Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Increase the edge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

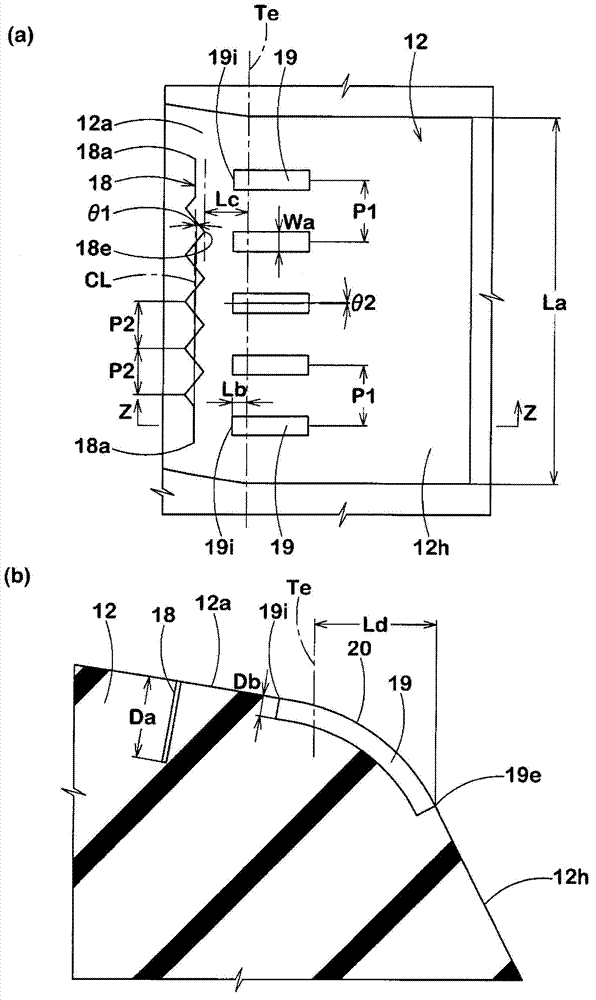

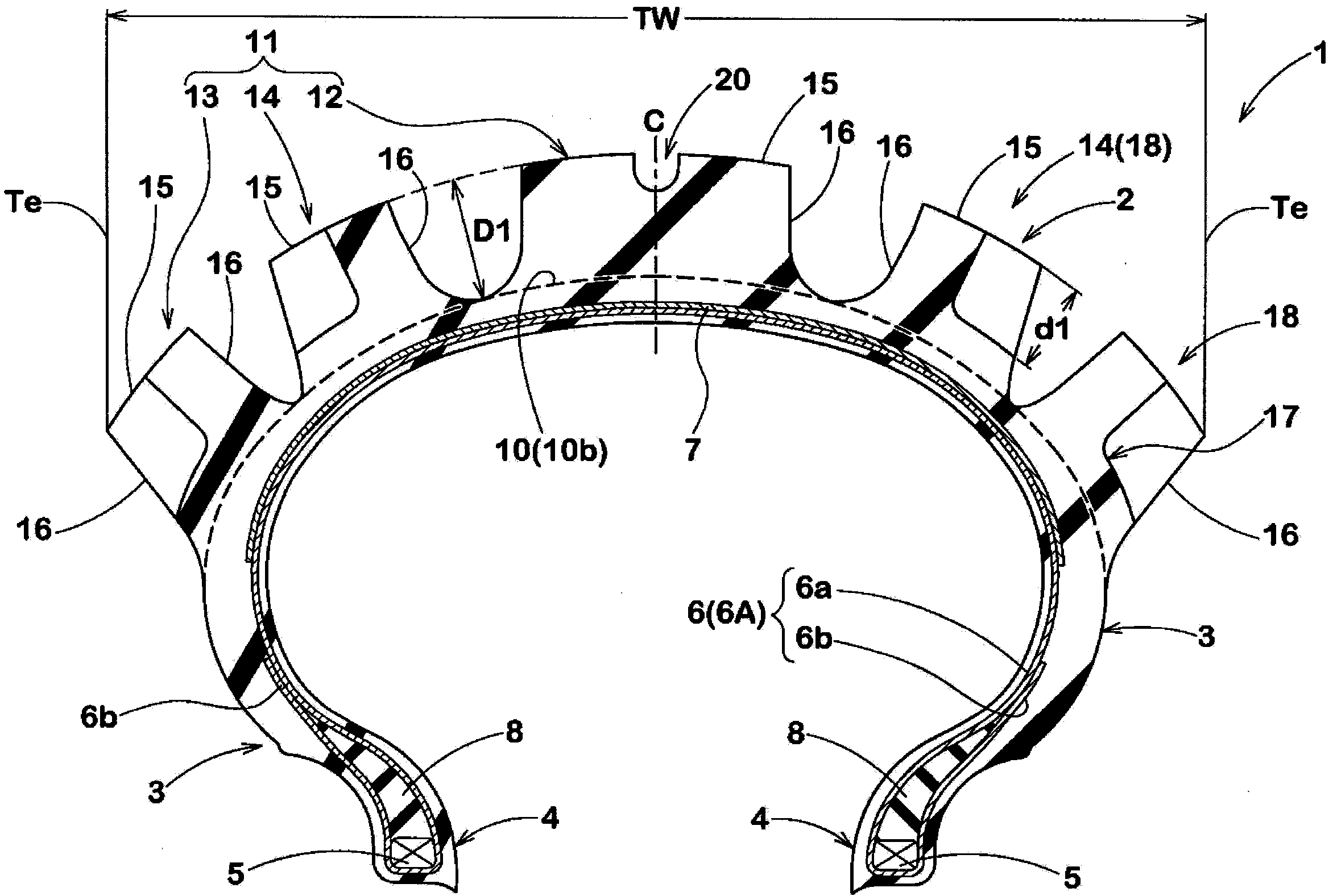

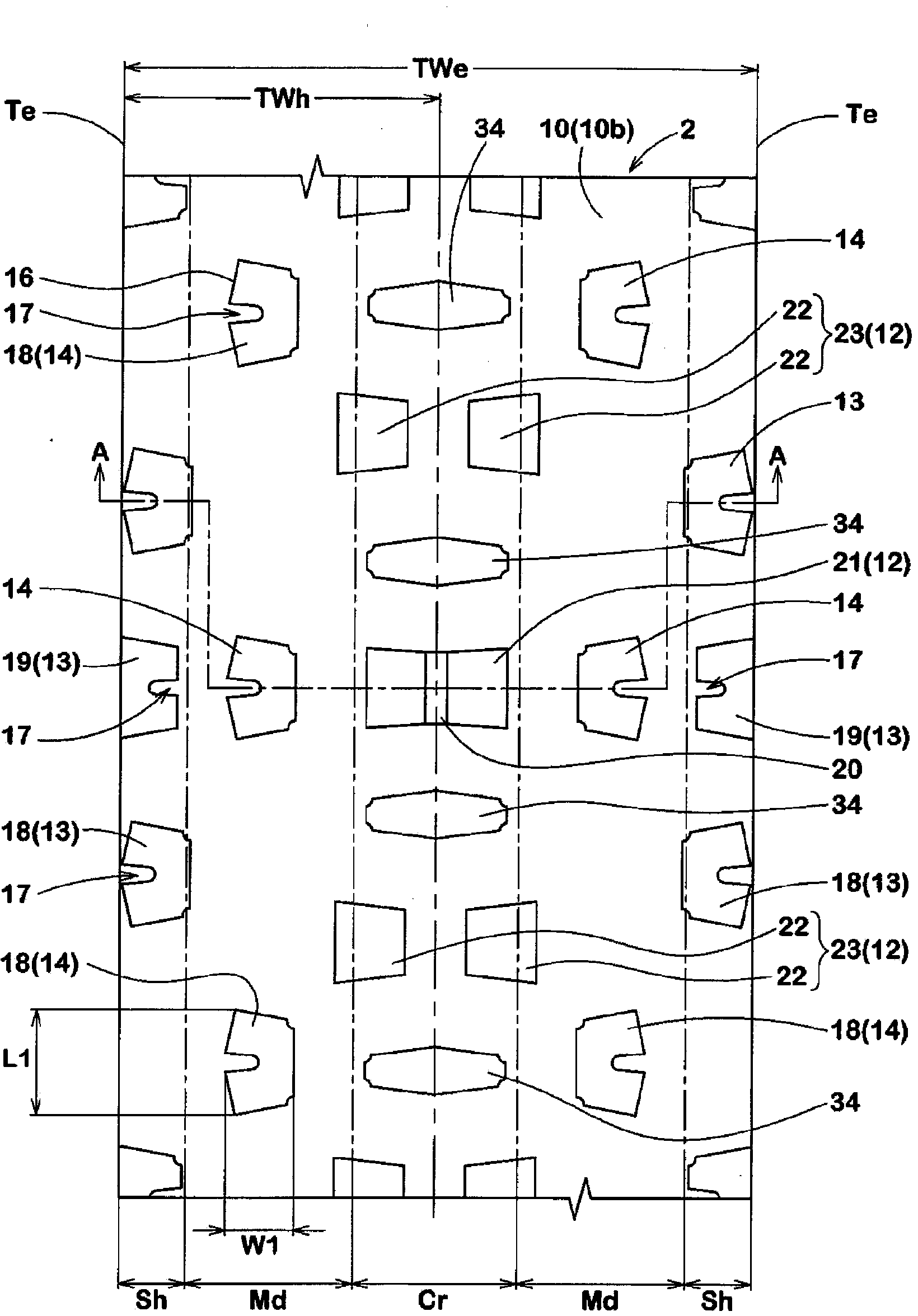

Pneumatic tire

ActiveCN103029526AImprove rigidityImprove cornering performanceTyre tread bands/patternsMechanical engineeringTread

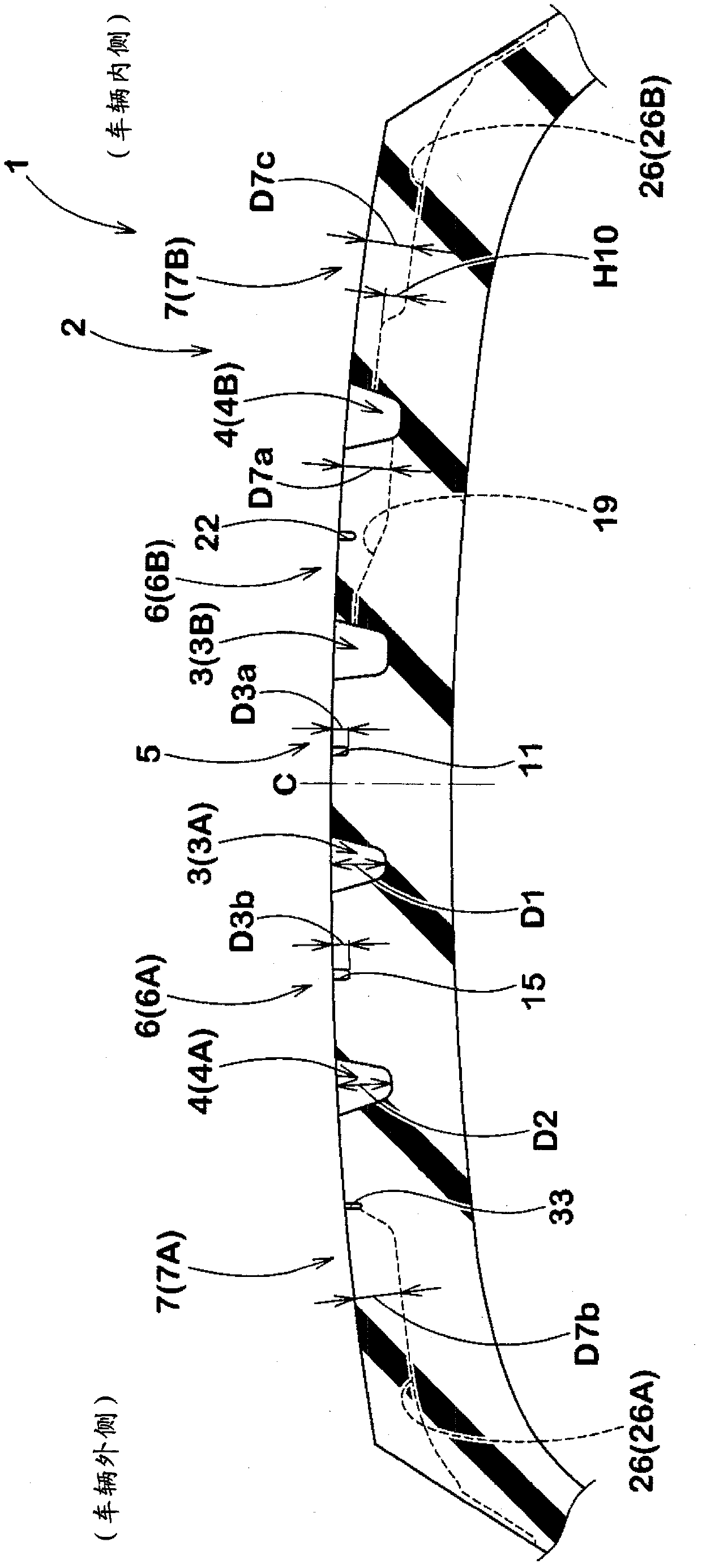

The present invention provides a pneumatic tire capable of evenly improving cornering performance and behavior in critical cornering on snowy / icy roads. The direction of the pneumatic tire to be arranged to a vehicle is specified. Outboard shoulder block (12) and inboard shoulder blocks (13) are formed at a tread portion (2). Both the outboard / inboard shoulder blocks (12, 13) are provided with sipes. The outboard shoulder blocks (12) have an axial width more than the axial width of the inboard shoulder blocks (13). The circumferential sipe (18) of the outboard shoulder blocks (12) extending at an angle of not more than 10 degrees with respect to the tire circumferential direction is arranged at the side of an outboard tread edge (Te) of the vehicle in sipes (17). The outboard shoulder block (12) has an axially outer sidewall (12h) of which surface is provided with a plurality of narrow buttress grooves (19) extending radially inwardly from the outboard tread edge (Te).

Owner:SUMITOMO RUBBER IND LTD

Tread structure of pneumatic tire for motorcycle

ActiveCN104029567AImprove tire drainage performanceImproves tire grip in wet conditionsTyre tread bands/patternsEngineeringTread

The invention discloses a tread structure of a pneumatic tire for a motorcycle. A tread comprises a plurality of main pattern groove groups which are formed in a staggered manner by using the center of the tread as a symmetry center, wherein first auxiliary fine diamond pattern grooves are formed among the main pattern groove groups, and each first auxiliary fine diamond pattern groove comprises a fine diamond part which is provided with a plurality of tangent planes and a fine groove which is connected with the fine diamond part. The fine diamond parts and the fine grooves of the auxiliary fine diamond pattern grooves are designed to be in mutual connection, so that water films can be effectively broken, the water drainage performance of the tire is effectively improved, and the wet land gripping performance of the tire is improved.

Owner:CHENG SHIN RUBBER XIAMEN IND

Pneumatic tire

ActiveCN102729737ASmooth dischargeImprove drainage capacityTyre tread bands/patternsEngineeringTread

A pneumatic tire has an asymmetrical tread pattern. An outboard central main circumferential groove extends zigzag and is made up of alternate minor and major groove segments. The major groove segments incline at an angle of from 5 to 30 degrees with respect to the tire circumferential direction. An inboard central main circumferential groove is widest in main circumferential grooves. outboard middle axial grooves are widest in axial grooves. The distance Li of the widthwise center line of the straight inboard central main circumferential groove from the tire equator is less than the distance Lo of the amplitude center line of the zigzag outboard central main circumferential groove from the tire equator.

Owner:SUMITOMO RUBBER IND LTD

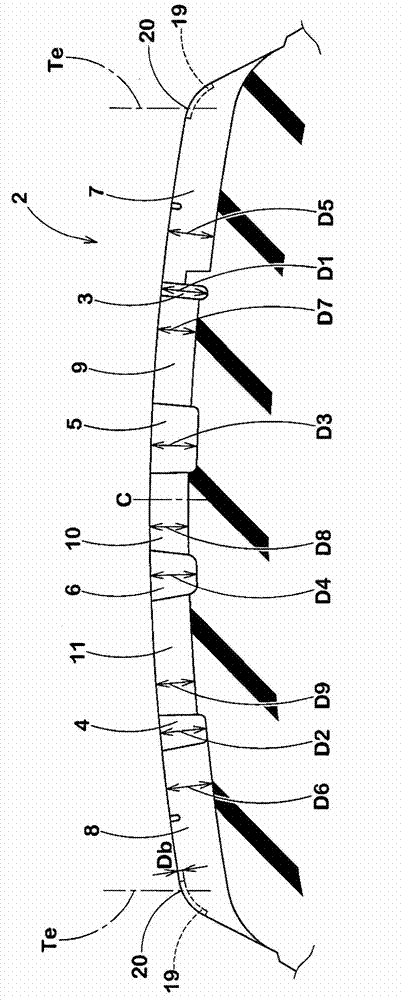

Pneumatic tire

ActiveCN102700366AImprove on-snow performanceRealize white noiseTyre tread bands/patternsLanding zoneEngineering

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire for running on rough terrain

ActiveCN103373180AIncrease the edgeIncrease frictionOff-road vehicle tyresMotorcycle tyresTerrainEngineering

