Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce inventory levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

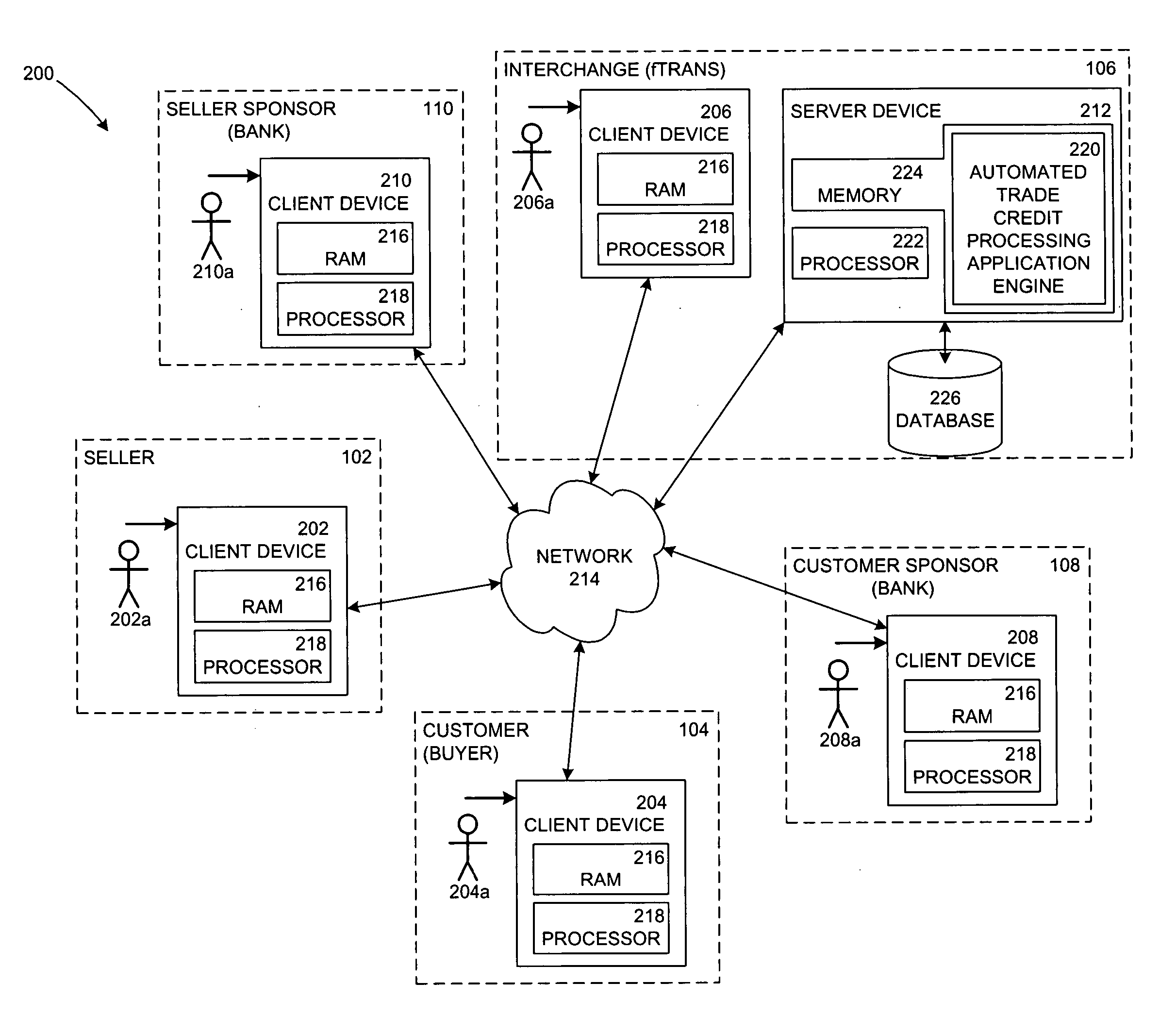

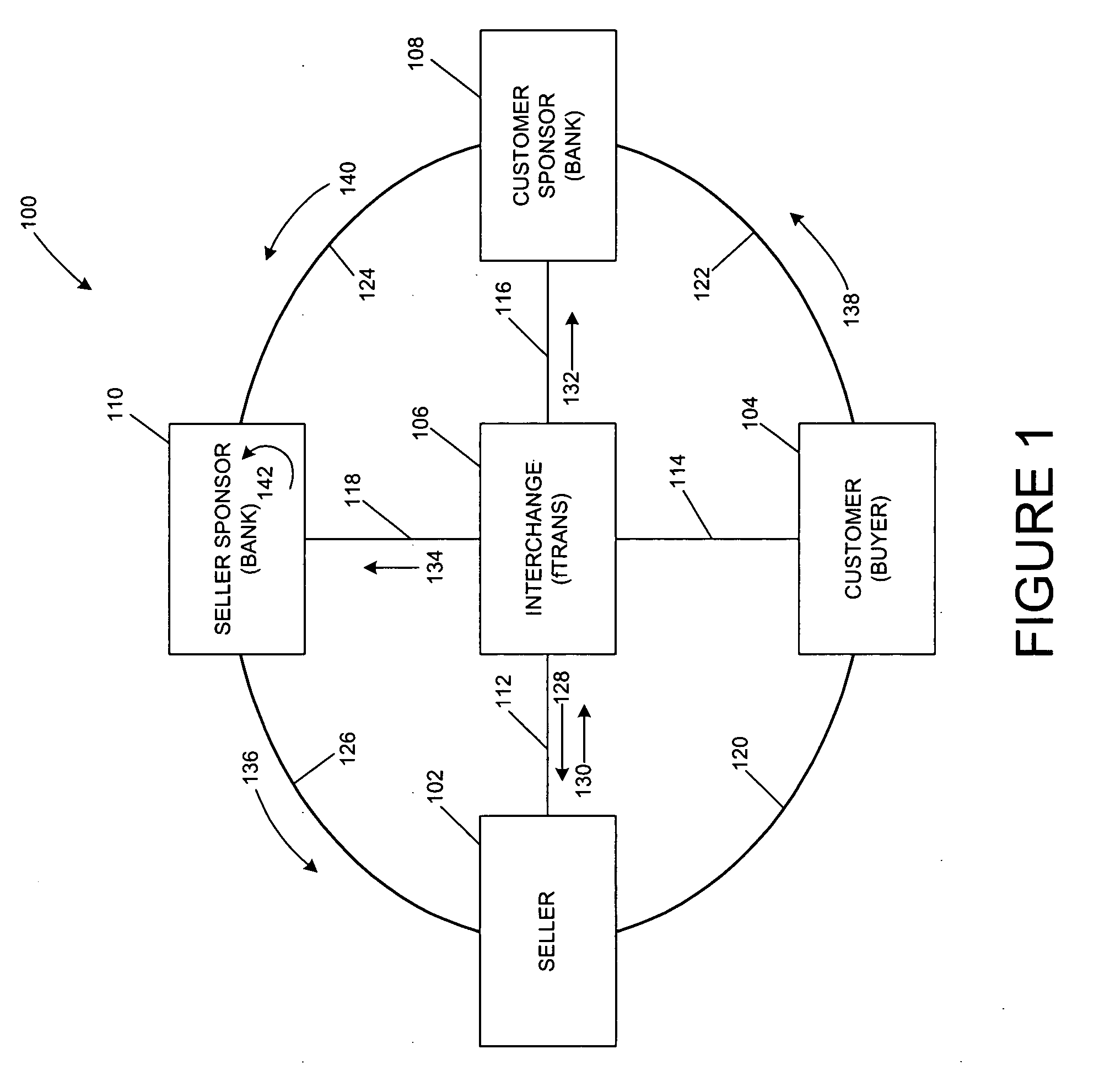

Systems and methods for automated processing, handling, and facilitating a trade credit transaction

InactiveUS20060173772A1Automates processing and handling and facilitatingHighly secure and liquid collateralFinancePaymentInvoice

The present invention relates to methods and systems for automated processing, handling, and facilitating a trade credit transaction. One embodiment of the invention can comprise an automated trade credit processing application engine. The automated trade credit processing application engine can be adapted to approve a customer for a purchase using trade credit, and cause an invoice associated with the purchase to be assigned to a customer sponsor. The automated trade credit processing application engine can be further adapted to determine an advance for a seller sponsor to pay to a seller associated with the purchase, wherein the customer sponsor can guarantee payment of some or all of the invoice to the seller sponsor. Moreover, the automated trade credit processing application engine can be adapted to determine an allocation for the payment, wherein the allocation can be applied by the seller sponsor to an account associated with the seller, after a customer sponsor makes a payment against the invoice to the seller sponsor.

Owner:FTRANS

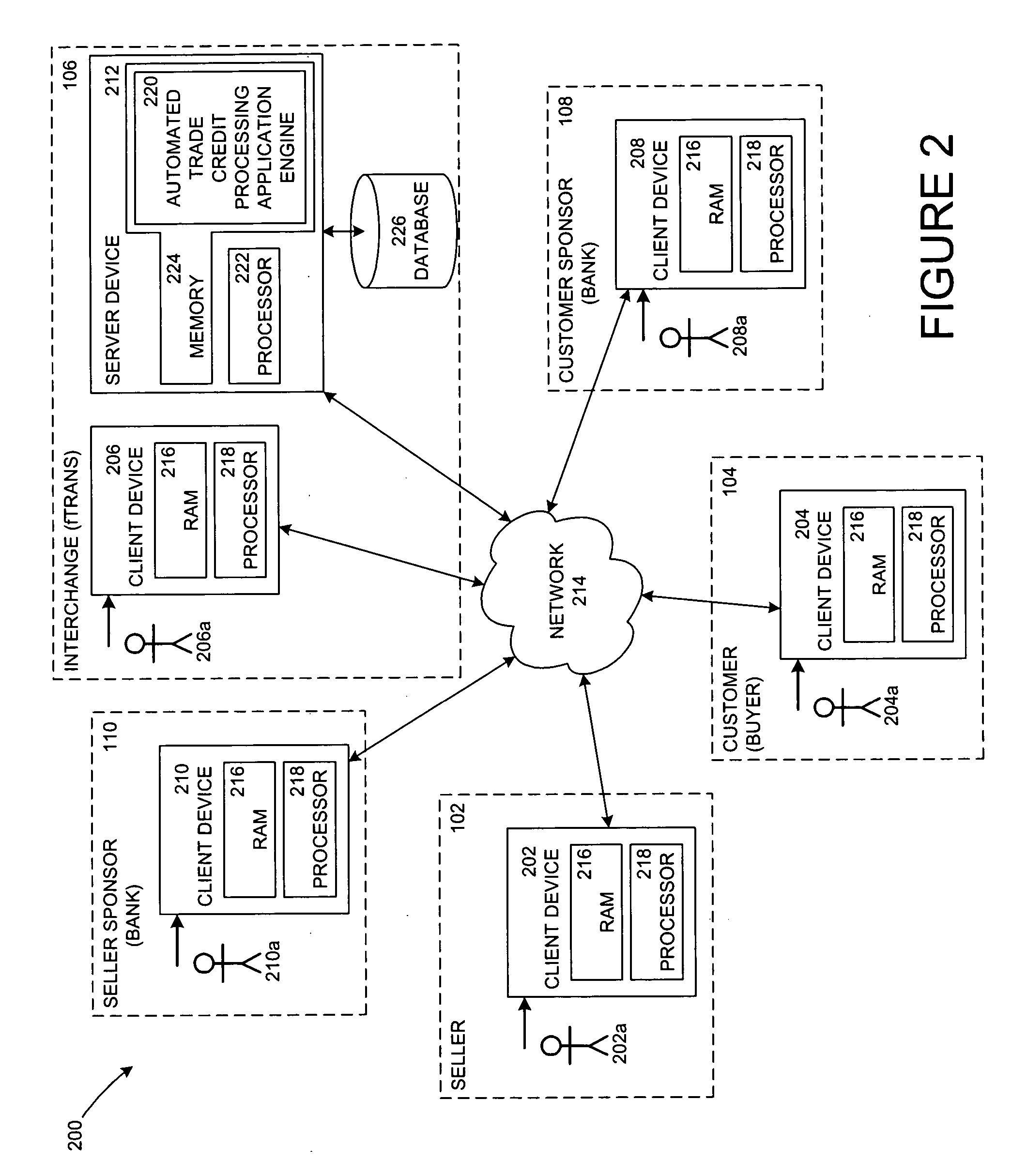

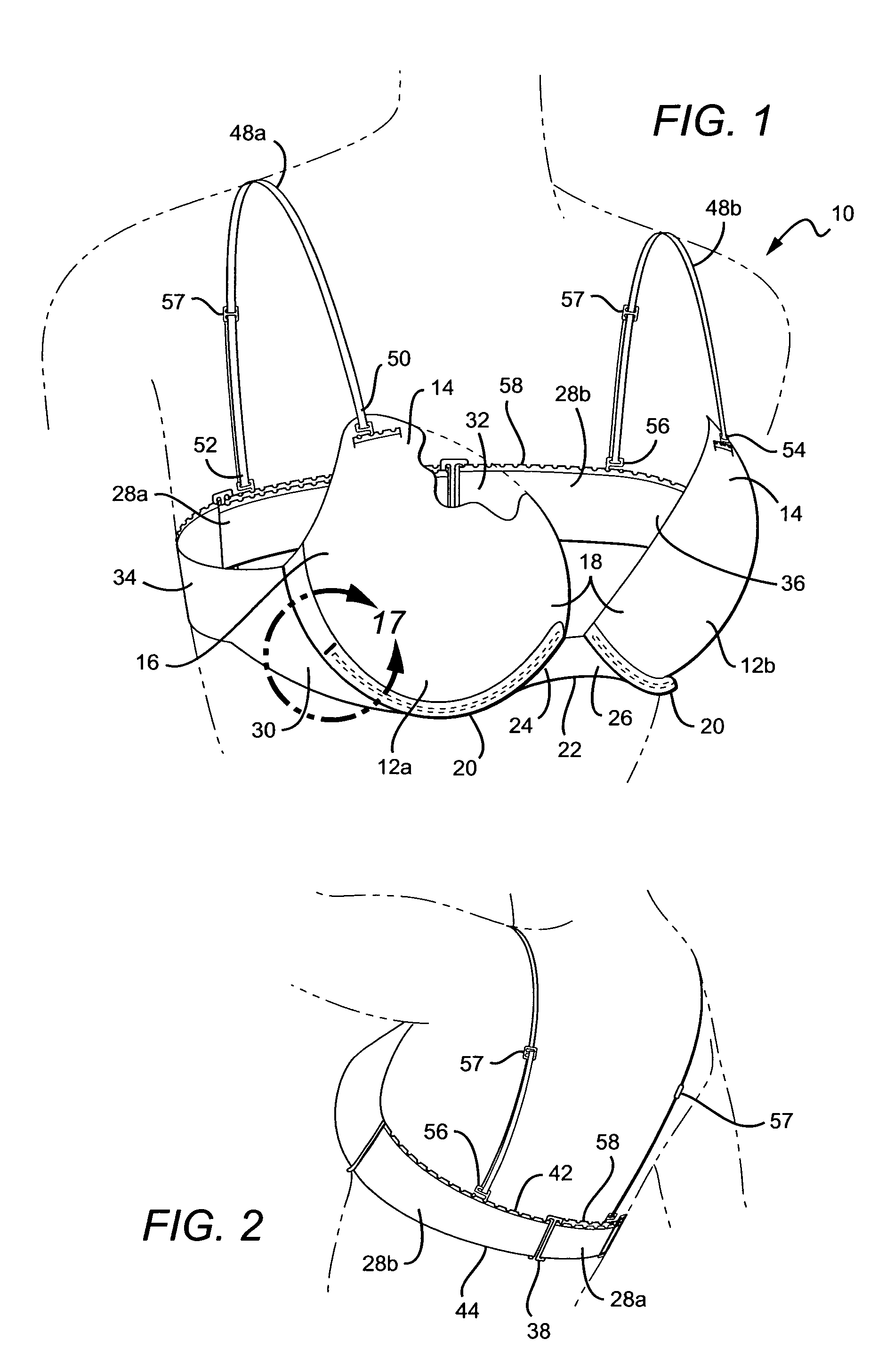

Adjustable bra

InactiveUS7232359B1Easy to useReduce manufacturing costShoulder strapBrassieresEngineeringBreasts size

The present invention is directed to an adjustable bra having first and second bra cups; one or more adjustable back bands connected to the respective bra cups; first and second detachable shoulder straps connected at one end to the respective bra cups and connected at the other end to the adjustable back band or bands; a removable or non-removable underwire in each bra cup that is shorter in length than standard underwire; and a plurality of shoulder strap fastener receiving elements incorporated along an entire length of the back band or bands, wherein the shoulder strap fastener receiving elements are adapted to receive and attach the first and second shoulder straps anywhere along the entire length of the back band or bands, including to both single and double layer back bands to enable a wearer to adjust the fit and comfort of the bra to a wearer's breast size and dimension.

