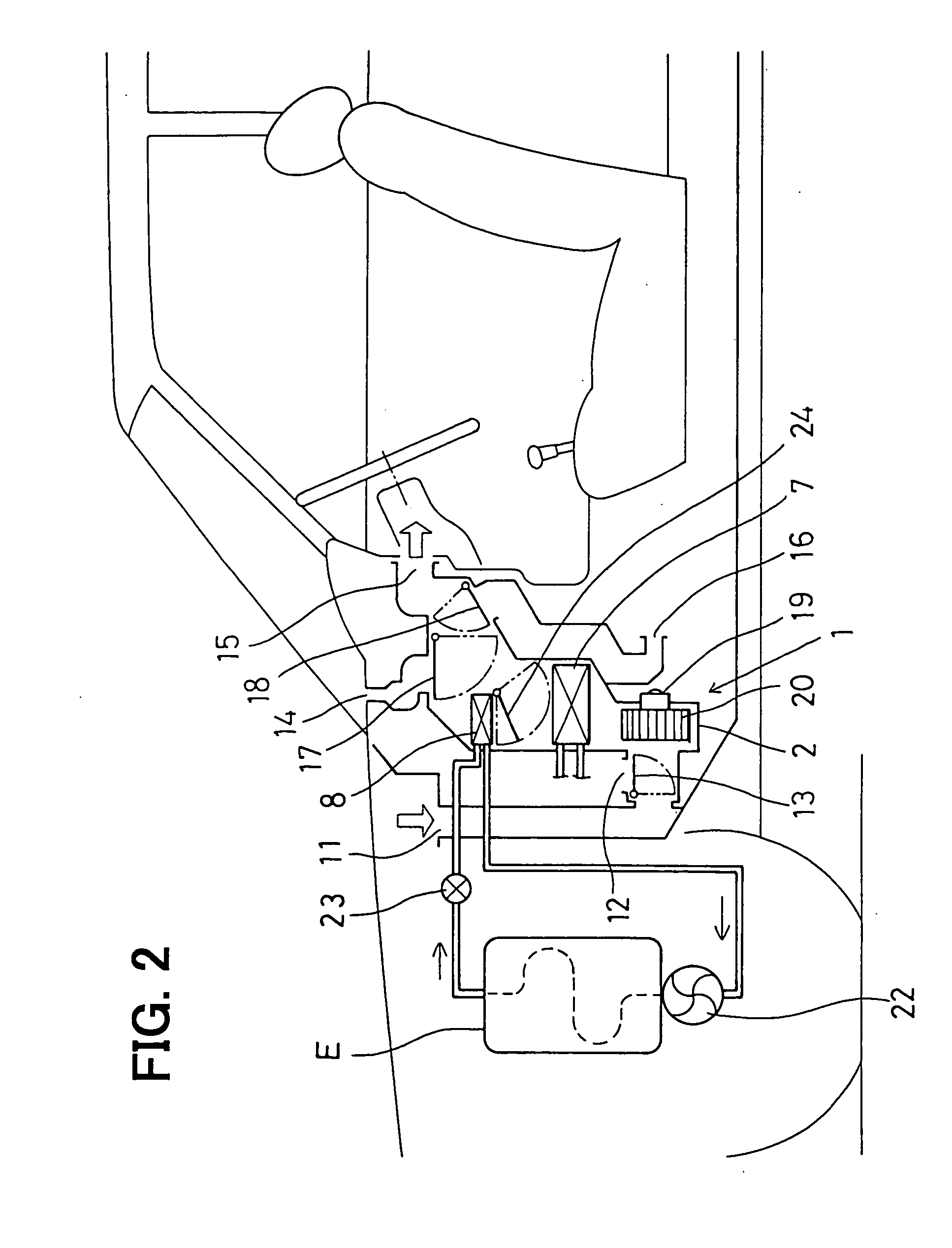

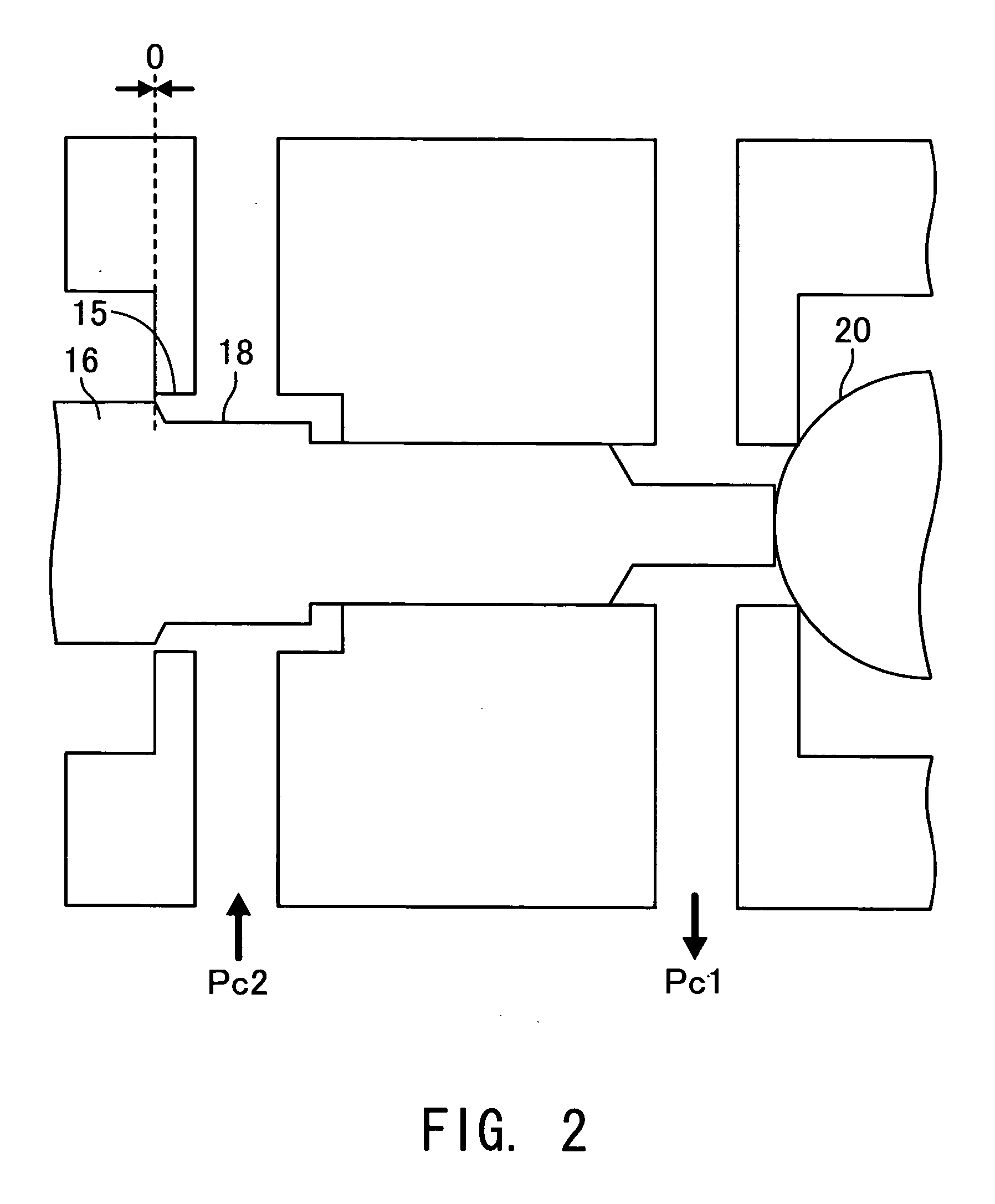

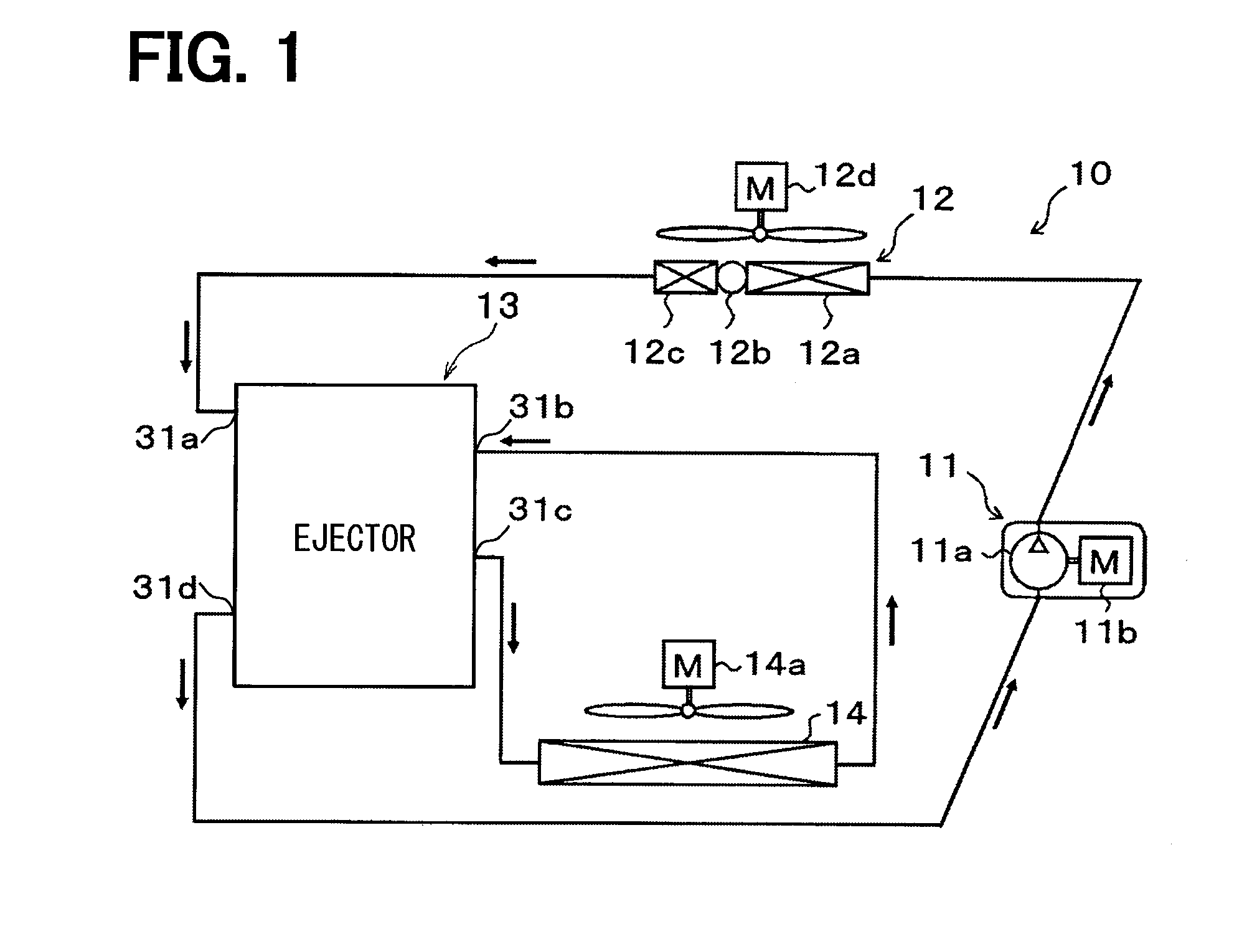

Refrigeration cycle system

InactiveUS20040112073A1Reduce refrigerant consumptionReduce liftMechanical apparatusAir-treating devicesGas phaseEngineering

A refrigeration cycle for a vehicle air conditioning system allows the refrigerant-to-refrigerant heat exchanger to exchange heat between a high-pressure liquid refrigerant, which is delivered from the sub-cooling condenser and directed to the evaporator, and a low-pressure refrigerant having a liquid and gas phase, which is delivered from the evaporator and directed to the compressor. The refrigeration cycle also allows the amount of the refrigerant circulating through the refrigeration cycle to be adjusted in response to the level of sub-cooling upstream of a throttle hole of a reverse sub-cooling control valve to thereby indirectly control the level of superheating on the outlet side of the evaporator. This provides improvements both in the amount of heat to be exchanged between refrigerants in the refrigerant-to-refrigerant heat exchanger and the cooling performance of the evaporator.