Owner:SUMITOMO RUBBER IND LTD

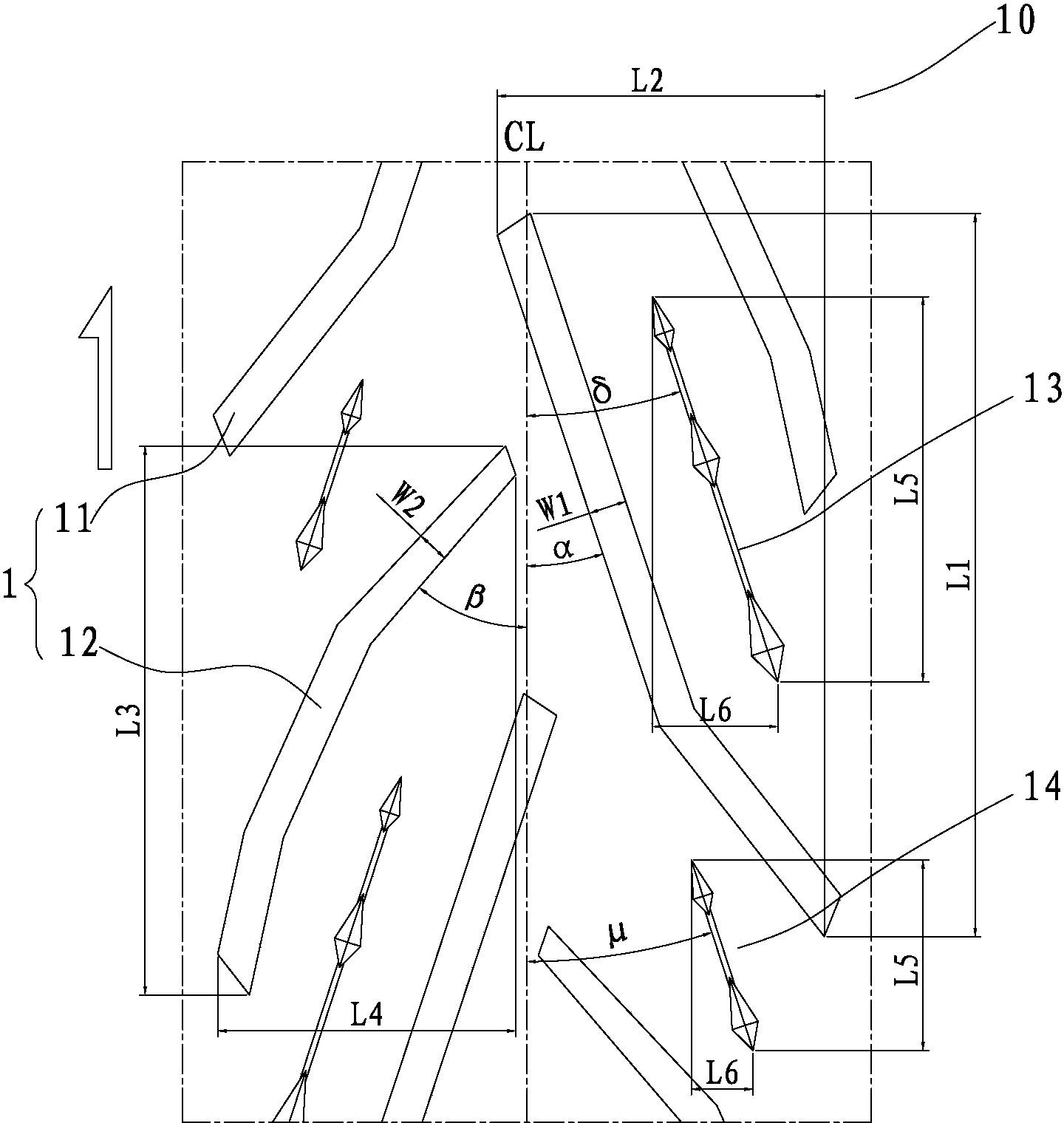

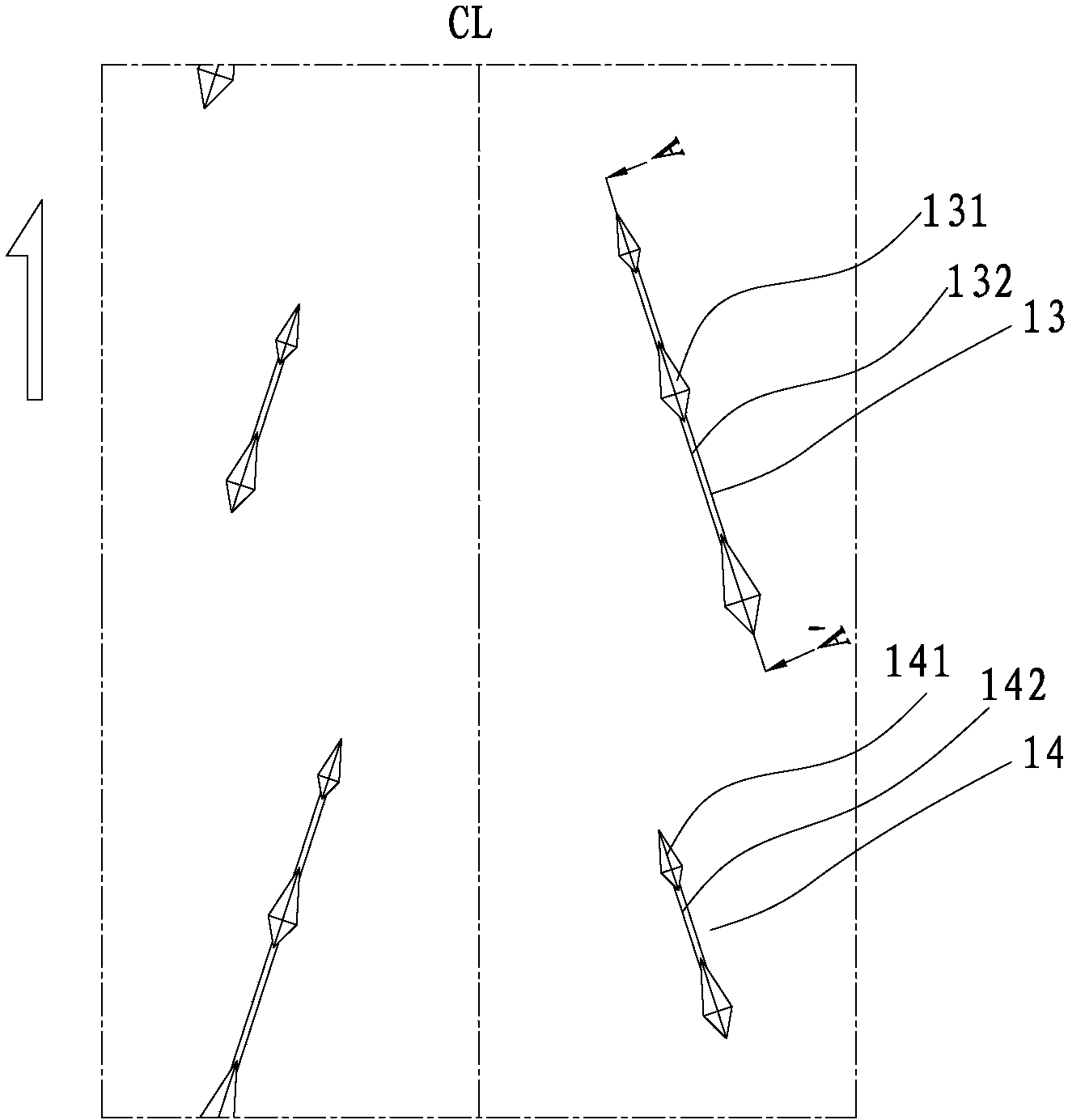

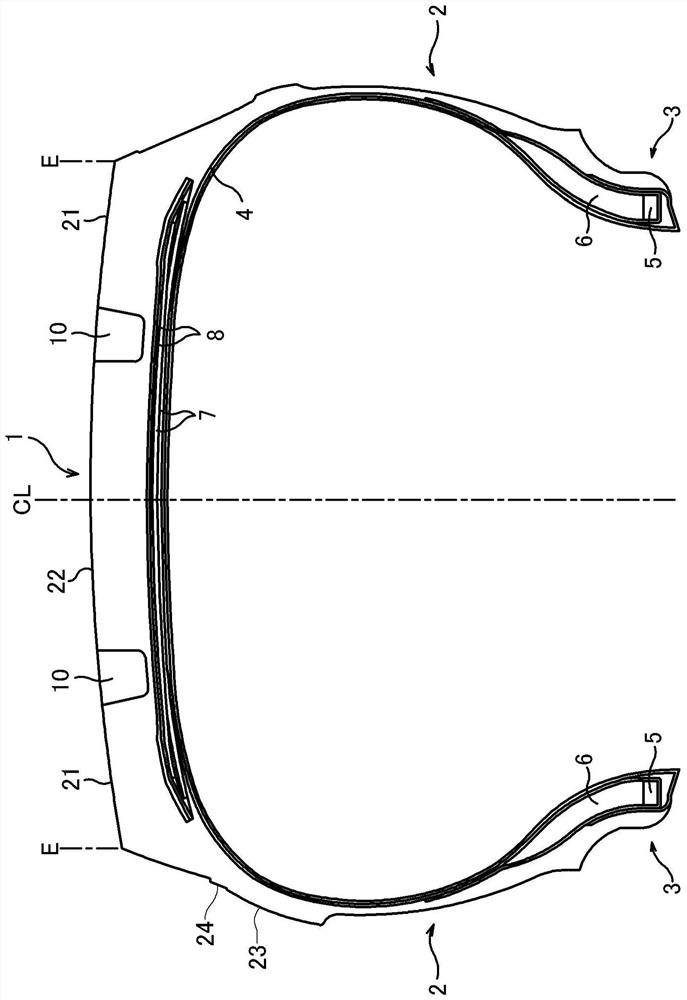

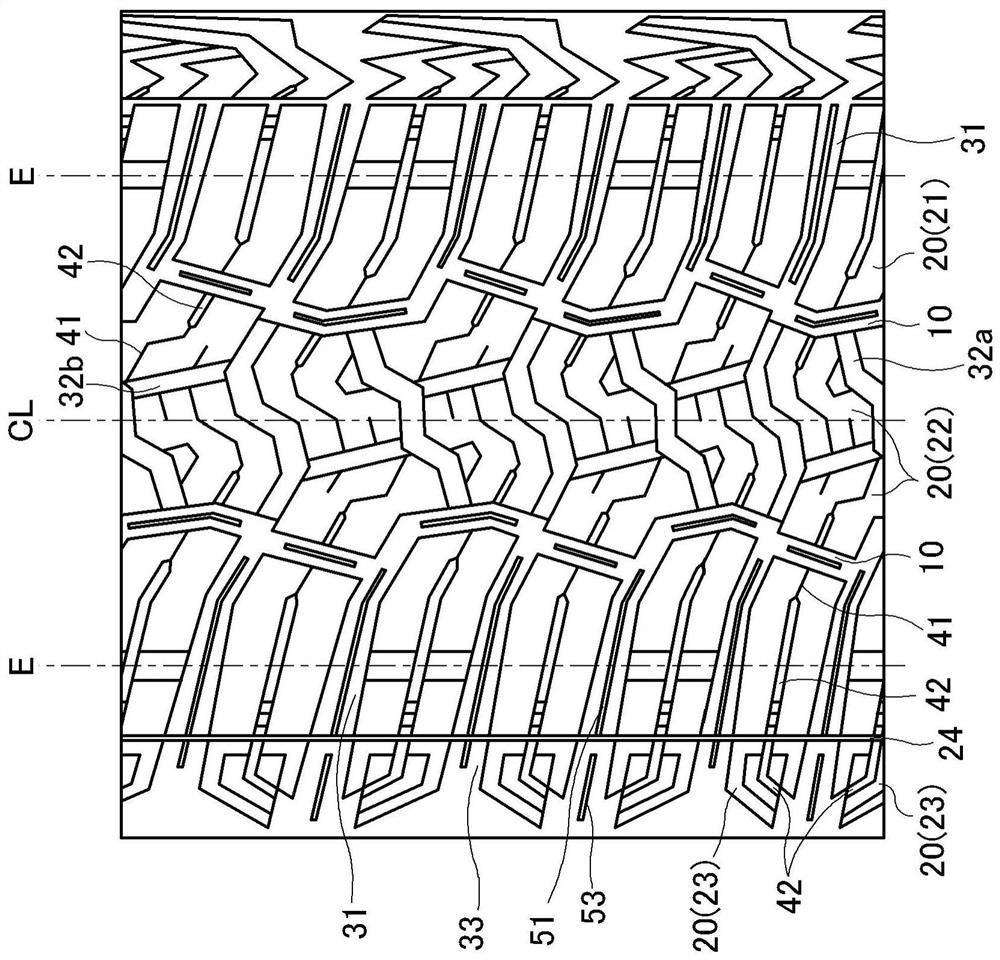

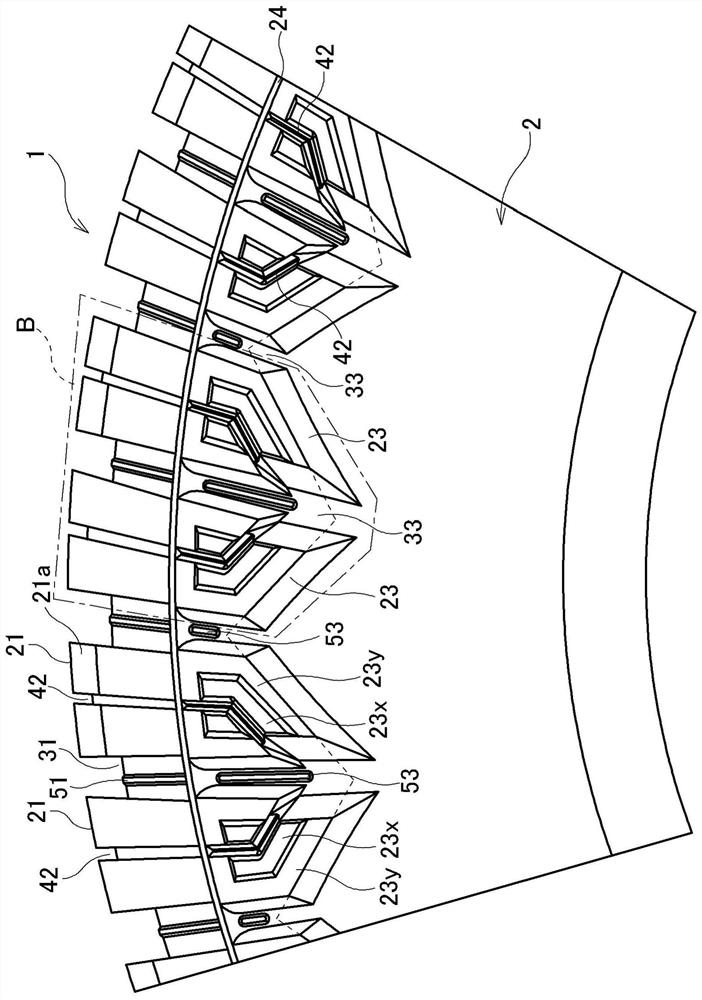

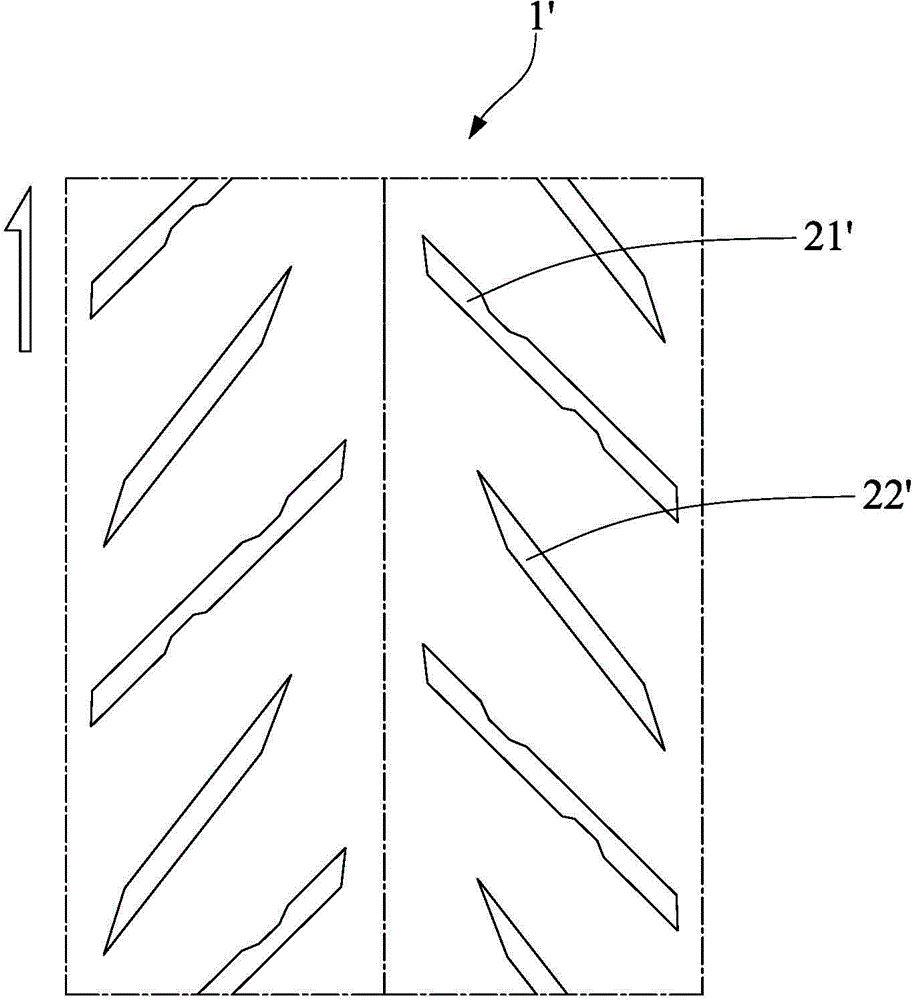

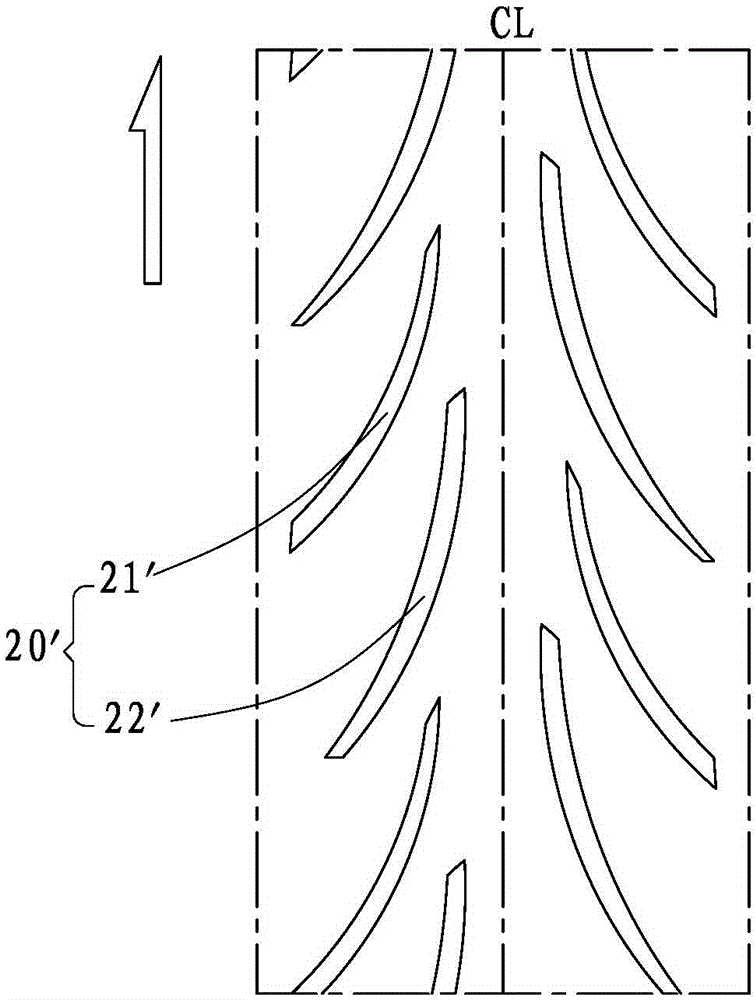

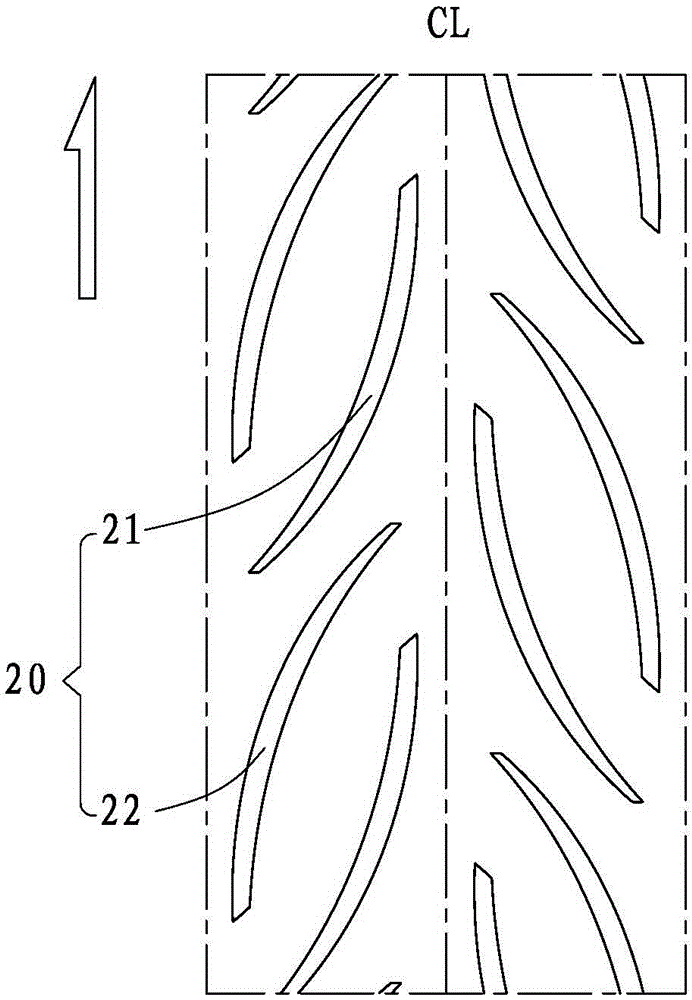

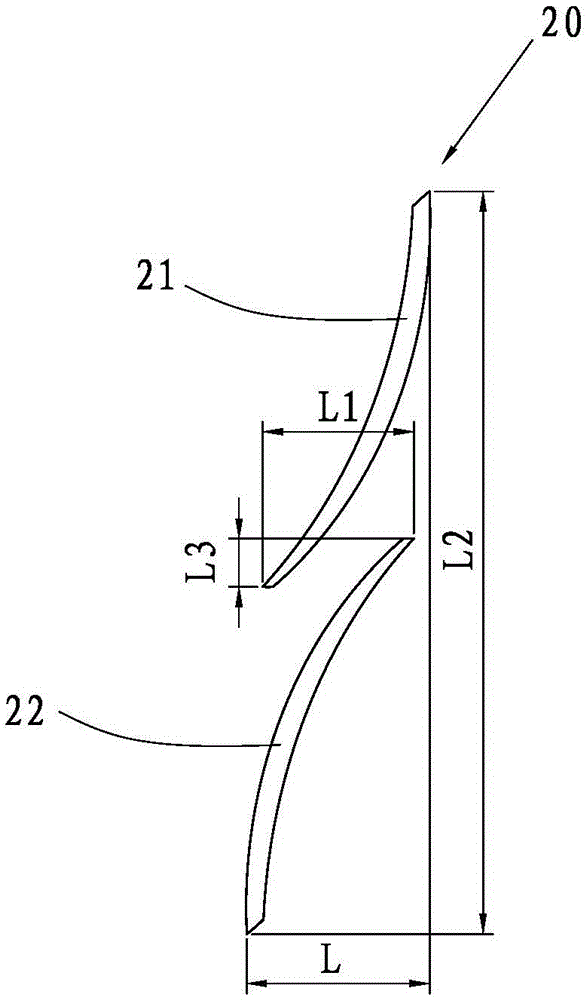

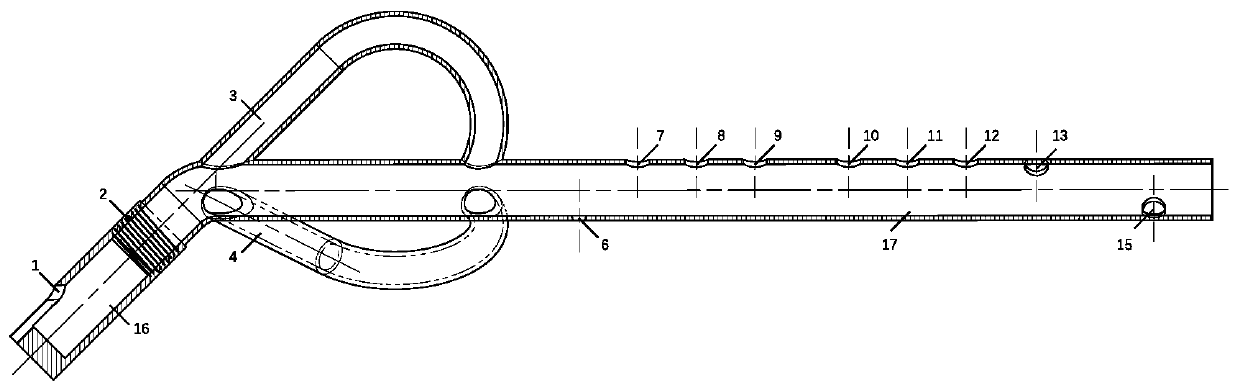

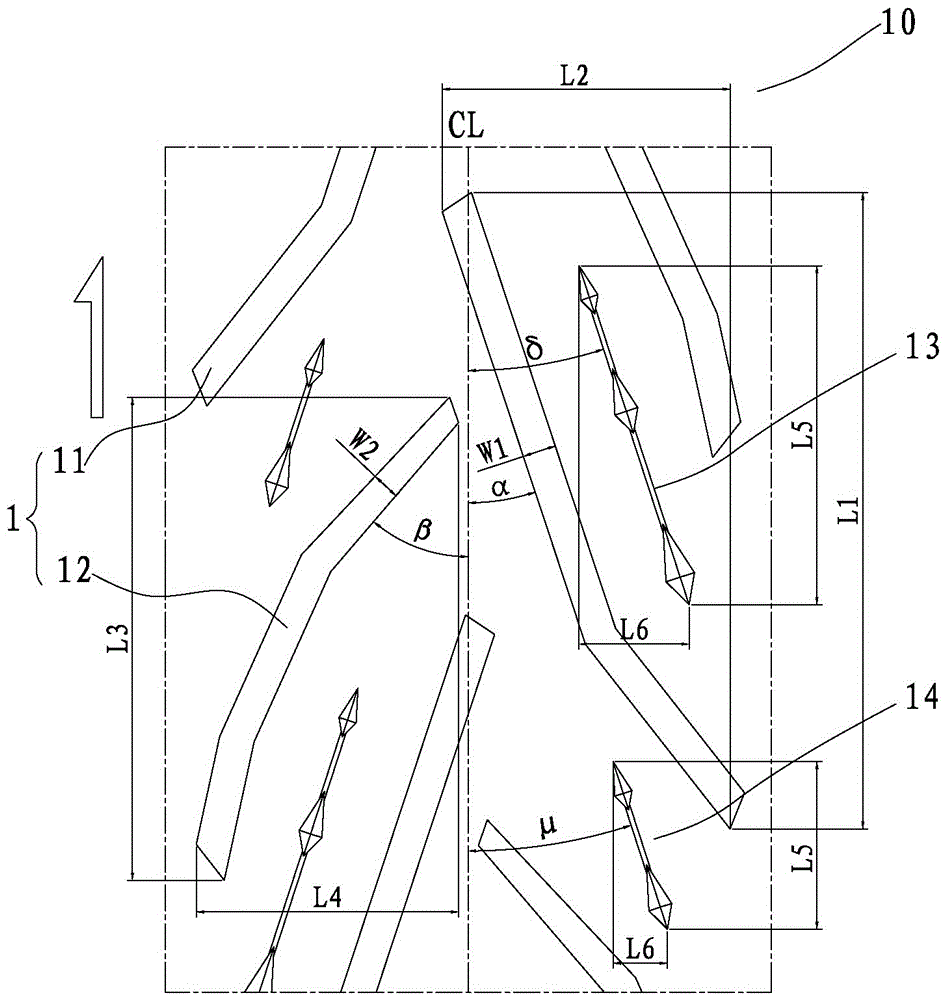

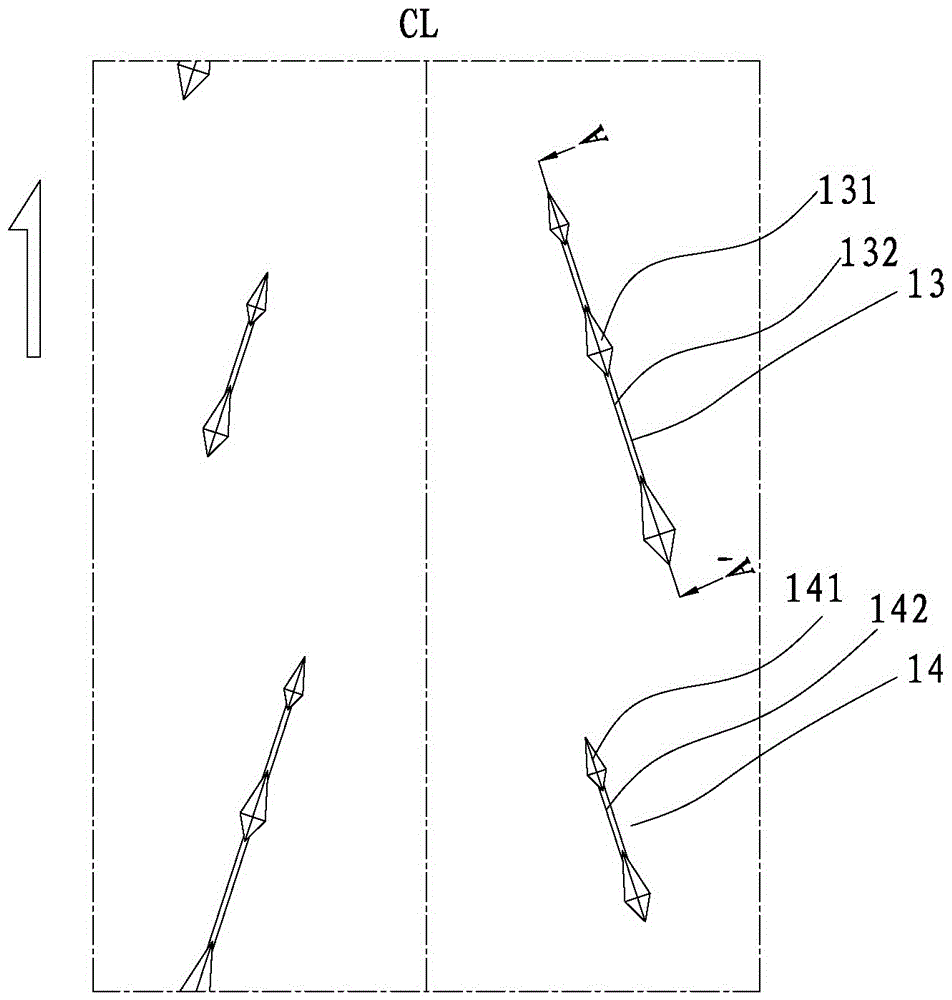

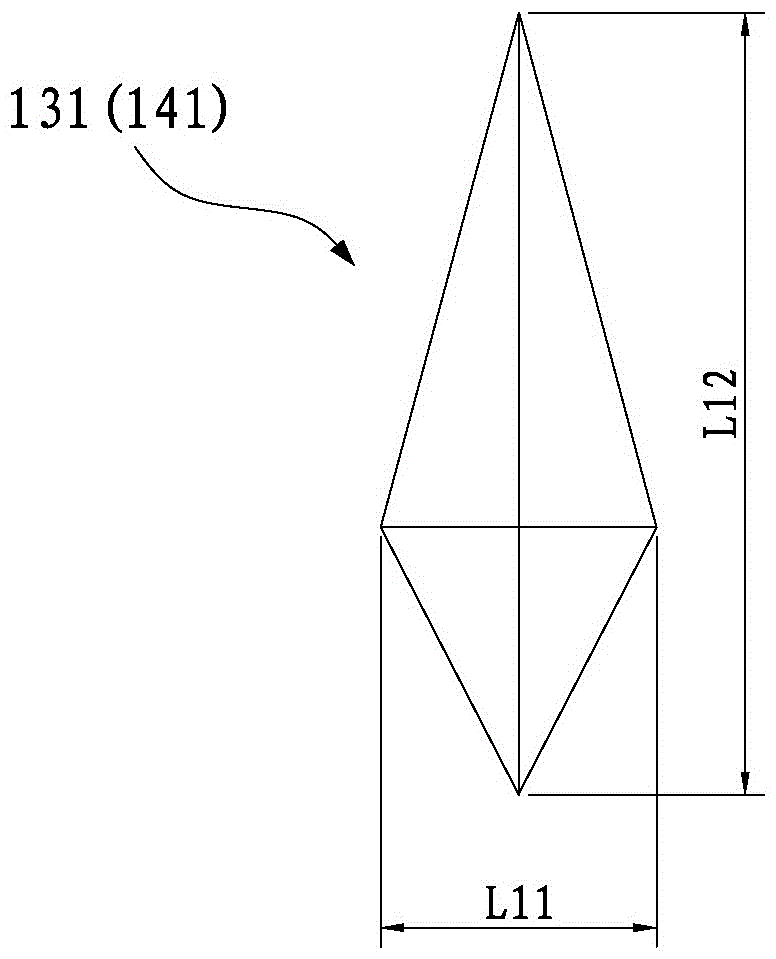

Motorcycle tire for rough terrain

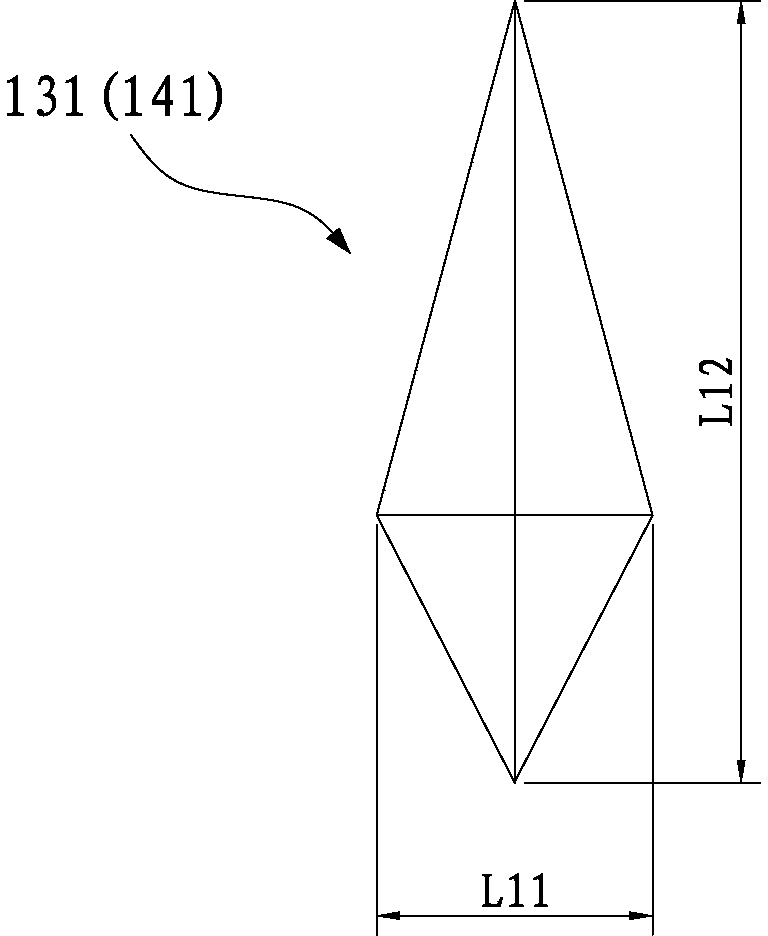

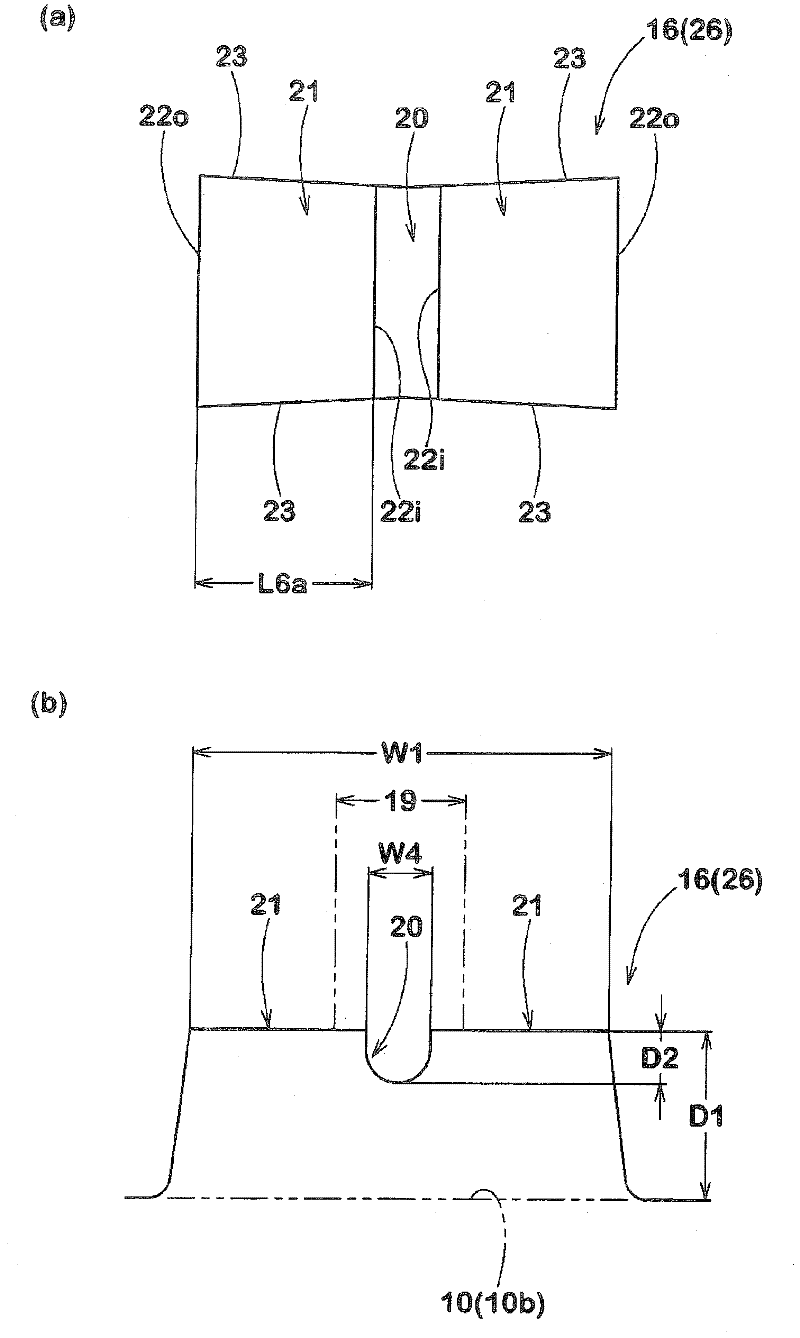

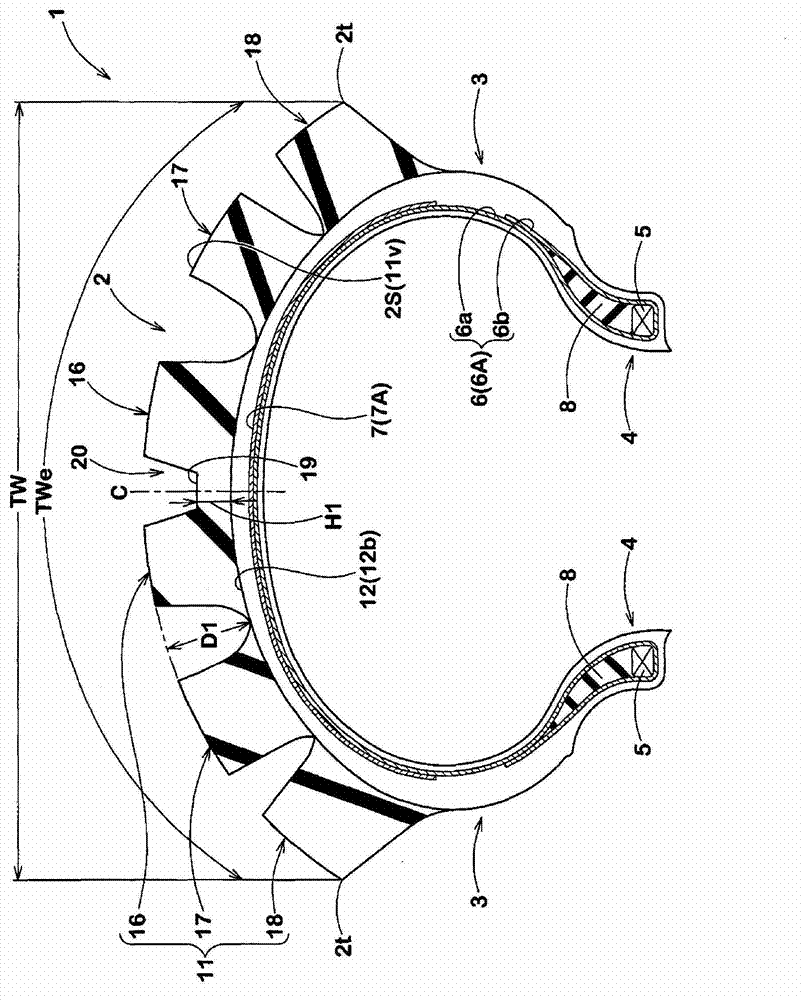

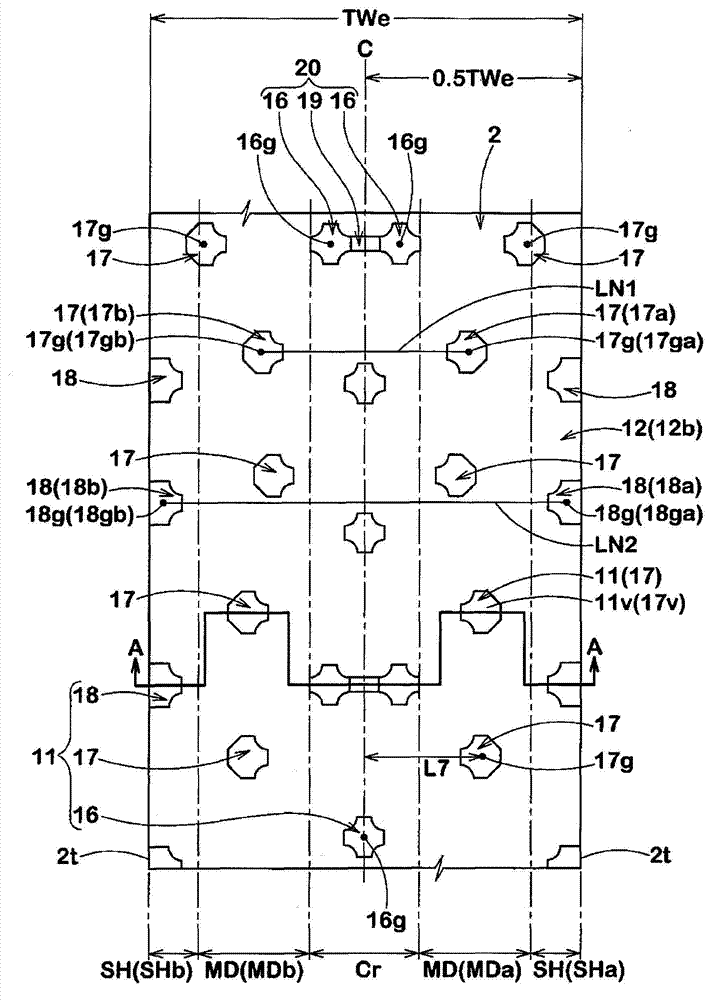

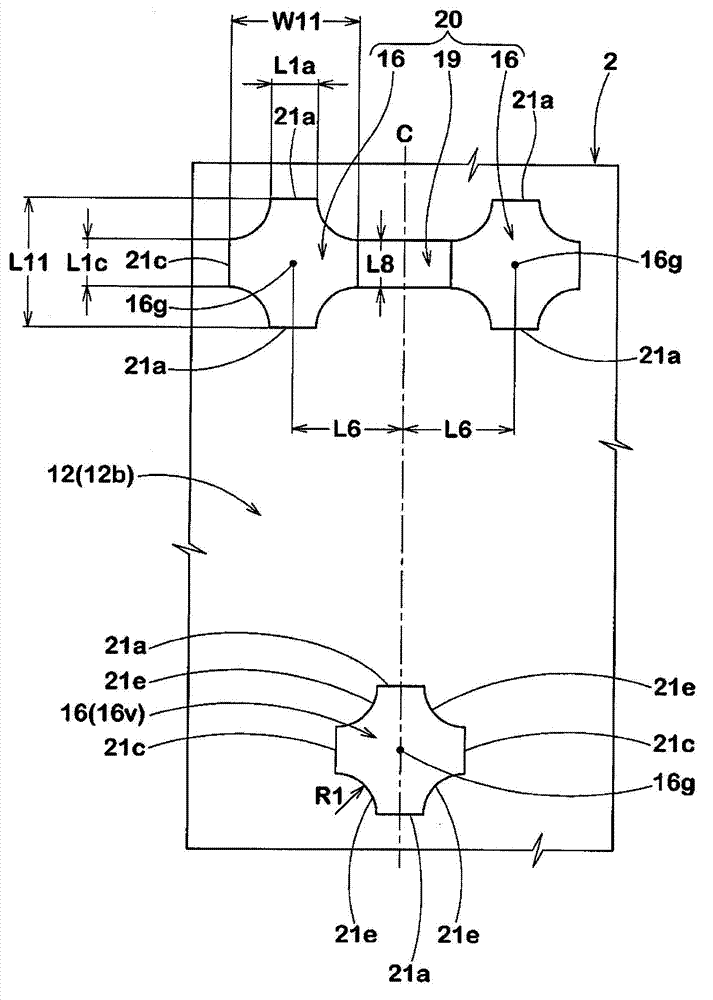

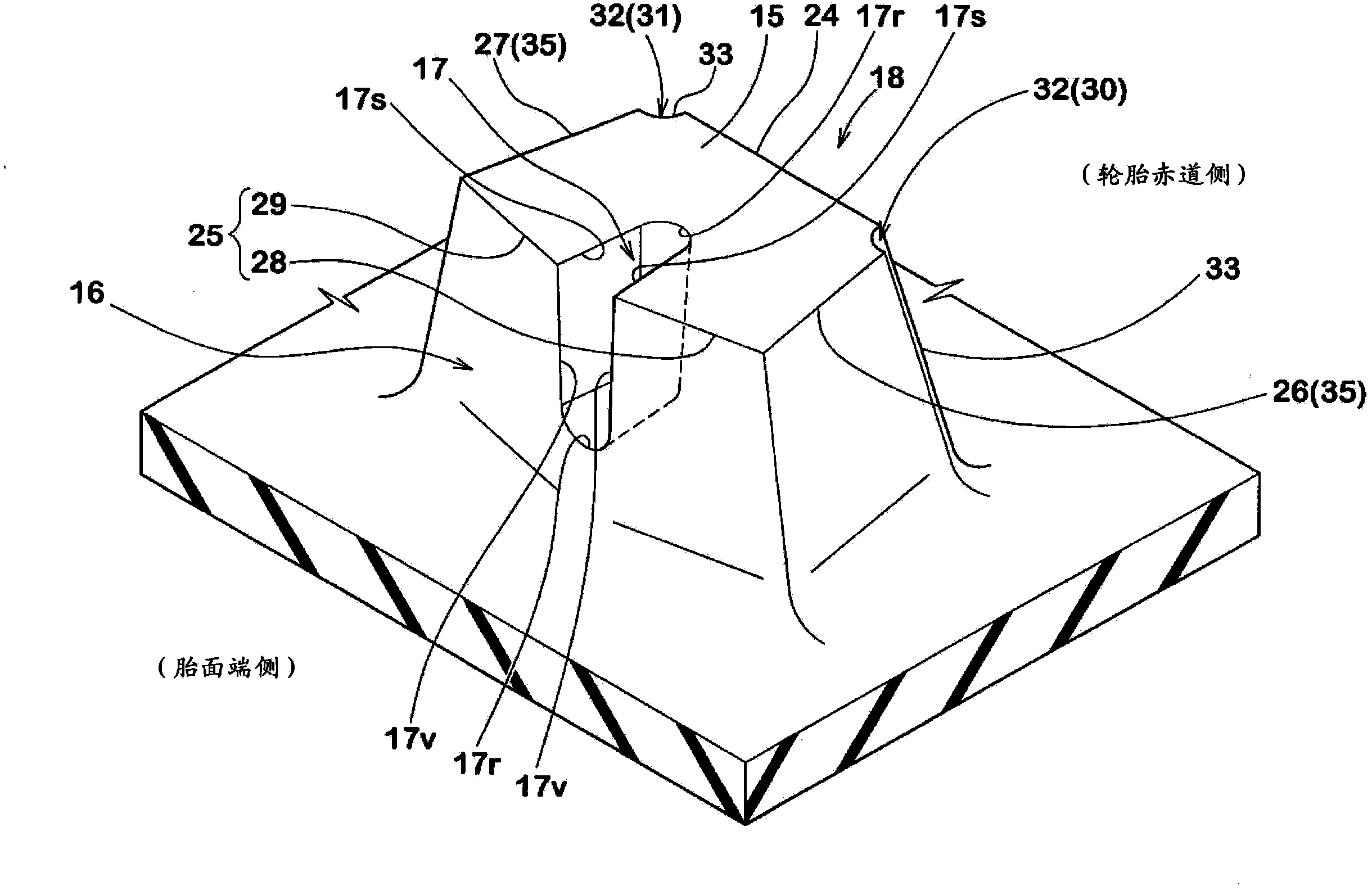

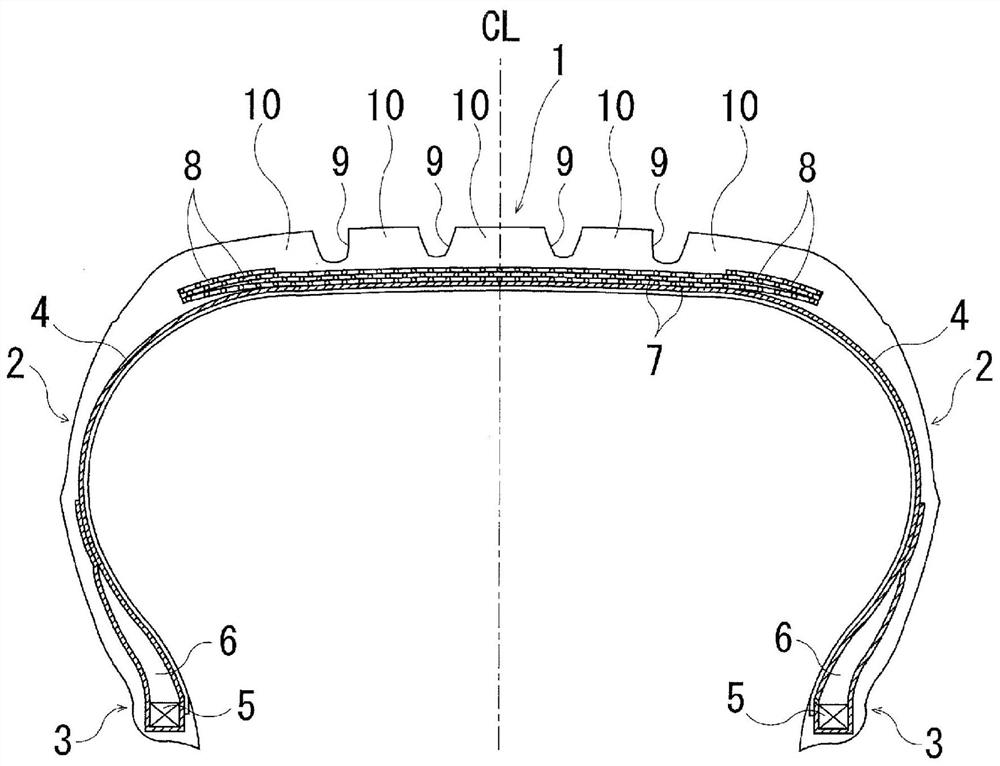

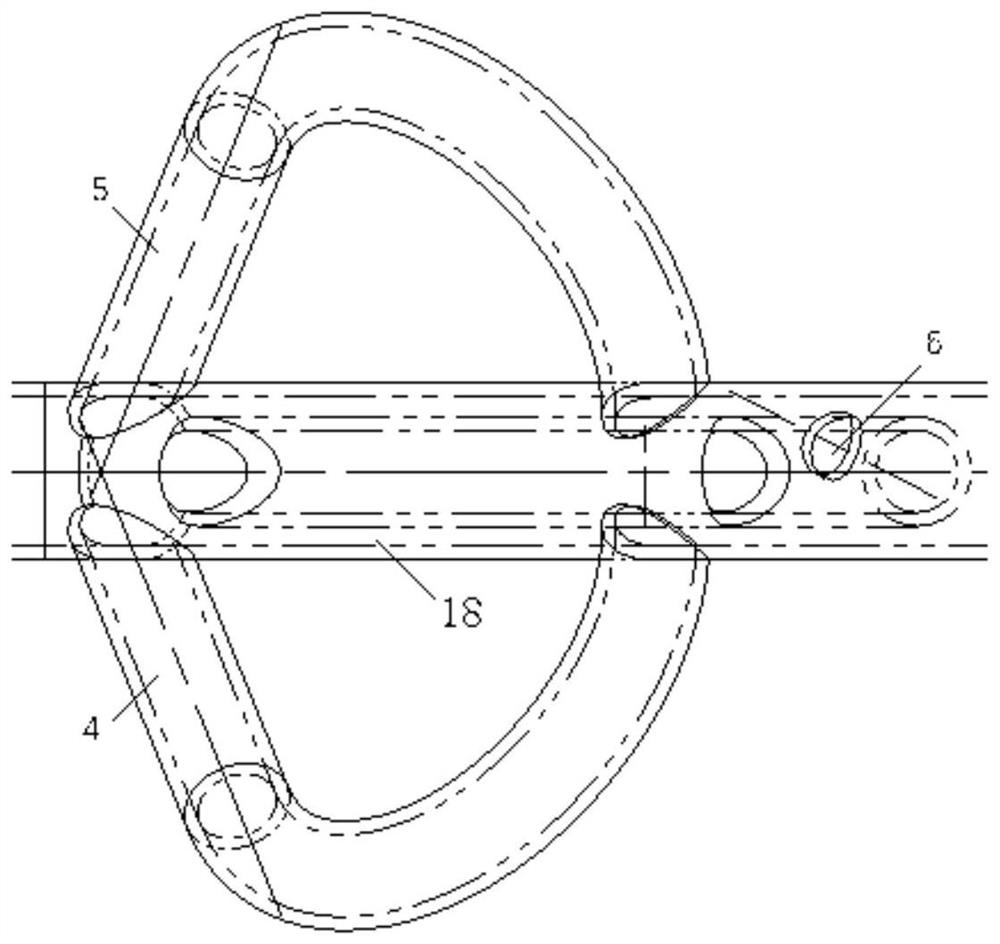

ActiveCN102555683AIncrease the edgeImprove traction performanceOff-road vehicle tyresMotorcycle tyresTerrainLarge aspect ratio

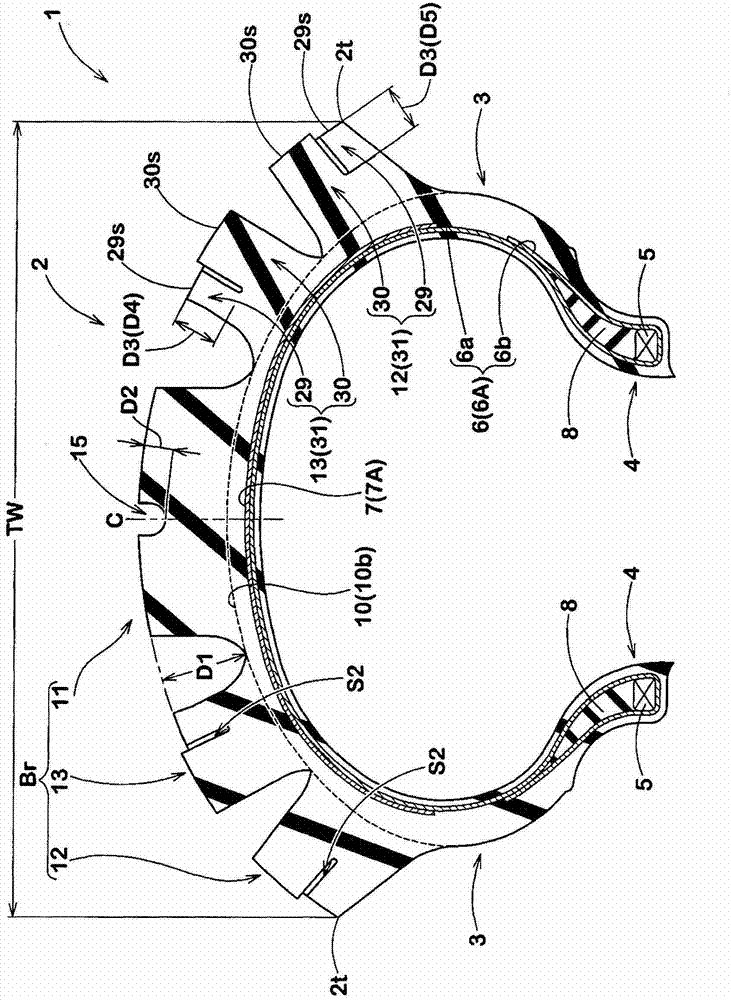

