Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157results about How to "Reduce knocking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

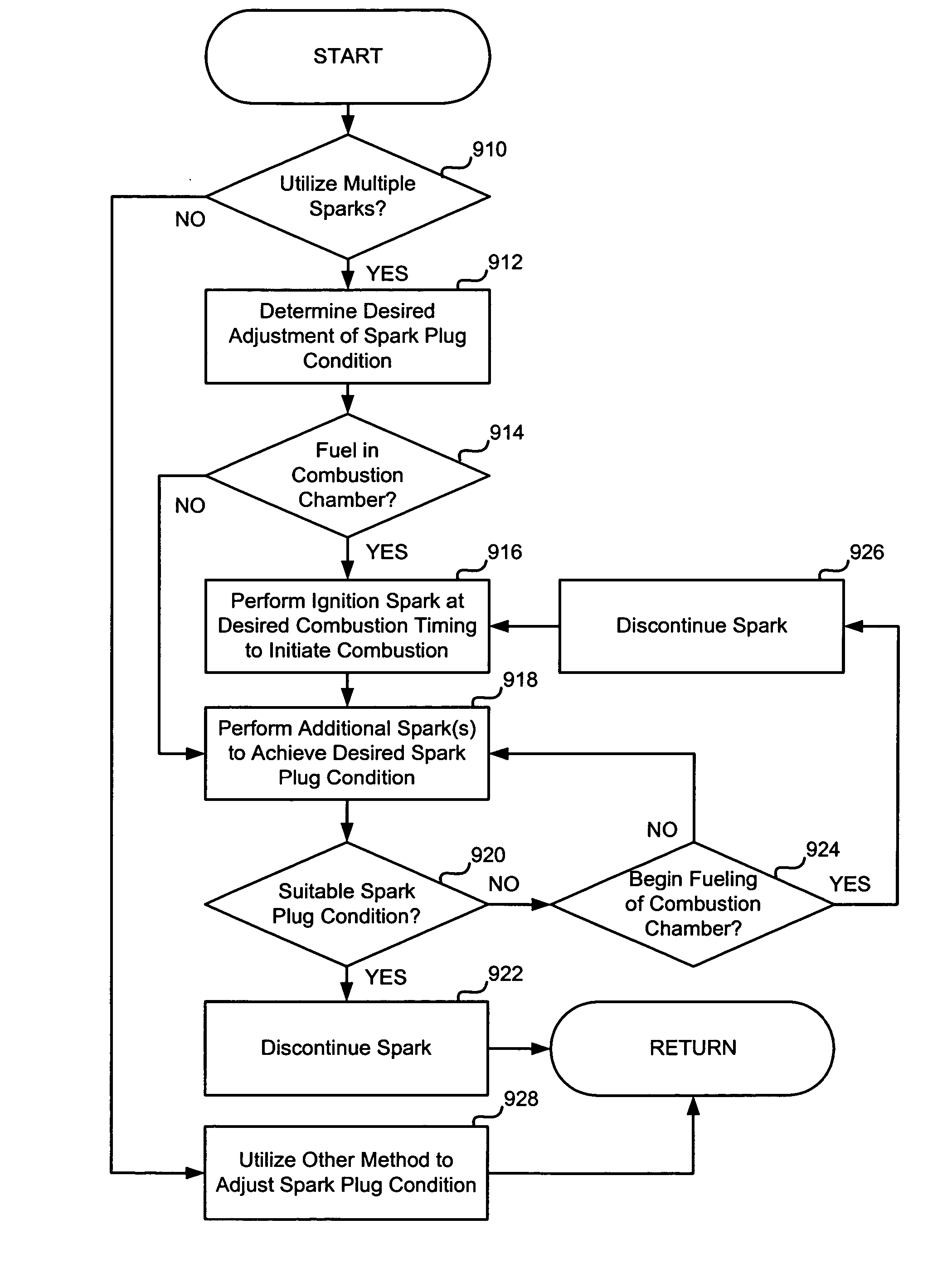

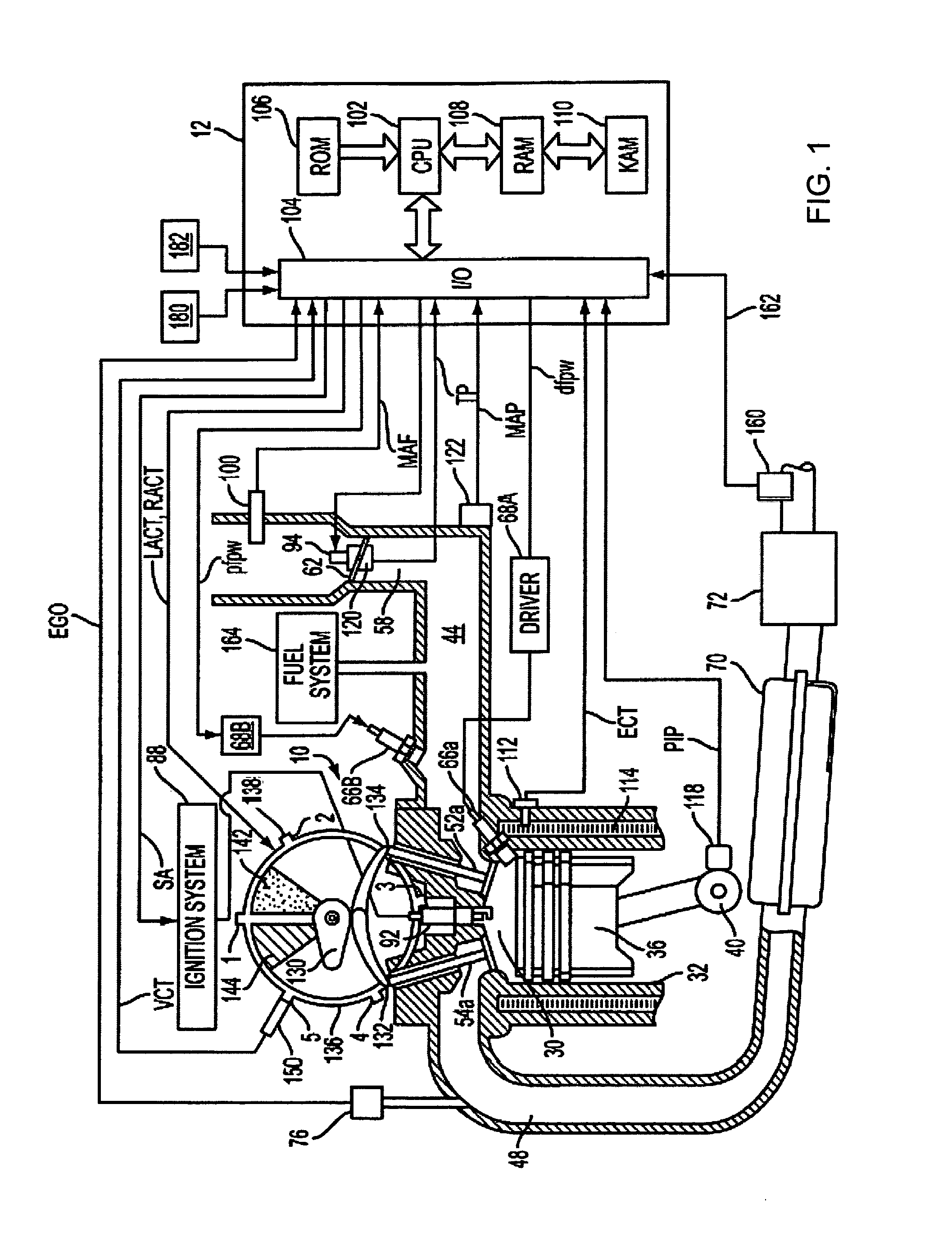

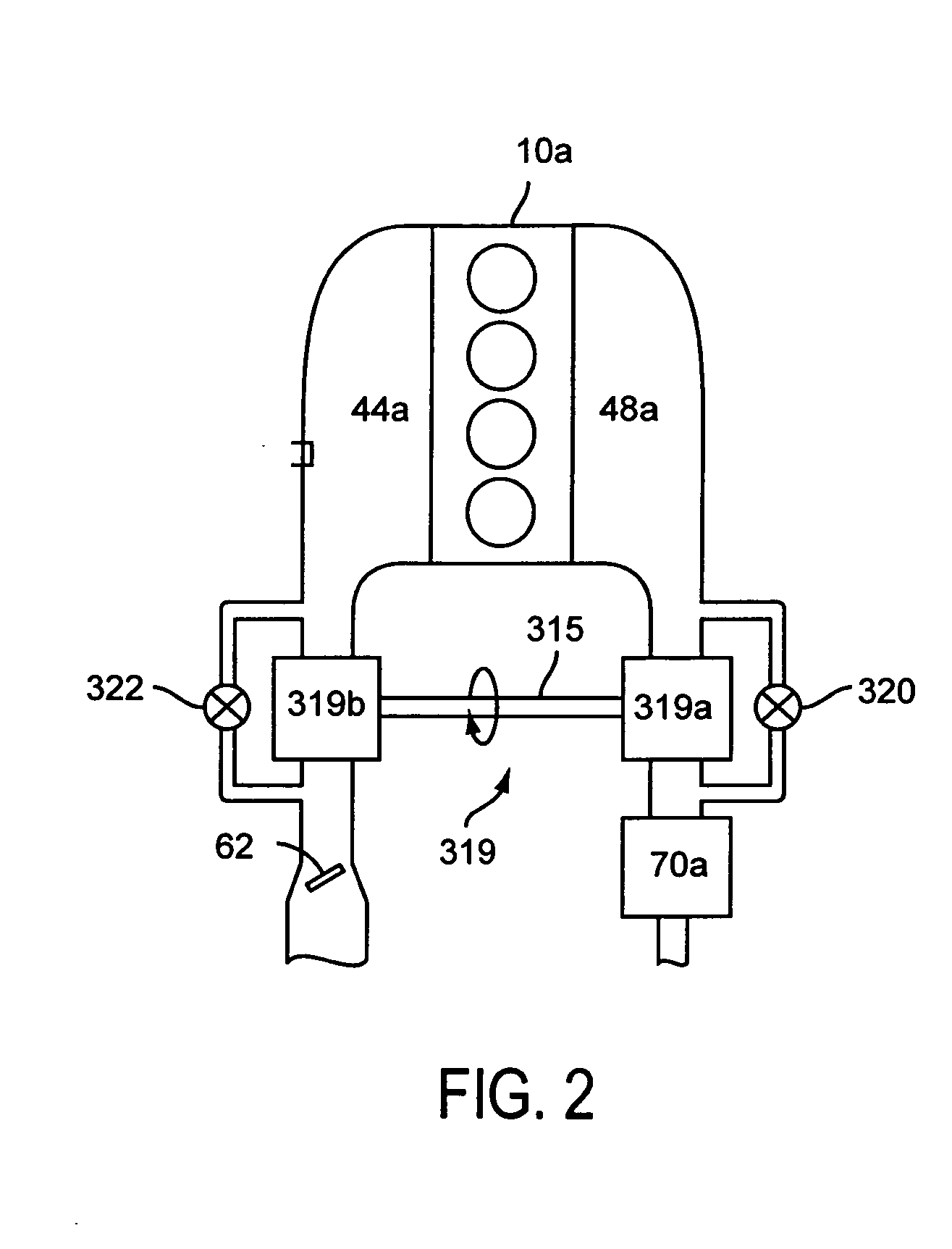

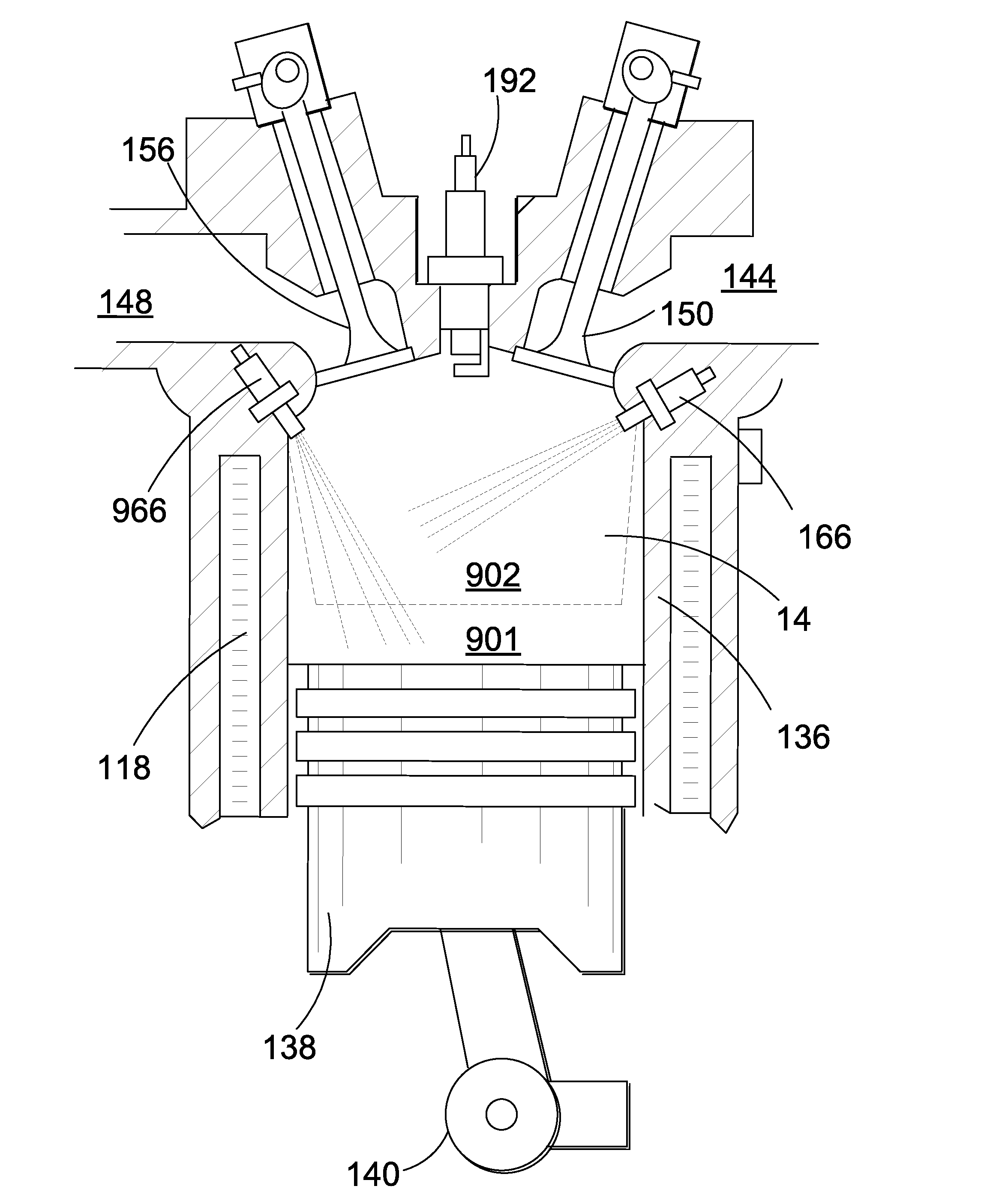

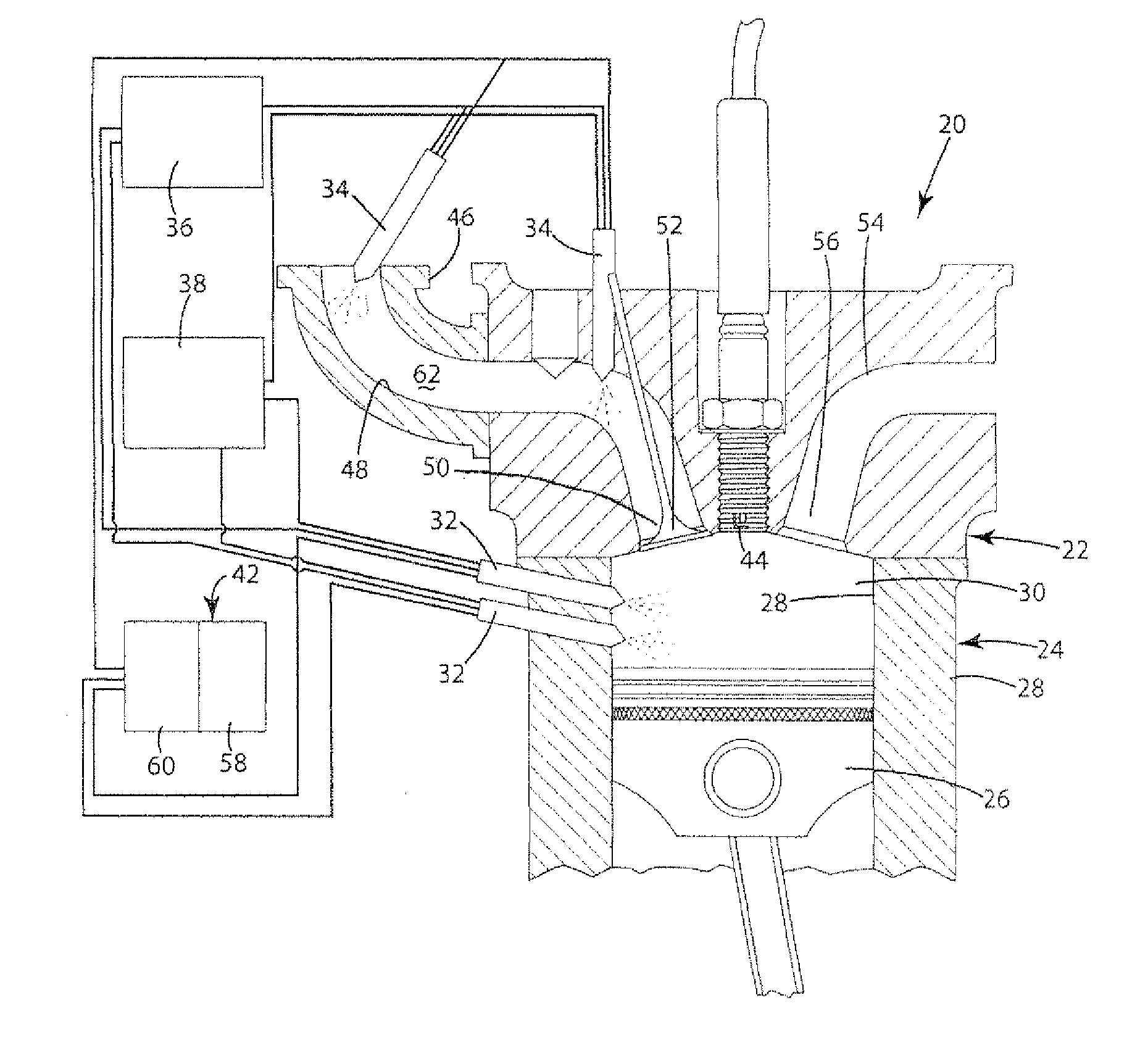

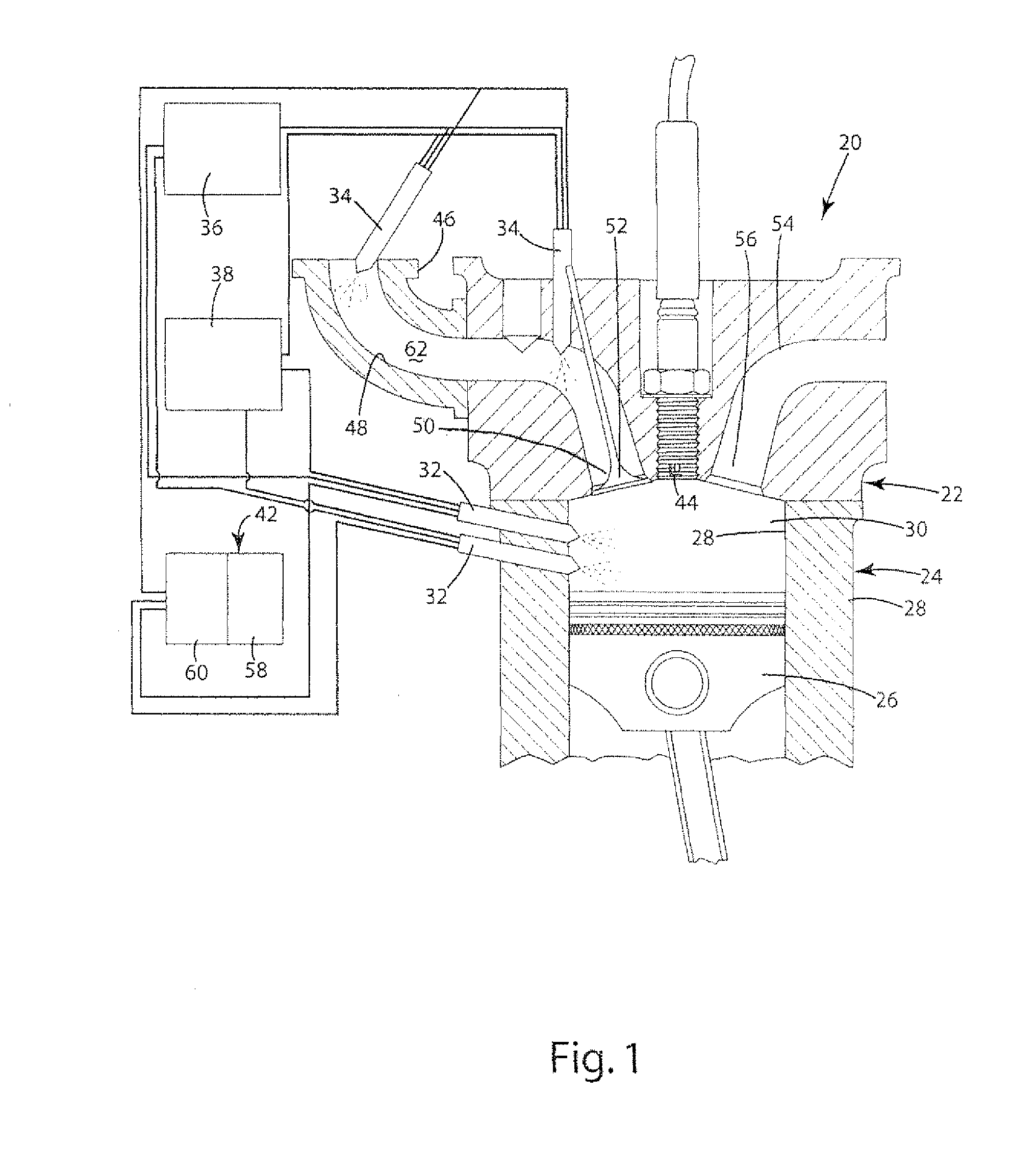

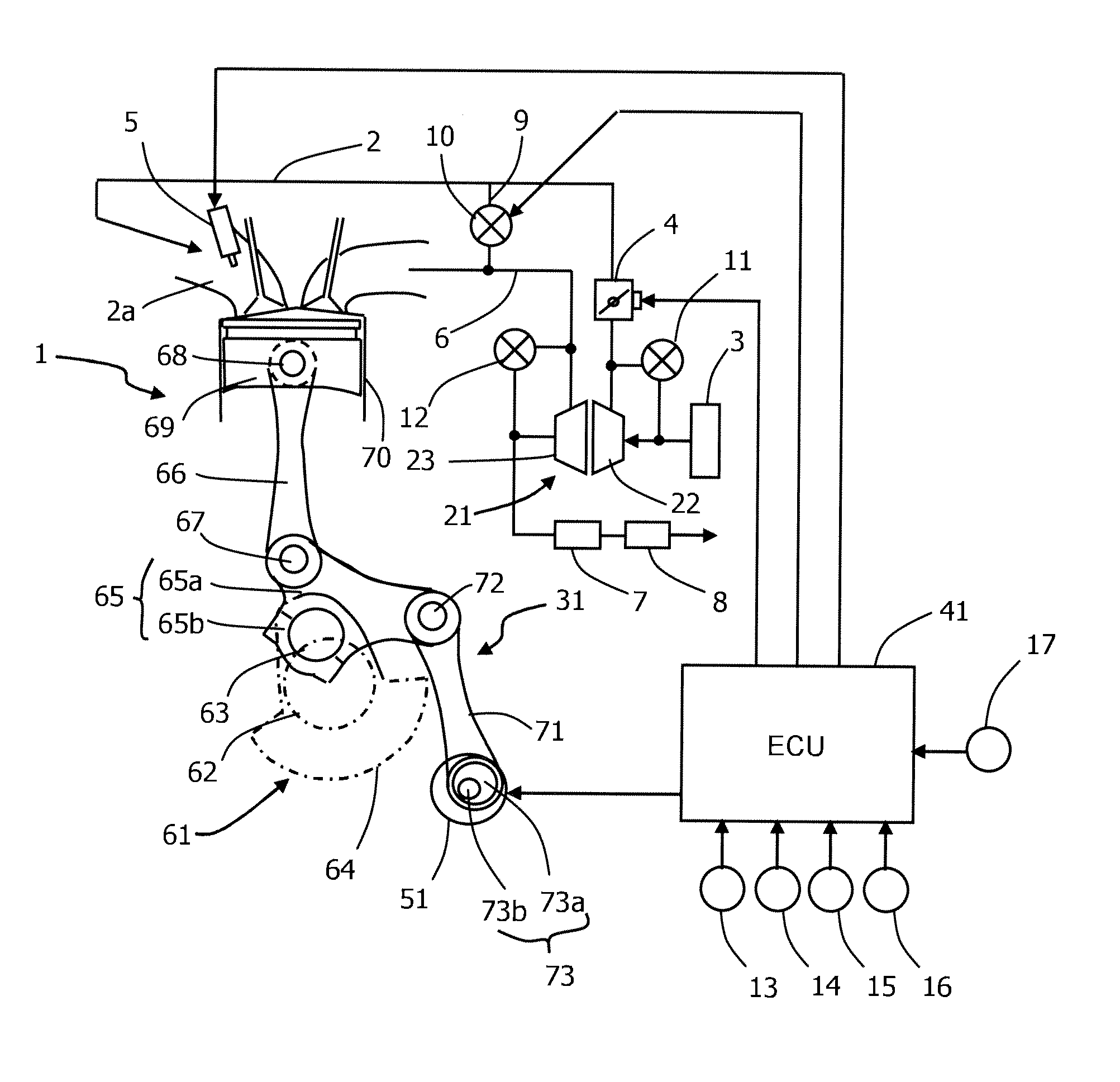

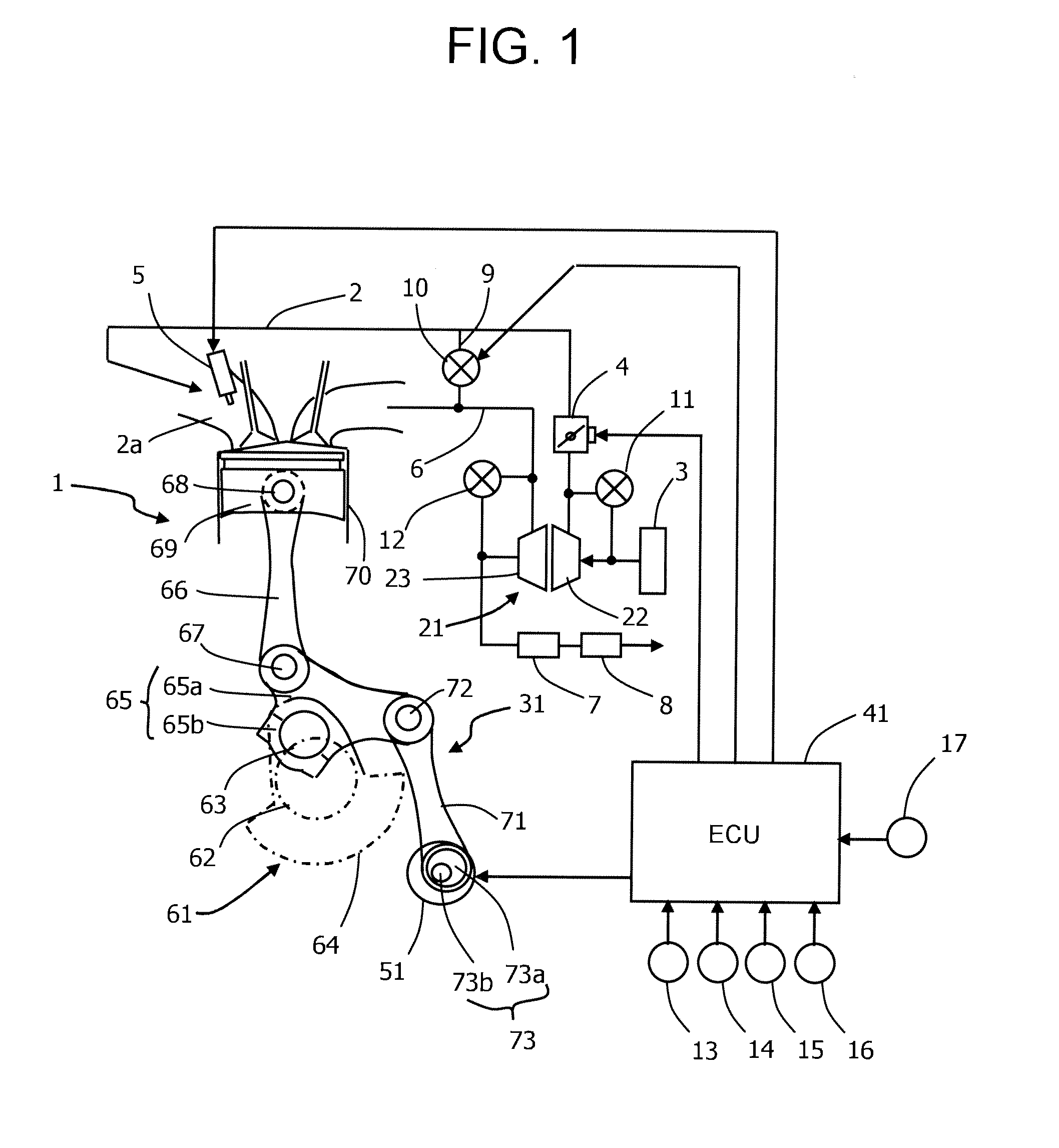

First and second spark plugs for improved combustion control

InactiveUS20070215101A1Low costImprove charge cooling effectElectric ignition installationCombustion enginesCombustion chamberInternal combustion engine

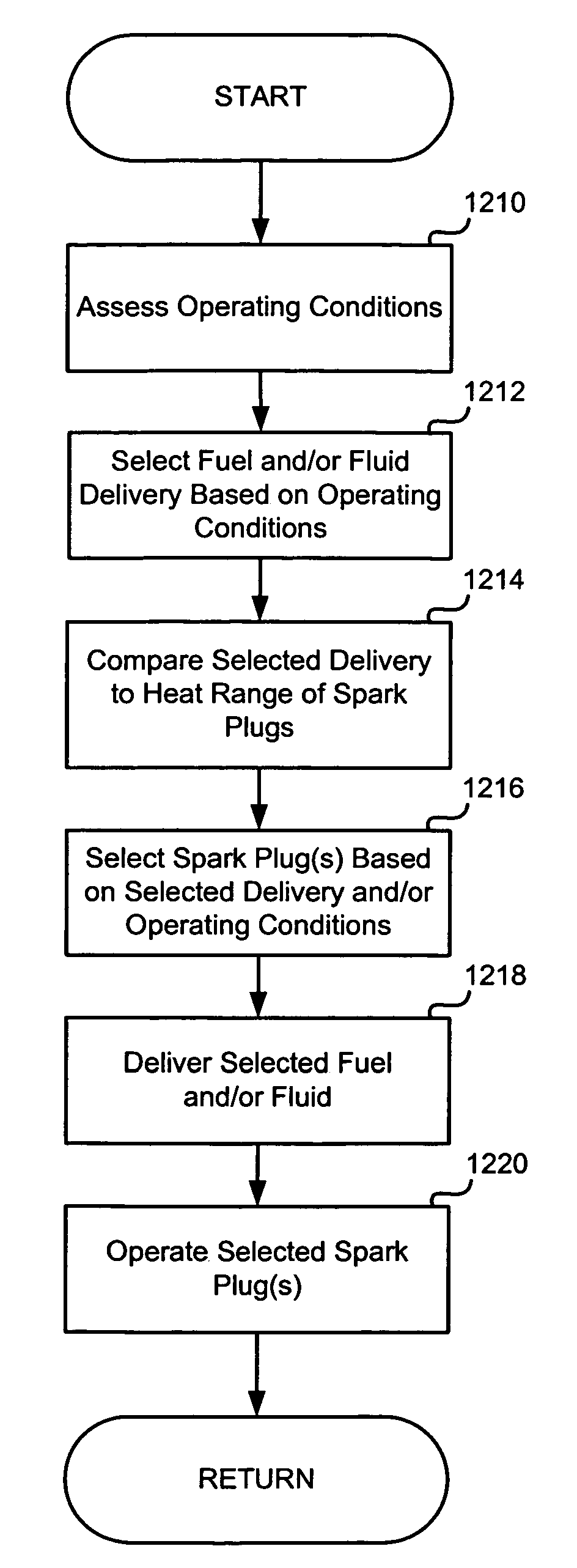

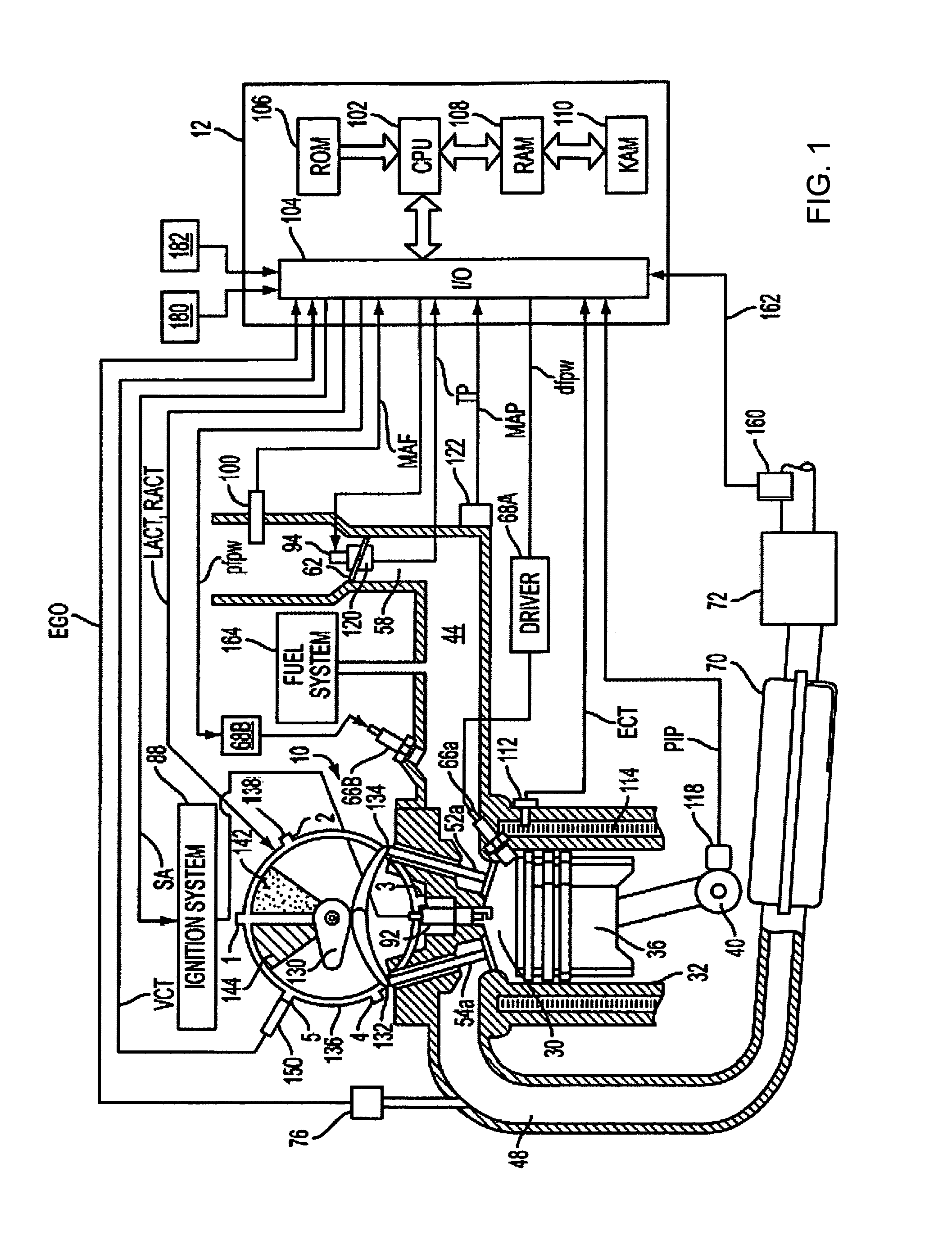

A method of operating an internal combustion engine having at least one combustion chamber including a first spark plug and a second spark plug, wherein the first spark plug is configured to operate at a higher temperature than the second spark plug, the method comprising of varying at least a resulting ratio of an amount of a fuel and an amount of a fluid delivered to the combustion chamber responsive to a first condition, and selectively using at least one of the first spark plug and the second spark plug to ignite at least one of the fuel and the fluid delivered to the combustion chamber.

