Refrigerant System with Pulse Width Modulated Components and Variable Speed Compressor

a technology of pulse width modulation and compressor, which is applied in the direction of machines/engines, liquid fuel engines, lighting and heating apparatus, etc., can solve the problems of low operating speed, low limit of desirable compressor speed reduction, and low efficiency of scroll compressors, so as to achieve the effect of lowering the amount of refrigerant delivered to various locations in the refrigerant cycle and reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 301

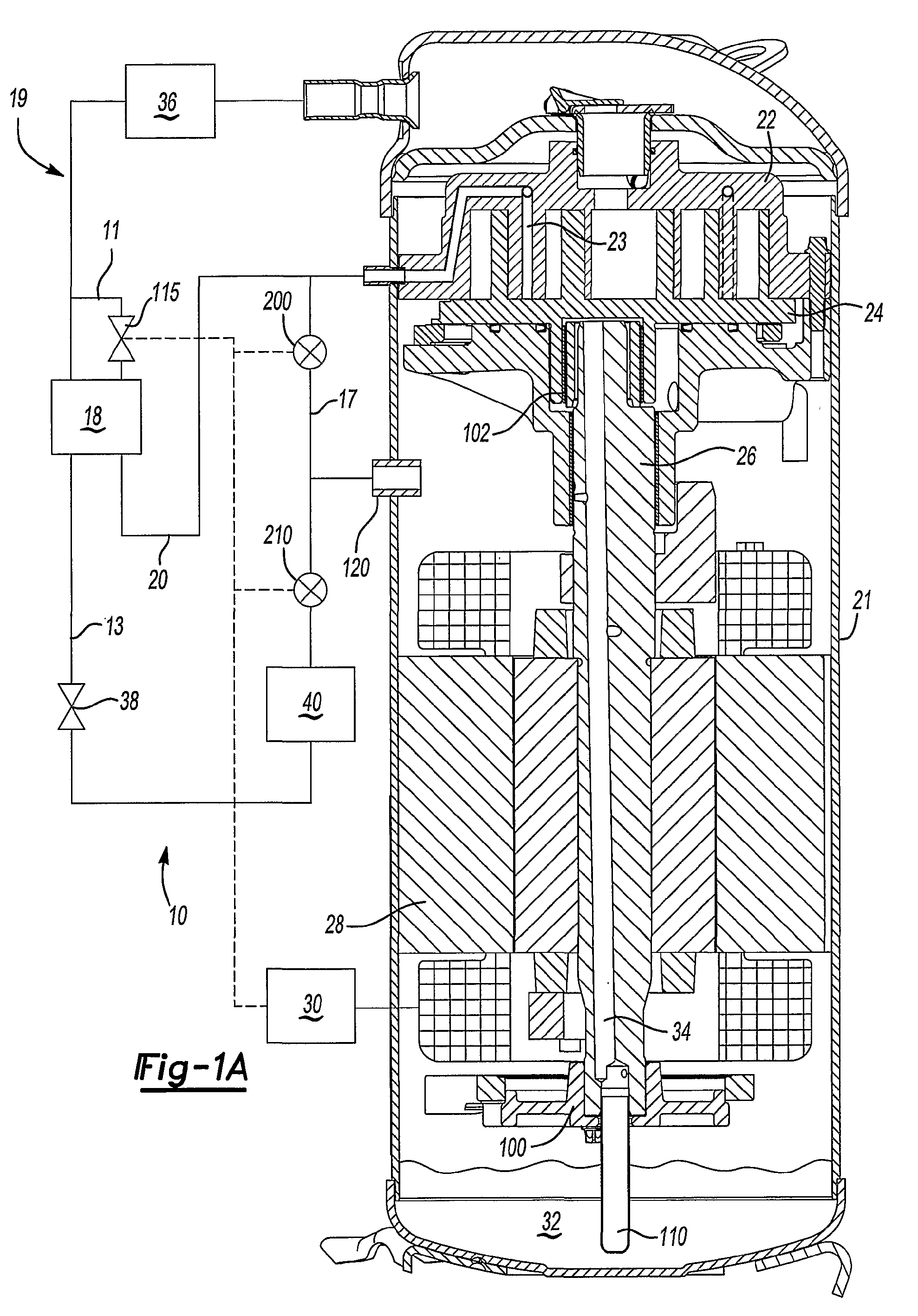

[0021]FIG. 1B shows an embodiment 301, schematically. It is known that the orbiting scroll member 302 and the non-orbiting scroll member 304 may be biased together by a gas in a chamber 306. Opening and closing the valve 310 can control pressure in chamber 306. As shown, the valve 312 communicates via line 308 with another pressure source that is at different pressure than pressure in the chamber 306 when the valve 310 is closed. When the pressure in the chamber 306 is reduced below a certain level the scroll members will separate from each and the amount of refrigerant pumped by the compressor is then reduced. When the pressure in the chamber 306 is increased above certain level the scrolls will come into contact with each other and then the normal compression process will resume. The valve can be controlled by a pulse width modulation control 312. Thus, by modulating the pressure in the chamber 306, the two scroll members 302 and 304 can be allowed to periodically move away from, ...

