Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Realize orderly delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Takeout delivery method and system

InactiveCN106485441ARealize orderly deliveryReduce delivery costsBuying/selling/leasing transactionsLogisticsDelivery costCycle time

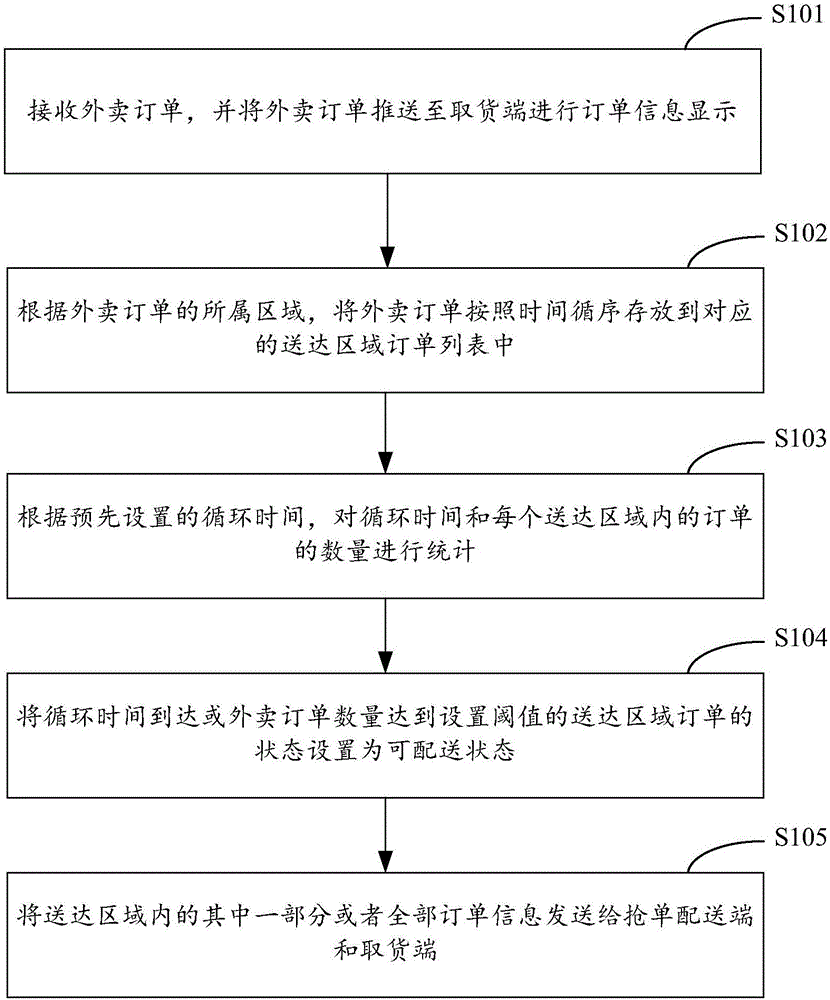

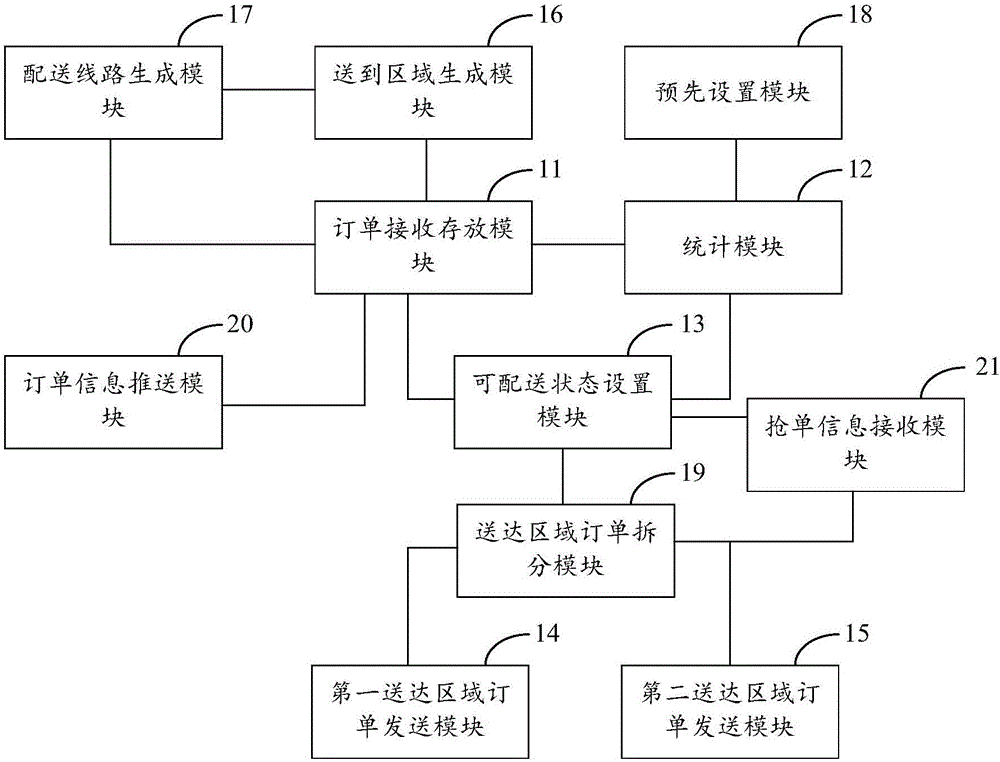

The invention discloses a takeout delivery method and system. The method comprises the steps of receiving takeout orders, pushing the takeout orders to a goods collecting end for performing order information display, and storing the takeout orders in a corresponding delivery region order list according to a time sequence; performing statistics on circulating time and an order quantity of each delivery region according to a preset circulating time; and when the preset circulating time is up or the takeout order quantity in a delivery region reaches a set threshold, setting the states of the orders in the delivery region to be deliverable states. Part or all of the order information in the delivery regions is sent to an order grabbing delivery end and the goods collecting end, so that the takeout orders can be orderly delivered; and a mode of separating goods collection from delivery is adopted for centralized delivery, so that the delivery cost is reduced and the delivery efficiency is improved.

