Interlocking component assembly system

a technology of interlocking components and assembly systems, which is applied in the direction of furniture joining, dismountable cabinets, fastening means, etc., can solve the problems of increasing assembly time, cost and frustration for users/assemblers, and low ease of assembly/disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

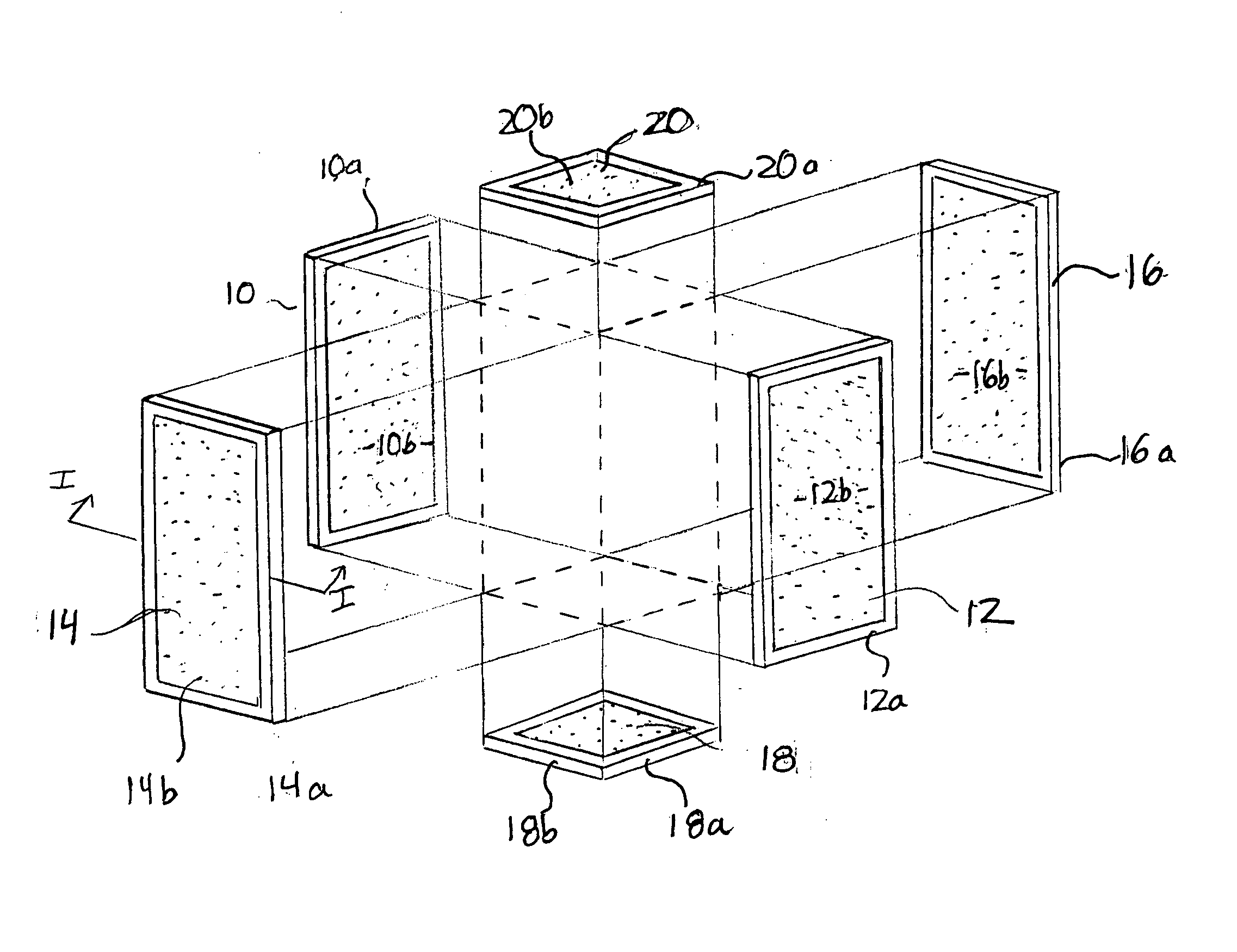

[0027] Referring to FIG. 1, a plurality of vertical interlocking flat panel / frame components 10, 12, 14 and 16 and horizontal interlocking flat panel / frame components 18 and 20 can be assembled to form an interlocking flat panel / frame unit according to the present invention. It should be appreciated that a variety of multi-sided or rectangular / square units can be assembled according to the present invention, with the specific shapes and sizes of the units being dictated by industry or customer requirements.

[0028] As shown in FIGS. 2a-2c, each vertical or horizontal component comprises an interlocking frame 12a, 18a and an integral flat panel 12b, 18b respectively. The panels and frames can be made of a variety of material, such as, metals, plastics, etc. The choice of material is dependent upon the industry (ANSI / BIFMA) requirements, as well as customer requirements such as function, cost, price point, etc. The frames 12, 18 are a unitary-channel shaped construction as described fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| assembly time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com