Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Realize stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

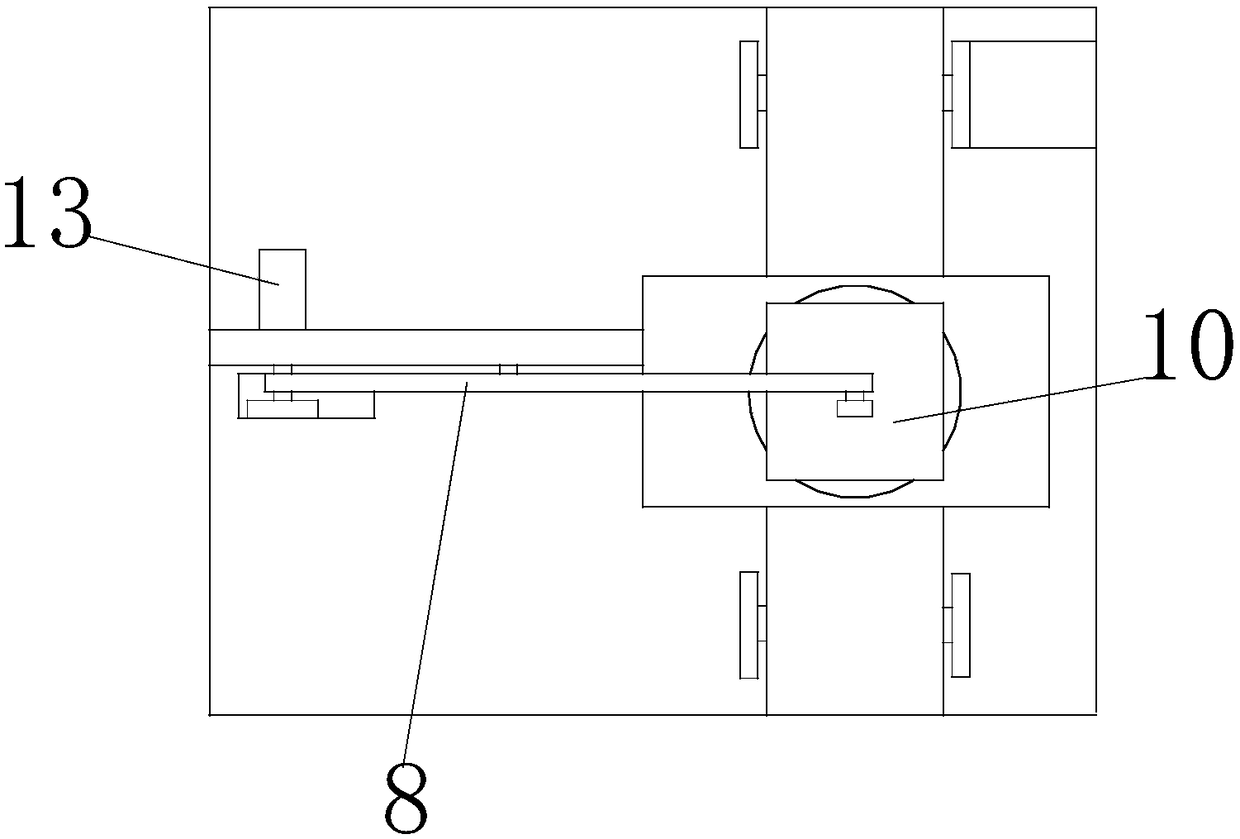

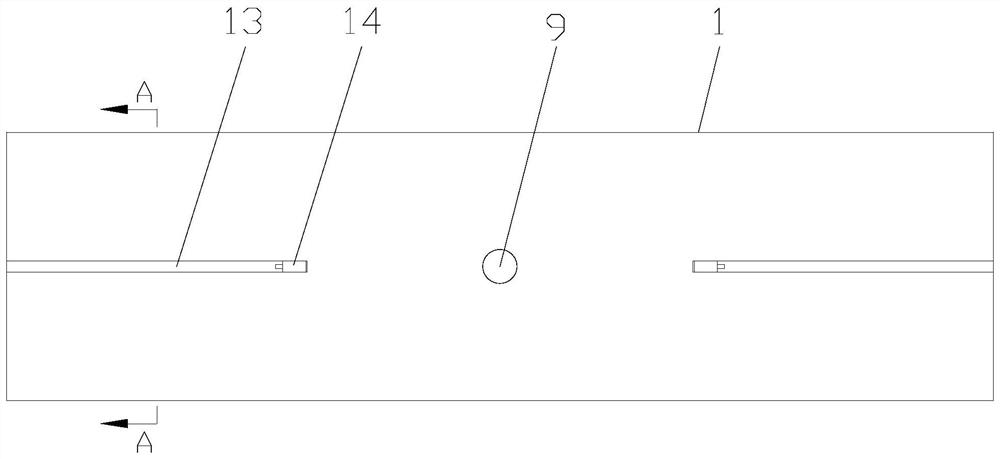

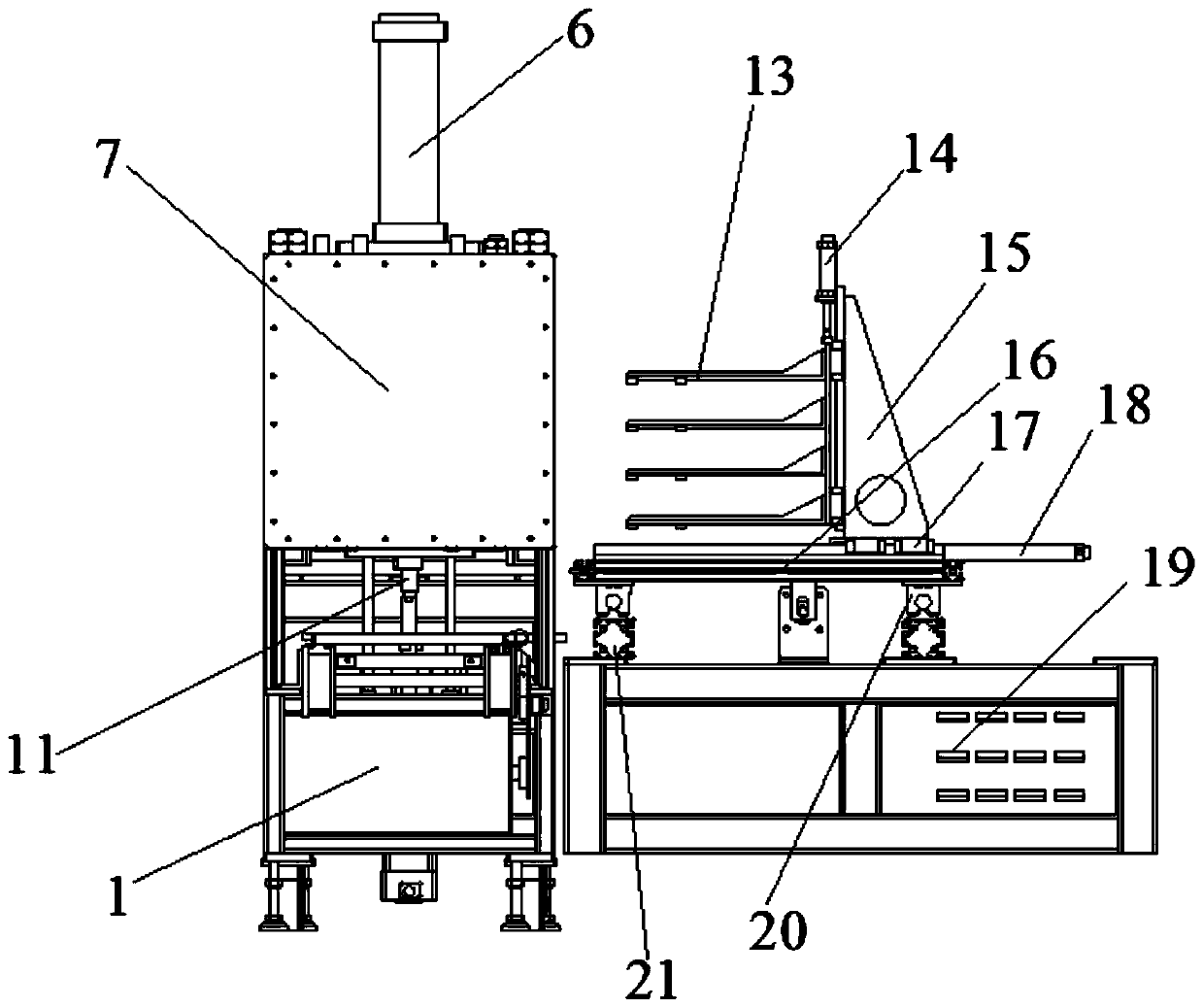

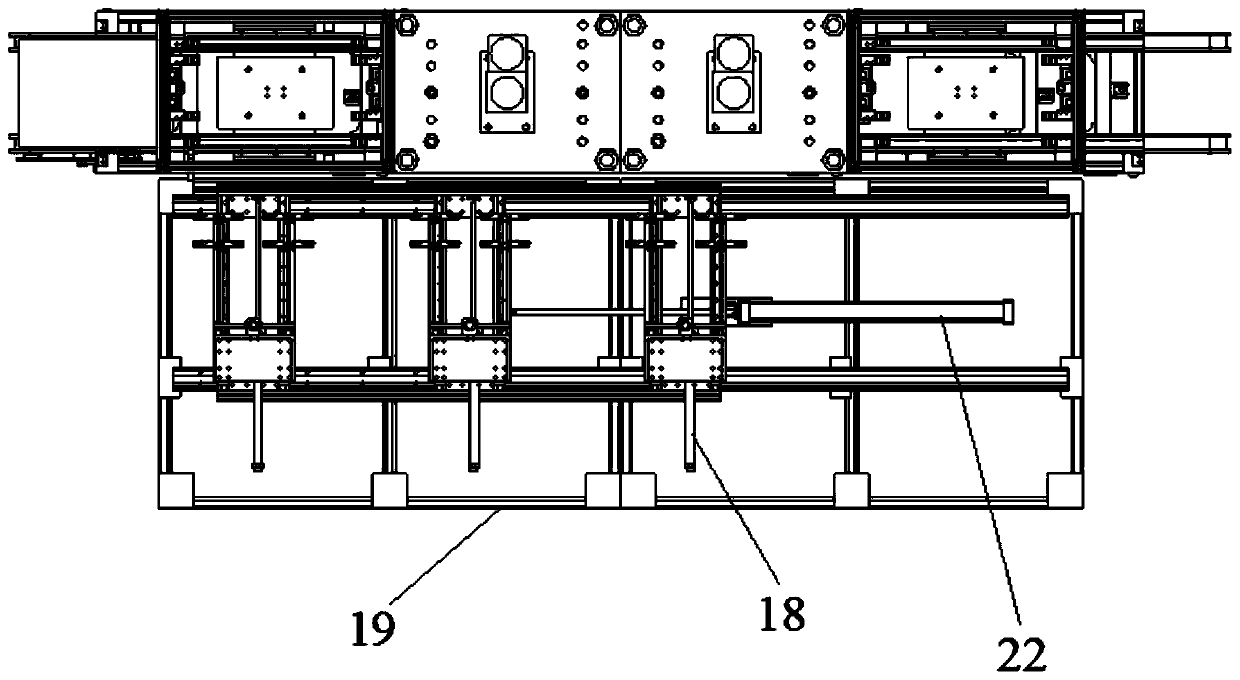

Automatic feeding device

InactiveCN102029330ARealize automatic feedingRealize stampingMetal-working feeding devicesPositioning devicesEngineeringUltimate tensile strength

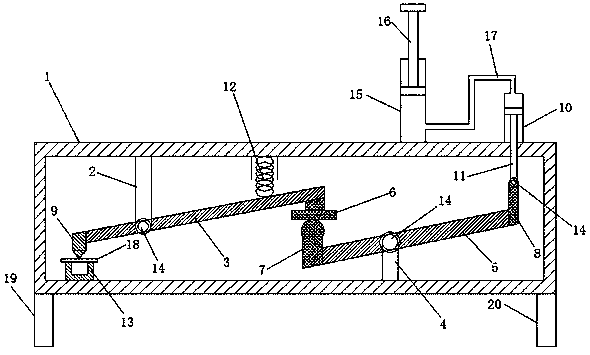

The invention relates to an automatic feeding device which comprises a base, a feeding box and a feeding cylinder, wherein the feeding box is vertically arranged on the upper surface of the base, a longitudinal feeding groove is arranged inside the feeding box, a horizontal channel communicated with the feeding groove is formed between the lower bottom surface of the feeding box and the base, the upper surface of the base at one side of the feeding box is provided with the feeding cylinder, the front end of the feeding cylinder is provided with a horizontal push plate moving in the horizontal channel of the feeding box, and the base at the other side of the feeding box is provided with a processing table. The automatic feeding device is a feeding machine with simple structure, simple operation and high automation, can realize automatic feeding and discharging, greatly improves the production efficiency, lowers the labor intensity of workers, and is suitable for being popularized and used in musical instrument industry or other industries.