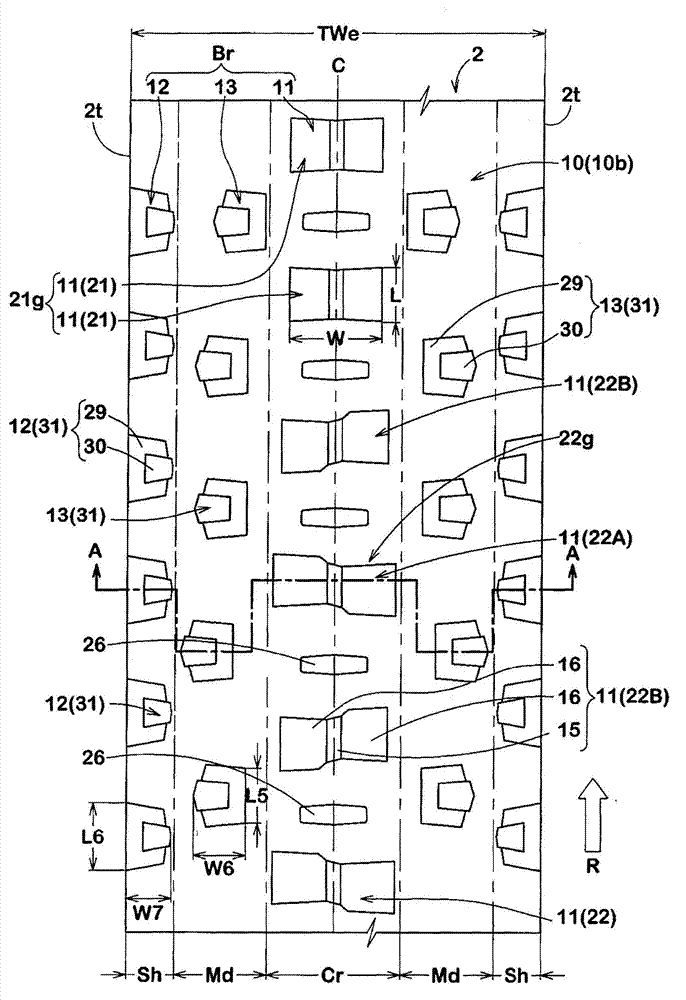

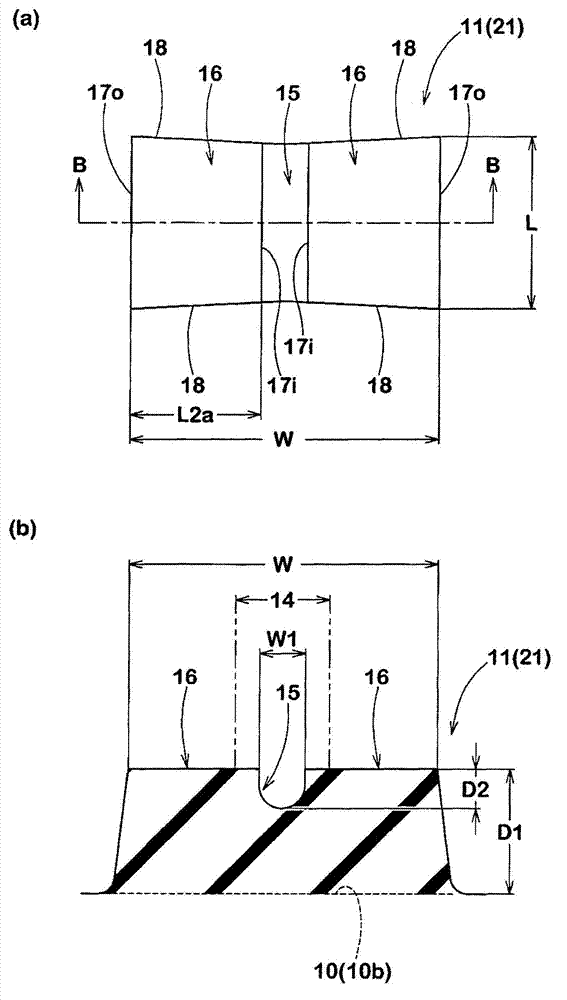

The invention provides a motorcycle tire (1) for rough terrain, which can maintain the traction performance and braking performance when a motorcycle travels straight and improve the turning performance. Blocks (11) include crown blocks (16) arranged in a center area (Cr) of a tread portion (2), shoulder blocks (17) arranged in a grounded junction (2t) of the tread portion, and middle blocks (18) arranged between the crown blocks (16) and the shoulder blocks (17). The crown blocks (16) have a smallest aspect ratio, which is a ratio (L / W) of the tire circumferential length L to the tire axial width W. and the shoulder blocks (17) have a largest aspect ratio.The crown block (16) is divided into two small block segments (21, 21) by one circumferentially extending slit (20) in a center portion of its widthwise direction to the tire circumferential direction. And the two small block segments (21, 21) includes a shift block (27) shifting in the tire circumferential direction through the extending slit (20)