Owner:FORD GLOBAL TECH LLC

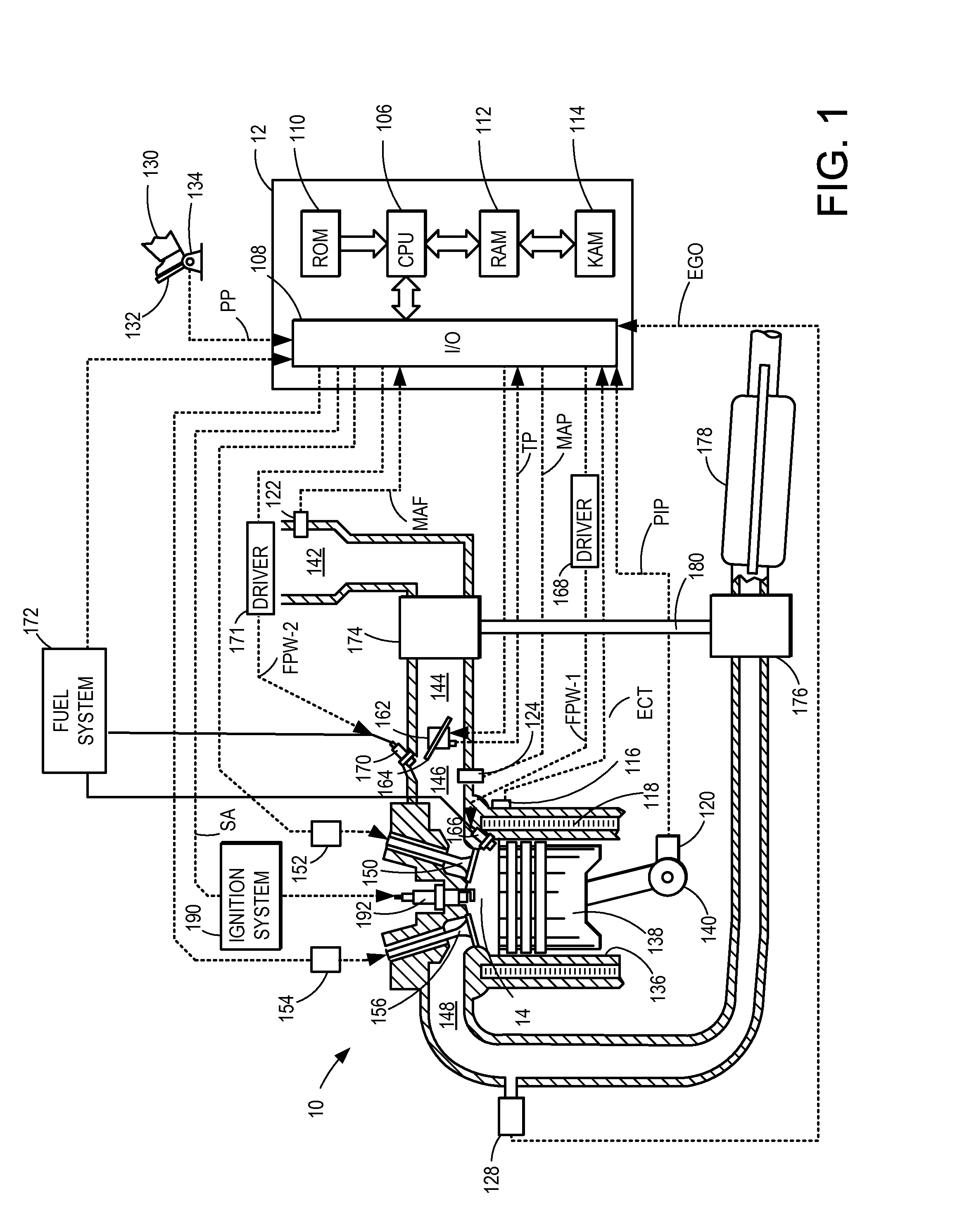

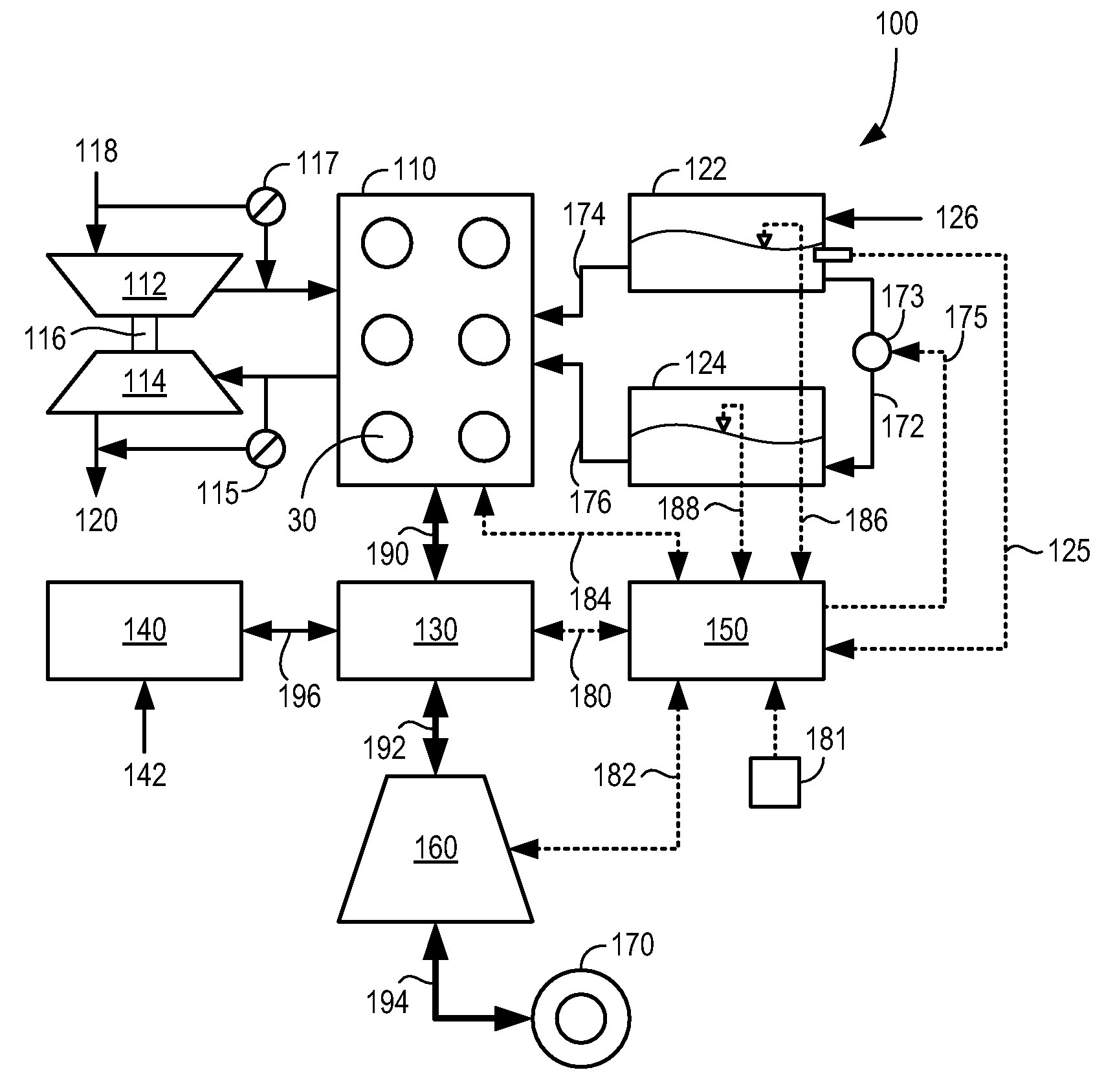

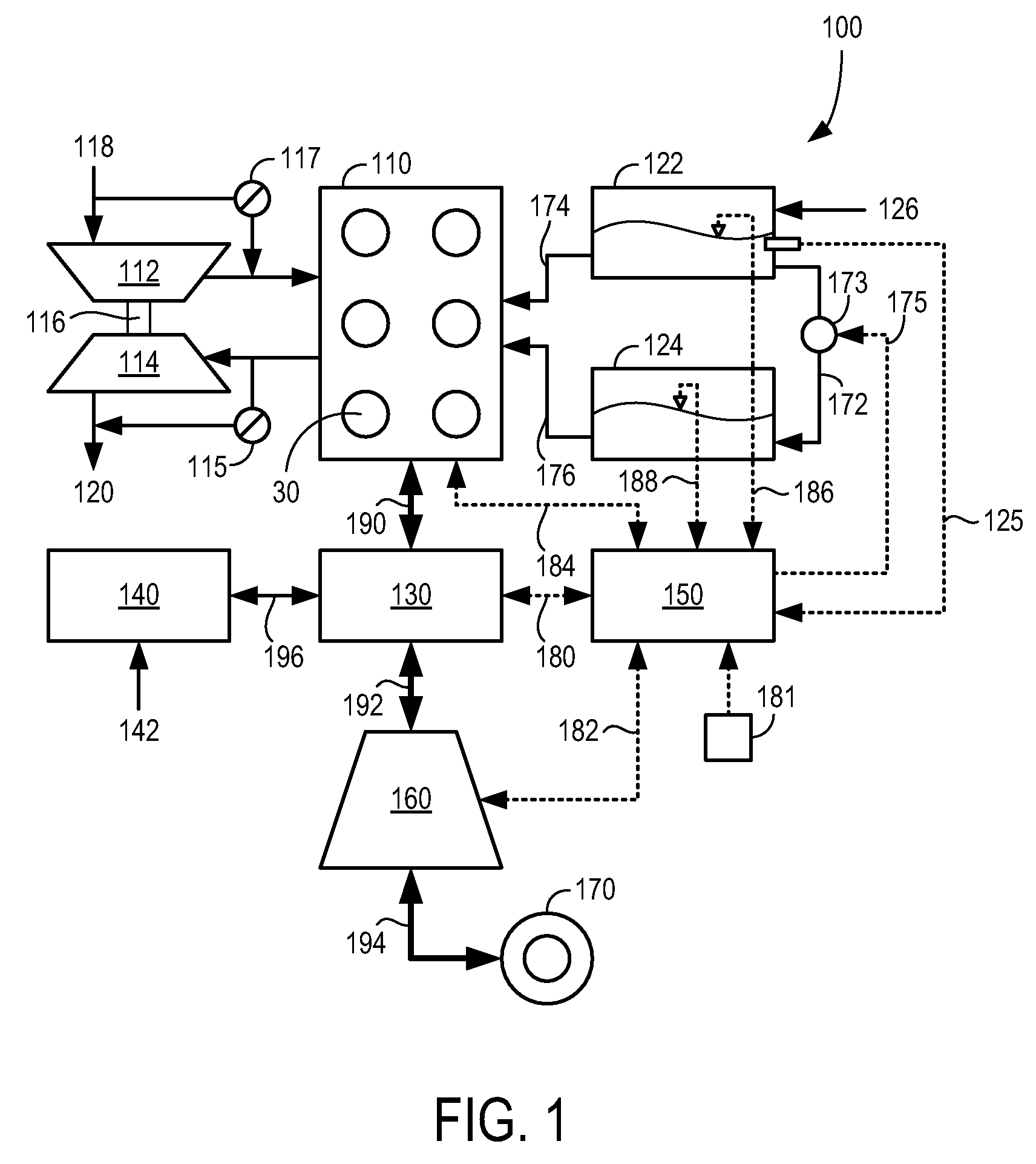

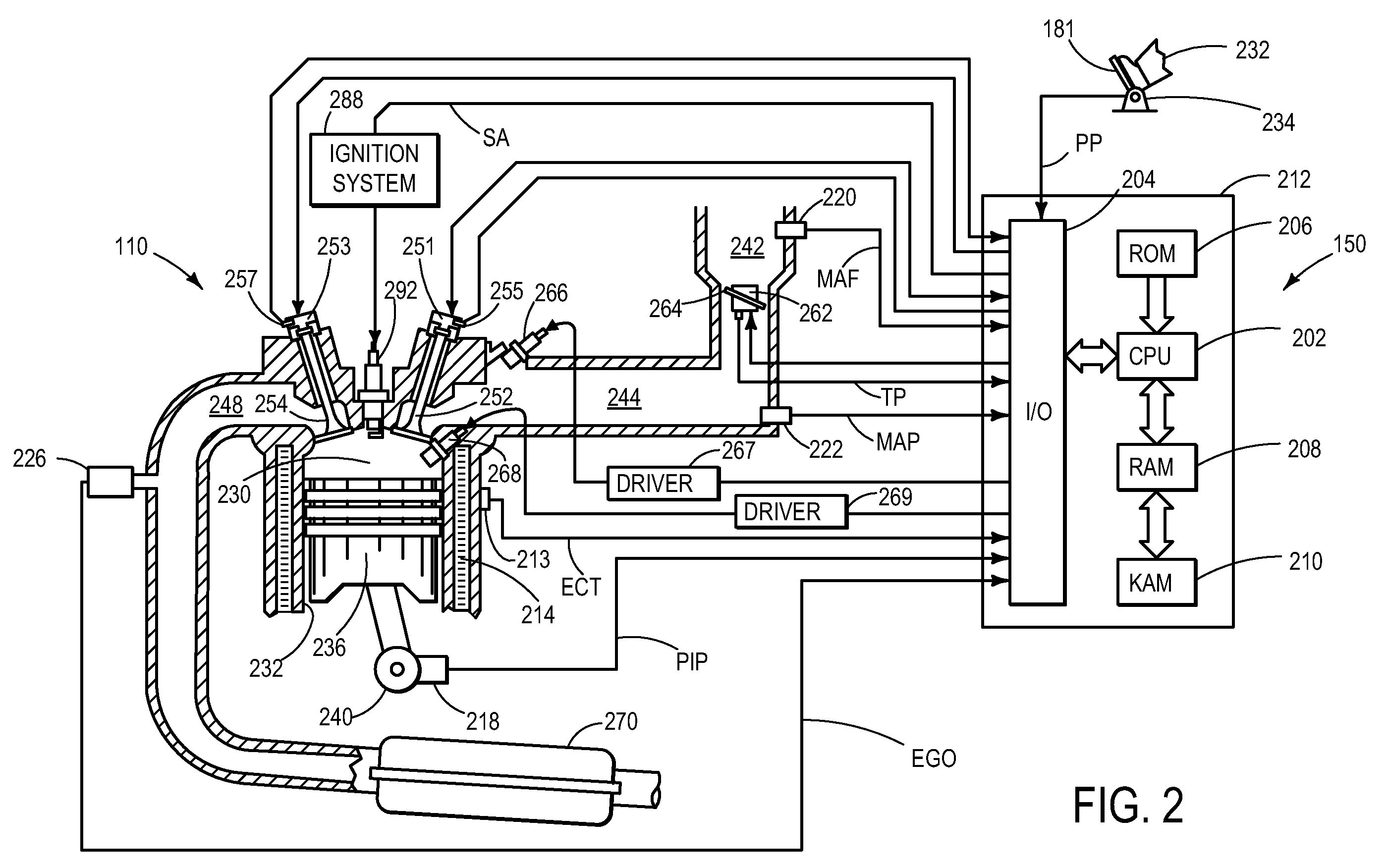

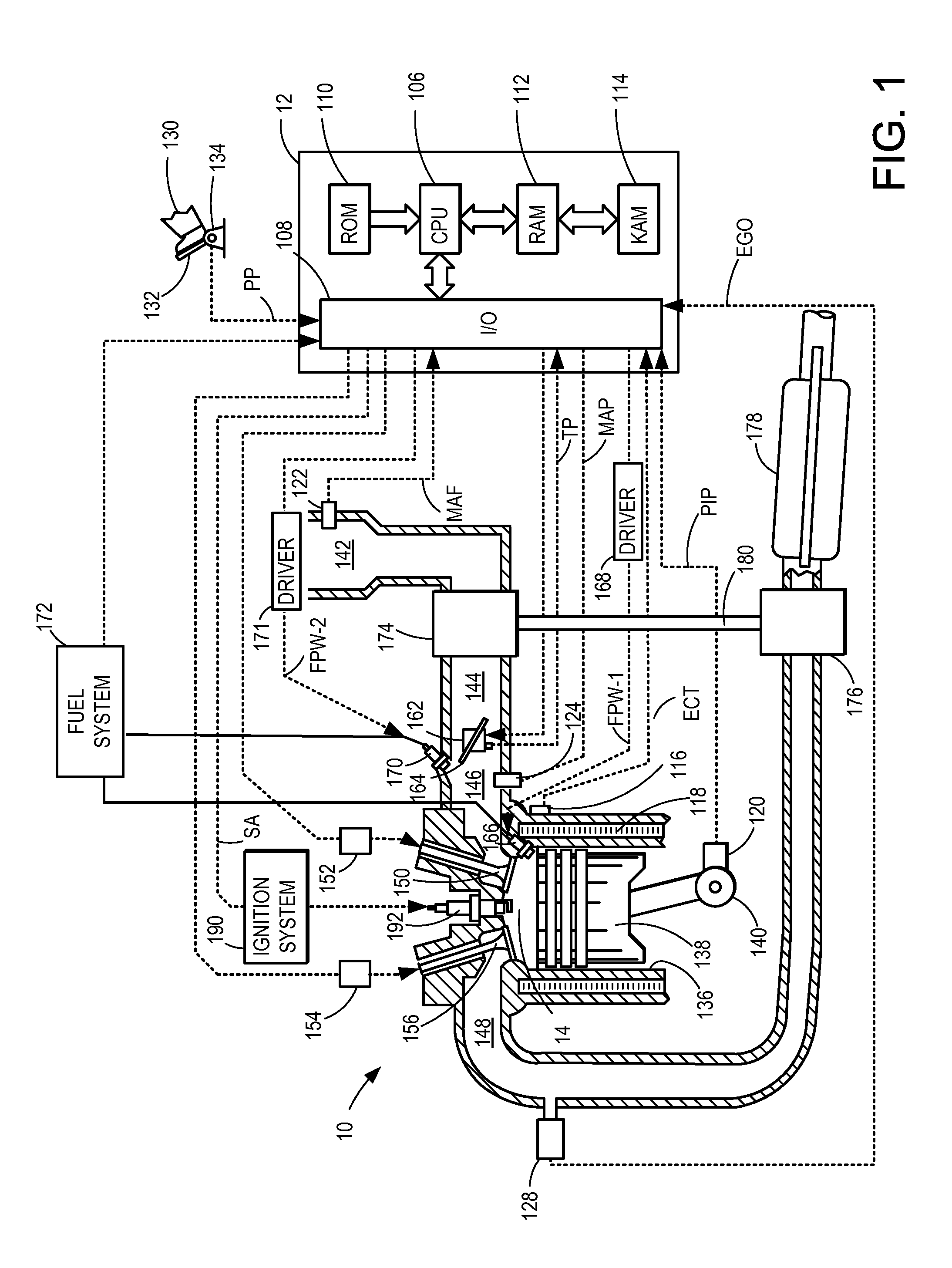

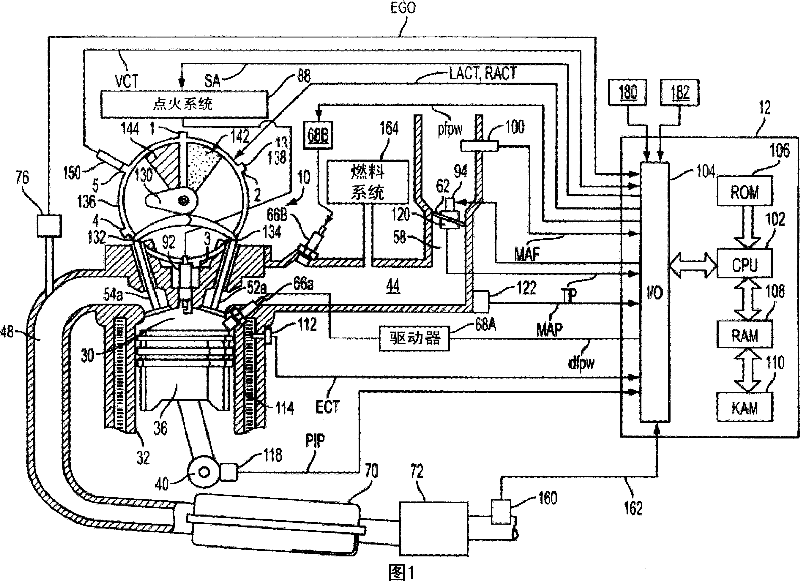

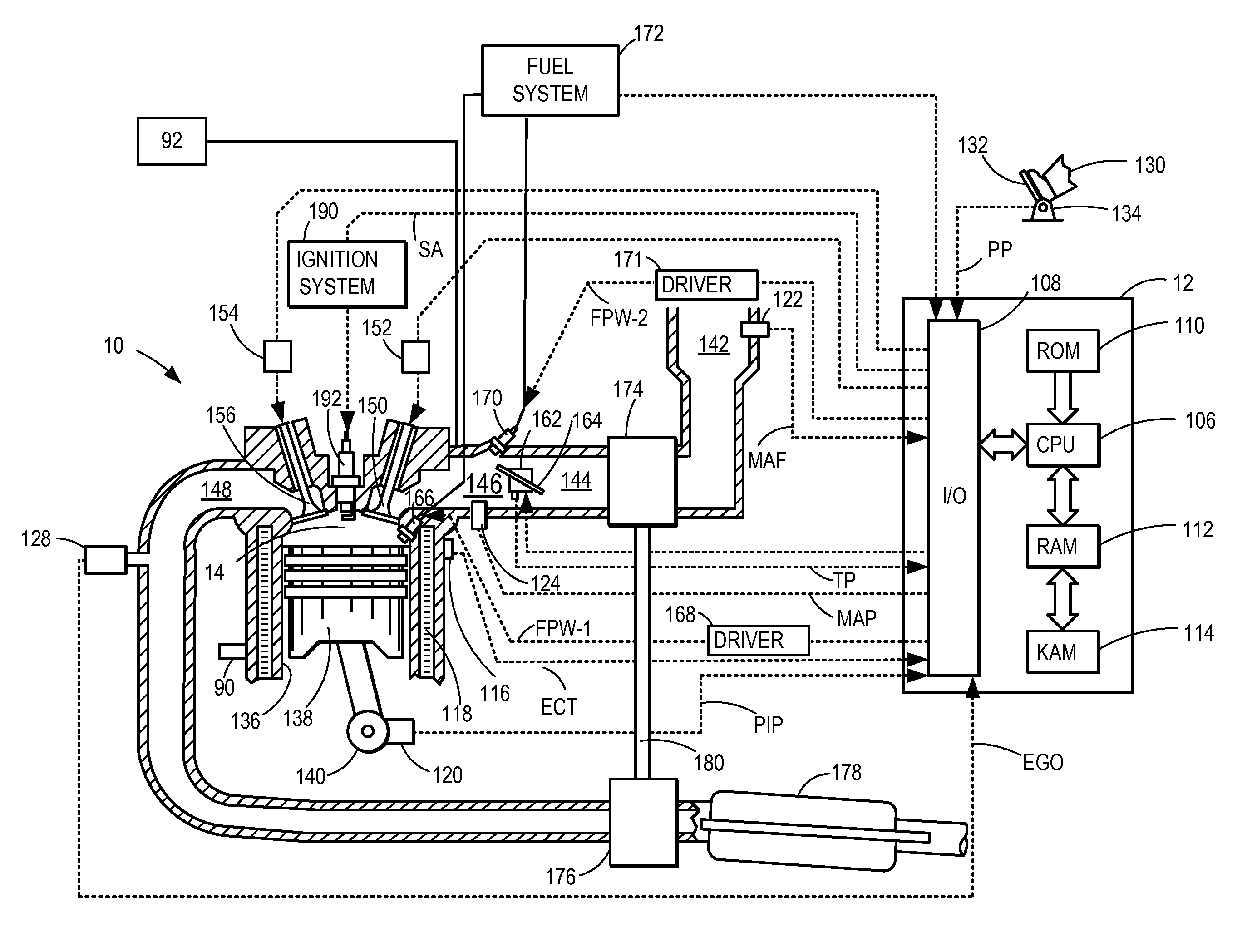

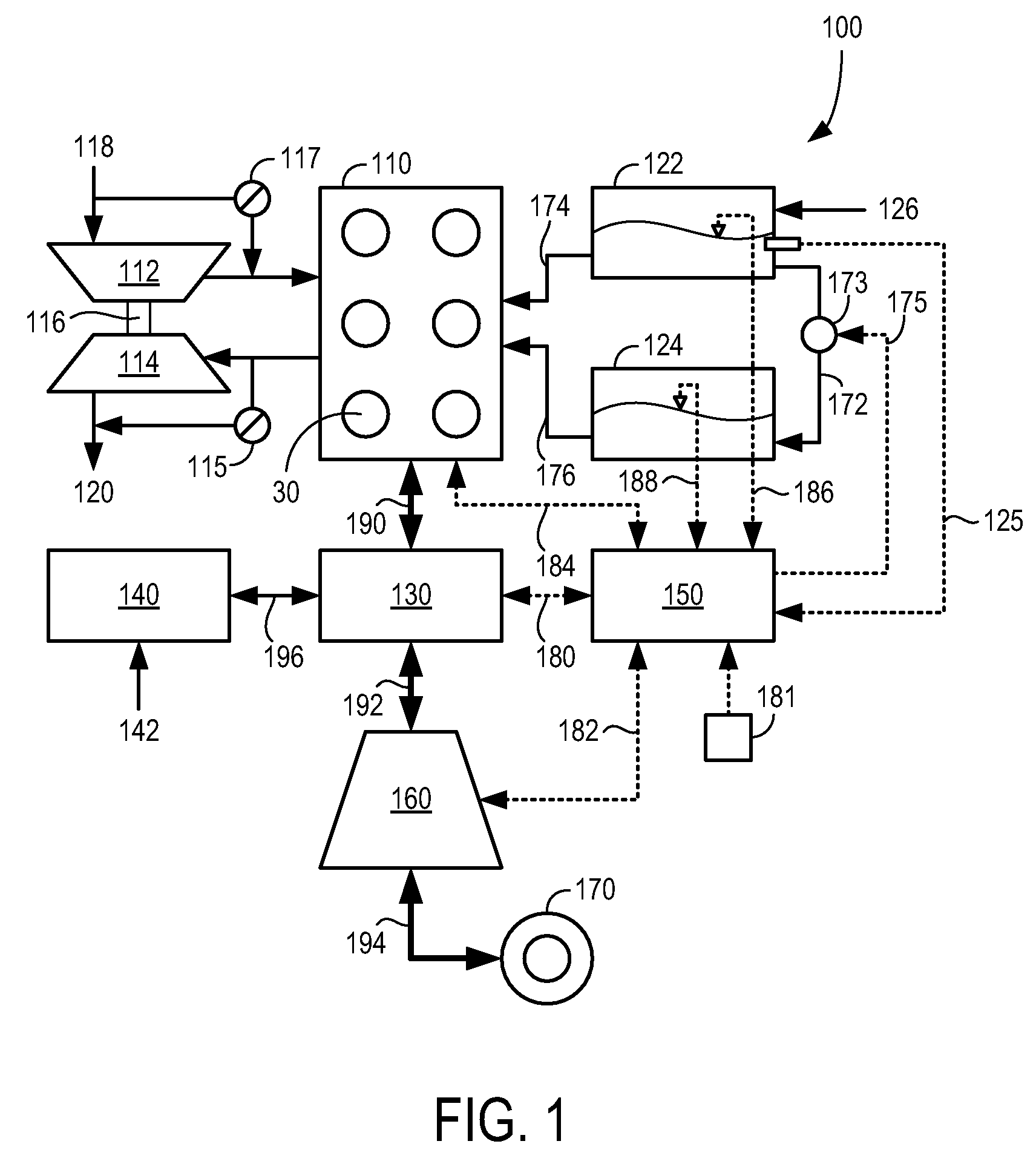

Fuel based cylinder knock control

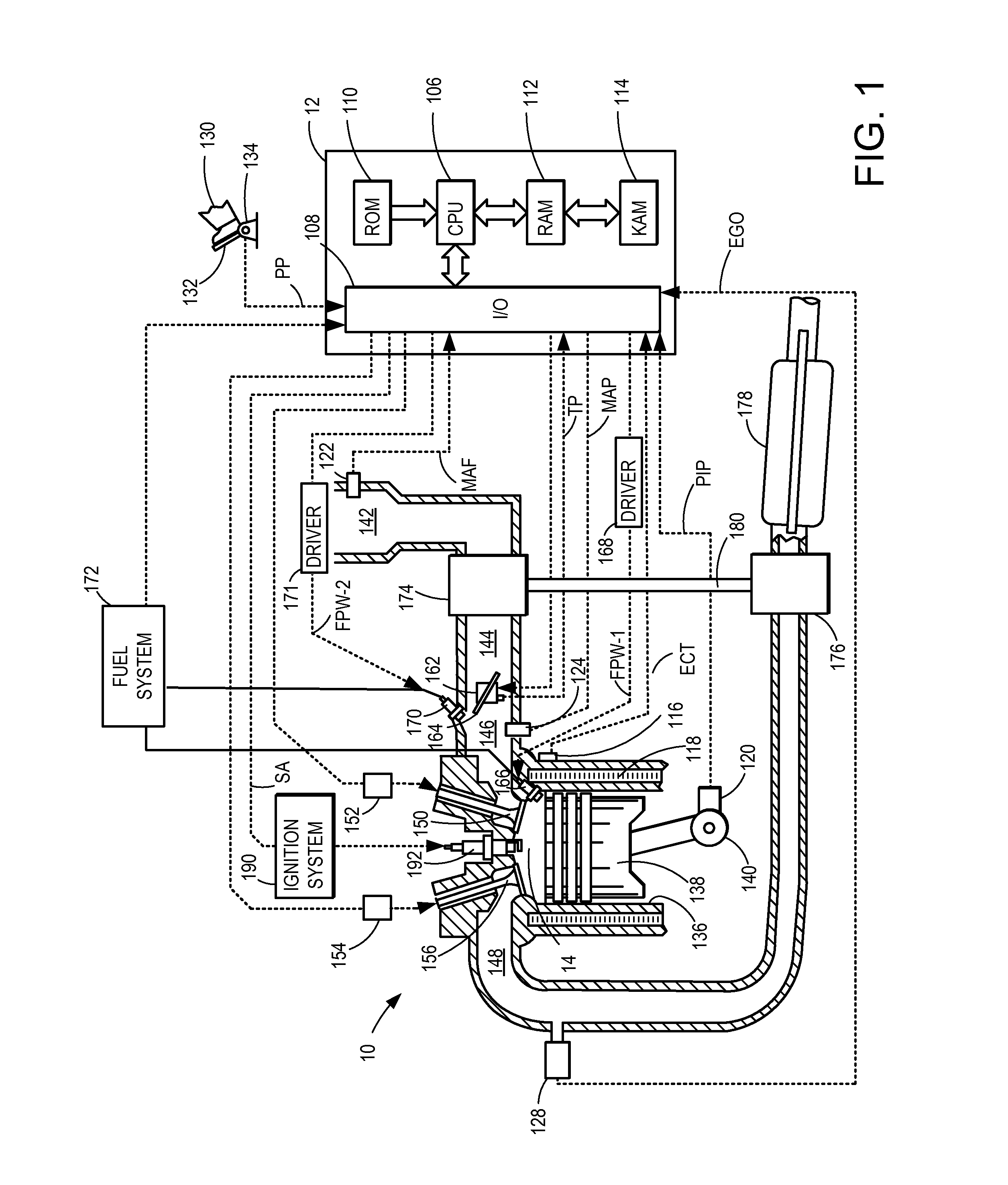

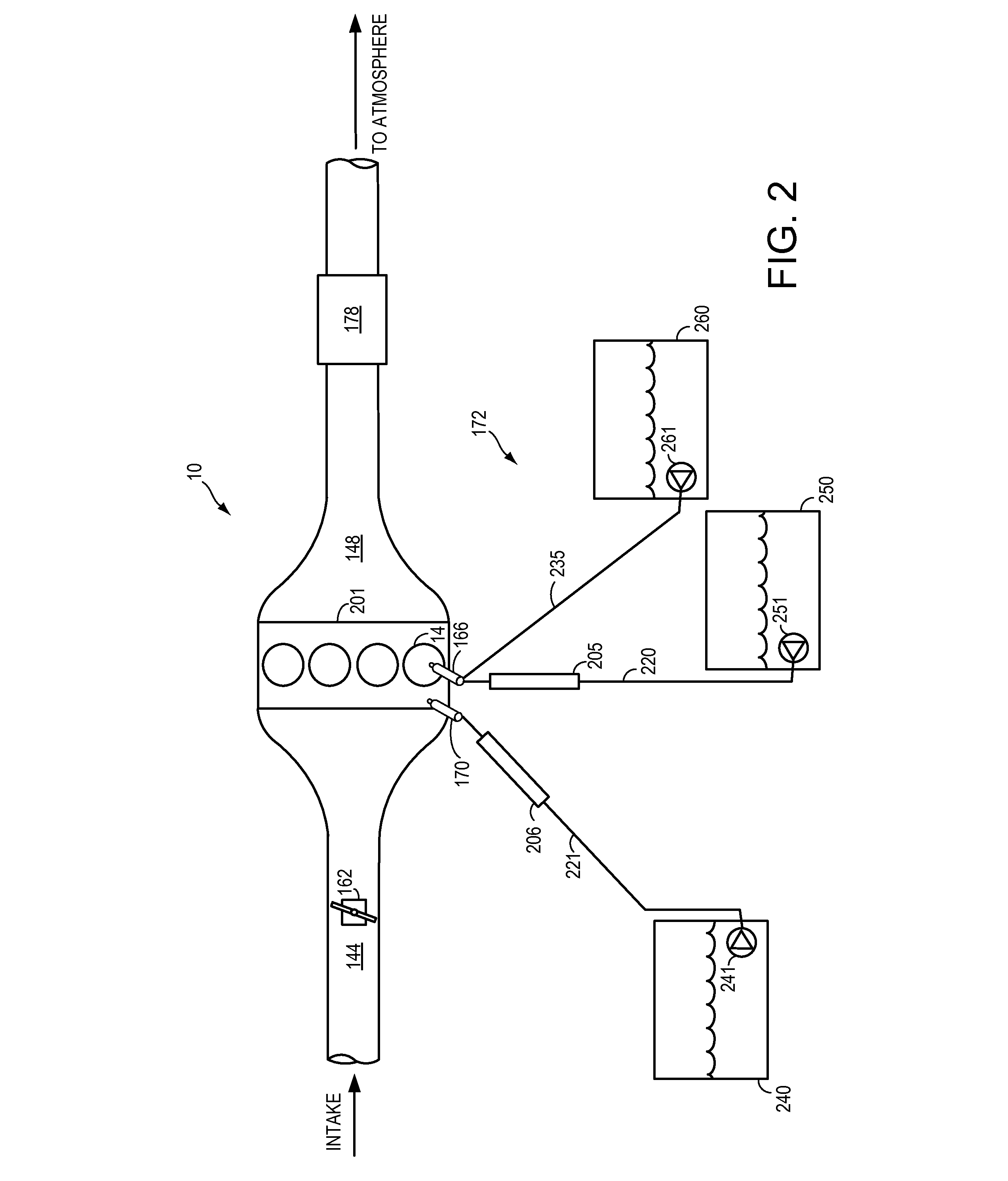

ActiveUS20090308367A1Improve engine performanceReduce knockingElectrical controlInternal combustion piston enginesInjectorAutomotive engineering