Owner:TIANJIN JINBAO MUSICAL INSTR

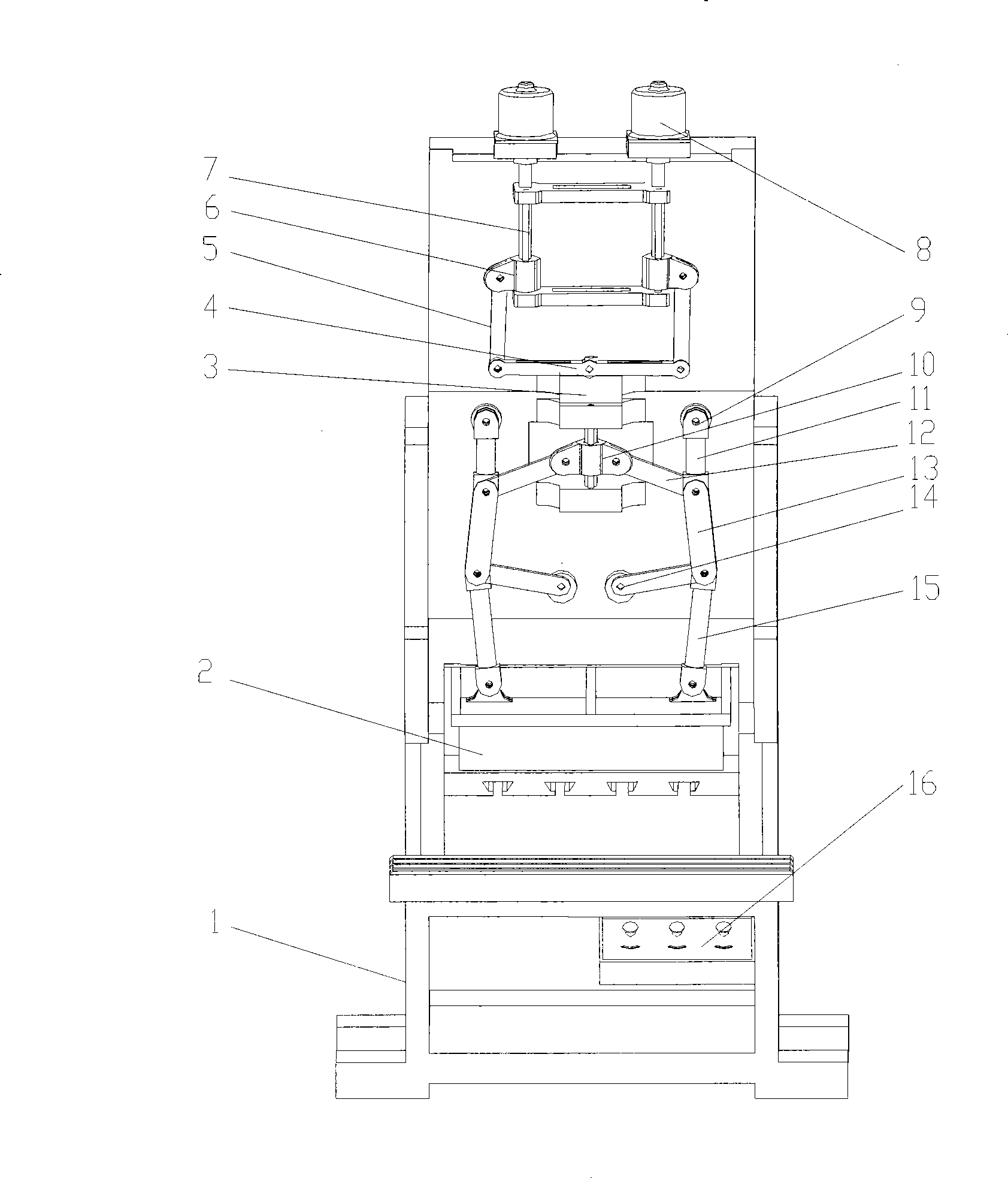

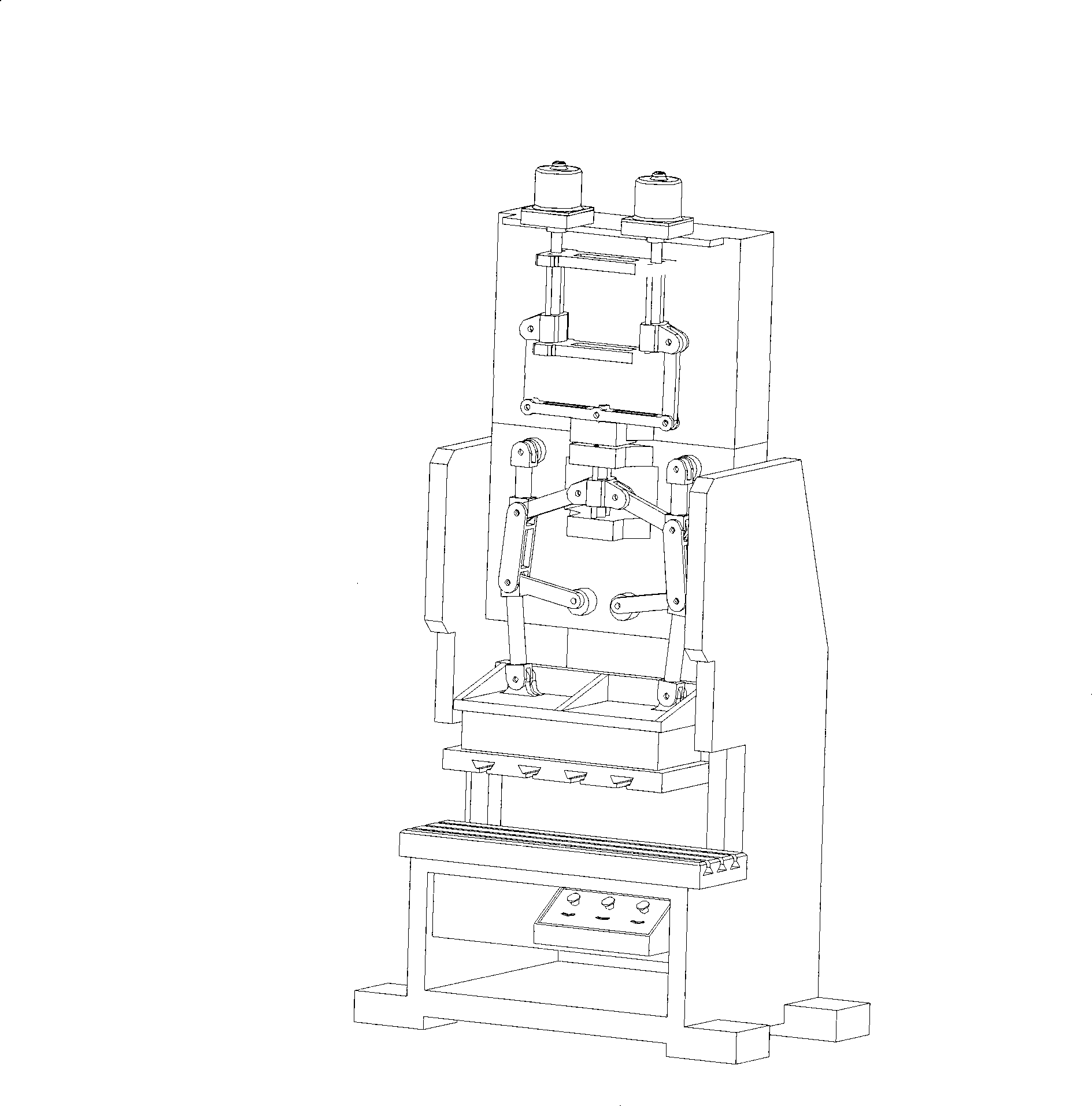

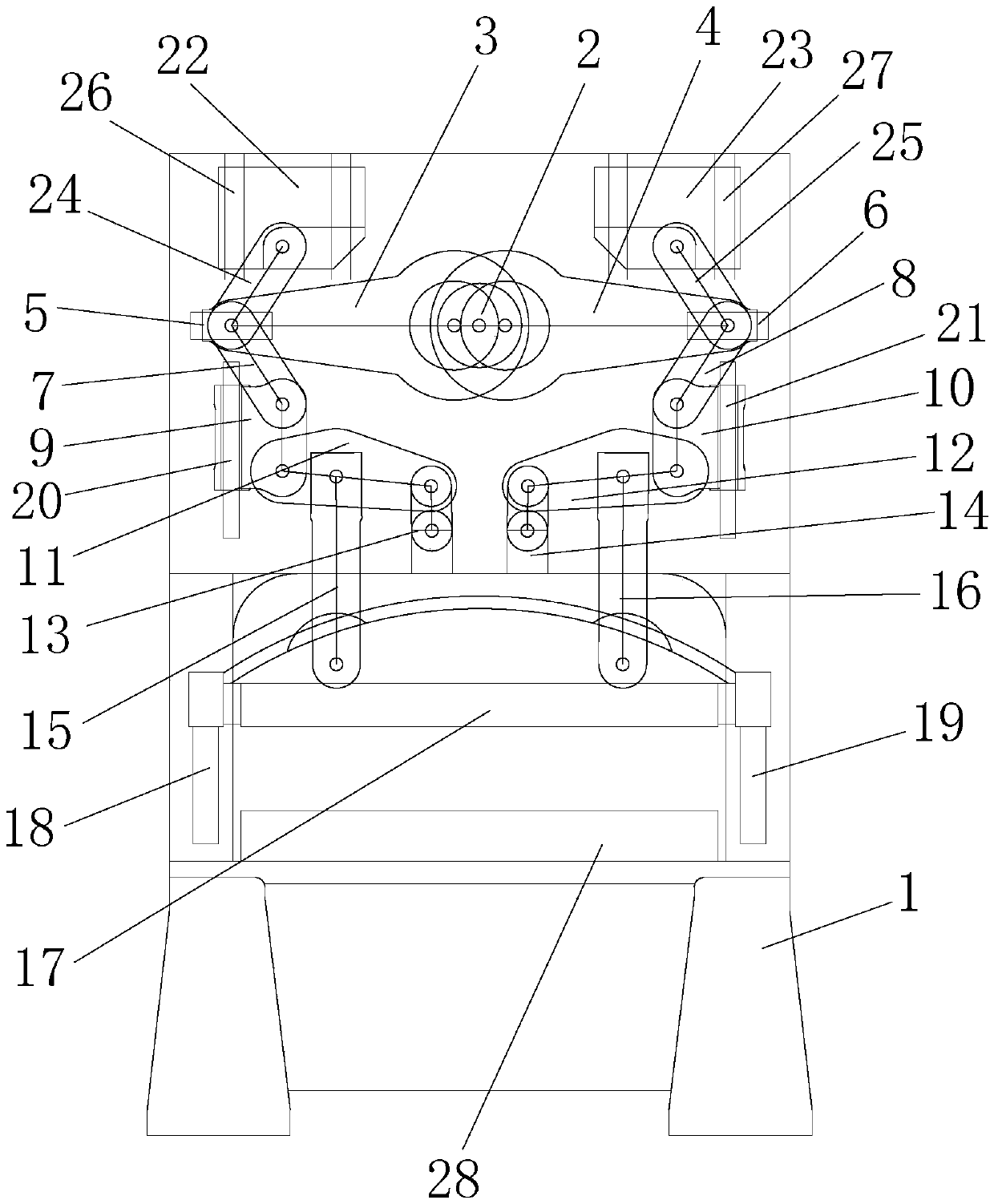

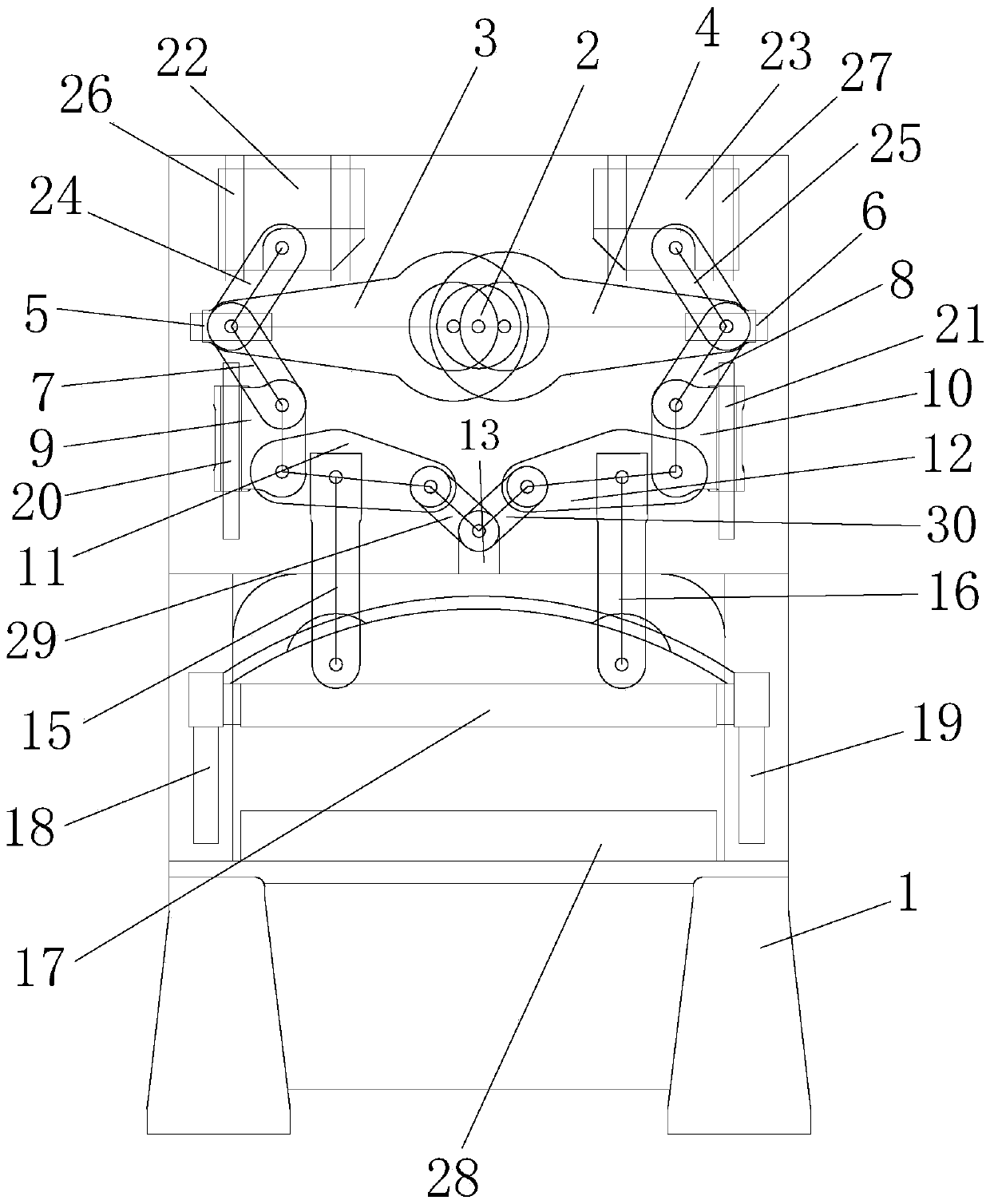

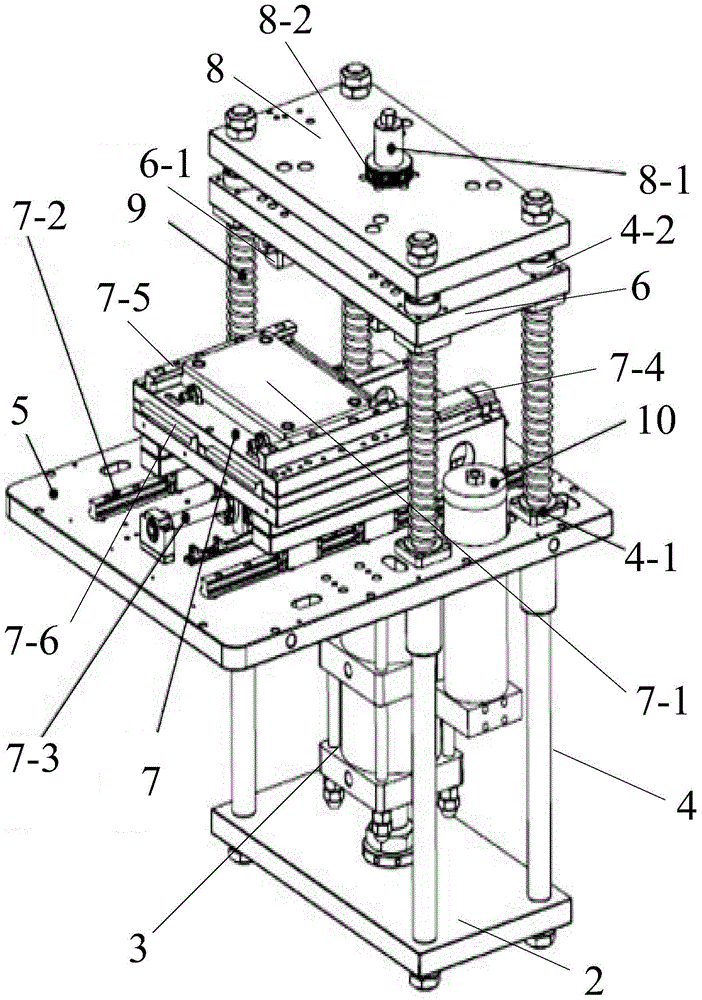

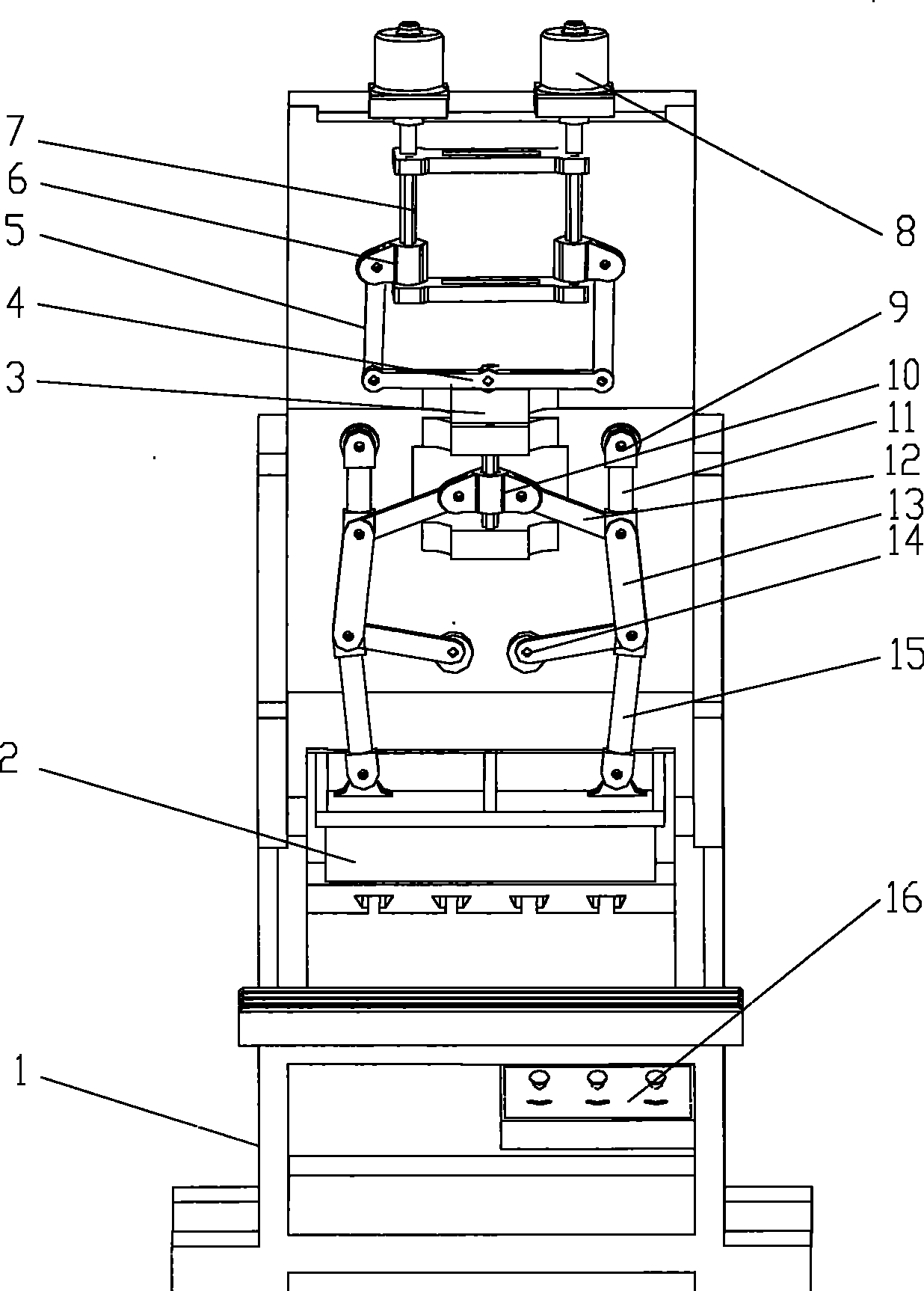

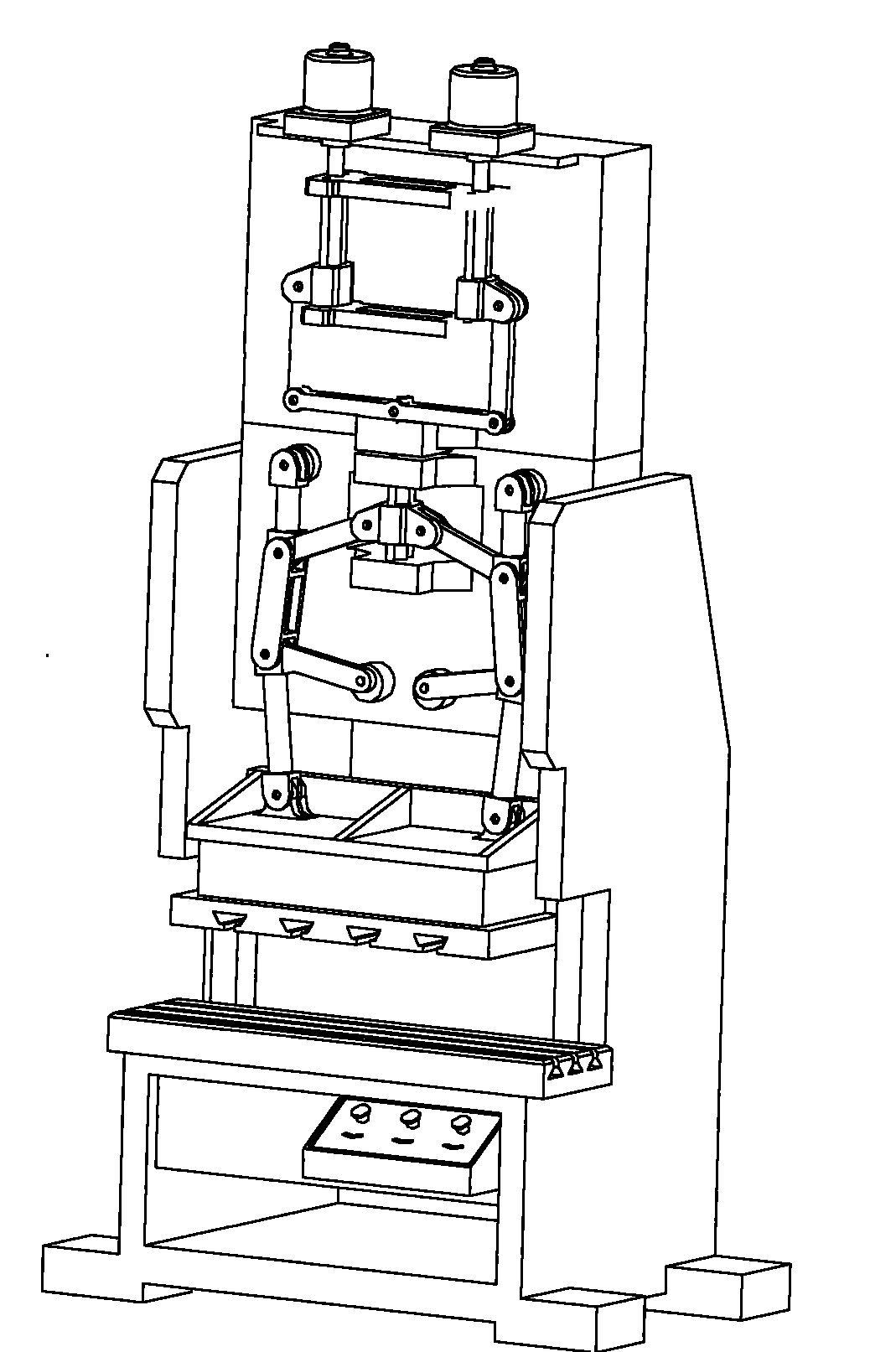

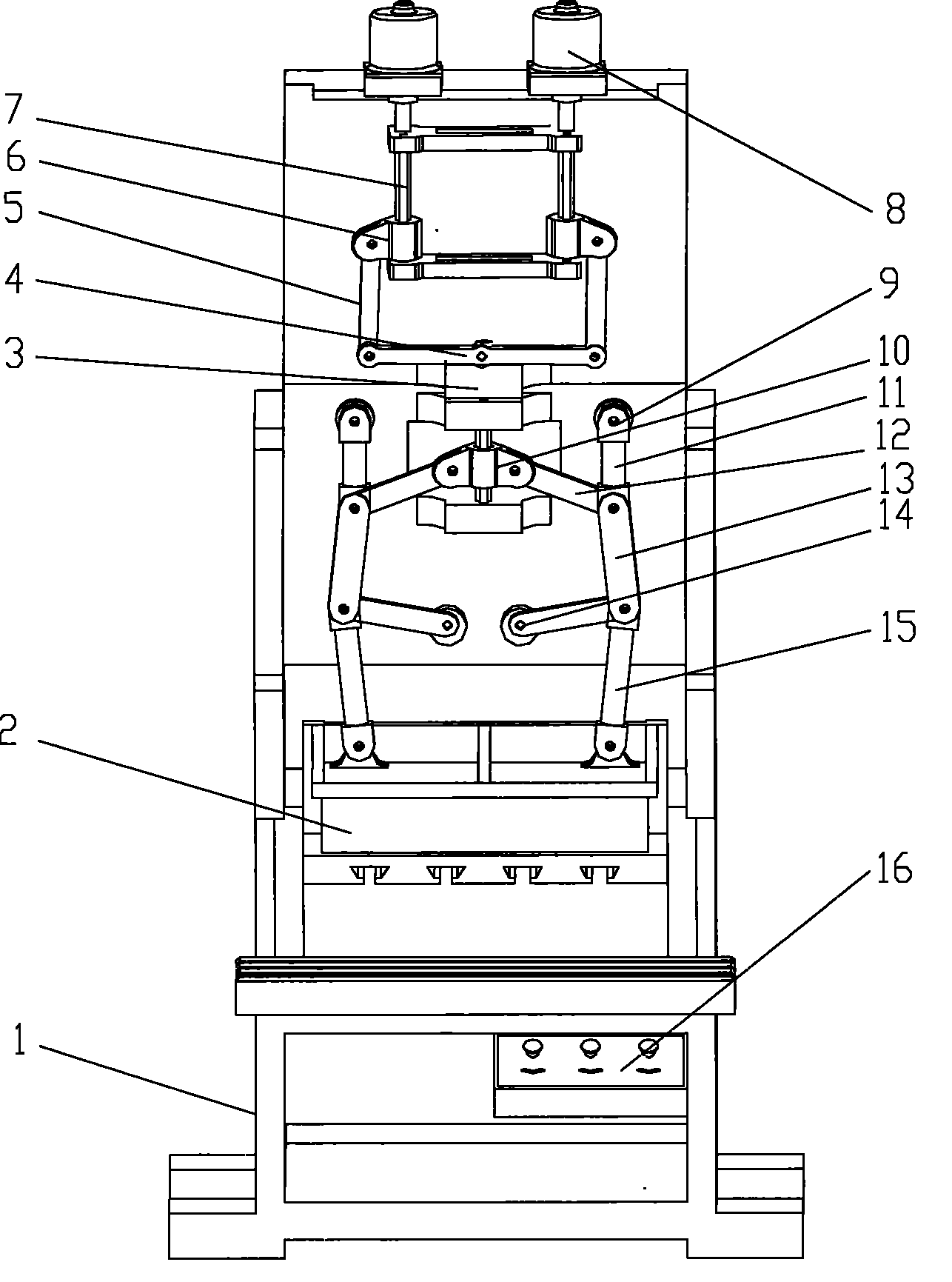

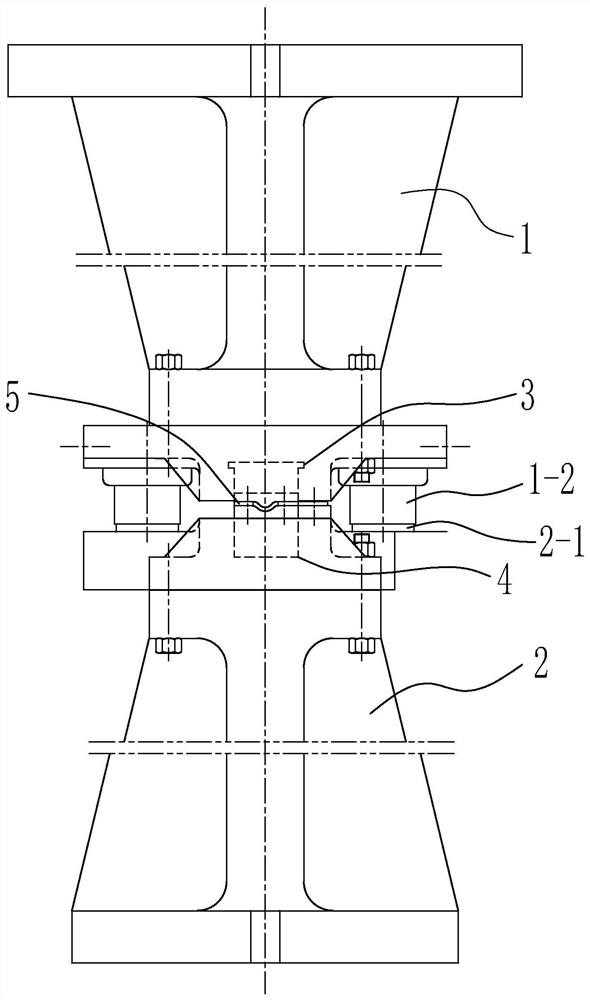

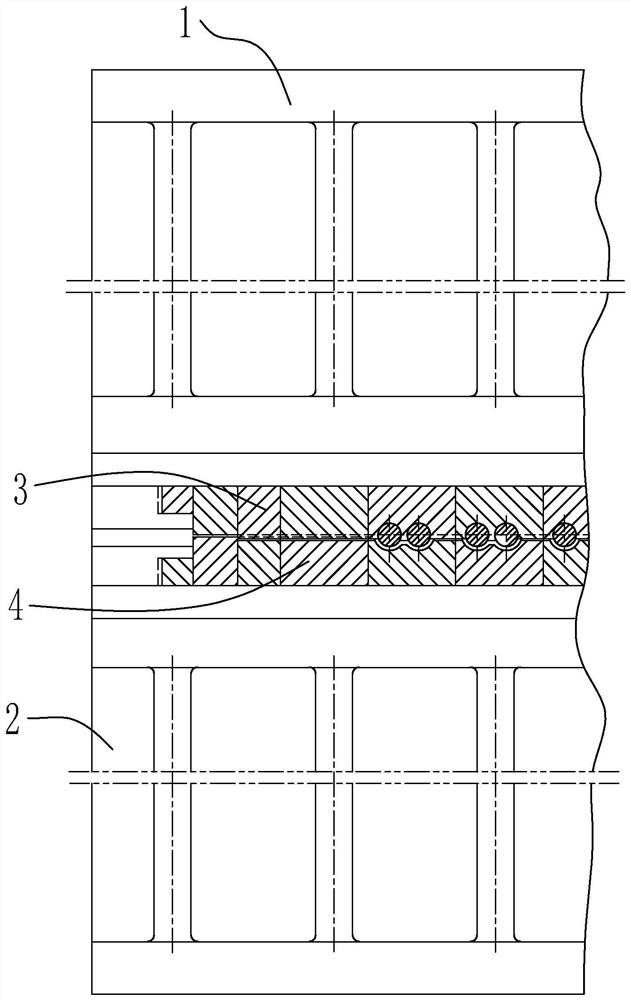

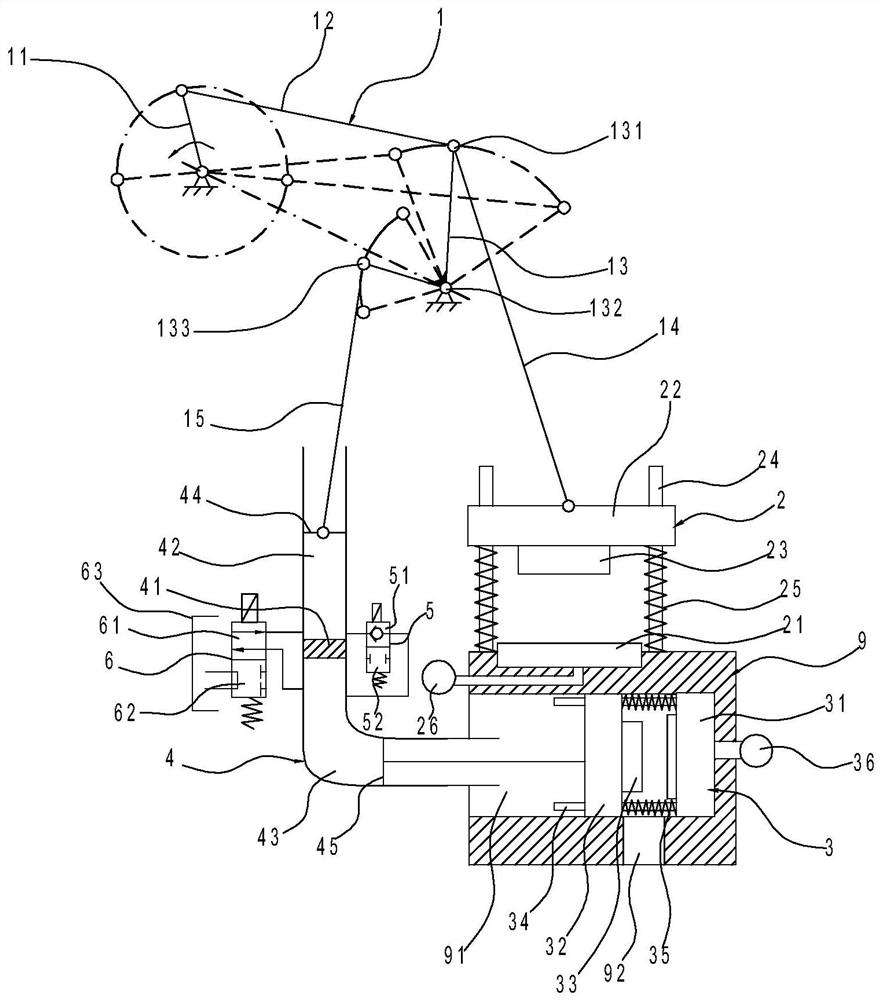

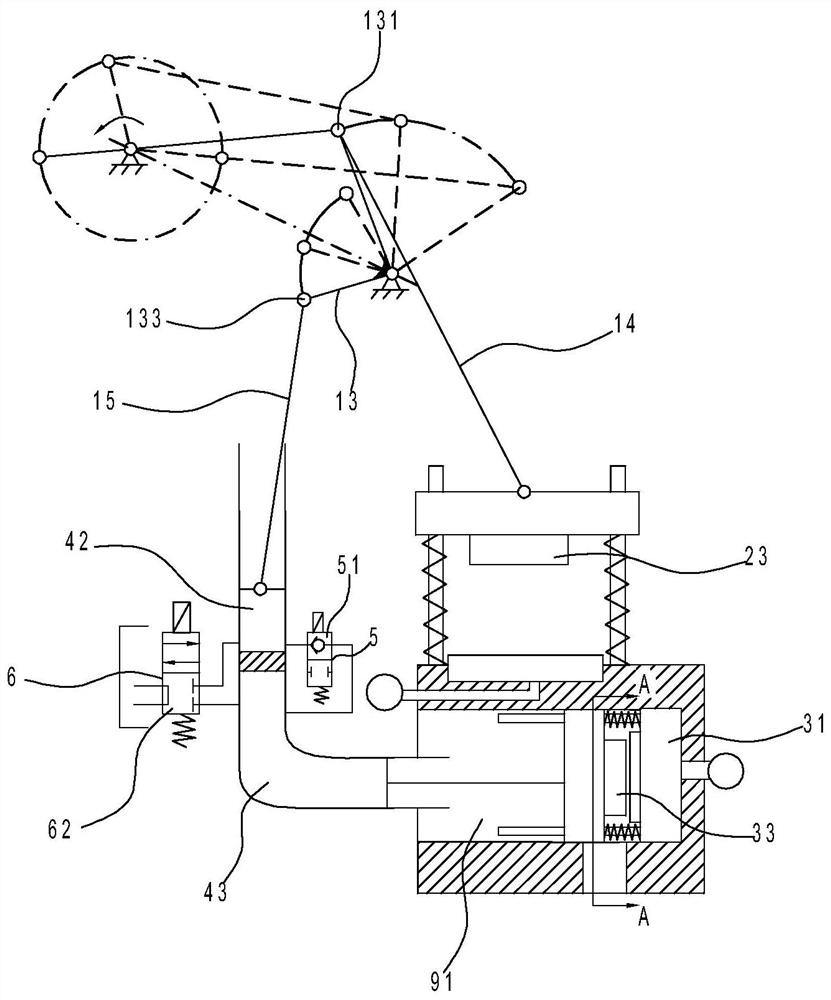

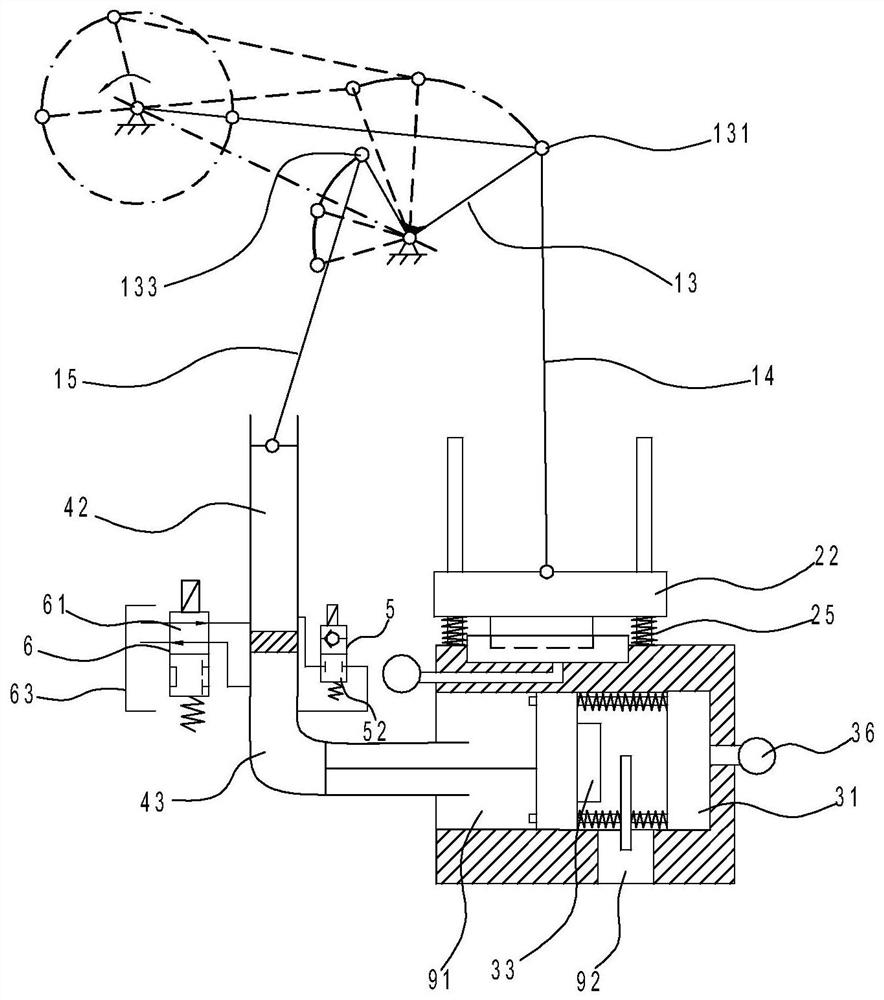

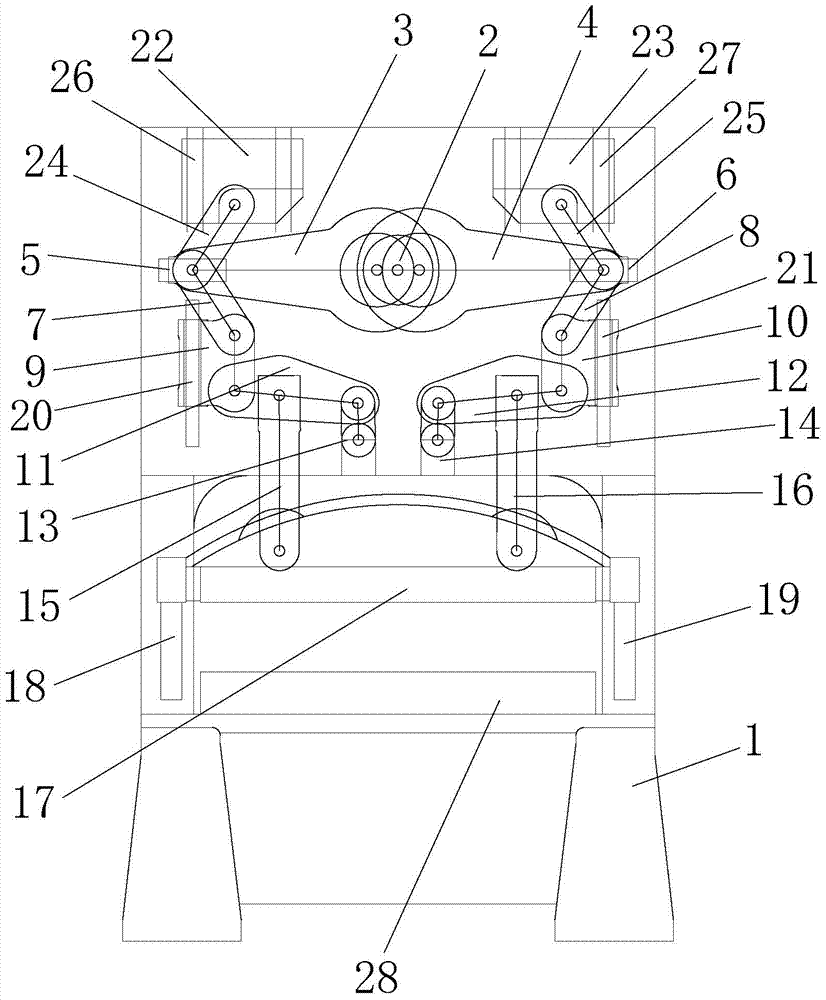

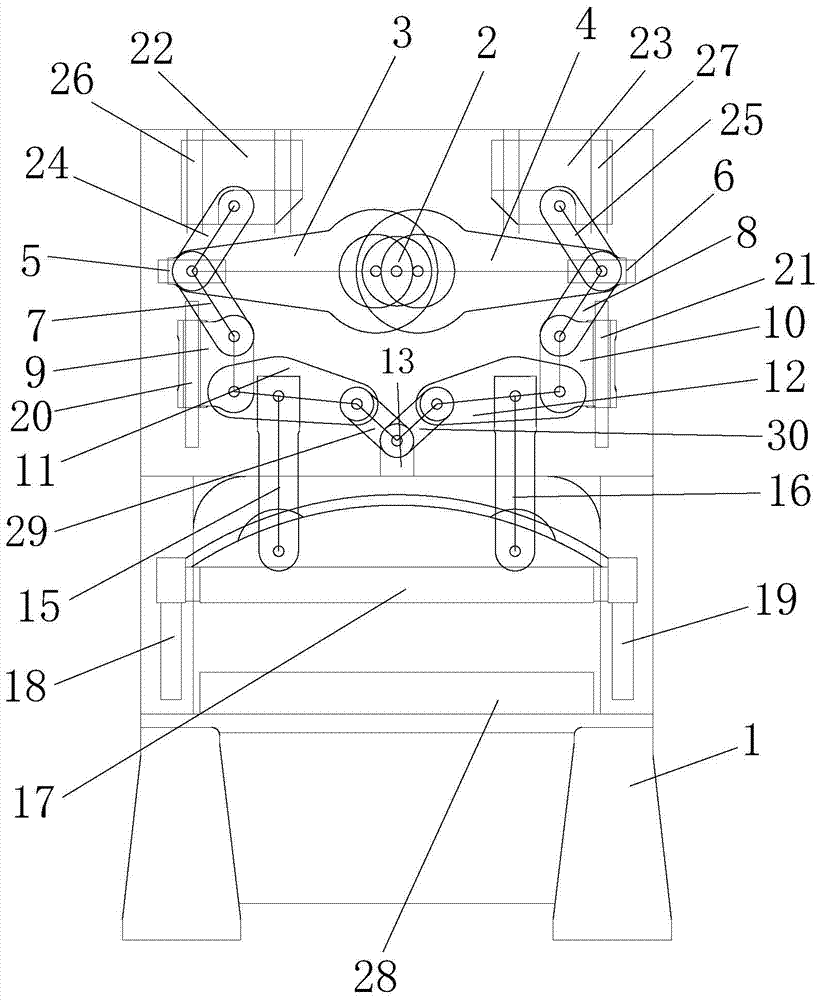

Double-motor mechanical coordination in-phase slider driven eight-bar servo pressure device

InactiveCN101396876AGuaranteed normal movementGuaranteed powerPress ramElectric machineryEngineering

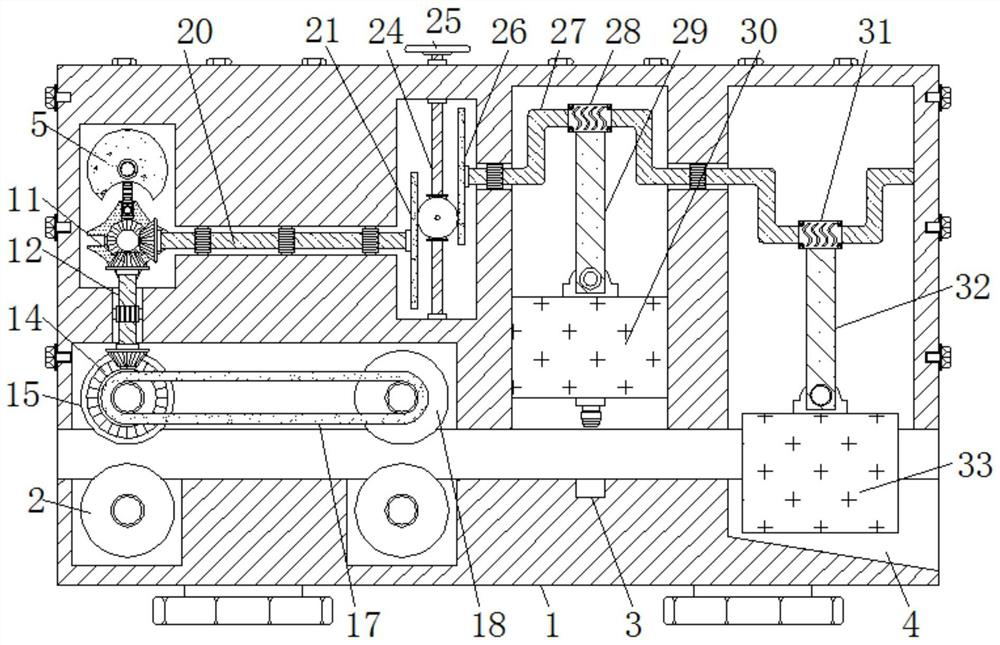

The invention relates to a key synchronizer driving eight-rod servo press coordinated with dual electric machinery. Two servomotors arranged symmetrically left and right are connected with a driving slide block by a key synchronizer driving mechanism coordinated with a set of dual electric machinery, and the driving sliding block is connected with a pressing slide block by two sets of eight-connecting bar pressing mechanism arranged symmetrically left and right. The key synchronizer driving mechanism coordinated with the dual electric machinery comprises a screw rod, a small connecting bar, a horizontal connecting bar and a sliding stand; each set of eight-connecting bar pressing mechanism comprises a short connecting bar, an upper elbow connecting bar, a lower elbow connecting bar and a punch connecting bar. The two servomotors can drive synchronously according to the set law of motion; the key synchronizer driving mechanism coordinated with the dual electric machinery can drive the driving slide block to move, and the driving slide block can push the pressing slide block to move by the two sets of eight-connecting bar pressing mechanism, therefore, the synthesis of the movement and the power of the two servomotors can be realized, and the large-tonnage ram pressure and movement are obtained, thus realizing the large-tonnage servo pressing with lower cost.

