Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Prevent mud bag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyamine strong inhibitor for drilling fluid, and preparation method thereof

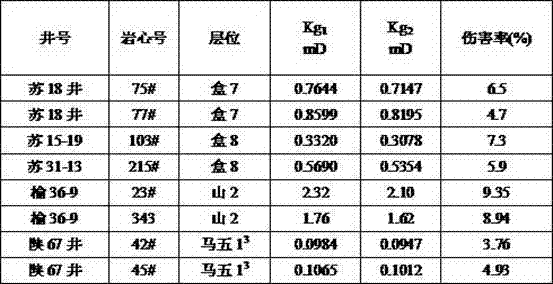

InactiveCN103087691AEnhanced inhibitory effectReduced tendency to absorb waterFlushingDrilling compositionSodium BentoniteInstability

The invention relates to a polyamine strong inhibitor for a drilling fluid. The polyamine strong inhibitor is prepared through the following step that: an amine compound and an epoxy compound are subjected to a reaction at a temperature of 90-110 DEG C in the presence of an alkali metal catalyst to synthesize the polyamine strong inhibitor for the drilling fluid, wherein the amine compound is polyether amine, alkyl amine, ether amine, tetraethylenepentamine, pentaethylenehexamine or polyethylene polyamine, and the epoxy compound is propylene oxide or ethylene oxide. According to the present invention, based on high temperature strong water sensitivity easy-instability stratum, special molecular structure design is adopted, such that the inhibitor has strong inhibition, and mud making of clay and hydration expansion of shale can be inhibited; and the inhibitor provides a stabilization effect for dynamic cutting force when the Xuanhua bentonite addition amount is up to 30%, wherein a debris rolling recovery rate can be more than 90%, a 8 h shale linear expansion rate is less than or equal to 10%, a temperature resistance performance is more than or equal to 180 DEG C, biological toxicity is low, and a LC50 value is more than 38010 mg / L.

Owner:CHINA PETROLEUM & CHEM CORP +1

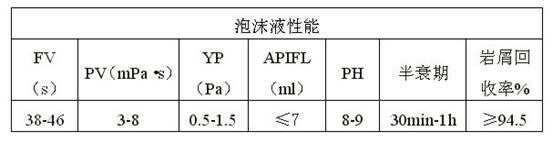

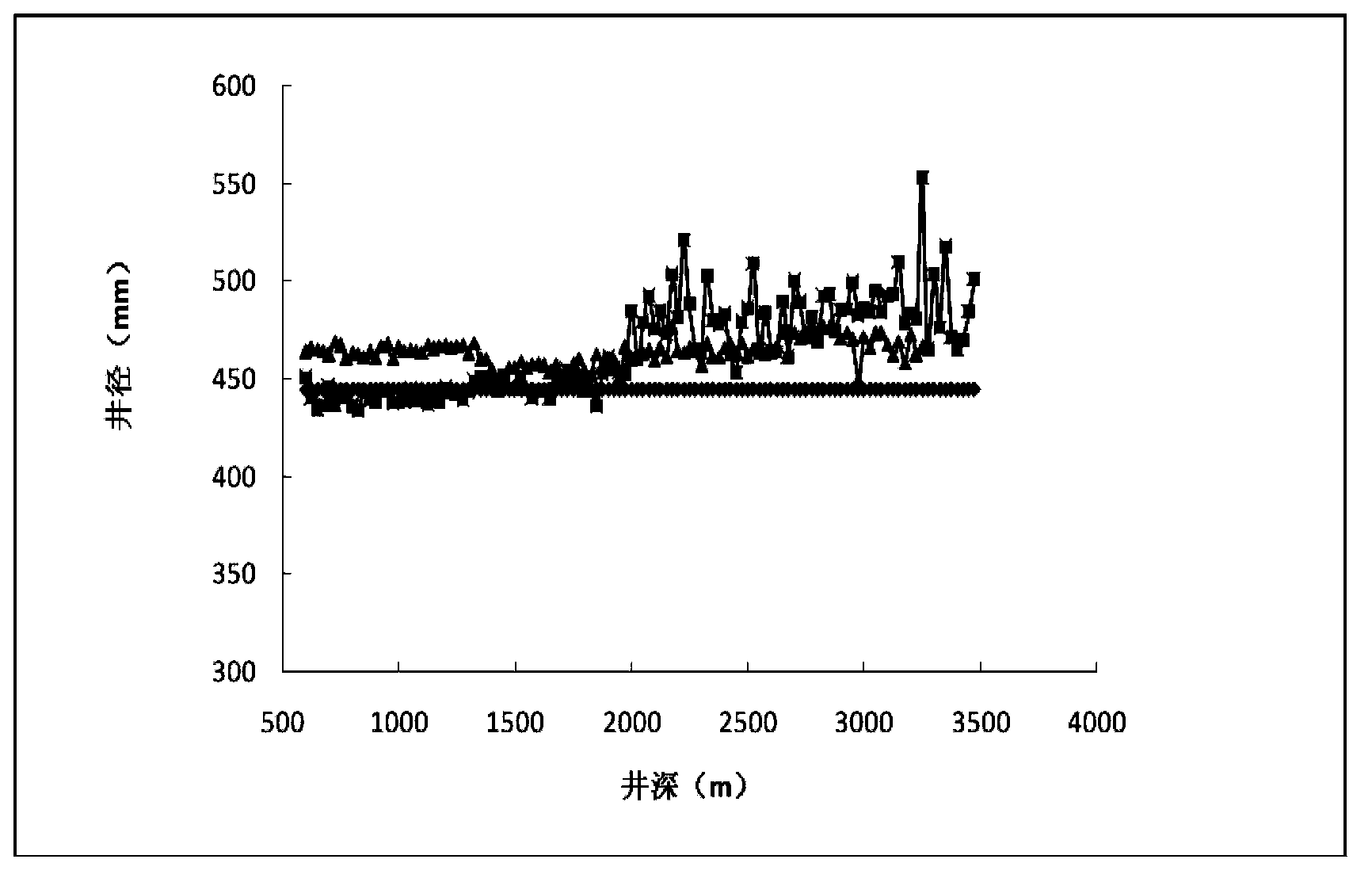

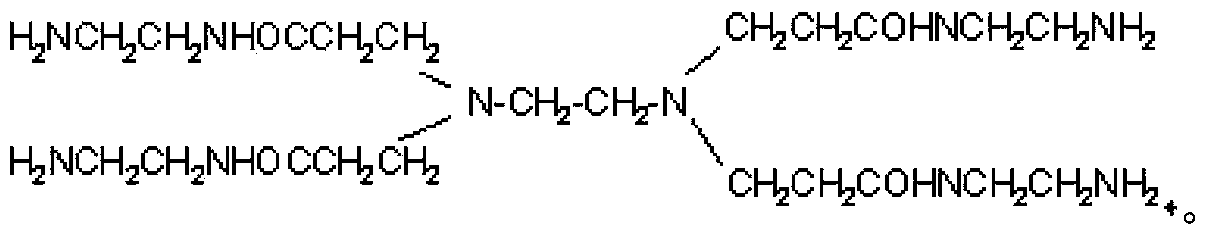

Strong inhibition type anti-collapse foam liquid for drilling

InactiveCN101798499AIncreased water carrying capacityPrevent immersionDrilling compositionFoaming agentCarrying capacity

The invention relates to foam liquid for drilling, in particular to strong inhibition type anti-collapse foam liquid for drilling, which is characterized by being prepared with the following components in parts by weight: 0.09-0.11 part of foam stabilizer, 0.36-0.44 part of foaming agent, 2.34-2.86 parts of anti-collapse agent, 2.7-3.3 parts of fluid loss additive and 94.51-93.29 parts of water. When complex situations such as formation water occur to gas drilling, the foam liquid of the invention can effectively improve the rock carrying capacity and the water carrying capacity and simultaneously protect the stability of the upper well wall. Laboratory studies shown that the foam liquid has high foaming capacity, the foaming capacity is more than or equal to 500 percent, the half-life is moderate, and the foam liquid can be easily controlled and is conducive to drilling engineering construction.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

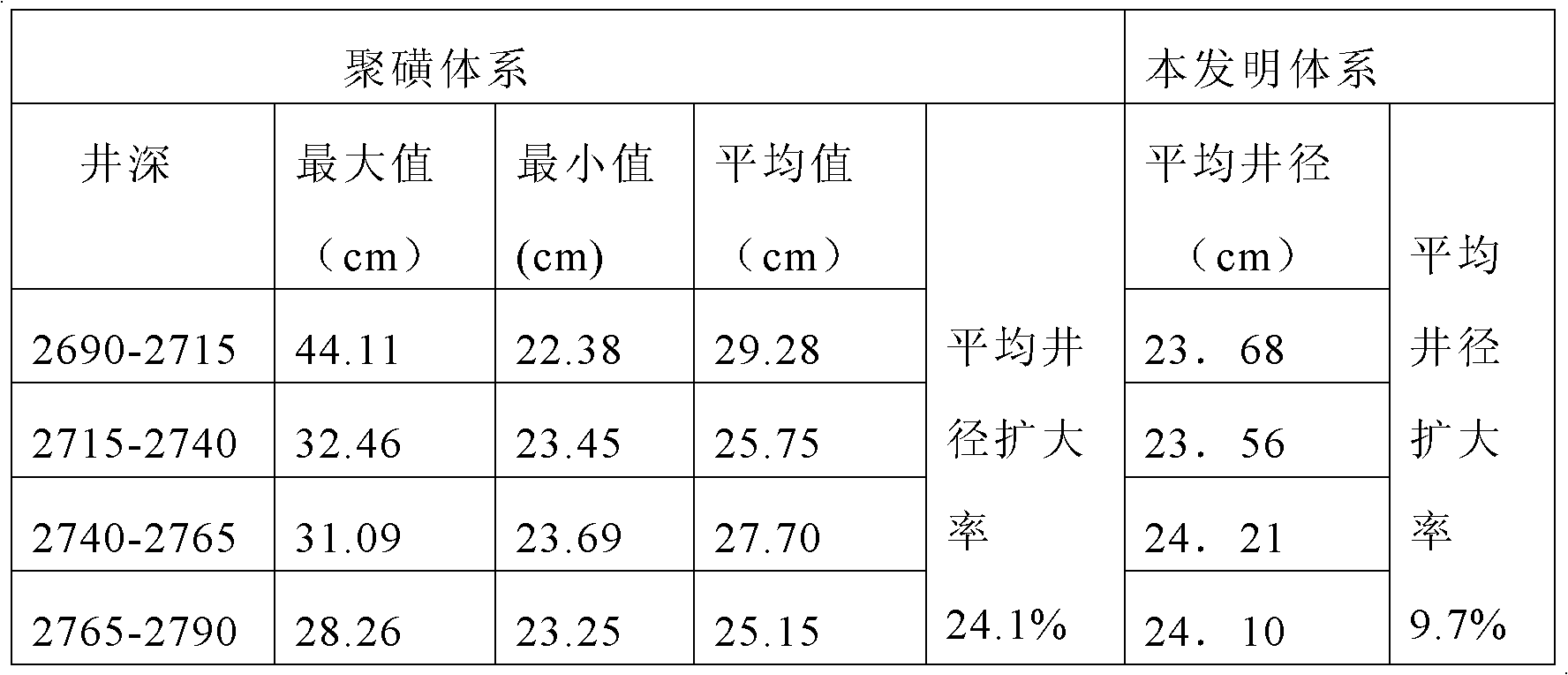

Process for preparing drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling

InactiveCN101892036AImprove anti-slump performanceImprove integrityDrilling compositionCelluloseWater dispersible

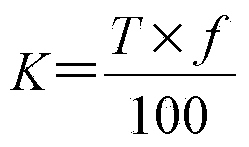

The invention relates to a process for preparing drilling fluid, in particular to a process for preparing the drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling. The process comprises a construction process and a dosage formula of treating agents and is characterized in that: according to the dosage formula, the treating agents are prepared by mixing clear water polymer original slurry, poly anionic cellulose (PAC), calcium carbonate (QS-4), carboxymethyl starch (CMS), sulfonated phenolic resin(SMP-2), water dispersible cation emulsified asphalt powder (SFT-1), sodium chloride(NaCL) and sodium formate (WT-1) in a mass ratio of 1,000:2-3:30-40:20-30:2-3:1.5-2:50-100:20; and the construction process comprises the following steps of: according to a circulation circle, uniformly mixing a coating agent PAC, a filtrate reducer CMS, a salt and high-temperature resistant filtrate reducer SMP-2 and an anti-sloughing lubricant SFT-1 for 12h at first; adding QA-4, NaCL, WT-1 into the mixture and uniformly mixing the mixture; and regulating the mixture to have a density Rho of 1.06 to 1.10g / cm<3>, a funnel viscosity T of 38 to 45s and an API water loss FL of 4 to 6ml. The process has the advantages of effectively preventing the balling of a sticking bit and a PDC bit at a lower curved section, reducing a frictional resistance and a torque, eliminating a sticking phenomenon, improving a mechanical drilling rate and ensuring downhole safety.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