Owner:DENSO CORP

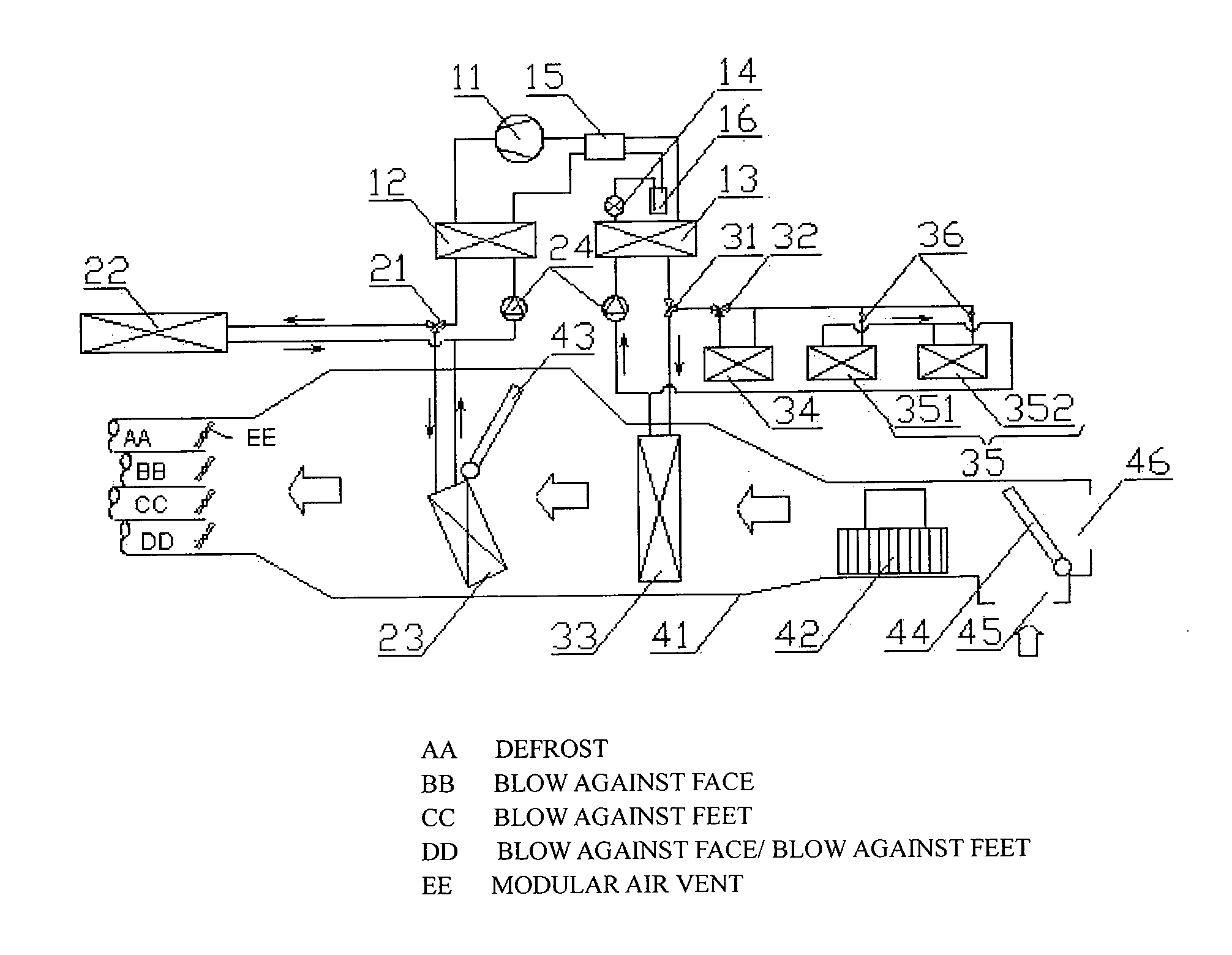

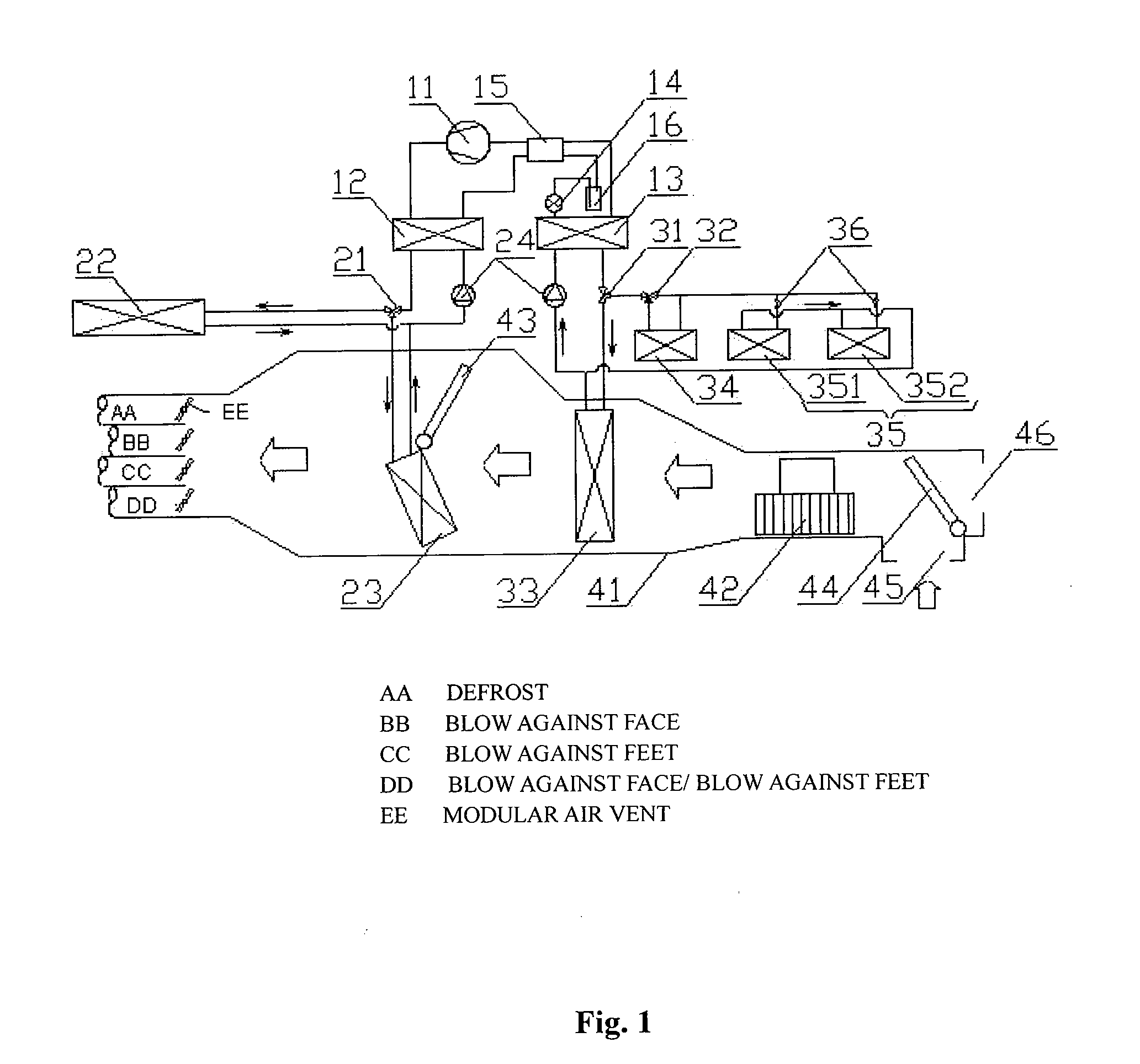

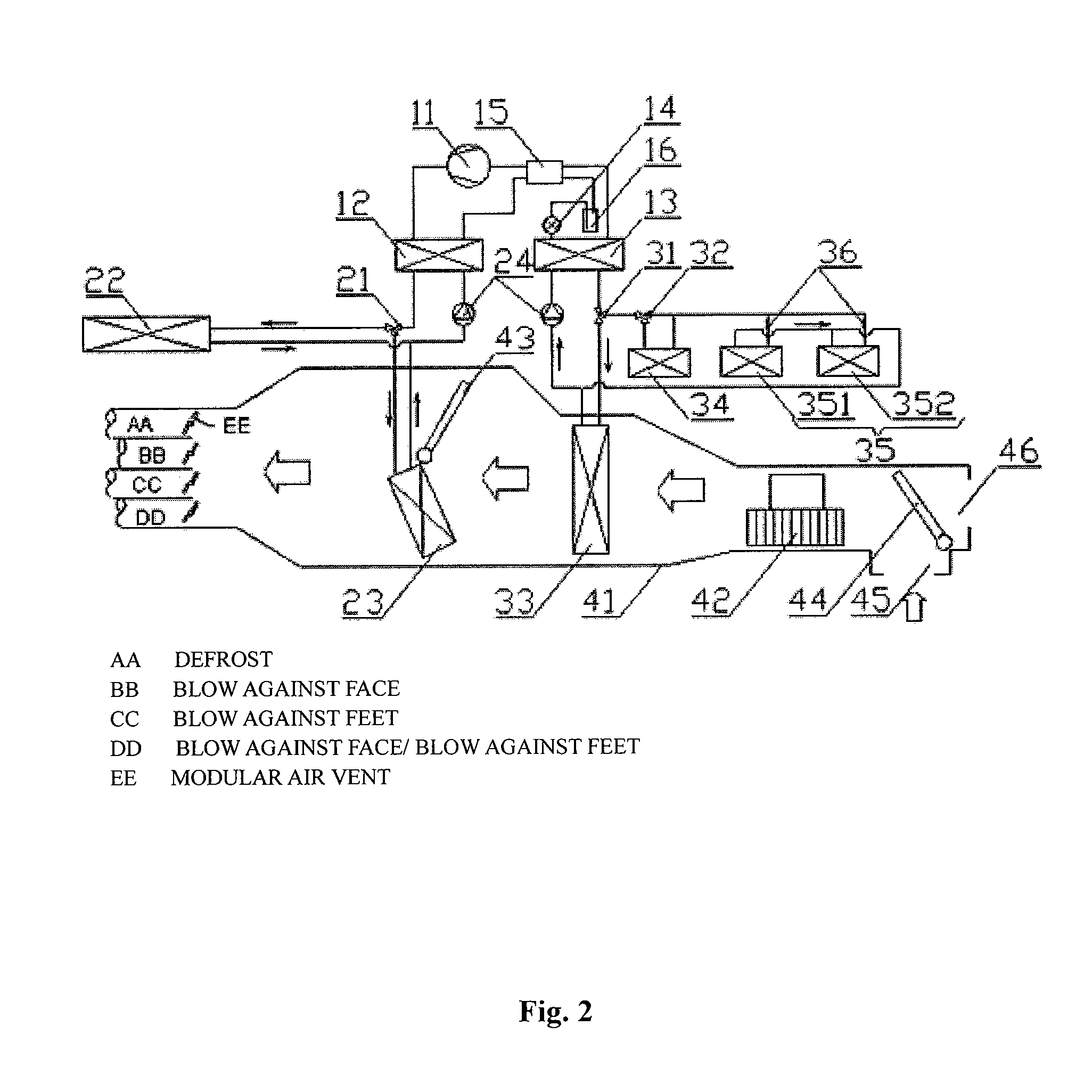

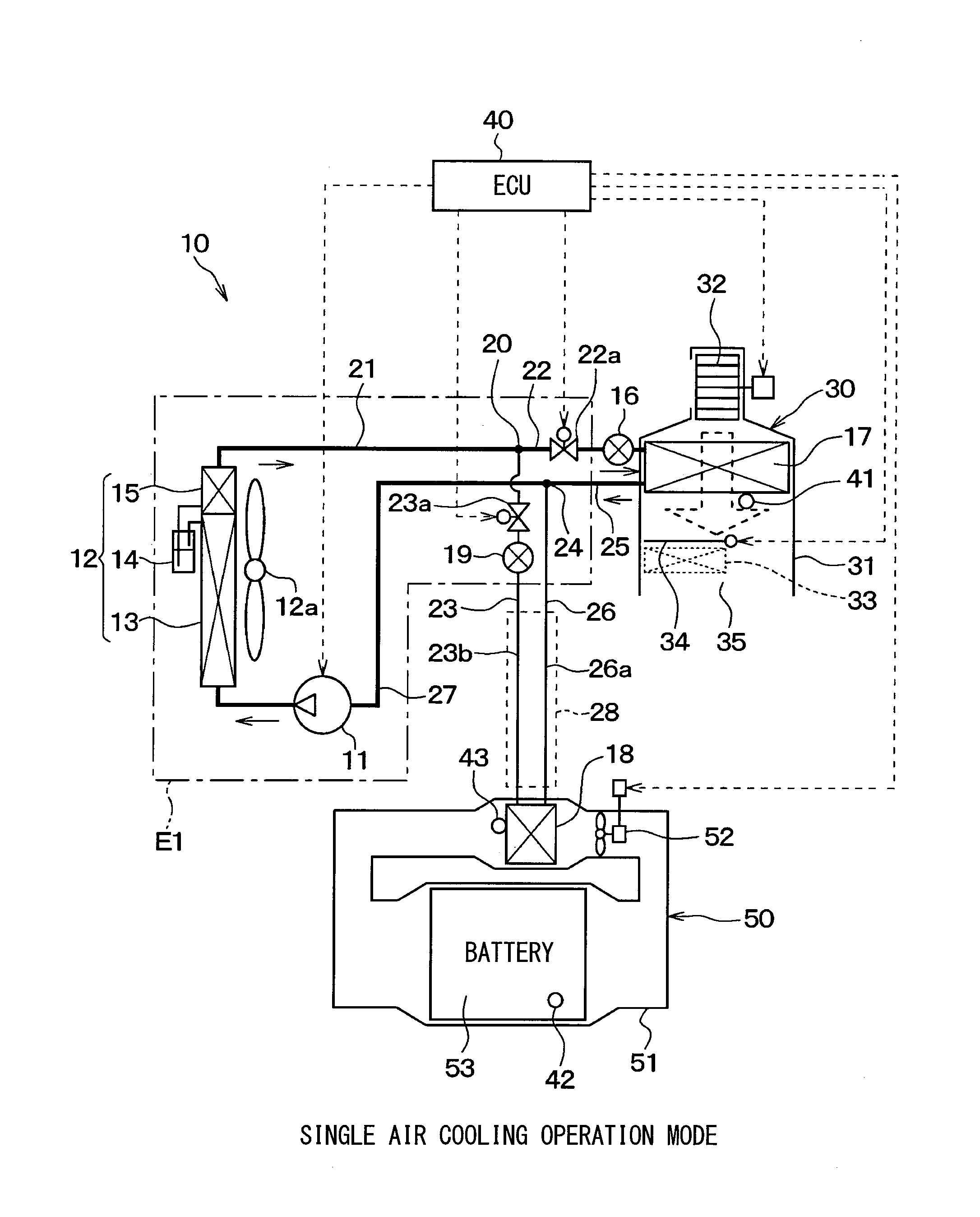

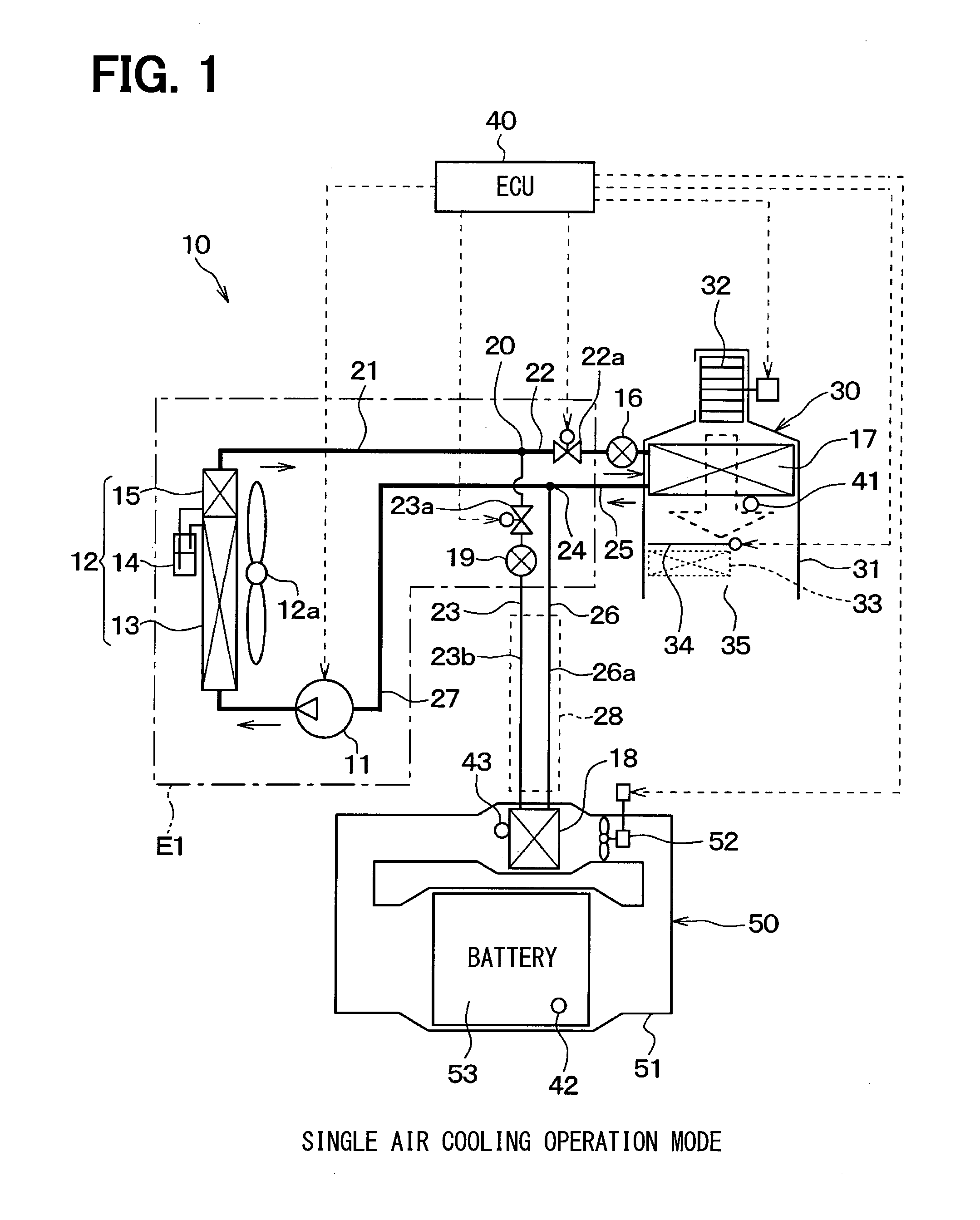

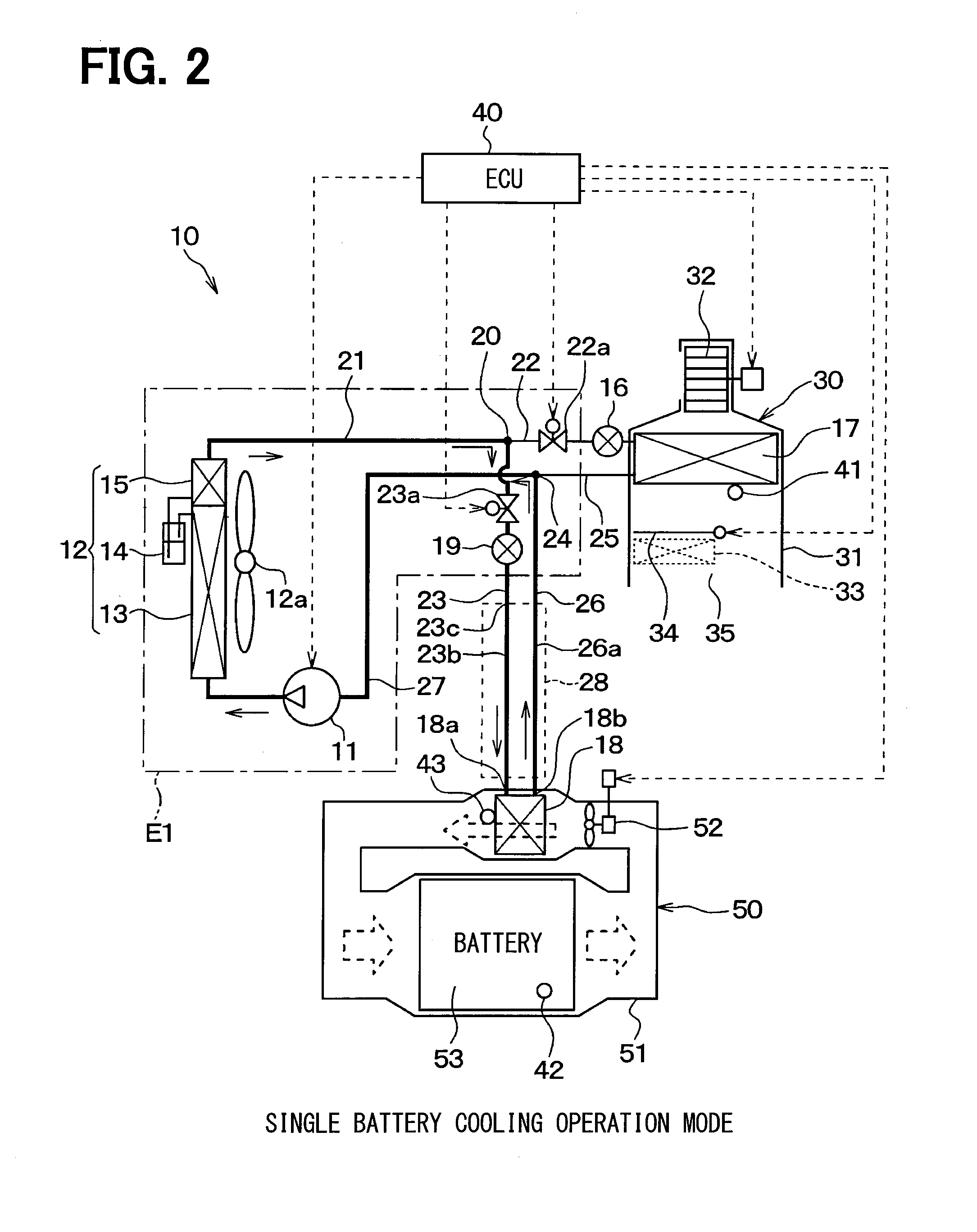

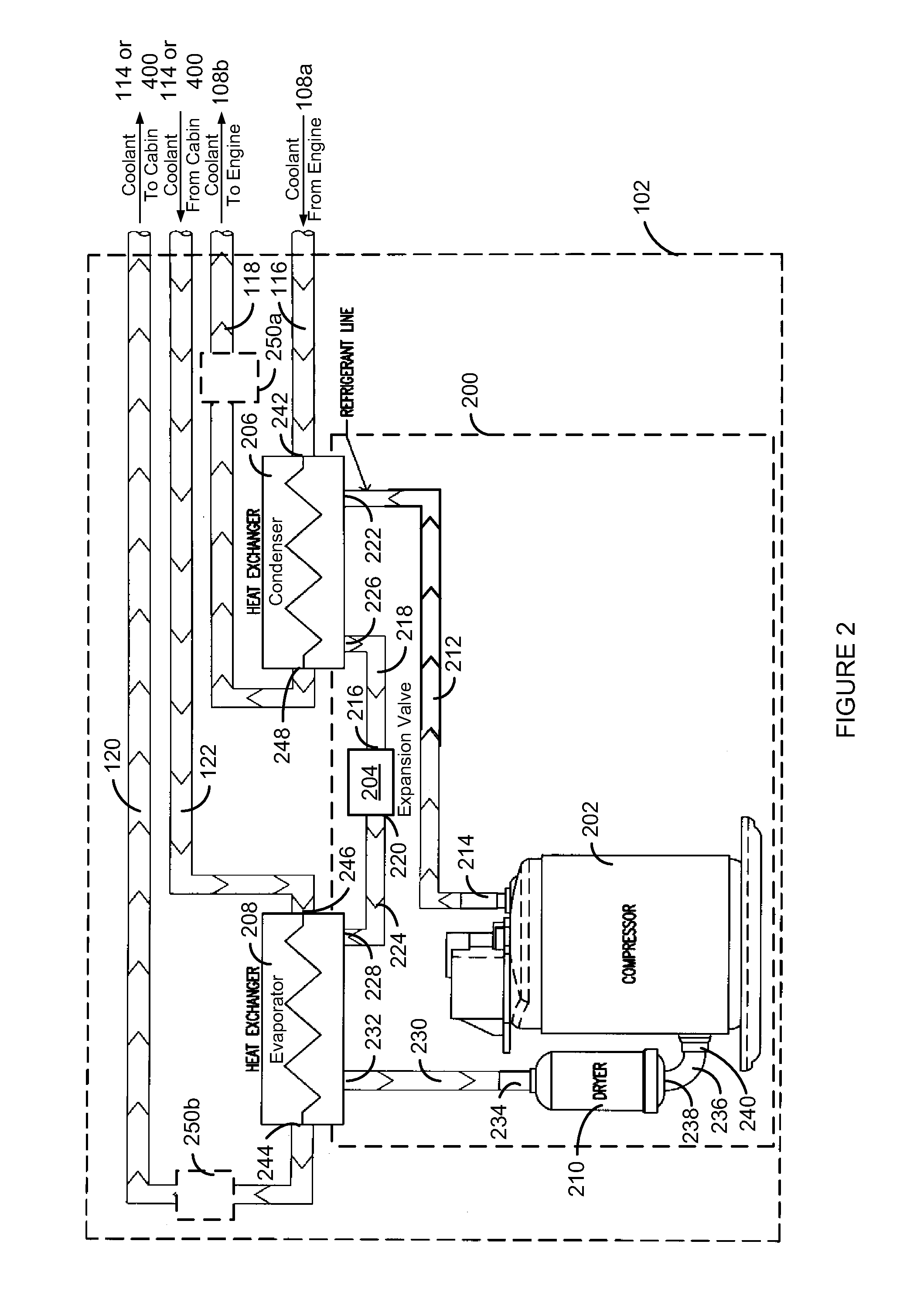

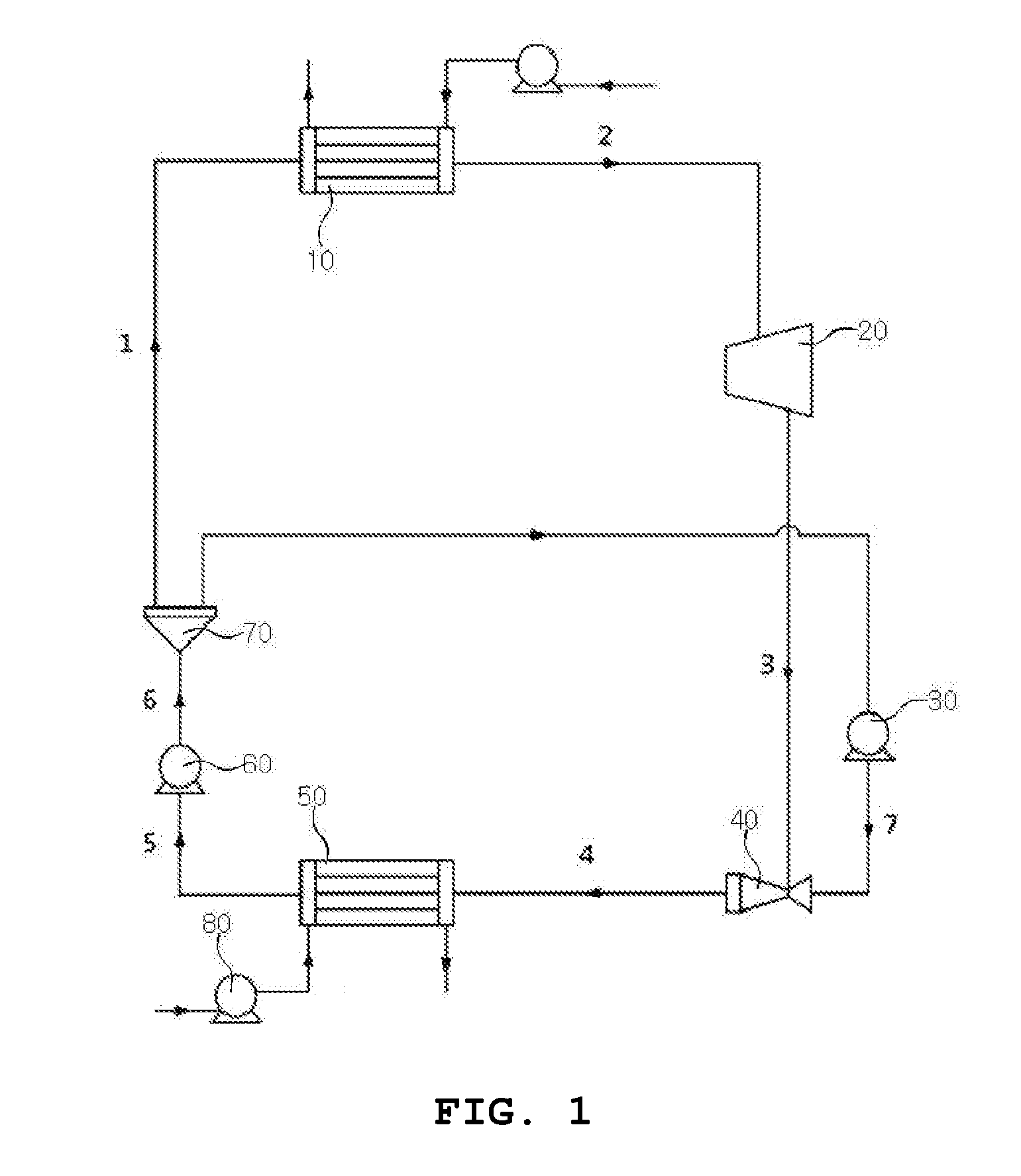

Electric Vehicle and Thermal Management System Therefor

ActiveUS20130206360A1Reduce wasteGood effectAir-treating devicesRailway heating/coolingCooling effectThermal management system

An electric vehicle and a thermal management system are provided, a cooling device thereof comprises a condenser (12), a throttling element (14) and an evaporator (13); a heat exchange device thereof comprises a first air cooled heat exchanger (22) and a heater (23); a heat recovery cooling device thereof comprises a heat emission component heat exchanger (35), a second air cooled heat exchanger (34) and a cooler (33); a passenger compartment temperature regulating device thereof comprises the heater (23) and a cooler (33). The first air cooled heat exchanger (22) and the heater (23) are in communication with the condenser (12) through a first flow regulating valve (21). The cooler (33) and the heat emission component heat exchanger (35) are in communication with the evaporator (13) through a second flow regulating valve (31). The second air cooled heat exchanger (34) is selectively connected in series to the heat emission component heat exchanger (35). The thermal management system ensures full utilization of heat, improves the cooling effect and the comfort level of the passenger compartment, reduces the amount of the charged coolant, and prevents the coolant from entering the passenger compartment.

Owner:HANGZHOU SANHUA RES INST CO LTD

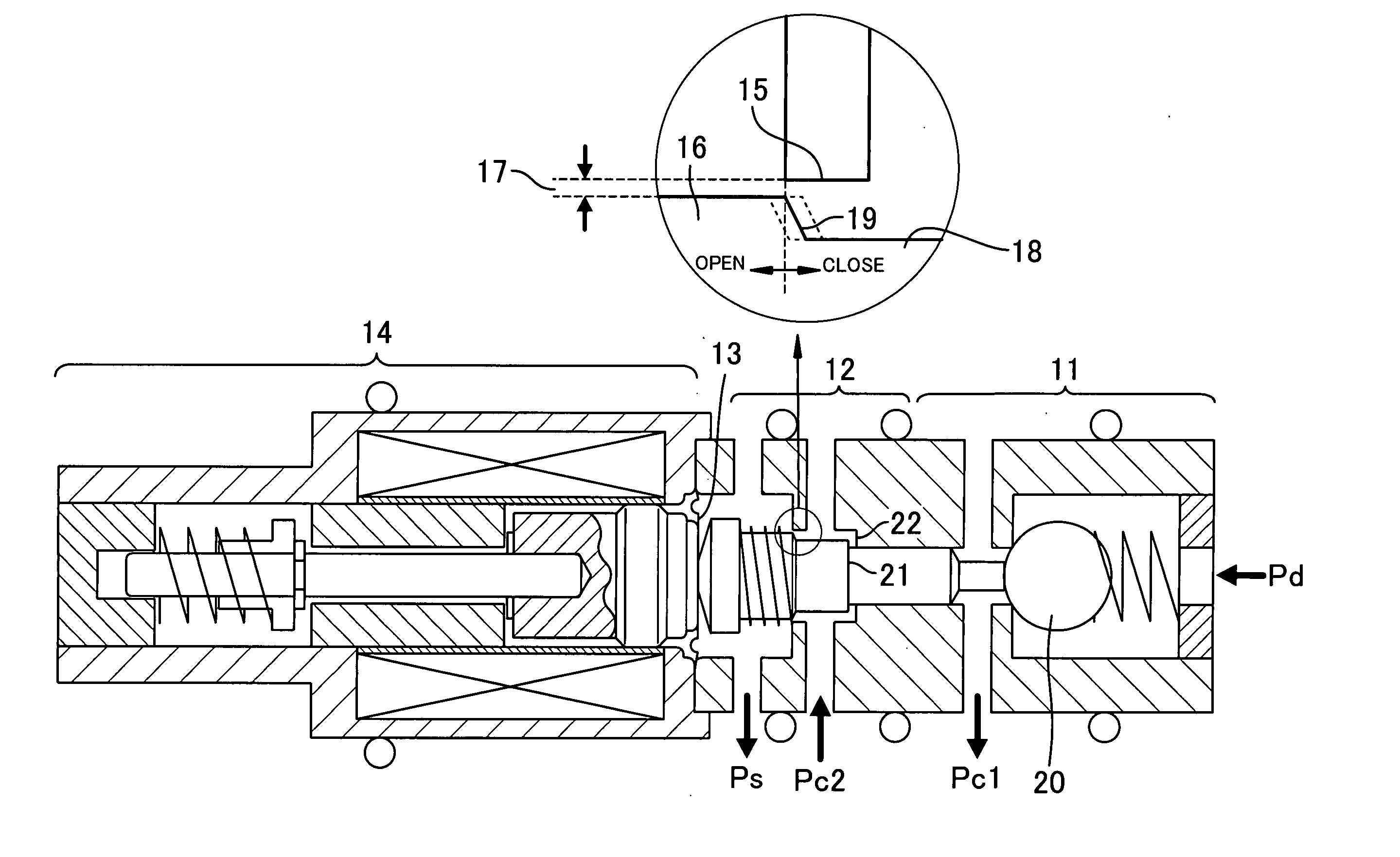

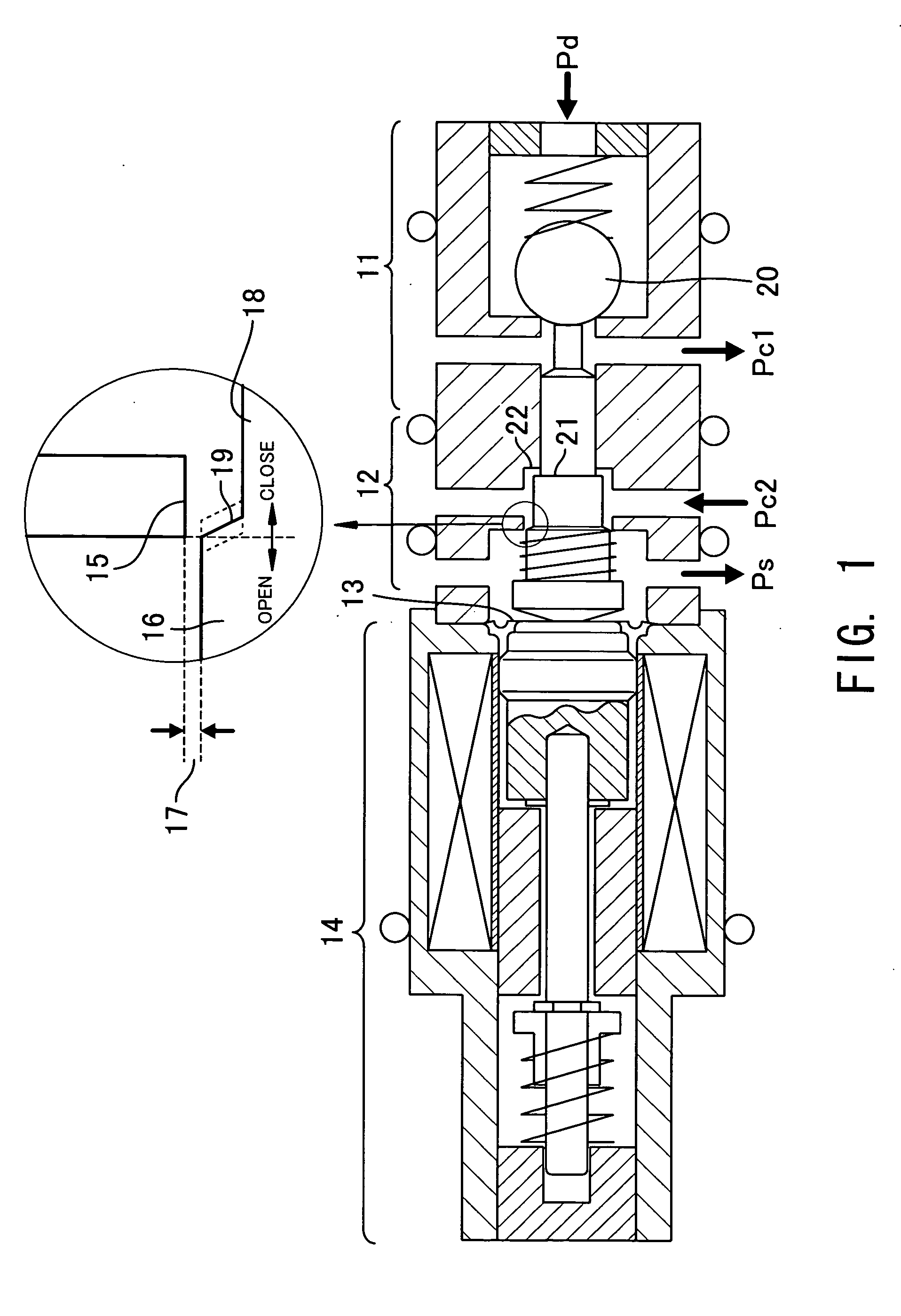

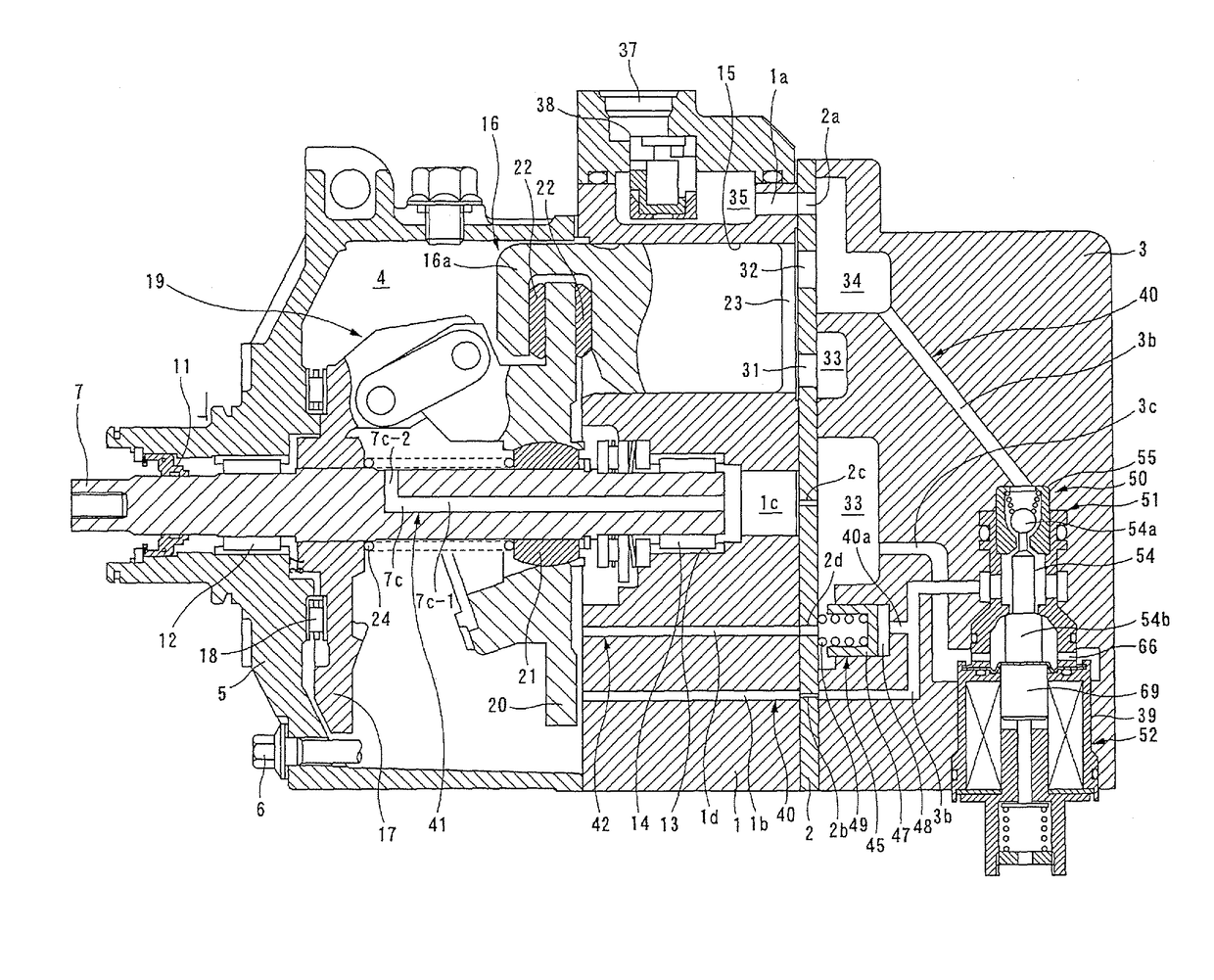

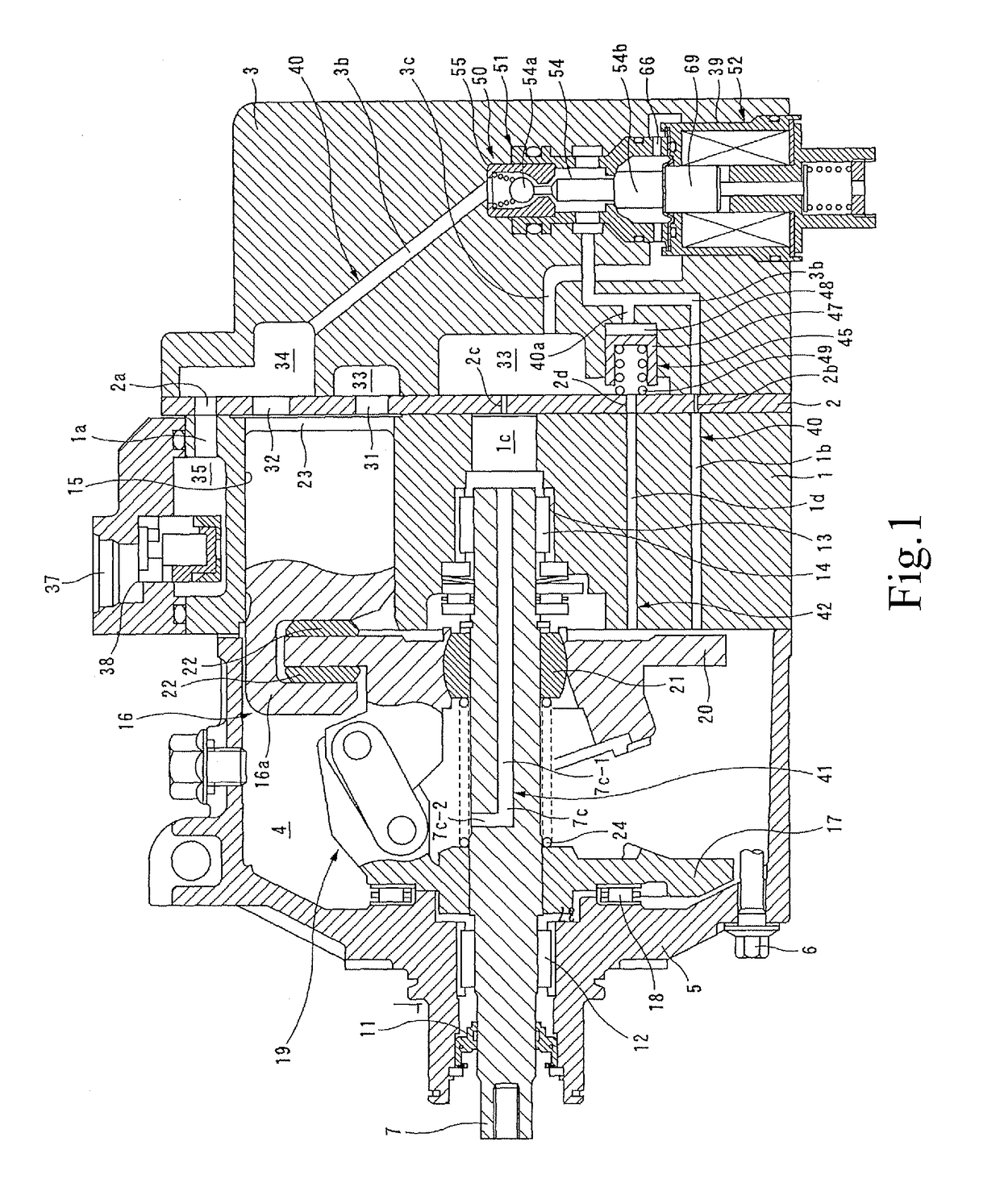

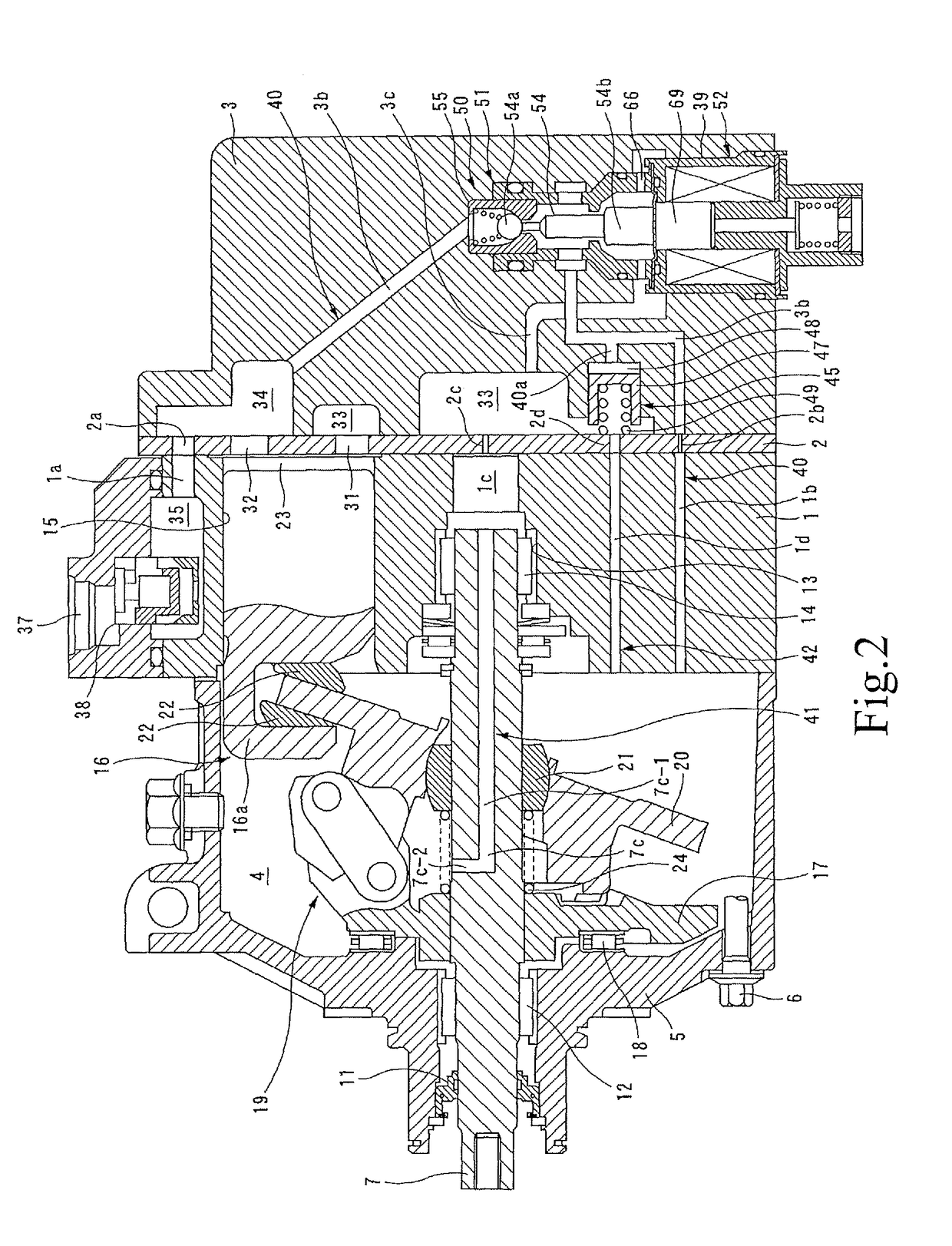

Control valve for variable displacement compressor

InactiveUS20050254961A1Reduce refrigerant consumptionImprove compression efficiencyPump controlMulti-stage pumpsSpool valveCrankcase

In order to reduce the amount of refrigerant circulating within a variable displacement compressor to thereby improve compression efficiency, a control valve is configured to comprise a ball valve for controlling the flow rate of refrigerant flowing from a discharge chamber to a crankcase, a spool valve for controlling the flow rate of refrigerant flowing from the crankcase to a suction chamber, a diaphragm for sensing suction pressure, and a solenoid for setting the suction pressure, wherein the spool valve starts flow rate control after the ball valve is fully closed or nearly fully closed, and the ball valve starts flow rate control after the valve lift of the spool valve is minimized or nearly minimized. As a result, a region is almost eliminated in which the ball valve and the spool valve are both open simultaneously during switching of flow rate control between the ball valve and the spool valve, which makes it possible to minimize the flow rate of the refrigerant circulating within the compressor without contributing to a refrigerating operation, to thereby improve the efficiency of the compressor.