Owner:合肥壹客送网络科技有限公司

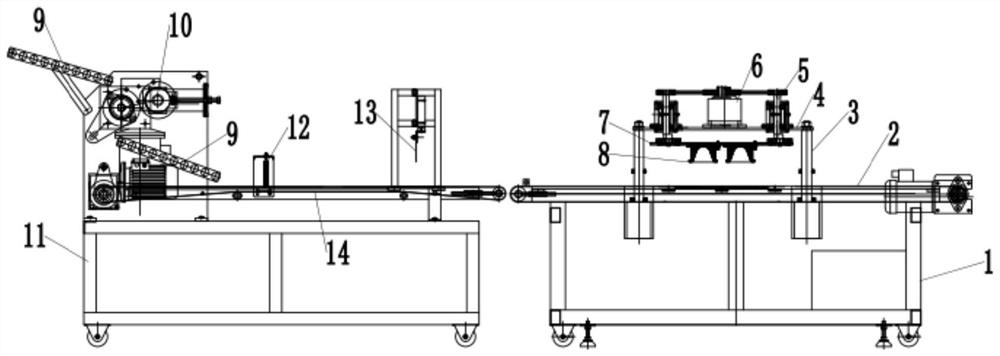

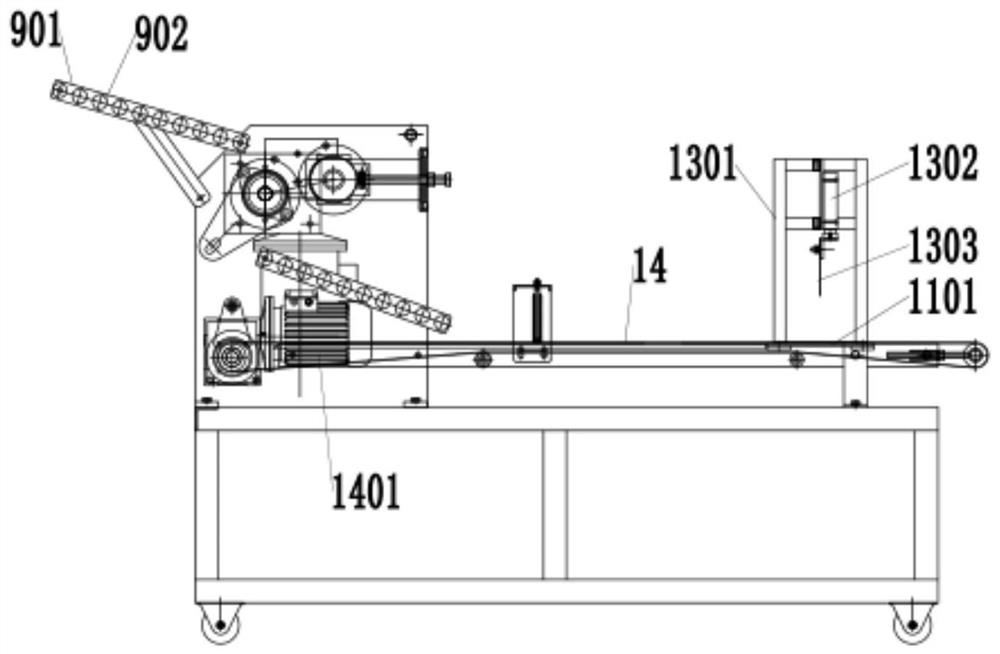

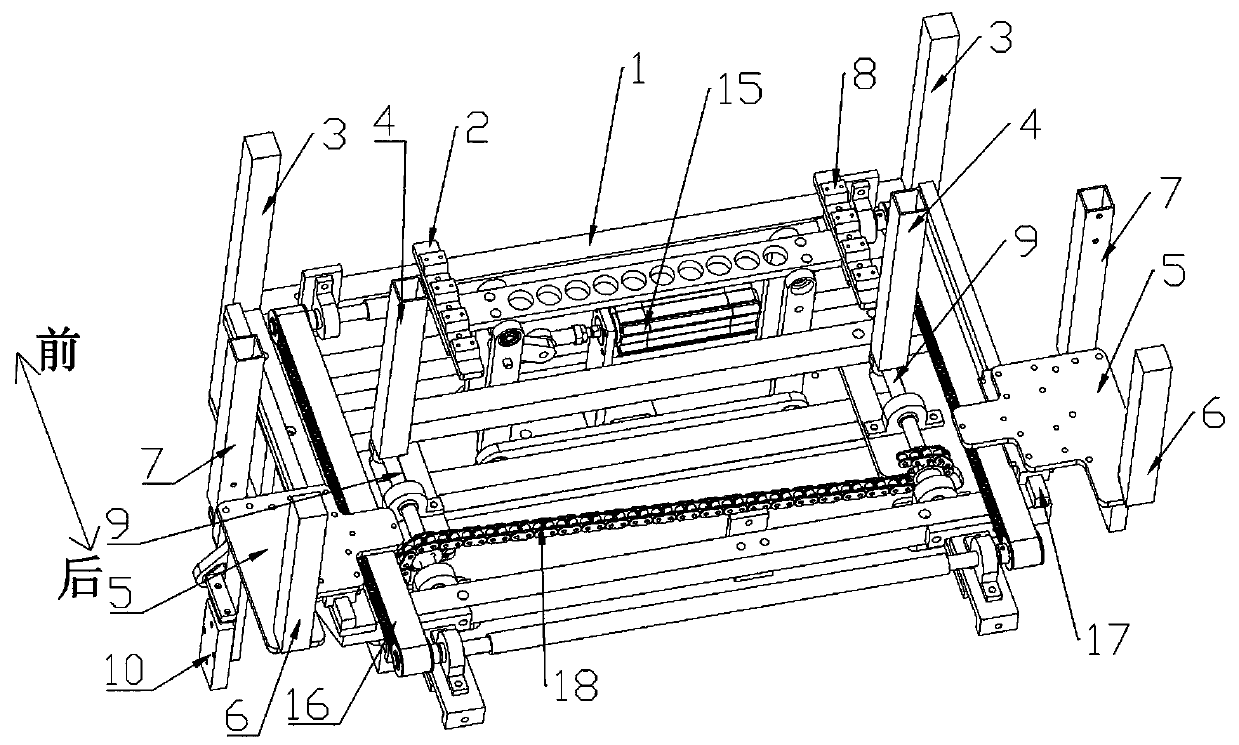

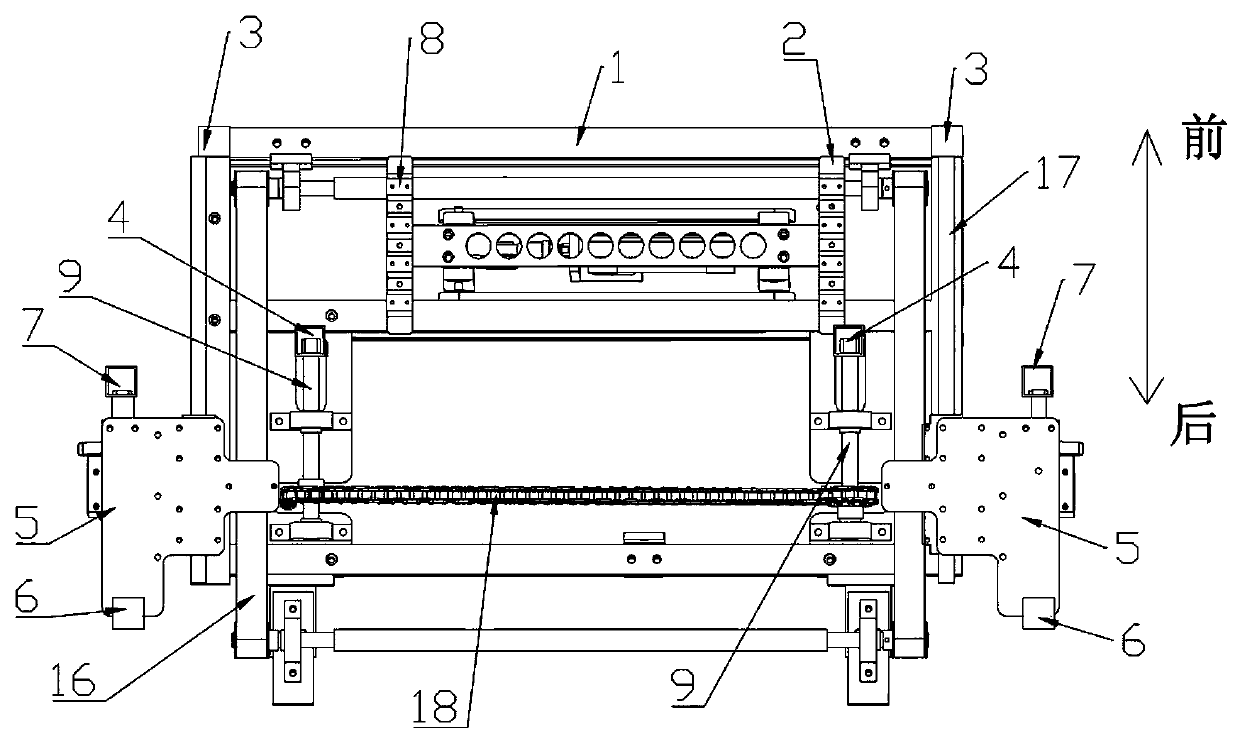

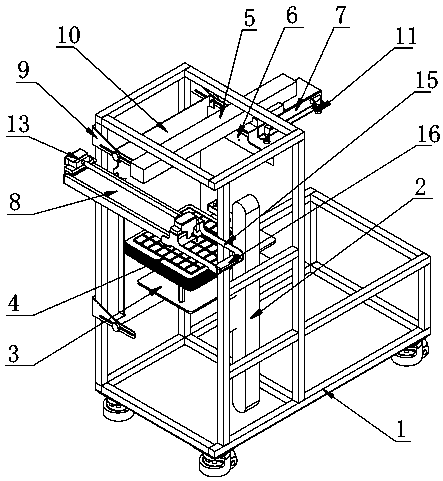

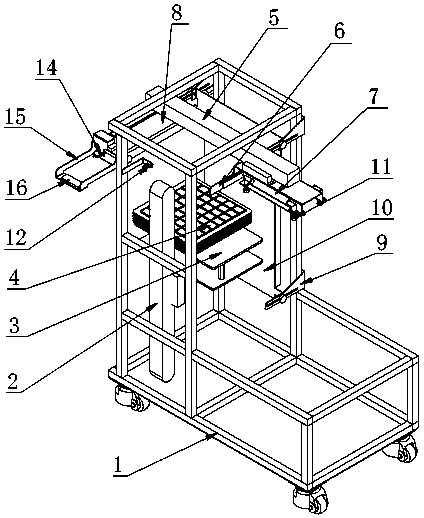

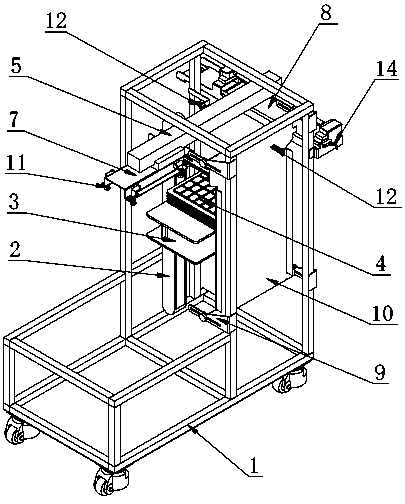

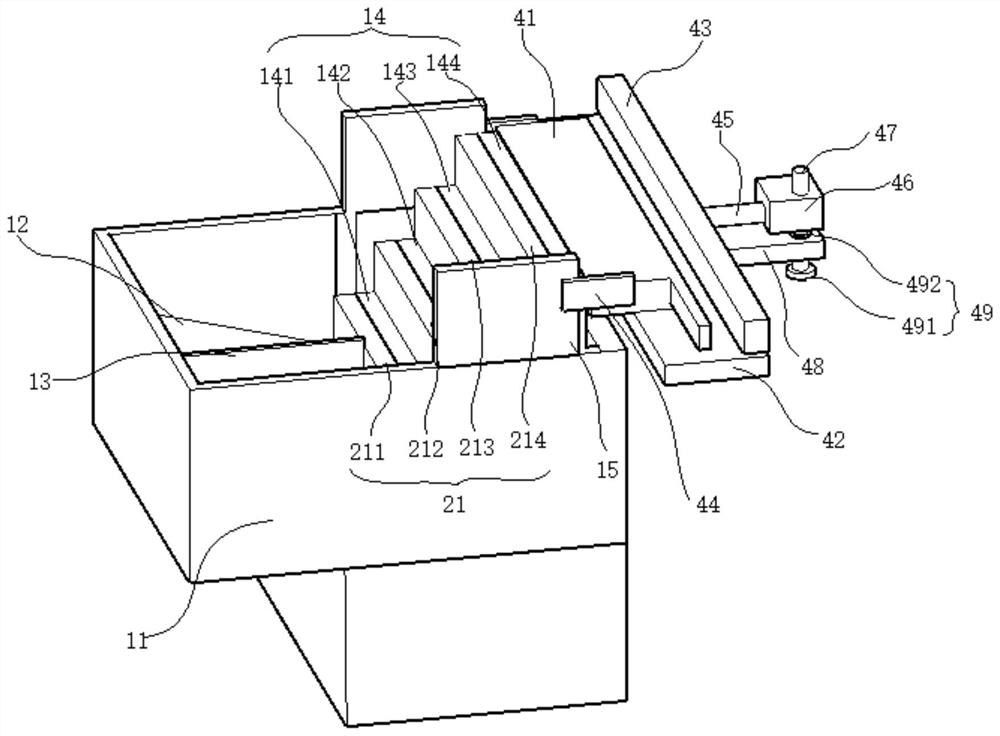

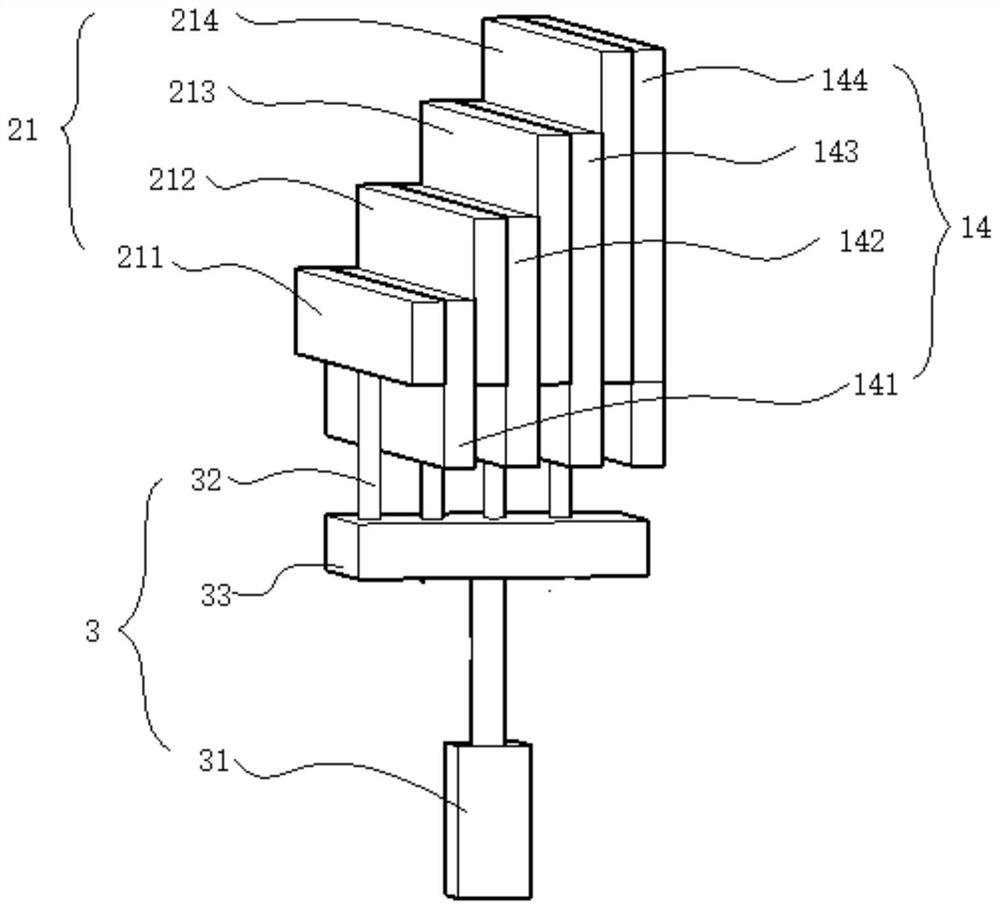

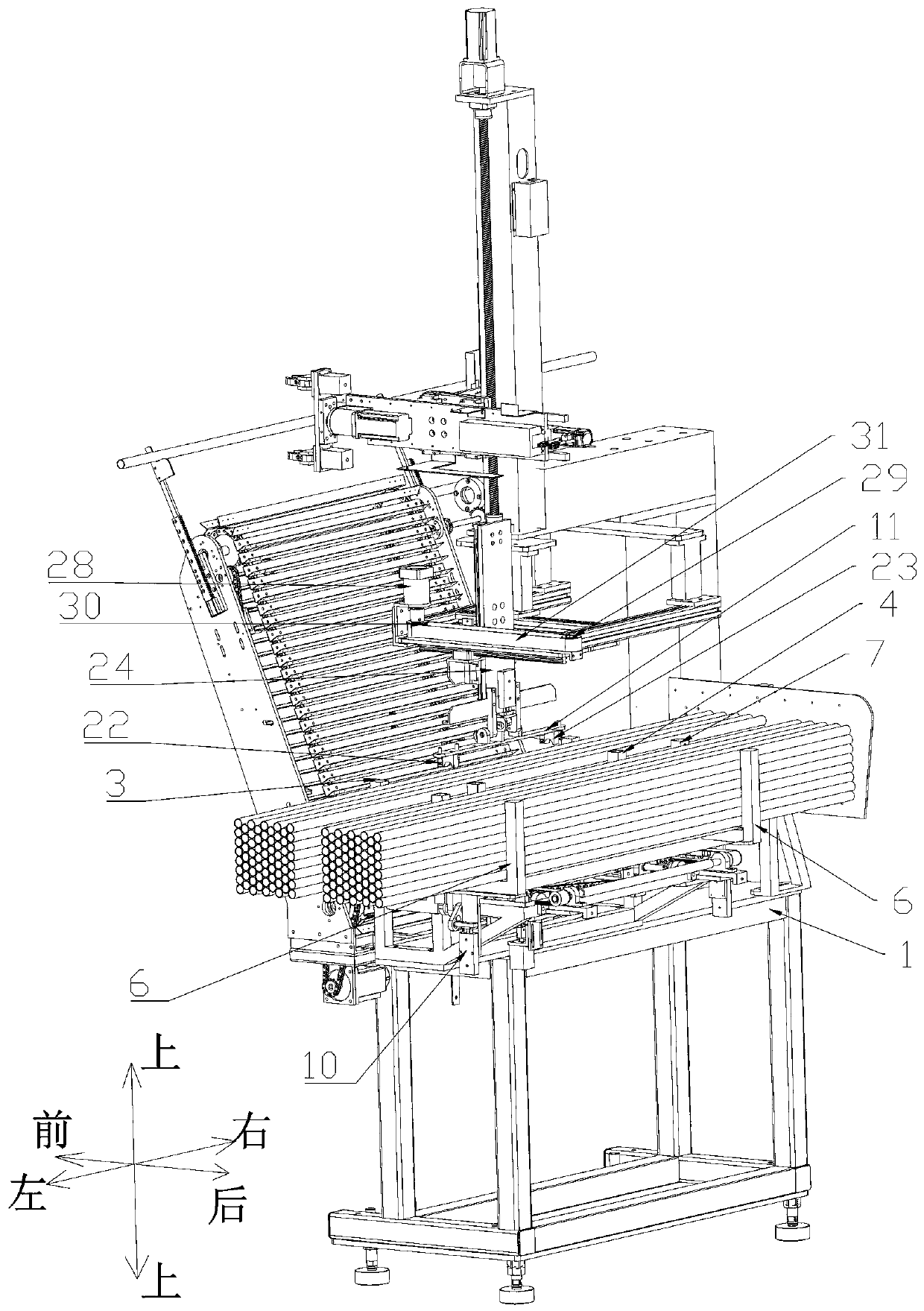

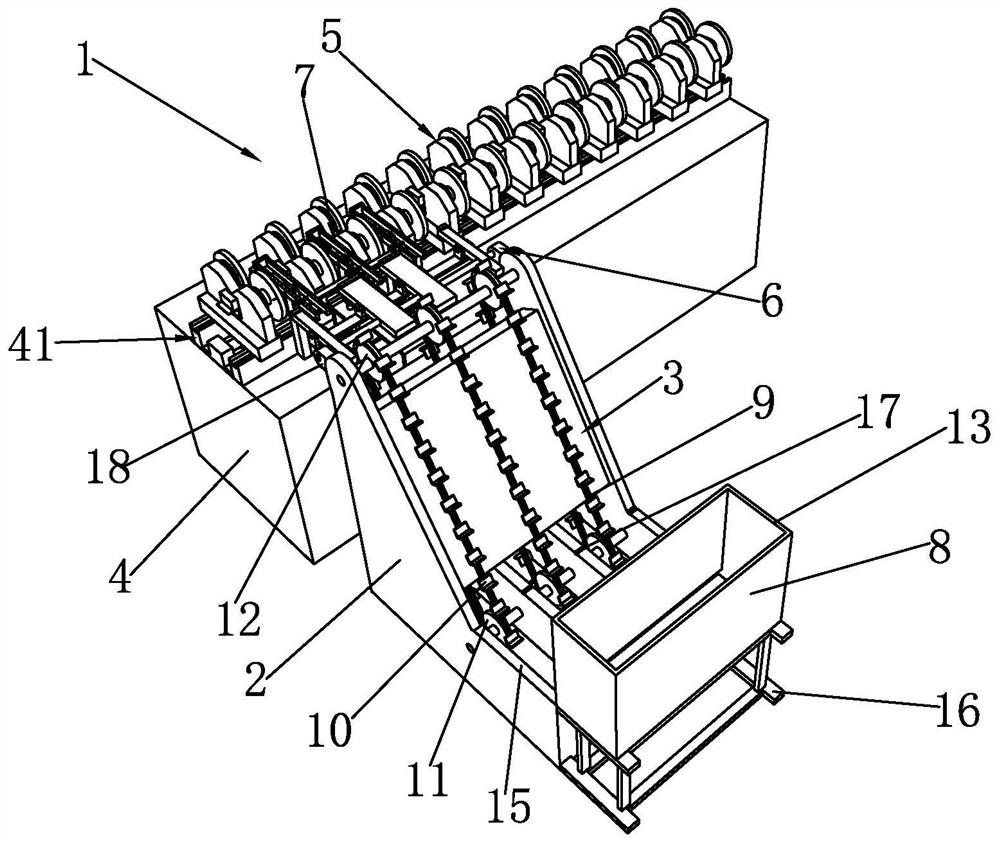

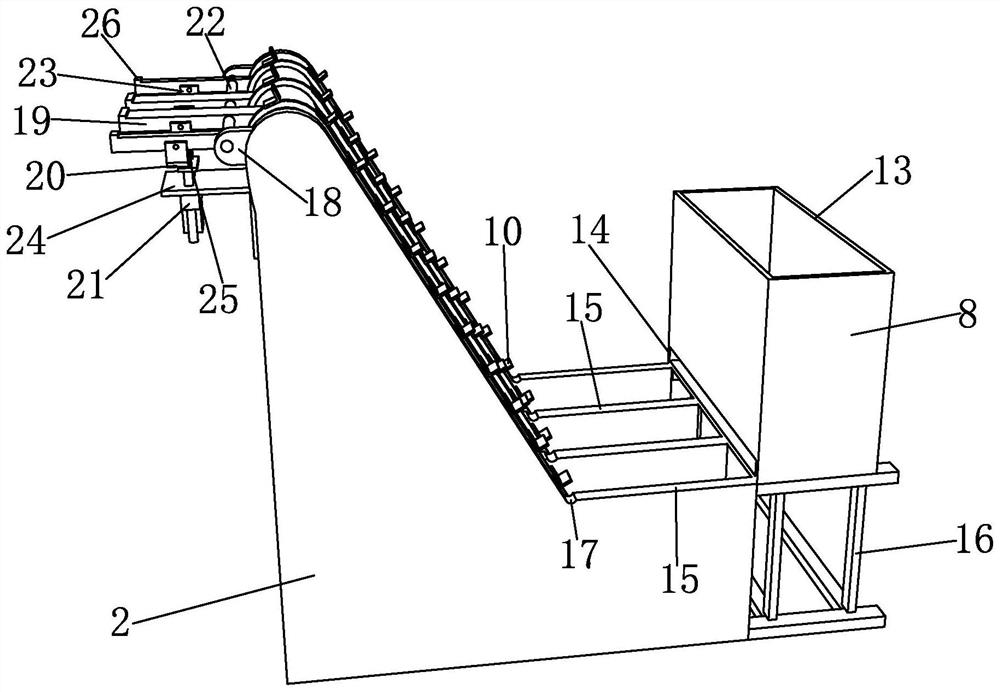

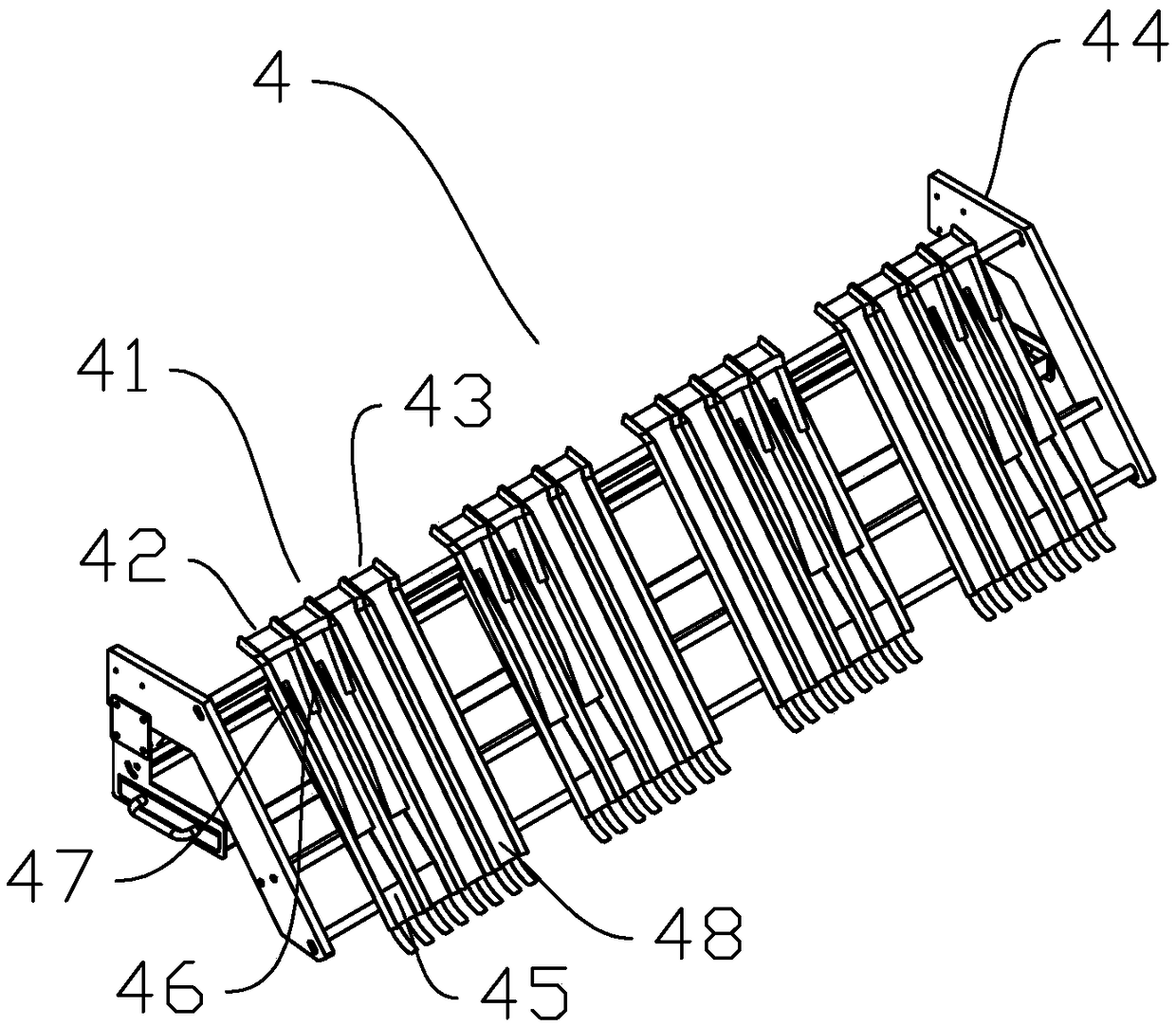

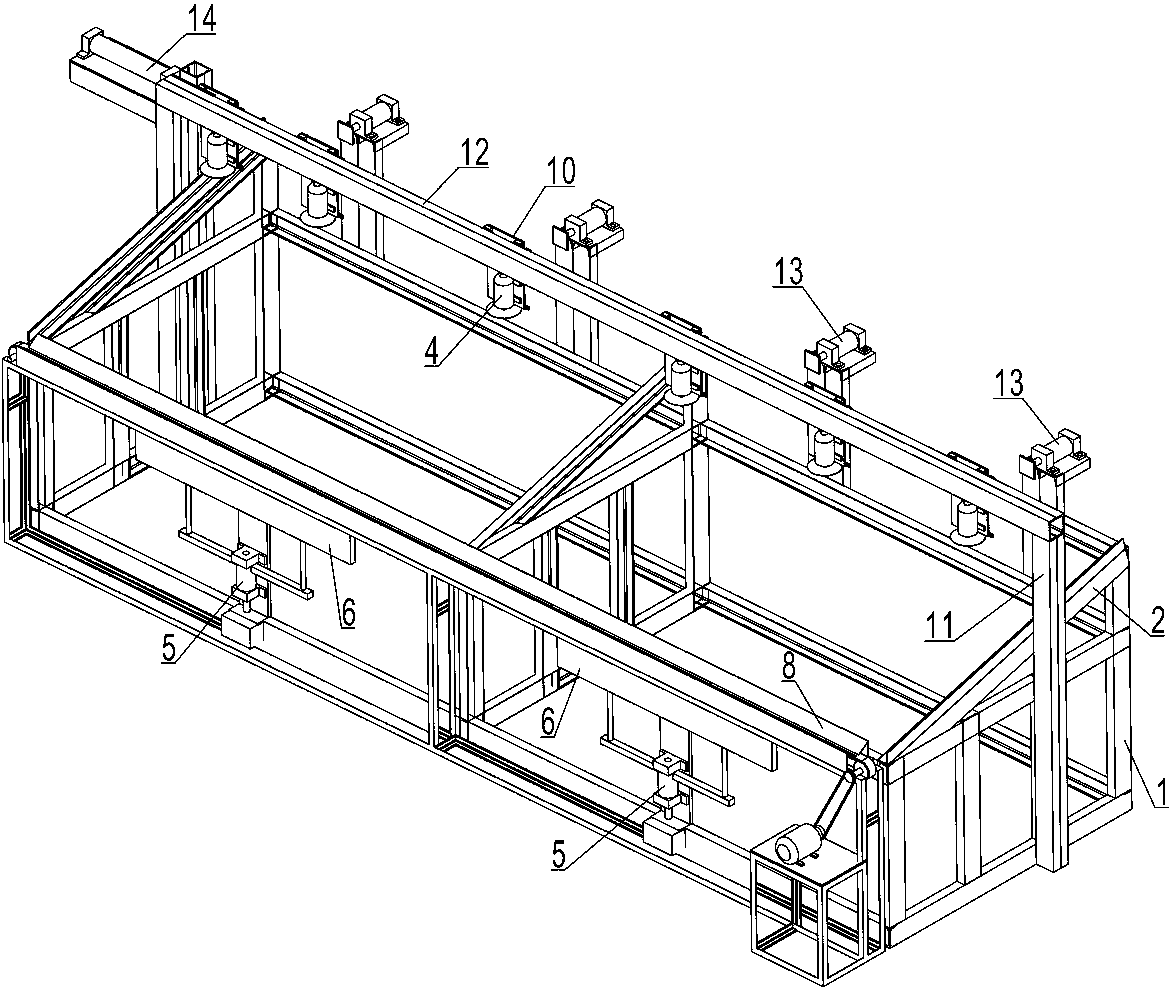

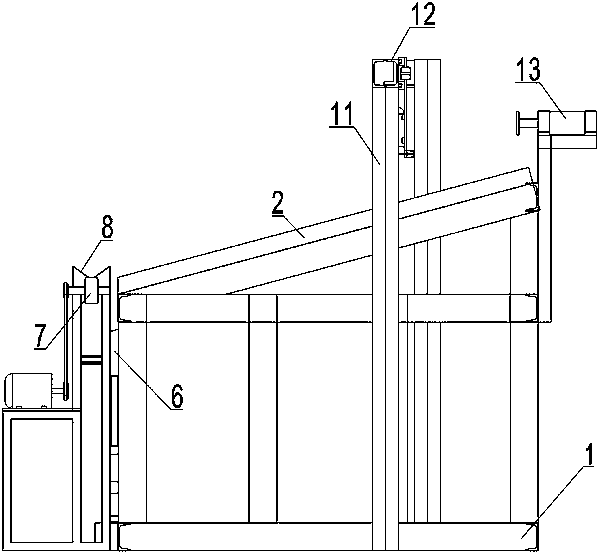

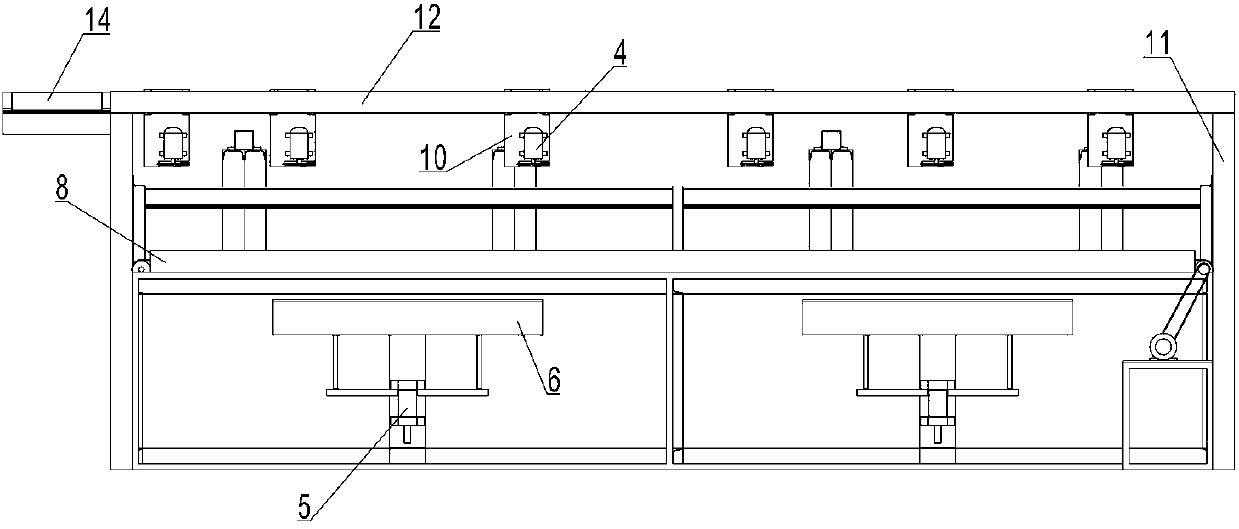

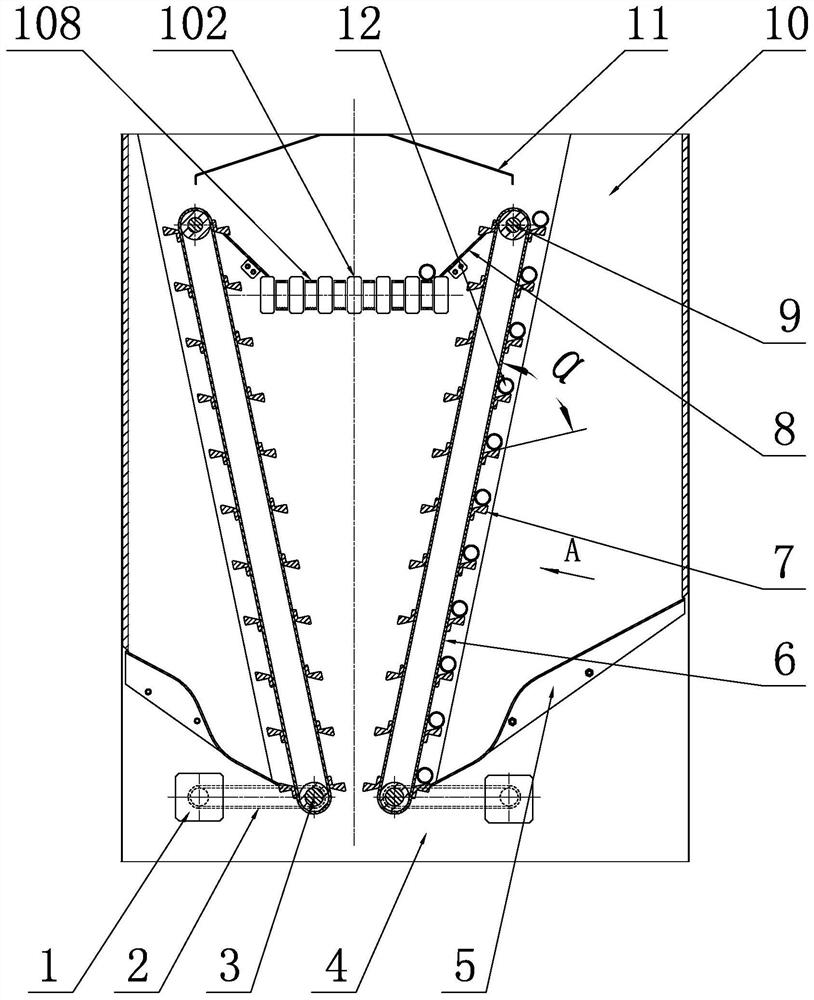

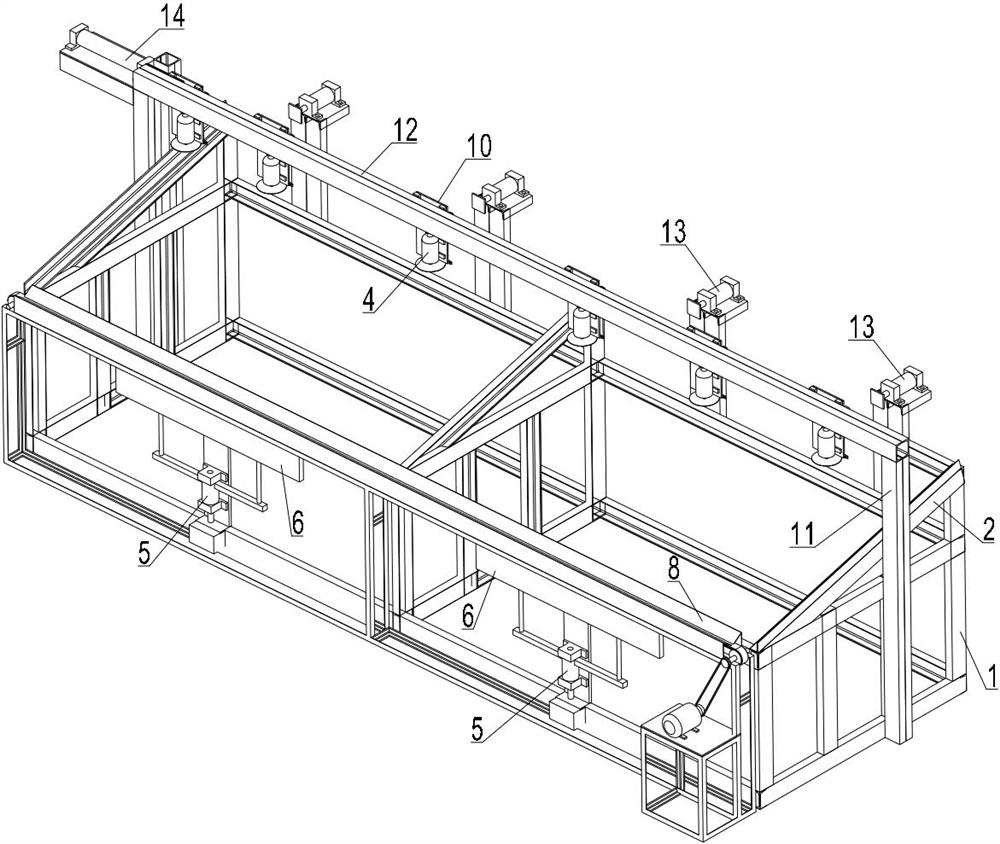

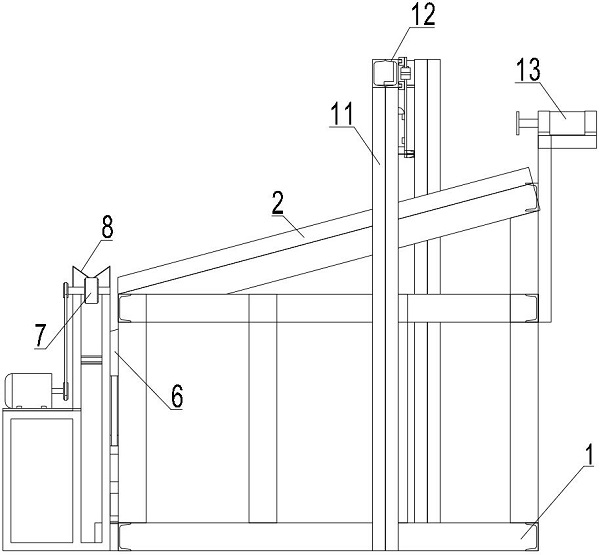

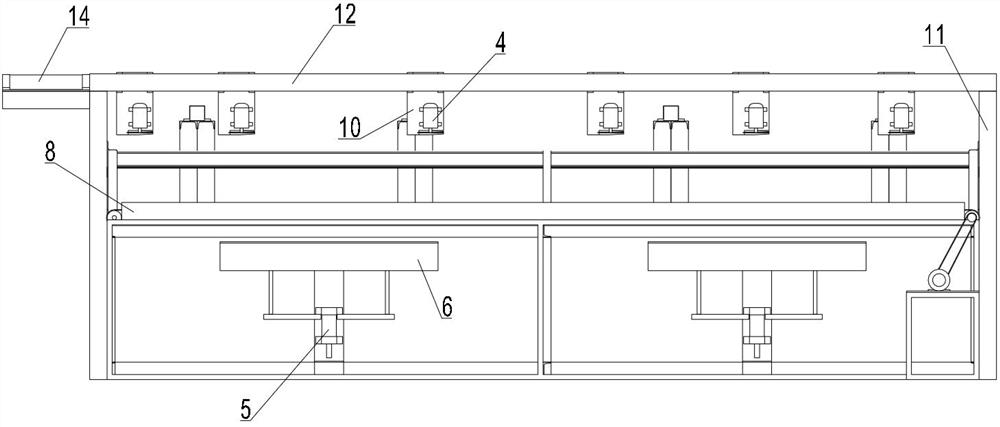

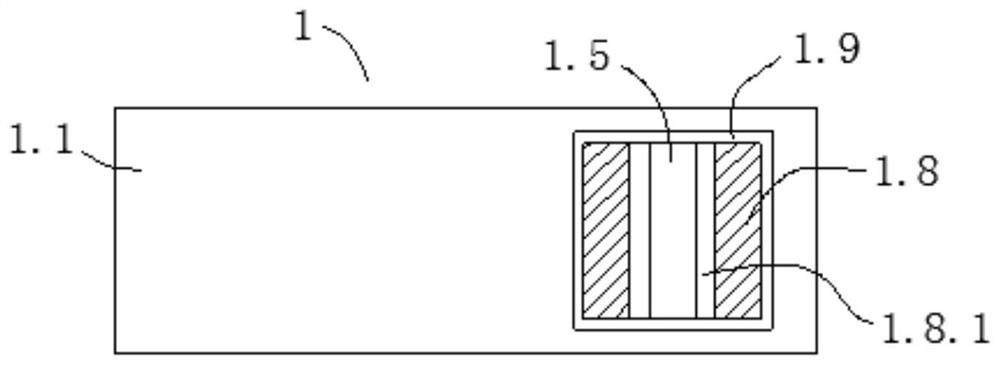

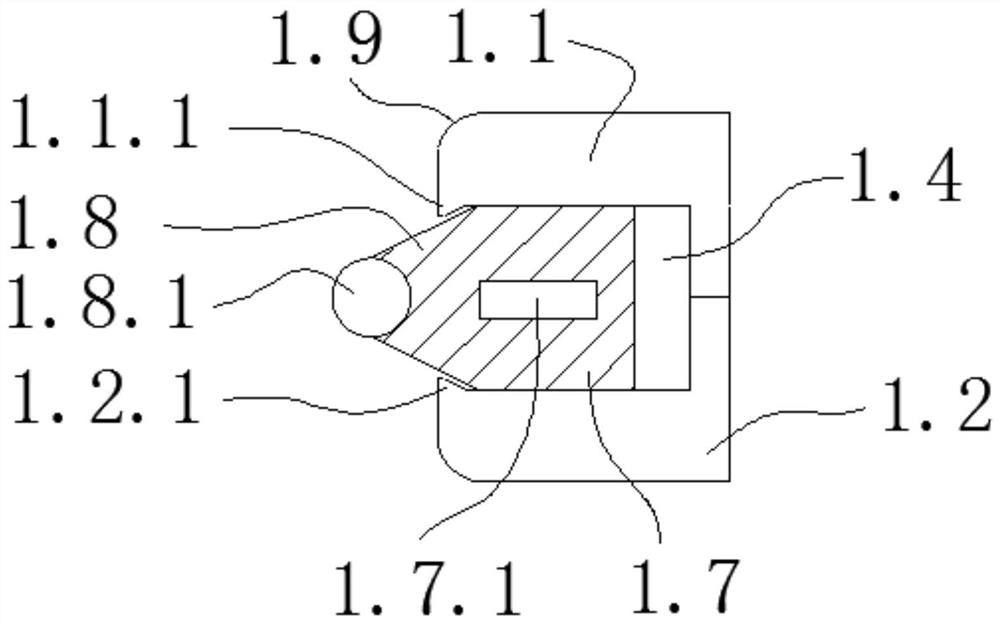

Automatic boxing system for glass product

PendingCN107856903ARealize orderly deliveryRealize fully automatic control modePackaging bottlesTransfer mechanismIndustrial engineering