Owner:RICHARDSON MARGARET A

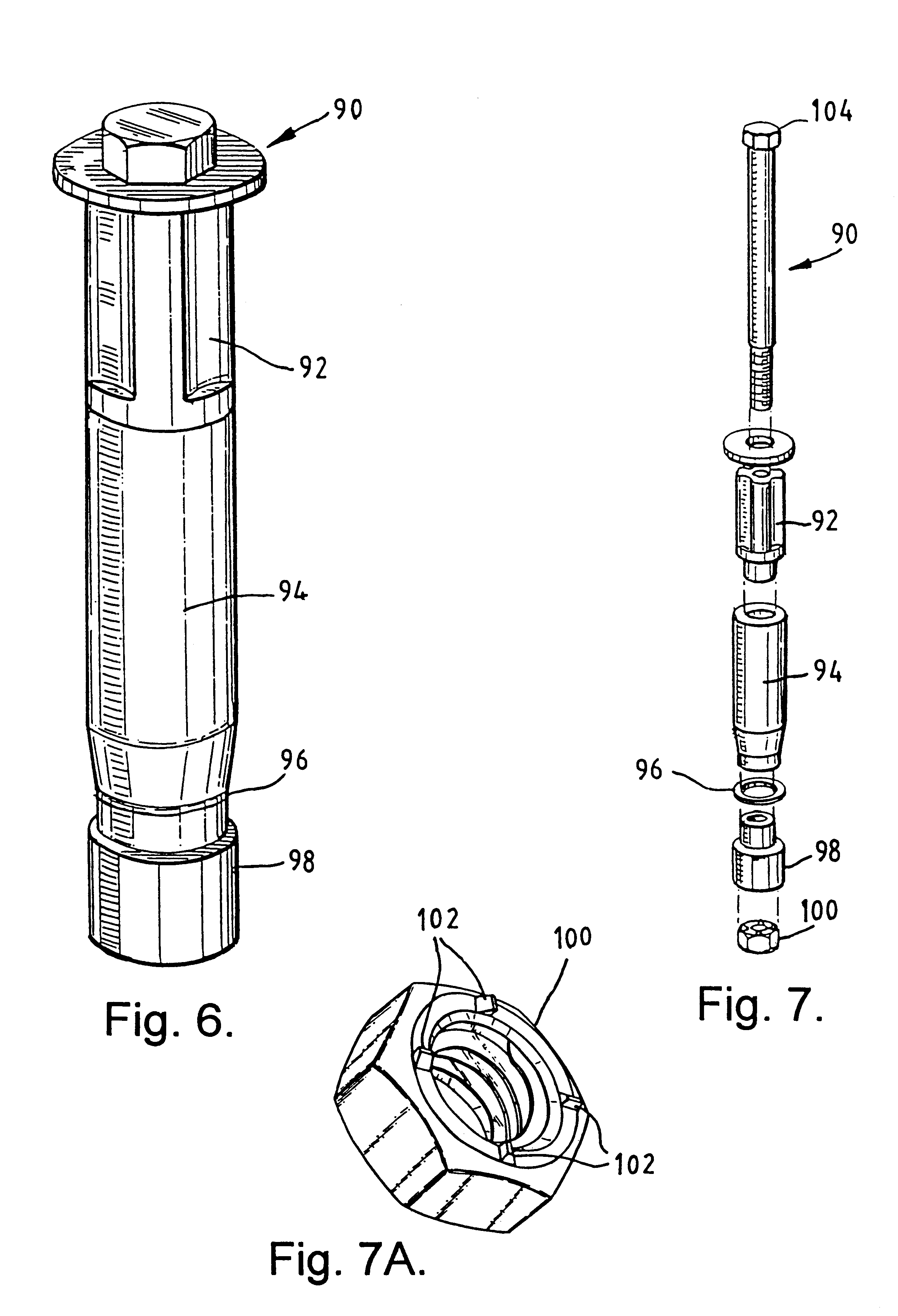

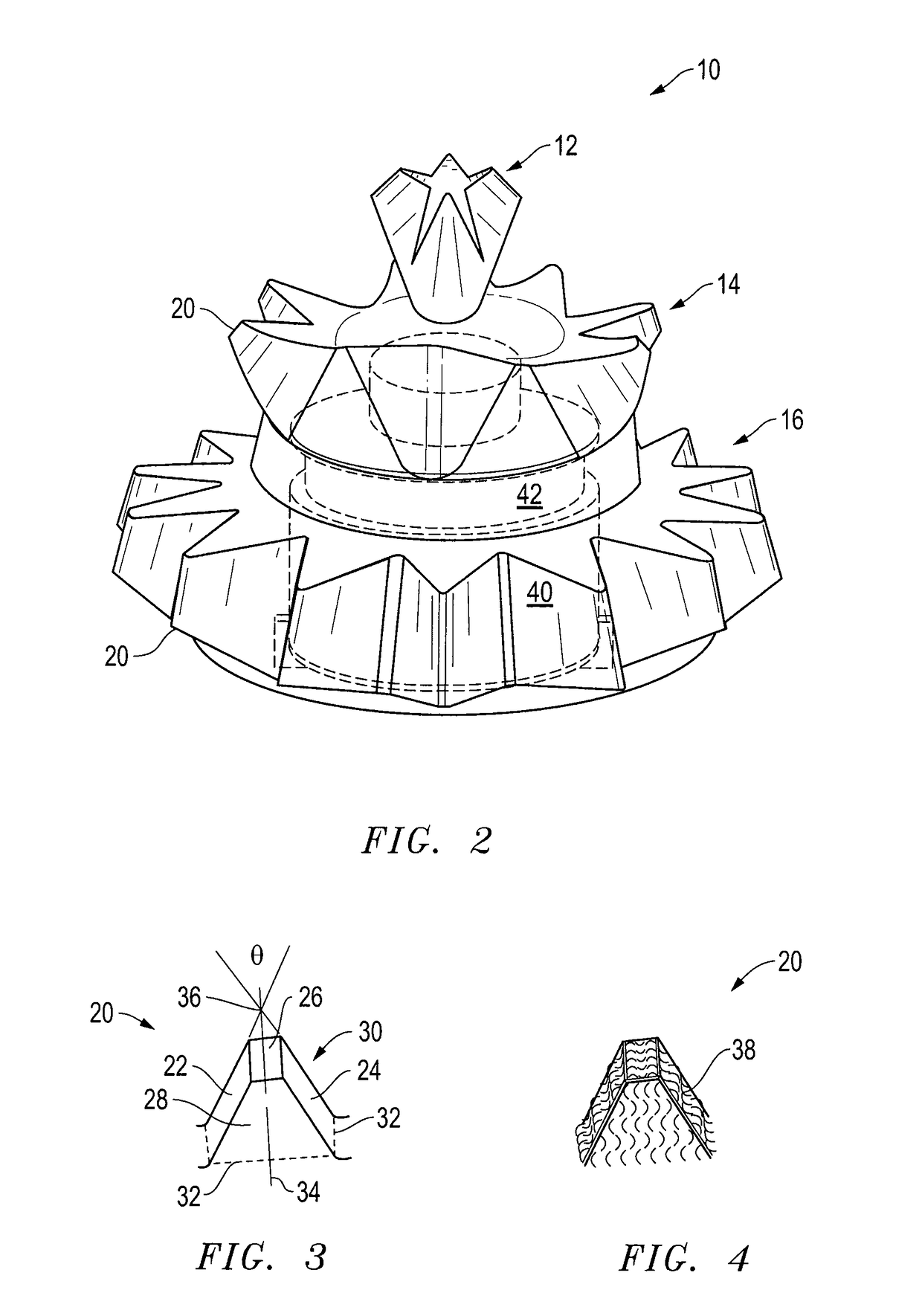

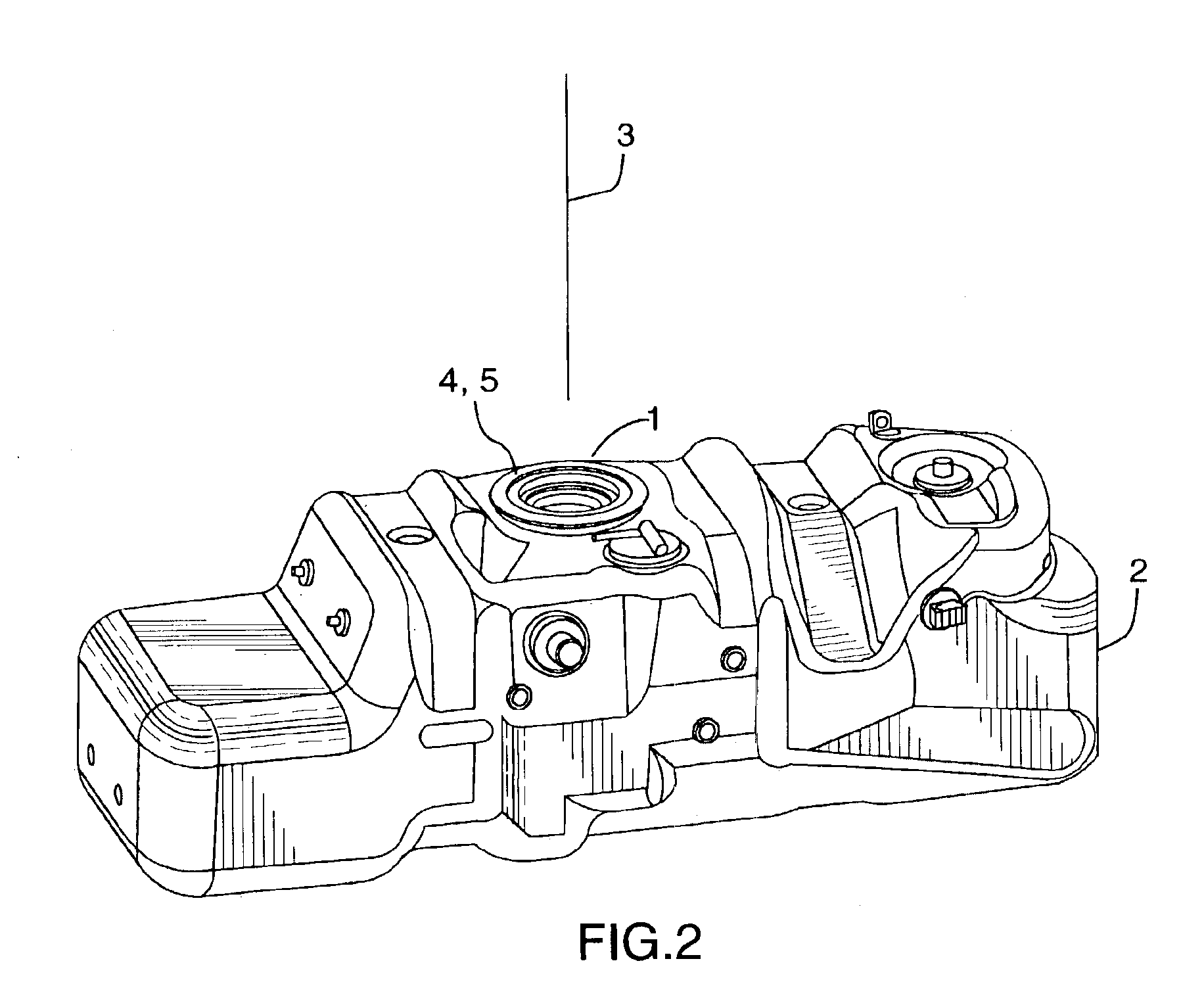

Anchoring device

InactiveUS6273655B1Reduce inventory levelsEasy to disassembleDowelsScrew threadBiomedical engineering

An anchoring device (10) comprises a resilient sleeve (16) for receiving an elongate member, such as a bolt (18), and first and second stoppers (20,21) for location on the bolt at respective ends of the sleeve. Movement of the stoppers (20,21) towards one another causes the sleeve (16) to expand radially. The inner first stopper (20) may engage one of the bolt head (22) and nut (24) to resist relative rotation thereof. Alternatively, the inner first stopper may be threaded.

Owner:MCALPINE

System and a method, including software and hardware, for providing real-time and synchronization views of supply chain information

ActiveUS7443282B2Quality improvementReduce impactDigital data processing detailsResourcesData sourceMiddleware

A system and method, including software and hardware, for providing an accurate, real-time, and synchronized view of supply chain information. The system utilizes various RFID technologies (like an RFID tag, an RFID reader, and an RFID middleware software) to collect and manage data in real time. It then implements a synchronization mechanism to synchronize supply chain data from various data sources within and across a company in near real time fashion to allow different types of enterprise users, both internal and external, to access the synchronized information and take synchronized action within an appropriate timeframe.