Owner:VALEO SYST THERMIQUES

Heat exchanger

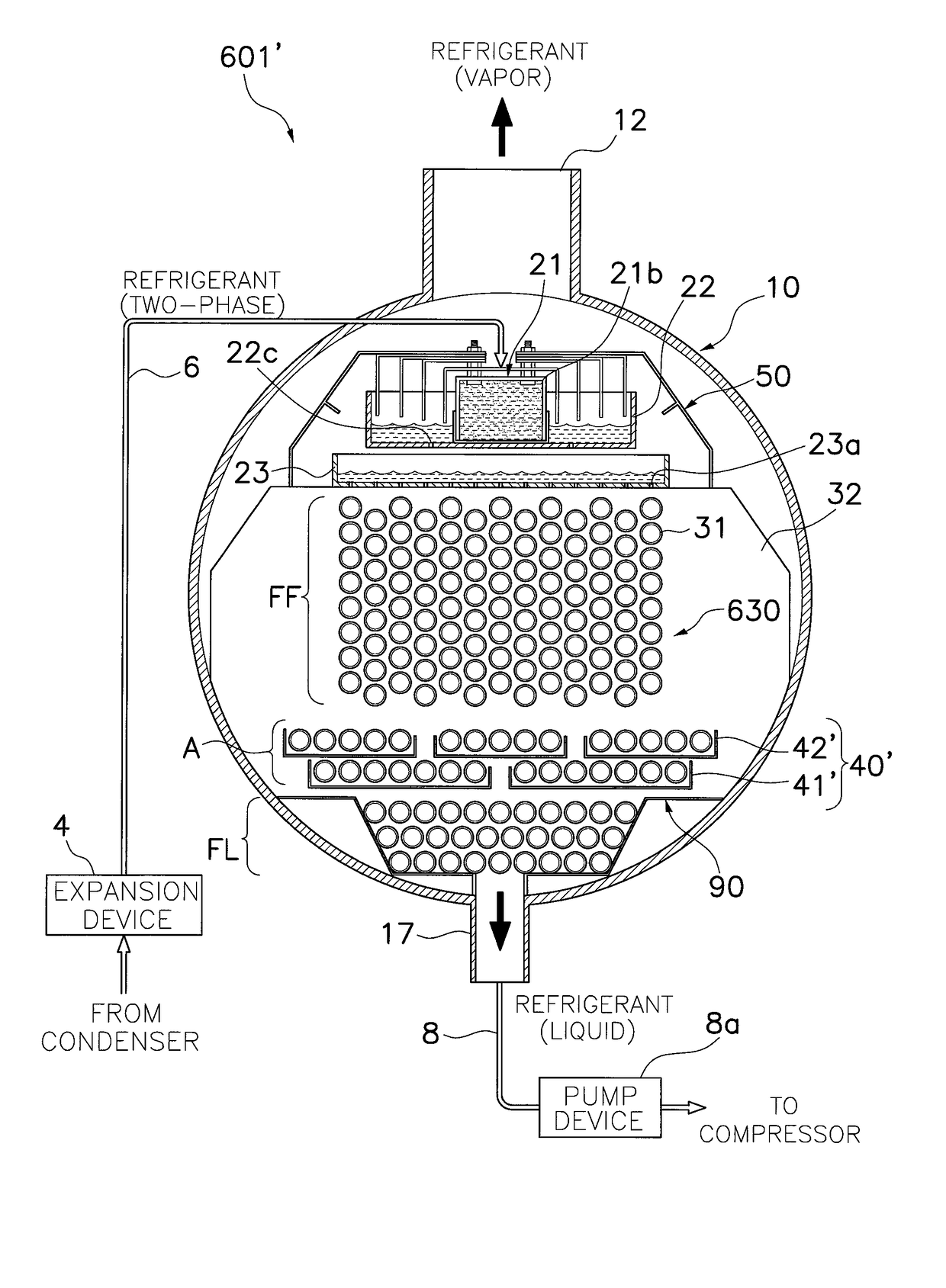

ActiveUS20150053378A1Reduce the amount requiredImprove performanceEvaporators/condensersStationary conduit assembliesEngineeringRefrigerant

A heat exchanger for a vapor compression system includes a shell, a distributing part disposed inside of the shell to distribute a refrigerant, a tube bundle and a trough part. The tube bundle includes a plurality of heat transfer tubes disposed inside of the shell below the distributing part. The tube bundle includes a falling film region disposed below the distributing part, an accumulating region disposed below the falling film region, and a flooded region disposed below the accumulating region at a bottom portion of the shell. The trough part extends under at least one of the heat transfer tubes in the accumulating region to accumulate the refrigerant therein. The trough part at least partially overlaps with the at least one of the heat transfer tubes in the accumulating region when viewed along a horizontal direction perpendicular to the longitudinal center axis of the shell.

Owner:DAIKIN IND LTD

Condenser

InactiveUS20090173102A1Remarkable effectMitigation of impairmentCompression machines with non-reversible cycleEvaporators/condensersEngineeringRefrigerant

A condenser including an inlet header and an outlet header spaced apart from each other and extending vertically, a plurality of flat refrigerant tubes arranged one above another in parallel at a spacing between the two headers and jointed at opposite ends thereof to the respective headers, and fins between respective adjacent pairs of refrigerant tubes. The inlet header admits a refrigerant into interior thereof therethrough, and the outlet header causes the refrigerant to flow out therethrough. The refrigerant admitted into the inlet header flows through the refrigerant tubes toward the outlet header. The number of refrigerant tubes positioned below the center of the refrigerant inlet with respect to the vertical direction is up to 21, preferably up to 16, more preferably up to 7. The condenser can be prevented from becoming impaired in condensation performance when the refrigerant has a compressor lubricant incorporated therein.

Owner:SHOWA DENKO KK

Refrigeration cycle device

InactiveUS20160010898A1Large pressure lossTemperature of refrigerant is highCompression machines with non-reversible cycleCompression machines with several evaporatorsRefrigerationRefrigerant

A first outward passage 22 and a second outward passage 23 are branched from a branch portion 20 to guide refrigerants to a first evaporator 17 and a second evaporator 18, respectively. In the second outward passage 23 with a longer refrigerant flow path of the first and second outward passages 22 and 23, a second decompressor 19 is disposed closer to the branch portion 20 rather than the second evaporator 18 in the second outward passage 23. Further, a part 23b of the second outward passage 23 located on the downstream side of the refrigerant flow with respect to the second decompressor 19 is defined by an inner pipe of a double pipe 28, and a part of a second return passage 26 is defined by an outer pipe of the double pipe 28.

Owner:DENSO CORP

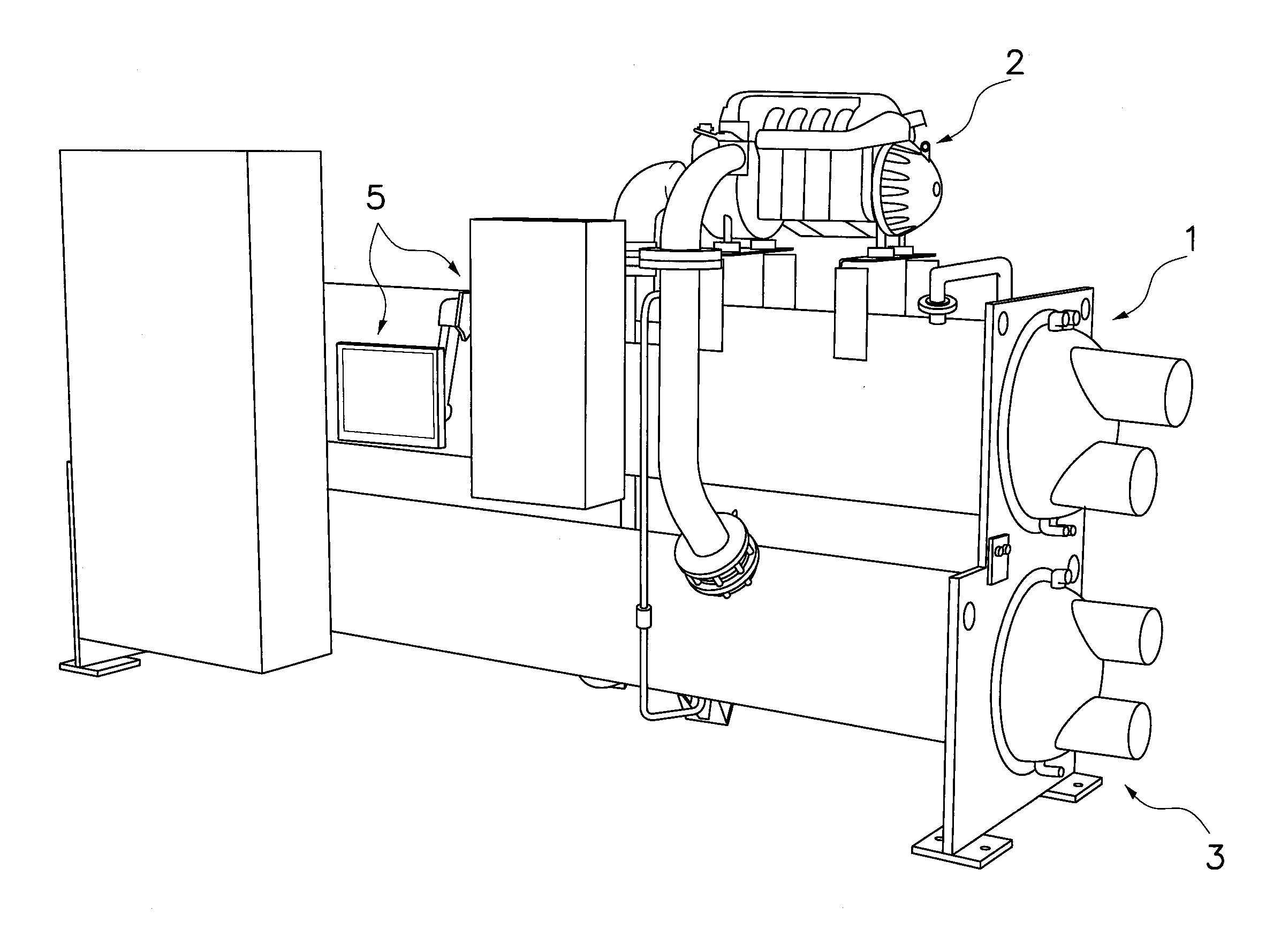

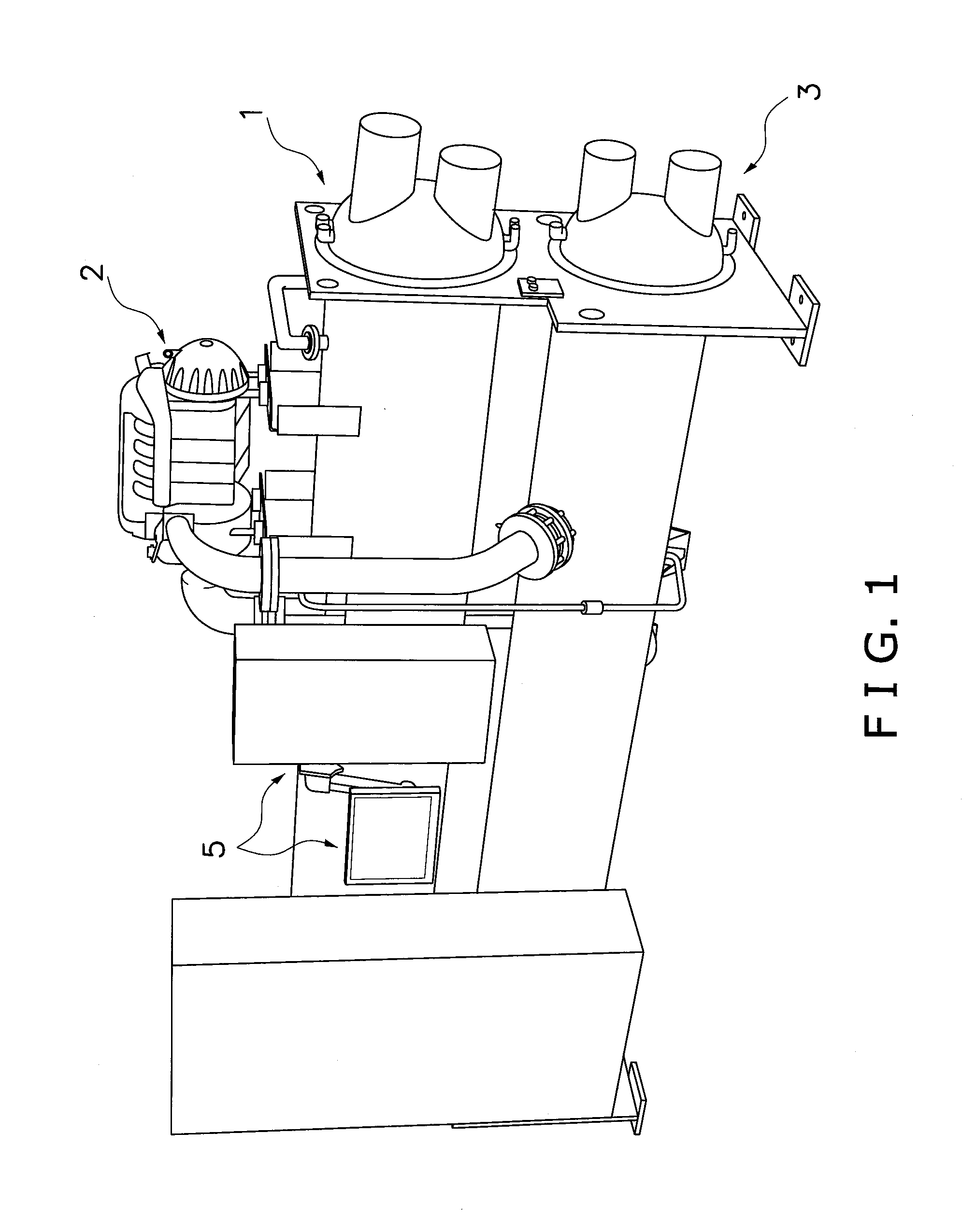

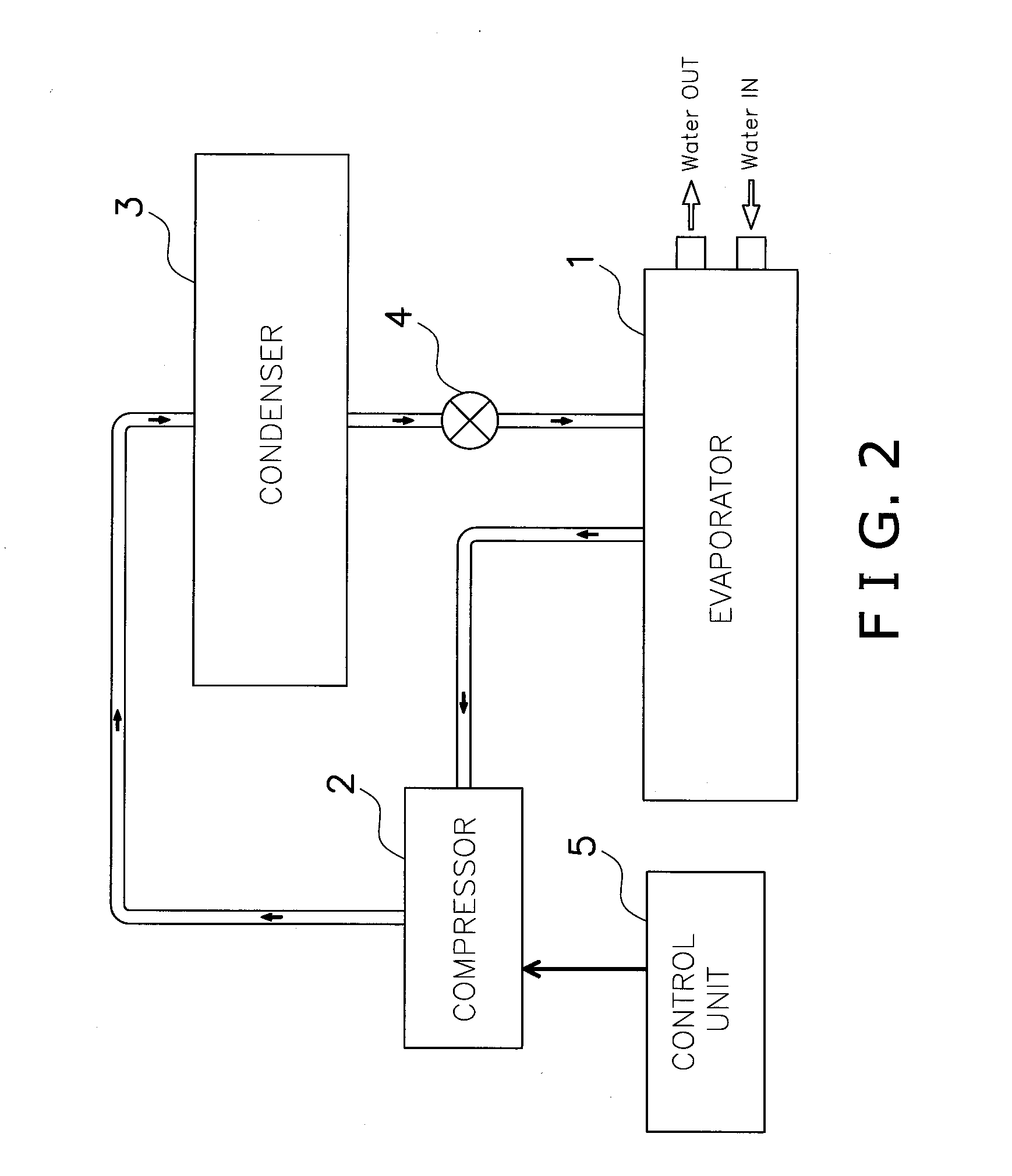

Refrigeration cycle apparatus

InactiveUS6880357B2Increase flow rateEfficient powerDomestic cooling apparatusCompression machines with non-reversible cycleDensity ratioEngineering

Owner:PANASONIC CORP

Diagnosing method for clothes treating apparatus and clothes treating apparatus with refrigerant leakage detecting means

ActiveUS20120079736A1Rapidly and easily detectingReduce refrigerant consumptionSolidificationLiquefactionEngineeringRefrigerant

A clothes treating apparatus includes a drum configured to accommodate therein an object to be dried, an air suction device configured to form a flow path of air introduced into the drum, an air exhaustion device configured to form a flow path of air exhausted from the drum, a condenser disposed to heat air sucked into the drum through the air suction device, an evaporator disposed to cool air exhausted from the drum the air exhaustion device, and a compressor and an expander configured to constitute a heat pump together with the condenser and the evaporator. The method includes a temperature detection step of detecting a temperature change of air passing through the condenser or the air suction device, and a determination step of determining that refrigerant leakage has occurred when a temperature decrease amount measured in the temperature detection step is more than a predetermined level.

Owner:LG ELECTRONICS INC

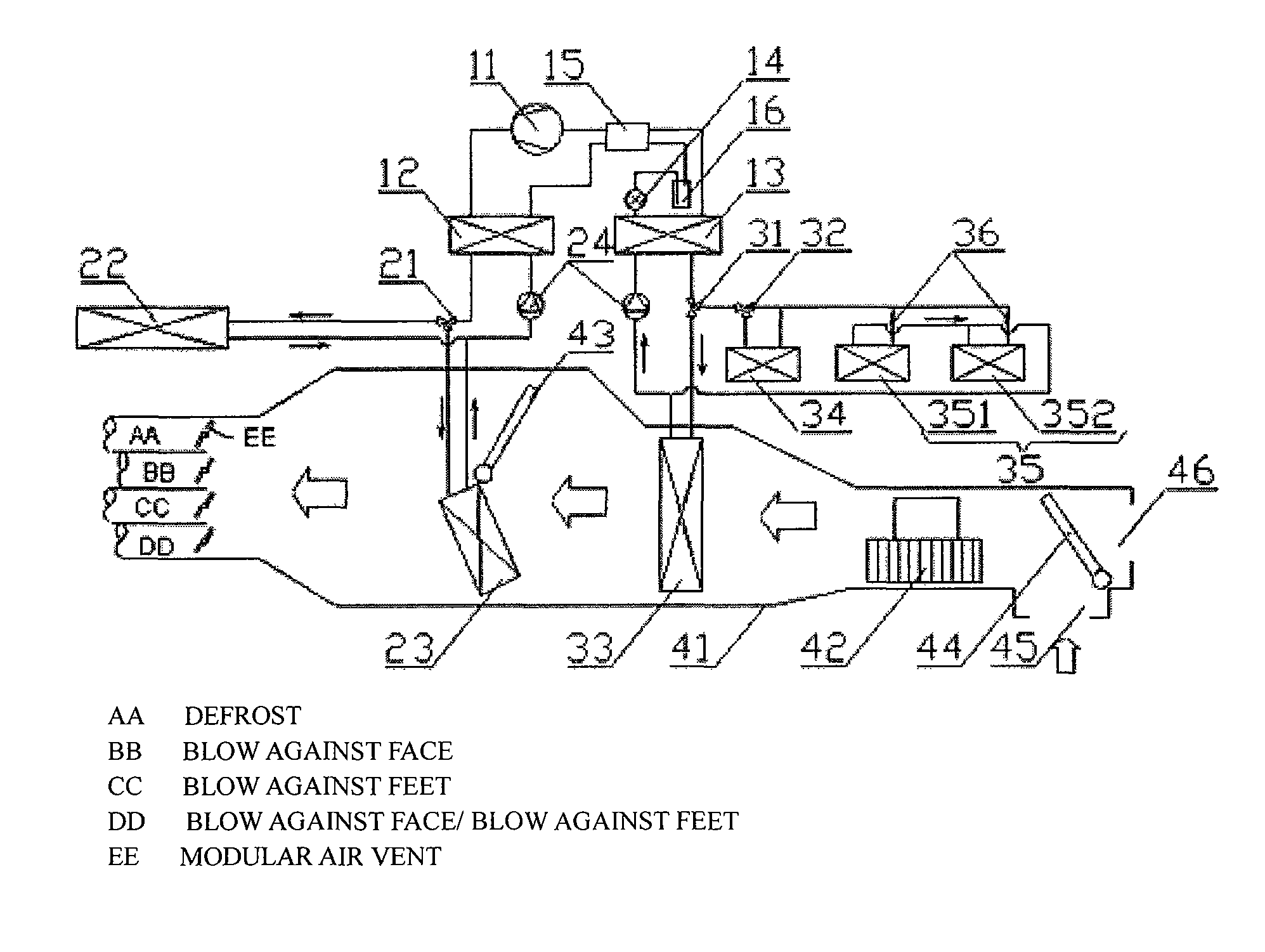

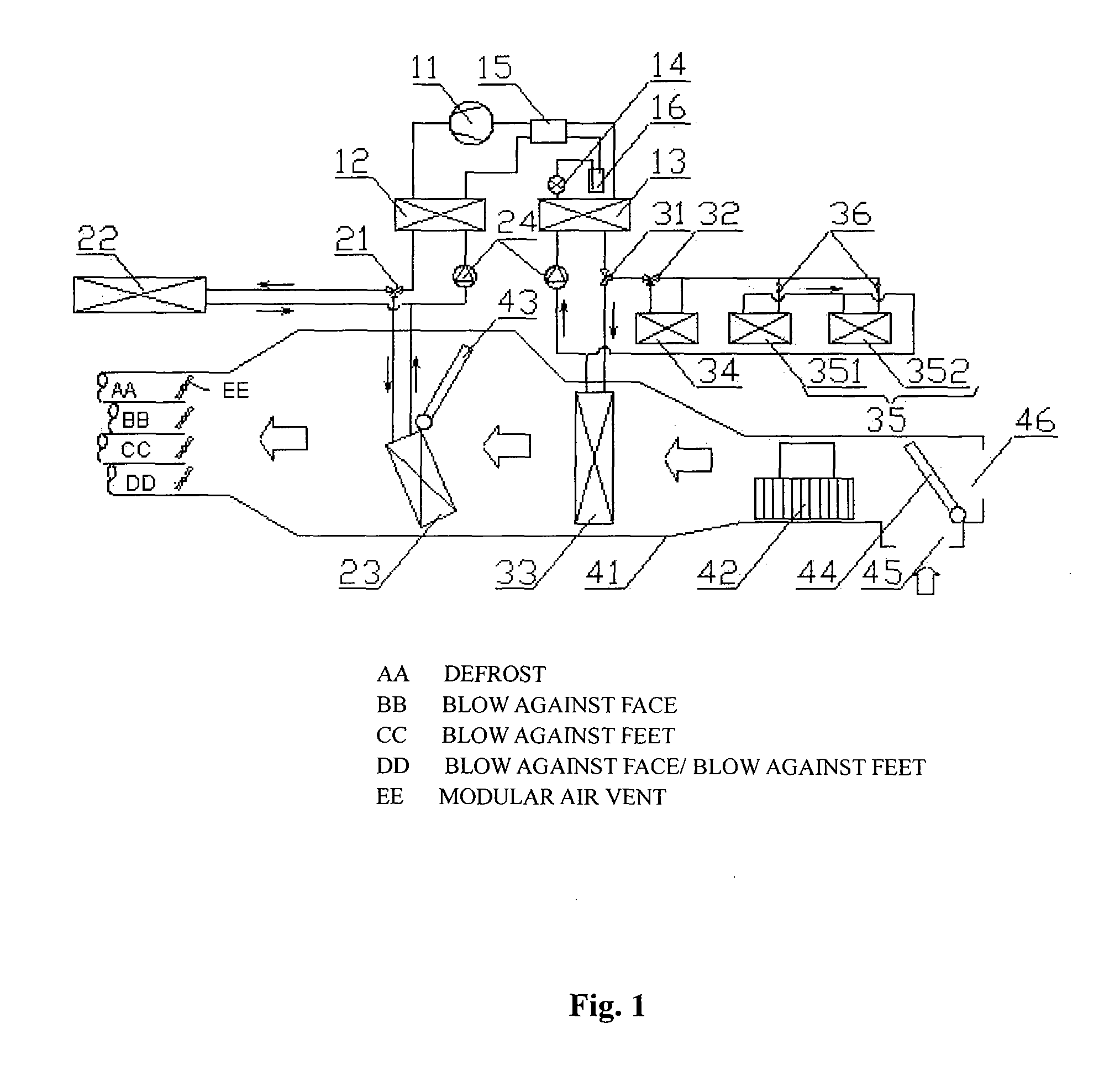

Air conditioning system for motor vehicles

ActiveUS20180281564A1Avoid sudden changesIncrease the amount of refrigerantAir-treating devicesMechanical apparatusAutomobile air conditioningEngineering

An air conditioning system for motor vehicles includes a compressor, a condenser, a plurality of air conditioning units connected in parallel with each other with respect to the compressor and the condenser, and a flow rate control unit configured to, when a specific one of the air conditioning units is additionally turned on or is turned off, prevent occurrence of a sudden change in refrigerant amount in the remaining air conditioning units.