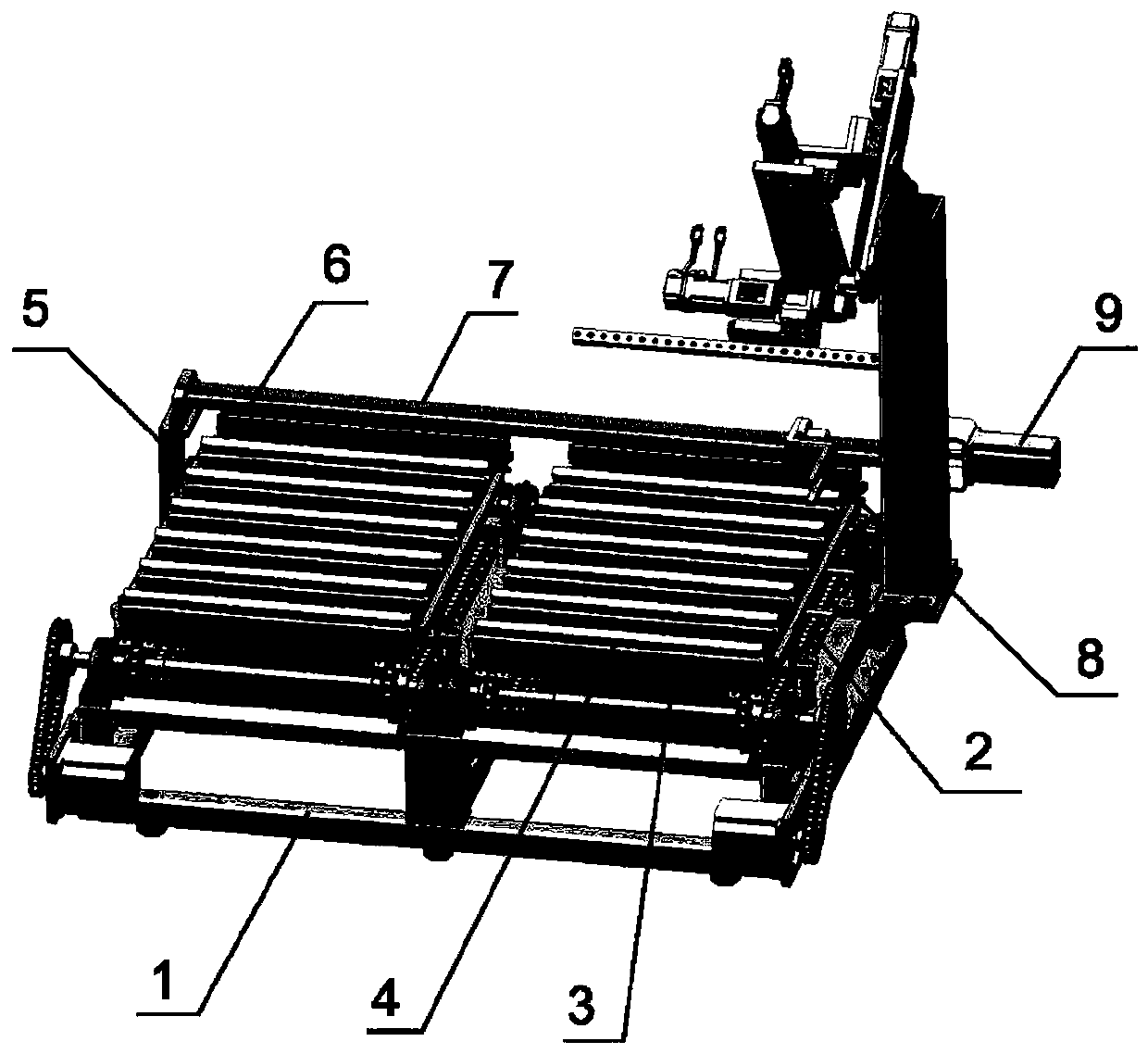

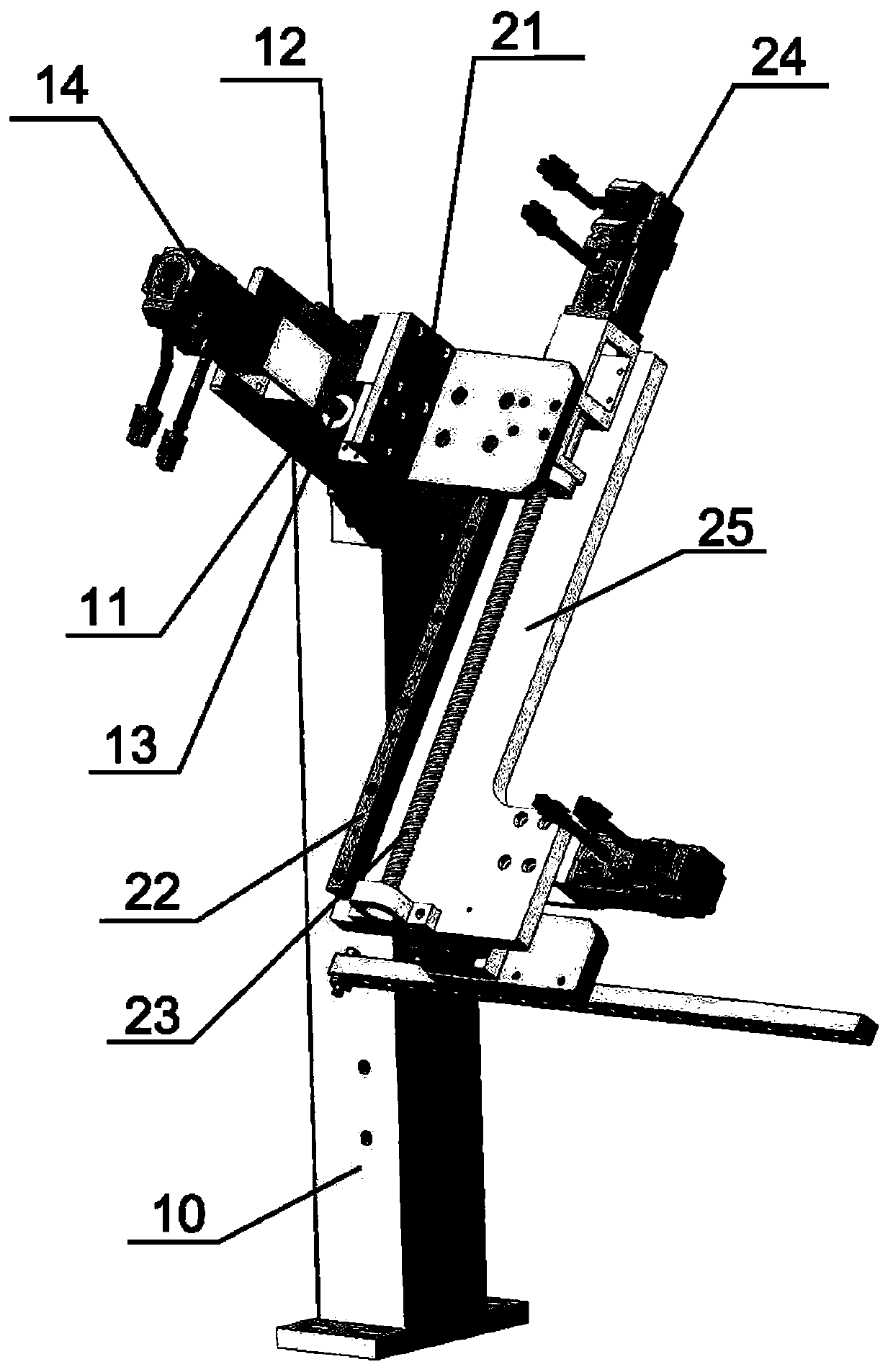

The invention relates to an automatic boxing system for a glass product. The automatic boxing system comprises a rack, a first conveying mechanism assembled on the rack, a material taking and transfermechanism used for transferring the processed glass product, a transfer mechanism correspondingly assembled at the output end of the first conveying mechanism, and a controller, wherein the materialtaking and transfer mechanism is assembled in the position, on the side surface of the output end of the first conveying mechanism, on the rack; the material taking position of a material taking device of the material taking and transfer mechanism corresponds to the position of a feeding platform; the transfer output position of the material taking device of the material taking and transfer mechanism corresponds to the position of box guide seats of the first conveying mechanism; the transfer mechanism is assembled in the position, corresponding to the output end of the first conveying mechanism, on the rack; and the position of a transfer mechanical hand of the transfer mechanism corresponds to the position of the box guide seats of the first conveying mechanism. According to the boxing system, a full-automatic control mode for the boxing process of the glass product is achieved, the boxed glass product is accurately and neatly arranged in order, damage of the glass product is effectively prevented, and production efficiency is greatly improved.

Owner:SHIJIAZHUANG LOYAL MACHINERY MFG

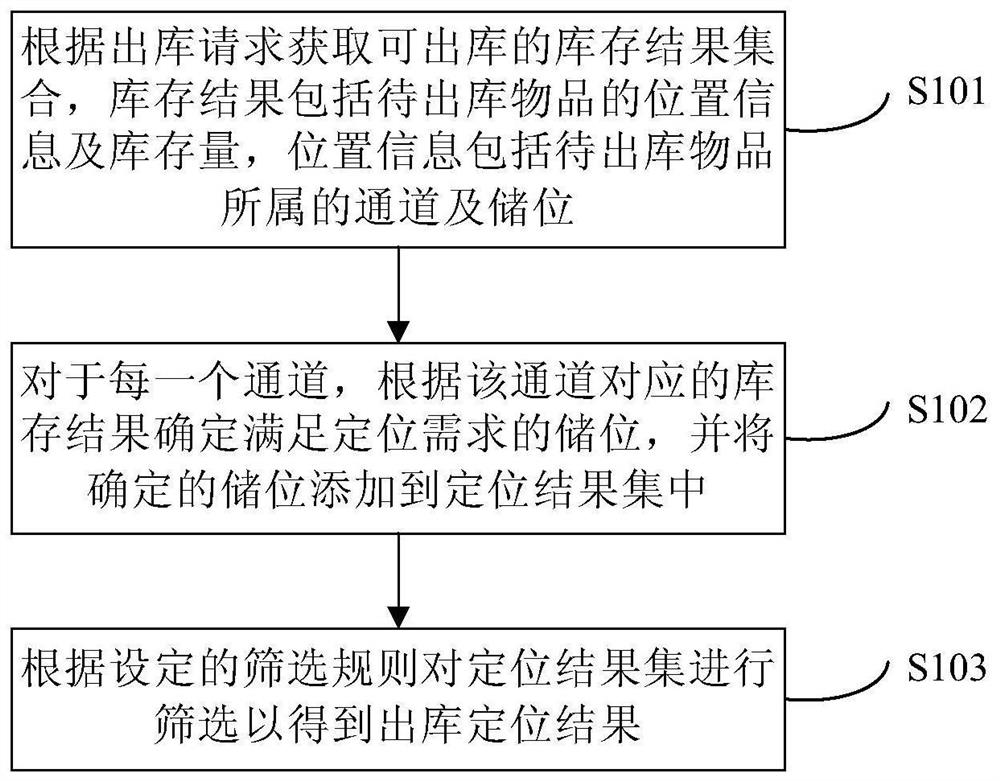

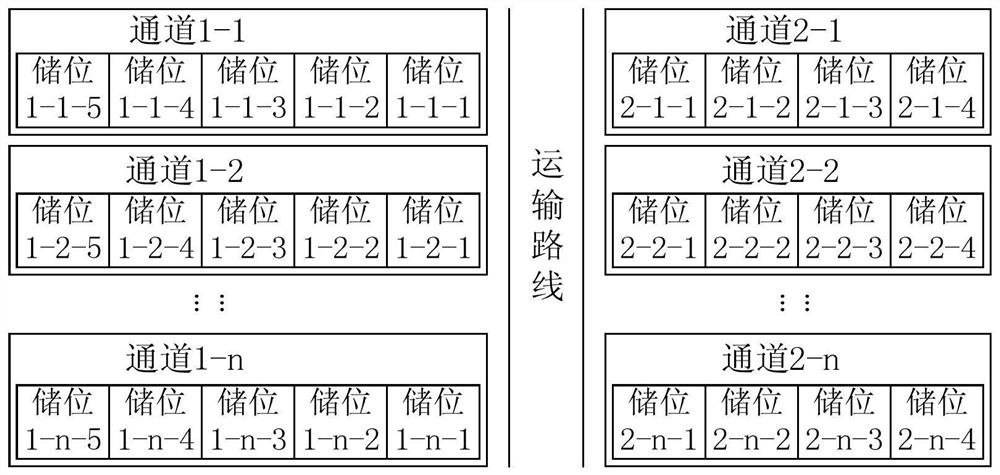

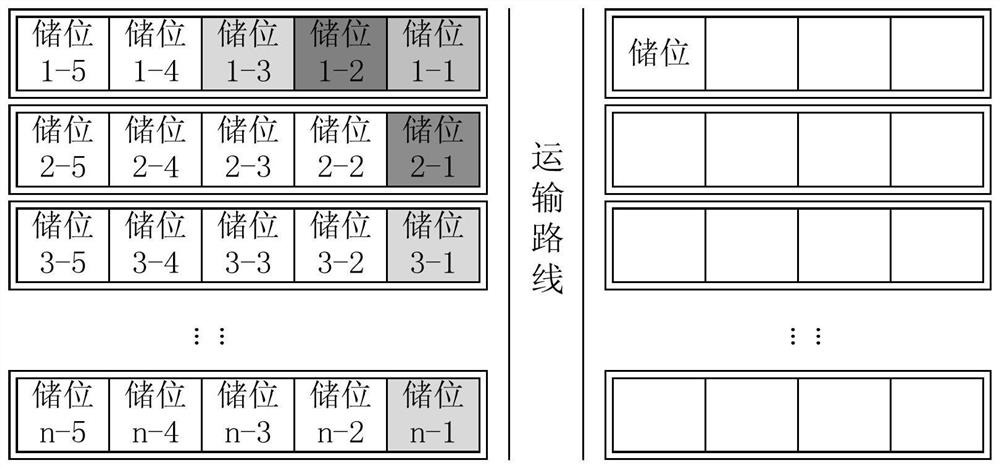

Method and device for warehouse-out positioning of multi-depth warehouse

PendingCN111932163ANo need to move frequentlyRealize orderly deliveryLogisticsData miningCarrying cost

The invention discloses a method and device for warehouse-out positioning of a multi-depth warehouse, and relates to the technical field of computers. The method comprises steps that an inventory result set capable of being delivered is acquired according to a delivery request, an inventory result comprises the position information and the inventory amount of to-be-delivered articles, and the position information comprises channels and storage positions to which the to-be-delivered articles belong; for each channel, a storage location meeting the positioning requirement is determined accordingto the inventory result corresponding to the channel, and the determined storage location is added into a positioning result set; and the positioning result set is screened according to a set screening rule to obtain an ex-warehouse positioning result. According to the method, the storage capacity and delivery efficiency of the warehouse can be effectively improved, meanwhile, inventory on the storage positions does not need to be frequently moved, and therefore carrying cost is reduced.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

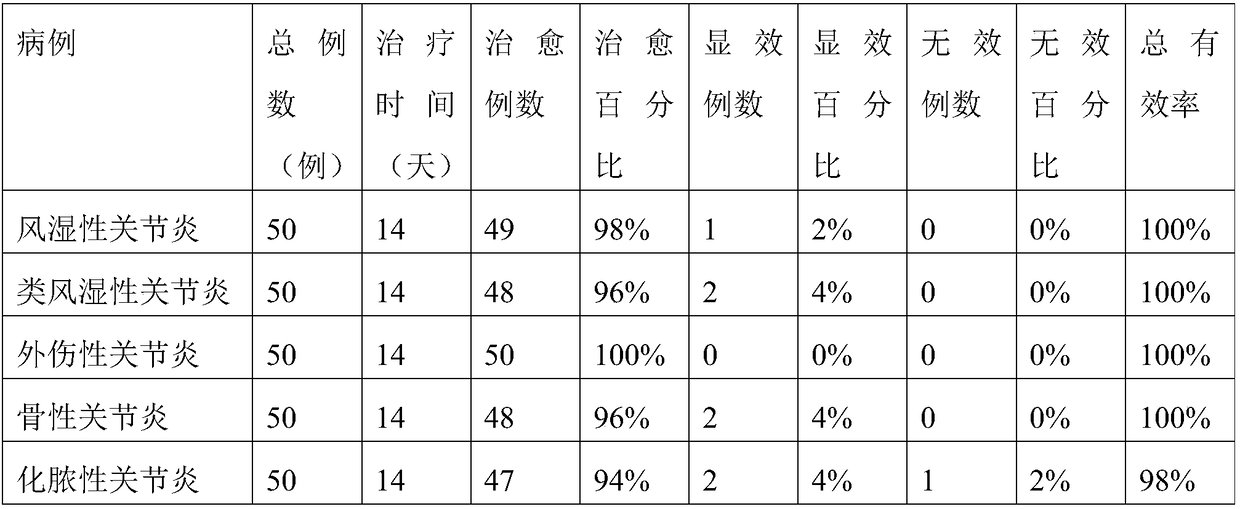

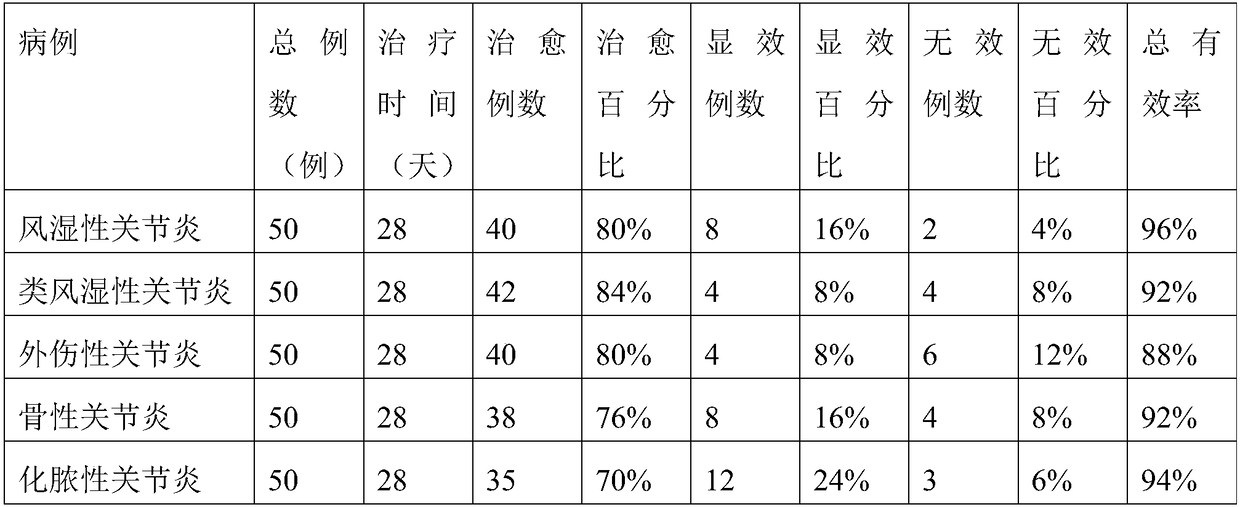

Graphene rheumatalgia patch and preparation method thereof

InactiveCN108295164AShorten treatment timeIncrease profitAnthropod material medical ingredientsHydroxy compound active ingredientsPelargonium x hortorumCentipede

The invention provides a graphene rheumatalgia patch and a preparation method thereof. The patch comprises a back lining layer, a medicine effect layer and an anti-sticking layer, wherein the medicineeffect layer is arranged between the back lining layer and the anti-sticking layer; raw medicine for treating the rheumatalgia is arranged in the middle position of the medicine effect layer, is prepared from medical resin, natural plant essential oil, pelargonium hortorum, chilli extract, glycerin, radix angelicae pubescentis, parasitism, poria cocos, liquorice root, honeycomb, stiff silkworm, centipede, semen strychni, radix notoginseng, rhizoma chuanxiong, radix paeoniae alba, radix rehmanniae recen, eucommia bark, obscured homalomena rhizome, radix achyranthis bidentatae, cassia twig, zaocys dhumnade, lumbricus, caulis sinomenii and beewax, and also is prepared from a graphene nanometer sheet used for releasing and transmitting medicine. The graphene nanometer sheet is of a two-dimensional structure; the raw medicine is loaded by the graphene nanometer sheet and thus enters a position under the skin of the rheumatalgia position. The graphene rheumatalgia patch has the advantages that the use is convenient and fast; safety and environment protection are realized; patients with rheumatalgia can be fast relieved; the medicine effect is fast achieved.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

