Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Realize positioning work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

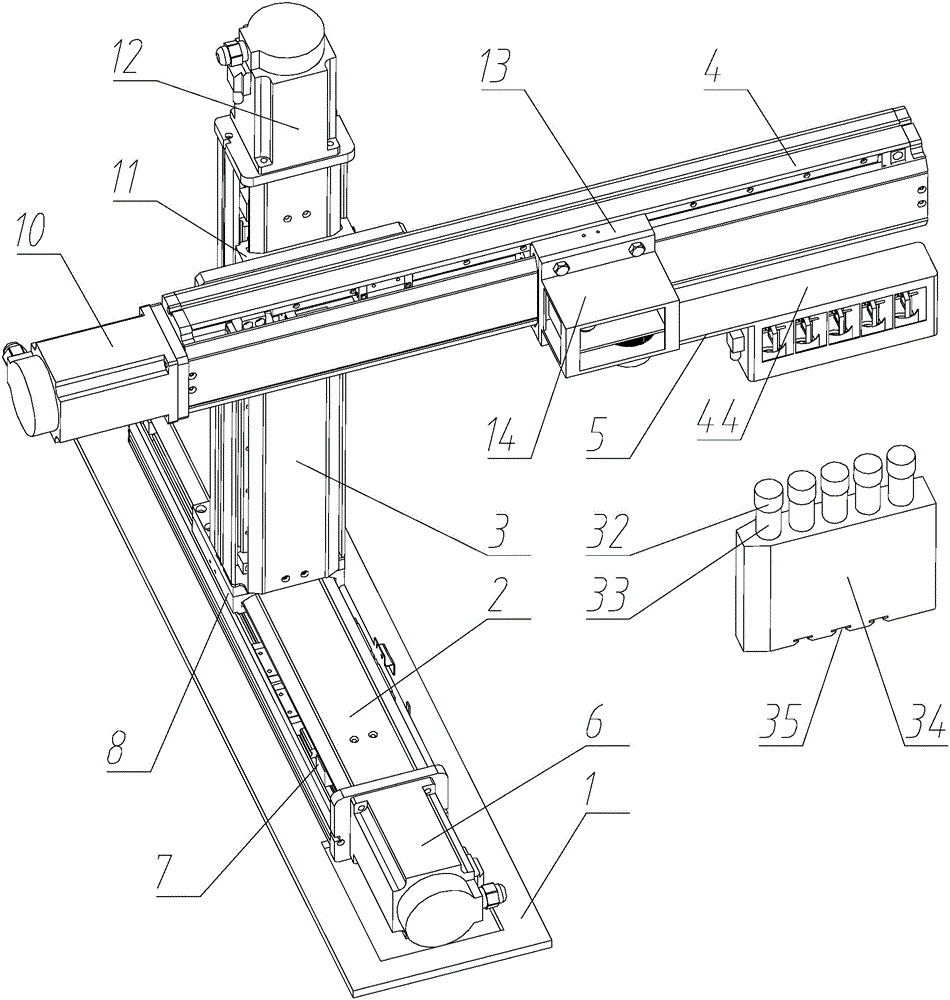

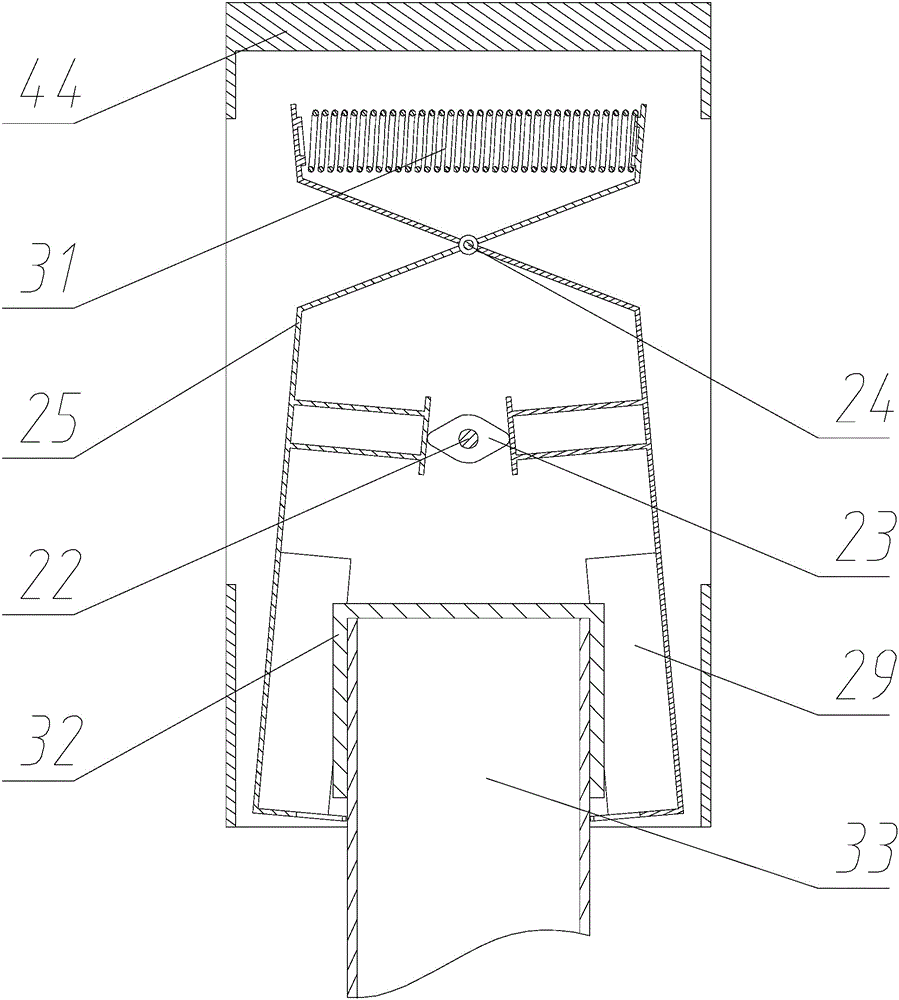

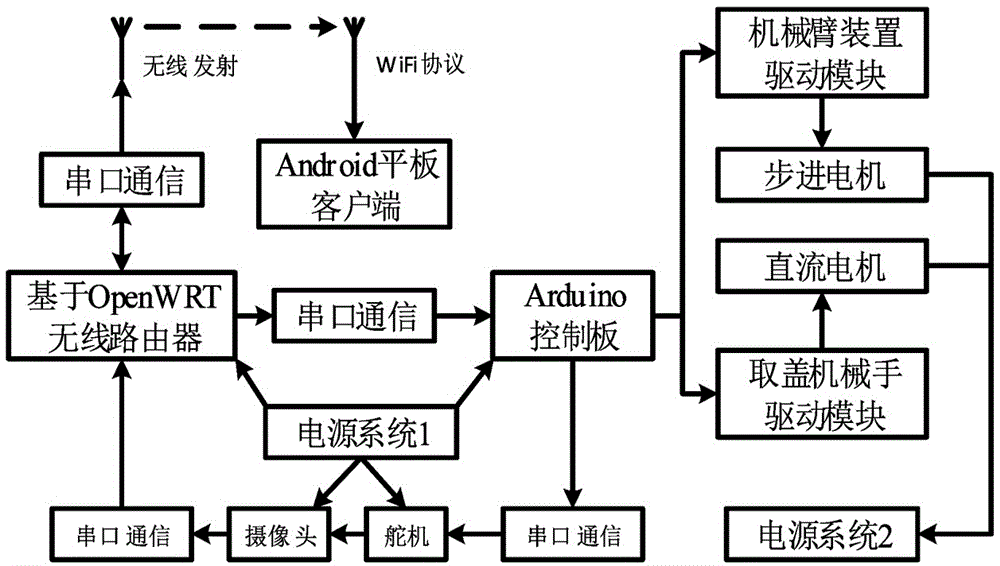

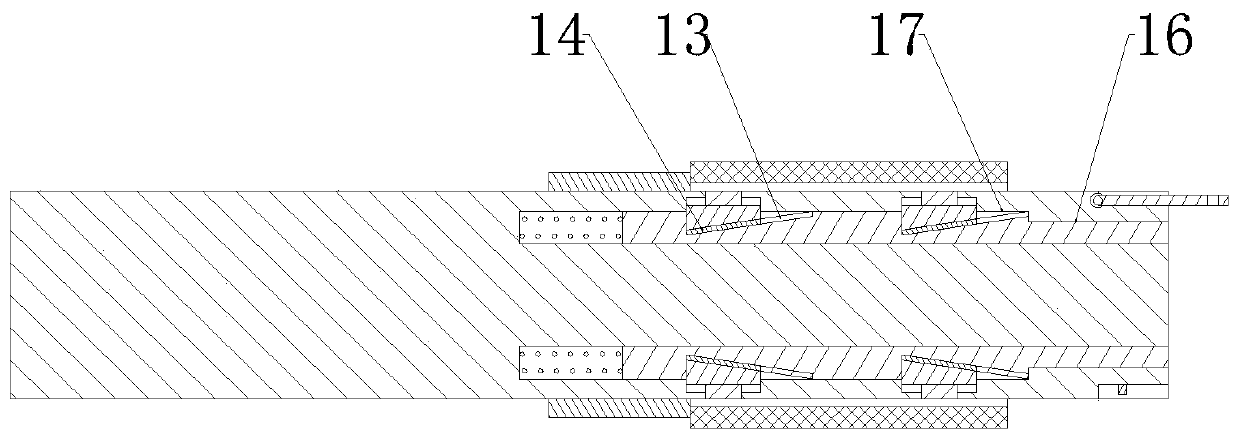

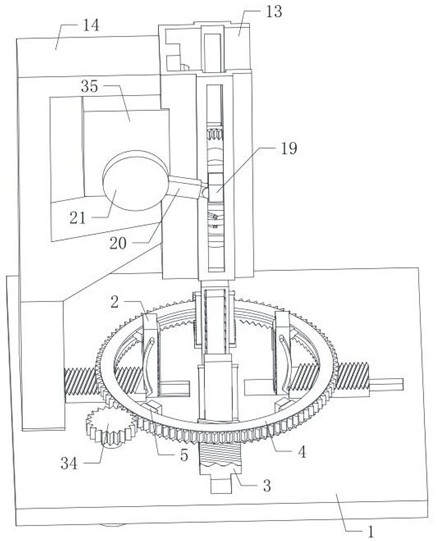

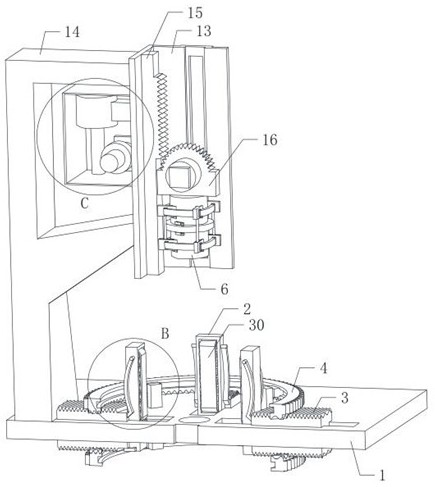

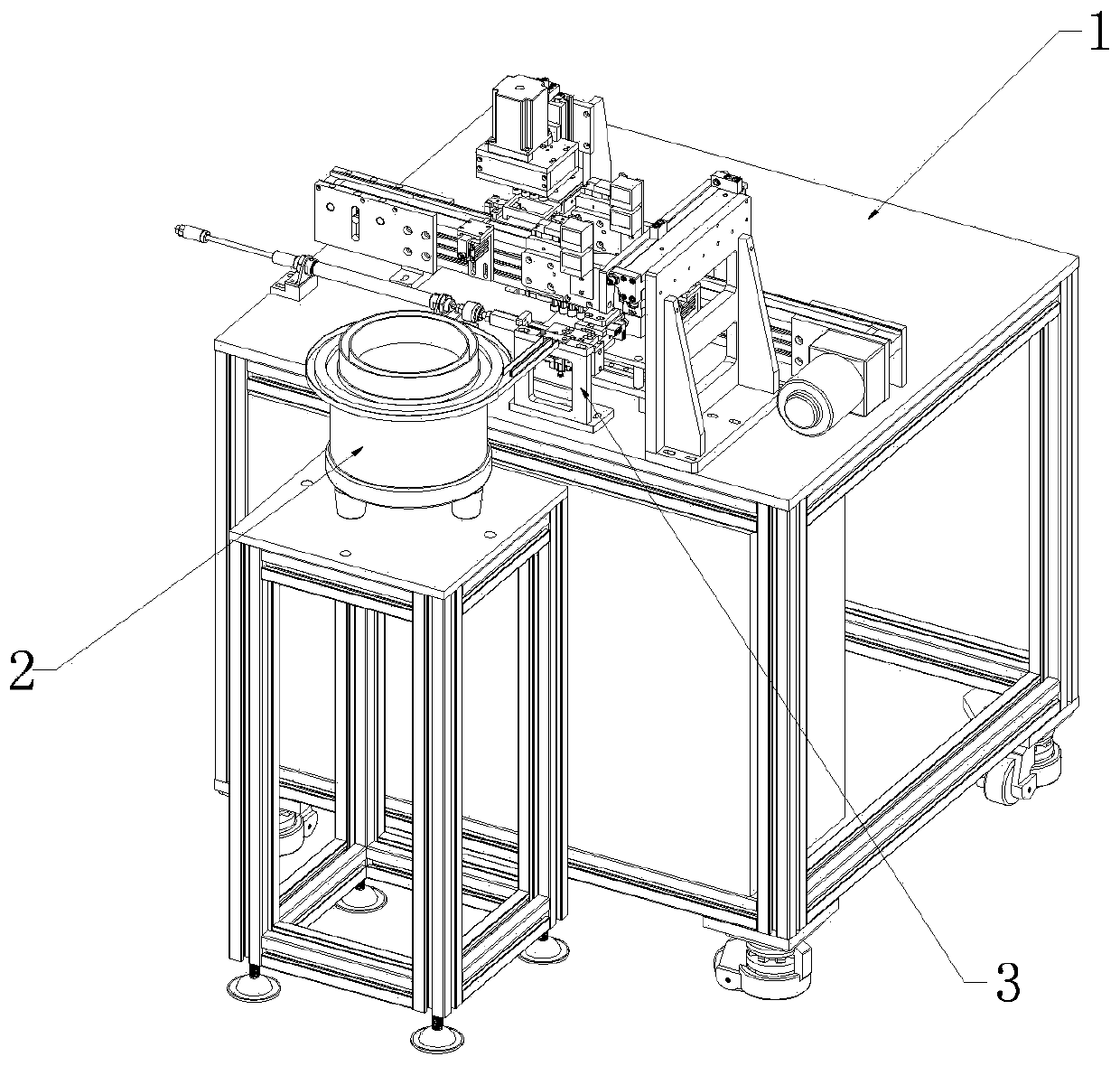

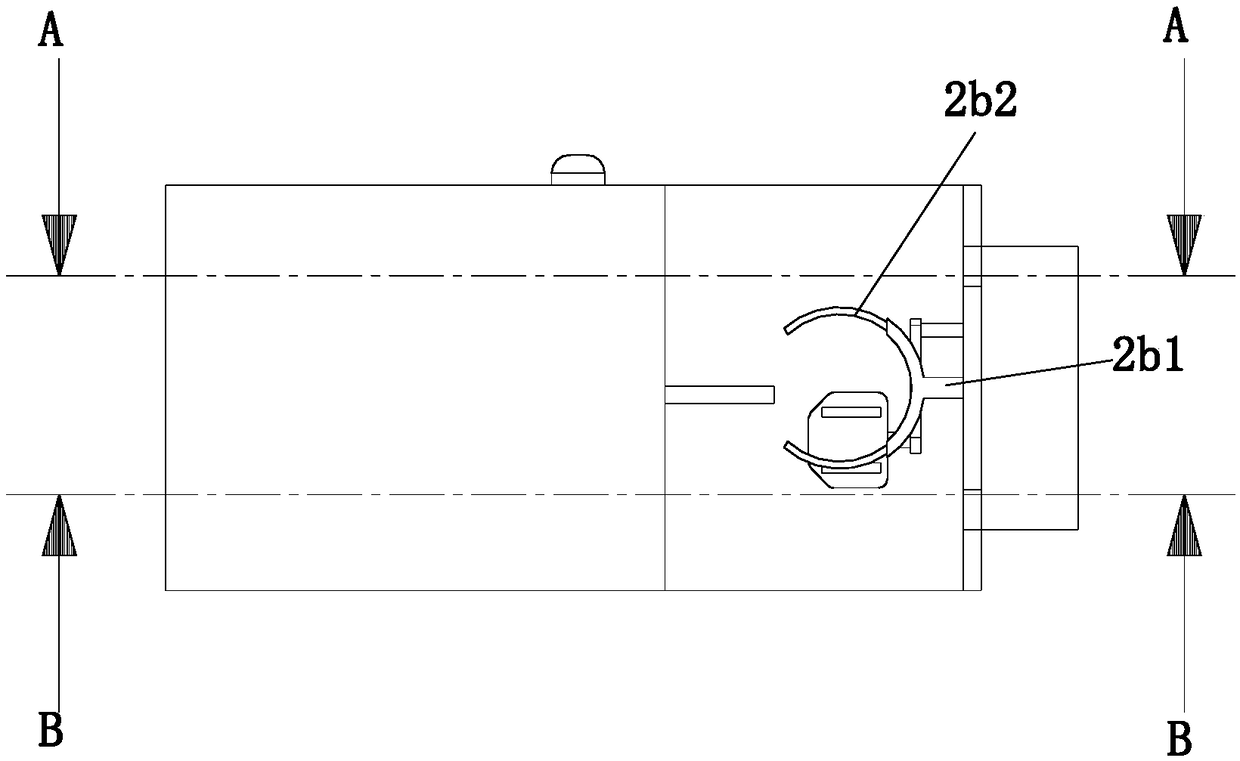

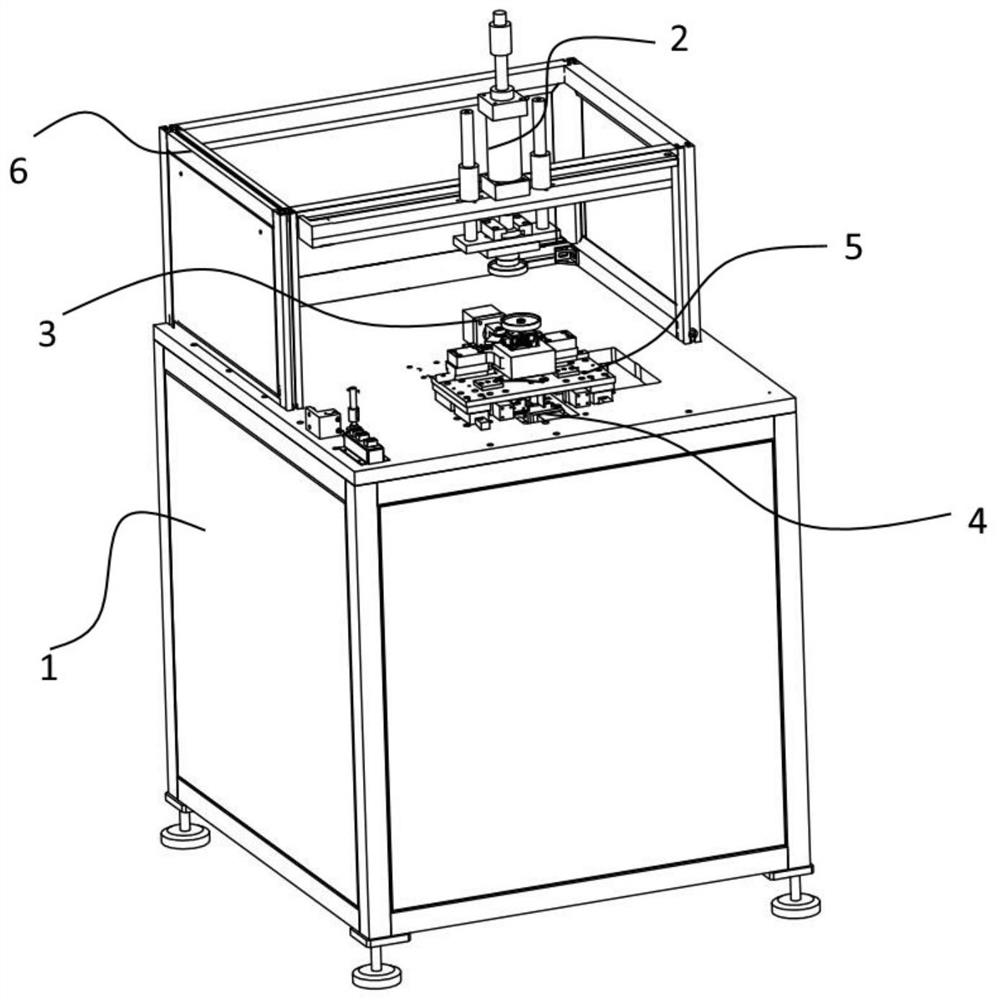

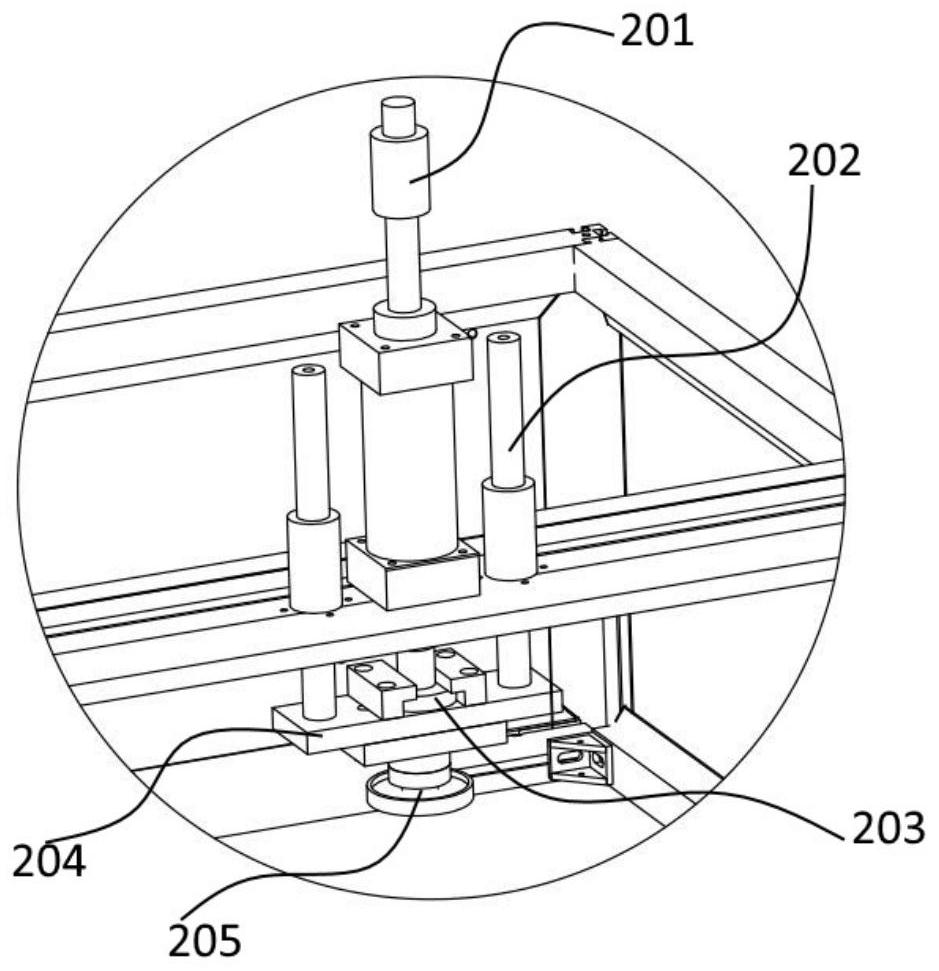

Automatic fast test tube cover taking robot and cover taking method

ActiveCN106272368AReduce the numberTime-consuming and laborious to solveProgramme-controlled manipulatorGripping headsBlood collectionEngineering

The invention relates to an automatic fast test tube cover taking robot and a cover taking method. The robot comprises a base, wherein an X-axis mechanical arm for controlling movements in front and back directions is arranged on the base, a Z-axis mechanical arm for controlling up and down movements is vertically arranged on the X-axis mechanical arm, a Y-axis mechanical arm for controlling left and right movements is vertically arranged on the Z-axis mechanical arm, and a cover taking mechanical hand is arranged on the Y-axis mechanical arm; and a mechanical arm rotation driving mechanism is arranged at one end of the cover taking mechanical hand, and a cover taking mechanism is arranged at the other end. The automatic fast test tube cover taking robot can automatically complete a cover taking task of a blood collection test tube, can adapt to blood collection test tubes and test tube racks in different specifications, and can recover test tube covers.