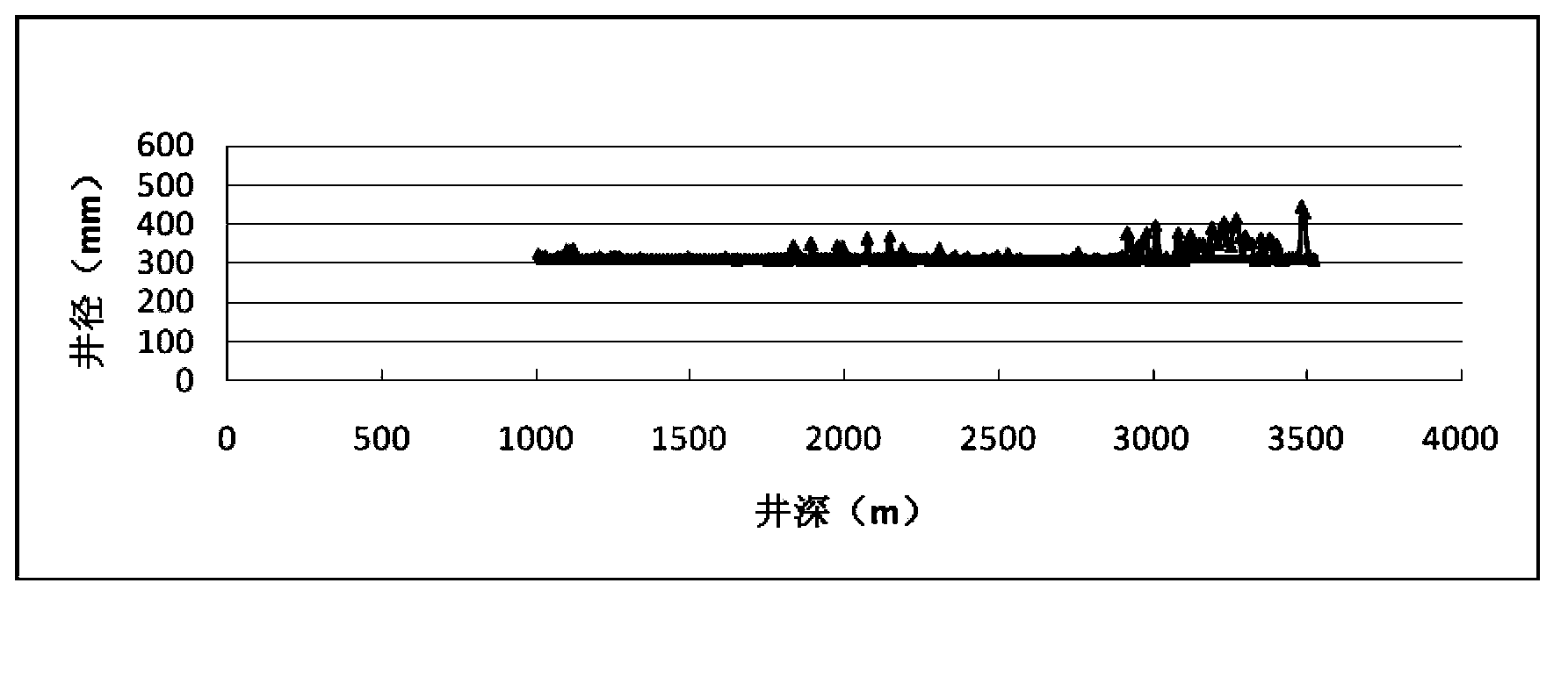

Dendritic multi-amino polymer drilling fluid used for mud rock well drilling

ActiveCN104130758AEnhanced inhibitory effectReduce plasticityDrilling compositionPotassiumWell drilling

The invention relates to a dendritic multi-amino polymer drilling fluid used for mud rock well drilling. The drilling fluid is characterized by consisting of a dendritic multi-amino polymer, drilling fluid bentonite, sodium carbonate, a polymer coating agent, potassium polyacrylate, a hydrolyzed polyacrylonitrile ammonium, a bit balling resistant lubricant and water. The dendritic multi-amino polymer drilling fluid can improve an inhibitive performance of the drilling fluid, can greatly improve the inhibitive performance on clay and drilled chips of the drilling fluid, can reduce plasticity of daub rock, can avoid water-absorption swelling and dispersing of the daub rock, can reduce friction resistance, can prevent bit balling, can increase a penetration rate and can ensure safety of a downhole operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Strong inhibition type anti-collapse foam liquid for drilling

InactiveCN101798499BIncreased water carrying capacityPrevent immersionDrilling compositionFoaming agentCarrying capacity

The invention relates to foam liquid for drilling, in particular to strong inhibition type anti-collapse foam liquid for drilling, which is characterized by being prepared with the following components in parts by weight: 0.09-0.11 part of foam stabilizer, 0.36-0.44 part of foaming agent, 2.34-2.86 parts of anti-collapse agent, 2.7-3.3 parts of fluid loss additive and 94.51-93.29 parts of water. When complex situations such as formation water occur to gas drilling, the foam liquid of the invention can effectively improve the rock carrying capacity and the water carrying capacity and simultaneously protect the stability of the upper well wall. Laboratory studies shown that the foam liquid has high foaming capacity, the foaming capacity is more than or equal to 500 percent, the half-life ismoderate, and the foam liquid can be easily controlled and is conducive to drilling engineering construction.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

Oil-based lubricant and application thereof

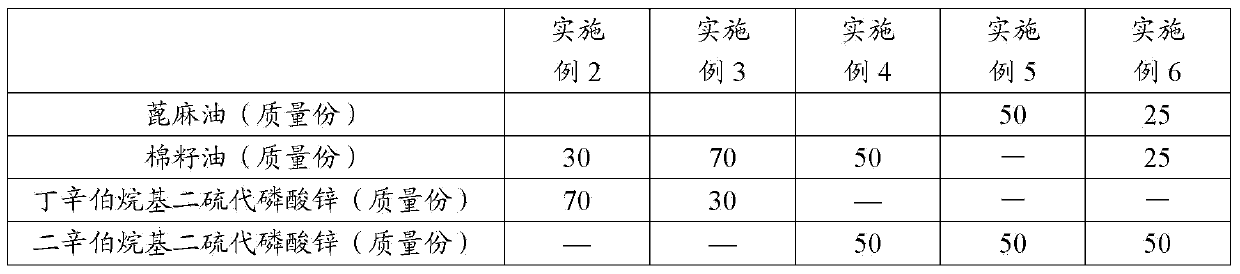

InactiveCN103694969AReduce frictional resistanceIncrease frictional resistanceDrilling compositionWater basedZinc

The invention relates to an oil-based lubricant and application thereof to a water-based drilling fluid. The oil-based lubricant comprises 30-70 parts of zinc dialkyl dithiophosphate and 30-70 parts of plant oil by mass. When the zinc dialkyl dithiophosphate and the plant oil are compounded into the lubricant for the water-based drilling fluid, a synergistic effect is achieved, so that the oil-based lubricant greatly reduces the rotating frictional resistance of a drill, has extreme pressure resistance and greatly improves the lubrication of the drilling fluid.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Shield mud system applicable to extra-large-diameter tunnel and preparation method

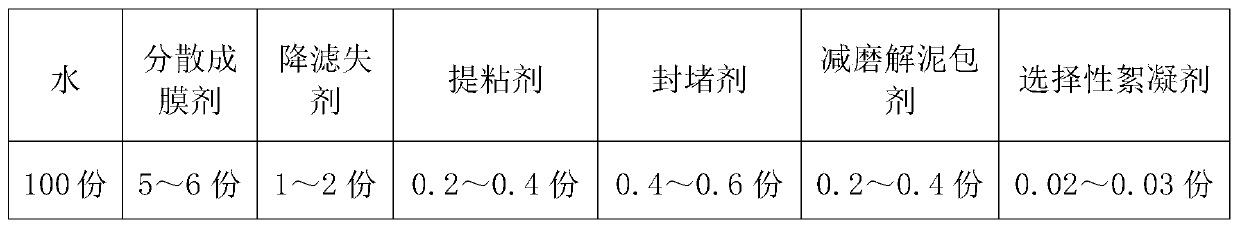

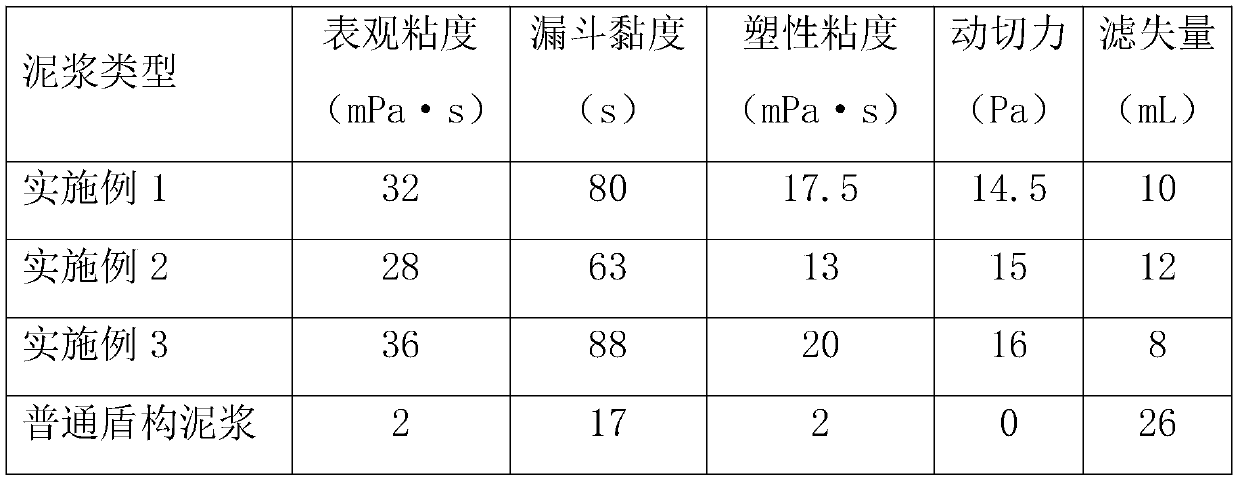

InactiveCN109762534AImprove recycling ratesQuality improvementDrilling compositionMud systemsFiltration

The invention provides a shield mud system applicable to an extra-large-diameter tunnel. The shield mud system is prepared from the following raw materials in parts by mass: 100 parts of water, 5 to 6parts of a dispersion film-forming agent, 1 to 2 parts of a filtration-reducing agent, 0.2 to 0.4 part of a viscosity improving agent, 0.4 to 0.6 part of a plugging agent, 0.2 to 0.4 part of an anti-wear and mud ball splitting agent and 0.02 to 0.03 part of a selective flocculating agent. The shield mud system provided by the invention has the beneficial effects that the shield mud system has unique 'lubrication and anti-wear performance' and has the effects of protecting a shield bit tool and improving the footage drilling efficiency; a dense mud film can be formed, the filtration loss amount is reduced and the soil pressure is balanced, so that the stability of a well wall is enhanced, the sticking coefficient can be reduced and a mud ball of the shield bit tool is prevented; and the shield mud system has good rheological performance, filtration-reducing performance and lubricating performance and can meet the requirements of shield mud drilling, and has the advantages of environment protection and low cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