Owner:IND TECH RES INST

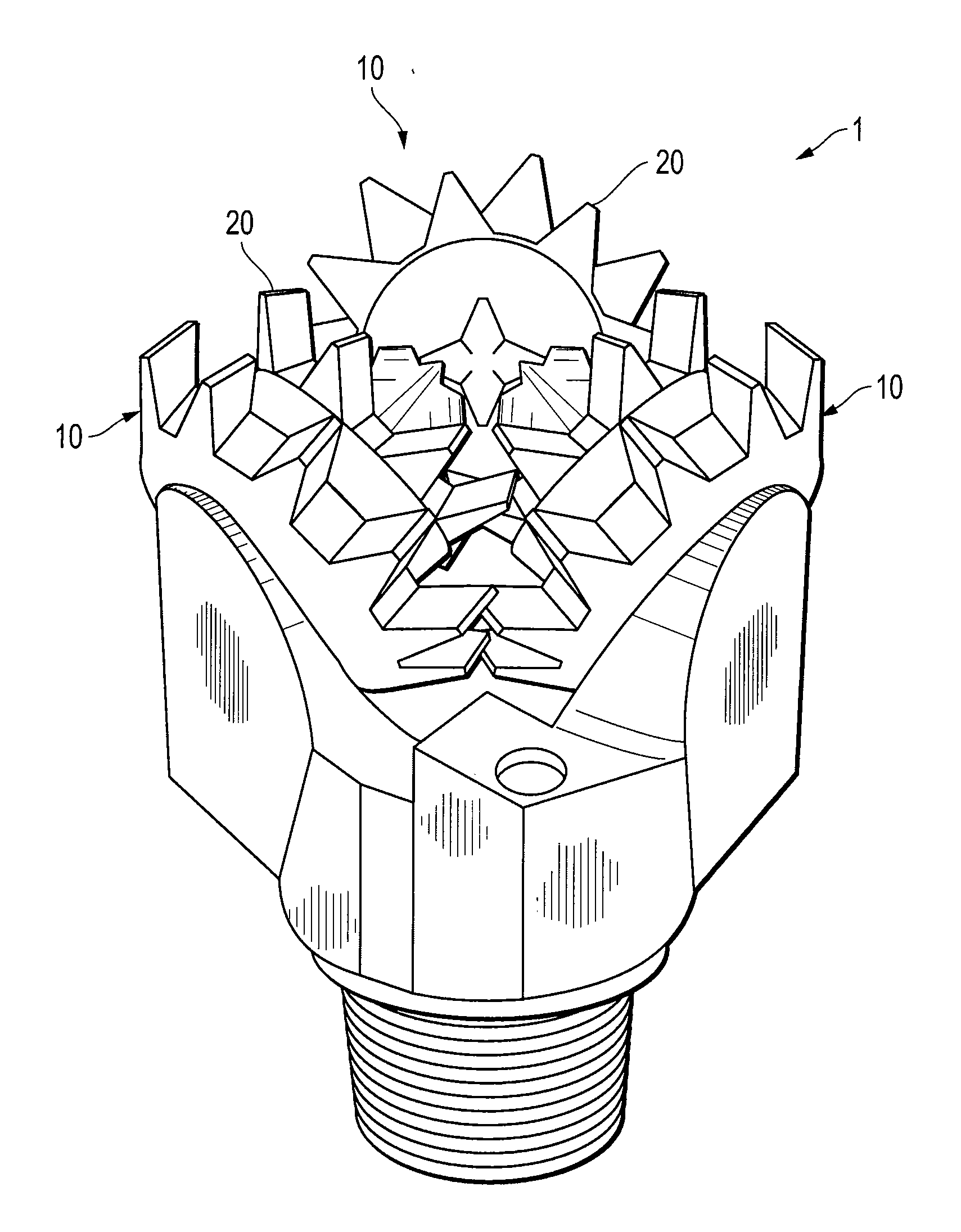

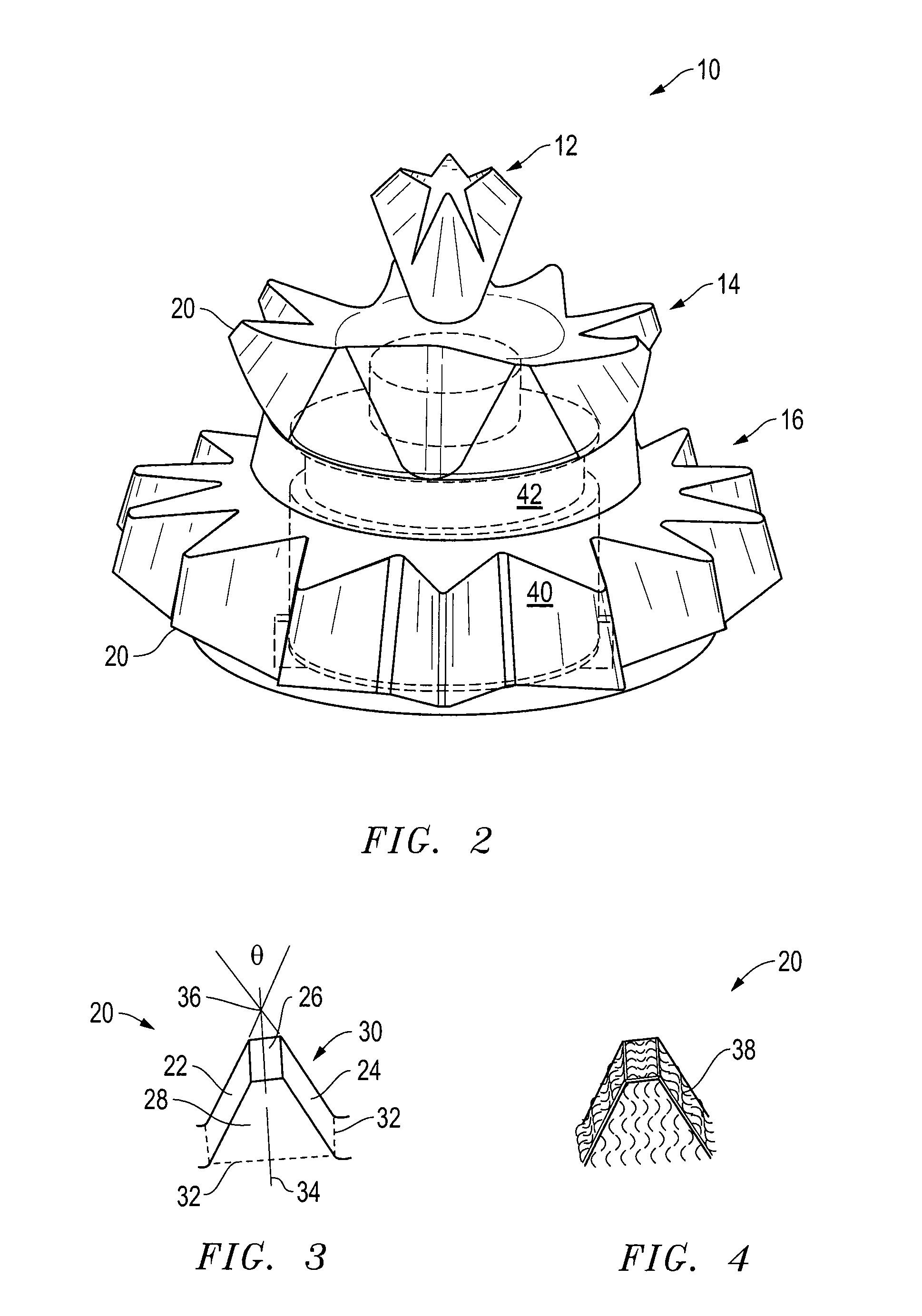

Method and apparatus for automated application of hardfacing material to rolling cutters of hybrid-type earth boring drill bits, hybrid drill bits comprising such hardfaced steel-toothed cutting elements, and methods of use thereof

InactiveUS20100181292A1Improve quality and consistencyFacilitate automatic collectionDrill bitsArc welding apparatusHybrid typeElectricity

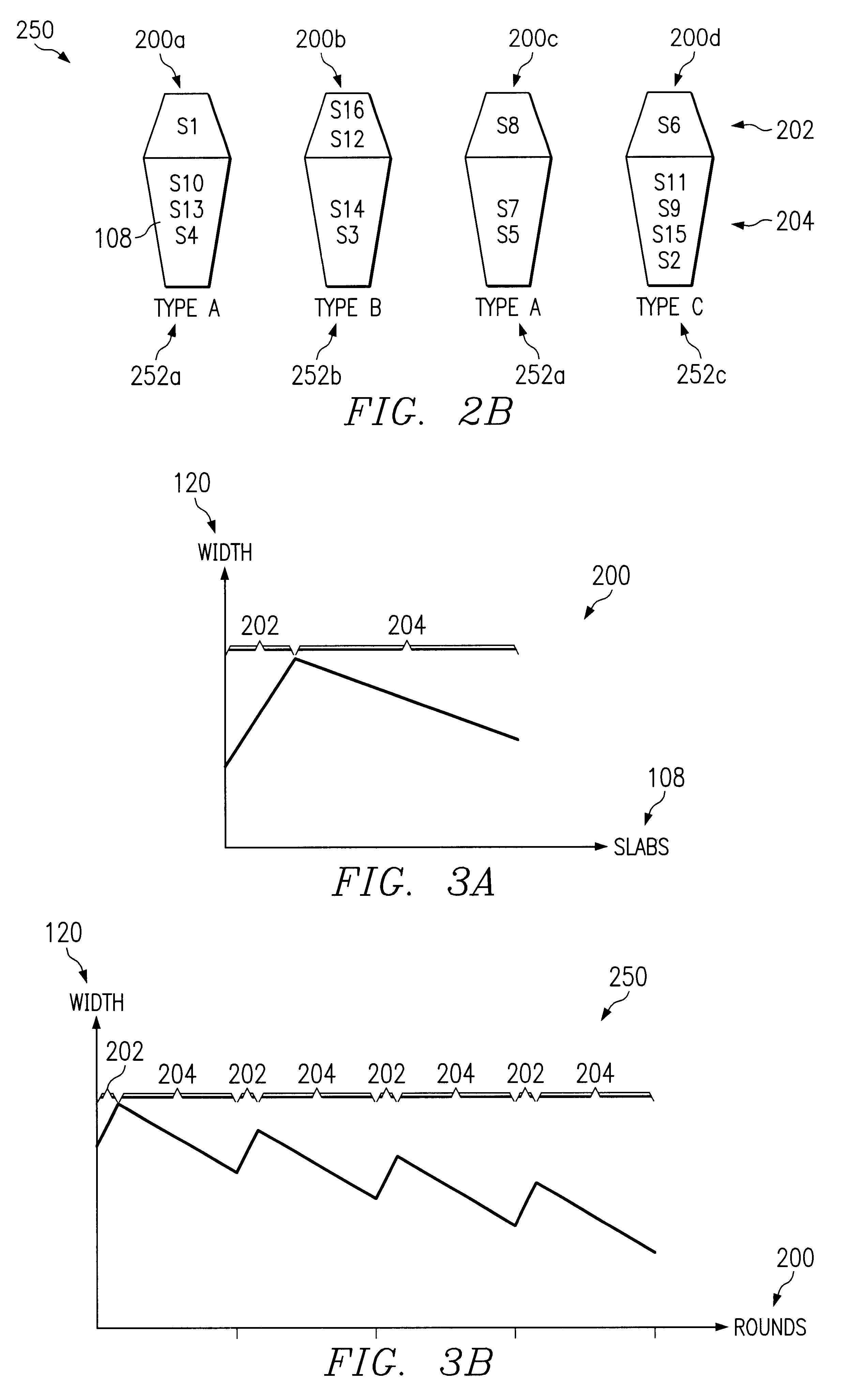

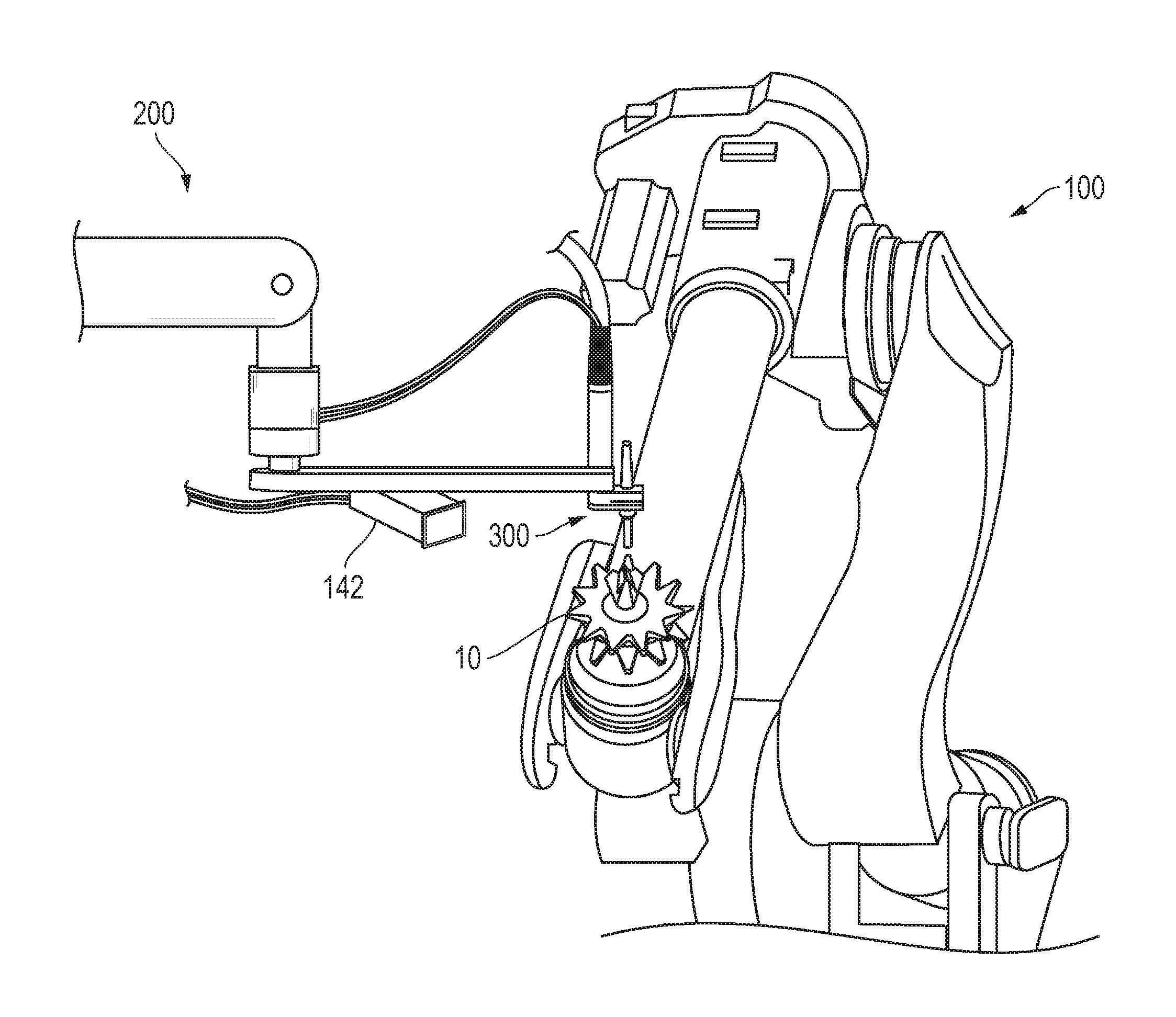

The present invention relates to a system and method for automated or “robotic” application of hardfacing to the surface of a steel-toothed cutter of a standard earth-boring rock bit or a hybrid-type rock bit. In particular, the system incorporates a grounded adapter plate and chuck mounted to a robotic arm for grasping and manipulating a rock bit cutter, particularly a hybrid rock bit cutter, beneath an electrical or photonic energy welding source, such as a plasma arc welding torch manipulated by a positioner. In this configuration, the torch is positioned substantially vertically and oscillated along a horizontal axis as the cutter is manipulated relative along a target path for the distribution of hardfacing. Moving the cutter beneath the torch allows more areas of more teeth to be overlayed, and allows superior placement for operational feedback, such as automatic positioning and parameter correction. In the preferred embodiment, sensors provide data to the control system for identification, positioning, welding program selection, and welding program correction. The control system, aided by data from the sensors, manipulates the robotically held cutter while controlling the operation and oscillation of the torch. These systems and methods can be applied to hardfacing steel teeth of the rolling cutters of both standard tri-cone or di-cone type rolling cone bits, as well as to hybrid-type earth boring drill bits.

Owner:BAKER HUGHES INC

Method and Apparatus for the Automated Application of Hardfacing Material to Rolling Cutters of Earth-Boring Drill Bits

ActiveUS20100065337A1Improve quality and consistencyFacilitate automatic collectionDrill bitsMetal-working drilling toolsRobotic armControl system

The present invention relates to a system and method for automated or “robotic” application of hardfacing to the surface of a steel-toothed cutter of a rock bit. In particular, the system incorporates a grounded adapter plate and chuck mounted to a robotic arm for grasping and manipulating a rock bit cutter beneath an electrical or photonic energy welding source, such as a plasma arc welding torch manipulated by a positioner. In this configuration, the torch is positioned substantially vertically and oscillated along a horizontal axis as the cutter is manipulated relative along a target path for the distribution of hardfacing. Moving the cutter beneath the torch allows more areas of more teeth to be overlayed, and allows superior placement for operational feedback, such as automatic positioning and parameter correction. In the preferred embodiment, sensors provide data to the control system for identification, positioning, welding program selection, and welding program correction. The control system, aided by data from the sensors, manipulates the robotically held cutter while controlling the operation and oscillation of the torch.

Owner:BAKER HUGHES INC

Versatile leg for a roof rack

InactiveUS20100237116A1Reduce inventory levelsSupplementary fittingsStowing appliancesEngineeringMechanical engineering

The invention relates to a leg for a roof rack, the leg being adapted to be attachable to a plurality of different mounting systems by which to attach the leg to a vehicle. The invention also relates to different mounting systems for attaching to the leg for attaching the roof rack leg to a mount on the vehicle. In addition, the invention relates to a permanent pad mount for attaching to a vehicle and for use with the leg of the invention and, preferably, with one of the mounting systems of the invention to attach a roof rack to the vehicle.

Owner:HUBCO AUTOMOTIVE

Method and apparatus for automated application of hardfacing material to rolling cutters of hybrid-type earth boring drill bits, hybrid drill bits comprising such hardfaced steel-toothed cutting elements, and methods of use thereof

InactiveUS8471182B2Improve quality and consistencyFacilitate automatic collectionDrill bitsArc welding apparatusHybrid typeElectricity

The present invention relates to a system and method for automated or “robotic” application of hardfacing to the surface of a steel-toothed cutter of a standard earth-boring rock bit or a hybrid-type rock bit. In particular, the system incorporates a grounded adapter plate and chuck mounted to a robotic arm for grasping and manipulating a rock bit cutter, particularly a hybrid rock bit cutter, beneath an electrical or photonic energy welding source, such as a plasma arc welding torch manipulated by a positioner. In this configuration, the torch is positioned substantially vertically and oscillated along a horizontal axis as the cutter is manipulated relative along a target path for the distribution of hardfacing. Moving the cutter beneath the torch allows more areas of more teeth to be overlayed, and allows superior placement for operational feedback, such as automatic positioning and parameter correction. In the preferred embodiment, sensors provide data to the control system for identification, positioning, welding program selection, and welding program correction. The control system, aided by data from the sensors, manipulates the robotically held cutter while controlling the operation and oscillation of the torch. These systems and methods can be applied to hardfacing steel teeth of the rolling cutters of both standard tri-cone or di-cone type rolling cone bits, as well as to hybrid-type earth boring drill bits.