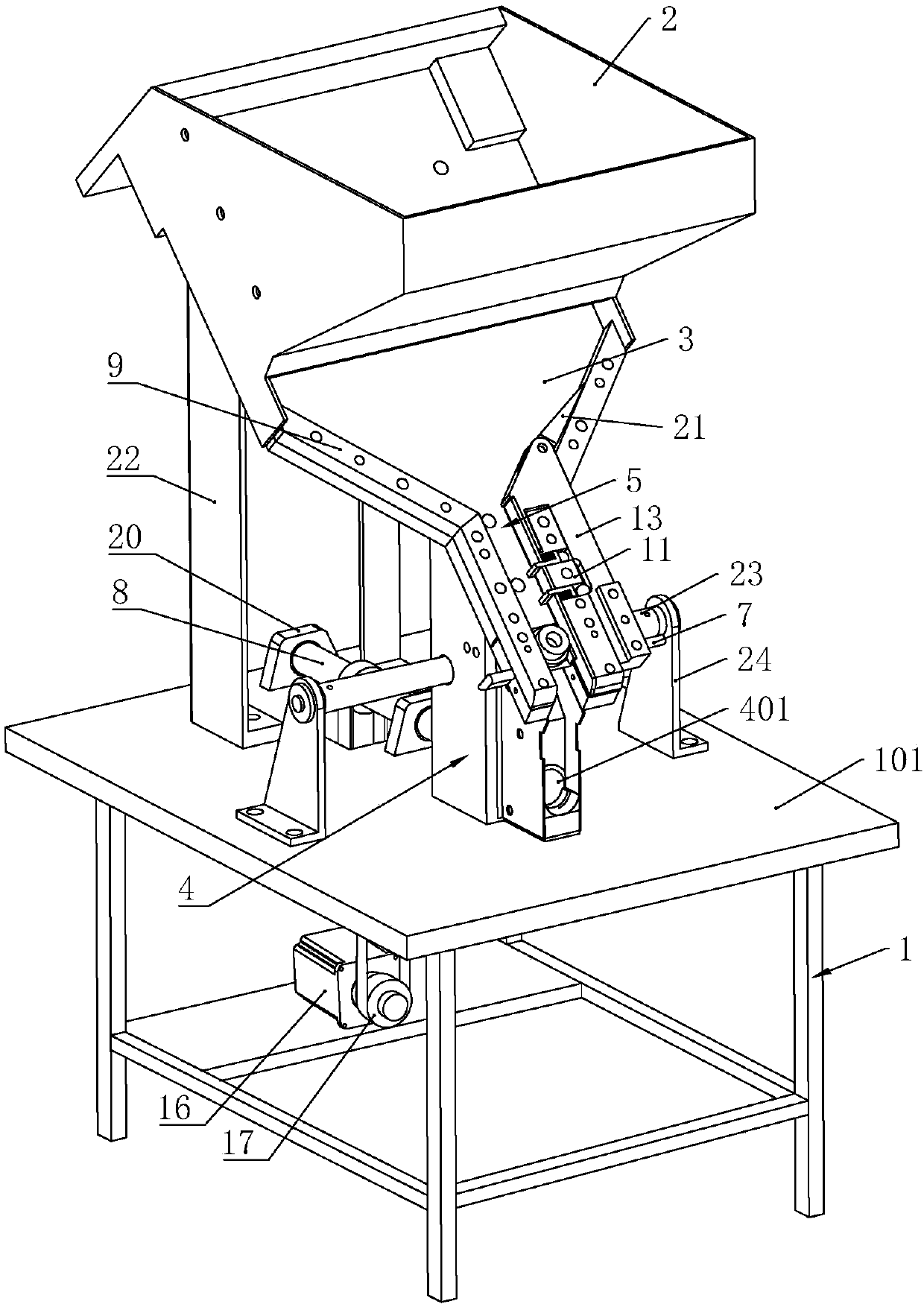

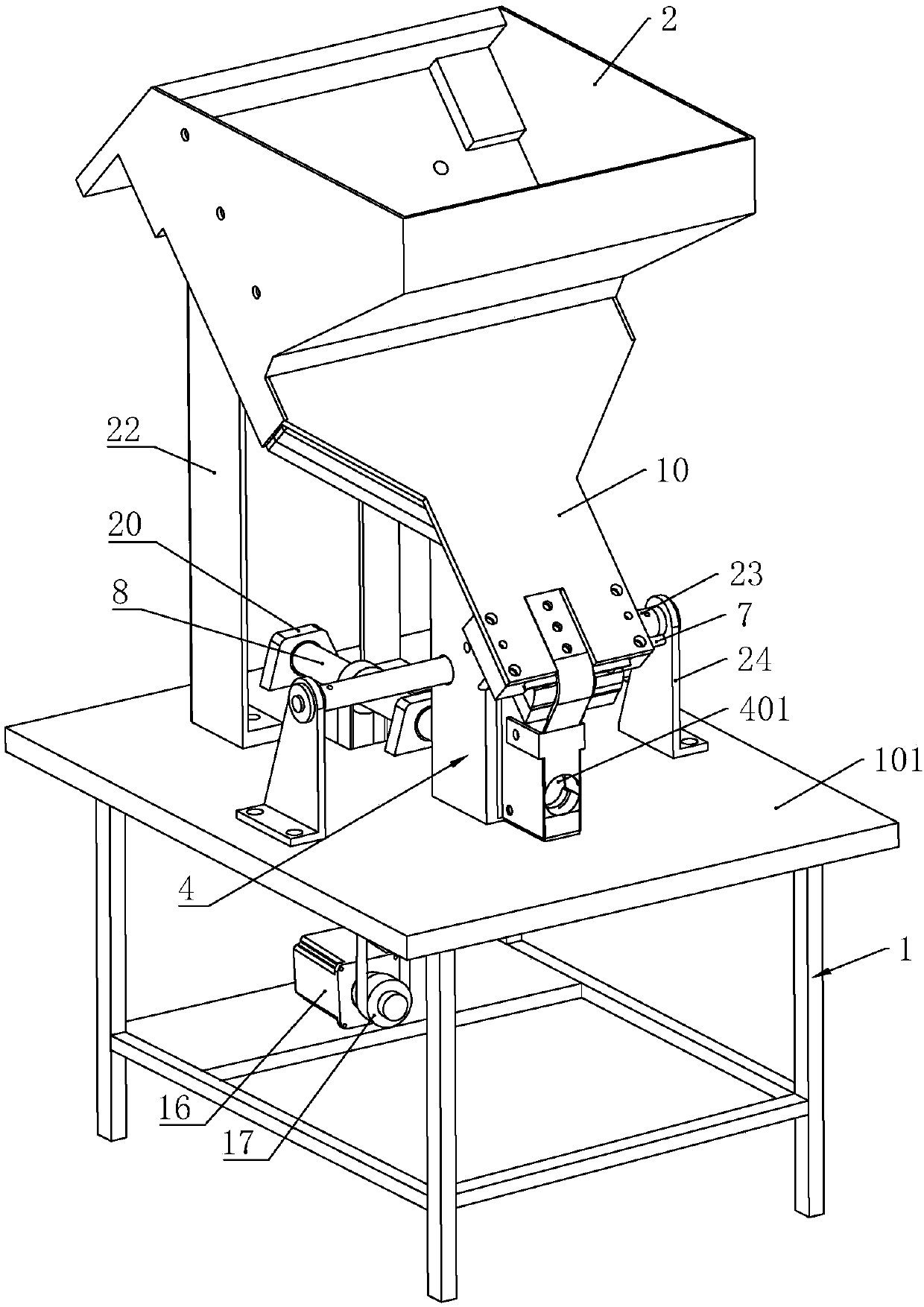

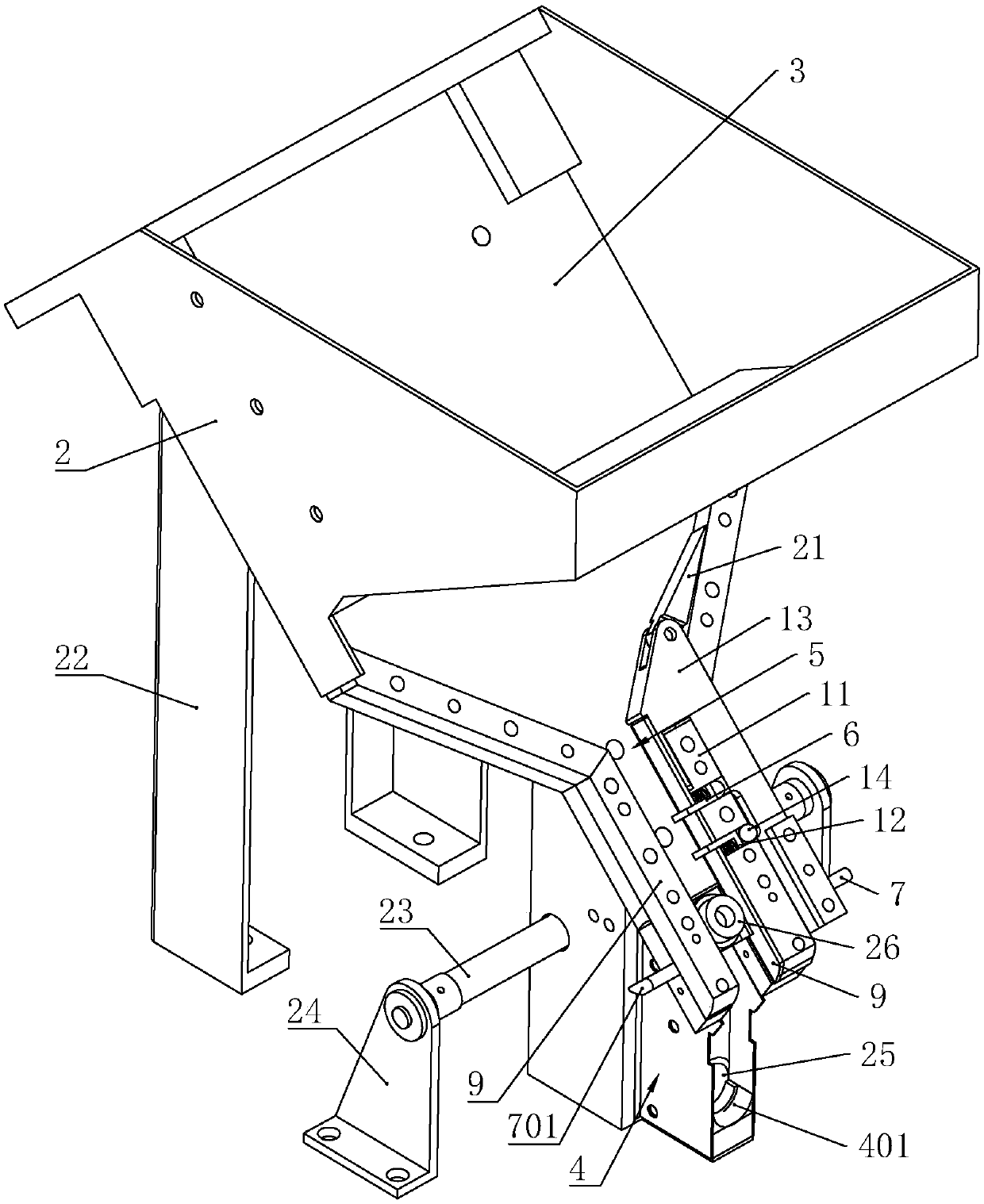

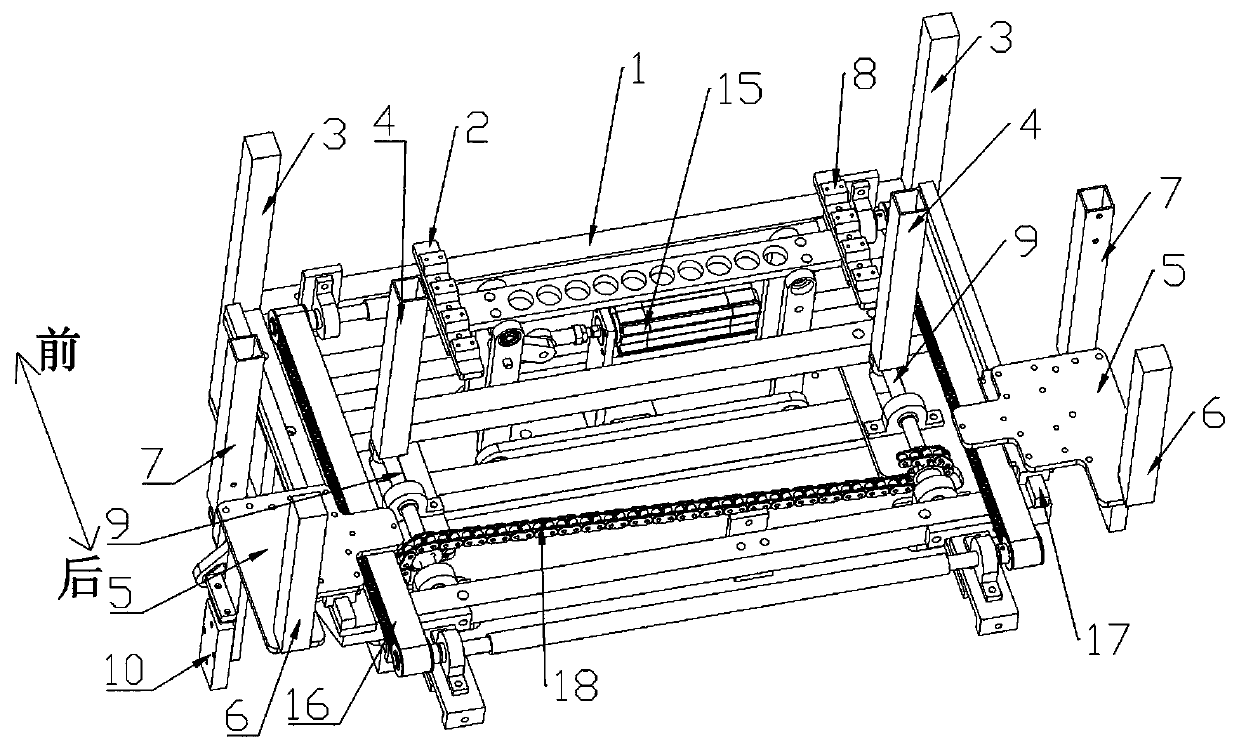

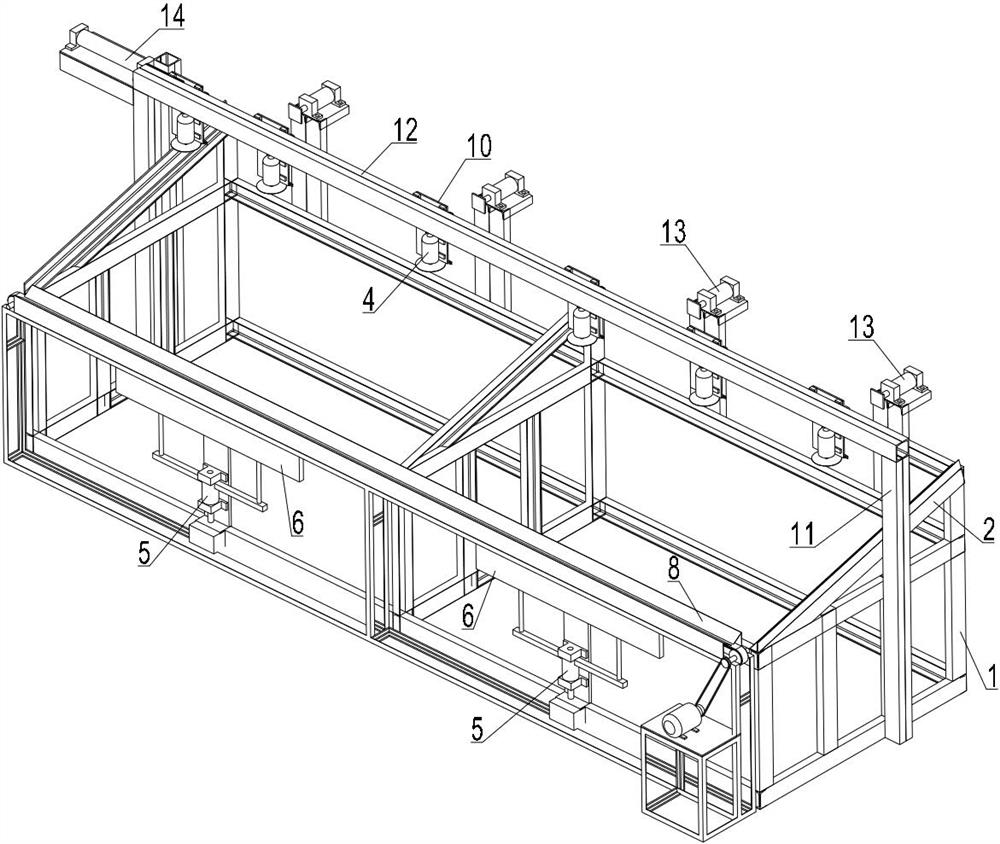

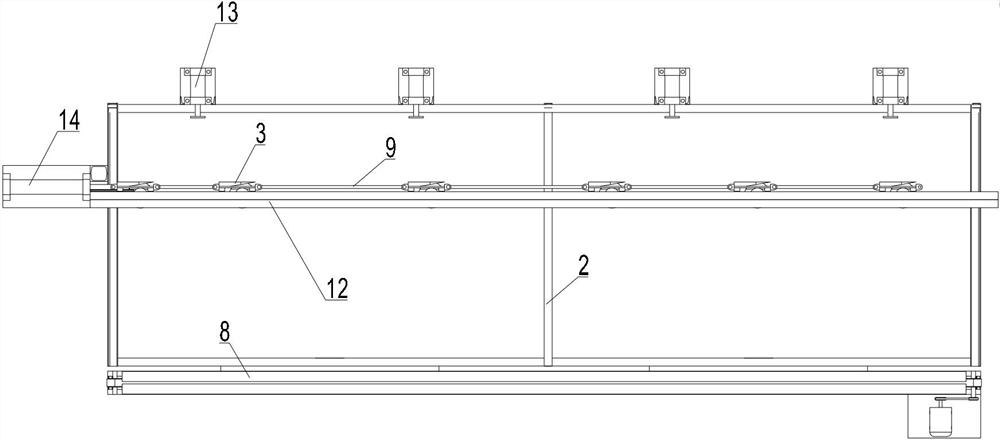

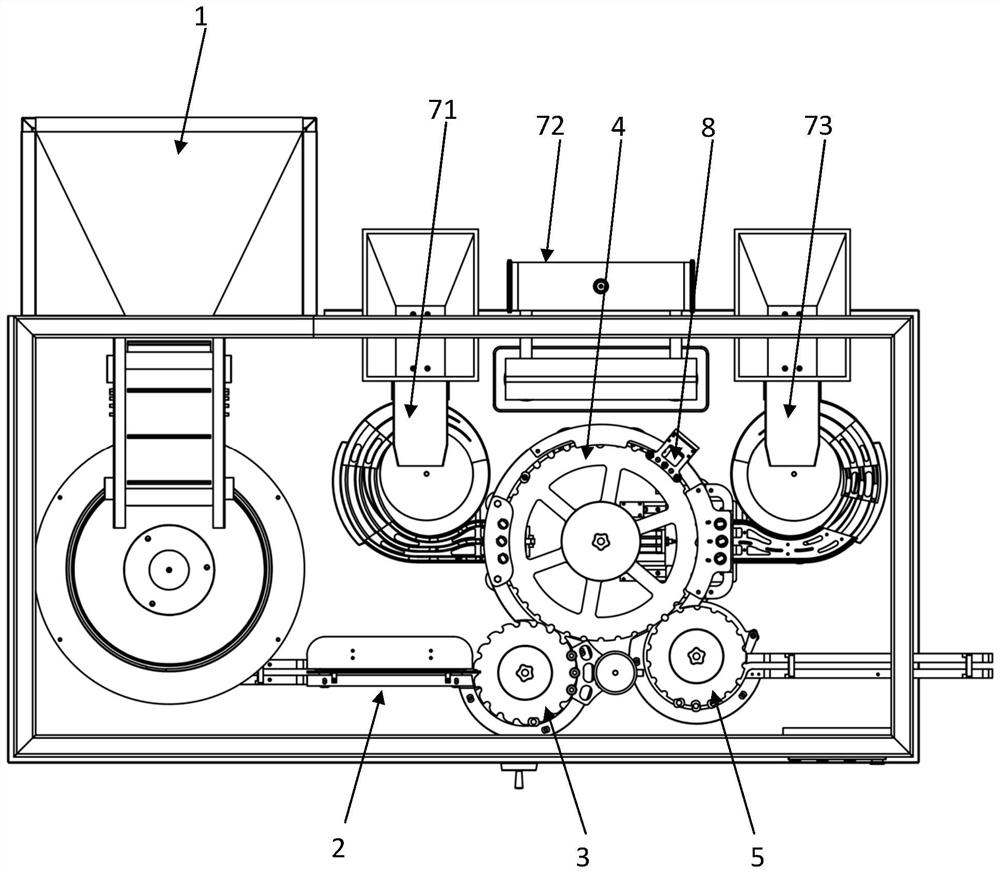

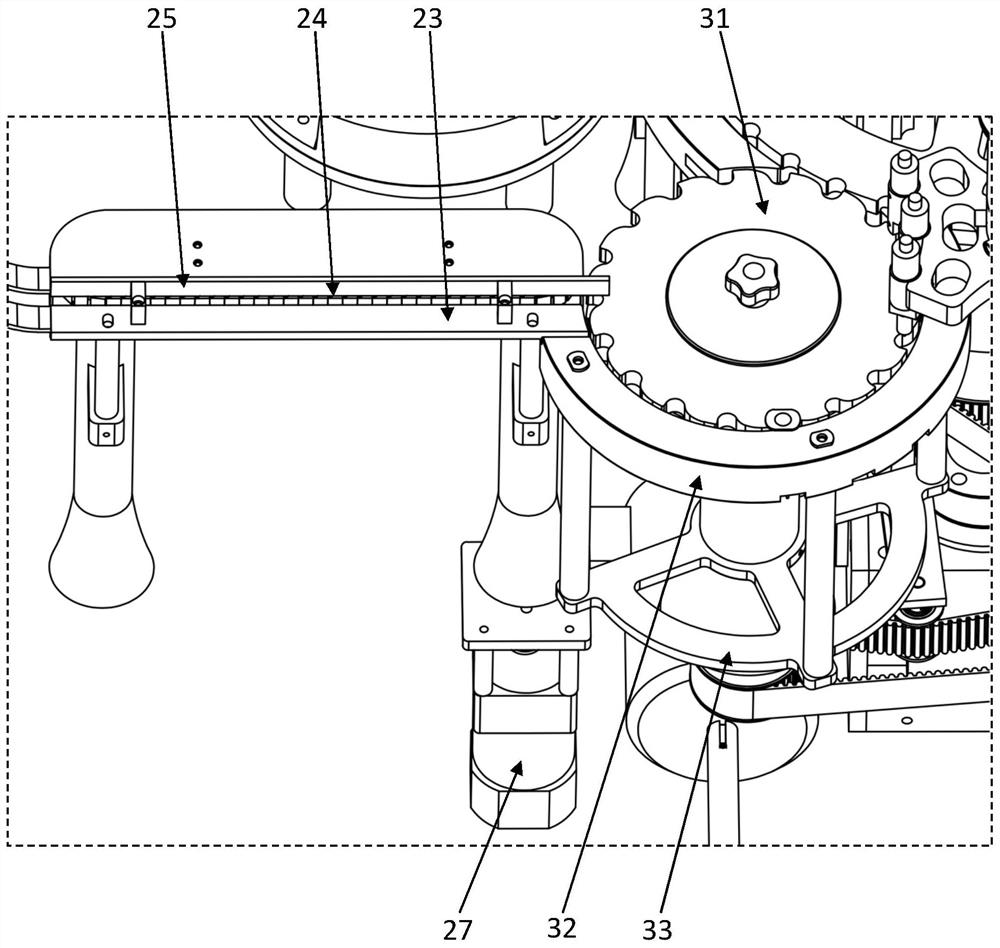

Imitation handmade steamed bun kneading device

PendingCN112075469AUniform tissueFlat surfaceDough shapingDough mixing/kneading machinesEngineeringSteamed bread

The invention discloses an imitation handmade steamed bun kneading device. The imitation handmade steamed bun kneading device comprises a dough blank processing mechanism and a kneading mechanism, wherein the dough blank processing mechanism comprises dough smoothing mechanisms, an extruding mechanism, a second rack, a slitting mechanism and a slitting mechanism; a second conveyor belt is arrangedat the upper end of the second rack; the extruding mechanism, the slitting mechanism and the slitting mechanism, which are connected with the second rack, are arranged above the second conveyor beltin sequence along a conveying direction; the dough smoothing mechanisms are arranged at upper and lower sides of the extruding mechanism; the kneading mechanism is located at one side of the dough blank processing mechanism; the kneading mechanism comprises a first rack, a first conveyor belt and a forming mechanism; the first conveyor belt is arranged at the upper end of the first rack; an inputend of the first conveyor belt is in butt joint with an output end of the second conveyor belt; the forming mechanism stretches across the first conveyor belt; the forming mechanism comprises a hoisting mechanism and a kneading mechanism; the hoisting mechanism is connected with the first rack; the kneading mechanism is located above the first conveyor belt; and the kneading mechanism is connectedwith the hoisting mechanism.

Owner:SHANDONG YINYING COOKING MACHINERY

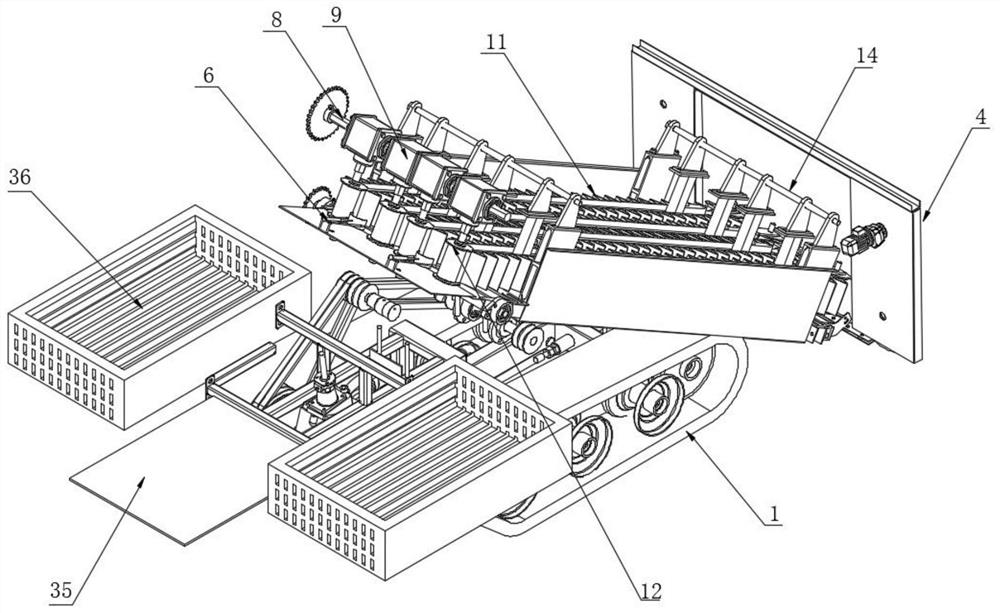

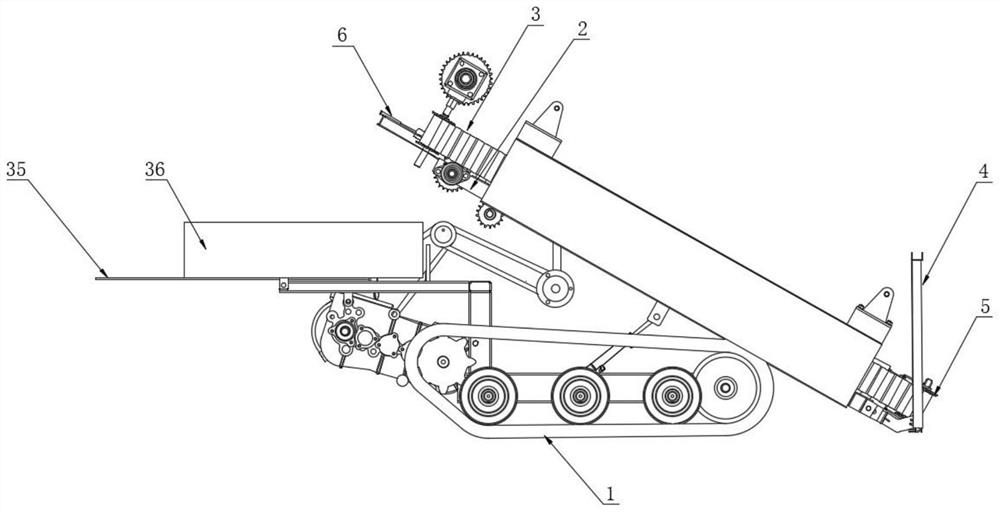

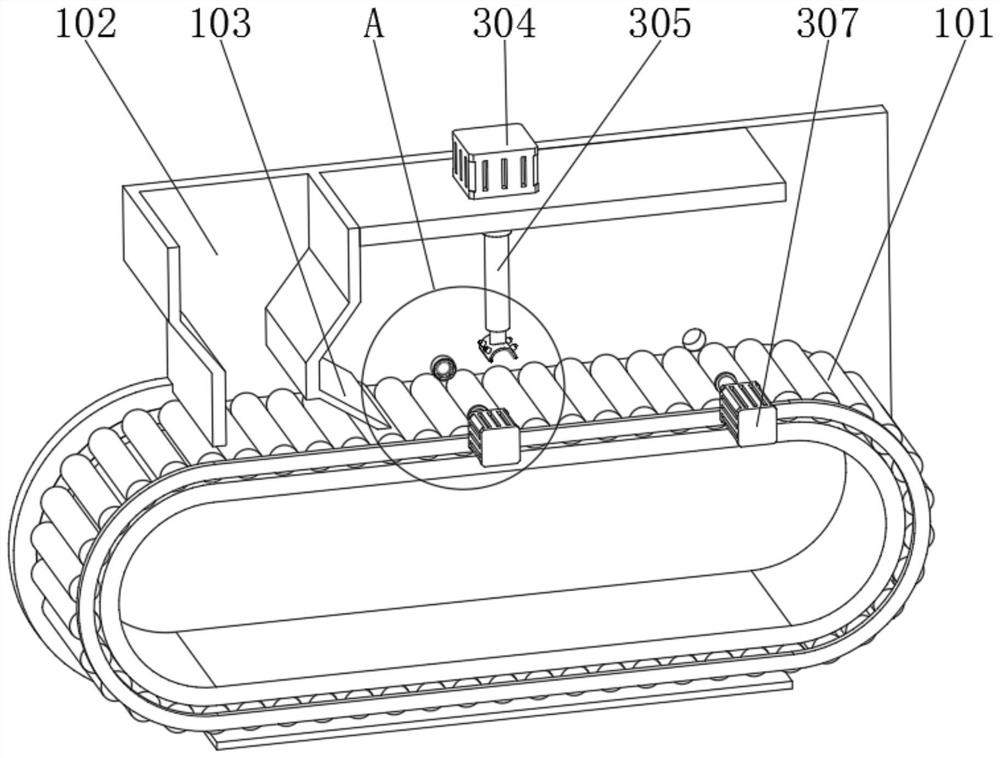

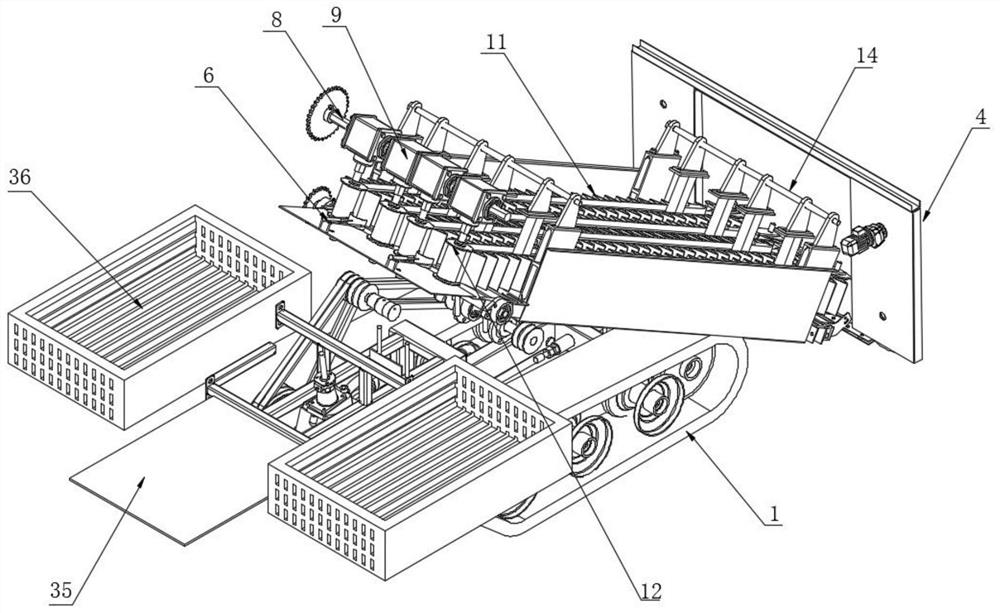

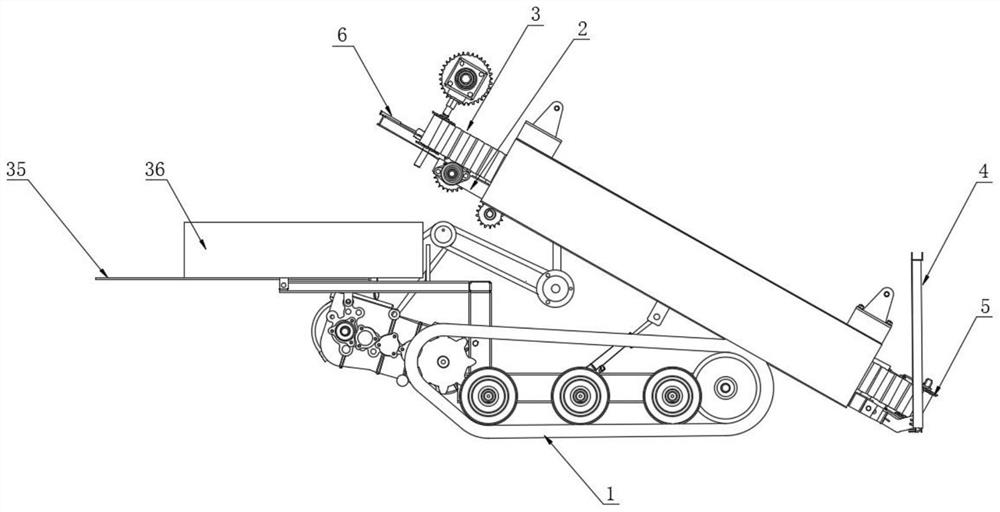

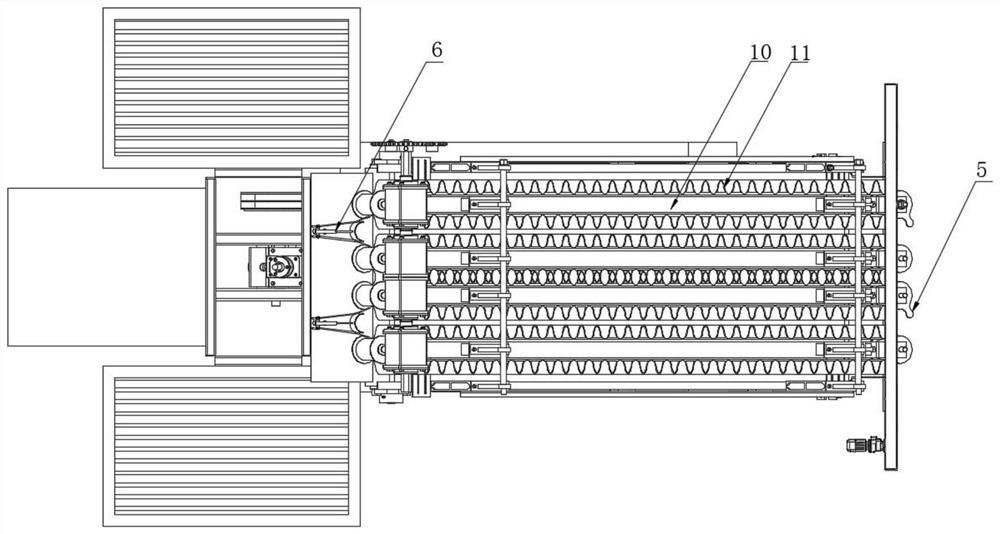

Novel light and simple ordered harvester for stem and leaf vegetables

ActiveCN113348856ACompact structureEasy and flexible operationMowersClimate change adaptationAgricultural engineeringMechanical engineering

The invention discloses a novel light and simple ordered harvester for stem and leaf vegetables, which comprises a crawler chassis and a header, wherein the crawler chassis is provided with a walking transmission system, the header is mounted on the crawler chassis, and the header comprises a rack, a vertical elastic clamping mechanism, a band saw cutting mechanism, a flexible sawtooth cam plate rotating and shifting mechanism and an elastic guide rod type moving and collecting mechanism, and a conveying belt is mounted in the middle of a rack. The novel light and simple ordered harvester has the advantages of being simple and compact in structure, flexible and light in operation, high in harvesting adaptability and universality and the like, various requirements of domestic hilly areas and facility greenhouse operation can be met, and efficient, low-loss and whole-plant mechanical orderly harvesting of stem and leaf vegetables is effectively achieved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