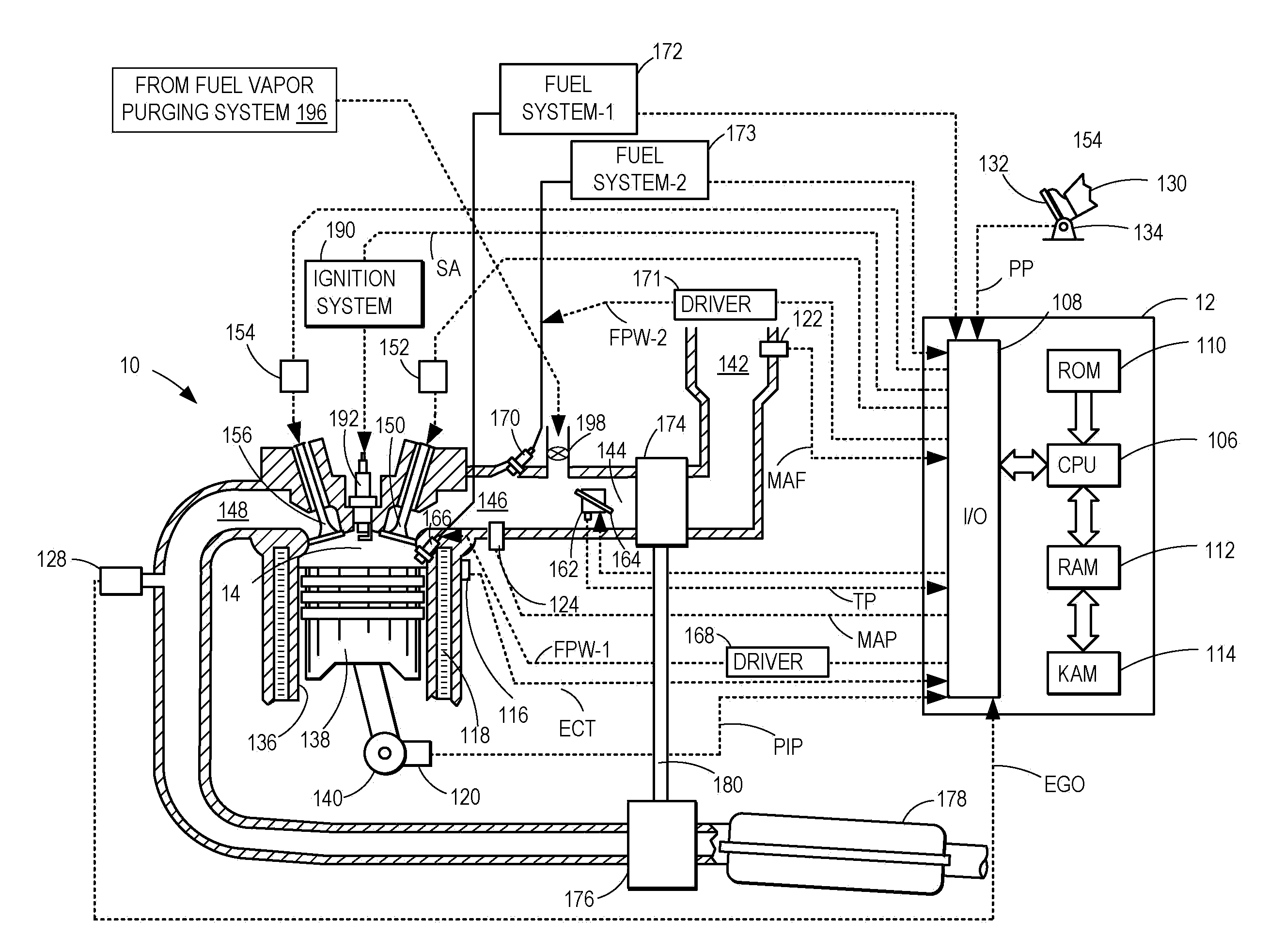

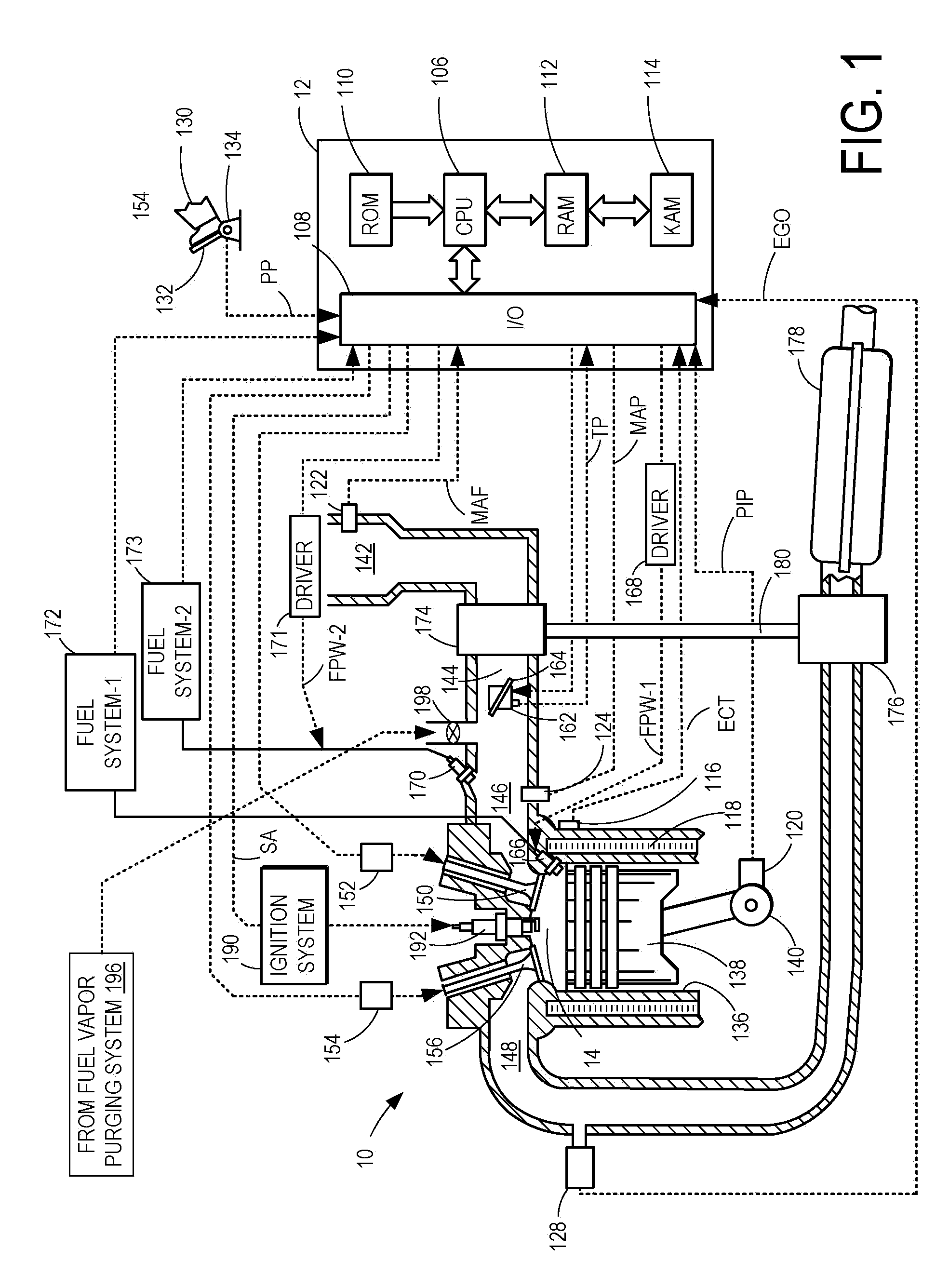

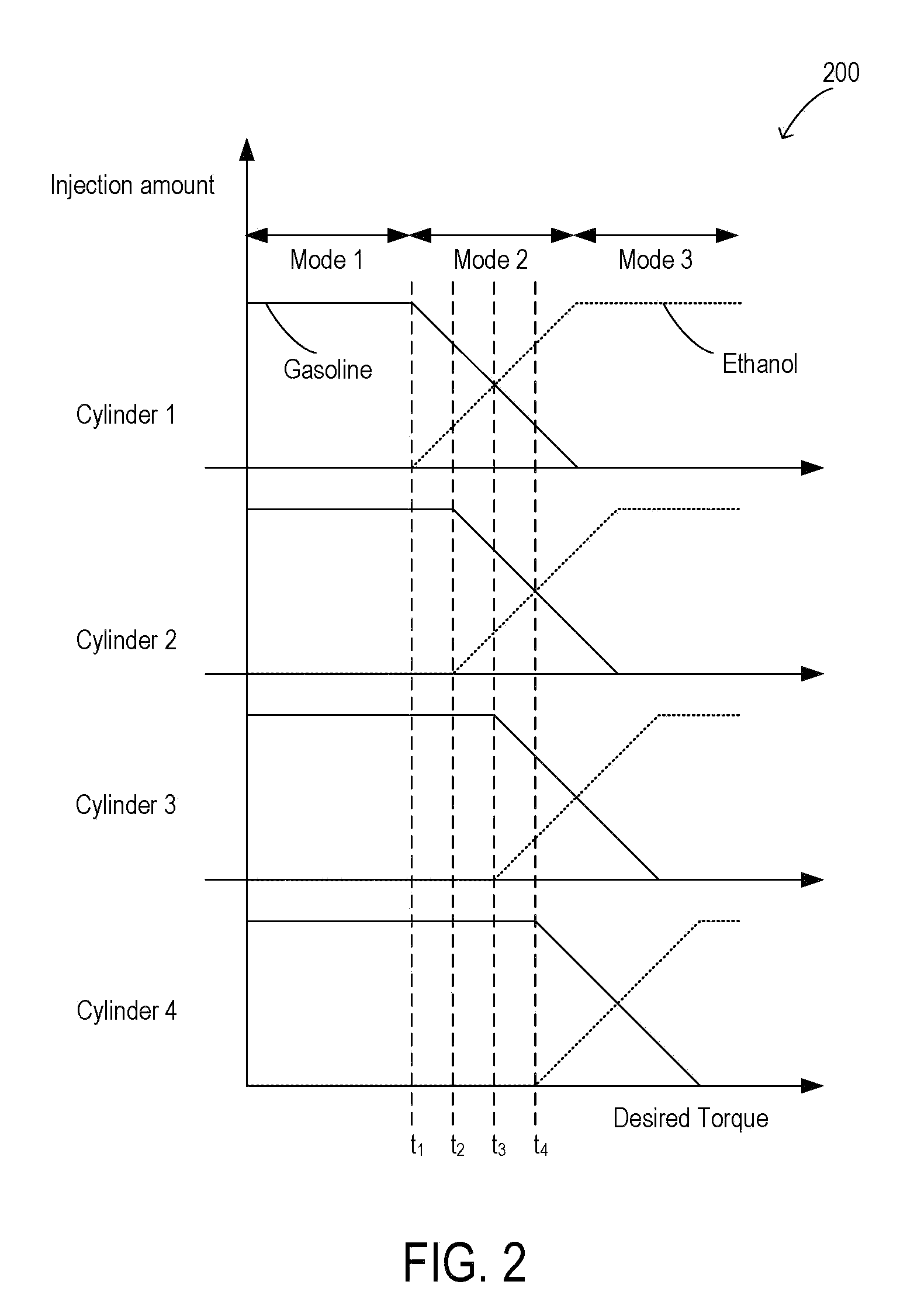

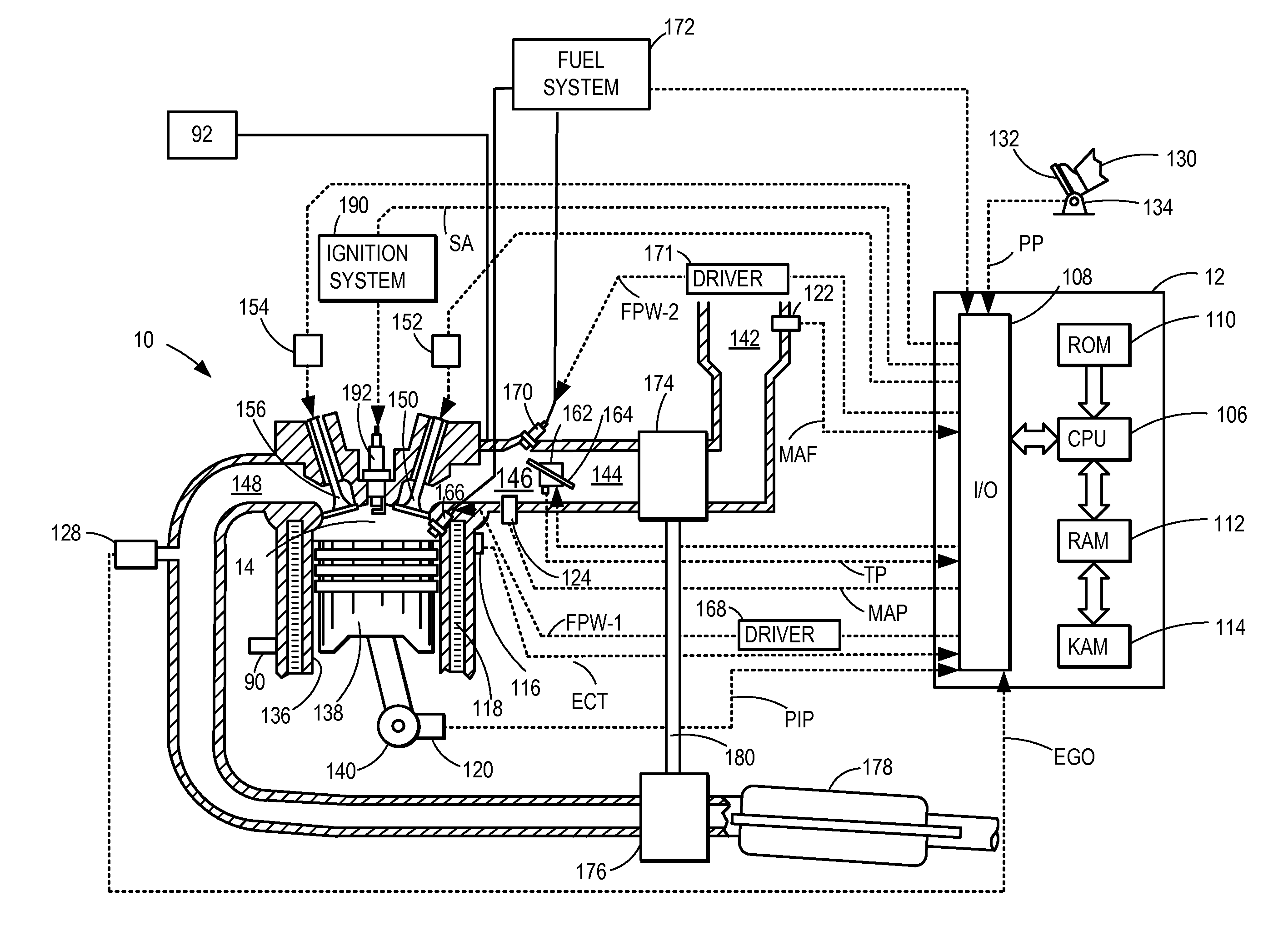

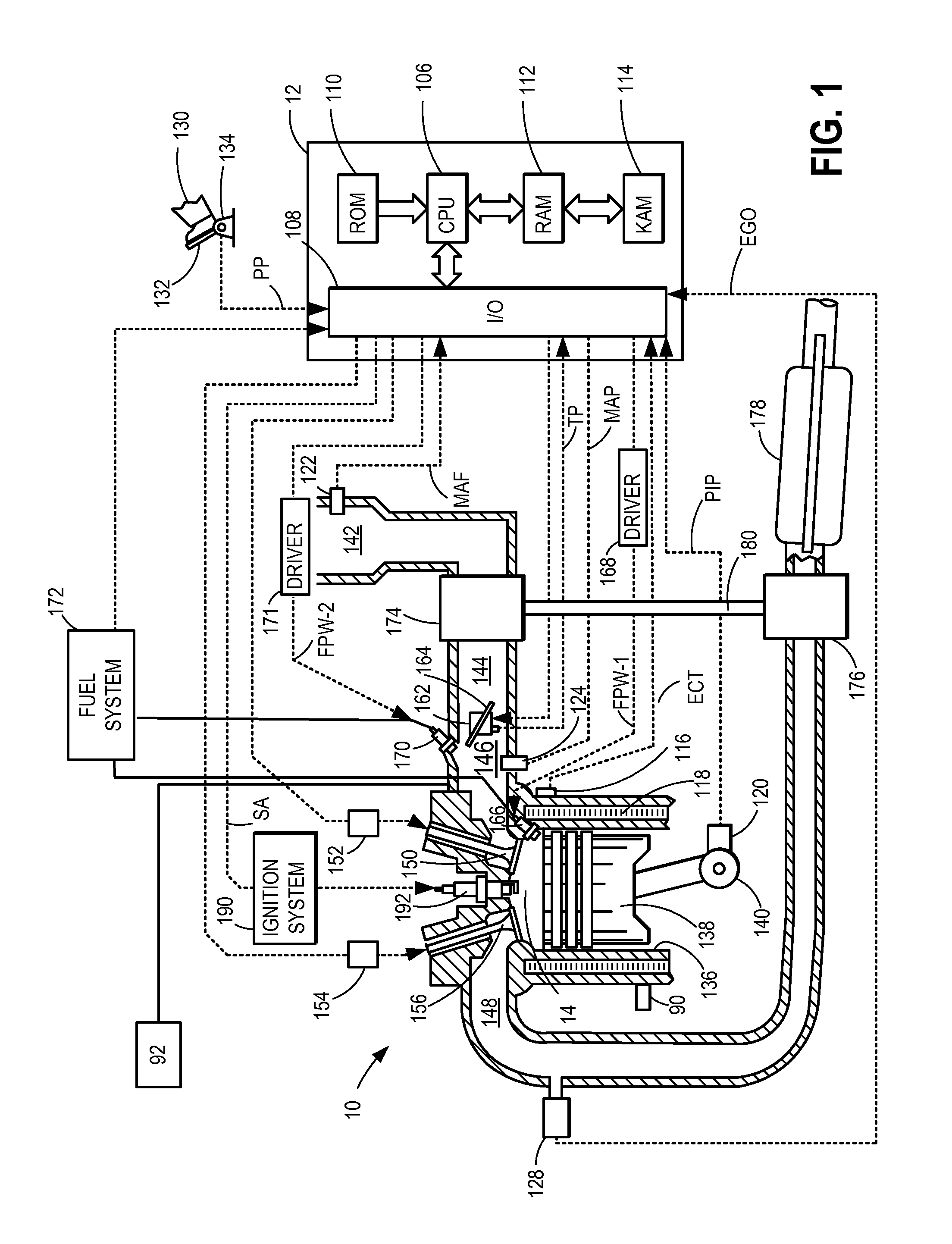

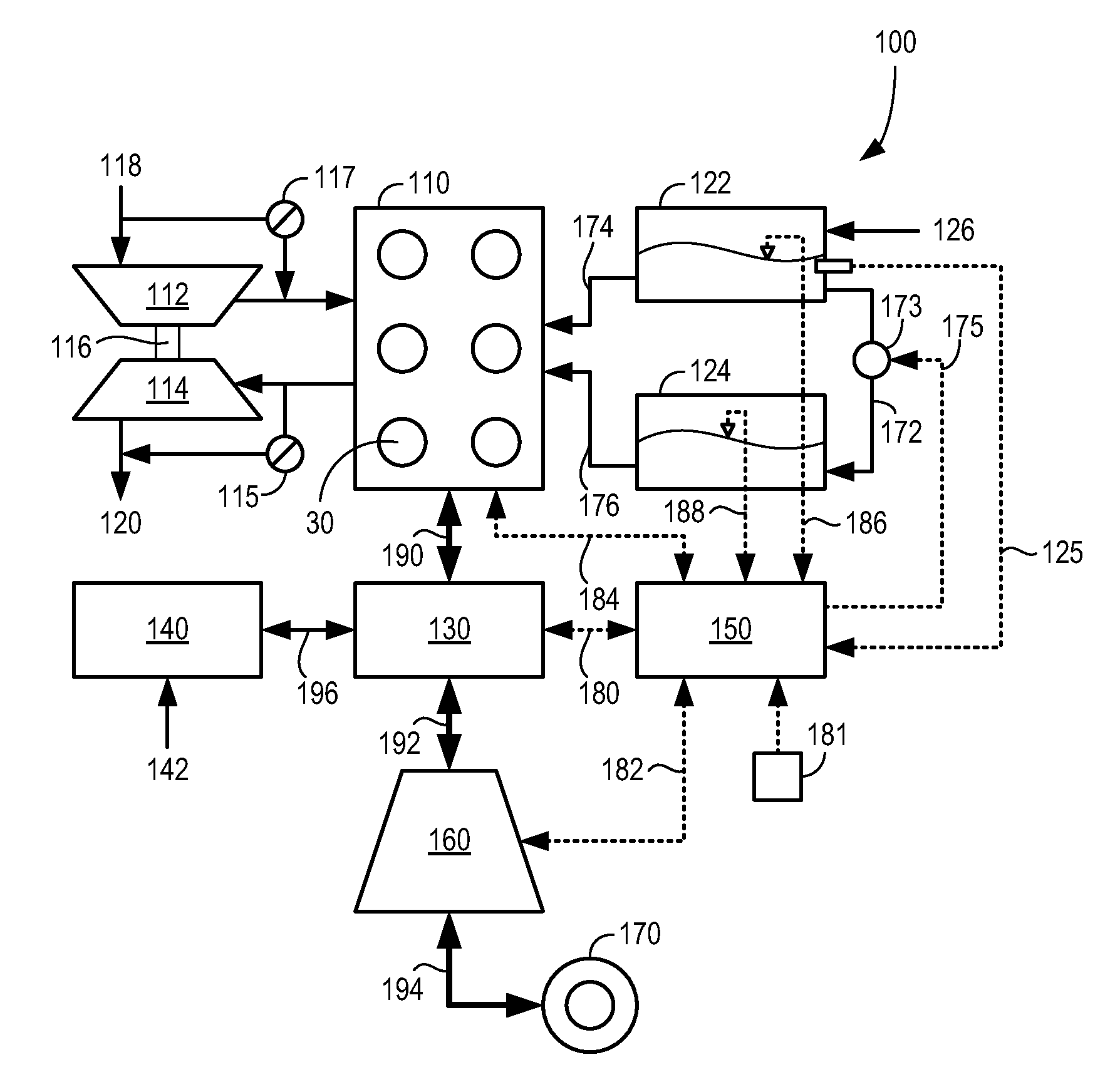

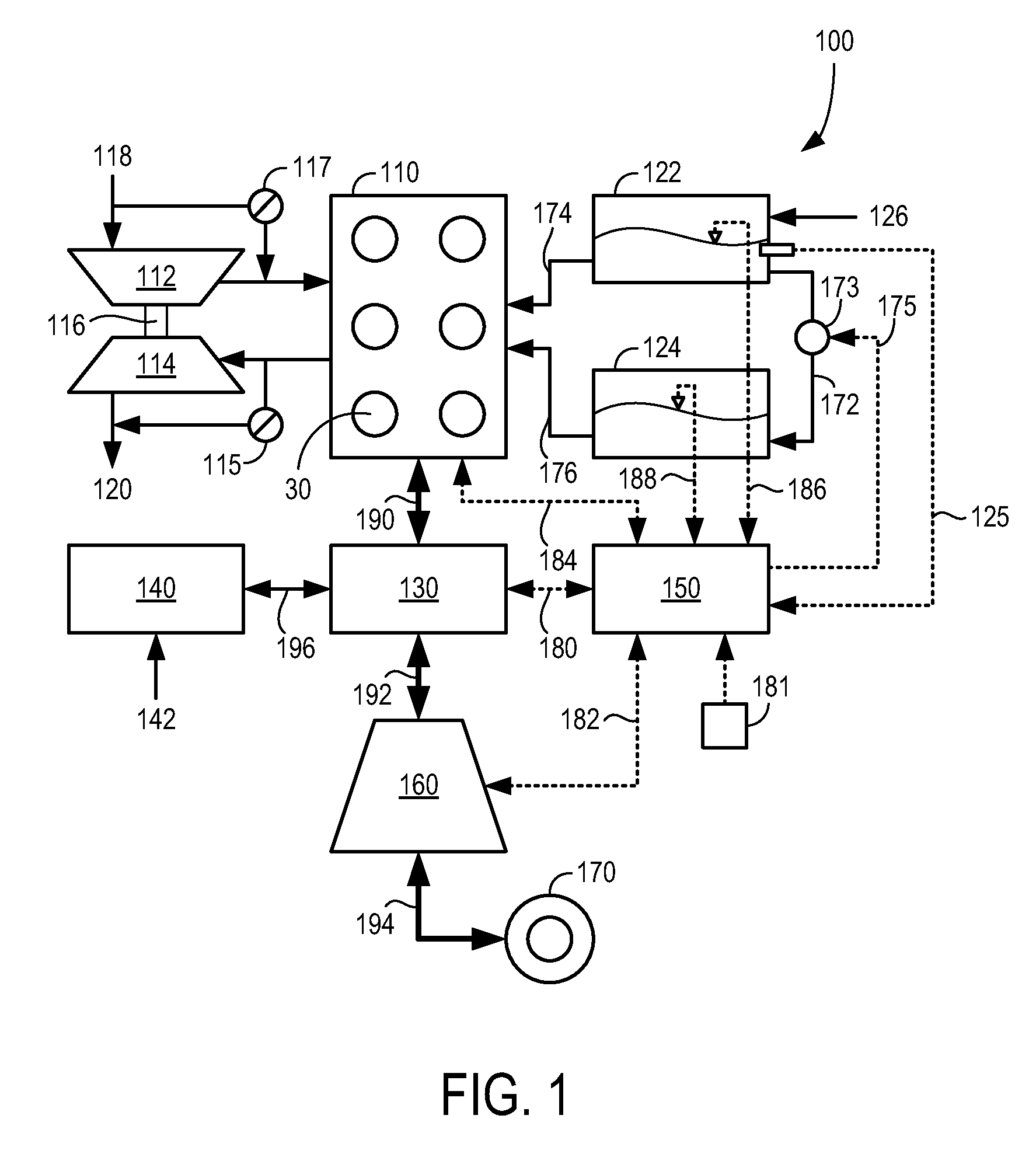

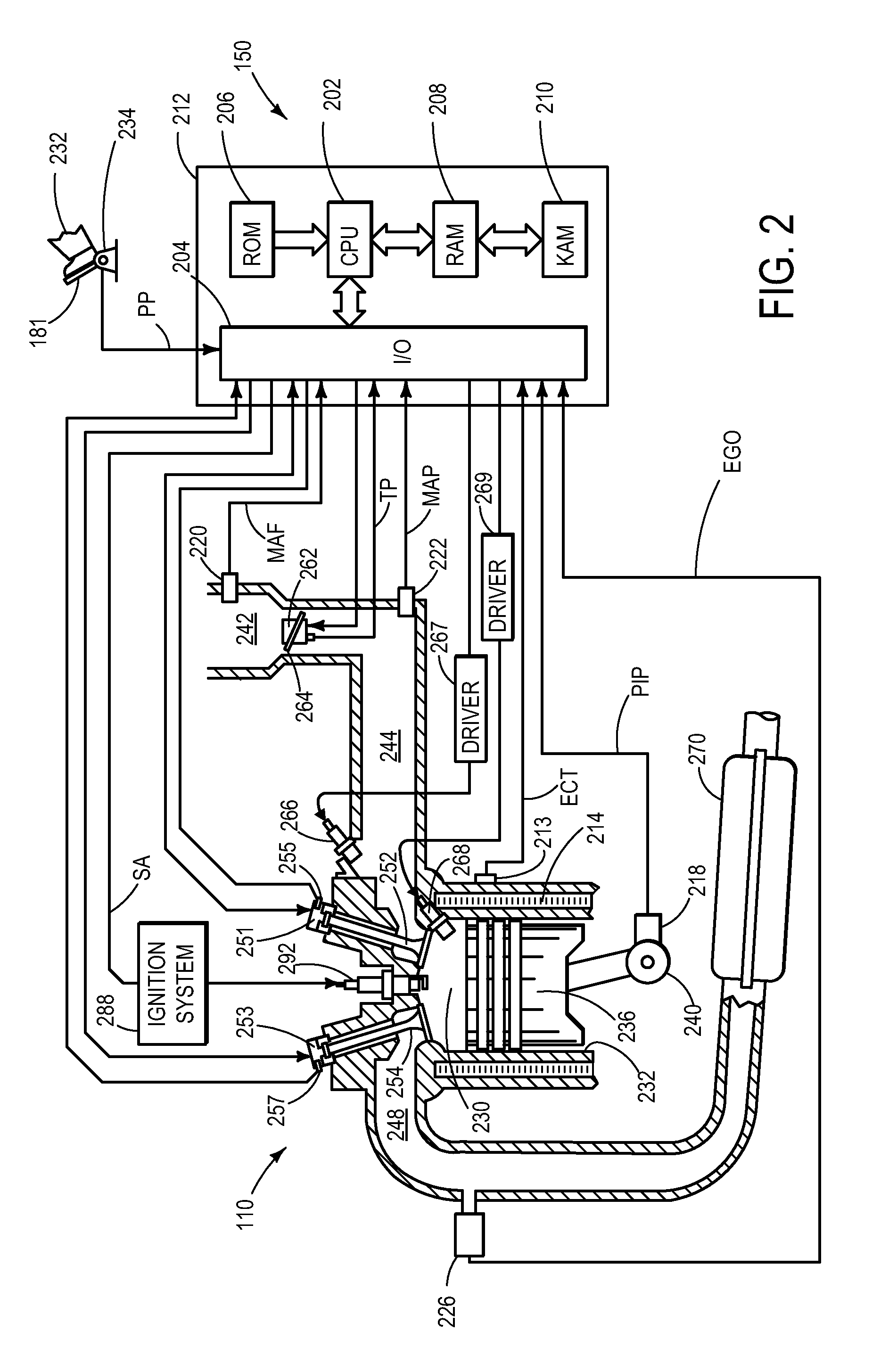

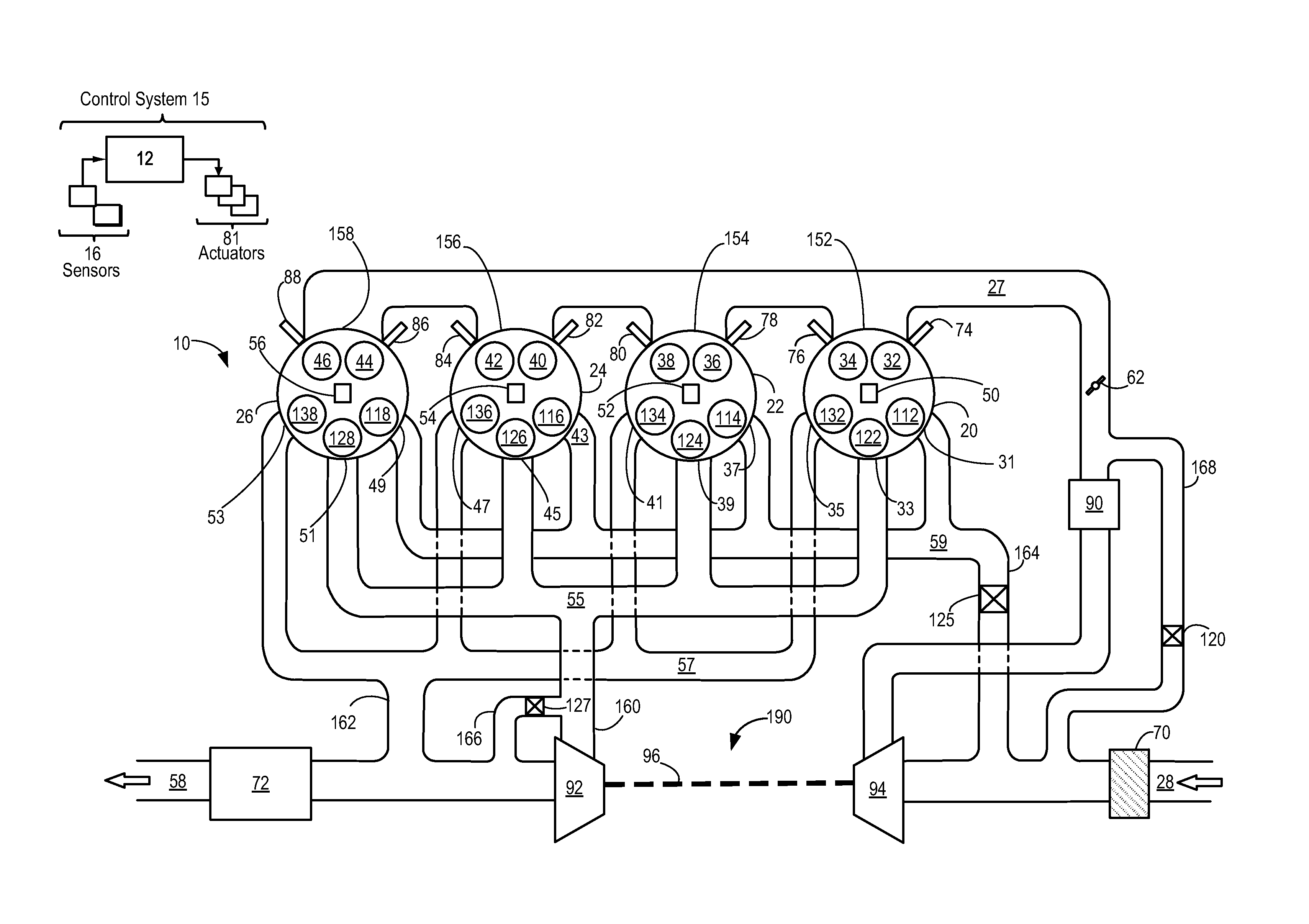

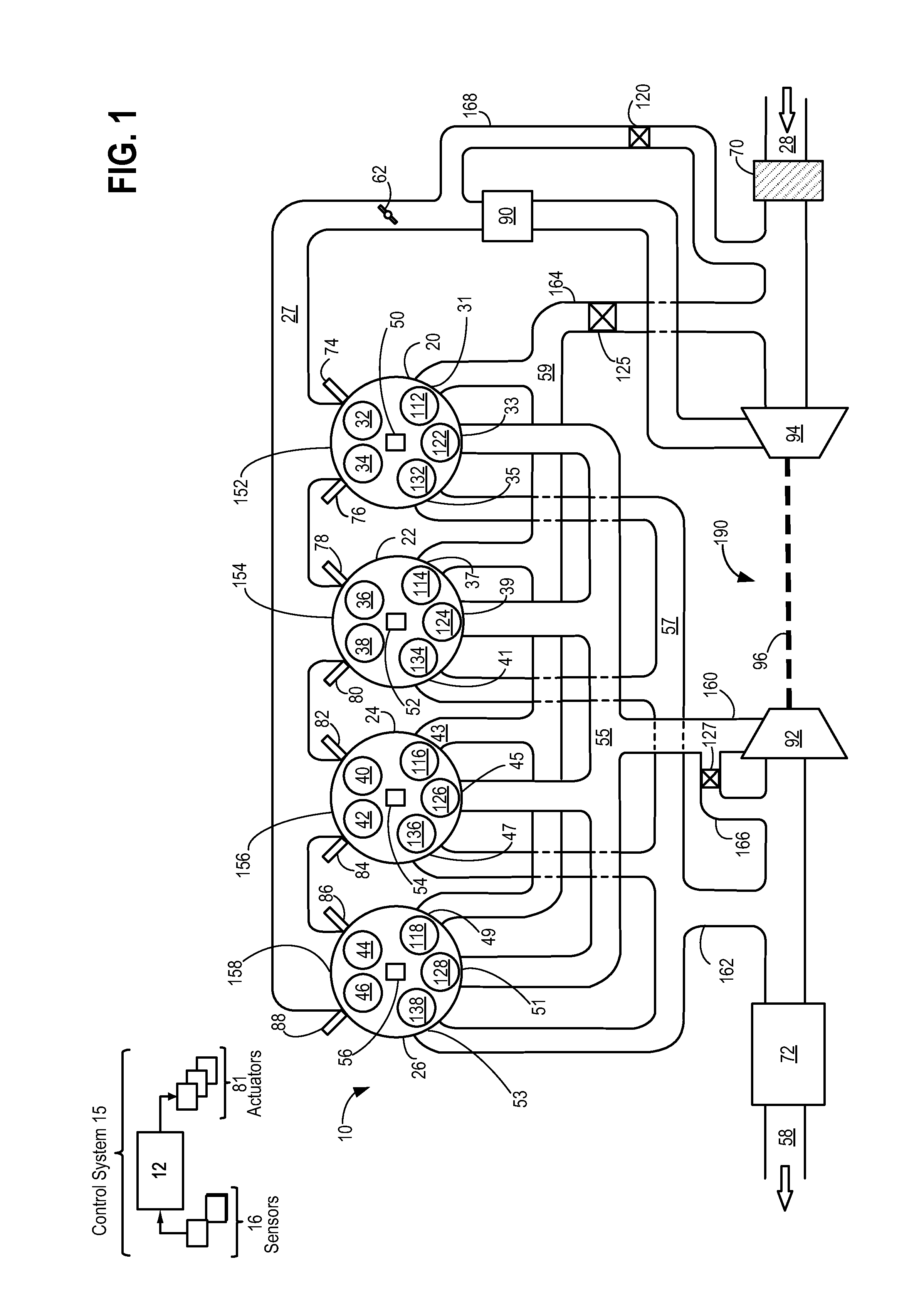

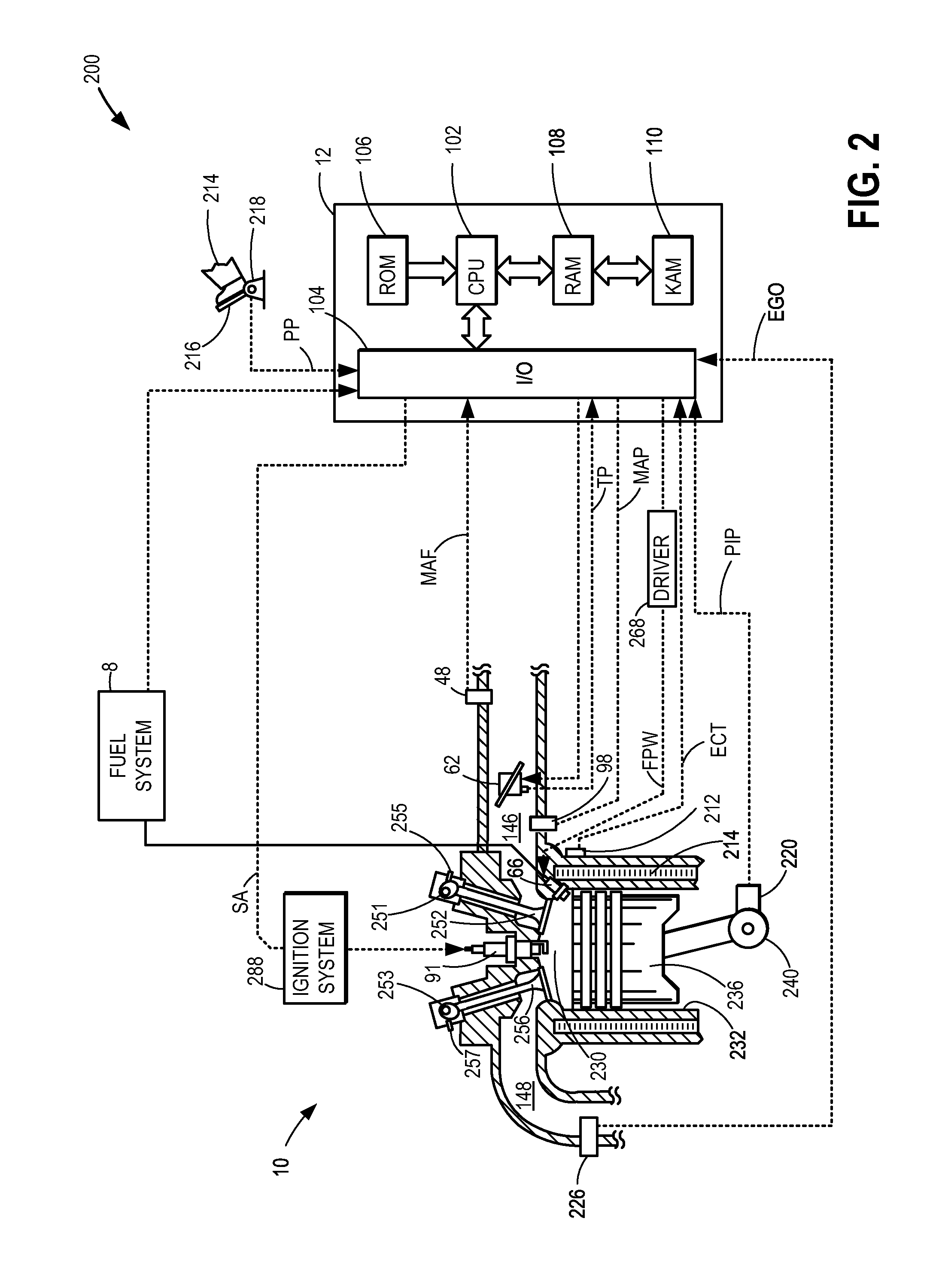

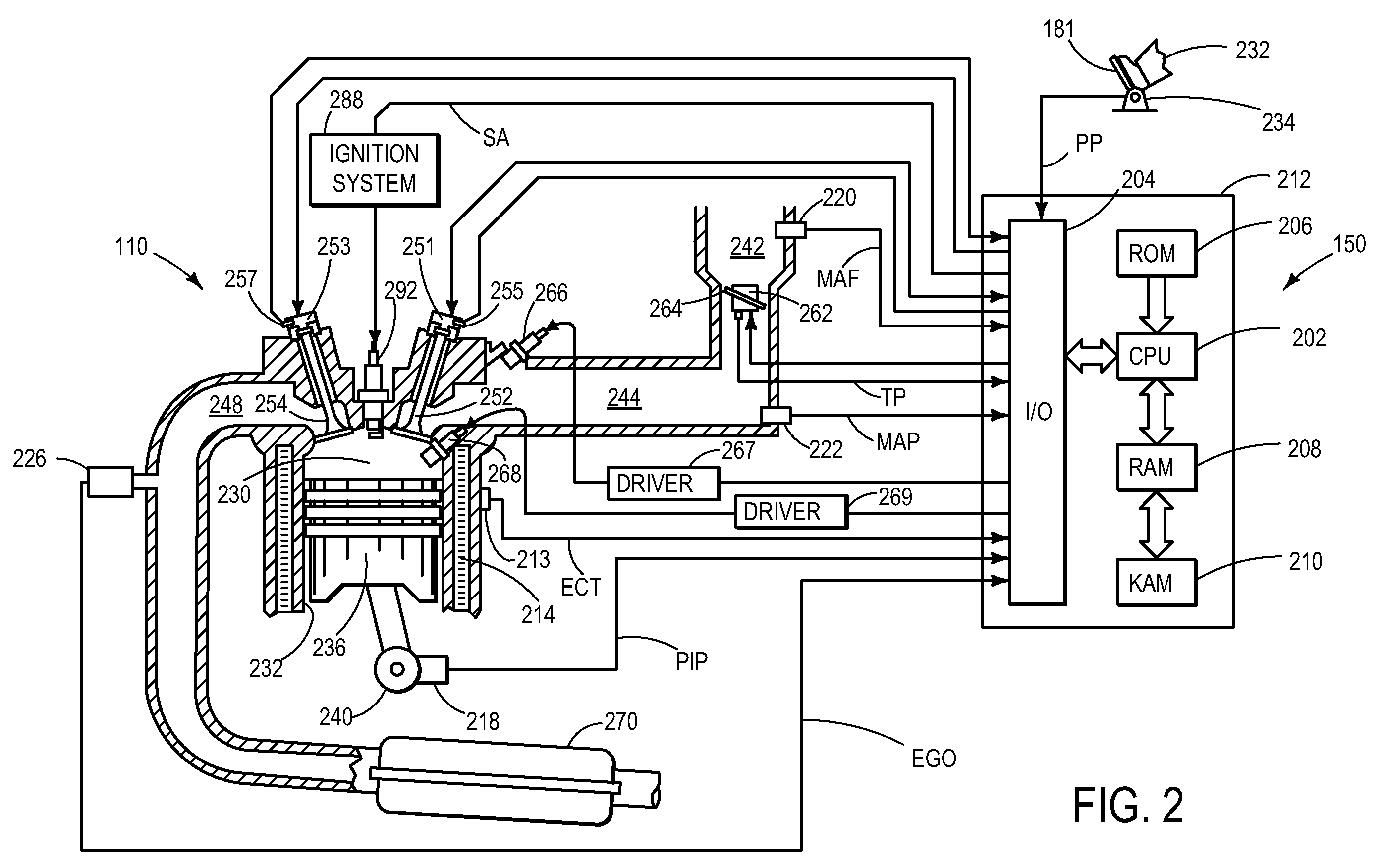

Various systems and methods are described for controlling engine operation of an engine having a plurality of cylinders, each cylinder including a first and second injector for delivering fuel to the cylinder. One example method comprises operating a first cylinder to combust fuel delivered from both the first and second fuel injector of the first cylinder, and operating a second cylinder to combust fuel delivered from only one of the first and second fuel injectors of the second cylinder. One example system comprises both a port injector and a direct injector coupled to both of a first and second cylinder of the engine with a first fuel reservoir coupled to the port injectors and a second fuel reservoir coupled to the direct injectors. The system further includes a controller configured to vary delivery of the fuels from the injectors to the cylinders during differing operating modes.

Owner:FORD GLOBAL TECH LLC

Method to improve blowthrough via split exhaust

InactiveUS9080523B1Increase engine power densityReduced fuel economyElectrical controlNon-fuel substance addition to fuelInlet valveEngineering

Methods and systems are provided for a boosted engine having a split exhaust system. One method includes reducing knock by flowing a combination of exhaust from towards the end of an exhaust stroke and blowthrough air to the intake of a compressor via a compressor inlet valve.

Owner:FORD GLOBAL TECH LLC

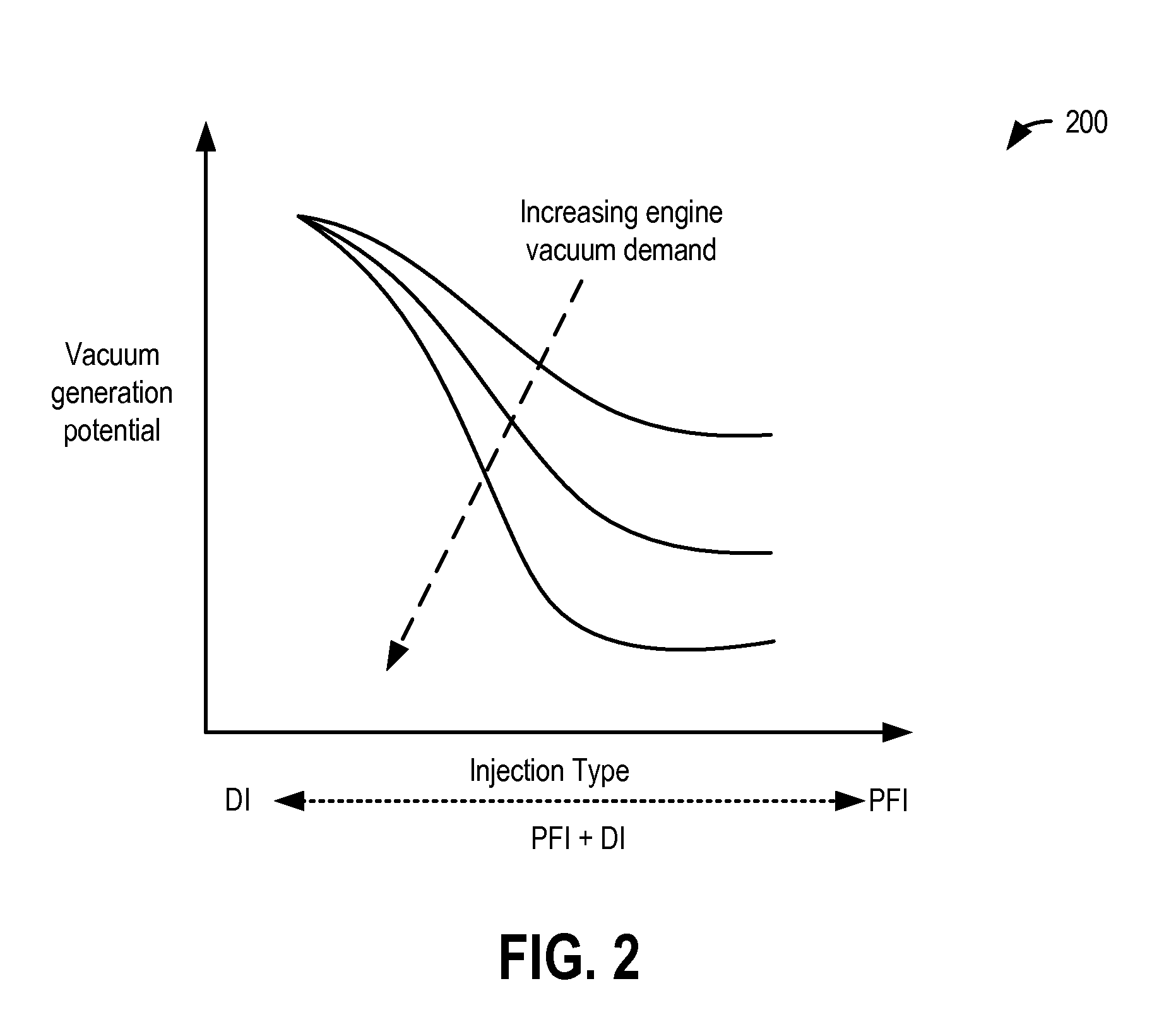

Method and system for vacuum control

ActiveUS20140261301A1Small droplet sizeImprove volumetric efficiencyElectrical controlInternal combustion piston enginesEngineeringCrankcase