Owner:HANON SYST

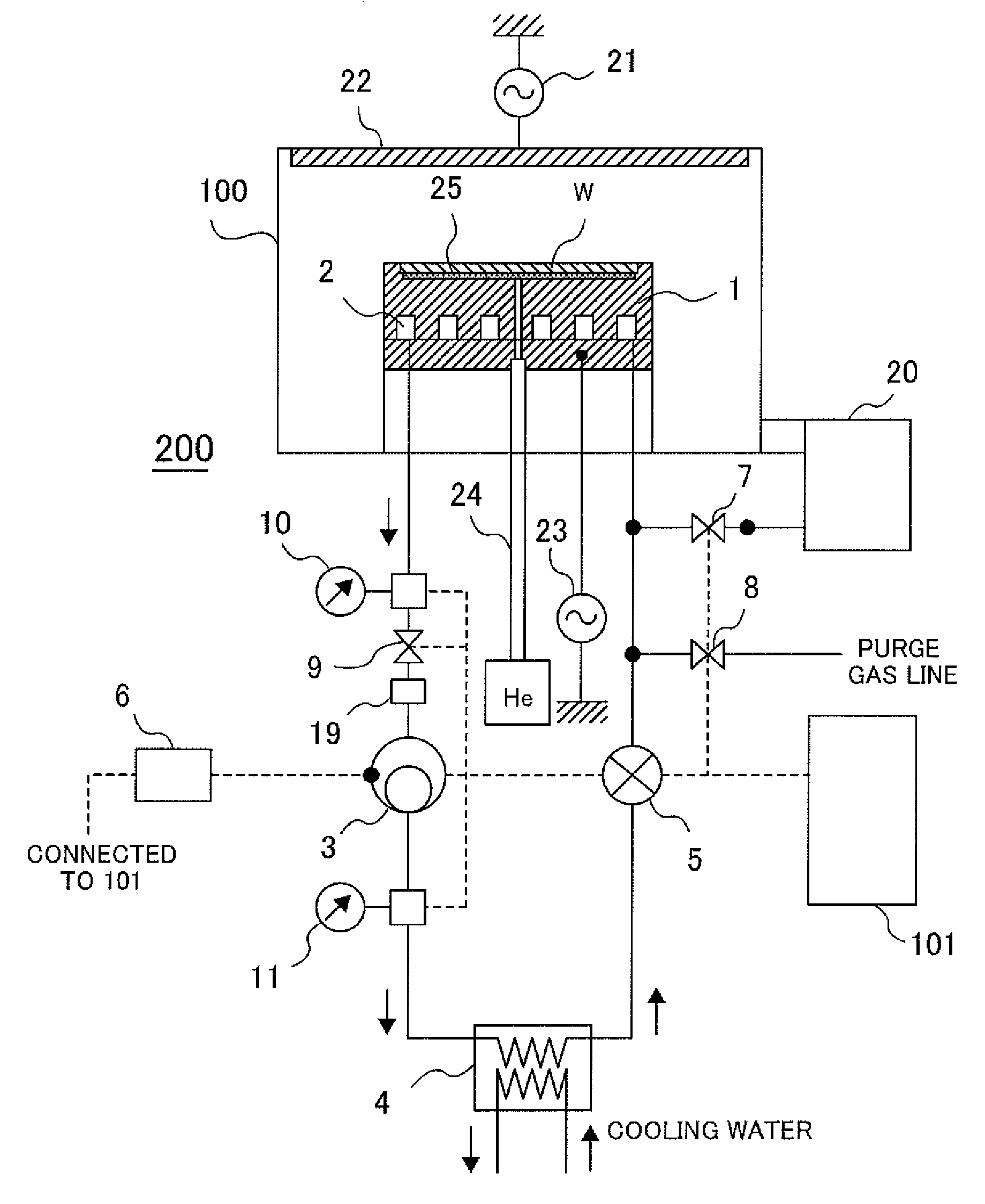

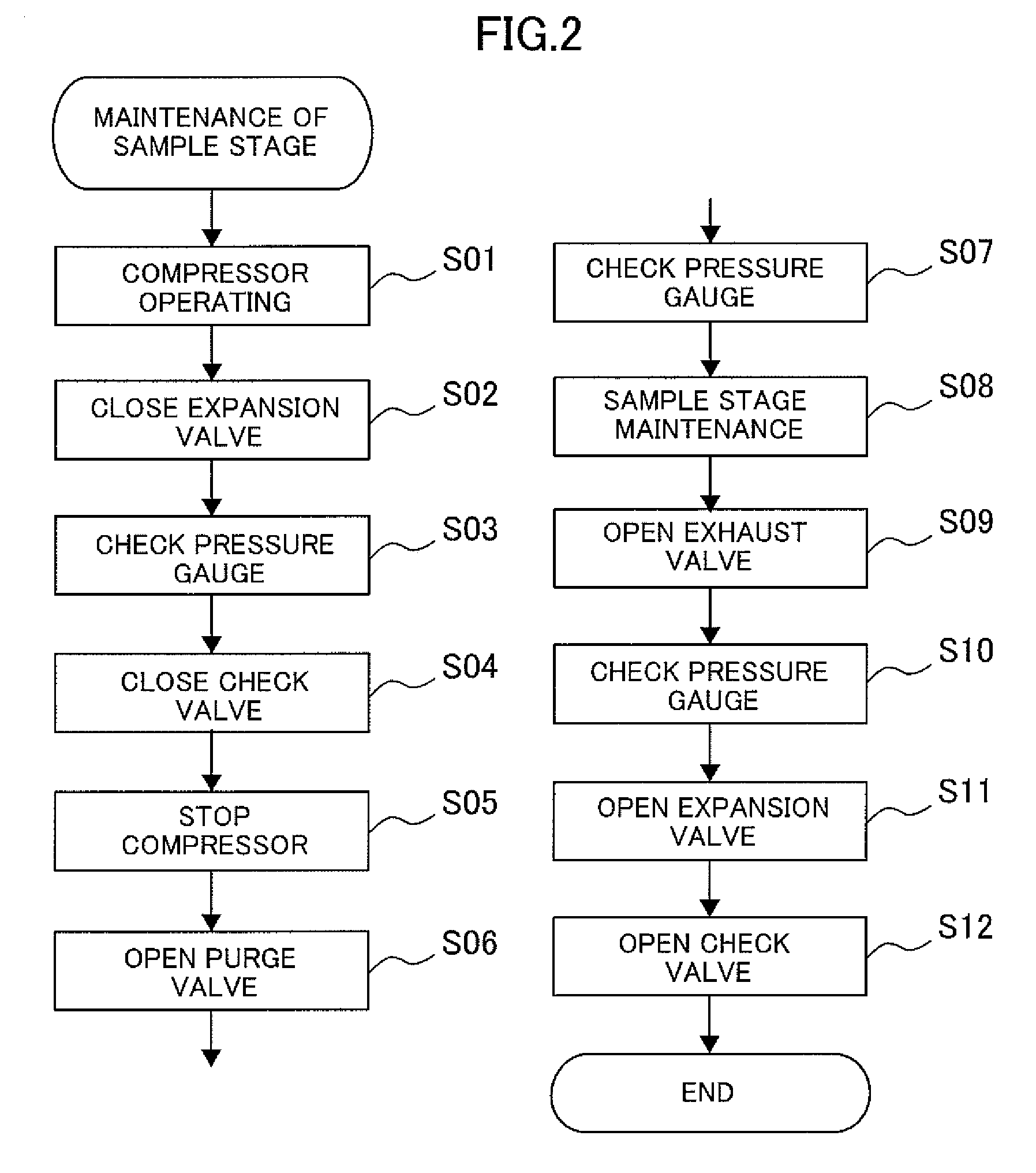

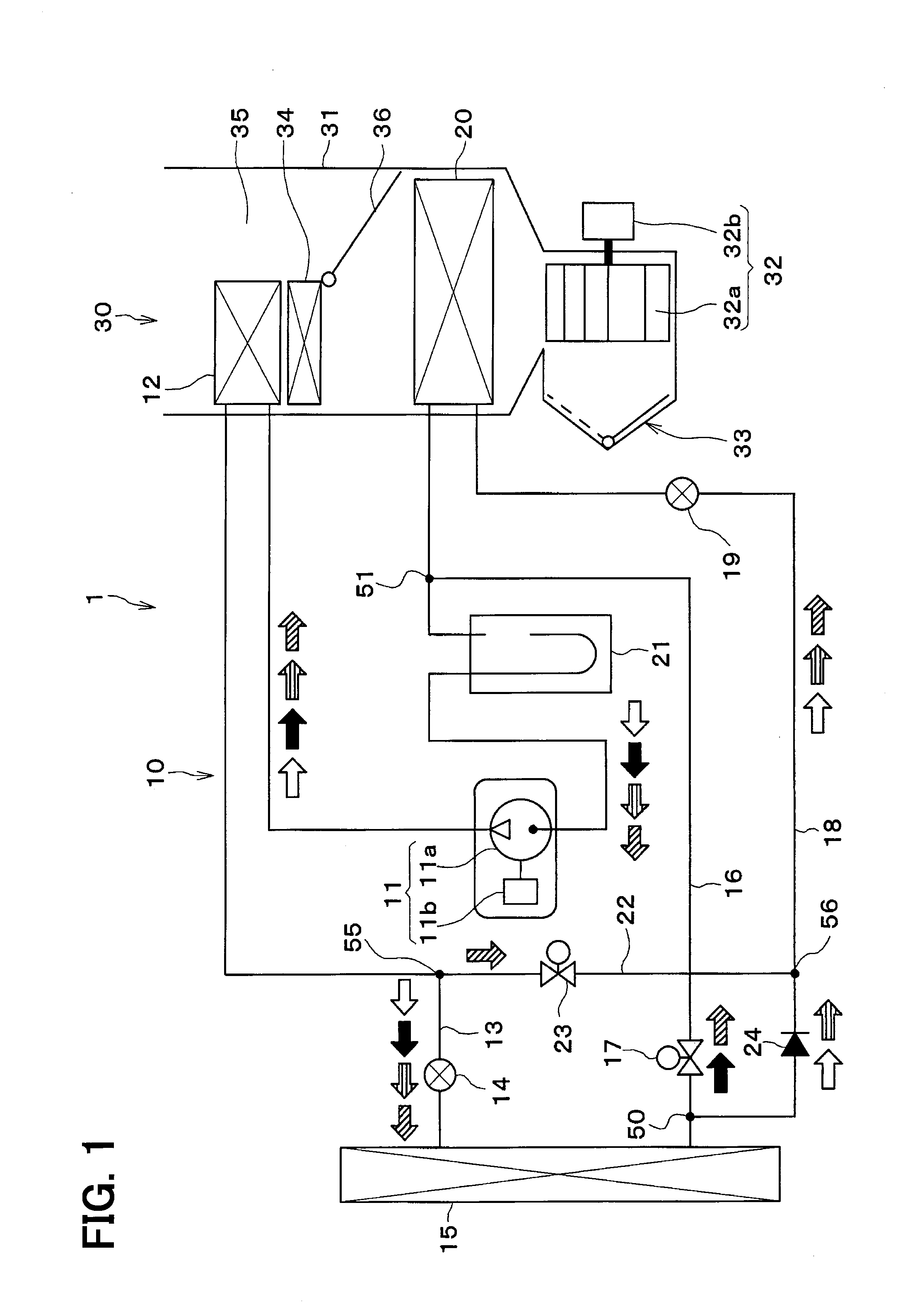

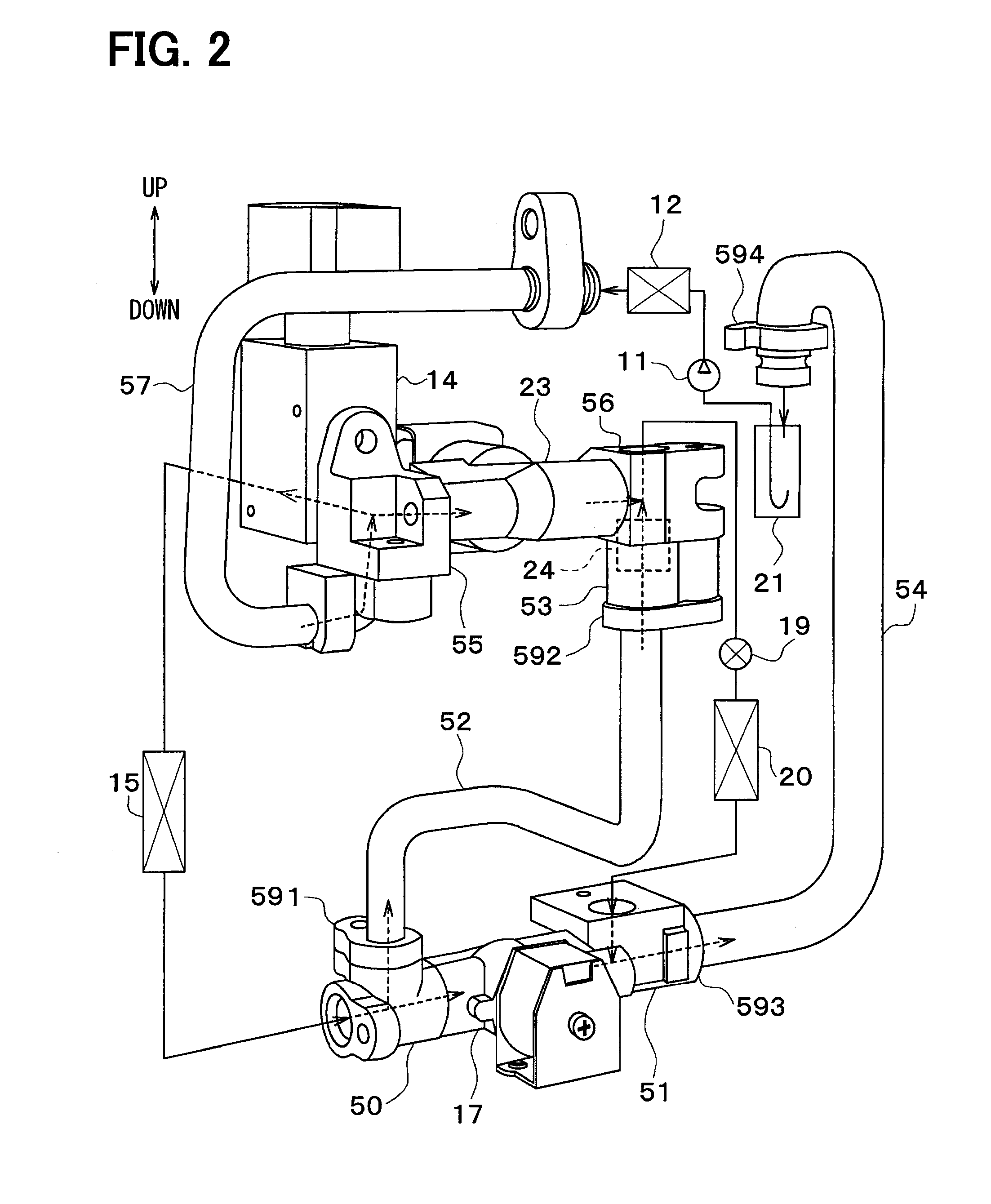

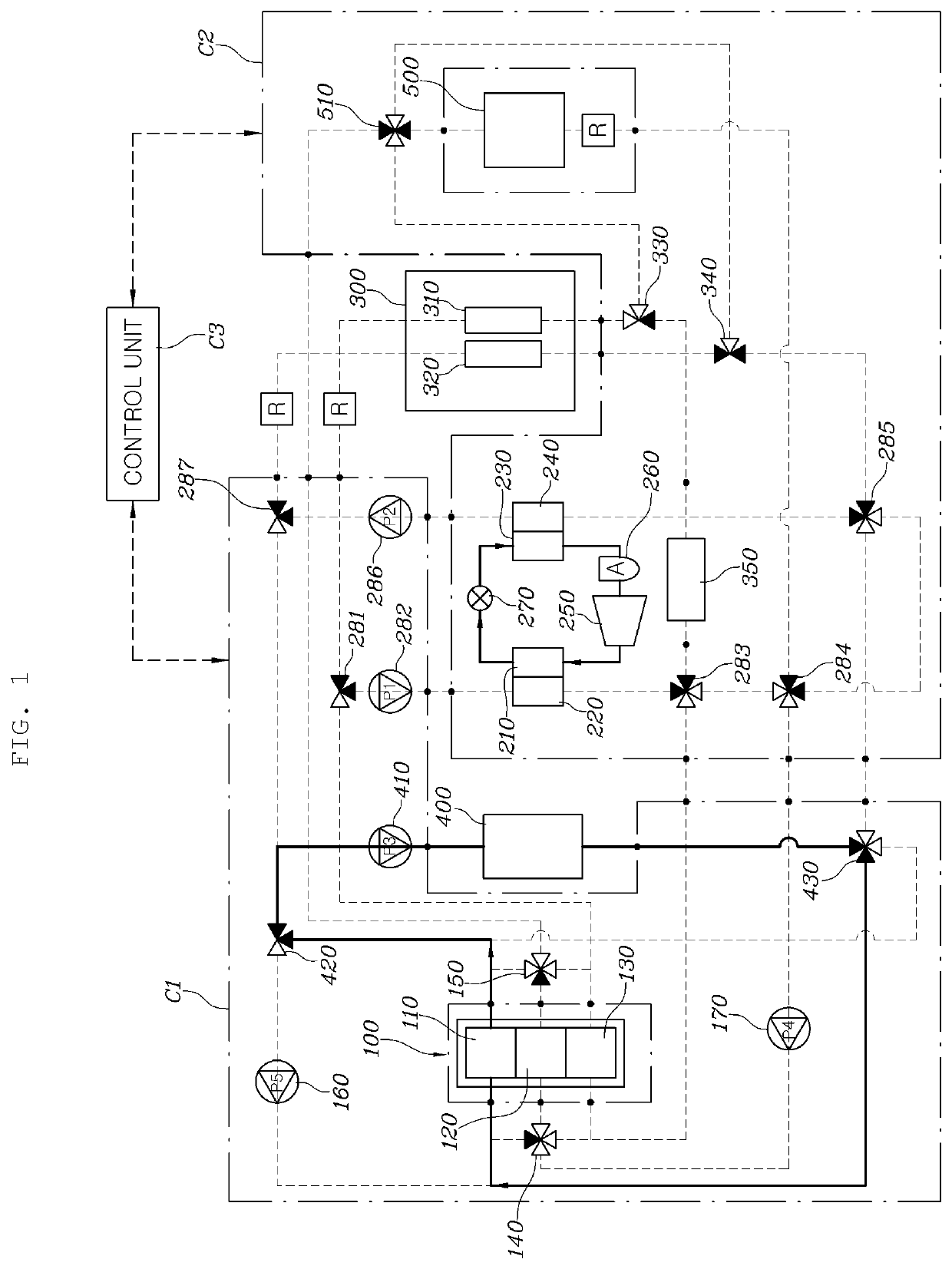

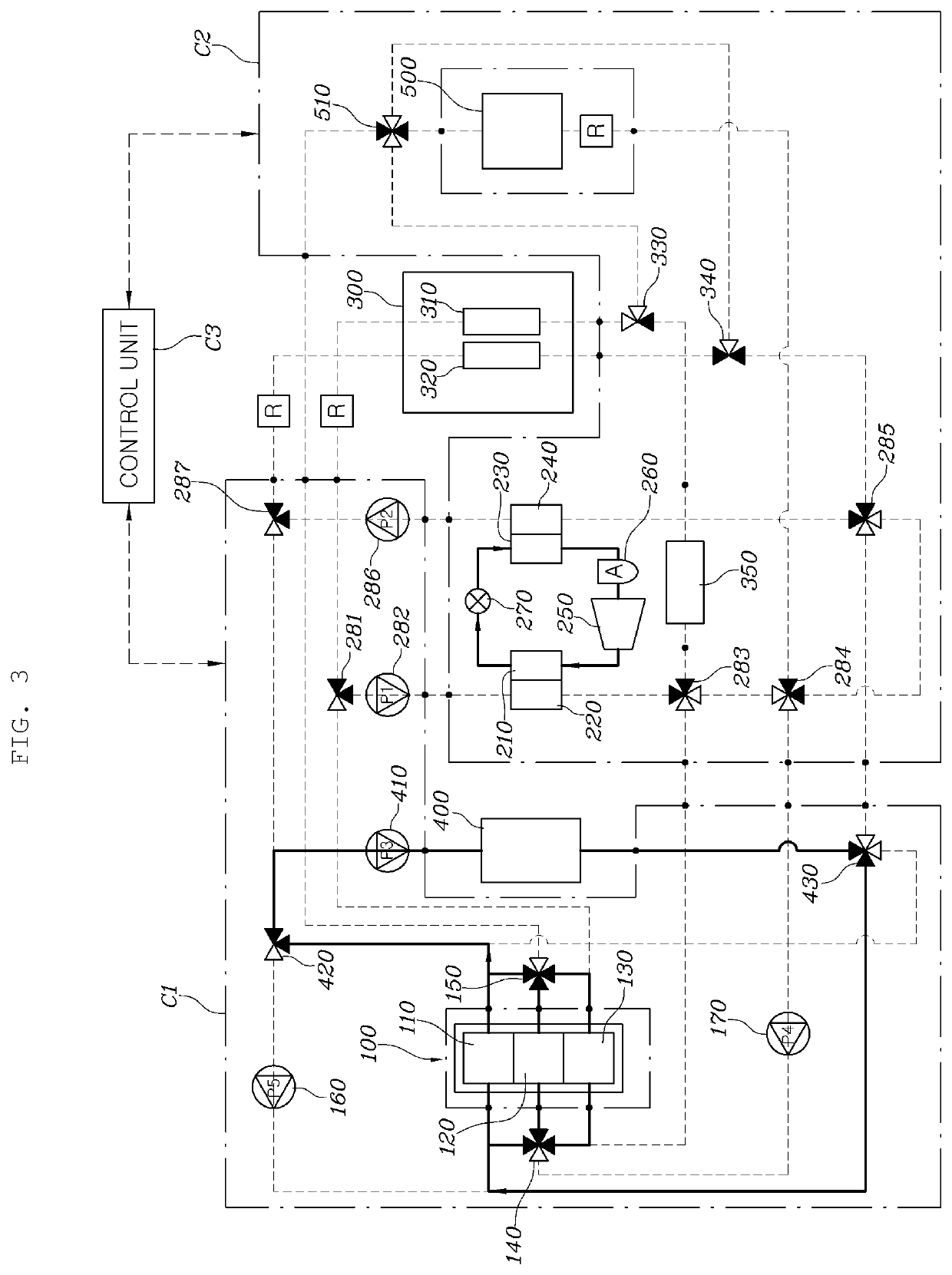

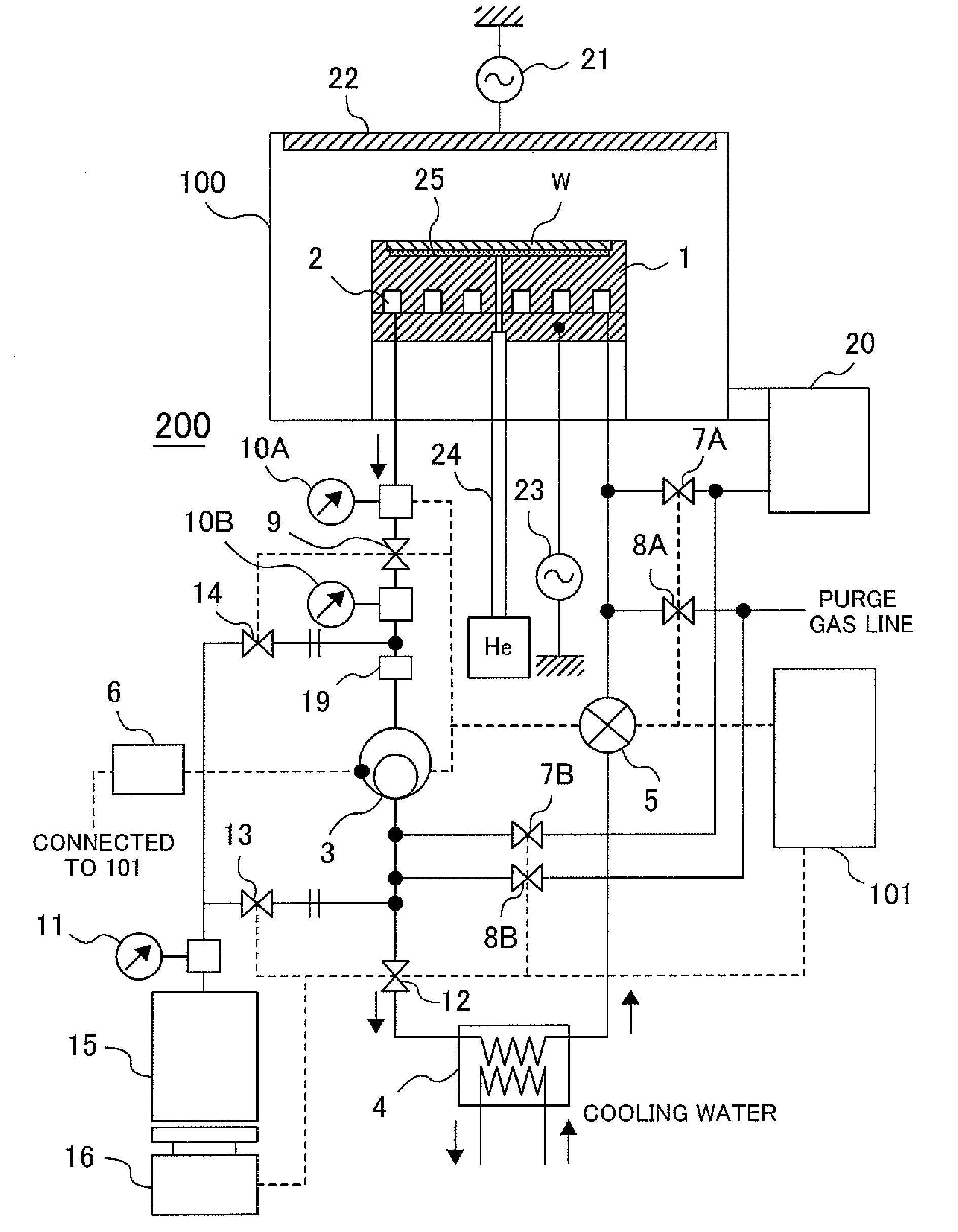

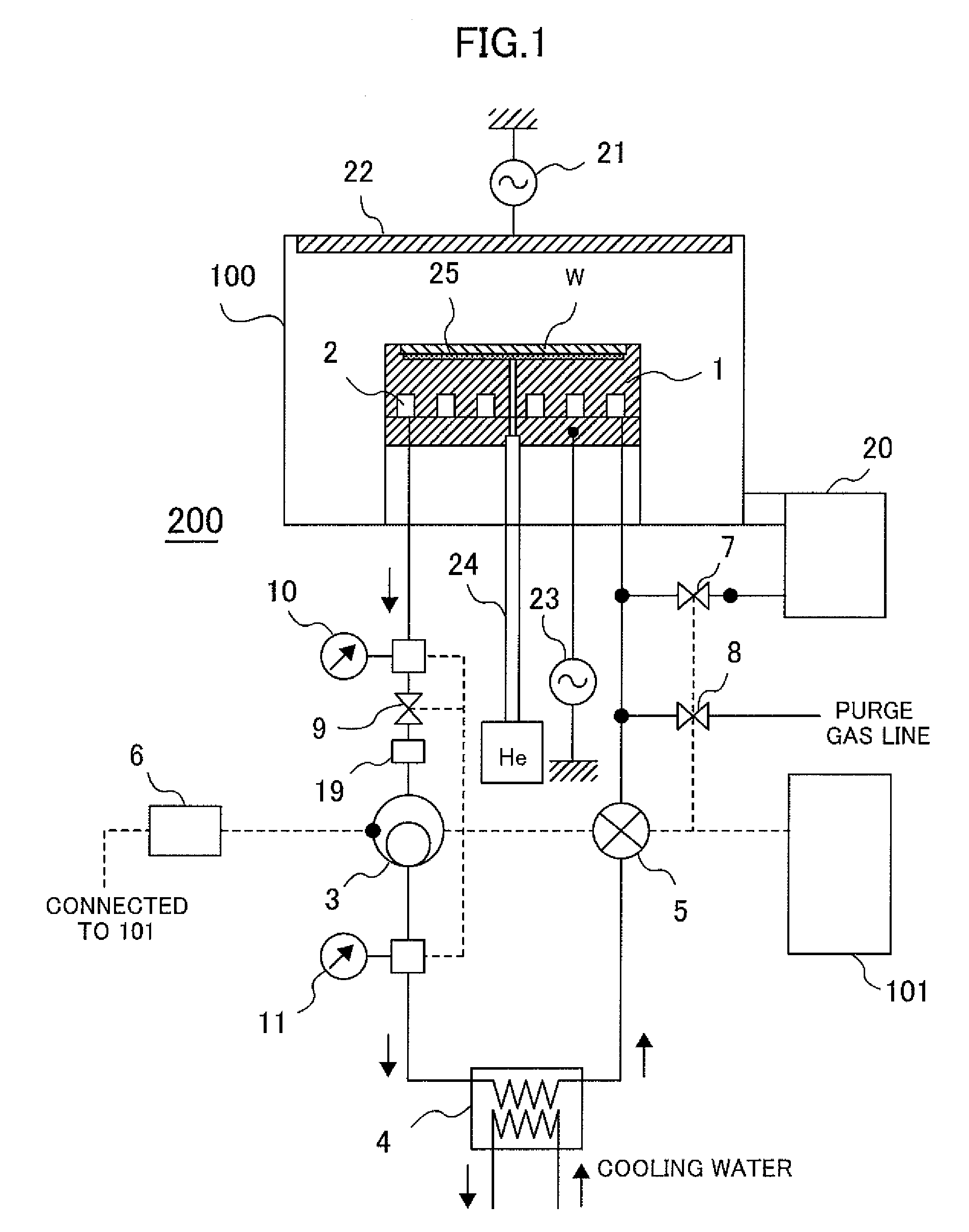

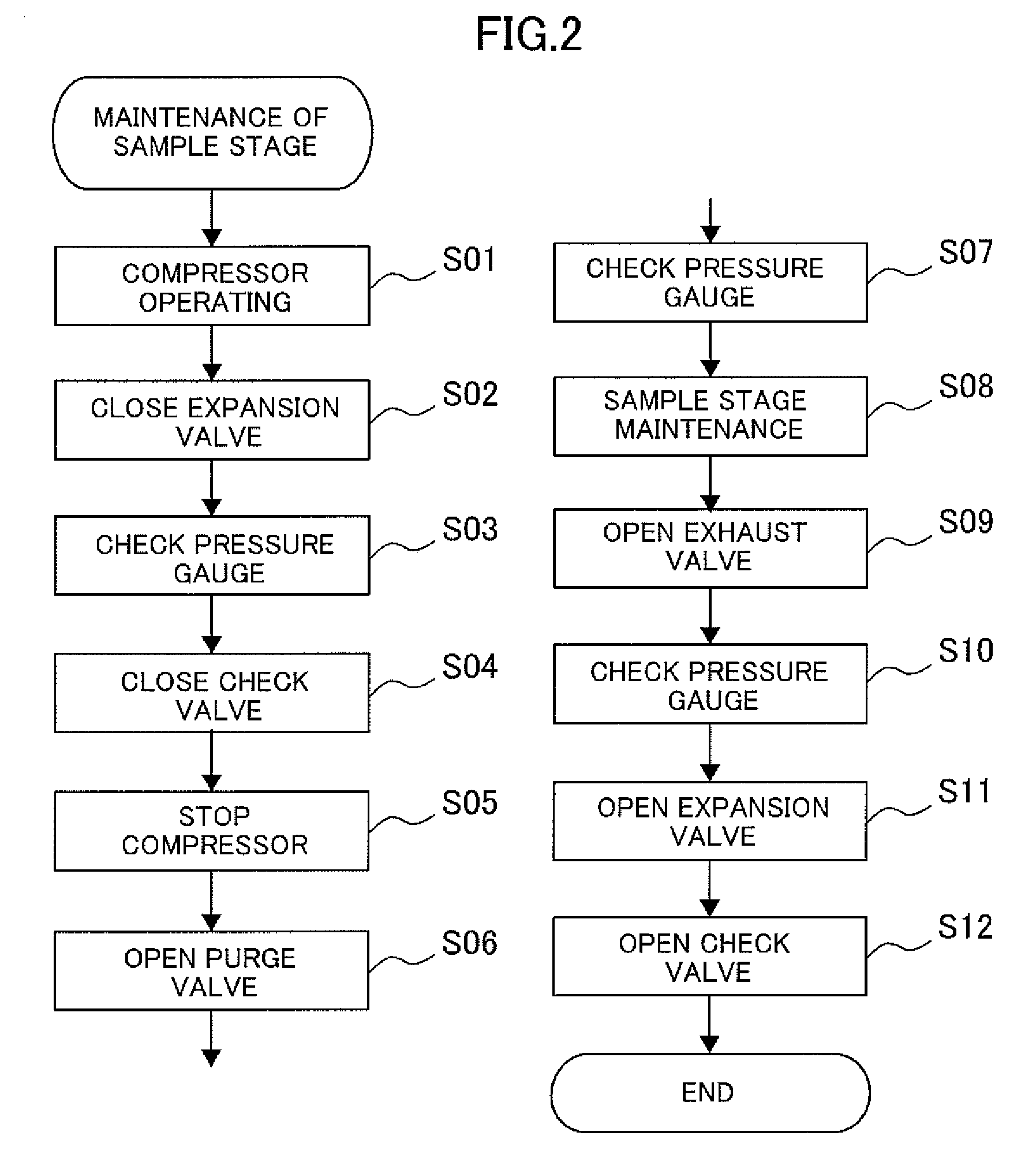

Plasma processing apparatus and maintenance method therefor

ActiveUS20100326094A1High maintenance costShorten the timeElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringCheck valve

