Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Prevent weed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

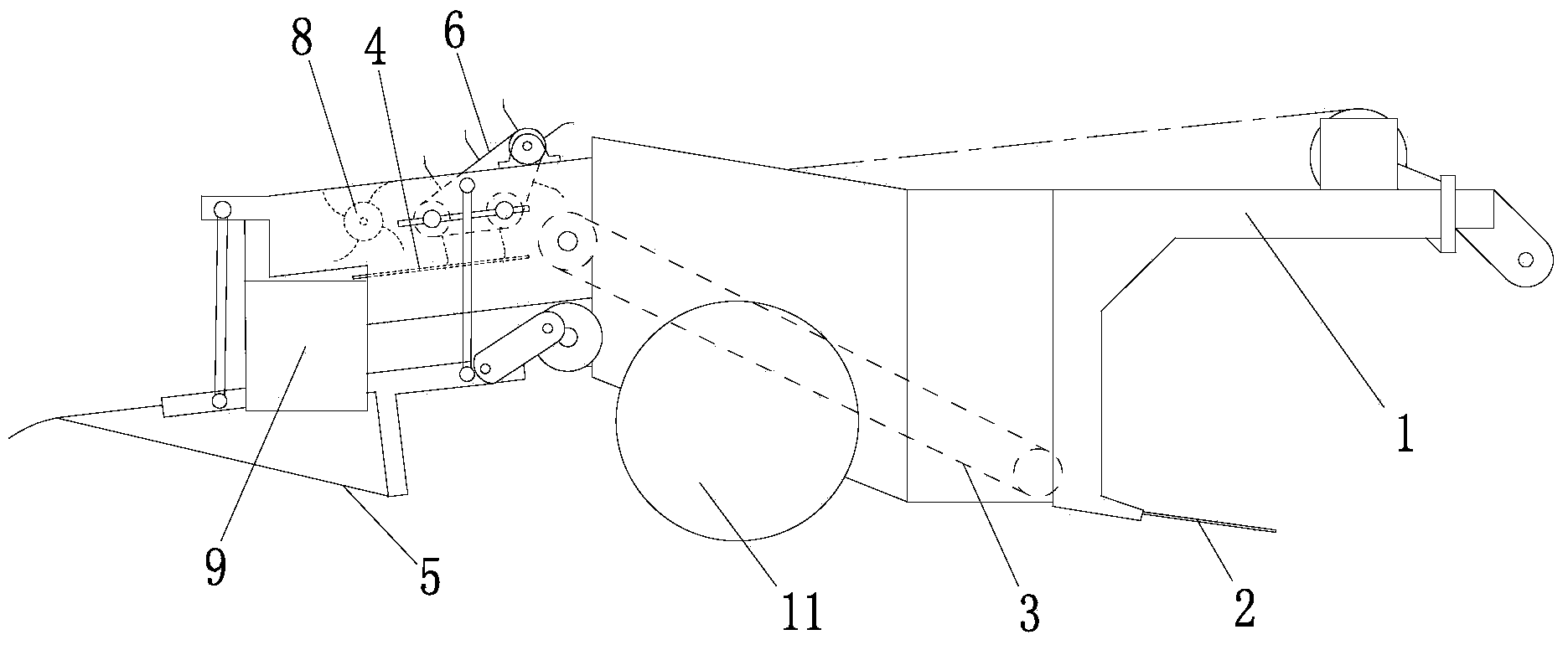

Harvester for harvesting straw covered winter potatoes

The invention discloses a harvester for harvesting straw covered winter potatoes. The harvester comprises a machine frame, a digger shovel, a power assembly and a conveying mechanism, wherein the digger shovel is arranged on the machine frame, and the conveying mechanism is arranged at the back end of the digger shovel. The output end of the conveying mechanism is provided with a straw potato separating screen, a straw removing assembly is arranged on the upper portion of the straw potato separating screen, and a potato soil separating mechanism is arranged on the lower portion of the straw potato separating screen. Due to the fact that the straw removing assembly is installed on the straw potato separating screen of the harvester, the straw can be discharged out of the harvester effectively and timely through the straw removing assembly, and the potatoes and the straw are separated while the straw blocking is prevented,. The harvester is simple and compact in structure and high in working efficiency and has wide market application and popularization prospects.