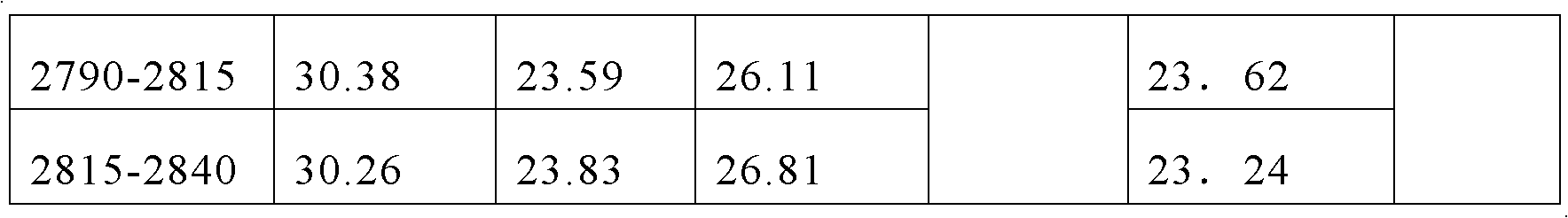

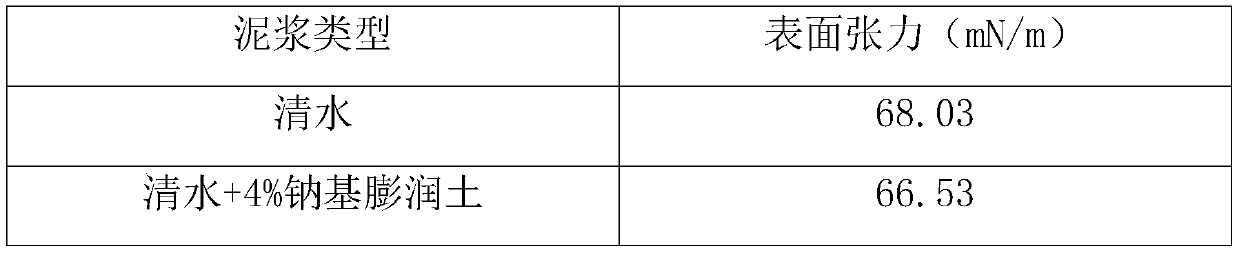

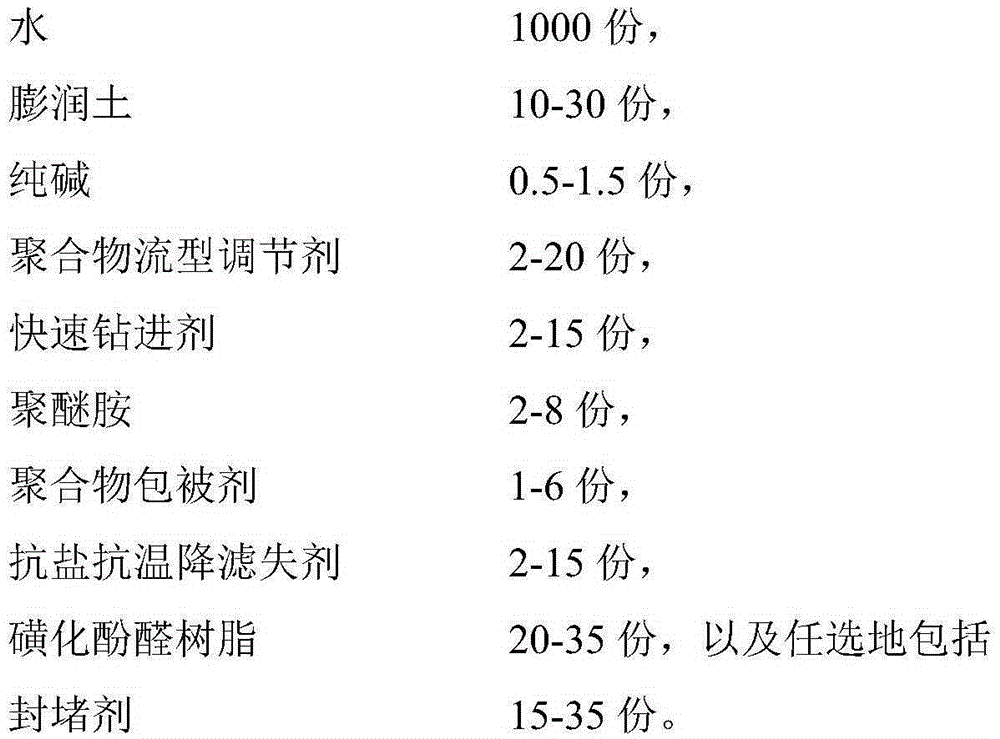

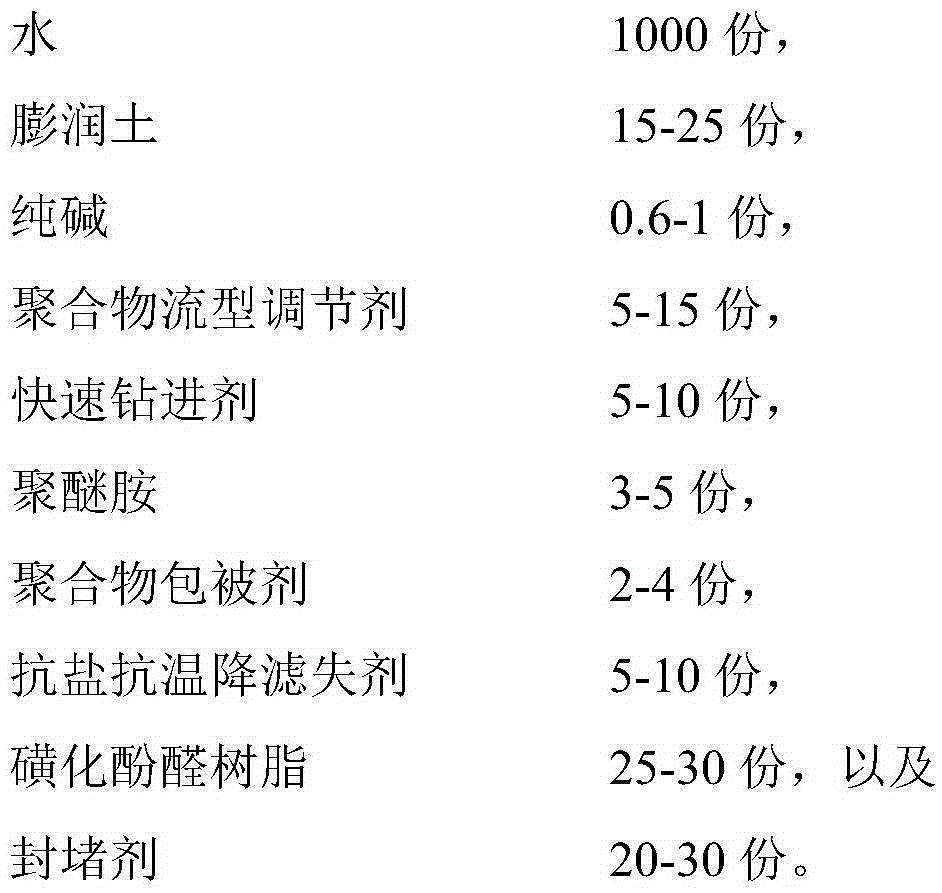

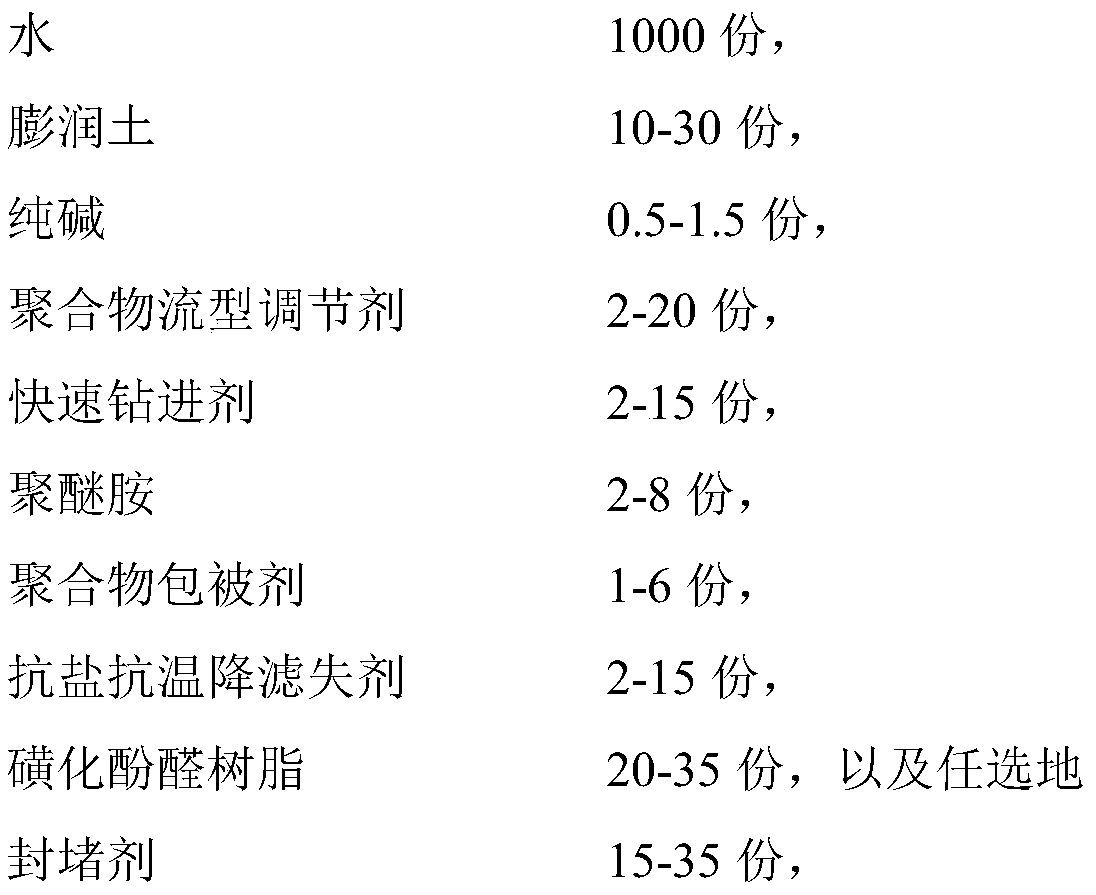

Drilling fluid for improving mudstone drilling speed, preparation method and application thereof

ActiveCN106543990AImprove the lubrication effectEnhanced inhibitory effectDrilling compositionRate of penetrationReducer

The invention relates to a drilling fluid for improving the mudstone drilling speed. The drilling fluid is prepared from the following components by weight: 1000 parts of water, 10-30 parts of bentonite, 0.5-1.5 parts of sodium carbonate, 2-20 parts of a flow pattern regulator, 2-15 parts of a fast drilling agent, 2-8 parts of polyether amine, 1-6 parts of a polymer coating agent, 2-15 parts of a salt-tolerant and temperature resistant filtrate reducer, 20-35 parts of sulfonated phenolic resin and optionally 15-35 parts of an plugging agent. The accelerating drilling fluid provided by the invention has excellent resistance to salt, calcium and bad soil, and can effectively improve the rate of penetration. The invention also relates to a preparation method of the drilling fluid. The method includes the steps of: adding bentonite and sodium carbonate into water, mixing the substances evenly, then conducting standing maintenance, then adding the polymer flow pattern regulator, the polymer coating agent, the fast drilling agent, polyether amine, the salt-tolerant and temperature resistant filtrate reducer, sulfonated phenolic resin and the plugging agent, mixing the substances evenly, and performing standing for standby use. The invention also relates to application of the accelerating drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