Owner:CHINA THREE GORGES UNIV

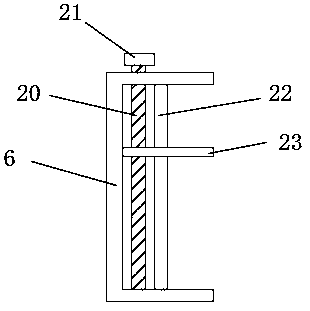

Mechanical electrical positioning device

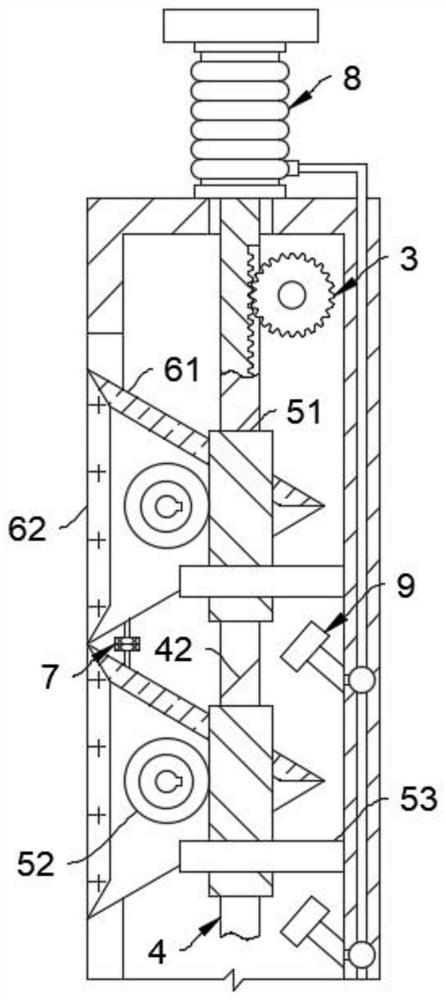

InactiveCN108705477ARealize positioning workTo achieve the purpose of positioningWork holdersLocking mechanismElectrical devices

The invention discloses a mechanical electrical positioning device which comprises a bottom plate. Two symmetrically-arranged vertical columns are fixedly connected to the upper side wall of the bottom plate, and a supporting plate is fixedly connected between the two vertical columns. An air cylinder is arranged below the supporting plate and fixedly connected with the upper side wall of the bottom plate. The output end of the air cylinder is fixedly connected with a telescopic rod, and the upper end of the telescopic rod is fixedly connected with a moving rod which is slidably connected withtwo symmetrically-arranged sliding blocks in a sleeved mode. A first rotating rod and a second rotating rod are rotationally connected to each sliding block, and fixing blocks are fixedly connected to the side walls of the sides, close to each other, of the two vertical columns correspondingly and located above the moving rod. The mechanical electrical positioning device has the advantages that through arrangement of a clamping mechanism, the mounting positioning effect on mechanical electrical equipment can be achieved, waggle of the equipment in the mounting process is reduced, and thus themounting error is avoided; and through arrangement of idler wheels, device transferring is facilitated, and through arrangement of a locking mechanism, the whole device can be fixed.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