Owner:SHANGHAI JIAO TONG UNIV

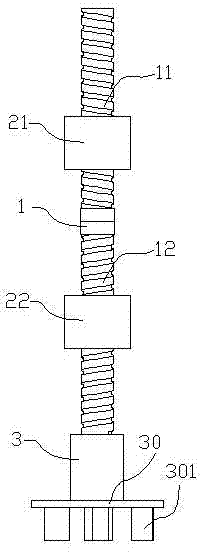

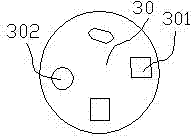

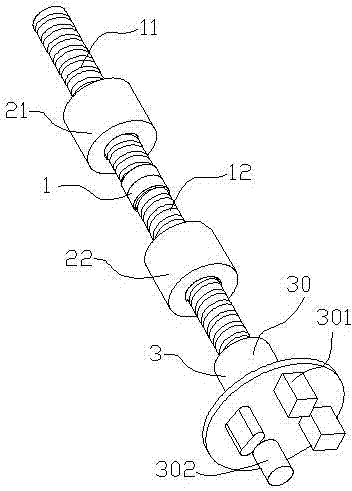

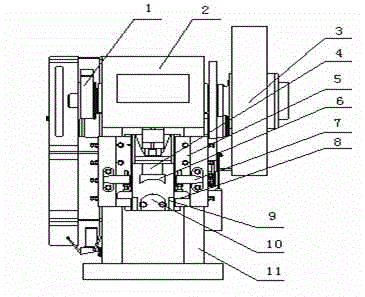

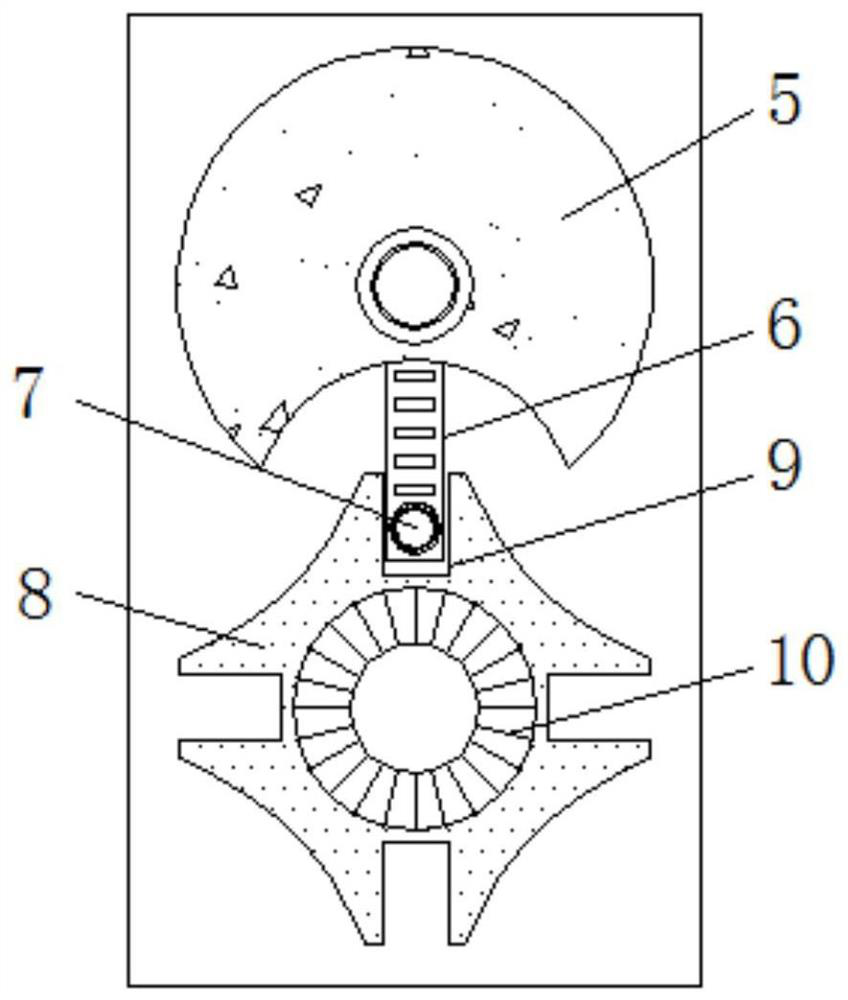

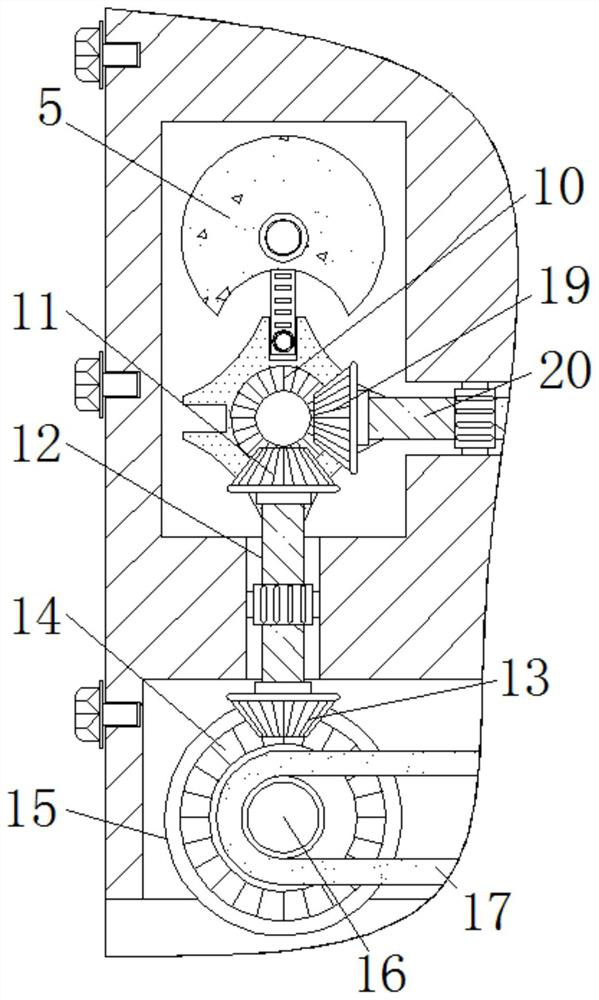

Servo main transmission device for novel numerical control turret punch press

InactiveCN102358060ARealize the function of changing positionsRealize stamping processing functionPress ramDynamic balanceDrive motor

The invention discloses a servo main transmission device for a novel numerical control turret punch press, and relates to a punch press, in particular to a multi-die head numerical control machining punch press. The servo main transmission device can adapt to production enterprises of various large scales, has high control precision, high capacity ratio and high station number expansion flexibility. The punch press comprises a controller, a machine body and a punching head, wherein the punching head is connected with the machine body through a positive-negative screw drive mechanism; the positive-negative screw drive mechanism comprises a screw, a first nut, a second nut, a first drive motor and a second drive motor, wherein the screw is provided with a positive thread and a negative thread; the first nut and the second nut are respectively connected with the positive thread and the negative thread movably; the first drive motor and the second drive motor drive the first nut and the second nut to perform forward and reverse rotation; the punching head is fixed to the bottom end of the screw; the first nut and the second nut are connected with the machine body movably; only the rotation freedom degrees of the first nut and the second nut around the axes per se are remained; and the first drive motor and the second drive motor are respectively connected with the controller. In the servo main transmission device for the novel numerical control turret punch press, the structure is simple, a servo control ratio mechanism is simple and is easy to realize, the precision is high, the device has no eccentric inertia load, the problem about dynamic balance does not needs to be considered, the running is balance, and the vibration is small.