In a plasma processing apparatus, a check valve is installed close to a refrigerant inlet of a compressor. When performing maintenance of a sample stage, refrigerant collected from a refrigerant flow path is temporarily stored in a flow path section extending from an expansion valve to the check valve, making it possible to perform the maintenance without changing the amount of refrigerant in the refrigerating cycle. With a refrigerant storage tank, a refrigerant supply valve, and a refrigerant discharge valve included in the refrigerating cycle, when maintenance of the compressor, a condenser, or the expansion valve is performed, the refrigerant collected from the refrigerating cycle can be put in use again.

Owner:HITACHI HIGH-TECH CORP

Diagnosing method for clothes treating apparatus and clothes treating apparatus with refrigerant leakage detecting means

ActiveUS8595953B2Rapidly and easily detectingReduce refrigerant consumptionSolidificationLiquefactionEngineeringRefrigerant

A clothes treating apparatus includes a drum configured to accommodate therein an object to be dried, an air suction device configured to form a flow path of air introduced into the drum, an air exhaustion device configured to form a flow path of air exhausted from the drum, a condenser disposed to heat air sucked into the drum through the air suction device, an evaporator disposed to cool air exhausted from the drum the air exhaustion device, and a compressor and an expander configured to constitute a heat pump together with the condenser and the evaporator. The method includes a temperature detection step of detecting a temperature change of air passing through the condenser or the air suction device, and a determination step of determining that refrigerant leakage has occurred when a temperature decrease amount measured in the temperature detection step is more than a predetermined level.

Owner:LG ELECTRONICS INC

Refrigeration cycle device

ActiveUS20150292780A1Reduce refrigerant leakageImprove cooling effectMechanical apparatusCompression machines with several evaporatorsCouplingRefrigeration

A refrigeration cycle device includes a flow channel coupling member which constitutes at least one of a branching portion and a joining portion of a third refrigerant passage and a branching portion and a joining portion of a bypass passage. One of three refrigerant ports of the flow channel coupling member is directly connected to one of two refrigerant ports of a first switching device or a second switching device, and a sealing mechanism preventing a refrigerant leakage is provided in a connecting portion between the refrigerant port of the flow channel coupling member and the refrigerant port of the first switching device or the second switching device. The flow channel coupling member is fixed to one of the switching devices at a position different from a position of the sealing mechanism.

Owner:DENSO CORP +1

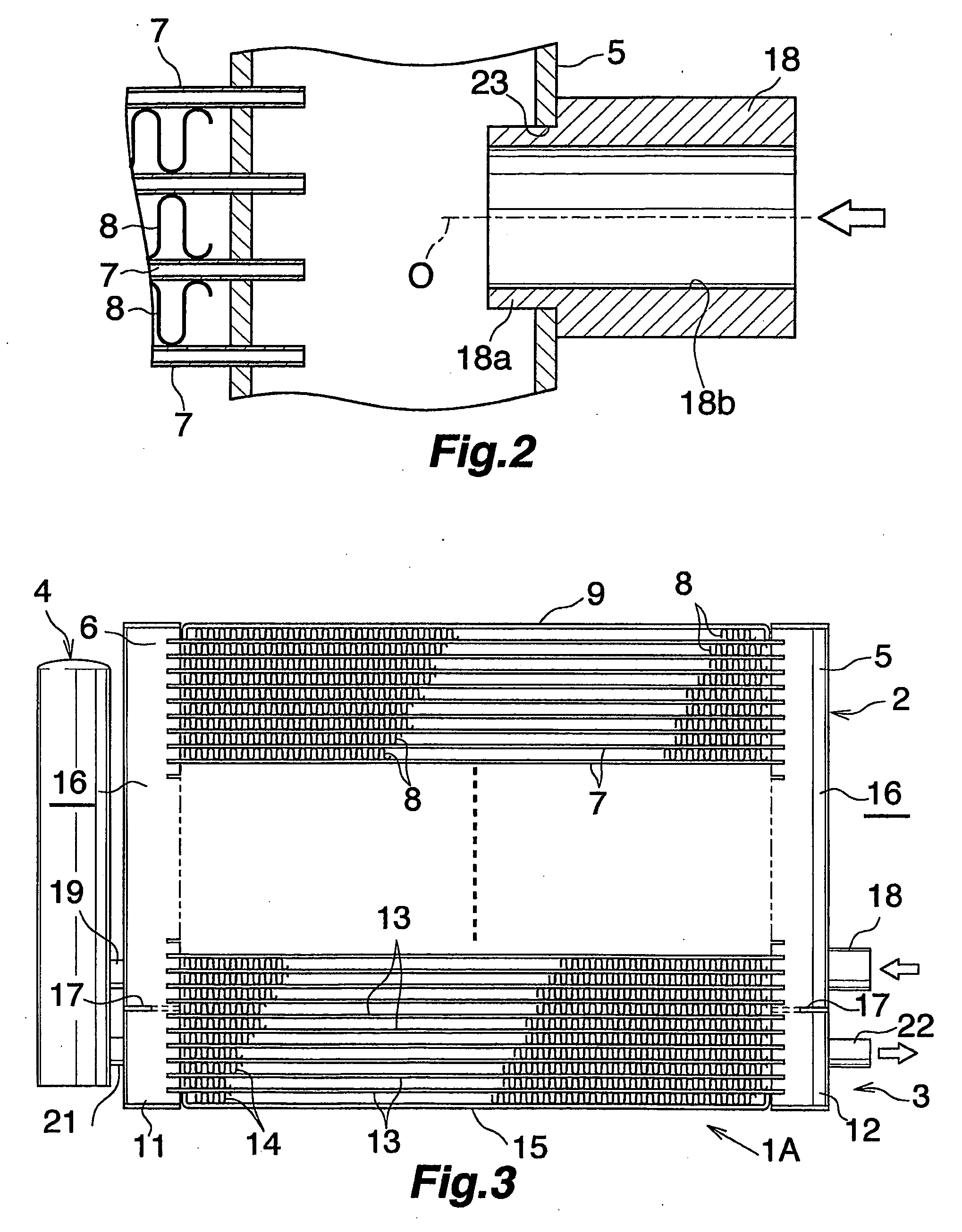

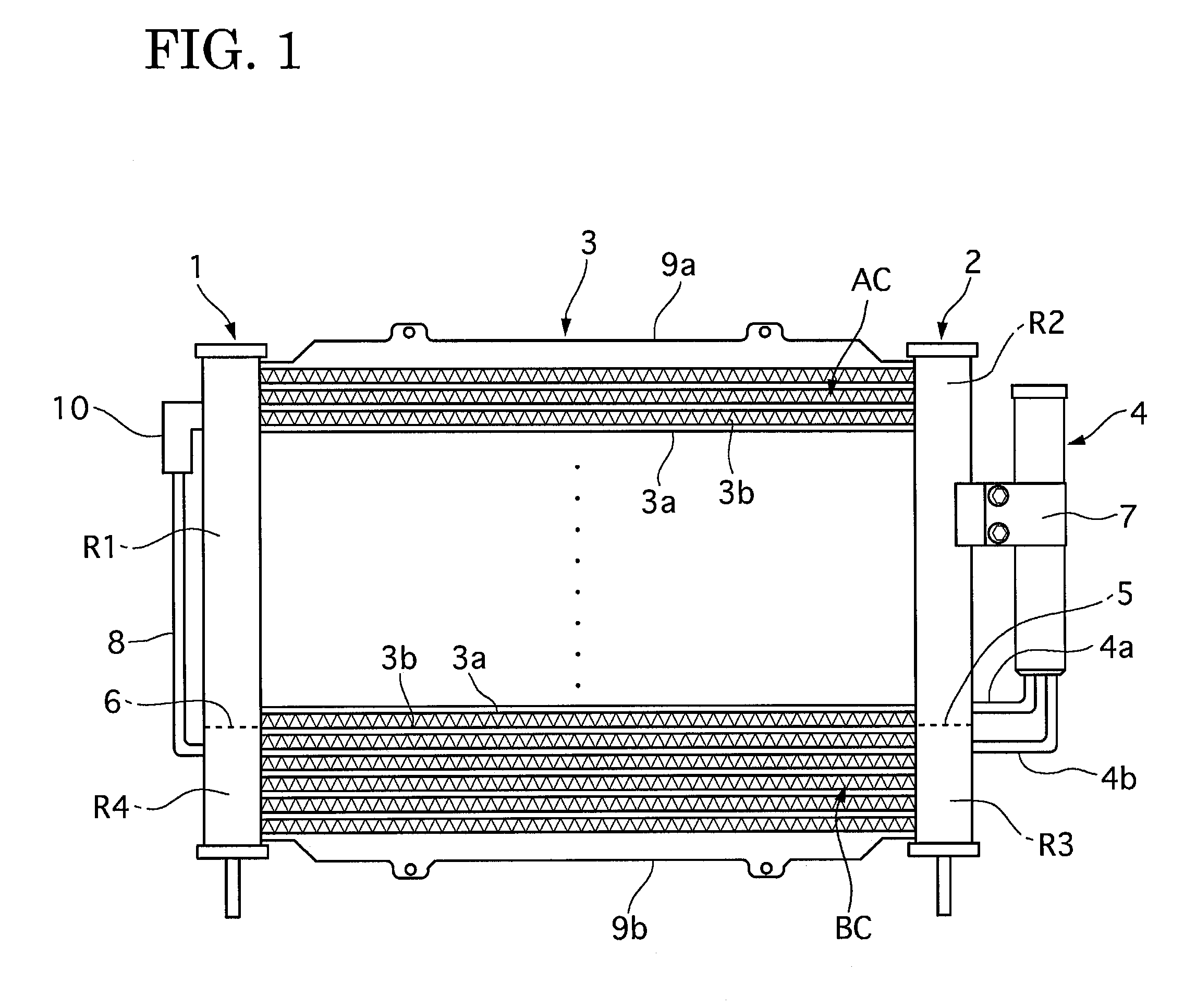

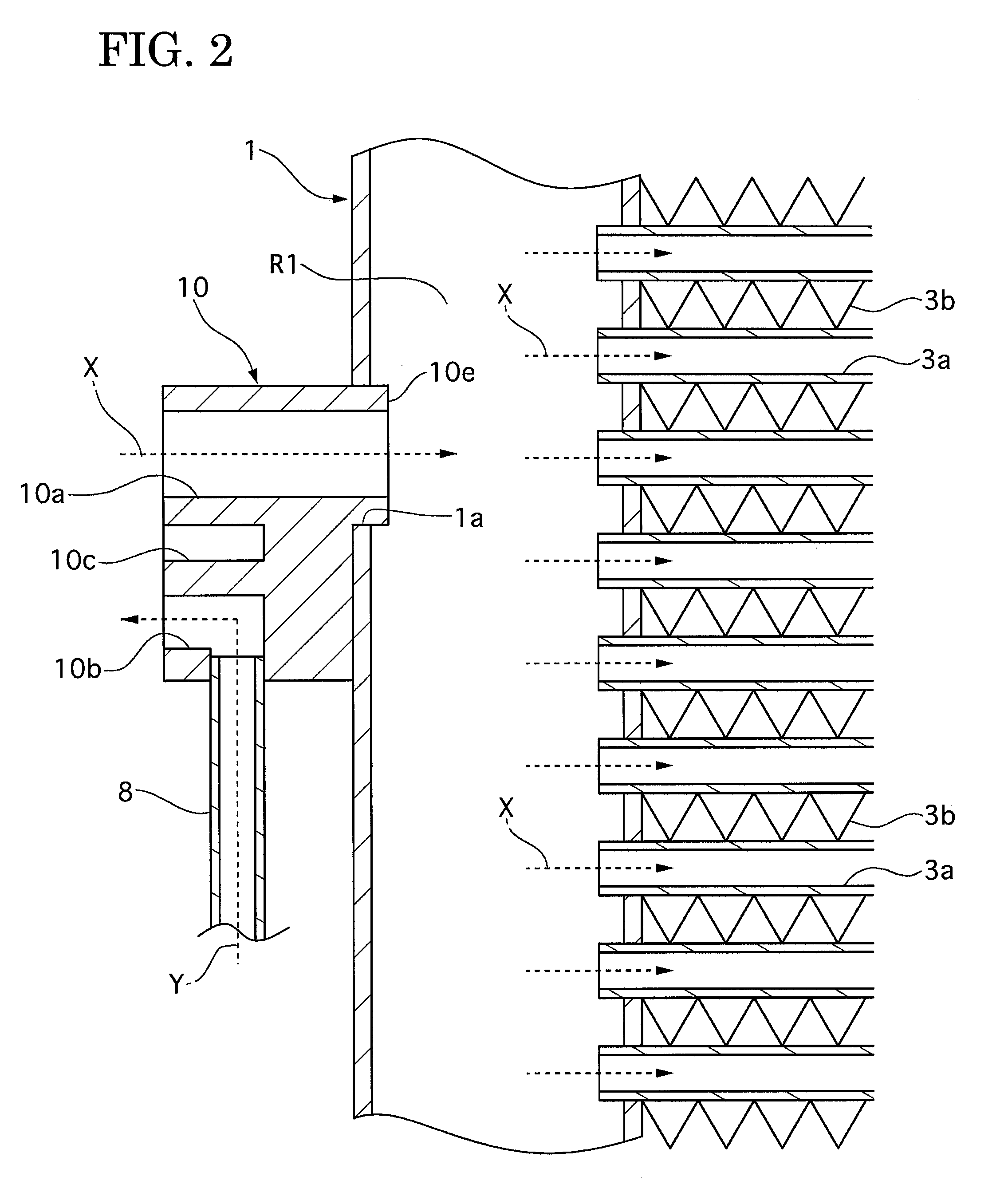

Liquid tank structure of heat exchanger

InactiveUS20090218084A1Calm downReduce refrigerant consumptionEvaporators/condensersSubcoolersPlate heat exchangerLiquid tank

In a liquid tank structure of a heat exchanger, a liquid tank 4 is attached to a heat exchanger having a heat exchanger core defining a condensation part AC and an under cooling part BC, and a pair of headers 1 and 2 each having an inlet part R1, R2 connected with the condensation part AC and an outlet part R3, R4. The condensed refrigerant from the inlet part R2 flows in the liquid tank 4 through an inlet port 1a of an inlet-port side connecting pipe 4a connected with the inlet part R2 of one header 2 of the pair of header. The condensed refrigerant Q accumulated in a bottom portion of the liquid tank 4 is discharged to the outlet part R3 through an outlet port b1 of an outlet-port side connecting pipe 4b connected with the outlet part R3 at a position under an inlet port a1. A sloshing suppression member 11, for suppressing a sloshing of the condensed refrigerant Q accumulated in the bottom portion of the liquid tank 4, has a passing-through ability of the condensed refrigerant and is provided in an inner space of the liquid tank 4 between the inlet port a1 and the outlet port b1.

Owner:CALSONIC KANSEI CORP

Continuous production technology and device for m-aminoacetanilide

ActiveCN109608353AGuaranteed purityGuaranteed conductivityOrganic compound preparationCarboxylic acid amides preparationAcetic acidAfter treatment

The invention discloses a continuous production technology for m-aminoacetanilide. After mother liquor absorbs hydrogen chloride gas, the obtained product, acetic acid and m-phenylenediamine are fed into a primary reaction kettle and subjected to an acylation reaction, and the feeding mas ratio of the fed m-phenylenediamine to the fed hydrogen chloride to the fed acetic acid to the fed mother liquor controlled to be 1:(0.3-0.4):(0.6-0.8):(7-8), one part of materials in the primary reaction kettle is fed into a reaction kettle and cycled, the other part of the materials is fed into a secondaryreaction kettle and reacts, then crystallization and centrifugation are carried out, and a finished product is obtained after treatment. According to the continuous production technology for m-aminoacetanilide, the whole m-aminoacetanilide is produced in a closed system, particularly, non-absorbed hydrogen chloride during the reaction and much acetic-acid waste gas generated when crystallization and centrifugal separation are carried out are absorbed to a final reaction kettle and continue to react, and inorganized gas discharging is reduced; meanwhile comprehensive utilization of resources isachieved, and the yield of the finished product is thus increased.