Owner:SOUTH CHINA AGRI UNIV

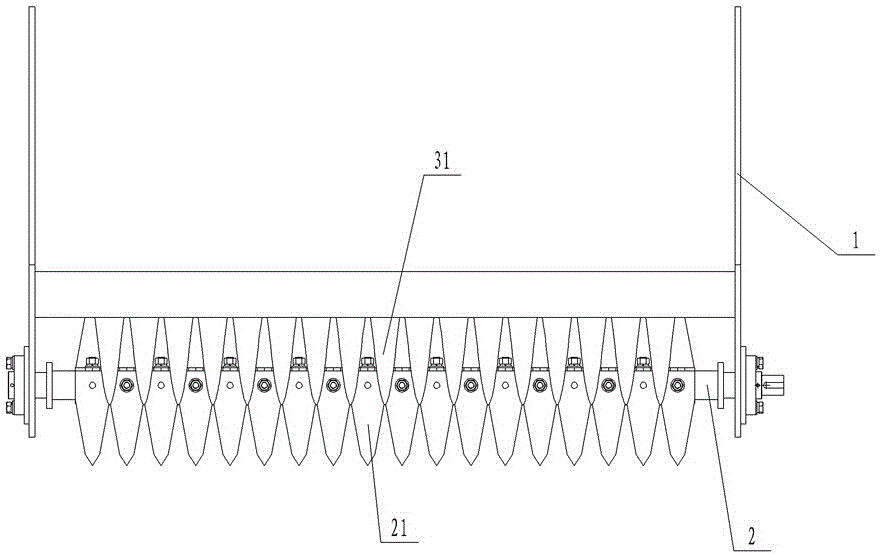

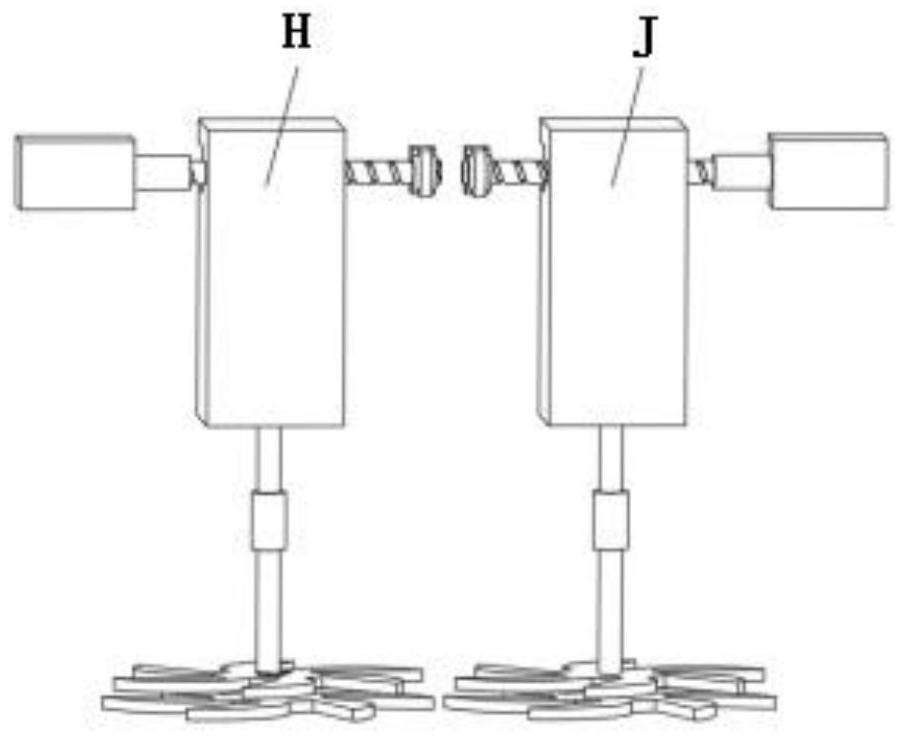

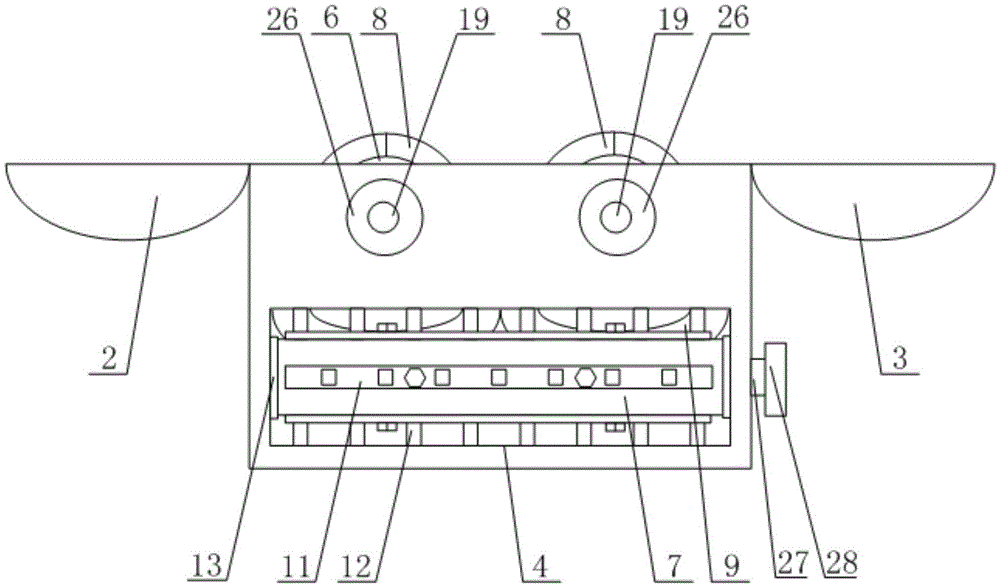

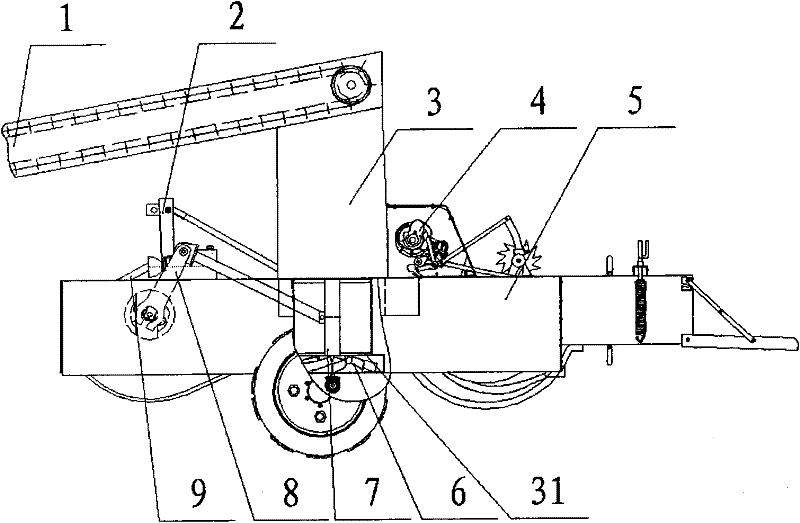

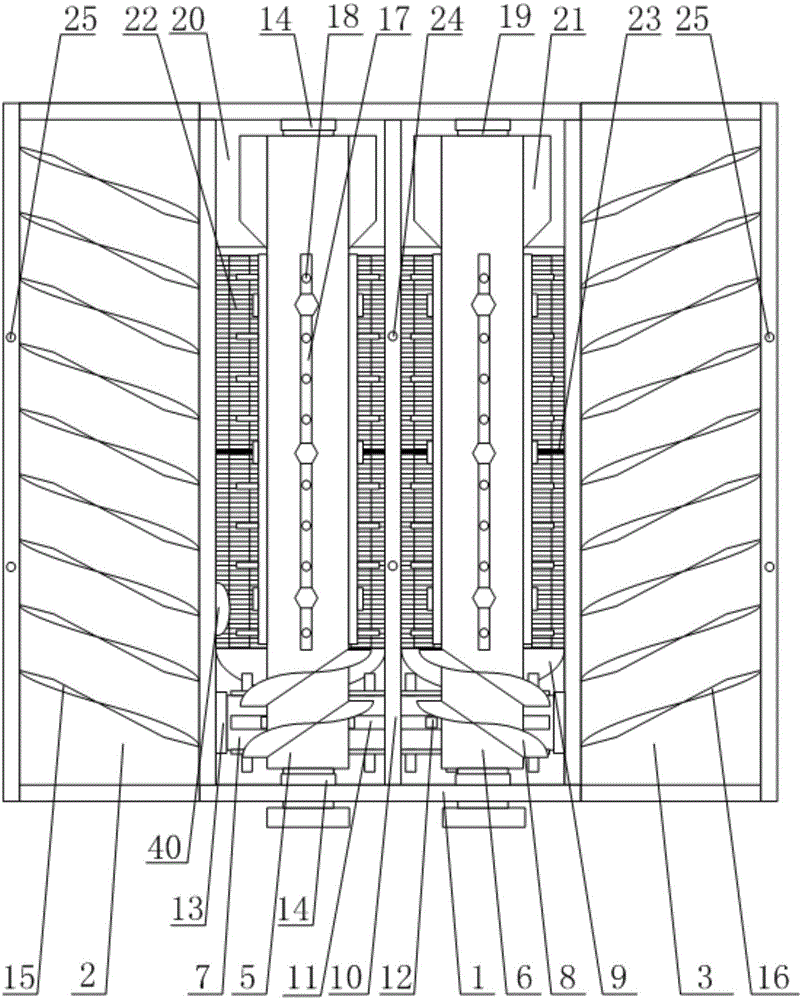

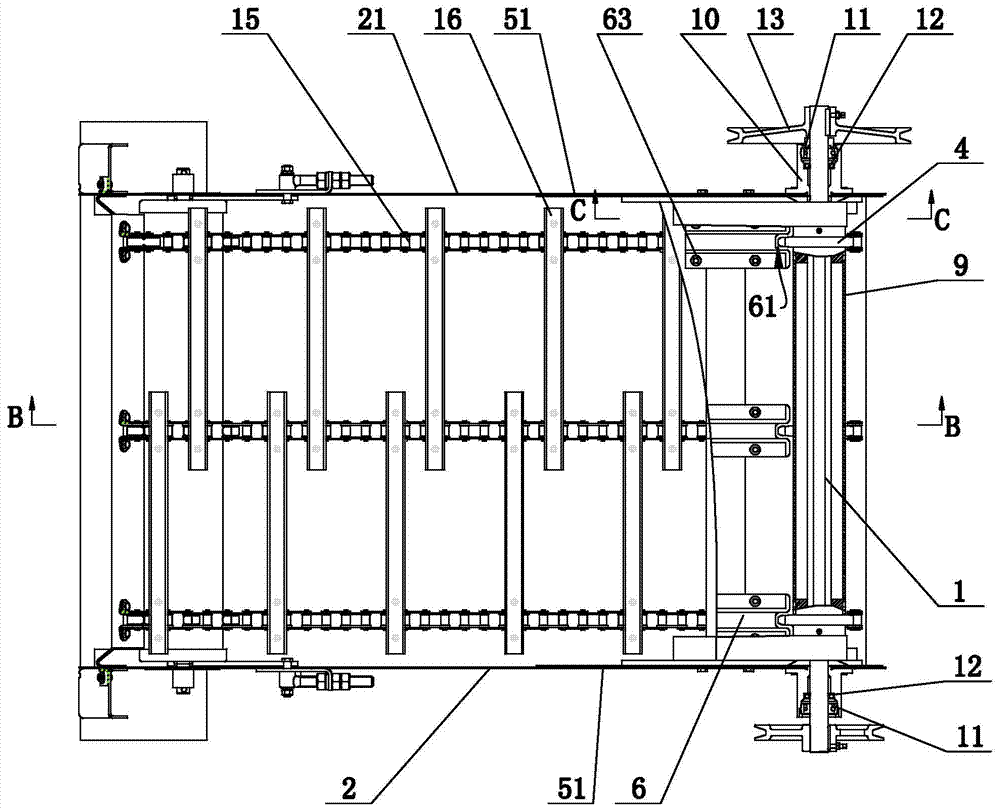

Cotton stalk pulling platform free of row controlling

InactiveCN104081931APrevent weedReduce work energy consumptionHarvestersEngineeringEnergy consumption

The invention relates to the field of agricultural implements, in particular to a cotton stalk pulling platform free of row controlling. The cotton stalk pulling platform free of row controlling comprises a rack. A bottom plate is arranged on the rack. A reel and an auger conveyer are arranged above the bottom plate. The cotton stalk pulling platform free of row controlling further comprises a stalk pulling roller which is arranged at the front end of the rack, a clearing roller located between the stalk pulling roller and the bottom plate and a stalk shifting roller located above the base plate, wherein the stalk pulling roller is located below the reel, the auger conveyer is located behind the stalk shifting roller and arranged above the stalk shifting roller, the stalk pulling roller comprises a stalk pulling shaft and a plurality of rows of V-shaped toothed plates which are arranged in the circumferential direction of the stalk pulling shaft, the V-shaped toothed plates are tangent to the contour of the stalk pulling shaft, the clearing roller comprises a clearing shaft and a plurality of rows of clearing teeth which are arranged in the circumferential direction of the clearing shaft, the tooth point of each clearing tooth is right opposite to the bottom tooth of the corresponding V-shaped toothed plate, and the stalk shifting roller comprises a stalk shifting shaft and rectangular plates which are arranged in the circumferential direction of the stalk shifting shaft. According to the cotton stalk pulling platform free of row controlling, the structure is simple, the cotton stalks can be pulled out completely without row controlling, and work energy consumption is greatly reduced.

Owner:滨州市农业机械化科学研究所

Stubble collecting and returning machine

The invention relates to the technical field of agricultural machinery and provides a stubble collecting and returning machine. The machine comprises a gear box, a tripod, a stander, a stubble collecting device knife pivot, a stubble collecting device knife bed, a stubble collecting knife, a stubble chopping knife, a returning device knife pivot, a returning knife bed, a returning knife, a fixed knife, a case and a copying sliding plate, wherein the gear box is mounted on the stander; the tripod is mounted on the stander by a suspension loop; the stubble collecting device knife pivot is horizontally mounted on the stander; the stubble collecting device knife bed is welded on the stubble collecting device knife pivot according to helix arrangement for mounting the stubble collecting knife and the stubble chopping knife; the returning device knife pivot is horizontally mounted on the stander; the returning knife bed is welded on the returning device knife pivot according to helix arrangement for mounting the returning knife; the case is mounted outside the returning device; the fixed knife is welded at the inner side of the front of the case; and the copying sliding plate is mounted on the case. When the machine works, the stubble collecting device collects the stubbles and throws the stubbles together with the straws into the returning device and the returning device crushes and returns the stubbles and the straws, thus realizing that the machine and the tools enter into the field once and carry out straw stubble collecting and returning operations simultaneously.

Owner:SHANDONG UNIV OF TECH

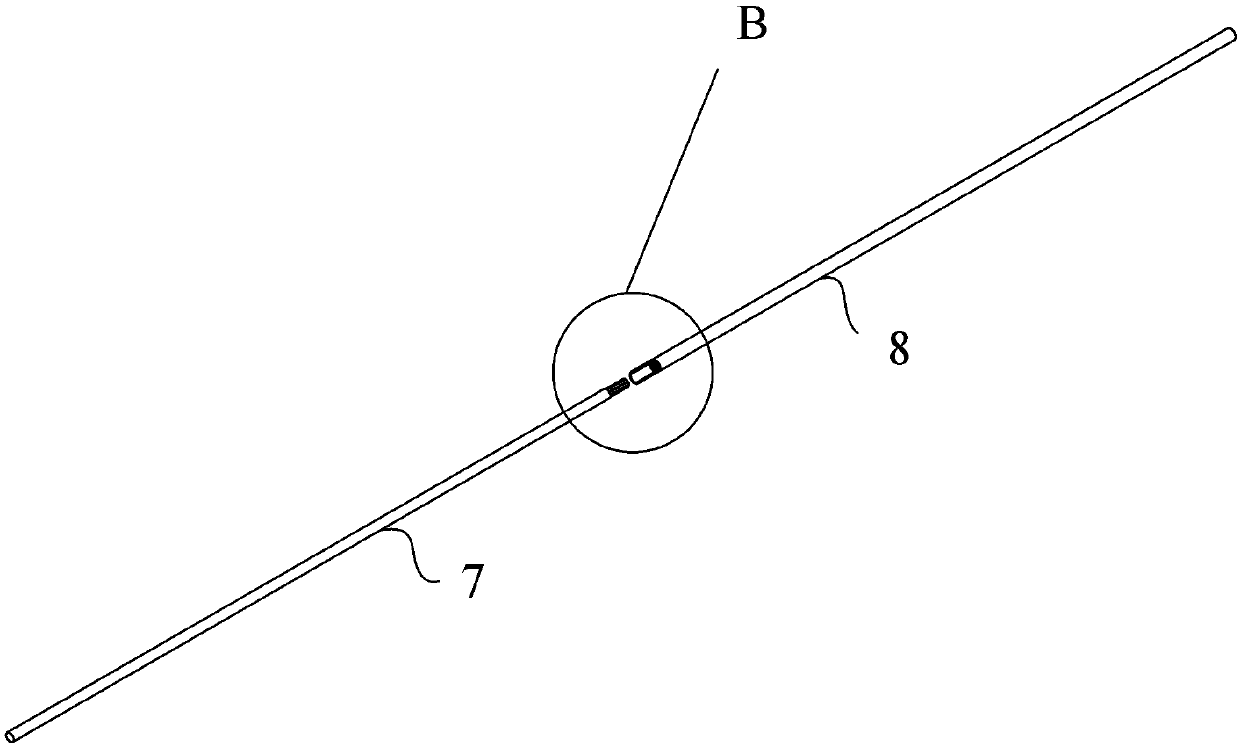

Longitudinal-axial-flow roller

The invention discloses a longitudinal-axial-flow roller, and belongs to the technical field of combine harvester threshing separating devices. The longitudinal-axial-flow roller comprises a roller body, a roller front shaft, a power input shaft, a roller front support and a roller rear support. The roller body comprises a feeding-in part and a roller body part, and an anti-tangling element is arranged between the roller front support and the feeding-in part and comprises a guiding crescent moon, a wedge-shaped roller front cover, a roller front cover seal cover and roller front protrusions wherein the guiding crescent moon and the wedge-shaped roller front cover are fixed to the roller front support, the guiding crescent moon comprises a disc and a guiding plate, one end of the disc is fixedly installed on the roller front support, and an opening is formed in the other end of the disc. The disc penetrates through an installing hole in the roller front cover, the roller front cover seal cover is fixed to the roller front cover, and the roller front protrusions are fixed to the front end face of the feeding-in part and located inside the opening. In harvesting, the roller front shaft is not likely to be tangled with weeds, working efficiency is high, kinds of crops are harvested without replacing the roller, and the requirements for earnings of a user are met.

Owner:LOVOL HEAVY IND CO LTD

Deep rotary tillage soil high-temperature aerial fog disinfection combined machine based on low-frequency ultrasonic resonance and working method

The invention discloses a deep rotary tillage soil high-temperature aerial fog disinfection combined machine based on low-frequency ultrasonic resonance and a working method, and relates to the fieldof agricultural machinery. The machine comprises a rotary tillage knife roll, the rotary tillage knife roll comprises a rotary tillage knife shaft, rotary tillage blades and spiral blades, the plurality of groups of spiral blades are uniformly distributed on the rotary tillage knife shaft in the axial direction, the spiral blades are mounted at the lower end of the rotary tillage knife shaft, therotary tillage knife shaft is of a hollow structure, a low-frequency ultrasonic resonance device is arranged in the hollow structure, the low-frequency ultrasonic resonance device can rotate along with the rotary tillage knife shaft, and the low-frequency ultrasonic resonance device sprays gas with a certain temperature to soil so as to disinfect the soil through aerial fog. According to the method, the high-temperature gas is used for carrying out disinfection and sterilization on the soil, a traditional soil disinfection mode is effectively replaced, the cost is advantageously saved, and pollution to the environment and the soil is reduced.

Owner:武汉投知家信息科技有限公司

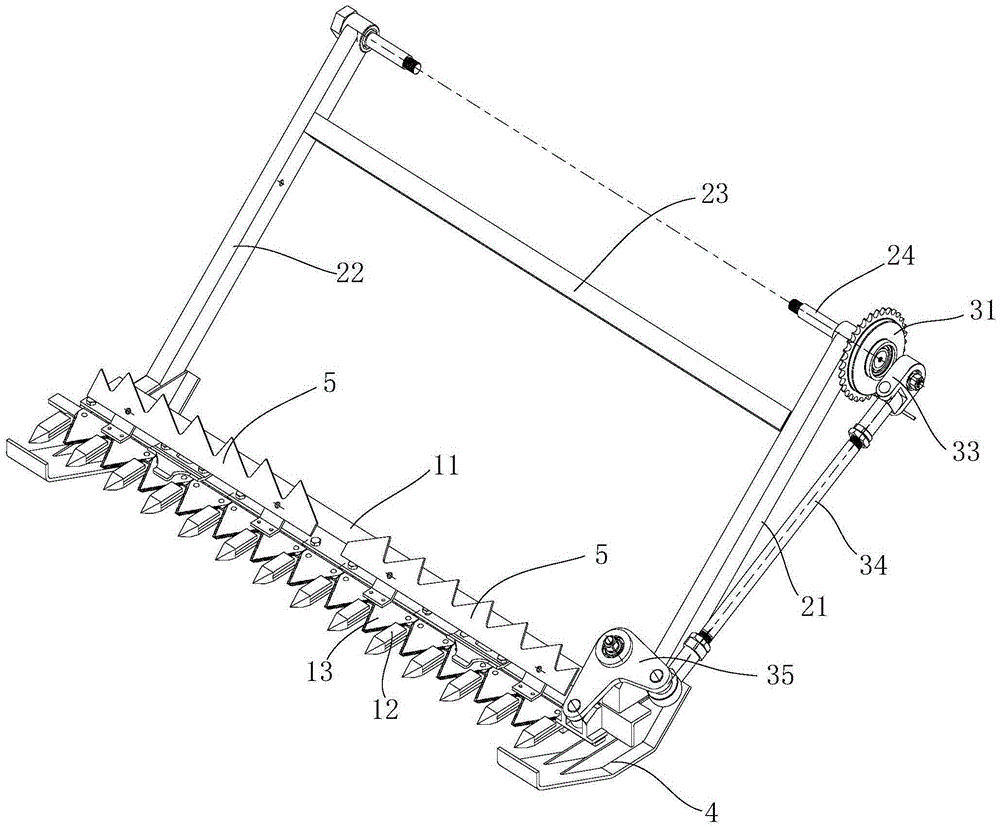

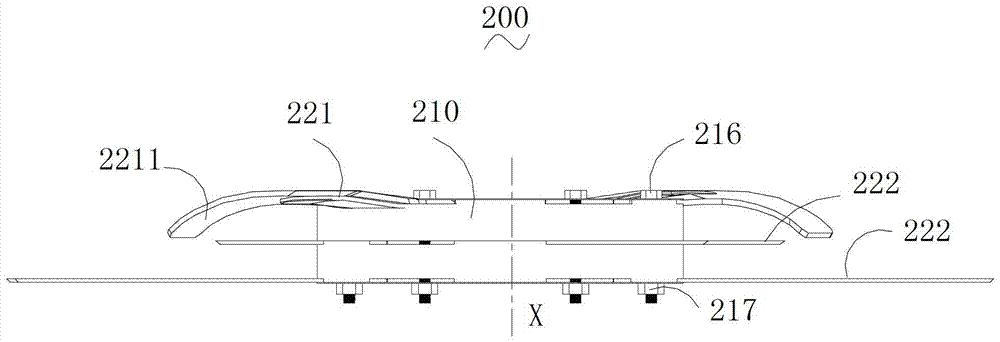

Harvester and cutting knife structure thereof

InactiveCN105340460AAvoid destructionIncrease the length of the exerciseMowersEngineeringPower transmission