embodiment 300

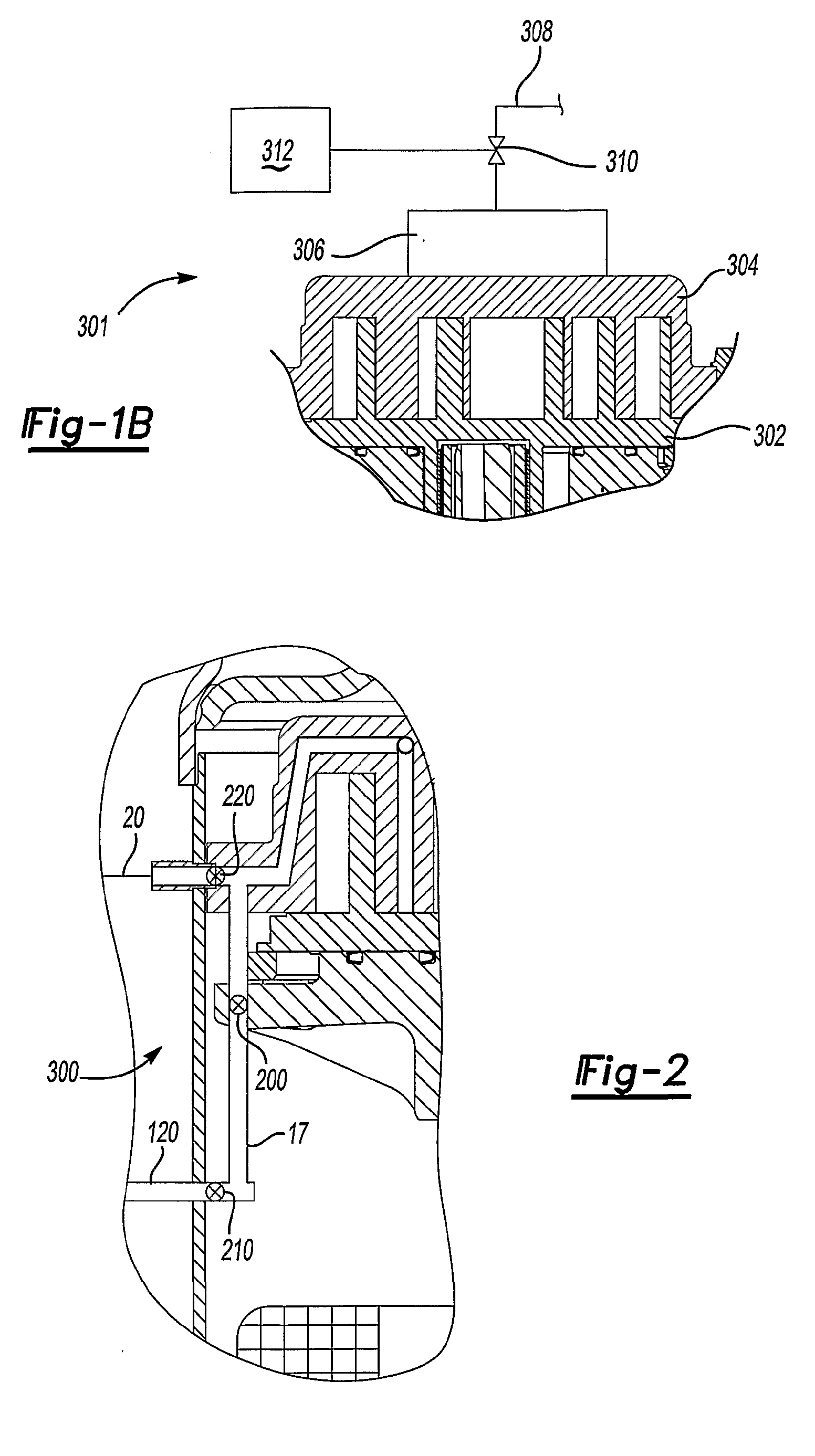

[0024]FIG. 2 shows another embodiment 300 wherein the valves 200 and 210 are internal of the compressor shell as are the flow passages. It should be noted that while in FIG. 2 the valves are all shown as located inside the compressor, a compressor designer may choose to locate some of them internally and some of them externally. In addition, the shut-off valve 220 for the economizer line is shown to be separate from the expansion valve. If the valve 220 is located externally, its function can be combined with the use of an expansion valve. Also while valves are shown as separate components, its function can be combined into a single three-way valve as known in the art. Each or some of the valves 220, 200 and 210 can be controlled by pulse width modulation techniques.

[0025]It should be understood that the motor control 30 includes a program that takes in inputs from various locations within the refrigerant system, and determines when a lower speed for the compressor motor would be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com