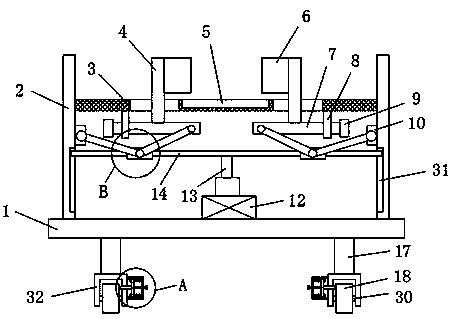

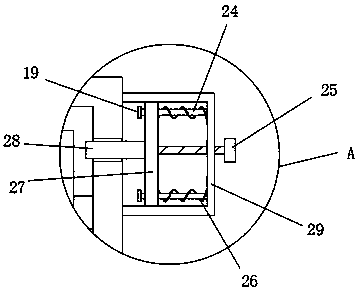

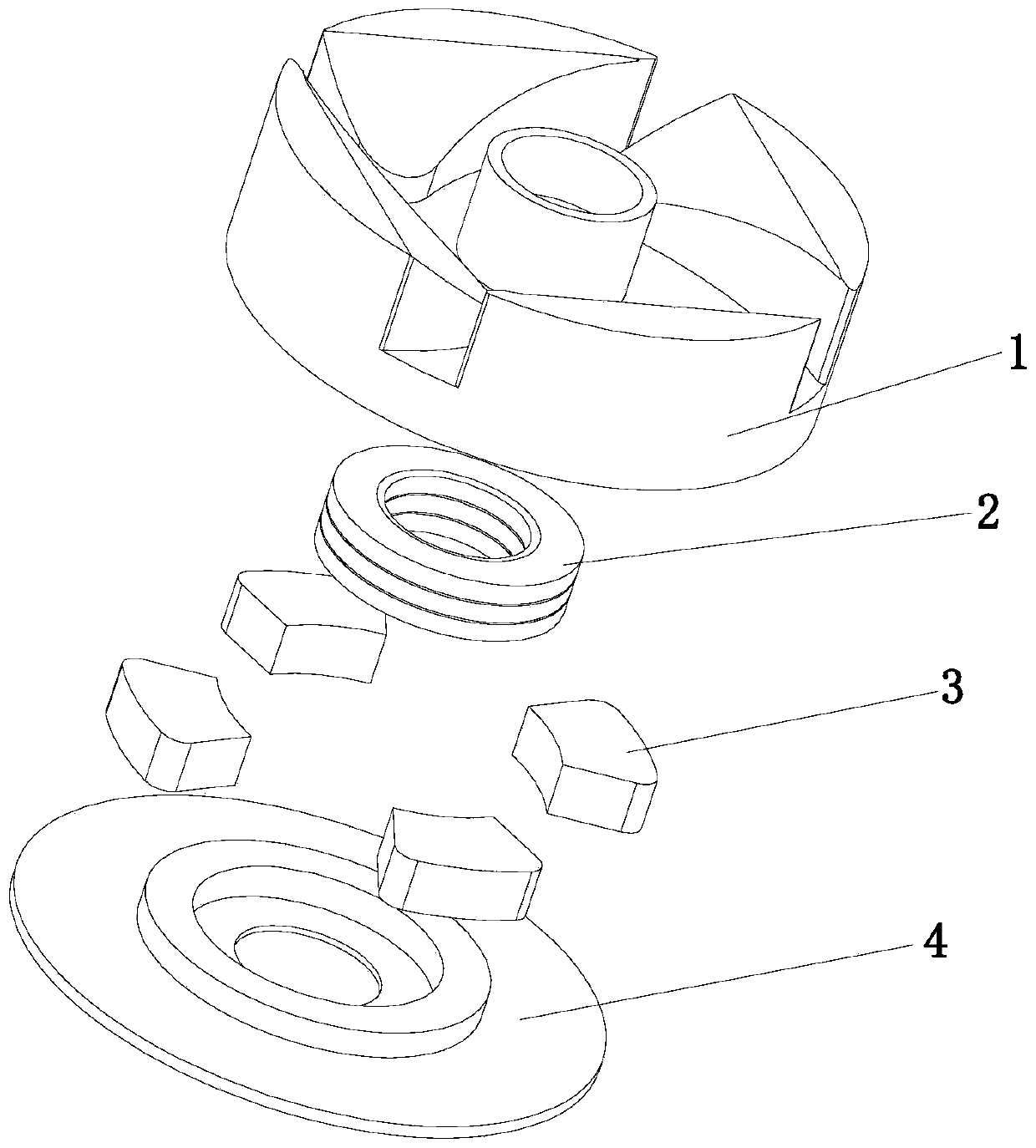

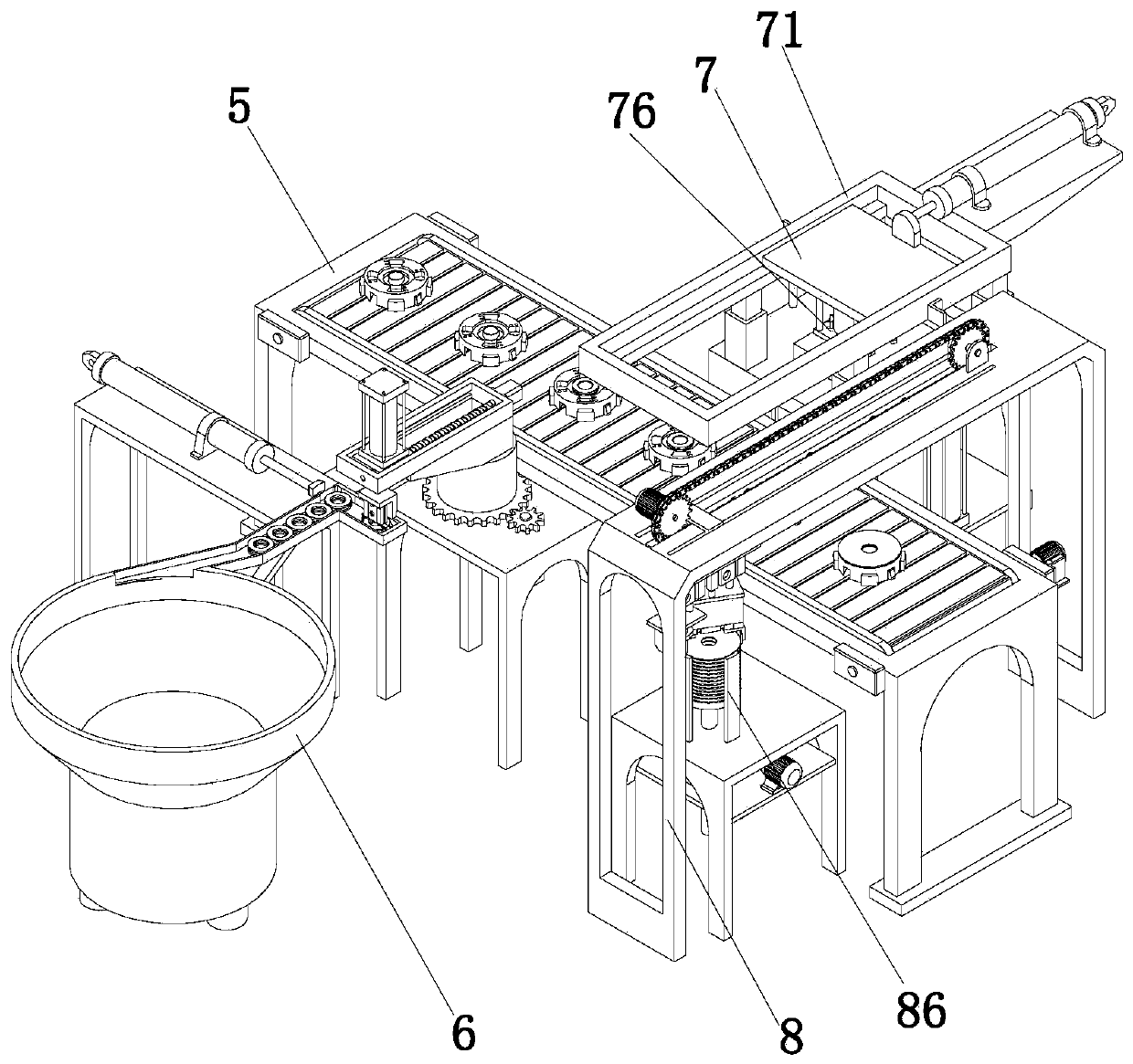

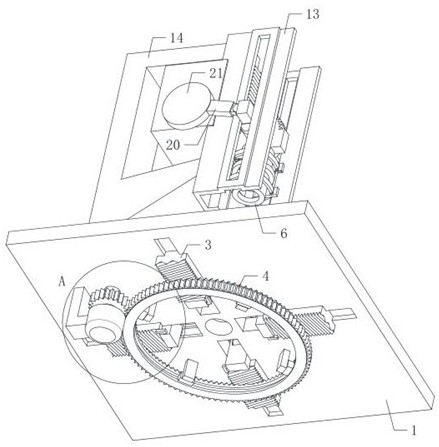

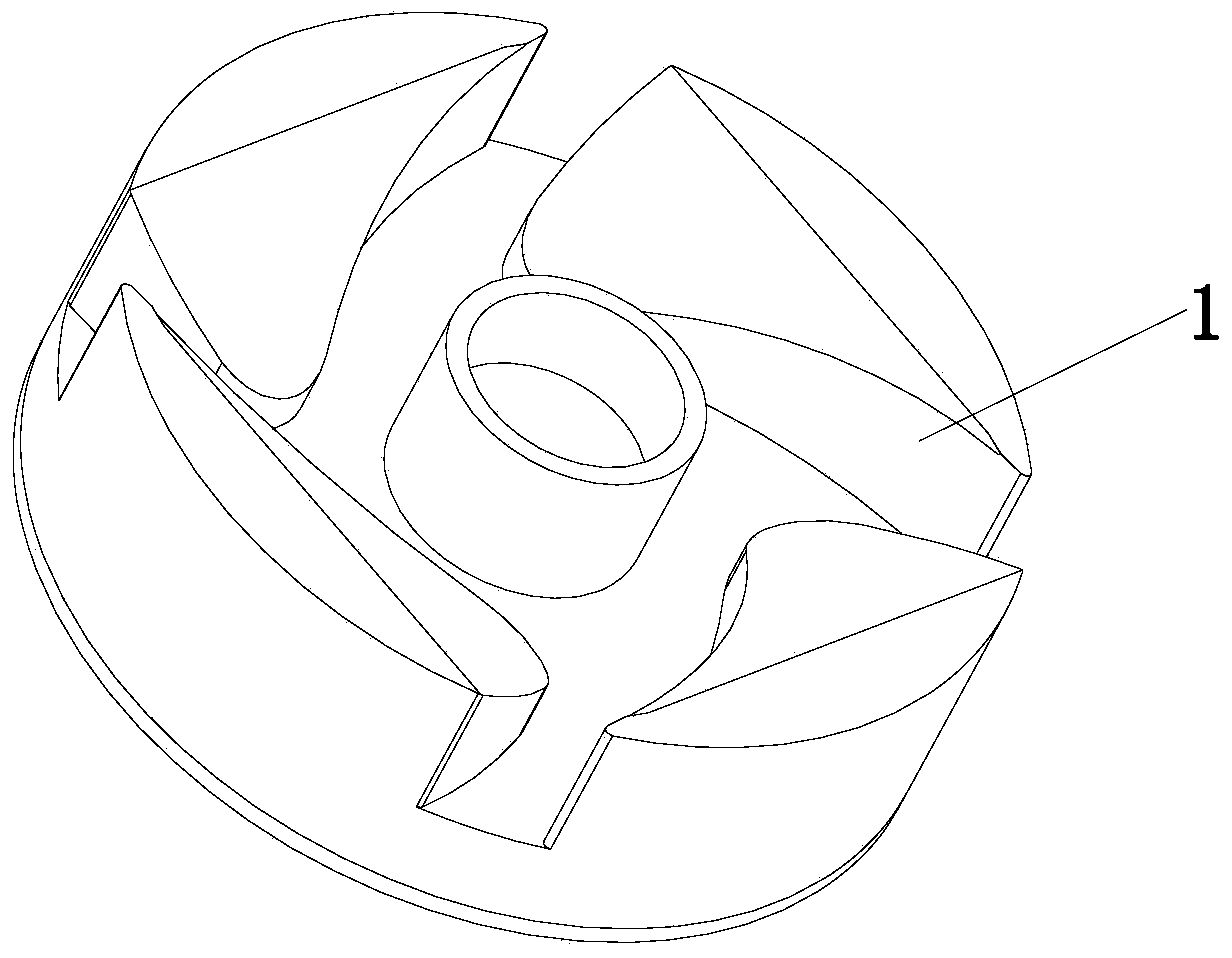

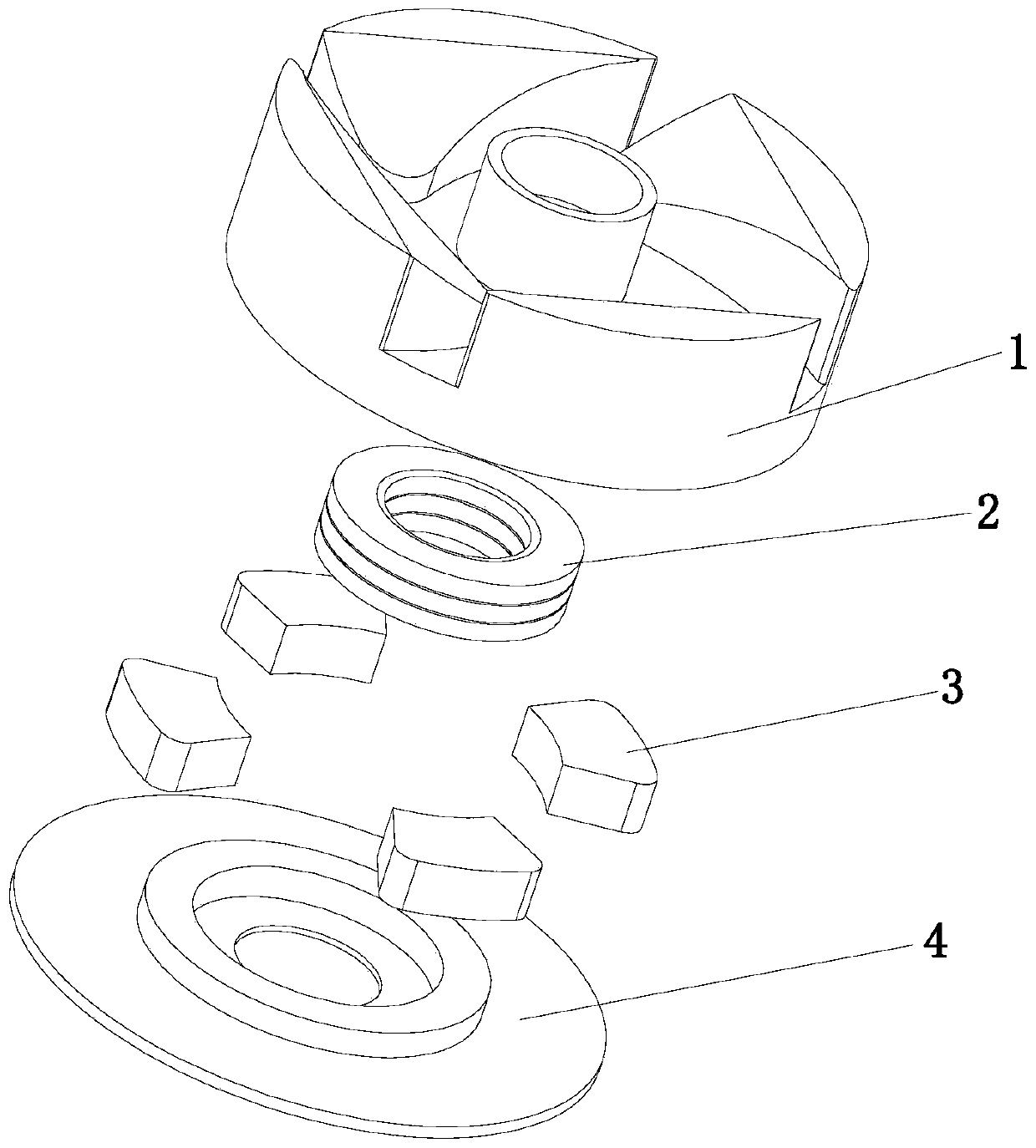

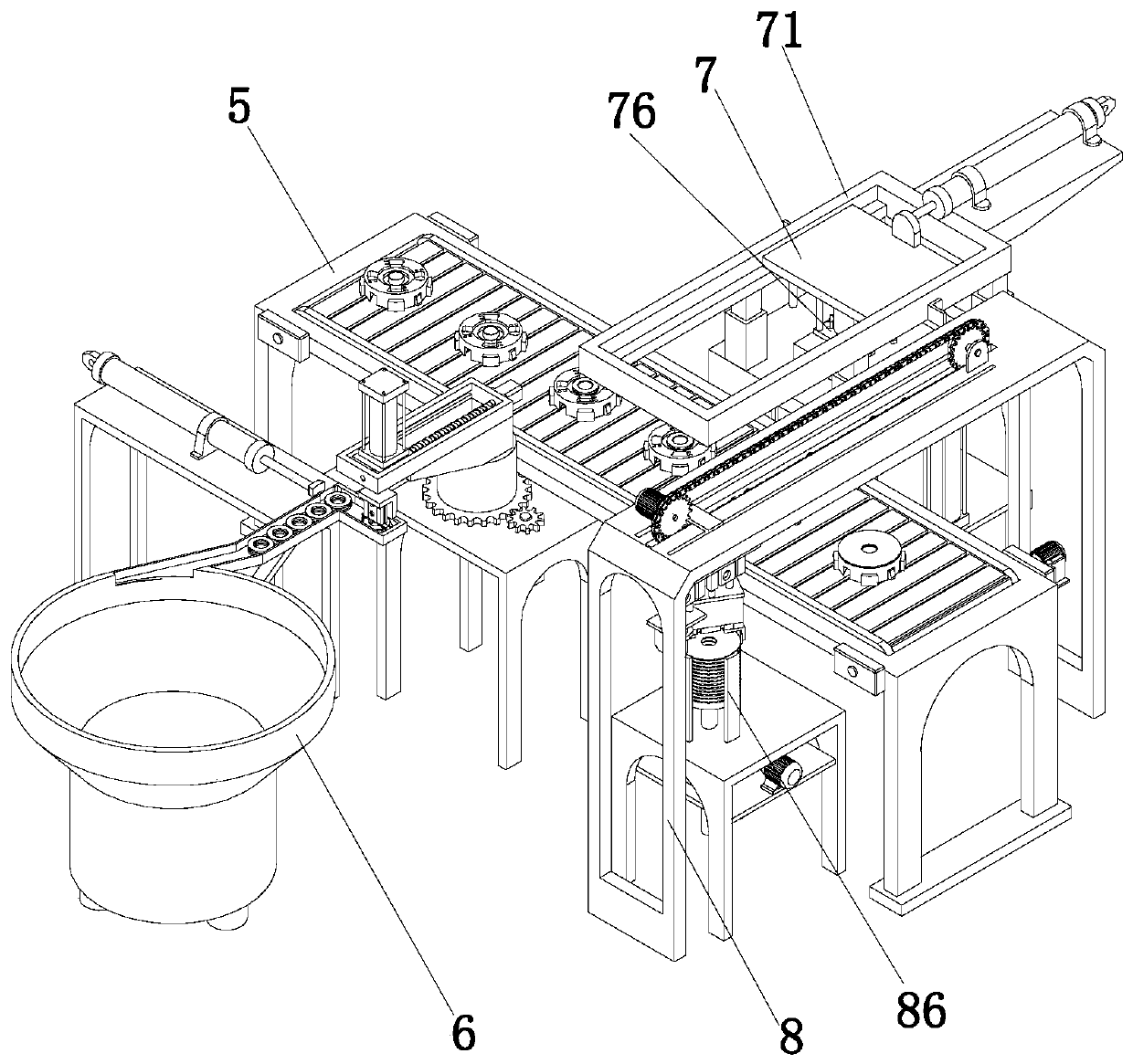

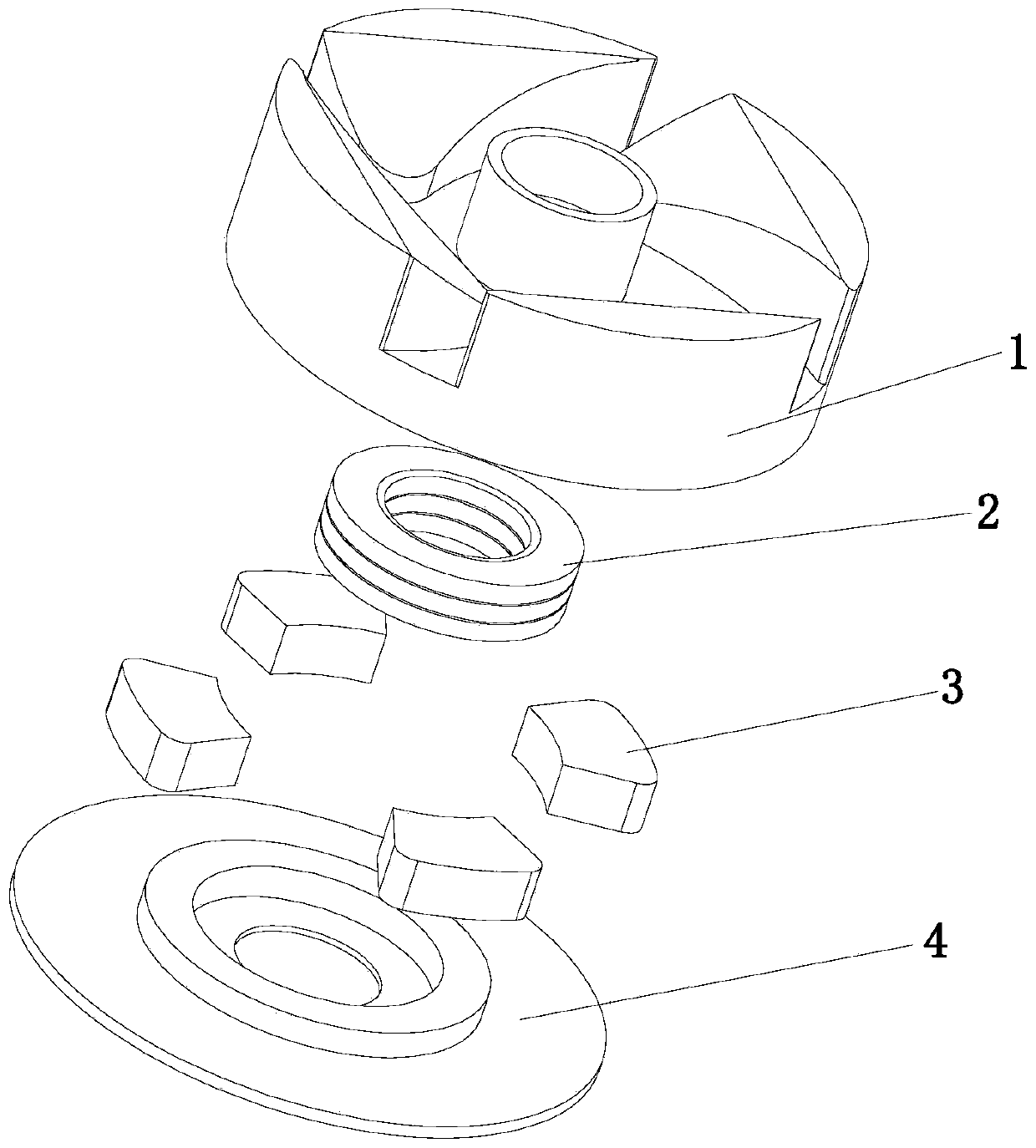

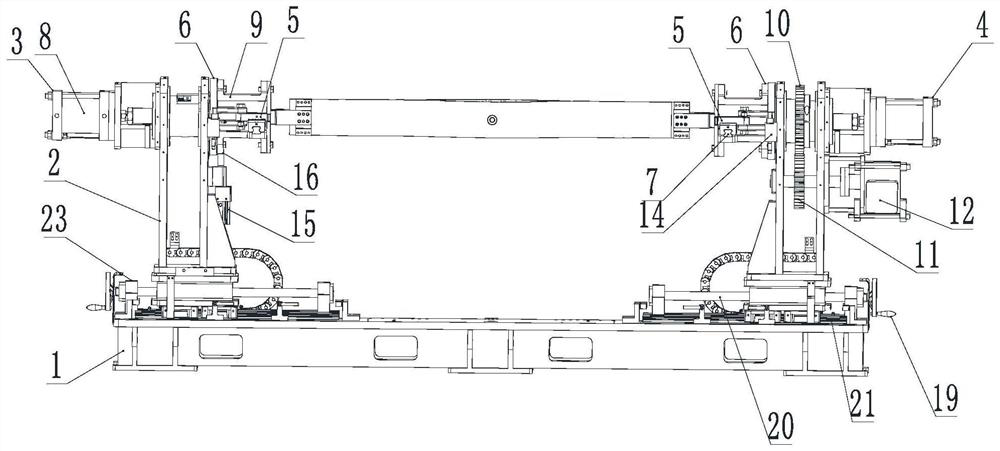

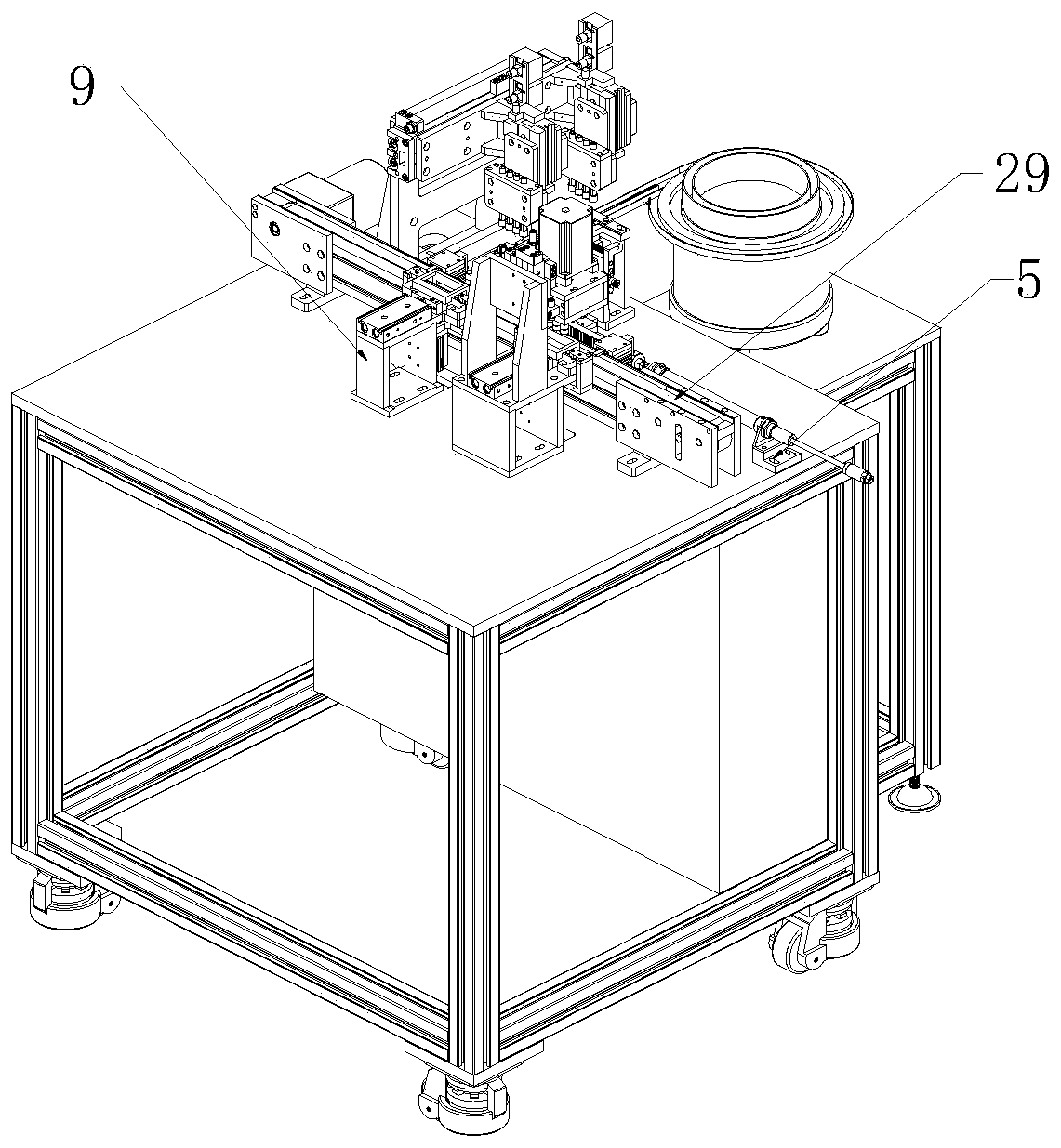

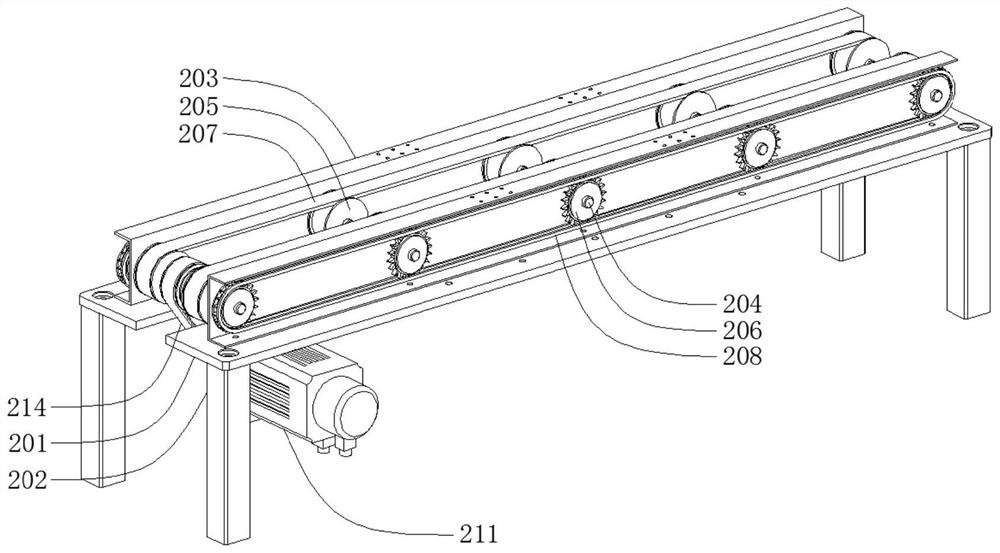

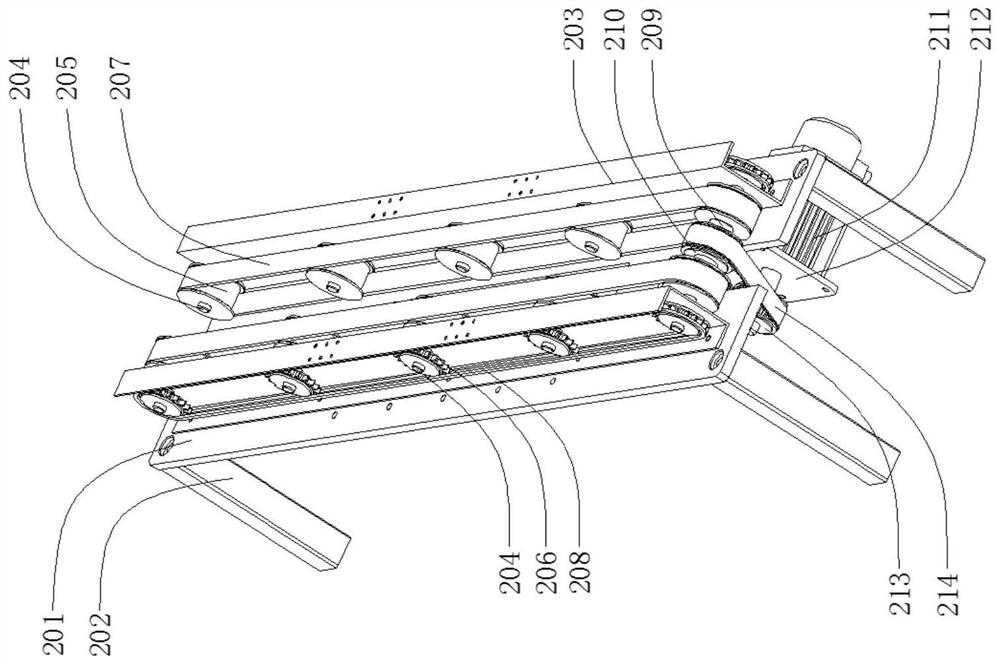

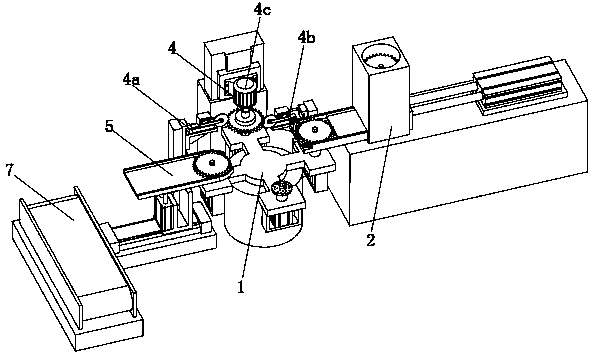

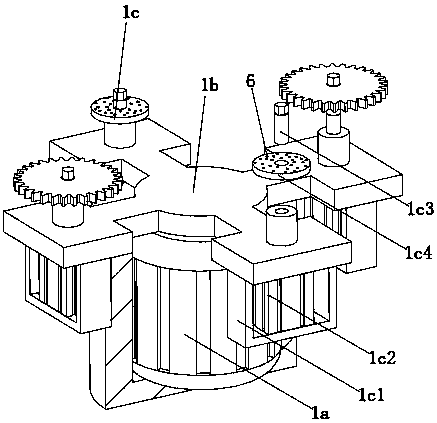

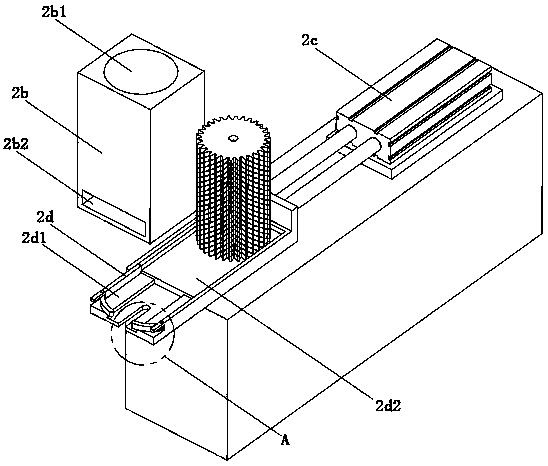

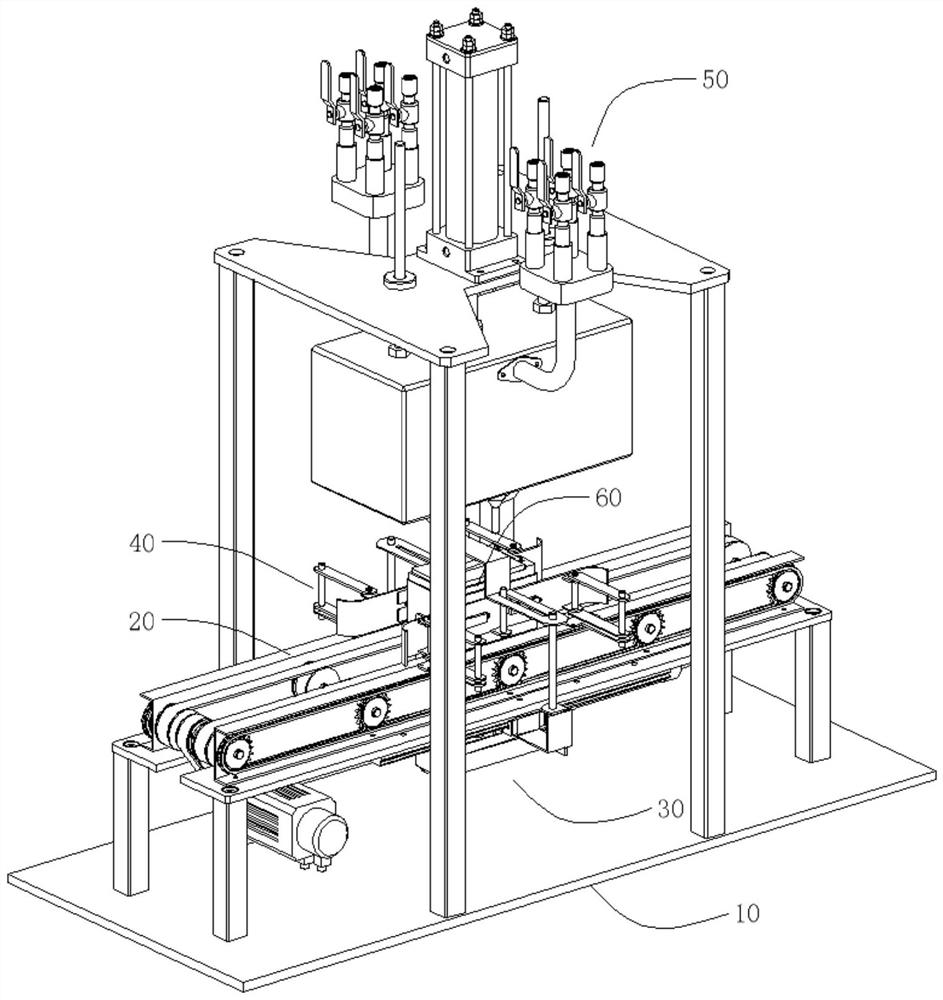

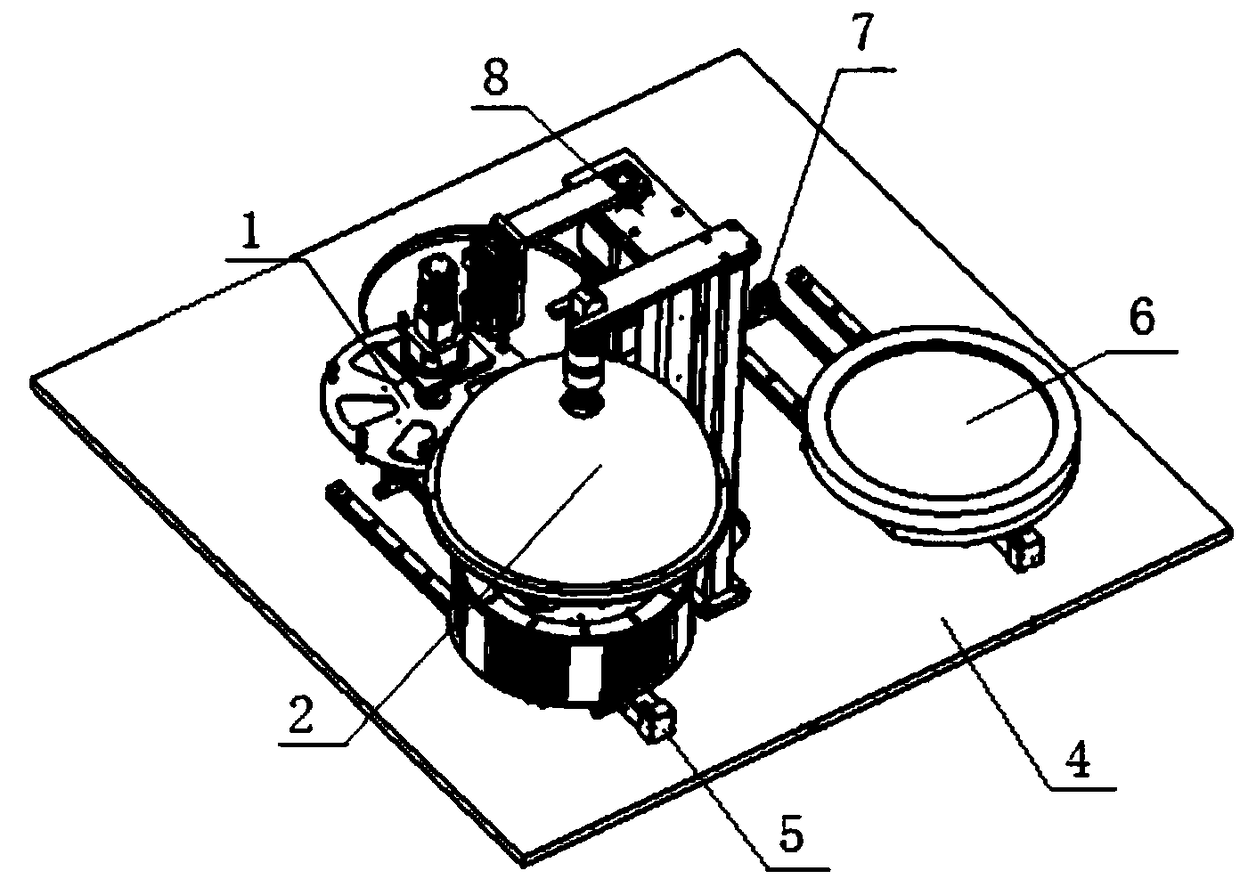

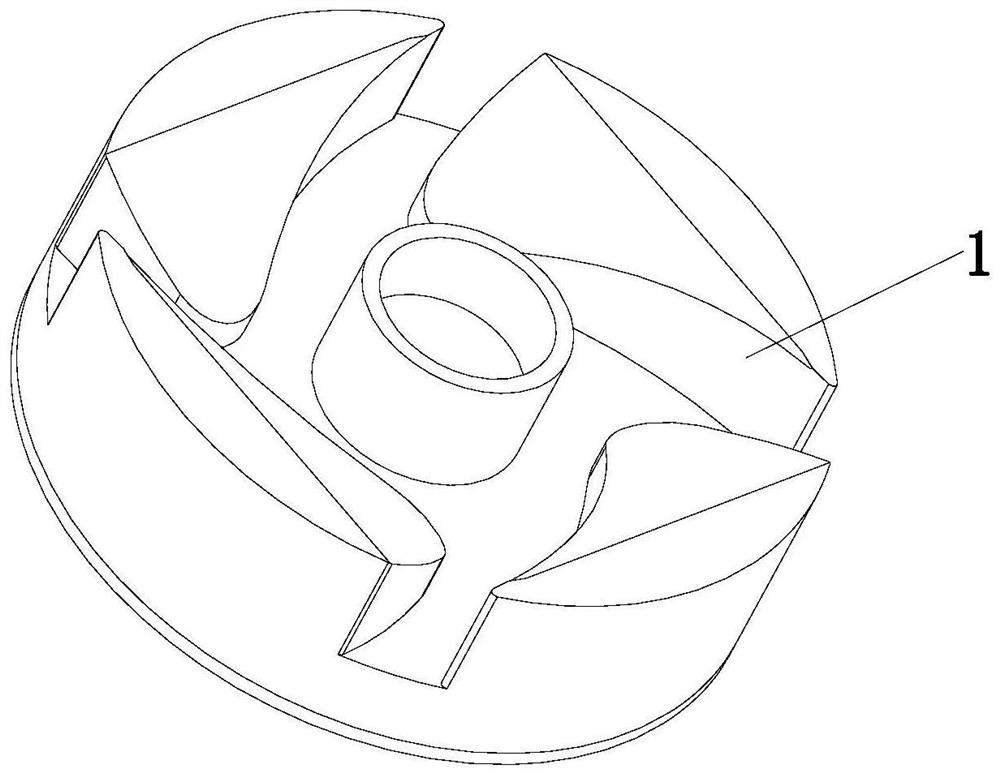

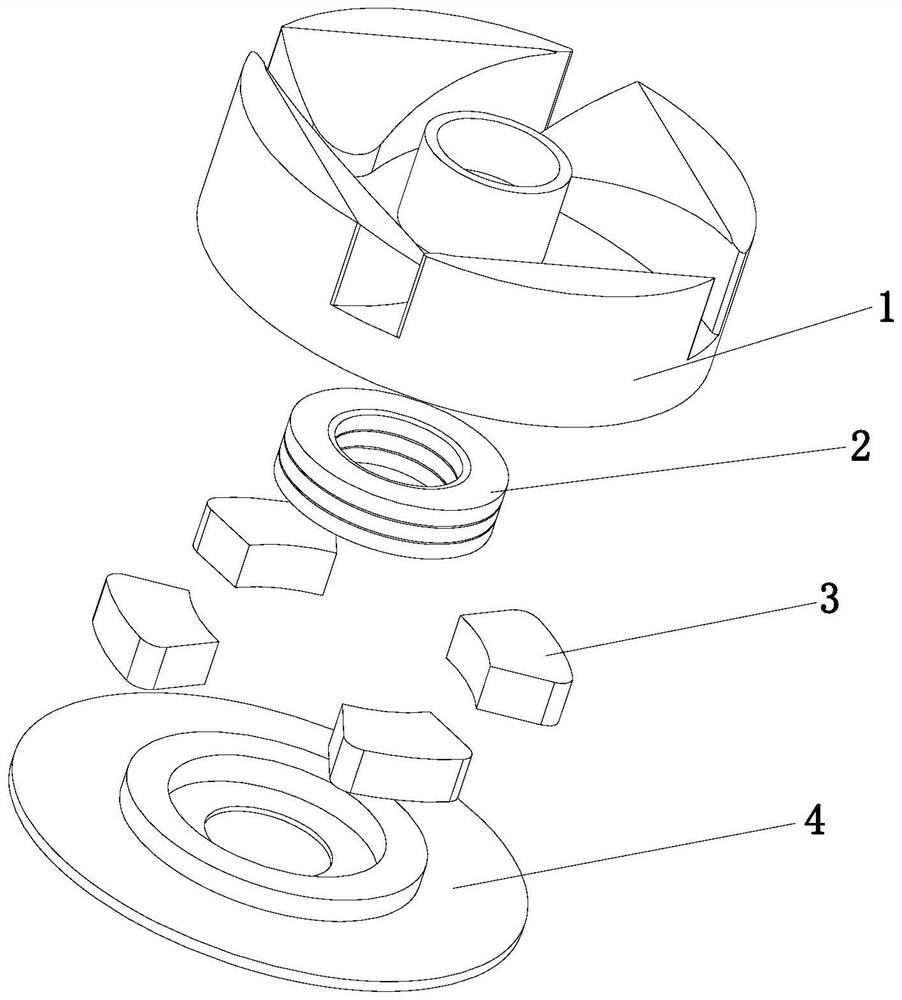

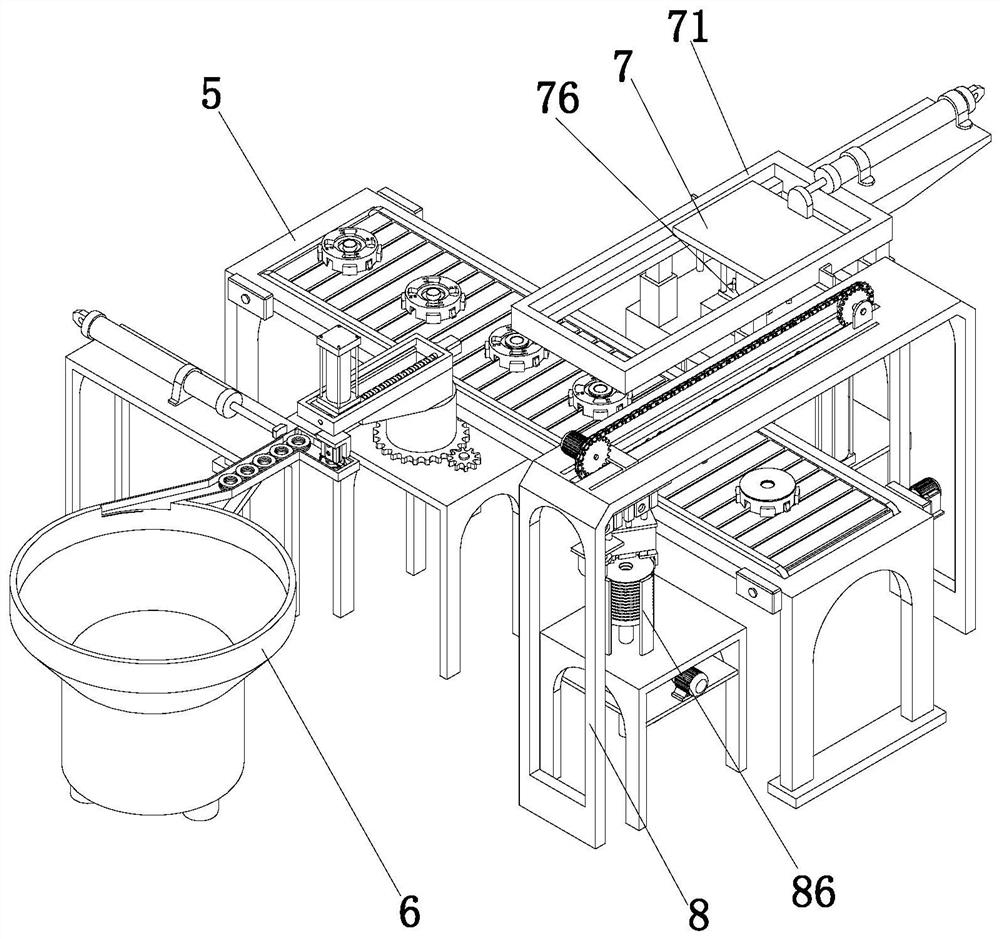

Assembly production line of centrifugal blood pump rotor

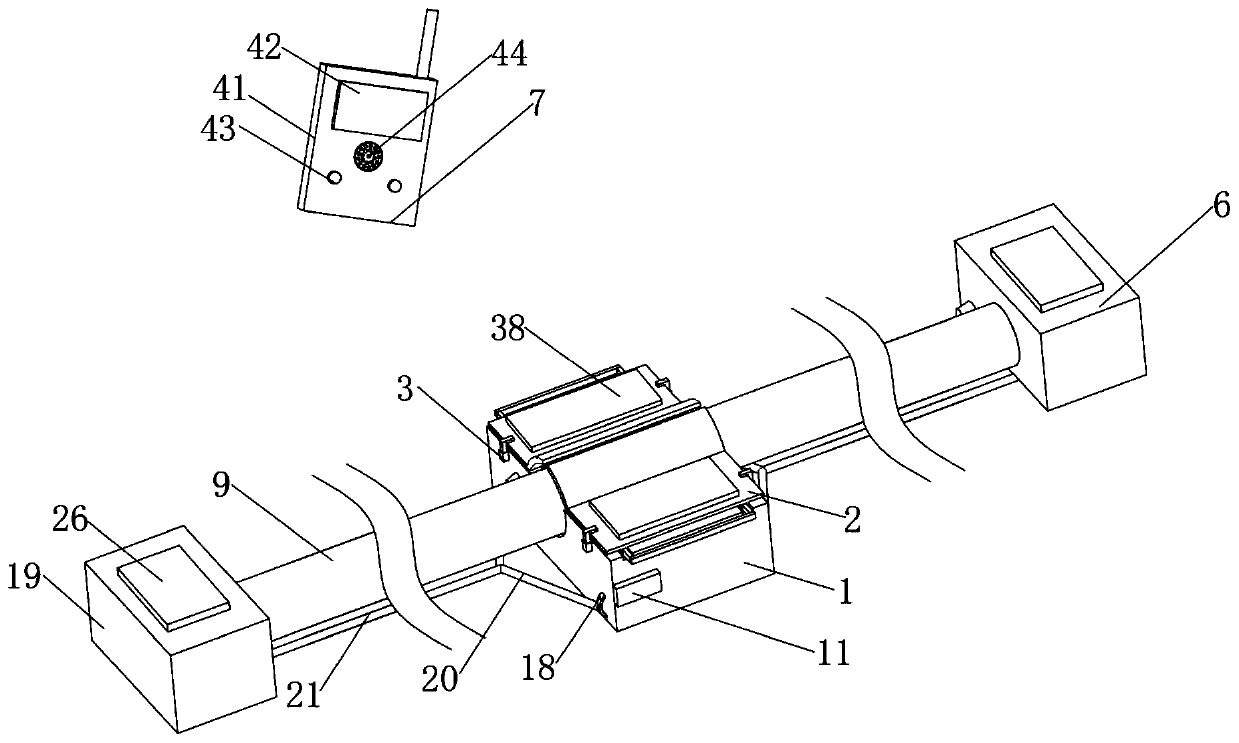

ActiveCN110900028ASolve efficiency problemsAddress the degree of automationMetal working apparatusWelding apparatusImpellerBlood pump

The invention discloses an assembly production line of a centrifugal blood pump rotor, and belongs to the technical field of assembling equipment. The assembly production line of the centrifugal bloodpump rotor involves a conveyor belt, a bearing magnetic stack press-fitting mechanism, a motor magnet installing mechanism and a base welding mechanism, wherein a plurality of limiting assemblies arearranged on the conveyor belt, the motor magnet installing mechanism comprises a sliding plate, a workbench, a material pushing assembly, a lifting assembly, a clamping assembly and a bearing frame,the clamping assembly comprises an installing plate, a four-jaw air cylinder and a limiting column arranged at the bottom of the installing plate, limiting plates are installed at the bottoms of clamping jaws of the four-jaw air cylinder, arc-shaped grooves are formed in the limiting plates, and four bearing rods are arranged between the installing plate and the sliding plate. According to the assembly production line, the bearing magnetic stack press fitting, the motor magnet installing and the base welding steps of the centrifugal blood pump rotor can be automatically completed, four motor magnets can be simultaneously installed in an impeller by the motor magnet installing mechanism, and a worker does not need to install the motor magnets one by one.