The invention provides a harvester. The harvester comprises a harvester body, a power transmission mechanism, a cutting knife and a cutting knife supporting mechanism. The cutting knife supporting mechanism comprises a left supporting arm and a right supporting arm which are arranged on the left side and the right side of the harvester body respectively. The rear ends of the supporting arms are connected with the harvester body. The front ends of the supporting arms are connected with the cutting knife. The power transmission mechanism is connected to the cutting knife from the left side or the right side of the harvester body. A reinforcement arm is connected between the left supporting arm and the right supporting arm. The two supporting arms are adopted for supporting. Supporting stability is improved, and the cutting knife can be stable and will not waggle. An anti-collision device is additionally arranged so that damage to the cutting knife caused by collision which is caused by improper operation can be effectively avoided. A straw walker can effectively remove cut grain stems and prevent grass blocking. The power transmission mechanism is arranged on the side face, the movement length of the cutting length is effectively increased, and grass cutting is thorough.

Owner:CHONGQING HWASDAN MACHINERY MFG

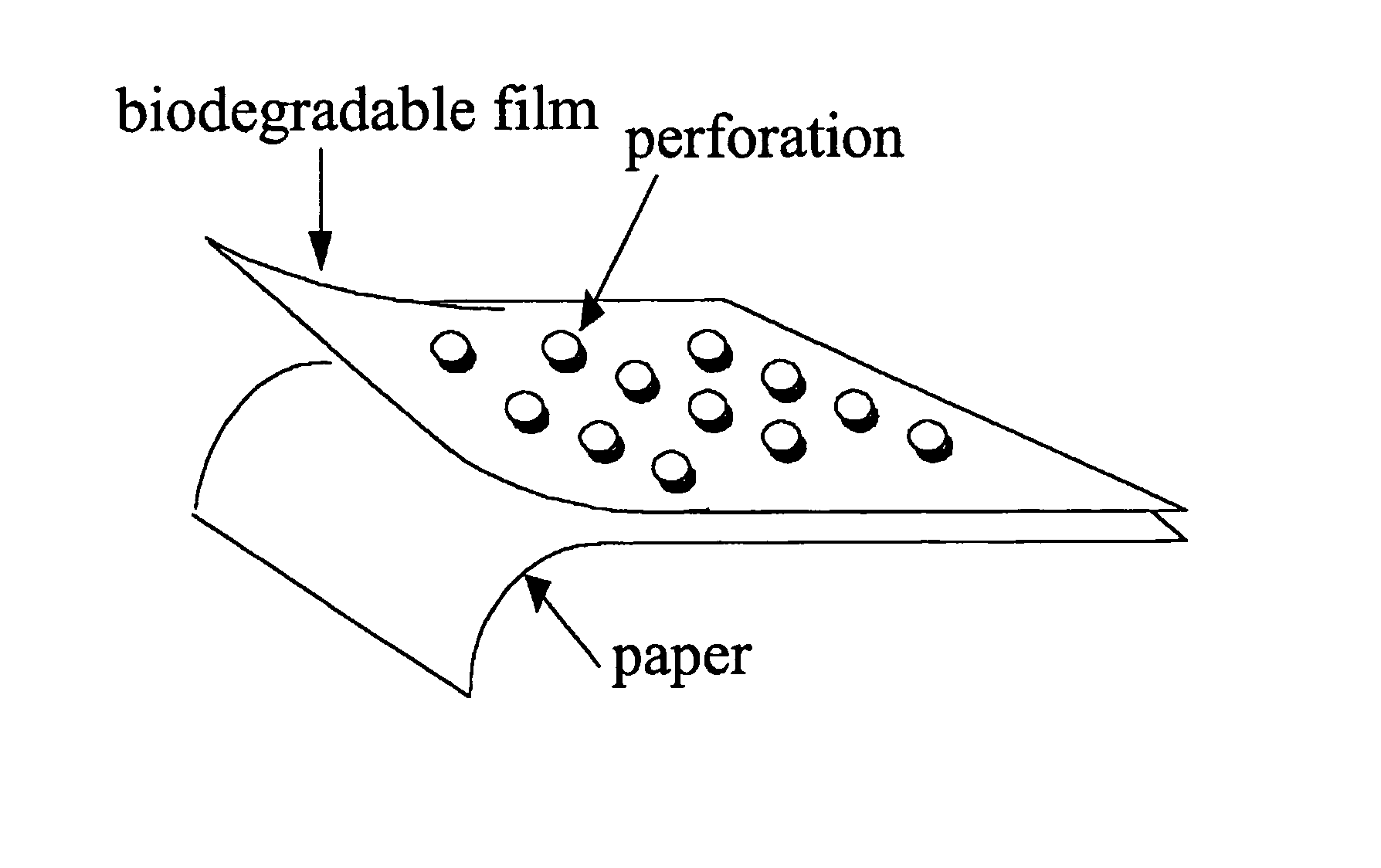

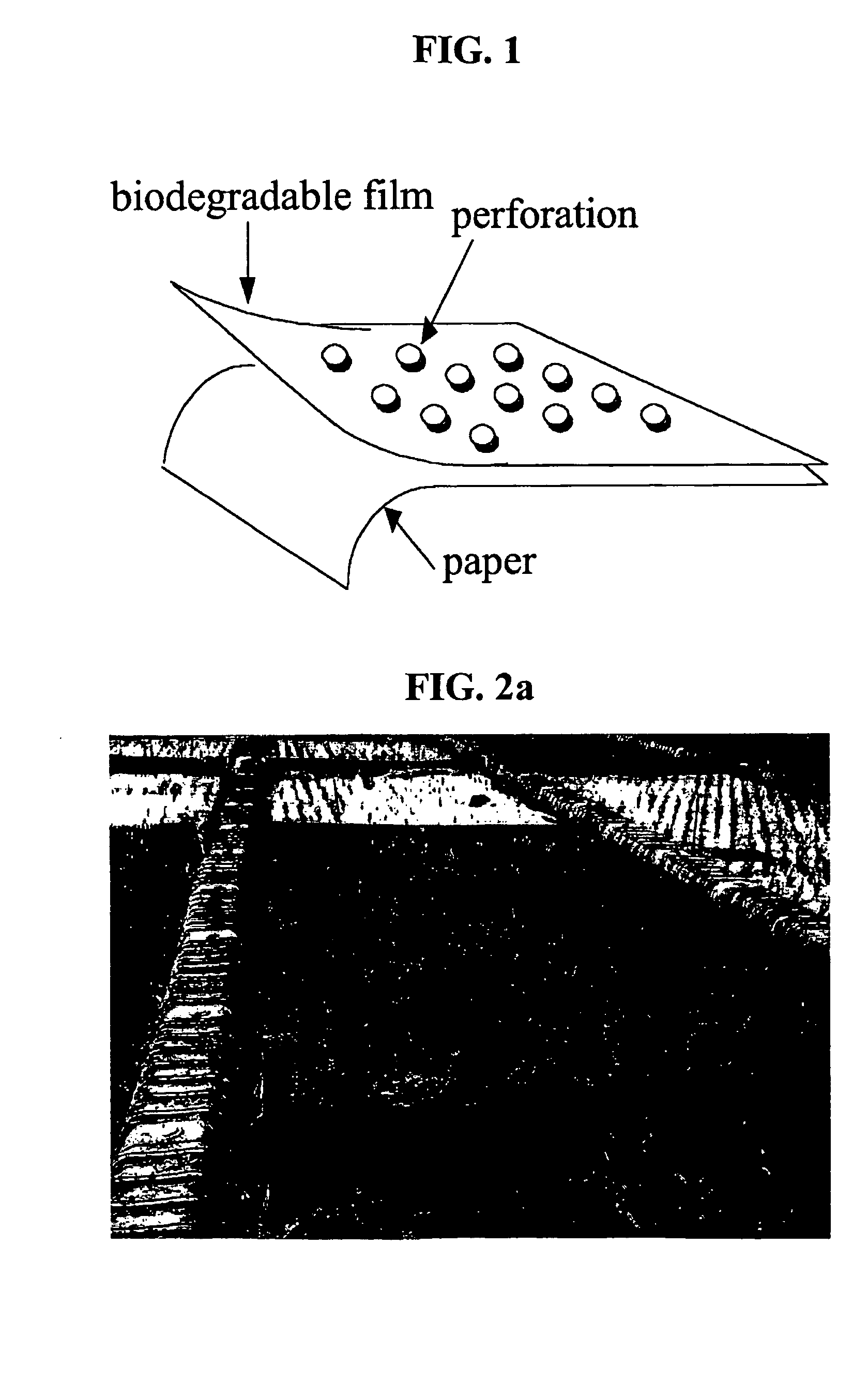

Biodegradable mulching-mat for preventing weeds and method for manufacturing the mat

InactiveUS20050072046A1Promote degradationMaintain good propertiesSpecial paperPaper/cardboardMoisture capacityPlastic mulch

There are provided a biodegradable mulching-mat for preventing weed in rice cultivation having improved biodegradability to be completely degraded in several months, good mulching properties of preventing the growth of weeds, elevating soil temperature and increasing soil moisture capacity, and good strength and durability; and a method for manufacturing said mulching-mat by means of extrusion molding.