Owner:江苏扬力数控机床有限公司

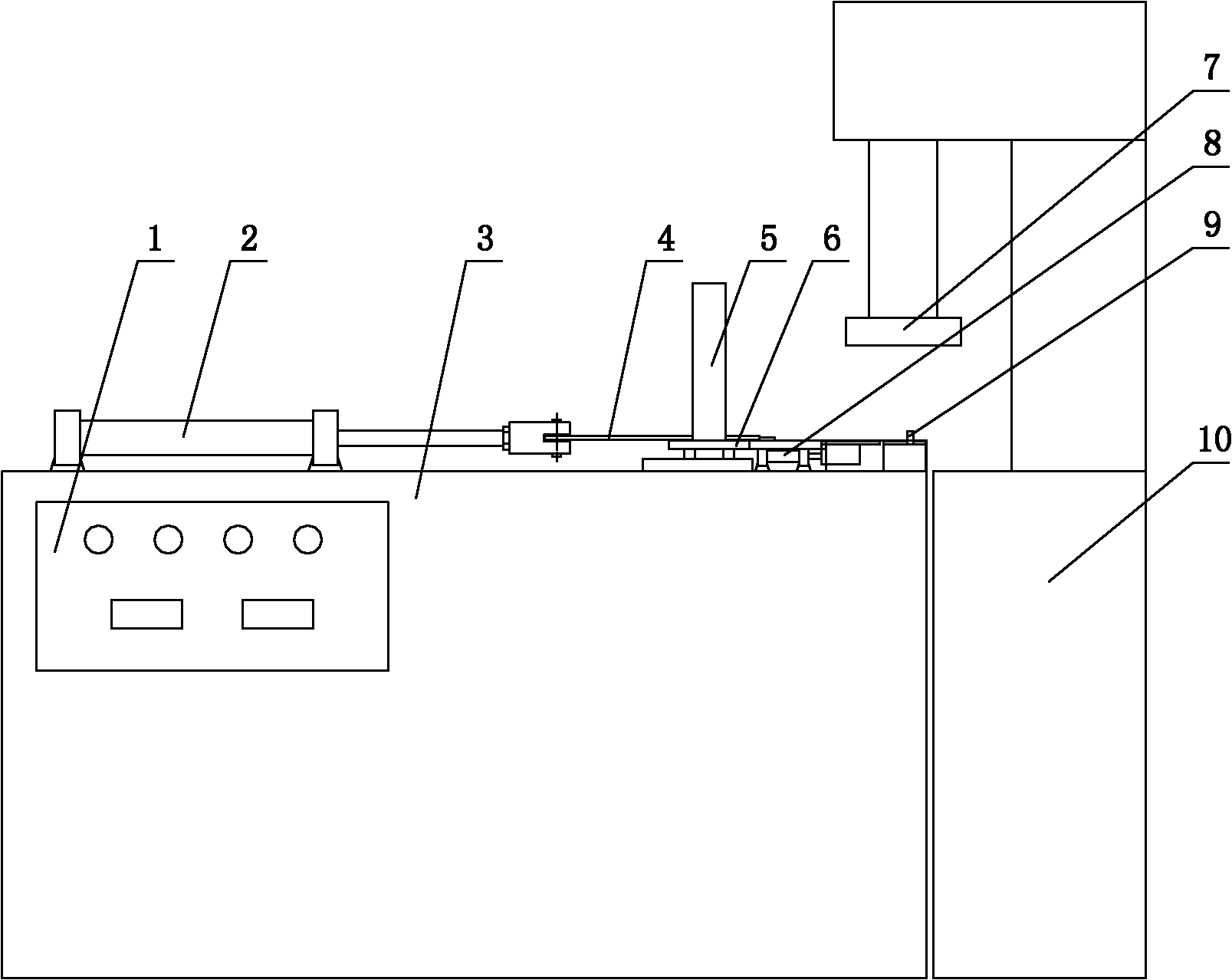

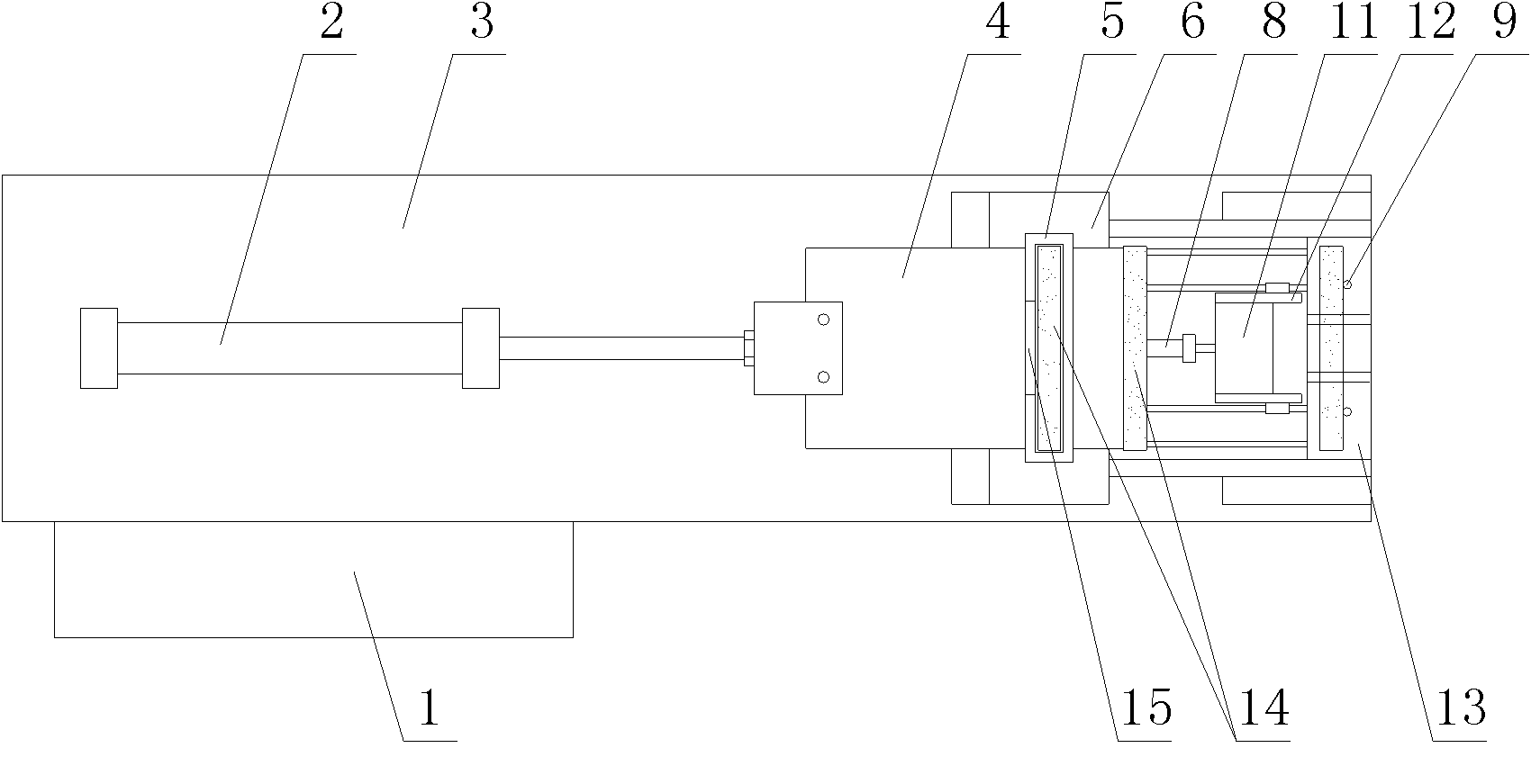

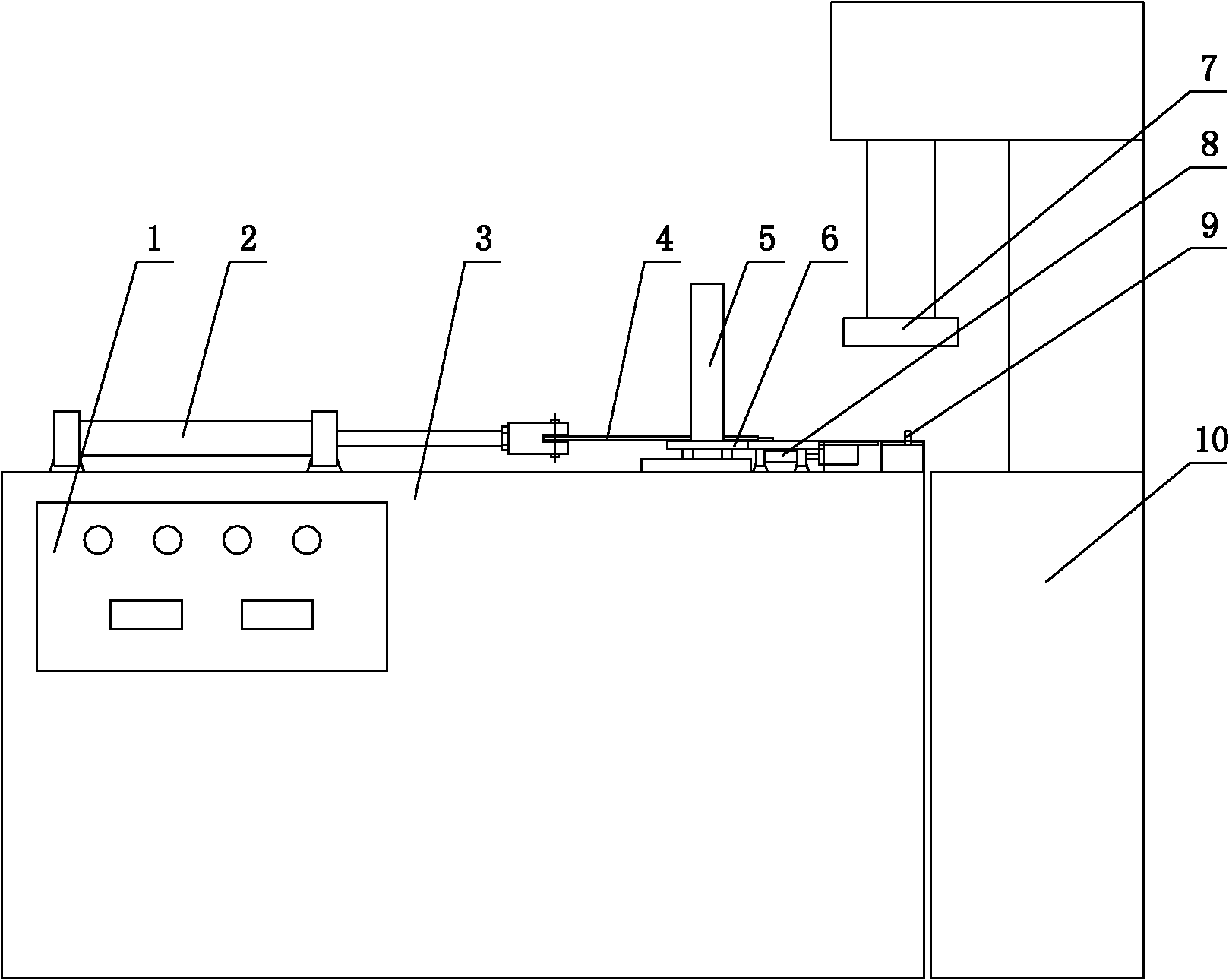

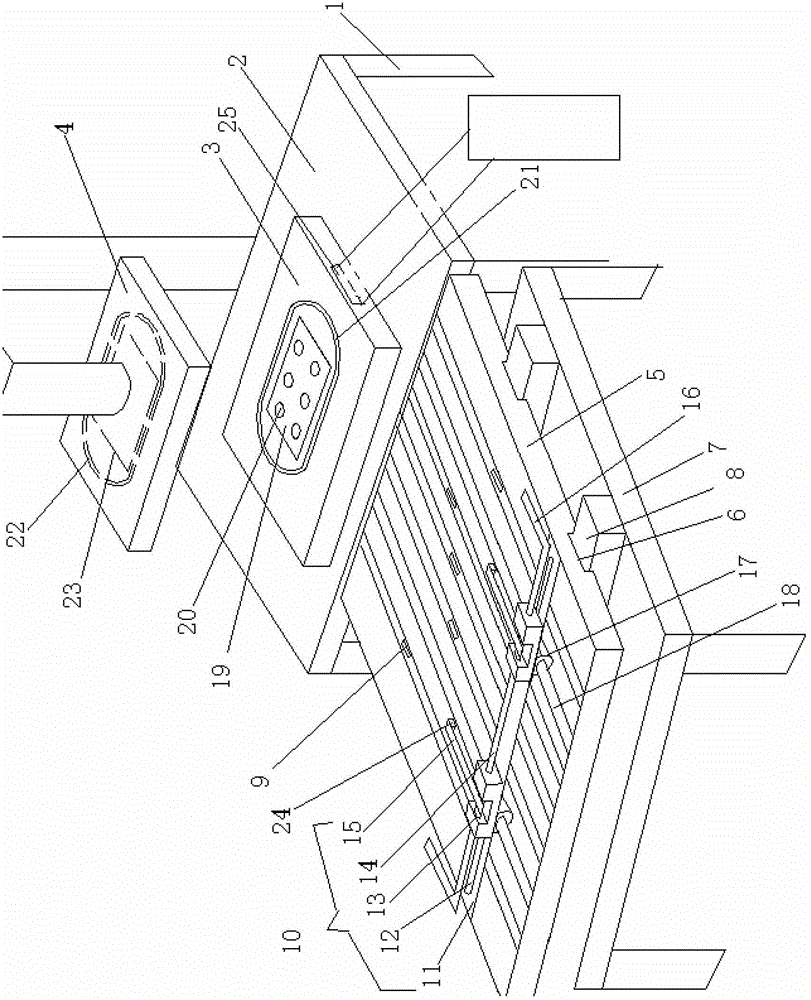

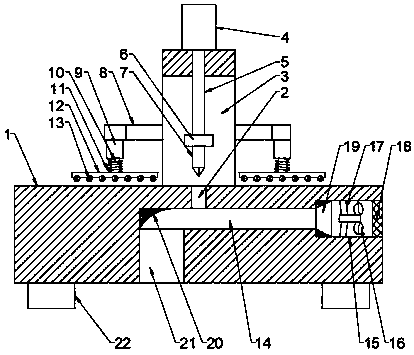

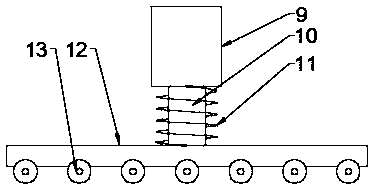

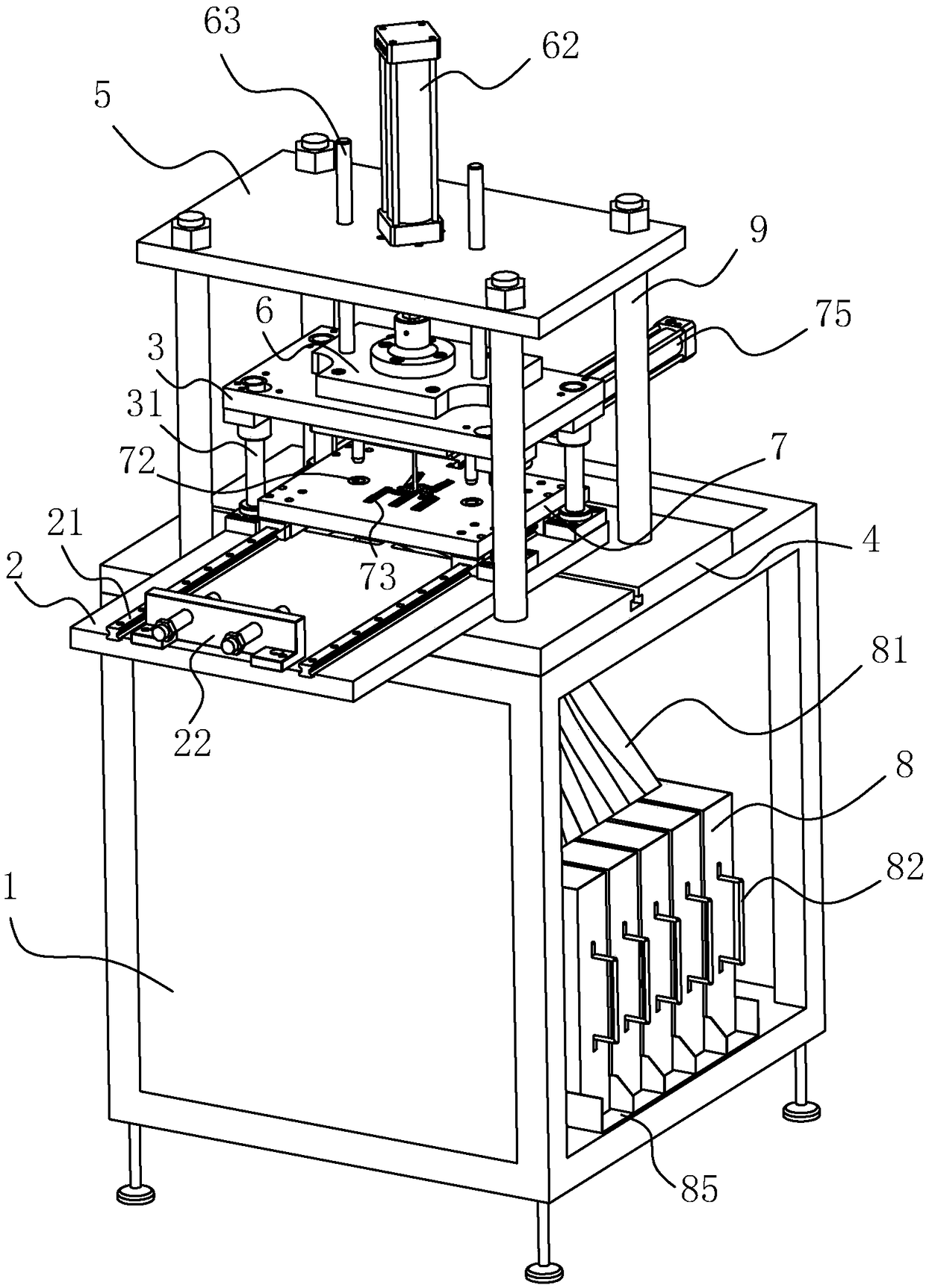

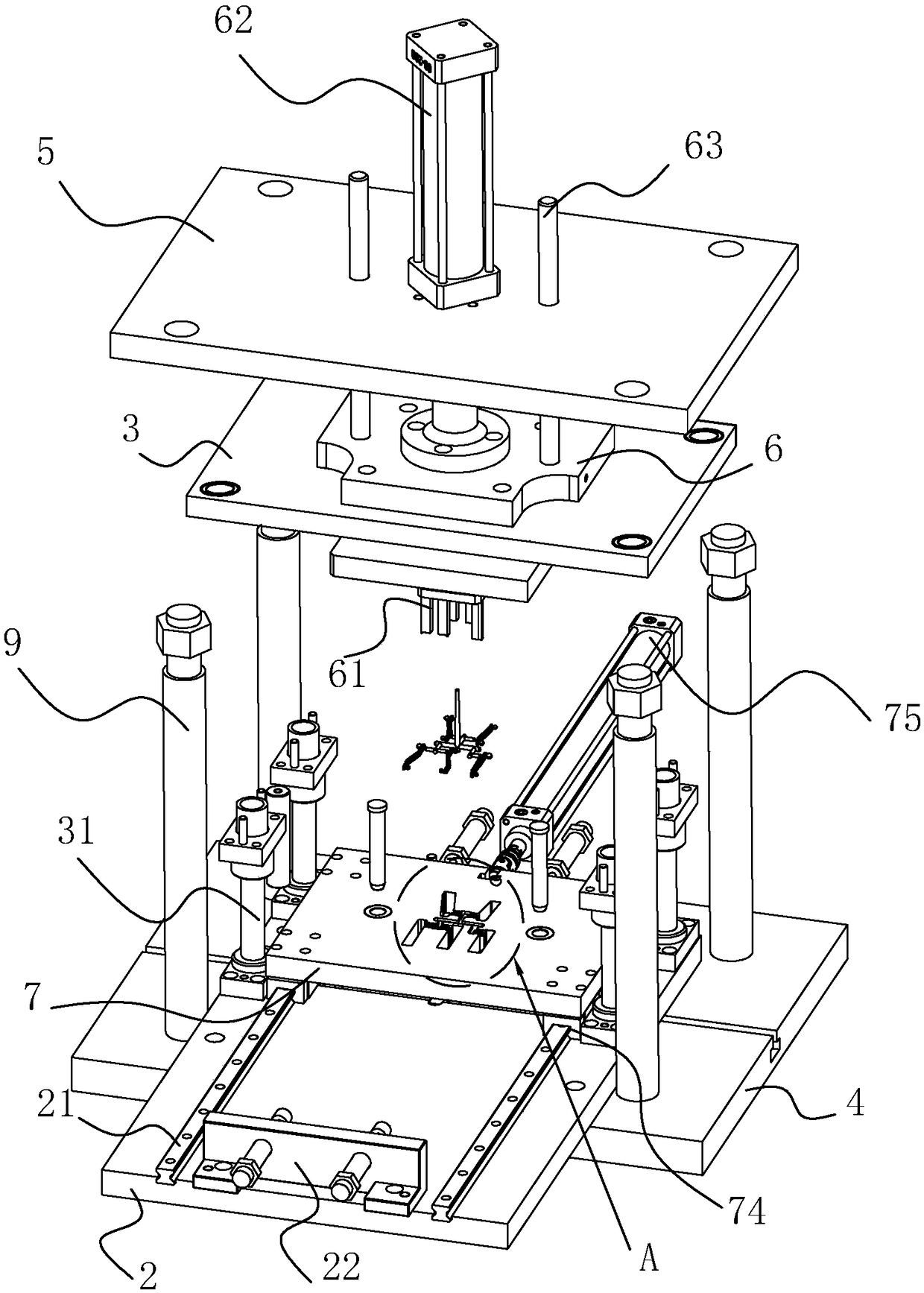

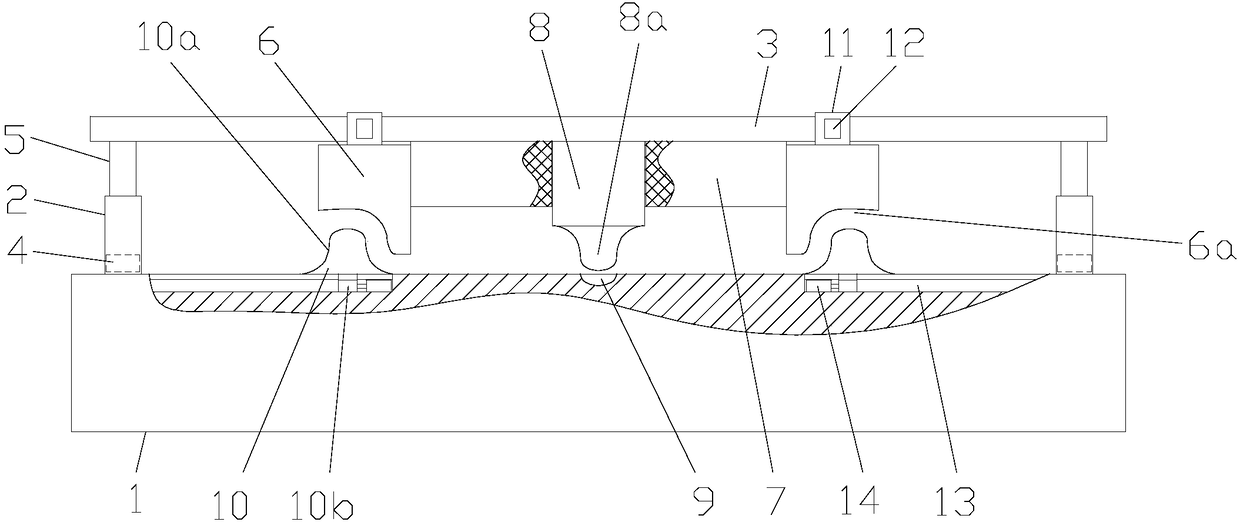

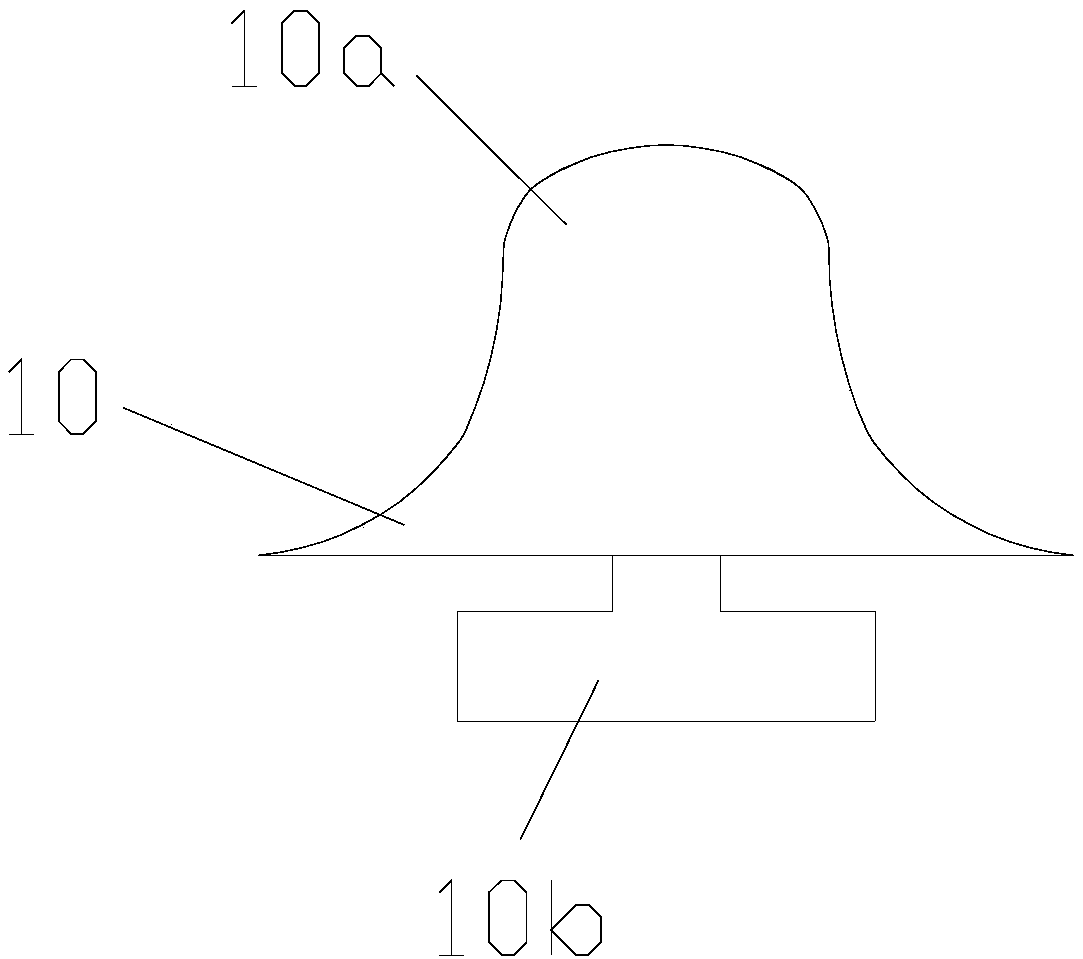

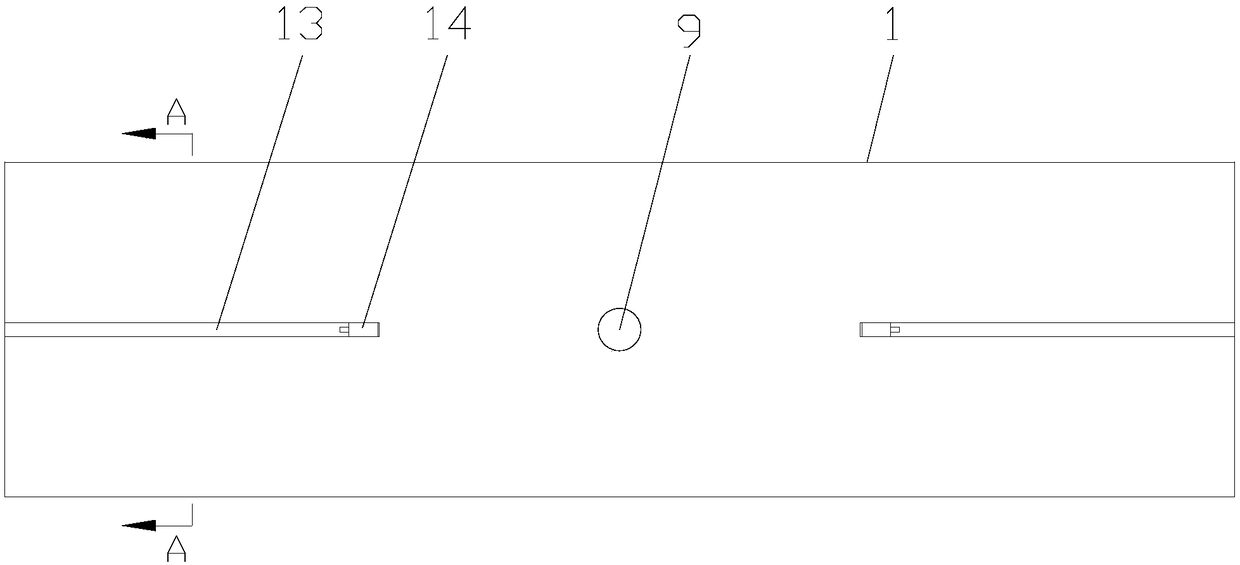

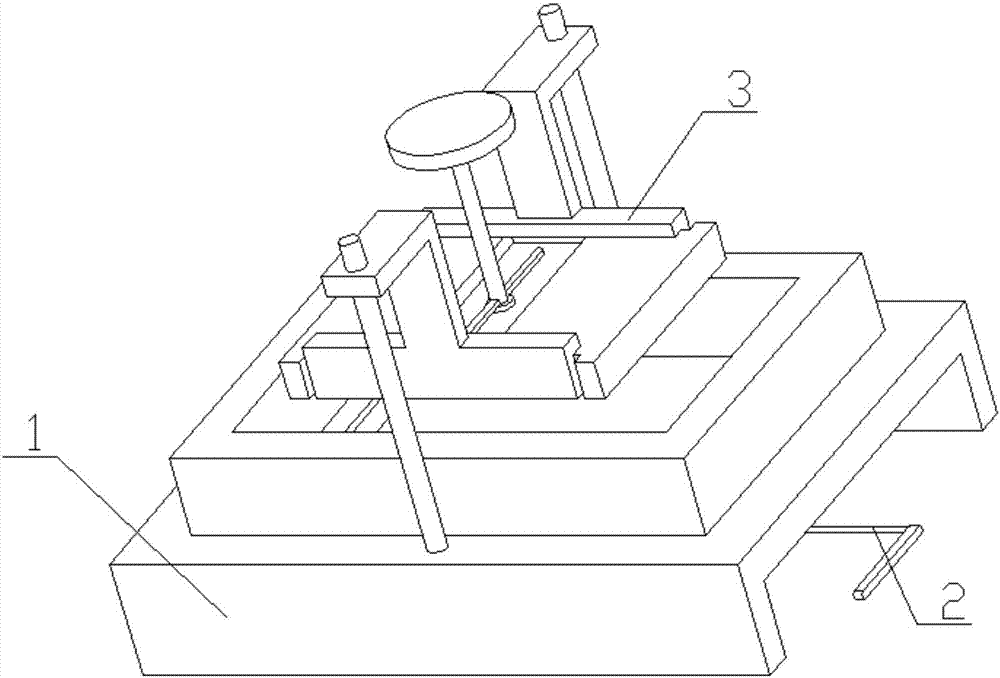

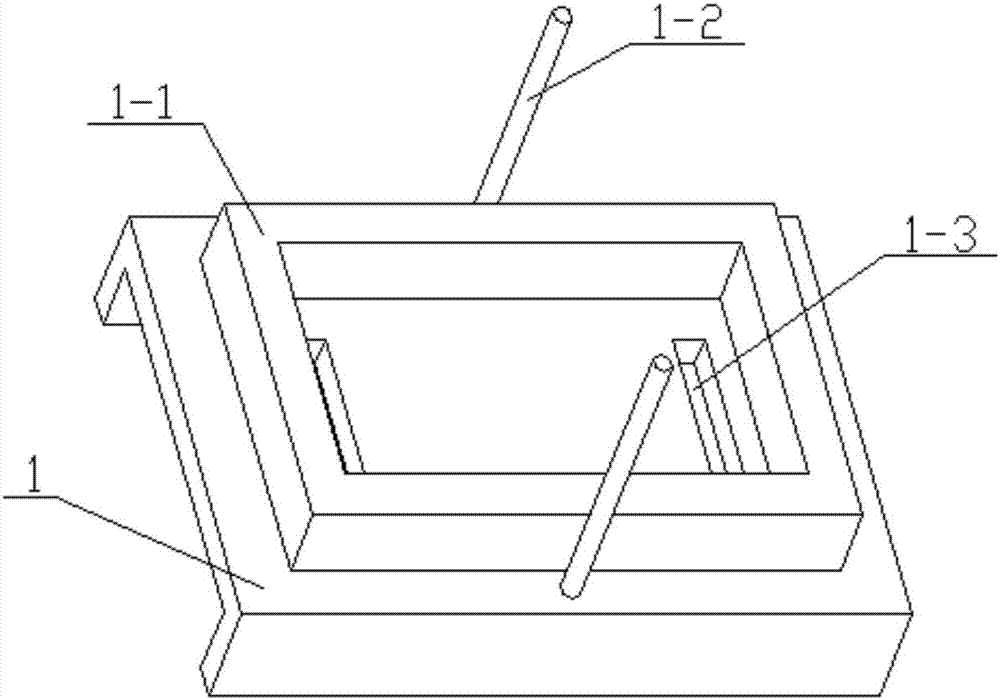

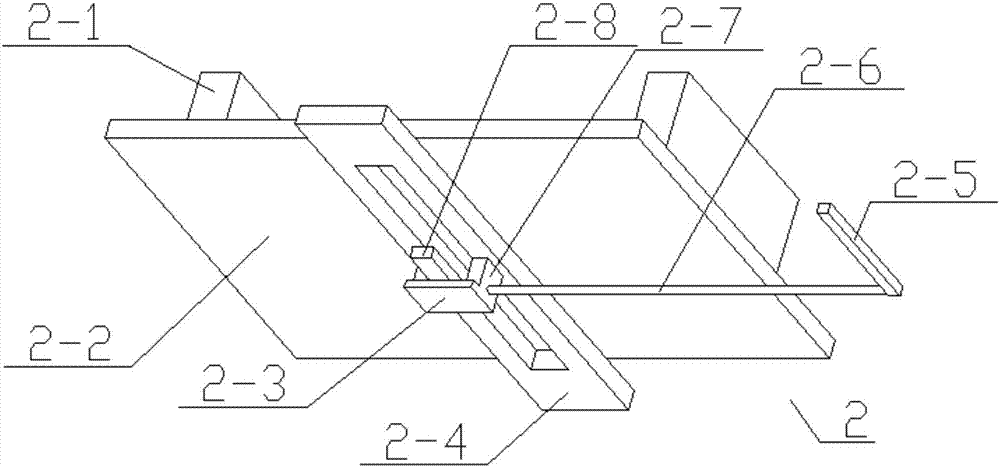

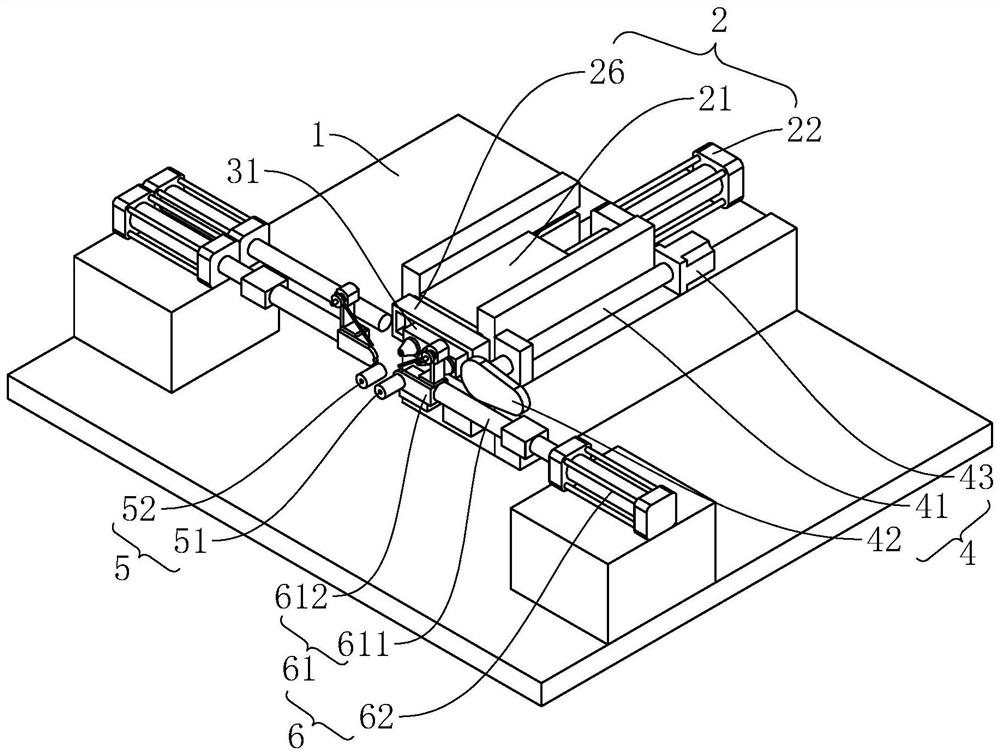

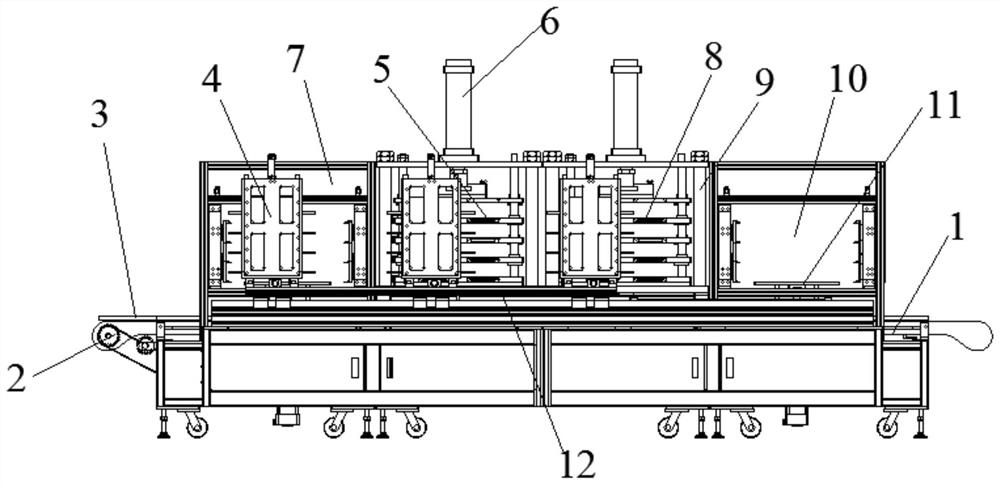

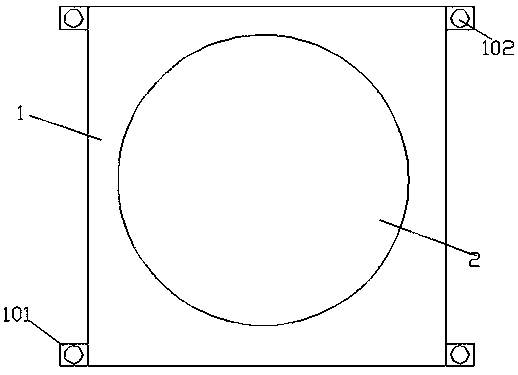

Automatic material feeding and discharging structure of punching machine for punching cover plate of iron wine box