Owner:韶关市武江区冠启自动化设备设计有限公司

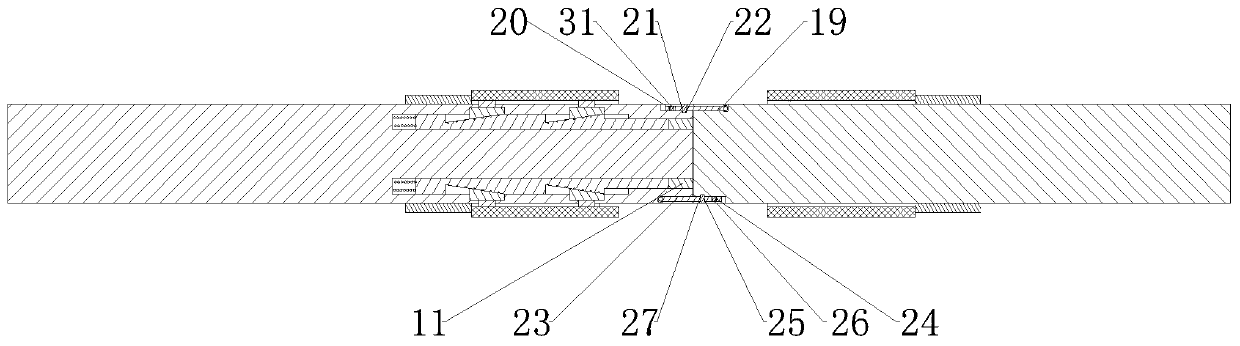

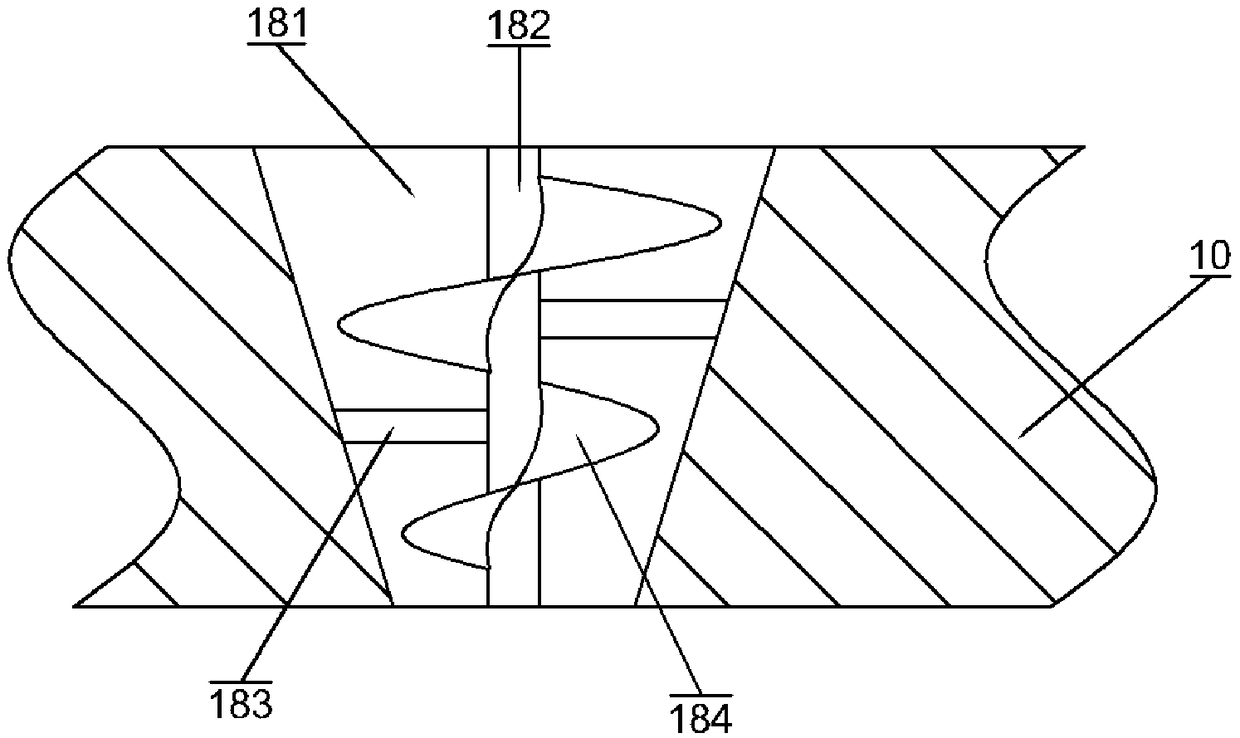

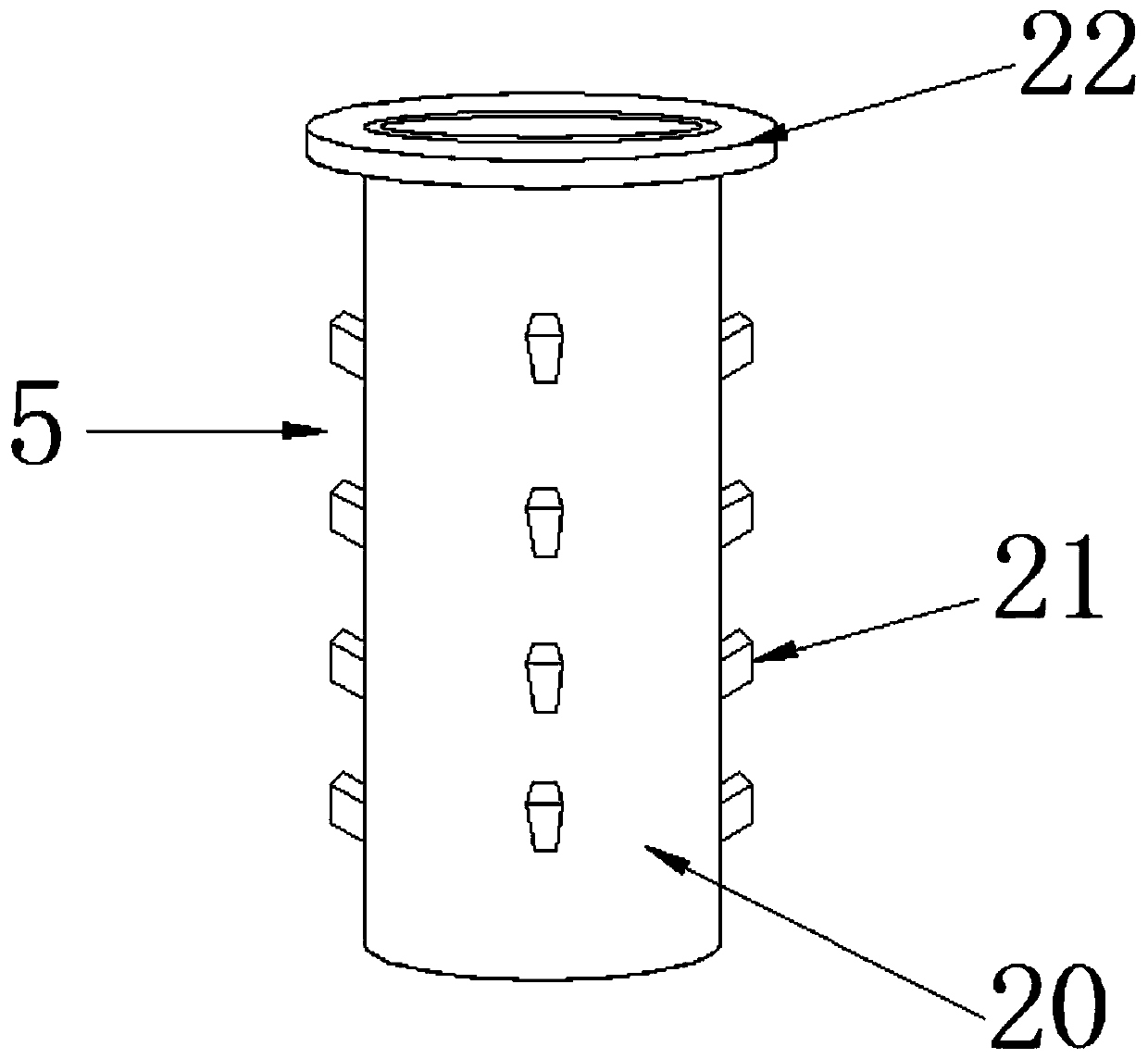

Detachable winding shaft structure

ActiveCN111003610ARealize positioning workRealize blanking workStructural engineeringMechanical engineering

The invention discloses a detachable winding shaft structure, which comprises a half shaft A and a half shaft B, wherein the half shaft B is detachably connected with the half shaft A through a connecting assembly; a plurality of annularly arranged locking grooves are formed in the inner side ends of the half shaft A and the half shaft B; telescopic notches corresponding to jacking notch grooves in number are formed in the outer ring surfaces of the half shaft A and the half shaft B; elastic pieces act on locking rods, so that the deepest part of each jacking notch groove can directly face a corresponding jacking sliding block, and the locking rods are located in the locking grooves respectively; and the inner side end of the half shaft B is provided with a plurality of jacking rods B which can be respectively placed in and matched with the plurality of locking grooves of the half shaft A. Through the arrangement of the locking rods and the jacking rods, the expansion arrangement of positioning bulges can be realized when the half shaft A and the half shaft B are connected, so that the positioning work of a winding drum is conveniently realized; and when the connecting assembly isunfastened, the positioning bulges can be accommodated, so that the discharging work of the winding drum is conveniently realized.

Owner:重庆巧琢工贸发展有限公司

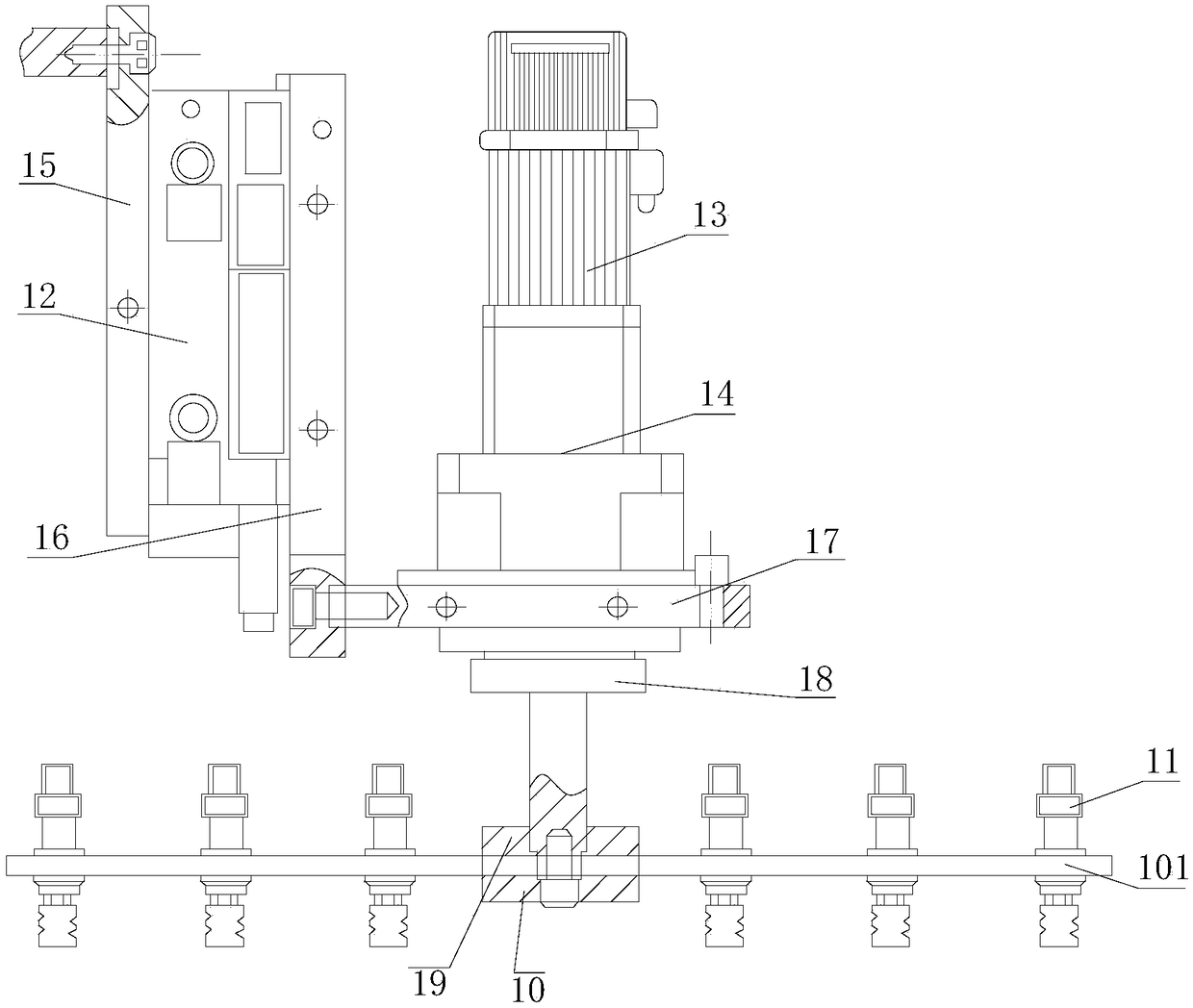

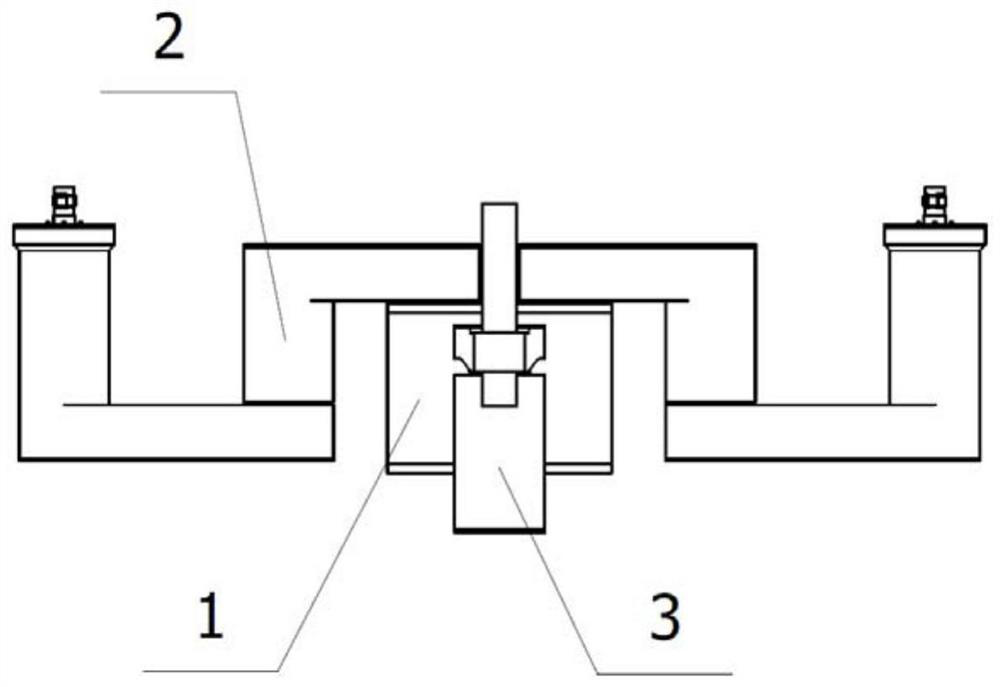

Three-phase asynchronous motor rotor mandrel press fitting device

ActiveCN114161116AImprove mobile stabilityHigh positioning accuracyWork holdersMetal working apparatusThree phase asynchronous motorElectric machine

The invention relates to the technical field of motor press-fitting equipment, in particular to a three-phase asynchronous motor rotor mandrel press-fitting device which comprises a bottom plate, an auxiliary hole is formed in the middle of the bottom plate, and a plurality of through grooves are evenly formed in the bottom plate and distributed in an annular mode. The length direction of the through groove is along the radial direction of the process hole in the bottom plate; the multiple sets of clamping plates are kept in the vertical direction; the equipment can effectively improve the positioning precision of the iron core, the motor shaft and the iron core can be conveniently kept opposite in position, the situation that the motor shaft collides and damages the iron core when the distance deviation between the axis of the motor shaft and the axis of the iron core is large is avoided, parts are conveniently protected, the press-fitting precision of the equipment is improved, and the production efficiency is improved. And meanwhile, the iron core can be conveniently and synchronously fixed, the situation that the motor shaft cannot be normally pressed into the iron core due to sliding deviation of the iron core caused by stress during press fitting is avoided, the running stability of equipment is improved, and the practicability is improved.

Owner:山东瑞博电机有限公司

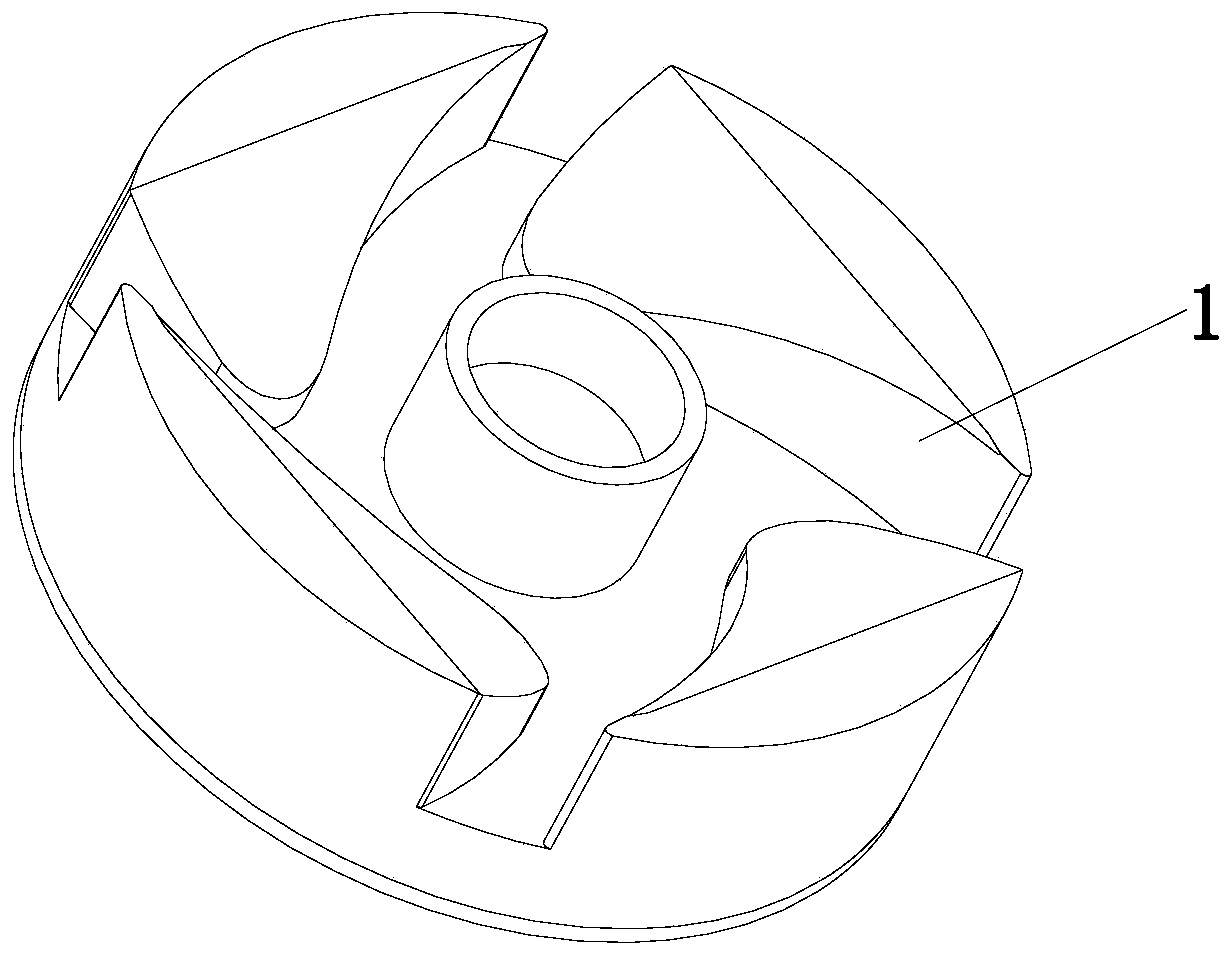

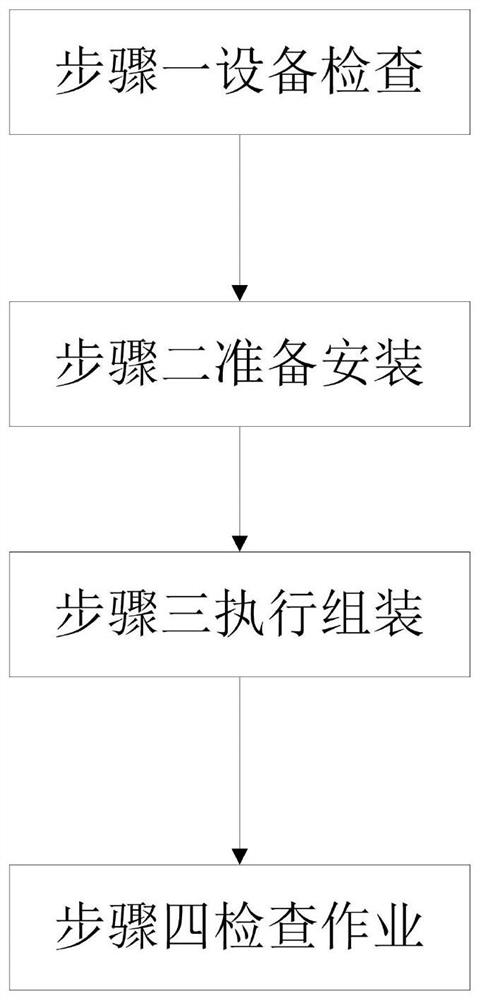

Production process of centrifugal blood pump rotor

ActiveCN110893546AReduce laborHigh degree of automationWelding/cutting auxillary devicesAssembly machinesElectric machineryImpeller

The invention discloses a production process of a centrifugal blood pump rotor, and belongs to the technical field of medical instrument production processes. The method comprises the following stepsthat 1, motor magnets and impellers are fed; 2, bearing magnetic stacks are pressed into the impellers; 3, the four motor magnets are pressed into the impellers, specifically, a conveying belt moves the pressed impellers to the position under a motor magnet mounting mechanism, and the motor magnet mounting mechanism presses the motor magnets into the impellers; and 4, a base is pressed onto the impellers and welded and formed. According to the method, the steps of bearing magnetic pile press fitting, motor magnet mounting and base welding of the centrifugal blood pump rotor can be automatically completed, the four motor magnets can be installed in the impellers at the same time through the motor magnet mounting mechanism, and workers do not need to install the motor magnets one by one; theprocess is ingenious in design and smooth in procedure connection, the produced products are good in consistency and high in yield, more than 70% of labor can be saved in the whole process, and a high economic value is achieved.

Owner:韶关市武江区冠启自动化设备设计有限公司

Automatic assembling process for centrifugal blood pump rotor

ActiveCN111085851ASolve efficiency problemsAddress the degree of automationAssembly machinesMetal working apparatusImpellerBlood pump

The invention discloses an automatic assembling process for a centrifugal blood pump rotor and belongs to the technical field of assembling equipment. The automatic assembling process comprises a conveyor belt, a bearing magnetic pile press-fitting mechanism, a motor magnet mounting mechanism and a base mounting mechanism. A plurality of limiting assemblies are arranged on the conveyor belt. The motor magnet mounting mechanism comprises a sliding plate, a worktable, a pushing assembly, a lifting assembly, a clamping assembly and a bearing frame. The clamping assembly comprises a mounting plate, a four-jaw air cylinder and a limiting column arranged at the bottom of the mounting plate. A limiting plate is mounted at the bottom of each clamping jaw of the four-jaw air cylinder. An arc-shapedgroove is formed in the limiting plate. Four bearing rods are arranged between the mounting plate and the sliding plate. According to the automatic assembling process, steps of press-fitting bearingmagnetic piles, mounting motor magnets and a base for the centrifugal blood pump rotor can be finished automatically. Four motor magnets can be mounted in an impeller simultaneously by the motor magnet mounting mechanism, and it is not needed to mount the motor magnets one by one by a worker.

Owner:韶关市武江区冠启自动化设备设计有限公司

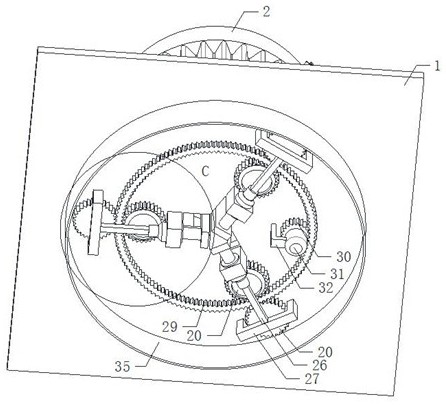

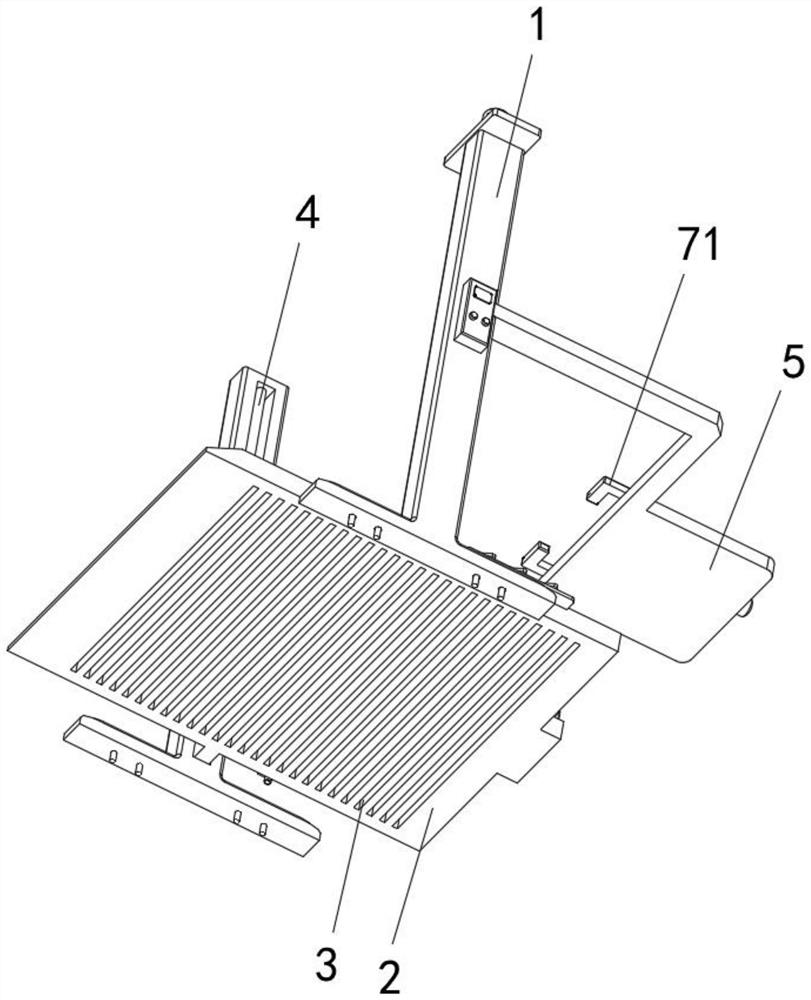

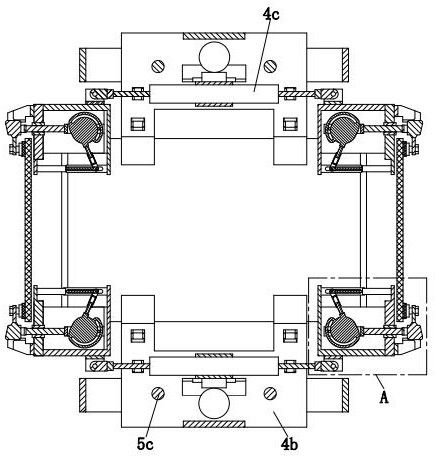

Three-phase asynchronous motor shell machining clamp

ActiveCN113858078ARealize positioning workImprove clamping strengthElectric machinesWork holdersThree phase asynchronous motorElectric machinery

The invention relates to the technical field of clamp equipment, in particular to a three-phase asynchronous motor shell machining clamp. The clamp comprises a placing table and a motor shell, the motor shell is placed on the top of the placing table, and multiple sets of clamping mechanisms are evenly arranged on the placing table and distributed in an annular mode; and each clamping mechanism comprises a base located on the outer side of the motor shell, the base is fixed to the top of the placing table, a swing rod is obliquely and rotationally installed on the top of the base, and a first arc-shaped push plate is installed at the outer end of the swing rod. Through synchronous clamping and fixing treatment on the inner wall and the outer wall of the motor shell, the clamping strength of the motor shell can be effectively improved, the diversity of clamping modes is improved, meanwhile, clamping, extruding and fixing are conducted through clamping tooth blocks, the action area when the motor shell is clamped can be effectively increased, the clamping strength is improved, the firmness of the motor shell is improved, and the practicability is improved.