Methods and systems are provided for adjusting a fuel injection split between a direct injection and a port injection based on engine vacuum demand. When more intake manifold vacuum is required, relatively more direct injection is used to take advantage of the associated throttling for generating vacuum. The vacuum may then be used for canister purging, crankcase ventilation, or actuating an engine vacuum consumption device.

Owner:FORD GLOBAL TECH LLC

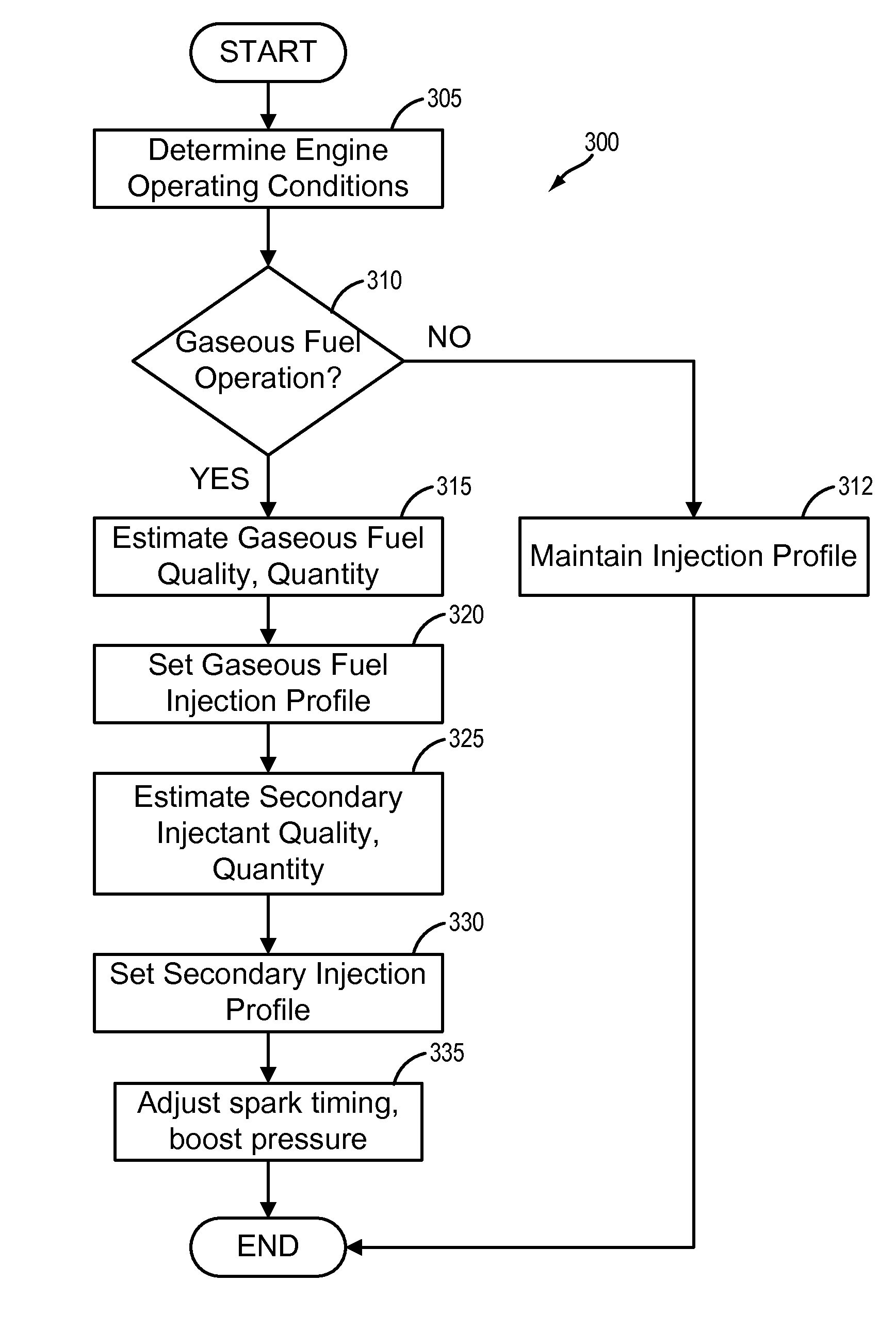

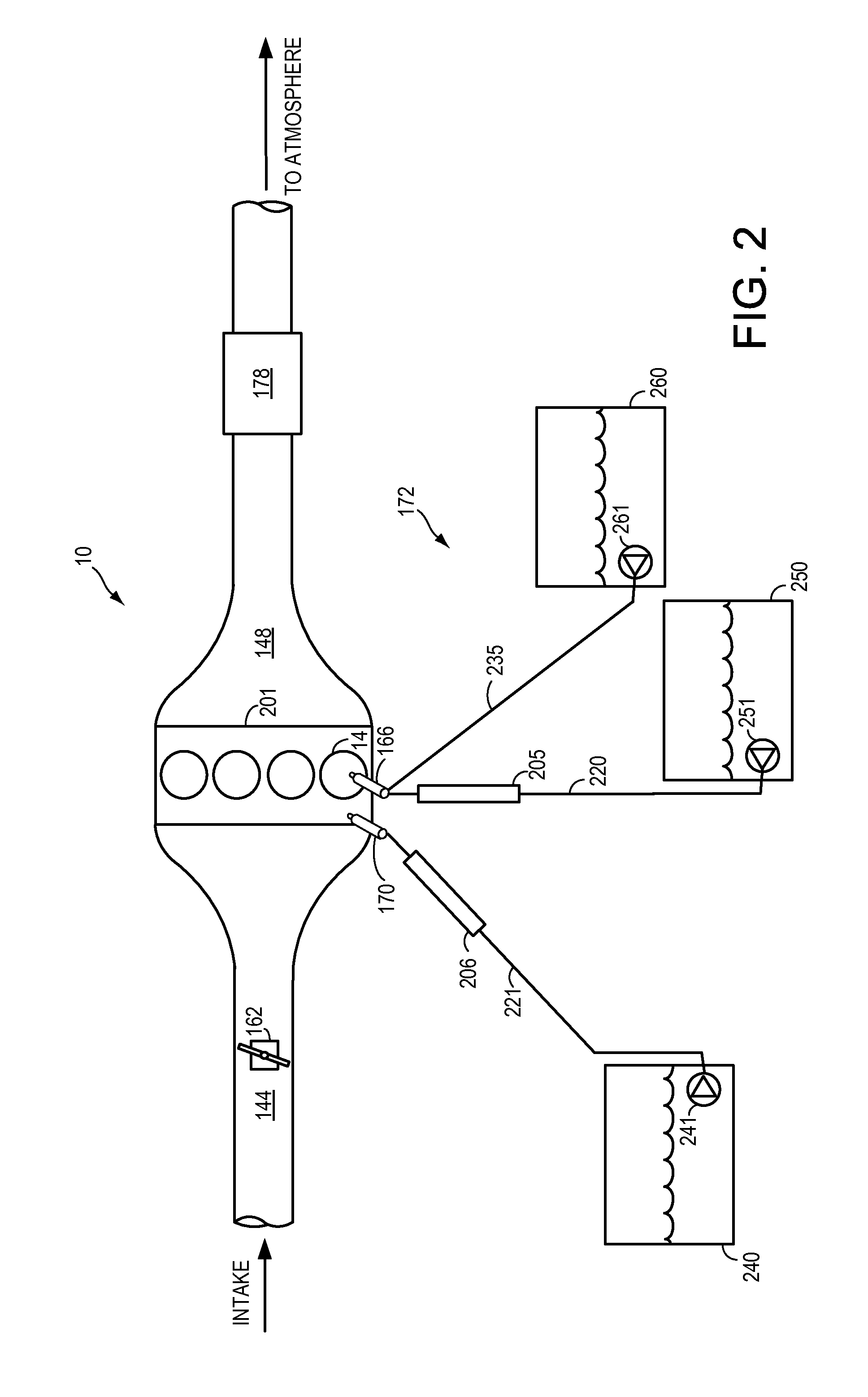

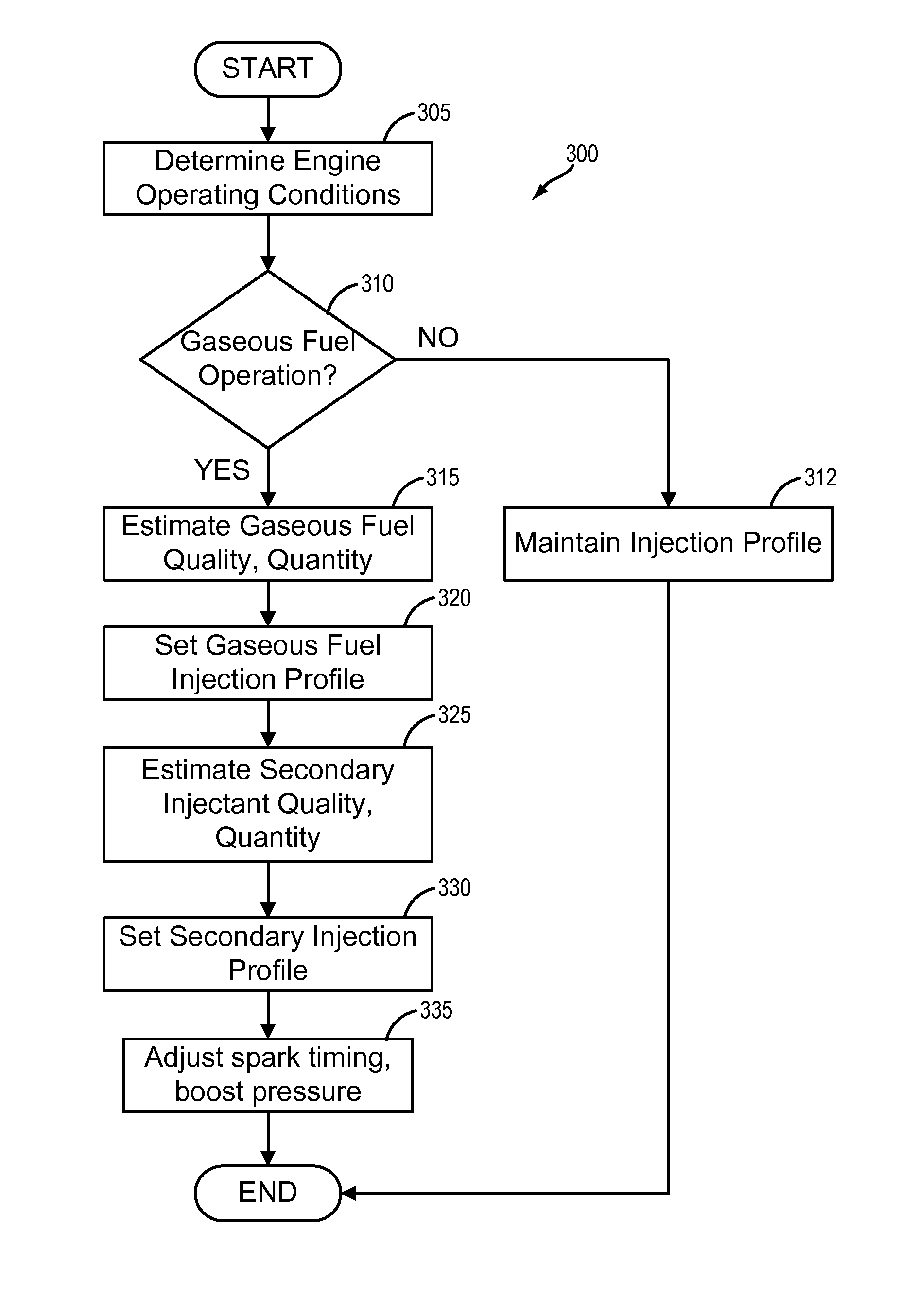

Direct injection of diluents or secondary fuels in gaseous fuel engines

ActiveUS20140331970A1Reduce exhaust emissionsHigh priceInternal combustion piston enginesExhaust gas recirculationCombustionDiluent

A method for operating an engine, comprising port injecting a first quantity of a first gaseous fuel in a cylinder cycle and direct injecting a second quantity of a secondary injectant in the cylinder cycle as a function of a desired air-to-fuel ratio (AFR), the desired AFR based on a temperature of an engine cylinder valve. The desired AFR may be outside the AFR range available during natural gas combustion alone and thus allows for cooler engine operation.

Owner:FORD GLOBAL TECH LLC

Control of peak engine output in an engine with a knock suppression fluid

InactiveUS20070219674A1Low costImprove charge cooling effectAnalogue computers for vehiclesElectrical controlOn boardHigh alcohol

A method for a vehicle traveling on the road, comprising of receiving a fuel mixture, said mixture having at least some alcohol, separating said fuel mixture into at least a first and second mixture on board the vehicle, where said first mixture has a higher alcohol concentration than said second mixture, delivering a first amount of said first mixture and a second amount of said second mixture to the engine in different ratios as an operating condition varies, and adjusting an engine operating parameter in response to availability of said first mixture.