Owner:BAKER HUGHES HLDG LLC

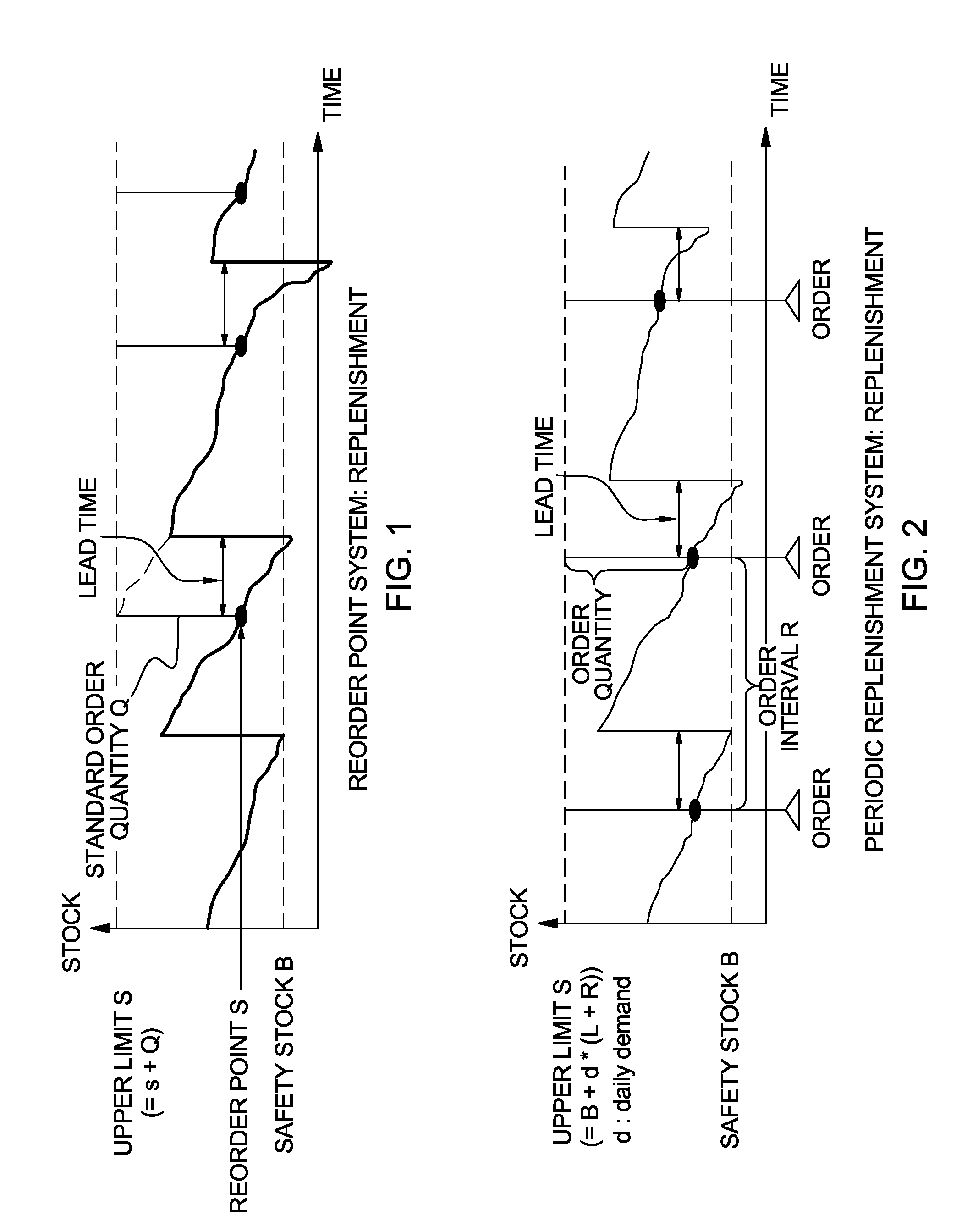

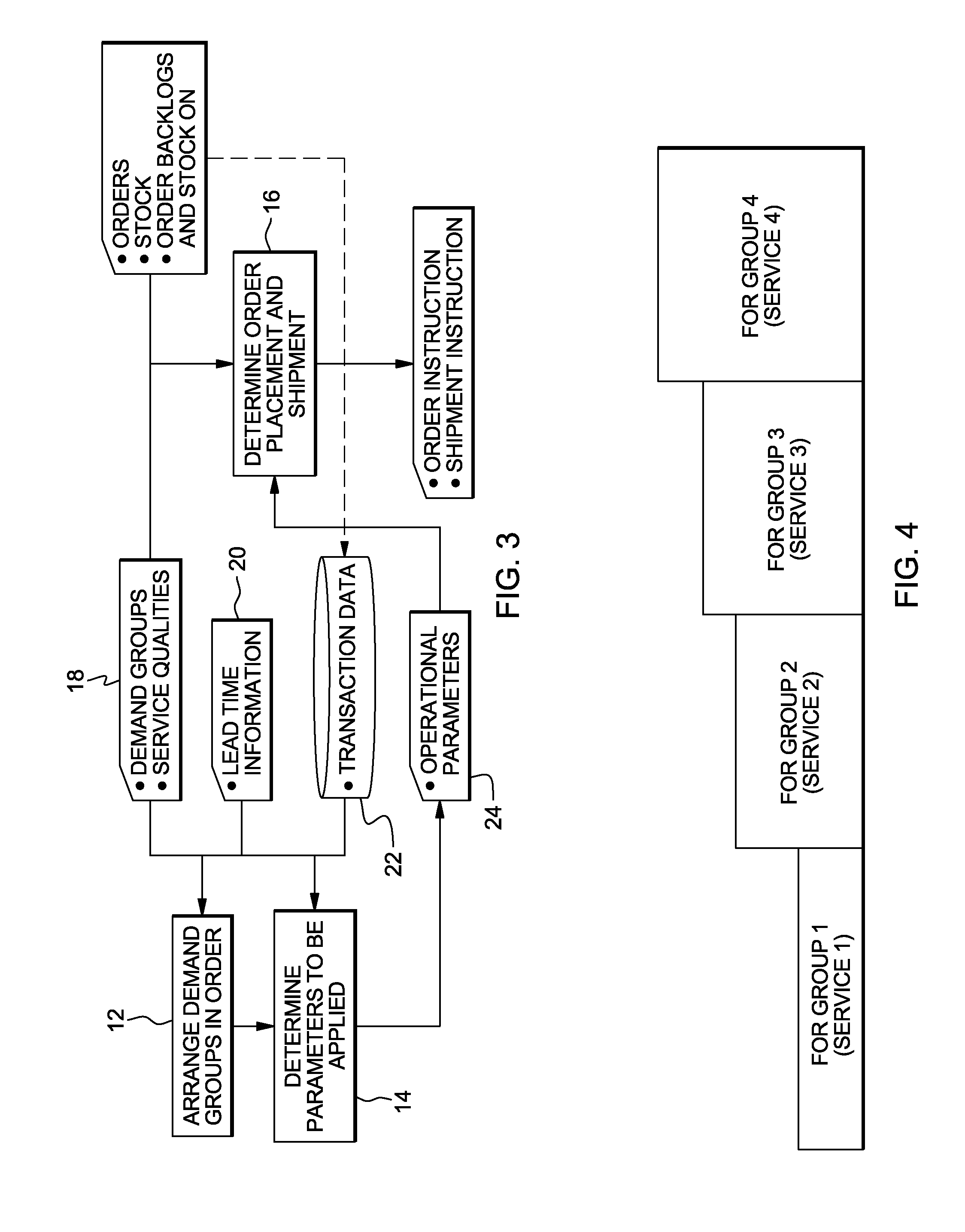

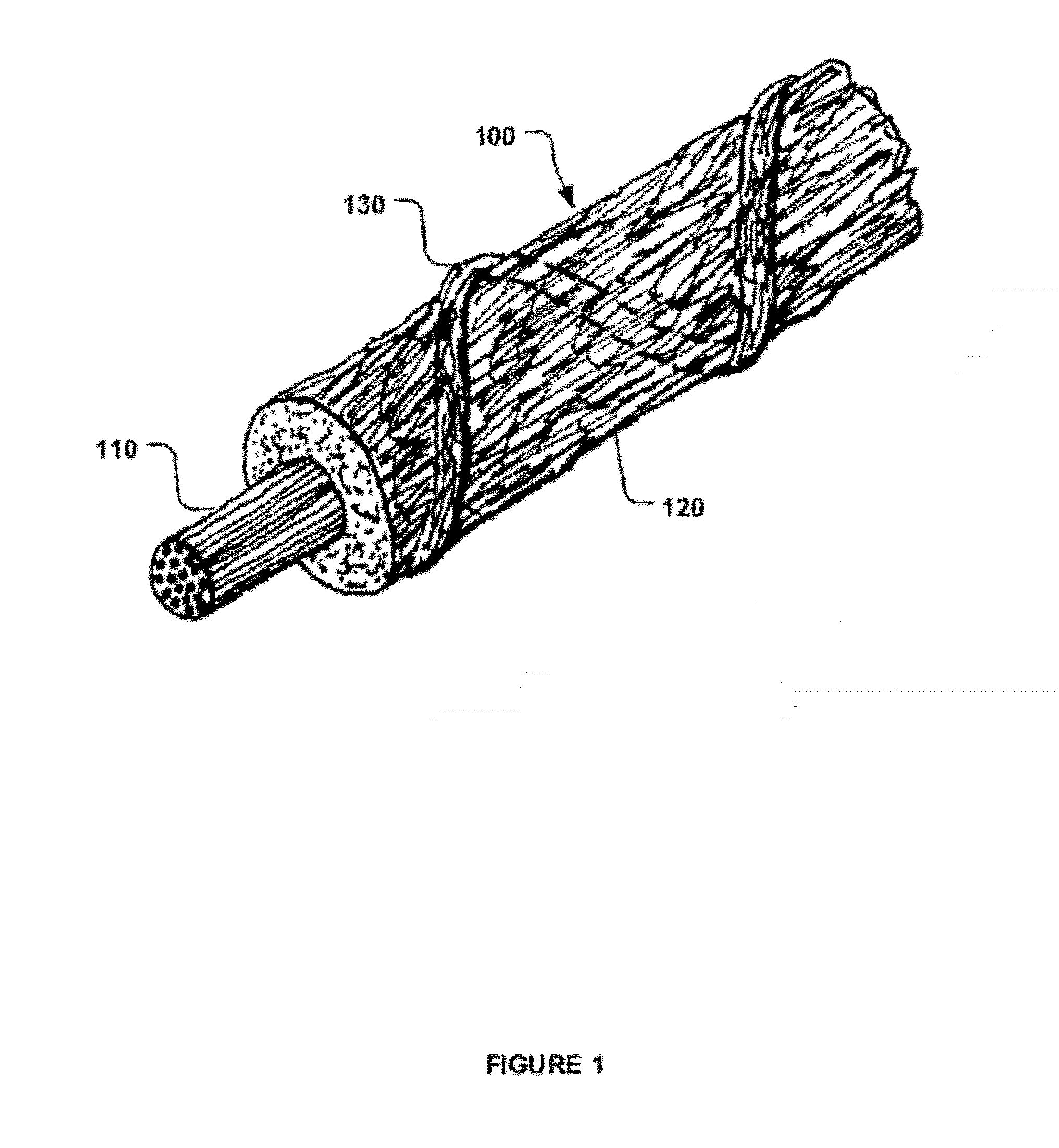

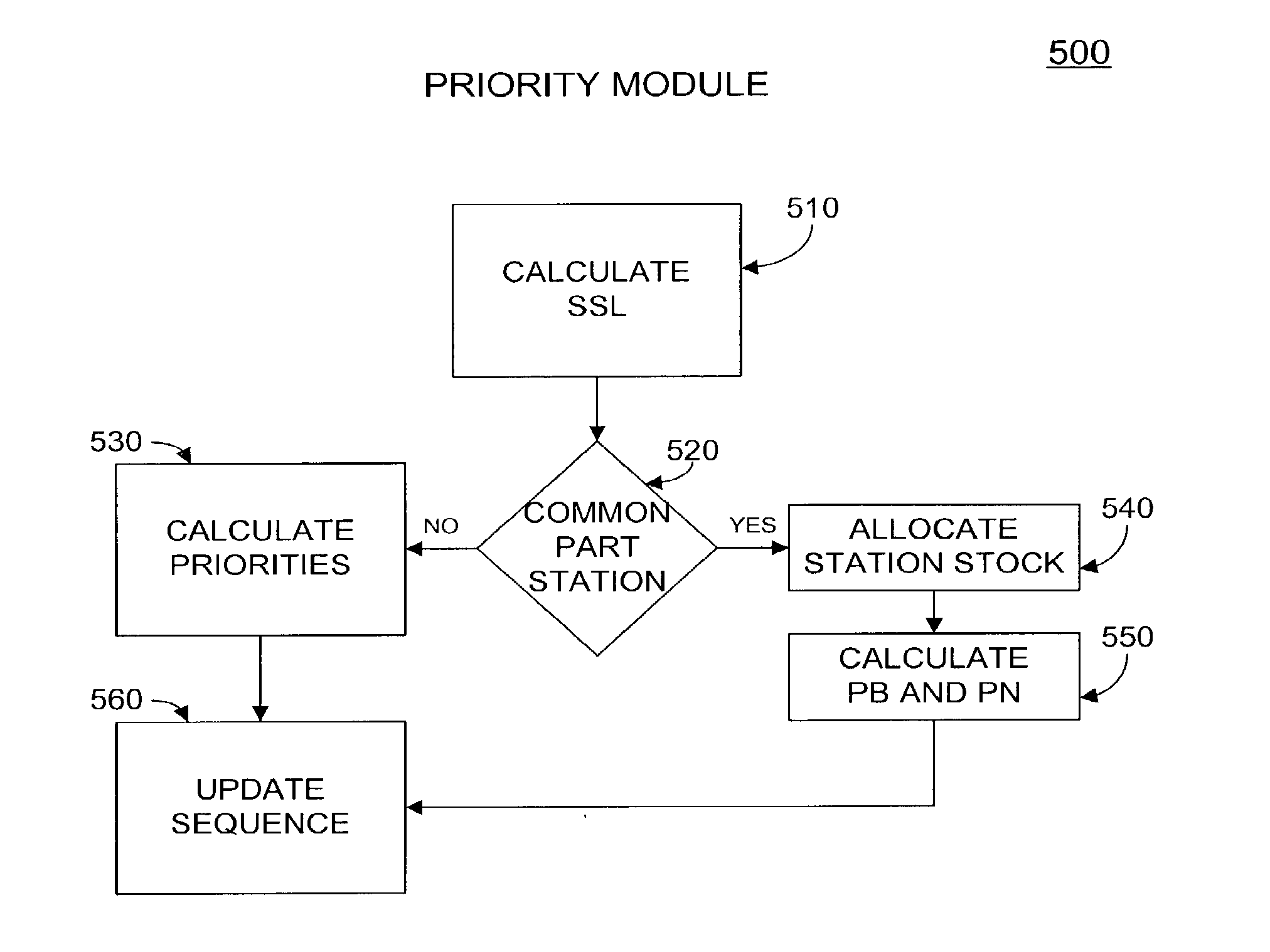

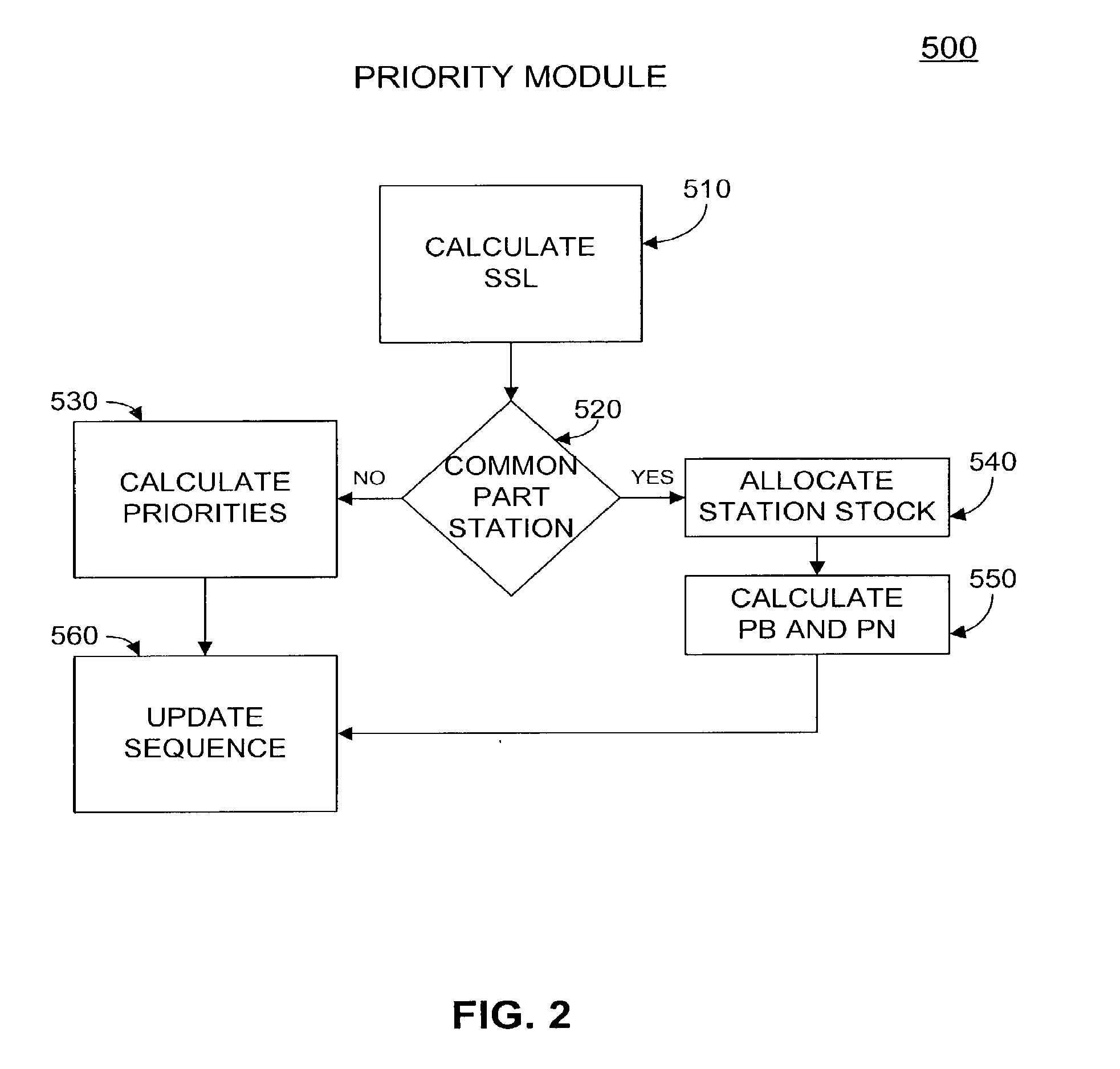

Efficient inventory management for providing distinct service qualities for multiple demand groups

An inventory management method for managing an inventory of goods for a plurality of demand groups with each demand group having at least one service quality, the method includes determining a total safety stock level for the plurality of demand groups that satisfies the distinct service quality of each demand group, determining a shipment limit Zi for each demand group Gi, wherein goods are shipped for a demand group Gi only if the inventory of goods for the demand group Gi exceeds the shipment limit Zi. Also disclosed is a computer program product and a method for an inventory management service.

Owner:IBM CORP

Structure of advertising box having modular lighting device and structure of same modular lighting device

InactiveUS20100073905A1Low costReduce inventory levelsNon-electric lightingMechanical apparatusElectricityLight guide

Disclosed are a structure of an advertising box having modular lighting devices and a structure of the modular lighting device. The structure of the advertising box includes a box and plural modular lighting devices fixedly installed inside a frame of the box. The modular lighting device has a housing, a light guide plate, a lighting unit and plural electrical connectors. The light guide plate is coupled with the housing while the lighting unit is optically coupled with a light incident surface of the light guide plate. At least one lateral side of the housing is provided with the electrical connectors, so that the lighting units in the modular lighting devices are electrically coupled with each other through the electrical connectors. The modular lighting devices enable replacement of lighting devices of uniform sizes and can form light sources of various sizes for use with different kinds of advertising boxes.