Owner:SUMITOMO RUBBER IND LTD

Sumitomo rubber ind

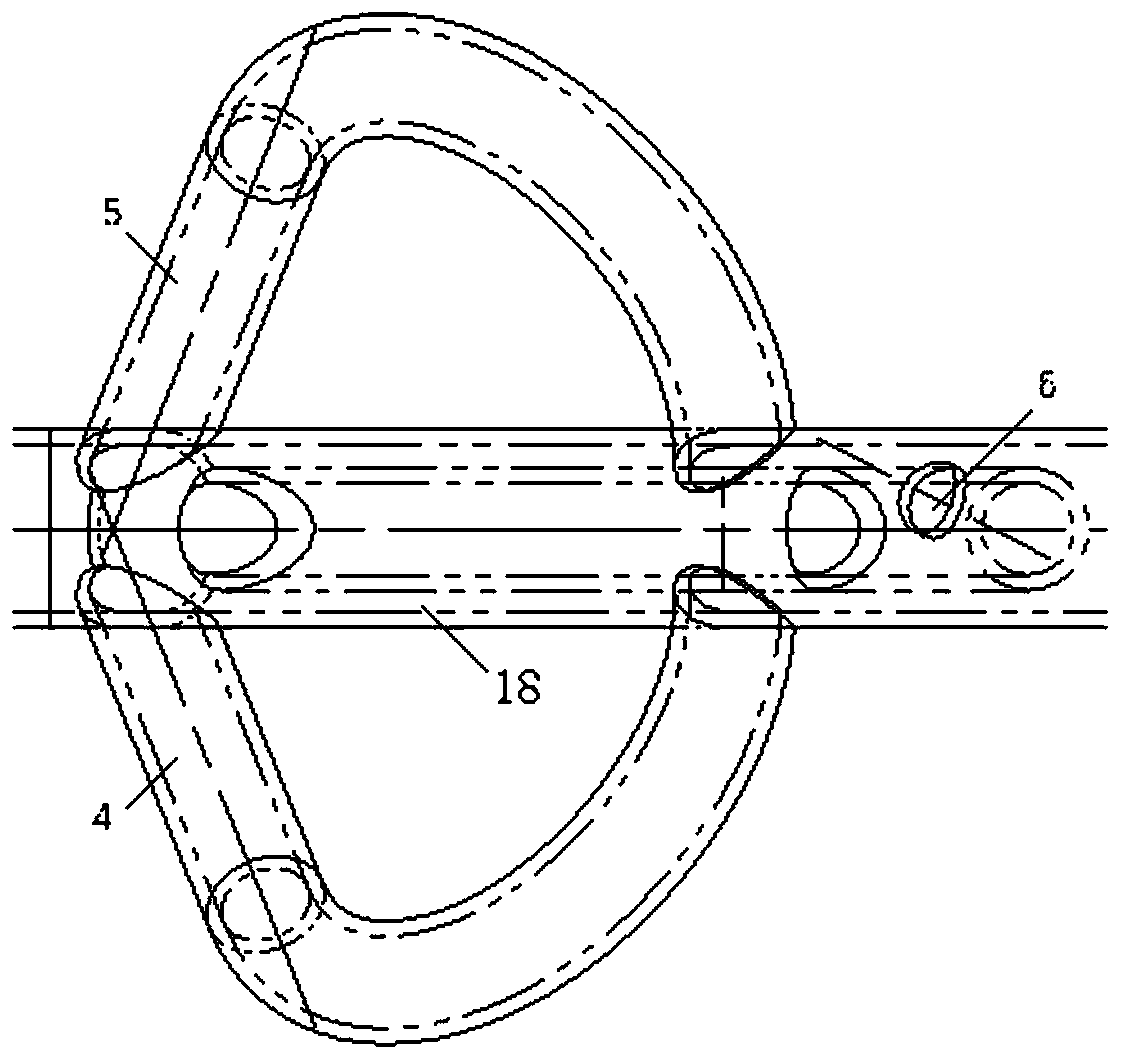

InactiveCN102874056AIncrease ground pressureSuppress left and right shakingOff-road vehicle tyresMotorcycle tyresTerrainMechanical engineering

A motorcycle tire for running on rough terrain comprises a tread portion provided with a plurality of blocks defining a block pattern. The blocks include center blocks whose centroids of their top surfaces are disposed within a center region of the tread portion defined as being centered on the tire equator and having a developed width of 25 % of a developed tread width. The top surface of each of the center blocks is provided with an axially extending edge extending straight and parallel with the tire axial direction, and arc edges curved convexly toward the centroid of the top surface and disposed on both sides of the axially extending edge in the tire axial direction.

Owner:SUMITOMO RUBBER IND LTD

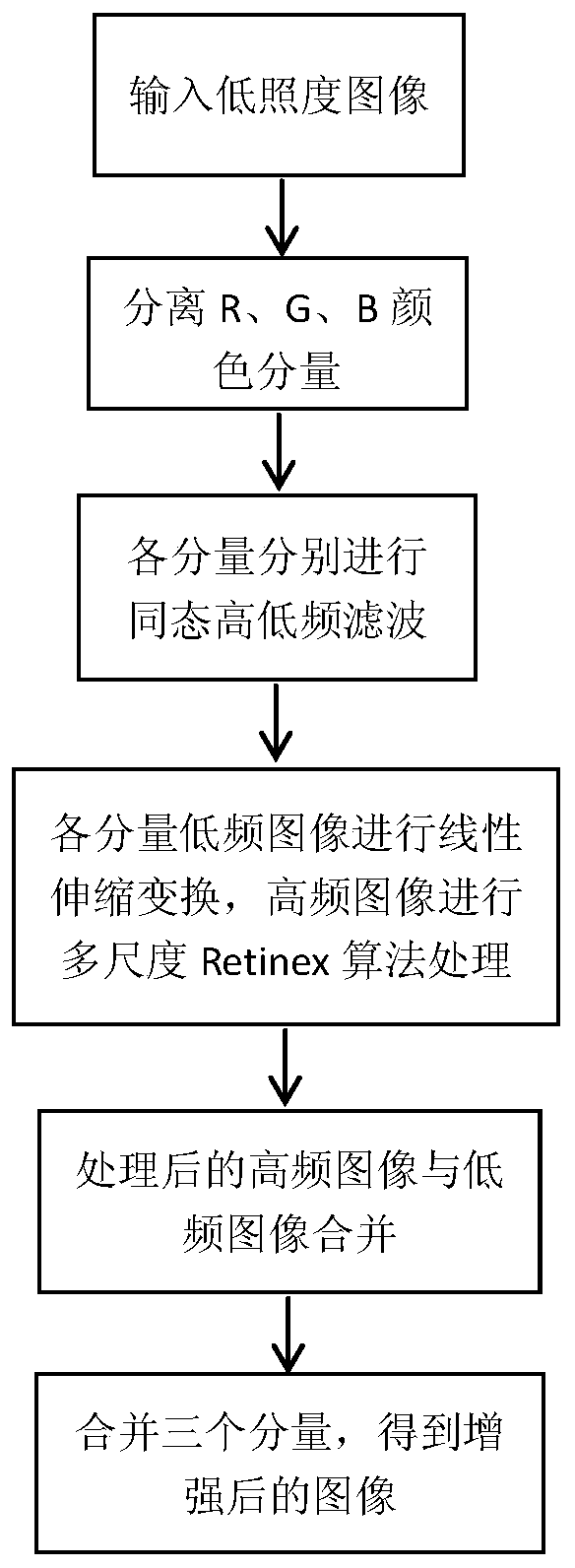

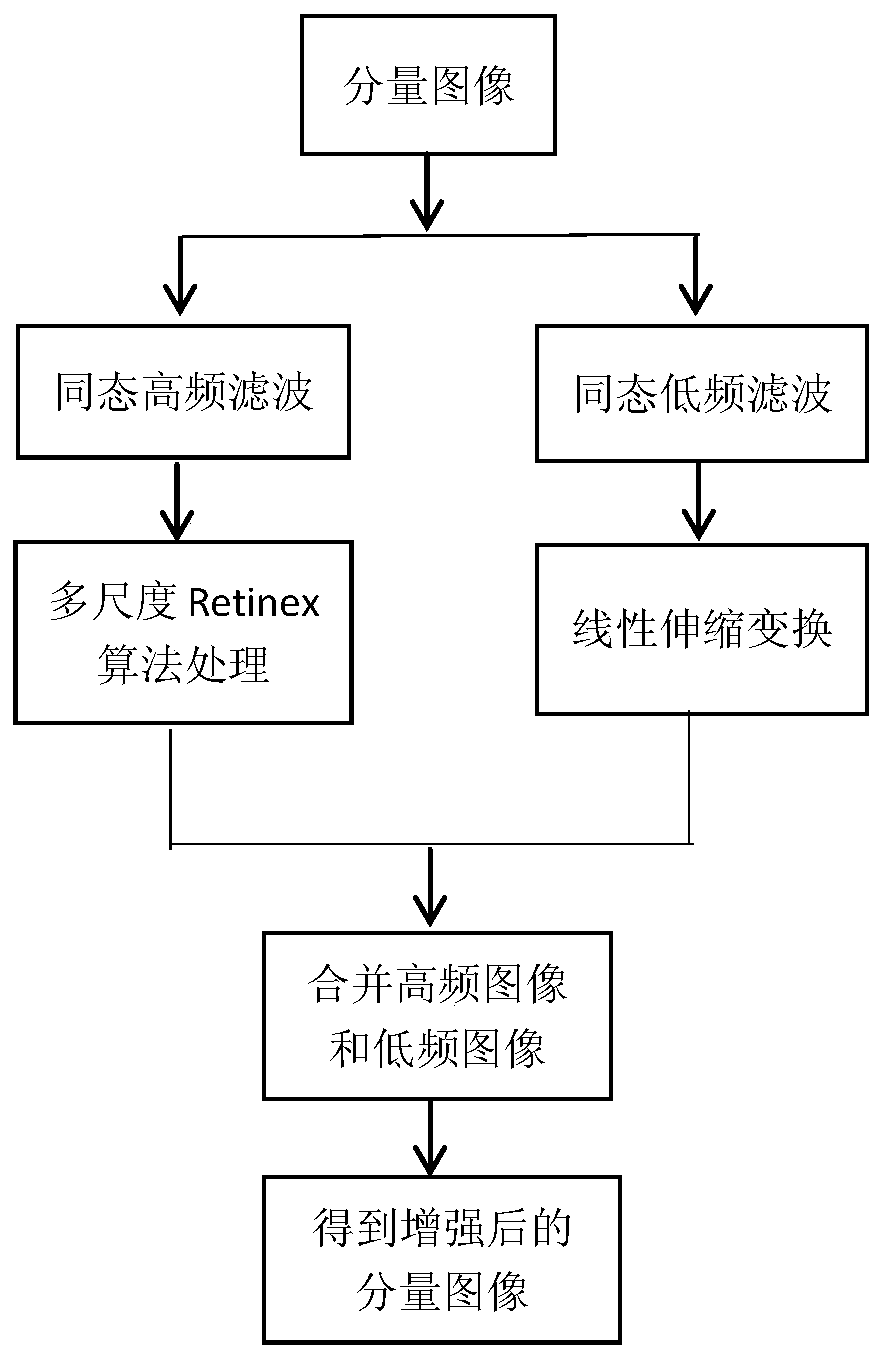

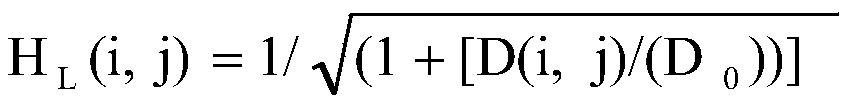

Enhancement method of low-illumination color image

ActiveCN110276729AIncrease the edgeStrong contrastImage enhancementImage analysisColor imageIlluminance

The invention discloses an enhancement method of a low-illumination color image. The method comprises the following steps: S1, inputting a low-illumination image; S2, performing color separation on the input image to obtain R, G and B component images; S3, performing homomorphic high-frequency filtering and homomorphic low-frequency filtering on the three component images to respectively obtain high-frequency and low-frequency images of each component; S4, performing linear scaling transformation on the low-frequency image of each component; S5, performing multi-scale Retinex algorithm processing on the high-frequency image of each component; S6, combining the high-frequency image and the low-frequency image after each component is processed; and S7, combining the three component images to obtain an enhanced low-illumination color image. According to the method, the low-illumination color image is enhanced, so that the enhanced image is clearer in detail and higher in contrast ratio, and a better visual effect is achieved.

Owner:ZHEJIANG UNIV OF TECH

Pneumatic tire

ActiveCN112689566AEfficient dischargeImprove soil dischargeOff-road vehicle tyresTyre tread bands/patternsClassical mechanicsMechanical engineering

Provided is a pneumatic tire that has improved travel performance and cut resistance on unpaved roads. According to the present invention, block groups B comprise: a pair of adjacent shoulder blocks 21 that sandwich a shoulder lug groove 31; and a pair of adjacent side blocks 23 that sandwich a side groove 33 that is positioned on a line that extends from the shoulder lug groove 31 that is between the pair of shoulder blocks 21. Contour lines L1 of tire-width-direction outside side surfaces of the shoulder blocks 21 and contour lines L3 of top surfaces of the side blocks 23 extend along the same straight lines. Contour lines L3 that, of the contour lines L3 of the top surfaces of the side blocks 23, are on the side that is away from the side groove 33 that is between the pair of side blocks 23 and contour lines L4 of narrow grooves 42 that are formed in the side blocks 23 are formed from straight portions L3a, L4a that extend along the tire radial direction on the shoulder block 21 side and inclined portions L3b, L4b that extend so as to converge toward the side groove 33 that is between the pair of side blocks 23.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire for rough terrain

ActiveCN103522843AIncrease the edgeKeep gripOff-road vehicle tyresMotorcycle tyresTerrainMechanical engineering