Owner:SK CHEM CO LTD

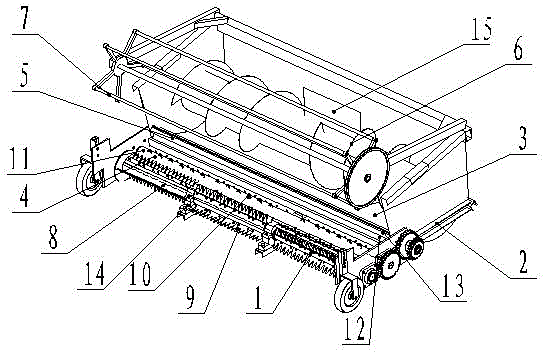

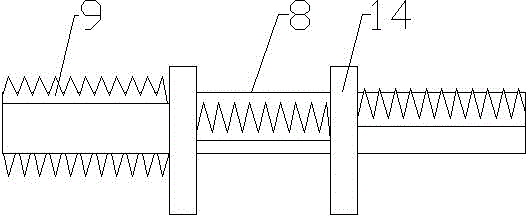

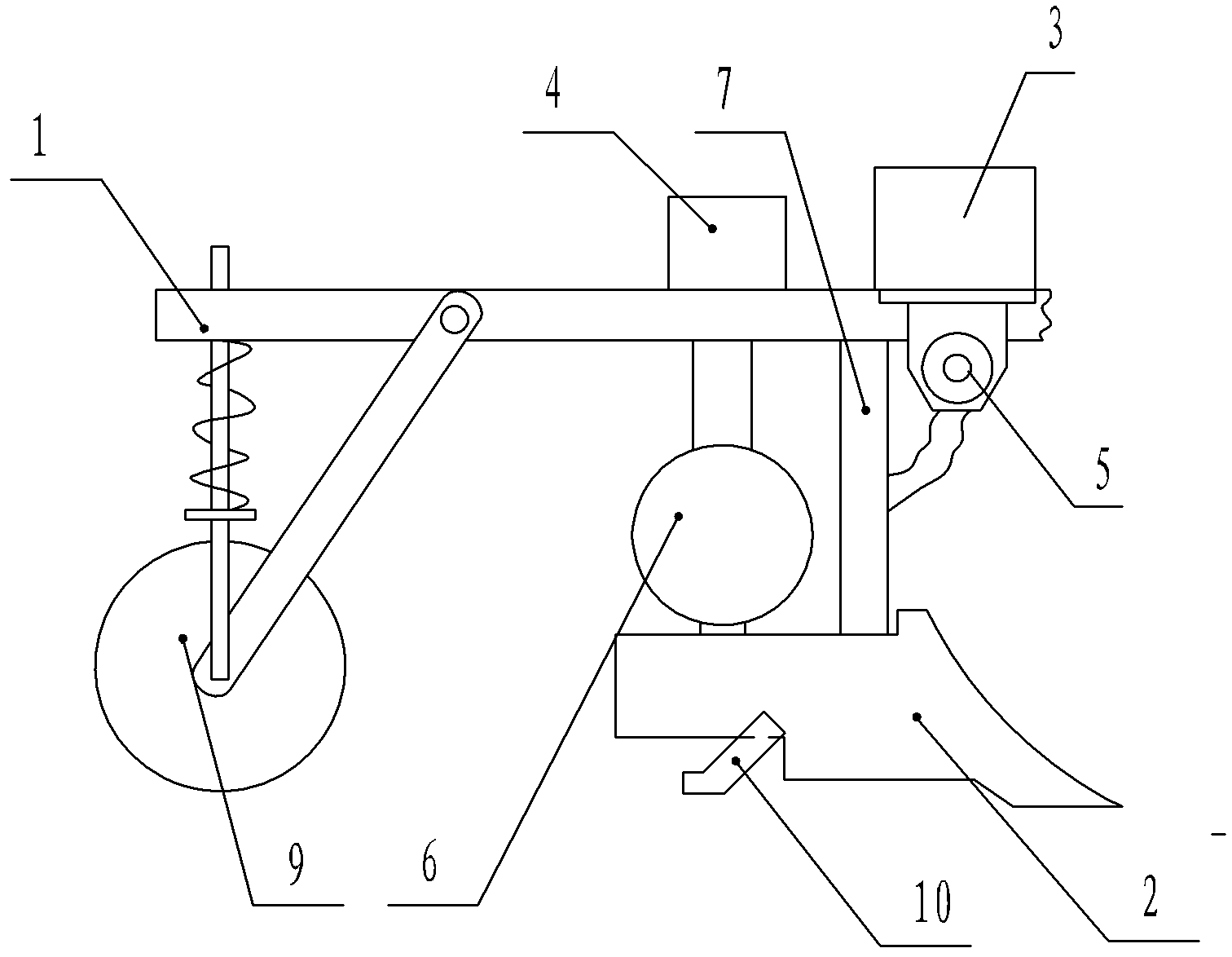

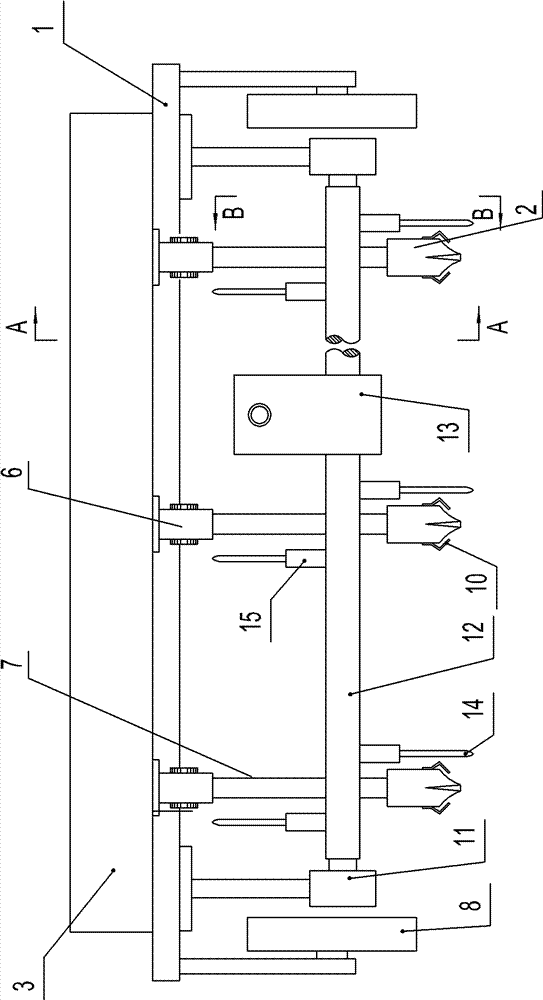

Seeder with seedling strip cleaner

InactiveCN102415234APrevent weedFront and rear dimensions shortenedSpadesPlantingSeederAgricultural engineering

The invention provides a seeder with a seedling strip cleaner. The seeder comprises a frame, furrow openers as well as a seedling box, a fertilizer box, seed-metering devices, fertilizer apparatuses, plow poles, ground wheels and roller sealers which are arranged on the frame, wherein the plow poles are all hollow; each furrow opener is fixed at the bottom of the frame by the plow pole; the plow poles extend into the lower ends in the furrow openers so as to serve as fertilizer discharge outlets; the upper ends of the plow poles are communicated with the fertilizer box by the fertilizer apparatuses; and the seed-metering devices which are communicated with the seed box are positioned above the rear ends of the furrow openers. The seeder is characterized in that: the bottom surfaces of thefurrow openers are raised in a ladder shape from front to back along the travelling direction; both sides, which are positioned between the fertilizer discharge outlets and the seed-metering devices,of the furrow openers are provided with scrapers; the seedling strip cleaner is arranged at the front ends of the furrow openers; the seeder comprises two axle bases which are suspended on the frame,a rotary knife shaft of which a horizontal bearing is arranged between the two axle bases, a power transmission mechanism and pairs of rotary knives which are arranged on the rotary knife shaft; eachpair of rotary knives are symmetrically arranged at an angle of 180 degrees; and one furrow opener is arranged right behind each pair of rotary knives. The seeder has a simple structure and excellentworking performance.

Owner:山东颐和农机制造有限公司

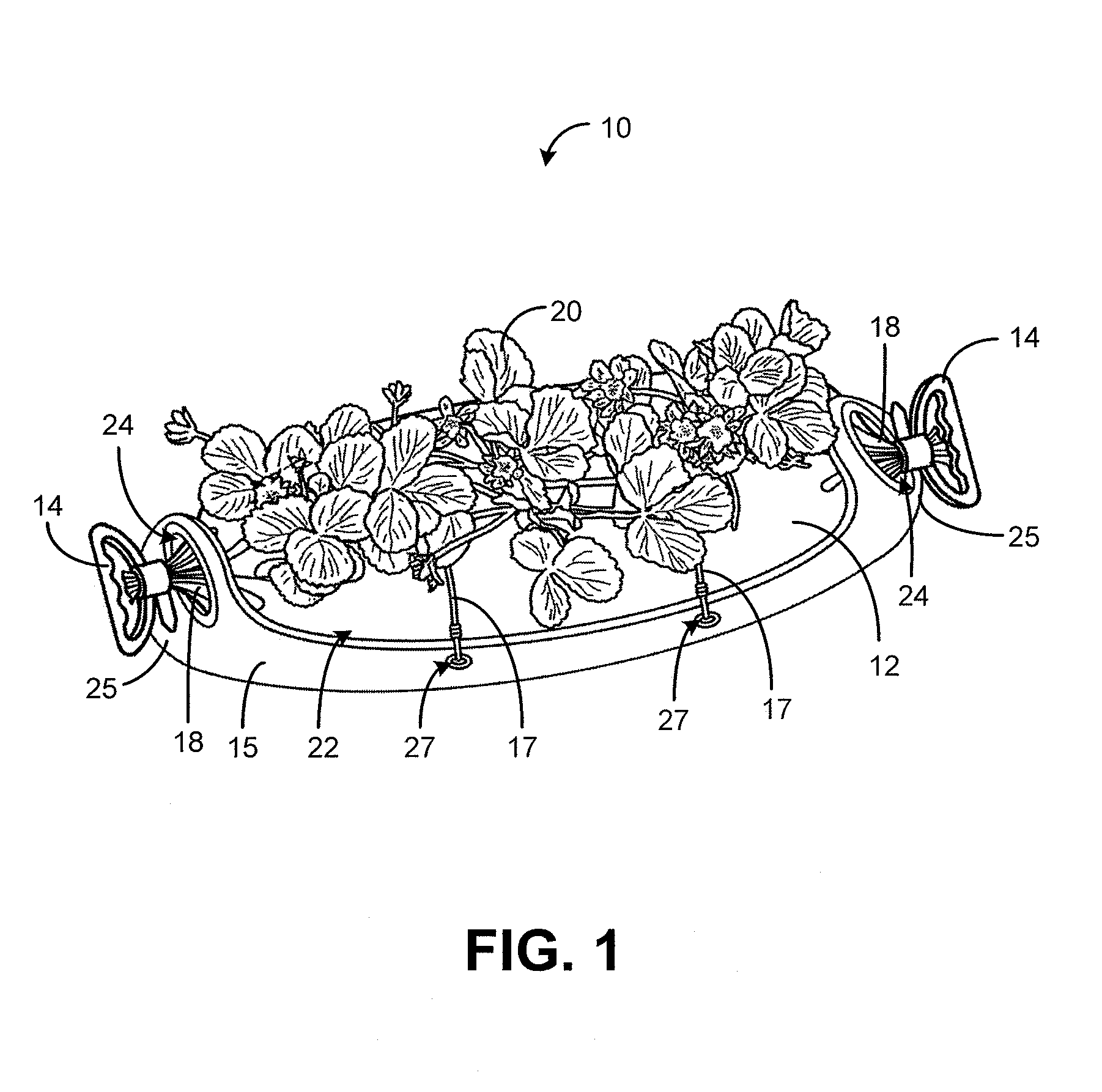

Portable planting system and method

ActiveUS8561347B1Prevent weedProvide stabilityGrowth substratesCulture mediaCropping systemEngineering

A portable planting system according to an exemplary embodiment of the present disclosure comprises a flexible, lightweight sack having an opening located in at least one end for receiving the soil. Opposing ends of the sack are held shut and supported by respective opposing handles which maintain the soil within the sack and allow the sack to be lifted and moved. Furthermore, the portable planting system comprises a liner which receives the sack. The liner has an upper opening for receiving the sack and opposing end openings for receiving the handles. Also, the portable planting system comprises one or more straps for containing the sack within the liner. Small holes can be poked in the exposed upper portion of the sack in order to plant individual plants and the sack prevents weeds from growing around the plants. The liner contains a portion of the water and provides stability to the portable planting system when the system is moved.

Owner:PARK HONG KU

Bounce-proof ditching device for wide and equal-height seeding

InactiveCN104996033AReduce bouncingAdaptablePlantingFurrow making/coveringEngineeringAgricultural machinery

The invention relates to a bounce-proof ditching device for wide and equal-height seeding, and belongs to the technical field of agricultural machinery. The ditching device comprises a tail wing, a bump, a scraper, a seeding box, a seed tube, a front cutting edge, a seed scattering plate, a seedbed, and the like. The ditching device is characterized in that: the device can be used for situations of no-tillage and wide seeding work; the tail wing, the bump, the scraper, the seeding box and the seed tube are welded to form an integral body; a seedbed leveling device composed by the tail wing, the bump and the scraper is arranged below the seeding box; the front part of the device is inlaid with the sliding knife type front cutting edge, so that the forward resistance is reduced, and grass entanglement is prevented; the seed scattering plate is arranged inside, so that seeds are scattered along the wide seedbed; the bump is arranged on the lower side, and scratches flanges are formed on the seedbed, so that seed bounce is reduced, and fixed-point and uniform seeding of seeds is facilitated. According to the device, equal-height and accurate seeding is achieved, the seeding quality is guaranteed, and the foundation for improving crop yield is laid.