Owner:FORD GLOBAL TECH LLC

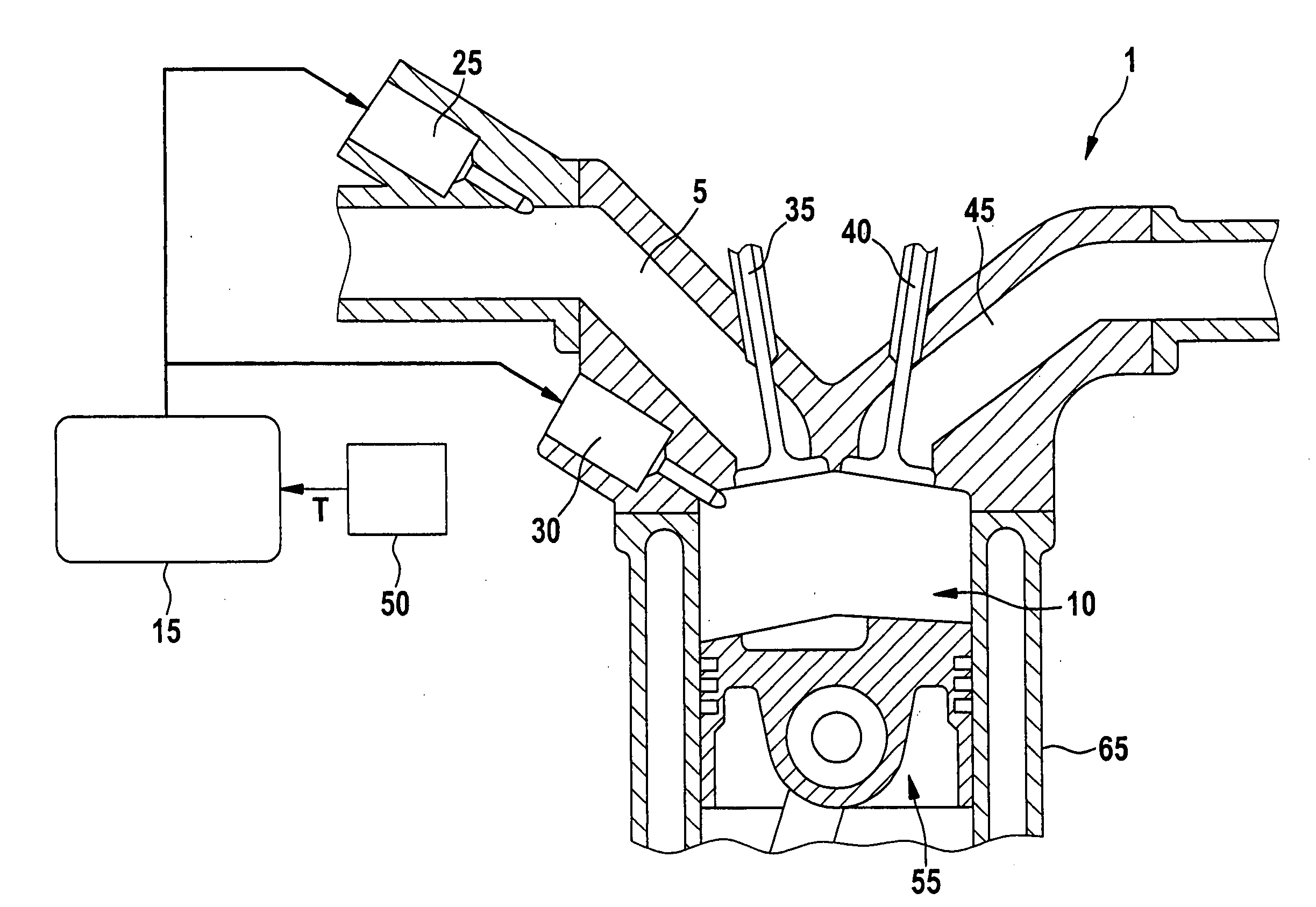

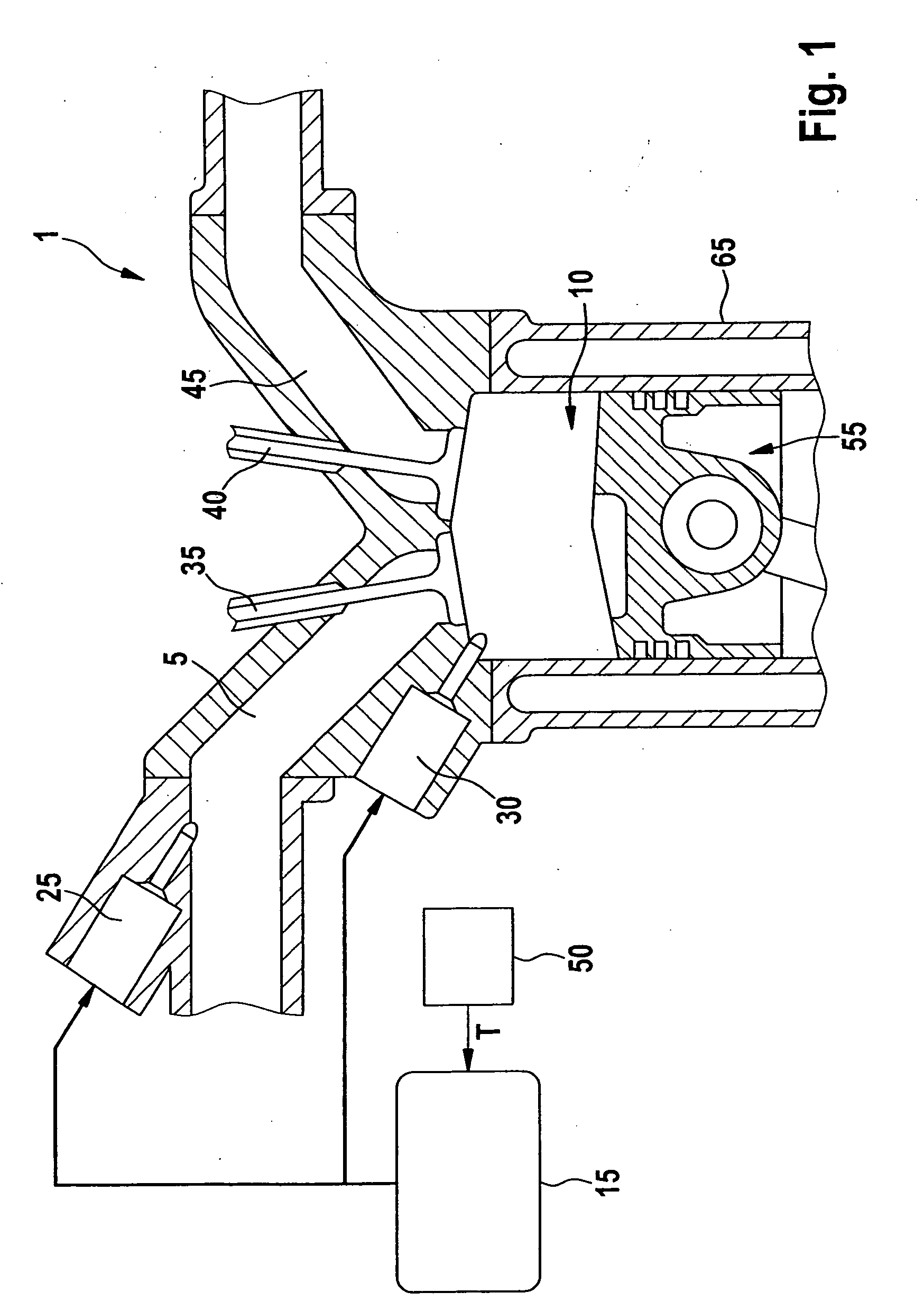

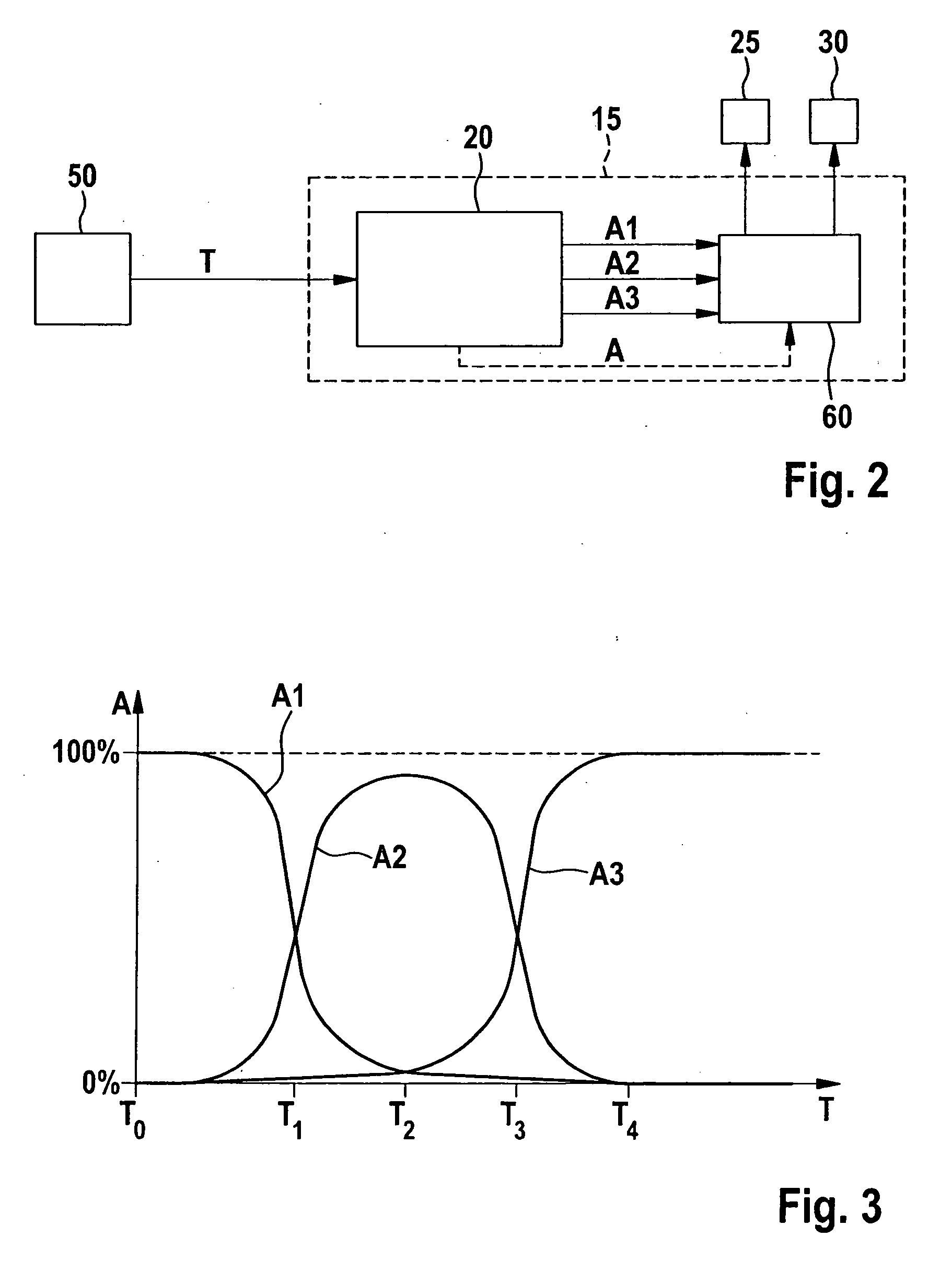

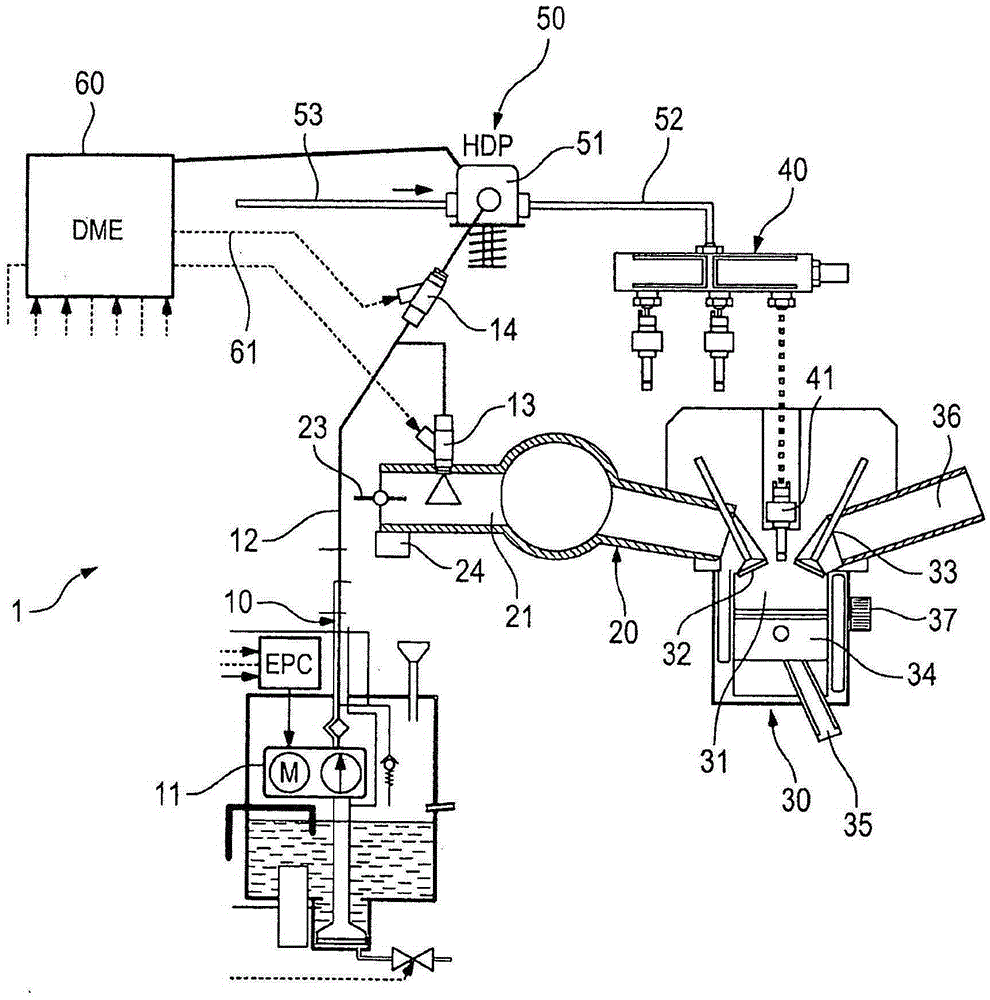

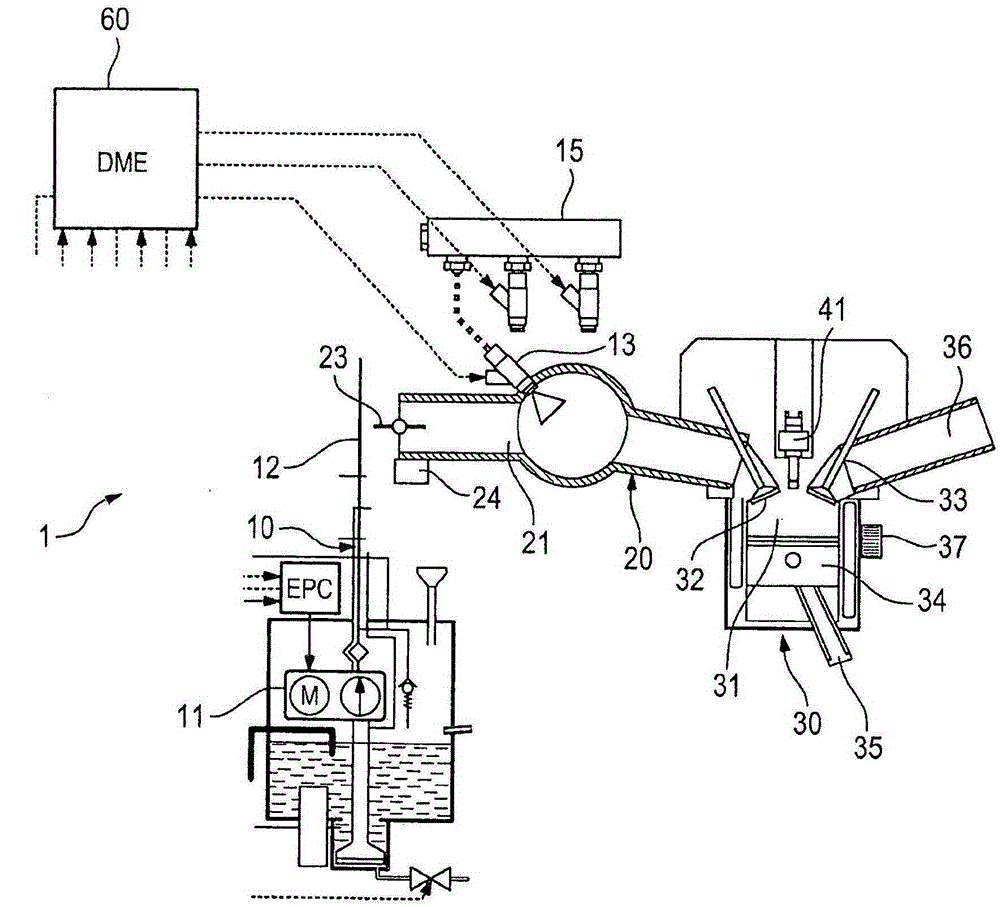

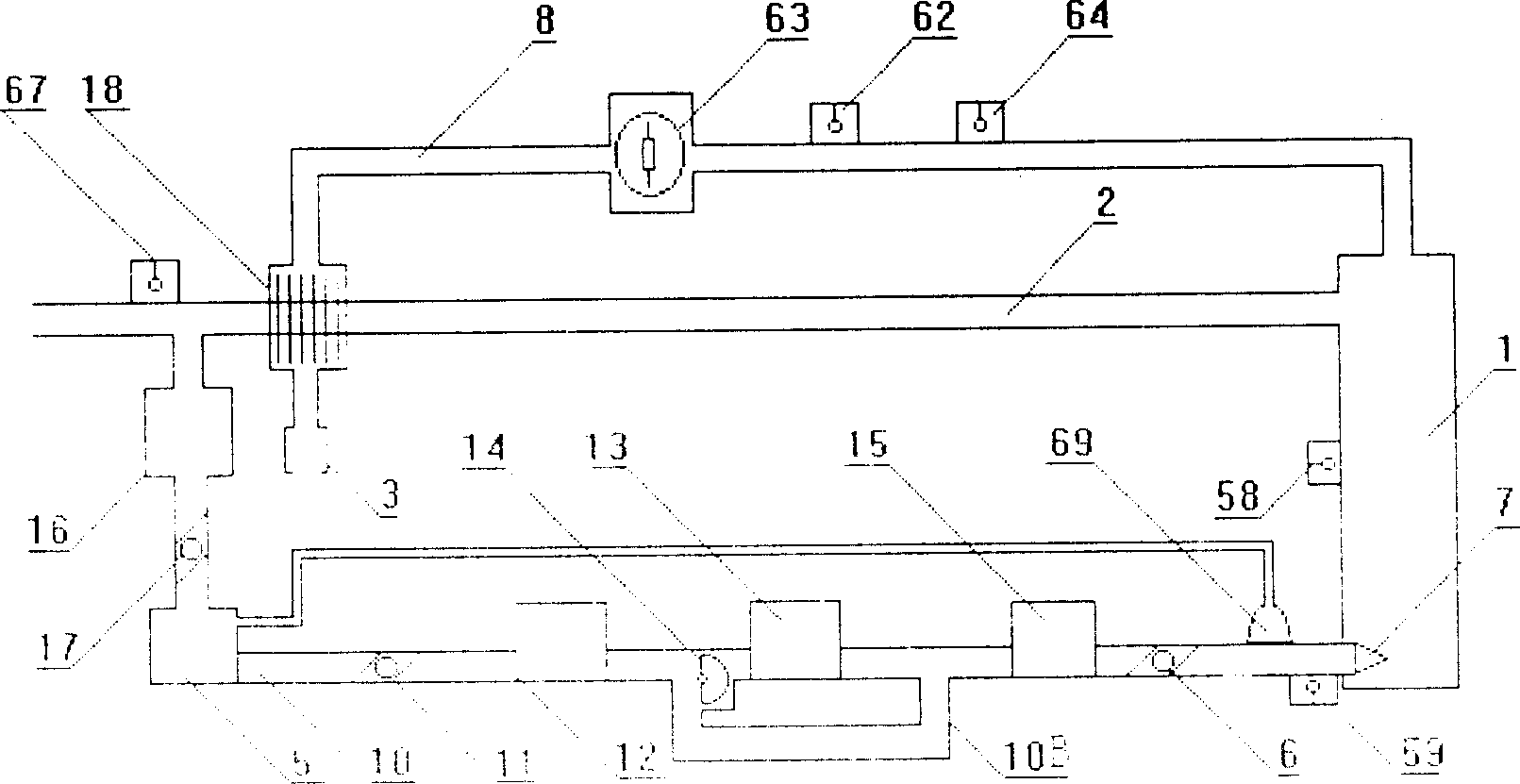

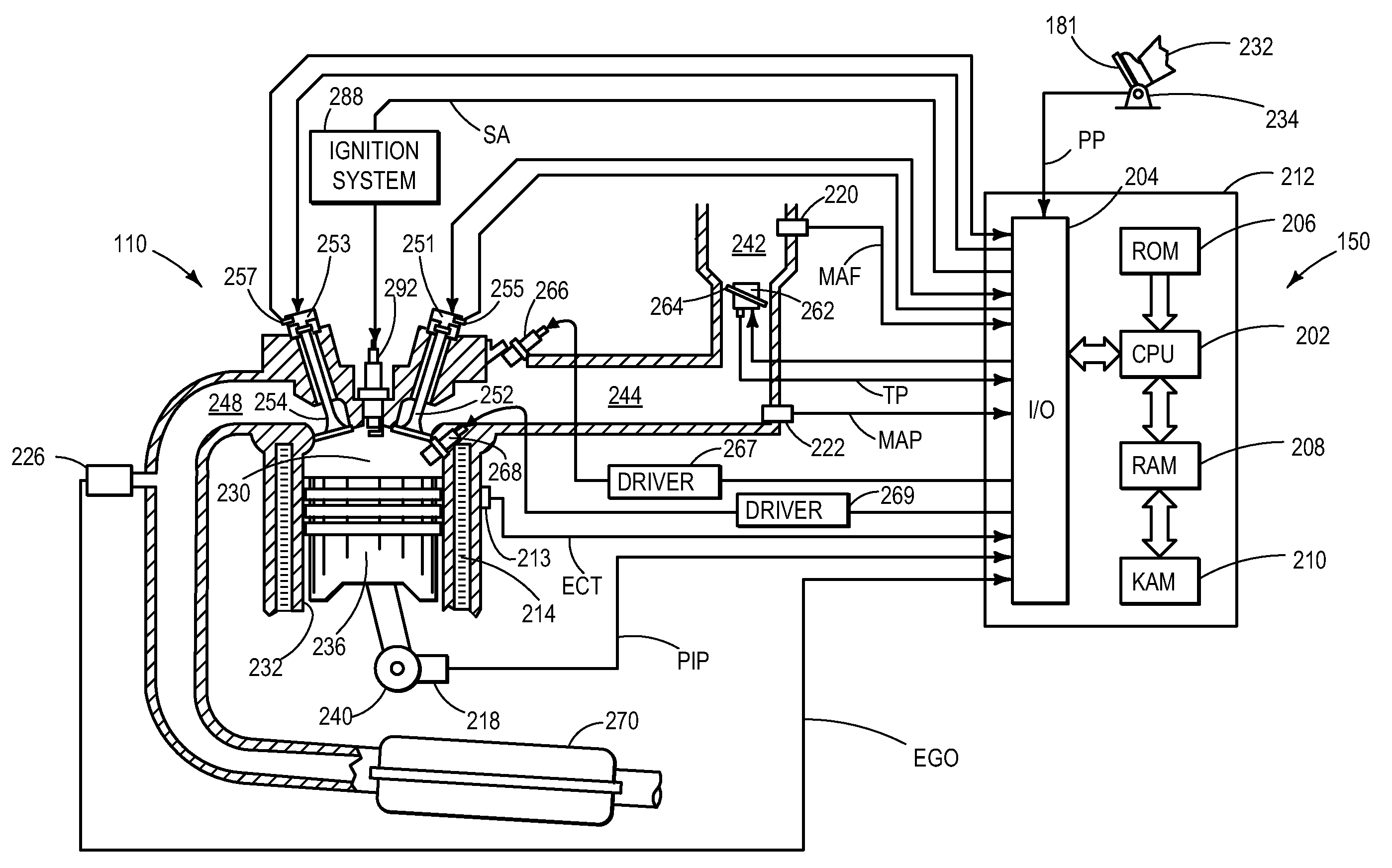

Method and device for operating an internal combustion engine

ActiveUS20090281709A1Reducing undesired emissionEasy to operateAnalogue computers for vehiclesElectrical controlExternal combustion engineInlet manifold

In a method for operating an internal combustion engine, a setpoint fuel quantity to be injected is subdivided into a first fuel quantity which is to be injected into an intake manifold of the internal combustion engine, and a second fuel quantity to be injected directly into a combustion chamber of the internal combustion engine. The subdivision of the fuel quantity is performed as a function of a temperature that is characteristic for the operation of the internal combustion engine, e.g., in a start of the internal combustion engine, and the ratio between the first fuel quantity and the second fuel quantity is continually modified as a function of the temperature.

Owner:ROBERT BOSCH GMBH

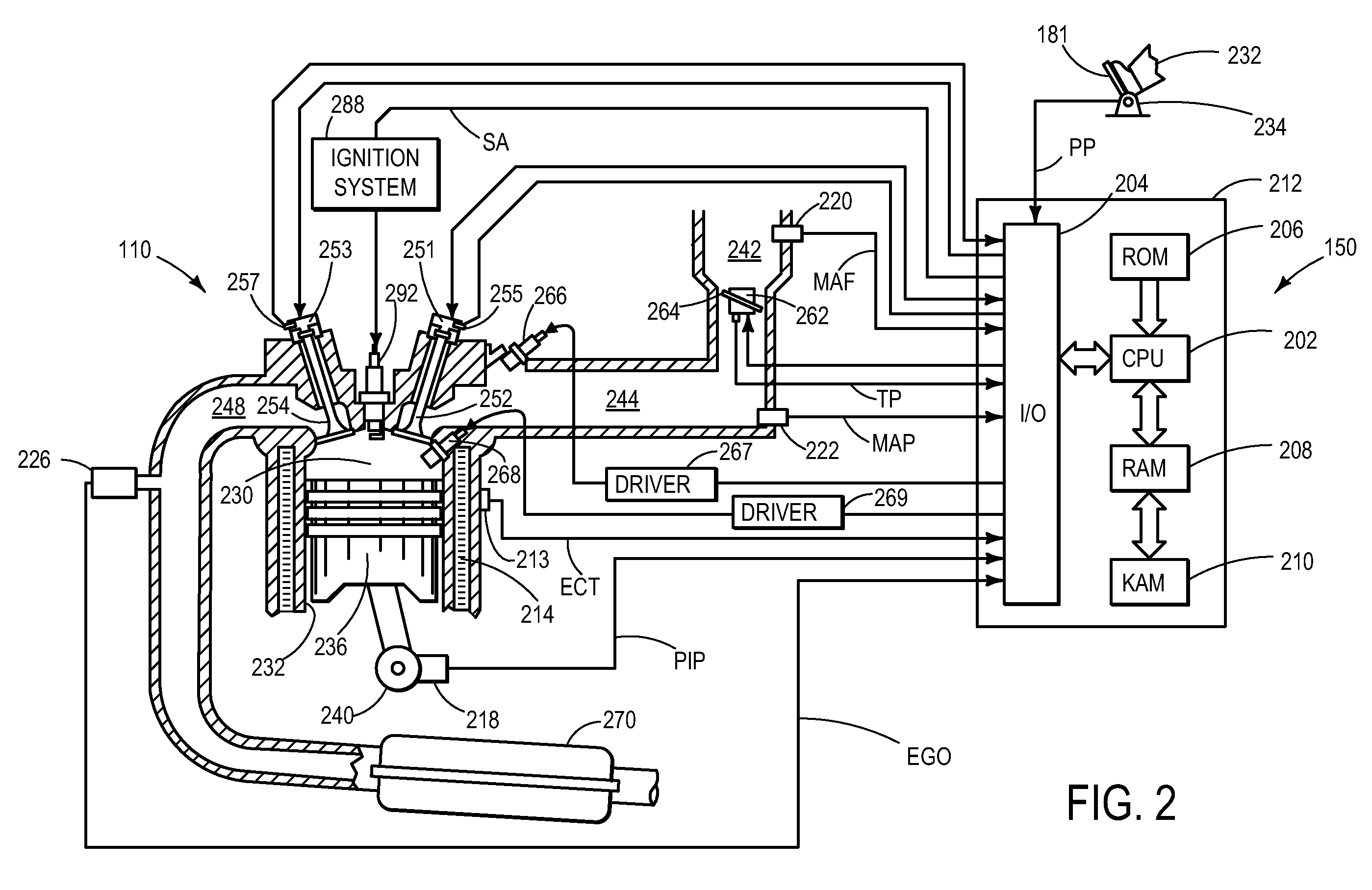

First and second spark plugs for improved combustion control

InactiveUS7578281B2Reduce knockingReduce restrictionsElectric ignition installationCombustion enginesExternal combustion engineInternal combustion engine

A method of operating an internal combustion engine having at least one combustion chamber including a first spark plug and a second spark plug, wherein the first spark plug is configured to operate at a higher temperature than the second spark plug, the method comprising of varying at least a resulting ratio of an amount of a fuel and an amount of a fluid delivered to the combustion chamber responsive to a first condition, and selectively using at least one of the first spark plug and the second spark plug to ignite at least one of the fuel and the fluid delivered to the combustion chamber.

Owner:FORD GLOBAL TECH LLC

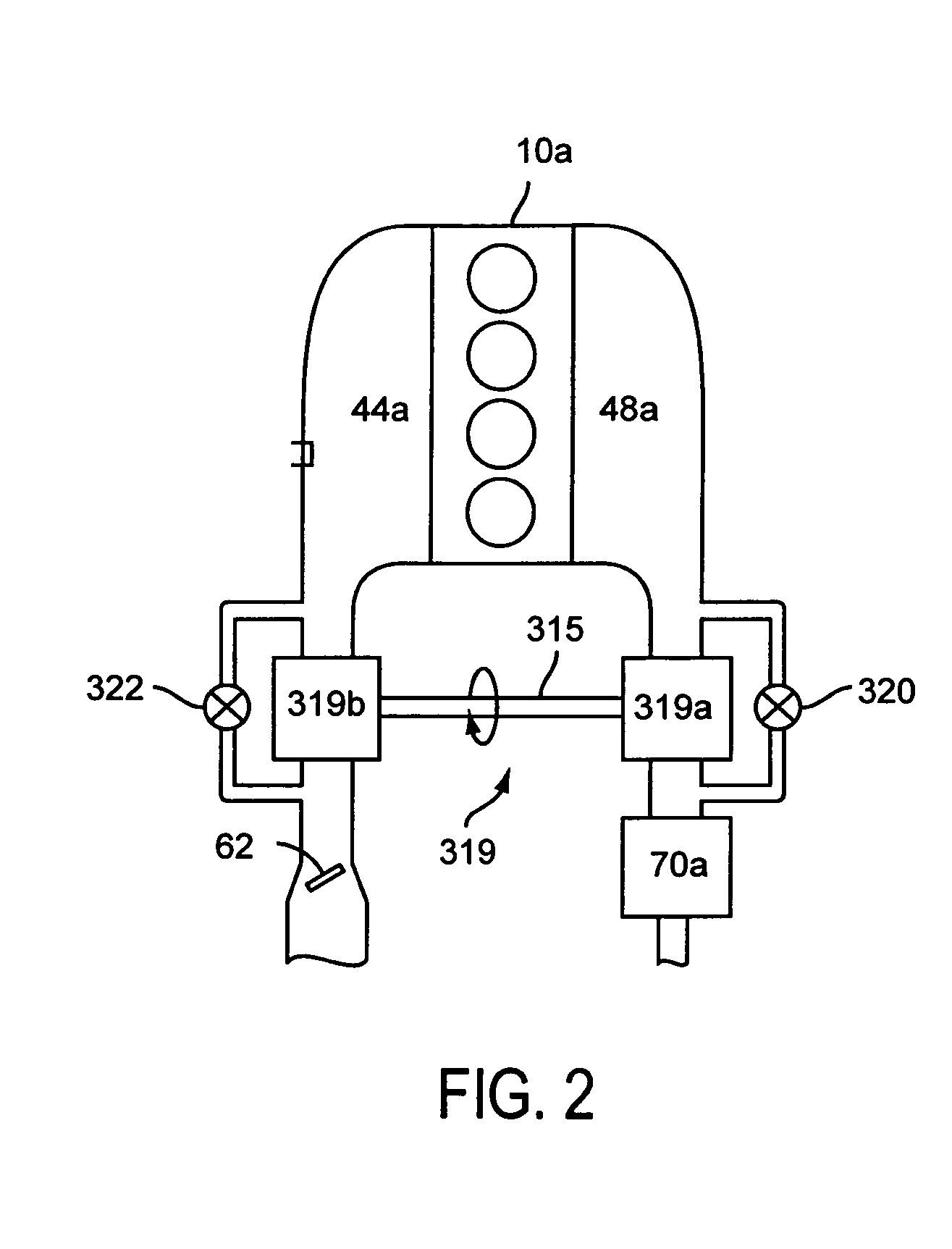

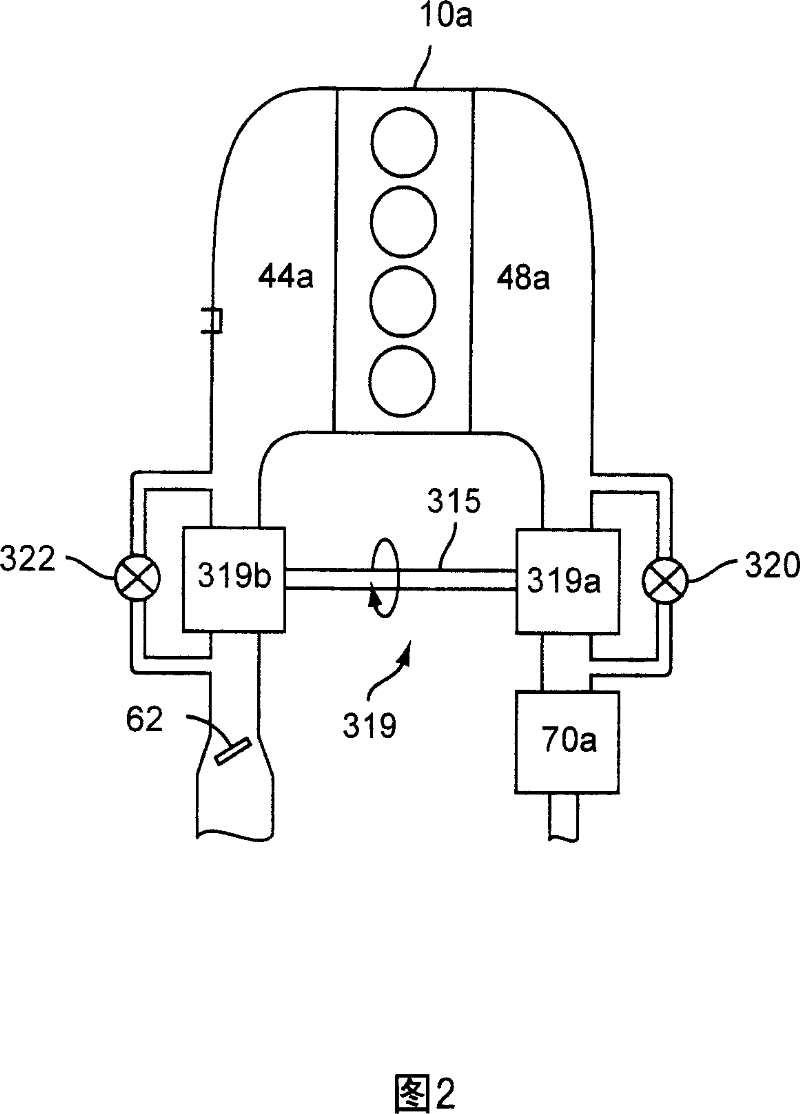

Hybrid vehicle propulsion system utilizing knock suppression

InactiveUS7676321B2Low costImprove cooling effectInternal combustion piston enginesElectric ignition installationCombustion chamberDrive wheel

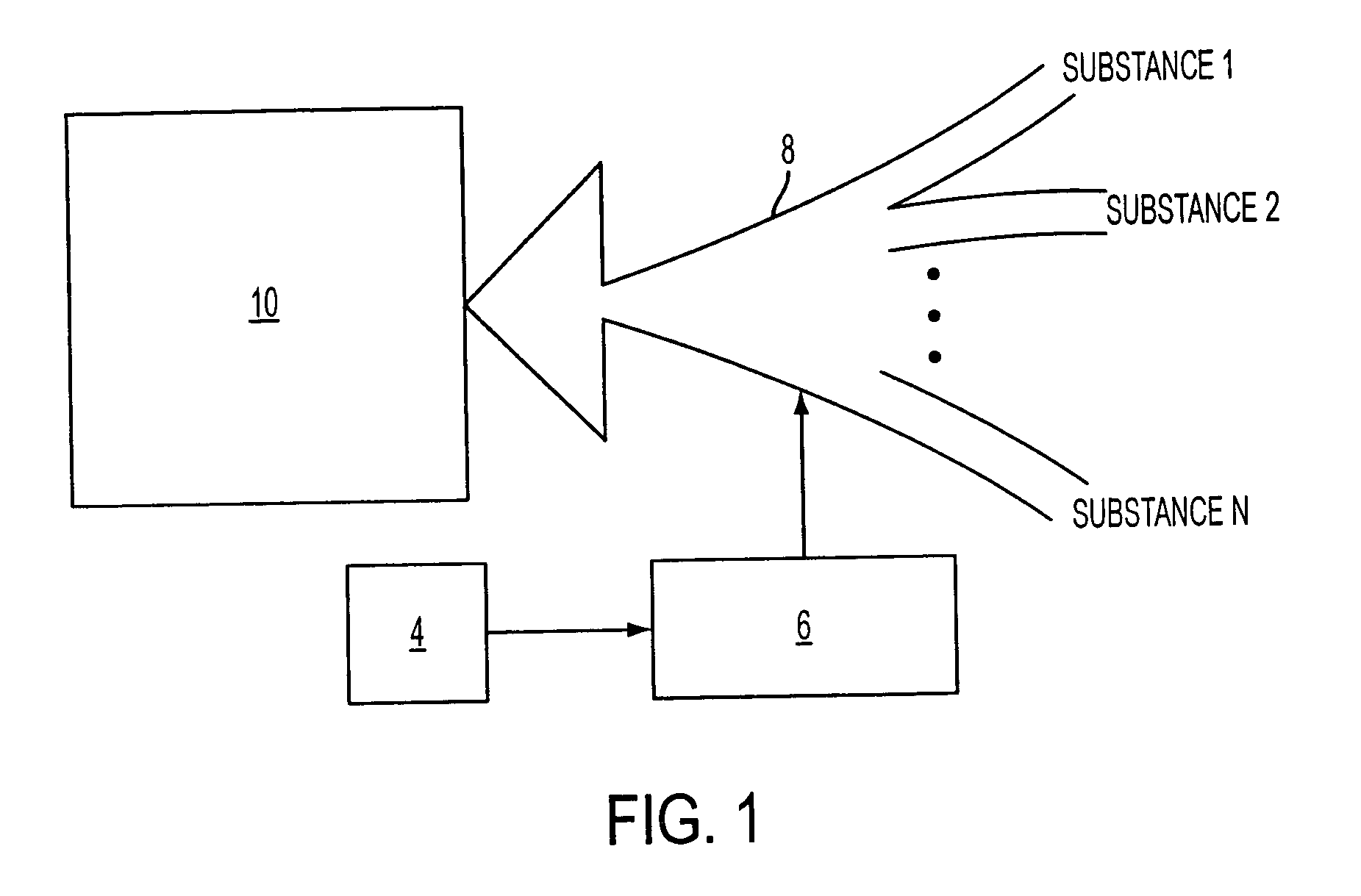

A hybrid propulsion system for a vehicle and method of operation are provided. As one example, the system comprises an engine including at least one combustion chamber, a motor configured to selectively propel the vehicle via the drive wheel, a fuel system configured to deliver a first substance and a second substance to the combustion chamber in varying relative amounts, wherein the first substance includes a fuel and the second substance includes a greater concentration of a knock suppressing substance than the first substance; and a control system configured to operate the fuel system to vary the relative amounts of the first substance and the second substance delivered to the combustion chamber in response to an operating condition while operating the motor to propel the vehicle.

