Seeder with seedling strip cleaner

A cleaner and seeder technology, which is applied to planting methods, tillage tools, agricultural machinery and tools, etc., can solve problems such as inability to prevent grass entanglement and congestion, failure to perform normal seeding, long front and rear dimensions of the seeder, etc. Achieve the effects of good soil penetration performance, simplified structure and low slip rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

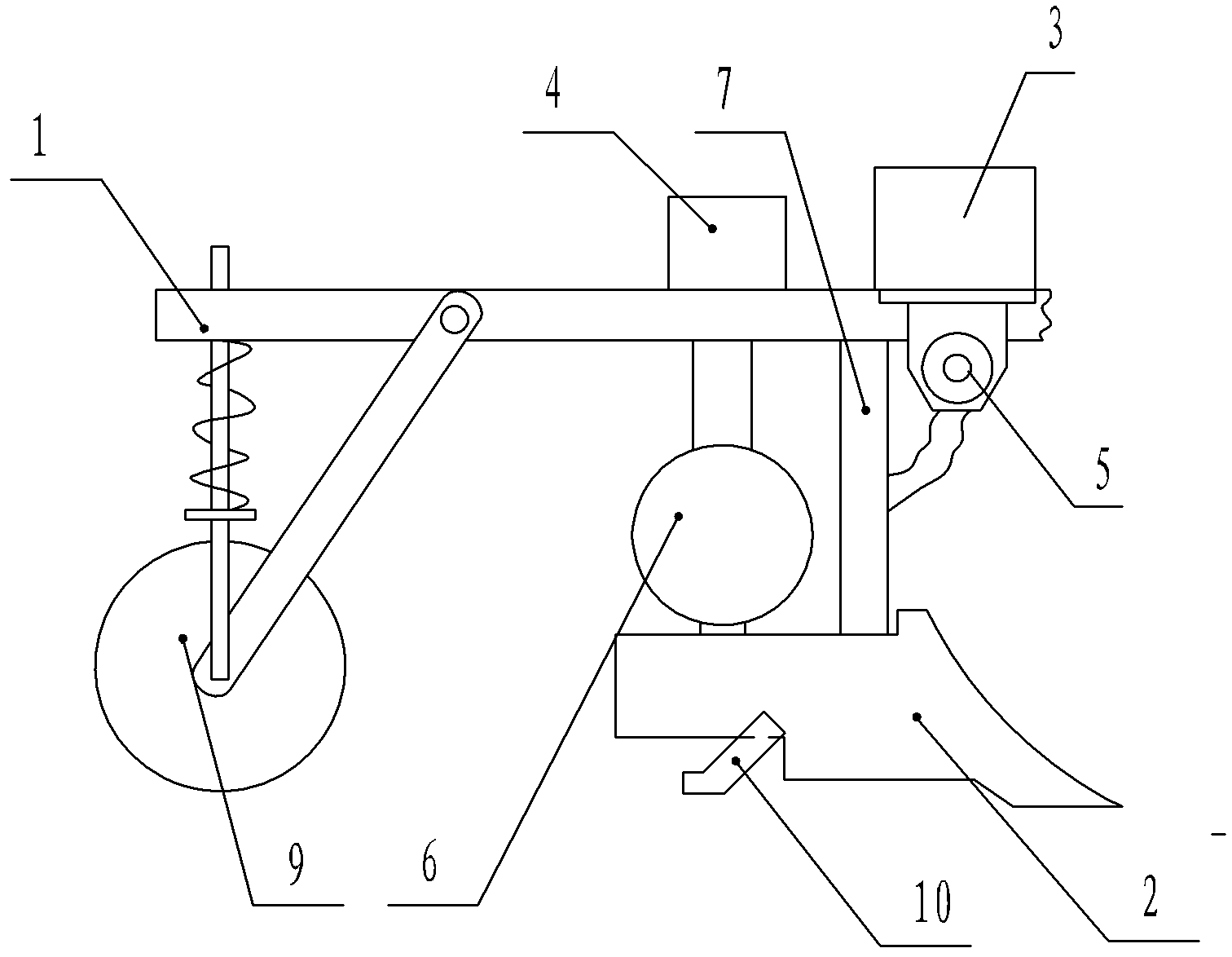

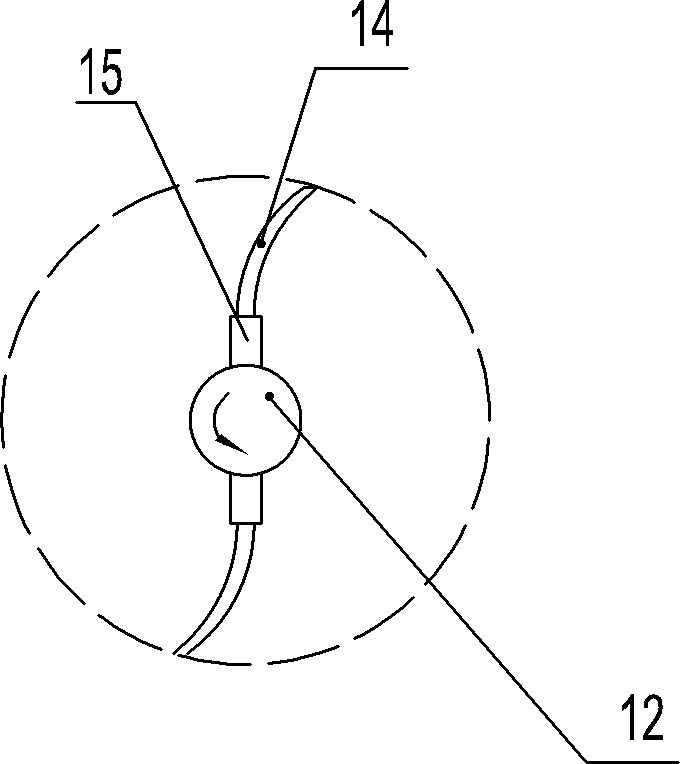

[0021] exist Figure 1-3 In the shown embodiment: comprise frame 1, a plurality of ditch openers 2 and the seed box 3 that is installed on the frame 1, fertilizer box 4, 3 seed meters 5, 3 fertilizer dischargers 6, 3 A plow post 7, two ground wheels 8 and three overburden suppressors 9, wherein each overburden suppressor 9 is located behind a furrow opener 2, and the ground wheel 8 is installed at the bottom of the frame 1 and is adjustable in height. 7 are all hollow, and each opener 2 is fixed on the bottom of the frame 1 through the plow column 7, and the lower end of the plow column 7 inserted into the opener 2 acts as a fertilizer discharge port, and the upper end of the plow column 7 passes through the fertilizer discharge device 6 Connected with the fertilizer box 4, the seed meter 5 connected with the seed box 3 is located above the rear end of the ditch opener 2. Along the direction of travel, the bottom surface of the ditch opener 2 rises in three steps from front to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com