Owner:山东瑞博电机有限公司

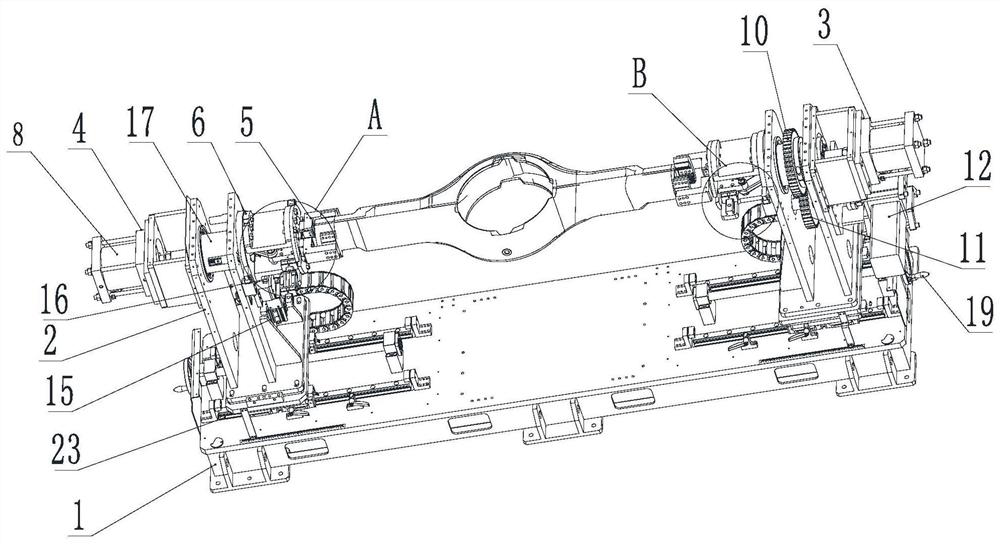

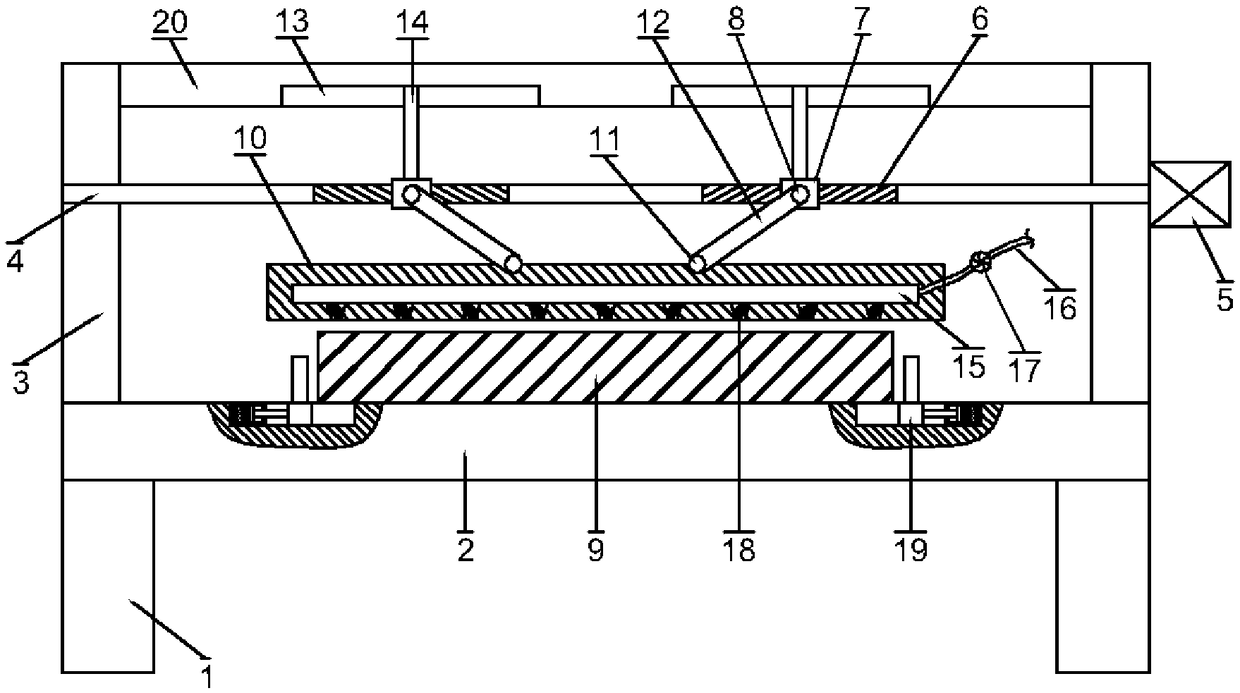

Pneumatic centering clamping and overturning mechanism for axle housing welding

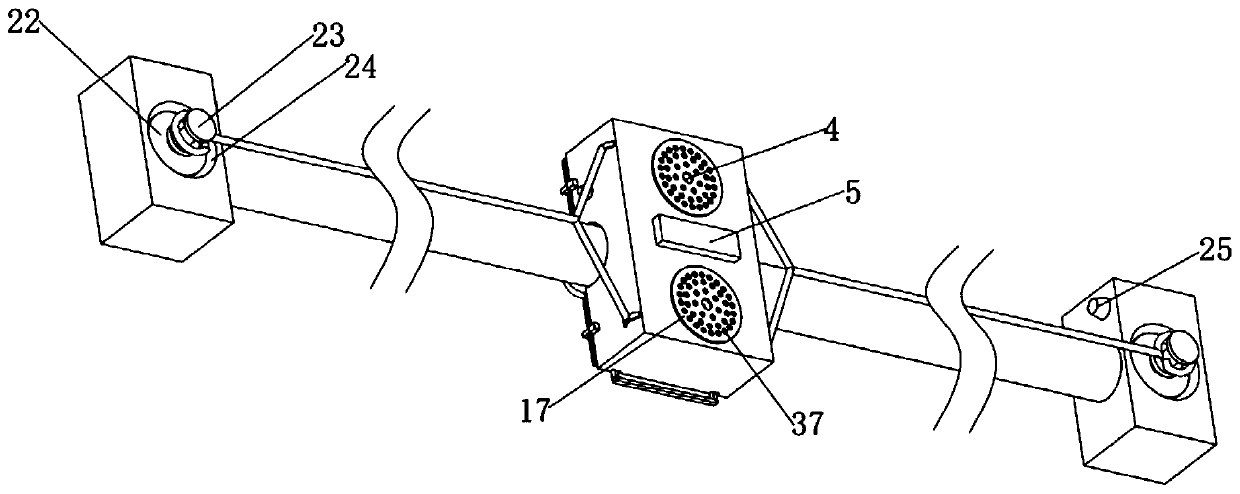

PendingCN112743282ABig expansionEasy to storeWelding/cutting auxillary devicesAuxillary welding devicesSupport planeWelding

The invention discloses a pneumatic centering clamping and overturning mechanism for axle housing welding, and belongs to axle housing positioning and clamping equipment. The problems that due to the size difference of the two ends of different axle housings, a clamping assembly cannot be adjusted to expand outwards, and consequently the axle housings are inconvenient to assemble, disassemble or clamp are solved. The pneumatic centering clamping and overturning mechanism for axle housing welding comprises a base, wherein supporting frames are arranged at the two ends of the base; a driving end clamping mechanism is arranged on one supporting frame, and a driven end clamping mechanism matched with the driving end clamping mechanism is arranged on the other supporting frame; the driving end clamping mechanism and the driven end clamping mechanism each comprise an overturning device; and a directional moving mechanism is arranged at the bottom of each supporting frame. The pneumatic centering clamping and overturning mechanism is suitable for positioning, clamping and welding of the axle housings of various lengths and sizes. The overturning devices achieve 360-degree dead-corner-free welding of the axle housings, the clamping assembly moves directionally, and synchronous centering clamping of the two ends of the axle housings is achieved through the cooperative movement of connecting rods and sliding rails.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

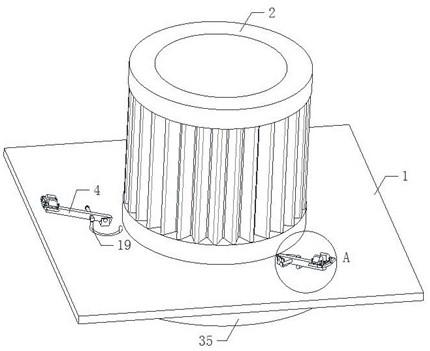

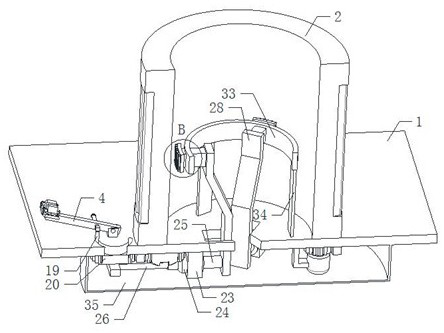

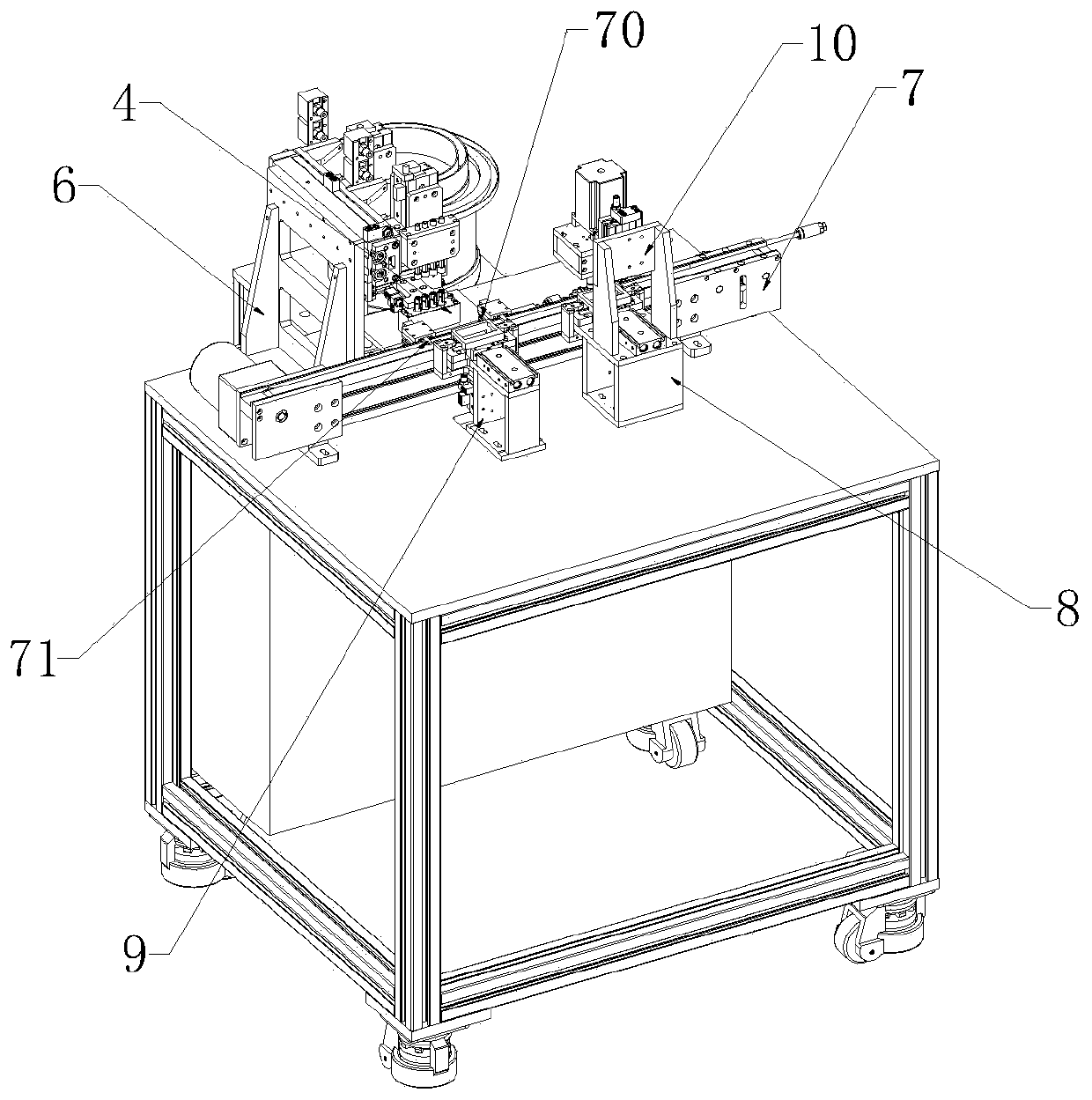

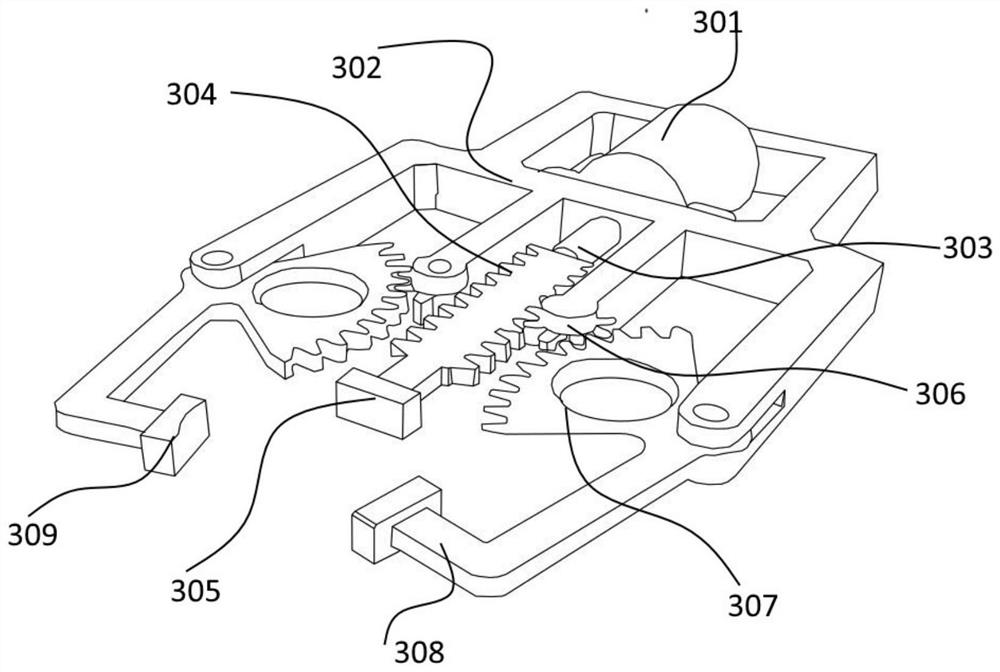

Upper shell assembling machine

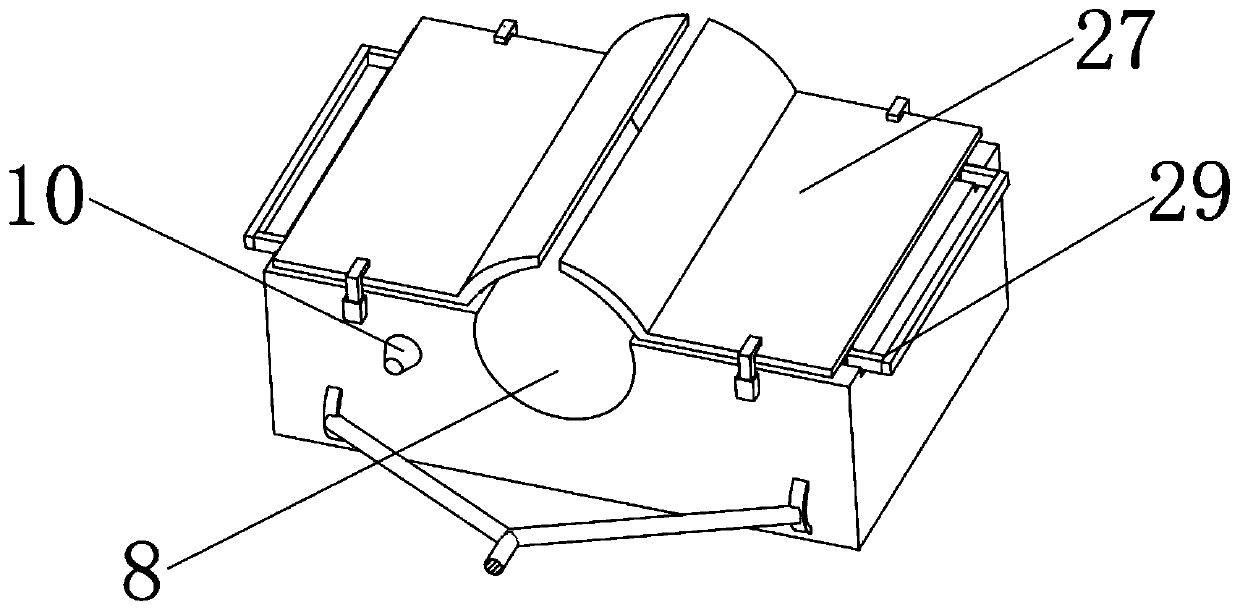

PendingCN111268399AAccurate correctionImprove reliabilityConveyor partsIndustrial engineeringRack and pinion

The invention provides an upper shell assembling machine. The upper shell assembling machine comprises a supporting platform, a vibration plate, a transfer support frame, a driving device mounting frame, a correction supporting frame and a feeding supporting frame are mounted on the supporting platform; a separation driving device is mounted on the transfer supporting frame, and a feeding transferplate is connected to the output end of the separation driving device; a plurality of groups of correction assemblies are rotatably connected to the correction supporting frame; a correction drivingdevice is mounted on the driving device mounting frame, and a transmission rack is connected to the output end of the correction driving device; and the feeding driving device is mounted on the feeding supporting frame, and a suction nozzle assembly is connected to the output end of the feeding driving device. According to the upper shell assembling machine, the feeding transfer plate is arranged,scattered upper shells can be placed in a transfer tank orderly one by one; the multiple correction assemblies and the transmission rack are arranged, the circumferential positions of the multiple upper shells can be adjusted at the same time; and a suction nozzle is arranged, and the feeding work of the upper shells in the correction process can be achieved.

Owner:CHONGQING LINGLONG AUTOMATION EQUIP CO LTD

A medical foot orthopedic training device

ActiveCN109172285AEasy to moveSolve long and short uncorrectable problemsChiropractic devicesEngineeringSelf locking

A medical foot orthodontic training device belongs to the field of medical devices and includes a support base plate, positioning mechanism, drive straightening mechanism, driving training institutions and lifting mechanisms, the drive straightening mechanism includes a mounting housing, lateral drive assembly, Adjustment assembly and straightening assembly, the bottom of the mounting housing is fixedly connected with the top of the support bottom plate, A lateral drive assembly, an adjusting assembly and a correcting assembly are all installed in that mounting house, the correcting assembly is mounted on the adjusting assembly and one end is protrude from the mounting housing, one end of the adjusting assembly is fixedly connected with the mounting housing, the other end is rotatably connected with the correcting assembly, and four self-locking universal wheels are arranged at the bottom of the lifting mechanism. The invention has the advantages of simple structure, simple fixation ofthe foot part of the patient in the correction process, improvement of the correction efficiency and effect of the leg part of the patient, adjustment of the correction angle of the leg part, satisfaction of the correction treatment of different patients, multi-functionalization and high practicability.

Owner:山东未来城建筑工程有限公司

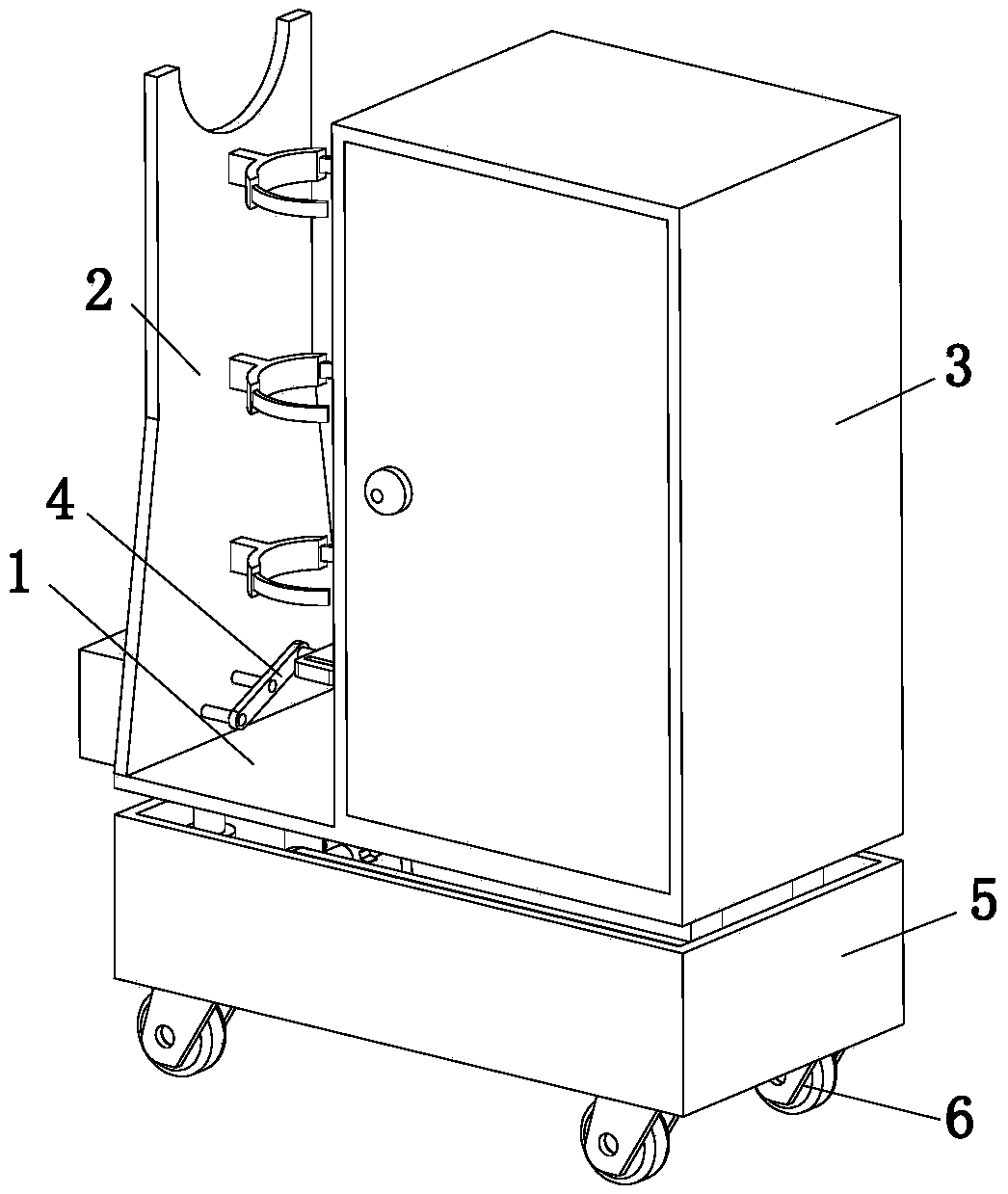

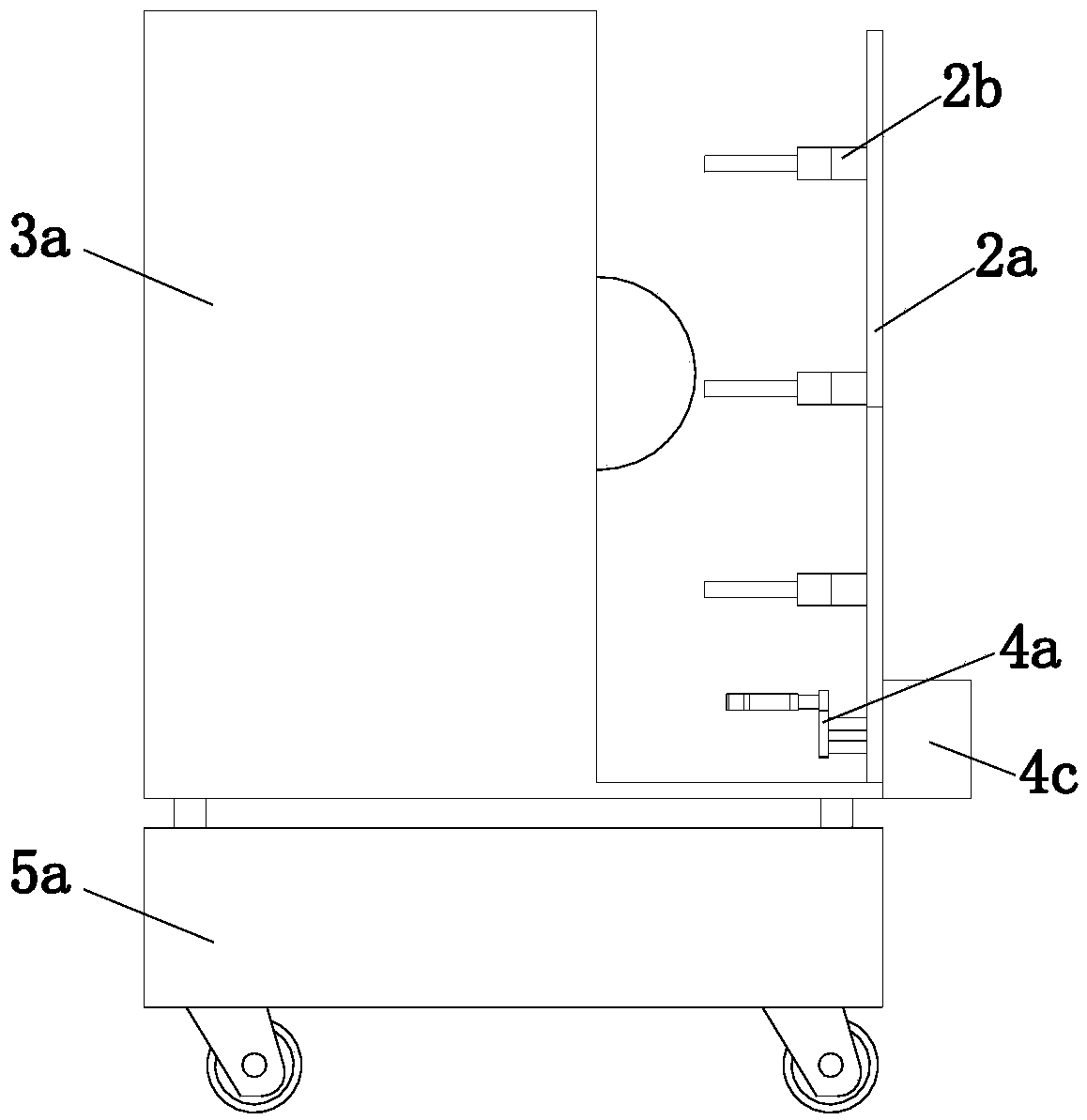

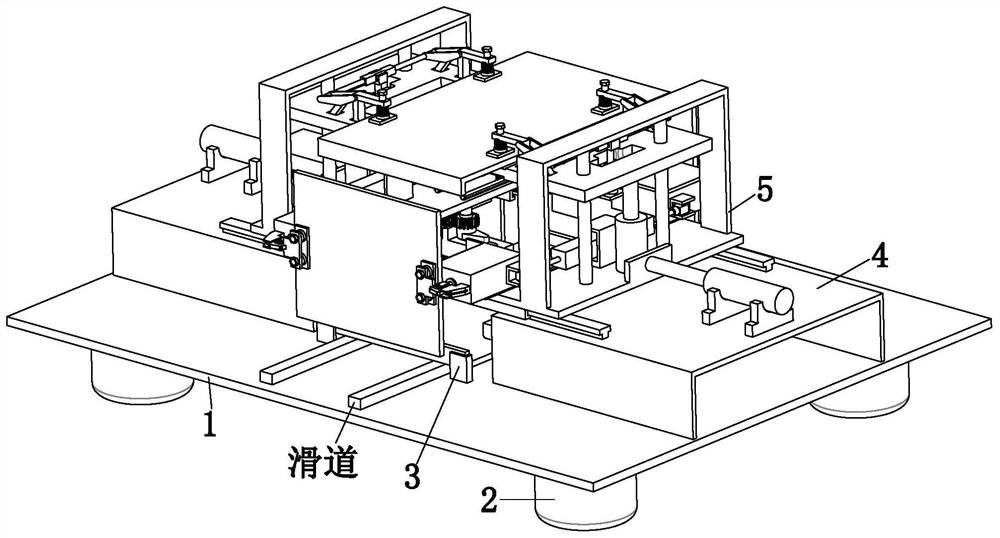

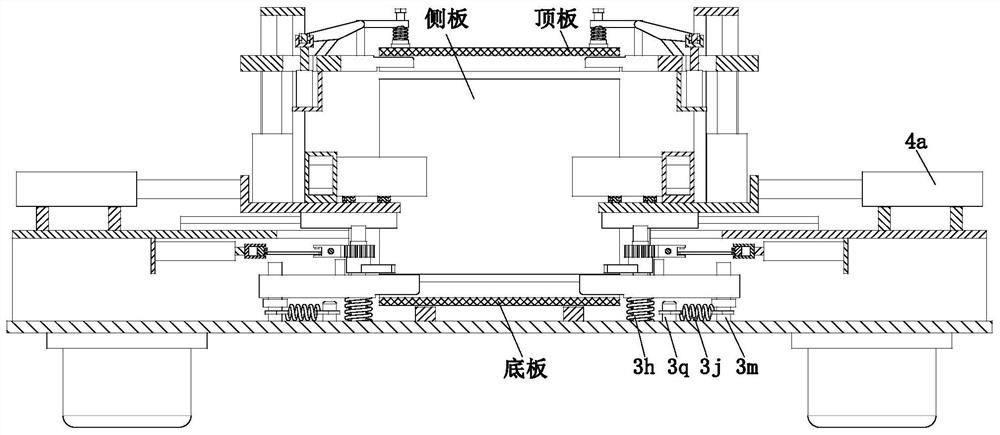

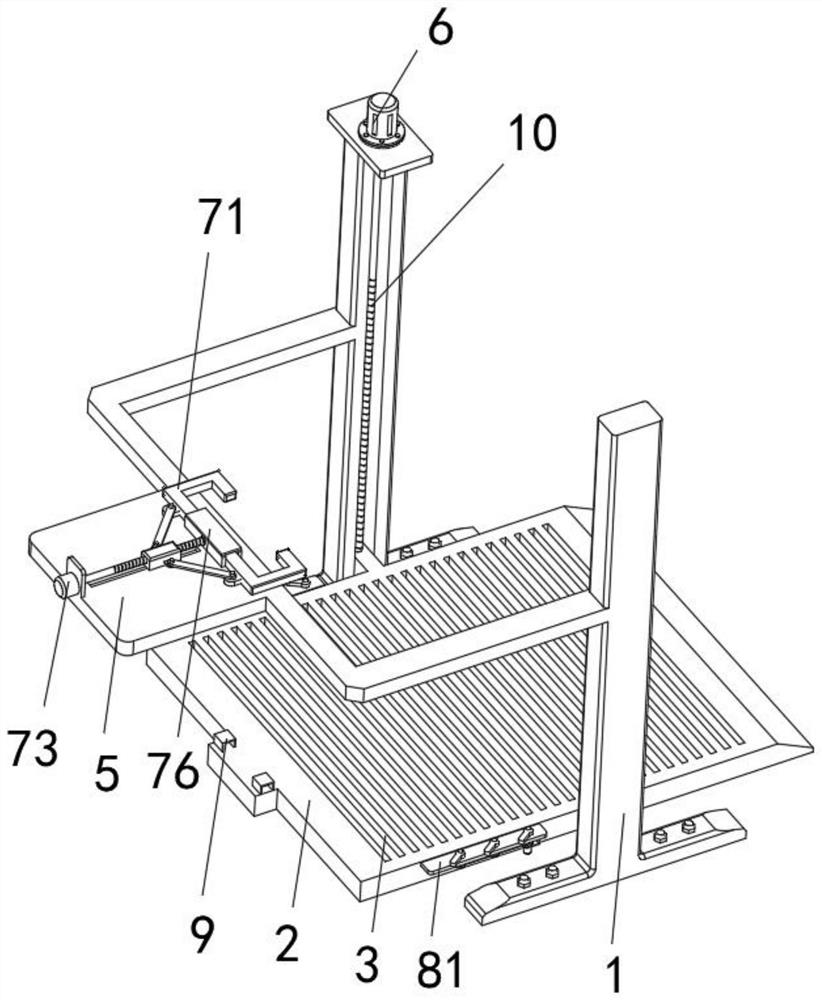

Automatic assembly process for electrical cabinet

InactiveCN112223180ARealize positioning workLarge assembly errorWork holdersStructural engineeringWorkbench