Owner:FORD GLOBAL TECH LLC

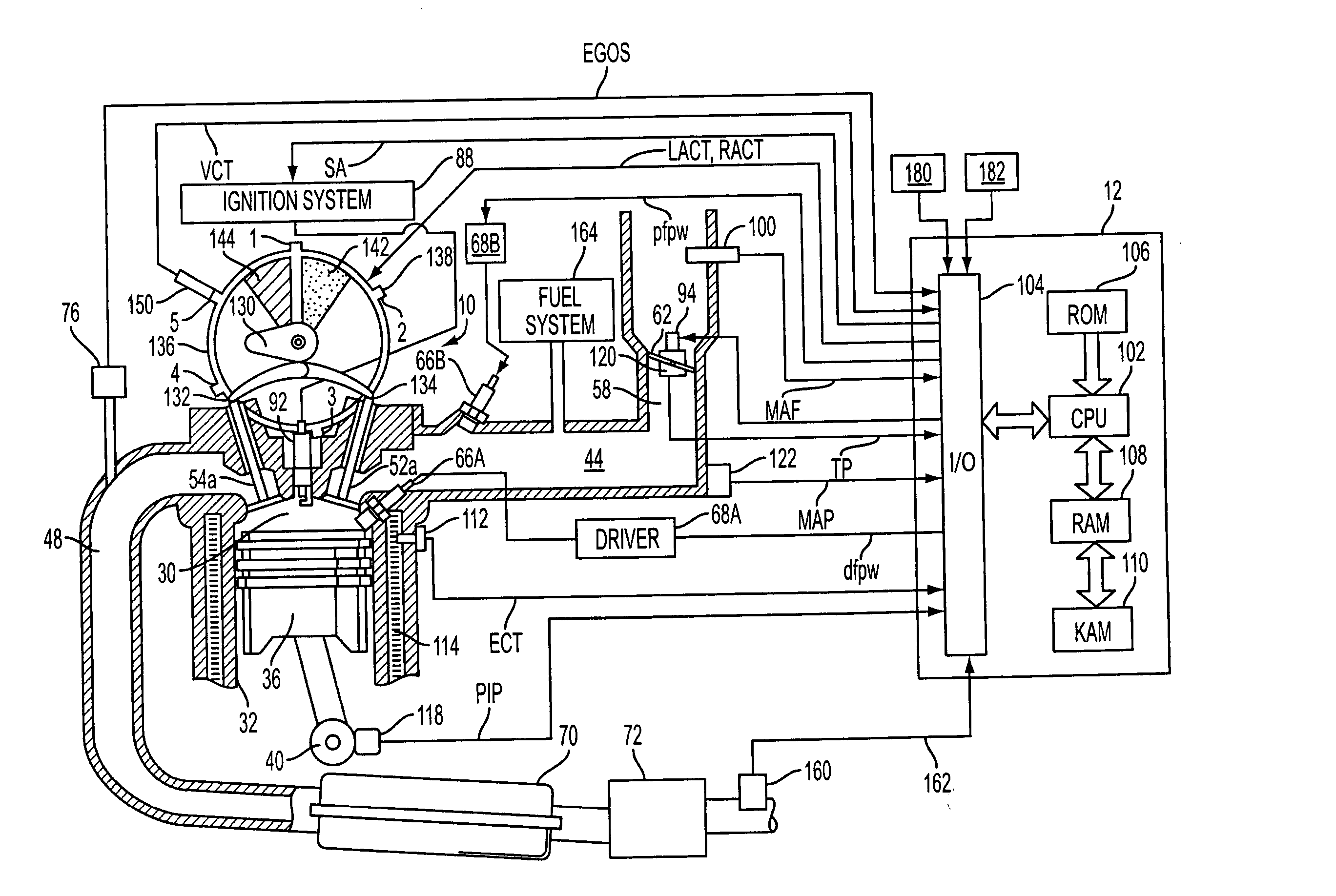

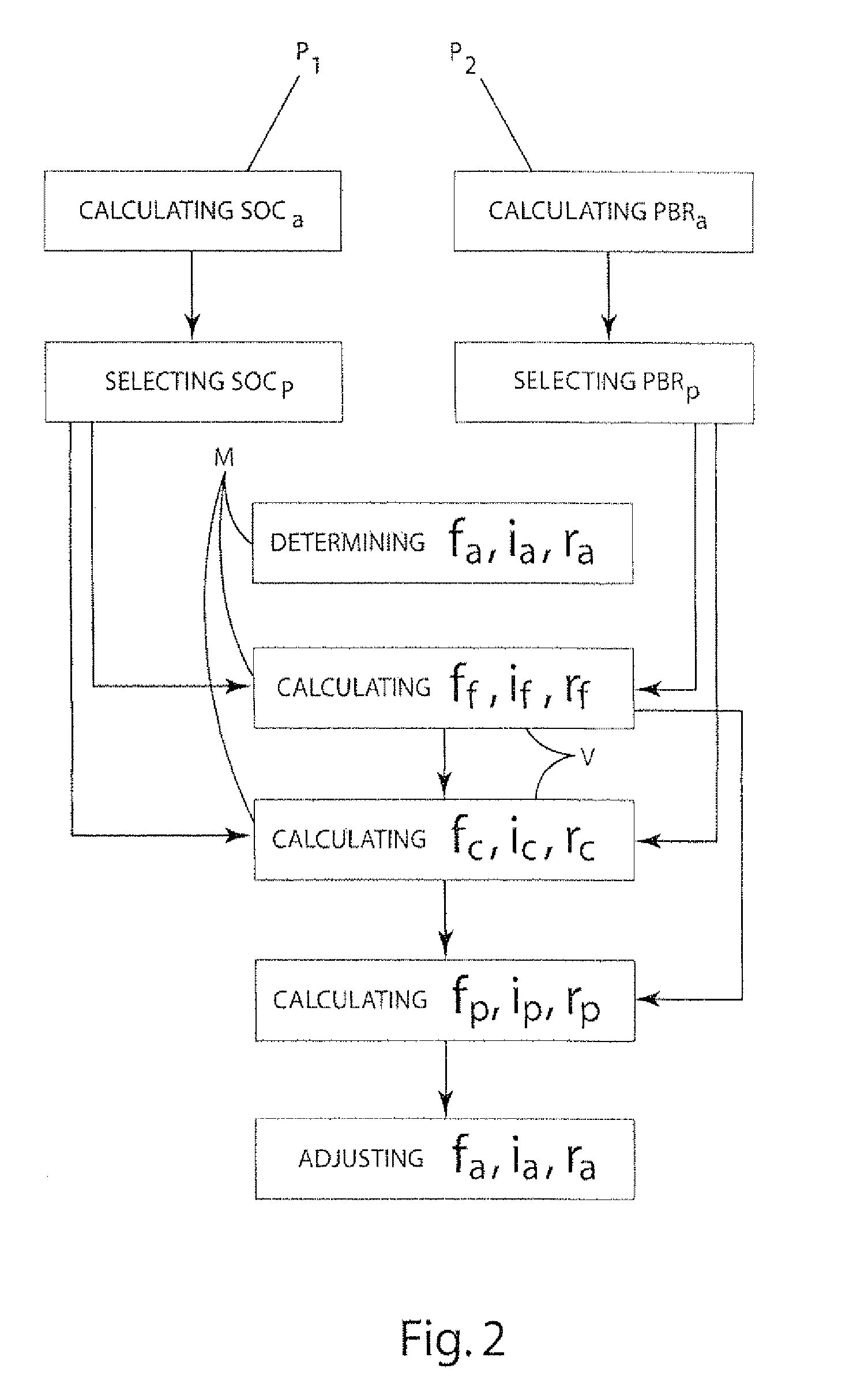

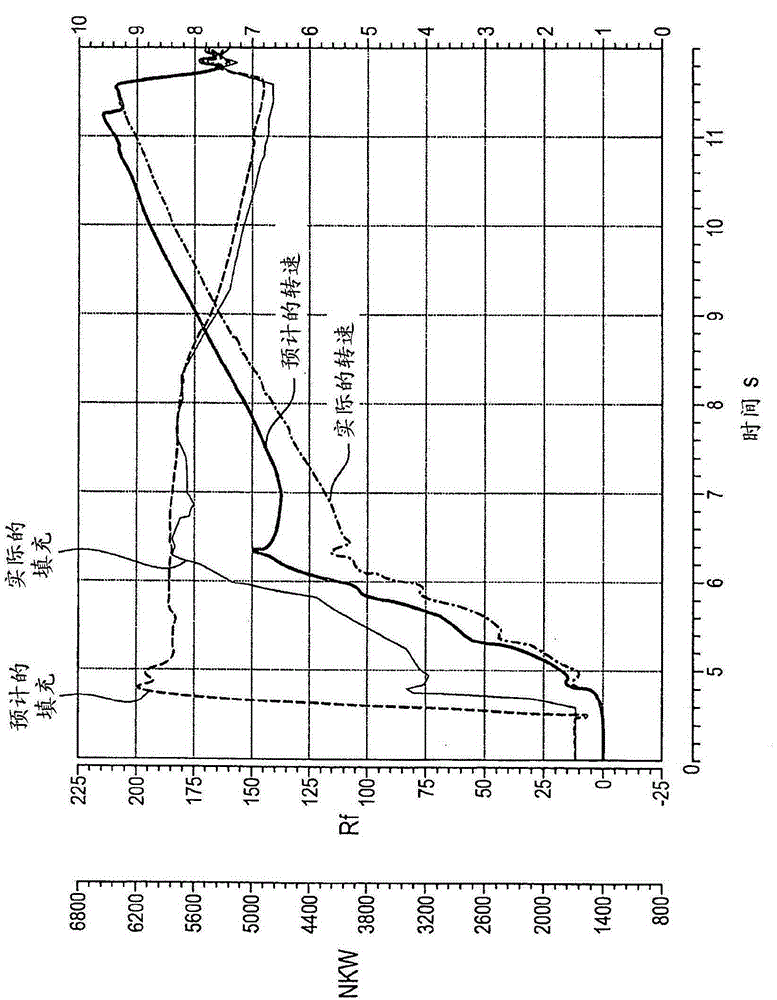

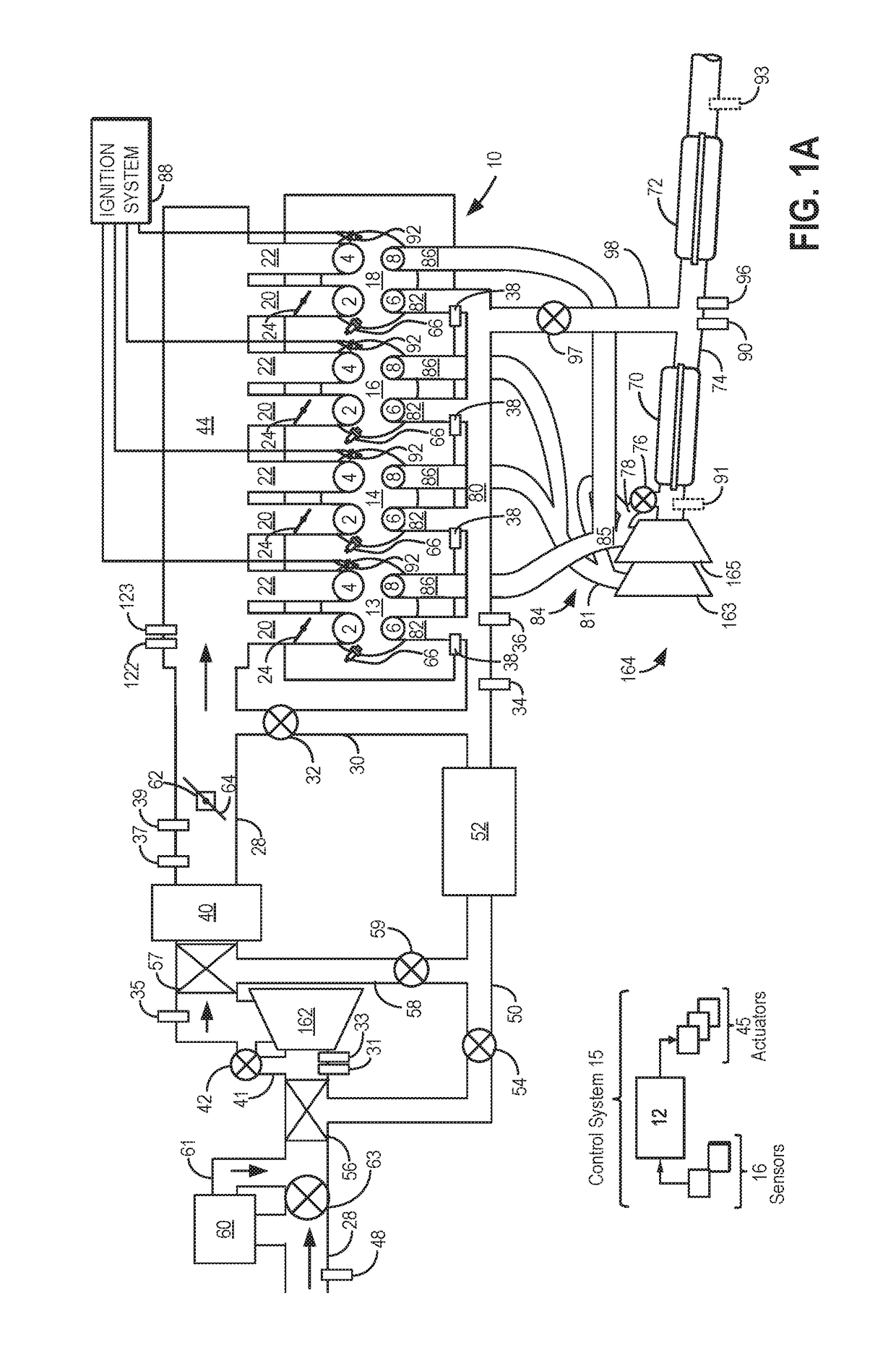

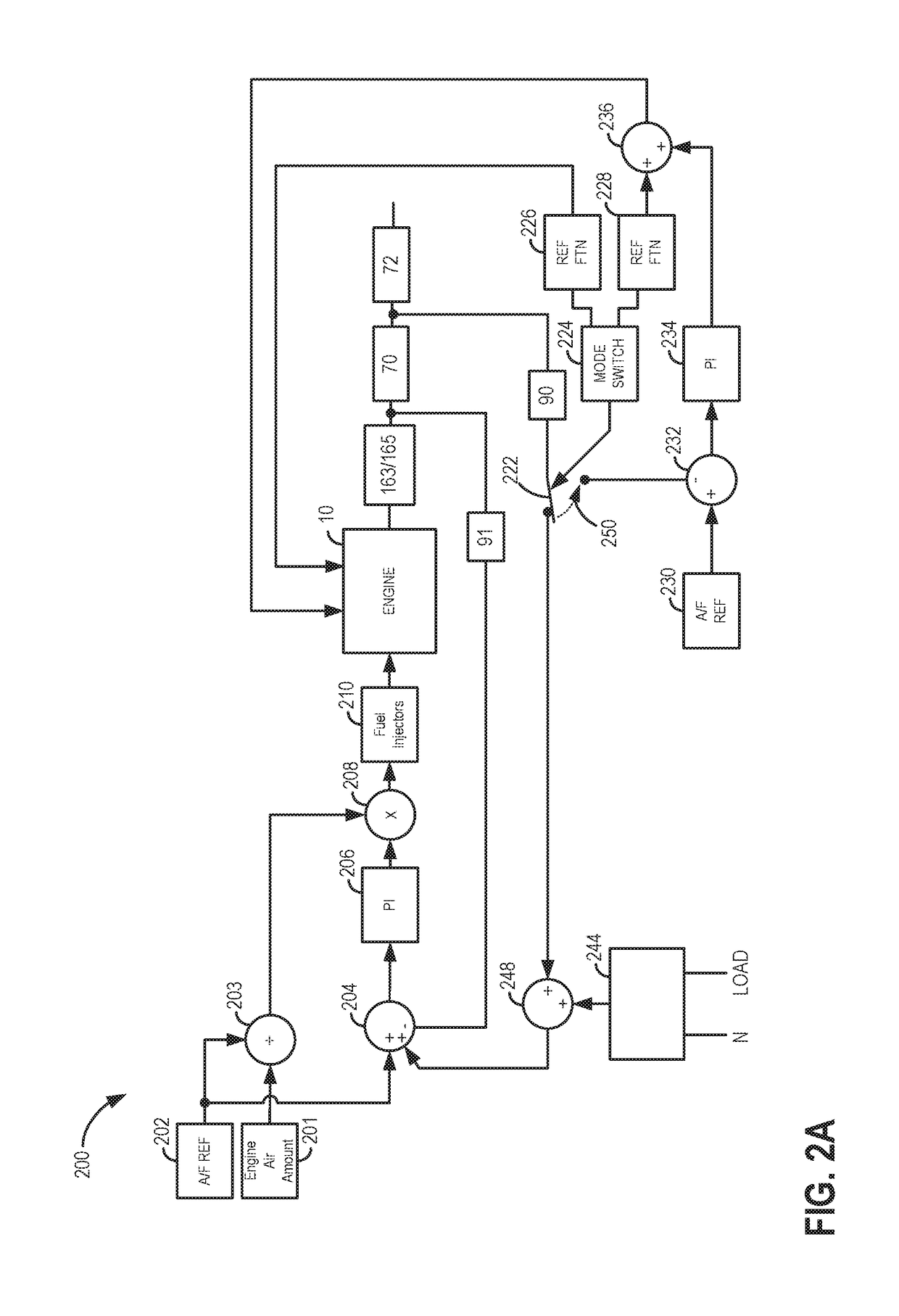

Methods Of Controlling An Internal Combustion Engine Including Multiple Fuels And Multiple Injectors

InactiveUS20110010074A1Improve fuel economyReduce knockingElectrical controlNon-fuel substance addition to fuelExternal combustion engineClosed loop

A method for controlling the start of combustion and peak burn rate of an internal combustion engine system on a cycle-to-cycle basis including multiple direct fuel injectors, multiple indirect fuel injectors, and multiple liquid fuels. The actual start of combustion and actual peak burn rate are calculated using in-cylinder pressure or ionization. A predetermined start of combustion and a predetermined peak burn rate are selected. The start of combustion and peak burn rate control algorithm includes controlling a fuel ratio, an injection ratio, and a residual gas recirculation ratio. A predetermined fuel ratio, a predetermined injection ratio, and a predetermined residual gas recirculation are calculated by combining feed forward ratios and closed loop control ratios corresponding to the three ratios. The predetermined ratios are employed so that the system achieves the predetermined start of combustion and predetermined peak burn rate.

Owner:VISTEON GLOBAL TECH INC

Direct injection of diluents or secondary fuels in gaseous fuel engines

InactiveUS20140331668A1Reduce exhaust emissionsHigh priceInternal combustion piston enginesNon-fuel substance addition to fuelDiluentExhaust gas recirculation

An engine system, comprising a first gaseous fuel source with a first gaseous fuel located therein coupled to one or more engine cylinders and an exhaust gas recirculation (EGR) system with a reform catalyst located therein, the reform catalyst reforming natural gas into a gas with a wider AFR operating range. The engine may thus operate at an AFR that may be outside of that available during natural gas combustion alone to allow for cooler engine operation.

Owner:FORD GLOBAL TECH LLC

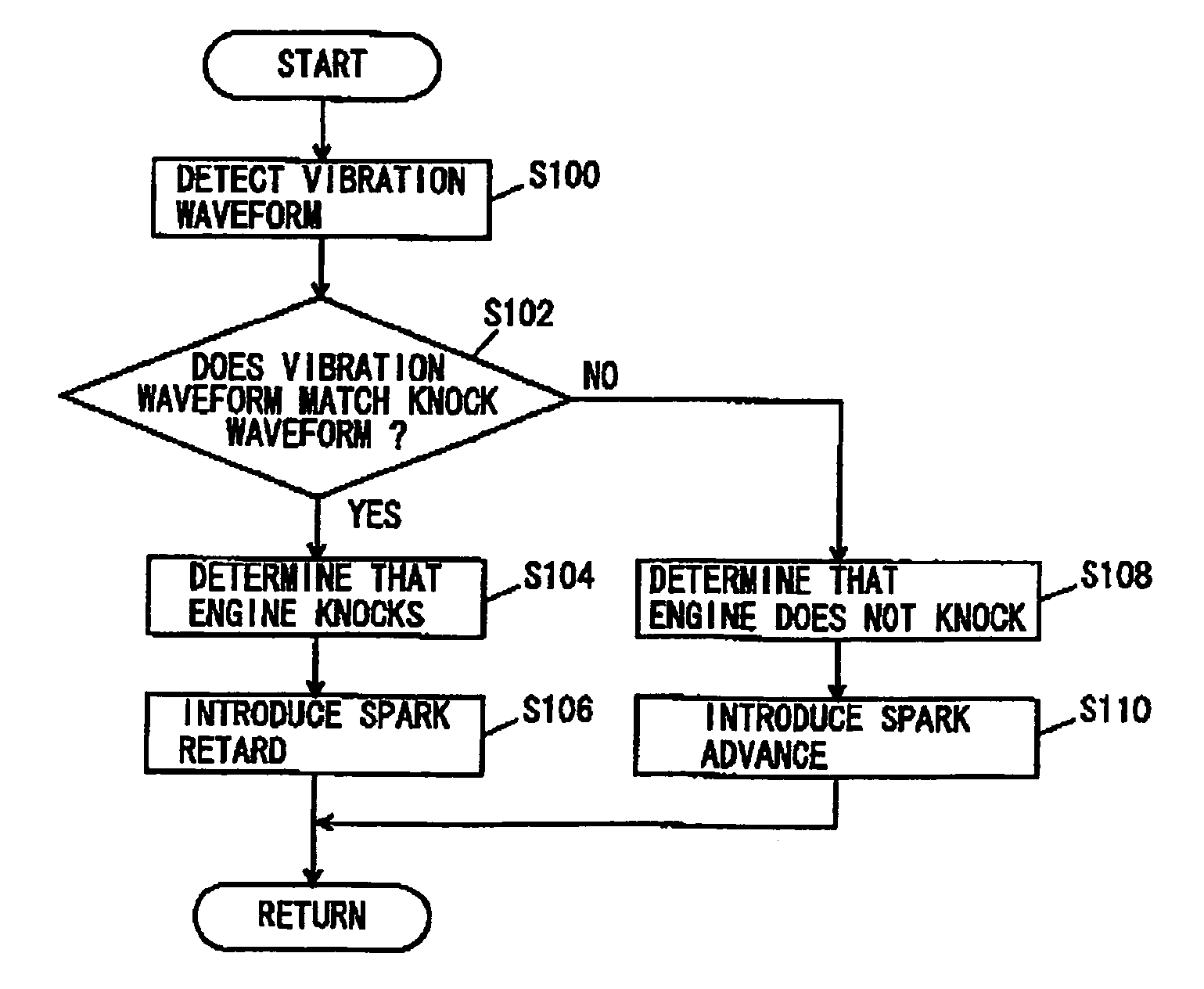

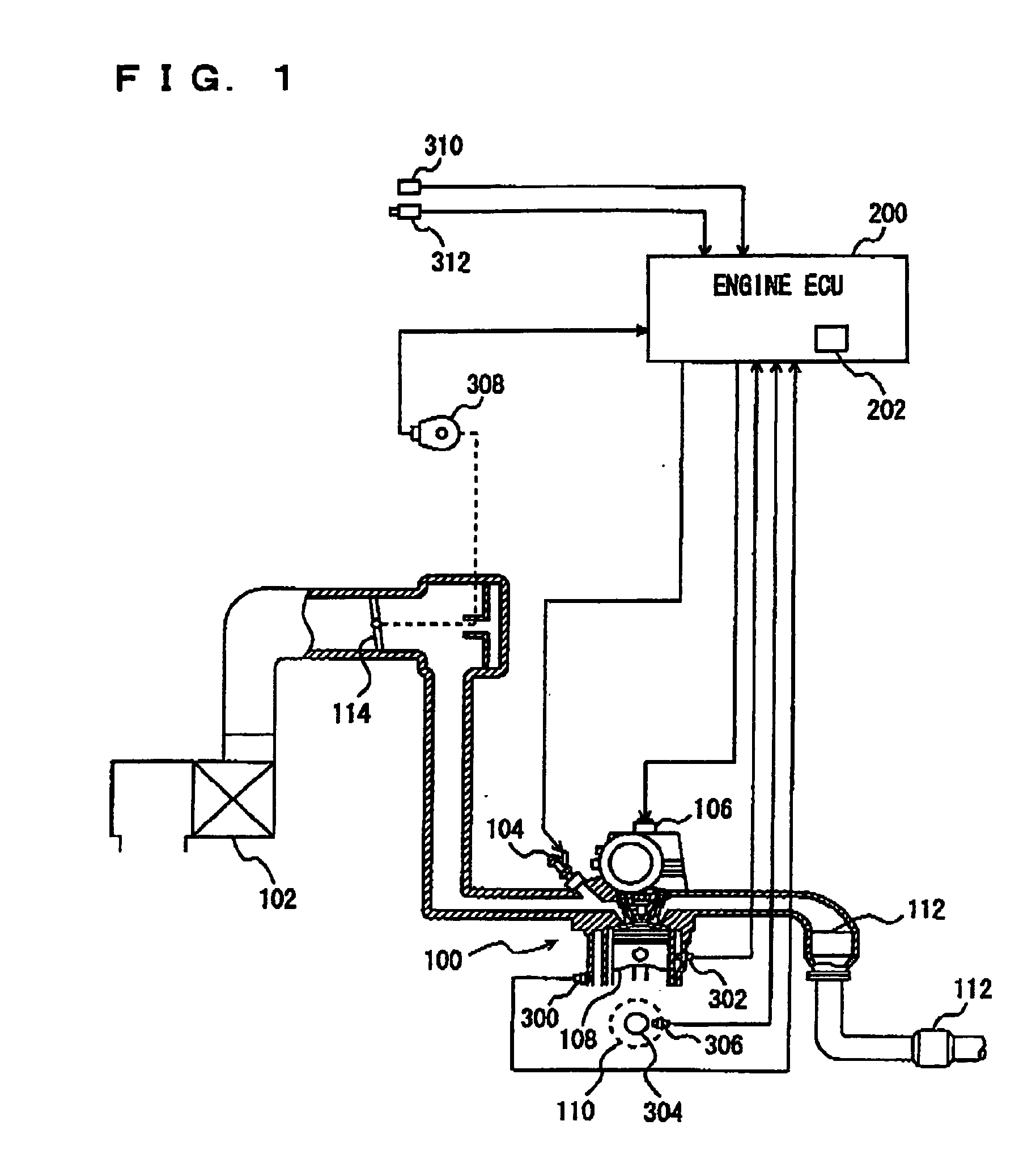

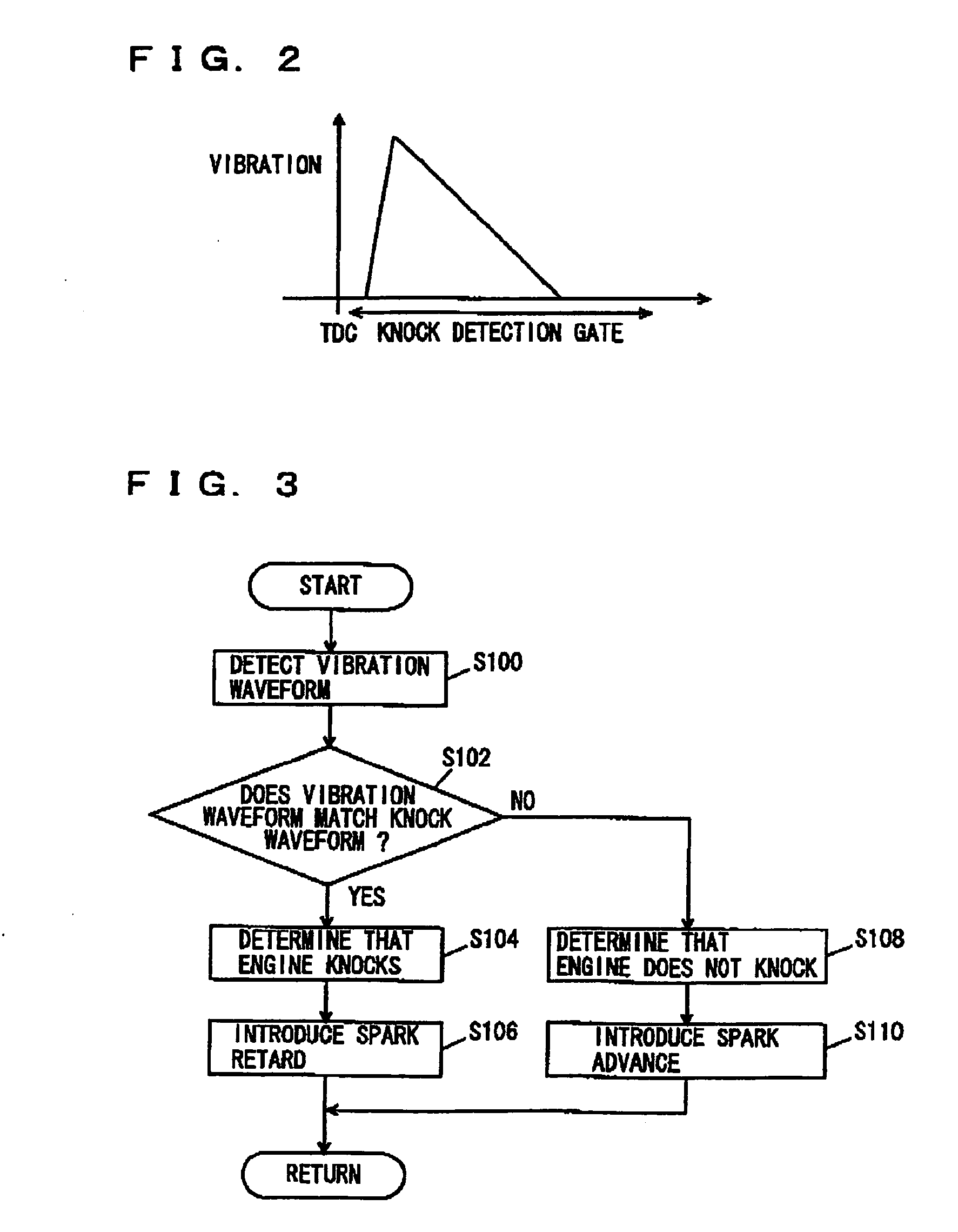

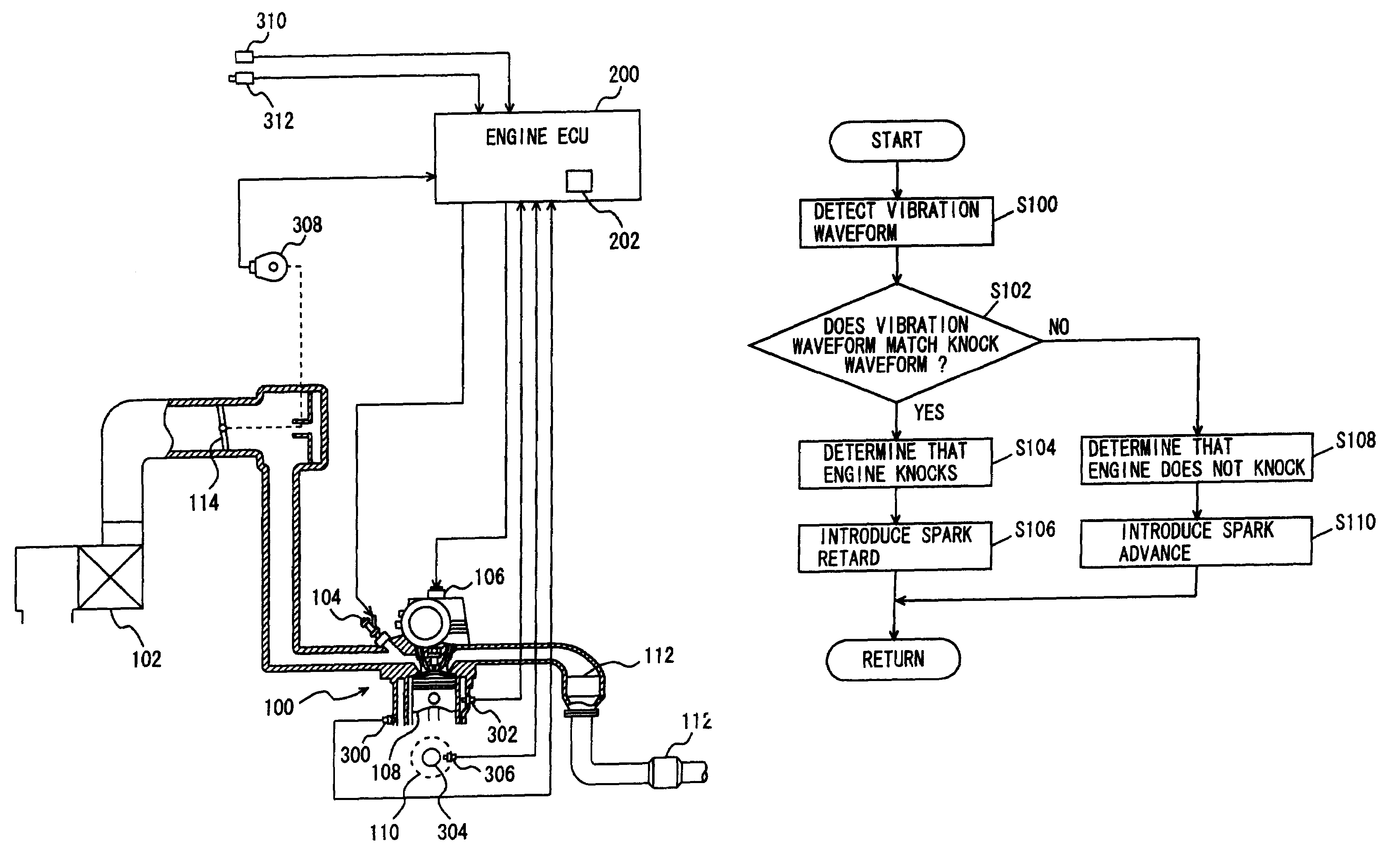

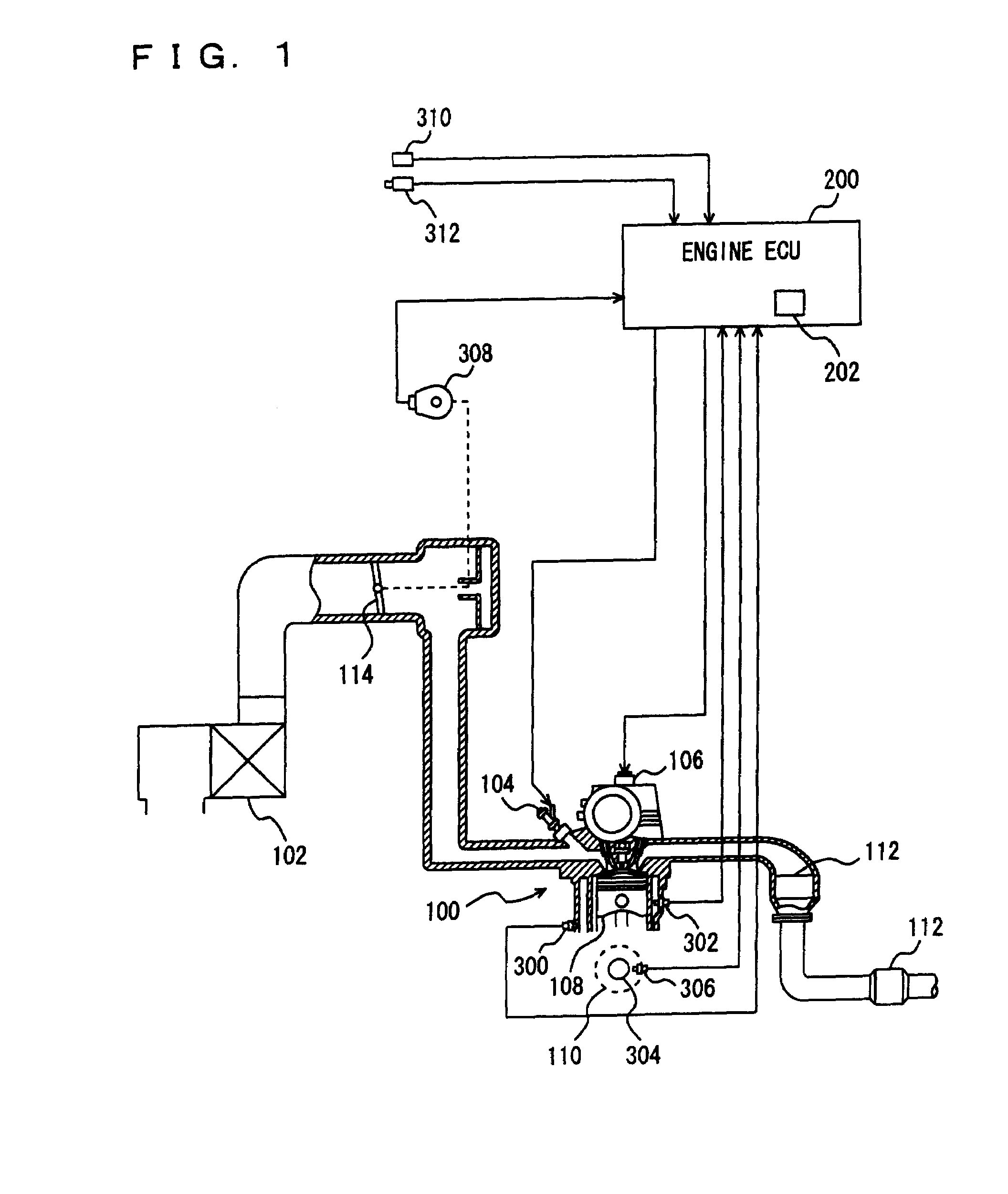

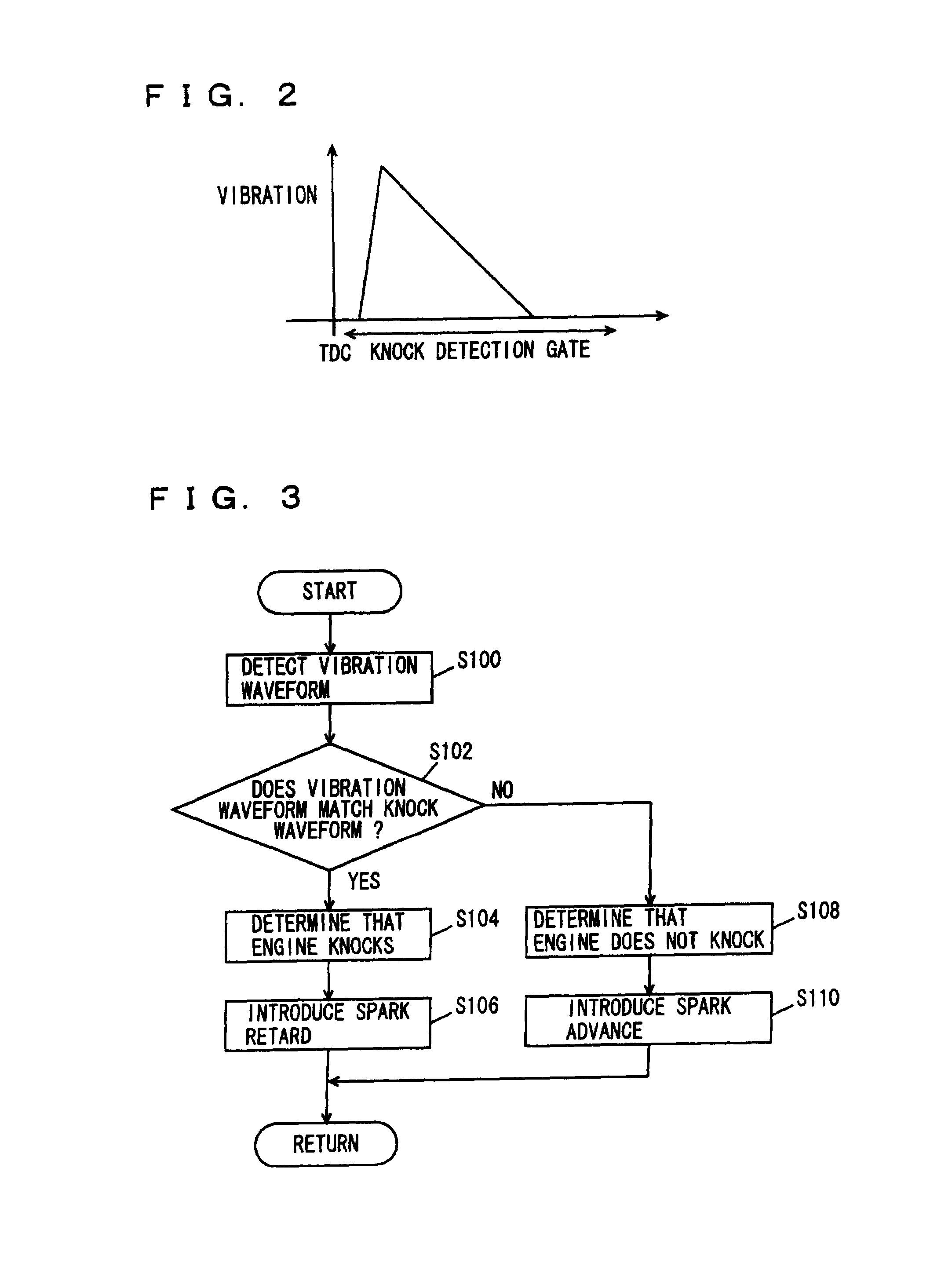

Internal combustion engine knock determination device and ignition control system including the same

ActiveUS20050251320A1Improve accuracyReduce knockingAnalogue computers for vehiclesElectrical controlInternal combustion engineIgnition control

Owner:TOYOTA JIDOSHA KK +1

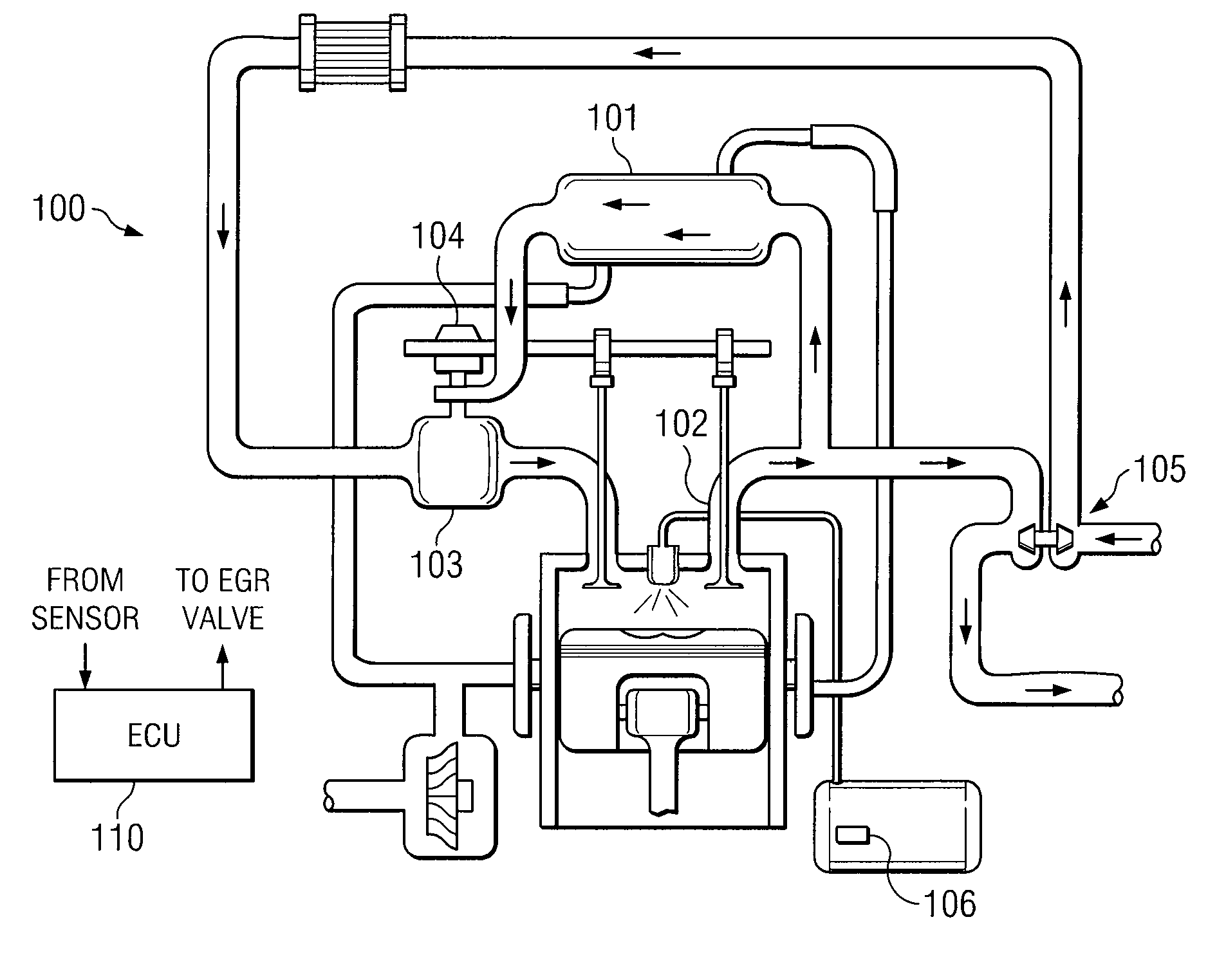

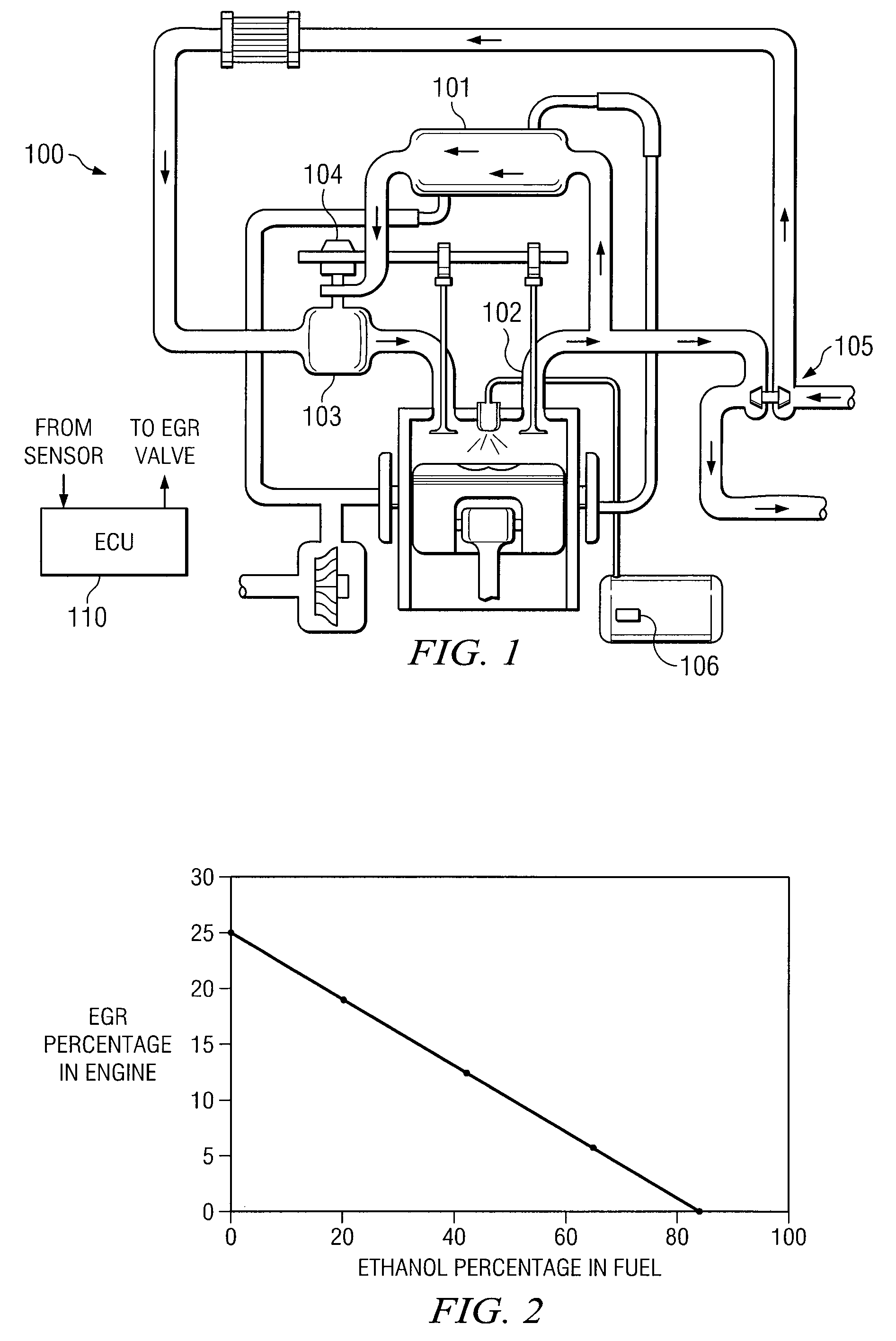

Flexible fuel engines with exhaust gas recirculation for improved engine efficiency

ActiveUS7487766B2Great engine knock resistanceImprove seismic performanceElectrical controlNon-fuel substance addition to fuelEngine efficiencyAlternative fuels

A method and system for use with flexible fuel engines capable of operating with arbitrary mixtures of gasoline and alternative fuel. The engine is equipped with an EGR loop and a control system, such that, as the relative amount of alternative fuel decreases, the amount of EGR provided to the engine increases.