InactiveCN102717000ARealize stampingReduce manual labor intensityMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention discloses an automatic material feeding and discharging structure of a punching machine for punching a cover plate of an iron wine box. The structure comprises a rack on which a working table is erected, wherein the working table is provided with a die holder and a punch, a material feeding frame is erected at the front end of the working table and is installed on a guide rail of a support through a guide slot, supporting cushion blocks are distributed on the material feeding frame, an overturning clamp support is arranged on the material feeding frame and comprises a fixed plate on which a fixed seat is installed through a regulating slot, a rotary shaft is rotatably installed on the fixed seat and is fixedly provided with a clamp plate, and the fixed plate is slidably installed on a guide rod through a guide sleeve; and a placing cavity is arranged in the middle of the die holder, air vents are distributed in the placing cavity, a die body outside the placing cavity is provided with an annular limit boss matched with an end cover, and magnetic sheets are fixedly arranged in a concave cavity at the inner side of an annular groove. According to the invention, all-around punching of plate materials is realized, during the punching process, the labor intensity is low, time and labor are saved, the working efficiency is improved, and meanwhile, waste materials are reduced according to the size of the plate materials.

Owner:ANHUI HONGYANG PACKAGING GRP

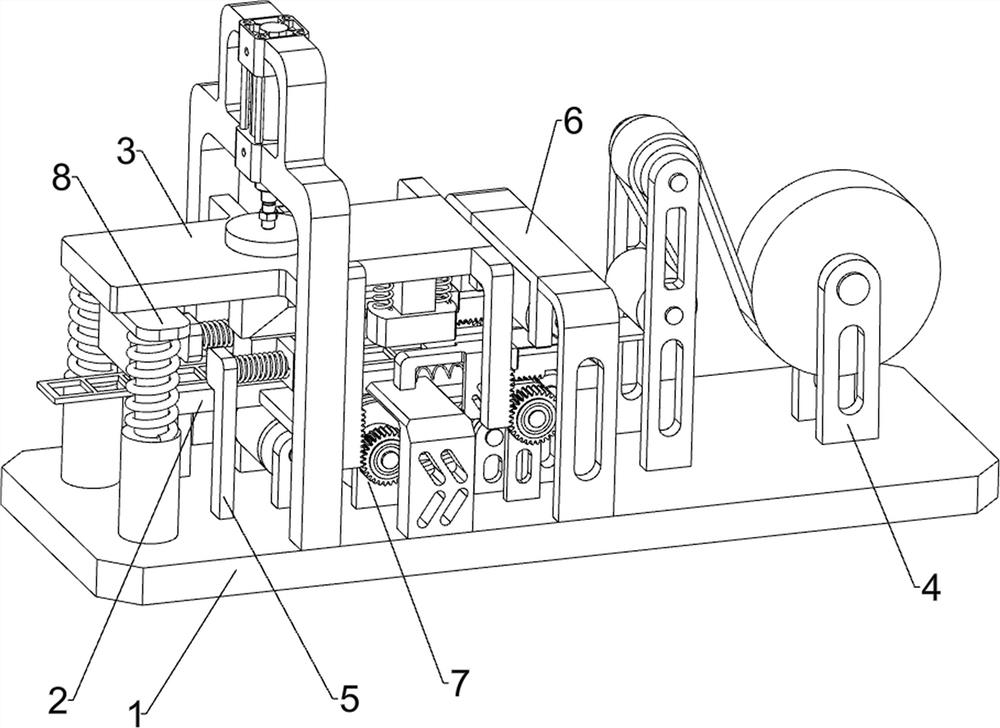

Square sheet stamping equipment for hardware

PendingCN112845773AAchieve placementRealize stampingMetal-working feeding devicesPositioning devicesEngineeringStructural engineering

The invention relates to stamping equipment, in particular to square sheet stamping equipment for hardware. According to the square sheet stamping equipment for the hardware, an iron sheet can be automatically pulled, the cut iron sheet can be automatically wound, and people can conveniently collect the square iron sheet. The square sheet stamping equipment for the hardware comprises a bottom plate, a stamping mechanism and a feeding mechanism, wherein a stamping platform is arranged on the bottom plate, the stamping mechanism is arranged on the bottom plate, and the feeding mechanism is arranged on the bottom plate. According to the equipment, the iron sheet is placed through the feeding mechanism, then the iron sheet is stamped in combination with the stamping mechanism, and therefore the square iron sheet is efficiently manufactured; and through cooperation between a material pulling mechanism and the stamping mechanism, the iron sheet is automatically pulled leftwards, and in this way, the iron sheet does not need to be pulled manually.

Owner:舒李兰

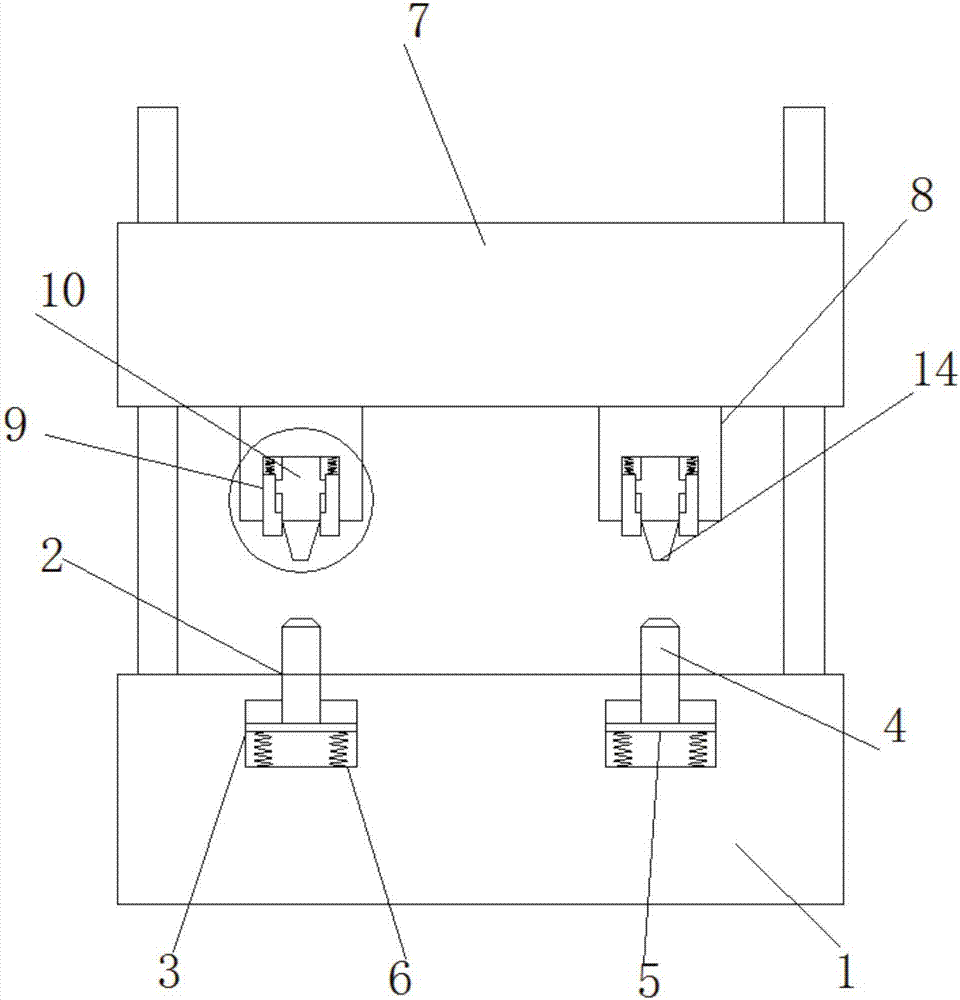

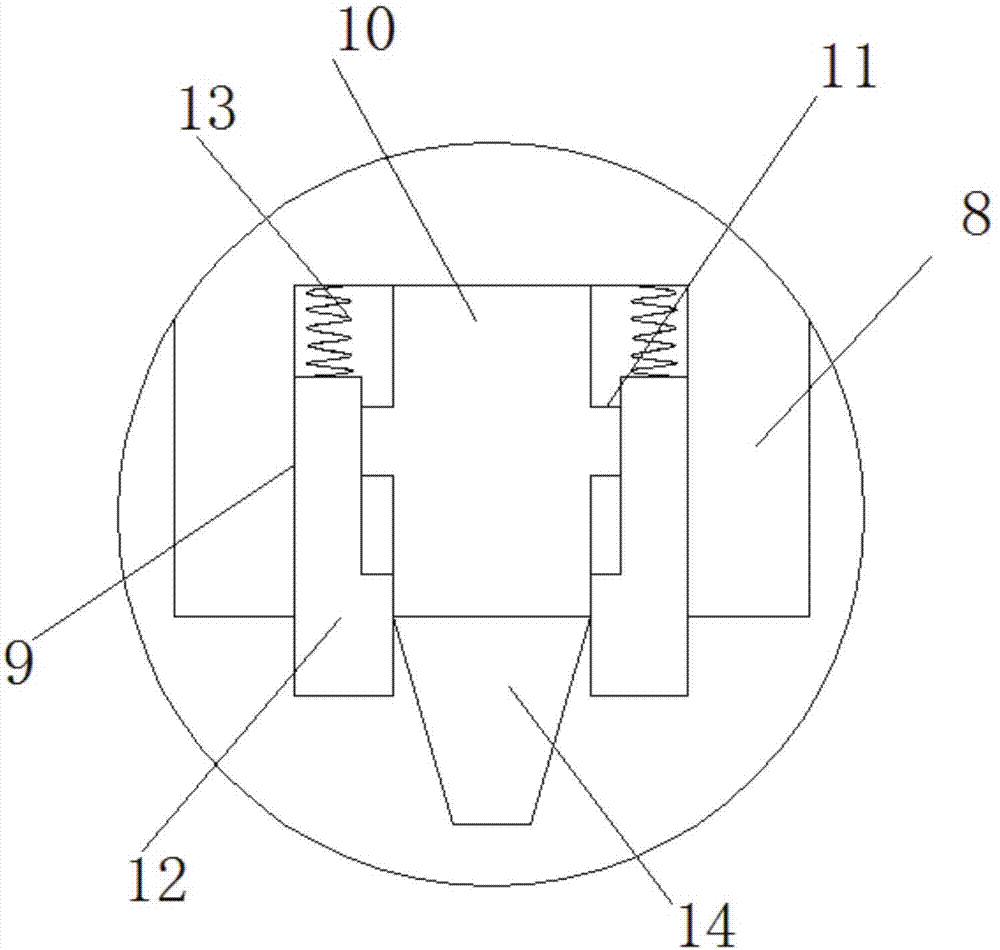

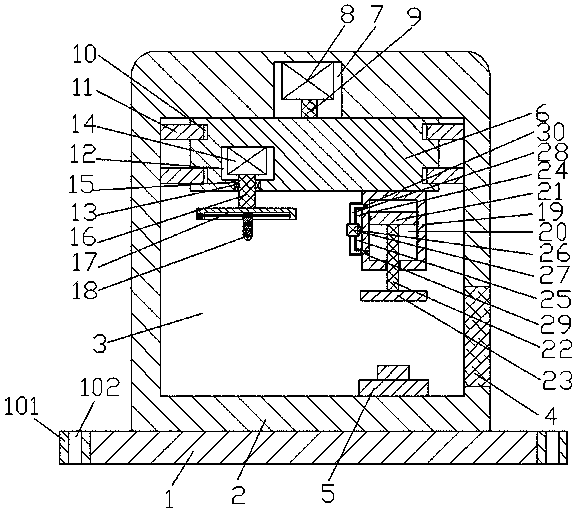

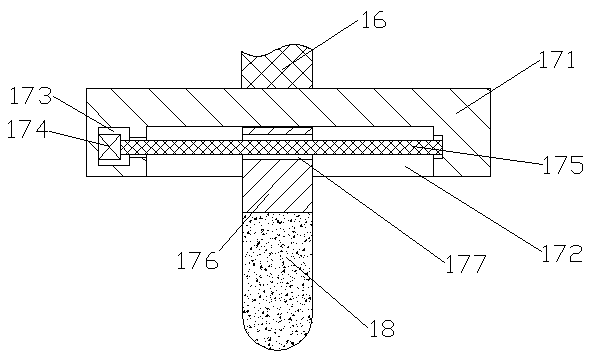

Rapid riveting mold for Teflon lining

InactiveCN106955934ASmooth and even connectionImprove processing efficiencyShaping toolsMechanical engineering

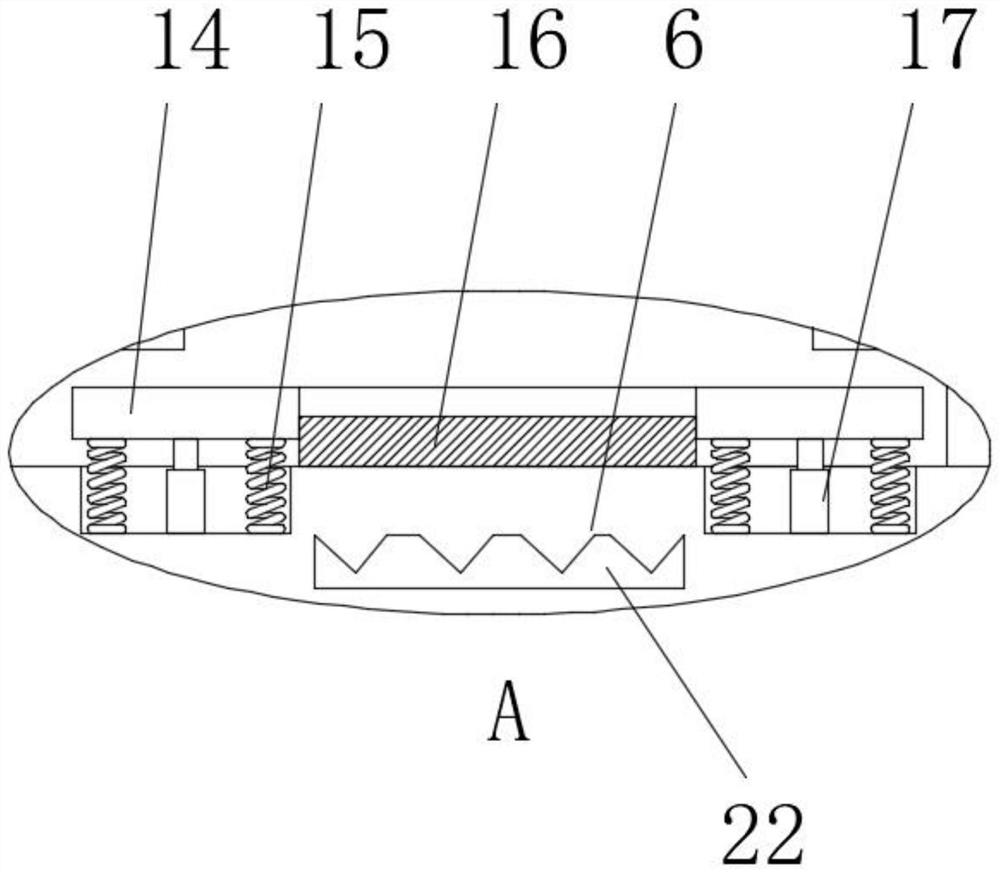

The invention discloses a rapid riveting mold for a Teflon lining. The rapid riveting mold comprises a lower mold, wherein two groups of first cylindrical chutes in symmetry are formed in the top of the lower mold; rectangular accommodation grooves are formed in inner walls of the bottoms of the first chutes; positioning columns are in sliding sleeve connection inside the first chutes; jacking plates are vertically mounted at one ends extending into the accommodation grooves, of the positioning columns; the jacking plates are in sliding connection with side walls of the accommodation grooves; first springs which are fixedly connected with the inner walls of the bottoms of the accommodation grooves are mounted on the sides, far away from the positioning columns, of the jacking plates; an upper mold is mounted right above the lower mold; two groups of lamination jacking columns in symmetry are mounted on the side, close to the lower mold, of the upper mold; the lamination jacking columns are positioned right above the positioning columns; second cylindrical chutes are formed in the sides, close to the lower mold, of the lamination jacking columns. By adopting the rapid riveting mold, stamping processing of the Teflon lining with a workpiece is achieved, the Teflon lining is stably and uniformly connected with the workpiece, and the processing efficiency of the Teflon lining with the workpiece is improved.

Owner:海口宗恒实业有限公司

Novel punching machine

The invention relates to a novel punching machine. The novel punching machine comprises a rack, a driving device, a crank shaft, a first crank shaft connection rod, a second crank shaft connection rod, a first horizontal guide block, a second horizontal guide block, a first adapter coupling connection rod, a second adapter coupling connection rod, a first vertical guide connection rod, a second vertical guide connection rod, a first lever, a second lever, a first mold adjusting connection plate, a second mold adjusting connection plate, a first slide block connection rod, a second slide block connection rod, a slide block and a worktable, wherein the driving device is in driving connection with the crank shaft; the crank shaft is in drive connection with the first crank shaft connection rod, and the second crank shaft connection rod respectively; and the slide block is located above the worktable. The novel punching machine provided by the invention has the advantages of simple structure, small inertia and high precision; the staying time of a bottom dead center is long, a punching surface of a punched workpiece is smooth and the quality of the punched workpiece is improved; and a stressed reversed impact force is small, abrasion to equipment is small and the service life of the equipment is prolonged.

Owner:MINGXUDONGGUAN PRECISION MACHINARY CO LTD

Punching device for paper processing based on rolling wheel pre-pressing technology

InactiveCN109227723AGuarantee punching qualityPrevent clogged punchingMetal working apparatusScrapCardboard

The invention discloses a punching device for paper processing based on a rolling wheel pre-pressing technology. The device comprises a base, a punched hole and a vertical frame are arranged in the middle of the top end surface of the base, and the vertical frame is arranged on the back side of the punched hole; a hydraulic cylinder is arranged at the top end of the vertical frame, the bottom endof a telescopic rod on the hydraulic cylinder penetrates through the top wall of the vertical frame and is fixedly connected with a punching head cooperating with the punched hole, and the telescopicrod is slidably connected with the vertical frame; connecting rods are symmetrically arranged at the bottoms of the left and right side ends of the vertical frame, telescopic sleeves are arranged at the bottom ends of the connecting rods, and telescopic rods are sleeved with inner cavities of the telescopic sleeves; pressing plates cooperating with the base are fixedly connected to the bottom endsof the telescopic rods, and several pressing wheels are uniformly arranged at the bottom ends of the pressing plates; by arranging the pressing plates and the pressing wheels, pre-pressing can be conducted on paper boards, the punching head can cooperate with the punched hole, the paper boards can be punched, and the punching quality of products can be effectively ensured; by arranging a suctionfan, paper scraps in the punched hole can be timely discharged, and it is effectively avoided that due to the fact that the paper scraps block the punched hole, the processing work is influenced.

Owner:WENZHOU SHI AN PACKING CO LTD

Automobile part pneumatic punching machine

InactiveCN108858448AEasy to joinRealize stampingMetal working apparatusEngineeringMechanical equipment

The invention relates to an automobile part pneumatic punching machine and the technical field of automobile part mechanical equipment. The automobile part pneumatic punching machine is mainly used for achieving the technical effect of cutting and punching a poured and formed automobile part. The automobile part pneumatic punching machine is characterized in that the automobile part pneumatic punching machine comprises a base; a lower die plate is fixedly arranged above the base; an upper die plate is arranged above the lower die plate; fixing columns support between the upper die plate and the lower die plate; a punching air cylinder is arranged on the upper die plate; the lower end of the punching air cylinder is connected with a punching die upper plate; an upper die punch cooperated with a to-be-punched automobile part is mounted below the punching die upper plate; a punching die lower plate is arranged on the lower die plate in a horizontal sliding manner; a containing groove forcontaining the to-be-punched automobile part is formed in the punching die lower plate; a lower die punch cooperated with the upper die punch is arranged below the containing groove; a collecting device for collecting the punched automobile part is further arranged below the containing groove; and a lower formwork plate is fixedly arranged between the lower die plate and the punching die lower plate.