The invention provides an automatic assembly process for an electrical cabinet, which uses auxiliary assembly equipment. The equipment is provided with a bottom plate, support legs, a positioning mechanism, an assembly mechanism and a limiting mechanism. The invention solves the problems that a bottom plate of an electrical cabinet needs to be manually placed on a workbench during electrical cabinet assembly and fixing operation, then other plates of the electrical cabinet are manually mounted and fixed, the electrical cabinet needs a large number of plates to be assembled, positioning and assembling operation of the plates can be completed only through cooperative operation of a plurality of workers, the labor intensity of the workers is increased through the operation mode, the working efficiency of electrical cabinet assembling operation is reduced, and meanwhile, a plurality of plates are difficult to assemble and position at the same time, the plates are also difficult to clamp and fix before assembly, and the clamping operation of the plates of the electrical cabinet cannot be automatically relieved after the assembly operation is completed.

Owner:JIANGSU JIANXIONG ELECTRIC CO LTD

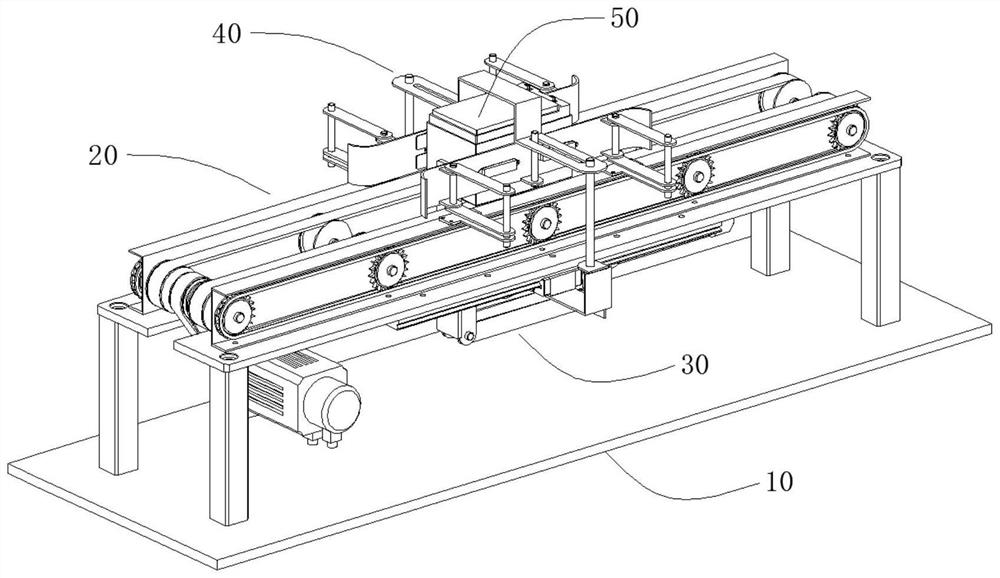

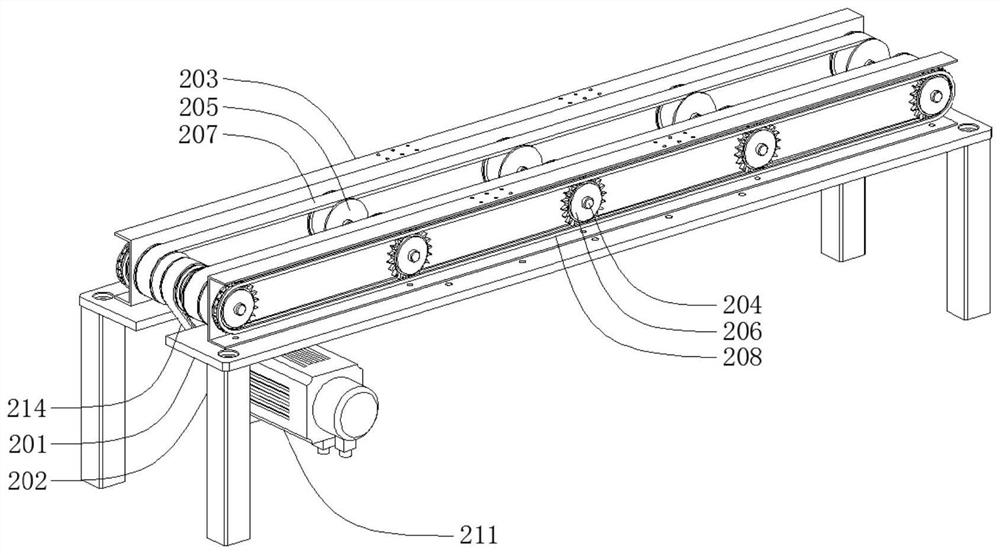

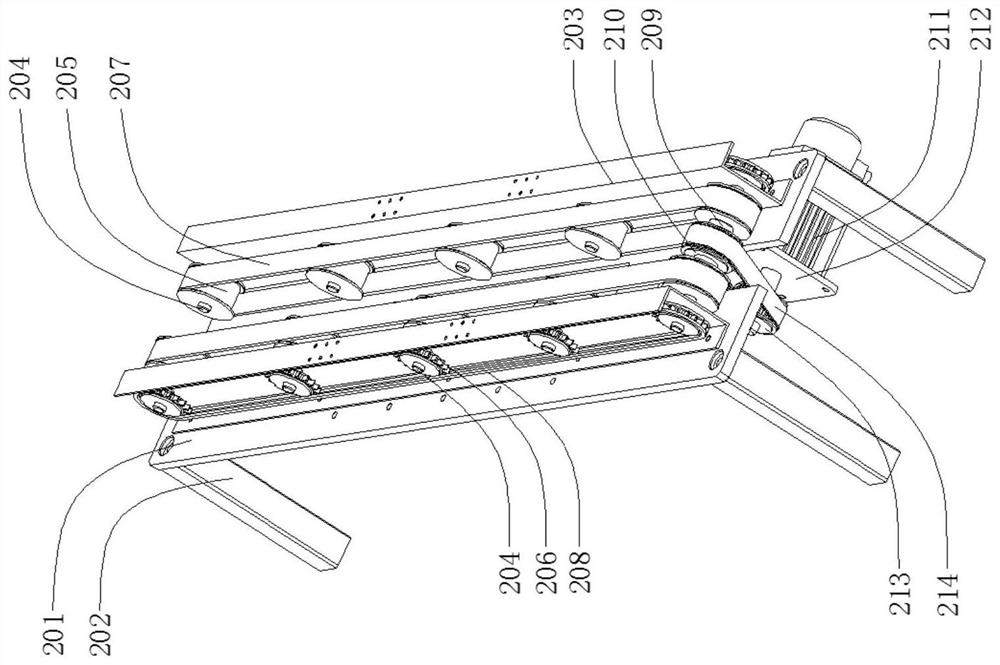

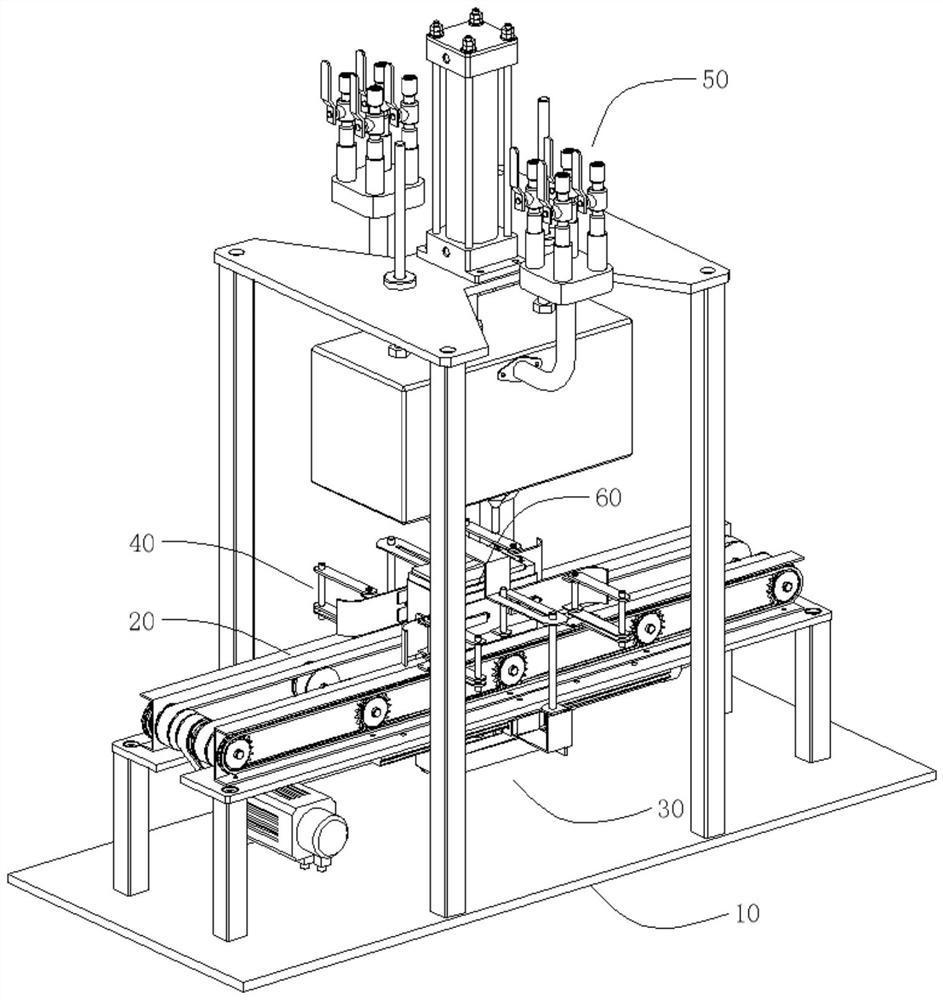

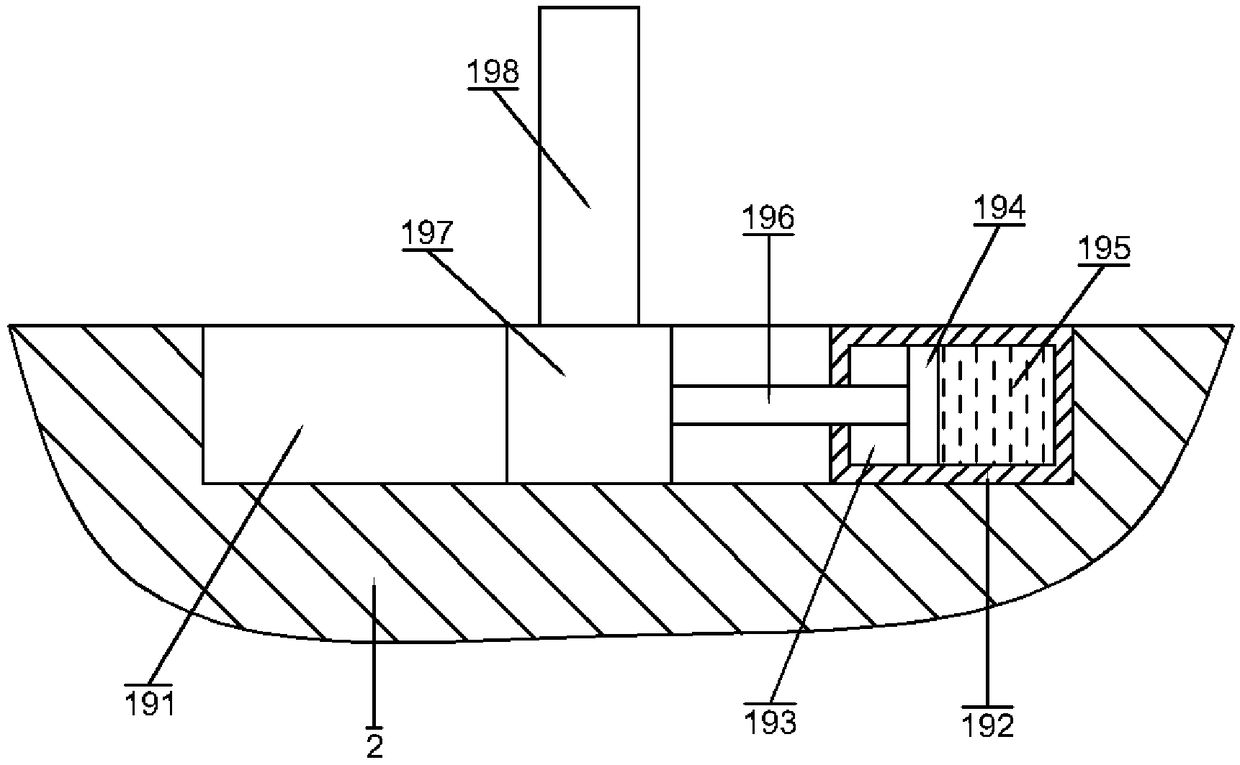

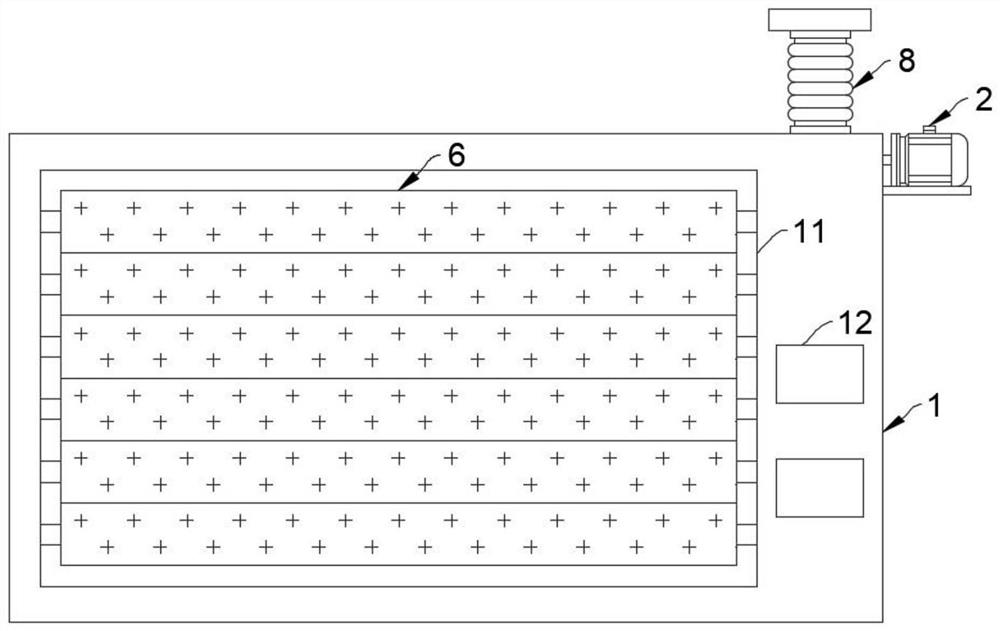

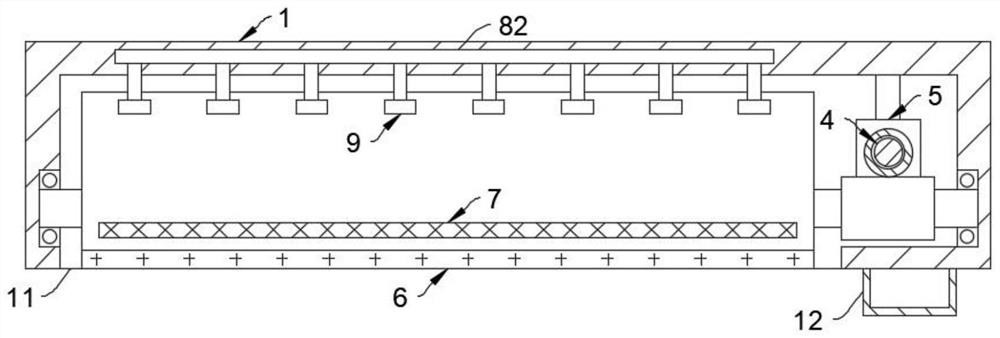

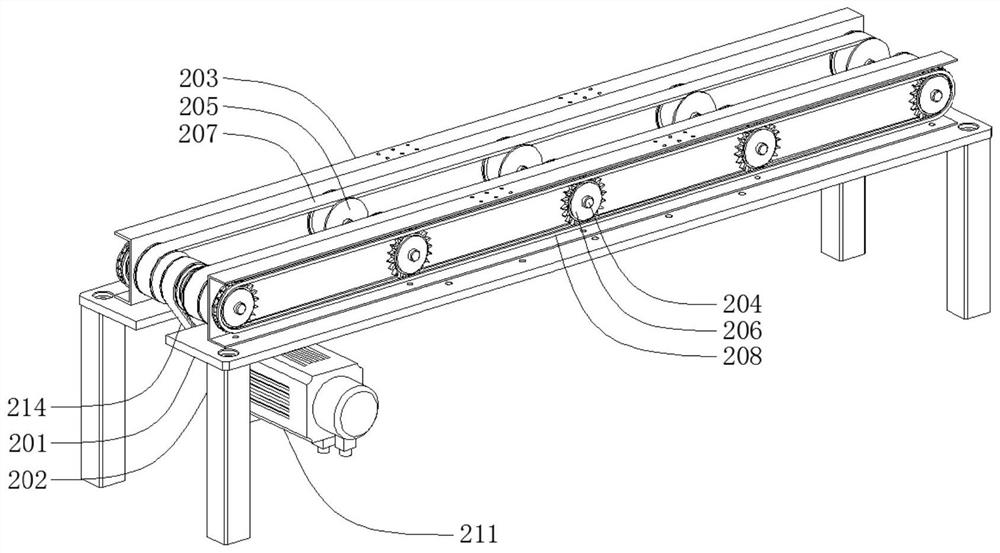

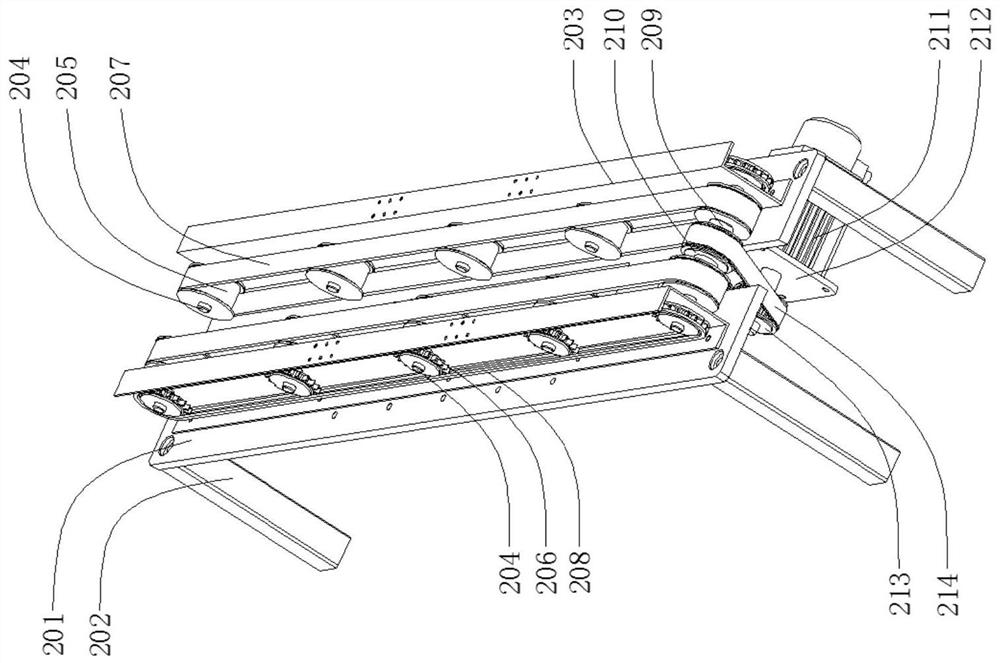

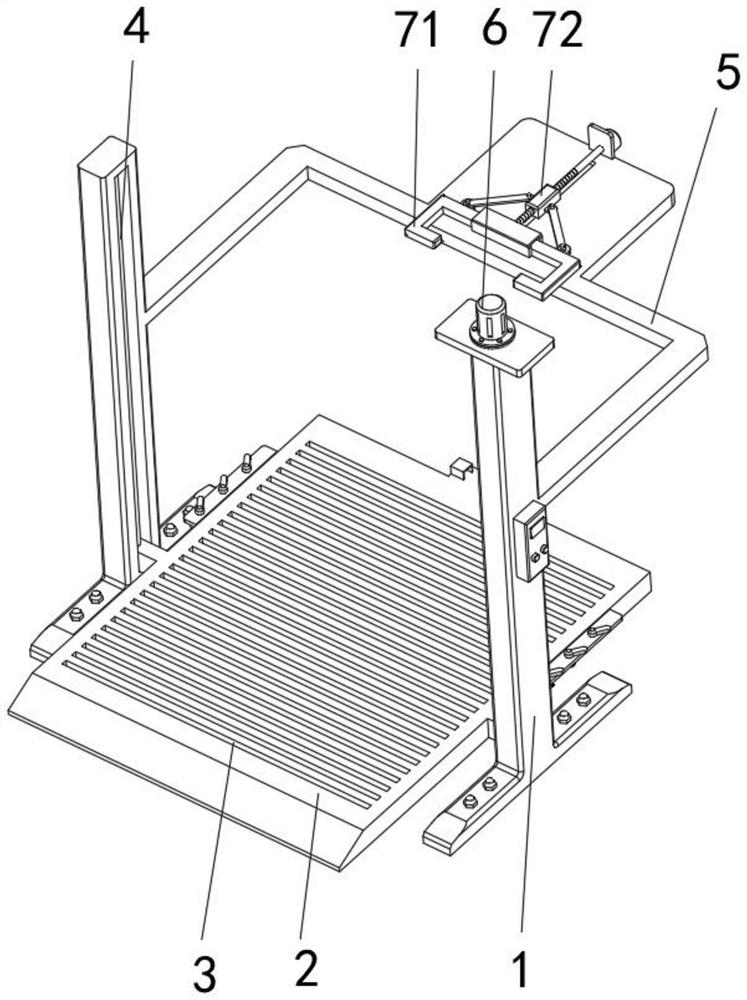

Liquid injection device for producing lithium ion battery

ActiveCN113381138ARealize the delivery workRealize positioning workCell component detailsElectric machineryEngineering

The invention discloses a liquid injection device for producing a lithium ion battery, and belongs to the technical field of lithium battery production. The liquid injection device comprises a workbench, a conveying mechanism, a positioning mechanism and a clamping mechanism; the workbench is horizontally arranged; the conveying mechanism is arranged on the upper side of the workbench and used for conveying lithium batteries before and after liquid injection; the conveying mechanism specifically comprises a supporting plate, a supporting column, a mounting strip, a connecting shaft and a driving motor; the positioning mechanism is arranged on the lower side of the conveying mechanism and used for positioning during liquid injection of the lithium batteries; and the positioning mechanism specifically comprises a telescopic air cylinder, a first hinge strip, a second hinge strip and a positioning strip; the clamping mechanism is arranged on the upper side of the conveying mechanism and used for clamping the lithium batteries during liquid injection; the clamping mechanism specifically comprises an overhanging strip, a clamping plate, a third hinge strip, a linkage column and a linkage strip. In conclusion, the liquid injection device has the advantages of reasonable design, ingenious structure and convenient use, and can achieve automatic conveying, automatic positioning and automatic clamping of the lithium batteries.

Owner:WUHU ETC BATTERY LTD

Injection device for electrolyte in lithium ion battery

ActiveCN113270698ARealize the delivery workRealize automatic deliveryFinal product manufactureCell component detailsHydraulic cylinderElectrical battery

The invention discloses an injection device for electrolyte in a lithium ion battery, and relates to the technical field of lithium battery production. The injection device comprises a workbench, a conveying mechanism, a positioning mechanism, a clamping mechanism and an electrolyte injection mechanism, wherein the conveying mechanism is arranged at the upper side of the workbench, is used for conveying the lithium battery before and after electrolyte injection, and comprises a supporting plate and a driving motor; the positioning mechanism is arranged at the lower side of the conveying mechanism, is used for positioning the lithium battery during liquid injection and comprises a telescopic air cylinder, a first hinge strip, a second hinge strip and a positioning strip; the clamping mechanism is arranged at the upper side of the conveying mechanism, is used for clamping the lithium battery during liquid injection, and comprises an overhanging strip, a clamping plate, a third hinge strip, a linkage column and a linkage strip; and the liquid injection mechanism is arranged at the upper side of the clamping mechanism, is used for injecting liquid into the lithium battery, and comprises a hydraulic cylinder and an electrolyte box. Therefore, according to the present invention, the automatic conveying, automatic positioning, automatic clamping and automatic filling of the lithium battery can be achieved.