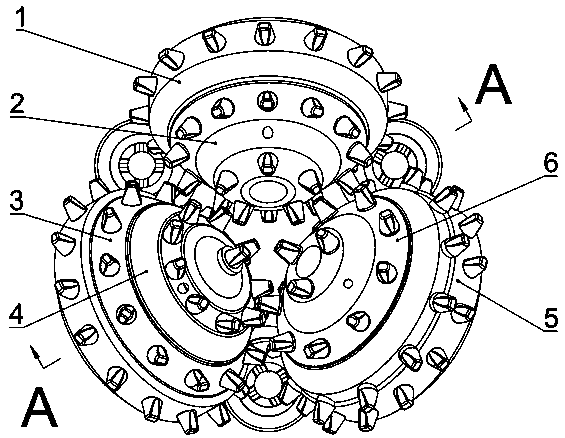

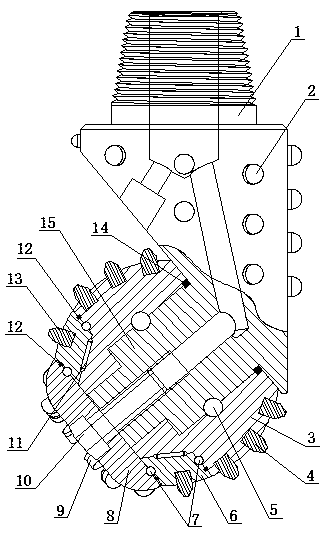

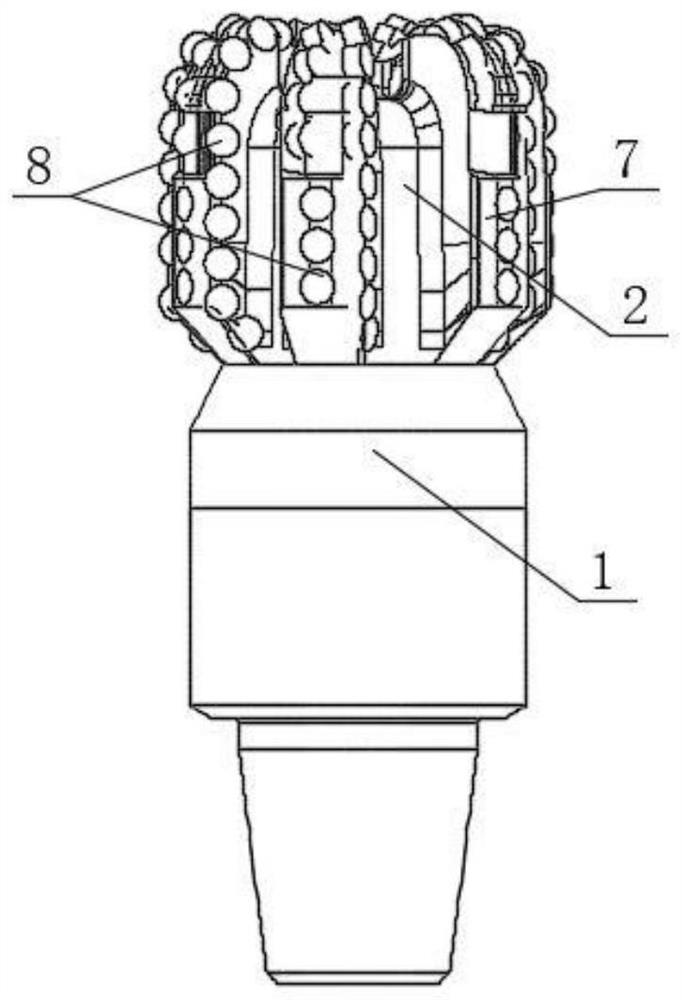

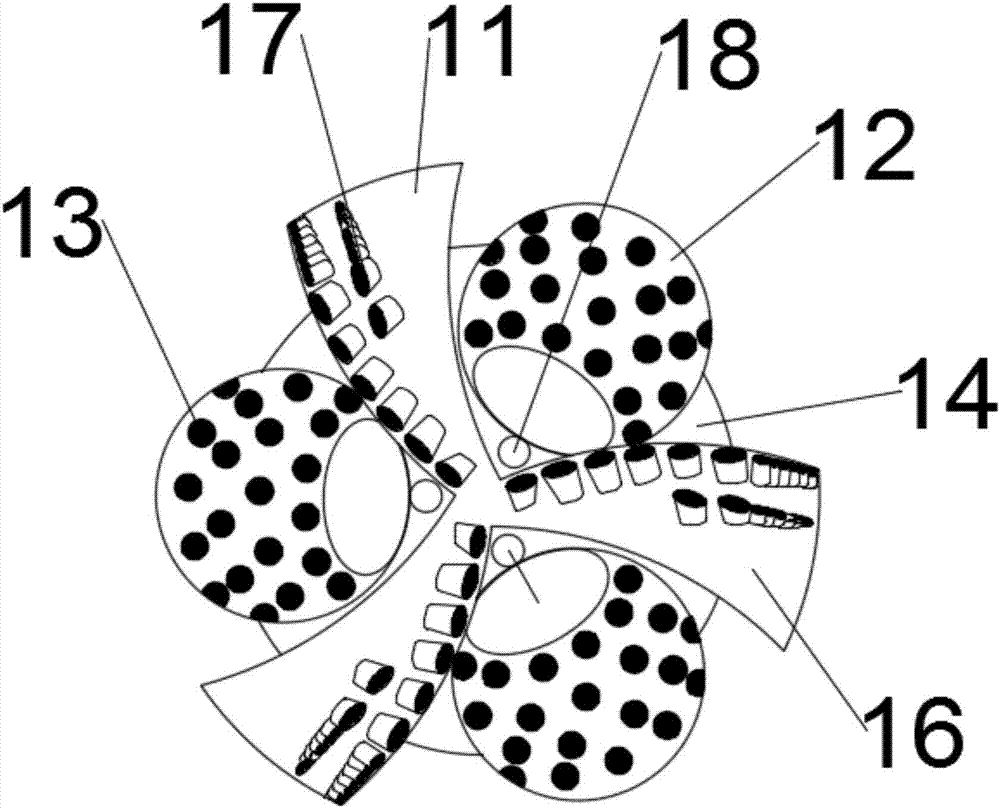

Split type tri-cone drill

PendingCN108442886AImprove scraping efficiencyImprove lubrication environmentDrill bitsSpray nozzleEngineering

The invention relates to a split type tri-cone drill which is mainly composed of a first cone set, a second cone set, a third cone set, teeth, bit legs, an oil storage compensation pressure balance system and a spraying nozzle. The three bit legs are separately connected to three cone lower bodies through biased bit-leg journals at the lower ends of the three bit legs. Three cone upper bodies areseparately installed on journals of the three cone lower bodies. During operation, the three cone lower bodies separately orbit with a drill body and rotate around the bit-leg journals; and the threecone upper bodies separately orbit with the drill body and rotate around journals of the three cone lower bodies, the task of scraping and crushing rocks is achieved, so that the tooth scraping efficiency of a small end tooth ring and a middle tooth ring is improved, and the rock crushing efficiency of the drill is improved.

Owner:SOUTHWEST PETROLEUM UNIV

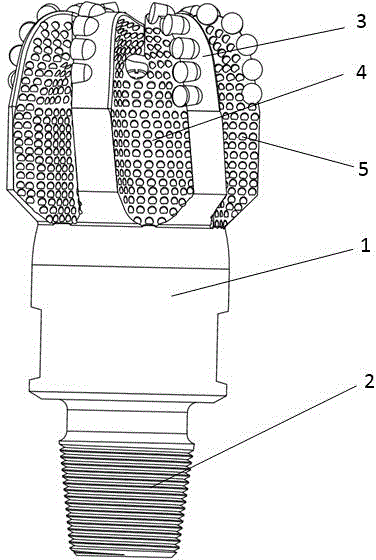

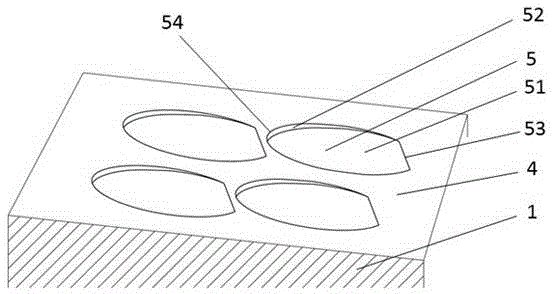

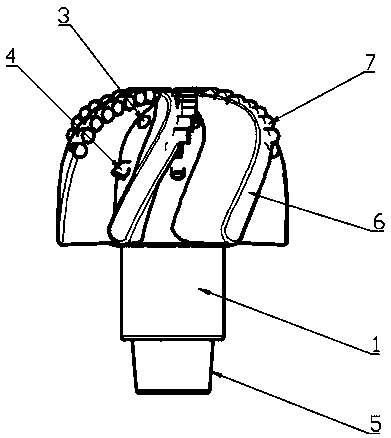

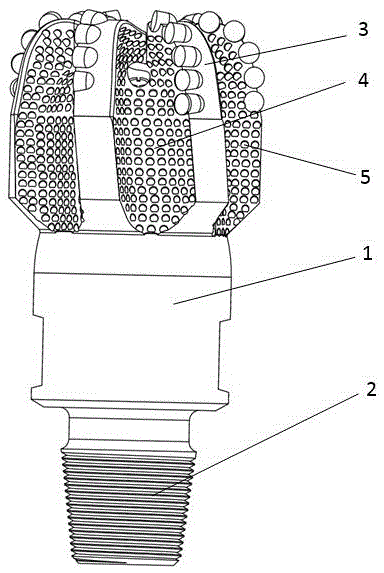

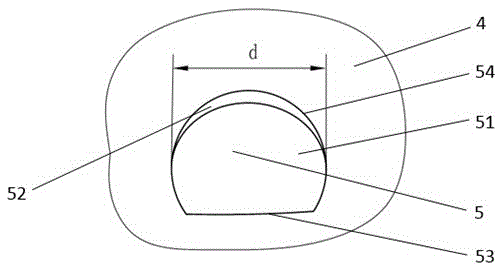

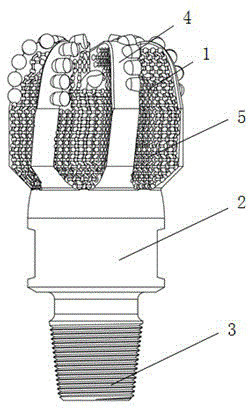

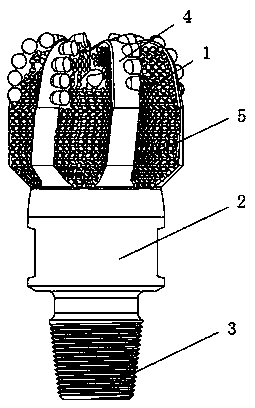

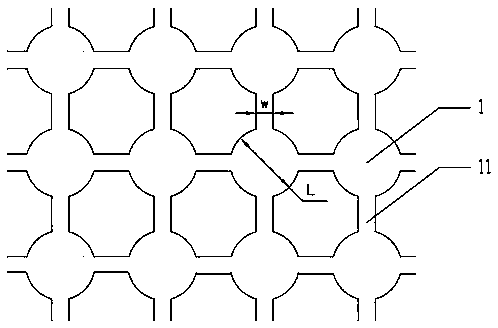

Balling-resistant PDC (polycrystalline diamond compact) drill bit with pits in surfaces of flow passages

ActiveCN103603604ASmooth transitionReduce contact areaDrill bitsWell drillingPolycrystalline diamond

The invention discloses a balling-resistant PDC (polycrystalline diamond compact) drill bit with pits in the surfaces of flow passages. The balling-resistant PDC drill bit comprises a drill bit body, the lower portion of the drill bit body is provided with a screwed joint connected with a drill rod, the upper portion of the drill bit body is provided with a plurality of blades, grooves between the blades form flow passage grooves of the drill bit, at least two pits are formed in the surface of each flow passage groove, and the bottom surface of each pit extends upwards from the deepest position of the pit bottom to the inclined plane of the surface of the corresponding flow passage groove. By the balling-resistant PDC drill bit, adhesion tendency of rock debris in the flow passage grooves is reduced obviously, and the flow passages are prevented from being blocked to achieve the purpose of resisting balling, so that drilling efficiency of the drill bit is improved, service life of the drill bit is prolonged, and drilling cost is lowered.