Owner:ZHEJIANG DIBANG CHEM

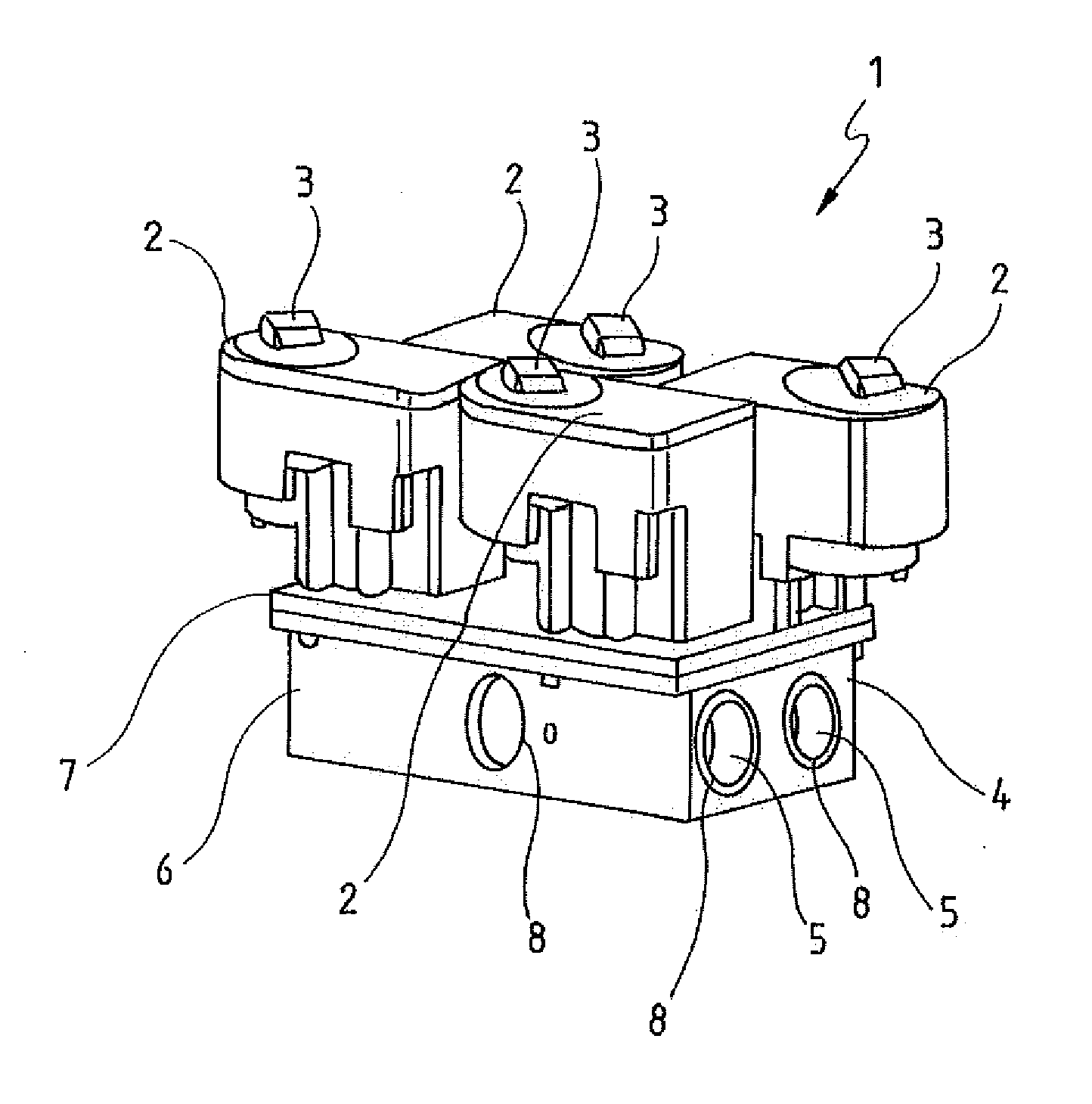

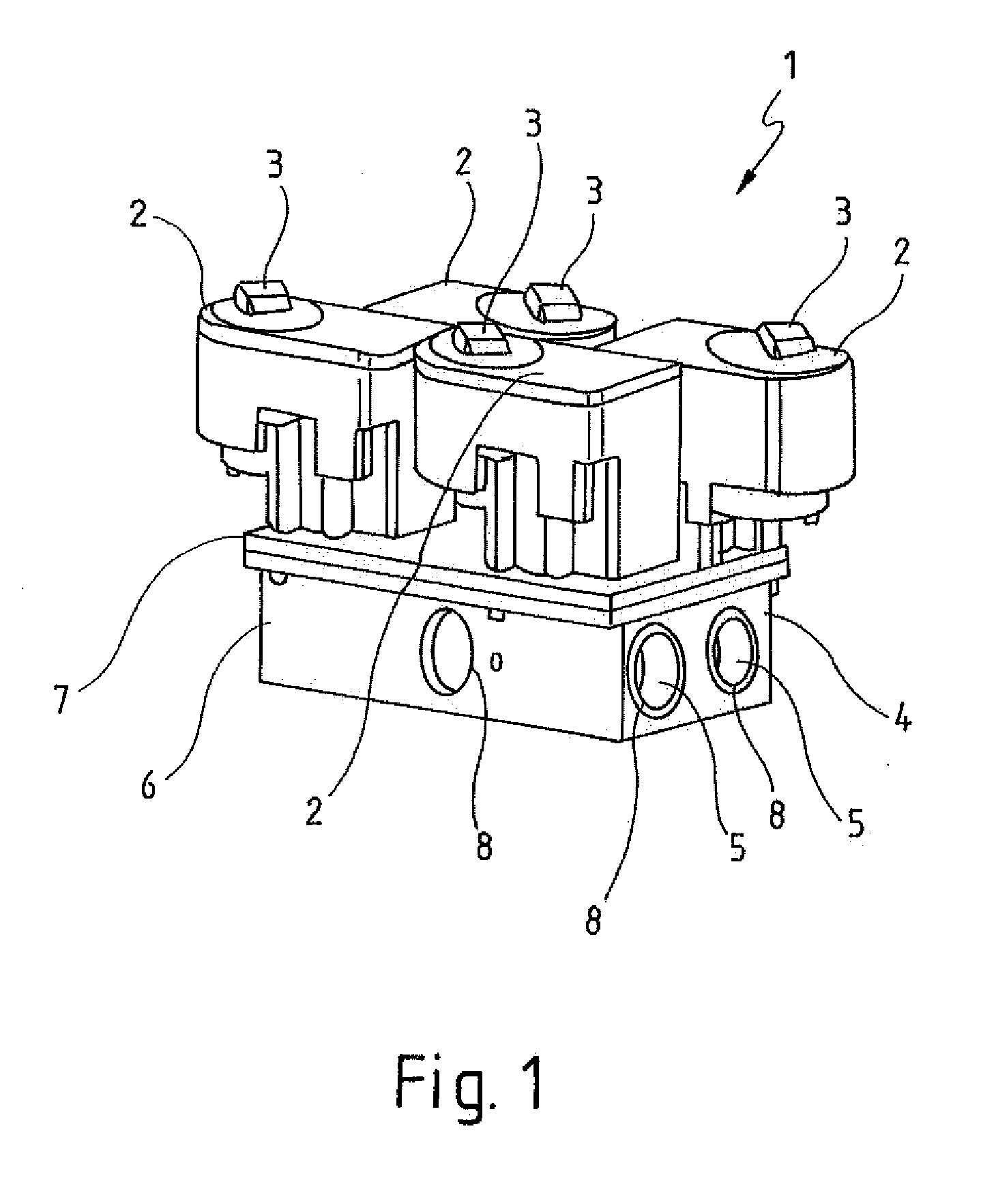

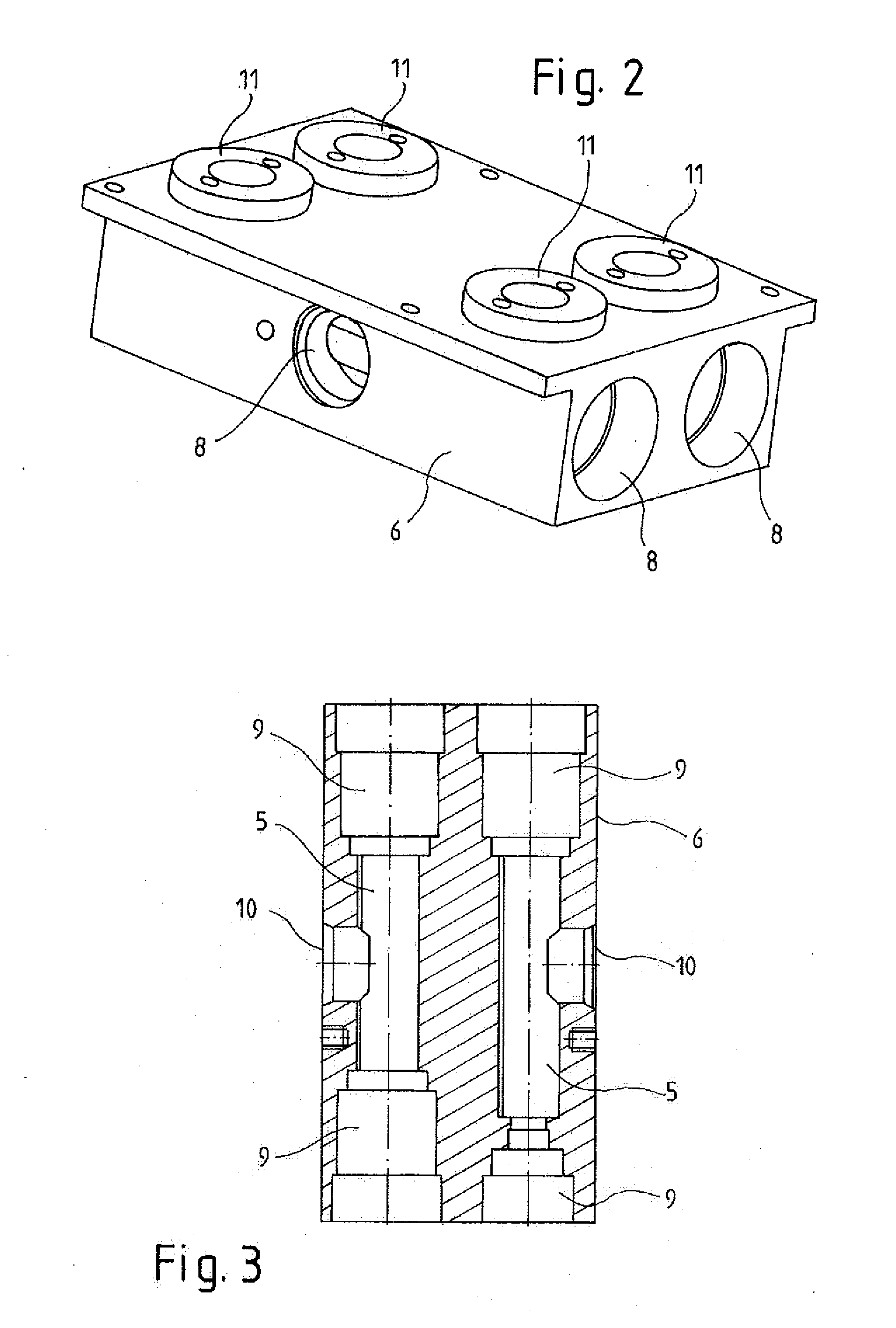

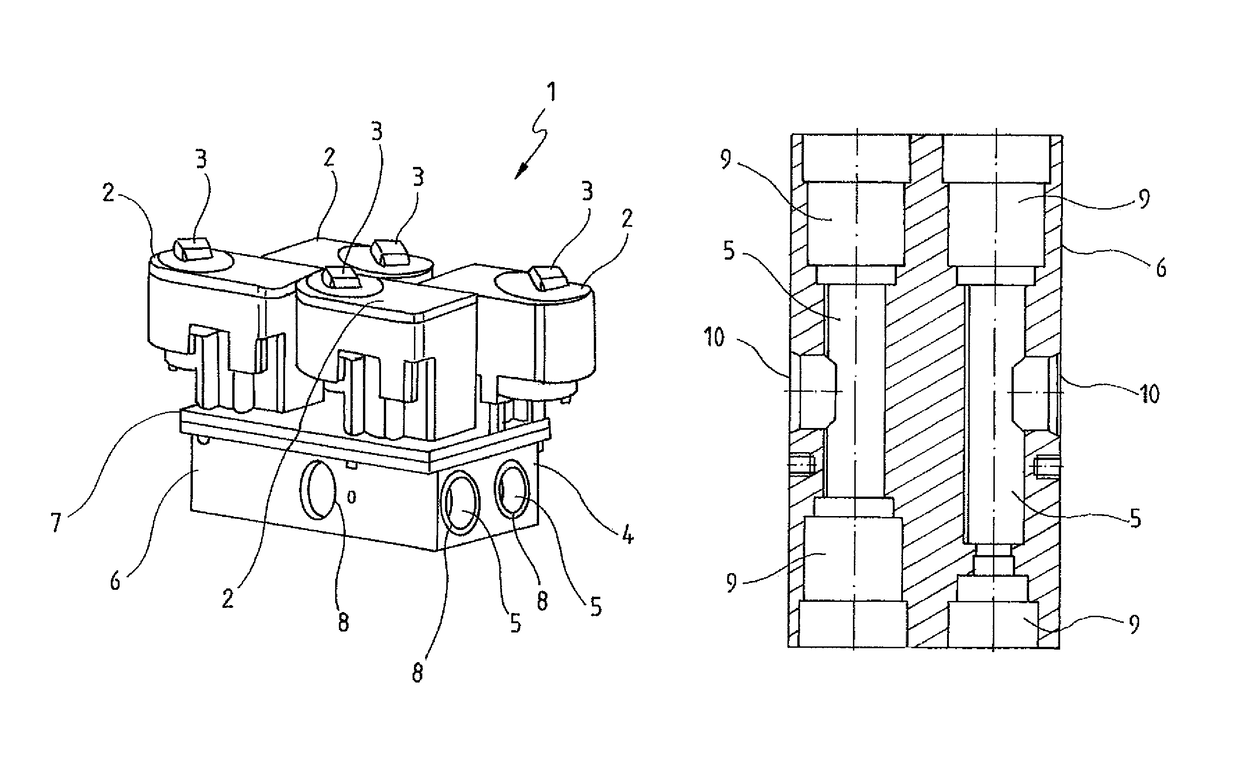

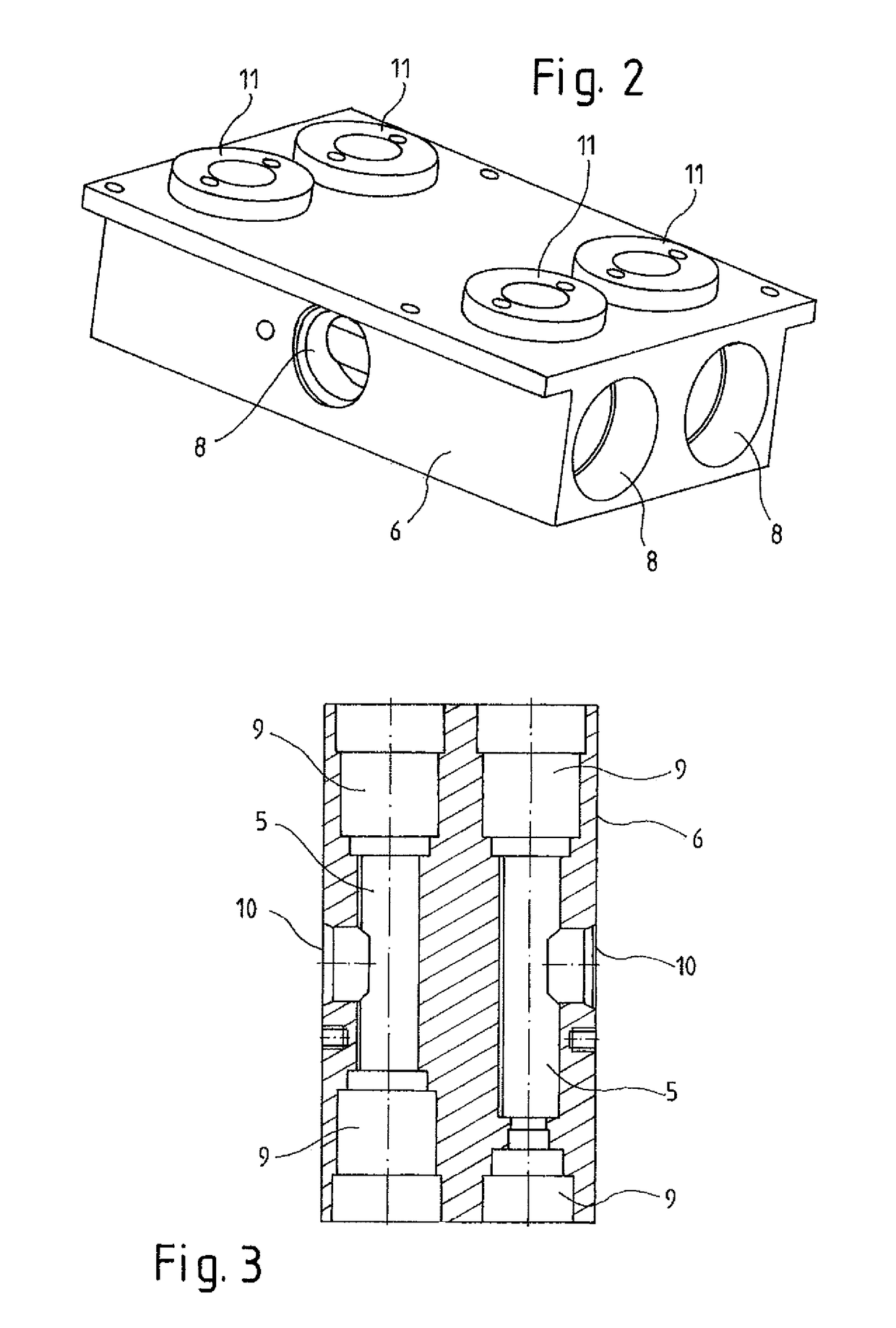

Valve block assembly for several valves

ActiveUS20150292647A1Reduce in quantityMinimal impactServomotor componentsVehicle heating/cooling devicesEngineeringVALVE PORT

A valve block assembly for multiple valves, in particular expansion valves and / or shut-off valves, includes a valve block having a plurality of flow paths for fluids and a plurality of adjustment units with assigned drive units, wherein the valve block is designed as comprising two parts, these being a flow path element with the flow paths and a limiting element.

Owner:HANON SYST

Heat exchanger

ActiveUS9759461B2Low costReduce refrigerant consumptionEvaporators/condensersVapor condensationEngineeringRefrigerant

A heat exchanger for a vapor compression system includes a shell, a distributing part disposed inside of the shell to distribute a refrigerant, a tube bundle and a trough part. The tube bundle includes a plurality of heat transfer tubes disposed inside of the shell below the distributing part. The tube bundle includes a falling film region disposed below the distributing part, an accumulating region disposed below the falling film region, and a flooded region disposed below the accumulating region at a bottom portion of the shell. The trough part extends under at least one of the heat transfer tubes in the accumulating region to accumulate the refrigerant therein. The trough part at least partially overlaps with the at least one of the heat transfer tubes in the accumulating region when viewed along a horizontal direction perpendicular to the longitudinal center axis of the shell.

