Pneumatic tire

A technology of pneumatic tires and tires, which is applied to heavy tires, tire parts, tire treads/tread patterns, etc., can solve problems such as uneven wear, achieve good balance, improve traction performance on snow, and avoid excessive reduction in rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

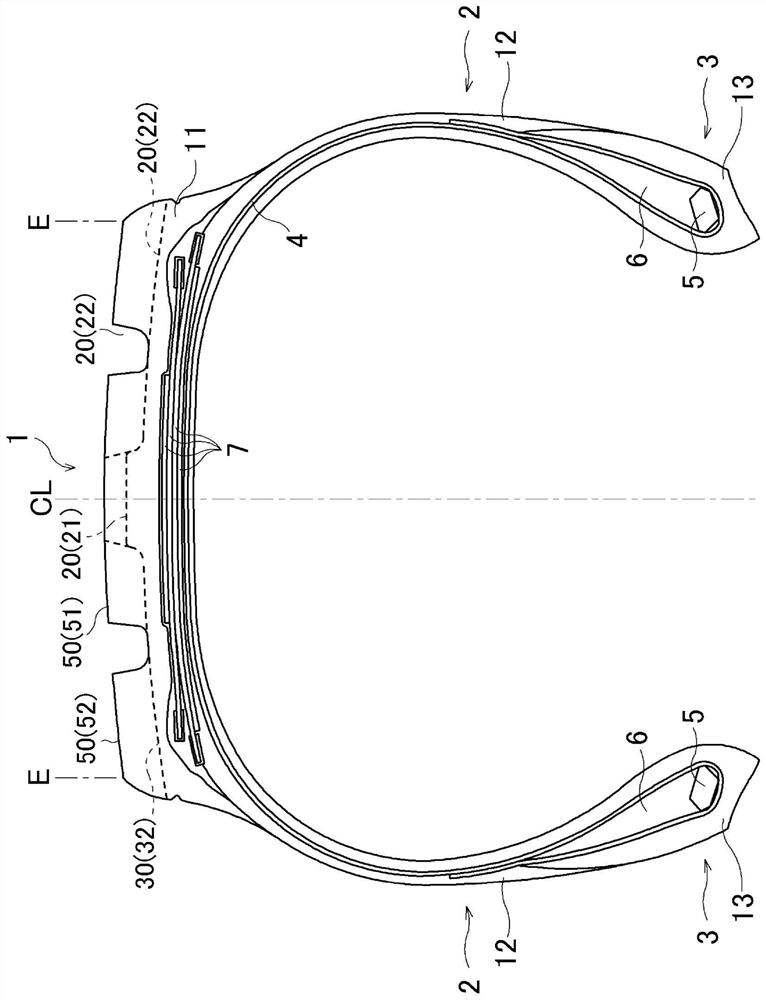

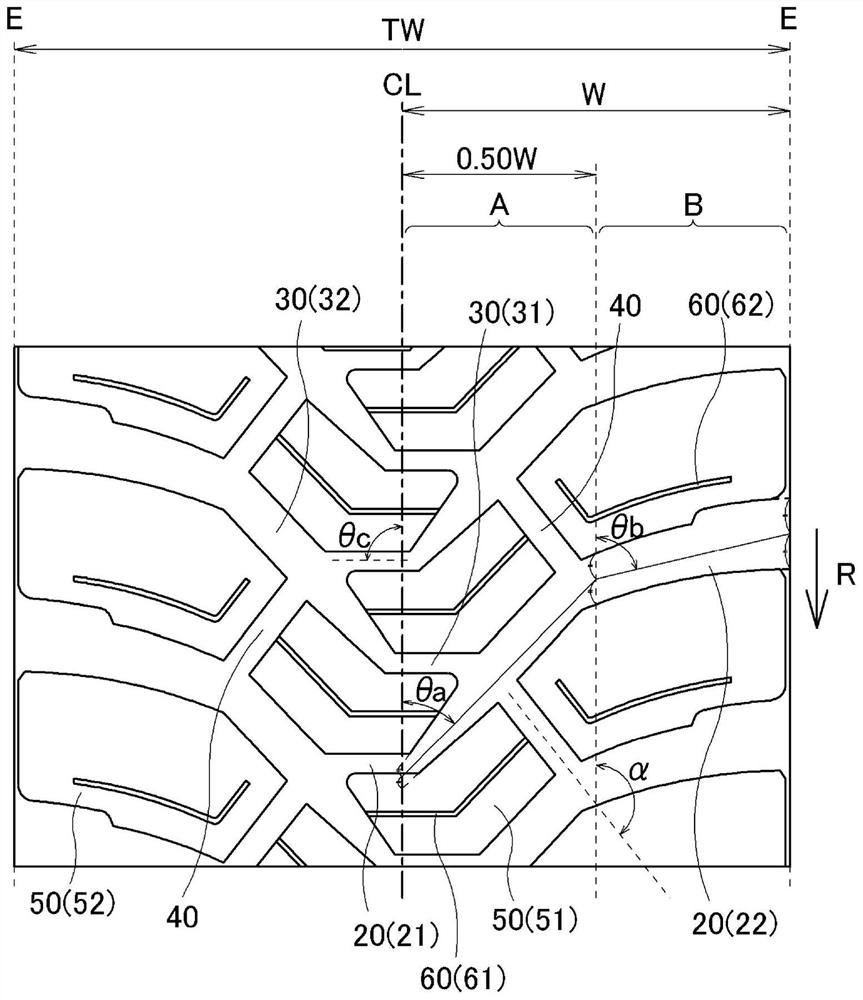

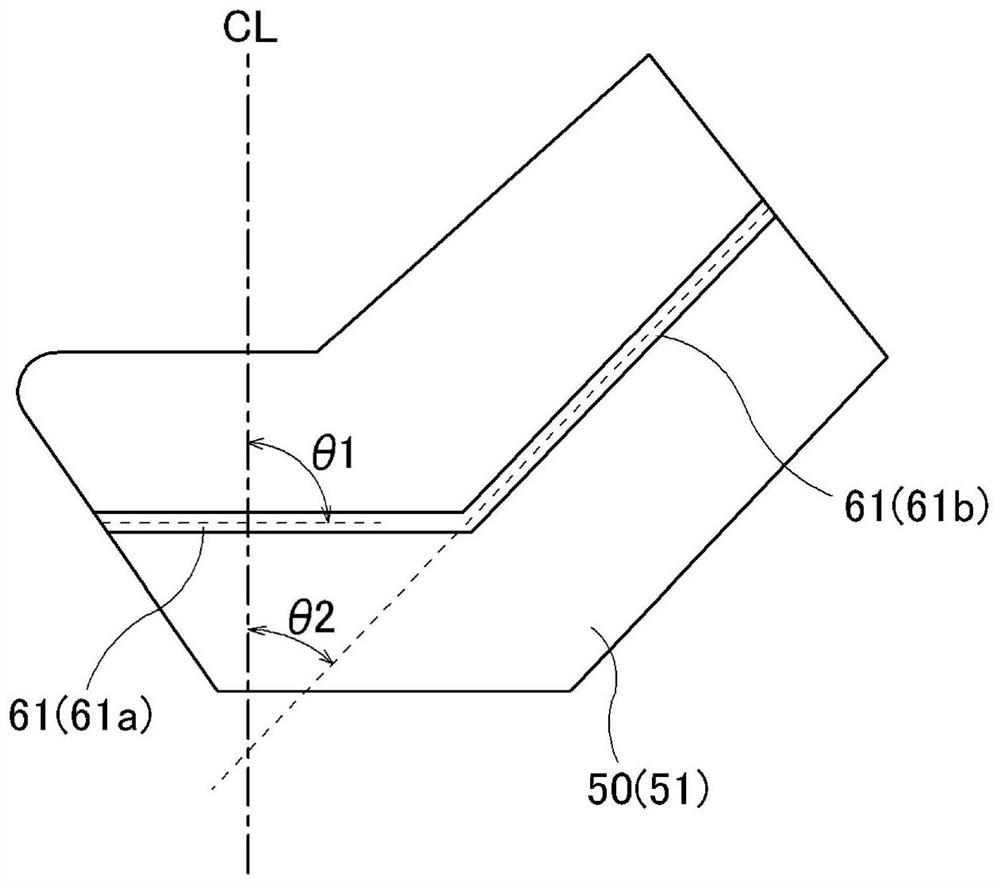

[0056] Made conventional example 1, 22 kinds of pneumatic tires of embodiment 1~21, the tire size of these pneumatic tires is 315 / 80R22.5, has figure 1 The illustrated basic structure sets the following contents as shown in Tables 1 and 2: the tread pattern as the base tone, the average angle θa of the second groove portion of the lug groove in the inner region A with respect to the tire circumferential direction, and the outer region A. In B, the average angle θb of the second groove portion of the lug groove relative to the tire circumferential direction, the angle θc of the first groove portion of the lug groove relative to the tire circumferential direction, the magnitude relationship between the average angle θa and θb, and whether it is shallow or not Groove, groove depth of shallow groove, shape of shallow groove, shape of central shallow groove, presence or absence of repetition of projected components projecting central shallow groove toward the tire equator (repetitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com