Owner:SHANDONG UNIV OF TECH

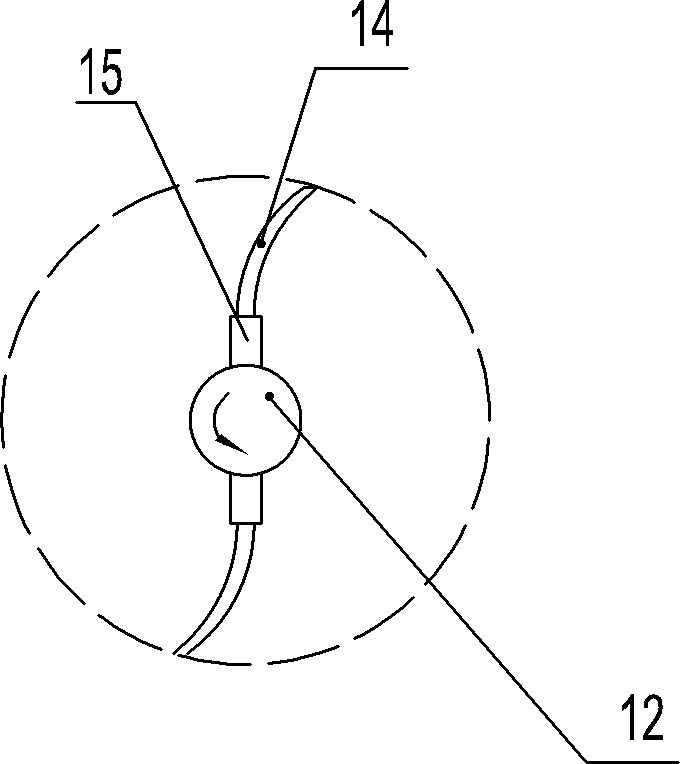

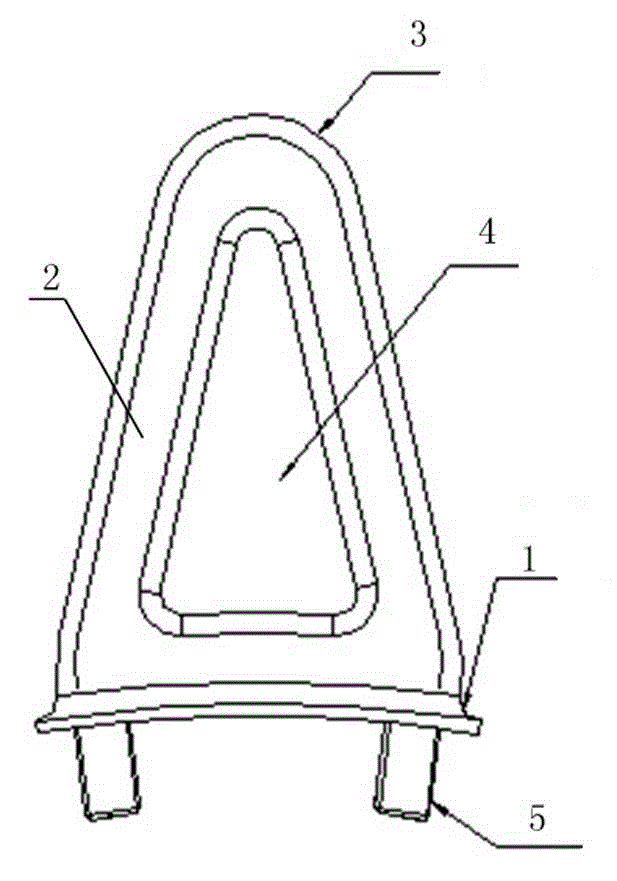

Cotton stalk pulling mechanism

The invention relates to a cotton stalk pulling mechanism and belongs to the technical field of agricultural machinery.The cotton stalk pulling mechanism comprises a pulling tooth roller shaft and a retreating tooth holder arranged on a frame, the retreating tooth holder is arranged above the rear of the pulling tooth roller shaft, pulling teeth are fixed on the pulling tooth roller shaft, a plurality of retreating teeth are fixed on the retreating tooth holder, a V-shaped gap forms between every adjacent two of the retreating teeth, each retreating tooth is an arc tooth extending forward down, and an outer arc surface of each arc tooth protrudes forward up; when the pulling tooth roller shaft rotates, a segment of each pulling tooth is rotated into the corresponding V-shaped gap, two sides of this segment are kept 2-5 mm away from two sides of the V-shaped gap constantly, and when the pulling tooth roller shaft drives the pulling teeth to rotate and pull out cotton stalks, the pulling teeth push the cotton stalks backwardly along the outer arc surfaces of the retreating teeth.The cotton stalk pulling mechanism has the advantage that the mechanism can automatically prevent entwining of weeds and cotton stalk peel and operate normally without additional cleaning devices.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

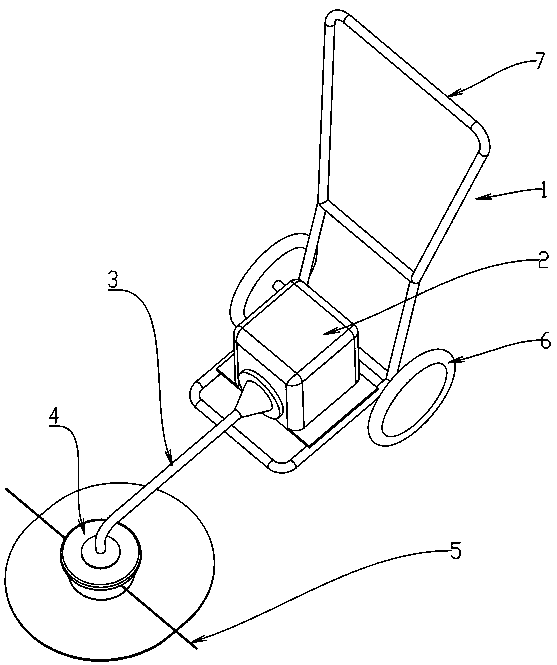

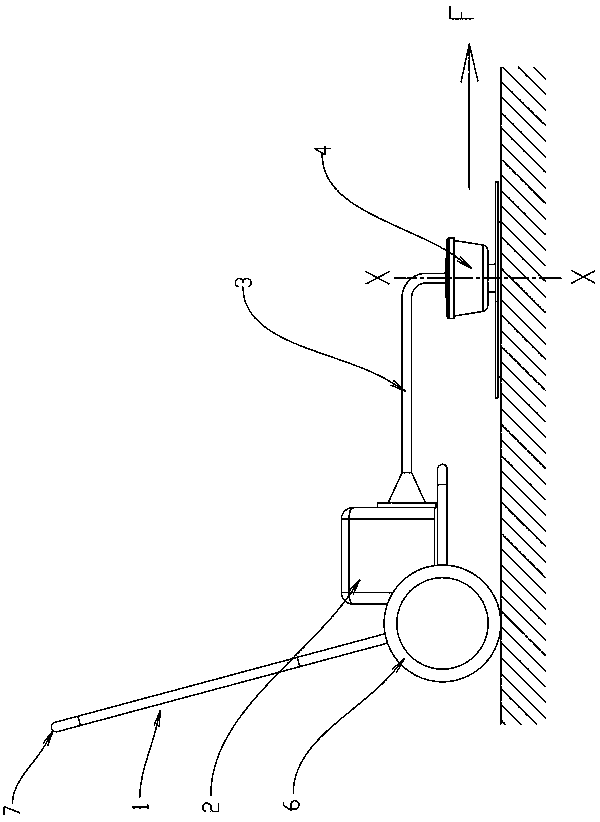

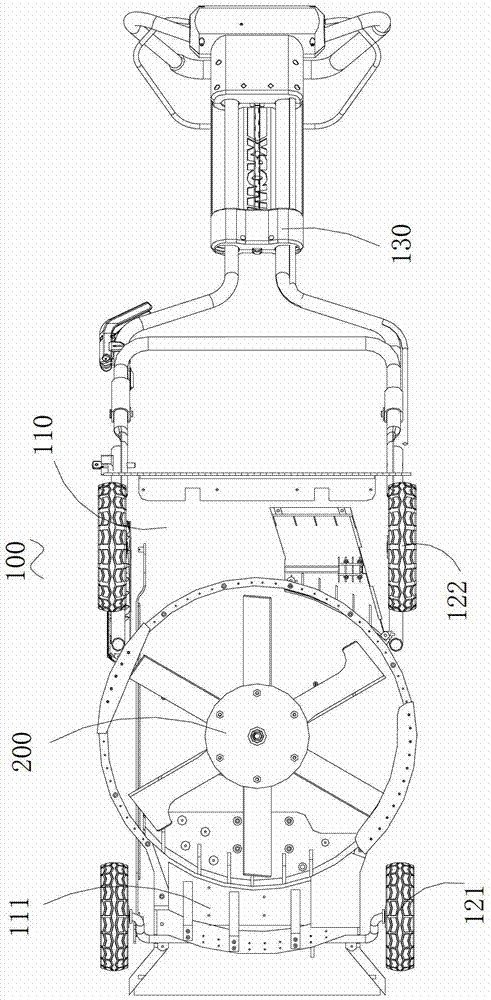

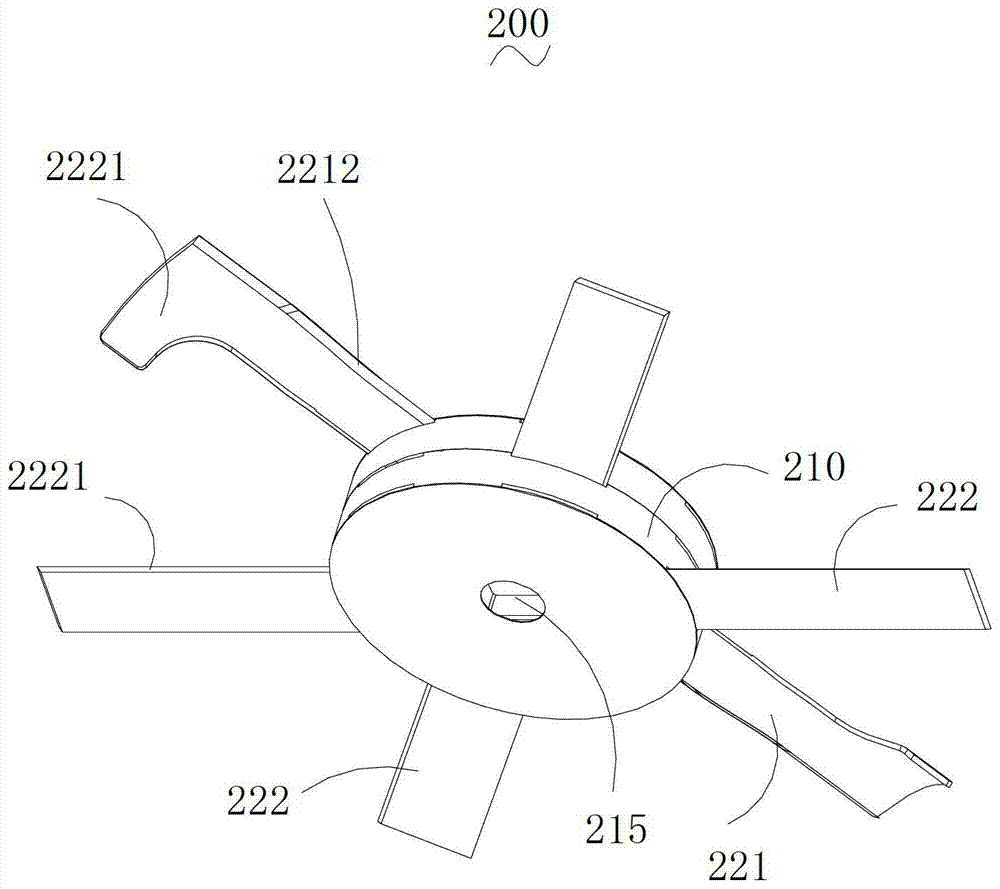

Walking type mower

The invention relates to a mowing device and provides a walking type mower. The walking type mower includes a rack for supporting, and a cutting tool is arranged on the rack; the cutting tool includesa holding member which rotates with a cutting tool mounting shaft as a center, a rope shaped cutting tool body held by the holding member, and a grounding member which rotates with a rotating shaft as a center relative to the holding member; the grounding member which rotates with the mounting shaft as a center relative to the holding member is arranged below the holding member, and a guide partwhich coincides with the traveling direction is arranged on the ground side of the grounding member. The walking type mower is provided with the grounding member capable of maintaining a stationary state when the walking type mower is in contact with the ground. Frictional resistance between the nylon rope holding member and the ground is reduced by means of a pinch bar on the grounding member when walking type mower moves forward to cut grass, and the walking type mower is easier to operate and moves in the desired direction.

Owner:YITIANJI POWER MACHINERY RES DEV LINYI

Driving type corrugated disc ditching device

PendingCN105594346AEasy to disassembleReduce radial forcePlantingServomotorsEngineeringEnergy consumption

The invention discloses a driving type corrugated disc ditching device which comprises a transplanter box shifting main beam and a machine frame. The device further comprises a power input part, a hydraulic drive part, a ditching assembly and a pressing and depth limiting part. The pressing and depth limiting part is arranged below the transplanter box shifting main beam, the power input part arranged on the machine frame drives the ditching assembly to work through the hydraulic drive part, and the ditching assembly comprises a plurality of ditching units. A hydraulic-drive corrugated disc is adopted for automatic ditching, the problem that ditching and soil piercing of untilled rice stubbly field are difficult can be solved, the rotation direction of the corrugated disc can be conveniently changed, the rotation direction of the corrugated disc is opposite to the machine forwarding direction in parcel of rice field with many stubbles and straw, the situations that weed is wound on a cutter head and soil is attached to the cutter head are avoided, the rotation direction of the corrugated disc should be consistent to the machine forwarding direction during work of normal parcel of rice field, and energy consumption is reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Combined harvester bridge driving axle structure and bridge device

The invention discloses a combined harvester bridge driving axle structure, and belongs to the technical field of combined harvesters. The structure comprises a bridge driving axle rotationally installed on an axle shell of a combined harvester. The bridge driving axle is located in the axle shell and is provided with a plurality of bridge driving axle chain wheels. A bridge inner support is fixed to the position, close to the bridge driving shaft, in the bridge shell. The bridge inner support is fixedly provided with a plurality of grass cutters used for preventing grass from being wound on the bridge driving shaft. An opening is formed in the middle of each grass cutter. The openings correspond to the bridge driving axle chain wheels one to one. The invention further provides a bridge device of the combined harvester. The structure and the device prevent the grass from being wound on the bridge driving shaft, a user does not need to stop the harvester and clean the harvester frequently, work efficiency is improved, and the situation that the harvester is not cleaned in time and accordingly machine parts are abraded or damaged in the early stage is avoided.