Owner:SINOLOGY ENTERPRISE

Versatile leg for a roof rack

InactiveUS20150239402A1Reduce inventory levelsSupplementary fittingsClassical mechanicsMechanical engineering

The invention relates to a leg for a roof rack, the leg being adapted to be attachable to a plurality of different mounting systems by which to attach the leg to a vehicle. The invention also relates to different mounting systems for attaching to the leg for attaching the roof rack leg to a mount on the vehicle. In addition, the invention relates to a permanent pad mount for attaching to a vehicle and for use with the leg of the invention and, preferably, with one of the mounting systems of the invention to attach a roof rack to the vehicle.

Owner:HUBCO AUTOMOTIVE

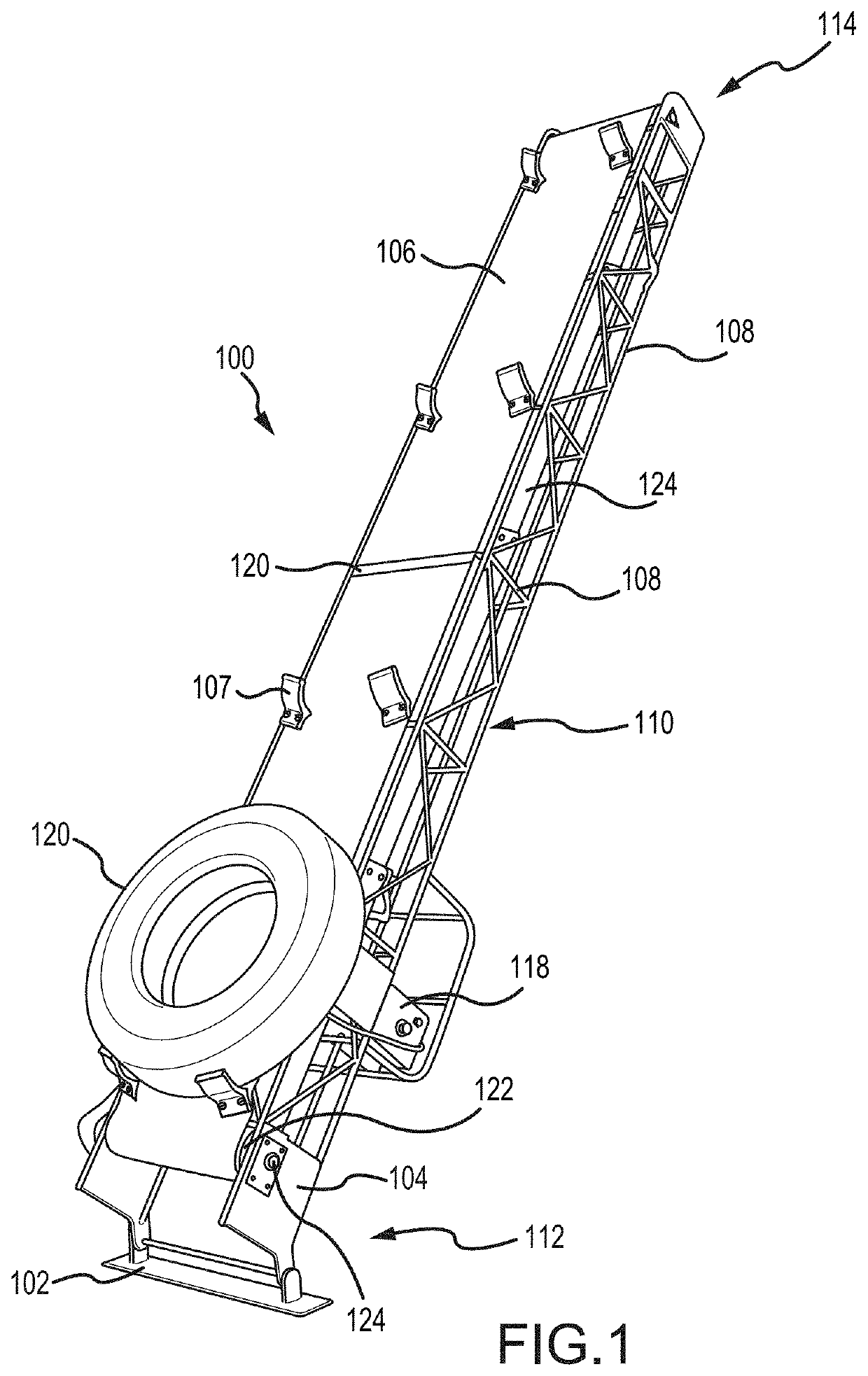

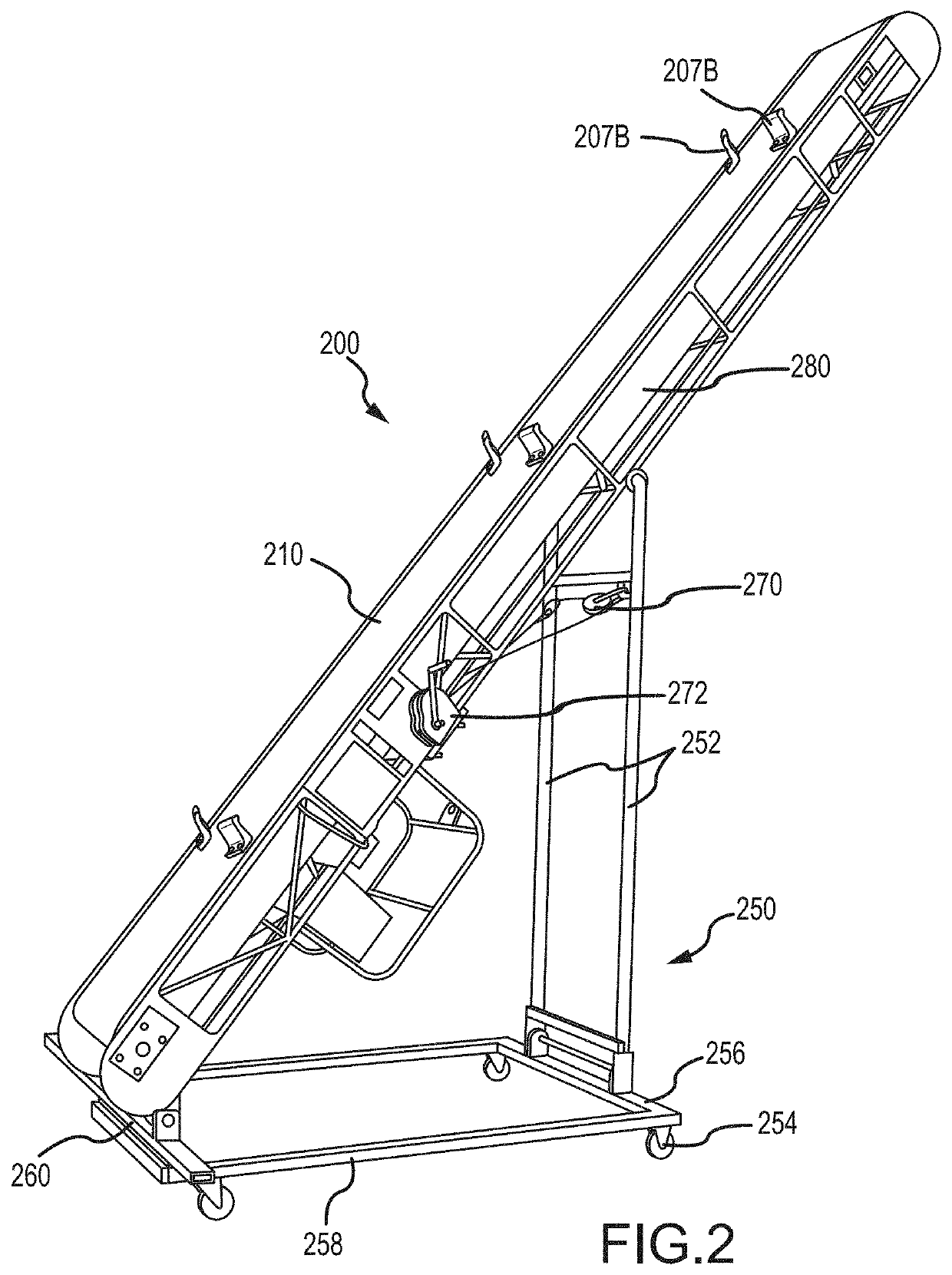

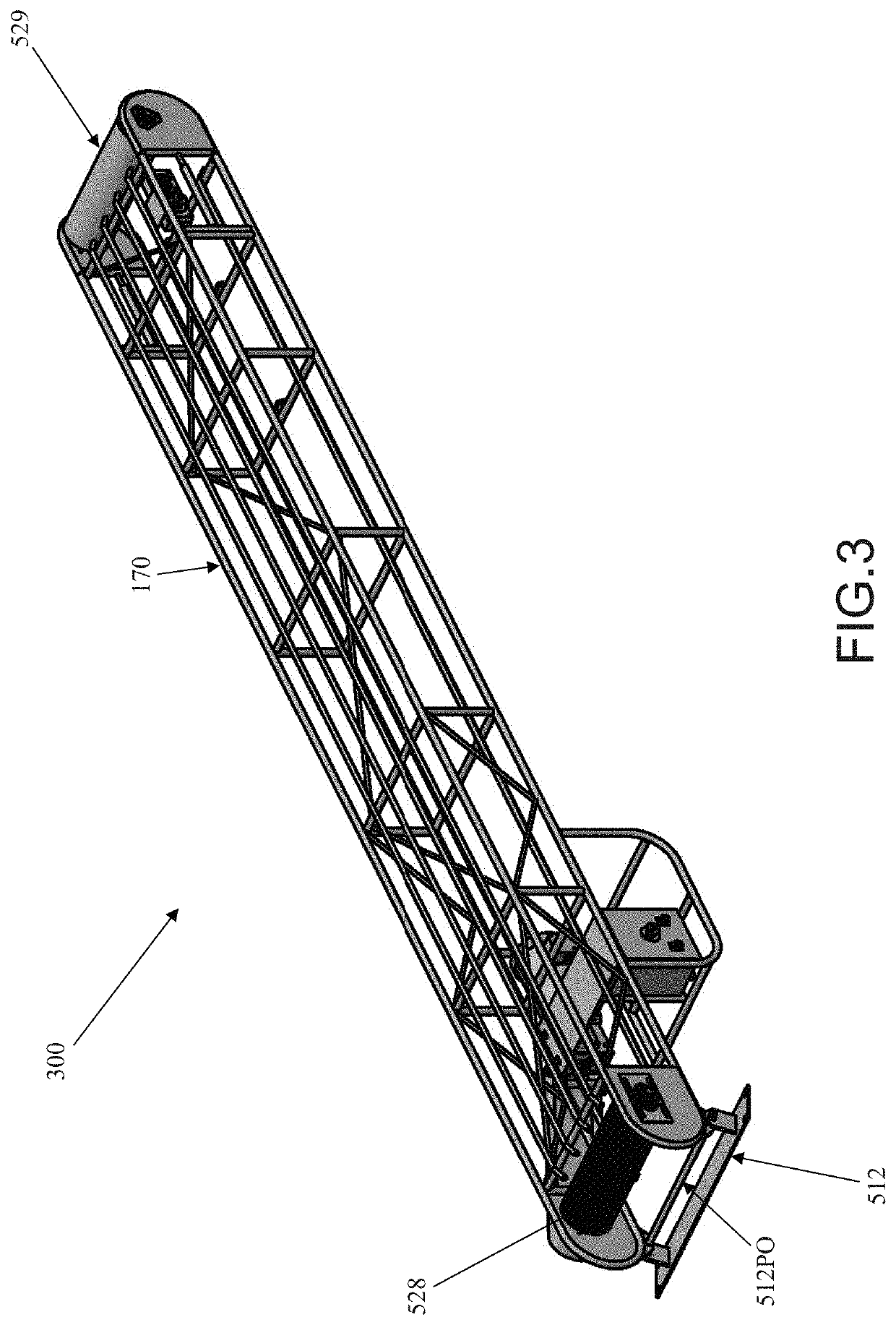

Method and system for conveying articles and an apparatus for doing the same

ActiveUS20200140198A1Facilitate efficiency in tire loadingEasy to unloadConveyorsSupporting framesConveyor beltLow friction

A conveyor for transporting and elevating articles and a method and system for conveying articles up inclines is provided. The conveyor has a conveyor belt and a plurality of support elements extending outward from the article-conveying surface of the conveyor belt advancing upward along the incline. The conveyor may be positioned at an inclined angle relative to the horizontal ground, i.e., between about 5° and 85° or the conveyor can be substantially vertical, i.e., about 90° relative to the horizontal ground. The support elements prevent conveyed articles from sliding down the conveyor belt on the inclined conveyor and carry and hold articles on substantially vertical conveyors. The article-conveying surface of the conveyor belt may provide a low-friction retention surface to articles leaning away from the conveyor belt on the incline.