Owner:SUMITOMO RUBBER IND LTD

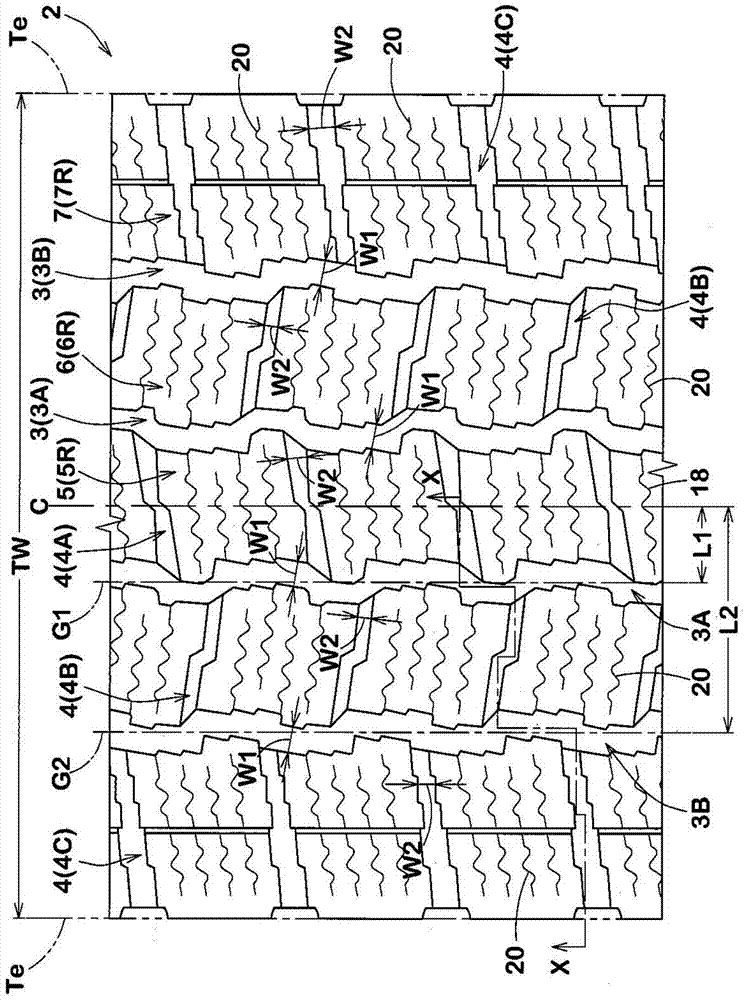

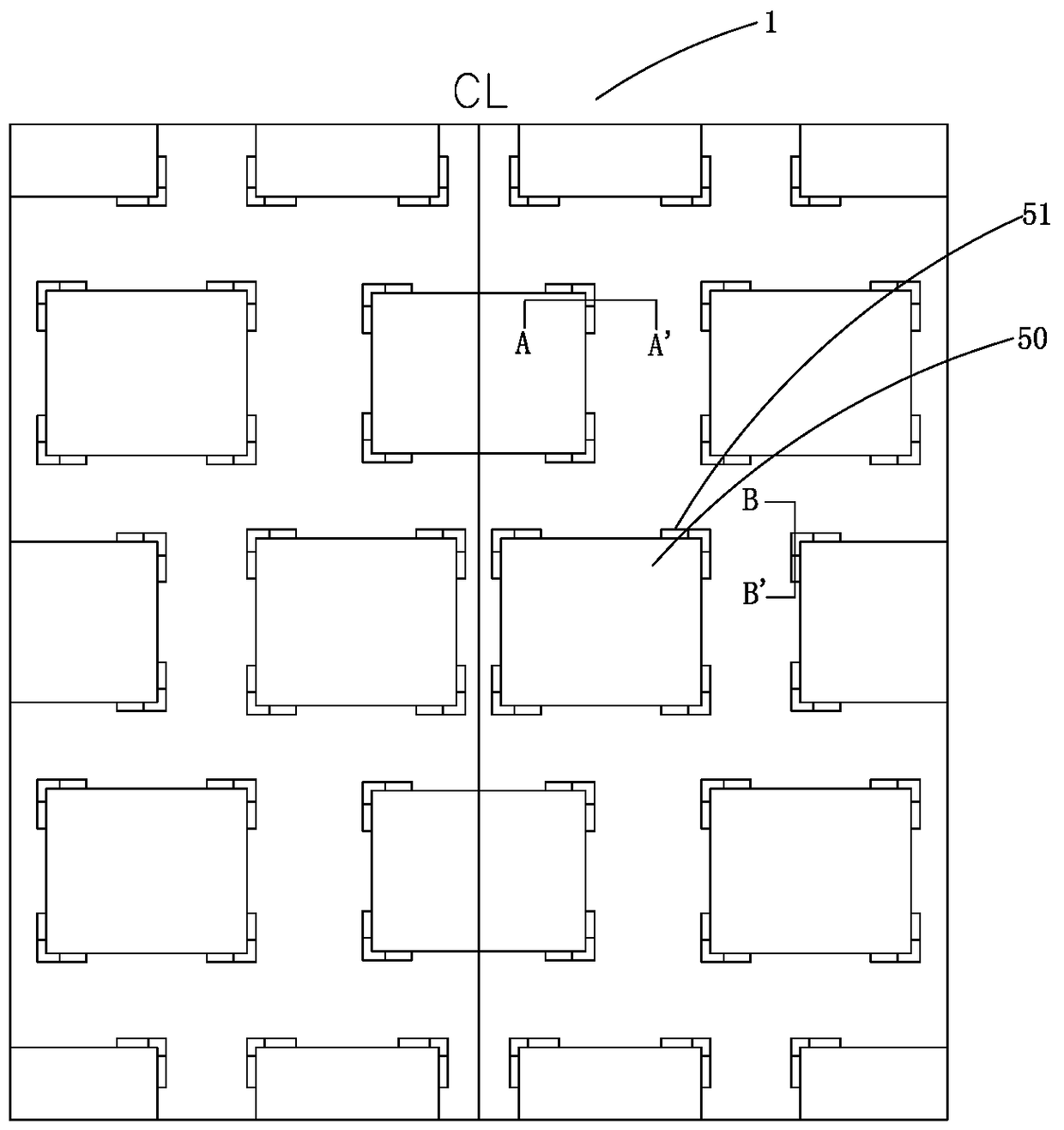

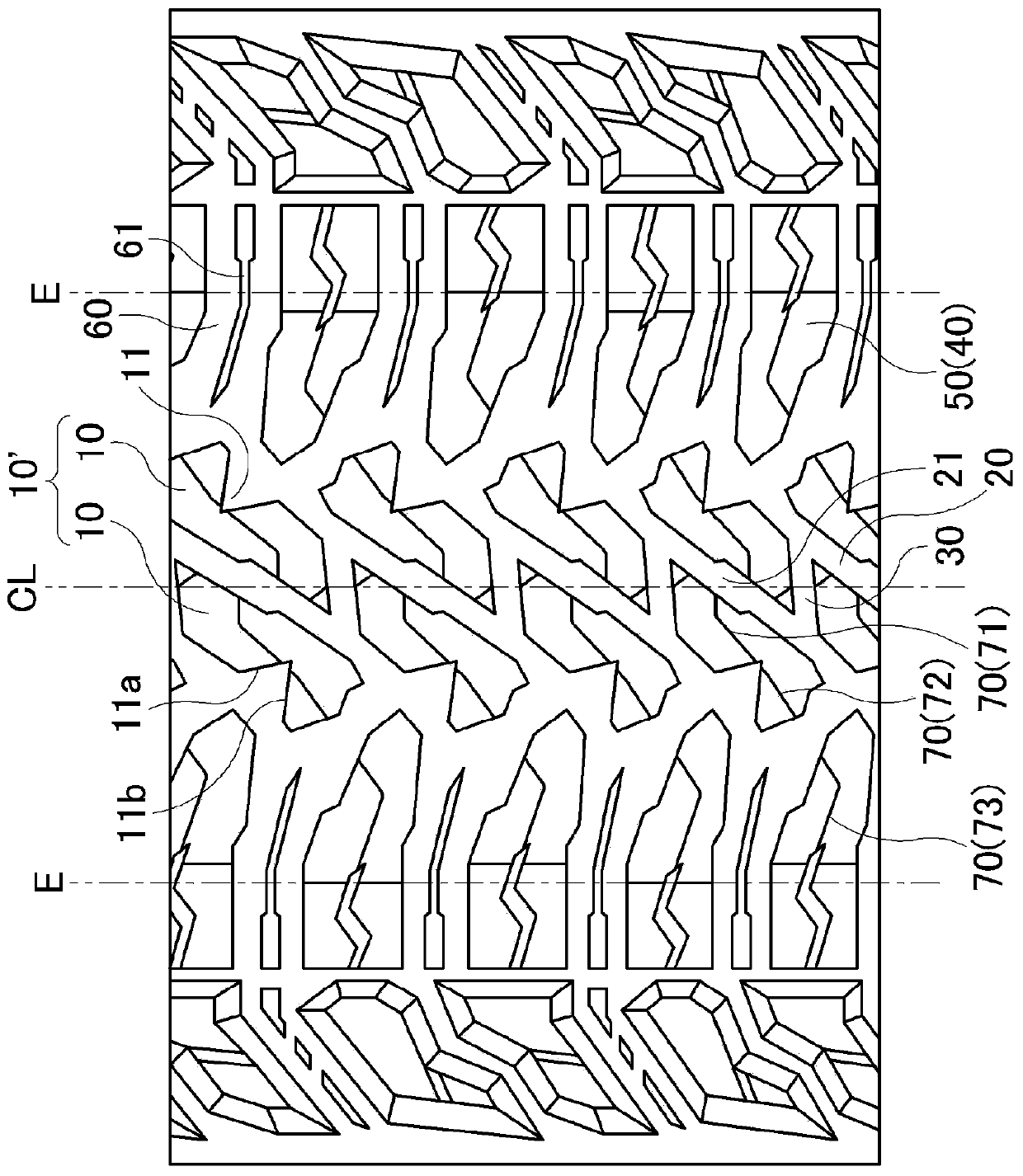

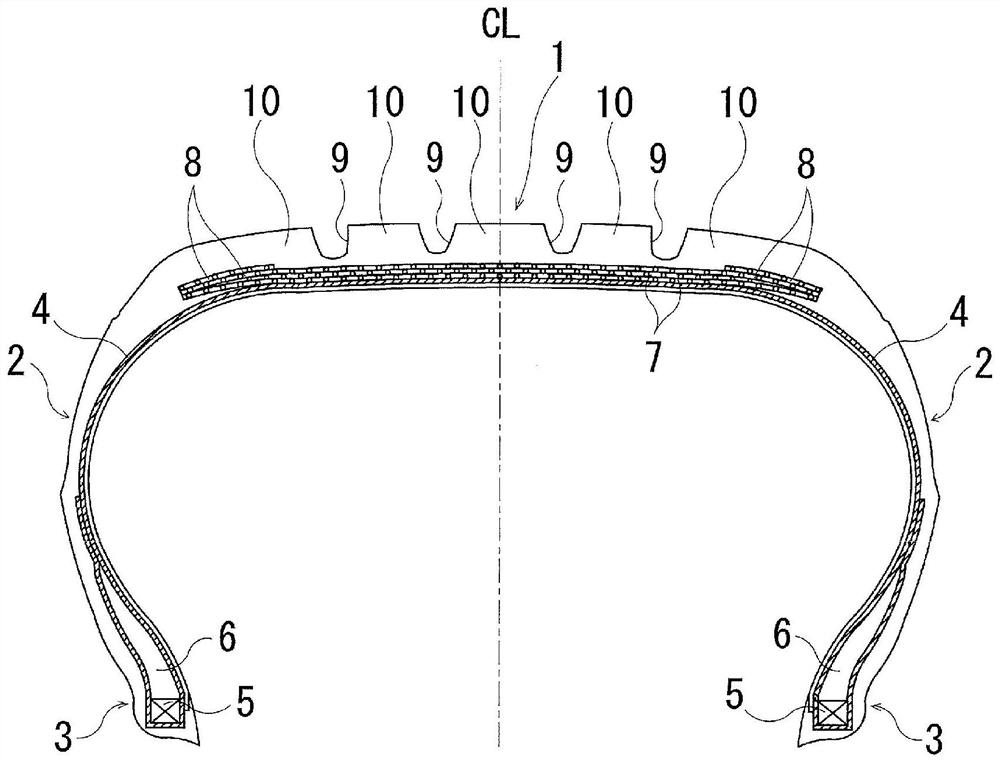

Pneumatic tire

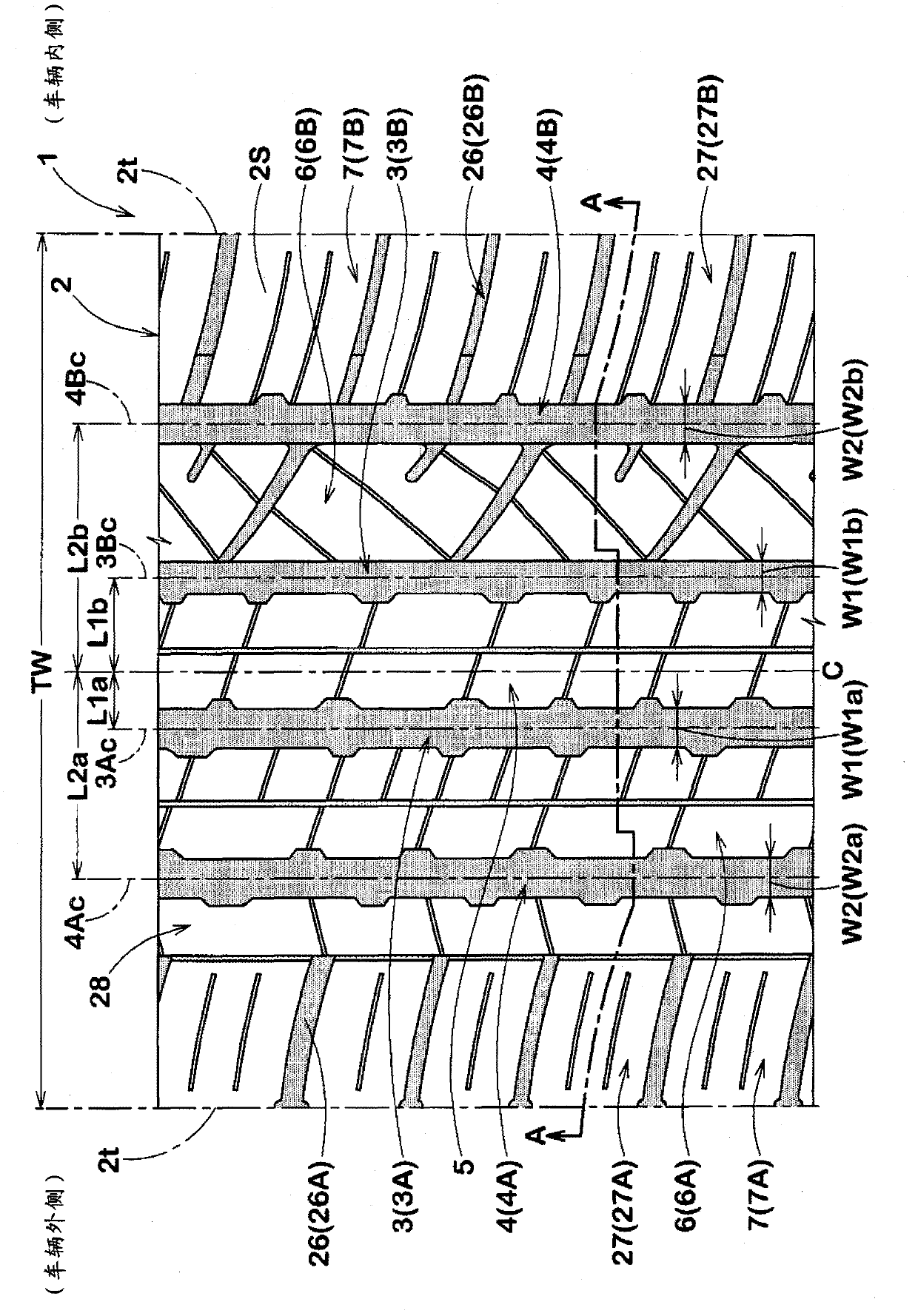

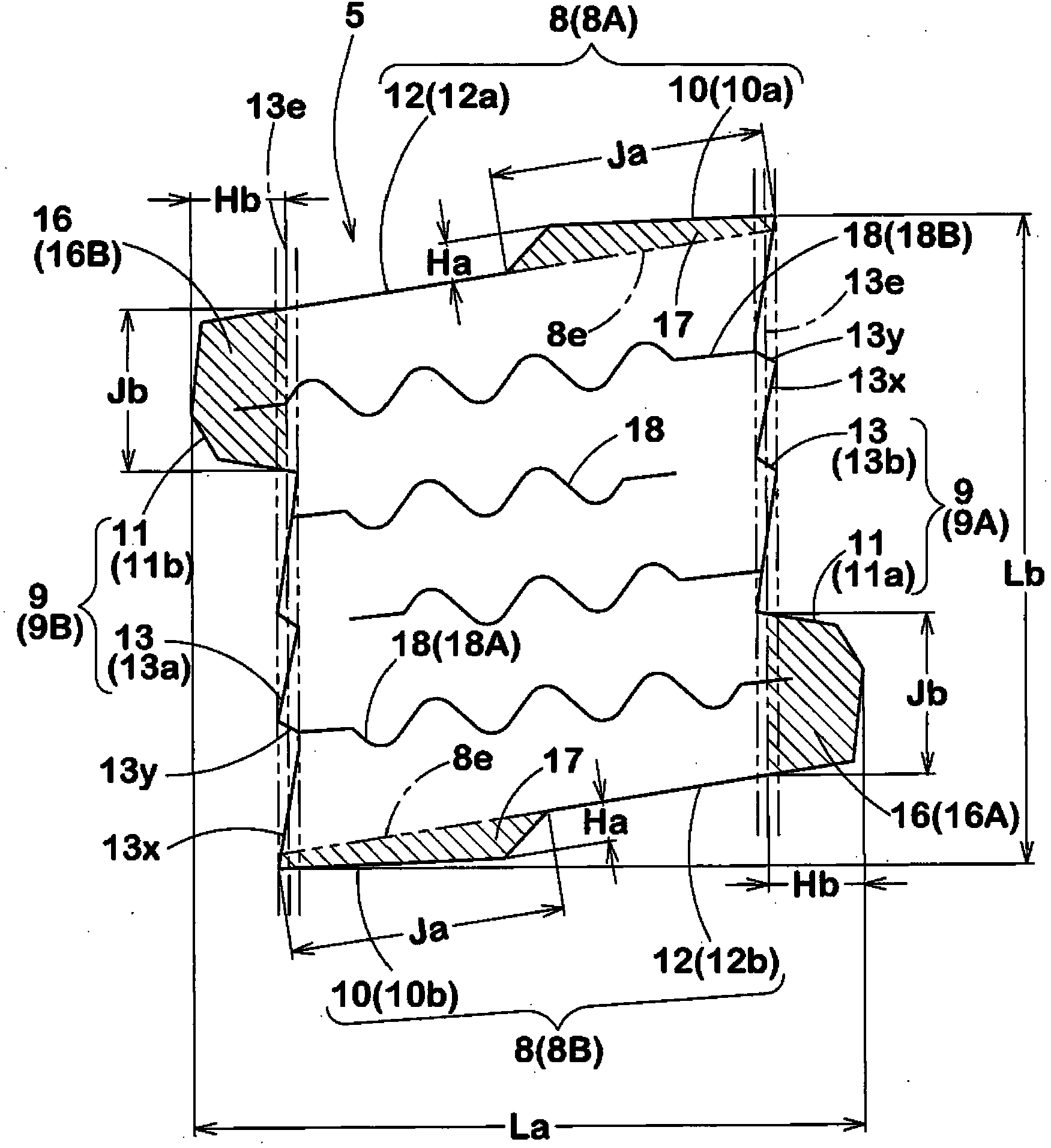

ActiveCN104139672AIncrease the edgeImprove cornering performanceTyre tread bands/patternsVertical projectionEngineering

A pneumatic tire according to the invention is capable of suppressing a decrease in drainage performance and snow-covered road performance and improving icy road performance. The pneumatic tire is provided with a pair of center pattern blocks (5) divided by center main grooves (3A, 3A) and a plurality of center lateral grooves (4A, 4A) on a tread portion (2) with intervals. The center pattern blocks (5) includes: end edges on two sides of the center pattern blocks (5) in the circumferential direction of the tire, that is a pair of lateral pattern block edges (8, 8), and end edges on two sides of the center pattern blocks (5) in the axial direction of the tire, that is a pair of vertical pattern block edges (9, 9). The lateral pattern block edges (8, 8) respectively has lateral projections (10, 10) protruding outwardly in the circumferential direction of the tire, the vertical pattern block edges (9, 9) respectively has vertical projections (11, 11) protruding outwardly in the axial direction of the tire, and a ratio (Lb / La) of the maximum length (Lb) of the center pattern blocks (5) in the circumferential direction of the tire and the maximum length (La) of the center pattern blocks (5) in the axial direction of the tire is 0.80 to 1.00.

Owner:SUMITOMO RUBBER IND LTD

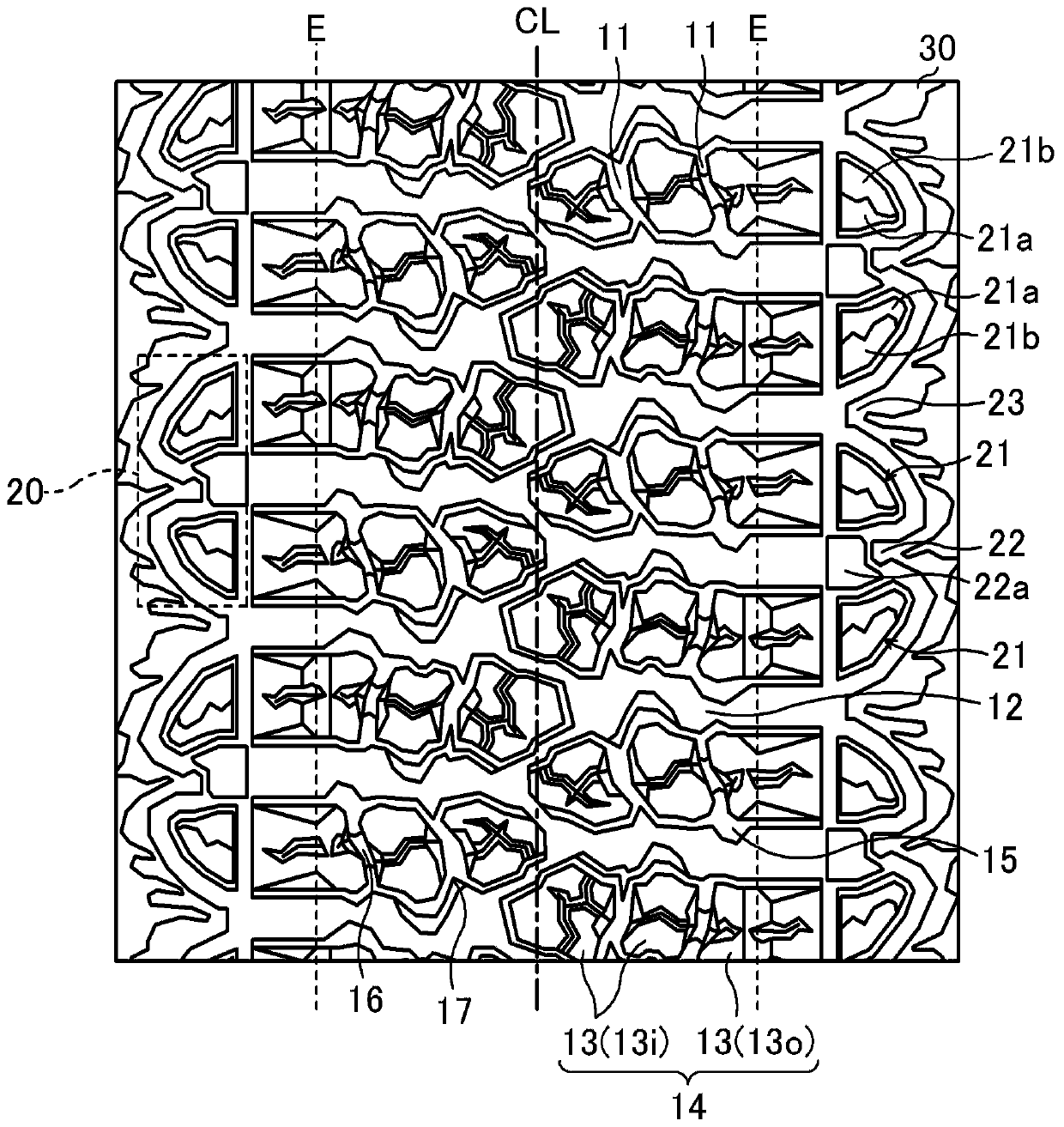

Pneumatic tire

ActiveCN110958949AImprove discharge effectGood balance of rigidityOff-road vehicle tyresTyre tread bands/patternsEngineeringMechanical engineering

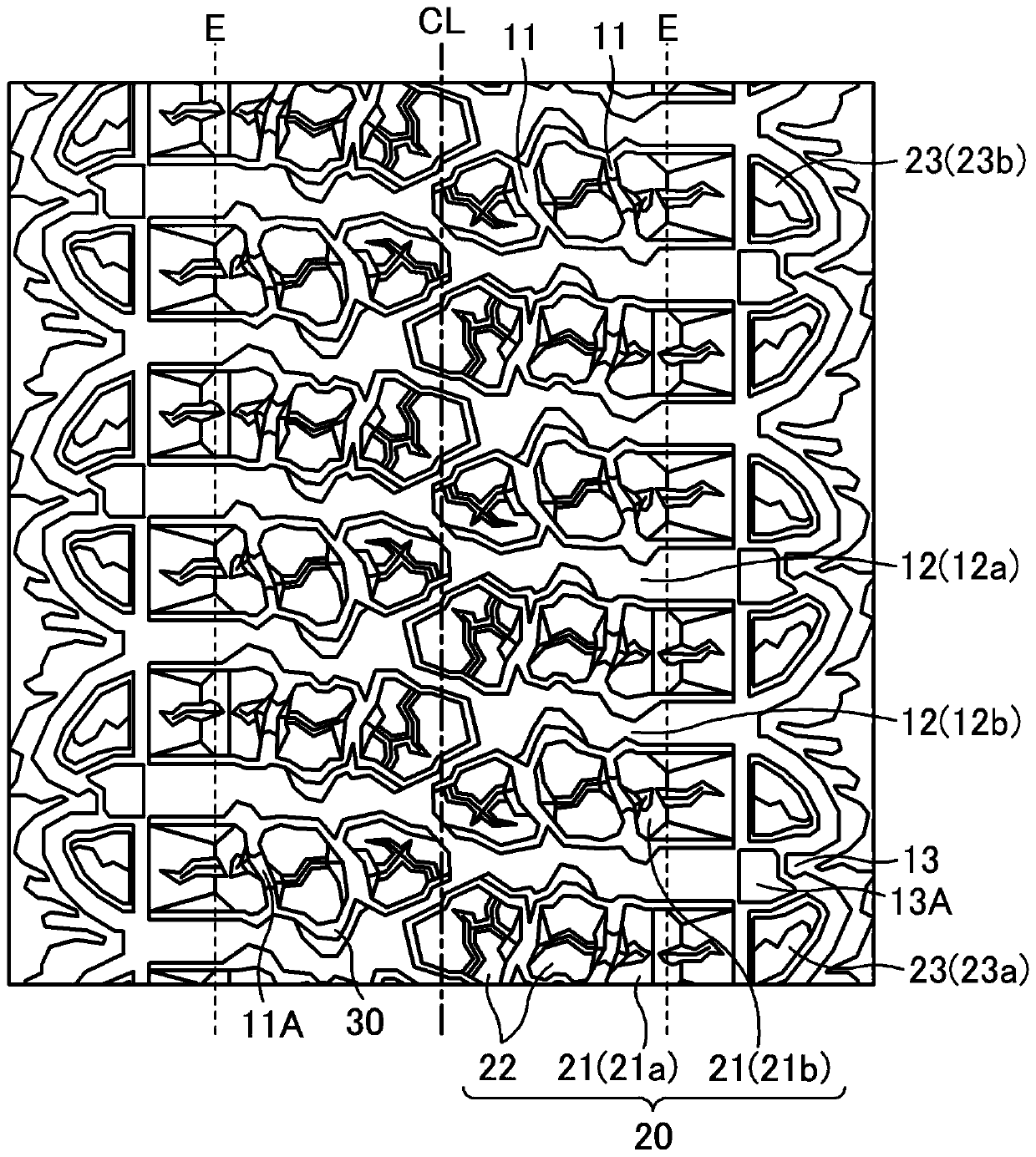

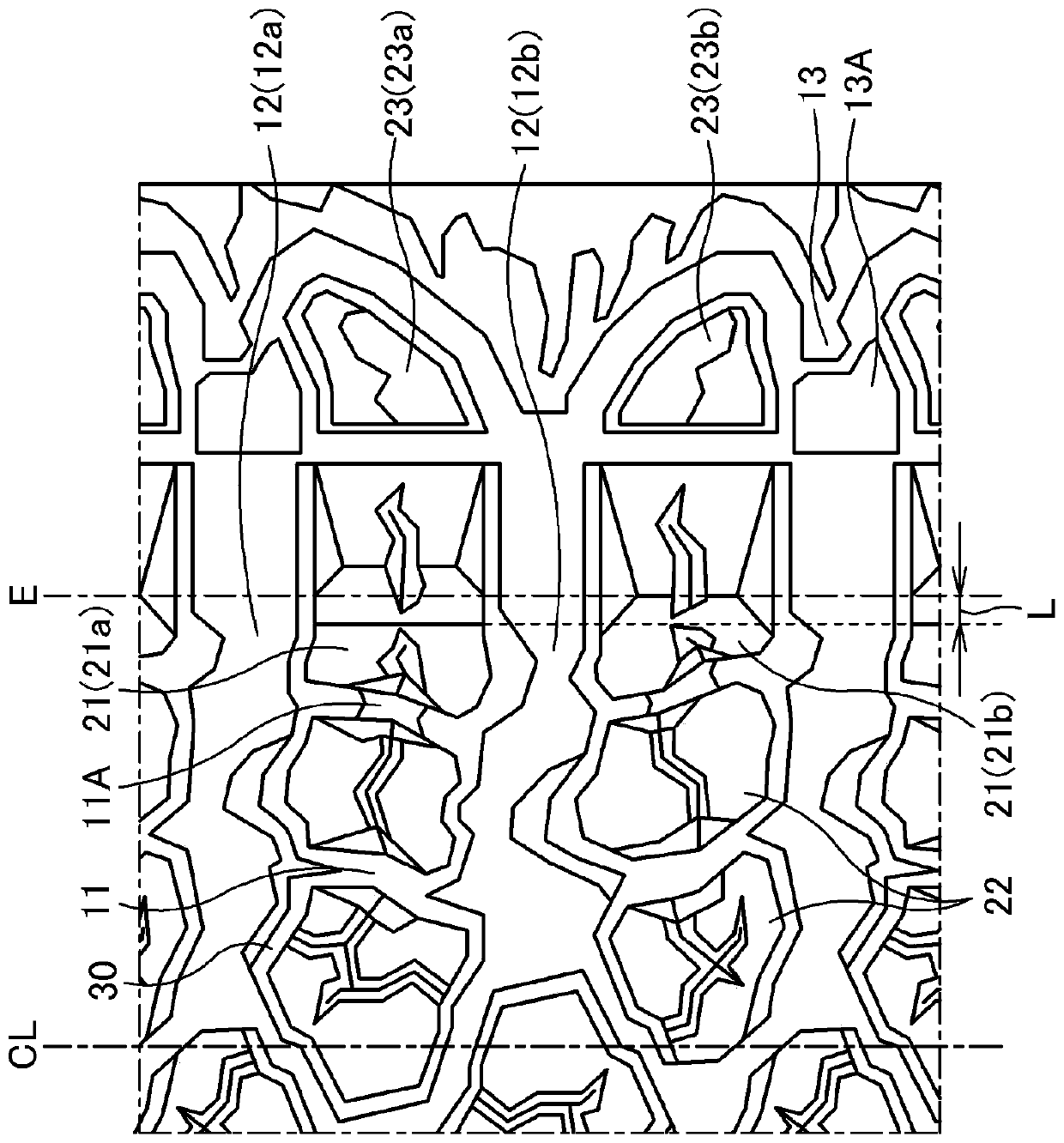

Provided is a pneumatic tire that is advantageous as an off-road tire, the tire having improved driving performance, wear resistance, and cut resistance on off-road surfaces. The pneumatic tire comprises a block pattern having a point-symmetrical structure. Narrow-width outer blocks (21a) and wide-width outer blocks (21b), outer ends of which have different positions with respect to the tire widthwise direction, are alternately disposed around the tire circumferential direction. From among side blocks (23) provided in a side region, large blocks (23a) having large projection areas are disposedto the outside of the narrow-width outer blocks (21a) with respect to the tire widthwise direction, and small blocks (23b) having small projection areas are disposed to the outside of the wide-widthoutside blocks (21b) with respect to the tire widthwise direction. Lateral grooves (12) and side grooves (13) are connected, with the widths of the side grooves (13) communicating with wide-width sections (12a), constituted by the lateral grooves (12) having wide widths at the positions of the outer blocks (21), decreasing inward in the tire radial direction, and the widths of side parts communicating with narrow-width sections (12b), constituted by the lateral grooves (12) having narrow widths at the positions of the outer blocks (21), increasing inward in the tire radial direction, yieldinga tapered shape such that the side blocks (23) decrease in block width toward the wide-width sections (12a) as distance inward in the tire radial direction increases.