Owner:SOUTHWEST RES INST

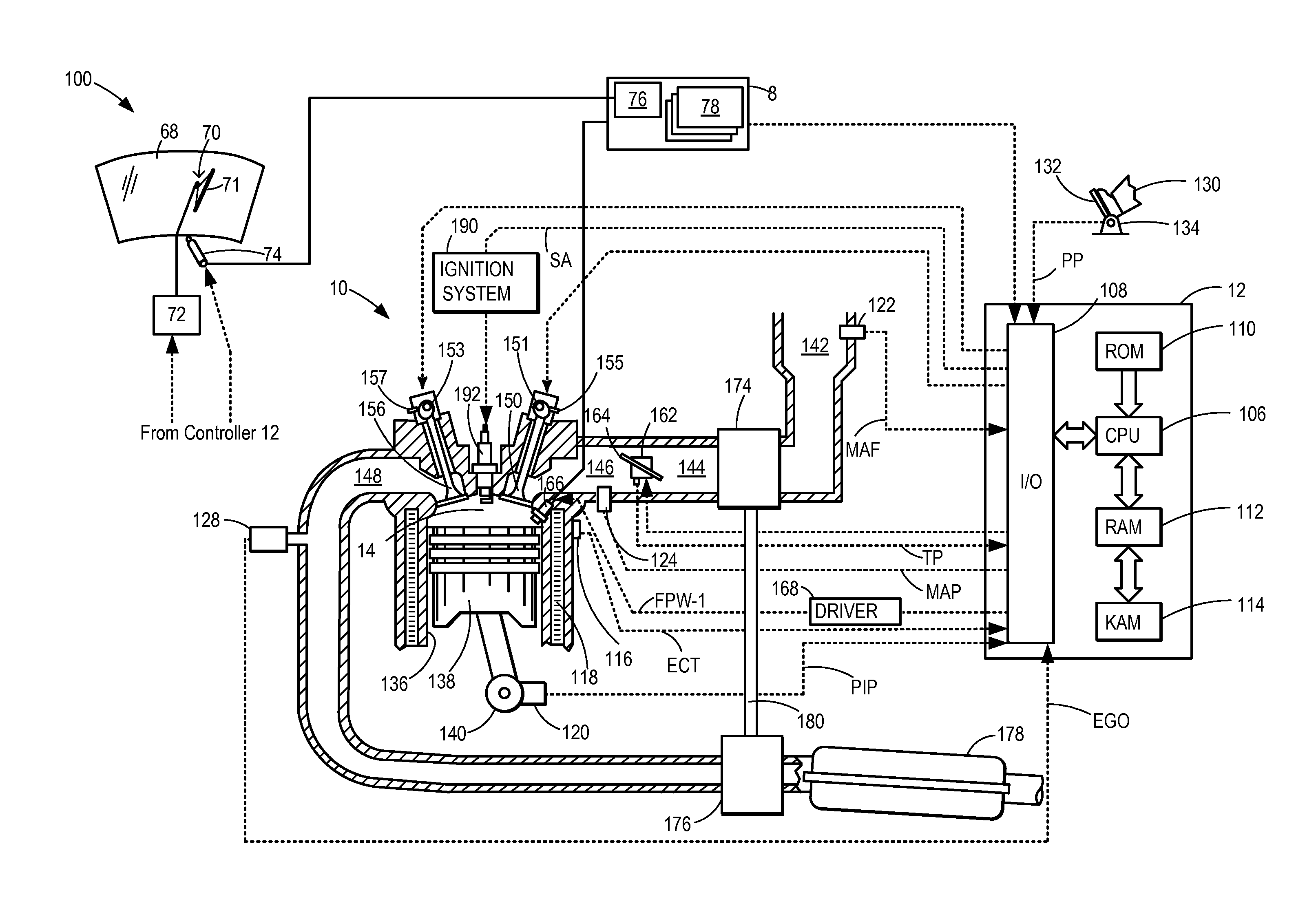

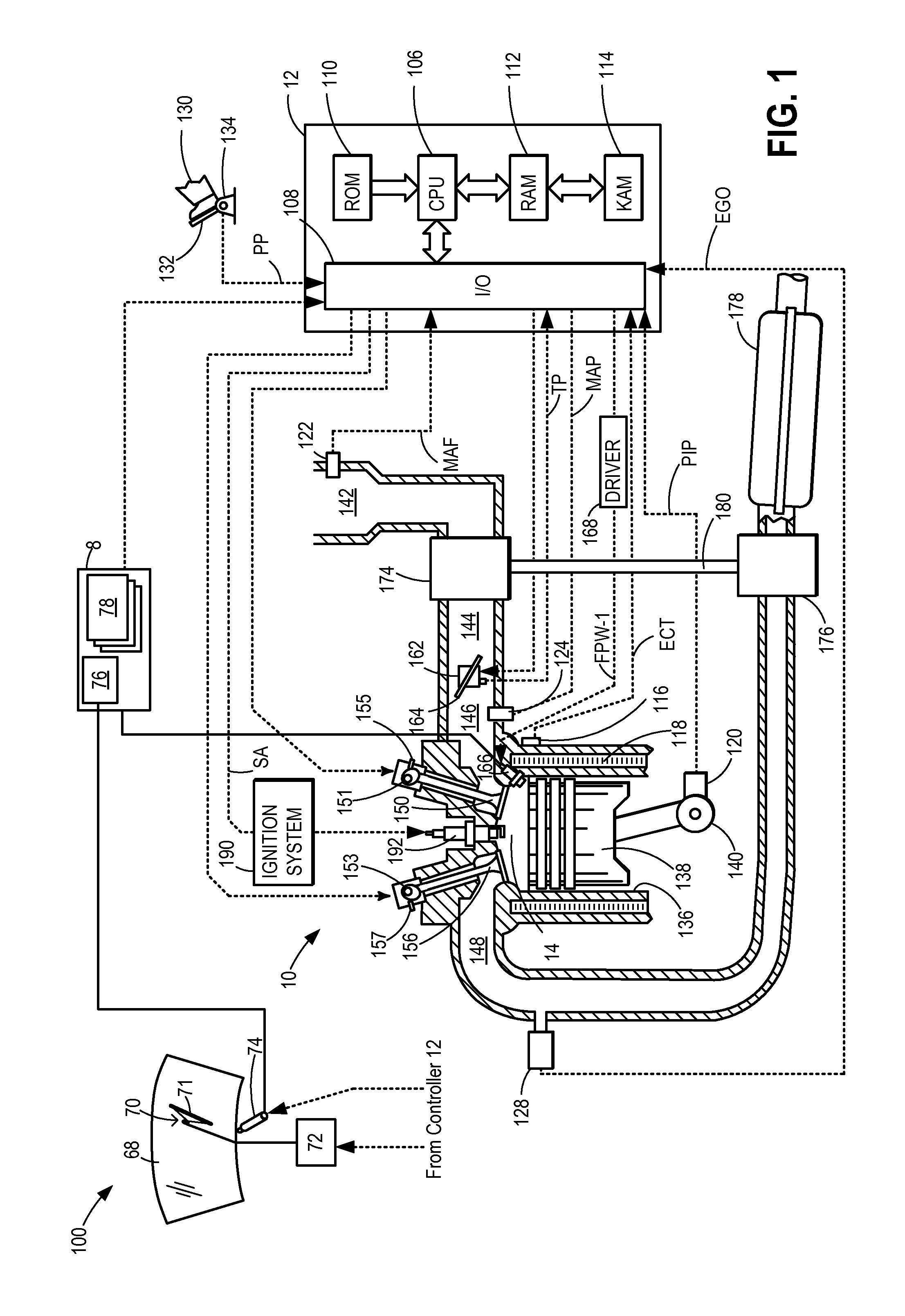

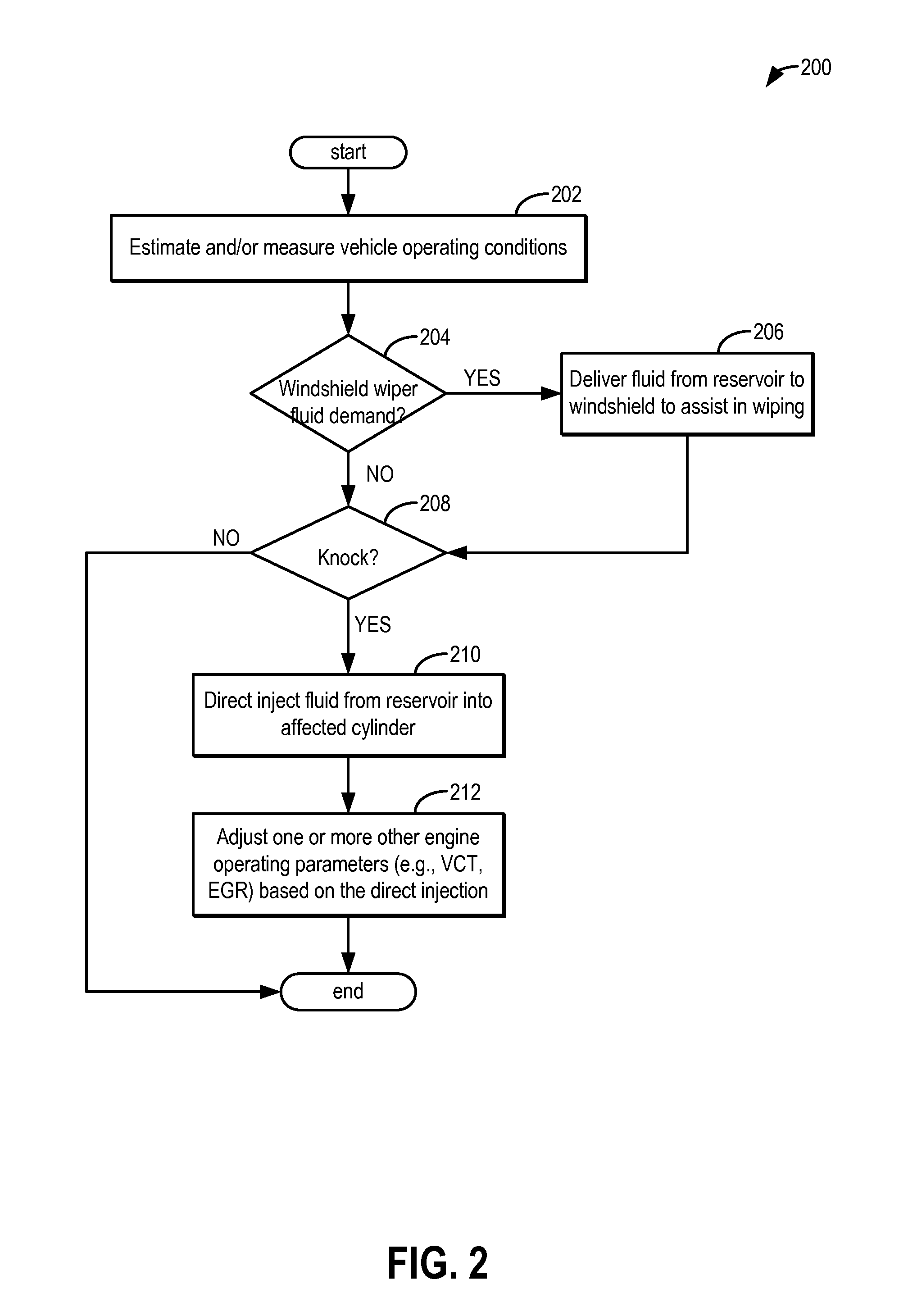

Method and system for engine control

InactiveUS20140200796A1Lower performance requirementsAccelerated dilutionAnalogue computers for vehiclesNon-fuel substance addition to fuelCombustionEngineering

Methods and systems are provided for use of a windshield wiper fluid having a reformulated composition including one or more non-ionic surfactants. The fluid is delivered to the windshield in response to an operator demand for wiping the windshield. The same fluid is also delivered to a cylinder in response to an indication of abnormal cylinder combustion.

Owner:FORD GLOBAL TECH LLC

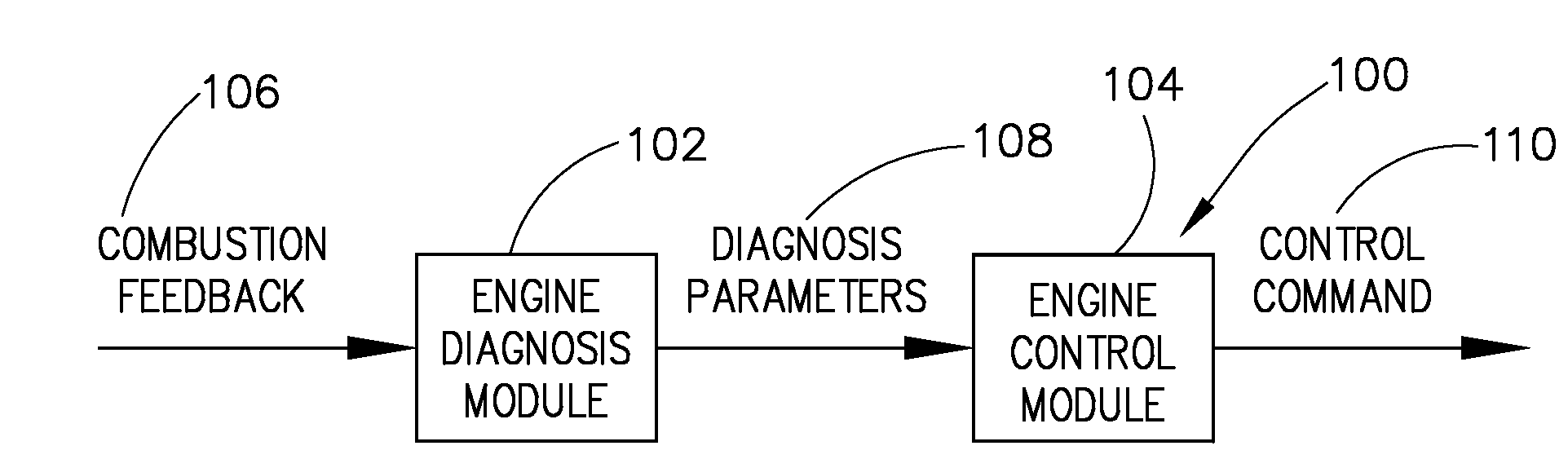

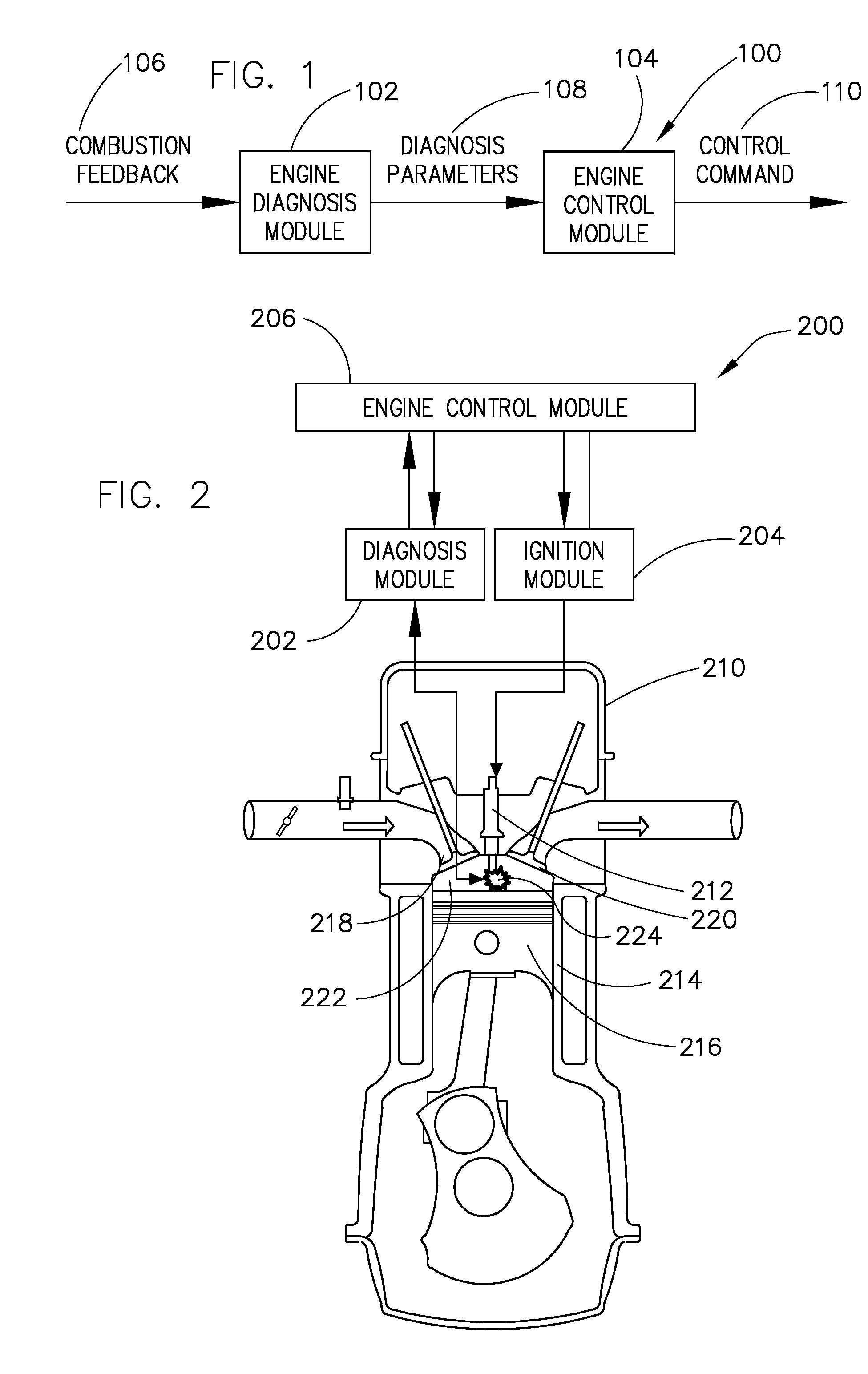

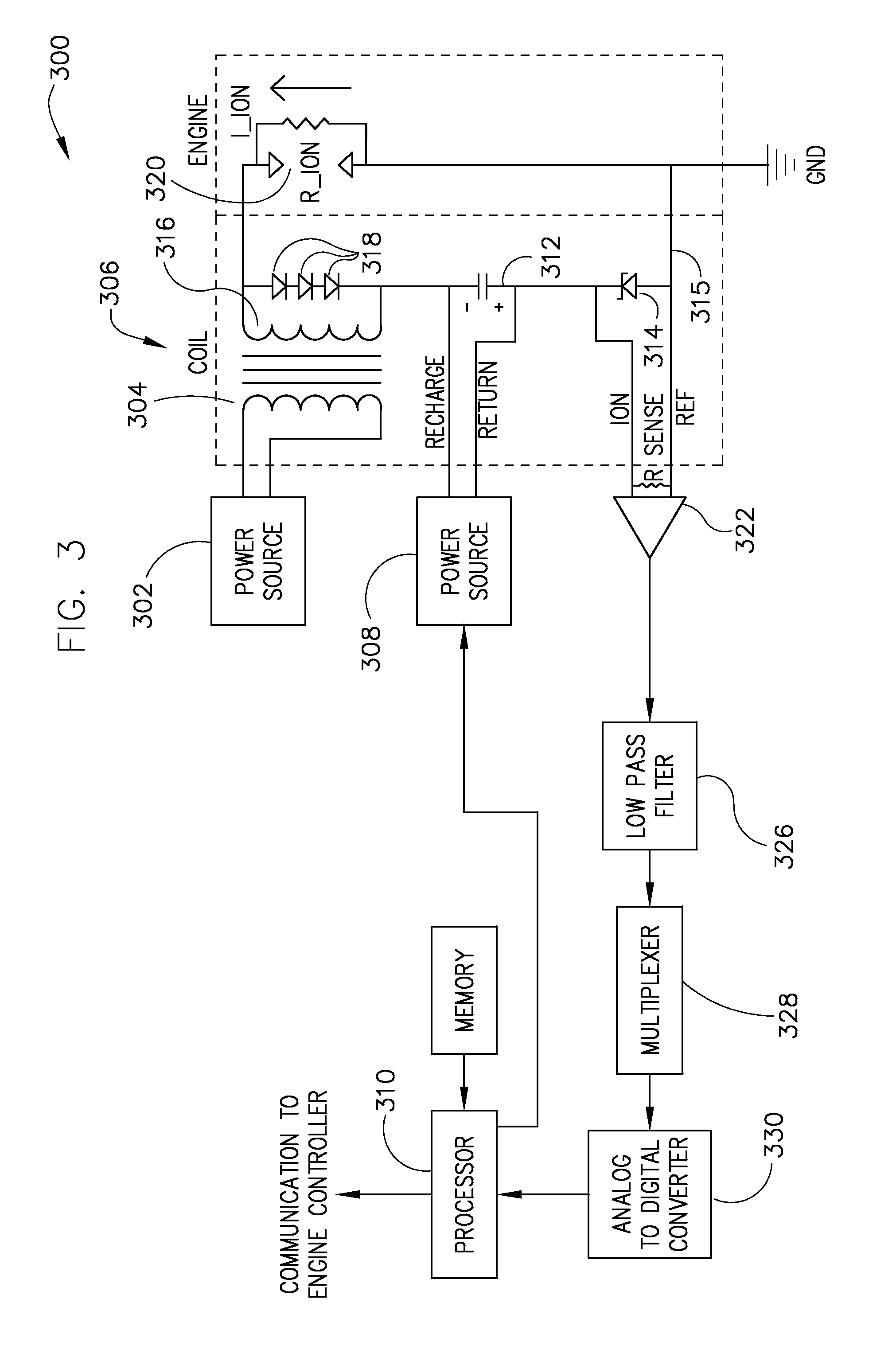

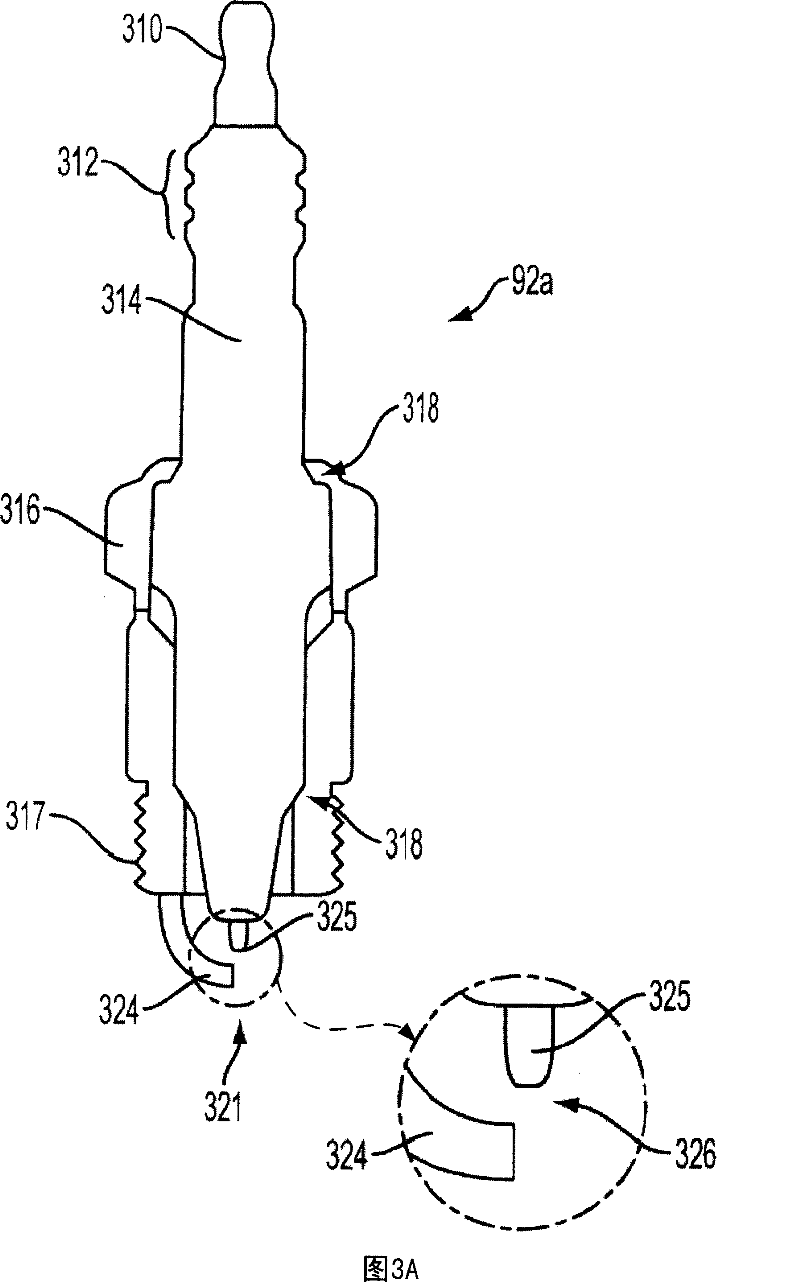

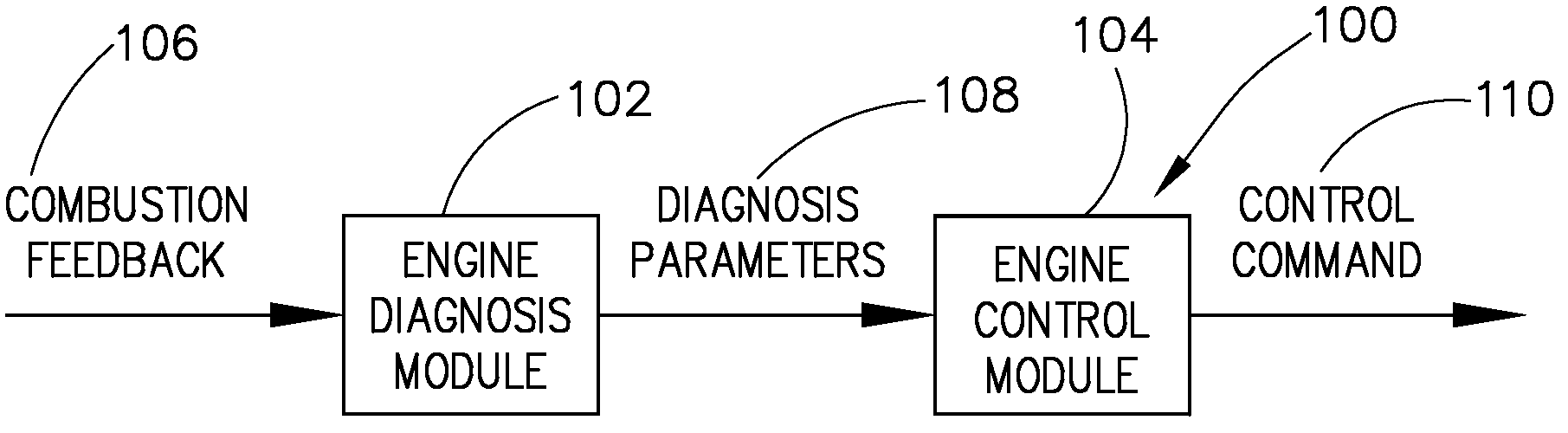

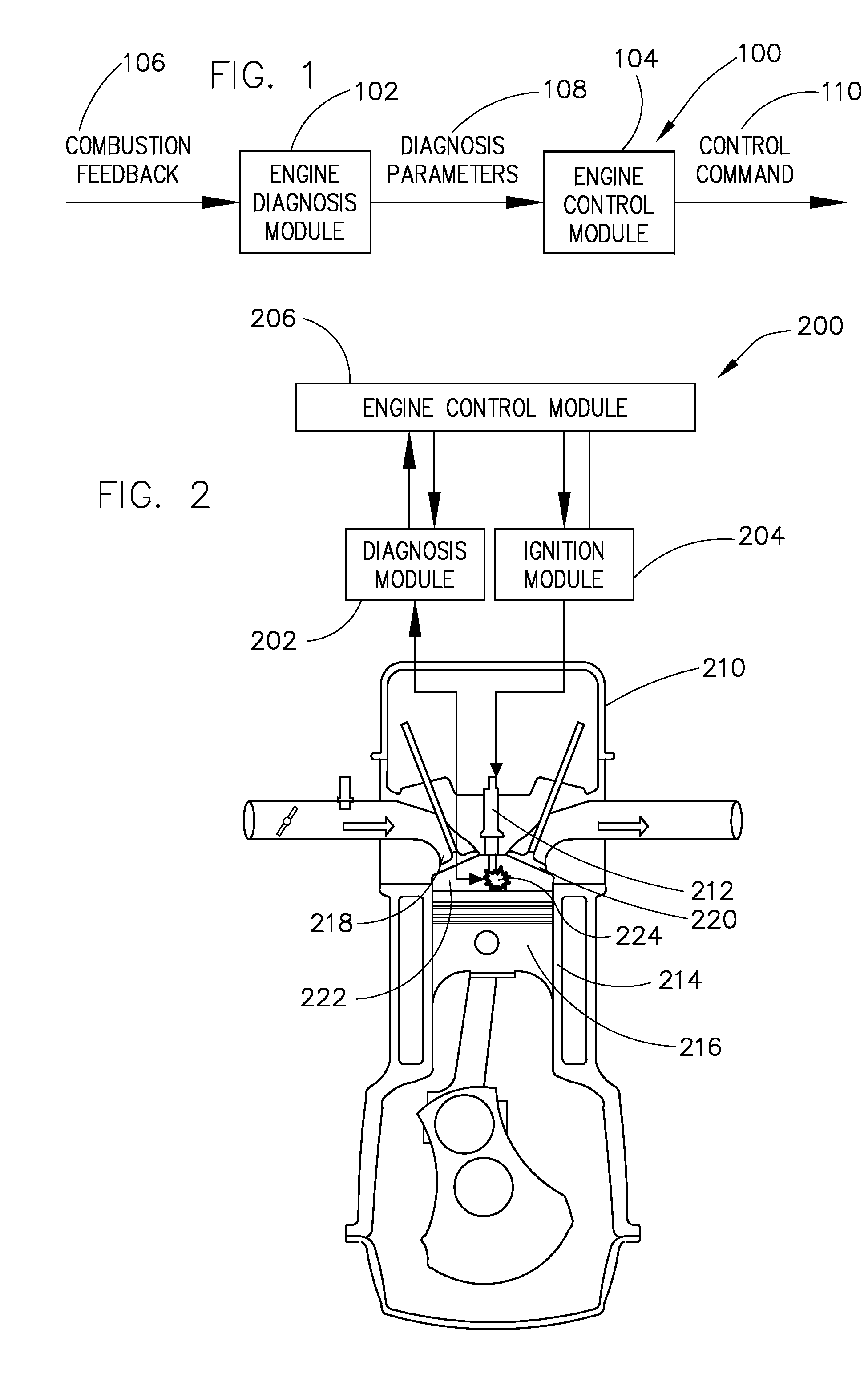

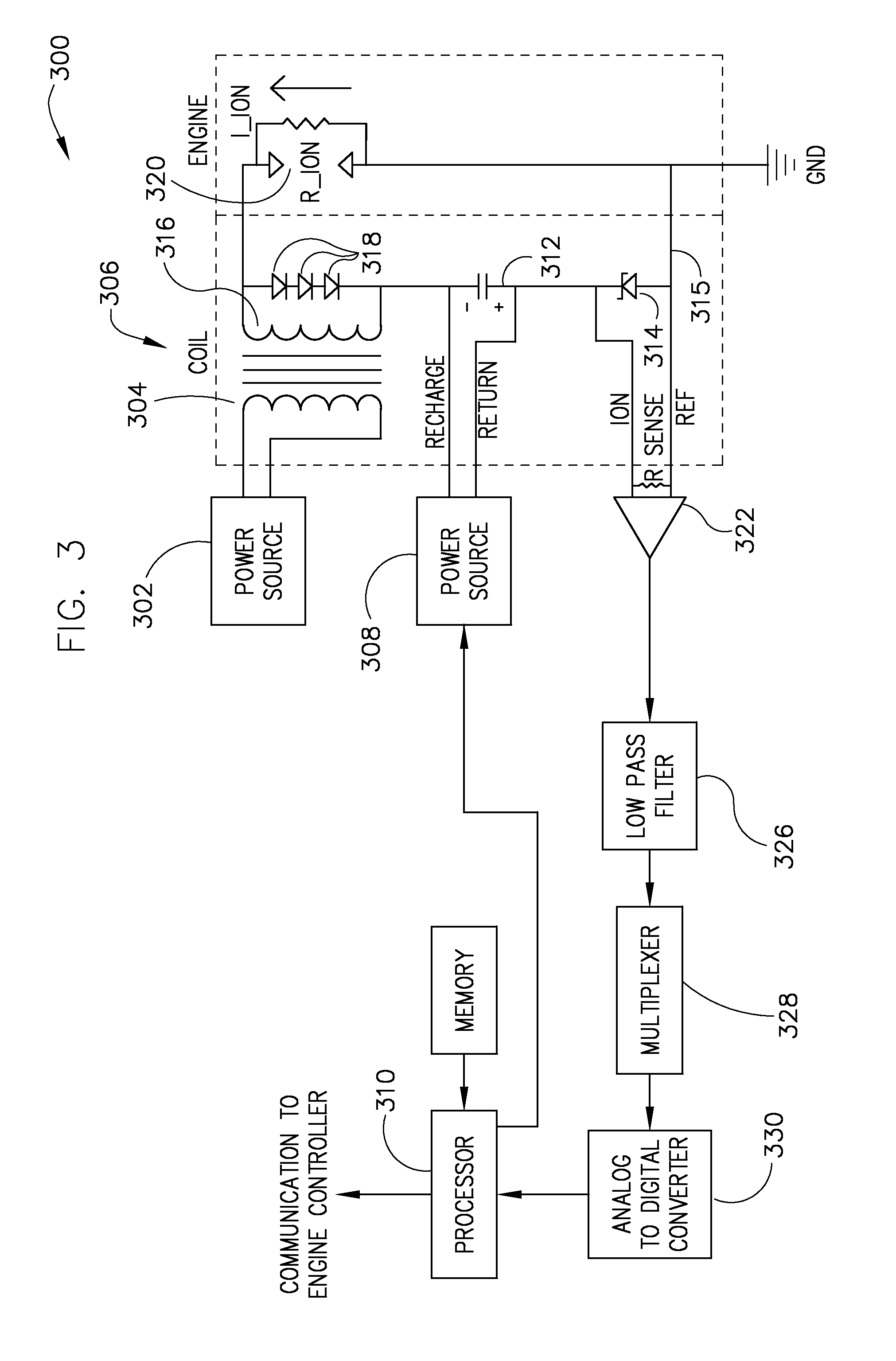

Method and system for closed loop combustion control of a lean-burn reciprocating engine using ionization detection

ActiveUS20090078234A1Maintain thermal efficiencyReduce knockingAnalogue computers for vehiclesAutomatic controlCombustion chamberClosed loop

A system and method for controlling knock in a lean burn internal combustion (IC) engine includes a spark plug having an electrode, and an electrical circuit configured to provide a first voltage to the electrode and detect an ion current during a thermal-ionization phase of the combustion process, and provide a second voltage to the electrode to create a spark and initiate a combustion process within a combustion chamber. The engine includes a controller configured to monitor the ion current for a knock condition that includes at least an incipient knock condition, determine a spark crank angle timing of the IC engine where the incipient knock occurs, and adjust the spark timing of the IC engine to operate at a crank angle that does not exceed a threshold level beyond an incipient knock set point.