Owner:MULTIELEVATOR

Intelligent inventory early warning and management system based on BIM (Building Information Modeling) model

PendingCN107133769AReduce inventory levelsPrecision productionForecastingLogisticsInformatizationInventory management

The invention relates to an intelligent inventory early warning and management system based on a BIM (Building Information Modeling) model. The method comprises the following steps: 1, a BIM model is imported to the system; 2, a cargo requirement task plan based on the BIM model is generated in the system, and the cargo requirement task plan is sent to a factory; 3, the BIM cargo requirement plan is subjected to model decomposition, and the material amount for needed component types is counted; 4, the system judges the current inventory; 5, the system judges an insufficient component material amount, if the cargo requirement plan time is smaller than needed time T, first-level inventory early warning is triggered, or otherwise, second-level inventory early warning is triggered; 6, coordinated purchasing is carried out on component list materials; and 7, the system detects whether the current inventory meets enterprise safety inventory. The informatization operation level of inventory management of a construction enterprise is enhanced.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

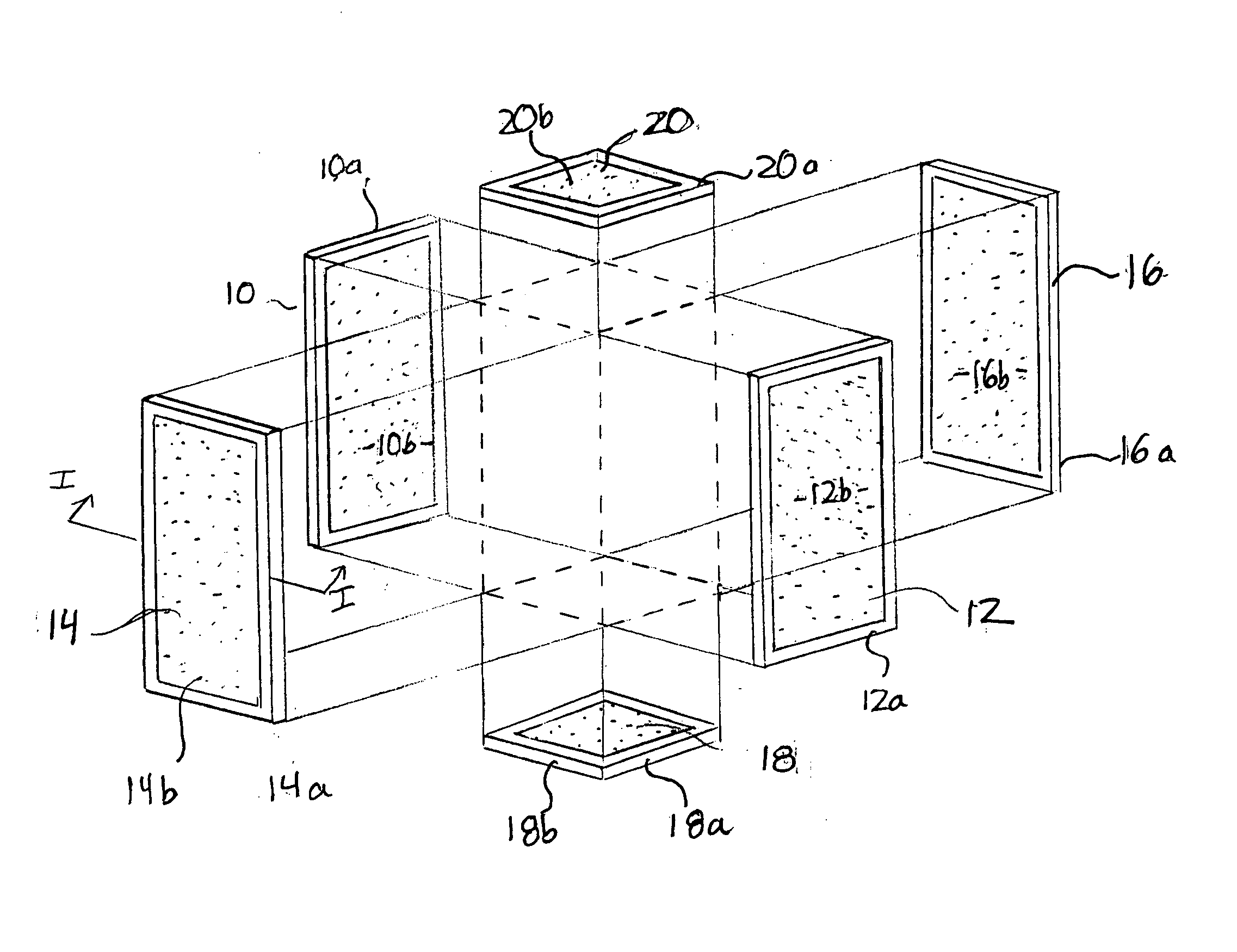

Interlocking component assembly system

InactiveUS20050023944A1Reduce inventory levelsLow investment costChestsDressing tablesEngineeringAssembly systems

An interlocking component assembly is made of a plurality of frame components and a plurality of panels. One panel is formed integrally with a respective frame to form a frame and panel component. A channel formed along the entire periphery of each of the frame components enables each of the frame and panel components to be interconnected. During assembly the channel of one frame component is inserted within a channel of another frame component to lock the components together along the length thereof. A plurality of locking tabs are disposed within the channel of each of the plurality of frame components. A plurality of apertures are also disposed within the channel of each of the plurality of frame components, wherein when the channel of a frame component is inserted within the channel of another frame component at least one locking tab is received within a corresponding aperture. This process is repeated until a three-dimensional unit is formed.

Owner:THAI UNIVERSAL OFFICE PRODS

Integrated materials management for commercial aircraft fleets including access to real-time on-board systems information

ActiveUS8423430B2Low costGood informationAnimal feeding devicesSpecial data processing applicationsMaintenance planningOn board

Owner:THE BOEING CO

Automatic feeding and blanking production line and control method thereof

The invention discloses an automatic feeding and blanking production line and a control method thereof. The automatic feeding and blanking production line contains two structure modes, namely, a U-shaped line layout and a line type line layout. A production line body is formed by basic units and meets the requirement of a modular assembly technology; each basic unit is divided into an upper layerand a lower layer, so that modular splicing can be realized, and multiple layout forms are realized; and in addition, a tray backflow function can be realized. The production line is further providedwith a tray and tool conveying mechanism for supporting quick changeover, a tray conveying control system, a single-station manual / automatic real-time switching control system, a production line conveyor line body transfer real-time control mechanism, a production line work-in-process temporary storage station design, and flexible and changeable production line arrangement forms. On the basis of the idea of lean production, the problems of high stock level, circulation difficulty, high manufacturing cost, low product quality, waste in space, time, manpower and tool, and the like existing actually are solved.

Owner:西安精雕精密机械工程有限公司

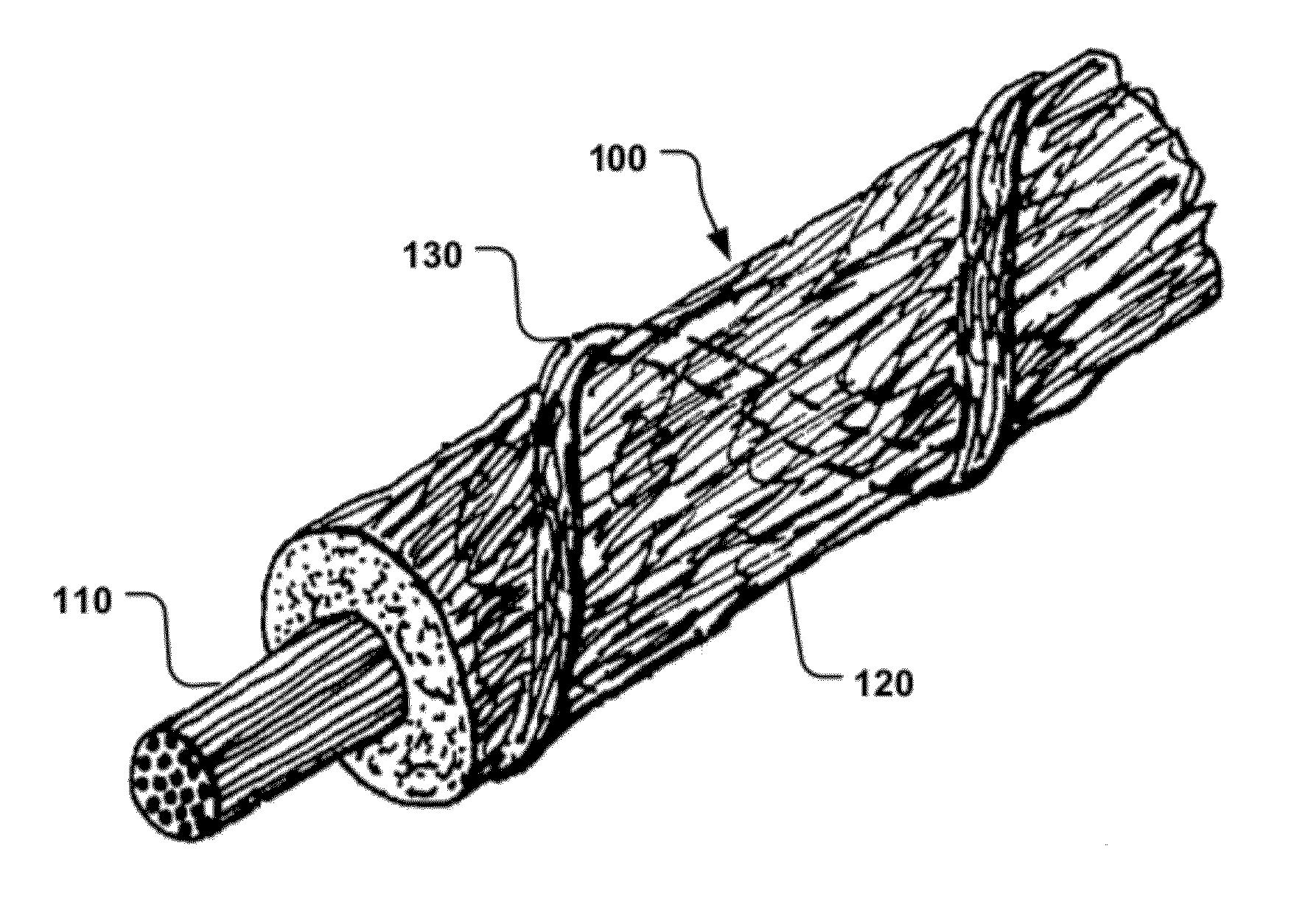

Coated fire barriers made from corespun yarns - coated fibers comprising the sheath of the corespun yarns

InactiveUS20120142241A1Preserve aesthetic propertyPreserve physical propertyFibre treatmentWarp knittingFiberYarn

The invention relates to a fire resistant flame barrier lightweight fabric substrate consisting of a high temperature resistant continuous filament fiberglass core and a low temperature resistant staple fiber sheath treated with a durable or non-durable fire retardant agent prior to yarn formation. The invention also discloses a process for making a fire resistant corespun yarn by treating fibers with fire retardant agent to make the sheath of the corespun yarn.

Owner:SPRINGS CREATIVE PRODS GROUP

Efficient inventory management for providing distinct service qualities for multiple demand groups

An inventory management method for managing an inventory of goods for a plurality of demand groups with each demand group having at least one service quality, the method includes determining a total safety stock level for the plurality of demand groups that satisfies the distinct service quality of each demand group, determining a shipment limit Zi for each demand group Gi, wherein goods are shipped for a demand group Gi only if the inventory of goods for the demand group Gi exceeds the shipment limit Zi. Also disclosed is a computer program product and a method for an inventory management service.

Owner:INT BUSINESS MASCH CORP

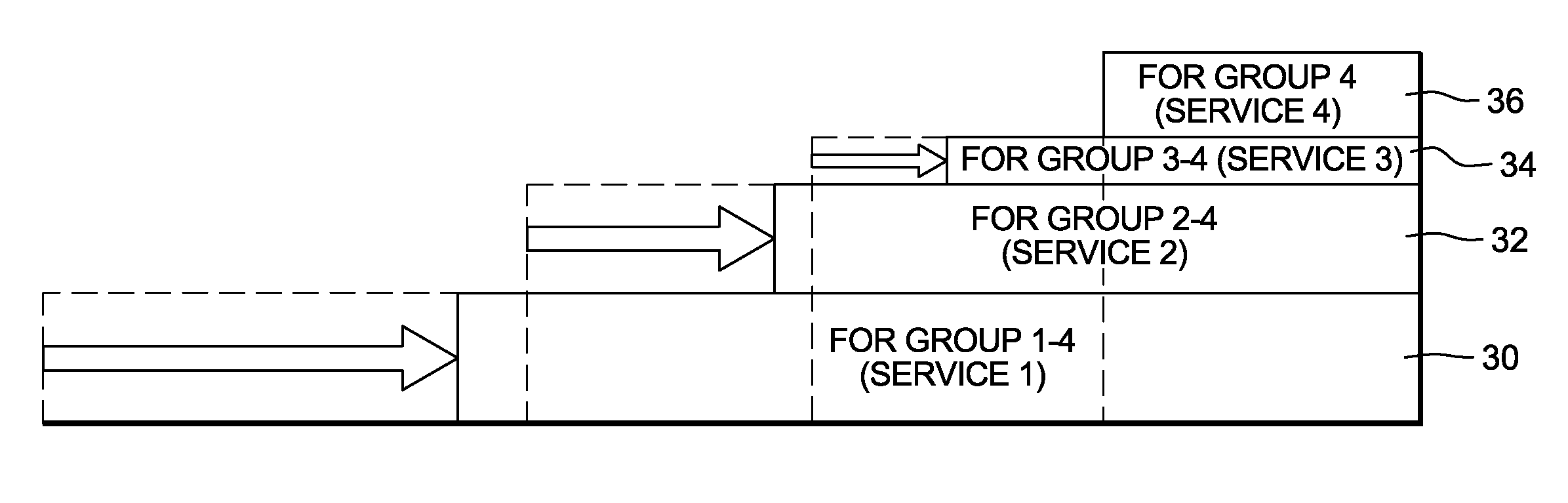

System and method for campaign planning

InactiveUS6560502B1Disadvantages in reduced eliminatedProblems and in reduced eliminatedTotal factory controlSpecial data processing applicationsComputer scienceRelative significance