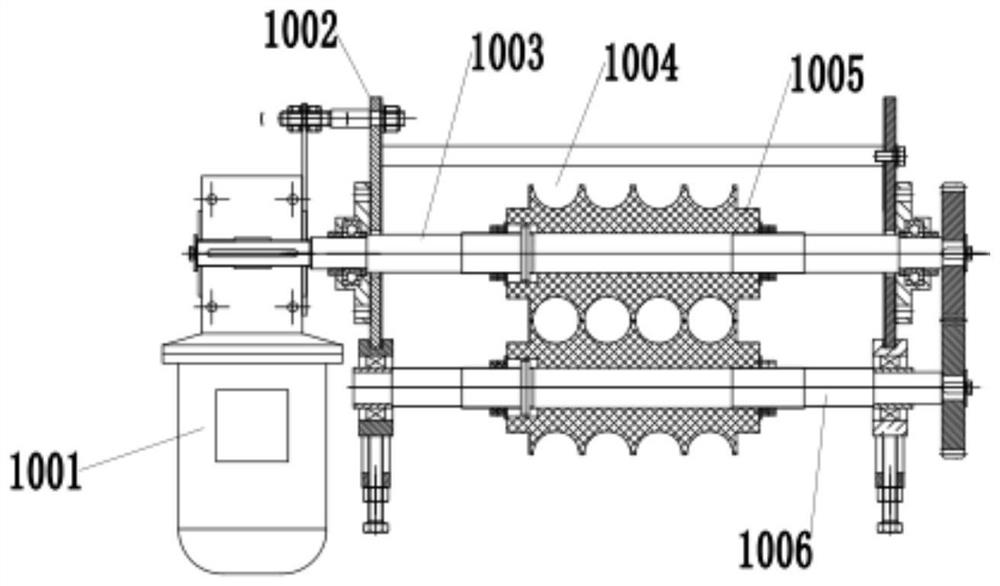

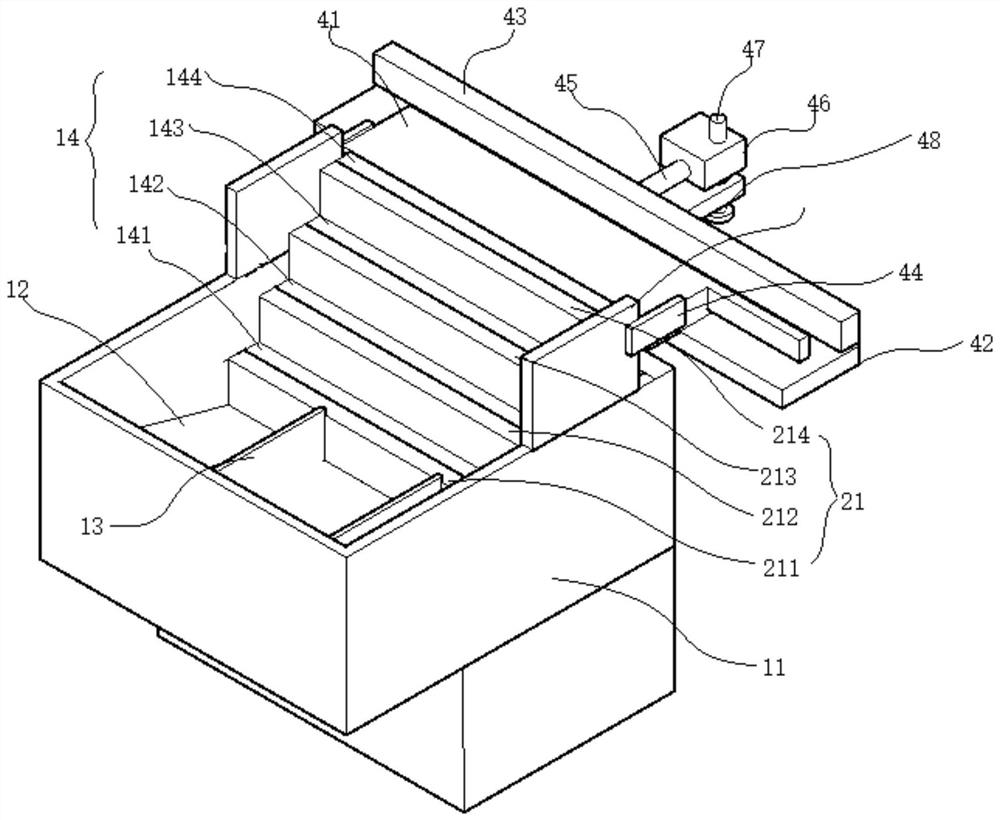

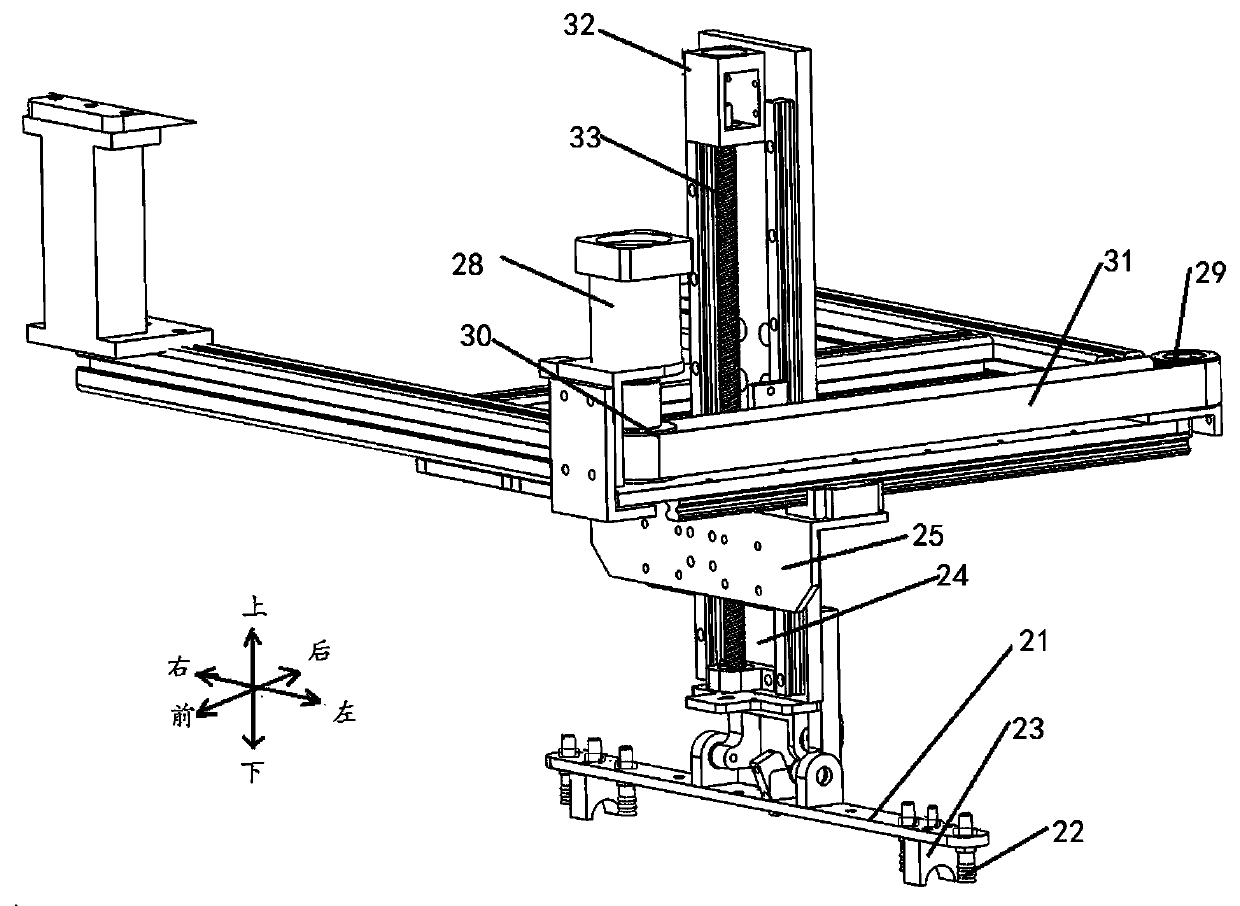

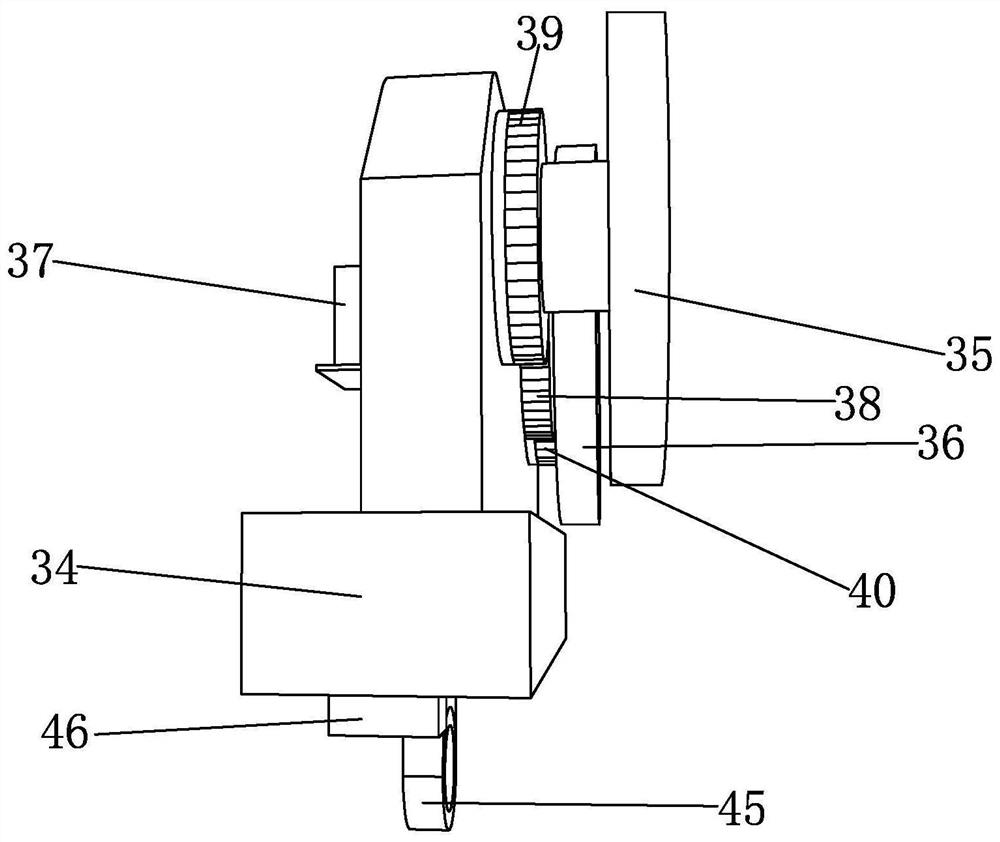

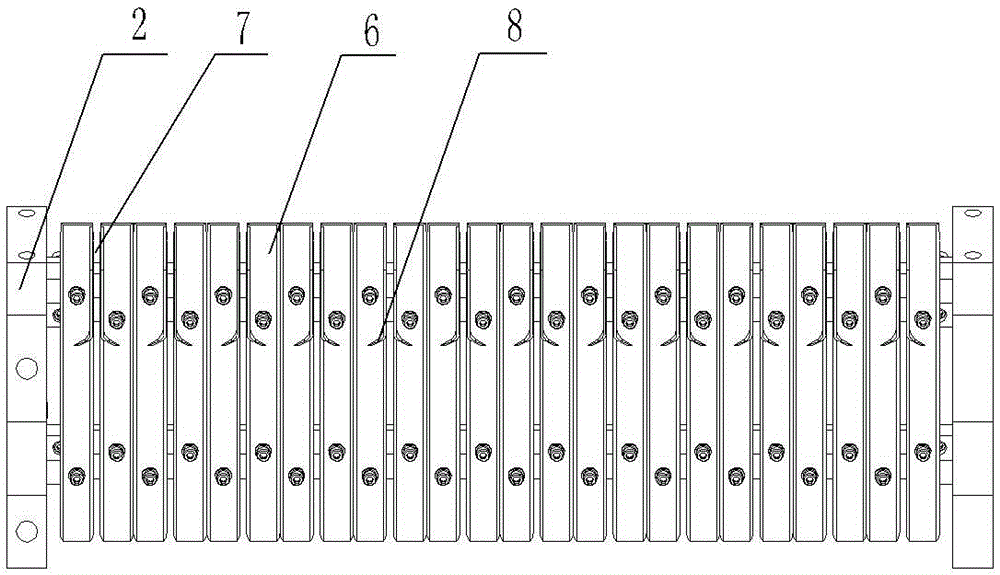

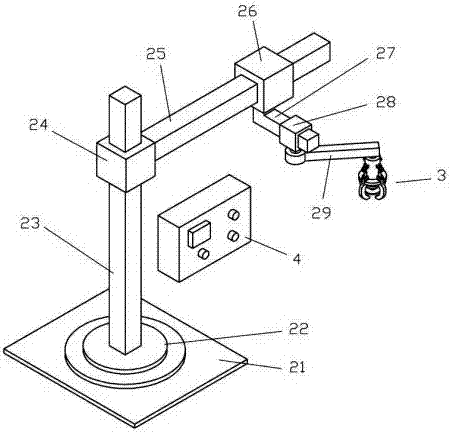

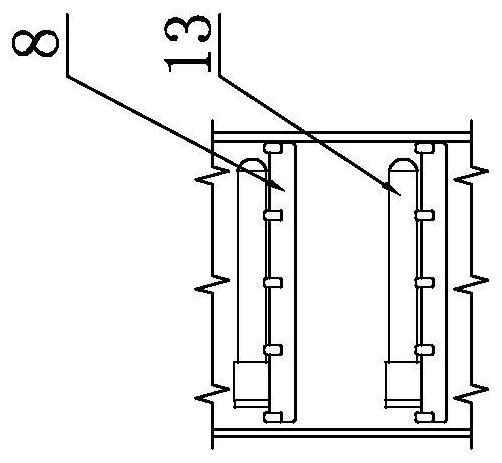

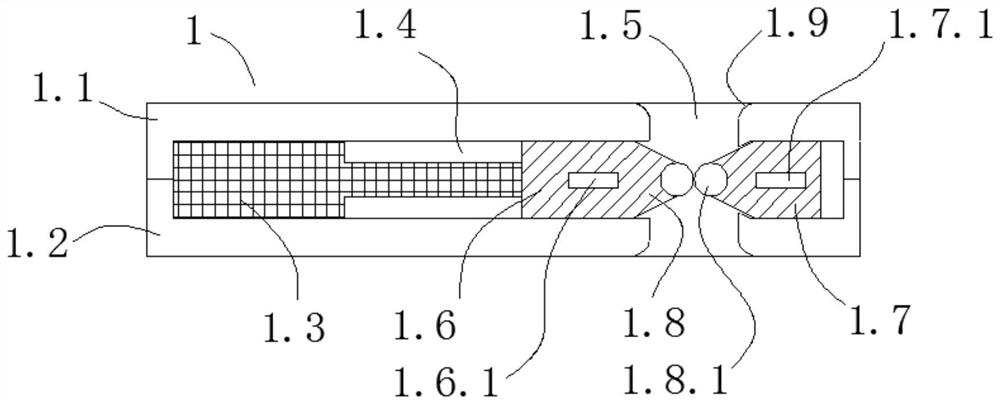

Tube supply device and tube supply method of automatic tube feeding machine of bottle making machine

PendingCN111018325AAvoid frictionGuarantee product qualityGlass reforming apparatusGlass productionTransfer mechanismEngineering

The invention discloses a tube supply device and a tube supply method of an automatic tube feeding machine of a bottle making machine. The tube supply device of the automatic tube feeding machine of the bottle making machine comprises a tube storage mechanism, a sucking disc assembly, a transfer mechanism and a push-up mechanism. The tube supply method comprises that a material tube is stored in the material tube storage space of the tube storage mechanism by the tube storage mechanism; the sucking disc assembly arranged at a tube taking position generates a negative pressure to adsorb the material tube at the material tube output port of the tube storage mechanism; the transferring mechanism drives the sucking disc assembly to transfer the material tube adsorbed by the sucking disc assembly to the material tube input port of the push-up mechanism; and the push-up mechanism conveys the material tube to the material tube input port of the tube grabbing and steering mechanism of the automatic tube feeding machine. According to the invention, with the method and the device, the product quality can be guaranteed, and the working efficiency can be improved; and the device and the methodare suitable for the automatic tube feeding machine of the bottle making machine, and are used for conveying material tubes to the material tube input port of the tube conveying and inserting mechanism of the automatic tube feeding machine.

Owner:SHIJIAZHUANG LOYAL MACHINERY MFG

Lithium battery automatic spot welding machine

InactiveCN113523663ALabor savingGuarantee product qualityWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingMechanical engineering

The invention relates to the technical field of lithium battery spot welding, and discloses a lithium battery automatic spot welding machine which comprises: a conveying frame used for pouring lithium batteries, arranging and conveying the lithium batteries; a processing box which is used for processing the lithium batteries inside the processing box; an overturning and inserting mechanism which is used for overturning the lithium batteries with the inverted positive and negative electrodes in the conveying process and inserting the lithium batteries; a mounting frame which is used for inserting the lithium batteries into a slotted hole in the mounting frame and carrying out subsequent welding processing; and a storage bin which is used for storing the mounting frame and nickel sheets for automatic mounting and welding. According to the lithium battery automatic spot welding machine, the lithium batteries are conveyed and detected, a sensor feeds back a detection result to achieve detection of positive and negative electrodes, then overturning is conducted through the overturning mechanism, and the transmission mechanism grabs the mounting frame to conduct mounting of the lithium batteries, mounting of nickel sheets and final welding, so that automatic production of the lithium battery pack is achieved, a large amount of labor force is reduced, production quality is guaranteed, and production efficiency is improved.

Owner:深圳比斯特自动化设备有限公司

Locknut assembling machine

InactiveCN107738092AAssembly precisionEfficient and orderly assemblyMetal working apparatusEngineeringAssembly machine

The invention belongs to the technical field of nut assembly, and provides a lock nut assembly machine, which includes a mounting frame, a body, an intermittent conveying device, a turning device and a screwing device; the body is fixed on the mounting frame, and is provided with a nut storage bucket and the nut conveying slideway connected with the nut storage bucket, and an assembly hole connected with the nut conveying slideway is provided at the bottom of the body; the intermittent conveying device includes two nuts that are slidably installed on the body to realize the on-off of the nut conveying slideway The baffle plate and the two nut baffles are alternately telescopically arranged; the turning device includes a turning lever installed on the body, and a hanging part and a nut turning part are arranged on the turning lever, and the nut turning part is connected with the nut conveying slideway; the screwing device includes The rotating shaft driven by the driving device, the end of the rotating shaft is fixedly installed with an adsorption magnet matched with the assembly hole. The invention facilitates the precise assembly of the anti-loosening nut, improves the assembly efficiency, and has simple structure and small volume.

Owner:WEIFANG 100TONG CASTING CO LTD

Automatic feeding machine

The invention relates to the field of cosmetic production equipment, in particular to an automatic feeding machine. The automatic feeding machine comprises a rack; the rack is provided with a verticallifting mechanism; a movable object table is arranged on the vertical lifting mechanism and used for containing stacked materials; a first pushing mechanism is arranged on the top of the rack; a first pushing board is arranged on the first pushing mechanism; a conveying belt is arranged at the position, in front of the pushing direction of the first pushing board of the first pushing mechanism, of the rack; a height sensing mechanism is arranged at the position, between the first pushing mechanism and the movable object table, of the rack; a suction cup mechanism is arranged at the position,behind the first pushing board, of the first pushing mechanism and comprises a suction nozzle; and the suction nozzle is connected with a vacuum tube. Through the reasonable structural design of the automatic feeding machine, materials can be effectively conveyed in order, the materials are prevented from being damaged in the conveying process, the efficiency is improved, and stability is high.

Owner:上海润美包装材料有限公司

Valve guide pipe drilling, loading and conveying apparatus

The present invention discloses a valve guide pipe drilling, loading and conveying apparatus, relating to the technical field of valve guide pipes. The apparatus of the present invention comprises a workbin, a loading unit and a conveying unit; the loading unit is positioned on one side of the workbin; the conveying unit comprises a conveying plate, a conveying belt and a first baffle plate; the conveying plate is positioned at the top end of a box body; the conveying belt is positioned under the conveying plate; the first baffle plate is positioned on the top wall of the conveying plate; theside wall of the first baffle plate, the side wall of the conveying plate and the conveying belt define a channel for conveying valve guide pipes; and the loading unit moves up and down, so that the valve guide pipes are loaded to the top end of the workbin from the bottom of the workbin in sequence, and then are conveyed onto the conveying belt from the conveying plate. The present invention hasthe beneficial effects that: the valve guide pipe drilling, loading and conveying apparatus can directly convey the valve guide pipes after loading and conveying, and moreover, only allows one valve guide pipe to pass through by adjusting the size of the channel to directly implement ordered conveying so as to conveniently drill the conveyed valve guide pipes.

Owner:辉门环新(安庆)粉末冶金有限公司

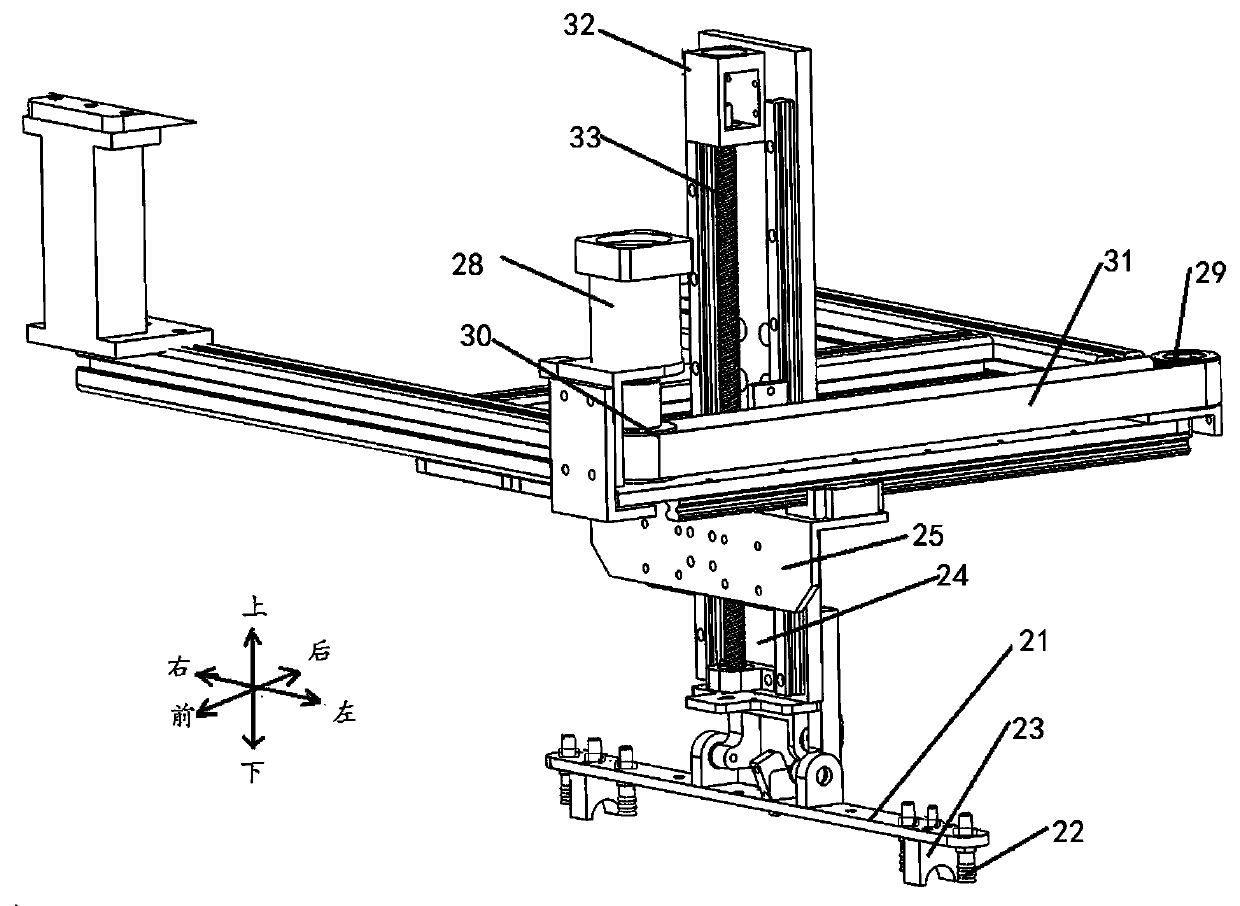

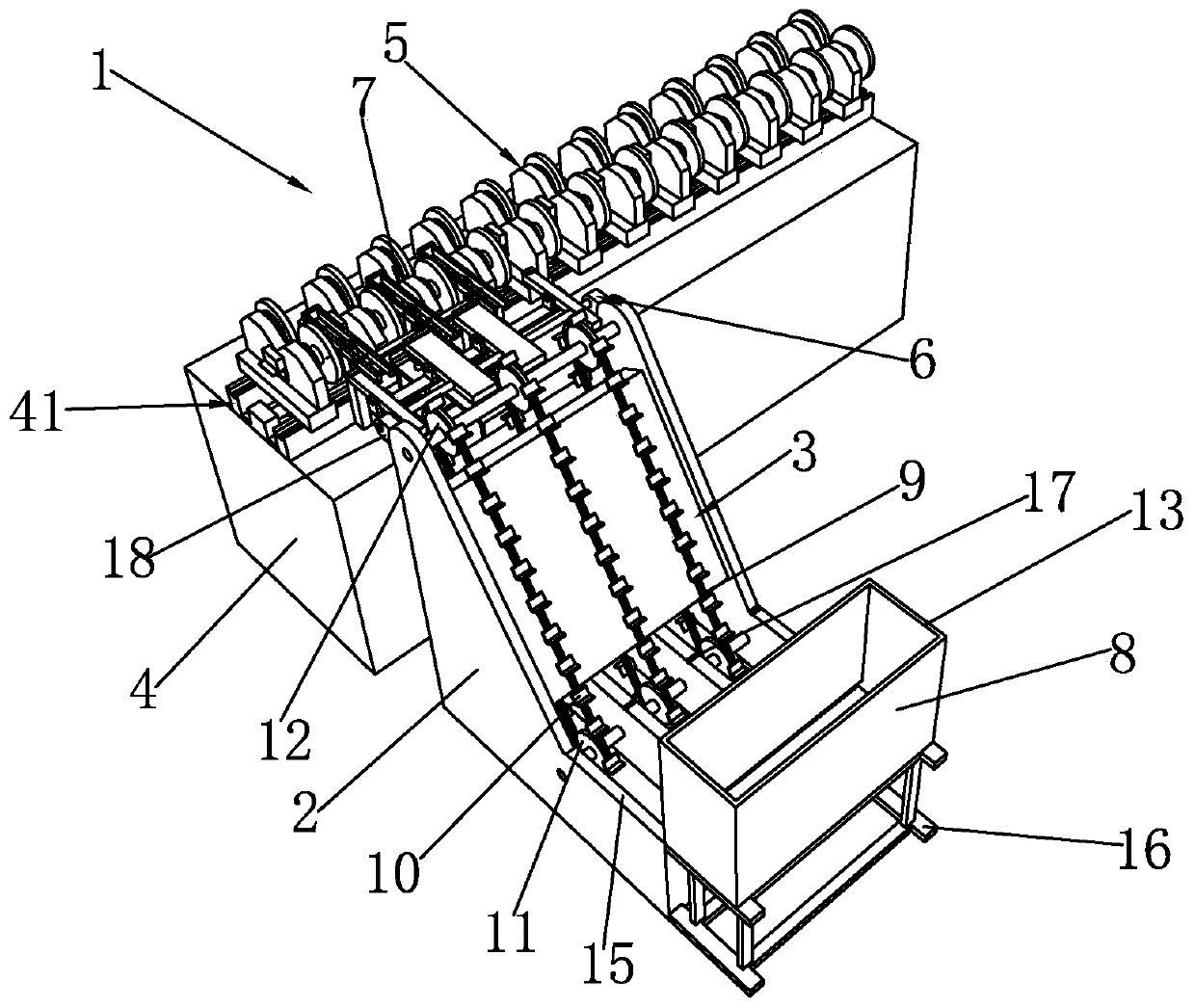

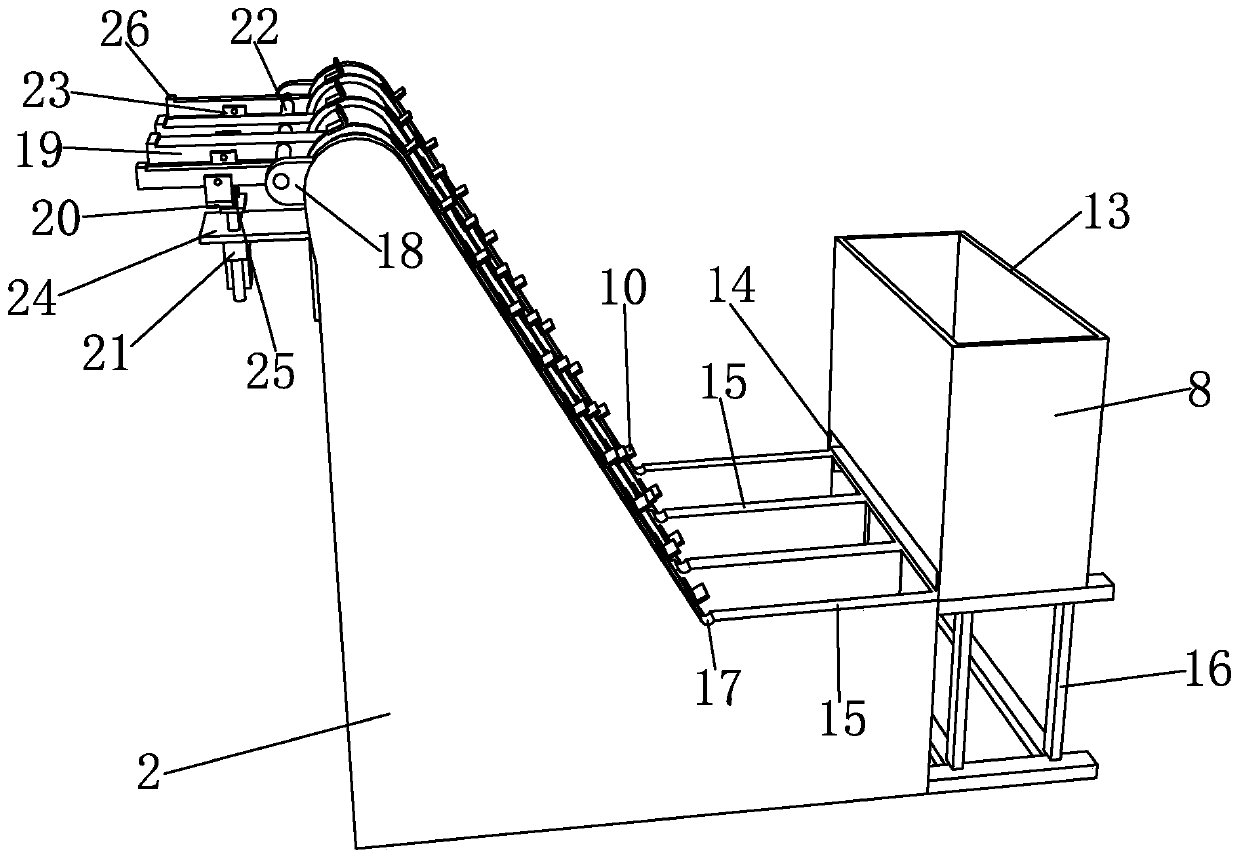

Automatic feeding device used for centerless grinding machine and feeding method thereof