Owner:WUHU ETC BATTERY LTD

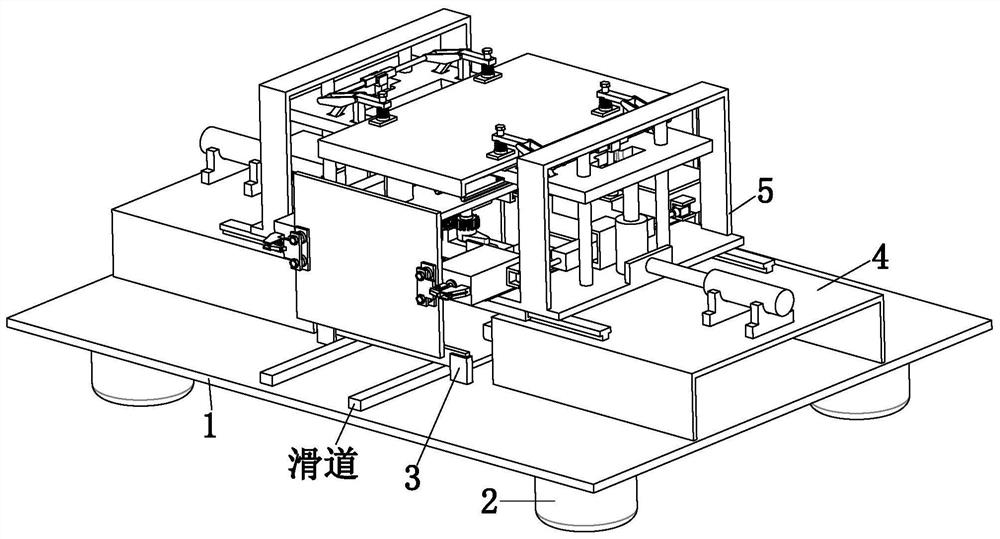

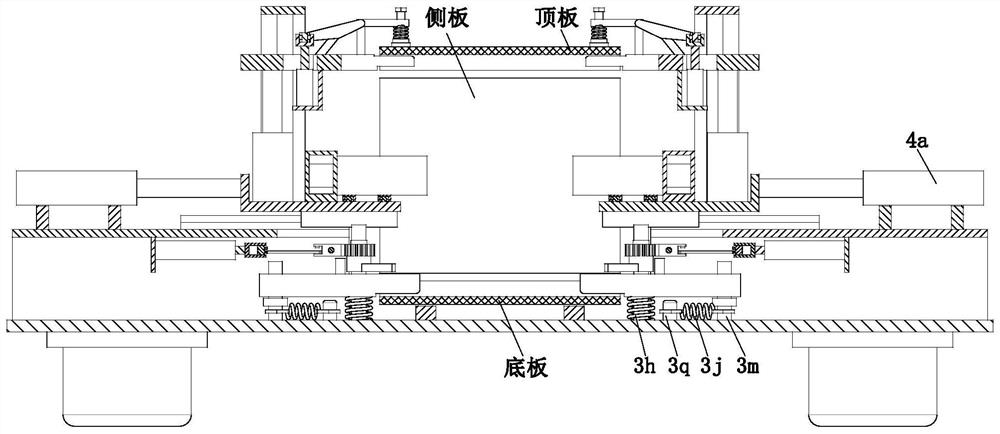

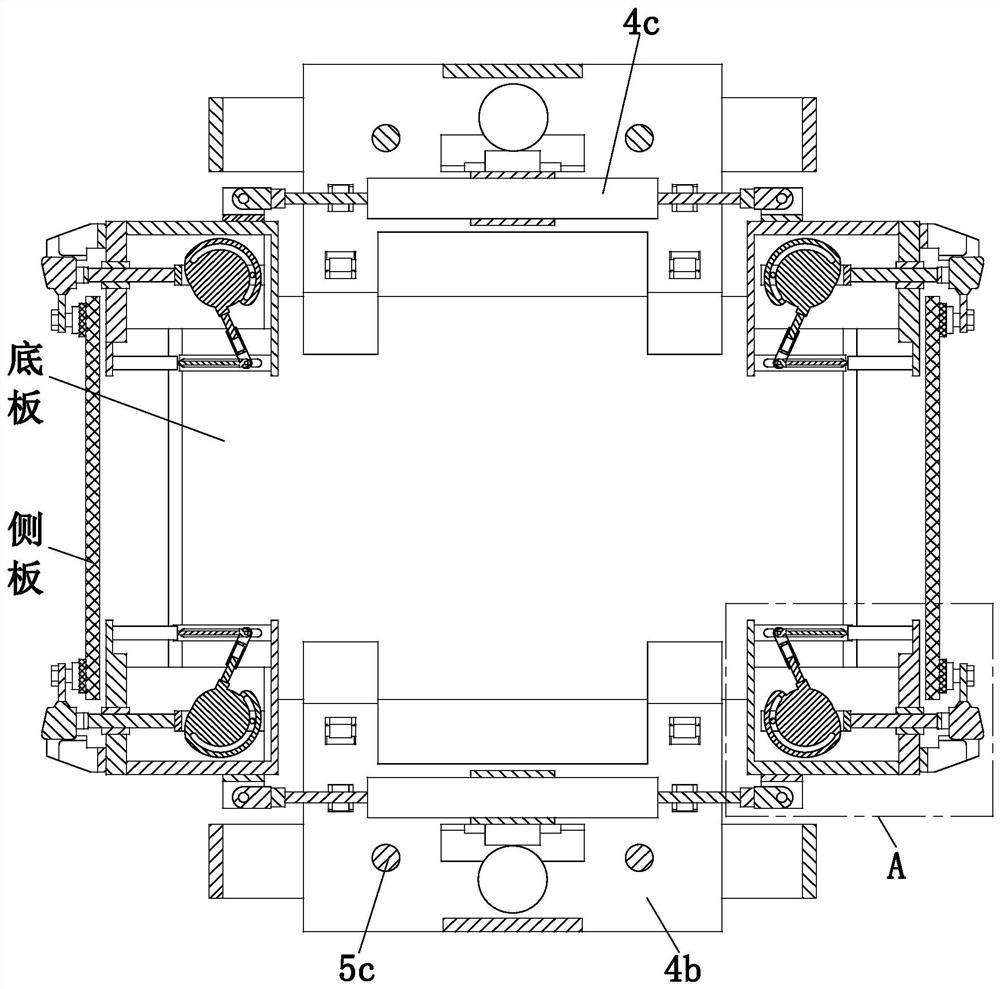

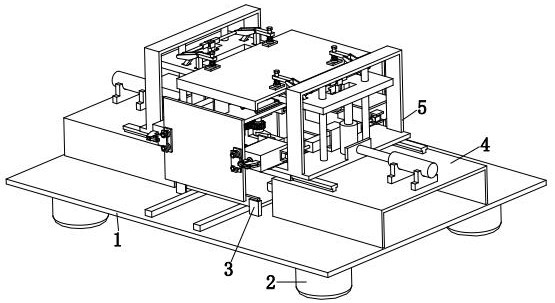

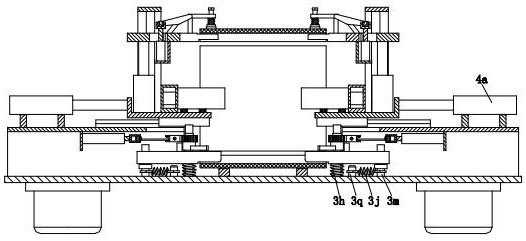

Automatic assembling machine for electric appliance cabinet

ActiveCN112372287ARealize positioning workLarge assembly errorAssembly machinesMetal working apparatusMachineWorkbench

The invention provides an automatic assembling machine for an electric appliance cabinet. The automatic assembling machine comprises a mounting bottom plate, supporting legs, a positioning mechanism,an assembling mechanism and a limiting mechanism. The automatic assembling machine solves the problems that during assembling and fixing operation of the electric appliance cabinet, a bottom plate ofthe electric appliance cabinet needs to be manually placed on a workbench, then other plates of the electric appliance cabinet are manually mounted and fixed, and relatively, many plates of the electric appliance cabinet need to be assembled, positioning and assembling operation of the plates can be completed only through cooperative operation of multiple workers, the labor intensity of the workers is increased through the operation mode, the working efficiency of the assembling operation of the electric appliance cabinet is reduced, and meanwhile, the multiple plates are difficult to assembleand position at the same time, the plates are difficult to clamp and fix automatically before assembling, and the clamping operation of the plates of the electric appliance cabinet cannot be automatically relieved after the assembling operation is completed.

Owner:JIANGSU JIANXIONG ELECTRIC CO LTD

Municipal pipeline dredging equipment

ActiveCN109056996ARealize positioning workDredging operation realizedSewer cleaningIndustrial engineeringLinkage concept

Owner:秭归县开明建筑有限责任公司

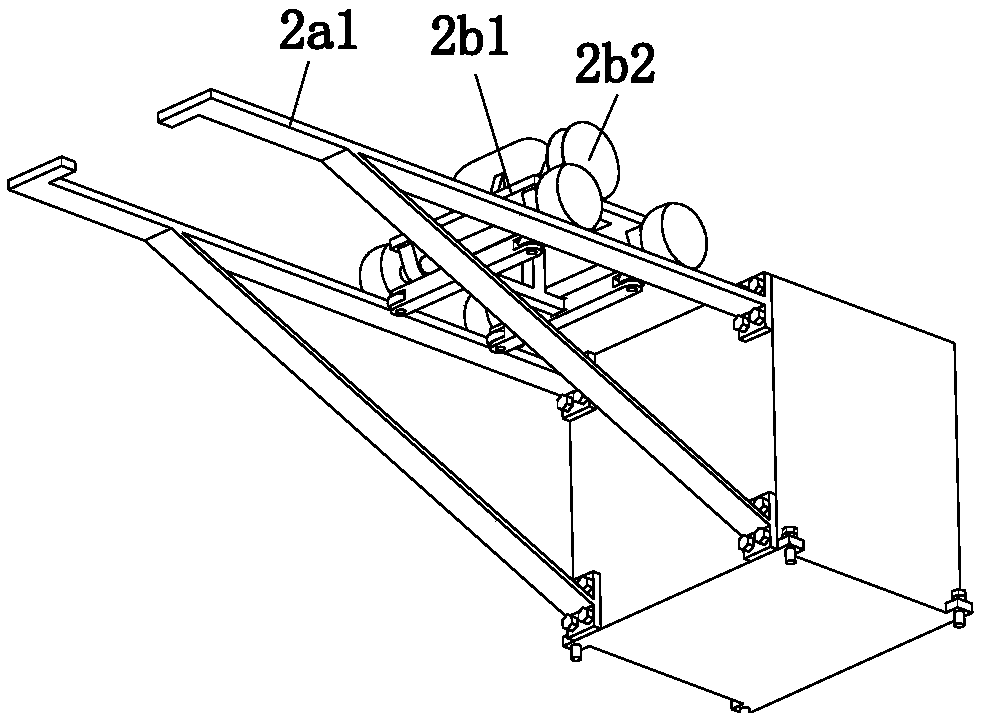

Double-face chamfering mechanism of gear

InactiveCN108015362ARealize positioning workMetal working apparatusGear-cutting machinesEngineeringMachining

The invention relates to the field of machinery machining, in particular to a double-face chamfering mechanism of a gear. The double-face chamfering mechanism comprises a conveying mechanism, a feeding mechanism, a machining mechanism and a discharge mechanism. The feeding mechanism comprises an installation table, a hopper, a feeding air cylinder and a feeding plate. The middle part of the hopperis provided with a material groove. The bottom of the hopper is equipped with a feeding hole allowing the feeding plate to penetrate. One end of the feeding plate extends towards the conveying mechanism and the other end of the feeding plate penetrates through the hopper to be fixedly connected with an output end of the feeding air cylinder. The feeding air cylinder is horizontally arranged on the installation table. The position where the feeding plate is close to the front half part of the conveying plate is provided with a first feeding groove. The position where the feeding plate is closeto the back half part of the feeding air cylinder is provided with a second feeding groove. The front part of the feeding plate is equipped with a U-shaped groove. The front end of the feeding plateis provided with two symmetrically-arranged limiting assemblies. Therefore, automatic feeding and locating operation are achieved during the gear chamfering process. Additionally, edges of upper and lower surfaces of the gear can be subjected to chamfering machining at the same time through a first chamfering assembly and a second chamfering assembly.

Owner:金方明

Plywood assembling machine for plywood machining based on vortex air exhaust drying theory

InactiveCN109397412AIncrease flow rateKeep dryPlywood pressesPretreated surfacesPulp and paper industryScrew thread

The invention relates to the technical field of plywood machining, in particular to a plywood assembling machine for plywood machining based on vortex air exhaust drying theory. The plywood assemblingmachine comprises four supporting legs, the top ends of the supporting legs are fixedly connected with a lower pressing plate, plywood is put on the lower pressing plate, and the two sides of the lower pressing plate are symmetrically and fixedly connected with two vertical plates; a rotary shaft is rotationally connected between the two vertical plates, and the right end of the rotary shaft is fixedly connected with a motor output shaft; and two thread sections are symmetrically arranged on the rotary shaft, and the threads of the two thread sections are reverse in spiral direction. The plywood assembling machine has the following effects that in order to further improve the drying effect, a spiral auger is arranged in a through hole, air is formed into a certain vortex shape in the following process, accordingly, the air flowing speed is increased, and the drying effect is improved; and the vortex-shaped air flows towards the periphery of the plywood after being sprayed out of the through hole, the drying range is broadened, and the drying effect is further improved.

Owner:姜宏鹏

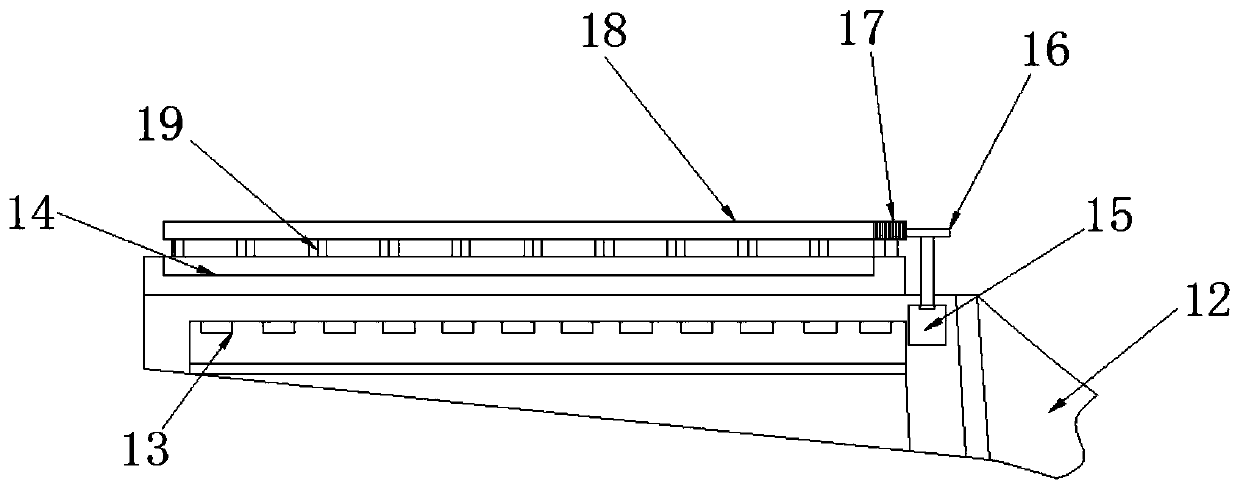

Teaching guide device based on new media technology

PendingCN113160620AReduce damage rateIncrease flexibilityWriting boardsCleaning using gasesGear wheelElectric machinery

Owner:贵州轻工职业技术学院

Intelligent monitoring and early warning device for distance between optical cable and ground based on Internet of Things technology

ActiveCN109283516BRealize positioning workRealize the function of intelligent monitoring and early warningElectromagnetic wave reradiationTelecommunicationsEmbedded system

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY TAIZHOU POWER SUPPLY +1

Noise detection device used for motor load and work method thereof

InactiveCN111730513AHeight adjustableAdjustable positionSubsonic/sonic/ultrasonic wave measurementWork holdersDrive shaftGear wheel

The invention discloses a noise detection device used for a motor load and a work method thereof. The noise detection device used for the motor load comprises a worktable, a clamping mechanism and a jacking mechanism, the worktable comprises a supporting frame arranged on the worktable and a detecting device mounted on the supporting frame, the clamping mechanism comprises a connecting frame mounted on the worktable, a clamping motor mounted on the worktable and connected with the connecting frame and a clamping assembly mounted on the output end of the clamping motor, the jacking mechanism comprises a driving shaft connected with a third conical gear, a fourth conical gear arranged on the other end of the driving shaft and a jacking assembly engaged with the fourth conical gear, through the clamping assembly, positioning work of the motor can be achieved, it is ensured that during detecting work of the motor, the motor cannot collide with the device to generate new noise, therefore, the detection precision of the detection device is not affected, and the detection precision of the device is ensured.

Owner:江苏省百斯特检测技术有限公司

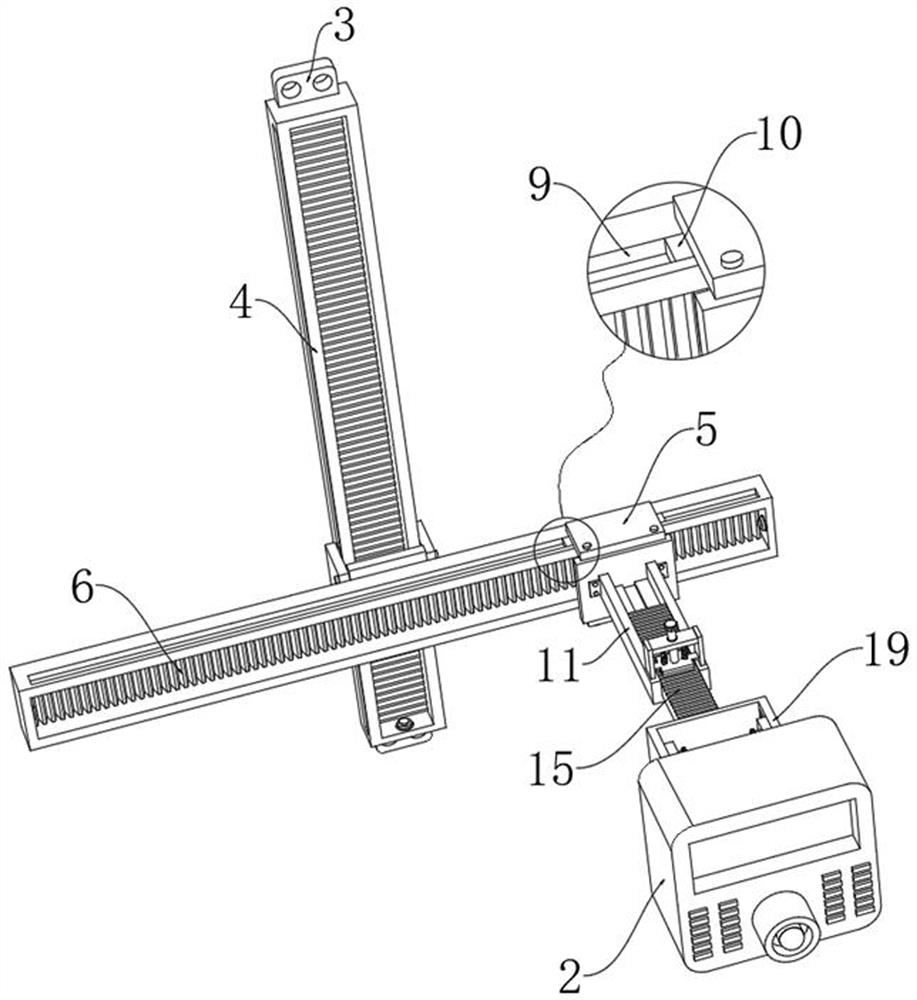

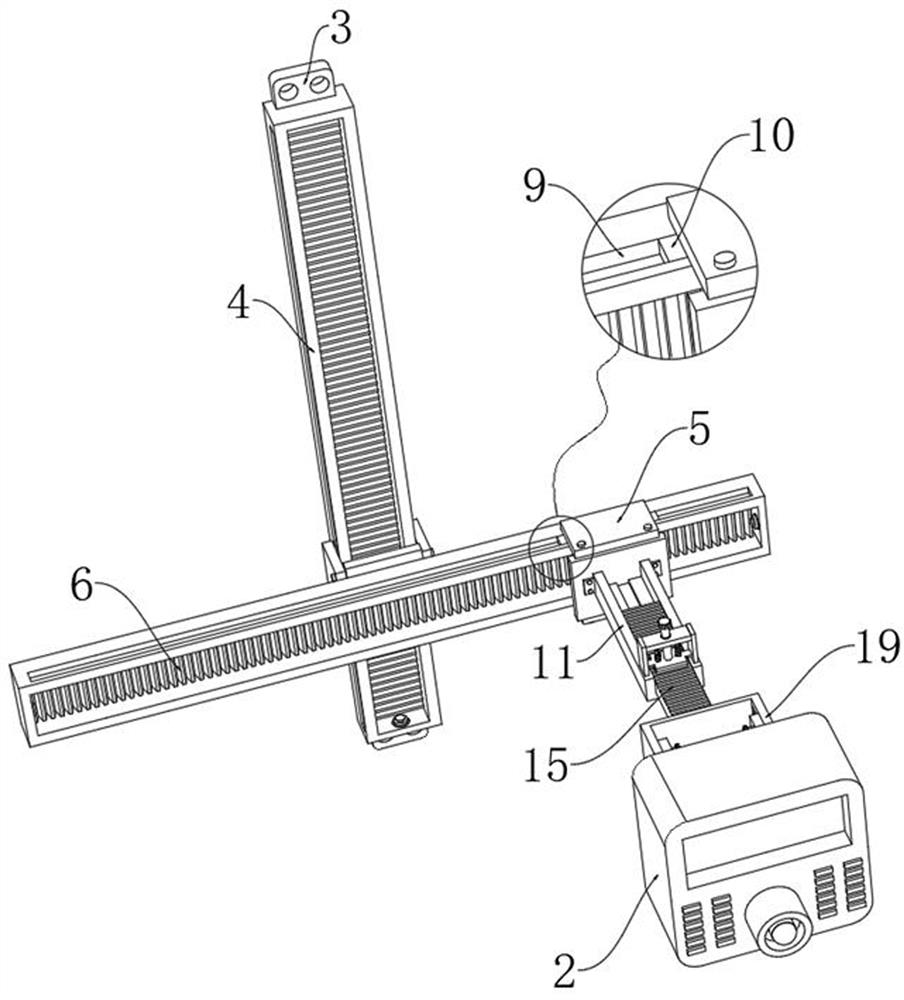

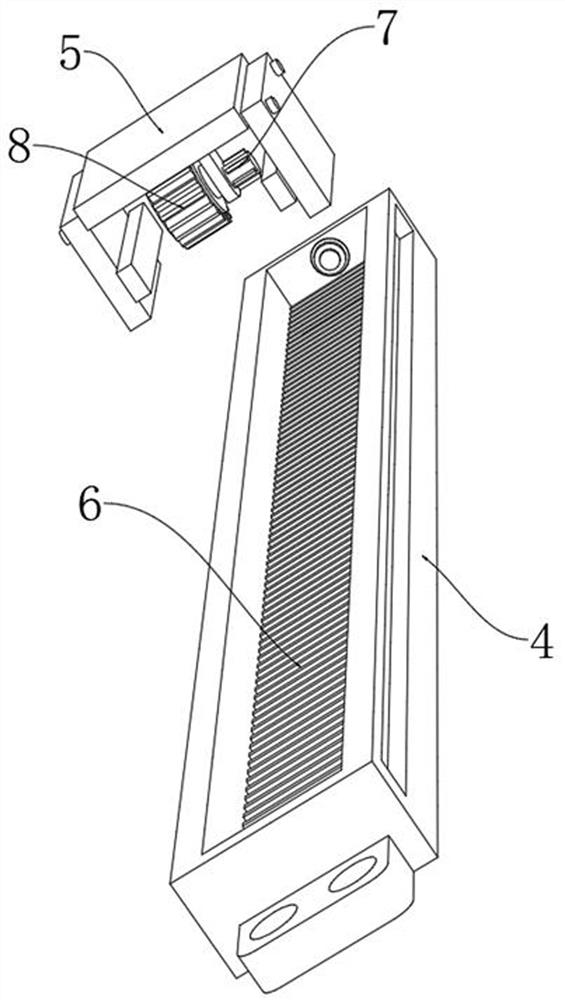

Device for detecting temperature of thermal power plant equipment

PendingCN114812828AEasy to adjust and useExpand the scope of detectionRadiation pyrometryEquipment temperatureThermodynamics

The invention discloses a thermal power plant equipment temperature detection device, which comprises a mounting platform, two moving assemblies, an extension adjusting assembly, an adjustable positioning assembly and an infrared thermometer, and is characterized in that the two moving assemblies are distributed in a cross shape. According to the invention, the infrared thermometer is correspondingly and additionally provided with the two moving assemblies which are distributed in a cross shape, so that the infrared thermometer can carry out large-range detection work in the master control box along with the moving interval of the two moving assemblies, the overall detection range is improved, and meanwhile, the infrared thermometer can be subjected to fixed-point detection according to actual needs, so that the detection efficiency is improved. The extension adjusting assembly can dynamically adjust the distance between the infrared thermometer and an object to be measured, rapid fine adjustment of the working angle of the infrared thermometer is achieved under the assistance of the adjustable positioning assembly, transfer and absorption of impact force borne by the infrared thermometer are achieved through the buffer part, damage to the infrared thermometer is reduced, and the service life of the infrared thermometer is prolonged. A good working environment can be provided for the infrared thermometer, and the service life of the infrared thermometer is prolonged.