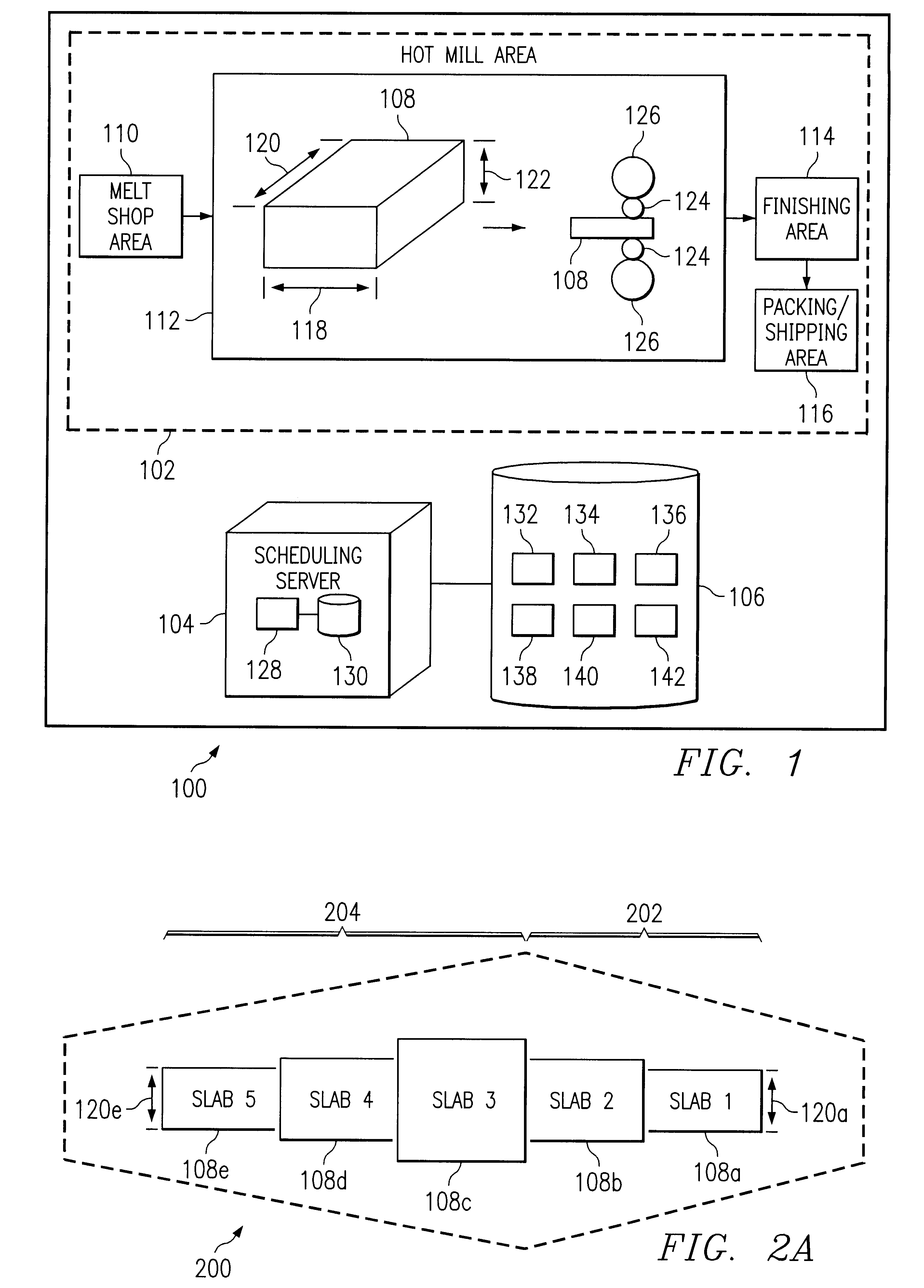

A system (100) for campaign planning includes a memory (106) operable to store at least two slab values (132) for each of a plurality of slabs (108). The slab values (132) for a slab are associated with at least two properties of the slab (108). The memory (106) is also operable to store at least one preference value (142) identifying a relative importance between the properties of the slabs (108). The system (100) also includes one or more processors (128) collectively operable to generate a sort value (400) for each of the slabs (108). The sort value (400) depends at least partially on the slab value (132) associated with the slab (108) and the preference value (142). The processor (128) is also operable to allocate the slabs (108) to a plurality of rounds (200) in a campaign (250). The slabs (108) are allocated in an order depending at least partially on the sort values (400) associated with the slabs (108).

Owner:BLUE YONDER GRP INC

Method and apparatus for the automated application of hardfacing material to rolling cutters of earth-boring drill bits

ActiveUS8698038B2Improve quality and consistencyFacilitate automatic collectionDrill bitsMetal-working drilling toolsRobotic armControl system

The present invention relates to a system and method for automated or “robotic” application of hardfacing to the surface of a steel-toothed cutter of a rock bit. In particular, the system incorporates a grounded adapter plate and chuck mounted to a robotic arm for grasping and manipulating a rock bit cutter beneath an electrical or photonic energy welding source, such as a plasma arc welding torch manipulated by a positioner. In this configuration, the torch is positioned substantially vertically and oscillated along a horizontal axis as the cutter is manipulated relative along a target path for the distribution of hardfacing. Moving the cutter beneath the torch allows more areas of more teeth to be overlayed, and allows superior placement for operational feedback, such as automatic positioning and parameter correction. In the preferred embodiment, sensors provide data to the control system for identification, positioning, welding program selection, and welding program correction. The control system, aided by data from the sensors, manipulates the robotically held cutter while controlling the operation and oscillation of the torch.

Owner:BAKER HUGHES HLDG LLC

Combination tool with automated tool change for robot assisted assembly

InactiveUS6836944B2Shorten cycle timeLow costAutomatic control devicesPrecision positioning equipmentTarget surfaceMechanical engineering

A method of assembling a part to a workpiece with a combination tool supported on a robot, where a mounting surface of the part is assembled on a target surface of the workpiece including the following steps. (a) Indexing to the assembly position. (b) Picking a part with the part gripper on the part delivery arm from a part supply station. (c) Indexing part delivery and workpiece preparation arms to the preparation position. (d) Simultaneously: engaging the part mounting surface with the part surface preparation module; and engaging the workpiece target surface preparation module with the target surface. (e) Indexing to the assembly position. (f) Using the previously set tool operating axis and calculated tool offsets, engaging the prepared part mounting surface with the prepared workpiece target surface. (g) Releasing the part gripper and withdrawing the tool from the part / workpiece assembly.

Owner:SYMBOTIC CANADA ULC

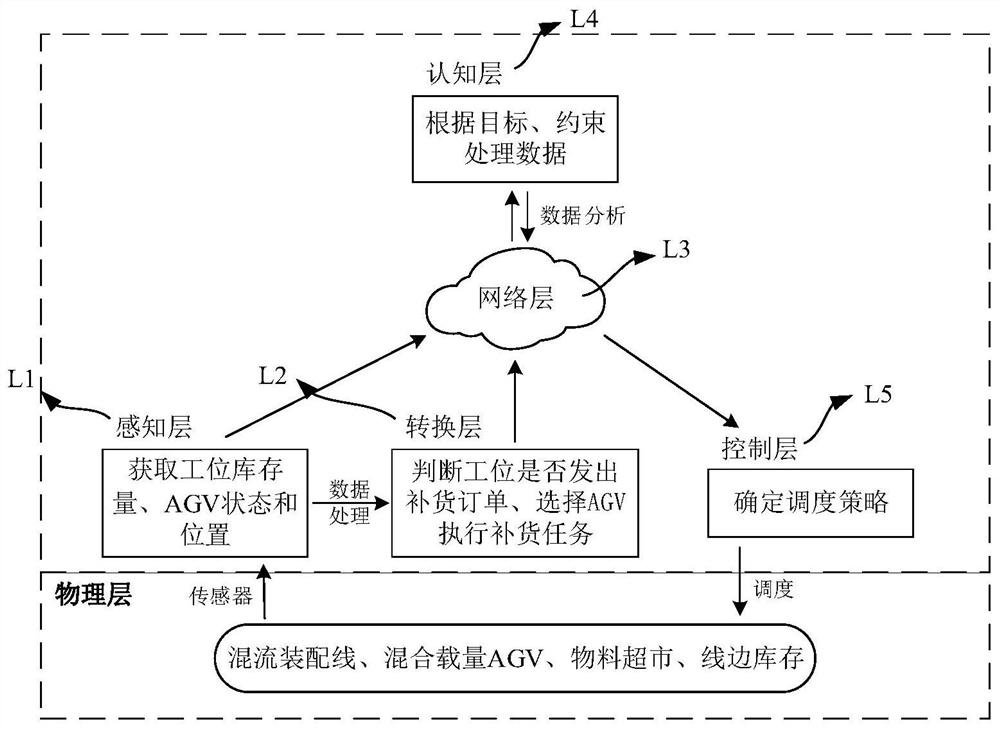

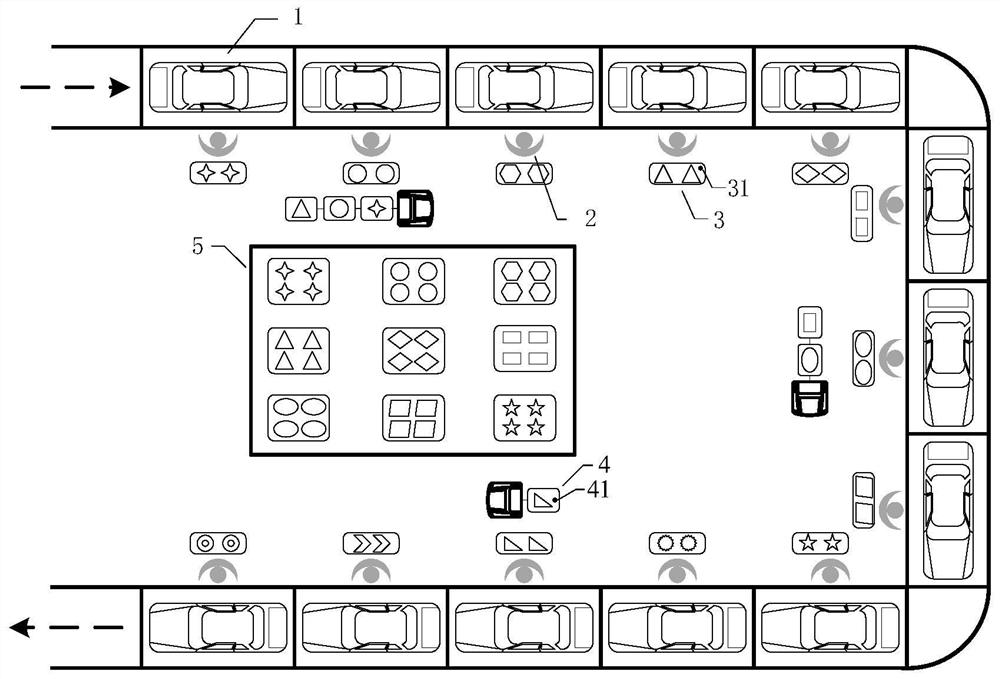

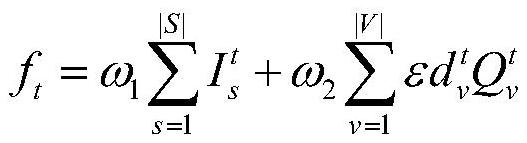

Mixed flow assembly line material distribution method and system based on static half-set strategy

ActiveCN112801483AExcellent delivery strategyReduce inventory levelsDesign optimisation/simulationResourcesControl layerMixed flow

The invention relates to a mixed flow assembly line material distribution method and system based on a static half-set strategy, and the system comprises: a sensing layer which obtains the remaining line side stock of each station and the state and position of a mixed load AGV in real time through a sensor; the conversion layer that is used for converting the data acquired by the sensing layer into useful information, determining whether a station has a replenishment demand or not, and summarizing material demands; the network layer that is connected with other layers to realize data exchange; the cognitive layer that determines an optimal material distribution scheduling strategy through data analysis according to the target function; and the control layer that determines a control strategy according to the cognition result of the cognition layer. Compared with the prior art, the invention considers the real-time inventory of each station, the state and position information of the AGV and the like, and has the advantages of effectively reducing the inventory level of the line side, improving the material distribution efficiency, reducing the operation cost and the like.

Owner:TONGJI UNIV

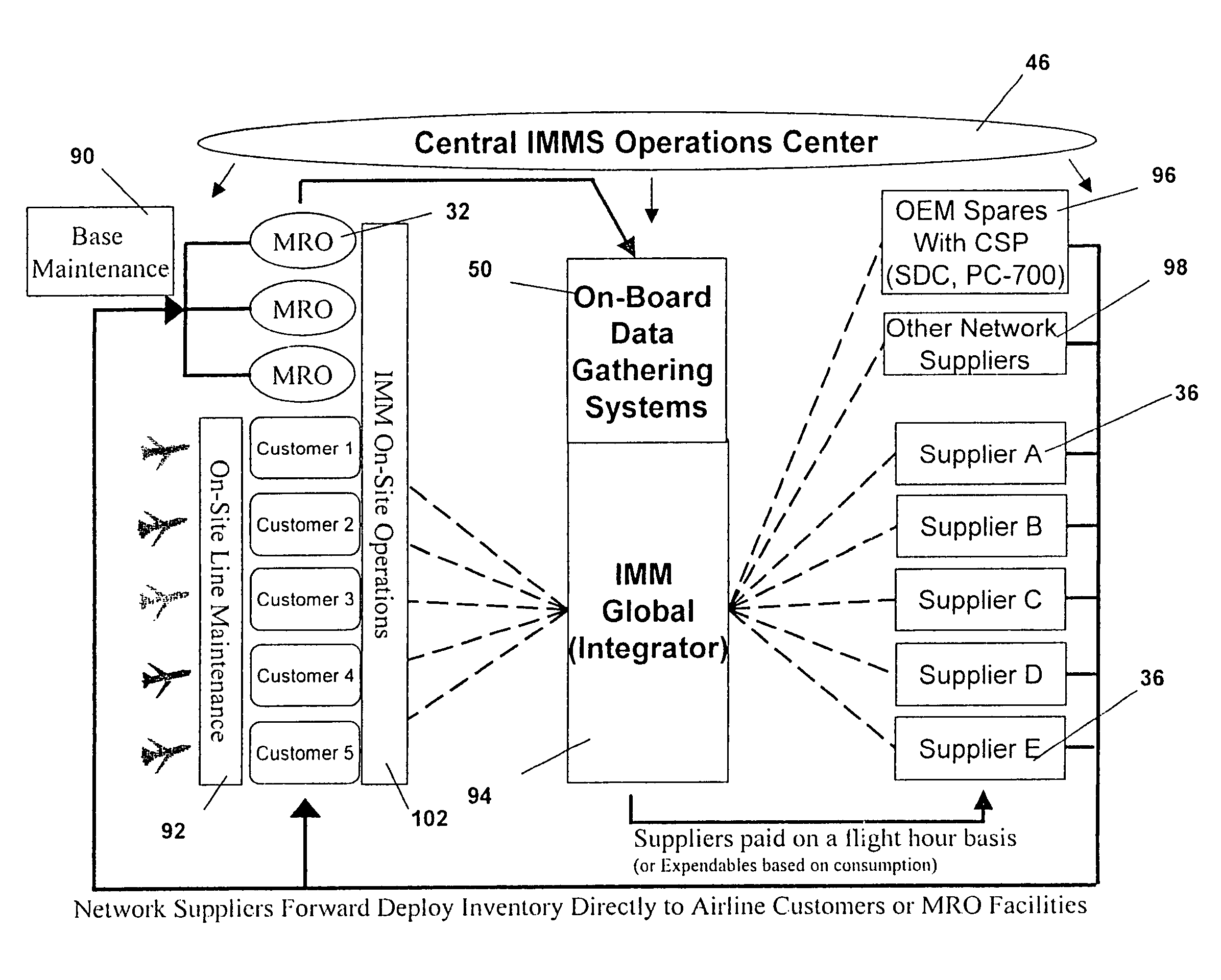

Integrated materials management for commercial aircraft fleets

ActiveUS8036955B2Low costGood informationDigital data processing detailsAnimal feeding devicesMaintenance planningOn board

Turnkey maintenance of a customer's aircraft fleet is managed by a single management service provider (MSP) controlling integrated maintenance and materials services from a central operations site. The MSP converts data received directly from on-board aircraft systems into information it uses to manage maintenance service providers and parts suppliers. The MSP contracts with and manages maintenance, repair and overhaul organizations (MROs) who perform the maintenance on the customers' aircraft at line and base stations. The MSP either remotely manages part inventories at the customer's site, or manages suppliers who deliver the parts to the MROs. Maintenance planning, scheduling and execution information is exchanged between the MSP, MROs, part suppliers and the customers through a shared data communication network controlled by the MSP. The MSP charges the customer for the maintenance services based on a flat rate per unit of aircraft flying time.

