Pneumatic tire

A technology of pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of excessive rigidity reduction of small block g, easy concentration of wear, etc., to prevent uneven wear , Improve the performance on snow and reduce the effect of poor rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

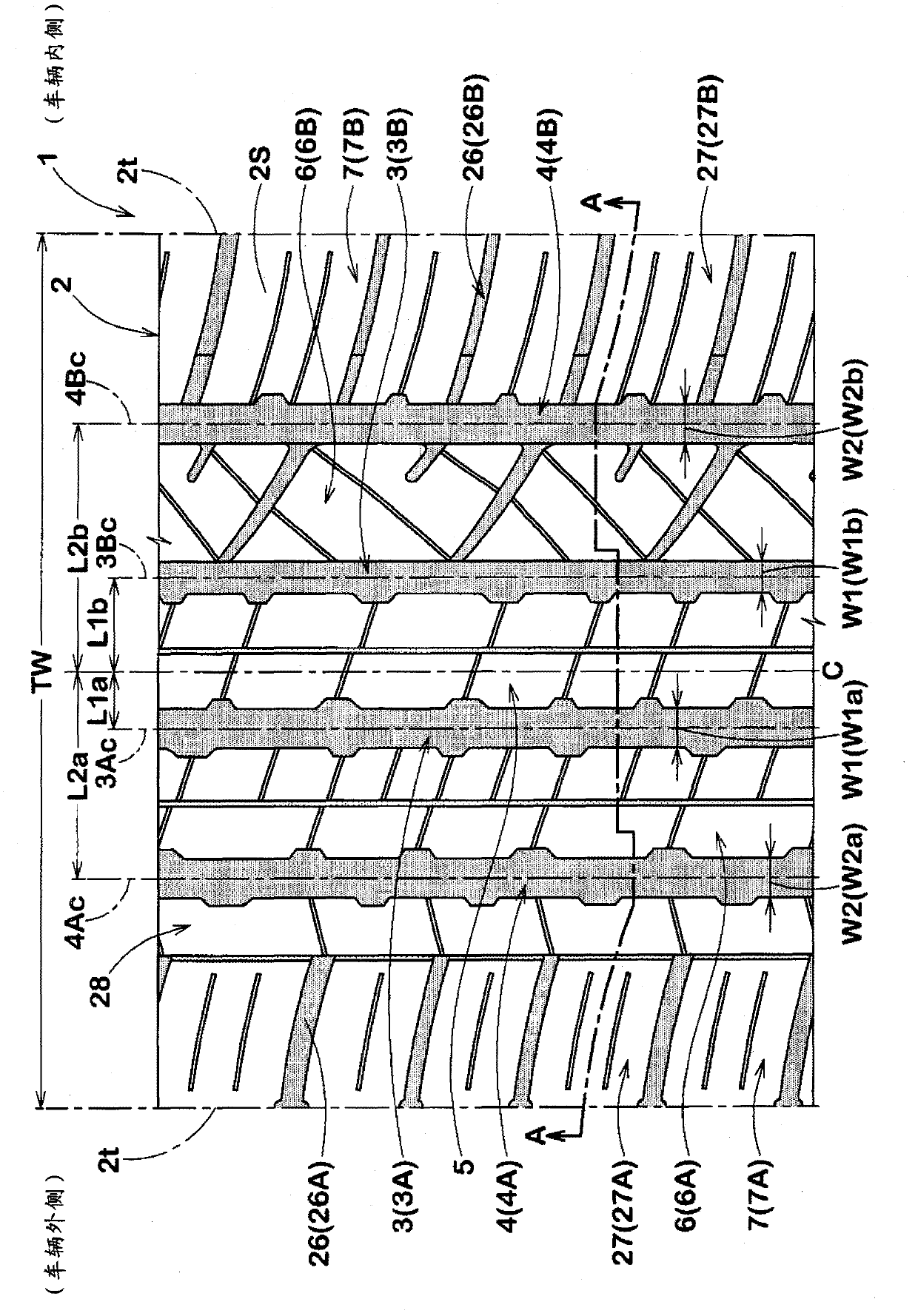

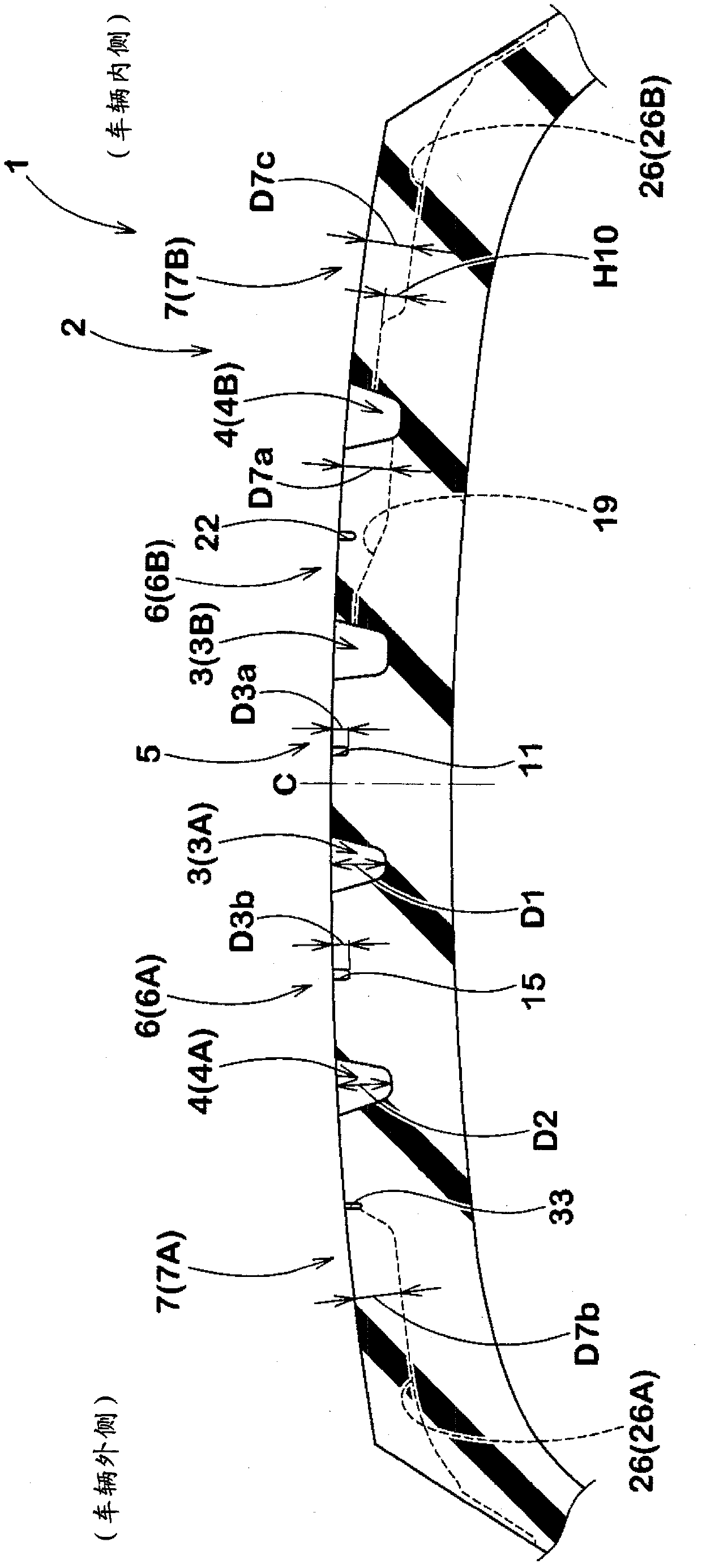

[0101] manufacturing form figure 1 The tires having the basic structure shown in Table 1 and the tires having the block elements and shoulder sipes shown in Table 1 were evaluated for their performance. Among them, the common specifications are as follows.

[0102] Tire size: P235 / 60R18

[0103] Rim size: 18×7.5

[0104] Tread width TW: 198mm

[0105] Central longitudinal groove:

[0106] Groove depth D1: 8.2mm

[0107] Groove width W1a of the outer central longitudinal groove: 8.7mm, distance L1a: 12.45mm

[0108] Groove width W1b of inner central longitudinal groove: 7.1mm, distance L1b: 20.85mm

[0109] Shoulder longitudinal groove:

[0110] Groove width W2: 8.7mm

[0111] Groove depth D2: 8.2mm

[0112] Distance L2a of outer shoulder longitudinal groove: 45.85mm

[0113] Distance L2b of inner shoulder longitudinal groove: 54.7mm

[0114] Central auxiliary groove, outer middle auxiliary groove:

[0115] Groove width W3a, W3b: 1.3mm, groove depth D3a, D3b: 2.5mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com