Owner:SOUTHWEST PETROLEUM UNIV +2

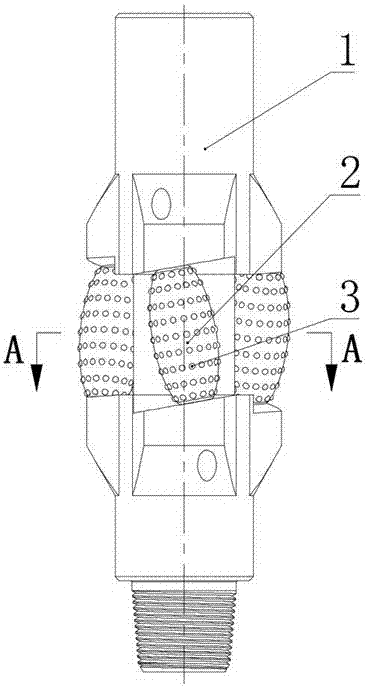

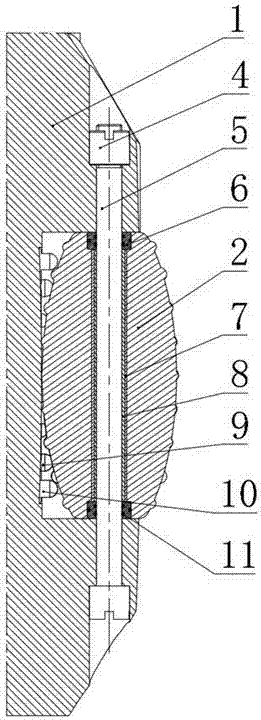

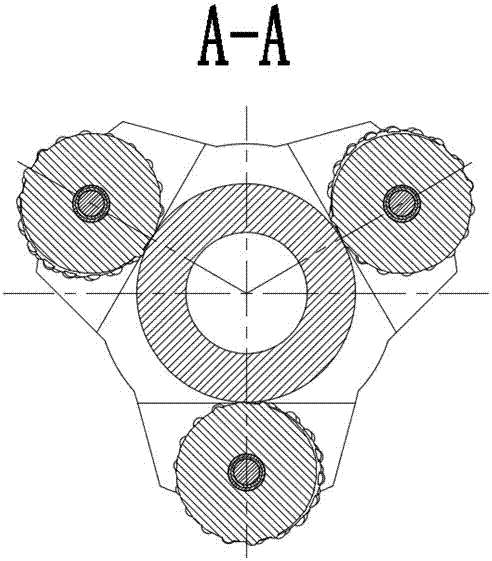

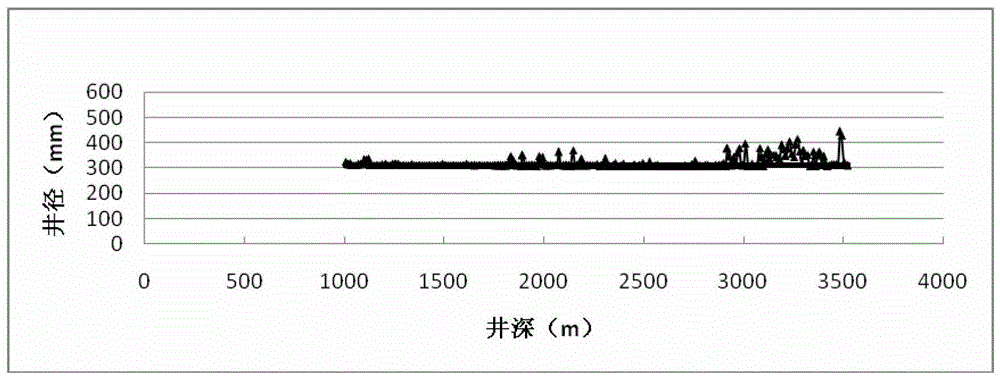

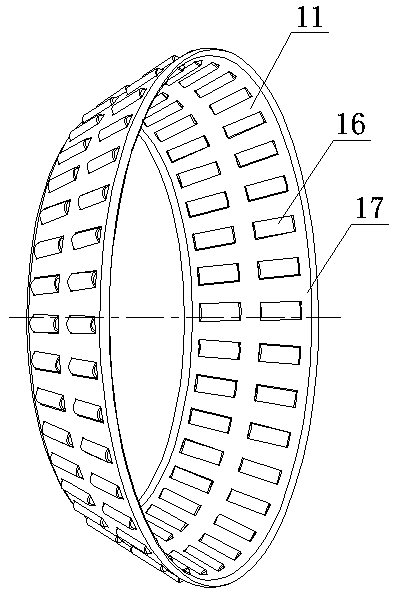

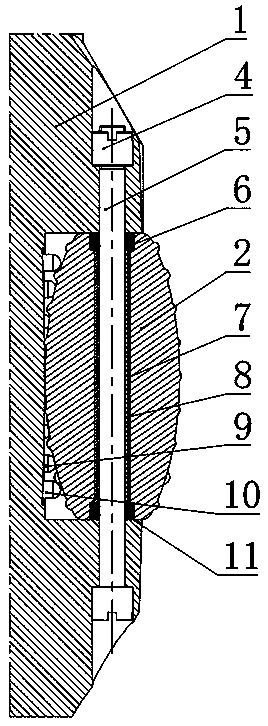

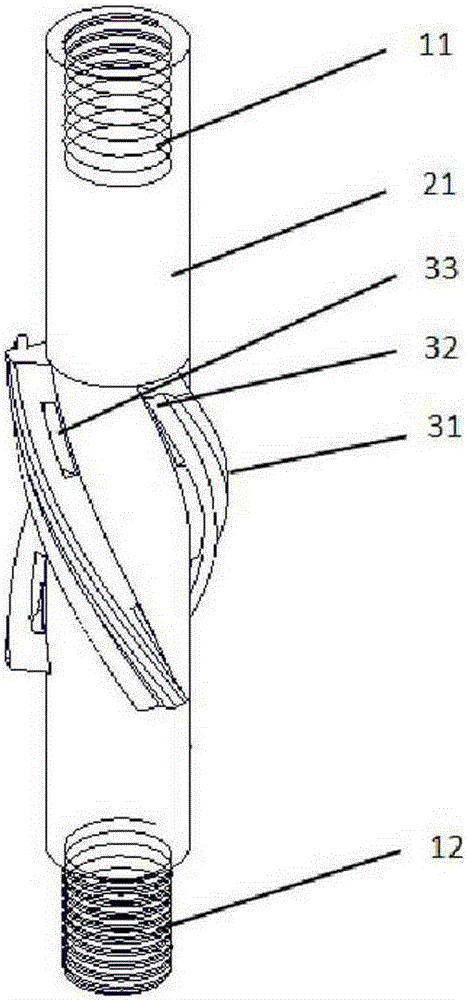

Anti-friction centralizer having anti-balling and boosted propelling functions

ActiveCN107130925ASolve obstaclesSolve the problem of encountering cardsDrilling rodsBorehole drivesRolling resistanceEngineering

The invention relates to an anti-friction centralizer having anti-balling and boosted propelling functions. The anti-friction centralizer comprises a body and roller assemblies, wherein the body is connected between underhole tools through threads, and the roller assemblies are arranged on prisms which are uniformly distributed outside the body along the circumferential direction; a certain included angle exists between the roller shaft of each roller assembly and the axial direction of the body; the body rotates in the drilling process, and the rollers spirally roll on a well wall to push an underhole tool to move forward and supply drilling pressure to a drill bit; alloy teeth are embedded to the outer surfaces of the rollers and positions, provided with the roller assemblies, of the body, so that the friction mode is changed into rolling friction, friction resistance of the underhole drill with the well wall in the drilling process can be reduced, and failure of roller balling can be prevented. The anti-friction centralizer has a relatively simple structure, low cost, high strength and long service life, and can be used for solving the technical problems of poor resistance reduction effect, complicated structure, low strength and short service life in the prior art.

Owner:DAQING DANNUO PETROLEUM TECH DEV

A dendritic polyamine-based polymer drilling fluid for mud rock drilling

ActiveCN104130758BEnhanced inhibitory effectReduce plasticityDrilling compositionAcrylonitrilePolyamine

The invention relates to a dendritic multi-amino polymer drilling fluid used for mud rock well drilling. The drilling fluid is characterized by consisting of a dendritic multi-amino polymer, drilling fluid bentonite, sodium carbonate, a polymer coating agent, potassium polyacrylate, a hydrolyzed polyacrylonitrile ammonium, a bit balling resistant lubricant and water. The dendritic multi-amino polymer drilling fluid can improve an inhibitive performance of the drilling fluid, can greatly improve the inhibitive performance on clay and drilled chips of the drilling fluid, can reduce plasticity of daub rock, can avoid water-absorption swelling and dispersing of the daub rock, can reduce friction resistance, can prevent bit balling, can increase a penetration rate and can ensure safety of a downhole operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