Owner:THE YOKOHAMA RUBBER CO LTD

Multi-frame image rapid reconstruction method on microsatellite platform

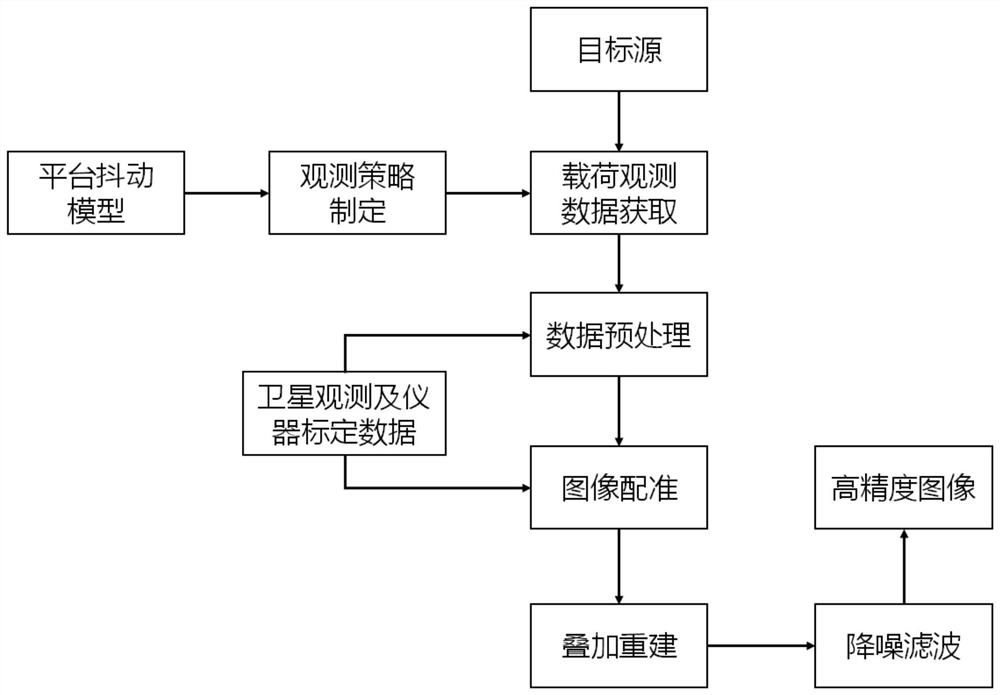

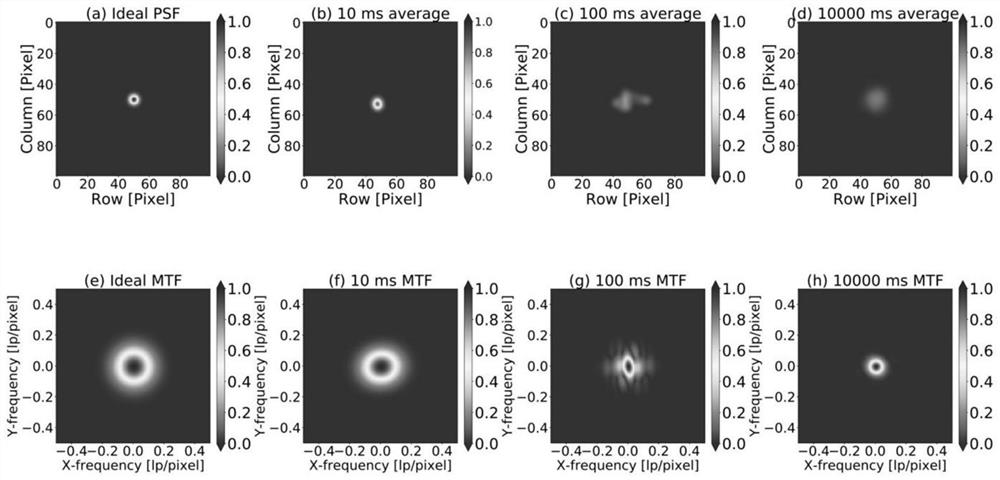

PendingCN112927177ARemove focal plane imaging blurImprove imaging resolutionImage enhancementImage analysisEarth observationComputation complexity

The invention relates to a multi-frame image rapid reconstruction method on a microsatellite platform. The method comprises the following steps of: a, establishing a load observation jitter model according to a power spectrum of the satellite platform; b, acquiring a short-exposure image in combination with a jitter model, and registering the image; c, performing multi-frame superposition reconstruction on the registered image; and d, carrying out noise reduction and filtering on the reconstructed image. According to the method, the problem of restoration of multiple frames of images with relative movement in an actual scene observed on a microsatellite platform can be accurately and quickly solved, the focal plane imaging blurring phenomenon caused by load pointing jitter in the imaging process is effectively removed, and the system imaging resolution is improved. Moreover, the method is low in calculation complexity, has the capability of on-satellite real-time operation, and is suitable for observation of different scenes such as astronomical imaging and earth observation based on microsatellites or similar spacecrafts.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Tread pattern structure of air-filled tyre used for motorcycle

ActiveCN104859379AIncrease the edgeImprovement ingredientsTyre tread bands/patternsAdditive ingredientMain channel

The invention discloses a tread pattern structure of an air-filled tyre used for a motorcycle. A tyre tread is composed of a plurality of pattern units which are symmetrical by taking the center line of the tread and are arranged in a staggered manner, wherein each pattern unit comprises two h-shaped pattern main channels which are arranged in the circumferential direction of the tread obliquely; the long edge of each h-shaped pattern main channel comprises a first folding line, a second folding line and a third folding line which extend from the center of the tread to the tyre shoulder, and the inclination angles of the first folding line, the second folding line and the third folding line relative to the center line of the tread are gradually increased; a fourth folding line and a fifth folding line form the cross edge and the short edge of each h-shaped pattern main channel, and the fourth folding lines communicate the third folding lines with the fifth folding lines; the fourth folding lines and the fifth folding lines extend from the middle part of the tread to the tyre shoulder. Each folding line extends from the center of the tread to the tyre shoulder obliquely, the functions of guidance and drainage performances can be guaranteed, the inclination angle of each folding line relative to the center line of the tread is gradually increased, the edge ingredients of the pattern channels are improved by using the change of angles, and therefore the traction performance and the wetland holding performance are improved.

Owner:CHENG SHIN ZHANGZHOU RUBBER IND

Tire tread structure of pneumatic tire of motorcycle

InactiveCN104029568AMake sure the tread is rigidHelps to expel stonesMotorcycle tyresTyre tread bands/patternsEngineeringAdditive ingredient

The invention discloses a tire tread structure of a pneumatic tire of a motorcycle. A tire tread comprises a plurality of main pattern groove groups which are formed in a staggered manner by using the center of the tread as a symmetry center, and each main pattern groove group comprises a first main pattern groove and a second main pattern groove which are formed in a tilt manner from the inner side of the tire tread to the outer side, wherein stone removing openings with irregularly polygonal edges are respectively formed in the front ends, the middle parts and the tail ends of the first main pattern groove and the second main pattern groove. The left sides and the right sides of the longitudinal main pattern grooves formed in the tire tread are arranged alternately, so that the guide performance and the water drainage performance of the tire are ensured. In order to improve the situation that the tire has better traction performance and stone removing functions on non-paved roads, the stone removing openings are formed in the front ends, the middle parts and the tail ends of the patterned main grooves, so that the rigidity of the tire tread can be ensured, and the stone removing is facilitated; at the same time, the stone removing openings are provided with the irregularly polygonal edges, the ingredients of the edges are high, so that the tire has better traction performance when the motorcycle is driven on the non-paved roads.

Owner:CHENG SHIN RUBBER XIAMEN IND

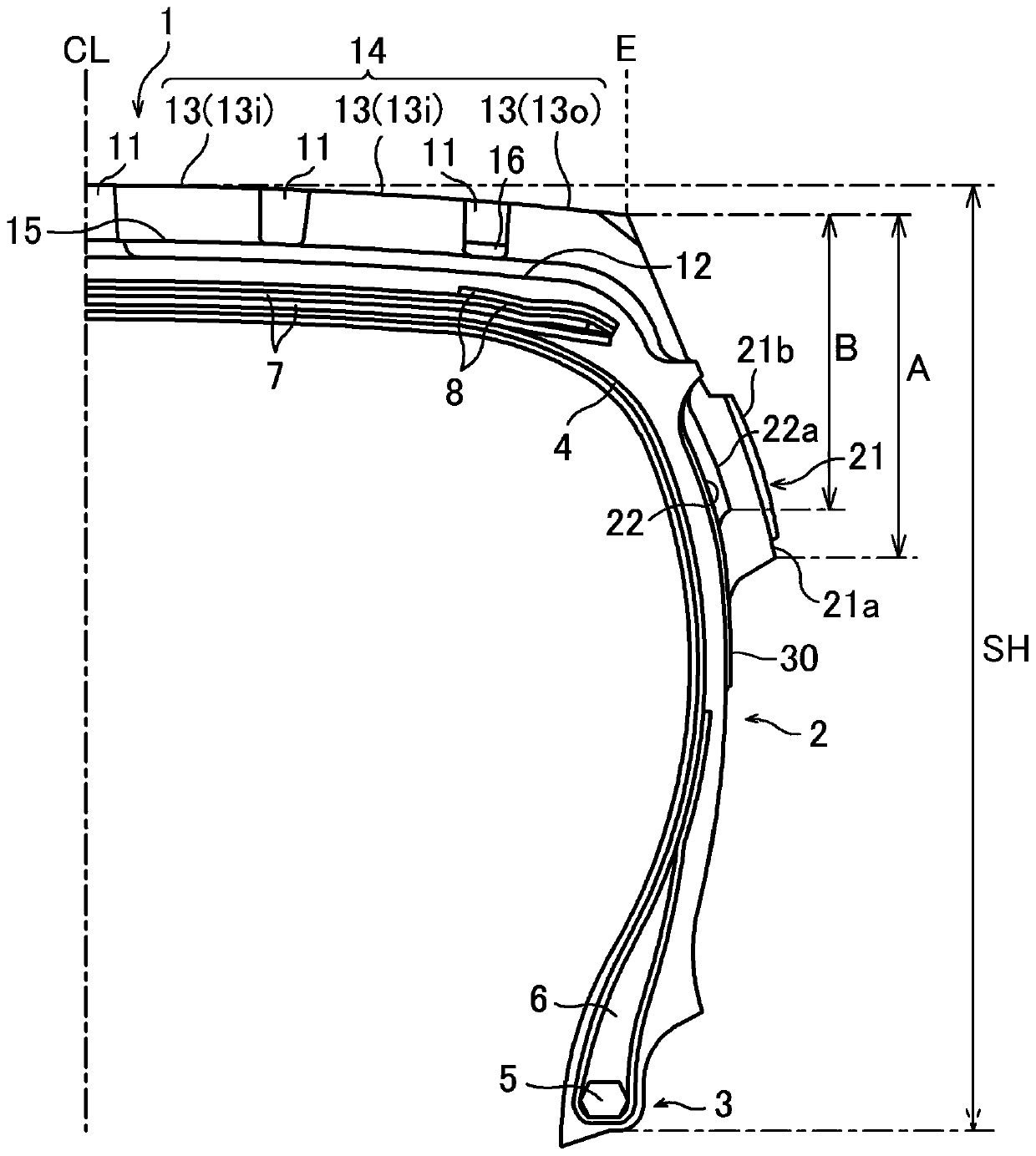

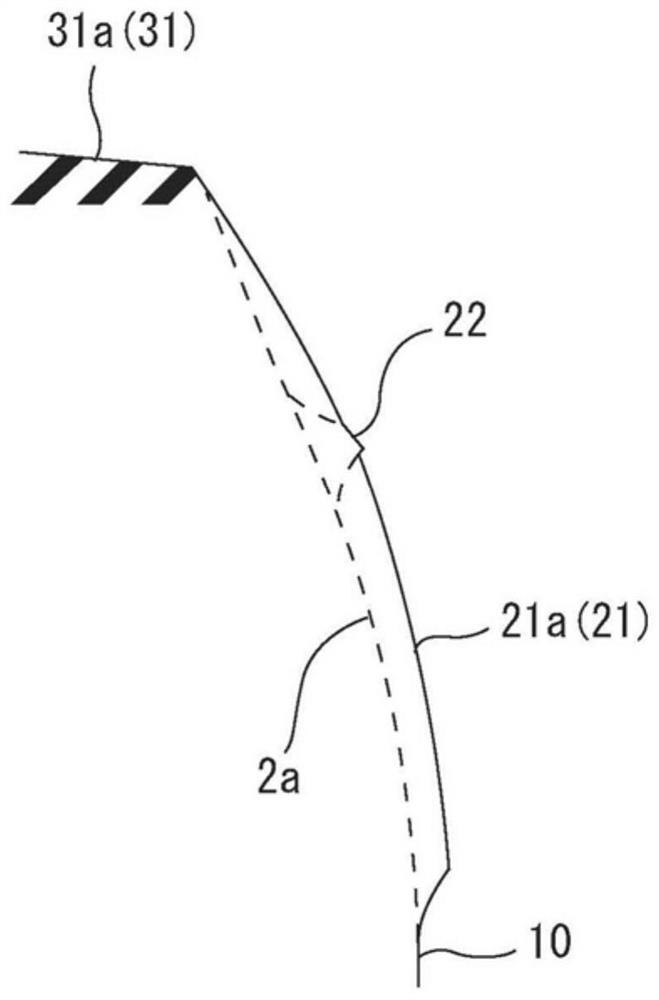

Pneumatic tire

PendingCN110914075AIncrease the edgeImprove rigidityOff-road vehicle tyresTyre tread bands/patternsShoulder regionStructural engineering

Provided is a pneumatic tire that is suitable as a tire for traveling on an unpaved road and that allows improvement of traveling performance and cut resistance on the unpaved road. A pair of side blocks 21, which extend in the tire width direction and face each other with a side groove 22 interposed therebetween, are provided in side regions located on the outer sides in the tire width directionof shoulder regions of a tread portion 1. Repetition elements 20 each comprising the side groove 22 and the pair of side blocks 21 are arranged at an interval in the tire circumferential direction. Atread of each of the side blocks 21 is formed into a protrusion and recess shape that comprises a reference surface 21a located on the side groove 22 side and a step portion 21b which is located on the side opposite to the side groove 22 side and protrudes from the reference surface 21a. A bottom raising portion 22a, which protrudes from the groove bottom and couples the pair of side blocks 21, isprovided in the side groove 22.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire tread pattern structure for two-wheeled vehicle

InactiveCN105252969AEnsure normal drainageIncrease the edgeTyre tread bands/patternsEngineeringTread

The invention discloses a pneumatic tire tread pattern structure for a two-wheeled vehicle. A tire tread comprises a plurality of inclined pattern main groove groups which are symmetrical with the center line of the tire tread and are arranged in a staggered manner; each inclined pattern main groove group comprises a first inclined pattern main groove and a second inclined pattern main groove which extend from a part, close to the center of the tire tread, to a tire shoulder in an inclined arc manner, and the arc shapes of the first inclined pattern main groove and the second inclined pattern main groove are arranged in a forward and reverse direction; each first inclined pattern main groove close to the center of the tire tread is in a downwards concave arc shape so as to be same with the rotation direction; each second inclined pattern main groove far from the center of the tire tread is in an upwards convex arc shape so as to be opposite with the rotation direction; the first inclined pattern main grooves and the corresponding second inclined pattern main grooves are in partial overlapping arrangement in the axial direction and the circumferential direction, so that a water discharging performance of a tire is ensured, edge constituents of the pattern grooves are increased, and dragging and braking performances are improved.

Owner:CHENG SHIN RUBBER (XIAMEN) IND LTD

pneumatic tire

ActiveCN104139672BIncrease the edgeImprove cornering performanceTyre tread bands/patternsVertical projectionEngineering

Owner:SUMITOMO RUBBER IND LTD

Tesla valve reverse flow principle-based novel music instrument

The invention discloses a novel wind instrument. The novel wind instrument structurally comprises a playing pipe, a Tesla valve tone change cavity and a center main pipe; eight sound pressing holes and two tuning holes are formed in the main pipe; the tail end of the playing pipe of the wind instrument is connected with the Tesla valve tone change cavity through a threaded joint; and the Tesla valve tone change cavity is connected with the center main pipe through welding. The Tesla valve tone change cavity has the capability of changing an internal flow field, generates an airflow sound on the basis of an original ordinary vertical bamboo flute sound, and can effectively change the original tone of a vertical bamboo flute. The novel wind instrument is novel in structure and unique in tone, and can be widely popularized and applied.

Owner:ZHEJIANG UNIV

pneumatic tire

ActiveCN109955655BImprove the decorative effectReduce edge componentsOff-road vehicle tyresTyre tread bands/patternsShoulder regionStructural engineering

Provided is a pneumatic tire capable of improving the protective effect and decorative effect of buttress areas. The pneumatic tire is provided with a plurality of lug grooves (8) extending from the shoulder area (3S) of the tread portion (3) toward the outside in the tire width direction and reaching the buttress area (2B) of the sidewall portion (2). ; and pattern blocks, which are divided by a plurality of horizontal grooves (8). The pattern blocks divided by a plurality of horizontal grooves (8) include: the shoulder block (31) arranged in the shoulder area (3S), and the buttress block (31) arranged in the buttress area (2B) twenty one). The buttress region (2B) is provided with an annular rib (22) that cuts across the buttress block (21) and extends annularly along the tire circumferential direction. At least some of the lug grooves (8A) among the plurality of lug grooves (8) are provided with widened portions (23) to increase the width of the annular rib (22).

Owner:TOYO TIRE & RUBBER CO LTD

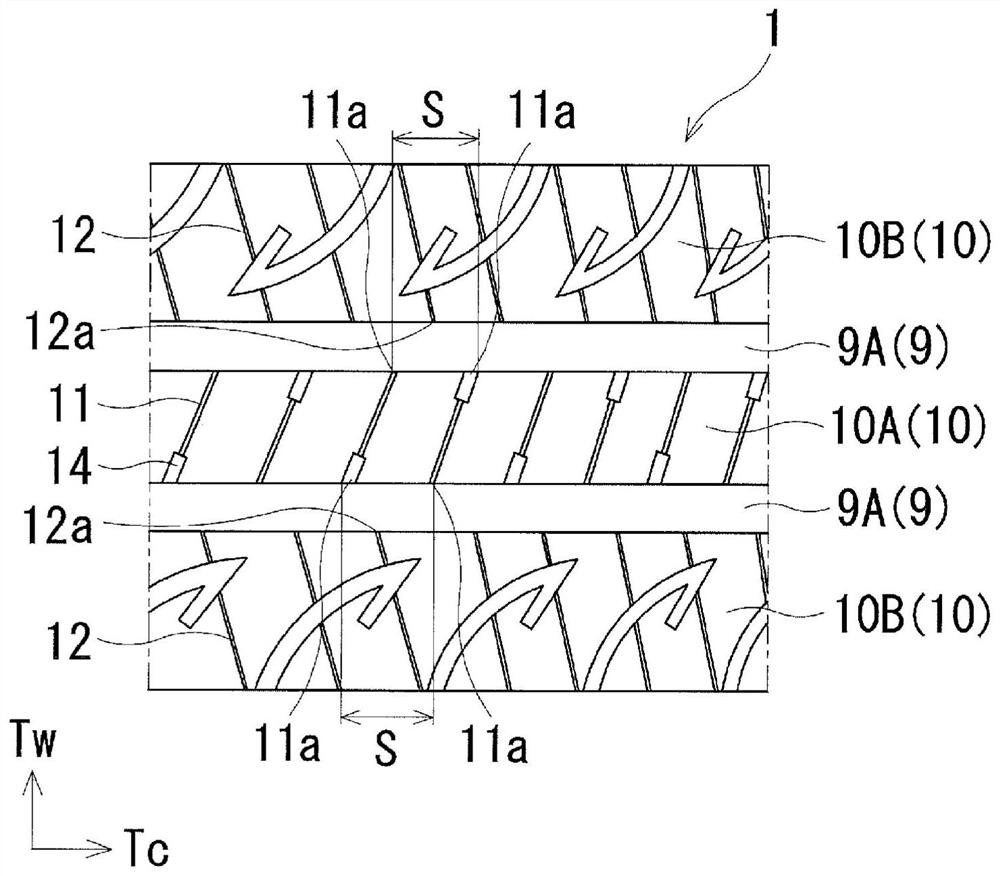

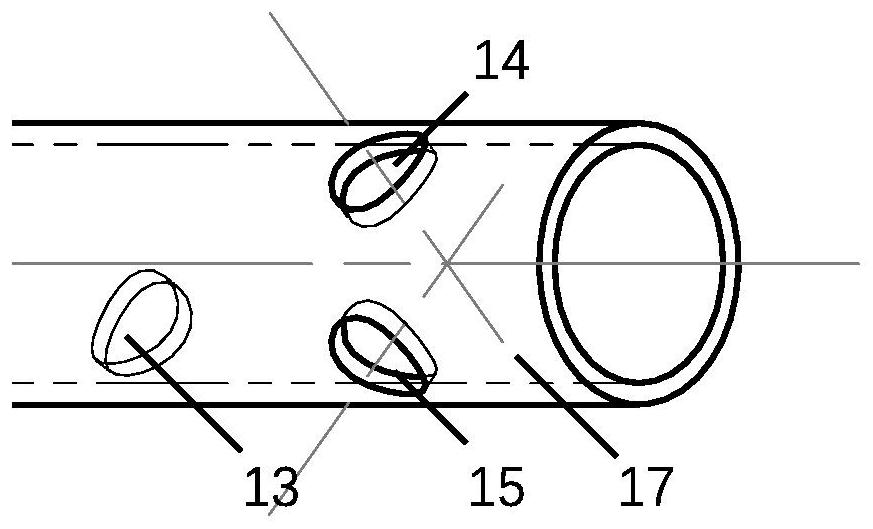

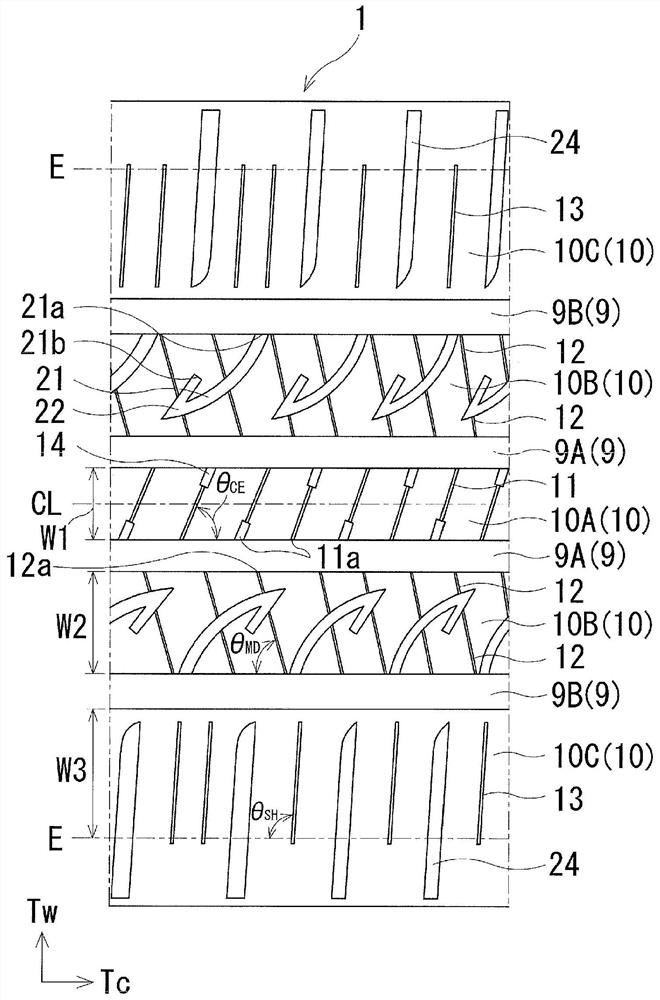

Pneumatic tire

ActiveCN111936323ASuppress noiseReduce noiseTyre tread bands/patternsEngineeringMechanical engineering

The present invention provides a pneumatic tire in which snow performance is improved while the occurrence of pattern noise is suppressed. A center land part (10A), intermediate land parts (10B), andshoulder land parts (10C) are each provided with a plurality of sipes (11, 12, 13) arranged at intervals in the circumferential direction of the tire. The sipes (11) each have, at one end thereof, a large-width section (14), which is formed to have a large groove width. The sipes (13) extend from outside a grounding end (E), in the width direction of the tire, toward outer main grooves (9B). The directions in which the sipes (11, 13) extend, with respect to the circumferential direction of the tire, are opposite to the direction in which the sipes (12) extend. The inclination angle theta CE ofthe sipes (11), the inclination angle theta MD of the sipes (12), and the inclination angle theta SH of the sipes (13) satisfy the relationship theta CE < theta MD < theta SH <90 degrees. Ends (12a)of the sipes (12) adjacent to inner main grooves (9A) are located between ends (11a) of the sipes (11). At least the sipes (11) or the sipes (12) are located on the meridian of the tire at any position on the entire circumference of the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