ActiveCN110549178AAvoid the phenomenon of fallingAvoid collisionRevolution surface grinding machinesCenterless grindingMechanical engineering

The invention discloses an automatic feeding device used for a centerless grinding machine and a use method thereof. The feeding device comprises a body, a material conveying table is arranged on oneside of the body, a material conveying assembly is arranged on the material conveying table, a feeding table is arranged on the other side of the body, feeding assemblies are transversely and evenly distributed on the feeding table, a first transfer assembly is arranged on the side, close to the feeding table, of the material conveying table, a second transfer assembly is arranged on the side, close to the material conveying table, of the feeding table, the first transfer assembly is matched with a second transfer assembly, and the first transfer assembly and the second transfer assembly transfer workpieces into the feeding assemblies from the material conveying assembly. The use method of the automatic feeding device comprises the steps of a, preparing before use, b, discharging, c, material conveying, d, workpiece transfer and e feeding. The falling phenomenon in the conveying process of the workpieces can be avoided, the workpieces are prevented from colliding in the process of being fed into the centerless grinding machine, the machining efficiency is greatly improved, and the machining loss rate is reduced.

Owner:XINCHANG HAIBO MACHINERY

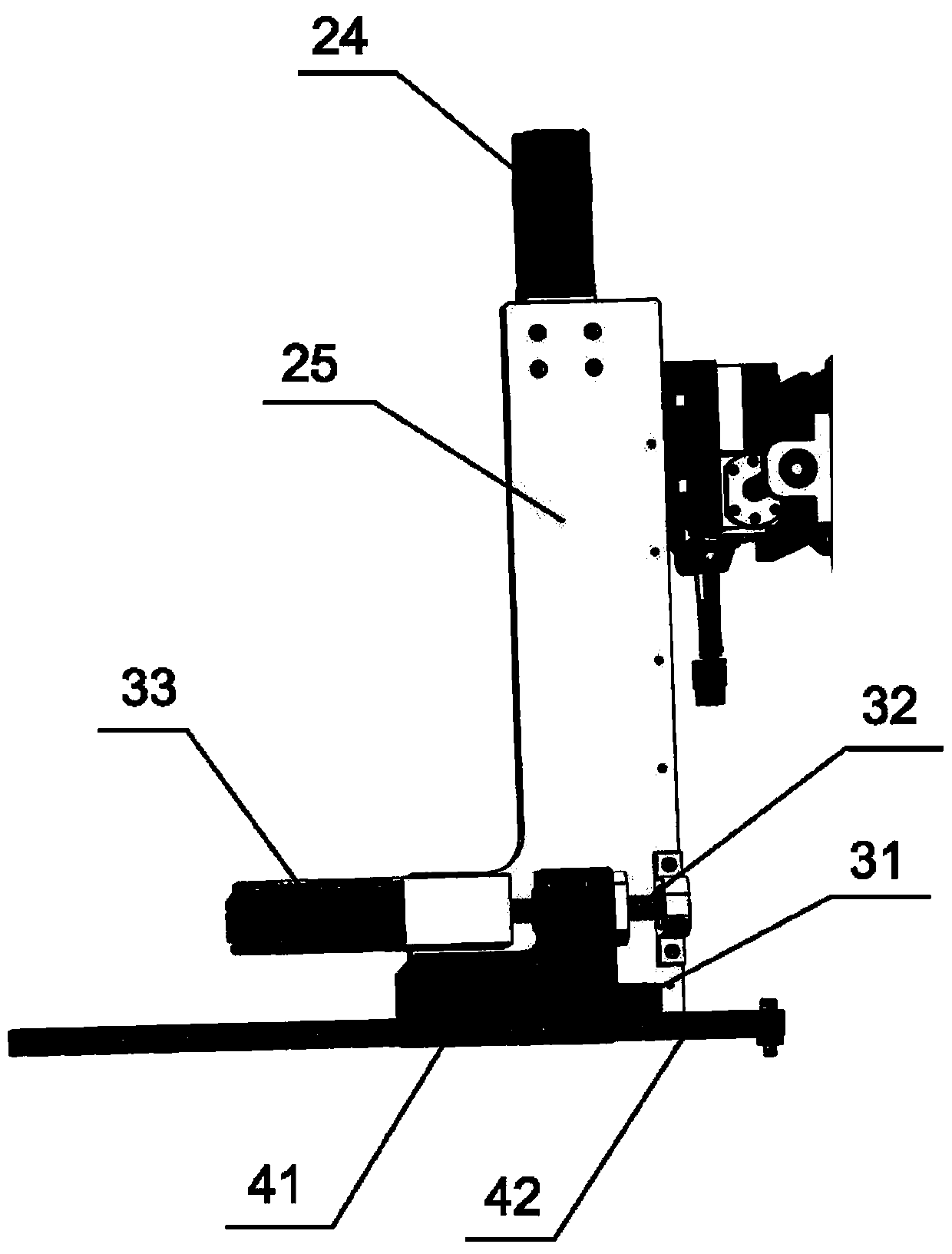

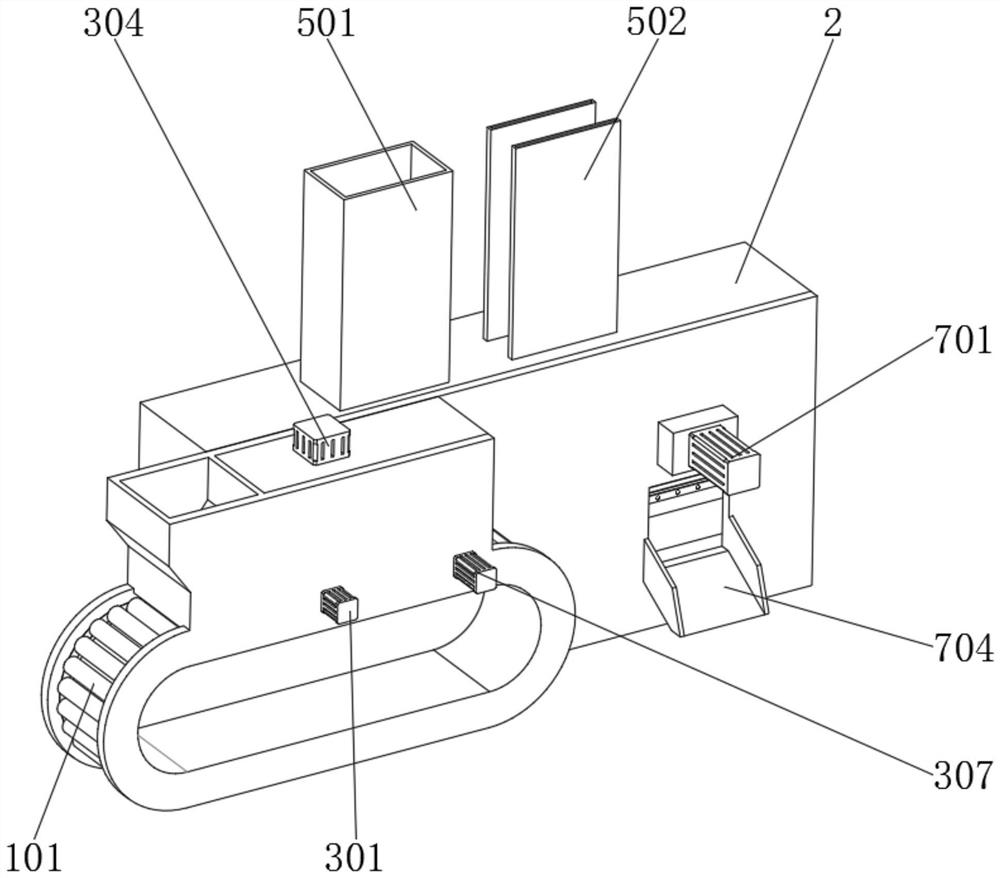

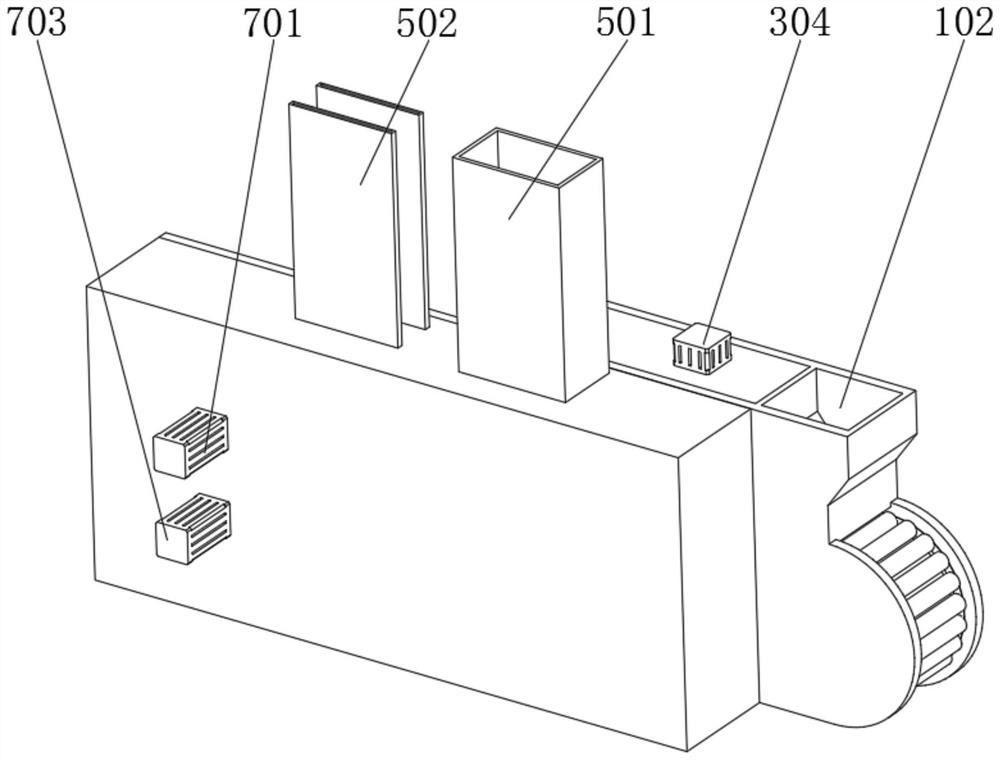

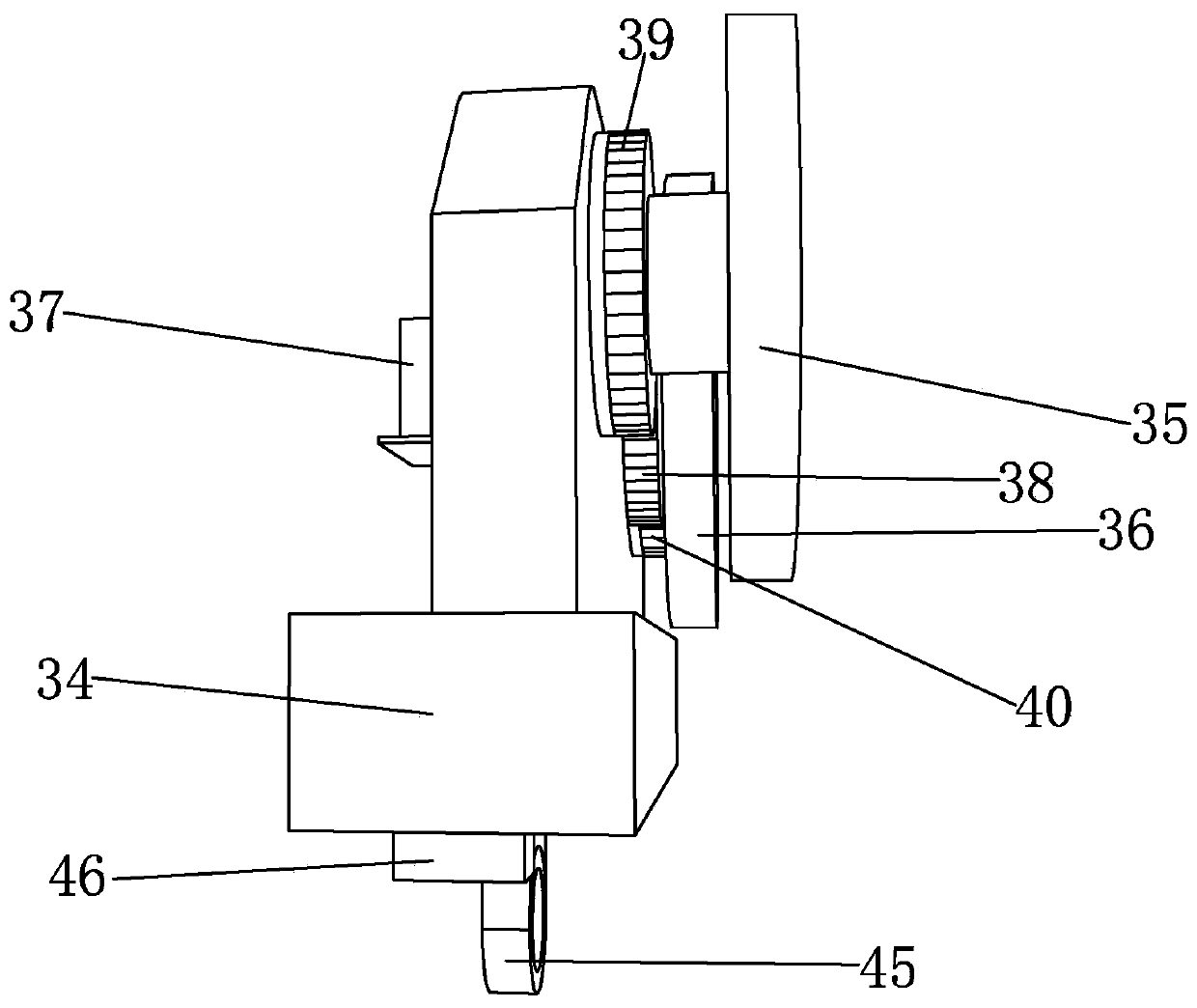

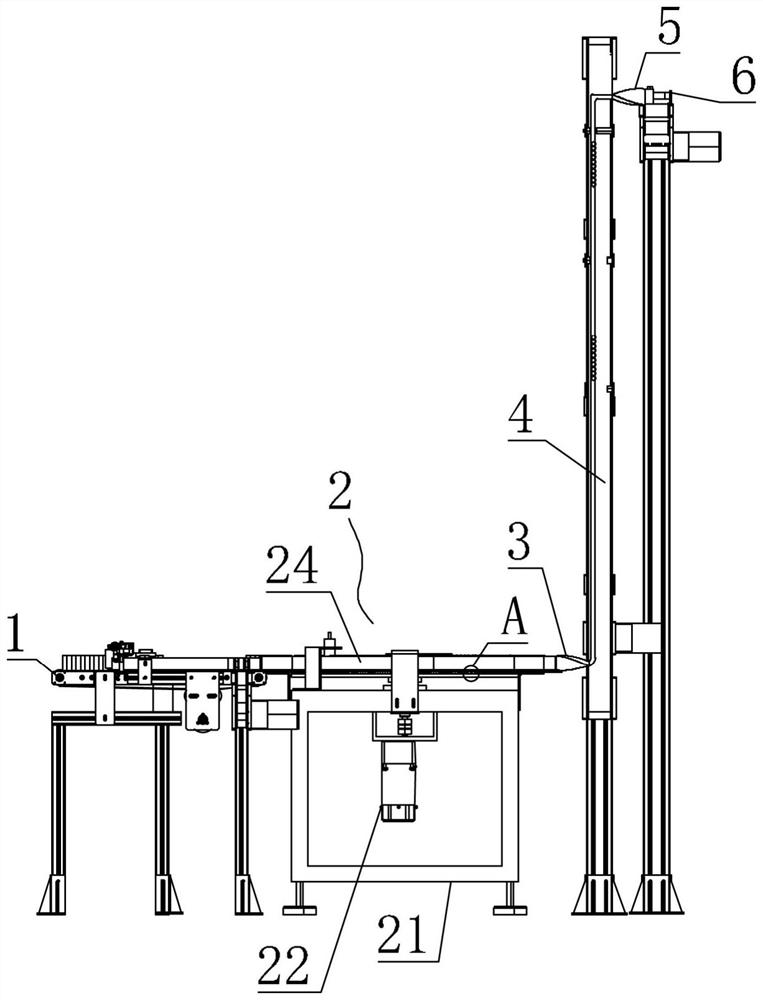

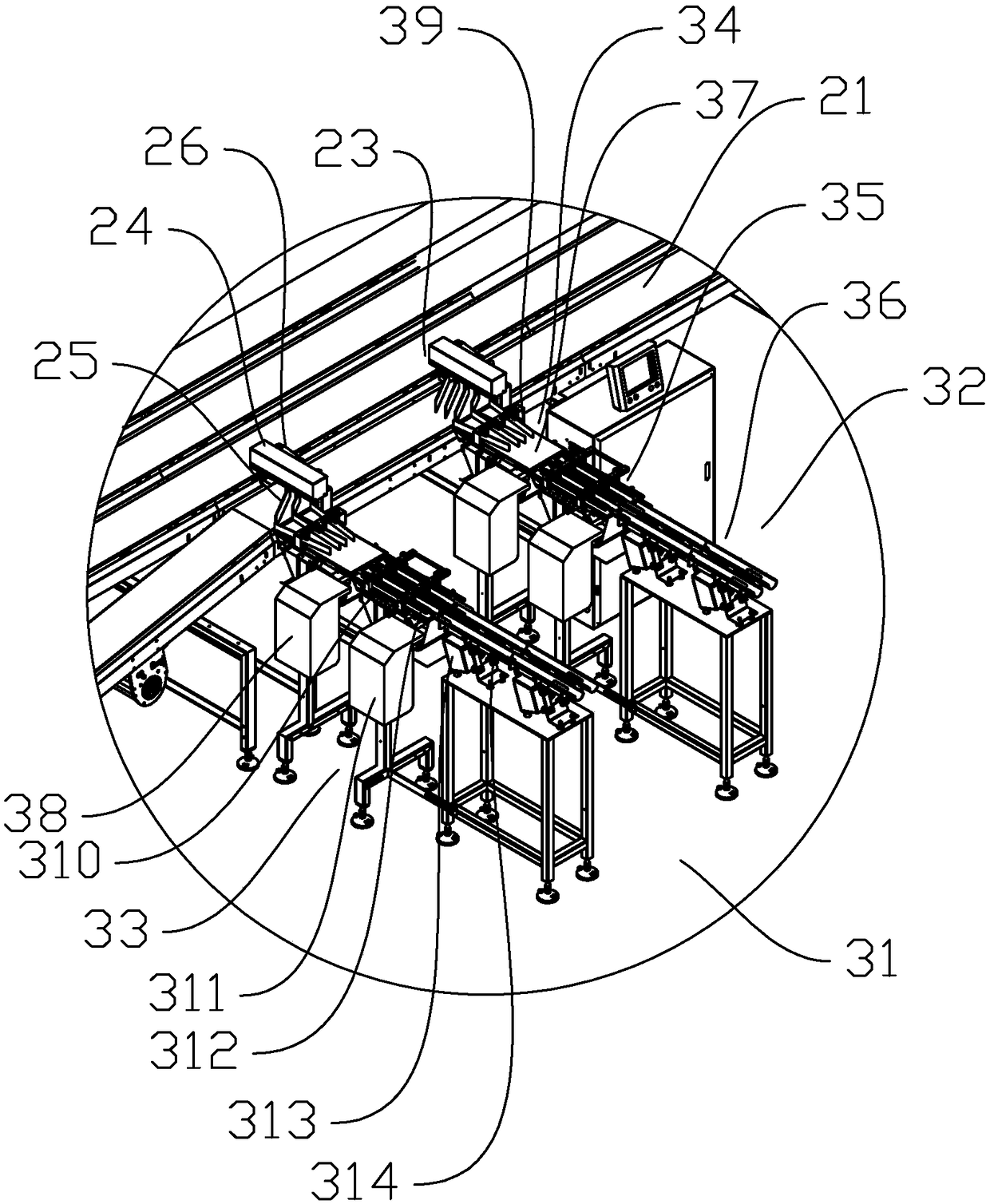

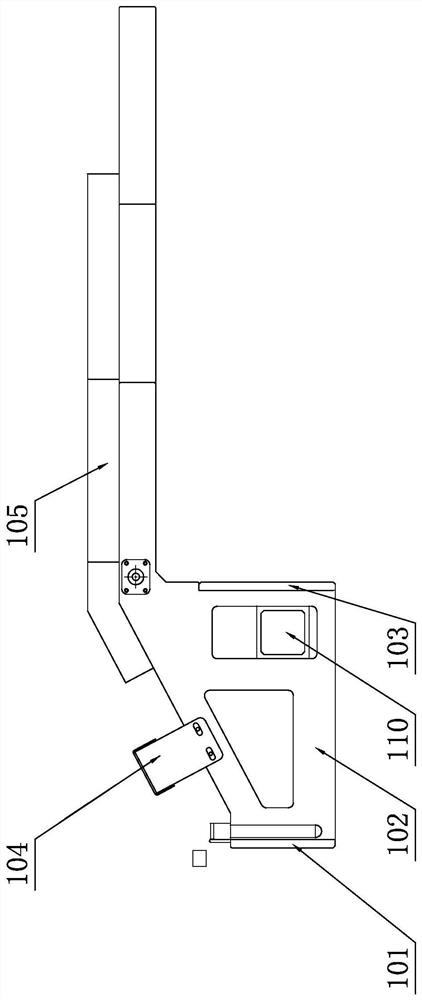

Material pipe transferring mechanism and material pipe transferring method of automatic pipe feeding machine of bottle making machine

PendingCN111018326ARealize continuous workReduce frictionGlass reforming apparatusGlass productionMachineTransfer mechanism

The invention discloses a material pipe transferring mechanism and a material pipe transferring method of an automatic pipe feeding machine of a bottle making machine. The material pipe transferring mechanism comprises a rack, a sucking disc assembly for adsorbing a material pipe, a transferring assembly for transferring the sucking disc assembly and a first connecting plate assembled on the rackand used for connecting the sucking disc assembly and the transferring assembly. The material pipe transferring method comprises that the sucking disc assembly moves to an initial position through thetransferring assembly, and generates a negative pressure to adsorb a material pipe arranged at the material storage output port of the automatic pipe feeding machine of the bottle making machine, andthe material pipe is transferred through the transferring assembly. According to the invention, with the method and the mechanism, the product quality can be guaranteed, and the working efficiency can be improved; and the mechanism and the method are suitable for the automatic pipe feeding machine of the bottle making machine, and are used for conveying material pipes to the material pipe input port of the push-up mechanism of the automatic pipe feeding machine.