Owner:LOVOL HEAVY IND CO LTD

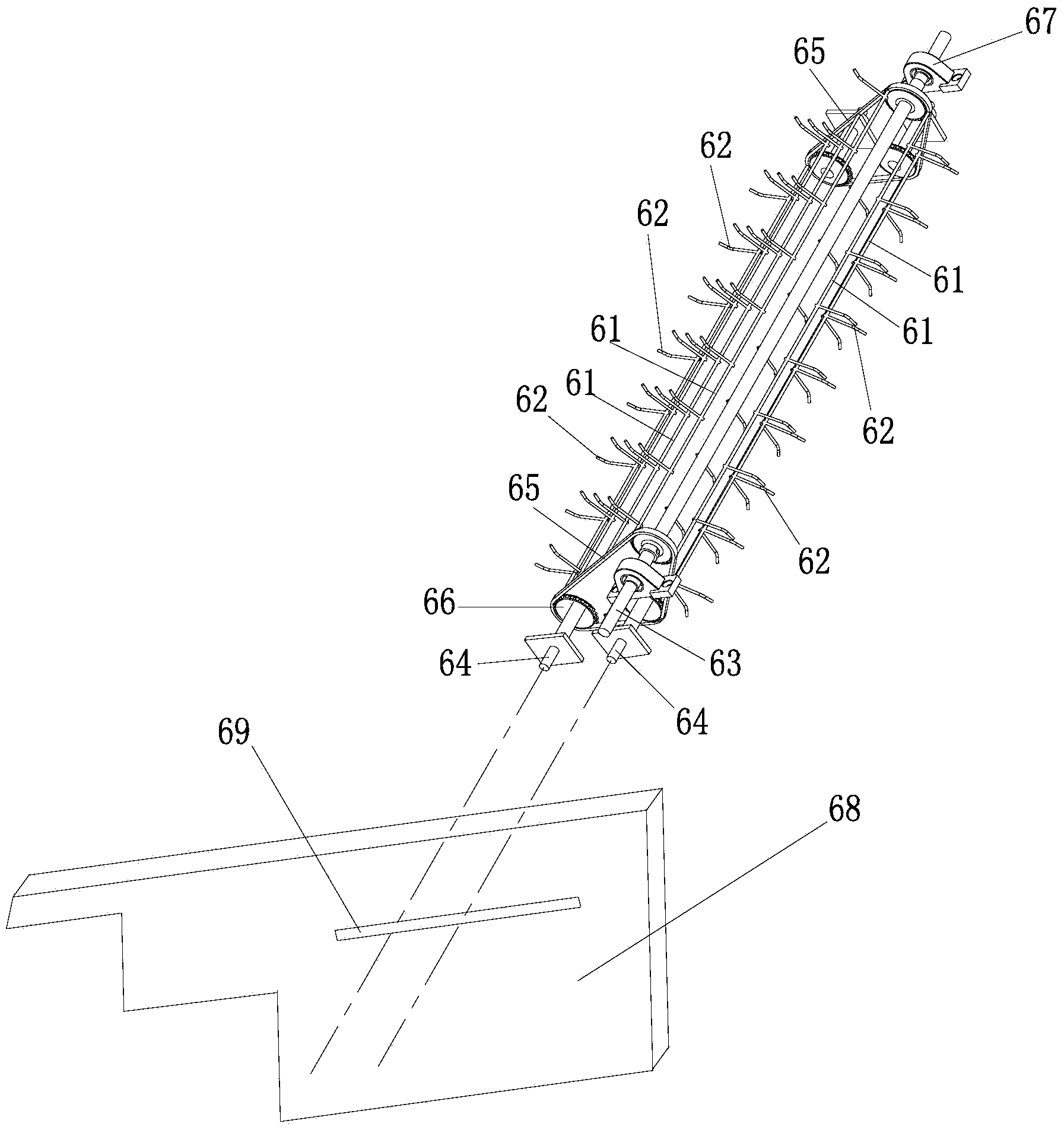

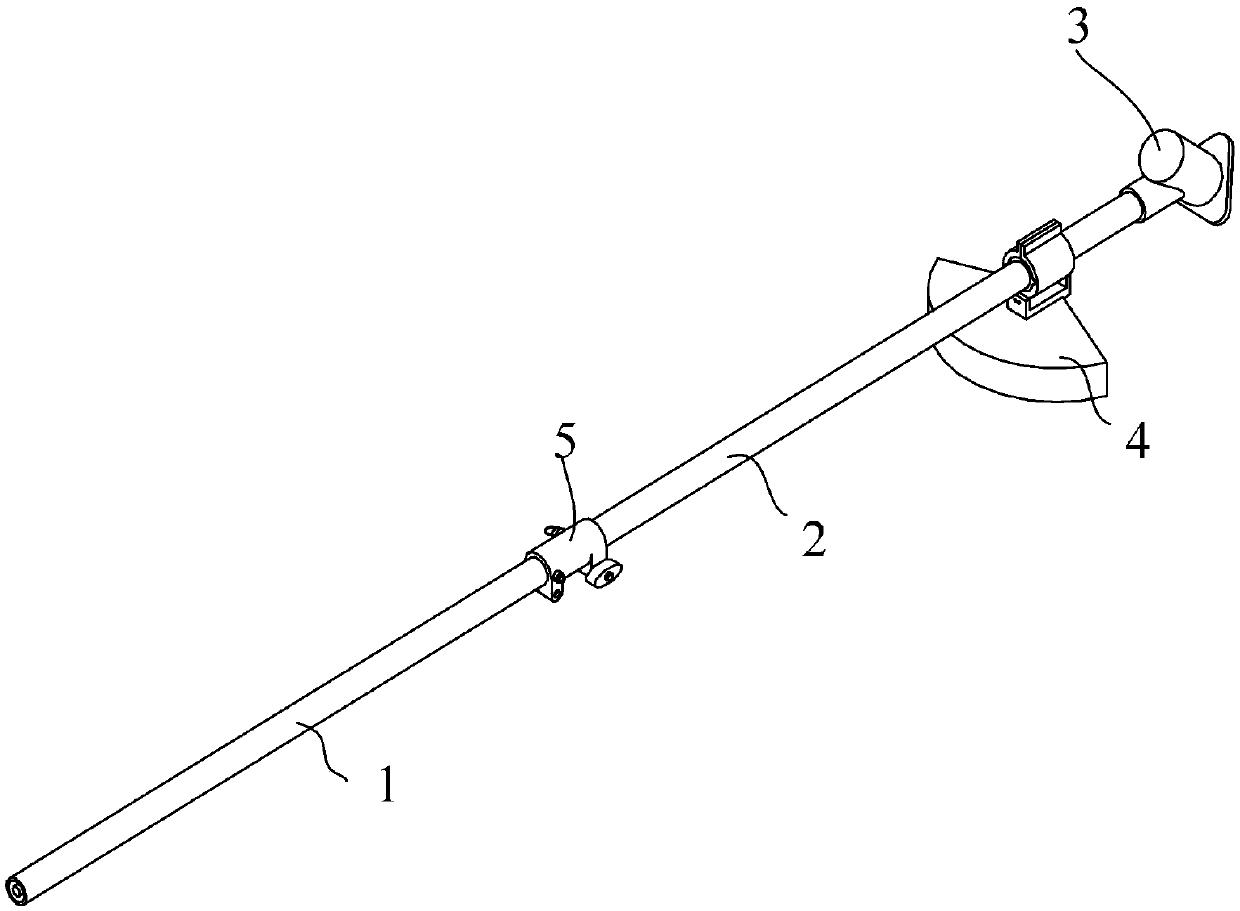

Stalk pulling roller capable of preventing grass intertwining

PendingCN108040594APrevent weedGuaranteed automatic tooth cleaningHarvestersEngineeringMechanical engineering

The invention relates to a stalk pulling roller capable of preventing grass intertwining and belongs to the technical field of agricultural machinery. The stalk pulling roller comprises a stalk pulling shaft and a plurality rows of V-shaped toothed plates and is characterized in that the stalk pulling shaft is rotatably arranged on a rack, the V-shaped toothed plates are circumferentially arrangedon the stalk pulling shaft at intervals, a rotary disk is fixed at each of the two ends of the stalk pulling shaft, a shell fixed on the rack covers the outer side of each rotary disk, and a triggering rack group located between each shell and the corresponding rotary disk is fixed on the inner side of the shell; U-shaped clamp seats are arranged at two ends of each row of V-shaped toothed platesin a clamped manner, push plates fixed on the corresponding U-shaped clamp seats are arranged on two sides of each row of V-shaped toothed plates, drive racks are fixed on the U-shaped clamp seats, rotary shafts penetrates the rotary disks, one ends of the rotary shafts are provided with drive gears constantly meshing with the drive racks, the other ends of the rotary shafts are provided with triggering gears, and the triggering gears mesh with the racks in the triggering rack groups when the rotary shaft rotates to a set position. The stalk pulling roller has the advantages that intertwininggrass can be cleaned from inside to outside, tooth cleaning can be achieved, and grass intertwining of the toothed plates can be prevented.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

Potato pick-up machine

ActiveCN104303712AAvoid broken skinSmall running resistanceHarvestersAgricultural engineeringExcavator

The invention relates to technical field of the agricultural machinery and specifically relates to a potato pick-up machine for use with a traction machine. According to the potato pick-up machine, due to the design of a pin shaft of a potato soil excavator and a pin moving device, a shovel head is enabled to have an excellent copying effect, and the resistance to the whole machine is lower so that the potato pick-up machine is capable of picking up potatoes conveniently; a rubber sleeve is put on each rake tooth to effectively prevent the potatoes from peel breakage; a cutter is designed to automatically cut off impurities on a hoisting chain plate and effectively prevent the hoisting chain plate from being twined with grass; due to the design of a guide plate support and a guide plate, the potatoes are prevented from being thrown out when falling into a collecting box and can be protected against peel breakage and damage; due to the design of a movable base plate, the base of the collecting box is capable of going down one section by one section, and therefore, the height of the potatoes falling into the collecting tank is reduced and the peel breakage and the damage of the potatoes are effectively reduced.

Owner:青海林丰农牧机械制造有限公司

Sine peak valley type seedling strip soybean precision no-tillage planter

PendingCN113207365AIncrease profitIncrease productionPlantingAgriculture gas emission reductionFertilizerAgricultural engineering

The invention provides a sine peak valley type seedling strip soybean precision no-tillage planter. The planter comprises a rack, a land wheel, a seedling strip cleaning and preparation device, a fertilization mechanism and a seeding unit; the land wheel is arranged at the forefront of the rack; the fertilization mechanism comprises a fertilizer box, a fertilizer apparatus and a fertilizer placer; the fertilizer box is arranged above the rack; the fertilizer apparatus is installed on the fertilizer box and located under the fertilizer box; the fertilizer placer is arranged below an outlet of the fertilizer apparatus; the fertilizer placer is installed on the rack and located behind the land wheel; the seedling strip cleaning and preparation device comprises a gearbox, a cutter shaft and a stubble cleaning cutter; the seeding unit comprises a seed box, a rear supporting beam, a seed-metering furrow opener, a seed-metering device, a seed distributor and a press wheel assembly; the seed box is installed on the rear supporting beam; the seed-metering device is arranged below the seed box; the seed-metering furrow opener is arranged in front of the seed-metering device; a press wheel is connected with the fertilizer apparatus and the seed-metering device through transmission mechanisms to provide power for the fertilizer apparatus and the seed-metering device; and the seeding unit is installed on the rack through a parallel four-bar mechanism.

Owner:SHANDONG UNIV OF TECH +1

Planting technology of pinellia ternata

InactiveCN112450015AIncrease productionImprove qualityRoot crop cultivationRoot growthPinellia tuberifera

The invention relates to a planting technology of pinellia ternata and belongs to the field of medicinal plant planting. Pinellia ternate plants are short and small, soil needs to be loosened and weeds need to be removed frequently in the growth period, the farmland running to weeds is avoided, the roots of pinellia ternate grow around tubers, and the root systems of pinellia ternate are intensively distributed on a surface soil layer with the depth of about 10-15 cm, so that early removal and removal of tender weeds need to be achieved. In the harvesting process, a traditional harvesting method is adopted, the harvesting efficiency is low, and besides pinellia ternate has the characteristics that subterraneous stems are extremely short, 1-2 root tubers and a large number of fibrous rootscan be generated on the stems, root tips of large root tubers are often rotten off, and the root tubers can also be propagated, by means of the traditional harvesting method, tuber harvesting is insufficient, and a large number of root tubers and fibrous roots are difficult to sort, thereby greatly influencing the yield. The planting technology of pinellia ternata overcomes the defects, the yieldand quality of pinellia ternate are effectively improved by adopting the methods of seed selection, soil preparation, planting, management, harvesting and storage, and the economic efficiency of farmer households is improved.