Owner:DAIKIN IND LTD

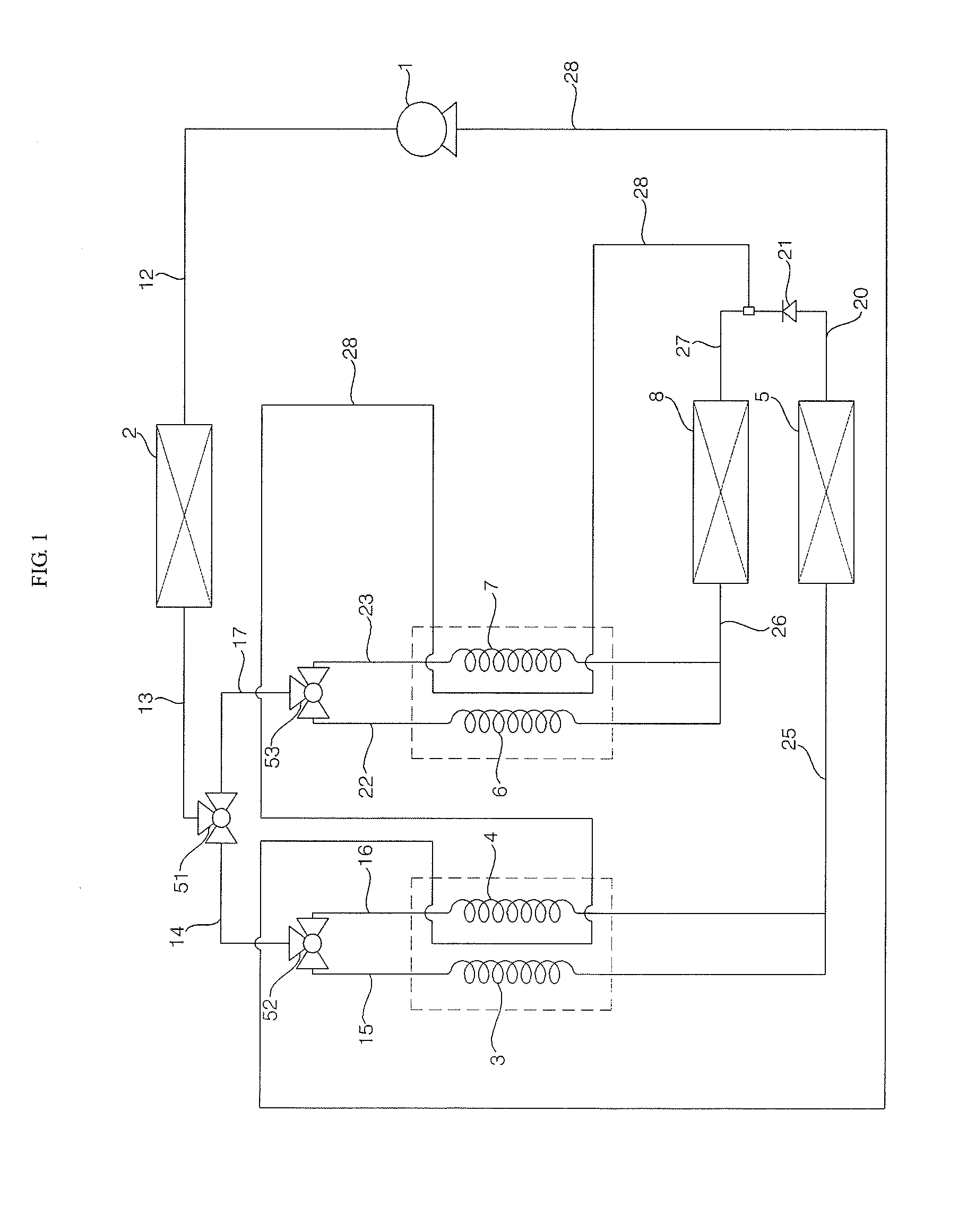

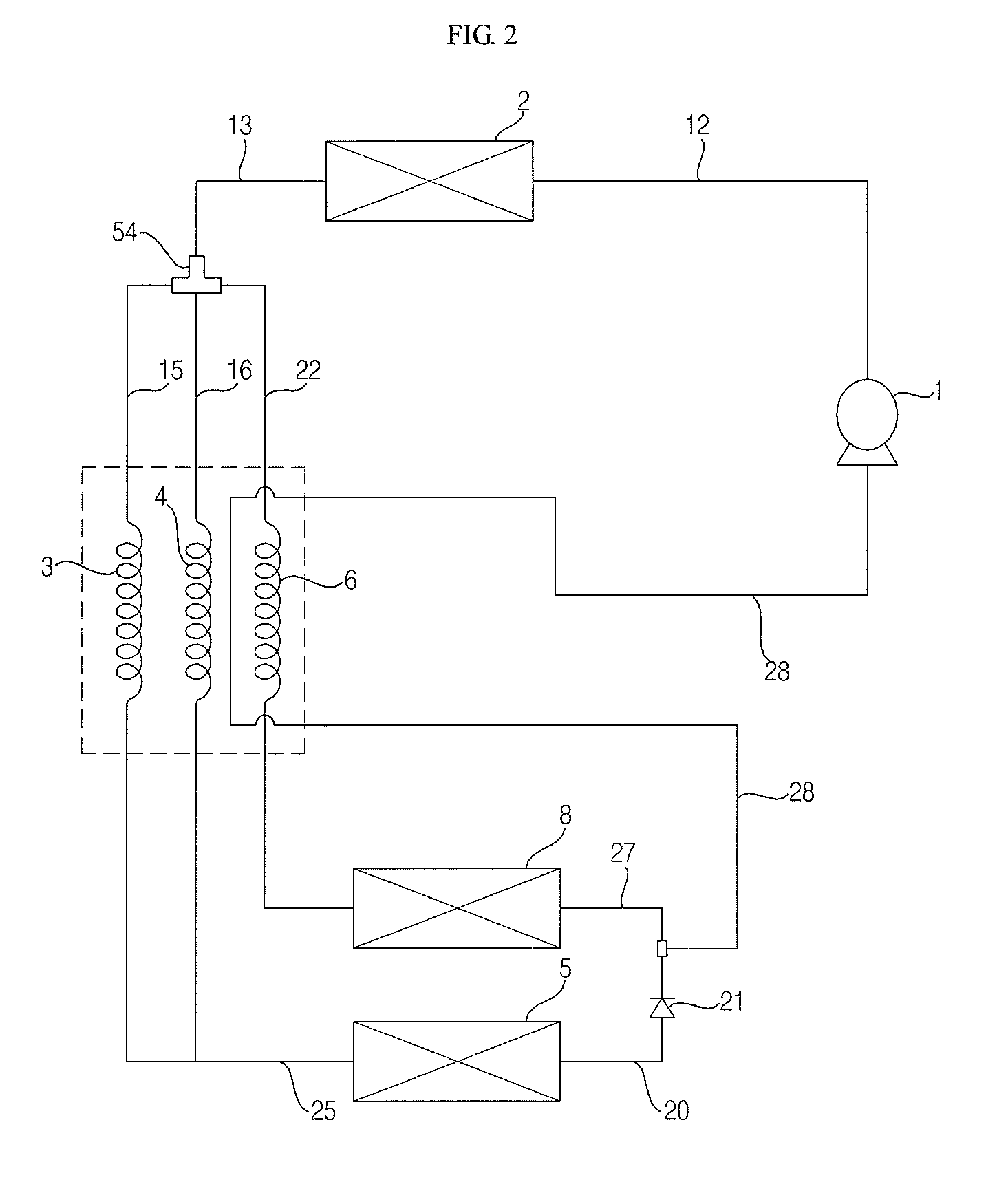

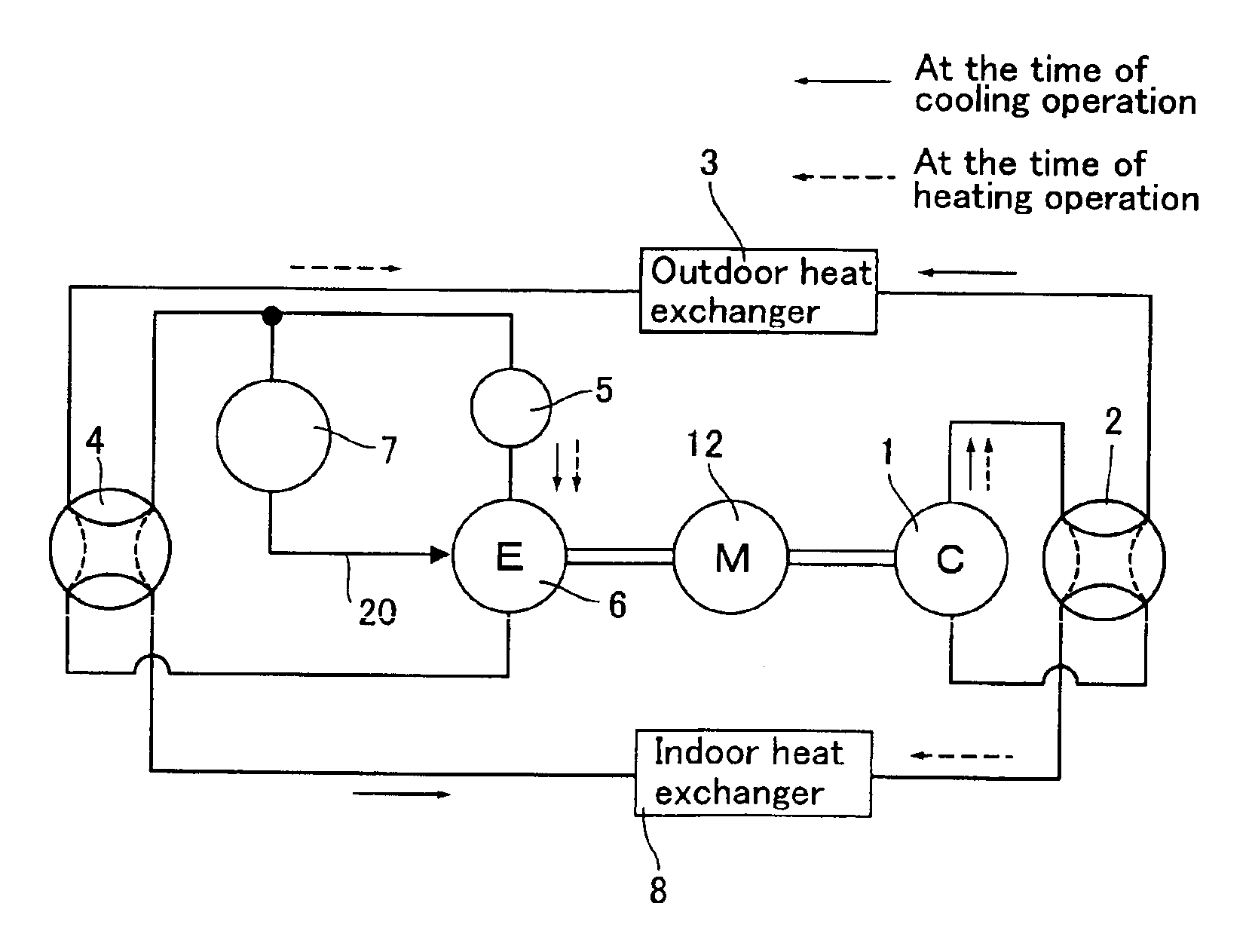

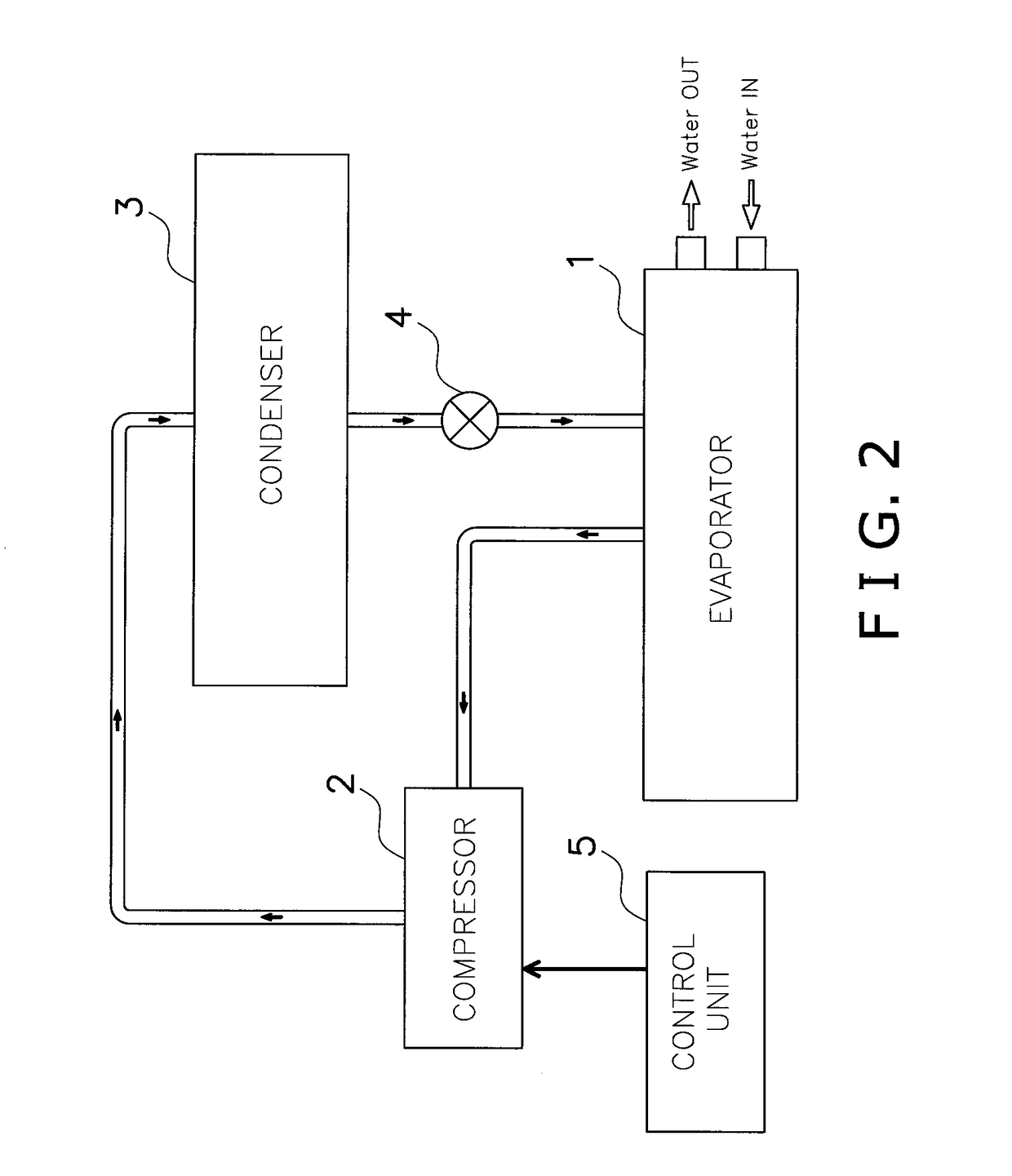

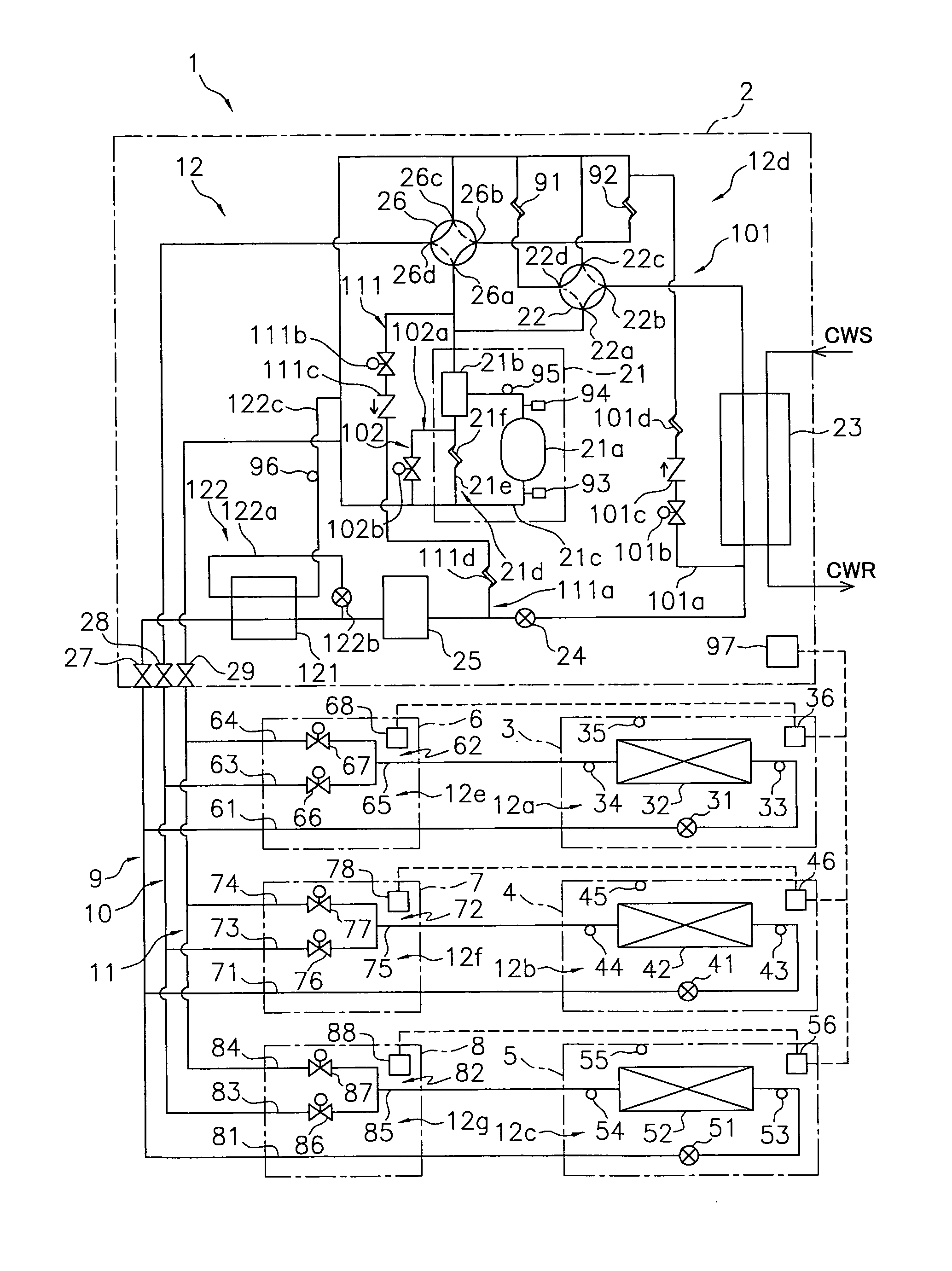

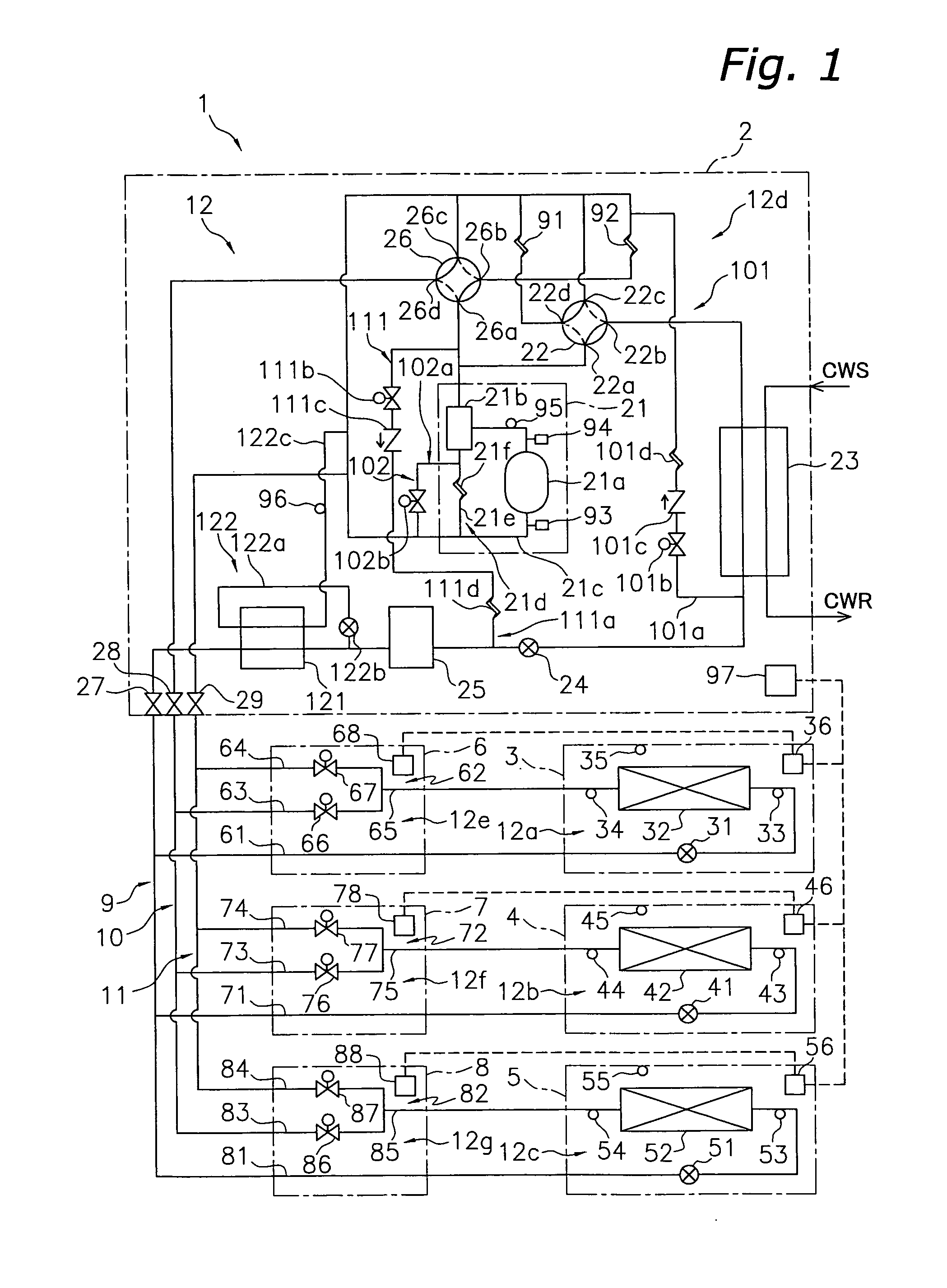

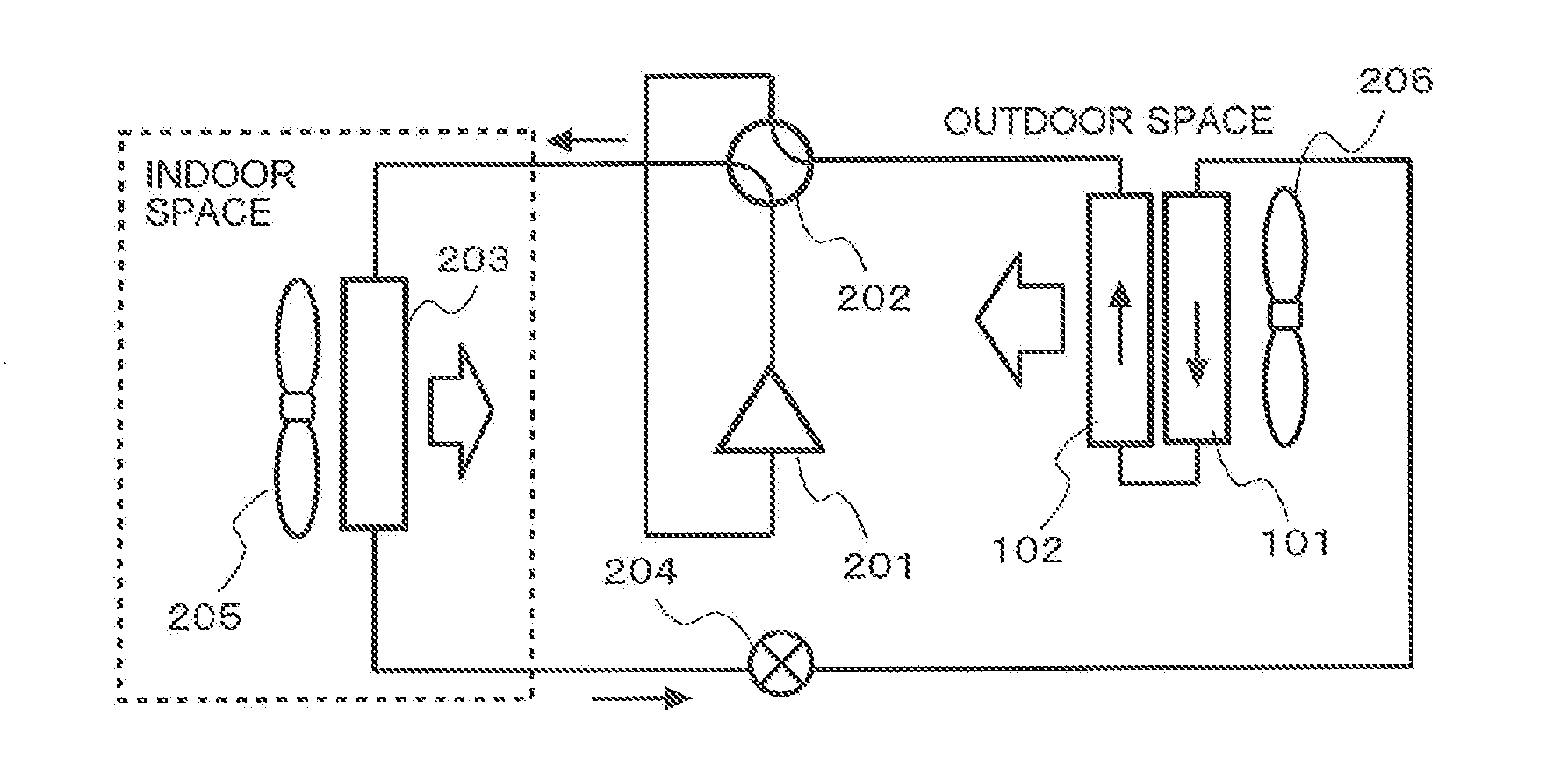

Air Conditioner

InactiveUS20080236189A1Liquid compression can be preventedReduce refrigerant consumptionCompressorCompression machines with non-reversible cycleEvaporationEngineering

An air conditioner (1) including a heat source side heat exchanger (23) constructed such that, when it functions as the evaporator for a refrigerant, the refrigerant flows in from the lower side and flows out from the upper side and having a refrigerant circuit (12) capable of switching to cause the heat source side heat exchanger (23) and use side heat exchangers (32, 42, 52) to function individually as the evaporator or the condenser for the refrigerant. The range of control when evaporation ability of the heat source side heat exchanger (23) is controlled by a heat source side expansion valve (24) is expanded. When the heat source side heat exchanger (23) is operated to function as the evaporator, the air conditioner (1) causes the refrigerant discharged from a compression mechanism (21) through a first bypass circuit (102) to bypass to the suction side of the compression mechanism (21), switches the heat source side heat exchanger (23) to operation in which it functions as the condenser, and closes the heat source side expansion valve (24). By this, a freezing machine oil collected in the heat source side heat exchanger (23) through a first oil return circuit (101) is returned to the suction side of the compression mechanism (21) from the lower part of the heat source side heat exchanger (23).

Owner:DAIKIN IND LTD

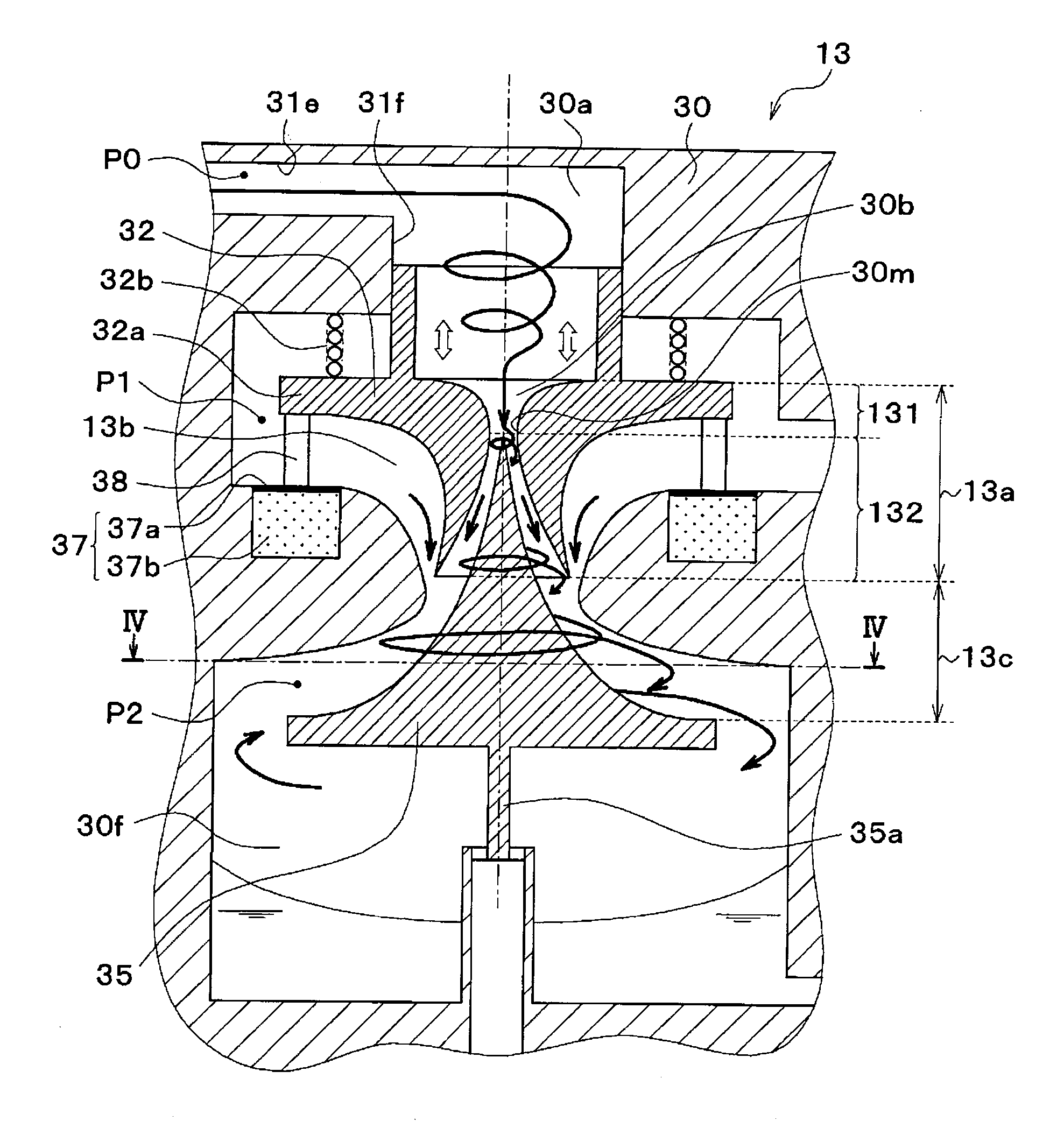

Ejector

InactiveUS20150330671A1Reduce refrigerant consumptionLower limitCompression machines with non-reversible cycleJet pumpsEngineeringRefrigerant

An ejector includes a body part having a depressurizing space in which a refrigerant flowing out of a swirling space is depressurized, a suction passage that draws a refrigerant from an external, and a pressurizing space in which the refrigerant from the depressurizing space is mixed with the refrigerant from the suction passage, a conical passage formation member that is arranged in the body part, and a driving device that displaces a nozzle body of the body part forming the depressurizing space. A nozzle passage is defined on an outer peripheral side of the passage formation member in the depressurizing space, a diffuser passage is formed on an outer peripheral side of the passage formation member in the pressurizing space, and an actuating bar that couples the driving device with the nozzle body is arranged without crossing the diffuser passage.

Owner:DENSO CORP

Air-conditioning apparatus for vehicle

ActiveUS20200338956A1Effectively dividingEfficient integrationAir-treating devicesElectric machinesElectrical batteryHigh voltage battery

An air-conditioning apparatus for a vehicle may include a radiator module; a refrigerant module; a hot portion for heat-exchanging with a condenser and a heater core of an internal air-conditioning module; a cold portion for heat-exchanging with an evaporator and a cooling core of the internal air-conditioning module; an electric portion for heat-exchanging with an electric component; a battery portion for heat-exchanging with a high-voltage battery; a connection module for connecting the hot portion, the electric portion, or the battery portion to any one or more radiators among a first radiator, a second radiator, and a third radiator; and a control unit configured of controlling the operations of a compressor and a valve.