Owner:SHIJIAZHUANG LOYAL MACHINERY MFG

An automatic feeding device and feeding method for a centerless grinder

ActiveCN110549178BAvoid the phenomenon of fallingAvoid collisionRevolution surface grinding machinesProcess engineeringIndustrial engineering

Owner:XINCHANG HAIBO MACHINERY

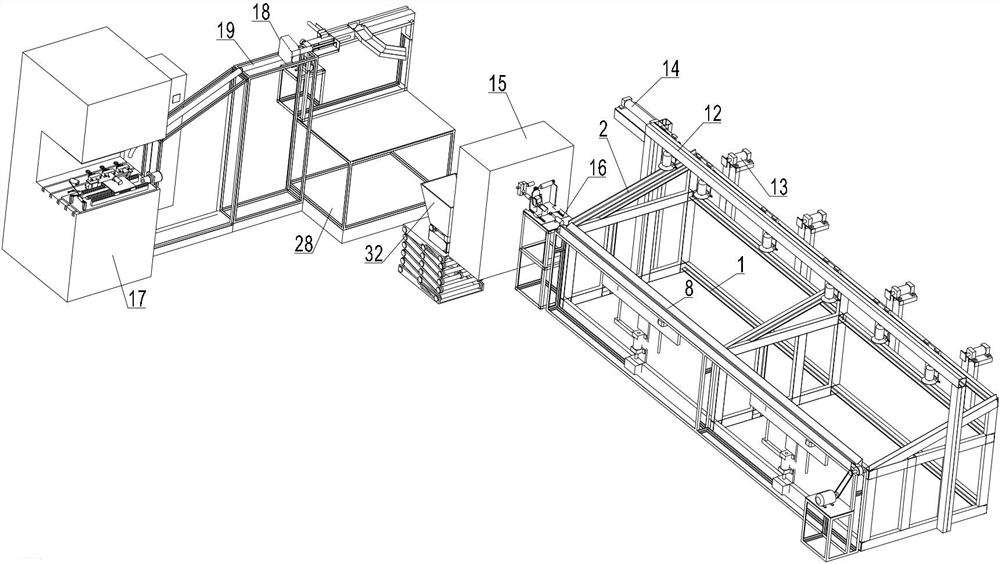

Hot forging combined machine tool

ActiveCN109926831BReduce deliveryImprove work efficiencyOther manufacturing equipments/toolsMetal working apparatusAssembly lineMachine

The invention relates to a hot forging combined machine tool and belongs to the technical field of machining machine tools. The hot forging combined machine tool comprises a rod material unbinding device, an automatic calibration device, a material cutter used for cutting the rod materials into rod material sections, an automatic feeding device which receives the rod material sections conveyed bya lifting device and lifts and sorts the rod material sections and a hot forging machine, wherein the rod material unbinding device, the automatic calibration device, the material cutter, the rod material section, the automatic feeding device and the hot forging machine are sequentially arranged to combine an assembly line. A conveying device and a heating device are arranged between the materialoutlet end of the automatic feeding device and the hot forging machine. The hot forging combined machine tool is high in mechanical degree and capable of achieving automatic unbinding, automatic feeding and other work. The hot forging combined machine tool can lower the labor intensity, improve the work efficiency and has good comprehensive use performance.

Owner:HEBEI UNIV OF ENG

Pre-Filled Duct Irrigator Filling Machine

ActiveCN112455743BRealize orderly deliveryThreaded caps applicationLiquid materialEngineeringCatheter

Owner:上海亚力机械科技有限公司

Candy single-twist machine

The invention relates to a candy single-twist machine. The candy single-twist machine comprises a candy conveying mechanism, wherein the candy conveying mechanism is arranged at the lower end of a candy arranging tray; the candy conveying mechanism comprises an upper shell, a lower shell and a pushing device, wherein the upper shell is arranged at the upper end of the lower shell, and the upper shell and the lower shell are detachably connected; a cavity which is transversely arranged is arranged between the upper shell and the lower shell, the upper shell and the lower shell are provided witha through hole, wherein the through hole is vertically penetrate through the upper shell and the lower shell, and the through hole is in communication with the cavity; the pushing device is arrangedin the cavity, and the pushing device is connected to the lower shell; a first moving head and a second moving head are arranged in the cavity, and the first moving head and the second moving head arearranged on the two sides of the through hole respectively; the first moving head is connected to the pushing device; a first magnet block is arranged in the first moving head, and a second magnet block is arranged in the second moving head; and the first magnet block and the second magnet block are magnetically attracted. Compared with the prior art, candies are not prone to wear, so that the quality problem of the candies can be avoided, and orderly conveying of the candies can be realized.

Owner:衡阳市港佳华食品有限责任公司

Flower shell conveyor

PendingCN114476598AAvoid bumpingNo toppling phenomenonControl devices for conveyorsRotary conveyorsAgricultural engineeringStructural engineering

The invention discloses a flower shell conveyor, which belongs to the field of flower shell conveying and comprises a first conveying mechanism, a feeding disc mechanism, a first steering feeding piece, a lifting conveying mechanism, a second steering feeding piece and a second conveying mechanism which are sequentially arranged along the conveying direction, the first conveying mechanism, the feeding disc mechanism, the lifting conveying mechanism and the second conveying mechanism are each provided with a magnet used for attracting the flower shells so that the flower shells can be kept in the state of standing on the conveying planes of all the mechanisms and not toppling over in the conveying process, and discharged materials of the feeding disc mechanism are conveyed to the lifting conveying mechanism through a first steering feeding piece. And the discharged material of the lifting conveying mechanism is conveyed to the second conveying mechanism through the second steering feeding piece, so that the flower shells stand on the conveying plane of the second conveying mechanism when being conveyed to the second conveying mechanism, and therefore, the flower shells stand on the conveying plane of the second conveying mechanism when being conveyed to the second conveying mechanism. According to the flower shell conveyor, flower shells are conveyed in order, and the flower shells cannot topple over in the conveying process.

Owner:厦门三圈电池有限公司

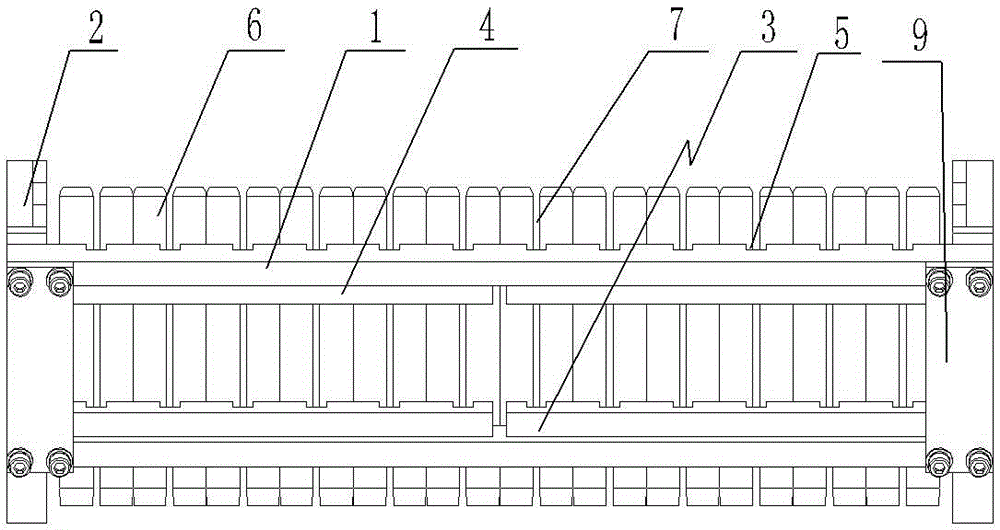

Nail conveying device

InactiveCN105397882ARealize orderly deliveryStapling toolsNailing toolsEngineeringMechanical engineering

The invention relates to the technical field of wooden tray processing, in particular to a nail conveying device. By means of the nail conveying device, nail conveying can be achieved conveniently, rapidly and orderly. The nail conveying device comprises two first transverse plates which are arranged in parallel. The two ends of the first transverse plates are fixedly installed on an end supporting frame. Two U-shaped installation racks which are arranged symmetrically are arranged between the two first transverse plates. Each U-shaped installation rack comprises a transverse strip installed on end supporting seats and two second transverse plates abutting against the first transverse plates. Grooves are formed in the lower ends of the first transverse plates and the lower ends of the second transverse plates respectively in a one-to-one correspondence mode. Sliding groove guide rails are arranged at the two ends of each groove. A nail conveying gap is formed between every two adjacent slide groove guide rails, the slide groove guide rail at one end is fixedly installed at the bottoms of the first transverse plates, and the slide groove guide rail at the other end is fixedly installed at the bottoms of the second transverse plates.

Owner:WUXI ZHENGYANG MACHINERY

Multichannel feeding device for sandwich biscuits

PendingCN108792495ARealize automatic flipRealize orderly deliveryMechanical conveyorsMechanical engineeringSandwich biscuit

Owner:FOSHAN RUIPUHUA PACKING MACHINERY CO LTD

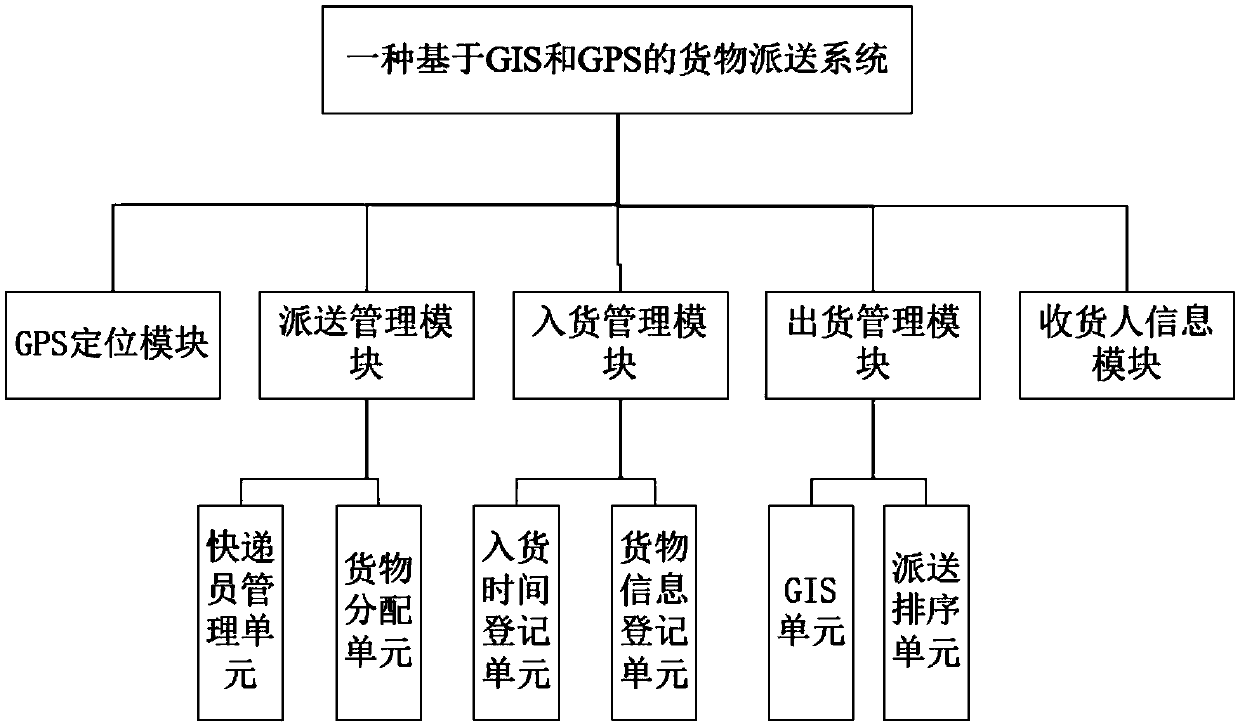

Goods delivery system based on GIS and GPS

InactiveCN110322181ARealize orderly deliveryFast deliveryGeographical information databasesLogisticsDelivery systemTransport engineering

The invention particularly relates to a goods delivery system based on a GIS and a GPS. The system comprises a GPS positioning module, a delivery management module, a goods incoming management module,a goods outgoing management module, and a consignee information module. The goods incoming management module records the received goods information, and the goods outgoing management module is responsible for the delivery sorting according to the received goods information. The delivery management module arranges courier to deliver different goods according to the delivery order of the goods andplans the shortest delivery route of the goods based on the GIS, and the GPS positioning module is used for obtaining the real-time position of each courier. Compared with the prior art, through the cooperation of all the modules, the delivery and receiving information is registered, ordered delivery of goods is achieved, the courier position obtained by the GPS positioning module is beneficial for supervising the courier to conduct rapid delivery, the shortest delivery route is planned, and the delivery efficiency is greatly improved.

Owner:国通北斗卫星信息化应用中心股份有限公司

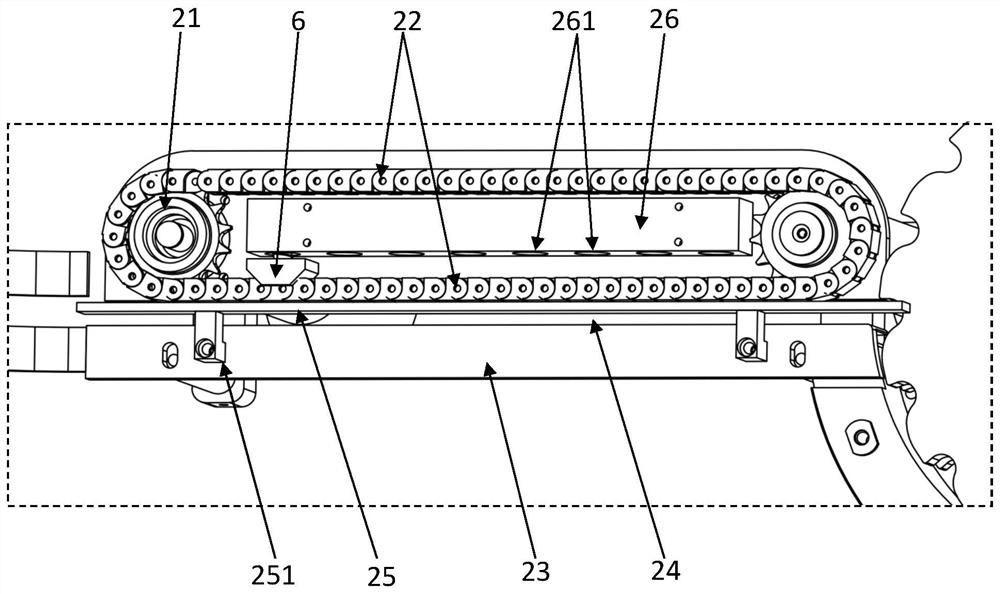

Conveying device for relay electronic elements

PendingCN106944804AImprove adaptabilityRealize orderly deliveryMetal working apparatusTransmission beltMulti degree of freedom

The invention discloses a conveying device for relay electronic elements. The conveying device comprises an independent selection conveying line for the relay electronic elements and a multi-degree-of-freedom pickup unit, wherein the independent selection conveying line for the relay electronic elements can carry out independent selection transportation on massive relay electronic elements; the multi-degree-of-freedom pickup unit is located below one side of the independent selection conveying line for the relay electronic elements, picks up the independently selected relay electronic elements and conveys the independently selected relay electronic elements to the next procedure; the independent selection conveying line for the relay electronic elements comprises a bottom plate and a side plate, the side plate is vertically fixed to the bottom plate, two transmission belt wheels are mounted on the side plate, and the two transmission belt wheels are connected through a conveying belt; and the included angle between the linear conveying direction of the conveying belt and the horizontal direction is 45-60 degrees, and the outer side surface of the conveying belt is uniformly provided with independent selection units. The ordered conveying and pickup of the elements are realized through the independent selection conveying line and the multi-degree-of-freedom pickup unit, convenience is provided for the next assembling process, the assembling progress is accelerated, and the production efficiency is increased.

Owner:苏州格联威智能科技有限公司

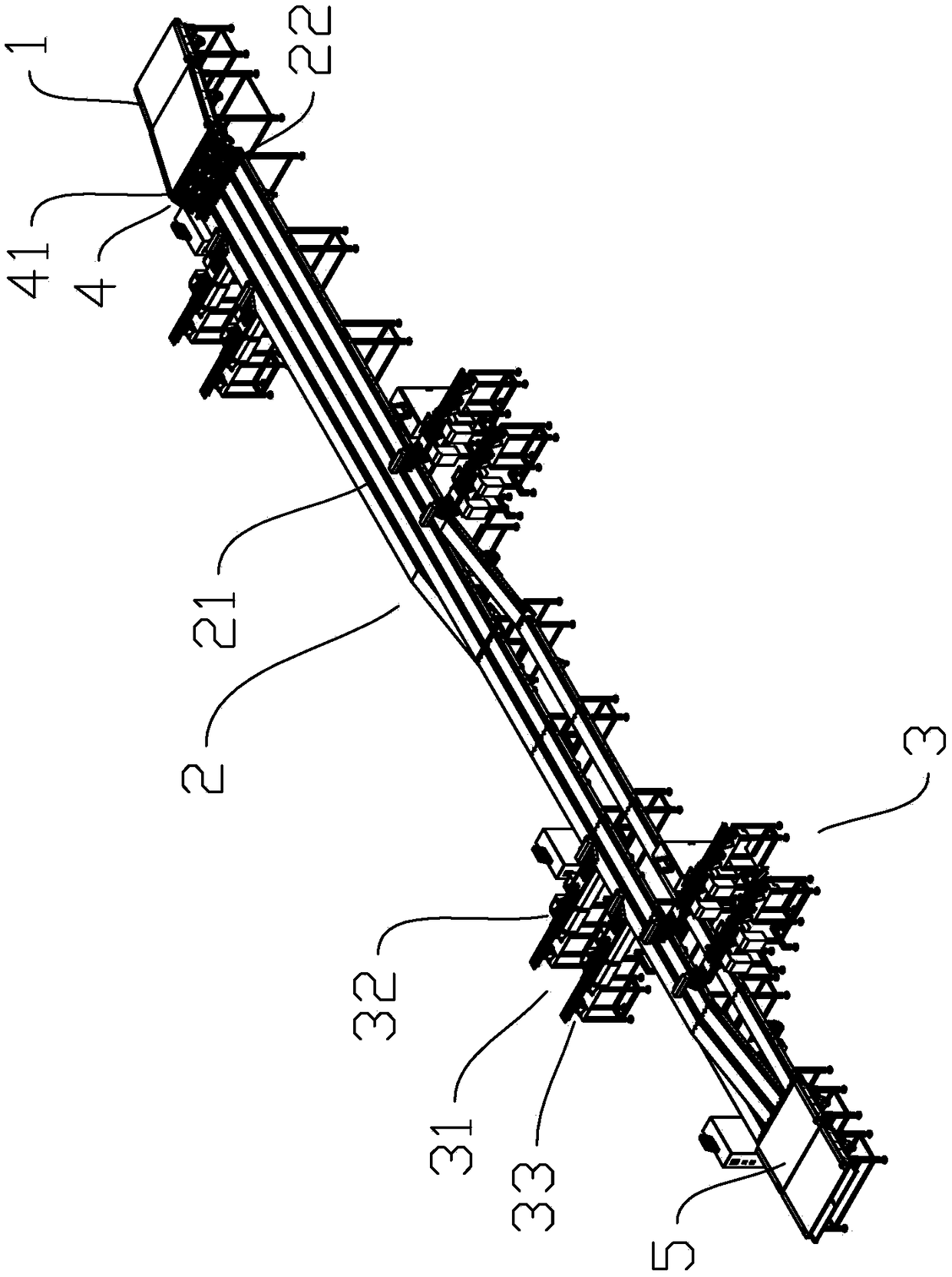

Automatic unbundling device for bars

ActiveCN109969509ARealize unified actionImprove unityUnpacking by cuttingElectric machineryEngineering

The invention relates to an automatic unbundling device for bars and belongs to the technical field of bar machining equipment. The automatic unbundling device for bars comprises a supporting assembly, an unbundling assembly and a feeding assembly. The supporting assembly comprises a bottom supporting frame and a slope discharging frame which is used for conveying the bars from the unbundling assembly to the feeding assembly; the unbundling assembly comprises an oblique hook which is used for hooking bundling strips and a cutting motor which is provided with cutting blades; and the feeding assembly comprises a jacking plate which is disposed below the discharging end of the slope discharging frame and driven by a jacking cylinder to move and a conveying belt which is disposed on the side surface of the jacking cylinder. According to the automatic unbundling device for bars, all the functional assemblies cooperate with one another, and unbundling and orderly conveying of the bars are achieved. The bundled metal bars can be automatically unbundled, discharged and conveyed, the whole working process is high in mechanization degree, working is stable, and the comprehensive using properties are good.

Owner:HEBEI UNIV OF ENG

Material taking and conveying system of labeling machine

InactiveCN112389787ARealize the feeding functionSimplify the feeding processConveyorsControl devices for conveyorsStructural engineeringBlood sampling

The invention belongs to a feeding device of a labeling machine, and particularly relates to a material taking and conveying system of the labeling machine. The material taking and conveying system comprises a hopper, wherein the top of the hopper is open, and the hopper can contain blood sampling test tubes. A first belt conveying mechanism is arranged in the hopper, clamping jaws are distributedon the first belt conveying mechanism at intervals, the clamping jaws and a first belt can clamp blood sampling test tubes, and a material output at the top of the first belt conveying mechanism is connected with a material input of a test tube conveying mechanism. Partition plates are distributed in parallel at intervals and fixed by a front vertical plate and a rear vertical plate, each partition plate is divided into a horizontal rear section and a slide-shaped inclined front section, second belt conveying mechanisms capable of bearing the blood sampling test tubes are arranged in intervals formed by the rear sections of the partition plates, and the interval between every two adjacent partition plates is larger than the diameter of the blood sampling test tubes and smaller than the diameter of blood sampling test tube caps. According to the material taking and conveying system of the labeling machine, the technical problems that existing products are tedious to operate for feedingmanually are effectively solved, the feeding function of the blood sampling test tubes in a disordered stacking state is effectively achieved, the feeding process is simplified, and the feeding timeis greatly shortened.

Owner:石家庄泽厚科技有限公司 +1

A new light and simple orderly harvester for stem and leaf vegetables

ActiveCN113348856BCompact structureEasy and flexible operationClimate change adaptationMowersAgricultural engineeringConveyor belt

The invention discloses a novel light and simple orderly harvester for stem and leaf vegetables, which includes a crawler chassis installed with a walking transmission system and a header, the header is installed on the crawler chassis, and the header includes a frame, A vertical elastic clamping mechanism, a band saw cutting mechanism, a flexible sawtooth cam disc dial mechanism and an elastic guide rod type mobile collection mechanism, and a conveyor belt is installed in the middle of the frame. The present invention has many advantages such as simple and compact structure, flexible and light operation, strong harvest adaptability and versatility, etc., can meet the various needs of domestic hilly areas and facility greenhouse operations, and effectively realizes high-efficiency, low-loss, and whole-scale harvesting of stem and leaf vegetables. Strains are mechanized and orderly harvested.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

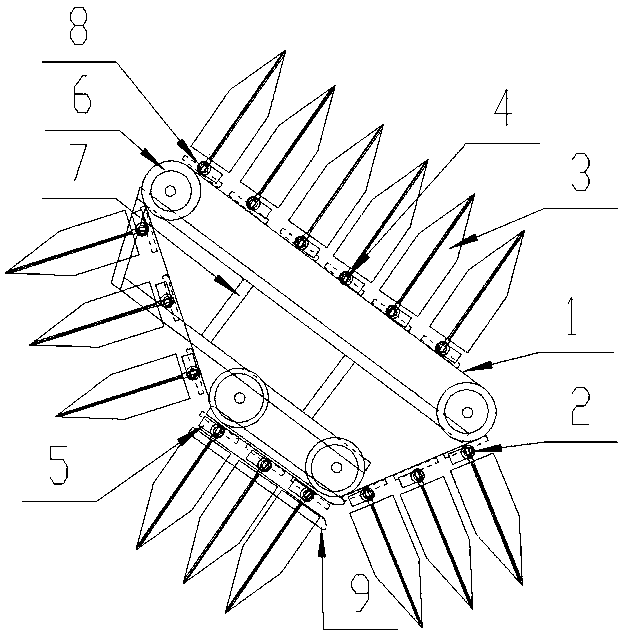

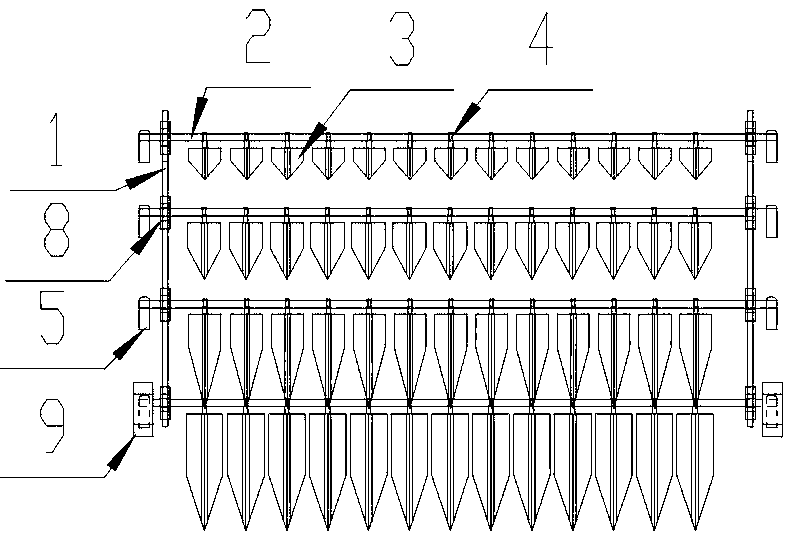

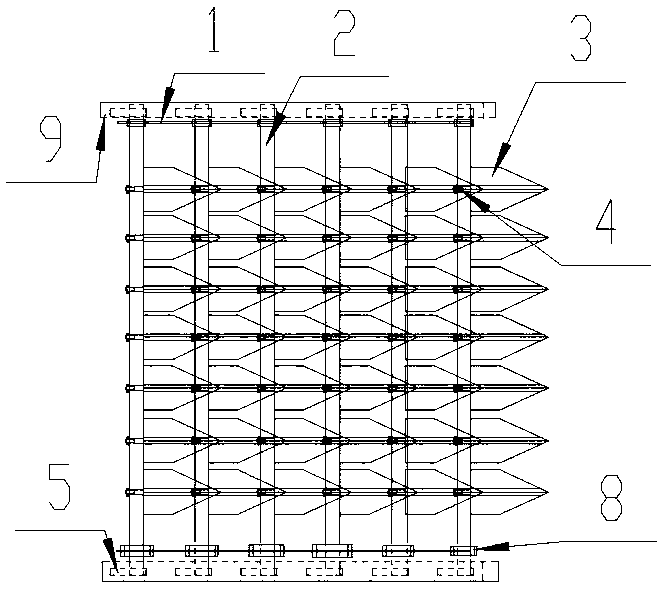

Four-blade type vegetable supporting device acting on vegetable leaves and stems

PendingCN109463111ARealize orderly deliveryRealize supportHarvestersDrive shaftAgricultural engineering

The invention relates to a four-blade type vegetable supporting device acting on vegetable leaves and stems. A vegetable supporting main transmission shaft is perpendicular to the advancing directionof a harvester, three vegetable supporting secondary transmission shafts are arranged, the connection lines between the vegetable supporting main transmission shaft and the circle centers of the threevegetable supporting secondary transmission shafts form an inverted trapezoid, an included angle is formed between the lower bottom edge of the inverted trapezoid and a horizontal plane, and two parallel vegetable supporting transmission chains are arranged on the vegetable supporting main transmission shaft and the vegetable supporting secondary transmission shafts through transmission chain wheels and mounted on the two sides of a bracket. The vegetable supporting transmission chains are provided with rotating pipe brackets, a rotating pipe is arranged on each rotating pipe bracket, a four-blade type vegetable supporting combination is vertically connected to each rotating pipe, each sliding block is in rigid connection with the two ends of the corresponding rotating pipe, and a slidinggroove is formed below each rotating pipe bracket. When the device is used for supporting vegetables, the sliding blocks slide into the sliding grooves, the sharp edge of each four-blade type vegetable-supporting combination faces the roots of the vegetables. The device can support the vegetables in different directions and carry out orderly conveying.

Owner:江西悦丰农业科技有限公司

A bar automatic unbundling device

ActiveCN109969509BRealize orderly deliveryRealize unified actionUnpacking by cuttingTransmission beltElectric machinery

The invention relates to an automatic bar unbundling device, which belongs to the technical field of bar processing equipment. An automatic bar unbundling device, including a support assembly, an unbundling assembly, and a feeding assembly; the support assembly includes a bottom support frame and an inclined plane discharge rack for transporting the bar from the unbundling assembly to the feeding assembly, and the unbundling assembly includes The oblique hook used to hook up the binding strip and the cutting motor for setting the cutting blade, the feeding assembly includes a lifting plate arranged under the discharge end of the inclined discharge rack and driven by the jacking cylinder and set on the side of the jacking cylinder conveyor belt. The various functional components of the invention cooperate with each other to realize the unbundling and orderly delivery of bars. The invention can automatically unbundle, discharge and convey the whole bundle of metal bars, and the whole working process has high degree of mechanization, stable operation and good comprehensive performance.