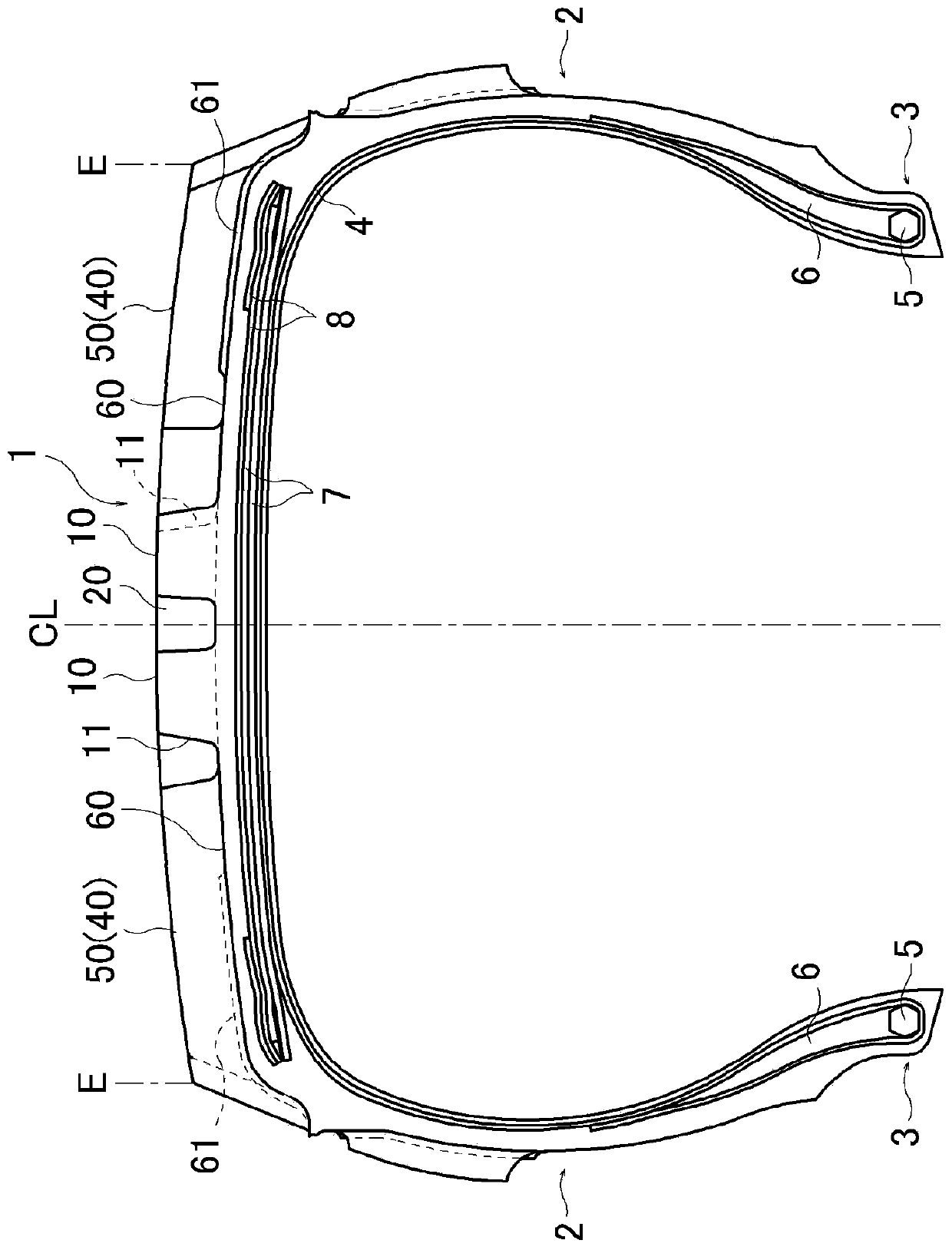

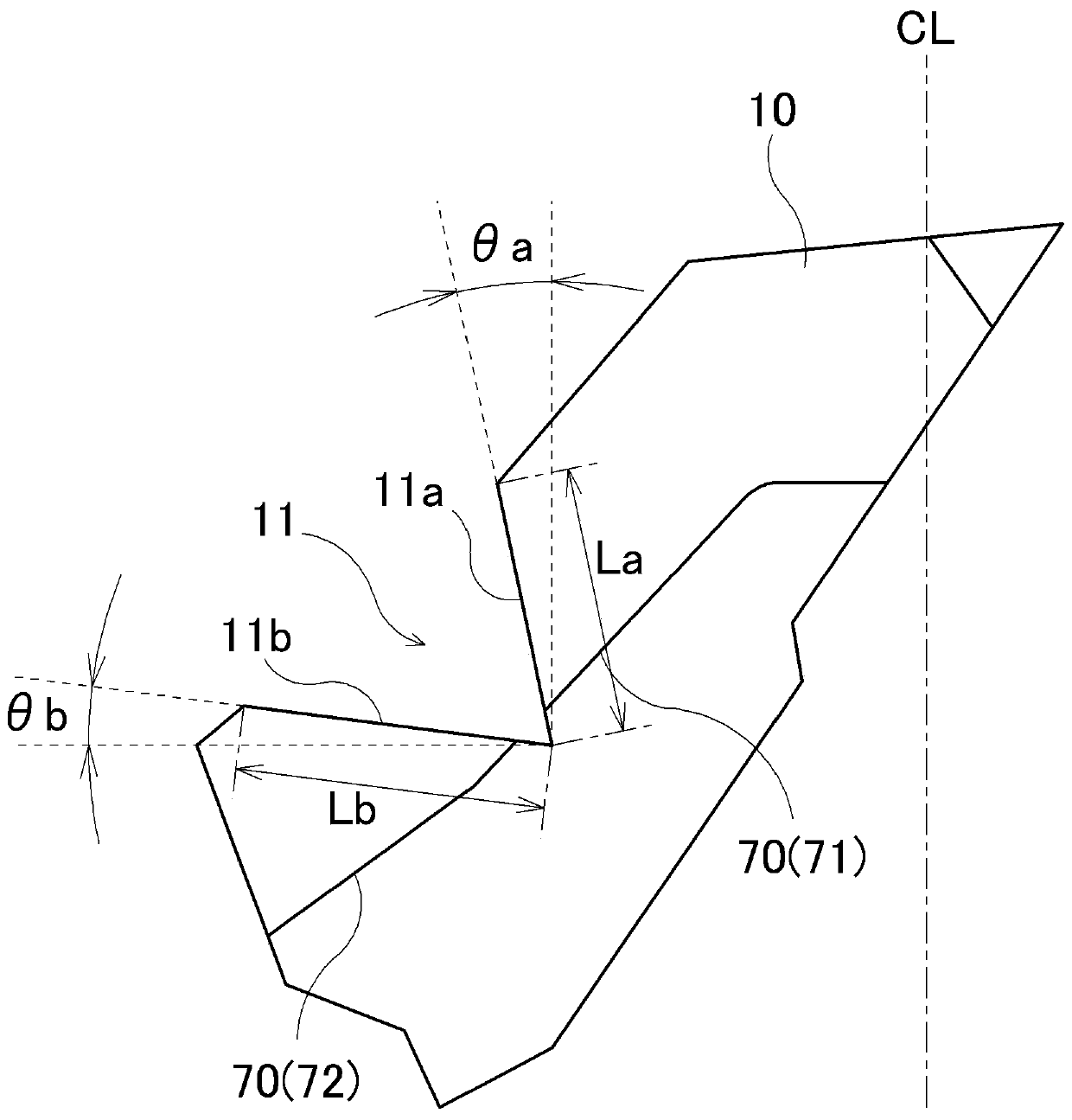

Pneumatic tire

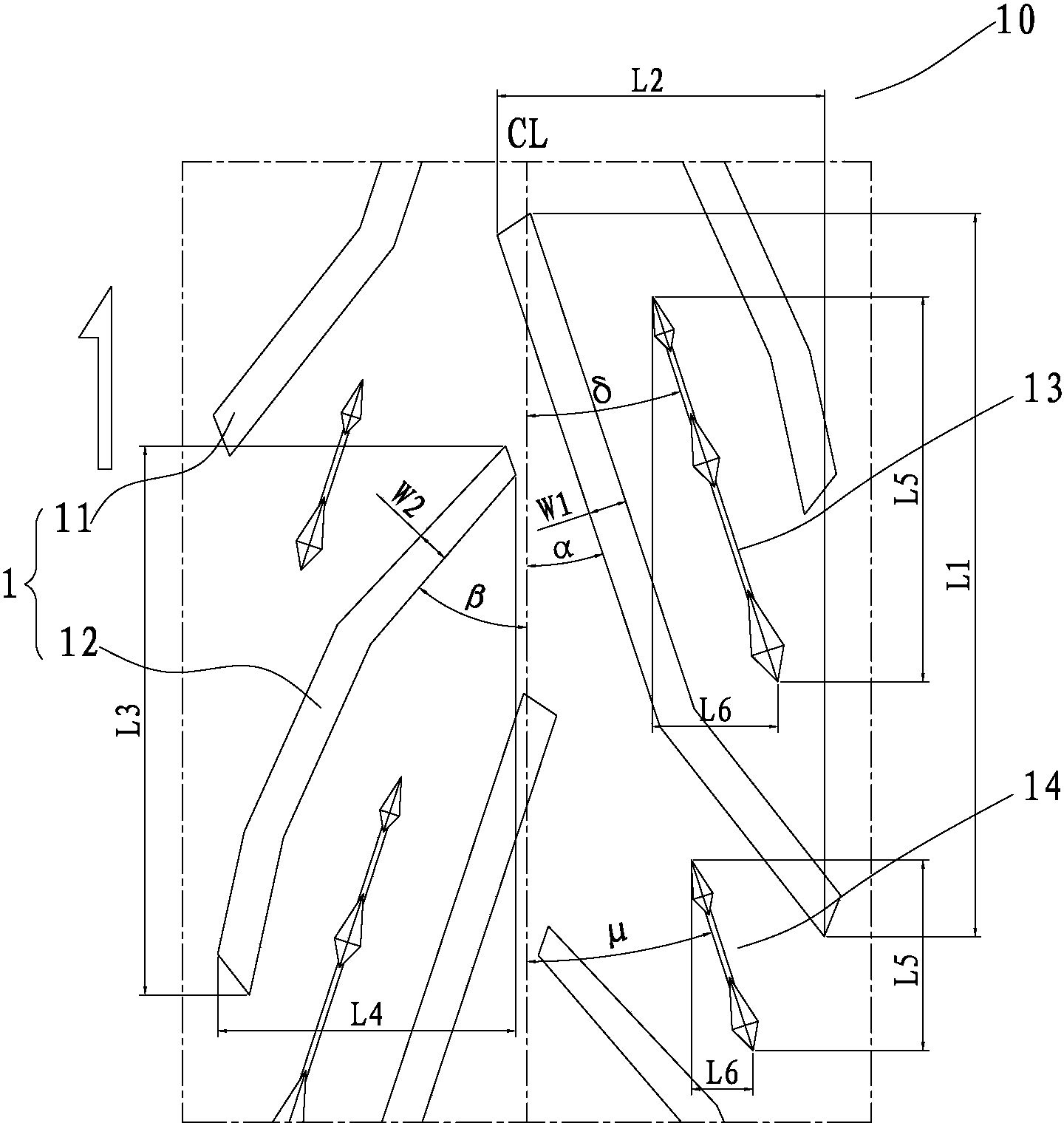

ActiveCN110214090AIncrease the edgeEffective controlHeavy duty tyresHeavy duty vehicleGroove widthEngineering

Provided is a pneumatic tire that is suitable for use as a tire for traveling on unpaved roads and that improves traveling performance on unpaved roads. Center blocks 10, which are provided in a center region of a tread section 1, are arrayed so as to form a pair of center blocks 10 between which there are interposed inclined grooves 30 that extend in an inclined direction with respect to a tire circumferential direction. The center blocks 10 are made to extend so as to straddle a tire equator CL from one side to the other side of the tire equator CL. Notches 11, which are each composed of a first wall 11a and a second wall 11b connected to each other in a V shape, are provided in treads in each center block CL. The first walls 11a are made to extend at an angle within + / -20 degrees with respect to the tire circumferential direction. The second walls 11b are made to extend at an angle of + / -10 degrees with respect to a tire width direction. Inclined grooves 20 are each constituted by asee-through portion 21 and an expanded portion 22 having a larger groove width than the see-through portion 21. A width SW of a see-through region S that can extend without intersecting an extensionline of the see-through portion 21 is made to be equal to or greater than 30% of a tread width TW.

Owner:THE YOKOHAMA RUBBER CO LTD

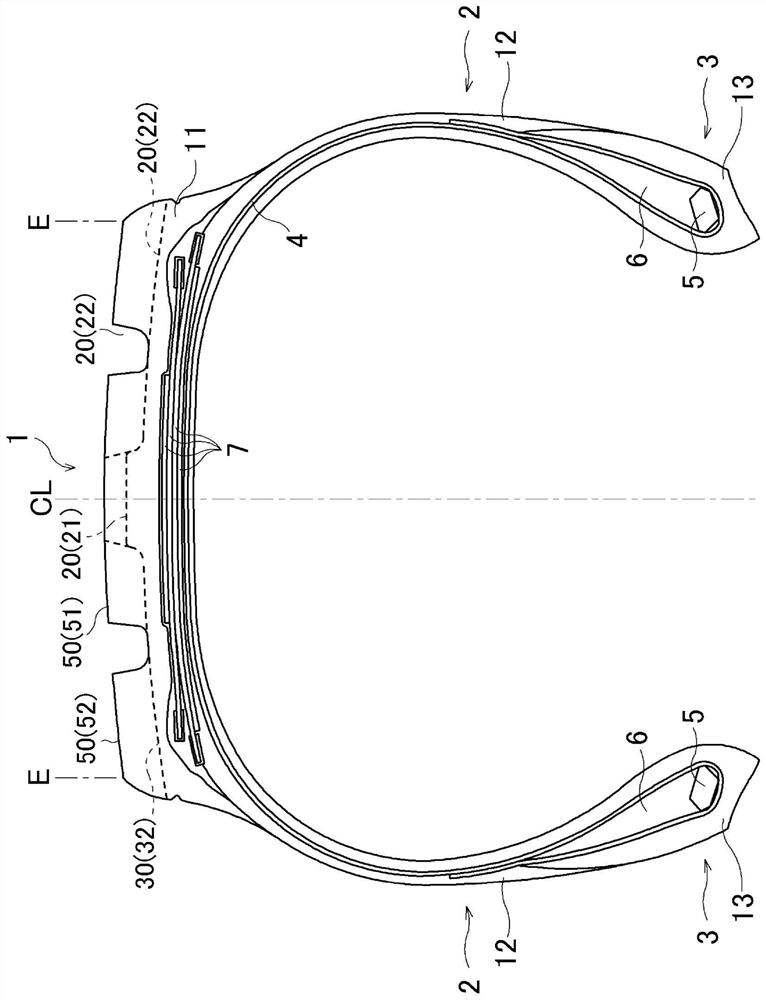

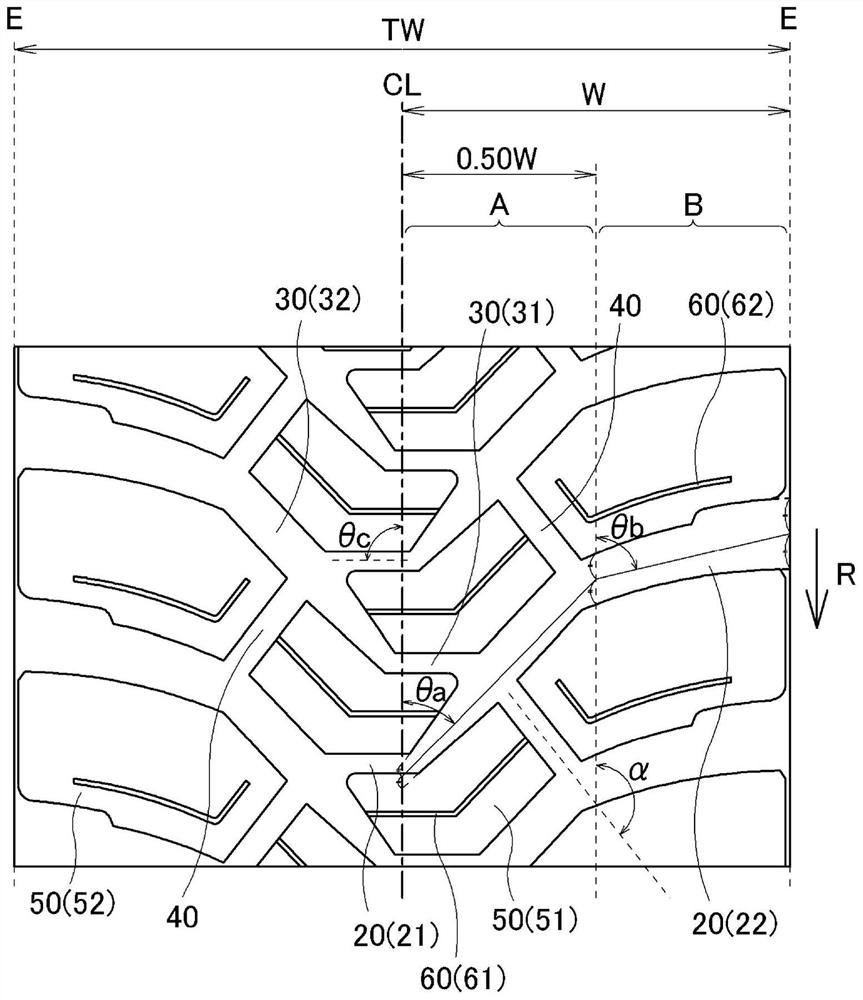

Pneumatic tire

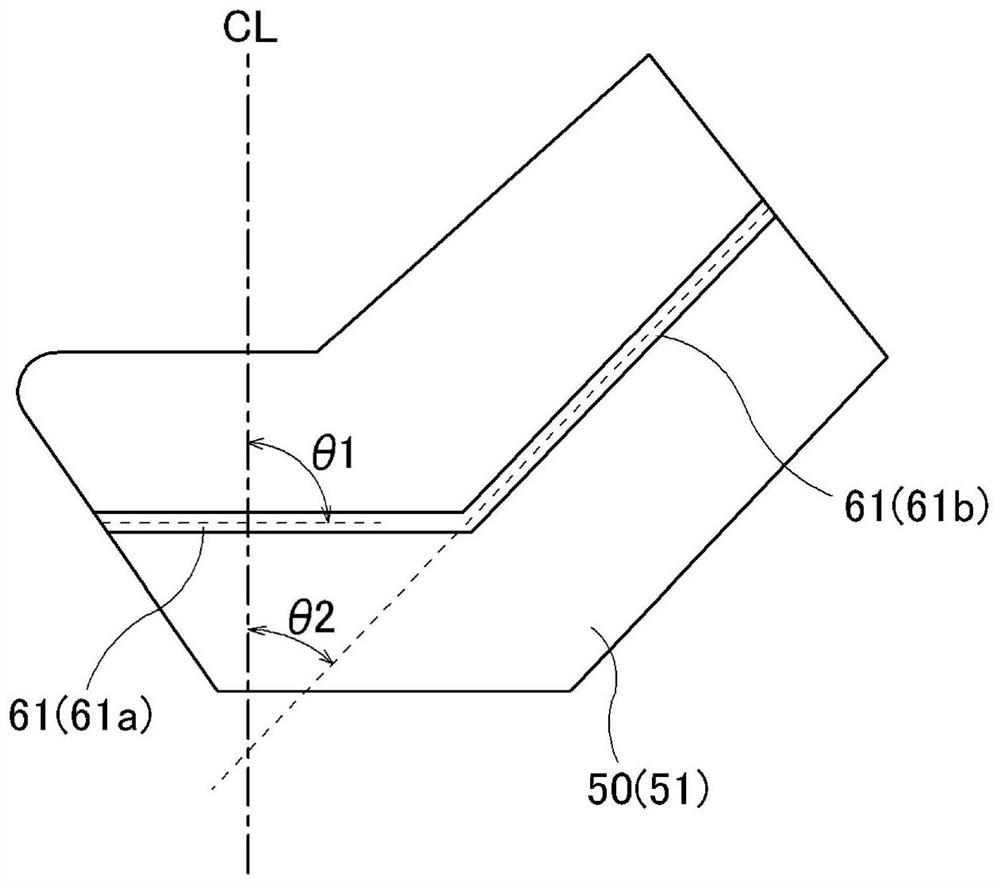

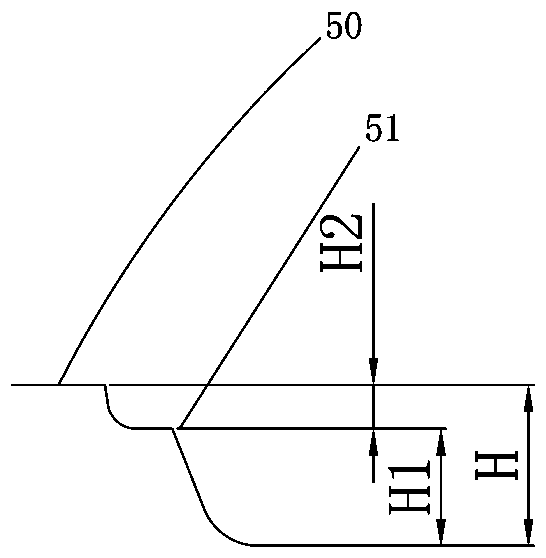

ActiveCN111989229AIncrease the edgeImprove traction performanceHeavy duty tyresHeavy duty vehicleAcute angleRoad surface

Provided is a pneumatic tire that allows improvement of snow traction performance while favorably maintaining performance in resistance to uneven wear and maintaining traveling performance on an unpaved road. Lug grooves (20, 30) are alternately arranged, the lug grooves (20, 30) comprising first groove portions (21, 31) intersecting with a tire center line CL and extending in the tire width direction and second groove portions (22, 32) respectively inclined, from ends of the first groove portions (21, 31), at acute angles in the tire circumferential direction relative to the first groove portions (21, 31) so as to extend to tread ends E on one side and the other side relative to the tire center line. The other ends of the first groove portions (21, 31) are in communication with the respective second groove portions (32, 22), of the lug grooves (30, 20), adjacent to each other in the tire circumferential direction. The first groove portions (21, 31) are arranged on a stepping-in side relative to the ends of the tread end E sides of the lug grooves (20, 30). The second groove portions (22, 32) are curved or bent such that the average angle theta in an inner side region A of the second groove portions (22, 32) becomes smaller than the average angle theta in an outer side region B of the second groove portions (22, 32). A shallow groove (60) is formed on a tread surface of ablock (50) demarcated by the lug grooves (20, 30) and circumferential narrow grooves (40) for connecting the adjacent second groove portions (22) and the adjacent second groove portions (32) in the tire circumferential direction, in such a manner that the shallow groove (60) has at least one bent point.