Owner:HYUNDAI MOTOR CO LTD +2

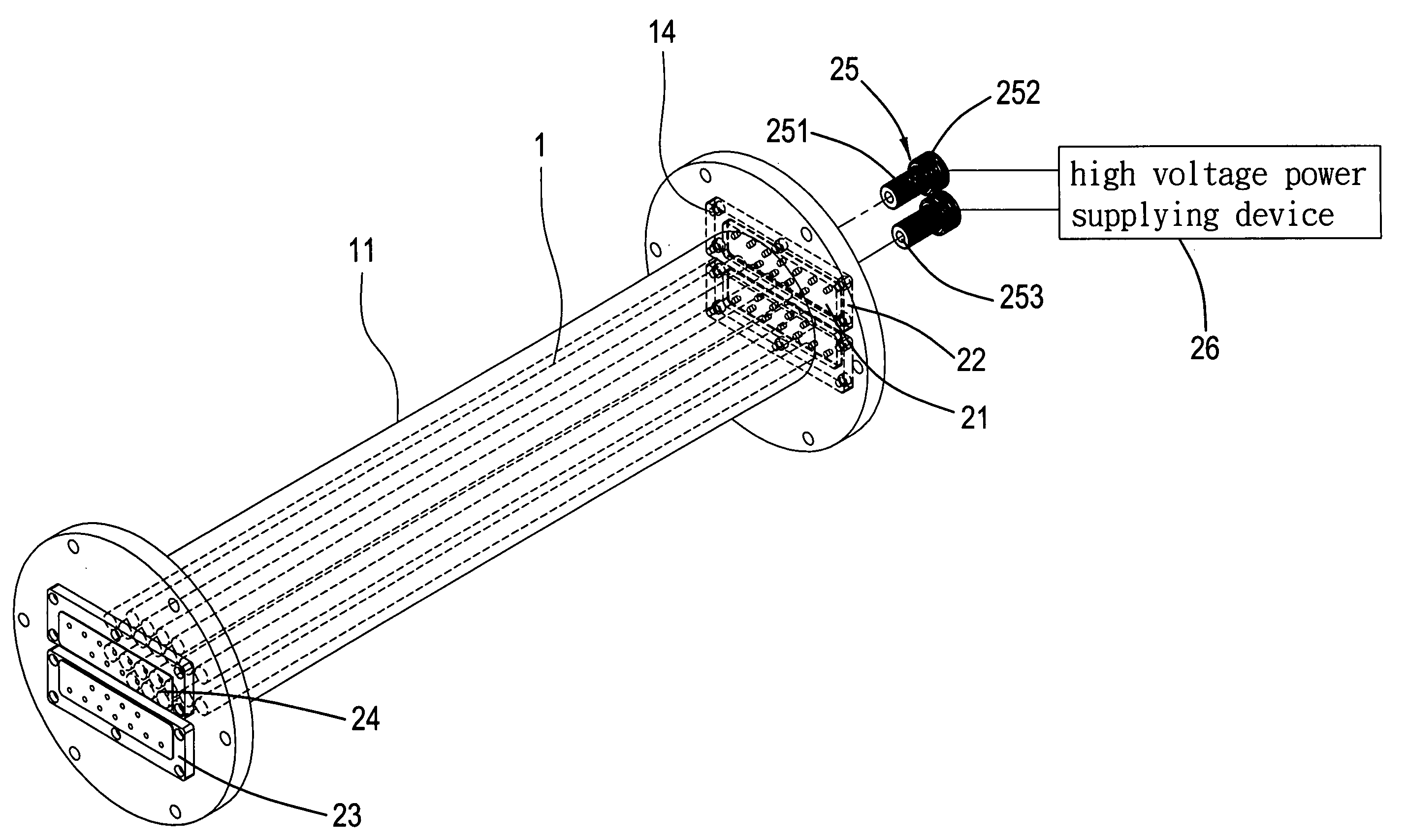

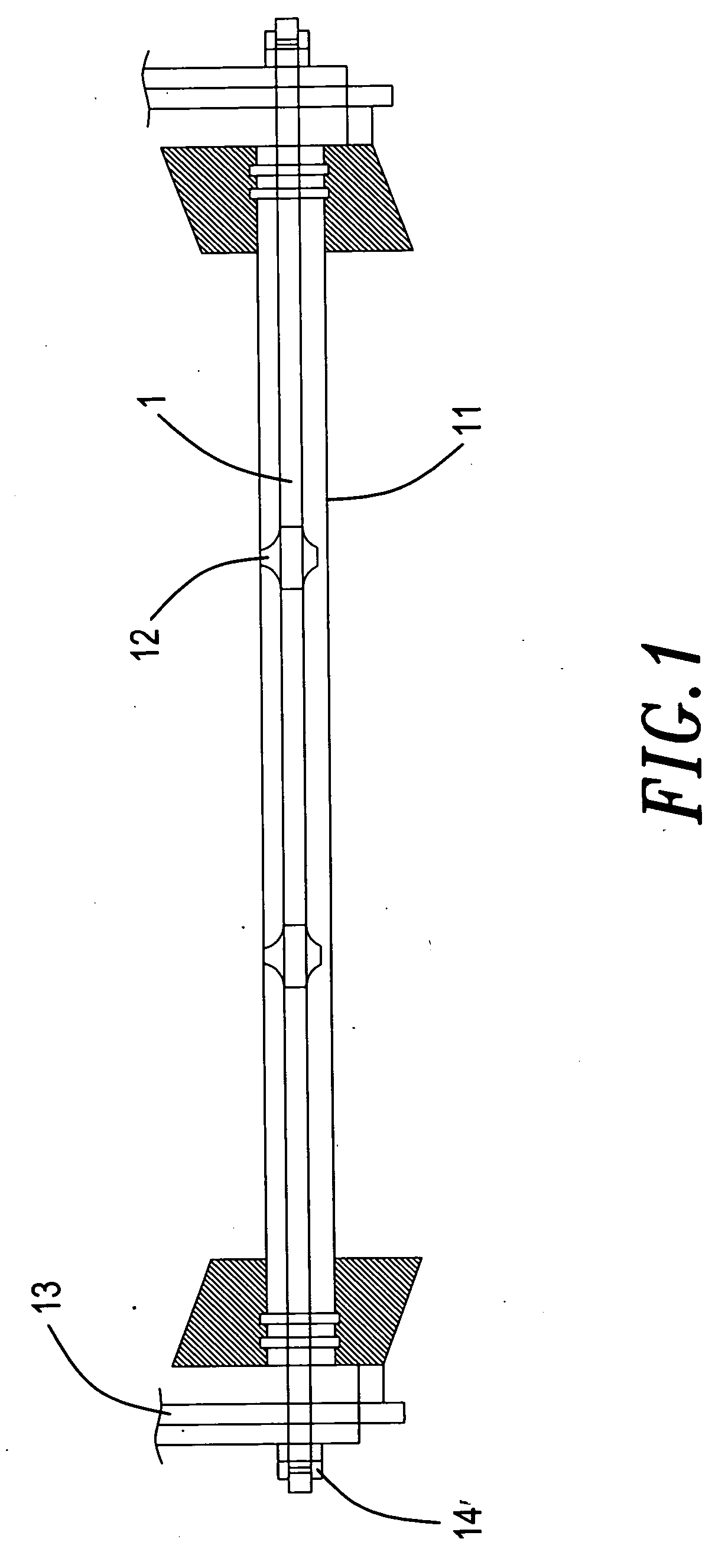

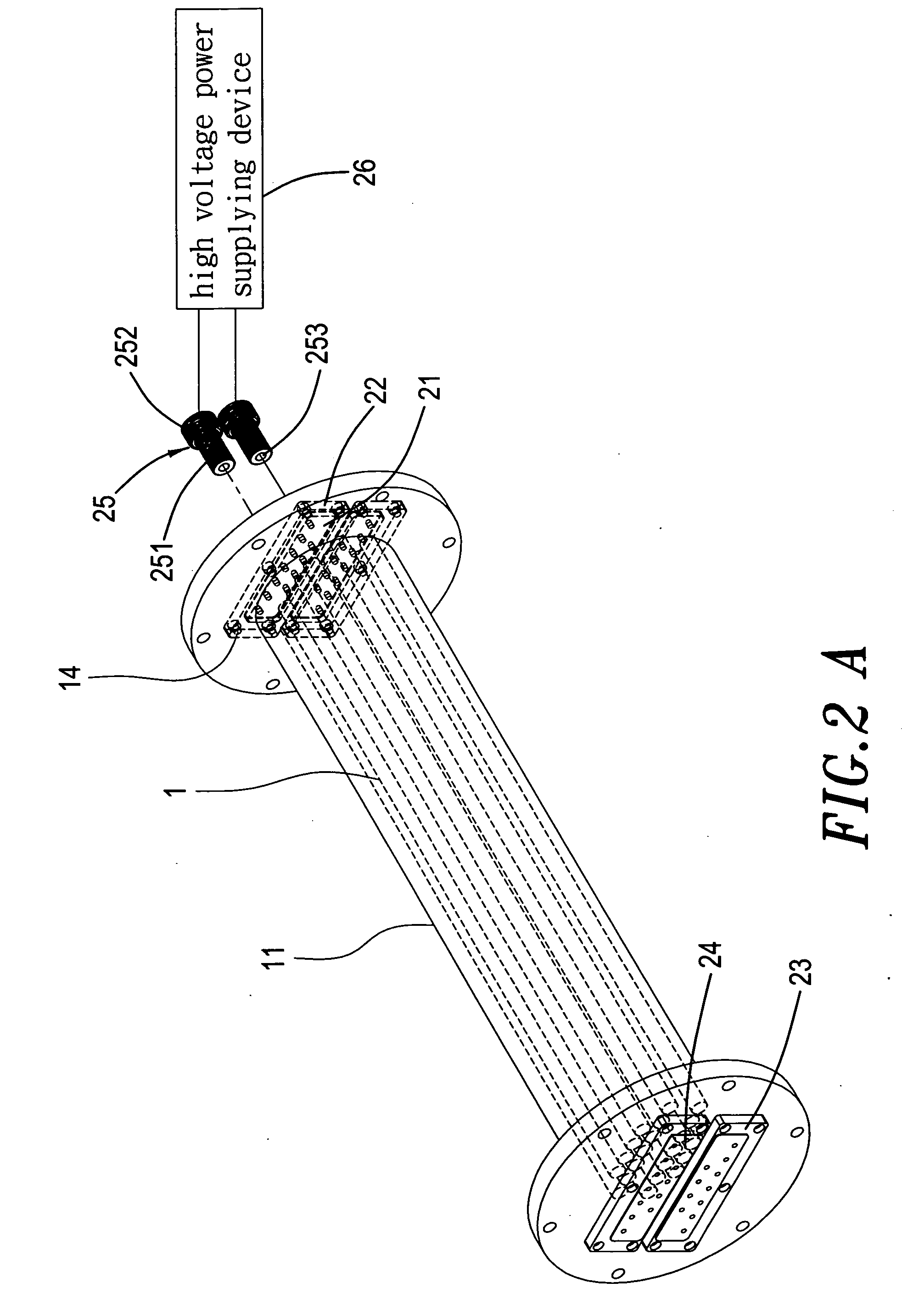

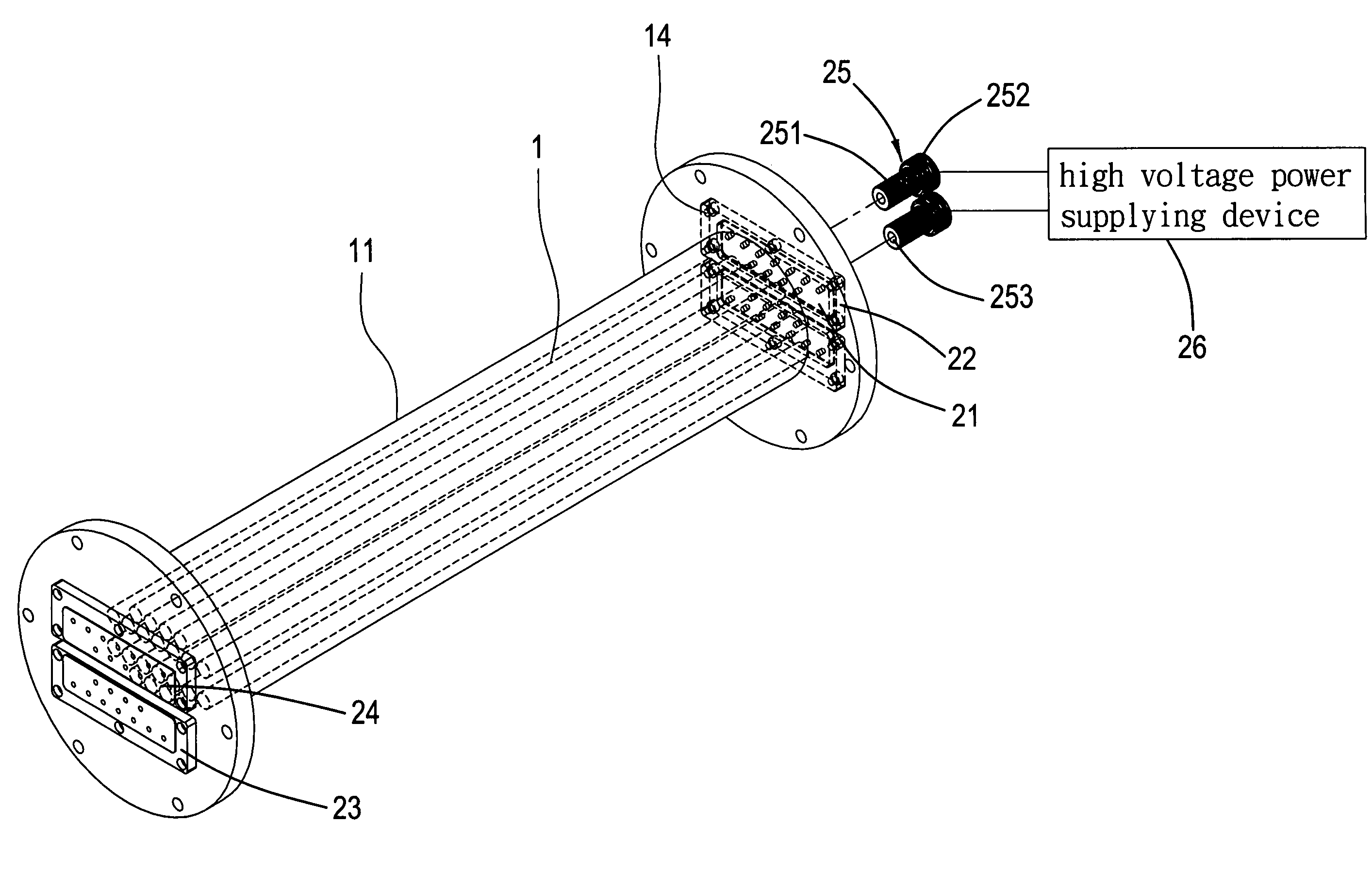

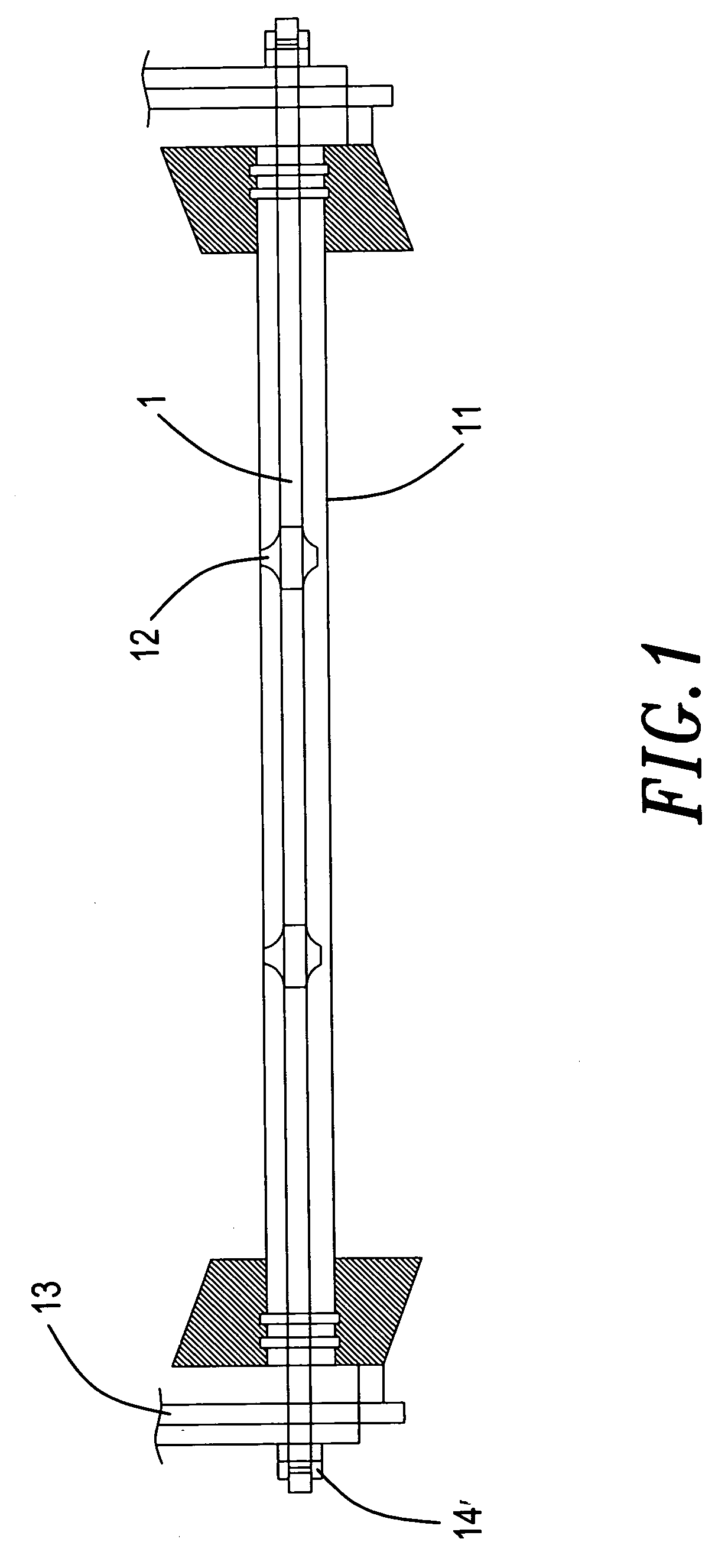

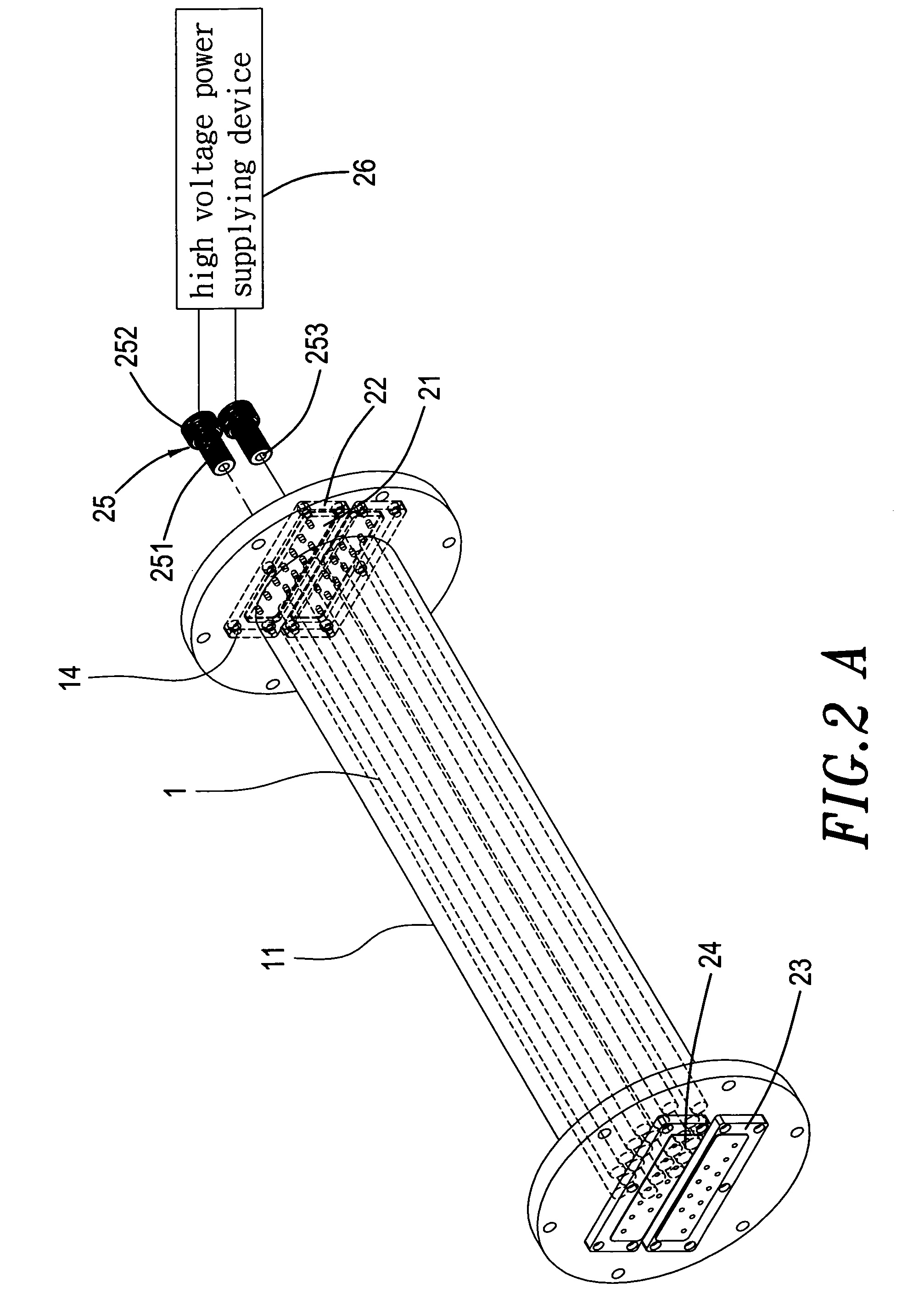

Electrohydrodynamic evaporator device

InactiveUS20070051129A1Reduced dimensionReduce volumeEvaporators/condensersIndirect heat exchangersVoltage dropEngineering

An electrohydrodynamic evaporator device (EHD) has an EHD electrode. An electric field is generated upon a fluid of low conductivity inside the evaporator device and an enhanced thermal transport effect is then achieved since a thermal boundary layer near a thermal transport surface is caused to have a greater perturbation while a very small voltage drop. With the EHD utilized, size, weight, cost and required refrigerant amount of the evaporator device are reduced. Further, thermal transport efficiency of the alternative refrigerant is improved, making the EHD evaporator device in compliance with associated refrigerant regulations made by CFC and achieve the purposes of environmental protection and energy saving.

Owner:NAT TAIPEI UNIV OF TECH

Plasma processing apparatus and maintenance method therefor

ActiveUS8833089B2High maintenance costShorten the timeElectric discharge tubesCompression machinesEngineeringCheck valve

Owner:HITACHI HIGH-TECH CORP

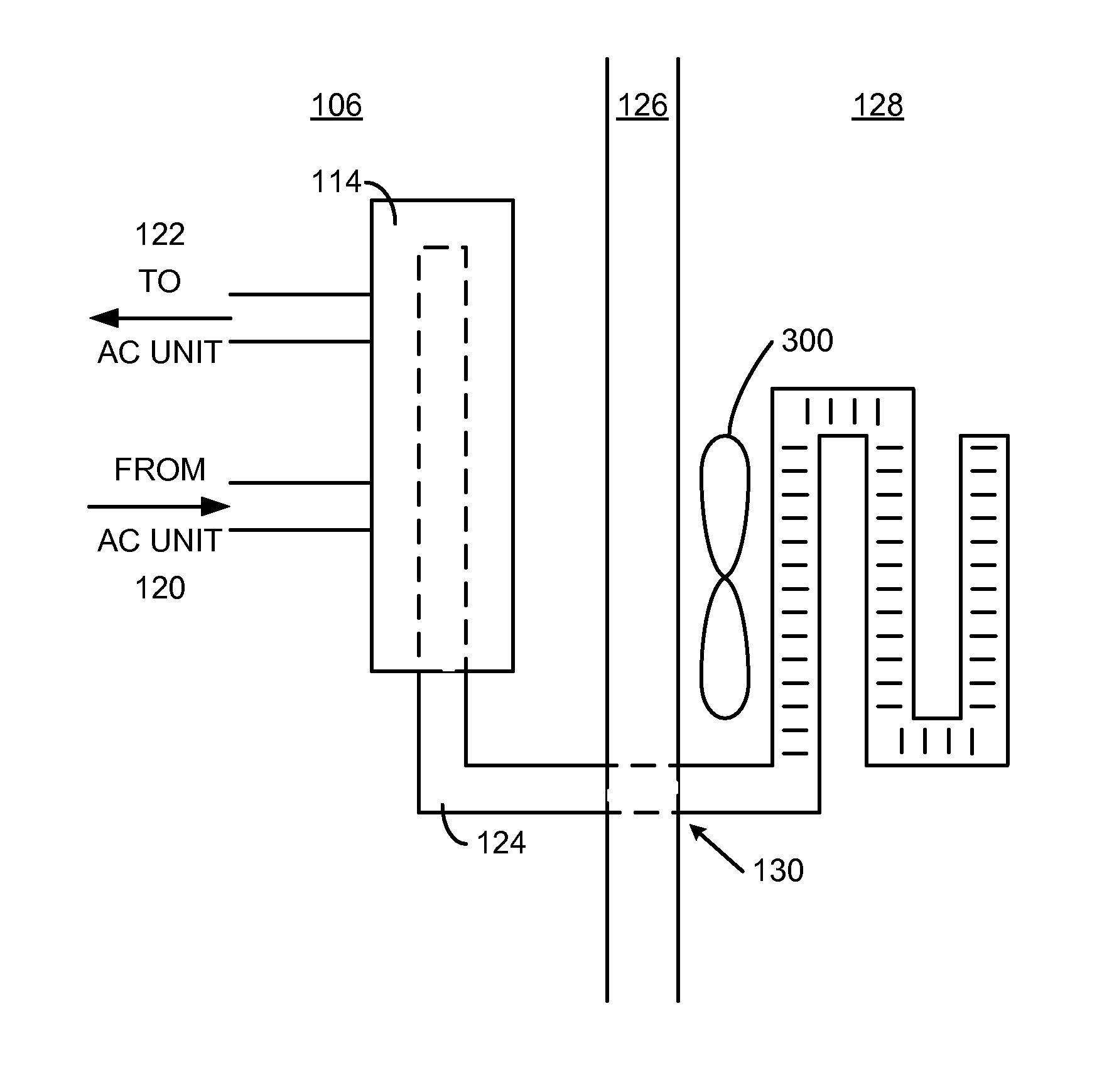

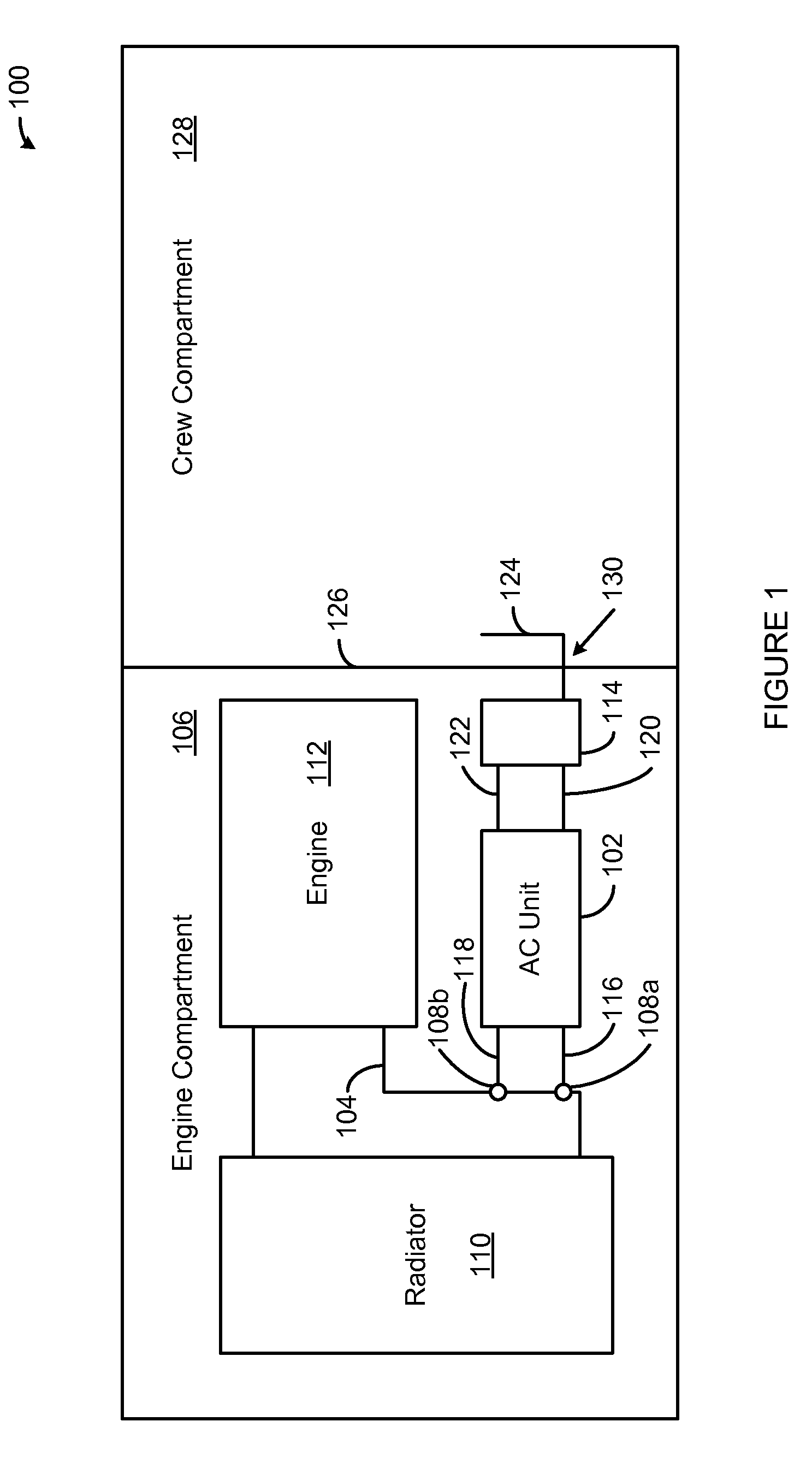

Vehicle air conditioner

InactiveUS8544292B2Easy to installEasy to removeAir-treating devicesRailway heating/coolingEngineeringRefrigerant

The present invention provides an air conditioner for a vehicle that includes a closed refrigeration loop. The closed refrigeration loop includes a compressor, a refrigerant-to-coolant heat exchanger, a coolant-to-refrigerant heat exchanger and a refrigerant dryer in series fluid connection with one another. An engine coolant outlet connector is connected to the coolant-to-refrigerant exchanger. A compartment inlet connector connected to the coolant-to-refrigerant heat exchanger. A compartment outlet connector connected to the refrigerant-to-coolant heat exchanger. An engine coolant inlet connector connected to the refrigerant-to-coolant heat exchanger.

Owner:OMNITHERM +1

Electric vehicle and thermal management system therefor

ActiveUS9428032B2Reduce wasteGood effectAir-treating devicesRailway heating/coolingTraffic capacityPlate heat exchanger

Owner:HANGZHOU SANHUA RES INST CO LTD

Valve block assembly for several valves

ActiveUS9683671B2Reduce in quantityImpact pressure lossServomotor componentsVehicle heating/cooling devicesEngineeringVALVE PORT

Owner:HANON SYST

Electrohydrodynamic evaporator device

InactiveUS7269971B2Reduced dimension and volume and weightReduce refrigerant consumptionEvaporators/condensersIndirect heat exchangersVoltage dropThermal transport

An electrohydrodynamic evaporator device (EHD) has an EHD electrode. An electric field is generated upon a fluid of low conductivity inside the evaporator device and an enhanced thermal transport effect is then achieved since a thermal boundary layer near a thermal transport surface is caused to have a greater perturbation while a very small voltage drop. With the EHD utilized, size, weight, cost and required refrigerant amount of the evaporator device are reduced. Further, thermal transport efficiency of the alternative refrigerant is improved, making the EHD evaporator device in compliance with associated refrigerant regulations made by CFC and achieve the purposes of environmental protection and energy saving.

Owner:NAT TAIPEI UNIV OF TECH

Variable capacity compressor

ActiveUS20180187665A1Decrease amount of refrigerantDecrease strokeMulti-stage pumpsPositive-displacement liquid enginesEngineeringBack pressure

[Object] To provide a variable capacity compressor configured to achieve an enhancement of an activation performance of a compressor and reduce an amount of internally circulating refrigerant during an intermediate stroke in a simple structure.[Solving Means] A supply passage 40 configured to cause a discharge chamber 34 and a control pressure chamber 4 to communicate with each other; a first bleed passage 42 configured to cause the control pressure chamber 4 and an inlet chamber 33 to communicate with each other; a first control valve 50 configured to adjust an opening degree of the supply passage 40; and a second control valve 45 provided on the first bleed passage 42 are provided, and the second control valve 45 includes: a spool 47 housed in a spool housing recess formed on a bleed passage and configured to open and close the first bleed passage 42, a back pressure chamber 48 formed behind the spool 47, and biasing means (compression spring 49) configured to bias the spool 47 in a direction of opening the first bleed passage 42. The back pressure chamber 48 of the second control valve 45 is selectively connected to the discharge chamber 34 or the inlet chamber 33 via the first control valve 50.

Owner:VALEO JAPAN CO LTD

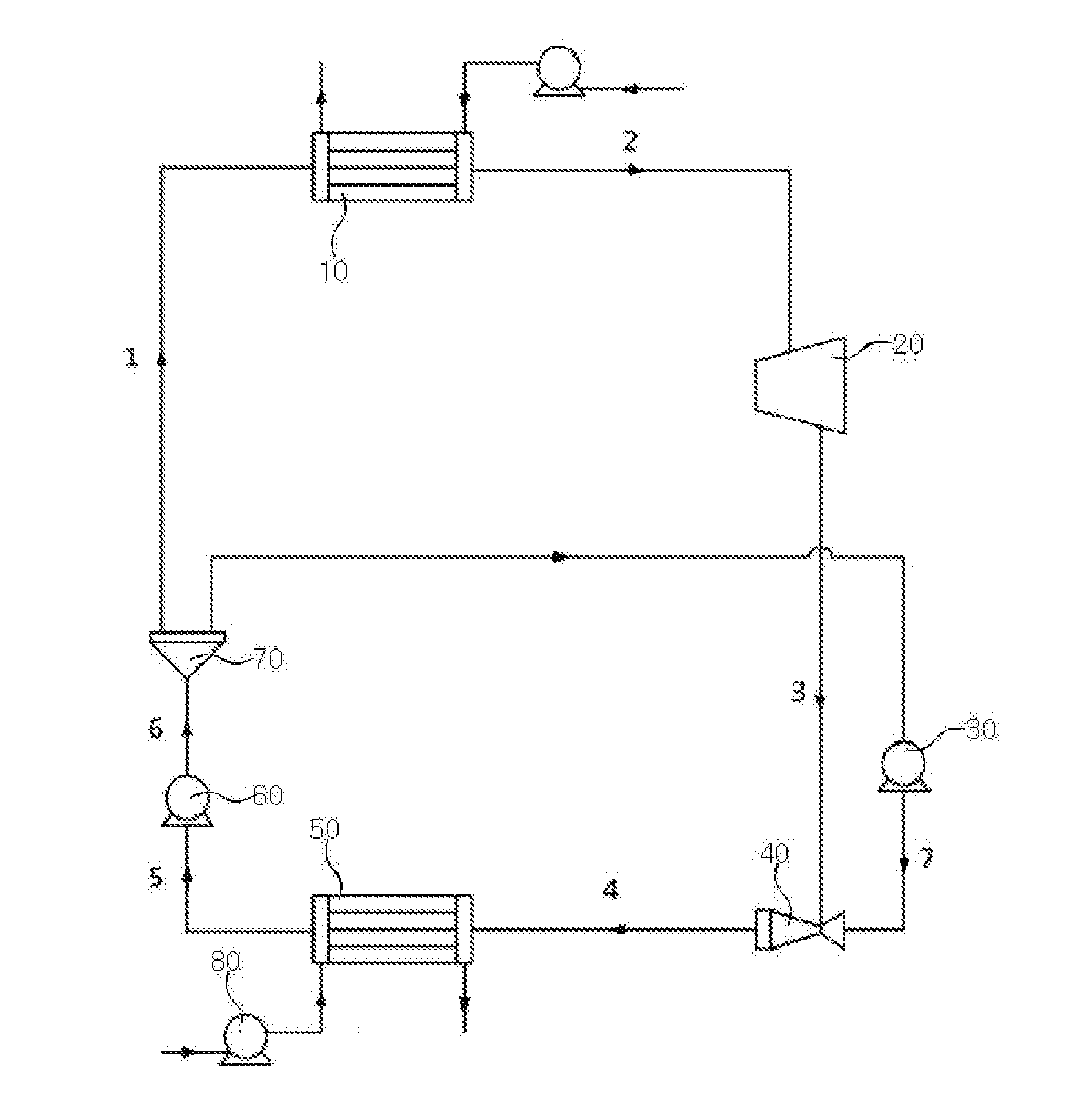

High efficiency ocean thermal difference power generating system using liquid-vapor ejector and motive pump

ActiveUS20160341184A1Increase efficiency of systemReduce amount of heatSteam engine plantsMechanical power devicesSeawaterEvaporator

There is provided a high efficiency ocean thermal difference power generating system by using liquid-vapor ejector and motive pump comprising: an evaporator for changing transferred refrigerant liquid into refrigerant vapor with high temperature and high pressure by the thermal exchange with surface seawater; a vapor-liquid divider which is installed at the outlet part of the evaporator and divides the refrigerants to liquid-state refrigerant and vapor-state refrigerant respectively; a distributor which is installed at the inlet of the evaporator and distributes the refrigerants flowed into the evaporator to multi-paths; a turbine for generating electric power by using the high pressure refrigerant vapor transferred from the liquid-vapor divider or the evaporator; a motive pump for increasing the pressure of the refrigerant liquid distributed from the distributor or the liquid-vapor divider; a liquid-vapor ejector for mixing the low pressure refrigerant vapor which passed the turbine and the high pressure refrigerant liquid which passed a motive pump, thereby proceeding expansion and compression; a condenser for condensing the refrigerants which was mixed in the liquid-vapor ejector by the thermal exchange with deep seawater; and a refrigerant circulation pump for increasing the pressure of the refrigerants which was condensed in the condenser up to the evaporation pressure and for circulating.

Owner:KOREA INST OF OCEAN SCI & TECH

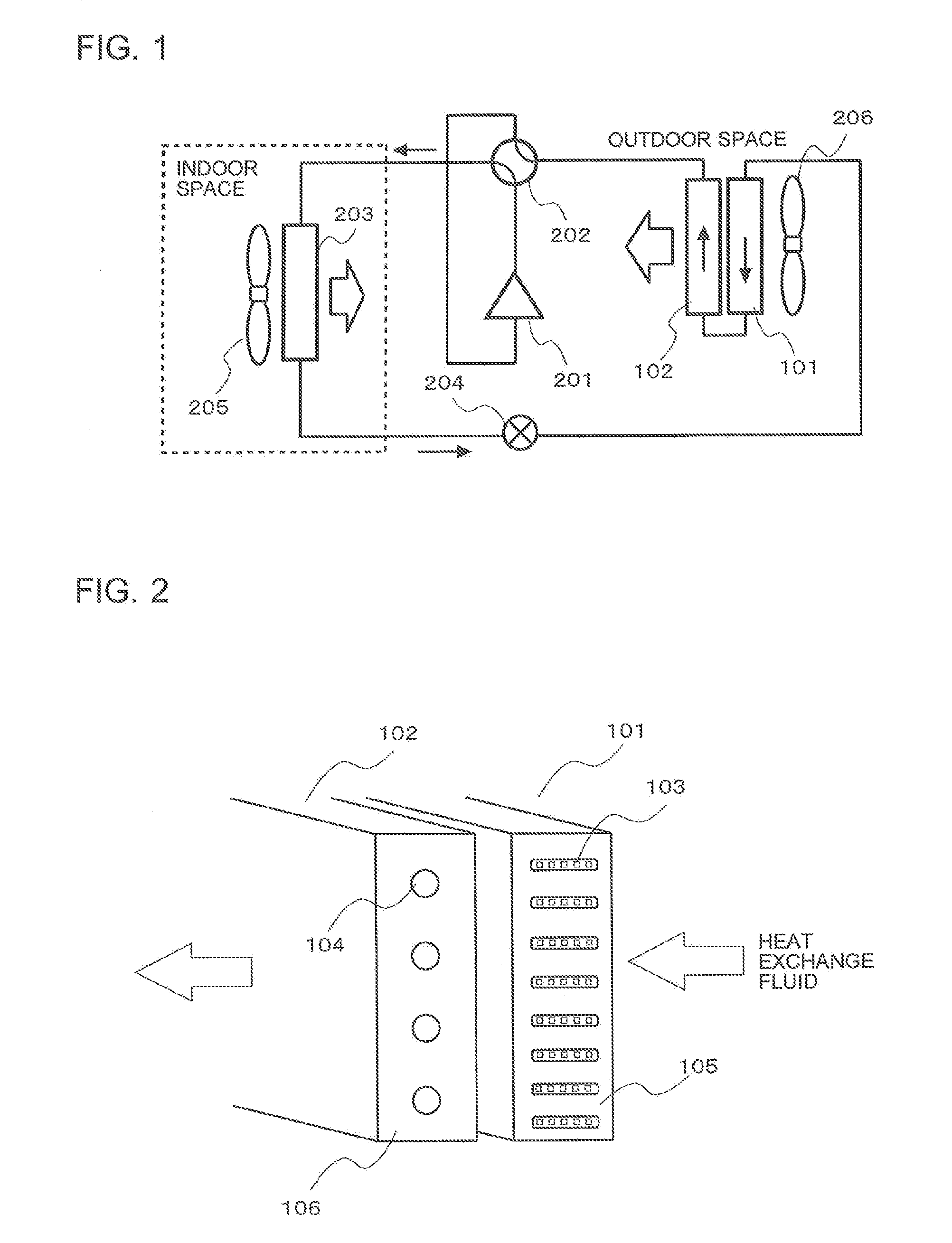

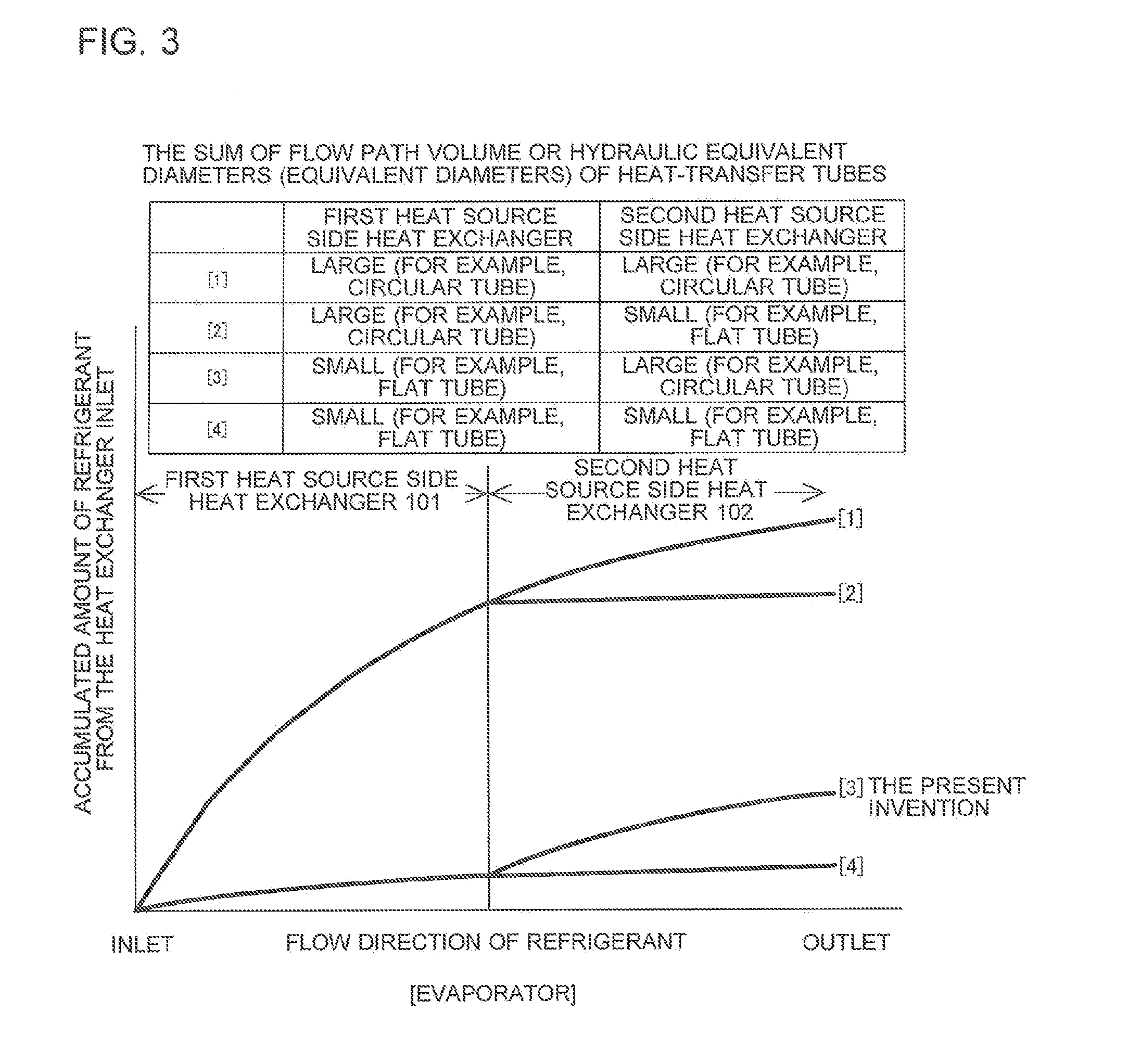

Heat exchanger and refrigeration cycle apparatus using the same heat exchanger

ActiveUS20160245589A1Reduce refrigerant consumptionReduce total pressure lossHeat exhanger conduitsEvaporators/condensersEngineeringRefrigeration

A heat exchanger including a first heat exchanger disposed on upstream side of a heat exchange fluid and a second heat exchanger disposed on downstream side of the heat exchange fluid, which are connected in series in a flow path of a heat medium, wherein the heat medium flows from the first heat exchanger to the second heat exchanger so as to be parallel to the flow of the heat exchange fluid when the heat exchanger serves as an evaporator, the heat medium flows from the second heat exchanger to the first heat exchanger so as to be opposed to the flow of the heat exchange fluid when the heat exchanger serves as a condenser, and a sum of flow path volume of first heat-transfer tubes of the first heat exchanger is smaller than a sum of flow path volume of second heat-transfer tubes of the second heat exchanger.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com