Owner:THE BOEING CO

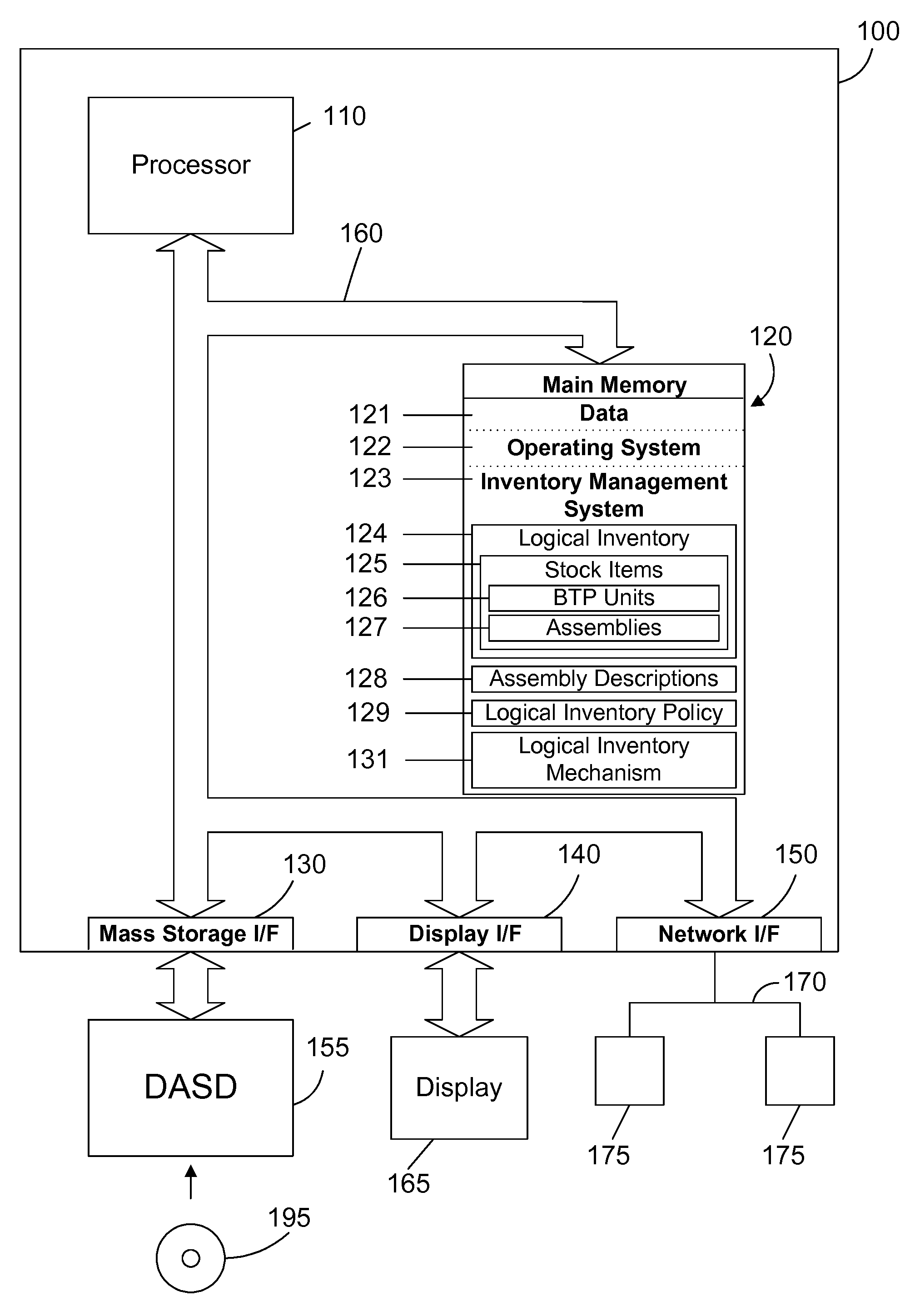

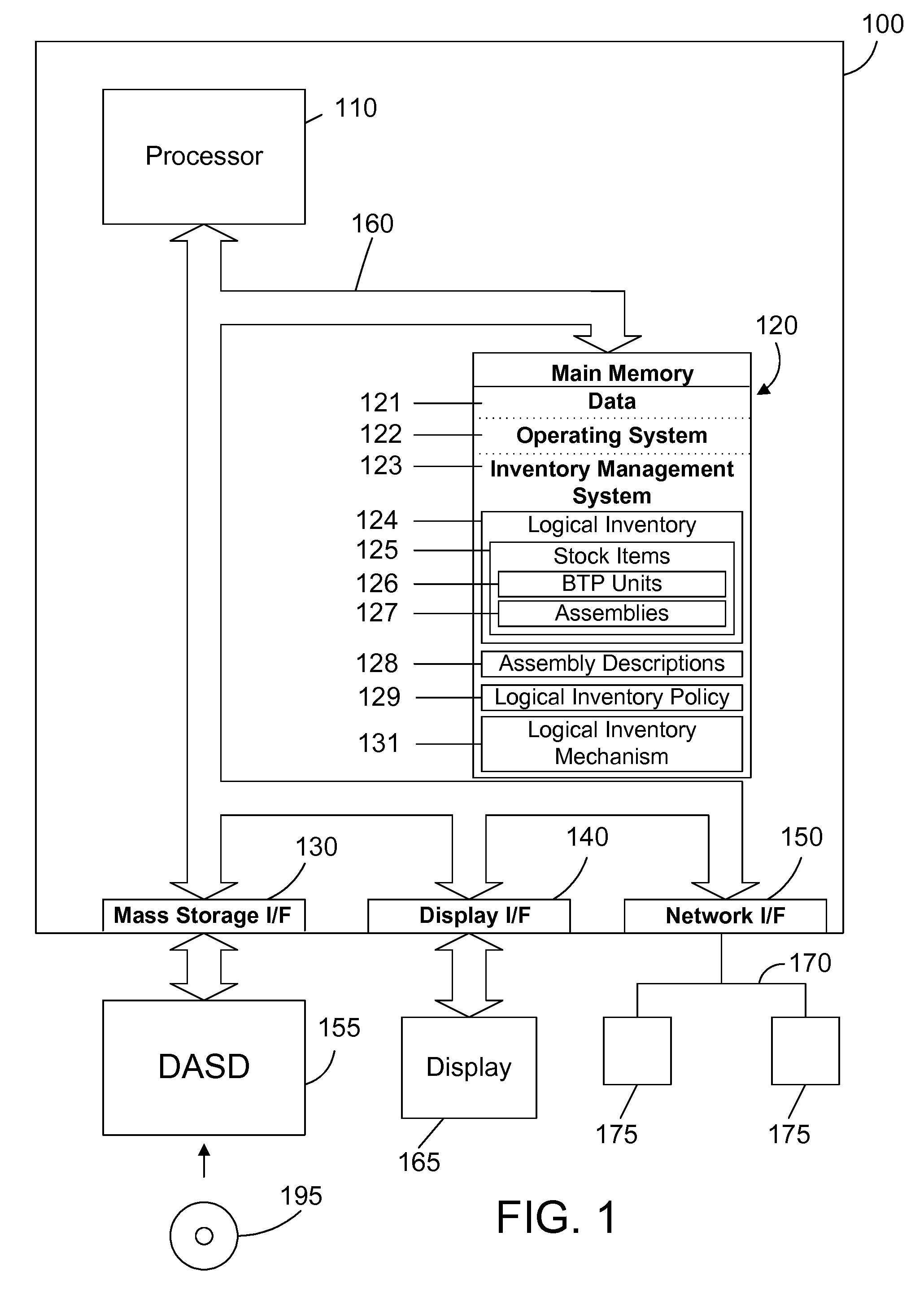

Inventory mechanism that generates logical inventory from assemblies in inventory

InactiveUS20080201001A1Improve efficiencyReduce inventory levelsSpecial data processing applicationsControl systemEngineering

A logical inventory mechanism takes components in assemblies into account when determining purchase requirements. The inventory control system determines assemblies that are available, determines their components and whether or not each component may be reused, then adjusts physical inventory to generate therefrom logical inventory based on physical inventory plus parts in the assemblies that may be reused if the assemblies are disassembled. By computing logical inventory that would be available by disassembling assemblies, inventory levels may be reduced, thereby enhancing the efficiency of an inventory control system that includes the logical inventory mechanism. Assemblies in inventory thus may be used in two very different matters, as the starting point for a higher-level assembly, or to be disassembled to use one or more reusable components in the assembly in a different assembly.

Owner:IBM CORP

Constraint-based production planning and scheduling

InactiveUS20100287020A1Simple modelReduced production cycle timeForecastingResourcesBusiness enterpriseCustomer order

The present invention is a constraint-based planning tool that specifically addresses the needs of complex discrete and process industries by providing a computationally efficient method and system for fulfillment of customer orders in a supply chain. By comprehensively synchronizing and optimizing the flow of materials through the enterprise, the present invention creates a feasible plan for manufacturing operations that simultaneously optimizes both material and capacity constraints by planning and scheduling multiple customer orders, planning for use the various resources located in remote locations needed to fulfill such orders, and scheduling the used resources for replenishment at appropriate times so that the resources meet the needs of the orders.

Owner:BLUE YONDER GRP INC

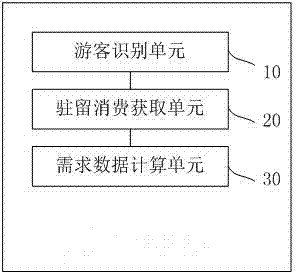

Scenic spot consumption monitoring method and device

ActiveCN106912009ACarry out effectivelyMonitor operating conditionsLocation information based serviceMarket data gatheringTemporal informationProgram planning

The invention discloses a scenic spot consumption monitoring method and device. The scenic spot consumption monitoring method comprises the following steps of determining a scenic spot, where a tourist is, through a mobile terminal held by the tourist; obtaining consumption data of the scenic spot in an appointed time interval and the residence time information of the tourist; and, periodically counting the tourist consumption data and the residence time data of the scenic spot, and calculating the consumption data of the scenic spot. By means of the method and the device disclosed by the invention, adaptive adjustment of the scenic spot can be carried out with the help of the state information; therefore, the technical support is provided for adjustment of the scenic spot; the adjustment rationality is ensured; furthermore, matching between planning requirements and practical requirements can be realized easily; the best state of the scenic spot can be kept; and thus, the tourist experience is improved.

Owner:BEIJING BOCO COMM TECH

Inventory mechanism that generates logical inventory from assemblies in inventory

InactiveUS8700497B2Improve efficiencyReduce inventory levelsAnimal feeding devicesSpecial data processing applicationsControl systemEngineering

Owner:INT BUSINESS MASCH CORP

Control method of a medical equipment interlayer supply and demand structure

InactiveCN109493132AReduce the probability of out of serviceImprove support capabilitiesMarketingInformation transmissionAssistive technology

The invention belongs to the technical field of medical equipment management and assistance, and particularly relates to a control method of a medical equipment interlayer supply and demand structure.According to the control method of the medical equipment middle layer supply and demand structure, on one hand, the middle layer management structure is provided; Based on the mechanism, integrationfrom the short to the sales end to the storage management system can be realized; the market demand and the production capacity are uncertain; reducing inventory levels as much as possible, Control ofloss of stock absence, the probability that a client cannot service is reduced; the guarantee capability of the whole purchase and sale structure is improved; meanwhile, corresponding requirements and capacities of a production end and a sales end are converged through an interlayer structure; the information transmission efficiency and processing capability are improved, the profit distributionstep in the purchase and sale structure is scientifically controlled, the balance of profits of the production end and the sale end is ensured to be balanced when the purchase and sale structure is hooked, extreme or abnormal distribution is prevented, and the long-term effectiveness of the whole purchase and sale structure is effectively ensured.

Owner:武汉利恩达医疗科技有限公司

A virtual replacement method for an electronic product production line

ActiveCN107862110BReduce wasteGood line balanceProgramme controlDesign optimisation/simulationProduction lineLayout planning

The invention discloses a method for virtual production change of an electronic product production line, which comprises the following steps: according to the layout planning of the mainstream pipeline and the special production platform required for the change of electronic product production, modeling in the simulation system, and establishing a three-dimensional Model library; modularize the established 3D model library and package it; combine the 3D model library to solve the unit modular algorithm, implement the whole line and schedule the algorithm, and determine the initial plan for product replacement; the special production platform realizes flexible scheduling , the rapid reconstruction of the 3D model library realized in the host computer; the whole line assembly of the 3D model library, and the compilation of logic scripts for the reconstructed 3D model library and finally repackaging; the reconstructed 3D model library On the test module of the upper computer, the virtual test of the whole production line of the mainstream pipeline is carried out; the test results of the production change are generated, and the production line optimization design plan is generated according to the test results of the production change.

Owner:GUANGDONG UNIV OF TECH

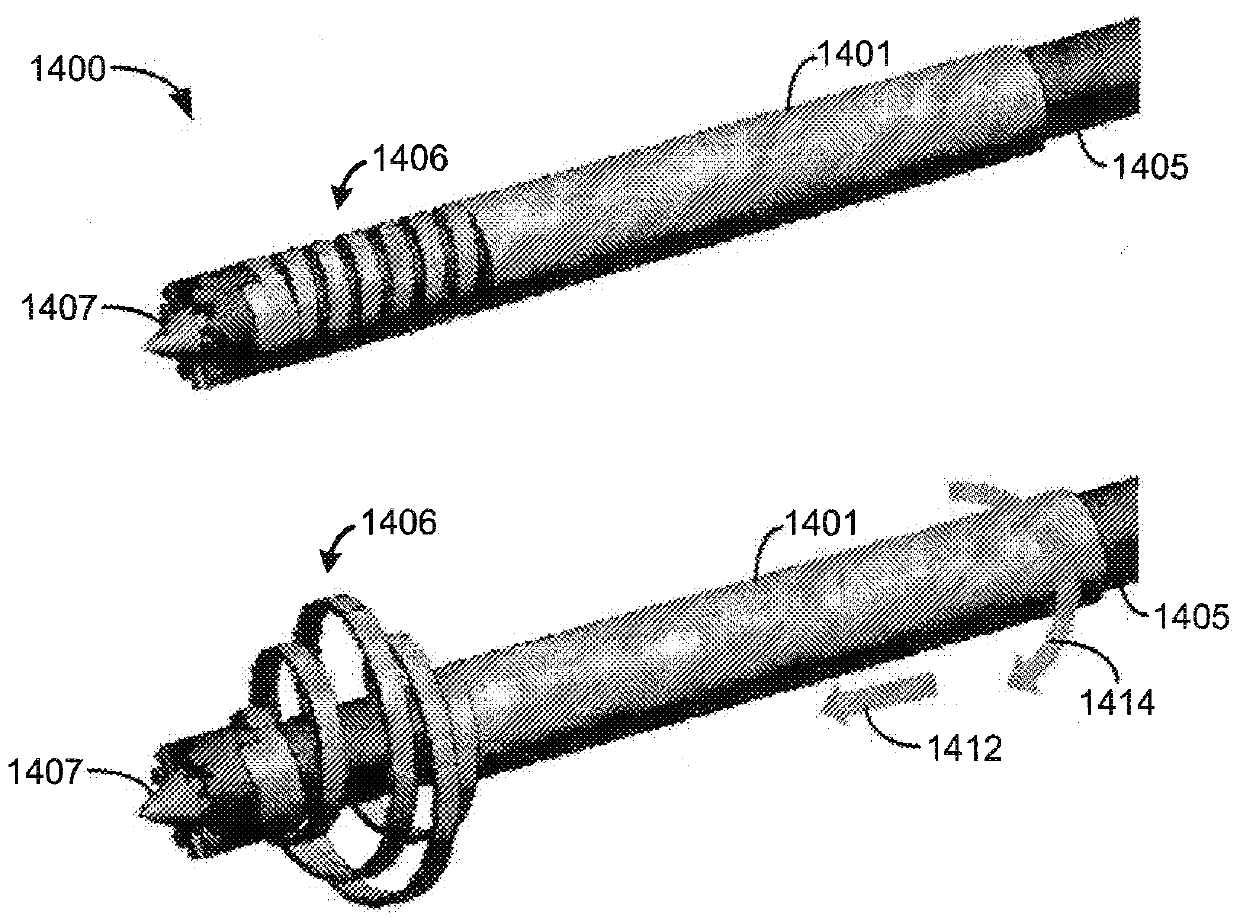

Surgical Instruments

A hollow retrograde reamer that is adjustable to produce tunnels of various diameters. The hollow retrograde reamer substantially reduces the risk of tunnel misposition and / or misalignment and can be adjusted to produce a range of tunnel diameters, allowing for reduced inventory levels for surgical cases.

Owner:SMITH & NEPHEW PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com