Double-face chamfering mechanism of gear

A gear, double-sided technology, used in gear cutting machines, components with teeth, gear teeth manufacturing devices, etc., can solve problems such as slow processing speed, gear noise, and scrapped gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

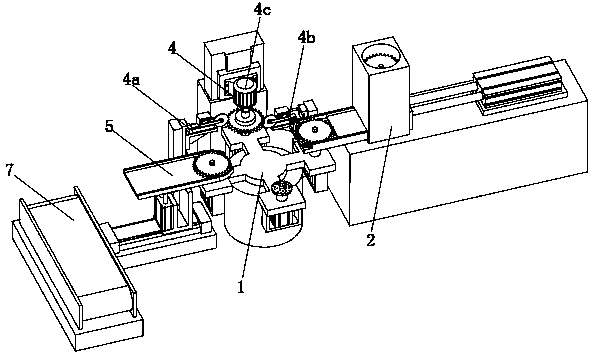

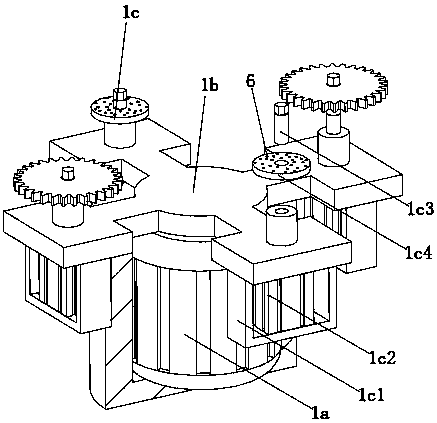

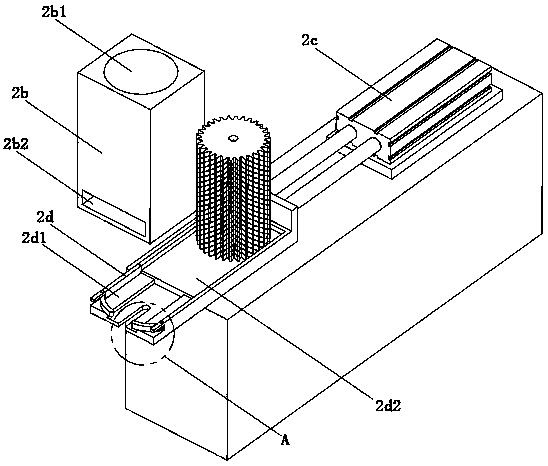

[0028] refer to Figure 1 to Figure 10 The shown gear double-sided chamfering device includes a conveying mechanism 1, a feeding mechanism 2, a processing mechanism 4 and a blanking mechanism 5, and the feeding mechanism 2, the processing mechanism 4 and the blanking mechanism 5 are arranged in a circle in sequence On the side of the conveying mechanism 1, the feeding mechanism 2 includes a mounting table 2a, a hopper 2b, a feeding cylinder 2c and a feeding plate 2d, the hopper 2b is in a rectangular structure and is vertically arranged on the upper end of the mounting table 2a, and the hopper The middle part of 2b is provided with a trough 2b1 for placing gears, and the bottom of the hopper 2b is provided with a feeding hole 2b2 for the feeding plate 2d to pass through. One end of the feeding plate 2d extends to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com