Owner:袁学亮

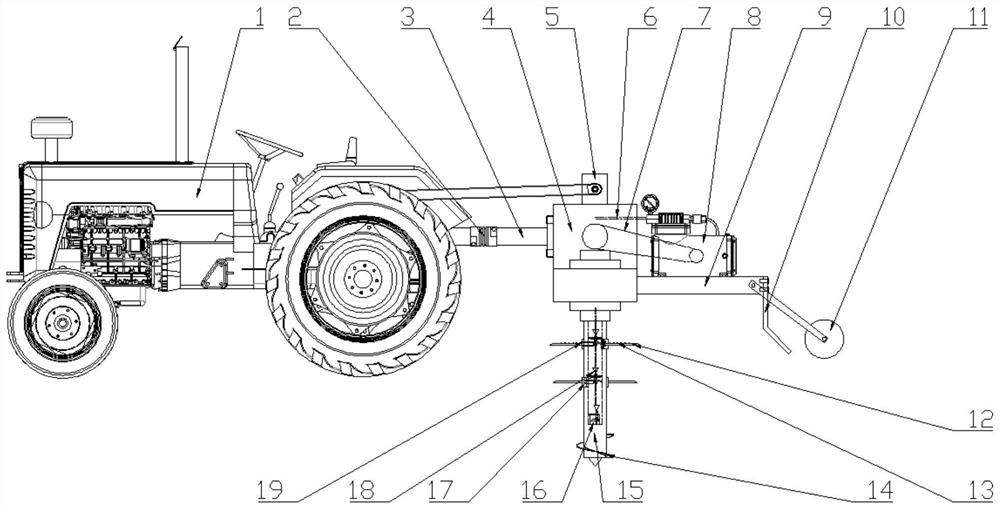

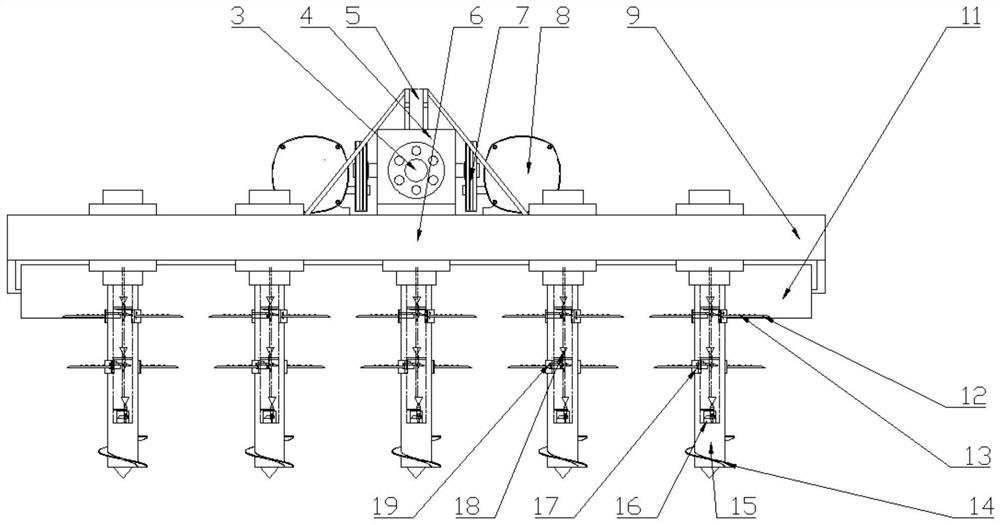

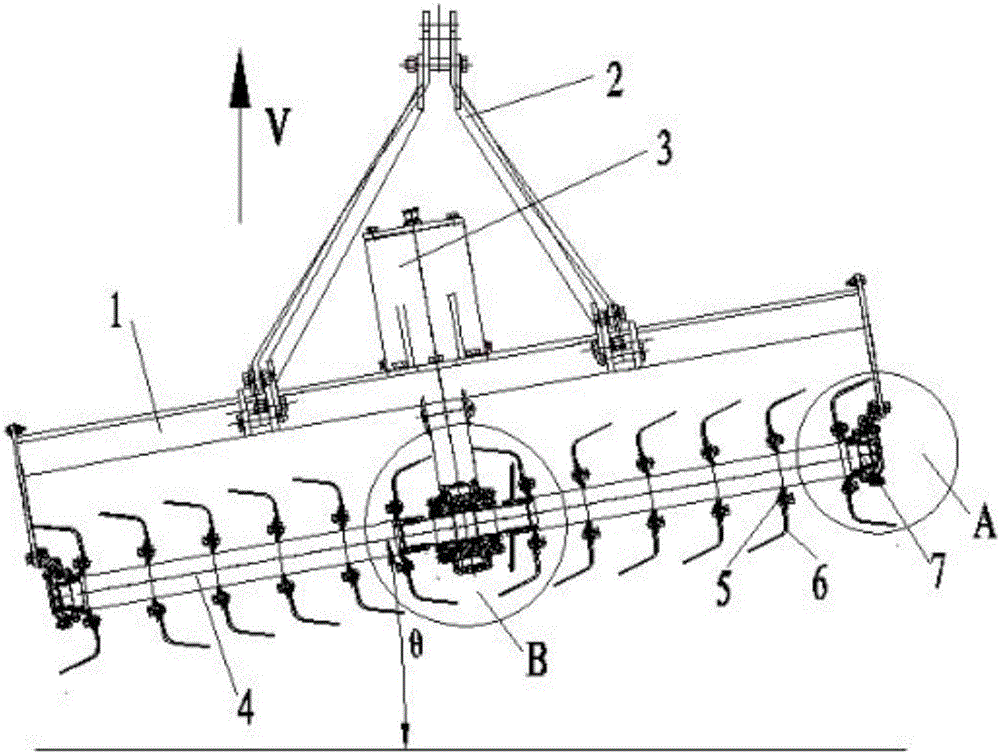

Intermediate driven small-angle oblique deep rotary tilling device

InactiveCN106489317AGuaranteed no omissionAvoid interferenceTilling equipmentsDrive shaftAgricultural engineering

The invention discloses an intermediate driven small-angle oblique deep rotary tilling device. The device comprises a rack, a suspension part, a gearbox and knife rolls, wherein the gearbox is positioned at the center of the rack; the output shaft of the gearbox is a spline shaft, and two sides of the output shaft are respectively connected with on end of the knife rolls on two sides of the output shaft; the other end of each knife roll is arranged in the bearing of a bearing block, and the bearing block is fixed inside the rack through screws; each knife roll comprises a rotary tilling blade, a blade disk and a blade shaft; the knife rolls are obliquely arranged in a plane, and form a theta-degree angle with a driving shaft of a truck tractor. According to the intermediate driven small-angle oblique deep rotary tilling device, soil under the gearbox can be removed, the gearbox is prevented from interfering with untilled land during working, lateral force is greatly reduced, high-reliability deep tillage and excellent grass-burying and stubble-cleaning capability can be achieved. The intermediate driven small-angle oblique deep rotary tilling device is applied to the technical field agricultural machinery.

Owner:JIANGSU UNIV

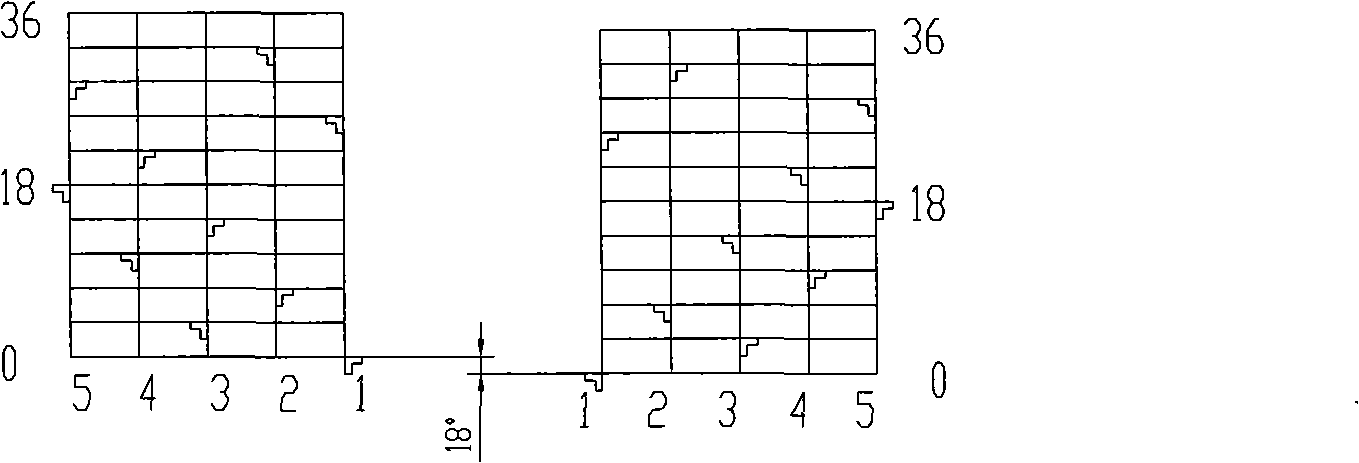

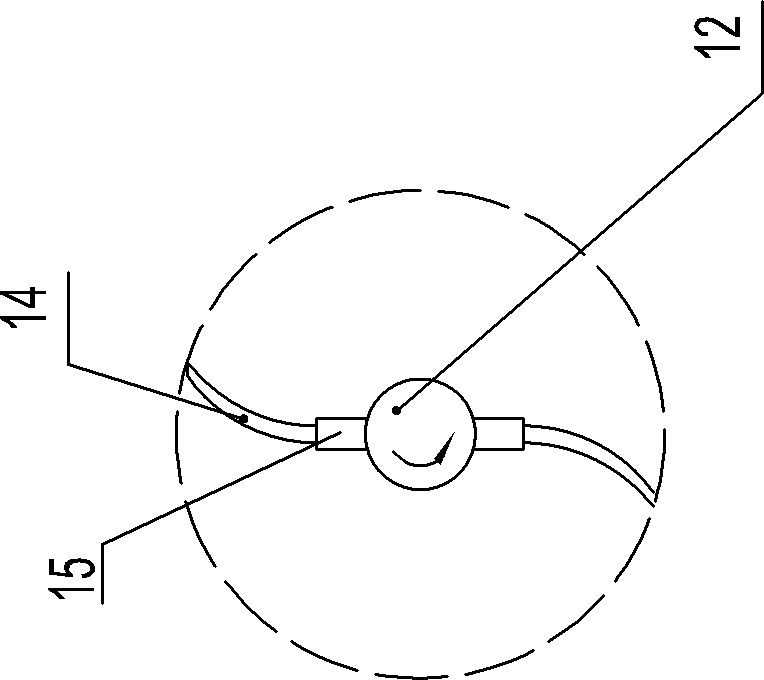

Arrangement method of rotary tillage stubble smashing blade on knife roller

InactiveCN101313643AEven by forceSmall shock and vibrationCrop conditionersMowersHelical lineLeft half

The invention provides a method for the arrangement of rotary tillage stubble-breaking blades in a knife roller, belonging to the agricultural machinery field. The method comprises the following steps that: the knife roller is evenly divided into a left half knife roller and a right half knife roller, and the blades of the left half knife roller and the right half knife roller are arranged along a spiral line respectively; for the spiral lines of the two half knife rollers, the rotary directions are opposite and the rising angels(theta) are the same; starting positions of the spiral lines of the left half knife roller and the right half knife roller are different with theta / 2=180 degree / N, and the blades in the same spiral line are the same in direction, and the blades in two adjacent spiral lines of the same half knife roller are opposite in direction, and the number of blades arranged on each spiral line are equal to that of cutter heads of each half knife roller, and N is the total number of blades of the left half knife roller or the right half knife roller. The knife rollers arranged according to the method of the invention can ensure that better working quality and little power consumption are achieved when the machine utilizes the same blade of the same knife roller in the rotary tilling operation as well as the stubble-breaking operation, and the operations are smooth.