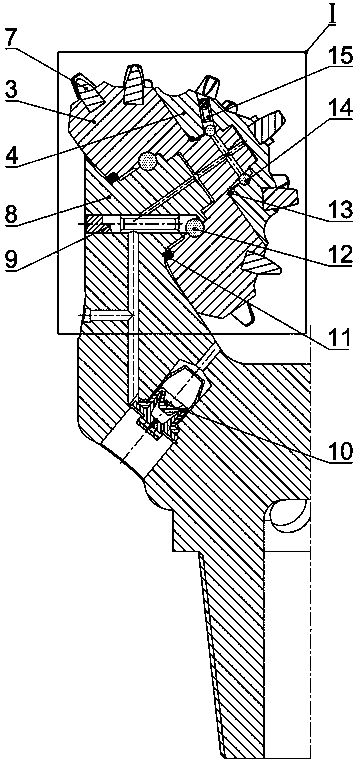

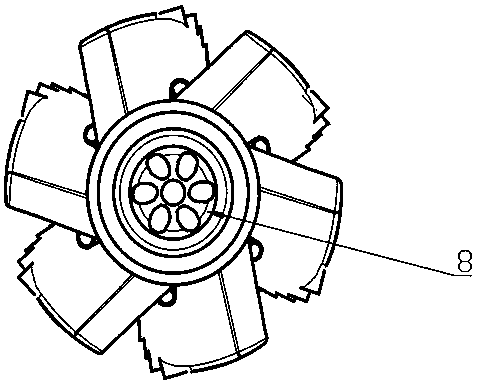

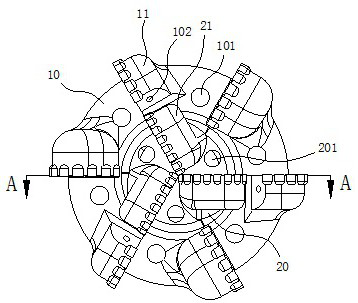

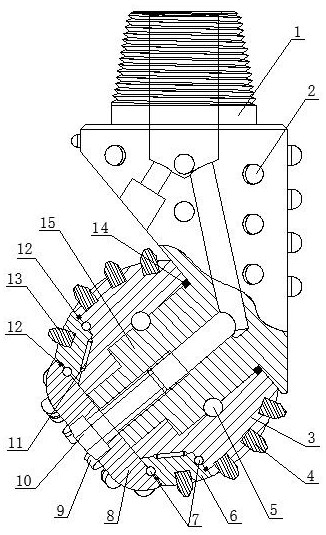

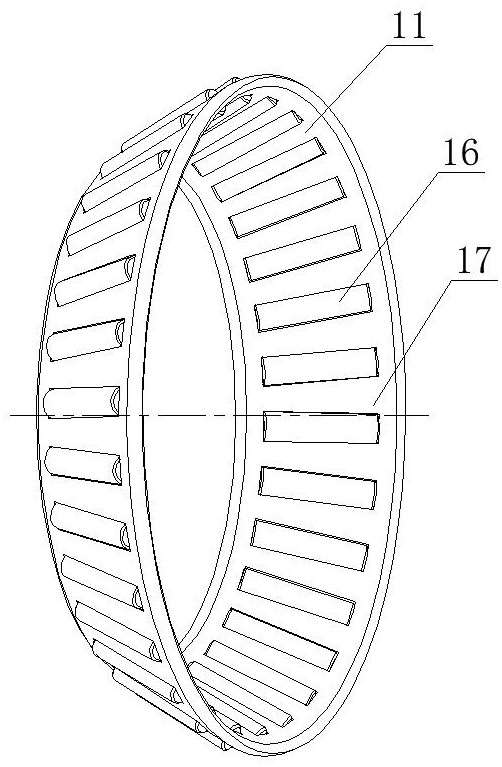

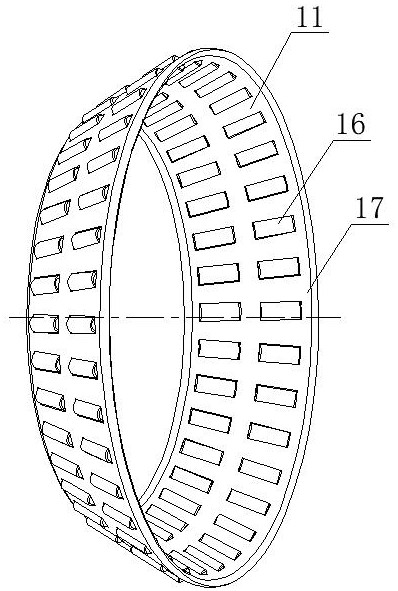

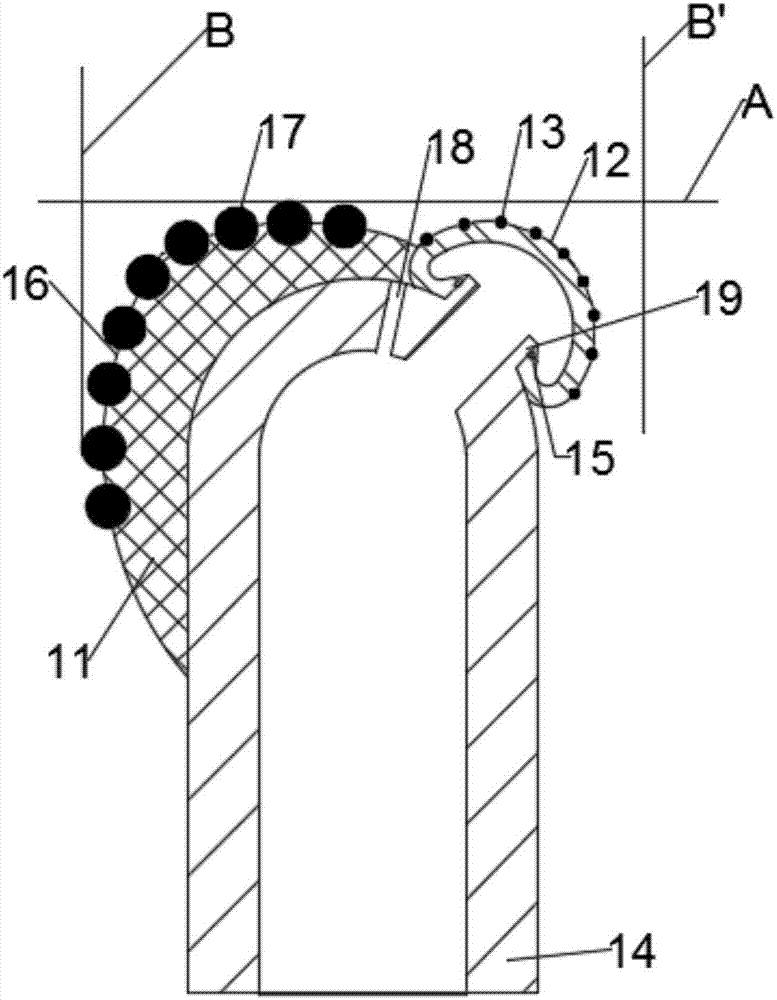

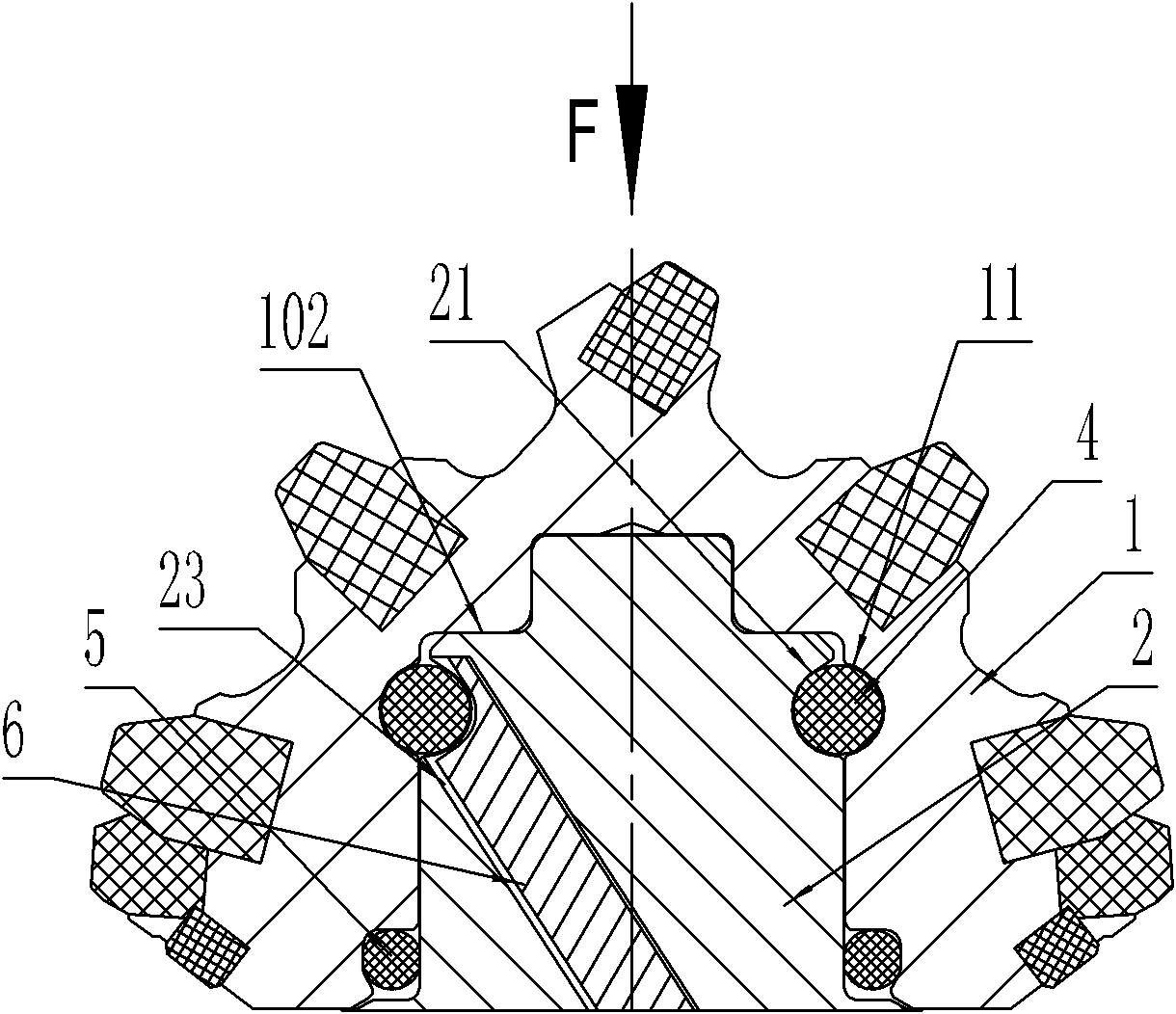

Combined single cone bit with rolling gear ring

The invention discloses a combined single cone bit with a rolling gear ring. The combined single cone bit comprises a bit body (1), a cone (3), cone teeth (4) and a palm journal (15); the bit body (1)is provided with gauge protection teeth (2), the palm journal (15) is arranged at the lower end of the bit body (1), the cone (3) is rotatably connected with the palm journal (15), the cone (3) is rotatably connected with the rolling gear ring (6), a needle bearing (11) is arranged between the inner circle of the rolling gear ring (6) and the cone (3) and used for achieving relative rotating of the cone (3) and the rolling gear ring (6), rolling gear ring teeth (13) are arranged on the rolling gear ring (6), a fixed cutting structure (8) is fixed to one end of the palm journal (15), and fixedcutting teeth (9) are evenly distributed on the fixed cutting structure (8). The combined single cone bit has the advantages that the rock breaking efficiency of the bit is improved advantageously, bit balling is effectively prevented, and the service life of the bit is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

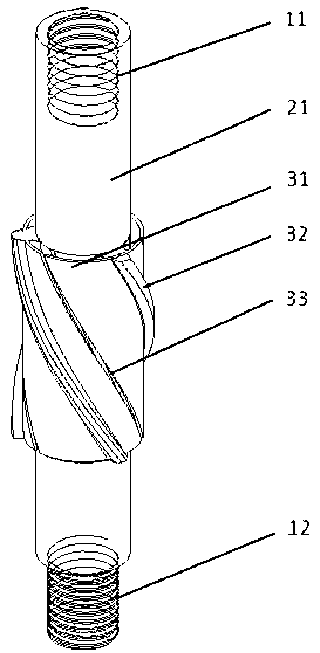

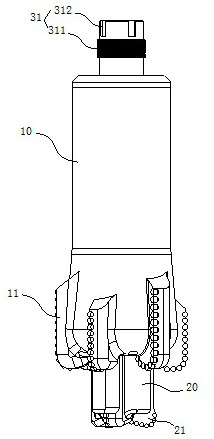

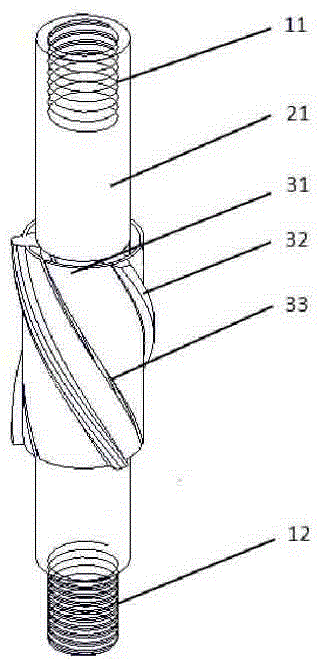

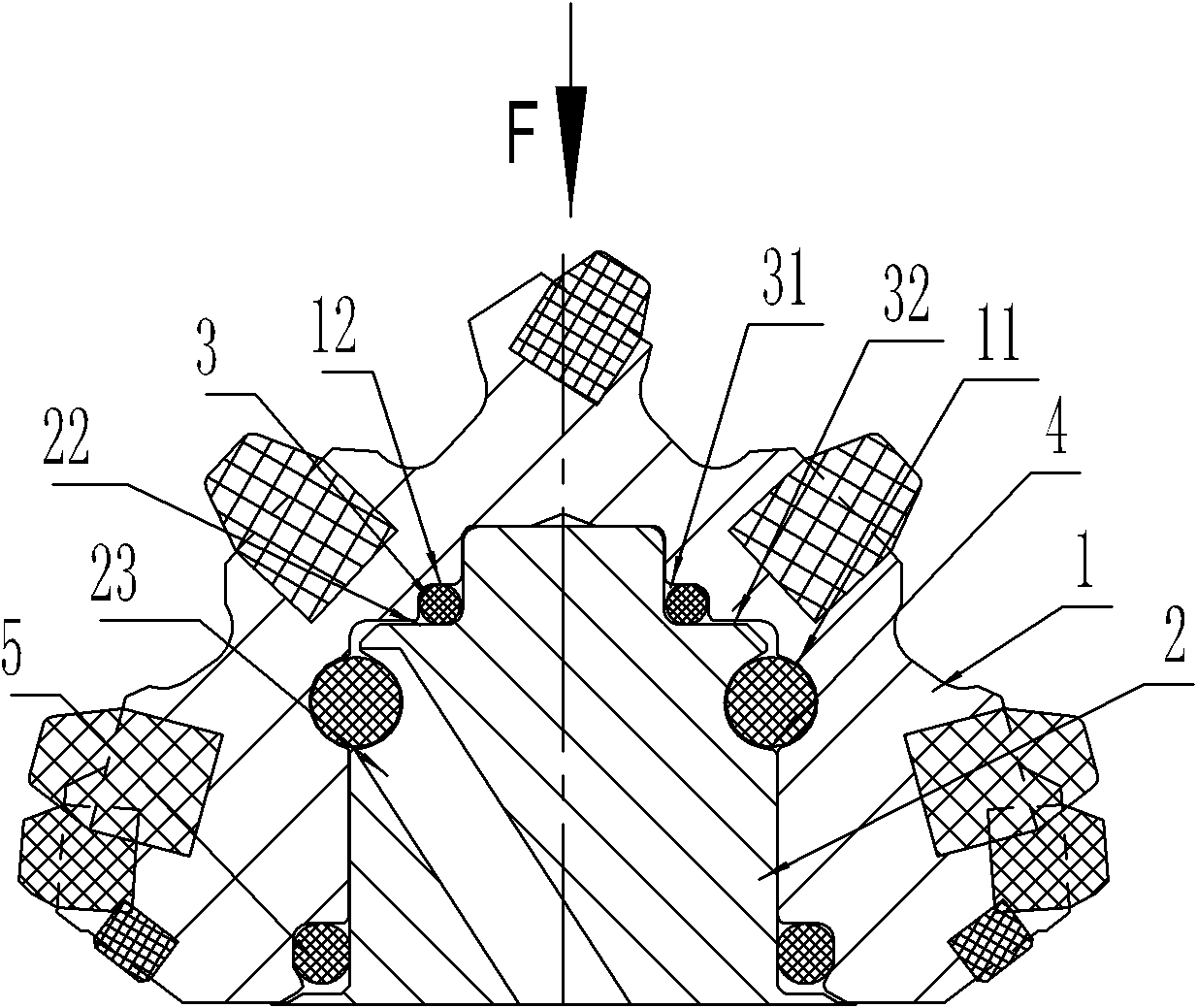

Open type spiral wing mud drum-preventing centralizer for well drilling

InactiveCN103306614ASimple structureLow investment costDrilling rodsDrilling casingsWell drillingEngineering

The invention discloses an open type spiral wing mud drum-preventing centralizer for well drilling. The open type spiral wing mud drum-preventing centralizer for well drilling comprises a tubular centralizer body (21), wherein at least one spiral centralizing wing (31) is arranged on the outer wall of the middle section of the centralizer body (21); a mud block cutting belt (32) extending along the spiral centralizing wing (31) is arranged on one side of the spiral centralizing wing (31); and the mud block cutting belt (32) and the centralizer body (21) maintain preset distance. The mud block cutting belt is arranged on one side of the spiral centralizing wing, so after mud blocks scraped from the wall of the well by the spiral centralizing wing gather to a certain degree, the state that the mud blocks continue to form a large mud drum can be changed under the action of the mud block cutting belt and can be changed into the state of a relatively thin and long strip; after more and more mud blocks are accumulated, the mud blocks are pushed to the lower part of the mud block cutting belt, so that the mud blocks are washed away by high-speed liquid and mud drums of the centralizer are prevented.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Closed spiral wing anti-balling centralizer for well drilling

InactiveCN103321594ASimple structureLow investment costDrilling rodsDrilling casingsEngineeringHelix

The invention discloses a closed spiral wing anti-balling centralizer for well drilling. The closed spiral wing anti-balling centralizer for well drilling comprises a tubular centralizer body (21), at least one spiral centralizer wing (32) is arranged on the outer wall of the middle section of the centralizer body (21), a coaxial closed barrel (31) is arranged in the middle section of the centralizer body (21), the external diameter of the closed barrel (31) is smaller than that of each spiral centralizer wing (32), the closed barrel (31) and the centralizer body (21) form an annular space, and a clod discharge chute (33) communicated with the annular space is formed in the outer wall of the closed barrel (31). Owing to the structure of the closed barrel and the clod discharge chute, clod can enter the annular space formed by the closed barrel and the centralizer body through the clod discharge chute and then is taken away by high-speed fluids passing the annular space when the clod scraped from the wall of a well by the centralizer wings is gathered to a certain extent, and balling of the centralizer is prevented.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Speed-increasing drilling bit for downhole local pressure reducing

PendingCN107842316ARelieve pressureImprove cutting efficiencyDrill bitsConstructionsDiamond cuttingThermodynamics

The invention belongs to the technical field of drilling tool equipment, and specifically discloses a speed-increasing drilling bit for downhole local pressure reducing. The speed-increasing drillingbit comprises an alloy steel core, and a plurality of cutter blades are evenly distributed on the alloy steel core; the cutter blades are each in a turbine blade shape, and the top ends of the cutterblades are converged in the center line of the alloy steel core; the cutter blades are provided with diamond cutting teeth; and the number of the cutter blades is 5-9, and the cutter blades and the alloy steel core are of an integrated structure. The speed-increasing drilling bit for downhole local pressure reducing can effectively improve the drilling speed and has good stability.

Owner:邓立宇

Anti-friction centralizer with anti-mud bag and pressurized propulsion function

The invention relates to an anti-friction centralizer having anti-balling and boosted propelling functions. The anti-friction centralizer comprises a body and roller assemblies, wherein the body is connected between underhole tools through threads, and the roller assemblies are arranged on prisms which are uniformly distributed outside the body along the circumferential direction; a certain included angle exists between the roller shaft of each roller assembly and the axial direction of the body; the body rotates in the drilling process, and the rollers spirally roll on a well wall to push an underhole tool to move forward and supply drilling pressure to a drill bit; alloy teeth are embedded to the outer surfaces of the rollers and positions, provided with the roller assemblies, of the body, so that the friction mode is changed into rolling friction, friction resistance of the underhole drill with the well wall in the drilling process can be reduced, and failure of roller balling can be prevented. The anti-friction centralizer has a relatively simple structure, low cost, high strength and long service life, and can be used for solving the technical problems of poor resistance reduction effect, complicated structure, low strength and short service life in the prior art.