Owner:南通金池塑胶有限公司

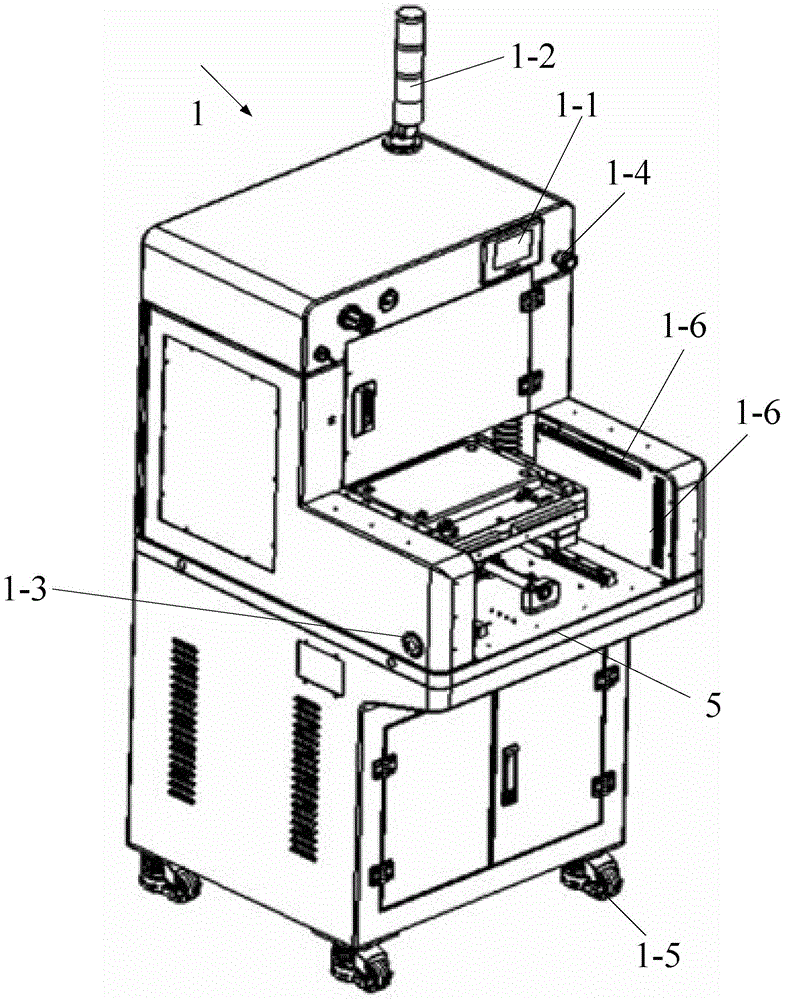

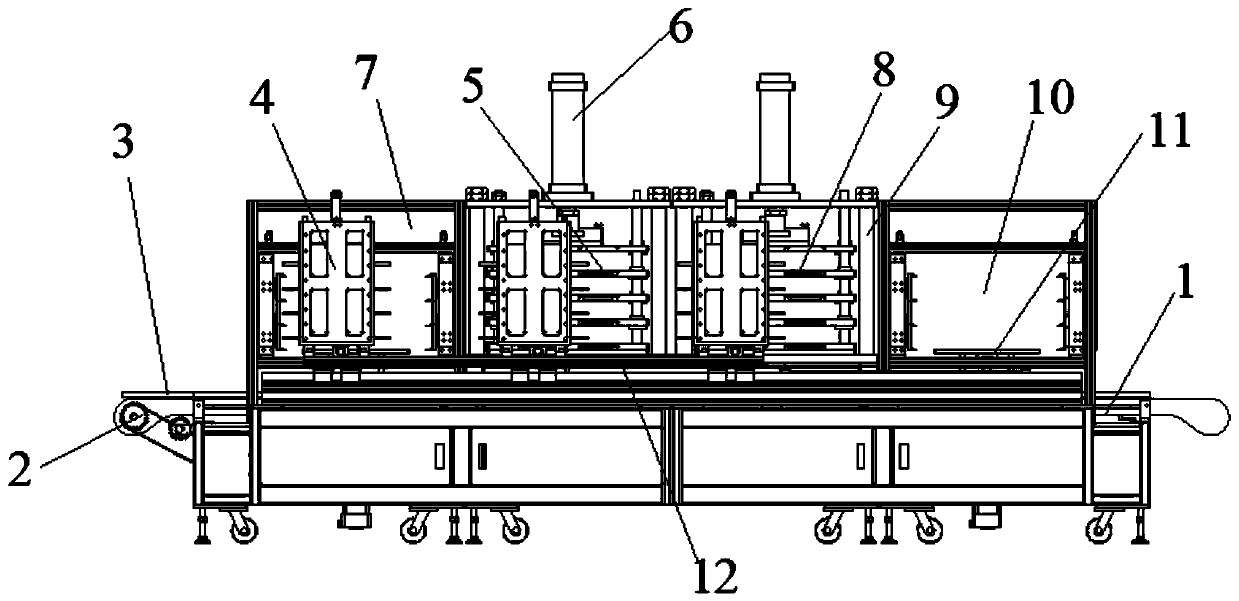

Press machine

The invention discloses a press machine. The press machine comprises a box, a control system, a bottom plate, an air cylinder, guiding columns, a supporting table, an upper die plate loading plate, an upper die plate, a height adjusting plate, a lower die plate loading device and a lower die plate. One end of the air cylinder is connected with the bottom plate, and the other end of the air cylinder is connected with the supporting table. The lower ends of the guiding columns are vertically fixed to the bottom plate. The middles of the guiding columns sequentially penetrate the supporting table and the upper die plate loading plate. The upper ends of the guiding columns are fixedly connected with the height adjusting plate. The parts, between the supporting table and the upper die plate loading plate, of the guiding columns are sleeved with force assisting springs. The distance between the upper die plate loading plate and the height adjusting plate can be adjusted. The provided press machine can punch different products, the utilization rate is high, cost is saved, product damage can be avoided in the punching process, and the qualification rate of products is increased.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

Double-motor mechanical coordination in-phase slider driven eight-bar servo pressure device

InactiveCN101396876BGuaranteed normal movementGuaranteed powerPress ramElectric machineryEngineering

The invention relates to a key synchronizer driving eight-rod servo press coordinated with dual electric machinery. Two servomotors arranged symmetrically left and right are connected with a driving slide block by a key synchronizer driving mechanism coordinated with a set of dual electric machinery, and the driving sliding block is connected with a pressing slide block by two sets of eight-connecting bar pressing mechanism arranged symmetrically left and right. The key synchronizer driving mechanism coordinated with the dual electric machinery comprises a screw rod, a small connecting bar, ahorizontal connecting bar and a sliding stand; each set of eight-connecting bar pressing mechanism comprises a short connecting bar, an upper elbow connecting bar, a lower elbow connecting bar and a punch connecting bar. The two servomotors can drive synchronously according to the set law of motion; the key synchronizer driving mechanism coordinated with the dual electric machinery can drive the driving slide block to move, and the driving slide block can push the pressing slide block to move by the two sets of eight-connecting bar pressing mechanism, therefore, the synthesis of the movement and the power of the two servomotors can be realized, and the large-tonnage ram pressure and movement are obtained, thus realizing the large-tonnage servo pressing with lower cost.

Owner:SHANGHAI JIAOTONG UNIV

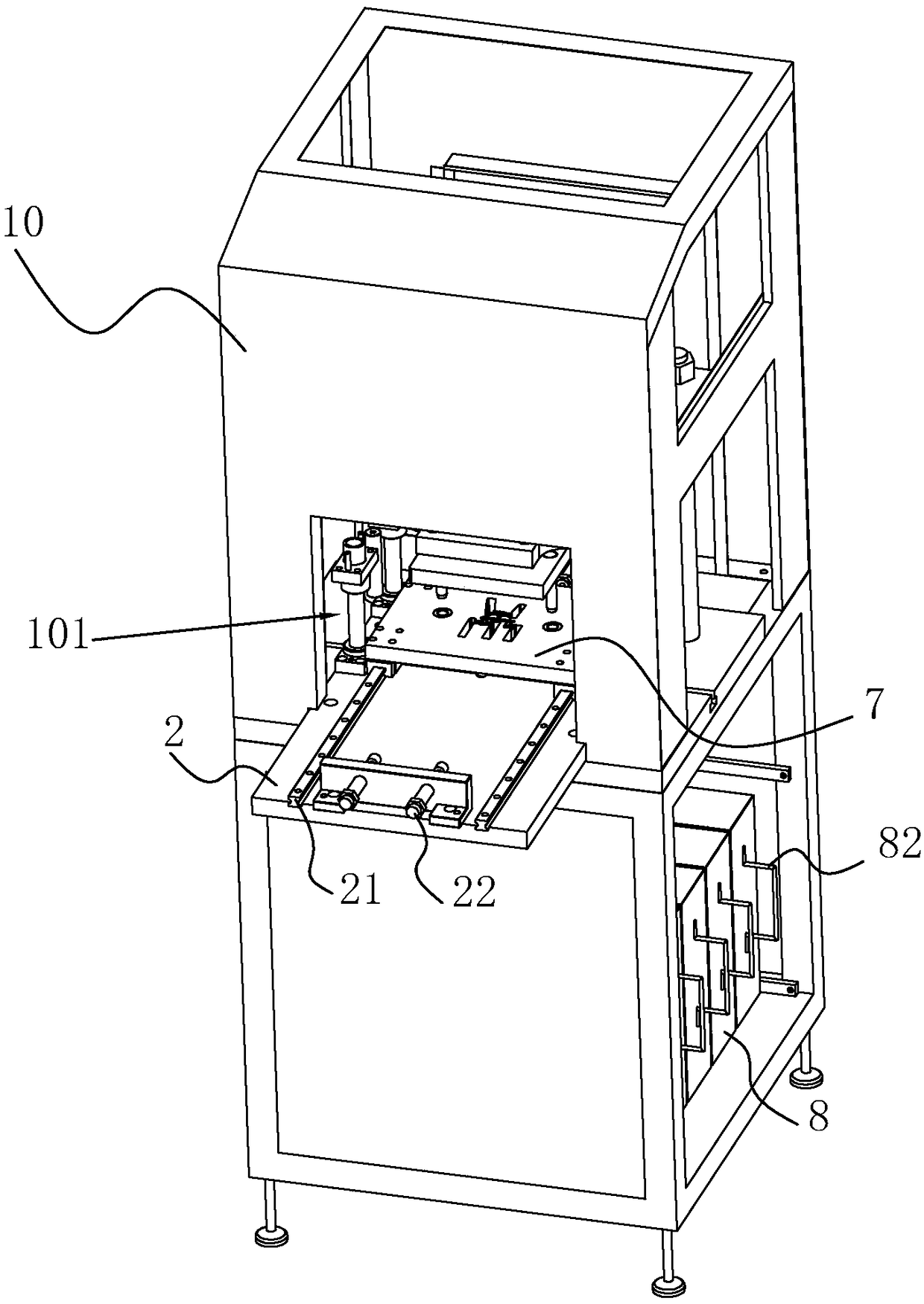

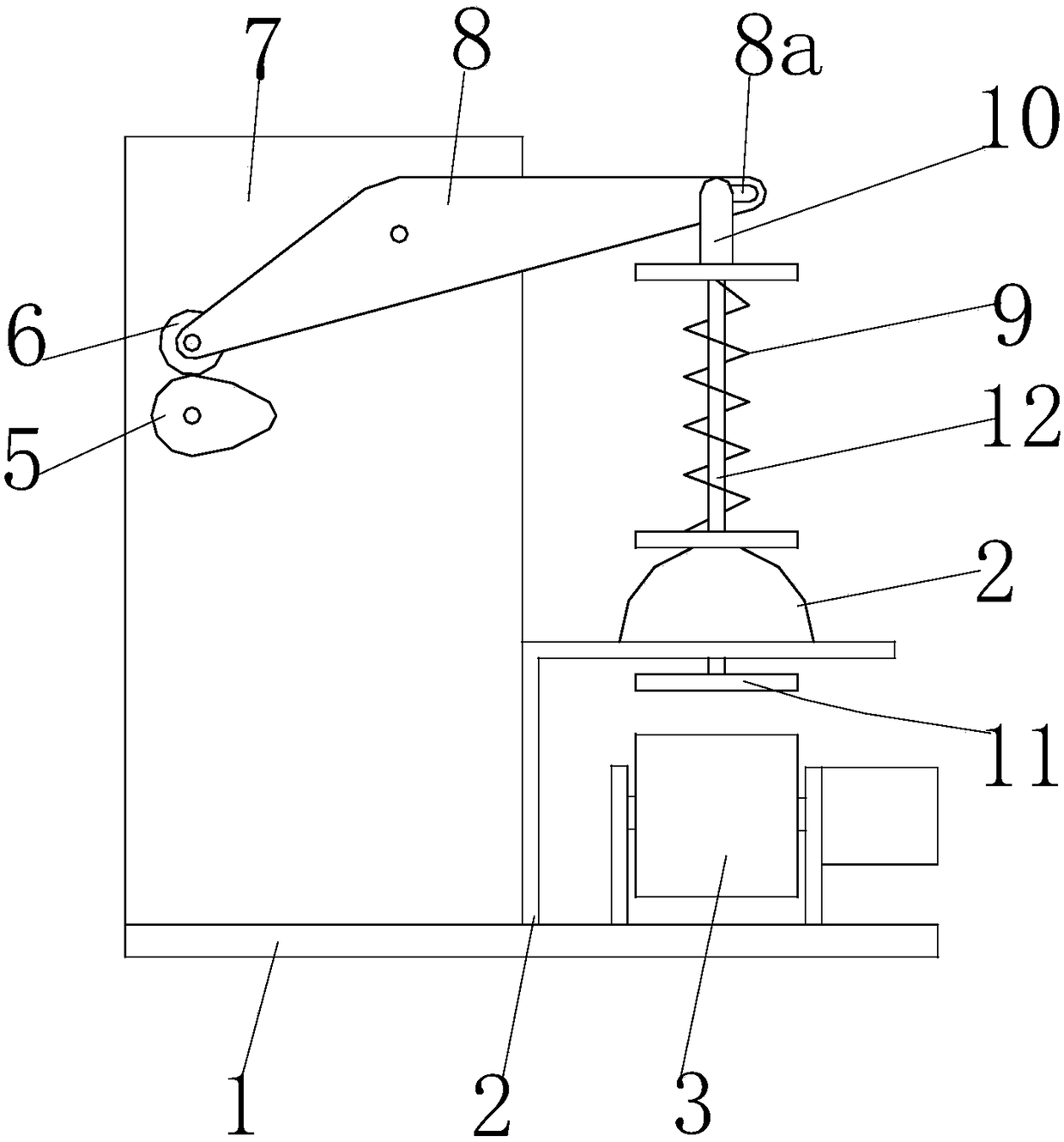

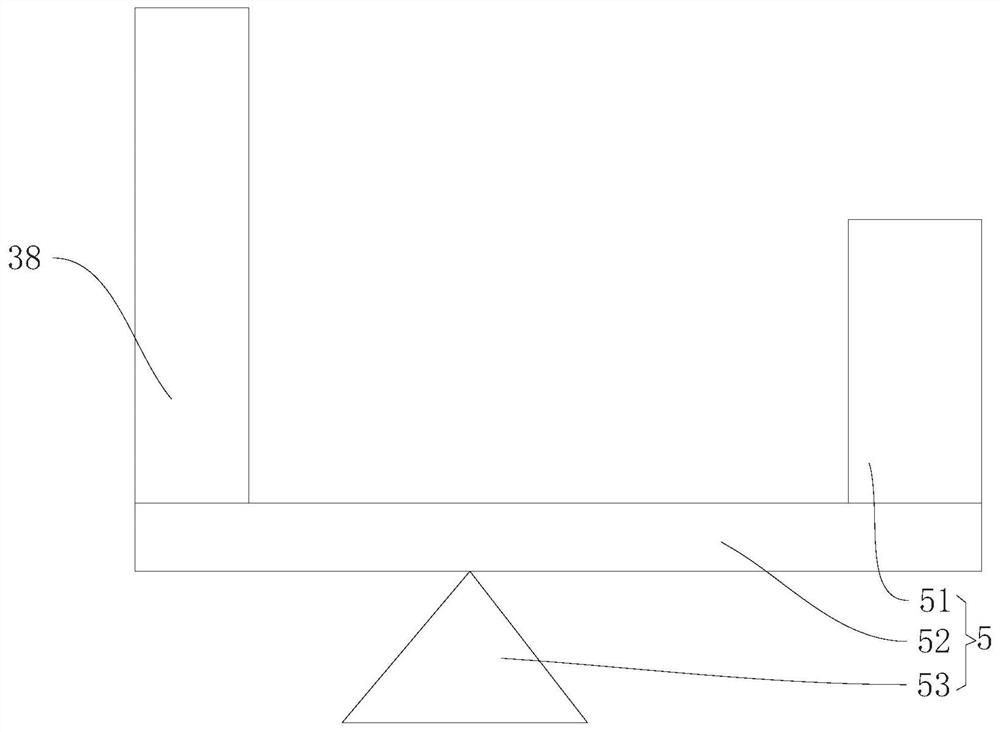

Automatic stamping device for edible oil packaging box

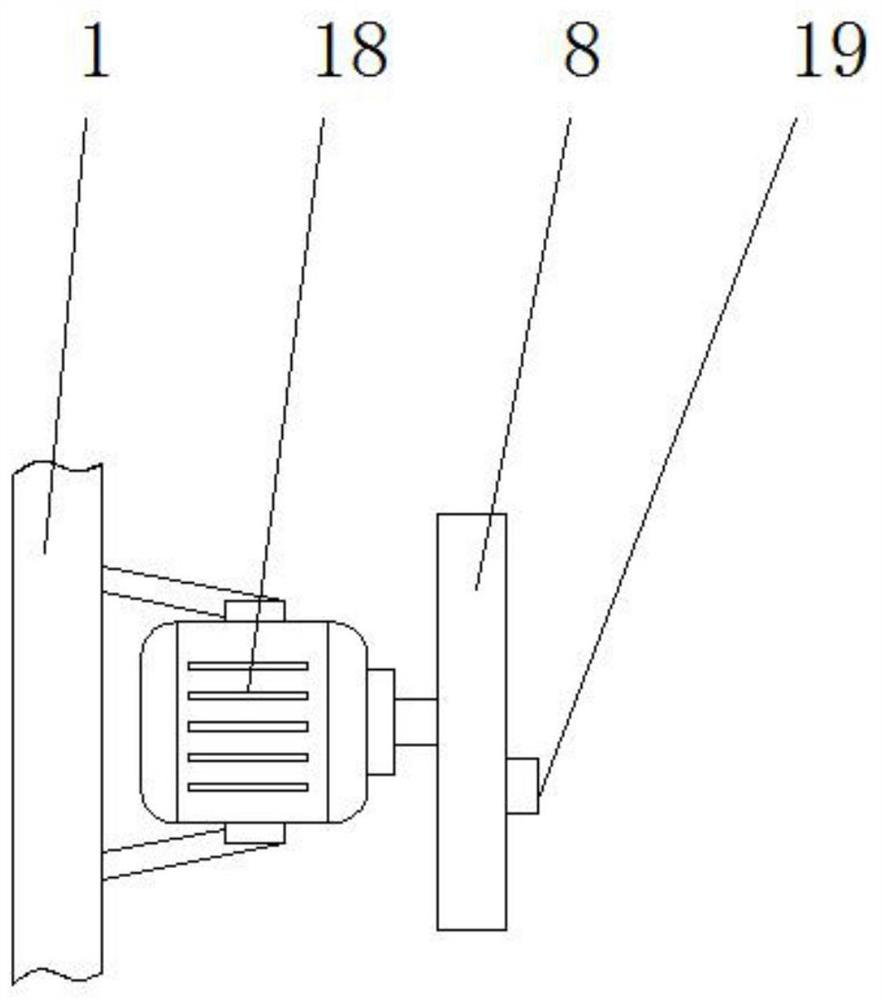

The invention relates to an automatic stamping device for an edible oil packaging box. The automatic stamping device comprises a bottom plate, a vertical plate and a conveying belt are arranged on theleft side and the right side of the bottom plate correspondingly, a motor is installed on the vertical plate, the motor is connected with a cam, a bearing wheel is mounted at the upper end of the camin a carried mode, the bearing wheel is connected with a prying rod, the middle of the prying rod is hinged to the vertical plate, a matching groove is formed in the right side of the prying rod, thematching groove is connected with an upper bearing seat in hinging and sliding modes, and the lower end of the upper bearing seat is fixedly provided with a guide rod and a spring correspondingly. According to the device, the degree of automation is high, on the basis of conveying edible oil packaging boxes, through the rotation of the cam and the elastic tension of the spring, a seal is controlled to slide up and down in a reciprocating mode, so that the large-batch edible oil packaging boxes can be automatically stamped one by one, and the manpower is saved relatively.

Owner:ANHUI GUANGMING GRAIN & OIL IND

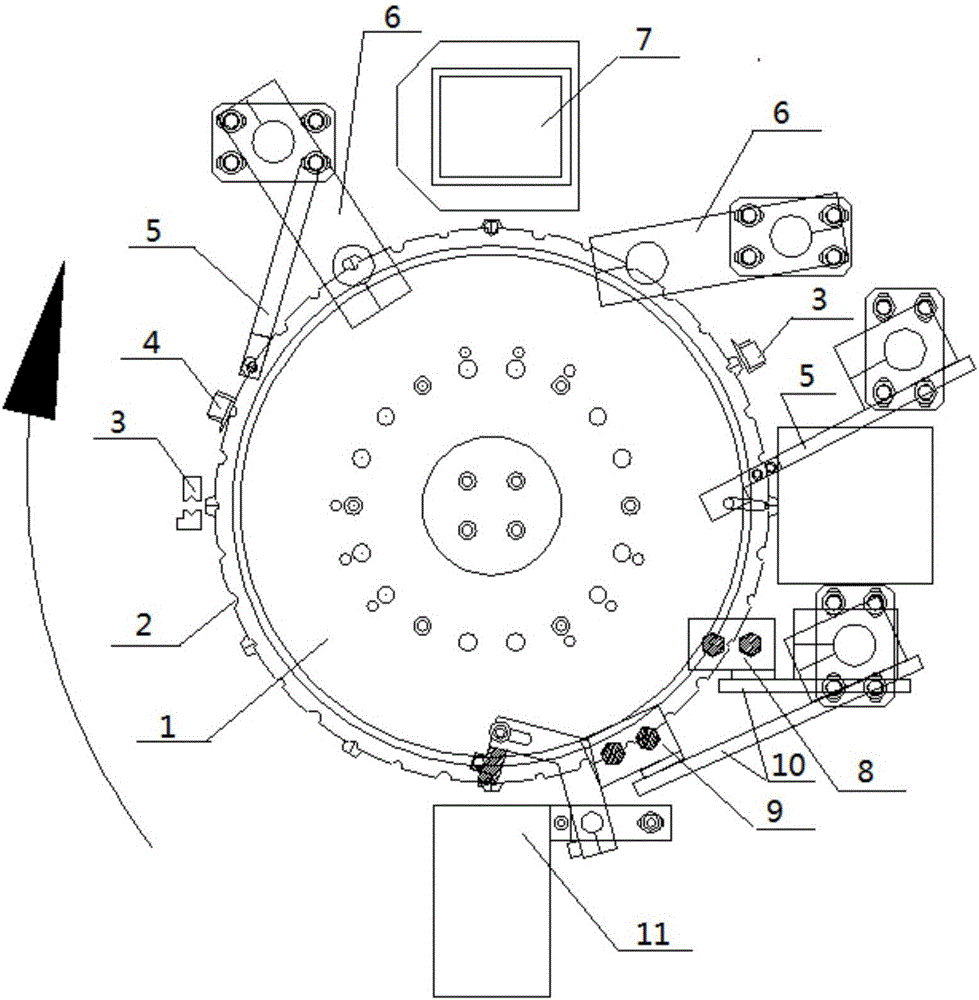

Capacitance element disk stamp seal device

InactiveCN106847559AImprove continuityEasy to detectCapacitor manufactureCapacitanceElectrical polarity

The invention discloses a capacitance element disk stamp seal device. The device comprises a stand column which is driven by a stepping motor to rotate in a stepping mode, a clamping round disk which is arranged on the stand column and is used for clamping capacitance elements, a feeding clamp, a first polarity detection work station, a first badness removal work station, a first heating work station, a stamp seal ink jetting work station, a second heating work station, a second polarity detection work station, a second badness removal work station, a cold light illuminating work station and a discharging clamp, wherein the feeding clamp, the first polarity detection work station, the first badness removal work station, the first heating work station, the stamp seal ink jetting work station, the second heating work station, the second polarity detection work station, the second badness removal work station, the cold light illuminating work station and the discharging clamp are arranged at the periphery of the clamping round disk in sequence, the outer edge of the clamping round disk is uniformly provided with clamping grooves which have at least two specifications and are used for accommodating the capacitance elements, the clamping grooves with different specifications are distributed in sequence, and are formed in circulation. According to the capacitance element disk stamp seal device, continuous automatic stamp seal and detection of the capacitance elements are achieved, and stamp seal and detection of the capacitance elements with different specifications can be achieved without assembling and disassembling.

Owner:YANGZHOU SHENGYANG ELECTRONICS

Punch forming system

The invention discloses a punch forming system and relates to the field of machining. The punch forming system is used for conducting punch forming on arc-shaped grooves in isolation plates for traffic isolation strips. The punch forming system comprises a base and a machine head. A punch is arranged at the bottom of the machine head and connected with a drive wheel. An upper female die is arranged at the bottom of the punch, and a lower male die is arranged at the position, opposite to the bottom of the upper female die, of the base. The two ends of the lower male die are provided with positioning mechanisms which are fixed to the base and are not in contact with the lower male die. The punch forming system further comprises a material disengaging device and a brake device. The punch forming system has the beneficial effects that punching on metal isolation strip plates can be rapidly achieved, the arc-shaped grooves can be formed in the surfaces of the isolation strip plates, the appearance is attractive, reflection to lamp light is avoided, and the effect on driven vehicles is reduced.

Owner:TIANJIN SHENGXINPENG TRAFFIC FACILITIES

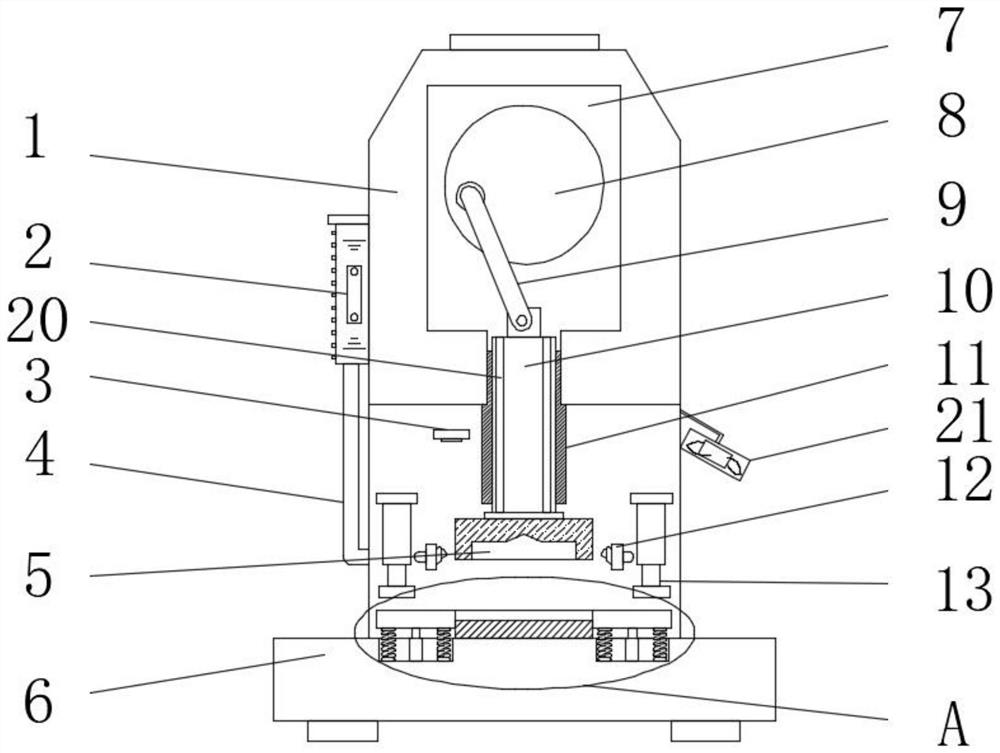

High-punching-energy punching machine driven by servo pure motor

InactiveCN112439819ARealize stampingImprove stamping effectPress ramElectric machineryProcess engineering

The invention discloses a high-punching-energy punching machine driven by a servo pure motor, and relates to the field of punching. The high-punching-energy punching machine driven by the servo pure motor comprises a base. When the high-punching-energy punching machine driven by the servo pure motor is used, a spring plays a role in buffering, so that the displacement probability of a workpiece isreduced; a punching die can accurately punch the workpiece, so that the punching quality of the workpiece is improved; after punching is completed, under the action of the elastic restoring force ofthe spring, an annular supporting plate moves upwards to drive impacted waste to move upwards by a certain distance; and a finished product is continuously placed on a fixing plate, so that the impacted waste is separated from the impacted finished product, an operator can conveniently separate the waste from the finished product, the working difficulty of the operator is reduced, and the workingefficiency of the device is improved; According to the high-punching-energy punching machine driven by the servo pure motor provided by the invention, a stamping effect can be improved by increasing stamping energy while punching is achieved, and meanwhile, the impact resistance of the base can be improved by changing the shape of the base.