Owner:JILIN UNIV

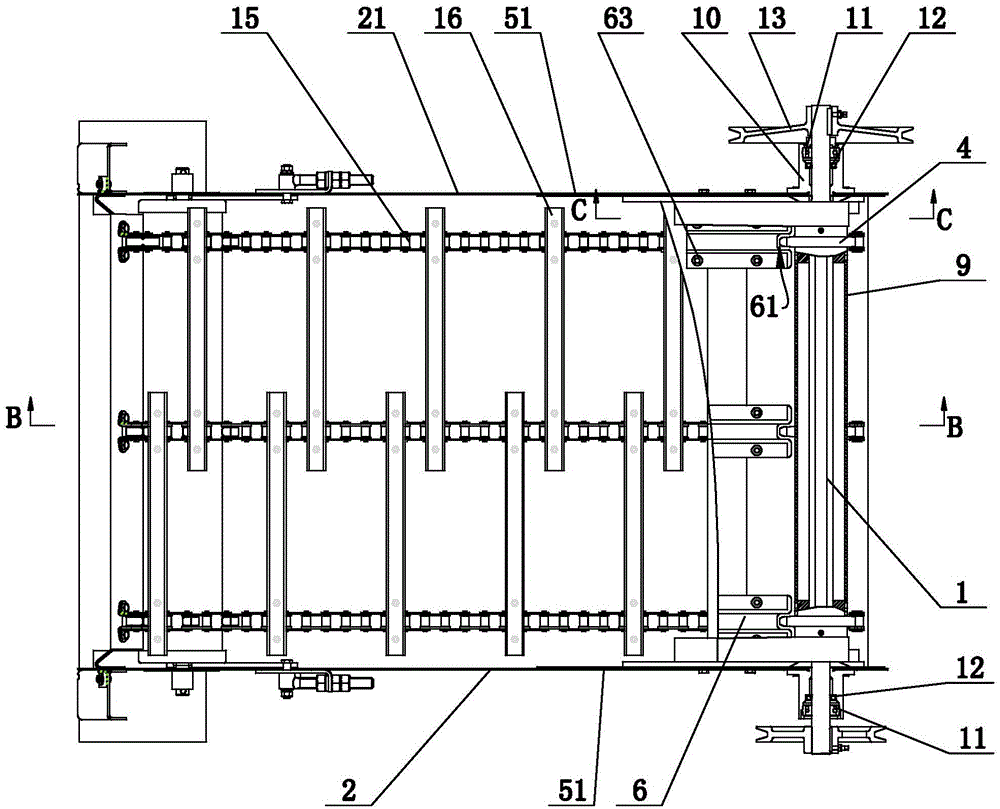

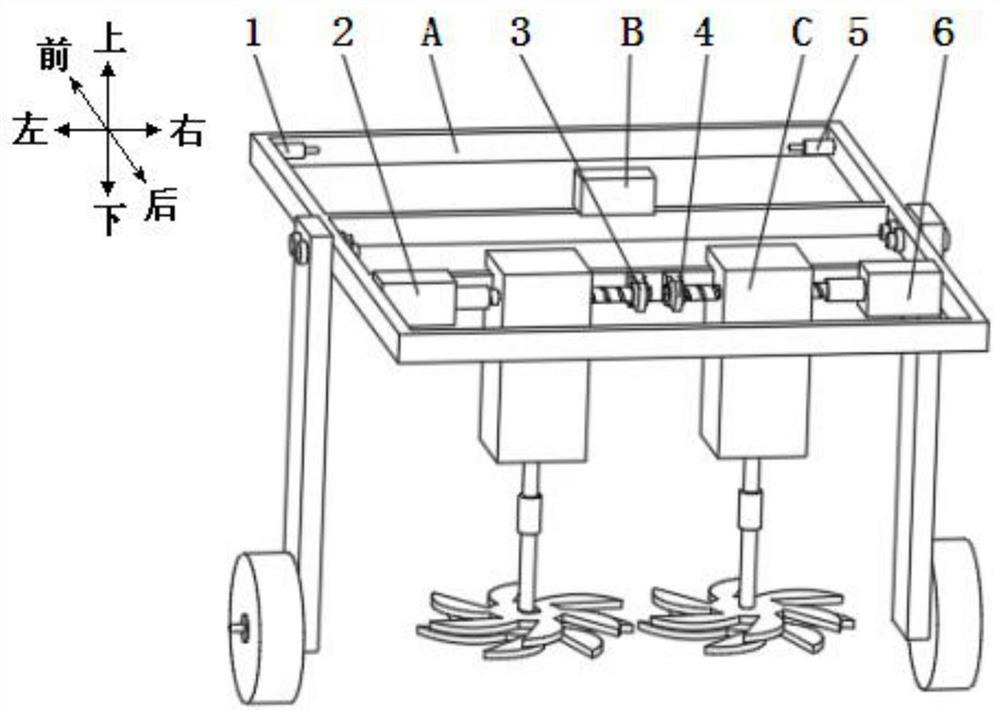

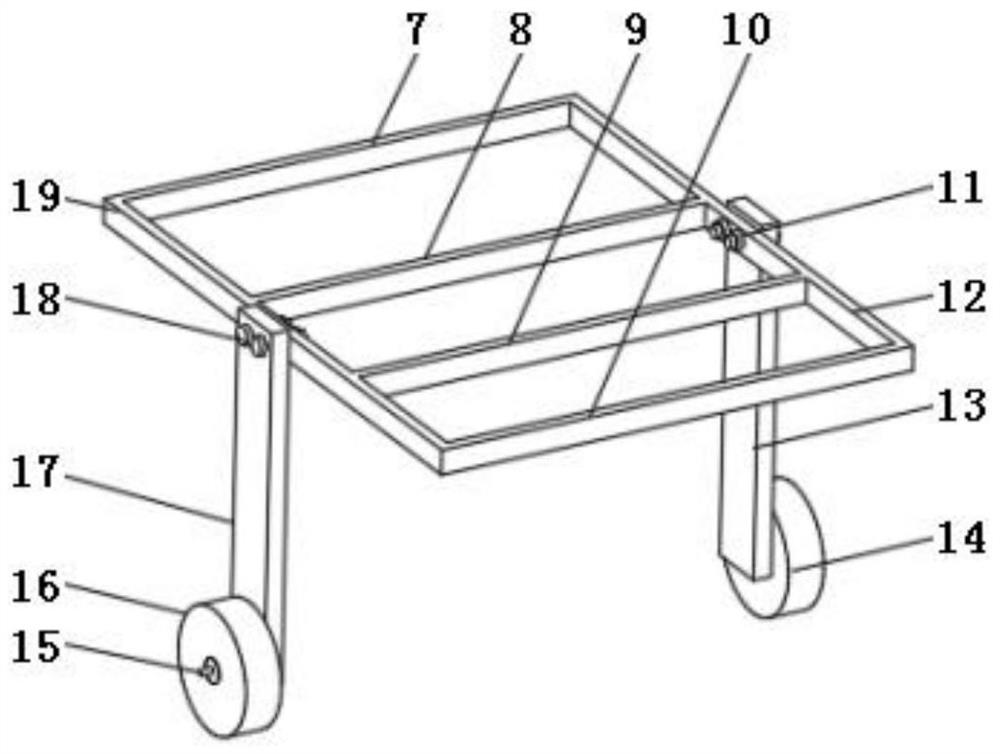

A kind of weeding device between corn plants

ActiveCN109906686BPrecise positioningImprove accuracySoil-working equipmentsData processing systemAgricultural engineering

A corn inter-row weeding device belongs to the technical field of agricultural machinery. The invention consists of a main frame, an information data processing system, an inter-row weeding mechanism, two laser displacement sensors I, two servo motors, and two bearing seats I, wherein the laser displacement sensor I and the laser displacement sensor II are respectively fixed on the inside of the left longitudinal beam and the right longitudinal beam in the main frame, the information data processing system is fixed on the middle of the upper plane of the first beam in the main frame, and the weeding device between plants is fixed on the first horizontal beam in the main frame. On the second crossbeam; the laser displacement sensor is mainly responsible for providing the position and width information of the corn plant, the weeding device between the plants is mainly used to remove the weeds between the plants, and the information data processing system is responsible for receiving the position and width of the corn plant and the speed information of the device, Furthermore, the inter-row weeding device is controlled to remove weeds; the invention can be used for a long time in the corn cultivating period, and can automatically remove weeds around the corn plants in combination with circuit control, and has a simple structure and strong practicability.

Owner:JILIN UNIV

Threshing cylinder tooth component of whole-feed harvesting machine

The invention provides a threshing cylinder tooth component of a whole-feed harvesting machine. The threshing cylinder tooth component comprises an installing base. The installing base is provided with cylinder teeth, the cylinder teeth are formed by forging of a 45# material, the cylinder teeth and anti-winding pieces inside the cylinder teeth are integrated, and no gap is formed between the anti-winding pieces and the cylinder teeth. The center of each cylinder tooth is in a cone shape, the protruded top ends are in an arc shape, and the two sides are of a symmetrical shape structure. Due to the fact that an integrated forging structure mode is adopted, the production cost is lower, the integral strength of the cylinder teeth is higher, and the anti-winding pieces and the external teeth are combined to be a whole to protect cylinder tooth gaps from weed winding; the top ends of the cylinder teeth are in an arc shape, the load is light during running, and the grain breakage rate is low; the two sides of the cylinder teeth are of the symmetrical shape structure, when one side is abraded, the other side can be turned and used, and the threshing cylinder tooth component is more economical and practical.

Owner:湖北双兴智能装备有限公司

Novel split-type lawn mower

PendingCN109089524AQuick installationQuick releaseMowersAgricultural engineeringAgricultural machinery

The invention belongs to the field of agricultural machinery, and particularly relates to a novel split-type lawn mower. The novel split-type lawn mower comprises a driving device and a split-type lawn mowing device; the split-type lawn mowing device comprises a connecting soft shaft, a split type connecting aluminium pipe component and a novel tool head component; the novel tool head component isconnected with the split type connecting aluminium pipe component through a novel hexangular connecting piece; a novel buckling grass baffle plate is arranged on the split type connecting aluminium pipe component. The novel split-type lawn mower is reasonable in overall structural design, wherein the quick connecting and disassembling efficiency of two sections of aluminium pipes of the split type lawn mower can be remarkably improved through the arrangement of the split type connecting aluminium pipe component, so that the operation is more convenient and quick; quick assembling and disassembling of a user is also realized by the novel buckling grass baffle plate; through the arrangement of the novel hexangular connecting piece, the mounting efficiency can be improved remarkably, the disadvantages of rotating and inclining of machines and tools at a front end and a rear end are effectively avoided, and the novel hexangular connecting piece is practical and convenient; the arrangementof novel anti-grass tangling blades achieves the purpose of normal lawn mowing, and can also prevent the blades from grass tangling effectively.

Owner:山东大易通用机械有限公司

A double longitudinal axial flow thresher for combine harvester

The invention discloses a dual-vertical shaft axial-flow thresher for combine harvesters, comprising a housing, a left top cover, a right top cover, a feeding bin, a left threshing cylinder, a right threshing cylinder and a feeding cylinder; the feeding cylinder is rotatably mounted within the feeding bin and used for conveying straws from a conveying trough into the housing; the left threshing cylinder and the right threshing cylinder vertically mounted in parallel within the housing are used for dual-vertical shaft threshing. The dual-vertical shaft axial-flow thresher is high in throughput and durability and has promising application prospect.

Owner:刘龙君 +1

Blade-type straw collecting device

Owner:CHINA AGRI UNIV

Cutting device and lawnmower with same

The invention discloses a cutting device. The cutting device comprises a turnplate, and a plurality of cutting blades which are circumferentially mounted at different phases of the turnplate, wherein the cutting blades are arranged in at least two different cutting planes in the axial direction of the turnplate; flanges capable of causing a downward airflow are arranged on free end parts of the cutting blades in the topmost cutting plane. When the cutting blades rotate for mowing, the downward airflow is formed at the flanges, and mown grass can be downwardly pressed to prevent blockage of grass at the front end, so that the cutting device has a relatively high cutting efficiency. The mower with the cutting device also is relatively high in efficiency.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Threshing system for combine harvesters

ActiveCN104541796AImprove structural strengthImprove threshing efficiencyThreshersEngineeringCombine harvester

The invention provides a threshing system for combine harvesters, comprising a threshing mechanism, a screening mechanism and a secondary threshing mechanism. The threshing mechanism is used for dual-vertical shaft threshing of straws conveyed by a conveying trough. The screening mechanism is used for screening threshed grain to obtain clean grain. The secondary threshing mechanism is capable of conveying incompletely screened straws into the threshing mechanism for secondary threshing, and threshing effect is further improved. The threshing system is high in throughput, allows complete threshing, is high in durability and has promising application prospect.

Owner:江苏新品建设工程有限公司

Vertical axial flow drum

The invention discloses a longitudinal axial flow drum, which belongs to the technical field of combine harvester threshing and separation devices, and comprises a drum body, a drum front shaft, a power input shaft, a drum front bracket and a drum rear bracket, and the drum body includes a feeding part and a drum The body, the anti-winding element is provided between the front support of the roller and the feeding part, and the anti-winding element includes: a material guide crescent and a wedge-shaped roller front cover fixed on the front support of the roller, and the material guide crescent includes Disc and material guide plate, one end of the disc is fixedly installed on the front support of the drum, and the other end has an opening; the disc passes through the installation hole of the front cover of the drum; it is fixed on the front of the drum The front cover cover of the drum on the cover; the front protrusion of the drum fixed on the front end face of the feeding part, and the front protrusion of the drum is located in the opening. During the harvesting operation, the front axle of the drum is not easy to entangle the grass, and the working efficiency is high, which realizes the simultaneous harvesting of various crops, and does not need to replace the drum, which meets the user's profit demand.

Owner:LOVOL HEAVY IND CO LTD

Seeder with seedling strip cleaner

InactiveCN102415234BPrevent weedFront and rear dimensions shortenedSpadesPlantingAgricultural engineeringSeedling

Owner:山东颐和农机制造有限公司

Drive Shaft Structure and Bridge Crossing Device of Combine Harvester

The invention discloses a bridge crossing driving shaft structure of a combine harvester, which belongs to the technical field of combine harvesters, and comprises a bridge crossing driving shaft, the bridge crossing driving shaft is rotatably mounted on the bridge crossing housing of the combine harvester, and A plurality of bridge drive shaft sprockets are mounted on the bridge drive shaft inside the bridge housing, and a bridge inner support is fixedly installed in the bridge housing near the position of the bridge drive shaft. A number of grass cutters are fixedly installed on the inner support of the bridge to prevent the driving shaft of the bridge from being entangled with grass. An opening is arranged at the middle position of the grass cutter, and the opening is aligned with the sprocket of the driving shaft of the bridge. One to one correspondence. The invention also discloses a bridge crossing device for a combine harvester. The invention avoids the weeding of the driving shaft of the bridge, and the user does not need to stop frequently for cleaning, which improves the working efficiency and avoids early wear or damage of machine parts caused by untimely cleaning.

Owner:LOVOL HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com