Owner:THE YOKOHAMA RUBBER CO LTD

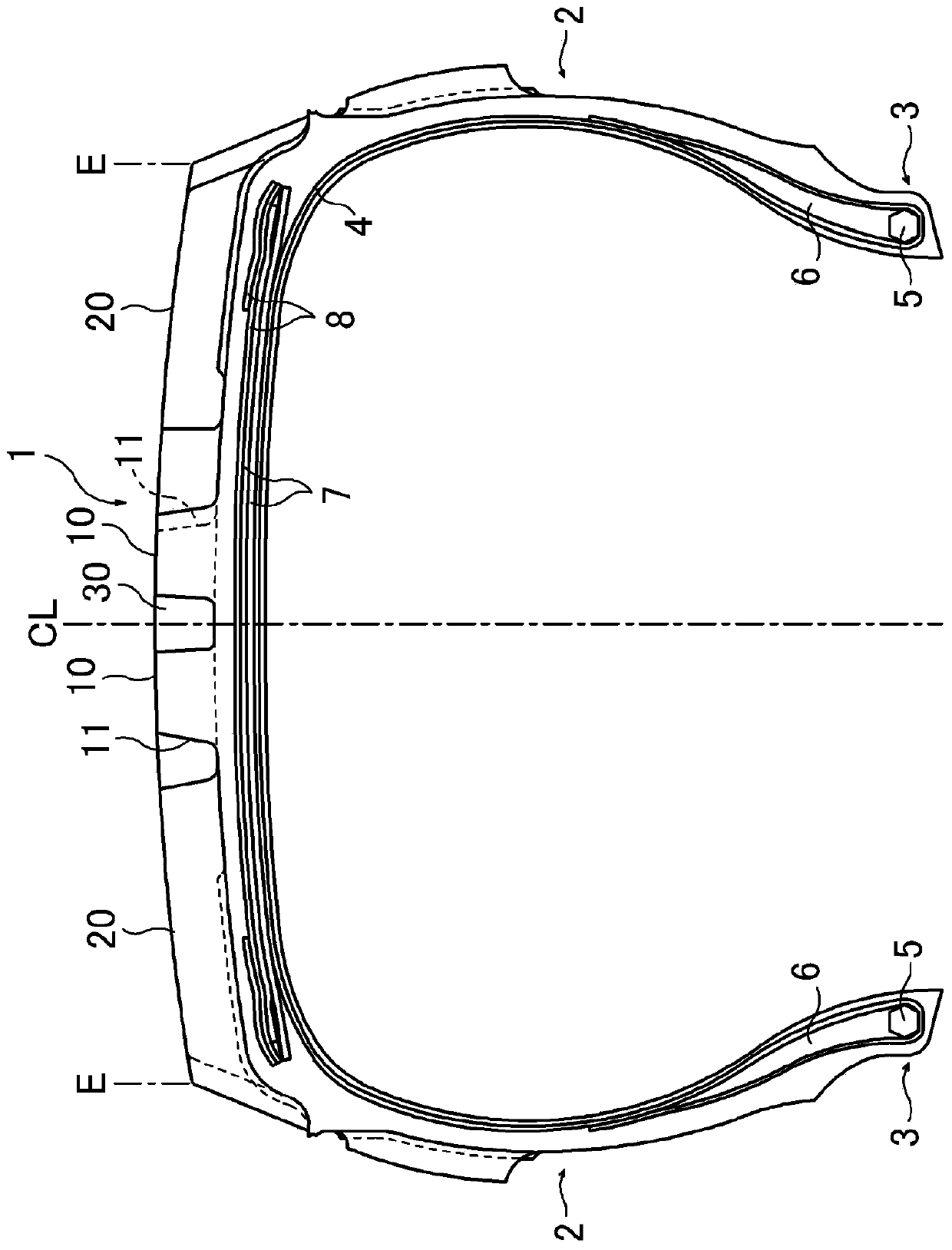

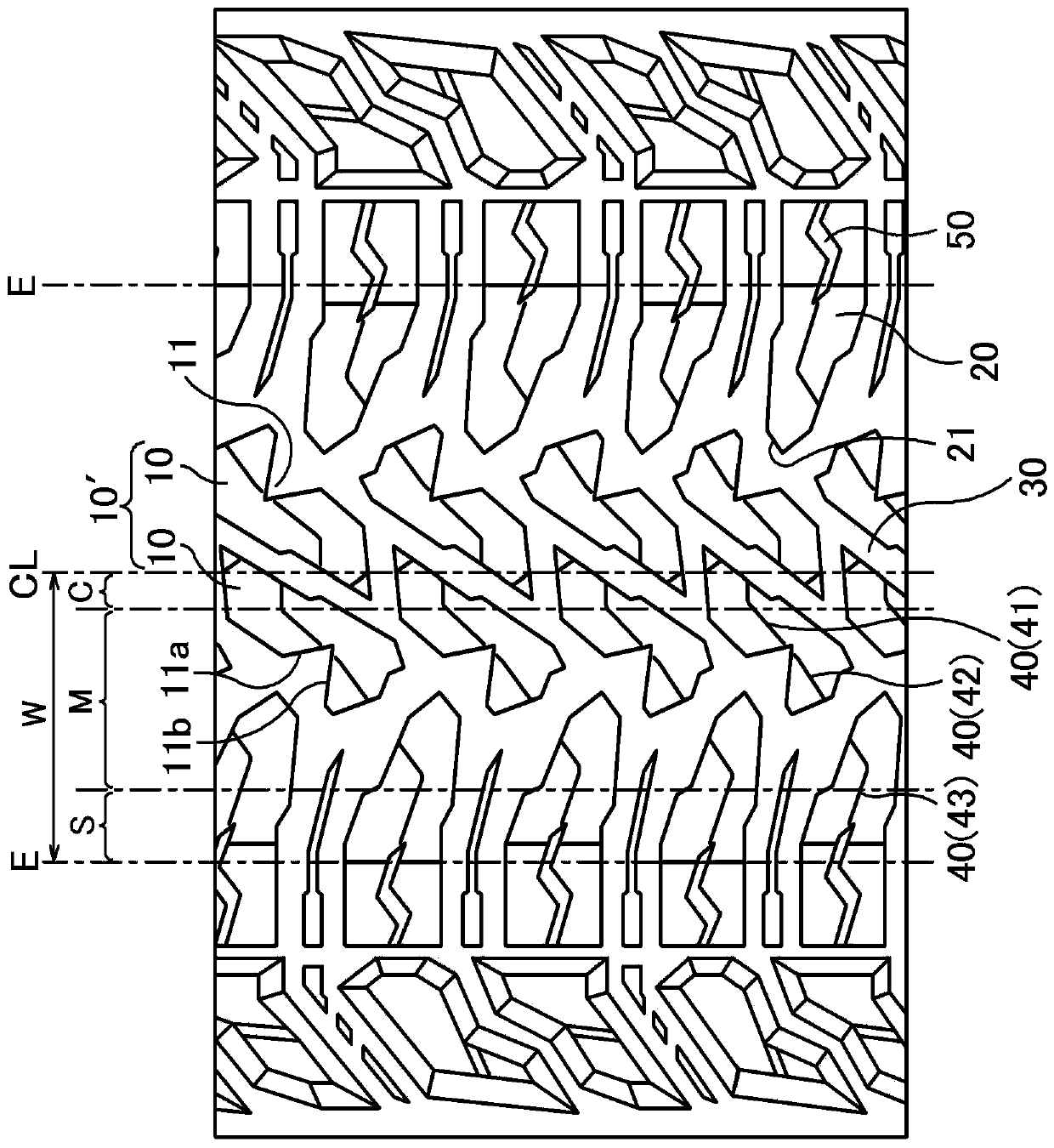

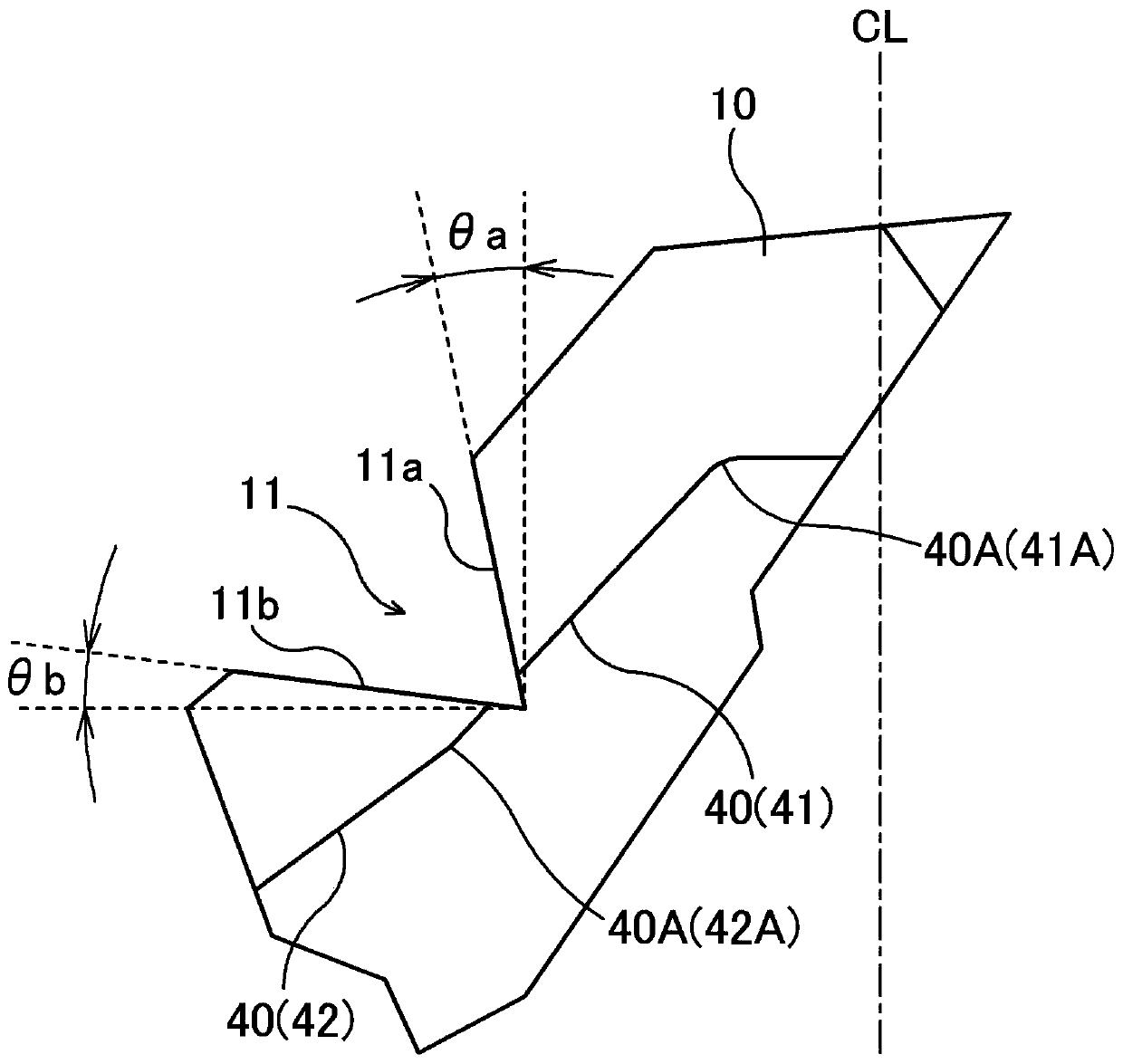

Pneumatic tire

ActiveCN110198848ACurb dumpingEffective controlOff-road vehicle tyresTyre tread bands/patternsMechanical engineeringTread

The present invention provides a pneumatic tire that is suitable for use as a tire for traveling on unpaved roads, and that improves traveling performance and damage resistance on unpaved roads. Center blocks 10, which are provided in a center region of a tread section 1, are arrayed so as to form a pair of center blocks 10 between which there are interposed inclined grooves 30 that extend in an inclined direction with respect to a tire circumferential direction. The center blocks 10 are made to extend so as to straddle a tire equator CL from one side to the other side of the tire equator CL.Notches 11, which are each composed of a first wall 11a and a second wall 11b connected to each other in a V shape, are provided in treads in each center block CL. The first walls 11a are made to extend at an angle within + / -20 degrees with respect to the tire circumferential direction; the second walls 11b are made to extend at an angle of + / -10 degrees with respect to a tire width direction; andthe average angle of sipes, which are respectively formed in the center blocks 10 and shoulder blocks 20, lies within 90 degrees + / -10 degrees in a first region C, lies within 130 degrees + / -10 degrees in a second region M, and lies within 70 degrees + / -10 degrees in a third region S with respect to the tire equator CL. Each sipe is configured to have at least one curved portion.

Owner:THE YOKOHAMA RUBBER CO LTD

A motorcycle pneumatic tire tread structure

ActiveCN104029567BImprove drainage capacityImprove wet grip performanceTyre tread bands/patternsEngineeringTread

The invention discloses a tread structure of a pneumatic tire for a motorcycle. A tread comprises a plurality of main pattern groove groups which are formed in a staggered manner by using the center of the tread as a symmetry center, wherein first auxiliary fine diamond pattern grooves are formed among the main pattern groove groups, and each first auxiliary fine diamond pattern groove comprises a fine diamond part which is provided with a plurality of tangent planes and a fine groove which is connected with the fine diamond part. The fine diamond parts and the fine grooves of the auxiliary fine diamond pattern grooves are designed to be in mutual connection, so that water films can be effectively broken, the water drainage performance of the tire is effectively improved, and the wet land gripping performance of the tire is improved.

Owner:CHENG SHIN RUBBER (XIAMEN) IND LTD

Pneumatic tire tread pattern structure for adventure rally cars

PendingCN109130708AHigh strengthIncrease the edgeOff-road vehicle tyresMotorcycle tyresEngineeringRoad surface

The invention discloses a pneumatic tire tread pattern structure for adventure rally cars. The structure includes multiple protrusive pattern blocks and multiple wrapping parts arranged on the cornersof the pattern blocks respectively, and the pattern blocks are circumferentially arranged on the tire tread at intervals. According to the structure, by arranging the wrapping parts on the corners ofthe pattern blocks, the pattern blocks can be protected, the strength of each patter block is improved, and the edge components of the pattern blocks are increased, so that the situation that the pattern blocks fall off during running on a highway is avoided. Therefore, during a long trip on the highway pavement and the cross-country pavement, the service life of a tire can be ensured, and excellent traction performance is achieved.

Owner:CHENG SHIN RUBBER (XIAMEN) IND LTD

Pneumatic tire

ActiveCN110191813AGuaranteed rigidityImprove resistance to damageHeavy duty tyresHeavy duty vehicleEngineeringStructural engineering

Provided is a pneumatic tire suitable for traveling unsealed roads and capable of maintaining high levels of both traveling performance on unsealed roads and resistance to block damage. Center blocksprovided in a center region of a tread 1 are arranged so as to form a pair sandwiching therebetween an inclined groove extending inclined relative to the tire circumferential direction. Each center block is extended so as to straddle the tire equator from one side of the tire equator to the other side. A notch comprising a first wall and a second wall connected in a V shape in the tread road surface is formed in each center block. The first wall is extended in the tread road surface at an angle of no more than + / -20 DEG relative to the tire circumferential direction and the second wall is extended at an angle of + / -10 DEG relative to the tire width direction. The wall surface angles for both the first wall and the second wall are made greater than the wall surface angle of the wall surfacehaving the notch provided therein.

Owner:THE YOKOHAMA RUBBER CO LTD

A new musical instrument based on the reverse flow principle of tesla valve

ActiveCN110544464BSolve health problemsLow gas consumptionWind musical instrumentsFluteWind instrument

The invention discloses a novel wind instrument, the structure of which comprises a blowing pipe, a Tesla valve sound changing cavity and a central main pipe; the main pipe is provided with eight sound-pressing holes and two sound-correcting holes, and the end of the wind playing pipe of the wind instrument is connected to the pipe through a threaded joint. The voicing cavity of the Tesla valve is connected, and the phonic cavity of the Tesla valve is connected with the central main pipe by welding. The cavity of the Tesla valve has the ability to change the internal flow field. Based on the original sound of the ordinary flute, the sound of air flow can be generated, which can effectively change the tone of Xiao Yuan. The invention proposes a novel wind instrument with novel structure and unique timbre, which can be widely popularized and applied.

Owner:ZHEJIANG UNIV

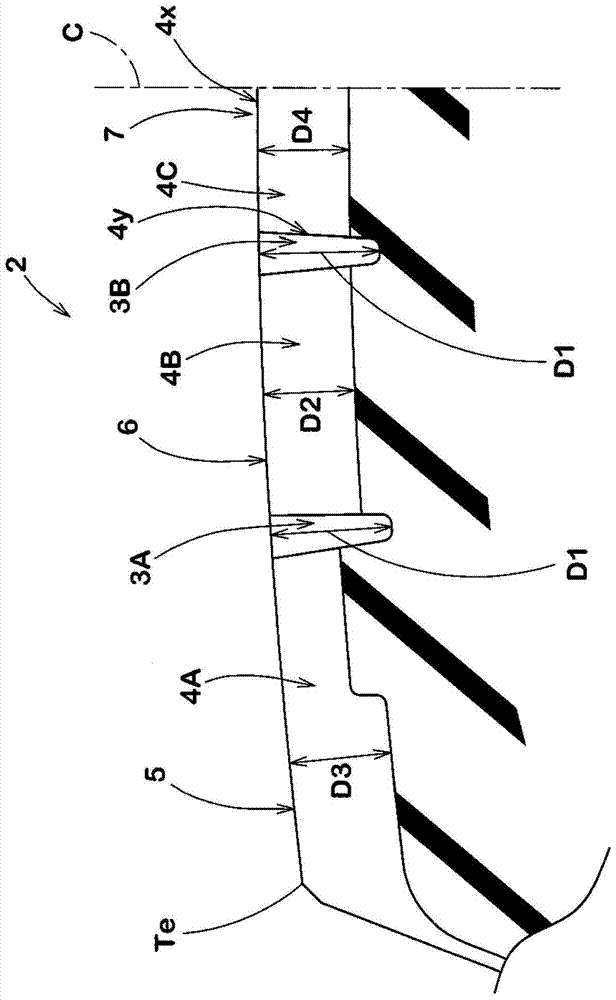

pneumatic tire

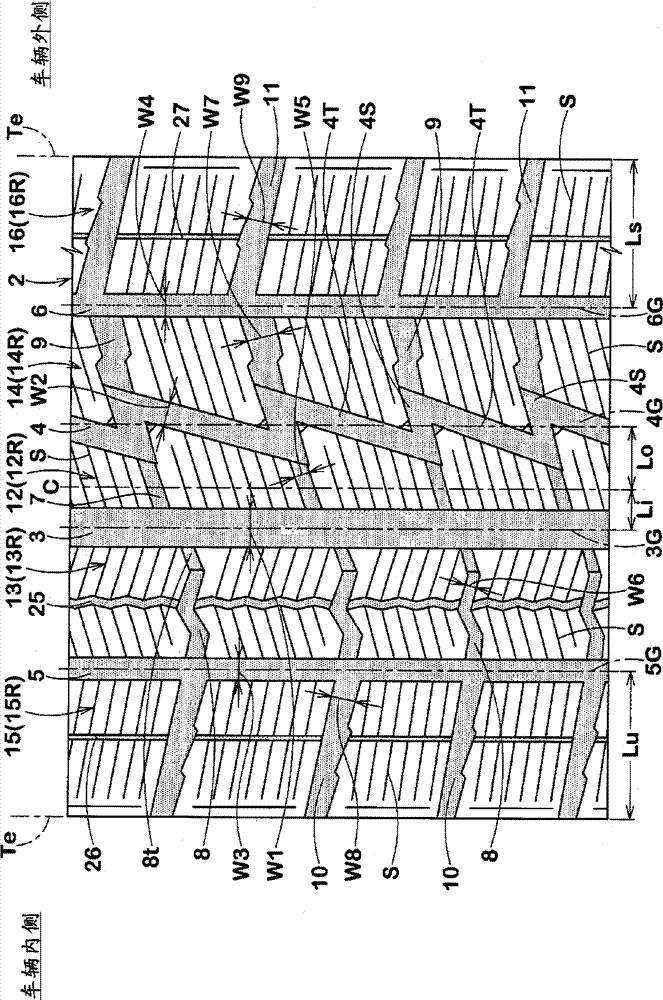

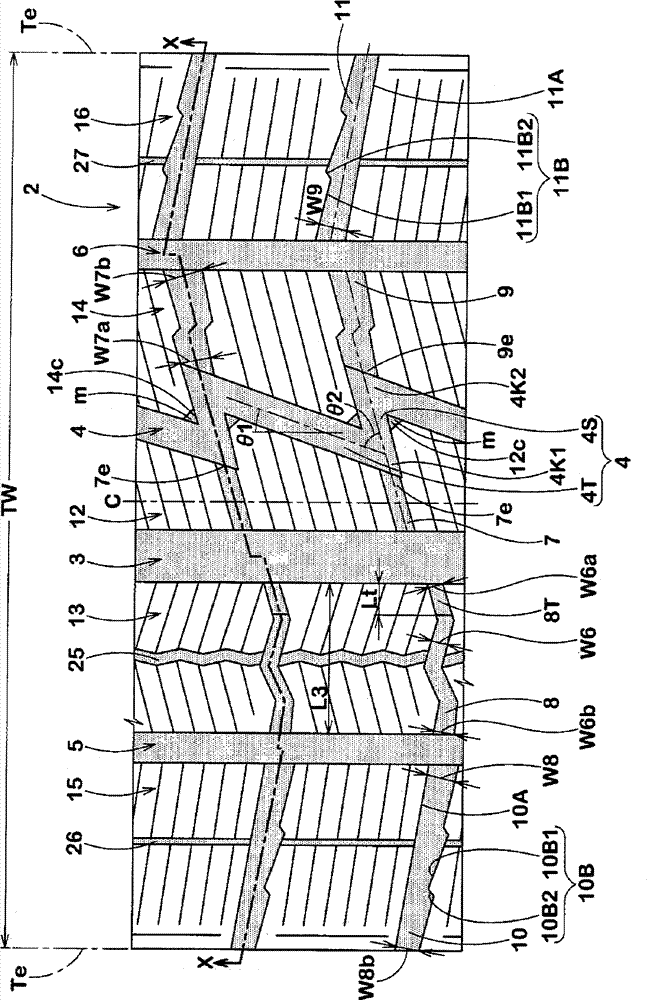

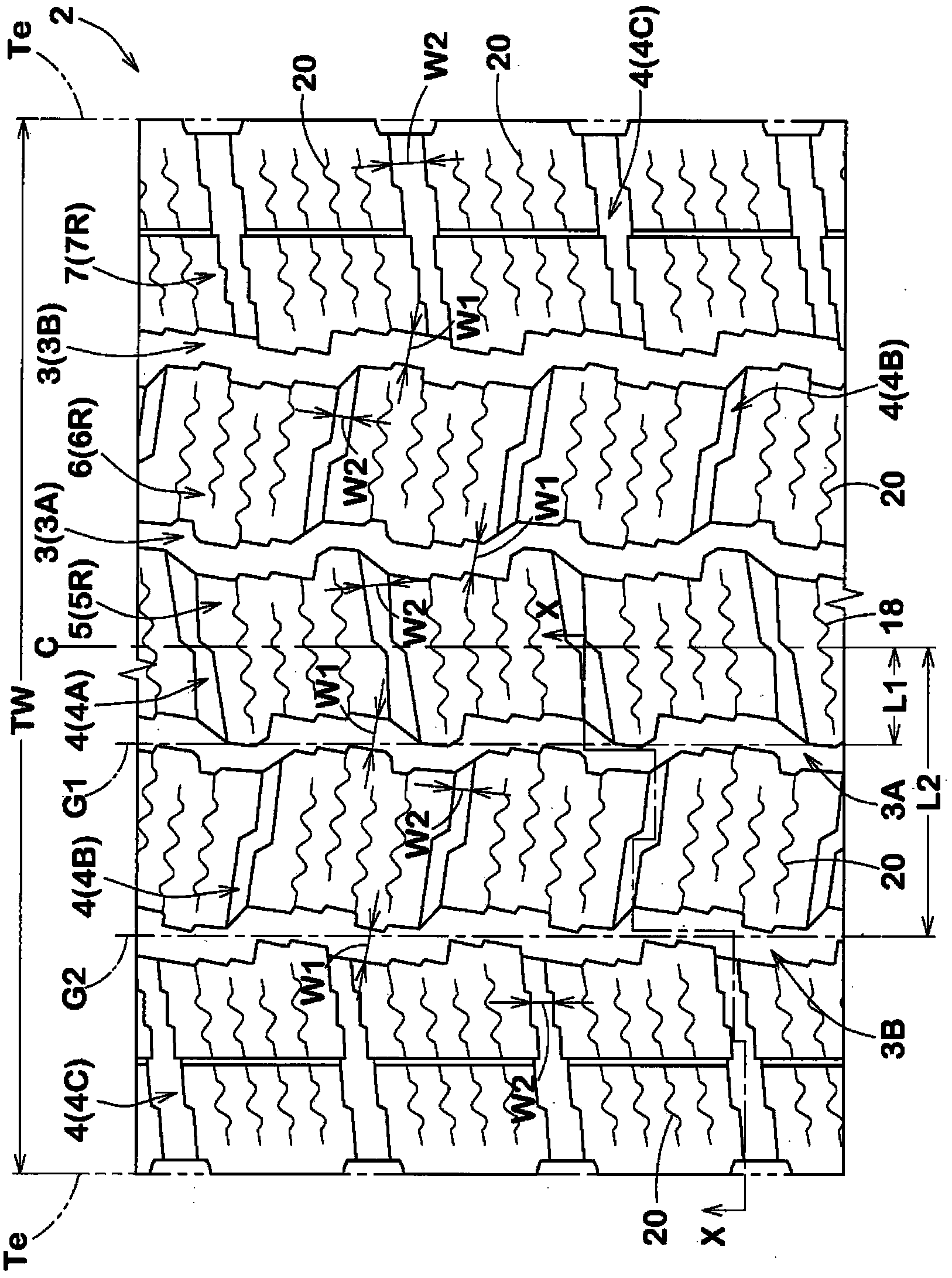

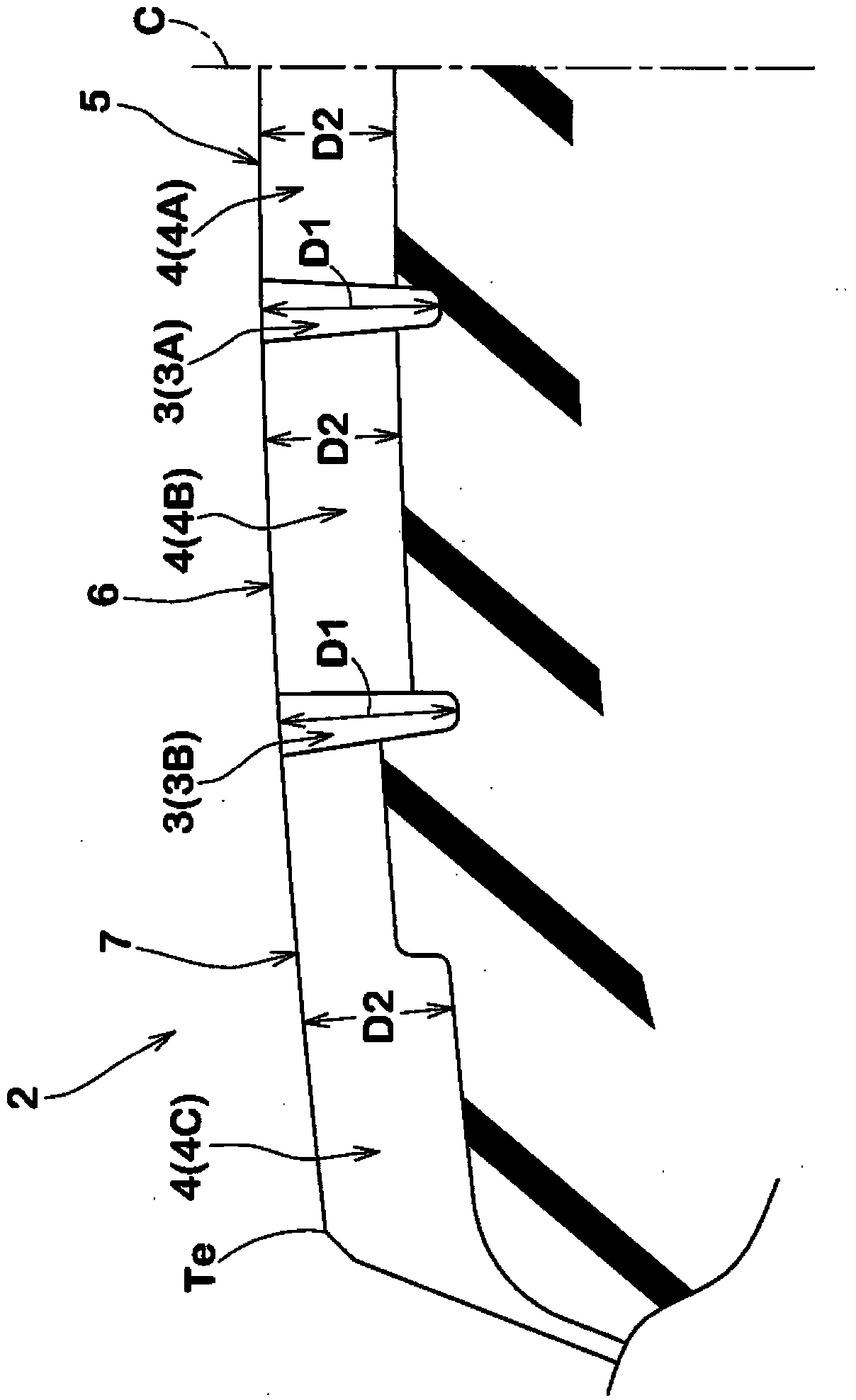

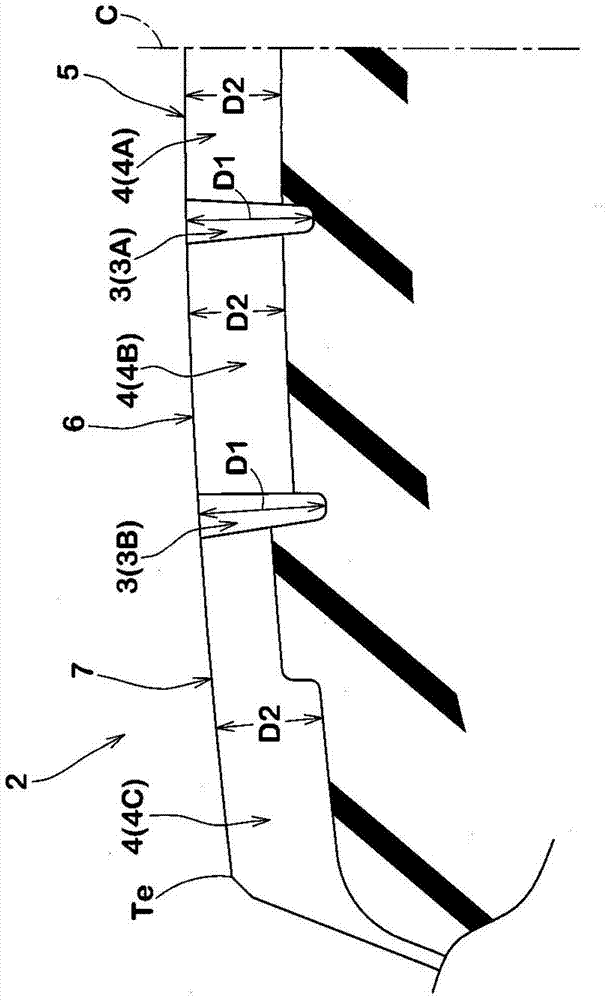

ActiveCN104723799BImprove rigidityImprove icy road performanceTyre tread bands/patternsGroove widthEngineering

The present invention provides a pneumatic tire which improves drainage performance, snow road performance and icy road performance in a balanced manner. Intermediate blocks (6) divided by shoulder main grooves (3A), central main grooves (3B) and intermediate lateral grooves (4B) are provided at intervals on the tread portion (2). The average groove width W2g of the middle lateral groove (4B) is 7% to 11% of the maximum length La of the middle block in the tire circumferential direction. The middle block lateral edge (10) consists of a middle inner part (11) extending obliquely to one side from the central main groove, a middle central part (12) connected to the middle inner part and bent to one side, and a middle central part (12) connected to the middle central part. The middle outer part (13) is connected to the outer part and inclined to one side and connected to the shoulder main groove. In addition, the middle inner longitudinal edge (17) and the middle outer longitudinal edge (18) are composed of a plurality of circumferential pieces (20) inclined opposite to the direction of the middle inner portion, and axial pieces (21) connecting the circumferential pieces. ) to form bumps.

Owner:SUMITOMO RUBBER IND LTD

Rubber composition for tire and tire including same

ActiveCN113195617AStable performance on dry roadsReduce resistanceSpecial tyresTyre tread bands/patternsPolymer scienceButadiene Dioxide

Provided are: a rubber composition for a tire which is excellent in terms of dry steering stability, wet steering stability, low-rolling resistance, and on-snow performance; and a tire including the same. The rubber composition is characterized by being formed by adding 80-100 parts by mass of an inorganic filler and 0.5-5 parts by mass of alkylsilane having a C3-C20 alkyl group to 100 parts by mass of a diene rubber comprising a total 100 mass% of 20-45 mass% of a natural rubber, 20-45 mass% of a styrene butadiene rubber, and 20-45 mass% of a butadiene rubber, wherein the rubber hardness at 23 deg C is 68 or more.

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com