Owner:DAQING DANNUO PETROLEUM TECH DEV

Directional jet cooling PDC drill bit

ActiveCN112681980AFast flowIncrease flow rateEarth drilling toolsDrill bitsMining engineeringFoundation engineering

The invention discloses a directional jet cooling PDC drill bit, and belongs to the technical field of drilling of petroleum and gas, mine engineering, geothermal wells, building foundation engineering construction, geology, hydrology and the like. The directional jet cooling PDC drill bit comprises a drill bit body and a plurality of blades, wherein each blade is provided with cutting teeth; the drill bit body is further provided with a plurality of sets of directional nozzles and conventional nozzles, each set of directional nozzles and conventional nozzles are located between the two corresponding adjacent blades, and outlets of each set of directional nozzles correspond to tooth tips of the cutting teeth on the corresponding blade. When the cutting teeth of the drill bit cut rock, slurry jetted from the directional nozzles is directionally jetted to the tooth tips, cutting the rock, of the cutting teeth, the rapid cooling and temperature lowering effects on the cutting teeth are achieved, heat damage, caused by cutting heat, to the cutting teeth is prevented, the performance of the cutting teeth is greatly improved, the service life of the drill bit is prolonged, the footage of the single drill bit is increased, rock debris generated by cutting of the cutting teeth can be removed through the slurry jetted from the directional nozzles, the rock debris cannot be attached to the cutting teeth, and bit balling is prevented; meanwhile, the slurry jetted from the directional nozzles is high in flow speed and pressure, the cutting teeth can be assisted in rock breaking, and the rock breaking efficiency of the drill bit is improved.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

Illegal cooking oil lubricant and preparation method thereof

The invention discloses an illegal cooking oil lubricant and a preparation method thereof. The illegal cooking oil lubricant comprises the following components in percentage by weight: 40%-60% of illegal cooking oil, 0.5%-1.5% of sodium sulfite, 1%-3% of sorbide oleate, 0.02%-0.04% of antioxidants, 0.2%-0.3% of extreme-pressure antiwear agents, 0.05%-0.1% of formaldehyde, 1.0%-1.2% of sodium hydroxide and the balance of water. Through the illegal cooking oil lubricant disclosed by the invention, the problem that torque and friction resistance are reduced through lubrication in the drilling process of a horizontal well is effectively solved, moreover, a new way is provided for the recycling of the illegal cooking oil, and the preparation cost of the lubricant can be reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Open spiral wing anti-mud bag centralizer for drilling

InactiveCN103306614BSimple structureLow investment costDrilling rodsDrilling casingsWell drillingEngineering

The invention discloses an open type spiral wing mud drum-preventing centralizer for well drilling. The open type spiral wing mud drum-preventing centralizer for well drilling comprises a tubular centralizer body (21), wherein at least one spiral centralizing wing (31) is arranged on the outer wall of the middle section of the centralizer body (21); a mud block cutting belt (32) extending along the spiral centralizing wing (31) is arranged on one side of the spiral centralizing wing (31); and the mud block cutting belt (32) and the centralizer body (21) maintain preset distance. The mud block cutting belt is arranged on one side of the spiral centralizing wing, so after mud blocks scraped from the wall of the well by the spiral centralizing wing gather to a certain degree, the state that the mud blocks continue to form a large mud drum can be changed under the action of the mud block cutting belt and can be changed into the state of a relatively thin and long strip; after more and more mud blocks are accumulated, the mud blocks are pushed to the lower part of the mud block cutting belt, so that the mud blocks are washed away by high-speed liquid and mud drums of the centralizer are prevented.

Owner:CHINA NAT OFFSHORE OIL CORP +1

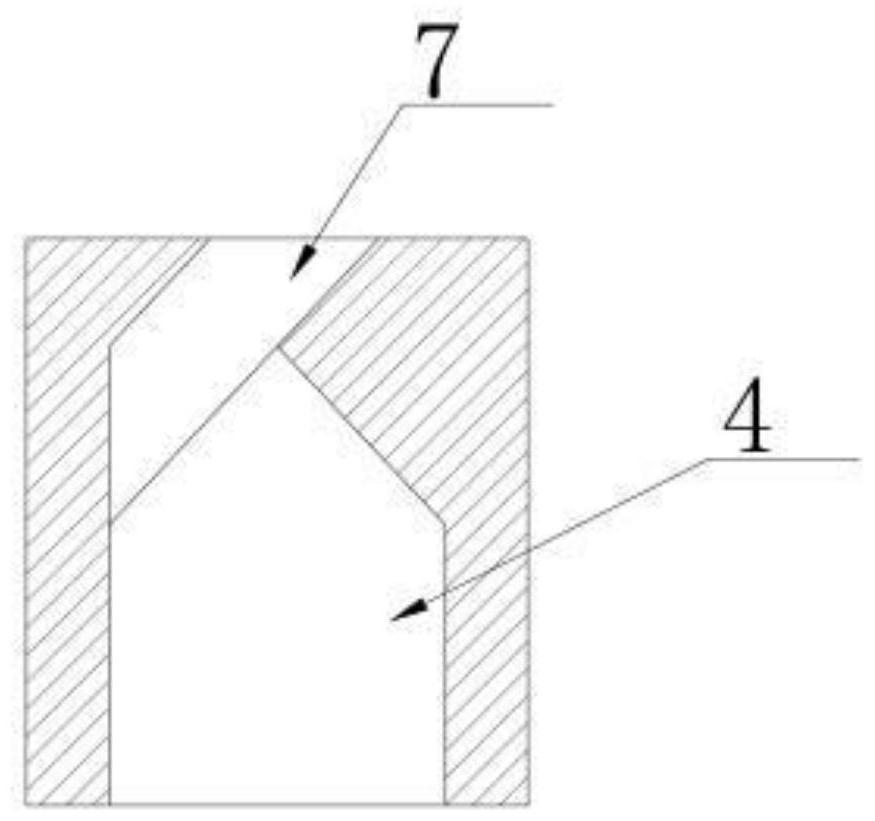

An anti-mud bag PDC drill bit with pits on the surface of the runner groove

The invention discloses a balling-resistant PDC (polycrystalline diamond compact) drill bit with pits in the surfaces of flow passages. The balling-resistant PDC drill bit comprises a drill bit body, the lower portion of the drill bit body is provided with a screwed joint connected with a drill rod, the upper portion of the drill bit body is provided with a plurality of blades, grooves between the blades form flow passage grooves of the drill bit, at least two pits are formed in the surface of each flow passage groove, and the bottom surface of each pit extends upwards from the deepest position of the pit bottom to the inclined plane of the surface of the corresponding flow passage groove. By the balling-resistant PDC drill bit, adhesion tendency of rock debris in the flow passage grooves is reduced obviously, and the flow passages are prevented from being blocked to achieve the purpose of resisting balling, so that drilling efficiency of the drill bit is improved, service life of the drill bit is prolonged, and drilling cost is lowered.

Owner:SOUTHWEST PETROLEUM UNIV +2

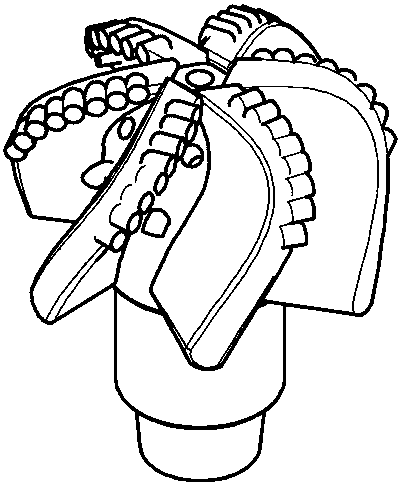

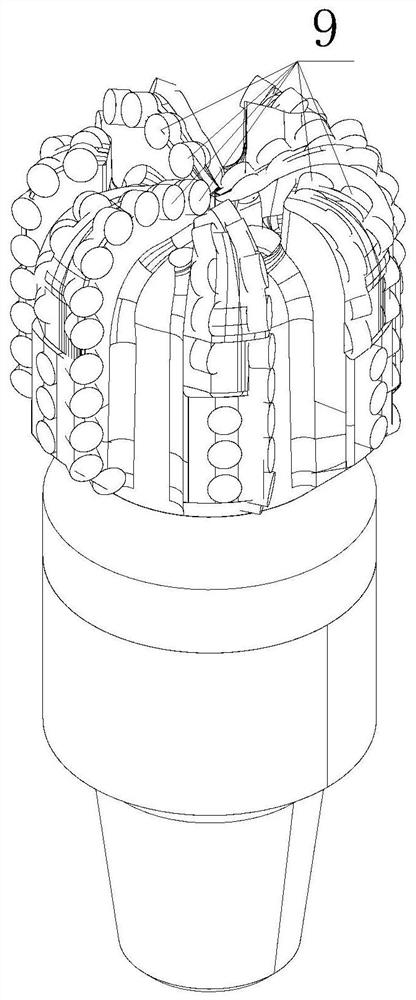

Special drill bit for rotary steering of superhard formation

The invention relates to the technical field of deep drilling, in particular to a special drill bit for rotary steering of superhard formations, which comprises a connector, a working main body and a cutting component, the working main body is fixedly connected with the upper end of the connector, and the cutting component is fixedly connected with the working main body; the cutting assembly comprises a cutting block set and a cutting tooth set, the cutting block set is fixedly connected to the outer circle of the working body, and the cutting tooth set is arranged on the cutting block set. A heat conduction cavity, a dry ice function chamber, a flow guide opening set and a heat dissipation hole set are sequentially arranged in the connecting body from top to bottom, a first flow guide opening and a second flow guide opening are oppositely formed in the flow guide opening set at intervals, and a first heat dissipation mesh and a second heat dissipation mesh are oppositely formed in the heat dissipation hole set at intervals. The problems that in the prior art, heat dissipation is not timely in the high-speed using process of a drill bit, and the drilling effect is poor when the drill bit faces a superhard stratum are solved.

Owner:四川中安嘉盛石油科技有限公司

A pdc bit suitable for tight mudstone formations

The invention belongs to the field of drilling equipment, and in particular relates to a PDC drill bit suitable for tight mudstone formations, comprising an outer cutting unit; an inner cutting unit; a connecting rod; a locking mechanism and a diamond composite cutting tooth. It moves in the circumferential direction, and realizes the locking and release between the two cutting units through the locking mechanism. When cutting the fluffy formation, the inner cutting unit acts as a pilot bit and protrudes in front of the outer cutting unit, and the outer cutting unit acts as a reaming bit. The area around the inner cutting unit is reamed to improve the overall drilling capacity of the drill bit. At this time, there is a large gap between the inner blade and the outer blade, which can avoid the mud bag at the front end of the bit; when cutting tight mudstone formations, The inner cutting unit and the outer cutting unit can be kept flush, thereby dispersing cutting stress, ensuring stable drilling process and avoiding chipping. The invention can switch back and forth between the two working stations, so as to adapt to the complex formation environment where the soft and hard are interlaced.