Owner:JINGNENG SHIYAN THERMAL POWER CO LTD

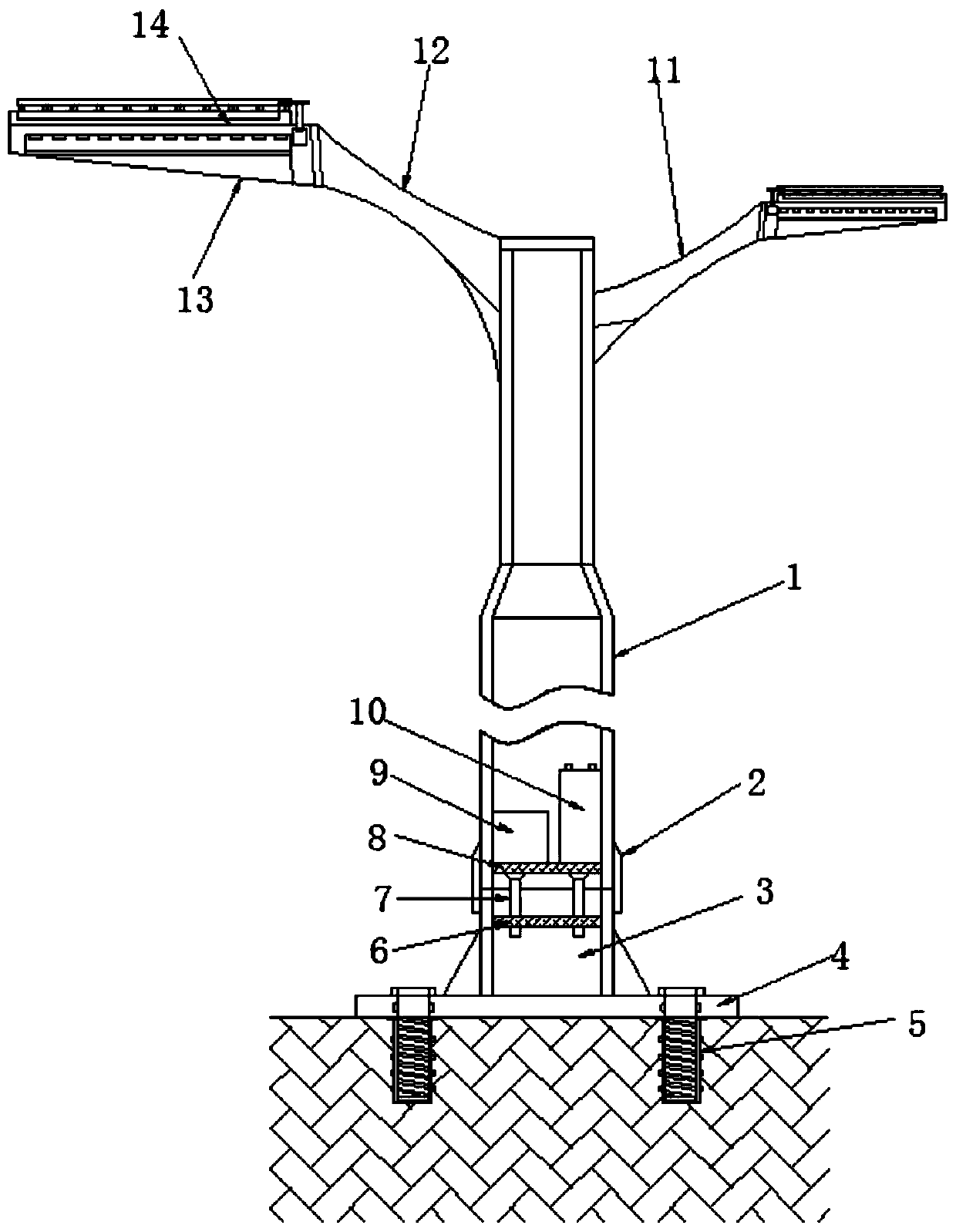

Convenient-to-install street lamp based on new energy sources

InactiveCN110500548AFacilitate device installation workImprove connection strengthMechanical apparatusElectric circuit arrangementsEngineeringNew energy

The invention discloses a convenient-to-install street lamp based on new energy sources. The convenient-to-install street lamp comprises a lamp post, wherein a base is arranged at the bottom end of the lamp post; the base comprises a case plate; a fixing pipe is fixed at the top of the base plate; the same rotating sleeve is connected in a sleeving way onto a connecting position of the fixing pipeand the lamp post through screw threads; a fixing plate is fixed inside the lamp post; a position limiting plate is fixed inside the fixing pipe; a plurality of position limiting posts are fixed at the bottom of the fixing plate; the position limiting posts are movably inserted and connected onto the position limiting plate; a sub lamp frame and a main lamp frame are respectively fixed at the topend of the lamp post; a sub lamp is fixed on the sub lamp frame; a main lamp is fixed on the main lamp frame; and a photovoltaic panel is fixed at the top end of each of the sub lamp and the main lamp. The convenient-to-install street lamp has the advantages that the sealing and fixing work can be performed at a seam part between the lamp post and the fixing pipe; the position limiting posts arranged at the bottom of the fixing plate arranged in the lamp post can be inserted and connected onto the position limiting plate; the positioning work before device installation is realized; and the device installation work is convenient.

Owner:金华市秸和环保技术咨询有限公司

Electrolyte injection device in a lithium-ion battery

ActiveCN113270698BRealize the delivery workRealize positioning workFinal product manufactureCell component detailsHydraulic cylinderElectric machinery

The invention discloses an electrolyte injection device in a lithium ion battery, relates to the technical field of lithium battery production, and includes a workbench, a conveying mechanism, a positioning mechanism, a clamping mechanism and a liquid injection mechanism, wherein the conveying mechanism is arranged on the workbench The upper side is used to realize the delivery before and after the lithium battery injection. The delivery mechanism includes a support plate and a drive motor. The positioning mechanism is located on the lower side of the delivery mechanism and is used to realize the positioning of the lithium battery injection. The positioning mechanism includes a telescopic cylinder. , Hinge strip 1, Hinge strip 2, and positioning strip. The clamping mechanism is located on the upper side of the conveying mechanism and is used to clamp the lithium battery when liquid is injected. The clamping mechanism includes an overhang strip, a clamping plate, and a hinge strip 3. , a linkage column and a linkage strip. The liquid injection mechanism is arranged on the upper side of the clamping mechanism and is used to realize the liquid injection of the lithium battery. The liquid injection mechanism includes a hydraulic cylinder and an electrolyte tank. In summary, the present invention can realize automatic delivery, automatic positioning, automatic clamping and automatic filling of lithium batteries.

Owner:WUHU ETC BATTERY LTD

Anti-falling device for stereo garage

ActiveCN113323473ARealize positioning workRealize the anti-drop functionParkingsElectric machineryEngineering

The invention provides an anti-falling device for a stereo garage, and relates to the technical field of parking equipment. The anti-falling device comprises two symmetrically-arranged supports and a parking plate arranged between the supports, a limiting rod is fixedly connected to the interior of one support, a lifting motor is fixedly installed at the top of the other support, lifting screws are fixedly connected to the output end of the lifting motor, the lower ends of the lifting screws are rotatably inserted into the bottoms in the supports, one side of the parking plate is slidably arranged on the limiting rod, the other side of the parking plate is arranged on the lifting screws in a threaded mode, a mounting frame is fixedly connected between the two supports, a first anti-falling assembly is mounted on the mounting frame, and second anti-falling assemblies are fixedly connected to the side walls of the two sides of the parking plate. According to the anti-falling device, a first anti-falling assembly and a second anti-falling assembly are adopted, the position of an automobile is fixed, in this way, the anti-falling function is achieved, the safety of the automobile is guaranteed, and harm to personnel is also avoided.

Owner:HEFEI WEIHUA INTELLIGENT PARKING EQUIP

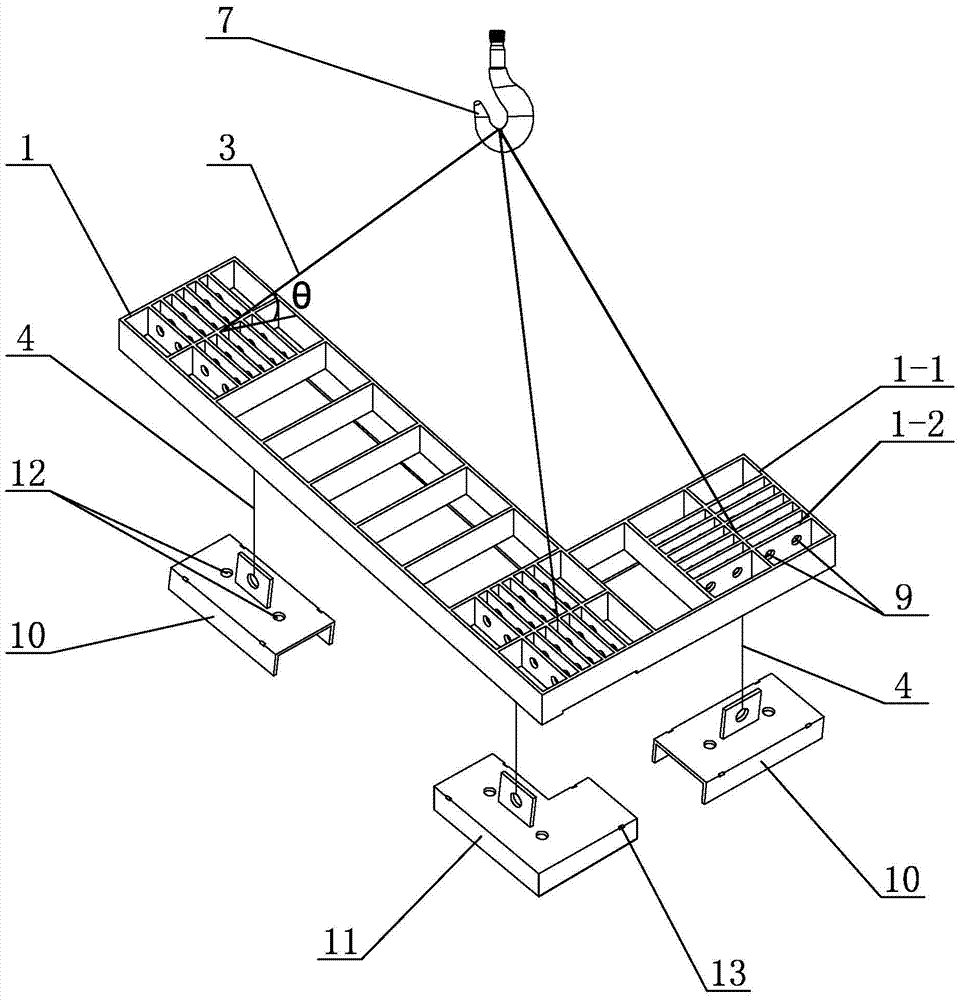

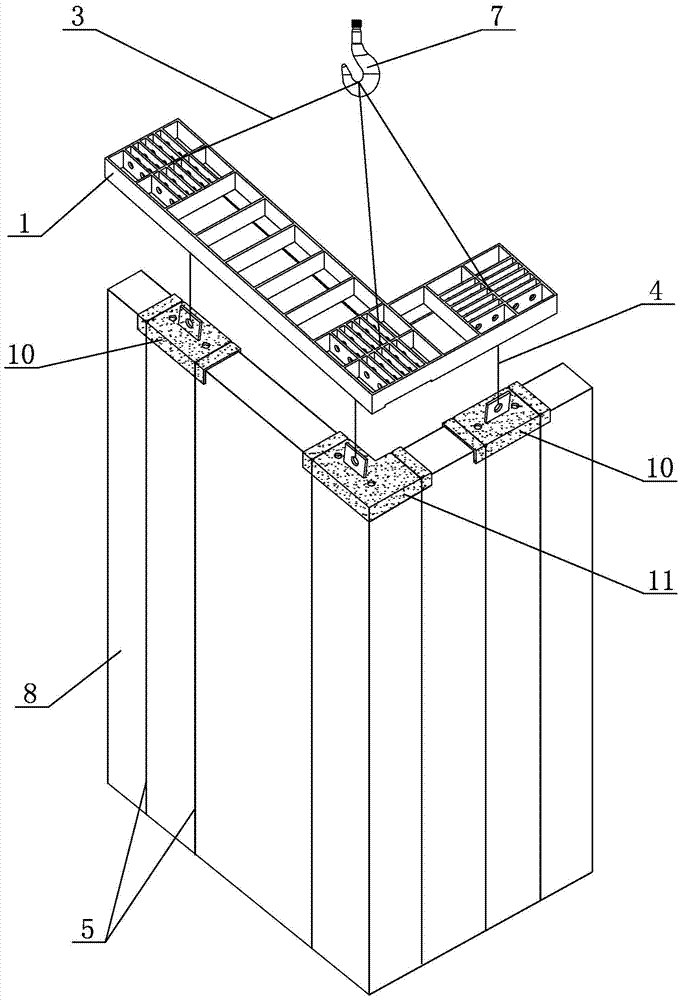

Natural centering hoisting method of block pattern masonry wall

ActiveCN105625734BRealize safe liftingAccurately calculate the center of gravity positionBuilding material handlingBrickStructural engineering

The invention discloses a natural centering hoisting method for agglomeration mode brick wall pieces, relates to a hoisting method for agglomeration mode brick wall pieces, and aims to solve the problems of poor stability in a hoisting process and severe influence on a matching degree of reassembly after hoisting due to difficulty in realization of uniform and accurate positioning of the brick wall pieces of various shapes since the conventional brick pieces for building and constructing are various in shapes. The natural concentrating hoisting method comprises the following steps: I, selecting balance beams; II, calculating the gravities of hollow block masonry wall pieces; III, connecting the balance beams with lifting hooks by using a plurality of hoisting ropes; IV, determining a hoisting area of the hollow block masonry wall pieces according to collinearity of three centers, and setting a plurality of cover plate assemblies below an area M; V, connecting various members according to the area M determined in the step IV; VI, driving the lifting hooks to hoist the hollow masonry wall pieces. The natural centering hoisting method is used for hoisting the wall pieces.

Owner:HARBIN DACHENG GREEN BUILDING TECH DEV

Intelligent identifying and automatic grabbing device for dials of quartz clocks

InactiveCN109484852AOptimize assembly processReduce manufacturing costClock support devicesArticle feedersCamera lensImaging processing

The invention discloses an intelligent identifying and automatic grabbing device for dials of quartz clocks. The device comprises a grabbing mechanism and an image acquisition mechanism; the grabbingmechanism is arranged on one side of the image acquisition mechanism; the image acquisition mechanism comprises an industrial camera, an industrial lens and a light source; the industrial camera is incommunication connection with a computer through a USB interface; and an image processing system is arranged inside the computer. According to the device, a visual inspection system is applied to theassembly process of the dials of the quartz clocks, so that intelligent and automatic assembly is realized, the assembly technology of the quartz clocks is improved, the production cost of the quartzclocks is reduced, and meanwhile, the manufacturing precision and the timing precision of the quartz clocks are improved; human eyes are replaced by machines in the aspect of vision, so that intelligent identification and positioning work is realized for image acquisition and processing; and the blank in the intelligent aspect in the quartz clock manufacturing industry is filled in the assembly technology of the quartz clocks, the technology can also be a guide for similar assembly technologies, and the development of the visual inspection system in industrial application is promoted.

Owner:FUJIAN UNIV OF TECH

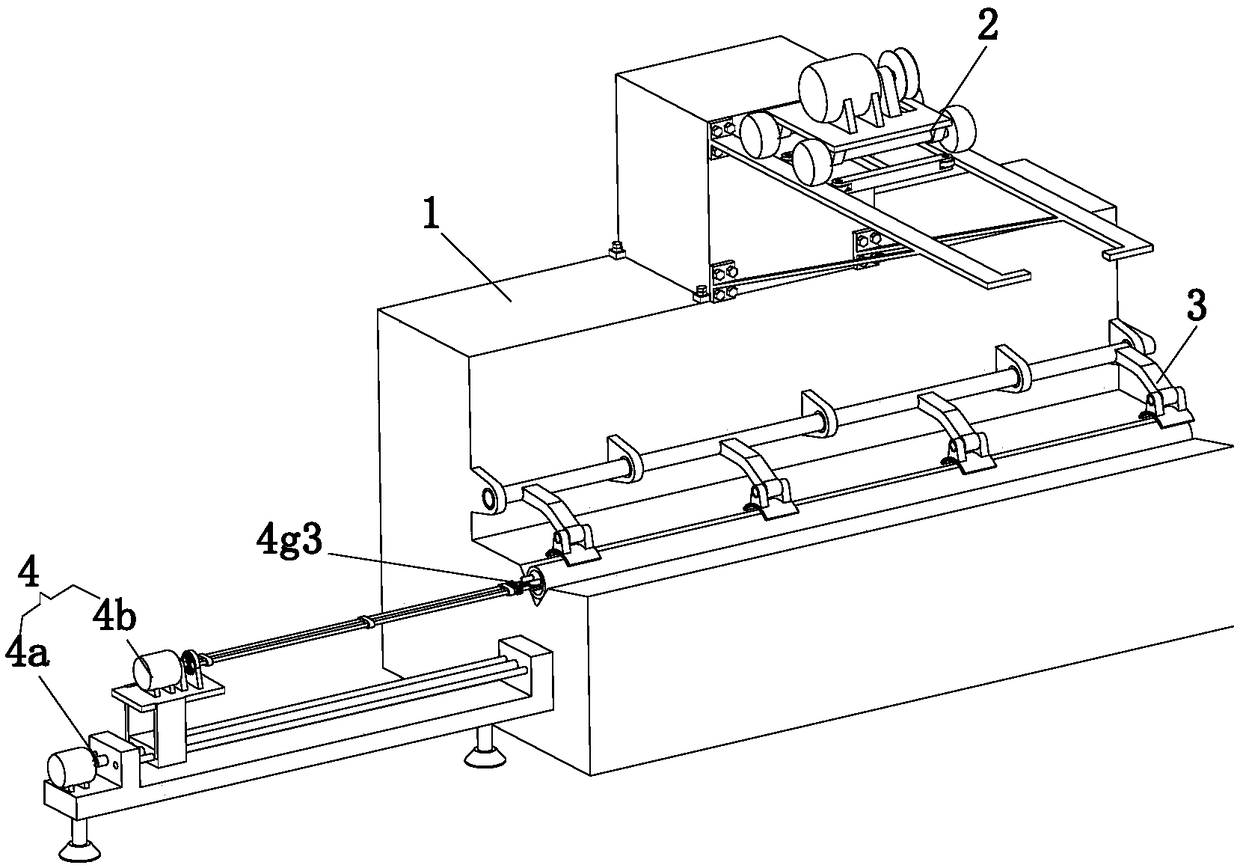

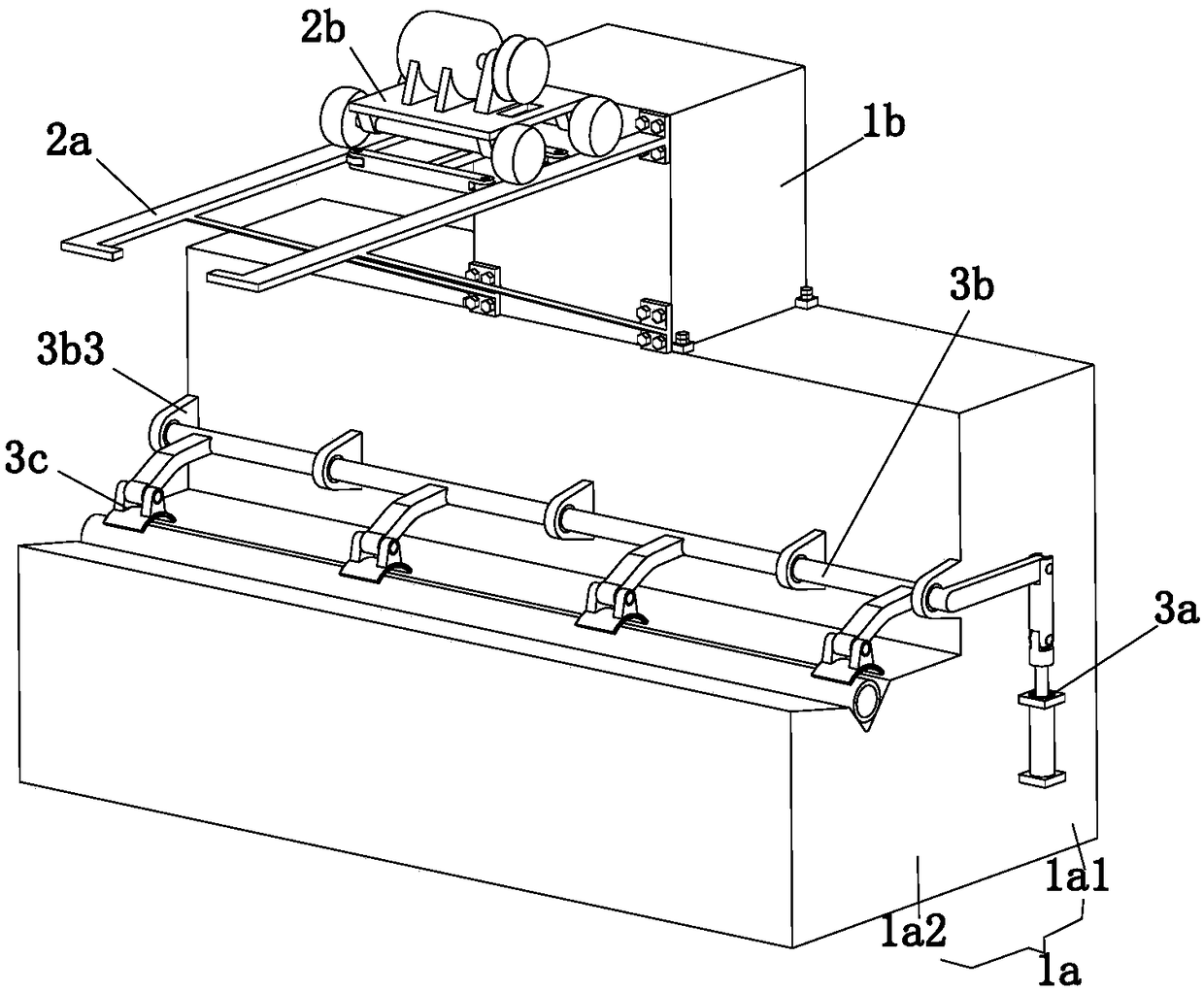

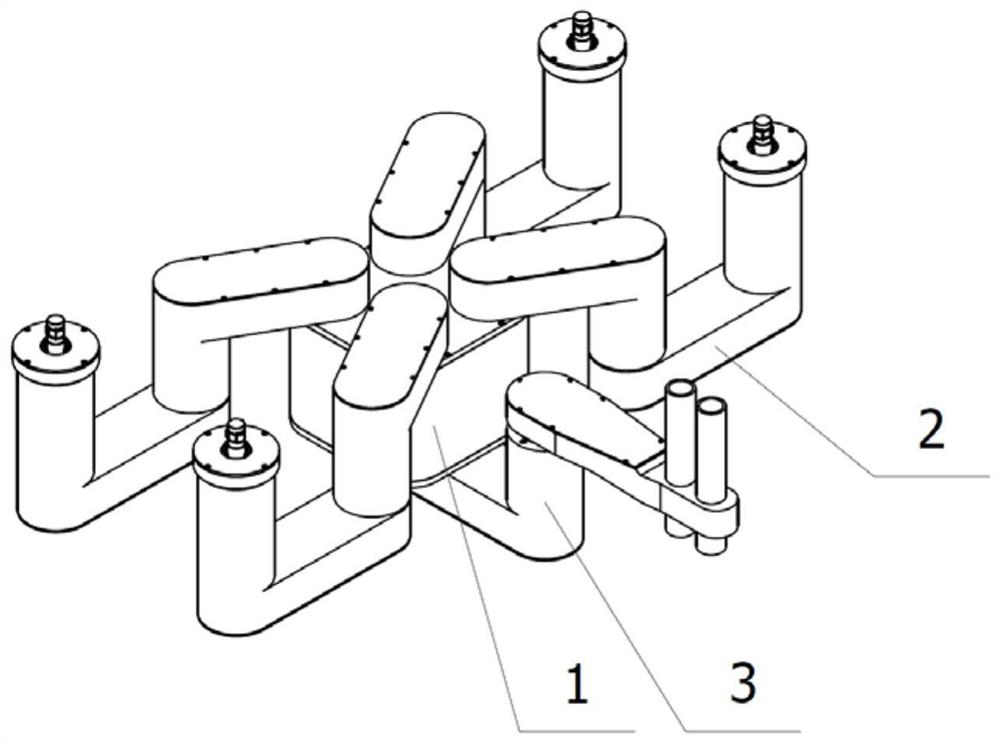

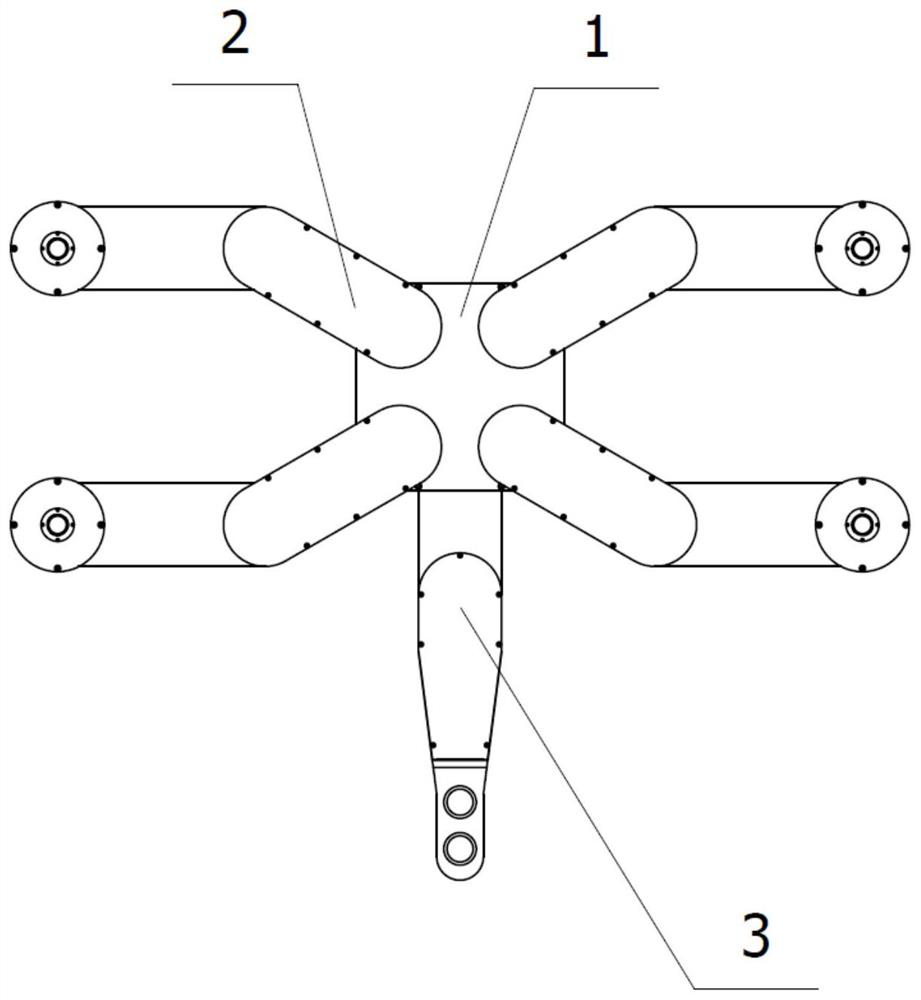

Foot type robot for overhauling heat transfer pipes of steam generators of multiple specifications

The invention relates to a maintenance robot, in particular to a foot type robot used for maintenance of steam generator heat transfer pipes of multiple specifications, and aims to solve the problems that an existing crawling type SG heat transfer pipe maintenance robot is not flexible enough in motion mode and poor in structural adaptability, and the foot type robot comprises a base module, an operation arm module and four leg modules. The base module comprises a base box body, a shoulder joint motor module and four hip joint motor modules; four hip joint motor modules are arranged at the upper end of the base box body, a shoulder joint motor module is arranged at the bottom end of the base box body, the top output end of each hip joint motor module is connected with one leg module, and the bottom output end of each shoulder joint motor module is fixedly connected with the operation arm module. The invention belongs to the field of equipment maintenance.

Owner:HARBIN INST OF TECH

An automatic assembly machine for electrical cabinets

ActiveCN112372287BRealize positioning workImprove work efficiencyAssembly machinesMetal working apparatusAssembly machineElectrical equipment

Owner:JIANGSU JIANXIONG ELECTRIC CO LTD

Production process of a centrifugal blood pump rotor

ActiveCN110893546BReduce laborHigh degree of automationWelding/cutting auxillary devicesAssembly machinesImpellerMedical equipment

The invention discloses a production process of a centrifugal blood pump rotor, which belongs to the technical field of medical device production process, and comprises the following steps: Step 1. Motor magnets and impellers are loaded; Step 2. Bearing magnetic stacks are pressed and installed in the impeller: 3. Four motor magnets are pressed into the impeller: the conveyor belt moves the pressed impeller to the bottom of the motor magnet installation mechanism, and the motor magnet installation mechanism presses the motor magnet into the impeller; Step 4. The base is pressed into the impeller and welded Forming, the invention can automatically complete the steps of pressing the bearing magnetic pile of the rotor of the centrifugal blood pump, installing the motor magnet and welding the base. The installation operation is carried out one by one; the process design of the present invention is ingenious, the connection between the processes is smooth, the produced product has good consistency, and the yield rate is high. In the whole process, more than 70% of labor can be saved, and it has good economic value.

Owner:韶关市武江区冠启自动化设备设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com