Stamping device and stamping pipe

A technology of mold printing and pulling device, which is applied in the field of mold printing tubes, and can solve the problems that heat shrinkable tubes cannot be realized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

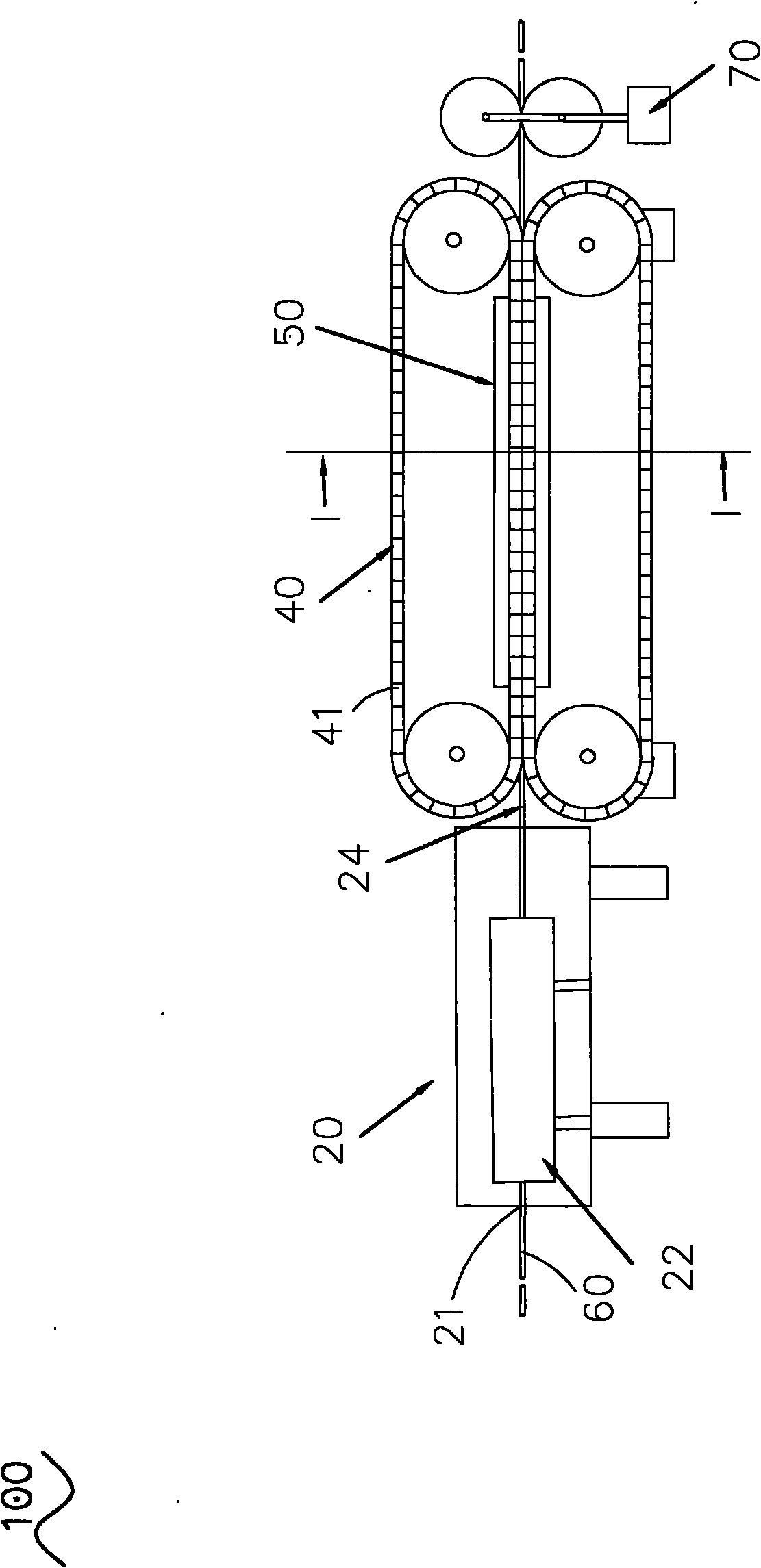

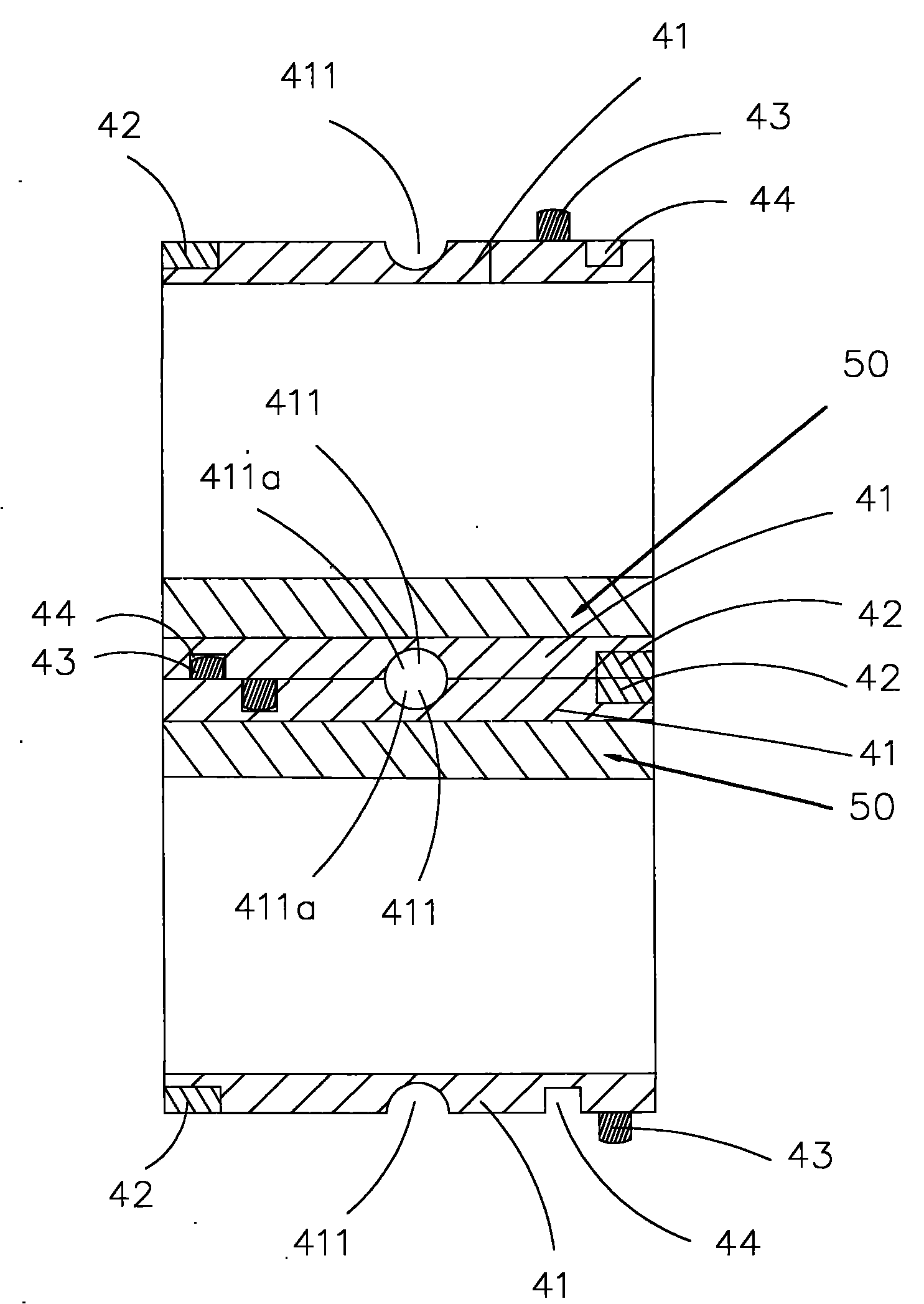

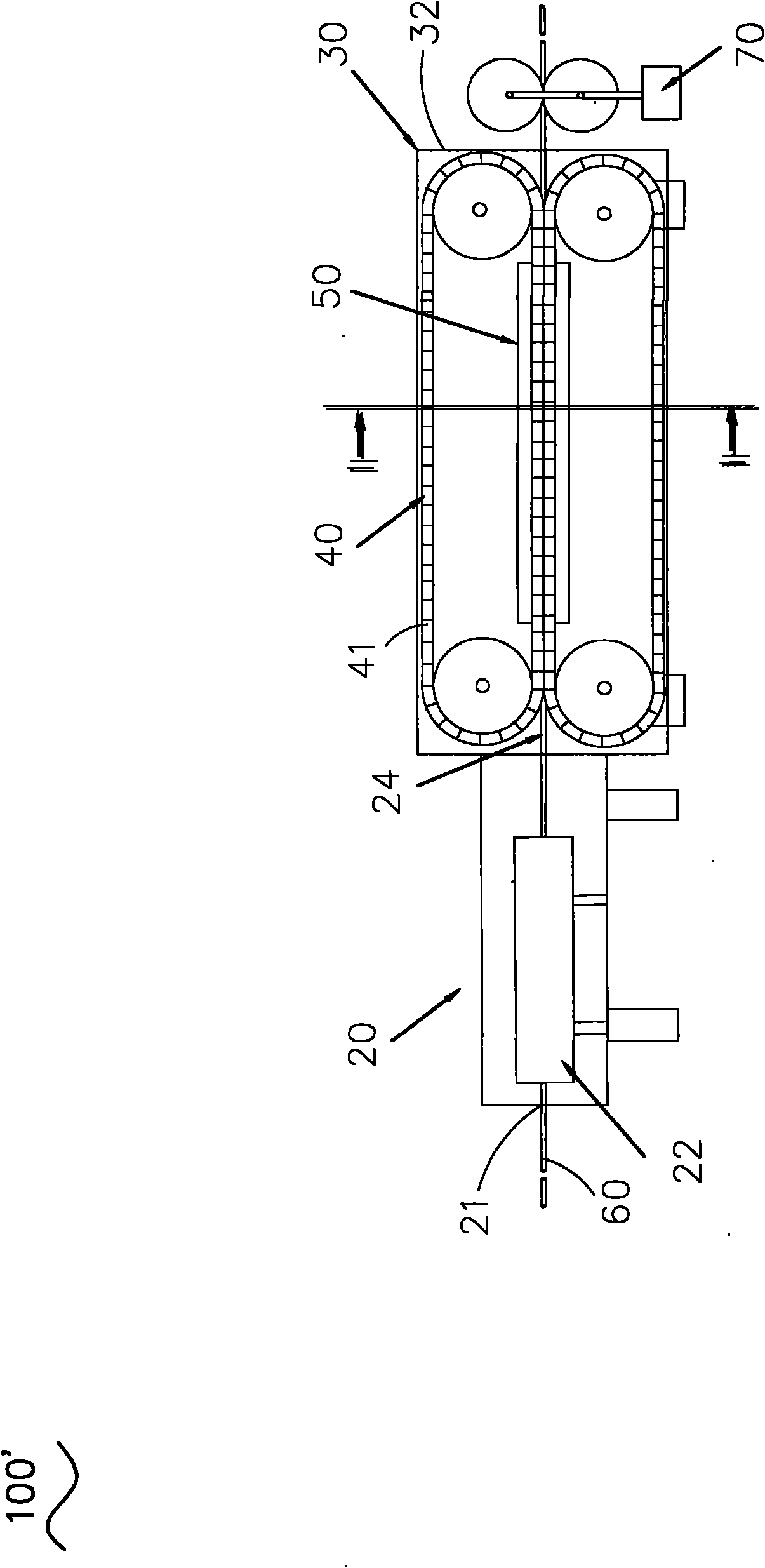

[0040] see figure 1 and figure 2 , which discloses the first embodiment of the stamping device 100 of the present invention, the stamping device 100 of the present invention includes a sealed box 20, an air pressure regulating device (not shown in the figure), two crawlers 40, several shoes 41 and traction device 70.

[0041] The sealing box 20 is a hollow sealing box, which is roughly in the shape of a cylinder, and has a perforation 21 passing through the sealing box 20. The perforation 21 has an annular hole wall, and the hole wall is in sealing connection with the outer wall of the sealing box 20. A hollow airtight box is formed. The perforation 21 is used as a passage for the heat-shrinkable tube 60 to penetrate. Of course, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com