Owner:SHENGLI OIL FIELD WANHE OIL CONSTR TECHN LIMITED LIABILITY +1

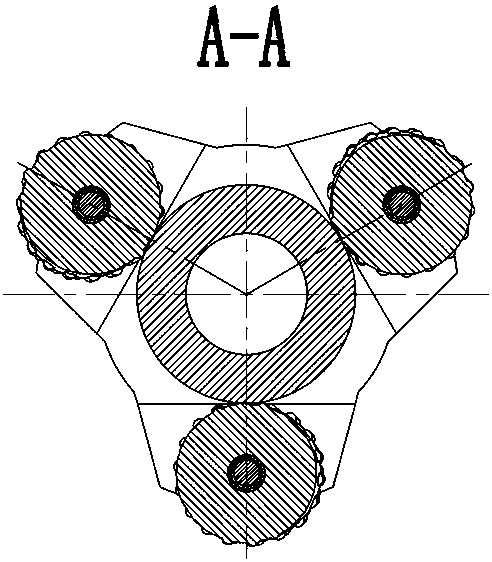

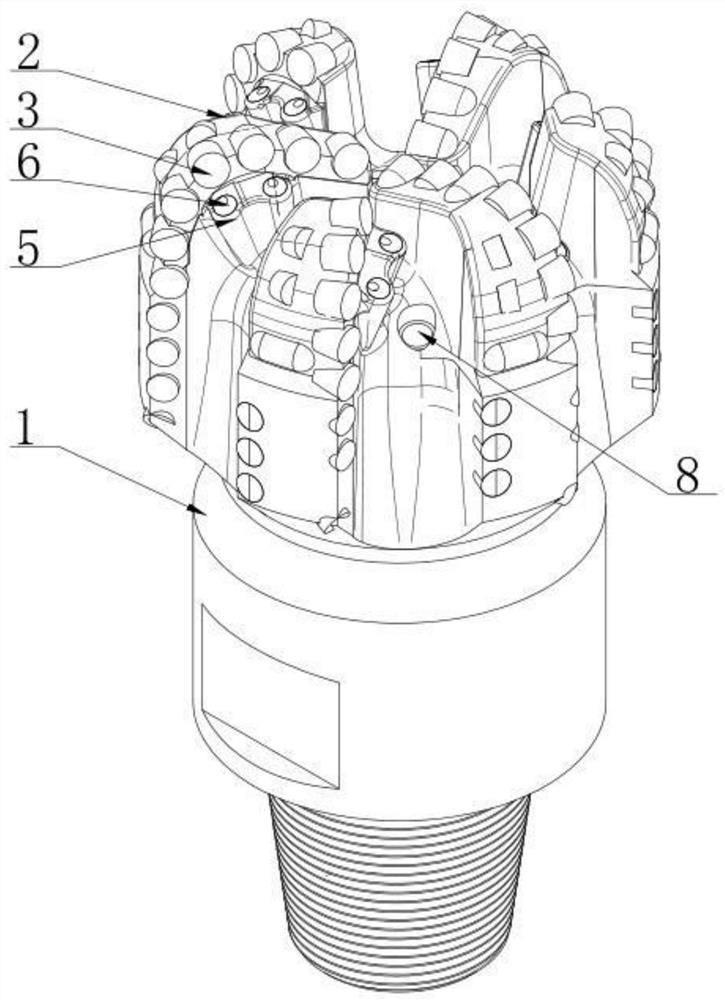

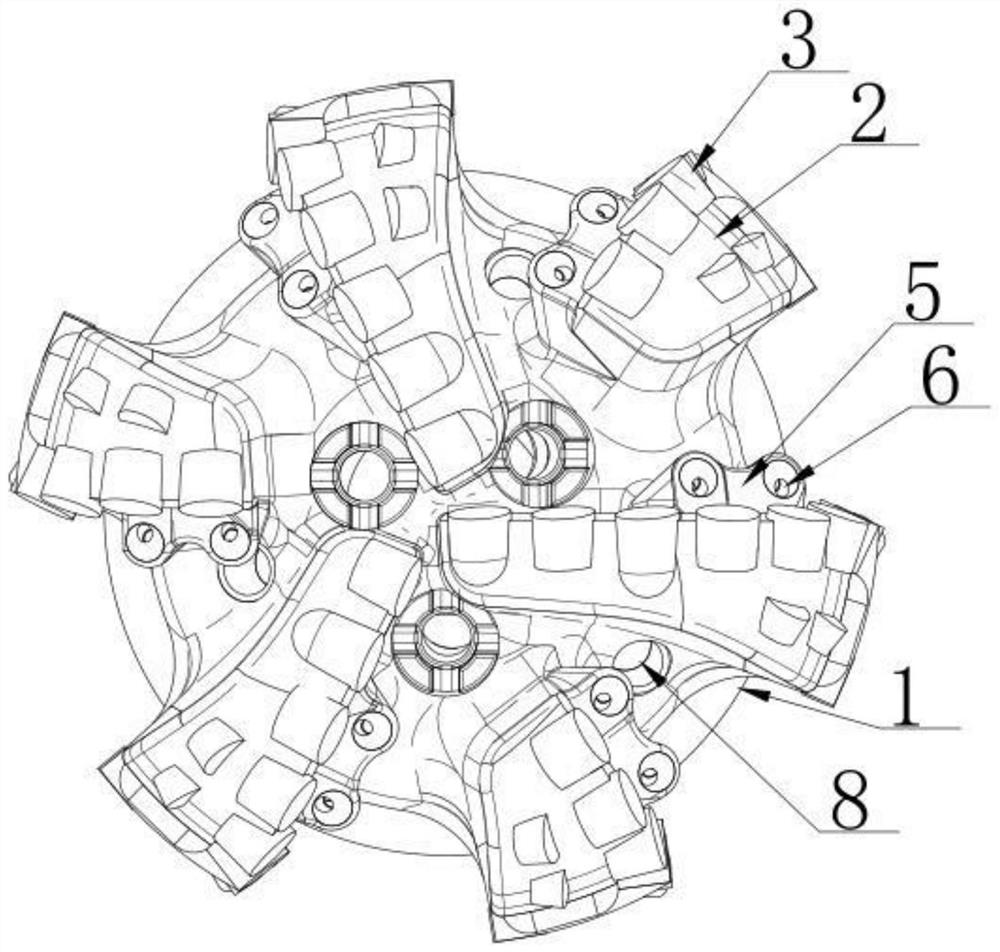

A combined single-cone drill bit with a rolling ring gear

The invention discloses a combined single-cone drill bit with a rolling ring gear, comprising a drill body (1), a cone (3), a cone tooth (4) and a palm journal (15), the drill body (1) is provided with gauging teeth (2), the palm journal (15) is arranged at the lower end of the drill body (1), and the cone (3) is rotationally connected with the palm journal (15). A rolling ring gear (6) is rotatably connected to the gear wheel (3), and a needle bearing (11) is arranged between the inner ring of the rolling gear ring (6) and the gear wheel (3), for realizing the gear wheel (3) ) and the rolling ring gear (6), the rolling ring gear teeth (13) are arranged on the rolling ring gear (6), and a fixed cutting structure (8) is fixed at one end of the tooth palm journal (15). Fixed cutting teeth (9) are evenly distributed on the cutting structure (8). The invention has the advantages of improving the rock-breaking efficiency of the drill bit, effectively preventing the drill bit from bagging, and prolonging its service life.

Owner:SOUTHWEST PETROLEUM UNIV

Enclosed screw wing anti-mud bag centralizer for drilling

InactiveCN103321594BSimple structureLow investment costDrilling rodsDrilling casingsWell drillingEngineering

The invention discloses a closed spiral wing anti-balling centralizer for well drilling. The closed spiral wing anti-balling centralizer for well drilling comprises a tubular centralizer body (21), at least one spiral centralizer wing (32) is arranged on the outer wall of the middle section of the centralizer body (21), a coaxial closed barrel (31) is arranged in the middle section of the centralizer body (21), the external diameter of the closed barrel (31) is smaller than that of each spiral centralizer wing (32), the closed barrel (31) and the centralizer body (21) form an annular space, and a clod discharge chute (33) communicated with the annular space is formed in the outer wall of the closed barrel (31). Owing to the structure of the closed barrel and the clod discharge chute, clod can enter the annular space formed by the closed barrel and the centralizer body through the clod discharge chute and then is taken away by high-speed fluids passing the annular space when the clod scraped from the wall of a well by the centralizer wings is gathered to a certain extent, and balling of the centralizer is prevented.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A kind of drilling fluid for increasing mudstone drilling speed and its preparation method and application

ActiveCN106543990BImprove the lubrication effectEnhanced inhibitory effectDrilling compositionRate of penetrationReducer

The invention relates to a drilling fluid for improving the mudstone drilling speed. The drilling fluid is prepared from the following components by weight: 1000 parts of water, 10-30 parts of bentonite, 0.5-1.5 parts of sodium carbonate, 2-20 parts of a flow pattern regulator, 2-15 parts of a fast drilling agent, 2-8 parts of polyether amine, 1-6 parts of a polymer coating agent, 2-15 parts of a salt-tolerant and temperature resistant filtrate reducer, 20-35 parts of sulfonated phenolic resin and optionally 15-35 parts of an plugging agent. The accelerating drilling fluid provided by the invention has excellent resistance to salt, calcium and bad soil, and can effectively improve the rate of penetration. The invention also relates to a preparation method of the drilling fluid. The method includes the steps of: adding bentonite and sodium carbonate into water, mixing the substances evenly, then conducting standing maintenance, then adding the polymer flow pattern regulator, the polymer coating agent, the fast drilling agent, polyether amine, the salt-tolerant and temperature resistant filtrate reducer, sulfonated phenolic resin and the plugging agent, mixing the substances evenly, and performing standing for standby use. The invention also relates to application of the accelerating drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

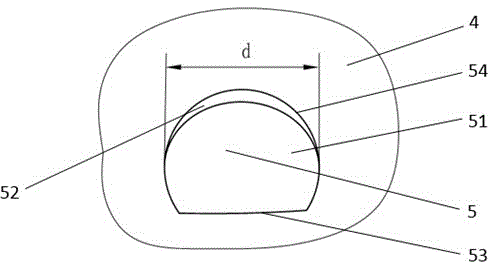

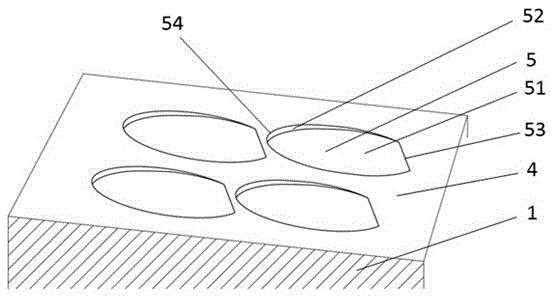

Balling-resistant PDC (polycrystalline diamond compact) drill bit with communicated pits in surfaces of flow channels

ActiveCN103603605AAvoid accumulationStable lubricating fluid compensation capabilityDrill bitsPolycrystalline diamondDrill bit

The invention discloses a balling-resistant PDC (polycrystalline diamond compact) drill bit with communicated pits in the surfaces of flow channels. The balling-resistant PDC drill bit comprises a drill bit body. A threaded connector connected with a drill pipe is arranged on the lower portion of the drill bit body, a plurality of blades are arranged on the upper portion of the drill bit body, grooves formed in positions among the blades form flow channel grooves of the drill bit, and the pits which are communicated with one another are arranged on parts or all of the surfaces of the flow channel grooves. Compared with a conventional PDC drill bit, the balling-resistant PDC drill bit with the communicated pits in the surfaces of the flow channels has the advantages that the quantity of rock debris adhered on the flow channel grooves can be obviously reduced, blockage of the flow channels can be prevented, the purpose of balling resistance can be achieved, accordingly, the drilling efficiency of the drill bit can be improved, and the well drilling cost can be reduced.

Owner:四川川石金刚石钻头有限公司

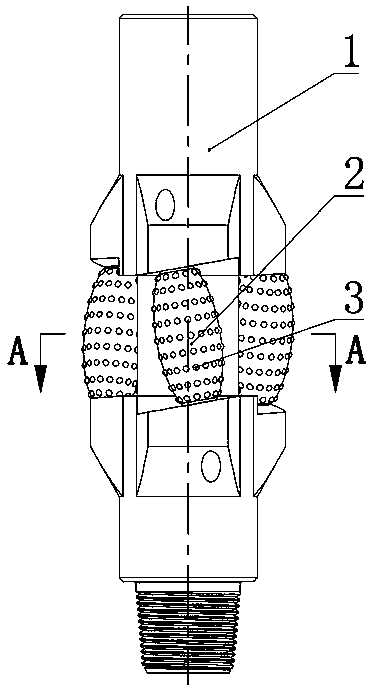

Composite drill applicable to middle Yangtze Cambrian system shale gas exploitation

PendingCN107143287AImprove drilling efficiencyLow costDrill bitsConstructionsMining engineeringShale gas

The invention discloses a composite drill applicable to middle Yangtze Cambrian system shale gas exploitation. The composite drill comprises a drill body, the inside of the drill body is provided with a flushing cavity, the front end of the body is provided with a cutting part, the top of the cutting part protrudes outward to form an arc top face, the cutting part is prominently provided with three evenly distributed main cutting blades, the main cutting blades extend to the arc top face and are converged at the arc top face, the portions, located at the gaps of the converging part of the cutting blades, of the arc top face are provided with three nozzles, the nozzles are communicated with the flushing cavity inside the drill body, the cutting part is further provided with a shaft neck part, the shaft neck part is provided with an opening, the opening is communicated with the flushing cavity, the top end of the shaft neck part is connected with a spherical sub cutting face in a clamping mode, and several particle-shaped subsidiary cutting blades are inlaid on the sub cutting face. According to the composite drill applicable to the middle Yangtze Cambrian system shale gas exploitation, the advantages of a PDC drill and a roller bit are combined, the hole drilling efficiency is improved, the application range of the drill is expanded at the same time, the cost is lowered, and the composite drill is applicable to the middle Yangtze Cambrian system shale gas exploitation.

Owner:YICHANG SHENDA PETROMACHINE

Rolling thrust device for cone bit bearing

The invention discloses a rolling thrust device for a cone bit bearing. The rolling thrust device is characterized in that: a thrust steel ball group is arranged between a cone and a cone leg thrust surface; and a radial position of the thrust steel ball group is controlled in a steel ball runway which is arranged on the cone, or on the cone leg or on the cone and the cone leg at the same time. The device reduces friction of the axial thrust surface of the cone bit bearing and prolongs the service life of the cone bit bearing.

Owner:TIANJIN LILIN GASOLINEEUM MACHINERY

The anti-mud bag pdc drill bit with through pits on the surface of the runner

ActiveCN103603605BNot easy to accumulateAvoid accumulationDrill bitsWell drillingPolycrystalline diamond

The invention discloses a balling-resistant PDC (polycrystalline diamond compact) drill bit with communicated pits in the surfaces of flow channels. The balling-resistant PDC drill bit comprises a drill bit body. A threaded connector connected with a drill pipe is arranged on the lower portion of the drill bit body, a plurality of blades are arranged on the upper portion of the drill bit body, grooves formed in positions among the blades form flow channel grooves of the drill bit, and the pits which are communicated with one another are arranged on parts or all of the surfaces of the flow channel grooves. Compared with a conventional PDC drill bit, the balling-resistant PDC drill bit with the communicated pits in the surfaces of the flow channels has the advantages that the quantity of rock debris adhered on the flow channel grooves can be obviously reduced, blockage of the flow channels can be prevented, the purpose of balling resistance can be achieved, accordingly, the drilling efficiency of the drill bit can be improved, and the well drilling cost can be reduced.

Owner:四川川石金刚石钻头有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com