Owner:HUBEI JINHELI ELECTROMECHANICAL TECH CO LTD

Double-lever force application type stamping machine

InactiveCN107718622ARealize stampingScientific and reasonable designPress ramBraced frameEngineering

The invention discloses a double-lever force-assisted stamping machine. The upper support column is welded on the left side of the top inside the support frame, the lower support column is welded on the right side of the bottom inside the support frame, and the left lever arm passes through the The movable pin is installed on the bottom of the upper support column, and the right lever arm is installed on the top of the lower support column through the movable pin. The pad is welded on the right end of the left lever arm, and the booster lifting column is welded on the right lever On the left end of the force arm, the top of the booster column is pushed against the bottom end of the spacer, the connecting column is welded on the right end of the right lever arm, and the force cylinder is welded and fixedly installed on the right side of the support frame, adding The booster cylinder column is installed in the booster cylinder, and the bottom end of the booster cylinder column is installed on the connecting column through a movable pin. The invention has the advantages of scientific and reasonable design, simple structure and convenient use.

Owner:芜湖挺优机电技术有限公司

Automatic stamping device capable of stamping metal plates with different lengths

PendingCN113441637AImprove automation performanceRealize stampingPerforating toolsMetal-working feeding devicesCircular discDrive wheel

The invention relates to the technical field of stamping, and discloses an automatic stamping device capable of stamping metal plates with different lengths, which comprises a shell, driven wheels are movably connected in the left side of the shell, a stamping hole is formed in the shell, a cut-off hole is formed in the right side of the interior of the shell, the interior of the shell is movably connected with an incomplete disc, and the bottom of the incomplete disc is fixedly connected with a vertical rod. According to the automatic stamping device capable of stamping the metal plates with different lengths, the incomplete disc rotates, the metal plate at the top of the driven wheels is moved rightwards intermittently, and therefore the effect that the metal plate is automatically pushed into a stamping machine, and the automation of the device is improved is achieved. A rotating cross rod is rotated, then, a rotating bent rod is made to drive the stamping speed of the stamping device to be changed, at the moment, a cut-off block can cut off the metal plates of different lengths, and therefore the effect of stamping the metal plates of different lengths can be achieved.

Owner:何景华

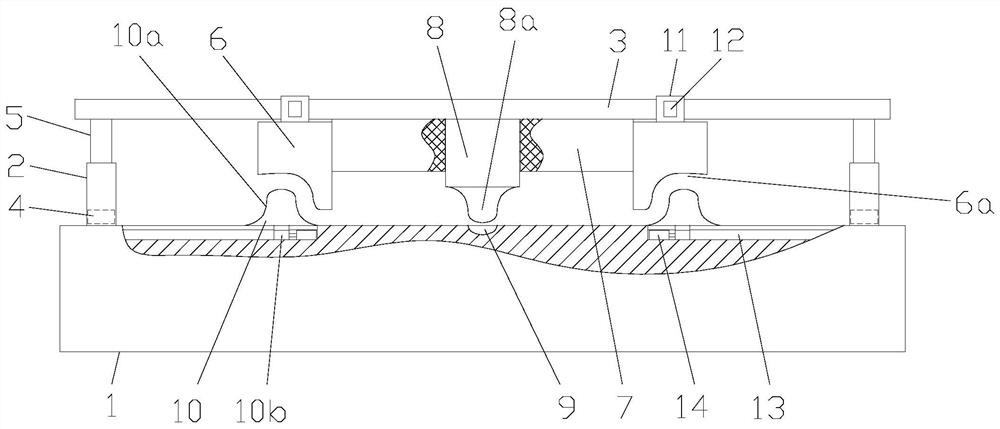

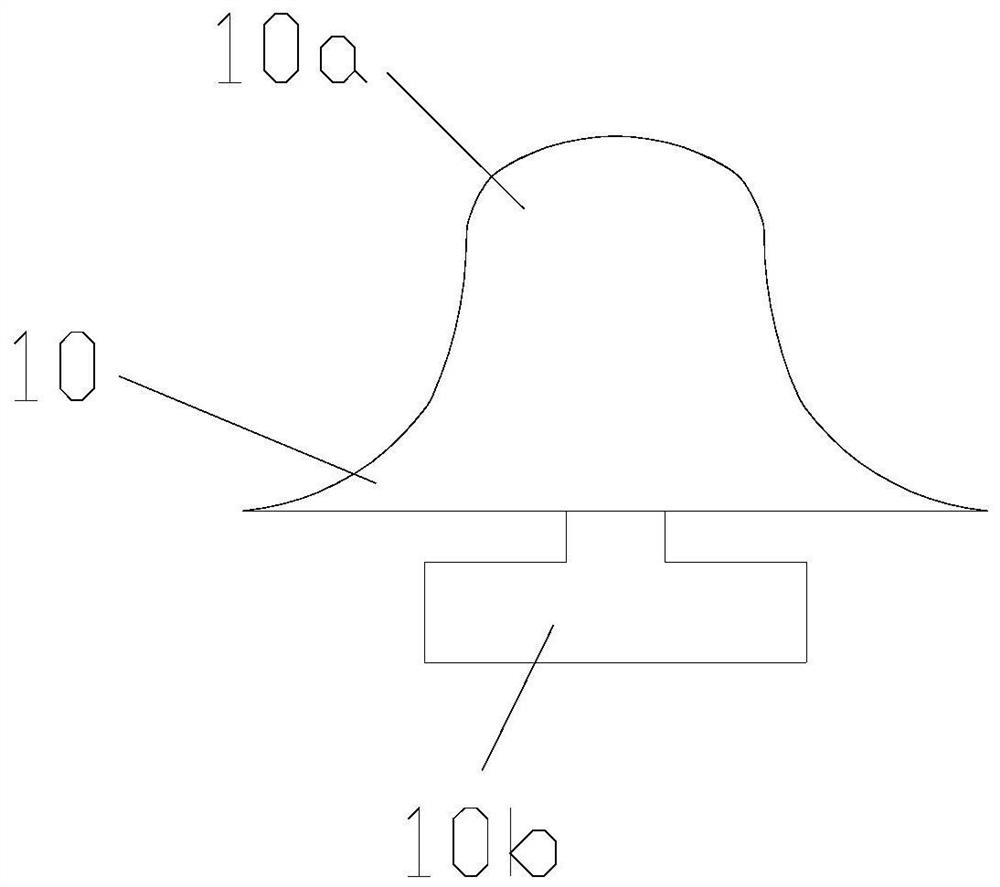

Combined type bracket forming device

InactiveCN111922206ARealize stampingReduce the problem of high manufacturing costShaping toolsMechanical engineeringEconomizer

The invention provides a combined type bracket forming device, and belongs to the technical field of stamping dies. The combined type bracket forming device aims at solving the problems that as the specifications of existing brackets are more, the variety of brackets manufactured through composite pressing molds is single, and the manufacturing cost of the composite pressing molds is increased. The combined type bracket forming device comprises an upper connecting portion, a lower connecting portion, an upper combination mold and a lower combination mold. The upper combination mold is detachably connected with the upper connecting portion, the lower connecting portion is detachably connected with the lower combination mold, the upper connecting portion and the lower connecting portion areslidingly arranged, and the upper connecting portion can move relative to the lower connecting portion up and down. The upper combination mold and the lower combination mold are arranged and arrangedinto multiple combination forms, so that the requirements of brackets of different specifications are met, the universality is high, by means of one combined type bracket forming device, stamping of the bracket products of multiple specifications can be achieved, and the problems that traditional composite pressing molds have multiple varieties, and the manufacturing cost of the molds is high arereduced. The combined type bracket forming device is suitable for stamping of brackets on economizer heated surface tube panels.

Owner:HARBIN BOILER

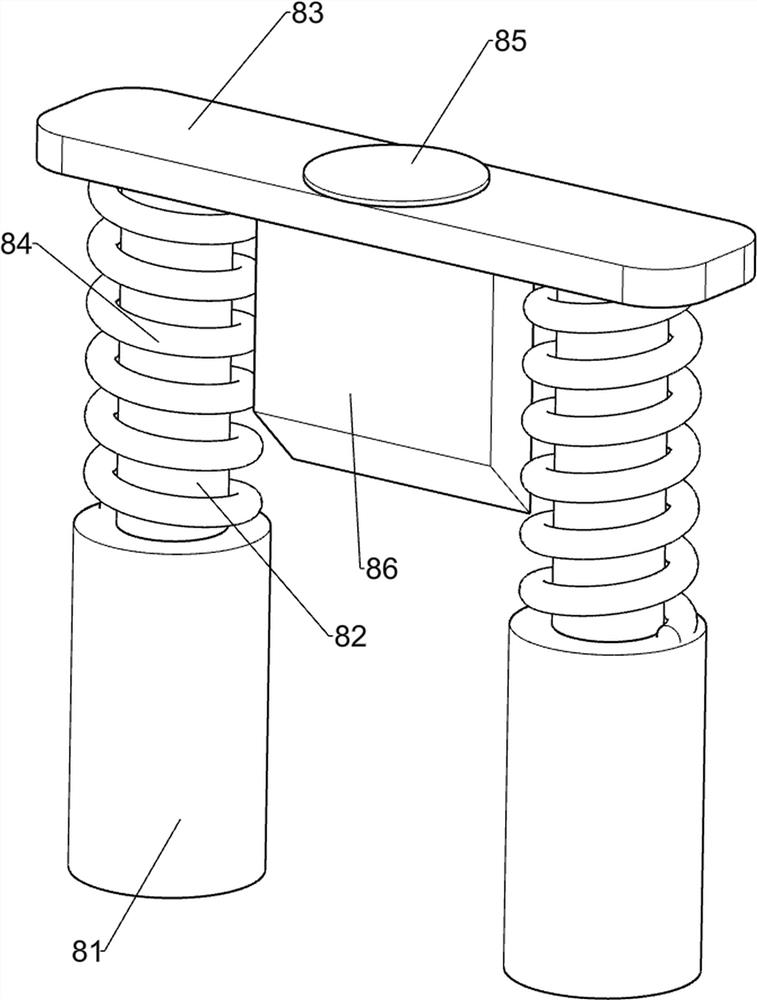

Adjustable clamping device for workpiece fastening

InactiveCN108405736AQuick snapEfficient fasteningMetal-working feeding devicesPositioning devicesEngineeringSupport plane

The invention discloses an adjustable clamping device for workpiece fastening. The adjustable clamping device for workpiece fastening comprise a working platform and a pressing mechanism, wherein a support frame of the pressing mechanism comprises a lifting rod assembly and a cross support beam; a pressing block II and a buffer piece are fixed to the bottom part of the middle of the cross supportbeam; two pressing blocks I are slidably arranged on the cross support beam along a horizontal direction; two sliding mechanisms are arranged on the cross support beam; two ejecting blocks are arranged on the top surface of the working platform, are located right under the corresponding pressing blocks I, and are slidably arranged on the working platform along a horizontal direction; arc-shaped notch parts are arranged at the lower ends of the two pressing blocks I; ball heads I are arranged at the upper ends of the two ejecting blocks; a ball head II is arranged at the lower end of the pressing block II; and a concave cavity is arranged on the top surface of the working platform. The adjustable clamping device for workpiece fastening provided by the invention can be used for high-efficiently and quickly fastening workpieces, is beneficial to improving the production efficiency and reducing the cost, can realize stamping operation, and is simple in overall structure, convenient to assemble and disassemble, capable of being freely adjusted according to the sizes of the workpieces, wide in application range and convenient to use.

Owner:重庆恩光科技有限公司

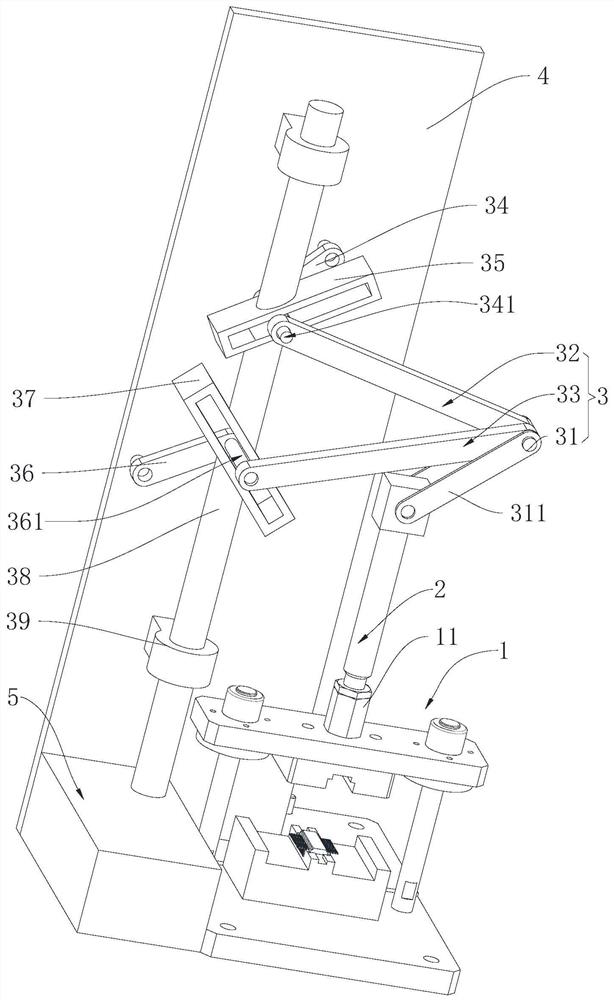

Manual stamping device

The invention relates to the technical field of stamping, in particular to a manual stamping device. The manual stamping device comprises a supporting base and a stamping rod, wherein a driving assembly for driving the stamping rod to ascend and descend is arranged on one side of the stamping rod, and the driving assembly comprises a main hinge rod, a first auxiliary hinge rod and a second auxiliary hinge rod; one end of the main hinge rod is hinged on the stamping rod, and the first auxiliary hinge rod and the second auxiliary hinge rod are hinged to the other end of the main hinge rod; a first connecting rod is hinged to the other end of the first auxiliary hinge rod, and a second connecting rod is hinged to the other end of the second auxiliary hinge rod; a mounting plate is arranged onone side of the supporting base, and one end of the first connecting rod and one end of the second connecting rod are rotationally connected to the mounting plate; a driving rod is arranged on one side of the mounting plate, and a first driving groove and a second driving groove are formed in the driving rod; the first driving groove drives the first connecting rod to rotate; and the second driving groove drives the second connecting rod to rotate. By driving the driving rod, lifting of the main hinge rod is achieved, and then stamping of the stamping rod is achieved. A motor is not needed, and energy is saved.

Owner:ZHUHAI DAHENGQIN TECH DEV CO LTD

Automobile oil tank forming mold

InactiveCN107962116AThe lower mold is convenientConvenient corner locationShaping toolsEjection devicesFuel tankEngineering

The invention discloses an automobile oil tank forming mold. The automobile oil tank forming mold comprises a lower mold body, a demolding component and an upper mold body; the lower mold body is provided with a concave die, a guide column and demolding grooves; the upper end of the lower mold body is connected with the concave die in a welding manner; the lower mold body is symmetrically providedwith two demolding grooves; the two demolding grooves are symmetrically welded on the lower mold body; two demolding blocks are symmetrically welded at the upper end of a push plate; a grooved plateis provided with a rectangular groove; the two sides of the rectangular groove at the middle position of the grooved plate are connected with two rotary rod base plates by means of welding; and rotaryrods are rotationally matched with the two rotary rod base plates.

Owner:赵月玲

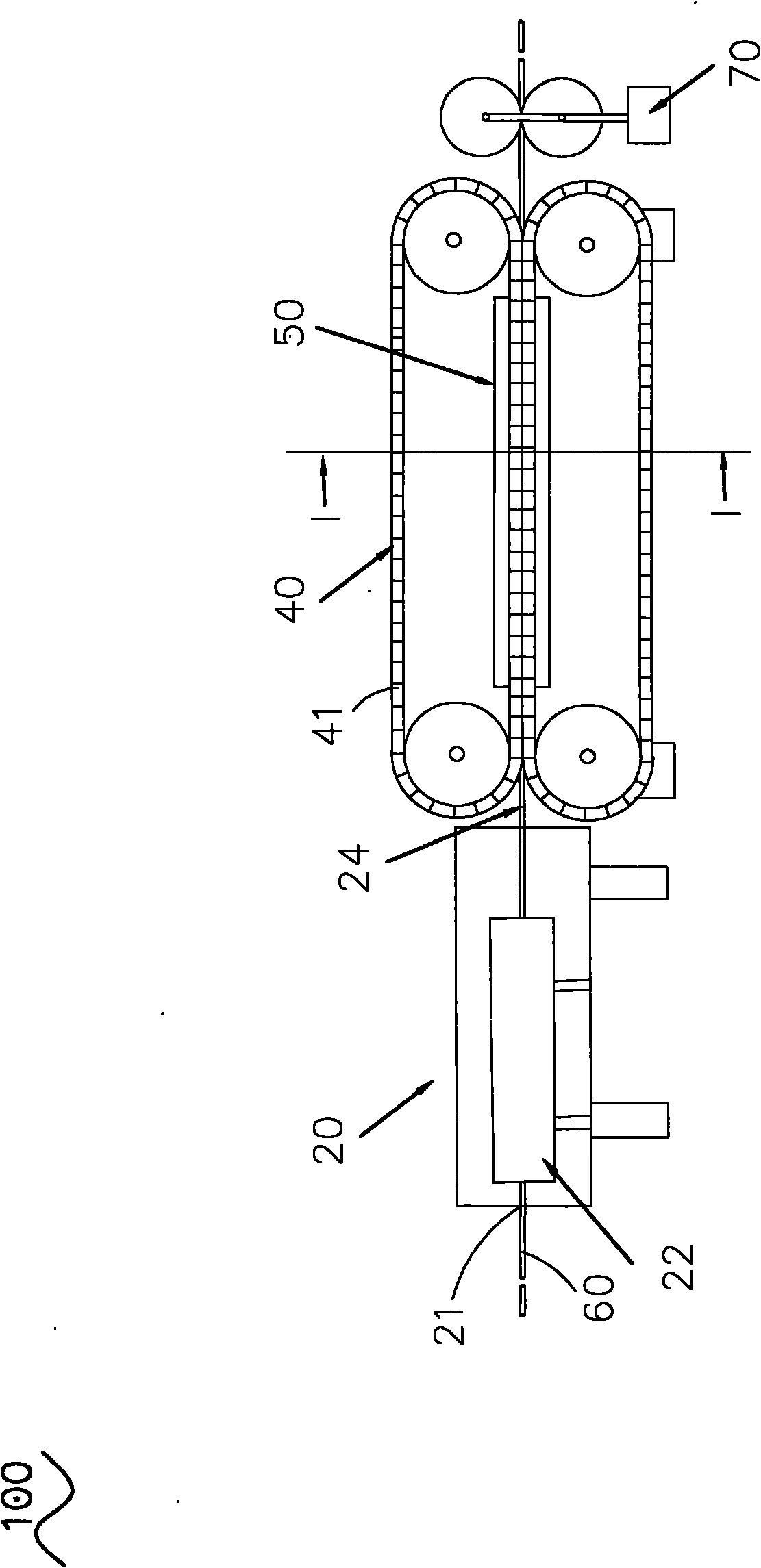

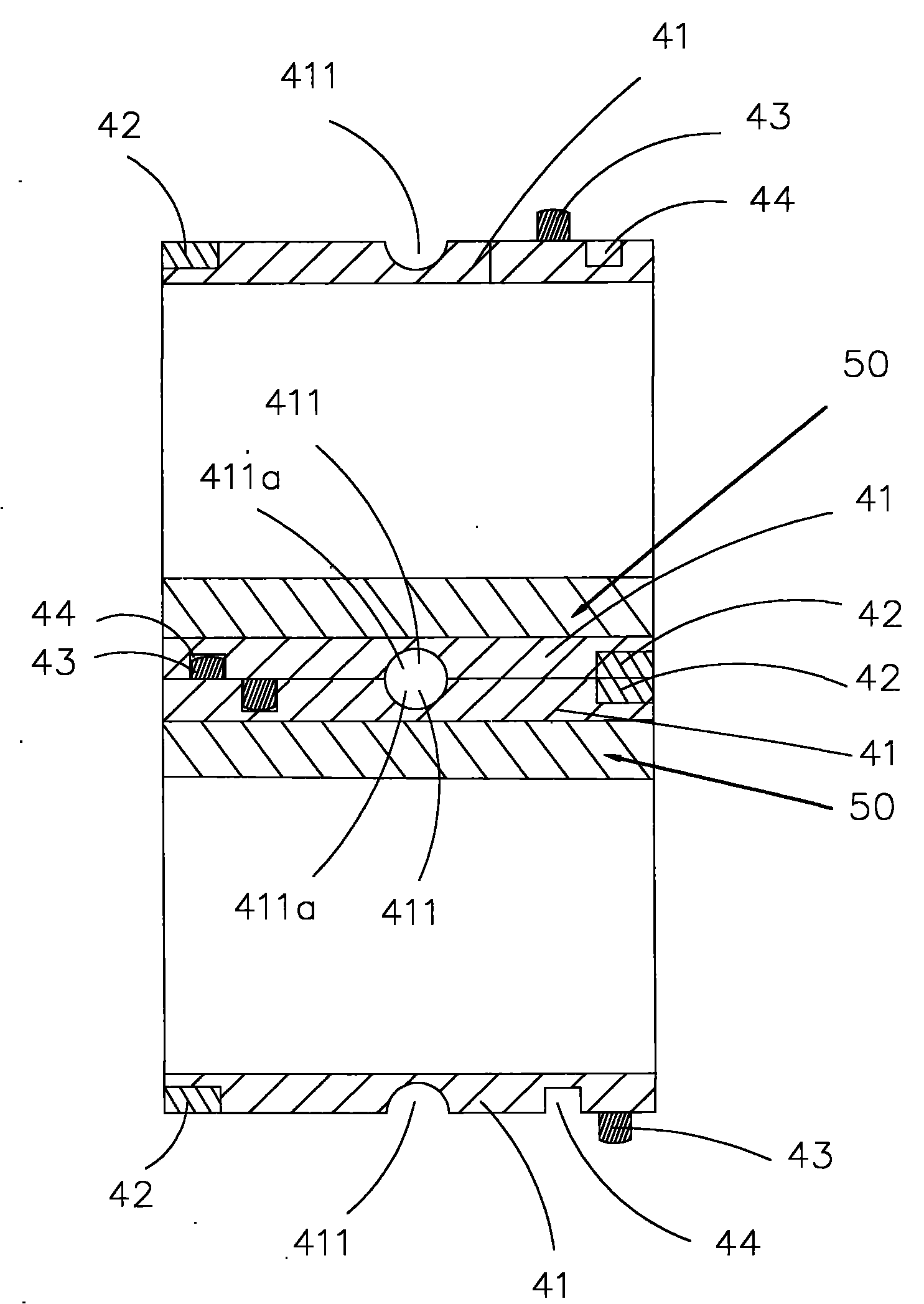

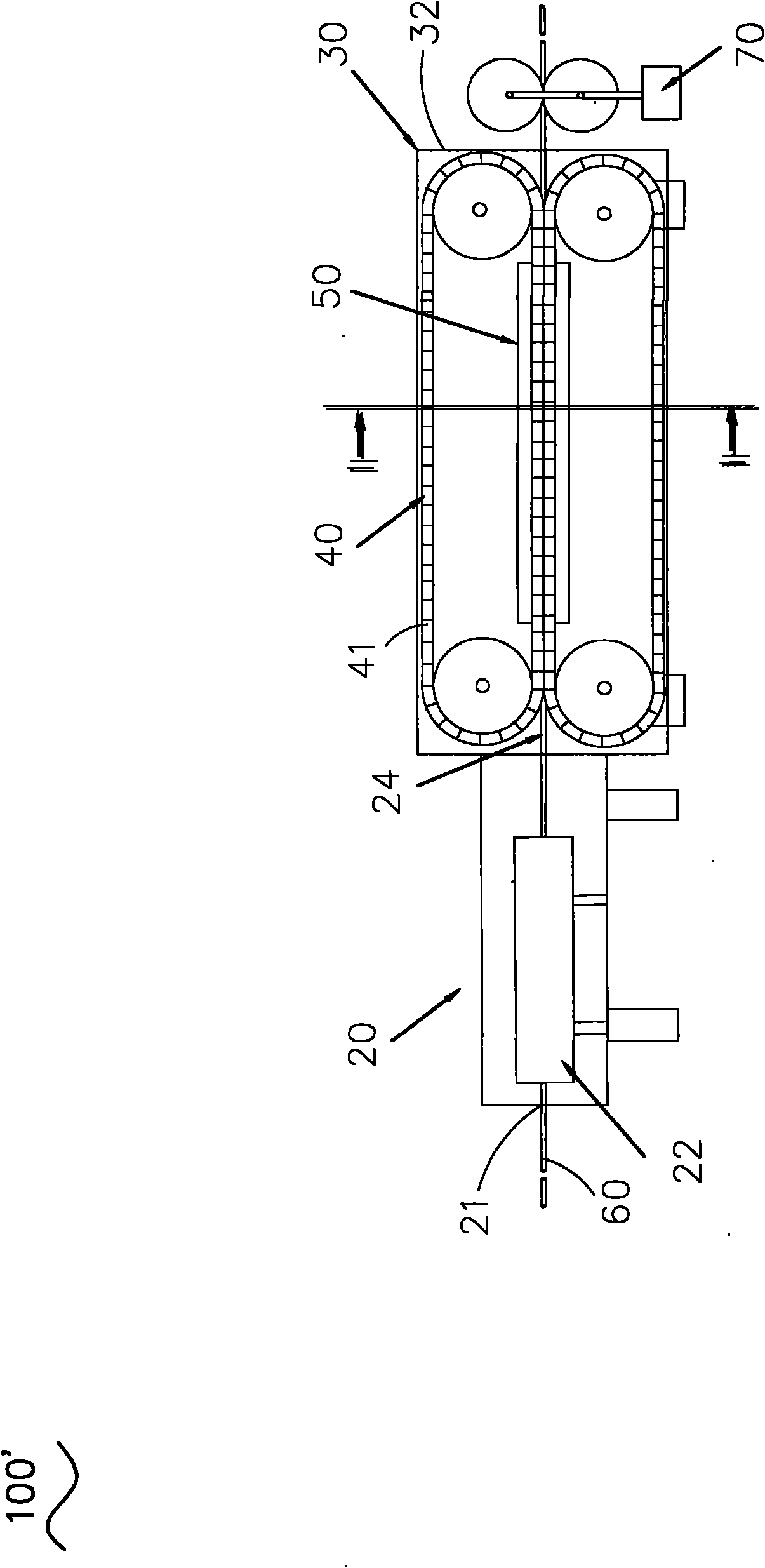

Stamping device and stamping pipe

The invention discloses a stamping device. The stamping device comprises a sealing box, an air pressure regulation device, two tracks, a plurality of track blocks and a drawing device; the sealing box is adjacent to two tracks; the sealing box is provided with a through hole; the through hole is provided with a hole wall which is in sealed connection with an outer wall of the sealing box to form a hollow sealing box body; a plurality of track blocks are arranged on the tracks; the track blocks are provided with model parts which are provided with corresponding patterns; and the two tracks are adjacent in the vertical direction and can move in an opposite direction. In the stamping device, a thermal shrinkage pipe passes through the through hole of the sealing box to be prevented from being expanded before stamping, and is drawn by the drawing device to advance, and expanded by the air pressure regulation device, and two tracks are adjacent in the vertical direction and move in the opposite direction, so that the stamping is realized and large-scale continuous expansion and stamping of the thermal shrinkage pipe are realized. Moreover, the invention also discloses a stamping pipe on which a stamping mark disappears when the stamping pipe is heated; and the stamping is finished when the stamping pipe is expanded, so the stamping mark can disappear when the stamping pipe is heated and shrunk.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