Owner:HEBEI UNIV OF ENG

A candy single twist machine

The invention relates to a candy single-twisting machine, comprising a candy conveying mechanism placed at the lower end of the sugar sorting tray, the candy conveying mechanism includes an upper casing, a lower casing and a pushing device, the upper casing is placed at the upper end of the lower casing, and the upper casing The body and the lower shell are detachably connected; a cavity arranged horizontally is provided between the upper shell and the lower shell, and a cavity vertically passing through the upper shell and the lower shell is also provided on the upper shell and the lower shell. Perforation, the perforation is connected with the cavity; the pushing device is arranged in the cavity, and the pushing device is connected with the lower casing; the first moving head and the second moving head are arranged in the cavity, and the first moving head and the second moving head are respectively located at the two sides of the perforation. side; the first moving head is connected with the pushing device; the first moving head is provided with a first magnet block, and the second moving head is provided with a second magnet block; the first magnet block and the second magnet block are magnetically attracted. Compared with the prior art, the present invention is not easy to cause wear to the candy, avoids quality problems of the candy, and can also realize orderly delivery of the candy.

Owner:衡阳市港佳华食品有限责任公司

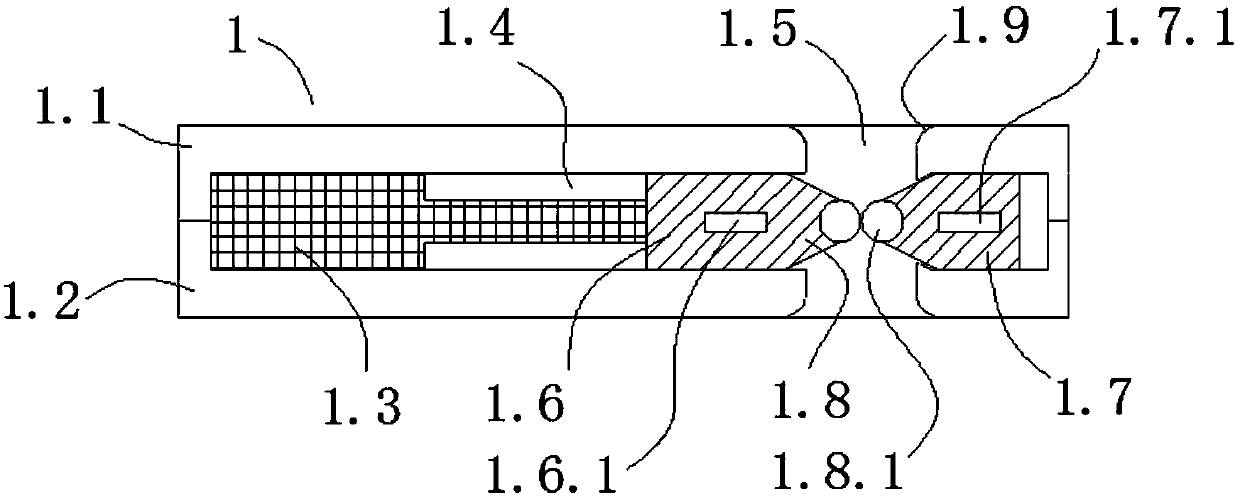

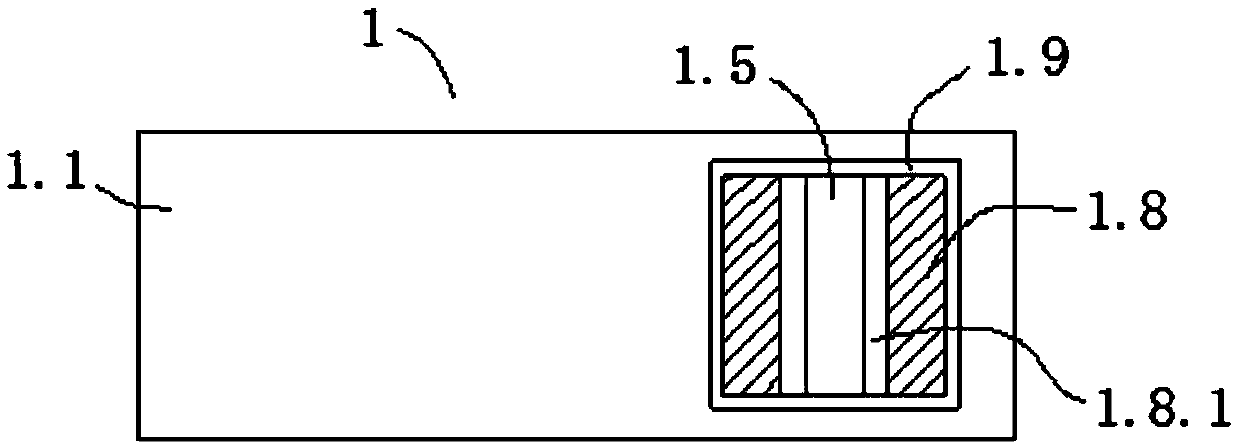

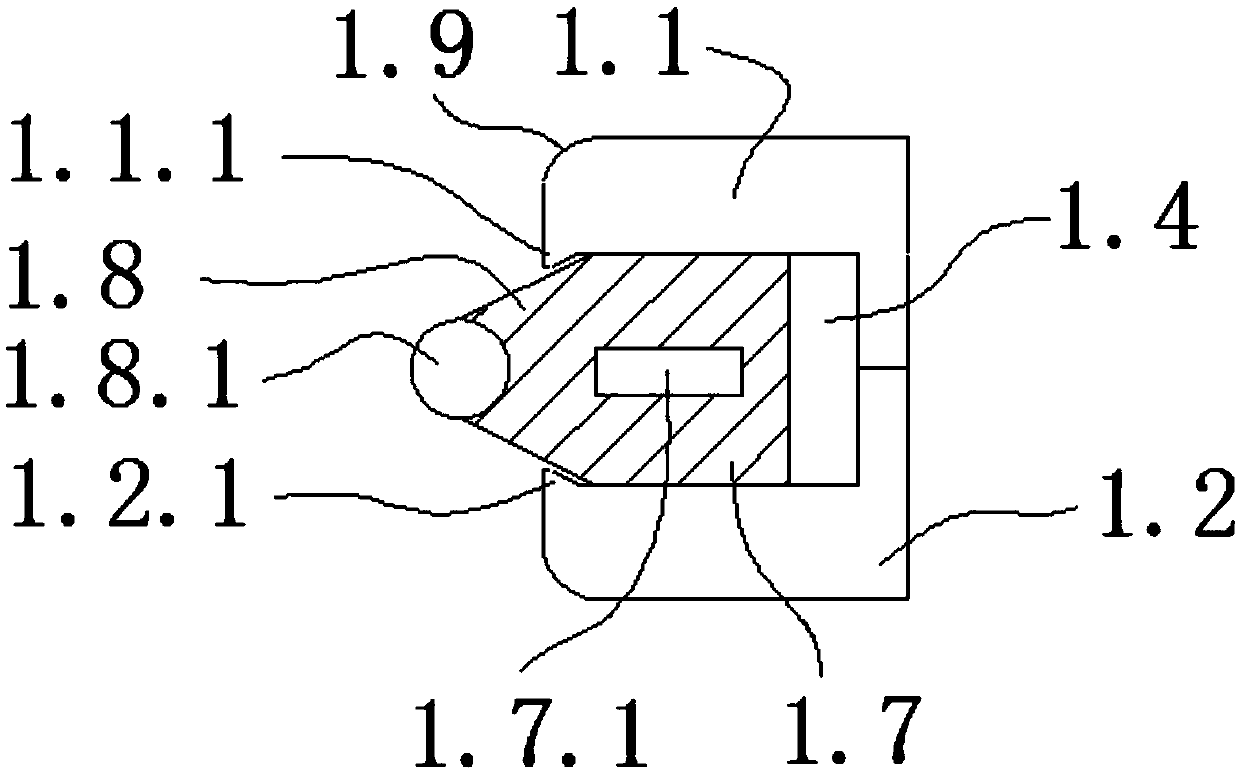

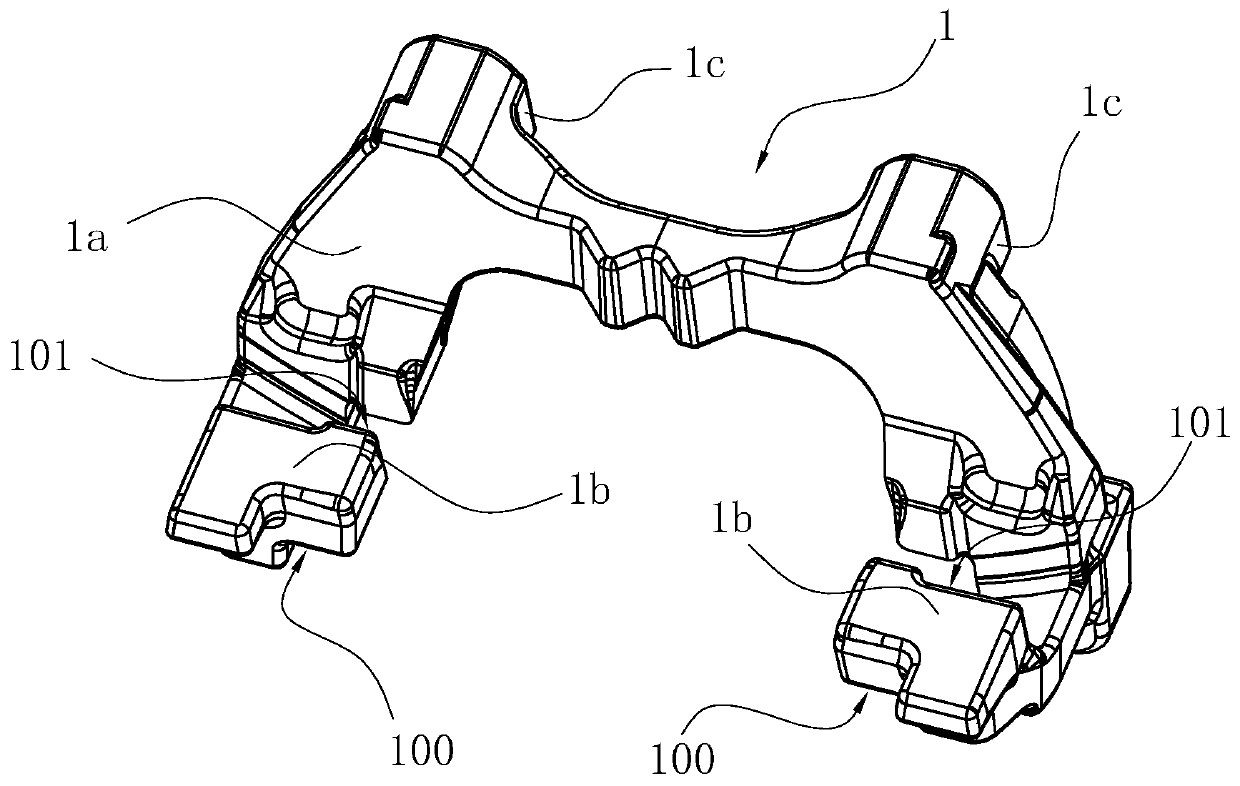

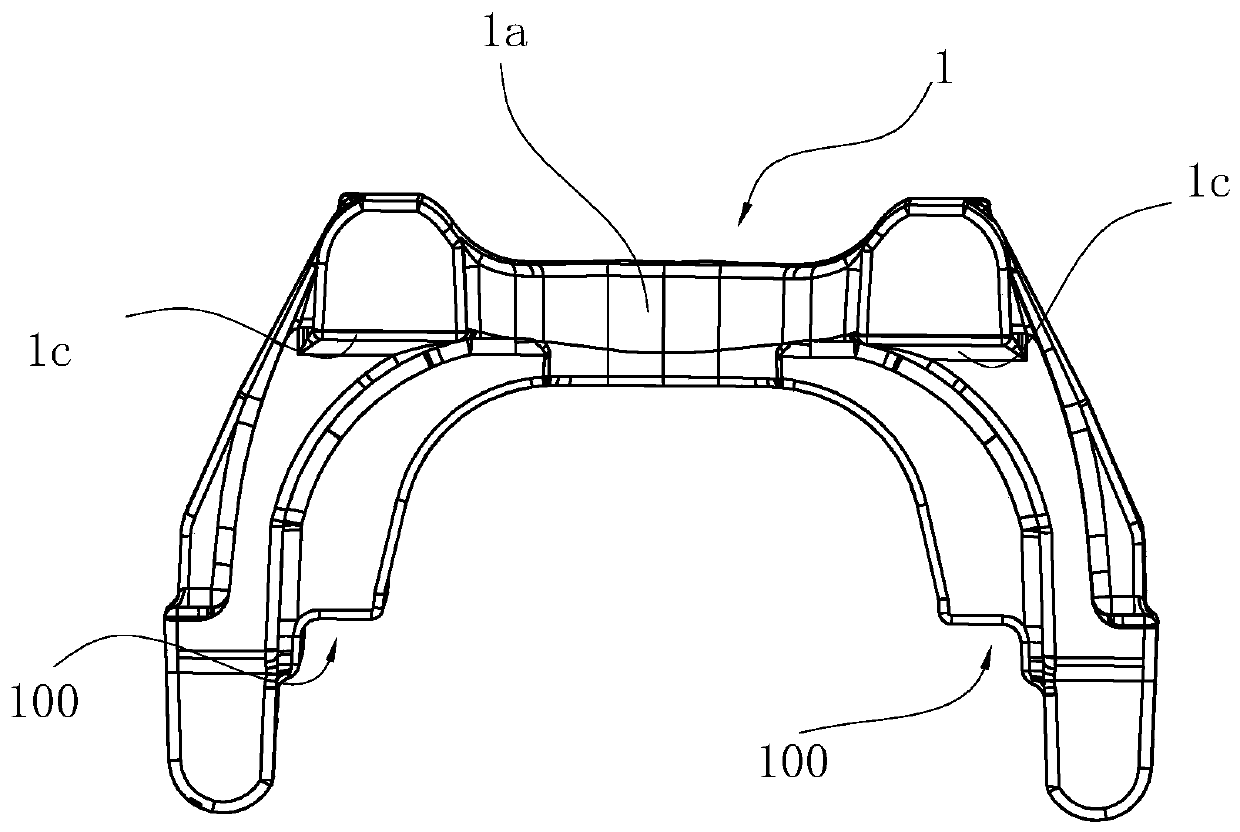

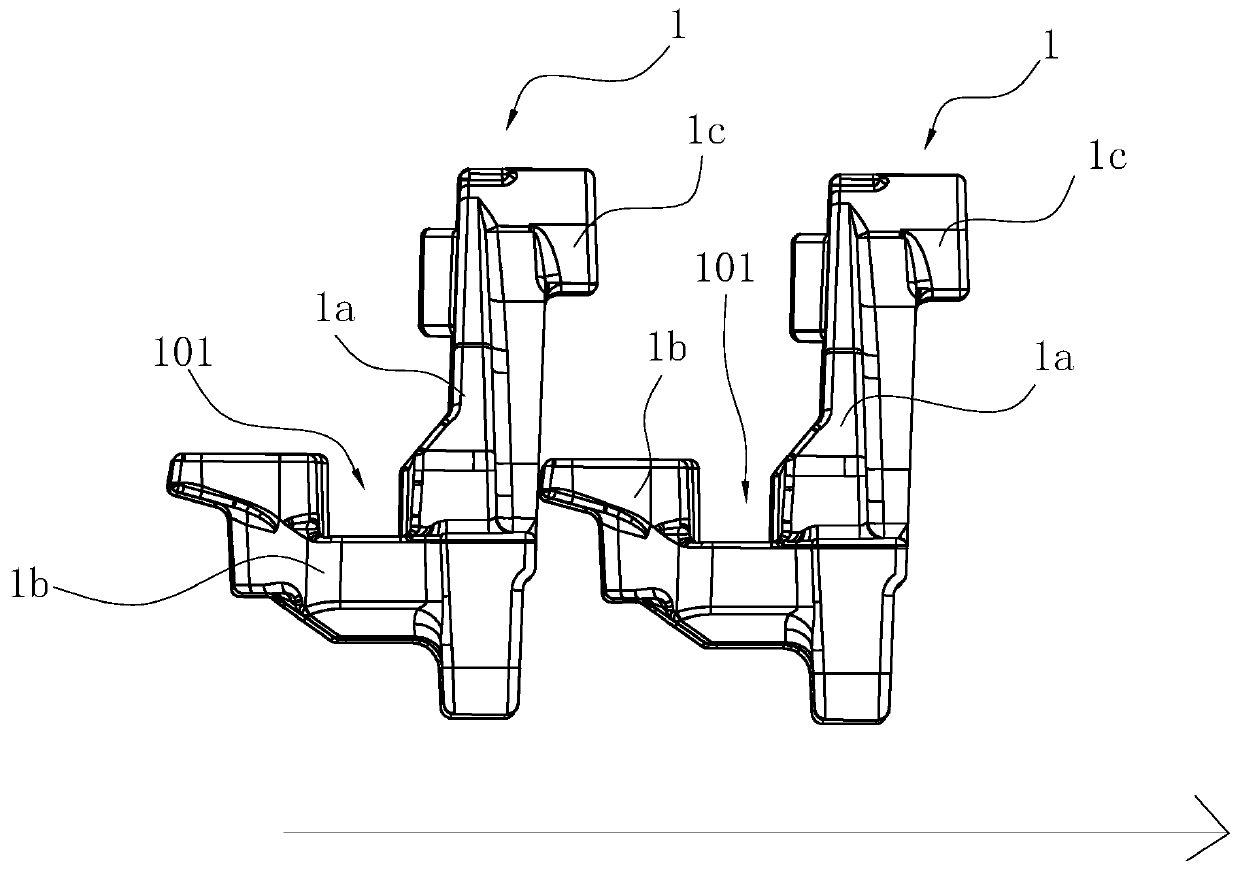

Feeding device for automatic production line of brake caliper support

PendingCN110255127AStable arrangementRealize orderly deliveryConveyorsPackagingProduction lineCalipers

The invention relates to a feeding device for an automatic production line of a brake caliper support. The feeding device comprises a fixed support and a workpiece conveying mechanism, wherein the workpiece conveying mechanism comprises at least one group of chain conveying components used for placing the brake caliper supports, and each chain conveying component is arranged on the fixed support and can convey the brake caliper support placed on the chain conveying component from the first end to the second end; each chain conveying component comprises two parallel conveying chains, and the two conveying chains are respectively matched in two symmetrical putting grooves of the bottom of the brake caliper support; and the distance between the two conveying chains is consistent with the distance between the two putting grooves of the brake caliper support. The feeding device can enable the brake caliper supports to be arranged smoothly on the conveying chains to realize the orderly conveying of workpieces, which greatly facilitates a subsequent manipulator to grab at the second end of each chain conveying component. Thus, the feeding efficiency is effectively improved.

Owner:ZHEJIANG CHR INTELLIGENT EQUIP

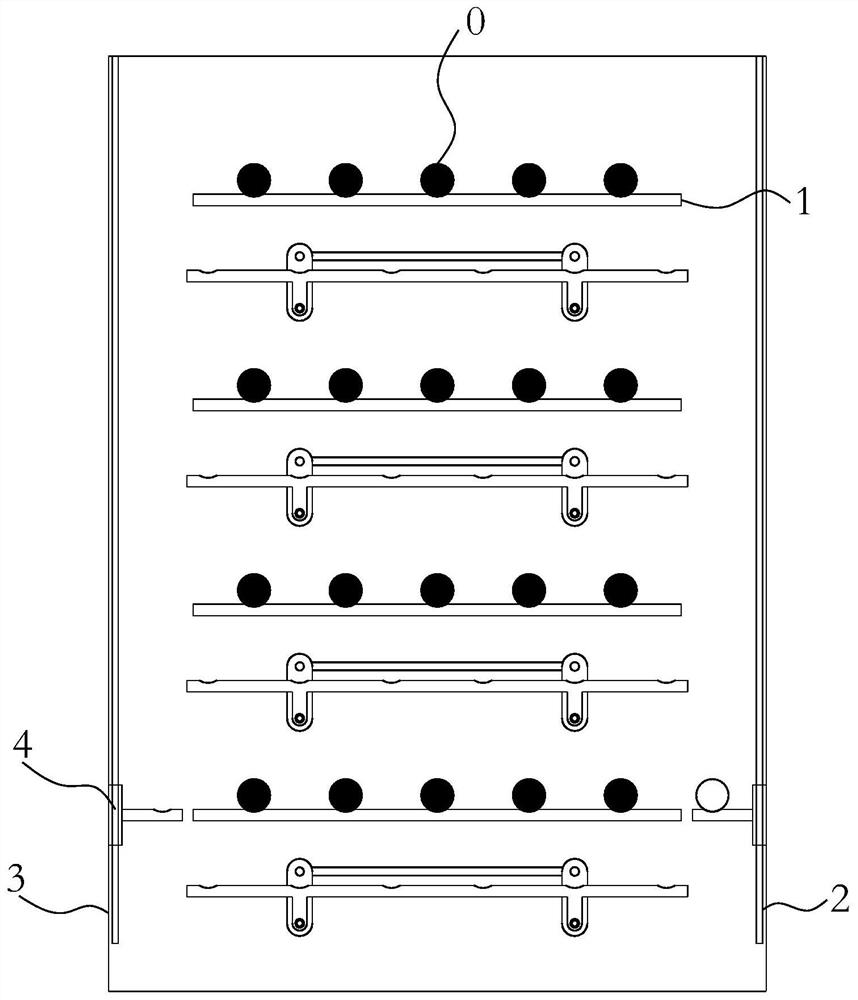

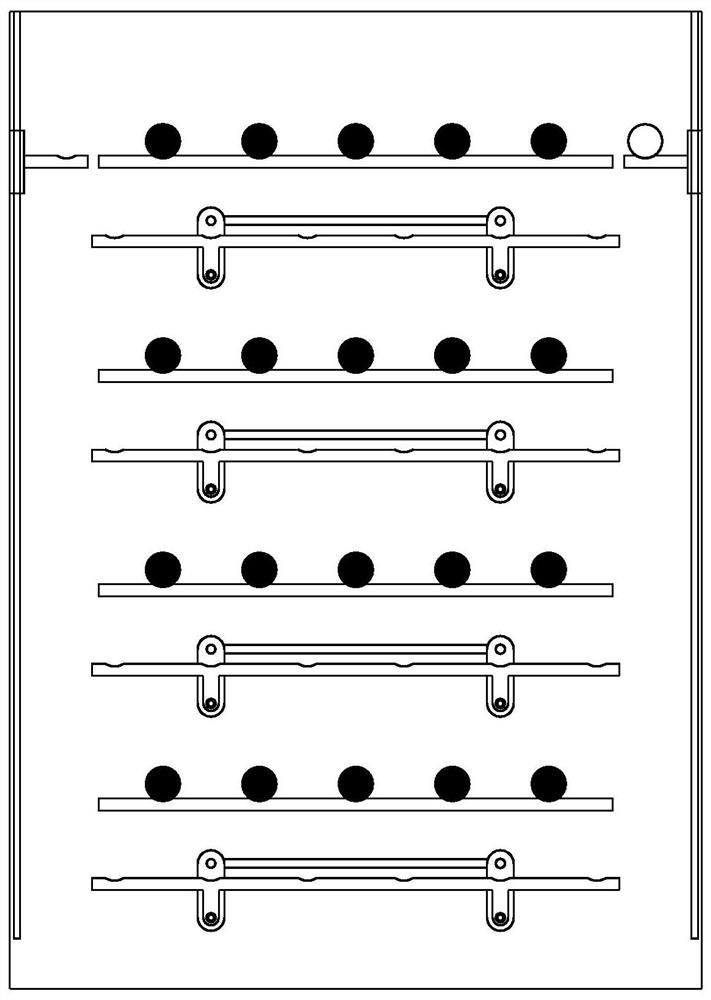

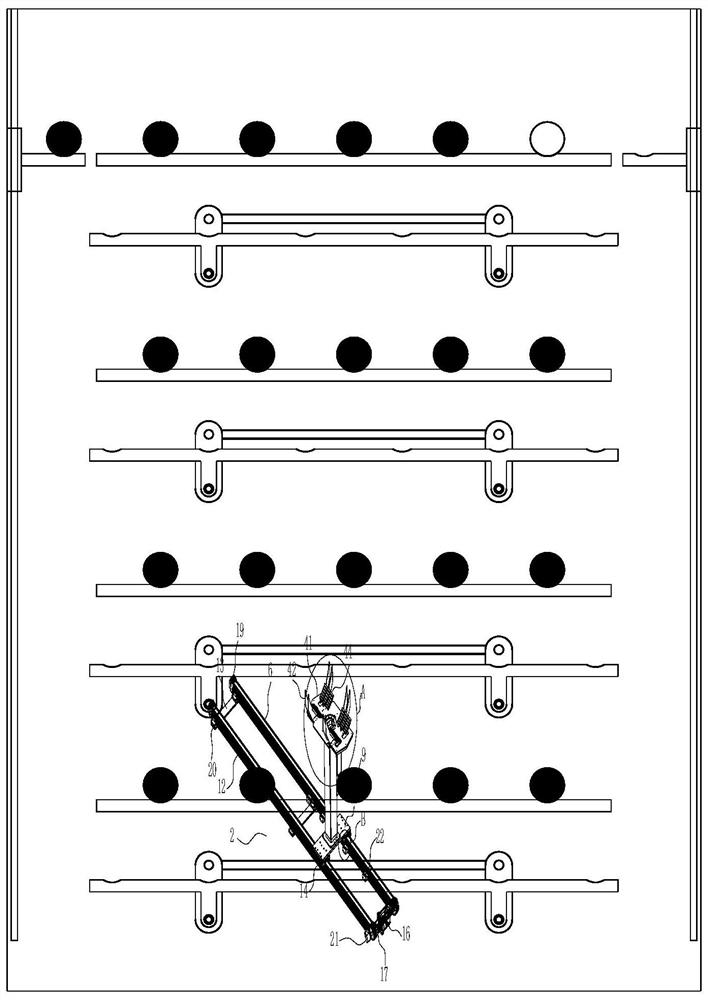

Gas tank supporting platform

InactiveCN112744500ARealize orderly deliveryAvoid confusionContainer filling methodsLifting framesNew energyEngineering

The invention relates to the technical field of new energy automobiles, and aims to provide a gas tank supporting platform. The gas tank supporting platform comprises a plurality of layers of supporting frames, wherein each supporting frame comprises two supporting strips which are arranged side by side and extend in the transverse direction; a plurality of pairs of tank grooves are correspondingly distributed in the upper edges of the two supporting strips in the length direction of the supporting strips; gas tanks stretch across the two supporting strips and are placed in the tank grooves; a tank conveying mechanism is arranged below each layer of supporting frame; each tank conveying mechanism comprises a swinging frame; each swinging frame comprises two swinging supporting rods which are arranged side by side and extend in the transverse direction; two vertical connecting rods are arranged at positions, which are close to two ends, of each swinging supporting rod; a plurality of pairs of tank grooves are correspondingly distributed in the upper edges of the two swinging supporting rods in the length direction of the swinging supporting rods; and the number of the tank grooves in each swinging supporting rod is one pair greater than that of the tank grooves in the corresponding supporting strip. By the gas tank supporting platform, the gas tanks can be conveyed orderly and conveniently, and the gas tanks can be changed one by one.

Owner:金源鸿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com