Automatic fast test tube cover taking robot and cover taking method

A technology of robots and test tubes, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as test tube damage, low manual operation efficiency, and contamination of biological samples, and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

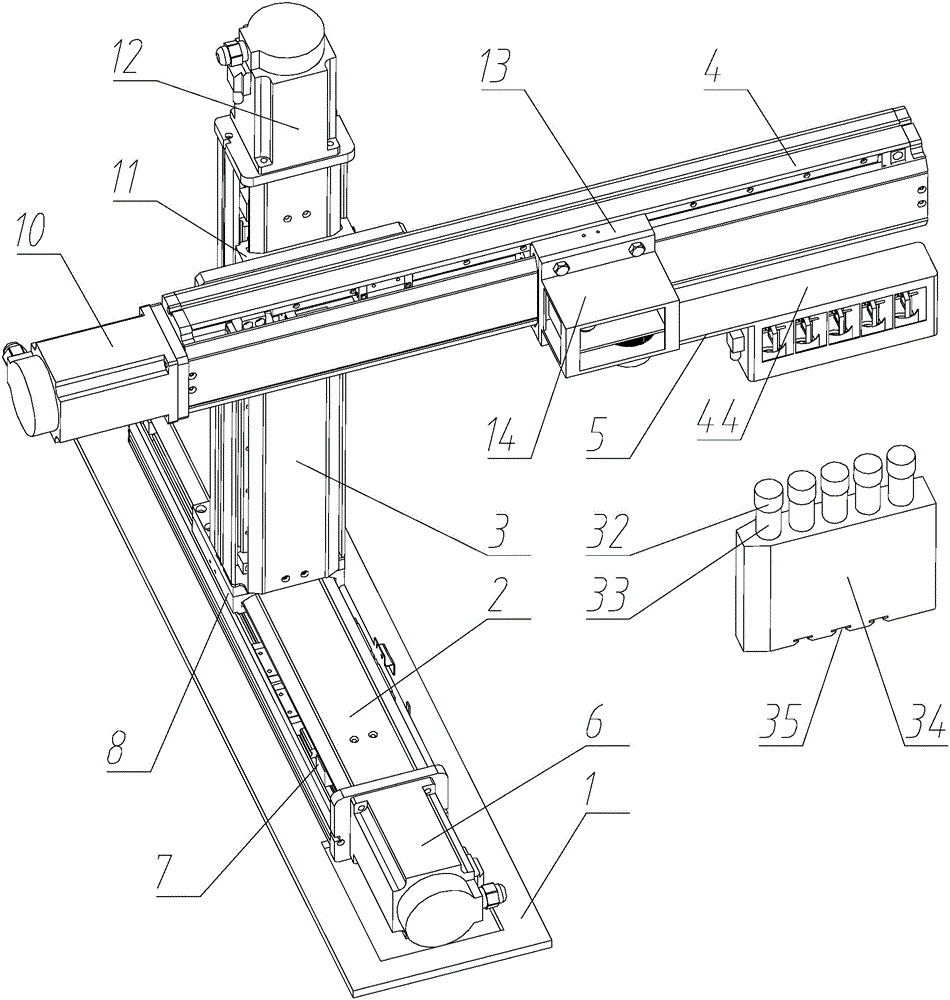

[0051] Such as Figure 1-11 , an automatic and fast test tube capping robot, which includes a base 1, an X-axis mechanical arm 2 for controlling front and rear movement is installed on the base 1, and a Z-axis mechanical arm 2 for controlling up and down movement is vertically installed on the X-axis mechanical arm 2. Arm 3, the Z-axis mechanical arm 3 is vertically equipped with a Y-axis mechanical arm 4 that controls left and right movement, and the Y-axis mechanical arm 4 is equipped with a cover removal robot 5;

[0052] Further, one end of the cap removing manipulator 5 is equipped with a mechanical arm rotation drive mechanism, and the other end is equipped with a cap removing mechanism.

[0053] Further, the X-axis mechanical arm 2 is mounted on the base 1 by screws, the X-axis mechanical arm 2 includes an X-axis stepping motor 6, and the output shaft of the X-axis stepping motor 6 is connected to the X-axis through a coupling 36. The ball screw 40 is connected, the ba...

Embodiment 2

[0063] The method for automatically removing caps by using the automatic fast test tube cap removal robot described in any one of the rights includes the following steps:

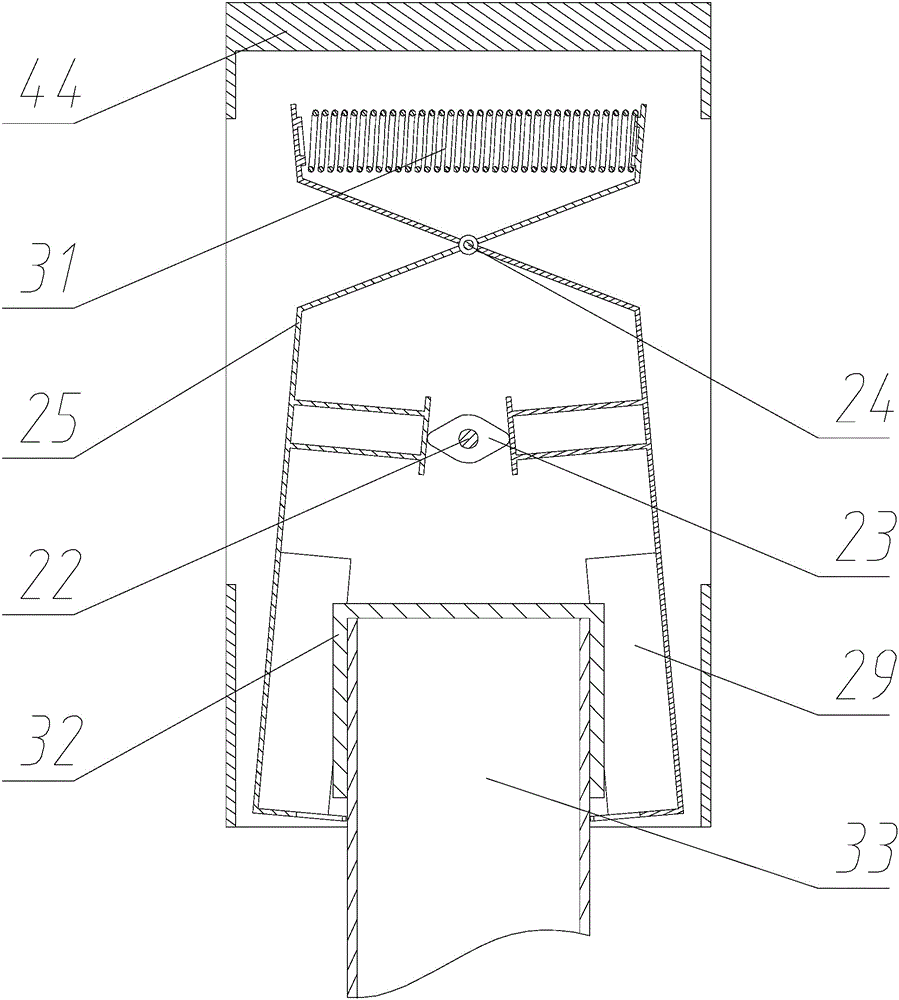

[0064] Step 1: In the positioning stage, in the initial state, the cover removal manipulator 5 rotates to the direction where the test tube holder 34 is located, the test tube clamp 25 is in the open state, the cam follower 28 is in contact with the far rest point of the cam 23, and the Y-axis mechanical arm 4 is vertical. Rise to the highest point in the straight direction, the solenoid valve is locked, the robot is installed on the designated process position of the assembly line through the base 1, the test tube 33 with the sample is pre-fixed in the test tube rack 34, and the test tube rack 34 is stuck on the assembly line conveyor belt through the chute 35 , the test tube 34 can be placed horizontally or vertically on the conveyor belt. When the test tube rack and the test tube move to the middle positi...

Embodiment 3

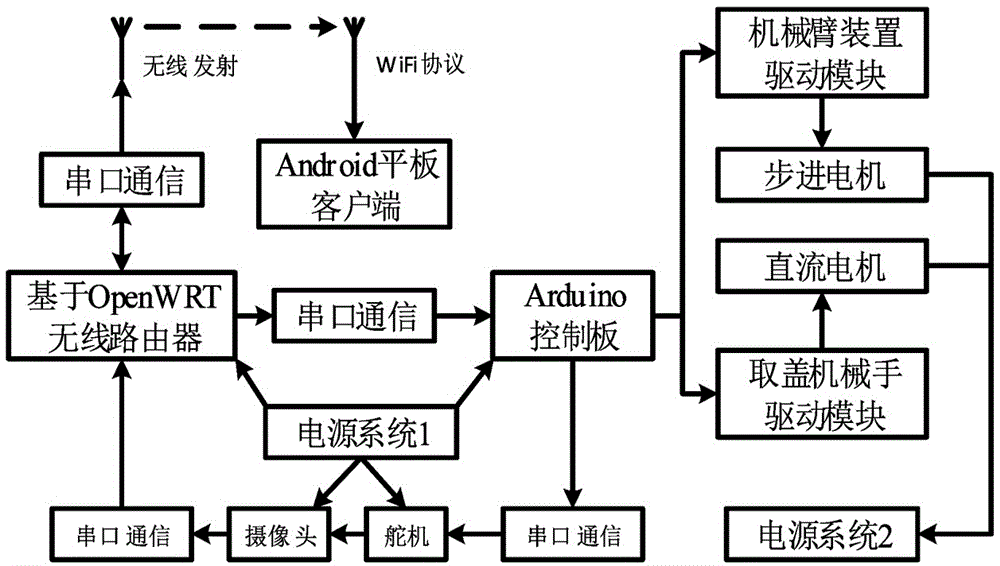

[0074] Such as Figure 11 As shown, the robot control system for the automatic and rapid test tube cap removal of the present invention mainly adopts the control mode of the three-level distributed structure of "upper computer + embedded system + lower computer". The control device of the control system is composed of an upper computer and an Arduino control board. The upper computer is a tablet computer based on the Android system, a router equipped with an embedded system is used as a server for wireless communication, and an AVR single-chip microcomputer on the Arduino control board is used as a lower computer. The tablet computer is responsible for receiving the video signal from the camera and sending control instructions to the Arduino control board, and the control board is responsible for receiving the control instructions sent by the tablet computer and converting them into matching control signals to control the manipulator to complete specified actions. Each motor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com