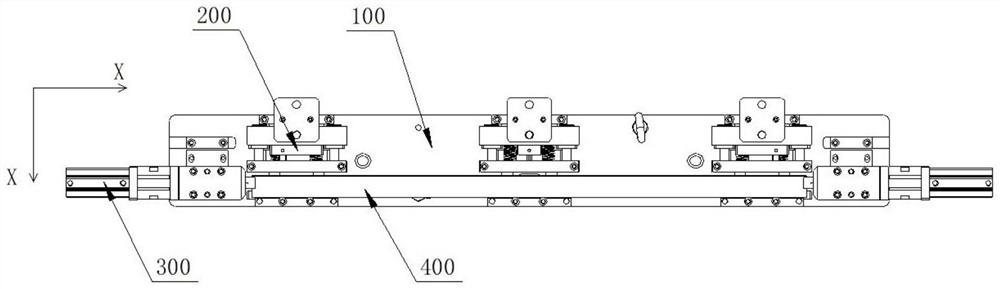

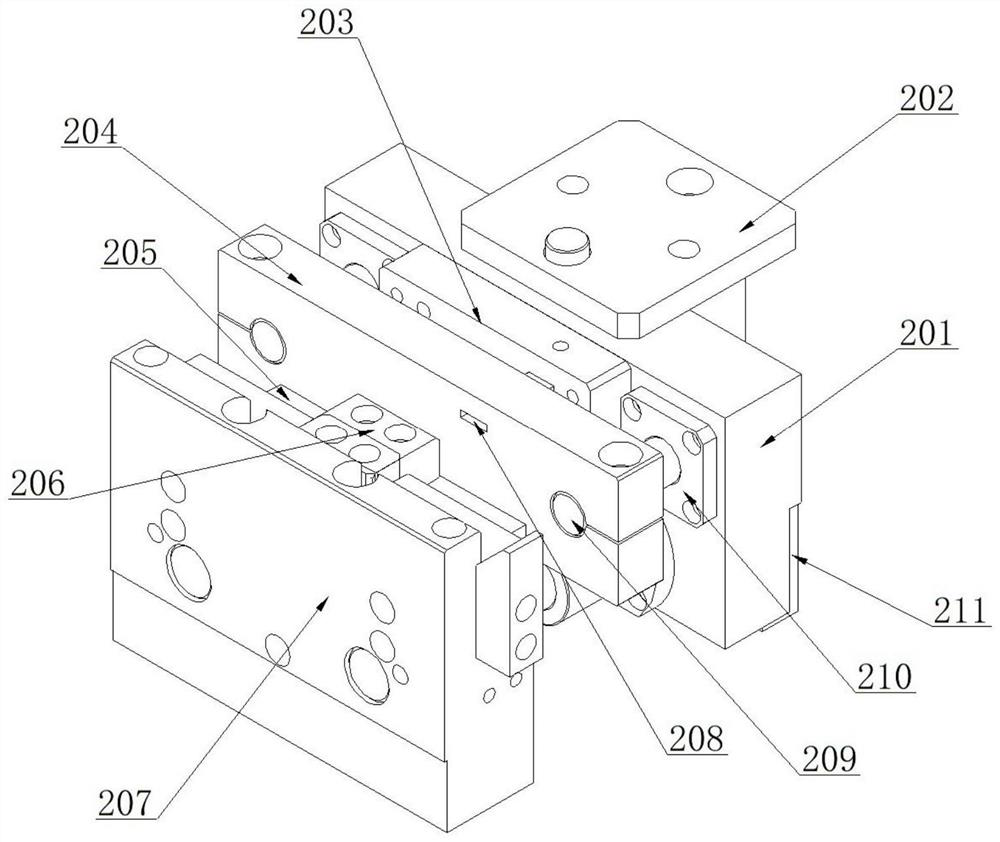

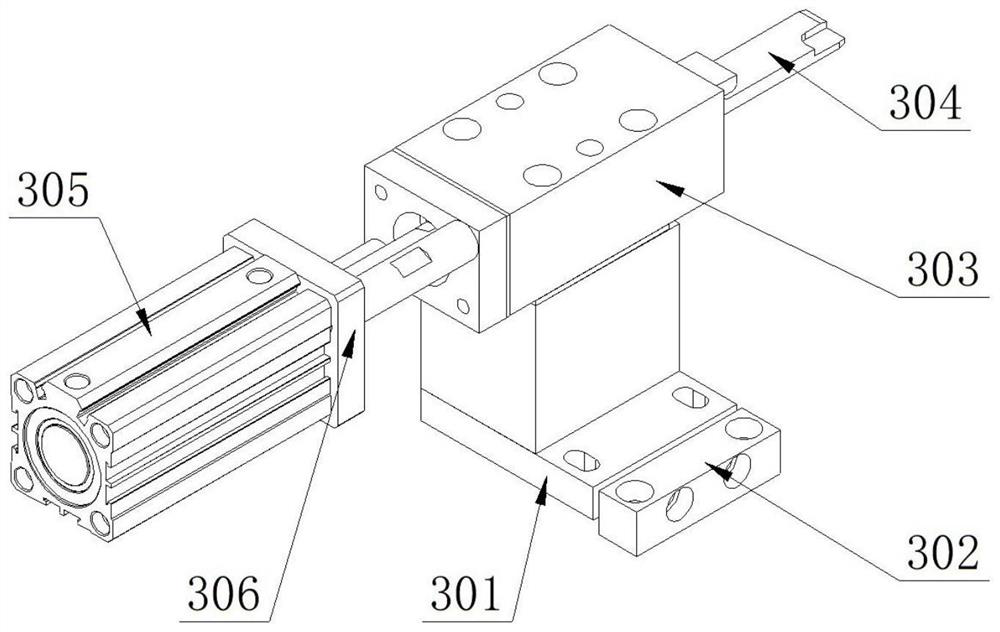

Transverse stamping die and stamping method of photovoltaic panel aluminum alloy frame

The invention relates to the field of stamping, in particular to a transverse stamping die and a stamping method of a photovoltaic panel aluminum alloy frame. A transverse stamping die comprises a die base; the die plug block mechanism is horizontally arranged in the first direction of the die base, and the die plug block mechanism is used for fixing a workpiece to be stamped; and the station die is horizontally arranged in the second direction of the die base, and the station die is used for containing the workpiece and stamping the workpiece. According to the transverse stamping die provided by the invention, stamping machining of a workpiece is completed in the horizontal direction, on the basis of saving time, improving the production efficiency and reducing the production cost, the machining precision is guaranteed, and flexible machining can be achieved.

Owner:上海寅铠精密机械制造有限公司

Adjustable clamping device for workpiece fastening

InactiveCN108405736BQuick snapEfficient fasteningMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses an adjustable clamping device for fastening workpieces, which includes a working platform and a pressing mechanism. The support frame of the pressing mechanism includes a lifting rod assembly and a horizontal support beam, and a pressure block II and a buffer member are fixed in the middle of the horizontal support beam. There are two briquetting blocks 1, which are respectively slidably arranged on the cross support beam along the transverse direction. The cross support beam is provided with two sliding mechanisms, and the top surface of the working platform is provided with two top blocks. It is located directly below the corresponding pressing block I, and the two top blocks are respectively slidably arranged on the working platform along the transverse direction. The lower end of the block II is provided with a ball head II, and the top surface of the working platform is provided with a concave cavity. The invention can not only realize high-efficiency and fast fastening of workpieces, improve production efficiency, reduce costs, but also realize stamping operation, and the overall structure is simple, easy to assemble and disassemble, and can be freely adjusted according to the size of workpieces. It has a wide range of applications and is easy to use .

Owner:重庆恩光科技有限公司

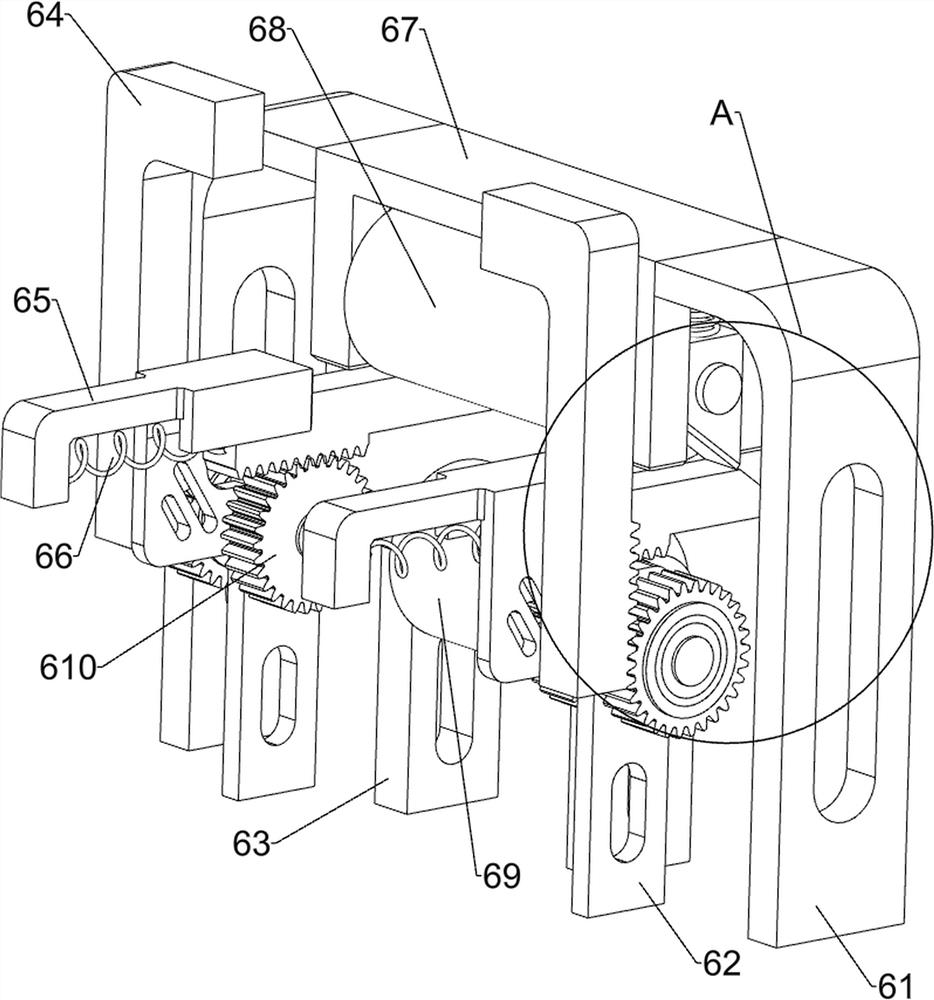

A double-station sheet metal stamping method

ActiveCN111745017BRealize stampingRealize stamping on the stamping tableEjection devicesCrankGear wheel

The invention discloses a double-station sheet metal stamping method, which is characterized in that it includes the following steps: step S1, placing the strip-shaped strips in the feeding channel of the gear belt and the feeding rail respectively; The front end of the belt enters the cavity of the upper fixed mold; in step S3, the active crank rotates to drive the swinging member to swing clockwise to realize stamping of the strip on the upper fixed mold; The material hole is unloaded; step S4, the plate strip in the upper material rail is inserted into the material hole and moved into the cavity of the lower fixed mold; step S5, the driving crank continues to rotate, and the stamped plate parts stamped in the upper fixed mold Blow off the upper fixed mold cavity, and at the same time, close the lower movable mold and the lower fixed mold; step S6, repeat steps S2 to S5, to realize double-station continuous stamping of sheet metal parts. The invention provides that two workpieces can be stamped synchronously during one stamping cycle, and the sheet metal stamping efficiency of the plate is improved.

Owner:永清县鑫海金塑有限公司

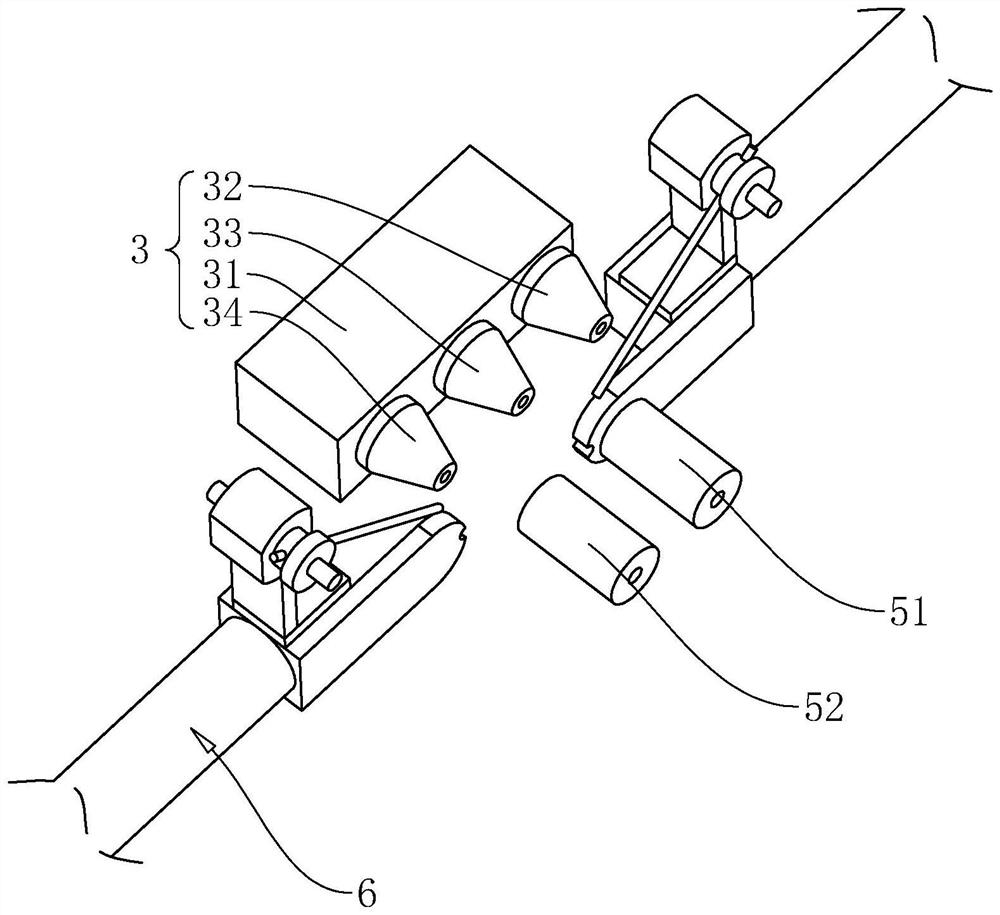

Cold heading machining equipment

InactiveCN114226622AFast processingIncrease productivityForging/hammering/pressing machinesForging press detailsEngineeringMachine

The invention relates to the technical field of cold heading, in particular to cold heading machining equipment which is characterized in that the cold heading machining equipment comprises a rack and further comprises a punch module, the punch module comprises a fixing block, and a pre-heading punch, a rough heading punch and a fine heading punch are sequentially arranged on the fixing block; the mold module is arranged on the machine frame, and the mold module comprises a first mold and a second mold; the upsetting and pressing power mechanism is arranged on the machine frame, and the upsetting and pressing power mechanism is used for achieving the upsetting and pressing action; the die changing power mechanism is used for realizing a die changing action; and the feeding mechanism is arranged on the machine frame, and the feeding mechanism is used for conveying the upset material and the substrate to the position of a mold. The contact machining device has the effect of improving the contact machining efficiency of the cold heading machining device.

Owner:DONGGUAN HUANO ALLOY

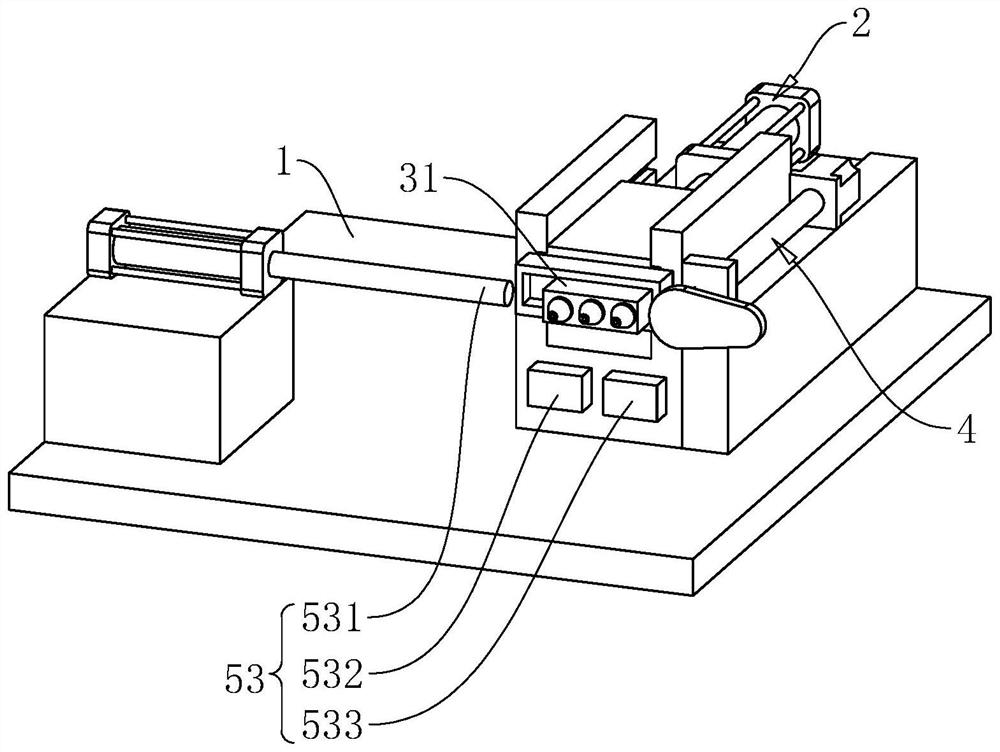

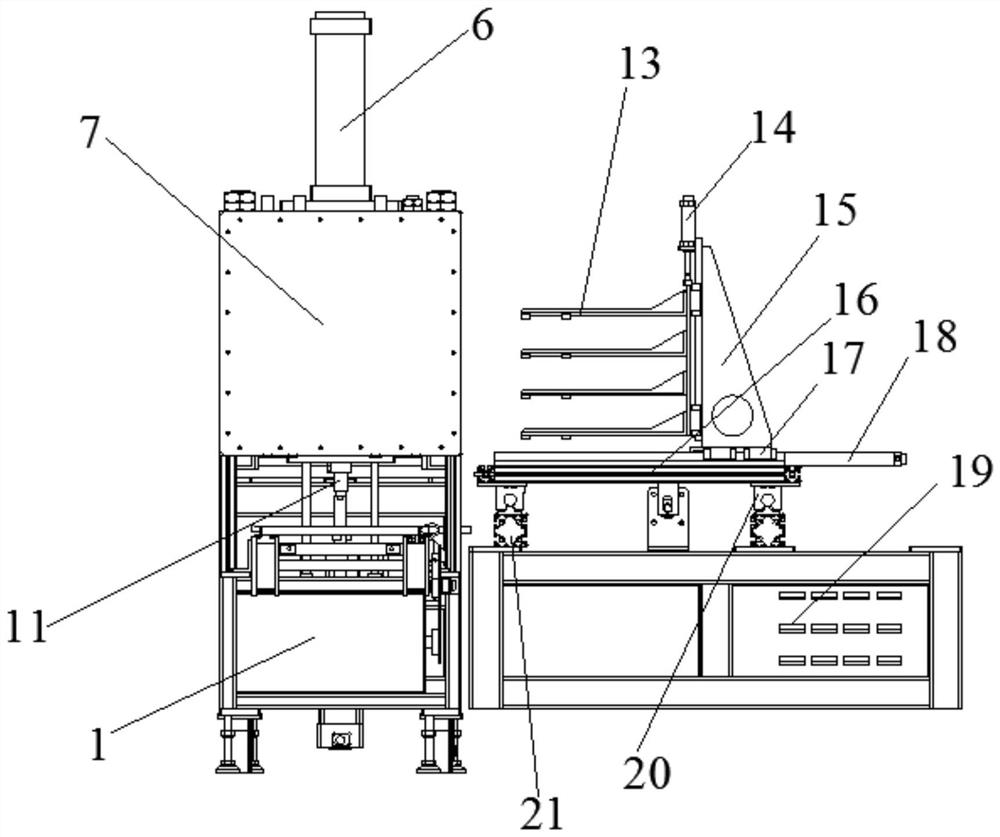

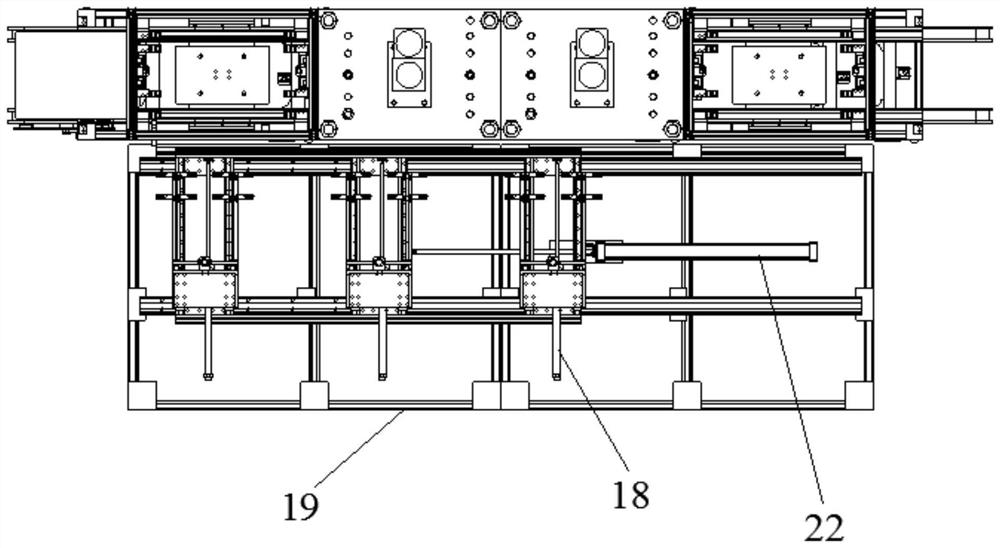

Stamping equipment for guard plate of computer case

ActiveCN111531027AAvoid misalignmentImprove transfer efficiencyPerforating toolsMetal-working feeding devicesHydraulic cylinderStamping

The invention discloses stamping equipment for a guard plate of a computer case. The stamping equipment realizes simultaneous stamping machining of a plurality of blank plates at one time, adopts a manipulator for automatic transferring, and improves the efficiency of blank transferring and stamping. According to the stamping equipment, anti-backlash-dislocation mechanisms are arranged, when the blank plates located on the lower layer and forming dies located on the lower layer generate backlash acting force on forming dies and the blank plates above the same to enable the blank plates to be dislocated at the moment when a stamping hydraulic cylinder stamps the plurality of blank plates simultaneously, the anti-backlash-dislocation mechanisms can prevent adverse effects generated when theplurality of blank plates are stamped simultaneously effectively, each anti-backlash-dislocation mechanism comprises an anti-backlash driver and a detection and triggering mechanism, and the detectionand triggering mechanisms are arranged so that the driving action time of the anti-backlash drivers can be located at the moment after the action of the stamping hydraulic cylinder to prevent the influence of the backlash effect of the backlash force on the stamping hydraulic cylinder from causing the influence of dislocation between the forming dies and the blank plates.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

A new type of punch

Owner:MINGXUDONGGUAN PRECISION MACHINARY CO LTD

Stamping equipment for computer case shield

ActiveCN111531027BImprove transfer efficiencyImprove stamping efficiencyPerforating toolsMetal-working feeding devicesHydraulic cylinderStamping

The invention discloses a stamping device for computer case guard plates, which realizes simultaneous stamping processing of multiple blank plates at one time, and adopts a manipulator for automatic transfer, which improves the efficiency of blank transfer and stamping. The invention sets anti-recoil The dislocation mechanism, the anti-recoil dislocation mechanism is configured to enable the stamping hydraulic cylinder to simultaneously stamp multiple blank plates, and the blank plate in the lower layer and the forming die in the lower layer react to the forming die and blank plate above it. The impact force causes the blank plate to be dislocated, which can effectively prevent the adverse effects of simultaneous stamping on multiple blank plates. The anti-recoil dislocation mechanism includes an anti-recoil driver and a detection and trigger mechanism. By setting the detection and trigger mechanism, it can be The driving action time of the anti-recoil driver is located immediately after the action of the stamping hydraulic cylinder, so as to prevent the impact of the recoil force on the recoil action of the stamping hydraulic cylinder from causing the misalignment of the forming die and the blank plate.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

High-wear-resistance composite resin filling material equipment

InactiveCN108311799ARapid stampingRealize stampingLaser beam welding apparatusSteering wheelLaser cutting

The invention discloses high-wear-resistance composite resin filling material equipment. The equipment comprises a base and a machine box, wherein fixing blocks are arranged on the four corners of thebase at the same time, and fixing holes are formed in the fixing blocks; an empty groove is formed inside the machine box, and a steering wheel is arranged at the upper end of the empty groove; a placing cavity is formed in the left side of the interior of the steering wheel, and a second motor is fixedly connected to the upper end wall of the placing cavity; a steering hole is rotatably connected with a third steering shaft through a bearing inside the steering hole, and the lower end of the third steering shaft is fixedly connected with an annular cutting device; a laser cutting knife is arranged at the lower end of the annular cutting device, and a cylinder body is fixedly connected to the right side of the lower end face of the steering wheel; and a pushing cavity is formed in the cylinder body, and a pushing plate is arranged in the pushing cavity.

Owner:车传东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com