Owner:WOODWARD GOVERNOR CO

Direct injection of diluents or secondary fuels in gaseous fuel engines

InactiveUS20140331642A1Reduce exhaust emissionPrice riseInternal combustion piston enginesEngine controllersEngine knockingAir–fuel ratio

A method for a turbocharged engine, comprising: during high load conditions, in response to an elevated engine temperature, after port injecting a first quantity of a first gaseous fuel, direct injecting a second quantity of a second, liquid fuel at a first timing that is a function of a desired air-fuel ratio. In this way, engine power may be maximized while simultaneously decreasing the maximum combustion temperature and mitigating engine knock.

Owner:FORD GLOBAL TECH LLC

Method for controlling combustion in an internal combustion engine and the internal combustion engine

ActiveCN105569864AReduce consumptionCompliance improvementElectrical controlNon-fuel substance addition to fuelExternal combustion engineUltimate tensile strength

In a method for controlling combustion in an internal combustion engine with at least one cylinder (30), knock intensity in the cylinder (30) by means of a knock sensor (37) is detected. A predetermined setpoint ignition angle of the cylinder (30) corresponding to a target exhaust gas temperature is adjusted, and a fluid admixture in the cylinder (30) is controlled in dependence on the detected knock intensity.

Owner:BAYERISCHE MOTOREN WERKE AG

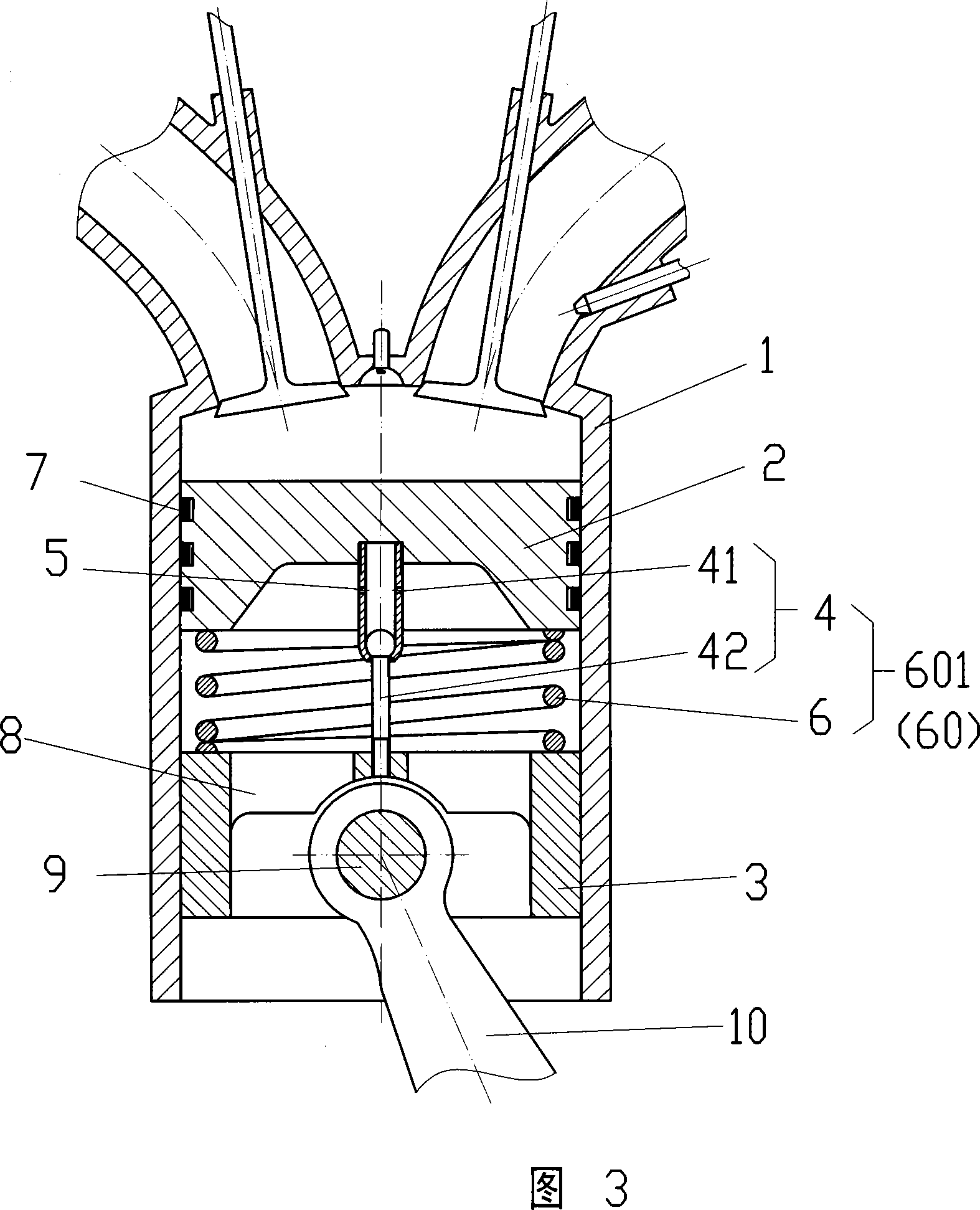

Internal combustion steam thermal engine

InactiveCN1405442ACombustion reductionReduced preparation processNon-fuel substance addition to fuelMachines/enginesCombustion chamberSprayer

The invention relates to an internal combustion steam engine that is based on the internal combustion thermodynamic generator. The variable radiators are taken out from the traditional engine, while the warm keep cover, and heat absorbing water spray system formed by water tank, low pressure water pump, water cooling heat exchanger, high pressure pump, high water sprayer, are installed on the outside of traditional engine and connected through the water delivery pipe according to the above order, thereof, the high pressure water sprayer if installed on the high temperature part of the firebox; besides, by reforming the fuel atomization and spraying device onto the air-changing channel to make engine save energy and the more environment-protective.

Owner:赵晶

First and second spark plugs for improved combustion control

InactiveCN101037968AReduce restrictionsReduce dirtElectrical controlMachines/enginesExternal combustion engineInternal combustion engine

A method of operating an internal combustion engine has at least one combustion chamber including a first spark plug and a second spark plug, wherein the first spark plug is configured to operate at a higher temperature than the second spark plug, and the method comprises of varying at least a resulting ratio of an amount of a fuel and an amount of a fluid delivered to the combustion chamber responsive to a first condition. By selectively using different spark plugs, the pre-ignition and spark plug fouling can be reduced, and simultaneously limitation to some combination of a fuel and a fluid is reduced, thereby knock can be further diminished.

Owner:FORD GLOBAL TECH LLC

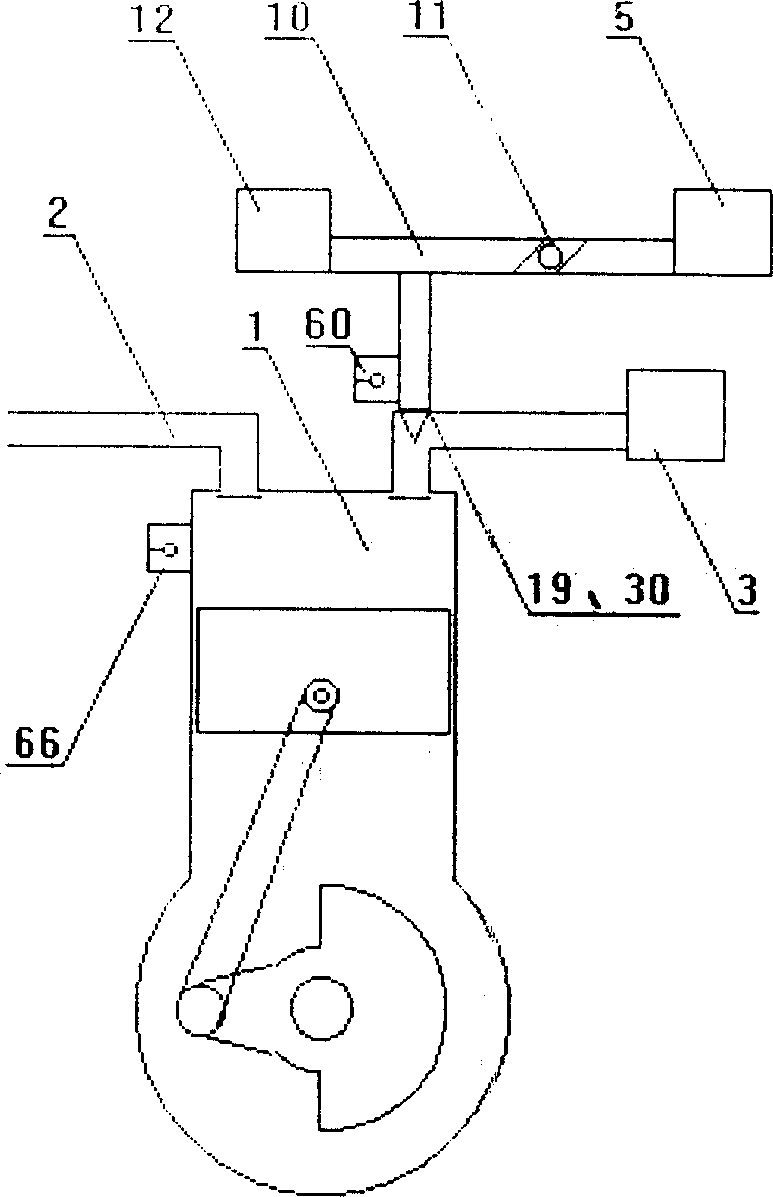

Internal combustion engine control device and method

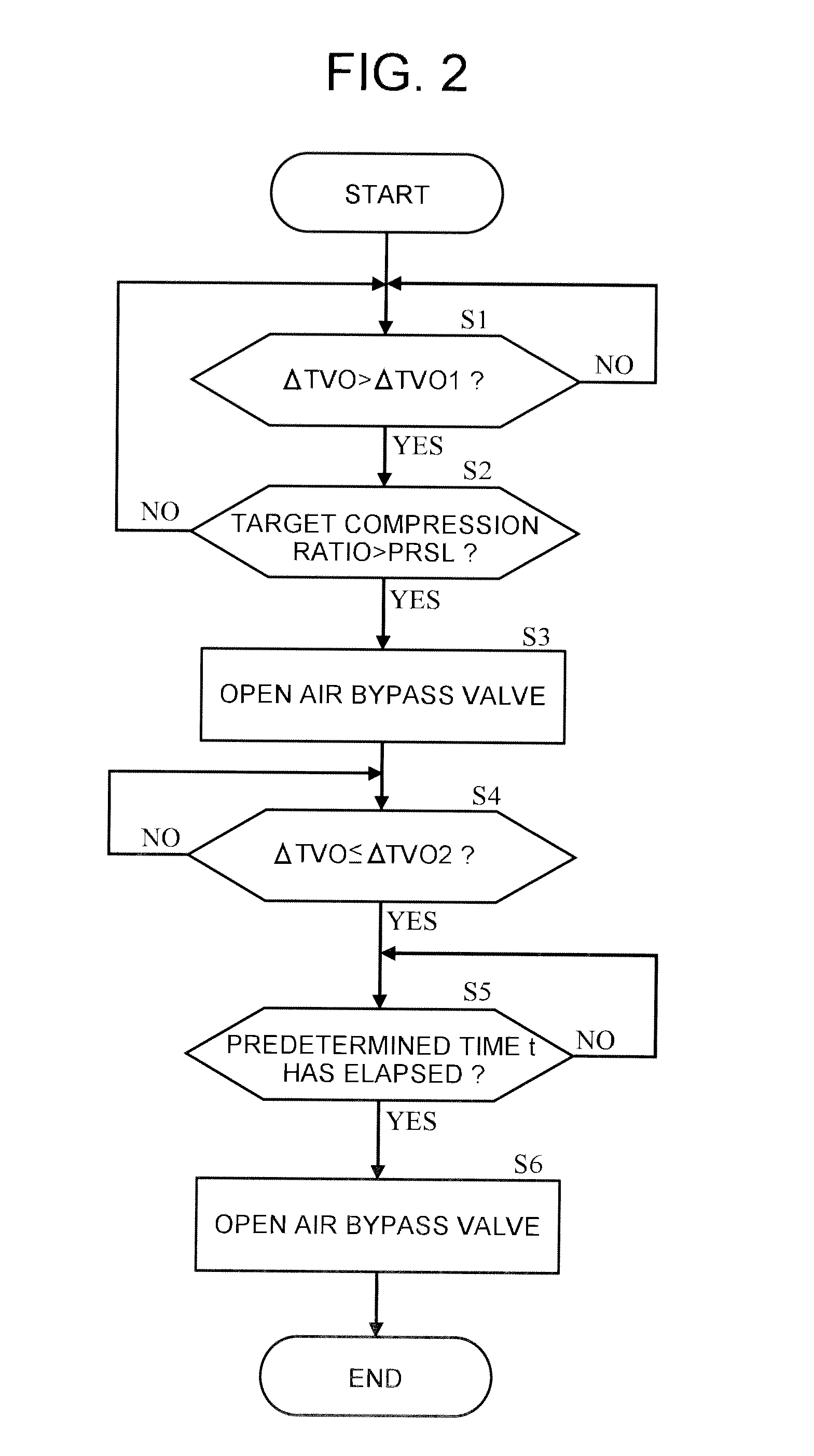

InactiveUS20150219024A1Satisfactory fuel economyIncrease compression pressureValve arrangementsElectrical controlTurbochargerControl theory

In an internal combustion engine equipped with a variable compression ratio mechanism, the occurrence of knocking is reduced during deceleration. When it is determined that a target compression ratio of the variable compression ratio mechanism is greater than a threshold PRSL during the deceleration, an air bypass valve interposed in a passage for bypassing a compressor of an exhaust turbo supercharger is opened to return intake air upstream (between the compressor and a throttle valve) of the throttle valve to upstream of the compressor, thereby reducing intake pressure upstream of the throttle valve and reducing in-cylinder compression pressure to reduce the occurrence of knocking.

Owner:HITACHI AUTOMOTIVE SYST LTD

Hybrid Vehicle Propulsion System Utilizing Knock Suppression

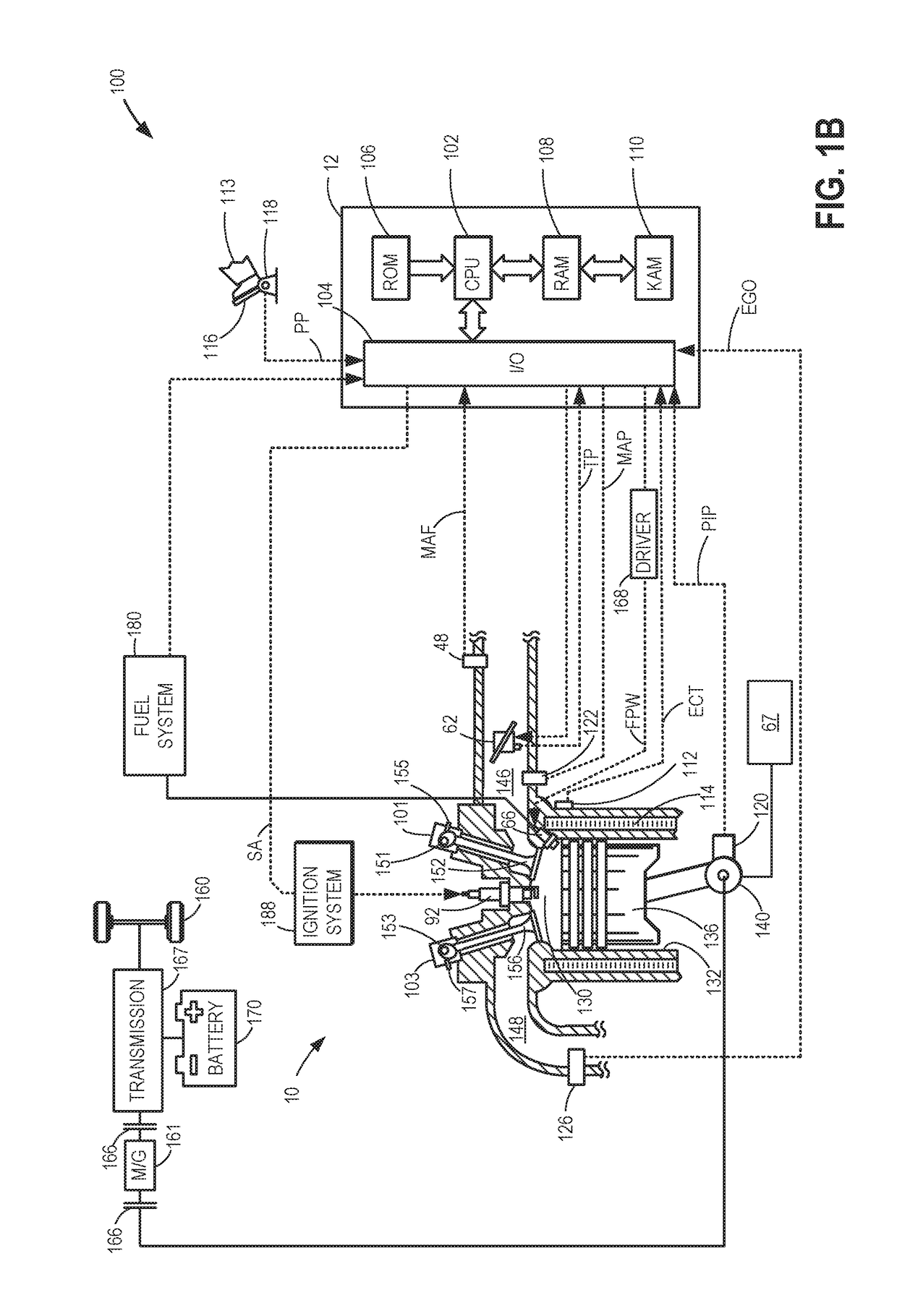

InactiveUS20100116245A1Low costImprove cooling effectInternal combustion piston enginesDigital data processing detailsCombustion chamberDrive wheel

A hybrid propulsion system for a vehicle and method of operation are provided. As one example, the system comprises an engine including at least one combustion chamber, a motor configured to selectively propel the vehicle via the drive wheel, a fuel system configured to deliver a first substance and a second substance to the combustion chamber in varying relative amounts, wherein the first substance includes a fuel and the second substance includes a greater concentration of a knock suppressing substance than the first substance; and a control system configured to operate the fuel system to vary the relative amounts of the first substance and the second substance delivered to the combustion chamber in response to an operating condition while operating the motor to propel the vehicle.

Owner:FORD GLOBAL TECH LLC

Method to improve blowthrough via split exhaust

InactiveUS20150198099A1Reduce the temperatureMitigate engine knockElectrical controlInternal combustion piston enginesInlet valveAerospace engineering

Owner:FORD GLOBAL TECH LLC

Internal combustion engine knock determination device and ignition control system including the same

ActiveUS7263430B2Improve accuracyReduce knockingAnalogue computers for vehiclesElectrical controlInternal combustion engineIgnition control

Owner:TOYOTA JIDOSHA KK +1

Method and system for closed loop combustion control of a lean-burn reciprocating engine using ionization detection

ActiveUS7798125B2Maintain thermal efficiencyReduce knockingAnalogue computers for vehiclesAutomatic controlCombustion chamberClosed loop

A system and method for controlling knock in a lean burn internal combustion (IC) engine includes a spark plug having an electrode, and an electrical circuit configured to provide a first voltage to the electrode and detect an ion current during a thermal-ionization phase of the combustion process, and provide a second voltage to the electrode to create a spark and initiate a combustion process within a combustion chamber. The engine includes a controller configured to monitor the ion current for a knock condition that includes at least an incipient knock condition, determine a spark crank angle timing of the IC engine where the incipient knock occurs, and adjust the spark timing of the IC engine to operate at a crank angle that does not exceed a threshold level beyond an incipient knock set point.

Owner:WOODWARD GOVERNOR CO

Method and system for vacuum control

ActiveUS9556784B2Improve volumetric efficiencyIncrease powerElectrical controlInternal combustion piston enginesCrankcaseFuel injection

Owner:FORD GLOBAL TECH LLC

Hybrid Vehicle Propulsion System Utilizing Knock Suppression

ActiveUS20090038585A1Reduce the amount requiredLow costElectrical controlInternal combustion piston enginesDrive wheelExternal combustion engine

A hybrid vehicle propulsion system and method of operation have been provided. As one example, the system comprises an internal combustion engine including at least a combustion chamber configured to propel the vehicle via at least a drive wheel, a motor configured to propel the vehicle via at least a drive wheel, an energy storage device configured to store energy that is usable by the motor to propel the vehicle, a fuel system configured to deliver gasoline and alcohol to the combustion chamber in varying relative amounts, a control system configured to operate the motor to propel the vehicle and to vary the relative amounts of the gasoline and alcohol provided to the combustion chamber in response to an output of the motor.

Owner:FORD GLOBAL TECH LLC

High-efficiency engine

InactiveCN101042069AReduce high temperature and high pressure holding timeReduce lossesMachines/enginesCombustion chamberEngineering

A highly efficient engine comprises the cylinder, piston, guide, piston pin and linking lever with active linking device between the piston and the guide, with the linking device setting as prepressure shrinkable spring or nonspring linking device with the guide connecting with the linking lever. With better location of the guide having low temperature and better lubrication, and the piston bearing up and down forces, it can greatly reduce the friction and wearing between the piston and the cylinder. Apart from that, it can quickly reduce the top dead end high temperature and pressure retain time, with greatly reduced shock, improved torque, with higher, more efficient, energy saving and environment protective design.

Owner:靳宇男

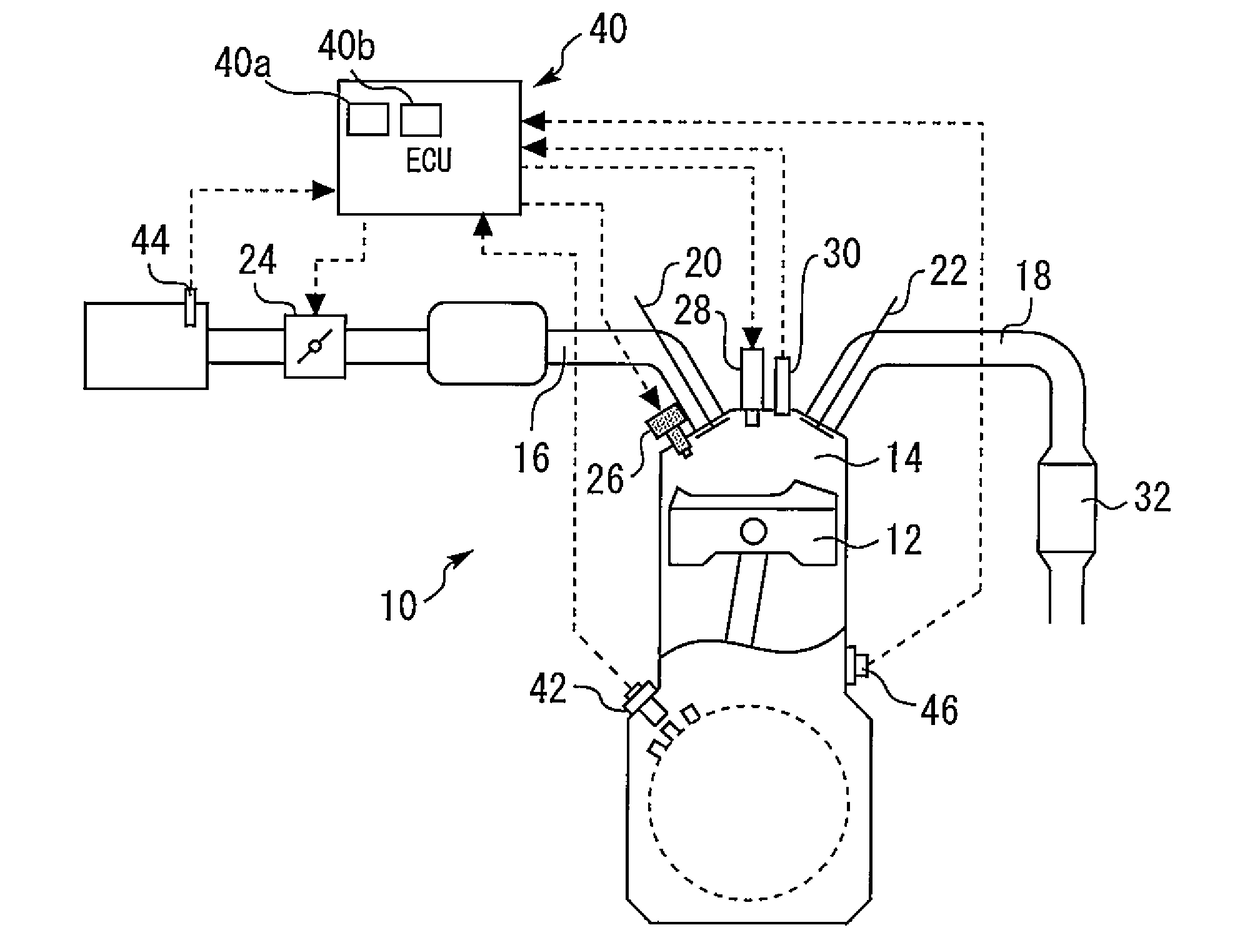

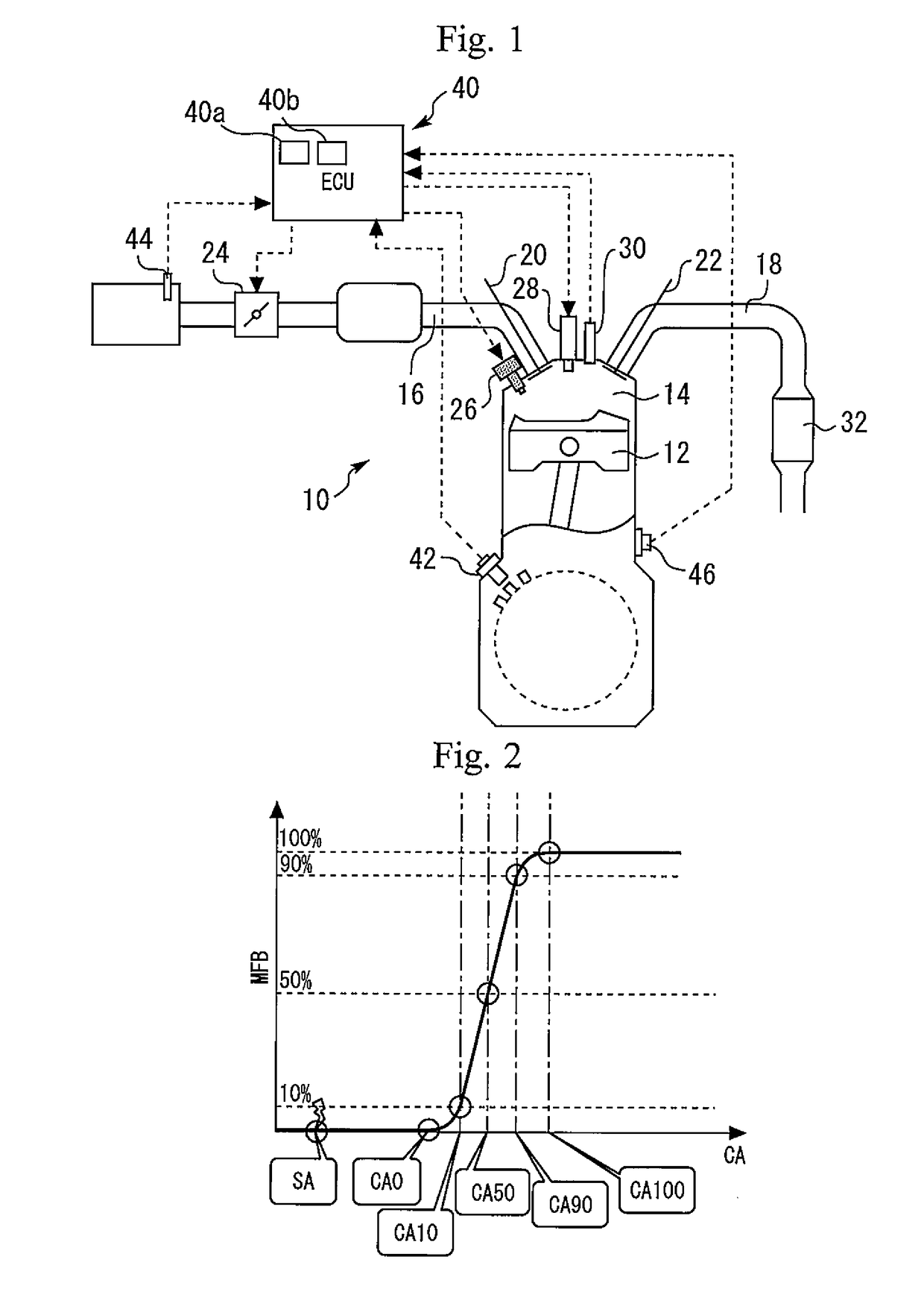

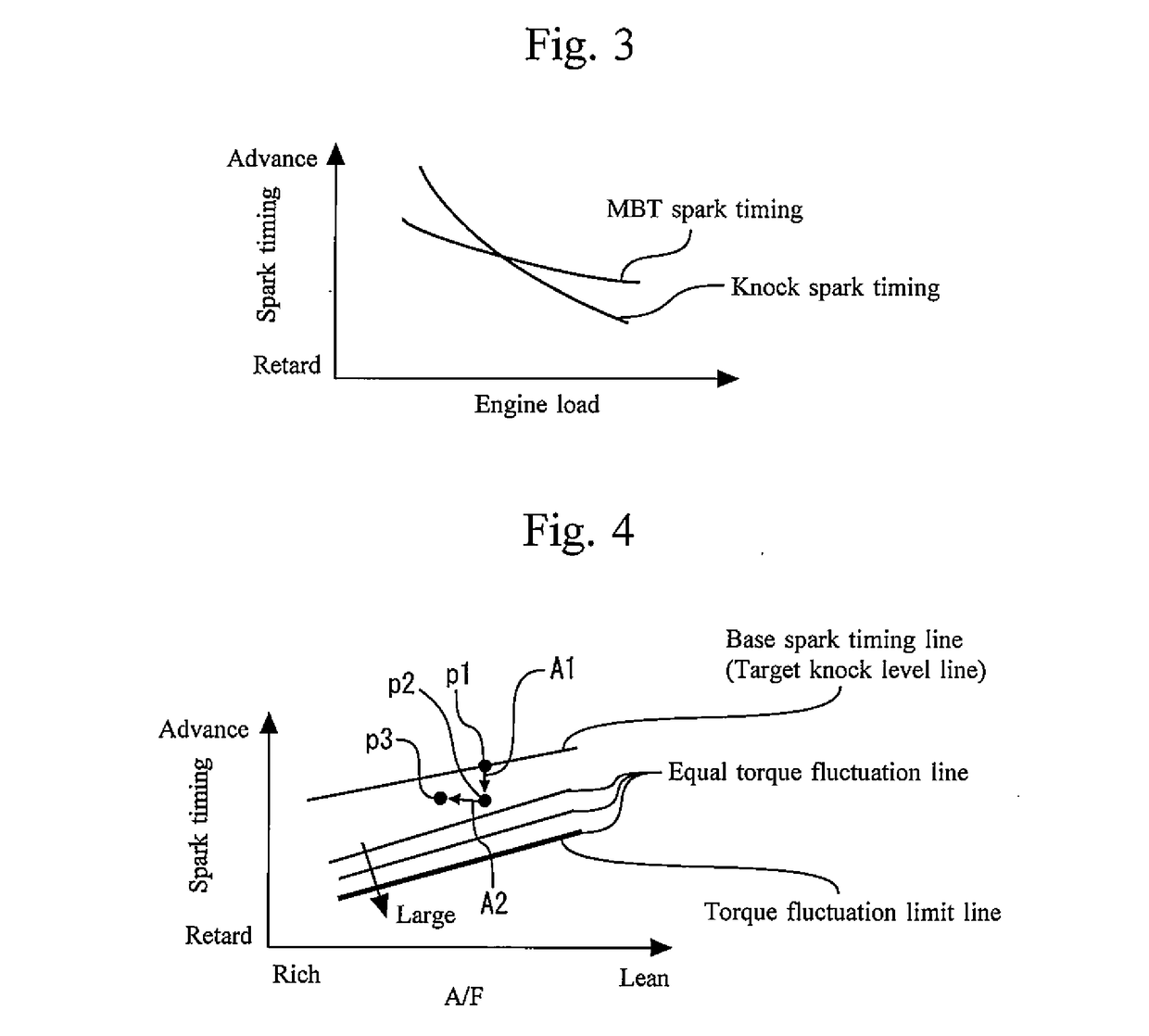

Control apparatus for internal combustion engine

InactiveUS20170226956A1Reduce knockingImprove torque fluctuationElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

A control apparatus for an internal combustion engine is provided to calculate, on the basis of the output values of the in-cylinder pressure sensor, a combustion index value which indicates the stability of combustion. If reduction of knock is required, the spark timing is retarded. An increment of injected fuel is executed in such a manner that a combustion index value that indicates the actual stability of combustion at a retard execution cycle that is a combustion cycle at which the retard of the spark timing is executed approaches a target value of a combustion index value that indicates the stability of combustion at a before-retard cycle.

Owner:TOYOTA JIDOSHA KK

Systems and methods for a split exhaust engine system

InactiveUS10145315B2Improve power densityReduce knockingElectrical controlInternal combustion piston enginesExhaust valveInlet valve

Methods and systems are provided for operating a split exhaust engine system that provides blowthrough air and exhaust gas recirculation to an intake passage via a first exhaust manifold and exhaust gas to an exhaust passage via a second exhaust manifold. In one example, an intake valve timing, exhaust valve timing of a first set of exhaust valves coupled to the first exhaust manifold, and a position of an exhaust gas recirculation (EGR) valve in an EGR passage may be adjusted in coordination with one another in response to a condition at a compressor. The EGR passage may be coupled between the intake passage, upstream of the compressor, and the first exhaust manifold.

Owner:FORD GLOBAL TECH LLC

Hybrid Vehicle Propulsion System Utilizing Knock Suppression

InactiveUS20090038586A1Reduce amountLow costInternal combustion piston enginesElectric ignition installationCombustion chamberOperant conditioning

A hybrid propulsion system for a vehicle and method of operation are provided. As one example, the system comprises an engine including at least one combustion chamber, a motor configured to selectively propel the vehicle via the drive wheel, a fuel system configured to deliver a first substance and a second substance to the combustion chamber in varying relative amounts, wherein the first substance includes a fuel and the second substance includes a greater concentration of a knock suppressing substance than the first substance; and a control system configured to operate the fuel system to vary the relative amounts of the first substance and the second substance delivered to the combustion chamber in response to an operating condition while operating the motor to propel the vehicle.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com